Patents

Literature

30results about How to "Excellent extreme pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mercaptobenzothiazolyl imidazoline derivative, and preparation method and application thereof

ActiveCN104177353AReaction conditions are easy to controlHigh yieldOrganic chemistryAdditivesEthylenediamineWater based

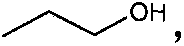

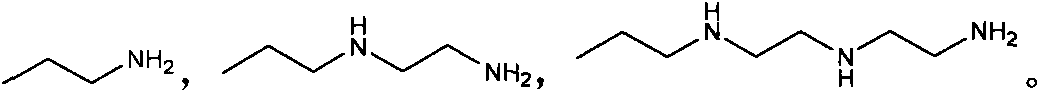

The invention relates to a synthesis technique and application of a 2-mercaptobenzothiazole derivative containing iminazole group. The synthesis technique comprises the following steps: reacting the raw material 2-mercaptobenzothiazole with chloroacetic acid, diethylenetriamine, N-hydroxyethylenediamine, ethylenediamine, triethylenetetramine and tetraethylenepentamine; and by using xylene or toluene as a water carrying agent, reacting the 2-mercaptobenzothiazole with diethylenetriamine, N-hydroxyethylenediamine and other amines in a mole ratio of 1:1.1, wherein the reaction temperatures are respectively 130-160 DEG C and 180-220 DEG C, and the reaction times are respectively 4 hours or so and 2 hours or so. The method is simple to operate, and has the advantages of high yield and controllable reaction conditions. The product 2-mercaptobenzothiazolyl imidazoline derivative can be used in a copper corrosion inhibitor, rust inhibitor, water-based lubricating oil additive or the like.

Owner:新疆金雪驰科技股份有限公司

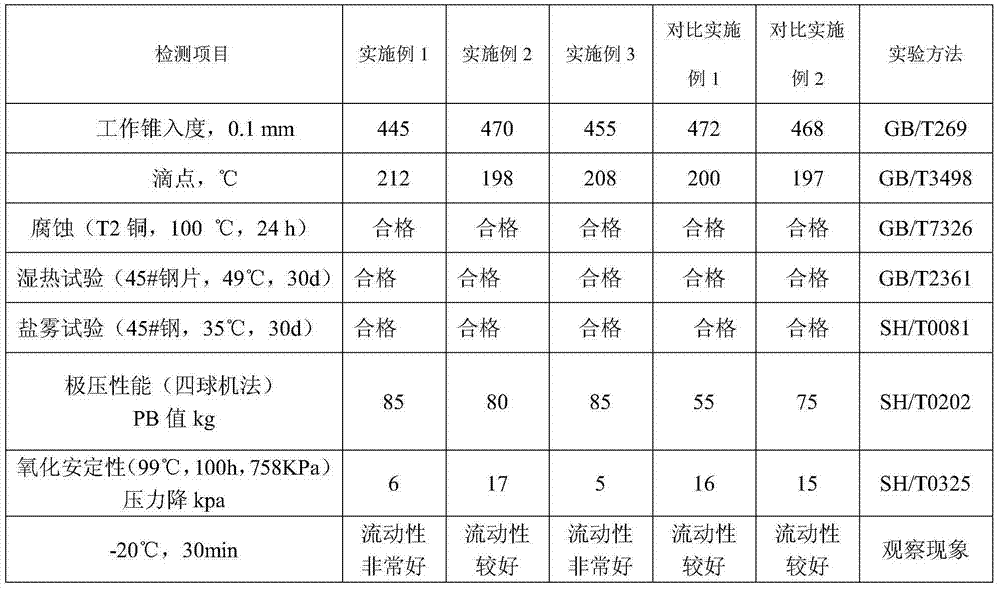

Method for preparing lithium-based (lithium-based calcium-based) lubricating grease by using waste vegetable oil and application

InactiveCN104498131AExcellent extreme pressureCorrosion resistanceThickenersAdditivesEmulsionProcess engineering

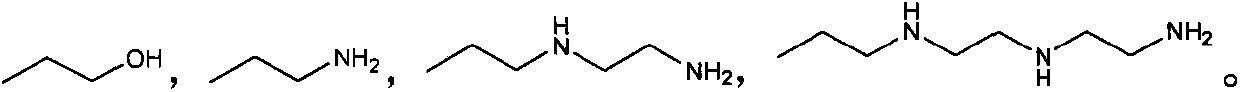

A method for preparing a lithium-based, calcium-based lubricating grease by using waste vegetable oil, and belongs to the technical field of chemical processing of waste vegetable oil. The method comprises the following steps: 1) the waste vegetable oil is subjected to pickling, alkali washing, water washing, decoloration and a series of crafts to obtain pure refined waste oil; and 2) 12-hydroxystearic acid and a prepared hydrated LiOH or LiOH-CaO-H2O emulsion with a certain proportion are added to the refined waste oil prepared in the step 1, and after a saponification reaction, the lithium-based grease or the lithium-based calcium-based lubricating grease is prepared. The method utilizes useful components of the waste vegetable oil to the greatest extent, the prepared lubricating grease obtains good tribological property technical indexes, the production cost of the lubricating grease is saved, the dual effects of waste pollution treatment and waste comprehensive utilization are achieved, and the preparation method is simple in process and is easily put into actual production.

Owner:EAST CHINA JIAOTONG UNIVERSITY

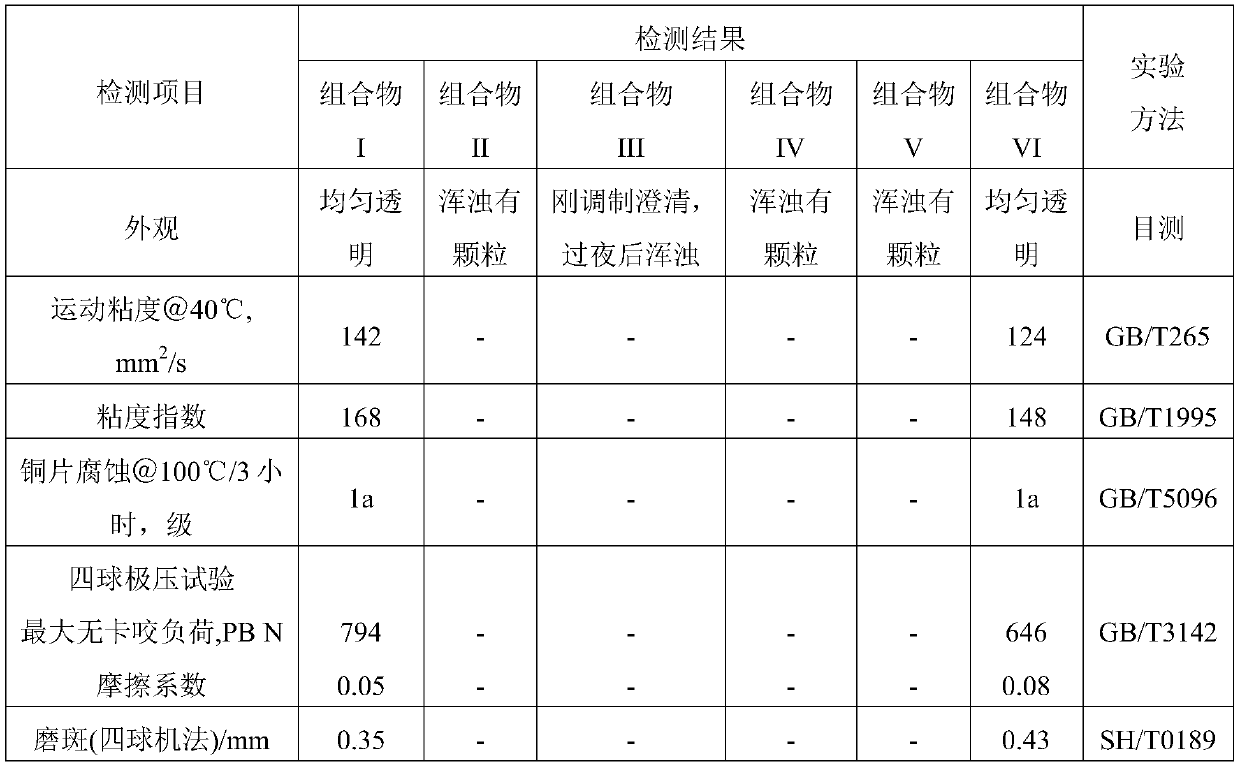

Metal cutting fluid with excellent extreme pressure property

The invention discloses a metal cutting fluid with an excellent extreme pressure property. The metal cutting fluid comprises the following raw materials in parts by weight: 20-50 parts of palm oil, 5-15 parts of a modified compound extreme pressure additive, 4-8 parts of modified molybdenum disulfide, 3-5 parts of xanthate, 2-5 parts of pentaerythritol oleate, 1-3 parts of neopentyl polyol ester, 2-5 parts of fatty acid imidazoline borate, 3-6 parts of diethanolamide oleic acid borate, 2-5 parts of barium petroleum sulfonate, 4-6 parts of heptadecyl imidazoline, 1-3 parts of phytic acid, 3-5 parts of sodium nitrite, 1-4 parts of benzotriazole, 3-6 parts of boric acid, 2-5 parts of dimer acid potassium, 4-8 parts of sodium oleate, 3-6 parts of diethylene glycol, 2-5 parts of dialkyl ether amine, and 8-12 parts of water. The metal cutting fluid has an excellent extreme pressure property.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Stainless steel tube drawing oil

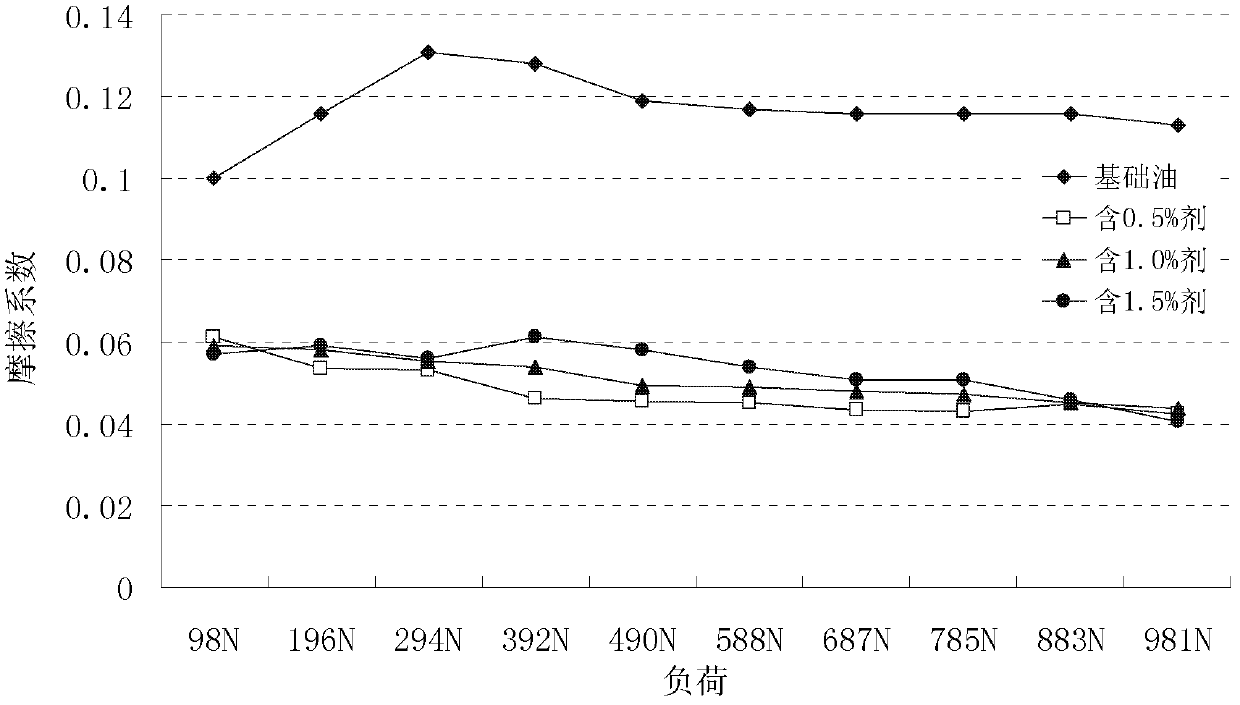

InactiveCN107619699AReduce coefficient of frictionExcellent extreme pressureLubricant compositionParaffin oilsBase oil

The invention relates to stainless steel tube drawing oil, comprising, by weight, 2.5-11% of an extreme pressure agent, 3-8% of medium-chain chlorinated fat, 1.8-4.0% of an antioxidant anticorrosion agent, 3-7% of an oil lubricant, 0.5-1.5% of an anticorrosion agent, 10-20% of paraffin-based base oil, and the balance of base oil. The stainless steel tube drawing oil has very low friction coefficient, excellent extreme pressure performance and excellent lubricating performance, and can effectively protect dies and extend their service lives.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

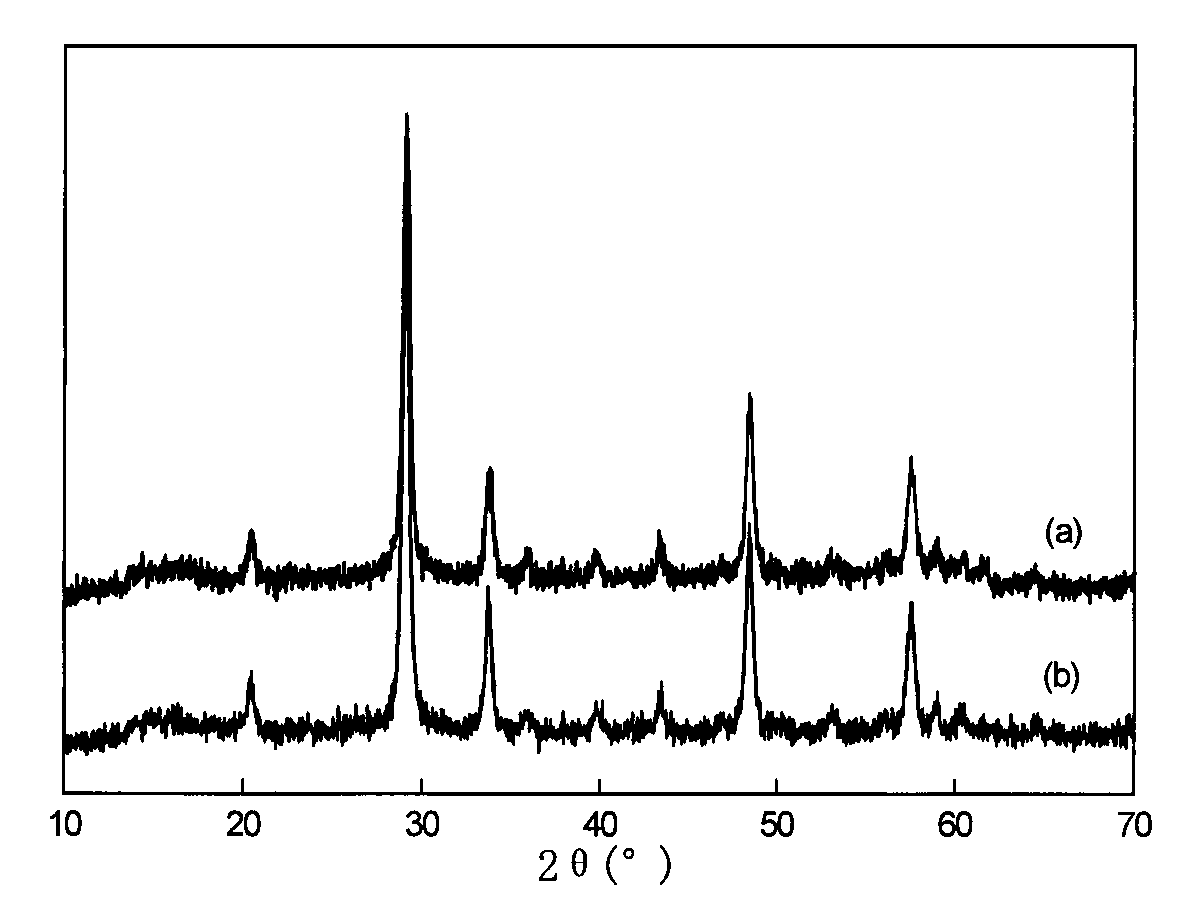

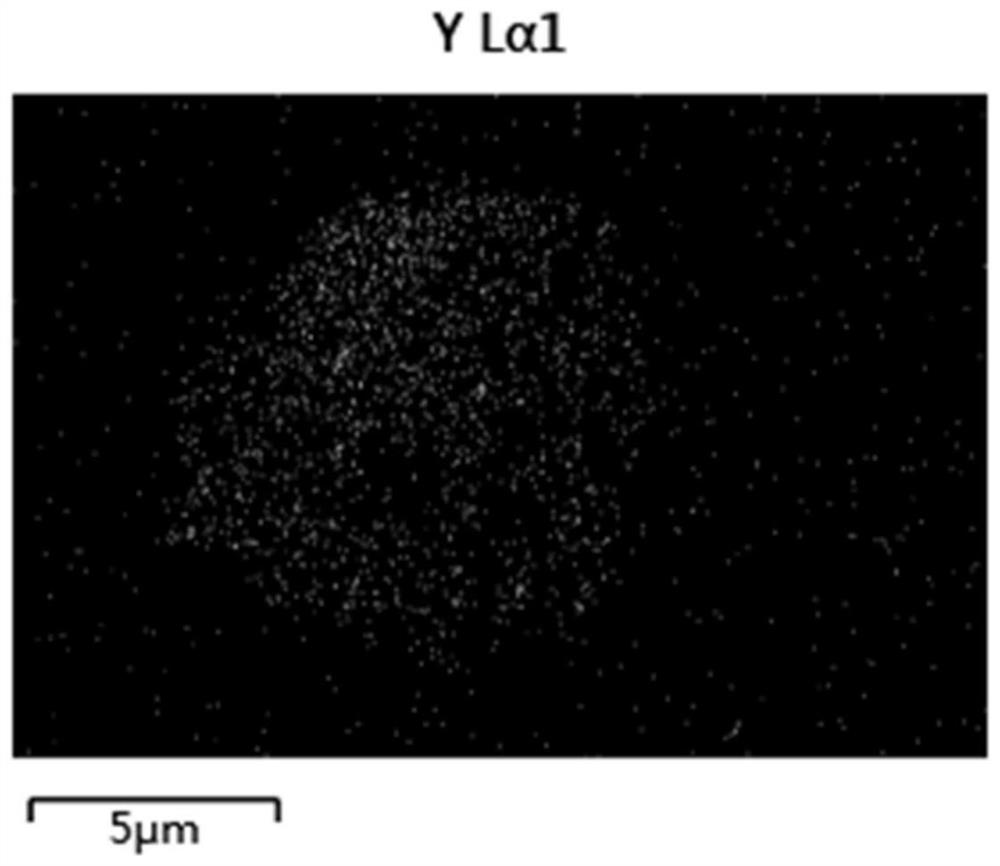

Method for preparing surface-modified nanometer yttrium oxide by emulsion polymerization and application thereof

InactiveCN101638524AOvercoming easy reunionOvercome the disadvantage of non-oil solubilityAdditivesPigment treatment with macromolecular organic compoundsFriction effectWear resistant

The invention discloses a method for preparing surface-modified nanometer yttrium oxide by emulsion polymerization and an application thereof. The preparation method has the following steps of: first,preparing nanometer yttrium oxide suspension, adding emulsifier dodecyl trimethyl ammonium chloride, ultrasonically processing, stirring and diffusing for 3h; then, heating to 60 DEG C in nitrogen atmosphere, adding monomer styrene and butyl acrylate with a fixed quality ratio, and finally adding initiator ammonium persulphate to initiate polymerization reaction at 75 DEG C; drying the compound particles obtained after the finishing of the polymerization reaction to obtain the surface-modified nanometer yttrium oxide; and directly ultrasonically diffusing the modified nanometer yttrium oxidein liquid paraffin base oil or finished lubricant as an extreme-pressure, wear-resistant and anti-friction additive. The surface-modified nanometer yttrium oxide has excellent extreme-pressure, wear-resistant and anti-friction effects.

Owner:GUANGDONG UNIV OF TECH

Steel pipe cold drawing oil

InactiveCN107629836AEffective protectionExtended service lifeAdditivesWear resistantTrimethylolpropane

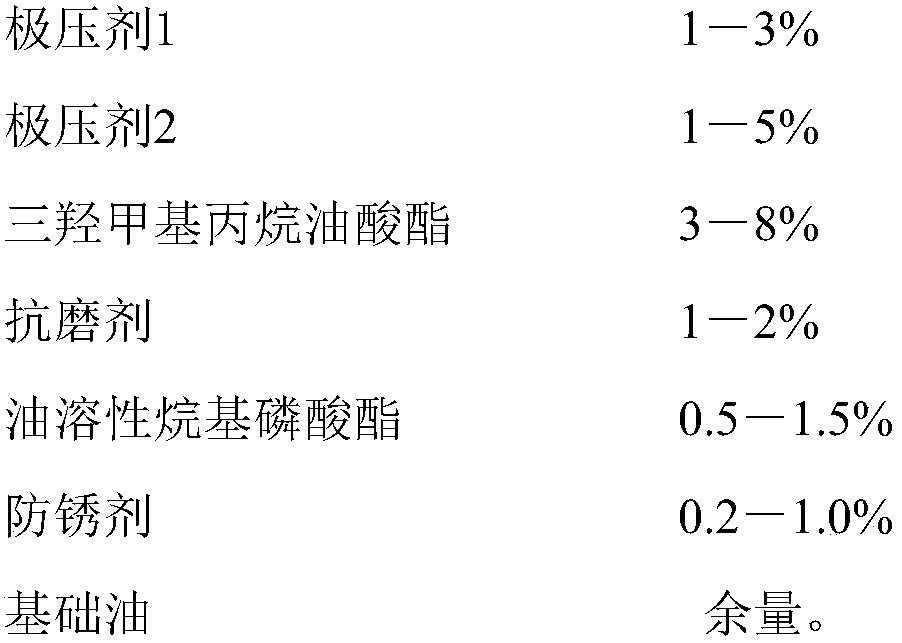

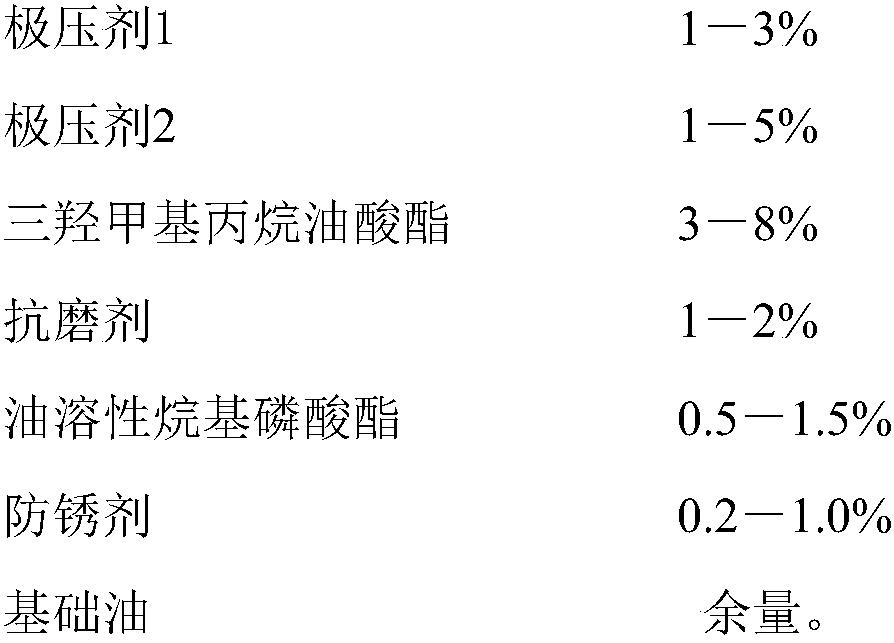

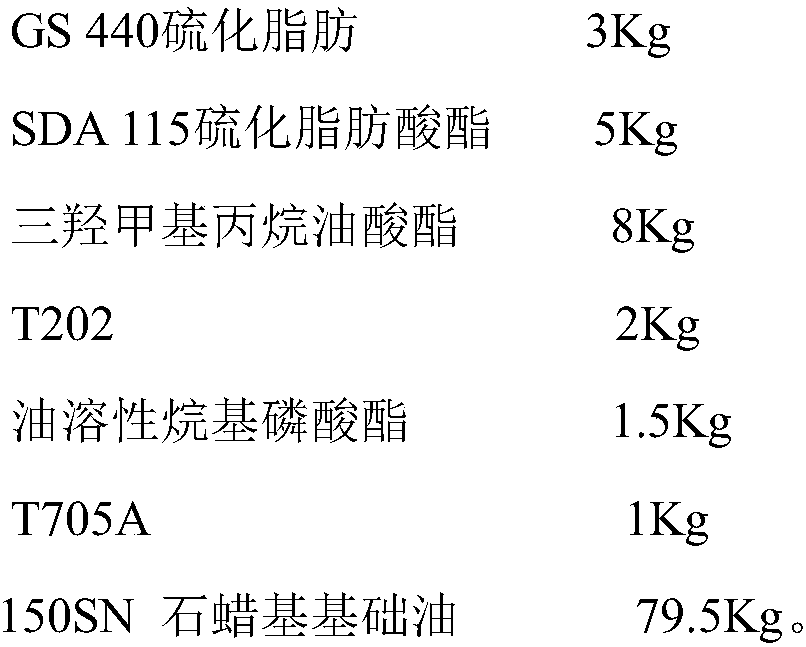

The present invention relates to a steel pipe cold drawing oil, which comprises the following raw material components by weight: 1-3% of an extreme pressure agent 1, 1-5% of an extreme pressure agent2, 3-8% of trimethylolpropane oleate, 1-2% of a wear-resistant agent, 0.5-1.5% of oil-soluble alkyl phosphate, 0.2-1.0% of an anti-rust agent, and the balance of base oil. The steel pipe cold drawingoil of the present invention has excellent extreme pressure lubrication performance and extremely low friction coefficient, and is suitable for the cold drawing process of stainless steels, carbon steels, alloy steels and other difficultly-processed pipes.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

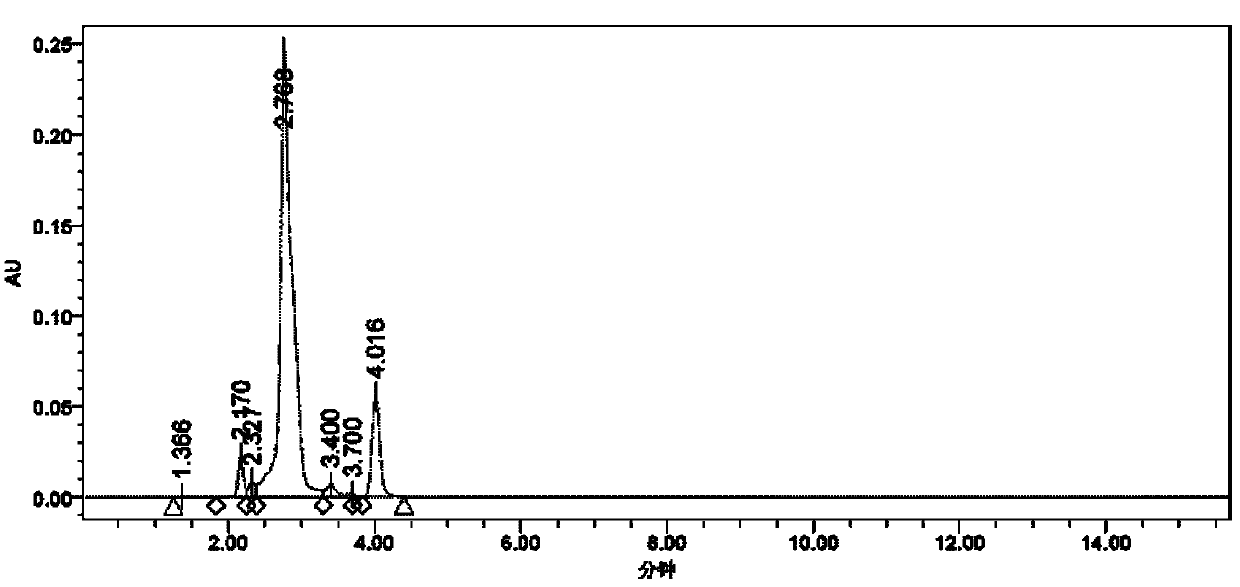

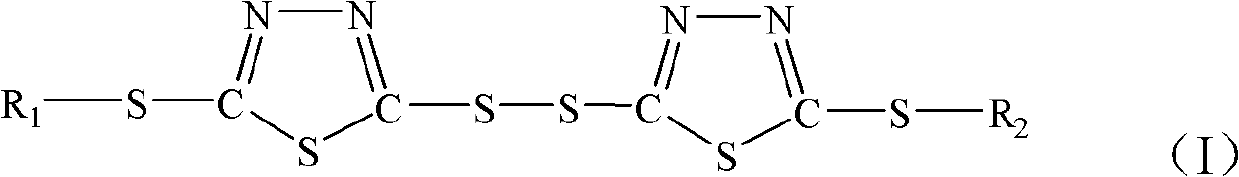

Double thiadiazole derivative and preparation method thereof

ActiveCN103319435AExcellent extreme pressureExcellent friction reductionOrganic chemistryAdditivesAlkaneAlkyl substitution

The invention discloses a double thiadiazole derivative lubricant additive and a preparation method thereof, wherein 2,5-dimercapto-1,3,4-thiadiazole is adopted as a raw material, the 2,5-dimercapto-1,3,4-thiadiazole and halogenated alkane are subjected to a nucleophilic substitution reaction under a catalyst effect to generate monoalkyl thiadiazole, and the monoalkyl thiadiazole is subjected to a coupled reaction under an oxidizing agent effect to obtain bis-5,5'-dithiodi-(1,3,4-thiadiazole-2-thioalkyl) additive, wherein the additive is characterized in that excellent extreme pressure property and antifriction property are provided for the lubricant with the additive, and the additive can be adopted as a lubricant additive to be separately used or is compounded with other additives to be used, and is applicable for industrial lubricating oils and lubricating greases.

Owner:PETROCHINA CO LTD

Meta drawing oil

InactiveCN108559585AReduce coefficient of frictionExcellent extreme pressureAdditivesRust converterLow friction

The invention relates to the technical field of lubricating oil, in particular to metal drawing oil. The metal drawing oil comprises the following components in parts by weight: 2.5-3.5 parts of anti-oxygen and anti-corrosion agent; 3.5-8.0 parts of anti-rust agent; 3.5-4.5 parts of metal deactivator; 0.001-0.002 parts of anti-foam agent; 1.4-2.6 portions of friction modifier; the viscosity indeximprover is 0.5-1.5 parts; 13.0-26.5 parts of extreme pressure antiwear agent; 0.5-1.5 parts of oiliness agent; base oil: the balance; the metal drawing oil has the beneficial effects that the drawingoil has very low friction coefficient, excellent extreme pressure and lubricating property, which can effectively protect the mould and prolongs the service life of the mould.

Owner:广州富飞化工科技有限公司

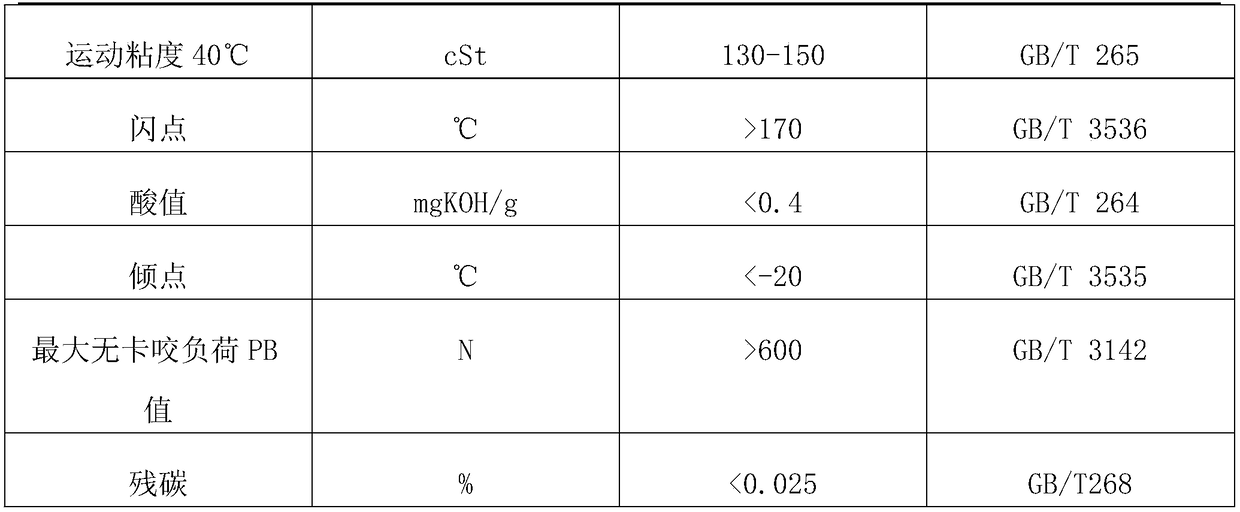

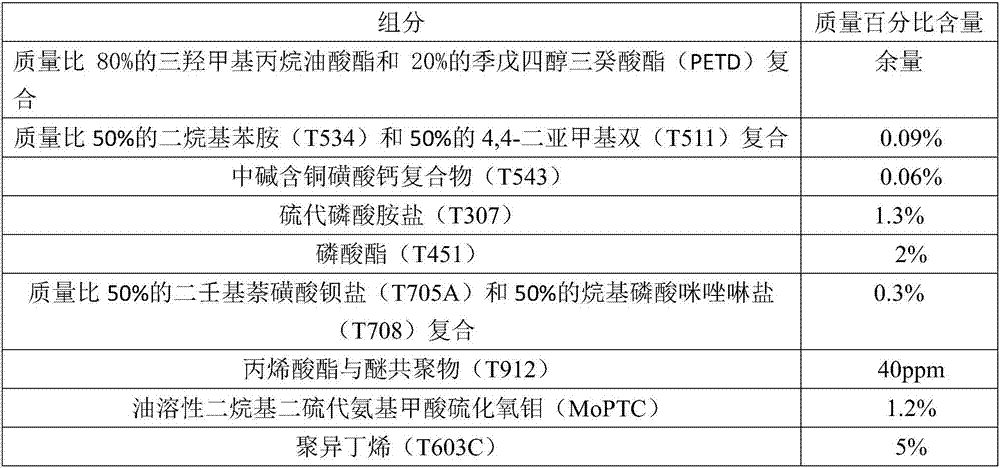

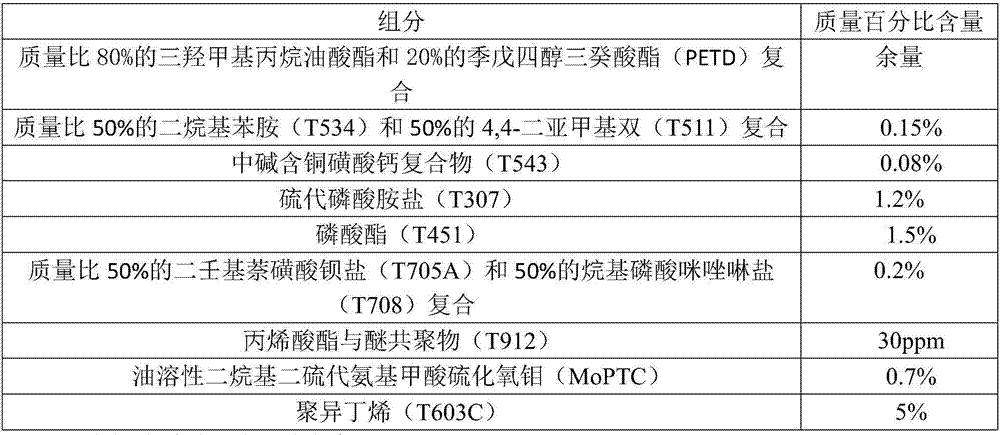

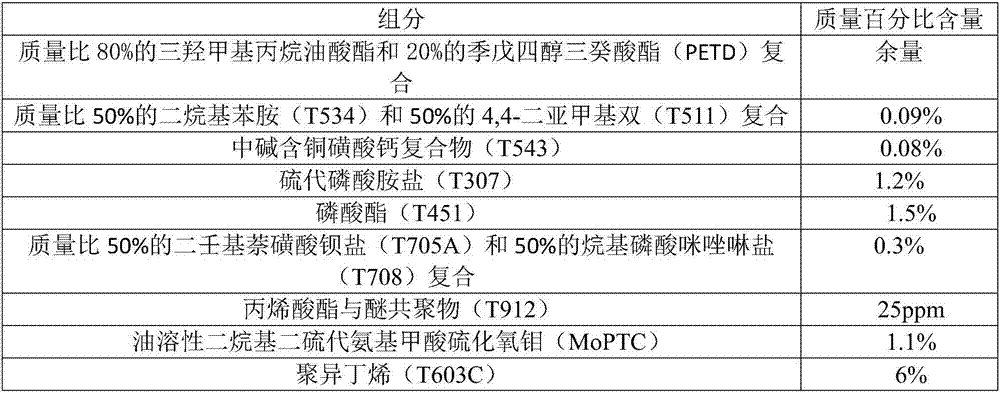

Environment-friendly extreme-pressure anti-wear anti-flame turbine oil composition

InactiveCN107418677AGood oxidation stability and rust resistanceImprove Oxidation StabilityLubricant compositionTotal synthesisPentaerythritol

The invention discloses an environment-friendly extreme-pressure anti-wear anti-flame turbine oil composition. Trimethylolpropane trioleate with a mass ratio of 80% and pentaerythritol tetradodecanoate (PETD) with a mass ratio of 20% are compounded as total-synthesis compound base oil, the total-synthesis compound base oil is matched with varieties of compound additives, and the compound additives include an antioxidant, a metal activating agent, an anti-wear agent, a friction modifier, an anti-rust agent, an anti-foaming agent, an antioxidant preservative and a viscosity index improver. The composition disclosed by the invention has the characteristics of good oxidation stability and anti-rust property, foam resistance, demulsibility, extreme pressure, air release performance and environmental friendliness.

Owner:GUANGXI UNIV

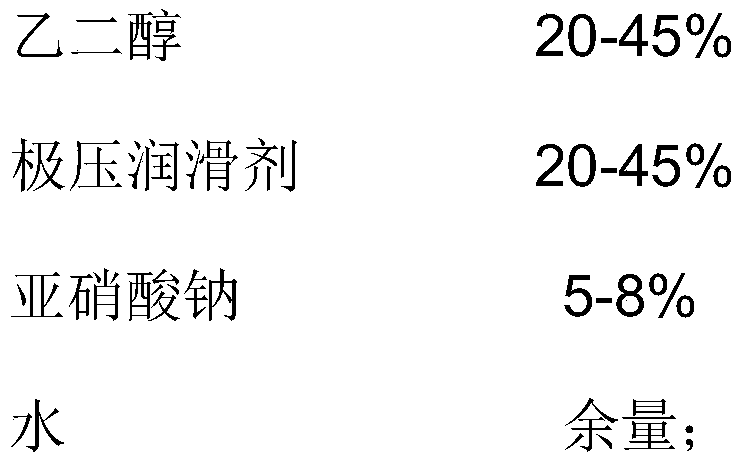

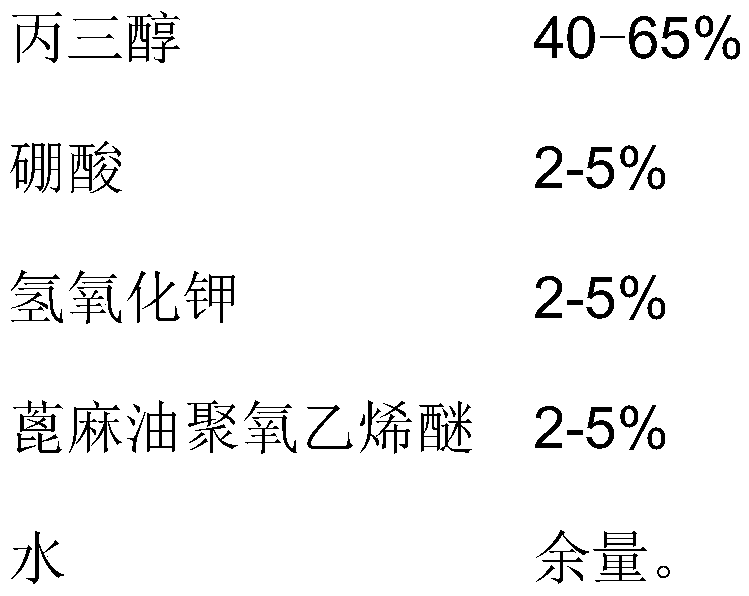

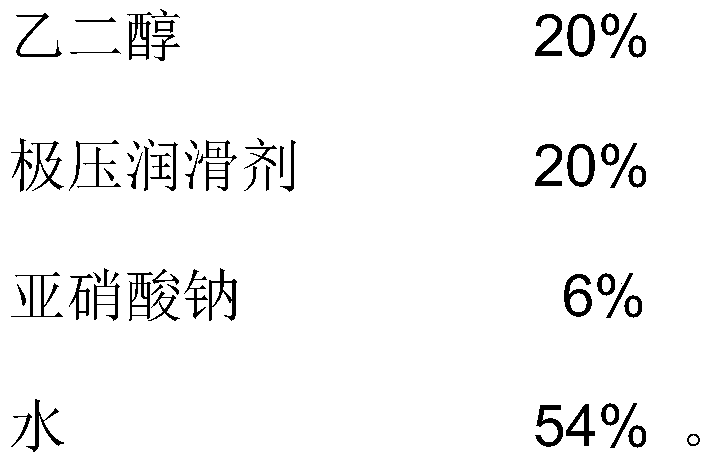

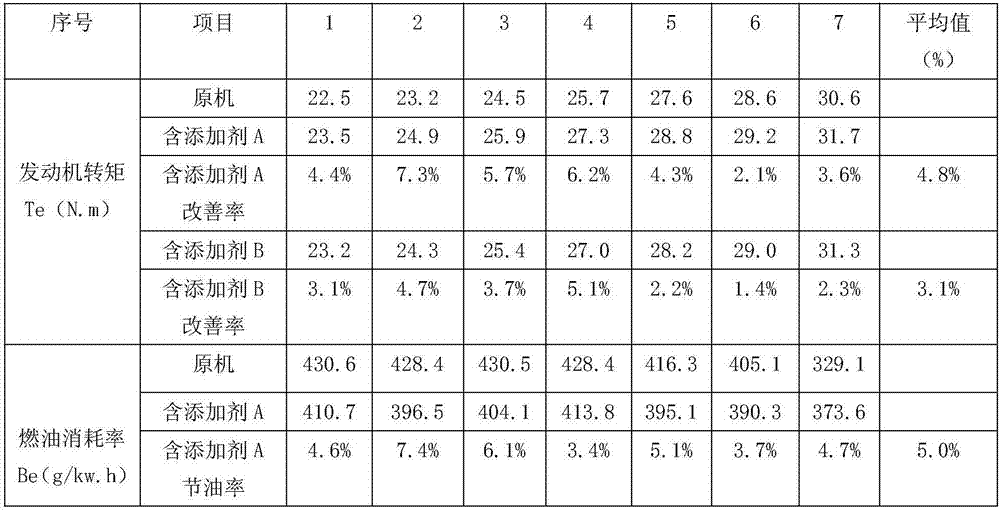

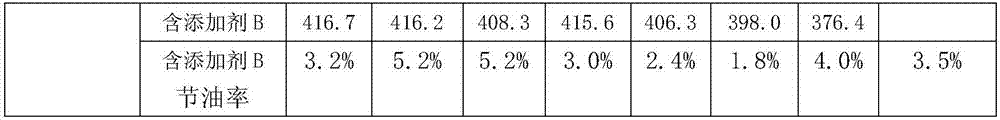

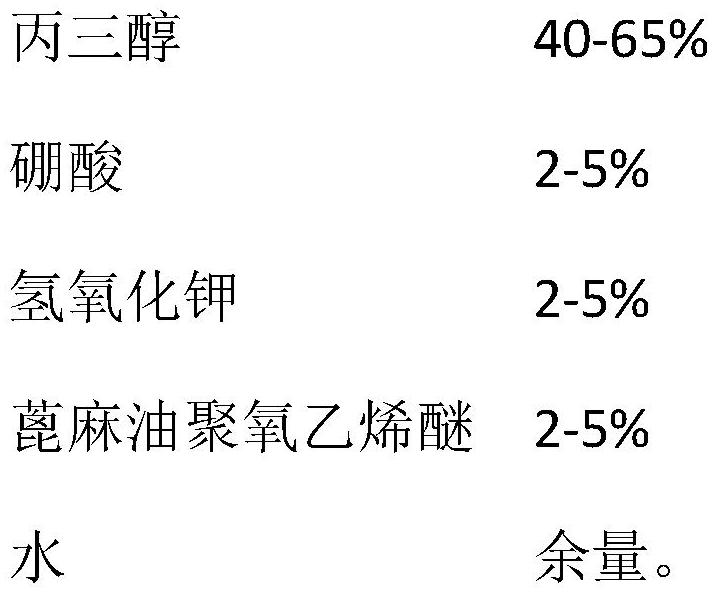

High-performance environmentally-friendly antifreeze solution for hydraulic supports, and preparation method thereof

ActiveCN110499146AGood effectAffordableHeat-exchange elementsLubricant compositionGlycerolPotassium hydroxide

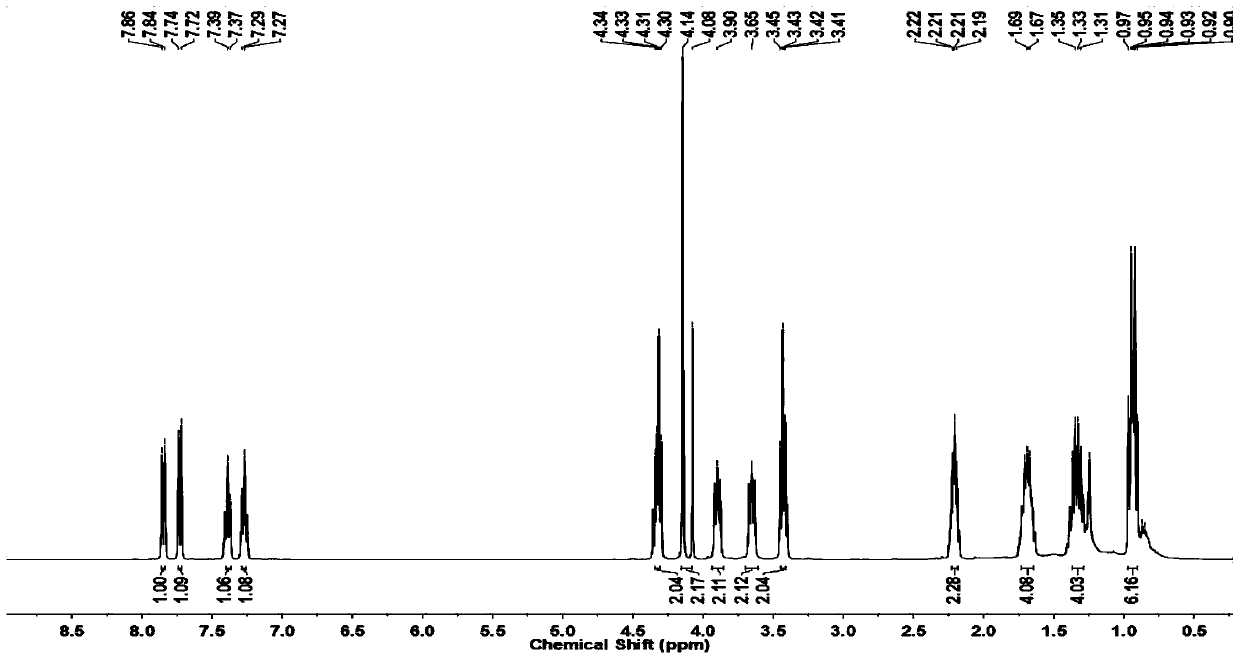

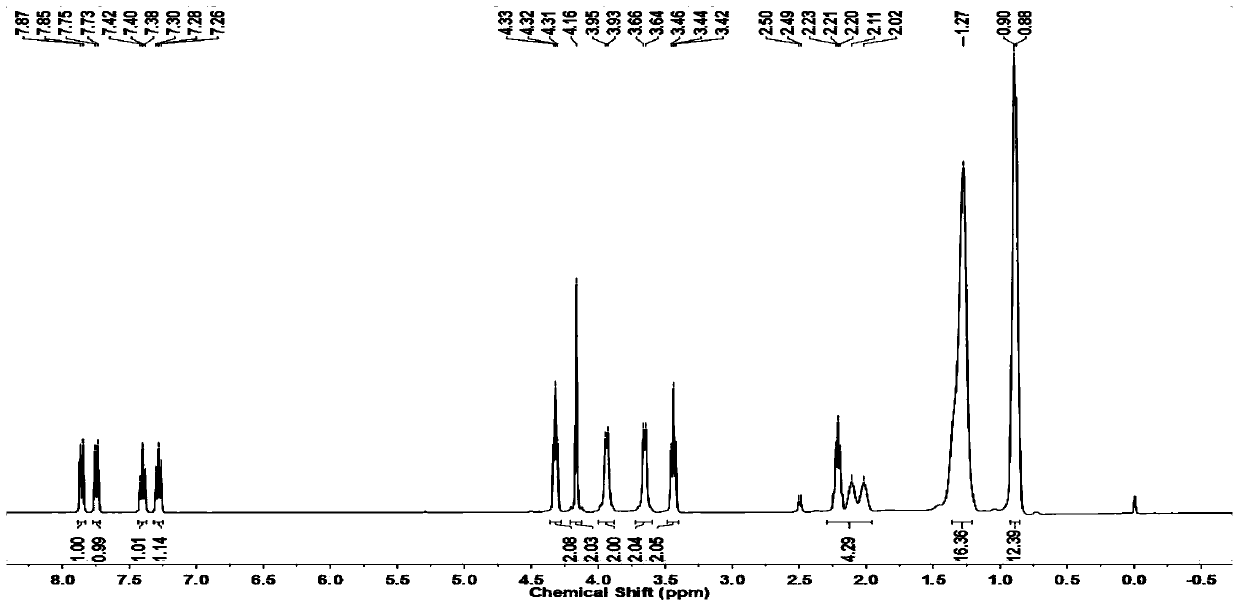

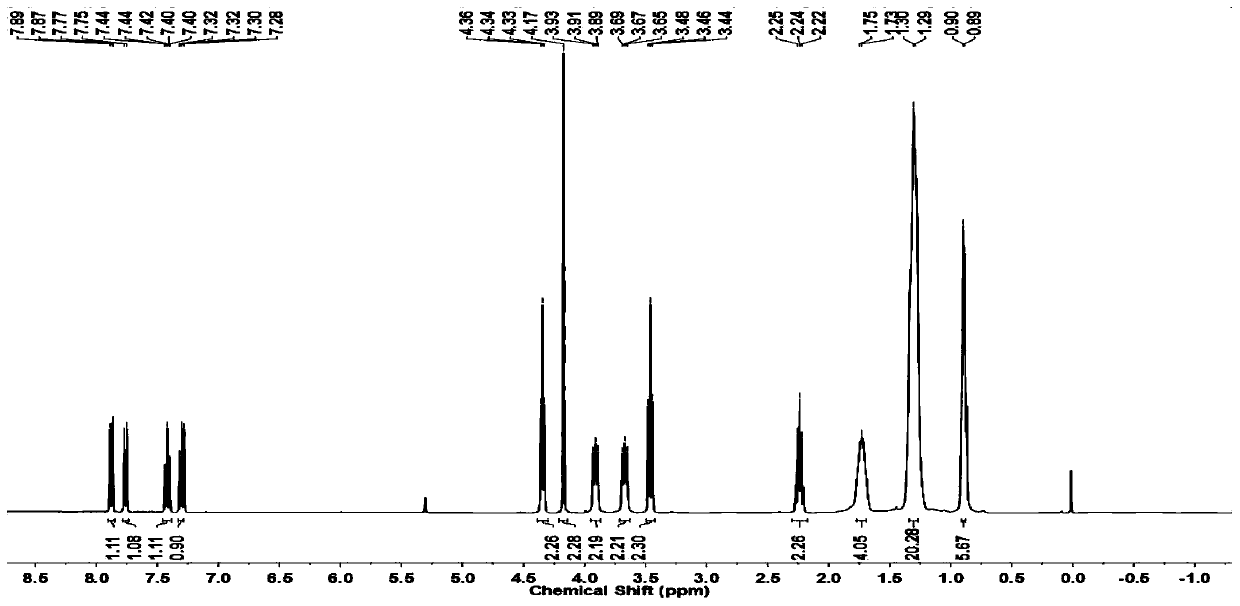

The invention provides a high-performance environmentally-friendly antifreeze solution for hydraulic supports. A preparation method of the antifreeze solution comprises the following steps: stirring and reacting glycerol, castor oil polyoxyethylene ether, boric acid, potassium hydroxide and water at 60 DEG C to generate an extreme pressure lubricant; and mixing ethylene glycol used as a main anticoagulant, sodium nitrite used as an antirust agent, the extreme pressure lubricant, sodium nitrite and water according to a certain ratio, and performing stirring and blending at 35-40 DEG C until thesystem is uniform and transparent in order to obtain the stable-performance antifreeze solution for hydraulic supports. The antifreeze solution has the advantages of low antifreeze point, stable usestate, good lubrication, rust prevention, extreme pressure and compatibility properties, and simplicity in production; the preparation method has the advantages of shortening of the production periodby half, avoiding of long-time high-temperature saponification reaction process in the production process, reduction of the material cost, safety and environmental protection; and insoluble substancesare not mixed into the product, so that the product quality is high.

Owner:淄博爱科工矿机械有限公司

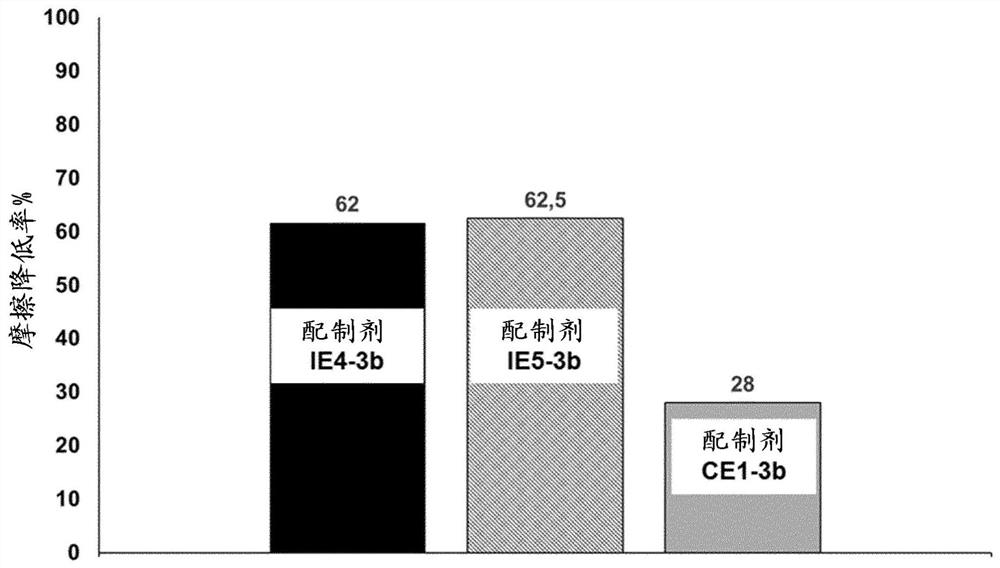

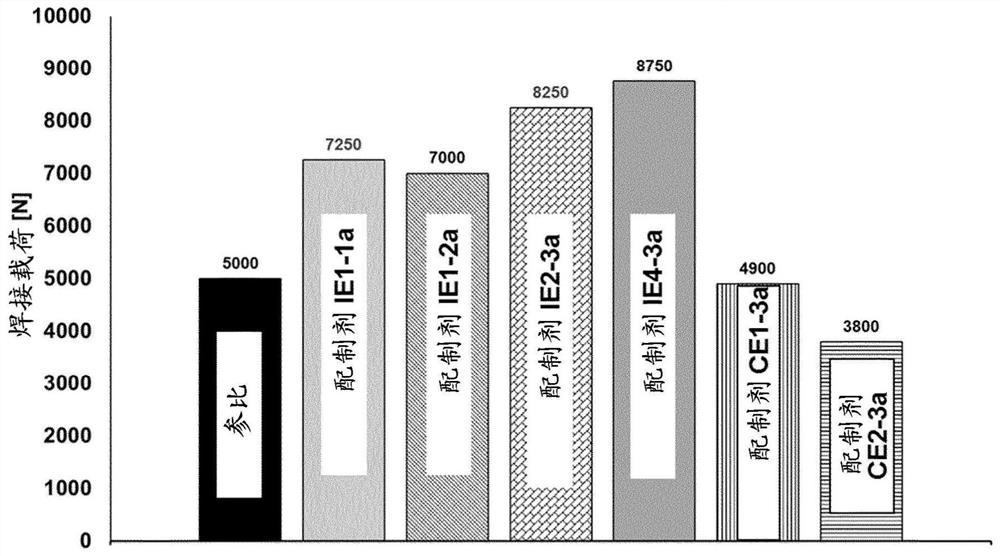

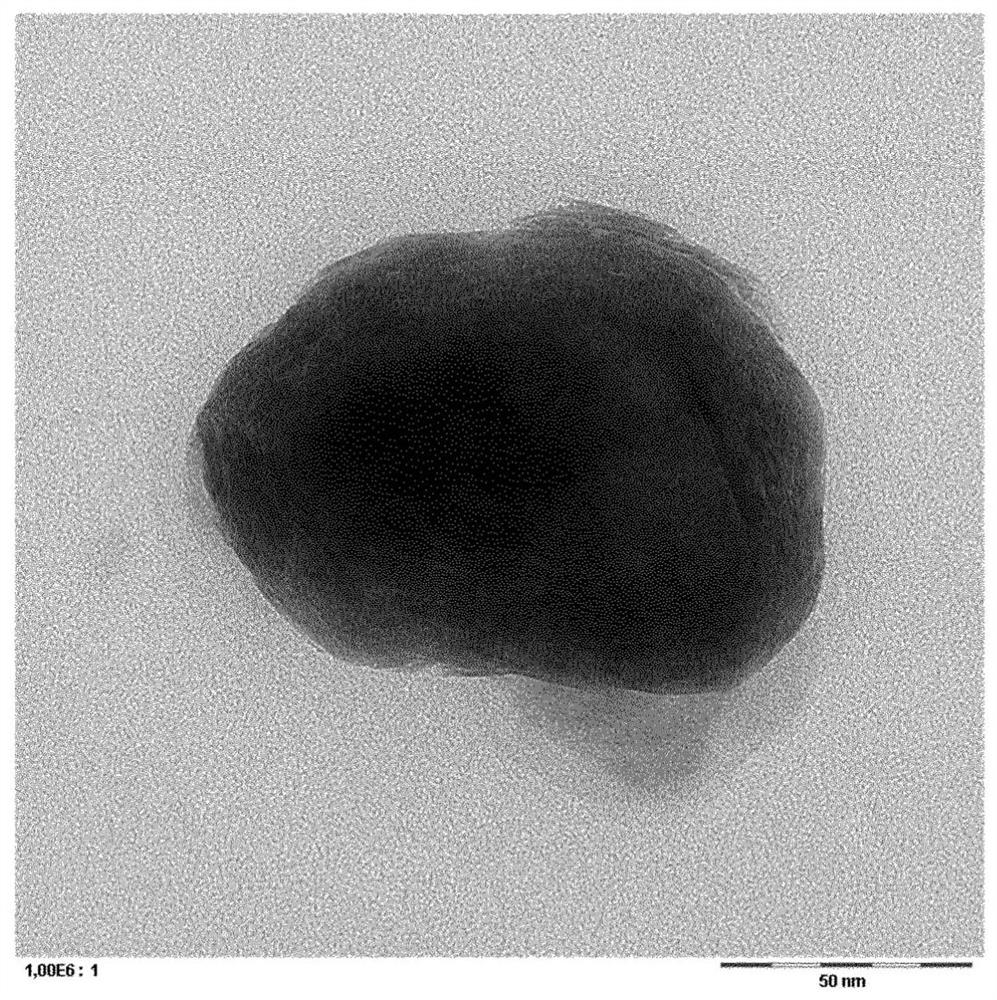

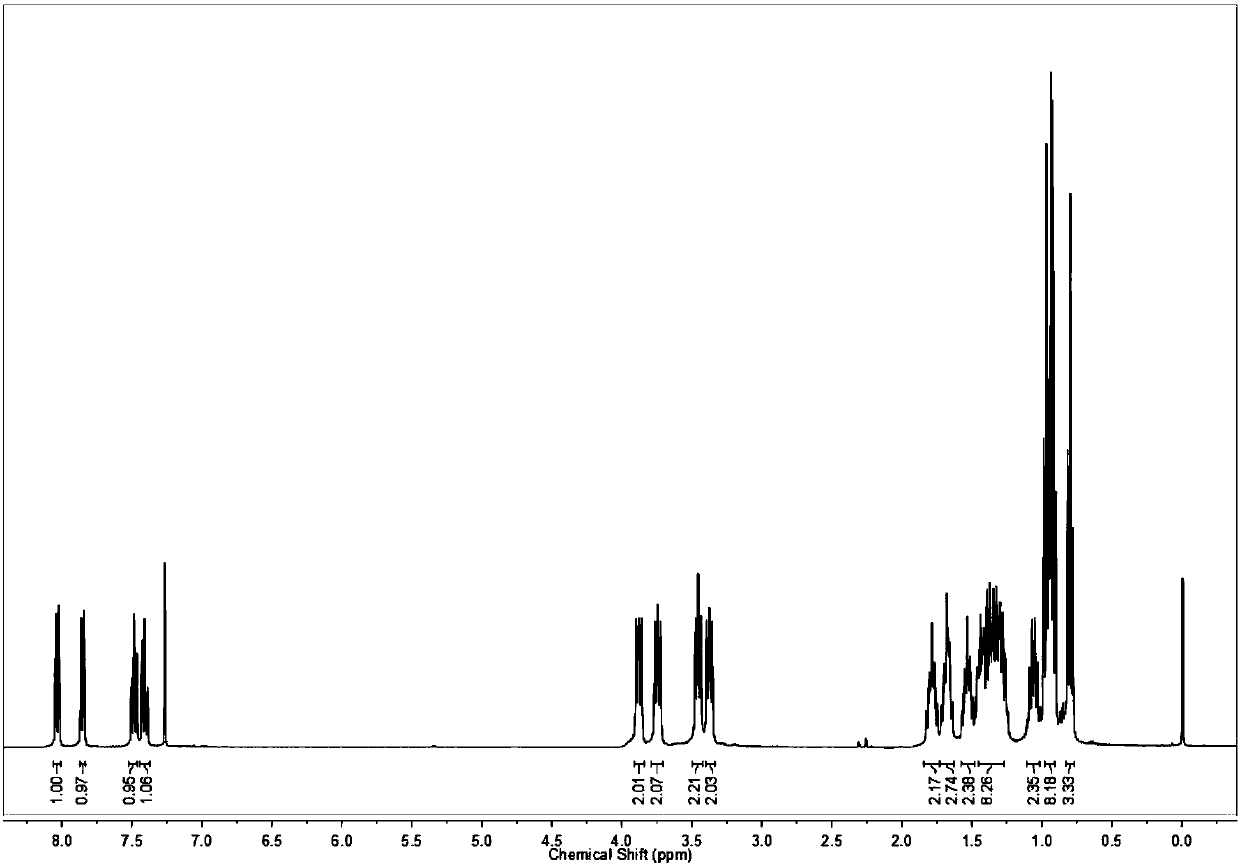

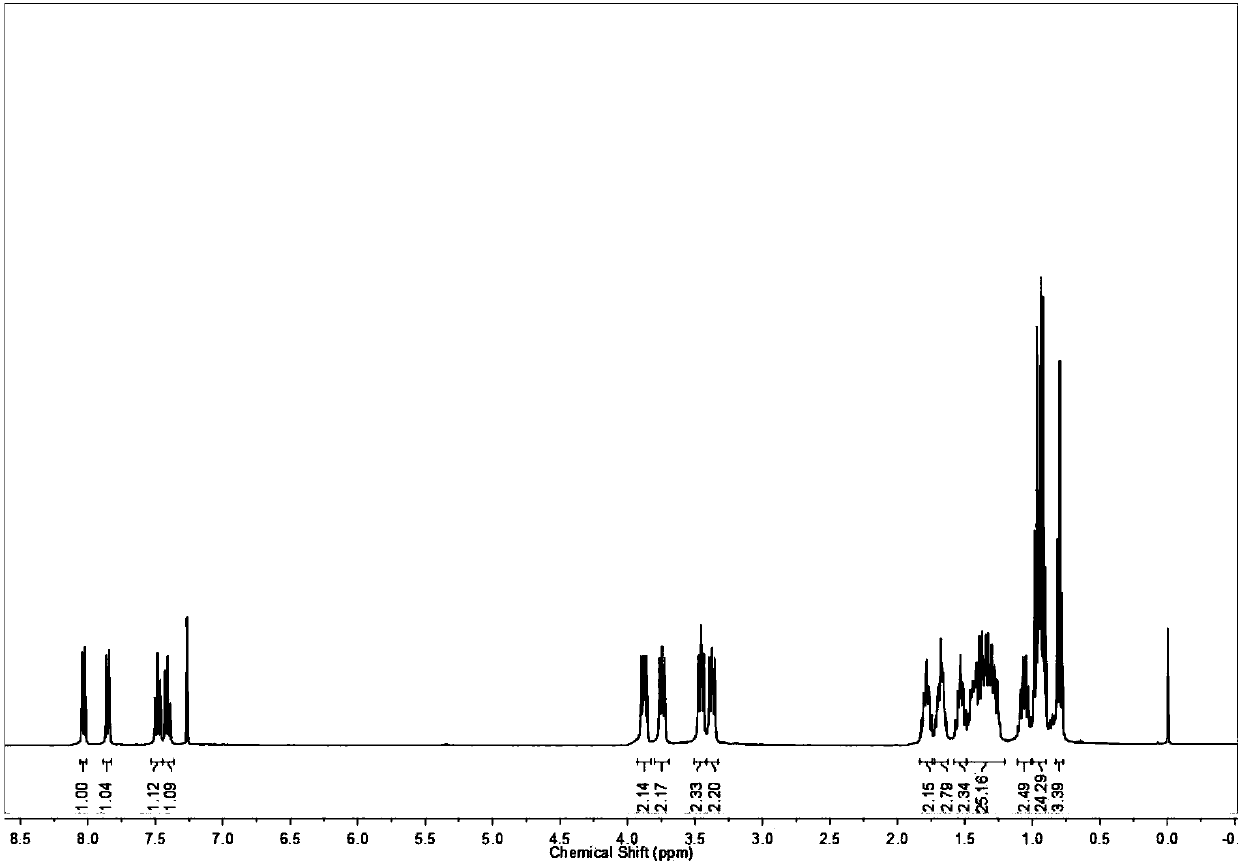

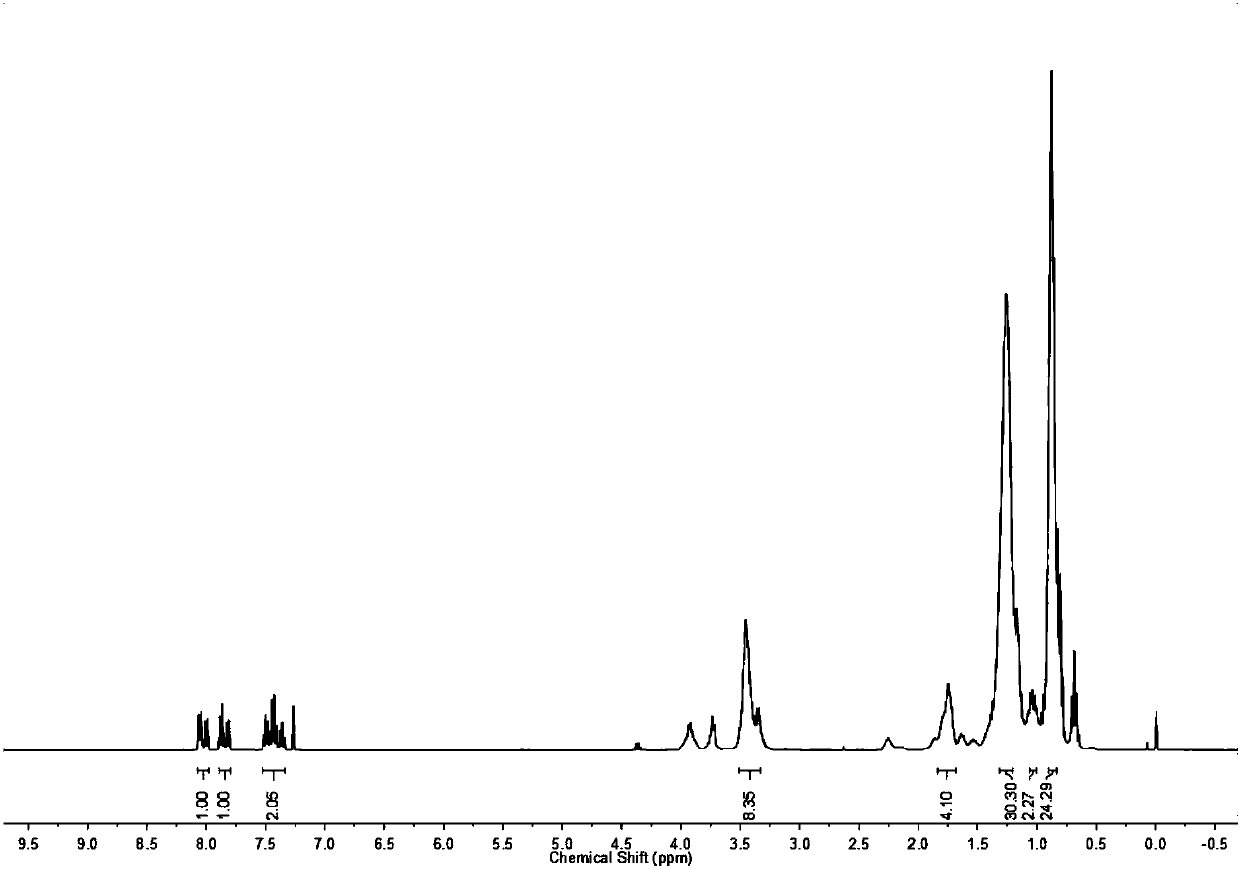

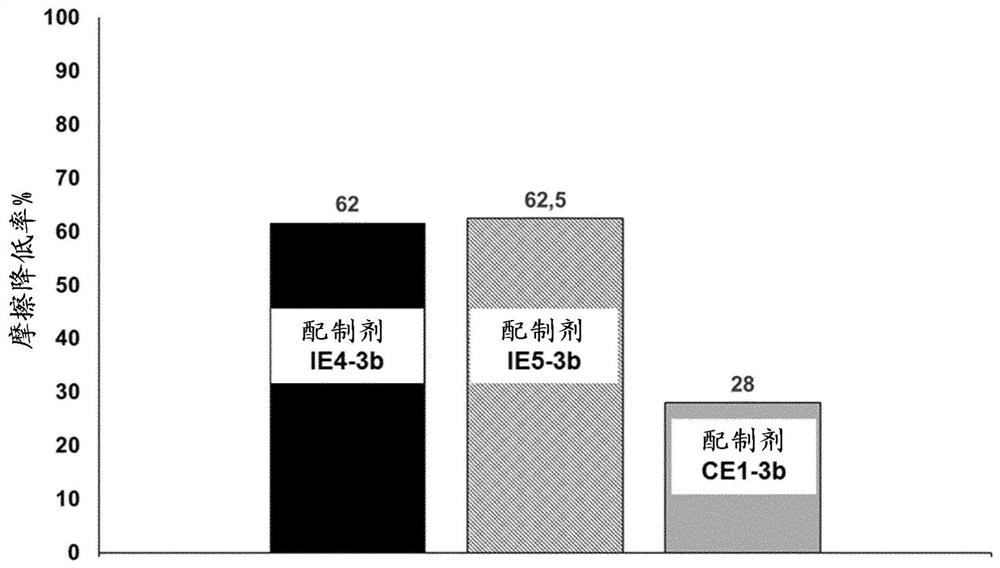

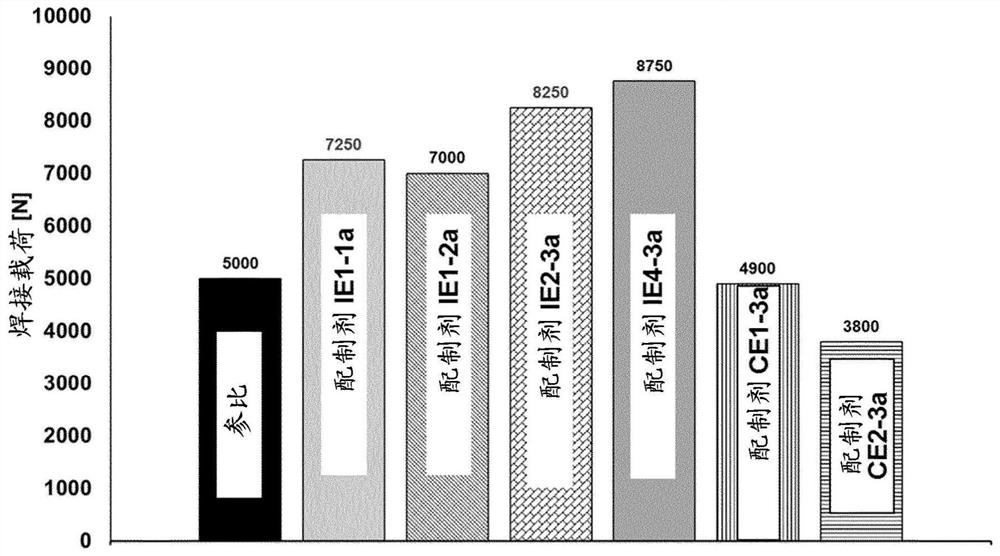

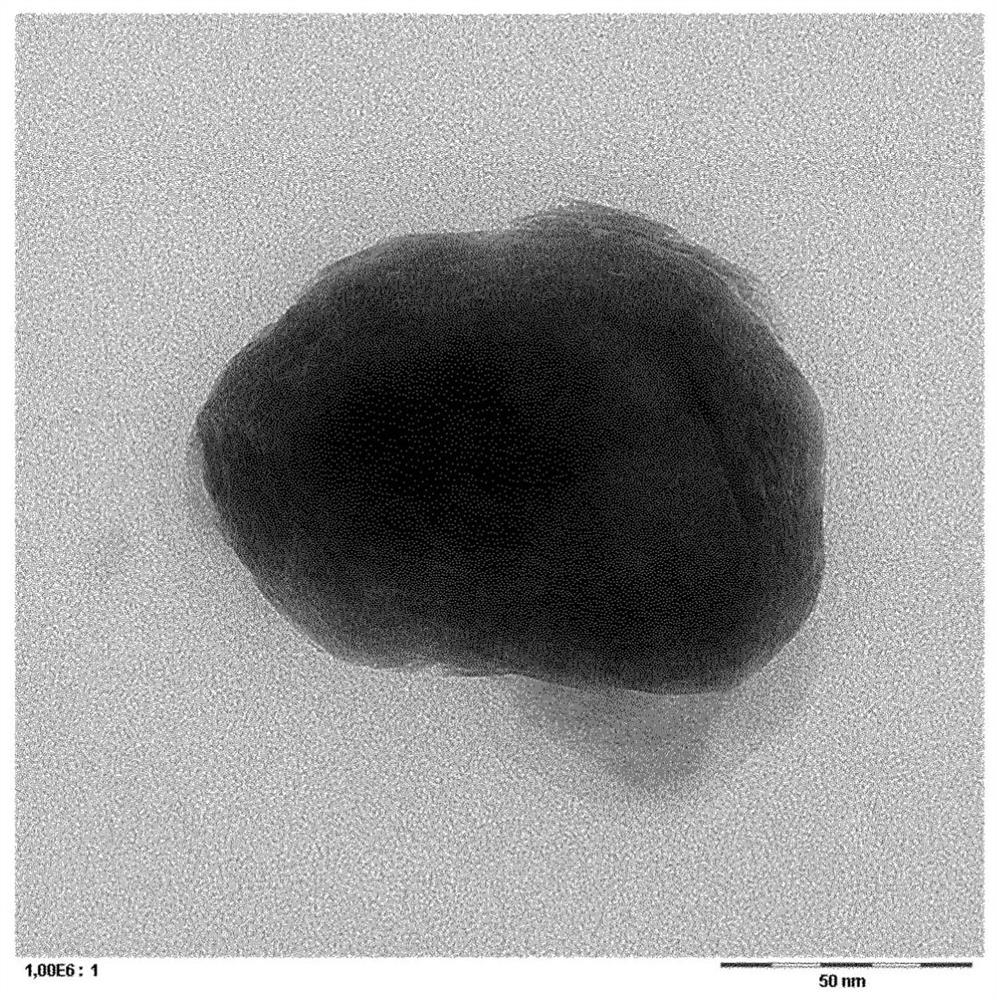

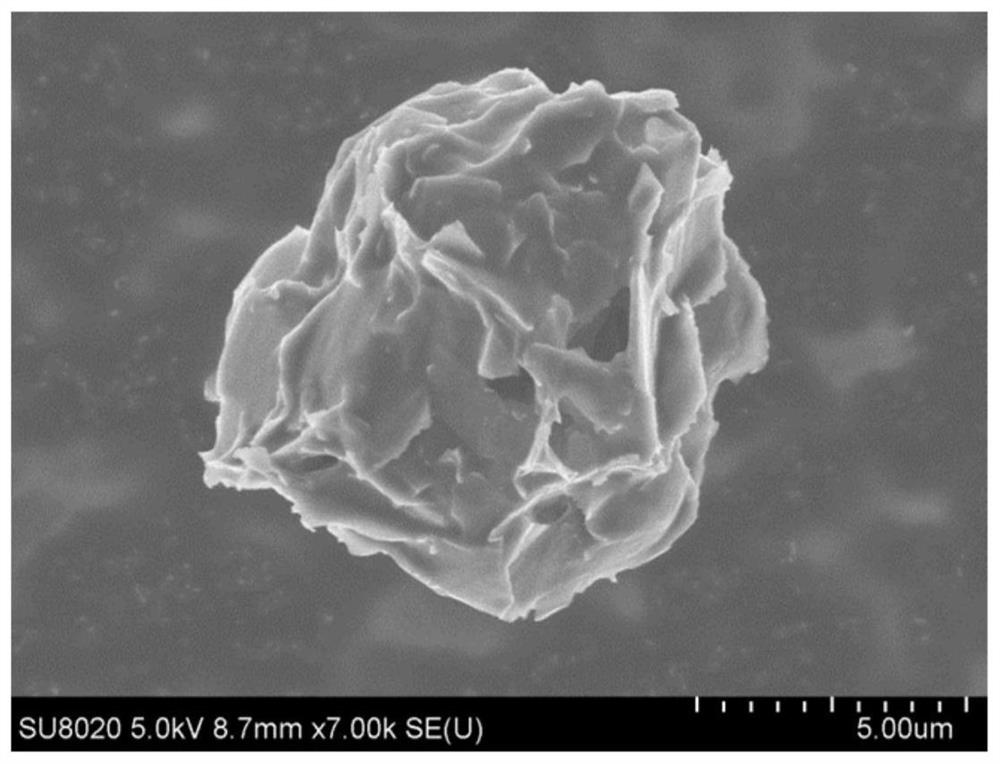

Polymeric-inorganic nanoparticle compositions, manufacturing process thereof and their use as lubricant additives

ActiveCN111655827AExcellent extreme pressureGood anti-frictionMaterial nanotechnologyAdditivesNanoparti clesMaterials science

The invention relates to polymeric-inorganic nanoparticle compositions and preparation processes thereof. The invention also relates to an additive and lubricant compositions comprising these polymeric-inorganic nanoparticle compositions, as well as to the use of these polymeric-inorganic nanoparticle compositions in an oil lubricant formulation to improve tribological performance, in particular to improve extreme pressure performance and friction reduction on metal parts.

Owner:EVONIK OPERATIONS GMBH

Nano graphite fluoride lubricant oil and preparation method therefor

The invention discloses nano graphite fluoride lubricant oil and a preparation method therefor. The nano graphite fluoride lubricant oil is prepared from the following ingredients in parts by weight:250-350 parts of base oil, 10-15 parts of detergent, 5-18 parts of dispersant, 3-10 parts of foam inhibitor, 5-15 parts of viscosity index improver, 15-30 parts of nano graphite fluoride, 1-2 parts ofemulsifier, 10-25 parts of extreme-pressure antiwear additive, 2-5 parts of pour point depressant and 3-9 parts of alcohols. According to the nano graphite fluoride lubricant oil prepared by the preparation method, a layered structure of the nano graphite fluoride is prone to sliding, the friction factor is small, and thus, the nano graphite fluoride lubricant oil has an excellent lubricating property. The graphite fluoride is highly stably dispersed in lubricant oil, is uniform in dispersion, is of a nanometer scale, is very small in particle size, easily enters a friction area and will deposit on a microscopic friction area of a worn-out surface under pressure to exert a self-repairing action, so that the nano graphite fluoride lubricant oil has excellent extreme-pressure and antiwear properties, can adapt to harsh environmental conditions such as high temperatures and extreme pressure and is environmentally friendly.

Owner:张家港希弗新能源科技有限公司

Micro-emulsified cutting fluid

InactiveCN103589494AImprove the lubrication effectExcellent anti-rustLubricant compositionChemical industryAntiseptic Agent

The invention discloses micro-emulsified cutting fluid, belonging to the technical field of chemical industry. The micro-emulsified cutting fluid is prepared from the following components in percentage by weight: 15-25% of petroleum sodium sulfonate, 2-6% of mineral oil, 6-10% of alcohol ether, 3-8% of alcohol amine, 0.5-1.5% of rust preventer, 1-5% of extreme pressure agent, 1-3% of microbicide, 0.05-0.3% of defoamer, 0.1-0.5% of antiseptic, 0.4-1.2% of antioxidant and the balance of water. The micro-emulsified cutting fluid disclosed by the invention has the advantages that good lubrication, rust prevention, extreme pressure, cooling and cleaning are integrated; the foam inhibiting and removing capacity is strong, the hard water resistance is good, and the cleaning performance is good; the micro-emulsified cutting fluid is water-soluble machining fluid and is stable in long term; the waste liquid treatment is convenient and environmental-friendly; the service life of a cutter is prolonged, and the surface quality of workpieces is improved.

Owner:安徽顺驰电缆股份有限公司

Triethanolamine-modified gutter oil-based method for preparation of metal cutting fluid

A triethanolamine-modified gutter oil-based method for preparation of metal cutting fluid comprises the following steps: filtering gutter oil to remove insoluble substances, adding the filtrate into a reaction vessel, adding an inorganic acid aqueous solution of the same volume, warming up and stirring for a reaction, cooling the reaction system to room temperature, standing for liquid separation, washing an oil phase by the use of water of the same volume for three times so as to obtain acid-treated gutter oil; and adding the acid-treated gutter oil into a reaction kettle, adding triethanolamine while stirring, stirring at room temperature for a reaction, successively adding auxiliary base oil, chlorinated paraffin, petroleum sodium sulfonate, alkylphenol polyoxyethylene, sodium napthionate, s-triazine and benzotriazole, and stirring to obtain the required product. The method is simple to operate and easy to realize. By the method, the metal cutting fluid with excellent performance can be obtained, and comprehensive utilization of wastes can be realized.

Owner:XIJING UNIV

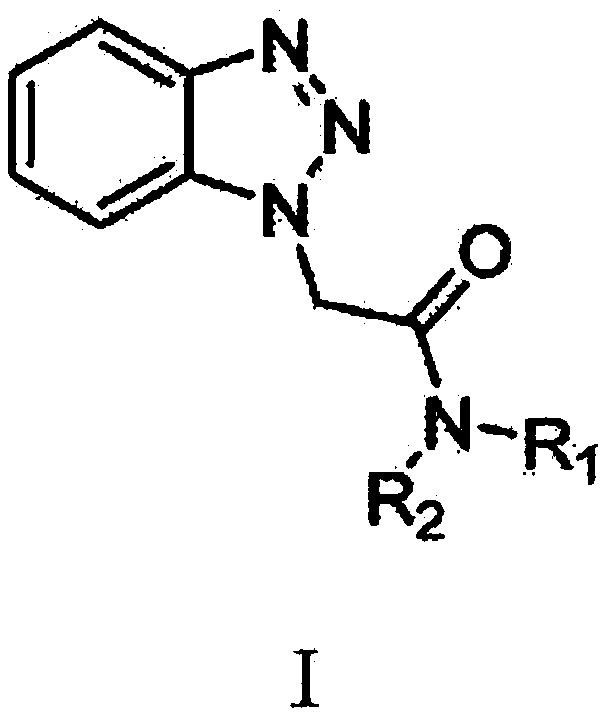

Multifunctional lubricant additive for dithioamino acid triazine derivative and preparation method and application of multifunctional lubricant additive

InactiveCN108048163AImprove thermal stabilityImprove corrosion resistanceOrganic chemistryAdditivesOil additiveTriazine derivative

The invention discloses a multifunctional lubricant additive for a dithioamino acid triazine derivative and a preparation method and application of the multifunctional lubricant additive. The dithioamino acid triazine derivative is of a structure shown as a general formula I. The preparation method comprises the following steps: firstly introducing dialkyl amine onto a tri-polychlorostyrene piperazine structure, then introducing 2-mercaptobenzothiazole, and finally carrying out a nucleophilic substitution reaction with carbon disulfide and dialkyl amine or piperidine to obtain the multifunctional lubricant additive for the dithioamino acid triazine derivative shown as the general formula I. The dithioamino acid triazine derivative has the characteristics of simple preparation method, mildtechnological conditions, easily obtained raw materials, low synthesis cost, high synthesis yield and the like; the derivative can be used for extreme pressure, abrasion resistance, antifriction of alubricant and application of an anti-corrosion additive, the bearing capacity of base oil can be obviously improved, the abrasion resistance and antifriction performance are improved, and the additiveis an environmentally-friendly multifunctional lubricant additive.

Owner:DONGGUAN UNIV OF TECH

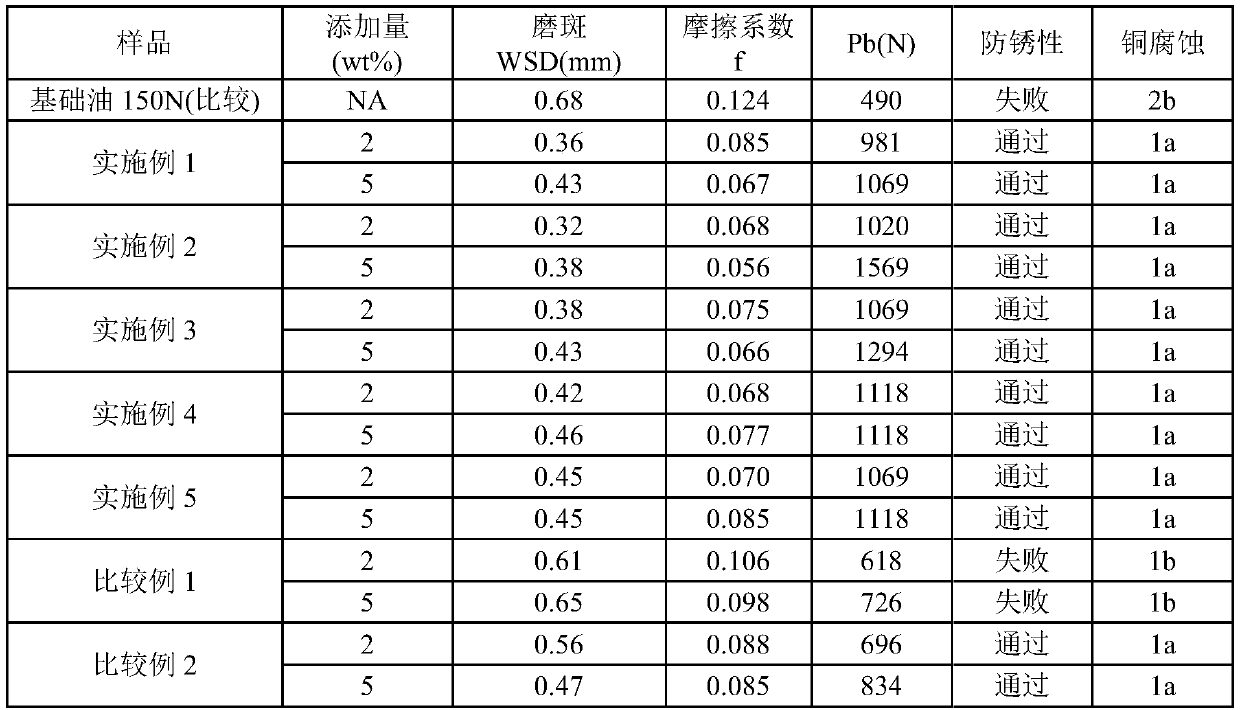

Lubricating oil composition and its preparation method

The invention provides a lubricating oil composition and a preparation method thereof. The lubricating oil composition is prepared from the following components: (a) base oil, (b) fatty acid, (c) alkylsilane and (d) hydrophilic fumed silica, wherein, counted on the basis that the total mass of the base oil (a) is 100 percent, the addition amount of the fatty acid (b) is 0.1 to 3 percent by mass, and is preferably 0.3 to 2 percent by mass; the addition amount of the alkylsilane (c) is 0.1 to 1 percent by mass, and is preferably 0.5 to 1 percent by mass; the addition amount of the hydrophilic fumed silica (d) is 0.3 to 6 percent by mass, and is preferably 0.5 to 3 percent by mass. The lubricating oil composition provided by the invention has excellent wear-reduction, anti-abrasion, extreme-pressure, anti-oxidation, viscosity-temperature and corrosion-prevention performance, is excellent in overall performance, and can be applicable to the lubrication of a device under various loads; the abrasion and the friction of the device can be greatly lightened; the energy consumption is reduced; the service life is prolonged. The preparation method of the lubricating oil composition, which is provided by the invention, is simple, and is suitable for industrialized production; raw materials are easily obtained.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

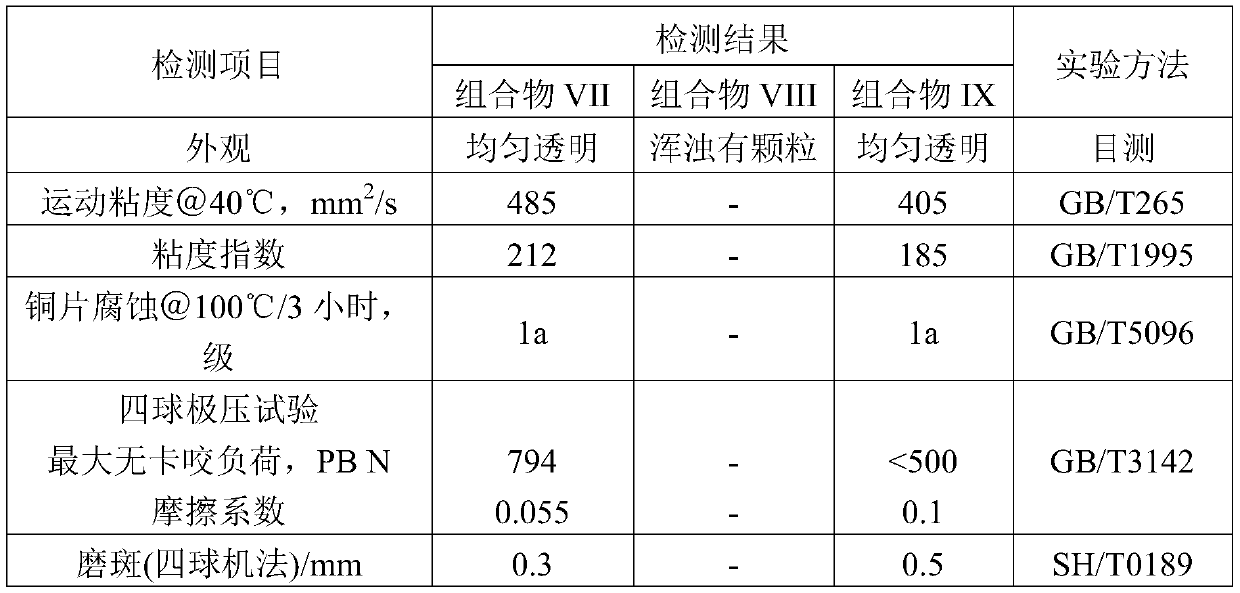

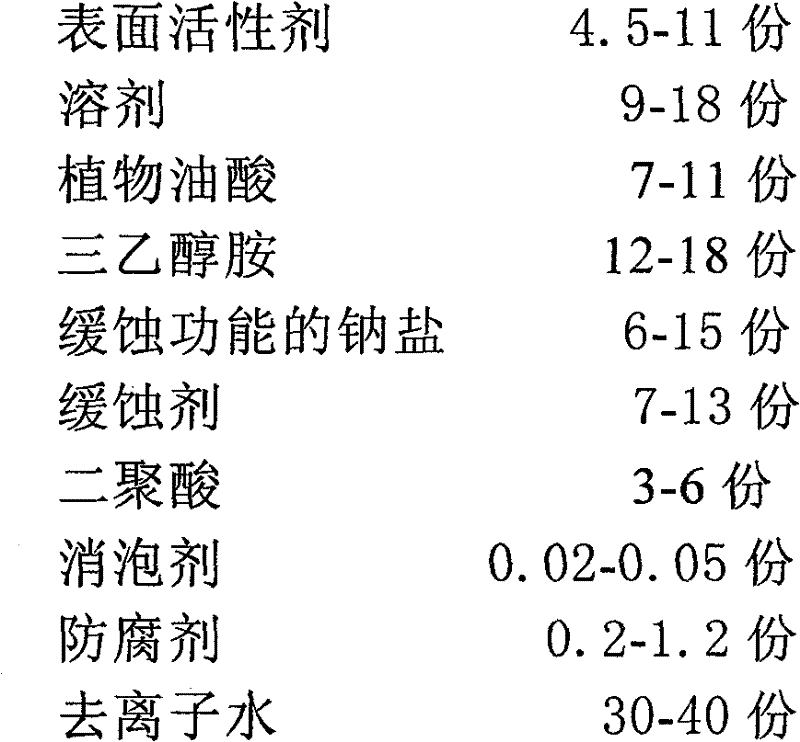

Water-based response type multifunctional metal machining liquid and preparation method thereof

InactiveCN101519622BImprove cooling effectImprove the lubrication effectLubricant compositionWater basedThermal deformation

The invention relates to a water-based response type multifunctional metal machining liquid, the composition formula of which comprises a surfactant, a solvent, plant oleic acid, triethanolamine, sodiThe invention relates to a water-based response type multifunctional metal machining liquid, the composition formula of which comprises a surfactant, a solvent, plant oleic acid, triethanolamine, sodium salts with a corrosion inhibitive function, an inhibiter, dimeric dibasic acid, a defoamer, a preservative, deionized water, defoamer 903, preservative 1227, deionized water, and the like. The metaum salts with a corrosion inhibitive function, an inhibiter, dimeric dibasic acid, a defoamer, a preservative, deionized water, defoamer 903, preservative 1227, deionized water, and the like. The metal machining liquid is nontoxic, harmless and pollution-free, has no harm to human bodies or corrosion to metal surfaces, has no abnormal taste or deterioration after long time usage, and has superiorl machining liquid is nontoxic, harmless and pollution-free, has no harm to human bodies or corrosion to metal surfaces, has no abnormal taste or deterioration after long time usage, and has superiorauxiliary machining functions of cooling, lubricating, cleaning, extreme pressure, rust prevention, and the like. The metal machining liquid can be used for the metal working of devices for machining,auxiliary machining functions of cooling, lubricating, cleaning, extreme pressure, rust prevention, and the like. The metal machining liquid can be used for the metal working of devices for machining, milling, planning, drilling, boring, punching, wire-electrode cutting, and the like, and is especially suitable for high-grade numerical control machines. The machining liquid has high physical stabimilling, planning, drilling, boring, punching, wire-electrode cutting, and the like, and is especially suitable for high-grade numerical control machines. The machining liquid has high physical stability and small surface mightiness, and can effectively reduce the machining temperature, reduce the thermal deformation of workpieces and cutting tools, increase the abrasion resistance of the cuttinglity and small surface mightiness, and can effectively reduce the machining temperature, reduce the thermal deformation of workpieces and cutting tools, increase the abrasion resistance of the cutting tools, increase the machining precision and the surface finish quality of the workpieces to a great extent, effectively remove dirt on the surfaces of the workpieces, and prolong the natural antirusttools, increase the machining precision and the surface finish quality of the workpieces to a great extent, effectively remove dirt on the surfaces of the workpieces, and prolong the natural antirust time of the processed workpieces to be longer than 45 days.time of the processed workpieces to be longer than 45 days.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

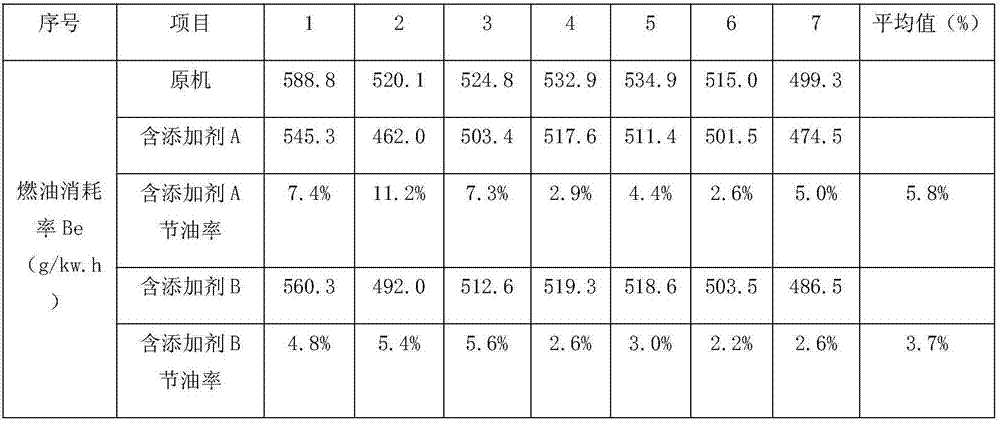

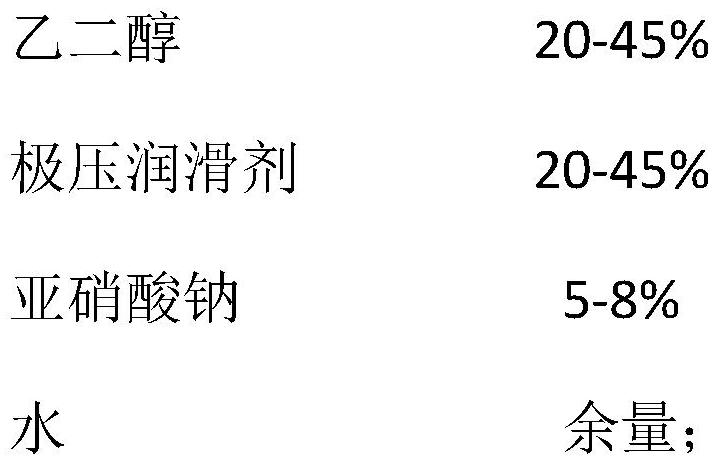

Network lattice nanosphere lubricating oil improver

The invention relates to a network lattice nanosphere lubricating oil improver, which belongs to a chemical composition and relates to a composition additive for improving the performance of lubricating oil. The lubricating oil improver includes polyethylene glycol and organic molybdenum, wherein the weight proportion of polyethylene glycol is 1.5-35%, and the weight proportion of organic molybdenum is 65-98.5%, and the polyethylene glycol includes polyethylene glycol Diol 200, Macrogol 400, Macrogol 600, Macrogol 800, Macrogol 1000, Macrogol 1500, Macrogol 2000, Macrogol 4000, Polyethylene Glycol 6000, polyethylene glycol 8000, polyethylene glycol 10000 and polyethylene glycol 20000; the organic molybdenum includes dialkyl molybdenum dithiophosphate and dialkyl disulfide One or a mixture of two molybdenum carbamates. The invention can not only improve the combustion rate of fuel oil, but also greatly reduce the discharge of exhaust gas from fuel combustion.

Owner:广东新科态节能减排技术研究所有限公司

A kind of high-performance environment-friendly antifreeze liquid for hydraulic support and preparation method thereof

ActiveCN110499146BImprove performanceExcellent anti-rustHeat-exchange elementsLubricant compositionPotassium hydroxideGlycerol

Owner:淄博爱科工矿机械有限公司

Ester-containing benzothiazole derivative lubricating oil additive and preparation and application thereof

InactiveCN110205181AImprove thermal stabilityImprove corrosion resistanceOrganic chemistryAdditivesOil additiveEthyl Chloride

The invention provides an ester-containing benzothiazole derivative lubricating oil additive and preparation and application thereof. A preparation method comprises the steps that firstly, under the alkaline condition, dialkyl amine reacts with carbon disulfide to obtain dithiocarbamate salt; 2-mercaptobenzothiazole reacts with chloropropanol to obtain 3-(benzothiazole-2-ylthio)propyl-1-alcohol, and 3-(benzothiazole-2-ylthio)propyl-1-alcohol reacts with chloroacetyl chloride to obtain 3-(benzothiazole-2-ylthio)propyl-2-chloracetate; then 3-(benzothiazole-2-ylthio)propyl-2-chloracetate reacts with dithiocarbamate salt to obtain the ester-containing benzothiazole derivative lubricating oil additive as shown in the general formula I. Accordingly, the preparation method is simple, the processcondition is mild, raw materials are easy to obtain, the synthesis cost is low, the synthesis yield is high, the product serves as an extreme pressure, anti-wear, anti-friction and anti-corrosion additive of lubricating oil for use, the bearing capacity of base oil is obviously improved, and the anti-wear and anti-friction properties are improved.

Owner:DONGGUAN UNIV OF TECH

Polymer-inorganic nanoparticle compositions, methods for their manufacture and their use as lubricant additives

ActiveCN111655827BExcellent extreme pressureGood anti-frictionMaterial nanotechnologyAdditivesNanoparti clesMaterials science

The present invention relates to a polymer-inorganic nanoparticle composition and a preparation method thereof. The present invention also relates to additives and lubricant compositions comprising these polymer-inorganic nanoparticle compositions, and to the use of these polymer-inorganic nanoparticle compositions for improving tribological properties in oil lubricant formulations, in particular It is used to improve extreme pressure performance and friction reduction rate on metal parts.

Owner:EVONIK OPERATIONS GMBH

A kind of rare earth wear-resistant lubricating grease and preparation method thereof

ActiveCN111286393BEvenly dispersedTurn up compatibilityLubricant compositionMetallurgyPhysical chemistry

The invention relates to a rare earth wear-resistant lubricating grease and a preparation method thereof. The lubricating grease comprises: 0.005-0.1 wt% of a rare earth composite additive, 9-15 wt% of a thickener, and base oil as the balance. The lubricating grease product provided by the present invention has excellent extreme pressure and anti-wear properties, and further, the lubricant prepared by the method provided by the present invention effectively enhances the synergistic effect between nano-rare earth particles and graphene particles, so that the Prepared grease products with excellent extreme pressure and antiwear properties.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-abrasion-resistance magnetic engine oil

InactiveCN105219499AImprove wear resistanceExcellent extreme pressureAdditivesALUMINUM STEARATESPolyethylene glycol

The invention relates to high-abrasion-resistance magnetic engine oil, and belongs to the technical field of engine oil. The high-abrasion-resistance magnetic engine oil is prepared from, by weight, 60 parts to 80 parts of engine-oil base oil, 6 parts to 12 parts of jojoba seed oil, 2 parts to 5 parts of nanometer magnesium borate, 3 parts to 8 parts of sulfurized isobutylene, 5 parts to 8 parts of calcium sulfurized alkyl phenate, 6 parts to 9 parts of triethanolamine, 4 parts to 6 parts of polyethylene glycol, 1 part to 3 parts of petroleum sodium sulfonate, 3 parts to 8 parts of aluminum stearate, 2 parts to 4 parts of methyl acrylate, 2 parts to 4 parts of pentaerythritol, 0.1 part to 0.5 part of trimethylolpropane and 0.2 part to 1.5 parts of sulphur-phosphorus primary-secondary alkyl zinc salt. According to the high-abrasion-resistance magnetic engine oil, as the borate substance is added, good extreme pressure performance, good abrasion resistance and good friction reduction performance are achieved, excellent thermal oxidation stability performance, good corrosion resistance and good sealing adaptability are achieved, toxicity is avoided, energy can be greatly saved, consumption can be greatly reduced, environment protection is facilitated, and economic benefits can be sufficiently achieved.

Owner:崔子扬

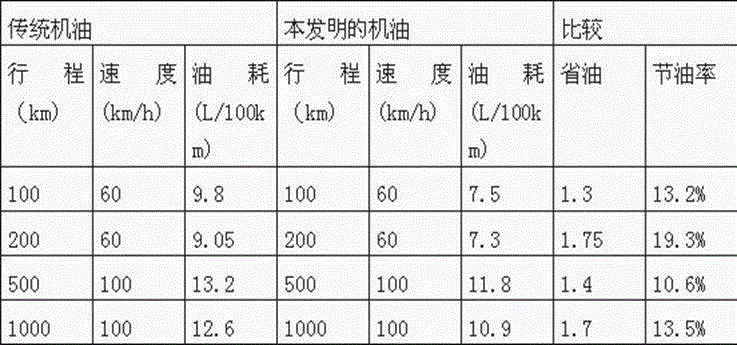

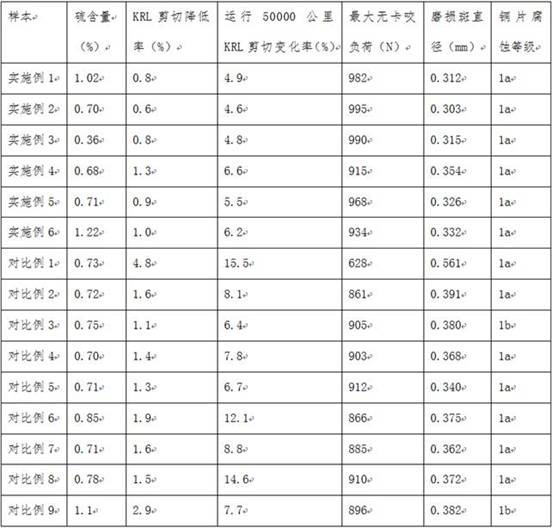

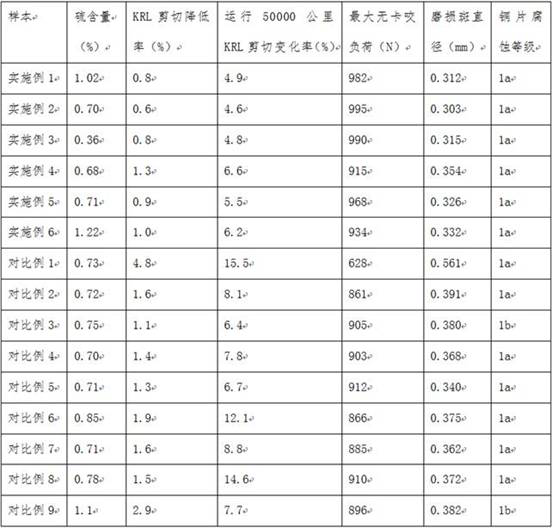

A vehicle gear lubricant with low sulfur and low shear viscosity loss

The invention relates to vehicle gear lubricating oil with low sulfur and low shear viscosity loss, belonging to the field of chemical technology. The composition comprises the following components by mass percentage: vehicle gear oil compounding agent: 2-6%, 1-propylene and ethylene polymer: 20%-40%, high-viscosity polyalphaolefin: 15%-30%, Synthetic ester: 5%‑15%, nano-rare earth friction reducer: 1%‑5%, organic friction modifier: 1%‑5%, alkylnaphthalene (AN): 5%‑15%, pour point depressant: 0.3 ‑1%, demulsifier: 0.01‑0.05%, defoamer: 50‑200PPM, metal deactivator: 0.05‑0.1%, rust inhibitor: 0.05‑0.5%, antioxidant: 0.1‑1.0%, base oil :margin. The lubricating oil KRL of the invention has high shear stability, low shear viscosity loss and low sulfur content in the product.

Owner:江西龙威环保科技发展有限公司

Special lubricating grease for high-dropping-point extreme-pressure drill collar threads

InactiveCN111040847ADrop point highImprove anti-wear performanceLubricant compositionPolyolefinAlpha-olefin

The invention provides special lubricating grease for high-dropping-point extreme-pressure drill collar threads. The special lubricating grease for the high-dropping-point extreme-pressure drill collar threads comprises the following components in percentage by weight: 22-27% of synthetic calcium sulfonate, 4-6% acetic acid, 3-5%of dodecanoic acid, 1.5-3% of micro-powder boric acid, 0.8-1.2% of calcium hydroxide, 23-28% of refined paraffin base oil, 22-25% of poly-alpha olefin oil, 0.1-0.4% of micro-powder graphene, 3-6% of antimony dialkyl dithiocarbamate, 2-5% of molybdenum oxysulfide di-n-butyldithiocarbamate, 1-4% of zinc dialkyl dithiophosphate and 1-4% of copper thiophosphate. The special lubricating grease for the high-dropping-point extreme-pressure drill collar threads has the advantages of extreme-pressure wear resistance, oxidation resistance, medium resistance, lubricating property and excellent protective performance, and can ensure the normal drilling requirement of a drill collar.

Owner:融润化工科技有限公司

Preparation method of maintenance agent for lubricating and protecting wire rope

InactiveCN103614199BGood high and low temperature performanceExcellent extreme pressureLubricant compositionAntioxidantColloid

The invention relates to a preparation method of a maintenance agent for lubricating and protecting a wire rope, which comprises the following steps: 1) heating base oil and base grease to 80-90 DEG C, and uniformly mixing; 2) sequentially adding an antioxidant, a rust inhibitor, colloidal graphite, nano molybdenum disulfide and a thickener into the mixed solution obtained in the step 1), stirring uniformly, and keeping the temperature at 80-90 DEG C; and 3) when the material obtained in the step 2) is cooled to 80 DEG C below, carrying out homogeneization treatment with a triple-roller mill to obtain the wire rope maintenance agent. The wire rope maintenance agent has the advantages of favorable high / low temperature properties, favorable extreme pressure property, high rust resistance and high corrosion resistance.

Owner:天津市津冠润滑脂有限公司

Netted crystal lattice nanosphere lubricating oil improving agent

The invention provides a netted crystal lattice nanosphere lubricating oil improving agent, which belongs to a chemical composition and relates to a composition additive used for improving the performance of lubricating oil. The lubricating oil improving agent comprises, by weight, 1.5 to 35% of polyethylene glycol and 65 to 98.5% of organic molybdenum, wherein polyethylene glycol is one selected from or a mixture of more selected from the group consisting of polyethylene glycol 200, polyethylene glycol 400, polyethylene glycol 600, polyethylene glycol 800, polyethylene glycol 1000, polyethylene glycol 1500, polyethylene glycol 2000, polyethylene glycol 4000, polyethylene glycol 6000, polyethylene glycol 8000, polyethylene glycol 10000 and polyethylene glycol 20000, and organic molybdenum is one selected from or a mixture of oxymolybdenum dialkyldithiophosphate and molybdenum dialkyldithiocarbamate. The lubricating oil improving agent not only can improve the combustion rate of fuel oil and substantially reduce exhaust emission during combustion of fuel oil.

Owner:广东新科态节能减排技术研究所有限公司

Triethanolamine-modified gutter oil-based method for preparation of metal cutting fluid

InactiveCN103589476BIn line with the development conceptLow biological toxicityBase-materialsAlkylphenolOil phase

A triethanolamine-modified gutter oil-based method for preparation of metal cutting fluid comprises the following steps: filtering gutter oil to remove insoluble substances, adding the filtrate into a reaction vessel, adding an inorganic acid aqueous solution of the same volume, warming up and stirring for a reaction, cooling the reaction system to room temperature, standing for liquid separation, washing an oil phase by the use of water of the same volume for three times so as to obtain acid-treated gutter oil; and adding the acid-treated gutter oil into a reaction kettle, adding triethanolamine while stirring, stirring at room temperature for a reaction, successively adding auxiliary base oil, chlorinated paraffin, petroleum sodium sulfonate, alkylphenol polyoxyethylene, sodium napthionate, s-triazine and benzotriazole, and stirring to obtain the required product. The method is simple to operate and easy to realize. By the method, the metal cutting fluid with excellent performance can be obtained, and comprehensive utilization of wastes can be realized.

Owner:XIJING UNIV

Multifunctional oil additive and preparation method and application thereof

ActiveCN111363602AExcellent extreme pressureImprove wear resistanceAdditivesFunctional monomerOil additive

The invention relates to a multifunctional oil product additive and a preparation method and application thereof. The preparation method comprises the following steps: in the presence of an acid neutralizer and a solvent, carrying out an alkylation reaction on the chlorinated paraffin, a first functional monomer and a second functional monomer, wherein the first functional monomer is dialkyl dithiocarbamate, and the second functional monomer is one or more of 2-mercaptobenzothiazole, 2, 5-dimercaptothiadiazole, triazole, benzotriazole and methylbenzotriazole. The preparation method is simple,the raw materials are easy to obtain, the cost is low, and the prepared oil additive not only has excellent extreme pressure, wear resistance and friction reduction performance, but also has good corrosion resistance and rust resistance.

Owner:玛可索(苏州)石化有限公司

Low-sulfur and low-shear viscosity loss vehicle gear lubricating oil

ActiveCN111808665AReduce corrosionImprove surface strengthLubricant compositionPolyolefinAlpha-olefin

The invention relates to low-sulfur and low-shear viscosity loss vehicle gear lubricating oil and belongs to the technical field of chemistry. The composition is prepared from the following componentsin percentage by mass: 2%-6% of vehicle gear oil complexing agent, 20%-40% of 1-propylene and ethylene polymer, 15%-30% of high-viscosity poly alpha olefin, 5%-15% of synthetic ester, 1%-5% of nano rare earth anti-friction agent, 1%-15% of an organic friction modifier, 5%-15% of alkyl naphthalene (AN), 0.3%-1% of a pour point depressant, 0.01%-0.05% of a demulsifier, 50-200 PPM of an antifoamingagent, 0.05-0.1% of a metal deactivator, 0.05-0.5% of an antirust agent, 0.1-1.0% of an antioxidant, and the balance of base oil. The lubricating oil KRL is high in shear stability, low in shear viscosity loss and low in product sulfur content.

Owner:江西龙威环保科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com