Patents

Literature

48results about How to "Improve extrusion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

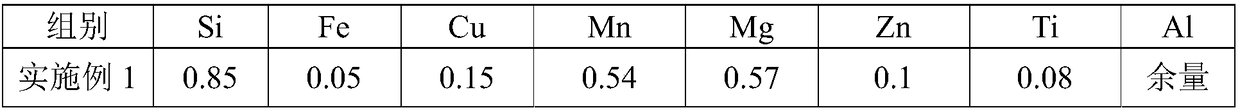

Al-Mg-Si-Cu alloy and preparation method and application thereof

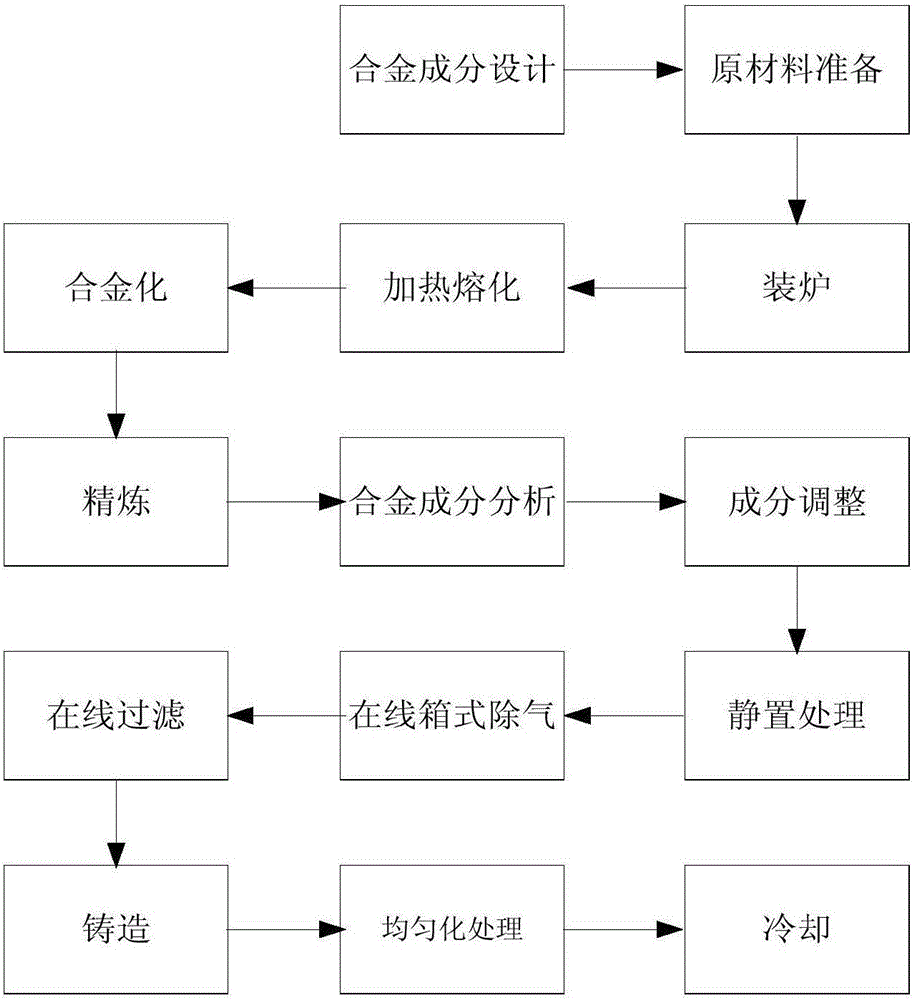

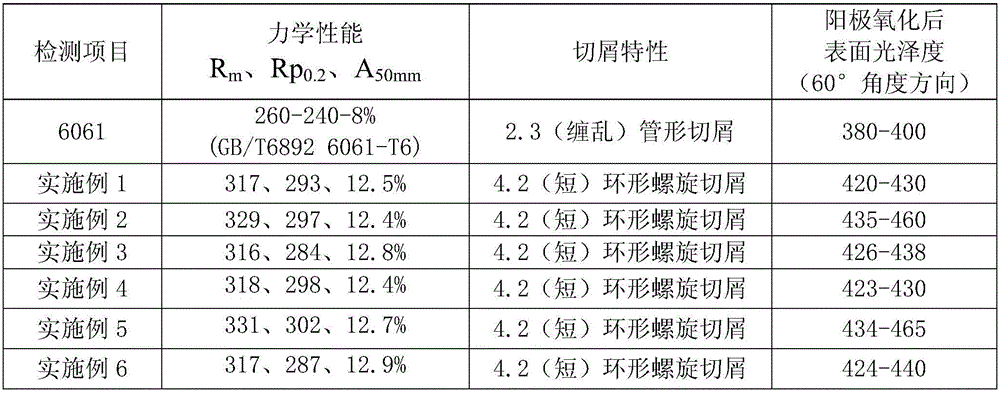

The invention discloses Al-Mg-Si-Cu alloy and a preparation method and application thereof. The Al-Mg-Si-Cu alloy comprises, by mass, 0.6%-0.8% of Si, 1.0%-1.2% of Mg, 0.25%-0.5% of Fe, 0.2%-0.4% of Cu, 0.1%-0.15% of Mn, 0.1%-0.2% of Cr, 0.10%-0.20% of Zn, 0-0.10% of Ti, smaller than 0.15% of other impurities, and the balance Al. The Al-Mg-Si-Cu alloy has high strength and excellent anodic oxidation performance, meanwhile also has great chip cutting performance and can be used for manufacturing industrial aluminum alloy materials, such as electronic equipment structural connecting pieces, with high-quality requirements for high strength, decorative surfaces and a large quantity of CNC processing.

Owner:中山瑞泰铝业有限公司

Nano diamond nano copper composite lube additive

The invention discloses a diamond nanometer copper compounded lubricating oil additive in nanometer technical domain and mechanical fluid oil technical domain, which is characterized by the following: the nanometer diamond and nanometer copper are prepared to lube oil additive with diverse functional requirement; the high lubricating and high-intensity low restoring type fits for precision equipment, new device, high-grade car and gearbox and can diminish adding quantity of nanometer copper; the high lubricating and high-intensity high restoring type fits for wearing machinery and equipment and car and can enlarge the adding quantity of nanometer copper power. This invention possesses good dispersibility and does not need stirring and so on disposing craft.

Owner:孙文志

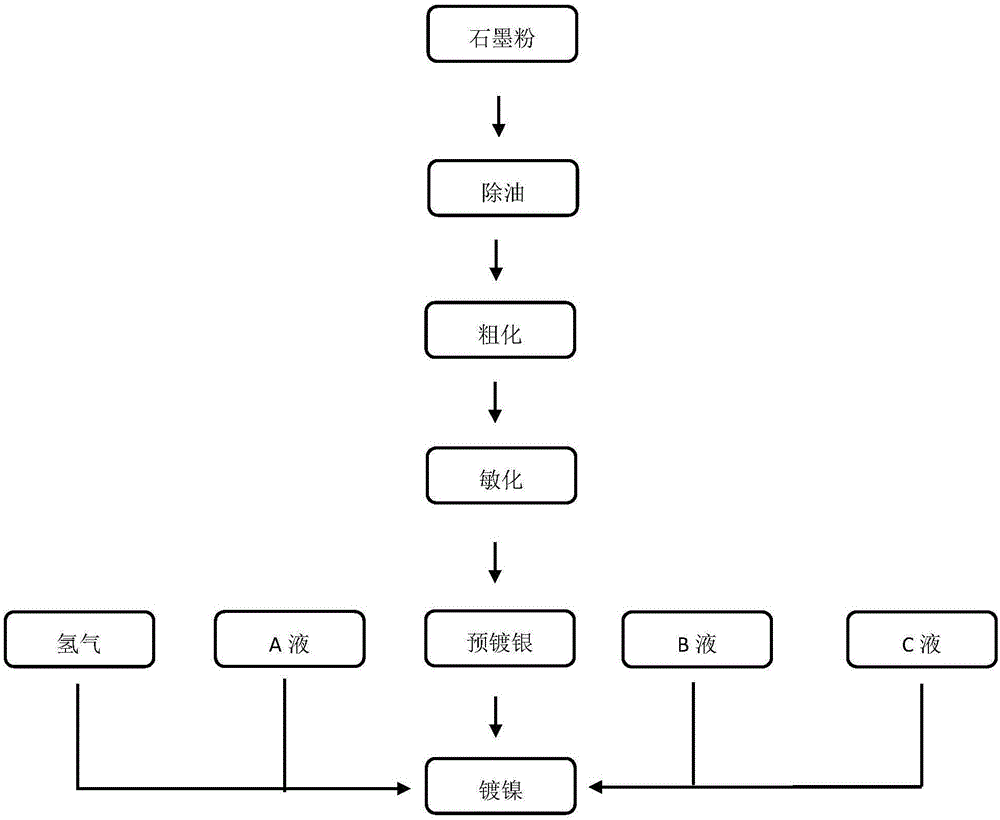

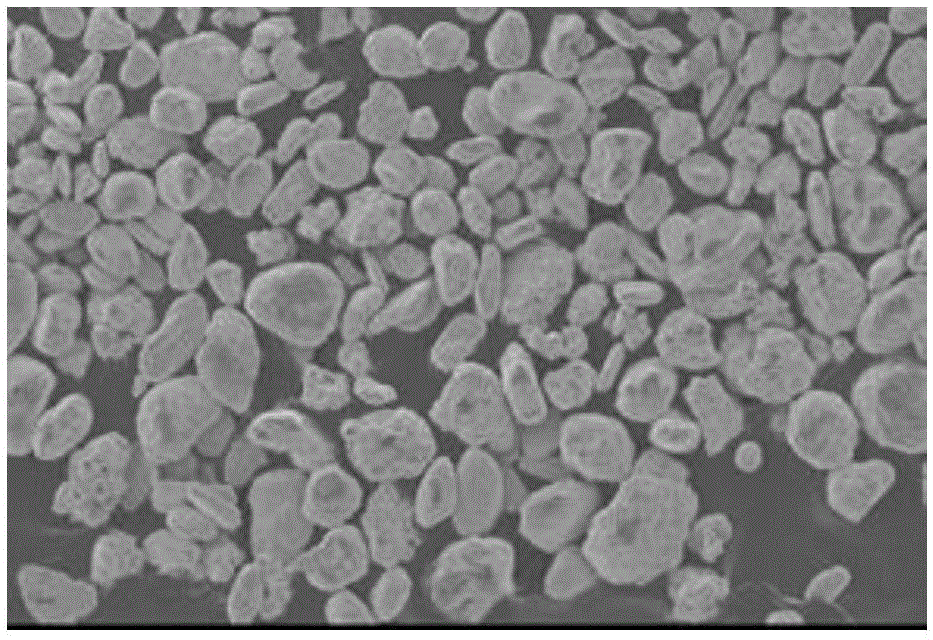

Preparation method of nickel-coated graphite powder for electroconductive rubber of electromagnetic shielding material

ActiveCN105063580AImprove bindingHigh purityLiquid/solution decomposition chemical coatingHydrogenFiltration

The invention discloses a preparation method of nickel-coated graphite powder for electroconductive rubber of an electromagnetic shielding material. The preparation method is characterized in that the nickel-coated graphite powder is obtained by carrying out silver plating and hydrogen gas reduction nickel plating after graphite powder is subjected to surface degreasing, coarsening and sensitizing and then carrying out washing, suction filtration and drying. According to the preparation method disclosed by the invention, an excellent interface bonding force is obtained as a coarsening and pre-silver plating layer which is arranged between a nickel plating layer and a graphite powder interface is used as a nickel plating active point, nickel plating is carried out by adopting a hydrogen reduction method, the surface of a pure nickel layer is reduced, and the electromagnetic conductivity is better than that of other reduction nickel plating methods, so that the nickel-coated graphite powder has excellent anti-shearing performance, excellent anti-extrusion performance and excellent electromagnetic conductivity when the nickel-coated graphite powder is mixed with rubber.

Owner:重庆新福佰科技有限公司

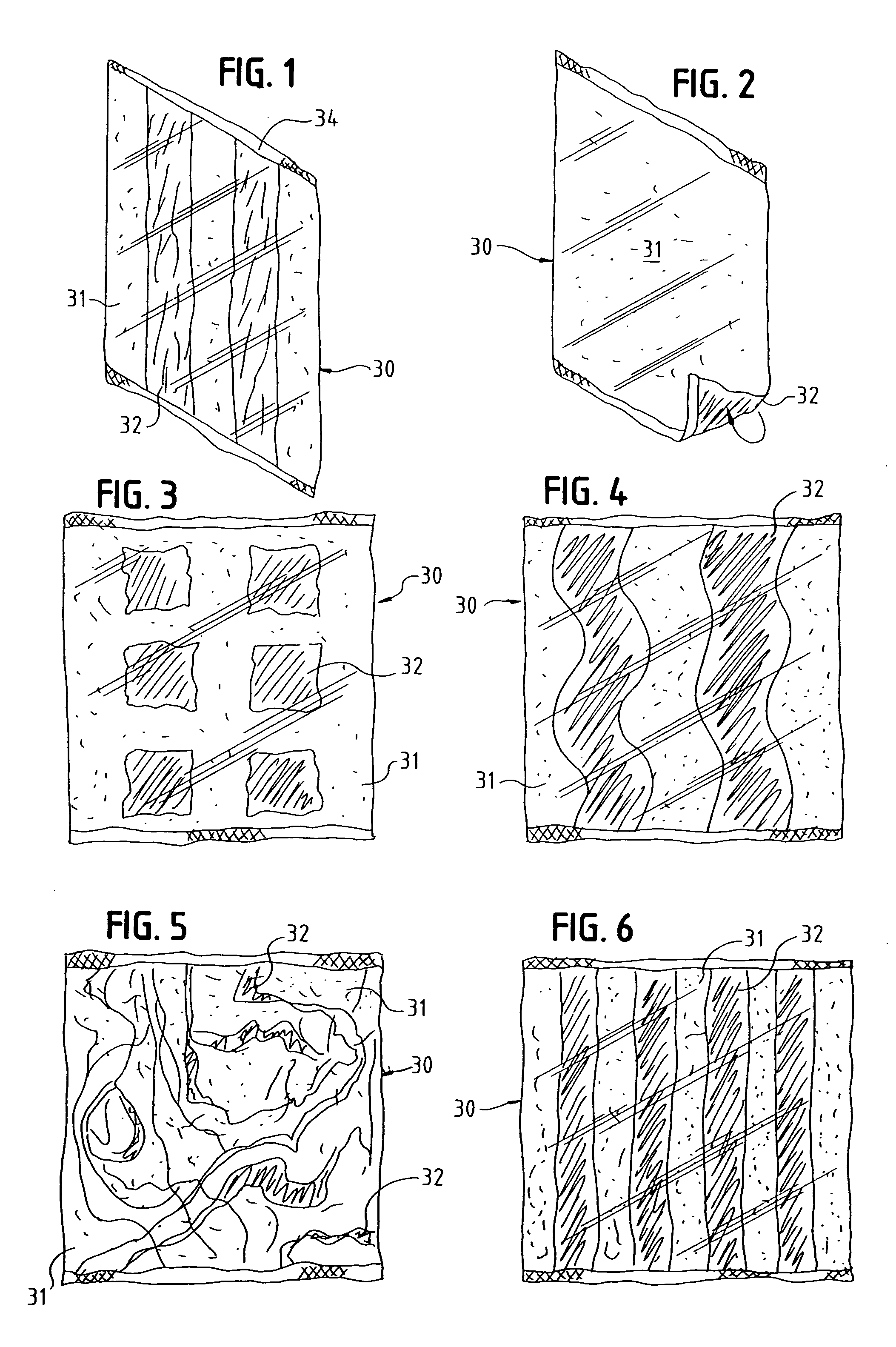

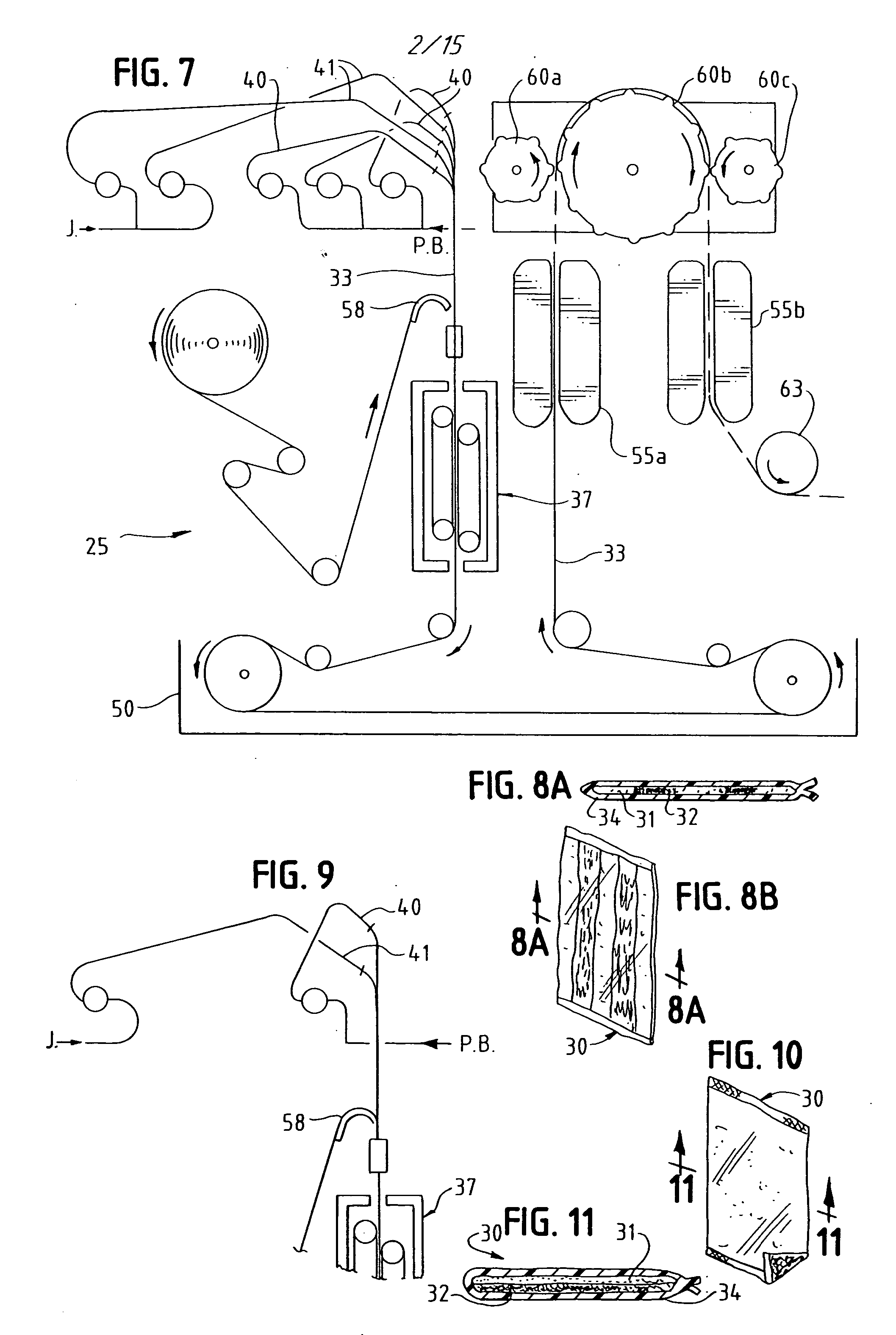

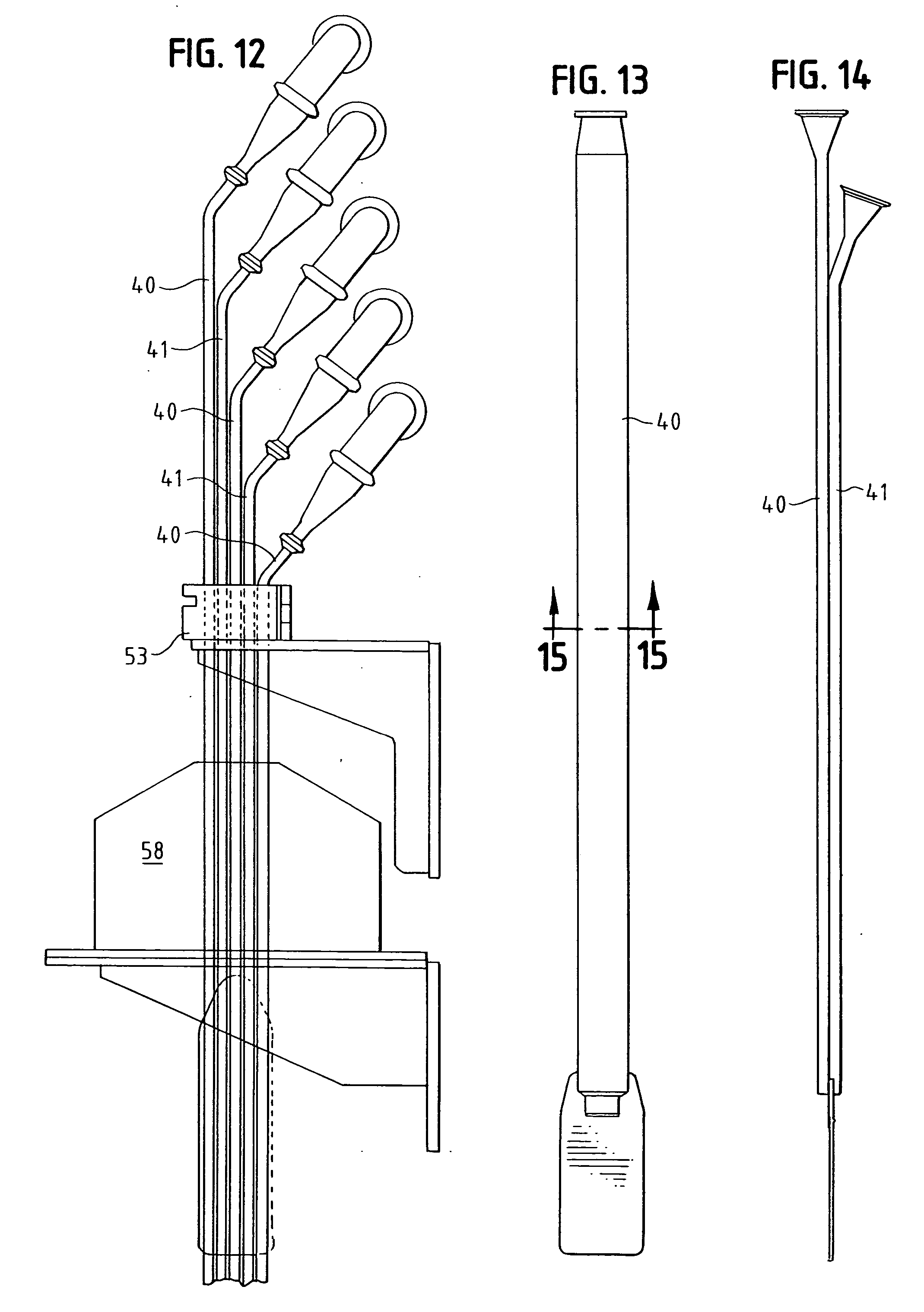

Food slice consisting of two or more food items, and processes for making and packaging same

InactiveUS20050170053A1Reduce foamingImprove extrusion performanceConfectionerySweetmeatsEngineeringMoisture

Packaged food portions, such as food slices, consisting of two or more food items, such as peanut butter and jelly, and processes for making them. The food portion is provided with sufficient viscosity and textural properties to enable its formation into a cohesive mass which can be extruded while maintaining the individual identity and organoleptic attributes of each food item within the food portion. The food portion may be shaped into a slice or other configuration prior to or during its encasing within a flexible packaging material. Product formulations which provide for minimal moisture migration between the different food items within the food portion and for optimum product stability, as well as processes and methods for providing and processing these formulations, are also disclosed.

Owner:SCHREIBER FOODS

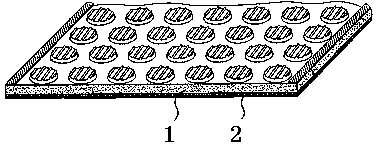

Gray rubber quartz plate and preparation method thereof

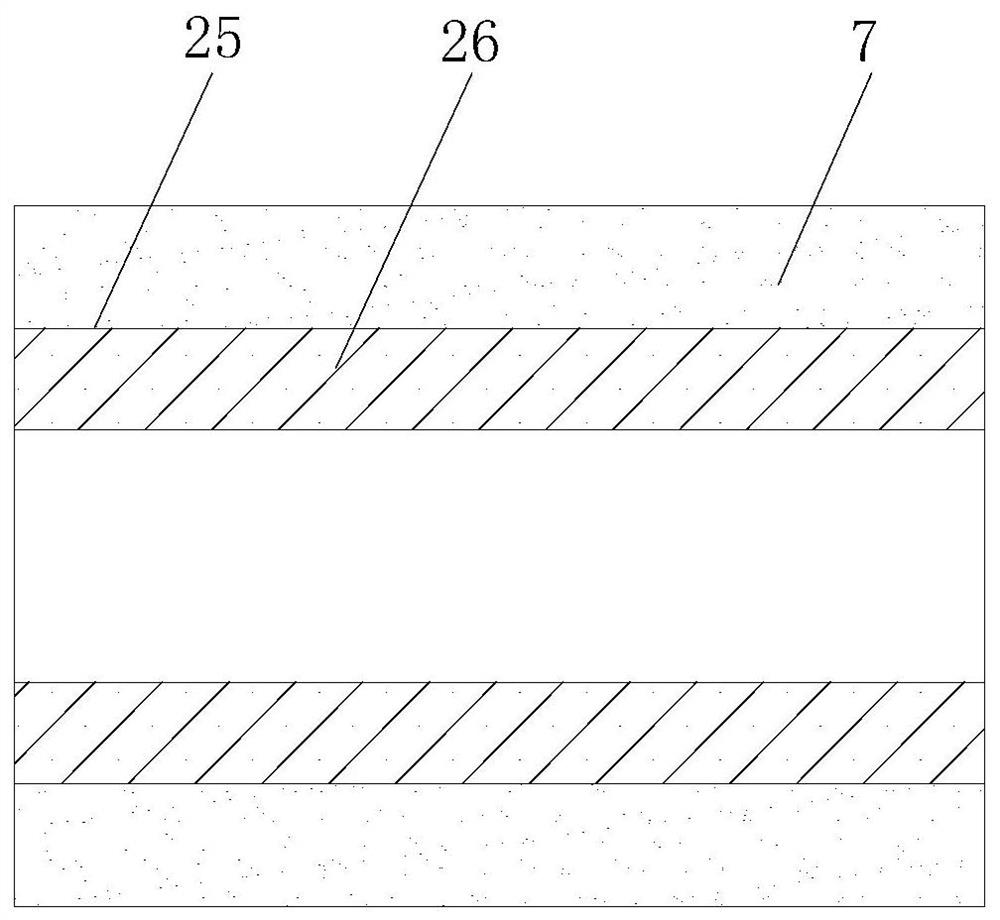

ActiveCN102617943AImprove wear resistanceGood acid and alkali resistanceRubber layered productsRough surfacePolymer science

The invention belongs to the technical field of rubber quartz plates, and particularly discloses a gray rubber quartz plate and a preparation method of the gray rubber quartz plate. The gray rubber quartz plate has the technical scheme that the quartz plate comprises a plate body and a rough surface layer, and is characterized in that the plate body comprises the following materials in parts by weight: 100 parts of rubber, 5.9-29 parts of quartz powder, 10-52 parts of white carbon black, 4-18 parts of activating agent, 0.8-5.5 parts of accelerating agent, 0.9-8.5 parts of vulcanizing agent, 2-50 parts of softener, 0.8-1.1 parts of coloring agent, 0.8-2 parts of bonding agent, 1-5 parts of anti-aging agent and 1.8-4.0 parts of solubilizer. The wear-resistant performance as well as the acid-resistant and alkaline-resistant properties of the rubber quartz plate can be improved, the heat absorption and the high light reflection can be reduced, and the service life is greatly prolonged.

Owner:李彦峰

Metal cutting fluid with excellent extreme pressure property

The invention discloses a metal cutting fluid with an excellent extreme pressure property. The metal cutting fluid comprises the following raw materials in parts by weight: 20-50 parts of palm oil, 5-15 parts of a modified compound extreme pressure additive, 4-8 parts of modified molybdenum disulfide, 3-5 parts of xanthate, 2-5 parts of pentaerythritol oleate, 1-3 parts of neopentyl polyol ester, 2-5 parts of fatty acid imidazoline borate, 3-6 parts of diethanolamide oleic acid borate, 2-5 parts of barium petroleum sulfonate, 4-6 parts of heptadecyl imidazoline, 1-3 parts of phytic acid, 3-5 parts of sodium nitrite, 1-4 parts of benzotriazole, 3-6 parts of boric acid, 2-5 parts of dimer acid potassium, 4-8 parts of sodium oleate, 3-6 parts of diethylene glycol, 2-5 parts of dialkyl ether amine, and 8-12 parts of water. The metal cutting fluid has an excellent extreme pressure property.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

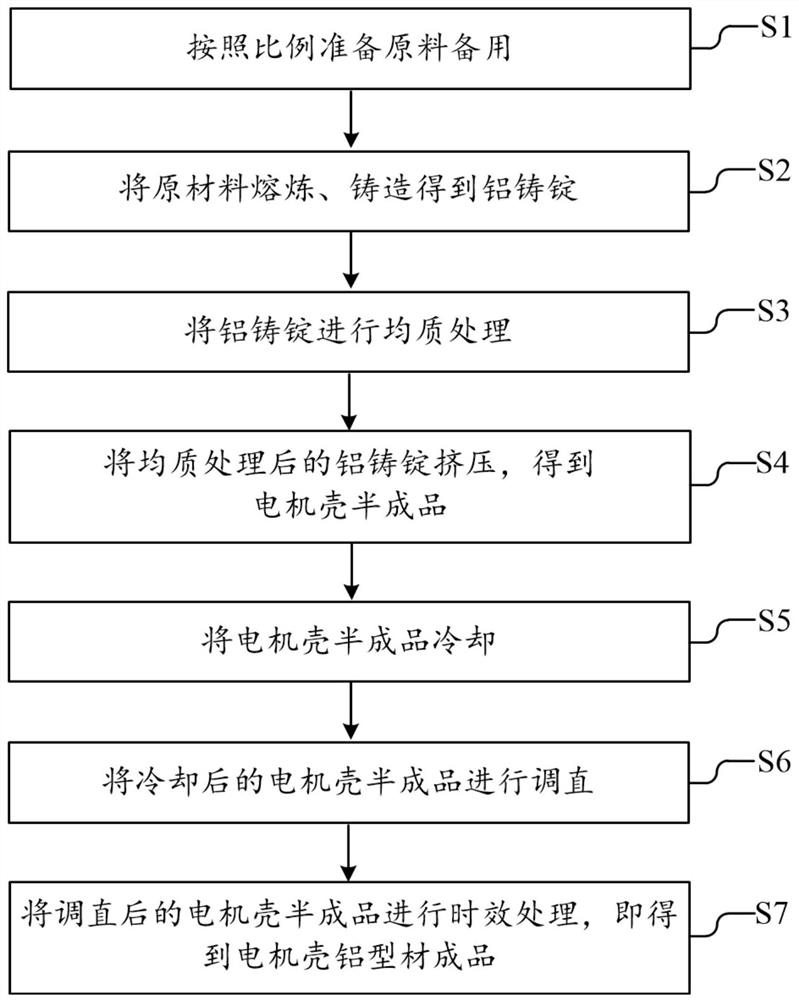

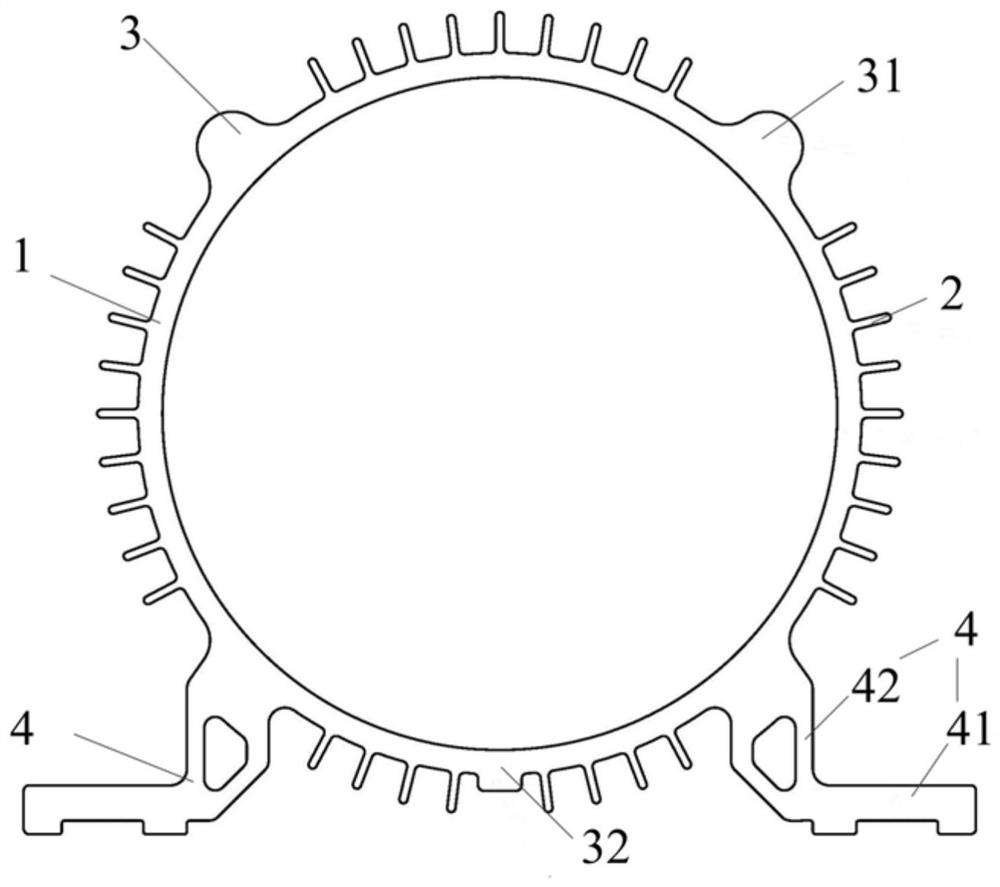

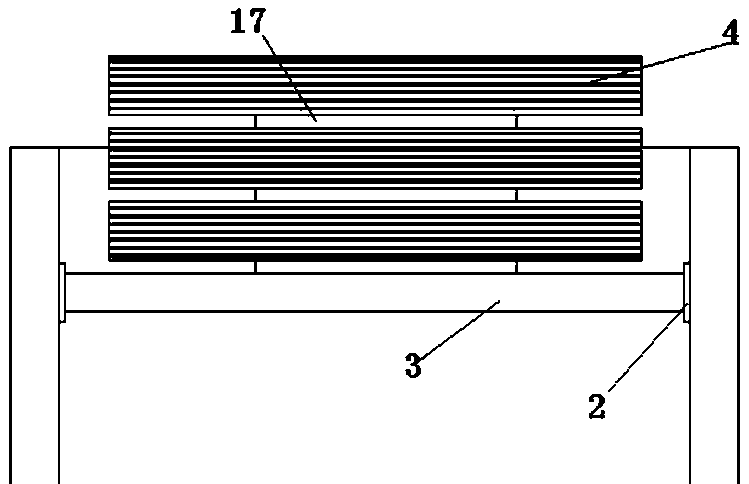

Preparation method for motor shell aluminum profile, motor shell and motor

ActiveCN112226657AImprove mechanical propertiesImprove the extrusion effectExtrusion control devicesManufacturing dynamo-electric machinesMetallurgyElectric machine

The invention discloses a preparation method for motor shell aluminum profile. The preparation method comprises the following steps that raw materials are prepared in proportion, an aluminum ingot isobtained after smelting and casting, homogenizing and extruding are conducted on the aluminum ingot to obtain a semi-finished motor shell, and cooling, straightening and aging are conducted on the semi-finished motor shell to obtain the finished motor shell aluminum profile. Correspondingly, the invention further discloses a motor shell which is prepared by adopting the above preparation method. The invention further discloses a motor which comprises the motor shell. By means of the method, the aluminum profile which is low in cost and good in mechanical property and extrusion property can beobtained, and the method can be suitable for production of motor shells in complex shapes; Meanwhile, the extrusion speed can be increased, and the production efficiency is improved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

Dealcoholization sealant for photovoltaic assembly and preparation method thereof

InactiveCN109666448AGood storage stabilityImproved cross-linking functionNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkFire retardant

The invention belongs to the technical field of sealing materials, and particularly relates to dealcoholization sealant for a photovoltaic assembly and a preparation method thereof. The dealcoholization sealant for the photovoltaic assembly is prepared from the following raw materials in parts by weight: 80 to 100 parts of polyalkoxy silicon base-terminated polydimethylsiloxane, 20 to 30 parts offiller, 4 to 6 parts of flame-retardant agent, 3 to 5 parts of titanium dioxide color paste, 1.5 to 2.5 parts of water removal agent, 2 to 4 parts of cross0linking agent, 0.4 to 0.6 part of organic tin chelate catalyst and 0.8 to 1.2 parts of compound coupling agent. The preaparation method of the dealcoholization sealant for the photovoltaic assembly comprises the following steps: (1) measuring all raw materials according to the weight ratio; (2) adding the polyalkoxy silicon base-terminated polydimethylsiloxane, the filler, the flame-retardant agent and the titanium dioxide color paste intoa vacuum kneading machine, dehydrating, blending, kneading for 4 to 6 hours, and cooling to the room temperature; and (3) adding a dewatering agent, a cross-linking agent, organic tin chelate catalystand a compound coupling agent, and sufficiently mixing, so as to obtain the dealcoholization sealant for the photovoltaic assembly. The dealcoholization sealant for the photovoltaic assembly has thecharacteristics of short curing time, high adhesion strength and good aging resistance.

Owner:安徽兆拓新能源科技有限公司

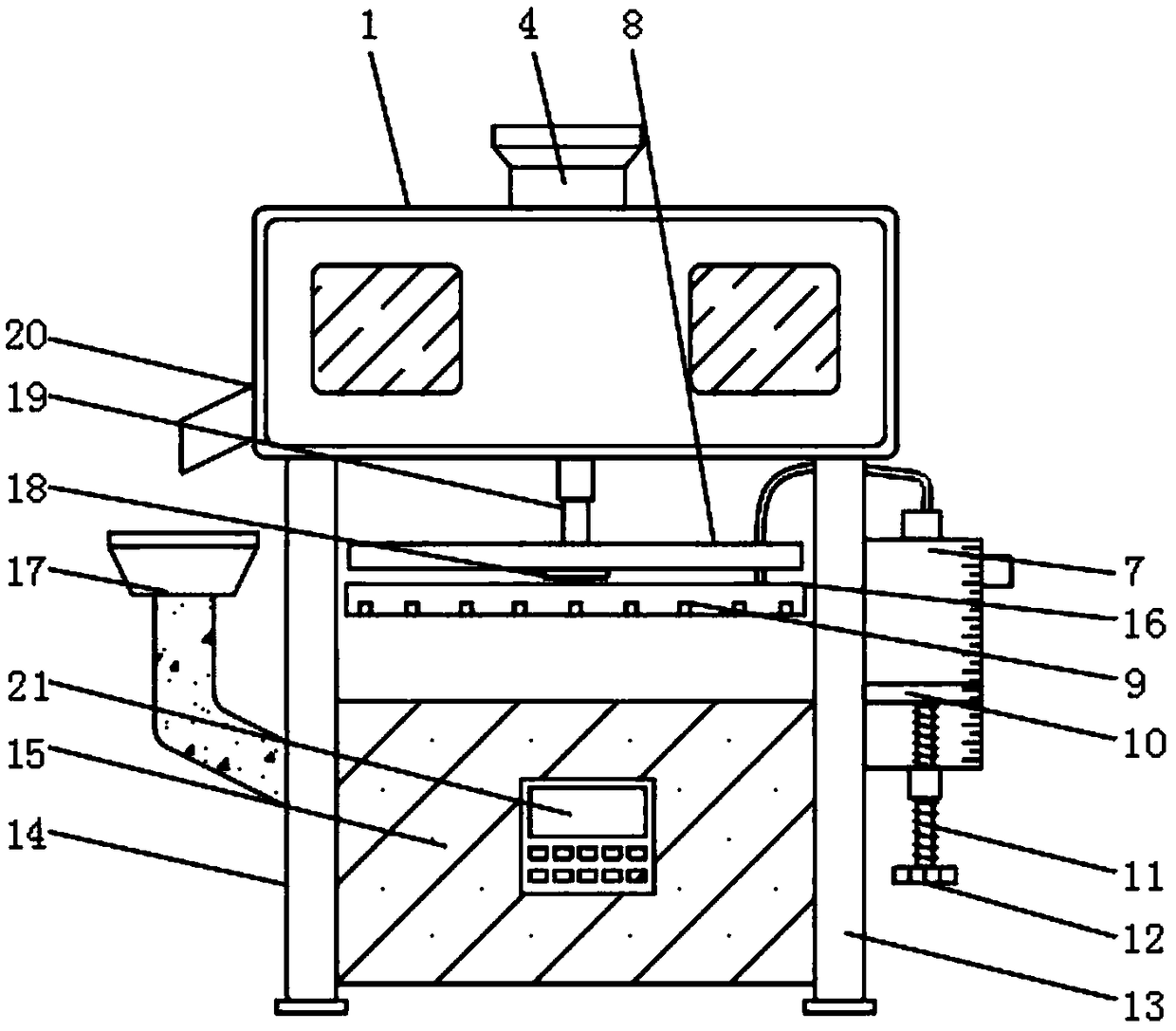

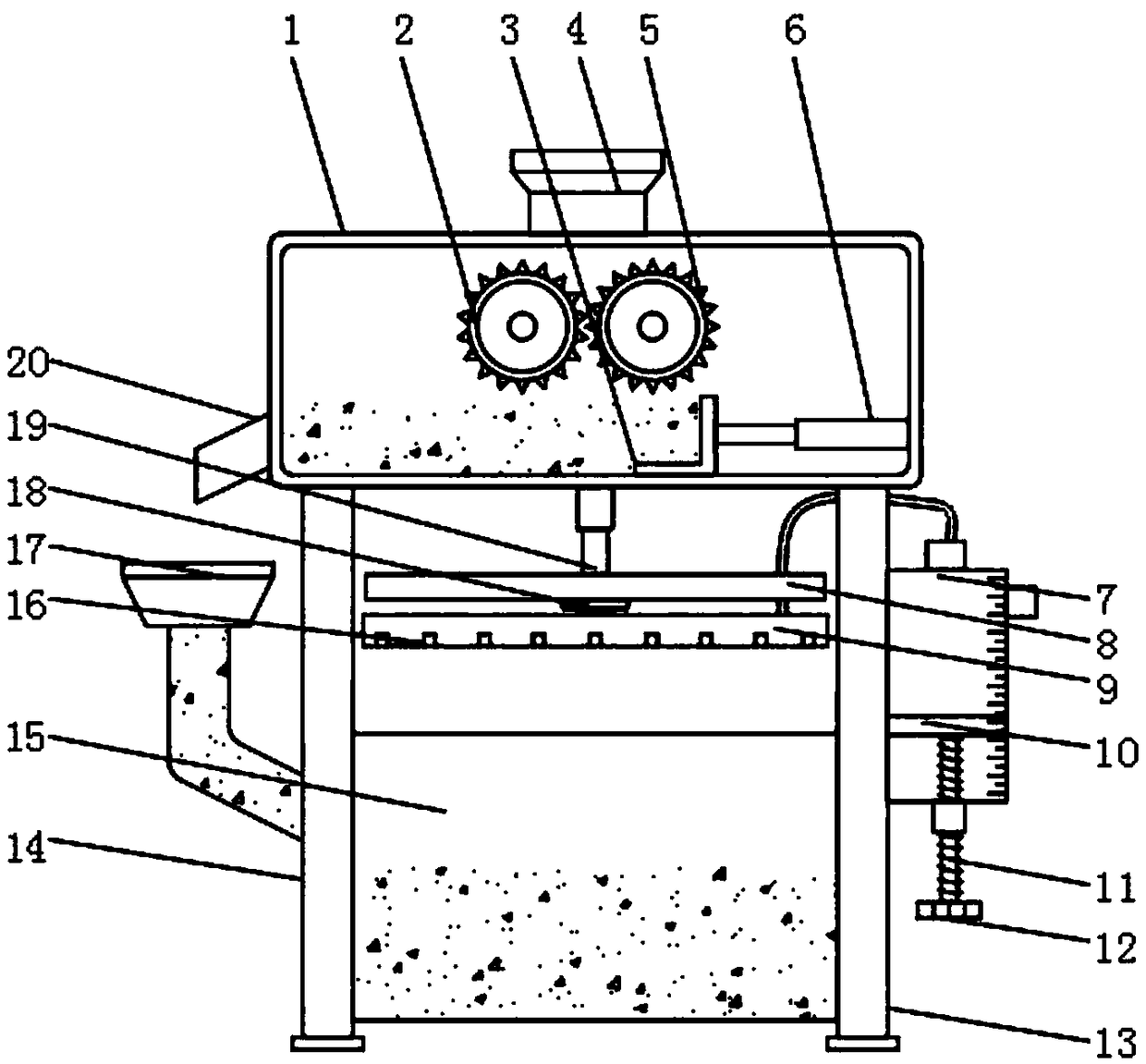

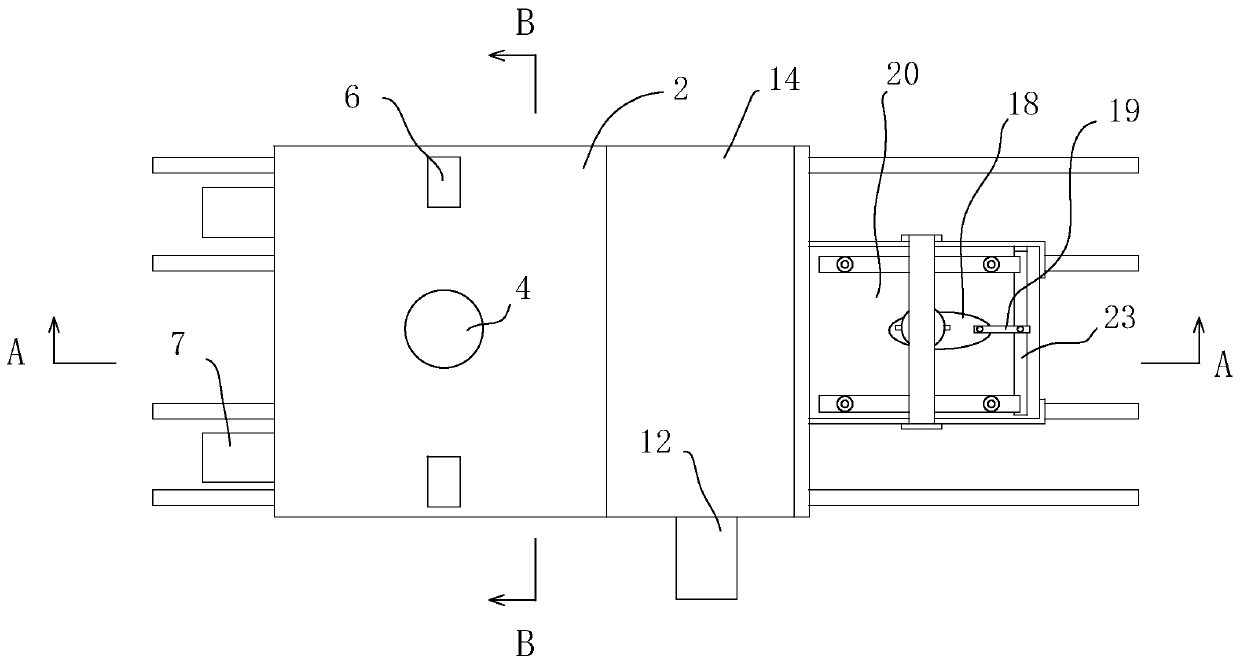

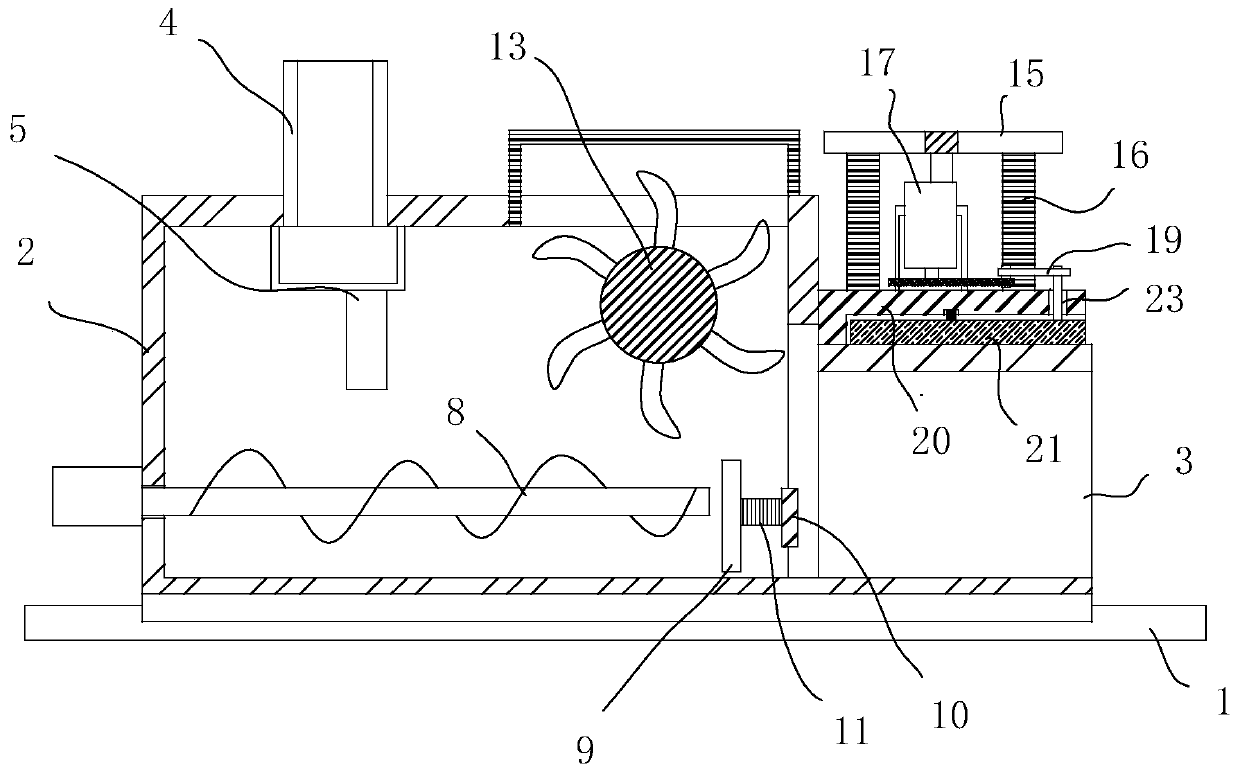

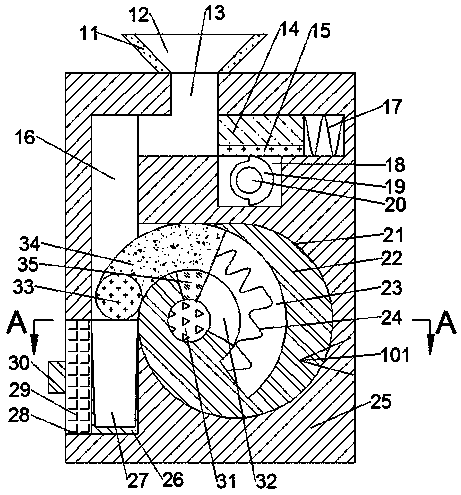

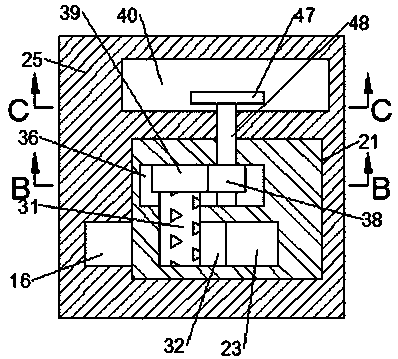

Energy-saving and environment-friendly solid garbage breaking and packing device

ActiveCN108889372AAvoid the problem of poor molding effectEasy to handleGrain treatmentsPressesEngineeringForce sensor

The invention discloses an energy-saving and environment-friendly solid garbage breaking and packing device which comprises a packer body and an upper pressing plate, wherein a syringe is arranged onone side of a right bracket, and a grinding cylinder is arranged on the top of the right bracket; a push plate is arranged at a position, which is close to the lower side of second grinding teeth, ofthe interior of the grinding cylinder; and an electric hydraulic rod is arranged at the joint of the grinding cylinder and the push plate. According to the arrangement of the electric hydraulic rod and the push plate, the ground garbage can be conveniently pushed out by users, and the problem that the grinding cylinder is easily blocked due to excessive garbage in the cylinder is solved. Accordingto the arrangement of the syringe and an injection orifice, the ground garbage can be conveniently subjected to molding extrusion by the users, and the problem that the garbage is scattered due to poor coagulability is solved. According to the arrangement of a PT124G / 113 pressure sensor, the low pressure strength of the lower pressing plate can be conveniently monitored in real time by the user,and the problem that the garbage molding effect is poor due to strong or weak lower pressure strength of the lower pressing plate is solved.

Owner:广州国寰环保科技发展有限公司

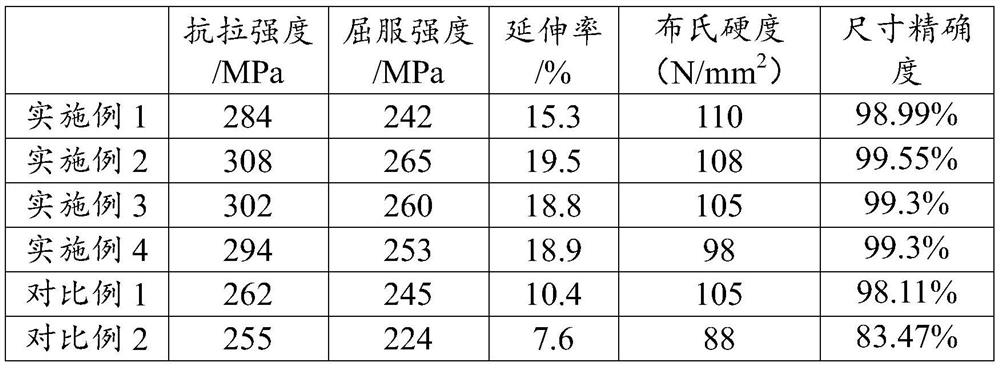

Yttrium-containing 6063 aluminum alloy and preparation method

ActiveCN109913676AImprove extrusion processing performanceHigh tensile strengthBorideRoom temperature

The invention belongs to the technical field of alloy and specially relates to yttrium-containing 6063 aluminum alloy and a preparation method for the same. The yttrium-containing 6063 aluminum alloyprovided by the invention, by mass, comprises the following ingredients including 0.45%-0.54% of Si, 0.52%-0.56% of Mg, no more than 0.35% of Fe, no more than 0.05% of Cu, no more than 0.07% of Mn, nomore than 0.05% of Zn, 0.0075%-0.01% of Ti, 0.1%-0.2% of Y (yttrium), 0.0015%-0.002% of B and the balance being Al. The aluminum alloy and the method provided by the invention have the beneficial effects that scopes of low contents of elements such as Mg and Si are determined; and the strength of the yttrium-containing 6063 aluminum alloy is enhanced through simultaneous precipitation of boridesand intermetallic compounds. According to results of the embodiment, the tensile strength of the yttrium-containing 6063 aluminum alloy provided by the invention reaches 230MPa and the elongation of the yttrium-containing 6063 aluminum alloy reaches 25% under a room temperature.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

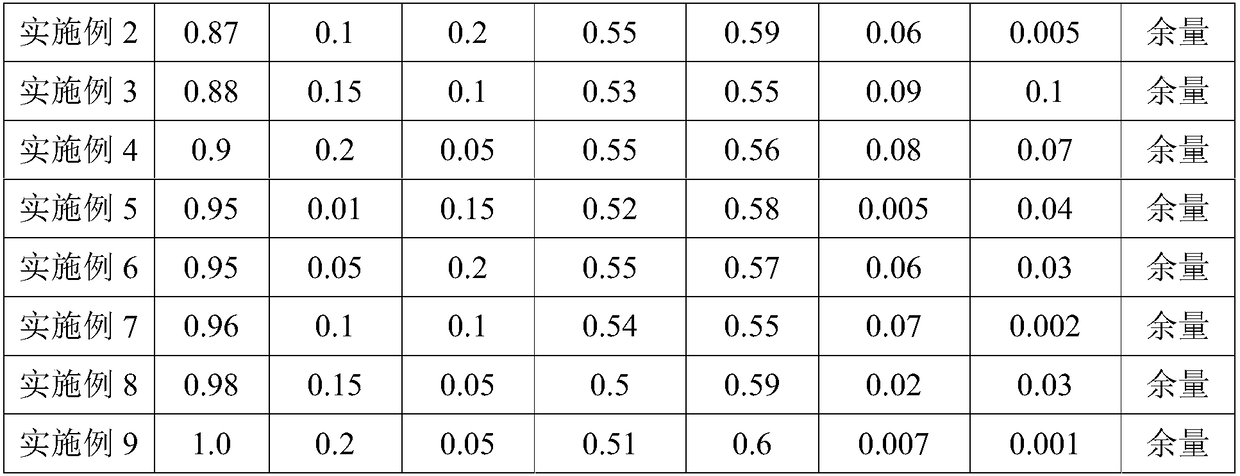

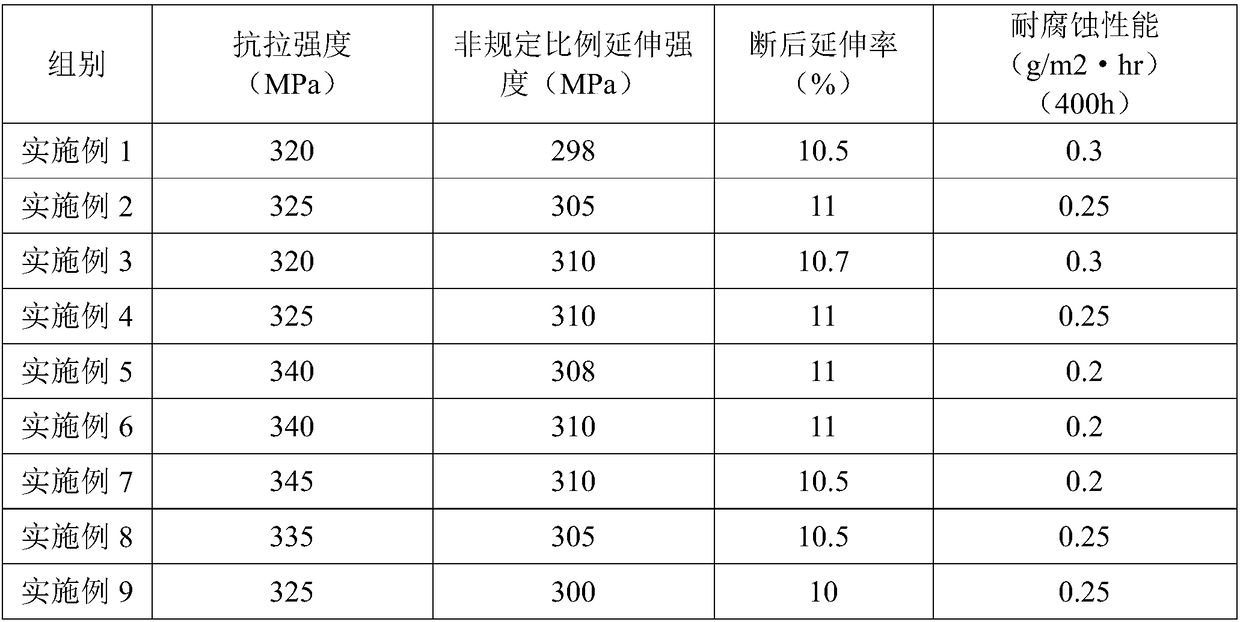

Aluminum alloy and production method thereof

The invention discloses an aluminum alloy and a production method thereof. The ratio of Si / Mg / Mn is adjusted, the proportions of Mg and Mn components are reduced, and the proportion of an Si componentis improved to ensure the overall strength of the aluminum alloy and make the aluminum alloy have good extrusion properties. In addition, the corrosion resistance of the aluminum alloy is improved bylowering the content of Fe / Cu / Zn.

Owner:佛山金兰铝厂有限公司

Edge cutting and bending one-time forming die for bracket of automobile fuel tank

InactiveCN110899506AEase of ejectionEasy to eject automaticallyShaping toolsVibration suppression adjustmentsFuel tankMotronic

The invention discloses an edge cutting and bending one-time forming die for a bracket of an automobile fuel tank, and belongs to the field of automobile fuel tanks. The edge cutting and bending one-time forming die comprises a base, wherein the side faces of the top of the base are fixedly connected with supporting frames, the top of each supporting frame is fixedly sleeved with a hydraulic mechanism, the bottom ends of the hydraulic mechanisms are fixedly connected with an extrusion block, each supporting frame is movably sleeved with a moving sleeve, one side of each moving sleeve is fixedly connected with the side face of the extrusion block through a connecting plate, the bottom of each moving sleeve is in transmission connection with the top of the base through a movable spring, andthe top of the base is fixedly connected with a module. By arranging a port, a containing cavity, an electric push rod and an ejector block, the formed bracket can be automatically ejected out in theproduction and manufacturing process of the bracket of the automobile fuel tank, the bracket is separated from the module, the problem that because the bracket is tightly attached to the module, it isdifficult to take out the die is avoided, and thus convenience is brought to die taking of the formed die.

Owner:十堰沃森油箱附件有限公司

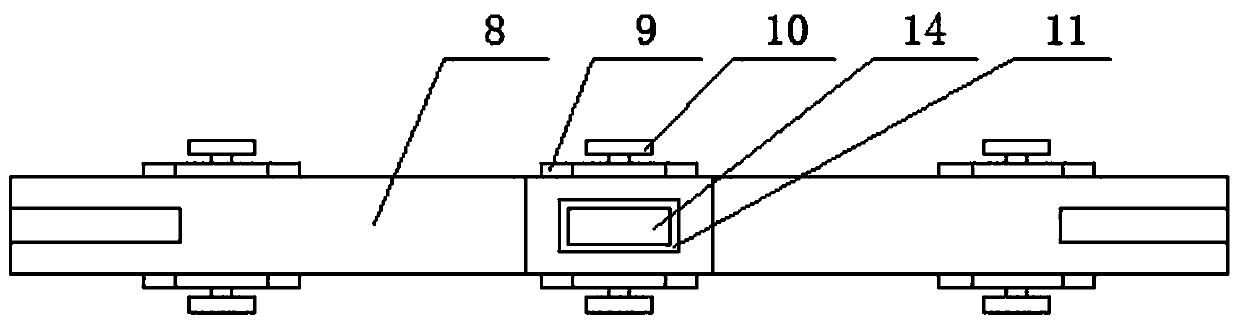

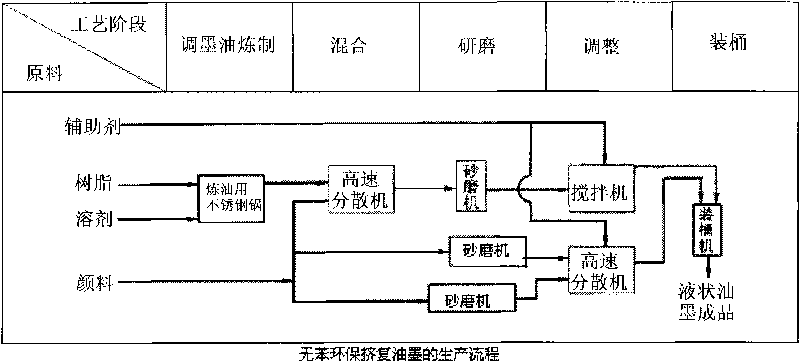

Benzene-free environment-friendly extruding-compositing ink

The invention belongs to the technical field of new material environment protection and discloses a benzene-free environment-friendly extruding-compositing ink which comprises the following main raw materials in mass percentage: 5-25% of SBS resin, 5-25% of modified EVA resin, 1-2% of HR-type dispersant, 50-75% of methyl-carbonate and 5-8% of pigment. The benzene-free environment-friendly extruding-compositing ink proposed by the invention has the characteristics of low viscosity, good leveling property, large solid content, bright color, high color concentration, excellent stipple reproducibility, and application in layering sammeld ruck; the ink membrane has high peeling strength and extruding-compositing performance, wherein the peeling strength can reach 5N / 15mm-10N / 15mm, and the extruding-compositing strength is over 0.9N.

Owner:LUOYANG TIANXIA INDAL

Method for manufacturing solar energy battery board frame section bar

ActiveCN101635321AImprove toughnessGood toughness, not easy to deform; good corrosion resistanceFinal product manufactureSemiconductor devicesSlagRare earth

The invention relates to a method for manufacturing a solar energy battery board frame section bar, which comprises the following technical steps: adding an aluminum ingot into a smelting furnace to smelt and uniformly stirring aluminum liquid; after the aluminum liquid is stirred, carrying out first refinement; refining and uniformly scattering a slagging agent on aluminum slag; adding a magnesium ingot, aluminum-silicon medium alloy and rare earth alloy and fully stirring and mixing uniformly; carrying out second refinement and degassing; guiding refined aluminum liquid into a casting machine to cast; heating an aluminum bar on an aluminum bar heating furnace and extruding for molding on an extruder; and after the aluminum bar is extruded and molded, placing the aluminum bar into a heat treatment furnace to heat and preserve heat to obtain the solar energy battery board frame section bar. The section bar has bright surface, high strength, favorable toughness and corrosion resistance, lower manufacture cost and light weight, is difficult to deform, can be recycled and can save energy resources, reduce the environmental pollution and strengthen the running reliability.

Owner:江苏锦绣铝业有限公司

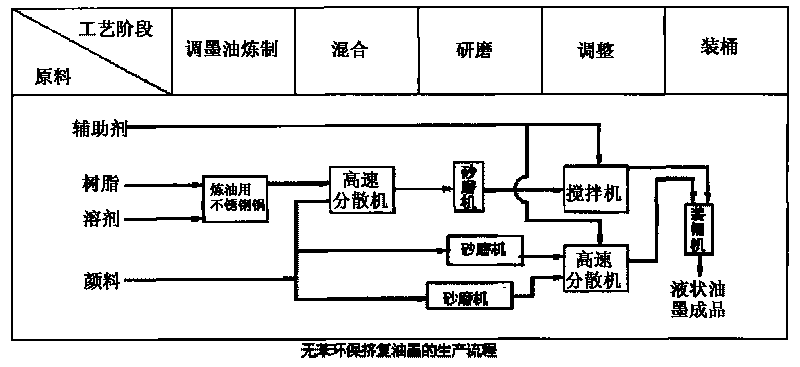

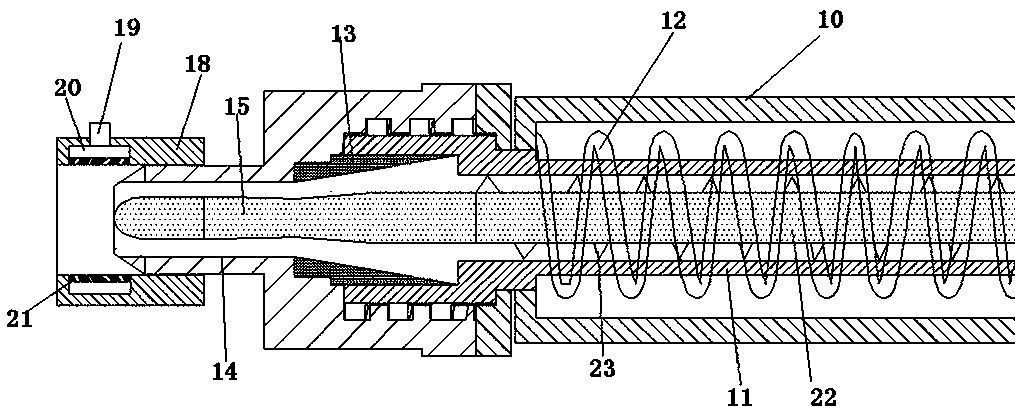

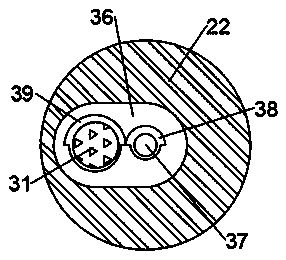

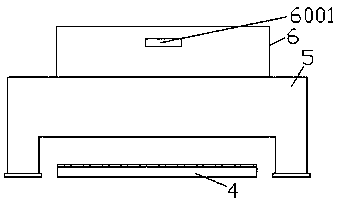

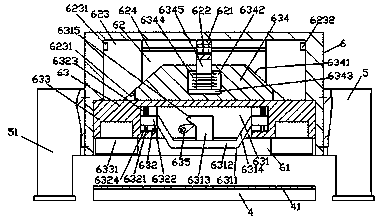

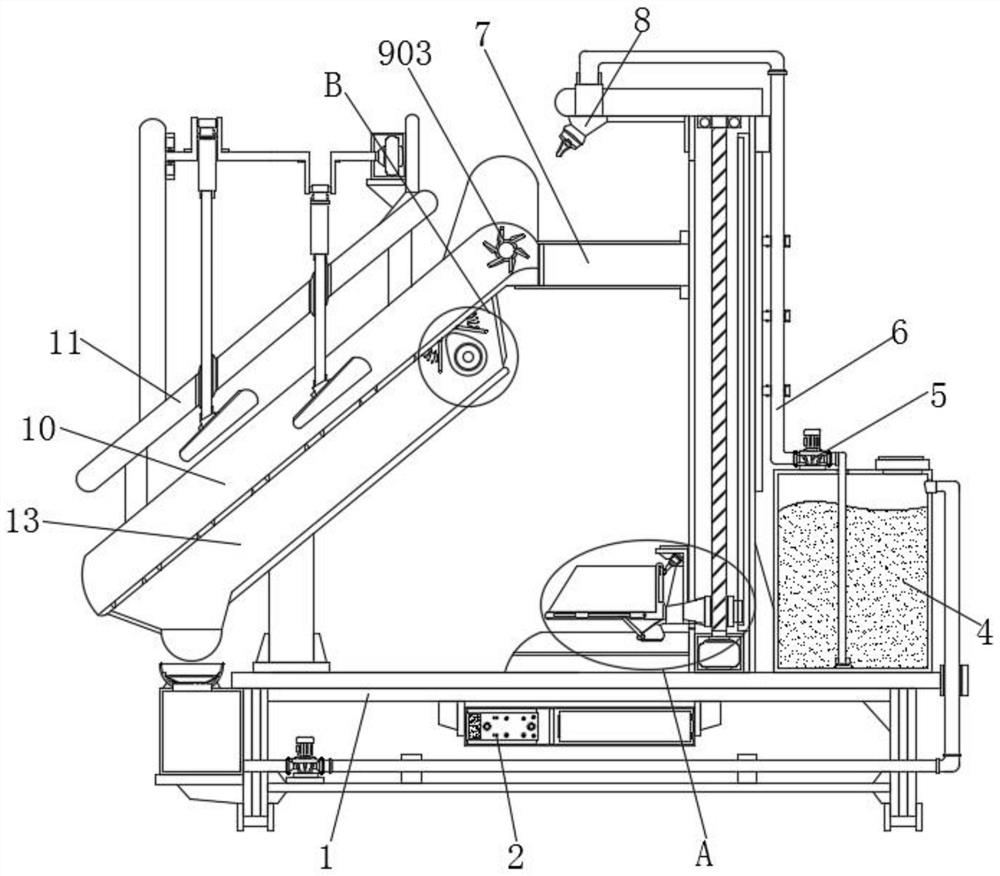

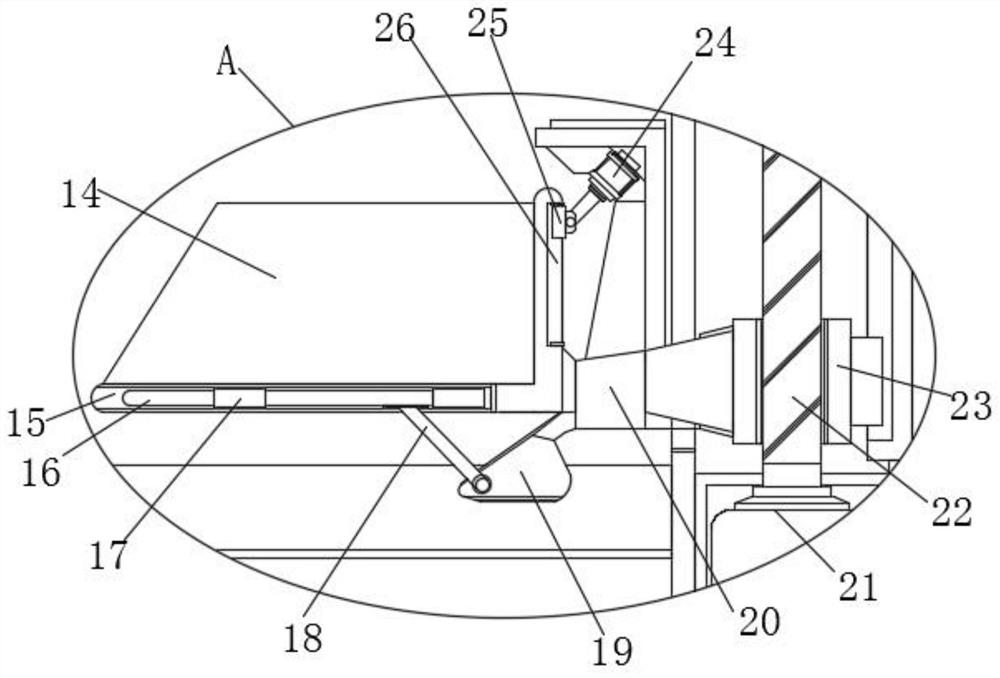

Rubber tube extrusion molding device

ActiveCN109263016AImprove extrusion performanceGuaranteed performanceTubular articlesRubber materialEngineering

The invention discloses a rubber tube extrusion molding device. The rubber tube extrusion molding device disclosed by the invention can greatly improve an extrusion molding effect on a rubber tube andensure performance of the rubber tube. According to the rubber tube extrusion molding device disclosed by the invention, vortex is utilized to heat a material at the front end of extrusion molding and keep the material warm, a temperature of a raw material is accurately controlled, and extrusion molding performance is ensured; meanwhile, non-contact heating is utilized by the rubber tube extrusion molding device disclosed by the invention; thus, not only is the volume of an extruded part reduced, but also performance of the raw material is ensured; an overheat effect of contact type heating to a rubber material is avoided. An air blowing structure of an air blowing assembly of the rubber tube extrusion molding device disclosed by the invention is of a reasonable structure, can effectivelyreduce adhesion and can prevent too cold shrinkage; in addition, self-weight downward pressing mode is utilized by the rubber tube extrusion molding device disclosed by the invention to discharge thematerial, so that discharging evenness is ensured, and the problem of pores or too much or too hard discharging is solved.

Owner:河南方元机电有限公司

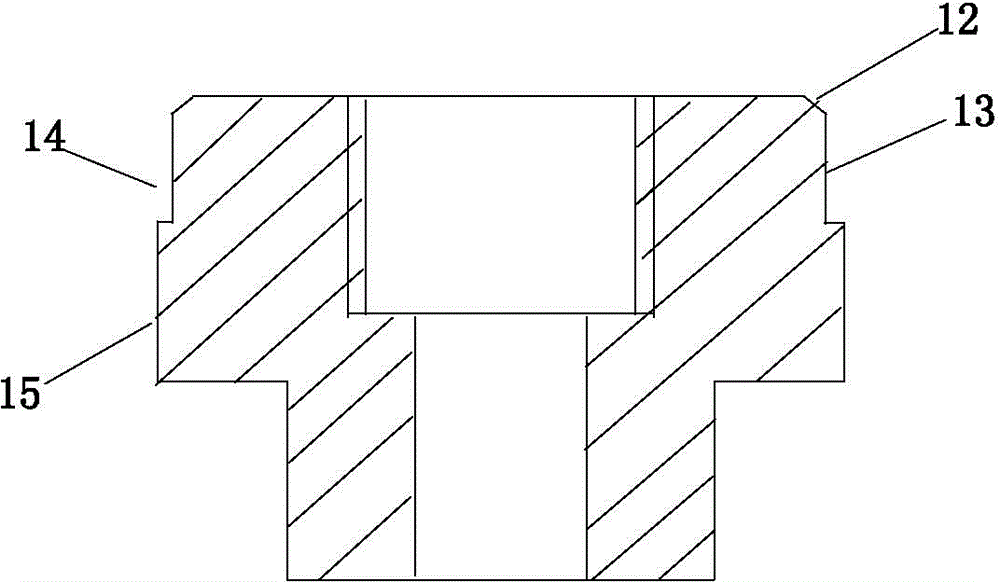

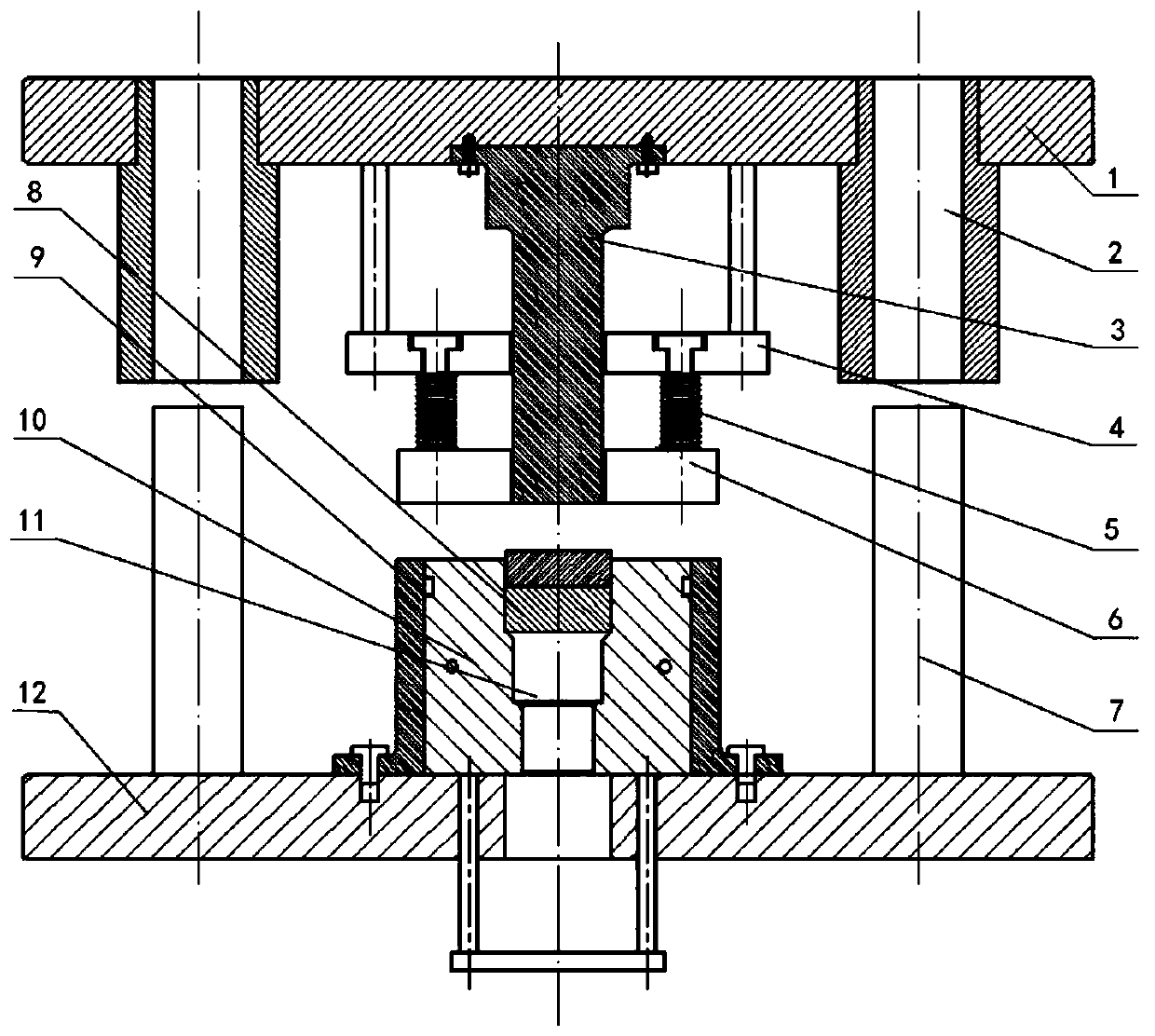

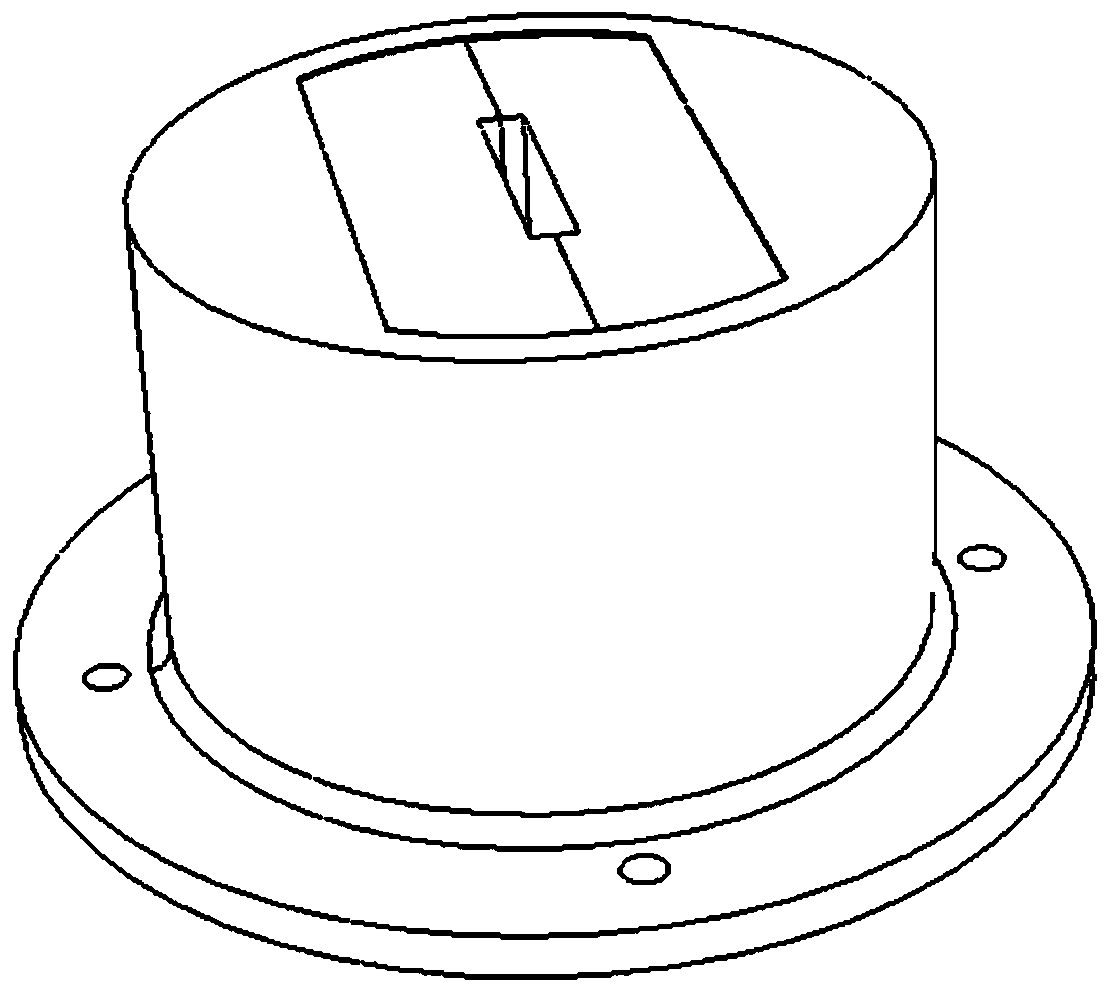

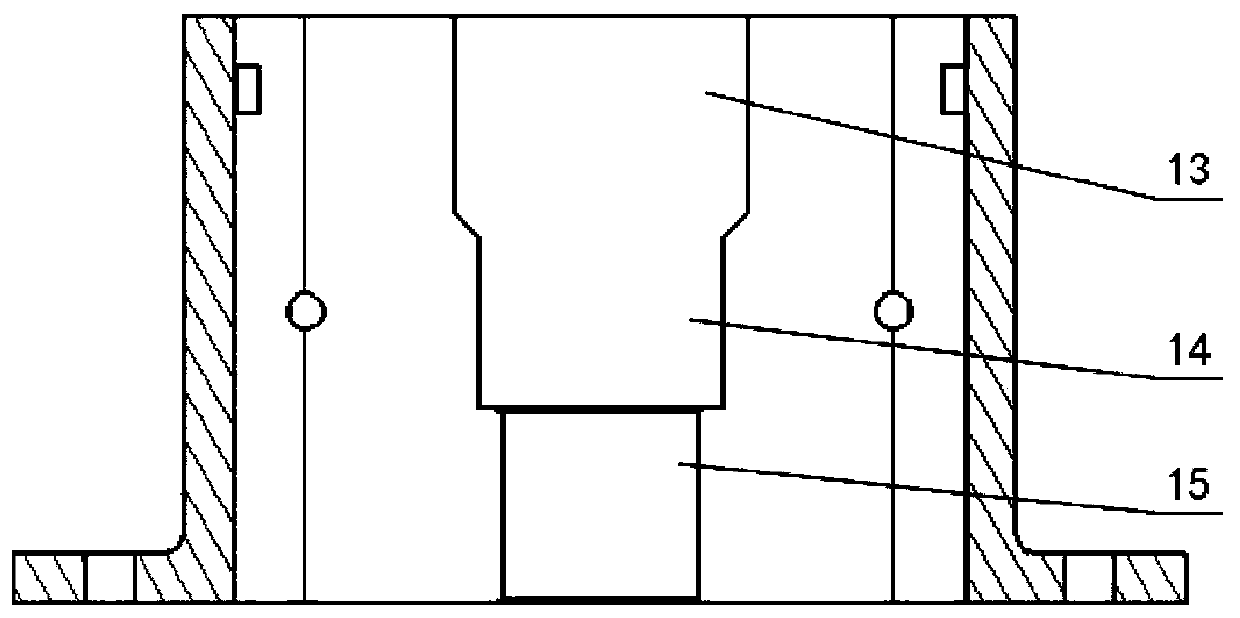

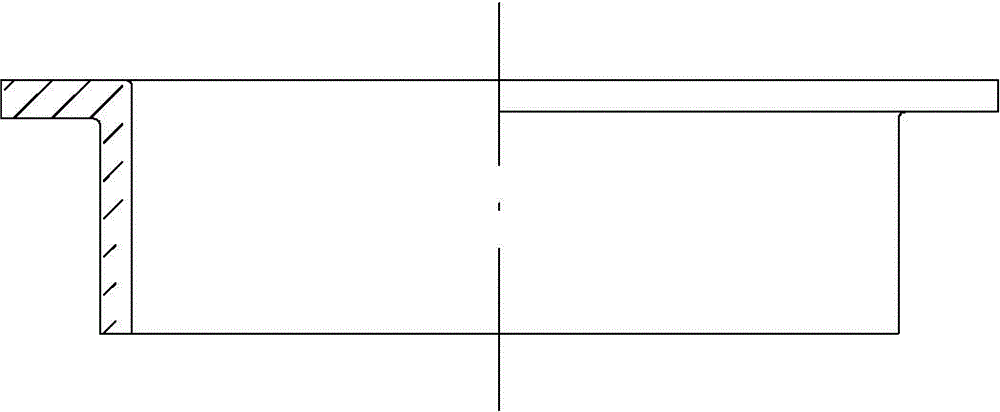

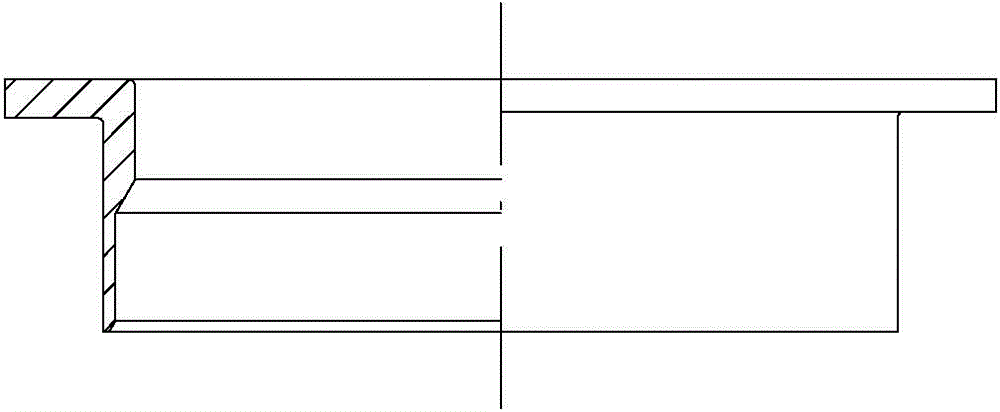

Non-pollution cold extruding molding method and cold extruding mould for packaging container flange

ActiveCN103551439AImprove working environmentReduce manufacturing costShaping toolsManufacturing cost reductionEngineering

The invention discloses a non-pollution cold extruding molding method and a cold extruding mould for a packaging container flange. The method is characterized in that a flange workblank with consistent flange boss thickness, which is subjected to punch forming by blanking and molding moulds, is under the effect of a male die with reverse pyramidal upper end, materials on a flange boss axially flow along the flange, wall thickness needed by turning threads is finally formed in a flange hole, and a flange finished product is obtained by subsequent corner cut, thread turning and electroplating. The non-pollution cold extruding molding method and the cold extruding mould for the packaging container flange has the advantages that the structure is simple, the manufacturing is simple, pollution does not exist, the rate of finished products is improved, and the manufacture cost is reduced.

Owner:张有龙

Polymer alloy for rubber ducts and preparation method thereof

ActiveCN102838791AGood weather resistanceImprove flame retardant performanceRigid pipesPolymer alloyAlloy

The invention discloses polymer alloy for rubber ducts. The alloy comprises the following raw materials in part by weight: 20 to 30 parts of CM135B, 70 to 80 parts of NBR3305, 4 to 6 parts of magnesium oxide, 4 to 6 parts of coumarone resin, 25 to 35 parts of high abrasion carbon black, 60 to 80 parts of general purpose carbon black, 5 to 15 parts of white carbon black, 6 to 12 parts of dibutyl ester, 1.2 to 2.5 parts of sulphur, 0.5 to 1.5 parts of accelerating agents CZ, 3 to 8 parts of composite curing agents EataMixTCHC, 10 to 20 parts of distilled aromatic extracts(DAE), 0.5 to 1.5 parts of anti-aging agents RD, 0.3 to 0.8 part of antiscorching agents CTP and 15 to 25 parts of white bole. According to the invention, the alloy improves the abrasion resistance, the ozone aging resistance, the weathering ageing resistance and the fire resistance of acrylonitrile-butadiene rubber, improves the rolling and the extruding of rubber stocks, improves the fineness of the rubber stocks, reduces shrinking percentage, improves the tensile strength and the tearing resistance of the rubber stocks, has small permanent deformation, improves the oil resistance and the corrosion resistance of the rubber stocks, prolongs the service life, effectively reduces production costs and further increases the quality of products.

Owner:河南亿博科技股份有限公司

Carrier for denitration catalyst

ActiveCN103349991AImprove extrusion performanceSave energyPhysical/chemical process catalystsDispersed particle separationThermal stabilityMetal

The invention discloses a catalytic carrier for a denitration catalyst. The carrier adopts metatitanic acid as a raw material, has more lasting thermal stability than other carriers for catalysts at the temperature of 1000 DEG C, can work in harsh environments for a long time, and has a broad-spectrum property in the catalytic ability after being mixed with other metals or metal oxides for forming.

Owner:CHONGQING MINFENG CHEM

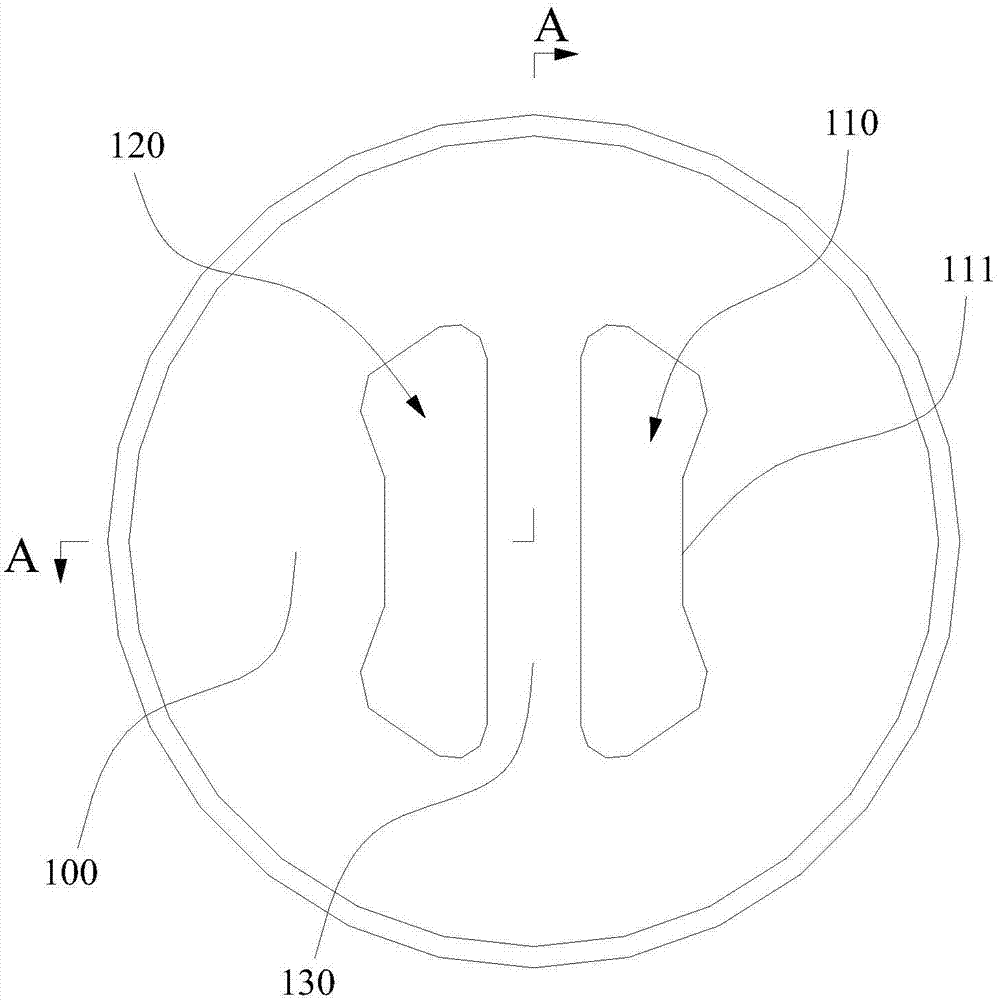

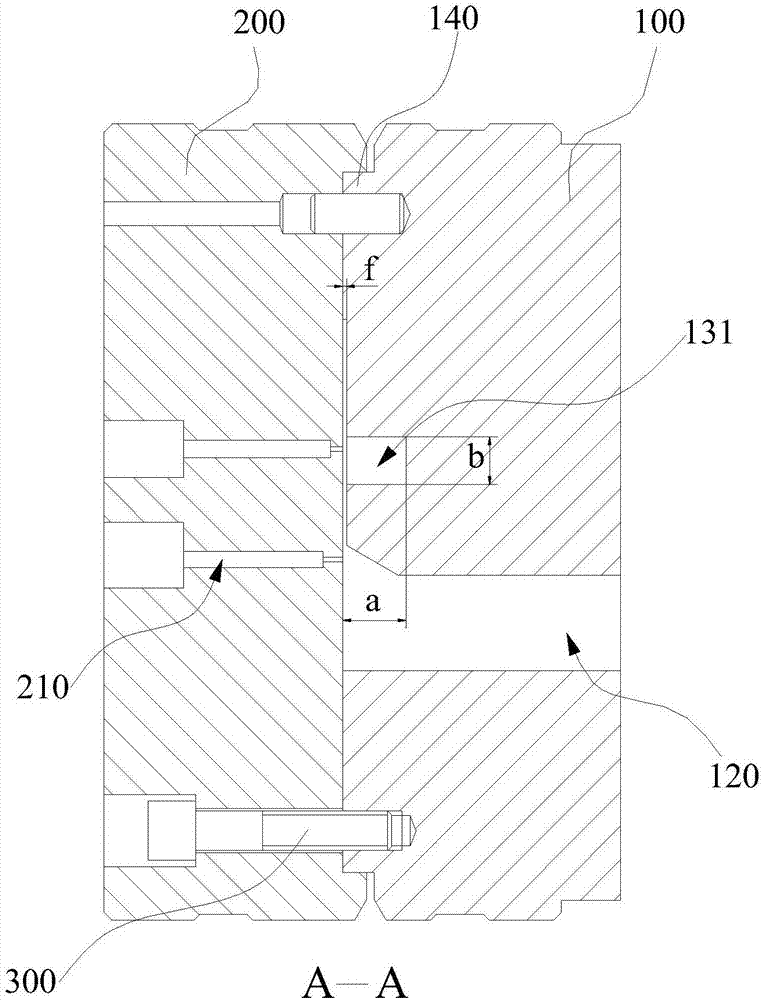

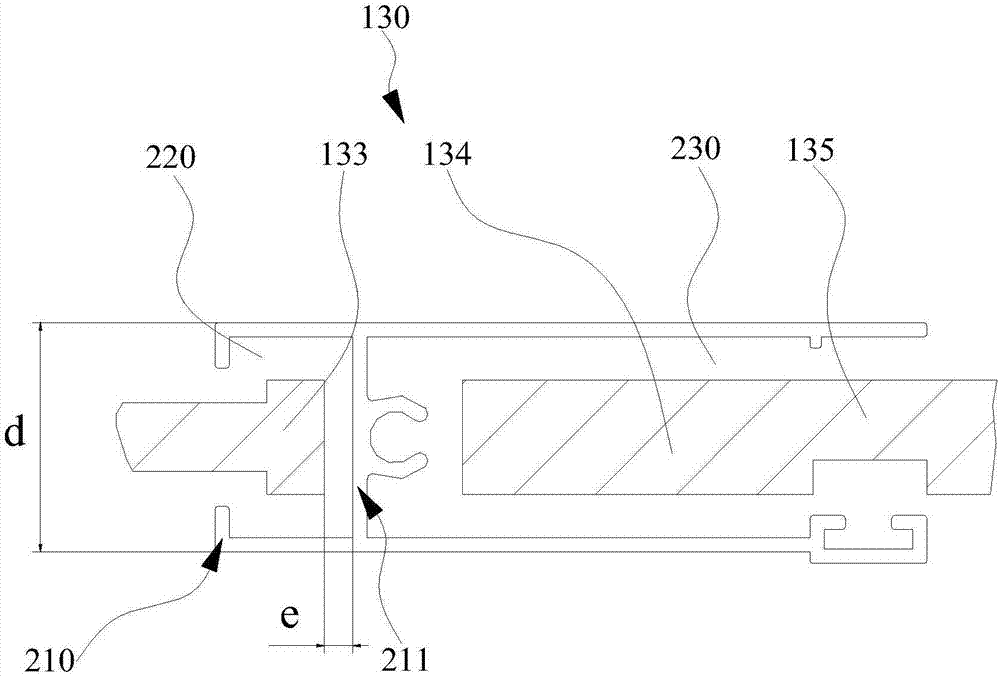

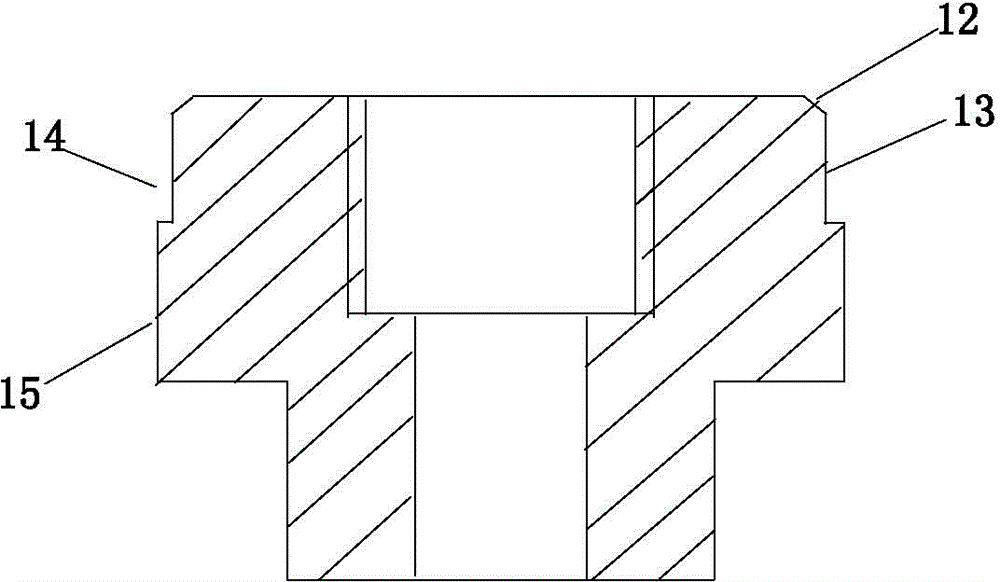

Diversion protection type extrusion die

The invention discloses a diversion protection type extrusion die which comprises an upper die and a lower die. Die holes used for forming semi-hollow profiles are formed in the lower die. The upper die is provided with a first tap hole and a second tap hole. A bypassing bridge is arranged between the first tap hole and the second tap hole. When the upper die is matched with the lower die, the end face, close to the lower die, of the bypassing bridge is located in the area defined by the die holes. Due to the fact that the end face, close to the lower die, of the bypassing bridge is located in the area defined by the die holes, the bypassing bridge has a shelter function on a cantilever defined by the die holes, during extrusion, liquid metal does not impact the cantilever in the direction from the upper die to the lower die, meanwhile, during extrusion forming, the liquid metal flows into the die through the first tap hole and the second tap hole which are located in the two sides of the die holes and enters the die holes from the two sides of the die holes, stress of the cantilever can be reduced, that is, the bending moment borne by the root of the cantilever is reduced, and the strength of the die is improved.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

Extrudable cementatious material

InactiveCN1376138AImprove extrusion performanceGood moldabilityCeramic shaping apparatusAdhesiveTackifier

A method and treatment agent for treating gelled material for extrusion, comprising adding a tackifier and a dispersant in an amount sufficient to enhance the effect of the tackifier to the gelled material. By increasing the effectiveness of the tackifier, extrudability can be maintained with less tackifier or lower grade (cheaper) tackifier than conventionally used, or for the same amount of tackifier as compared to conventional agent to improve extrusion performance.

Owner:JAMES HARDIE INT FINANCE BV

Asymmetric continuous large-deformation extrusion die for magnesium alloy

The invention discloses a magnesium alloy asymmetric continuous large-deformation extrusion processing die, and belongs to the field of non-ferrous metal plastic forming. The asymmetric continuous large-deformation extrusion processing die comprises an upset-extruding cavity at the upper part and an extruding cavity at the lower part, and a forming channel hole can be designed to be in an asymmetric type. The extrusion deformation of one side of a casting material is large while the extrusion deformation at the other side is small, so that the deformation is intensified. Die cores are detachable, and various types of die cores which can be suitable for different sizes are designed, so that different production requirements can be met. After one casting material is deformed, the casting material can be quickly replaced with the next casting material, so that continuous production is realized. The die is mainly used for realizing continuous extrusion forming of a sheet of a magnesium alloy sheet-shaped casting material, and the magnesium alloy sheet-shaped part which is uniform in structure and optimized in performance can be obtained through the processing technology.

Owner:JILIN UNIV

Lanthanum-containing 6063 aluminum alloy and preparation method

The invention belongs to the technical field of alloys, and particularly relates to a lanthanum-containing 6063 aluminum alloy and a preparation method thereof. The lanthanum-containing 6063 aluminumalloy provided by the invention is prepared from the following components in percentage by mass: 0.45 to 0.54 percent of Si, 0.52 to 0.56 percent of Mg, less than or equal to 0.35 percent of Fe, lessthan or equal to 0.05 percent of Cu, less than or equal to 0.07 percent of Mn, less than or equal to 0.05 percent of Zn, 0.01 to 0.05 percent of Ti, 0.005 to 0.02 percent of La, 0.001 to 0.006 percentof C and the balance of Al. According to the lanthanum-containing 6063 aluminum alloy and the preparation method thereof, specific small content ranges of the elements, such as Mg and Si, are determined; and the strength of the lanthanum-containing 6063 aluminum alloy is improved through common precipitation of carbides and intermetallic compounds. Embodiment results show that the lanthanum-containing 6063 aluminum alloy provided by the invention achieves the tensile strength of 177 MPa and the elongation of 23.8 percent at room temperature.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

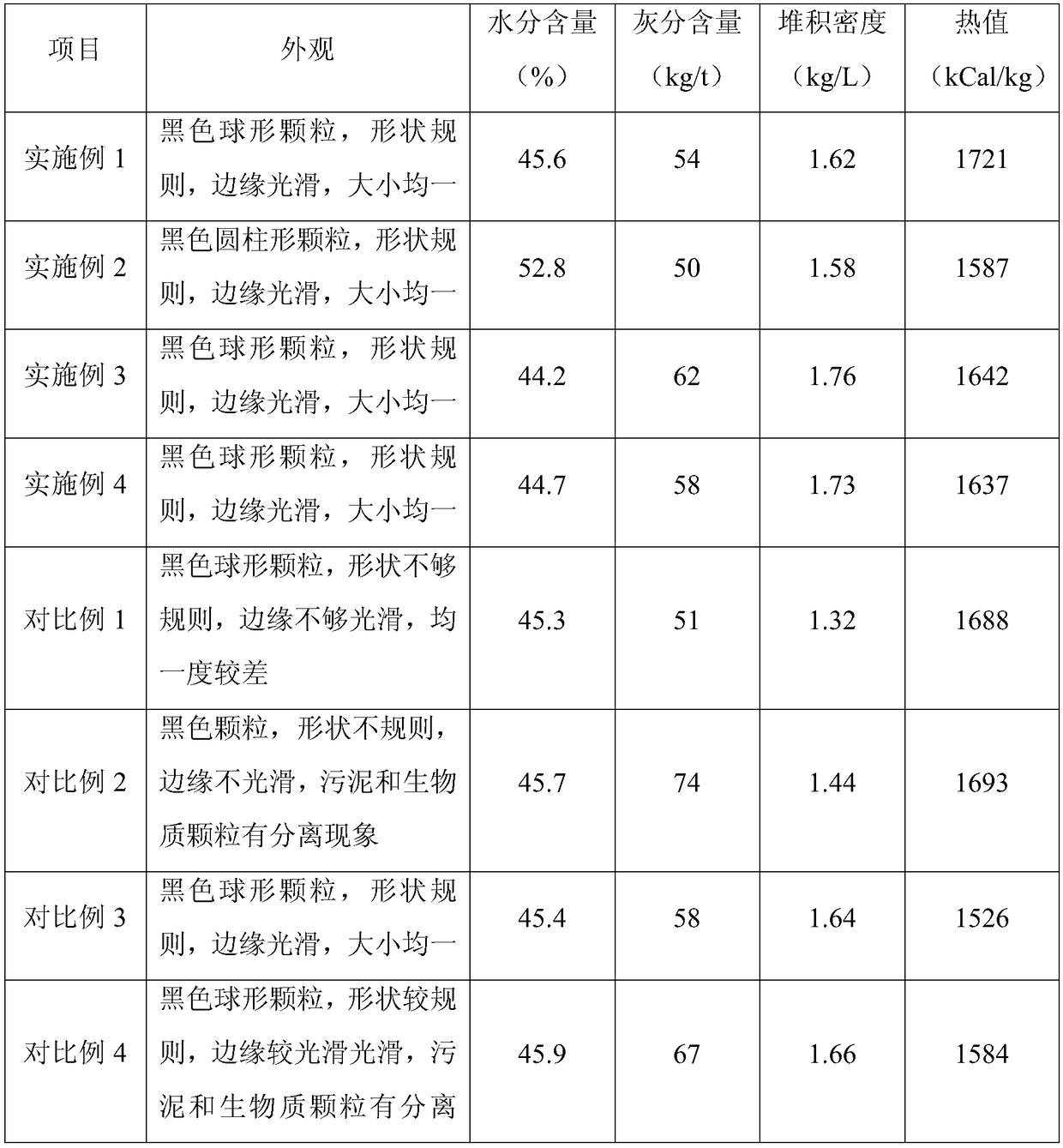

Biomass straw sludge fuel and preparation method thereof

PendingCN109370699AImprove flammabilityIncrease fuel calorific valueBiofuelsSolid fuelsEnvironmental resistanceSludge

The invention discloses a biomass straw sludge fuel. The biomass straw sludge fuel comprises the following raw materials in parts by weight: 100 parts of sludge containing 55-70% of water, 50-500 parts of biomass straw particles, and 1-10 parts of hydroxypropyl methyl cellulose. A preparation method of the biomass straw sludge fuel comprises the following steps: S1, feeding biomass straws into a crusher; crushing the biomass straws into particles being 1 mm in particle size; S2, feeding the sludge, the biomass straw particles and the hydroxypropyl methyl cellulose into a mixing tank through aquantitative feeding machine; stirring and uniformly mixing under normal temperature; S3, feeding the uniformly-mixed materials into a sludge forming machine for extruding and forming to obtain the biomass straw sludge fuel. According to the method, the sludge is converted into flammable fuel; the calorific value of the fuel is high; the flammable performance is high; the fuel can still be particle-shaped after flaming; little flying ash is adsorbed into the dust particles, so that little flying dust is produced; the method is clean and environmentally friendly.

Owner:HEFEI GUOHUI ENVIRONMENTAL PROTECTION TECH

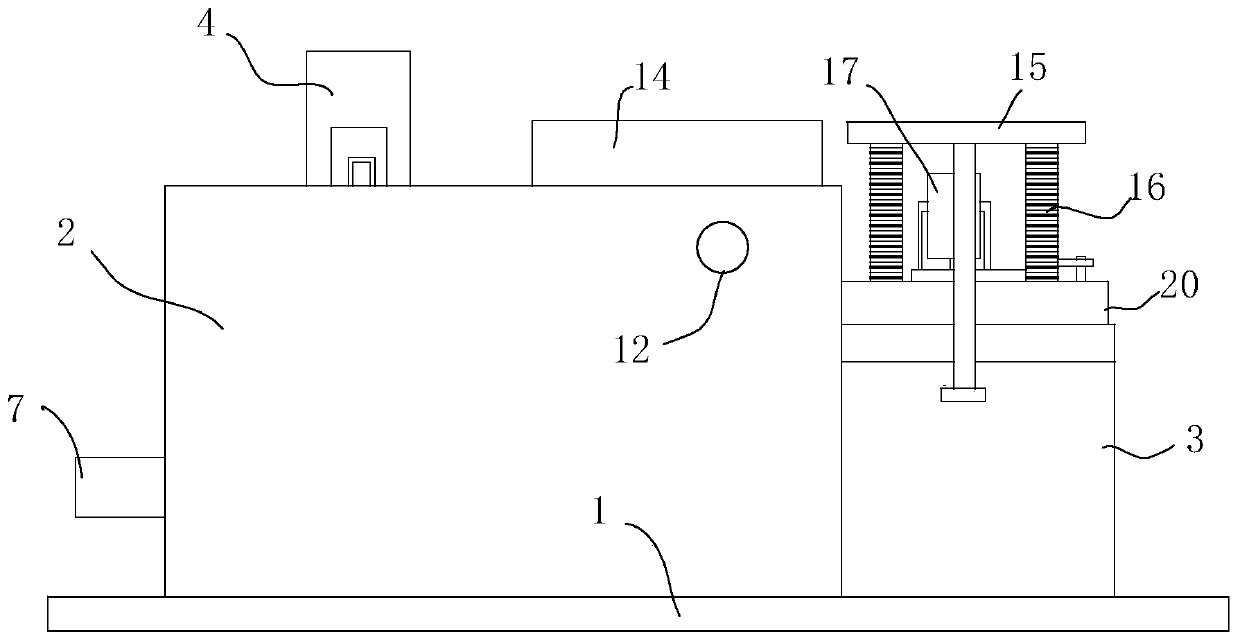

Building formwork manufacturing device

ActiveCN111267213AConvenient centralized transferInhibition of segregationFeeding arrangmentsArchitectural engineeringStructural engineering

The invention aims to provide a building formwork manufacturing device used for solving the technical problem about building formwork manufacturing. The building formwork manufacturing device comprises a box body mechanism, a slurry inlet mechanism, a concentration mechanism, a transfer mechanism and a compaction mechanism, wherein slurry is temporarily stored in the front portion of the box bodymechanism, and the slurry is extruded on the rear portion of the box body mechanism; the slurry inlet mechanism injects the slurry to the two sides in the front portion of the box body mechanism separately; the concentration mechanism is used for stirring the slurry in the box body mechanism and transferring the slurry to the middle; the transfer mechanism is used for transferring the slurry in the box body mechanism from the front portion to the rear portion; and the compaction mechanism is arranged on the rear portion of the box body mechanism and cooperates with the box body mechanism to extrude the slurry to form building formworks.

Owner:杨凌天域新材料科技有限公司

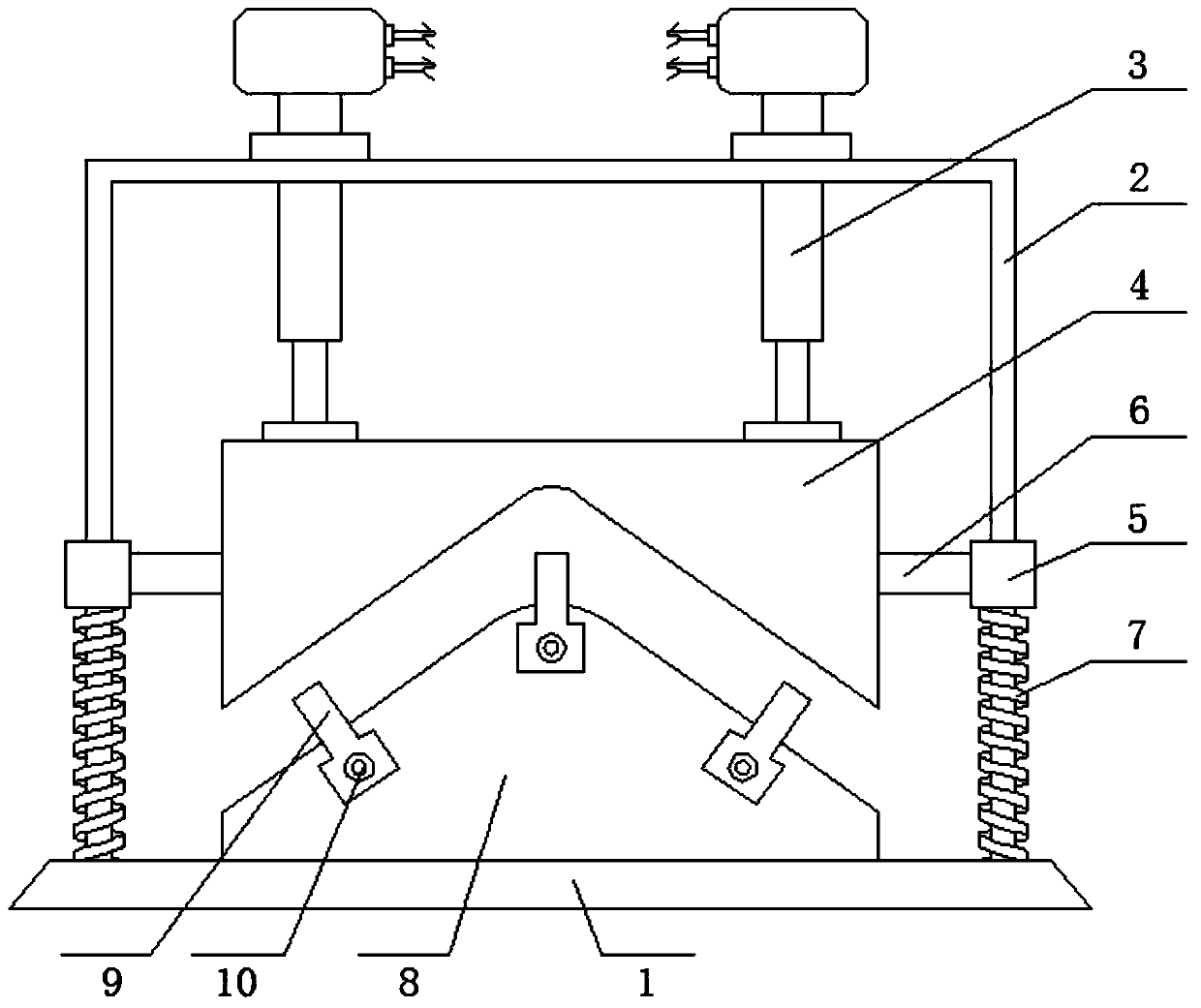

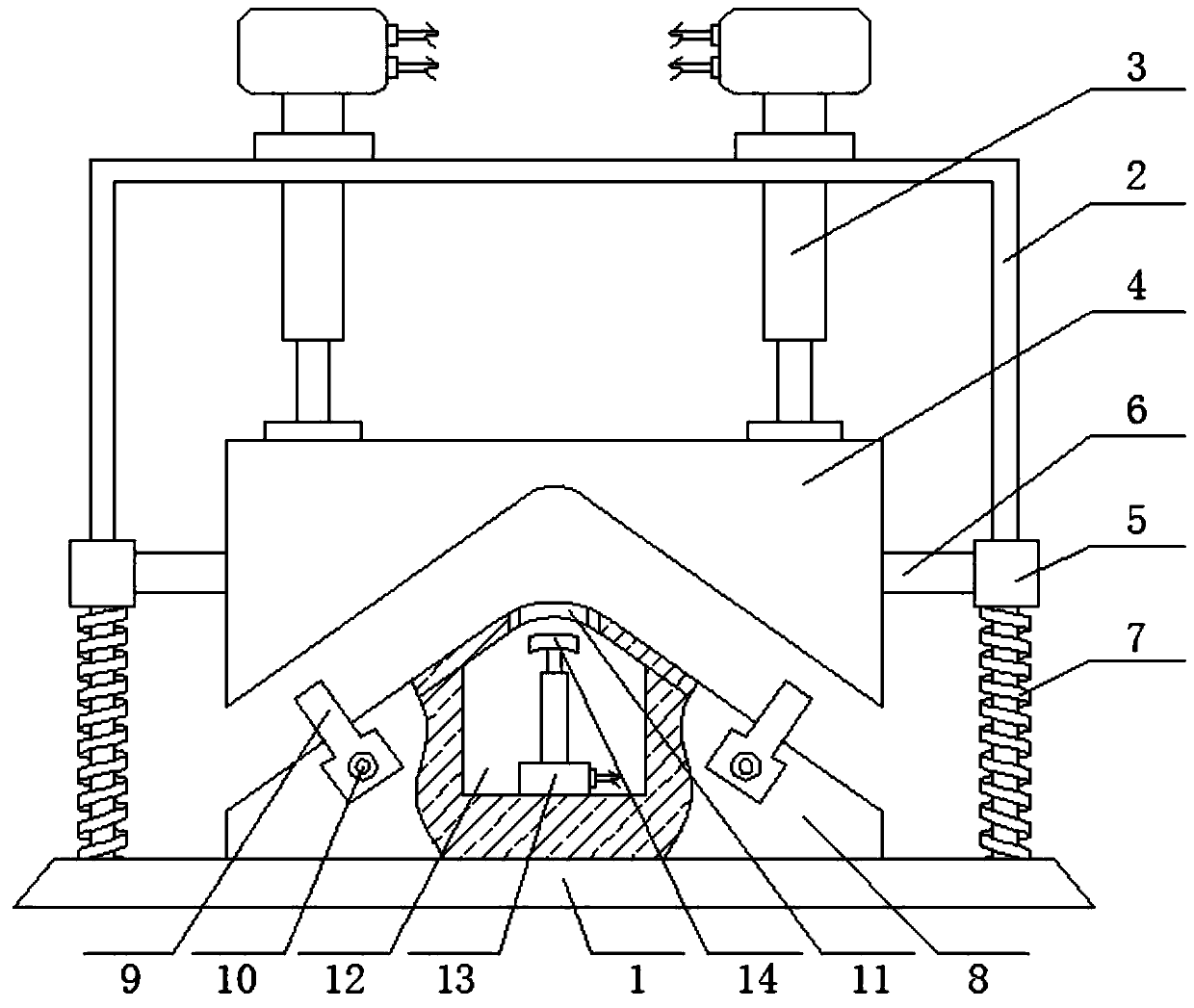

Springing type garbage extruder

InactiveCN111347705AImprove extrusion performanceImprove recycling efficiencyPressesStructural engineeringCircular disc

The invention discloses a springing type garbage extruder. The springing type garbage extruder comprises a machine body. An extrusion cavity is formed in the machine body. A collection barrel is placed on the bottom wall of the extrusion cavity. A collection cavity with an opening being upward and used for storing extruded garbage is arranged in the collection barrel. An extrusion control mechanism capable of extruding and conveying garbage and providing power for a motion component in a device is arranged in the machine body. The extrusion control mechanism comprises a motor, an extrusion block used for conveying and extruding garbage and a disc. A power cavity is formed on the rear side of a round cavity. The motor is fixedly arranged on the right wall of the power cavity. According to the springing type garbage extruder, two springing extrusion manners are adopted, the extrusion forming effect of garbage is effectively improved, dispersed garbage large in occupied space can be extruded into small block structures, the garbage recovery efficiency is improved, and the number of adopted garbage cans is reduced.

Owner:SHAOXING SHANGYU BINGFANG ENVIRONMENTAL PROTECTION EQUIP CO LTD

Gray rubber quartz plate and preparation method thereof

ActiveCN102617943BGood high and low temperature resistanceImprove insulation performanceRubber layered productsRough surfacePolymer science

The invention belongs to the technical field of rubber quartz plates, and particularly discloses a gray rubber quartz plate and a preparation method of the gray rubber quartz plate. The gray rubber quartz plate has the technical scheme that the quartz plate comprises a plate body and a rough surface layer, and is characterized in that the plate body comprises the following materials in parts by weight: 100 parts of rubber, 5.9-29 parts of quartz powder, 10-52 parts of white carbon black, 4-18 parts of activating agent, 0.8-5.5 parts of accelerating agent, 0.9-8.5 parts of vulcanizing agent, 2-50 parts of softener, 0.8-1.1 parts of coloring agent, 0.8-2 parts of bonding agent, 1-5 parts of anti-aging agent and 1.8-4.0 parts of solubilizer. The wear-resistant performance as well as the acid-resistant and alkaline-resistant properties of the rubber quartz plate can be improved, the heat absorption and the high light reflection can be reduced, and the service life is greatly prolonged.

Owner:李彦峰

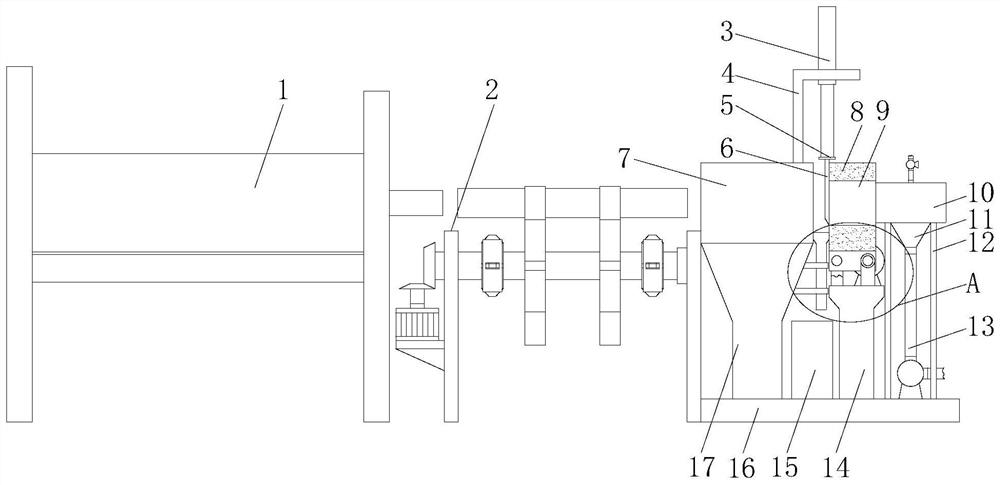

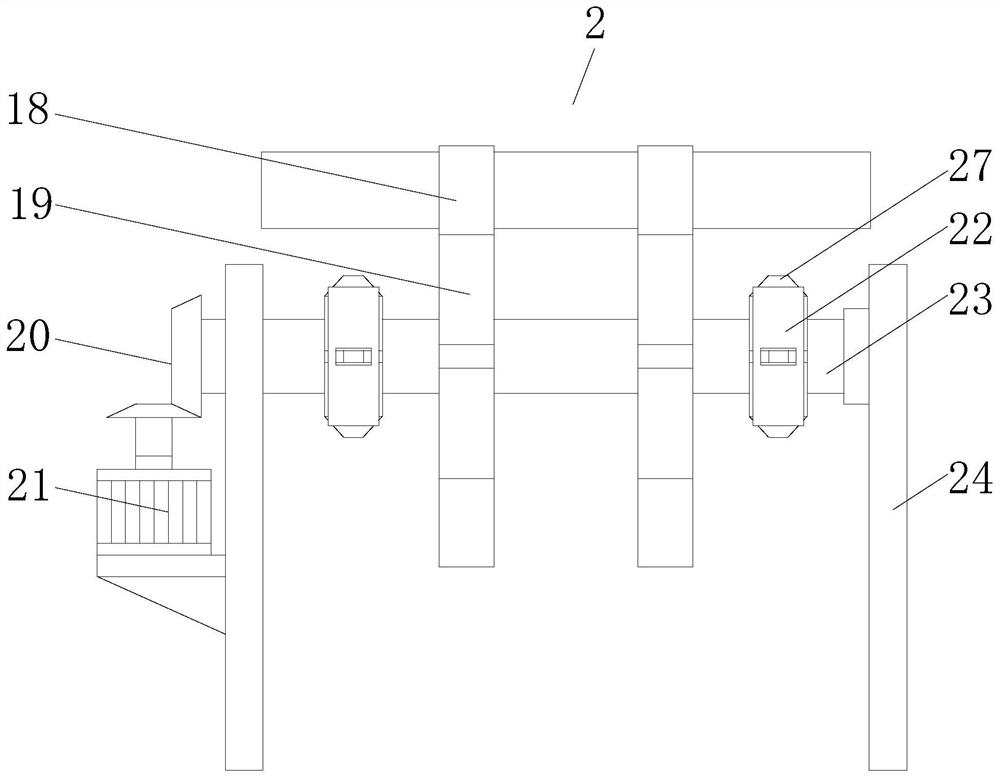

A high-efficiency extrusion device for aluminum production

ActiveCN110918670BRealize limitShorten the timeExtrusion diesOther manufacturing equipments/toolsHydraulic cylinderElectric machinery

Owner:广宁县恒福灯饰铝材有限公司

Garbage extrusion processing unit

InactiveCN108215269AMake compression workImprove extrusion performancePlastic recyclingPress ramEngineeringMechanical engineering

The invention discloses a garbage extrusion processing unit which comprises a machine base and a compressor fixedly installed in the machine base. A first containing groove is formed in the bottom face of the compressor, a second containing groove extending upwards is arranged on the top wall in the first containing groove in a communicating manner, a rising and falling sliding conveying block isconnected into the first containing groove in a sliding conveying fit manner, a pushing guide block extending into the second containing groove and being in sliding conveying fit is fixedly arranged at the top of the rising and falling sliding conveying block, first inclined ends are equally arranged on the left and right sides of the pushing guide block, a protruding block is fixedly arranged atthe position, opposite to the top of the pushing guide block, on the top wall in the second containing groove, a third containing groove is formed in the bottom face of the rising and falling slidingconveying block, rotary connecting containing grooves extending front and back are equally arranged on the left and right sides of the third containing groove, a pressing block extending front and back is connected into each rotary connecting containing groove in a rotary fit manner, and an extrusion device is connected into the third containing groove in a matched manner. The garbage extrusion processing unit is simple in structure and convenient to operate, the garbage extrusion molding effect is strengthened, and the garbage extrusion working efficiency is improved.

Owner:周四海

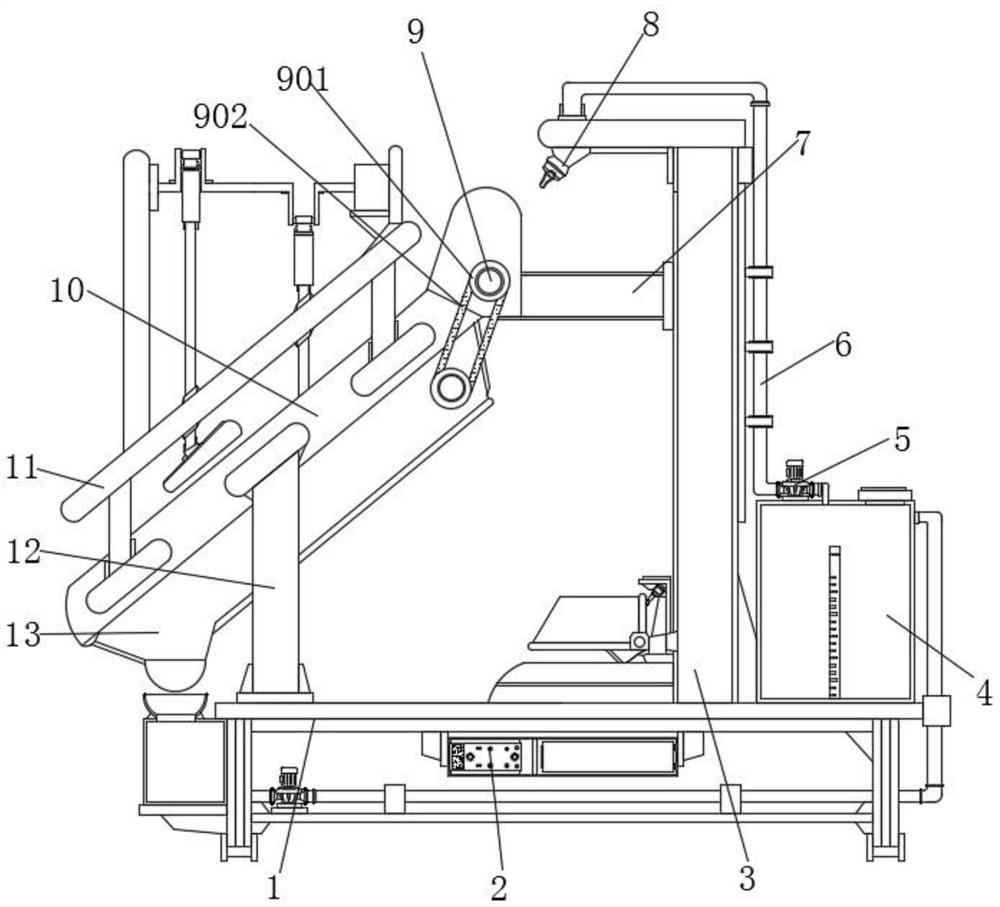

Cooked beef and mutton product processing and feeding device and using method thereof

PendingCN113973898AImprove feeding efficiencyImprove delivery efficiencyMulti-step food processesMeat/fish preservation by freezing/coolingWater storage tankMechanical engineering

The invention relates to a cooked beef and mutton product processing and feeding device and a using method thereof. The device comprises a mounting seat; one side of the top of the mounting seat is provided with a water storage tank and a mounting groove; the two ends of the other side of the top of the mounting seat are provided with fixing columns; the tops of the ends, close to each other, of the two fixing columns are provided with a material guide table; U-shaped connecting arms are arranged at the tops of the two ends of one side of the mounting groove; the U-shaped connecting arms are connected with the material guide table; and flow guide grooves which are connected with each other are formed in the bottom of the outer side of the material guide table. According to the cooked beef and mutton product processing and feeding device and the using method thereof, meat foodstuff needing to be processed is placed through a material placing seat, the foodstuff placed on the material placing seat is conveniently and automatically guided into the material guide table to be fed and conveyed through the height lifting of the material placing seat and the cooperation of the material placing seat andan inclined structure; and the sliding and guiding range of the foodstuff is widened through automatic stretching of a guide plate, the foodstuff is prevented from falling in the feeding period, and the guidance quality of foodstuff feeding is improved.

Owner:青海祁连亿达畜产肉食品有限公司

Non-pollution cold extruding molding method and cold extruding mould for packaging container flange

ActiveCN103551439BImprove working environmentReduce manufacturing costShaping toolsManufacturing cost reductionEngineering

The invention discloses a non-pollution cold extruding molding method and a cold extruding mould for a packaging container flange. The method is characterized in that a flange workblank with consistent flange boss thickness, which is subjected to punch forming by blanking and molding moulds, is under the effect of a male die with reverse pyramidal upper end, materials on a flange boss axially flow along the flange, wall thickness needed by turning threads is finally formed in a flange hole, and a flange finished product is obtained by subsequent corner cut, thread turning and electroplating. The non-pollution cold extruding molding method and the cold extruding mould for the packaging container flange has the advantages that the structure is simple, the manufacturing is simple, pollution does not exist, the rate of finished products is improved, and the manufacture cost is reduced.

Owner:张有龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com