Non-pollution cold extruding molding method and cold extruding mould for packaging container flange

A forming method and cold extrusion technology, which are applied in the field of non-polluting cold extrusion forming methods for packaging barrel flanges and cold extrusion molds, can solve the problems of inconsistent extrusion height, prolonging the manufacturing cycle, polluting the environment, etc., and achieve mold processing Convenience, improved yield, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

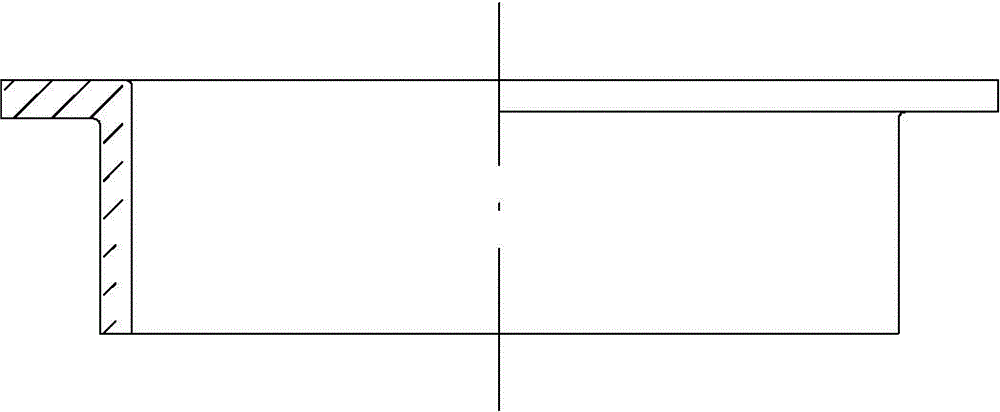

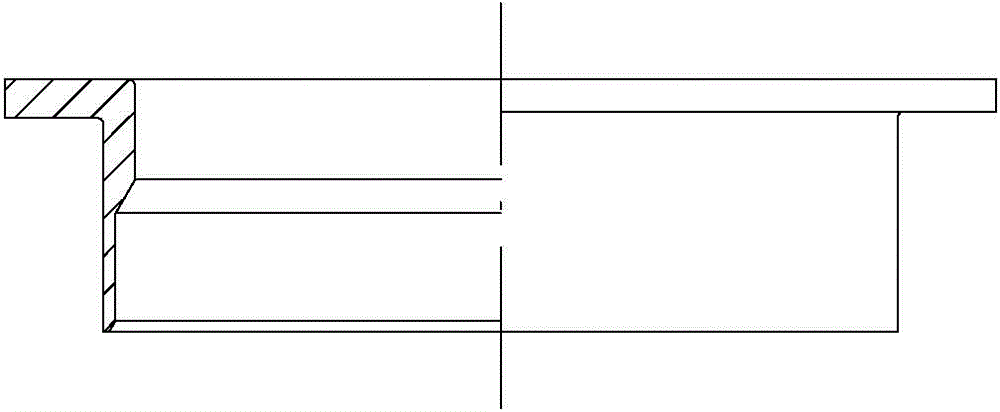

[0022] Such as Figure 1-5 shown.

[0023] A pollution-free cold extrusion molding method for the flange of a packaging container. First, the cold extrusion punch is improved, and the image 3 The small-diameter cylindrical action surface of the shown cold extrusion punch is changed to Figure 5 The conical active surface shown, the modified punch is mounted on the Figure 4 Start the cold extrusion equipment on the mold shown, so that the flange blank formed by blanking and forming modules with the same thickness of the flange boss can be extruded through the line contact extrusion of a punch with an upper end in the shape of an inverted cone. Function, during the extrusion process or before extrusion, cold pressure oil can be added to the punch to improve the fluidity of the material, so that the material on the flange boss can flow along the axial direction of the flange, that is, figure 1 Flange bosses shown are consistent with flange blanks extruded into figure ...

Embodiment 2

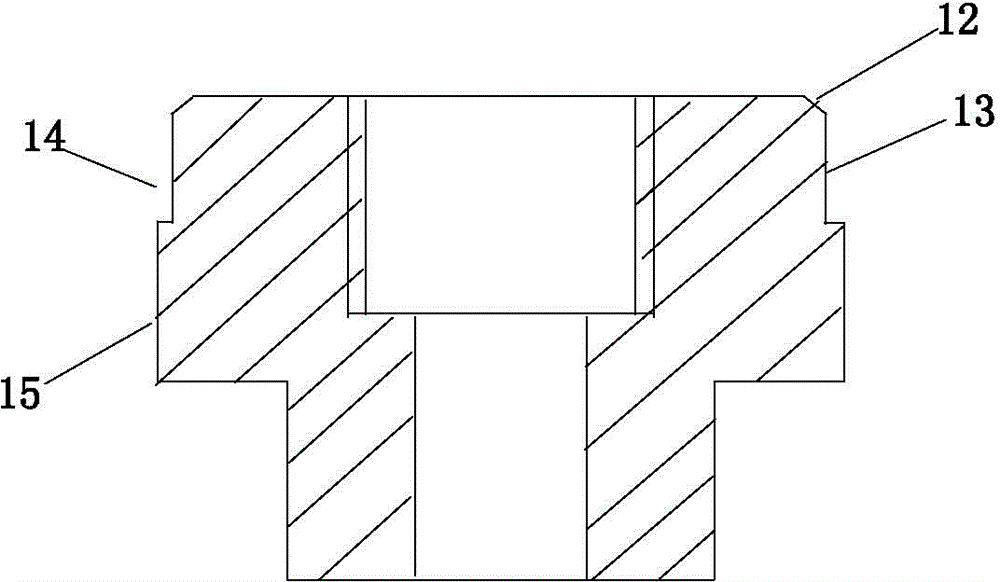

[0025] Such as Figure 4 , 5 shown.

[0026] A cold extrusion molding die, which includes an upper die 3, a mandrel 4, a die 6 and a punch 7, the mandrel 4 is installed in the upper die 3 and is offset against the punching rod 1, and the upper die 3 and the upper die 2 Connected, the upper template 2 is connected with the extrusion head of the cold extrusion equipment and moves up and down accordingly, the punch 7 is installed in the die 6, the lower part of the punch 7 is supported on the punch holder 8, and the punch holder 8 Installed on the positioning plate 10, the positioning plate 10 is installed on the lower template 11, and the lower template 11 is installed on the workbench of the cold extrusion equipment, such as Figure 4 As shown, the push rod 9 for separating the die 6 from the punch 7 to facilitate the removal of the flange semi-finished product 5 is installed in the positioning plate 10, and the upper end of the punch 7 is provided with an extrusion zone 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com