Automatic control system and method of petroleum drilling machine

An automatic control system and control system technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve problems such as difficult debugging, installation of discrete components, time-consuming and labor-intensive connections, and easy misconnection and misoperation. Achieve good working environment and office environment, improve visibility and precision, and operate conveniently and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

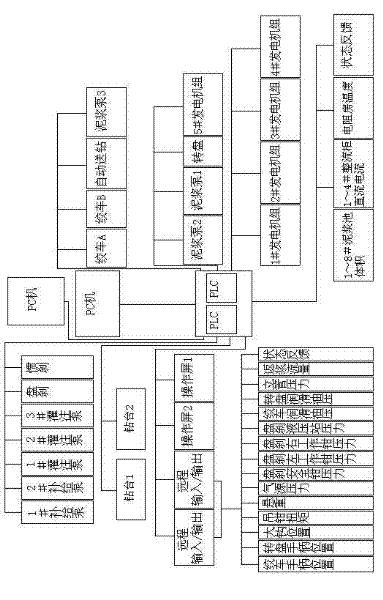

[0044] Such as figure 1 As shown, the automatic control system of the oil drilling rig in this embodiment includes a master station and a plurality of slave stations.

[0045] The PLC controller and its redundant PLC controller installed in the integrated cabinet are the main station of the entire control system. Its analog input module collects the volume of No. 1 to No. 8 mud pools, the DC current of No. 1 to No. 4 rectifier cabinets and the temperature of the resistance room. Its digital input module collects the running status feedback signals and alarm signals of each actuator, where the signals include the running status of 1~5# generator sets, brake unit prohibition, warning silence, 1~3# mud pump fan running status, 1 ~3# mud pump air pressure circuit status, 1~3# mud pump filling pump running status, 1~3# mud pump spray pump running status, 1~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com