Energy-saving and environment-friendly solid garbage breaking and packing device

An energy-saving, environmentally friendly, and solid-state technology, applied in the field of balers, can solve the problems of no injection barrel, no pressure sensor, and inability to push out easily, so as to reduce emissions, improve extrusion molding effects, and simplify processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

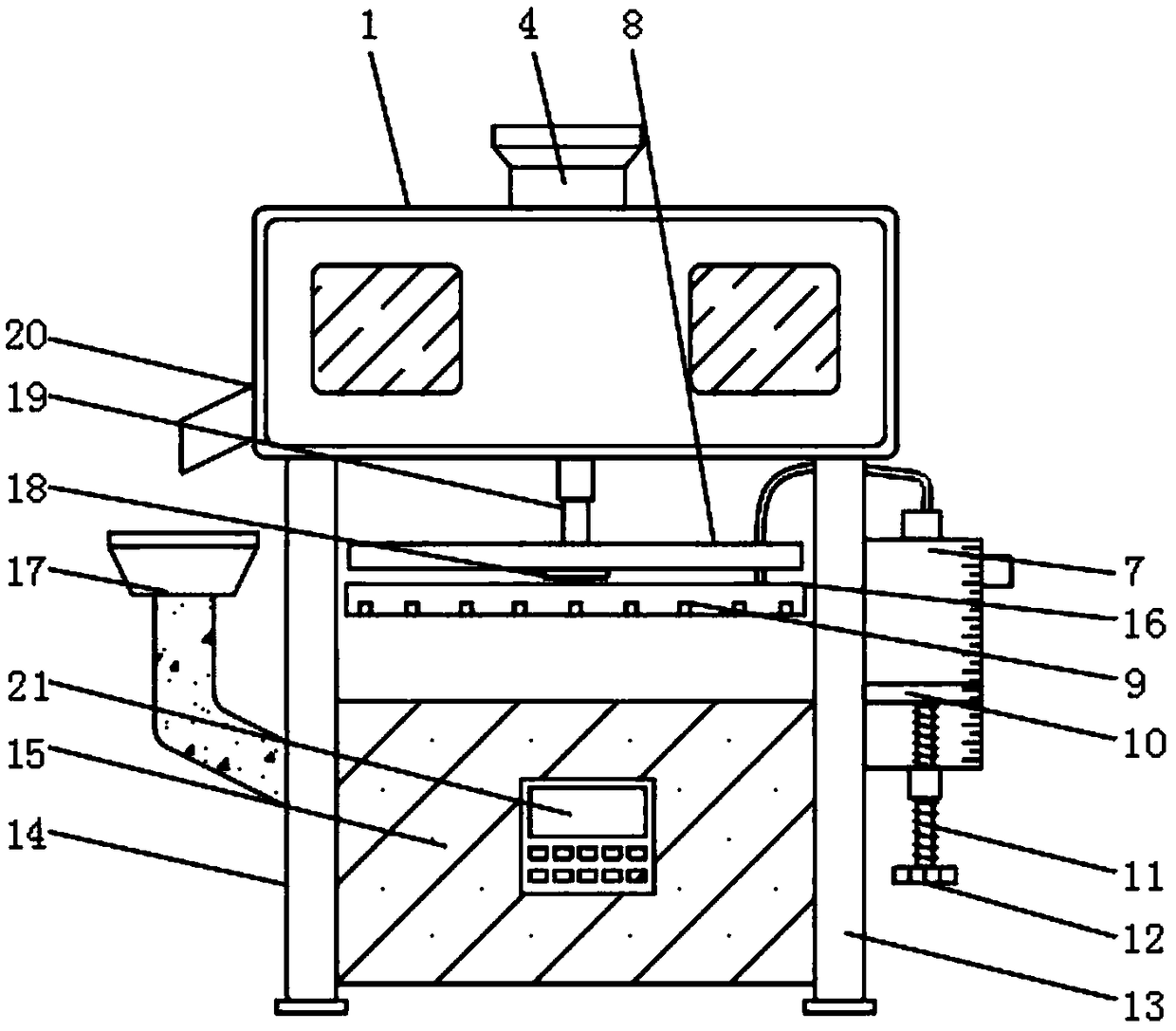

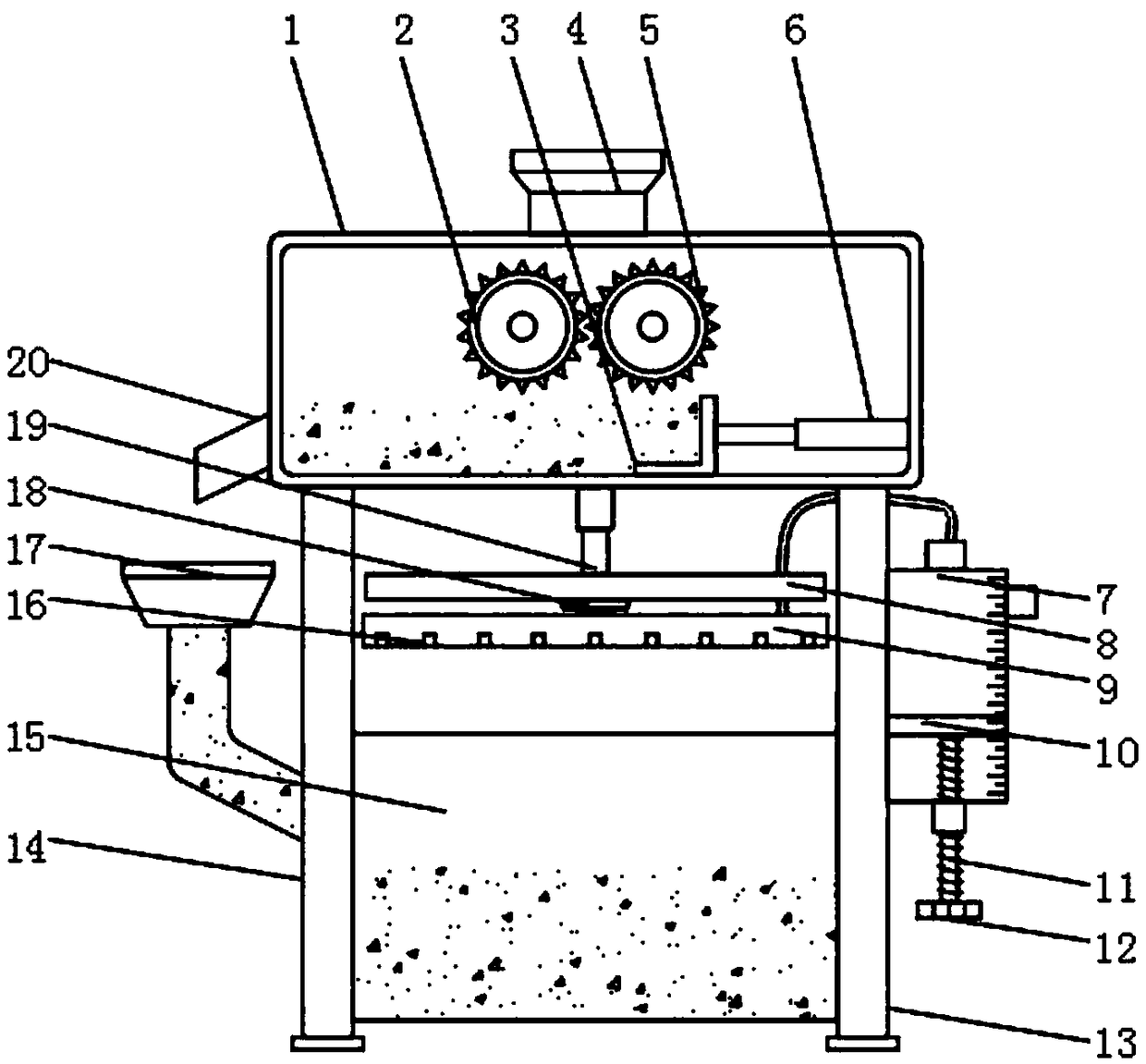

[0020] Example: refer to Figure 1-2 , the present invention provides a technical solution, an energy-saving and environment-friendly solid waste crushing packing device, comprising a packing machine body 15 and an upper platen 8, one end of the packing machine body 15 is provided with a right bracket 13, and the other side of the packing machine body 15 One end is provided with left support 14, and the front surface of baler body 15 is provided with control switch 21, and one side of left support 14 is provided with second feeding port 17, and one side of right support 13 is provided with injection cylinder 7, and right support 13 is provided with a crushing cylinder 1, the inside of the injection cylinder 7 is provided with a piston 10, and the inside of the injection cylinder 7 is embedded with a threaded rod 11 near the bottom of the piston 10, and the bottom end of the threaded rod 11 is fixedly equipped with a rotating handle 12. A cylinder 19 is provided at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com