Patents

Literature

300 results about "GRINDING TOOTH" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

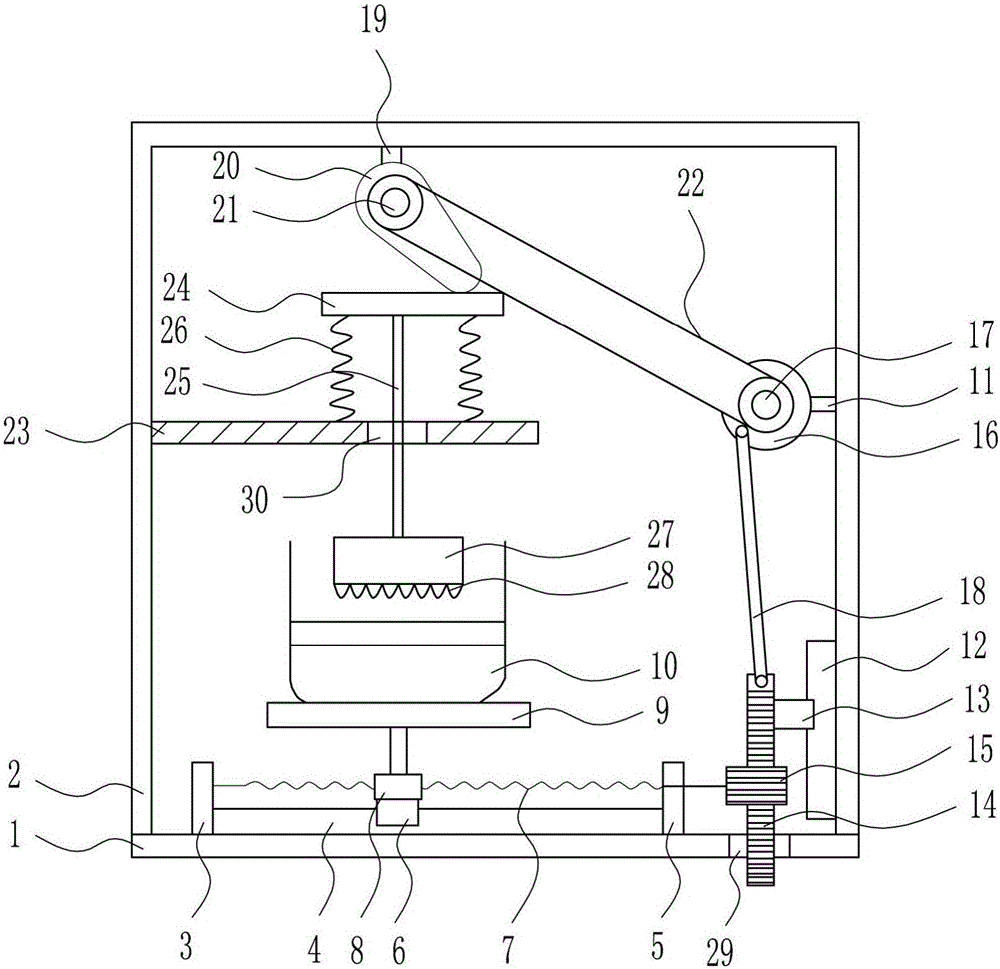

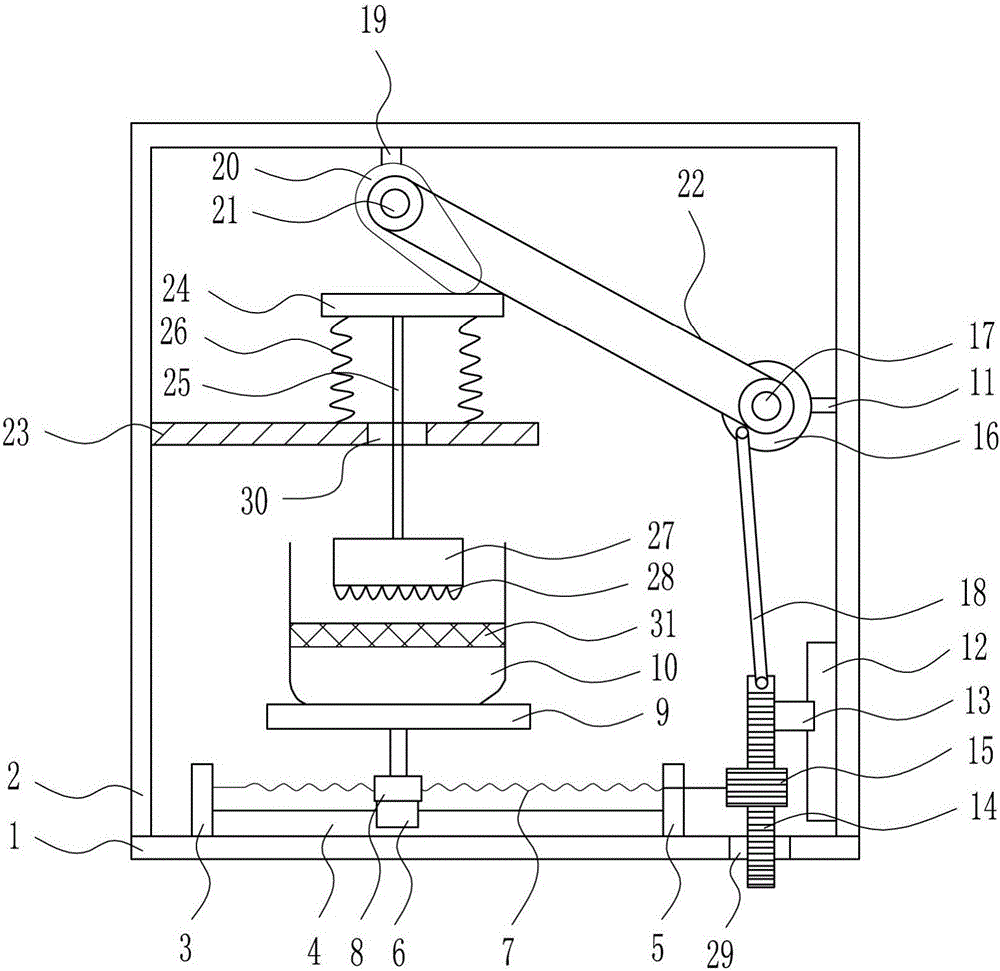

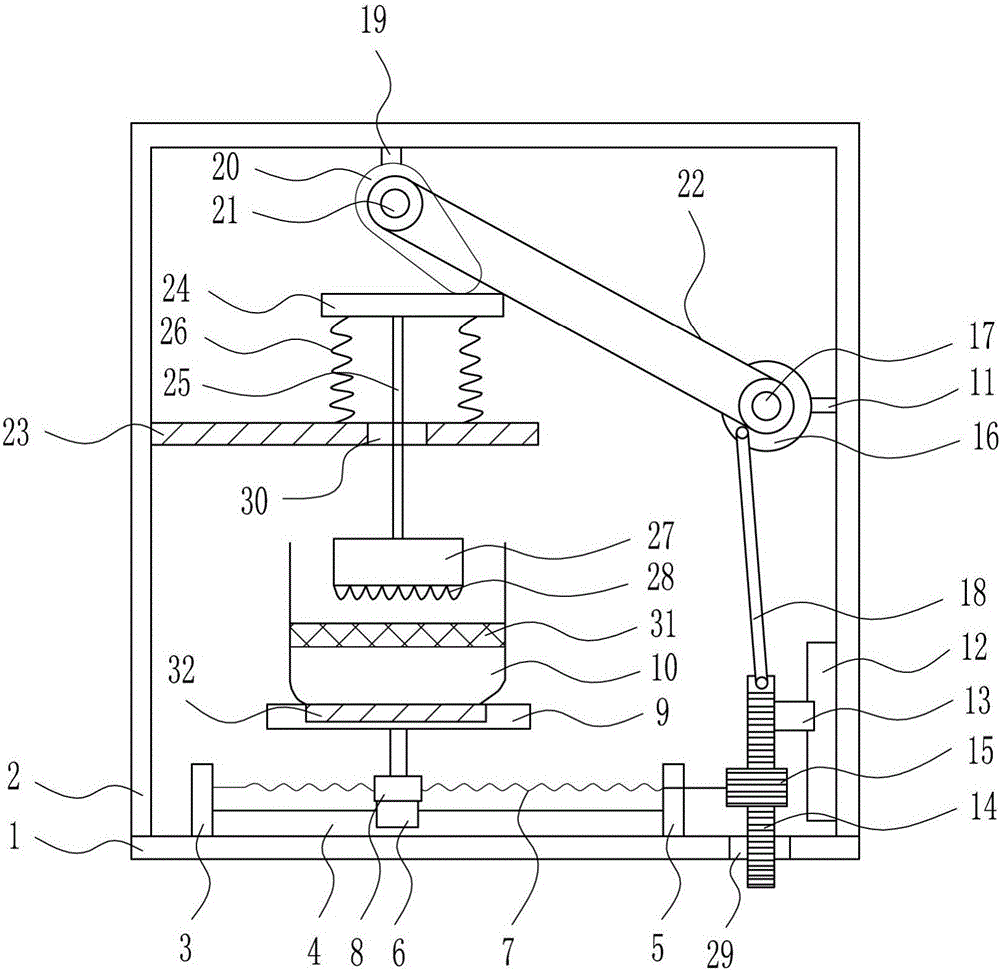

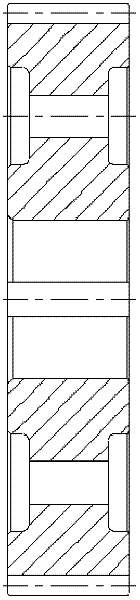

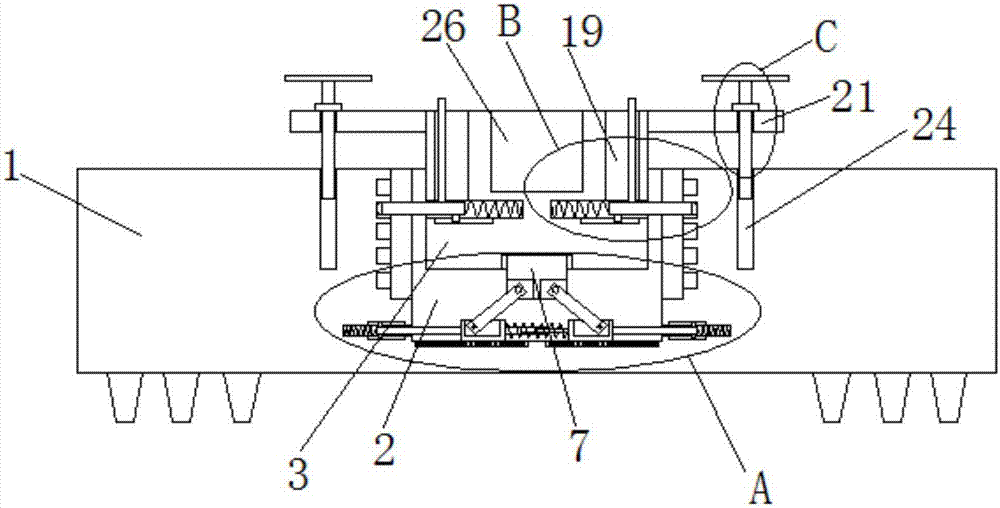

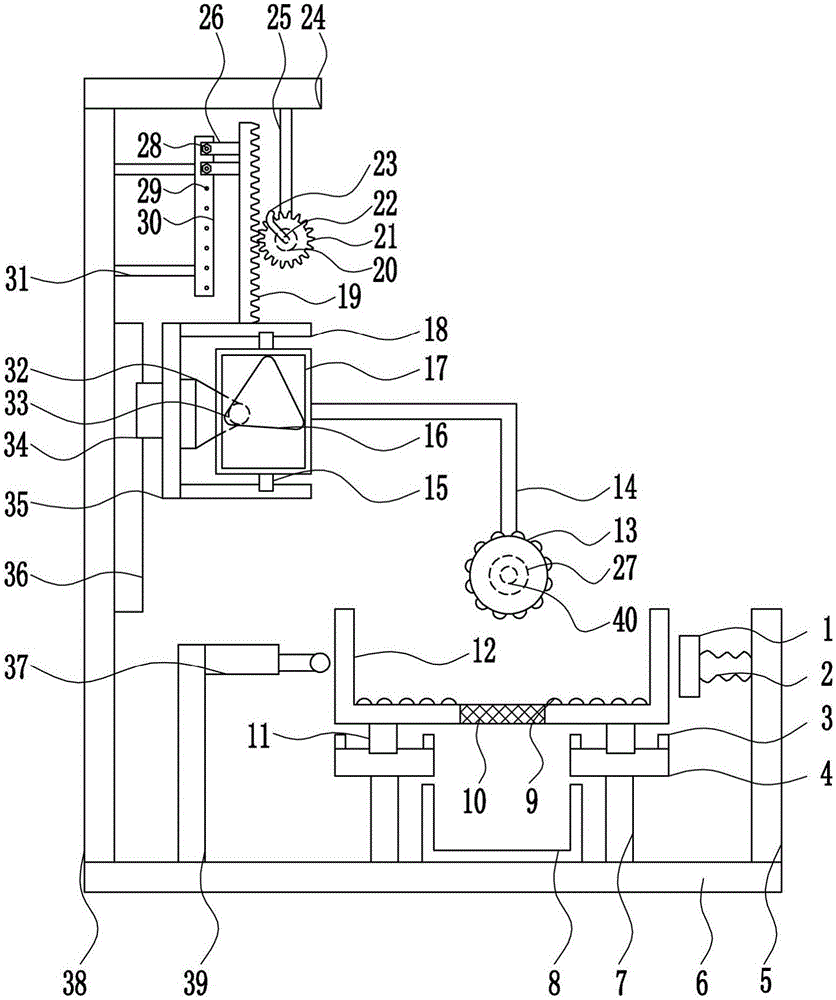

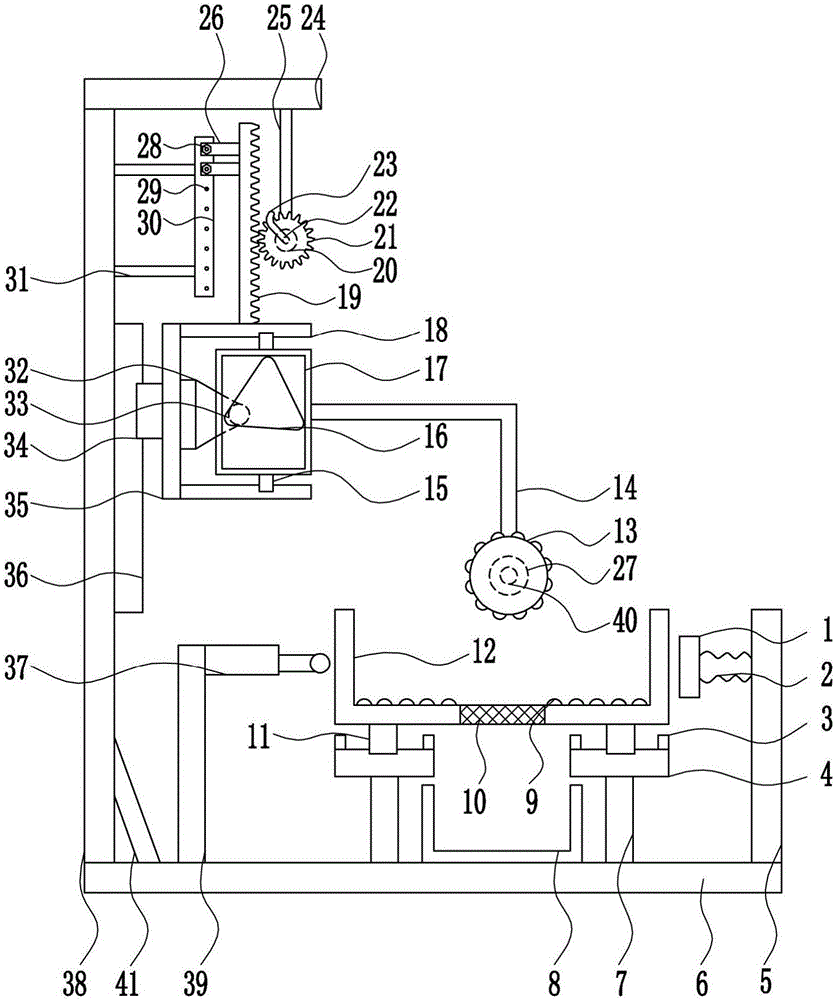

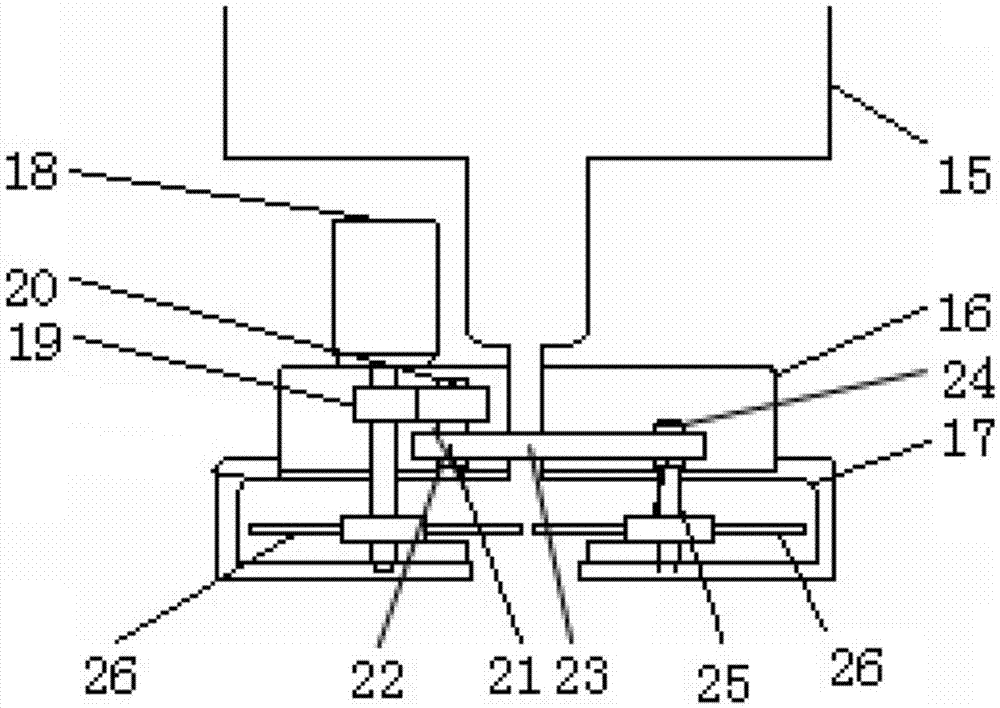

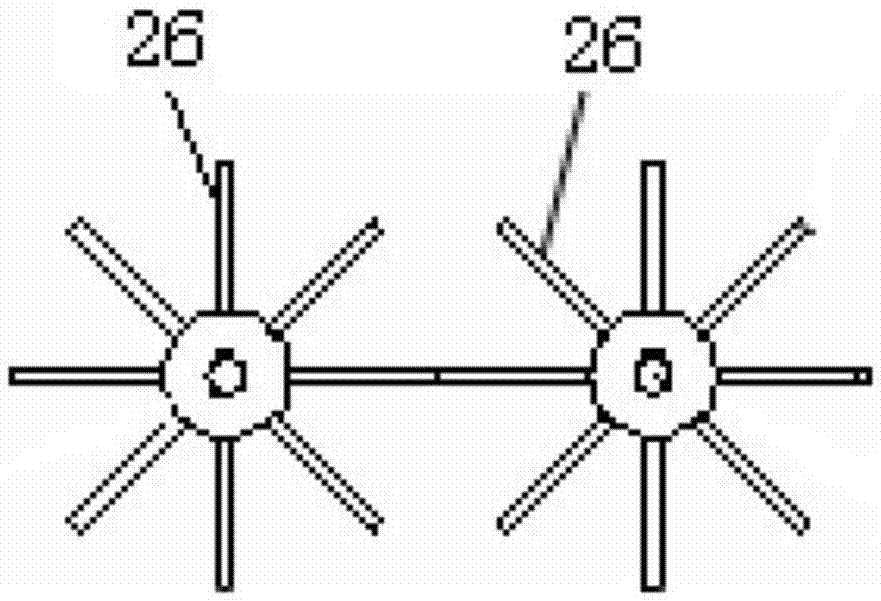

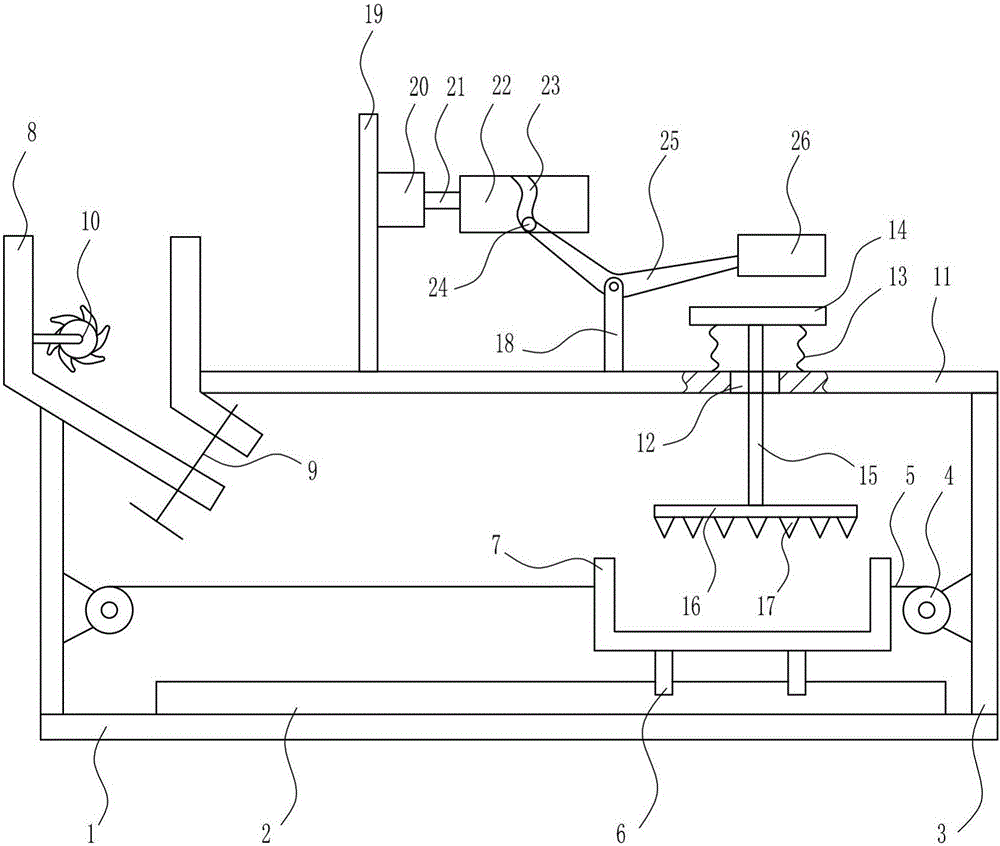

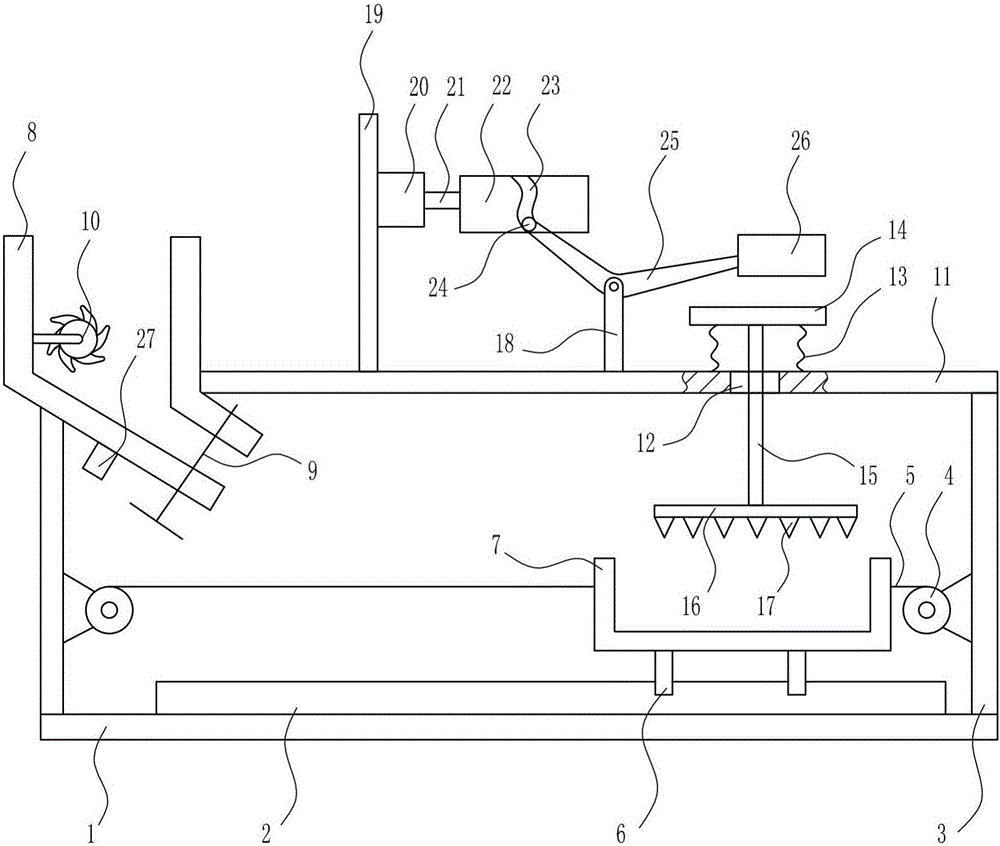

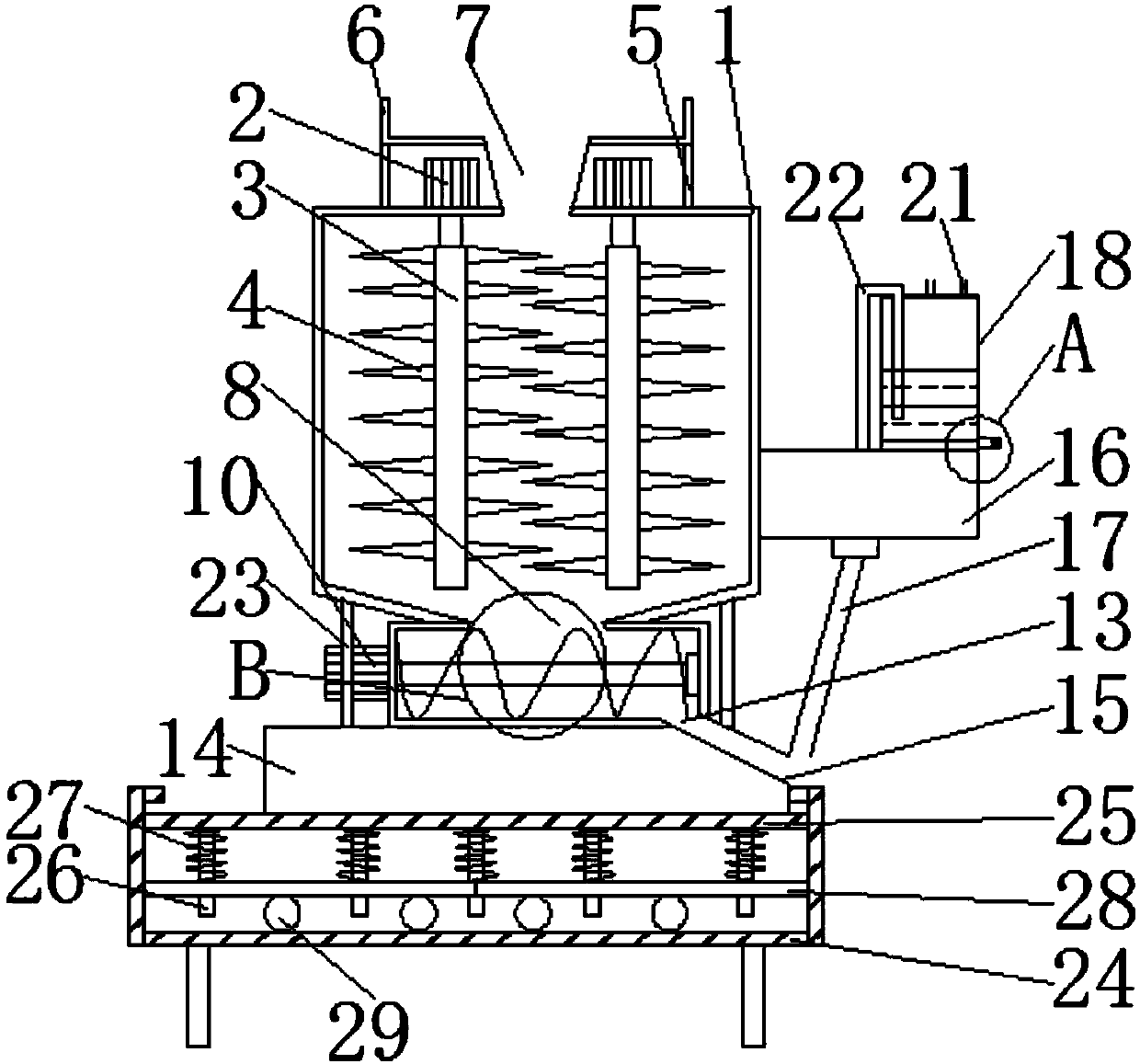

Medical rapid traditional Chinese medicine grinding device

InactiveCN106582929AImprove work efficiencyReduce labor intensityGrain treatmentsDrive wheelMedicine

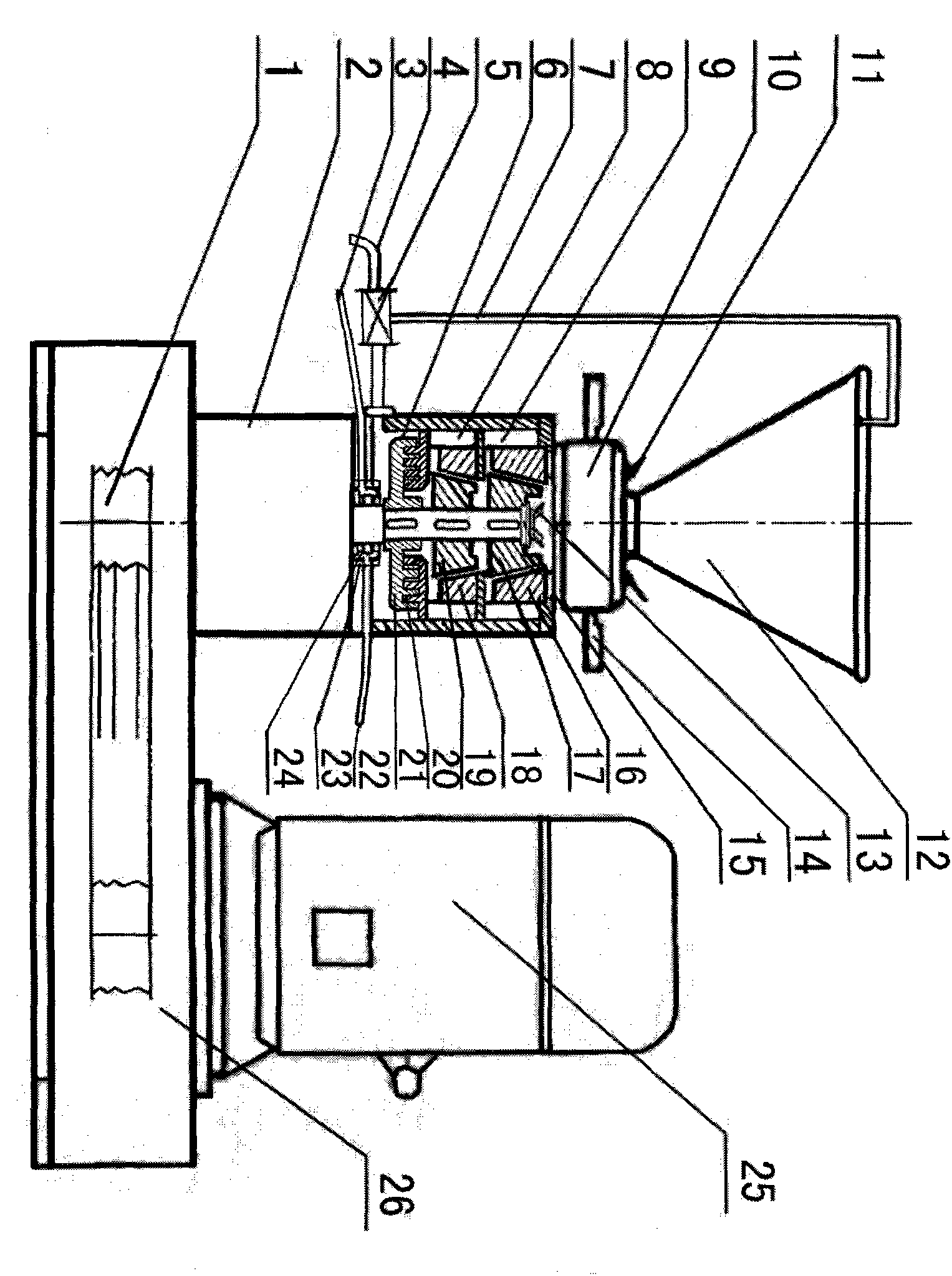

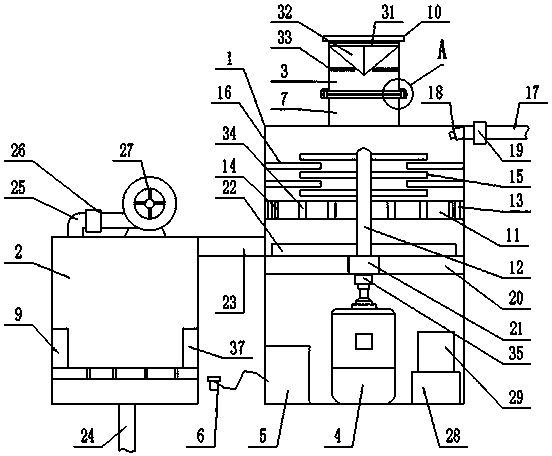

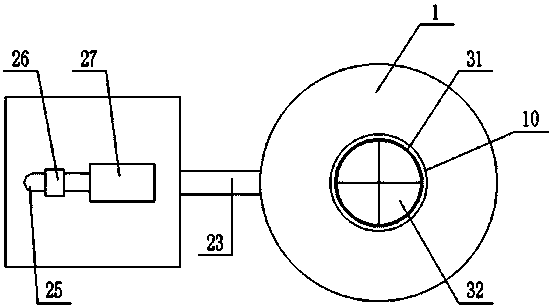

The invention relates to a grinding device, in particular to a medical rapid traditional Chinese medicine grinding device. The medical rapid traditional Chinese medicine grinding device is high in work efficiency, saves time and labor, and can relieve labor intensity. The medical rapid traditional Chinese medicine grinding device comprises a base plate, an N-shaped rack, a left bearing base, a first slide rail, a right bearing base, a first slide block, a screw rod, a nut, a holding plate, an iron grinding box, a first supporting rod, a second slide rail, a second slide block, a rack, a gear, a disc, a driven wheel, a connecting rod, a second supporting rod, a cam, an electric wheel, a belt, a guide plate, a fixing plate, a lifting rod, springs, a press block and grinding teeth, wherein the N-shaped rack is arranged at the top of the base plate. The medical rapid traditional Chinese medicine grinding device has the effects of being high in work efficiency, saving time and labor, and being capable of relieving labor intensity.

Owner:林大红

Quenching and tempering method in tooth punching process of gear with medium-hard tooth surface

InactiveCN102501035AHigh hardnessReduce pittingSolid state diffusion coatingFurnace typesHobbingTempering

Owner:NANJING JINXIN TRANSMISSION EQUIP

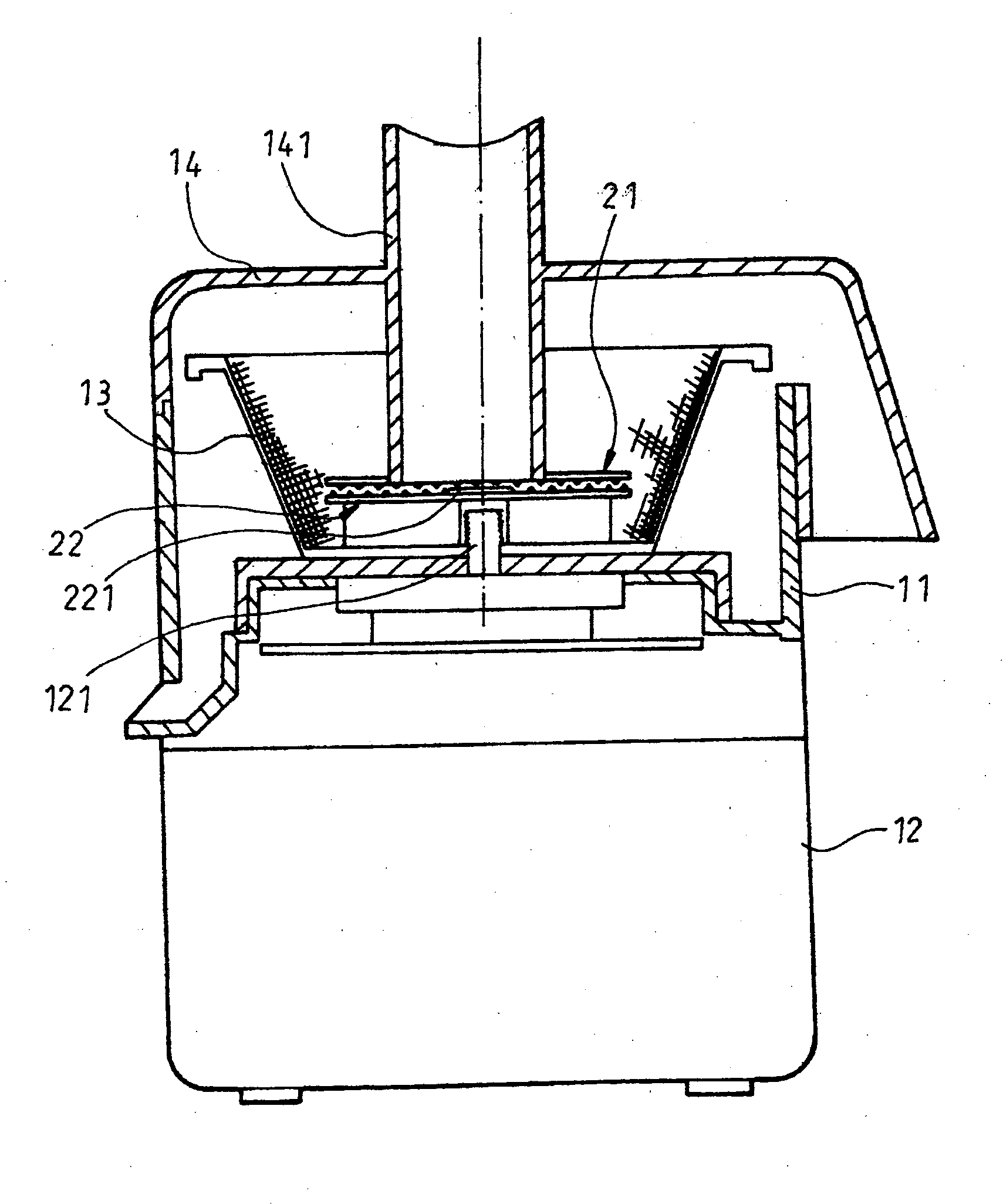

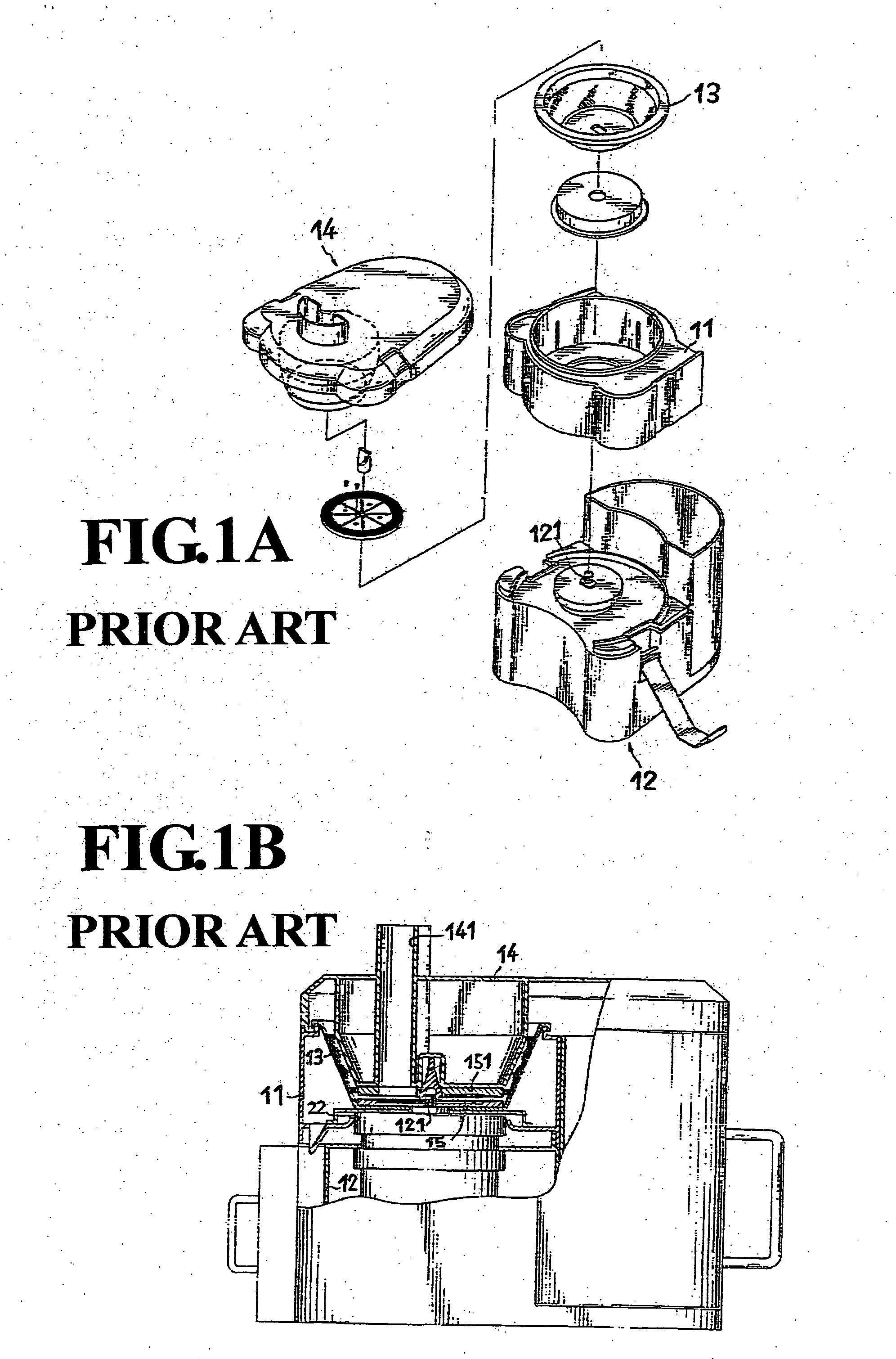

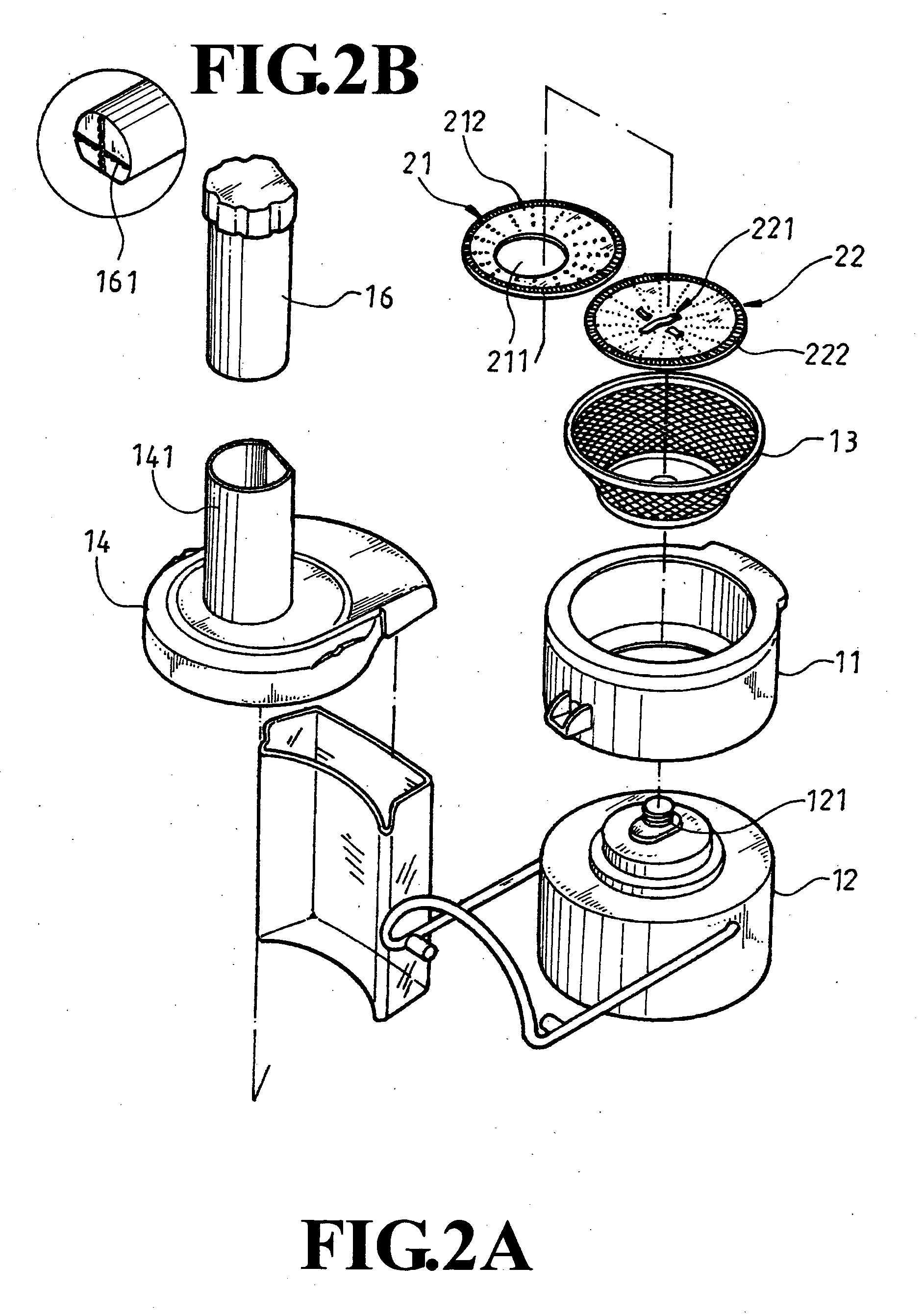

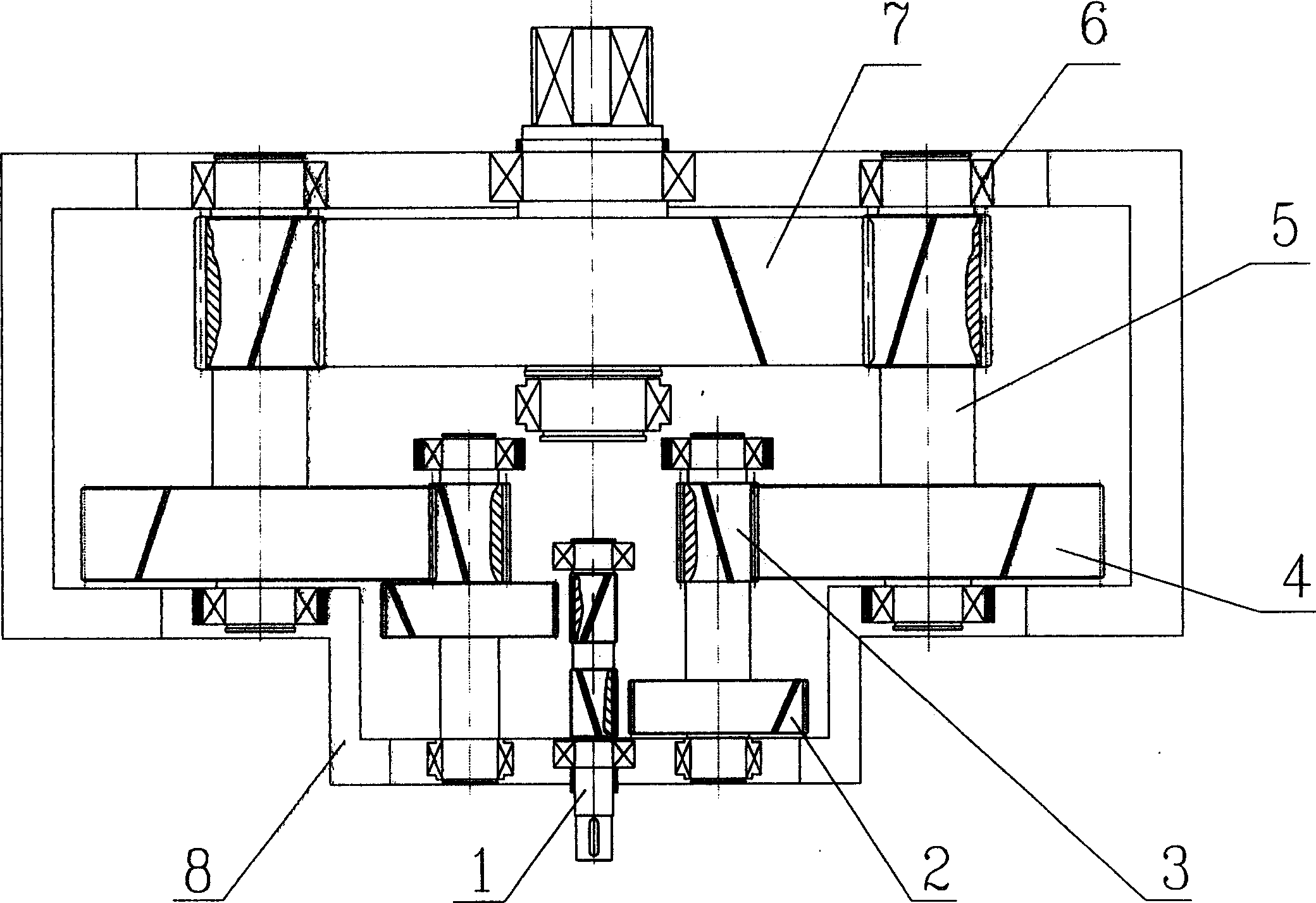

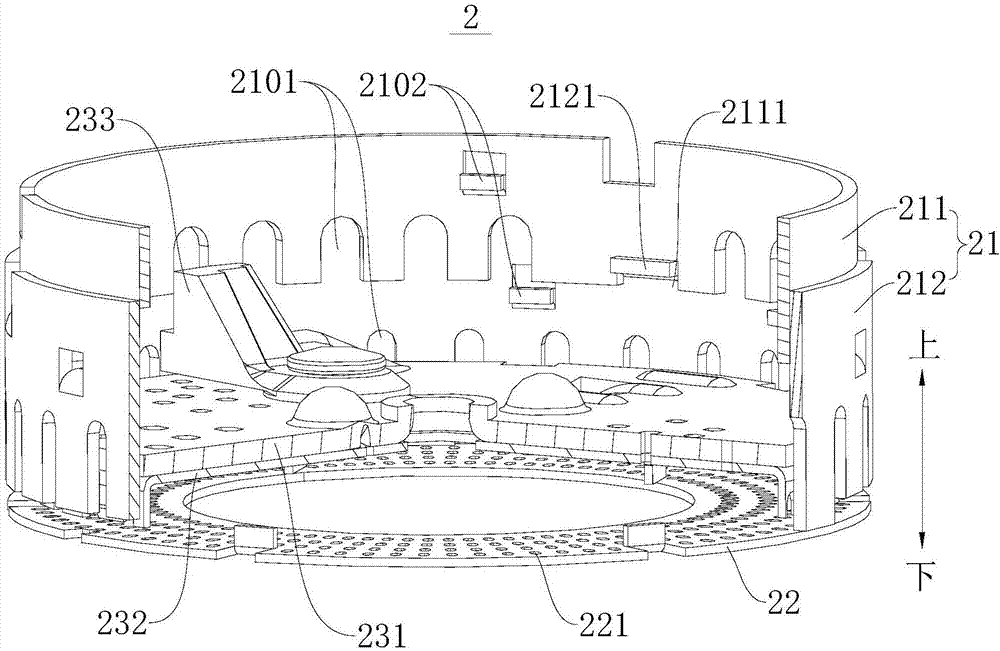

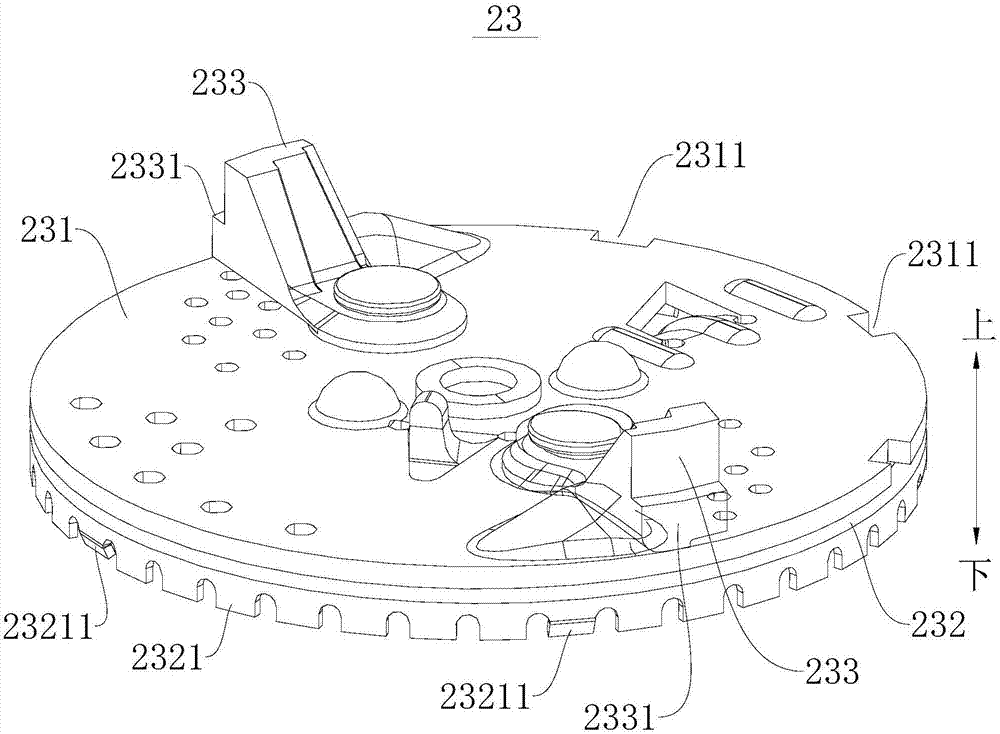

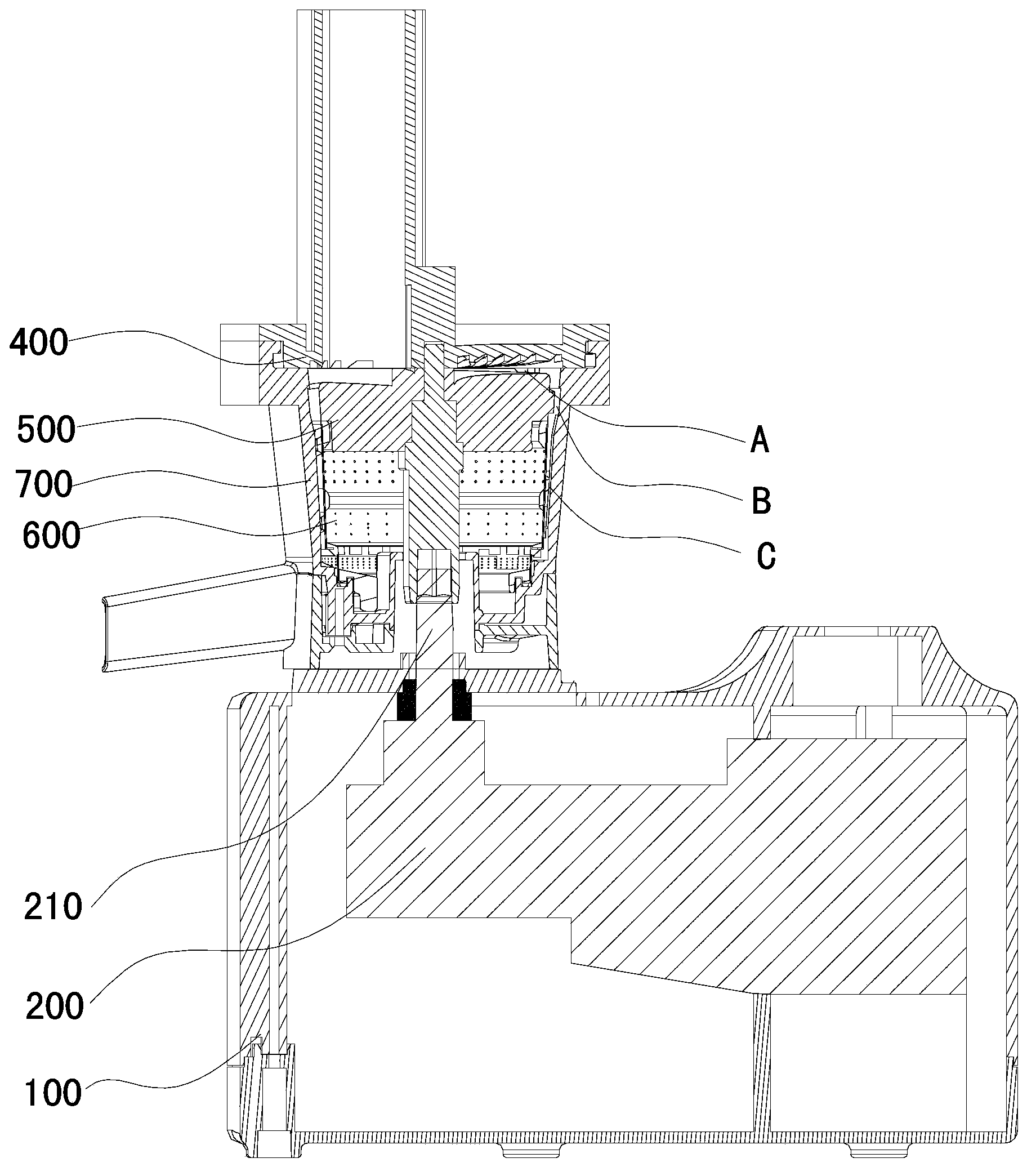

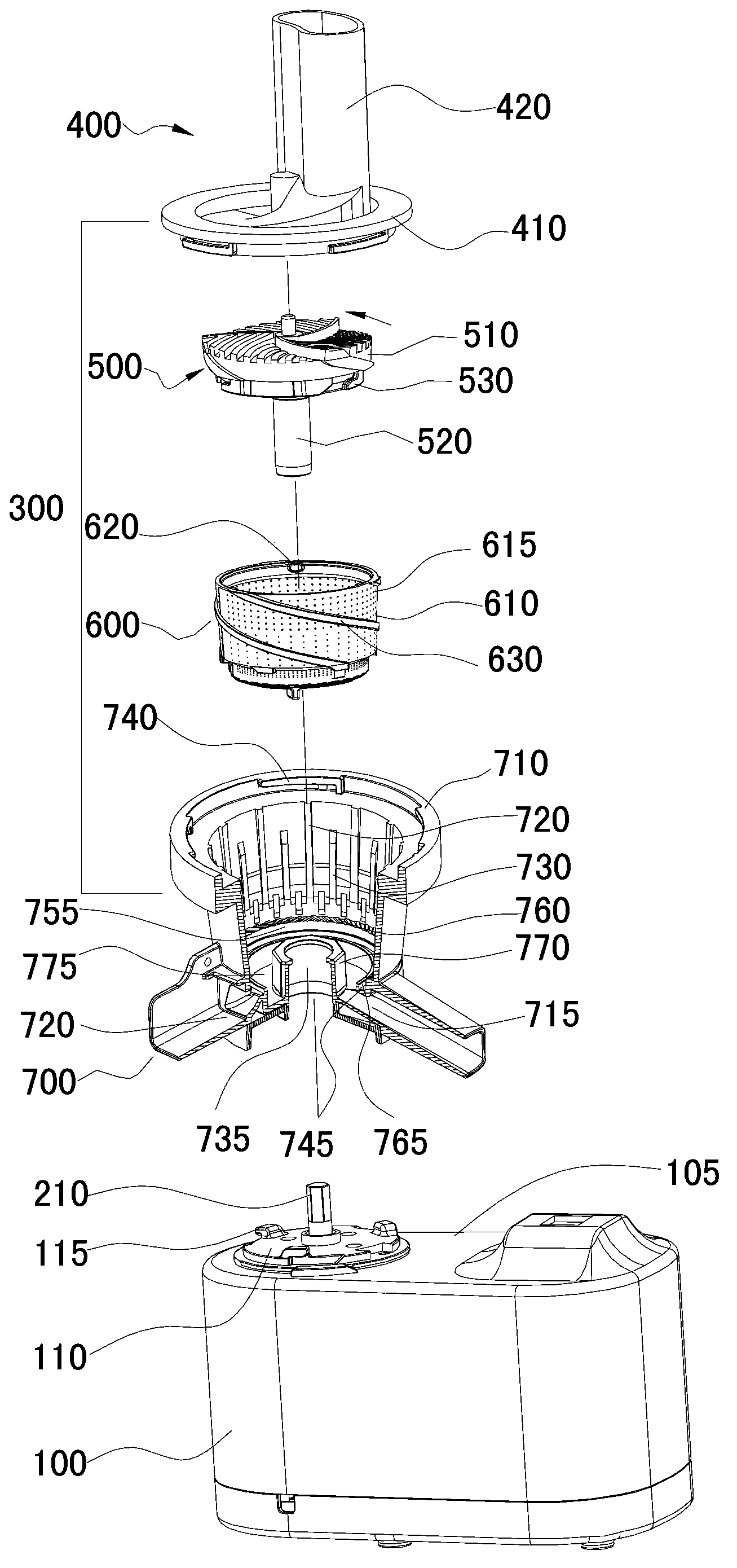

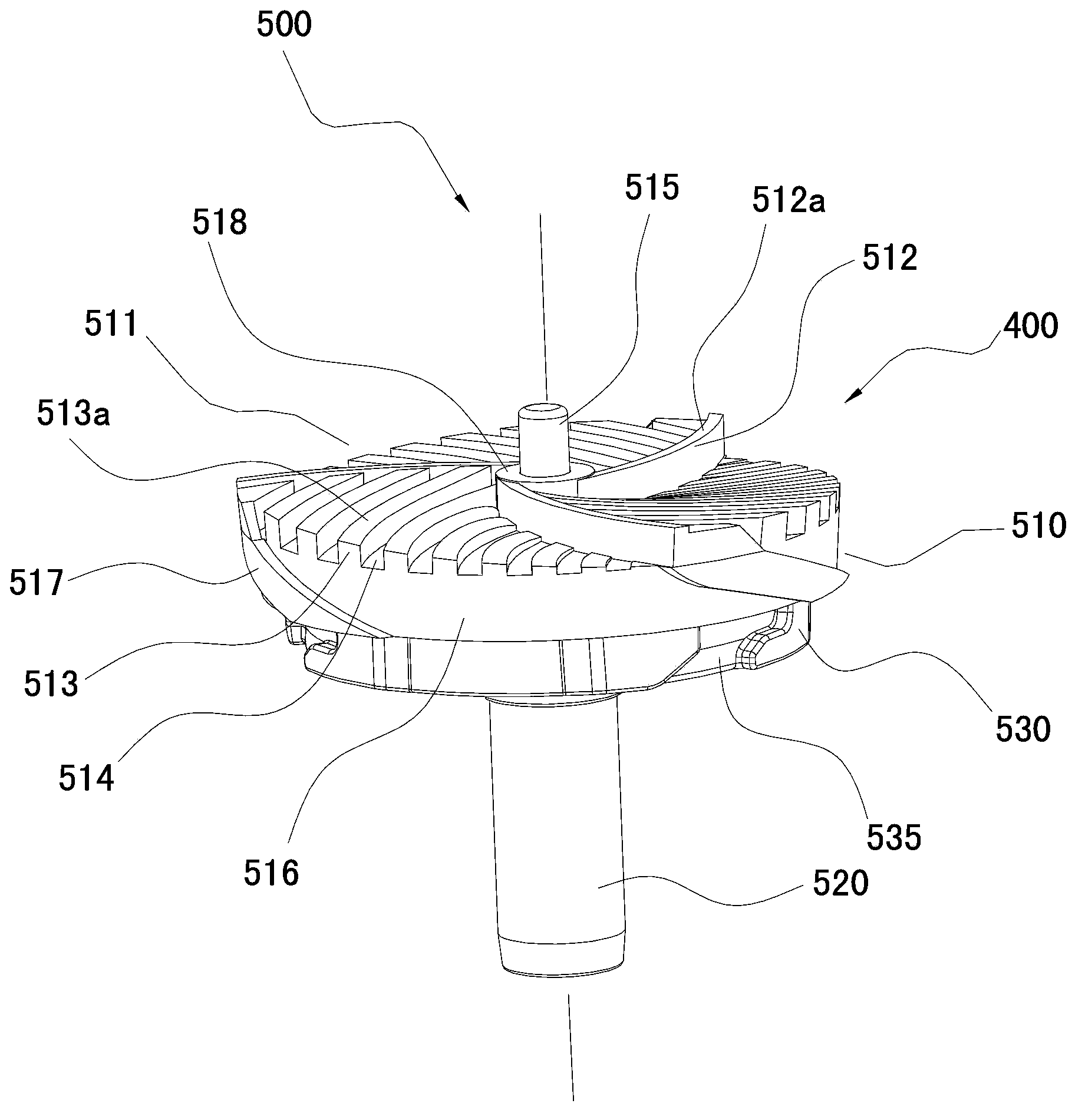

Food processor with combined grinding and juice extracting functions

InactiveUS20080115677A1Increase the areaEliminate dead areasJuice extractionGrain treatmentsEngineeringProcessor design

A food processor designed for grinding beans and cereals as well as extracting juice from fruits and vegetables includes a bowl, a base, a strainer basket, a cover, an upper grinding disc fixedly mounted around a bottom of a feed tube formed on the cover, and a lower grinding disc firmly connected to and driven by a driving mechanism on the base to rotate at high speed. Since the lower grinding disc is provided at a central area with differently shaped central blades and along a circumferential edge with multiple grinding teeth, the feed tube is offset from but overlaps a center of the lower grinding disc, and the upper grinding disc is provided with grinding teeth corresponding to the lower grinding disc, an expanded grinding area is available on and between the two grinding discs, and any dead area of grinding may be eliminated.

Owner:GREAT YEN ELECTRIC FOOD GRINDER

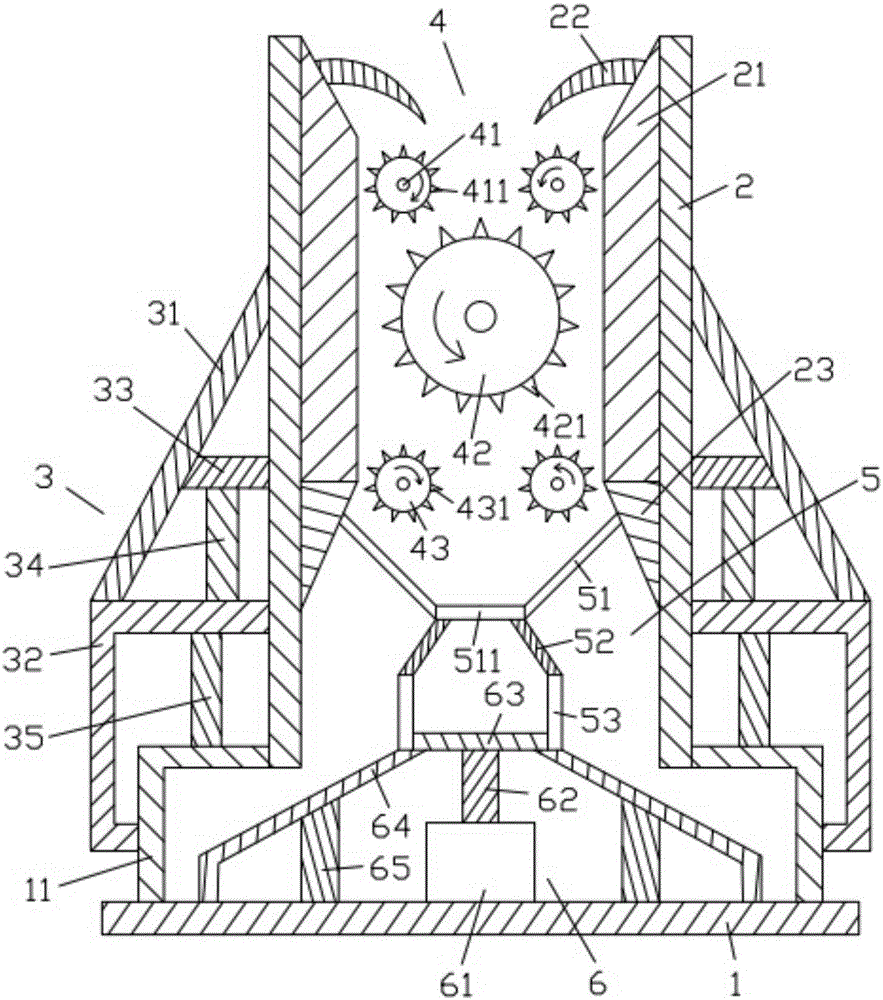

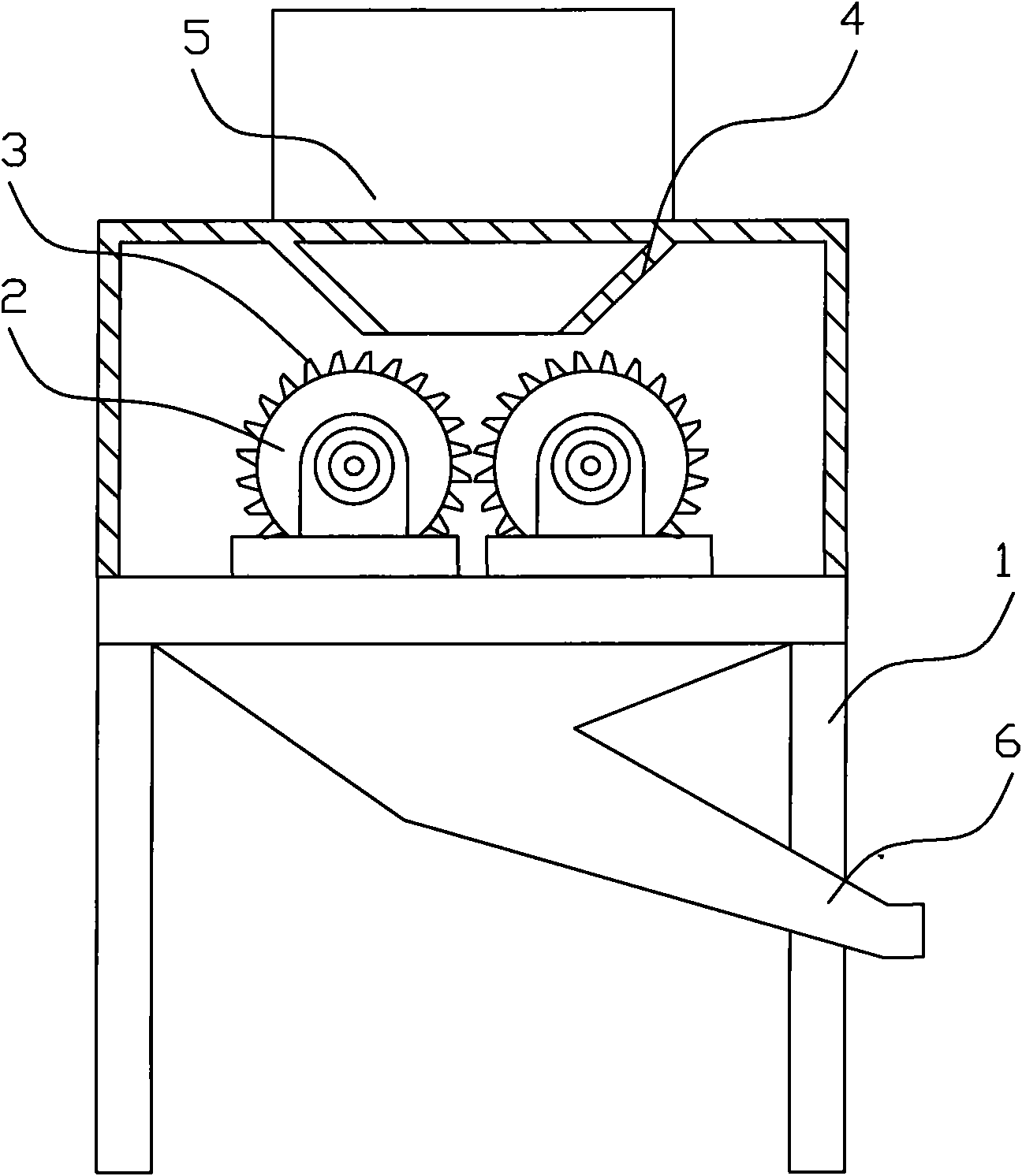

Novel maize grinding device

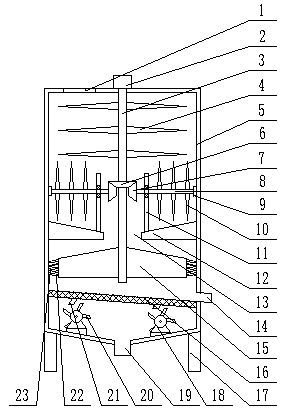

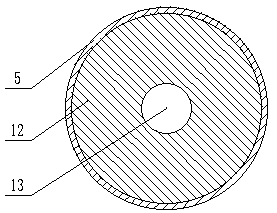

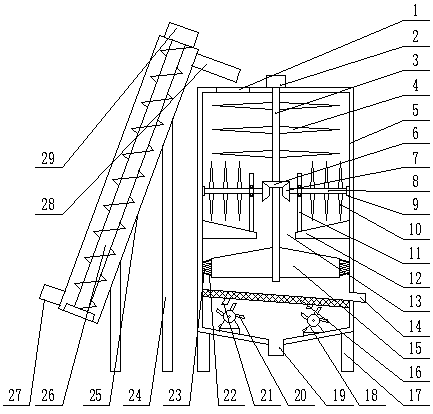

The invention discloses a novel maize grinding device. The novel maize grinding device comprises a bottom plate, a frame body, a fixing device, a grinding device, a feed divider and a rotating device, wherein the bottom plate comprises a first bracket, the frame body comprises a material collecting plate, an elastic plate and a triangular block, the fixing device comprises a first slanting rod, a second bracket, a first cross rod, a first vertical rod and a second vertical rod, the grinding device comprises a first grinding wheel, a first grinding tooth, a second grinding wheel, a second grinding tooth, a third grinding wheel and a third grinding tooth, the feed divider comprises a feed dividing screen, a through hole, a feed dividing plate and a filter screen, the rotating device comprises a motor, a rotating shaft, a rotating disk, a slanting plate and a first vertical rod, one end of the first bracket is fixedly connected with the side surface of the frame body, and one side surface of the triangular block is fixedly connected with the inner surface of the frame body. The novel maize grinding device disclosed by the invention is simple in structure and convenient to use, can be used for sufficiently grinding maize, reducing the production cost and filtering the ground maize, so that the intensity of manual labor is relieved, and the whole grinding operation is efficient and quick.

Owner:周午贤

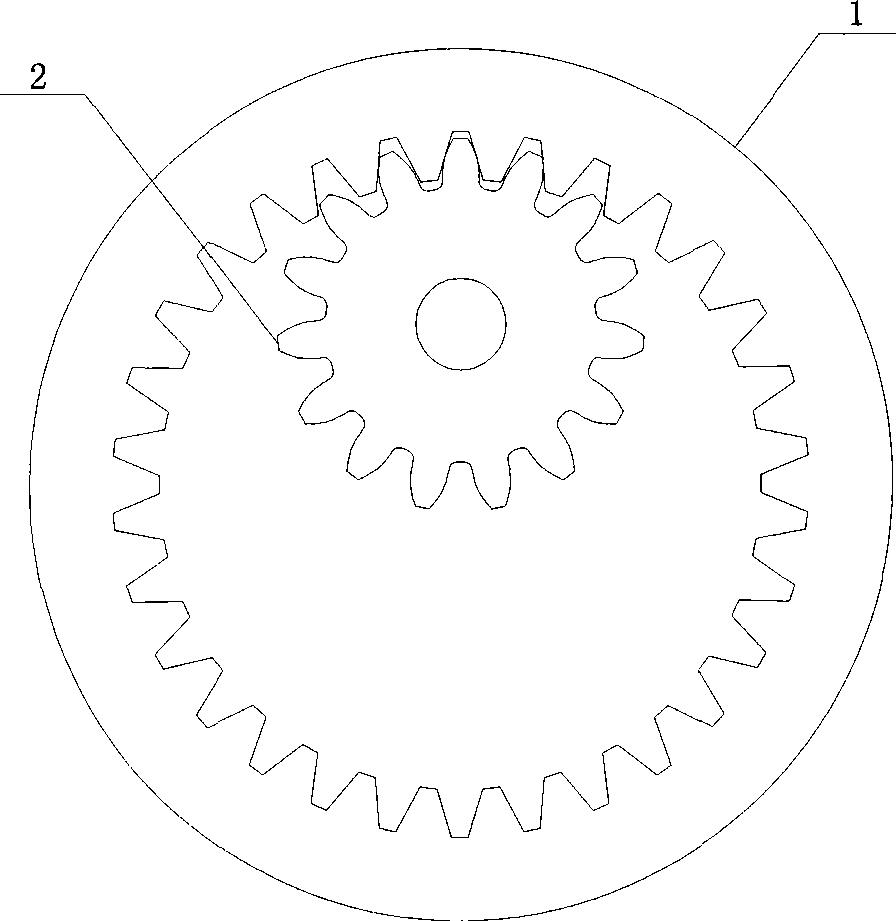

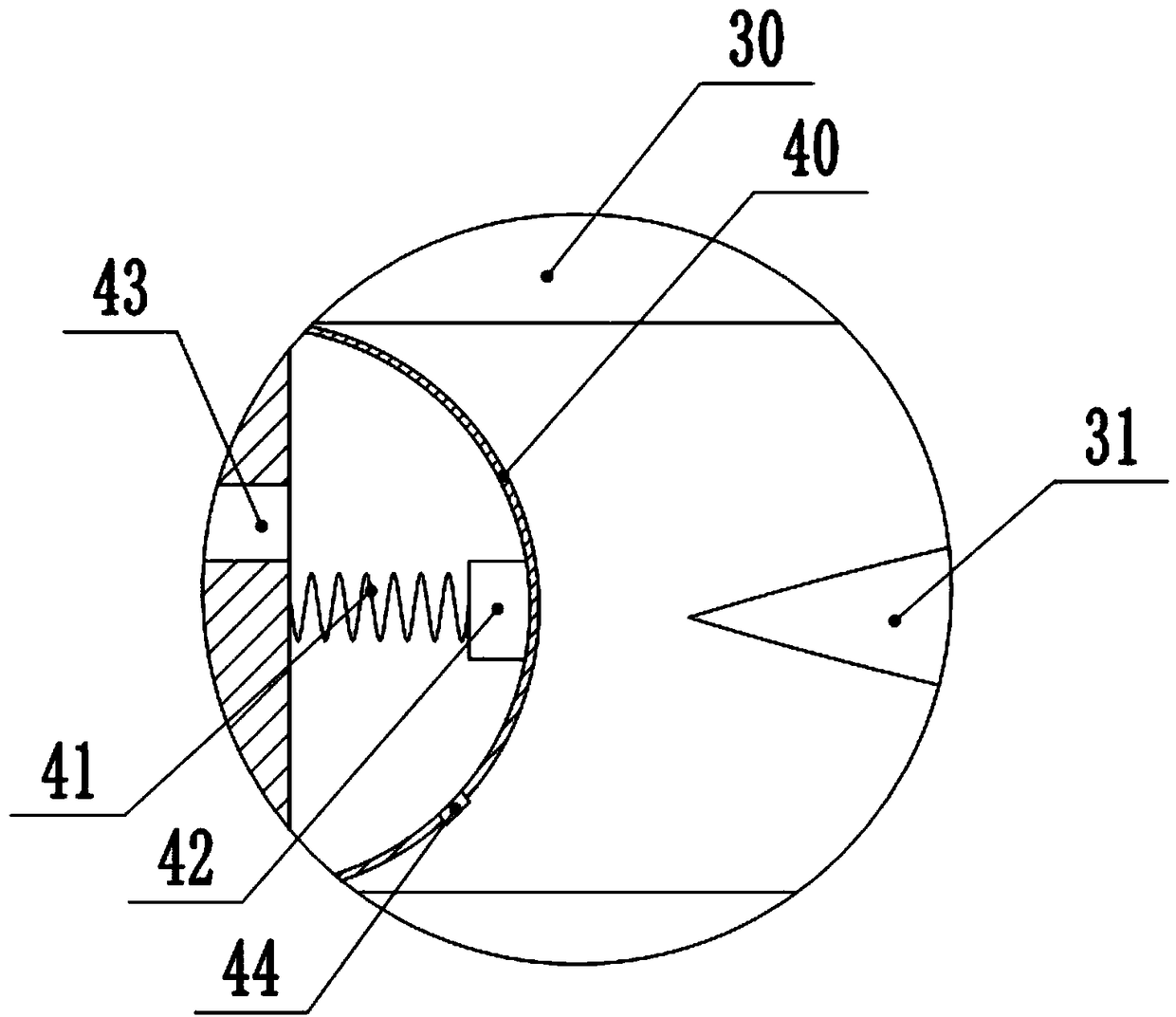

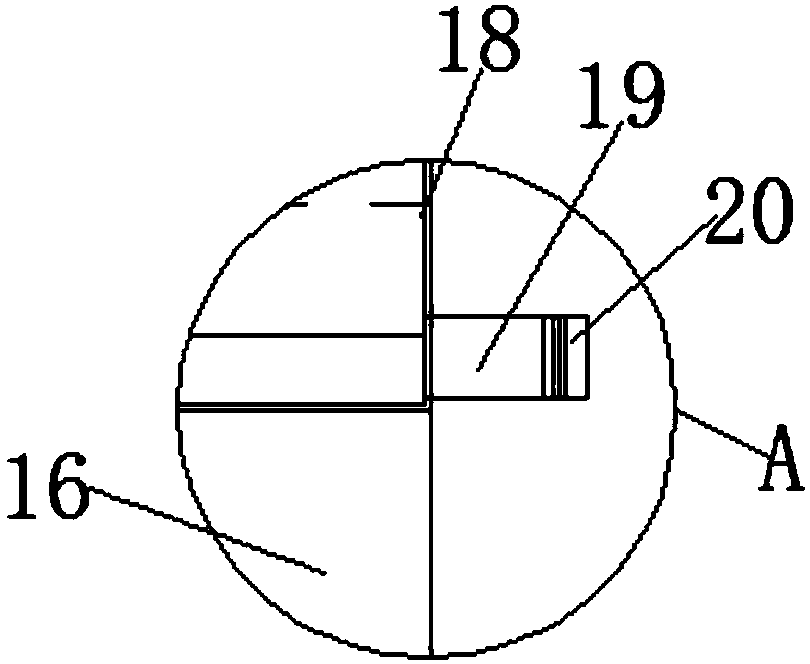

Ultra-hard material grinding fluted disc

InactiveCN107322494AEffective protectionExtended service lifeBonded abrasive wheelsSuperhard materialArchitectural engineering

The invention discloses an ultra-hard material grinding fluted disc which comprises a fluted disc body. A first circular groove is formed in the center of the side, away from teeth, of the fluted disc body. An installation base is installed inside the first circular groove, and one side of the installation base extends out of the first circular groove, a buffer module protecting the fluted disc body is arranged on the inner wall of the side, away from an opening, of the first circular groove, the two sides of the installation base are symmetrically provided with locking modules for fixing the installation base, the buffer module assists the locking modules for fixing the installation base, the buffer module comprises two fixing blocks which are symmetrically installed on the inner wall of the side, away from the opening, of the first circular groove in a sliding mode, and the two fixing blocks are each rotationally provided with a connecting rod. The buffer module can effectively protect the fluted disc body, the service life of the fluted disc body is prolonged, due to the combined action of the buffer module and the locking modules, the fluted disc body can be conveniently and rapidly disassembled and assembled, and therefore people can conveniently use the fluted disc body.

Owner:ZHENGZHOU JIACHEN CHEM TECH CO LTD

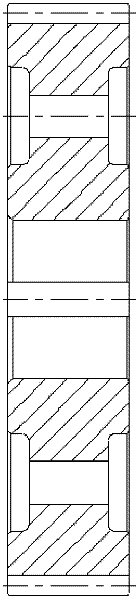

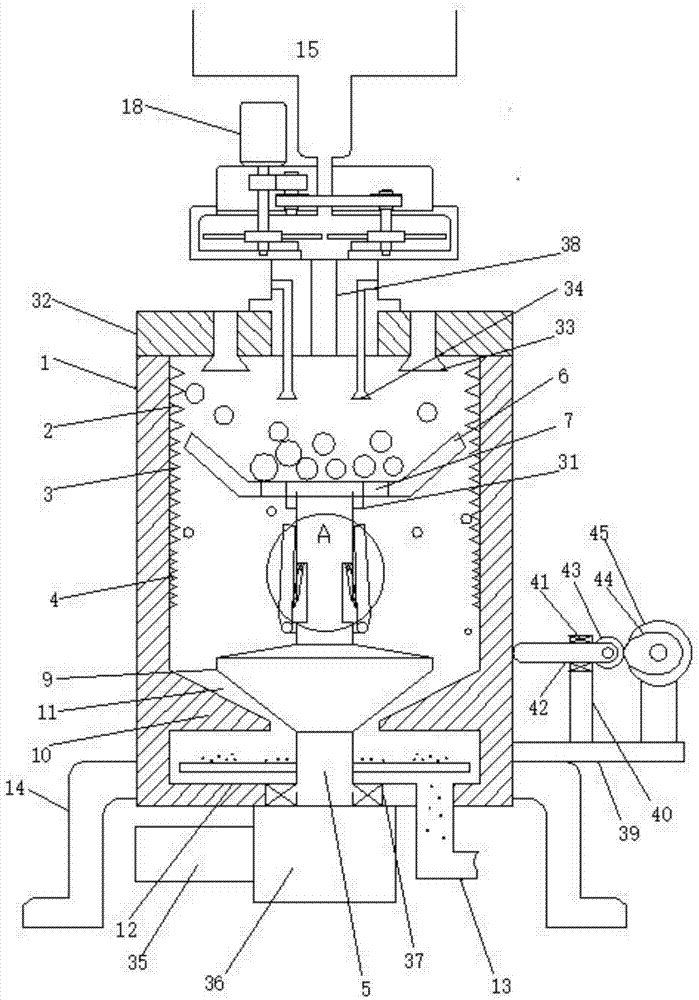

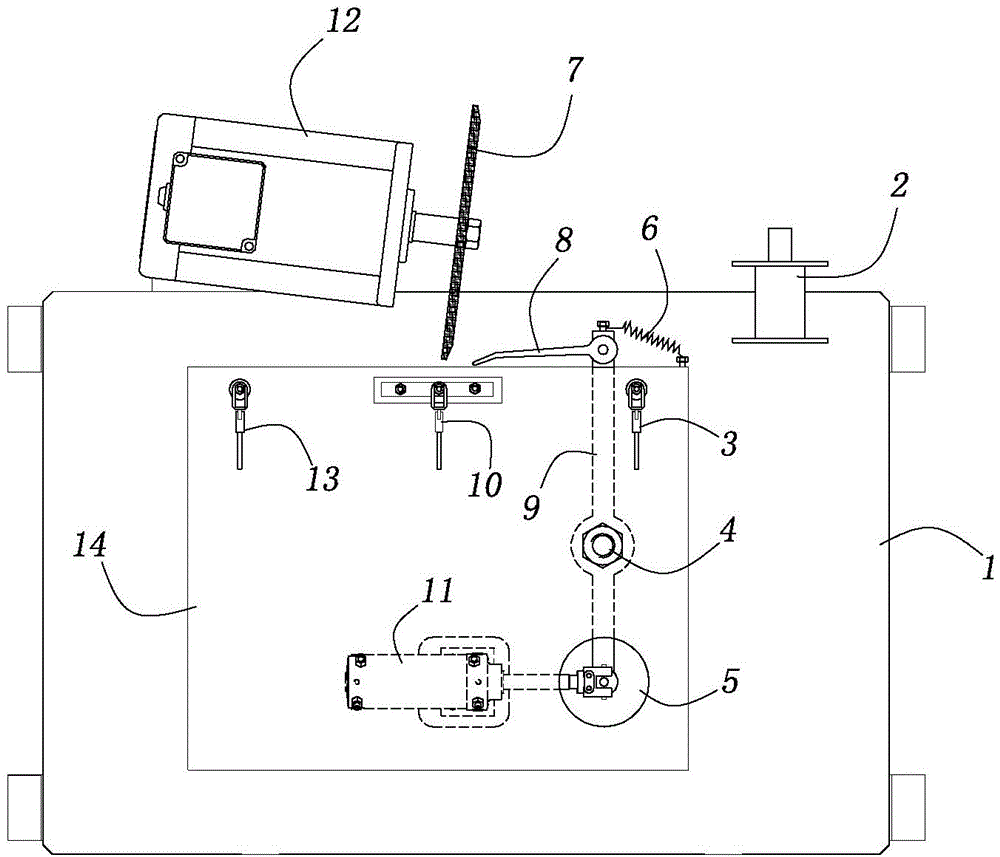

Multi-stage crushing/grinding/emulsifying colloid mill

The invention discloses a multi-stage crushing / grinding / emulsifying colloid mill. The multi-stage crushing / grinding / emulsifying colloid mill consists of a belt pulley, a main unit, a hopper, a stirring spinning blade, a handle, a shell, a first-stage stator, a first-stage rotor, a second-stage stator, a second-stage rotor, an emulsifier stator, an emulsifier rotor, a mechanical sealing water cooling joint, a mechanical sealing water cooling jacket, a mechanical sealing set, a motor, a base and the like, wherein the main unit and the motor are arranged on the base; two transmission wheels are arranged in the base; the hopper is arranged above an adjusting device and is a cone-shaped stainless steel product; a lug boss is arranged at the center of the bottom of the adjusting device; the stirring spinning blade is arranged in the lug boss; the first-stage stator is sleeved with the first-stage rotor; the second-stage stator is sleeved with the second-stage rotor; grinding teeth are arranged on the rotor and the stator respectively; the emulsifier stator is arranged right above the emulsifier rotor and is glued with the emulsifier rotor; the mechanical seal set is arranged below the emulsifier rotor. The multi-stage crushing / grinding / emulsifying colloid mill has the advantages of large discharge amount, high safety and the like.

Owner:杨剑英

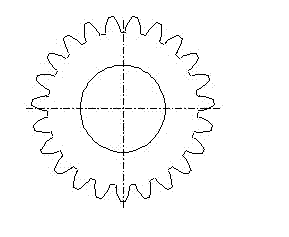

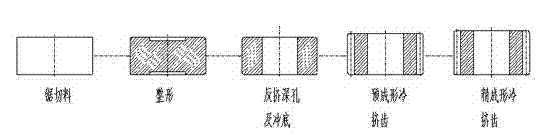

High-modulus straight-tooth cylindrical gear cold extrusion technology and special die thereof

The invention discloses a high-modulus straight-tooth cylindrical gear cold extrusion technology which comprises the following steps of: shearing or sawing a blank and charging the blank; shaping the blank; and performing counter-extrusion deep hole treatment and bottom impact treatment to form a hollow blank, then performing pre-forming cold extrusion tooth treatment and fine-forming cold extrusion tooth treatment, and performing an isothermal normalization or annealing technology and lubrication treatment between the two working procedures. In the prior art, the type of gear processed by the conventional forming technology needs to be ground, polished or lapped to reach the precision requirement. Compared with the prior art, the high-modulus straight-tooth cylindrical gear cold extrusion technology has the advantages that a straight-tooth cylindrical gear processed by the technology has high tooth-shaped precision and the tooth-direction precision reaching the level 9 to 10, and the tooth surface does not need subsequent processing. The working procedures of the technology are simple, the efficiency is high and heating is not needed, so that the energy consumption is greatly reduced; the die can be used for more than 100 thousand of times; and the cost is greatly reduced.

Owner:TAICANG JIUXIN PRECISION MOLD

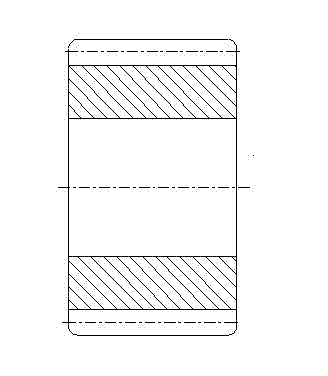

Processing method for internally toothed annulus

The invention provides a processing method for an internally toothed annulus, which comprises the following steps: selecting a low-carbon steel tooth billet and carrying out rough lathing after the tooth billet is forged and normalizing treatment is performed; roughly machining the tooth billet into a tooth profile; conducting carburizing, quenching and high temperature tempering on the toothed part, and finally carrying out the shot peening; conducting finish machining on a datum plane; and conducting finish machining on the tooth profile through tooth grinding. The method solves the hardness problem of the toothed surface of the internally toothed annulus, adopts a low carbon steel material, carries out tough tooth punching before heating, and grinds the toothed part after cemented quenching; the hardness of the toothed surface can reach HRC 58 to 62, so as to thoroughly eliminate the pitting corrosion of the toothed surface and prolong the service lives of parts; as the tooth grinding process is carried out after heating, the precision of the toothed annulus can be above 6 grade; as the precision grade of the toothed part is improved after the tooth grinding process, the transmission of the toothed annulus becomes smoother; and as the tooth punching process is carried out before heating, the parts are low in hardness in the normalized condition, which provides convenience for tooth punching and improves the processing efficiency.

Owner:NANJING JINXIN TRANSMISSION EQUIP

Environment-friendly garbage processor

InactiveCN108325655AReduce pollutionImprove secondary utilizationDomestic plumbingMedical waste disposalElectricityImpeller

The invention discloses an environment-friendly garbage processor including a machine shell, a storage box, a feeding cylinder, a crushing and grinding device, a driving motor, a water supply device,a drainage device, a drying device, a controller and a switch; a sending cylinder is arranged at the center of the upper end of the machine shell, and a feeding cylinder is arranged above the sendingcylinder and is internally provided with an anti-splashing device; the crushing and grinding device jointly consists of a grinding cutterhead, a rotating shaft, a grinding gear ring, cutterhead grinding teeth, a cutting knife and a baffle knife; the water supply device jointly consists of a water supply pipe, a nozzle and a first solenoid valve; the drainage device jointly consists of a drainage plate, a drainage impeller and a drainage pipe; a drain pipe is connected at the bottom of the storage box, a filter plate, an electric heater and an ultraviolet sterilization lamp are arranged in thestorage box, and an exhaust pipe is connected at the top end of the storage box. The environment-friendly garbage processor has the beneficial effects of simple structure and high practicability.

Owner:阚建发

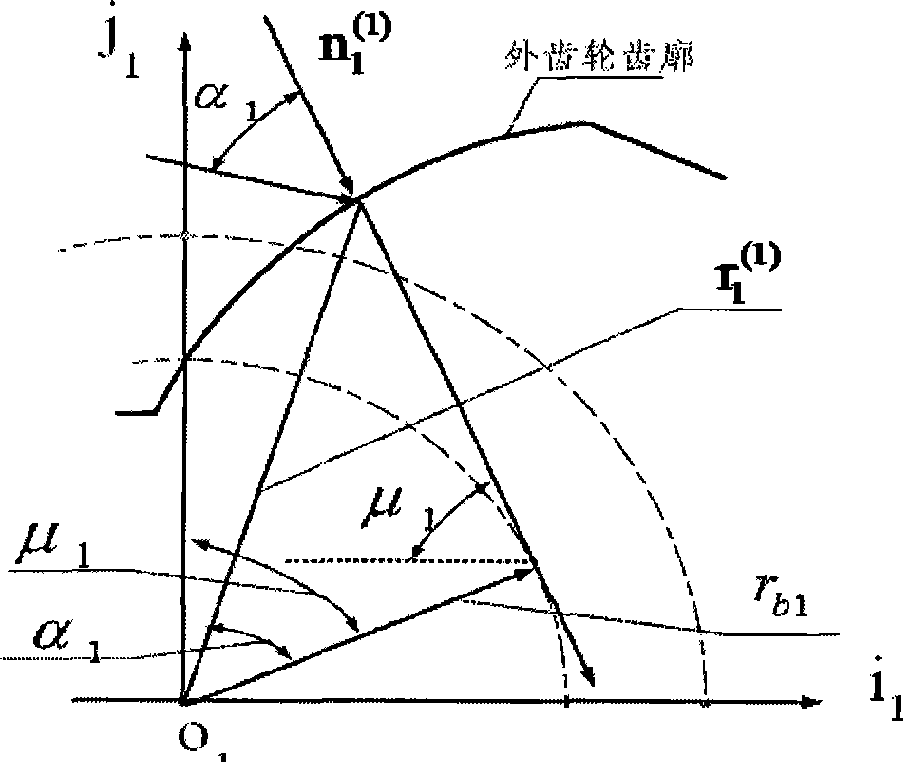

Straight line-involute profile inner-gearing cylindrical gear pair

InactiveCN101476614AImprove manufacturing precisionHigh precisionToothed gearingsPortable liftingGear wheelEngineering

The invention discloses a meshed cylindrical gear pair in a linear-involute tooth profile, which comprises an internal gear and a gear in meshing transmission with the internal gear. The tooth profile of the internal gear is linear, and the tooth profile of the gear in meshing transmission with the internal gear is involute. The tooth profile of the internal gear is changed into a straight line from an involute, grinding teeth can be shaped only by linearly finishing by a grinding wheel, the finishing efficiency is remarkably improved, and the precision can reach grade 4 to 6; and the internal gear adopts low-carbon steel carburization quenching, not only has high tooth surface strength, but also does not need to adjust quality before quenching, and improves the gear shaping processing efficiency greatly, so the meshed cylindrical gear pair radically solves the problems of low processing efficiency of the internal gear, poor precision and low tooth surface hardness, and promotes overall performances of a high-speed heavy duty speed reducer (speed increaser) containing the internal gear pair made in China.

Owner:HENAN UNIV OF SCI & TECH

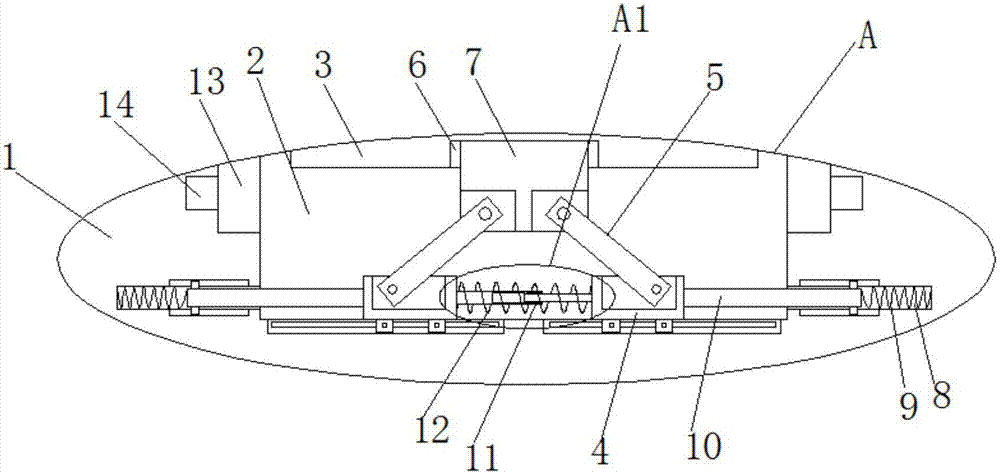

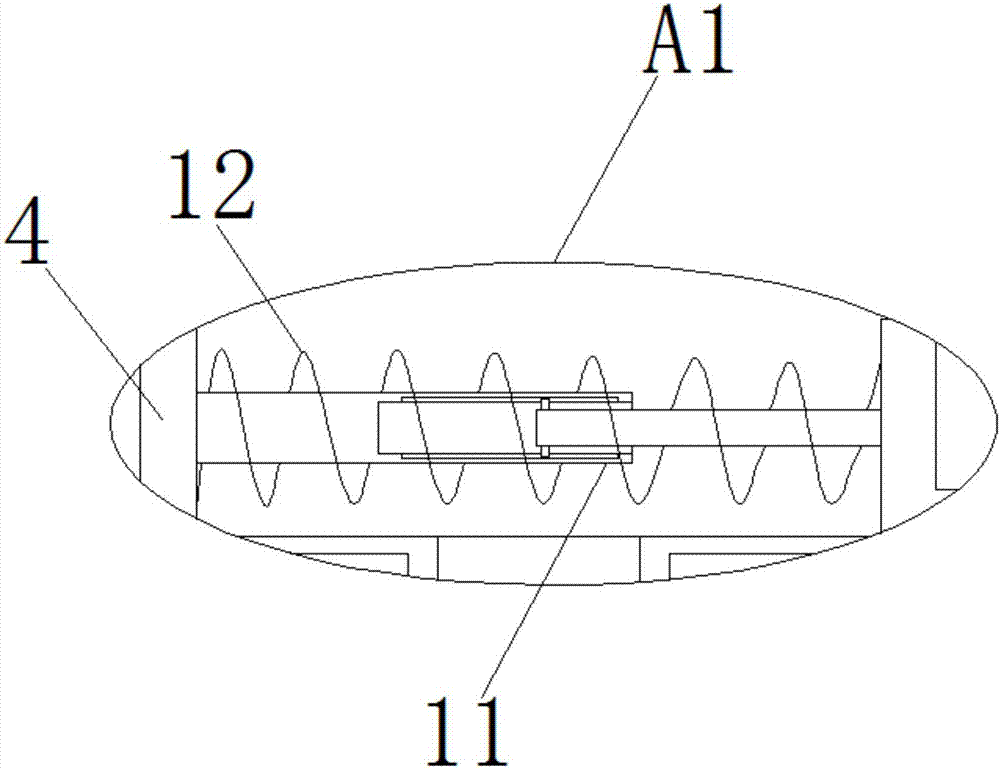

Fodder grinding device for feeding farm

The invention relates to a fodder grinding device, in particular to a fodder grinding device for a feeding farm. The fodder grinding device for the feeding farm is uniform in grinding and good in grinding effect and saves time and labor; in order to achieve the technical aims, the fodder grinding device for the feeding farm comprises a baffle, a spring, a check block, a first sliding rail, a right frame, a bottom plate, a first support, a collecting frame, grinding teeth, a screen plate, a first sliding block, a grinding frame, a roller and the like; a left frame is welded to the left end of the top of the bottom plate, a top plate is welded to the top of the left frame, a second support is welded to the right side of the bottom of the top plate, and the bottom end of the second support is connected with a first bearing pedestal in a bolt connection manner. The effects of being uniform in grinding and good in grinding effect and saving time and labor are achieved, the important effect exerted by the device shows the good grinding effect, the work efficiency is improved, and safety is high.

Owner:江苏蜀星饲料科技有限公司

Chinese medicinal material crushing and grinding device convenient to discharging

PendingCN109012937AImprove crushing efficiencyImprove grinding qualityGrain treatmentsEngineeringGRINDING TOOTH

The invention discloses a Chinese medicinal material crushing and grinding device convenient to discharging. The Chinese medicinal material crushing and grinding device convenient to discharging comprises a shell and supporting legs. A first rotating shaft is connected with the middle of the upper end of the shell through a rotating motor, a first crushing blade is fixedly connected with the outerside of the upper end of the first rotating shaft, and a second crushing blade is arranged below the first crushing blade. A second inclined body is arranged below the second crushing blade, the outer edge of the second inclined body is fixedly connected with first grinding teeth, and the inner side wall of the shell is fixedly connected with second grinding teeth. A screen arranged obliquely isarranged below the second inclined body, elastic blocking plates are fixedly connected with the two sides of the lower end of the screen, vibrating motors are arranged below the elastic blocking plates, and a feeding barrel arranged inclined is arranged on the left side of the shell. According to the Chinese medicinal material crushing and grinding device convenient to discharging, the structure is simple, design is reasonable, automatic feeding can be completed, meanwhile, screening can be carried out after crushing and grinding, the screening speed is high, and a batch of Chinese medicinal materials which meet the requirements can be quickly produced.

Owner:TONGLING FENGDAN PLANTING TECH DEV

Kiwi fruit pulping apparatus

InactiveCN108402429AFully brokenIncrease contact timeRotating receptacle mixersTransportation and packagingActinidiaInlet valve

The invention relates to the technical field of jam preparation equipment, and specifically discloses a kiwi fruit pulping apparatus. The kiwi fruit pulping apparatus comprises a pulping barrel; a stirring shaft is arranged at a bottom of the pulping barrel; a bottom of the stirring shaft is connected with a transmission mechanism; a planetary gear set is connected between the stirring shaft and the pulping barrel; pulp beating rods are arranged on an inner wall of the pulping barrel; stirring blades are arranged on the stirring shaft, wherein one row of the stirring blades are permanent magnets; air bags are arranged on a side wall of the pulping barrel; pressure springs are arranged in the air bags, and are connected with push blocks, wherein the push blocks are permanent magnets and areopposite to close ends of the stirring blades with regard to magnetic poles; an one-way water inlet valve is formed on the pulping barrel, and is connected with a water supply device; one-way water outlet valves are arranged on the air bags; a first millstone is fixed on the pulping barrel; a second millstone is arranged under the first millstone; through holes are formed in the first millstone and the second millstone; and grinding teeth are arranged on an lower surface of the first millstone and an upper surface of the second millstone. Uniform kiwi pulp with relatively fine particle size can be prepared by adopting the technical scheme of the kiwi fruit pulping apparatus.

Owner:WUCHUAN COUNTY JINFENG KIWI CROP FARMER PROFESSIONAL COOP

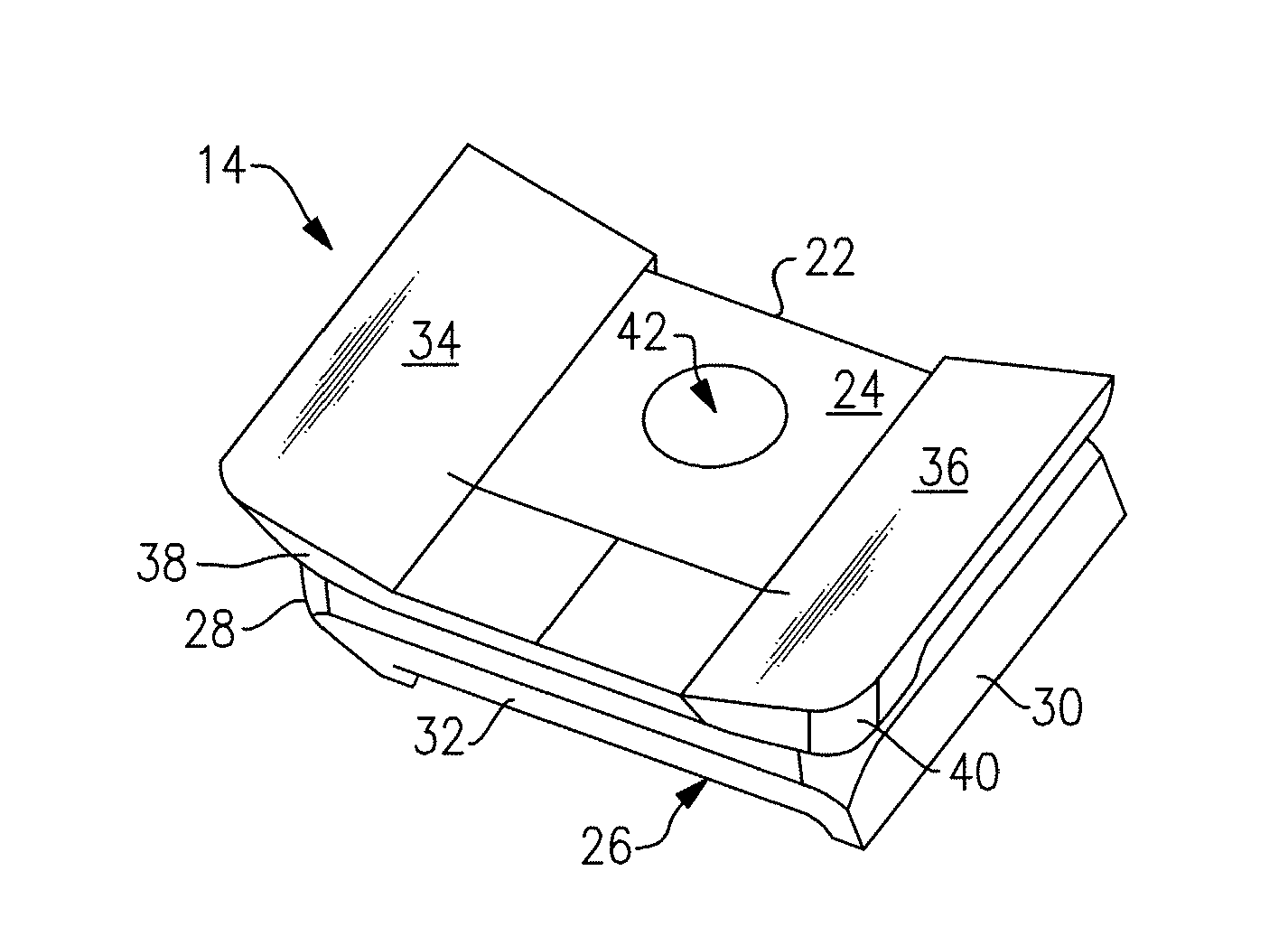

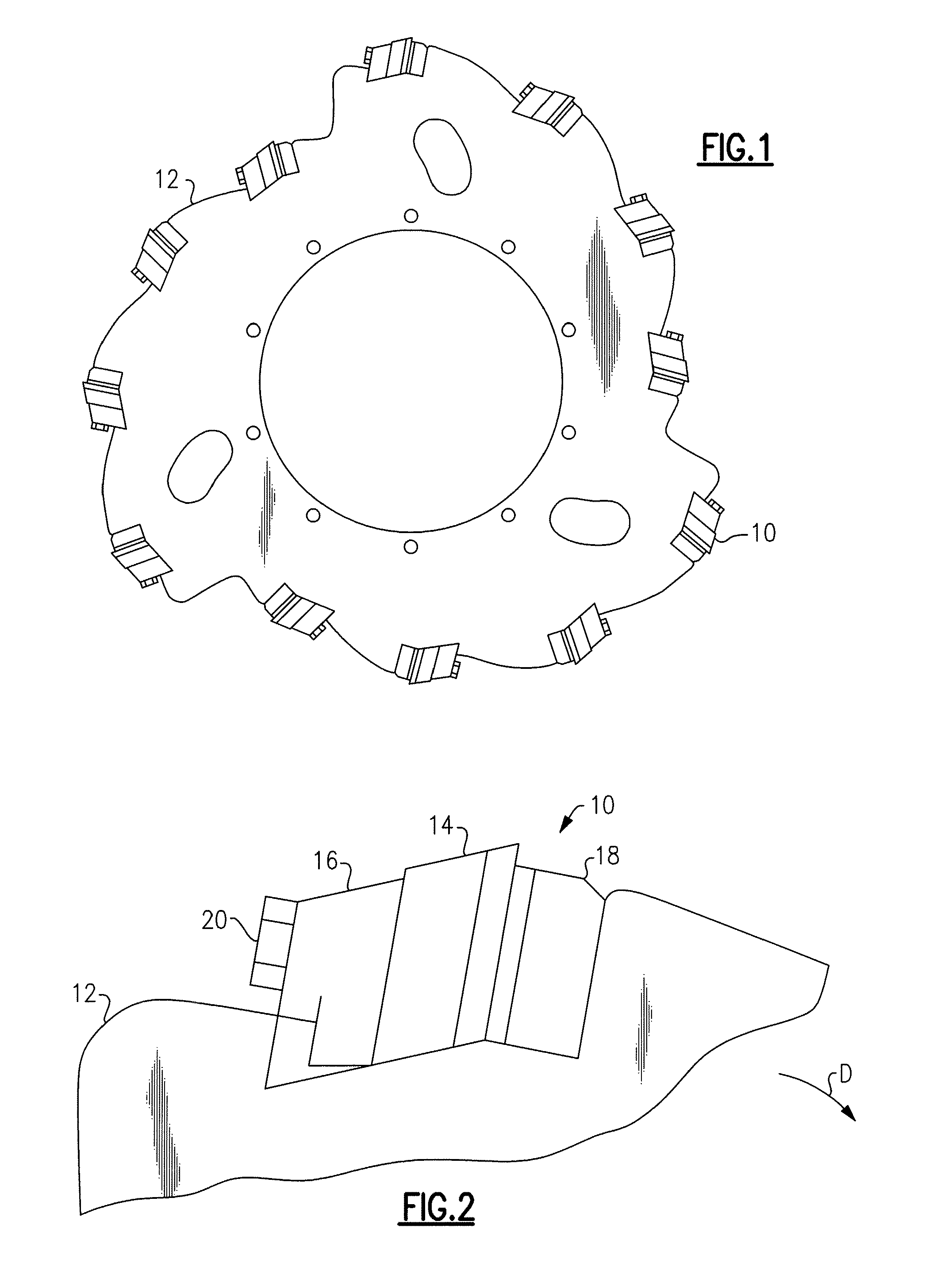

Stump grinding tooth assembly

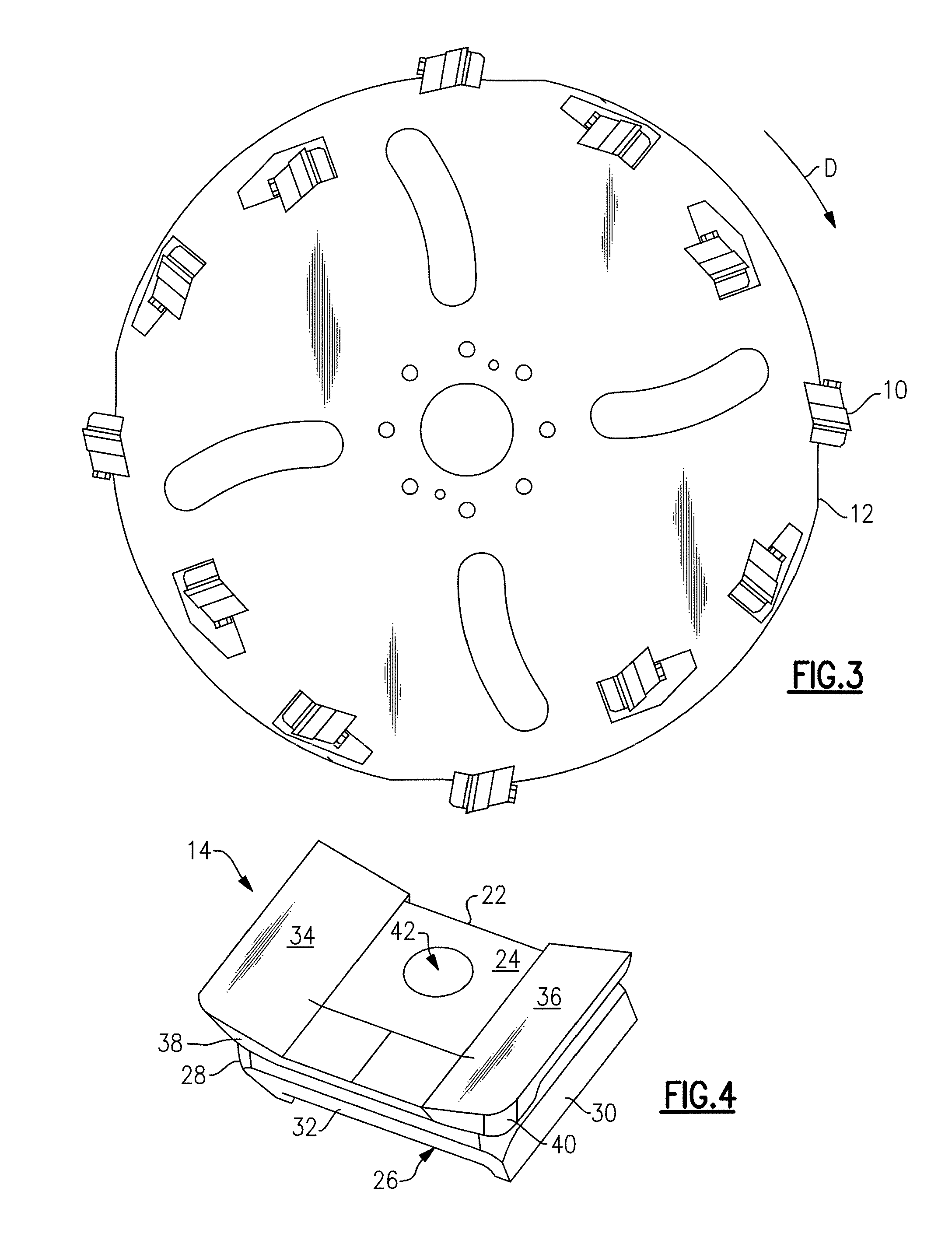

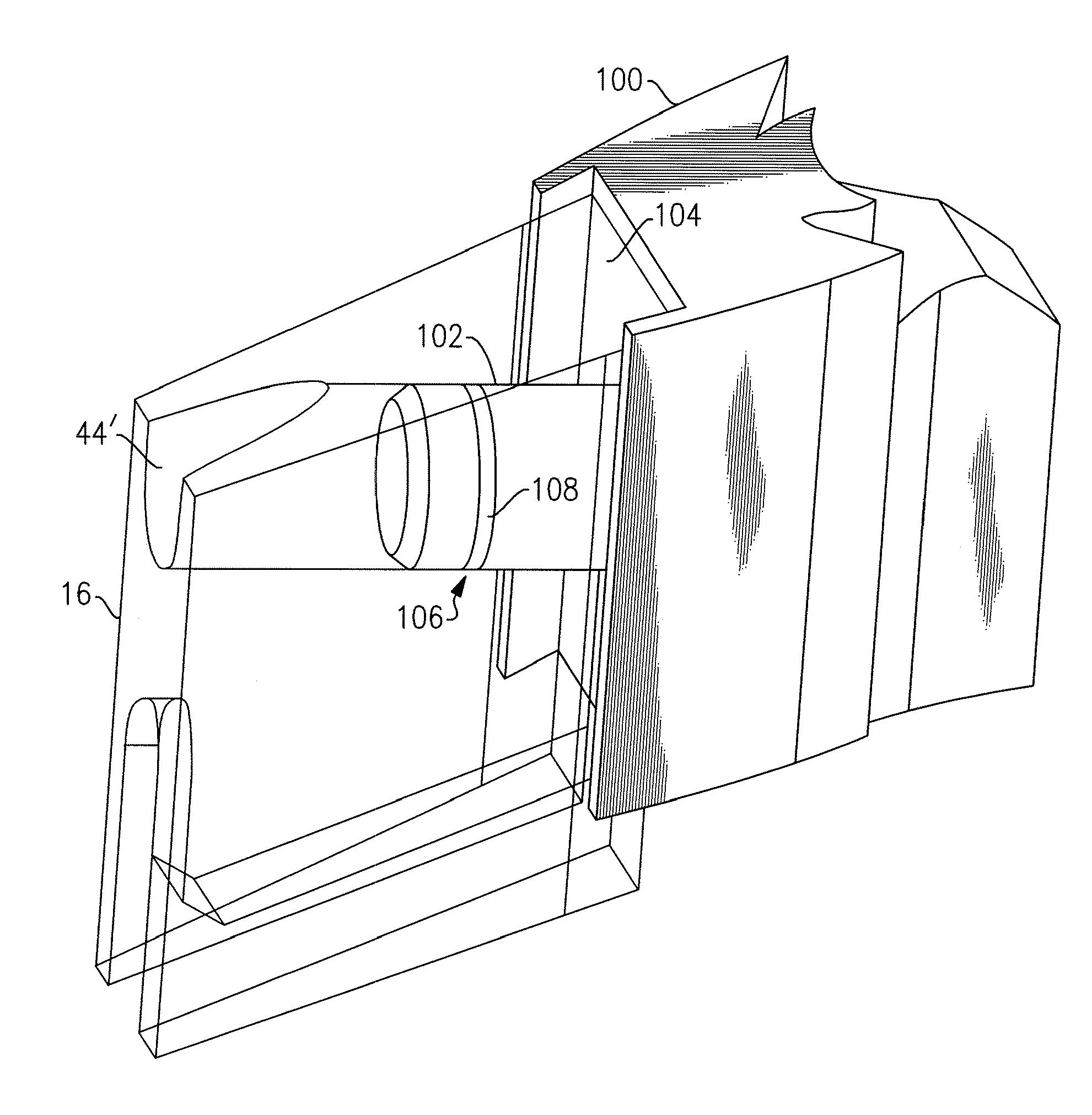

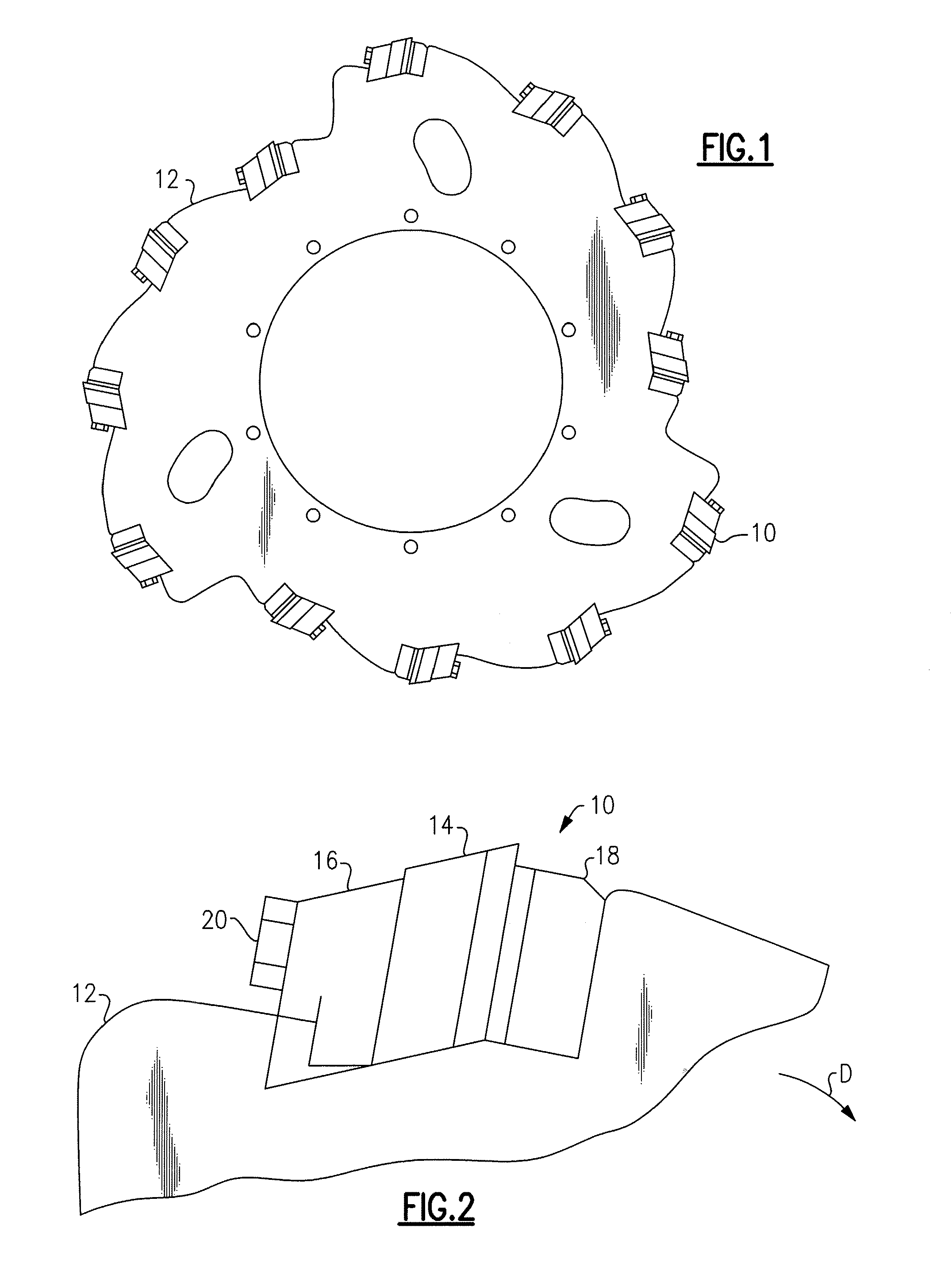

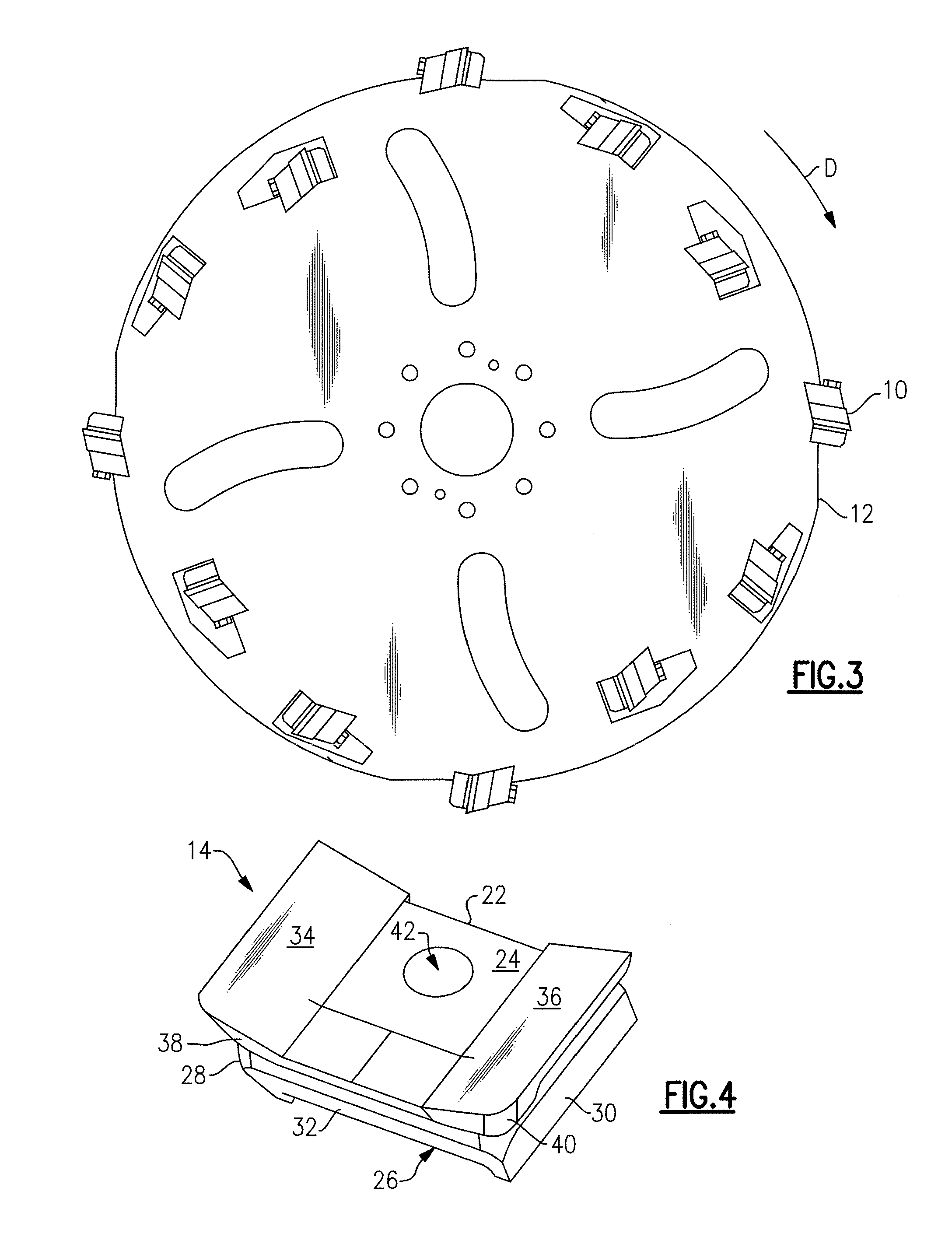

ActiveUS9137954B2Increased durabilityReduce laborMulti-purpose machinesProfiling/shaping machinesEngineeringGRINDING TOOTH

A stump cutting assembly mounted to a stump cutting wheel. Stump cutting assembly is a stump cutting tooth interconnected to the wheel by a holder or block that is fixed to wheel by welding or other equivalent process, an optional debris deflector and a fastener that interconnects tooth and deflector to holder. As wheel rotates about its axis of rotation, the tooth cuts away at wood or other debris in which it comes into contact through the side to side and / or longitudinal movement of a stump grinder unit.

Owner:LEONARDI MFG

Stump Grinding Tooth Assembly

ActiveUS20120024425A1Increased durabilityReduce laborMulti-purpose machinesProfiling/shaping machinesEngineeringGRINDING TOOTH

A stump cutting assembly mounted to a stump cutting wheel. Stump cutting assembly is a stump cutting tooth interconnected to the wheel by a holder or block that is fixed to wheel by welding or other equivalent process, an optional debris deflector and a fastener that interconnects tooth and deflector to holder. As wheel rotates about its axis of rotation, the tooth cuts away at wood or other debris in which it comes into contact through the side to side and / or longitudinal movement of a stump grinder unit.

Owner:LEONARDI MFG

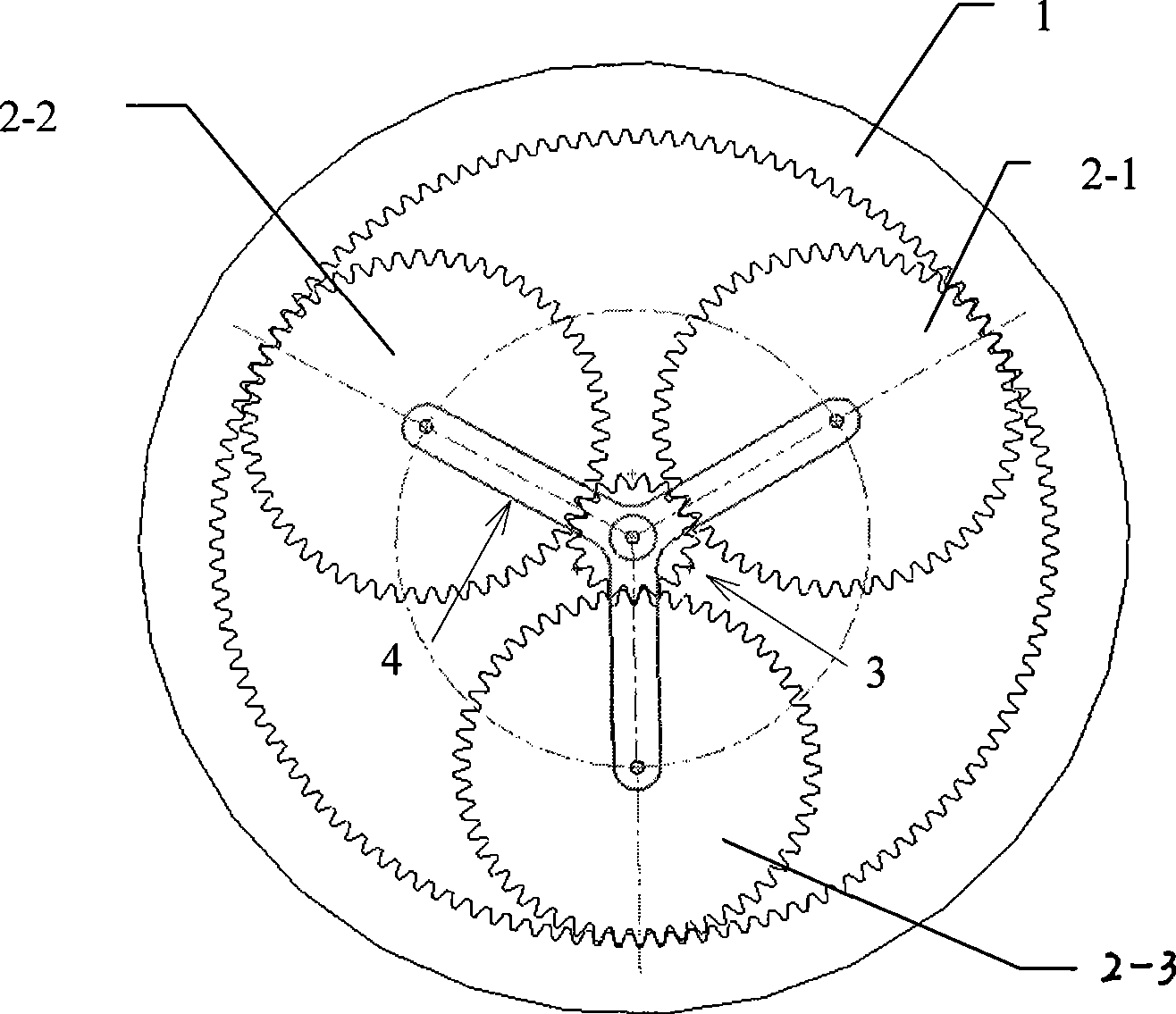

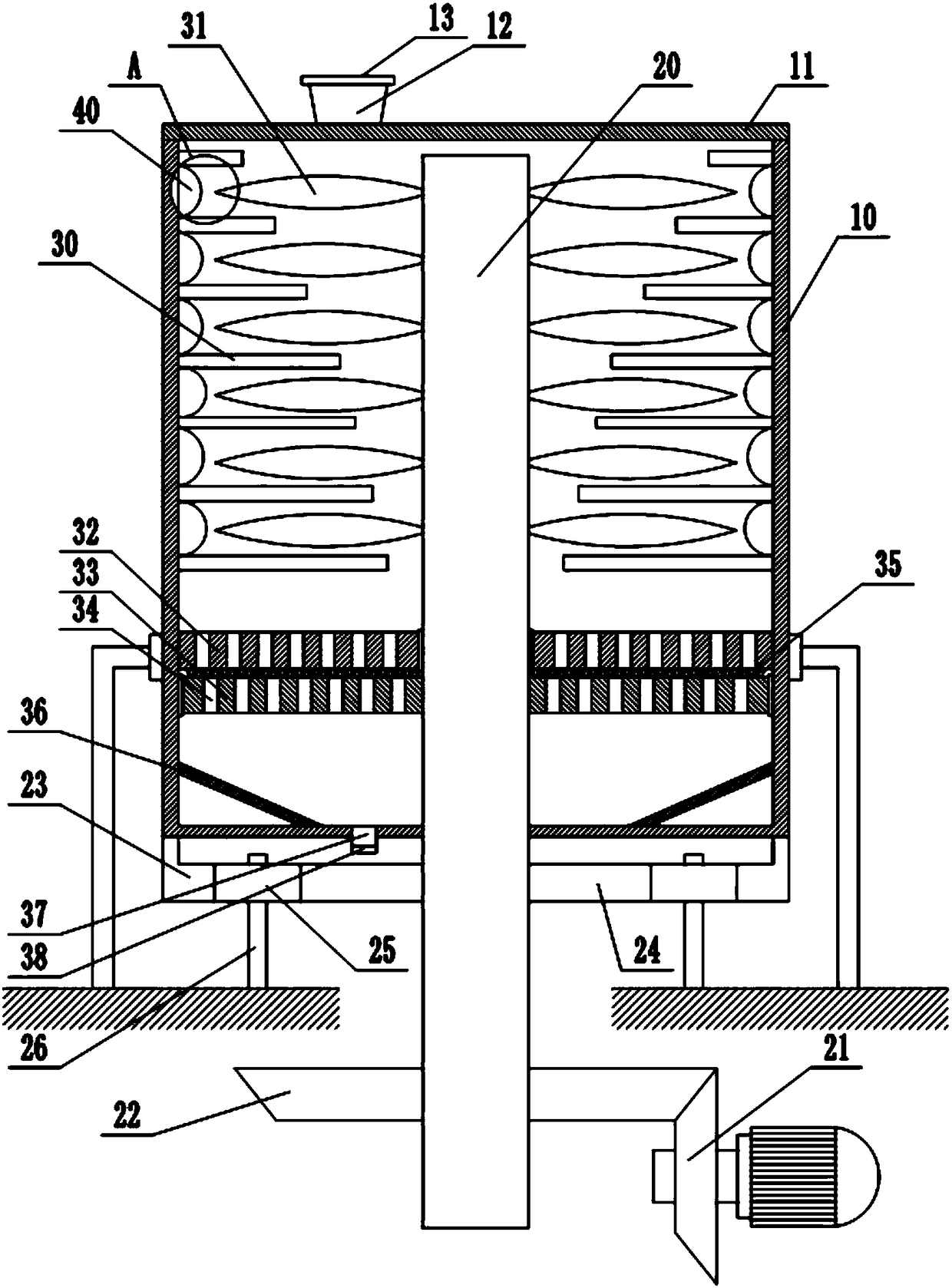

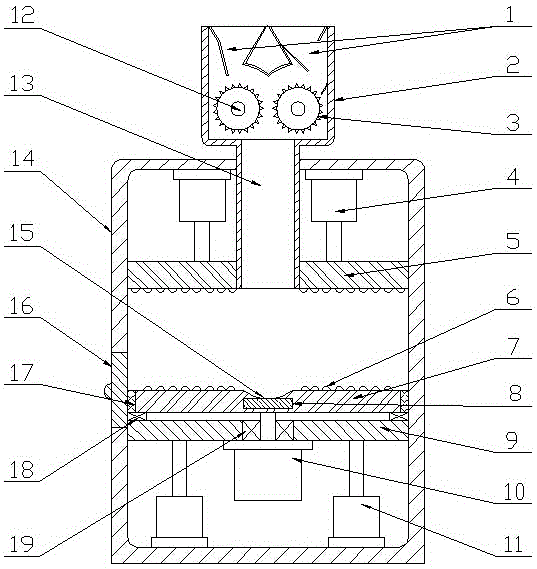

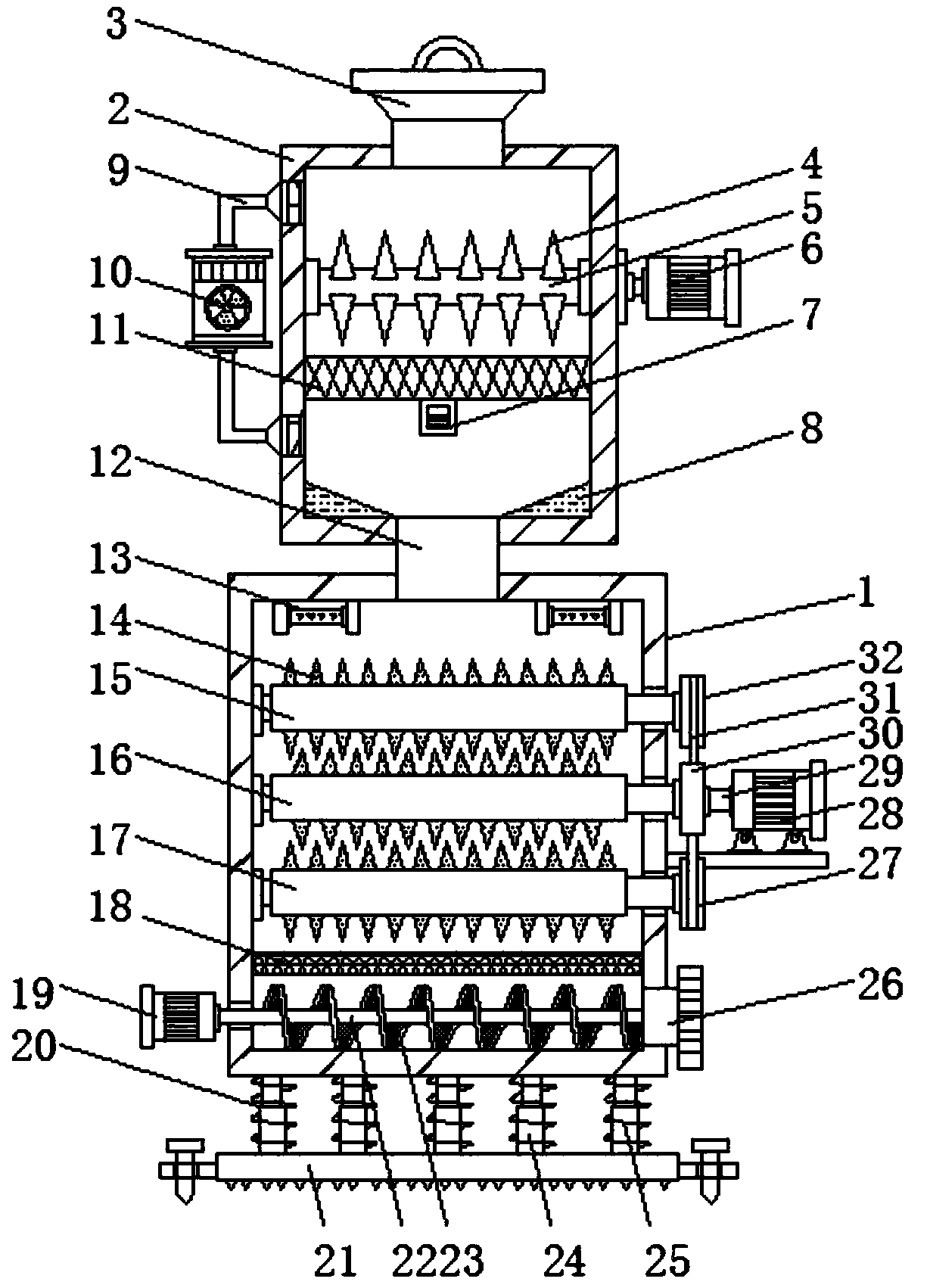

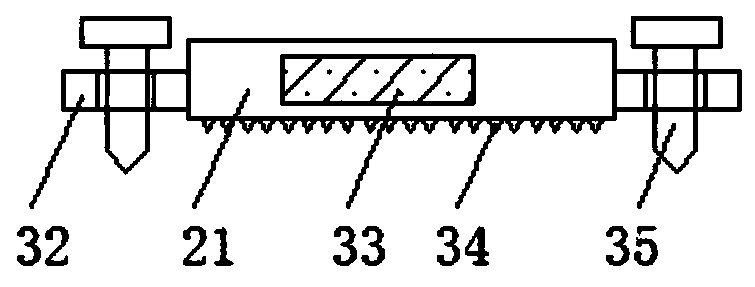

Three-level centrifugal corn grinder preventing feed from being bridged and grinding method

The invention provides a three-level centrifugal corn grinder preventing feed from being bridged and a grinding method. The corn grinder comprises a conveying mechanism, and is characterized in that the conveying mechanism is communicated with a grinding barrel, and first-level grinding teeth, second-level grinding teeth and third-level grinding teeth are sequentially arranged on the inner wall of the grinding barrel from top to bottom; a main shaft is arranged in the grinding barrel, first-level rotating supporting plates are arranged on the top of the main shaft and provided with first-level powder falling ports, air cylinder installing grooves are formed in the middle of the main shaft, and second-level grinding mechanisms are arranged in the air cylinder installing grooves; an upper cone grinder is arranged on the lower side of the main shaft, a lower cone grinder used in cooperation with the upper cone grinder is arranged on the side wall of the grinding barrel, and a conical grinding cavity is formed between the upper cone grinder and the lower cone grinder; and powder scraping pulp is arranged on the lower side of the lower cone grinder, a powder discharging pipeline is arranged at the bottom of the grinding barrel, and ground feet are arranged on the outer wall of the grinding barrel.

Owner:WEIFANG UNIV OF SCI & TECH

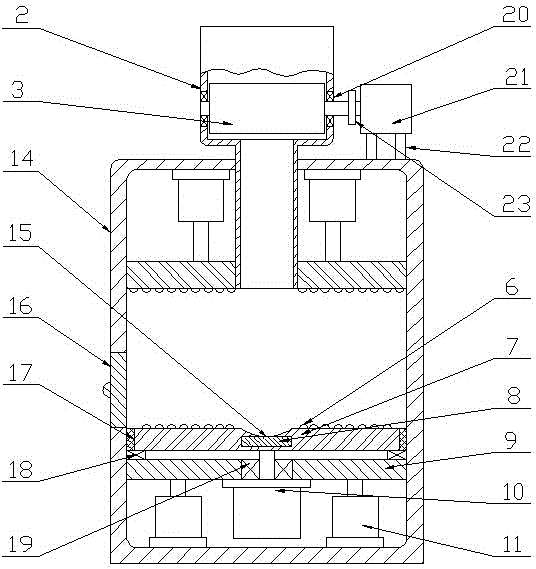

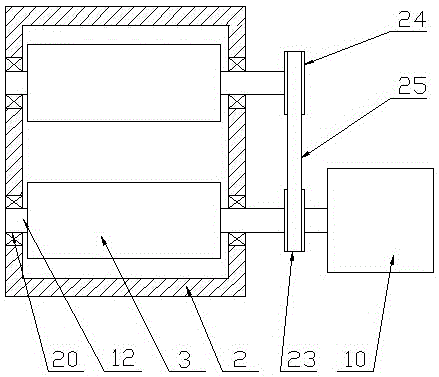

Coarseness and fineness integrated iron ore hydraulic pulverizer

InactiveCN106423379AImprove crushing effectTo achieve the separation effectCocoaGrain treatmentsIronstoneGranularity

The invention provides a coarseness and fineness integrated iron ore hydraulic pulverizer. The coarseness and fineness integrated iron ore hydraulic pulverizer is provided with an upper coarse pulverizing chamber and a lower fine grinding pulverizing chamber. The discharge port end on the bottom of the coarse pulverizing chamber communicates with the fine grinding pulverizing chamber through a discharge channel. The fine grinding pulverizing chamber is internally provided with an upper pressure cylinder, a lower pressure cylinder, an upper pressing plate, a lower pressing plate, a grinding rotary table and a grinding motor. The upper pressing plate is an annular pressing plate, the inner edge of the upper pressing plate is matched with the outer wall of the discharge channel, and the outer edge of the upper pressing plate and the outer edge of the lower pressing plate are matched with the inner wall of the fine grinding pulverizing chamber. At least one side of the fine grinding pulverizing chamber is provided with a discharge door. The upper pressure cylinder is installed between the upper side wall of the fine grinding pulverizing chamber and the upper pressing plate, and the lower pressure cylinder is installed between the lower side wall of the fine grinding pulverizing chamber and the lower pressing plate. The grinding motor is installed on the lower pressing plate, an output shaft of the grinding motor penetrates the lower pressing plate to be fixedly connected with the grinding rotary table, and grinding teeth are arranged on the lower surface of the upper pressing plate and the upper surface of the grinding rotary table in a staggered manner. The coarseness and fineness integrated iron ore hydraulic pulverizer is simple in structure and can achieve coarseness and fineness integrated pulverizing conveniently to meet machining requirements of iron ore produces with different grain size grades.

Owner:国龙寿

Pharmaceutical triaxial grinding machine

The invention discloses a pharmaceutical triaxial grinding machine. The pharmaceutical triaxial grinding machine comprises a grinding box and a pre-smashing box. The side wall of the pre-smashing boxis provided with a smashing motor. An output shaft of the smashing motor is connected with a smashing cutter shaft through a speed reducer. The smashing cutter shaft is horizontally arranged on the upper portion of the inner cavity of the pre-smashing box. The outer wall of the smashing cutter shaft is provided with smashing blades. The pre-smashing box and the grinding box communicate through a material guiding pipe. A first grinding roller shaft, a second grinding roller shaft and a third grinding roller shaft are sequentially and horizontally arranged in the grinding box from top to bottom.The outer walls of the first grinding roller shaft, the second grinding roller shaft and the third grinding roller shaft are all provided with grinding teeth. The pharmaceutical triaxial grinding machine is simple in structure and convenient to use, before medicinal material grinding, under smashing of the smashing blades in the pre-smashing box, large-chunk medicinal materials can be effectivelysmashed into particles, convenience is provided for follow-up medicinal material grinding, and the medicinal material grinding time is saved.

Owner:金结娥

Hard tooth face sugar press used reducer and hard tooth face processing method

InactiveCN1908461AExtended service lifeReduce weightToothed gearingsSolid state diffusion coatingCarbon layerEngineering

The invention relates to a speed reducer of sugar maker with rigid tooth surface, and relative rigid tooth surface treatment, wherein it comprises: the I gear axle, I large gear, II gear axle, II large axle, III gear axle, and III large gear are made from high-strength alloy steel; the rigidity of tooth surface is HRC58-62; the treatment comprises: machining the blank, and rolling tooth on it; immerging carbon, checking the depth of carbon layer and the metal structure, quenching, and tempering at low temperature to form the rigid tooth surface; then strengthening the tooth root, and refining it; abrading the tooth to form high-accuracy rigid tooth surface, whose accuracy level is not lower than six level of ISO1328 standard. And the invention has the advantages that: since all gears have rigid tooth surfaces, the abrasion resistance and load ability of gear are improved to reduce or avoid point corrosion, and prolong the service life, reduce the weight and reduce the volume.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

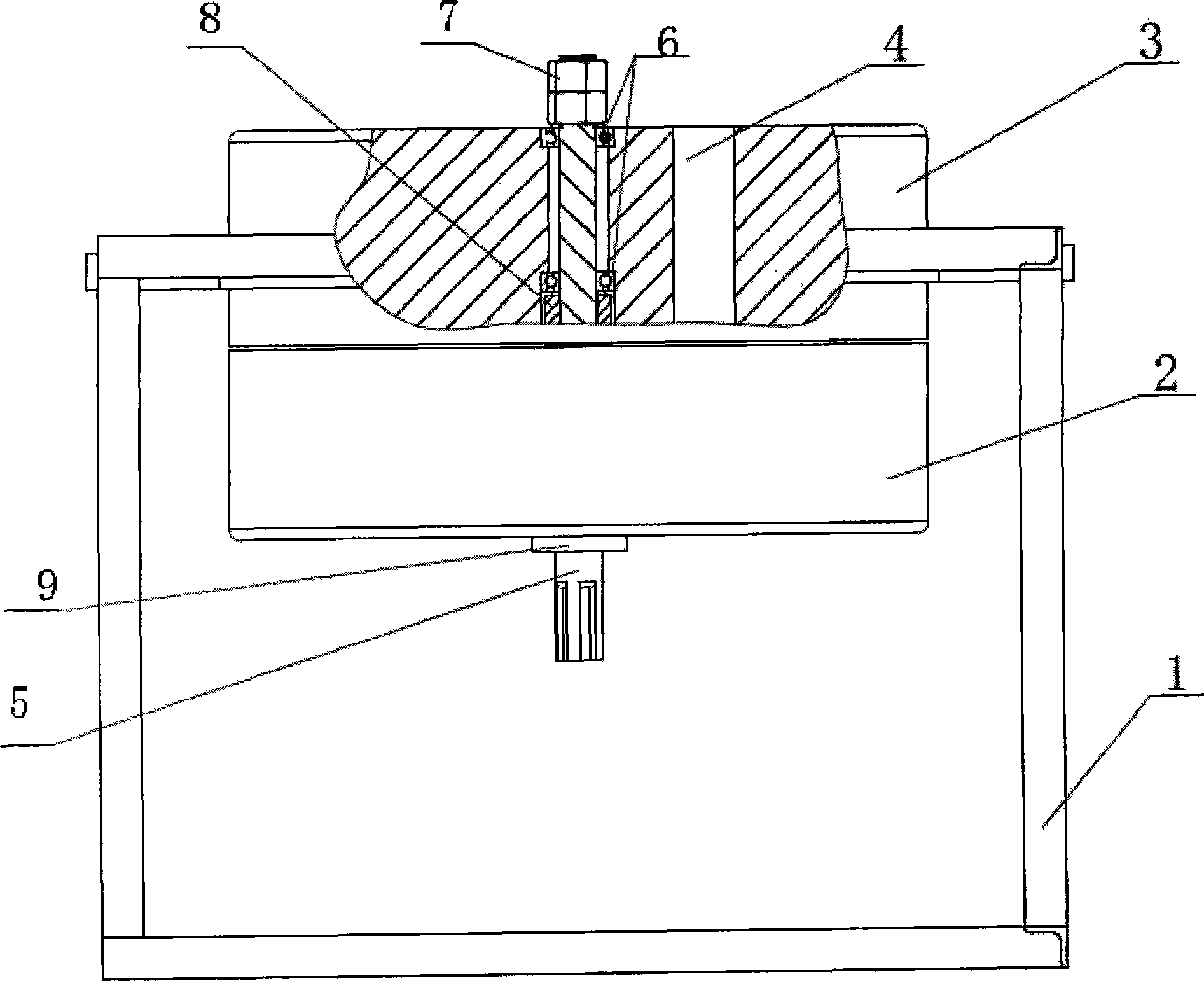

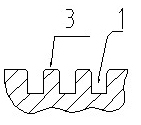

Vertical mechanical stone mill

InactiveCN101417253ASolve the shortcomings of fast wearExtend your lifeCocoaGrain treatmentsRepair timeDrive shaft

The invention provides a vertical mechanical stone mill, consisting of a fixed bracket, a lower grinding disc, an upper grinding disc, and a power transmission shaft which is arranged at the central hole of the lower grinding disc and the upper grinding disc; one end of the power transmission shaft is connected with a power mechanism; the upper grinding disc is provided with a grain inlet; the upper grinding disc is fixedly connected with the fixed bracket; the top end of the power transmission shaft is provided with an adjusting nut and the bottom end thereof is provided with a supporting shoulder; the power transmission shaft is fixedly connected with the lower grinding disc; the clearance between the upper grinding disc and the lower grinding disc is more than or equal to 0mm; a bearing is arranged between the power transmission shaft and the central hole of the upper grinding disc; and the lower end of the bearing is provided with an adjusting washer. The upper grinding disc and the lower grinding disc have a certain clearance and are not contacted with each other; no matter the change of the feeding quantity of the grains, the direct contact of the upper grinding tooth and the lower grinding tooth is not generated, the clearance is not increased under the action of the grains, the defect of the quick abrasion of the grinding tooth is thoroughly solved, the service life of the grinding tooth is prolonged, the repairing time is reduced, the production efficiency and the one-step powder yield of the flour are improved, the power dissipation is reduced, the working noise is reduced, and the energy resource is saved.

Owner:周培莒

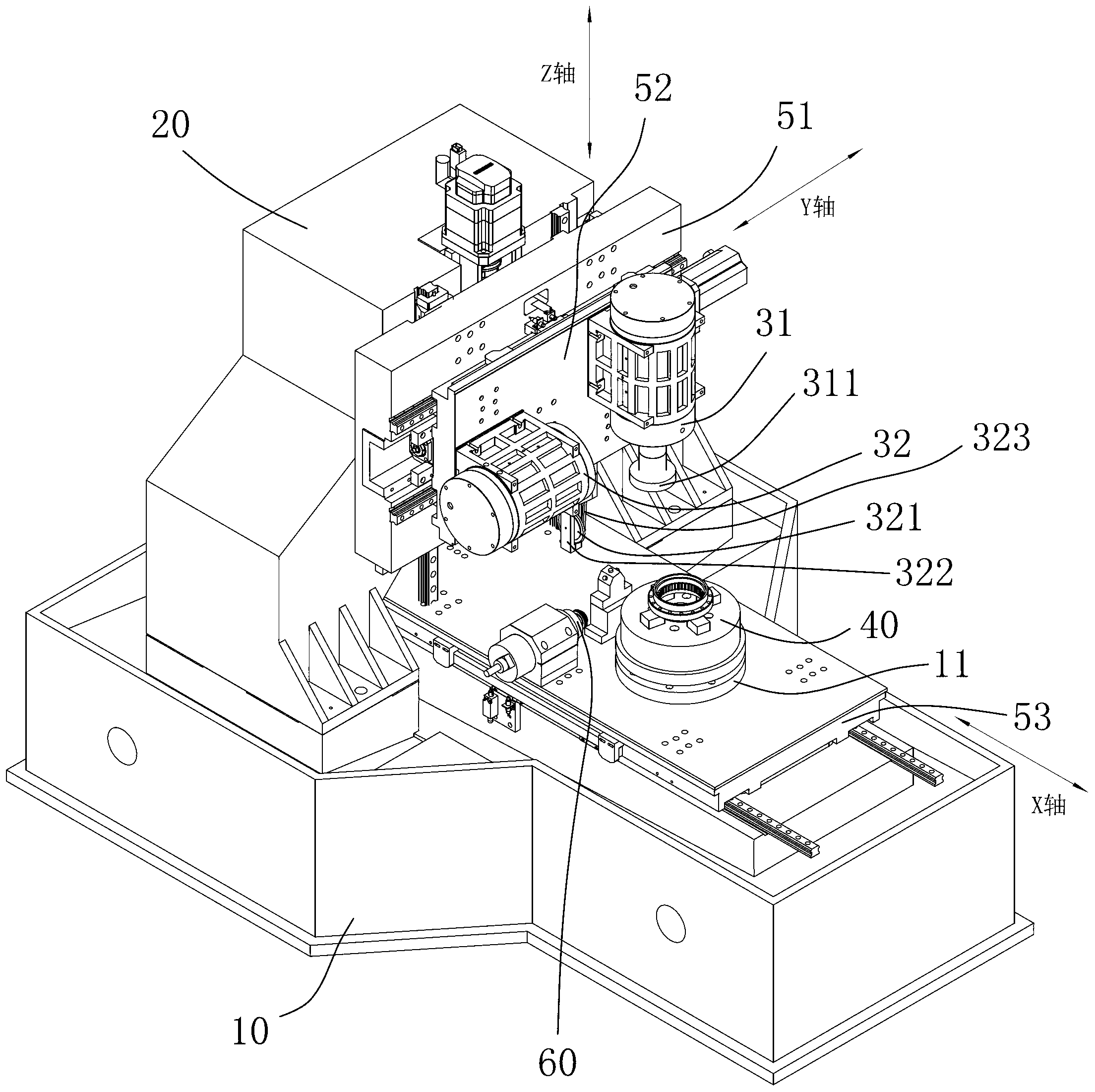

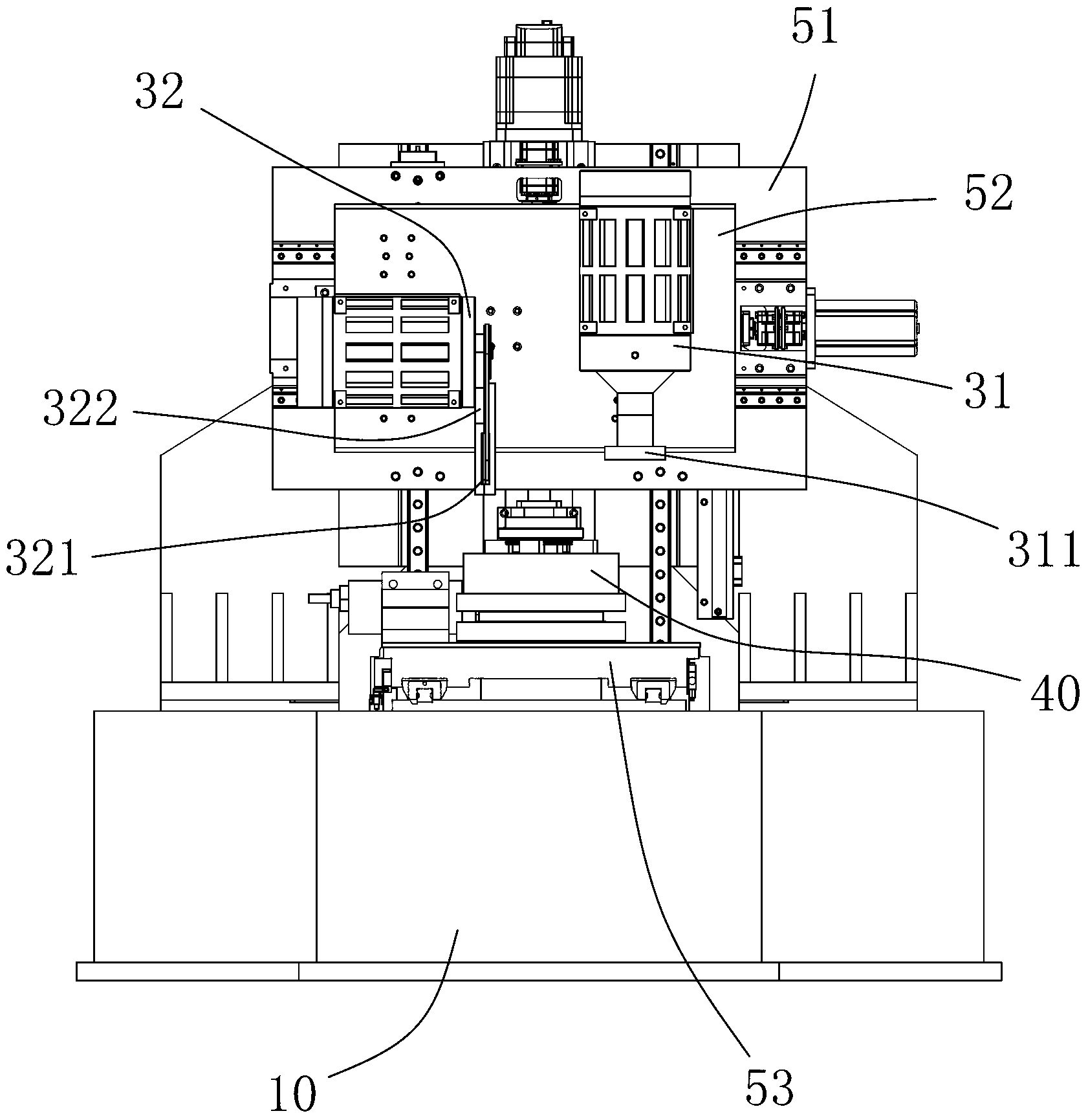

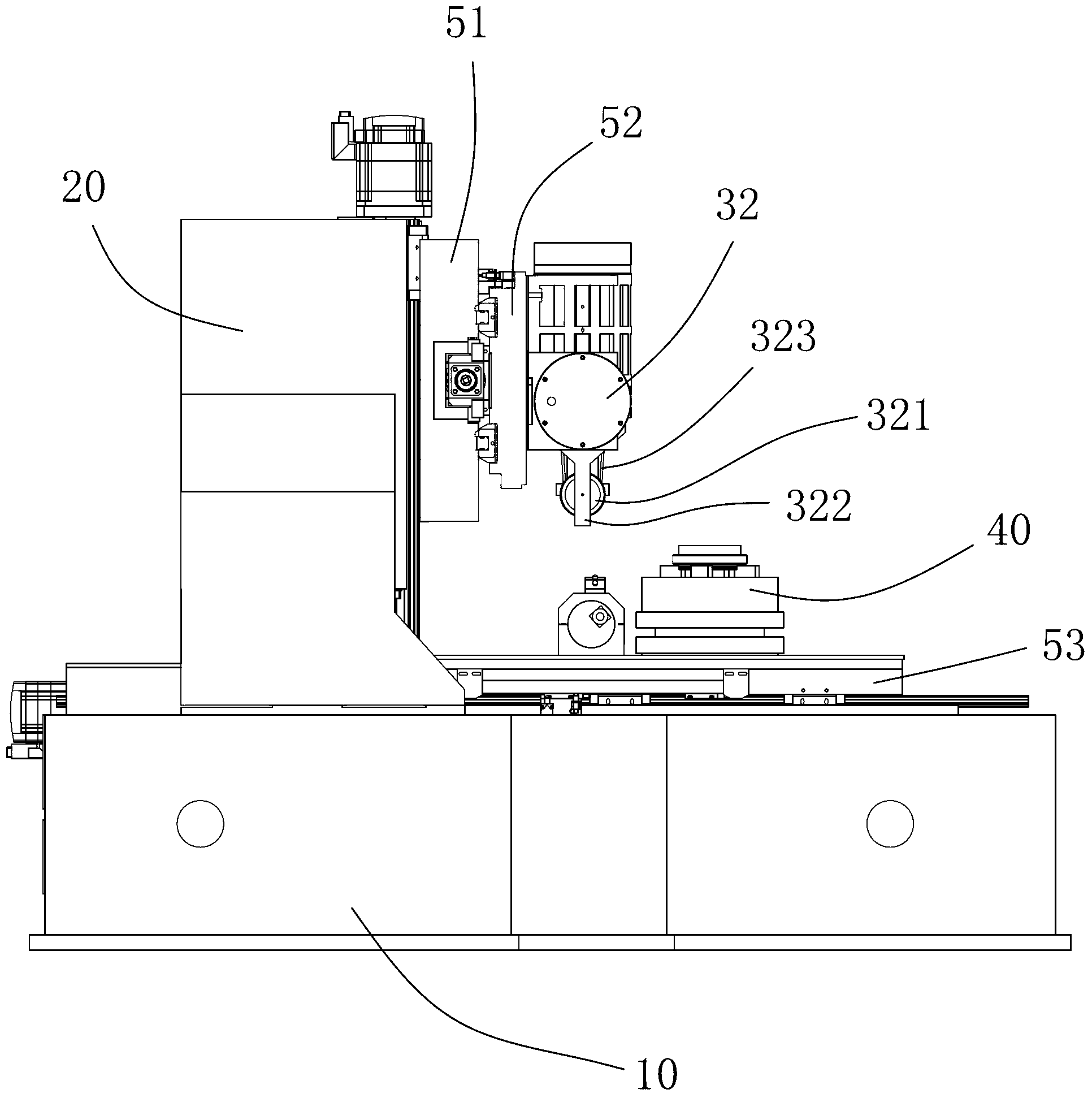

Composite grinding lathe for grinding pin wheel housing

ActiveCN103264342AGuaranteed grinding precisionEasy to operateGrinding machinesStructural engineeringGrinding wheel

The invention discloses a composite grinding lathe for grinding a pin wheel housing. The composite grinding lathe comprises a lathe bed, a stand column arranged on the lathe bed, a first grinding wheel spindle and a second grinding wheel spindle, wherein the first wheel spindle and the second wheel spindle are arranged on the stand column. A workpiece clamp is arranged on the lathe bed, a sliding mechanism enabling the workpiece clamp to move relative to the first wheel grinding wheel spindle and the second grinding wheel spindle is arranged on the lathe bed, a barrel-shaped grinding wheel is arranged at an output end of the first grinding wheel spindle, and a disc-shaped grinding wheel driven by the second grinding wheel spindle is arranged below the second grinding wheel spindle. The disc-shaped grinding wheel can extend into the pin wheel housing through control over the sliding mechanism, the disc-shaped grinding wheel rotates at a high speed to grind tooth grooves of the pin wheel housing, after all the tooth grooves on the profile of the inner edge of the pin wheel housing are grinded, the sliding mechanism is controlled to enable the barrel-shaped grinding wheel to be aligned with the end circle end face and the outer circle end face of the pin wheel housing to finish grinding the tooth grooves on the profile of the inner edge of the pin wheel housing, the inner circle end face and the outer circle end face in a one-shot clamping, therefore, grinding accuracy can be guaranteed effectively, and operation is convenient. The composite grinding lathe for grinding the pin wheel housing is suitable for the technical field of grinding.

Owner:GUANGZHOU CITY AGILE MFG

Crushing device for unformed dog food

InactiveCN106582997AImprove crushing effectEasy to operateFeeding-stuffGrain treatmentsEngineeringElectric control

The invention relates to a dog food crushing device, in particular to a crushing device for unformed dog food. The crushing device for the unformed dog food aims to achieve the technical effects of being good in crushing effect, easy to operate and capable of improving work efficiency. In order to achieve the technical effects, the crushing device for the unformed dog food comprises a base plate, a sliding rail, two supports II, electric wire reels, a stay wire, sliding blocks, a crushing frame, a feeding hopper, an electric control valve, an electric crushing wheel, a fixed plate II, a spring, a pressing plate II, a lifting rod, a pressing plate I, grinding teeth, a support I, a fixed plate I, a motor, a rotating shaft, a cylindrical cam, an arc connection rod, a clamping block and a rubber hammer. The two supports II are arranged on the top of the base plate in a bilateral symmetry manner. The sliding rail is arranged on the portion, between the two supports II, of the top of the base plate. The electric wire reels are symmetrically arranged on the inner sides of the supports II. The crushing device for the unformed dog food achieves the effects of being good in crushing effect, easy to operate and capable of improving work efficiency.

Owner:赖传柏

Plastic grinder

The invention discloses a plastic grinder. The plastic grinder comprises a machine frame, wherein two grinding rollers are arranged on the machine frame side by side; the grinding rollers are in transmission connection with a driving device; a plurality of rows of grinding teeth are arranged on the grinding rollers; a feed port of the machine frame is formed above the grinding rollers; a discharge port is formed below the grinding rollers; a feed squeezer, namely a spiral feeder is arranged at the tail end of the feed port; the plurality of rows of grinding teeth are spirally arranged on the external circumference of the grinding rollers; and the grinding teeth on the two grinding rollers are mutually staggered. Due to the adoption of the technical scheme, plastic is squeezed by the spiral feeder before being fed into the feed port, so that the grinding effect is better after the plastic is fed into the grinder.

Owner:王维东

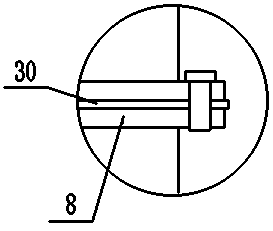

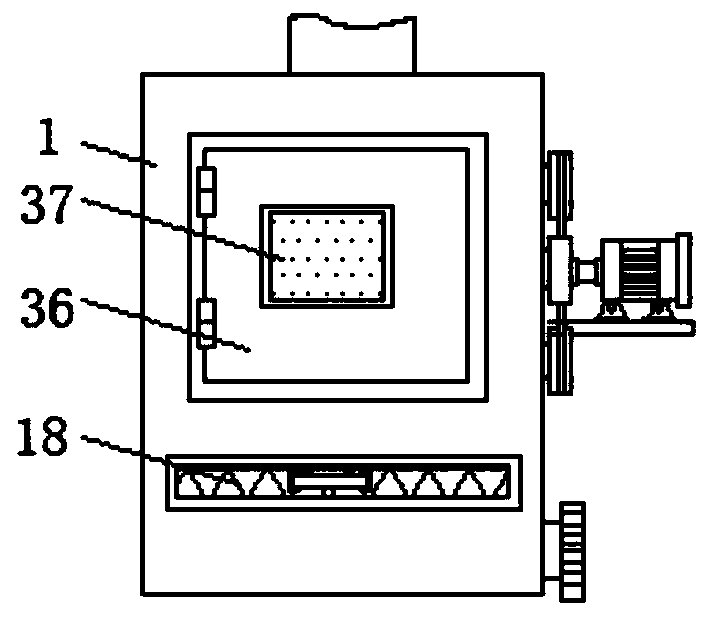

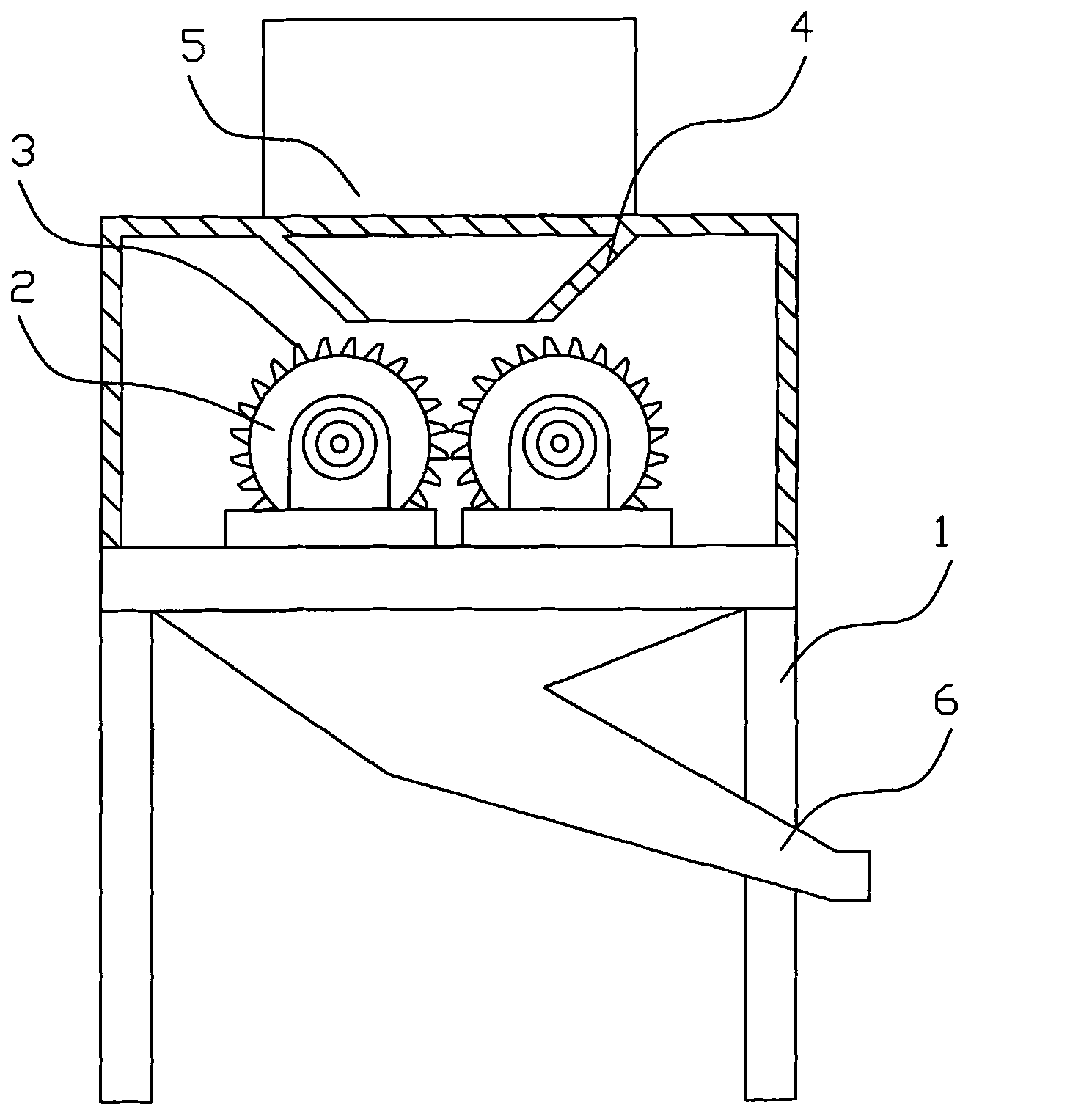

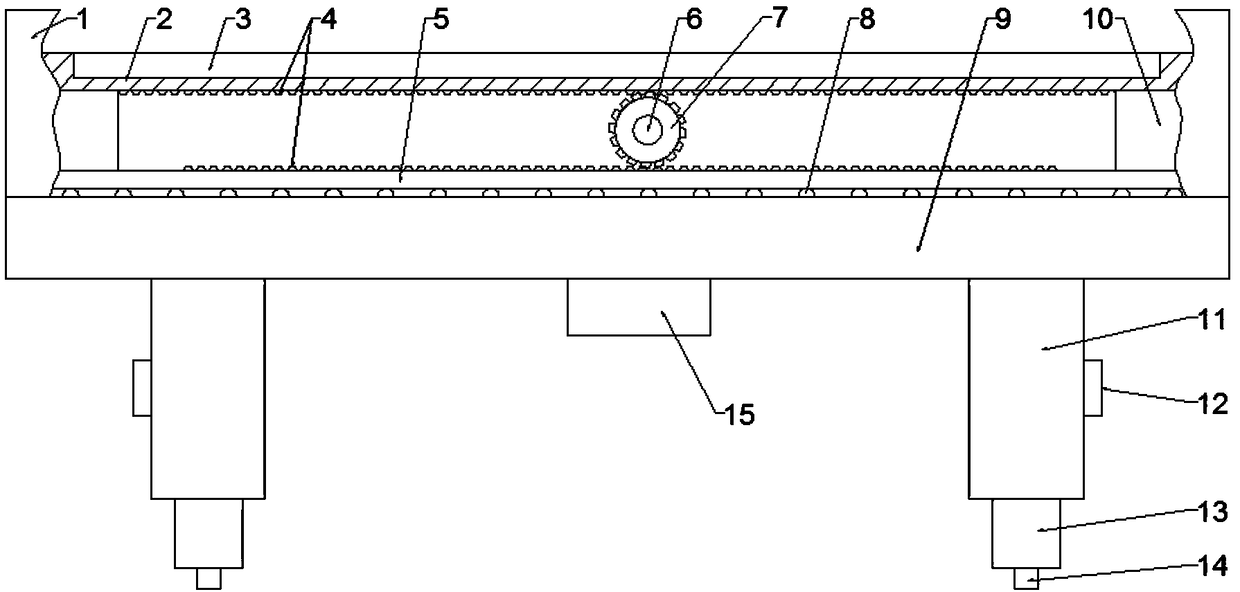

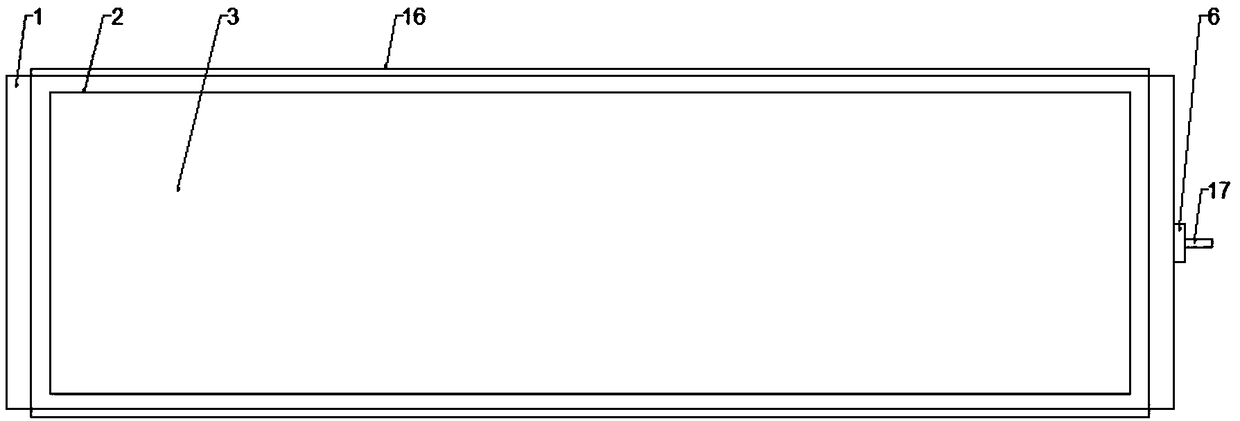

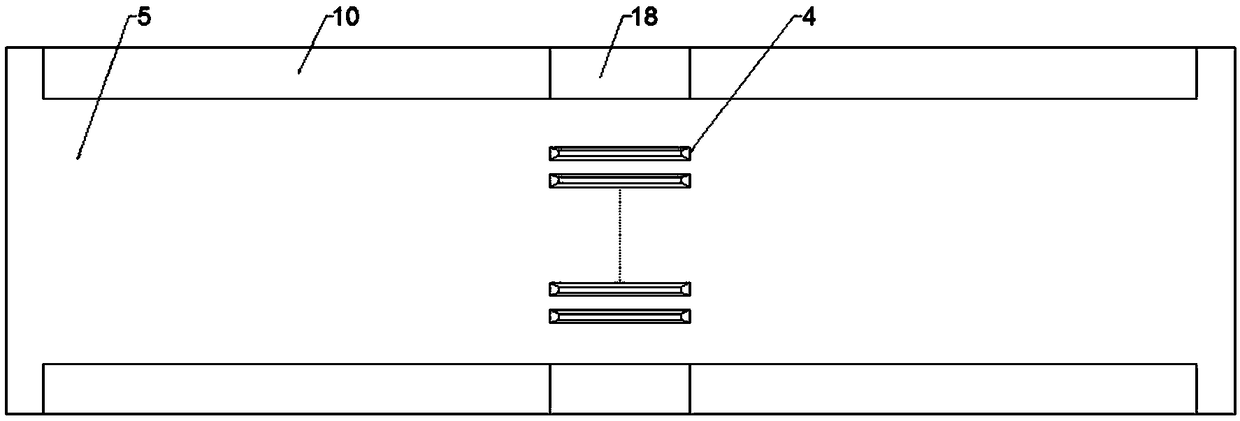

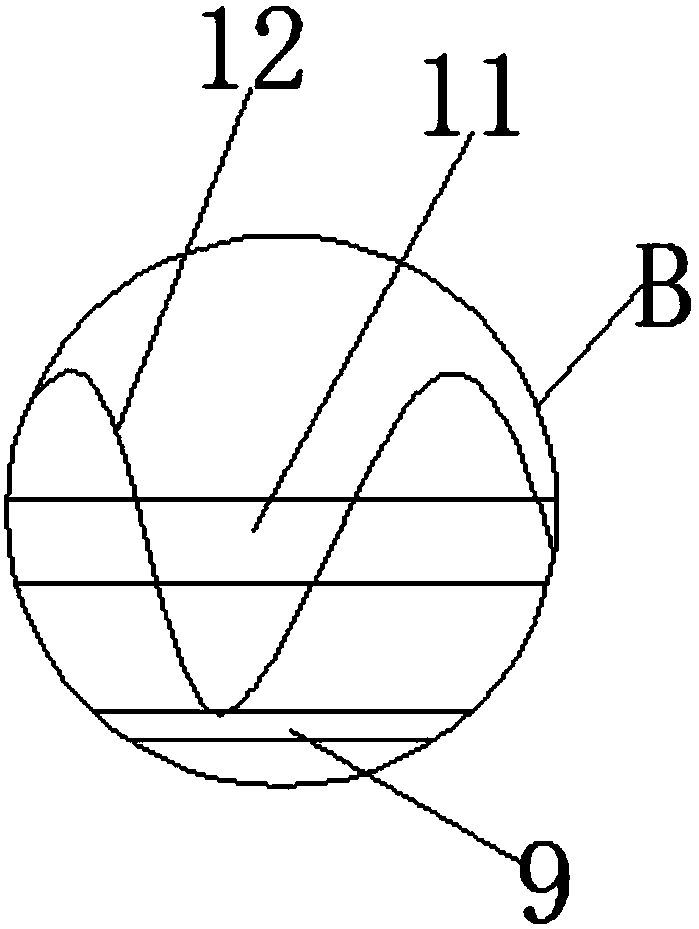

Gear grinding machine for grinding teeth of circular band saw blade

InactiveCN104148738ASimple structureEasy to buildSawing tools dressing arrangementsDrive motorGrinding wheel

The invention relates to a gear grinding machine for grinding teeth of a circular band saw blade. The gear grinding machine comprises a worktable (1), a mounting plate (14) is arranged on the worktable (1) through a plurality of spacers, a first end clamp (3), a middle clamp (4) and a second end clamp (13) are arranged at the edge of one side of the mounting plate (14), a connecting rod (9) with the middle portion connected with the mounting plate (14) through a hinged shaft (4) is arranged below the mounting plate (14), an air cylinder (11) is fixedly connected under the mounting plate (14), and one end of a piston rod of the air cylinder (11) is connected to the rear end of the connecting rod (9) in a hinged manner; a push rod (8) made of elastic metal materials is mounted at the front end of the connecting rod (9), a cylindrical end with the diameter equal to the pitch of the band saw blade is arranged at the front end of the push rod (8), and a spring (6) is arranged between the front end of the connecting rod (9) and the mounting plate (14); a rotating base provided with a rotating drive motor is arranged on the worktable (1), and a gear grinding motor (12) with a grinding wheel (7) is arranged on the rotating base.

Owner:TIANJIN LIDDELL AUTOMOTIVE COMPONENTS

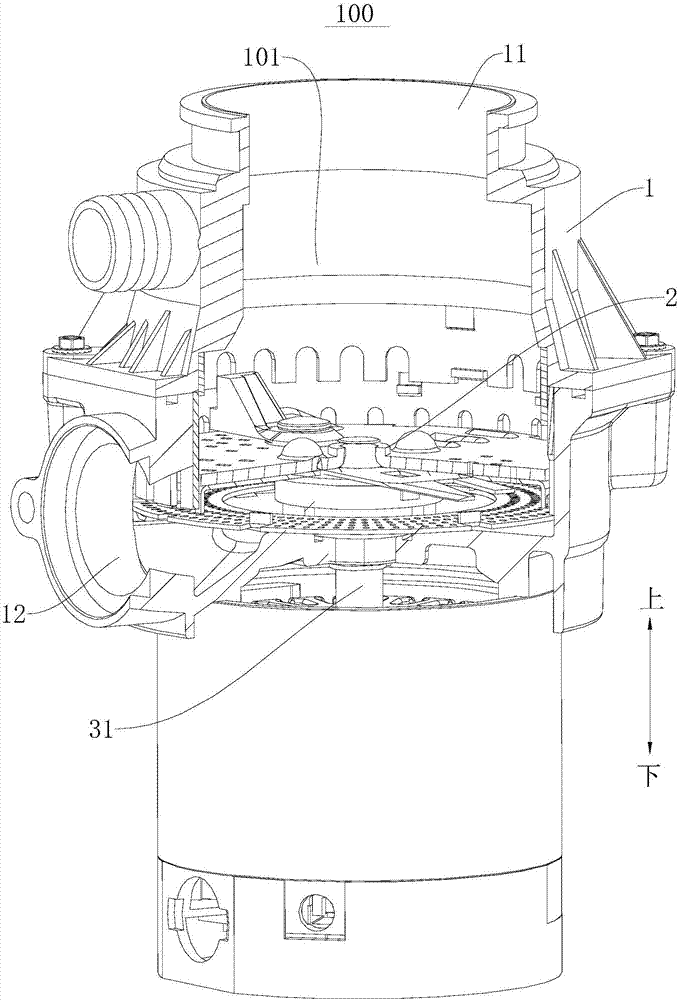

Crushing device and food waste crusher with same

ActiveCN106861840AAvoid cloggingImprove grinding efficiencyDomestic plumbingGrain treatmentsEngineeringReamer

The invention discloses a crushing device and a food waste crusher with the crushing device. The crushing device comprises a grinding ring, a grinding disc and a cutterhead assembly. The grinding disc is arranged below the grinding ring. The cutterhead assembly is rotationally arranged in the grinding ring. The cutterhead assembly comprises a main cutterhead and a grinding and cutting cutterhead, wherein a grinding reamer is arranged on the main cutterhead, and grinding gaps are formed between the grinding reamer and the inner peripheral face of the grinding ring; and the grinding and cutting cutterhead is arranged below the main cutterhead, multiple grinding teeth which extend downwards and are arranged at intervals in the peripheral direction are formed in the periphery of the grinding and cutting cutterhead, and grinding gaps are formed between the grinding teeth and the inner peripheral face of the grinding ring, grinding and cutting teeth which extend in the up-down direction are formed in at least one of the grinding and cutting cutterhead and the grinding disc. The grinding and cutting teeth are located on the inner sides of the grinding teeth and extend between the grinding and cutting cutterhead and the grinding disc. According to the crushing device, the structure is simple and reasonable, the crushing efficiency is high, the grinding and cutting are comprehensive, and a sewer can be effectively prevented from being blocked.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

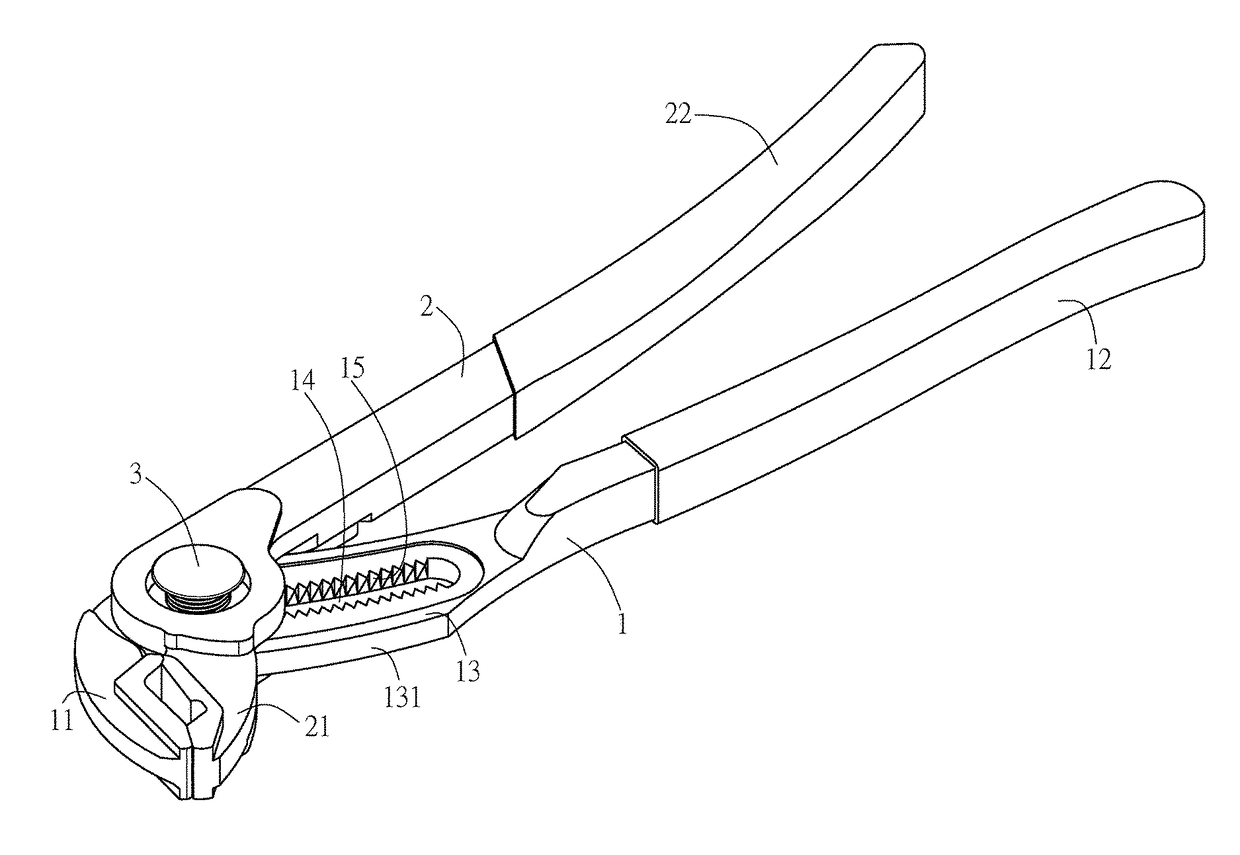

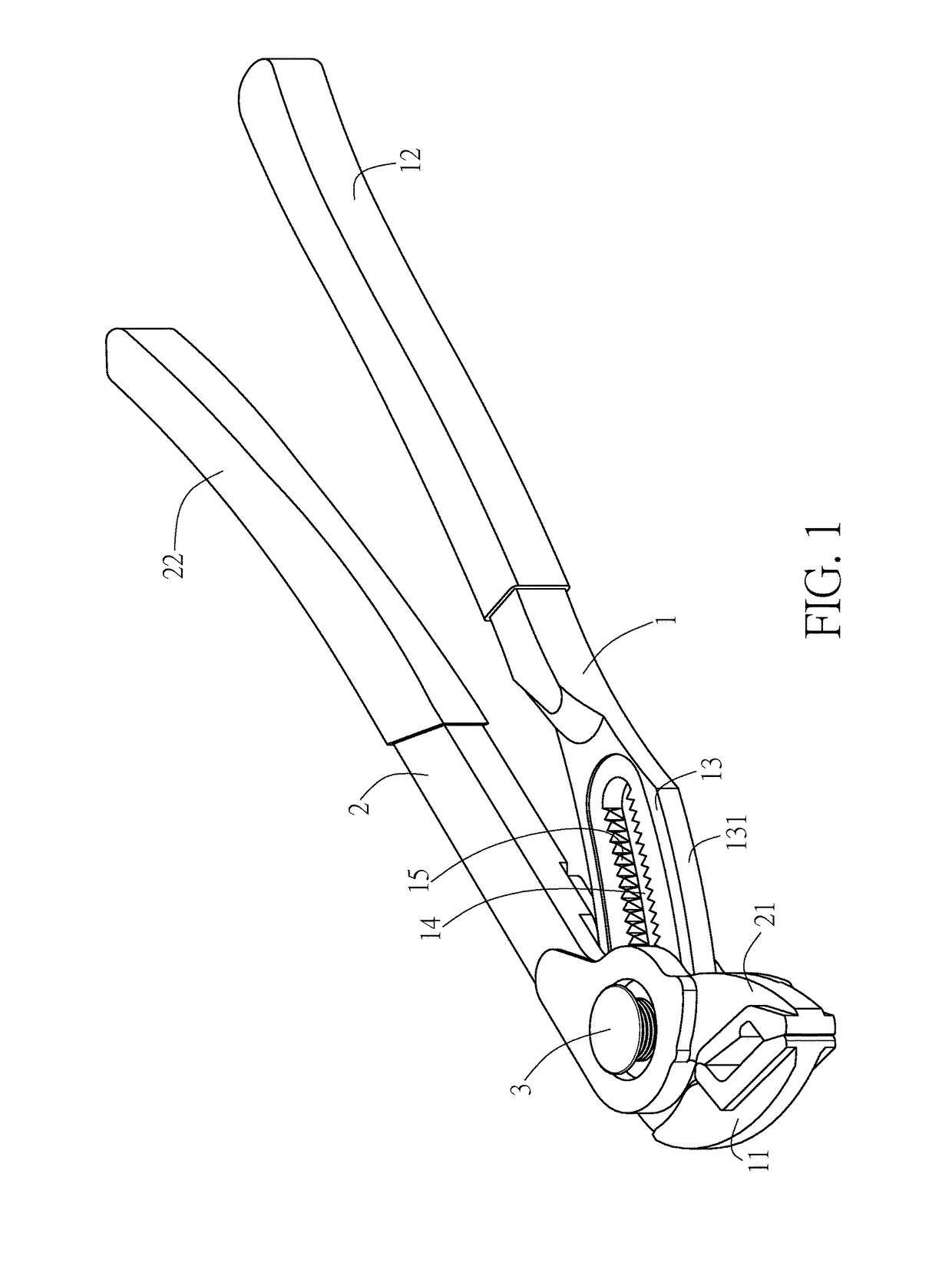

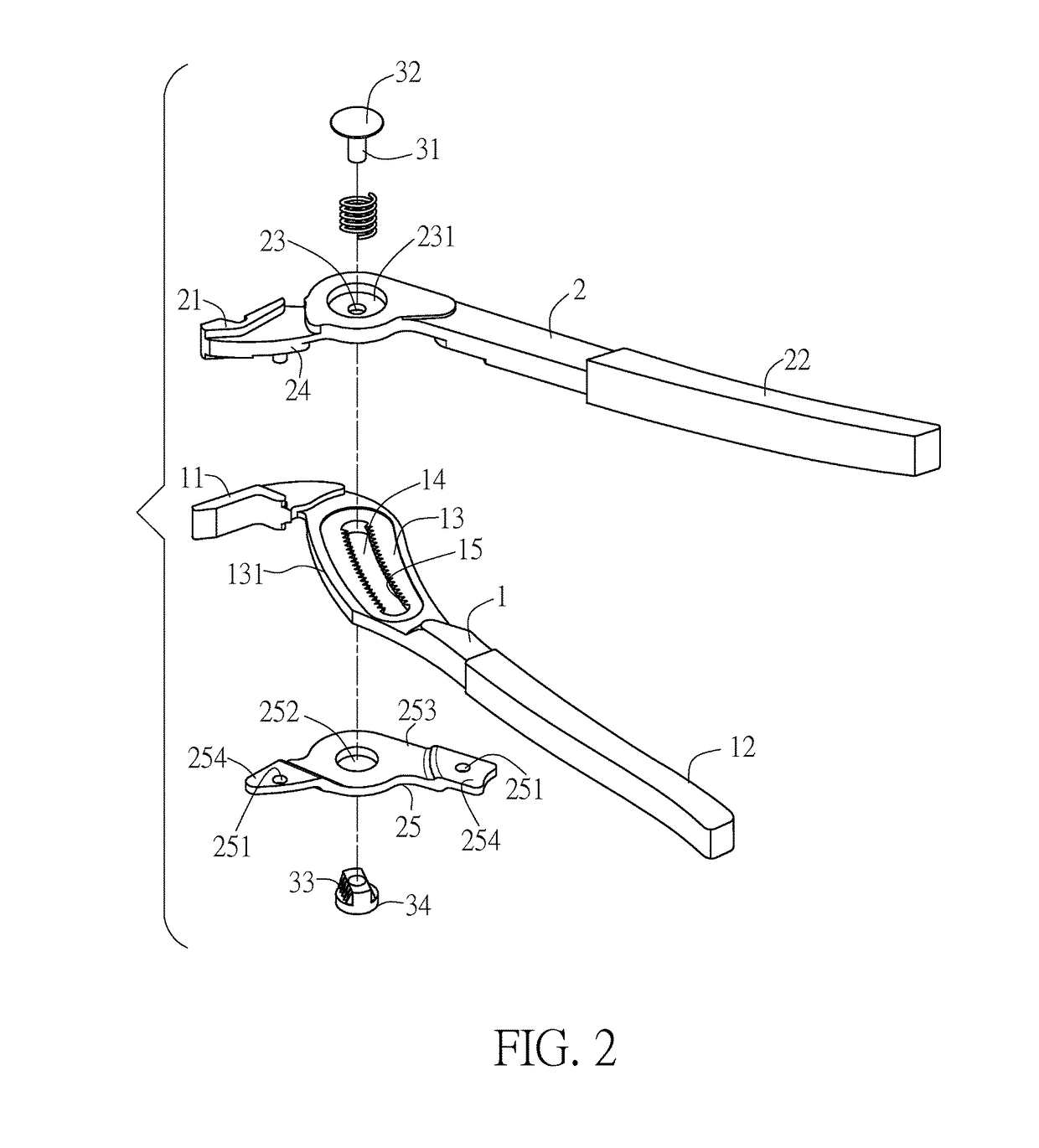

Water pipe wrench structure

A water pipe wrench structure consisting of a first wrench body and a second wrench body pin jointed by a control component. The first wrench body includes an actuating piece. A tooth space is positioned on this actuating piece. This actuating piece and a tooth piece extend with a uniform curvature. The second wrench body includes a perforation to pass the control component through this perforation and the tooth space. This control component includes a column piece and a grinding tooth piece, and the grinding tooth piece can be moved by pressure, so that the grinding tooth piece can be engaged to or separated from the tooth space and thus end the movement of the control component.

Owner:CHEN JIN FU

Transfer bed for medical use

PendingCN108743059ASolve the problem that it is easy to cause secondary harm to patientsStretcherNursing bedsPatient needBed load

The invention discloses a transfer bed for medical use and relates to the field of medical devices. The transfer bed includes a bed board, support legs are arranged below the bed board, the two side faces, opposite to each other, of the bed board are provided with baffles, and the two baffles are located in the width direction of the bed board; a support block horizontally moving in the width direction of the bed board is connected between the two baffles, a transfer plate horizontally moving in the width direction of the bed board is arranged right above the support plate and located betweenthe two baffles, a gear is arranged between the transfer plate and the support plate and fixedly connected with a rotation shaft, and one end of the rotation shaft extends outside the corresponding baffle; the grinding-teeth support plate and the transfer plate are both provided with grinding teeth meshed with the gear; the several rows of grinding teeth on the transfer plate are distributed in the width direction of the transfer plate, and the several rows of grinding teeth on the support plate are distributed in the width direction of the support plate. The problem that in the prior art, when a transfer bed is used for transferring a patient, the patient needs to be uplifted directly and move back and forth between the transfer bed and an examination bed and thus secondary injuries to the patient are easily caused is solved.

Owner:YUQING COUNTY PEOPLES HOSPITAL

Juicer

The invention discloses a juicer. The juicer comprises a base, a driving mechanism, a juicing component, a first grinding plate, a second grinding plate and a filtering device, wherein the driving mechanism is arranged in the base; the juicing component is fixedly supported on the base; the juicing component comprises a shell; the shell is provided with an opening portion on the top, a juice outlet and a residue outlet; the first grinding plate is rotatably arranged in the shell and comprises a first grinding plate main body portion and a driving mechanism connecting portion; the first grinding plate main body portion is provided with a first grinding surface; first grinding teeth are arranged on the first grinding surface; the second grinding plate is fixedly arranged in the shell and comprises a second grinding plate main body portion; the second grinding plate main body portion is provided with a second grinding surface; the second grinding surface is opposite to the first grinding surface; the second grinding surface is provided with second grinding teeth and a feeding opening; food can enter the juicer via the feeding opening; and the filtering device is used for separating vegetable juice from juiced residues. The juicer has the remarkable advantages that the juicer is low in cost, long in service and high juicing speed; and a filtering hole in the filtering device is not easy to block.

Owner:FORTUNE TECH MFG CO LTD

Construction waste processing device

InactiveCN108014887ASolve the occupied spaceImprove crushing efficiencyGrain treatmentsArchitectural engineeringWaste material

The invention relates to the technical field of civil engineering and discloses a construction waste processing device which comprises a shell, wherein two first motors are arranged at the top of theshell; the output shafts of the first motors are fixedly connected with rotary rods; one side of each of the rotary rods is fixedly connected with grinding teeth; a bracket fixed on the top of the shell is arranged on one side of each of the first motors; a trough body is fixedly connected with the top of the bracket; a feeding hole is formed in the inner bottom wall of the trough body; a transporting hole is formed in the inner bottom wall of the shell; a transporting box is fixedly connected with the bottom of the shell; a second motor is arranged on one side of the transporting box; and theoutput shaft of the second motor is fixedly connected with a rotary shaft. According to the construction waste processing device, blocky waste on a construction site can be pulverized through the shell, the first motors, the rotary rods, the grinding teeth, the brackets, the trough bodies and the feeding hole, so that the problem that the blocky waste occupies the space is solved, space is savedfor the construction site; the two first motors enable the pulverizing efficiency of the blocky waste to be higher; and the feeding hole is V-shaped to enable feeding to be more convenient when the blocky waste is pulverized.

Owner:NANJING UNIV OF SCI & TECH

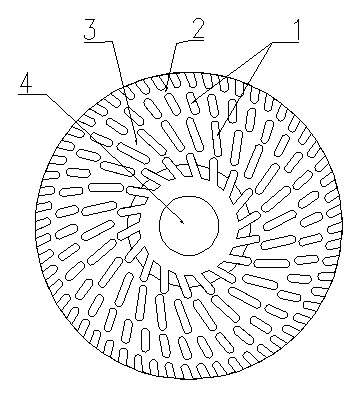

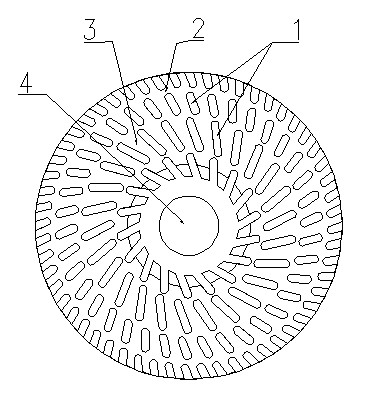

Grinding table of disc grinder for preparing synthetic fiber pulp

ActiveCN102086606AReduce specific edge loadWeaken cut-off functionPulp beating/refining methodsEngineeringResidence time

The invention discloses a grinding table of a disc grinder for preparing synthetic fiber pulp, which comprises a grinding plate, wherein the working surface of the grinding plate is provided with a plurality of grooves; the grooves are distributed in a multiple-layer concentric circle mode around the grinding plate; the grooves are evenly distributed on each layer of the concentric circle; grinding teeth are formed on the grinding plate between every two adjacent grooves on the same circle; and a pulp baffle plate is formed at the gap between any two adjacent layers. The invention can prolongthe the residence time of materials in the disc grinder, weaken the cut-off function of the grinding table, enhance the effects of crushing, kneading and fibrillation on the fibers, and greatly improve the microfibrillation degree of the pulp fibers.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com