High-modulus straight-tooth cylindrical gear cold extrusion technology and special die thereof

A spur gear and cold extrusion technology, which is applied to metal extrusion dies and other directions, can solve the problems of tooth shape influence, low material utilization rate, etc., and achieve the effects of cost reduction, energy consumption reduction, and simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

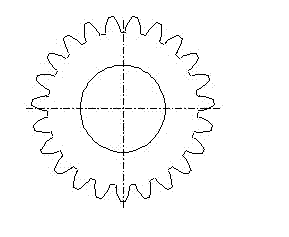

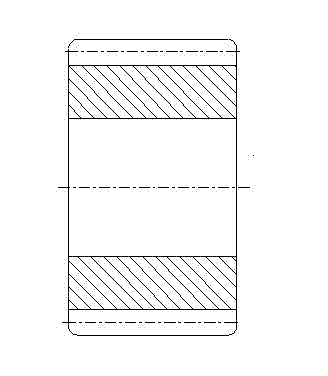

[0028] Such as figure 1 , figure 2 As shown, the spur gear produced by the present invention has a modulus greater than or equal to 4, and the central hole

[0029] A certain margin is reserved for subsequent machining, and the tooth profile accuracy is required to reach DIN 9 level and above.

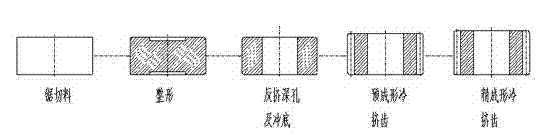

[0030] The cold extrusion process of large modulus spur gears provided in this embodiment mainly includes the following steps:

[0031] (1) Carry out blanking, 750°C annealing, shot blasting, phosphating and lubricating treatment on the billet in sequence;

[0032] (2) Shaping treatment, control the verticality tolerance between the end surface and the axis within 0.10mm, and control the parallelism tolerance between the two end surfaces within 0.05mm;

[0033] (3) Reverse extrusion deep hole treatment, control the size tolerance of the deep hole within ±0.10mm;

[0034] (4) The bottom punching process is formed into a hollow blank, and the thickness of the continuous skin is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com