Patents

Literature

41 results about "Extrusion tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Orthodontic Extrusion. Orthodontic Extrusion is a crown lengthening technique where a cosmetic outcome is desired. The procedure is used primarily where a tooth has fractured or decayed below the gum line. Orthodontic brackets are bonded from the tooth to be treated to adjacent teeth.

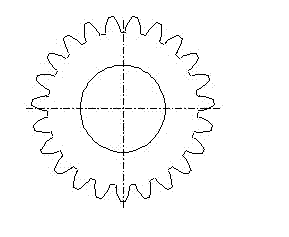

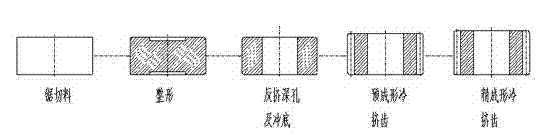

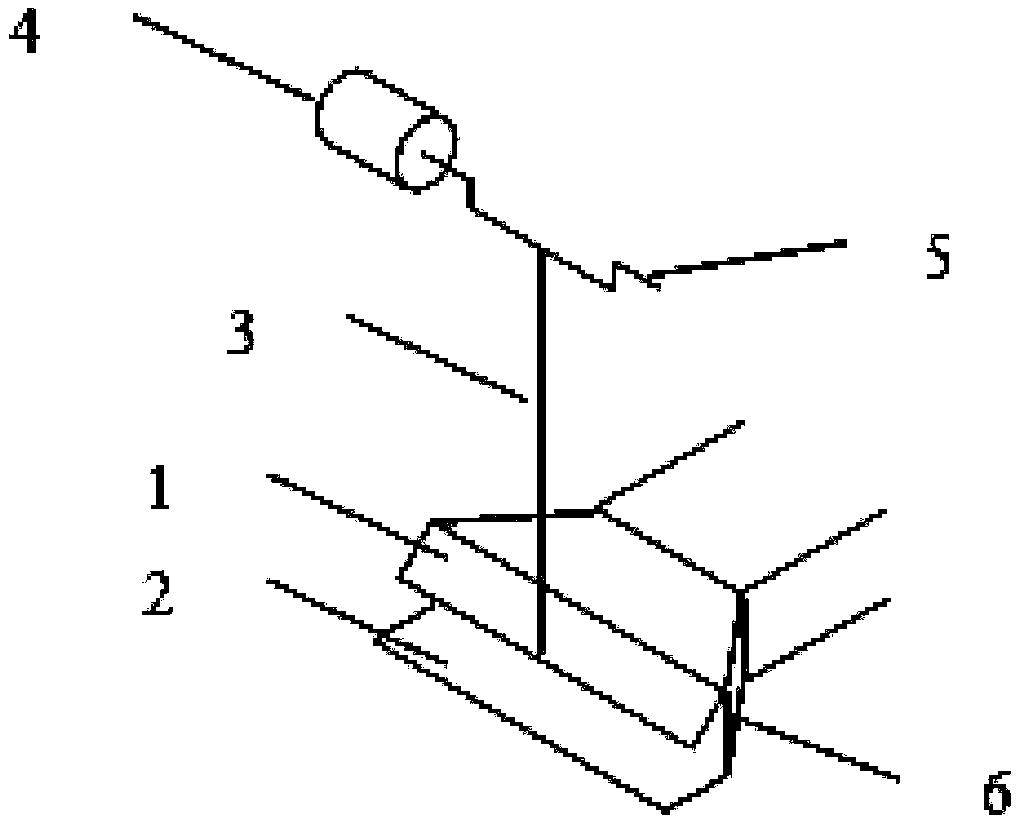

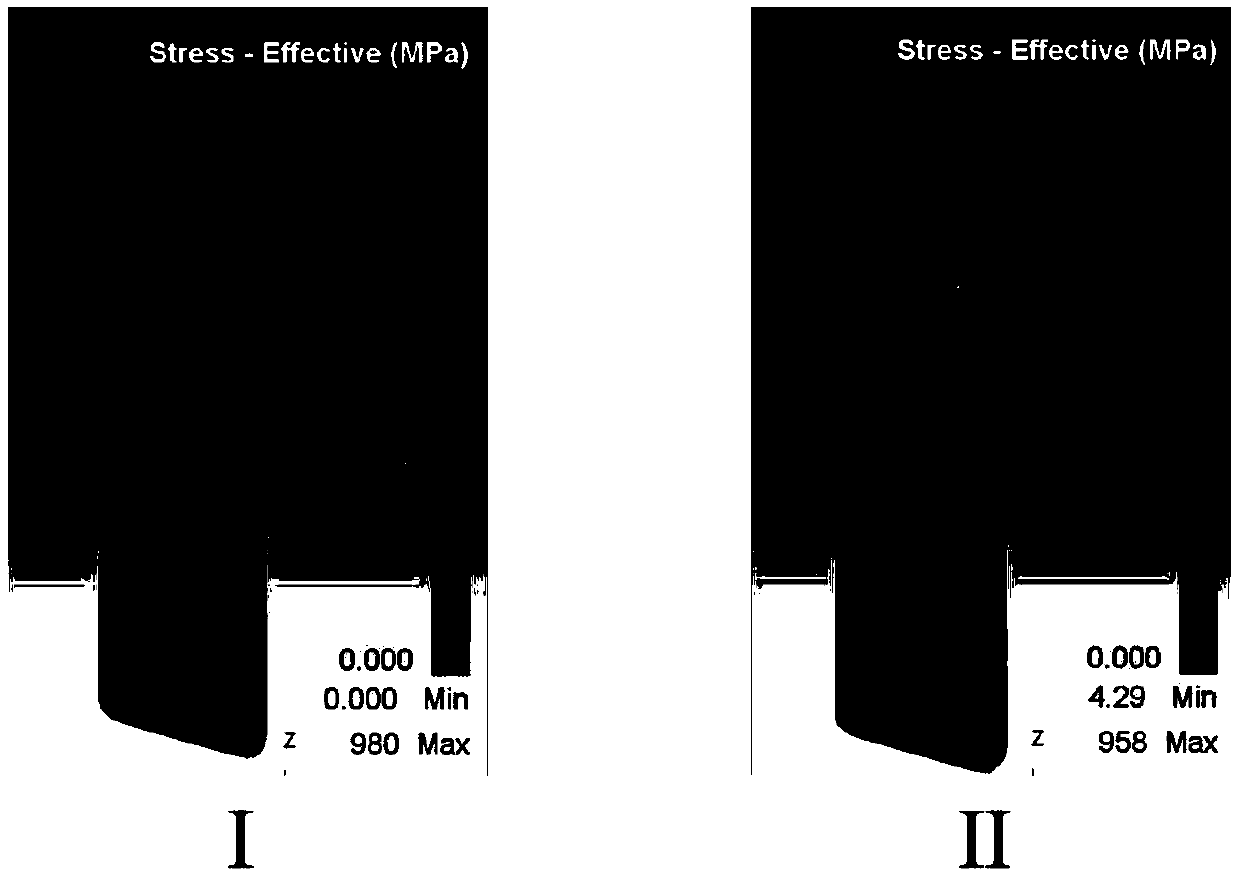

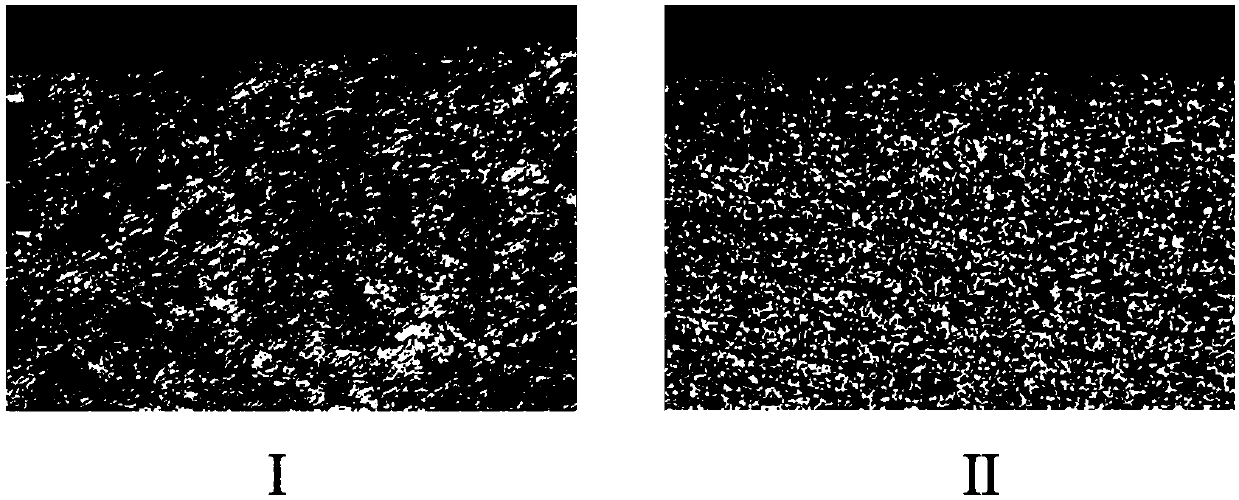

High-modulus straight-tooth cylindrical gear cold extrusion technology and special die thereof

The invention discloses a high-modulus straight-tooth cylindrical gear cold extrusion technology which comprises the following steps of: shearing or sawing a blank and charging the blank; shaping the blank; and performing counter-extrusion deep hole treatment and bottom impact treatment to form a hollow blank, then performing pre-forming cold extrusion tooth treatment and fine-forming cold extrusion tooth treatment, and performing an isothermal normalization or annealing technology and lubrication treatment between the two working procedures. In the prior art, the type of gear processed by the conventional forming technology needs to be ground, polished or lapped to reach the precision requirement. Compared with the prior art, the high-modulus straight-tooth cylindrical gear cold extrusion technology has the advantages that a straight-tooth cylindrical gear processed by the technology has high tooth-shaped precision and the tooth-direction precision reaching the level 9 to 10, and the tooth surface does not need subsequent processing. The working procedures of the technology are simple, the efficiency is high and heating is not needed, so that the energy consumption is greatly reduced; the die can be used for more than 100 thousand of times; and the cost is greatly reduced.

Owner:TAICANG JIUXIN PRECISION MOLD

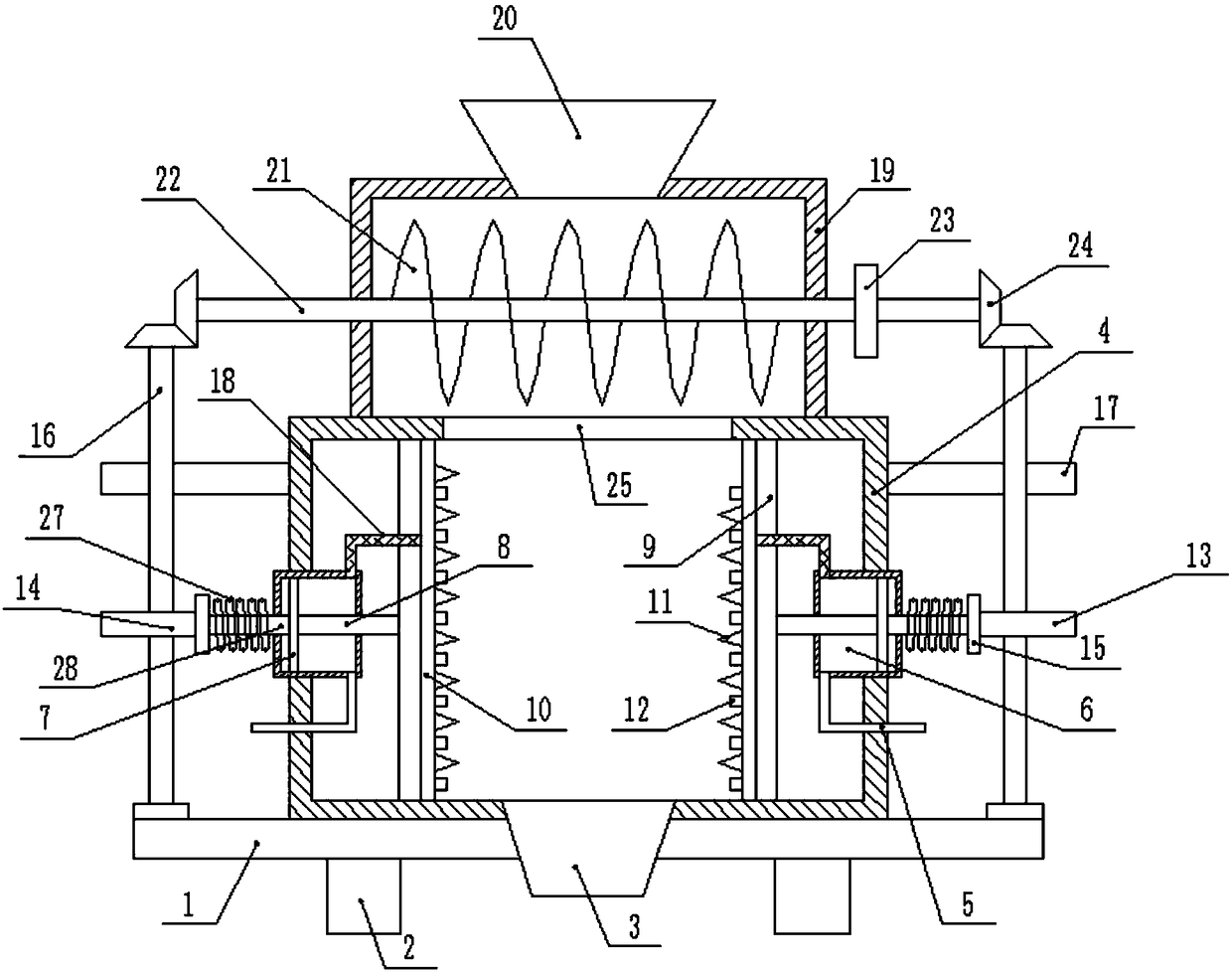

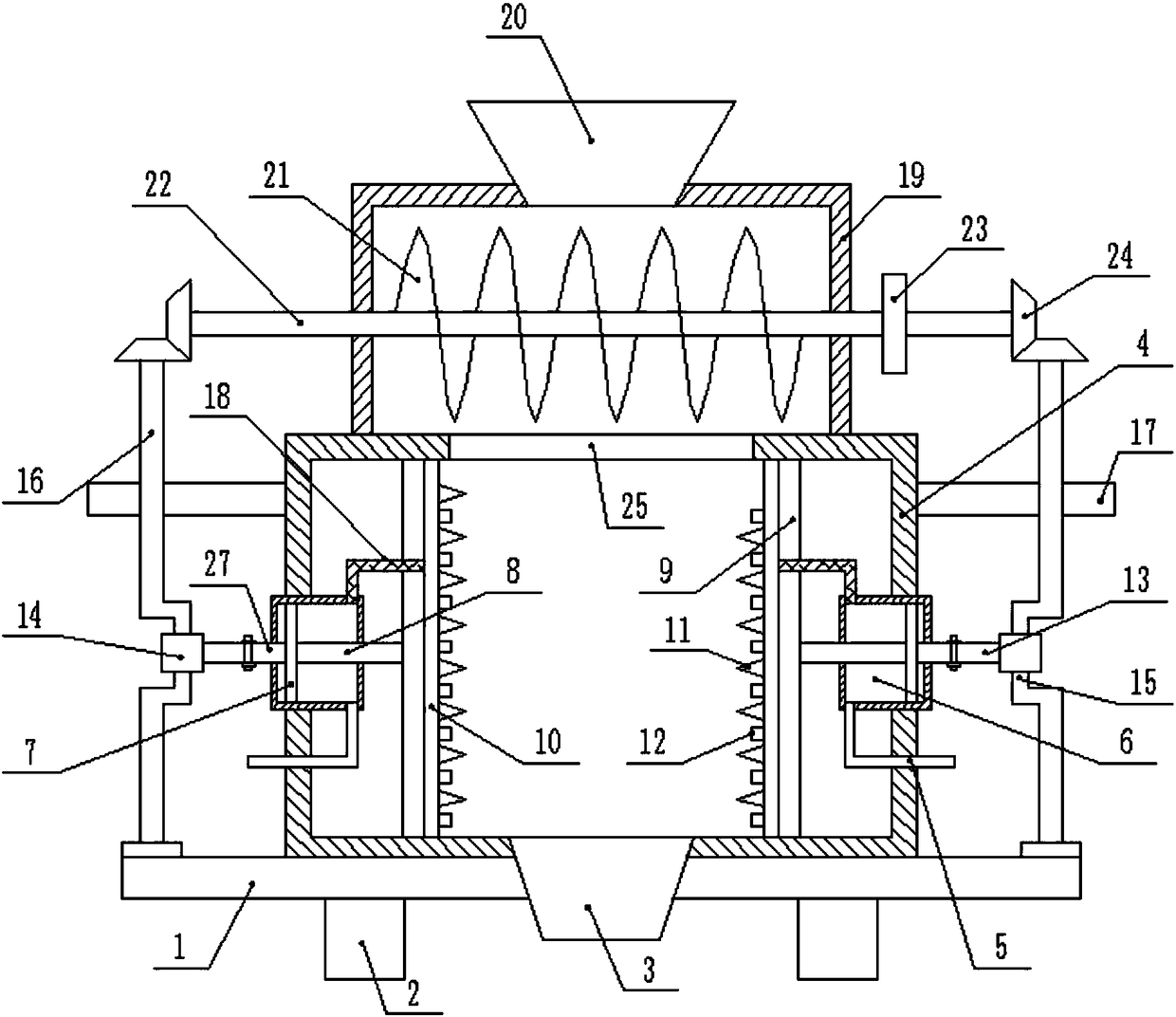

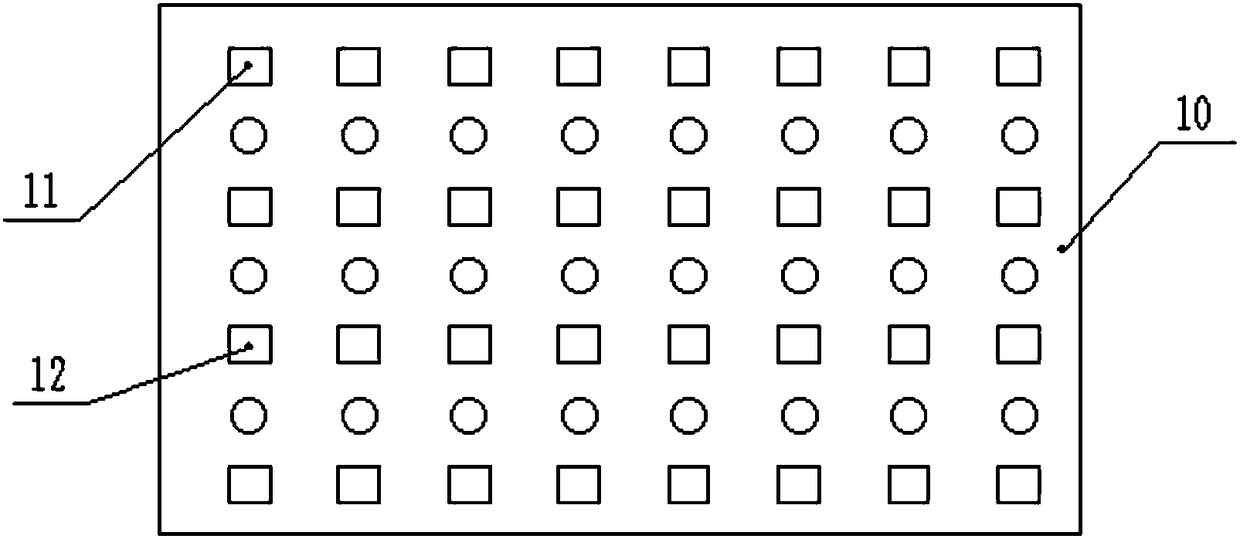

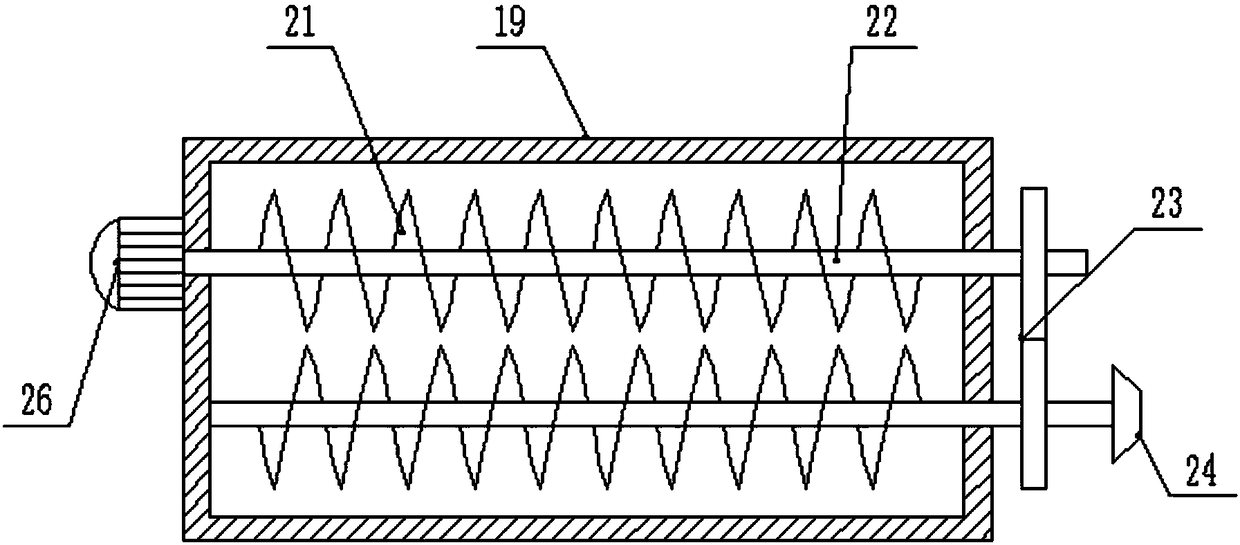

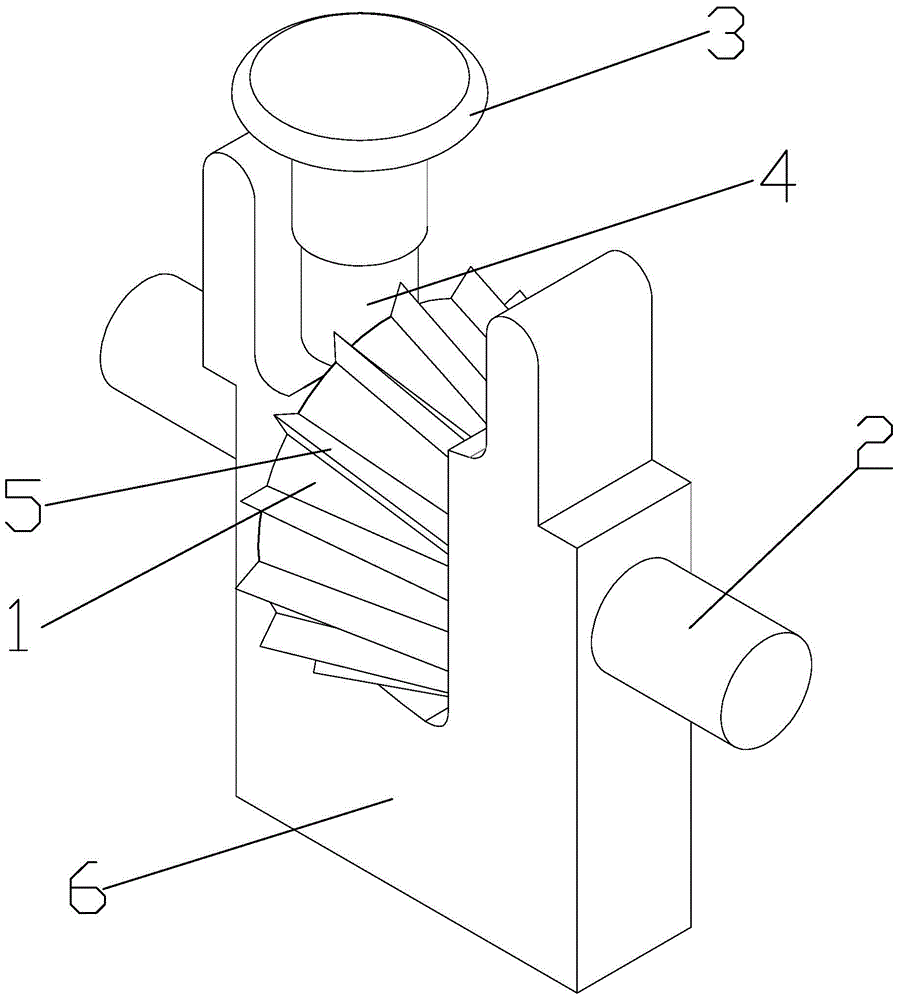

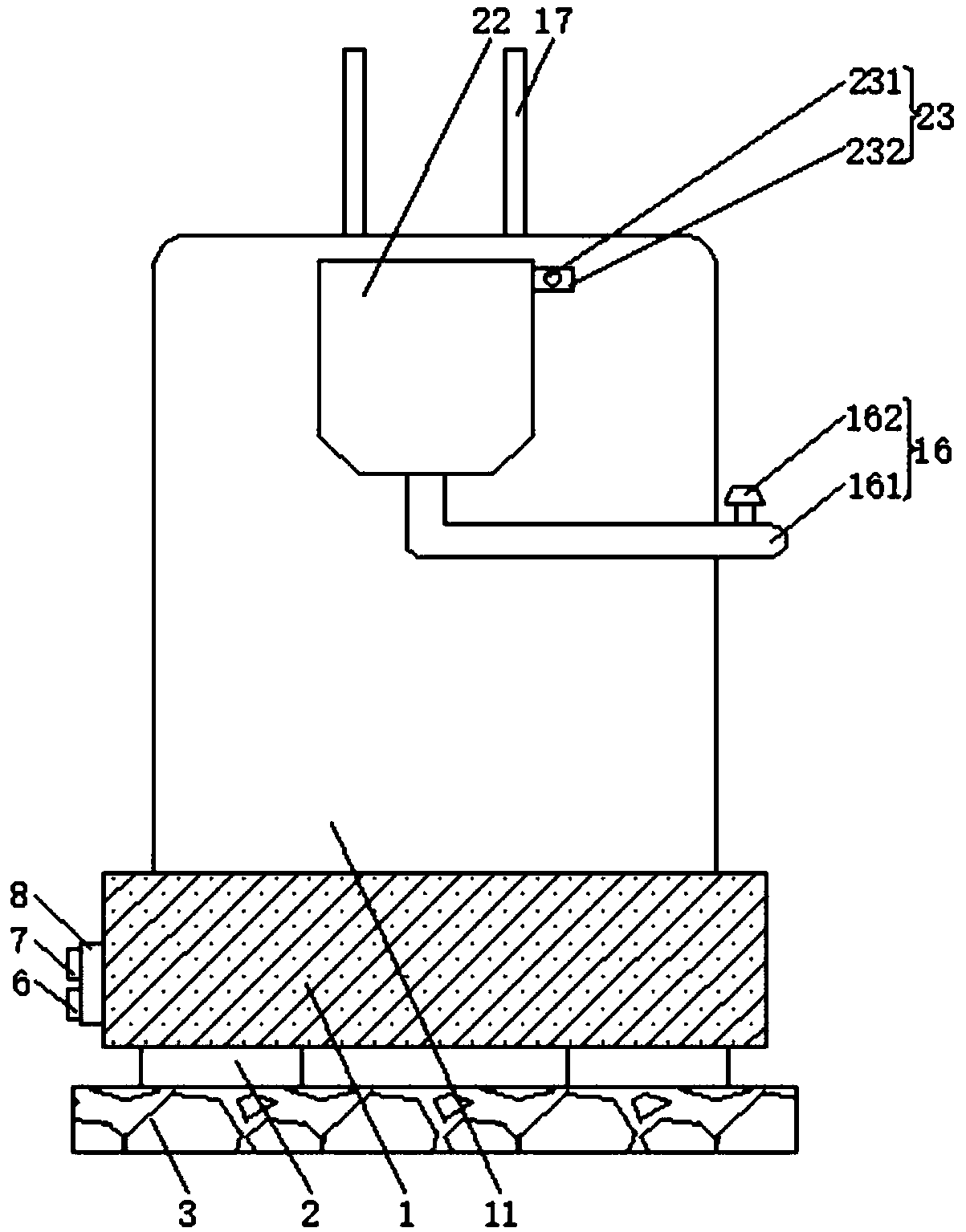

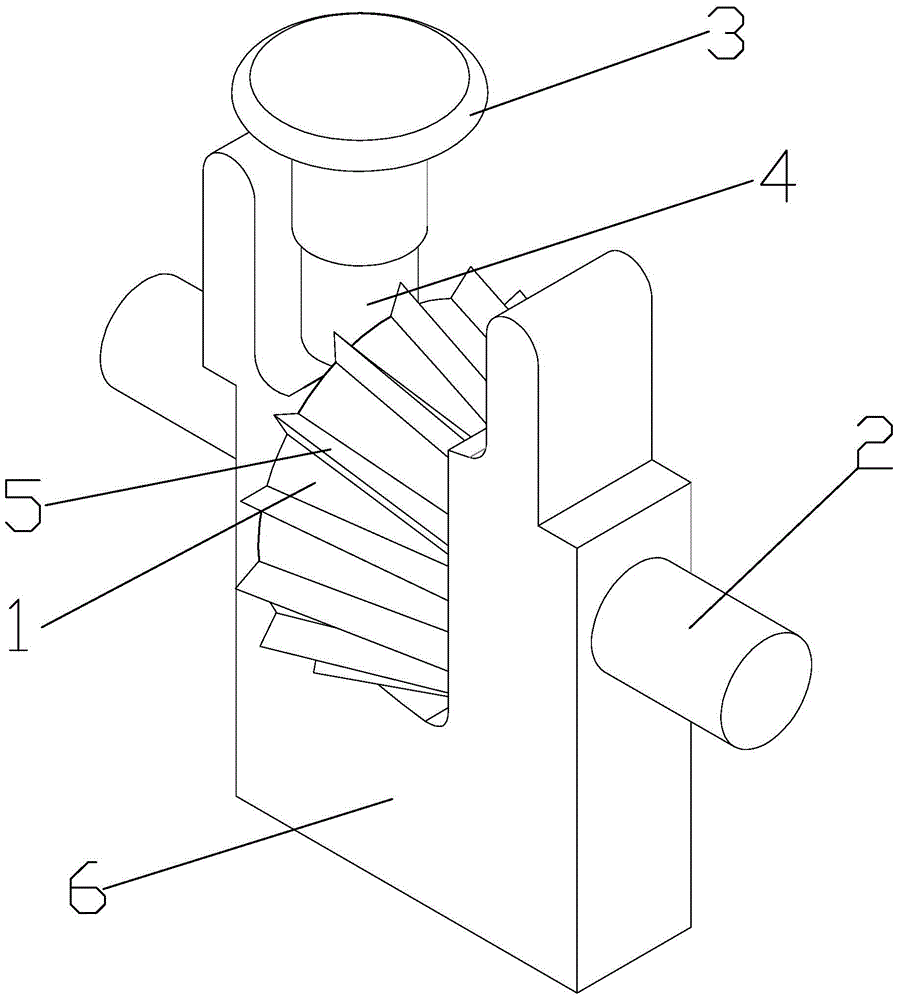

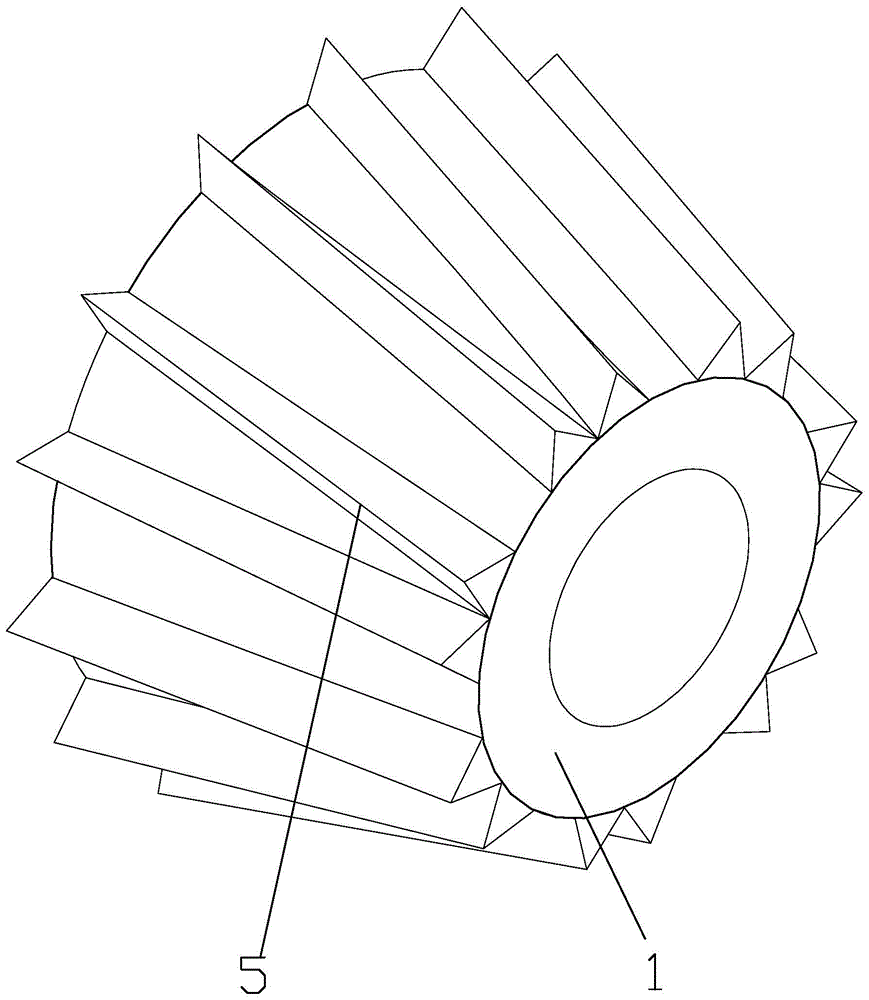

Cam type soil crushing and mixing device for ex-situ soil restoration and government

InactiveCN108620430AReasonable structureInnovative designTransportation and packagingMixersSpray nozzleAgricultural engineering

The invention discloses a cam type soil crushing and mixing device for ex-situ soil restoration and government. The cam type soil crushing and mixing device comprises a support base, wherein the upperend of the support base is provided with an extrusion box; extrusion plates are arranged at two sides inside the extrusion box; a drainage cavity is formed in the inner side of each extrusion plate;medicine spraying nozzles and extrusion teeth are uniformly arranged at the inner side of each drainage cavity at intervals; a piston rod is arranged at the outer side of each extrusion plate; a piston plate is connected to the outer side of each piston rod; a medicine guide cylinder is arranged at the outer side of each piston plate; the middle part of the upper end of the extrusion box is provided with a crushing box; a crushing shaft is arranged inside the upper end of the crushing box; the right end of the crushing shaft at the front end is connected with a bevel gear group; the lower endof the bevel gear group is connected with a rotating shaft; the middle part of the lower end of the rotating shaft is connected with a cam; the middle part of the outer side of each piston plate is provided with a press post; the outer side of each press post is connected with a press plate. The cam type soil crushing and mixing device has the advantages that the primary crushing and mixing on thesoil is realized; meanwhile, the extruding plates in the extrusion box extrude the soil again; the real-time automatic medicine adding mixing effects are achieved; the mixing effect of the restoration medicine and the soil is improved.

Owner:赵海平 +2

Energy-saving roller type grading machine

The invention relates to an energy-saving roller type grading machine applicable to non-flammable and non-explosive medium fine crushing with the machining compressive strength of less than or equal to 300MPa. The energy-saving roller type grading machine comprises two spindles which are fixed on a frame and are respectively mounted on a bearing block to rotate in opposite directions, wherein crushing extrusion rollers are respectively mounted on the two spindles; the two crushing extrusion rollers consist of hexagonal rotors and wear-resistant toothed plates; shearing teeth are mounted on the wear-resistant toothed plate of the first crushing extrusion roller; extrusion teeth are mounted on the wear-resistant toothed plate of the second crushing extrusion roller; a feeding hole, a discharge opening and a distributing device are respectively arranged above and below the space between the hexagonal rotors of the main frame. The whole set of equipment is low in power loss and pollution and meets the national energy-saving environment-friendly requirements; the equipment is wholly made of high-quality materials, quick-wear parts are made of wear-resistant and damage-resistant materials, the problem that the quick-wear parts are frequently replaced is solved, and the materials are saved. Moreover, the roller tooth shape is specially designed, steel bars, sawdust and other sundries in the materials are extremely effectively stripped, and accessible continuous operation is implemented.

Owner:上海建冶路桥机器设备有限公司

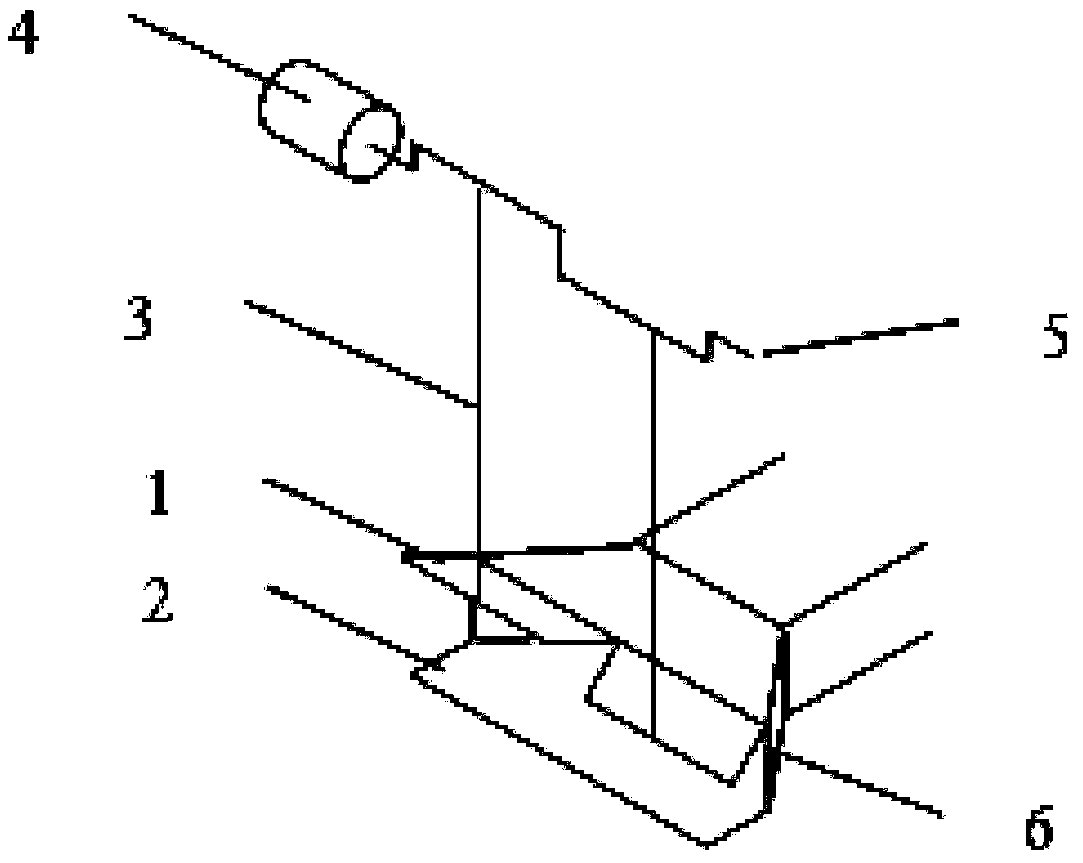

Crank type soil crushing and mixing device for heterotopic soil remediation and treatment

InactiveCN108607876AReasonable structureInnovative designRotary stirring mixersTransportation and packagingSoil remediationSpray nozzle

The invention discloses a crank type soil crushing and mixing device for heterotopic soil remediation and treatment, wherein the crank type soil crushing and mixing device comprises a support base; anextrusion box is arranged at the upper end of the support base, extrusion plates are arranged on both sides of the interior of the extrusion box, and a drainage cavity is arranged on the inner side of each of the extrusion plates; agent spray nozzles and extrusion teeth are arranged on the inner side of each drainage cavity uniformly at intervals; piston rods are arranged outside the extrusion plates; a piston plate is connected on the outer side of each piston rod; an agent leading cylinder is arranged on the outer side of each piston plate; a crushing box is arranged in the middle of the upper end of the extrusion box, crushing shafts are arranged in the upper end of the crushing box, the right ends of the crushing shafts are meshed with each other through a straight gear group, the right ends of the crushing shafts at the front end are connected with bevel gear groups, and the lower end of each bevel gear group is connected with a rotating shaft; the middle of the lower end of eachrotating shaft is provided with a crank; the middle of each crank is provided with a sliding sleeve; the inner side of each sliding sleeve is hinged with a connecting rod. According to the crank typesoil crushing and mixing device, soil is subjected to primary crushing mixing, at the same time, the soil is extruded again by the extrusion plates in the extrusion box, real-time automatic dosing and mixing effect is achieved, and the mixing effect of a remediation agent and the soil is increased.

Owner:赵海平 +2

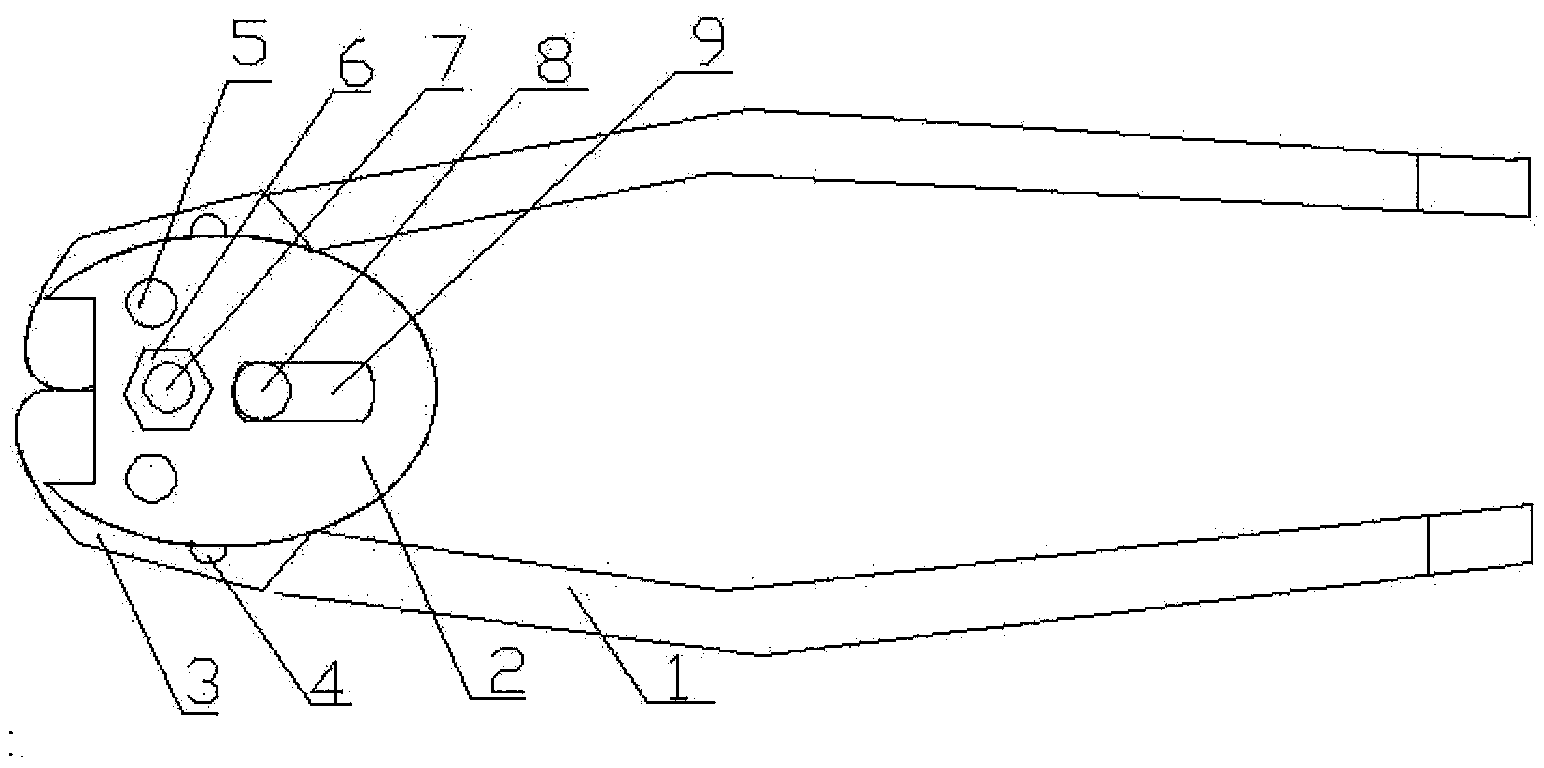

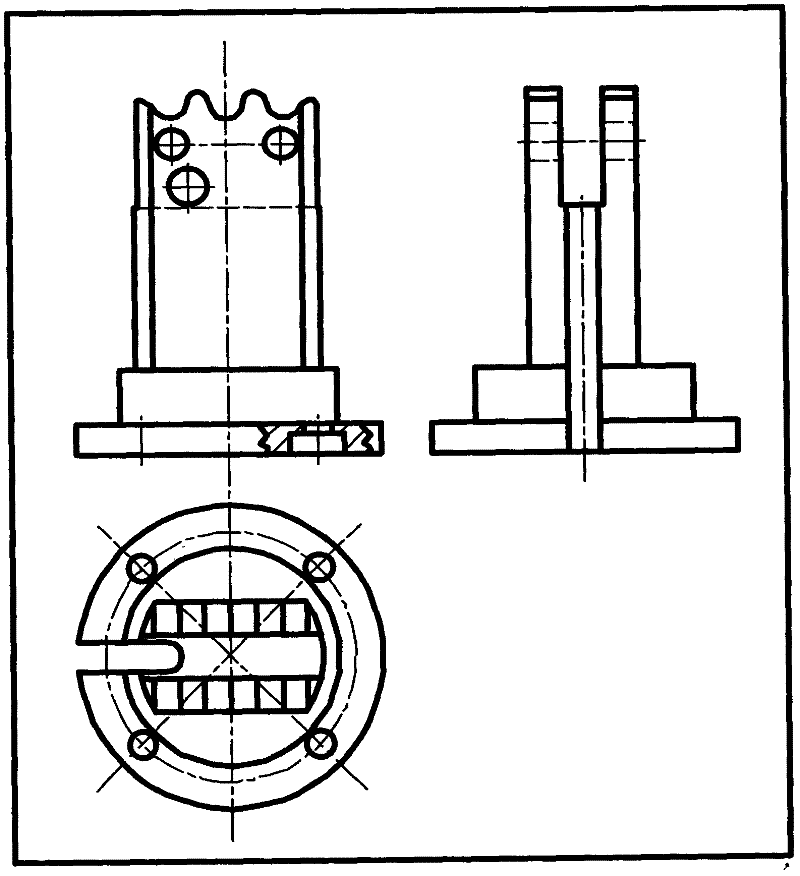

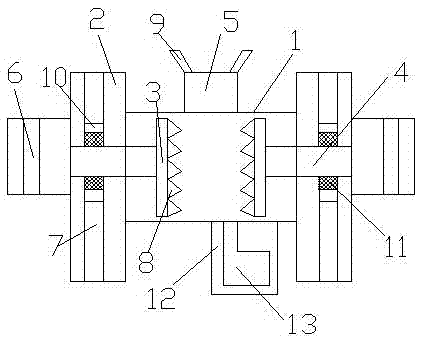

Packaging pliers

The invention provides a pair of packaging pliers. The pair of packaging pliers comprises handles, cover plates and extrusion tooth plates. The handles are hinged to the extrusion tooth plates through guide pins, the extrusion tooth plates are connected with the upper cover plate and the lower cover plate through shafts, the upper cover plate and the lower cover plate are positioned through nuts and screws, the two handles are connected through a pin shaft which can slide in a guide groove, and the handles are bent arms. The pair of packaging pliers has the advantages that the pair of packaging pliers is simple in structure, convenient to carry and capable of being widely applied to closing iron sheet openings in the packaging process, and labor is saved in the using process.

Owner:天津市大港包装机械厂

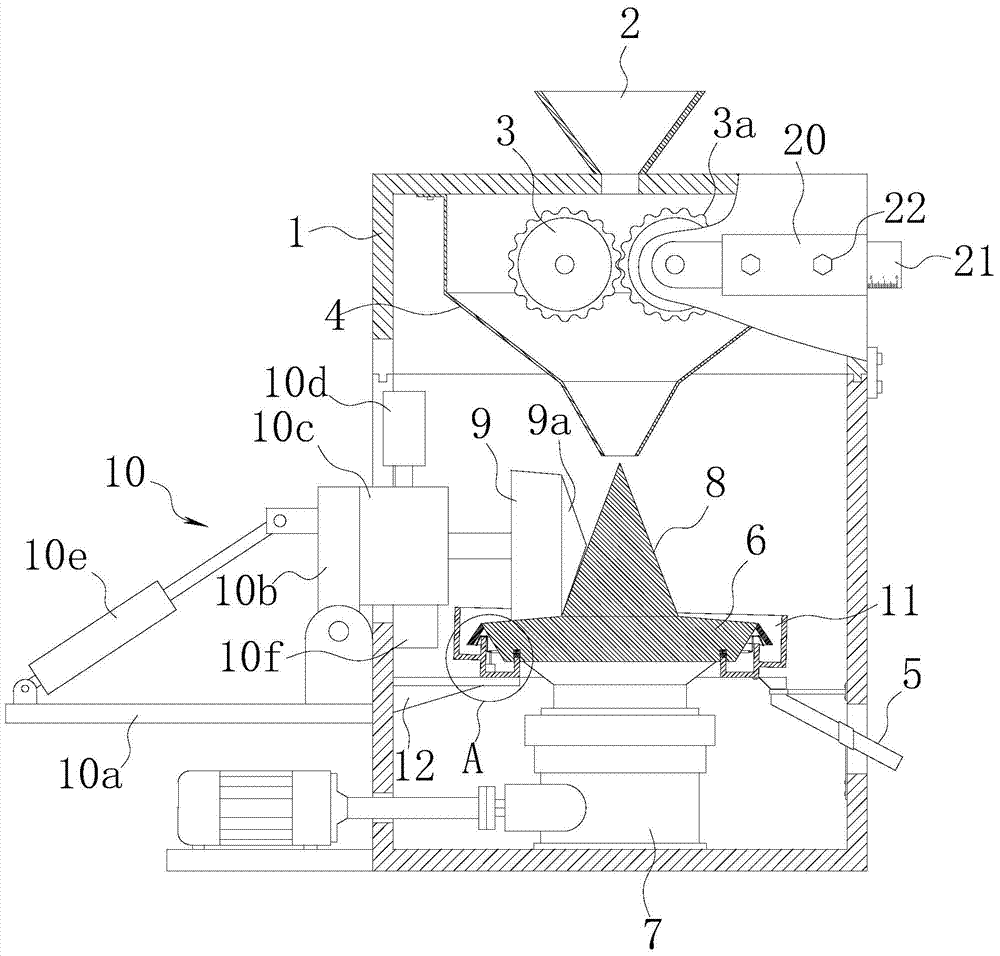

Olea europaea crushing and grinding equipment

InactiveCN104774683AAchieve flushingEasy outflowFatty-oils/fats productionExtrusion toothMechanical engineering

Belonging to the technical filed of olea europaea crushing equipment, the invention discloses olea europaea crushing and grinding equipment. The technical key point of the equipment lies in that it includes a casing, wherein the top of the casing is provided with an opening, a hopper is disposed at the opening, two mutually cooperating extrusion rolls are arranged on the upper part inside the casing, and the two extrusion rolls are respectively connected to a rotary driving motor. Several extrusion teeth are disposed on the surfaces of the two extrusion rolls along the circumferential direction, and two adjacent extrusion teeth cooperate to form an extrusion groove. The extrusion teeth on two extrusion rolls are engaged with each other, and at the time of engagement, the distance between the external end face of the extrusion tooth on the central axis connection line of the two extrusion rolls and a corresponding extrusion groove internal end face is 1-3.5mm. A guide hopper is arranged at the periphery of the two extrusion rolls, a rolling device is disposed below the guide hopper guide hopper in the casing, and the rolling device is connected to a discharge pipe. The invention aims to provide the olea europaea crushing and grinding equipment with the advantages of reasonable structure, convenient use and good use effect to be used for crushing and grinding of olea europaea.

Owner:梅州市广福吉祥投资有限责任公司

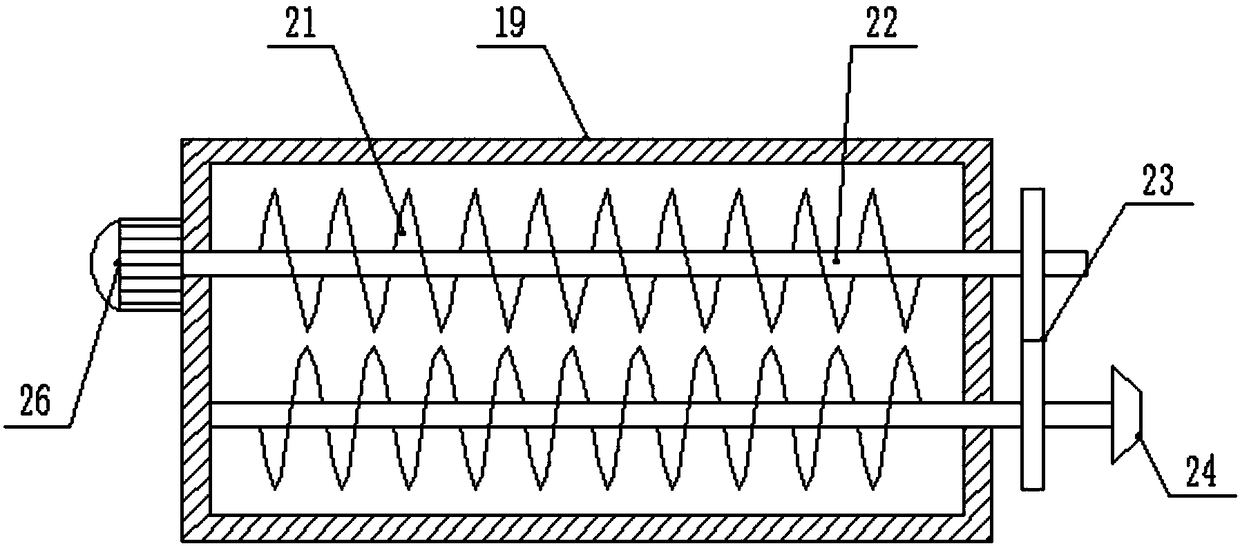

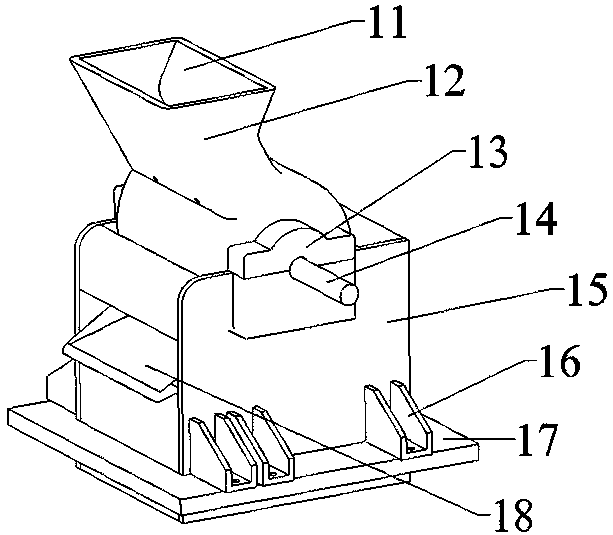

Multifunctional feeder of separator

The invention discloses a multifunctional feeder of a separator. A discharging pipe is connected with a hopper; supporting legs are mounted at the bottom of the hopper; a feeding screw is arranged inside the hopper and is driven by a driving mechanism to rotate; an opening is provided with a filter screen of which the middle is provided with a grate with the mesh being smaller than that of the filter screen in a covering way; a water pipe support is arranged at a corner, and the top end is provided with water spray nozzles spraying water towards the grate; each side wall of the hopper is also provided with a water delivery pipe of which one end communicates with the hopper through a water pump and the other end is connected with one of the water spray nozzles; screw blades on the feeding screw are provided with a plurality of groups of metal brushes; the edge parts of the opening vertically and upwards extend to form a rear baffle and two side plates, each side plate is provided with a telescopic cylinder of which the head of a telescopic rod is provided with an extrusion plate, and the two extrusion plates can be close to or apart away from each other; and a plurality of extrusion teeth are formed on the extrusion plates. Sand adhered to stone blocks can be washed before concrete mortar enters a sand and stone separator, the separation effect can be improved, meanwhile, the washing water can be saved, waste can be avoided, and massive materials can also be smashed and recovered.

Owner:芜湖恒固混凝土材料有限公司

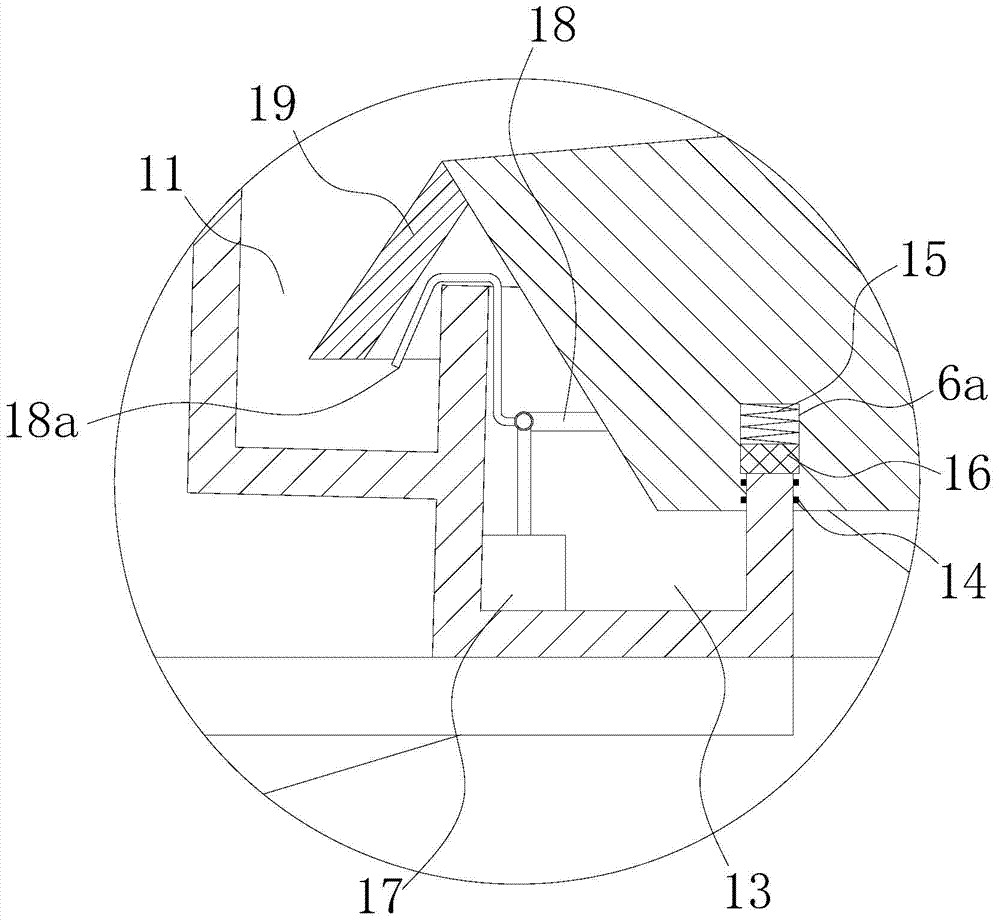

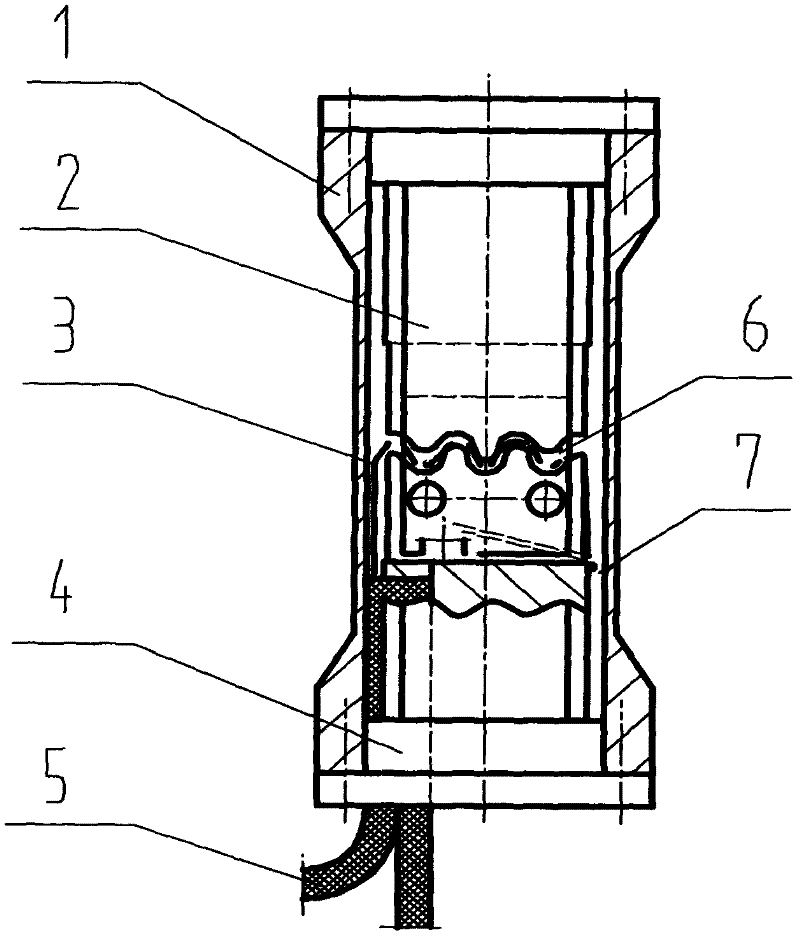

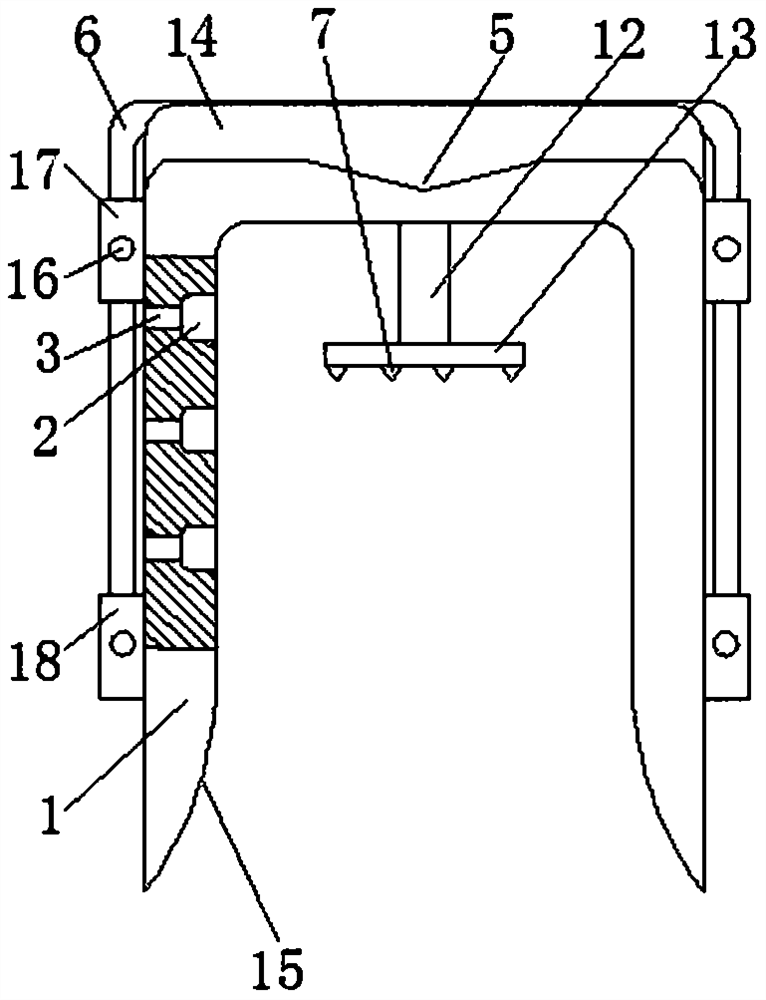

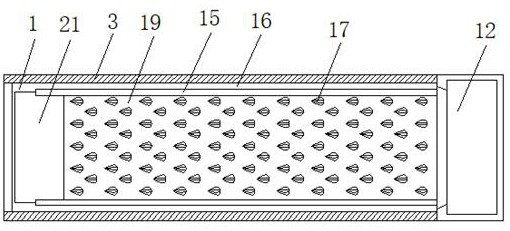

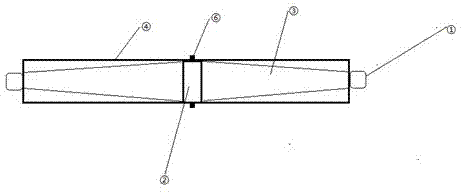

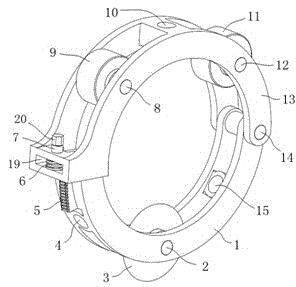

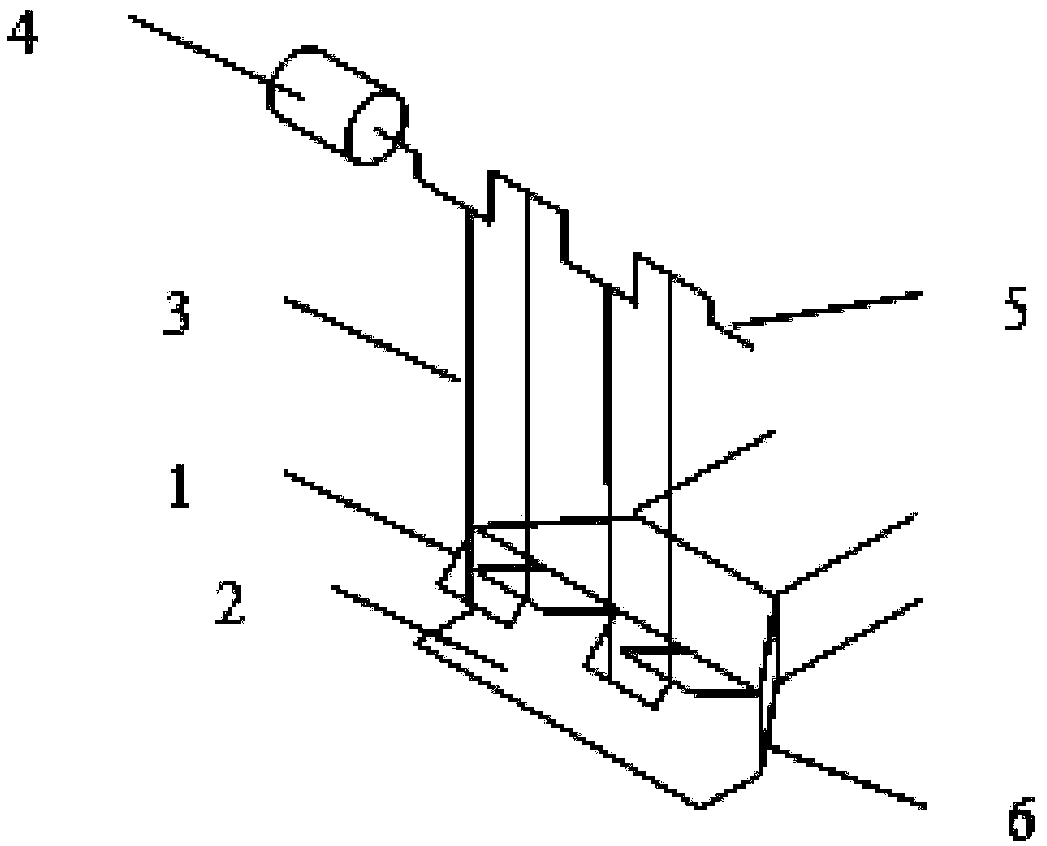

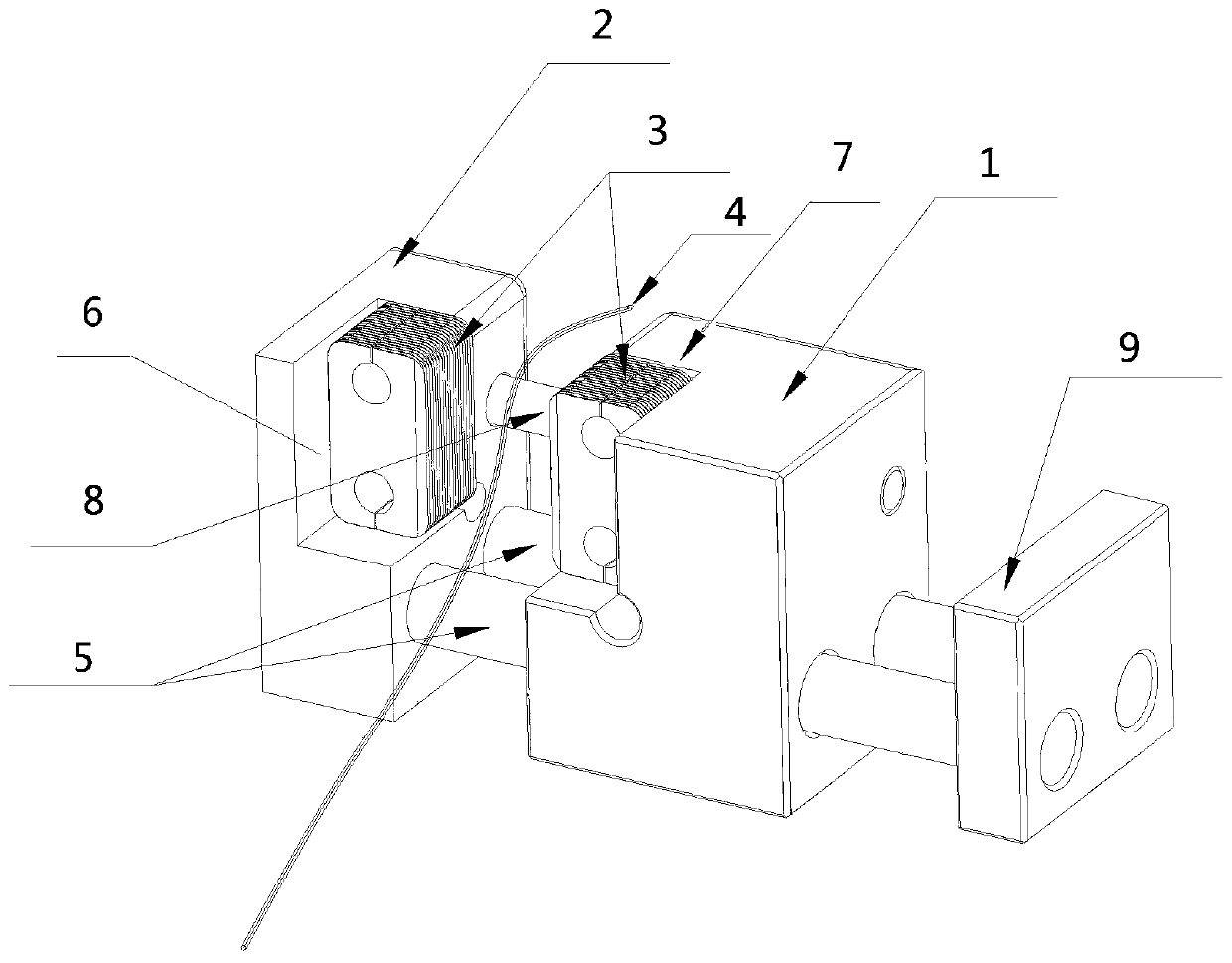

Micro-bend intensity modulated type optical fibre sensor

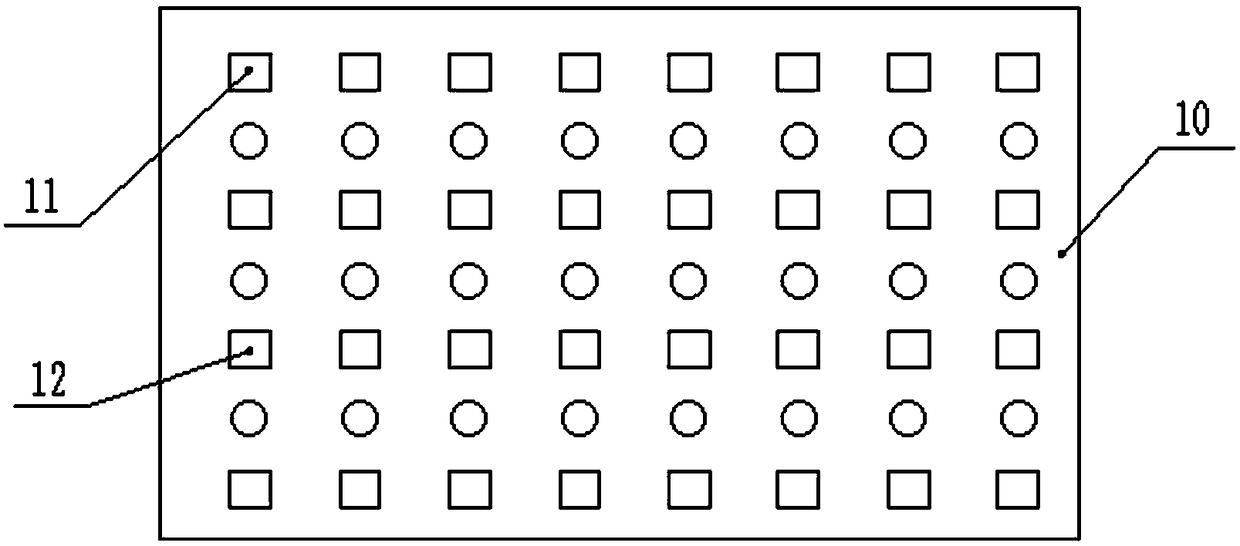

InactiveCN102519381AImprove visibilityEasy to packUsing optical meansInterference resistanceEngineering

The invention relates to an optical fibre sensor, which is used for measuring loading deformation conditions of objects, such as road bridges, long mechanical arms and the like by adopting a micro-bend light intensity modulation principle. A core part in the sensor is a micro-bend device, wherein the micro-bend device is in the form of non-uniform tooth tops and double rows of extrusion teeth; the non-uniform tooth tops can be used for avoiding breakage caused by stretching of a fibre core when the sensor is assembled and works; the double rows of extrusion teeth can be used for ensuring the number of effective teeth on the premise of not increasing the volume; therefore, the sensitivity of the sensor is ensured; the length compensation of an optical fibre is realized through a compensation spring device; and the integral assembly is ensured through a locating sheet. The sensor disclosed by the invention has the advantages of being simple in structure, low in volume, light in weight, strong in interference resistance capability, higher in measurement sensitivity, better in stability and low in cost.

Owner:GUANGZHOU NANYANG POLYTECHNIC

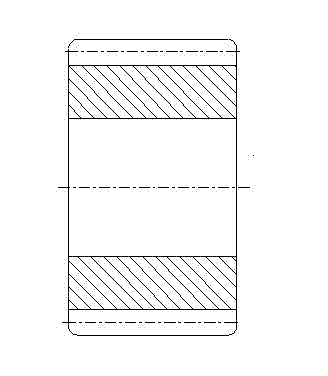

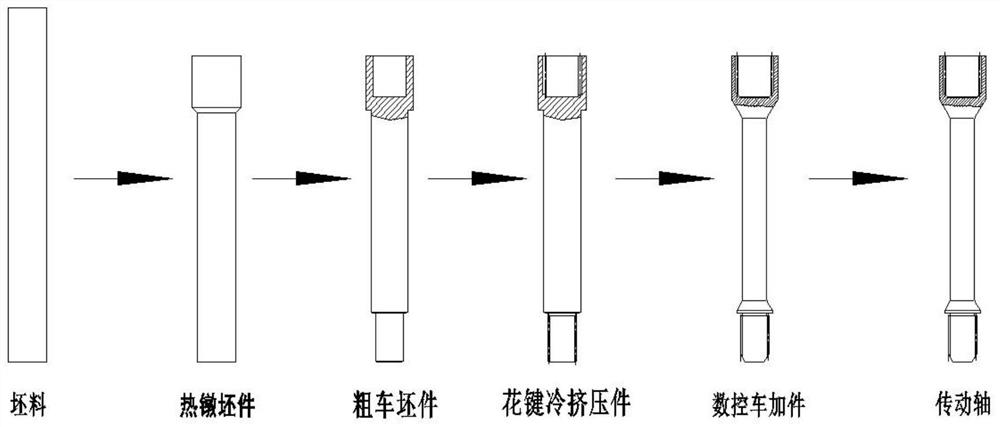

Manufacturing method for transmission shaft

The invention discloses a manufacturing method for a transmission shaft, and particularly relates to the technical field of machine manufacturing. The manufacturing method for the transmission shaft comprises the steps that round steel is subjected to local hot upsetting treatment to obtain a hot upsetting blank; the hot upsetting blank is drilled and turned to form an inner hole, and turning is carried out on the hot upsetting blank to reduce the diameter of the hot upsetting blank to obtain a rough turning blank; the rough turning blank is subjected to tooth extrusion forming machining treatment through using a cold extrusion tooth extrusion forming method to obtain a spline cold extrusion part with an inner spline and an outer spline; and the spline cold extrusion part is turned througha numerical control lathe to obtain a numerical control machined part, and finally, two outer circle surfaces on the numerical control machined part are ground to manufacture the transmission shaft.The technical scheme of the manufacturing method is adopted, the problem that an existing machining method for the transmission shaft is low in material utilization rate, low in production efficiency,low in dimensional precision, low in surface quality and high in production cost is solved, and the method can be used for manufacturing the transmission shaft with high precision.

Owner:CHONGQING UNIV OF ARTS & SCI

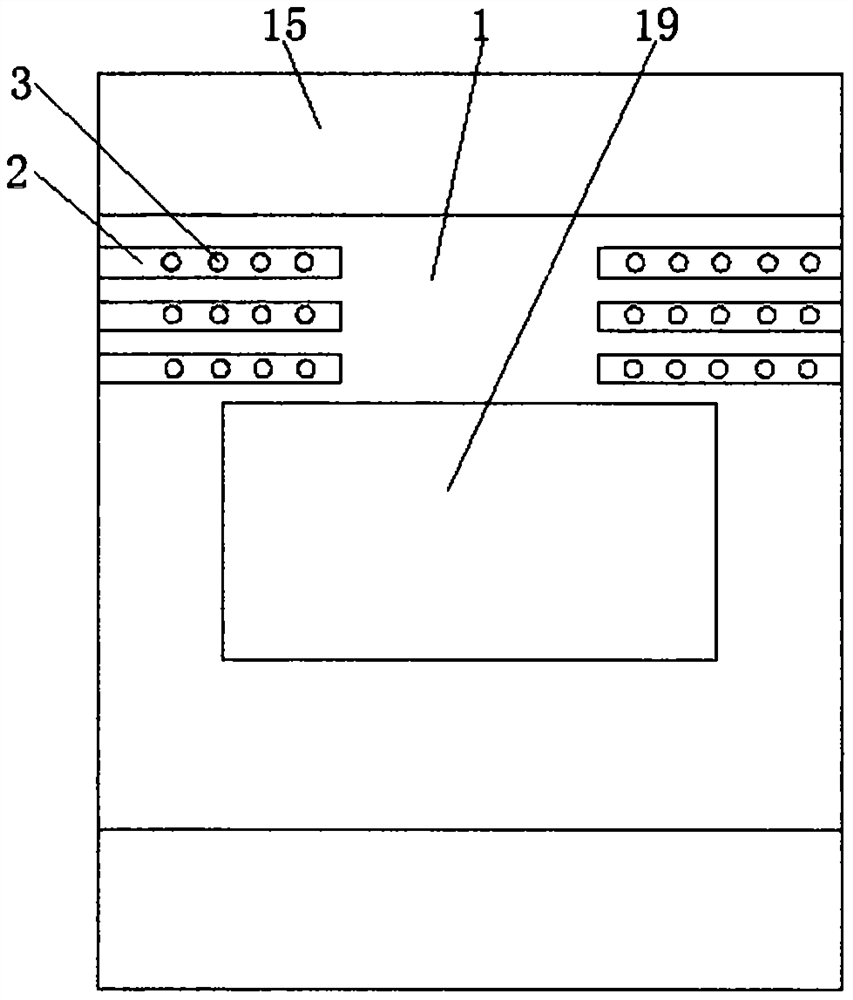

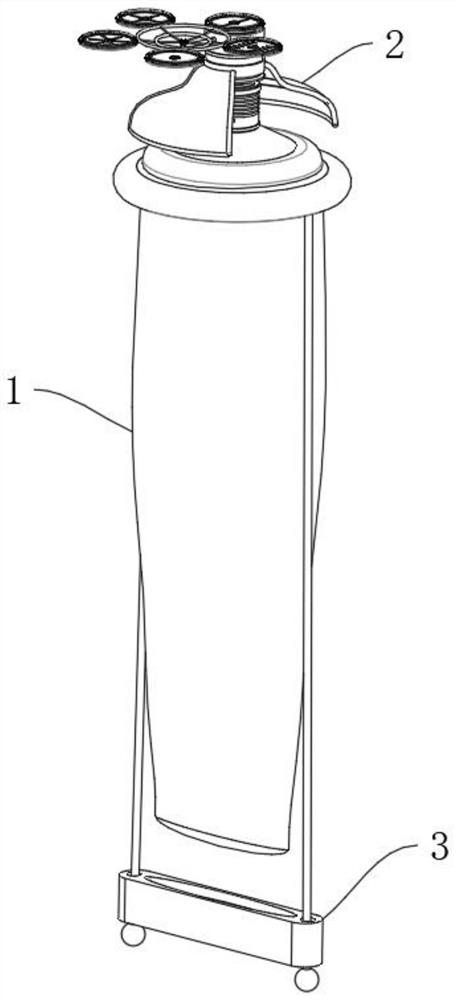

Oral care device used after oral and maxillofacial surgery

PendingCN112569015AFirmly connectedLess discomfortDentistryNon-surgical orthopedic devicesMaxillofacial oral surgeryMouth care

The invention provides an oral care device used after oral and maxillofacial surgery, and relates to the technical field of medical instruments. The oral care device used after oral and maxillofacialsurgery comprises a medical rubber sheet and an occlusion body, a square hole is formed in the middle of the upper side wall of the medical rubber sheet, a middle protrusion of the occlusion body is slidably connected with the square hole, two conical grooves are formed in the upper surface of the medical rubber sheet, and a conical protrusion is arranged on the lower surface of the occlusion body. The conical protrusions are connected with the conical grooves in a sliding mode, and steel hoop connecting grooves are formed in the positions, located on the edges of the two sides, of the upper surface of the meshing body. An outer cylinder drives the connecting plate and the extrusion teeth to press a yarn roll or a cotton ball into the tooth extraction position through the screws, a patientor a doctor does not need to press the yarn roll or the cotton ball for a long time, discomfort of the patient is reduced, ventilation is conducted through the ventilation grooves and the ventilationholes, and it can be guaranteed that the tooth extraction position has good breathability; and the medical rubber sheet and the occlusion body are connected to two sides of the tooth extraction position, so that a patient can normally eat.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Novel rubbish waste recovery extrusion device

A new type of rubbish recycling extrusion device, including a housing and an extrusion device, the housing is connected with an extrusion device, the extrusion devices are respectively installed on both sides of the housing, the extrusion plate and the push rod extend into the housing, The casing is provided with a feeding port, and the extrusion plate moves left and right under the drive of the push rod. The push rod is fitted with a positioning rod, and the two ends of the positioning rod are respectively supported in the extrusion device. The extrusion device is equipped with an extrusion plate, and the extrusion plate is provided with occlusal teeth, so that the garbage can be squeezed more tightly when being squeezed, which is convenient for the next step of garbage processing. The push rod is equipped with a positioning rod, which is controlled by The positioning rod fixes the propulsion rod, which is convenient for the propulsion rod to shake during the propulsion process, which affects the extrusion effect of the garbage. The positioning rod is provided with a set ring, and the set ring is provided with grease, which allows the push rod to move in the set ring More convenient, strong wear resistance.

Owner:YANGZHOU TAIDA ENVIRONMENTAL PROTECTION CO LTD

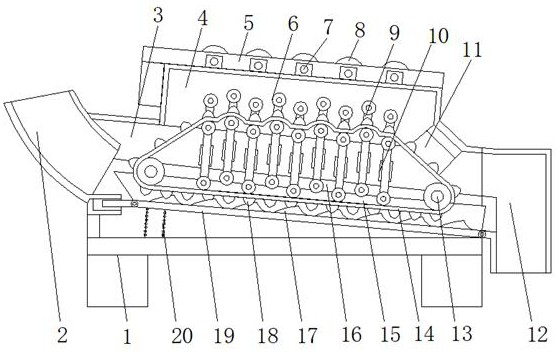

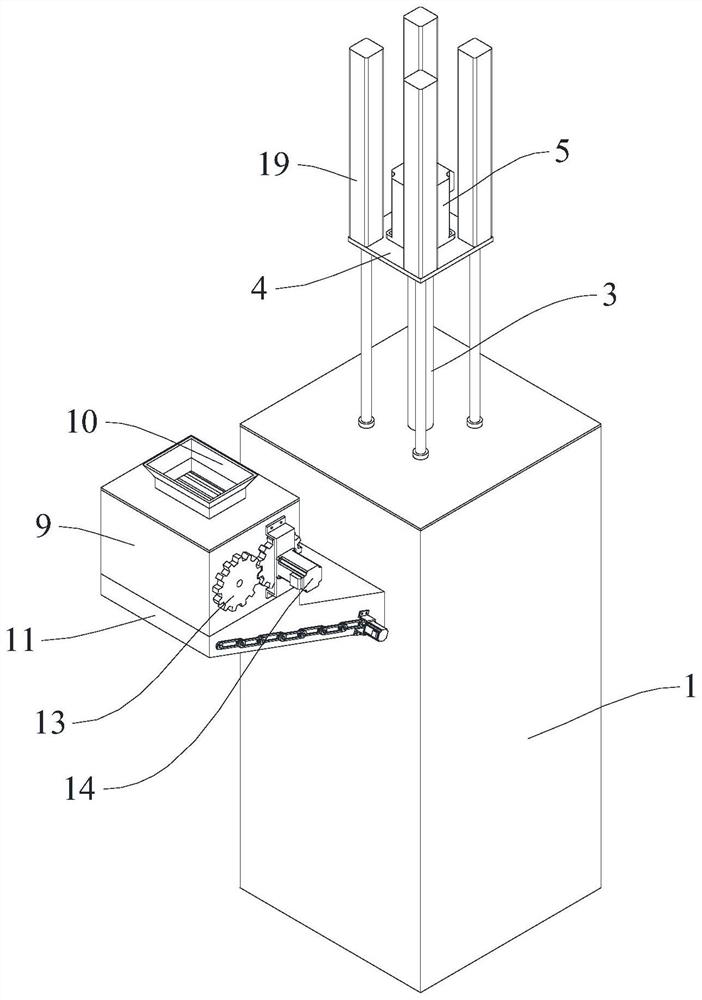

Shell pre-crushing treatment device for decorative material production

InactiveCN112604796AImprove processing efficiencyGuaranteed crushing effectGrain treatmentsExtrusion toothIndustrial engineering

The invention discloses a shell pre-crushing treatment device for decorative material production, and relates to the technical field of decorative material production. In order to solve the problem of non-uniform particle size distribution of fragments due to simple crushing by mechanical grinding, the shell pre-crushing treatment device specifically comprises a machine base, side plates are fixedly installed at the two sides of the top of the machine base correspondingly, a feeding hopper and a discharging hopper are fixedly installed between the two side plates and the end of the machine base correspondingly, an end cover is fixedly installed between the top ends of the two side plates, and installing grooves are formed in the side faces of the two side plates correspondingly. According to the shell pre-crushing treatment device, when a crushing chain plate moves above a bottom plate, through the arrangement of multiple supporting frames and guide rollers, the distance between the crushing chain plate and the bottom plate is fixed, the shell crushing effect is guaranteed while abrasion is reduced, the stability of the device in the operation process is improved, the extrusion crushing effect of extrusion tooth blocks and crushing teeth on shell pieces is improved, and the work efficiency is improved.

Owner:安徽新红胜装饰工程有限公司

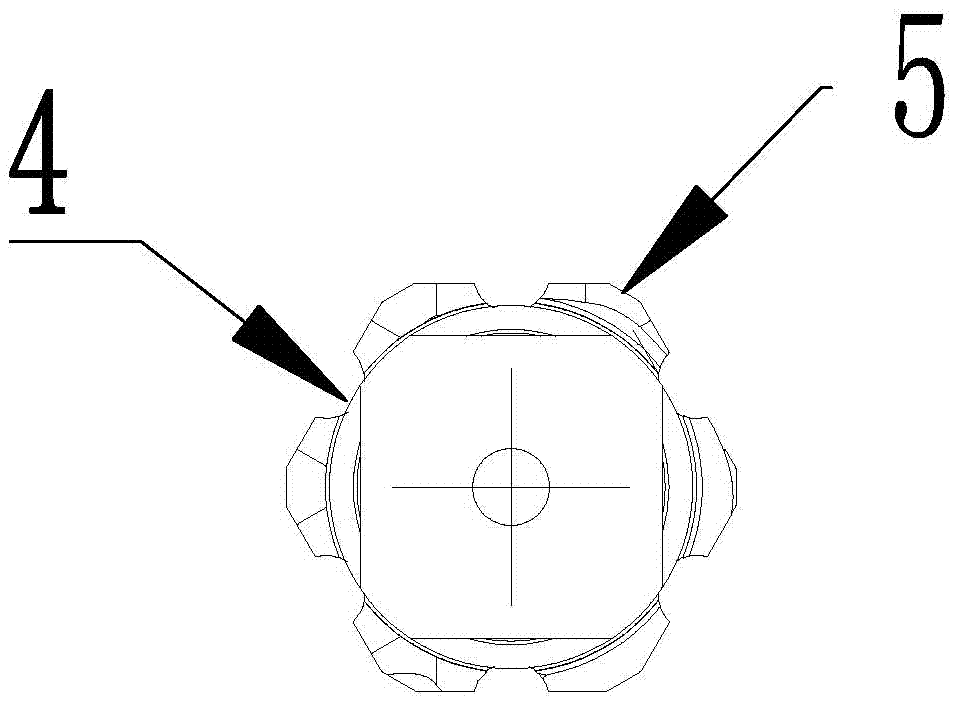

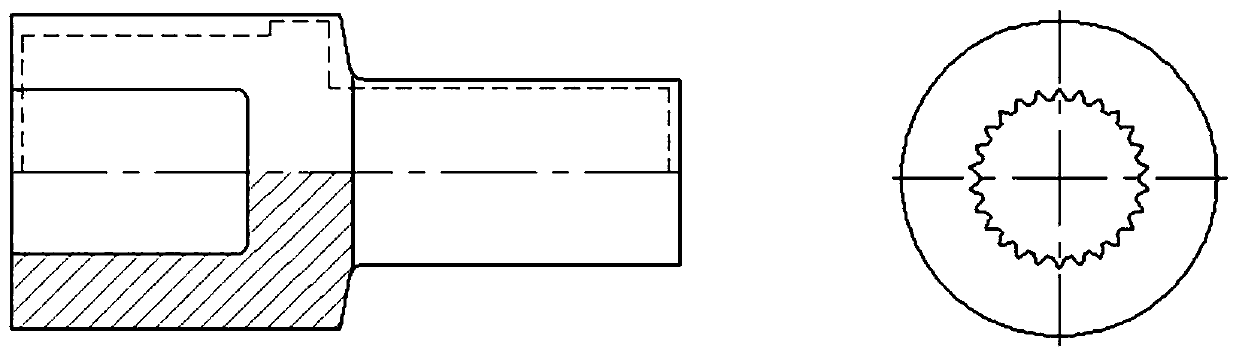

Technology for cold rolling extrusion teeth of cylindrical end face

ActiveCN104588783AOvercome processing defectsReduce processing inputGear teeth manufacturing toolsGear teethKilogram-forceMechanical equipment

The invention relates to a technology for cold rolling extrusion teeth of a cylindrical end face. The technology comprises the following steps that 1 a rolling tool is prepared, wherein the rolling tool is a hollow circular truncated cone adopting alloy steel as materials, and the outer surface of the rolling tool is provided with rack-shaped blades; 2 a to-be-machined workpiece is fixed in a fixture of a lathe, the rolling tool is inserted in a tool bar in a penetrating mode, and the tool bar is fixed on a carriage; 3 a machine tool is started, the revolving speed of the fixture is regulated to be at 1000 r to 1800 r, the carriage provided with the rolling tool is pushed to the direction of the end face of the workpiece to enable the outer surface of the rolling tool to make contact with the end face of the workpiece, and the rolling tool makes contact with the end face of the workpiece for three to five seconds under the environment of 30-kilogram force; 4 the carriage is loosened, the workpiece is taken down, the machine tool is switched off, the whole process is over, and machining of a small tooth face of the end face of the workpiece is completed. According to the technology for cold rolling extrusion teeth of the cylindrical end face, automation is achieved in the whole process, the defect that a traditional technology has to perform machining through mechanical equipment machining such as planing equipment and milling equipment is overcome, machining investment is small, and efficiency is high.

Owner:绍兴柯桥珂阳五金汽配厂

Two-head self-extruding toothpaste tube

InactiveCN103482200AIncrease profitChange understandingContainer handlesFlexible containersToothpasteEngineering

The invention discloses a two-head self-extruding toothpaste tube. The novel two-head self-extruding toothpaste tube is different from traditional toothpaste tube, and modification is conducted according to the two-head self-extruding toothpaste tube. The toothpaste tube used in the past is only provided with one head, in the design background, when remaining toothpaste in the toothpaste tube is not enough, the toothpaste cannot be extruded easily, waste of resources is prone to being caused, and the benefits of a user are damaged. Therefore, the two-head self-extruding toothpaste is produced, the bottom design is lifted to the middle part of the toothpaste, and the novel two-head toothpaste is manufactured. Due to the fact that the two heads of the two-head toothpaste and the middle bottom are designed to be symmetrical, two users can extrude the toothpaste conveniently at the same time, and a self-extruding device brings convenience for people to extrude the toothpaste. The two-head self-extruding toothpaste solves a lot of problems for the users.

Owner:南京丰海节能科技有限公司

olive crushing and grinding equipment

InactiveCN104774683BAchieve flushingEasy outflowFatty-oils/fats productionGrain treatmentsExtrusion toothMechanical engineering

Belonging to the technical filed of olea europaea crushing equipment, the invention discloses olea europaea crushing and grinding equipment. The technical key point of the equipment lies in that it includes a casing, wherein the top of the casing is provided with an opening, a hopper is disposed at the opening, two mutually cooperating extrusion rolls are arranged on the upper part inside the casing, and the two extrusion rolls are respectively connected to a rotary driving motor. Several extrusion teeth are disposed on the surfaces of the two extrusion rolls along the circumferential direction, and two adjacent extrusion teeth cooperate to form an extrusion groove. The extrusion teeth on two extrusion rolls are engaged with each other, and at the time of engagement, the distance between the external end face of the extrusion tooth on the central axis connection line of the two extrusion rolls and a corresponding extrusion groove internal end face is 1-3.5mm. A guide hopper is arranged at the periphery of the two extrusion rolls, a rolling device is disposed below the guide hopper guide hopper in the casing, and the rolling device is connected to a discharge pipe. The invention aims to provide the olea europaea crushing and grinding equipment with the advantages of reasonable structure, convenient use and good use effect to be used for crushing and grinding of olea europaea.

Owner:梅州市广福吉祥投资有限责任公司

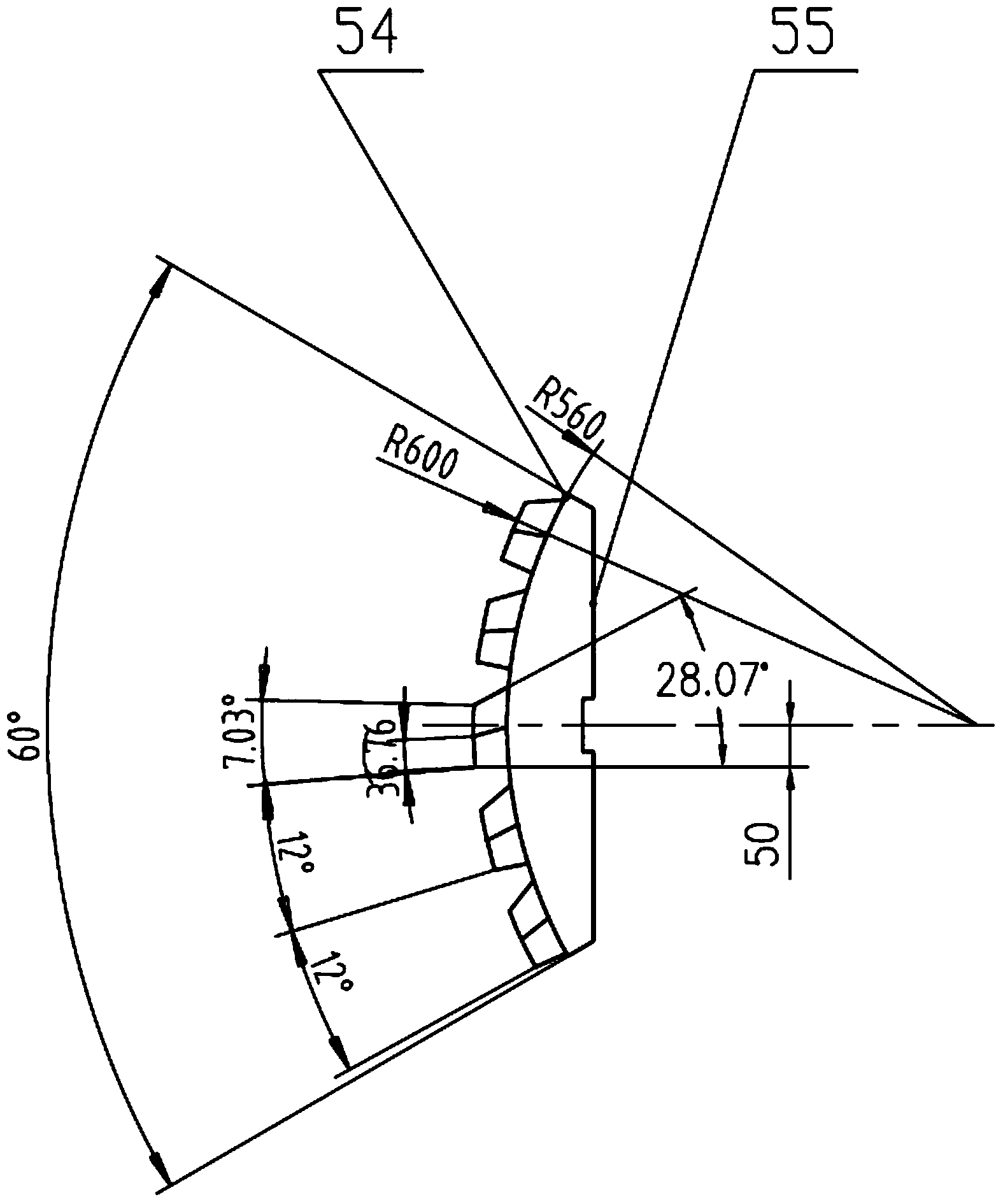

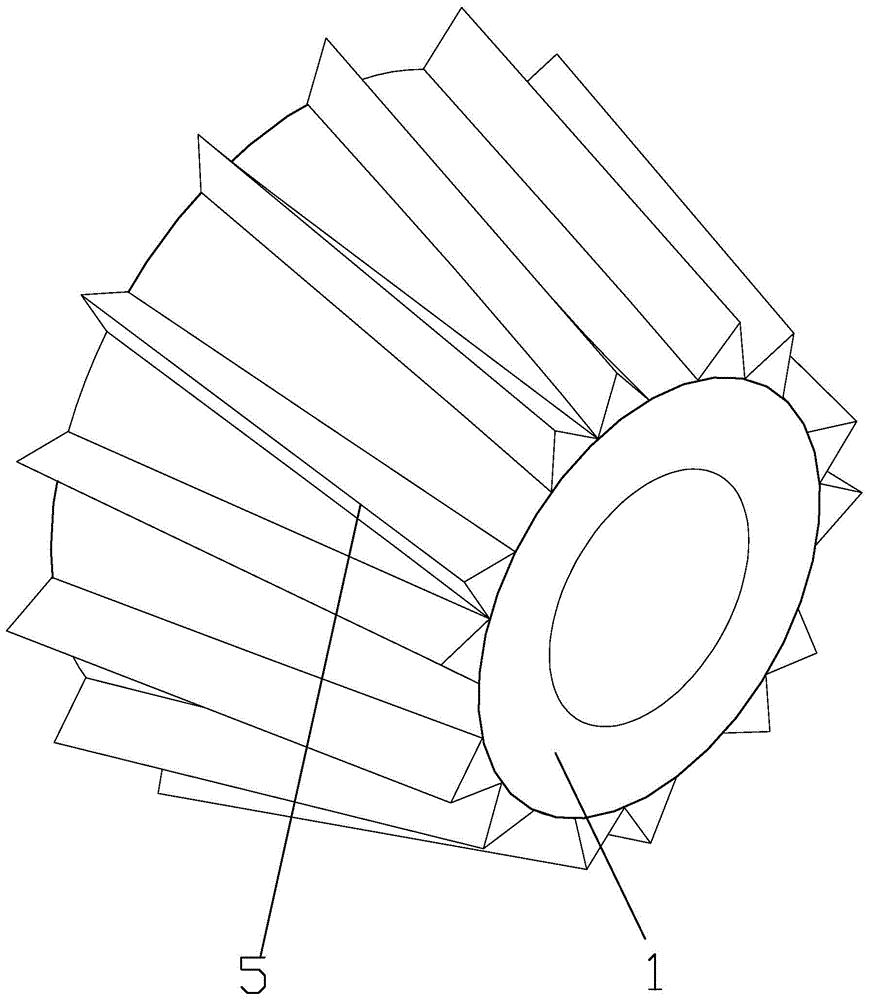

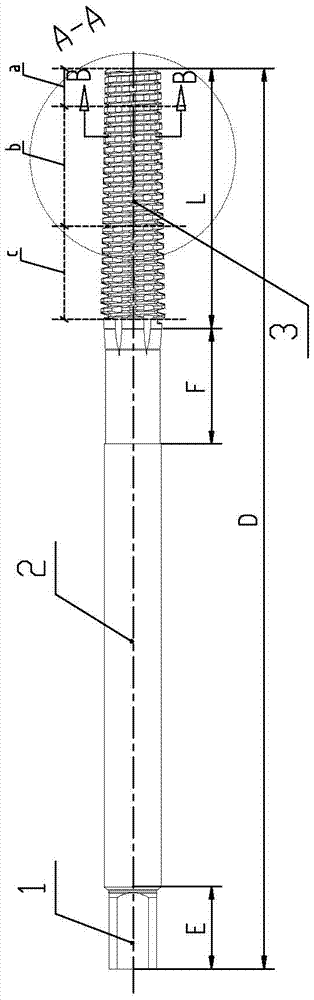

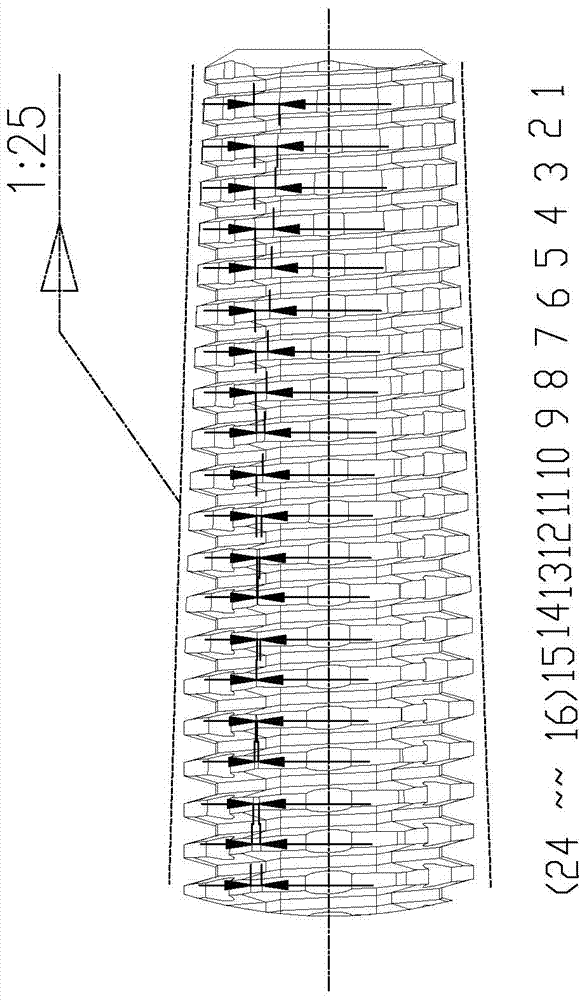

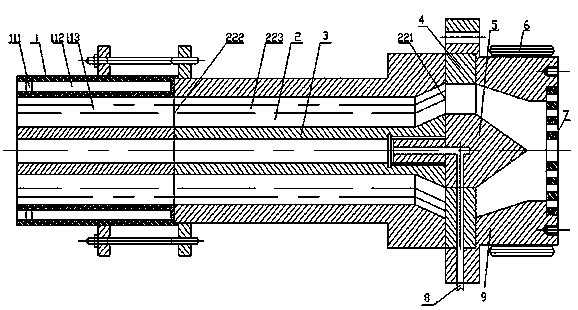

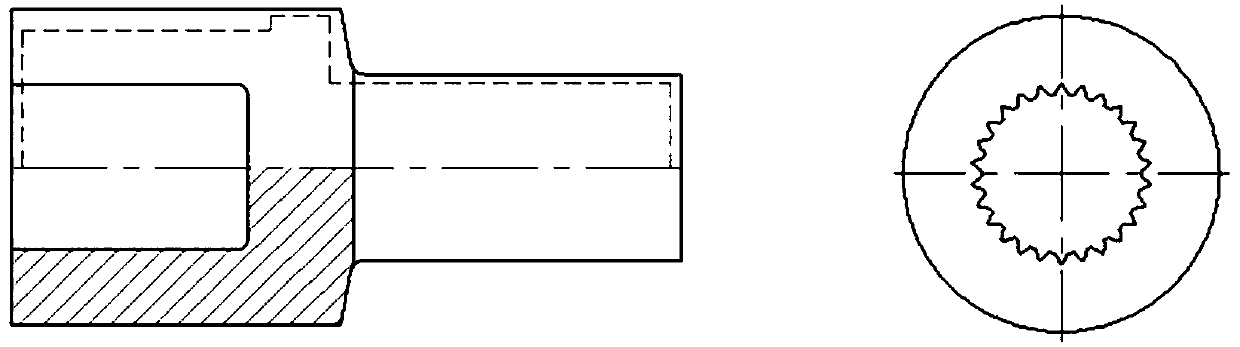

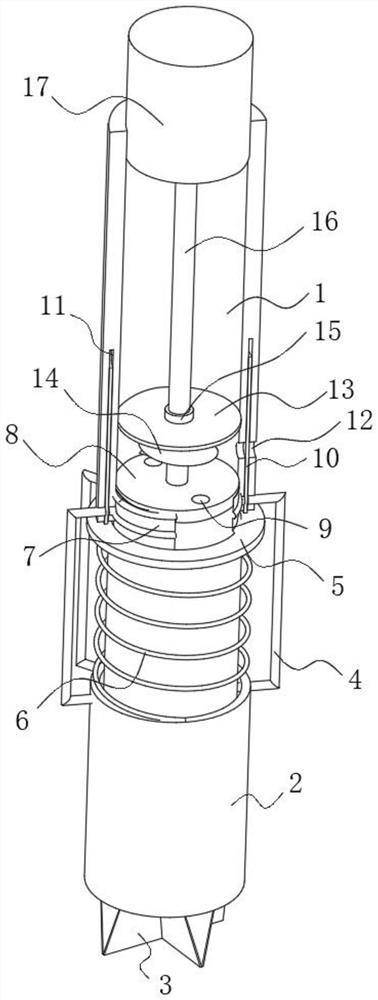

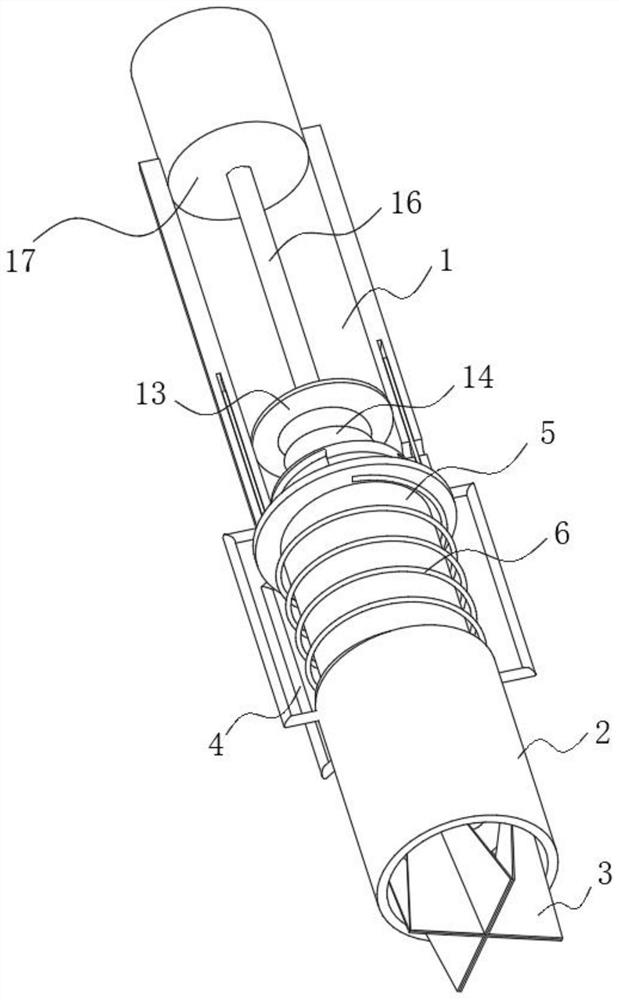

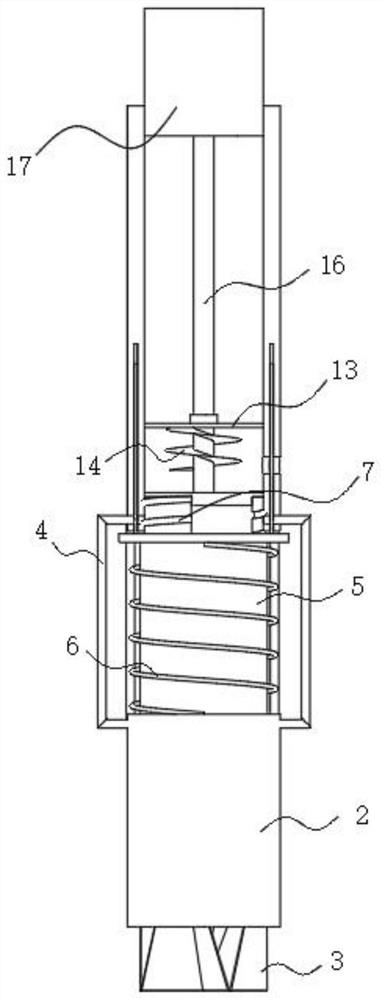

Outer diameter and tooth profile progressive extruding screw tap for trapezoidal inner threads

InactiveCN106862678AQuality improvementImprove featuresThread cutting toolsSurface roughnessEngineering

The invention discloses an outer diameter and tooth profile progressive extruding screw tap for trapezoidal inner threads. The outer diameter and tooth profile progressive extruding screw tap comprises a screw tap clamping end (1), a screw tap rod body (2) and a screw cap extruding body (3). The outer diameter and tooth profile progressive extruding screw tap is characterized in that the screw tap extruding body (3) comprises a guide part a, an extruding part b and a correcting part c; a ring of extruding edge valleys is formed between adjacent two rings of extruding teeth of the screw tap extruding body (3); each ring of extruding teeth is equipped with six extruding edges; each extruding edge and the positive section, in the length direction of the extruding screw tap, of the corresponding extruding edge are trapezoidal; a cooling liquid channel is formed between every two adjacent extruding edges; acting surfaces of the extruding edges and workpieces generate acting force perpendicular to the axial direction; the extruding screw tap continuously guides to perform thread processing; when the workpieces are slowly extruded with teeth, and are in contact with positions of the extruding edge valleys along with continuous growth of the teeth, the six extruding edge valleys perform flattening correcting on trapezoidal tooth tops grown out from the workpieces, so that inner threads with inner thread surface roughness Ra of 0.8-1.6 are obtained. The outer diameter and tooth profile progressive extruding screw tap can realize cold-extrusion processing of trapezoidal inner threads, and can improve surface quality and fatigue resistance of the processed threads.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

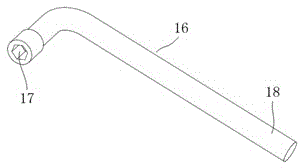

Extrusion type steel pipe cutter and fabrication method thereof

The invention discloses an extrusion type steel pipe cutter and a fabrication method thereof. According to the method, a circular cutter blade is assembled on a lower knife rest through a blade shaft; an idler wheel I is assembled on an upper knife rest through an idler wheel shaft I; an idler wheel II is assembled on the upper knife rest through an idler wheel shaft II; an extrusion wheel is assembled on an extrusion shaft; the lower end surface of the extrusion wheel is fitted to the bottom surface of an extrusion groove of the upper knife rest; the extrusion shaft is assembled on the upper knife rest; ridges on the extrusion wheel are engaged with extrusion teeth on the lower knife rest; the working end of an inserted link, an upper frame inserting hole of the upper knife rest and a lower frame inserting hole I and a lower frame inserting hole II of the lower knife rest are in clearance fit; the working end of the inserted link is inserted into the extrusion type steel pipe cutter when the extrusion type steel pipe cutter is used; an inner hexagon head of the inserted link is matched with an outer hexagon head on the extrusion shaft; rotation of the extrusion shaft is achieved by rotating the inserted link. According to the extrusion type steel pipe cutter, the circular cutter blade is inserted into the outer wall of a to-be-cut steel pipe in an extrusion manner, then a cutting groove is cut out from the outer wall of the steel pipe by virtue of the cutter blade and finally, the steel pipe is cut off.

Owner:陈晨

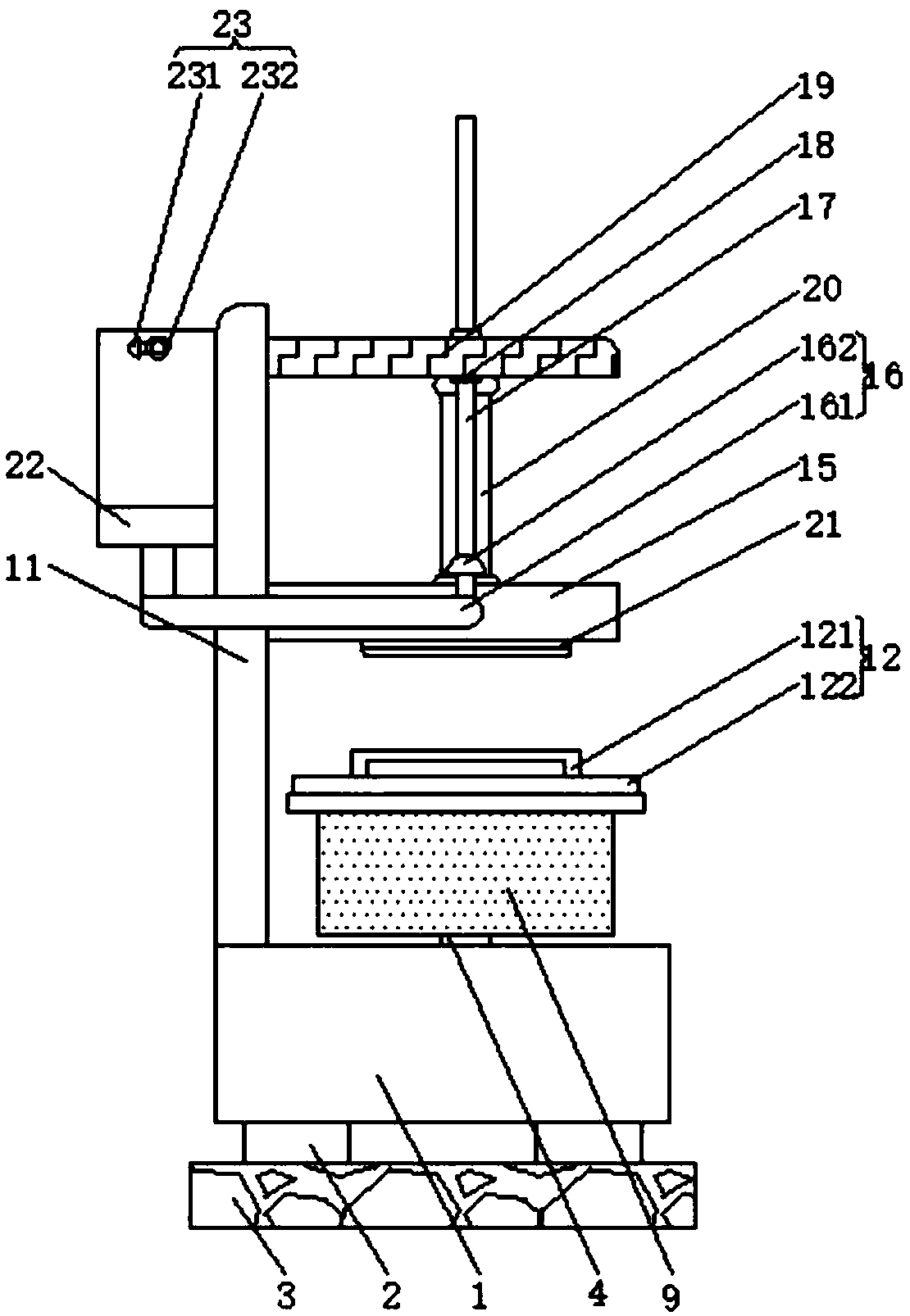

Tooth crushing device facilitating material collecting and used for tooth detection

PendingCN111036323ADoes not expand the spreadNo lossPreparing sample for investigationGrain treatmentsHydraulic cylinderEngineering

The invention discloses a tooth crushing device facilitating material collecting and used for tooth detection, and relates to the technical field of detection equipment. The tooth crushing device comprises a box body, the lower surface of the box body is fixedly connected with the upper surface of a bottom plate through four supporting legs, and the lower surface of the inner wall of the box bodyis fixedly connected with the lower surface of a driving device; and the driving device is positioned in a through hole. According to the tooth crushing device facilitating material collecting and used for tooth detection, liquid nitrogen makes contact with teeth by arranging a hydraulic cylinder, a pressing plate, a pressing box, a liquid nitrogen tank, a first guide pipe and a first valve; aftervolatilization of the liquid nitrogen is completed, the hydraulic cylinder is controlled to work, so that the hydraulic cylinder extends to drive the pressing plate to move downwards, the pressing plate moves downwards into the pressing box and extrudes the teeth, the teeth are effectively crushed, workers do not need to use tools to crush the teeth, chippings cannot be scattered around, the diffusion range of bacteria cannot be enlarged, operation is very convenient, and the sample loss cannot be caused after the teeth are crushed.

Owner:陕西前进齿科新技术开发有限公司

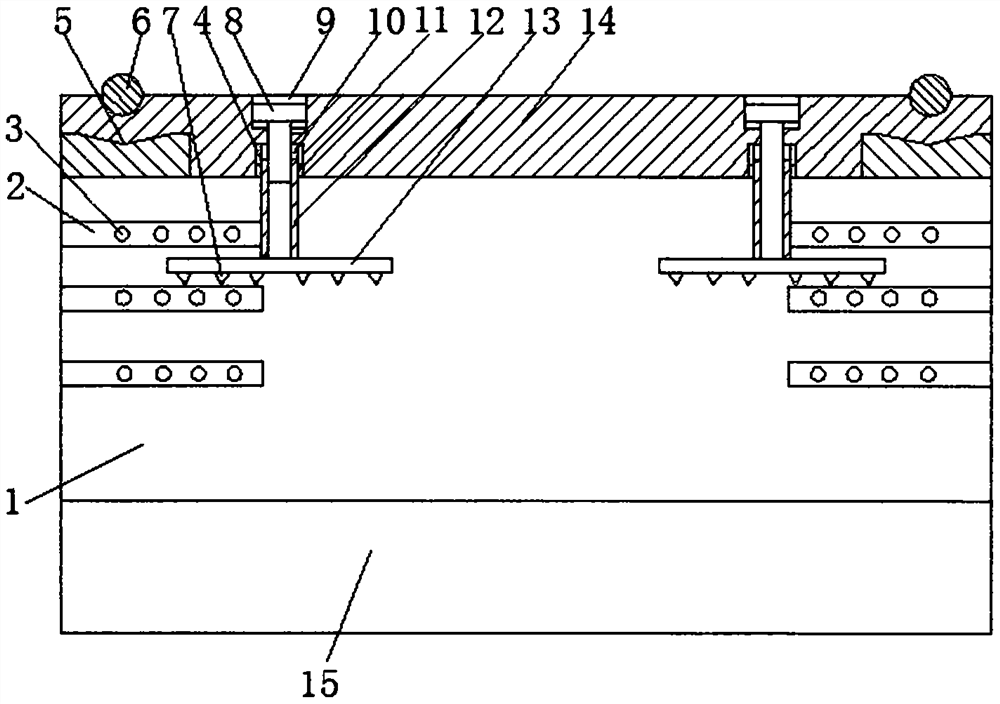

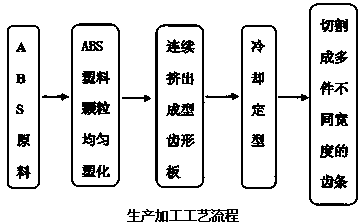

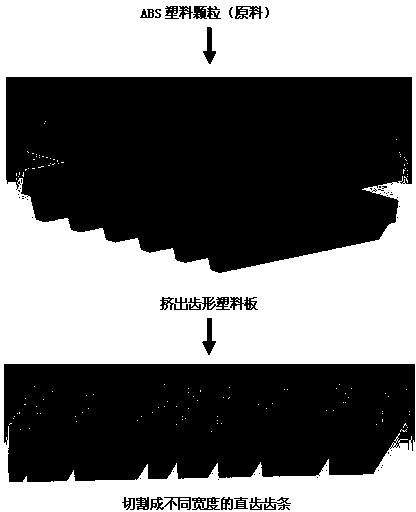

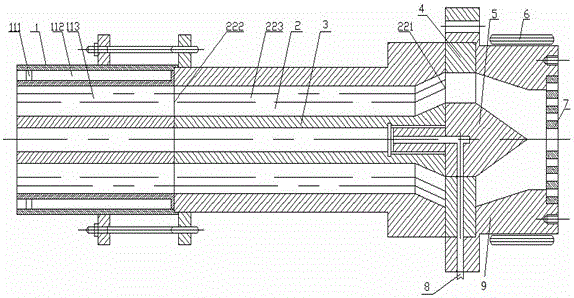

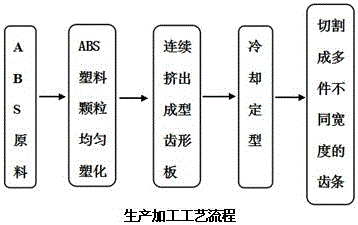

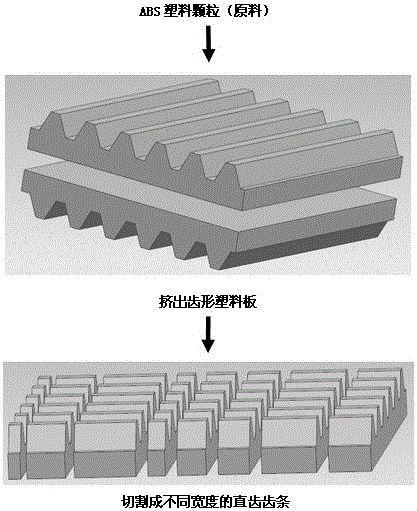

Plastic extrusion molding method for efficiently machining ABS (acrylonitrile butadiene styrene) straight-tooth racks

The invention discloses a plastic extrusion molding method for efficiently machining ABS (acrylonitrile butadiene styrene) straight-tooth racks and an extrusion tooth profile mold.The mold comprises a mold cavity, a core rod and a cooling and shaping sleeve, wherein the mold cavity defines a cavity and used for molding the straight-tooth racks, and tooth blanks are arranged on upper and lower inner surfaces of the cavity; the core rod is installed in the mold cavity and at least partially extends in the mold cavity to form upper and lower tooth profile cavities with the mold cavity, the mold cavity is provided with a mold input port and a mold output port, the mold input port is used for conveying ABS plastic in a molten state into the mold cavity, and the mold output port is used for conveying molded tooth profile piece blanks out of the mold cavity; and the cooling and shaping sleeve is located on the side of the output port of the mold cavity and used for cooling and shaping the tooth blanks. The method is simple in process, convenient to operate and higher in machining efficiency than an injection molding method.

Owner:SHANDONG JIANZHU UNIV

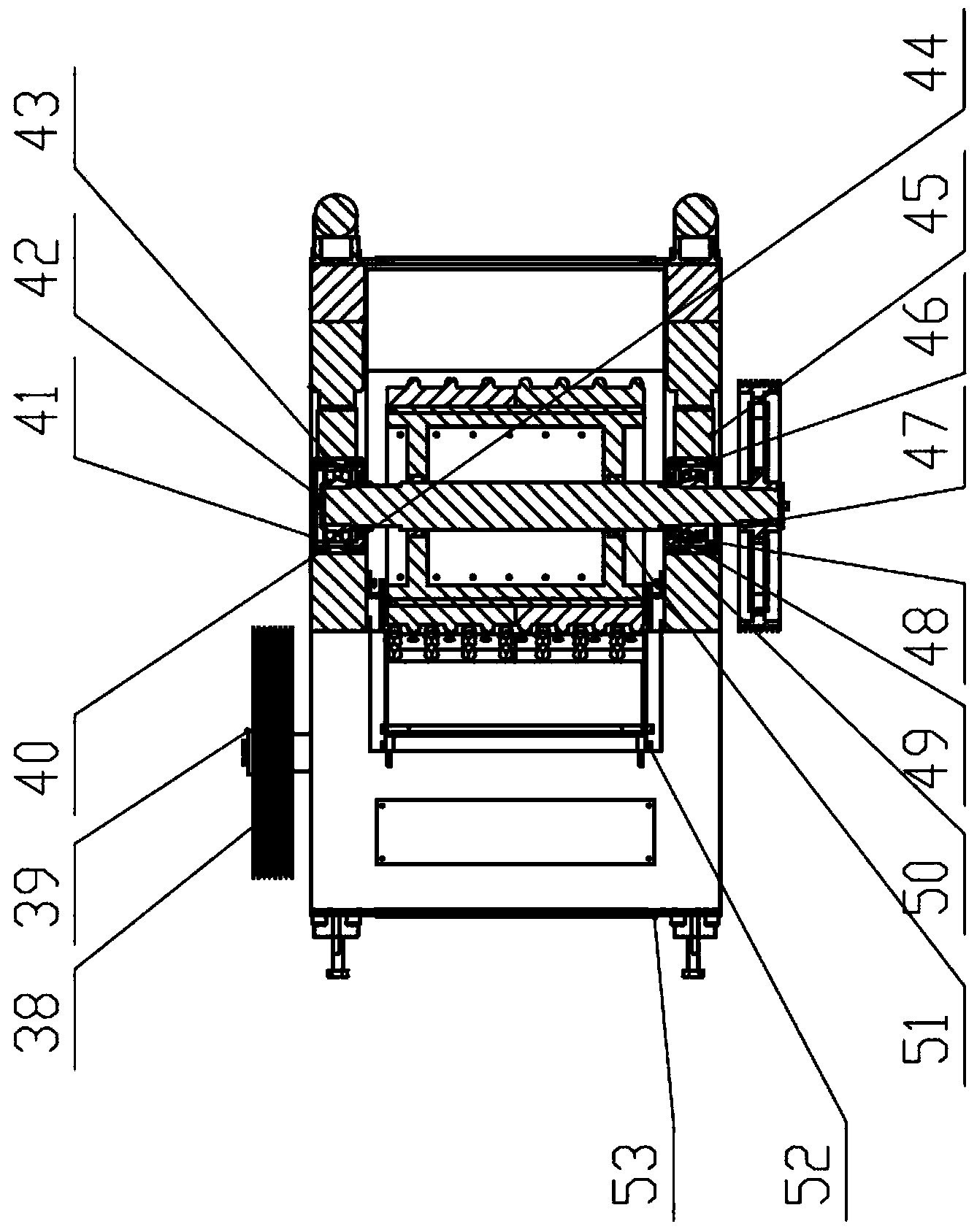

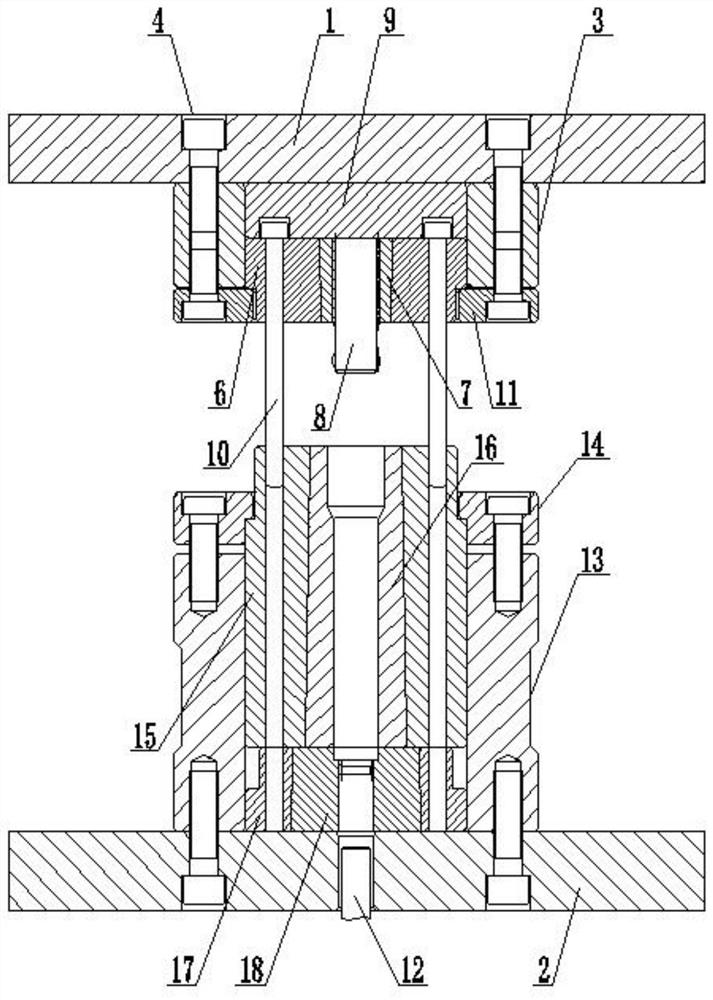

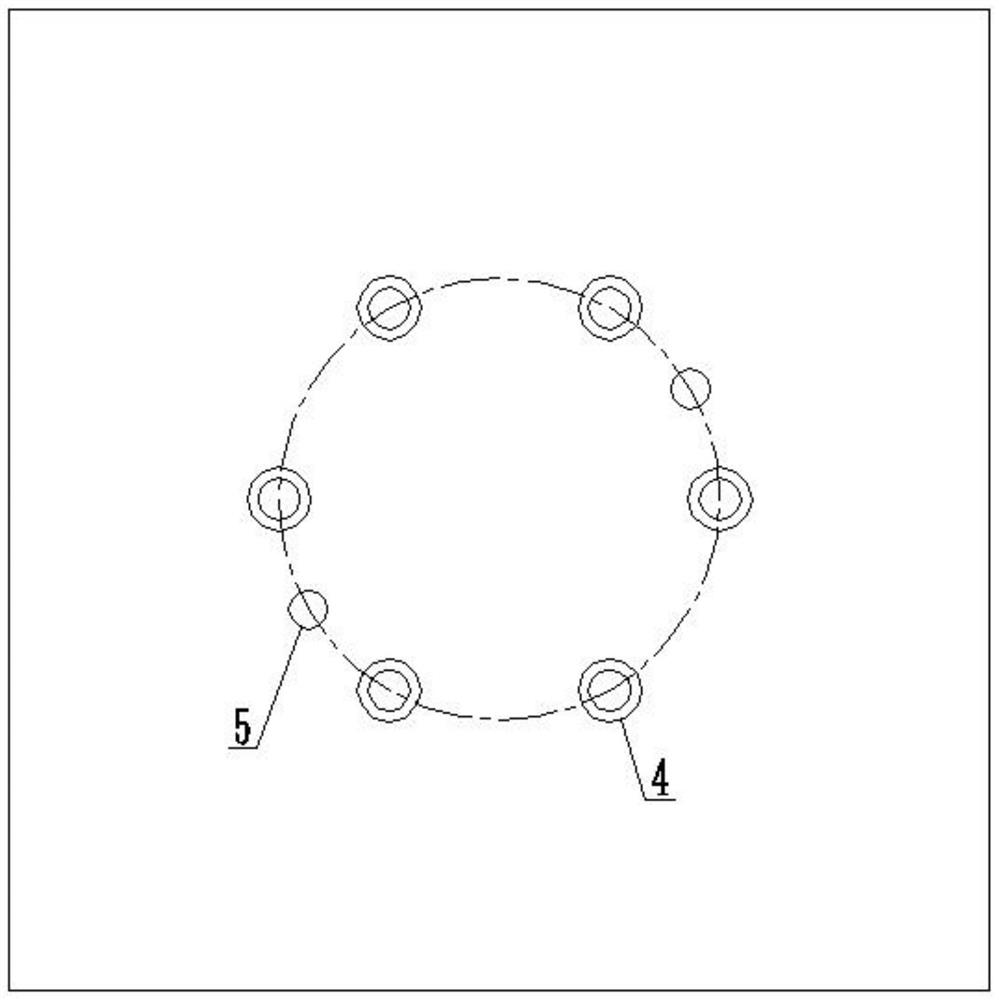

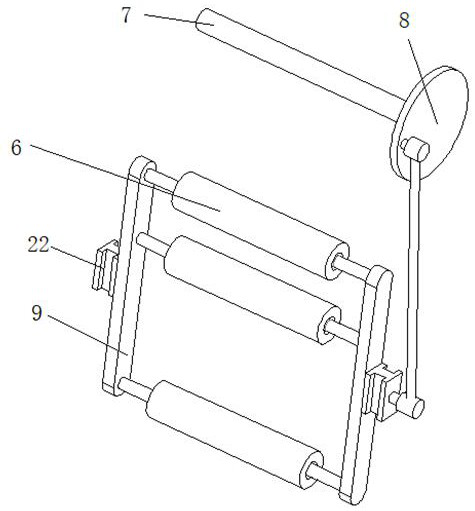

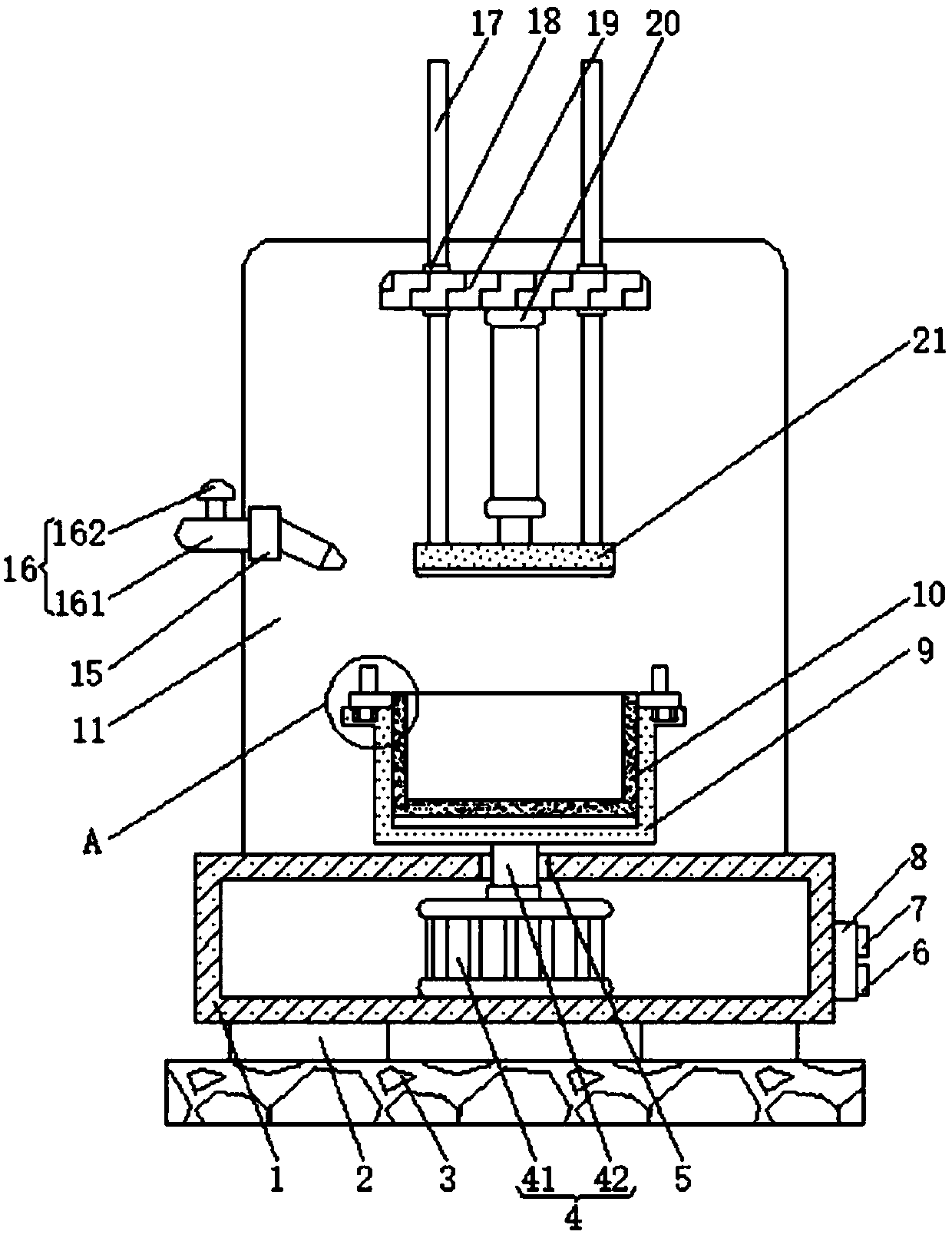

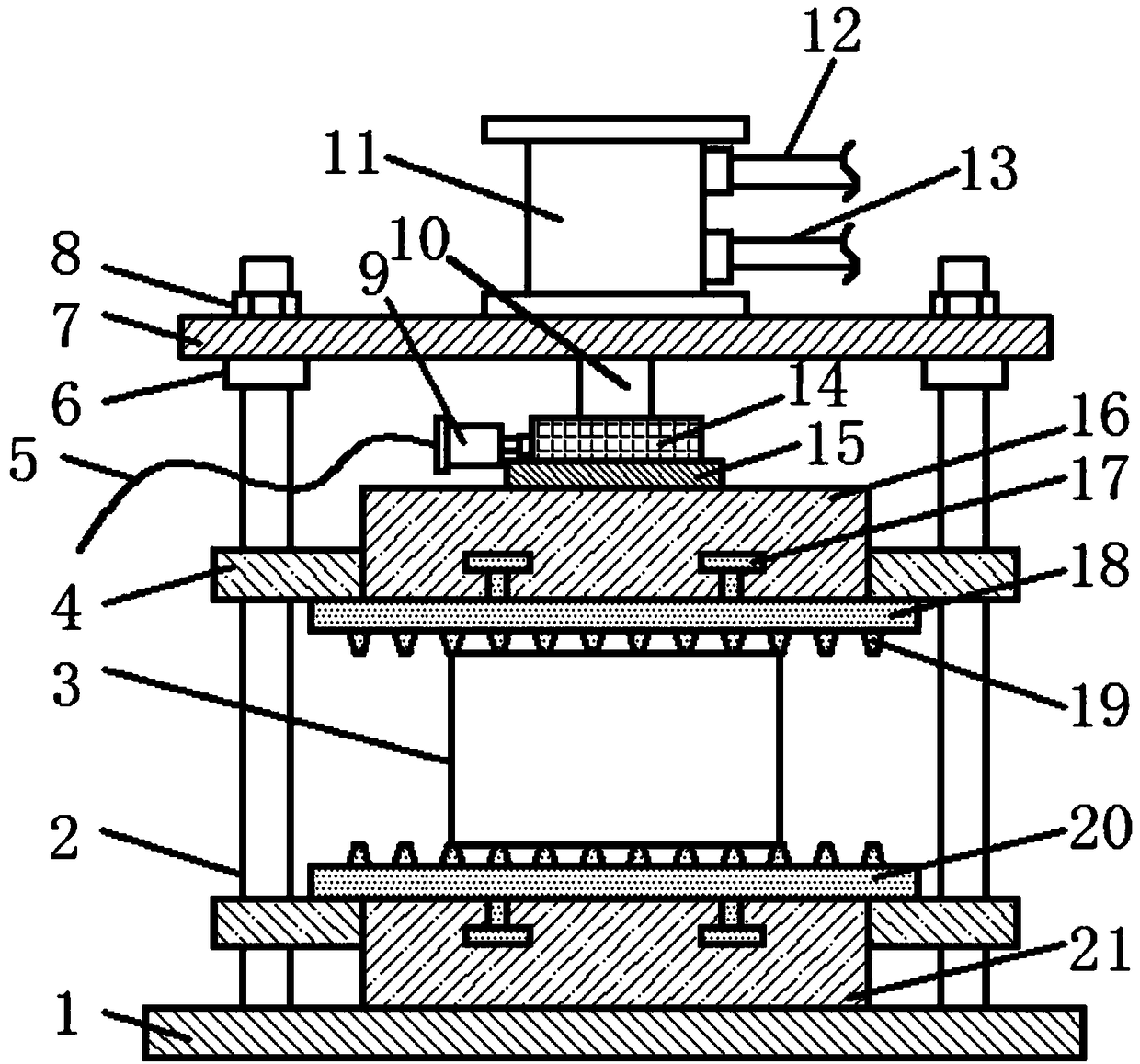

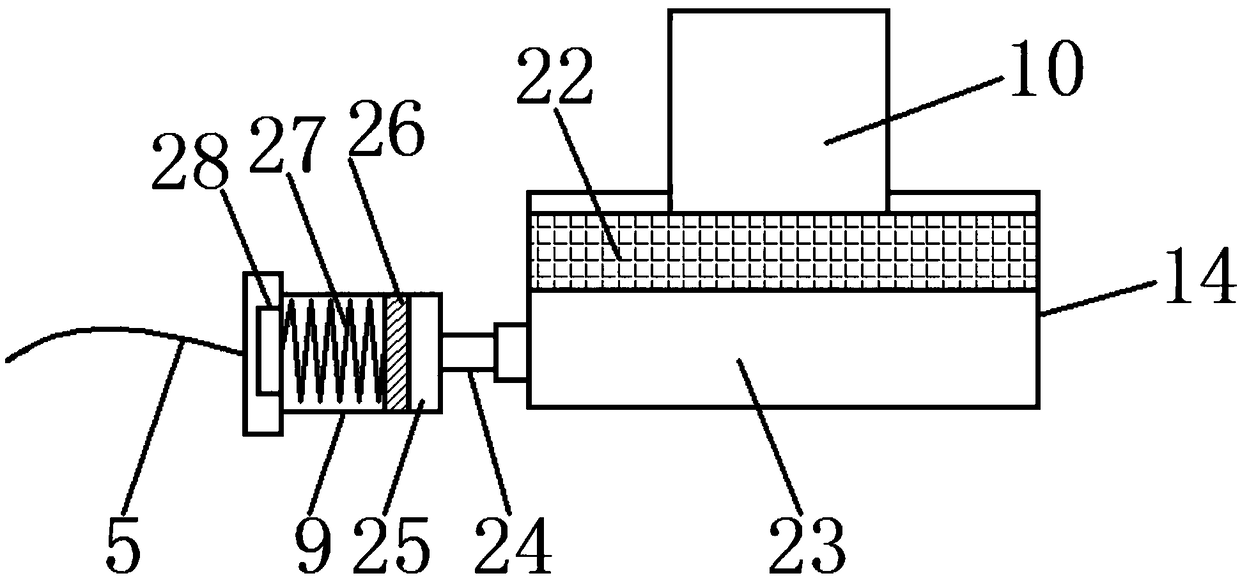

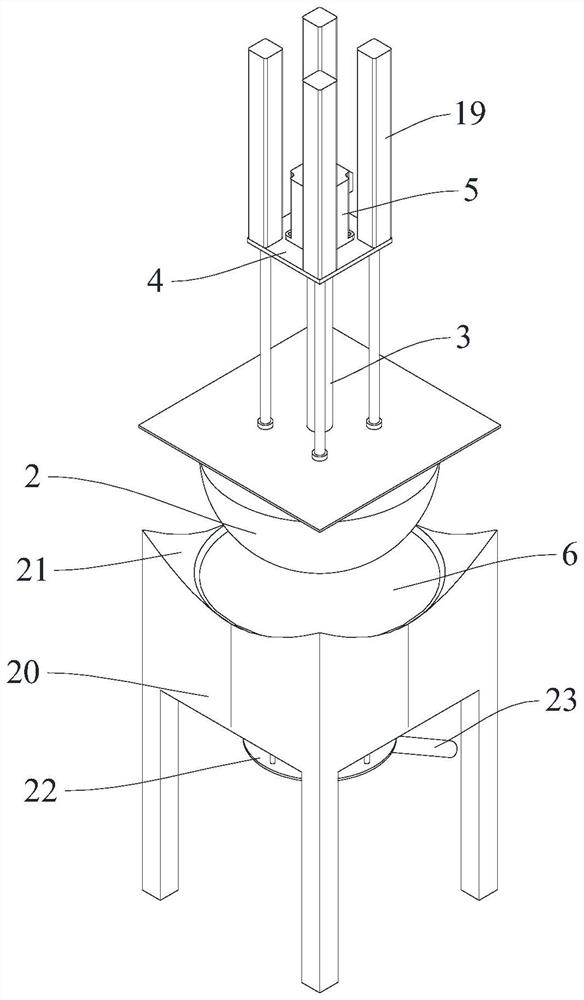

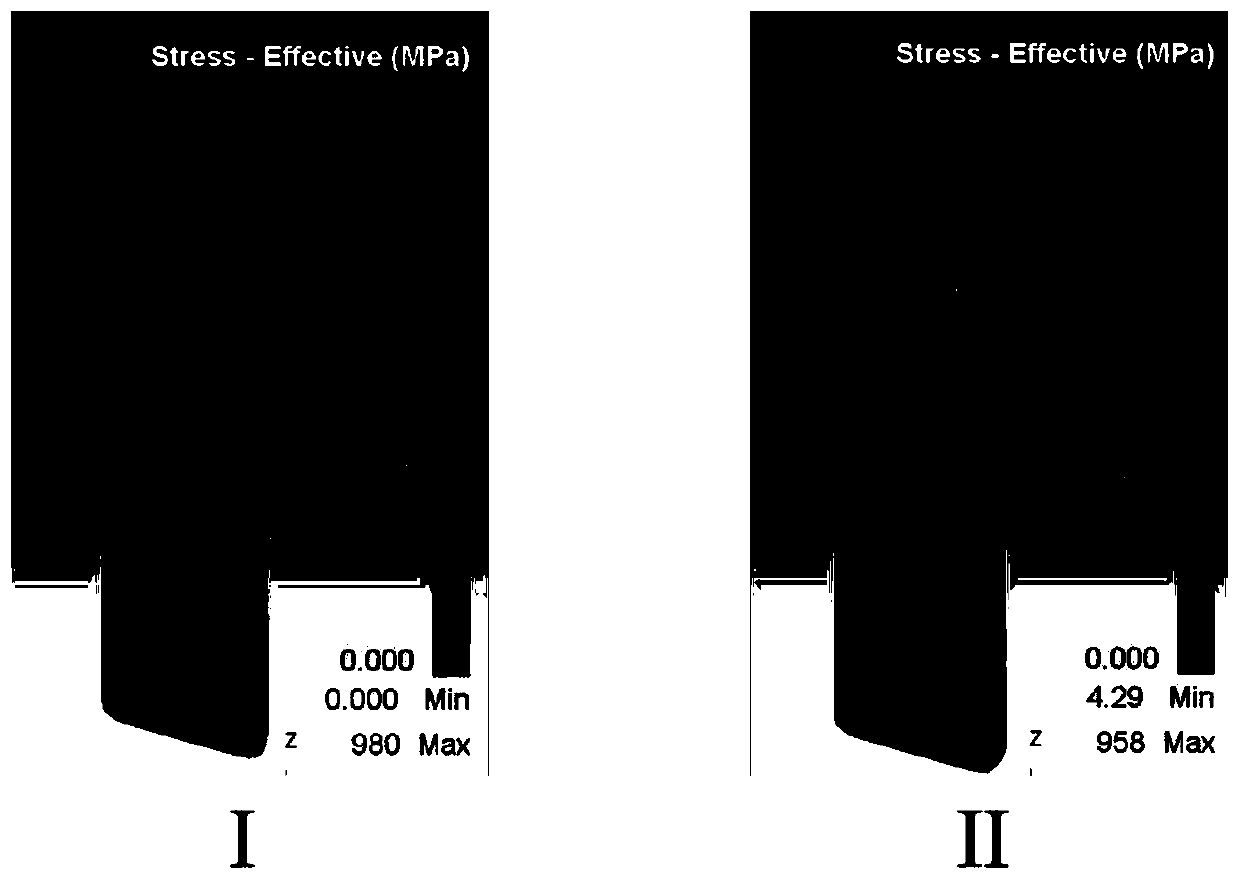

Extrusion experiment simulation device of reinforced concrete construction component

ActiveCN108562494AImprove stabilityStable structureMaterial strength using tensile/compressive forcesReinforced concreteArchitectural engineering

The invention discloses an extrusion experiment simulation device of a reinforced concrete construction component. The device includes a base, a cross beam plate, a piezoelectric detector, a hydraulicoil measurement cylinder, an upper pressing block and a lower pressing block; the lower pressing block is fixed to the middle of the upper end of the base, a guiding rod penetrates through the outerside of the lower pressing block, the cross beam plate is connected to the top of the guiding rod, an upper extrusion plate is installed at the bottom of the upper pressing block, multiple extrusion teeth are arranged at the bottom of the upper extrusion plate, the reinforced concrete construction component is placed under the extrusion teeth and on the lower extrusion plate, multiple extrusion teeth are arranged on the upper surface of the lower extrusion plate, and the lower extrusion plate is embedded in the lower pressing block. The stability of the connection between the cross beam plateand the guiding rod is improved, the lower extrusion plate and the upper extrusion plate are adopted for conducting extrusion operation on the reinforced concrete construction component clamped in themiddle, and the extrusion effect is great. The operation of detecting an extrusion force during simulation of extrusion is also achieved, and the extrusion force performed on the reinforced concreteconstruction component can be effectively detected.

Owner:安徽研砼建筑科技有限公司

A plastic extrusion molding method for efficiently processing abs straight tooth racks

The invention discloses a plastic extrusion molding method for efficiently machining ABS (acrylonitrile butadiene styrene) straight-tooth racks and an extrusion tooth profile mold.The mold comprises a mold cavity, a core rod and a cooling and shaping sleeve, wherein the mold cavity defines a cavity and used for molding the straight-tooth racks, and tooth blanks are arranged on upper and lower inner surfaces of the cavity; the core rod is installed in the mold cavity and at least partially extends in the mold cavity to form upper and lower tooth profile cavities with the mold cavity, the mold cavity is provided with a mold input port and a mold output port, the mold input port is used for conveying ABS plastic in a molten state into the mold cavity, and the mold output port is used for conveying molded tooth profile piece blanks out of the mold cavity; and the cooling and shaping sleeve is located on the side of the output port of the mold cavity and used for cooling and shaping the tooth blanks. The method is simple in process, convenient to operate and higher in machining efficiency than an injection molding method.

Owner:SHANDONG JIANZHU UNIV

Raw material grinding device for toothpaste production

According to the raw material grinding device for toothpaste production, toothpaste raw materials are crushed into particles through the crushing assembly, so that the follow-up grinding speed of the raw materials is increased, the driving part drives the mounting plate to move downwards, the mounting plate drives the rotating shaft to move downwards, and the rotating shaft drives the grinding block to move downwards to enter the bottom of the grinding pot; the first motor drives the rotating shaft to rotate, the rotating shaft drives the grinding block to rotate, the grinding block extrudes a toothpaste raw material to rub and rotate at the bottom of the grinding pot, so that the toothpaste raw material is rapidly ground into powder, the powdery toothpaste raw material falls into the containing box through the discharging through hole in the bottom of the grinding pot, and therefore a worker can conveniently take out the toothpaste raw material; the problems that an existing raw material grinding device is not thorough in raw material grinding and inconvenient in material taking, and consequently the production efficiency is low are solved.

Owner:中俄国际医学研究股份有限公司

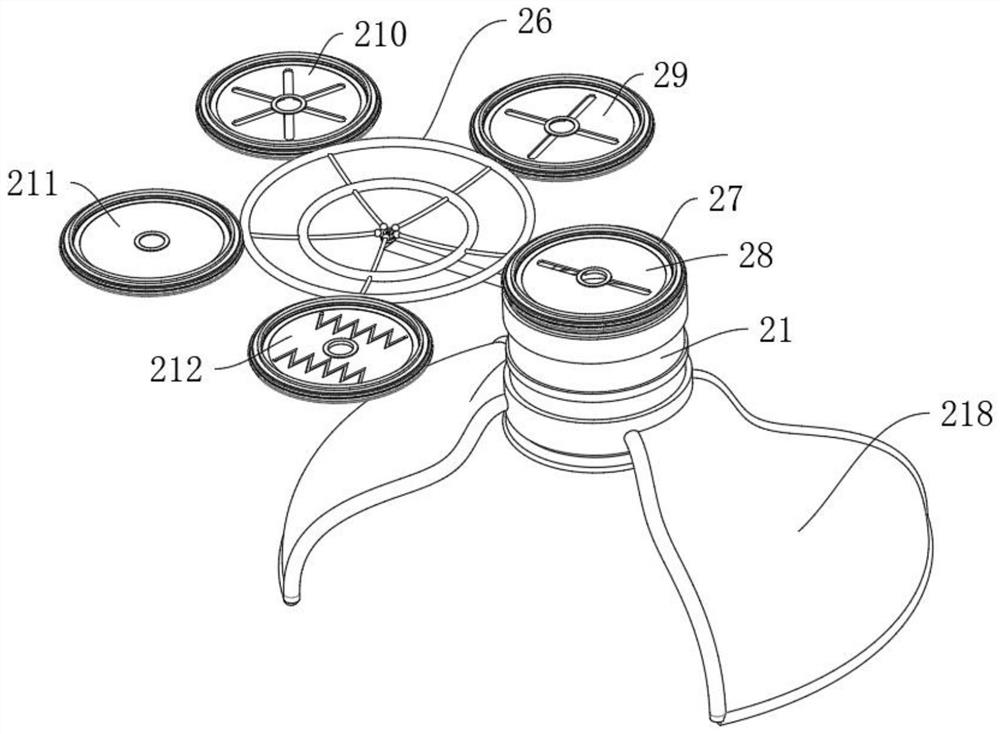

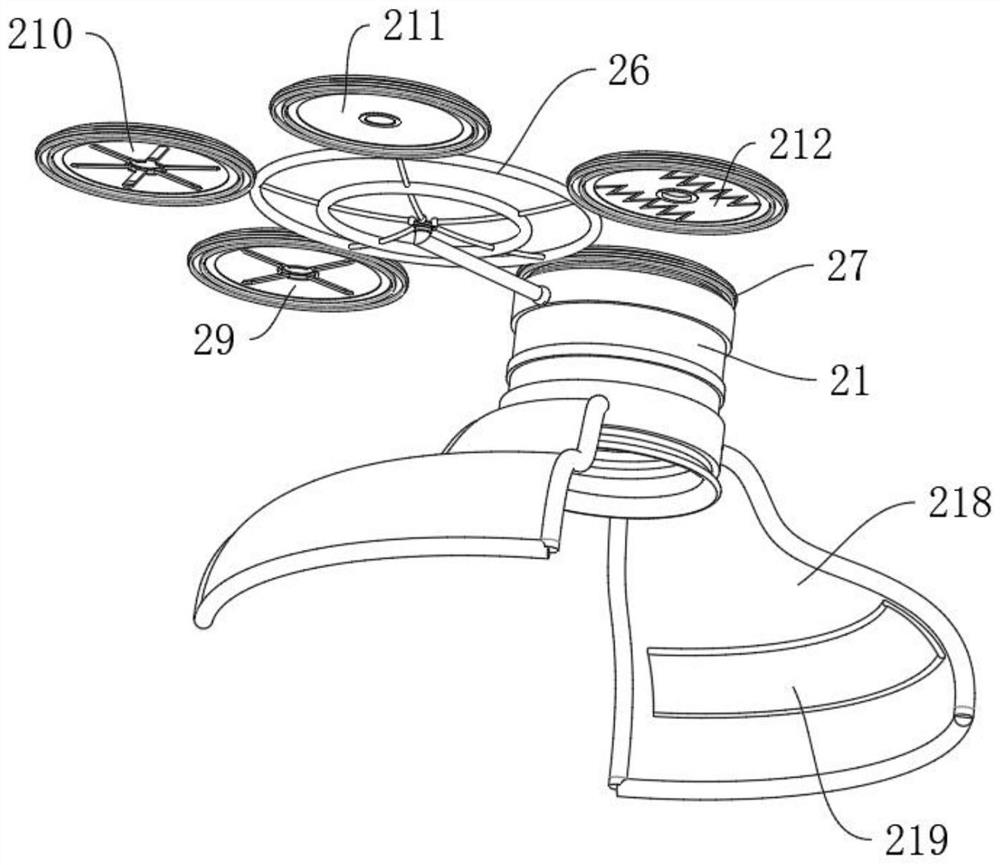

Toothpaste assembly with rotary disc extrusion port

The invention discloses a toothpaste assembly with a rotary disc extrusion port, and particularly relates to the field of toothpaste. The toothpaste assembly comprises a toothpaste bag body bearing mechanism, the top of the toothpaste bag body bearing mechanism is in threaded connection with a rotary disc type special-shaped flow guide toothpaste cover, and the toothpaste bag body bearing mechanism and the rotary disc type special-shaped flow guide toothpaste cover are arranged in a one-to-one correspondence manner; and a rapid auxiliary mechanism for toothpaste extrusion is fixedly mounted atthe bottom of the toothpaste bag body bearing mechanism. According to the toothpaste assembly, by arranging the rotary disc type special-shaped flow guide toothpaste cover, the toothpaste can be extruded from a first extrusion type flow guide discharging plate, a second extrusion type flow guide discharging plate, a third extrusion type flow guide discharging plate, a fourth extrusion type flow guide discharging plate and a fifth extrusion type flow guide discharging plate correspondingly by extruding a bag body for toothpaste bearing, different patterns and shapes are formed, and the interestingness of using the toothpaste by children is relatively enhanced.

Owner:程红梅

A process for cold-rolling and extruding teeth on the end face of a cylinder

ActiveCN104588783BOvercome processing defectsReduce processing inputGear teeth manufacturing toolsGear teethKilogram-forceMechanical equipment

The invention relates to a technology for cold rolling extrusion teeth of a cylindrical end face. The technology comprises the following steps that 1 a rolling tool is prepared, wherein the rolling tool is a hollow circular truncated cone adopting alloy steel as materials, and the outer surface of the rolling tool is provided with rack-shaped blades; 2 a to-be-machined workpiece is fixed in a fixture of a lathe, the rolling tool is inserted in a tool bar in a penetrating mode, and the tool bar is fixed on a carriage; 3 a machine tool is started, the revolving speed of the fixture is regulated to be at 1000 r to 1800 r, the carriage provided with the rolling tool is pushed to the direction of the end face of the workpiece to enable the outer surface of the rolling tool to make contact with the end face of the workpiece, and the rolling tool makes contact with the end face of the workpiece for three to five seconds under the environment of 30-kilogram force; 4 the carriage is loosened, the workpiece is taken down, the machine tool is switched off, the whole process is over, and machining of a small tooth face of the end face of the workpiece is completed. According to the technology for cold rolling extrusion teeth of the cylindrical end face, automation is achieved in the whole process, the defect that a traditional technology has to perform machining through mechanical equipment machining such as planing equipment and milling equipment is overcome, machining investment is small, and efficiency is high.

Owner:绍兴柯桥珂阳五金汽配厂

Chewing type anti-blocking salt feeding mechanism

The invention belongs to the technical field of salt harvesting in sea salt production, and provides a chewing type anti-blocking salt feeding mechanism. The technical scheme provides the salt feedingmechanism simulating a chewing action, and the problem of salt blocking in a salt inlet can be effectively solved. An extrusion plate is mounted at the upper edge of the salt inlet, and a lower panelof the salt inlet extends outwards to be used as an extrusion back plate matched with the extrusion plate; the extrusion plate is pivotally connected with the upper edge of the salt inlet and is connected with a crankshaft through a connecting rod, and the crankshaft is driven by a slowdown motor to drive the extrusion plate to do up-and-down reciprocating rotation extrusion through the connecting rod. One or more extrusion plates can be used. If multiple extrusion plates are used, the directions of motion of adjacent extrusion plates are opposite. The lower surface of the extrusion plate canbe provided with sawtoothed or strip-shaped extrusion teeth, so as to facilitate the buckling of salt blocks and breaking of the salt blocks.

Owner:DALIAN UNIV OF TECH

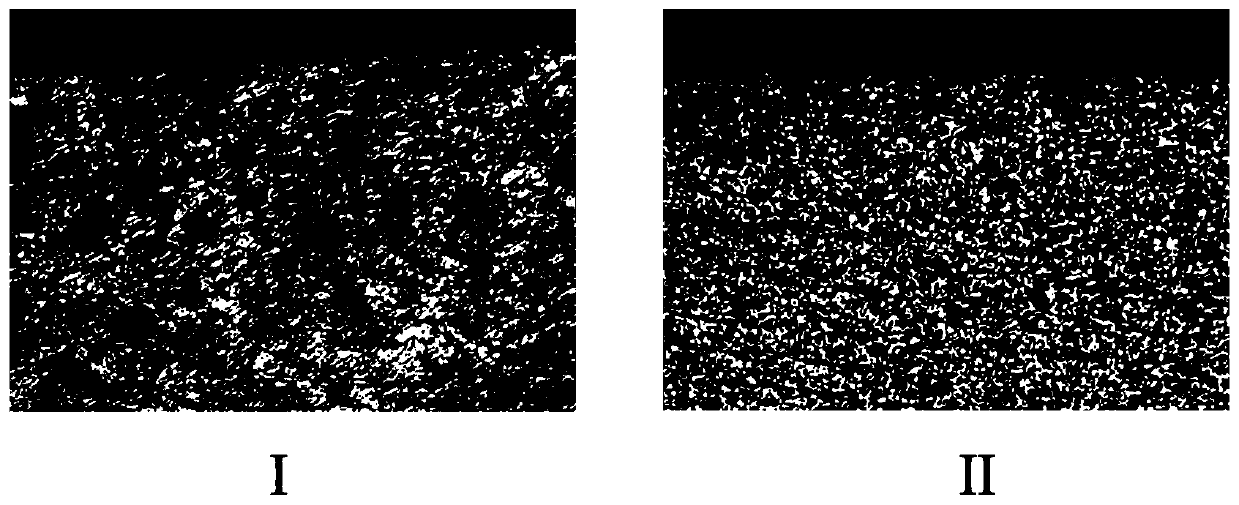

Manufacturing method for improving tooth profile precision of spline shaft forging

ActiveCN109622863AImprove performanceImprove machining accuracyEngine componentsHeating/cooling devicesExtrusion toothHeating furnace

The invention relates to a manufacturing method for improving the tooth profile precision of a spline shaft forging. The method comprises the steps that a forging blank is placed into a heating furnace and heated to 850 DEG C-900 DEG C; primary pre-forging forming is performed, specifically, the work procedure includes that forward extrusion rod forming is performed on the blank which is heated to850 DEG C-900 DEG C; a pre-forged workpiece is placed into the heating furnace and cooled to 560 DEG C + / -10 DEG C with the cooling rate being 70-90 DEG C / h; secondary pre-forging forming is performed on the pre-forged workpiece, specifically, the work procedure includes that backward extrusion cup forming is performed on the forging which is cooled to 560 DEG C+ / -10 DEG C; the pre-forged workpiece is placed into the heating furnace with the temperature being 680 DEG C to be subjected to heat preservation for 1-1.5 h, and then taken out of the furnace to be subjected to normalizing and air cooling; shot blasting treatment and phosphorus saponification treatment are performed on the pre-forged workpiece; and cold extrusion forming is performed on the pre-forged workpiece, specifically, thework procedure includes that cold extrusion tooth profile forming is performed on the pre-forged workpiece which is subjected to phosphorus saponification treatment.

Owner:JIANGSU HAIYU MACHINERY

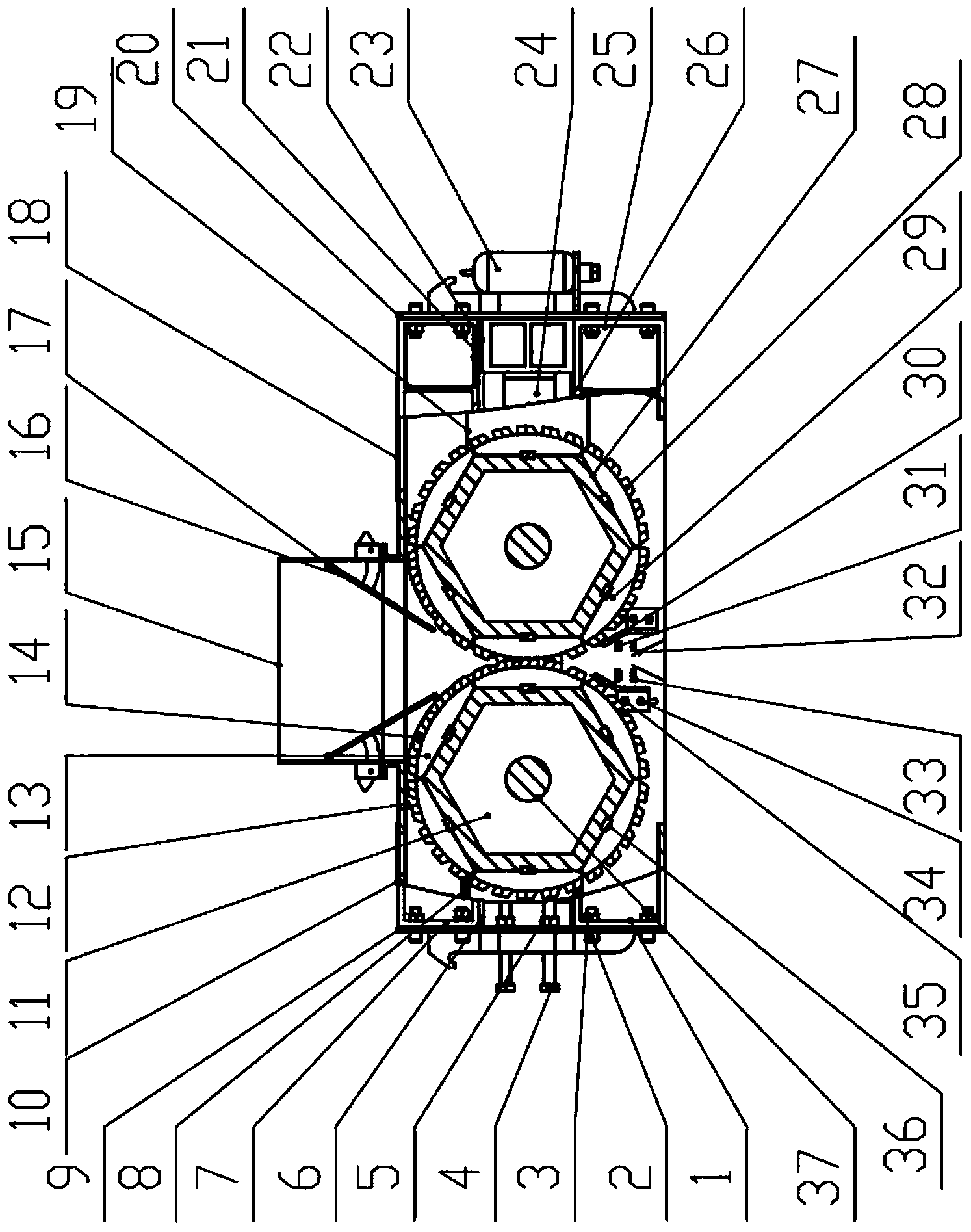

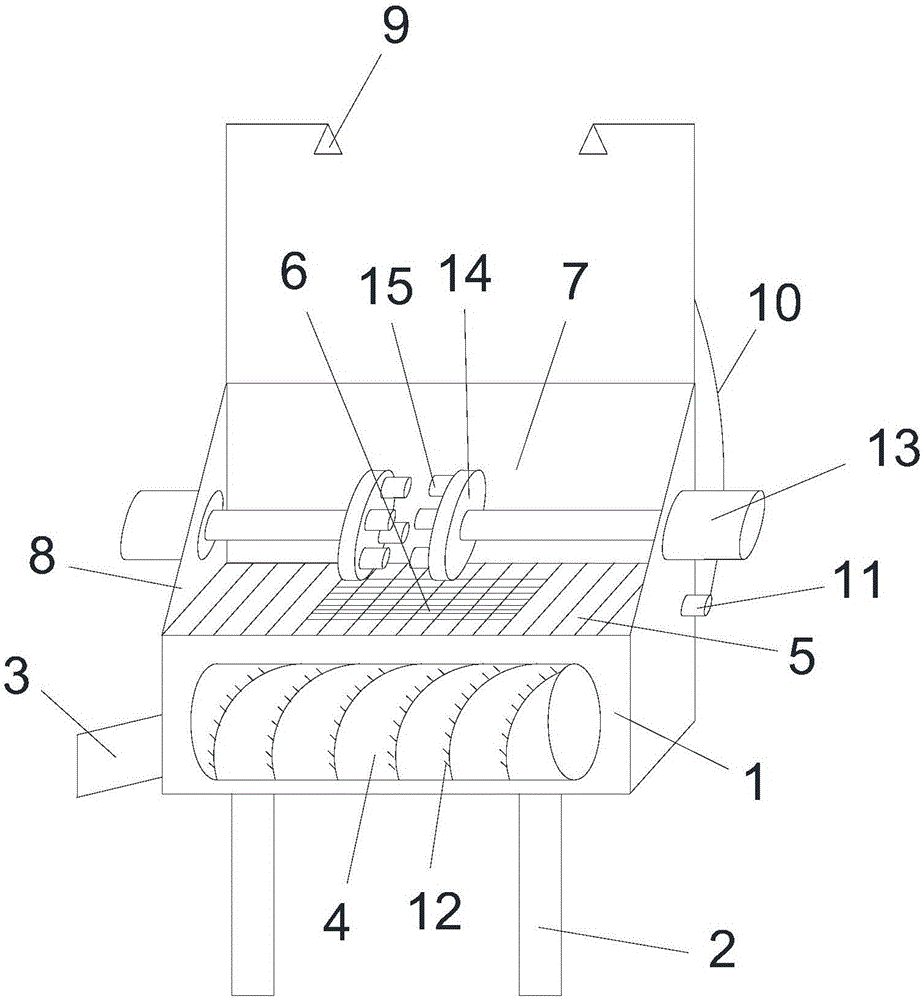

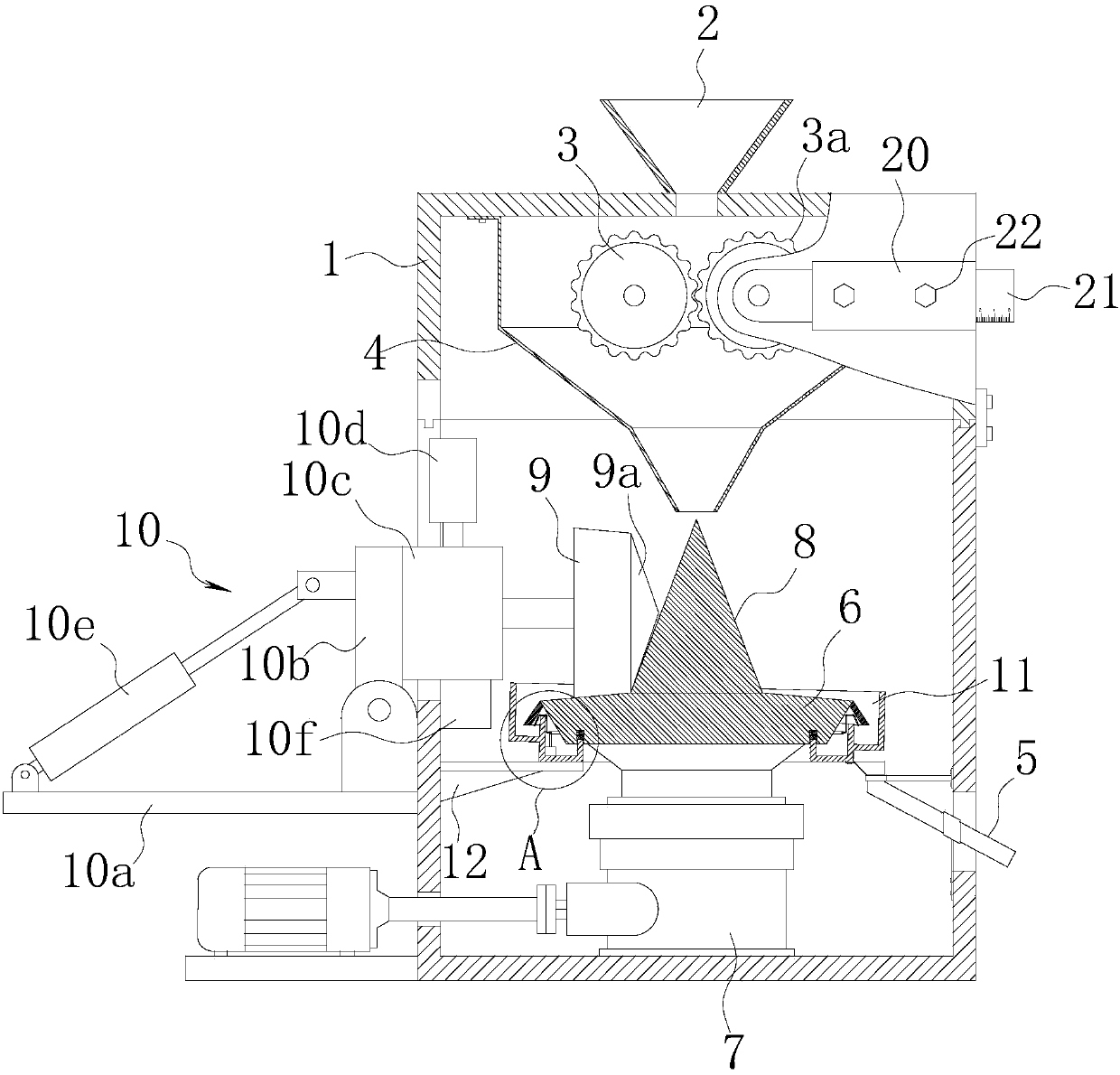

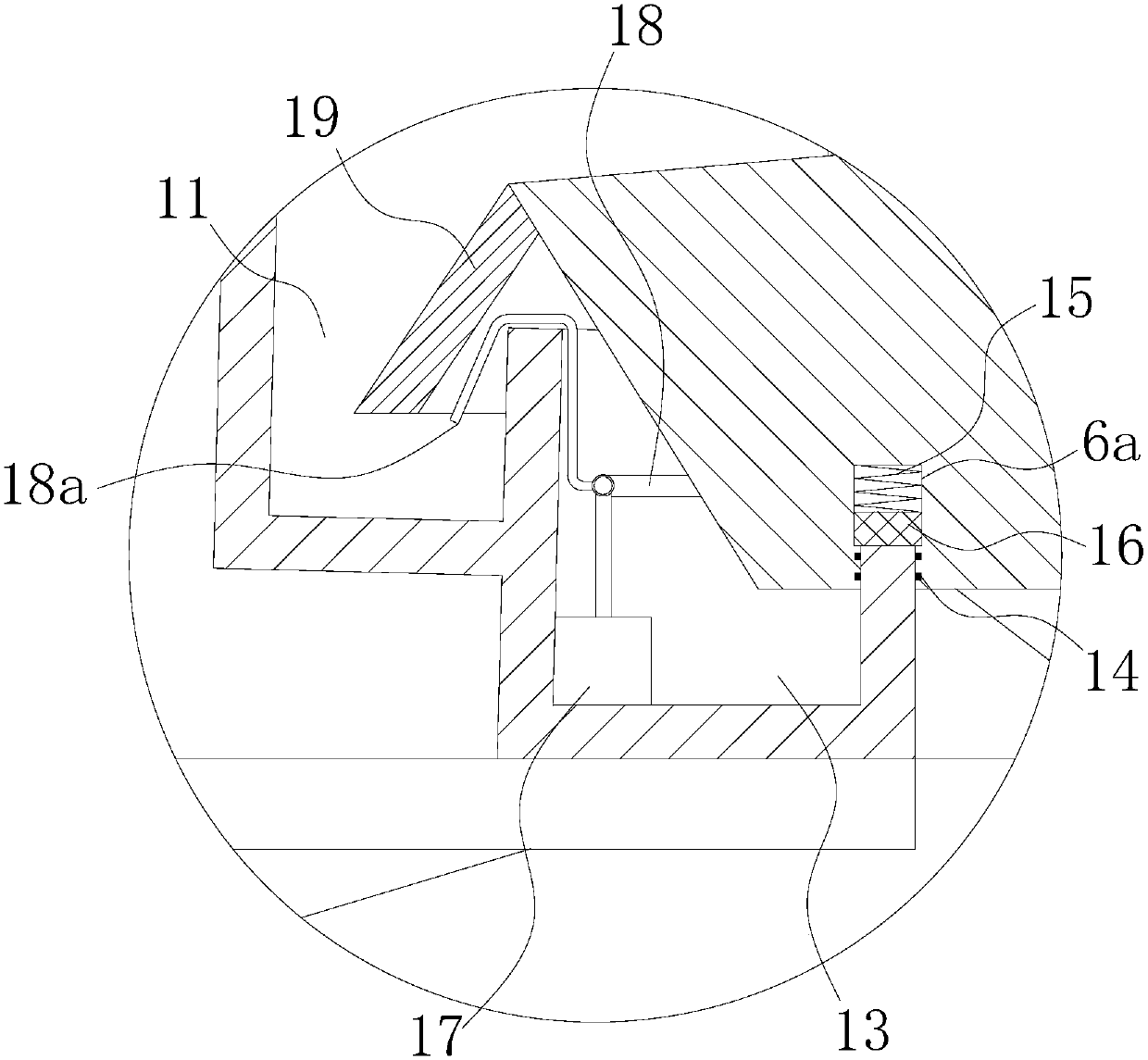

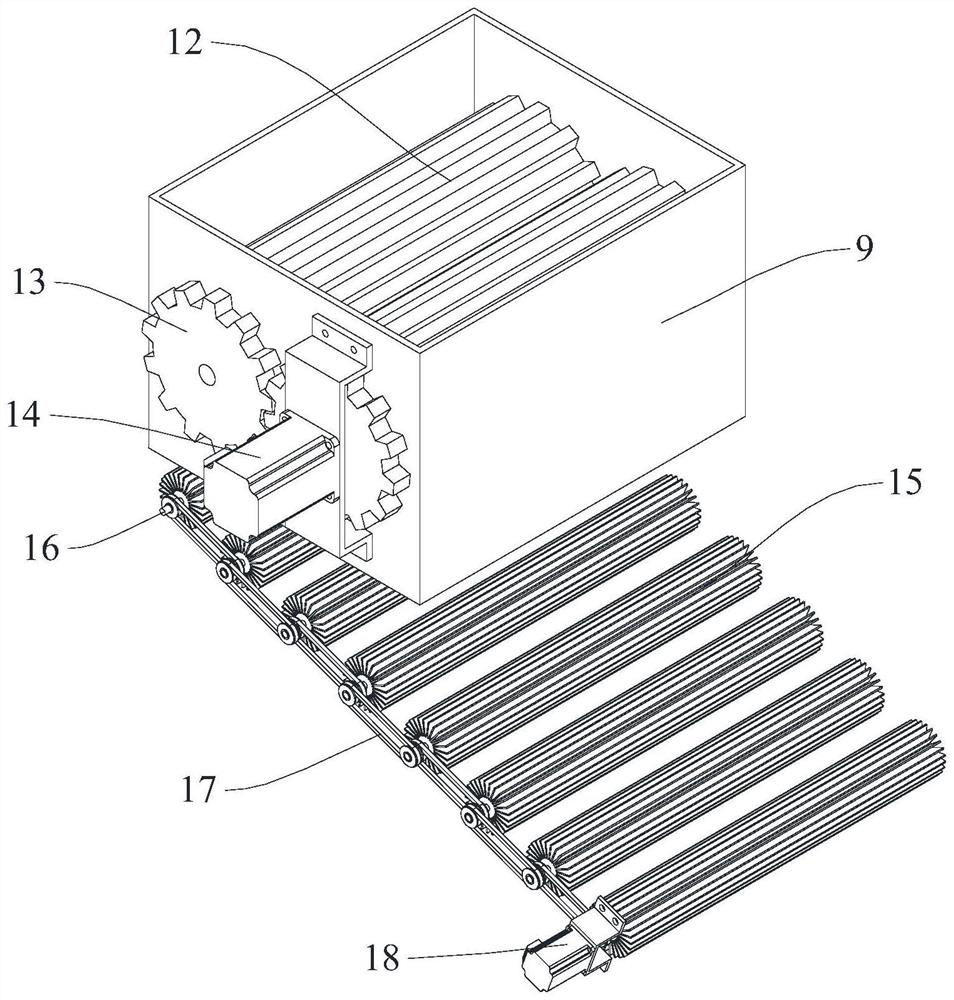

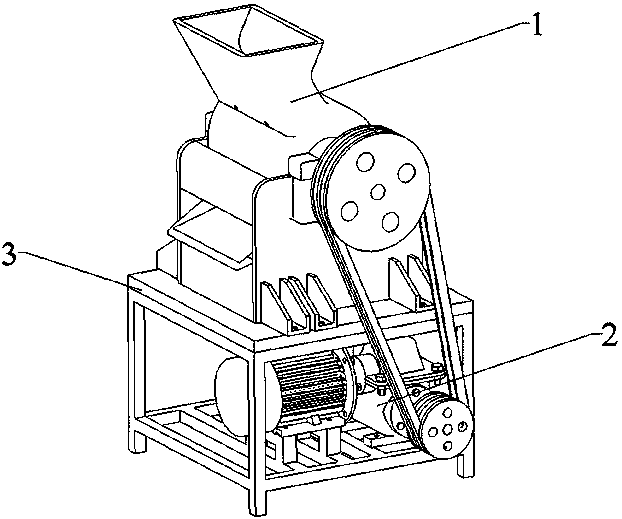

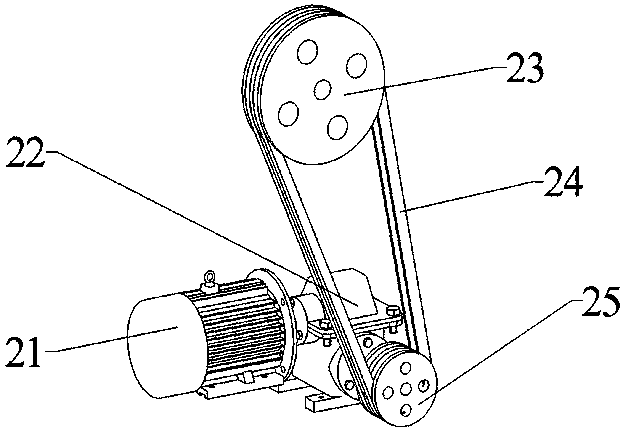

Single-roller extrusion type coconut shell-flesh separator

InactiveCN108464513AAchieve separationReduce labor intensityHuskingHullingBatch processingEngineering

The invention discloses a single-roller extrusion type coconut shell-flesh separator. The separator mainly comprises a shell-flesh separation system, a transmission system and a frame; the shell-fleshseparation system comprises a feeding port, a toothed roller extrusion shell, a toothed roller bearing, a toothed roller shaft, side plates, support feet, a discharging port, extrusion teeth, a cleaning comb plate and a toothed roller; and the transmission system comprises a motor, a speed reducer, a belt pulley I, belts and a belt pulley II. According to the single-roller extrusion type coconutshell-flesh separator, coconuts are extruded through the toothed roller, so that the obtained coconut flesh is relatively intact; the single-roller extrusion type coconut shell-flesh separator is suitable for separating coconut shells from coconut flesh of old coconuts, is beneficial to reducing the labor intensity of manual operation, improving the production efficiency and facilitating the subsequent processing for factories; and the separator is simple in structure and convenient to use, and has wide market prospect, and the application of the separator is beneficial to improving the mechanization level of coconut batch processing.

Owner:HAINAN UNIVERSITY

Drilling device facilitating installation of false tooth implant

PendingCN114699194AEffective deformationEasy to cleanDental implantsDental toolsEngineeringDentistry

The invention discloses a drilling device convenient for mounting a false tooth implant, which comprises a first drilling pipe and a second drilling pipe which are coaxially connected through a connecting frame, and the second drilling pipe is internally provided with a gingiva cutting device for cutting and pushing aside gingiva. A pressing pipe used for extruding the gingival cutting device is arranged between the first drilling pipe and the second drilling pipe, a screw tap used for drilling a gum is arranged in the first drilling pipe, and a rotating motor is arranged in the first drilling pipe in a sliding mode. The folding cutting edge is adopted, the elastic blade is arranged, the folding cutting edge can be effectively deformed, the folding cutting edge with the bottom bent by 90 degrees originally deforms under the action of external force, a circle is formed under the action of the pressing pipe, and therefore the gingiva can be cut open, and the gingiva can be cut off. In the downward pressing process of the pressing pipe, the bottom of the folding blade is driven to form a circle, the cut gingiva can be pushed aside, and the gum to be punched is exposed.

Owner:南通苏派义齿有限公司

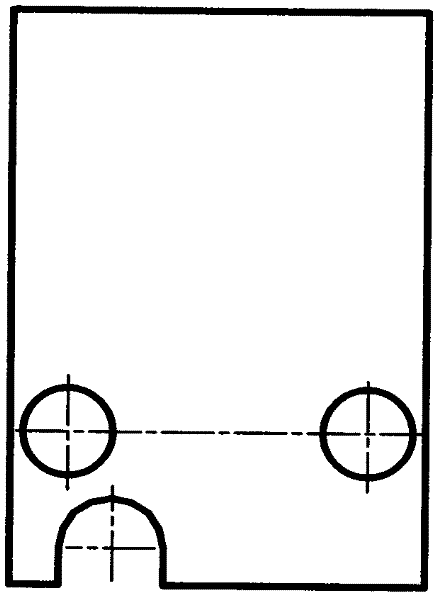

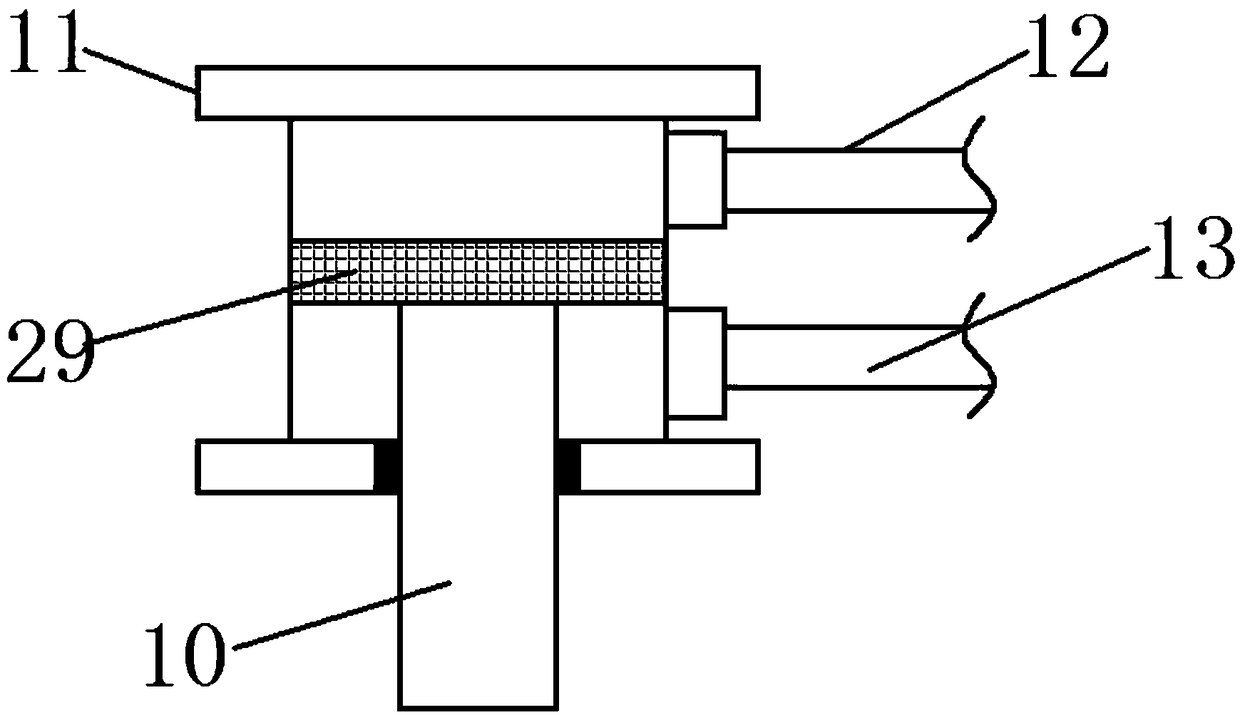

Motor excitation coil insulating layer breaking device

PendingCN111416490AAvoid red tapeEasy and fast connectionManufacturing dynamo-electric machinesElectric machineClassical mechanics

The invention relates to a motor excitation coil insulating layer breaking device. The device comprises a fixed clamping block, a movable clamping block and extrusion teeth which are fixedly arrangedon the opposite surfaces of the fixed clamping block and the movable clamping block respectively; the device further comprises a driving device; the driving device drives the fixed clamping block andthe movable clamping block to extrude each other, so that the insulating layer of a wire placed between the extrusion teeth on the fixed clamping block and the movable clamping block is crushed. The extrusion teeth are utilized, the wire is placed on the surfaces of the extrusion teeth, and the tips of the extrusion teeth are pressed to break the insulating layer of the wire by applying pressure to the extrusion teeth, so that a coil and a circuit are simply, conveniently and quickly connected to form a circuit loop, the tedious process of manual operation of workers is solved, production efficiency is greatly improved, and the defects of non-standardization and non-consistency of manual operation are avoided.

Owner:苏州汇智卓安自动化科技有限公司

A Manufacturing Method for Improving Tooth Profile Accuracy of Spline Shaft Forgings

ActiveCN109622863BImprove performanceImprove machining accuracyEngine componentsHeating/cooling devicesHeating furnaceExtrusion tooth

The invention relates to a manufacturing method for improving the tooth profile precision of a spline shaft forging. The method comprises the steps that a forging blank is placed into a heating furnace and heated to 850 DEG C-900 DEG C; primary pre-forging forming is performed, specifically, the work procedure includes that forward extrusion rod forming is performed on the blank which is heated to850 DEG C-900 DEG C; a pre-forged workpiece is placed into the heating furnace and cooled to 560 DEG C + / -10 DEG C with the cooling rate being 70-90 DEG C / h; secondary pre-forging forming is performed on the pre-forged workpiece, specifically, the work procedure includes that backward extrusion cup forming is performed on the forging which is cooled to 560 DEG C+ / -10 DEG C; the pre-forged workpiece is placed into the heating furnace with the temperature being 680 DEG C to be subjected to heat preservation for 1-1.5 h, and then taken out of the furnace to be subjected to normalizing and air cooling; shot blasting treatment and phosphorus saponification treatment are performed on the pre-forged workpiece; and cold extrusion forming is performed on the pre-forged workpiece, specifically, thework procedure includes that cold extrusion tooth profile forming is performed on the pre-forged workpiece which is subjected to phosphorus saponification treatment.

Owner:JIANGSU HAIYU MACHINERY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com