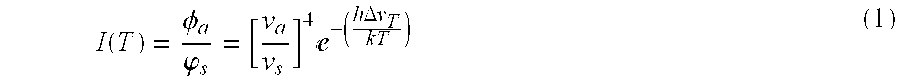

Patents

Literature

1138 results about "Optical fibre sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

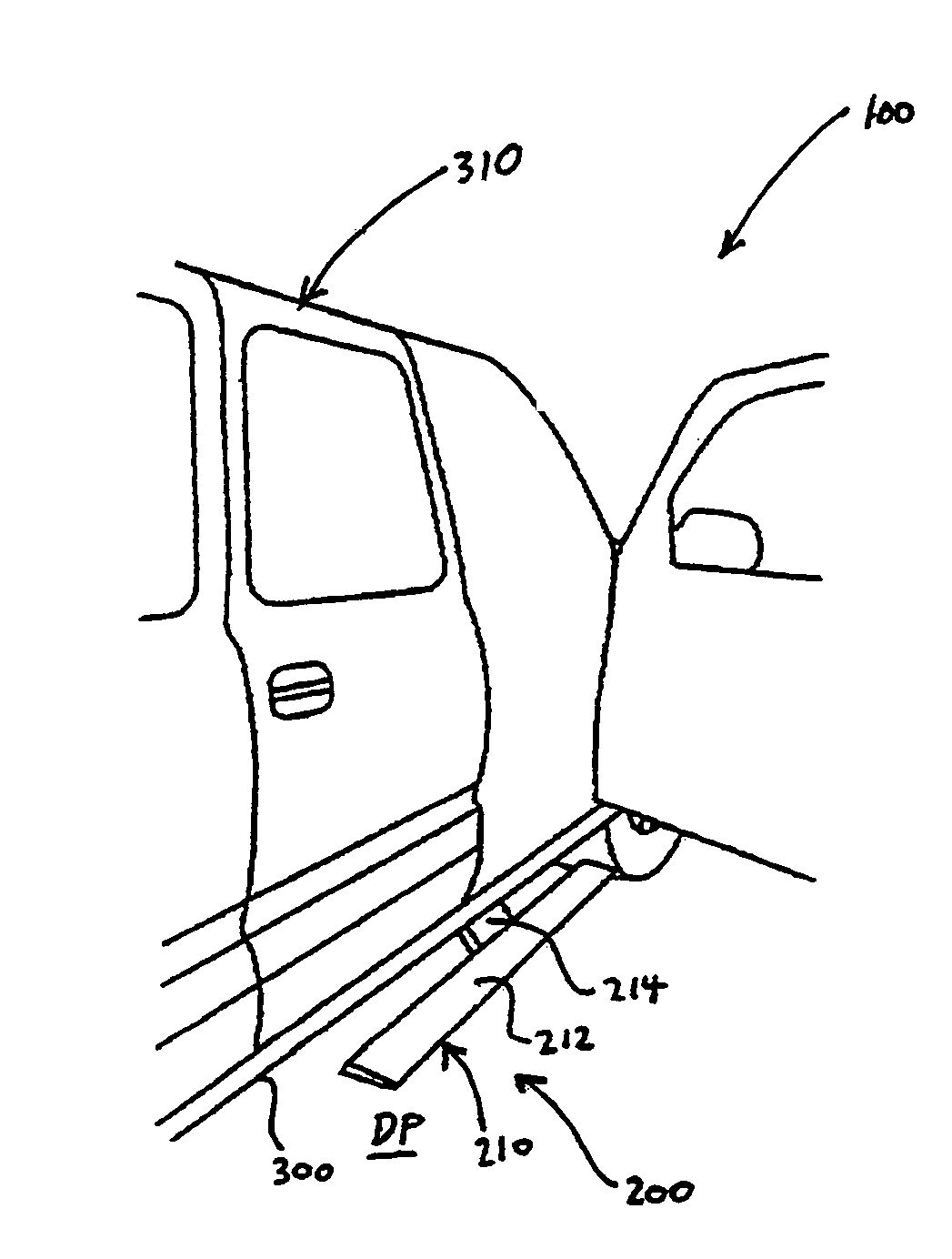

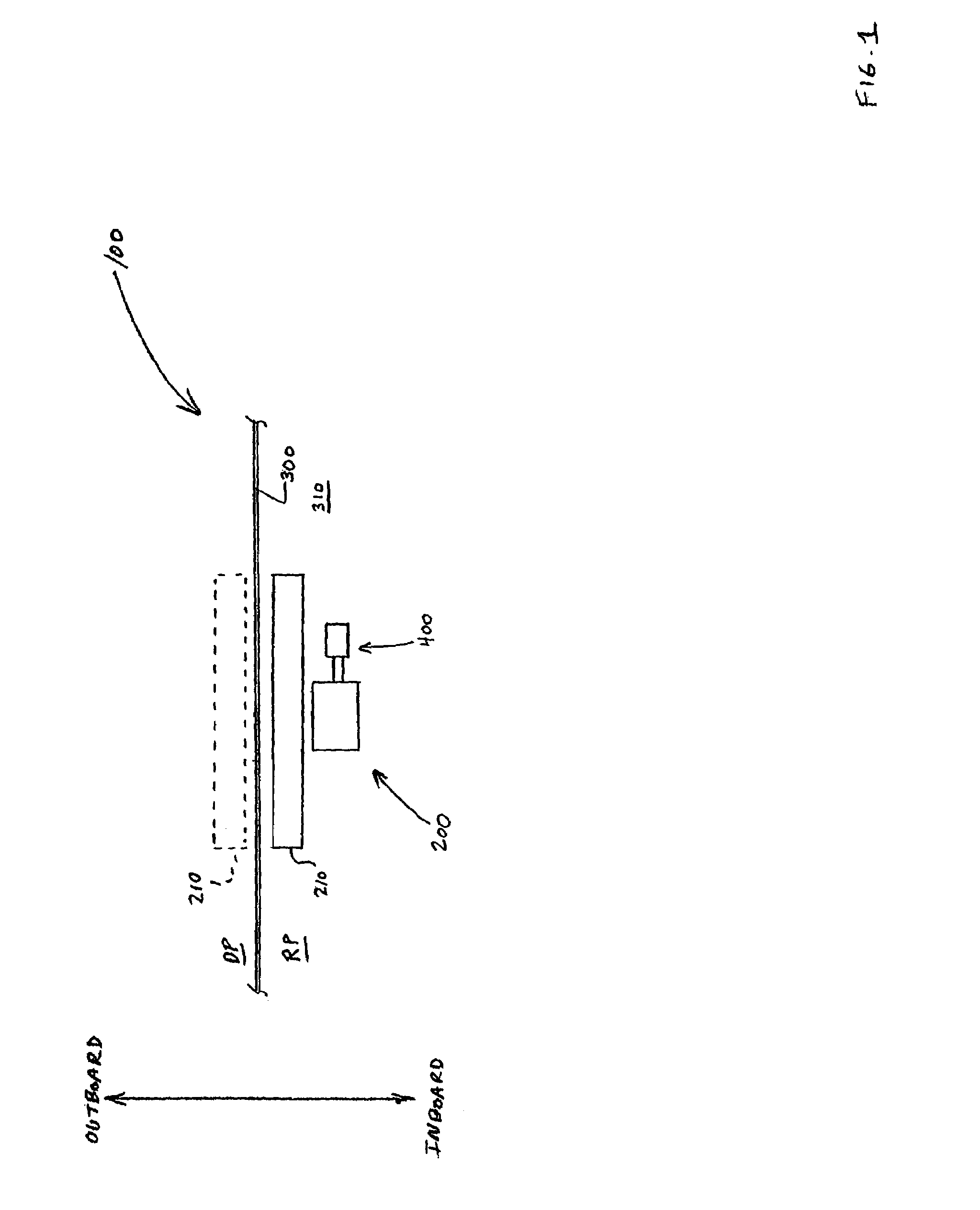

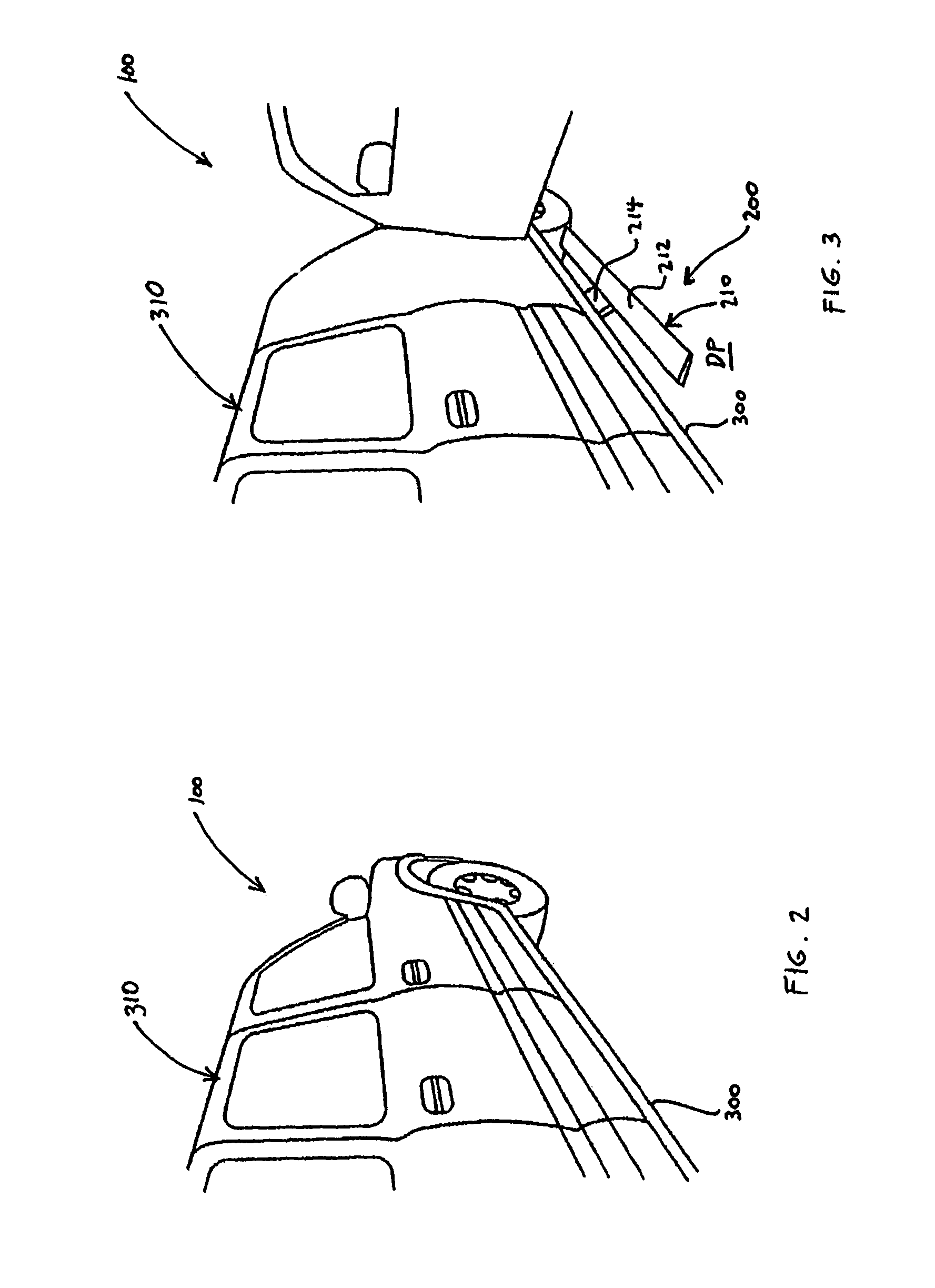

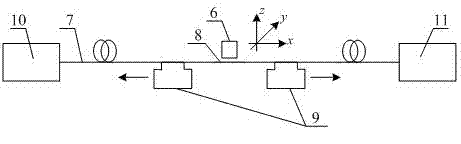

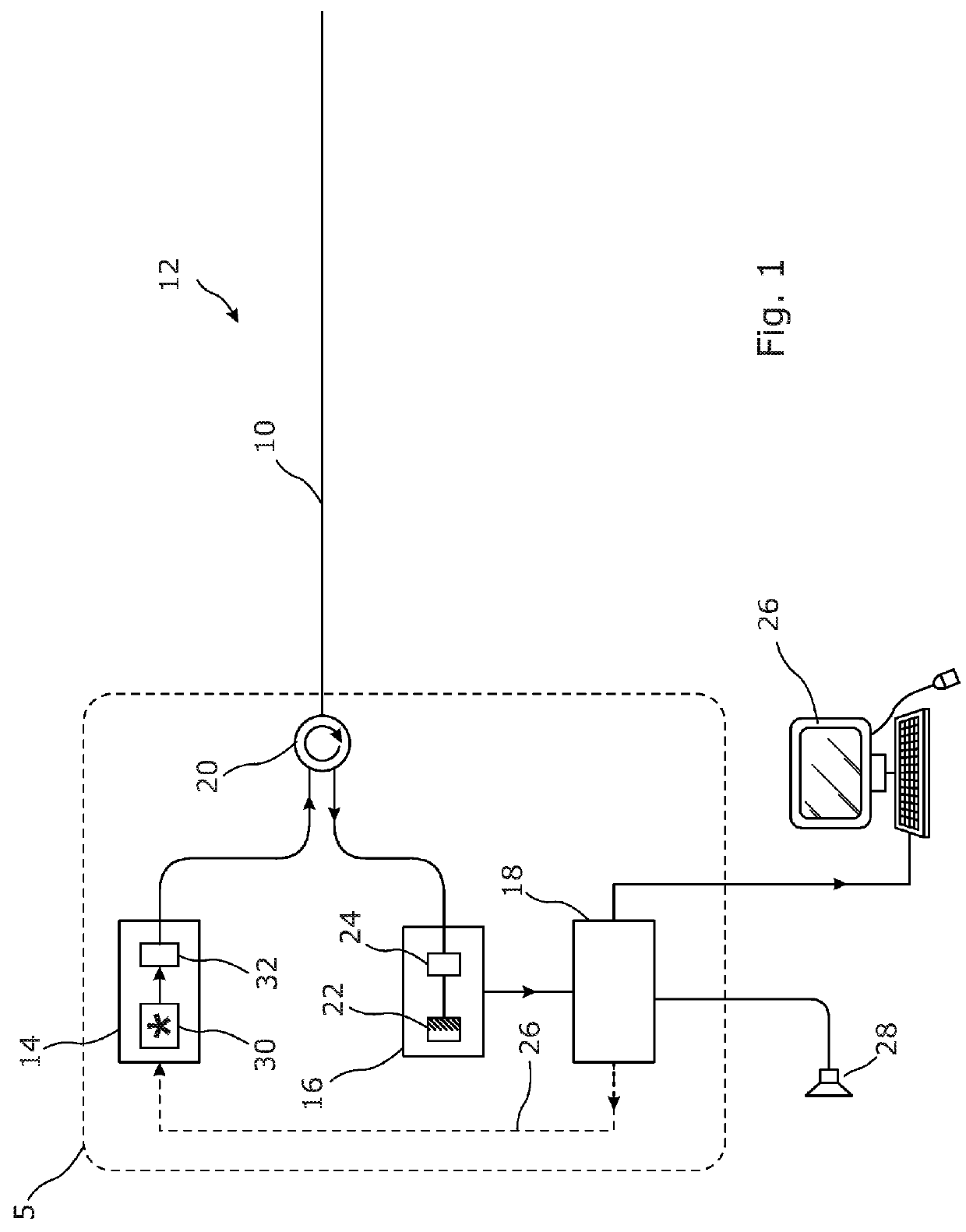

Drive systems for retractable vehicle step

A retractable step assist for a vehicle comprises a step, an actuator, an optical fiber sensor, and a safety. The step is movable between a retracted position and a deployed position that is downward and outboard from the retracted position. The actuator is mechanically connected to the step to position the step. The optical fiber sensor has an output that varies when pressure is applied to the optical fiber sensor. The safety is triggered by this output from the optical fiber sensor. The safety is configured to terminate retraction of the step when the optical fiber sensor senses pressure from an object pinched by the step deck.

Owner:LUND MOTION PRODS

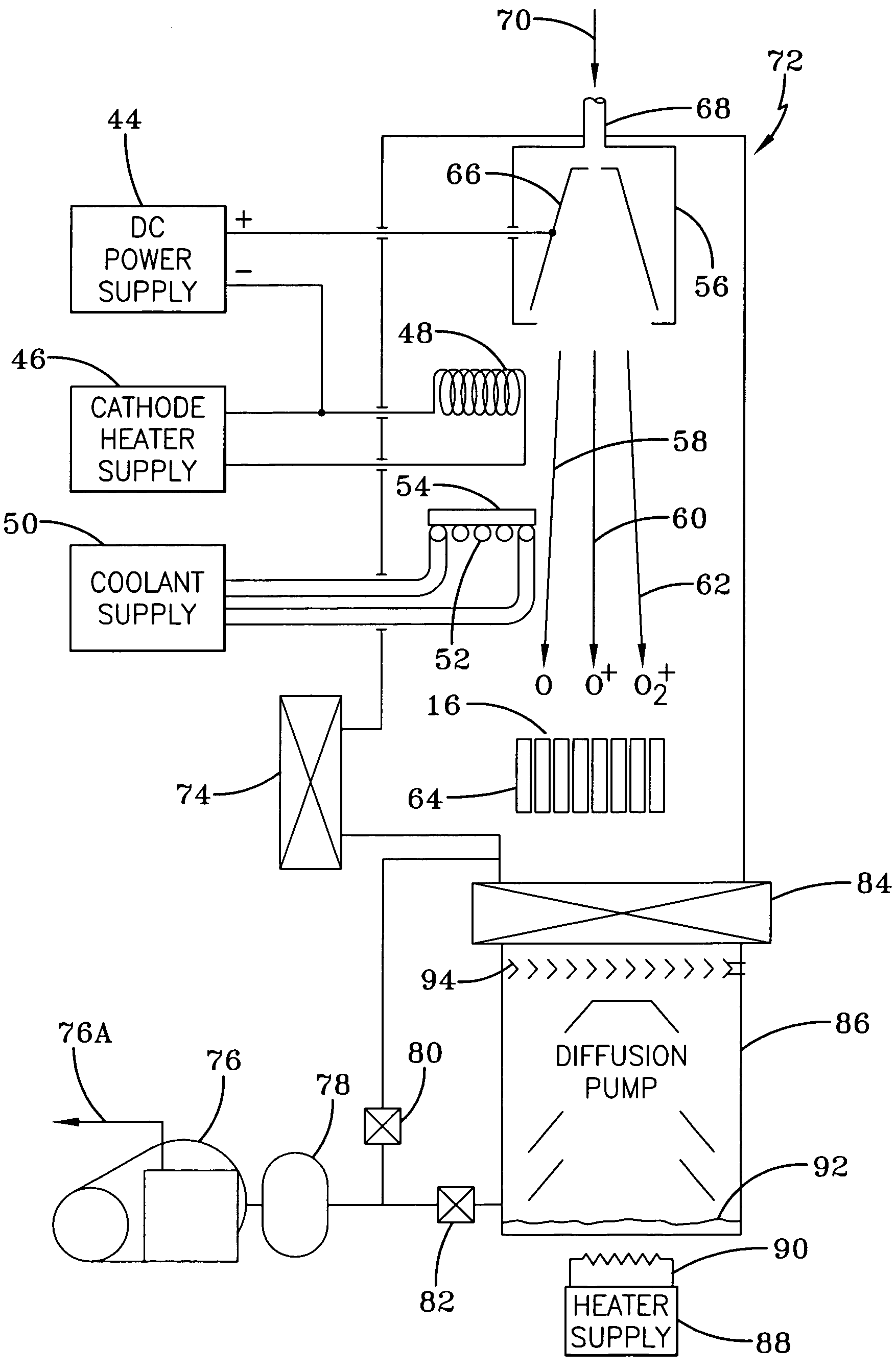

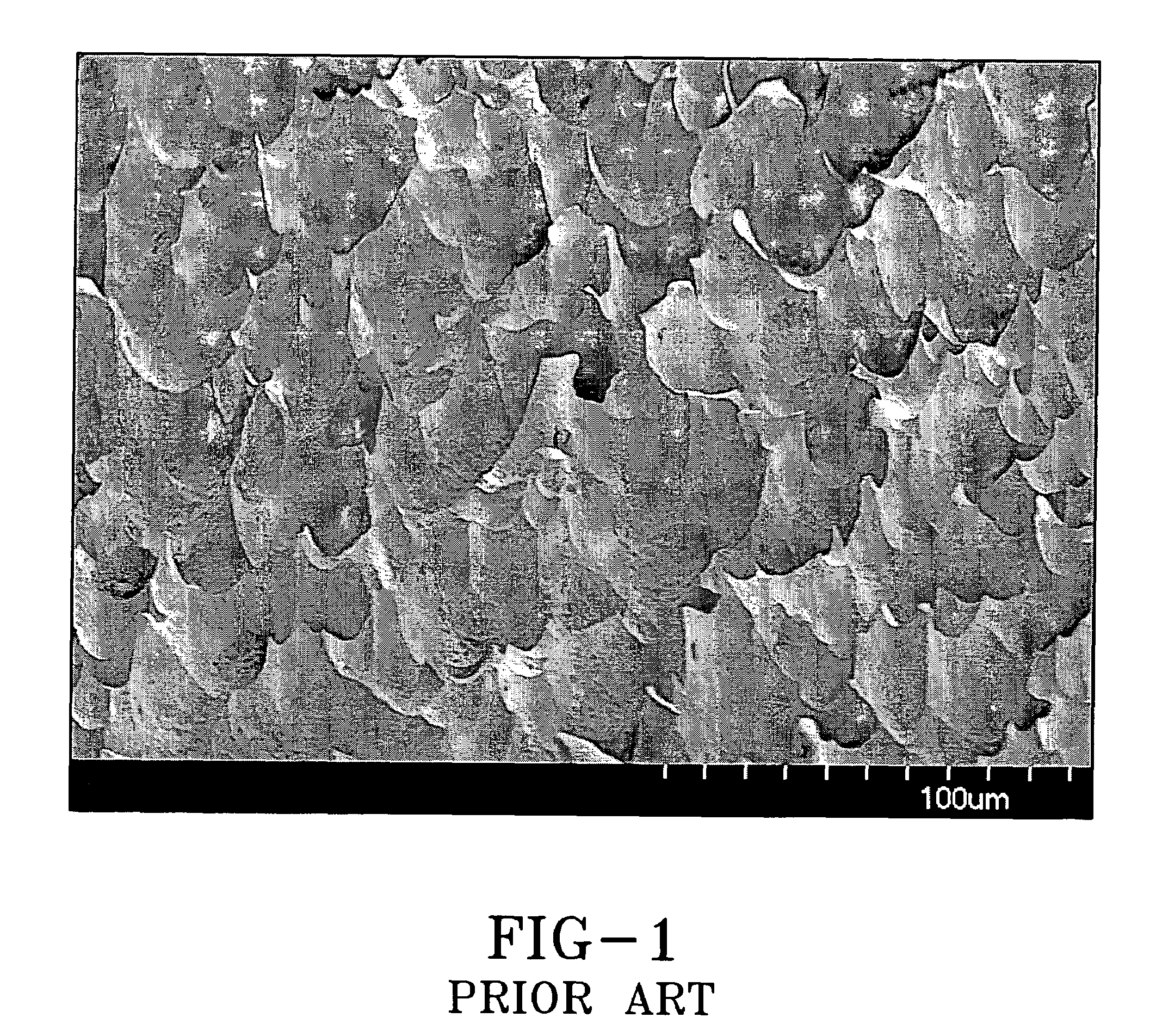

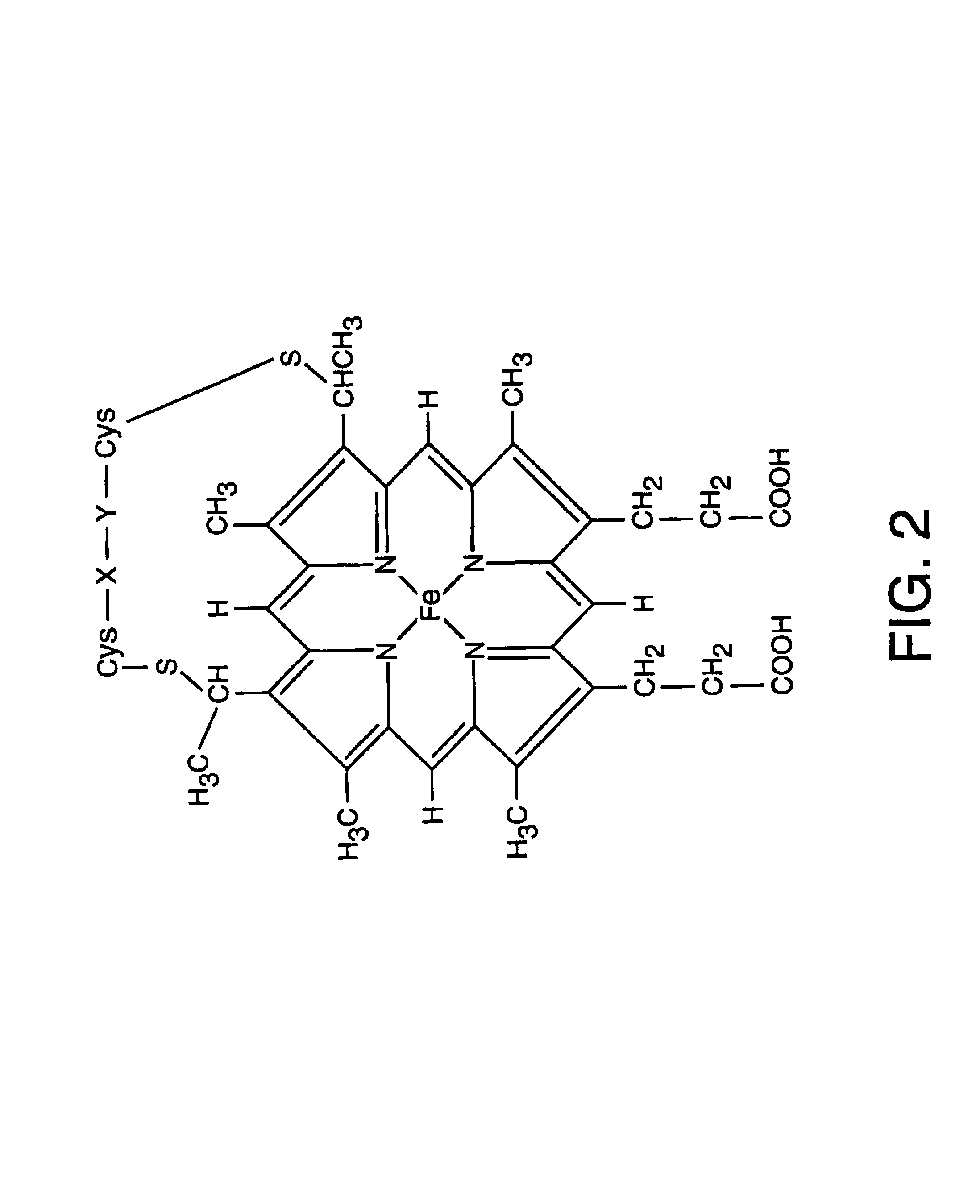

Method for texturing surfaces of optical fiber sensors used for blood glucose monitoring

InactiveUS7308164B1High aspect ratioMaterial analysis by optical meansCoupling light guidesCellular componentBlood sugar monitoring

Disclosed is a method and the resulting product thereof comprising a solid light-conducting fiber with a point of attachment and having a textured surface site consisting a textured distal end prepared by being placed in a vacuum and then subjected to directed hyperthermal beams comprising oxygen ions or atoms. The textured distal end comprises cones or pillars that are spaced upon from each other by less than 1 micron and are extremely suitable to prevent cellular components of blood from entering the valleys between the cones or pillars so as to effectively separate the cellular components in the blood from interfering with optical sensing of the glucose concentration for diabetic patients.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTRATOR NAT AERONAUTICS & SPACE ADMINISTRATION

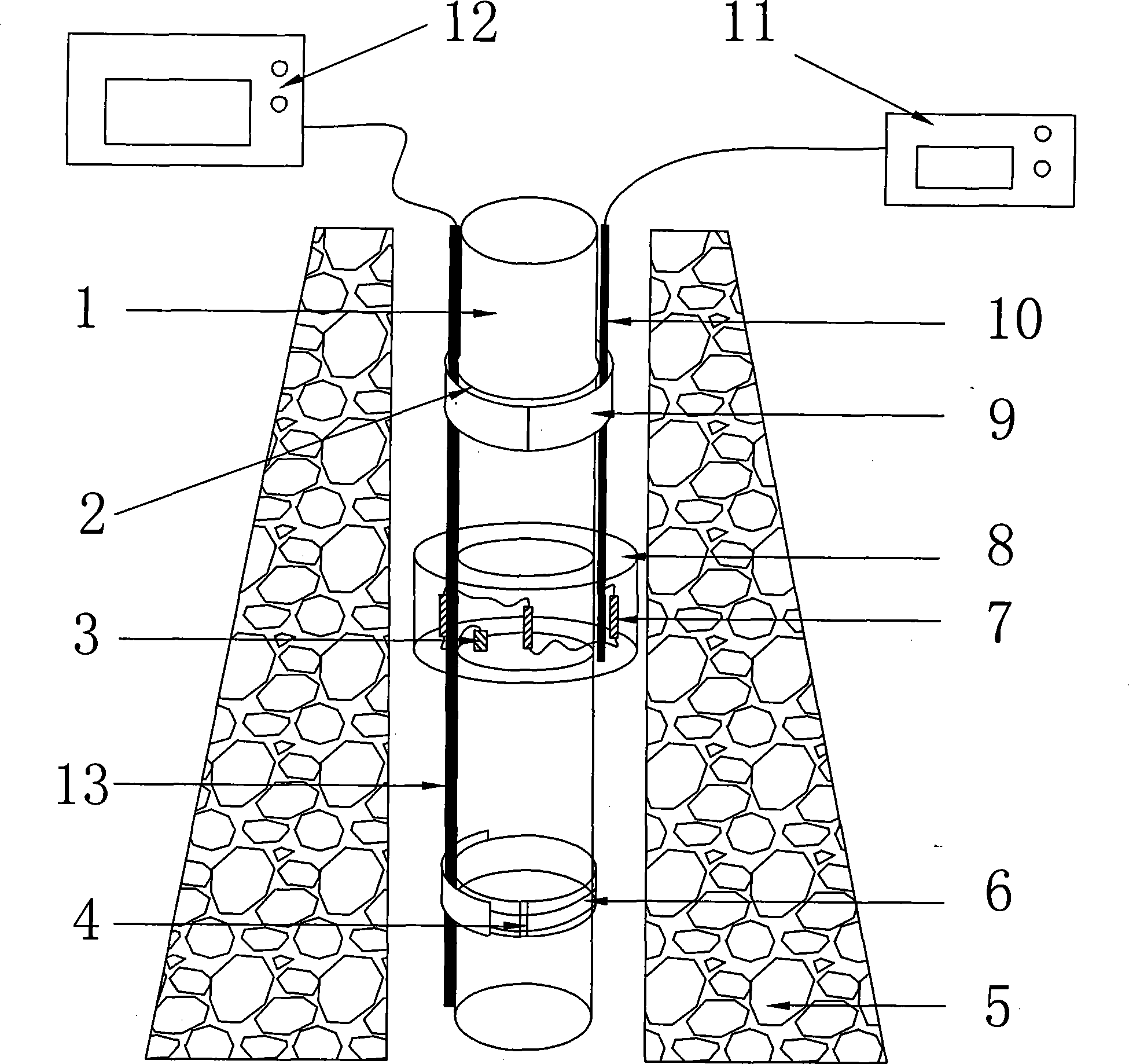

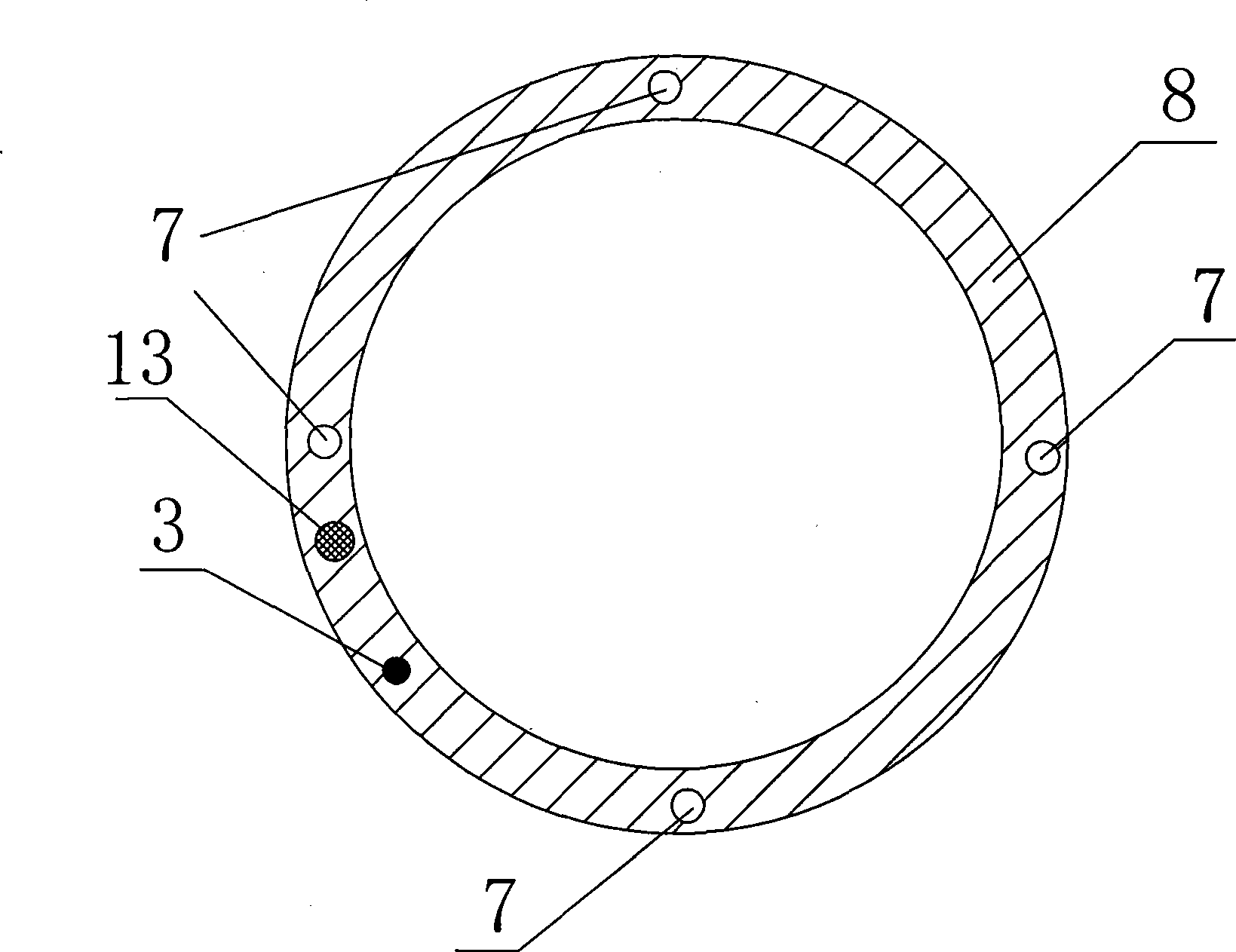

Method for monitoring downhole casing strain by using optical fibre sensor

InactiveCN101397904ARealize full well section monitoringAccurate measurementSurveyConstructionsGratingCircumferential strain

The invention relates to a method for monitoring the stress of a casing in a well by applying optical-fiber sensors, which mainly solves the problem that the existing research field of the casing erosion of an oil field and oil-water well does not have a direct method for monitoring the stress loading process of the casing in the well and the morphological characters of the casing erosion. The method is characterized in that: optical-fiber grating sensors are circumferentially arranged along the outer surface of the casing; a ground optical-fiber grating demodulation instrument connected with the optical-fiber grating sensors is utilized to monitor the circumferential strain Epsilon Theta of the casing and obtain the circumferential strain data of the casing; meanwhile, Brilliouin optical-fiber sensors are axially arranged along the outer surface of the casing; a ground Brilliouin optical-fiber demodulation instrument connected with the Brilliouin optical-fiber sensors is utilized to monitor the axial strain Epsilon Z of the casing and obtain the axial stain data of the casing; and the obtained circumferential strain Epsilon Theta and the axial strain Epsilon Z of the casing are utilized to obtain the stress of the outer layer of the casing in the well according to a ground stress explanation model. The method is characterized by being capable of permanently monitoring the deformation of the casing and obtaining corresponding stratum pressure under the condition without knowing the casing erosion and the stratum pressure.

Owner:DAQING OILFIELD CO LTD

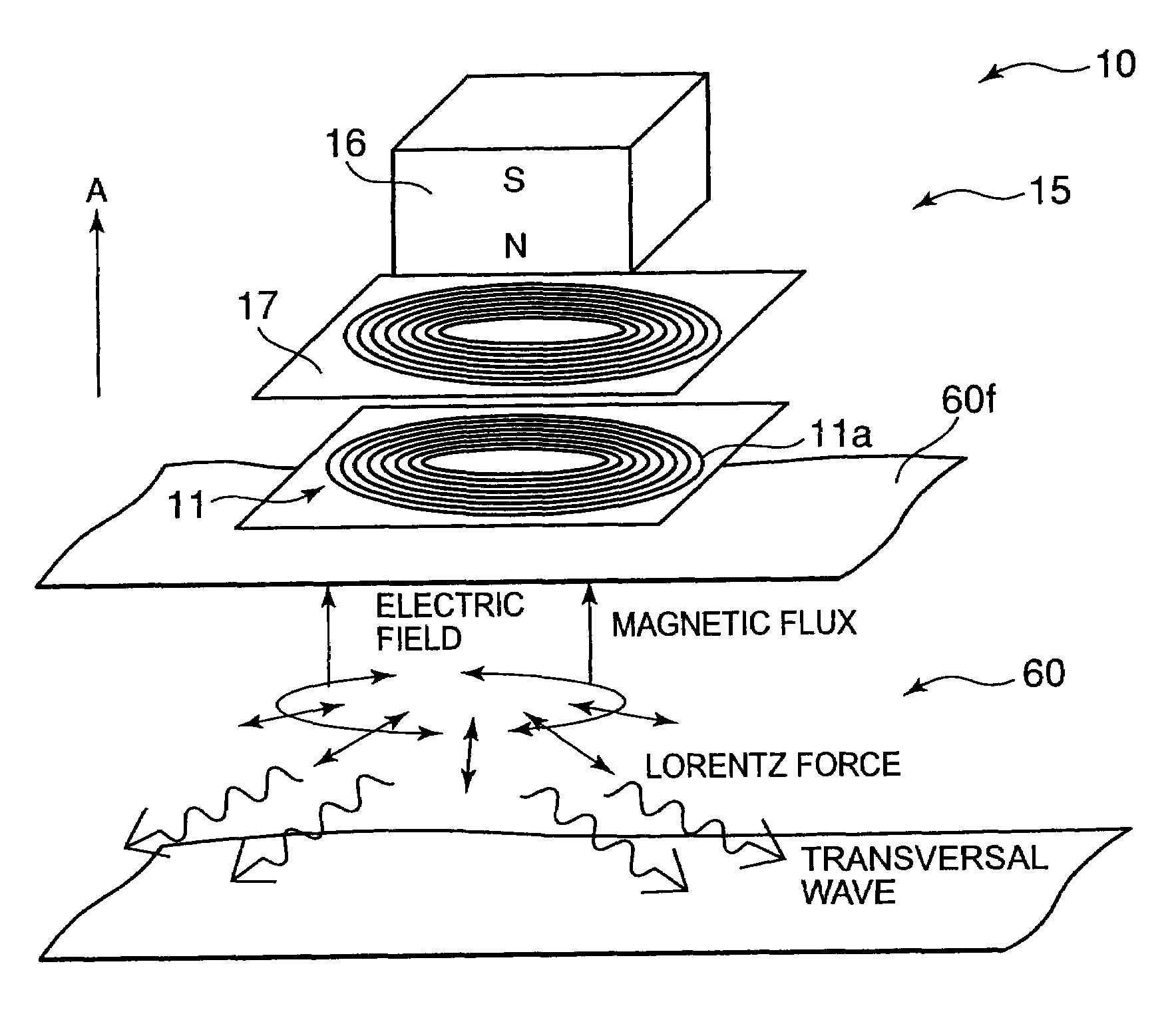

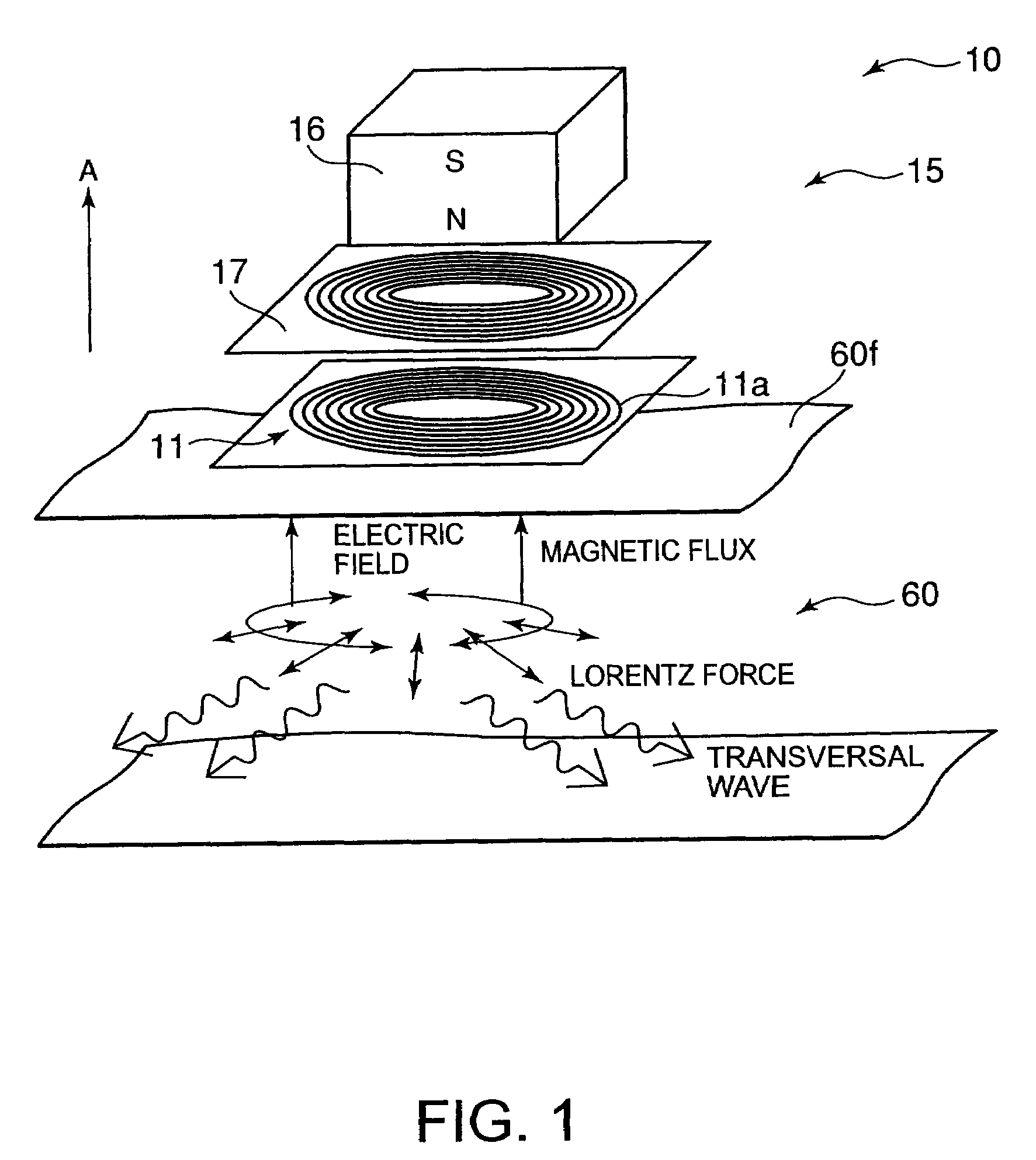

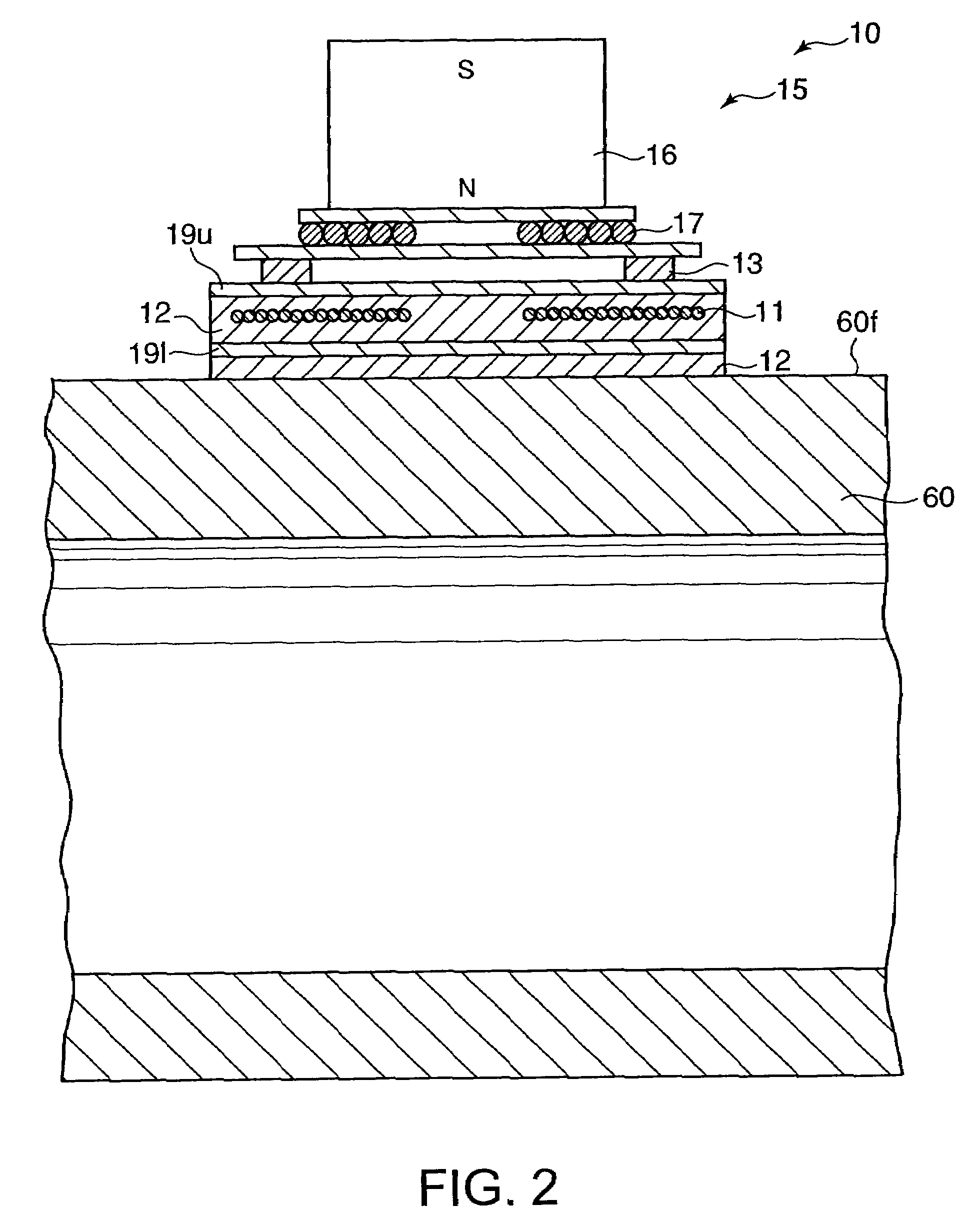

Active sensor, multipoint active sensor, method for diagnosing deterioration of pipe, and apparatus for diagnosing deterioration of pipe, and apparatus for diagnosis deterioration of pipe

ActiveUS7711217B2Reduce the numberShorten the timeAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansEngineeringOscillatory waves

An active sensor 10 is positioned on an outside of a pipe 60 so as to detect a thickness of the pipe. The active sensor comprises: an oscillator 15 capable of inputting oscillatory waves into the pipe and sweeping a frequency of the oscillatory waves within a desired range; and an optical fiber sensor mounted on the pipe, the optical fiber sensor detecting the oscillatory waves generated in the pipe.

Owner:KK TOSHIBA

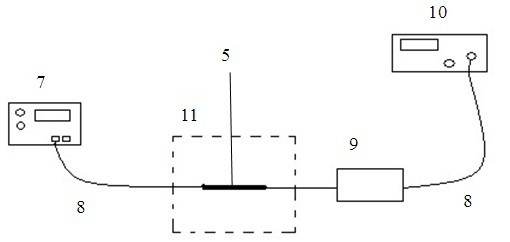

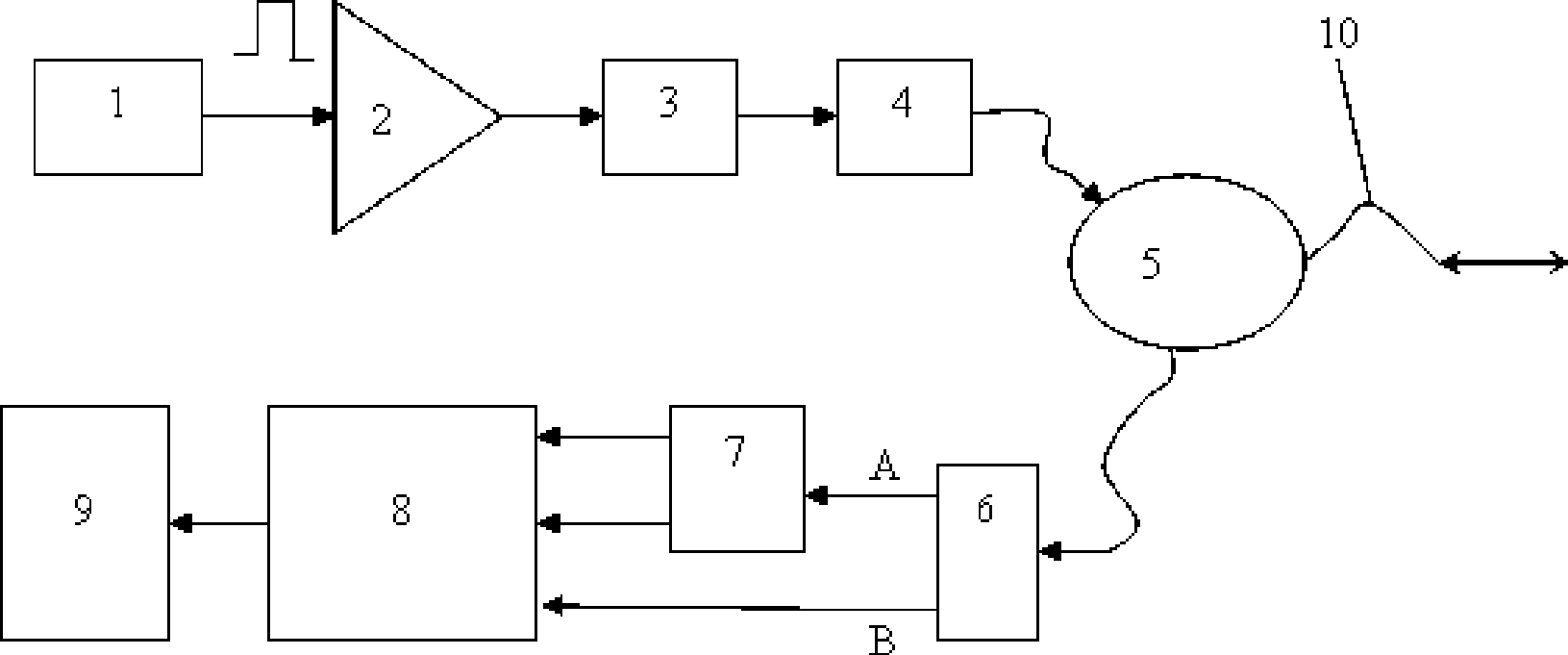

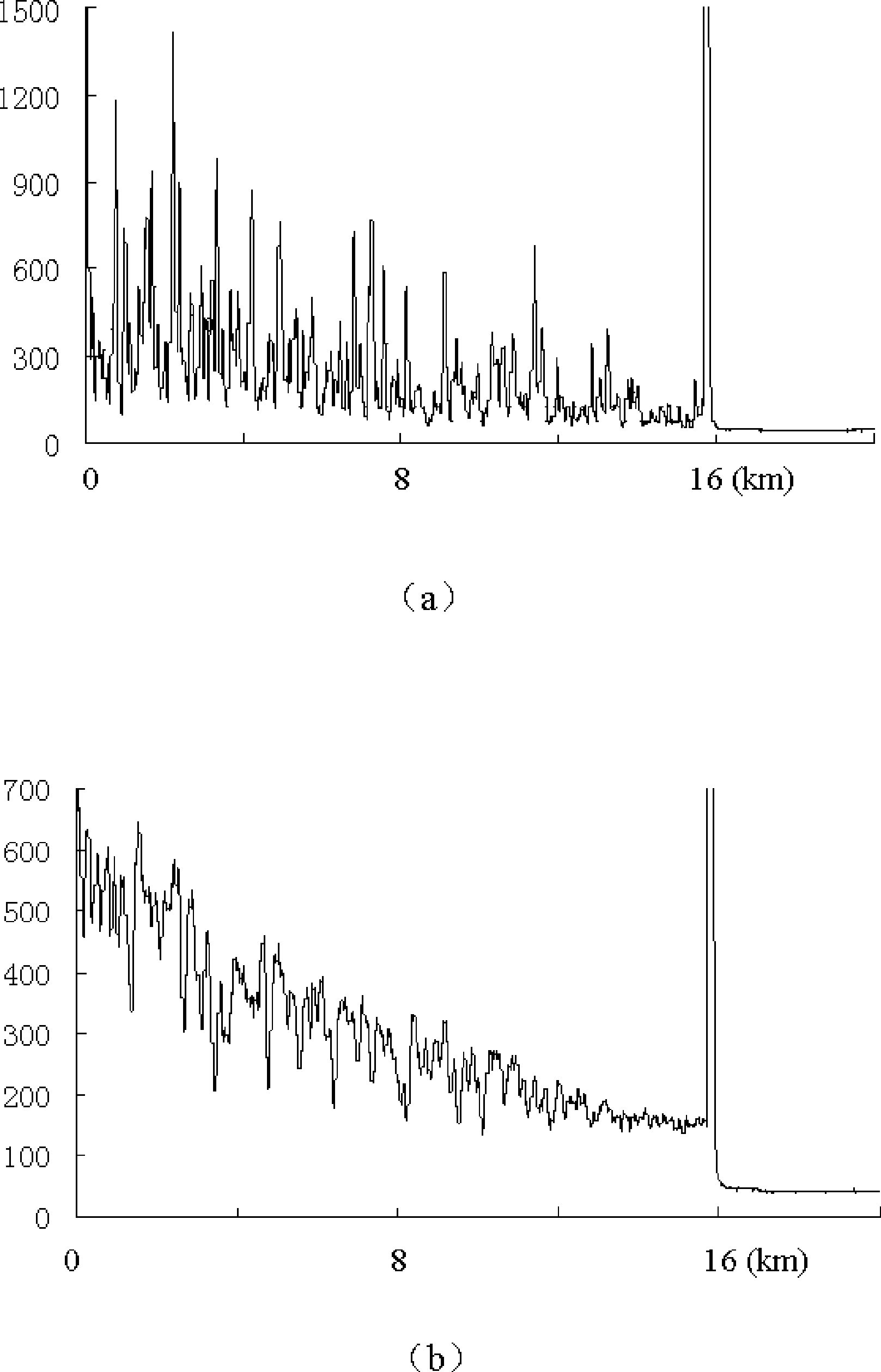

Optical fiber disturbance detection method and device

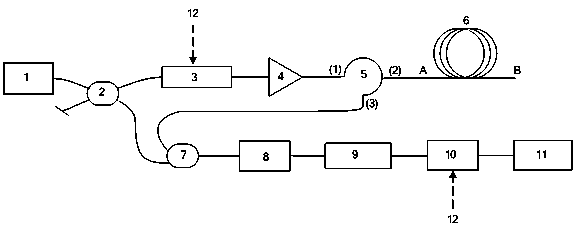

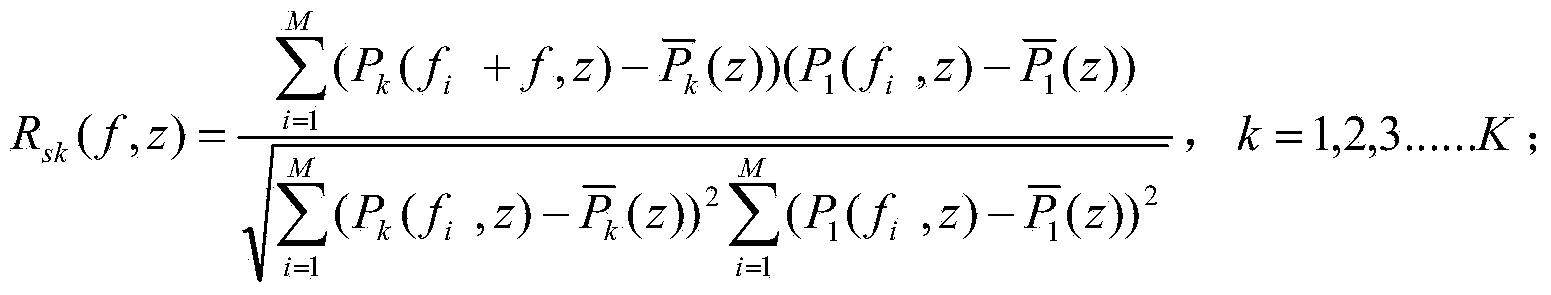

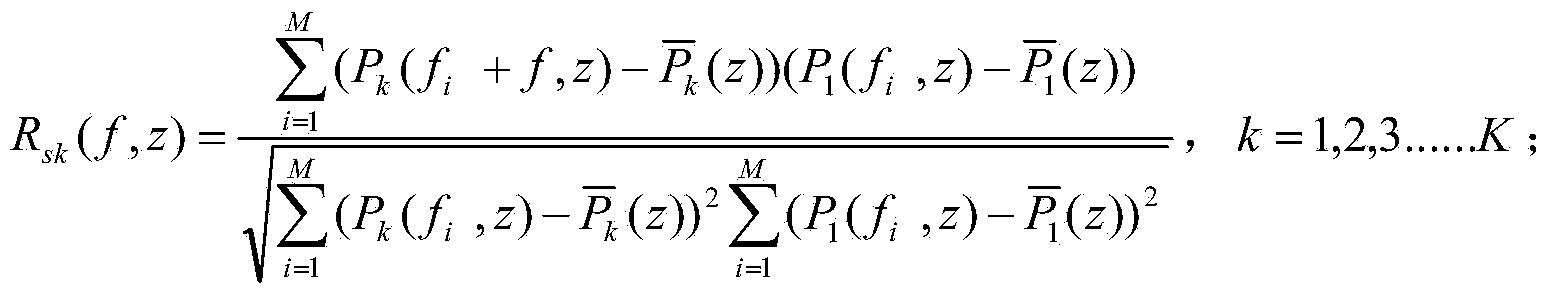

ActiveCN103954308ARealize simultaneous measurementSimple structureConverting sensor output opticallyContinuous measurementFiber optic sensor

The invention discloses an optical fiber disturbance detection method. According to the method, in the measuring process, segmentation frequency scanning is performed, a scattering curve of he same frequency light is used for measuring dynamic disturbance, correlation detection is performed on the distribution curve, obtained through K-set measurement, of the light power of backward Rayleigh scattering light of any point on a sensor fiber along with the frequency and the distribution curve, obtained through first-set measurement, of the light power of backward Rayleigh scattering light of the corresponding point along with the frequency so as to measure quasi-static disturbance, and therefore simultaneous measurement of dynamic disturbance signals and quasi-static disturbance signals is achieved, and the measuring function and application range of a full-distributed type optical fiber sensor are greatly expanded. The invention further discloses an optical fiber disturbance detection device. The device in a measuring system is simple in structure and low in cost, the measuring time is much shorter than the dynamic and quasi-static disturbance measuring time performed by utilizing two sets of systems, and the continuous measurement of dynamic and quasi-static disturbance can be achieved.

Owner:东莞先进光纤应用技术研究院有限公司 +2

Graphene film sensitized D-shaped optical fiber surface plasmon resonance (SPR) sensor and preparation method thereof

InactiveCN102621104AImprove sensitivityHigh strengthScattering properties measurementsChemical elementCvd graphene

The invention discloses a graphene film sensitized D-shaped optical fiber surface plasmon resonance (SPR) sensor. The sensor comprises a D-shaped optical fiber, wherein a silver film layer is arranged on the polished surface of the D-shaped optical fiber; and a graphene film layer is arranged on the surface of the silver film layer. A preparation method comprises the following steps of: (1) preparing the D-shaped optical fiber, and preparing the silver film layer on the polished surface of the D-shaped optical fiber; and (2) preparing the graphene film layer on the surface of the silver film layer. The D-shaped optical fiber is used as a light transmission medium, an SPR structure is formed by plating a silver film on the surface of the D-shaped optical fiber, the sensitivity of the SPR sensing structure is increased by depositing or growing a graphene film material on the surface of the silver film, and the sensor has the prominent advantages of small volume, light weight, high sensitivity, quick response and the like, and has wide application prospects in the aspect of detecting trace gas, liquid, chemical elements, deoxyribonucleic acid (DNA) and the like in the fields of biology, chemistry, medicine and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

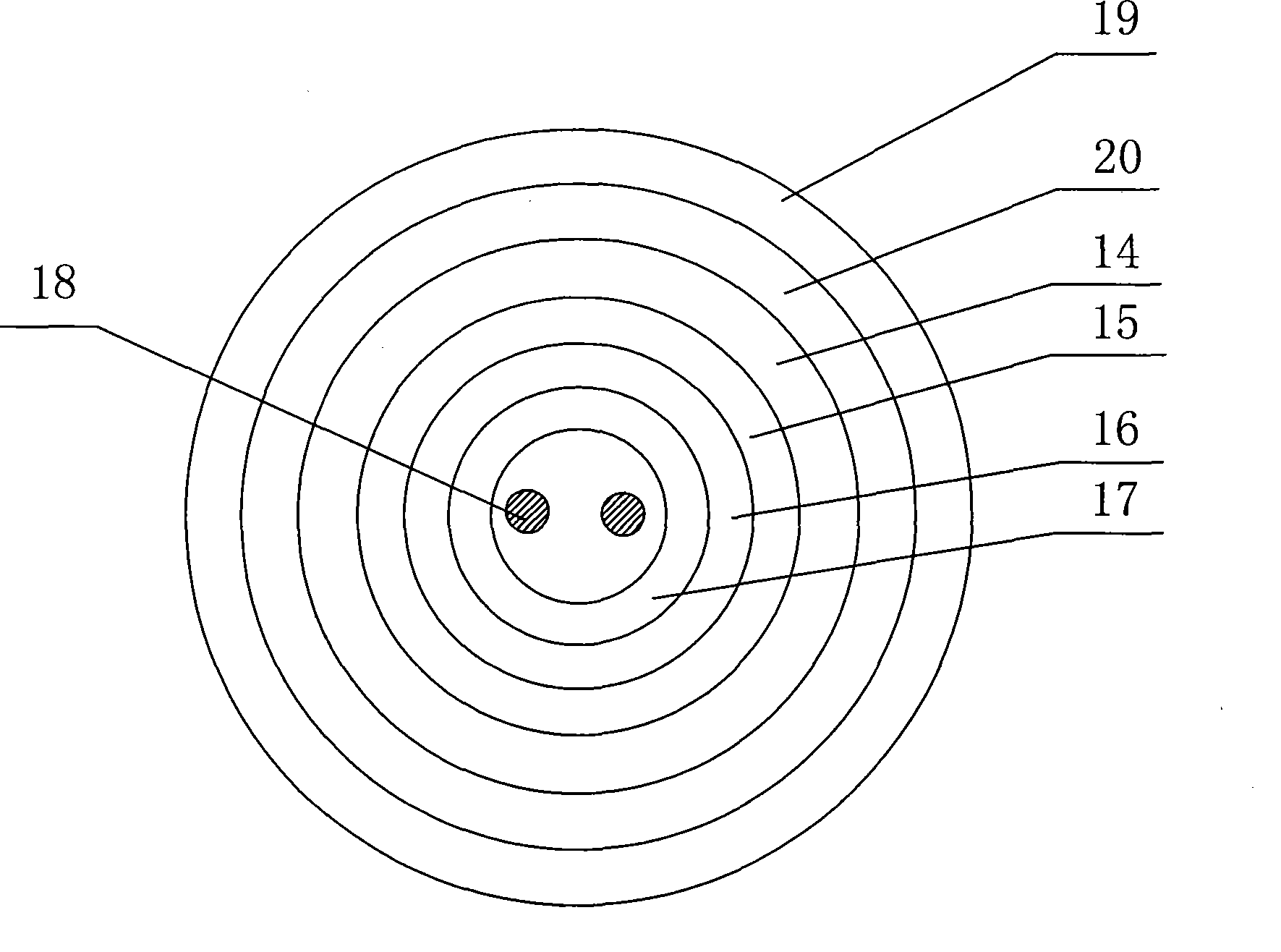

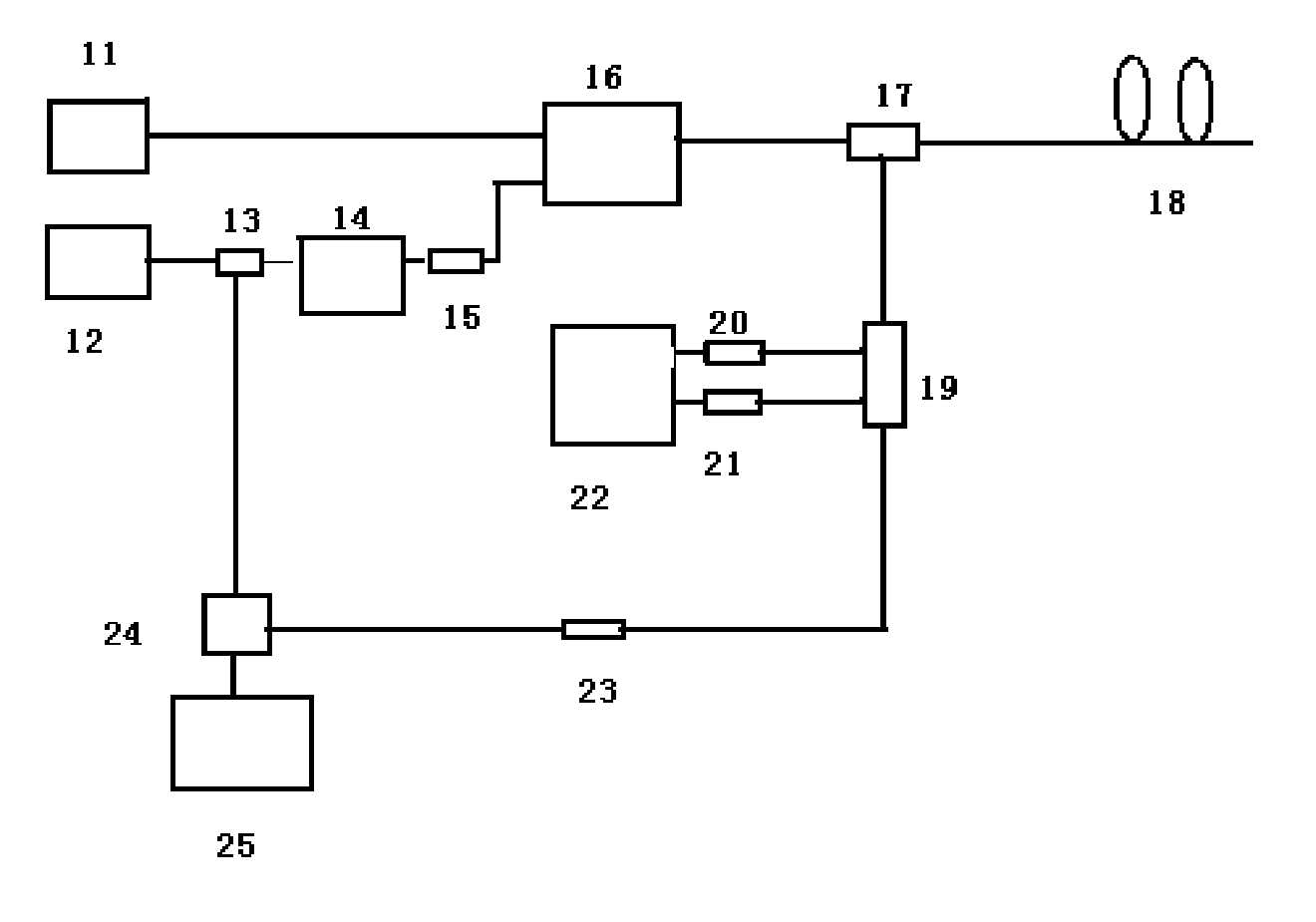

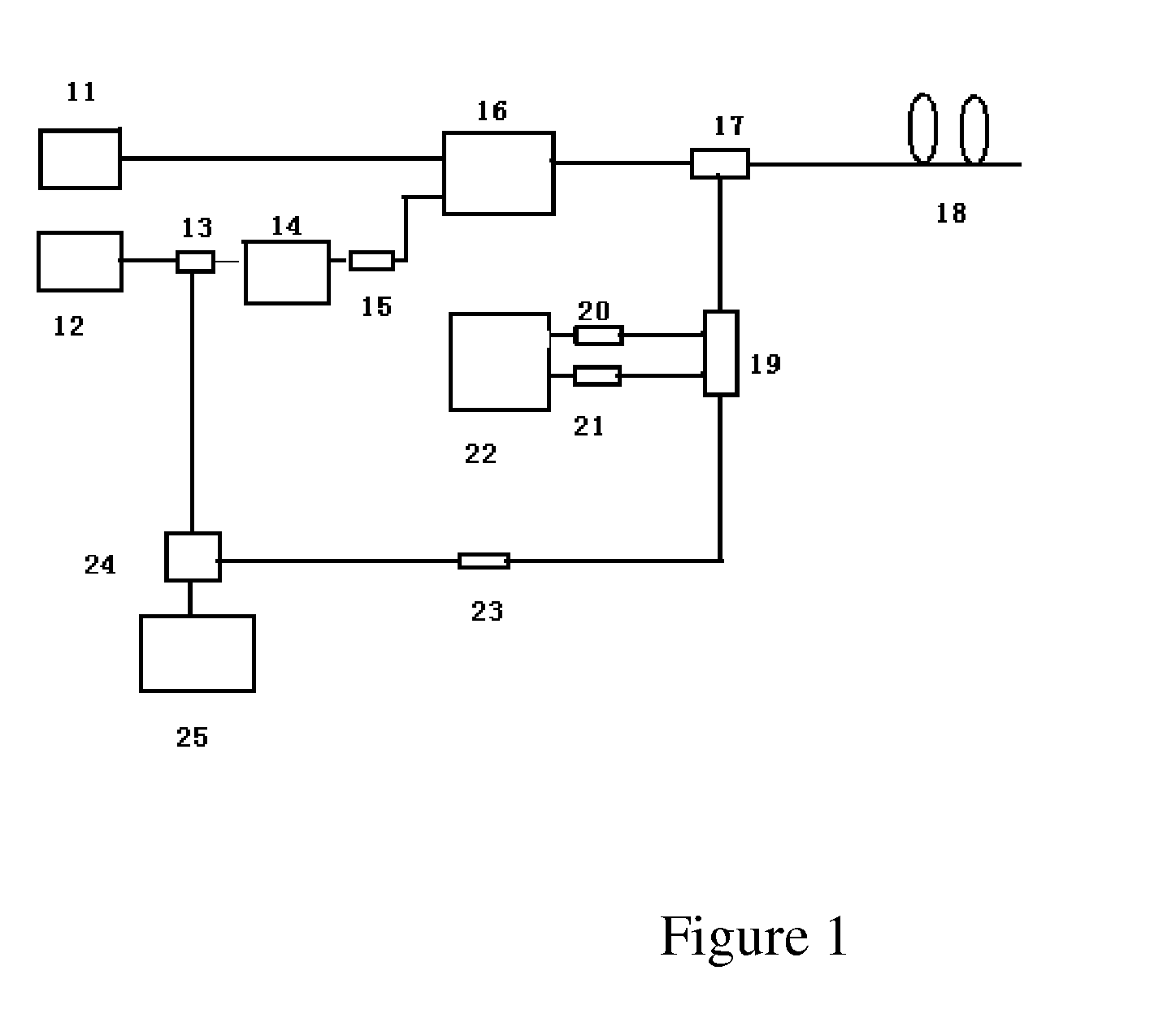

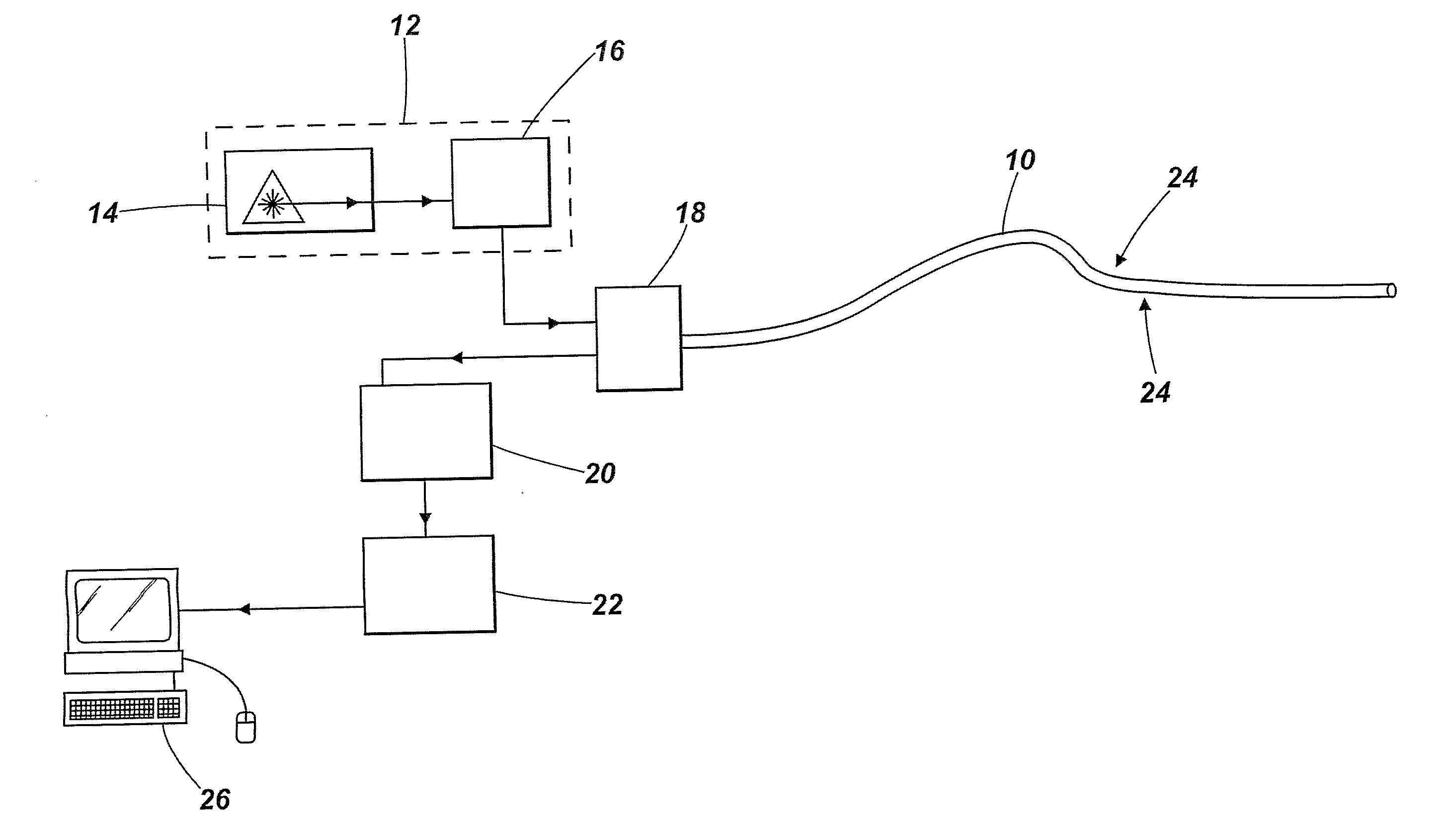

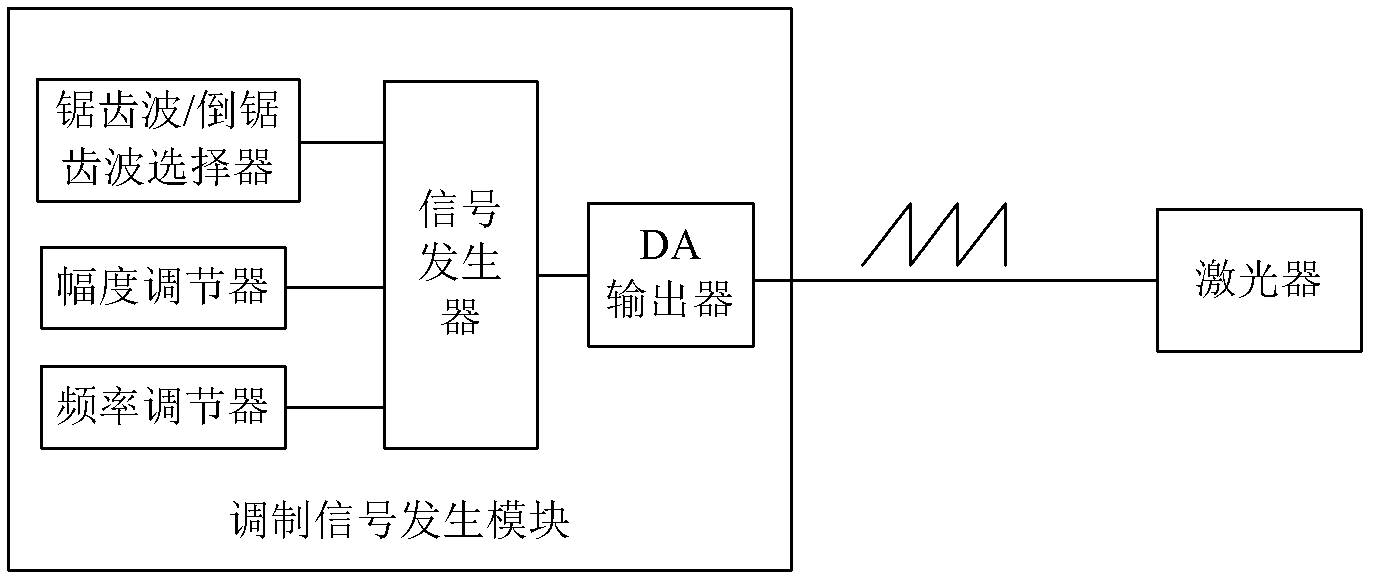

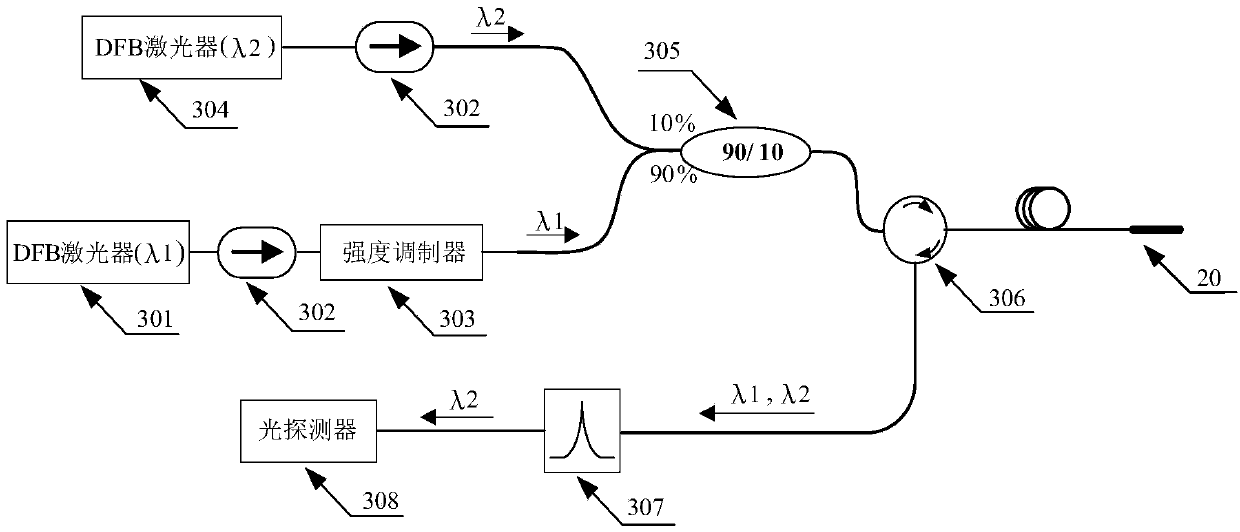

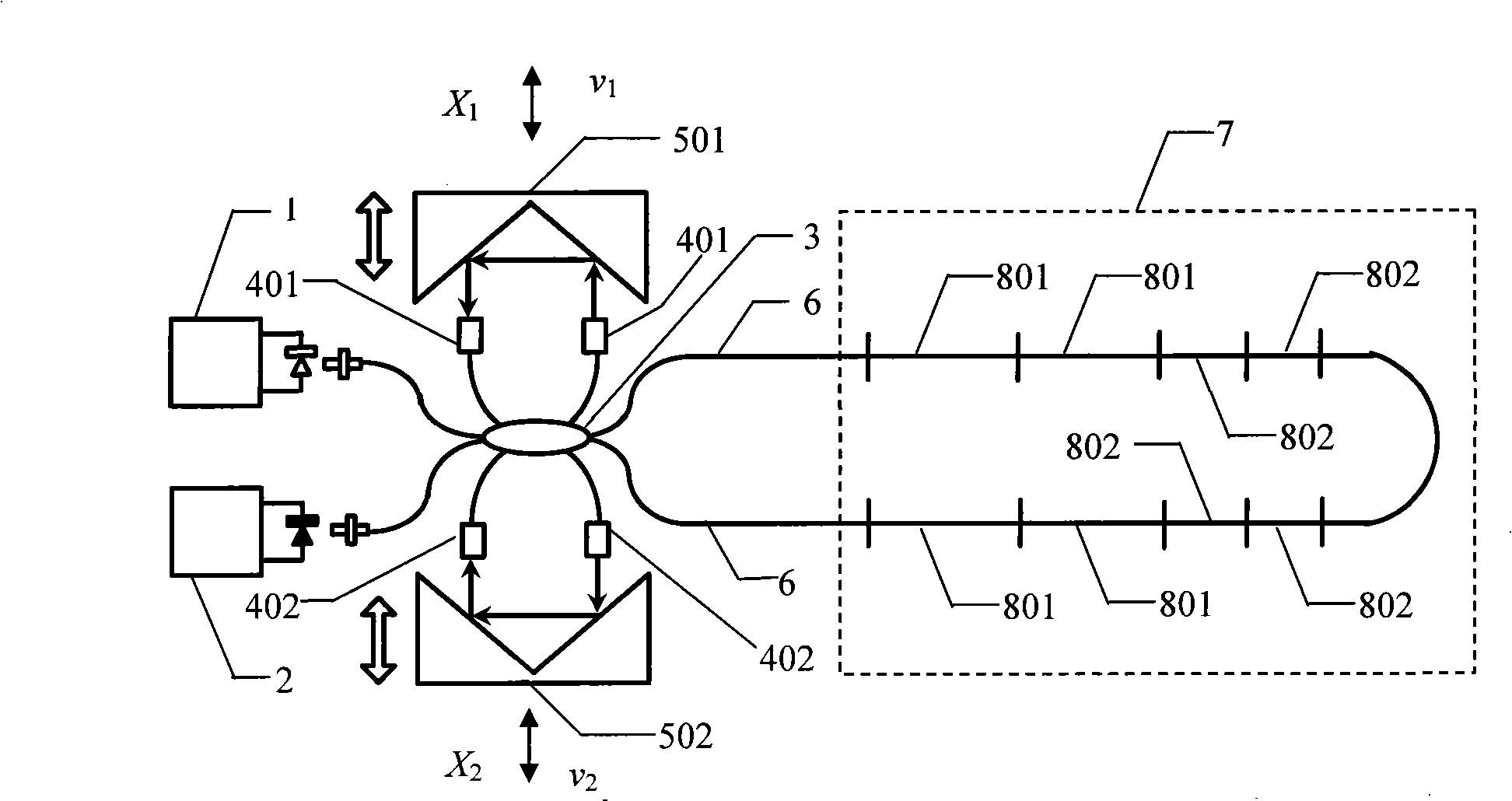

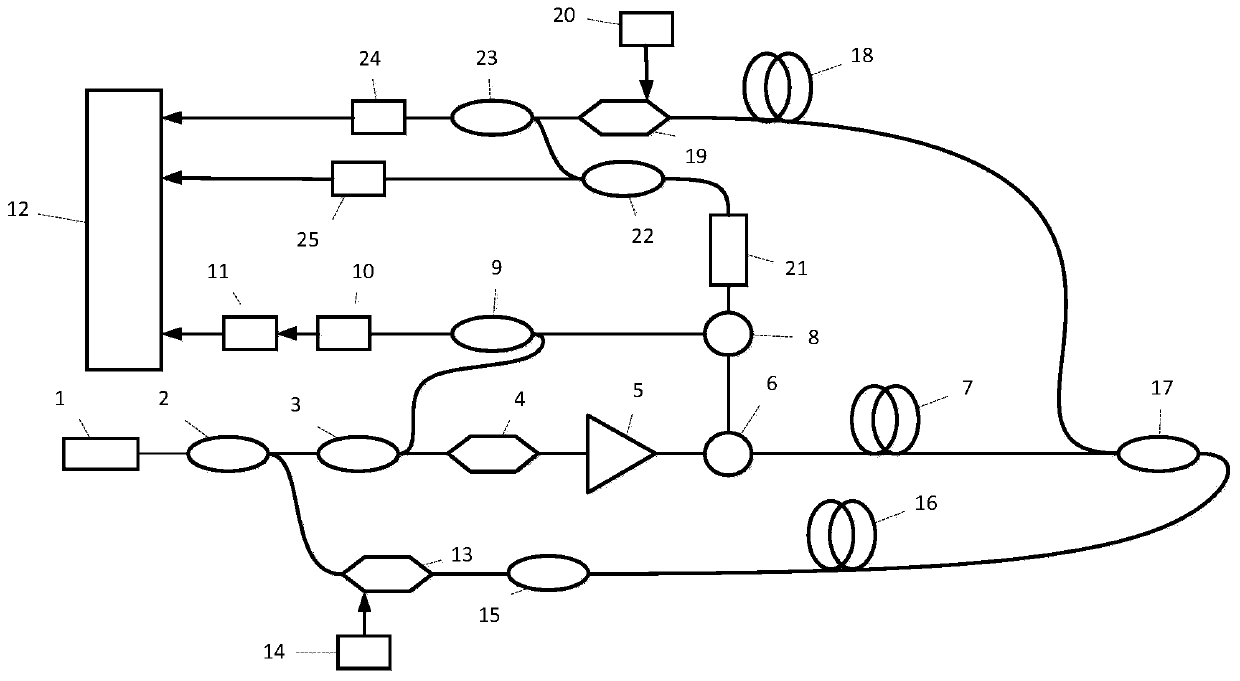

Distributed optical fiber sensor based on roman and brillouin scattering

InactiveUS20130020486A1Improve signal-to-noise ratioRealize measurementRadiation pyrometryForce measurementMechanical engineeringMaterials science

A distributed optical fiber sensor based on Raman and Brillouin scattering is provided. The distributed optical fiber sensor includes a semiconductor FP cavity pulsed wideband optical fiber laser (11), a semiconductor external-cavity continuous narrowband optical fiber laser (12), a wave separator (13), an electro-optic modulator (14), an isolator (15), an Er-doped optical fiber amplifier (16), a bidirectional coupler (17), an integrated wavelength division multiplexer (19), a first photoelectric receiving and amplifying module (20), a second photoelectric receiving and amplifying module (21), a direct detection system (22), a narrowband optical fiber transmission grating (23), a circulator (24) and a coherence detection module (25). The temperature and the strain can be measured simultaneously, and the signal-to-noise ratio of the system is enhanced.

Owner:CHINA JILIANG UNIV

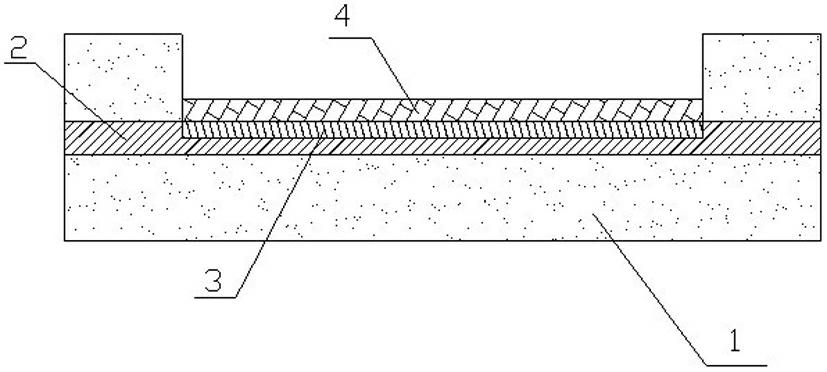

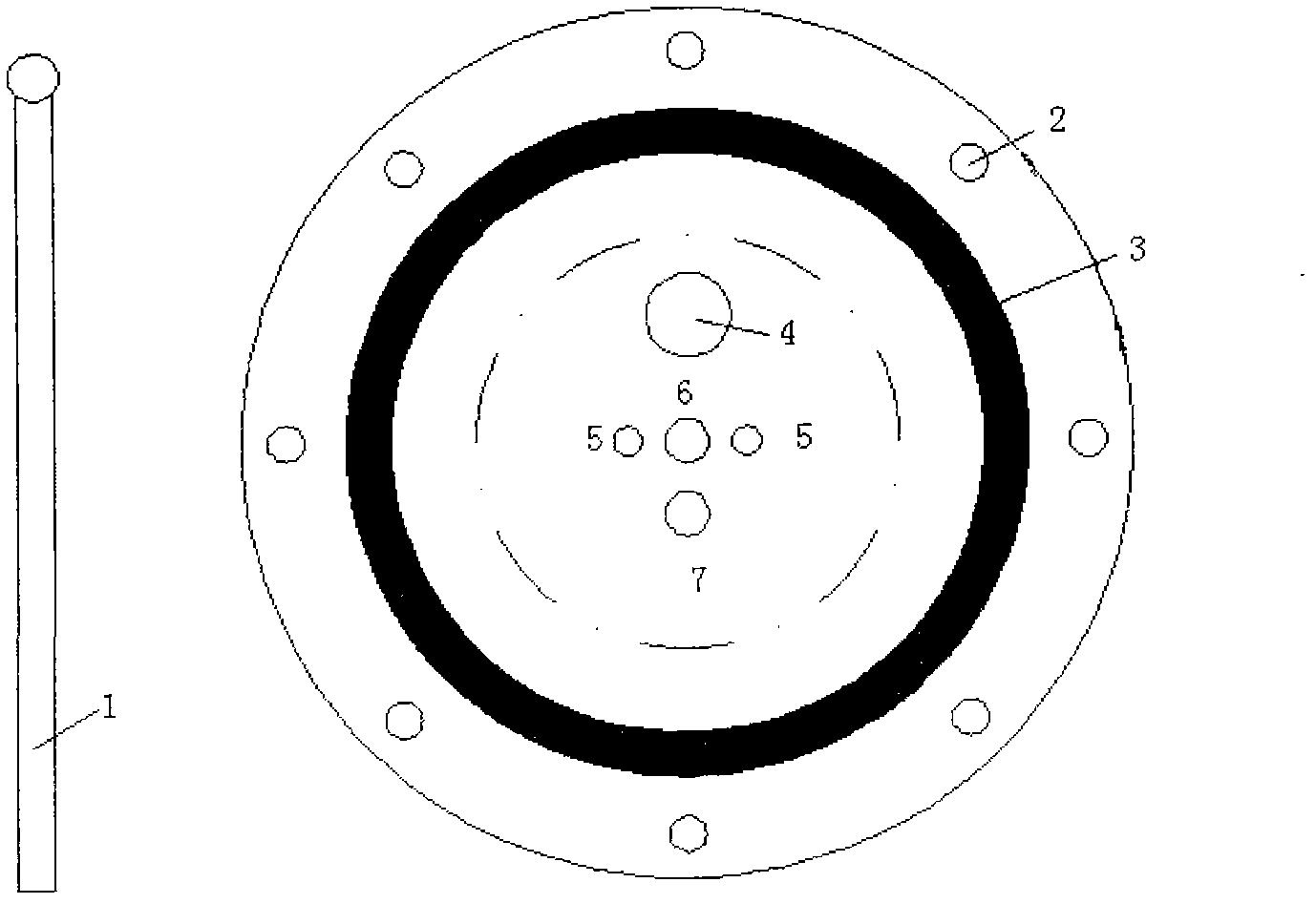

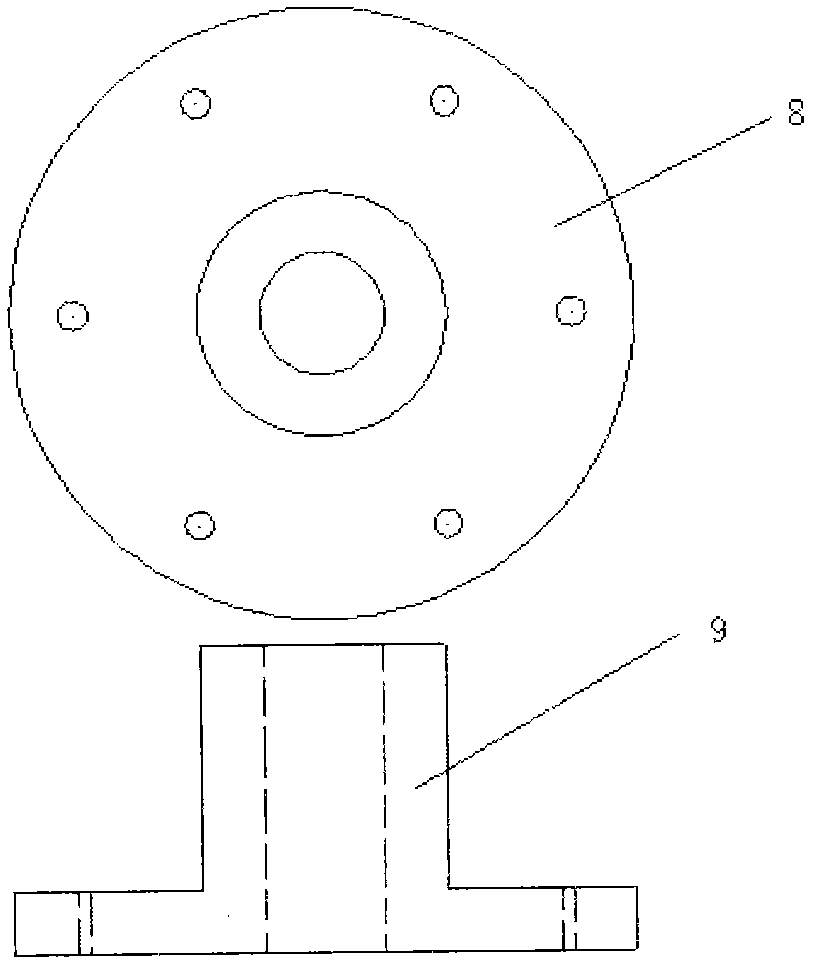

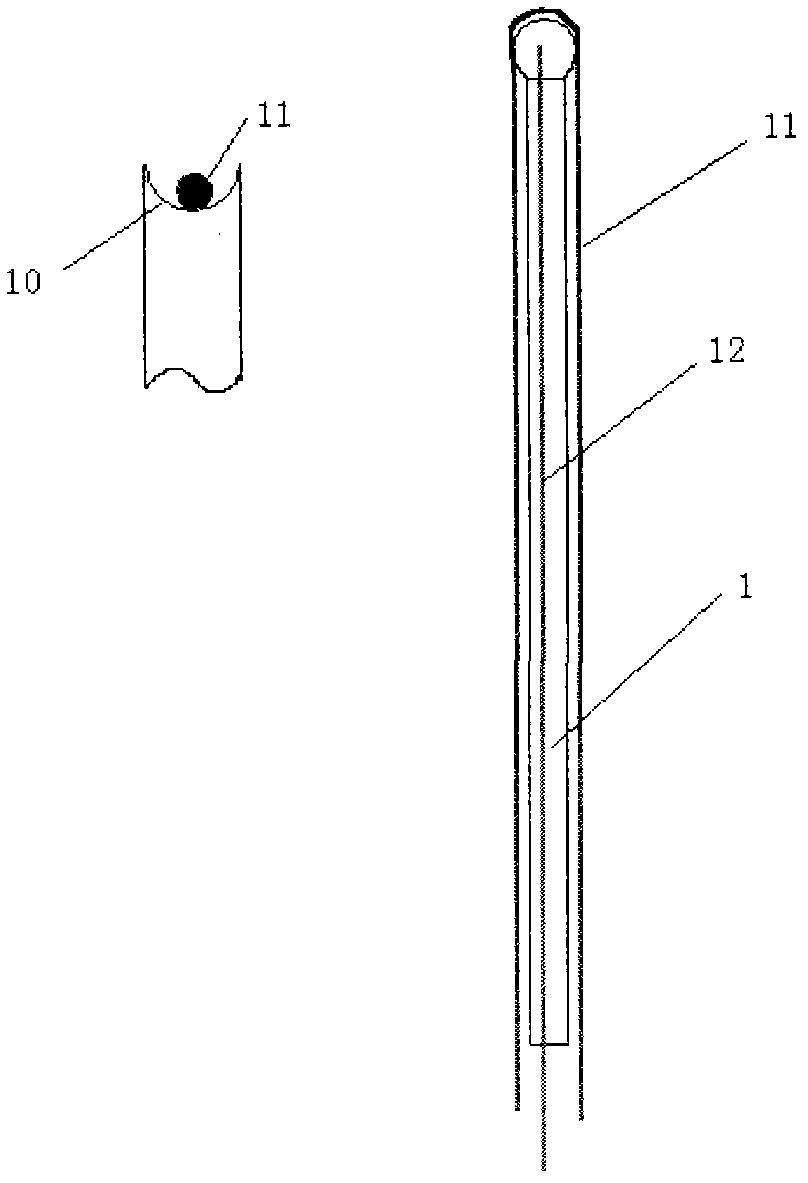

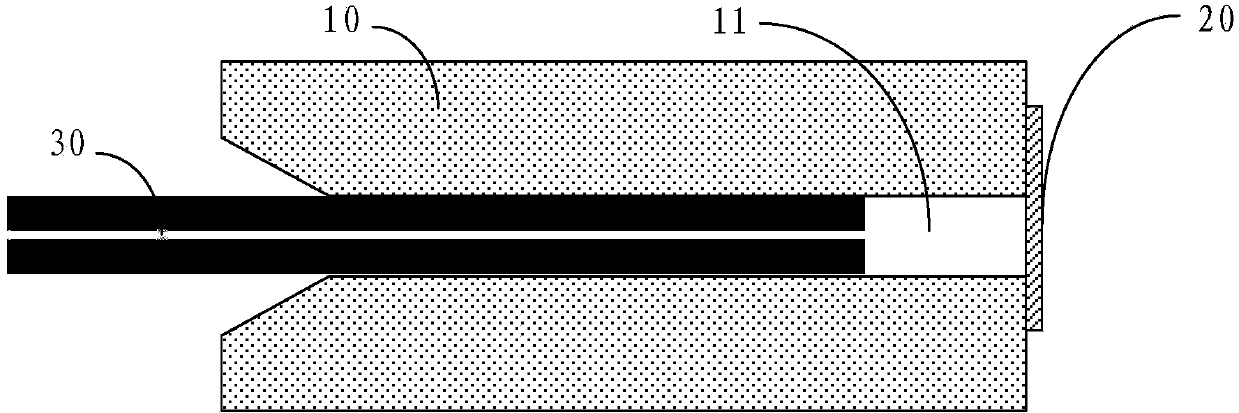

Tunnel surrounding rock radial stress strain distributed monitoring technology

The invention belongs to the technical field of geotechnical engineering monitoring, and relates to a distributed optical fiber sensing technology-based tunnel surrounding rock radial stress strain distributed monitoring technology. A distributed optical fiber sensor is conveyed to a hole bottom of a radial monitoring hole through a supporting rod member; the supporting rod member (1) and a grouting exhaust pipe (13) are plugged in the hole at a hole orifice through a hole orifice fixing system; a grouting hole (4) is connected to a grouting machine through a grouting pipe; a gap between the optical fiber sensor and a surrounding rock is filled by injecting grout which is matched with modulus of deformation of the surrounding rock into the hole, so that the optical fiber sensor and the surrounding rock cooperatively deform; the optical fiber sensor comprises a distributed optical fiber strain optical fiber sensor and a temperature optical fiber sensor; the distributed optical fiber sensor of each monitoring hole is connected in series to an optical fiber strain analyzer Brillouin optical time domain reflectormeter (BOTDR) by fusion welding; measurement and positioning functions ofBrillouin frequency shift on each point of an optical fiber are finished by measuring power of received Brillouin backscattered light; and strain distribution and temperature distribution in the radial direction in the surrounding rock can be obtained to evaluate and forecast the stability of the surrounding rock according to the linear relation between the Brillouin frequency shift and the strain as well as the temperature.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Optical fiber disturbance detection method and apparatus

ActiveCN101488805AImprove accuracyHigh sensitivityReflectometers dealing with polarizationSubsonic/sonic/ultrasonic wave measurementRayleigh scatteringTime domain

The invention relates to an optical fiber sensor. The invention discloses an optical fiber destabilization detecting method combining based on a phase sensitivity light time domain reflection and a polarization sensitivity light time domain reflection method and distributed optical fiber sensing system thereof to improve the detecting accuracy and reliability of the optical fiber destabilization. The method comprises: a. injecting an optical signal with determined polarization state into the optical fiber; b. receiving the back rayleigh scattering light in the optical fiber; c. diving the rayleigh scattering light into two bundles to perform the Phi-OTDR data acquisition and the POTDR data acquisition; d. determining the destabilization and position thereof based on the distortion points of the Phi-OTDR data and the POTDR data. The invention also discloses an optical fiber destabilization detecting device. The technical scheme of the invention is used for monitoring and protecting the optical cable lines, thereby greatly improving the precision and the sensitivity of the monitoring system and reducing the erroneous judgment rate and the missing report rate.

Owner:OPTICAL SCI & TECH (CHENGDU) LTD

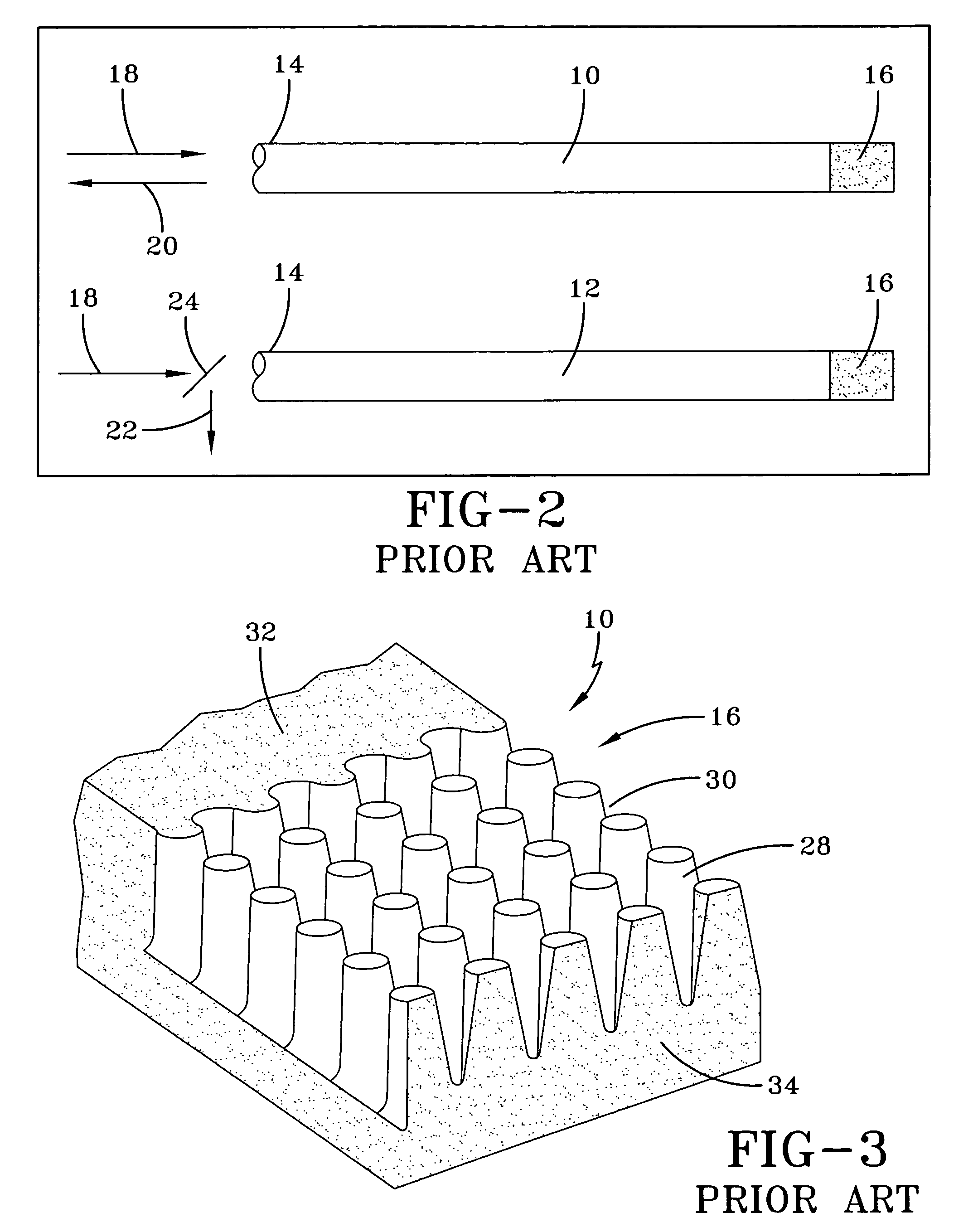

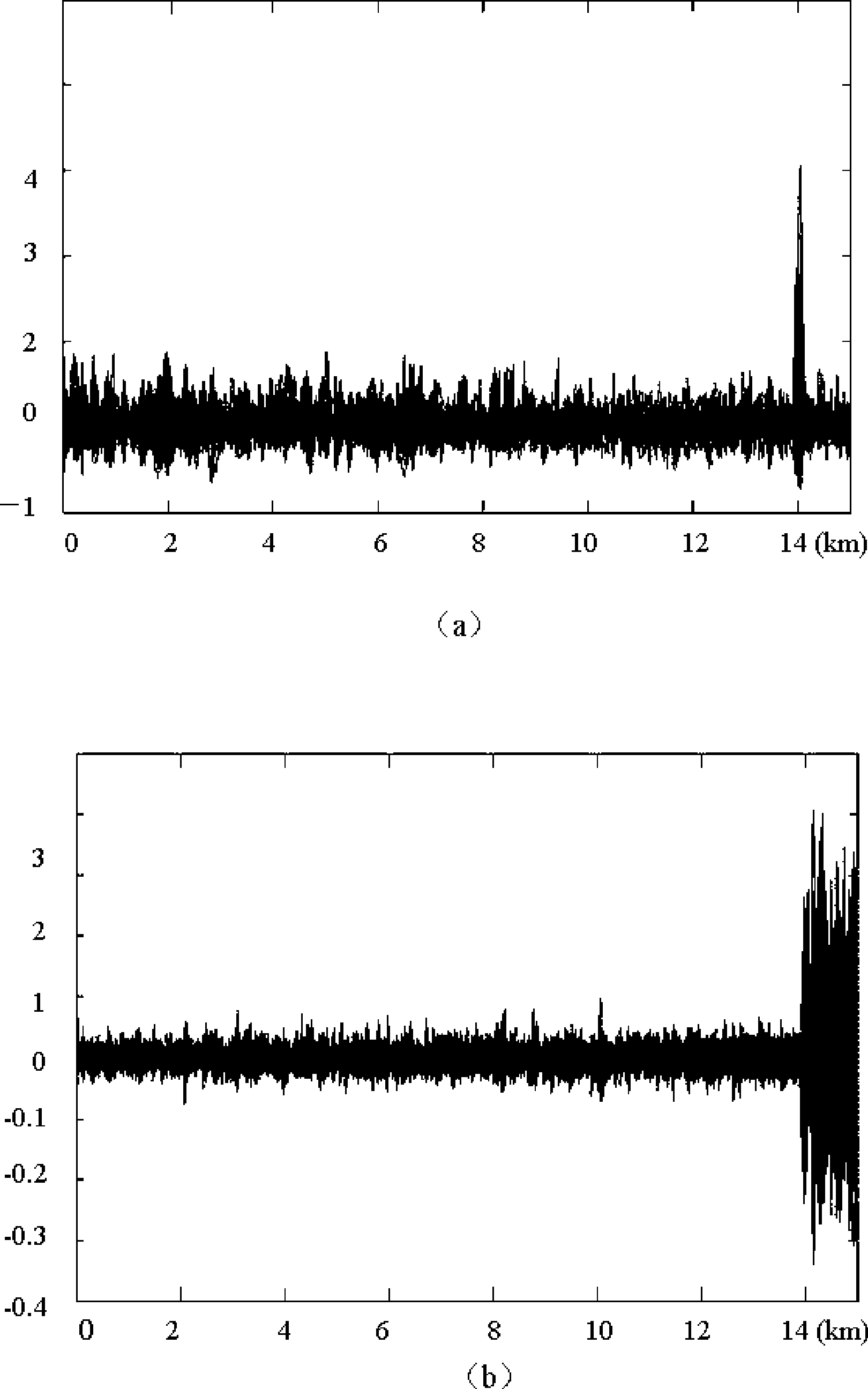

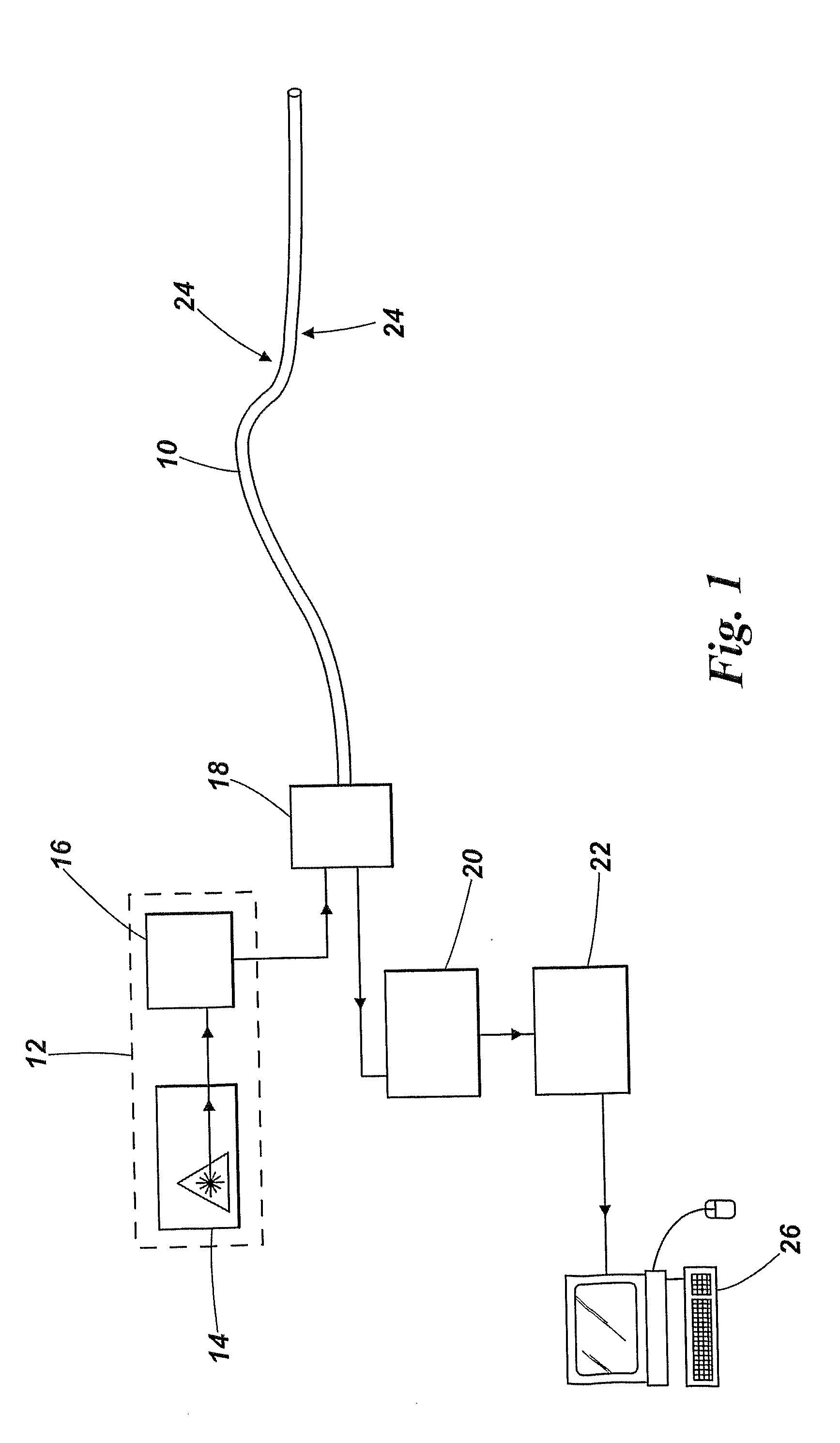

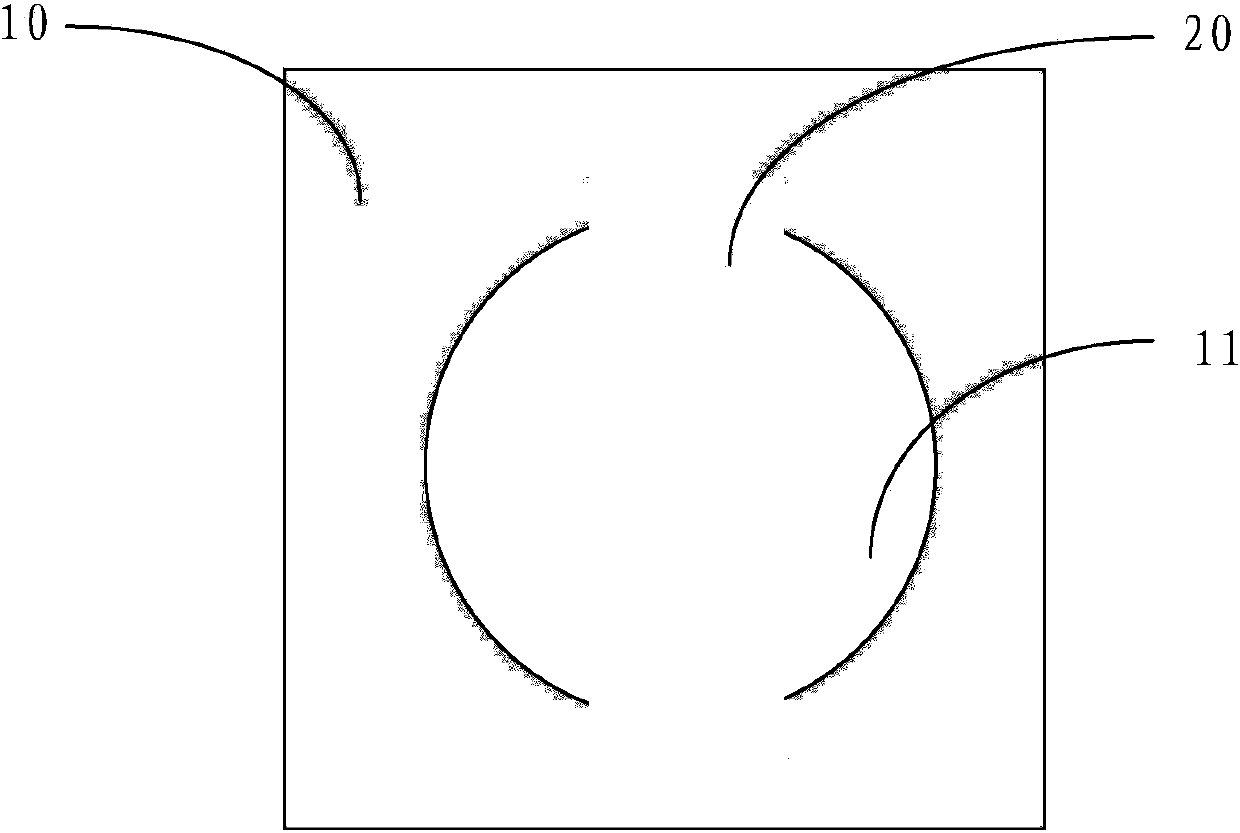

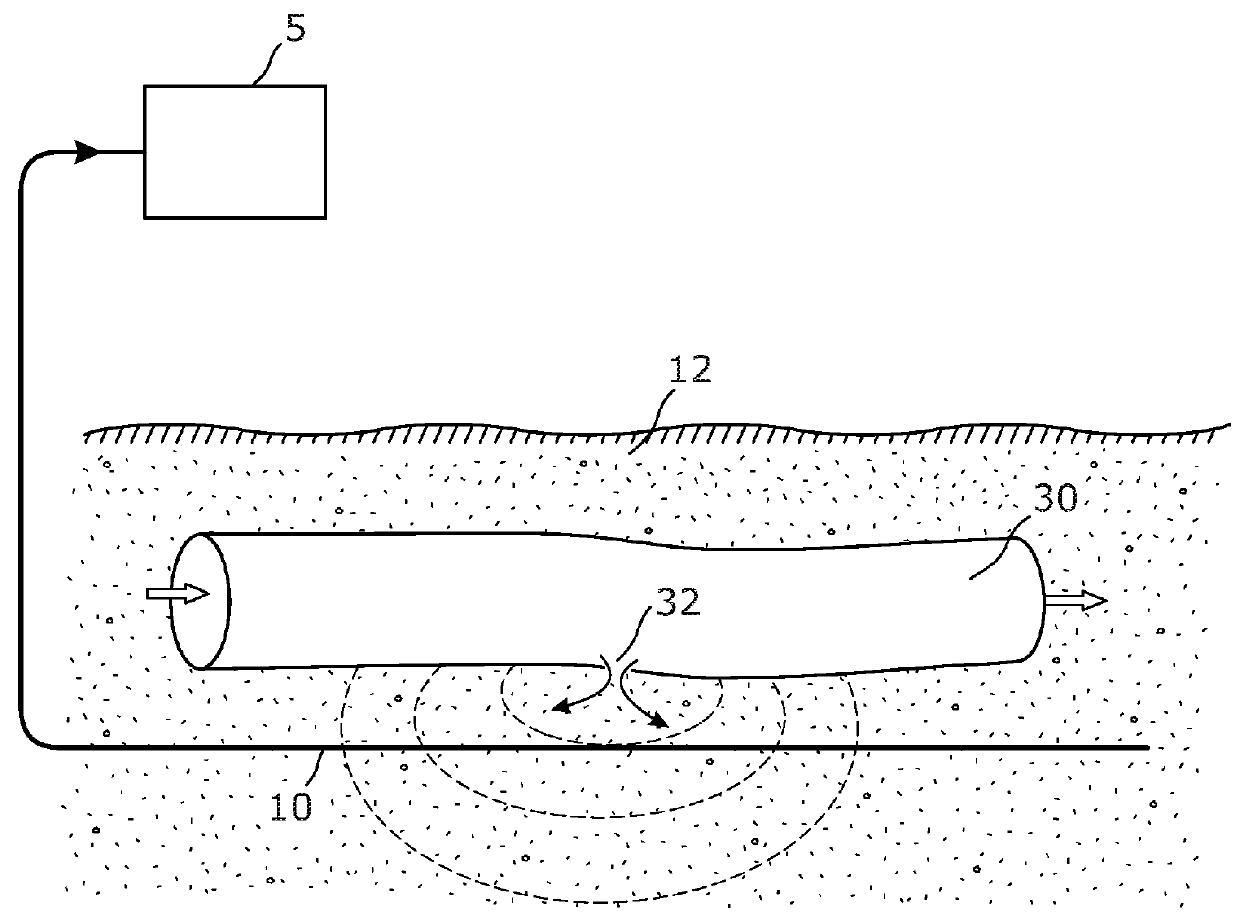

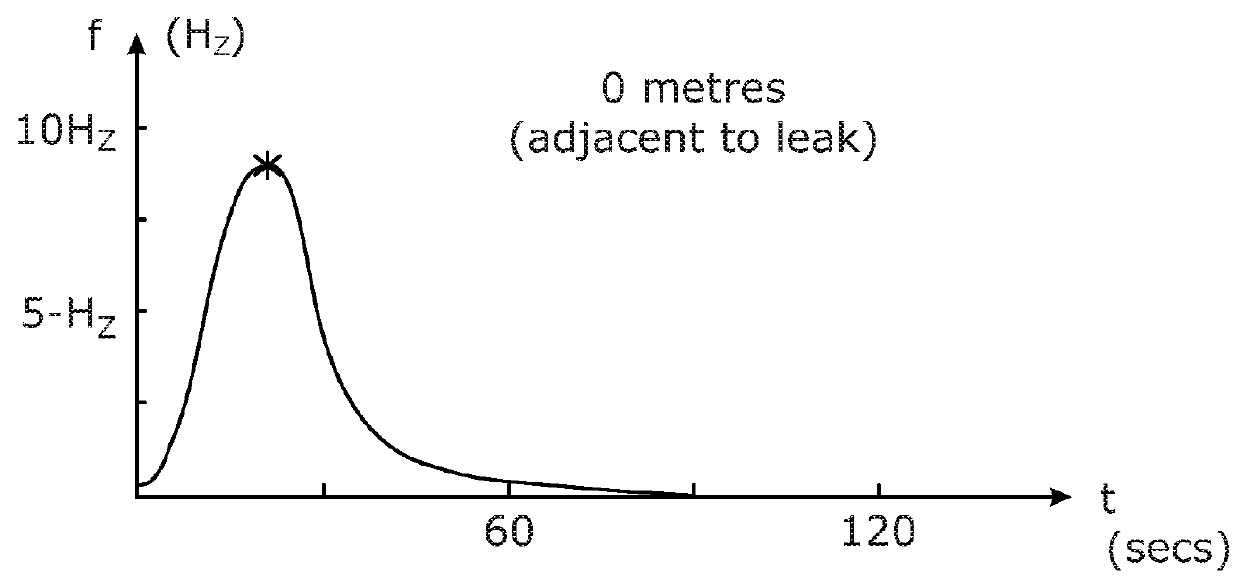

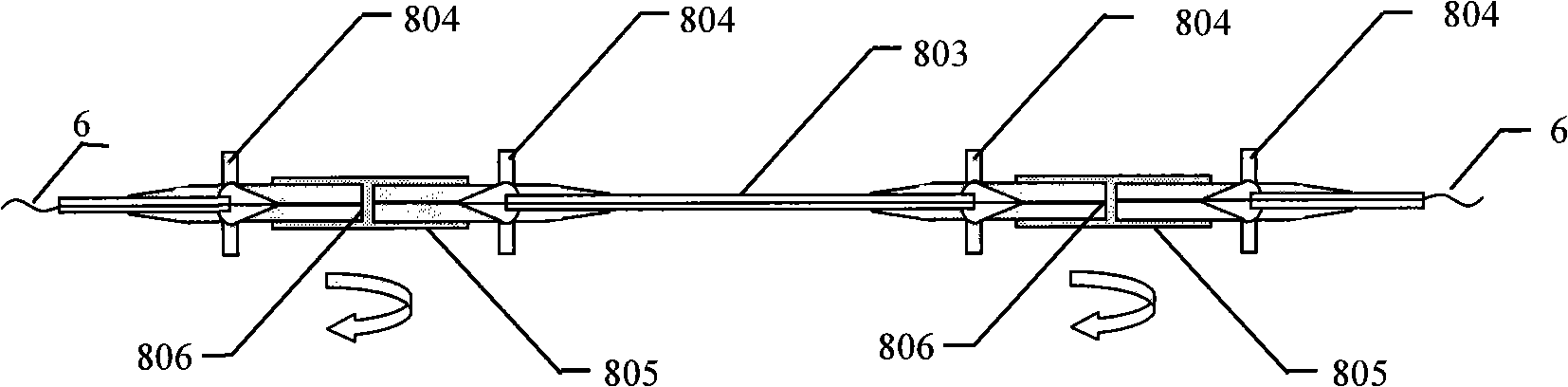

Distributed Optical Fibre Sensor

InactiveUS20110255077A1Reduce signal fadingResponse propertyForce measurementMaterial analysis by optical meansFadingOptical polarization

A distributed optical fibre sensor is described. The sensor uses a sensor fibre (10) having a low or zero intrinsic birefringence that is responsive to an environmental parameter (24) such as pressure. Probe light pulses having a diversity of launch polarisation states are used to reduce signal fading and polarisation dependent loss in the retardation beat frequency signals which are sensed (20) and then analysed (22) to determine the environmental parameter as a profile along the sensor fibre.

Owner:FOTECH SOLUTIONS

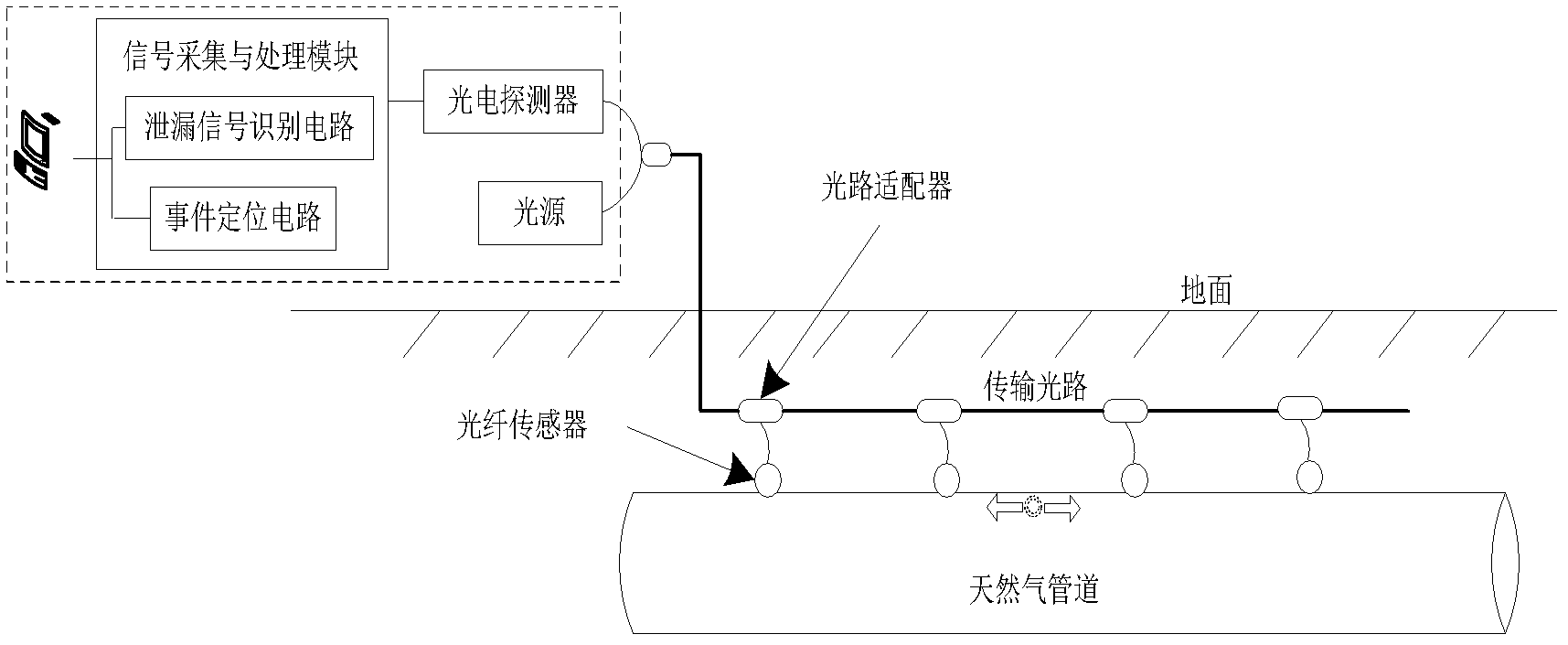

Optical fiber sensor-based natural gas pipeline leakage monitoring method and system and installation method for system

ActiveCN102997062ASolve power problemsSolve the distance problemPipeline systemsOptical pathFiber optic sensor

The invention discloses an optical fiber sensor-based natural gas pipeline leakage monitoring method, an optical fiber sensor-based natural gas pipeline leakage monitoring system and a system construction method. Optical fibers in a communication optical cable which is laid in the same channel of an oil and gas pipeline respectively serve as a transmitting optical fiber and a returning optical fiber; pipeline leakage optical fiber sensors are connected in parallel between transceiving transmitting optical fibers to form an optical path by an optical multiplexing technology; the pipeline leakage optical fiber sensors are uniformly arranged along the pipeline; laser light emitted from a light source is subjected to beam splitting through a transmission optical path and is transmitted to the sensors arranged on the wall of the pipeline; after the sensors pick up leakage vibration signals and noises propagated along the pipeline, the leakage vibration signals and the noises are returned to a photoelectric detector part of the system through the transmission optical path; the acquired vibration wave signals are analyzed and processed; and the position of a vibration wave source is determined by combining the propagation speed of the vibration wave on a pipeline body according to the time delay of the vibration waves propagated to a plurality of adjacent optical fiber sensors. By the method and the system, the flexibility is high; and the positioning accuracy is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

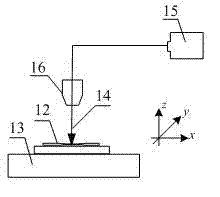

Resonant type Fabry-Perot optical fiber sensor, manufacturing method and air pressure detecting method

ActiveCN103994851AImprove applicabilitySmall creepFluid pressure measurement by optical meansResonanceEngineering

The invention provides a resonant type Fabry-Perot optical fiber sensor which comprises a sensor body and a through hole penetrating through the sensor body. One end of the through hole is provided with a graphene thin film for sensing the to-be-detected air pressure in an attached mode, and the other end of the through hole is provided with transmission optical fibers which penetrate through the through hole and are matched with the through hole. According to the resonant type Fabry-Perot optical fiber sensor, the air pressure of gas is calculated in the mode that graphene thin film resonant frequency changes are caused by damp of the gas to the graphene thin film, so that a closed Fabry-Perot cavity is not needed, and the manufacturing difficulty is reduced; the the original measurement thin film deformation quantity is replaced by resonance to further conduct air pressure measurement, and thin film material creeping caused by repeated film deformation is effectively reduced; digital frequency signals after probe laser detection are output after the sensor conducts detection, and result analysis can be conveniently carried out compared with light wave signals of an interferometric sensor. Stimulation and detection are carried out through the single transmission optical fibers, and long-distance air pressure measurement can be achieved, and the applicability of the sensor is greatly improved.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

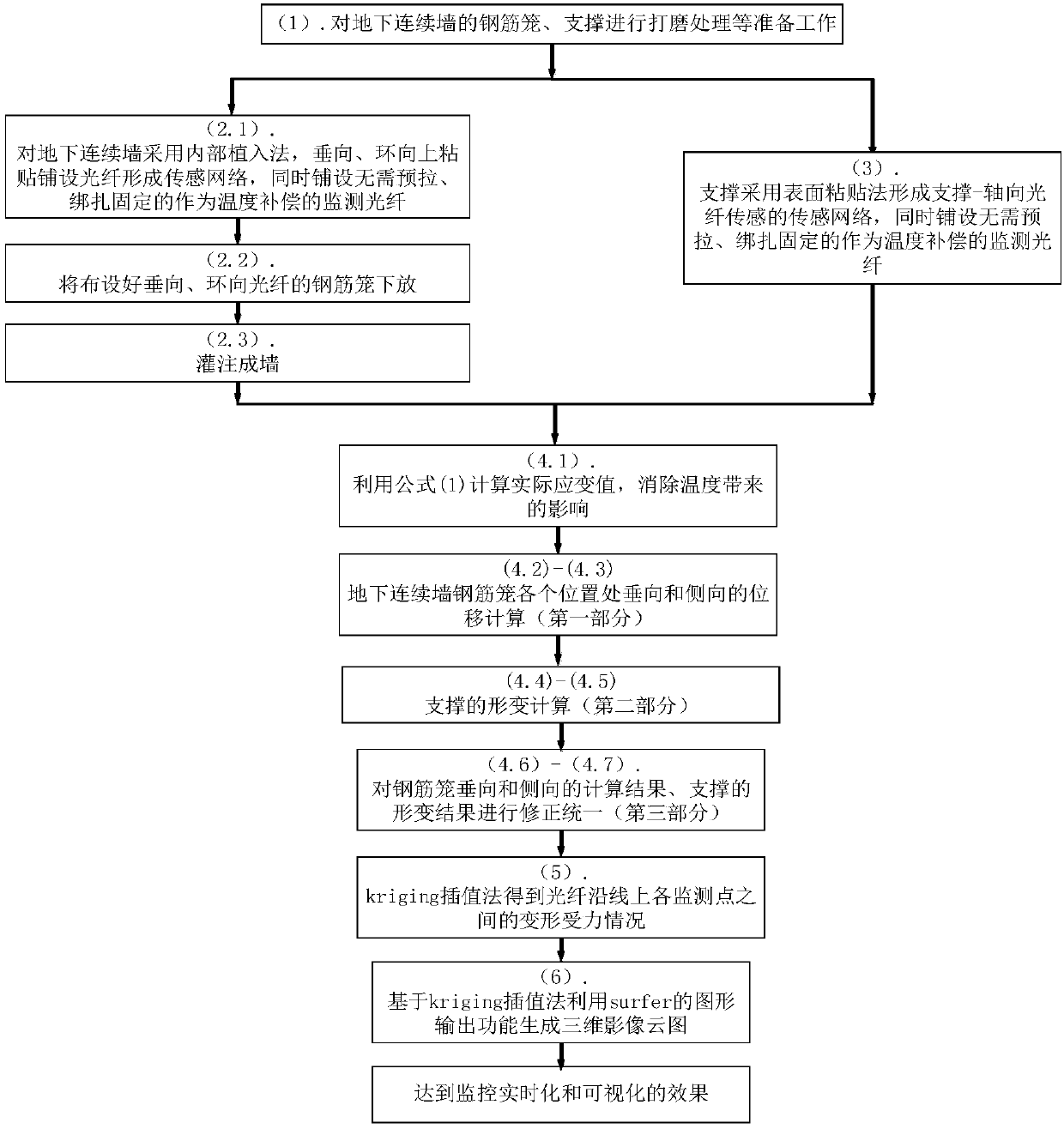

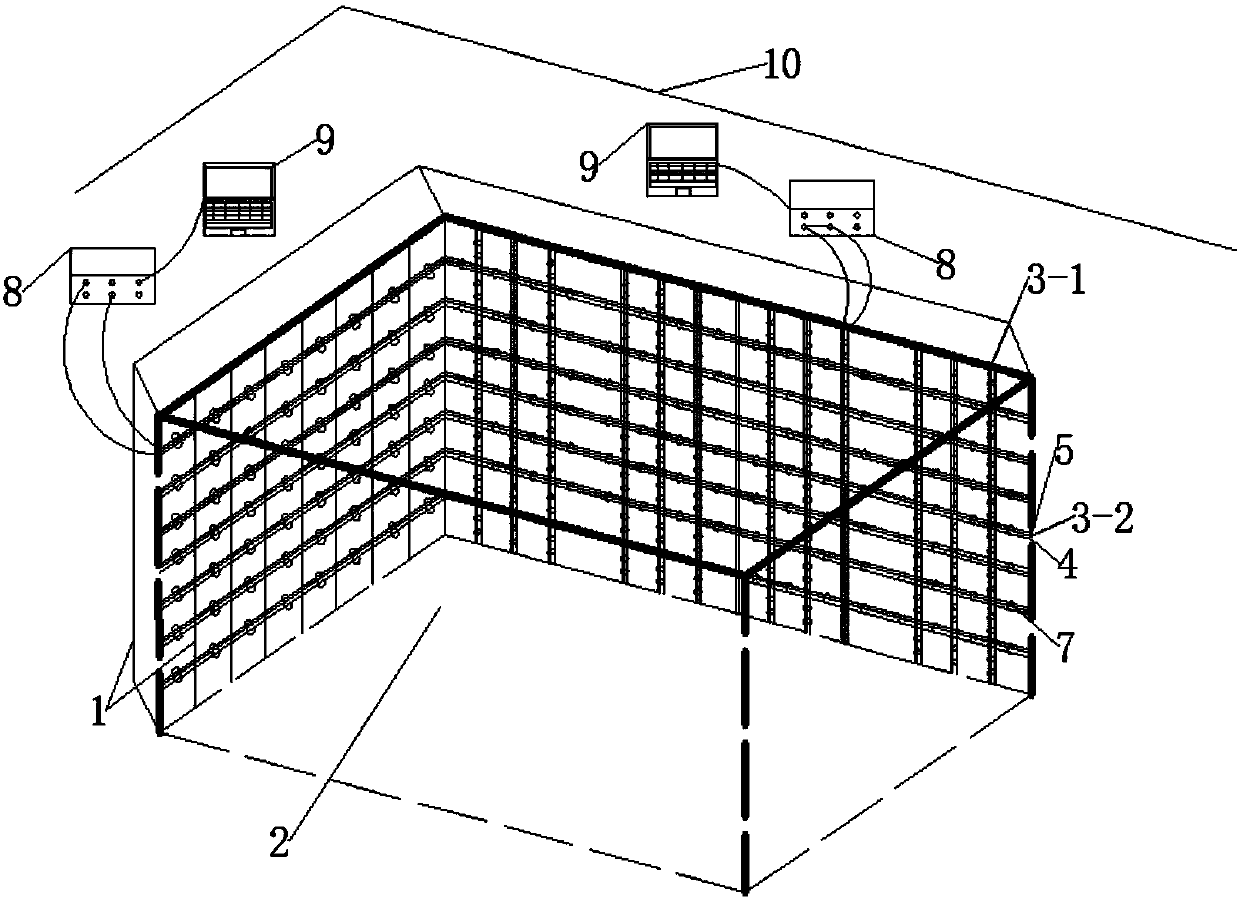

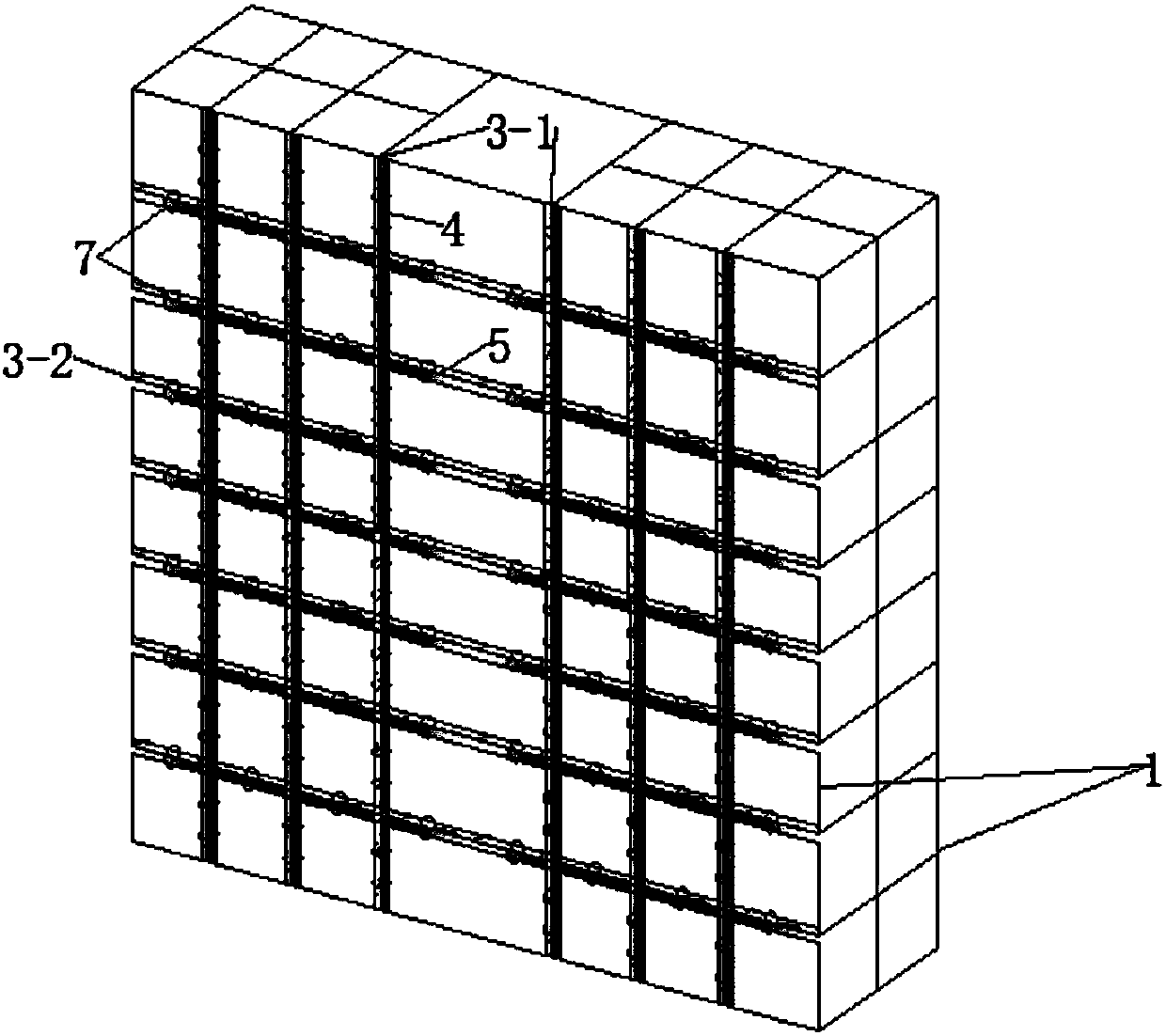

Foundation pit engineering three-dimensional monitoring network realization method based on distributed optical fiber sensors

ActiveCN107843203AExtensive application of monitoring and monitoringAvoid the disadvantages of traditional point monitoringUsing optical meansEngineeringMonitoring data

The invention provides a foundation pit engineering three-dimensional monitoring network realization method based on distributed optical fiber sensors, which relates to a scheme of laying optical fiber sensors on an enclosure and support structure, overall deformation and force bearing analysis on the enclosure and support structure and generation of a strain distribution cloud map. Based on the characteristics that the frequency changes of back Brillouin scattering light formed by scattering of optical wave molecules of the optical fibers and incident light are sensitive to strain and temperature and BOTDA sensing advantages and benefiting from the accurate, stable and real-time monitoring advantages of the optical fiber sensors, the optical fibers on the components are arranged to a three-dimensional monitoring network, comprehensive and three-dimensional deformation and force bearing monitoring can be carried out on enclosure and support components and other components in the foundation pit project, real-time monitored data are guided to surfer to generate a structure strain distribution cloud map, and the method of the invention is a visualized and three-dimensional monitoringmeasurement and control method.

Owner:TONGJI UNIV

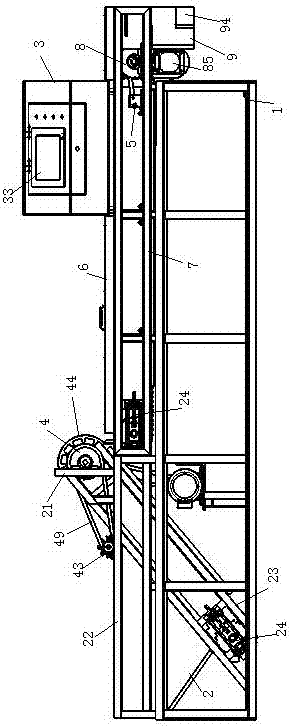

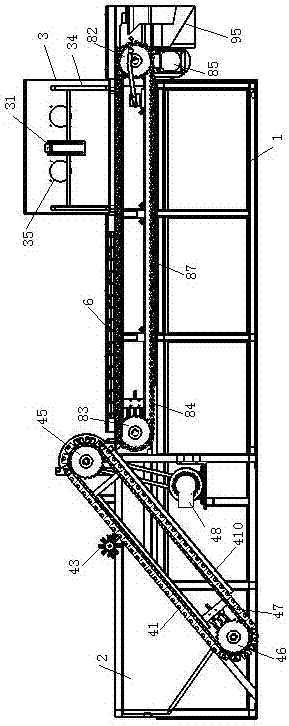

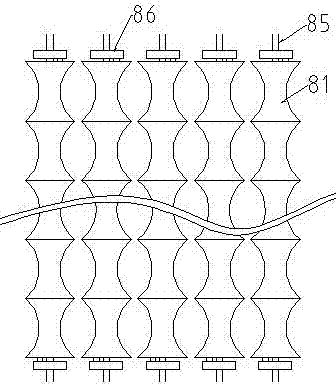

Red date intelligent selection equipment

ActiveCN107413678AImprove sorting efficiencyImprove detection accuracyClimate change adaptationSortingImaging processingControl engineering

The invention provides red date intelligent selection equipment. The red date intelligent selection equipment comprises a bottom supporting frame, a transmission supporting frame, a control box, a hopper, a feeding transmission device, a horizontal conveying device, a pneumatic mechanism and a division box. The transmission supporting frame is fixed to the upper portion of the bottom supporting frame. The horizontal conveying device is arranged in the transmission supporting frame and provided with a horizontal conveying belt composed of rollers. The hopper is arranged on one side of the bottom support frame. An inclined feeding plate is arranged in the hopper, and the feeding plate is connected with the feeding transmission device. The division box is fixed to the other side of the horizontal conveying belt. The control box is fixed to the middle of the transmission supporting frame. The pneumatic mechanism is arranged at the position, between the control box and the division box, of the transmission supporting frame. Industrial cameras and an industrial personal computer are arranged in the control box. An optical fiber sensor is arranged on one side of a chain wheel of the horizontal conveying device. According to the red date intelligent selection equipment, good dates and bad dates are separated through the image processing technology and the pneumatic mechanism, the detection precision is high, the red data sorting efficiency is improved, and the labor intensity is reduced.

Owner:郑州市中昕智能设备有限公司

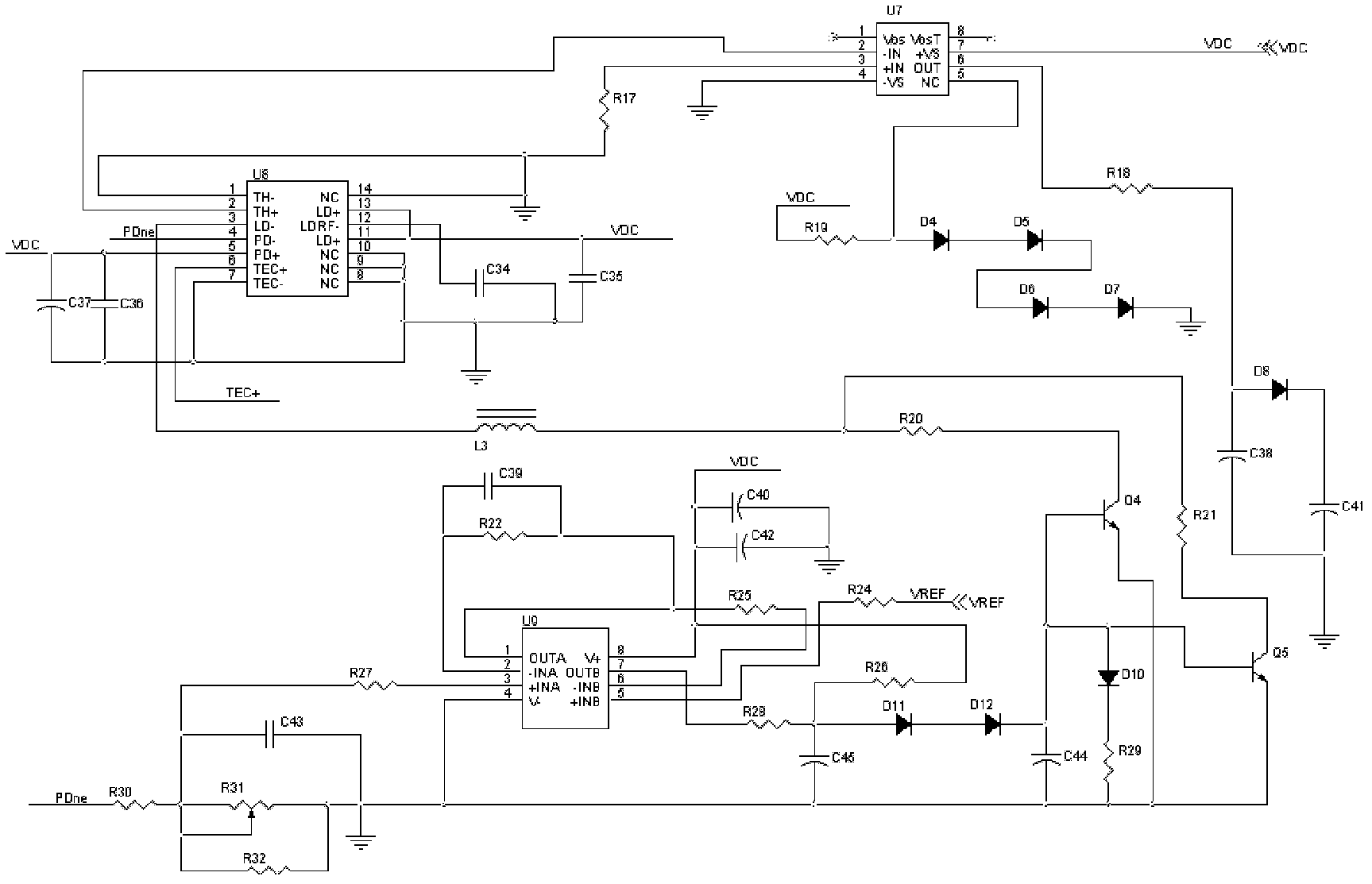

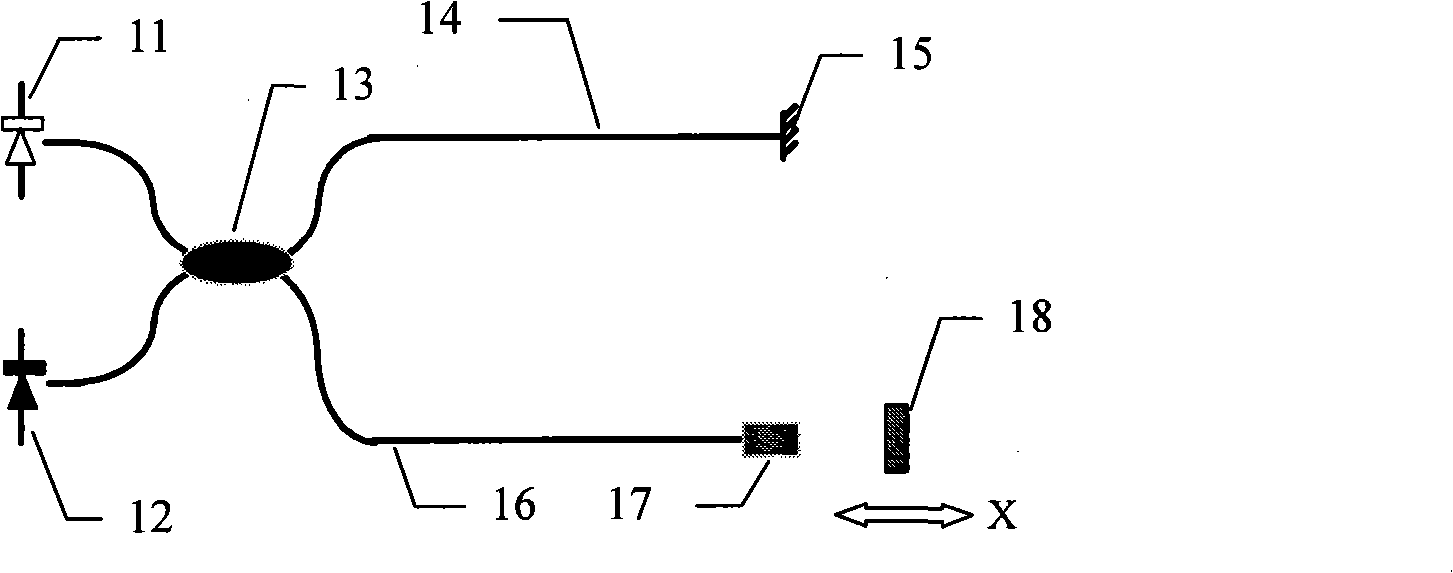

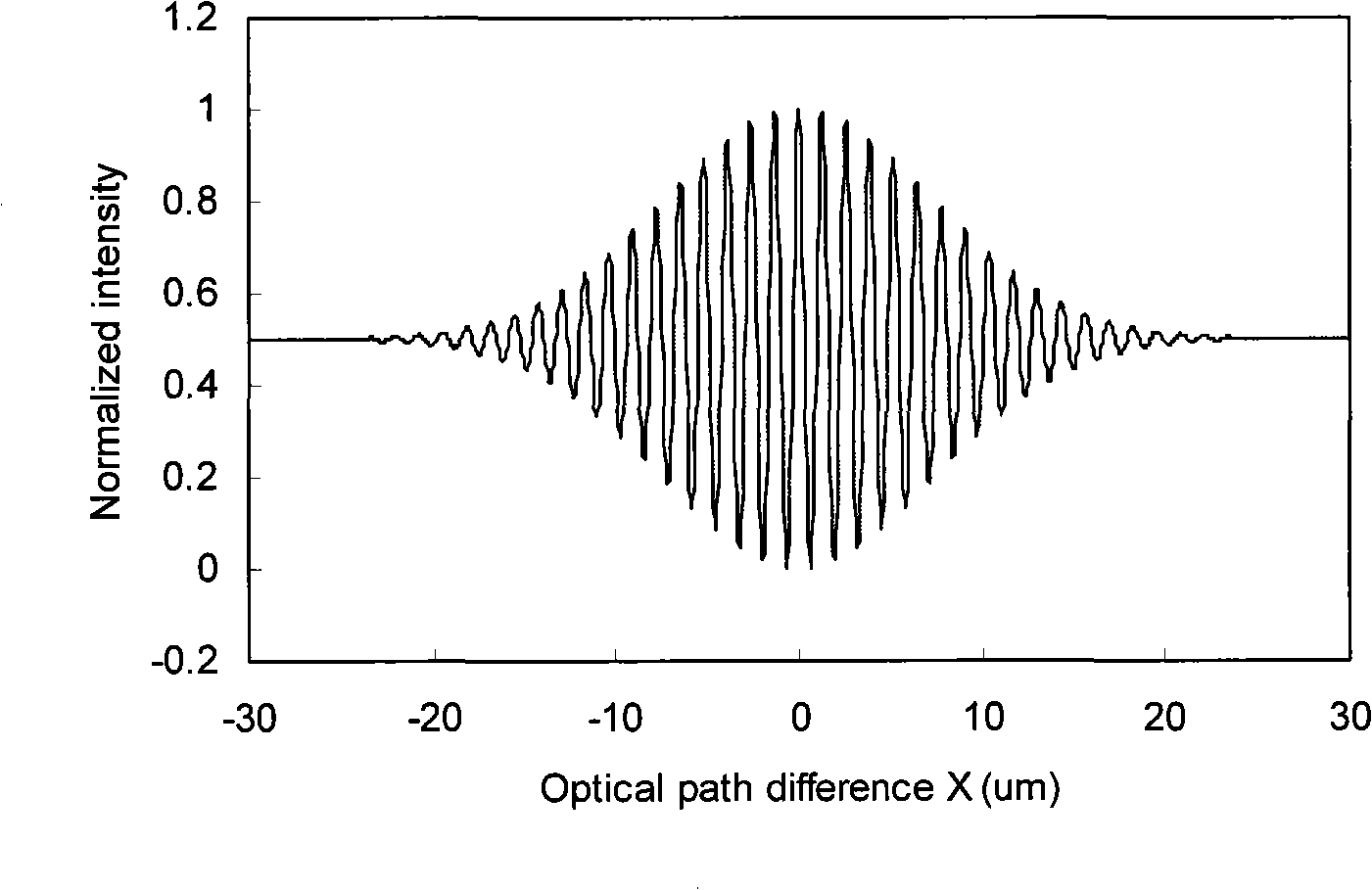

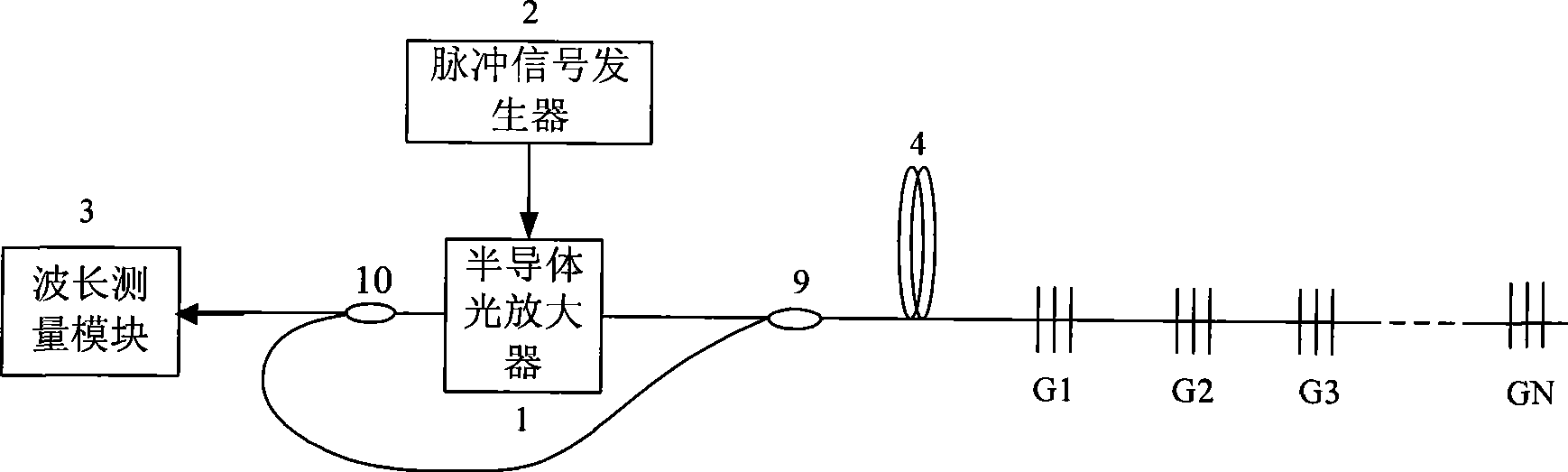

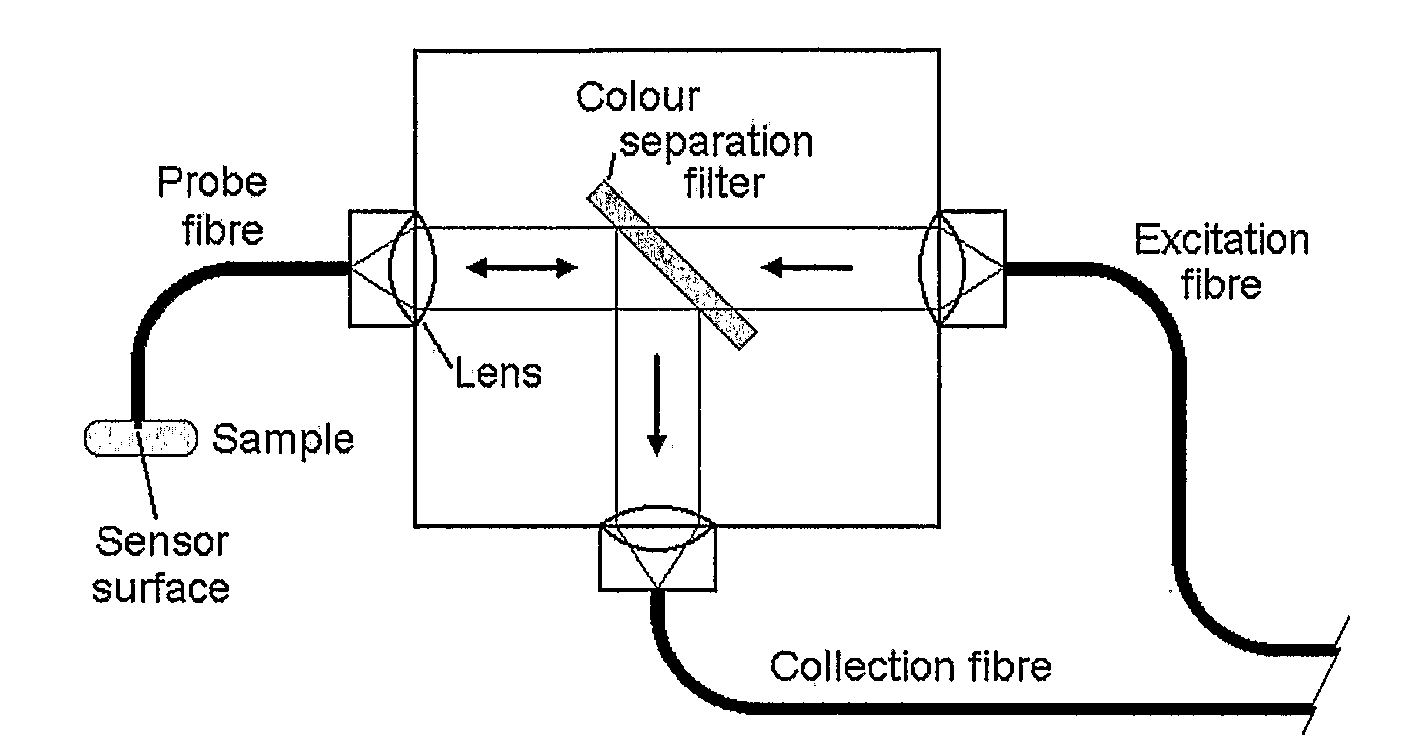

Simplifying type multiplexing white light interference optical fiber sensing demodulating equipment

InactiveCN101324444ASimple structureEasy to implementCoupling light guidesConverting sensor output opticallyPhotodetectorOpto electronic

The invention provides a simplified multiplexing white light interference fiber sensing demodulating device, which comprises a single-fiber two-way optical transmitting / receiving module, an optical fiber resonant cavity, a single-mode transmission fiber, and an optical fiber sensing array, wherein the single-fiber two-way optical transmitting / receiving module is composed of a semiconductor light source as the transmitting terminal, a semiconductor photodetector as the receiving terminal and related devices packaged together; and an optical fiber annular cavity is composed of an optical fiber coupler, an optical fiber self-focusing lens and a movable corner reflector. The device can achieve enquiry and measurement of a plurality of optical fiber sensors by embedding the single-fiber two-way optical transmitting / receiving module and the optical fiber resonant cavity in the single-mode optical fiber, and has the advantages of simple structure, easy implementation, no length restriction of the transmission cable, no influence caused by the external environment, and good stability and reliability. The device can be used for the measurement of physical quantities such as distributed deformation, strain and temperature, and can be used for multi-task sensing, multi-element sensing, local strain sensing, large-scale deformation sensing, etc.

Owner:HARBIN ENG UNIV

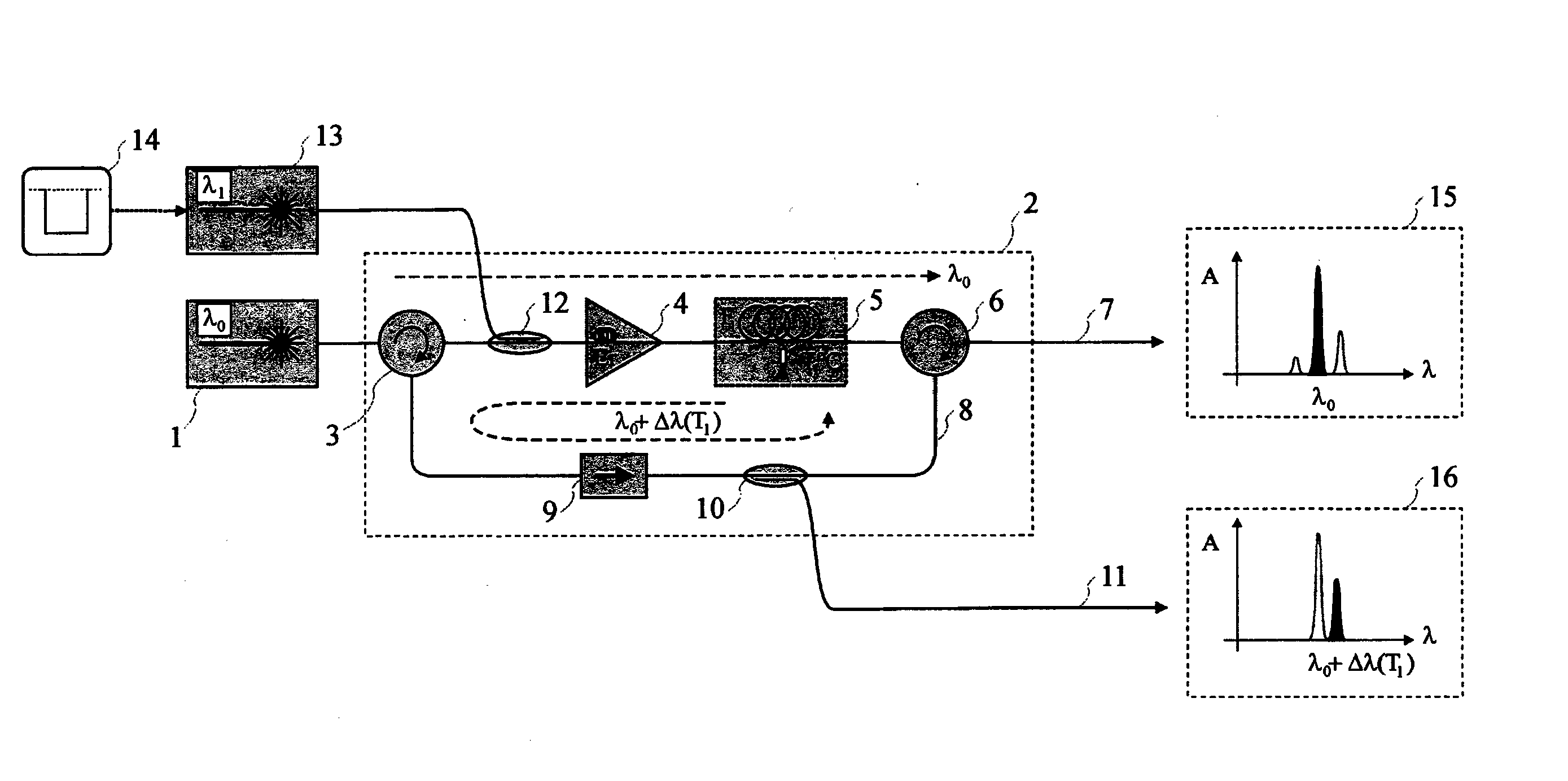

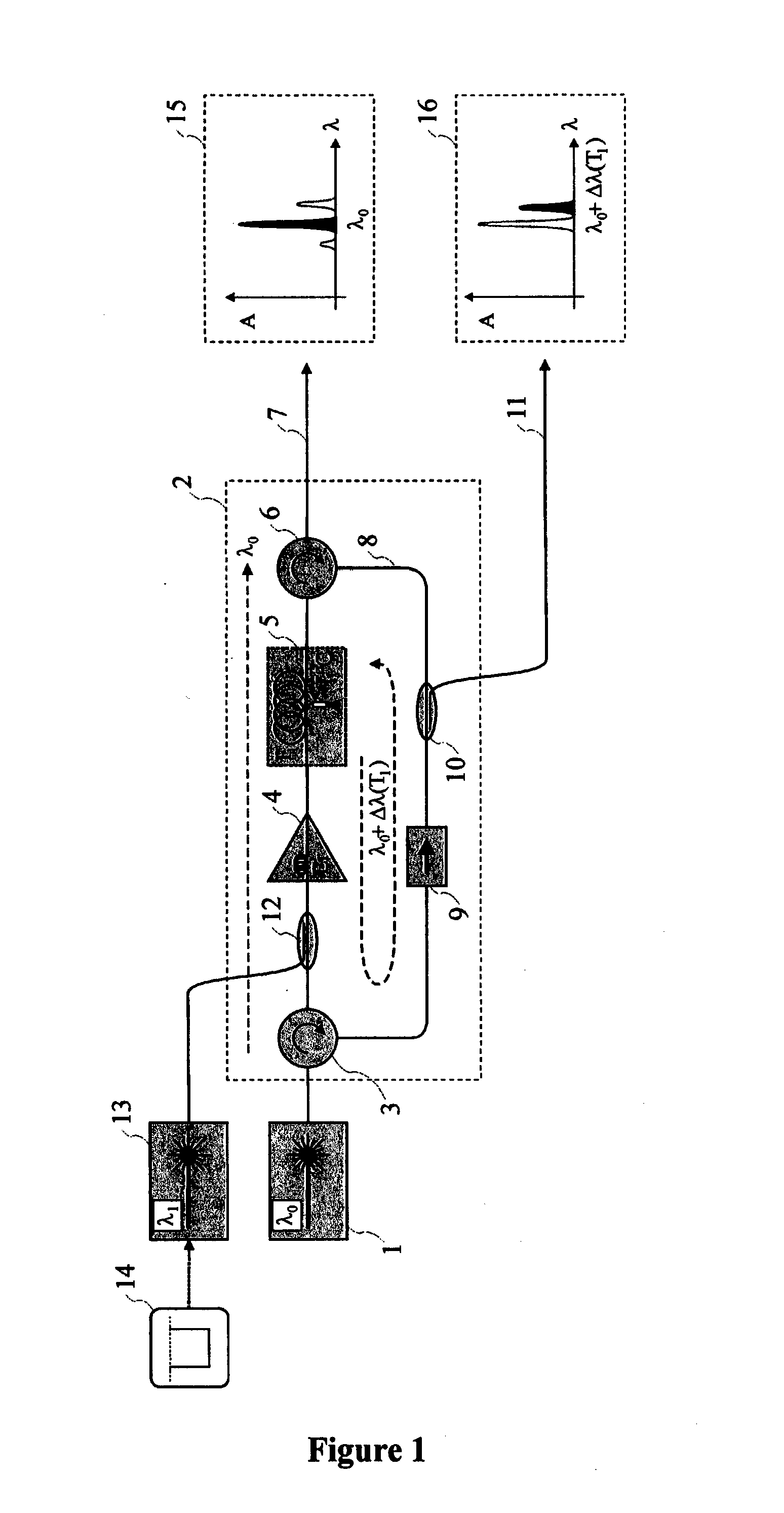

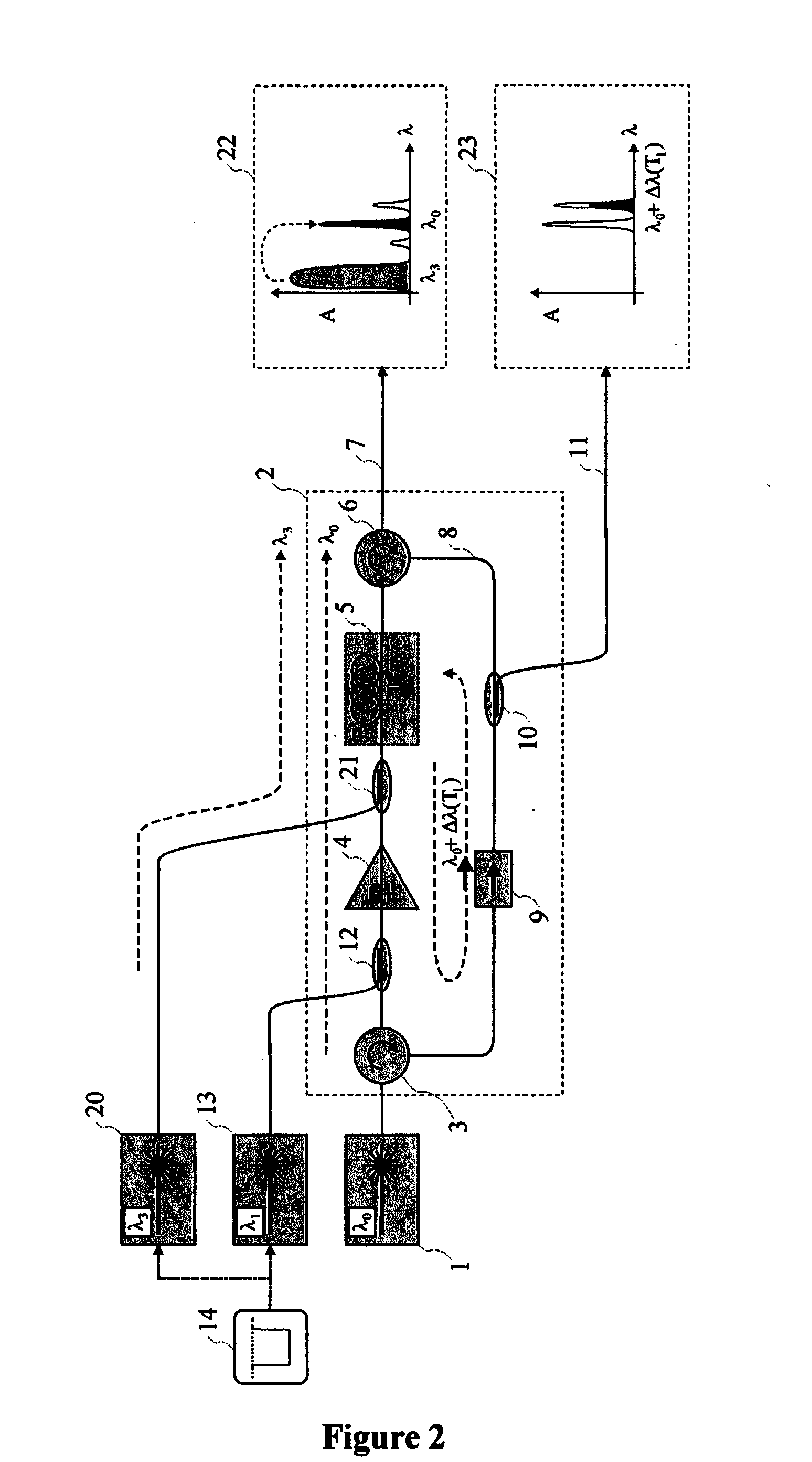

Apparatus for interrogating distributed stimulated brillouin scattering optical fibre sensors using a quickly tuneable brillouin ring laser

ActiveUS20150377656A1Break down levelControl performanceRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsLine widthRing laser

Device for measuring the distribution of strain and / or temperature along an optical fibre through the analysis of the stimulated Brillouin scattering, characterized by the fact that both the “optical pump” light from which the scattered energy is derived, and the “stimulus” or “probe” light that stimulates the scattering process are both derived by the same ring-type tuneable optical circuit that at the same type amplifies the amplitude of the “optical pump” light and generates, through a controlled Brillouin amplified scattering, the “probe” light having the spectrum linewidth required for the measurement needs and a wavelength shift with respect to the “optical pump” light that is accurately and quickly tuneable and fully adjustable within the range that is needed for interrogating a distributed optical fibre sensor.

Owner:BASTIANINI FILIPPO

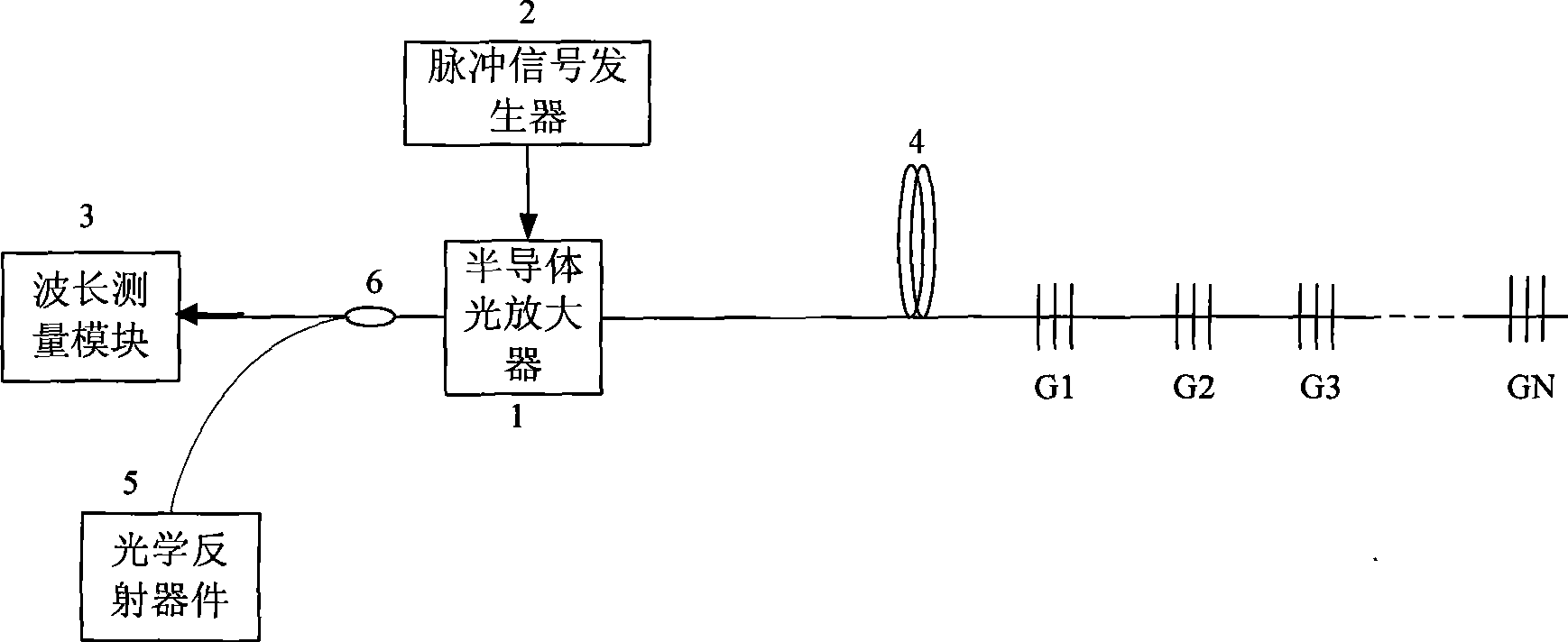

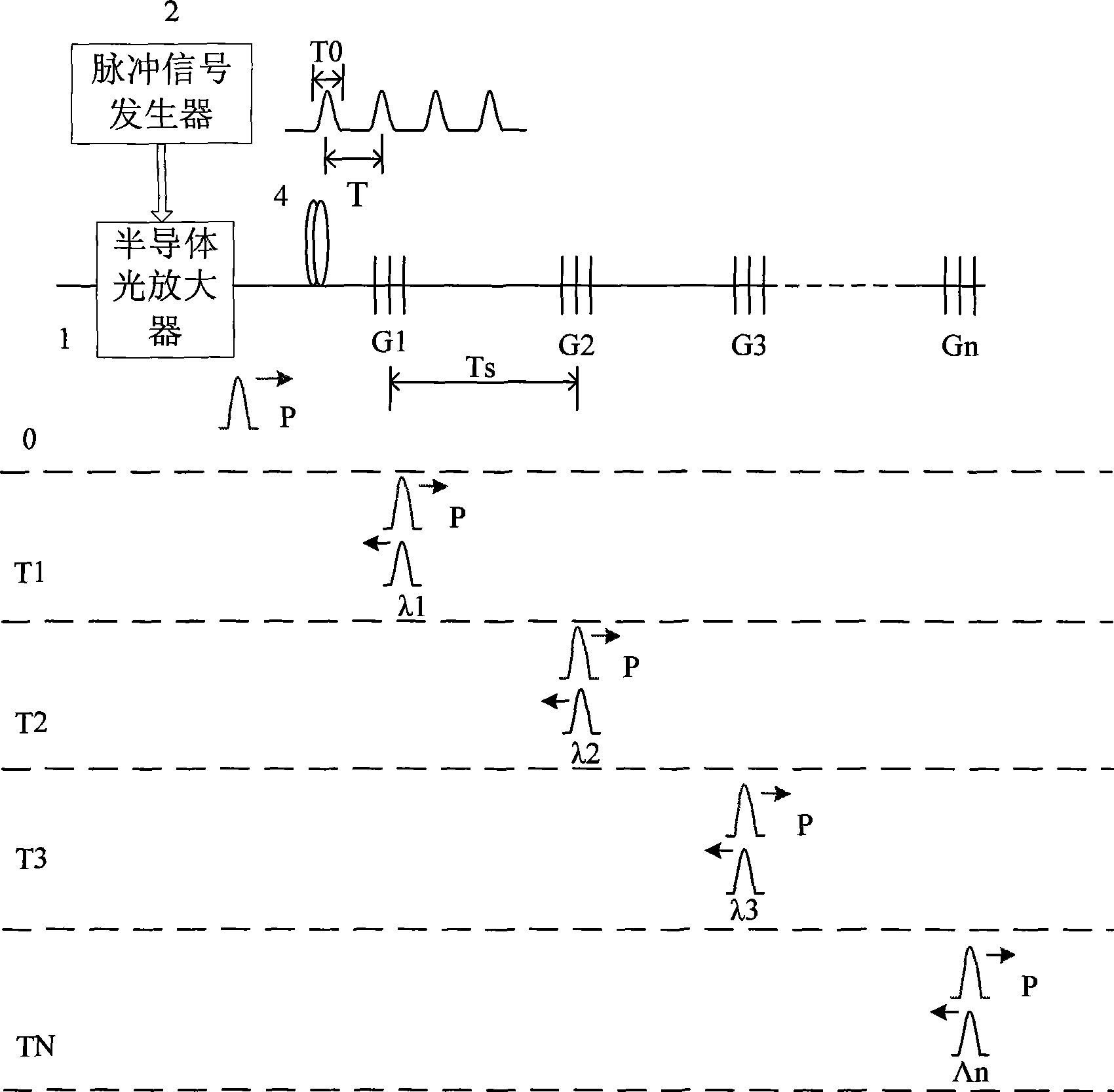

Time division multiplexing optical fiber sensing method and apparatus

ActiveCN101476900AIncrease the number of sensorsSimple structureConverting sensor output opticallyWavelength-division multiplexingFiber optic sensor

The invention discloses a time division multiplexing optical fiber sensing method and a device thereof, relates to an optical sensing method and a device thereof and overcomes the drawback of the wavelength division multiplexing optical fiber sensing demodulation technology of complicated wavelength demodulation equipment due to the use of different central wavelengths of optical fiber sensors and a small number of configured optical sensors due to the bandwidth limitation of the system. The method comprises: a semiconductor optical amplifier generates a pulse optical signal which enters a sensor array; the pulse optical signal is sequentially reflected by all sensors back to the semiconductor optical amplifier, and the opening and closing time of the semiconductor optical amplifier is controlled to allow an optical signal reflected back by a certain sensor to pass through selectively; and the measurement of a selected sensor is realized. The device comprises the semiconductor optical amplifier, a pulse signal generator, a wavelength measuring block, an optical fiber ring and a plurality of sensors, wherein the sensors, the wavelength measuring blocks and the pulse signal generator are communicated with a reflected signal input end, an amplified signal output end and a controlled end of the semiconductor optical amplifier respectively.

Owner:冷劲松

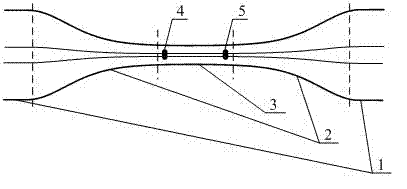

Optical fiber fused taper-based intrinsic Fabry-Perot device and manufacturing method thereof

ActiveCN102508337ASmall sizeHigh sensitivityCoupling light guidesConverting sensor output opticallyFemto second laserRefractive index

The invention provides an optical fiber fused taper-based intrinsic Fabry-Perot device and a manufacturing method thereof. The optical fiber fused taper-based intrinsic Fabry-Perot device comprises an optical fiber fused taper, wherein a first optical fiber internal reflection mirror and a second optical fiber internal reflection mirror are arranged in the optical fused fiber taper and radially change the reflection faces formed by reflection rates at the fiber core respectively along the interior of the optical fiber taper waist through femtosecond pulse laser. The diameter of the optical fiber fused taper is 10 to 50 microns; the distance between the first and second optical fiber internal reflection mirrors is 50 to 6000 microns. The device combines the high sensitivity characteristicscaused by a strong evanescent field of the optical fiber fused taper and easy detection characteristics of resonance peak shift for sensing of a Fabry-Perot cavity and enhances the sensitivity, response speed and reliability of an optical fiber sensor. The manufacturing method of the device is to etch the Fabry-Perot cavity by femtosecond pulse laser after adopting optical fiber biconical taper. Moreover, the device provided by the invention is simple and stable in structure, low in cost and high in repeatability and has the advantages of easy for batch processing of the device and the like. The device and method provided by the invention have broad application prospect in miniaturized and high-sensitive sensing areas.

Owner:SHANGHAI UNIV

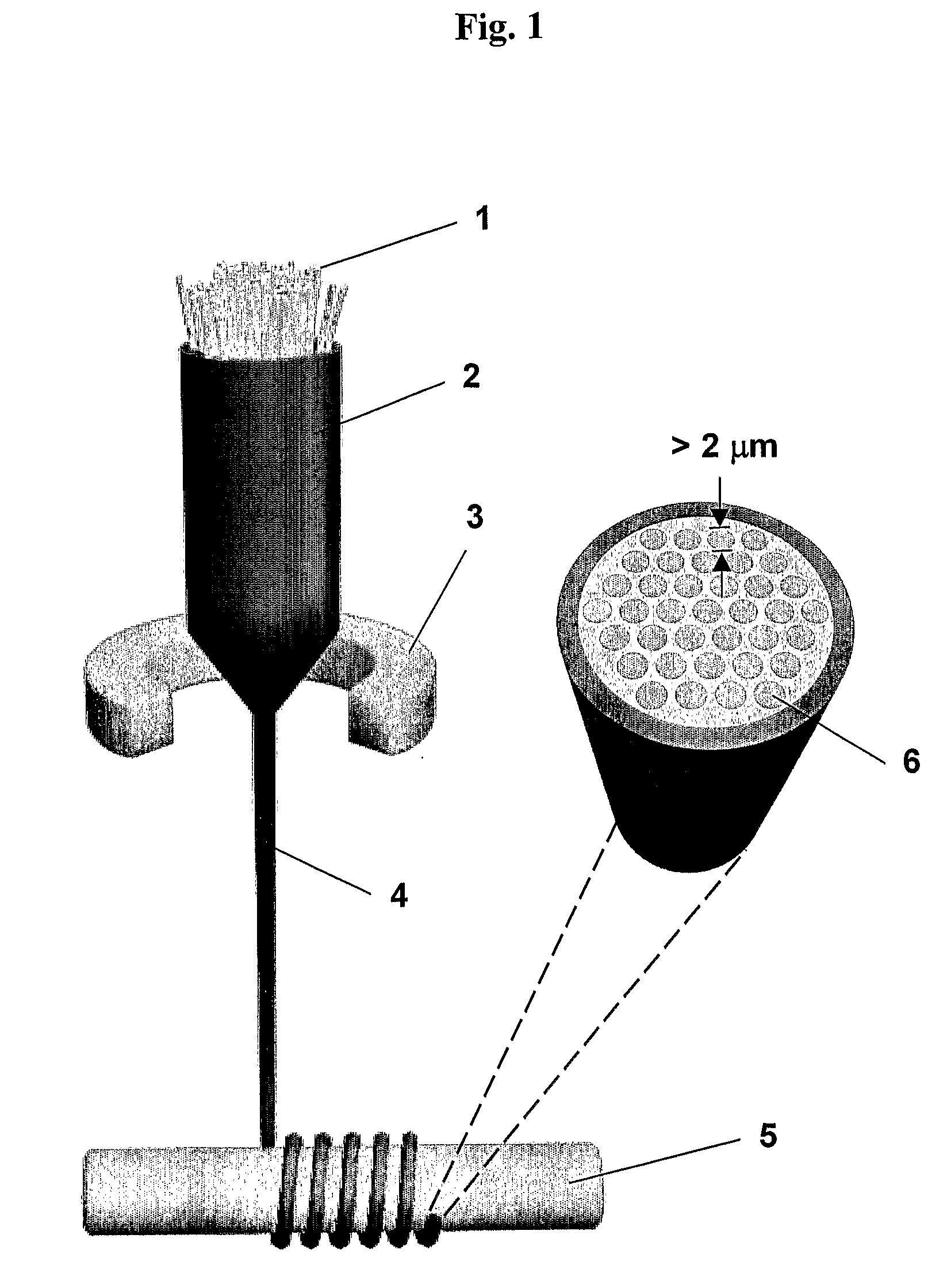

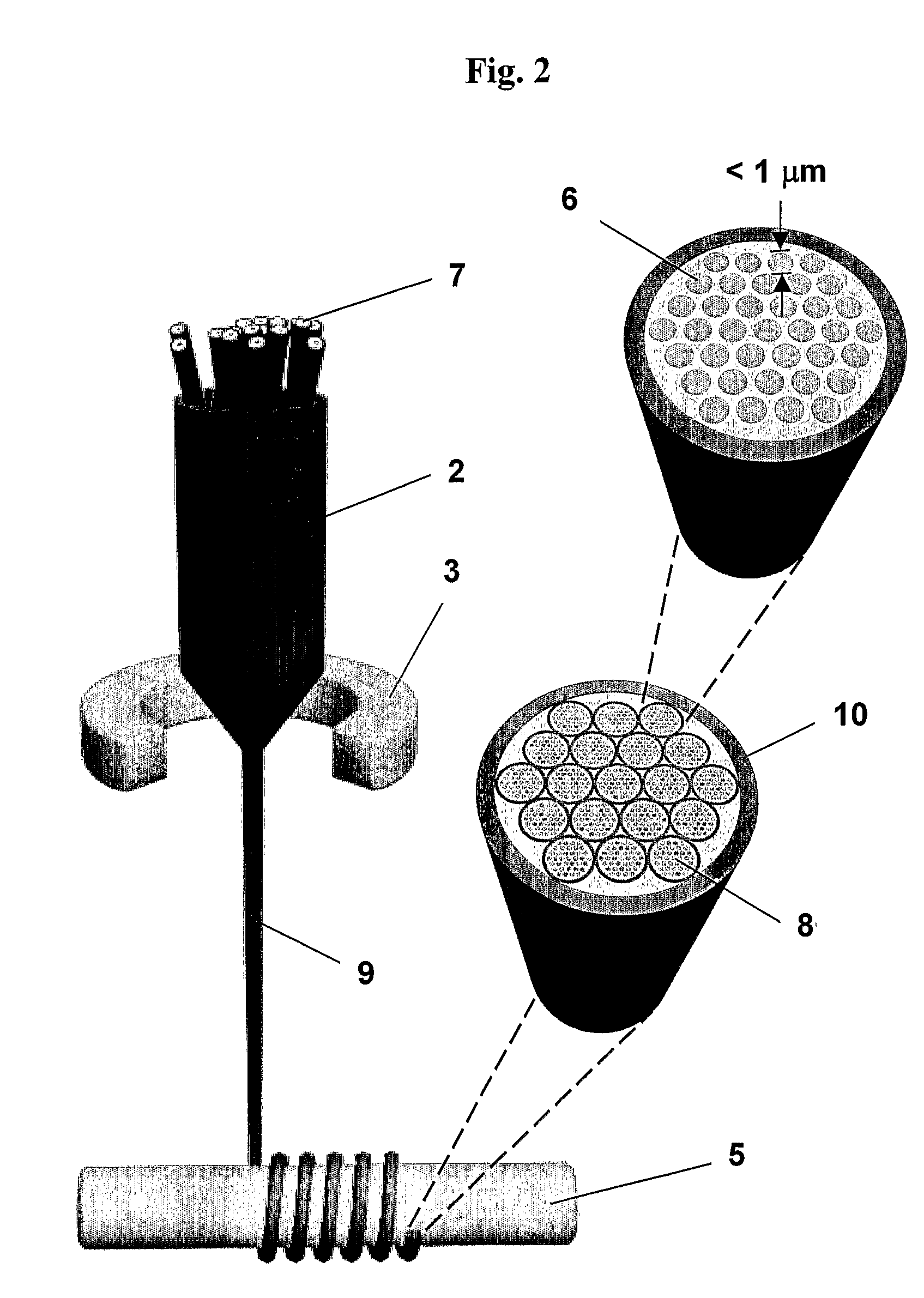

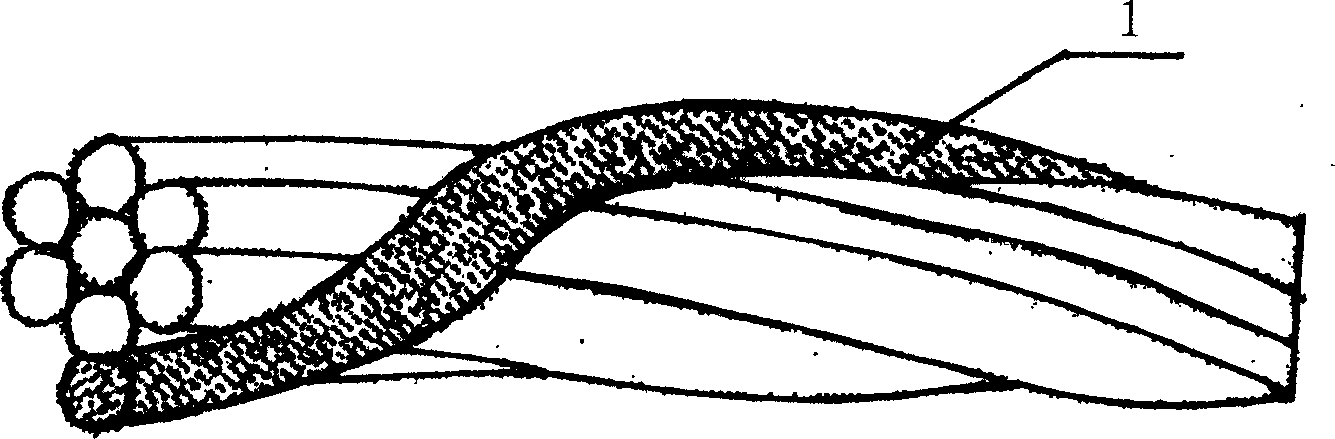

Fiber sensor production

InactiveUS20090041404A1Improved adhesion to surfaceFine surfaceMaterial nanotechnologyMaterial analysis by optical meansMetal coatingSurface relief

The invention relates to a method of generating an ordered deposition geometry on a surface of a compound optical fibre, which comprises: (a) arranging a plurality of optical fibres and / or compound optical fibres in common orientation and close packed configuration to form a bundle; (b) drawing the bundle under suitable conditions to produce a compound optical fibre of desired diameter; (c) processing the compound optical fibre to produce a substantially planar surface; (d) subjecting said surface to an etching agent to produce surface relief (e) subjecting said surface with relief to metal coating. The invention also covers a compound optical fibre having an ordered deposition geometry on a substantially planar surface that is substantially transverse to compound optical fibre longitudinal axis, wherein the compound optical fibre comprises individual optical elements of less than about 1000 nm in diameter.

Owner:SWINBURNE UNIVERSITY OF TECHNOLOGY

Optical sensors for the detection of nitric oxide

InactiveUS6900891B2Improve signal-to-noise ratioFast and sensitive enough to catchMaterial nanotechnologySpectrum investigationAnalyteMetal particle

Optical fiber sensors and fiberless optical sensors for measuring analytes, and in particular nitric oxide, are described utilizing metals, and more particularly, metal colloids. Proteins (or fragments thereof) with selective binding are immobilized on metal particles. The proteins may be dye-labeled for increased sensitivity.

Owner:RGT UNIV OF MICHIGAN

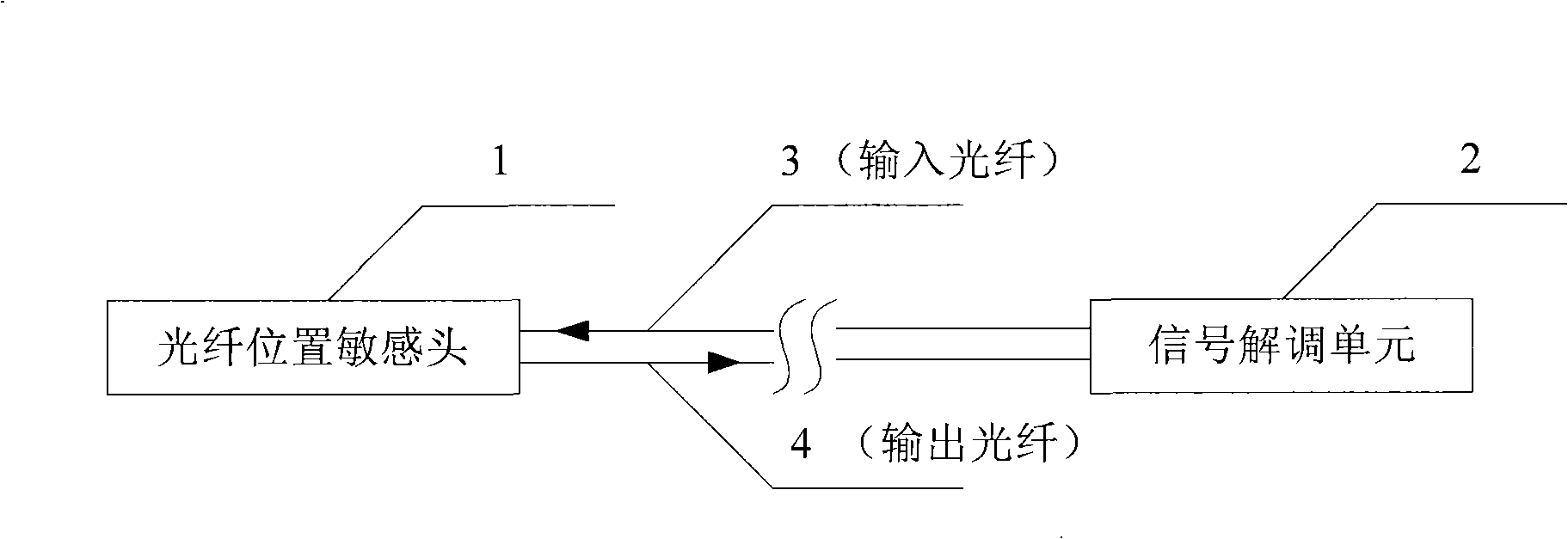

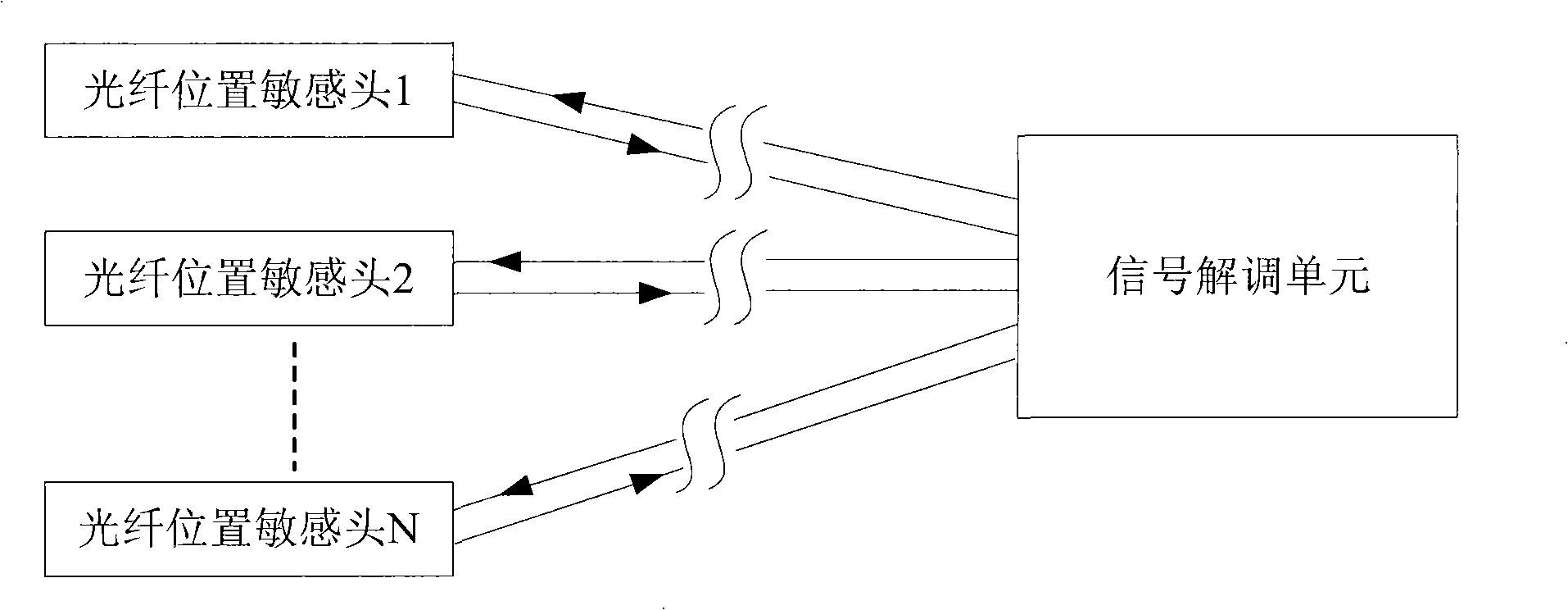

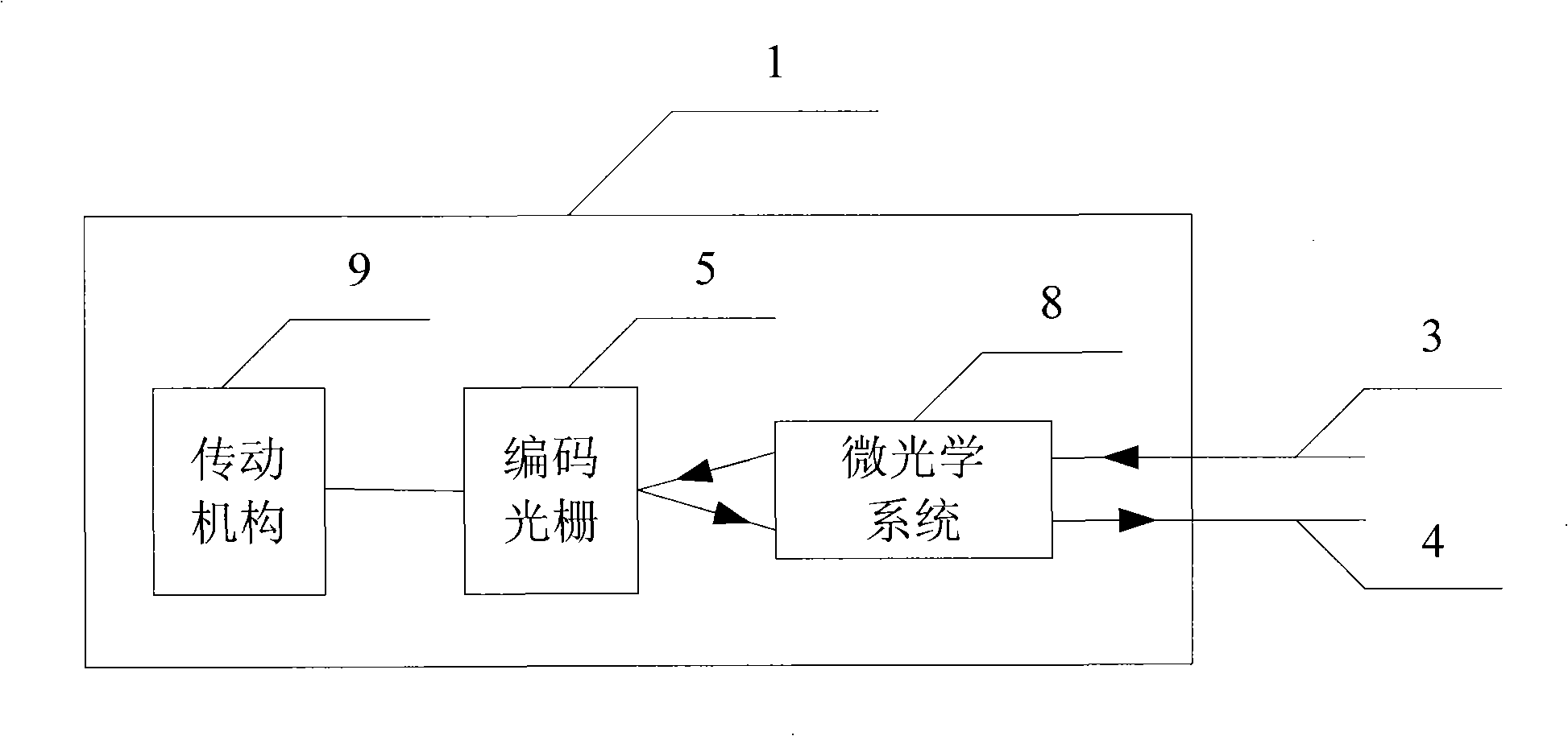

Optical fiber position digital encoder and uses thereof

InactiveCN101349576AHigh precisionWide Range Displacement SensingConverting sensor output opticallyCommunication interfaceGrating

The invention relates to an optical-fiber position digital encoder and an application thereof, which is characterized in that the optical-fiber position digital encoder is formed by an optical-fiber position sensing head and a signal demodulation unit, which are mutually separated and are connected through optical fibers, and can realize the distant detection. The optical-fiber position sensing head is passive, is installed in a structure, and is connected with a driving mechanism. An encoder which is formed by a main raster and an indication raster can modulate optical signals which are transmitted from the single demodulation unit into real-time phase change countable optical pulse sequence, and then return to the single demodulation unit on the measured displacement or angle quantity under the effect of the driving mechanism, then the actual displacement or angle values of the optical fiber position sensing head are calculated after being conducted with phase demodulation and pulse counting by the signal demodulation unit, and finally data loading is realized through a standard communication interface. And the displacement sensing with high precision and large range can be realized through the combination of the optical fiber position digital encoder with a driving and exchange mechanism, thereby further forming an optical fiber sensor based on the displacement and angle detecting principle.

Owner:吴亚明

Distributed Optical Fibre Sensor

ActiveUS20180094952A1Subsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansEngineeringAcoustics

The disclosure relates to distributed optical fibre sensors arranged to detect coherent Rayleigh backscatter from a sensing optical fibre disposed in an environment, and to determine an infrasonic signal in the backscatter, or to determine a change in the environment within an infrasonic frequency range from the backscatter.

Owner:VIAVI SOLUTIONS INC

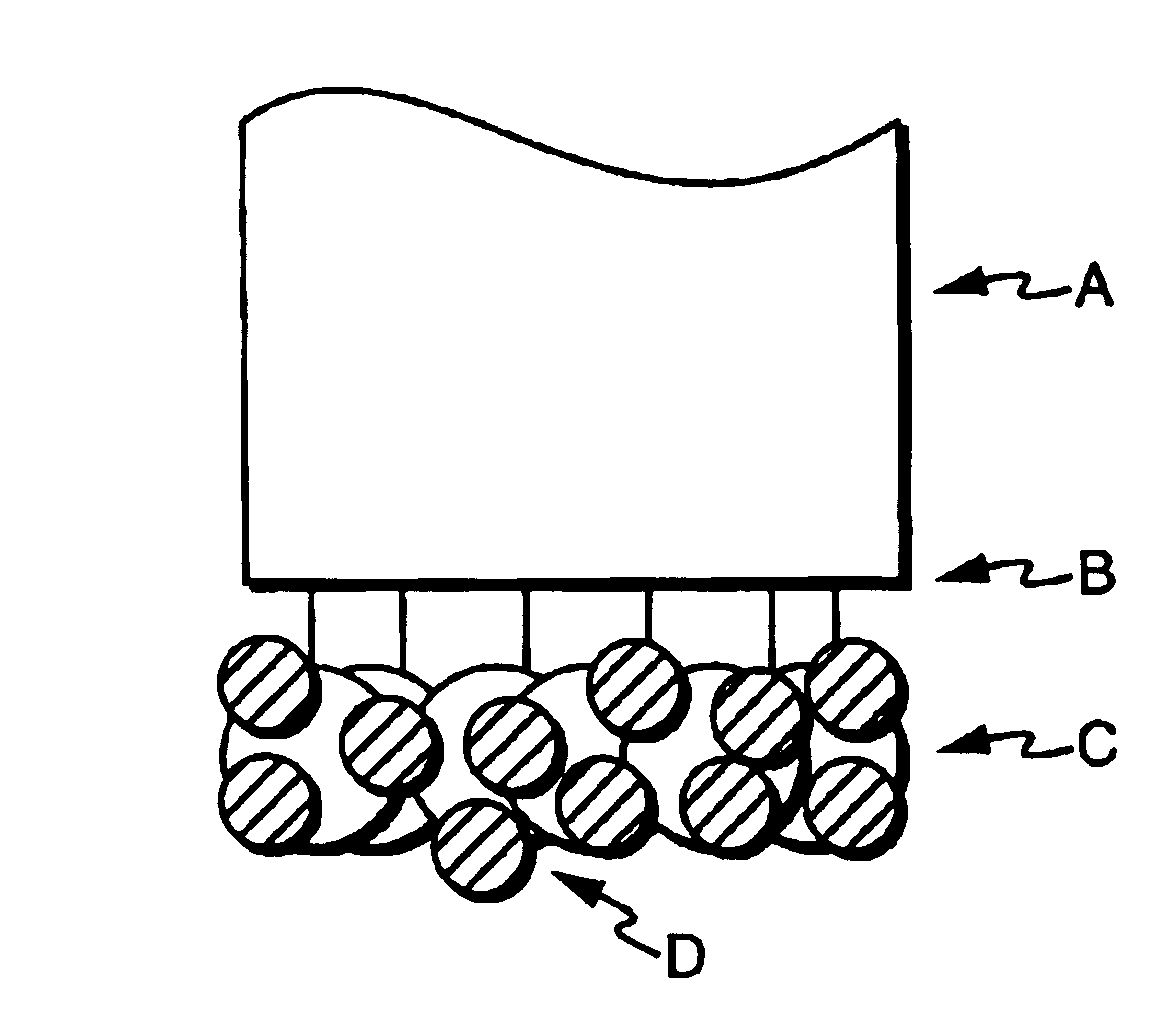

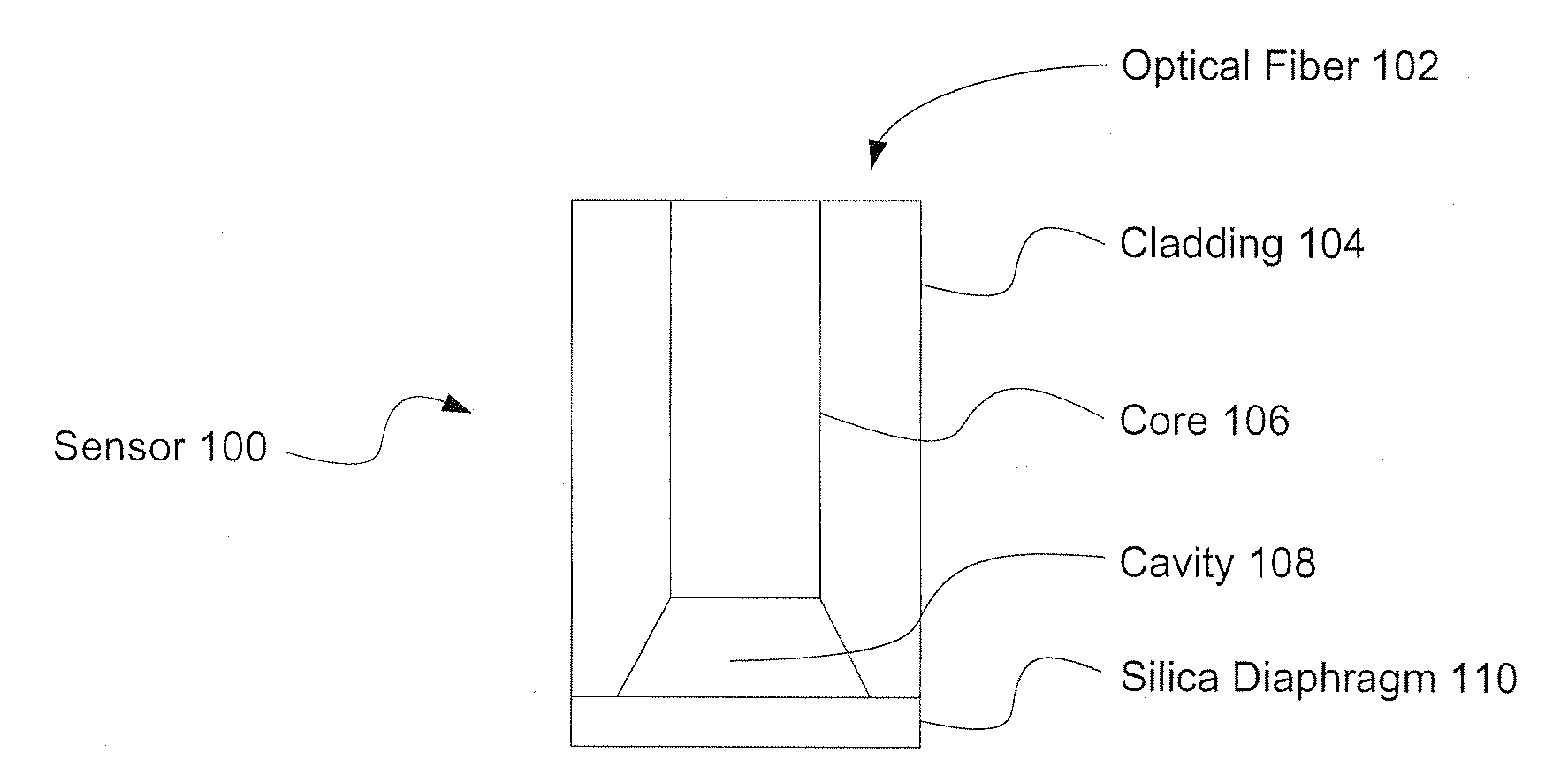

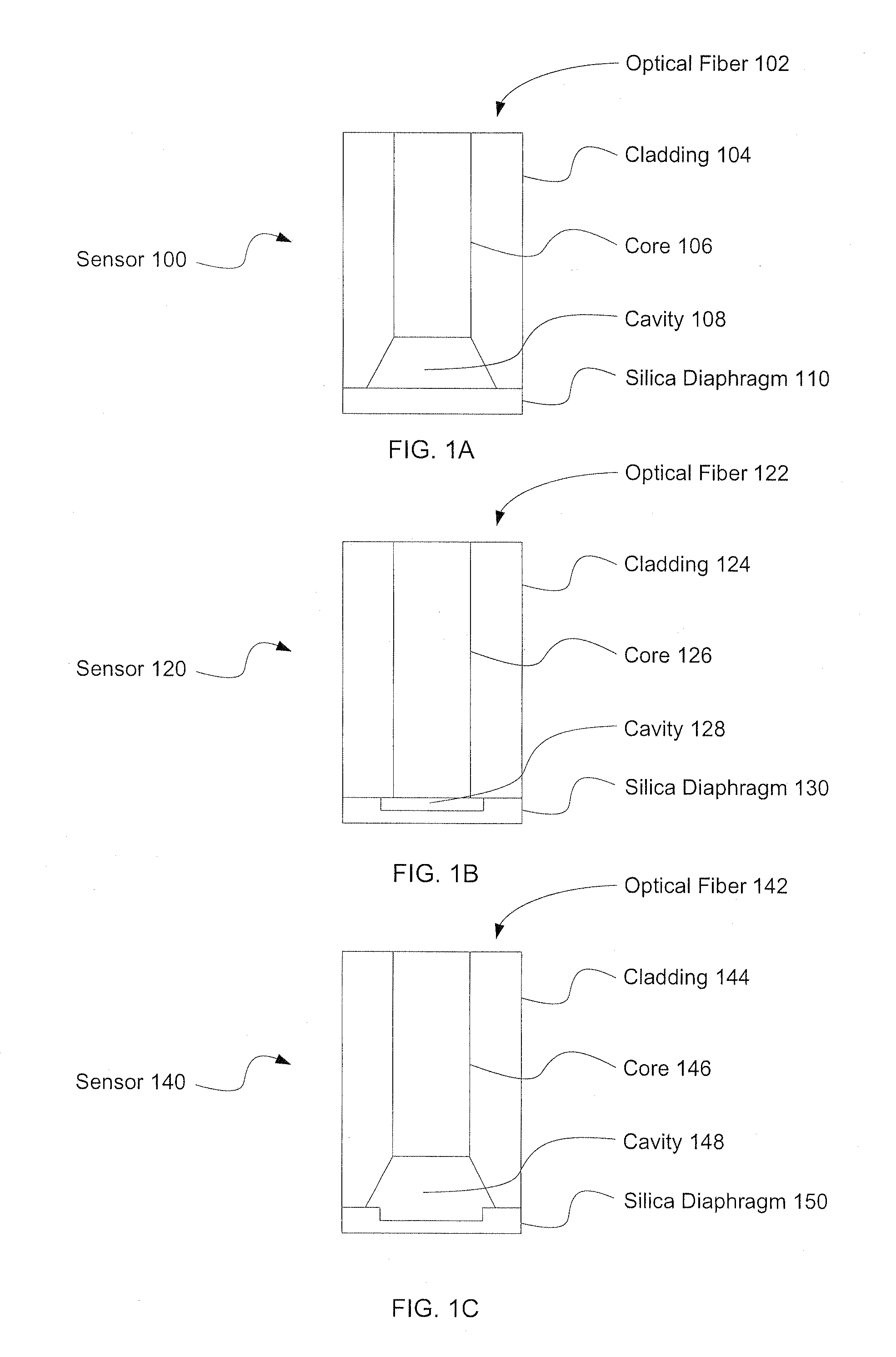

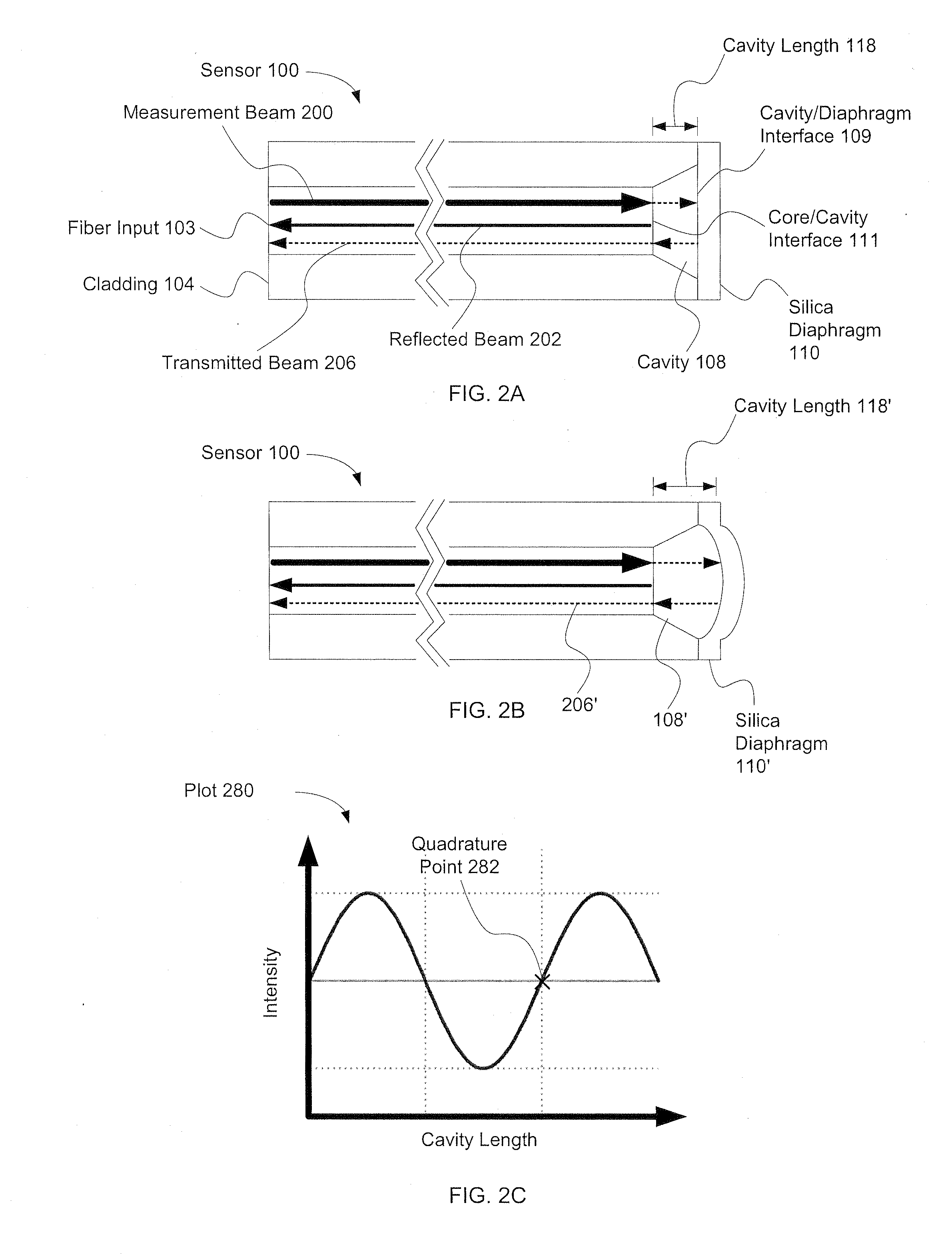

Optical Fiber Pressure Sensor With Uniform Diaphragm And Method Of Fabricating Same

ActiveUS20120116255A1Improve signal qualityUniform thicknessPerson identificationOptical articlesThin membraneEngineering

An optical fiber sensor (100) can be used to measure pressure with high sensitivity and fine resolution. As a (108) at the end of the sensor expands or contracts, the spectrum of a beam reflected from the end of fiber shifts, producing a change linked to pressure exerted on the sensor. Novel aspects of the present inventive sensor include the direct bonding of a silica thin film diaphragm (110) to the optical fiber with localized or confined heating and a uniform thickness of the diaphragm. The resulting sensor has a diameter that matches the diameter of the optical fiber. Because the sensor is all silica, it does not from temperature-induced error. In addition, the sensor can be very sensitive because the diaphragm can be very thin; it can also make highly repeatable measurements due to its very uniform thickness.

Owner:UNIV OF MASSACHUSETTS

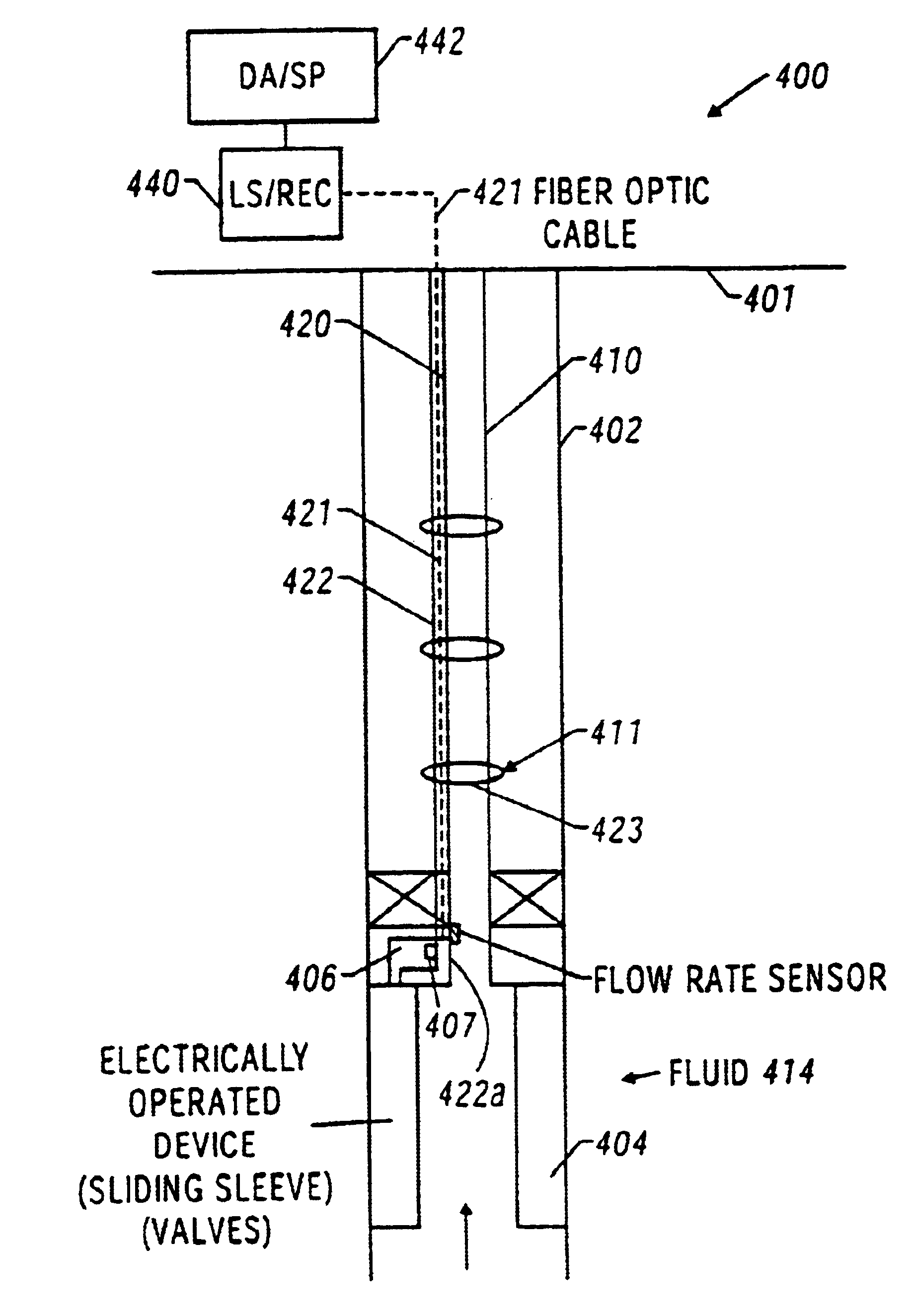

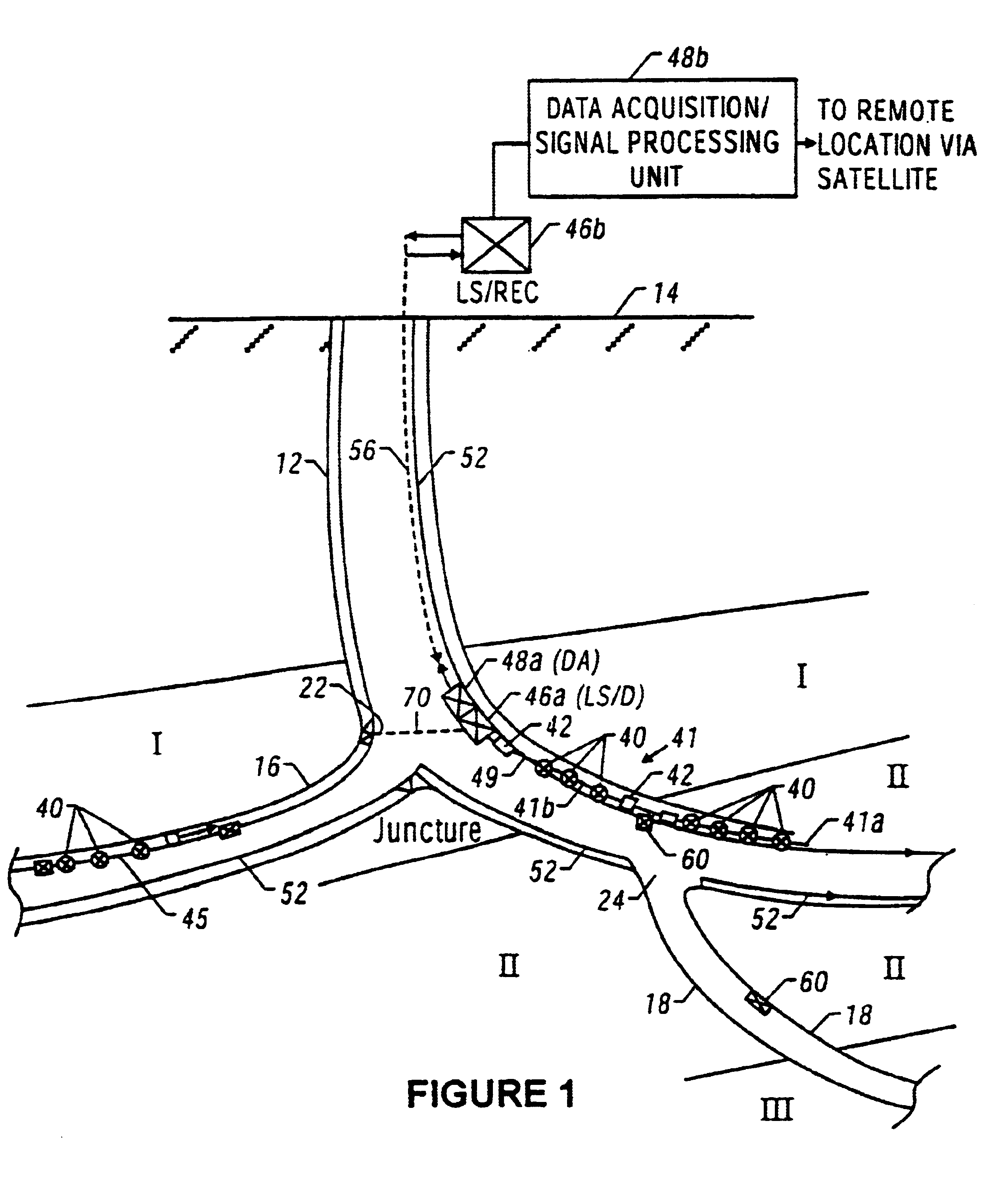

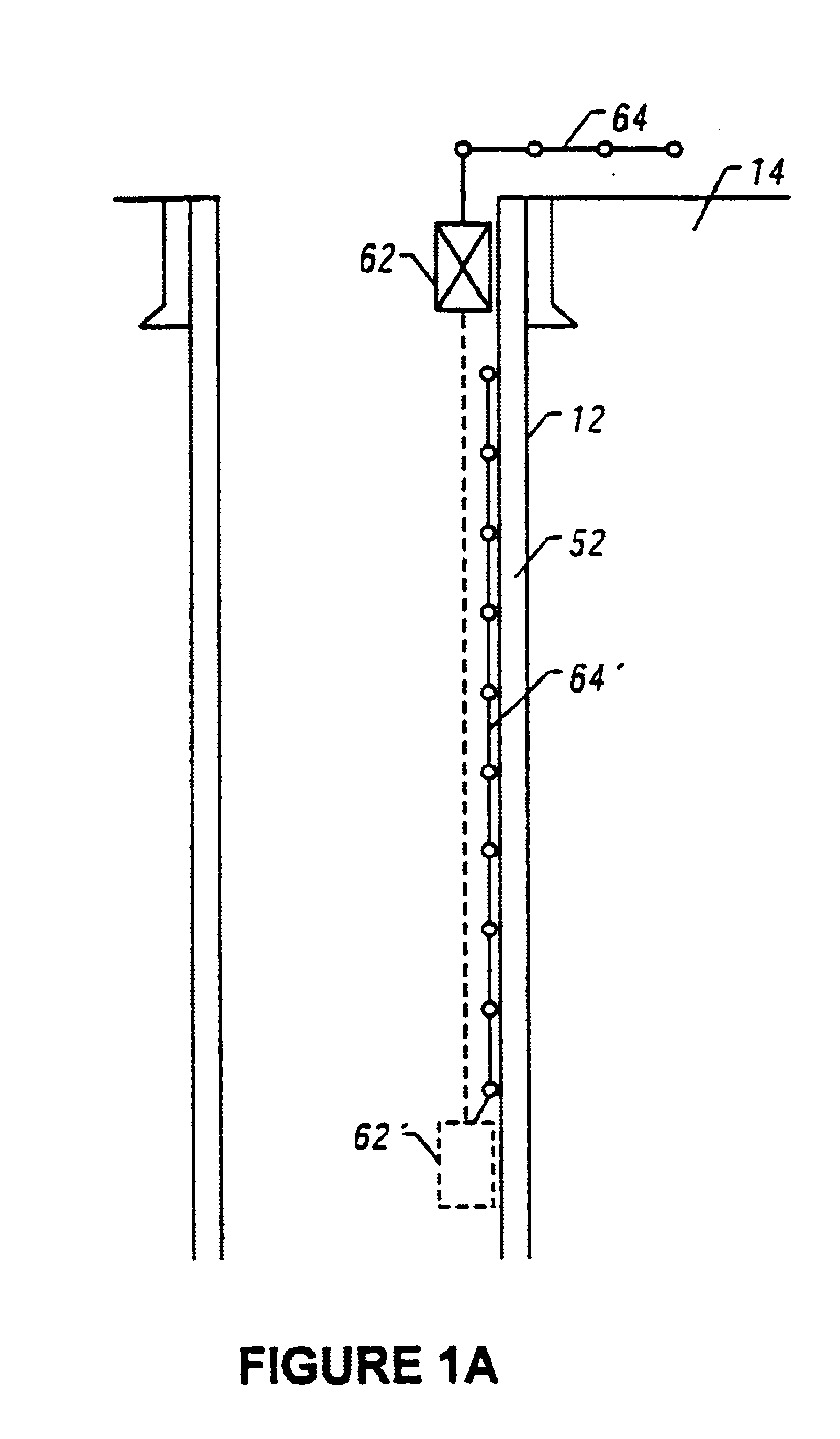

Method and apparatus of providing an optical fiber along a power supply line

InactiveUS6943340B2Enhanced overall recoveryEasy to operateConstructionsOptical prospectingProcess engineeringControl valves

Owner:SENSOR HIGHWAY LTD

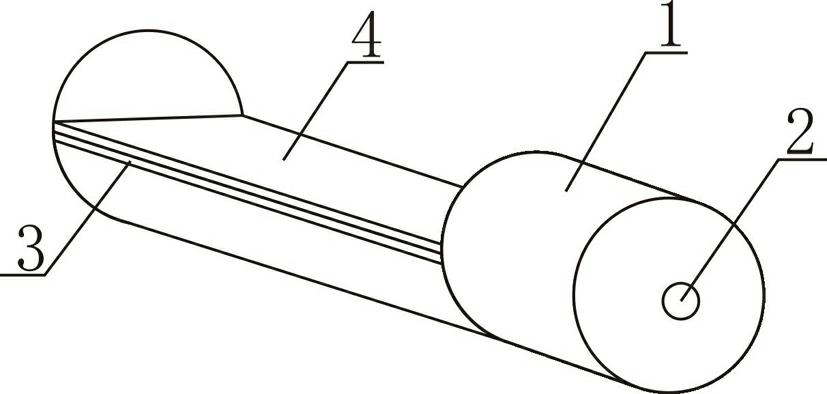

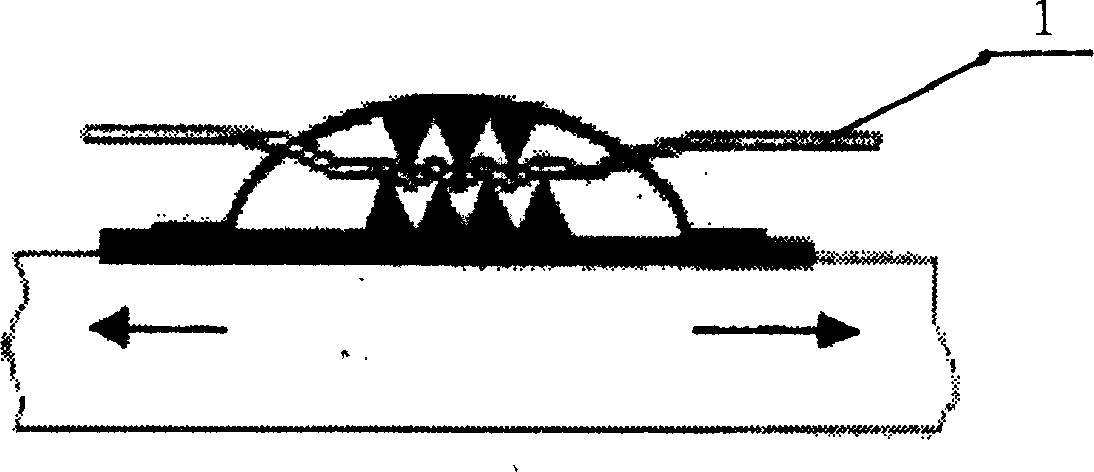

Snake type fiber-optical sensor burying and detecting method and its snake type fibre-optical sensor

InactiveCN1588013ATest destructionHigh deformation testMaterial analysis by optical meansCoupling light guidesTerrainBare fiber

The invention relates to the imbedding and test method for a snake optical fiber sensor and the snake optical fiber sensor. The method involves making and imbedding the optical fiber sensor, connecting the optical fiber sensor to a transition optical fiber with a bonding machine to position the the optical fiber sensor, testing the loss initial value, after excavating, test system loss changing curve of the optical fiber test system and observing the deformation and damage condition of the terrain; processing the OTDR test data with program. The bare fiber is covered with a bushing on the outside diameter and equipped with a protecting device on both end. The fiber can form many minor bend point used to monitor the deformation of rock whose strength is lower than quartz glass and the generating, developing, microdeformation and macrodeformation of the cranny of large deformed rocks. The initial deformation of the terrain, even the damage of materials,can be detected with the accuracy within plus or minus 0.01mm. The marodeformation reaches 35-50 mm, far higher than the concrete deformation detection. It is a distributed optical fiber detecting instrument, the fiber is connected with the detecting device, convenient to operating, detection is stable, highly accurate.

Owner:CCCC TUNNEL ENG +1

Apparatus for sensing demodulating double-datum length low coherent optical fiber ring network

InactiveCN101325455AIncrease the number of reusesOptical path scanning range increasedFibre transmissionMultiplexingRing network

The invention provides a double reference length low coherent optical fiber ring network sense demodulating equipment, comprising a wide spectrum optical source, a photo detector, an optical fiber 4*4 coupler, a self-focusing lens, a pyramid plane reflector groups, a monomode fiber, an optical fiber ring network composed a plurality of optical fiber sensors with different lengths in series; the wide spectrum optical source and the photo detector are connected with the two optical fiber input ends of the optical fiber 4*4 coupler, and the other two optical fiber input ends of which are respectively connected with the self-focusing lens, which the two optical fiber output ends of the optical fiber 4*4 couple are connected with the optical fiber ring network through the monomode fiber, and the other two optical fiber output ends of which are respectively connected with the self-focusing lens. According to the invention, through the durable optical fiber ring chamber of the double reference optical path, the expansion of the optical path scanning range can be realized, and the multiplexing number of the sensors is added, which has simple structure, easy implement, high accuracy of measurement and low cost and the like.

Owner:HARBIN ENG UNIV

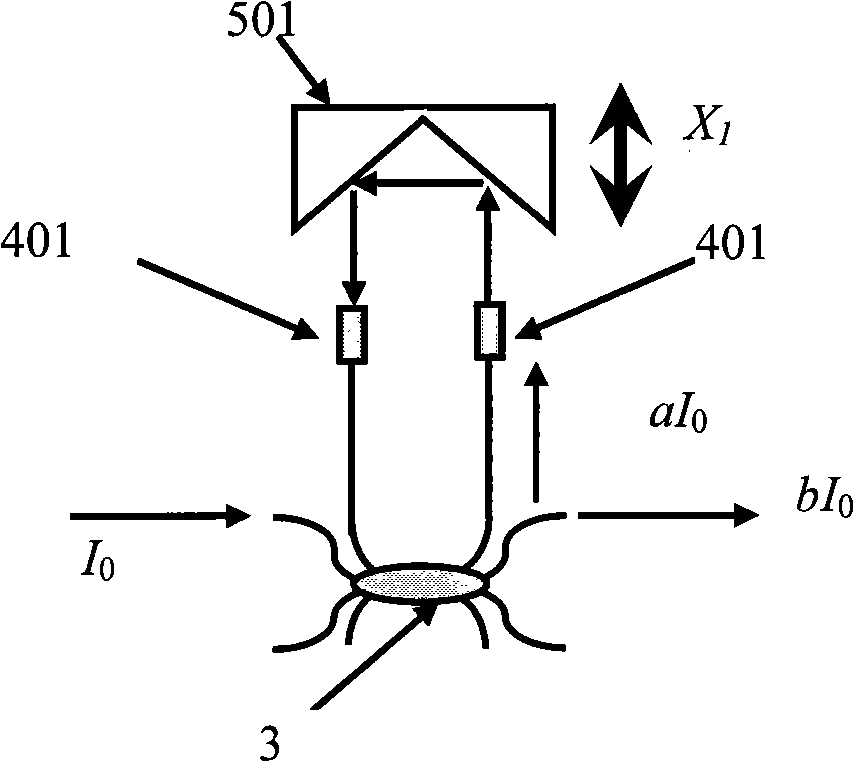

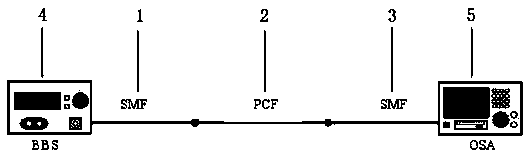

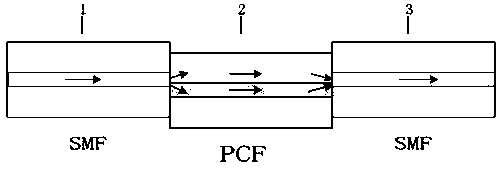

Interferometric optical fiber sensor based on pohotonic crystal optical fiber

InactiveCN104297208ASimple structureEasy to manufacturePhase-affecting property measurementsRefractive indexPhotonic-crystal fiber

The invention discloses an interferometric optical fiber sensor based on a pohotonic crystal optical fiber. The pohotonic crystal optical fiber at the middle section is connected with monomode optical fibers at two ends via core shift connecting structures, wherein the diameters of claddings of the monomode optical fibers at two ends are 125 microns, and the diameters of fiber cores are 8.3 microns; the pohotonic crystal optical fiber at the middle section is a PM-125 type pohotonic crystal optical fiber manufactured by the fiberhome telecommunication, the cladding diameter is 125 microns, the diameter of the fiber core is 7 microns, and the length is 5cm, and the section acts as a sensing region. The interferometric optical fiber sensor is not sensitive to temperature, and is relatively high in refractive index, and can act as a refractive index sensor, and meanwhile, influences on refractive index measurement precision caused by the change of temperature can be alleviated. The interferometric optical fiber sensor based on the pohotonic crystal optical fiber is simple in structure, is easy to manufacture, meanwhile can alleviate influences on the single-parameter measurement precision by temperature, is relatively high in practical value, and is suitable for the fields of industrial production, defense-related science and technology, medical treatment, people's livehood and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

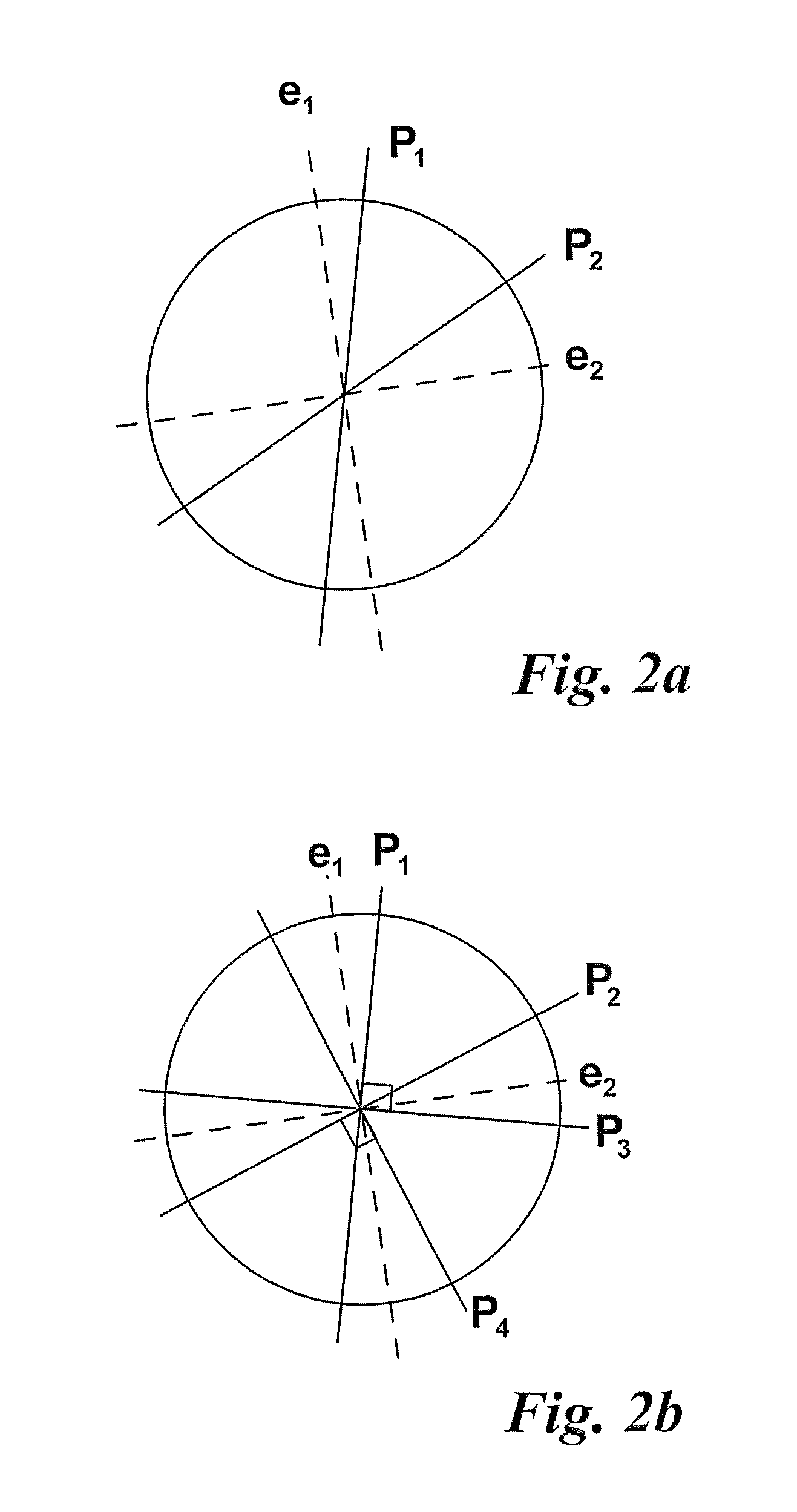

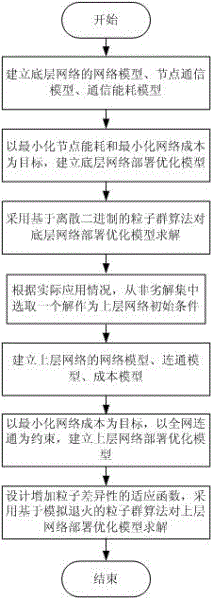

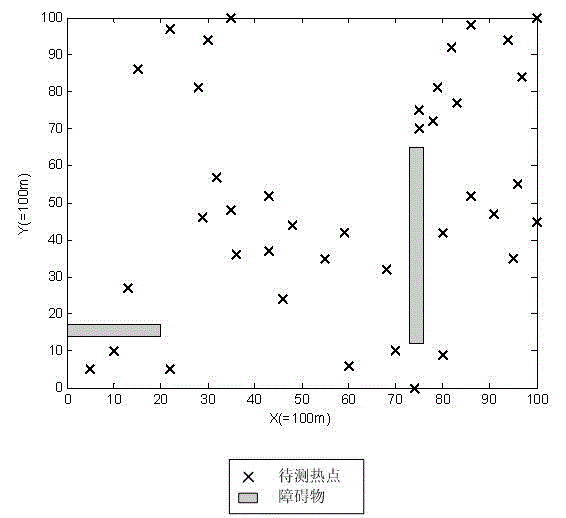

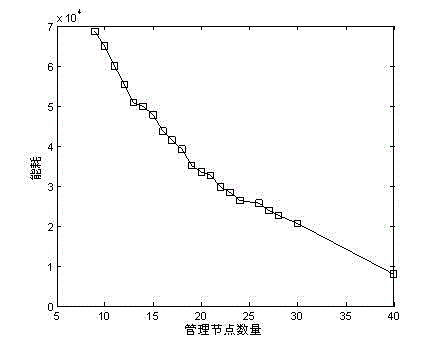

Wireless optical fiber sensor network deployment method based on particle swarm optimization

ActiveCN102625324AMeet monitoring requirementsIncrease diversityEnergy efficient ICTNetwork topologiesNetwork deploymentSensing data

The invention relates to a wireless optical fiber sensor network deployment method based on particle swarm optimization. The method comprises the following steps of: establishing a bottom layer network deployment optimization model specific to the aim of minimizing the energy consumption of an optical fiber sensor node and bottom layer network cost, and solving by adopting multi-target particle swarm optimization based on a discrete binary system to obtain a bottom layer network deployment scheme and realize distributed sensing of a monitored area; and establishing an upper layer network deployment optimization model on the basic of the bottom layer network deployment scheme specific to the aim of minimizing upper layer network cost under the constraining action of upper layer network full communication, designing a fitness function for increasing particle difference, and solving by adopting particle swarm optimization based on simulated annealing to obtain an upper layer network deployment scheme and realize multiple hop transmission of sensing data. Due to the adoption of the method, the energy consumption of the optical fiber sensor node can be lowered, the energy consumption of management nodes is balanced, the network life is prolonged, the quantity of deployed routing nodes and management nodes can be reduced on the premise of ensuring full network communication, and network cost is reduced.

Owner:SHANGHAI UNIV

Stress, temperature and vibration composite detection optical fiber sensor and signal processing method

ActiveCN110132329ASolve the separation problemHigh signal resolutionConverting sensor output opticallyFiber optic sensorVIT signals

Embodiments of the invention disclose a stress, temperature and vibration composite detection optical fiber sensor and a signal processing method. Laser light is divided into two beams; a part of thefirst beam of light is taken as local oscillator light, and the rest part is incident from the head end of a sensing optical fiber after passing through an acousto-optic modulator; after the second beam of light is subjected to frequency conversion by an electrooptical modulator, a part of the second beam of light is incident from the tail end of the sensing optical fiber, and the other part is used as reference light to be incident to a reference optical fiber; at the head end of the sensing optical fiber, the light transmitted backwards passes through a filtering raster, wherein reflected light and the local oscillator light interfere with each other, and after being detected, the reflected light is collected as a signal 1 through frequency reduction demodulation; a part of the transmitted light is directly detected and collected as a signal 2, and the other part interferes with the reference light and then is detected and collected as a signal 3; and envelope denoising is carried out on the signal 1, a vibration position is obtained by using a wavelet information entropy algorithm, the signal 2 is fitted to obtain stress or temperature distribution, envelope denoising is carriedout on the signal 3, and a vibration frequency is obtained through Fourier transform.

Owner:SHANTOU UNIV

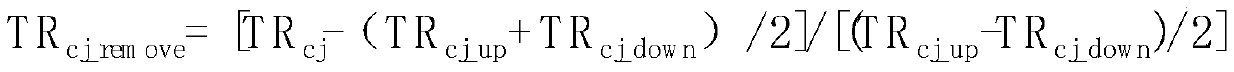

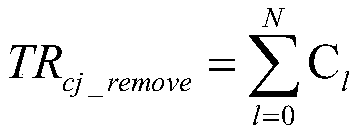

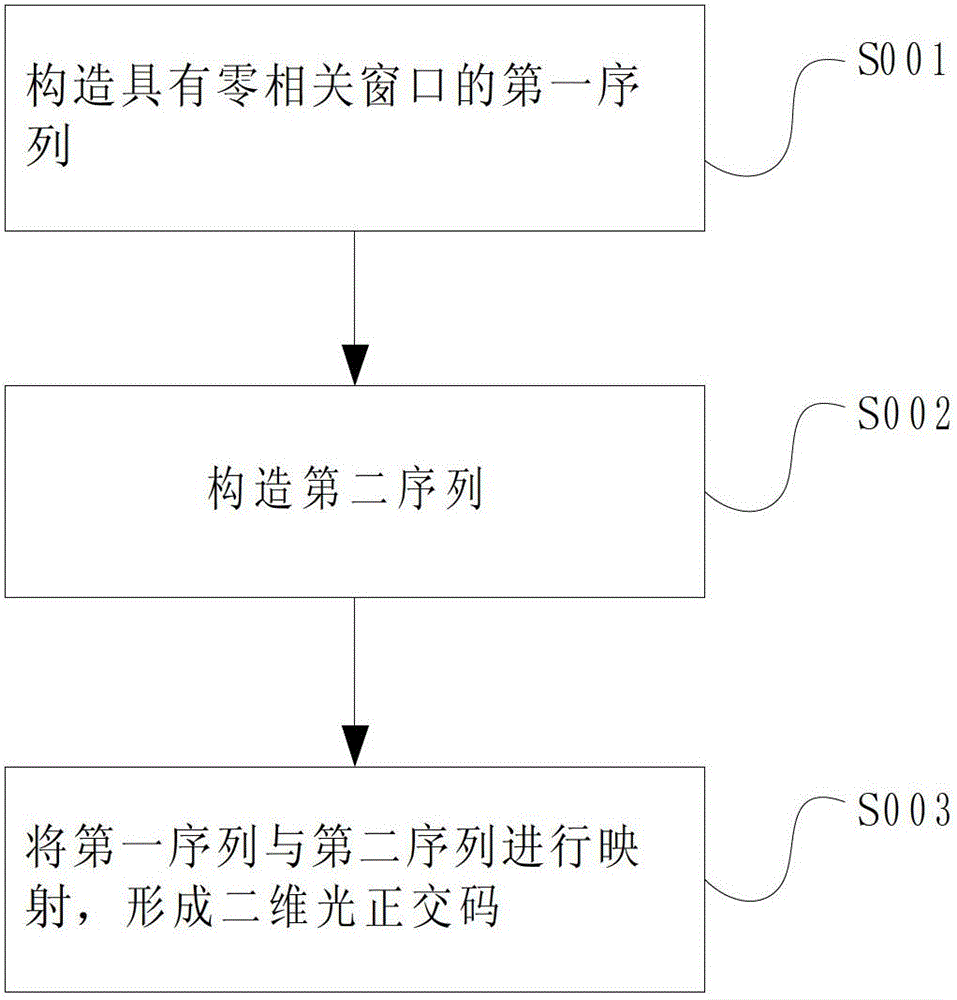

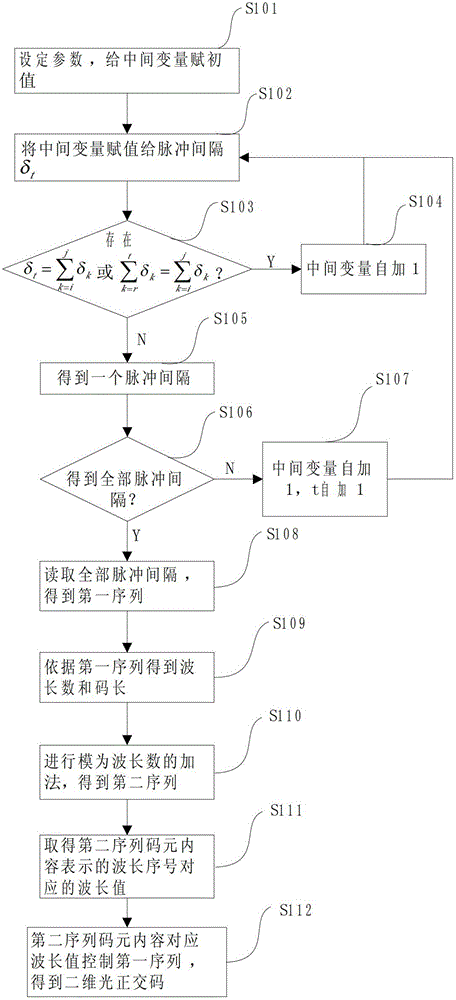

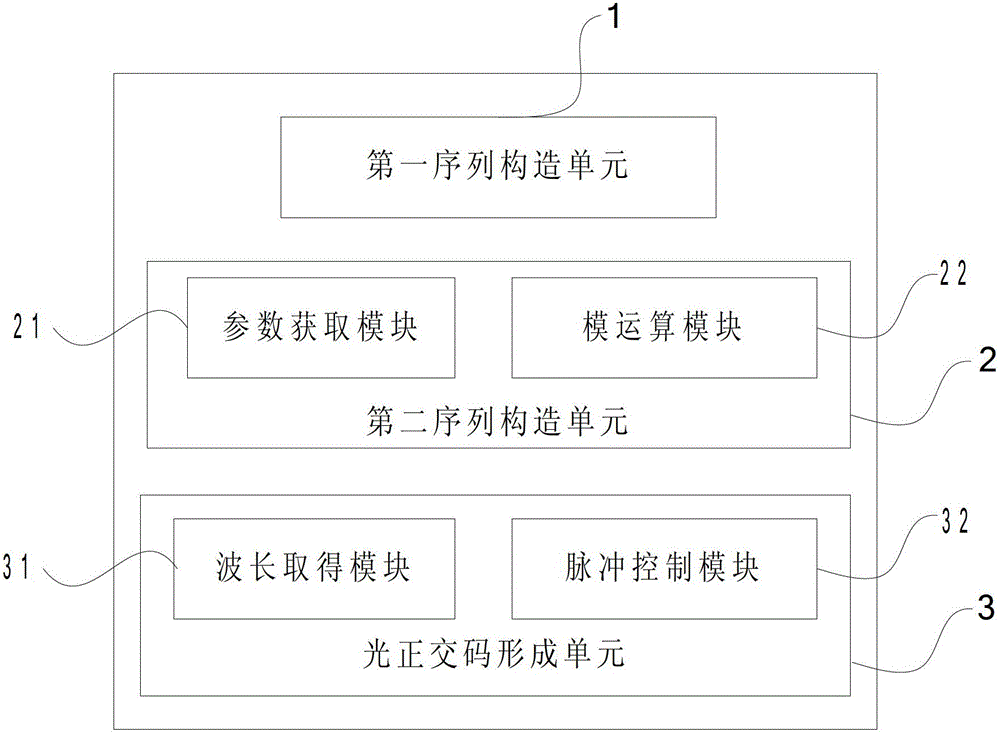

Method and device for forming two-dimensional optical orthogonal code with zero correlation window

ActiveCN102752067AEliminate distractionsCancel noiseMultiplex code generationOptical multiplexAccess networkCode division multiple access

The invention relates to a method for forming a two-dimensional optical orthogonal code with a zero correlation window, and the method comprises following steps of constructing a first sequence with the zero correlation window; constructing a second sequence; and mapping the first sequence and the second sequence to form the two-dimensional optical orthogonal code with the zero correlation window. The invention also relates to a device for realizing the method. The method and the device for forming the two-dimensional optical orthogonal code with the zero correlation window have following beneficial effects that the two-dimensional orthogonal code is completely orthogonal, i.e. the autocorrelation limit of the code is zero, cross-correlation limit of the code is also zero, and thus the multi-address interference and beat noise can be completely eliminated, the near-far effect of a two-dimensional optical code division multiple access (OCDMA) system also can be eliminated; therefore, the two-dimensional OCDMA system with large capacity can be realized, and the two-dimensional OCDMA system can be applied to an optical access network, an optical local area network, an optical code mark switching network, an optical fiber sensor network and the like.

Owner:SHENZHEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com