Foundation pit engineering three-dimensional monitoring network realization method based on distributed optical fiber sensors

A distributed optical fiber and optical fiber sensor technology, applied in the field of geotechnical engineering and foundation pit engineering monitoring, can solve the problems of large accidental errors, many manual operations, single-point monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

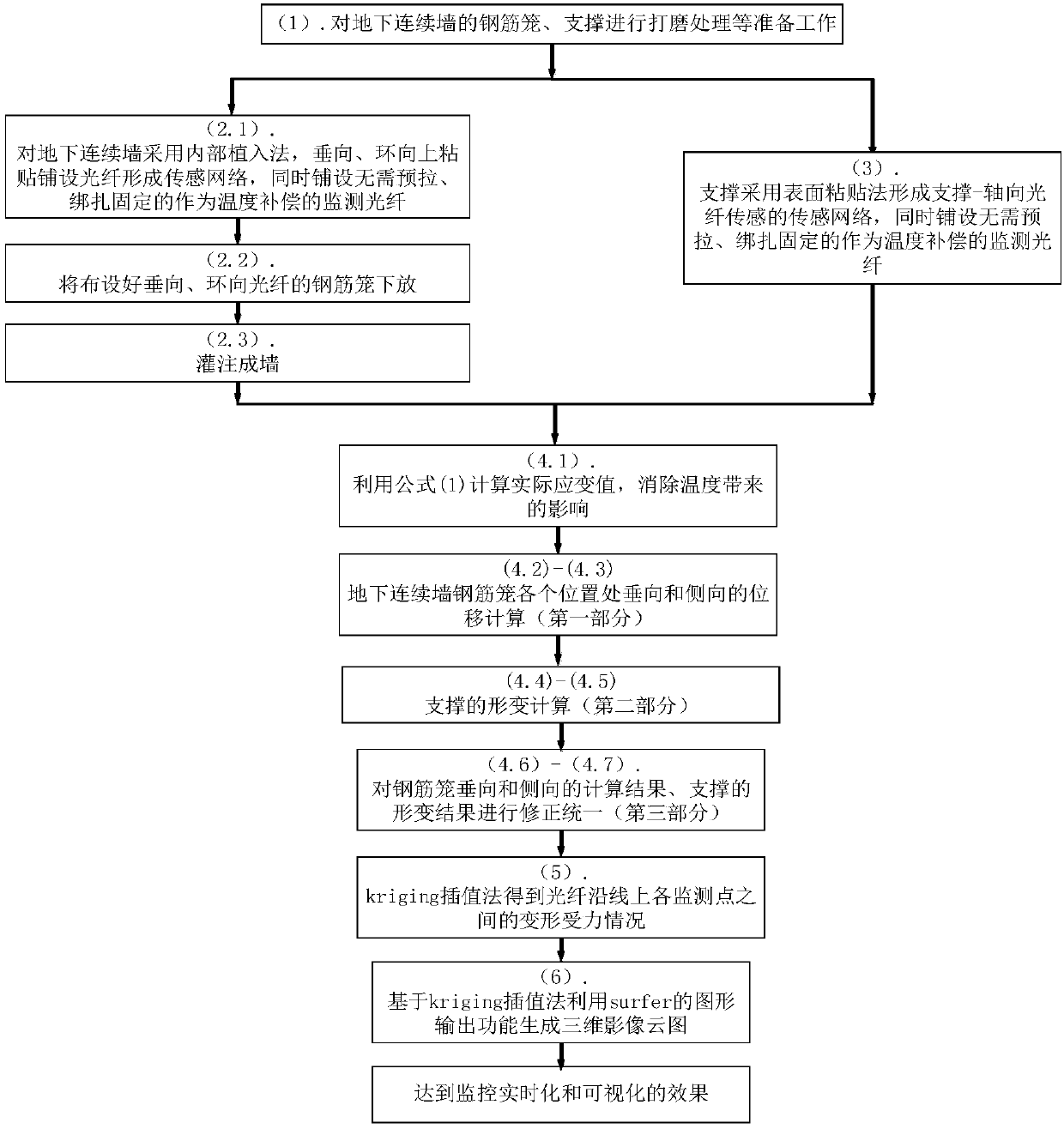

[0065] The invention provides a method for realizing a three-dimensional monitoring network of foundation pit engineering based on distributed optical fiber sensors. (The implementation steps are as follows figure 1 shown, where the number label is the order of the steps)

[0066] (1). Before the steel cage 1 of the underground diaphragm wall is lowered, the steel bars are polished to remove the sharp parts on the surface, so as to reduce unnecessary damage to the optical fiber sheath.

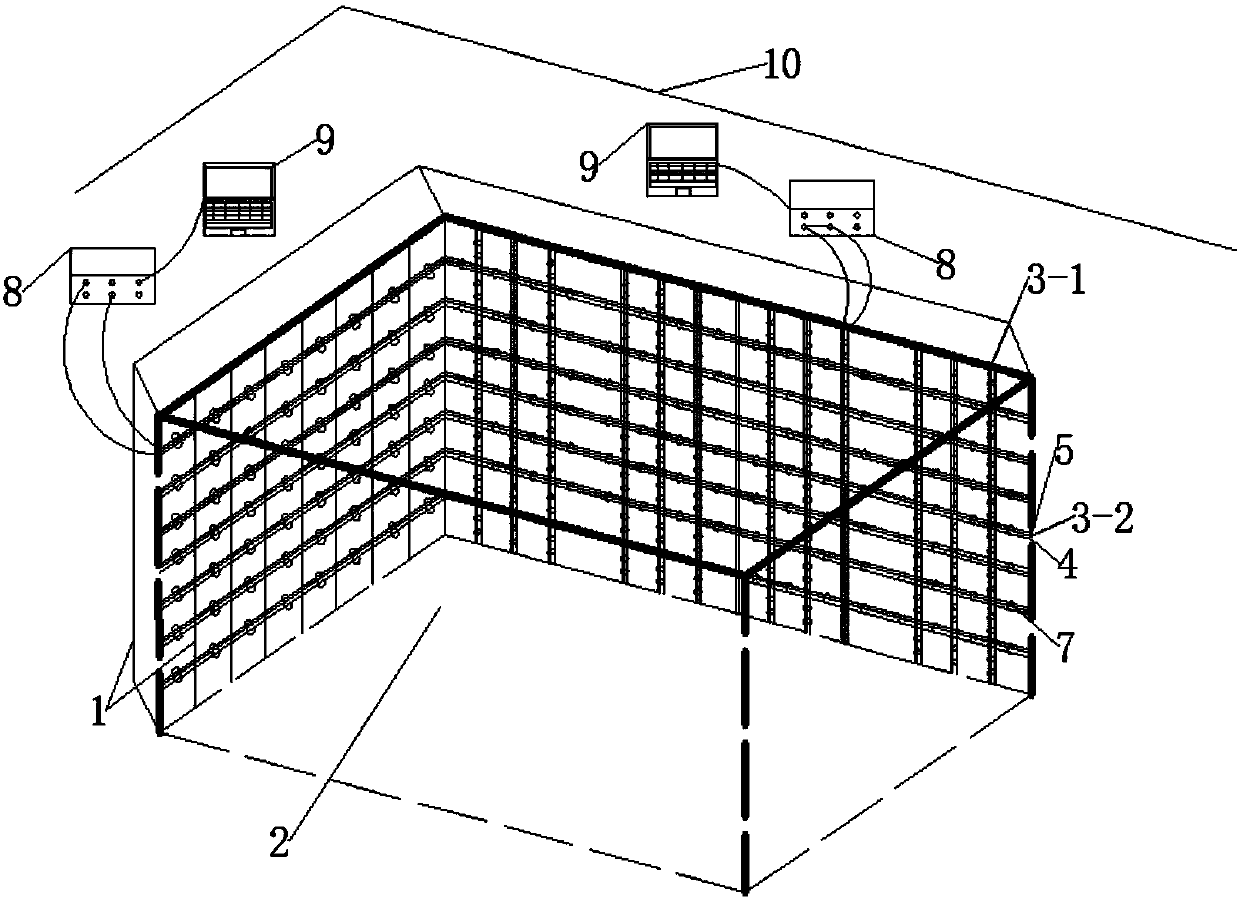

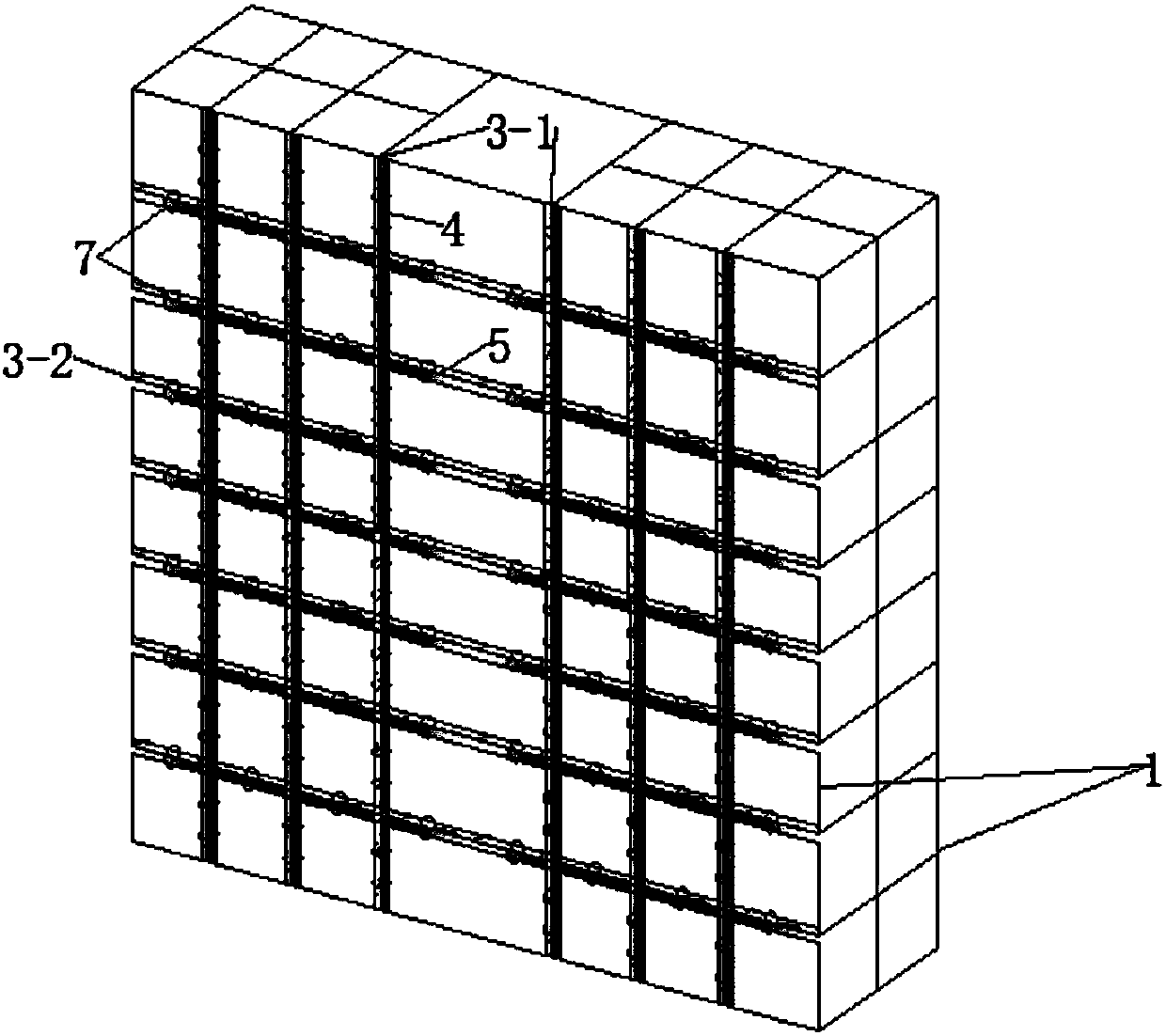

[0067] (2). In the reinforcement cage 1 of the underground diaphragm wall, the sensing optical fiber 4 for monitoring the strain and the sensing optical fiber 5 as temperature compensation are arranged. The arrangement of the sensing optical fibers 4 and 5 adopts the internal implantation method, mainly for the reinforcement cage 1 Lay sensing optical fibers 4 and 5 on the two sides facing and facing away from the foundation pit area, and lay the sensing fibers 4 and 5 on the two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com