Patents

Literature

466 results about "Strain distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

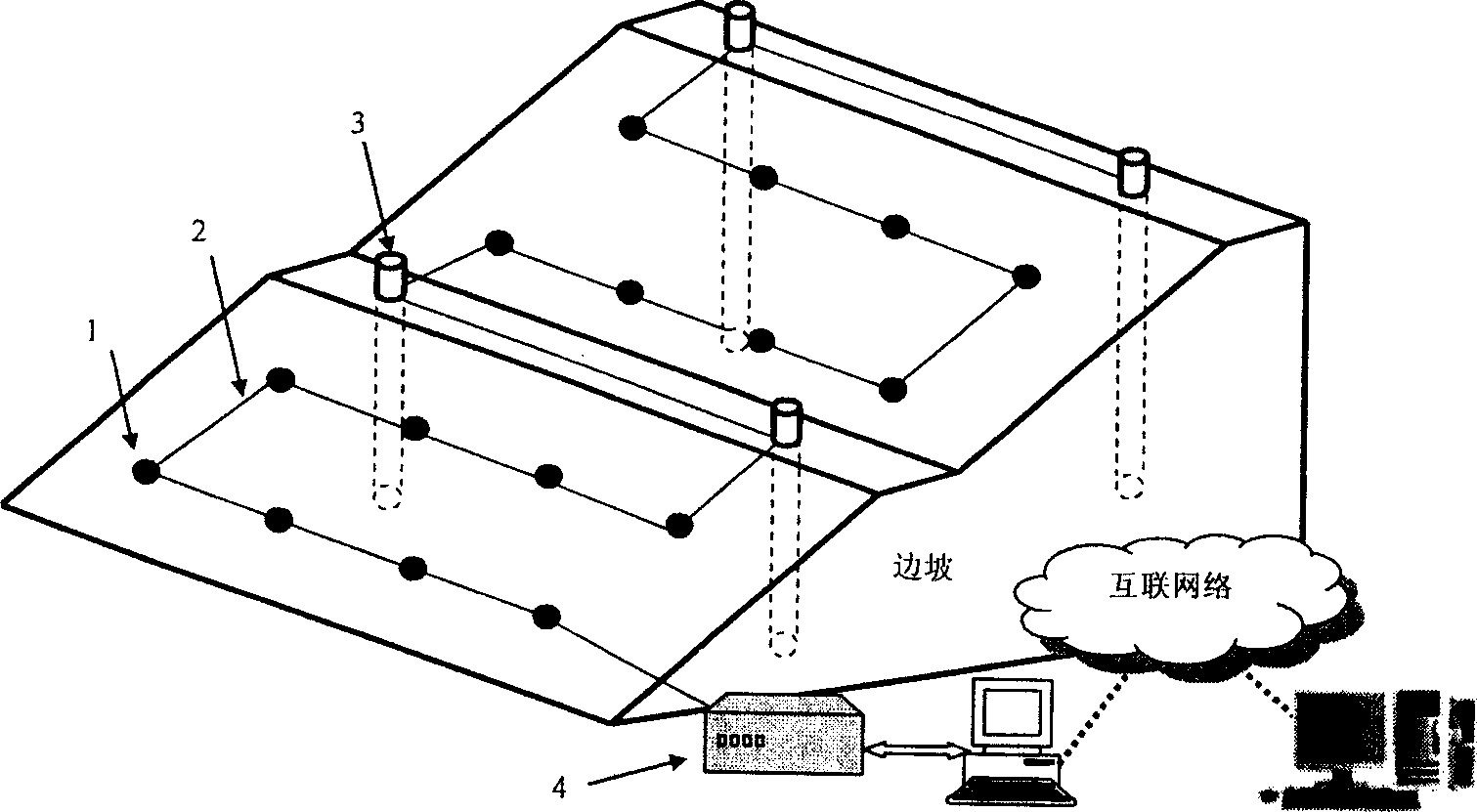

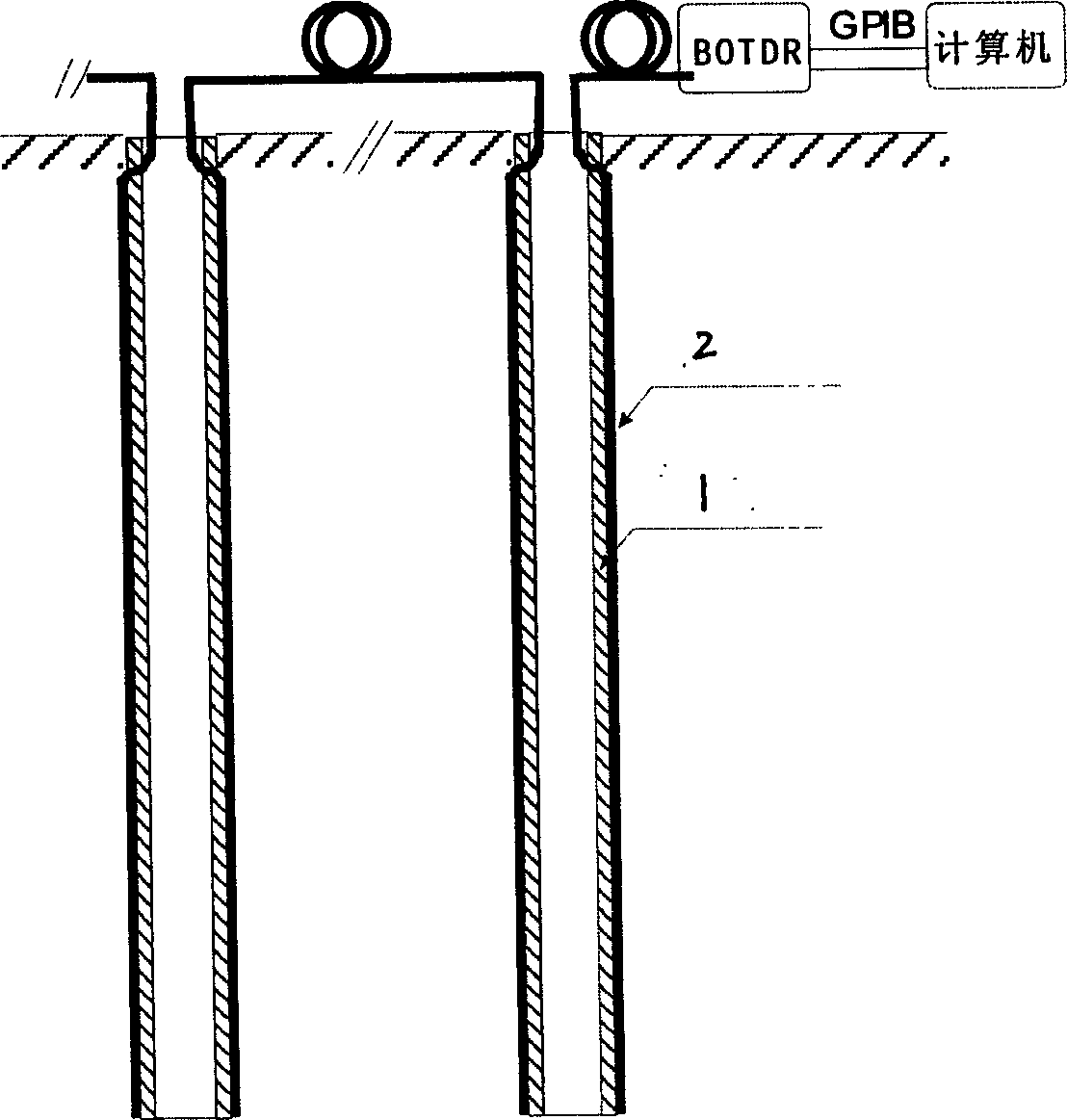

Method and system for monitoring soil property side slope distributive fiber optic strain

InactiveCN1901418AMaster the law of deformationDeformation fastThermometers using physical/chemical changesFluid-tightness measurementSoil propertiesFiber strain

This invention relates to a strain monitor system for slope distributed fibers, which lays out several parallel special optical cables along the slope or at least lays out one close to the slope top and the corner separately, adheres symmetrically two fibers on the outer surface of a tilt testing tube to get the distortion of deep soil helped by the strain of the tube, the special optical cables are melted orderly to constitute a sensor circuit to be connected to BOTDR, which links with remote computers via local computer and internet to constitute distributed fiber strain monitor system and gets the distortion or displacement of the slope by integrating and summing the measured strain distribution further to evaluate and preset to the side slope.

Owner:NANJING UNIV

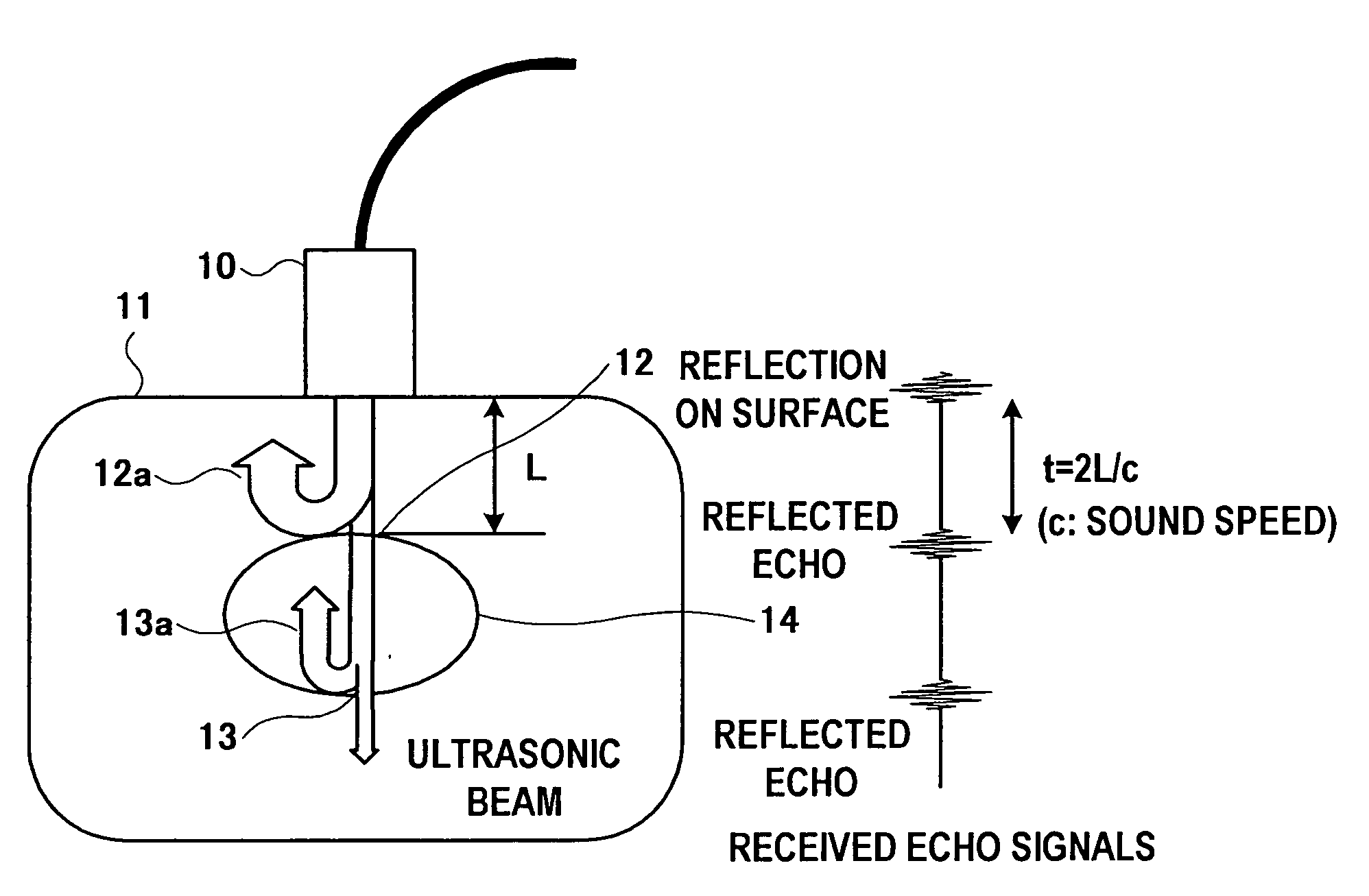

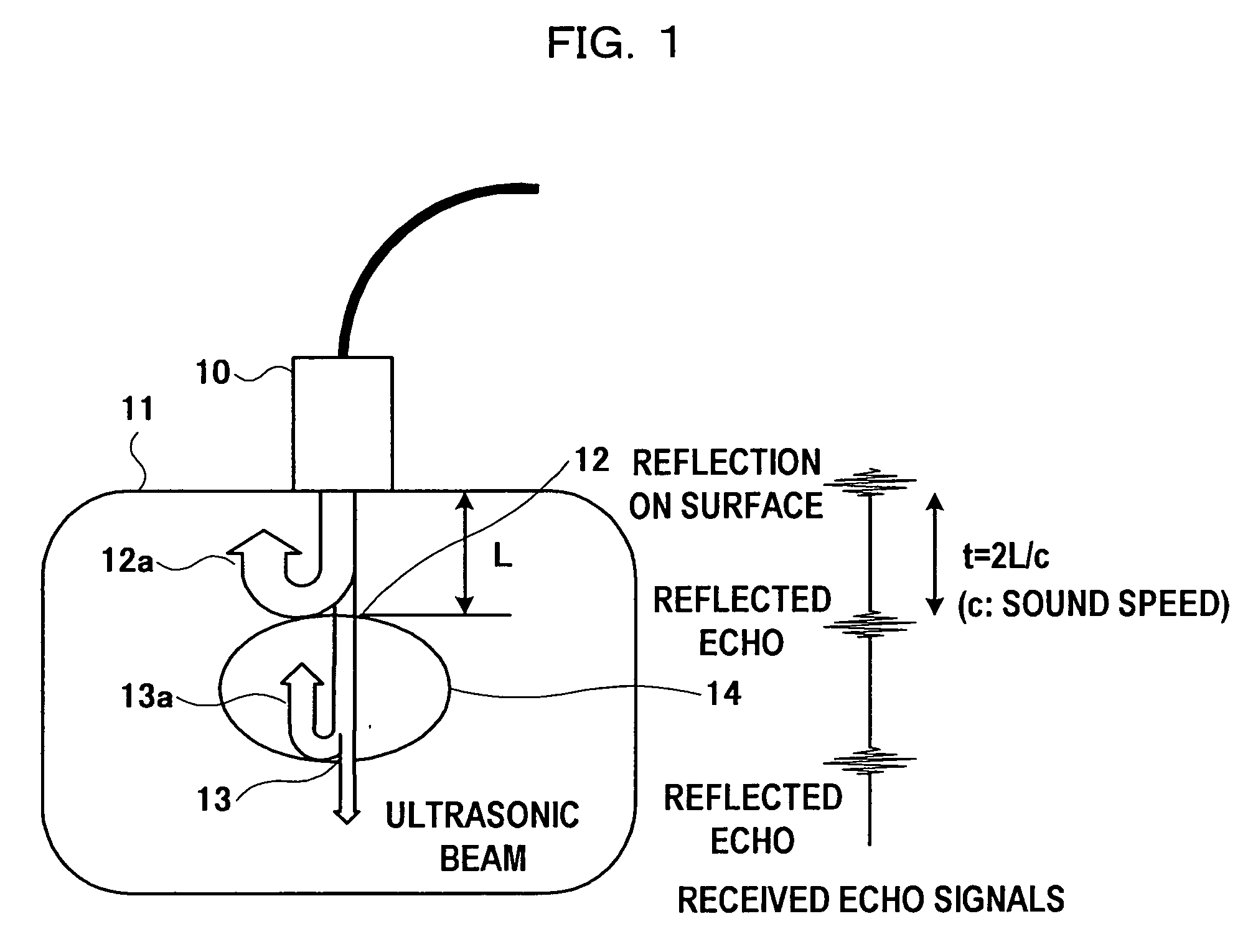

Ultrasonic diagnosis system and strain distribution display method

ActiveUS20060052696A1Ensuring sufficient uniformityCalculation stableOrgan movement/changes detectionCatheterCorrelation coefficientDiagnostic ultrasound

An ultrasonic diagnosis system and strain distribution display method utilizing an ultrasonic probe for performing transmission / reception of ultrasonic signals to / from a subject, a storage arrangement for storing the properties of signals detected with the ultrasonic probe, a correlation computer for calculating a correlation coefficient between the properties with and without pressure applied to the subject, and a phase difference between the received signals with and without application of pressure, based upon the properties stored in the storage arrangement with and without pressure applied to the subject, a computer for calculating a displacement of each measurement point, and a strain distribution of tissue of the subject due to application of pressure, based upon the correlation coefficient and phase difference calculated by the correlation computer, and a display for displaying the strain distribution.

Owner:SHIINA TSUYOSHI +1

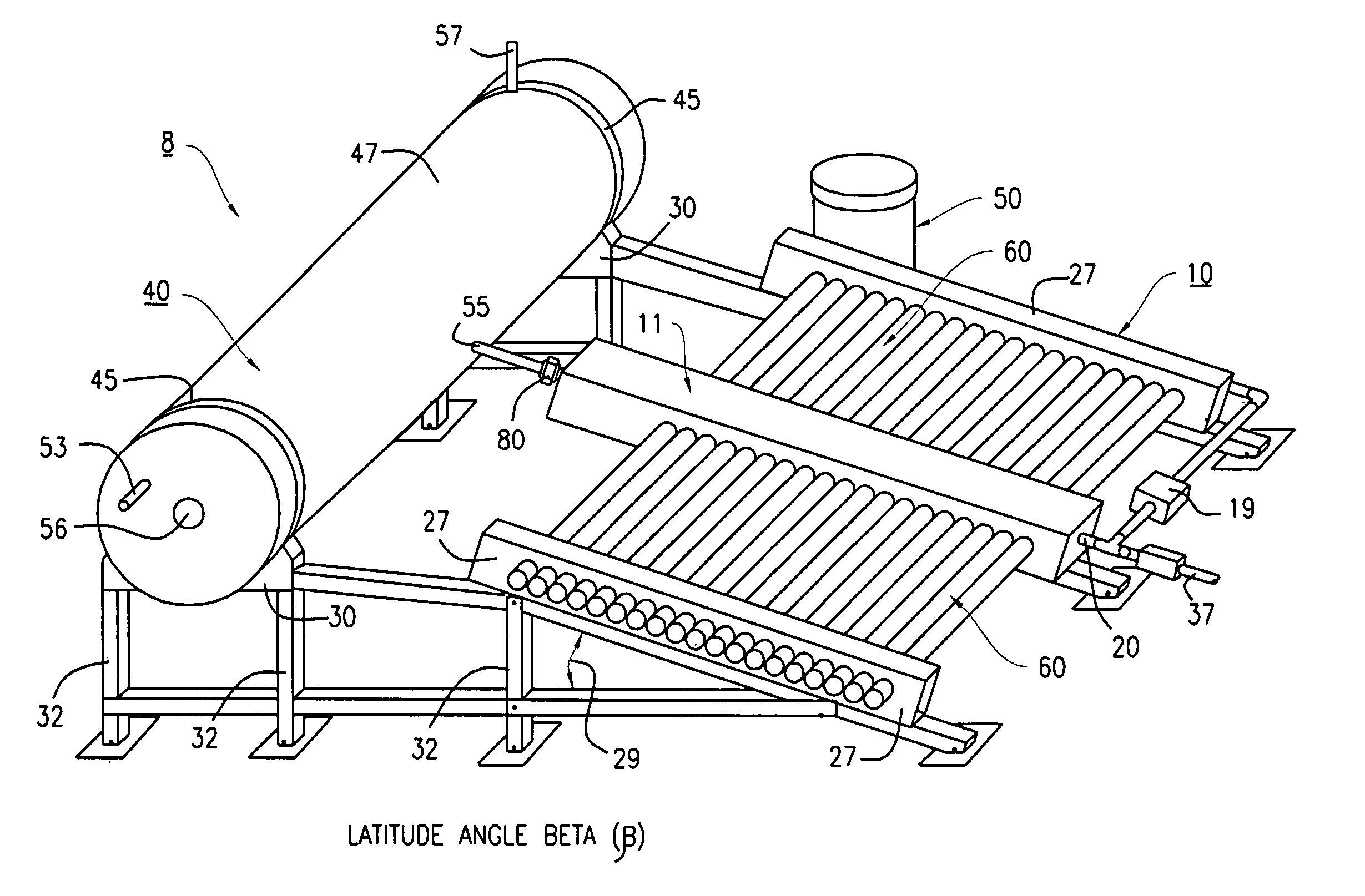

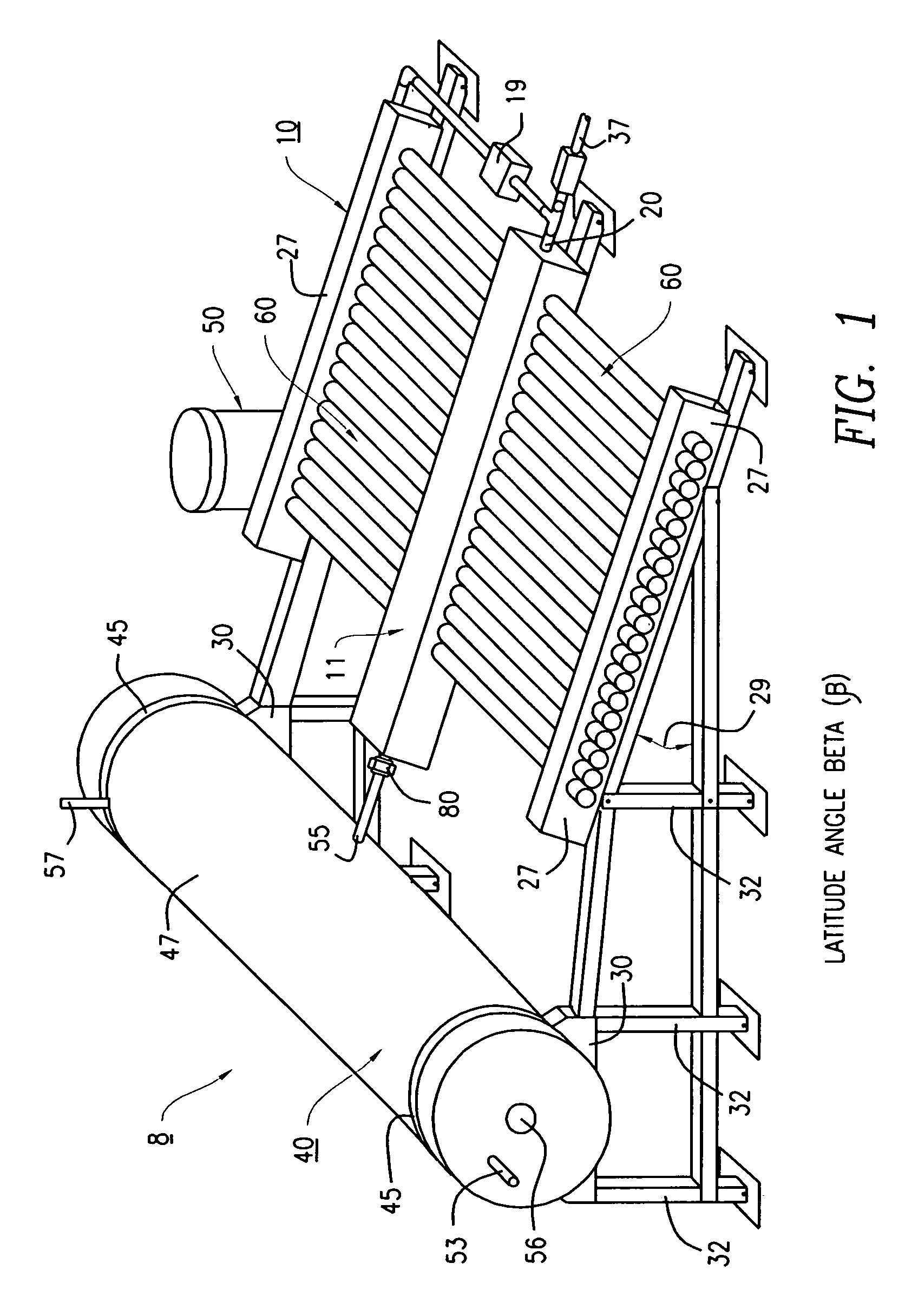

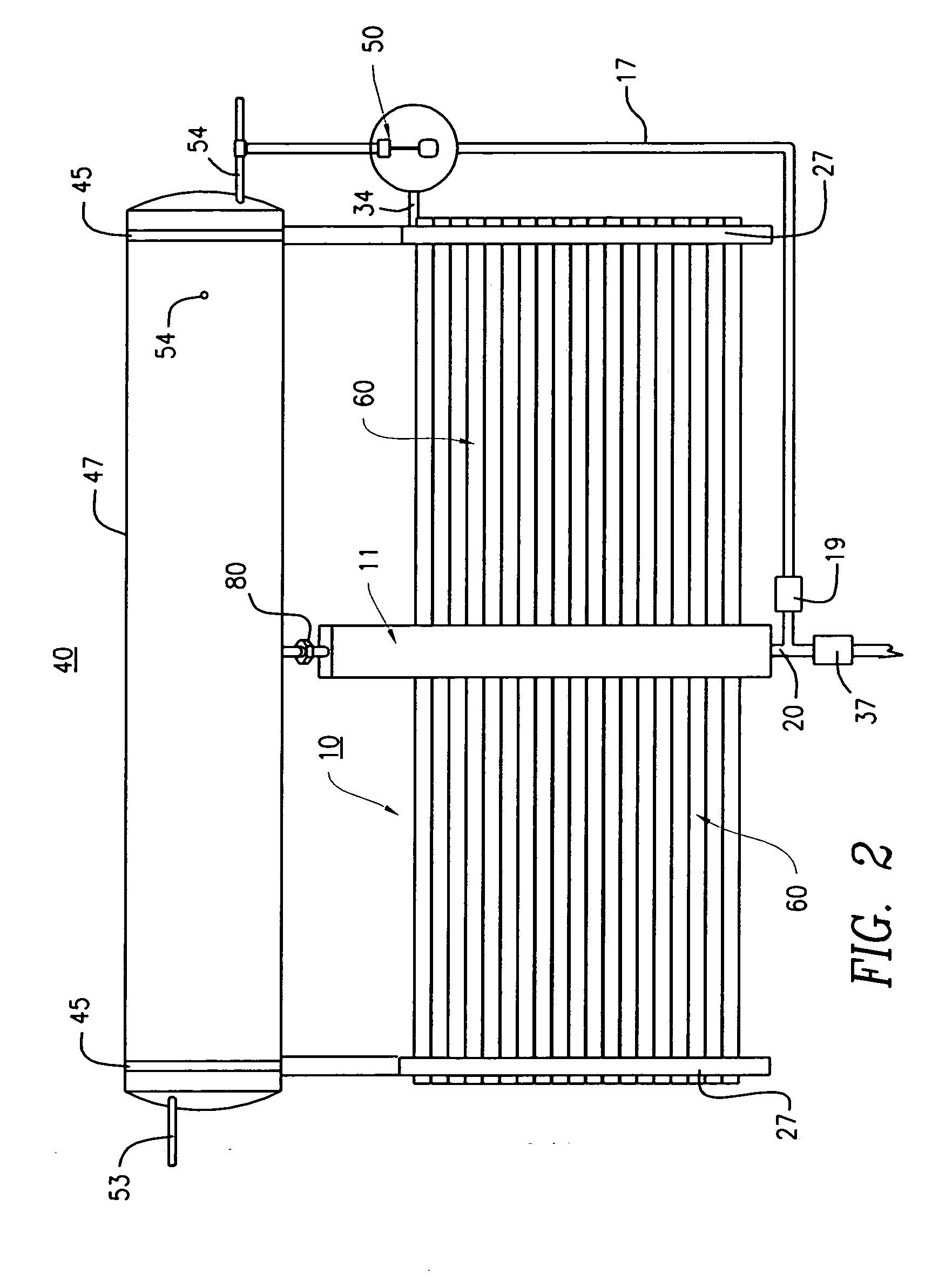

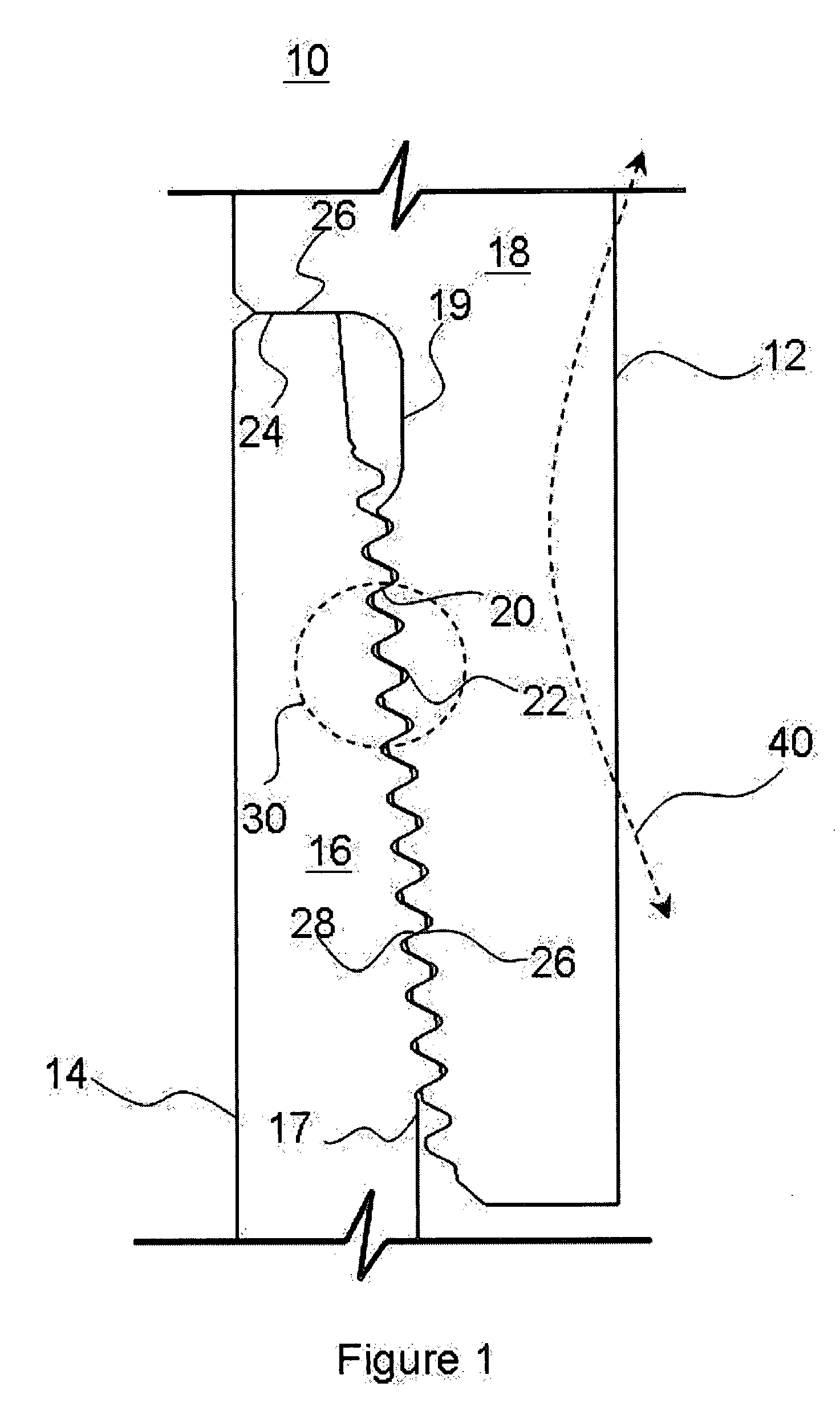

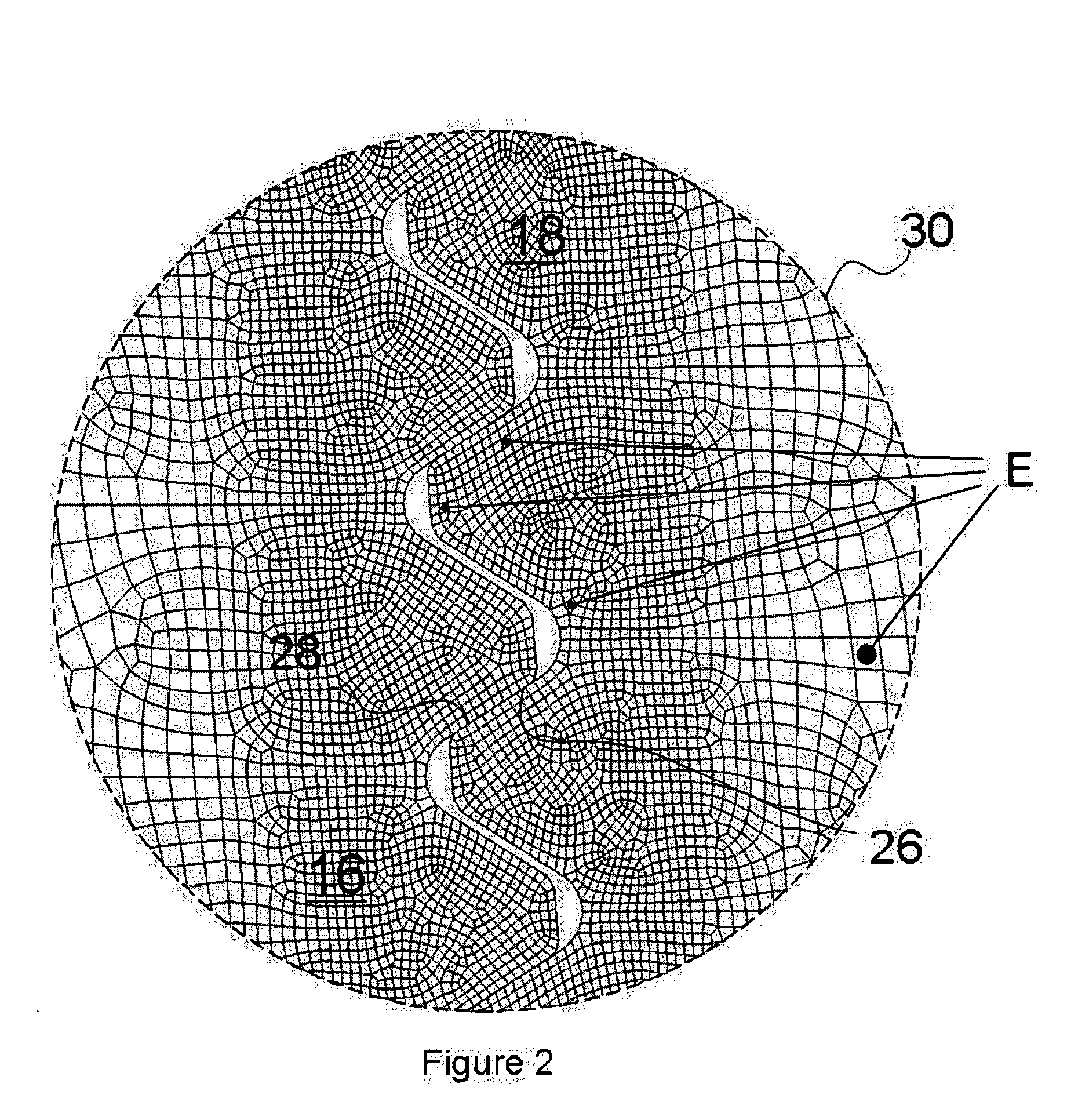

Integrated solar liquid heater, distiller and pasteurizer system

InactiveUS20070193872A1Improve storage densityImprove abilitiesSolar heating energyGeneral water supply conservationComposite constructionLiquid medium

The solar heating, distilling, and pasteurizing system of this invention comprises an integrated distillation column-reflector-bracket assembly, a heat storage system of composite construction, and at least one evacuated glass solar collector having selective absorption. The distillation column subassembly is filled with the fluid medium to be boiled which flows into the solar vacuum tube collectors where an evaporation process takes place. A float valve mechanism mounted to the frame automatically maintains the correct liquid level inside the distillation column. The height of float valve mechanism is adjustable by means of an adjustable float bracket. The distillation column subassembly collects and concentrates the steam or vapor generated inside the attached evacuated glass solar collector tubes. The column also separates the vapor from the boiling liquid medium and conducts the vapor into a heat and distilled fluid storage system. The reflector-bracket subassembly has a reflecting panel made from at least one sheet of reflective material typically flat or formed into a plurality of substantially parallel linear troughs shaped to concentrate solar radiation ideally. This reflector also acts as a means of further stress and strain distribution and dissipation into the structural elements of the bracket subassembly.

Owner:TECHNOSON PUERTO RICO

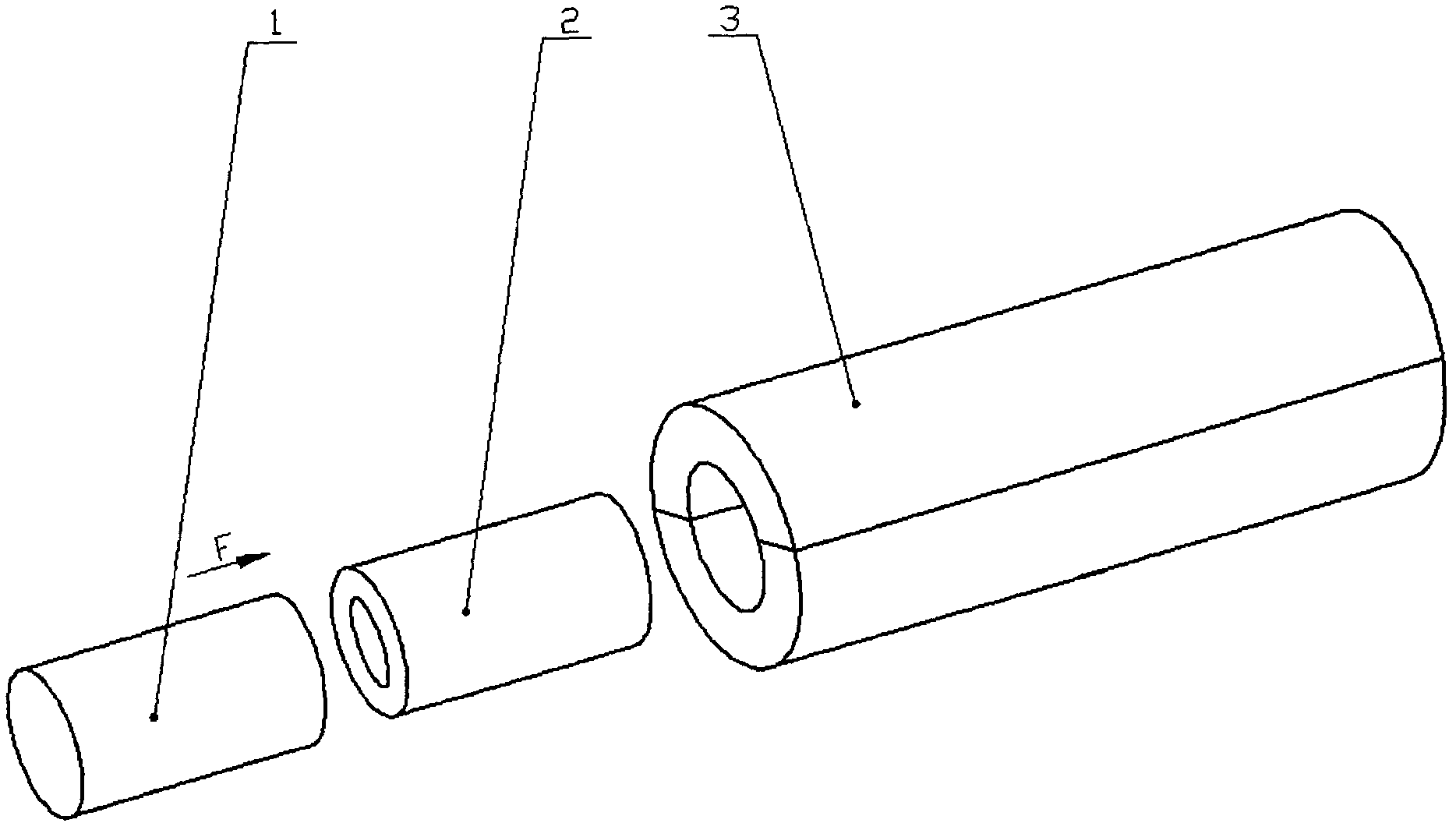

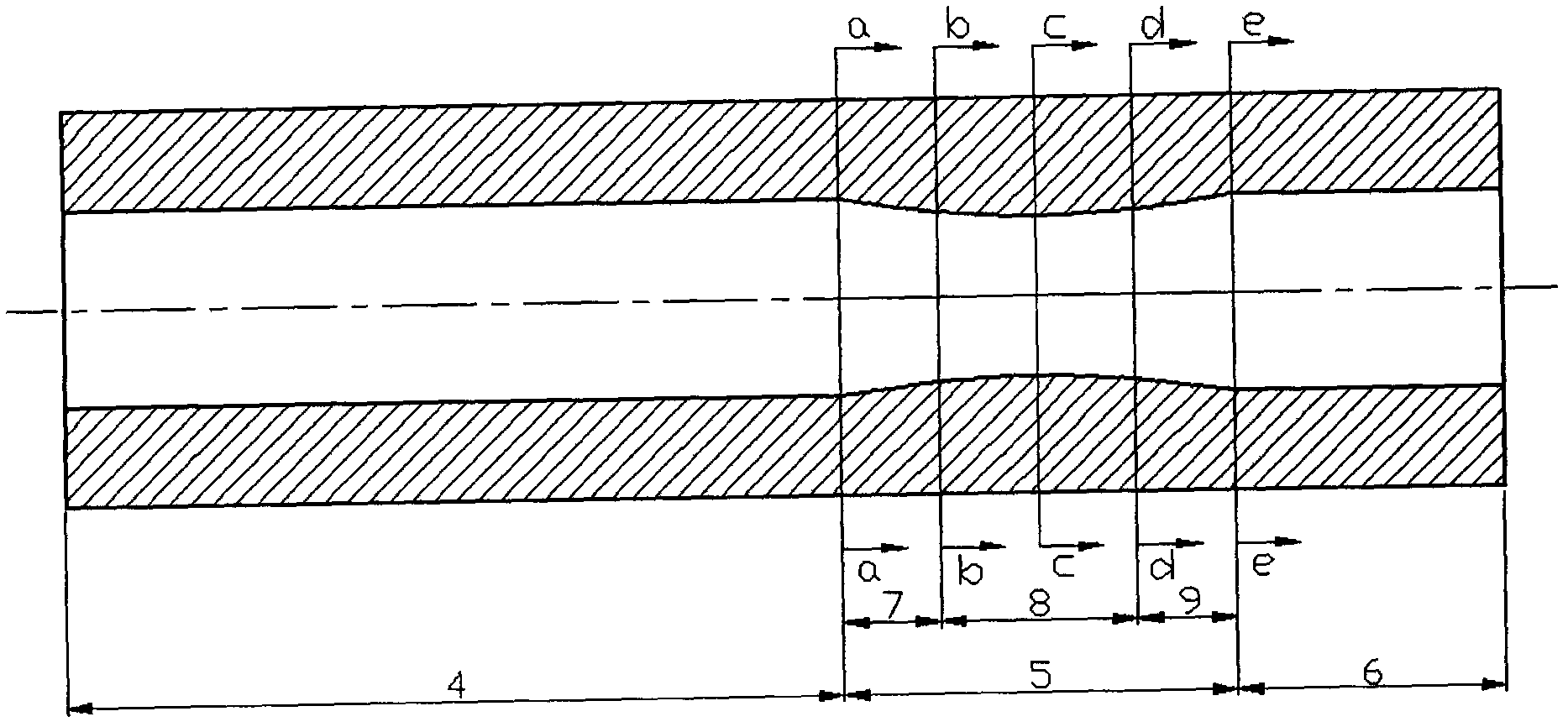

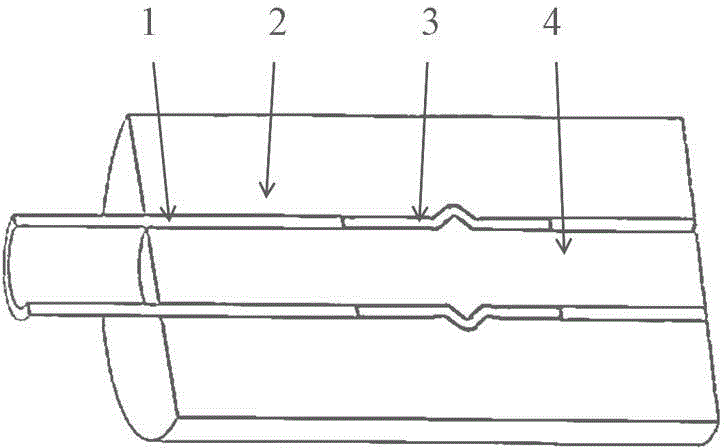

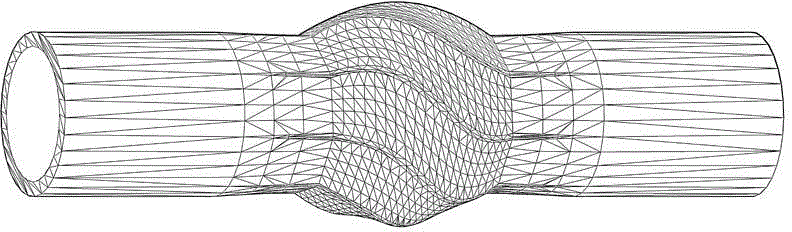

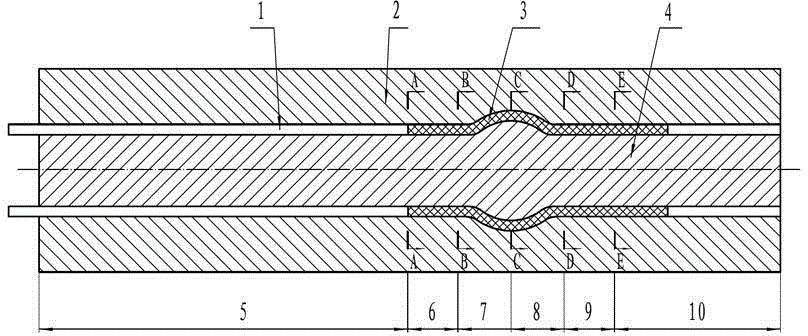

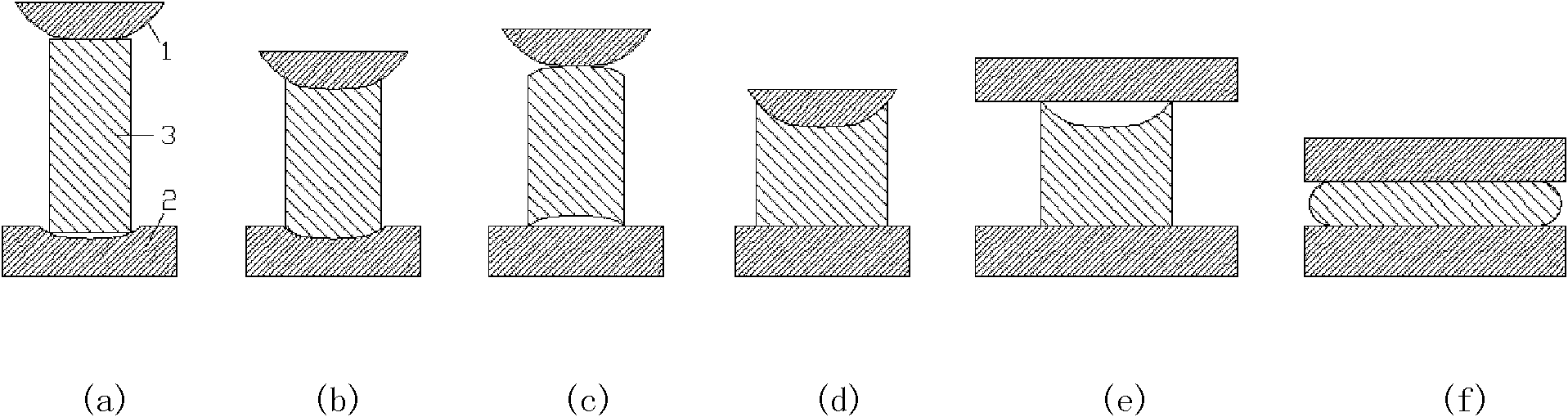

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

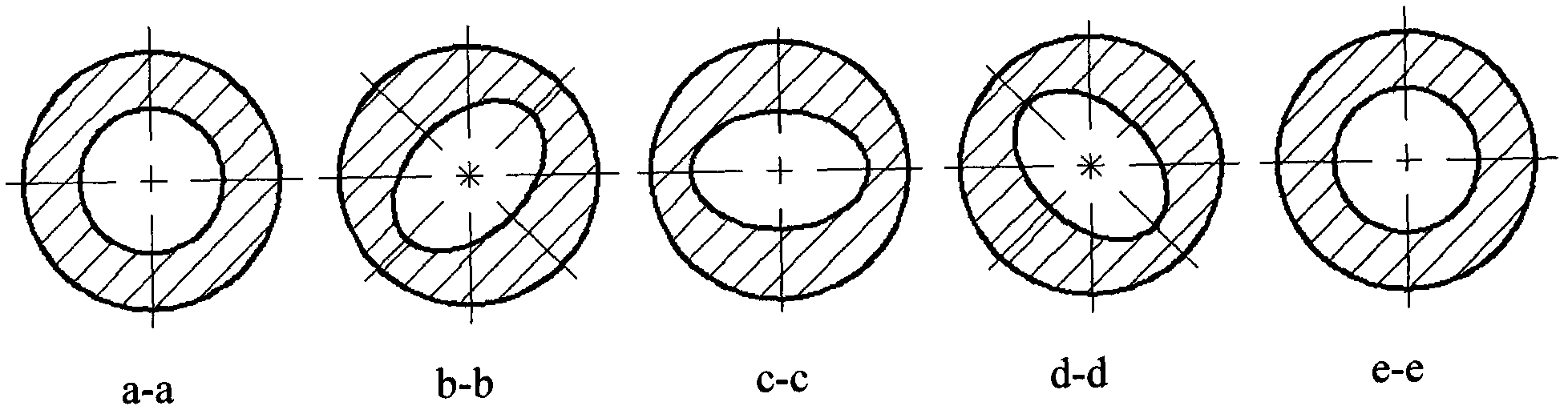

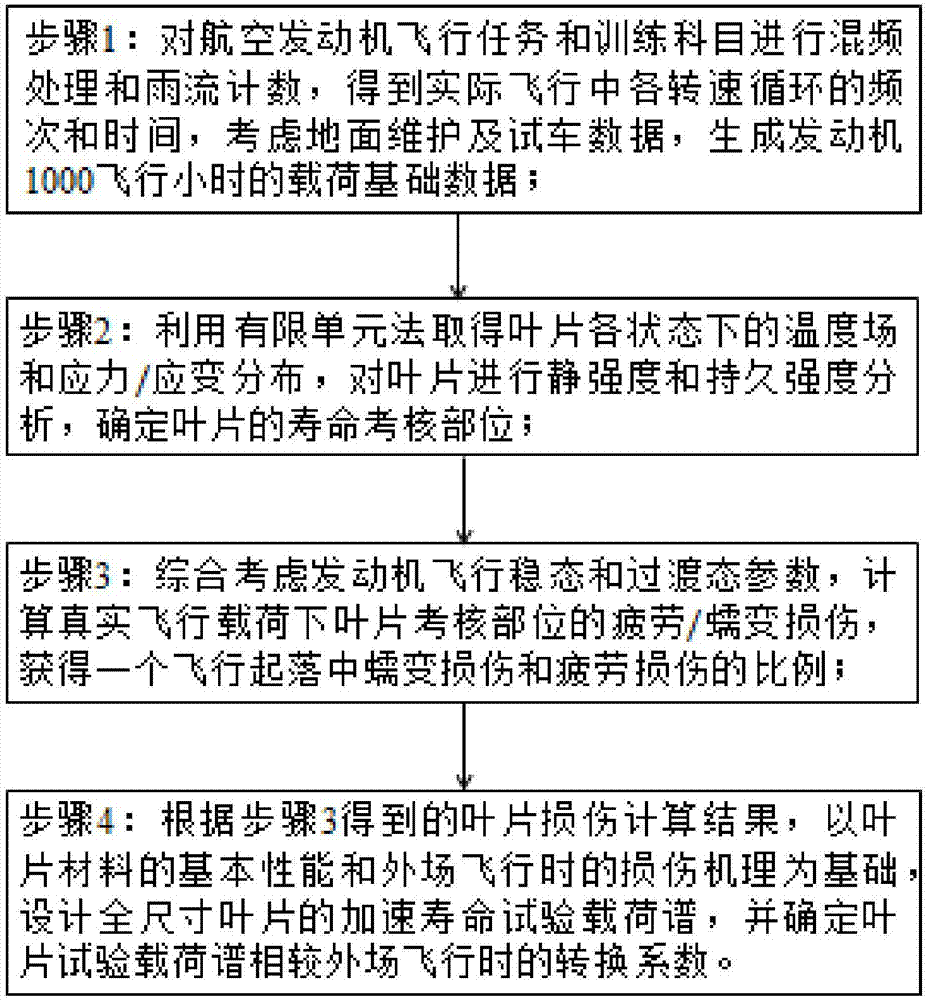

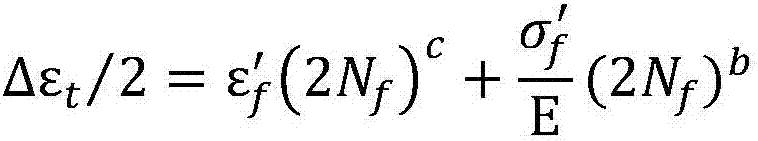

Turbine rotor blade accelerated life test load design method taking regard of flight damage

PendingCN107247002ADamage reasonably characterizedLife assessmentMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageAviation

The invention relates to a turbine rotor blade accelerated life test load design method taking regard of flight damage. The method includes: 1) conducting frequency mixing treatment and rain flow counting on aeroengine flight missions and training subjects to acquire the frequency and time of each rotation speed cycle in actual flight, thus obtaining the load basic data of an engine within certain flight hours; 2) acquiring the temperature field and stress strain distribution of the blade under all states by finite element method, analyzing the blade static strength and endurance, and determining a lifetime testing part of the blade; 3) calculating the fatigue damage and creep damage of the blade testing part under a true flight load to acquire a ratio of creep damage and fatigue damage during rise and fall of a flight; and 4) designing a accelerated life test load spectrum of a full-size blade, and determining a conversion coefficient of the blade test load spectrum relative to out-field flight. The method provided by the invention can be used for acquiring the technical life of the blade and studying the remaining life of the blade, and saves time and economic cost for the fatigue-creep lifetime test of the blade.

Owner:BEIHANG UNIV

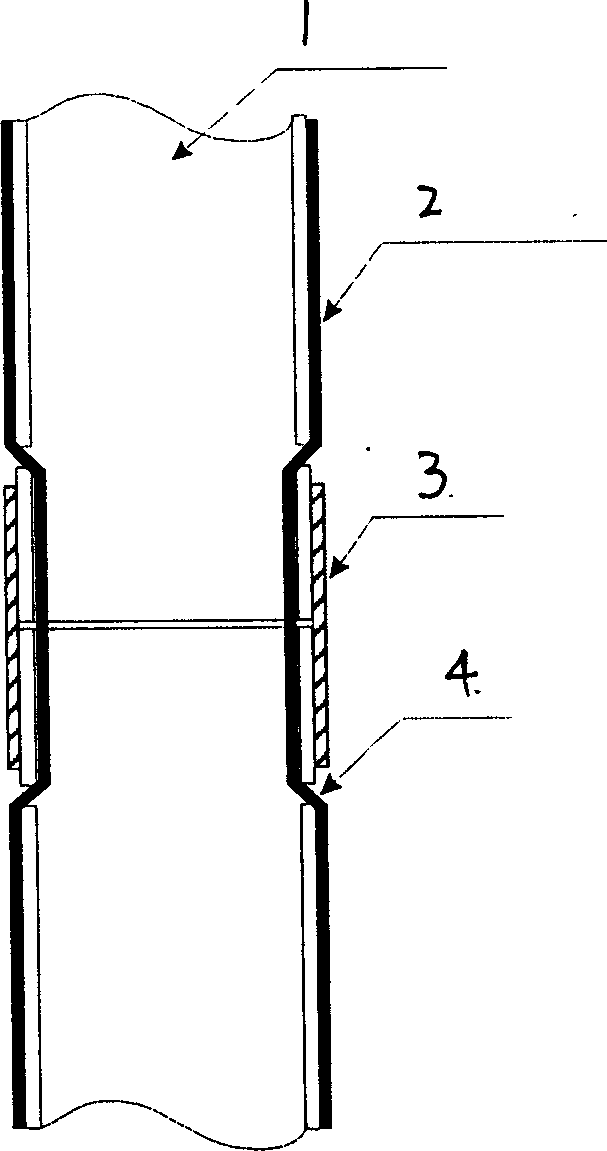

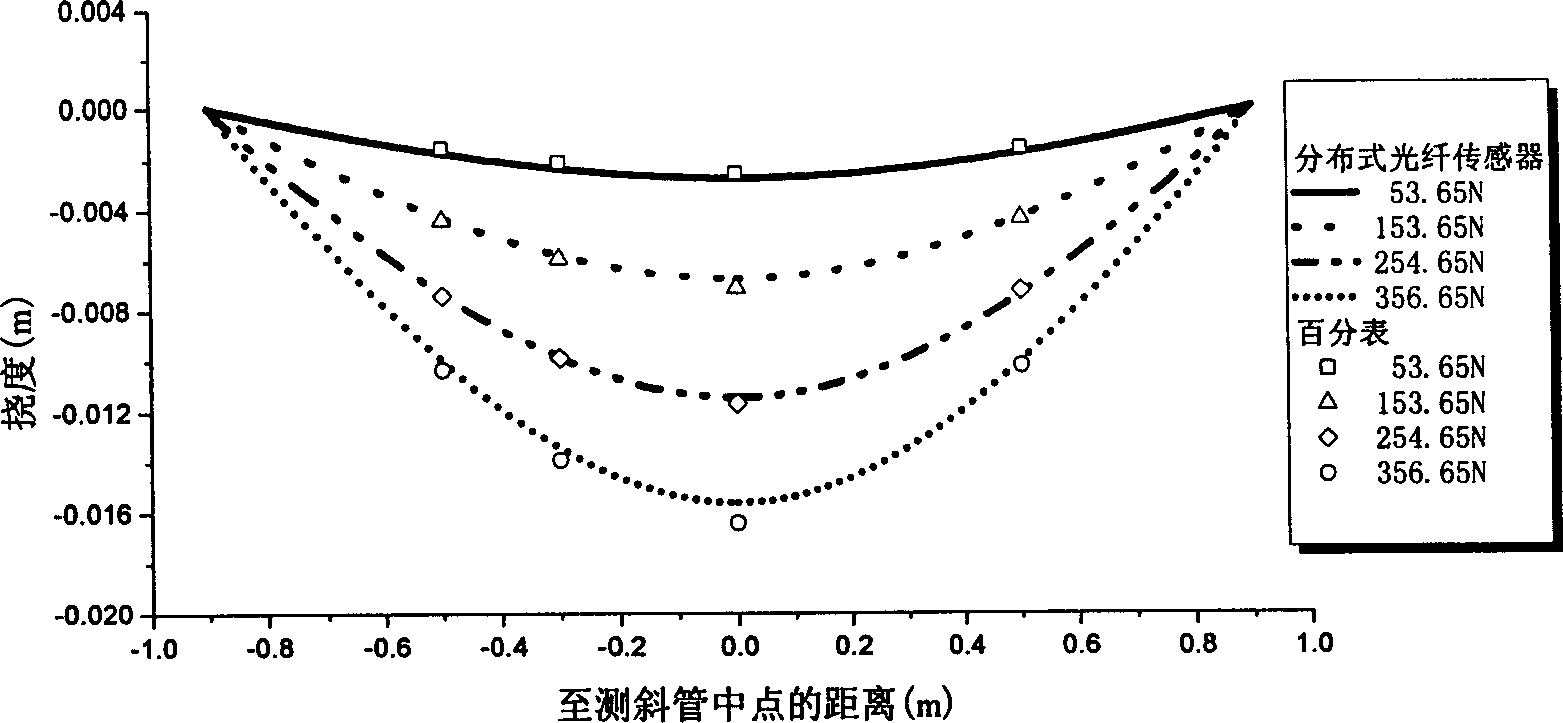

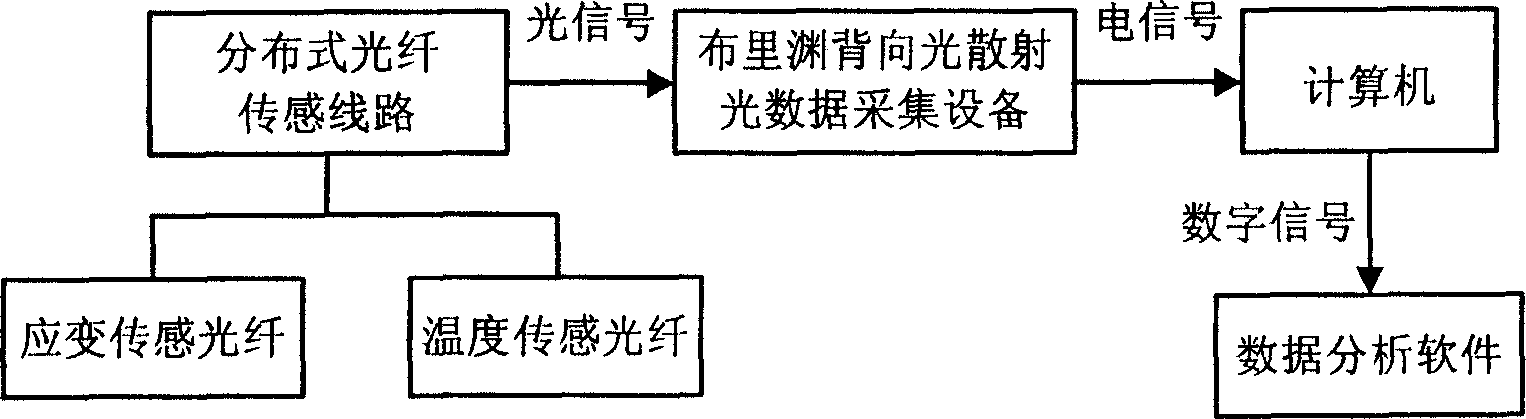

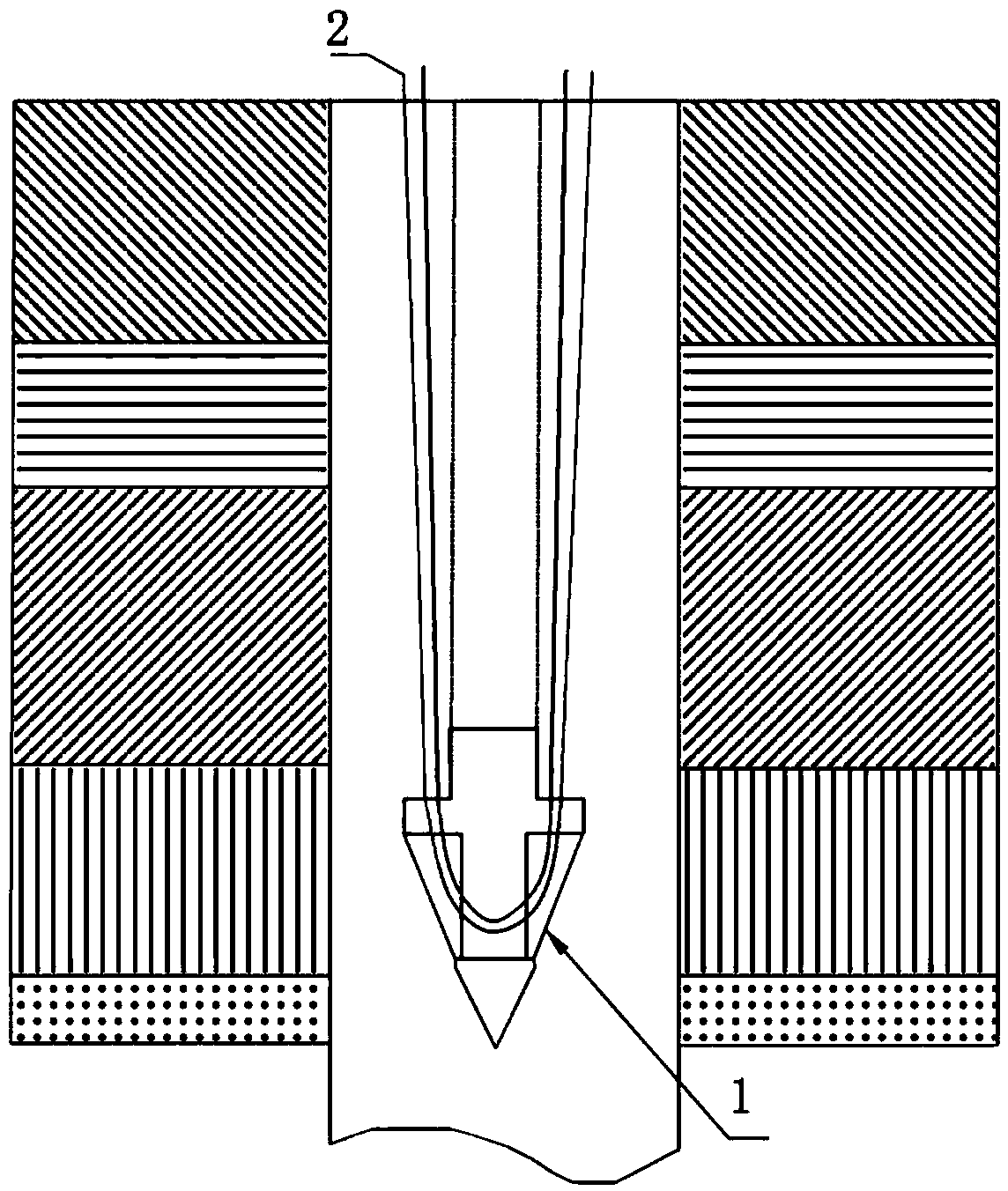

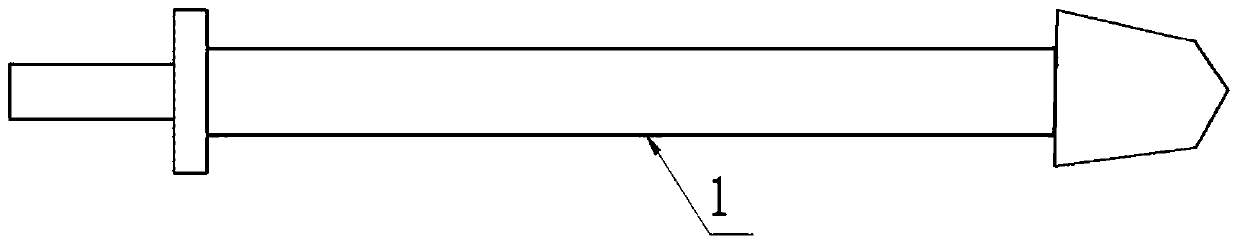

Distribution type optical fibre measuring method and system for deep deformation of soil

InactiveCN1598479ARealize remote monitoringRealize distributed monitoringUsing optical meansConverting sensor output opticallyFiberData collecting

The invention is a fixed measuring method and system for earth deep distortion, the measuring system is made up of slant pipe, distributed fiber sensing channel, data collecting device, computer control model, and data processing model. It uses distributed fiber sensing technology based on self Brillouin dispersion theory, the sensing fibers are pasted on the external surface of the slant pipe, and then the slant pipe is embedded in the earth for measuring the distortion and shift of earth. When the deep earth moves, the earth drives the slant measuring pipe to generate distortion, the strain capacity of the external wall of the slant measuring pipe is changed, then uses BOTDR to measure the strain distribution of the fiber on the external wall of the slant measuring pipe directly, the collection process of data can be realized by computer control model, the data is induced into the data processing model by the computer control model, and the distortion quantity can be worked out according to a certain arithmetic, thus the distortion or shift of earth can be acquired.

Owner:NANJING UNIV

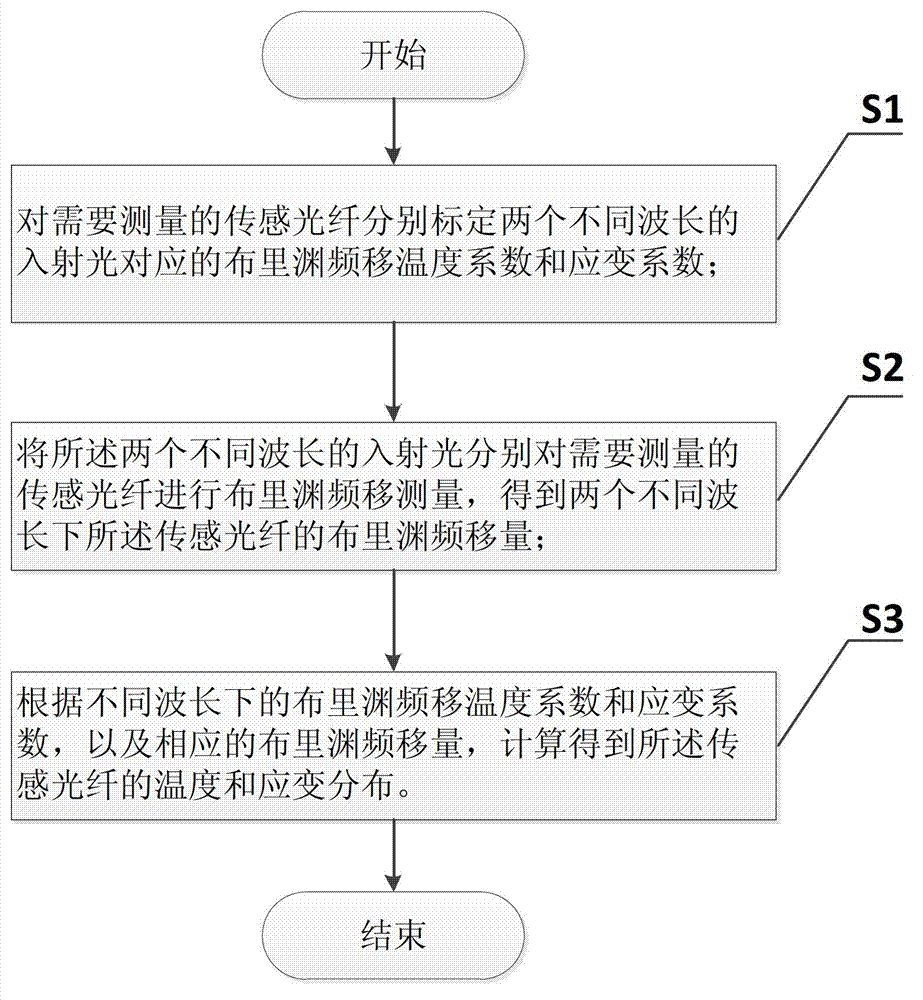

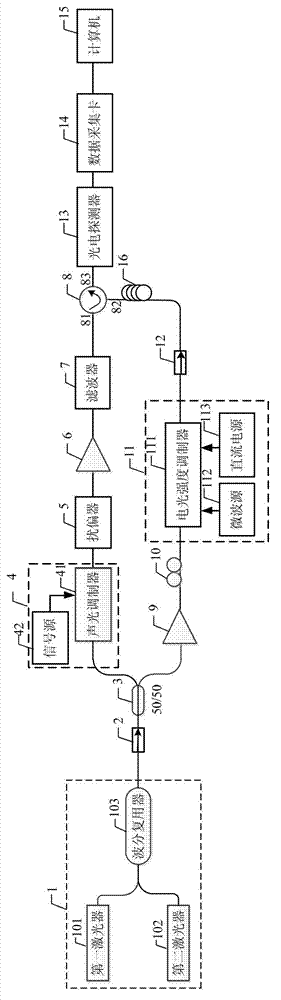

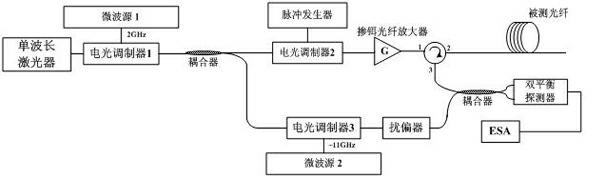

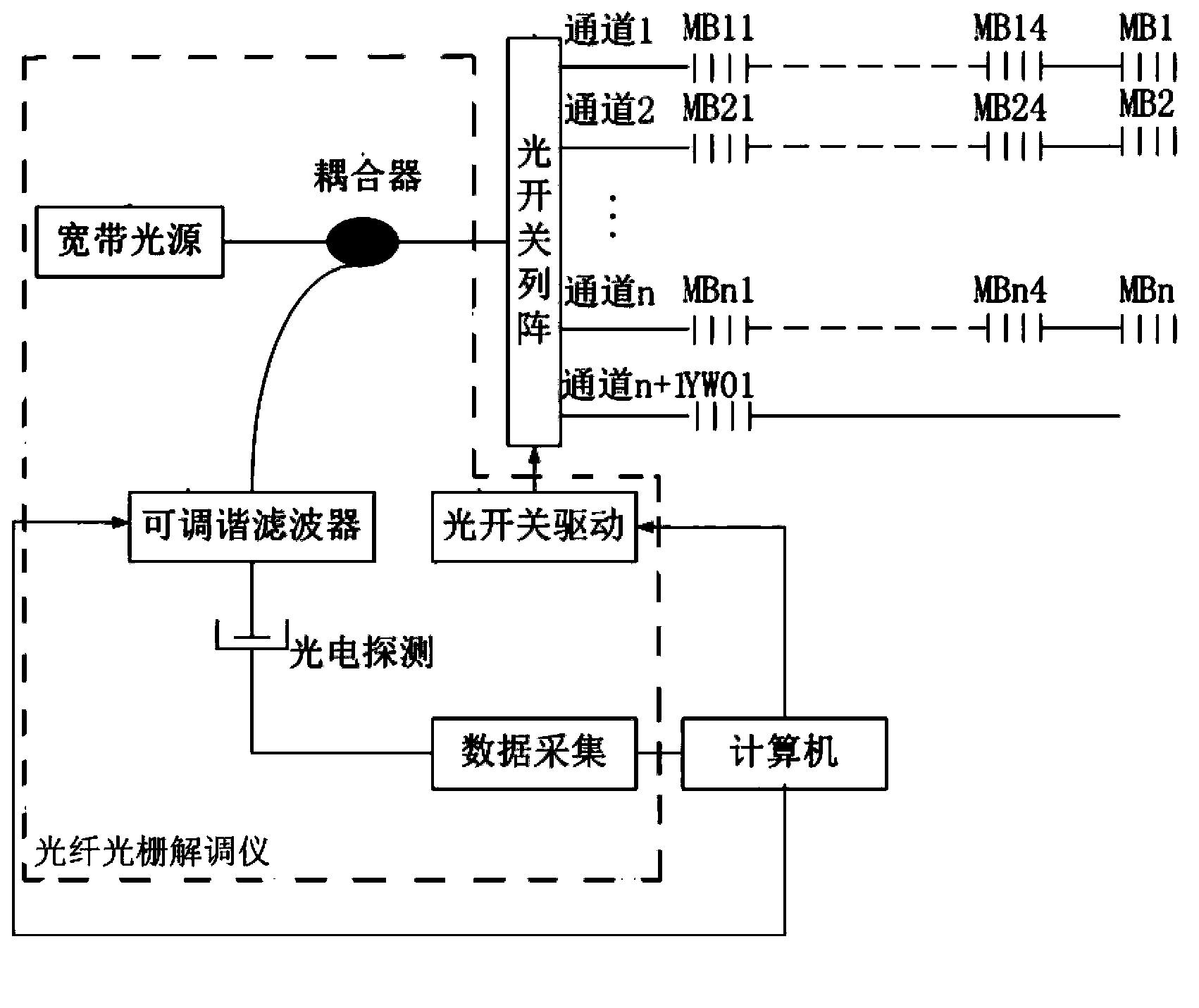

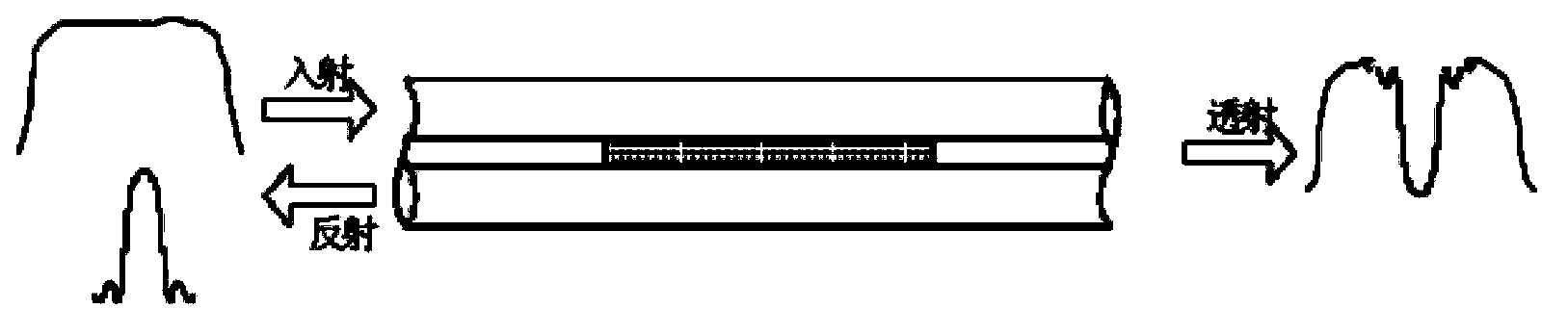

Distributed fiber sensing method and device for simultaneously measuring temperature and strain

InactiveCN103207033AAvoid measuringSimple structureThermometers using physical/chemical changesUsing optical meansMultiplexerLength wave

The invention belongs to the distributed fiber sensing technology, and provides a distributed fiber sensing method and a distributed fiber sensing device for simultaneously measuring temperature and strain. The method comprises the following steps of: calibrating Brillouin frequency shift temperature coefficients and strain coefficients of a sensing fiber to be measured, which correspond to incident light of two different wavelengths; measuring the Brillouin frequency shift quantity of the sensing fiber in the two different wavelengths; and calculating the temperature and strain distribution of the sensing fiber. Specifically, the incident light of the two different wavelengths can be sequentially and separately injected into the sensing fiber during measurement, and can also be simultaneously injected into the sensing fiber through a wavelength division multiplexer. By adopting the common single mode fiber, the cost is low and long-distance distributed sensing can be realized; and only the Brillouin frequency shift quantity in different pumping wavelengths is required to be measured, so that the measurement precision is effectively improved, and the structure of the system is relatively simple.

Owner:NAT UNIV OF DEFENSE TECH

Functionally strained optical fibers

InactiveUS6898355B2Eliminating and greatly reducing impactImproved strain distributionCladded optical fibreOptical articlesTensile strainFiber

The present invention introduces a concept of “smart” ribbons, which use functionally tensioned optical fibers during the manufacture of fiber optic ribbons to create fiber ribbons with controlled geometrical configuration, optimized strain distribution and reduced attenuation. The ribbons may have flat or bowed cross section and be straight along the length or curved in its plane, or twisted unidirectionally, or periodically. These shapes and residual stress-strain state are induced and controlled by using tension functions instead of traditional constant-value tension per fiber during the ribbon manufacture. Further, the present invention reduces signal loss and / or attenuation in ribbon fibers caused by an increase in the strain variation from tensile strain to compressive strain along the length of the individual fibers when ribbons are manufactured, stacked, stranded around a strength member or twisted and bent during cable installation. In a first embodiment of the present invention, either a symmetric or non-symmetric load distribution is applied across the fibers being placed or drawn into a ribbon structure to eliminate or control residual twist in a completed fiber ribbon. Additionally, in the present invention, the load distribution on the fibers of a ribbon can be varied (e.g. periodically changed) along the length of the ribbon to provide a ribbon with the required design characteristics for any particular application. In a second embodiment of the invention, a fiber optic ribbon is made up of a plurality of sub-unit ribbons arranged in substantially the same plane. Each sub-unit ribbon includes a plurality of optical fibers coated by sub-unit matrices.

Owner:ALCATEL LUCENT SAS

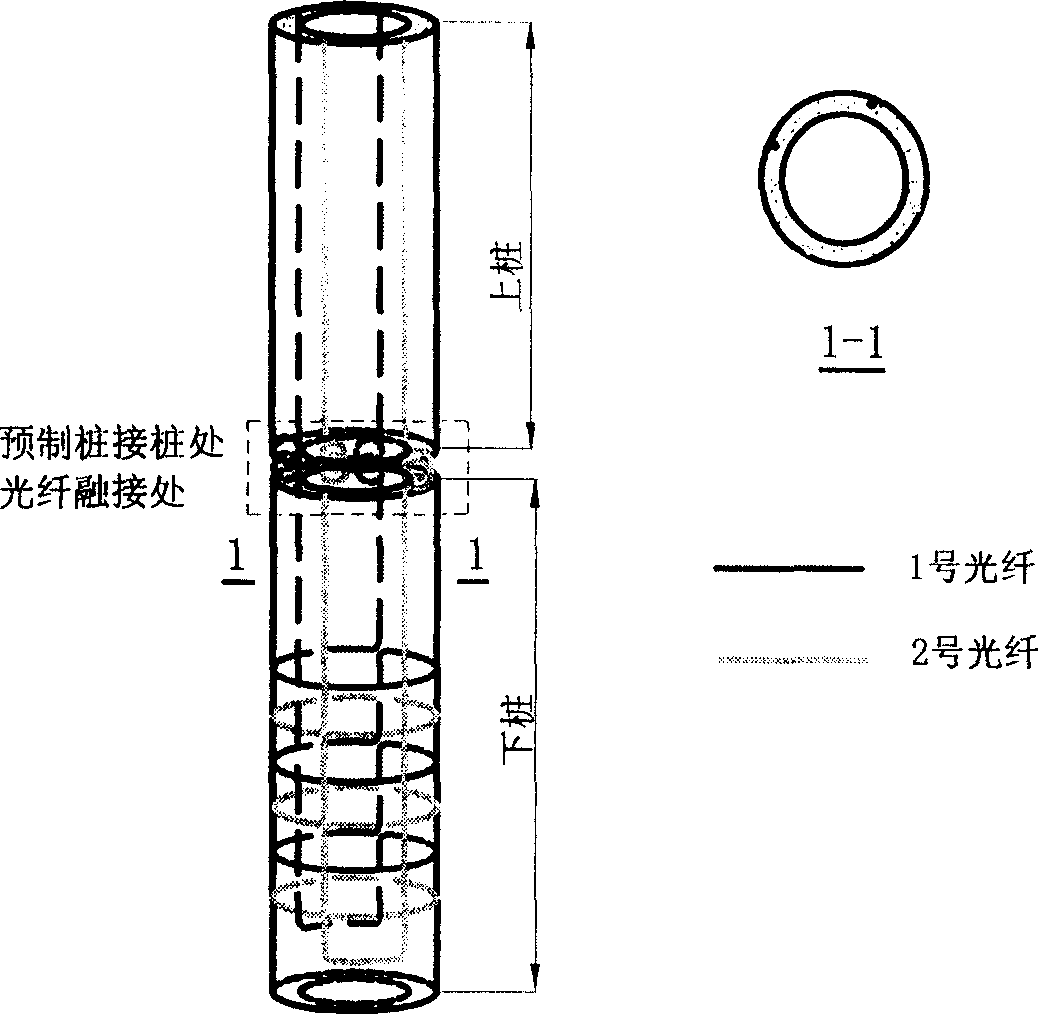

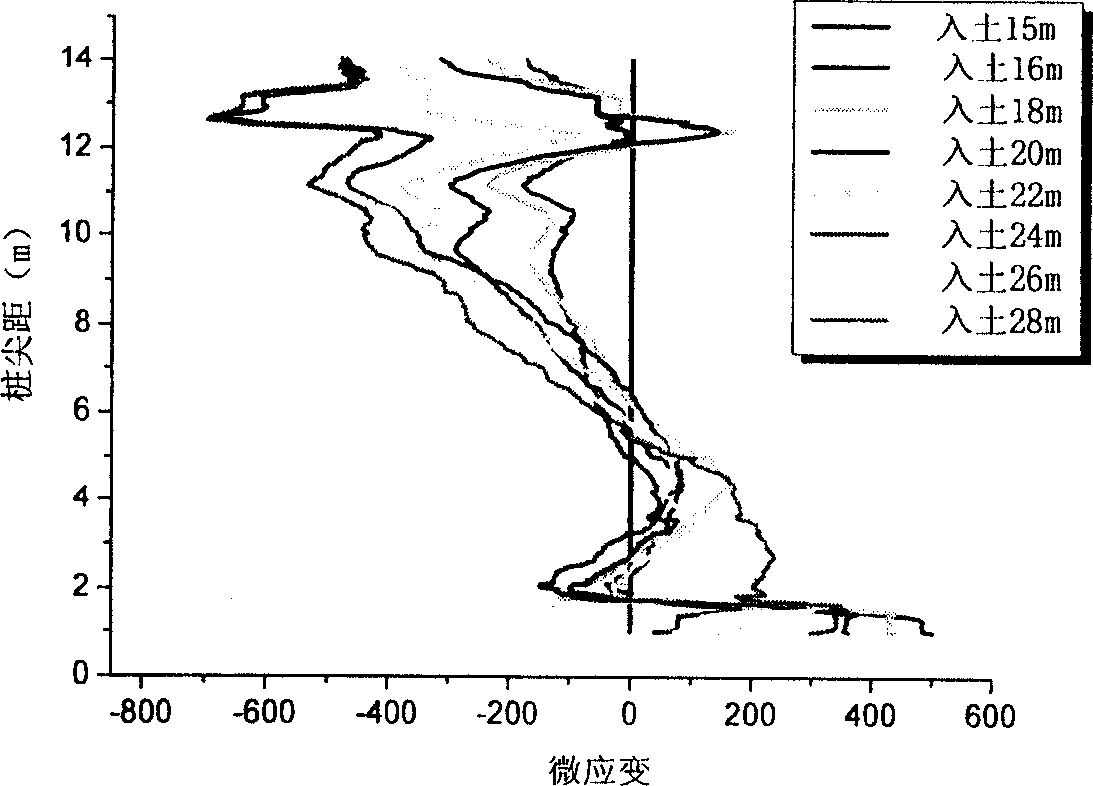

Distributive optical fiber detecting method and system for prefabricated pile damage

InactiveCN1900434ARealize quantitative evaluationRapid damage detectionFoundation testingConverting sensor output opticallyFiberLinear correlation

The method sets up sensing optical fiber on surface of prefabricated foundation pile to be measured. Both dependent variable and temperature sensed of the fiber are based on Brillouin backscattering. At incidence end of pulsed light, the method measures received light power of Brillouin backscattering so as to accomplish function of measuring and positioning Brillouin frequency shift on each points of optical fiber. In procedure of sinking pile, strain distribution is as basic parameter to reflect impaired character and degree of foundation pile. Based on linear correlation between Brillouin frequency shift and strain, temperature, the method carries out temperature compensation based on measured strain distribution and temperature distribution so as to obtain actual strain distribution on surface of foundation pile to be measured.

Owner:NANJING UNIV

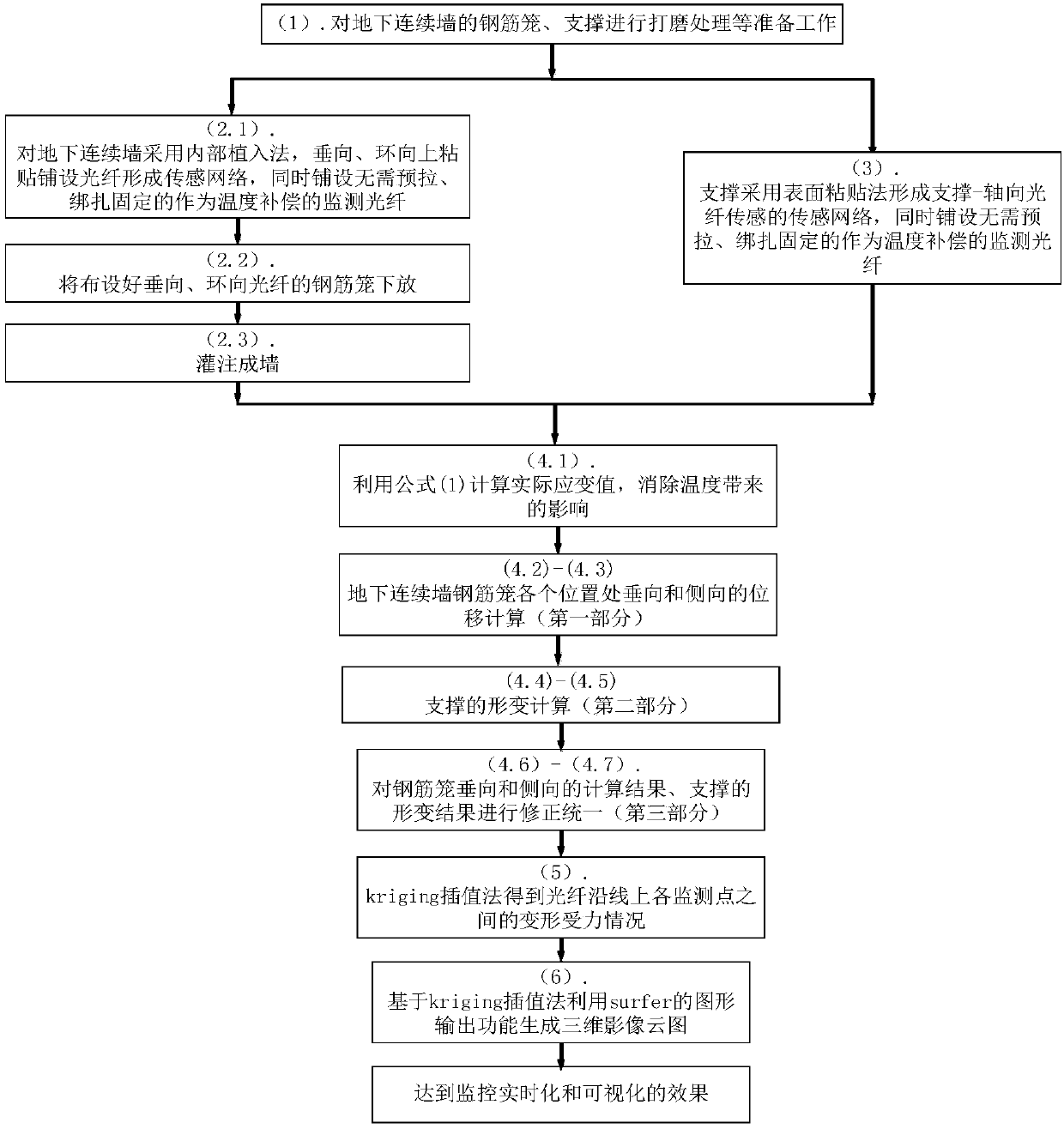

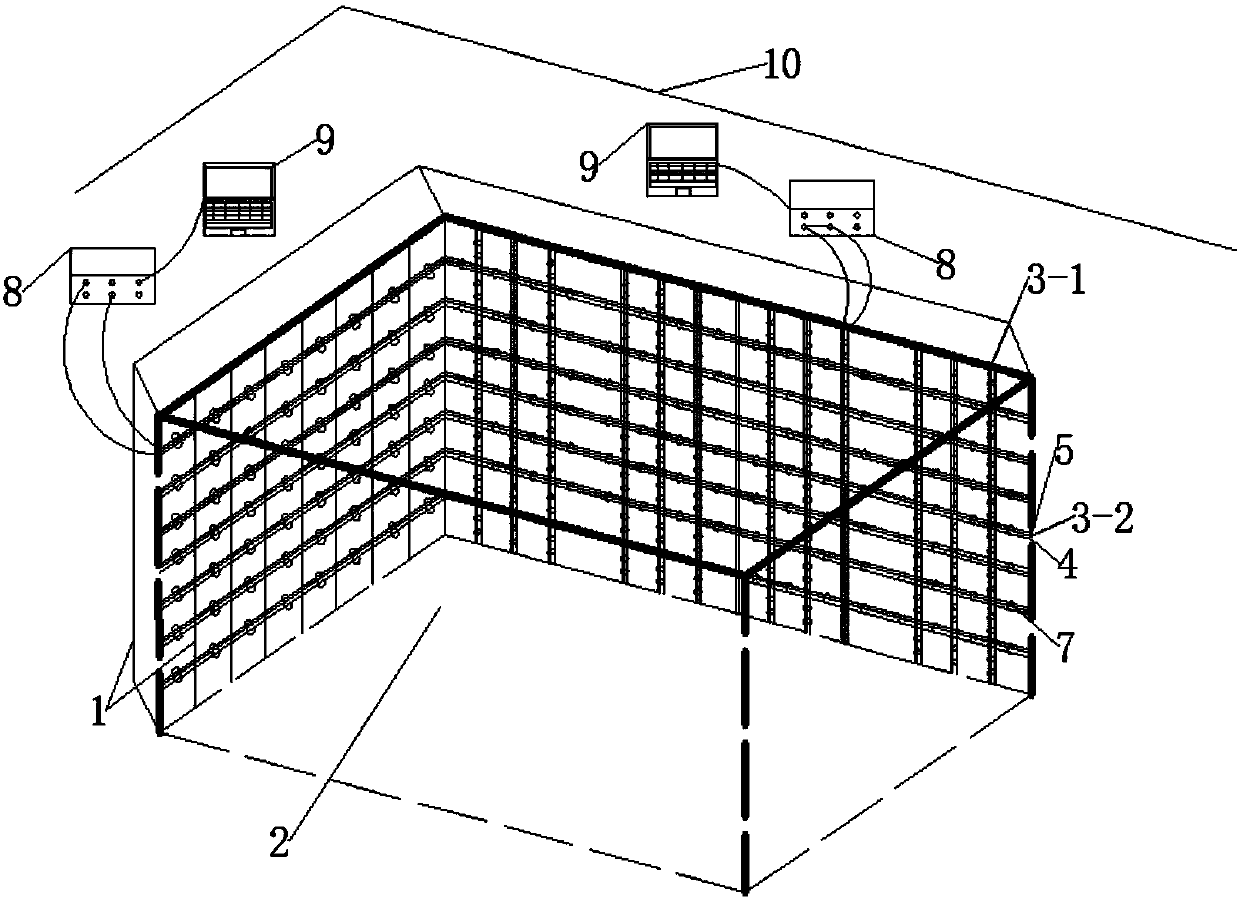

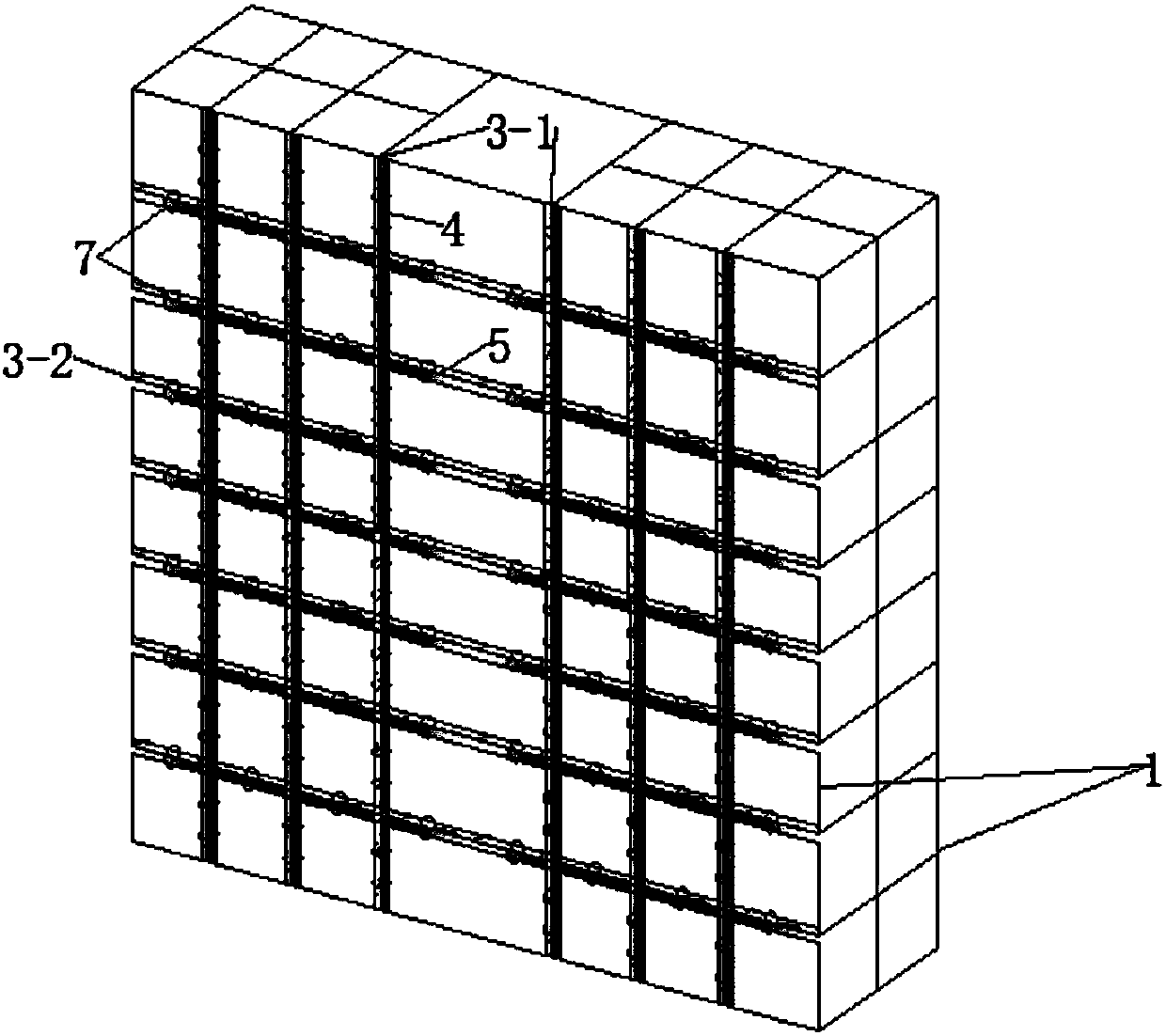

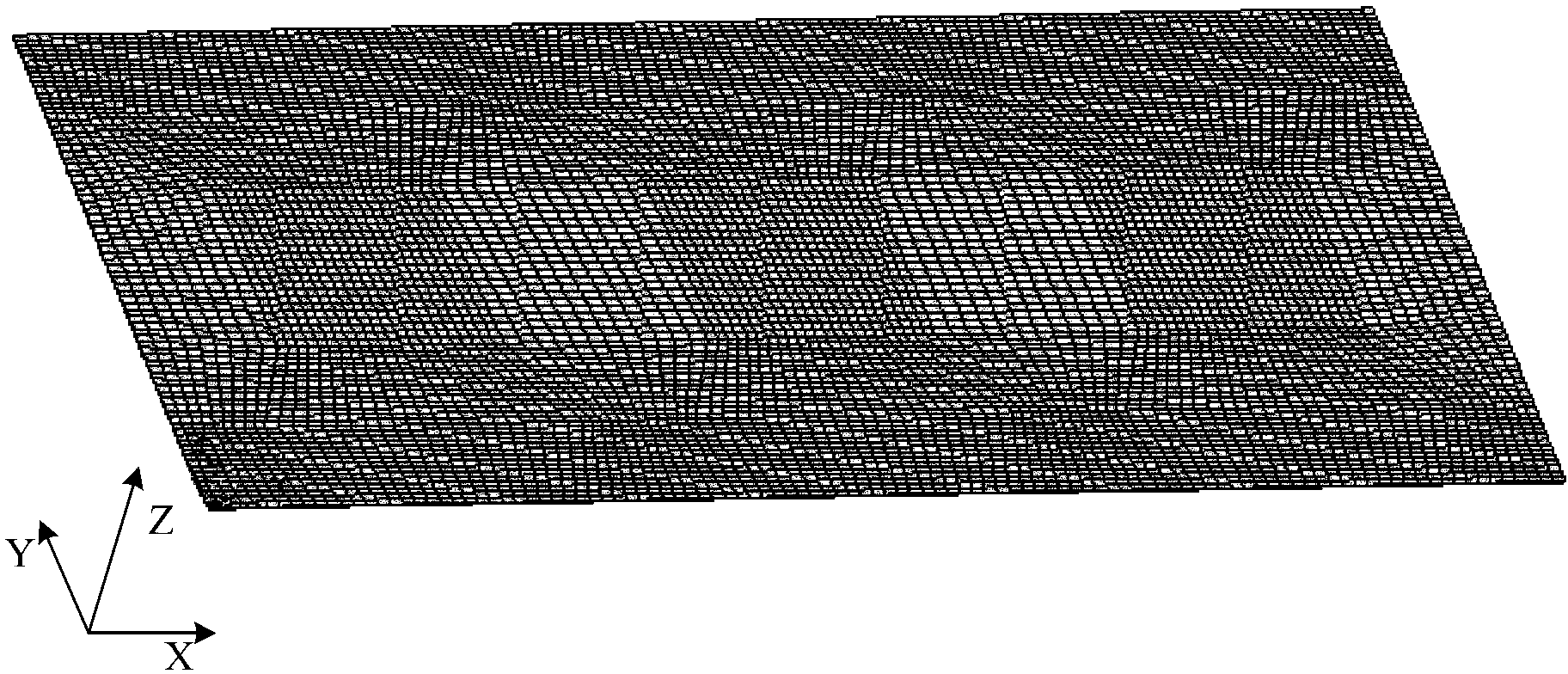

Foundation pit engineering three-dimensional monitoring network realization method based on distributed optical fiber sensors

ActiveCN107843203AExtensive application of monitoring and monitoringAvoid the disadvantages of traditional point monitoringUsing optical meansEngineeringMonitoring data

The invention provides a foundation pit engineering three-dimensional monitoring network realization method based on distributed optical fiber sensors, which relates to a scheme of laying optical fiber sensors on an enclosure and support structure, overall deformation and force bearing analysis on the enclosure and support structure and generation of a strain distribution cloud map. Based on the characteristics that the frequency changes of back Brillouin scattering light formed by scattering of optical wave molecules of the optical fibers and incident light are sensitive to strain and temperature and BOTDA sensing advantages and benefiting from the accurate, stable and real-time monitoring advantages of the optical fiber sensors, the optical fibers on the components are arranged to a three-dimensional monitoring network, comprehensive and three-dimensional deformation and force bearing monitoring can be carried out on enclosure and support components and other components in the foundation pit project, real-time monitored data are guided to surfer to generate a structure strain distribution cloud map, and the method of the invention is a visualized and three-dimensional monitoringmeasurement and control method.

Owner:TONGJI UNIV

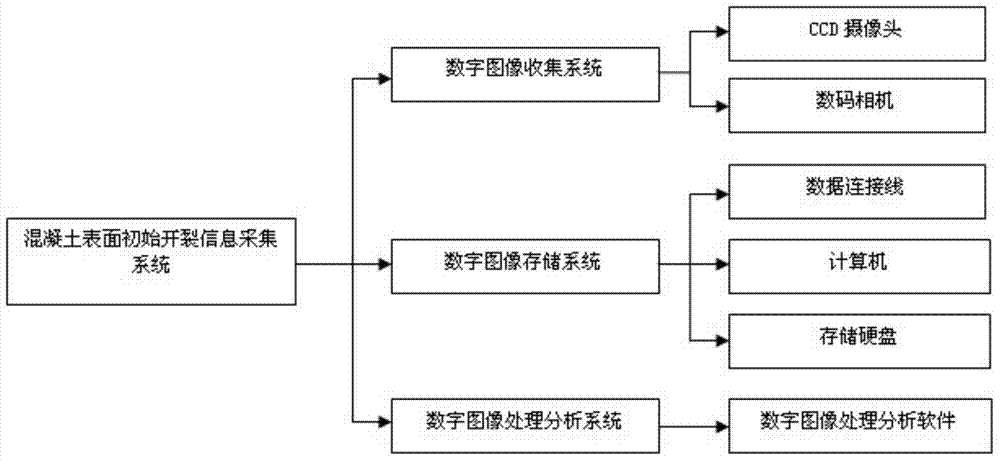

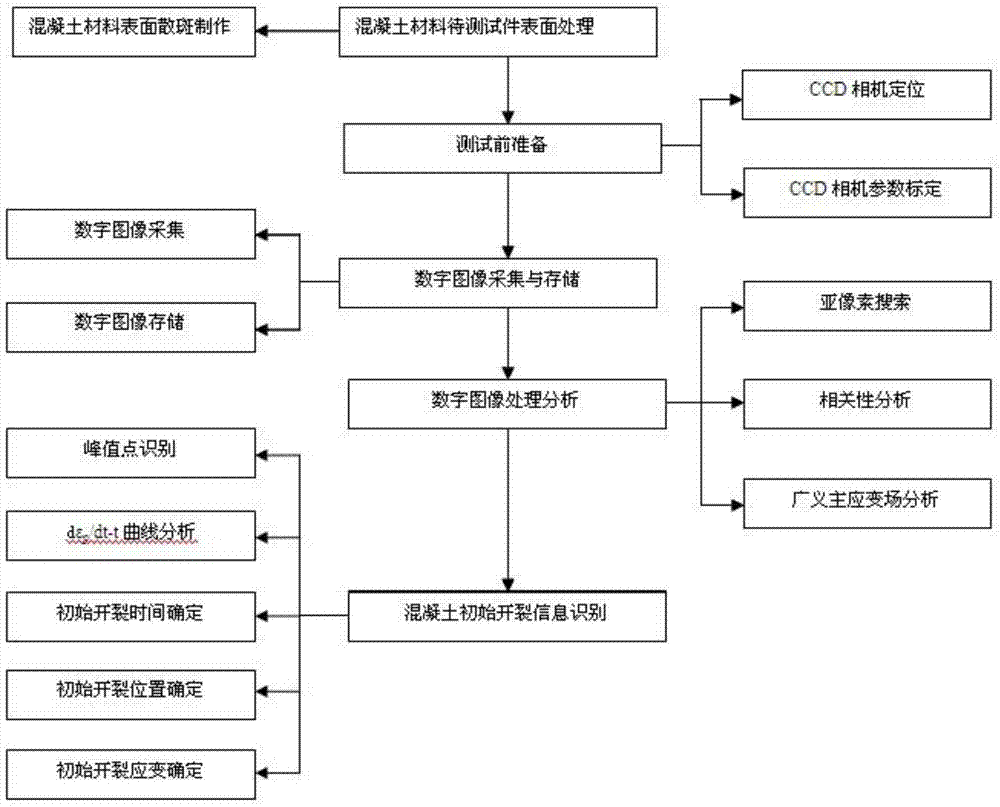

Acquisition system and identification method of concrete surface initial crack information

ActiveCN104330023AEasy to handleSimple and fast operationUsing optical meansBatch processingTime changes

The invention relates to the technical field of construction material detection and aims to provide an acquisition system and identification method of concrete surface initial crack information. According to the method, the image of the surface of a concrete material piece to be tested is shot by a digital camera, then the digital image is processed and analyzed through a digital image matching method, finally the initial crack position of concrete is identified through a main strain distribution map peak point, and the initial crack time of the concrete is judged through the time change rule of the peak point strain. According to the acquisition system and identification method of concrete surface initial crack information, the influence of a strain gauge size effect can be effectively avoided, a strain gauge is not pasted to the surface of the concrete, and the initial crack position of the concrete surface can be accurately determined. All test equipment of the method is reproducible, the initial crack information of the concrete material can be objectively, accurately and reasonably identified, according to the method, the concrete sample treatment is simple, the operation is simple, the batch processing can be realized, a lot of manpower cost is saved, and the test cost is low.

Owner:ZHEJIANG UNIV

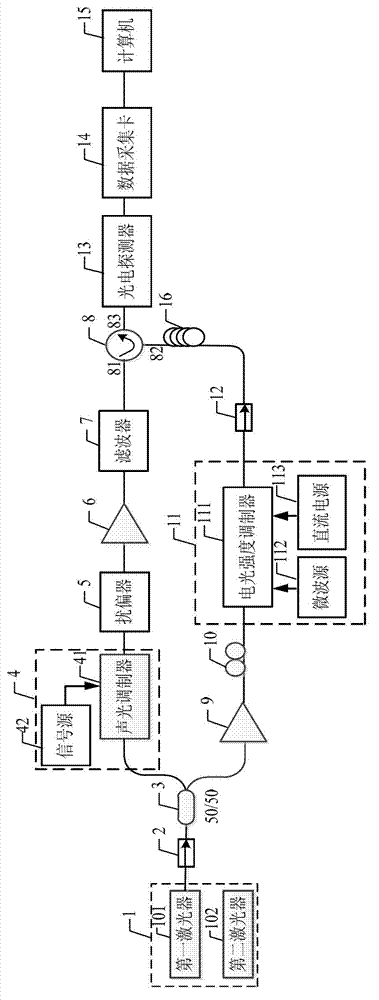

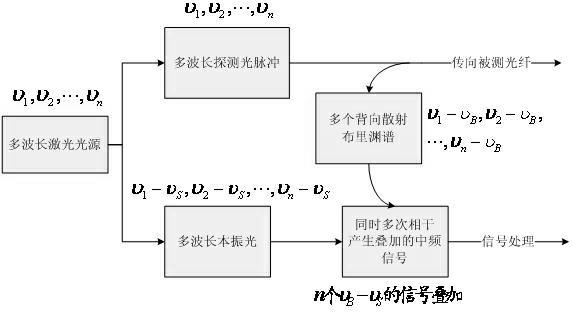

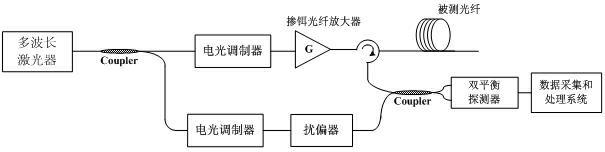

Multi-wavelength light source-based Brillouin optical time domain reflectometer

InactiveCN102589592AImprove utilization efficiencyIncrease the number of wavelengthsThermometers using physical/chemical changesUsing optical meansContinuous lightFiltration

The invention discloses a multi-wavelength light source-based Brillouin optical time domain reflectometer which comprises a multi-wavelength laser, a coupler, an electrooptical modulator, an erbium-doped optical fiber amplifier, an optical filter, a circulator, a double-balanced detector and a signal acquiring and processing system, wherein continuous light of the multi-wavelength laser is divided into two paths, wherein one path is modulated into pulse light through the electrooptical modulator and the other path is modulated to obtain continuous light of a local oscillator through an electrooptical modulator sideband. Multi-wavelength detection pulse light is amplified by the erbium-doped optical fiber amplifier, subjected to spontaneous emission noise filtration by the optical filter and is injected into a sensing optical fiber by the circulator. Stokes Brillouin back scattering light in the sensing optical fiber is coherent with local oscillator light through the circulator, is subjected to photovoltaic conversion through the double-balanced detector and then is fed into the signal acquiring and processing system to obtain a Brillouin scattering spectrum on the whole optical fiber and further obtain the temperature and strain distribution on the optical fiber.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST +1

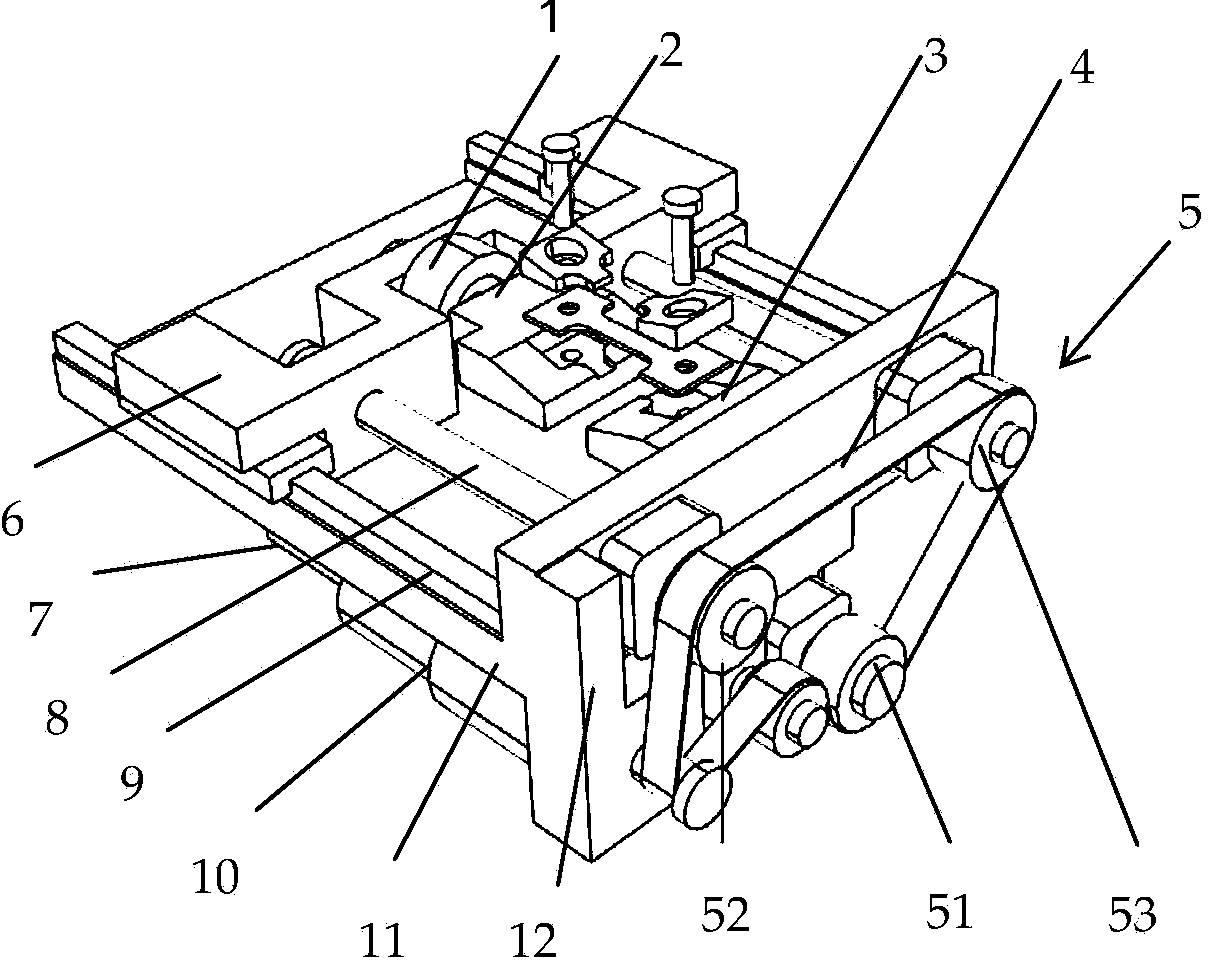

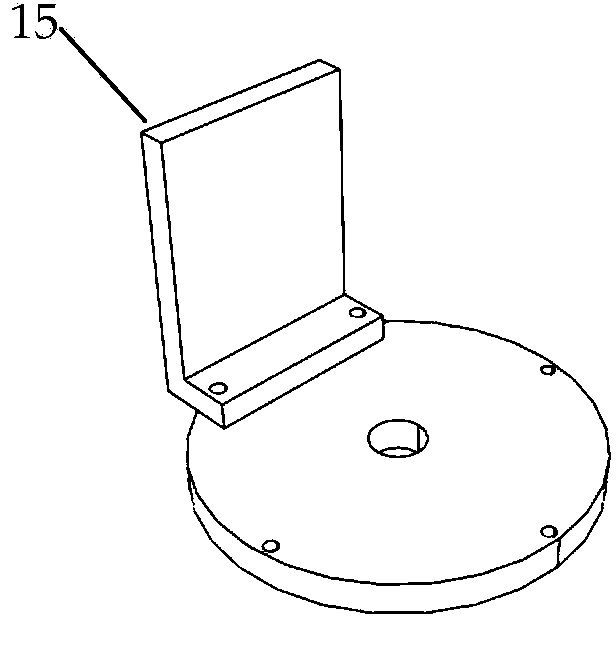

Synchronous radiation X-ray diffraction in-situ stretching device and application method thereof

ActiveCN103528888AEnsure safetyAvoid volatilityMaterial strength using tensile/compressive forcesX-rayData acquisition

The invention relates to the field of material structure research and performance in-situ test, and specifically relates to a synchronous radiation X-ray diffraction in-situ stretching device and an application method thereof. The device comprises three main components of a loader, a driver, and a fixing support. The loader is mainly manufactured by using high-strength aluminum alloy or titanium alloy, and comprises a pedestal, a load driving part, a load transmission part, a sample fixture part, a stretch sensor part, and a slide guide rail part. The driver is an integration of a data collection card and a motor driver, and is independent from the loader. The fixing support is manufactured from high-strength aluminum alloy, and has a detachable interface on the lower part. The device is designed based on an X-ray reflective optical path principle. Sample loading fixture and load sensor heights satisfy requirements. The device can be effectively applied in in-situ microstructure and performance integral tests. With the device, a dynamic process of stress and strain distribution of various phases of a material can be subjected to in-situ observation by using high-energy X-rays, and material mechanical performance mechanism can be analyzed on a micro-phase size.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

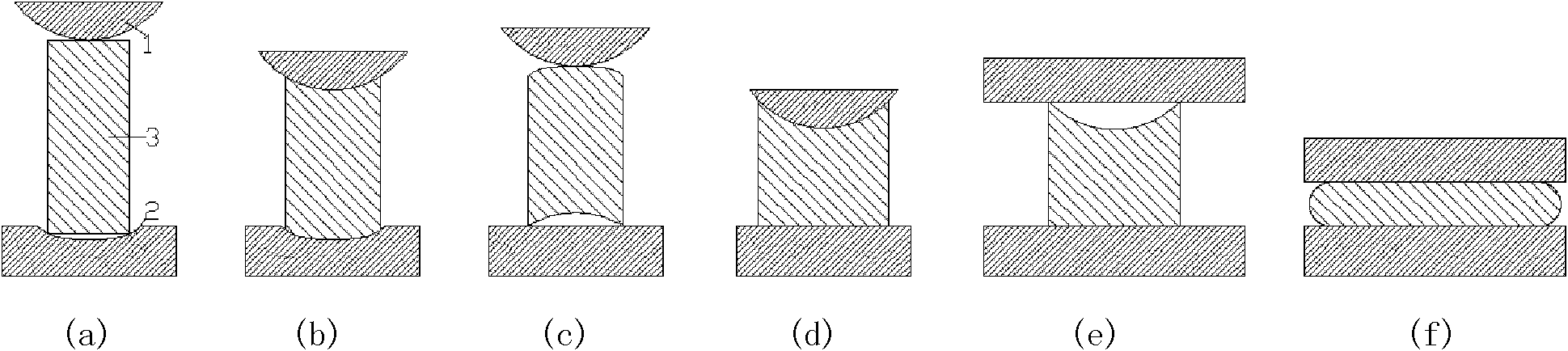

Equal channel forming die for thick-wall pipe and method of forming die for forming pipe

InactiveCN104307908AImproved strain distributionIncrease stressExtrusion diesDeformation effectShearing deformation

The invention relates to the technical field of forming pipes with thick walls (a ratio of pipe diameter to wall thickness is less than 20) of such metals as aluminum, copper and steel and round cross sections, and in particular discloses an equal channel forming die for a thick-wall pipe and a method of the equal channel forming die for forming the pipe. An equal channel corner variable-cross section twist extrusion forming technical scheme adopted by the invention is similar to combination of twist shear deformation and upsetting and drawing extrusion-bulging deformation on a cross section, thus realizing combination of multiple deformation modes in an extrusion process. The equal channel forming die disclosed by the invention has the advantages of good deformation effect, quick speed and high efficiency; and the equal channel forming die can overcome a shortcoming of a current process which is uneven in deformation, greatly improve stress-strain distribution and a deformation texture in the material, and simultaneously improve material performance.

Owner:TAIYUAN UNIV OF TECH

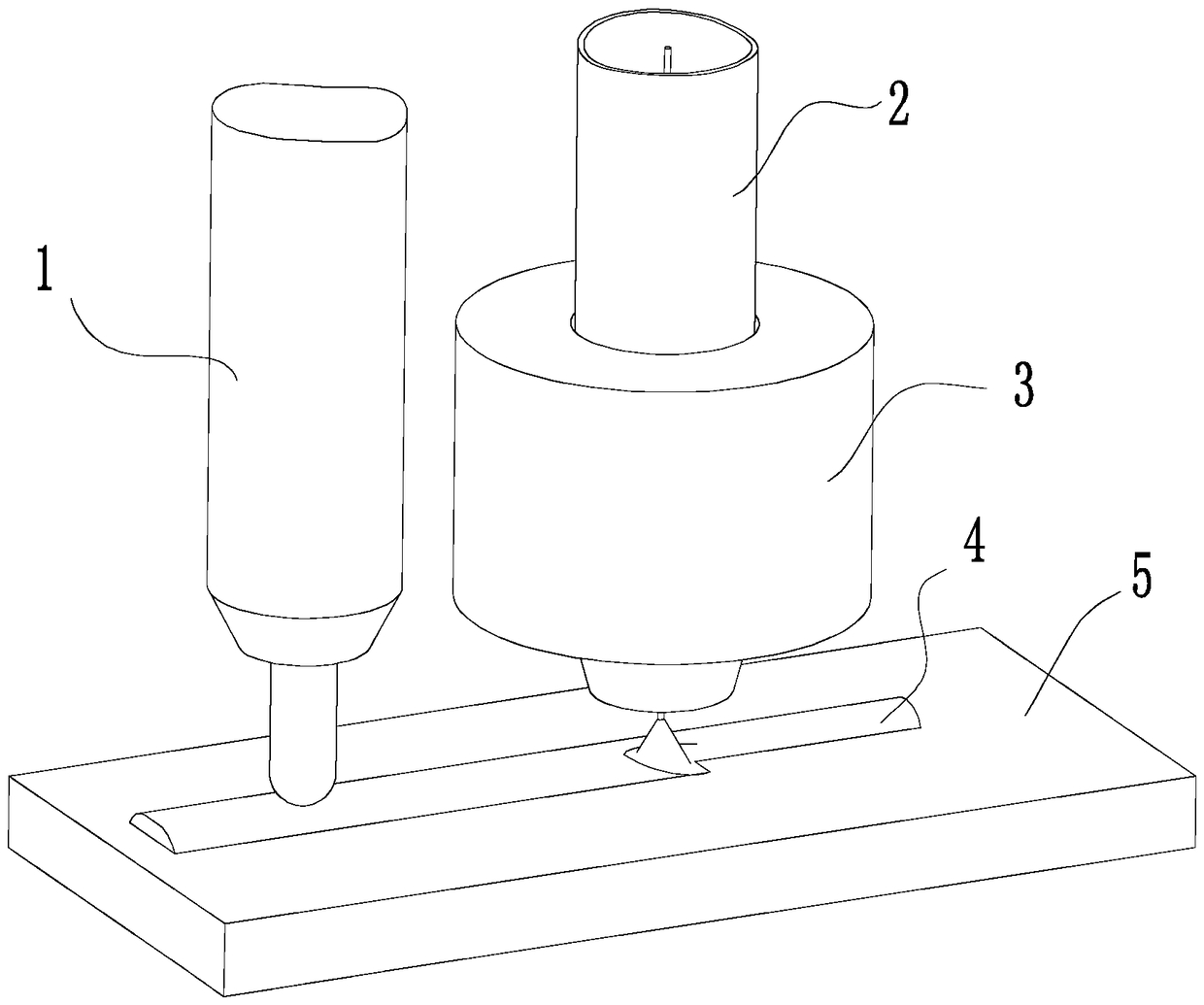

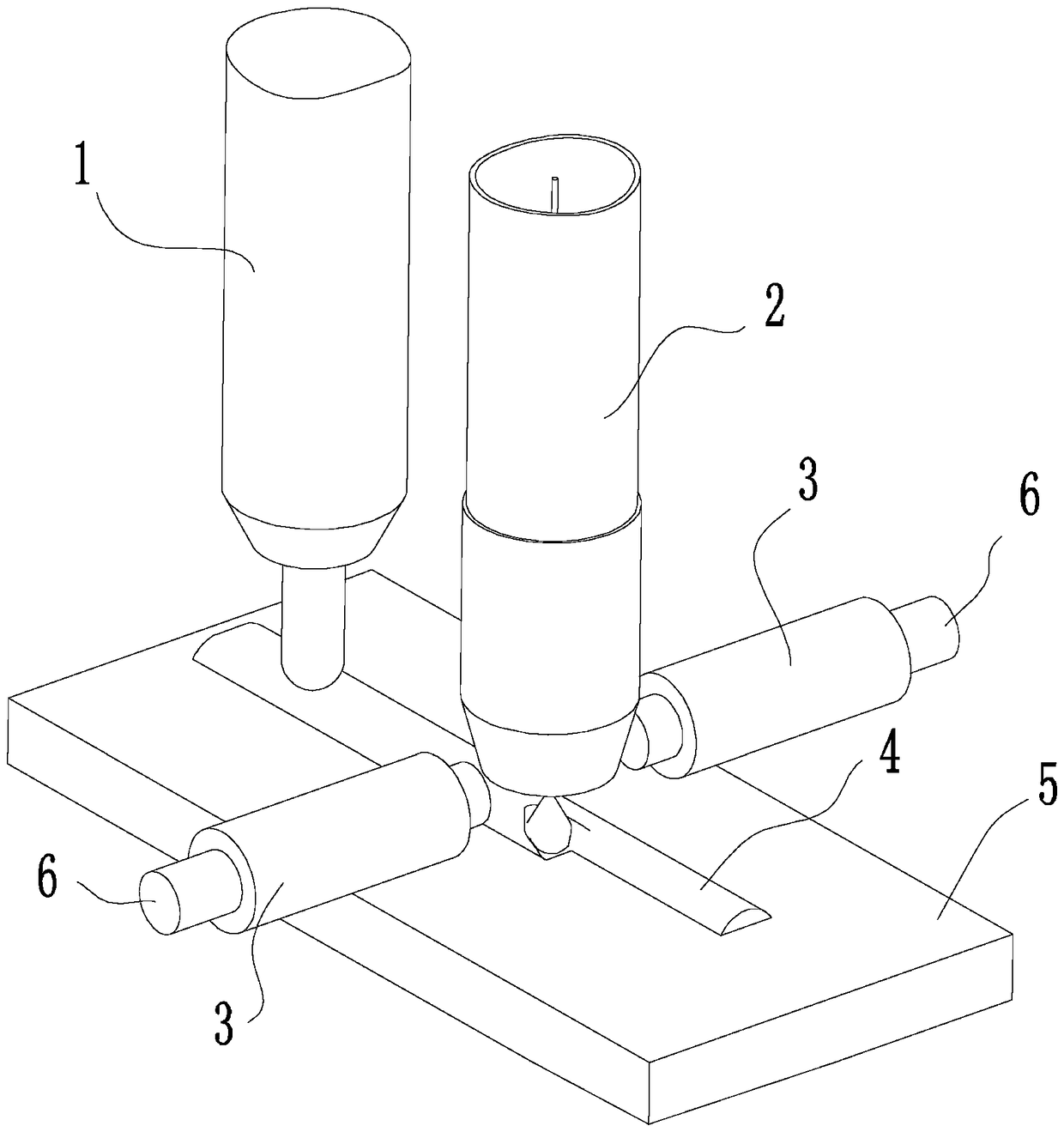

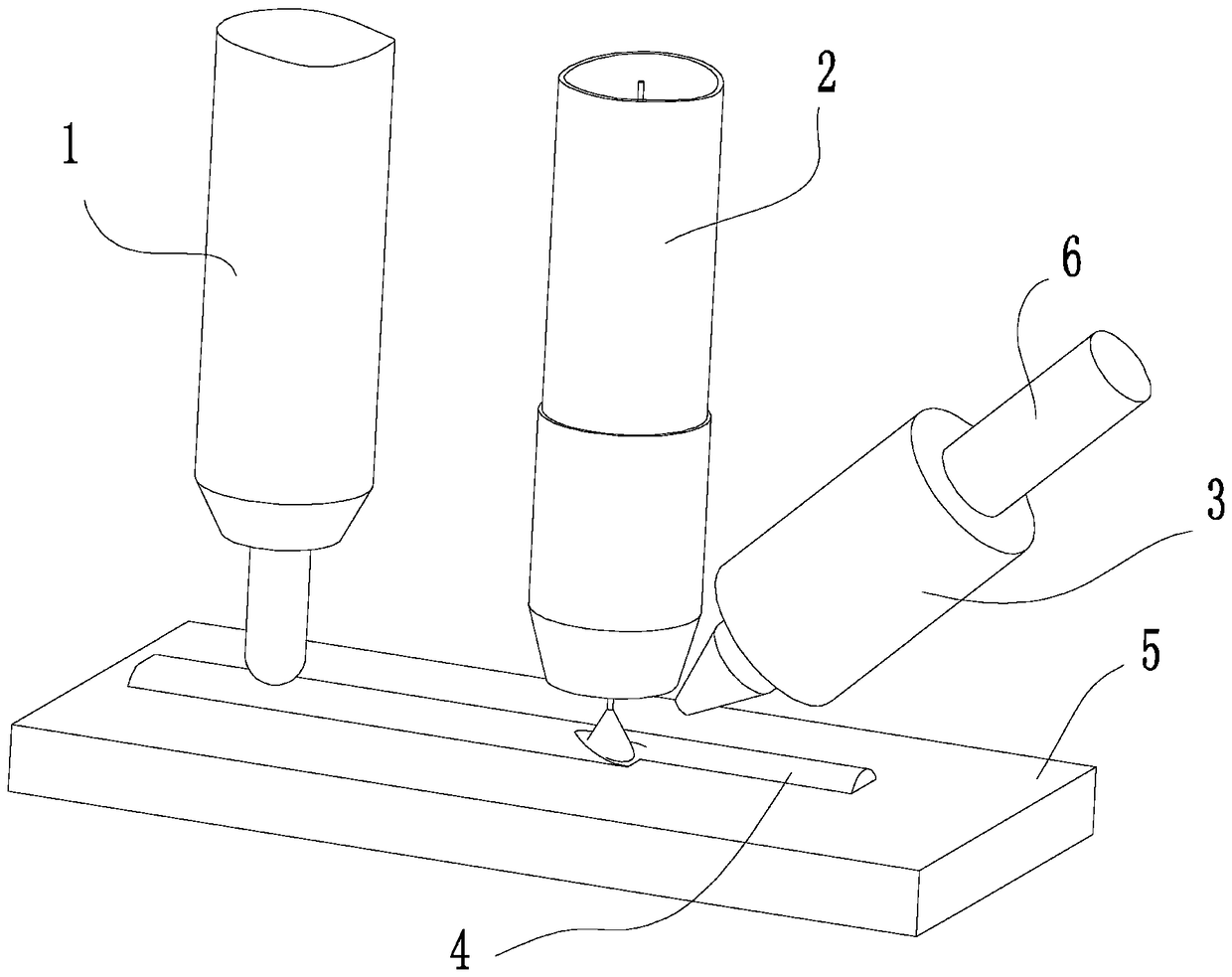

Electric arc additive manufacturing method and device with electromagnetic field and forced processing being combined for assisting

PendingCN108176913AGrain refinementHigh strengthAdditive manufacturing apparatusWelding accessoriesMelting tankCrack resistance

The invention discloses an electric arc additive manufacturing method and device with an electromagnetic field and forced processing being combined for assisting. Molten bath heat and mass transfer ischanged by additionally arranging the magnetic field, the stress distribution state of formed workpieces is further changed through plastic forced processing, and thus the fused deposition process can be changed. The method includes the whole forming processes of molten bath solidification and crystallization, solid-state phase transformation to recrystallization and plastic deformation. Variousphysical fields of electromagnetism, heat and force are used for acting on the workpiece forming process, the metallurgy, microstructure and stress-strain distribution state of formed parts are controlled, and hence the properties of the formed parts can be improved. Under the electromagnetic force action on an electric arc fused deposition molten bath by the magnetic field, the molten bath is stirred, and therefore crystal particles are refined, the forming structure is changed and the defects are overcome. A forced processing device followed by a welding gun is used for conducting plastic forced processing on welding beads, residual stresses of the welding beads are reduced, the crystal particles are refined, and the properties like fatigue resistance and crack resistance of the formed parts are improved.

Owner:CHINA THREE GORGES UNIV

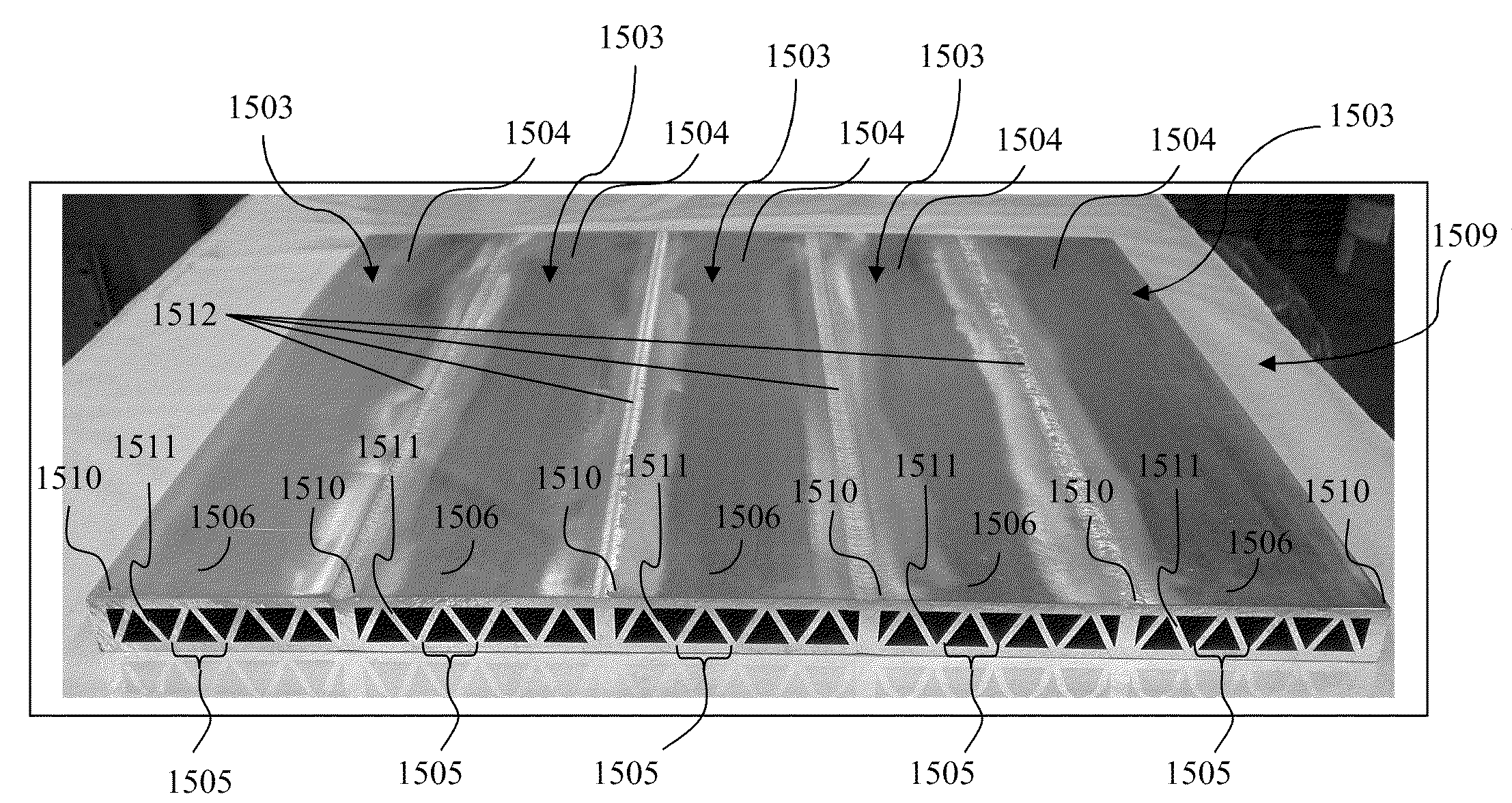

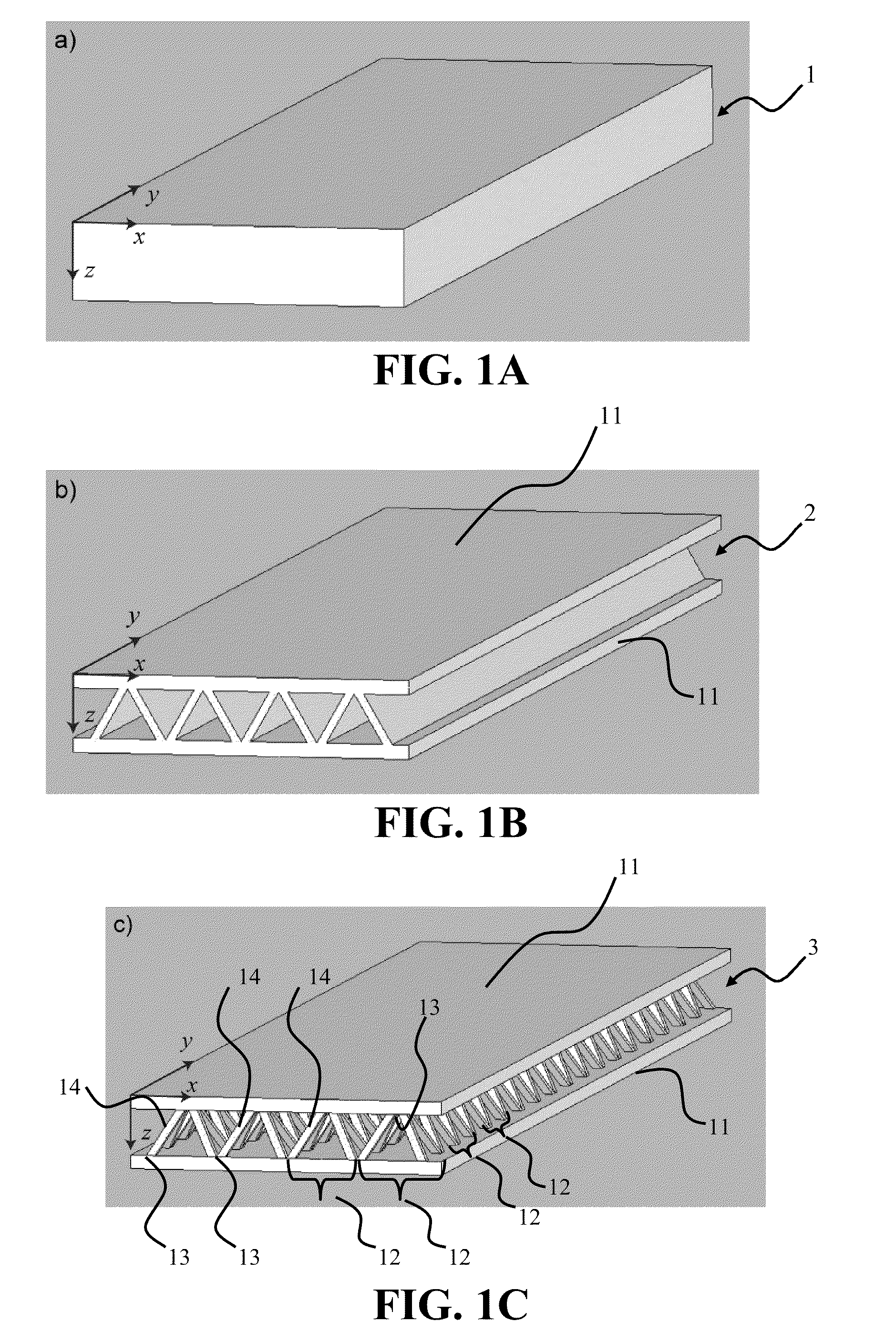

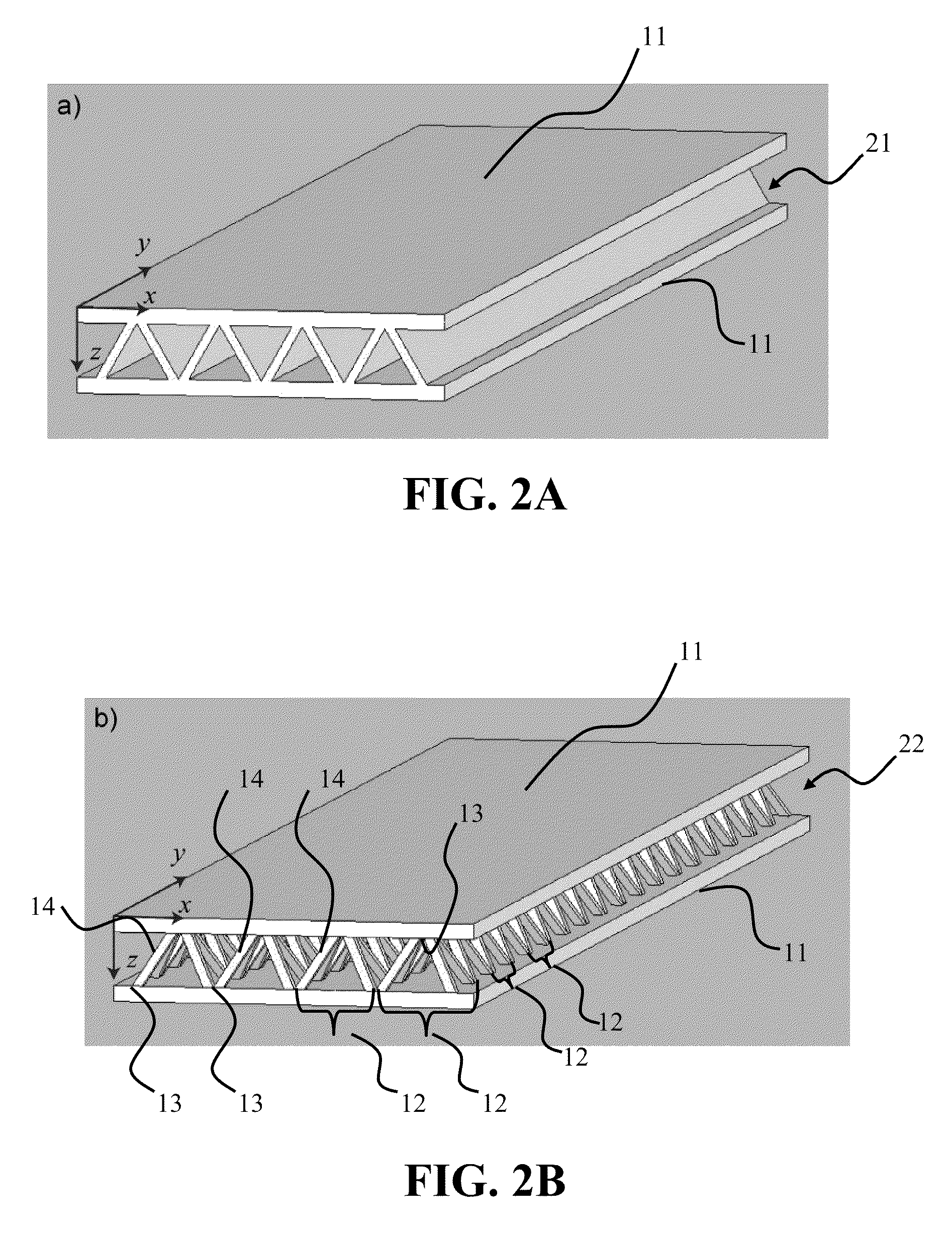

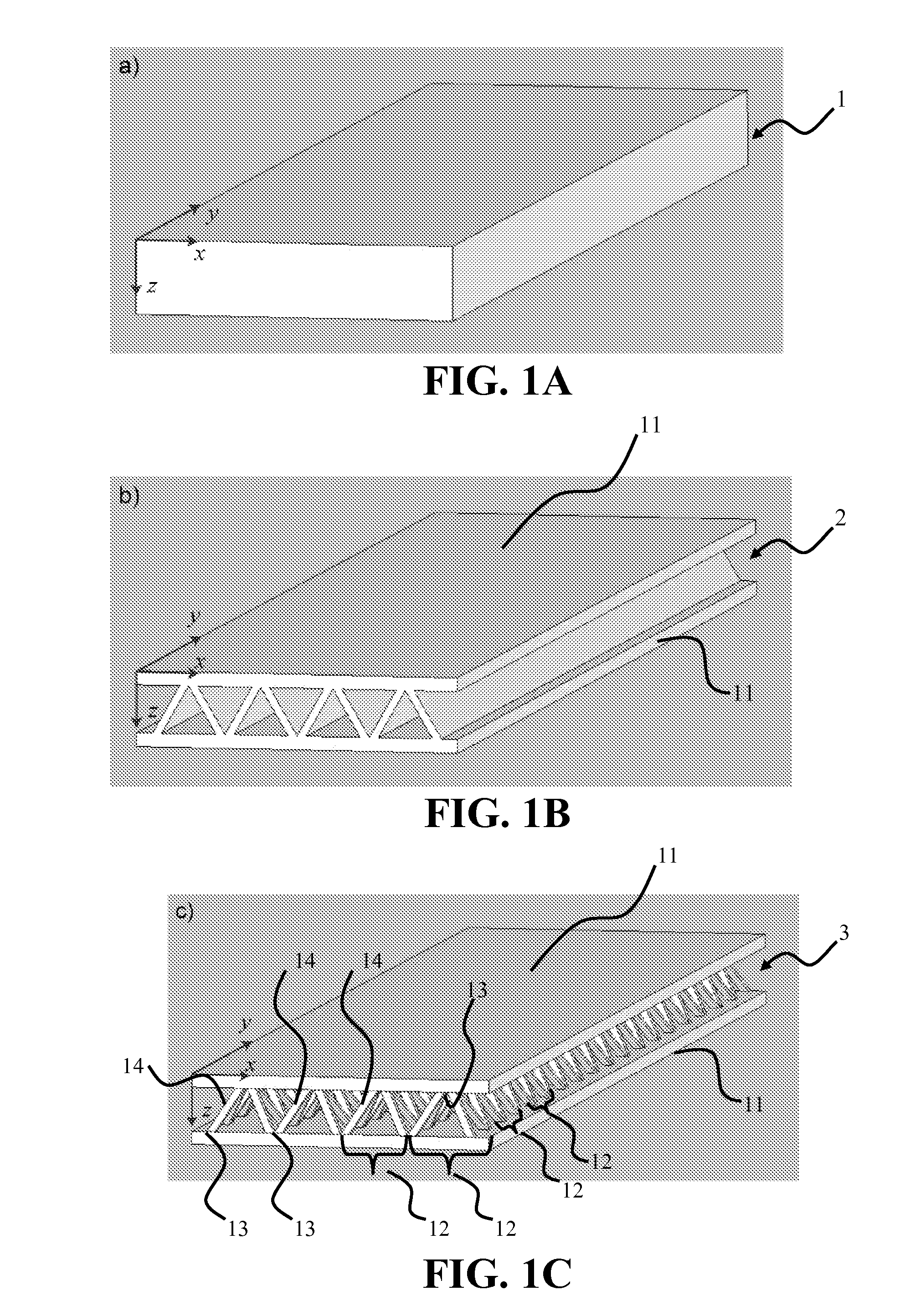

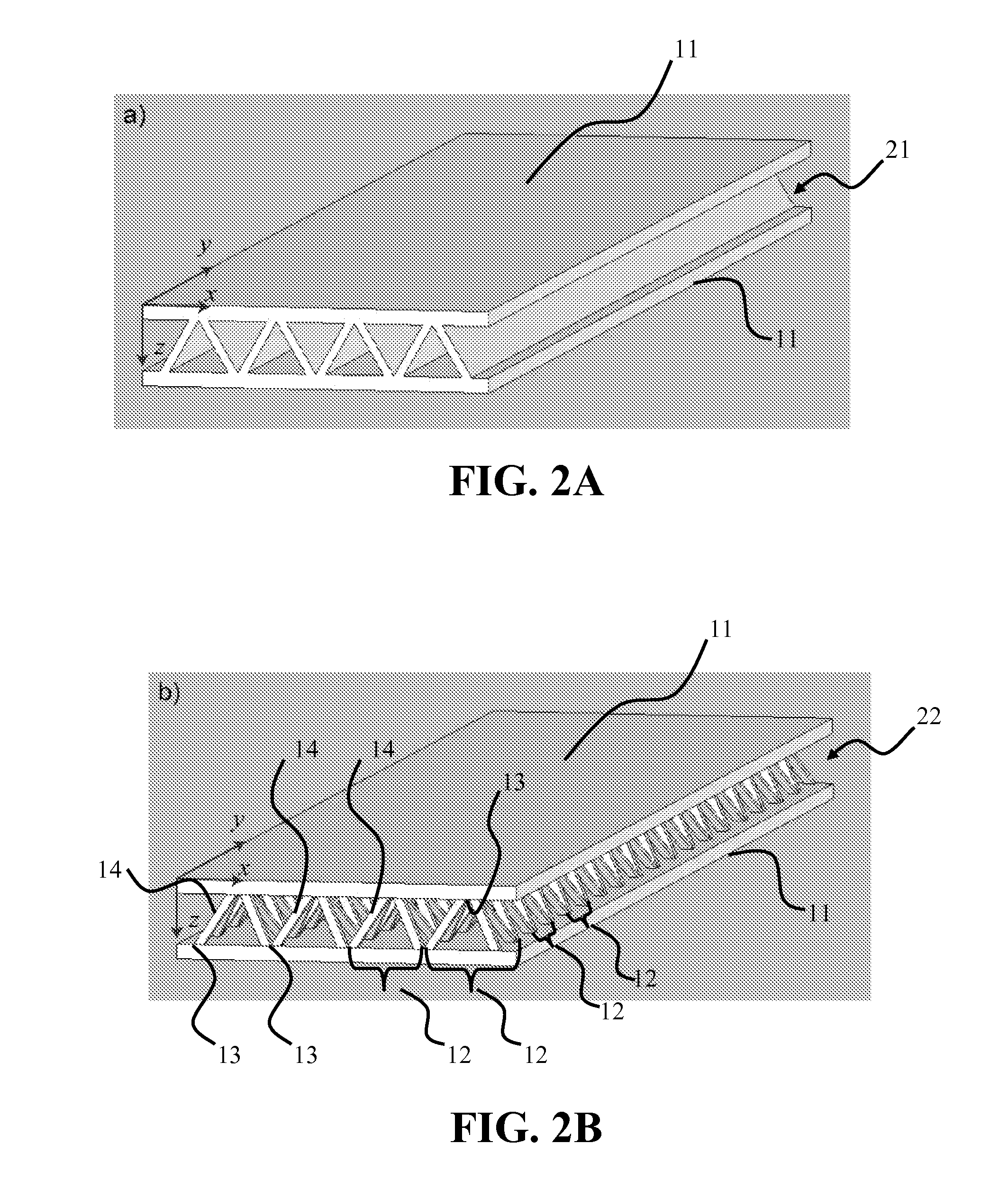

Manufacture of Lattice Truss Structures from Monolithic Materials

ActiveUS20090286100A1Elimination of bonding processLow densityArmoured vehiclesLayered productsIn planeTriple point

Methods and systems to manufacture bonded corrugation truss-based structures. This allows the ability to change the dimensions of the individual structural features of the corrugations, i.e. thickness of the core, face sheet thickness, relative density of the core, and the alloys. The nodal design which provides ideal stress / strain distribution for in-plane and out-off plane loading. The node has a curved / smooth triple point intersection which in turn can provide best load transfer interface with high integrity / toughness. The bonded corrugation truss based structure can be continuous to any length only limited by the volume of the extrusion billet and the press capacity. An aspect of the bonded corrugation structures may include friction stir welding of the face sheets or any fusion welding of panels with edge members for strengthening allows fabrication of panels of any width and length. Bonding panels enables the fabrication of structures of any width.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

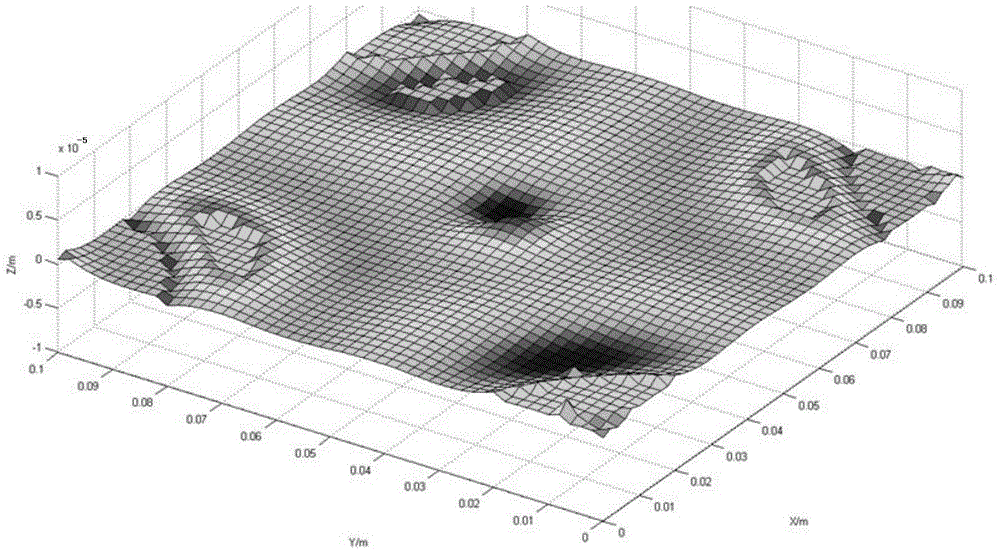

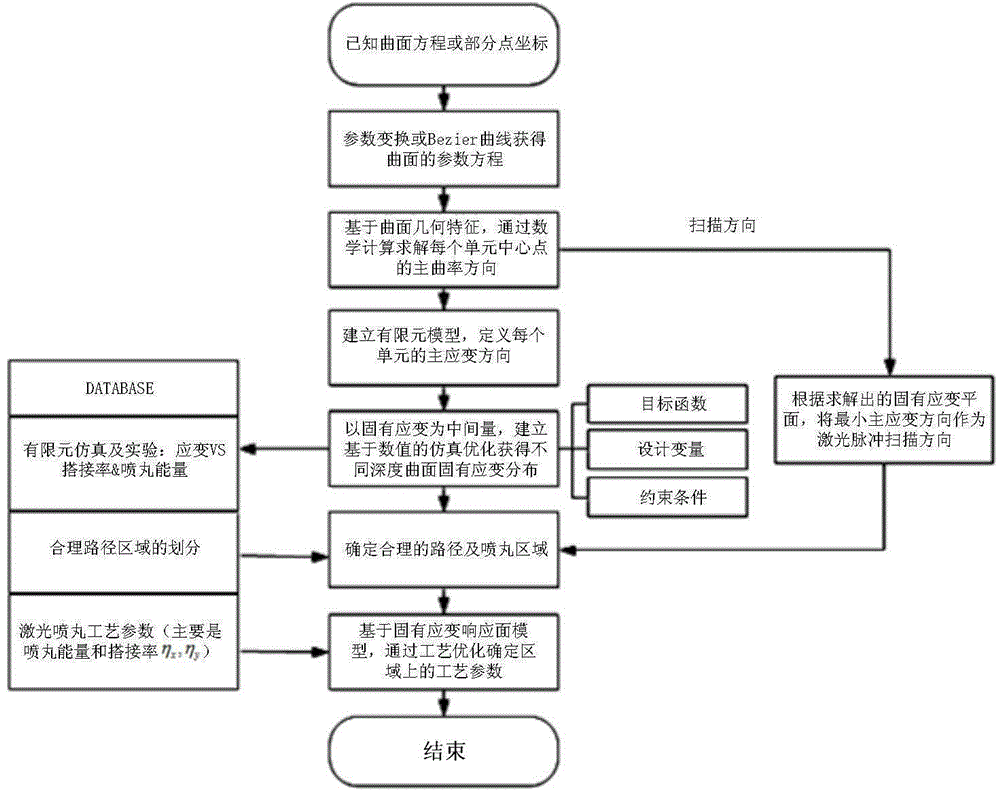

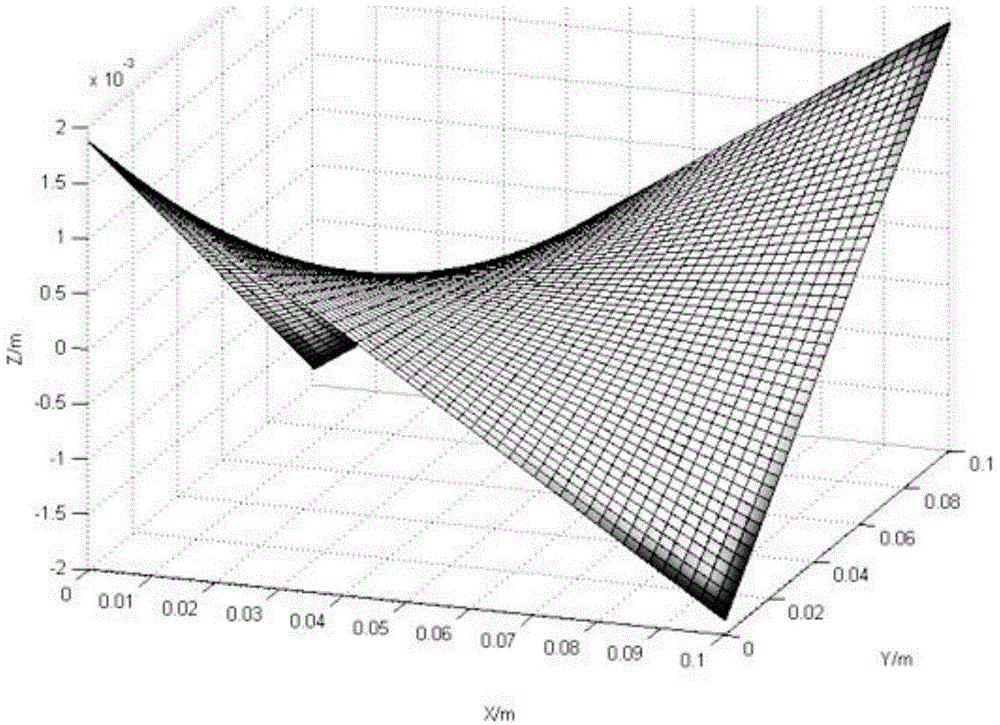

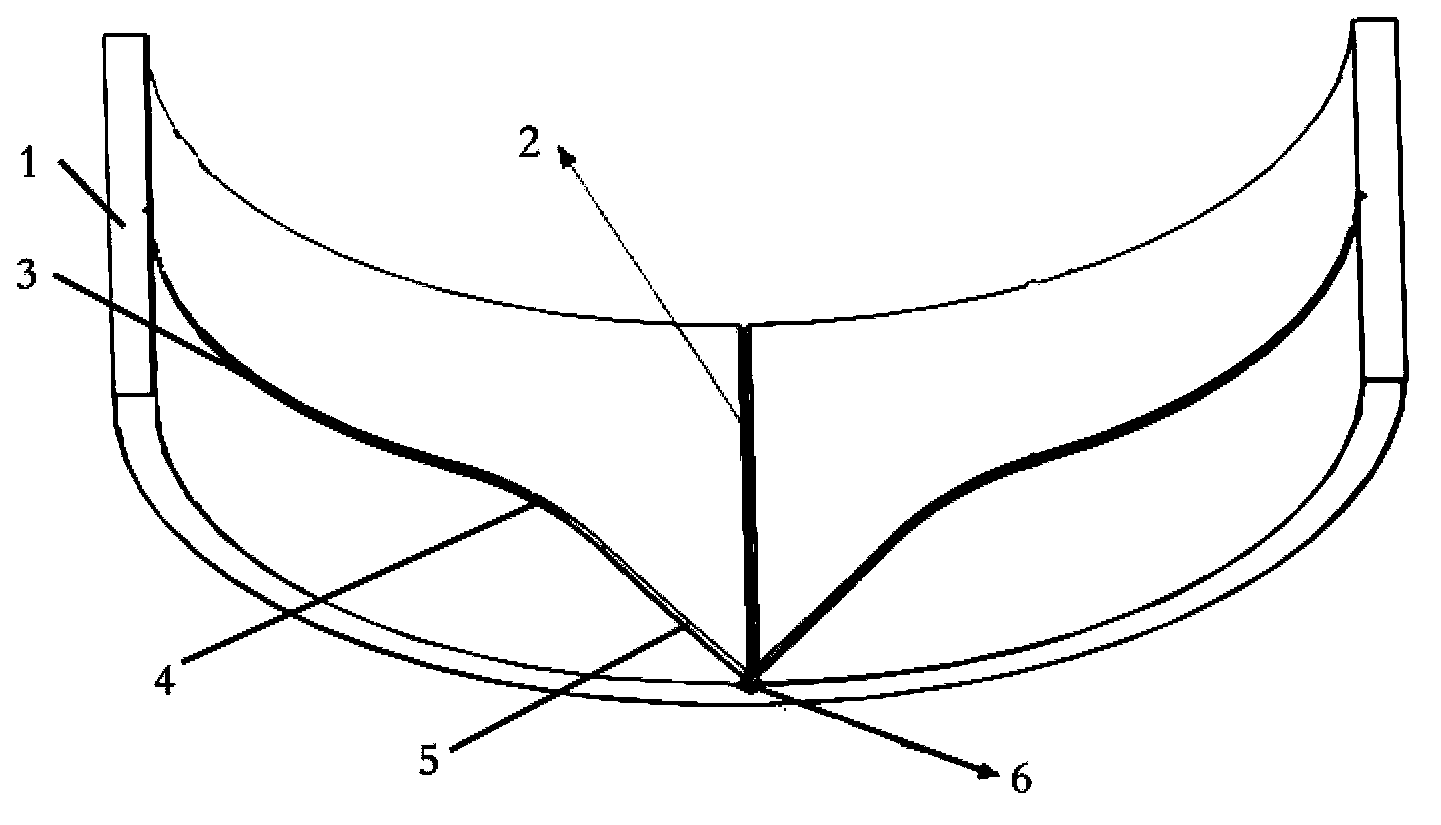

Method for determining laser peening forming process parameter of complex curved-surface-shaped workpiece

ActiveCN104899345AImprove fatigue resistanceAccelerated corrosionSpecial data processing applicationsElement modelStrain response

The invention provides a method for determining a laser peening forming process parameter of a complex curved-surface-shaped workpiece. The method comprises the following steps: according to a curved surface parameter equation of the workpiece, carrying out geometrical characteristic analysis on the curved surface of the workpiece to calculate a main strain direction so as to obtain a laser pulse scanning direction in laser peening forming; establishing a workpiece bending deformation finite element model which takes depth-direction inherent strain distribution as a deformation source, and optimizing an inherent strain field to obtain the inherent strain distribution of different positions of the workpiece along the depth direction, wherein an inherent strain direction is the main strain direction; and according to inherent strain response surface models under different laser peening forming process parameters and the inherent strain of different positions of the workpiece along the depth direction, optimizing the laser peening forming process parameters, and obtaining an optimal laser peening forming process parameter corresponding to different inherent strain fields on the surface of the workpiece. A non-elastic deformation problem can be converted into an elastic deformation problem to improve the efficiency and the precision of finite element simulation.

Owner:SHANGHAI JIAO TONG UNIV

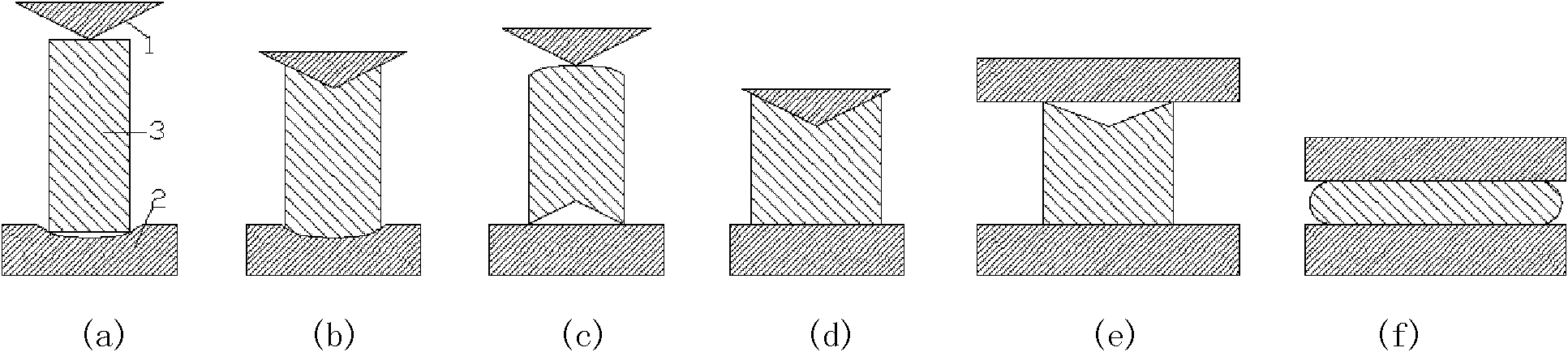

Hot upsetting process for cast ingot with large height to diameter ratio for ultra large ring forging

InactiveCN101972830AUniform stressUniform strain distributionMetal-working apparatusDiameter ratioIngot

The invention relates to a hot upsetting process, in particular to a hot upsetting process for a cast ingot with a large height to diameter ratio for an ultra large ring forging. The process is characterized by comprising the following steps of: 1) hanging a heated high-temperature cast ingot with a large height to diameter ratio on a lower female die; 2) adjusting the position of an upper male die so as to ensure that the central line of the upper male die is coincided with the central lines of the cast ingot and the lower female die; 3) driving the upper male die to move downward by using a power mechanism; 4) further moving the upper male die downward so as to continuously decrease the height to diameter ratio of the cast ingot; 5) reversing the cast ingot which is in a contact molding state by hot upsetting, replacing the lower female die by using a flat plate die and further lowering the upper male die; and 6) replacing the upper male die by using a flat plate die and further lowering the upper male die until the cast ingot is upset to a cast ingot with a required blank height and size so as to obtain an upset blank. On the premise of ensuring that the hot upsetting process of the cast ingot with the large height to diameter ratio is performed successfully, the process also ensures the stress, uniform strain distribution, small bulge and uniform internal structure of the unset blank after upsetting is finished and provides an unset blank with high performance for the manufacturing of a subsequent forging.

Owner:WUHAN UNIV OF TECH

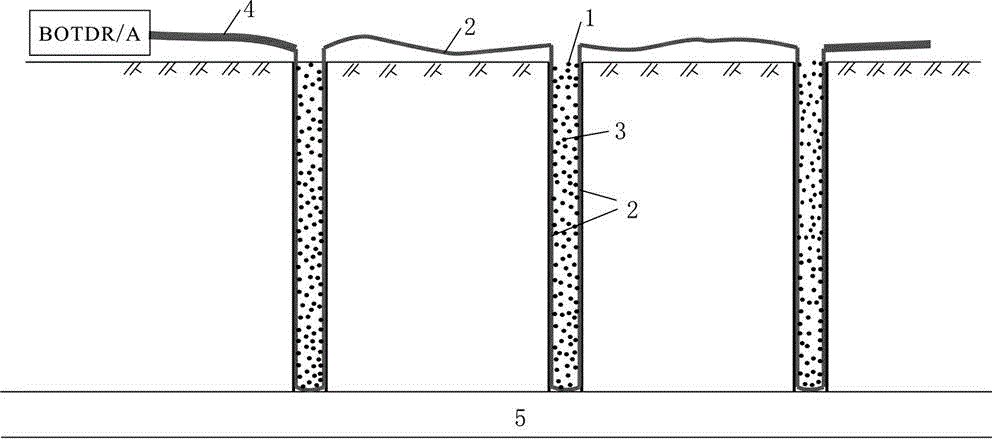

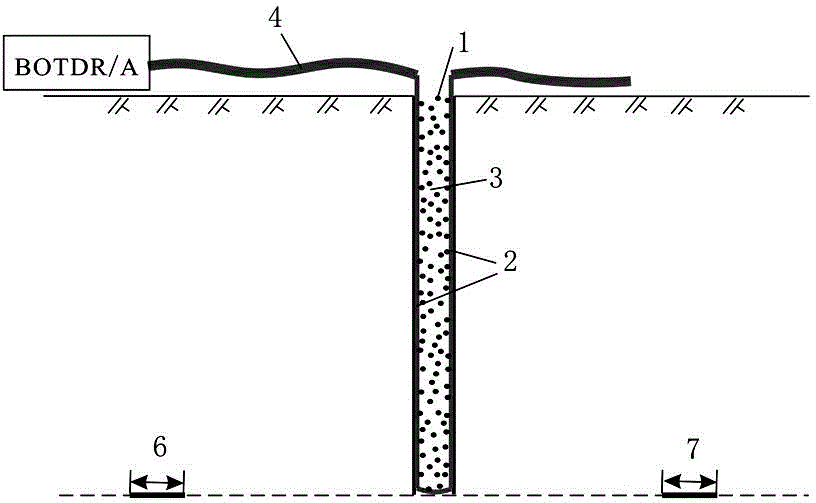

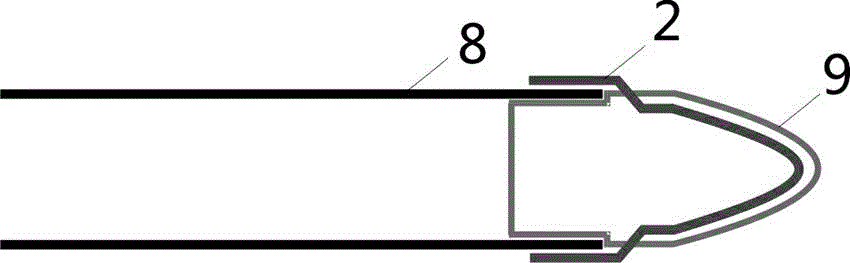

Borehole profile rock and soil mass layered deformation optical fiber measuring method

InactiveCN103438820ARealize distributed measurement of layered deformationOvercoming DiscontinuitiesUsing optical meansGround subsidenceMeasurement point

The invention discloses a borehole profile rock and soil mass layered deformation optical fiber measuring method. A measurement point is selected, and a soil layer is cataloged after being bored. When a hole is formed, a sensing optical fiber is laid and then the hole is backfilled. When the rock and soil mass around the sensing optical fiber deforms, the sensing optical fiber is driven to be deformed due to wrapping force of surrounding soil mass. Strain distribution of the sensing optical fiber is measured via BOTDR / A and other technologies so that strain distribution state of corresponding positions of a borehole profile is obtained. Integration of the corresponding positions is performed on the obtained strain along the optical fiber so that deformation state of each soil layer in deep rock and soil mass can be obtained. Therefore, distributed type measurement of borehole profile rock and soil mass layered deformation is realized. The method is applicable to the field of rock and soil mass deformation monitoring, such as ground subsidence, ground collapse, mines, etc.

Owner:NANJING UNIV +2

Inner surface stress and temperature monitoring method of internal combustion engine main bearing based on fiber bragg grating

ActiveCN103411550ASimultaneously monitor temperatureSimultaneous monitoring of strain changesThermometers using physical/chemical changesUsing optical meansFiberGrating

The invention provides an inner surface stress and temperature monitoring method of an internal combustion engine main bearing based on a fiber bragg grating. Fiber bragg grating strain sensors and fiber bragg grating temperature sensors for temperature compensation are respectively arranged on an internal surface of a to-be-tested main bearing so as to obtain strain changes of a bearing working surface; the fiber bragg grating strain sensors are arranged at all directions of the inner surface of a bearing so as to obtain the strain changes of the bearing at each direction; an engine oil temperature sensor is arranged in a waste engine oil pipe of the internal combustion engine so as to obtain engine oil temperature data; a fiber Bragg grating demodulation instrument is used to obtain center wavelength changes of the engine oil temperature sensor, and to convert the center wavelength changes into electrical signals; and engine oil temperature changes when the internal combustion engine works can be calculated. With the use of characteristics that the fiber bragg grating can simultaneously measure the strain and temperature and is small-sized and one-line-multi-point, the inner surface stress and temperature monitoring method of the internal combustion engine main bearing based on the fiber bragg grating can simultaneously monitor the temperature and strain distribution of the main bearing working when the internal combustion engine works, so as to provide accurate data to support optimization of the structural design of the internal combustion engine main bearing.

Owner:WUHAN UNIV OF TECH

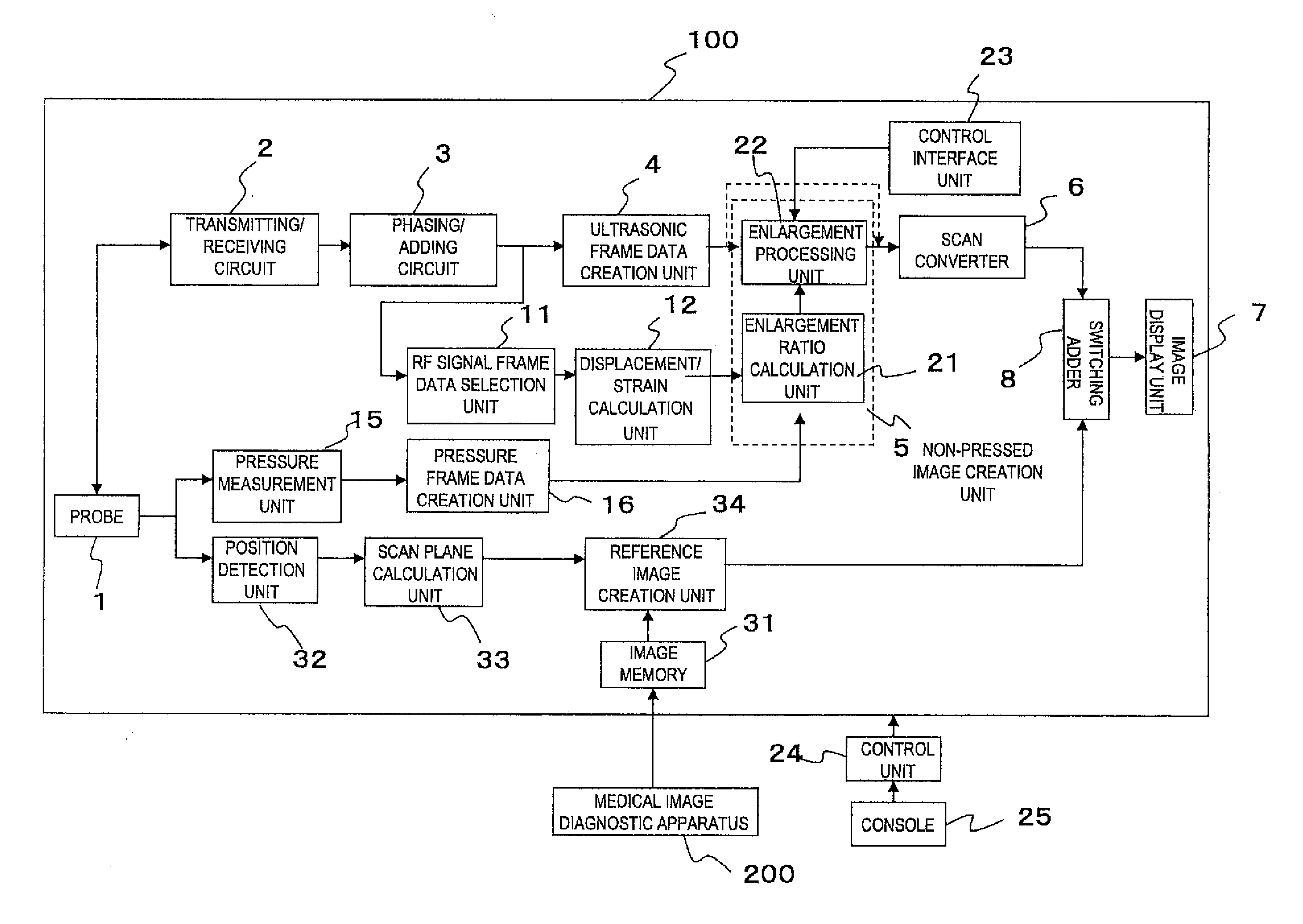

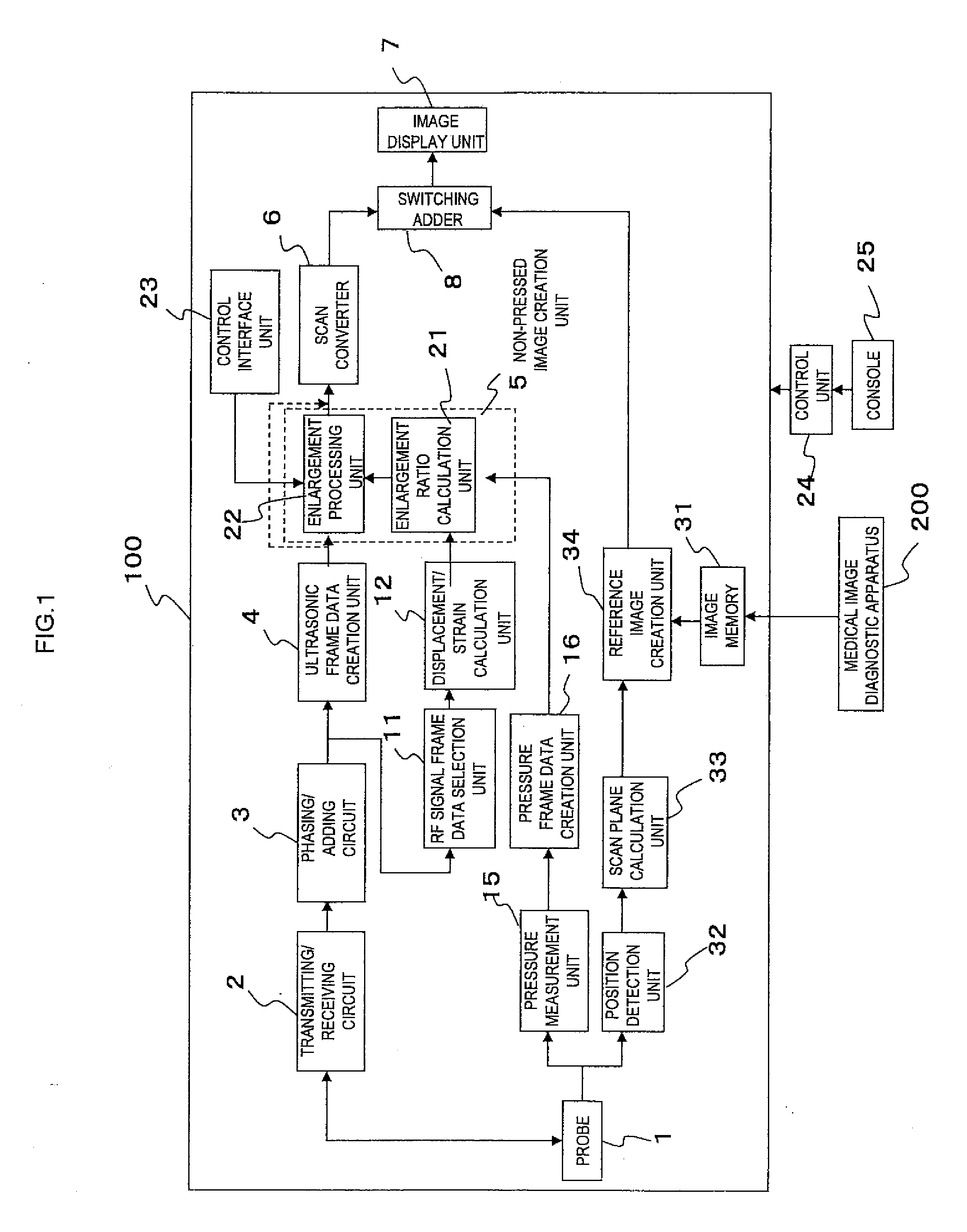

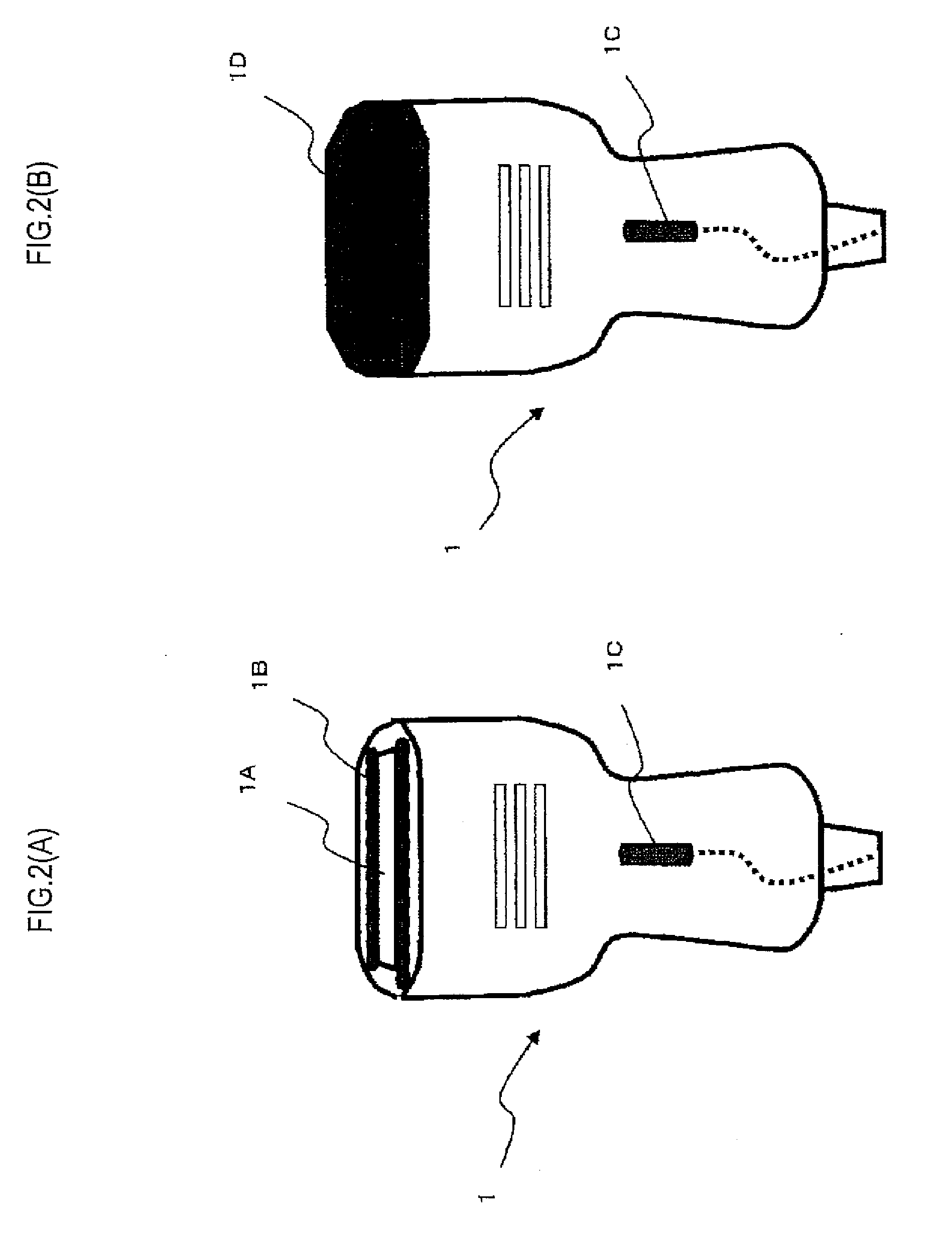

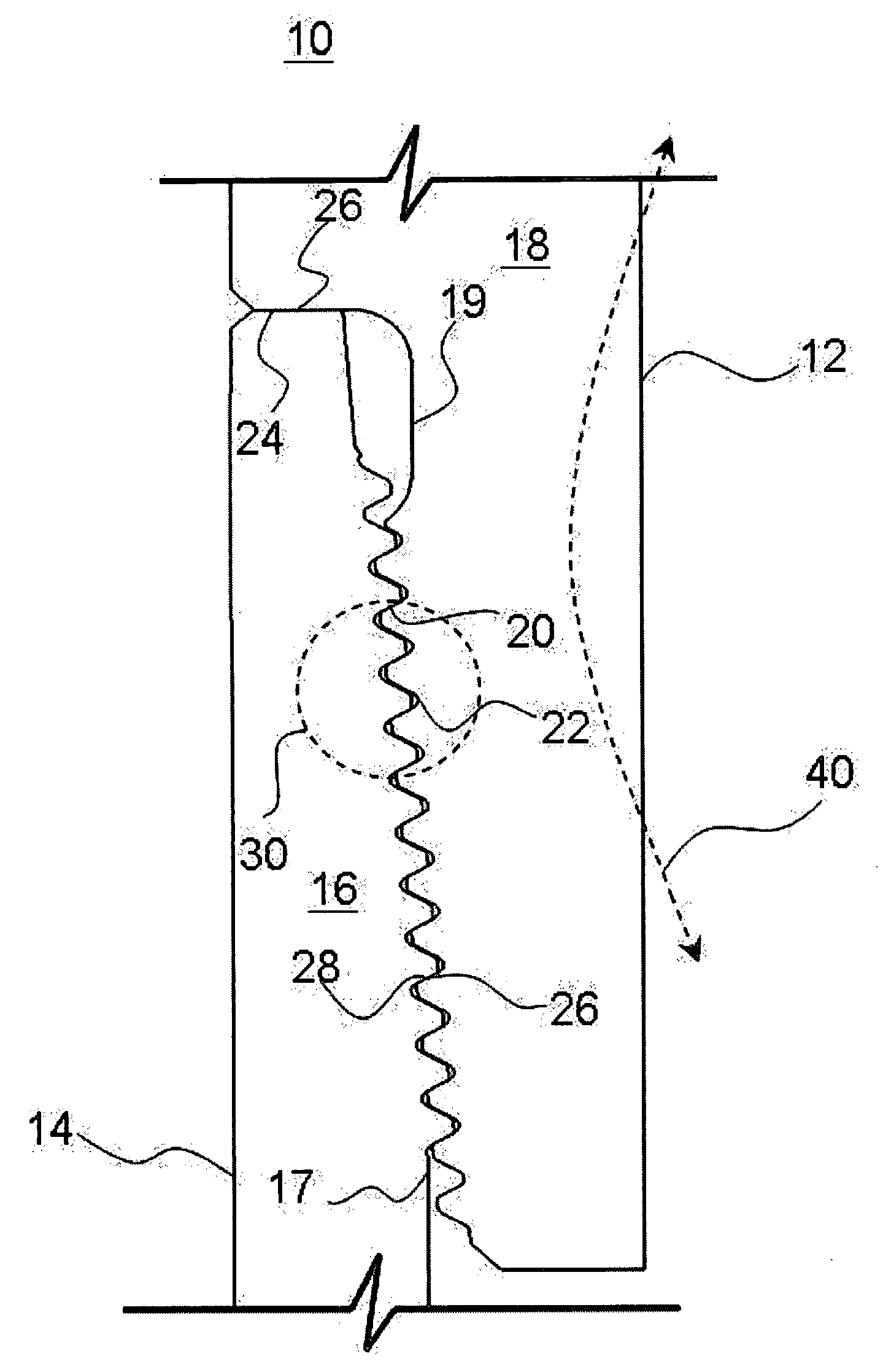

Ultrasonographic device

InactiveUS20100016724A1Accurate comparative observationHigh measurement accuracyWave based measurement systemsOrgan movement/changes detectionUltrasound deviceSonification

An ultrasonic diagnostic apparatus is characterized by including a displacement / strain calculation unit 12 which obtains a strain distribution of a body site on a scan plane when pressed by an ultrasonic probe 1 and a non-pressed image creation unit 5 which corrects an ultrasonic image on the basis of the strain distribution calculated by the displacement / strain calculation unit and generates a corrected ultrasonic image in a non-pressed state or a pressed image creation unit 40 which generates a corrected reference image obtained by adding, to the reference image, a strain equivalent to one in the ultrasonic image on the basis of the strain distribution obtained by the displacement / strain calculation unit 12, in order to accurately perform comparative observation of an ultrasonic image and a reference image captured by a medical diagnostic apparatus other than the ultrasonic diagnostic apparatus.

Owner:HITACHI MEDICAL CORP

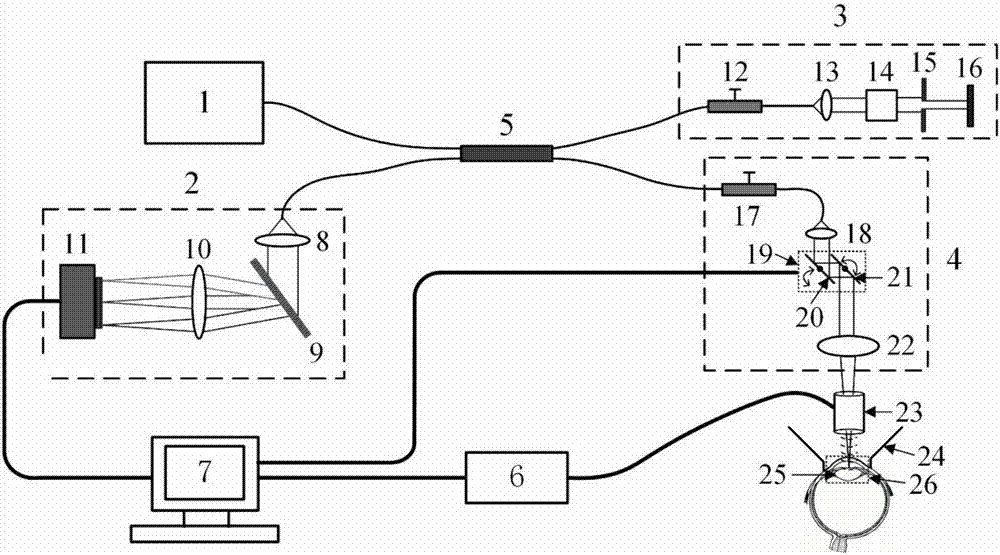

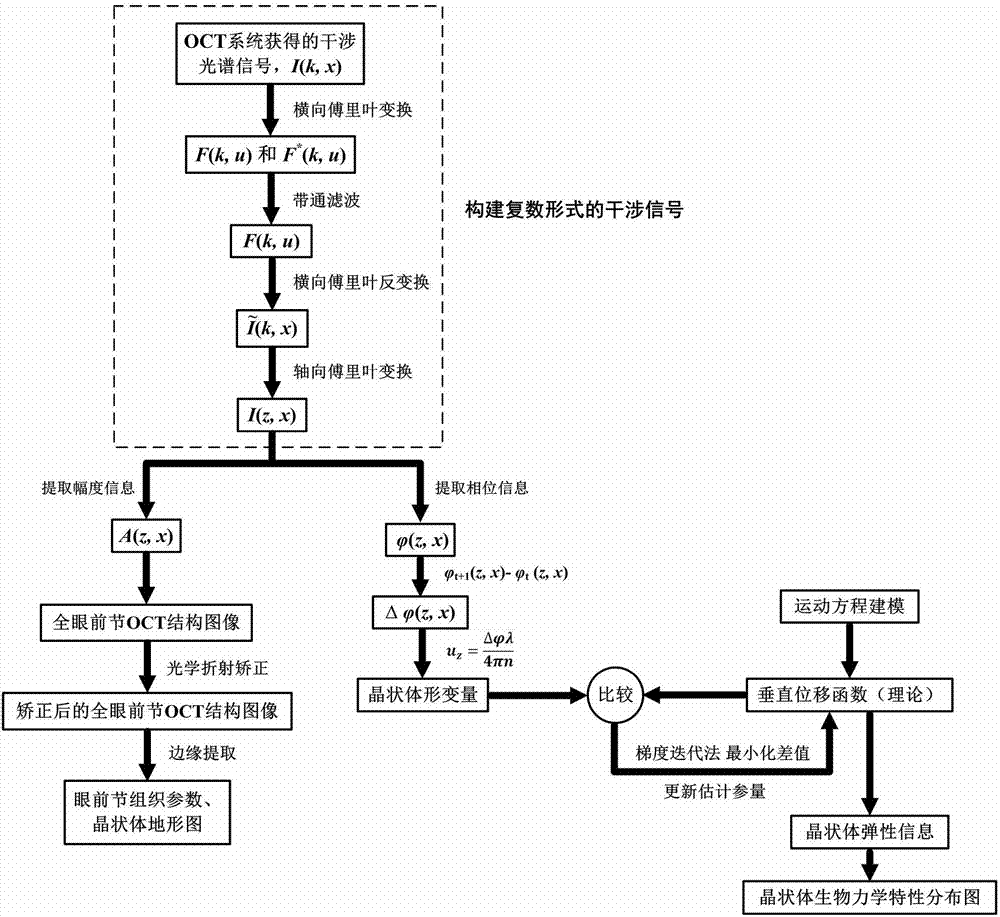

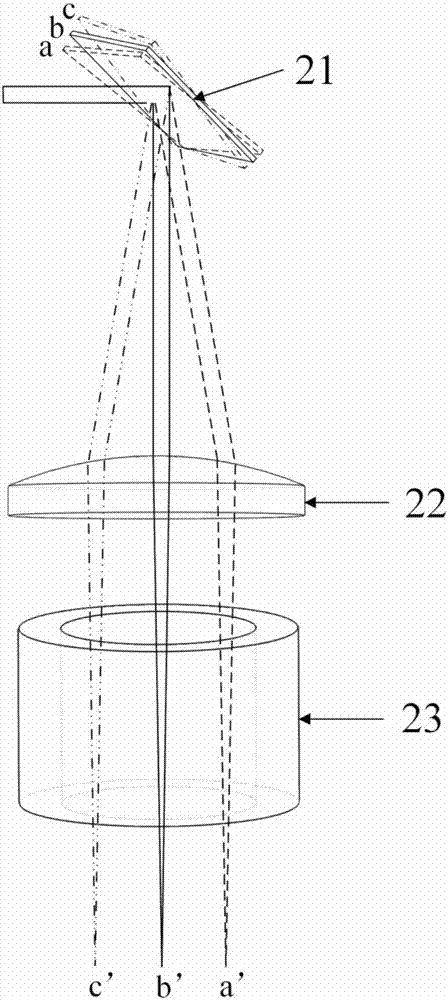

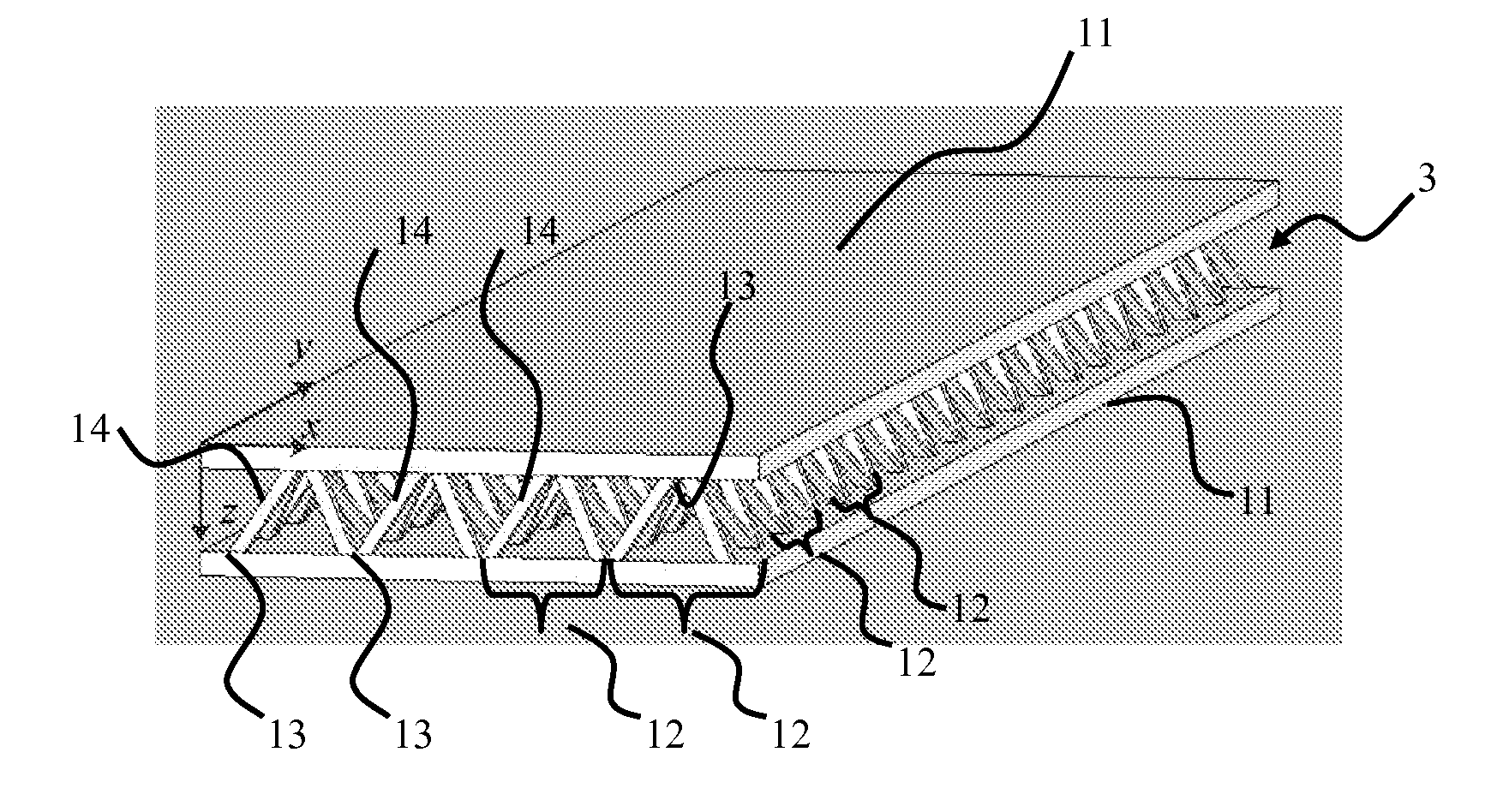

Crystalline lens biomechanics and optical property noninvasive in-vivo imaging system and measuring method

The invention discloses a crystalline lens biomechanics and optical property noninvasive in-vivo imaging system and a measuring method. The ultrasonic load system provides mechanical waves capable of enabling a crystalline lens to deform, a spectral domain OCT system achieves the structure and elastic imaging of the crystalline lens; on the basis of the yoke eliminating technology, OCT full-range imaging is achieved, full anterior segment two-dimensional or three-dimensional structure images from the anterior corneal surface to the retrolental surface, morphological and optical characteristic parameters of the crystalline lens are obtained through calculation, and a crystalline lens topographic map is constructed. Meanwhile, the phase sensitive OCT technology is utilized, strain distribution in the depth direction of the crystalline lens is obtained, and a two-dimensional or three-dimensional biomechanical characteristic distribution diagram of the crystalline lens is obtained through rebuilding. High-resolution imaging and precision measurement of biomechanics and optical properties of the crystalline lens provide the more comprehensive and complete imaging surveying basis for fundamental research, early diagnosis, operation plan formulating and postoperation result evaluation of cataract and other crystalline lens diseases, and the important practical significance and clinical significance are achieved.

Owner:浙江瑞瞳生物科技有限公司

Manufacture of lattice truss structures from monolithic materials

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

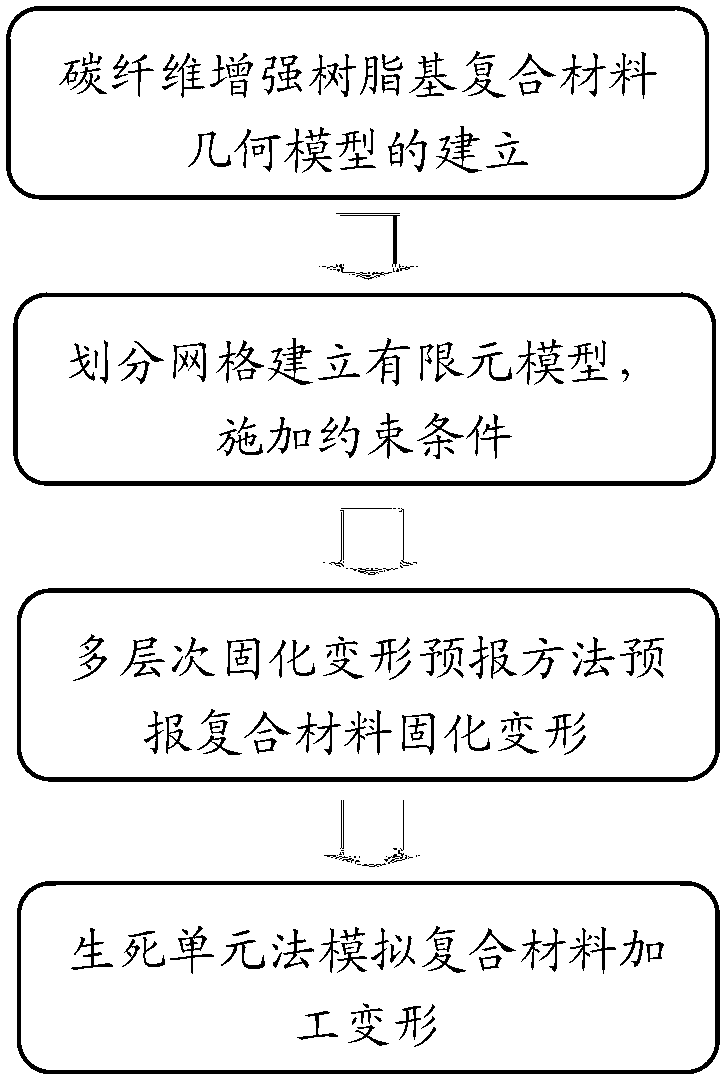

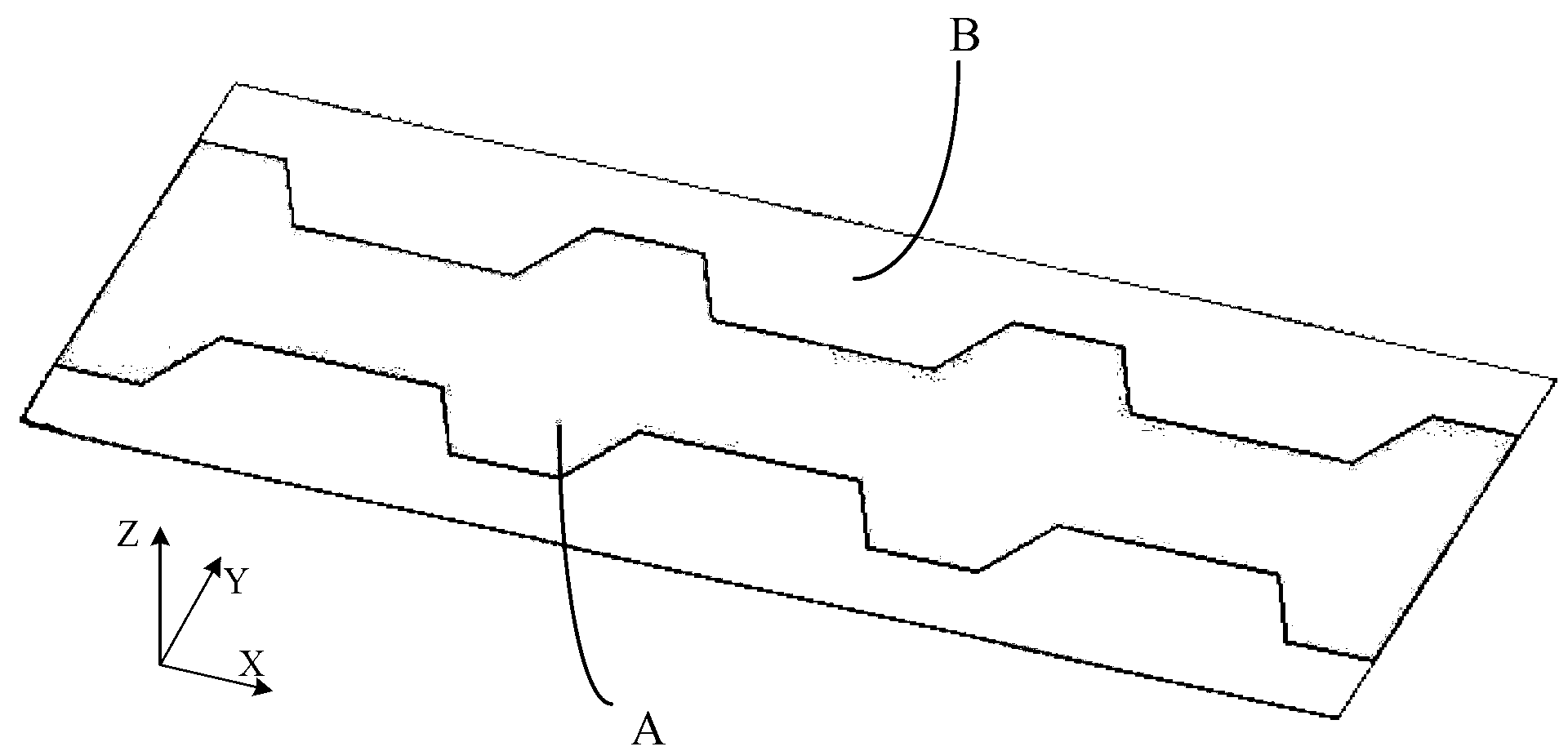

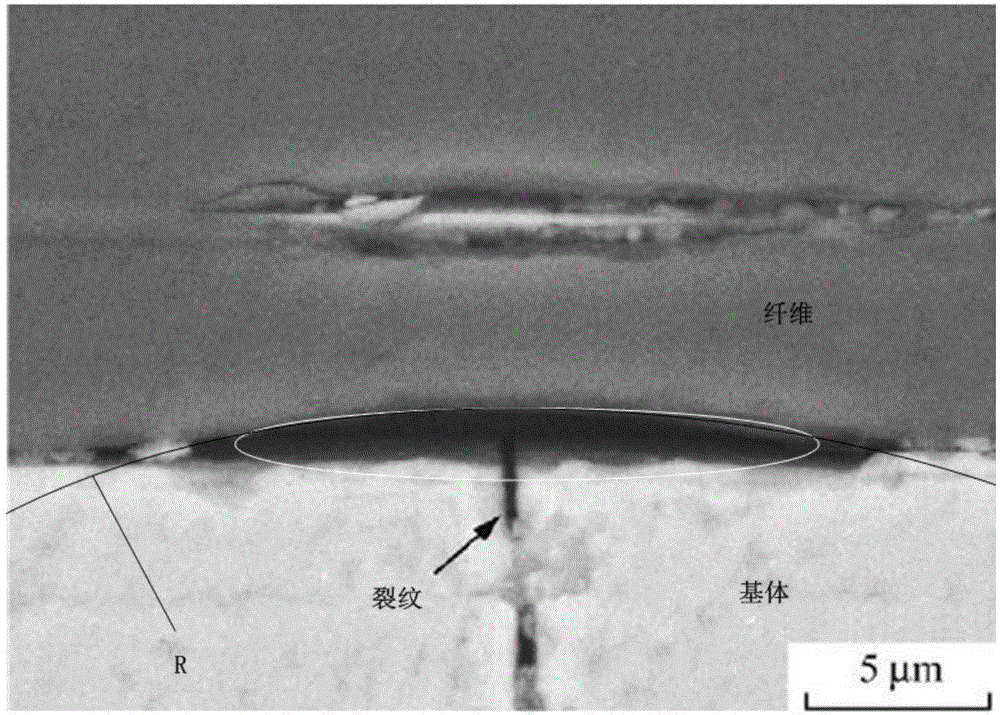

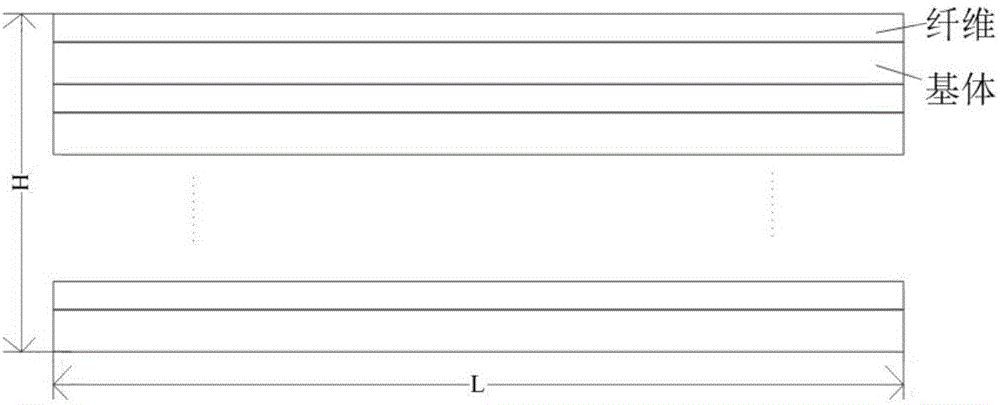

Simulation method for machining deformation of carbon-fiber-reinforced resin matrix composite

InactiveCN103294862ASolve the real problemEasy to masterSpecial data processing applicationsElement modelCarbon fibers

The invention provides a simulation method for machining deformation of carbon-fiber-reinforced resin matrix composite. The method includes: a, inputting modeling parameters in ANSYS software to build a geometric model; b, meshing the geometric model built in step a by a solid 185 unit, building a finite element model, and limiting the finite element model; c, simulating an autoclave process, calculating a solidification deformation value of the composite, and extracting a stress and strain distribution cloud graph; d, simulating a composite machining process by a method of killing or activating element to obtain machining deformation of the machined composite; and e, calculating the machining deformation value of the machined composite. The method has the advantages that simulation of accurate deformation prediction for the machining deformation of the carbon-fiber-reinforced resin matrix composite is realized, and the practical problems in composites engineering application are solved. The method is simple to operate and convenient to use. The software platform ANSYS is used, so that the method is well compatible and is convenient for technicians to master and use.

Owner:SHANGHAI AIRCRAFT MFG +1

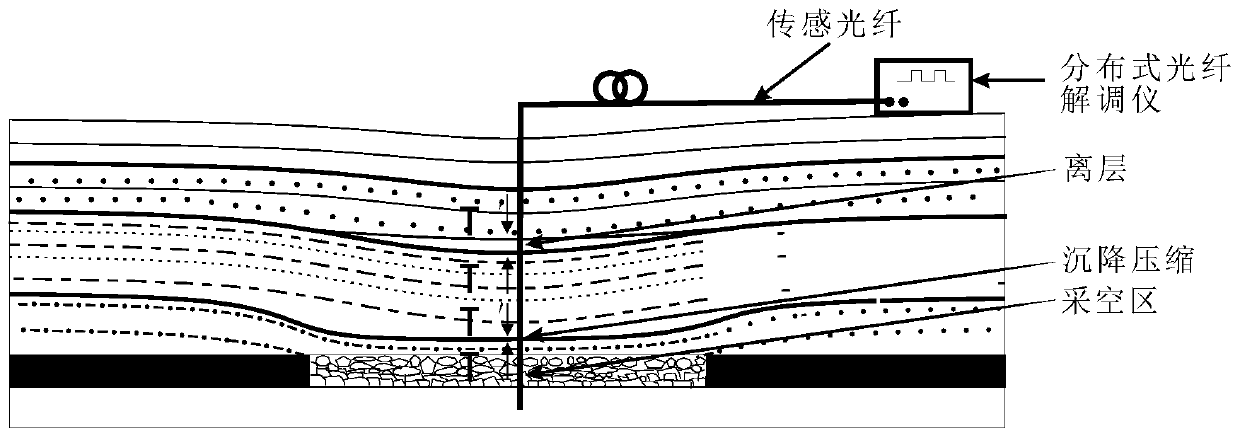

Distributive optical fiber detection method for mining overburden rock deformation

ActiveCN104315988AHigh precisionEasy to installUsing optical meansStress conditionsDeformation monitoring

The invention relates to a distributive optical fiber detection method for mining overburden rock deformation. According to the method, according to mining strata deformation features, drilling holes are arranged on the ground above a working face or the top plate of an intake airway or a ventilation airway of the working face, sensing optical fibers are buried in the drilling holes, concrete grout is adopted to seal the holes from inside to outside, and the reserved sensing optical fibers in the drilling holes are serially connected and are led to a monitoring room via a transmission optical cable. Initial value test is firstly carried out on the overburden rock body before mining, strata deformation caused by mining is measured when the working face approaches or is away facing the monitoring hole, the initial value is subtracted from the monitoring data of each frequency to serve as change values of the overburden rock of different time periods. Strain distribution of overburden rock deformation is obtained through analysis of the monitored data, overburden rock deformation damage height and stress condition caused by mining can be determined. The method has the advantages of being distributive, high in precision, simple and convenient in installation, and low in cost, and can be applied to the monitoring field of rock body deformation caused by various mining.

Owner:CHINA UNIV OF MINING & TECH

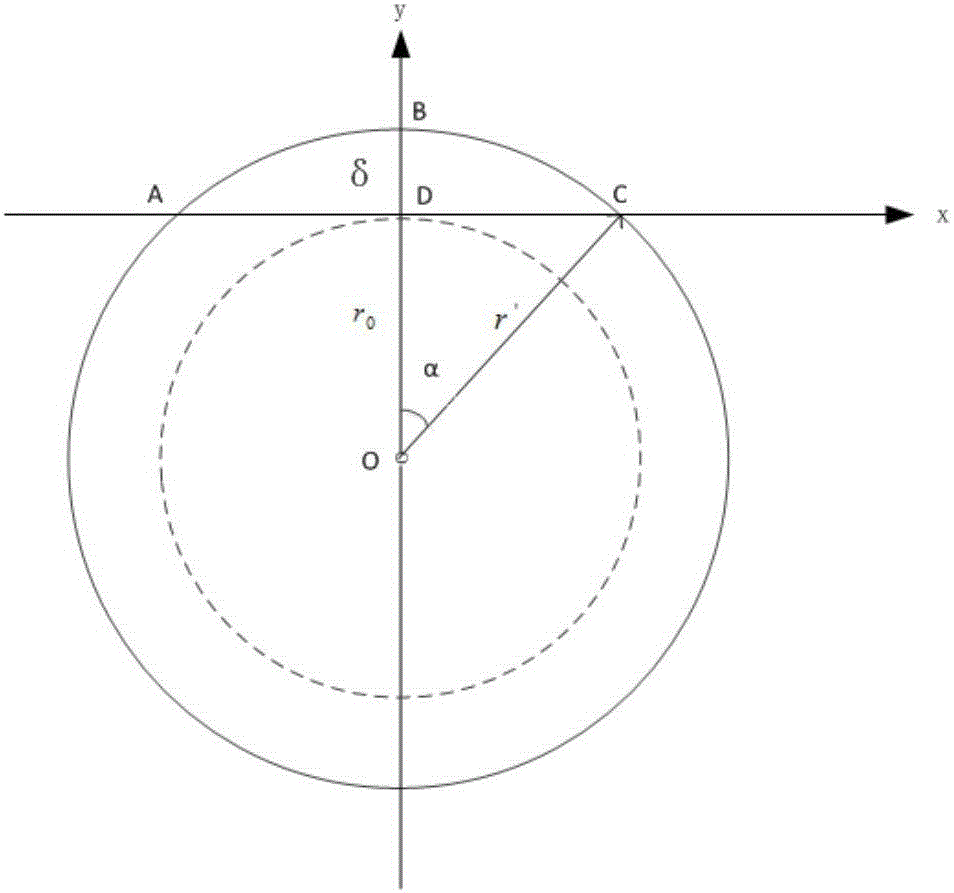

Method for predicting residual stiffness of two-dimensional braided ceramic matrix composite material after oxidation

ActiveCN105930579AResidual Stiffness PredictionStiffness PredictionDesign optimisation/simulationSpecial data processing applicationsMetallurgyResidual stiffness

The invention relates to a method for predicting residual stiffness of a two-dimensional braided ceramic matrix composite material after oxidation. The stiffness refers to elastic deformation resistance ability of the material under stress. By analyzing the stiffness of each component of the material, stress and strain distribution in the material can be determined. Therefore, the invention provides the method capable of accurately predicting the residual stiffness of the two-dimensional braided ceramic matrix composite material after oxidation. A kinetic model considering fiber oxidation is proposed, and based on this, a microscale model considering fiber oxidation and a mesoscale model of the two-dimensional braided ceramic matrix composite material are established. With the adoption of a finite element method, the residual stiffness of the material after oxidation is calculated by applying a periodic boundary condition. According to the method, the residual stiffness of the material in different oxidation temperature intervals at different oxidation time can be accurately predicted and does not need to be tested by a large amount of manpower and material resources through tests, so that a large amount of test costs are reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

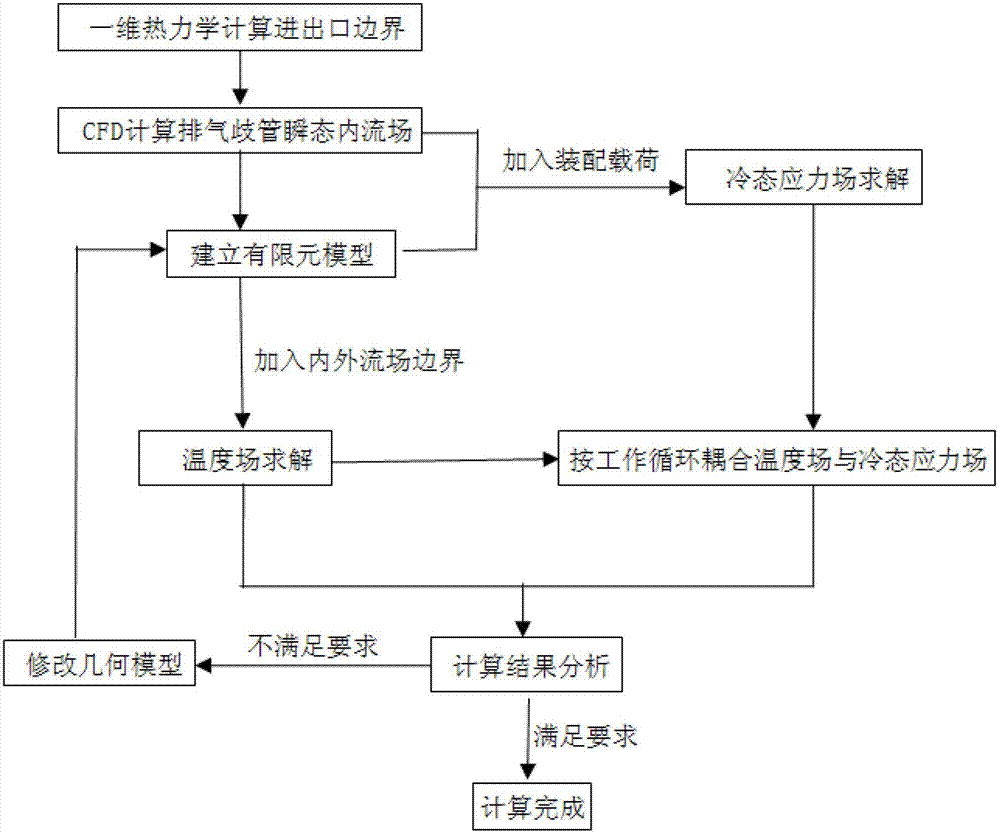

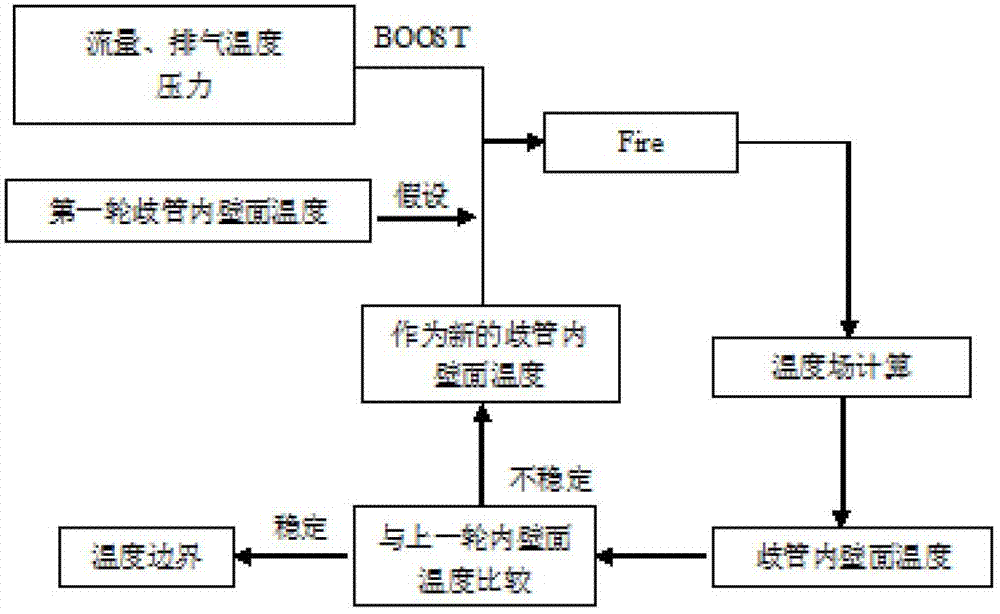

Finite-element analysis method for thermal mechanical strength of exhaust manifold

ActiveCN102855347AShorten the development cycleImprove development efficiencySpecial data processing applicationsStress distributionStructural reliability

The invention discloses a finite-element analysis method for thermal mechanical strength of an exhaust manifold, and aims to shorten the development period, reduce the development cost and perform virtual simulation on the mechanical performance and the structural reliability of an engine exhaust manifold in a digital model stage of the engine. By the method, the temperature field and a stress field of the engine exhaust manifold are calculated and solved by a finite-element method, so that temperature distribution, stress distribution, strain distribution, stud moment change and sealing pressure on the flange surface of the exhaust manifold of the engine exhaust manifold are obtained; and the structure of the engine exhaust manifold can be well designed.

Owner:CHERY AUTOMOBILE CO LTD

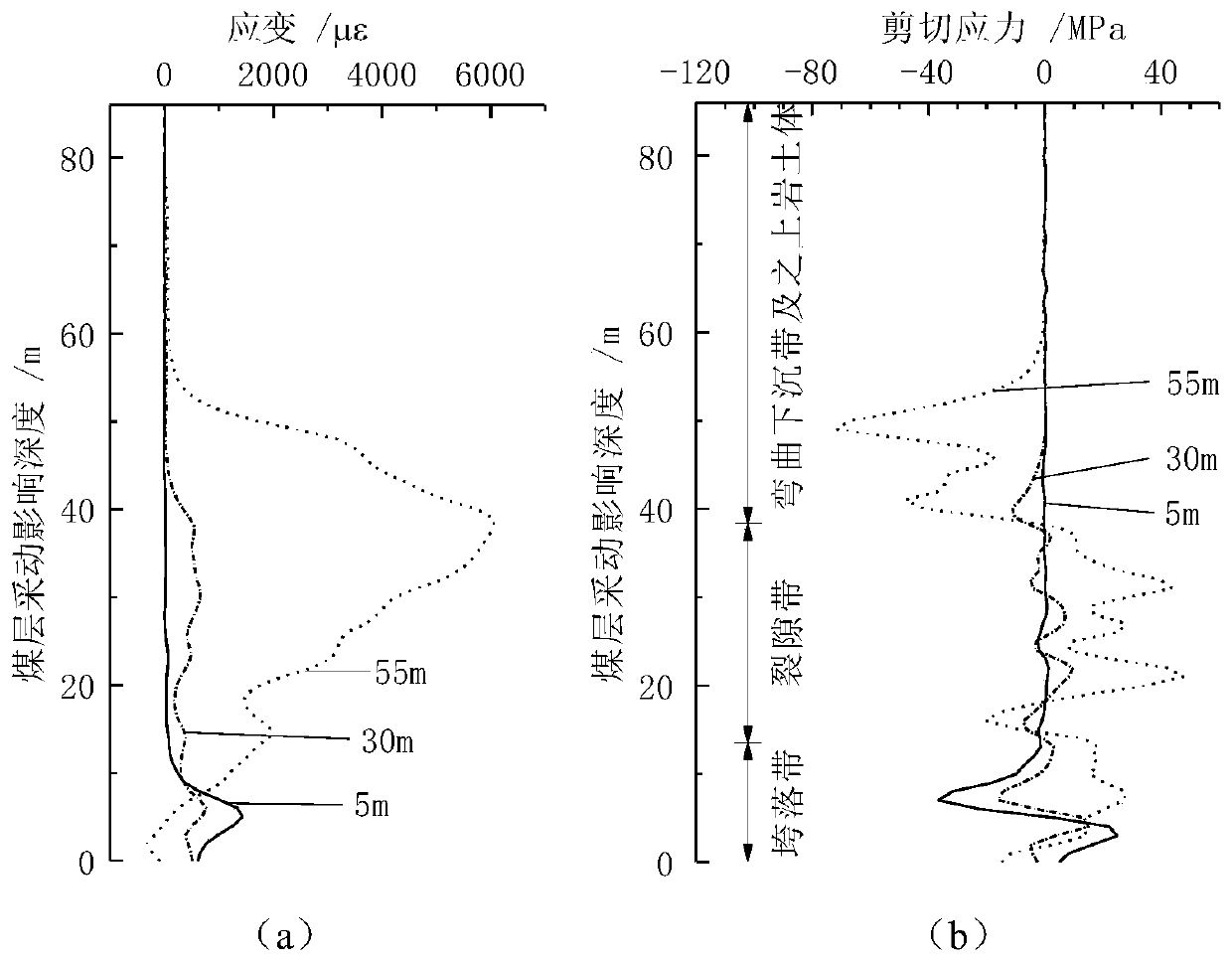

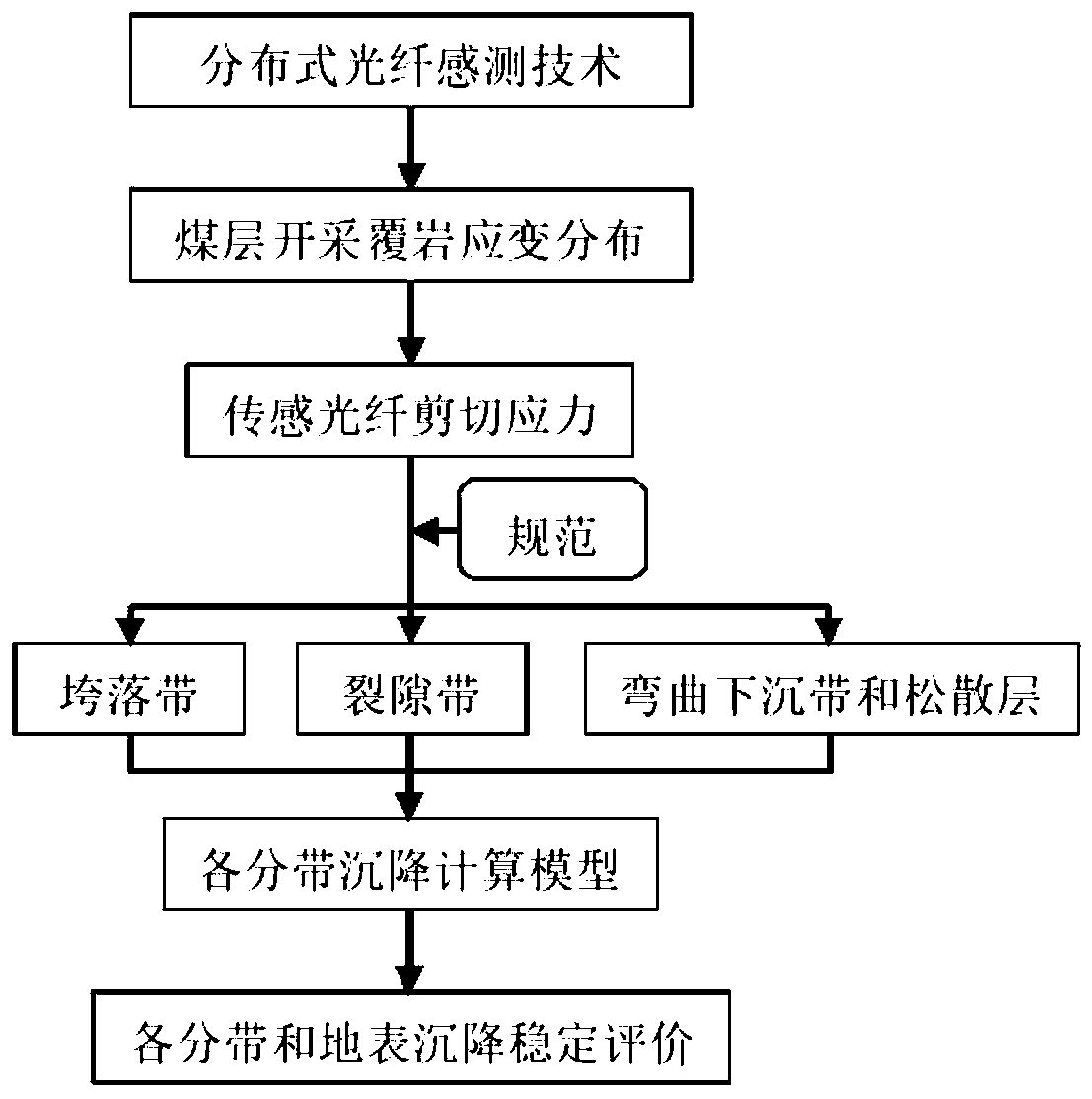

Coal seam mining overlying strata settlement state identification method

PendingCN111382504AWith distributed monitoringSimple processHeight/levelling measurementUsing optical meansMining engineeringCoal pillar

The invention provides a coal seam mining overlying strata settlement state identification method. According to the coal seam mining overlying strata settlement state identification method, a sensingoptical fiber is vertically mounted in a coal seam overlying strata in a drilling manner, strain distribution of the overlying strata along with time caused by coal seam mining is measured, the heightof a water guide fracture zone is determined based on shear stress and dependent variable values borne by the sensing optical fiber, and the development height of a caving zone and the development height of a fissure zone are comprehensively judged in combination with 'building, water body, railway and main roadway coal pillar reservation and pressed coal mining specifications'. A coal seam mining overlying strata zoning settlement calculation model is constructed, settlement amounts of caving zones, fissure zones, bending subsidence zones and rock-soil bodies above the caving zones, the fissure zones and the bending subsidence zones in the mining overlying strata are calculated, and the settlement amounts of the zones are accumulated to obtain a ground surface settlement amount caused bycoal seam mining. The coal seam mining overlying strata settlement state identification method has the advantages of distributed monitoring, simple and convenient process, high identification precision and the like, is suitable for mastering the deformation evolution rule of the coal seam mining overlying strata along with time and judging the settlement stability, and has wide practicability inthe technical field.

Owner:CHINA UNIV OF MINING & TECH

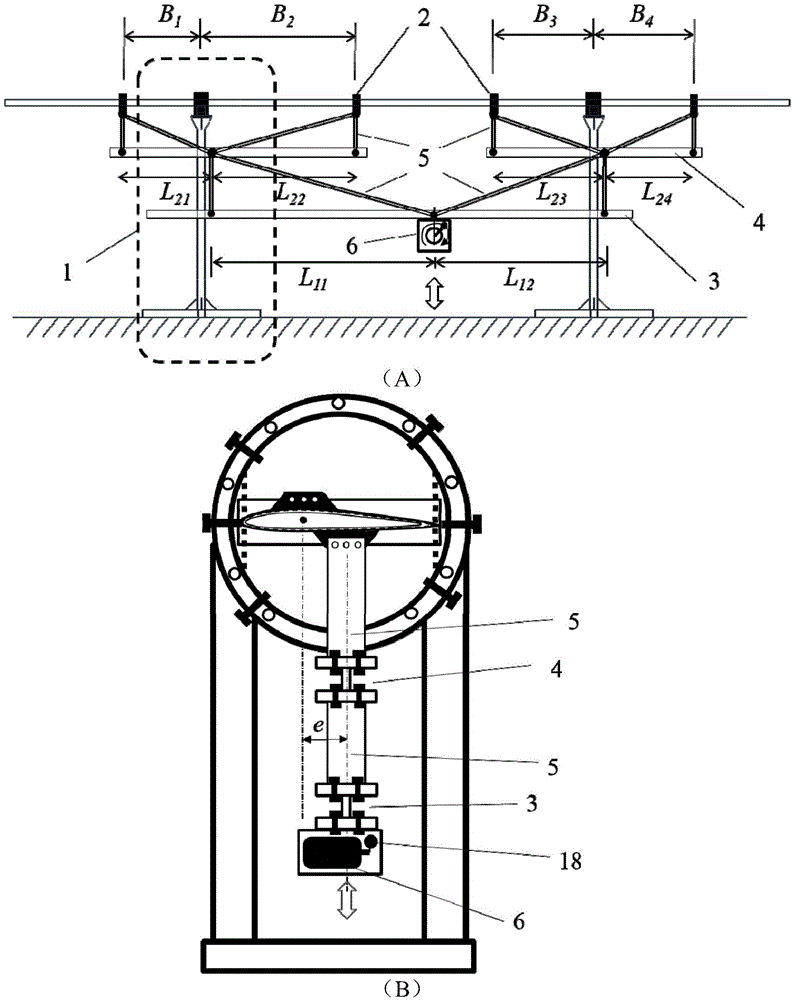

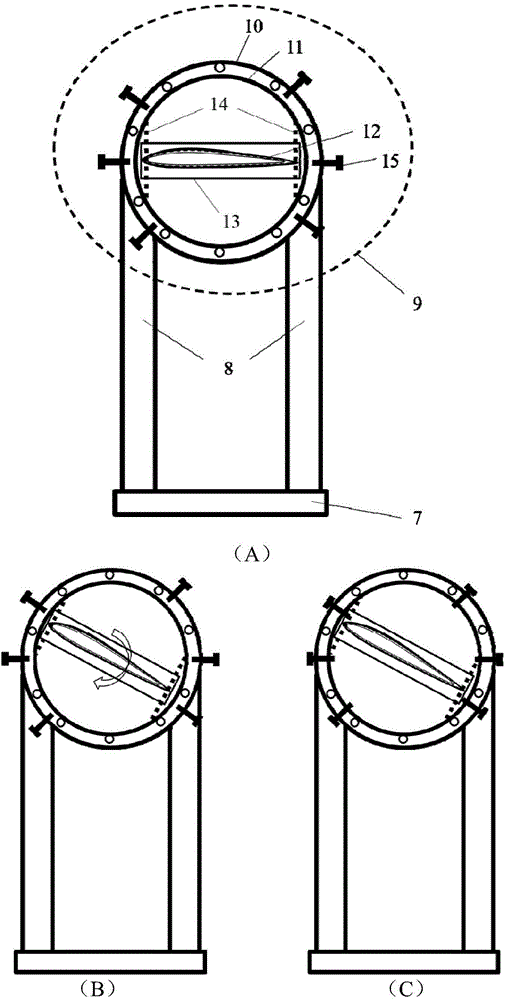

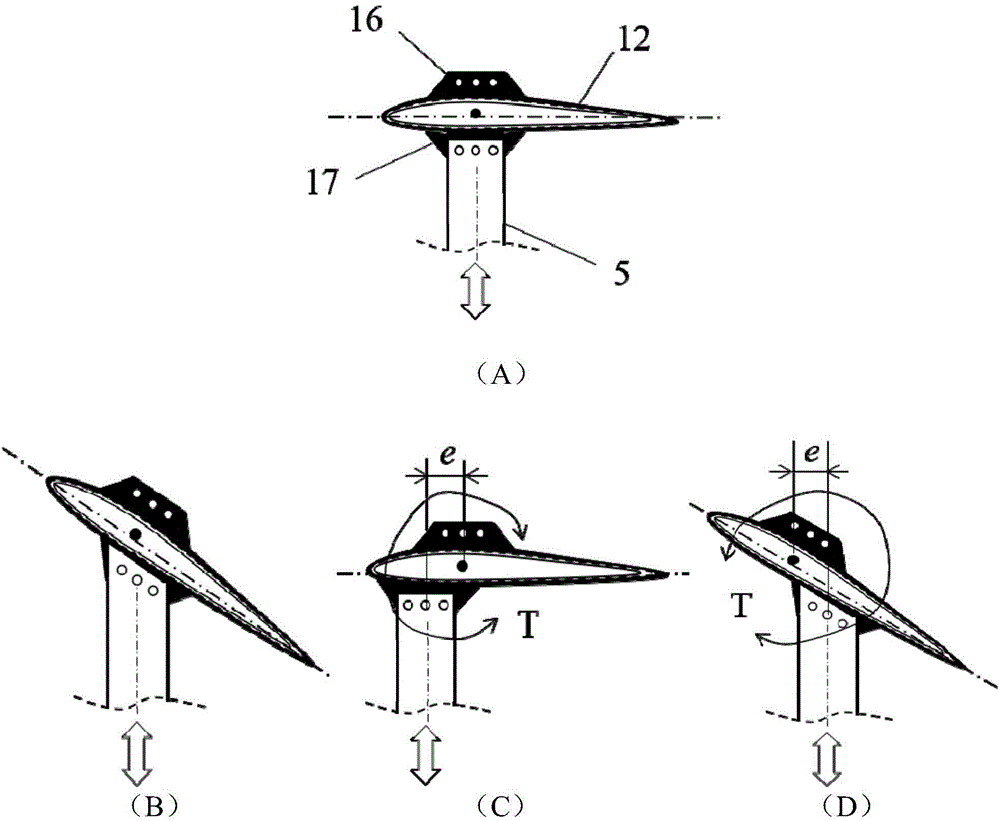

Device and method for testing structural fatigue of H-shaped vertical shaft wind turbine blade

ActiveCN104792516ATo reverse the realizationEvaluate fatigue structural performanceMachine part testingFatigue loadingStructural fatigue

The invention relates to a device and a method for testing the structural fatigue of an H-shaped vertical shaft wind turbine blade. The device comprises a support base component, a distribution beam, a loading hoop, a support connecting rod and an eccentric motor, wherein the distribution beam, the loading hoop and the support connecting rod are connected together by using bolts so as to form a whole load distribution system, so that the fatigue load which acts in an upper and lower reciprocation manner can be effectively conducted. When the device is used for experiment, the fatigue bending moment distribution of the blade under various working conditions can be simulated by adjusting the length L of the distribution beam and the position B of the loading hoop, and the fatigue stress state of the blade in axial torsion and multiple attack angles can be simulated by adjusting the structural modes of the support base component and the loading hoop; the strain distribution of the blade under the fatigue loaded condition can be measured, and furthermore, the fatigue structural property of the blade can be evaluated; by only exerting one external fatigue load to the device, combined fatigue loading modes such as bending, torsion and multiple attack angles of the blade can be achieved, and the device is simple and convenient to operate, accurate and reliable in result and relatively high in universality.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Connection fatigue index analysis for threaded connection

InactiveUS20080319720A1Low costImprove tool lifeComputation using non-denominational number representationScrew threaded jointsMathematical modelCoupling

A method for characterizing a threaded coupling such as between two tubular members is disclosed. In one embodiment, a threaded connection between a first tubular and a second tubular is considered, where the first tubular has a internally-threaded box structure and the second tubular has outer threads defining a pin structure. A mathematical model of the connection between the two tubulars is generated, and the mathematical model is permuted to reflect application of at least one flexing force to the joint. From the permuted model, a stress / strain distribution of the box and pin structures is derived. A connection fatigue index value is calculated based on the stress / strain distribution. In one embodiment, connection fatigue indices are computed for a variety of connection combinations, such that a user can compare the relative suitability of multiple box / pin combinations to select one that is deemed desirable for a particular use.

Owner:TH HILL ASSOC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com