Simulation method for machining deformation of carbon-fiber-reinforced resin matrix composite

A technology for reinforcing resin matrix and composite materials, which can be used in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems of rarely reported processing deformation of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

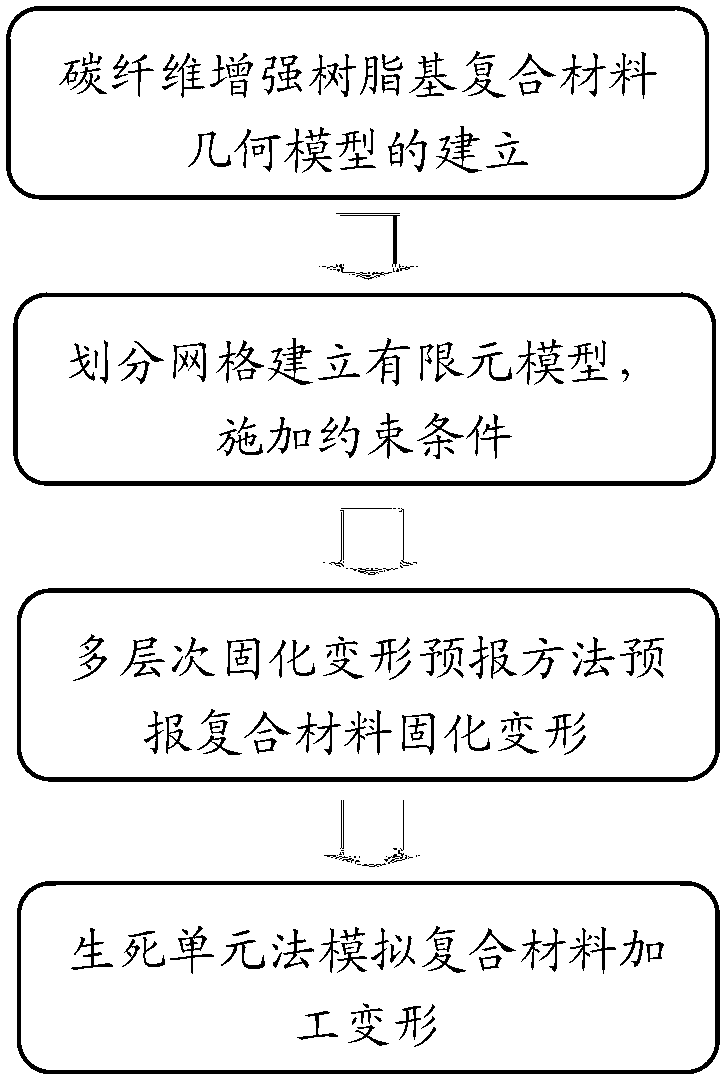

Method used

Image

Examples

Embodiment Construction

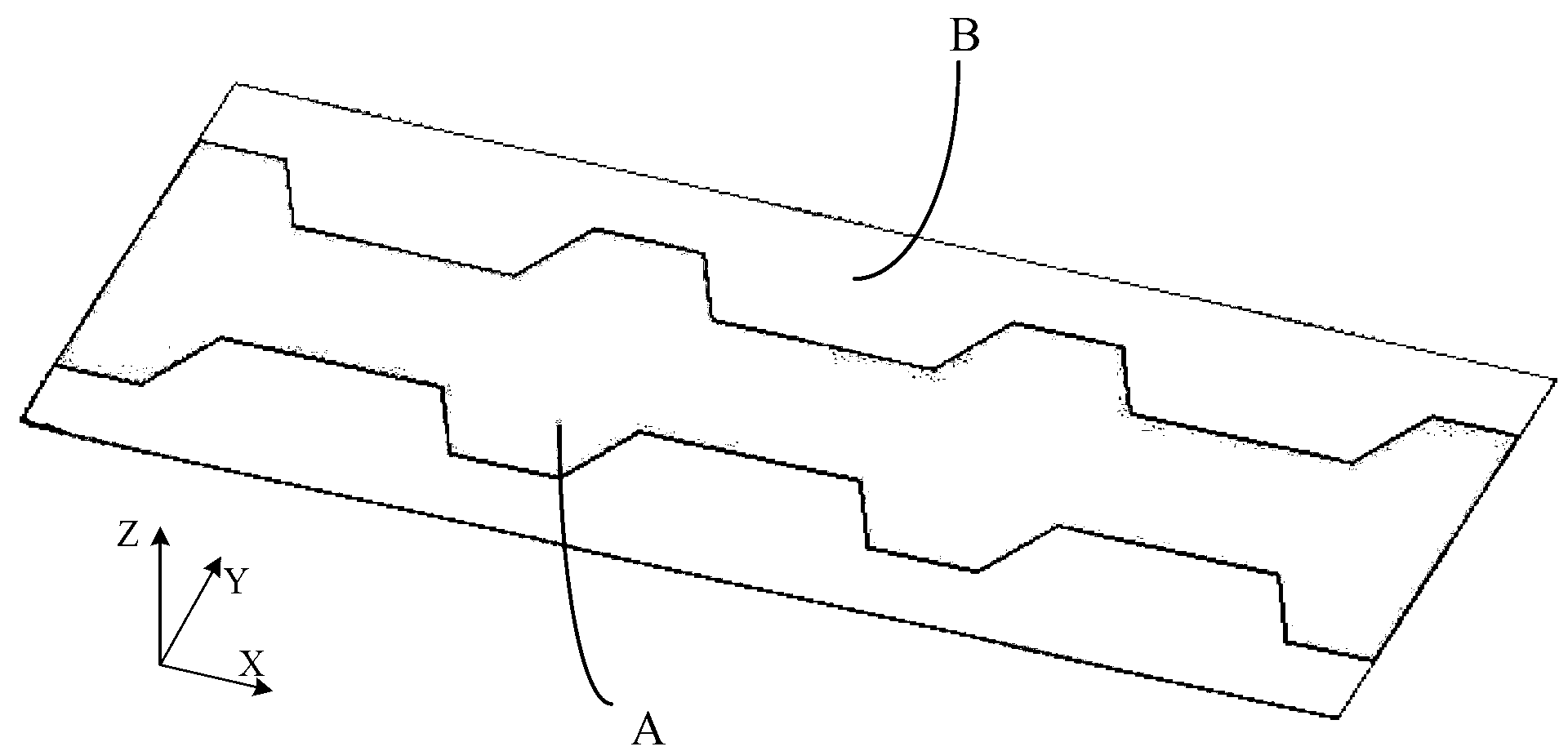

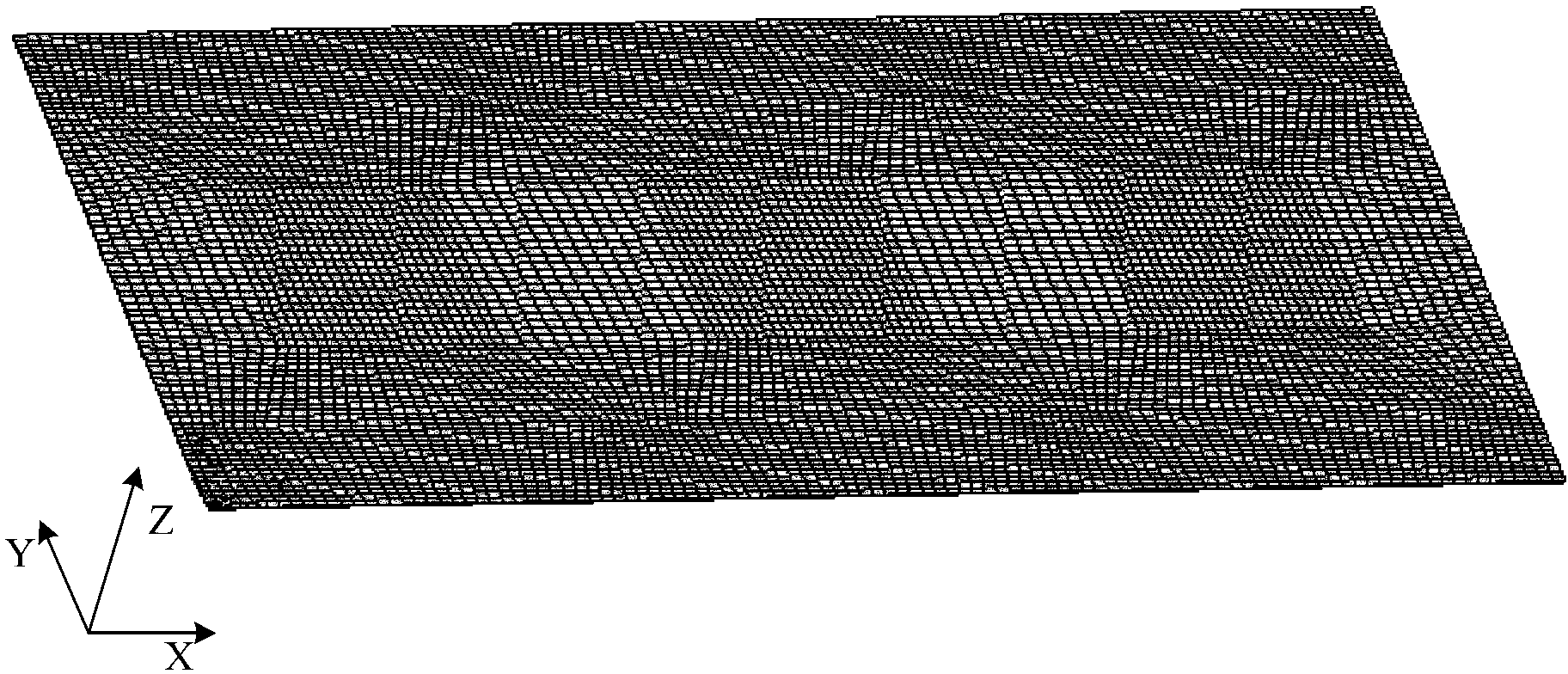

[0022] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

[0023] First of all, it needs to be explained that the simulation method of the present invention adopts the method of life-and-death unit to kill the unit that needs to be removed in machining. The so-called "killing" unit does not really delete the unit from the model, but Its stiffness matrix is multiplied by a small factor. The default value of the factor is generally 10 -6 . At this time, it is approximately considered that the stiffness matrix of the element is 0, then the stress vector of the element will also become 0. Therefore, when using the finite element method to simulate the removal of composite materials, the removal of elements can be equivalent to setting the elastic modulus of elements to 0. This is the theoretical basis for simulating the removal of composite materials by the birth-death element method.

[0024] For c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com