Patents

Literature

241 results about "Ansys software" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

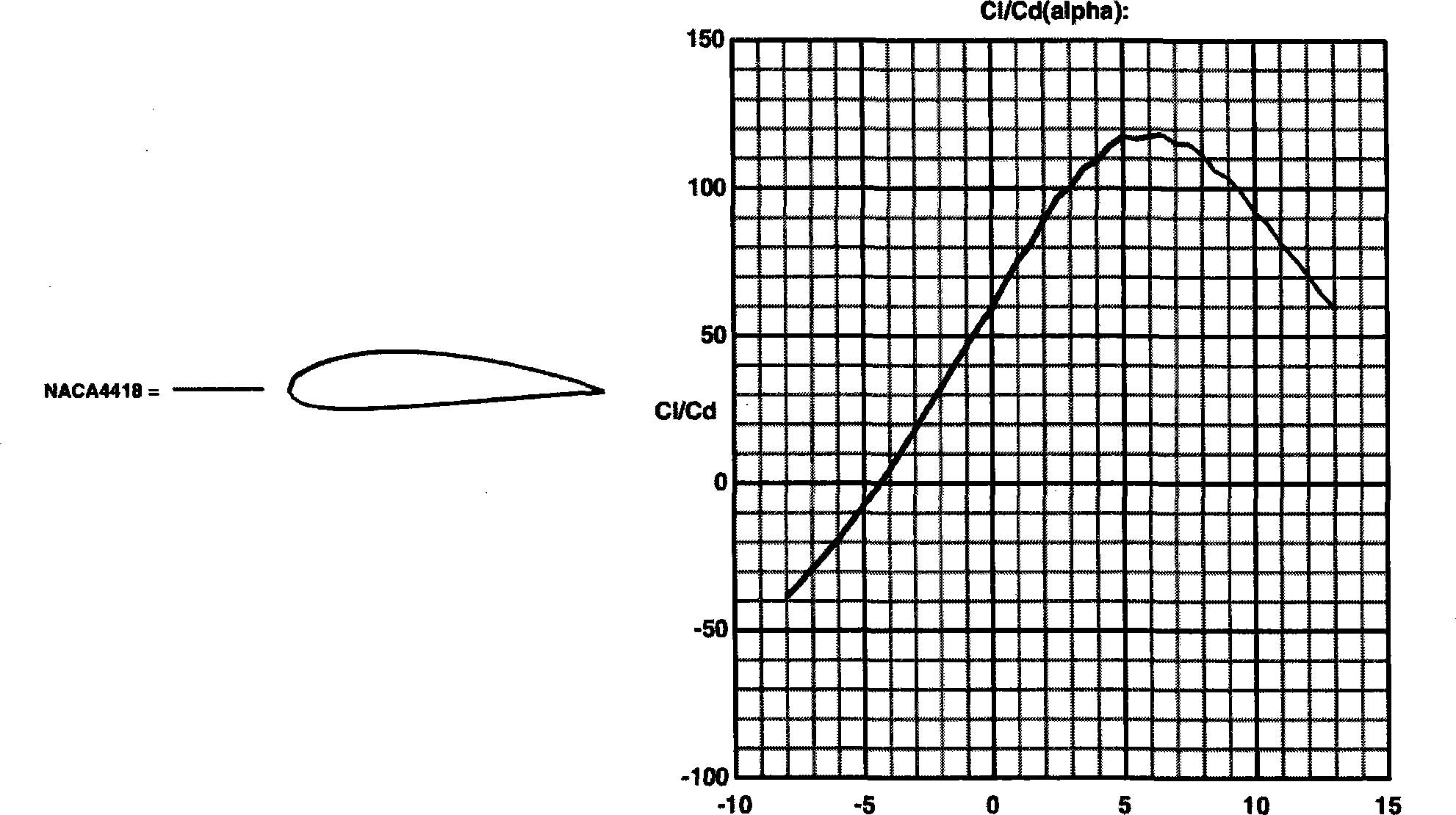

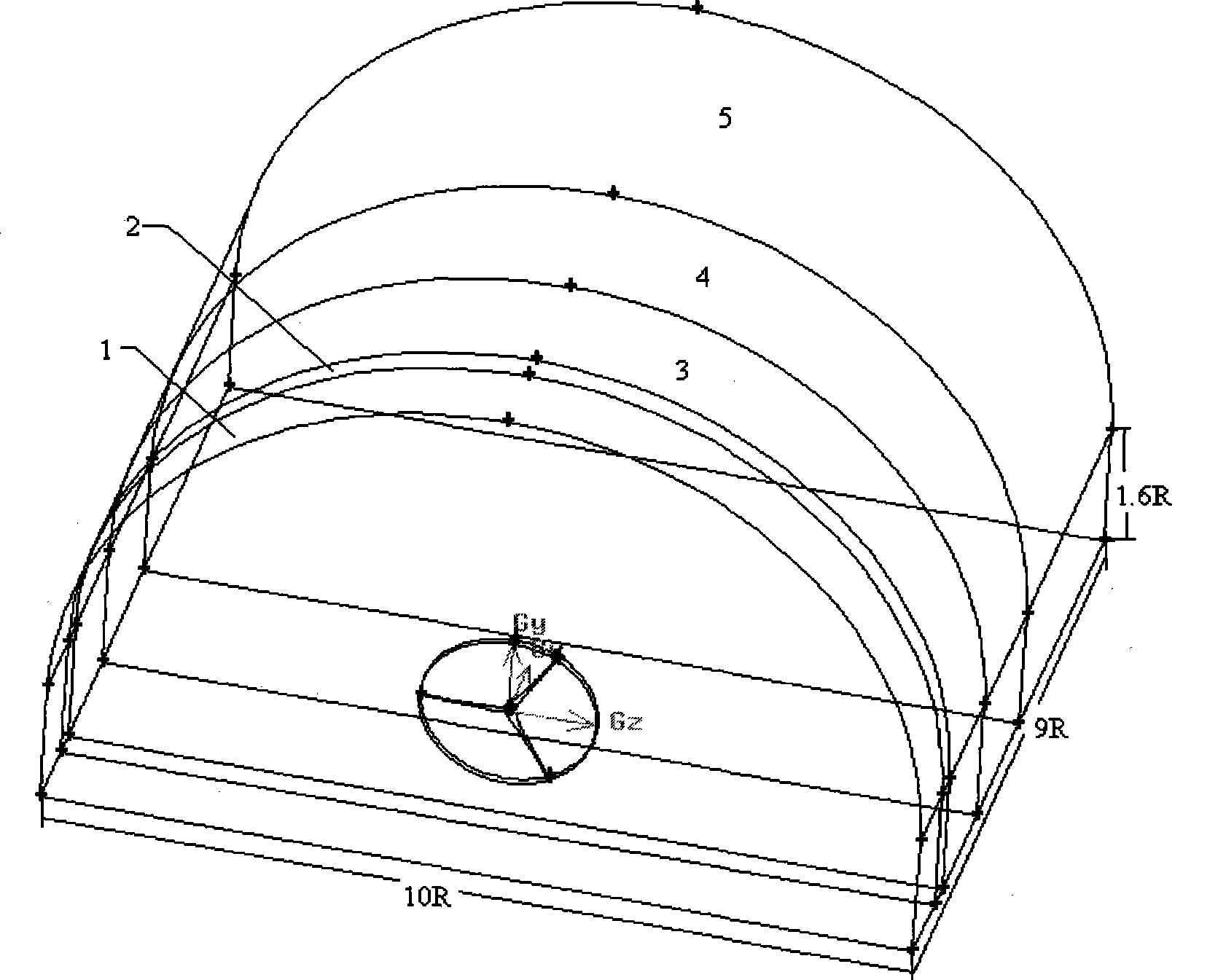

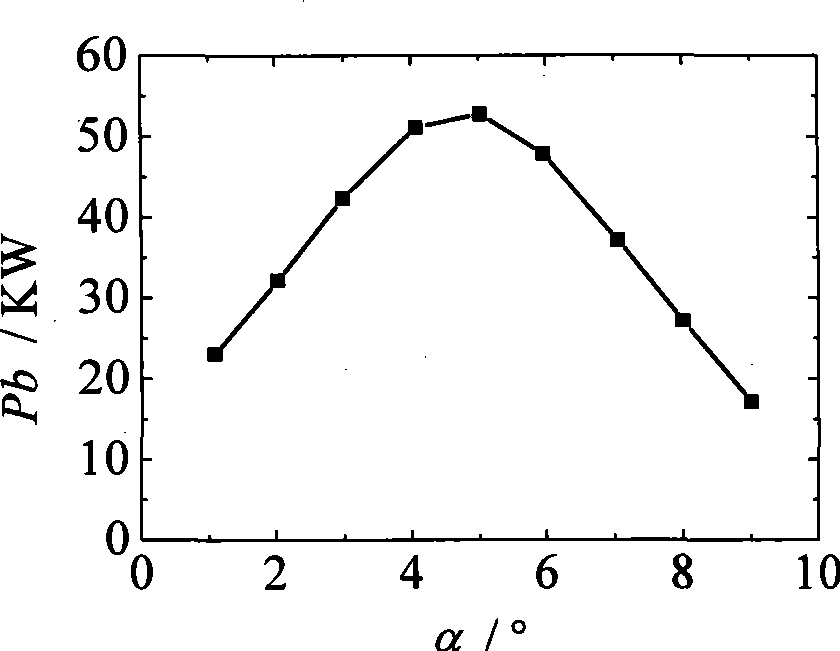

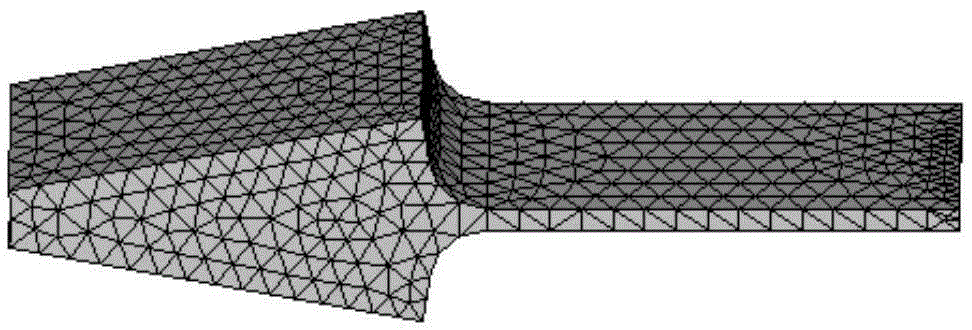

Method for analyzing fluid dynamics and structural mechanics of wind generator blades

InactiveCN101532906AReduce windward angleReduce the required powerMachine part testingAerodynamic testingEngineeringEntity model

The invention discloses a method for analyzing fluid dynamics and structural mechanics of wind generator blades, which comprises the following steps: combining CFD and CAE methods, determining each parameter of an impeller model by adopting the momentum blade element theory, designing an entity model of the blade, establishing a three-dimensional model of a windmill blade, a hub and a peripheral wind site based on a Gambit software platform, meshing the model by adopting a partial structuring method, setting a proper boundary condition, calculating the performance of a finite element based on a Fluent software platform, extracting the blade torsion and calculating the blade power and the blade efficiency, establishing a blade structural model based on an ansys software platform and meshing the blade structural model, applying load and restraint condition to the blade structural model, analyzing the mode of the blade structure, performing equal torque treatment for pressure distribution acquired by the Fluent software platform, applying pressure surface load to the ansys software platform, calculating the structural mechanics characteristics of the wind generator blades, and extracting blade deformation and stress distribution characteristics.

Owner:SOUTHEAST UNIV +1

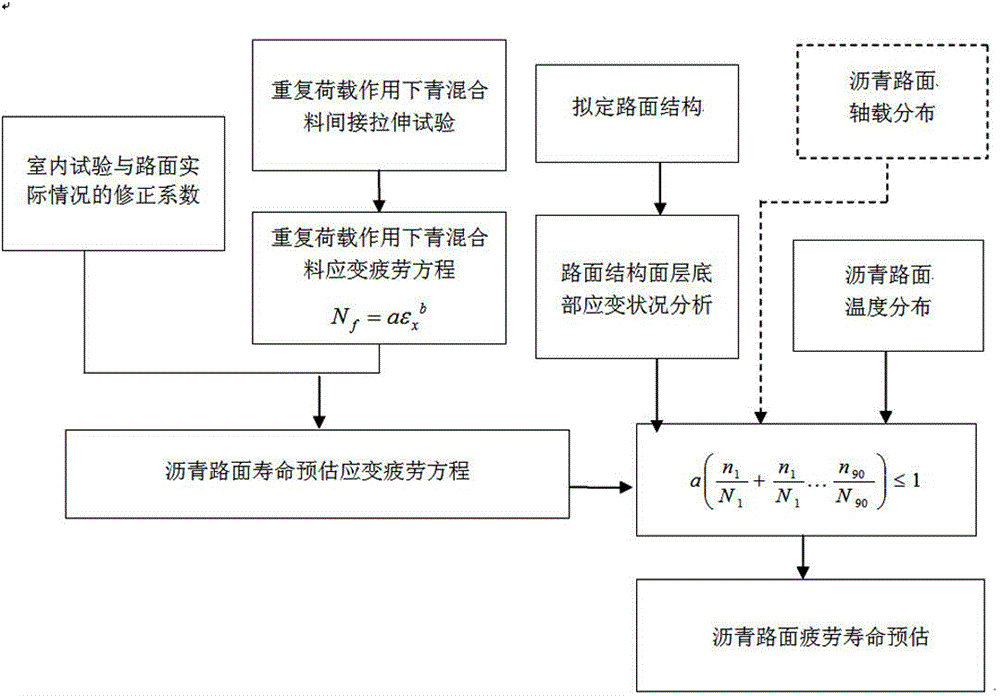

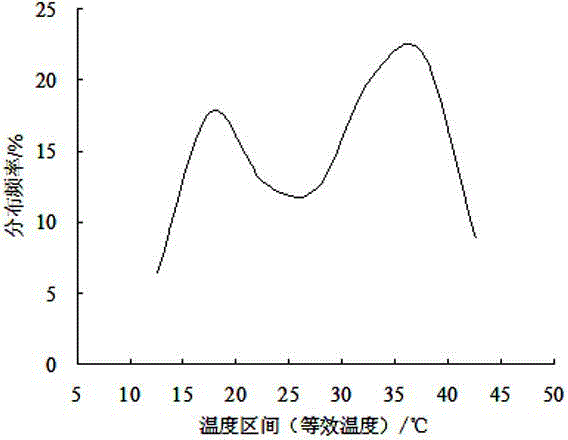

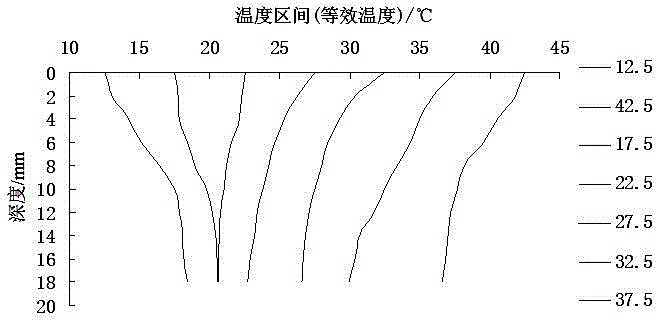

Fatigue life prediction method for high-modulus asphalt mixture pavement

InactiveCN104462843AAccurately describe attenuationAccurately describe the lawSpecial data processing applicationsUltrasound attenuationElement model

The invention provides a fatigue life prediction method for a high-modulus asphalt mixture pavement. The method comprises the steps that structural temperature distribution, pavement material dynamic modulus and temperature axle load distribution of the high-modulus asphalt mixture pavement serve as basis parameters; a fatigue strain equation is fit according to an indirect tension fatigue test result; ANSYS software is adopted to construct a pavement structure finite element model, and maximum tension strain of a bottom layer at different axle load levels in different temperature regions is calculated; according to the Miner fatigue cumulative damage rule, fatigue cumulative damage results of a high-modulus asphalt mixture at different axle loads and different temperatures are calculated according to the formula: . The fatigue life prediction method for the high-modulus asphalt mixture pavement has the technical advantages that temperature gradients and axle load distribution of the asphalt mixture pavement are fully considered, an accurate prediction model is established, the process and law of fatigue attenuation of the asphalt mixture are accurately described, the application range is wide, and calculation results are reliable, so a more reliable method is provided for structural design of the asphalt pavement.

Owner:CHONGQING JIAOTONG UNIVERSITY

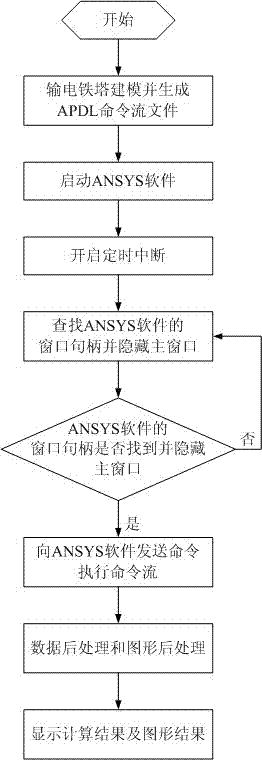

Method for performing structure analysis on steel pylon by using ANSYS software

ActiveCN102968542AReduce the difficulty of operationImprove targetingSpecial data processing applicationsGraphicsStructure analysis

The invention relates to a method for performing structure analysis on a steel pylon by using ANSYS software, which is applied to static analysis and dynamic analysis of the steel pylon. The method comprises the steps as follows: firstly completing modeling of the steel pylon through a self-control program, and generating an APDL (ANSYS parametric design language) command stream file which can be executed by the ANSYS software; then starting the ANSYS software in the background, and utilizing the form of sending command stream to the ANSYS software to complete structure analysis on the steel pylon; and finally displaying the data result and the graphic result in an assigned position of the self-control program. According to the invention, with the combination of the self-control program and the ANSYS software, the shortages of higher use difficulty and poorer pertinence in structure analysis of the steel pylon by the ANSYS software are solved, so that the structure analysis of the steel pylon is more convenient and faster, and a favorable analysis platform for technicians is provided.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

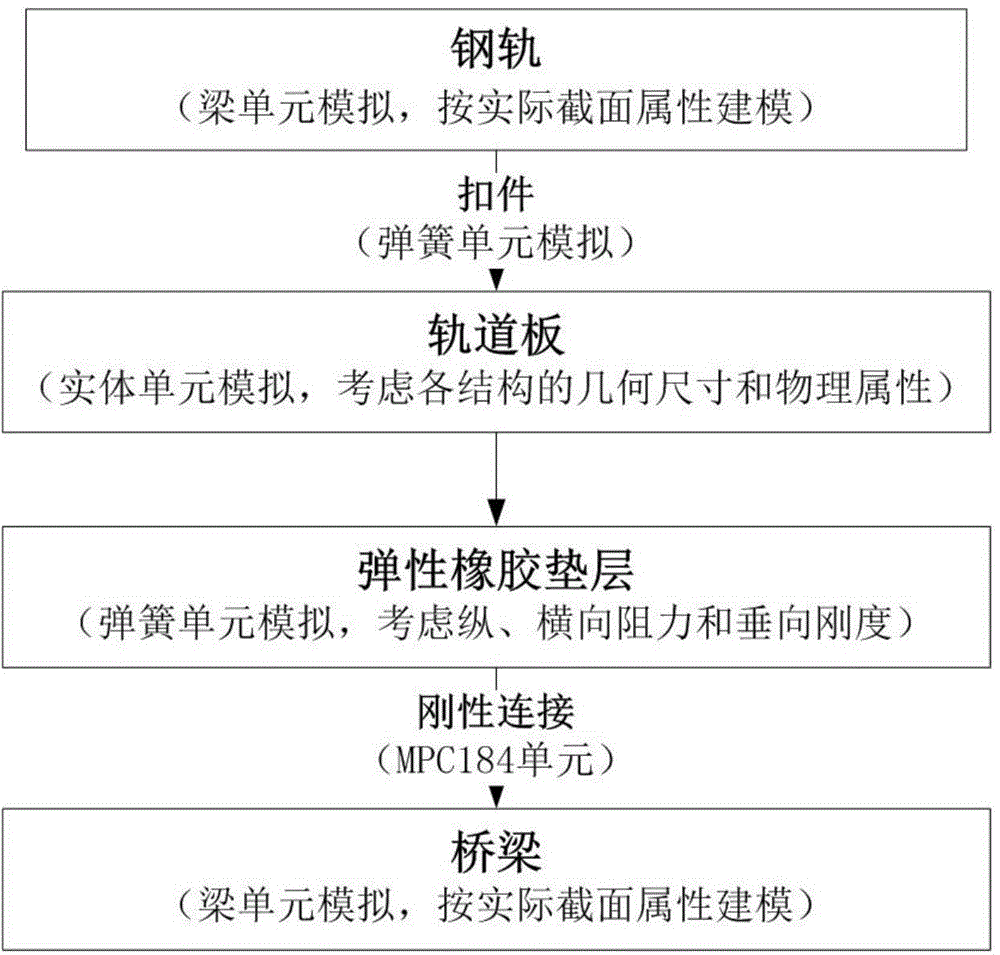

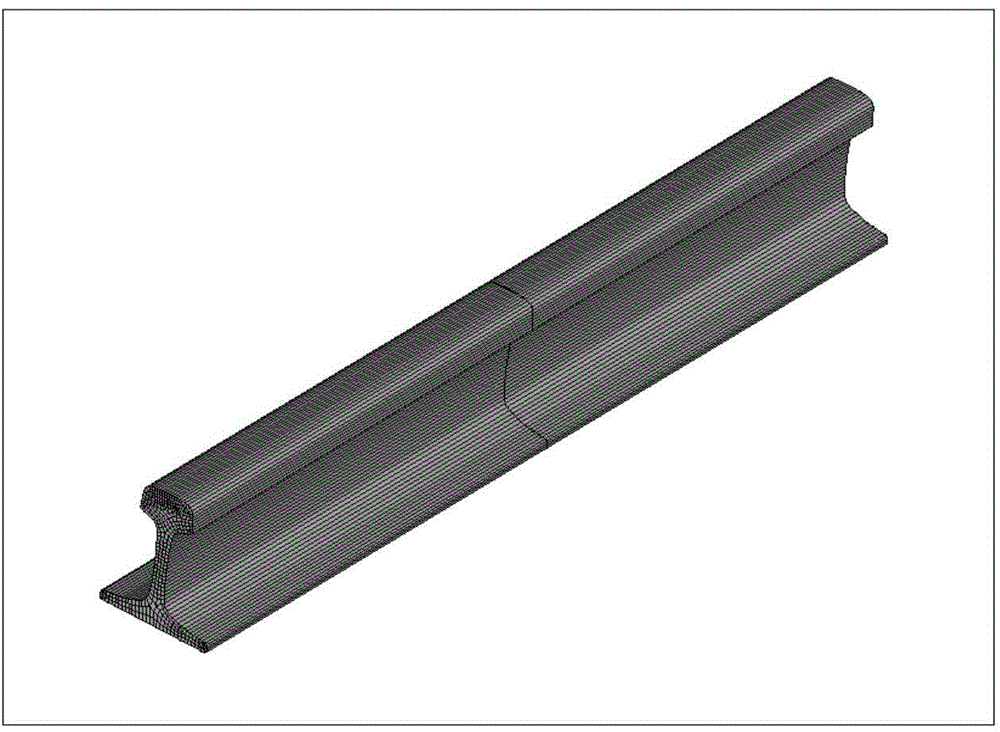

Method for designing jointless track of long and large bridge girder longitudinal butt plate type ballastless track for high-speed railway

InactiveCN102789531AFully consider longitudinal resistanceFully consider lateral stiffnessRailway tracksBridge structural detailsEngineeringSlurry

The invention relates to a method for designing a jointless track of a long and large bridge girder longitudinal butt plate type ballastless track for a high-speed railway. According to the method provided by the invention, ANSYS software is utilized to establish a latitude vertical space coupling statics model of the jointless track of the long and large bridge girder longitudinal butt plate type ballastless track for the high-speed railway, and ABAQUS software is utilized to establish a space coupling kinetic model. According to the method, the compositions of systems such as a steel rail, a fastener, track plates, a slurry placement layer, bed plates, a sliding layer, a consolidation mechanism, high-strength extruded sheets and L-shaped side check blocks, and structures such as supporting layers on a subgrade soil body and a road foundation and the action of high-speed vehicles are taken into full consideration, and friction factors of sliding layers on different bridge or friction plates, the longitudinal resistance of the fastener, the temperature difference of the bridge girder, the temperature difference of a ballastless track structure, the elastic modulus of the slurry placement layer and the like are calculated, so that the stress and deformation of the track and the bridge girder are obtained. The method provided by the invention is suitable for the design and computational check of the jointless track of the long and large bridge girder longitudinal butt plate type ballastless track for the high-speed railway, and providing service for the design calculation as well as conservation and maintenance of the high-speed railway.

Owner:BEIJING JIAOTONG UNIV

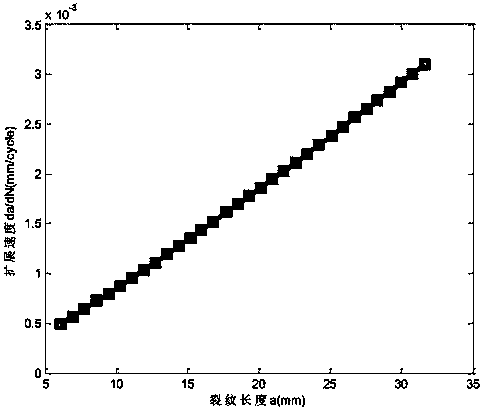

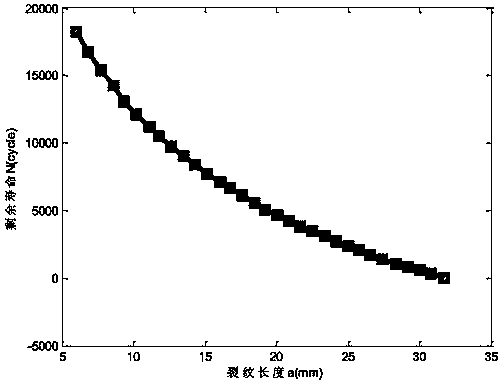

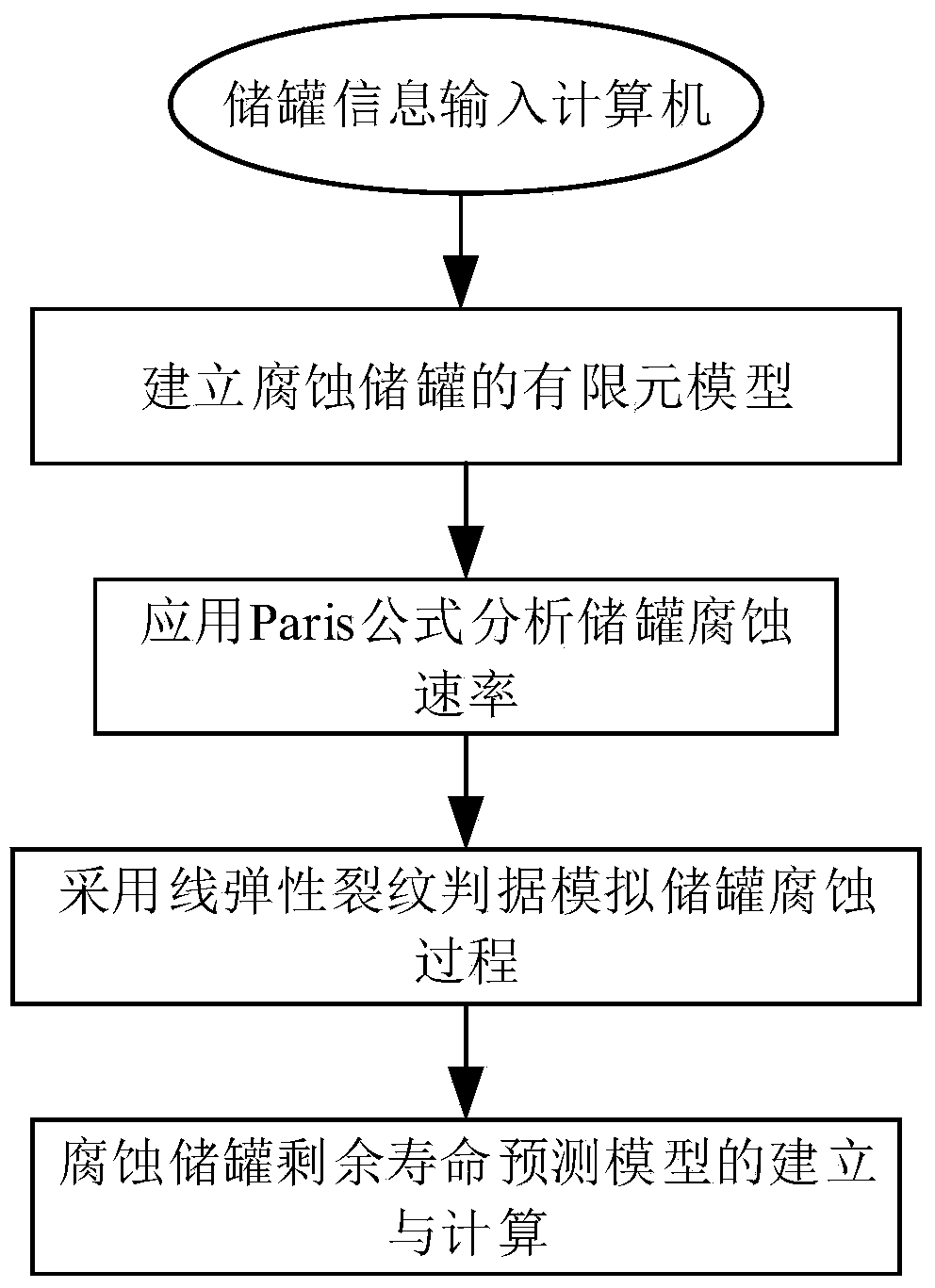

Method for predicting residual life of storage tank

InactiveCN103870662AEfficient prediction of remaining lifeTimely maintenanceSpecial data processing applicationsElement modelComputer support

The invention relates to a method for analyzing the residual life of a storage tank through ANSYS software. The method mainly comprises the following steps that (1) a computer supporting ANSYS is used, collected storage tank data are input to the computer in the form of a database or a text, a finite element model of the corroded storage tank is established through the ANSYS software, and corresponding boundary conditions and an external load are applied to the finite element model according to the actual stress condition of the storage tank; (2) regression processing is conducted on experimental data points through a fatigue crack propagation law Paris formula, and a corrosion fatigue rate equation under the corresponding conditions is obtained; (3) the critical invalid wall thickness when the storage tank loses efficacy is determined according to a predicted value of the corrosion rate; (4) according to the critical invalid wall thickness when the storage tank loses efficacy due to corrosion, a storage tank residual life prediction model is established, and the approximate analysis method is used for calculating the residual life of the storage tank under the condition of uniform corrosion.

Owner:QINGDAO UNIV OF SCI & TECH

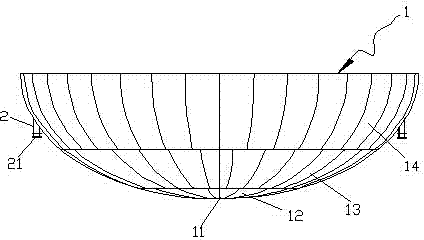

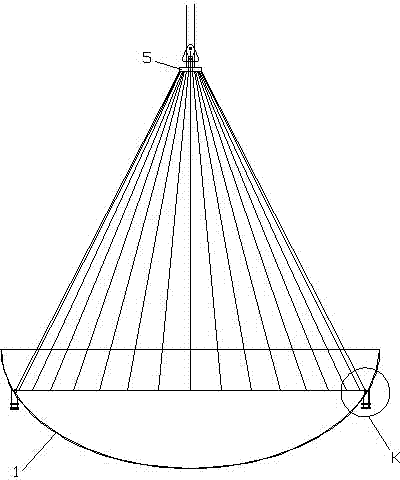

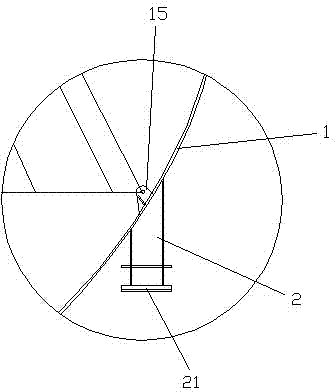

Method for hoisting steel safe bottom seal head at nuclear power station and special-purpose sling tool thereof

The invention discloses a method for hoisting a steel safe bottom seal head at nuclear power station and a special-purpose sling tool thereof. The method comprises the following steps: using Ansys software for analyzing and calculating the force when the bottom seal head is hoisted, designing a hanger distribution position and a hoisting scheme, designing and making the special-purpose sling tool; performing a loading test by a crane; performing the loading test by the special-purpose sling tool; performing a simulation test with an empty hook; testing the hoisting; hoisting in a formal mode, reinforcing and installing. The special-purpose sling tool comprises a suspension cable distributor, a release fastener, a secondary distributor, a compacting wire rope and an adjustable pull bar in order from up to down. The hoisting method does not require a specially-manufactured hoisting beam, inner force generated during a hoisting resisting process by self rigidity of the steel safe bottom seal head can be fully used, the circle suspension cable distributor and the adjustable pull bar can ensure uniform bearing of each hoisting point, deformation during the hoisting process is reduced to minimum, and hoisting requirement of the large-scale equipment in a nuclear power station can be accorded. The suspension cable has the advantages of reasonable design, simple structure and convenient connection.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

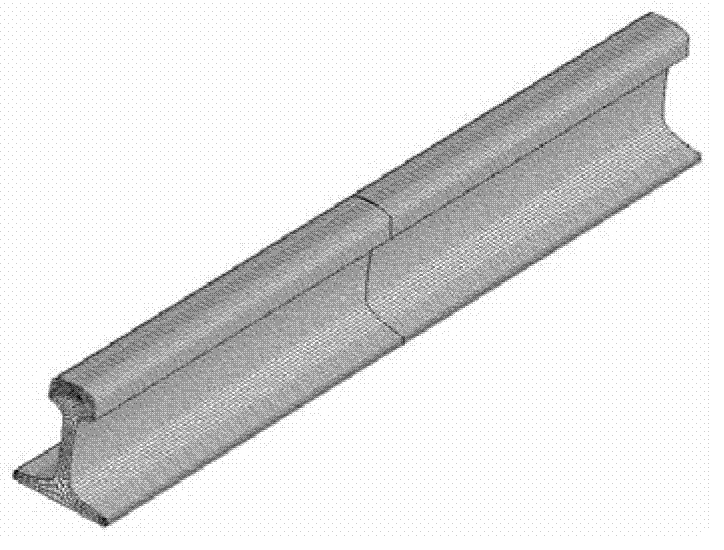

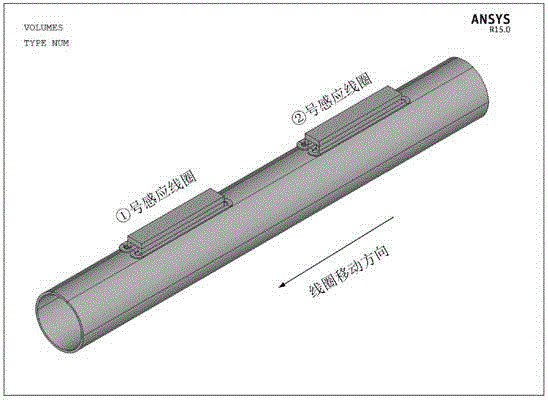

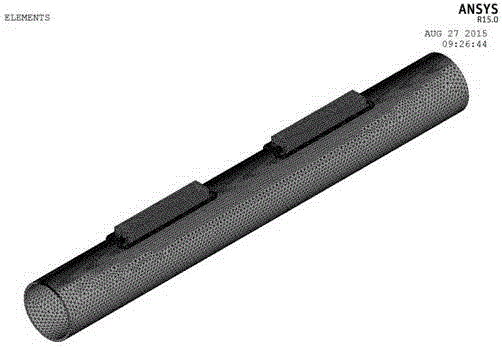

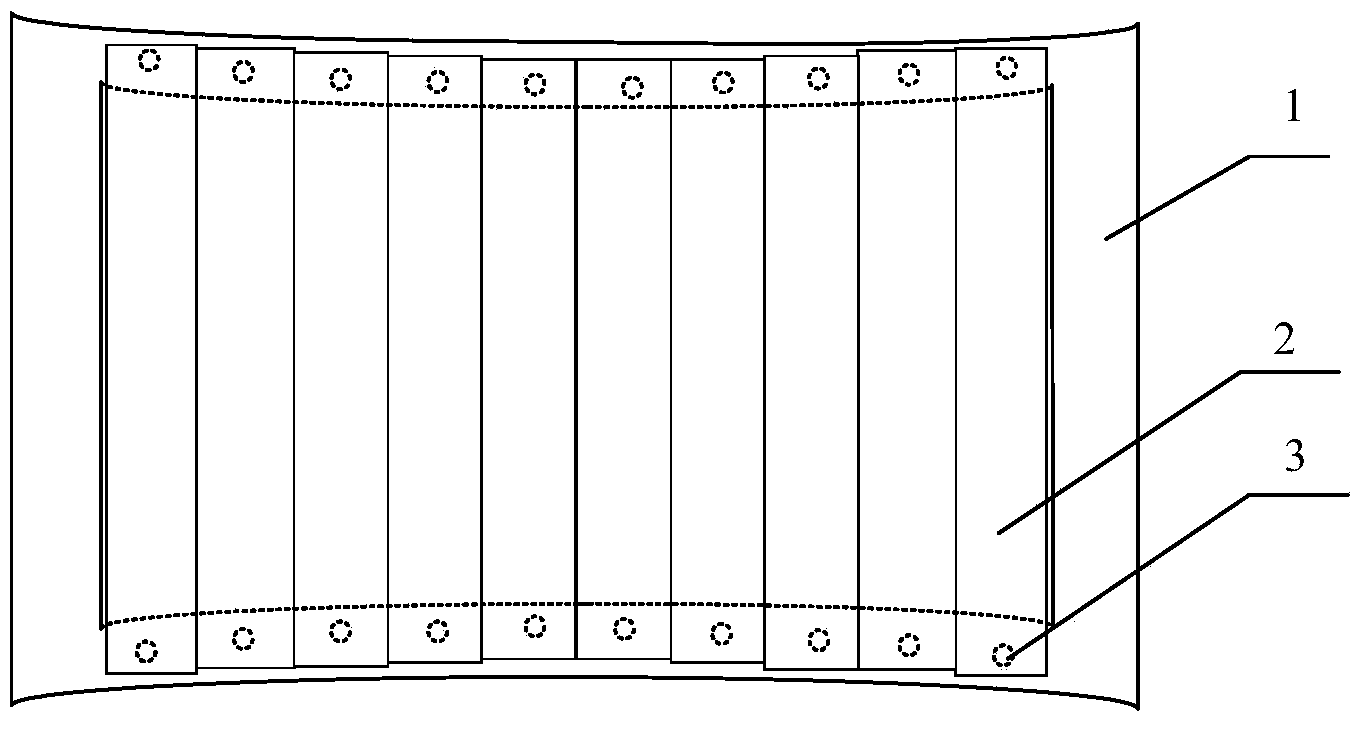

Method for dynamically simulating intermediate-frequency heat treatment process of longitudinal welded pipes

ActiveCN105740536AAchieve relative motionEasy to masterDesign optimisation/simulationSpecial data processing applicationsIntermediate frequencyHeat analysis

The invention discloses a method for dynamically simulating intermediate-frequency heat treatment process of longitudinal welded pipes. According to the method, the movement of welded pipes in practical production is replaced by the movement of induction coils, an ANSYS APDL language-based macro document library, and the macro document library comprises a control library, a parameter library, an environment library and a computation library, wherein the control library is used for controlling the execution sequences of macro documents in the parameter library; the parameter library comprises modeling parameters and load parameters when the coils are at different positions; the environment library is used for establishing geometric models, meshing, load application and solving types required by two physical environments: electromagnetic analysis and heat analysis; and the computation library is used for carrying out electromagnetic-thermal coupling computation on the induction heating process by adopting DO circulation and storing the solving result into a database. Compared with the prior art, the method is capable of dynamically simulating the intermediate-frequency heat treatment process of the longitudinal welded pipes, and the simulation is closer to the reality; through modifying the parameters, various production processes of the factories can be simulated; and the whole simulation process takes ANSYS software as a platform, so that the operation is automatic, the operation is simple and the factory technicians can grasp and use the method conveniently.

Owner:江苏金诺炉辊有限公司

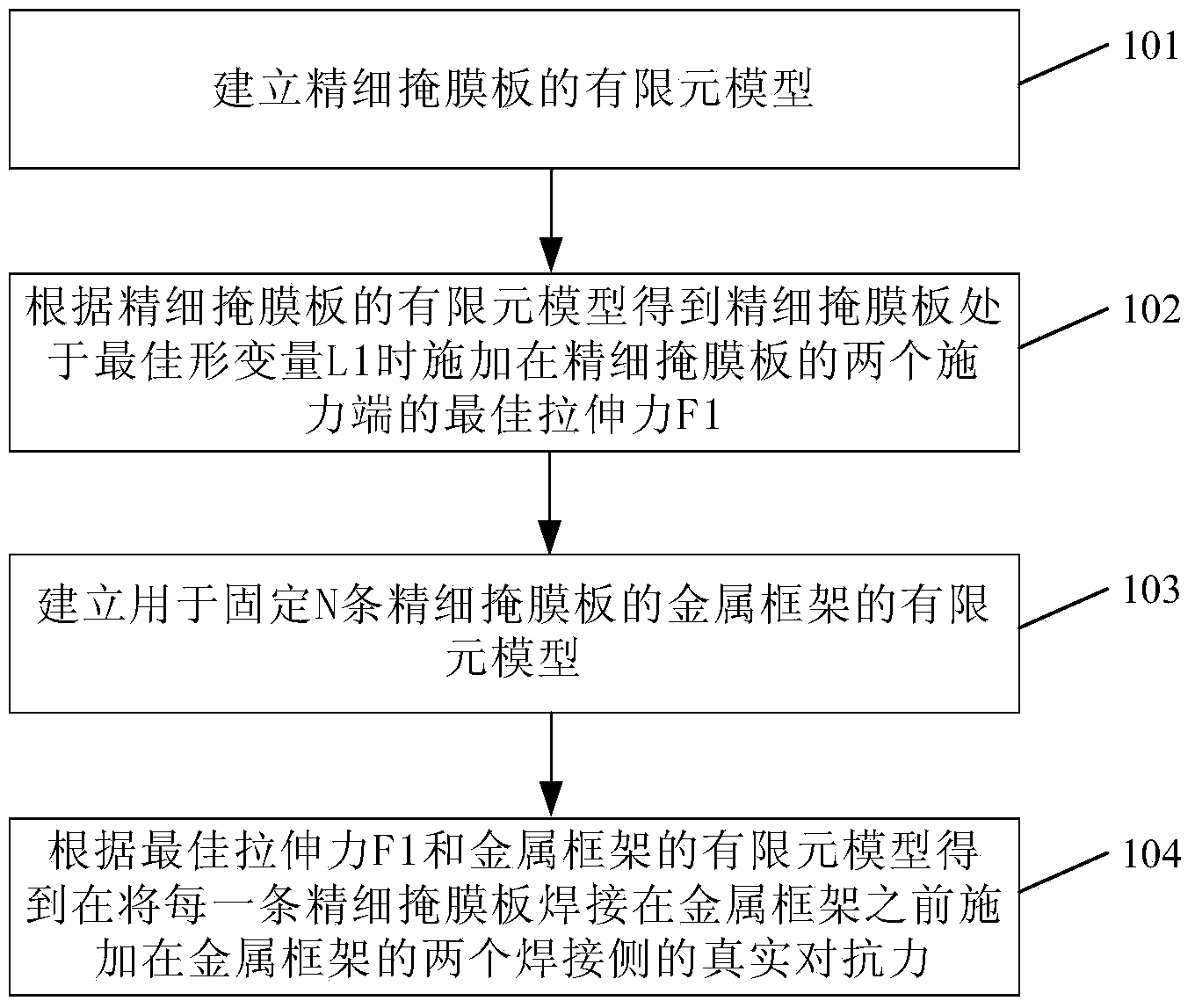

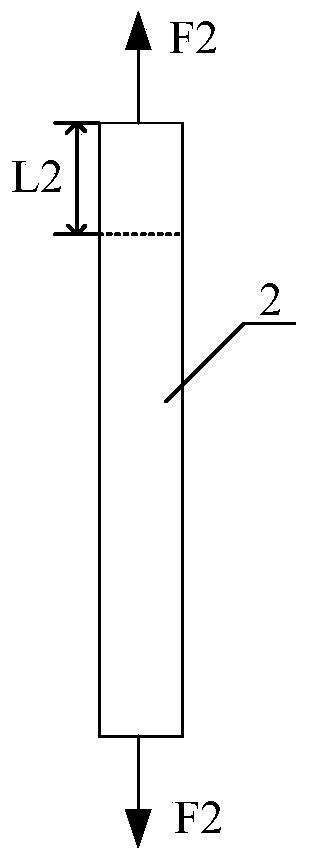

Fine mask screening process analysis method

ActiveCN104281747AAvoid Fine MasksReduce testing costsMaterial strength using tensile/compressive forcesDesign optimisation/simulationElement modelAnsys software

The invention discloses a fine mask screening process analysis method. The method includes that on the basis of simulation functions of ANSYS, finite element models of fine masks and a finite element model of a metal frame are established so that proper tensile force used for stretching the fine masks and enable the fine masks to be welded in front of the metal frame and correspond to true counter force applied to the metal frame. Physical tests are not needed during analysis, so that damage to the fine masks can be effectively avoided, and test cost is effectively saved.

Owner:BOE TECH GRP CO LTD +1

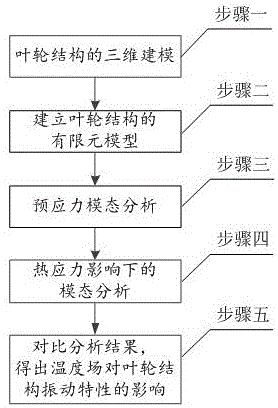

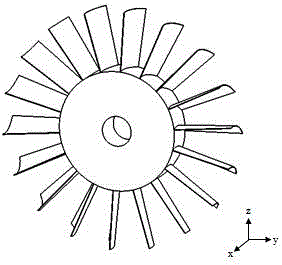

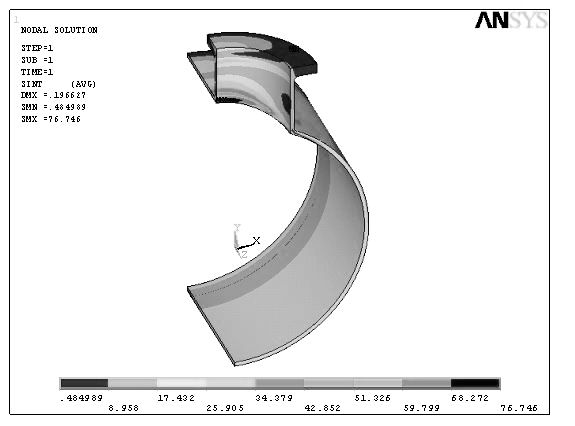

Finite element analysis method for thermal-coupled vibration characteristics of impeller structure

InactiveCN105930620AMake up for the disadvantageAccurate theoretical basisGeometric CADDesign optimisation/simulationElement analysisProcess module

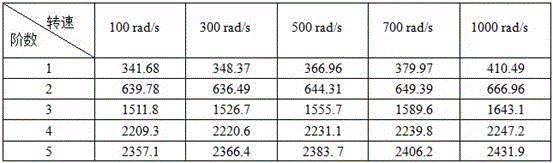

The invention provides a finite element analysis method for thermal-coupled vibration characteristics of an impeller structure. The technical scheme is that the finite element analysis method comprises the following steps: establishing a three-dimensional model of the impeller structure by utilizing a solidworks parameter modelling method; importing the three-dimensional model of the impeller structure into finite element analysis software ANSYS, setting the attributes, parameters, loads and constraints of materials according to the actual working conditions in an ANSYS software pre-processing module, and dividing finite element grids; calculating the first five orders of fixed frequencies of the impeller structure at different rotation speeds through an ANSYS software modal analysis module; calculating the first five orders of fixed frequencies of the impeller structure at different rotation speeds in high-temperature environment through considering the influences of a temperature field; comparing the fixed frequencies in above analysis to obtain the influences, caused by the temperature field, on the vibration characteristics of the impeller structure, so as to provide theoretical basis for the failure mechanism research of the impeller structure under the high-temperature environment.

Owner:UNIV OF JINAN

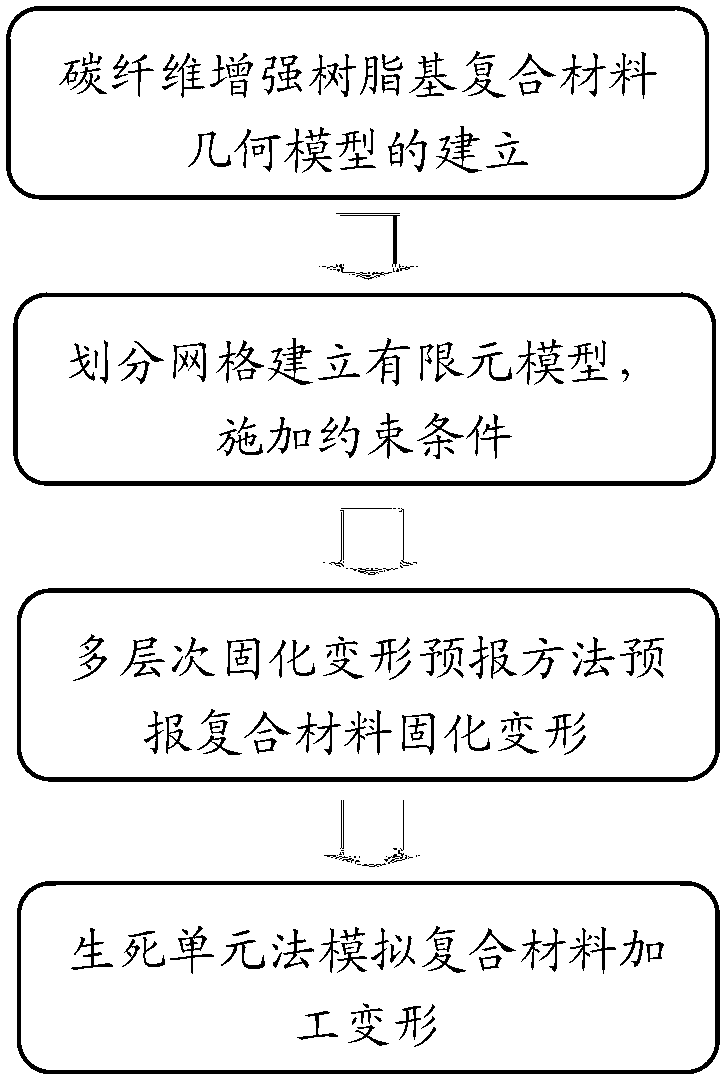

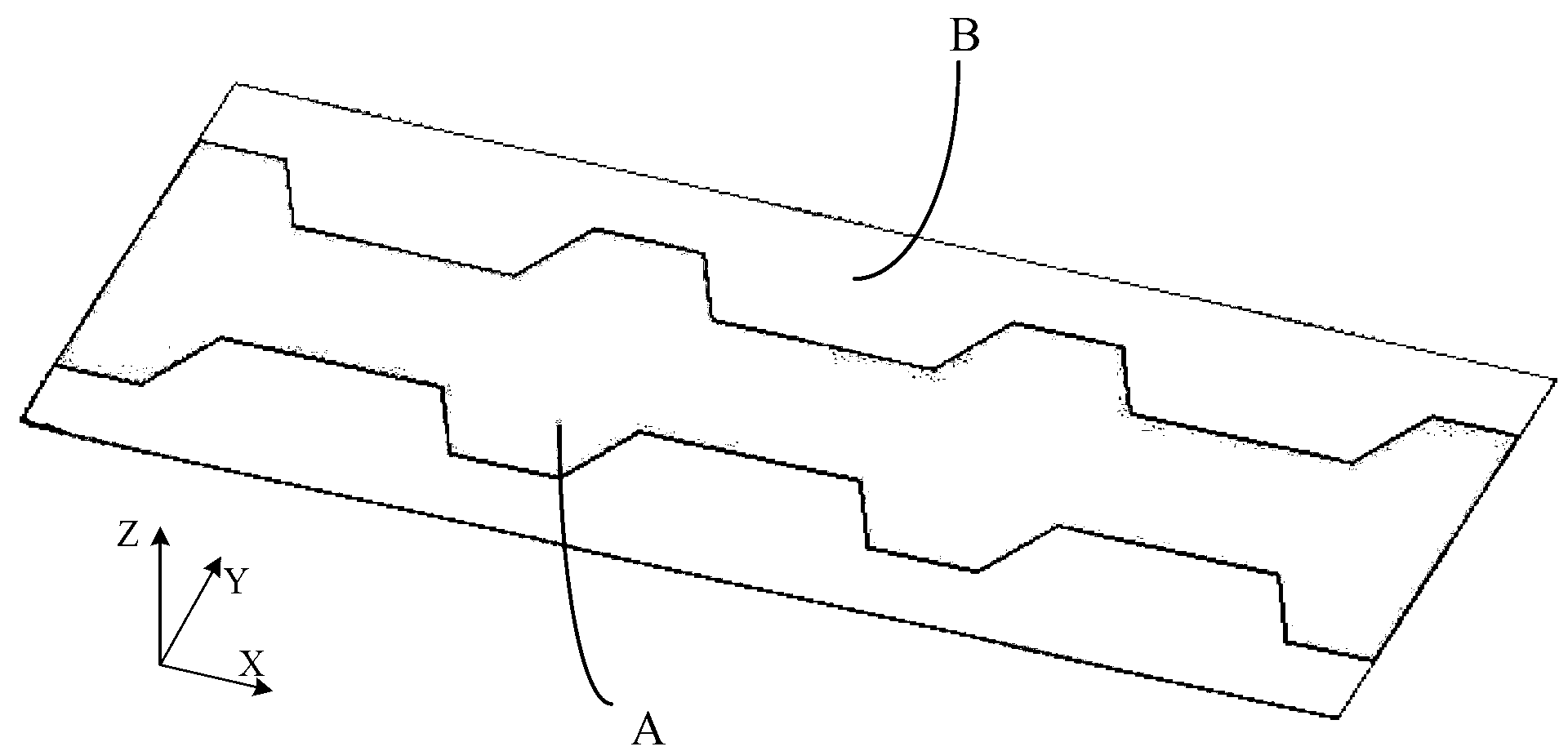

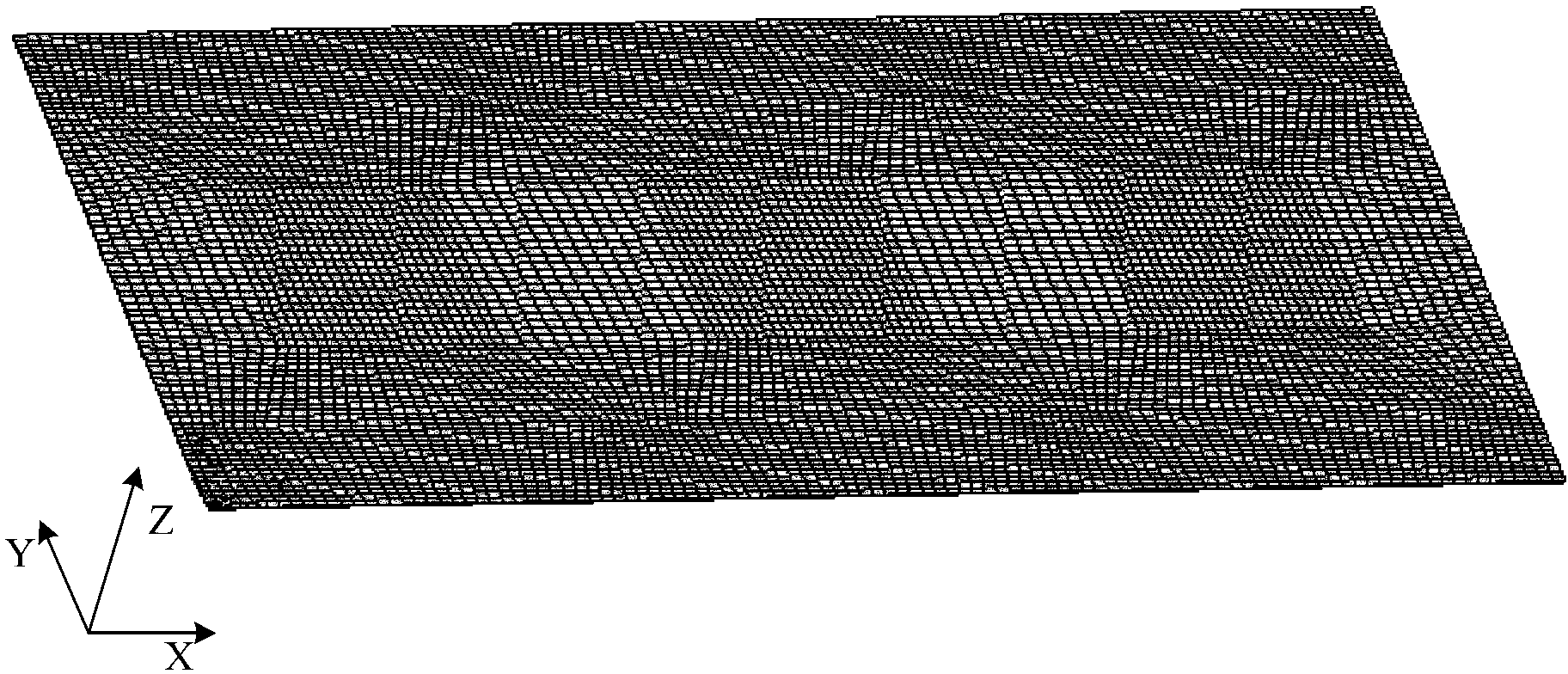

Simulation method for machining deformation of carbon-fiber-reinforced resin matrix composite

InactiveCN103294862ASolve the real problemEasy to masterSpecial data processing applicationsElement modelCarbon fibers

The invention provides a simulation method for machining deformation of carbon-fiber-reinforced resin matrix composite. The method includes: a, inputting modeling parameters in ANSYS software to build a geometric model; b, meshing the geometric model built in step a by a solid 185 unit, building a finite element model, and limiting the finite element model; c, simulating an autoclave process, calculating a solidification deformation value of the composite, and extracting a stress and strain distribution cloud graph; d, simulating a composite machining process by a method of killing or activating element to obtain machining deformation of the machined composite; and e, calculating the machining deformation value of the machined composite. The method has the advantages that simulation of accurate deformation prediction for the machining deformation of the carbon-fiber-reinforced resin matrix composite is realized, and the practical problems in composites engineering application are solved. The method is simple to operate and convenient to use. The software platform ANSYS is used, so that the method is well compatible and is convenient for technicians to master and use.

Owner:SHANGHAI AIRCRAFT MFG +1

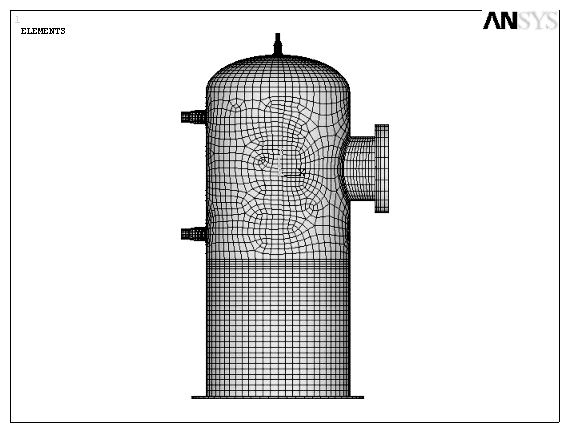

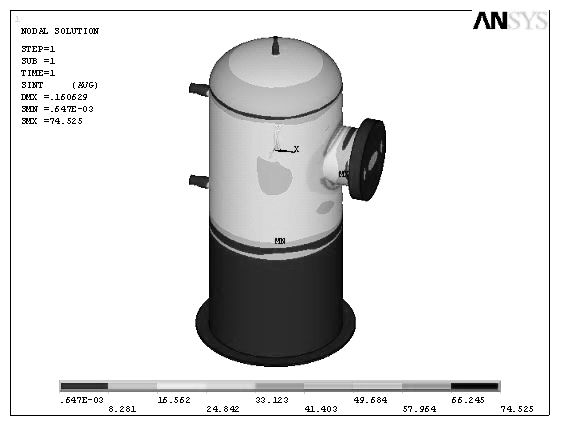

Method for carrying out stress analysis on first-class nuclear reactors through using ANSYS software

ActiveCN102184289AShorten design timeSave design costSpecial data processing applicationsElement modelDesign specification

The invention discloses a method for carrying out stress analysis on first-class nuclear reactors through using ANSYS software, belonging to the technical field of analysis and design methods for first-class nuclear reactors. The method comprises the following steps: firstly, after carrying out routine design according to a design specification, thus obtaining a design drawing; establishing a geometric model and a finite element model by using a simulation device in an ANSYS; carrying out analysis and calculation on all nuclear parts; extracting a stress analysis result; and carrying out strength assessment according to the specifications stipulated in subsections NB and NF of section III of ASME (American society of mechanical engineers), then obtaining a detailed design report. Compared with the prior art, the method disclosed by the invention summarizes and improves a method for carrying out analysis and design on first-class nuclear reactors through using ANSYS software; compared with an analytical method and a test method, by using the method disclosed by the invention, the design time is greatly shortened, the design expense is reduced, the analysis efficiency is greatly improved, and the analysis cost is reduced; and in the process of analysis, an entity is adopted for modeling a hexahedron unit, thereby improving the calculation accuracy.

Owner:大连船舶重工集团装备制造有限公司

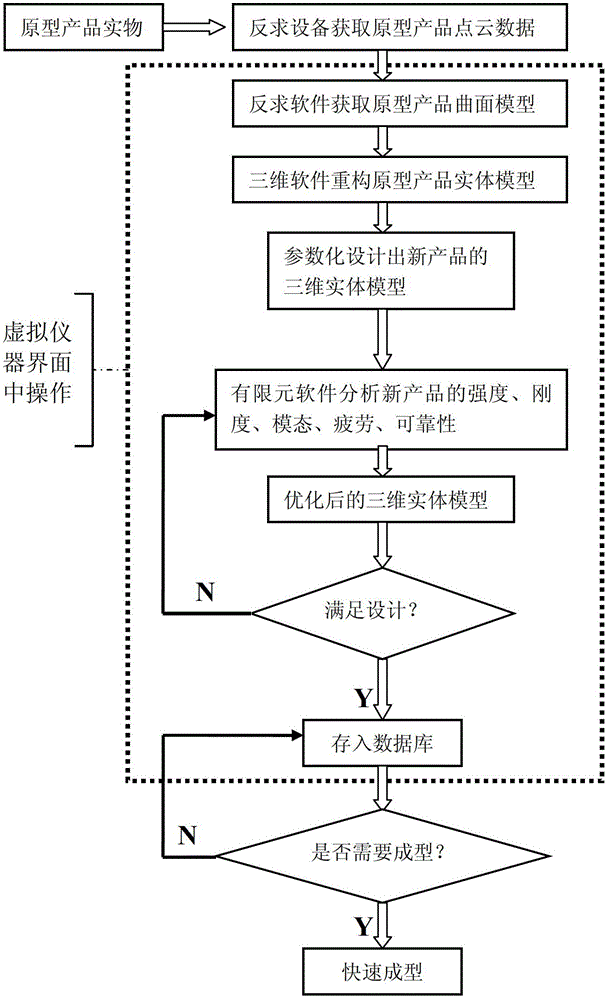

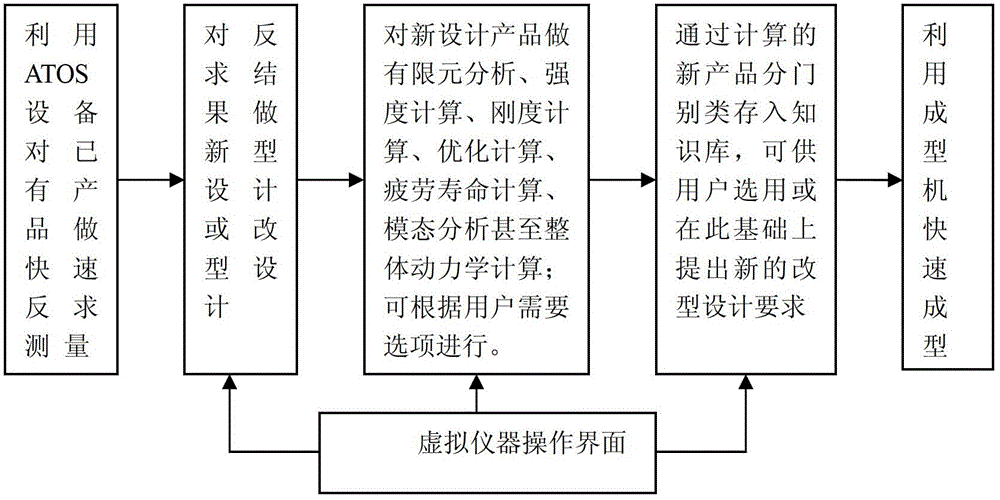

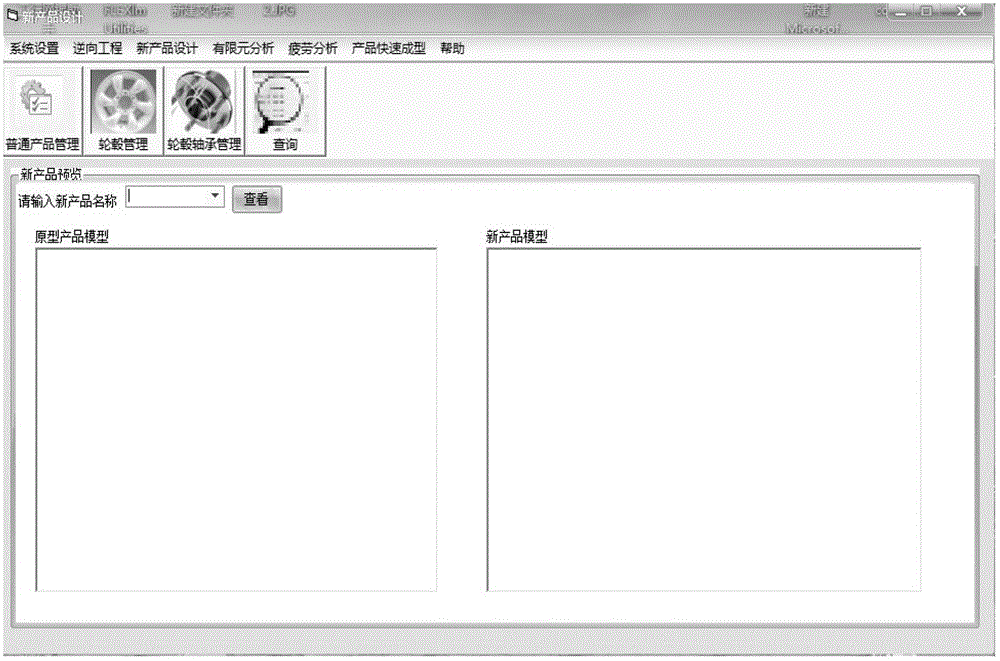

Method for quickly designing mechanical products based on virtual instruments and reverse engineering

InactiveCN103150447AAchieve innovative designFast reverse measurementSpecial data processing applicationsMeasuring instrumentSoftware engineering

The invention relates to a method for quickly designing mechanical products based on virtual instruments and reverse engineering. The method comprises the following steps of: acquiring the point cloud data through a prototype product model at first, obtaining a prototype product curved surface model through utilizing an imageware software according to the obtained point cloud data, utilizing CATIA software to form a prototype product solid model of the curved surface model, using a parametrization design to obtain a new product solid model, analyzing and computing the new model through utilizing ANSYS software so as to obtain a new product model which satisfies requirements, and finally, storing the model into a database and quickly forming through a quick forming machine. The method consists of a prototype product model data acquiring part, a data processing, analyzing and managing part with a computation and analysis software and a quick forming part. The data acquiring part is an optical measuring instrument, data measurement and acquisition can be realized through scanning, and the point cloud data of the model can be obtained.

Owner:HANGZHOU DIANZI UNIV

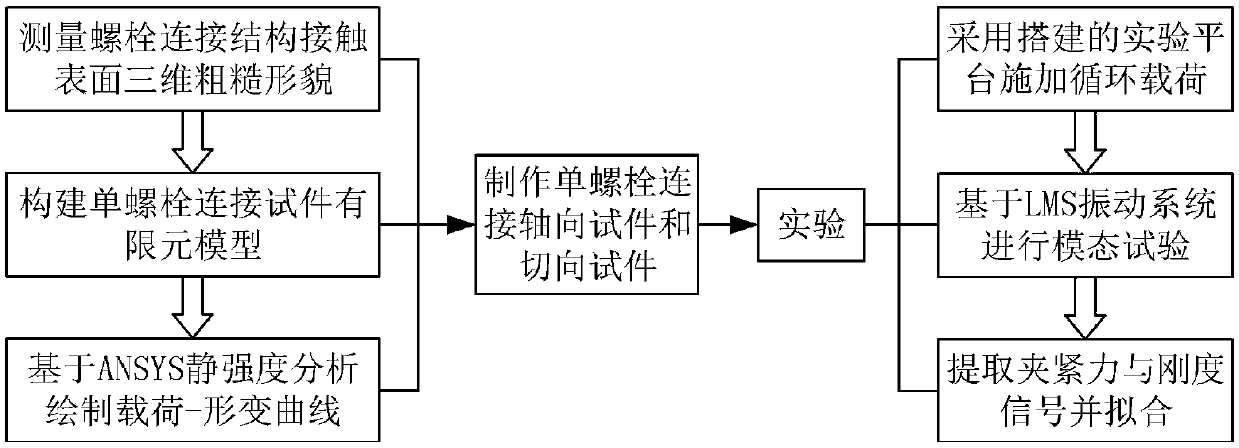

Experimental method for characterizing relaxation characteristics of bolted joint structure

ActiveCN108388696ASolve the problem of high costAvoid safety hazardsMachine part testingDesign optimisation/simulationElement modelExperimental methods

The present invention discloses an experimental method for characterizing relaxation characteristics of a bolted joint structure. The method comprises: constructing a finite element model of a singlebolted joint test piece based on the obtained three-dimensional rough shape of the contact surface of the bolted joint structure; performing static strength analysis on the single bolted jointed testpiece by using ANSYS software, and drawing the deformation curve of the single bolted jointed test piece under load conditions; making a single bolted joint axial test piece and a tangential test piece to analyze the influence law of the axial external load and the outward shear load on the relaxation characteristics of the bolted joint structure; establishing an experiment platform, and through the cyclic load control software, applying a cyclic load with a certain frequency on the single-bolt test piece clamped on the fatigue testing machine; performing the modal test on the single bolted joint test piece by using the LMS vibration system at the same time interval; and extracting a clamp force signal output by a pressure sensor and a stiffness signal in the modal test, and fitting the curve for the clamp force signal and the stiffness signal for comparison. The method disclosed by the present invention provides technical support for the relaxation determination and refastening of thejoint bolts of the key precise complicated components.

Owner:BEIJING UNIV OF TECH

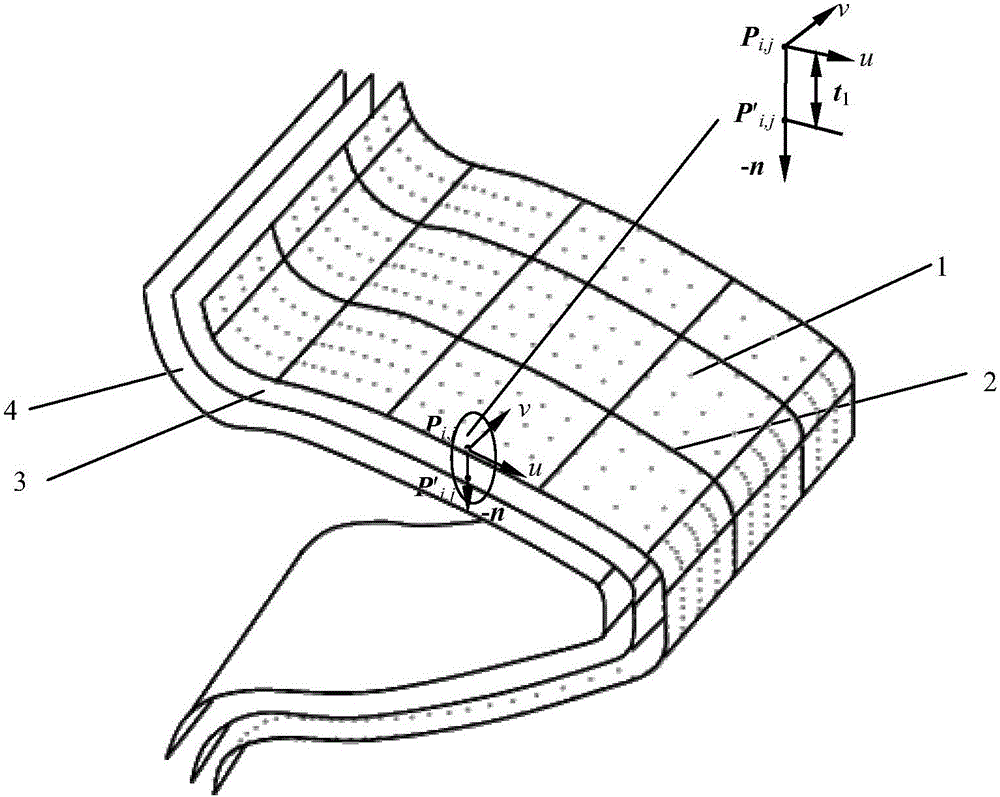

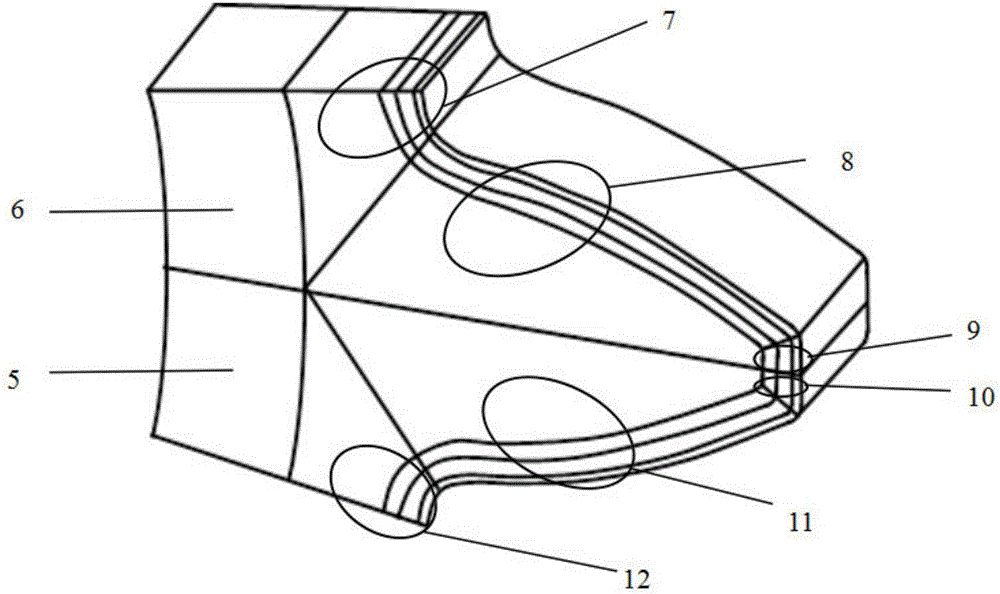

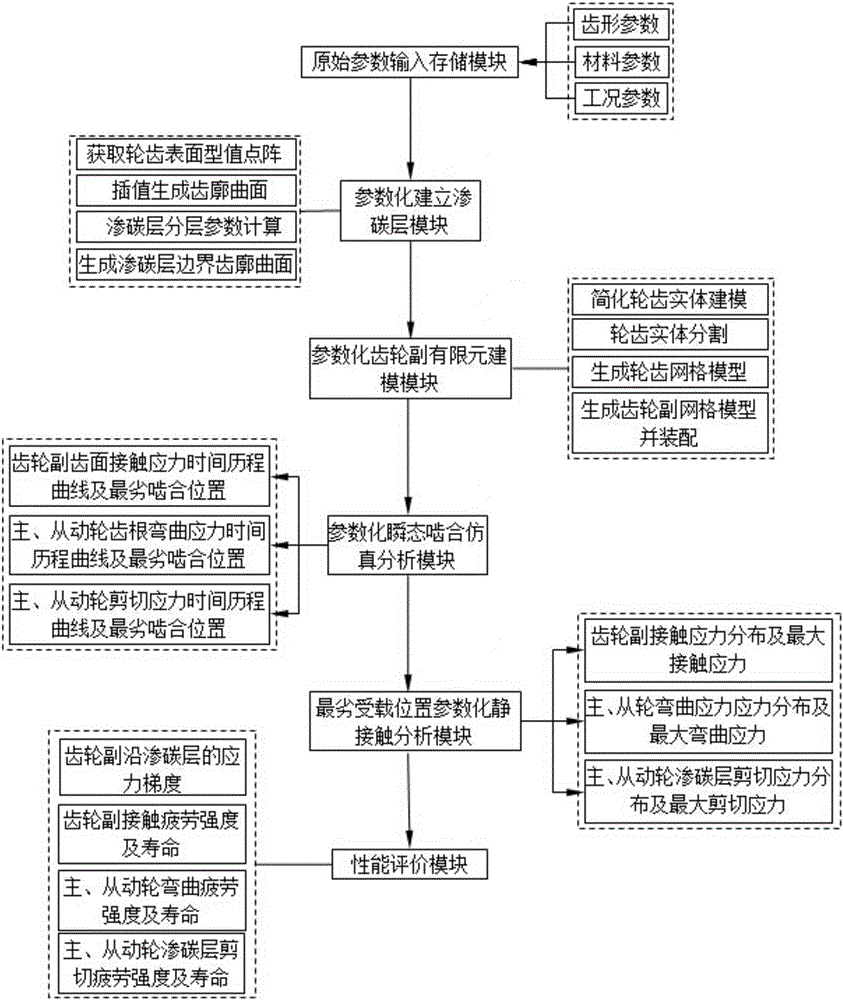

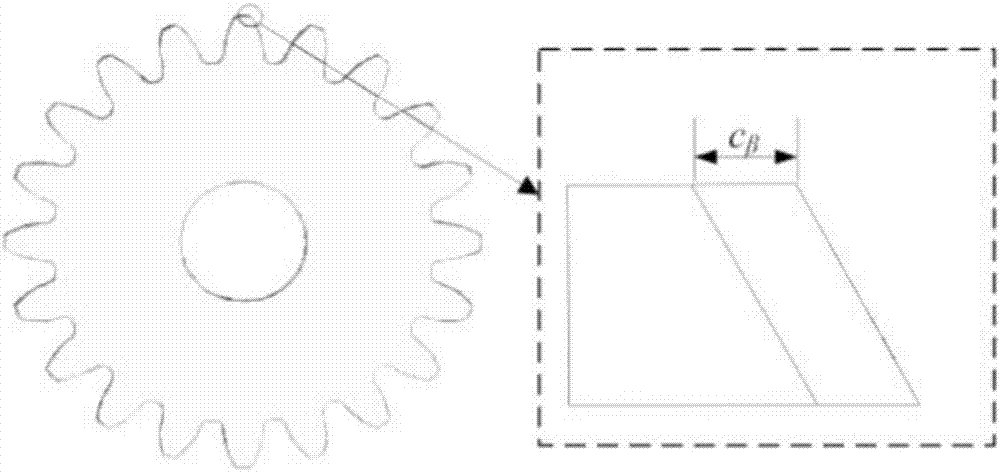

Carburizing cylindrical gear parameterized simulation and analysis method and CAE system

ActiveCN106021721AEffectively build solid modelsAccurately analyze fatigue lifeGeometric CADDesign optimisation/simulationTransient stateSimulation

The invention relates to a carburizing cylindrical gear parameterized simulation and analysis method and a CAE system. The simulation and analysis method comprises the following steps: firstly establishing a carburizing cylindrical gear parameterized single-gear profile curve and establishing homogeneous carburizing layers; finitely modeling a carburizing gear pair by utilizing finite element software; carrying out simulation and analysis on transient state meshing performance on the carburizing gear pair and carrying out static contact analysis on a gear pair at a worst loading position by means of the finite element software; and finally carrying out performance evaluation on the carburizing gear pair according to the analysis results, so as to provide basis form the follow-up structure optimization and carburizing process improvement of the carburizing gear. On the basis of the method, secondary development is carried out on ANSYS software so as to obtain the CAE system. According to the method, the gap that effective analysis cannot be carried out on the carburizing gears in the prior art is supplied, and the procedure of carrying homogeneous material processing on the carburizing gears in the traditional technology is replaced; and the parameterized simulation and analysis method is convenient to operate and accurate in analysis result, and can be used for correctly simulating and analyzing the actual conditions of the carburizing gears.

Owner:SHANDONG UNIV OF SCI & TECH

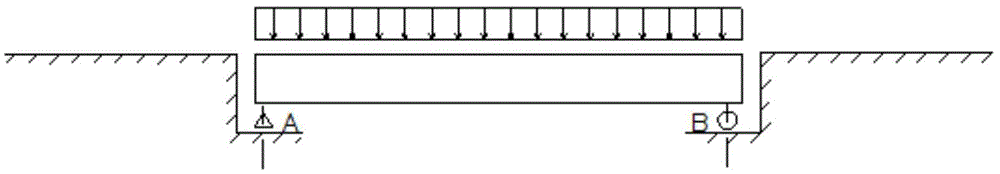

Simplified design method for continuously-welded rail of ballastless track of ultra-large bridge of railway

InactiveCN104992019AEasy to model and analyzeEasy to analyzeSpecial data processing applicationsTrackwayComputational model

The invention discloses a simplified design method for a continuously-welded rail of a ballastless track of an ultra-large bridge of a railway. The method comprises the steps of: S1, utilizing ANSYS software to perform analog simulation on the continuously-welded rail structure on the ultra-large bridge; S2, establishing a horizontal and vertical space coupling static model for the continuously-welded rail of the ballastless track of the ultra-large bridge of the railway, wherein modeling objects include a steel rail, a fastener, a track board, an elastic rubber pad layer, a limiting boss, a bridge and a pier; and S3, performing static analysis on the coupling static model. According to the technical scheme, on the basis of the simplified design method, static force of a continuously-welded rail-ballastless track-ultra-large bridge system of the railway can be accurately and effectively analyzed, relation of interaction between girders and rails is fully considered, modeling of the track structure is finished according to an actual state as far as possible, a computing model is simplified on the premise of ensuring the model to be fine, complete and accurate, and remarkable improvements are achieved in design in comparison with a conventional modeling method.

Owner:BEIJING JIAOTONG UNIV +1

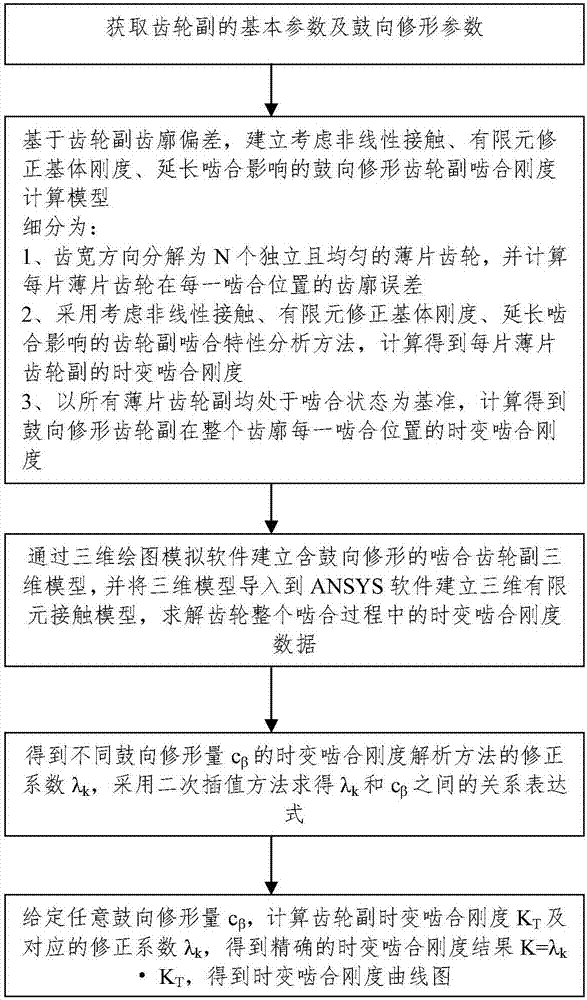

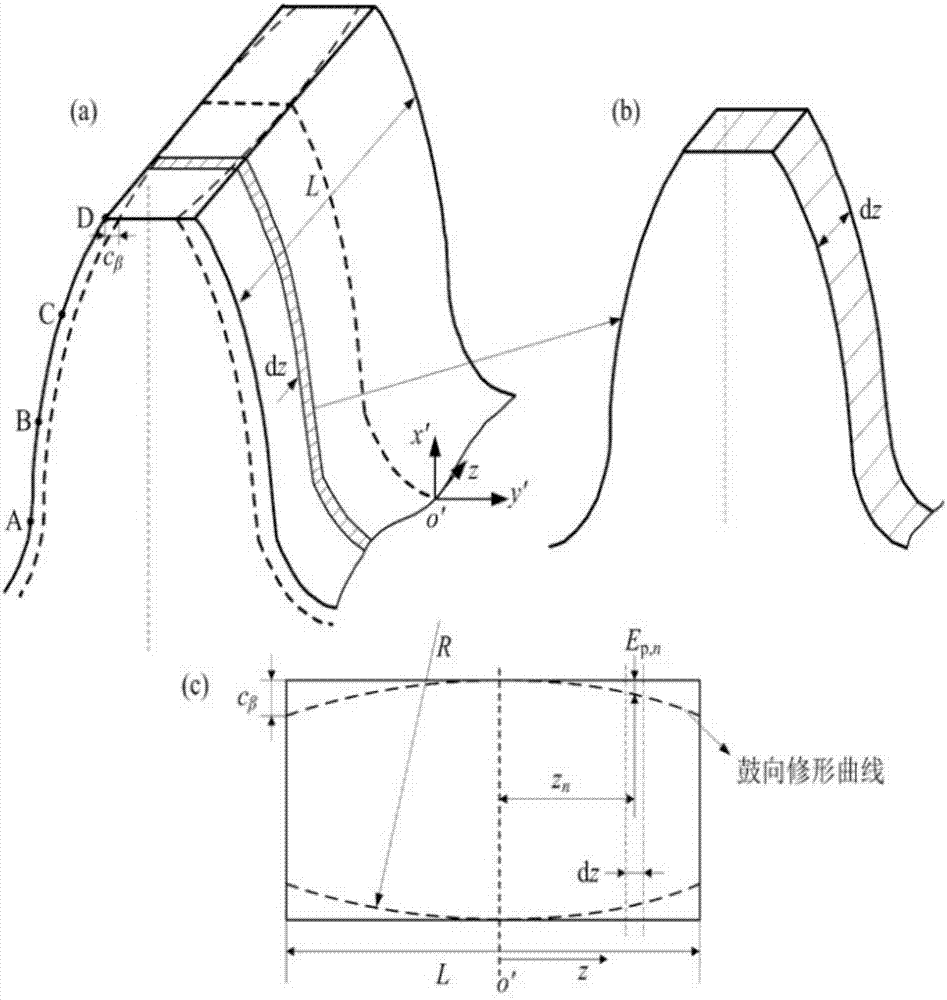

Amended gear pair meshing characteristic analysis method taking drum modification into consideration

ActiveCN107153736AThe meshing characteristics truly reflectLower performance requirementsGeometric CADDesign optimisation/simulationContact modelAnsys software

The invention relates to an amended gear pair meshing characteristic analysis method taking drum modification into consideration. In order to acquire basic parameters of a gear pair and drum modification parameters, gear teeth of the gear pair are divided into N independent even web gears in the direction of tooth width; the time-variant meshing stiffness of each web gear pair is calculated by adopting the gear pair meshing characteristic analysis method taking prolonging the meshing influence into consideration on the basis of the error of a gear profile of a drum modification gear pair; a meshing gear pair three-dimensional model comprising drum modification is established through three-dimensional drawing simulation software, the three-dimensional model is guided into an ANSYS software to create a three-dimensional finite element contact model, and time-variant meshing stiffness data in the whole meshing process of the gear are solved. The analysis method is simple in modelling process and low in calculated quantity, the requirement on a computer is low, and the calculation result is accurate and true.

Owner:NORTHEASTERN UNIV

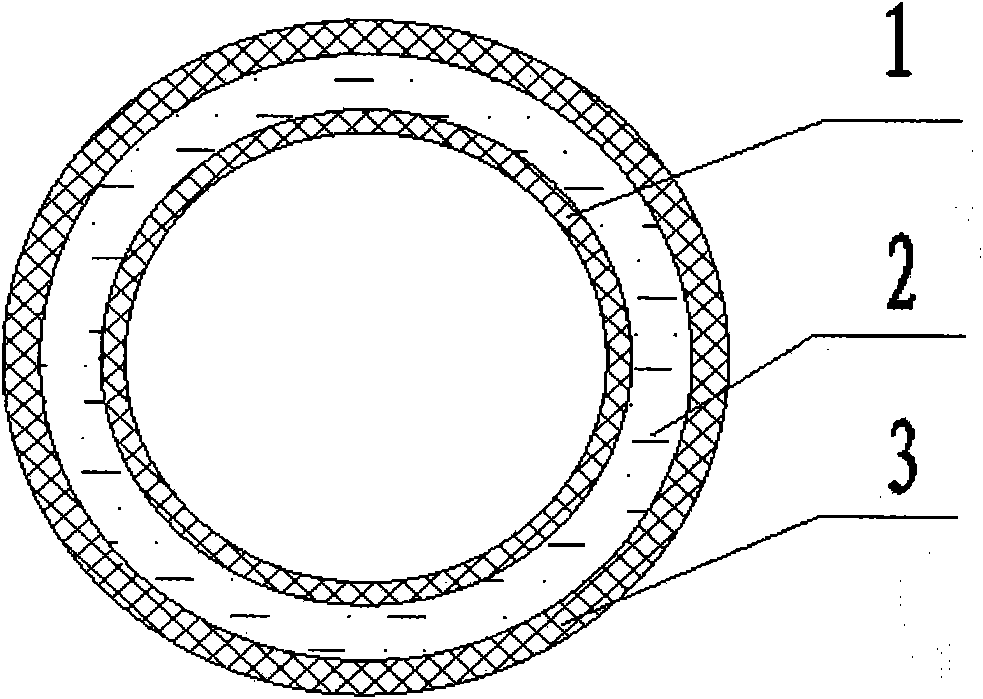

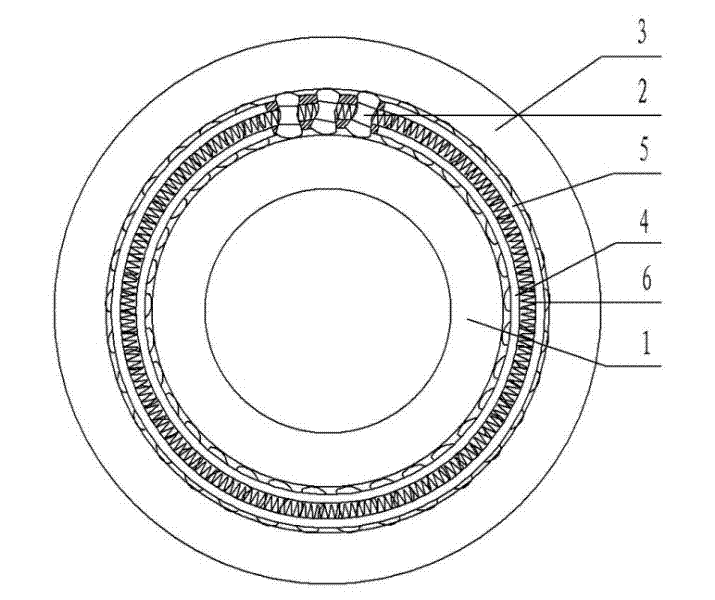

Composite material electric pole and structure design method thereof

ActiveCN101936085AIncreasing the thicknessReduce weightSynthetic resin layered productsTowersAnsys softwareEngineering

The invention discloses a composite material electric pole and a structure design method thereof. The method comprises the following steps of: (1) designing the wall thickness of the electric pole, wherein the wall of the electric pole sequentially comprises an inner skin, a sandwich layer and an outer skin; (2) determining used raw materials, a proportion and a molding mode; (3) manufacturing a sample according to the requirement of electric power circuit engineering and finishing testing to acquire the elastic modulus and the Poisson's ratio performance parameters of the inner skin, the outer skin and the sandwich layer; determining the thicknesses and the laying modes of the inner skin, the outer skin and the sandwich layer; (4) constructing a solid model by utilizing finite element software ANSYS and applying a load; carrying out analog computation to acquire stress and deflection values of different working conditions and comparing with a design requirement; if the stress and the deflection values meet the design requirement, finishing designing; and if the stress and the deflection values do not meet the design requirement, returning to the step (3), repeating the steps (3) and (4) until the design requirement is met to finish designing. The electric pole is designed by utilizing the ANSYS software, the requirement on the safety coefficient of the structure is met, and meanwhile, the whole bending resistance of the electric pole is improved, which provides a beneficial reference for the application of the composite material in the power industry.

Owner:北玻电力复合材料有限公司

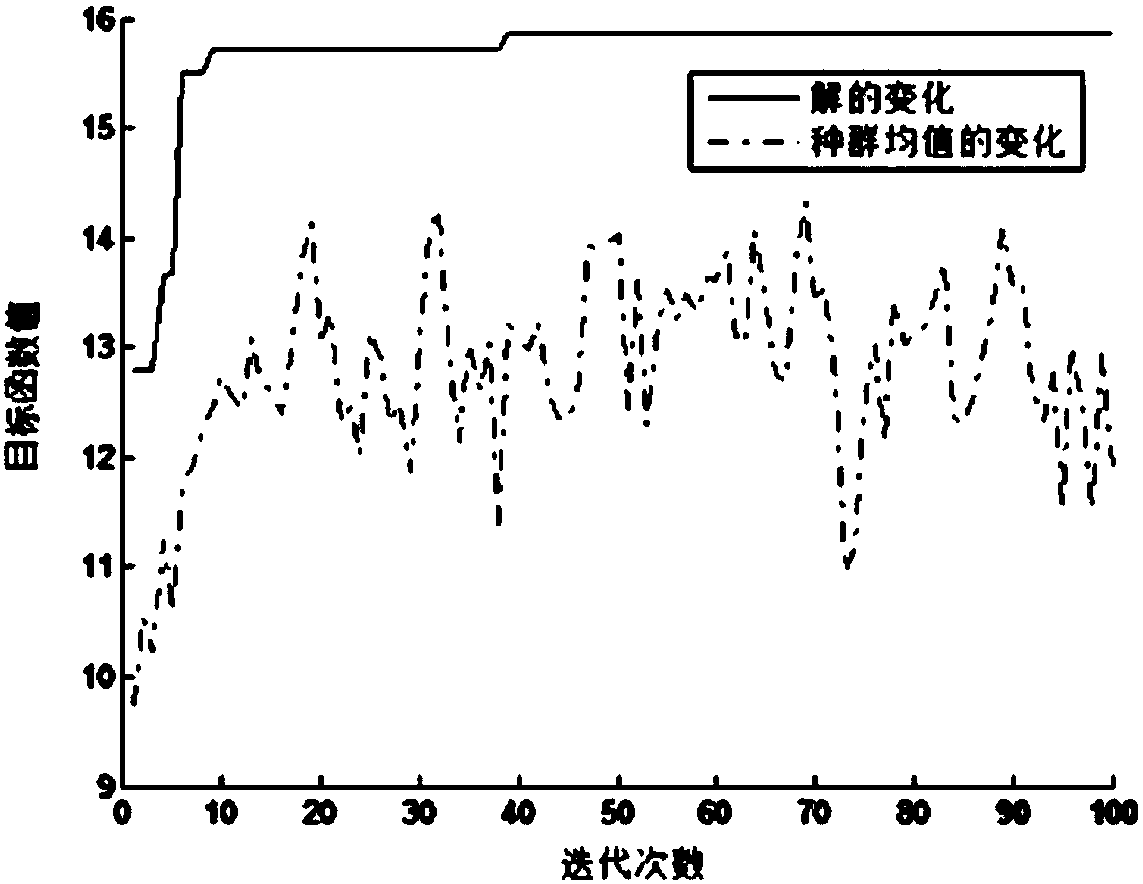

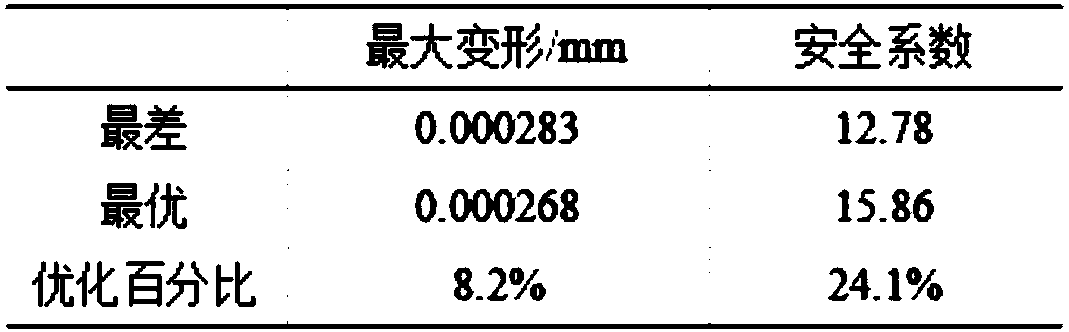

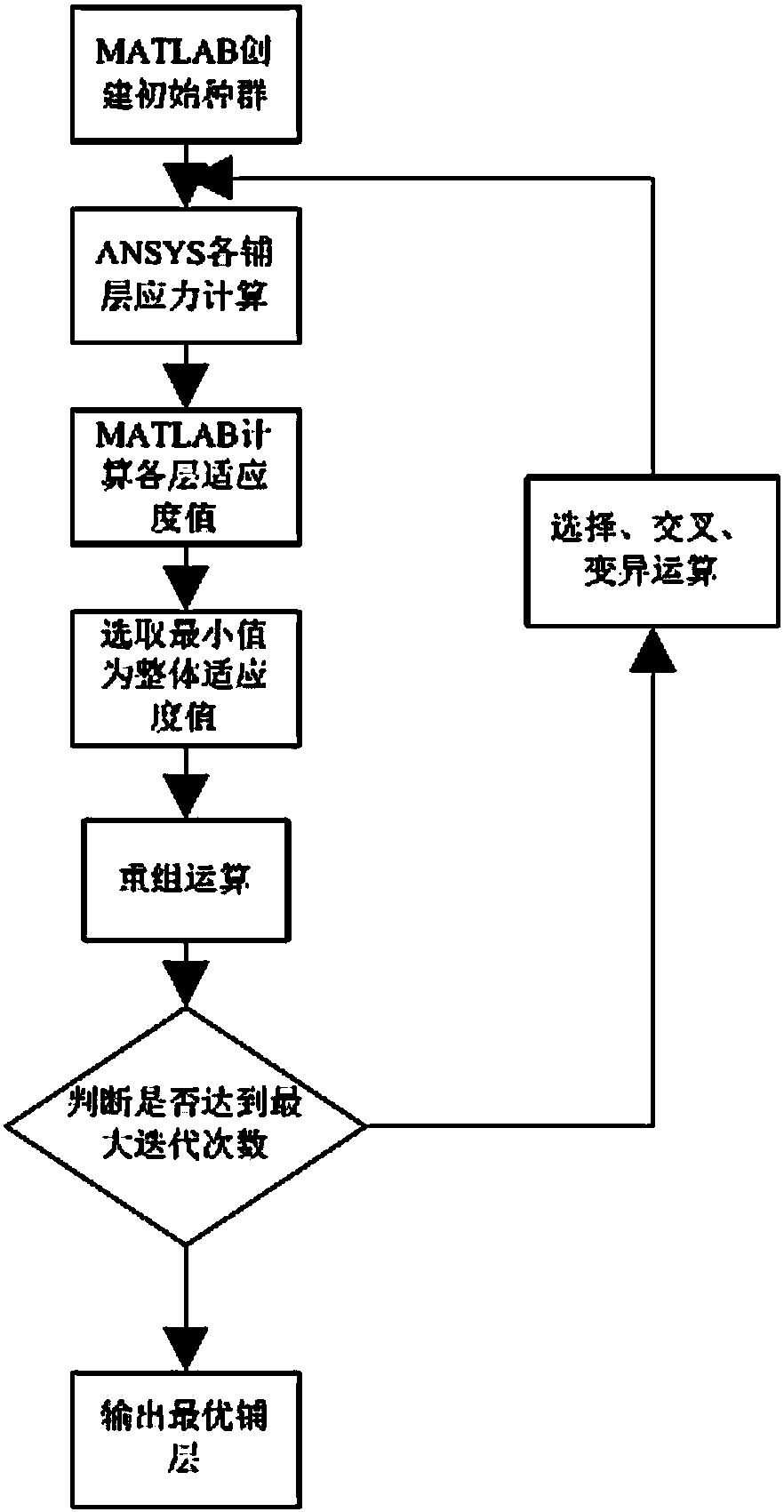

Ply optimization design method of vehicle anti-collision beams

InactiveCN107729701AReach the optimization goalGeometric CADSpecial data processing applicationsStructural analysisAnsys software

The invention discloses a ply optimization design method of vehicle anti-collision beams. The method comprises the step of structural analysis of the anti-collision beams of a carbon fiber composite material. During CFRP structural design, since the ply angle sequences are variable, an optimum design scheme cannot be obtained. According to the technical scheme, the ply angles serve as design variables; the standard ply 0 degree, + / - 45 degrees and 90 degrees serve as constraint conditions; an objective function is built according to a Tsai-Wu tensor theoretical strength ratio equation; makingthe strength of the anti-collision beams maximal serves as an optimization target, and the ply angle sequences in an anti-collision beam lamination board are determined. By means of the ply optimization design method of the vehicle anti-collision beams, a MATLAB is utilized to write a main program, while ANSYS software is called, node stress is analyzed and calculated, the operation returns to theMATLAB, and the strength ratio is calculated. When the strength ratio is optimal, the optimization target is achieved.

Owner:JIANGSU UNIV OF TECH

Finite element model building and updating method of sprag clutch wedge block surface stress

InactiveCN102184273AExtended service lifeImprove structural rigiditySpecial data processing applicationsSurface stressStress concentration

The invention relates to a finite element model building and updating method of sprag clutch wedge block surface stress. The building basis of the finite element model is that the wedge block is under the practical torsional load and wedge block lock state, the wedge, an inner ring and an outer ring are subjected to finite element meshing under the premise of ignoring the mutual effect of the inner and outer retainers and the spring on the wedge, then the finite element models of the wedge, the inner ring and the outer ring are built, and then an ANSYS software is adopted to judge the wedge block stress valve in the finite element model, if the valve meets the requirement, the building of the finite element model is reasonable, and if not, the wedge block geometry parameters namely the specific valve (design valve) should be revised according to the correction formula until the correction of the wedge block meets the finite element model. The final wedge block correction replaces the particular value of the wedge, the correction result improves the structure rigidity in the wedge block stress concentrated region, and the method can meet the requirements of practical torsional load, and further effectively improve the service life of the sprag clutch and save the practical experimentation cost.

Owner:LUOYANG BEARING RES INST CO LTD

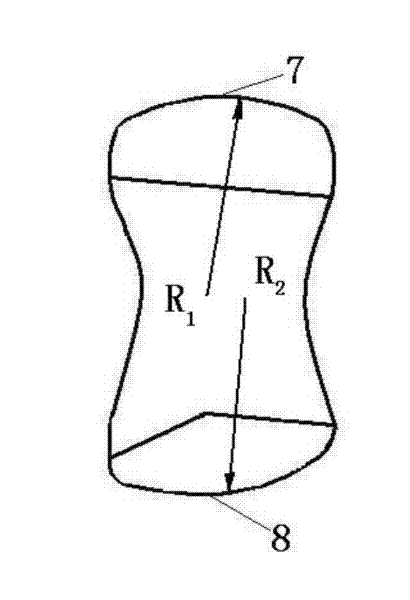

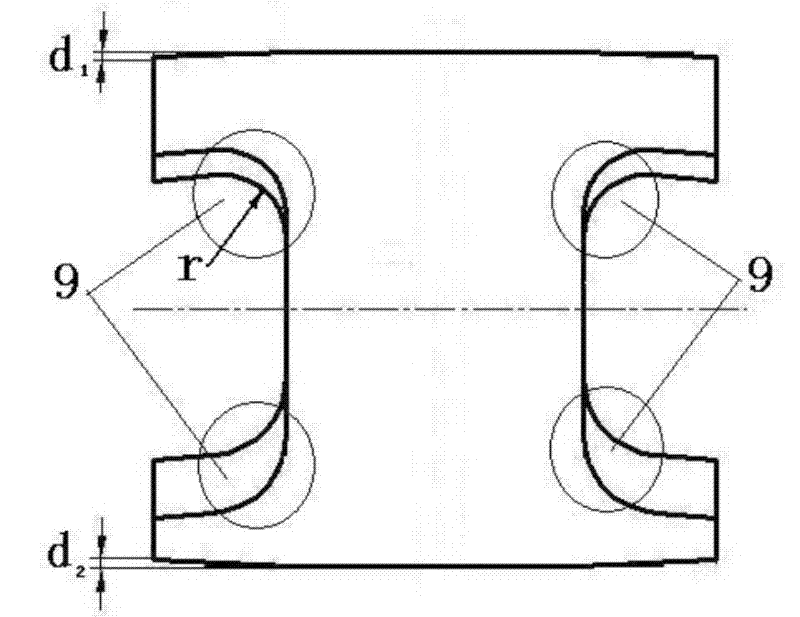

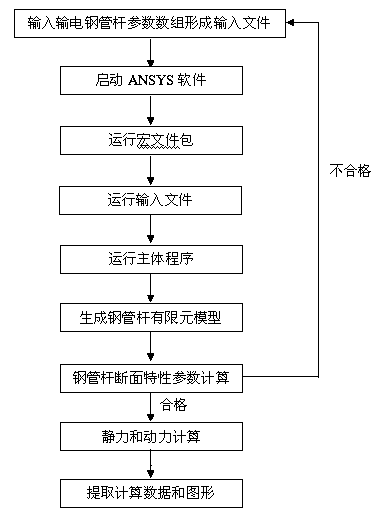

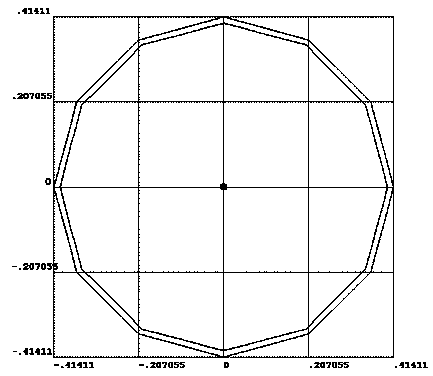

Finite element parametric modeling method of power transmission steel pipe pole

ActiveCN103514327AImprove efficiencyQuality improvementSpecial data processing applicationsGraphicsAnsys software

The invention discloses a finite element parametric modeling method of a power transmission steel pipe pole. Parameters of the steel pipe pole are identified and extracted, an APDL command stream file of ANSYS software is utilized, a finite element parametric modeling program of cylindrical segments and cross arms of different shapes, specifications and structural styles is established, steel pipe fracture surface characteristic parameter calculation, static calculation and dynamic calculation modules are developed, and after calculation is completed, needed data and images are automatically analyzed and extracted through a program. According to the finite element parametric modeling method, mechanical calculation efficiency and quality of the steel pipe pole are effectively improved, the defects that the ANSYS software is high in difficulty in mechanical calculation of the power transmission steel pipe pole, poor in pertinence, low in special software calculation precision, limited in calculation conditions, insufficient in calculation data and the like are overcome, and a good analysis platform is provided for technical staff.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

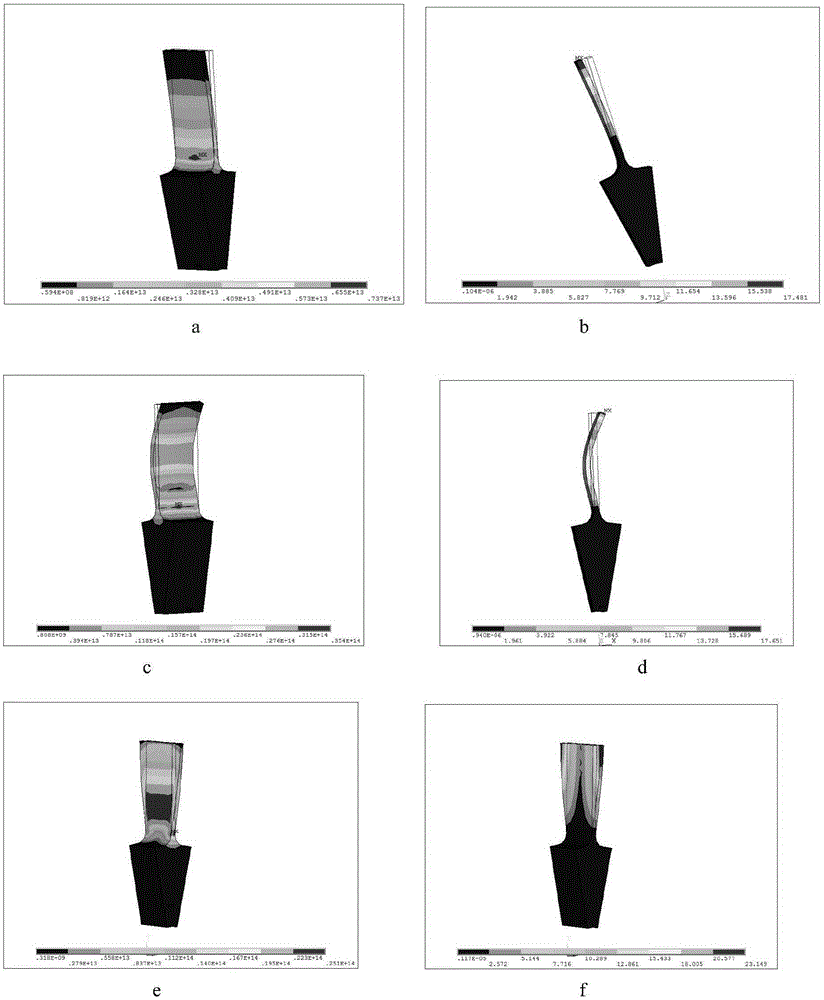

Method used for realizing blade fatigue crack detection through static blade displacement detection

ActiveCN105352713ARealize identificationFeasibleMachine part testingMaterial analysisStress distributionCentrifugation

The invention relates to the rotation machinery / blade detection technology field, realizes detection on a health state of a blade under extreme work environments, e.g., high temperature, high pressure, high centrifugation rotation speed, and so on, carries out fault diagnosis and realize identification on a crack blade at an early period of blade crack generation. The method comprises steps that, 1, finite analysis software Ansys1 is utilized to analyze the rotor blade; 2, modal simulation for the blade is carried out under a static state; 3, the blade is loaded with certain aerodynamic force in the Ansys software for analyzing stress distribution and deformation; 4, a model is established for the crack blade; 5, deformation of the crack blade in a certain rotation speed and at a specific depth is analyzed; and 6, vibration curves of a normal blade and a crack-adding blade in the work state are compared. The method is mainly applied to blade detection.

Owner:善测(天津)科技有限公司

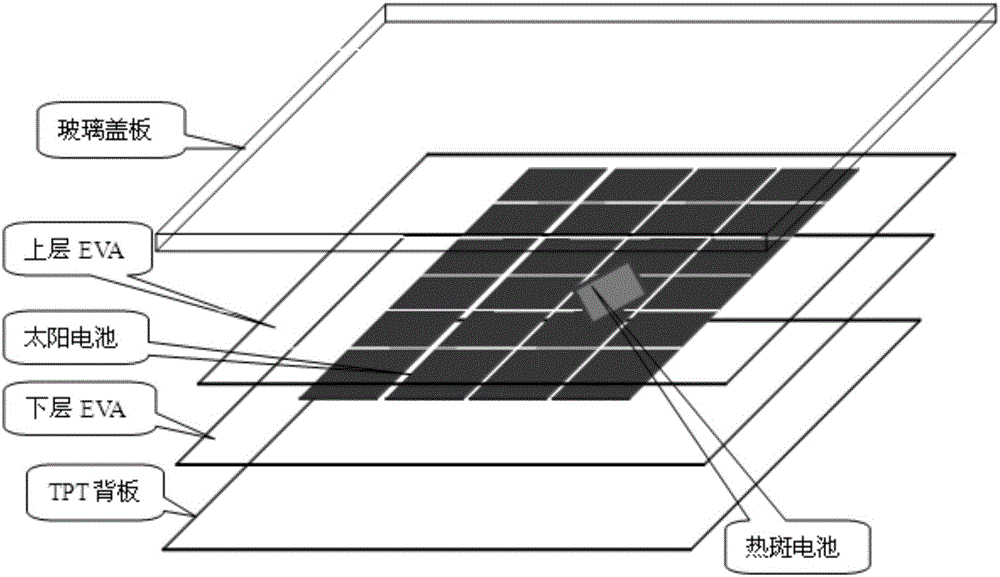

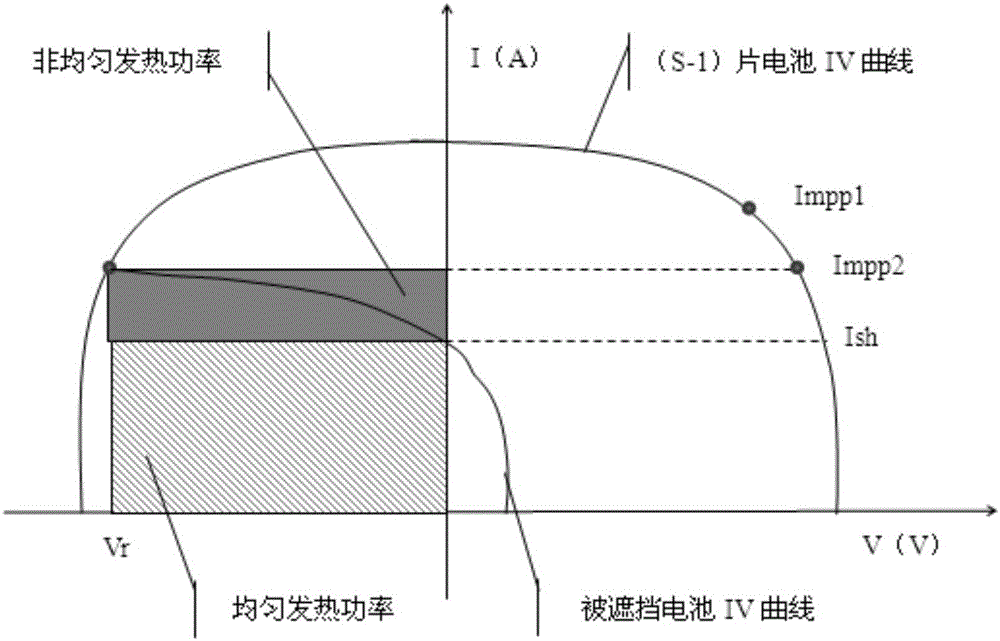

Photovoltaic assembly hot spot temperature calculating method

ActiveCN106066916ASimulated temperatureShorten the timeSpecial data processing applicationsAnsys softwareEngineering

The invention discloses a photovoltaic assembly hot spot temperature calculating method comprising the following steps: 1, using ANSYS software to simulate a photovoltaic assembly; 2, inputting heat conduction coefficients of each material; 3, simulating that a random cell sheet of the solar battery is blocked, wherein the blocked cell sheet represents the first internal heat source causing hot spot effect; 4, setting boundary conditions and changing a blocking proportion; 5, inputting heat power of the first internal heat source, and calculating heating intensity and the temperature up limit value thereof; 6, simulating that the blocked cell sheet has a fault location, wherein the fault location represents the second internal heat source causing hot spot effect by uneven heating; 7, setting boundary conditions, and changing blocked proportion of the blocked cell sheet having the fault location; 8, inputting total heat power by summing the first and second internal heat source, and calculating the heating intensity and temperature up limit value of the blocked cell sheet having the fault location. The photovoltaic assembly hot spot temperature calculating method can fast and simply calculate photovoltaic assembly hot spot temperature, thus reducing hot spot generating risks.

Owner:HOHAI UNIV CHANGZHOU

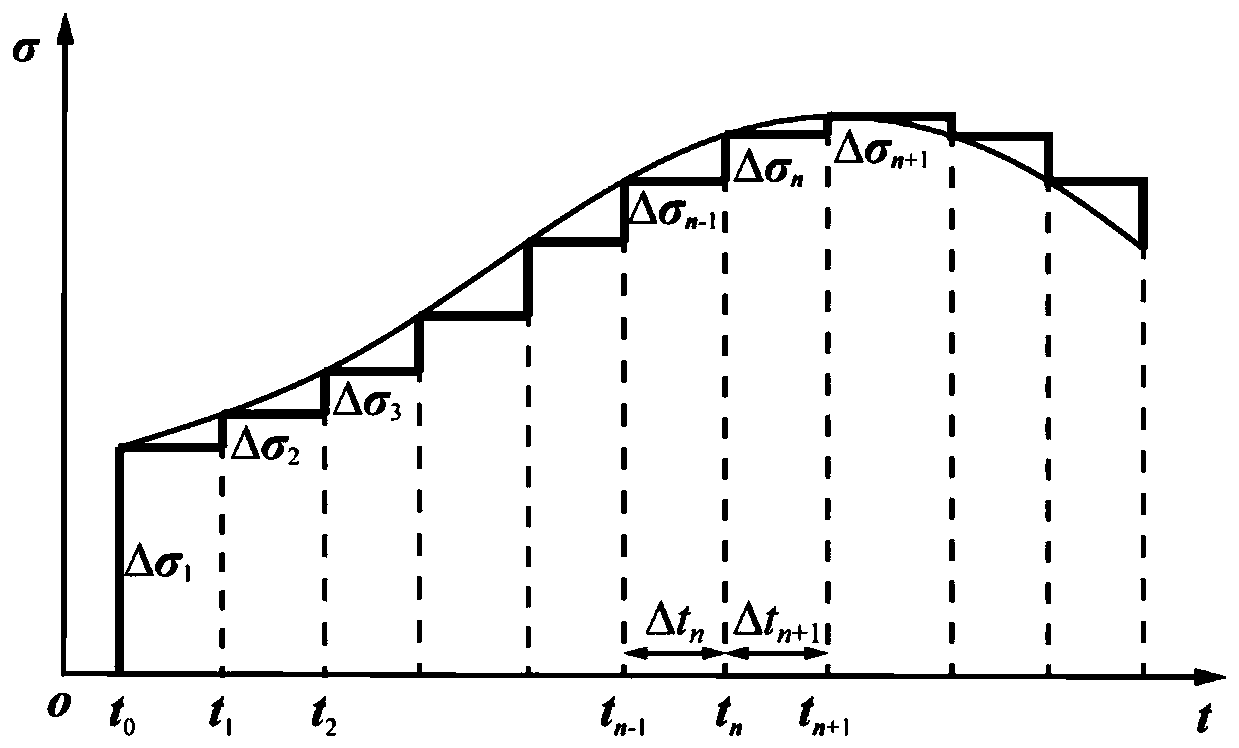

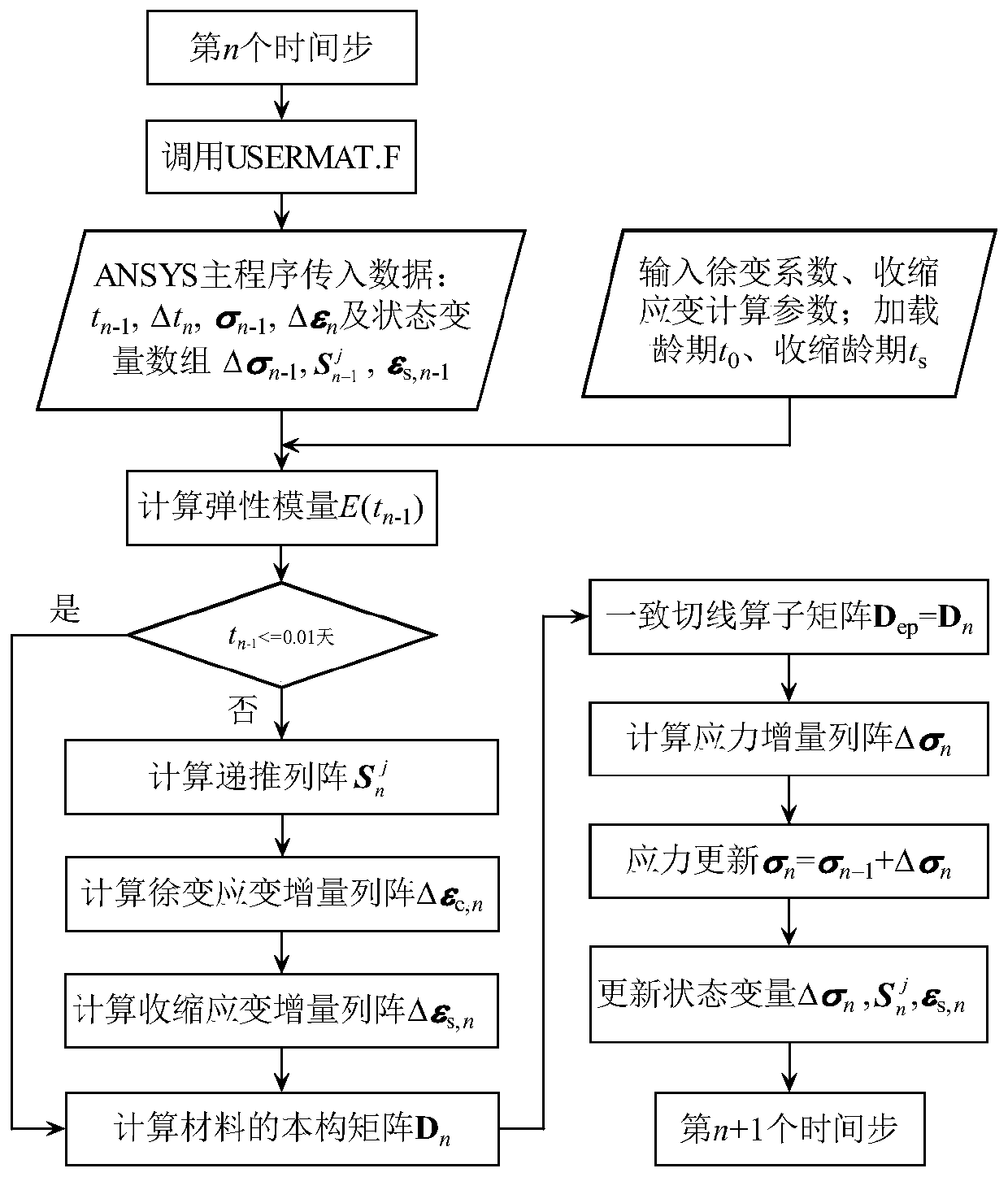

Entity finite element calculation method for time-varying effect of concrete structure

ActiveCN110162827AFine calculation of time-varying effectsOvercoming the disadvantage of difficulty in variable effectDesign optimisation/simulationSpecial data processing applicationsStress processStressed state

The invention relates to an entity finite element calculation method for a time-varying effect of a concrete structure, which comprises the following steps of: 1) discretizing the stress process of concrete according to a stepwise method, and deducing creep strain increment in an nth time period; 2) fitting the creep coefficient expression into an exponential series form by using Matlab software;3) substituting the creep coefficient fitting expression into a creep strain increment calculation formula, and establishing a concrete uniaxial creep strain increment recurrence calculation formula;4) considering the creep Poisson effect, and establishing a concrete time-varying constitutive equation in the constitutive structure of the entity unit material; and 5) developing the time-varying constitutive structure of the concrete in the USERMAT subprogram of the ANSYS software by using the Fortran language. Compared with the prior art, time-varying effect value prediction of the concrete structure in a complex stress process under a spatial stress state can be realized, and the joint with a creep and shrinkage model of a common design specification is good.

Owner:HOHAI UNIV

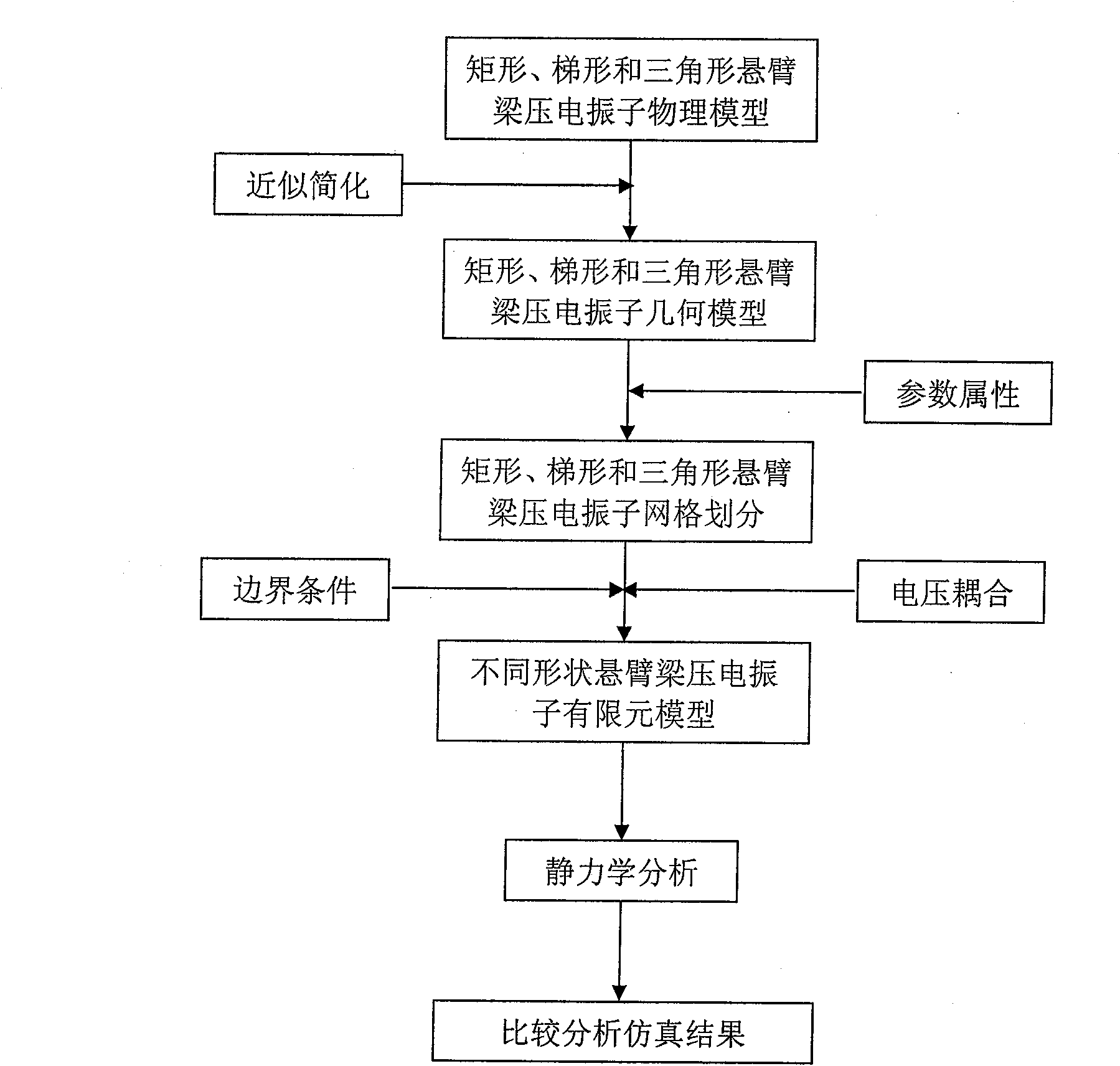

Method for vibrating power-generation analysis finite element by different shapes of cantilever beam piezoelectric vibrators

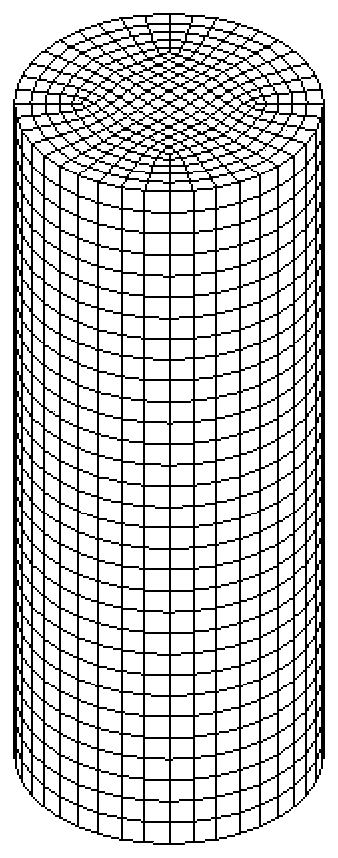

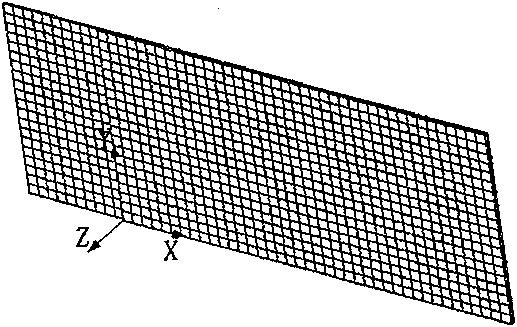

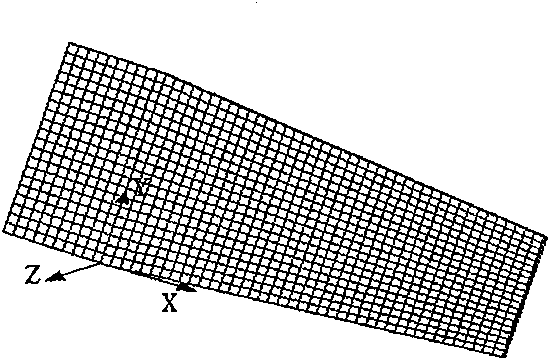

InactiveCN101620642ASemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityElement model

The invention discloses a method for vibrating a power-generation analysis finite element by different shapes of cantilever beam piezoelectric vibrators. The method comprises the following steps: utilizing soliworks software to respectively establish geometric models of rectangular, trapezoidal and triangular cantilever beam piezoelectric vibrators of which the length, the thickness and the root width are all equal through approximate simplification; respectively leading the geometric models into ansys software and implementing the following operational steps: S1: setting and distributing material properties and cell types of all parts of piezoelectric vibrators; S2: setting meshing properties and carrying out the meshing by adopting a mapping mode; S3: setting boundary conditions and voltage coupling restrains and establishing a finite element model of the cantilever beam piezoelectric vibrators; S4: utilizing the ansys software to apply a fixed load to the cantilever piezoelectric vibrators, carrying out static analysis and recording simulation results; and finally, comparing and analyzing the simulation results of three shapes of piezoelectric vibrators.

Owner:NAT UNIV OF DEFENSE TECH

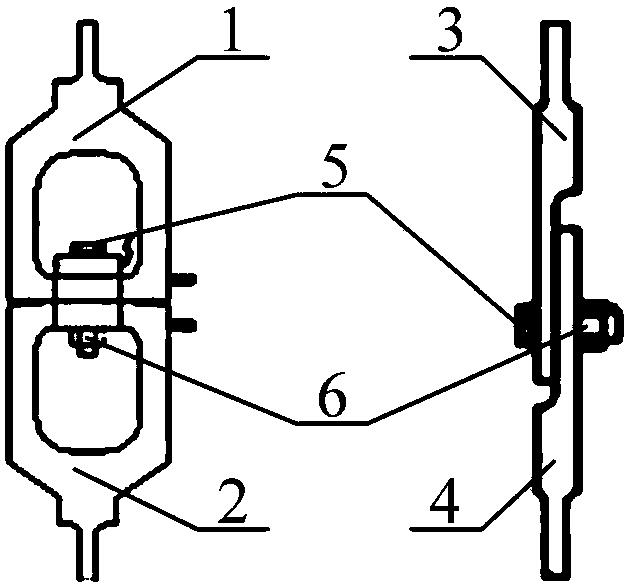

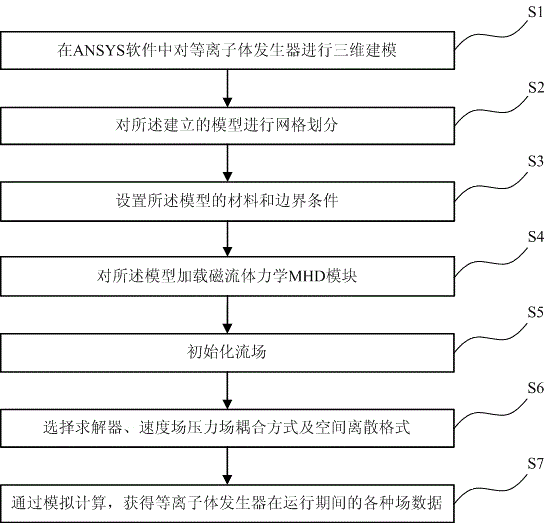

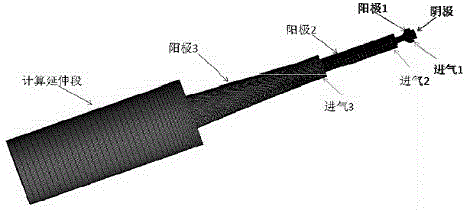

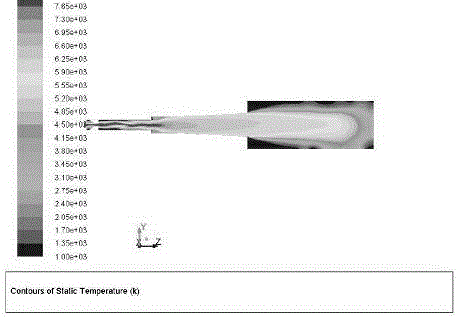

Simulation method for plasma generator

InactiveCN105160117AComprehensive and Accurate Modeling AnalysisSpecial data processing applicationsPlasma generatorModelling analysis

The invention provides a simulation method for a plasma generator. The method comprises: Step S1, performing three-dimensional modeling on the plasma generator in ANSYS software; Step S2, performing grid division on an established model; Step S3, setting material and boundary conditions of the model; Step S4, loading a magnetohydrodynamic (MHD) module for the model; Step S5, initializing a flow field; Step S6, selecting a solver, a velocity field and pressure field coupling mode and a spatial discretization format; and Step S7, obtaining various field data of the plasma generator during operation period through simulation calculation. According to the method, various difficulties in physical process researches and experimental processes of an existing plasma generator are overcome, comprehensive and accurate modeling analysis is performed on an electric field, a magnetic field, a thermal force field and the flow field of the generator, an analytic method desiderated for the industrial application of the plasma generator is provided, and the method can become important means for developing the plasma generator.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Soft-hard interbedded wall rock tunnel construction simulation method considering bedding action

ActiveCN106198208AAvoid non-convergenceIn line with the actual situation of the projectMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesTunnel wallElastic plastic

The invention provides a soft-hard interbedded wall rock tunnel construction simulation method considering bedding action, comprising the steps of S1, acquiring related physical parameters of wall rock: processing tunnel wall rock to be simulated into a standard test piece according to Regulation for Testing of Physical and Mechanical Properties of Rock by using rock conventional mechanical property test, and acquiring related physical parameters of wall rock through uniaxial / triaxial compression test and shear test; S2, imparting a wall rock simulation unit to the mechanical parameters acquired by the tests of step S1, and carrying out simulation analysis by using self-contained elastic-plastic constructive model of ANSYS software, dp rules and contact pair effect. The simulation method provided herein enables the simulation for changes and influences generated by bedding stress field, displacement field and the like in the whole process of soft-hard interbedded wall rock tunnel excavation, the problem that nonlinear analytical results fail to converge in the simulation process is solved, simulation results may indicate that whether bed separation and the like occur after tunnel excavation, the simulation better meets the engineering actuality, and the simulation results may guide actual tunnel construction.

Owner:中电建路桥集团有限公司 +1

Shielded gate guide shoe three-dimensional sliding friction characteristic simulation analysis method based on finite element

InactiveCN102799740AImprove accuracyMake up for the shortcomings of single feature analysisSpecial data processing applicationsElement modelCoupling

The invention discloses a shielded gate guide shoe three-dimensional sliding friction characteristic simulation analysis method based on a finite element. The guide shoe mechanism comprises a guide slot and a guide shoe slider, wherein the guide shoe slider slides on the guide slot. The analysis method comprises the following steps: a, establishing a finite element model of the guide shoe mechanism; b, dividing the grids of the finite element model of the guide shoe mechanism; c, carrying out contact setting; d, solving process control; e, setting a load step and a boundary condition; and f, extracting the analysis result subjected to simulation calculating analysis. According to the method, a parameterization finite element analysis model of the guide shoe sliding friction pair in a shielded gate system can be established by using an ANSYS software, the structural characteristics, mechanical characteristics and thermal characteristics of the guide shoe mechanism friction pair in the three-dimensional sliding process can be analyzed in a coupling manner by setting the contact parameter of the model, algorithm setting, and applying load and boundary condition, the defect of single characteristic analysis is overcome, and the calculating convergence and accuracy can be effectively controlled and analyzed.

Owner:宁波中车时代电气设备有限公司

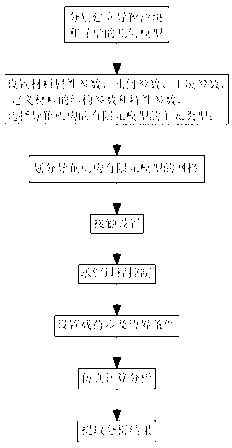

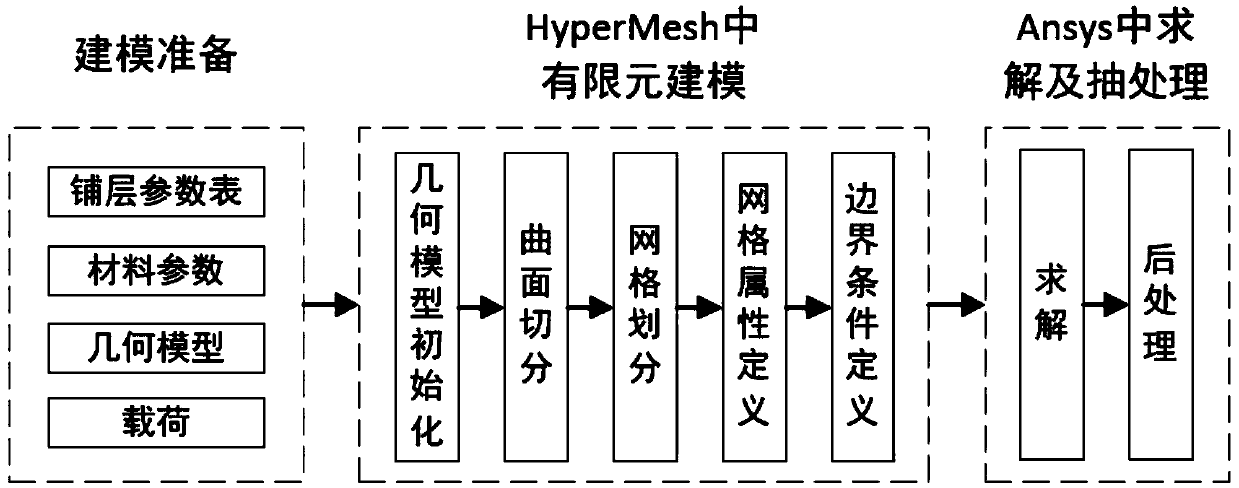

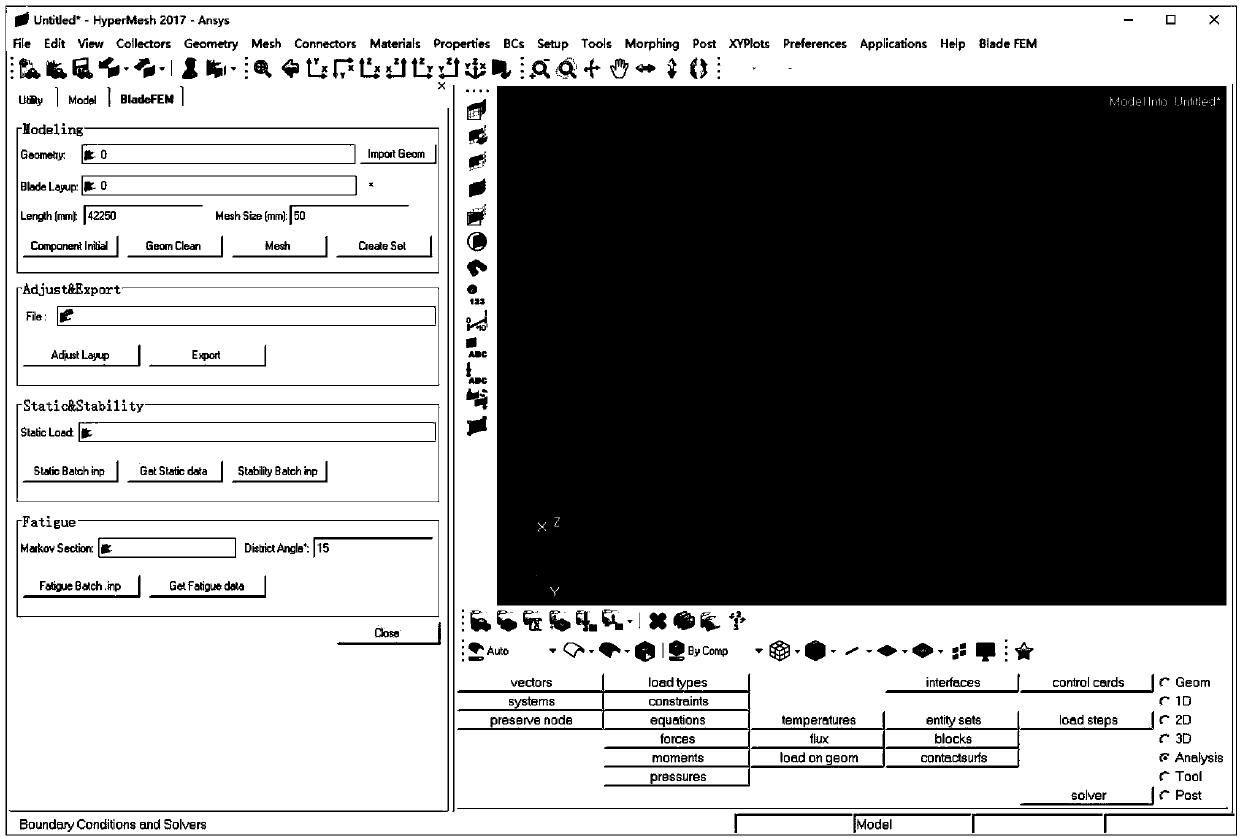

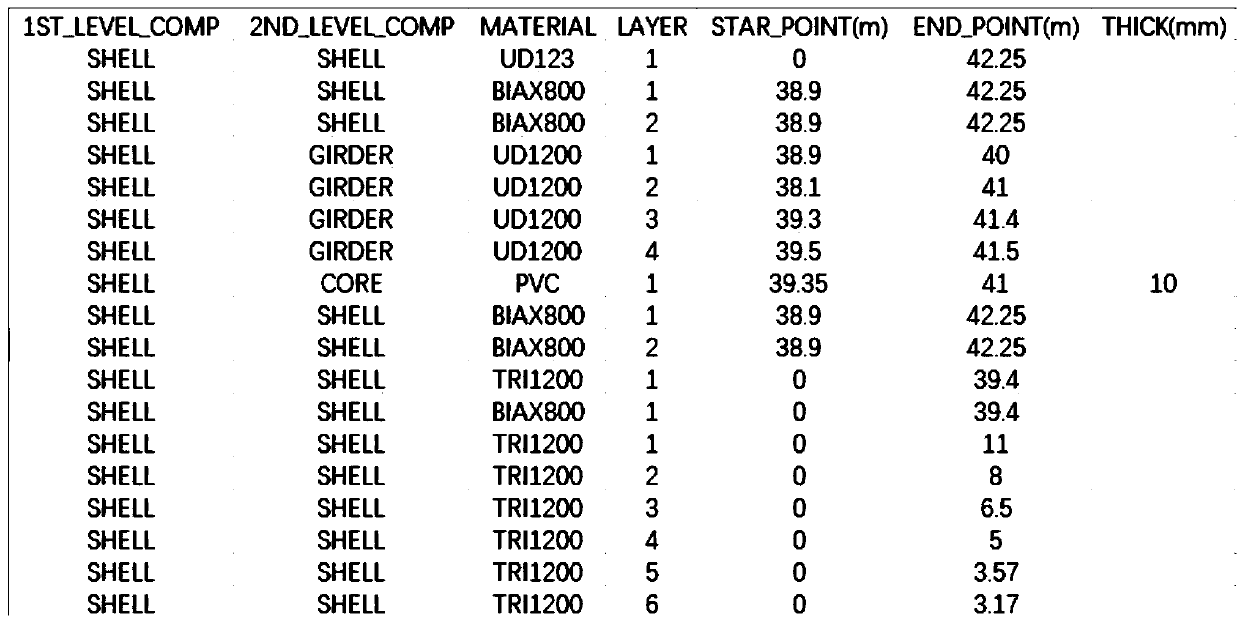

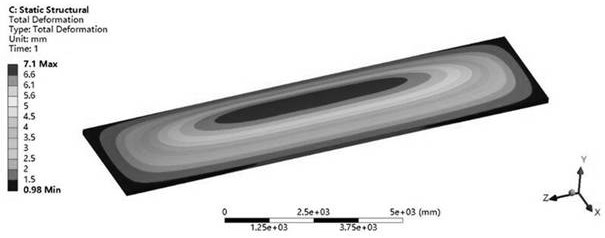

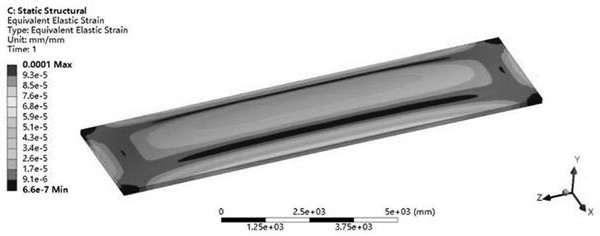

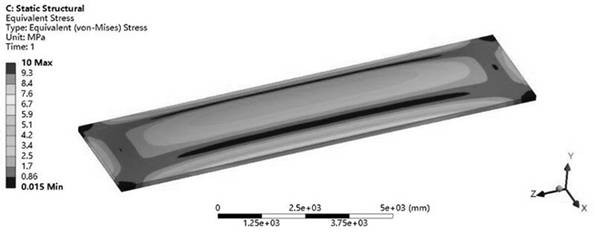

Finite element modeling method for wind turbine blades of wind generating set

ActiveCN109635414AMeet modeling needsEasy to operateDesign optimisation/simulationSpecial data processing applicationsElement modelElement modeling

The invention discloses a finite element modeling method for wind turbine blades of a wind generating set. The finite element modeling method comprises the steps that a blade laying layer parameter table is created according to a blade design laying layer graph; adding the material parameters required by the blade into a material library; constructing a blade geometric model by adopting three-dimensional modeling software; importing the blade layer paving parameter table and the blade geometric model into HyperMesh software through a blade finite element modeling plug-in; performing blade geometric model initialization, blade curved surface segmentation, lamination parameter table processing, grid division and grid attribute definition by using a blade finite element modeling plug-in to create a finite element model; and exporting the finite element model into a cdb file identified by Ansys software. The method has the advantages of high efficiency, simplicity in operation and high error correction capability, and has important practical significance for quickly and accurately establishing the finite element model of the fan blade.

Owner:中科国风科技有限公司

ANSYS-based multi-field coupling stress distribution simulation method for high-temperature carbonization furnace

ActiveCN111651908AGuaranteed reliabilityReduce design costDesign optimisation/simulationConstraint-based CADDimensional simulationWorking temperature

The invention discloses anANSYS-based multi-field coupling stress distribution simulation method for a high-temperature carbonization furnace and relates to the technical field of design analysis methods of high-temperature carbonization furnaces. The technical problem that the stress characteristics of different furnace chamber materials cannot be tested in the design stage of a high-temperaturecarbonization furnace in the prior art is solved. According to the adopted scheme, the method comprises the steps that establishing three-dimensional simulation model, respectively transmitting the fluid calculation domain and the structure calculation domain to a Blocking module of ICEM software and Mesh software to carry out mesh generation; setting in a FLUENT module of ANSYS software; transmitting data to ANSYS software; importing a temperature distribution result in an Imported Load option to obtain a temperature distribution result; carrying out simulation operation in the Solution option to obtain stress distribution characteristics of the muffle structure at different temperatures; under the same setting condition, judging the stress distribution state of the high-temperature carbonization furnace at different temperatures and airflow velocities by setting different working temperatures and airflow velocities to repeatedly carry out simulation calculation for multiple times, sothat the structural performance of the furnace chamber can be better predicted, and the basis for designing the muffle chamber structure and operation process parameters of the high-temperature carbonization furnace is provided.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

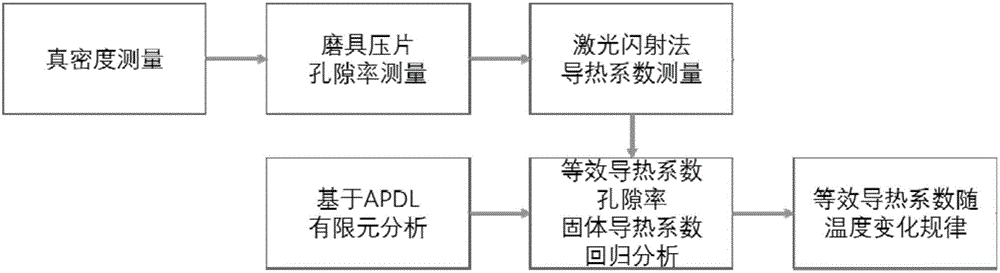

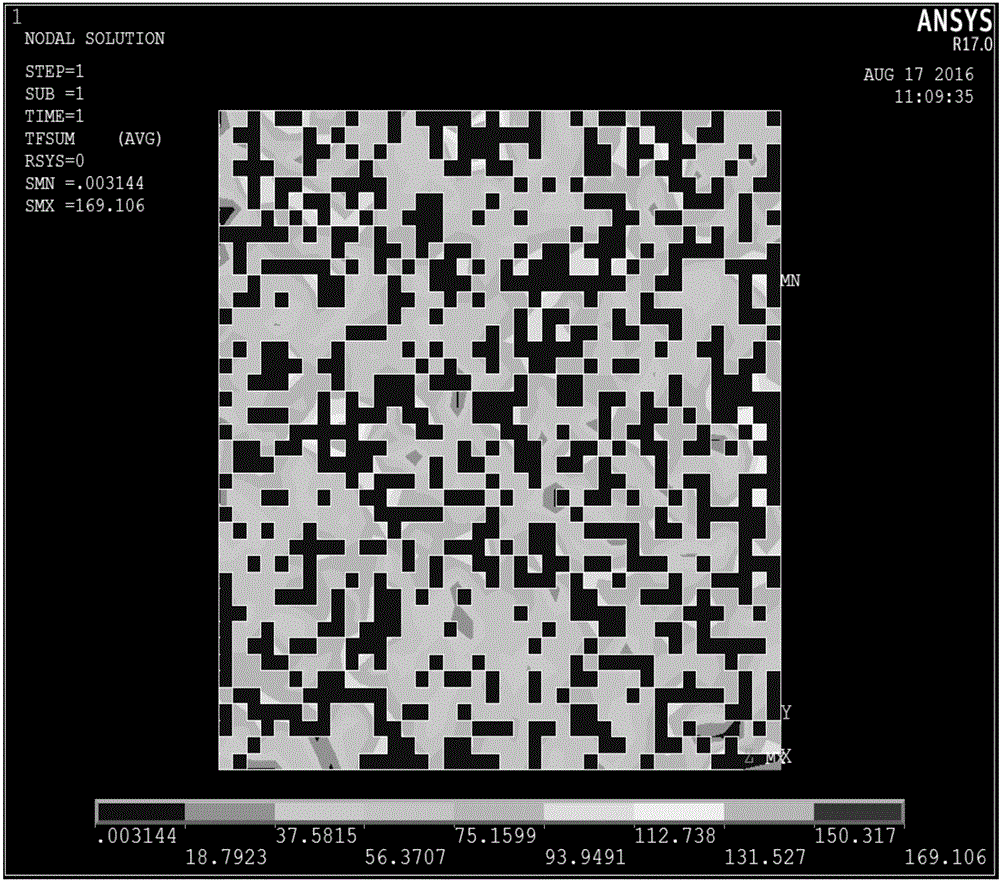

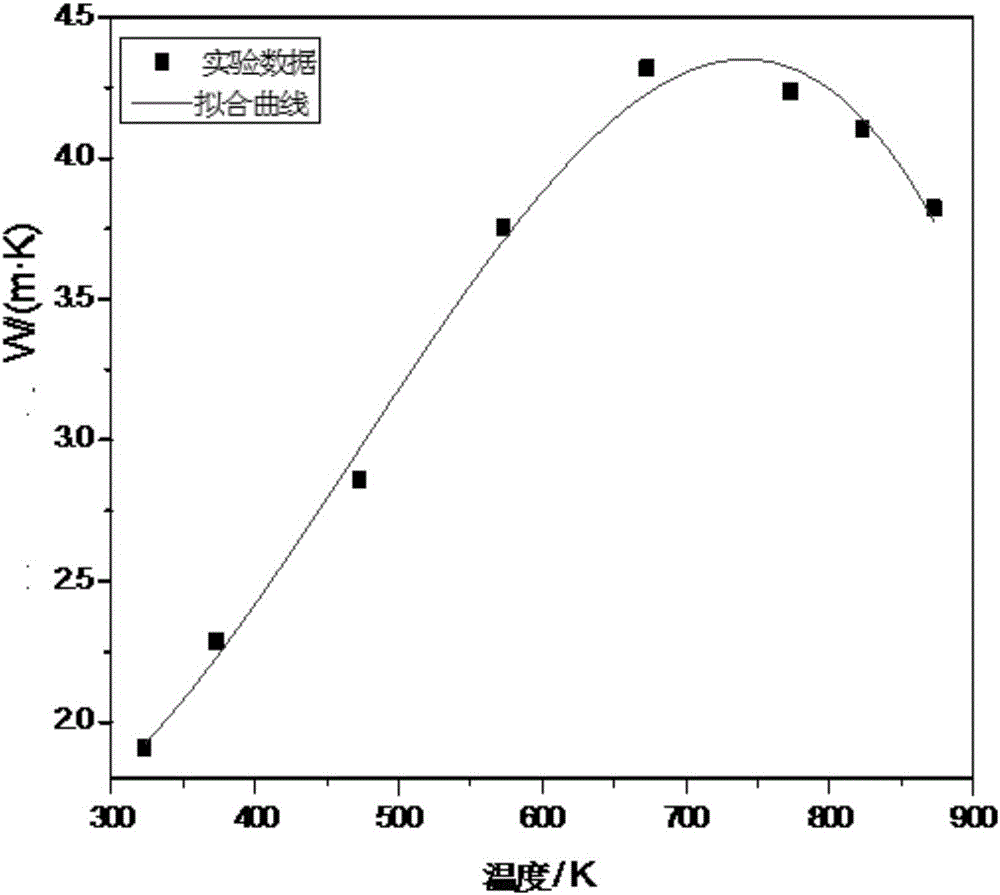

Porous medium equivalent thermal conductivity measurement method

InactiveCN106248725AConforms to the change law of equivalent thermal conductivity of porous mediaMaterial thermal conductivityPorous mediumThermal conductivity measurement

The invention relates to a porous medium equivalent thermal conductivity measurement method, and belongs to the field of porous medium heat transfer. According to the present invention, based on the APDL program in ANSYS software, the heat transfer process of a model is calculated by using a finite element numerical simulation method, the pore structure of a porous material is randomly distributed according to the volume pore, the relationship between the porous material model equivalent thermal conductivity and the porosity is analyzed, the true density of the porous medium is measured by using a true density meter, the thermal conductivity of the porous medium under a certain porosity is measured by using a laser flashing method, the finite element simulation result is combined, and the porous medium equivalent thermal conductivities at different temperatures are calculated.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com