Method for hoisting steel safe bottom seal head at nuclear power station and special-purpose sling tool thereof

A technology of steel containment and hoisting method, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of uneven force, high manufacturing cost, heavy weight of the bottom head, etc., to reduce hoisting deformation and Installation deviation, rigorous and orderly hoisting process, and the effect of reducing the risk factor of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

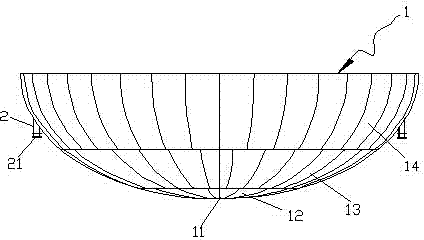

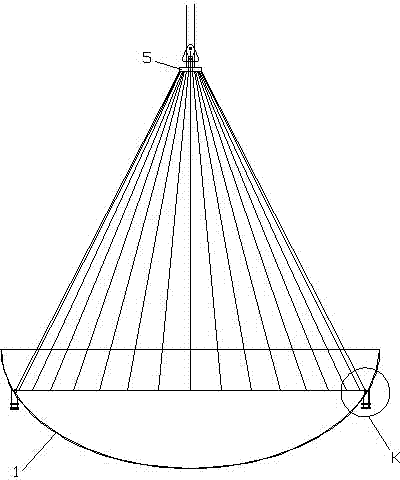

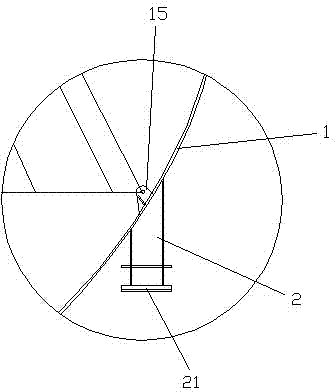

[0058] figure 1 with Figure 13 It is a schematic diagram of the hoisting principle and structure of the present invention.

[0059] The reference signs are: "ten" positioning reference line B, bottom head 1, first circle of steel plates 11, second circle of steel plates 12, third circle of steel plates 13, fourth circle of steel plates 14, lifting lugs 15, Support stub 2, flange plate 21, CR10 pillar 3, jack 4, sling distributor 5, distributor lug 5a, distribution hanging plate 5b, reinforcement plate 5c, reinforcement rib 5d, bottom plate 51, ring plate 52, top plate 53. Secondary distributor 6, pressed wire rope 7, adjustable pull rod 8, U-shaped connection end 81, shackle 9.

[0060] Such as Figure 1 to Figure 13 As shown, a method for hoisting the steel containment bottom head of a nuclear power plant according to the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com