Composite material electric pole and structure design method thereof

A composite material and design method technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as structural design of composite material poles that are not seen, and reduce corridor width, reduce The effect of labor intensity and safety margin improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] The design method of the present invention includes the steps of designing the wall thickness of the pole on the basis of the traditional pole structure and the step of coating the outer wall of the pole with an anti-aging function surface layer, and the specific steps are as follows:

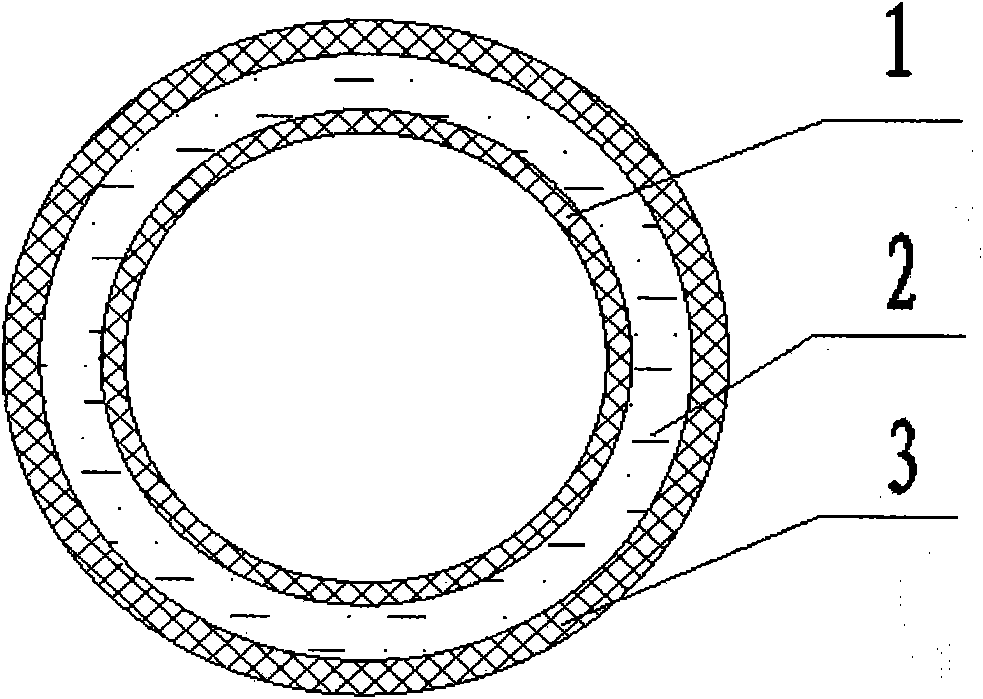

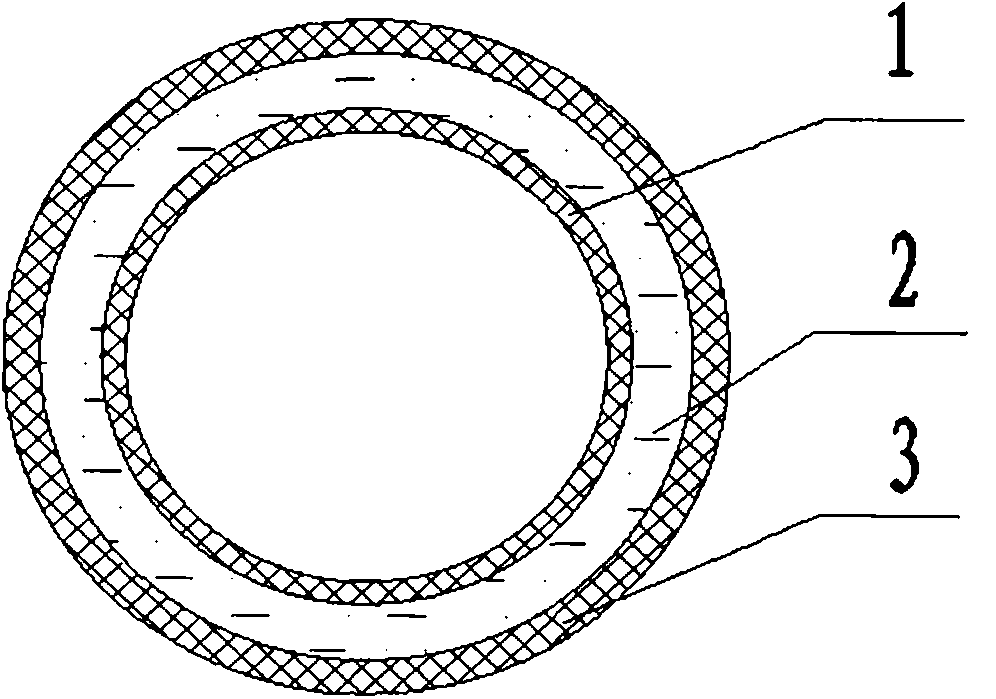

[0045] 1) The wall thickness of the composite pole is designed to be three layers, which are inner skin, sandwich layer and outer skin from the inside to the outside; wherein, the inner skin and the outer skin are both composed of glass fiber reinforced thermosetting resin winding layers ;

[0046] 2) Determine the raw materials and proportions used in the glass fiber reinforced thermosetting resin composite system in step 1); determine the material and molding method of the sandwich layer; wherein, the glass fiber reinforced thermosetting resin composite system is made of several layers of glass fiber The vinyl resin glue cured at normal temperature is impregnated and then wound accordi...

example 2

[0059] Design method of the present invention is basically identical with example 1, and its difference is:

[0060] Step 2) Among the raw materials and proportions used in the glass fiber reinforced thermosetting resin composite system, the glass fiber is 37 layers; the vinyl ester resin glue used is composed of 90 parts of vinyl ester resin, 1 part of curing agent, and 1 part of accelerator. 0.2 parts, 1 part anti-aging agent, 0.2 parts color paste;

[0061] Step 4) Determine the thickness of the inner skin, outer skin and sandwich layer, confirm that the inner skin thickness is designed to be 3mm according to the design ratio of inner skin thickness and outer skin thickness 2: 3, and the outer skin thickness design is 4.5mm;

[0062]Step 6) get the ratio of the allowable stress value 547MPa of the composite material electric pole design and the stress value 365MPa calculated through step 5) finite element software ANSYS program to obtain the safety factor value 1.49 of the ...

example 3

[0071] Design method of the present invention is basically identical with example 1, and its difference is:

[0072] Step 2) Among the raw materials and proportions used in the glass fiber reinforced thermosetting resin composite system, there are 37 layers of glass fiber, including 13 layers of inner cover sheet and 24 layers of outer skin; the vinyl ester resin glue used is composed of vinyl 95 parts of ester resin, 2 parts of curing agent, 1 part of accelerator, 2 parts of anti-aging agent, 0.6 parts of color paste;

[0073] Step 4) Determine the thickness of the inner skin, outer skin and sandwich layer, confirm that the inner skin thickness is designed to be 4mm according to the design ratio of inner skin thickness and outer skin thickness 1:2, and the outer skin thickness design is 8mm;

[0074] Step 5) In the finite element software ANSYS, apply the ANSYS program to build a solid model, apply a load on the solid model, and obtain the stress value 217MPa and the deflecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus of elasticity | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com