Patents

Literature

418results about How to "Increased safety margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

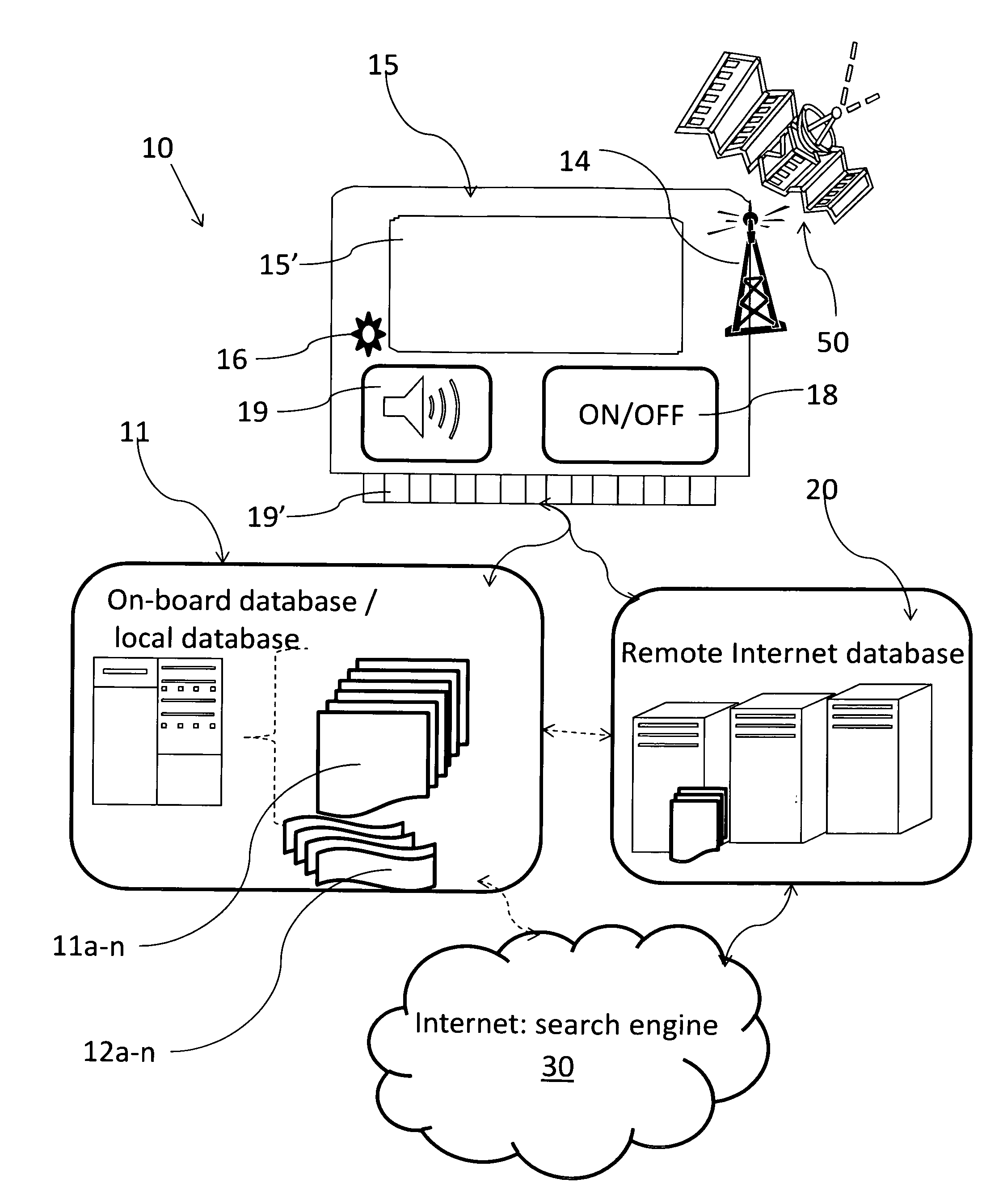

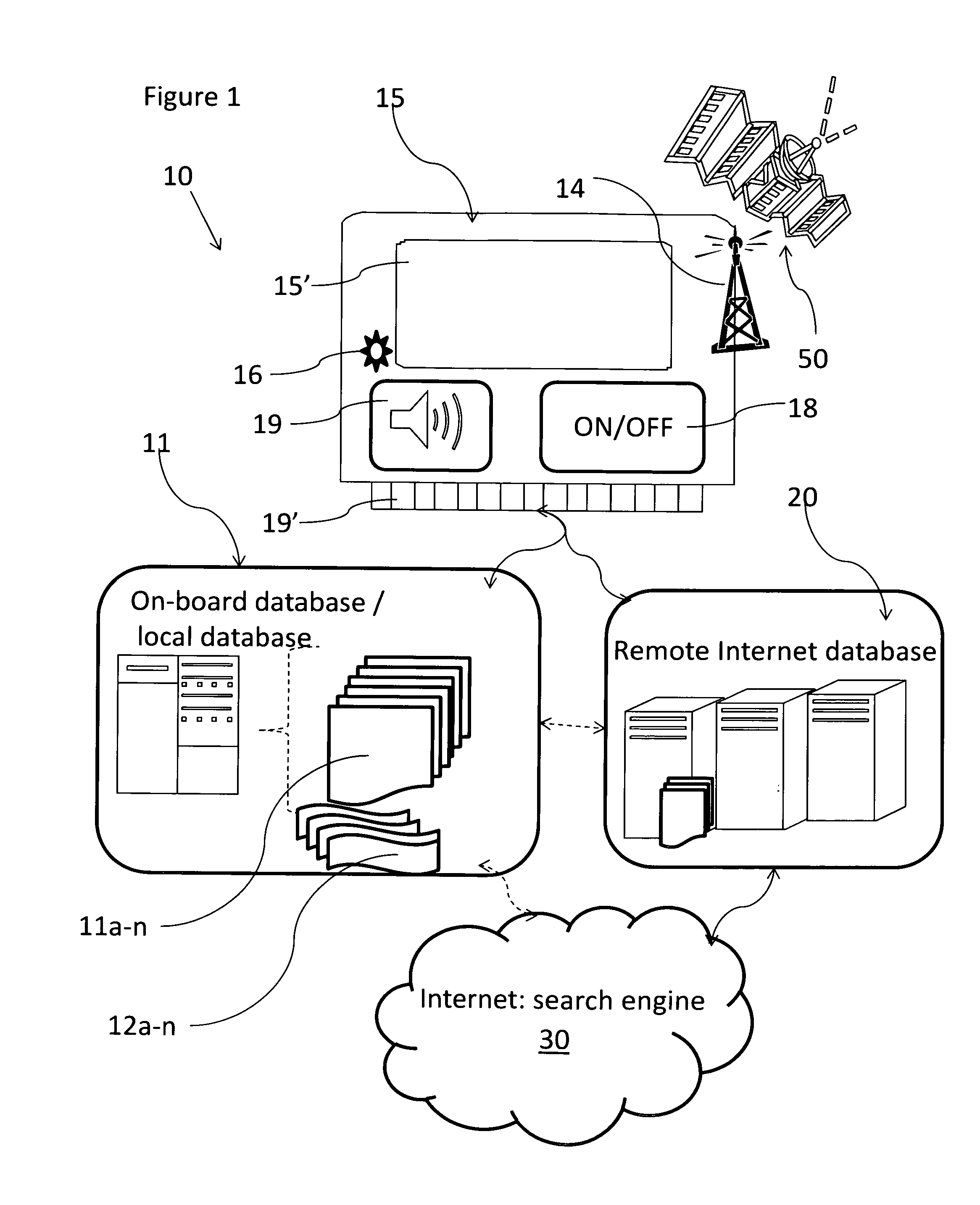

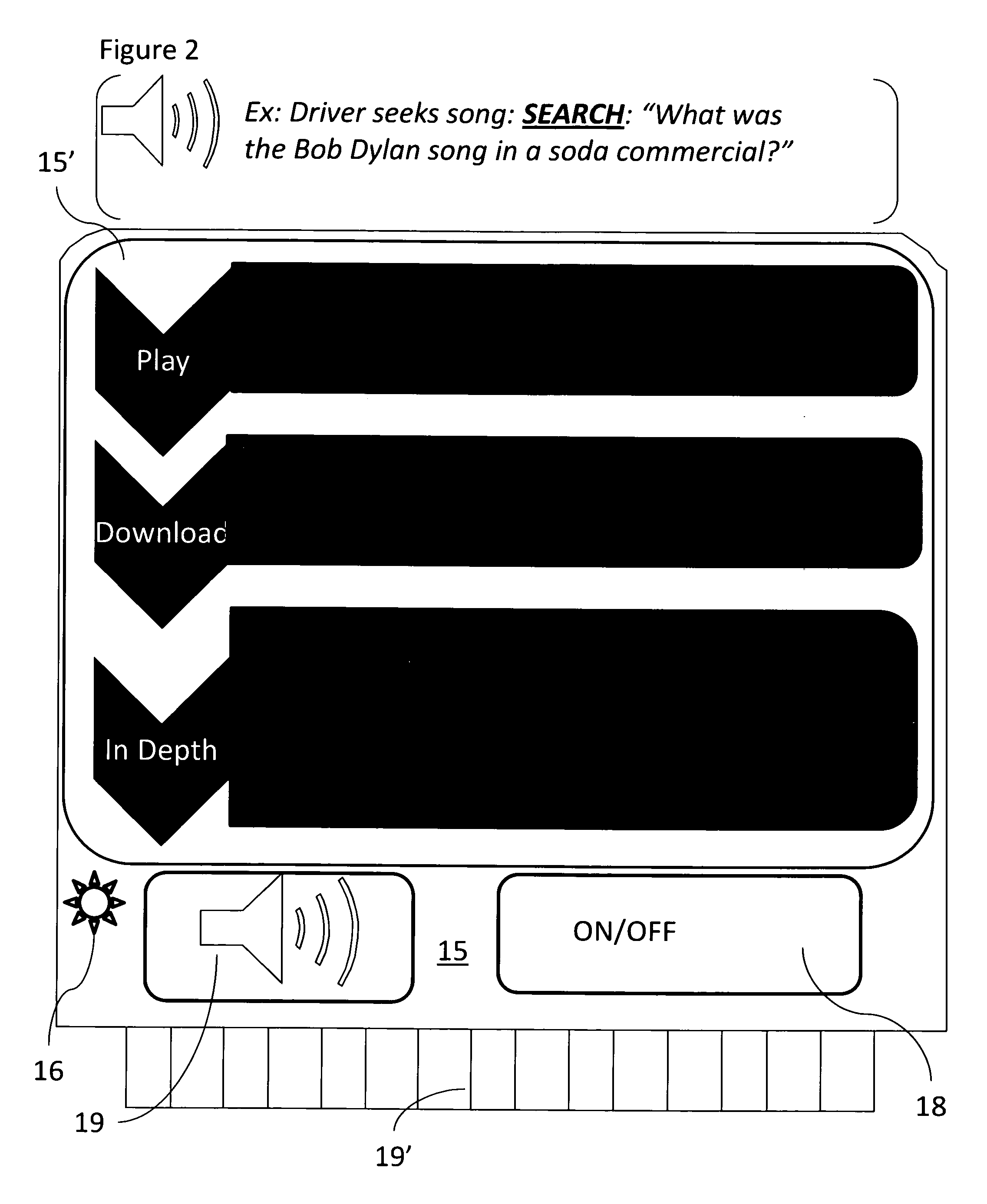

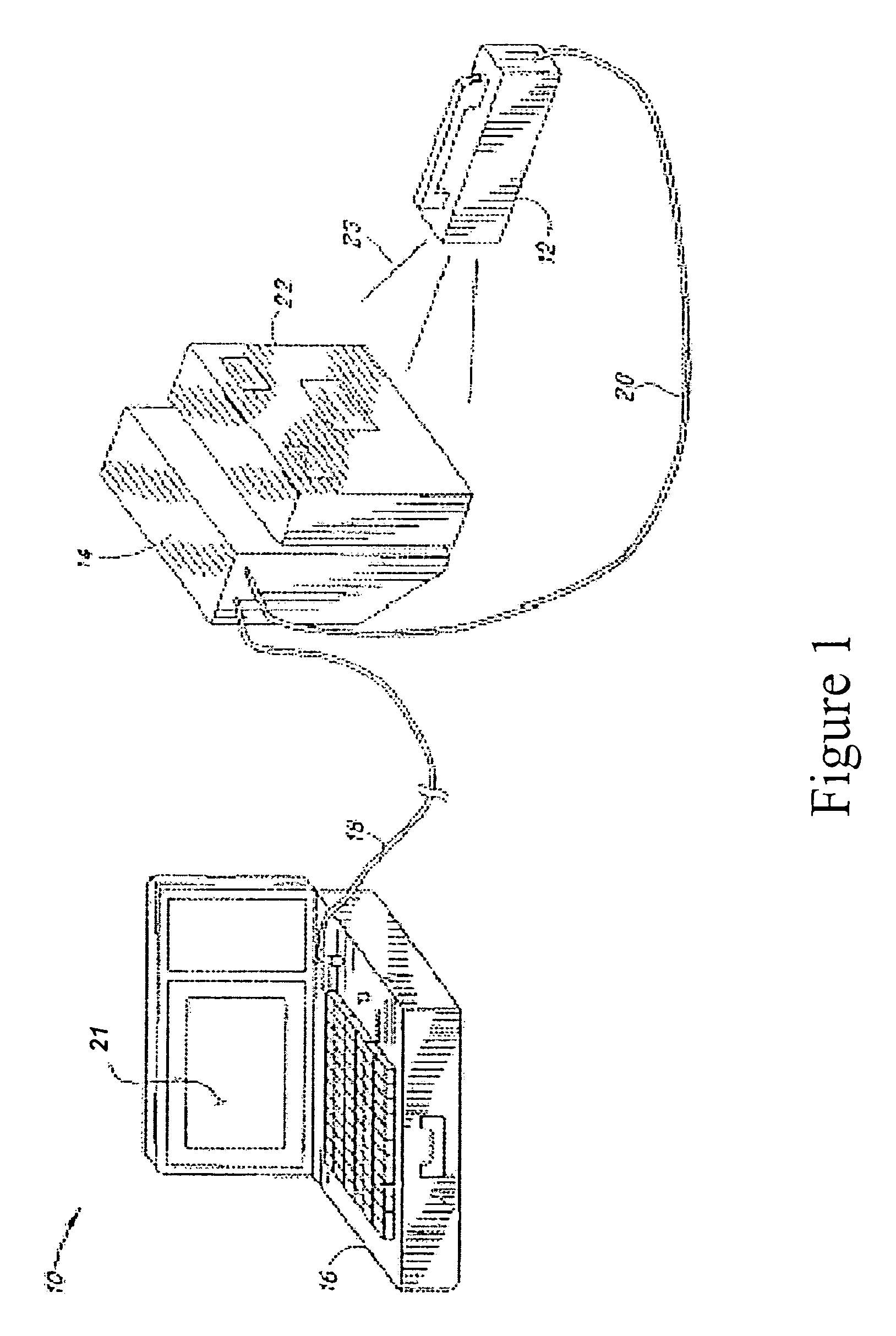

Music search and retrieval system

InactiveUS20140075306A1Reduce lossesImprove driving safetyMetadata audio data retrievalSound input/outputOn boardInformation retrieval

An on-board music search, retrieval and downloadable system has a plurality of musical works, each correlated with a music search code or identifier. The search code or identifier comprises a plurality of information including title, artist, era of song, genre, history of song, and song associations. Any one of the search codes or identifiers identified in an executed search retrieves the musical works associated therewith. The system provides an on-board database in communication with a remote database for searching a plurality of musical works correlated with a music search code or identifier, including a plurality of information such as title, artist, era of song, genre, history of song, and song associations. Any one of the search codes or identifiers identified in an executed search retrieves the musical works. The on-board music system provides easy song retrieval, enabling a driver to search and play songs without being distracted while driving.

Owner:REGA RANDY

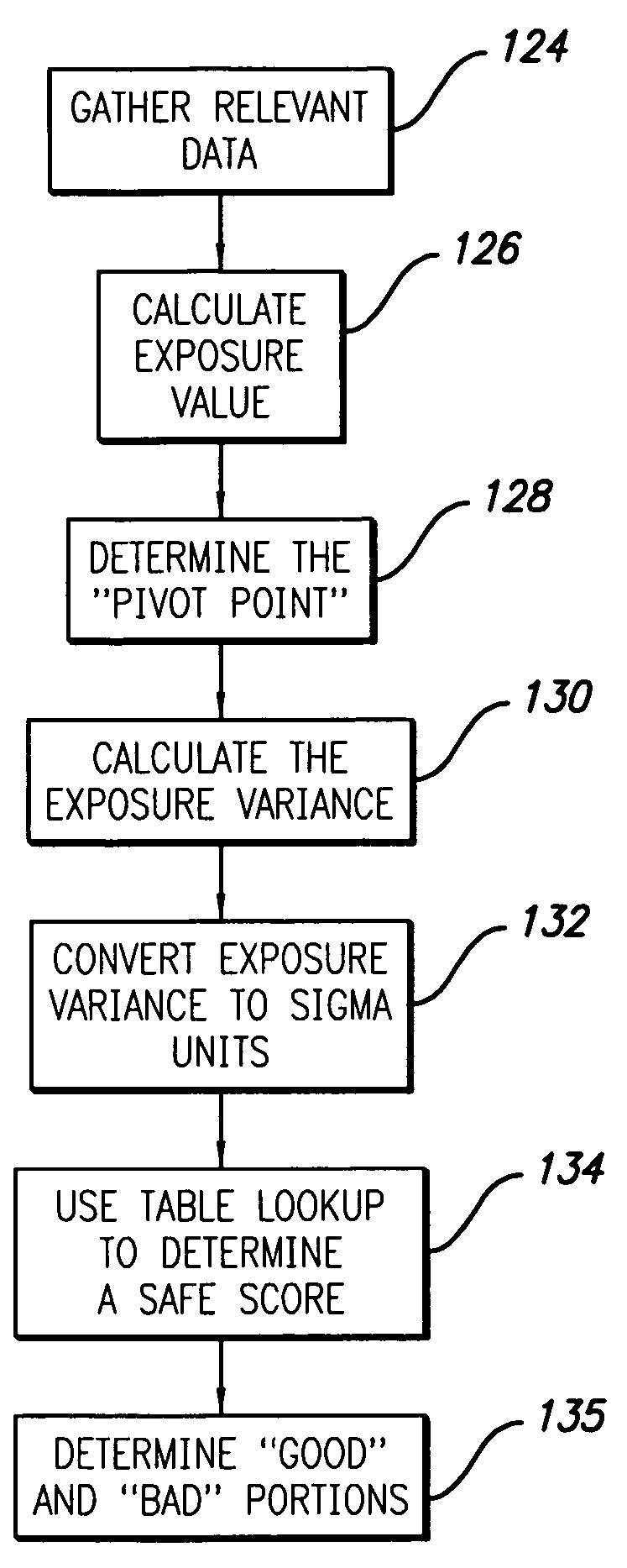

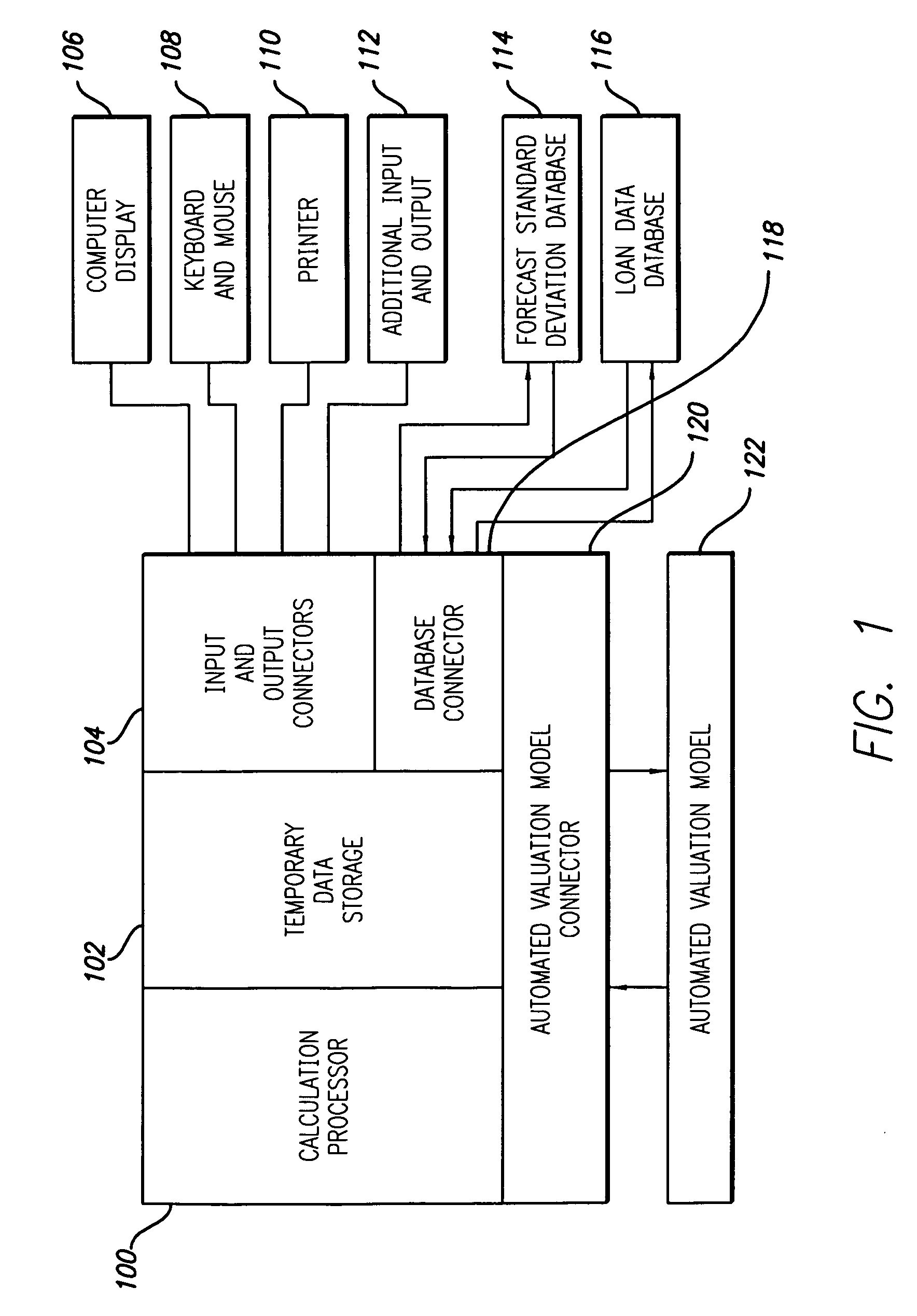

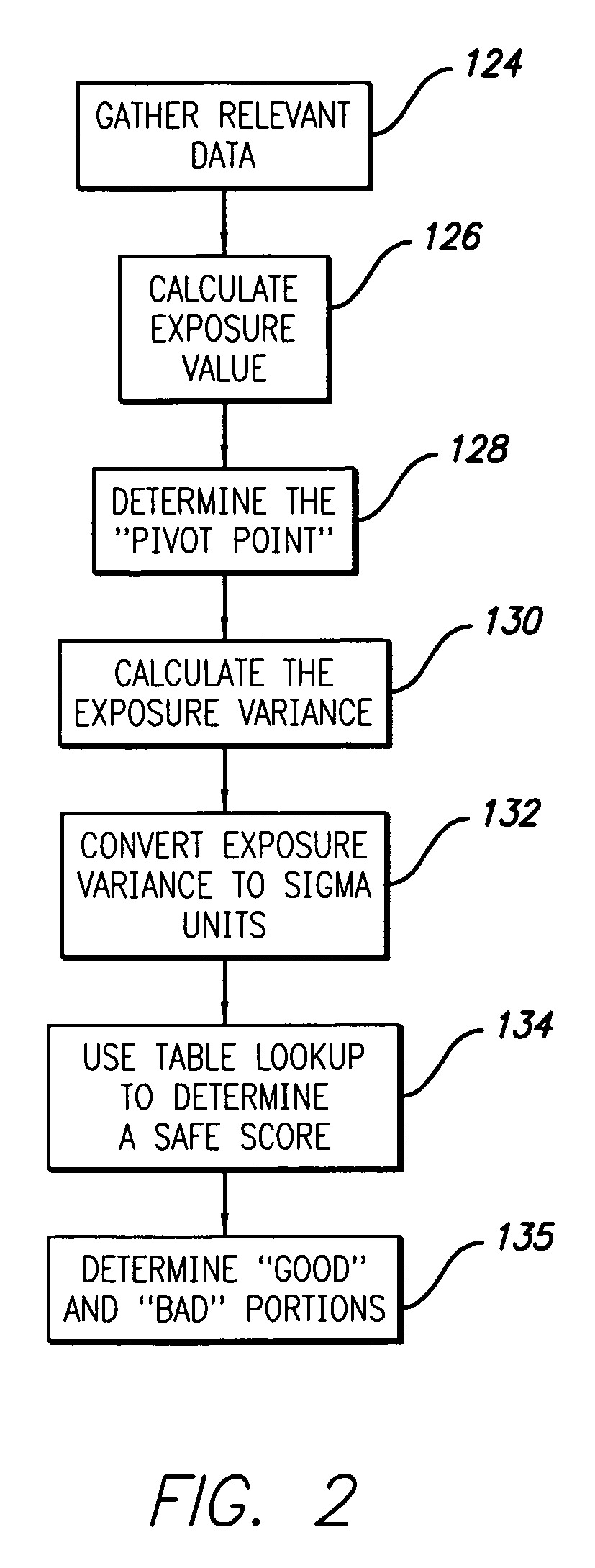

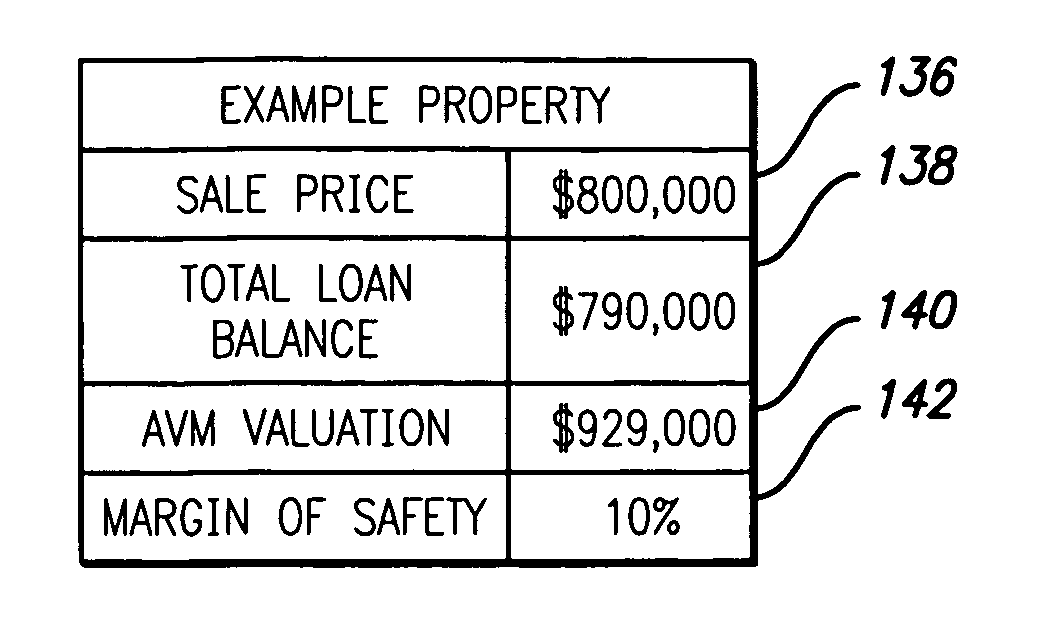

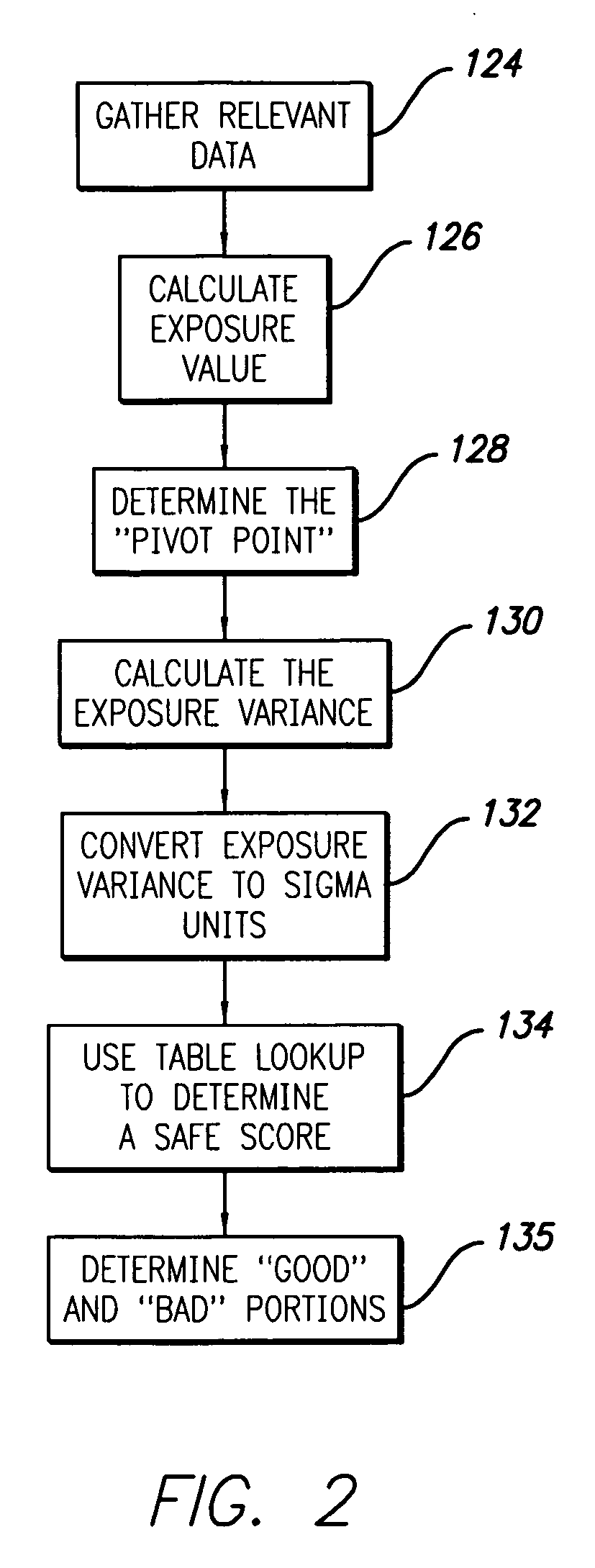

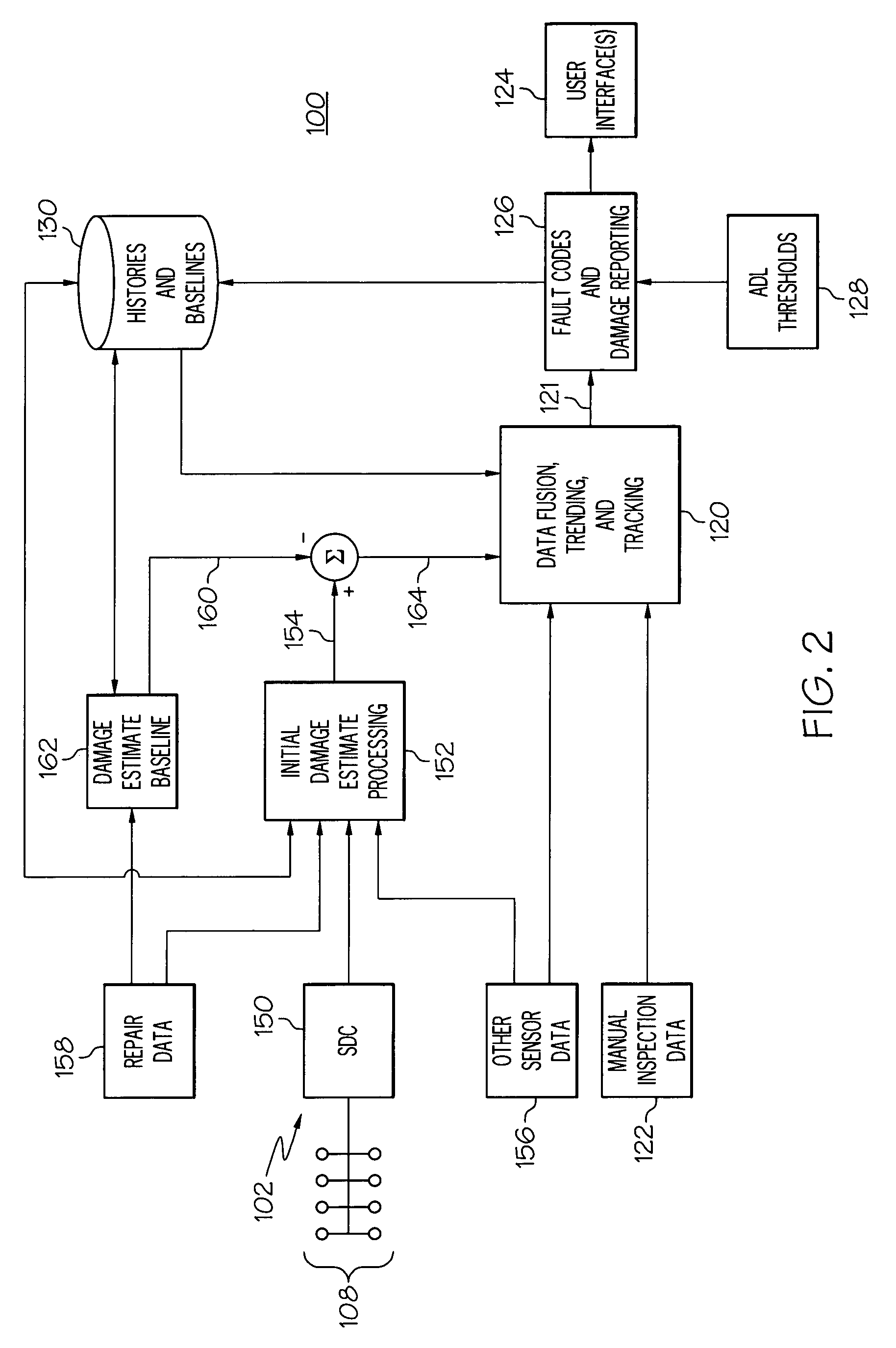

Method and apparatus for advanced mortgage diagnostic analytics

A method and apparatus for calculating individual or collective safe scores for properties with loans. These safe scores are useful in comparing the risk of loss due to exposure in the case of a default on the loan or loans being evaluated and may be used to objectively compare individual loans or groups of loans for such risk and for the worthiness for refinancing or additional lending.

Owner:CORELOGIC SOLUTIONS

Method and apparatus for advanced mortgage diagnostic analytics

A method and apparatus for calculating individual or collective safe scores for properties with loans. These safe scores are useful in comparing the risk of loss due to exposure in the case of a default on the loan or loans being evaluated and may be used to objectively compare individual loans or groups of loans for such risk and for the worthiness for refinancing or additional lending.

Owner:CORELOGIC SOLUTIONS

Antineoplastic combinations of CCI-779 and rituximab

InactiveUS20050272758A1Eliminate side effectsIncreased safety marginBiocideAntibody ingredientsPharmacologyNon-Hodgkin's lymphoma

Owner:WYETH

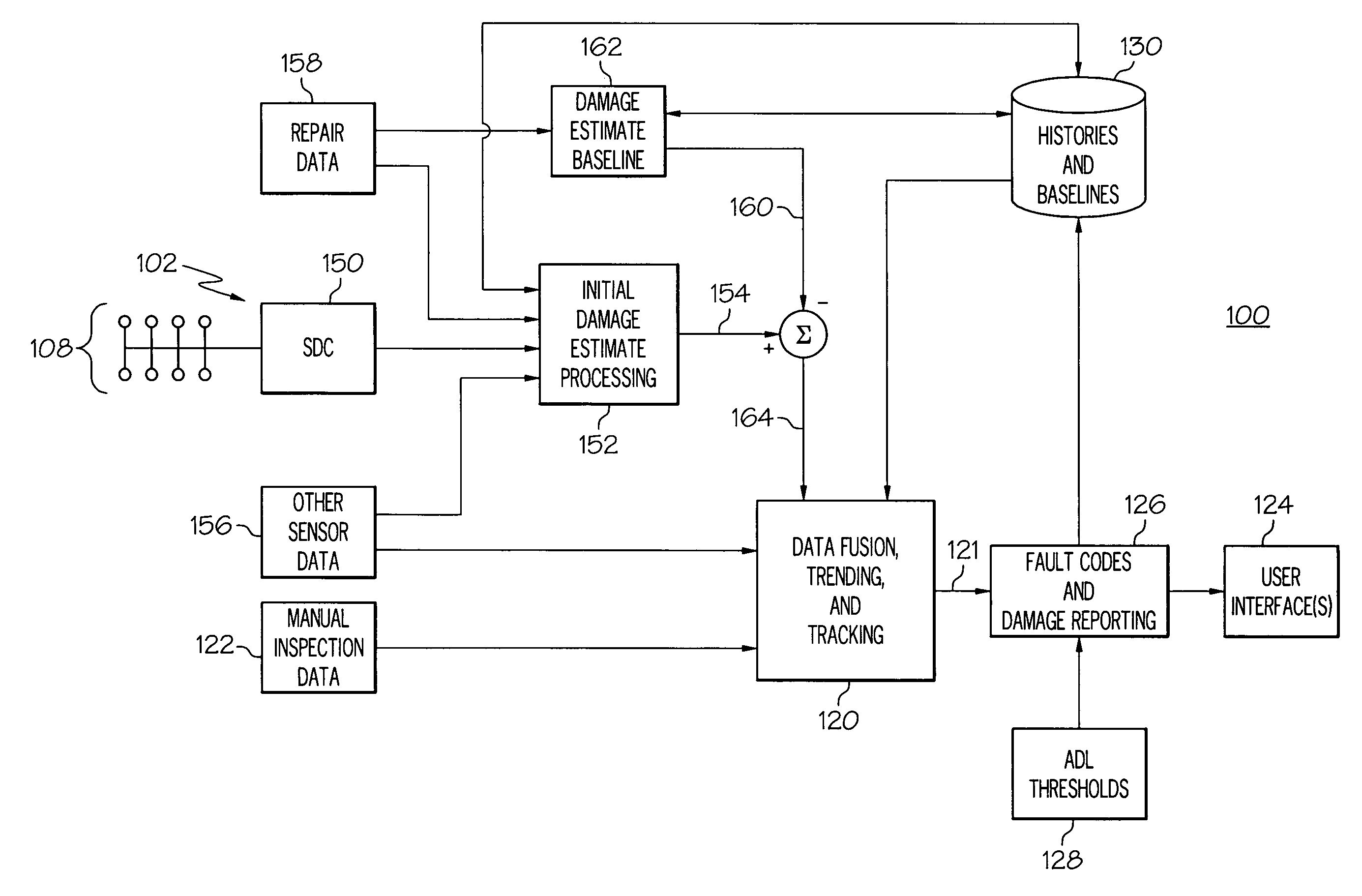

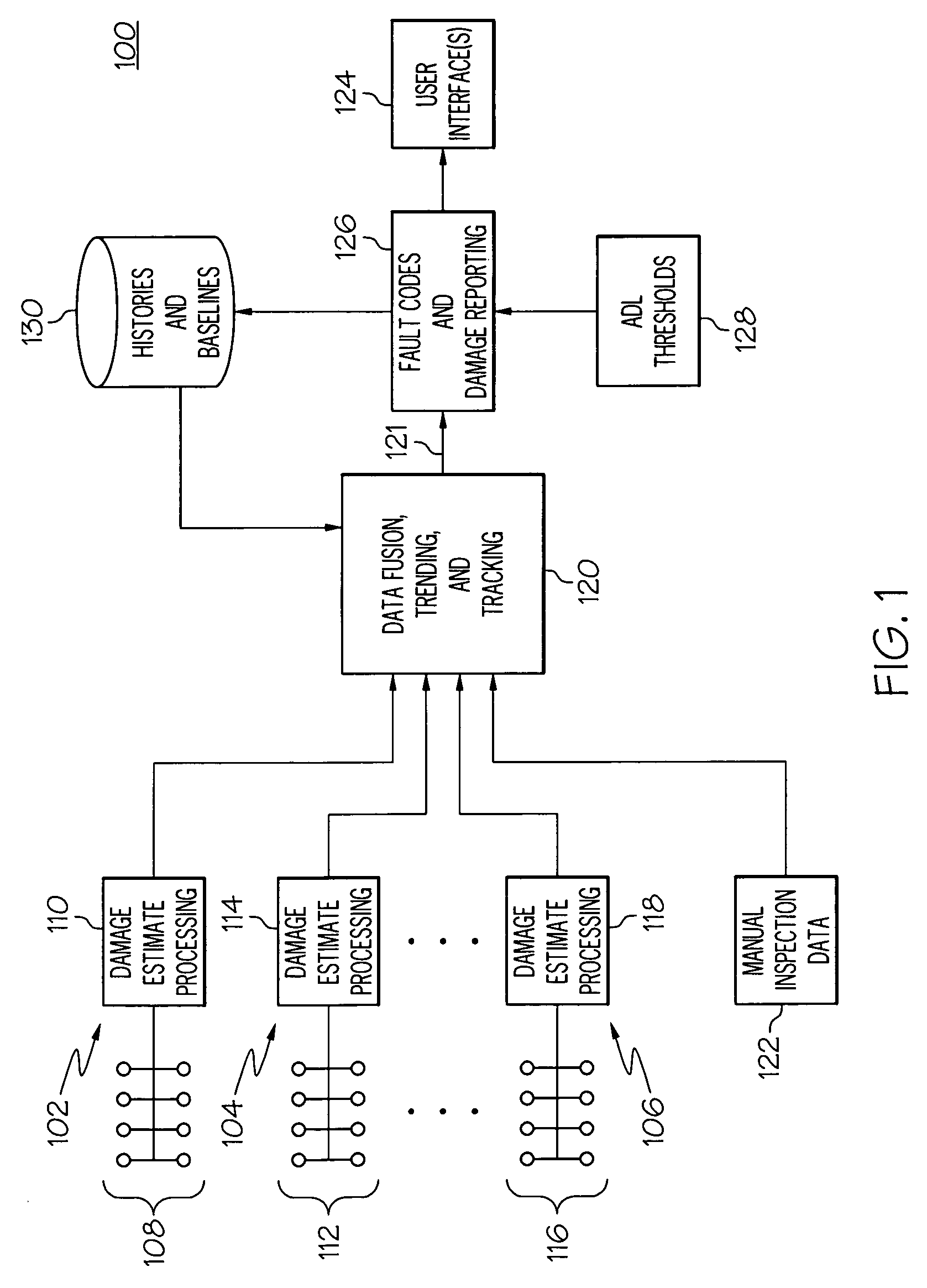

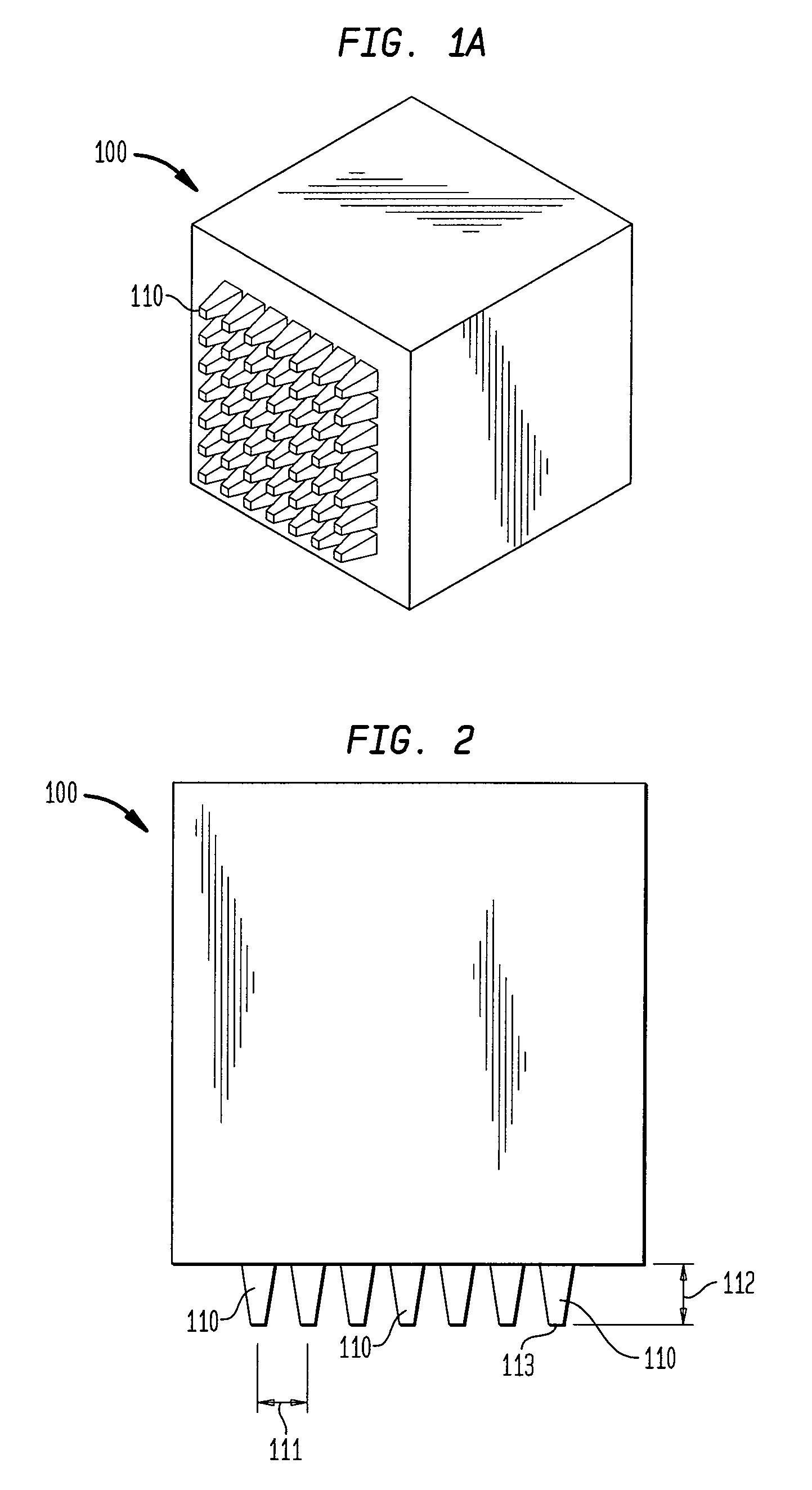

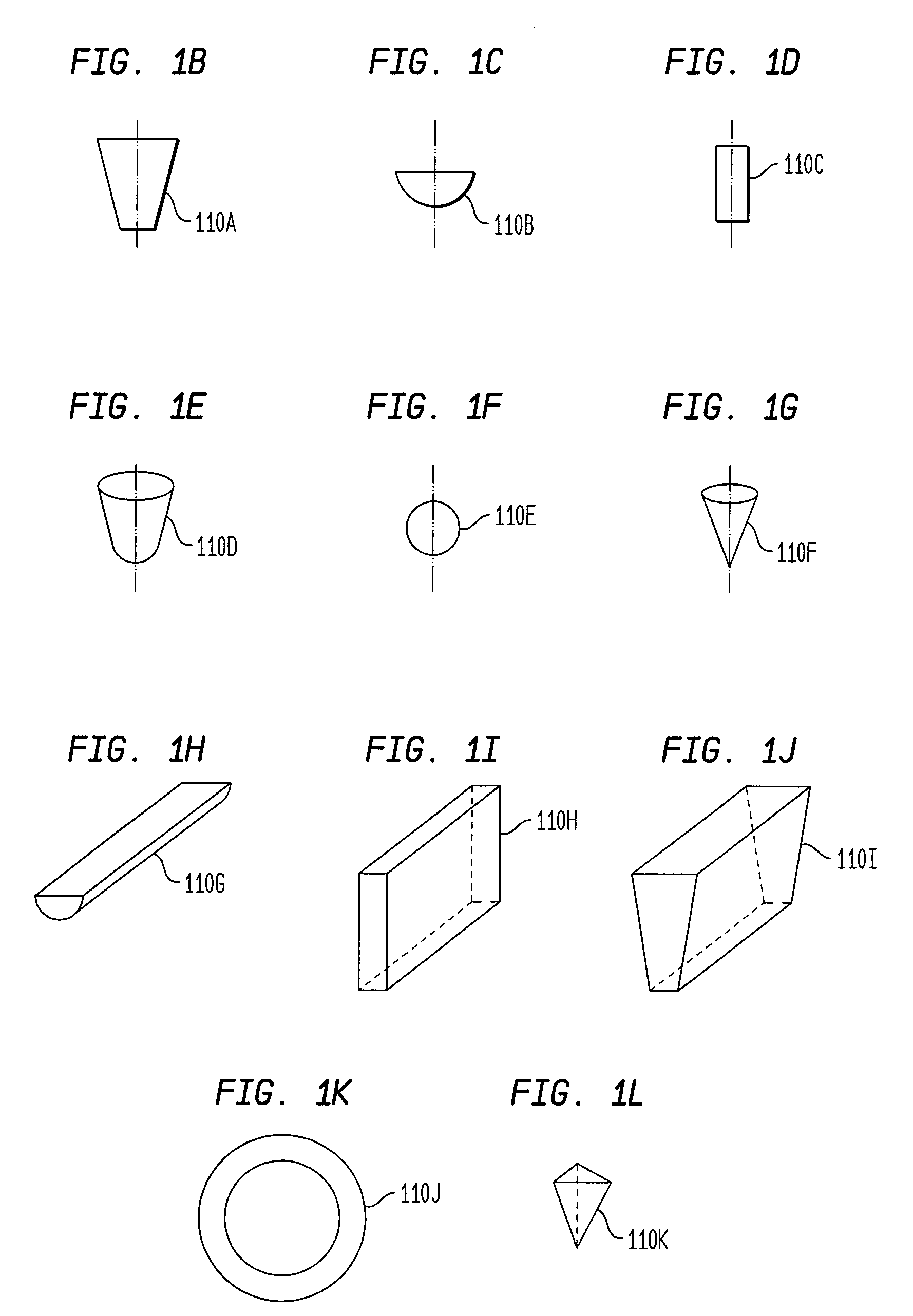

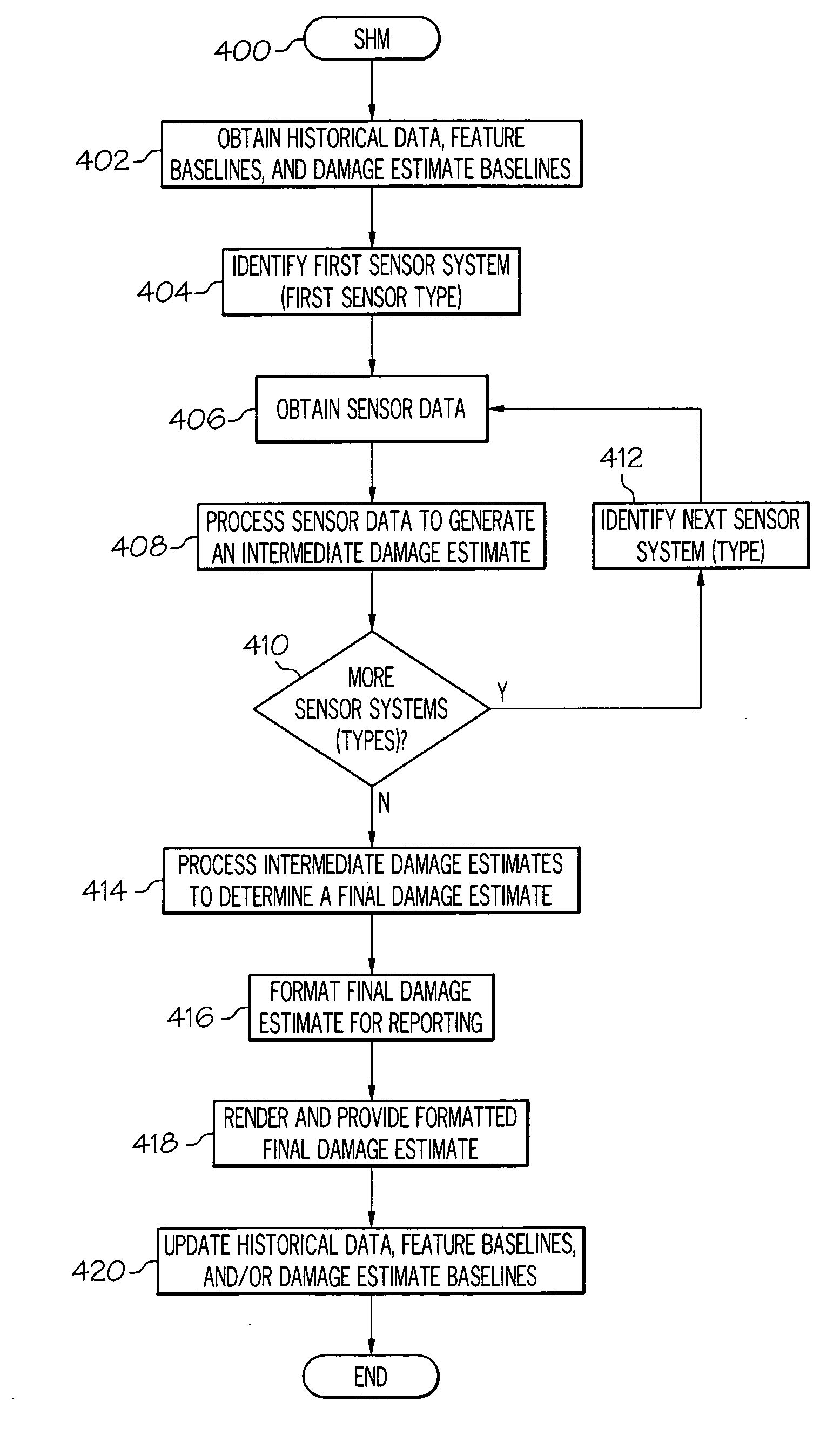

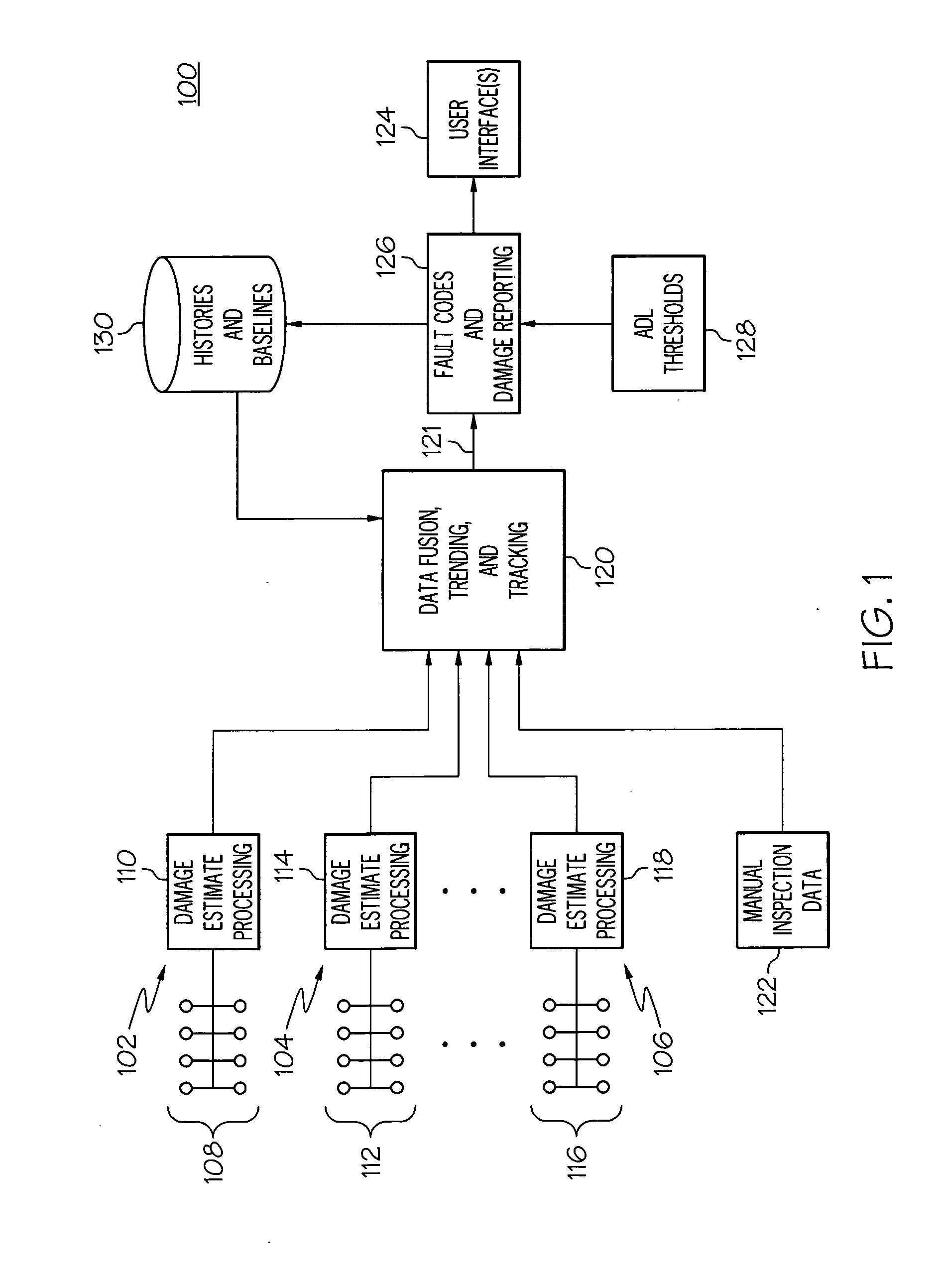

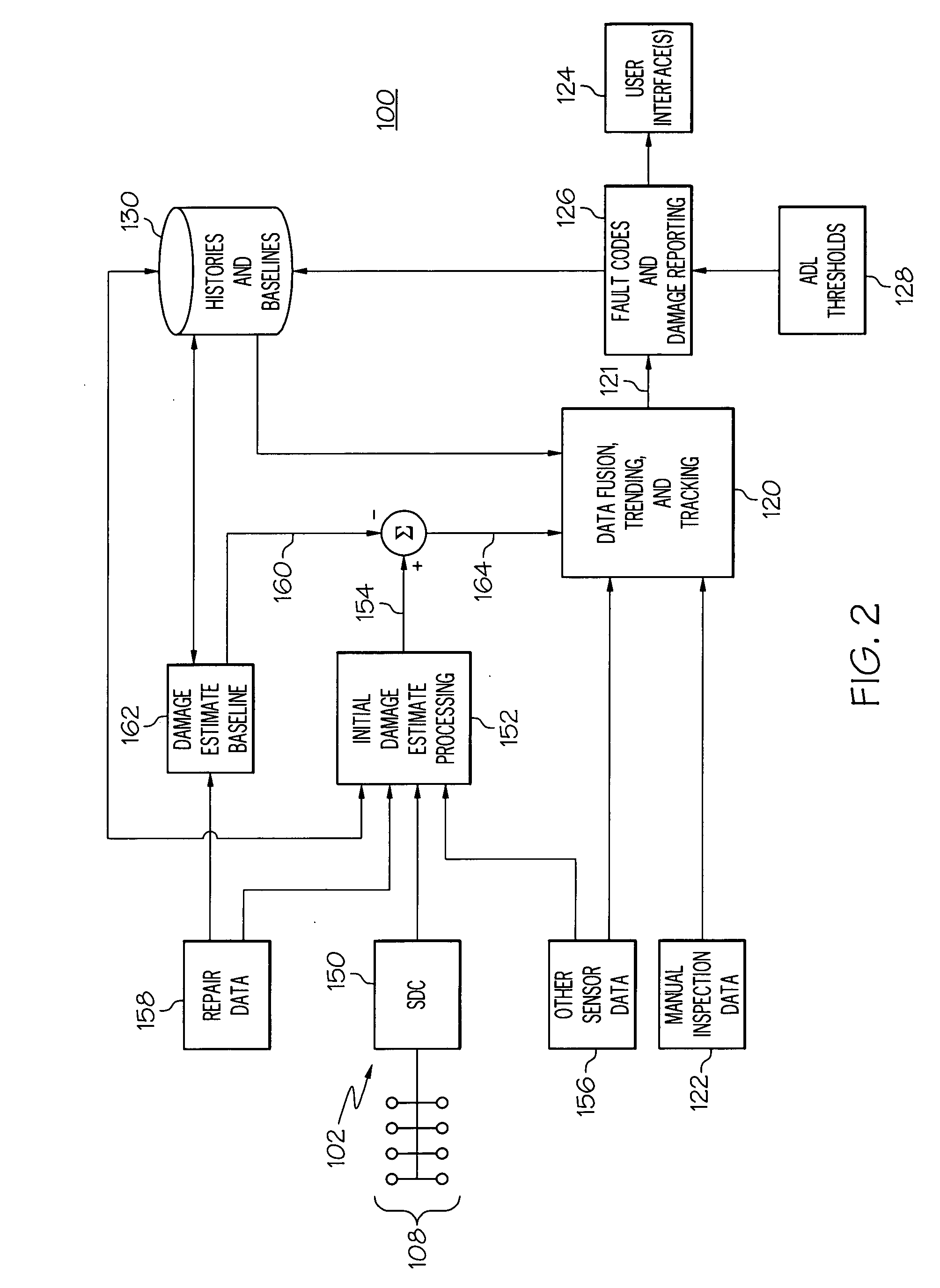

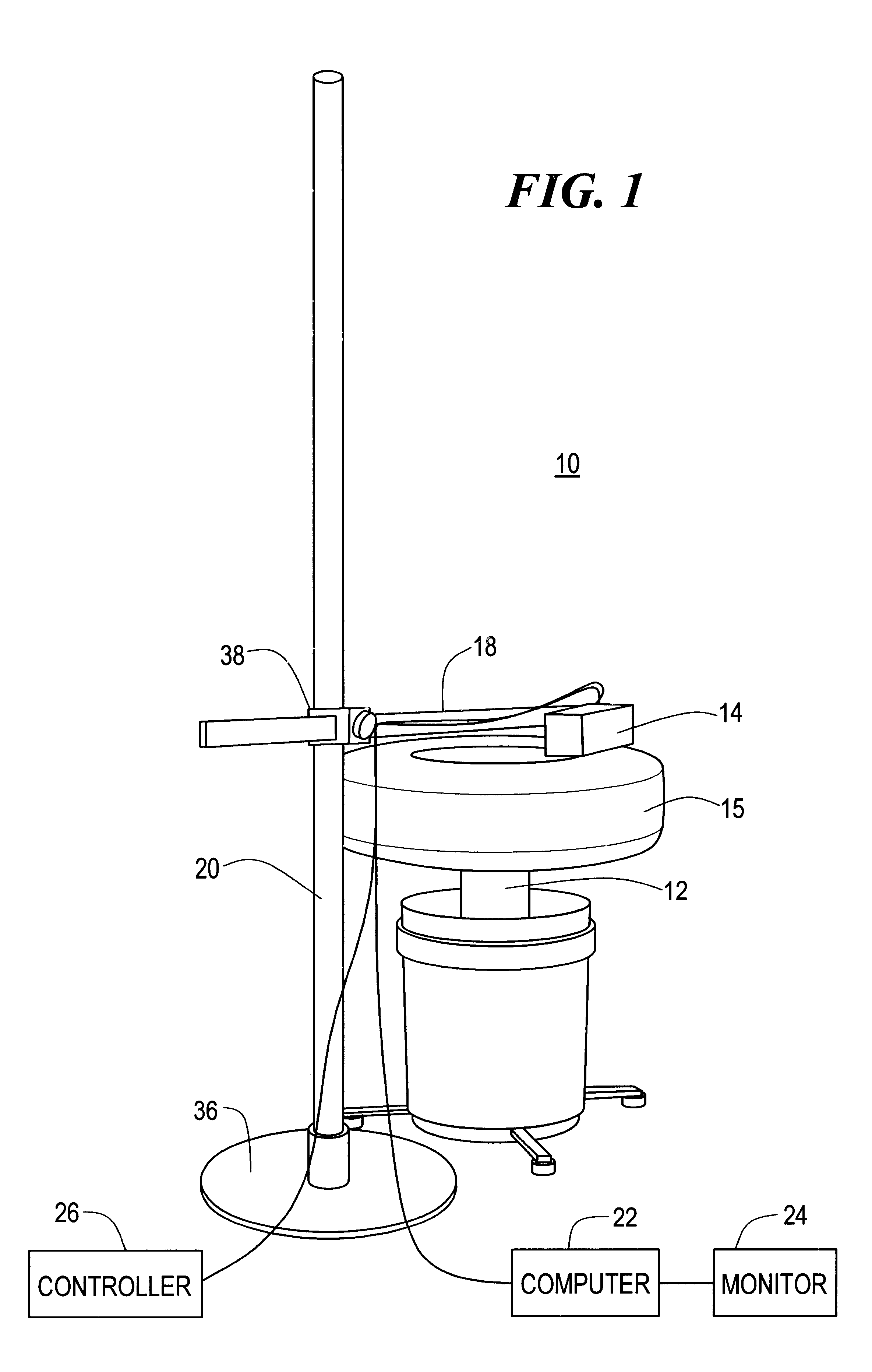

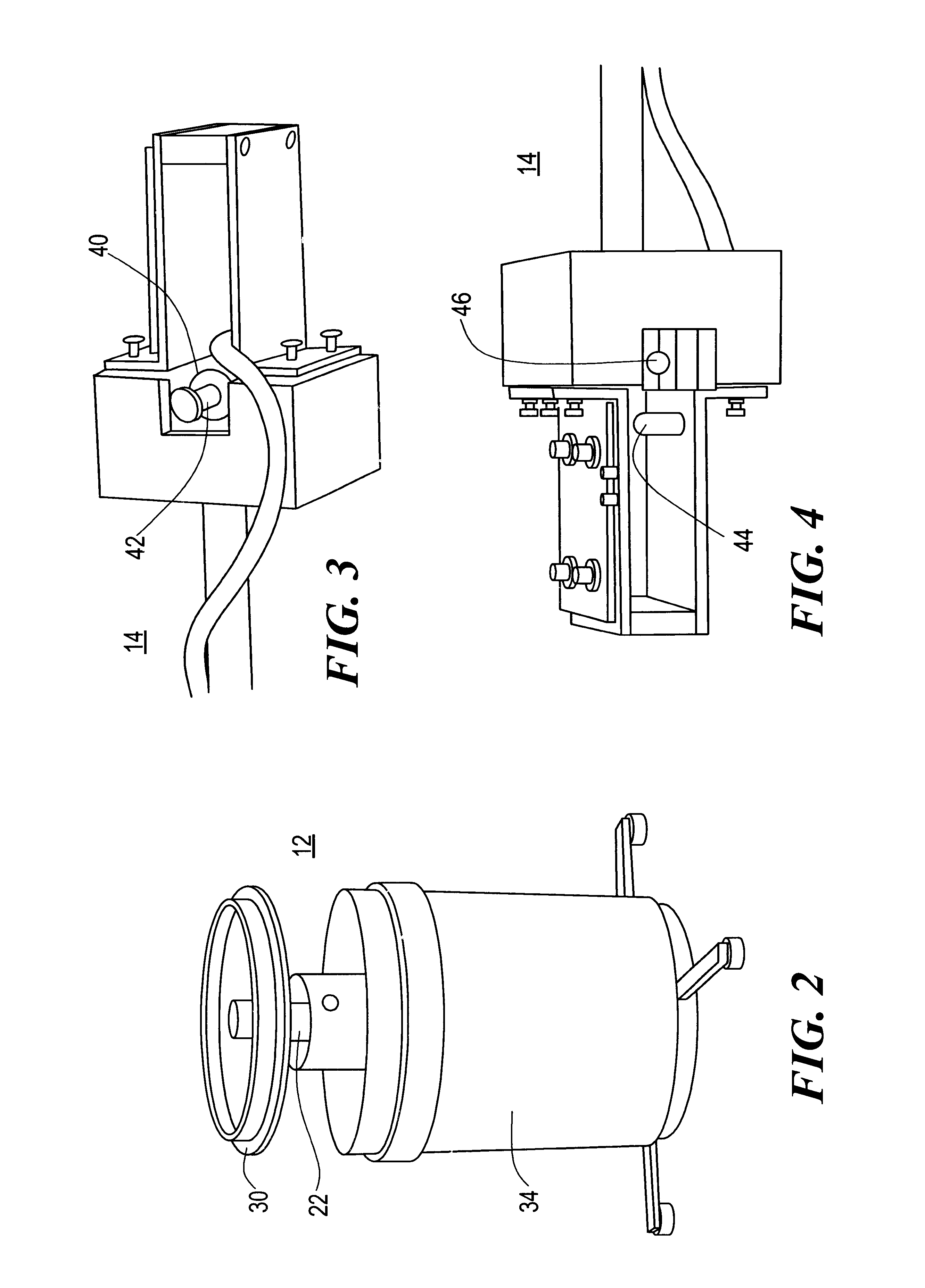

Structure health monitoring system and method

ActiveUS7103507B2Lower cost of ownershipIncreased safety marginVehicle testingPlug gaugesStructural health monitoringTime-Consuming

Owner:HONEYWELL INT INC

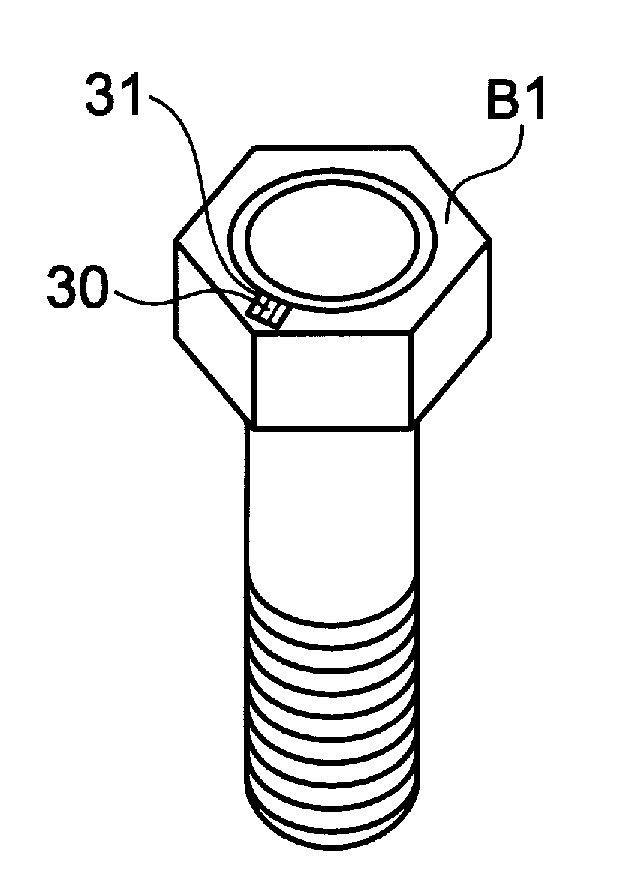

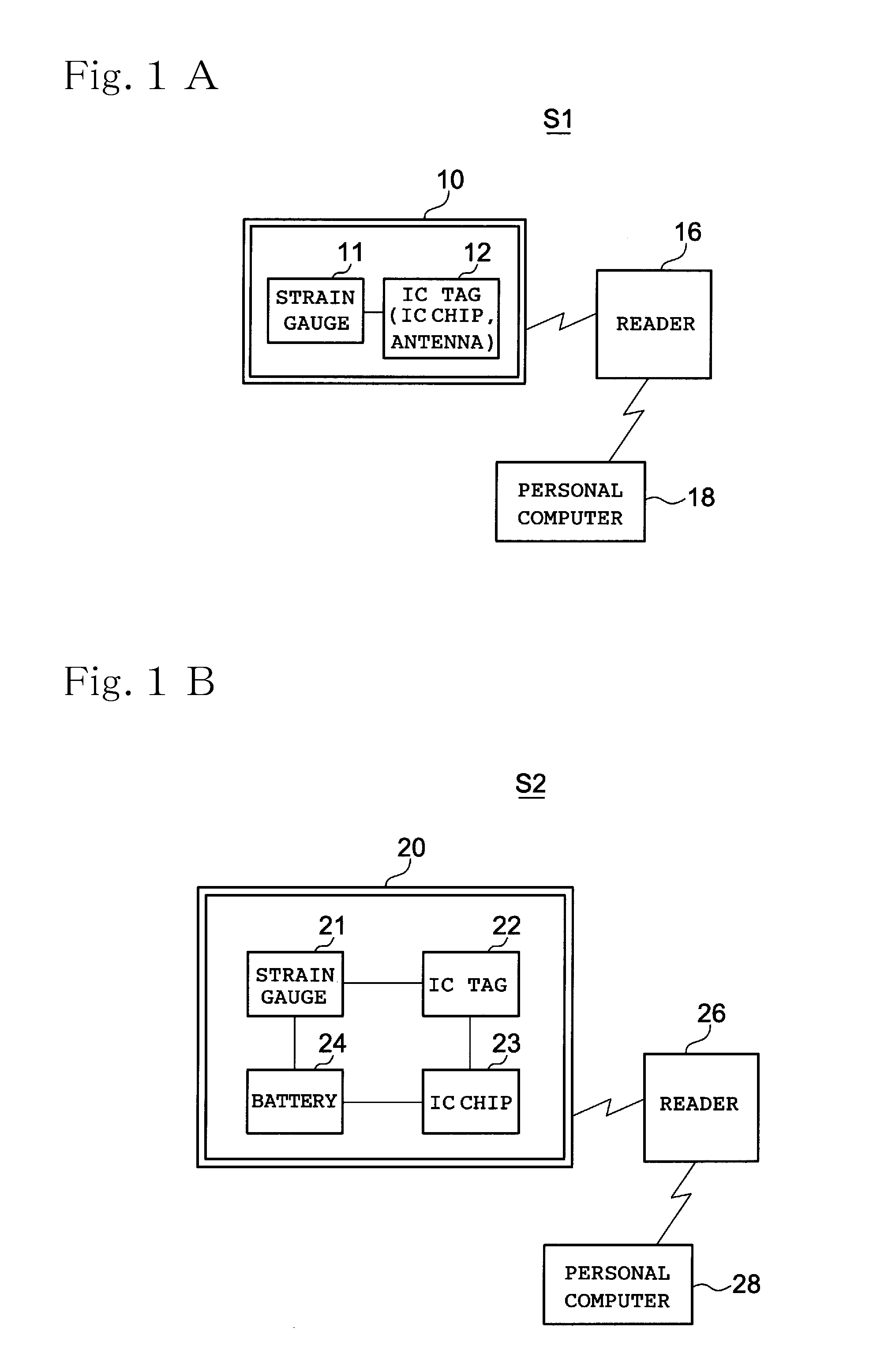

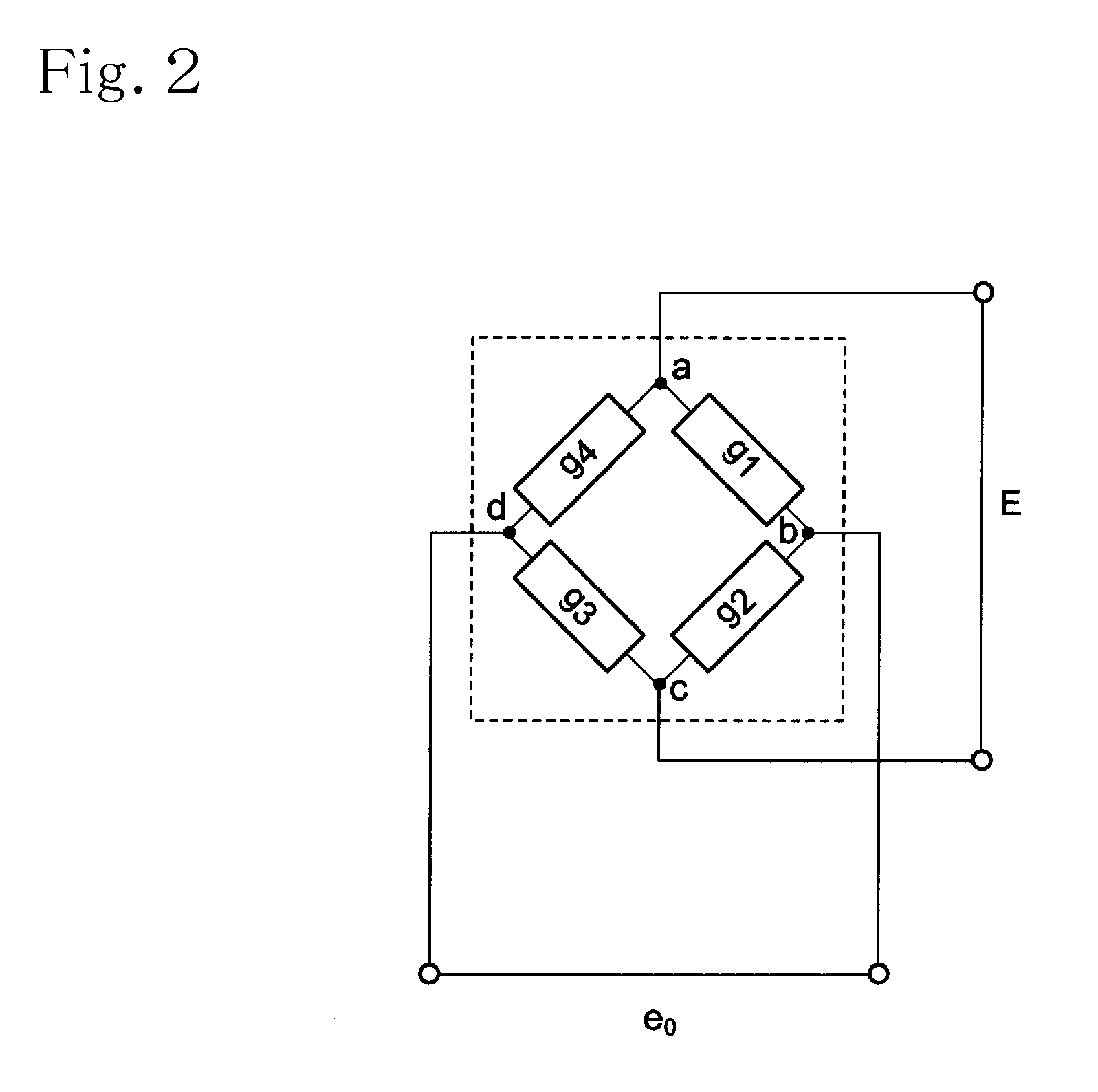

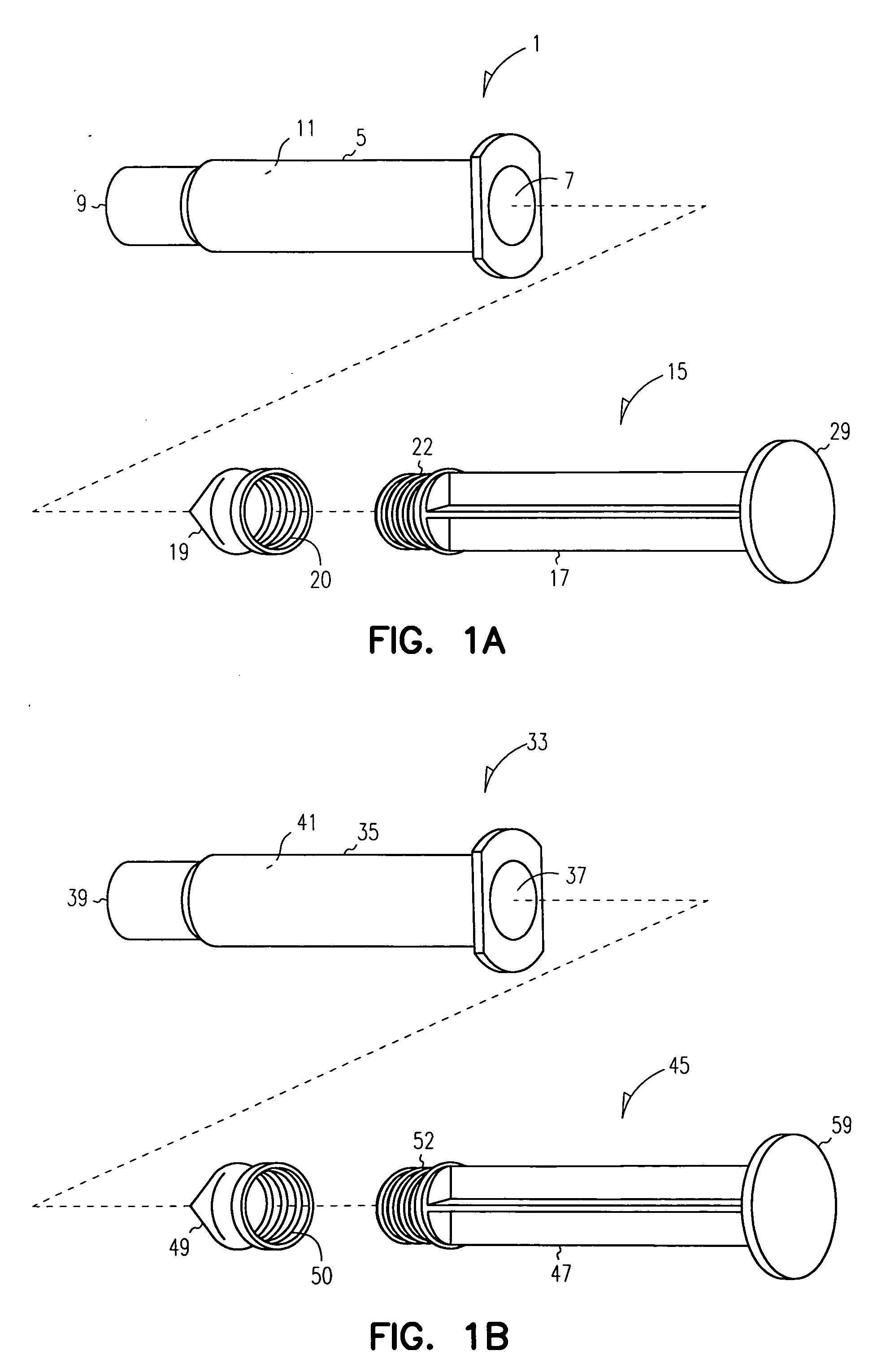

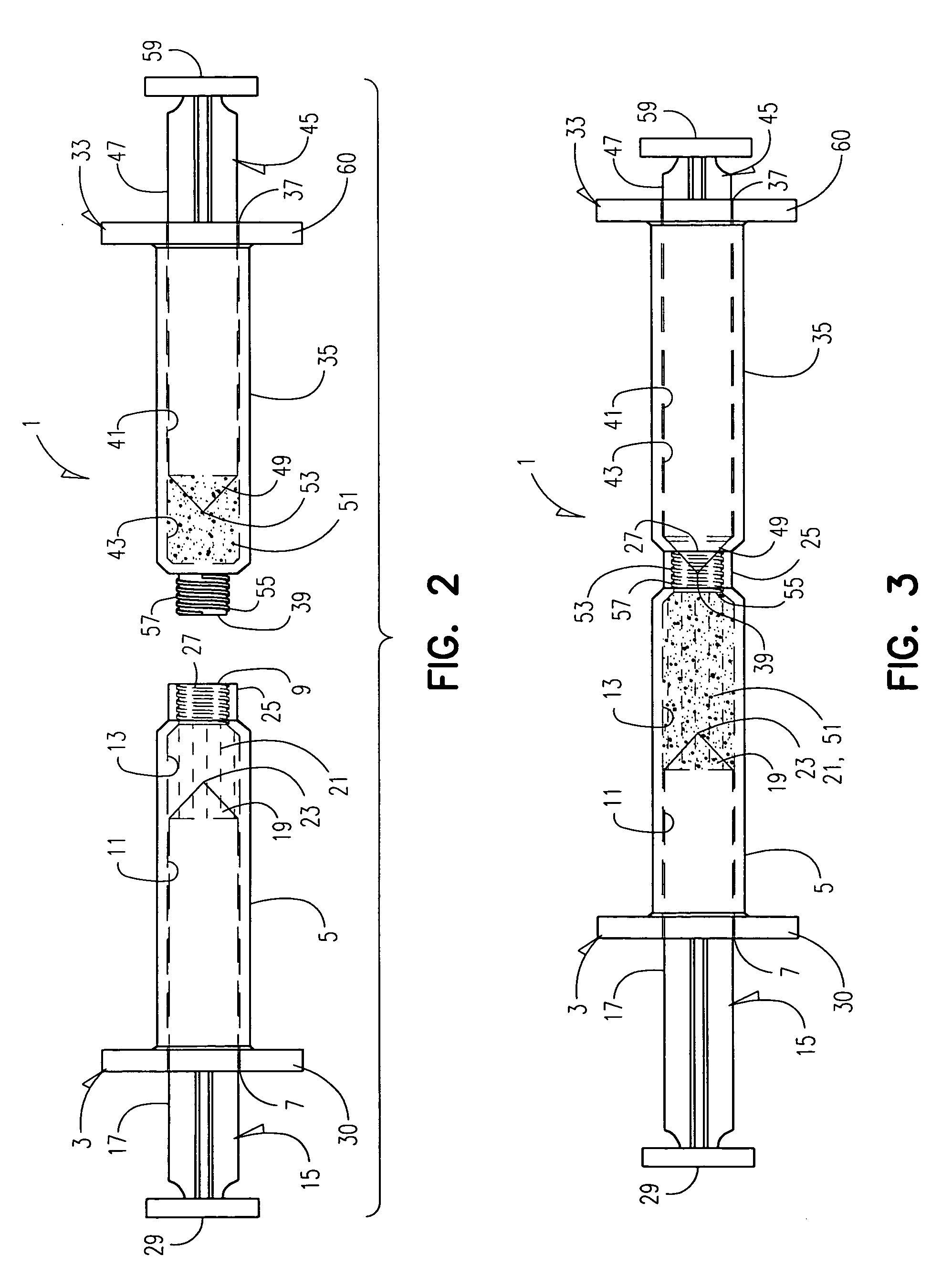

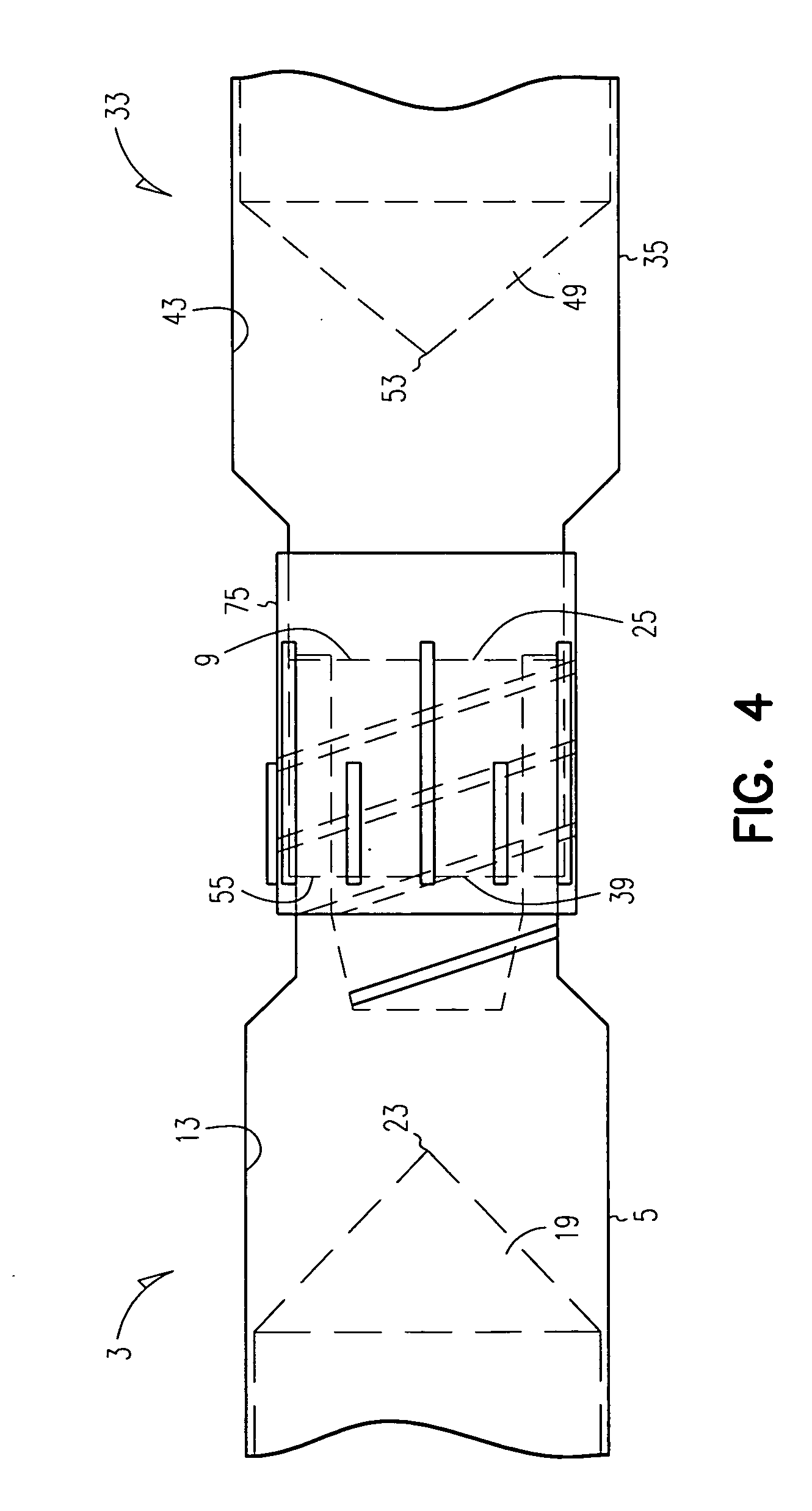

Fastening apparatus and system for detecting axial force thereof

InactiveUS20100054891A1Avoid accidentsLabor savingMeasurement of torque/twisting force while tighteningLoad modified fastenersAxial forceEngineering

A detecting system of a fastening apparatus that detects an axial force of the fastening apparatus including a bolt or a nut. The detecting system includes an axial force detector including a strain gauge and an IC tag, the strain gauge being provided at a predetermined location to detect an axial force value of the fastening apparatus, and the IC tag being connected to the strain gauge and wirelessly transmitting the detected axial force value and unique identification information. Power is supplied to the axial force detector. A reader reads data transmitted from the axial force detector.

Owner:FURUKAWA ELECTRIC POWER SYST

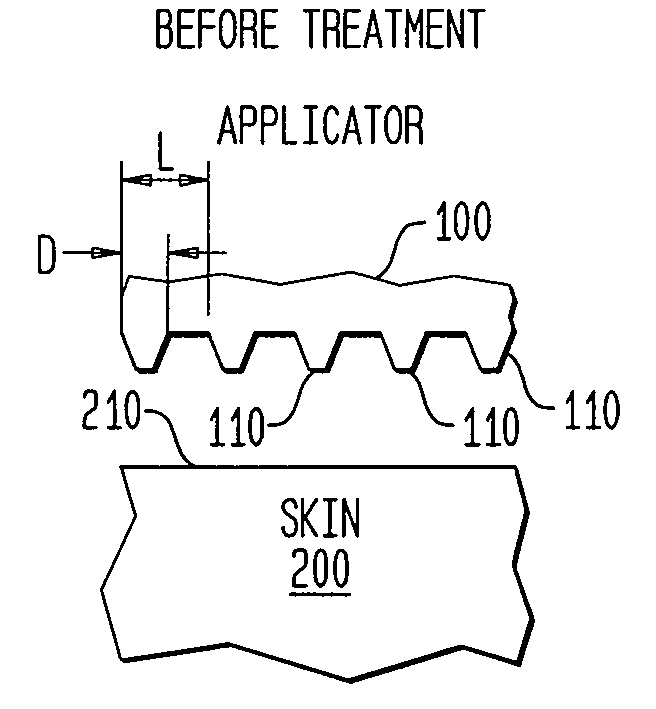

Method and apparatus for treatment of tissue

InactiveUS20100286673A1Improve permeabilityEfficiently deliver EMRDiagnosticsSurgical instrument detailsMedicineHair growth

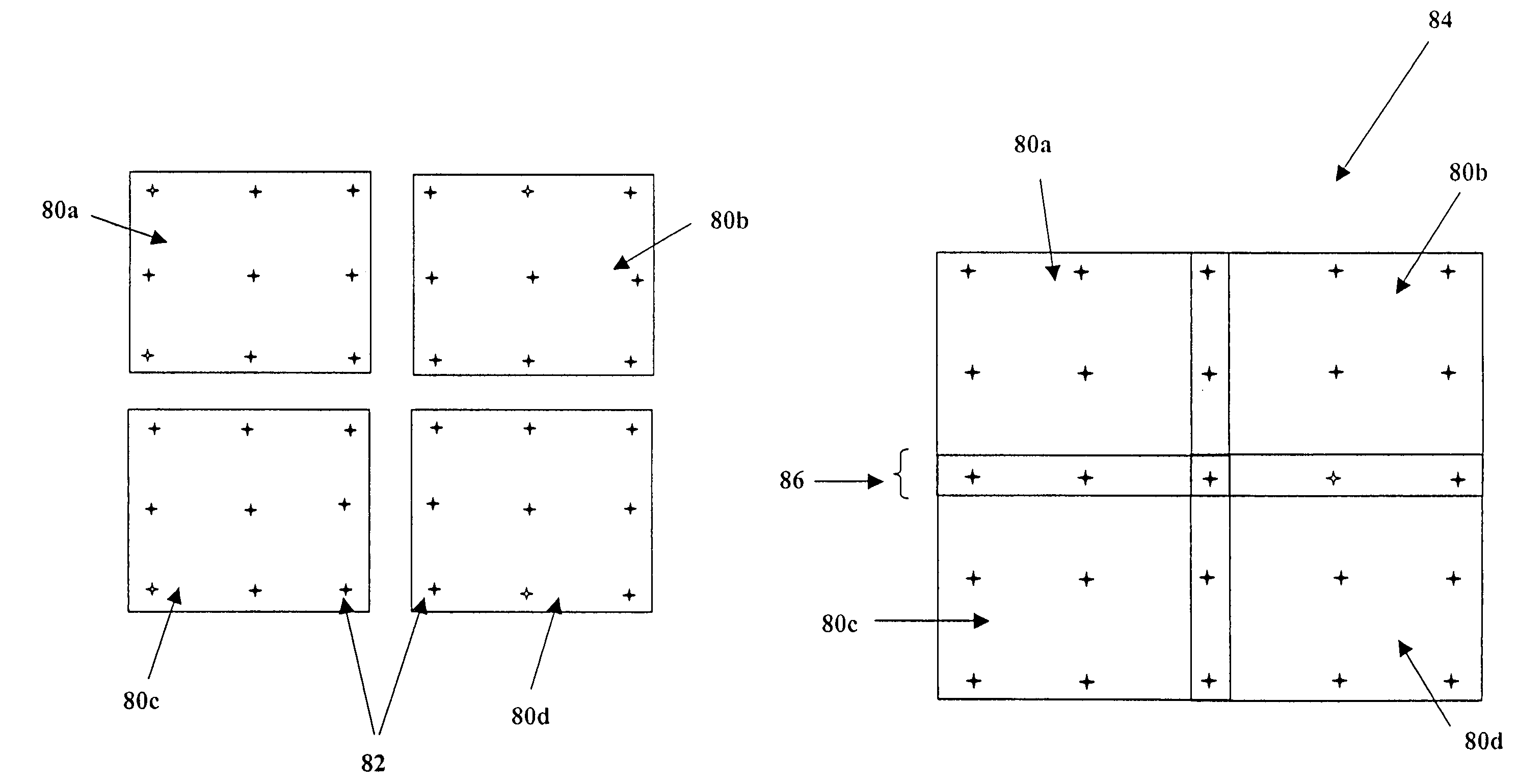

Devices and methods of treatment of tissue, such as skin tissue, with electromagnetic radiation (EMR) are disclosed that employ local deformation of tissue in small areas. Devices and methods employing local deformation are used to produce fractional lattices of EMR-treated islets in tissue for application including hair growth management.

Owner:PALOMAR MEDICAL TECH

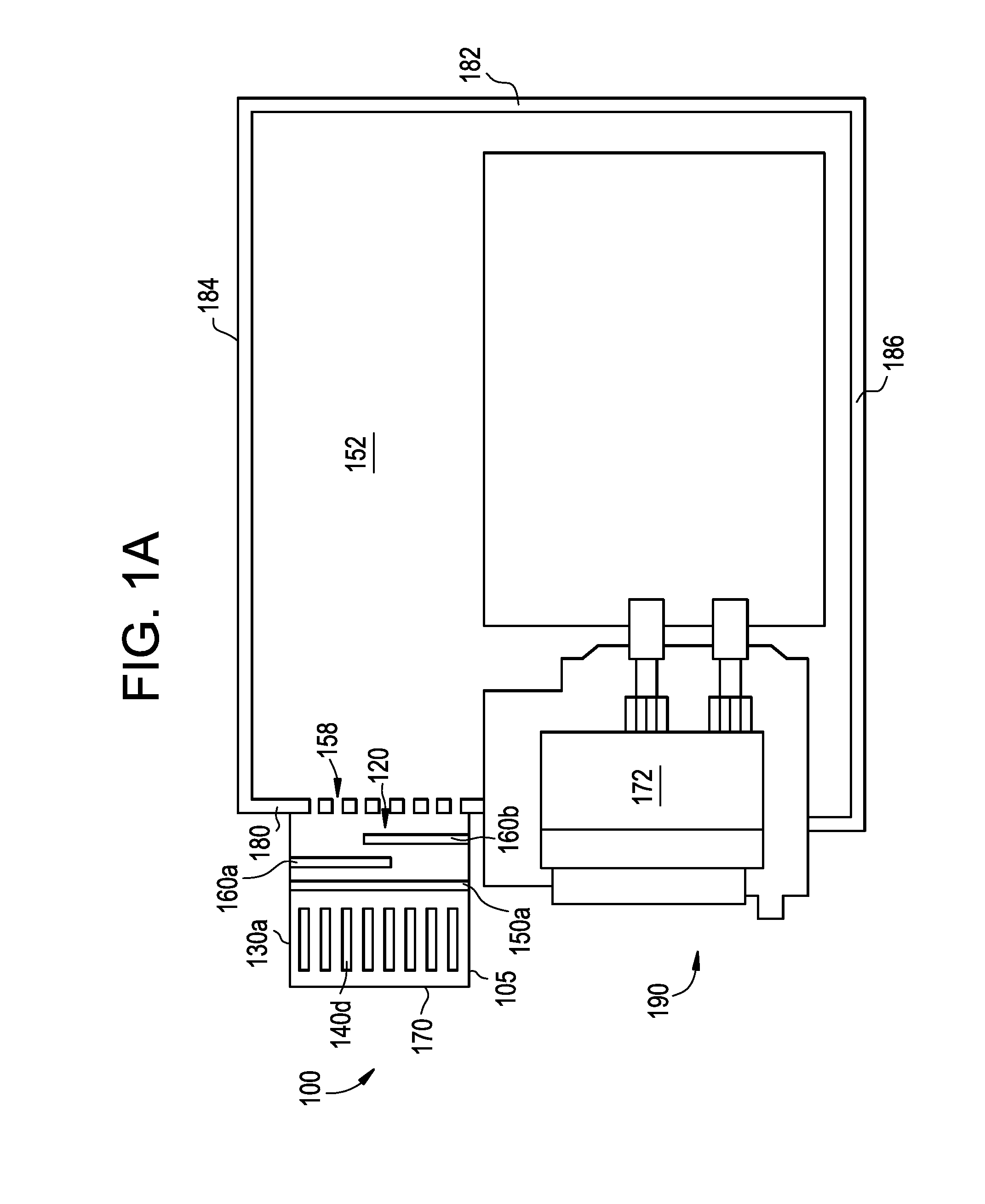

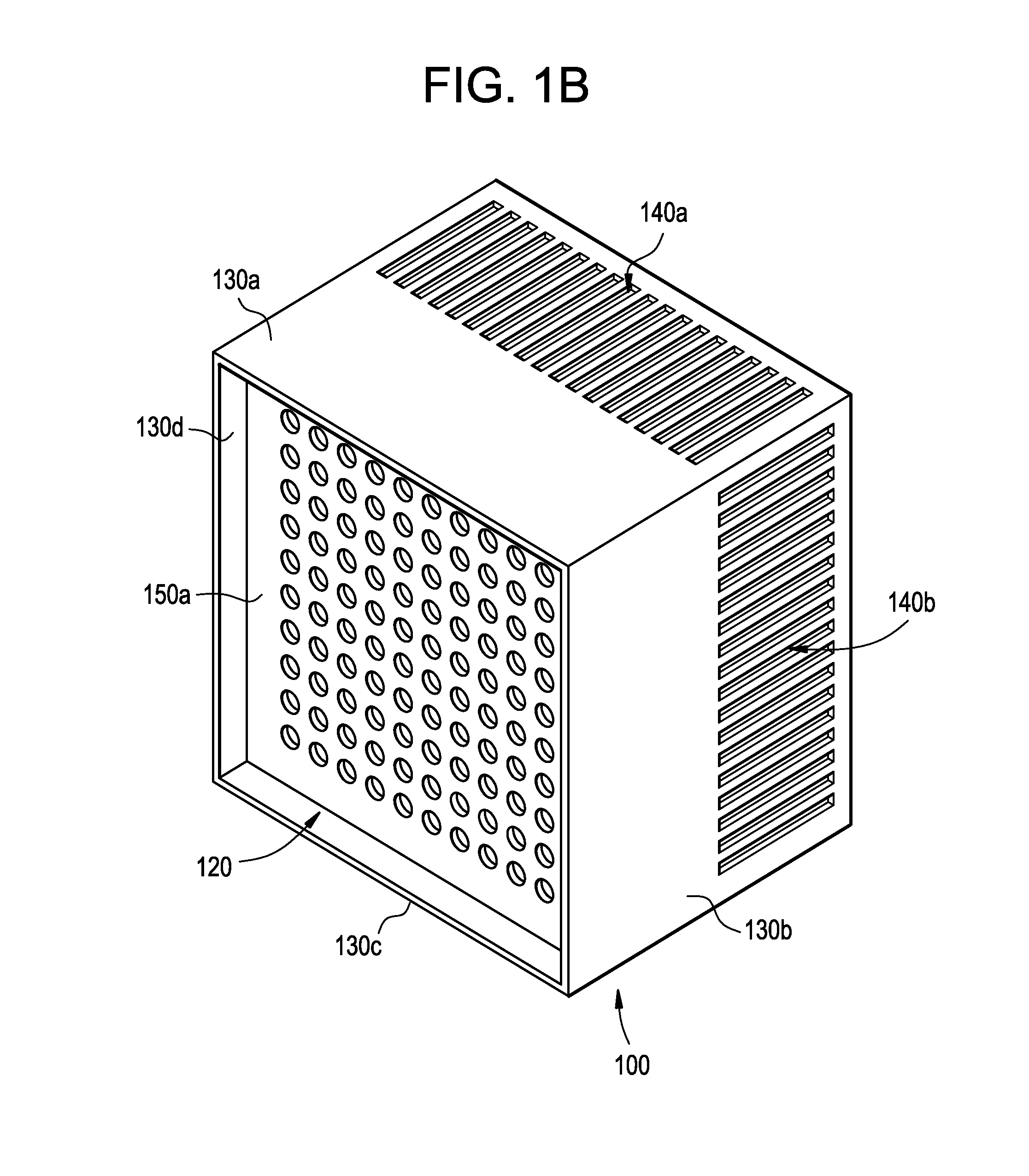

Structure health monitoring system and method

ActiveUS20060069520A1Increased safety marginLower cost of ownershipVehicle testingPlug gaugesStructure health monitoringHealth condition

A structure health monitoring (“SHM”) system according to the invention can be deployed in an onboard environment, such as an aircraft, to provide an ongoing damage assessment of structural components on the aircraft. The SHM system reduces or eliminates time consuming and costly manual inspections of aircraft. The SHM system can leverage known sensor technologies to collect sensor data indicative of the structural health of the monitored components. The sensor data is processed and baselined with sensor feature baselines and damage estimate baselines to provide an accurate final damage estimate for the monitored component. The final damage estimate can be further processed or formatted for compatibility with aircraft maintenance systems.

Owner:HONEYWELL INT INC

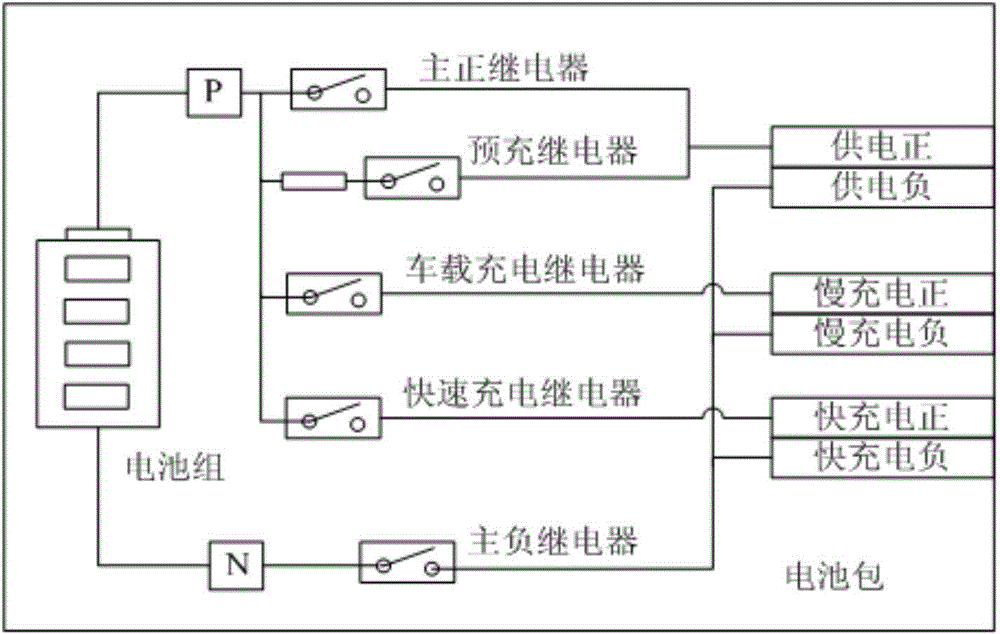

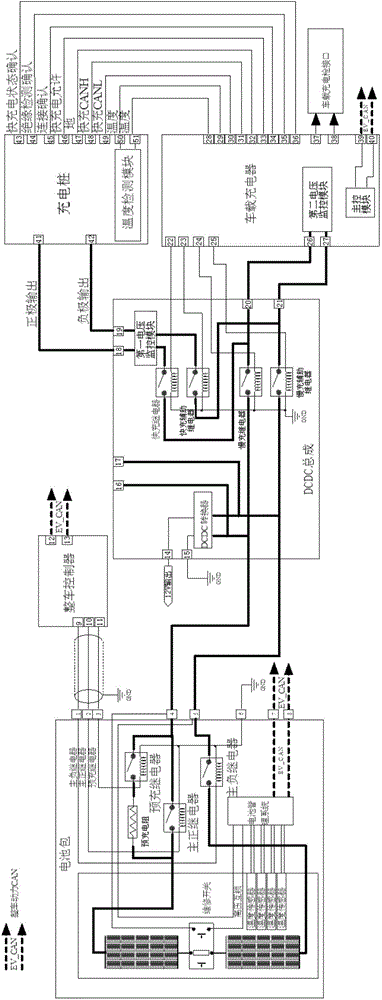

Electromobile charging system and charging control method

ActiveCN104600815AAchieve closureAvoid safety hazardsBatteries circuit arrangementsCharging stationsCharge controlEngineering

The invention provides an electromobile charging system which comprises a battery pack, a main positive relay, a main negative relay, an electromobile controller, a quick-charging relay, a quick-charging auxiliary relay, a slow-charging relay, a slow-charging auxiliary relay and an electromobile-mounted charger. Normally-open contacts of the quick-charging relay and the slow-charging relay are in series connection, and normally-open contacts of the quick-charging auxiliary relay and the slow-charging auxiliary relay are in series connection. The invention further provides a control method adopting the electromobile charging system for quick charging and slow charging. By the electromobile charging system and the charging control method, charging safety of an electromobile can be improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

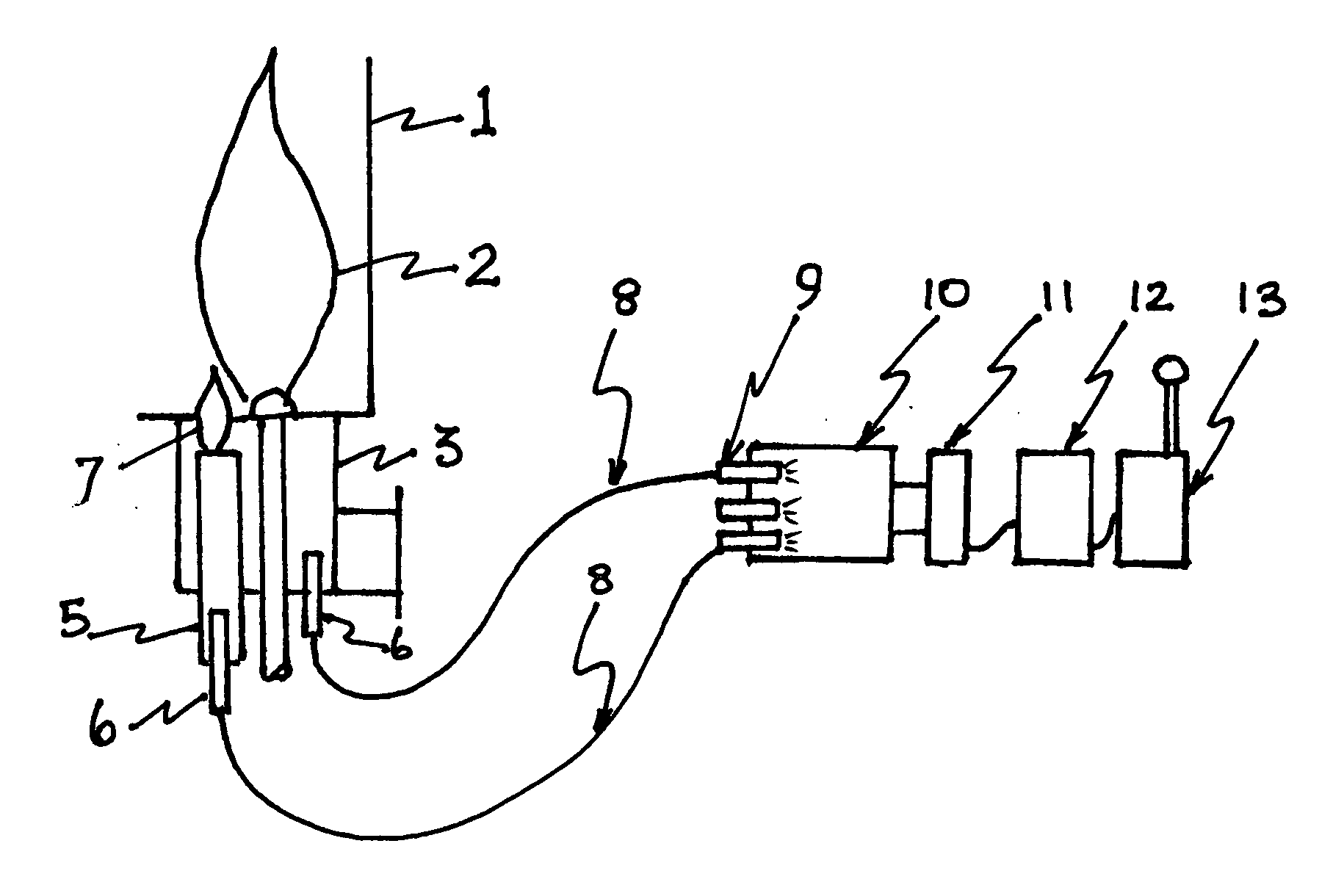

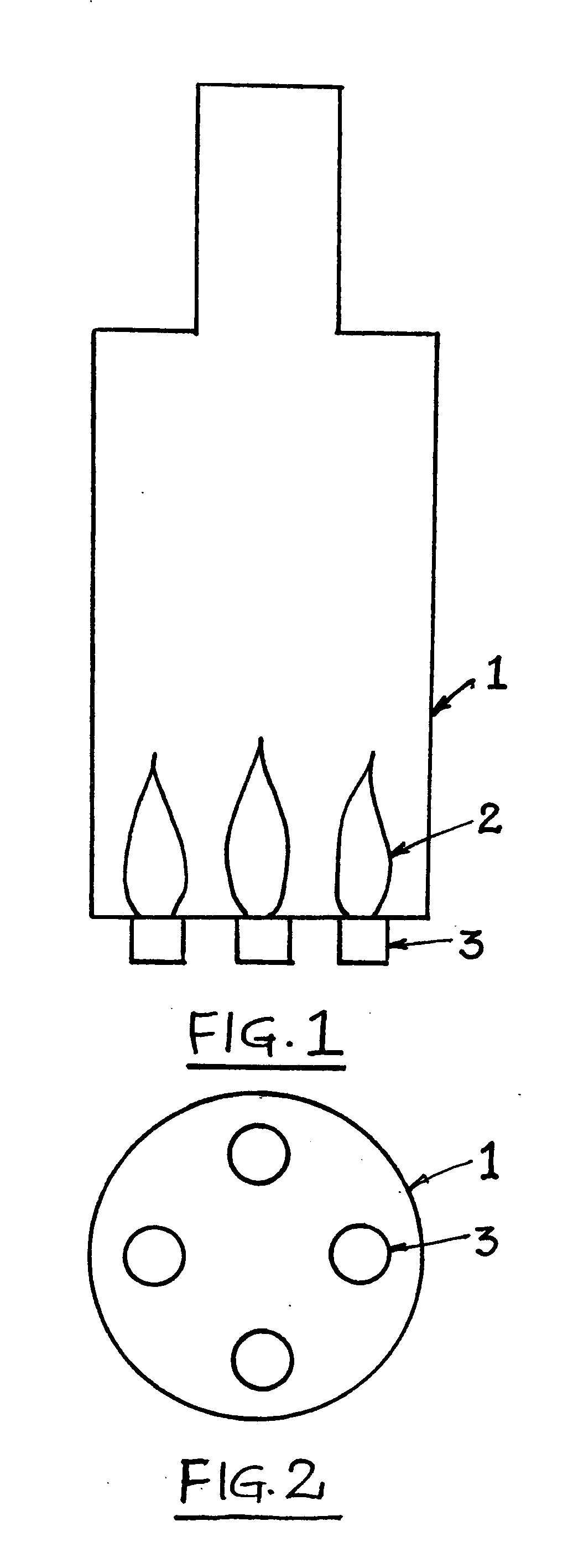

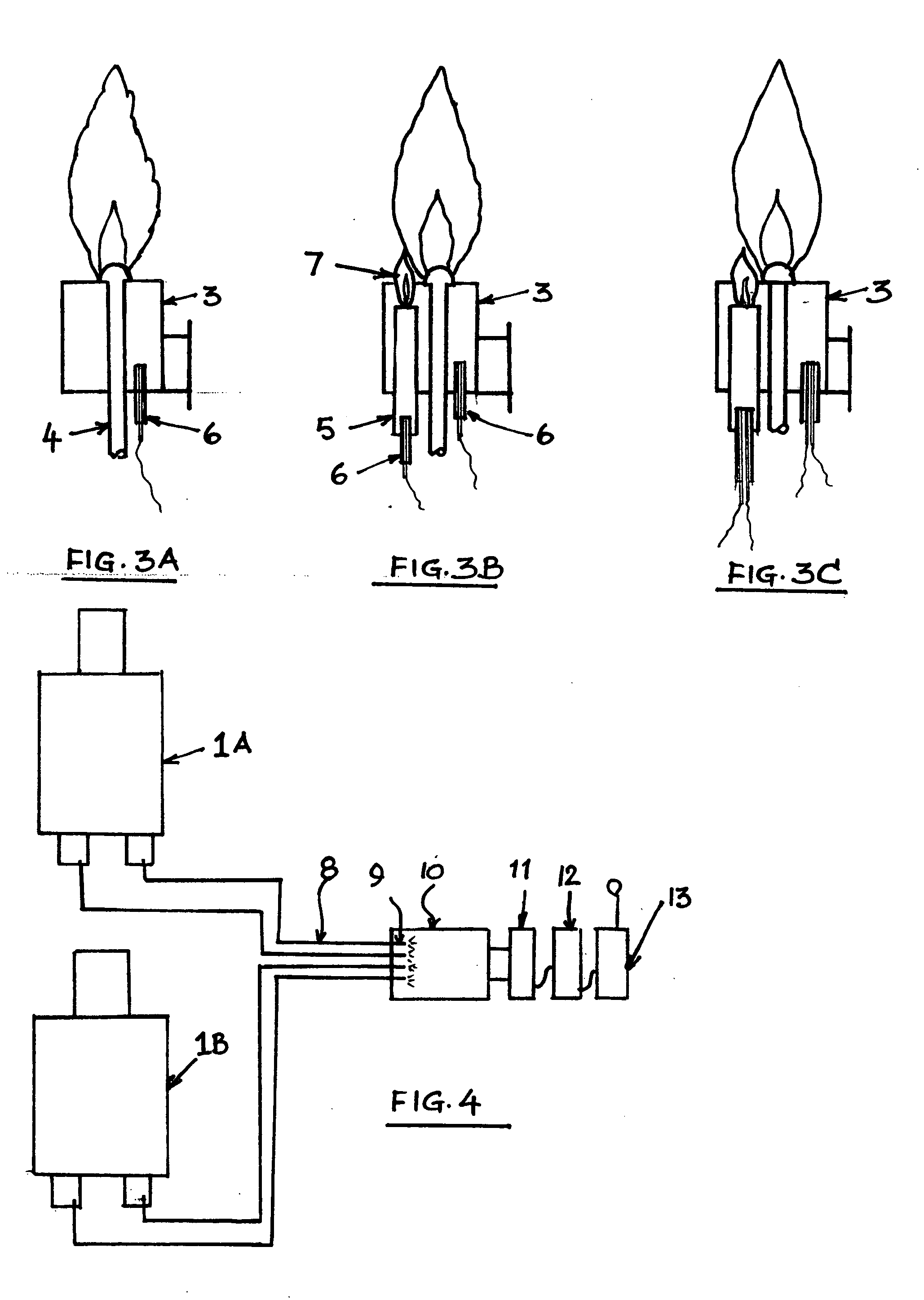

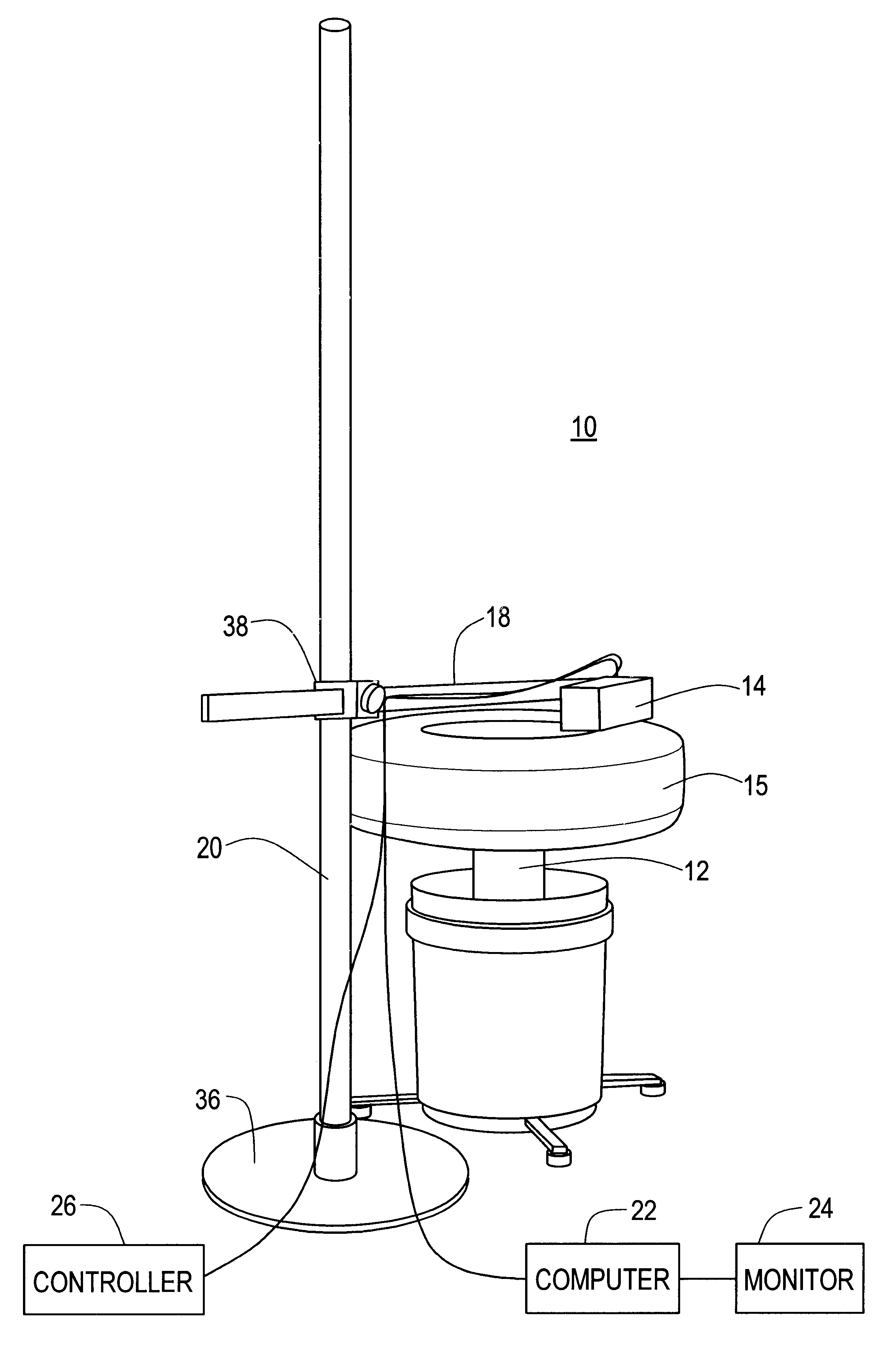

Monitoring of flames using optical fibers and video camera vision system

InactiveUS20050266363A1Increased safety marginLow costFuel supply regulationFlame sensorsFlareVisual perception

This invention relates to a flame detection method and apparatus. More specifically, this invention relates to a flame d on method and apparatus designed for simultaneously monitoring several flames of different types such as pilot flames and main flames of differing sizes and intensity. These detected flames can be in one combustion unit or in several combustion units such as industrial furnaces or ground flares. The underlying principle of the invention is to collect and transmit light from each of the flames by use of optical fibers and to insect the collected light by a video camera vision system at the other end of the optical fibers and to transmit the “live” images of the glows as well as the “on / off” status of the burners to the control room, through modern electronic communication techniques such as Ethernet and / or wireless radio units.

Owner:GANESHAN RAM

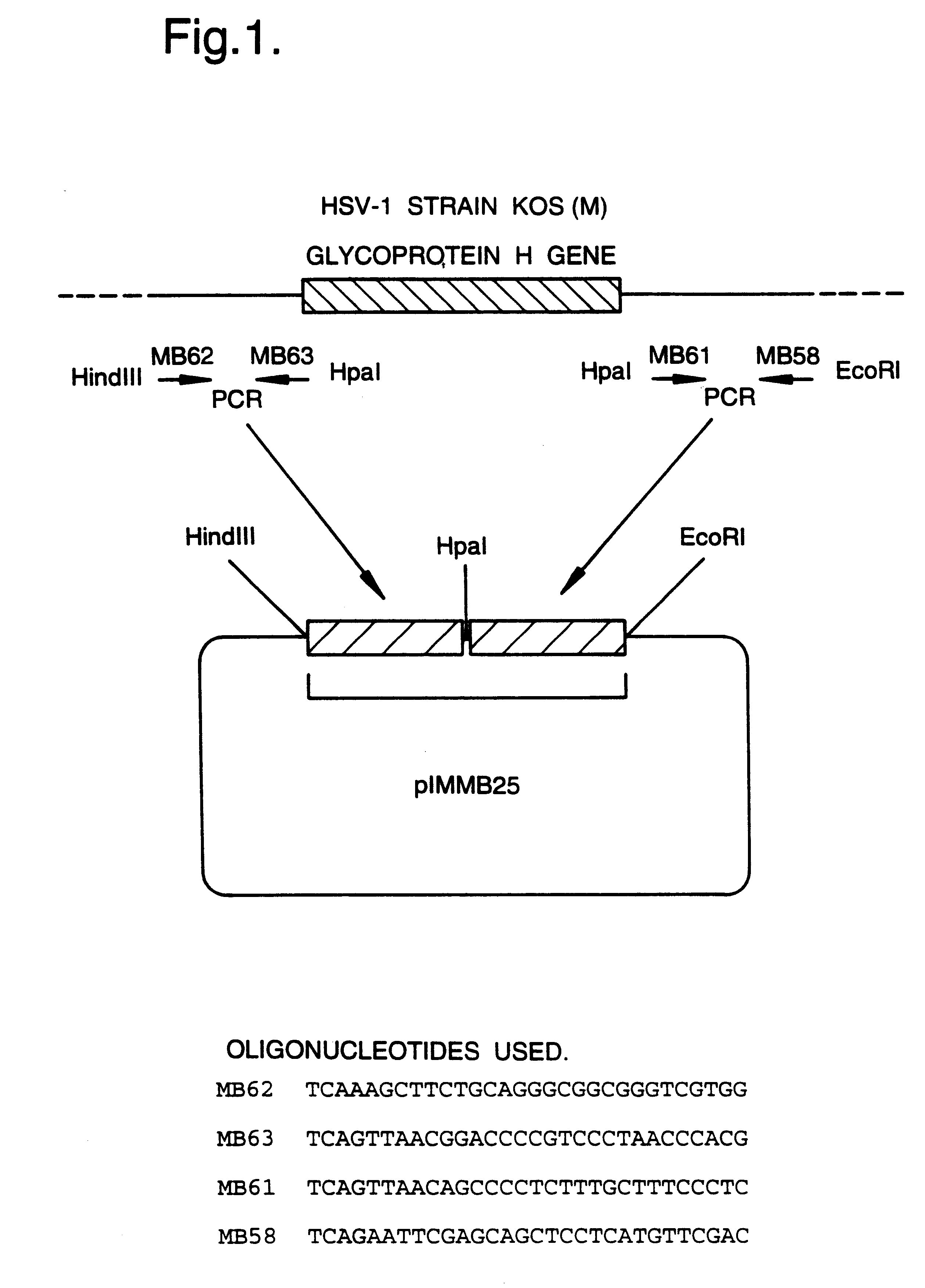

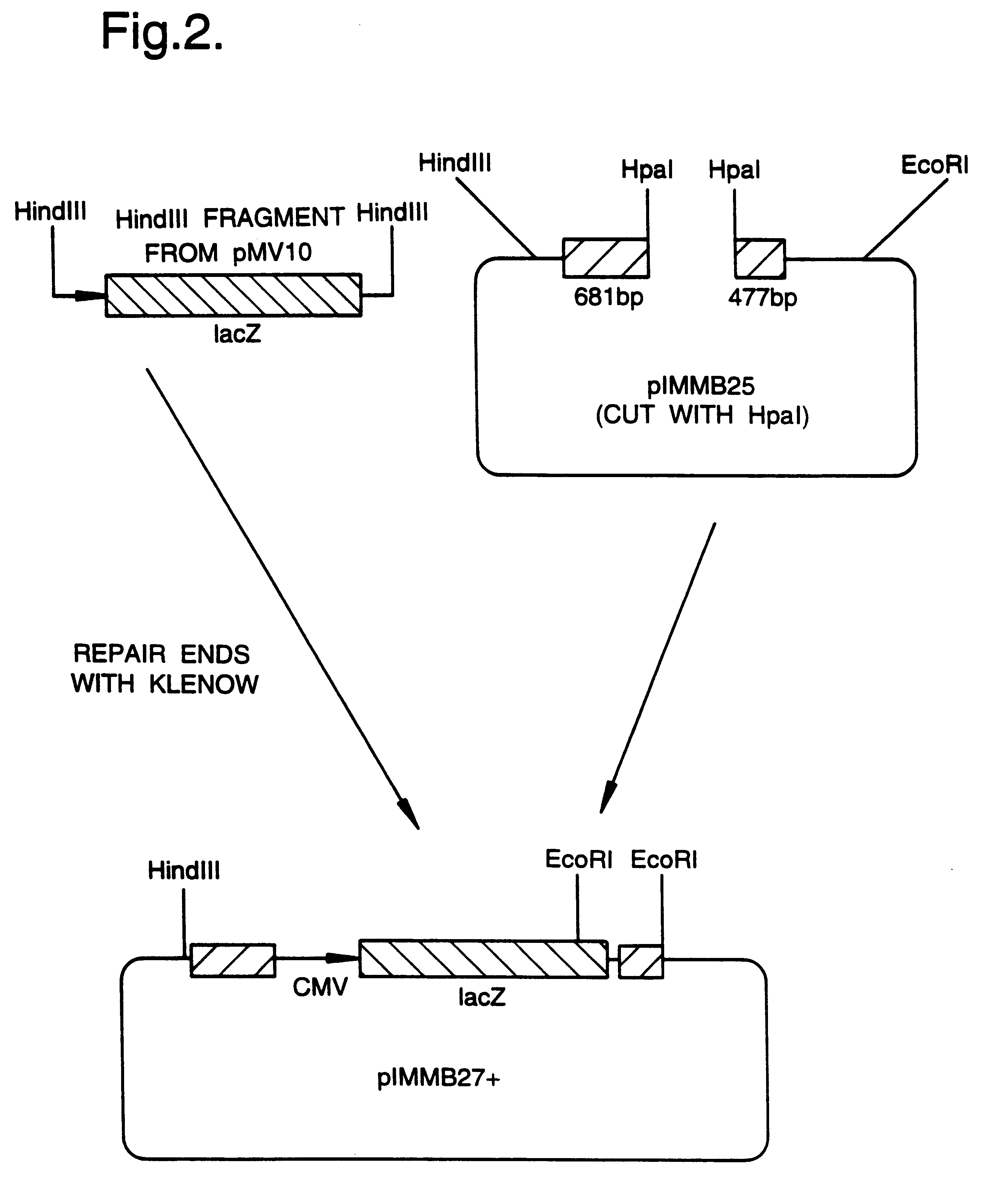

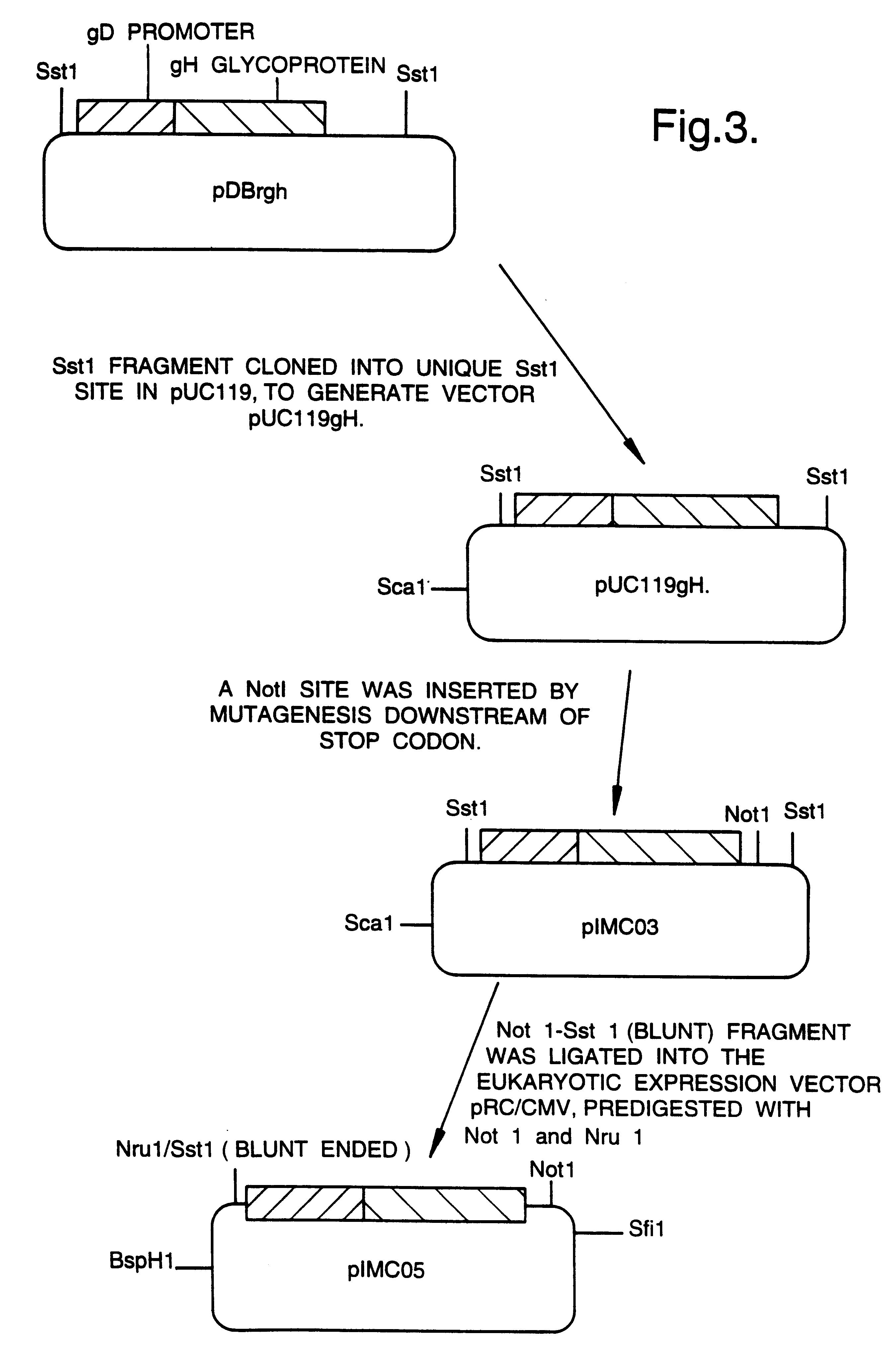

Recombinant virus vectors

InactiveUS6319703B1Risk minimizationReduced zero riskBiocidePeptide/protein ingredientsInfected cellCytopathic effect

A mutant herpesvirus that can be used a recombinant virus vector includes (a) a mutation such that the mutant virus has a reduced ability in comparison with a parent type to cause lysis of an infected cell, and (b) an inactivating mutation in a gene essential for the production of infectious virus. An example is a HSV1 mutant lacking the essential glycoprotein gH gene and having a mutation impairing the function of the gene product VP16. A heterologous gene can be carried at the site of the inactivated essential gene, e.g. a gene suitable for administering gene therapy. The vector has an increased margin of safety over known herpesvirus vectors in respect of incidence of cytopathic effects and / or risk of infection.

Owner:SPECK PETER G

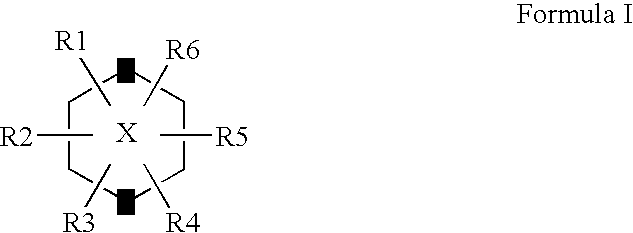

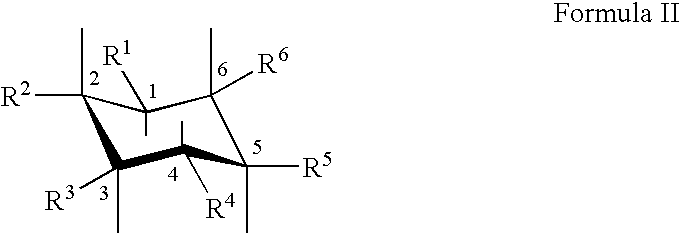

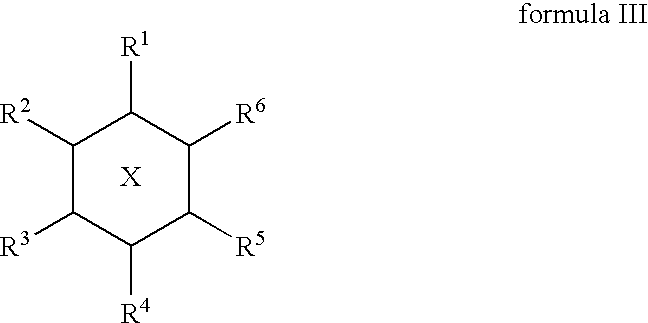

The Combination of a Cyclohexanehexol and a NSAID for the Treatment of Neurodegenerative Diseases

InactiveUS20100173960A1Preventing and reducing aggregation of AβMaintaining synaptic functionBiocideNervous disorderNeuro degenerationProtein folding

The invention relates generally to novel compositions and methods comprising one or more cyclohexanehexol and one or more NSAID. The compositions and methods provide beneficial effects in the treatment and prevention of diseases involving a disorder in protein folding and / or aggregation, and / or amyloid formation, deposition, accumulation, or persistence, in particular neurodegenerative diseases.

Owner:WARATAH PHARMA INC

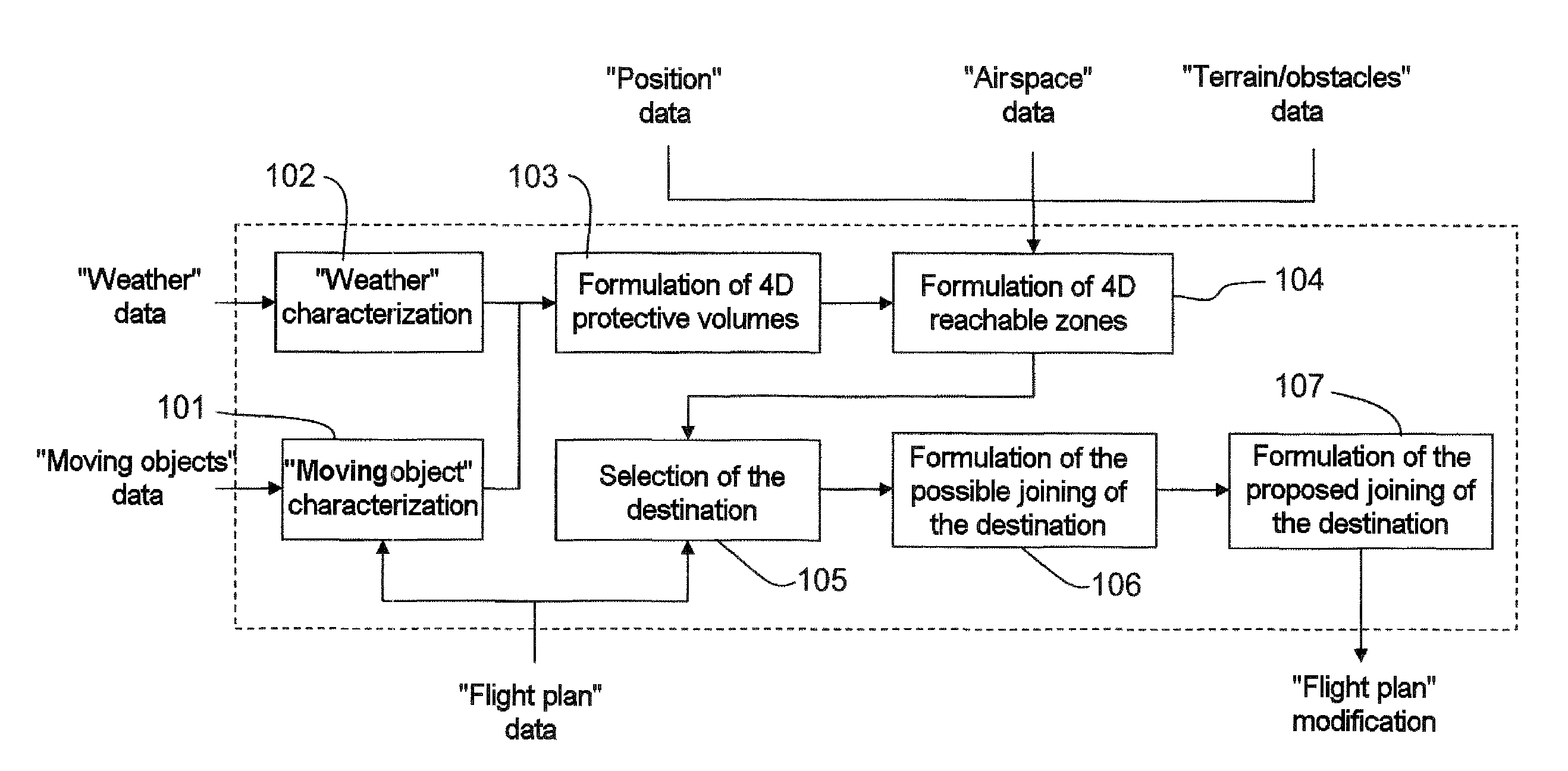

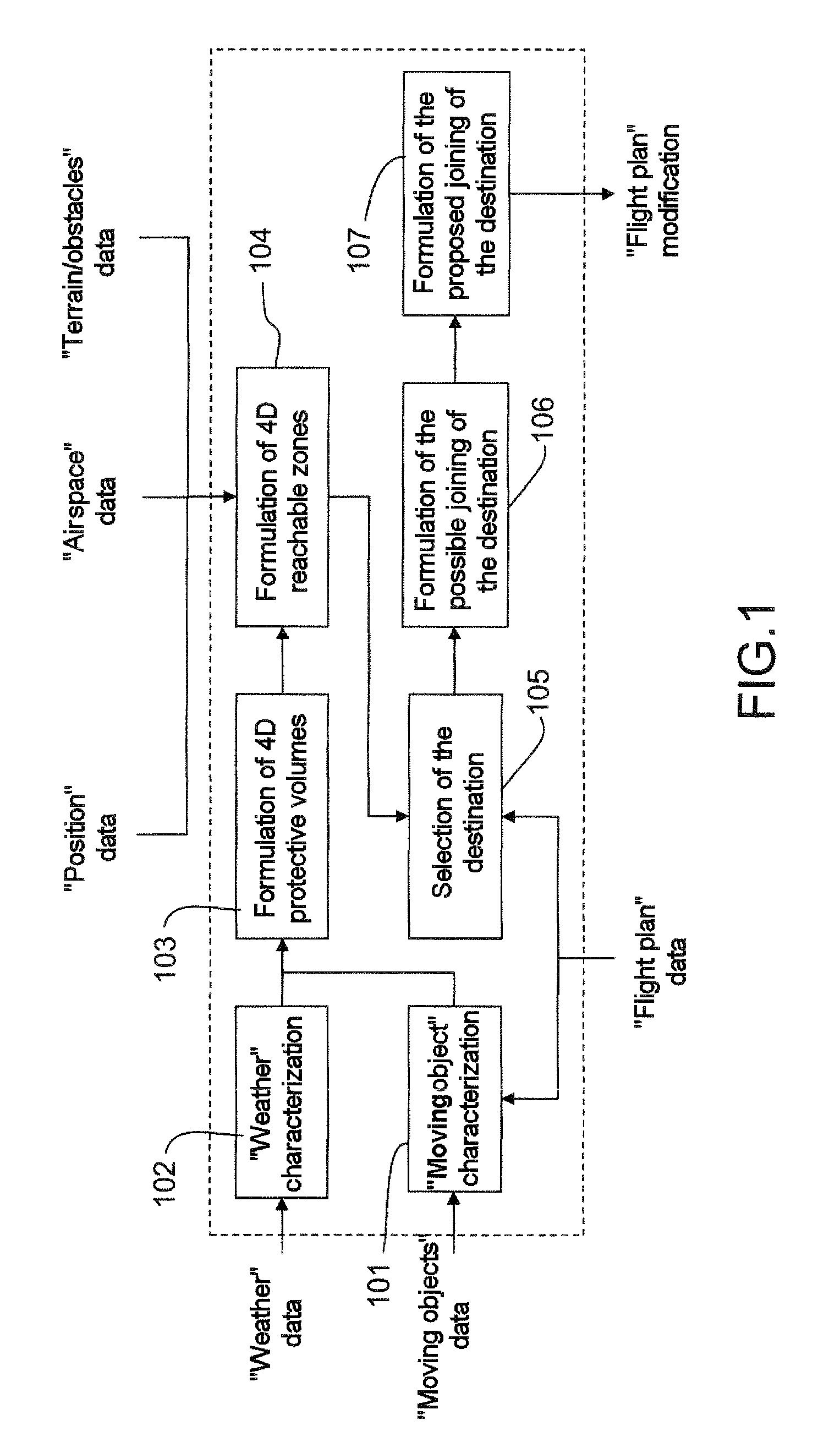

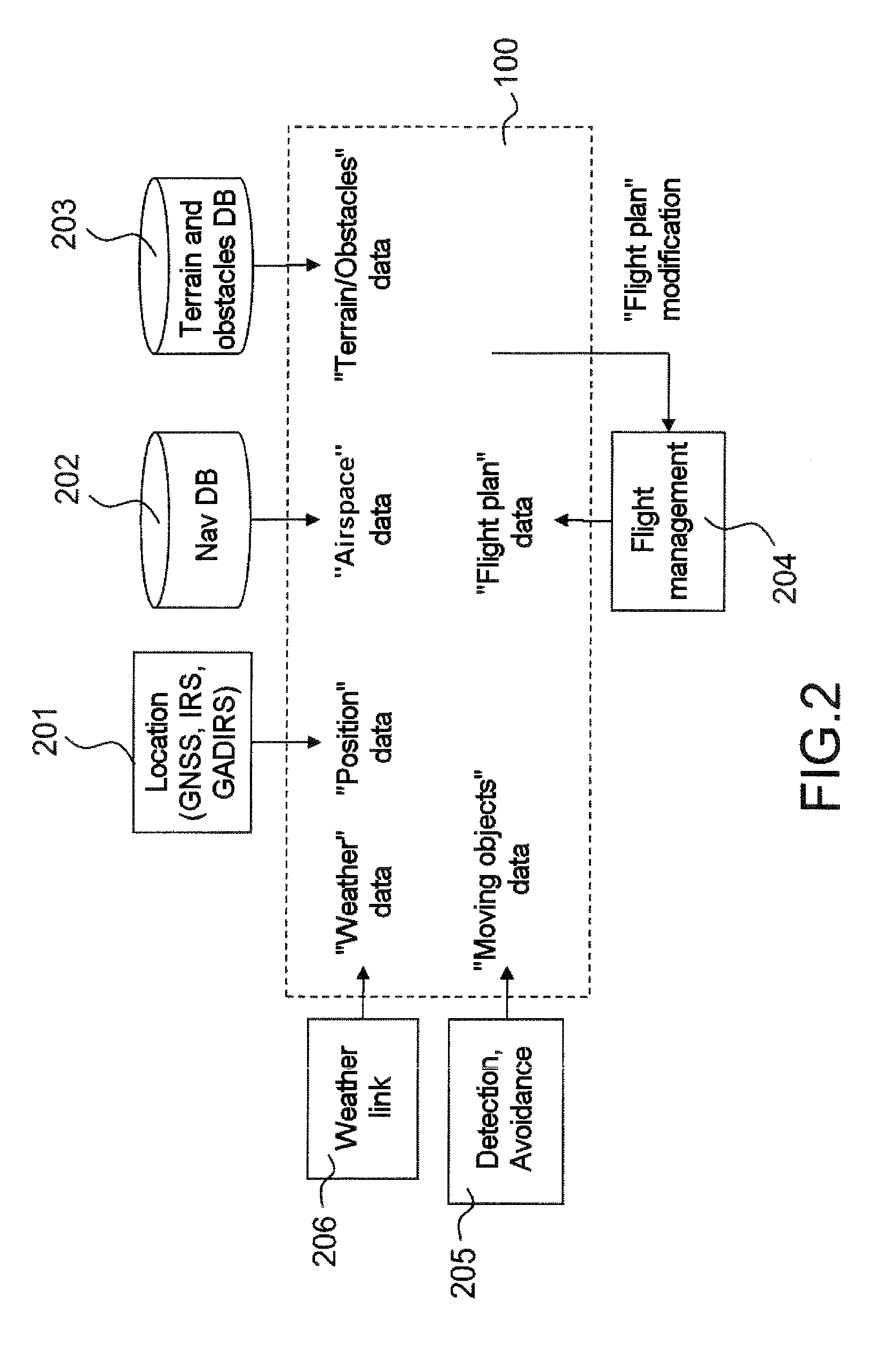

Device for Calculating a Flight Plan of an Aircraft

ActiveUS20100100308A1Increased safety marginAnalogue computers for vehiclesInstruments for road network navigationProgram planningAir space

The invention relates to a device for formulating a flight plan ensuring sufficient safety margins for a duration of a few minutes in relation to the set of flight constraints that could arise and comprising means for:detecting the surrounding moving objects (aircraft or meteorological phenomena),evaluating their type and the danger that they represent,formulating a reconfiguration flight plan ensuring a separation with these phenomena and taking best account of the constraints of the initially followed flight plan, avoiding prohibited or regulated airspaces and avoiding the surrounding relief with ad hoc operational margins.

Owner:THALES SA

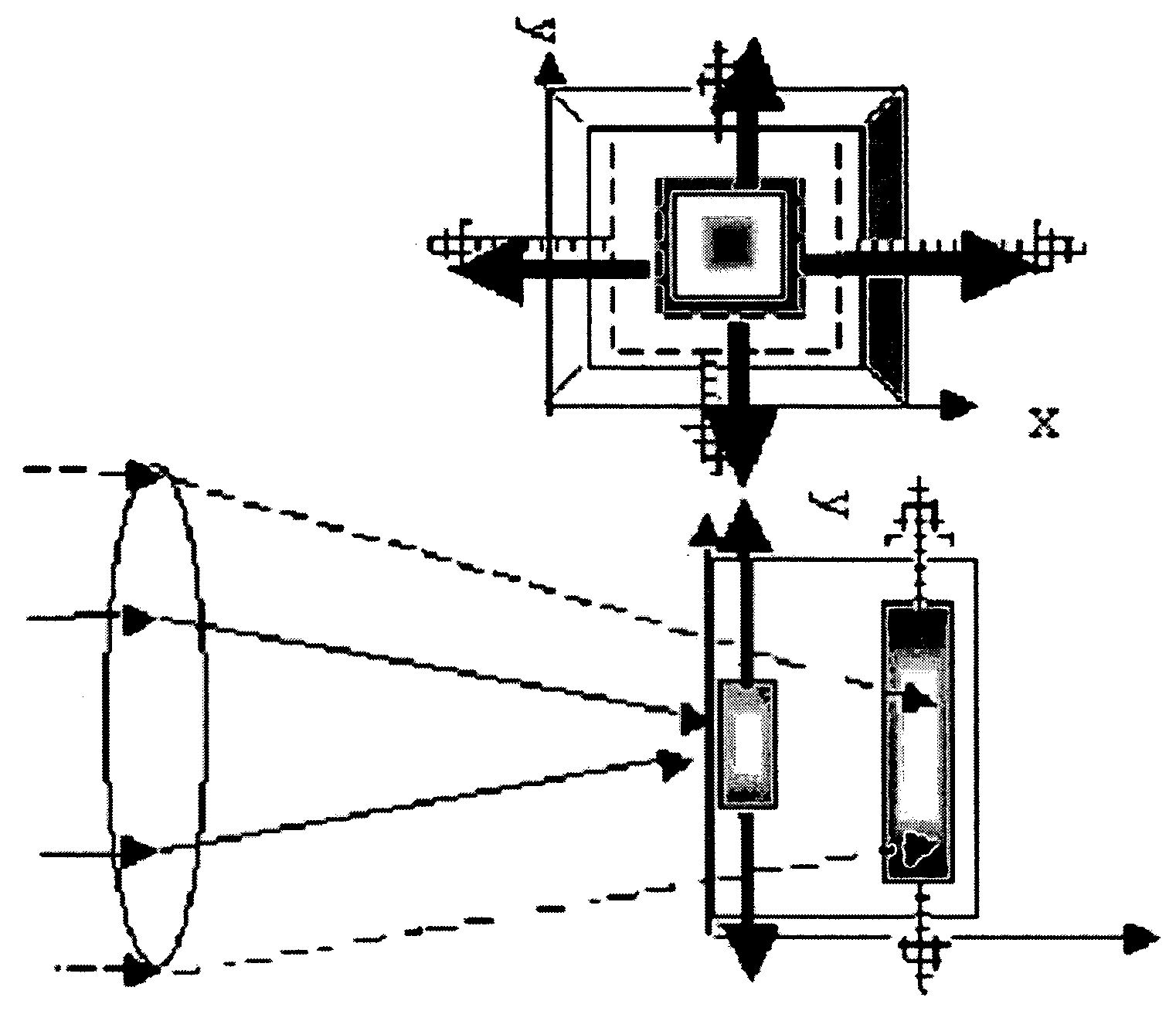

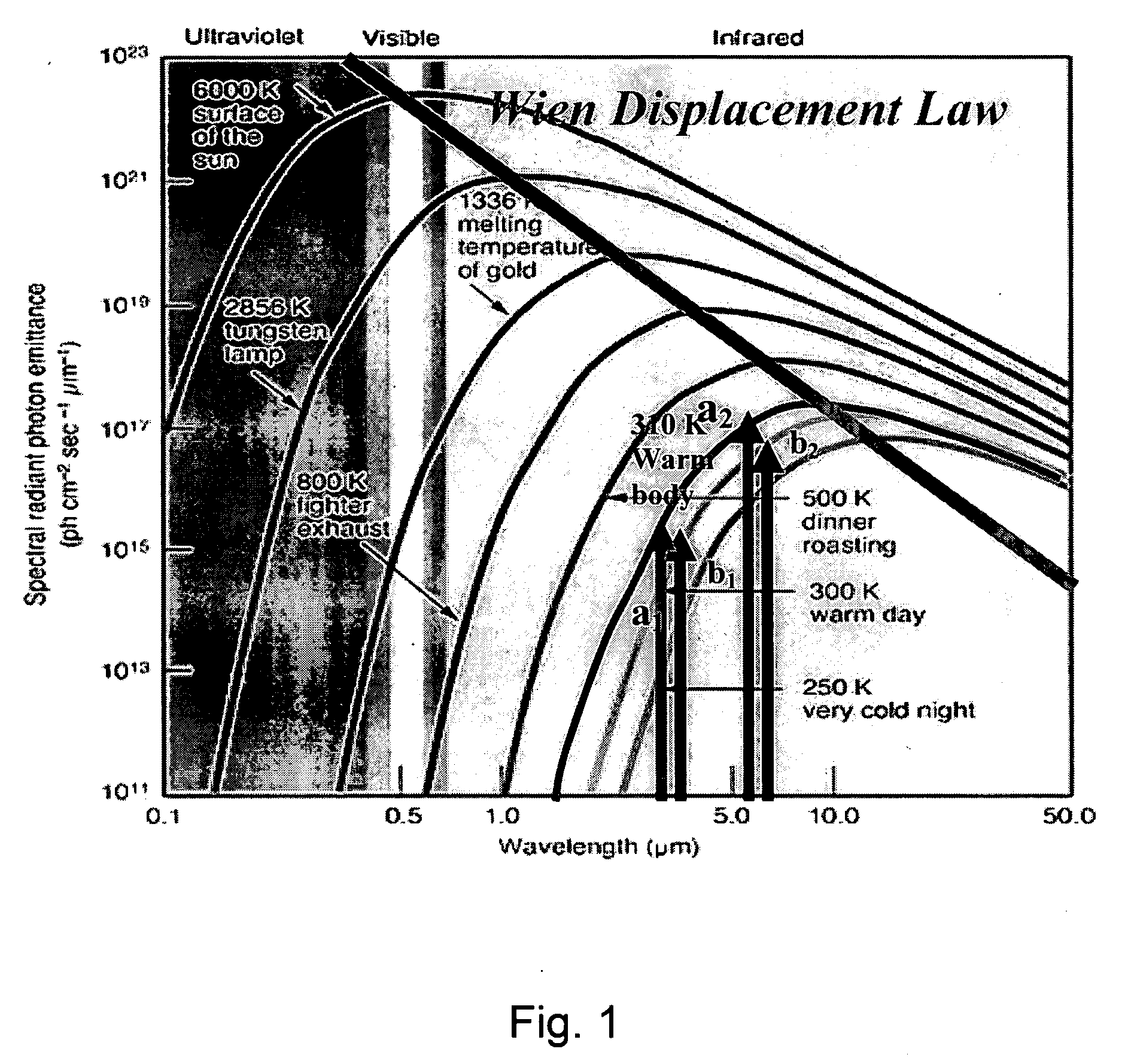

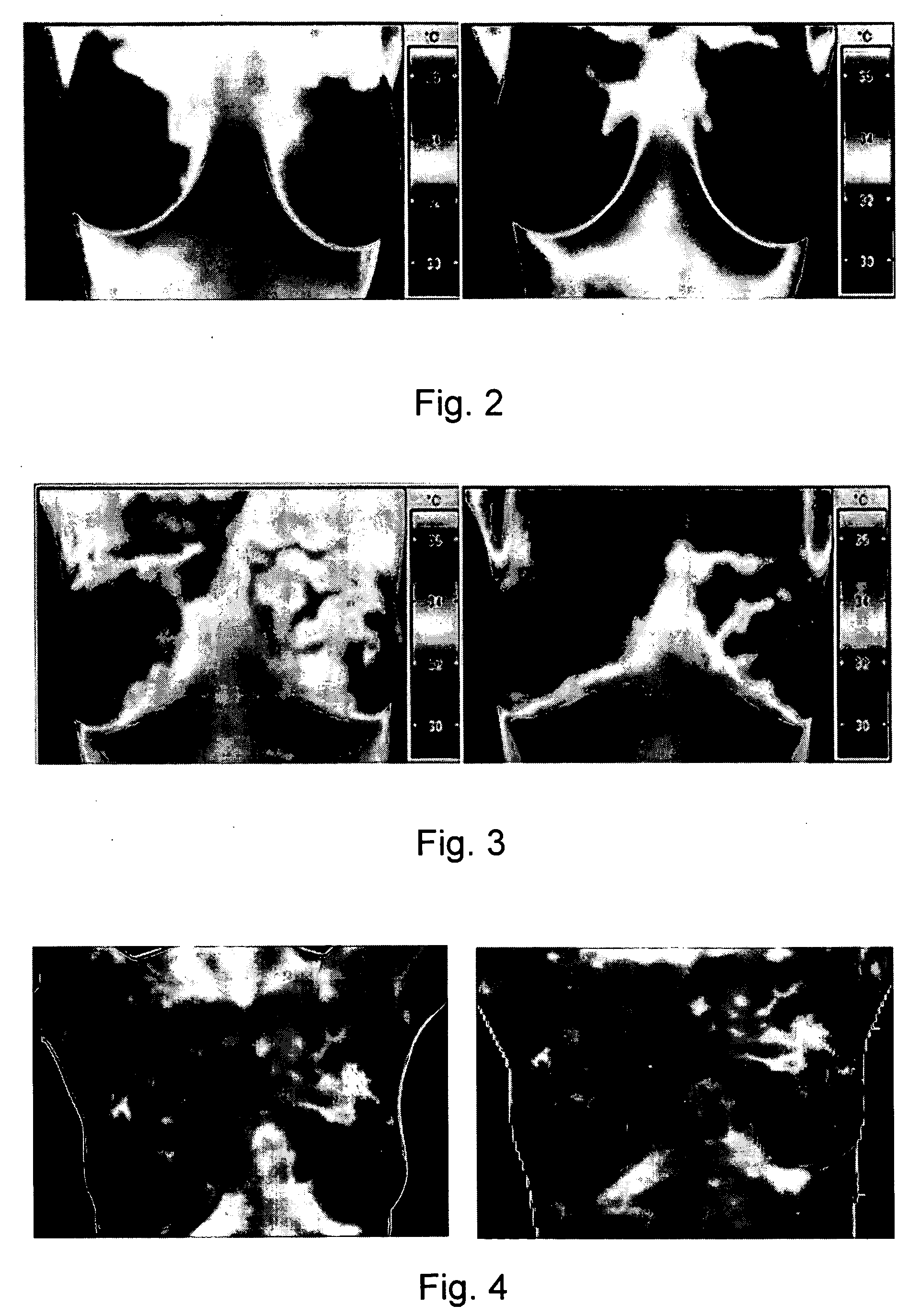

Infrared multi-spectral camera and process of using infrared multi-spectral camera

InactiveUS20060097176A1Facilitate interdisciplinary collaborationCaused instabilityImage enhancementImage analysisCarbon nanotubeDetector array

A process of performing a medical test includes taking multi-spectral images of an area of interest of a patient. The patient can be a human being or an animal, and can be known to be healthy or known to have health issues or problems. A multi-spectral camera includes a long-infrared charge-coupled device, a mid-infrared detector array, and a control device that synchronizes operation of the charge-coupled device and the detector array. The mid-infrared detector array can include carbon nanotubes. The carbon nanotubes can be detector elements. For example, the carbon nanotubes can be tuned-bandgap carbon nanotubes. Each pixel of resolution of the detector array can include a balanced Wheatstone bridge circuit including one of the tuned-bandgap carbon nanotubes. Adjacent pixels of the detector array can be arranged for orthogonal polarization.

Owner:SZU HAROLD

Tire defect detection system and method

InactiveUS6381547B1Improve test reliabilityReduce subjectivityTyre partsAnalysing solids using sonic/ultrasonic/infrasonic wavesDiscriminatorEngineering

A tire defect detection system including a support structure for receiving a tire; an actuator disposed proximate the tire for impacting the tire; a microphone disposed proximate the actuator for receiving a sound wave generated when the actuator impacts the tire; and a computer responsive to the microphone, the computer programmed to calculate a number of discriminator quantities from the resulting sound wave and to compare the calculated discriminator quantities with stored discriminator quantities indicative of a defect to determine whether a defect is present in the tire.

Owner:FOSTER-MILLER

Topical composition for treatment of skin disorders

InactiveUS20070142317A1Shelf life stableNon toxicBiocideFlow mixersDiseaseAdenosine Deaminase Inhibitor

The present invention provides for a topical composition that includes a topical carrier and an adenosine deaminase inhibitor. Suitable specific adenosine deaminase inhibitors include, e.g., deoxycoformycin (dCF), deoxyadenosine (dAdo), cladrabine (CdA), fludarabine (F-Ara-A), cytrabine (Ara-C), and thioguanine. The present invention also provides for a method to treat lymphocyte mediated skin diseases and to alleviate symptoms associated with such skin diseases. The method includes topically administering the composition to a mammal in need of such treatment. The present invention also provides for kits and syringe systems that include the adenosine deaminase inhibitor.

Owner:QLT USA INC

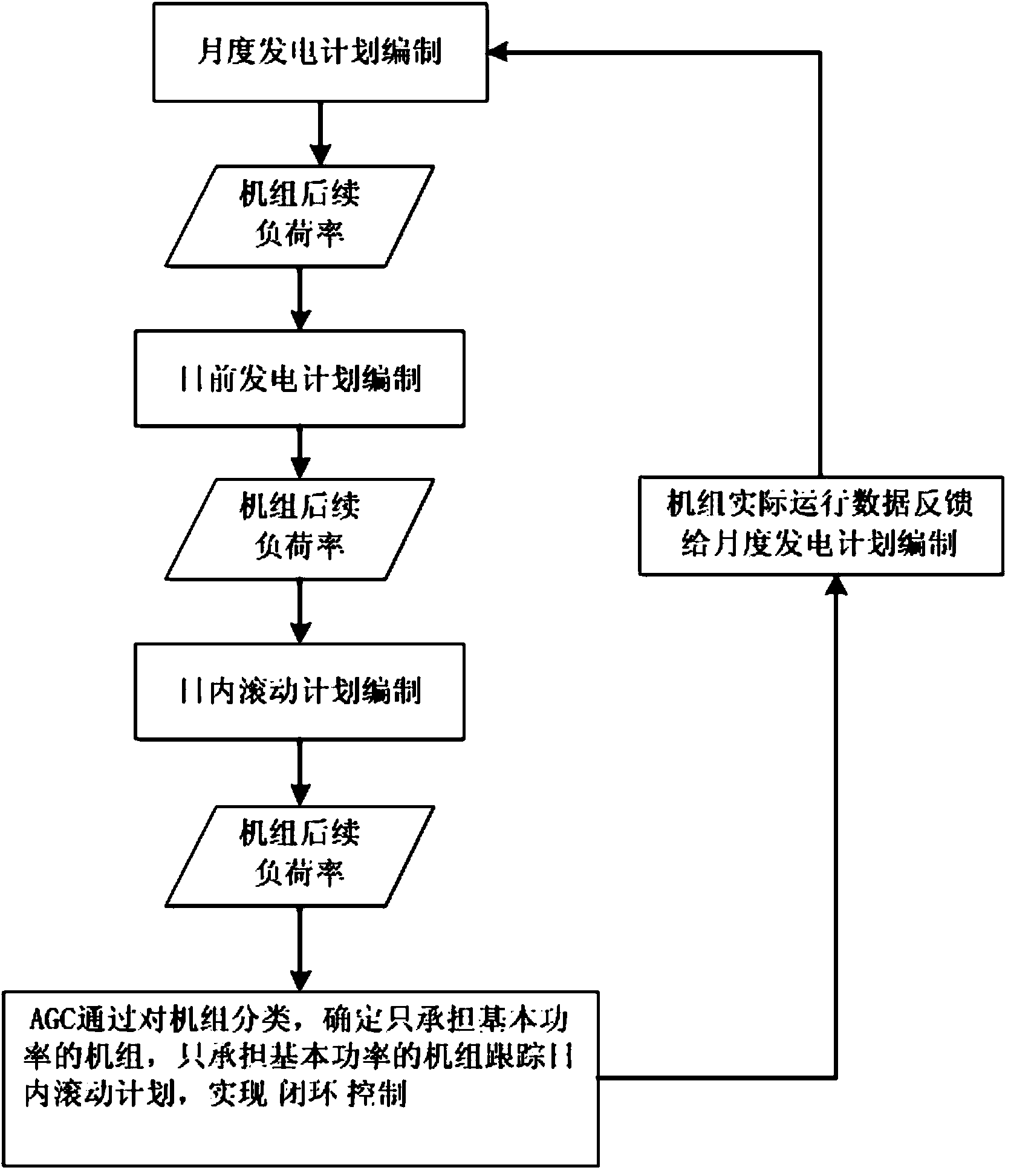

Multi-cycle generation scheduling coordinated optimization and closed-loop control method

ActiveCN103886388AIncreased safety marginRaise the level of leanForecastingSystems intergating technologiesProgram planningClosed loop

The invention discloses a multi-cycle generation scheduling coordinated optimization and closed-loop control method which comprises the following steps that first, a monthly generation schedule is made; second, a day-ahead generation schedule is made; third, an intra-day rolling schedule is made; fourth, AGC determines units which only bear basic power through unit classification, and the units which only bear basic power track the intra-day rolling schedule to achieve closed-loop control; fifth, actual operation data of the units are fed back to the monthly generation schedule, and the monthly generation schedule is corrected in a rolling mode. The multi-cycle generation scheduling coordinated optimization and closed-loop control method for the operation plan field is achieved, overall resource optimized allocation and safety constrained control on a longer time dimension are achieved, and the scheduling target for impartiality and openness plus energy conservation at the same time is achieved.

Owner:STATE GRID CORP OF CHINA +3

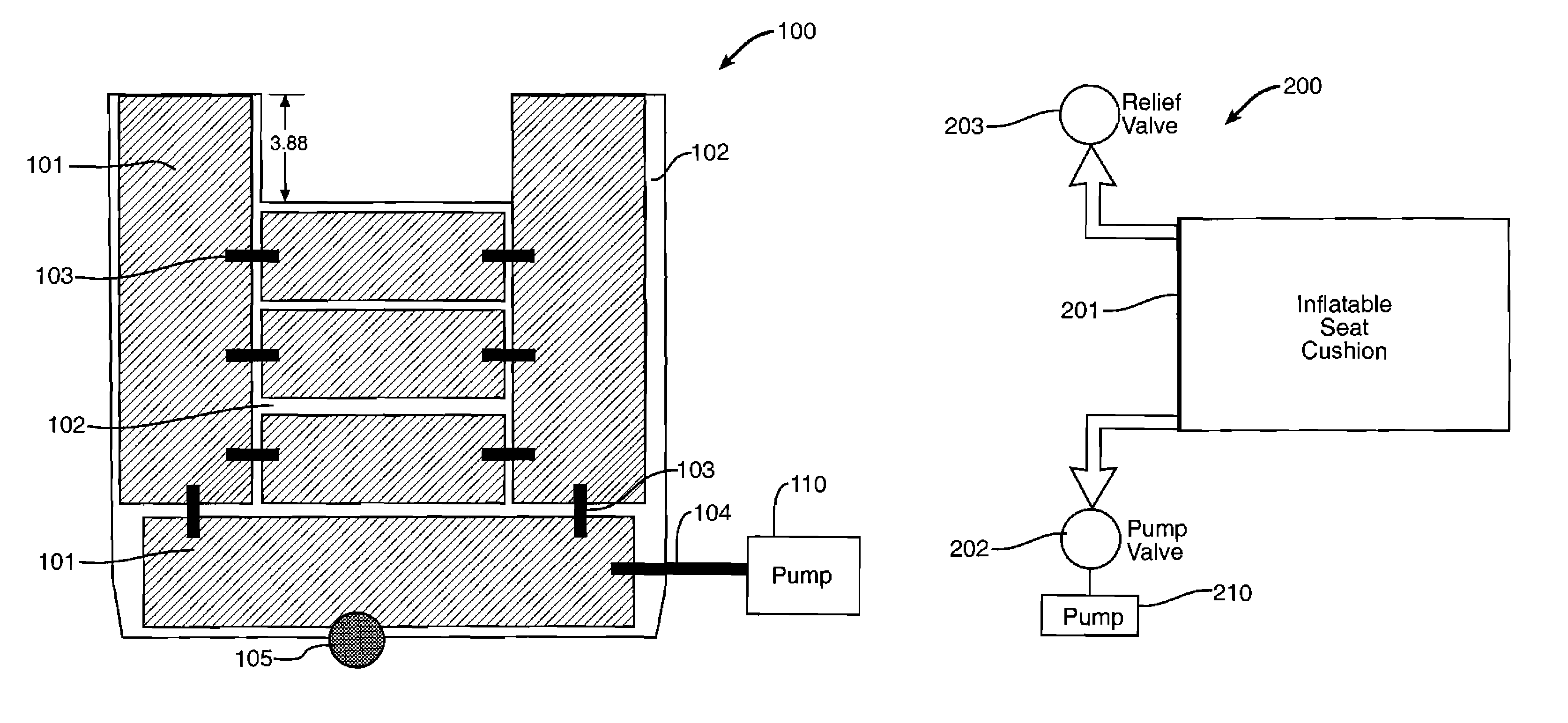

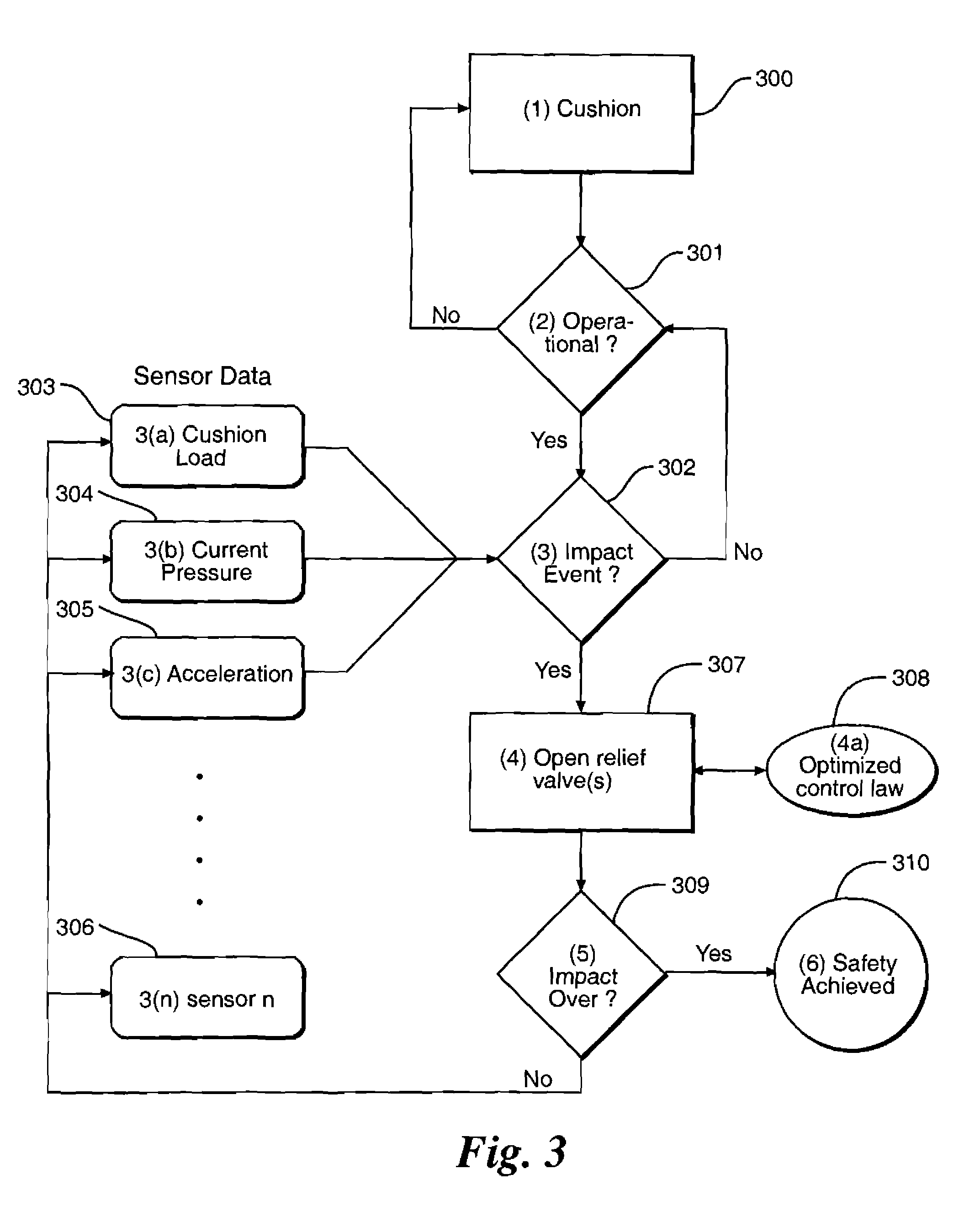

Seat cushion

InactiveUS8181292B1Weaken energyRapid and controlled deflationVehicle seatsStuffed mattressesSemi activeEngineering

A semi-active seat cushion is disclosed that comprises a plurality of chambers for containing a pressurized fluid, wherein each chamber is connected to at least one other chamber by an orifice that provides a fluid connection; a supply conduit for supplying a pressurized fluid to each of the plurality of chambers; and at least one relief valve that permits rapid and controlled deflation of the plurality of chambers.

Owner:US SECREATRY OF THE AIR FORCE THE

Design method for approach landing track of unpowered aircraft

InactiveCN104281153AIncrease maneuvering marginIncreased safety marginPosition/course control in three dimensionsAdaptive controlFlight vehicleComputer software

The invention discloses a design method for an approach landing track of an unpowered aircraft. When the flareout landing track is designed, assumed that the height of a flareout landing initial point is known, then, expressions of all track parameters are derived according to a geometrical relationship, and the flareout landing track is designed. In order to design the ideal flareout landing track, the proper height of the flareout landing initial point is found out through an optimization algorithm, track deduction is conducted along the landing track, and therefore the grounding dynamic pressure becomes the ideal grounding dynamic pressure. A deep glide landing track and the ideal flareout landing track form the optimal approach landing track. According to the design method, the aerodynamic force and the aerodynamic moment borne by the aircraft are taken into consideration, and the influences on the design of the landing track of aerodynamic data of deflecting of an aerodynamic control plane and putting of an undercarriage are also taken into consideration. The design method for the approach landing track is simple in principle, computer software is adopted for conducting optimization design, and the design efficiency is improved.

Owner:BEIHANG UNIV +1

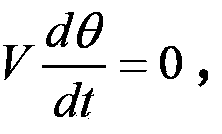

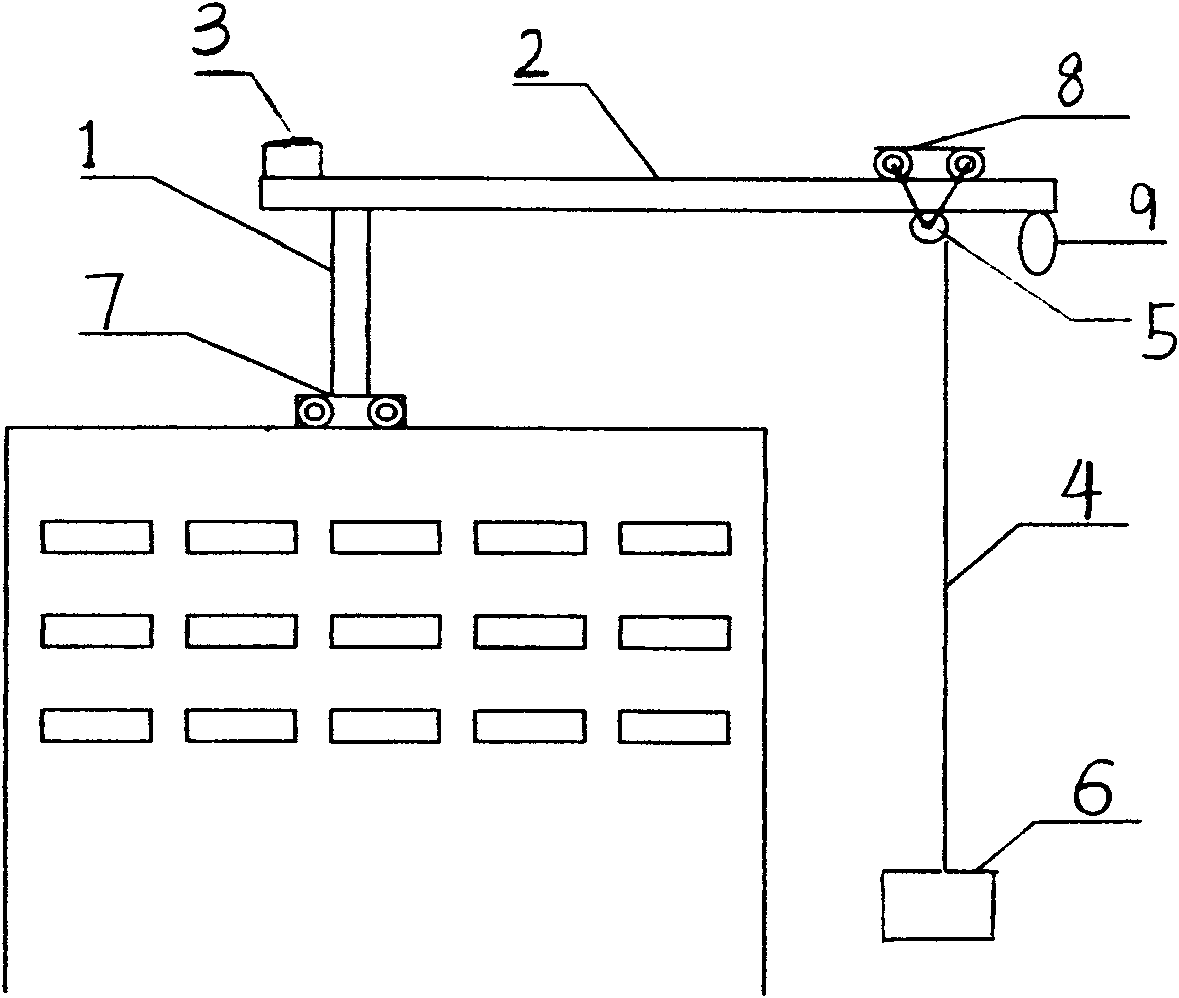

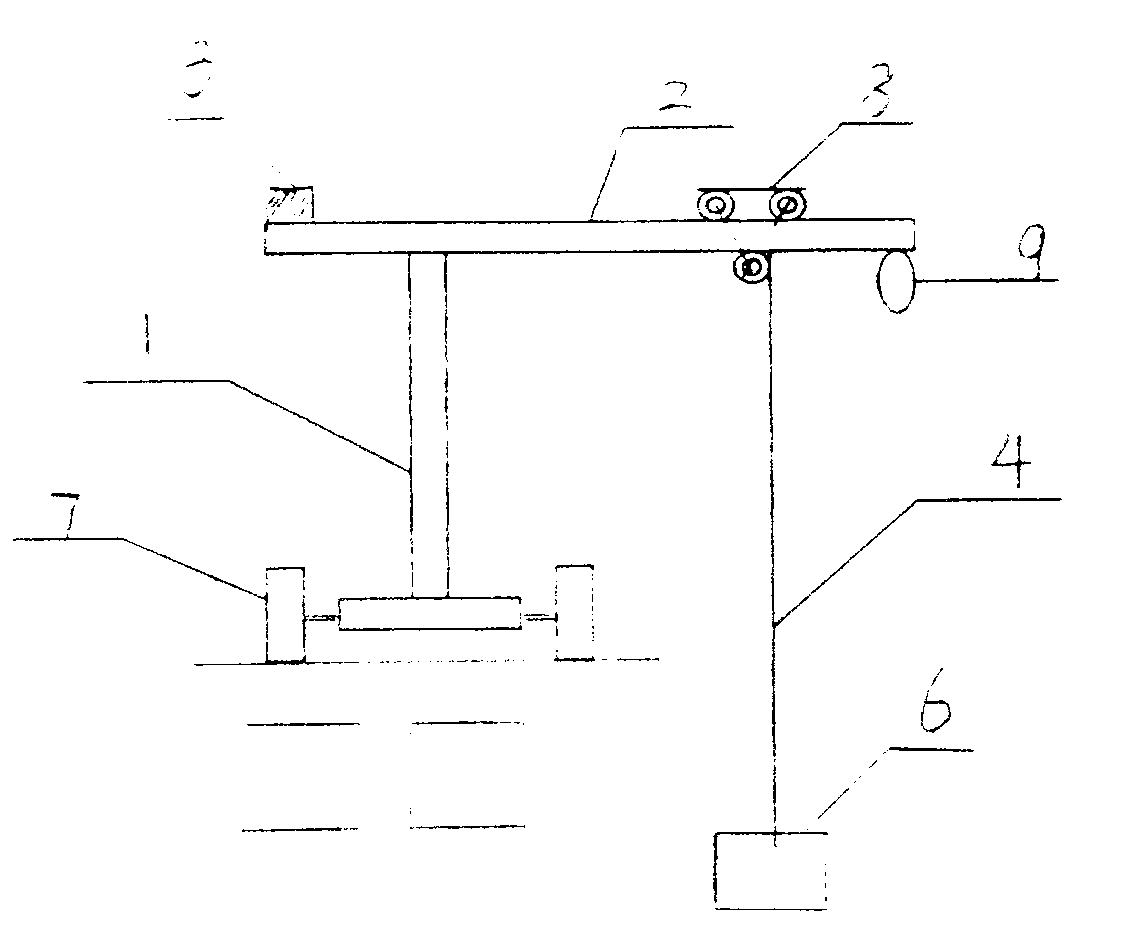

Firefighting and lifesaving device for high-rise building

InactiveCN102886107AImprove lifesaving efficiencyEliminate high-rise fire blind spotsFire rescueBuilding rescueRemote controlControl system

The invention discloses a firefighting and lifesaving device for a high-rise building, and discloses a building firefighting set, which belongs to a building firefighting set device. The firefighting and lifesaving device for the high-rise building comprises a control system and a firefighting and lifesaving device, wherein the firefighting and lifesaving device is arranged at any position on the top of the high-rise building; at least a wireless signal receiver-transmitter and a remote control end arranged on the firefighting and lifesaving device are arranged in the control system; an elevating device (3) is arranged on a firefighting and lifesaving frame, and is connected with a rotary firefighting and lifesaving arm (2) through an arm support (1); the firefighting and lifesaving arm (2) is provided with a sliding overhead travelling crane (8); and the arm support mechanism can also be placed on a walking mechanism (7), and movement on the top of a special-shaped high-rise building through a track (10) is realized. The firefighting and lifesaving device for the high-rise building provided by the invention has the advantages of remarkable firefighting and lifesaving effects, simple structure, low production difficulty and wide application range.

Owner:黄力华

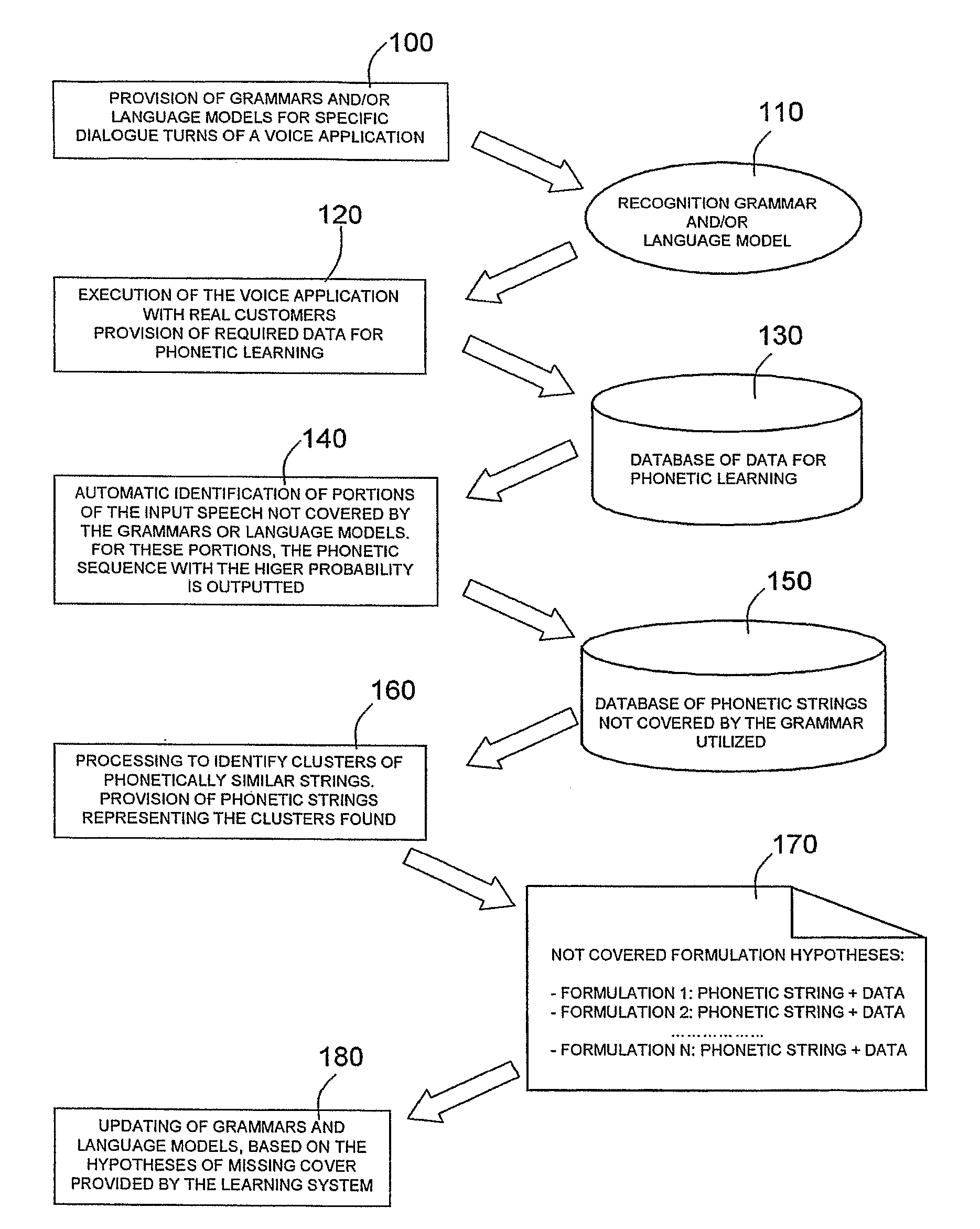

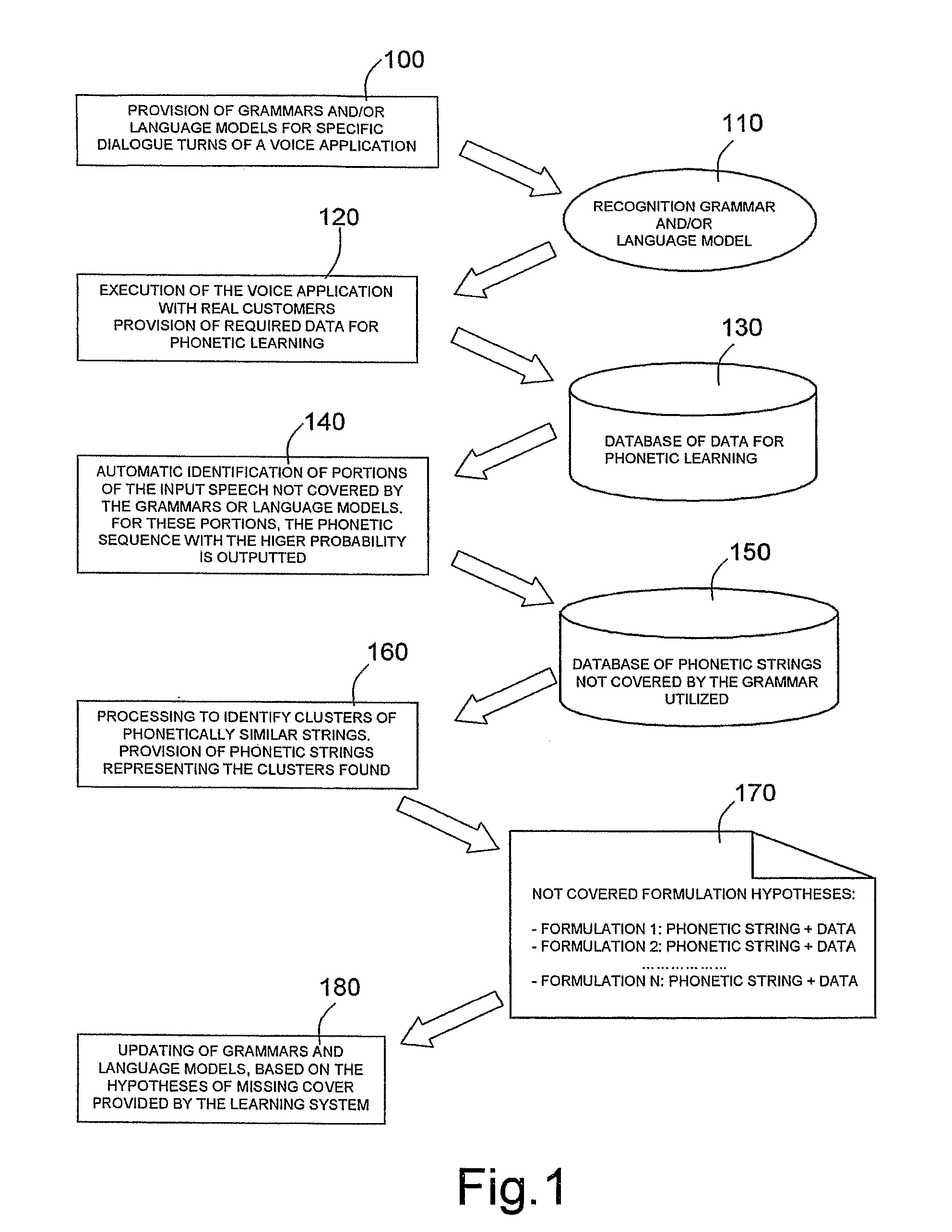

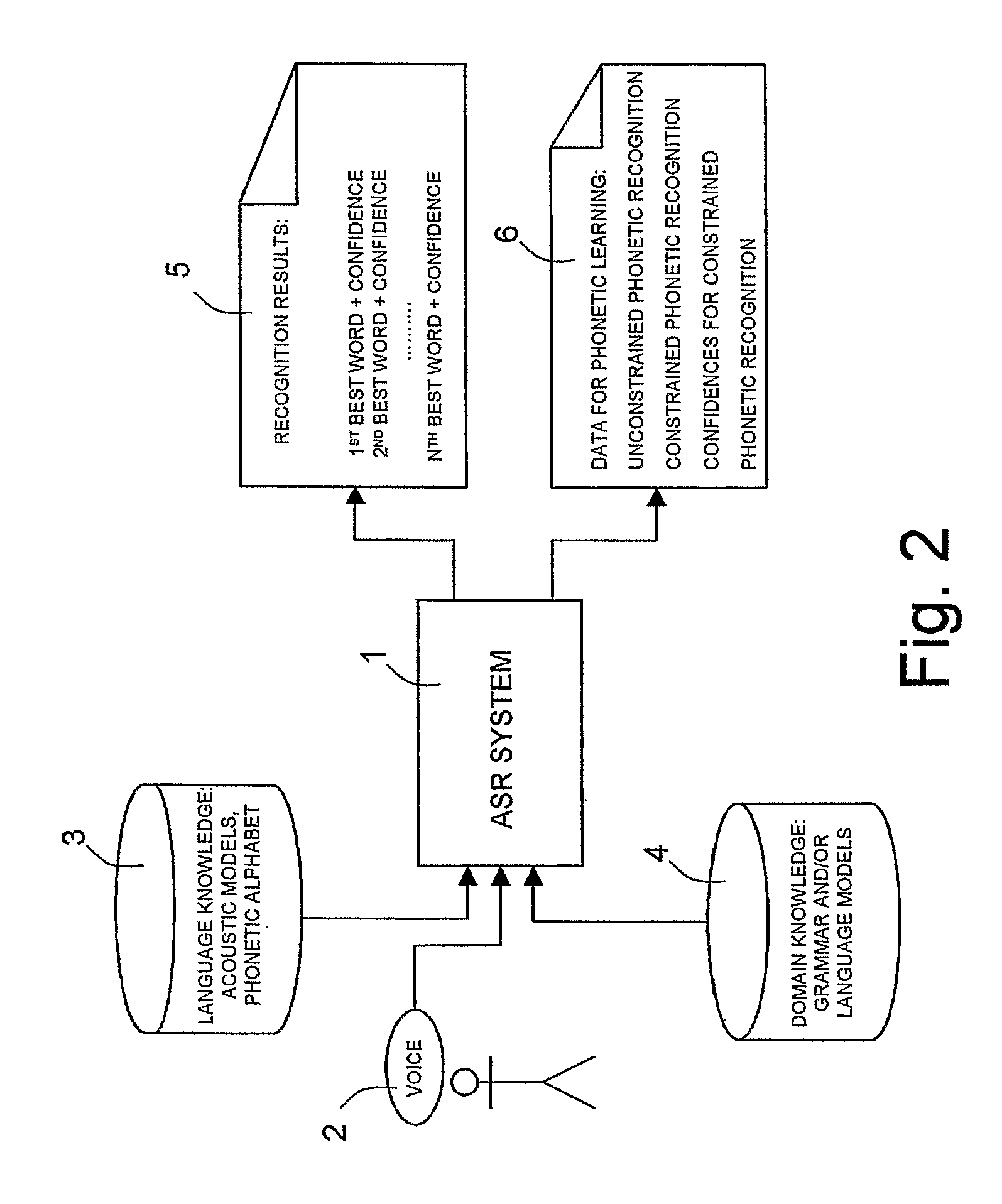

Method and System for Automatically Providing Linguistic Formulations that are Outside a Recognition Domain of an Automatic Speech Recognition System

A method for automatically providing a hypothesis of a linguistic formulation that is uttered by users of a voice service based on an automatic speech recognition system and that is outside a recognition domain of the automatic speech recognition system. The method includes providing a constrained and an unconstrained speech recognition from an input speech signal, identifying a part of the constrained speech recognition outside the recognition domain, identifying a part of the unconstrained speech recognition corresponding to the identified part of the constrained speech recognition, and providing the linguistic formulation hypothesis based on the identified part of the unconstrained speech recognition.

Owner:NUANCE COMM INC

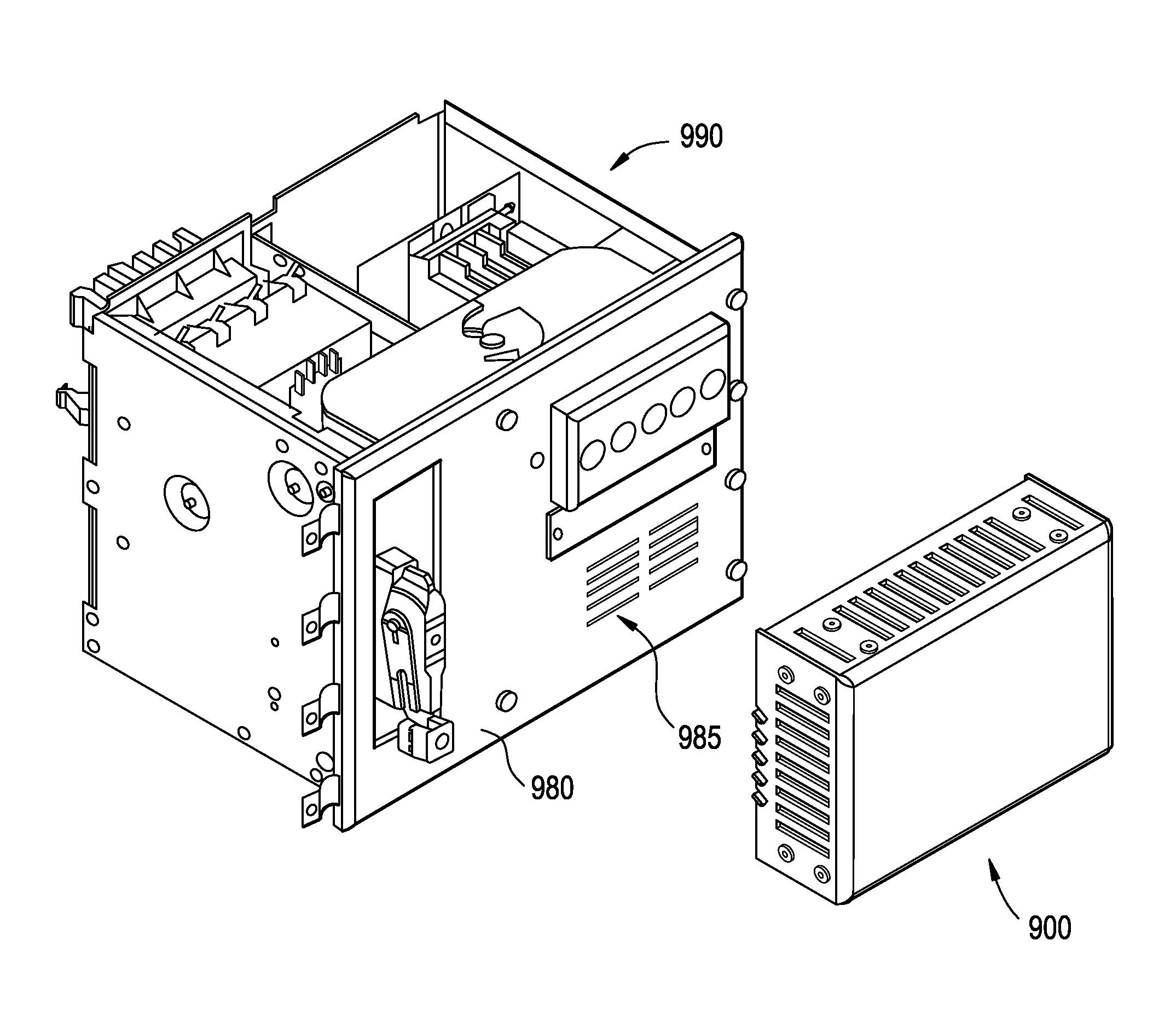

Muffler for enhanced arc protection

ActiveUS20140166623A1Preventing premature end-of-lifeEnhanced arc protectionSubstation/switching arrangement detailsSwitchgear arrangementsInterior spaceEngineering

A muffler for enhanced arc protection is described. In the case of an internal arc event in an electrical enclosure, the muffler exhausts arc gas and plasma parallel to the enclosure surface, instead of directly forward where persons may be located. The muffler includes perforated plates and baffle plates in its interior space. The perforated plates have offset perforation patterns from one another, and the baffle plates are provided on opposing walls, causing the plasma and gas to make multiple directional changes. The perforated plates also filter the arc gas and plasma. These directional changes and filtering result in an energy reduction from the exhaust, which provides an increased margin of safety. In addition, the muffler provides an adequate level of ventilation in the enclosure, thus keeping the components cool.

Owner:SCHNEIDER ELECTRIC USA INC

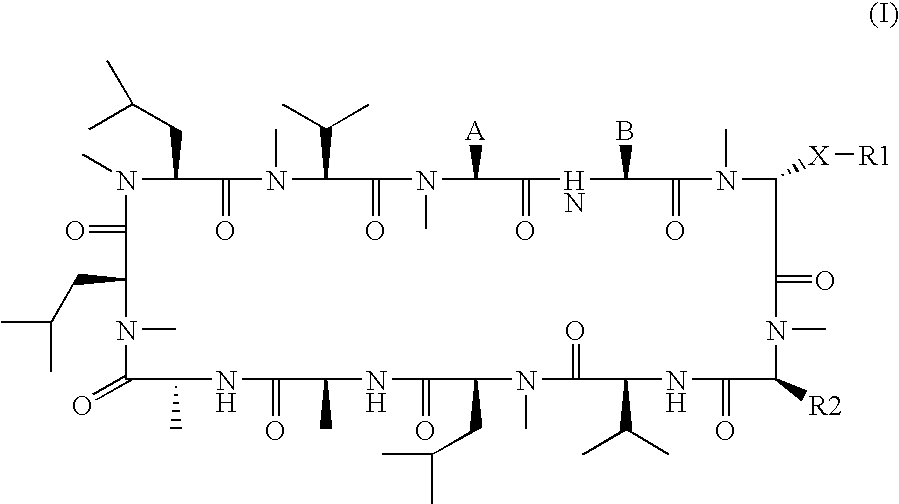

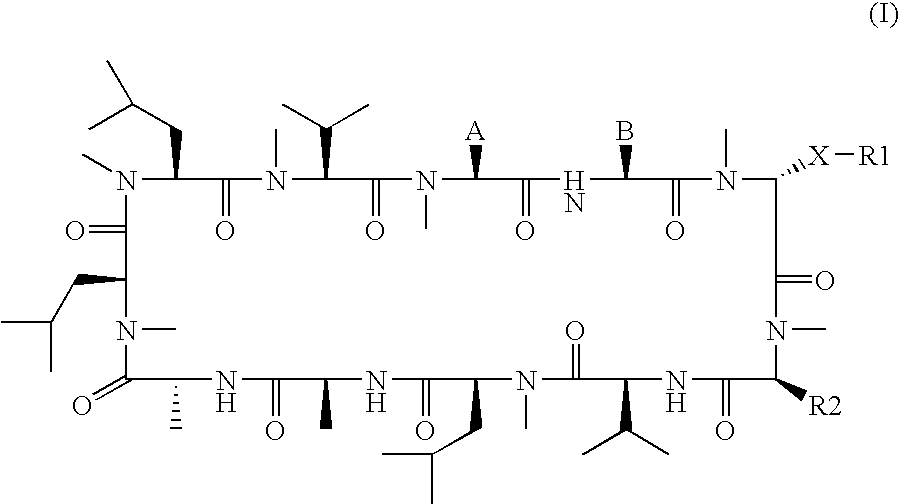

3-Ether and 3-thioether substituted cyclosporin derivatives for the treatment and prevention of hepatitis C infection

InactiveUS20060160727A1Increased safety marginImproved hepatotoxicityBiocideDigestive systemCyclosporinsPharmaceutical drug

Owner:SCYNEXIS INC

Treatment of endotoxemia using endotoxin neutralizing agents

InactiveUS20080031874A1Improve securityElevated level of endotoxinMicrobiological testing/measurementAntibody ingredientsCritically illMedicine

Methods and compositions for selecting a patient suffering from endotoxemia for treatment with an endotoxin neutralizing agent are disclosed comprising: (a) determining the level of endotoxin in the patient's blood; and (b) comparing the endotoxin level in the patient's blood to a predetermined threshold endotoxin level to determine if the patient has elevated endotoxin levels. The methods can further comprise treating patients identified as having elevated levels of endotoxin with an endotoxin neutralizing therapy. The methods provide increased safety and a reduction in risk for critically ill patients.

Owner:SANDERS MARTIN E

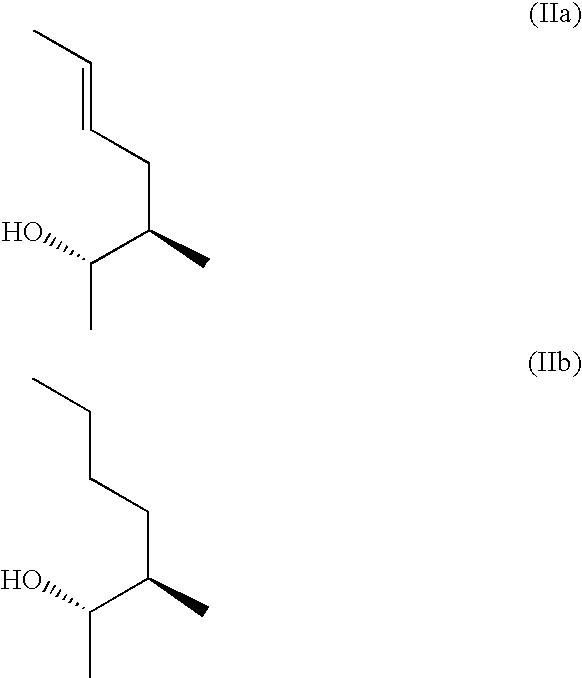

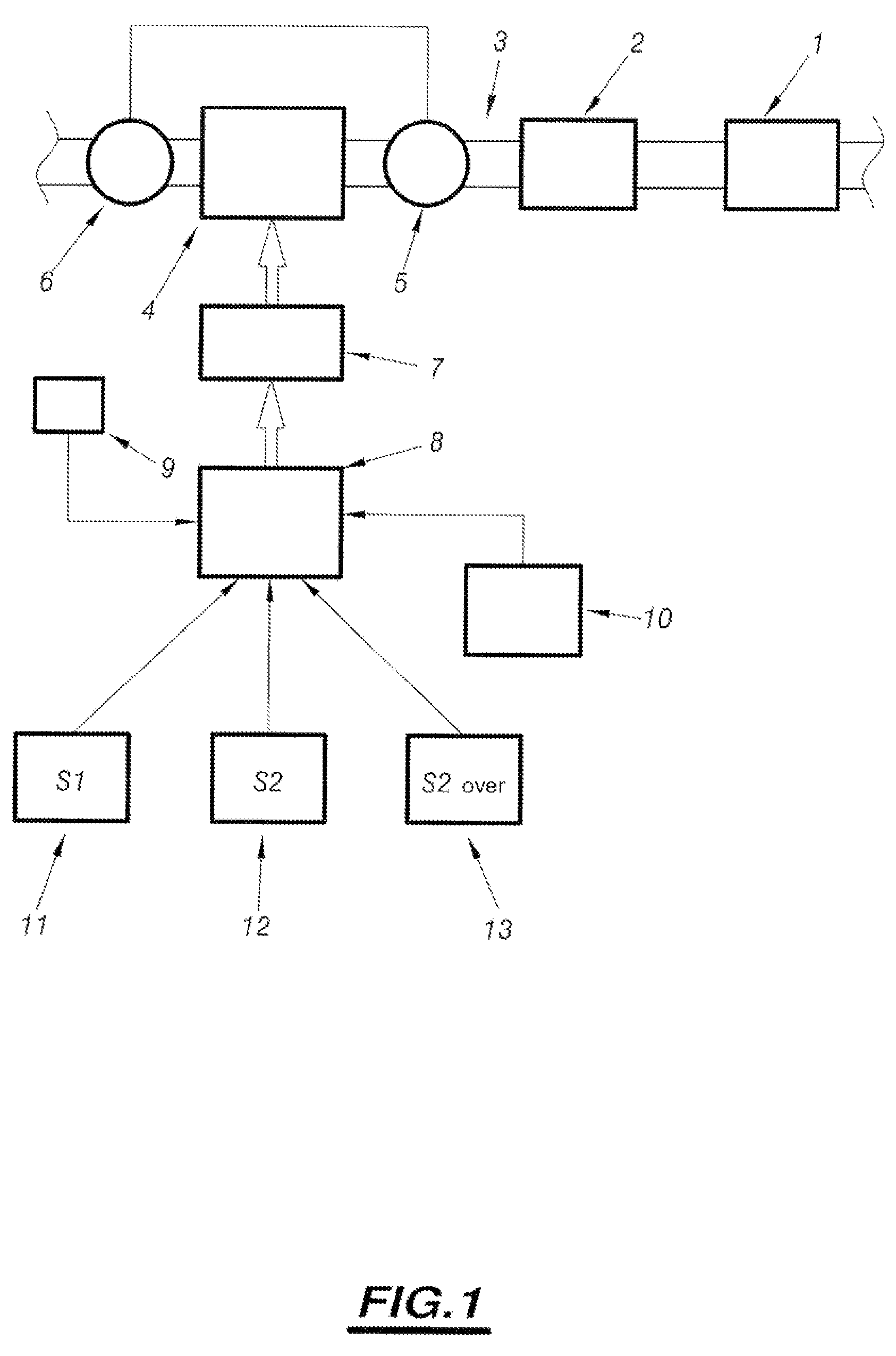

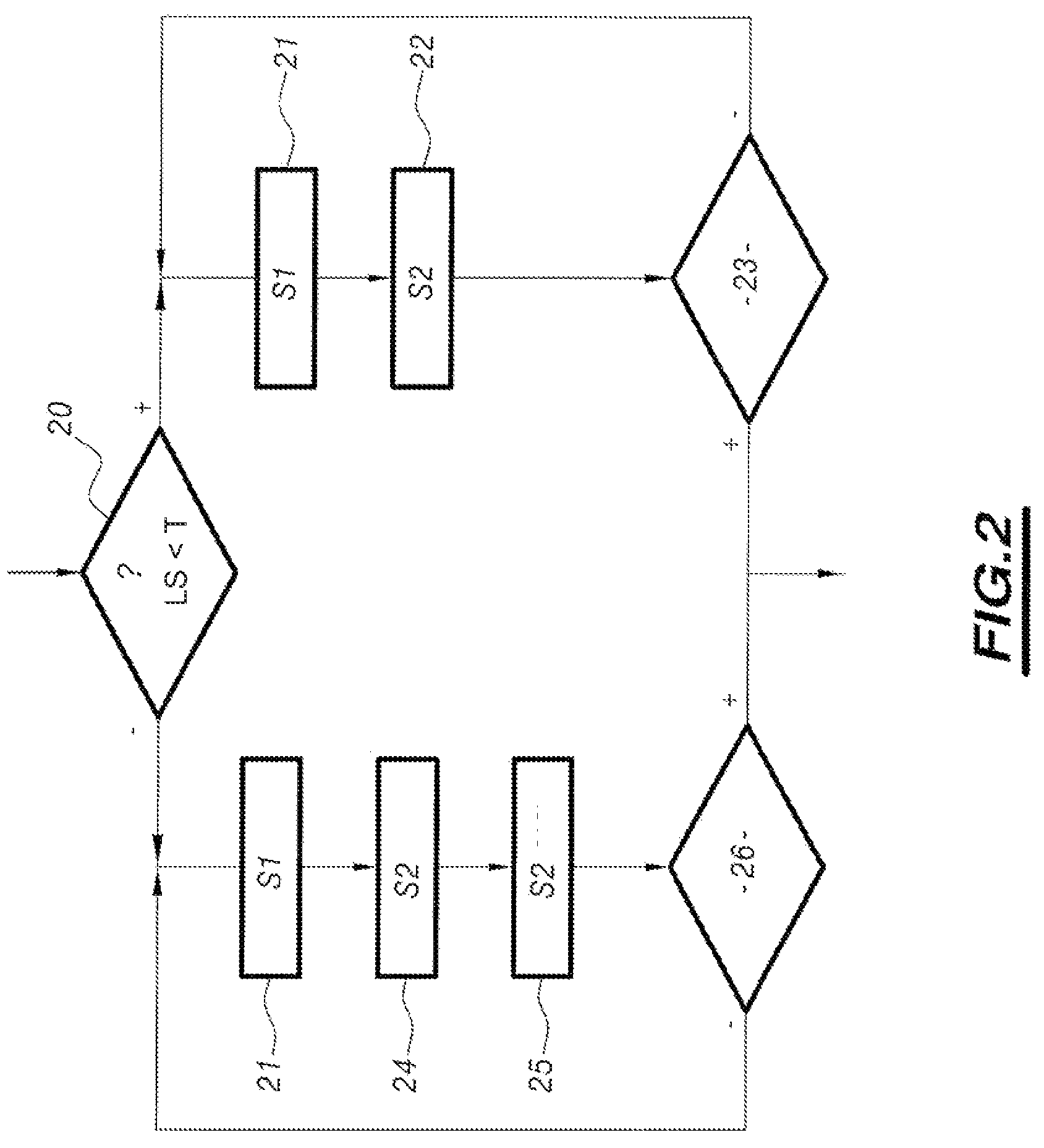

System for assisting regeneration of pollution management means

InactiveUS7631490B2Reduce over-consumptionIncreased safety marginElectrical controlInternal combustion piston enginesDiesel engineControl parameters

The invention concerns a system for assisting regeneration of pollution management means (1) integrated in an exhaust line (3) of a diesel engine (4), wherein the engine (4) is associated with common ramp means (7) injecting fuel into the cylinders thereof, based on at least one post-injection and adapted to implement, in isocouple, through modification of the engine operation control parameters, at least two strategies called level 1 and level 2 and a second regeneration strategy including level 1 strategies and a sequence alternating level 2 and over-calibrated level 2 strategies, enabling different thermal levels to be achieved in the exhaust line. The invention is characterized in that it comprises means (8) for analyzing the vehicle running conditions and means (8) for comparing same to threshold values, to implement the first regeneration strategy for running conditions higher than the threshold values or the second regeneration strategy for running conditions lower than the threshold values.

Owner:PEZHO SITROEN AUTOMOBILS SA

Portable system and method for non-intrusive radioscopic imaging

InactiveUS7336765B1Quickly and efficiently searchIncreased safety marginMaterial analysis by optical meansCharacter and pattern recognitionDigital signal processingImage resolution

Owner:LEIDOS

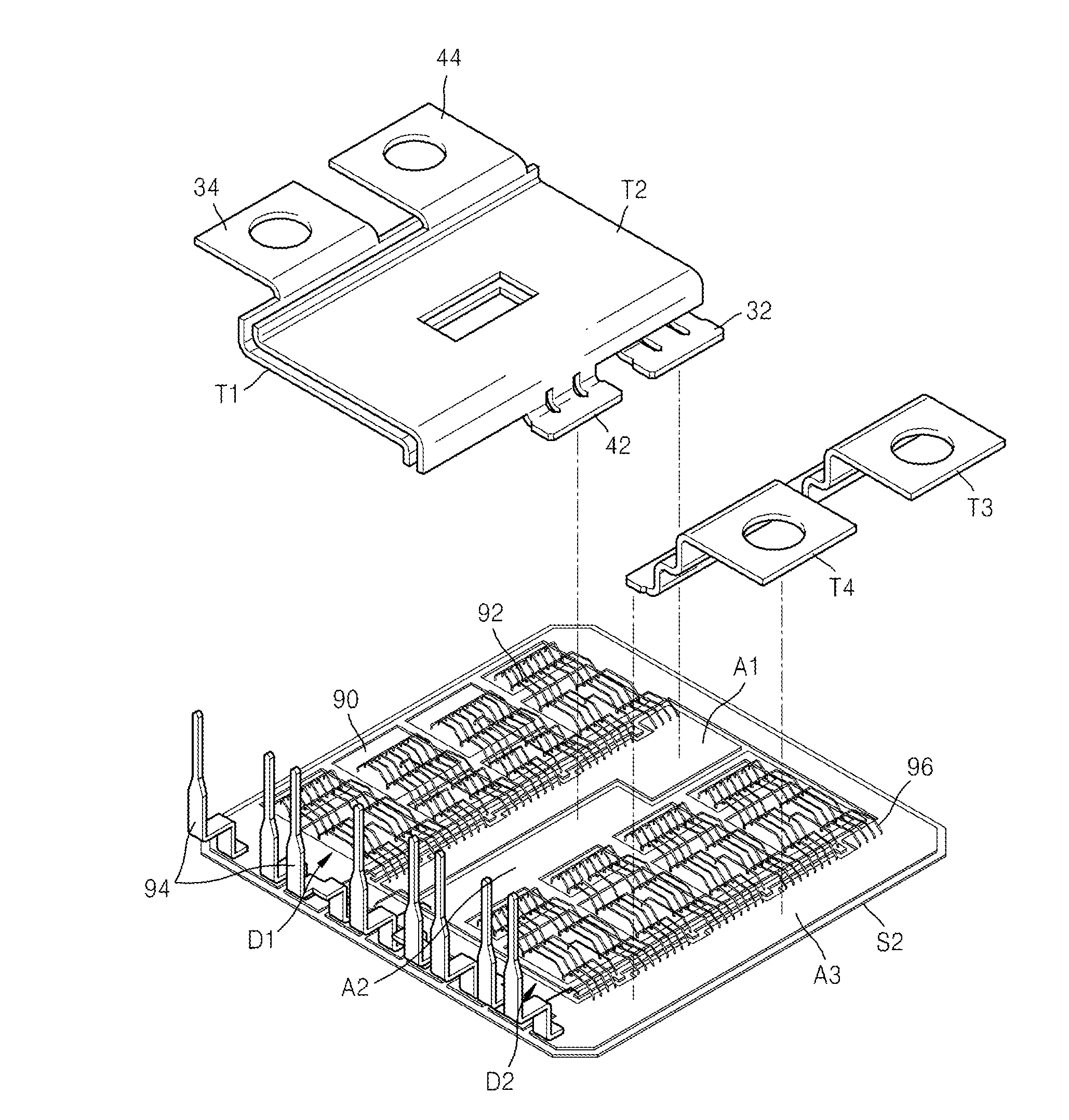

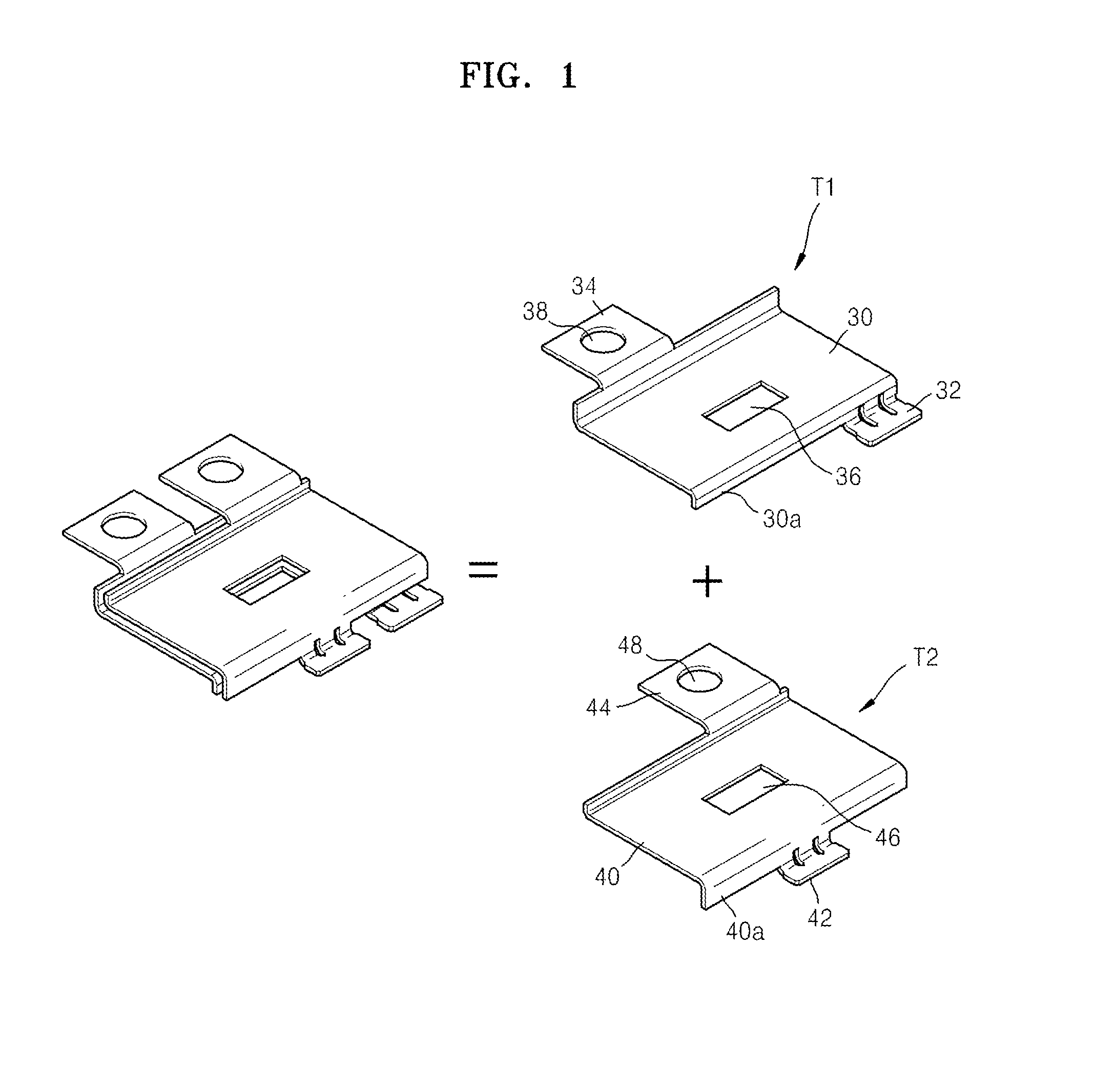

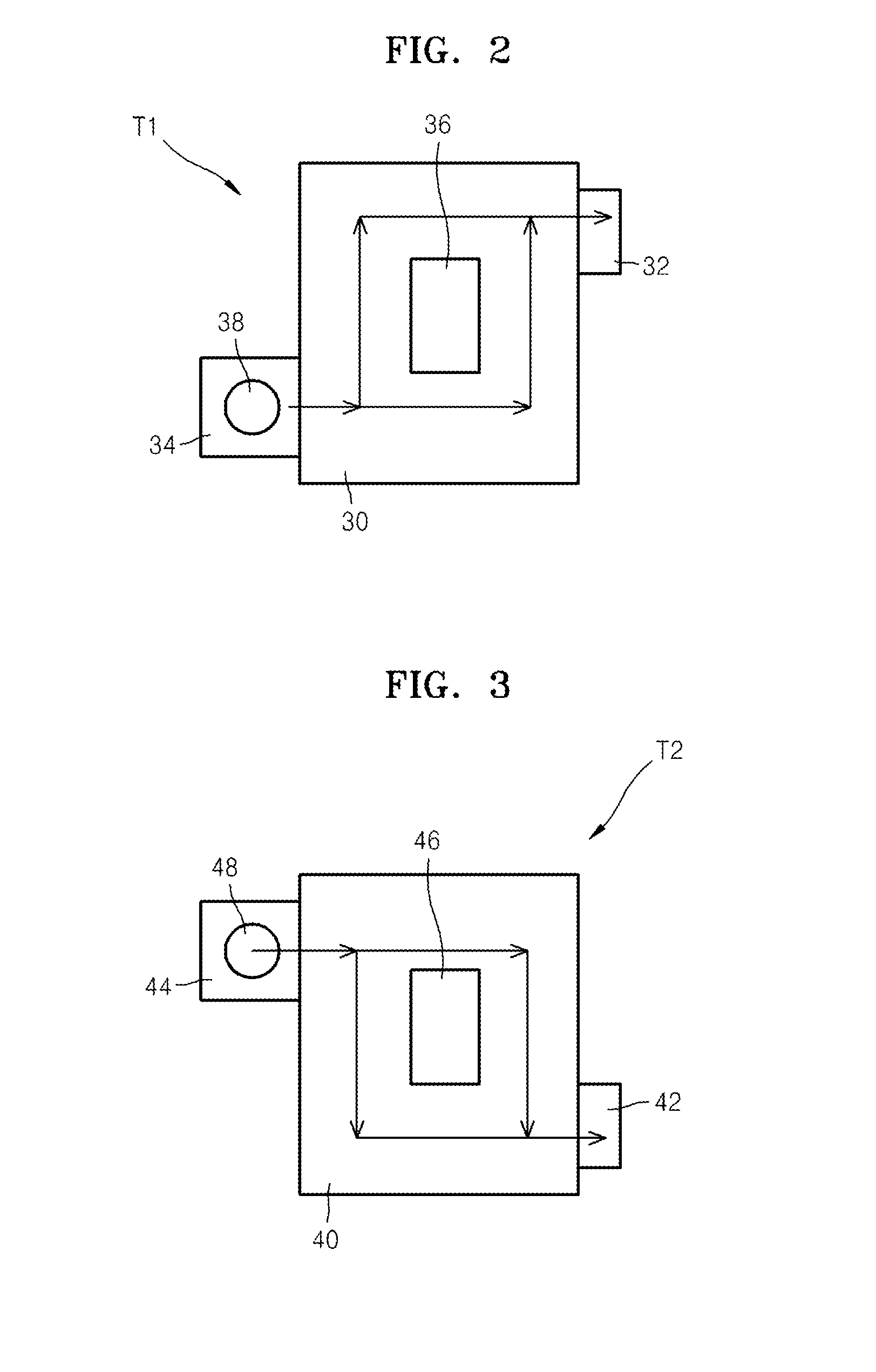

Substrate and terminals for power module and power module including the same

ActiveUS20140218871A1Efficient powerReduce voltage overshootElectrically conductive connectionsConversion constructional detailsElectrical polarityPower module

According to example embodiments, a substrate for a power module includes first to third parts spaced apart from each other, where the third part surrounds the first and second parts, and a conductive layer on the first to third parts. A terminal of a first polarity is connected to the first part, and a terminal of a second polarity is connected to the second part. The first and second terminals may be spaced apart from each other and each have a coupling part, a body, and a contact part. The bodies of the first and second terminals may overlap each other. A power module may include the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

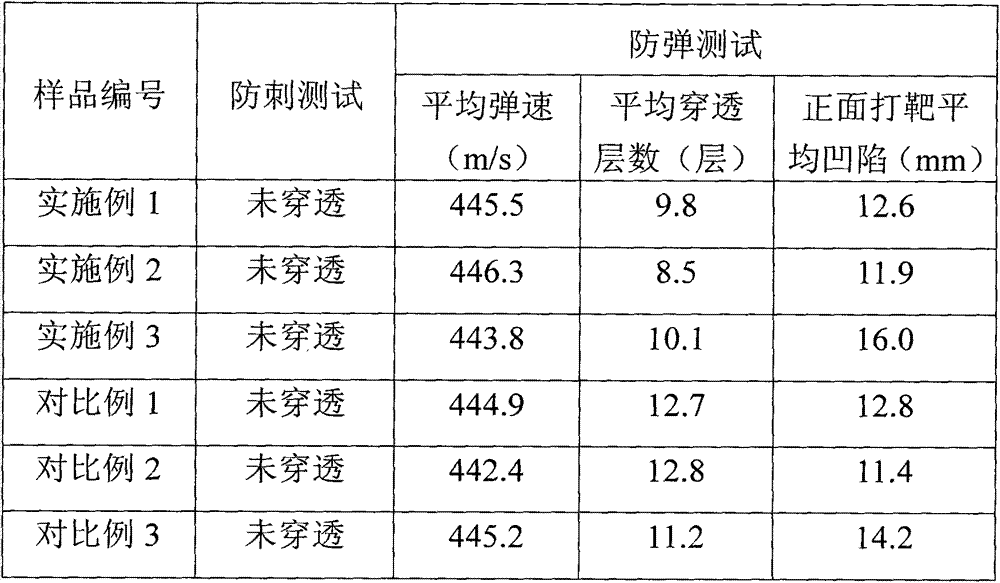

Multi-angle bulletproof and puncture-proof no-weft cloth and manufacturing method thereof

InactiveCN103783704AIt has dual functions of bulletproof and stabproofIncrease elasticitySynthetic resin layered productsLaminationFiberVolumetric Mass Density

The invention provides multi-angle bulletproof and puncture-proof no-weft cloth, and relates to the field of individual protection. The multi-angle bulletproof and puncture-proof no-weft cloth is mainly formed by compositing a plurality of layers of unidirectional fiber preimpregnated materials through different angles, and every two layers of unidirectional fiber preimpregnated materials are bonded through tackiness agents or adhesive films. According to the no-weft cloth, each layer of the cloth comprises at least one layer of unidirectional fiber preimpregnated materials, wherein the surface density of the each layer of unidirectional fiber preimpregnated materials is 55 g / m<2>+ / -5 g / m<2> or 110 g / m<2>+ / -5 g / m<2>. The invention further provides a manufacturing method of the multi-angle bulletproof and puncture-proof no-weft cloth. Puncture-proof no-weft clothes produced by the multi-angle bulletproof and puncture-proof no-weft cloth is high in safety margin and light, safe reliability of fighting personnel can be obviously improved, meanwhile, fighting efficiency of the fighting personnel is improved, and loads of the fighting personnel are reduced.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD

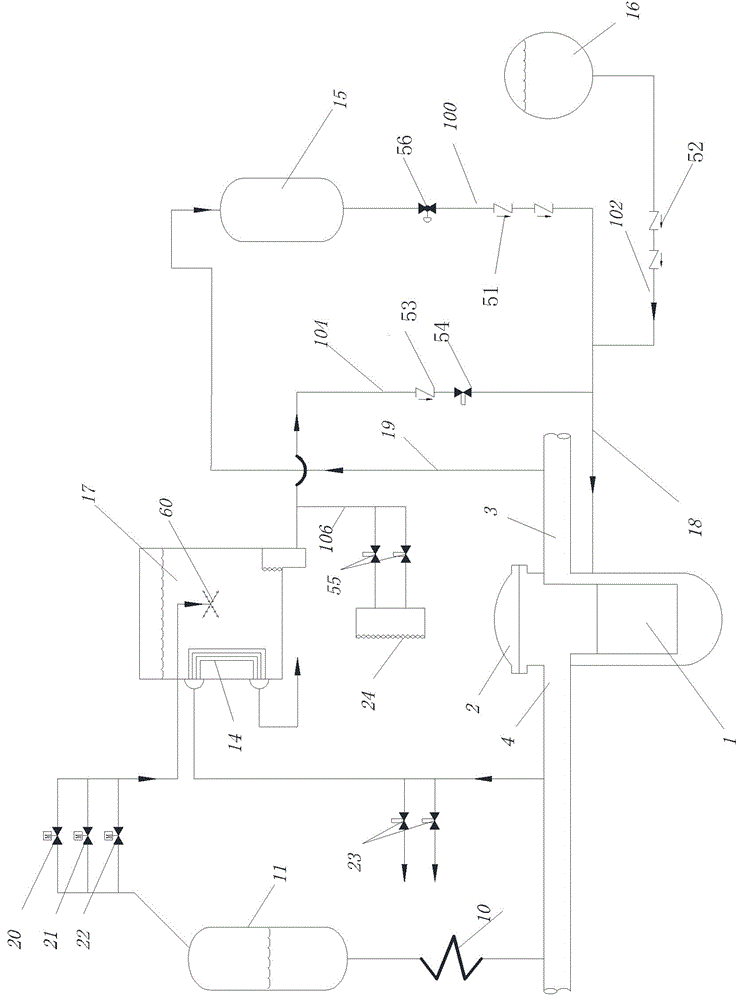

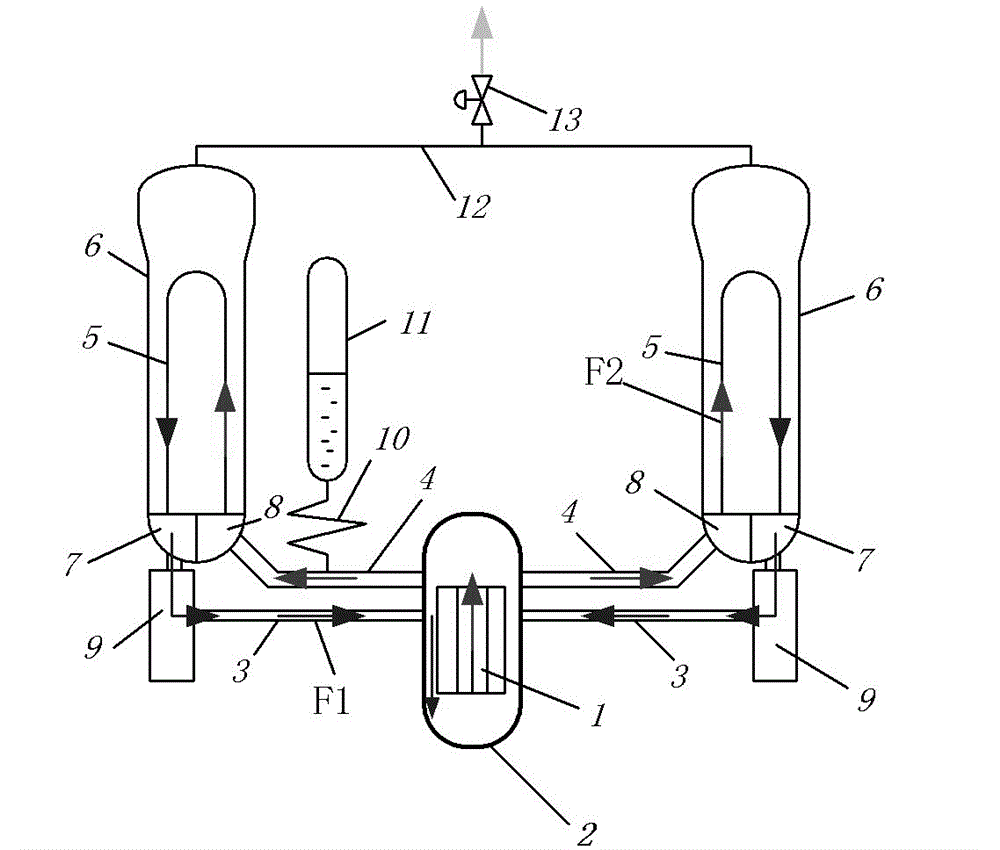

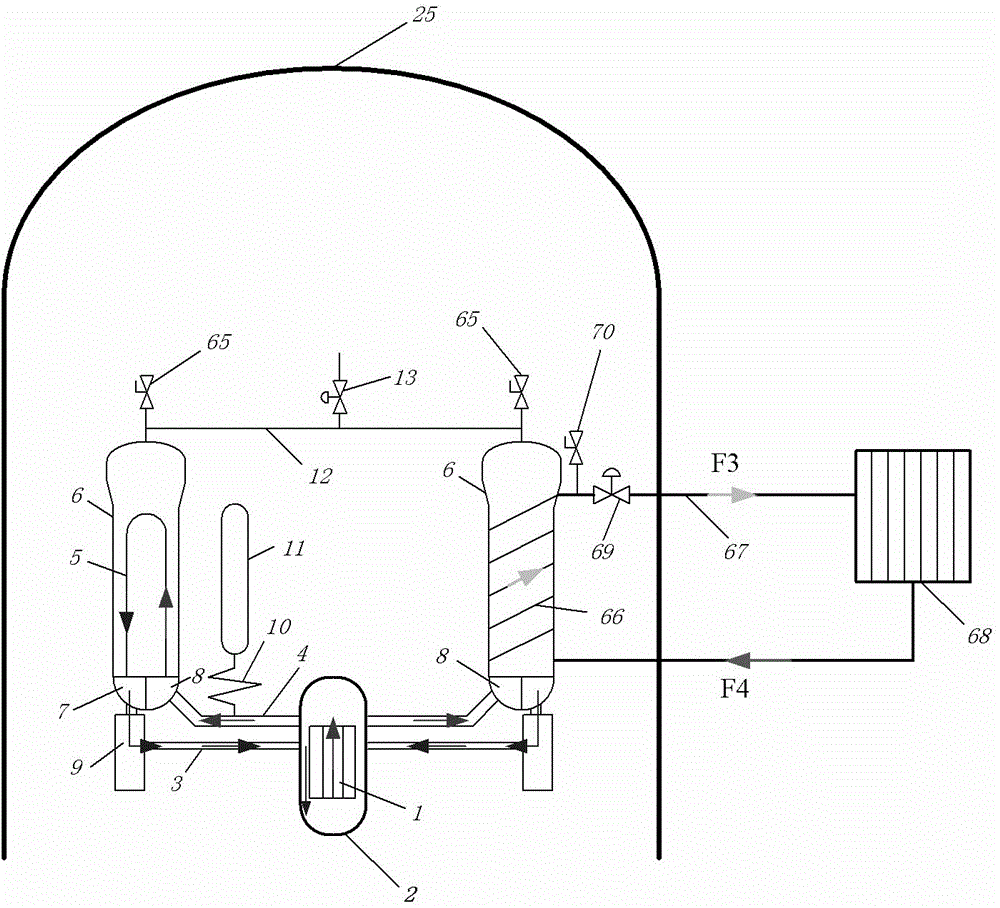

Passive residual heat removal system for nuclear power plant

ActiveCN105810256AConducive to production recoveryRelieve pressureNuclear energy generationCooling arrangementIsolation valveNuclear power

The invention relates to a passive residual heat removal system for a nuclear power plant. The passive residual heat removal system for the nuclear power plant comprises a steam generator shell heat exchanger, a heat exchange loop pipeline, a shell exterior heat exchanger, a pressure maintaining valve, an isolating valve and a heat transferring medium, wherein the heat exchange loop pipeline penetrates through a containment; the steam generator shell heat exchanger is distributed on a steam generator and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged outside the containment and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged at a high position relative to the position of the steam generator shell heat exchanger; the pressure maintaining valve and the isolating valve are arranged in the containment and are sequentially arranged between the steam generator shell heat exchanger and the shell exterior heat exchanger along a first flow direction of the heat transferring medium in the heat exchange loop pipeline; the passive residual heat removal system for the nuclear power plant is maintained in a relatively low pressure level by virtue of the pressure maintaining valve; and the isolating valve and a shutdown safety signal of a reactor are subjected to interlock opening to be used for continuously taking away heat in the steam generator during an accident.

Owner:STATE NUCLEAR HUAQING BEIJING NUCLEAR POWER TECH R & D CENT +1

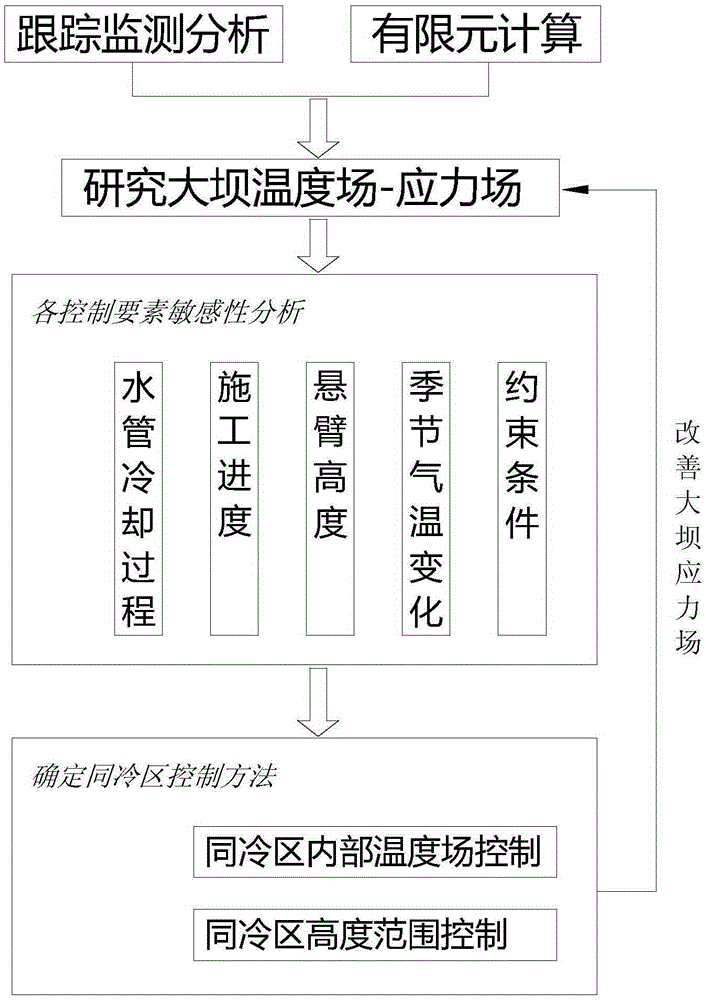

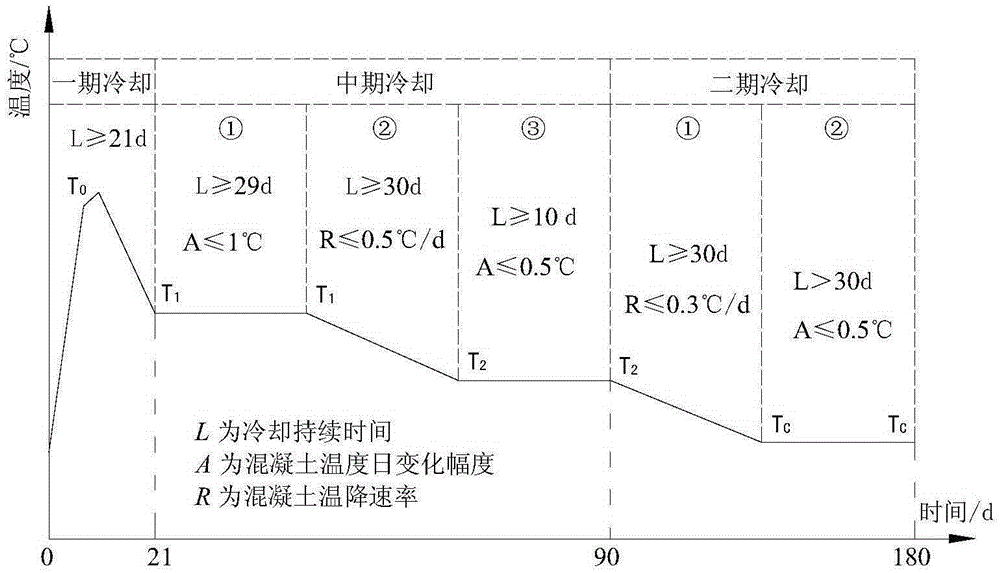

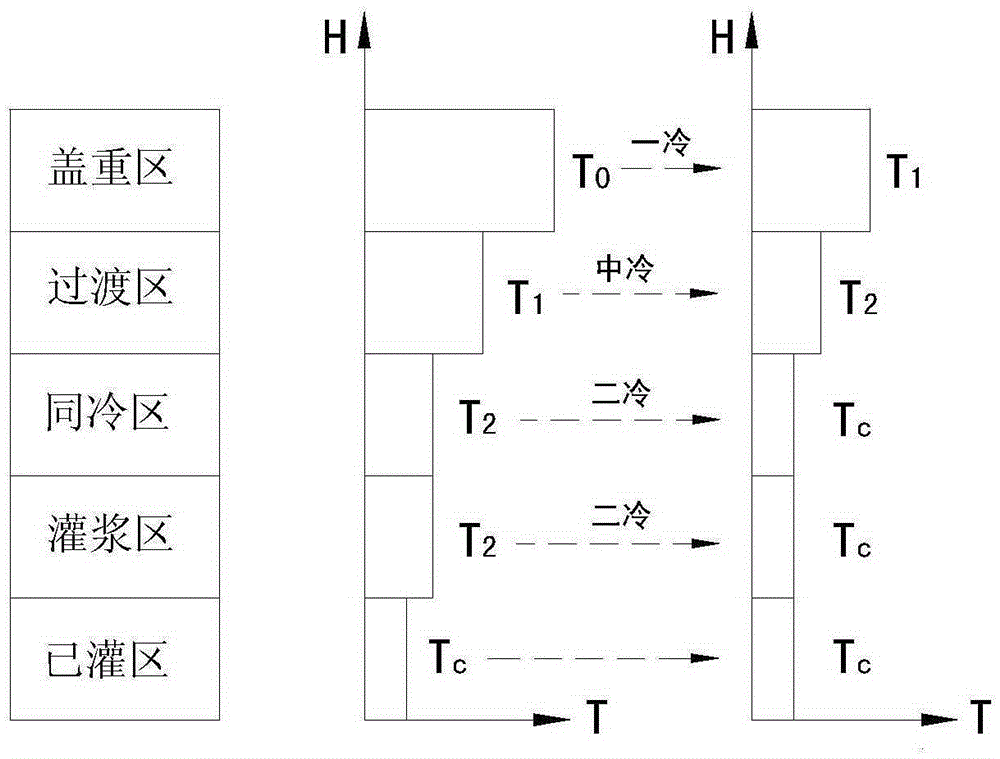

Temperature-control anti-cracking method used for concrete arch dam

ActiveCN105274968ARealize real-time regulationReduced risk of crackingFoundation engineeringArch damsTemperature controlEngineering

The invention discloses a temperature-control anti-cracking method used for a concrete arch dam with a good anti-cracking effect. The temperature-control anti-cracking method used for the concrete arch dam comprises synchronous-cooling area temperature control and synchronous-cooling area height range control which are synchronously carried out. A finite element method is adopted to carry out numerical calculation and optimized analysis on five factors of a water pipe cooling process, construction progress, cantilever height, seasonal temperature change and a constraint condition, so that temperature real-time control adaptive to the synchronous-cooling area height is realized, and the anti-cracking effect of the concrete arch damis relatively good.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com