Multi-angle bulletproof and puncture-proof no-weft cloth and manufacturing method thereof

A bullet-proof, stab-proof, weft-free technology, applied in chemical instruments and methods, protective clothing, lamination, etc., can solve the problems of poor flexibility in angle bending, complicated production process, uncomfortable wearing, etc., and achieve a high safety margin. , thin, comfortable and flexible to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

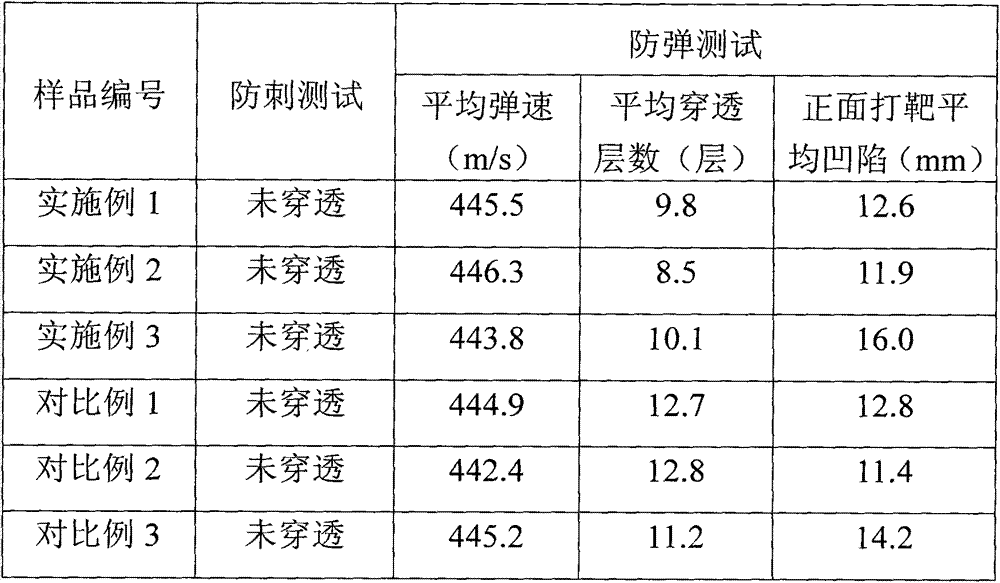

Examples

Embodiment 1

[0048] Continuous production method

[0049] First, weigh 10Kg of modified acrylate adhesive, add 1Kg of water, mix the glue thoroughly, and pour it into the glue tank for later use.

[0050] Install the aramid fiber package on the creel. After the fiber is drawn out from the creel, it passes through the infrared yarn breakage automatic stop control device. On the premise of ensuring that each fiber is in a normal state, the fiber enters the screen sealing reed module to realize the positioning of the fiber bundle in the facade space. The fiber bundle enters the surface density control module to realize the accurate positioning of the fiber bundle in the width direction. Afterwards, the precisely positioned fiber bundles enter the spreading module, so that the monofilaments of each bundle of fibers are evenly distributed within the width range to the greatest extent, and the spreading is realized. The evenly spread tow is sent to the gluing module for gluing to achieve unifo...

Embodiment 2

[0056] Sheet device manufacturing method

[0057] First weigh 1Kg of the modified acrylate adhesive and pour it into a plastic box for later use.

[0058] The aramid fiber is wound in parallel on the winding machine, and then the fiber is immersed in the above glue solution, and the unidirectional fiber prepreg is prepared by spinning through a specific spinning equipment. In this example, the above-mentioned adhesive is used. After dipping, spread the glue evenly with a squeegee, and dry it under a 50°C electric resistance wire. After the unidirectional fiber prepreg is completely dry, cut it at 0° and 45° , and then laminate the cut unidirectional fiber prepreg according to [0° / 45° / 90° / 135°], use adhesive or film to bond each layer, and use a press to press , the pressing process conditions are: temperature 120-140°C, pressure 10-20MPa, pressing time depends on the thickness of the sample, you can get [0° / 45° / 90° / 135°] four-layer bulletproof anti-stab non-weft cloth.

[0...

Embodiment 3

[0061] Sheet device manufacturing method

[0062] First weigh 1Kg of the modified acrylate adhesive and pour it into a plastic box for later use.

[0063] The aramid fiber is wound in parallel on the winding machine, and then the fiber is immersed in the above glue solution, and the unidirectional fiber prepreg is prepared by spinning through a specific spinning equipment. In this example, the above-mentioned adhesive is used. After dipping, spread the glue evenly with a squeegee, and dry it under a resistance wire at 50°C. After the unidirectional fiber prepreg is completely dry, rotate the cloth sample by 90°, and use The method is to carry out orthogonal compounding of the fiber filaments and the sample fiber filaments, and obtain two layers of interlaced fabric samples. The resulting product structure is correspondingly [0° / 90°]. Cut the fabric sample into a 400mm×400mm square fabric sample, stack the two layers of fabric samples in the direction of [0° / 90°, 0° / 90°], put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com