Patents

Literature

1265results about "Load modified fasteners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

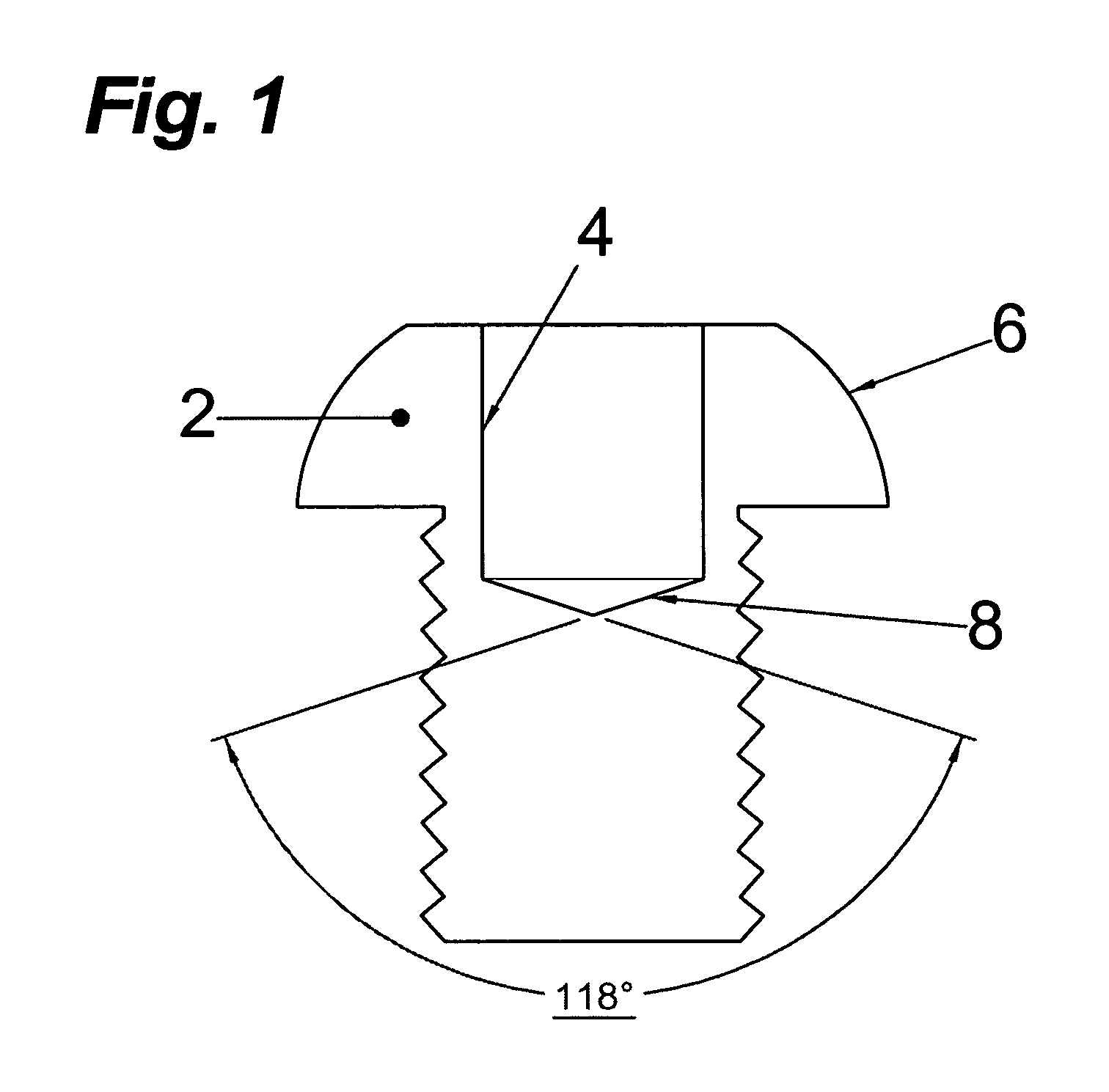

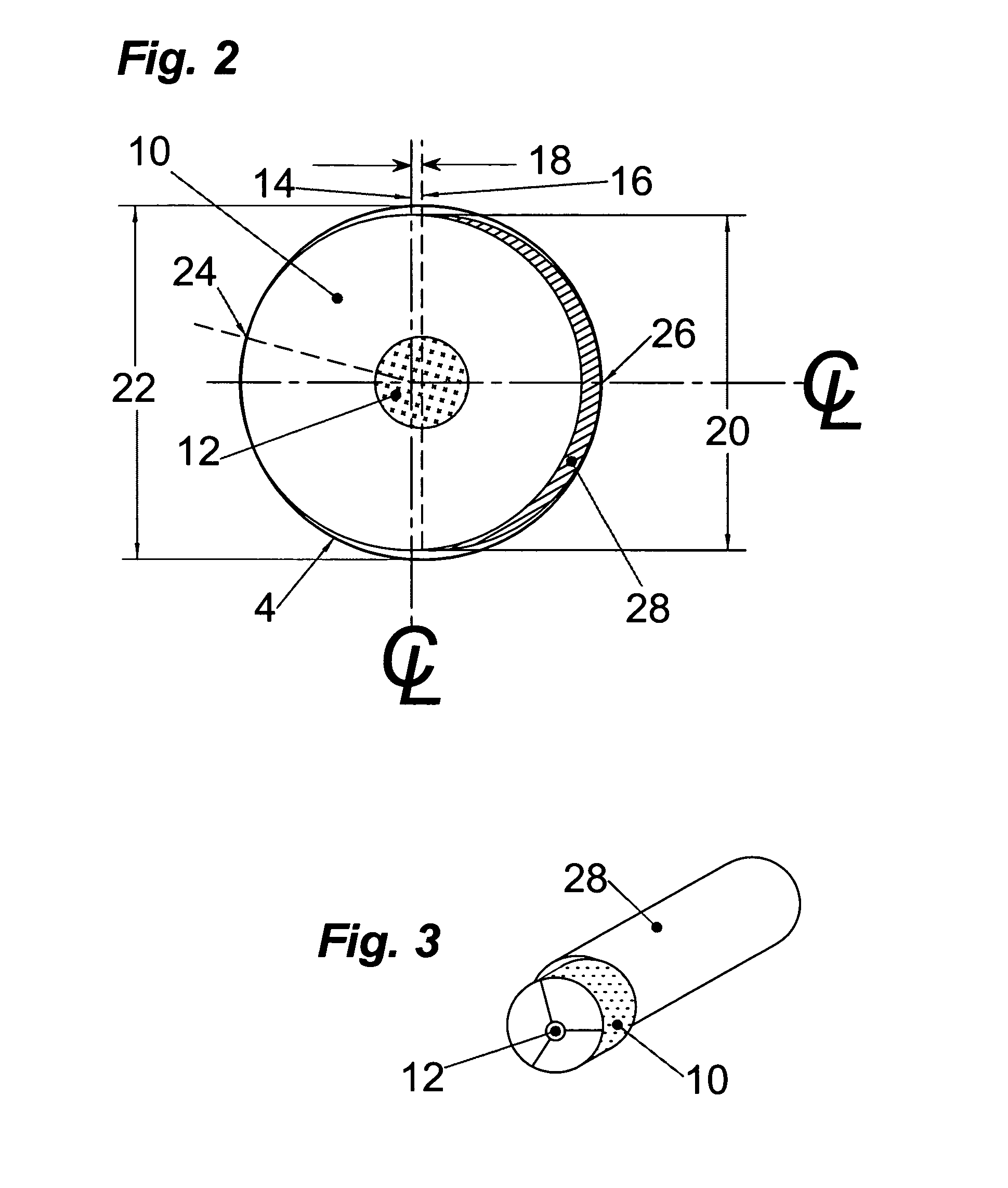

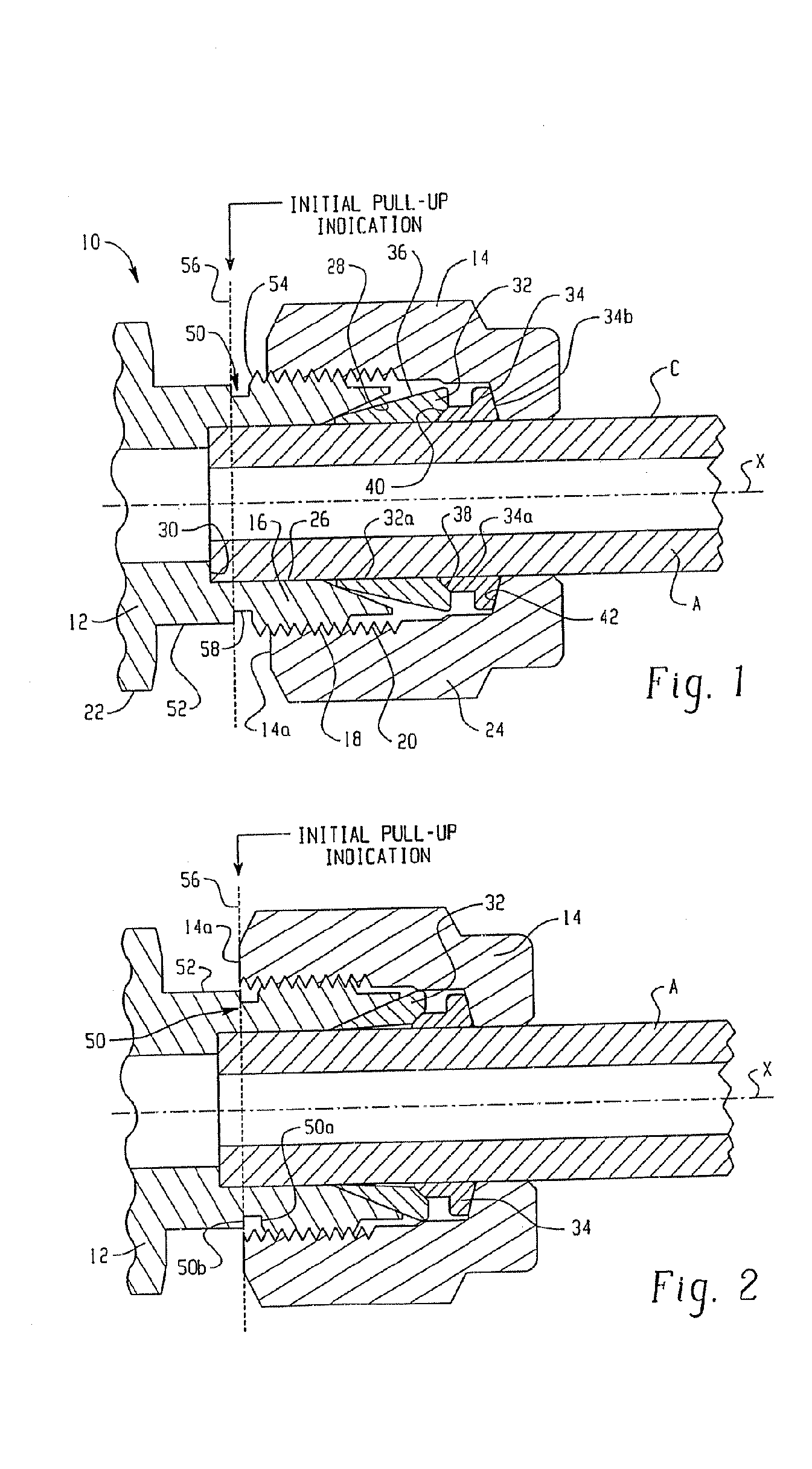

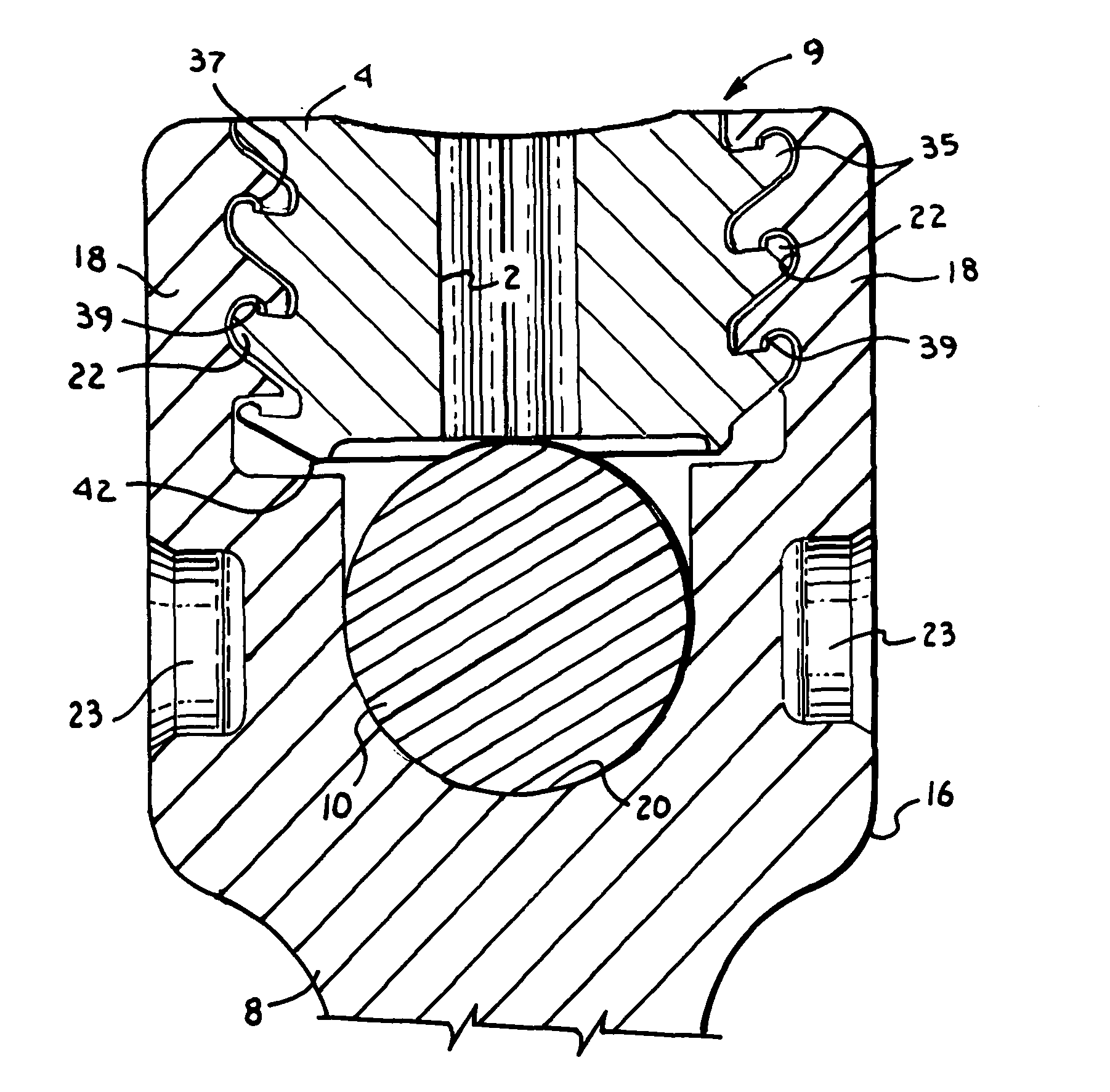

Torque-setting, tamper-resistant fastener and method and tool for use with same

A fastener includes a round, blind hole or pocket in its head. Installation and removal of the fastener is accomplished with a tool containing an eccentric segment on the end of a shaft. When rotated within the pocket, the eccentric segment displaces laterally relative to the shaft to provide a friction grip to the lateral wall of the pocket. The strength of the grip is proportional to the applied torque. Eccentric displacement allows rotation but prevents the tool from spinning out of the fastener thereby eliminating cam-out and surface damage resulting from contact with a spinning tool tip. The eccentric head of the tool can be made disposable and to shear off when a predetermined torque is reached. The smooth-sided round hole offers no purchase for commonly available tools; making the fastener tamper-resistance. In another embodiment, the fastener includes a raised portion in the pocket. A tool having a complementary opening shears off the raised portion at a predetermined torque.

Owner:FLESHER ROBERT W

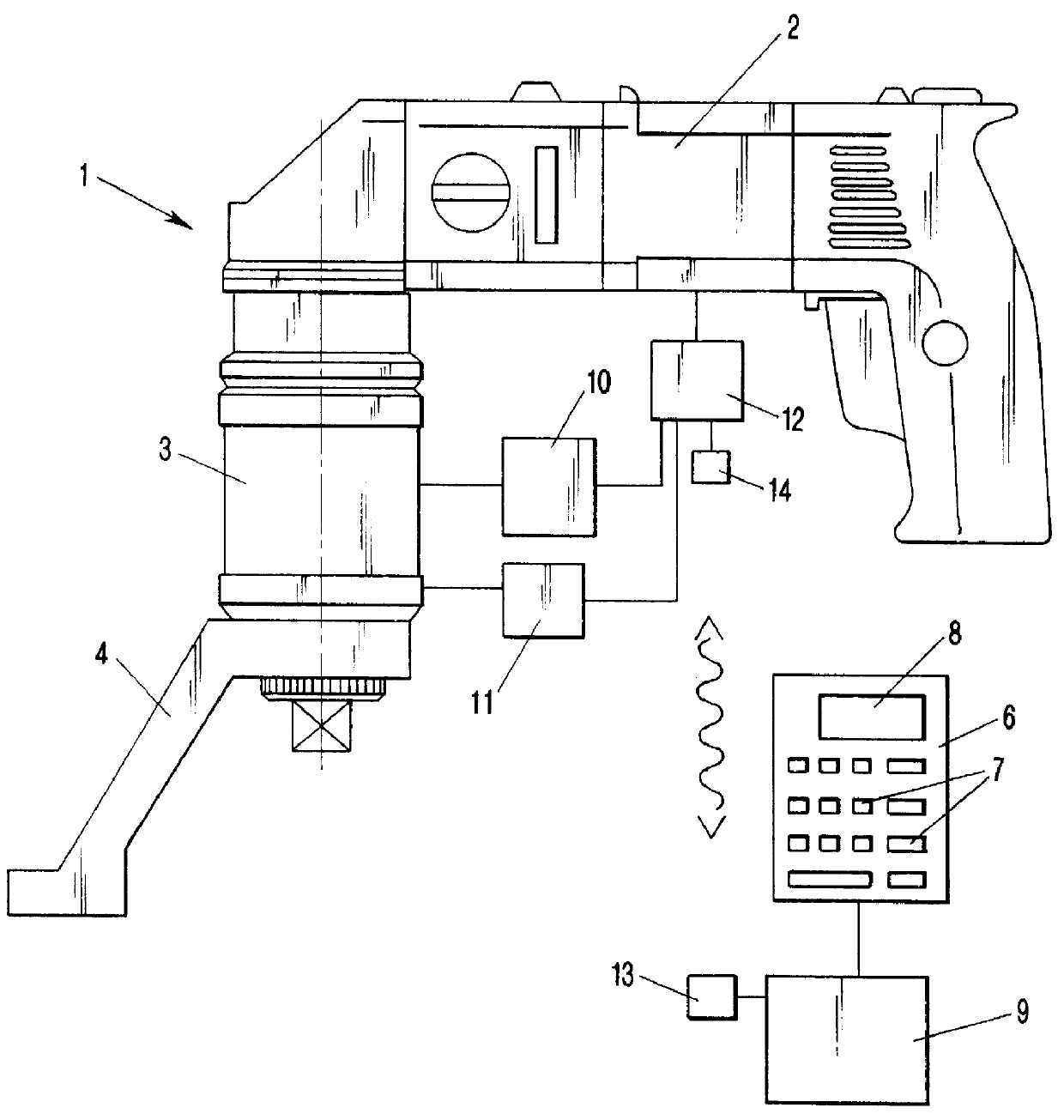

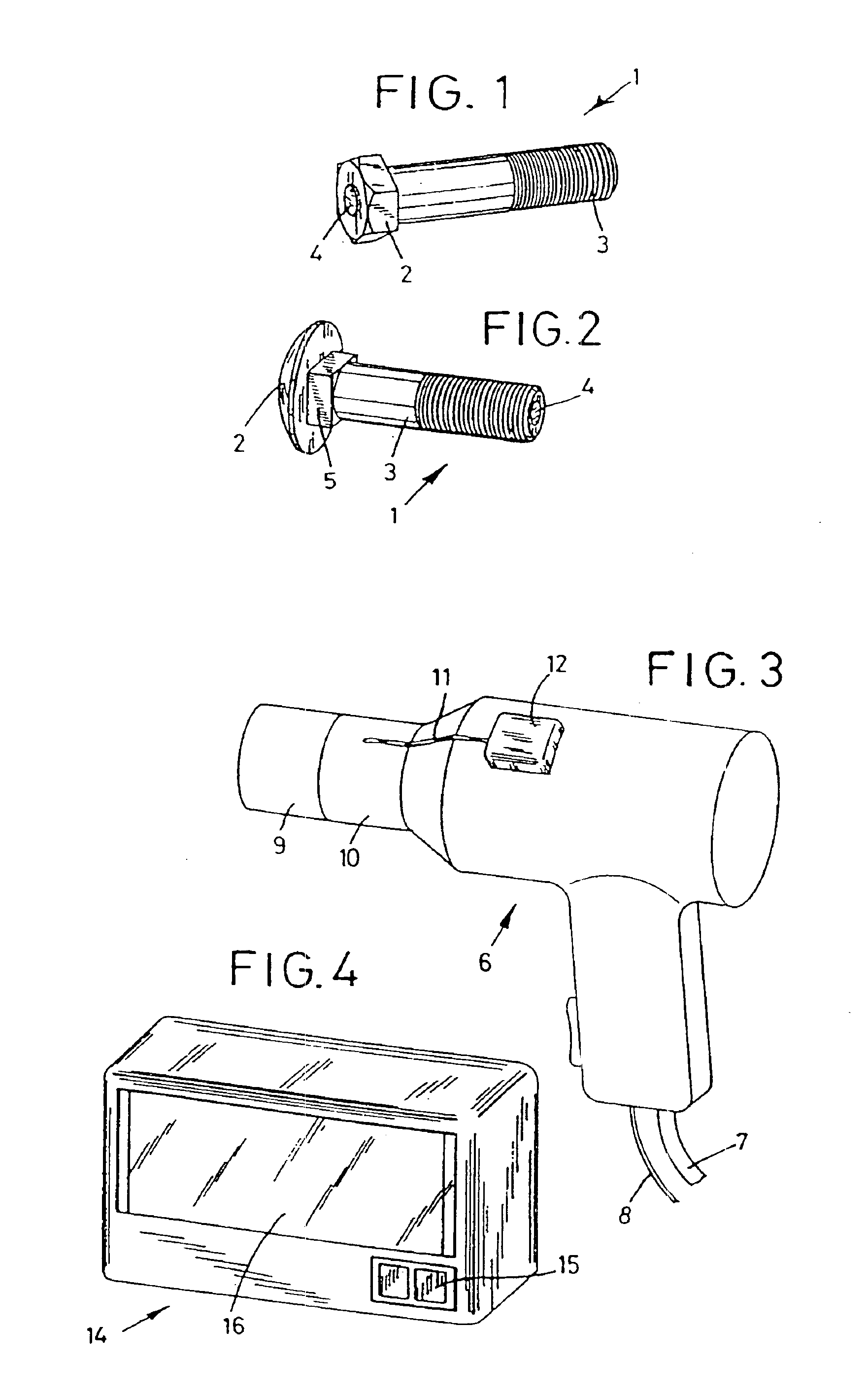

Power wrench

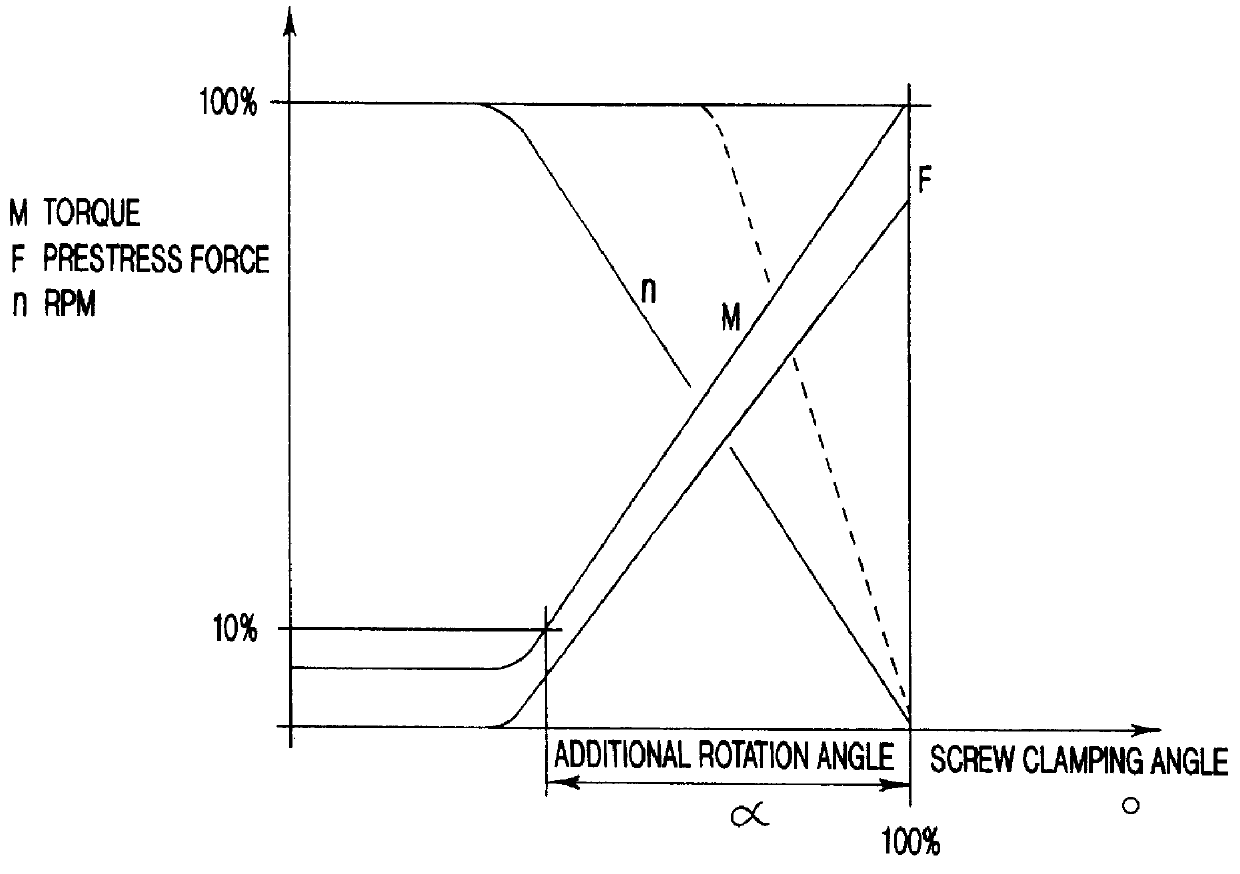

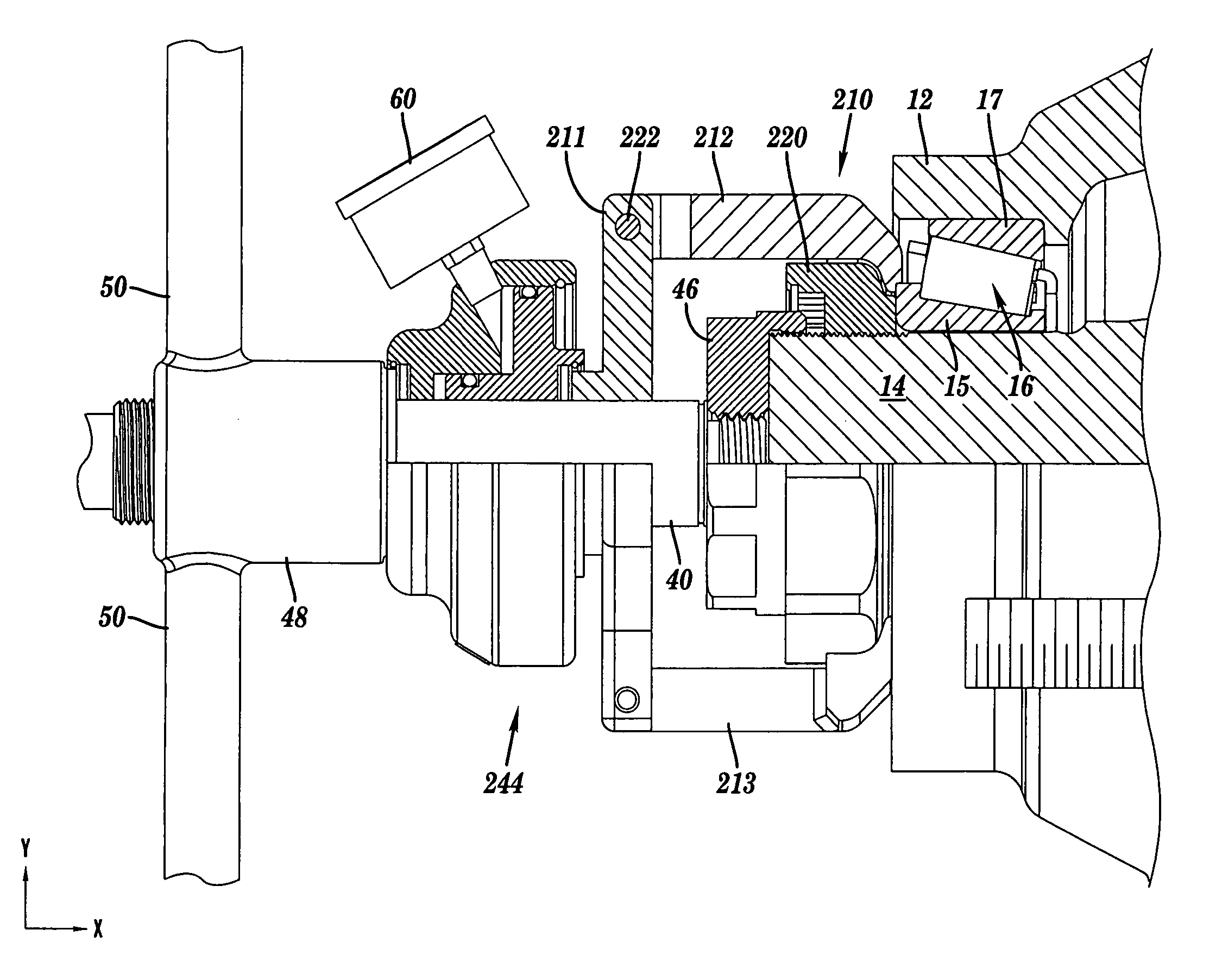

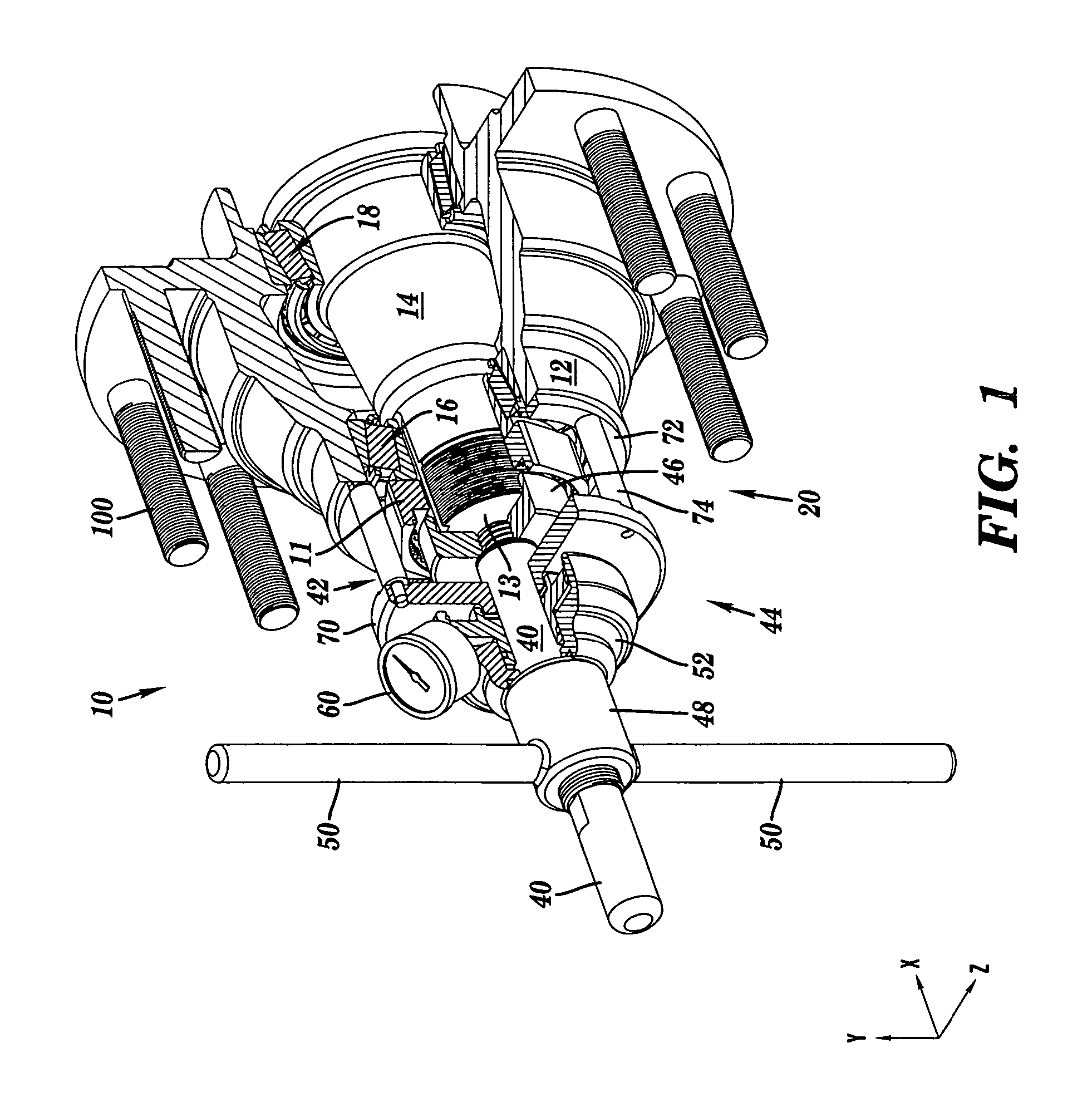

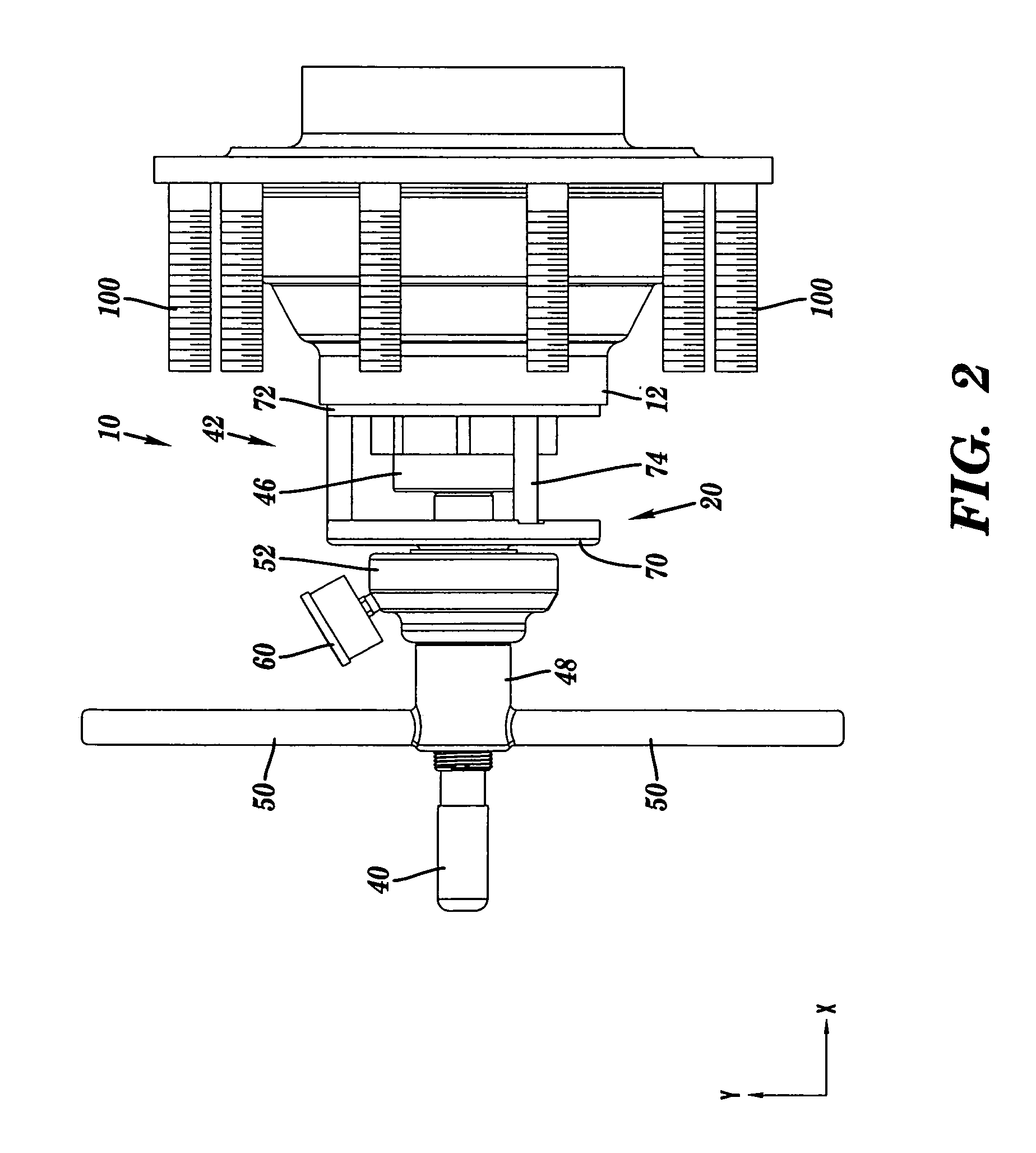

PCT No. PCT / EP97 / 05974 Sec. 371 Date Jul. 16, 1999 Sec. 102(e) Date Jul. 16, 1999 PCT Filed Oct. 29, 1997 PCT Pub. No. WO98 / 22263 PCT Pub. Date May 28, 1998A power screwdriver has a drive unit and an input circuit for inputting screw size, material quality, pitch, and clamping length of a screw. An evaluation circuit is provided for determining a nominal prestress force based on input screw size, material quality, and clamping length, for determining a nominal torque based on the nominal prestress force and the pitch, and for determining the screw clamping angle resulting from the nominal prestress force and the pitch. A sensing device for sensing the actual torque is provided, and a further sensing device for sensing the actual screw clamping angle is present. A control and switch-off device controls further rotation of the drive unit when the actual torque coincides with the nominal torque and switches off the drive unit when the actual screw clamping angle coincides with the nominal screw clamping angle. The nominal torque, based on which the additional rotation o f the drive unit is controlled until the nominal screw clamping angle is reached, is set to a value which is smaller than the torque corresponding to the nominal pretension force. An additional rotation angle of the drive unit, for reaching the nominal screw clamping angle corresponding to the nominal prestress force, is determined based on the difference between the nominal screw clamping angle and the adjusted screw clamping angle corresponding to the preset nominal torque and is used for switching off the drive unit.

Owner:HOHMANN JORG +1

Apparatus for providing a load on a bearing, the bearing having an inner race mounted to a shaft and the bearing retained by a nut

Owner:TEMPER +1

Destructible locking device

A locking device is disclosed for interlocking two members having aligned openings extending therethrough. The device includes a hollow cap and a pin with an enlarged head at one end and a nose at the opposite end. The pin is insertable through the aligned openings of the members, with its nose received in interlocked engagement within the cap, and with the two members captured between the cap and the enlarged head of the pin. A frangible portion of the pin is severable in response to relative rotation between its nose and enlarged head to thereby destructively disassemble the locking device.

Owner:INNER TITE A DIV OF YARA ENG

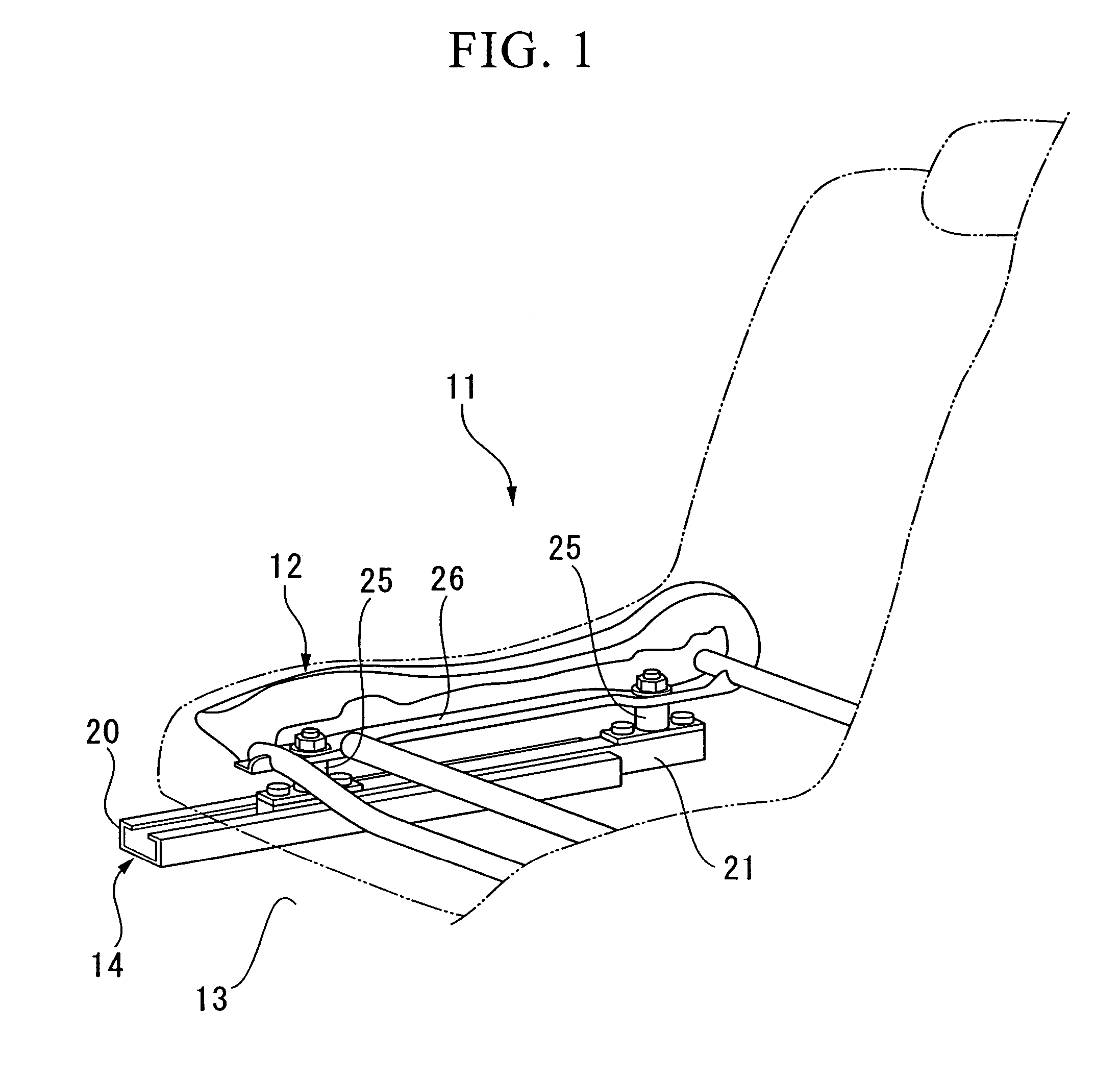

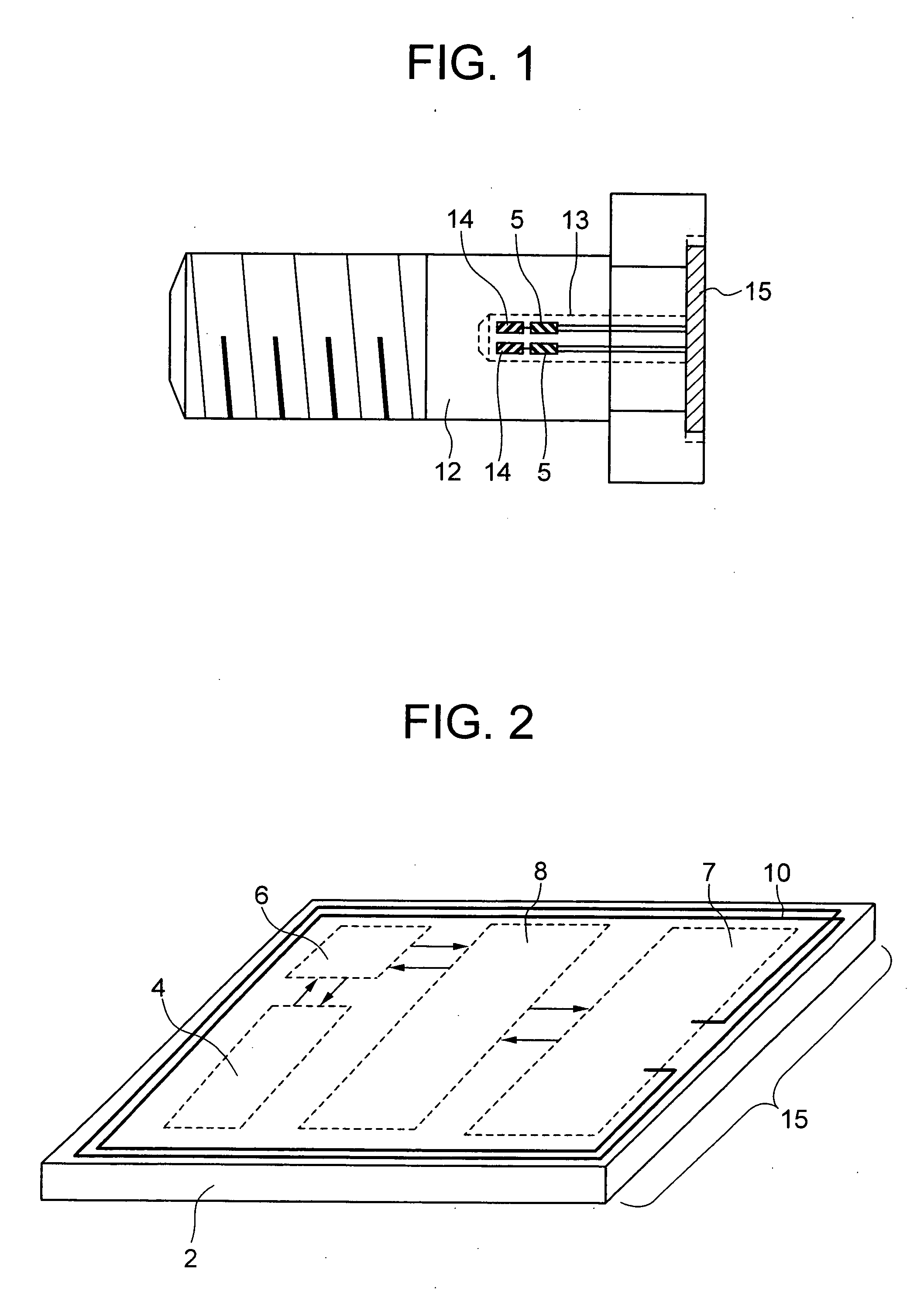

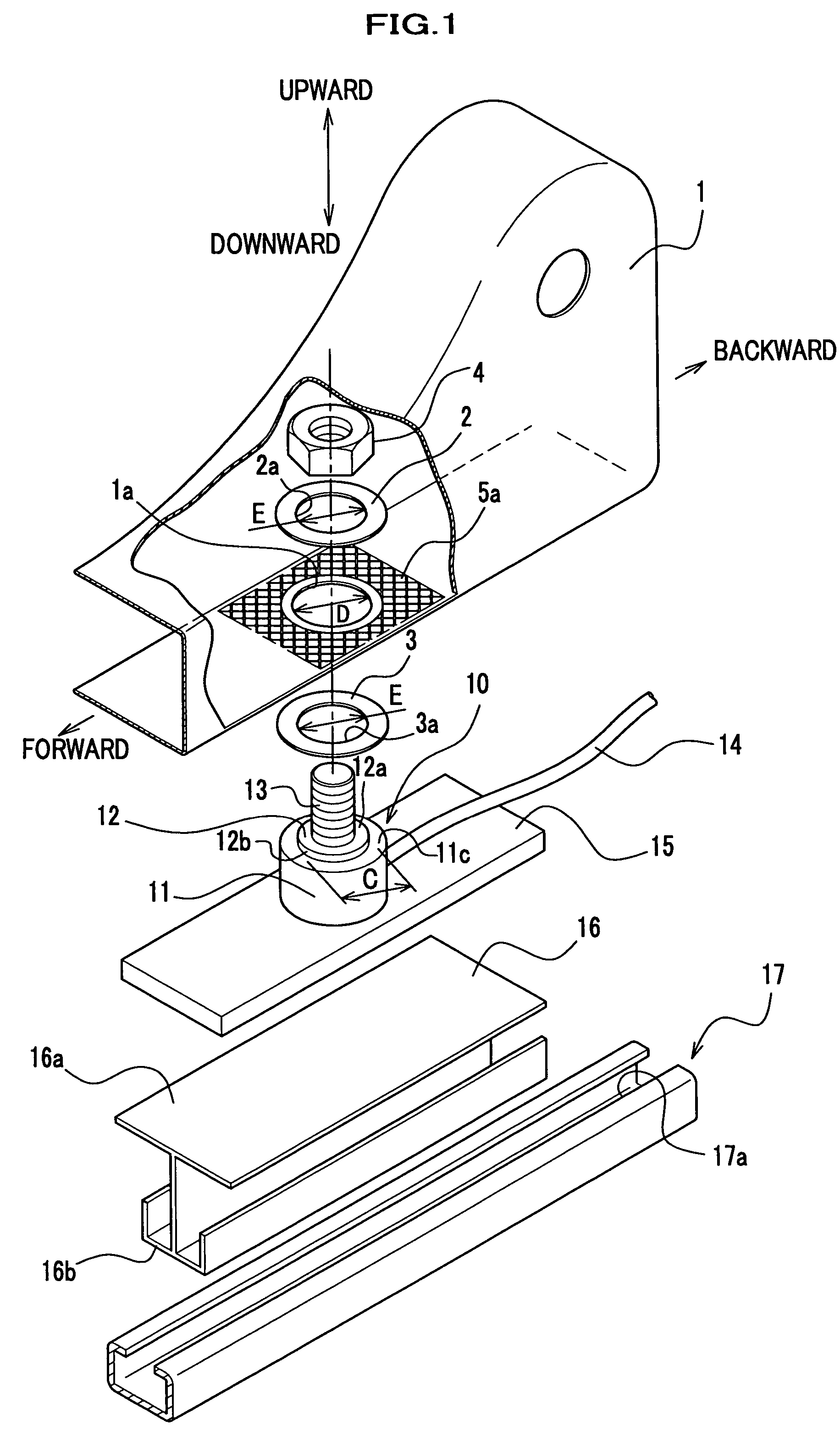

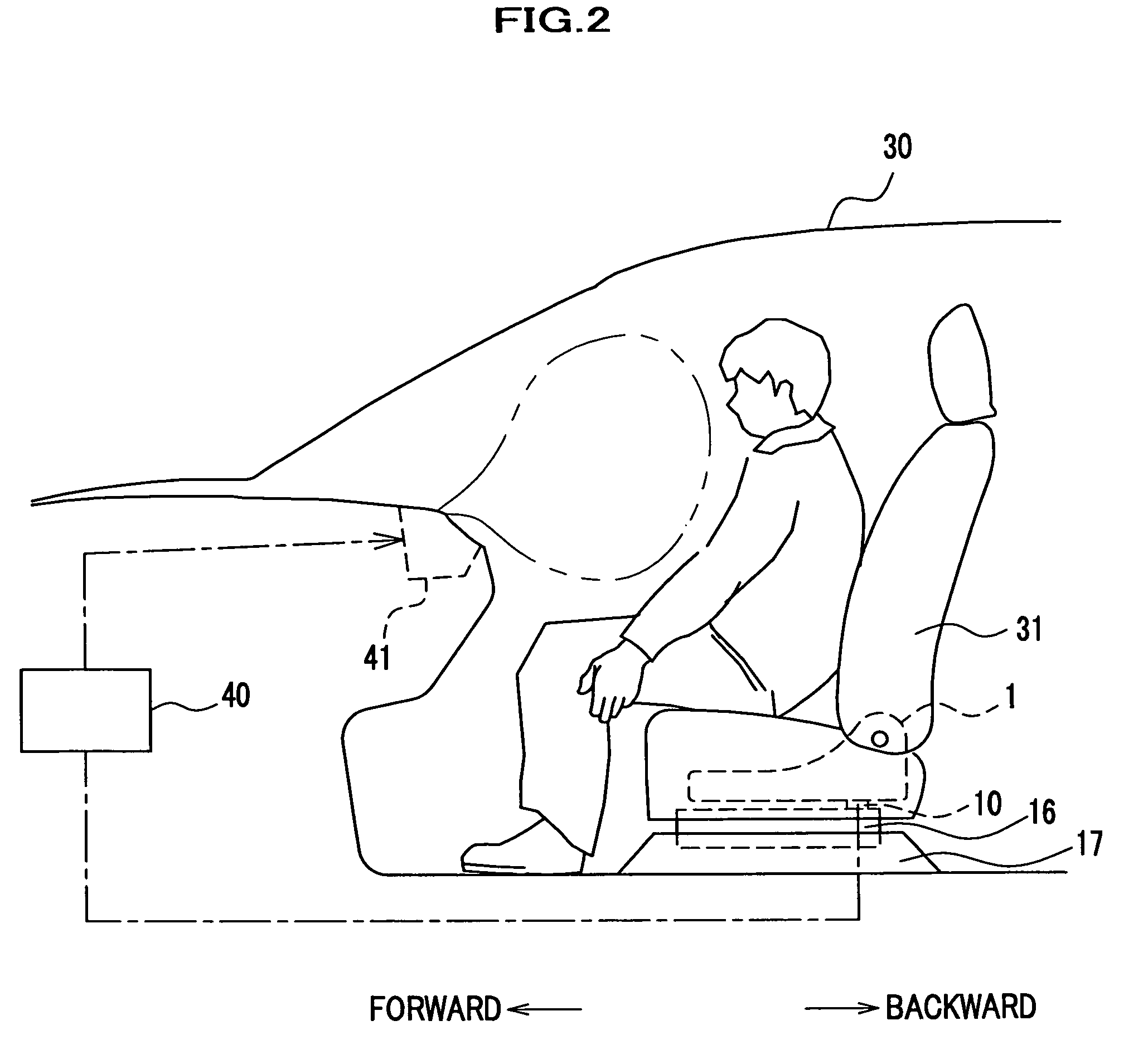

Load cell attachment structure

ActiveUS7373846B2Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

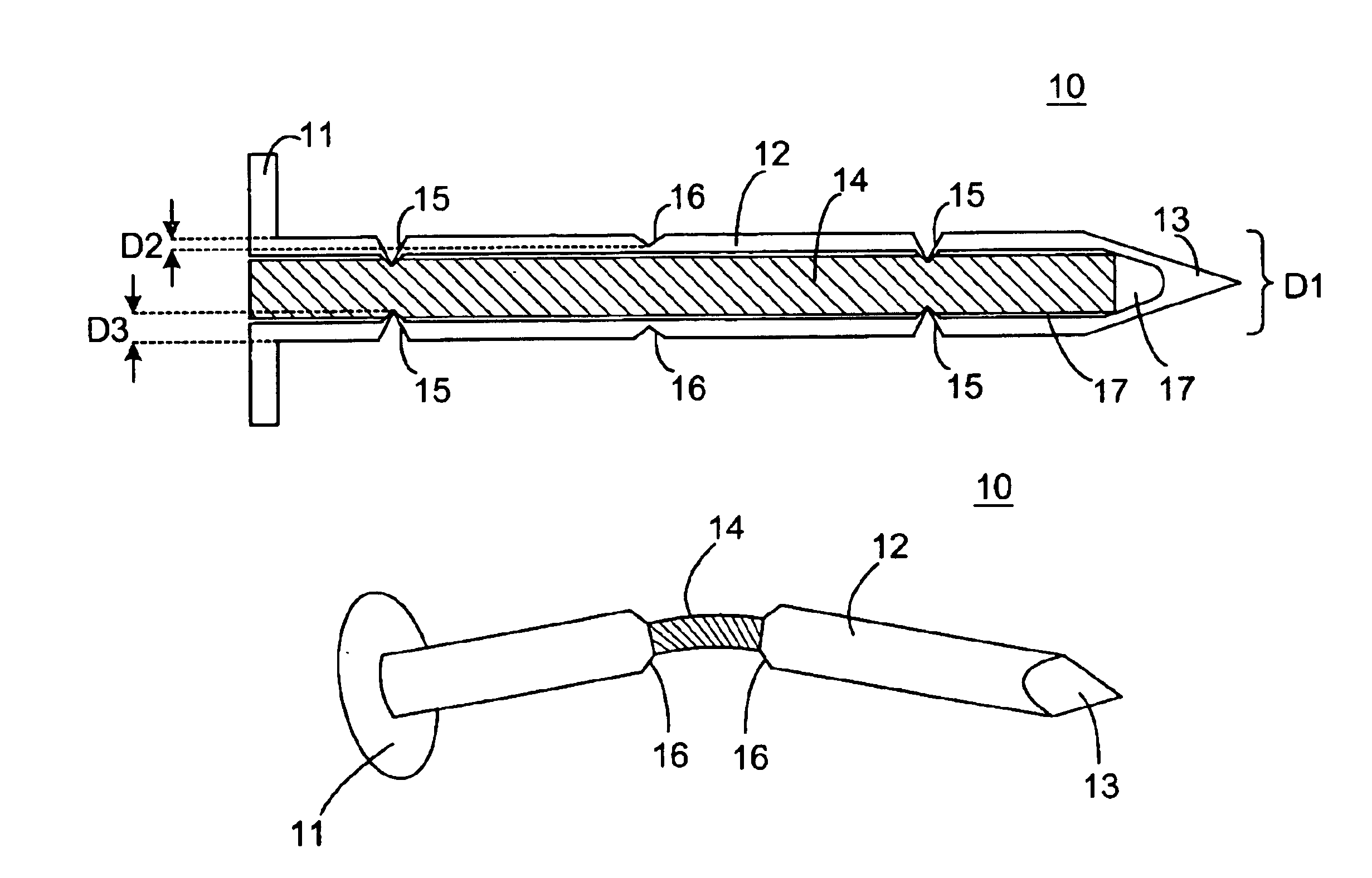

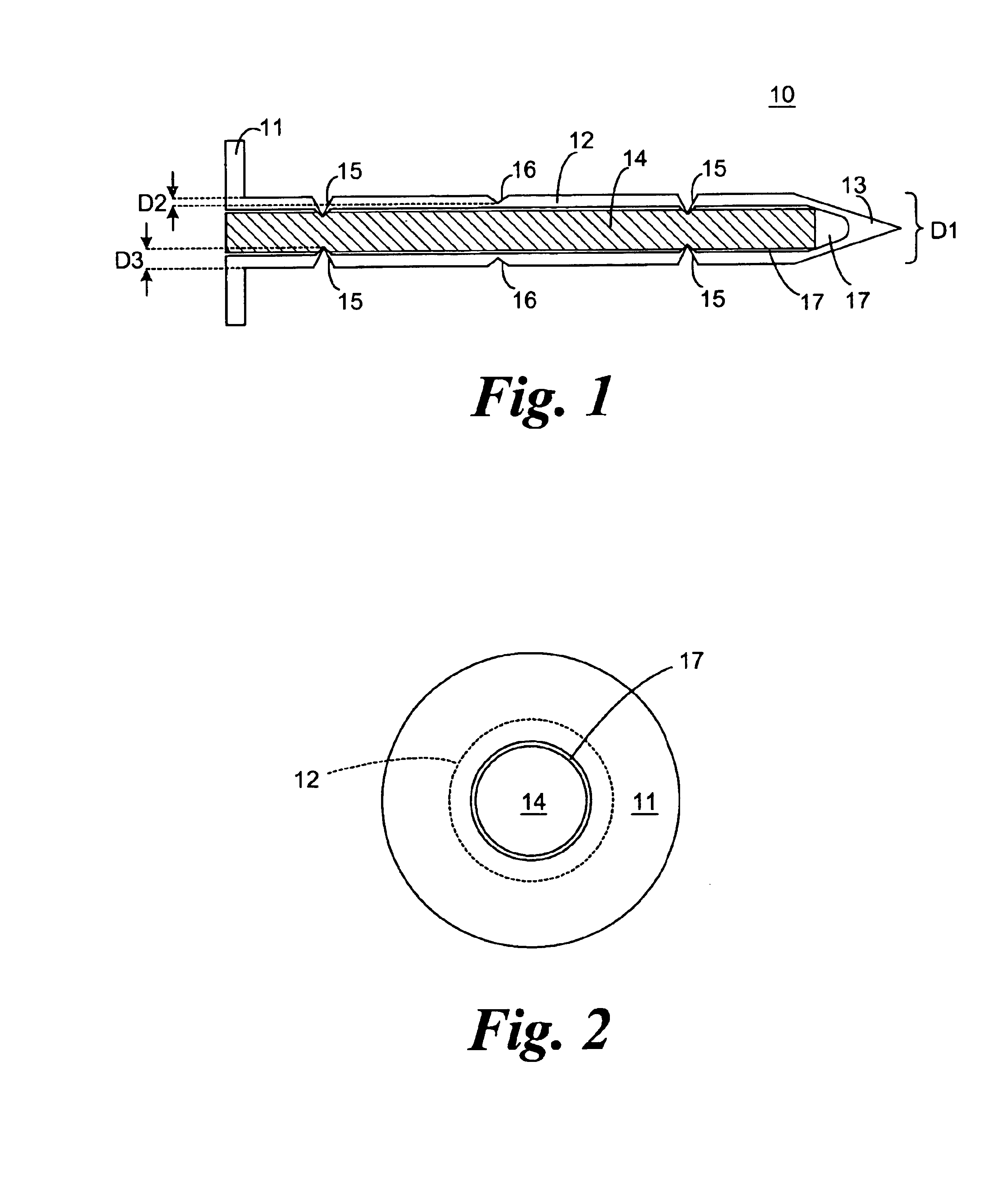

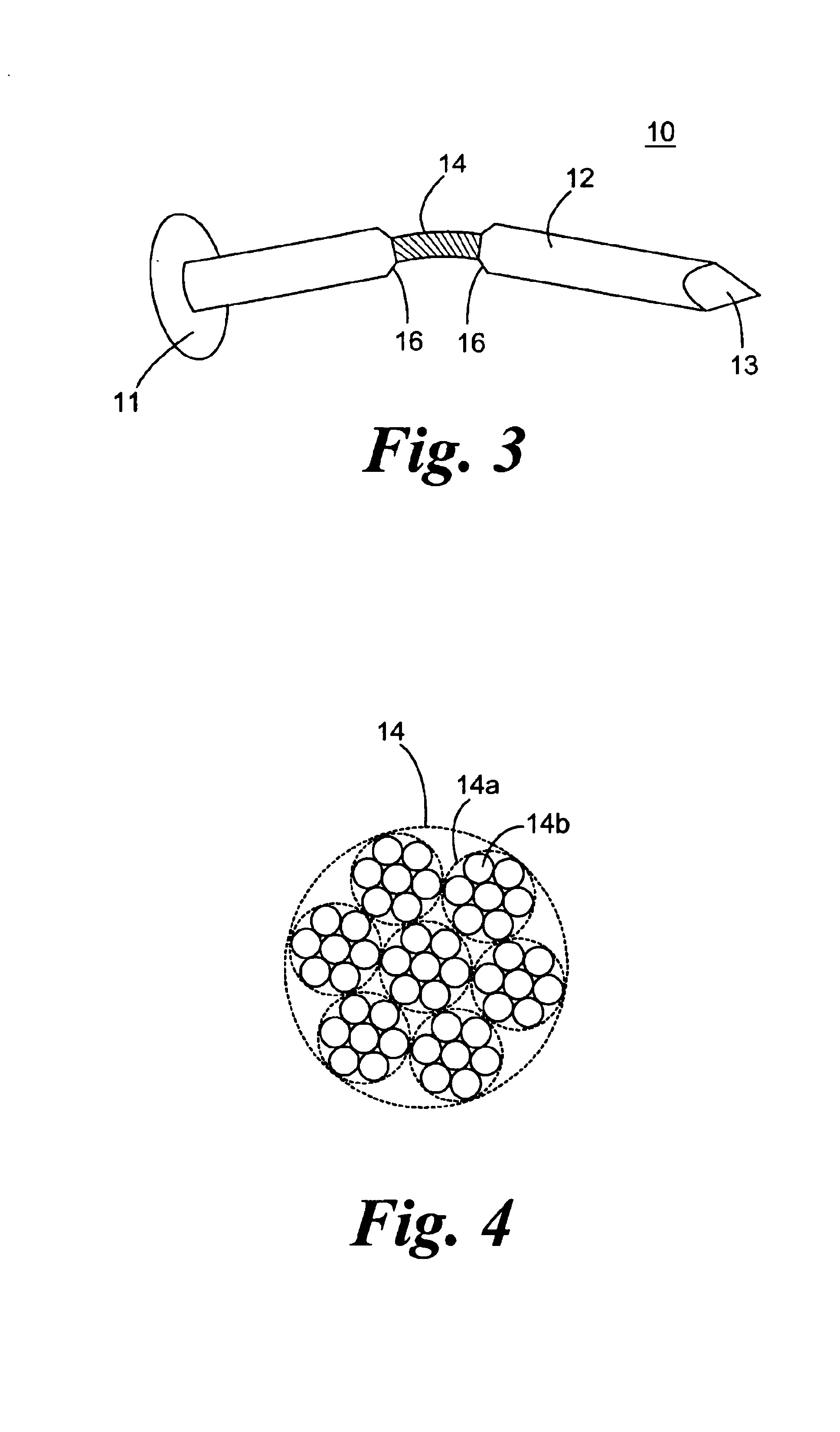

Fastener having supplemental support and retention capabilities

A fastener, such as a nail, screw, etc., which possesses supplemental support and / or retention capability is provided. The fastener includes an elongated auxiliary member secured interiorly to, exteriorly to, or along the shaft of the fastener. The auxiliary member is secured to the shaft at two or more portions of the shaft. The auxiliary member provides the shaft with additional support strength and / or enables fastened materials to be retained upon breakage or shearing of the shaft as a result of, for example, heavy tensile or shearing loads. To facilitate breakage or shearing of the shaft, the shaft may be provided with a deformation, such as a notch or reduced circumference, at one or more desired locations such that the shaft breaks or shears at the deformation(s), thereby allowing the auxiliary member to function as the sole member which retains the fastened materials. The auxiliary member may be sufficiently flexible and pliable such that, upon breakage or shearing of the shaft, retention of the materials is maintained but in a less stressed form.

Owner:NELSON CHARLES +2

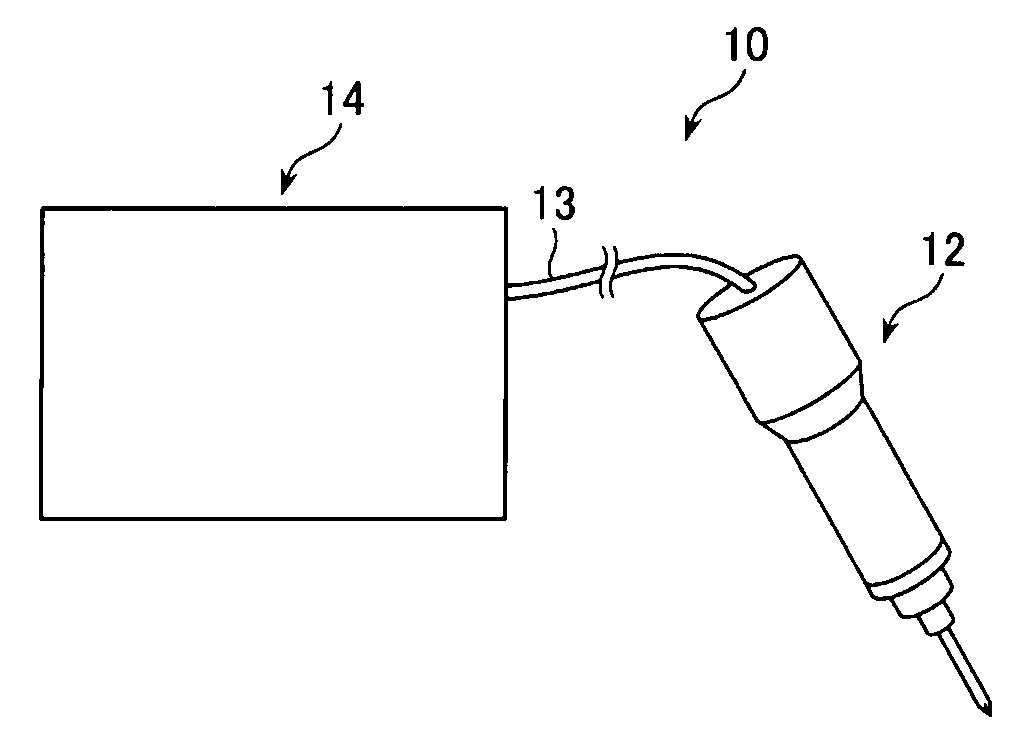

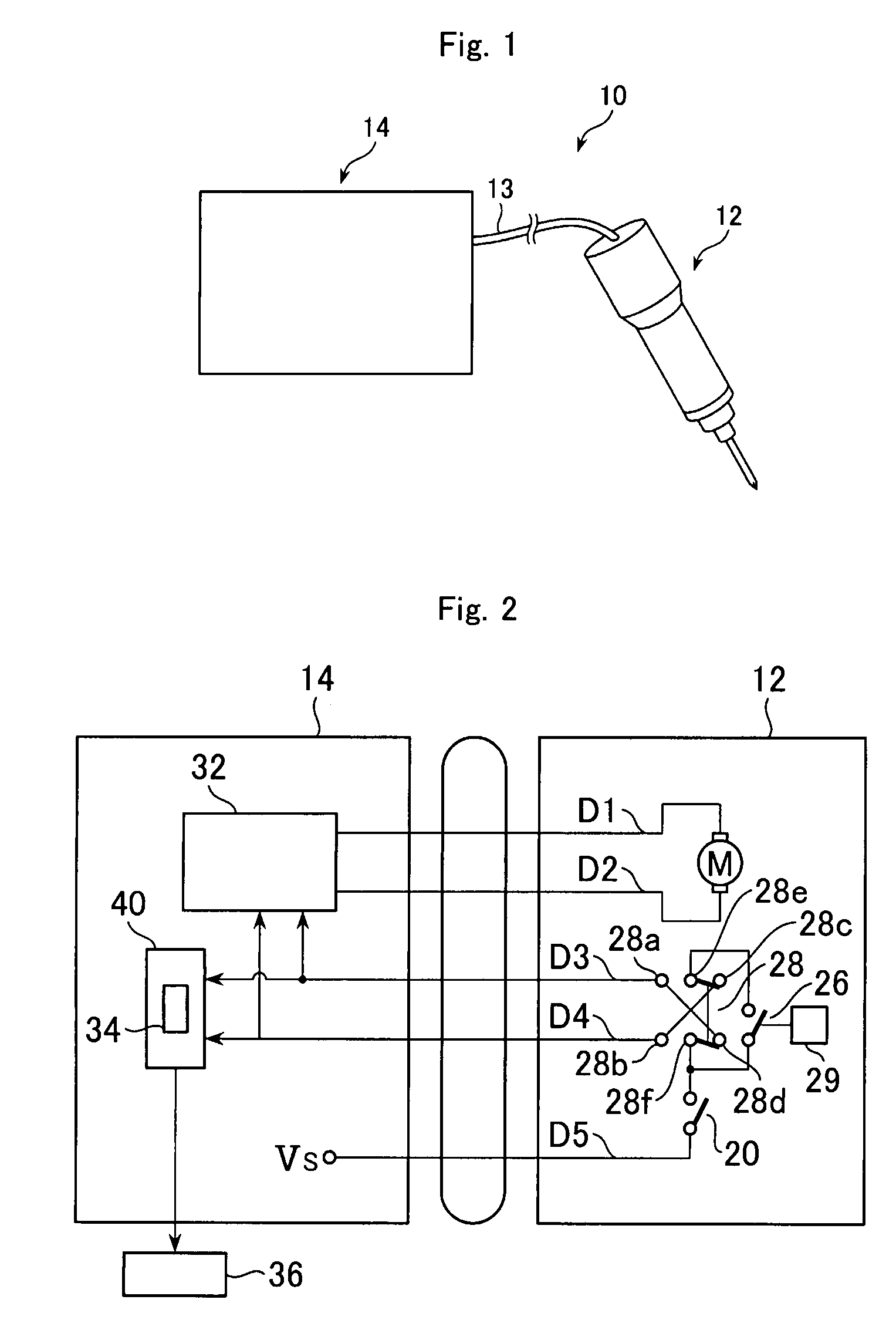

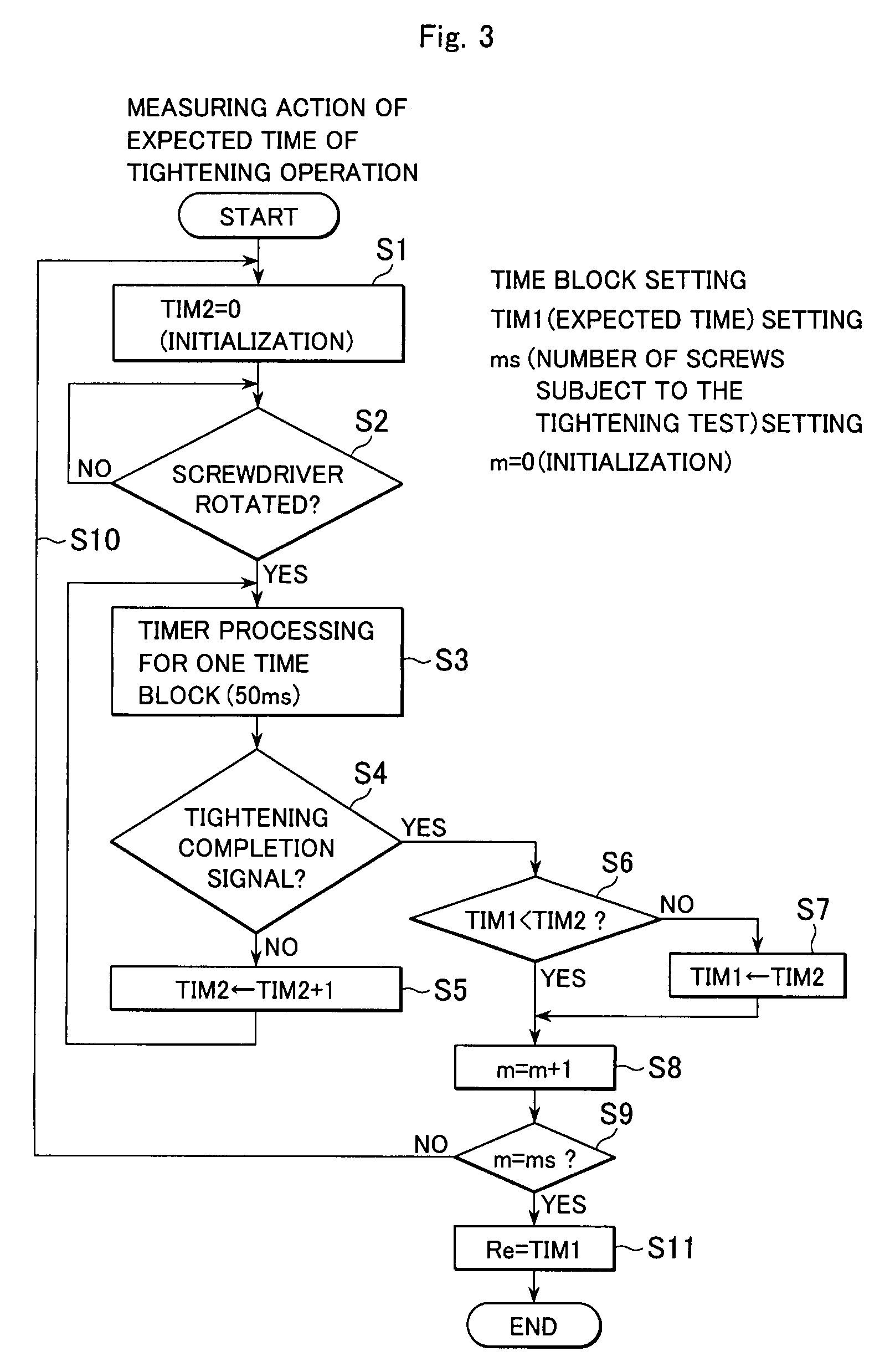

Electric screwdriver and a controller thereof

An object of the present invention is to provide an electric screwdriver device having a function for determining that a correct tightening operation has been carried out when the tightening operation has taken a time longer than a reference time predetermined for the tightening operation, characterized in comprising a novel feature for determining the reference time. The electric screwdriver device of the present invention comprises a torque monitor (40, S4) for monitoring whether or not a load torque in carrying out the tightening by using the electric screwdriver 12 has reached the tightening completion torque, a timer (40, S1, S5) for measuring the time consumed from the starting of the tightening operation until the tightening torque has reached the tightening completion torque, as the tightening operation time, and a reference time setter (40, S6-S10) for determining the reference time for a subsequent tightening operation based on a plurality of tightening operation time obtained from the timer in the tightening operations carried out for the predetermined number of screws.

Owner:NITTO KOHKI CO LTD

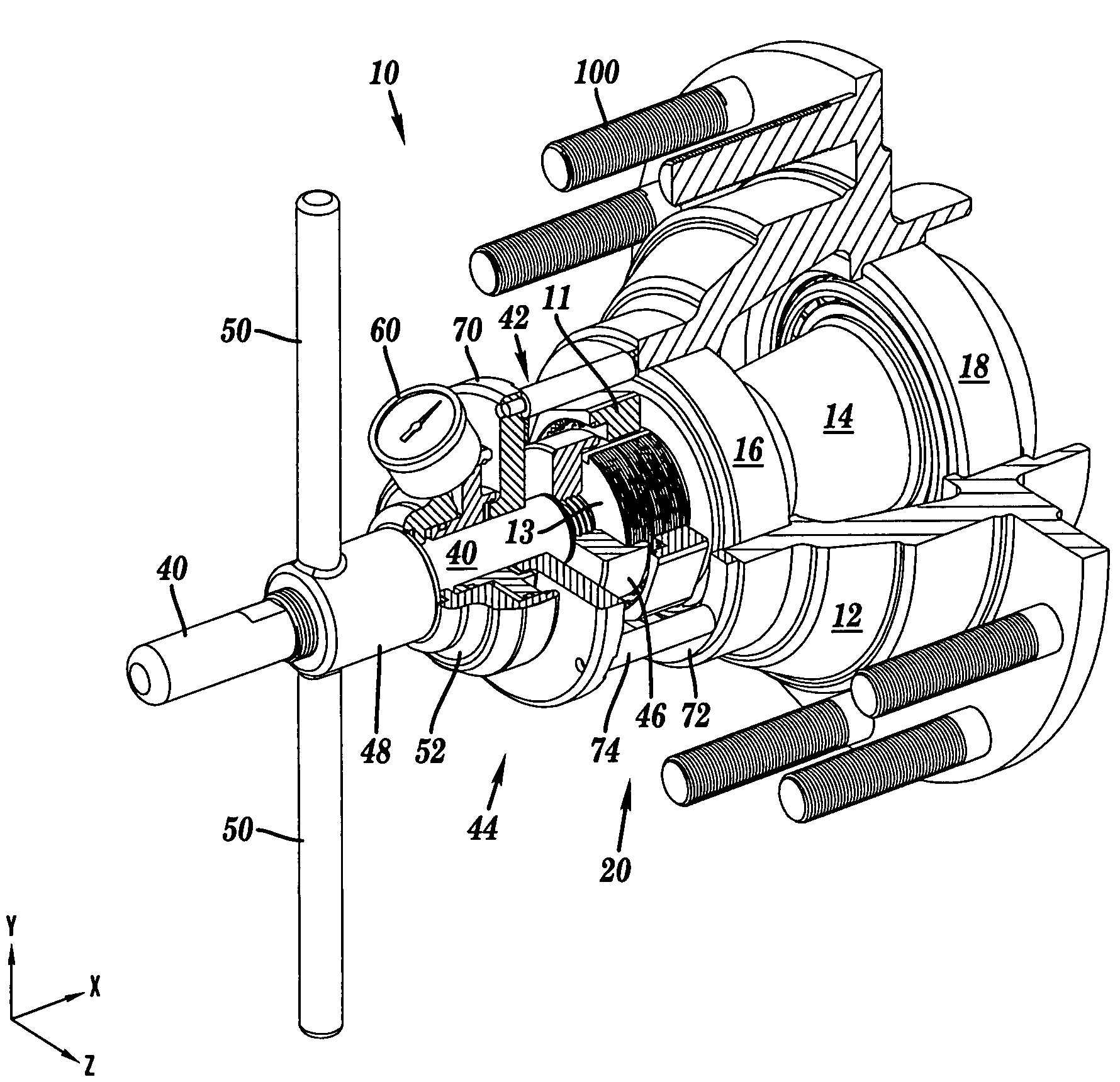

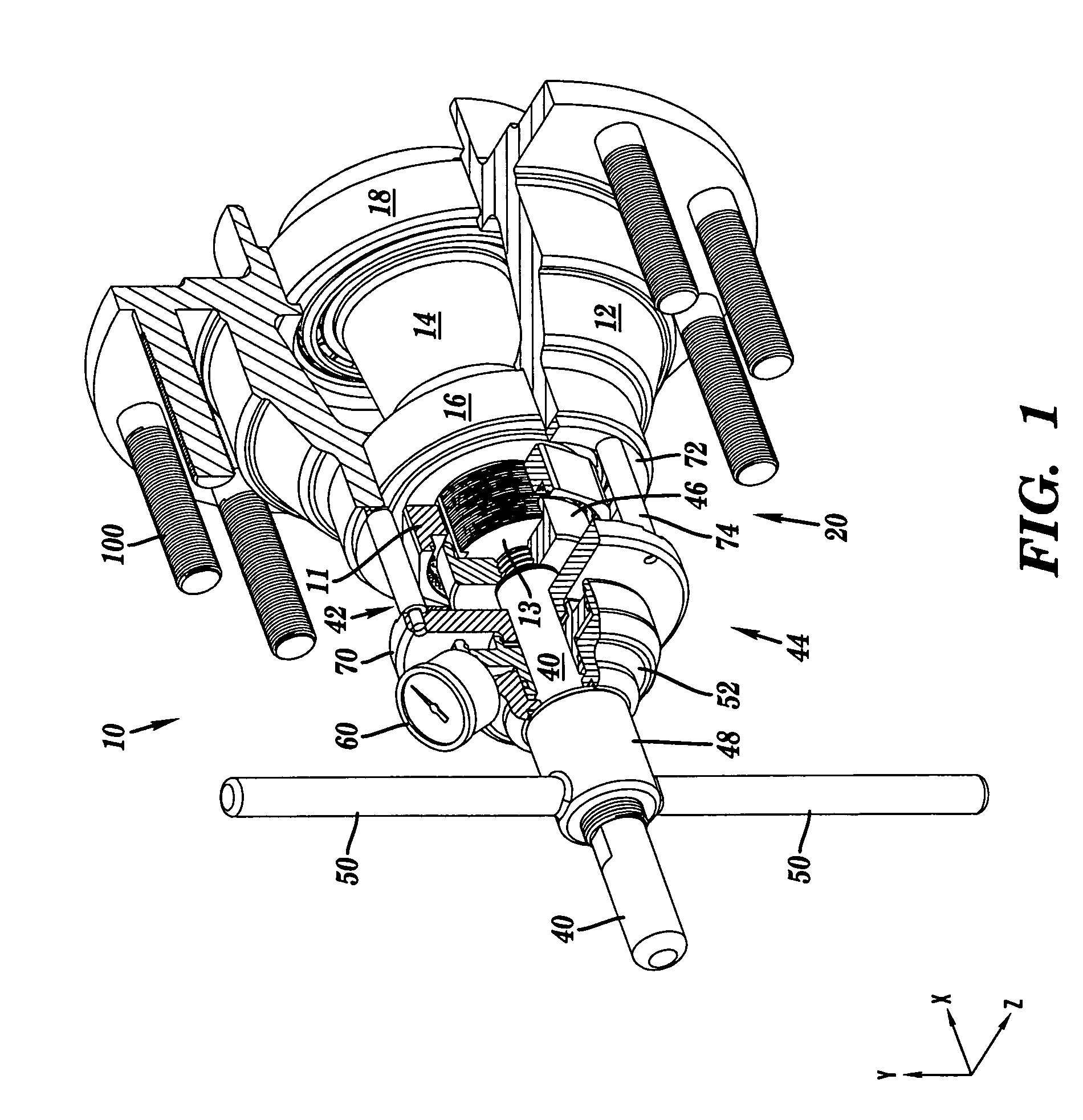

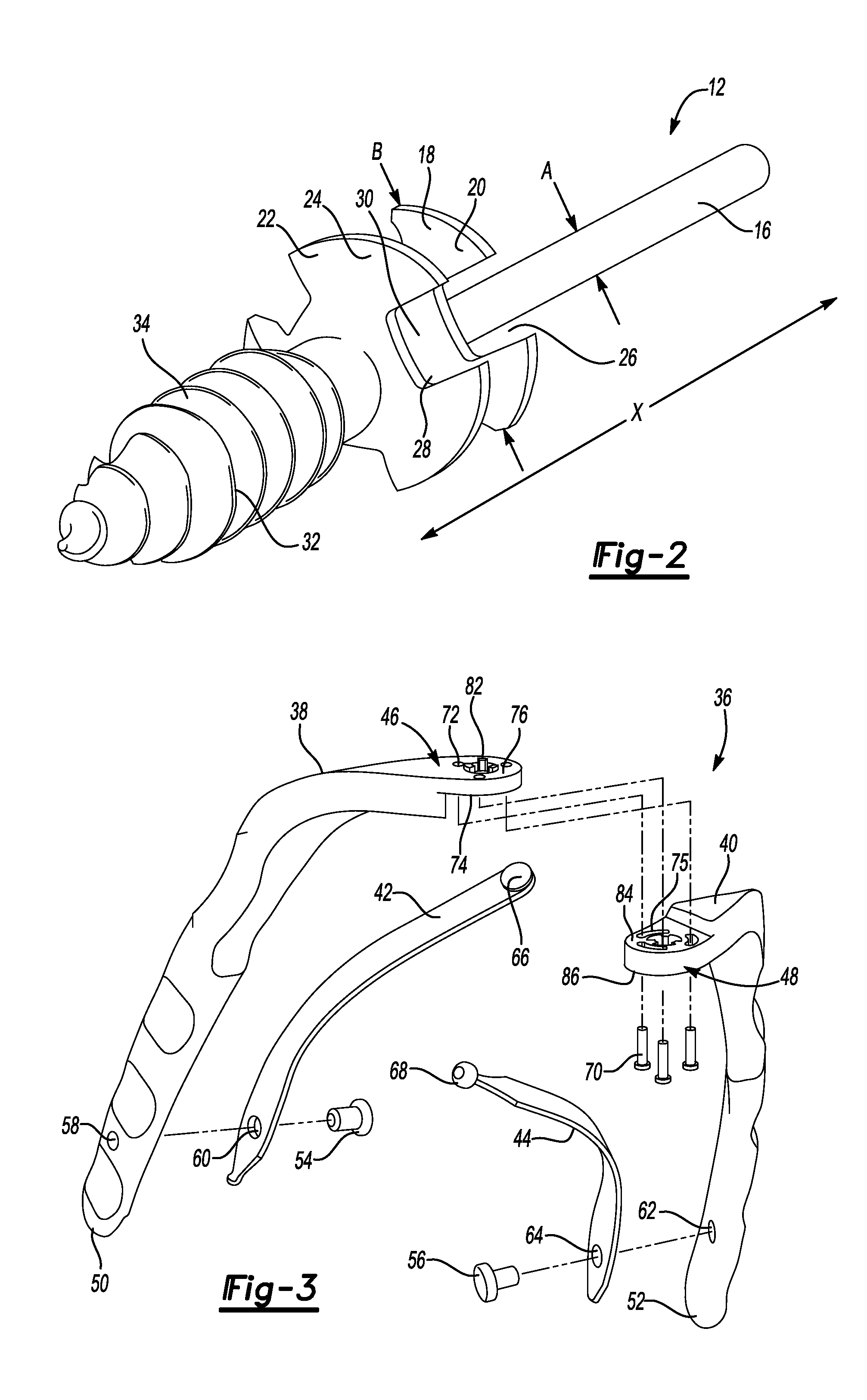

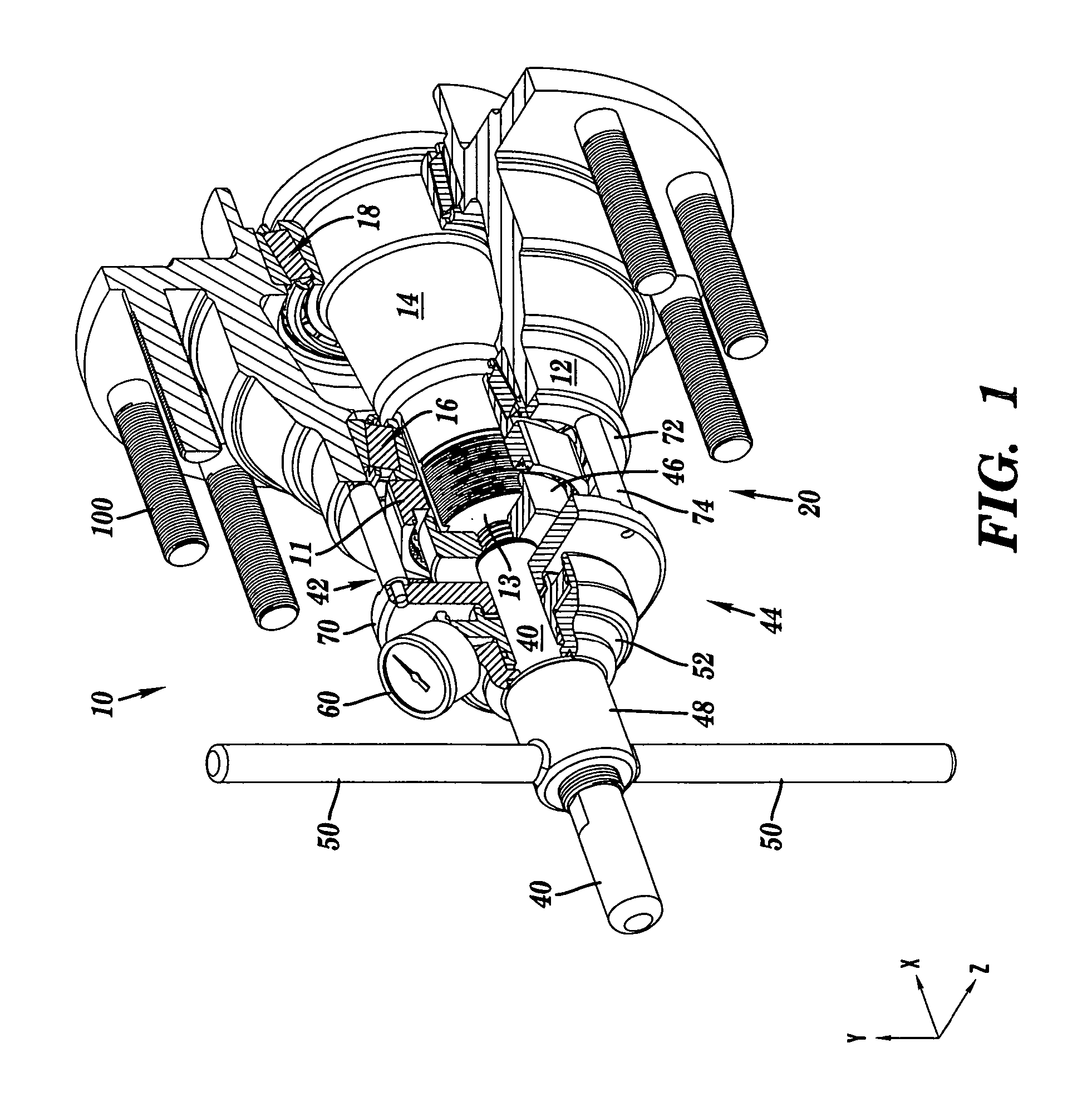

Method and apparatus for preloading a bearing

Methods and apparatus for preloading a bearing are provided. The apparatus includes a rod having a first end and a second end adapted to be removably mounted to a shaft; a device for compressing a hub against the outer race of a bearing to provide the preload to the bearing; and a cylindrical frame positioned between the device for compressing the hub and the hub. These methods and apparatus include preload monitoring devices whereby the mechanic can accurately monitor and regulate the preload to a bearing or bearing assembly. Aspects of the invention may also be used to adjust the endplay on a bearing or a bearing assembly. In one aspect, the preload to the bearing is transmitted through a housing having a fluid whose pressure can be detected and monitored. An apparatus for precisely rotating a nut and a tool for precisely rotating a nut are also provided.

Owner:TEMPER +1

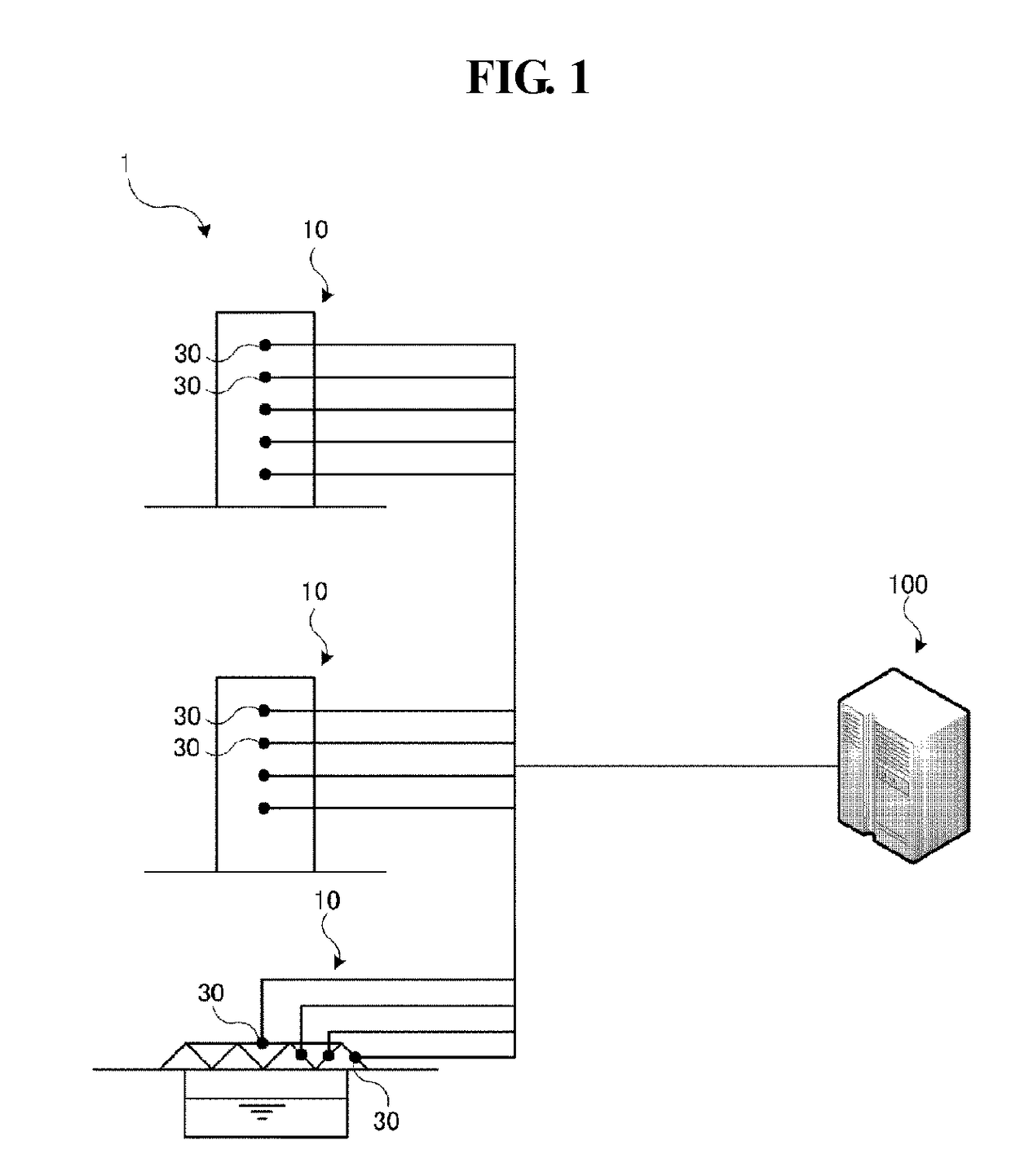

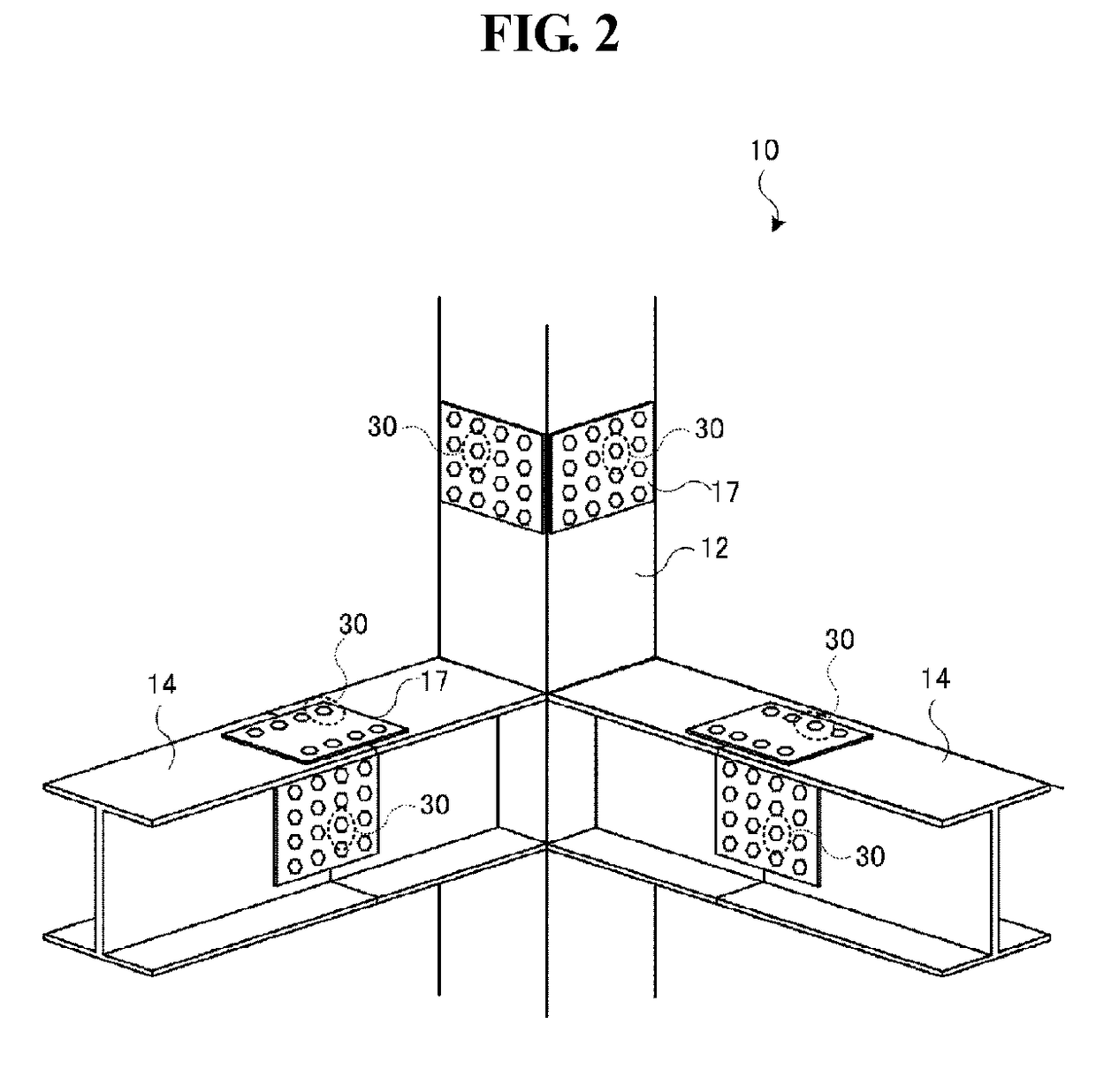

Independently calibrated wireless structural load sensor

InactiveUS8024980B2Testing/calibration apparatusMeasurement of torque/twisting force while tighteningStructural loadEngineering

A device includes a removable load element. The removable load element includes a pin portion and a housing portion. The pin portion extends from the housing portion. The pin portion includes a sensor. The housing portion includes an electronic circuit connected to the sensor.

Owner:LORD CORP

Blind fastener and nose assembly for installation of the blind fastener

InactiveUS6868757B2Reduce wall thicknessNot significantly weaken the sleeveRivetsLoad modified fastenersNoseBlind hole

A blind fastener for securing a plurality of workpieces is provided that has a sleeve, and a pin member. In an alternate embodiment, the blind fastener has a sleeve, a pin member and a nut. The sleeves have a head with a plurality of rearwardly sloping recesses disposed therein. The recesses are adapted to be engaged with a plurality of rearwardly sloping nibs disposed on one end of a nose secured to an installation tool. The pin members have a splined head adapted to be engaged with a splined driver secured to an installation tool. Use of the splined head on the pin member, the splined driver, rearwardly sloping recesses on the sleeve, and rearwardly sloping nibs on the nose eliminates camming out of the nibs from the recesses during installation of the blind fastener. A nose assembly for installation of the blind fastener is also provided.

Owner:HUCK INT INC

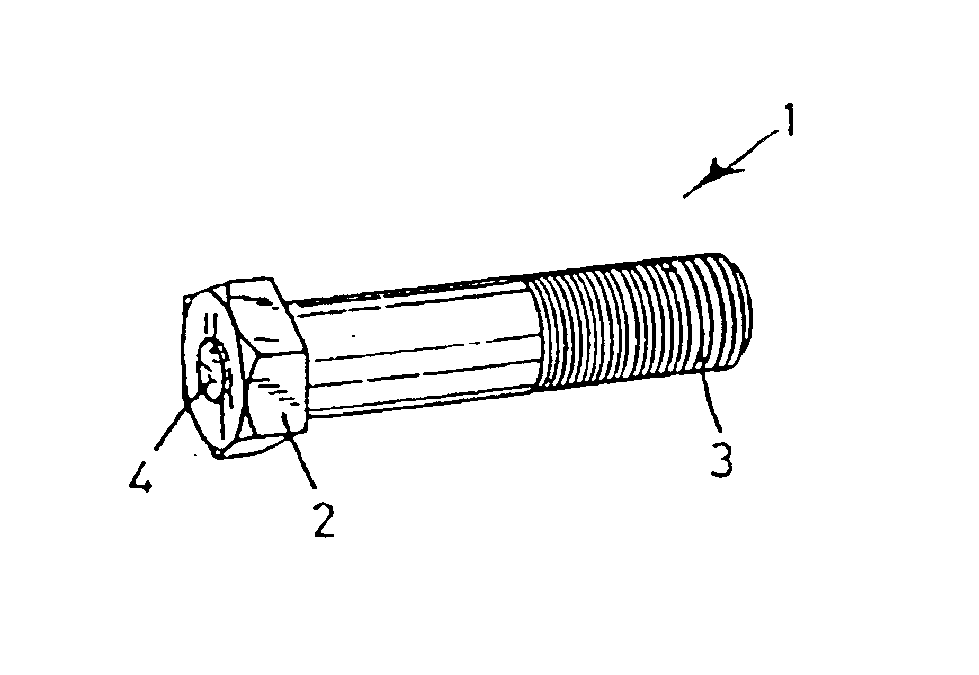

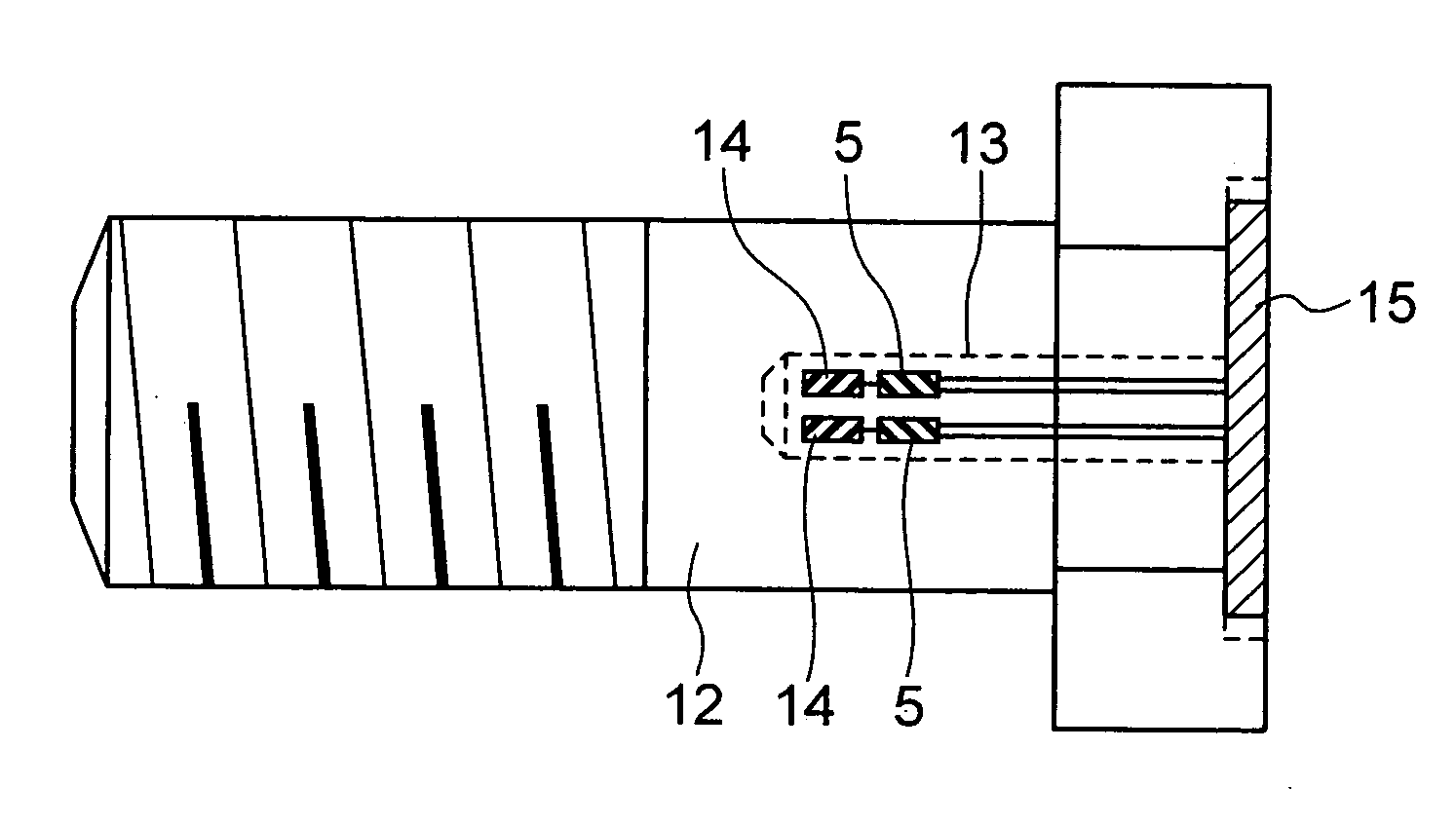

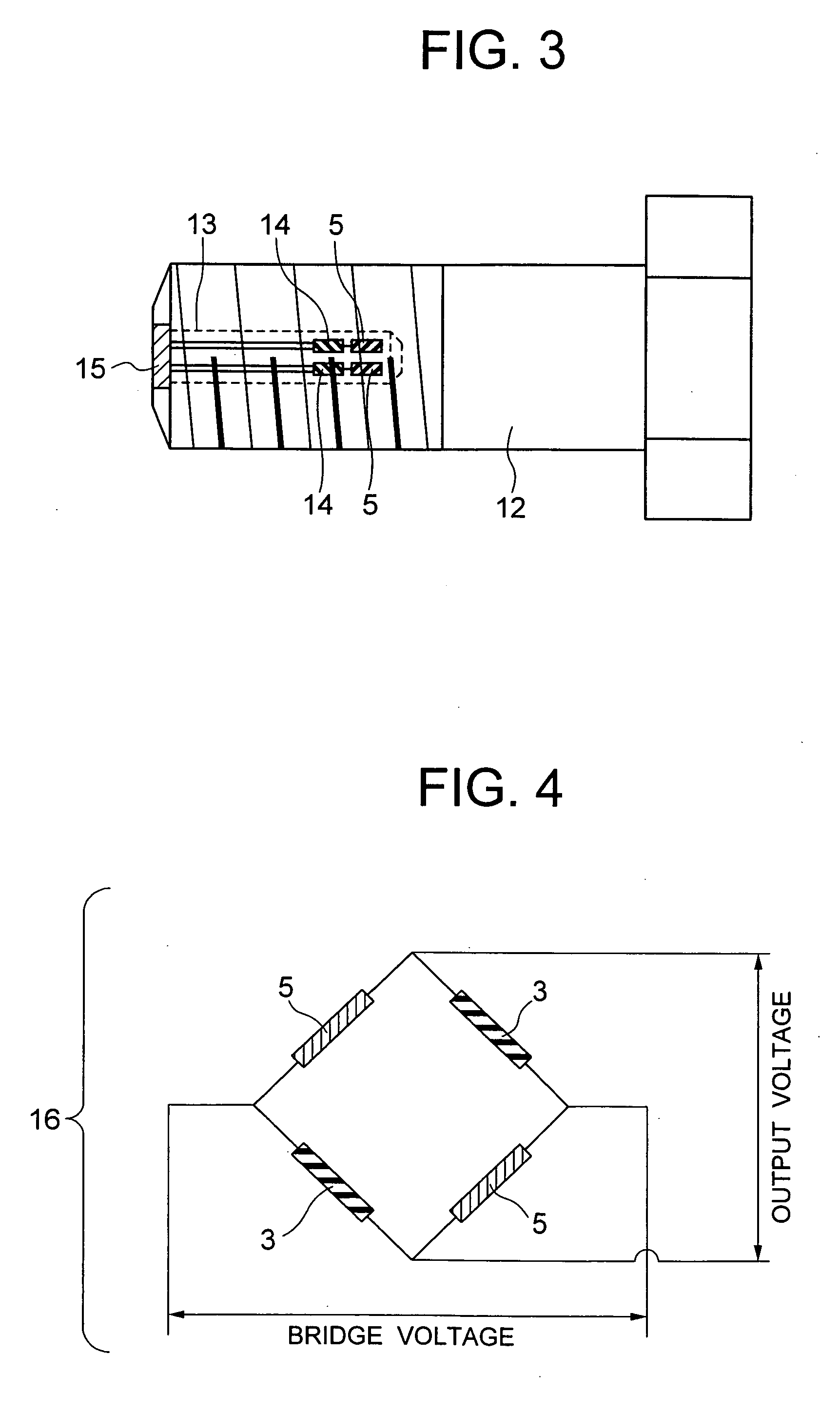

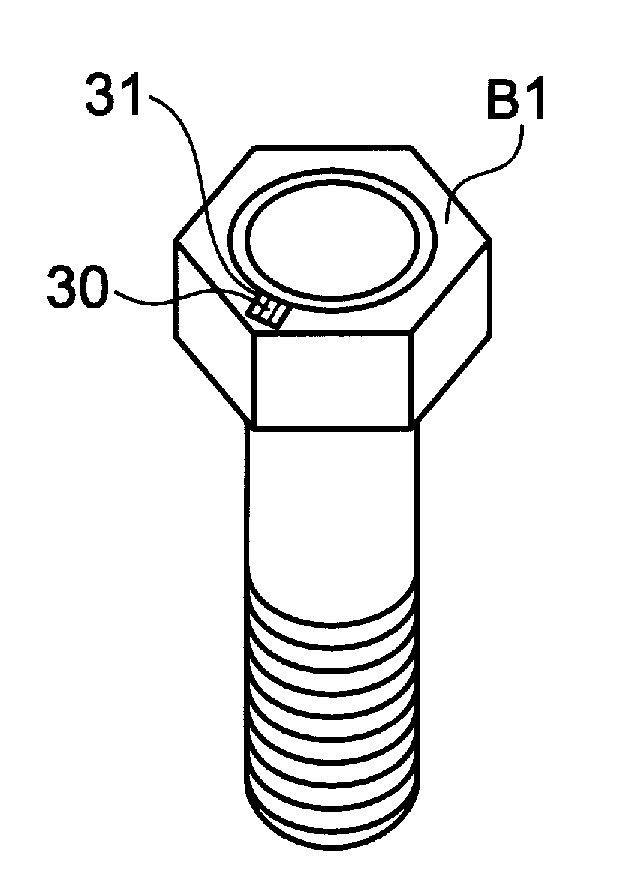

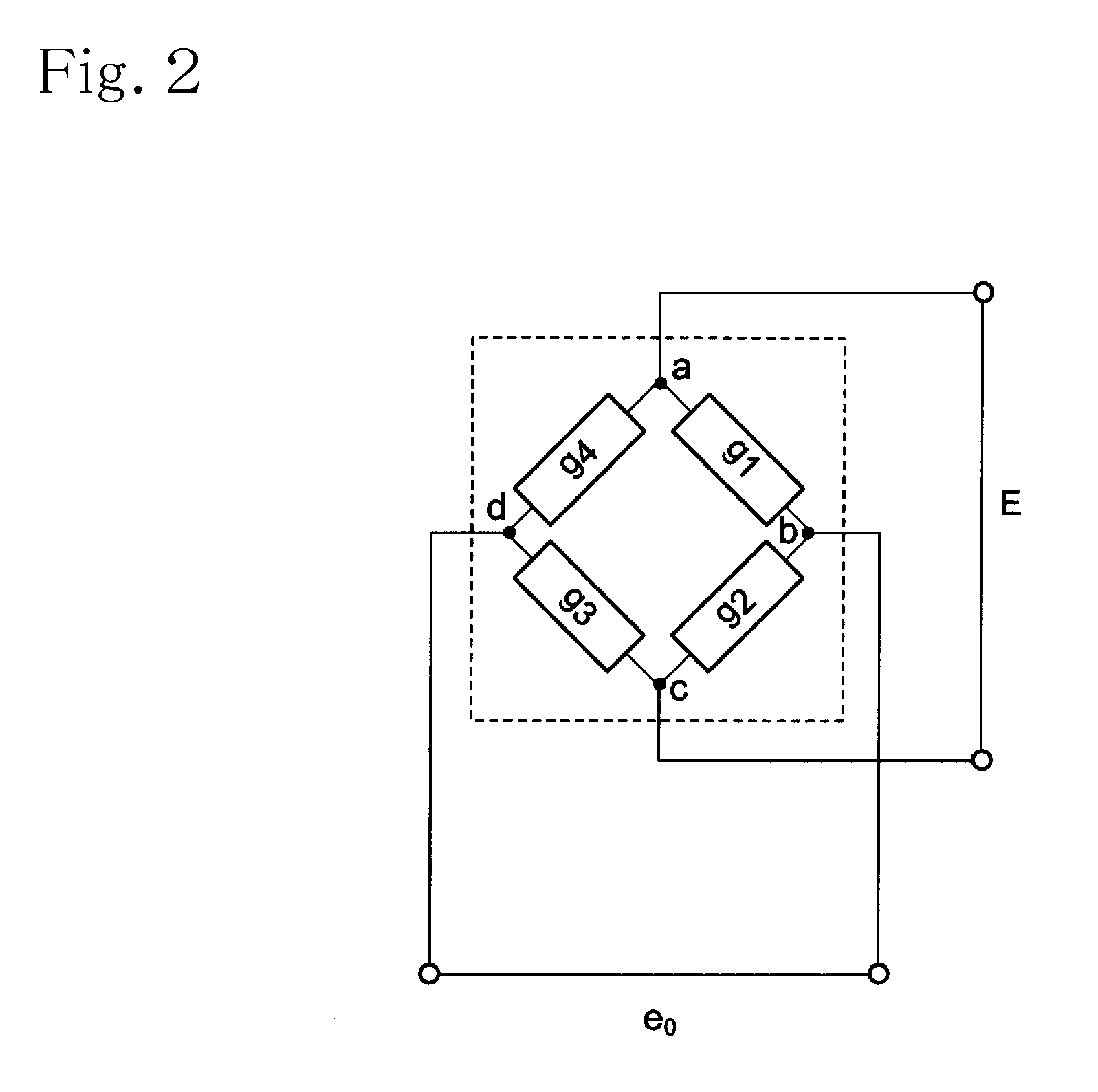

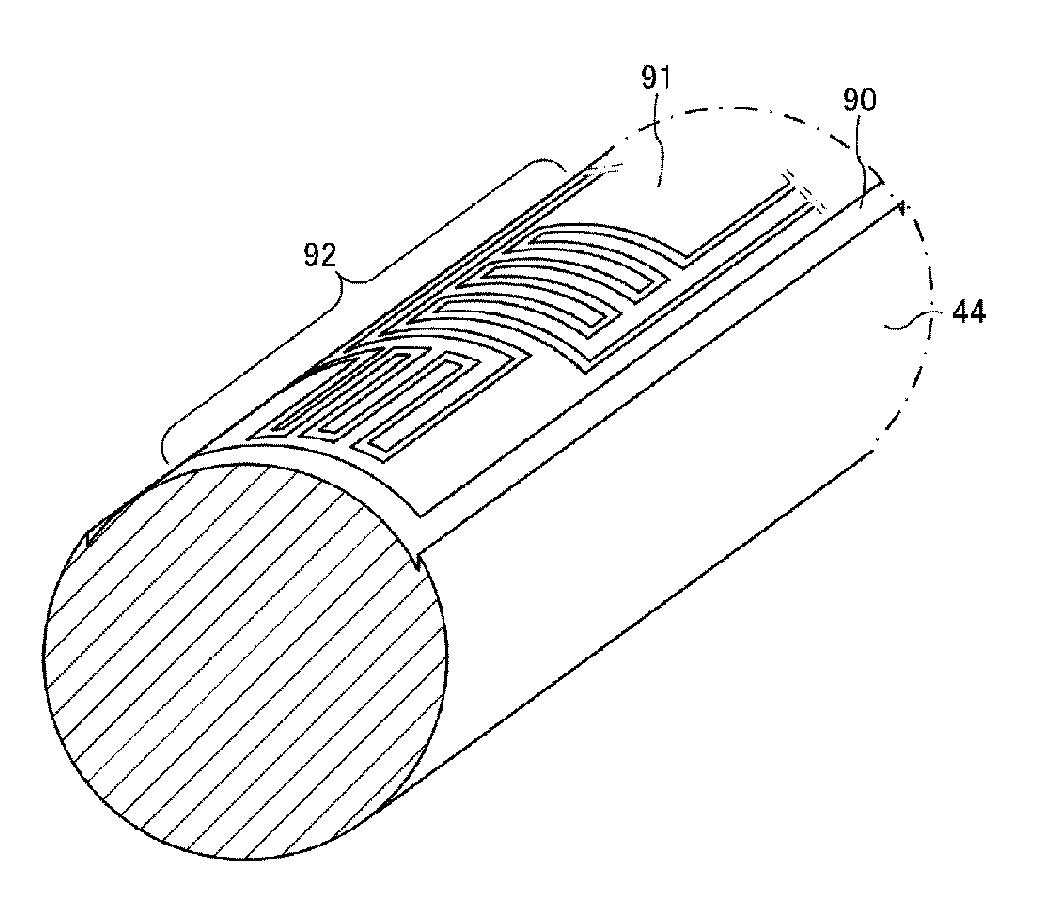

Bolt with function of measuring strain

ActiveUS20070017295A1Improve accuracyHigh precision measurementAcceleration measurement using interia forcesTesting/calibration apparatusElectrical resistance and conductanceEngineering

A bolt with a function of measuring strain, comprising a Wheatstone bridge circuit comprising a strain sensor and a dummy resistor, a translate circuit that amplifies a signal from the Wheatstone bridge circuit to convert the same into a digital signal, a transmitting circuit that transmits the digital signal outside the bolt, and a power circuit, by which electromagnetic wave energy received from outside the bolt is supplied as a power source for at least any one of the circuits.

Owner:HITACHI LTD

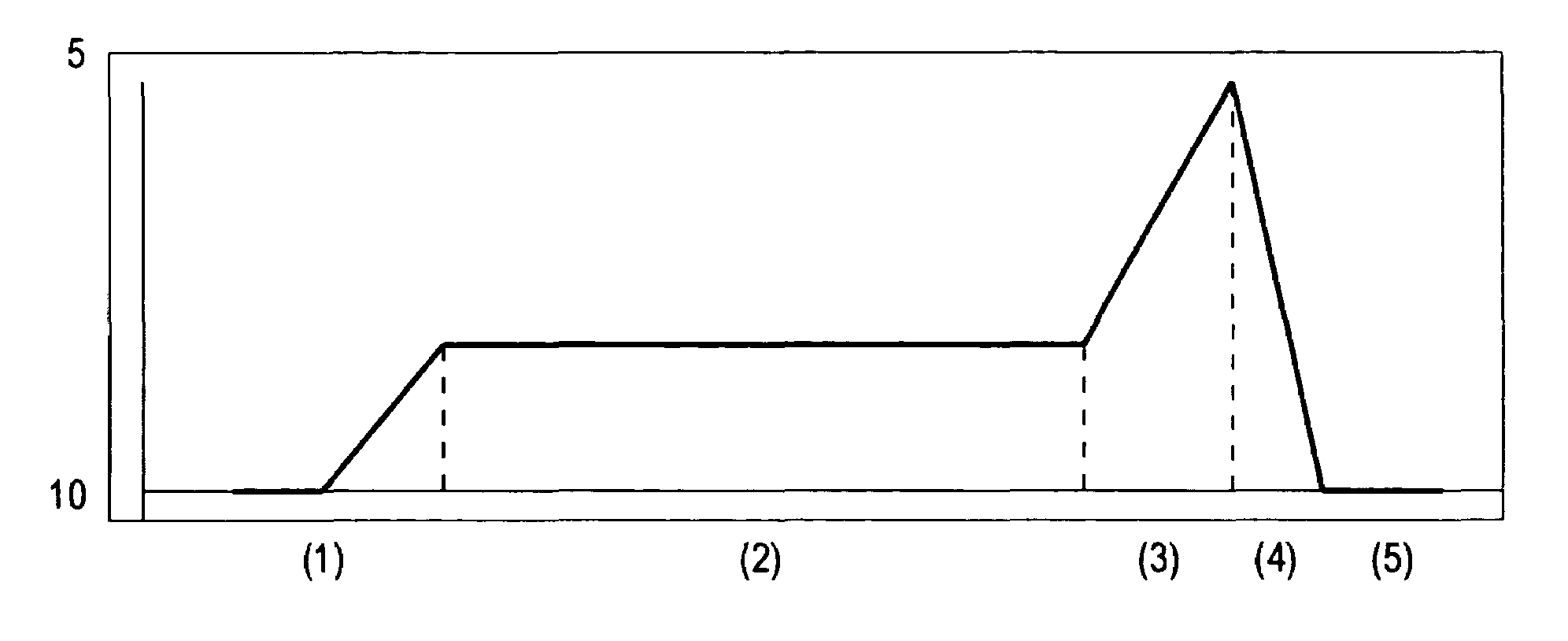

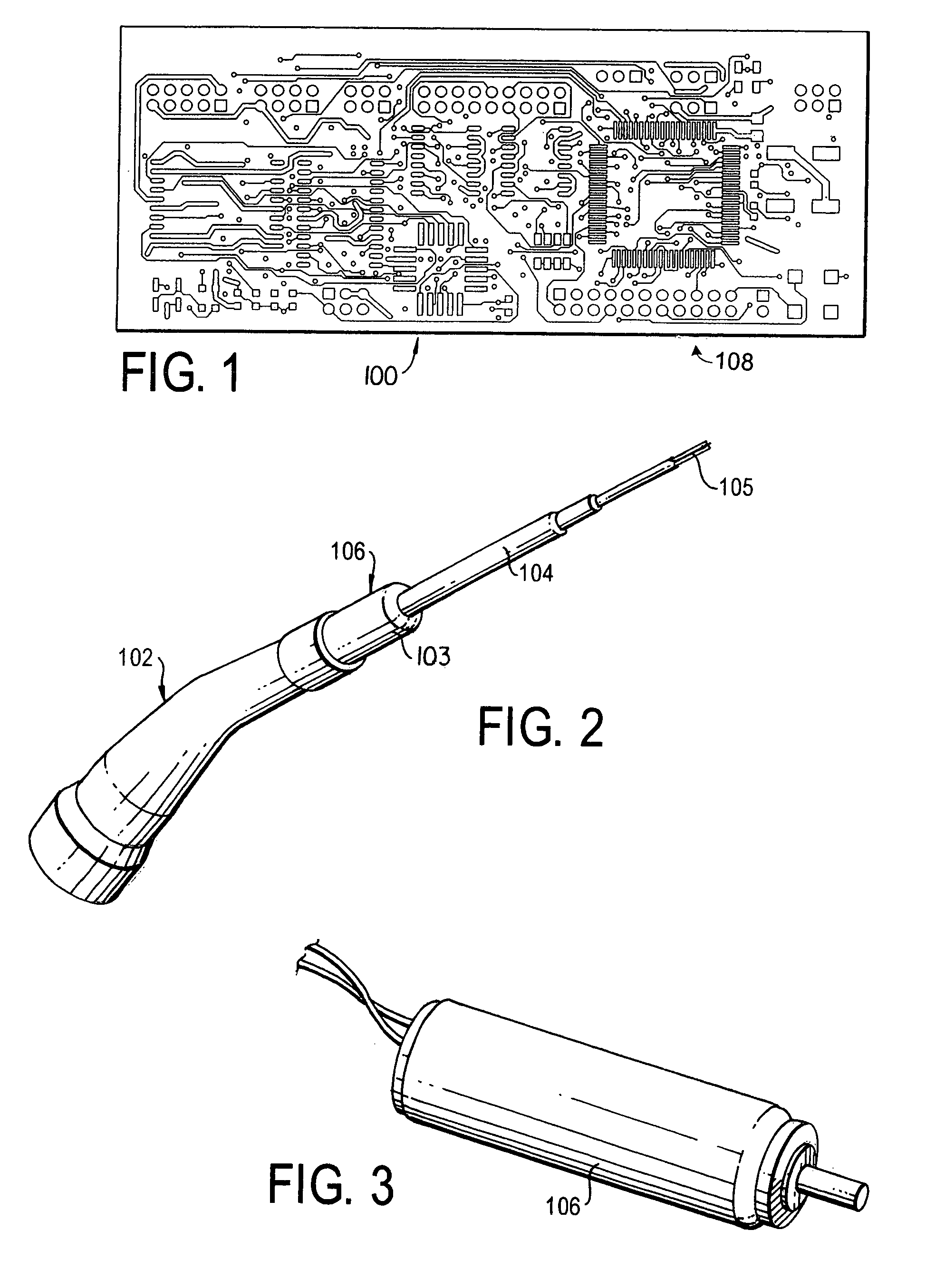

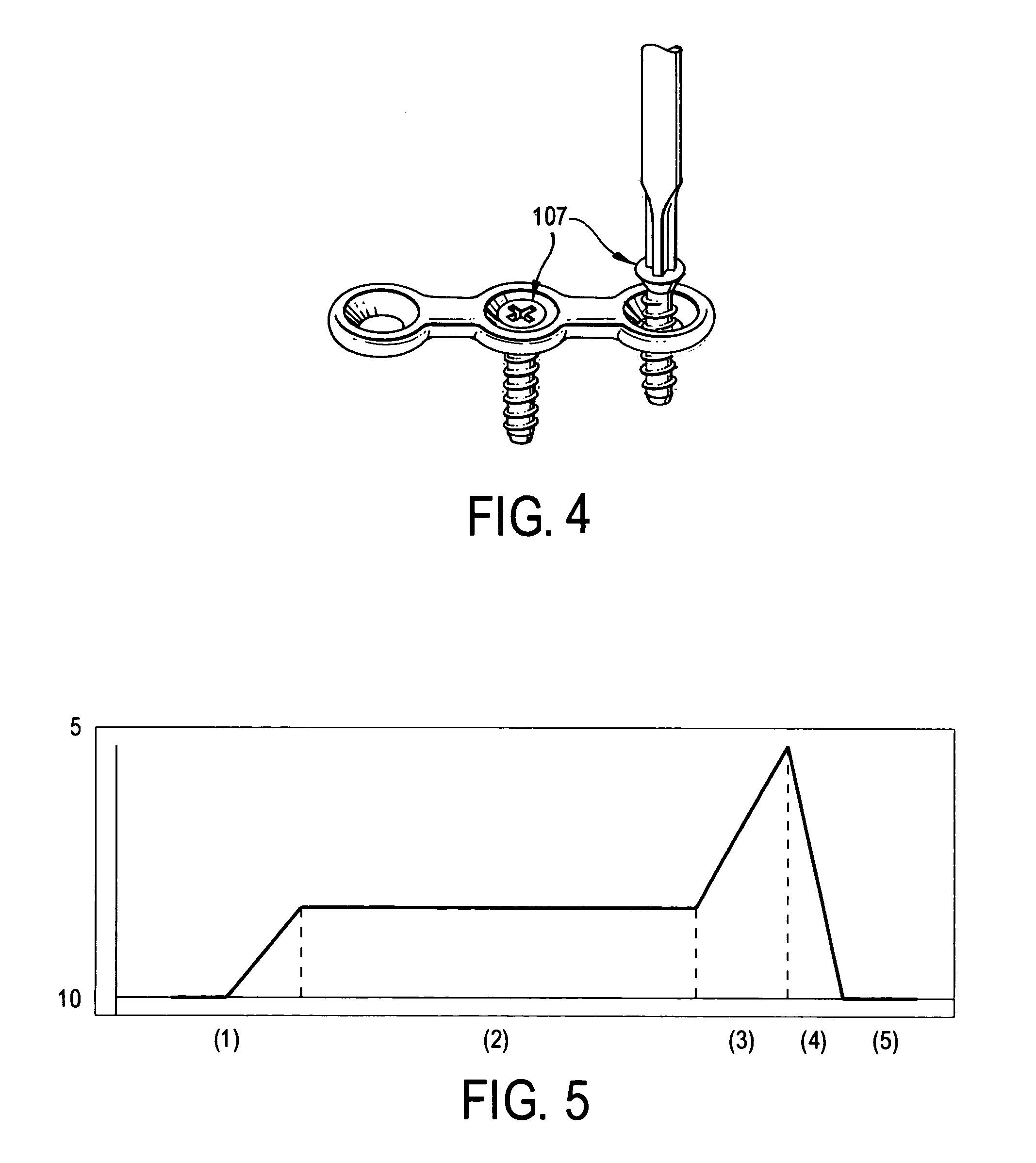

Method of monitoring and controlling the seating of screws to the optimum point of grip independent of screw size and material density

ActiveUS7091683B1Smoothes torque riseFalling smoothlyDC motor speed/torque controlDiagnosticsControl systemAnalog signal

A method of controlling a motor (106) used to drive a screwdriver bit (105) such that screws (107) are seated to the optimum point of grip between the screw (107) and the work piece material. An electronic control circuit controls the speed and output torque of the motor (106). The control system utilizes pulse width modulation (PWM) to control motor (106) speed and torque. The PWM signal controls the duty cycle of the transistors that supply current to the motor (106). The amount of current flowing through the motor (106) coils is proportional to the amount of torque the motor (106) is producing. Motor (106) current is measured as voltage produced across a precision resistor that is in series with the motor (106) coils. As the current in the motor (106) increases, the voltage across the resistor increases (V=IR). To accurately measure the torque, as measured by the voltage across the precision resistor, a capacitor with a resistor and / or a diode is used to average the analog signal that is measured by the microprocessor. The microprocessor further filters the analog signal using an averaging formula to produce a stable value corresponding to motor (106) torque / current. When a decrease in current, corresponding to a drop in torque, is detected at the optimum point of grip, the controller (100) stops the motor (106).

Owner:INTELLIGENT AUTOMATION DESIGN

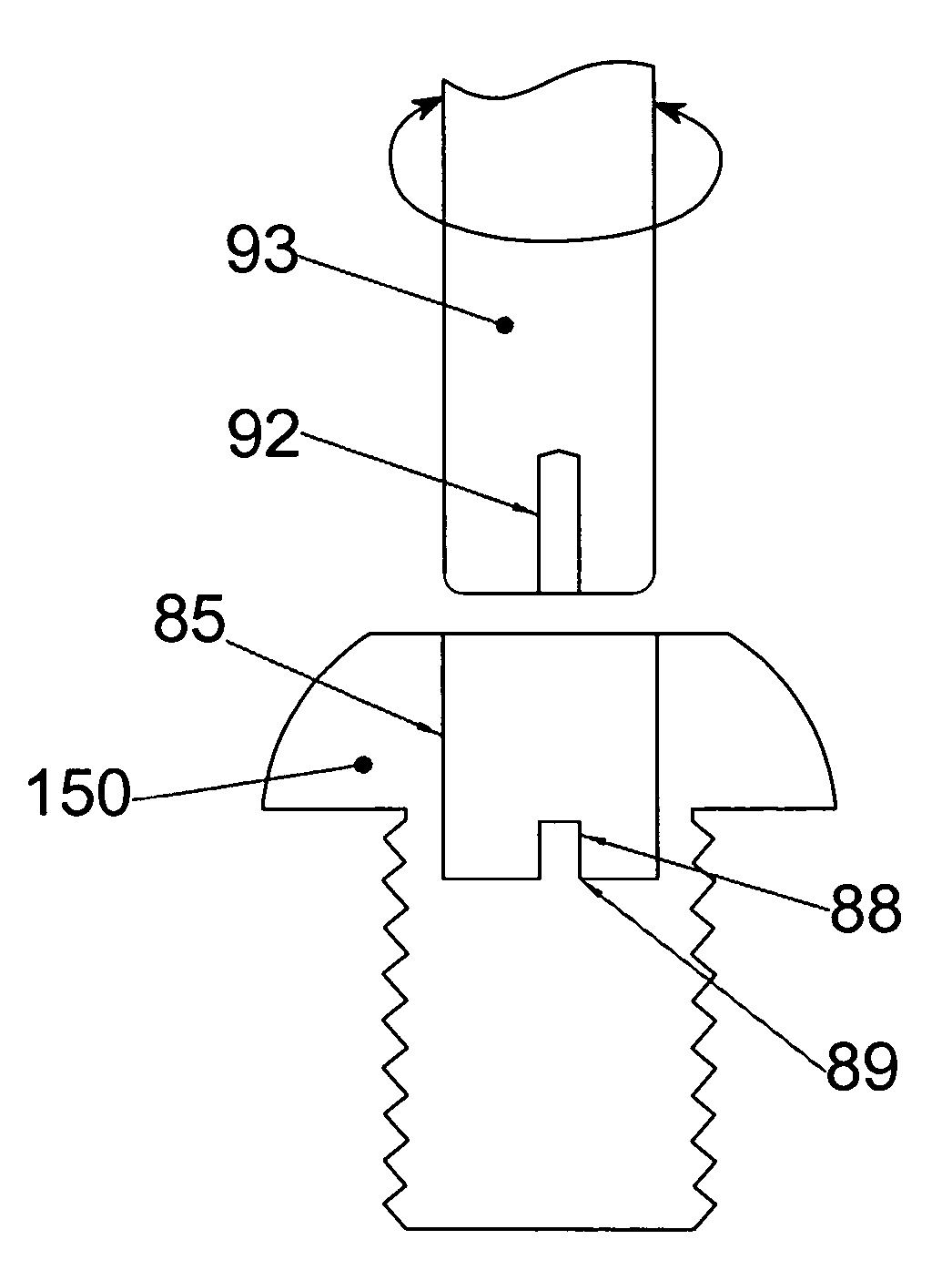

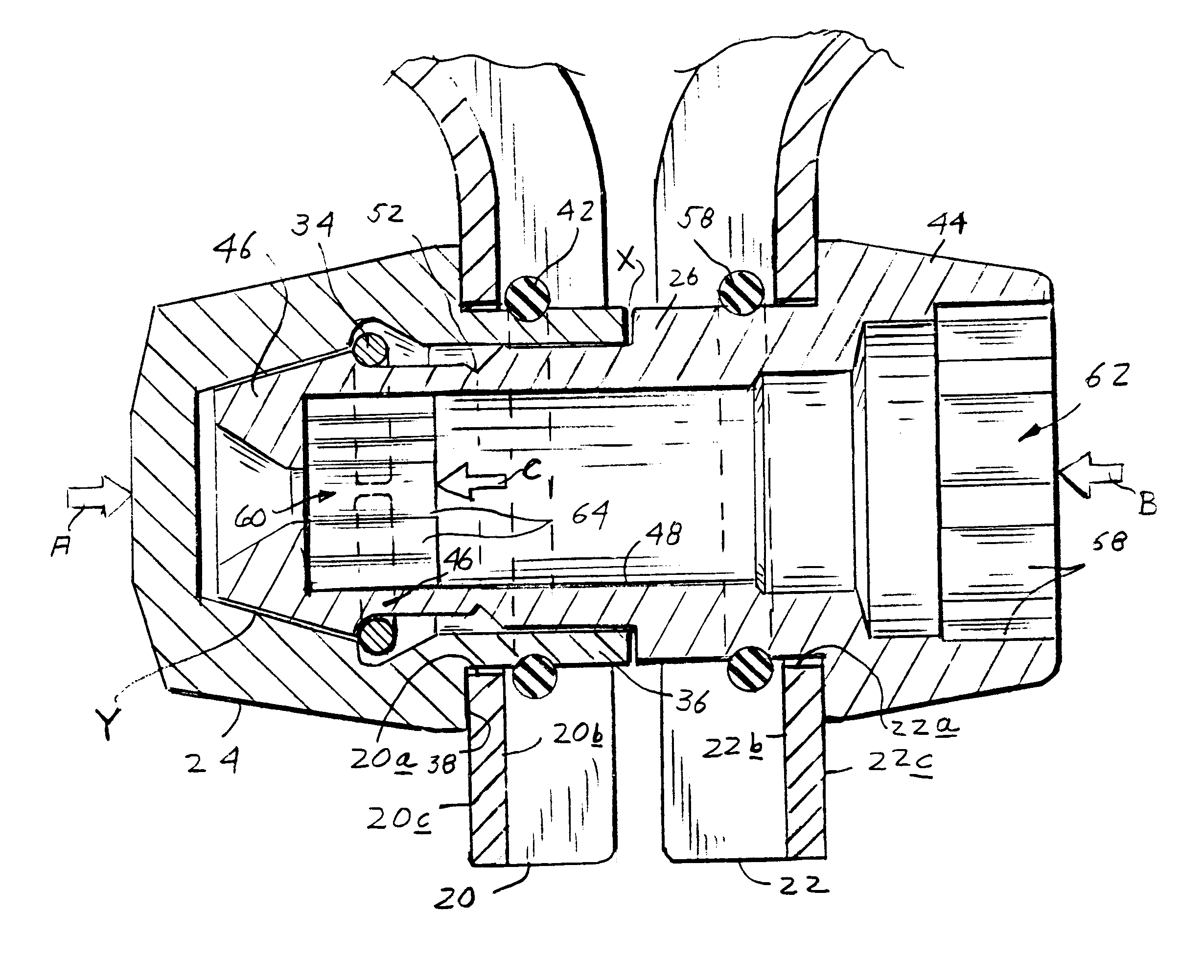

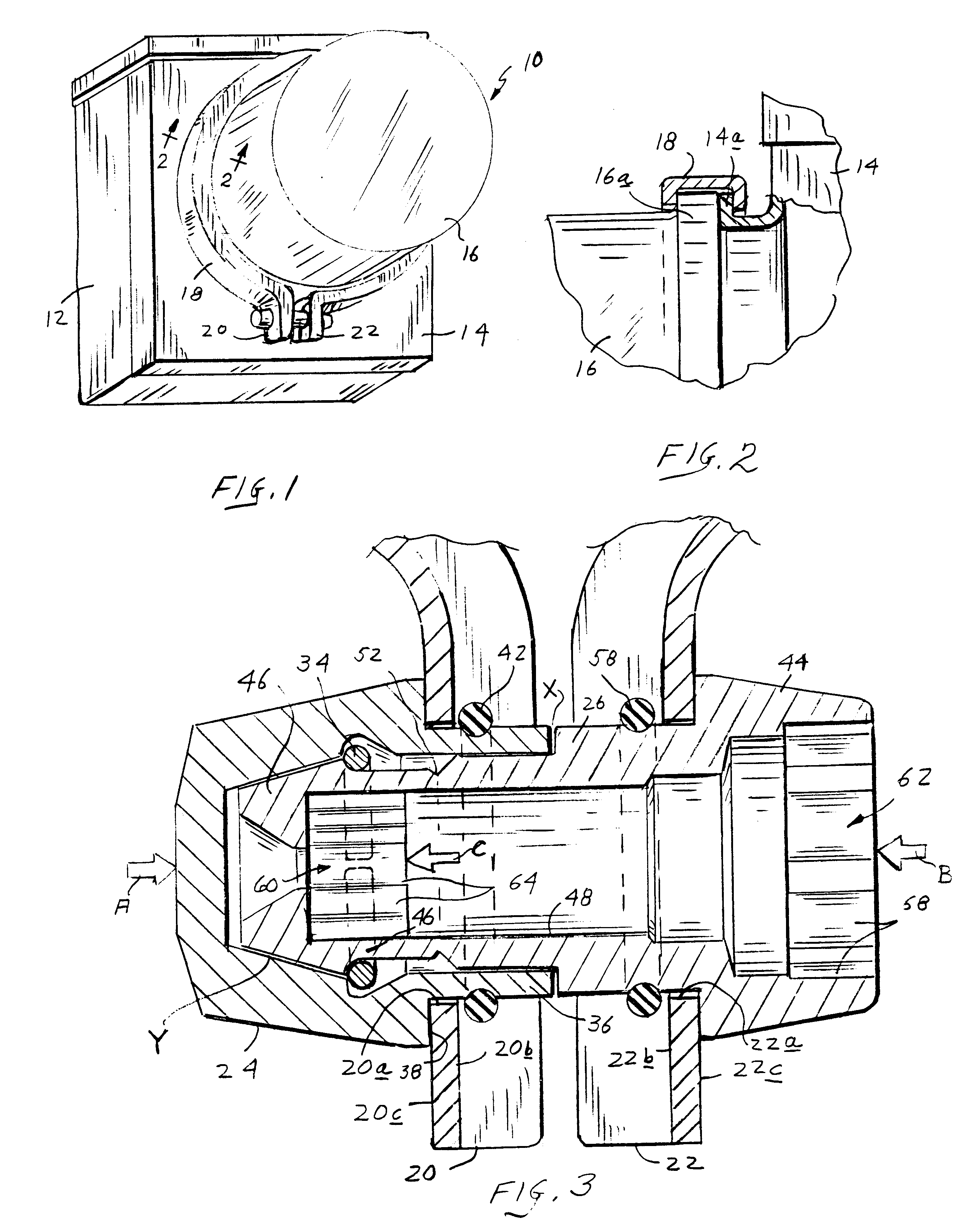

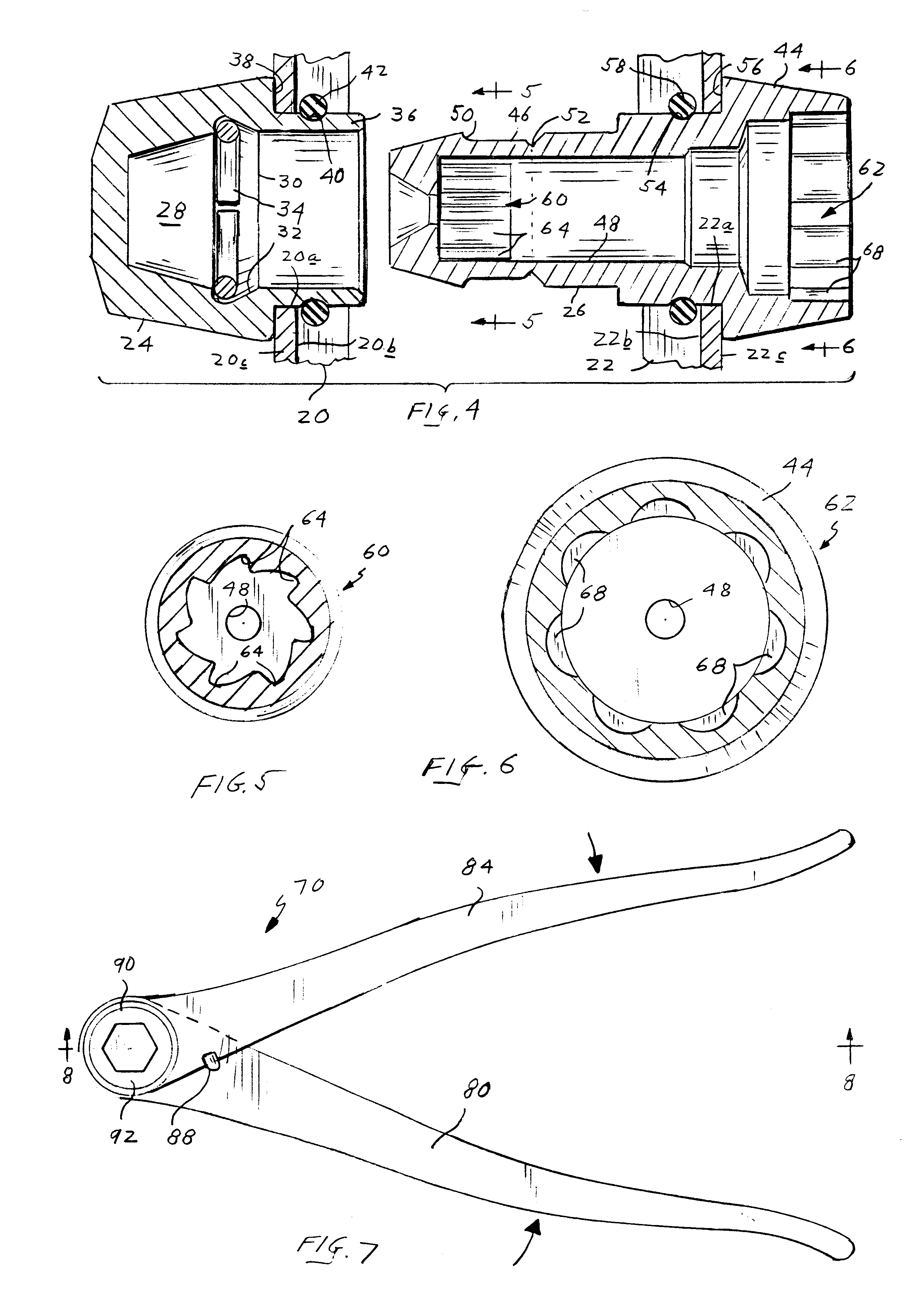

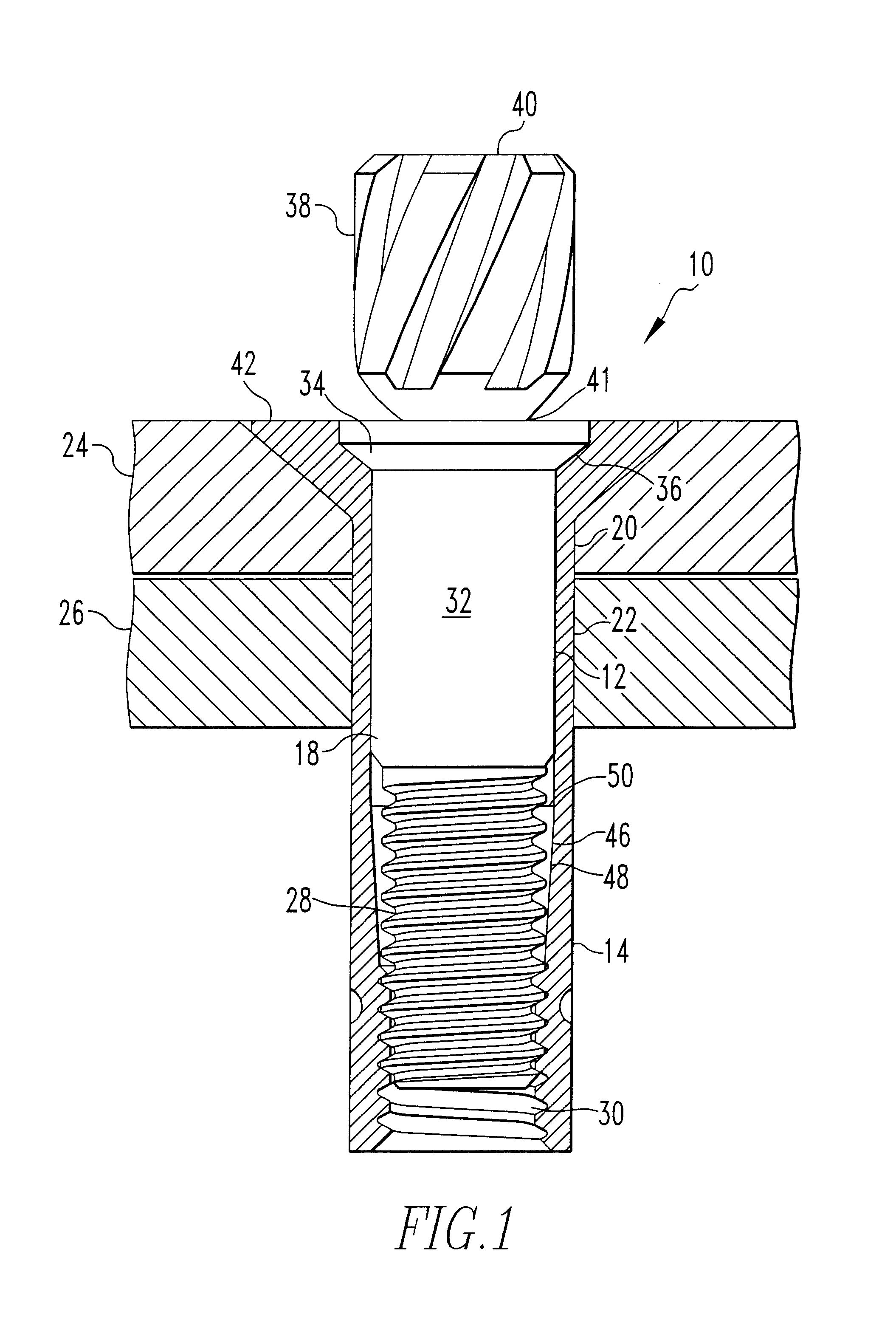

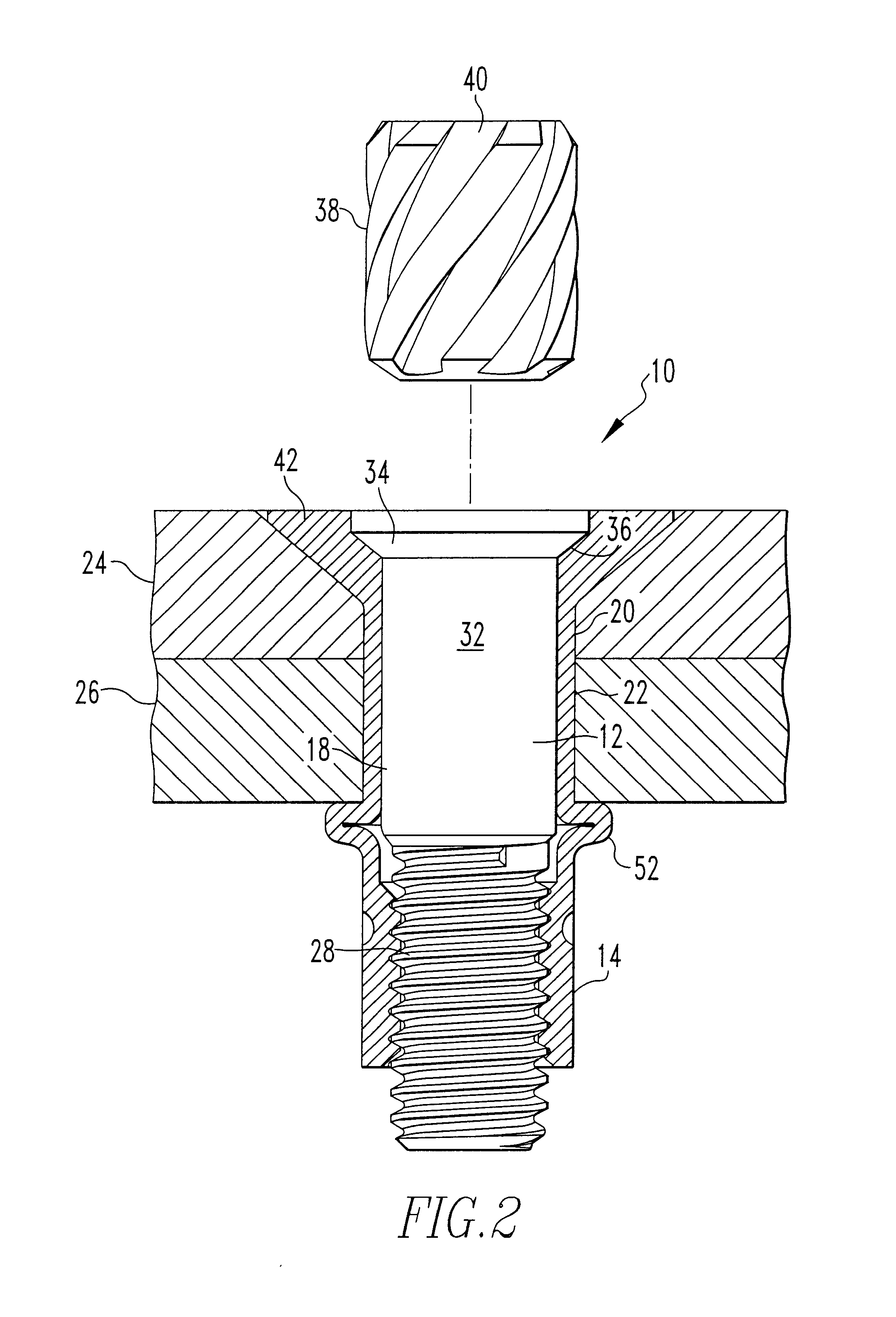

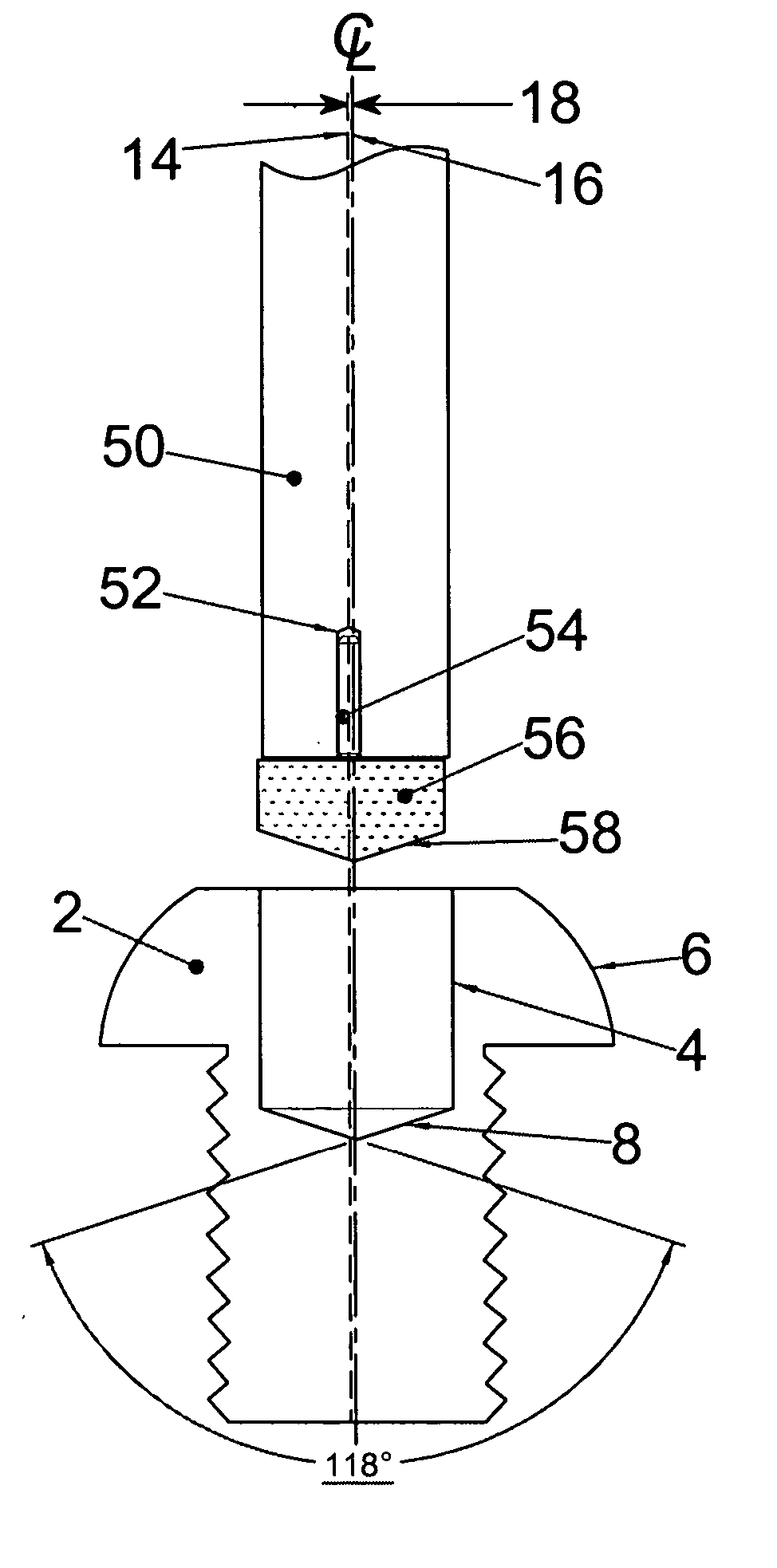

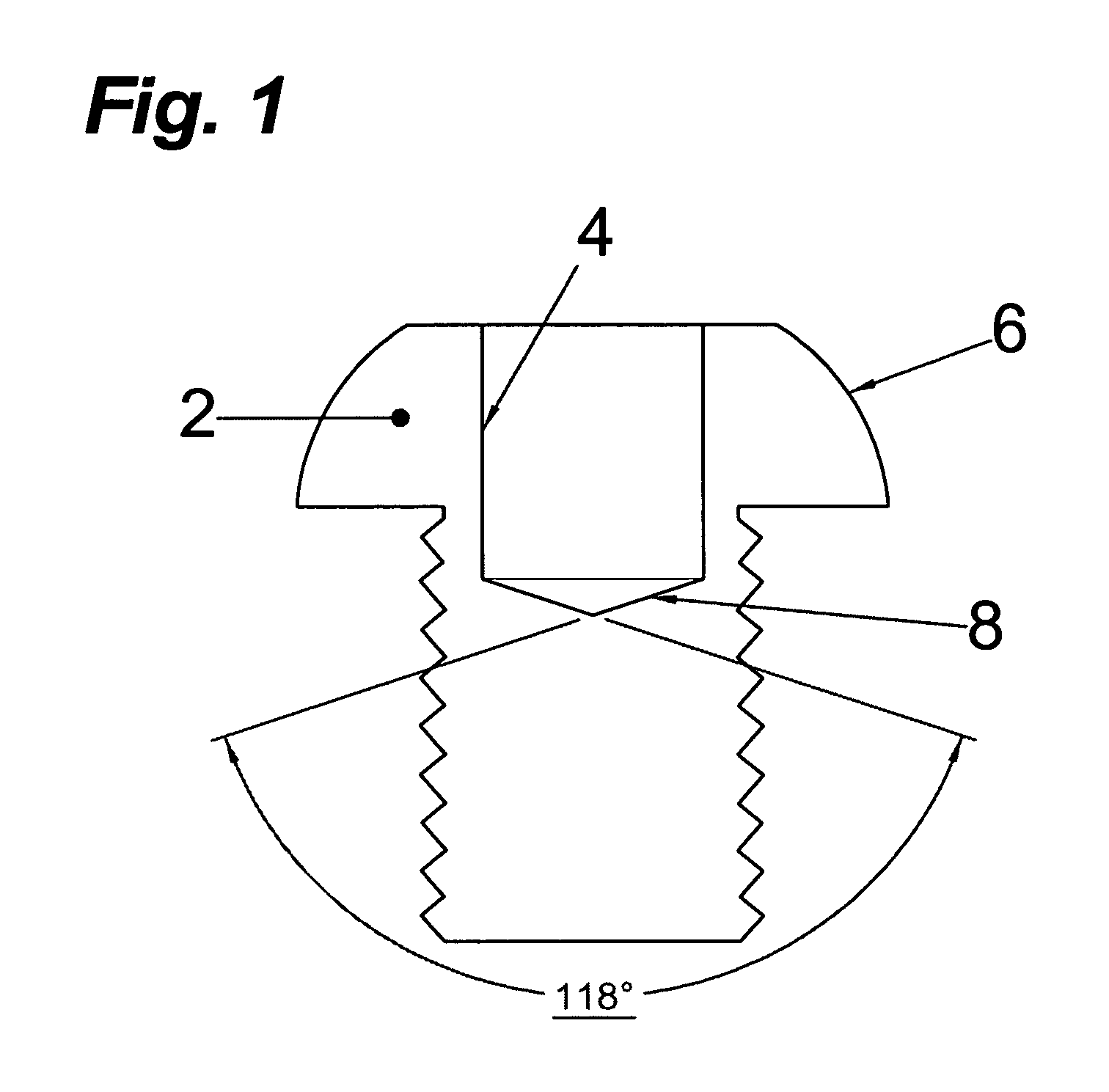

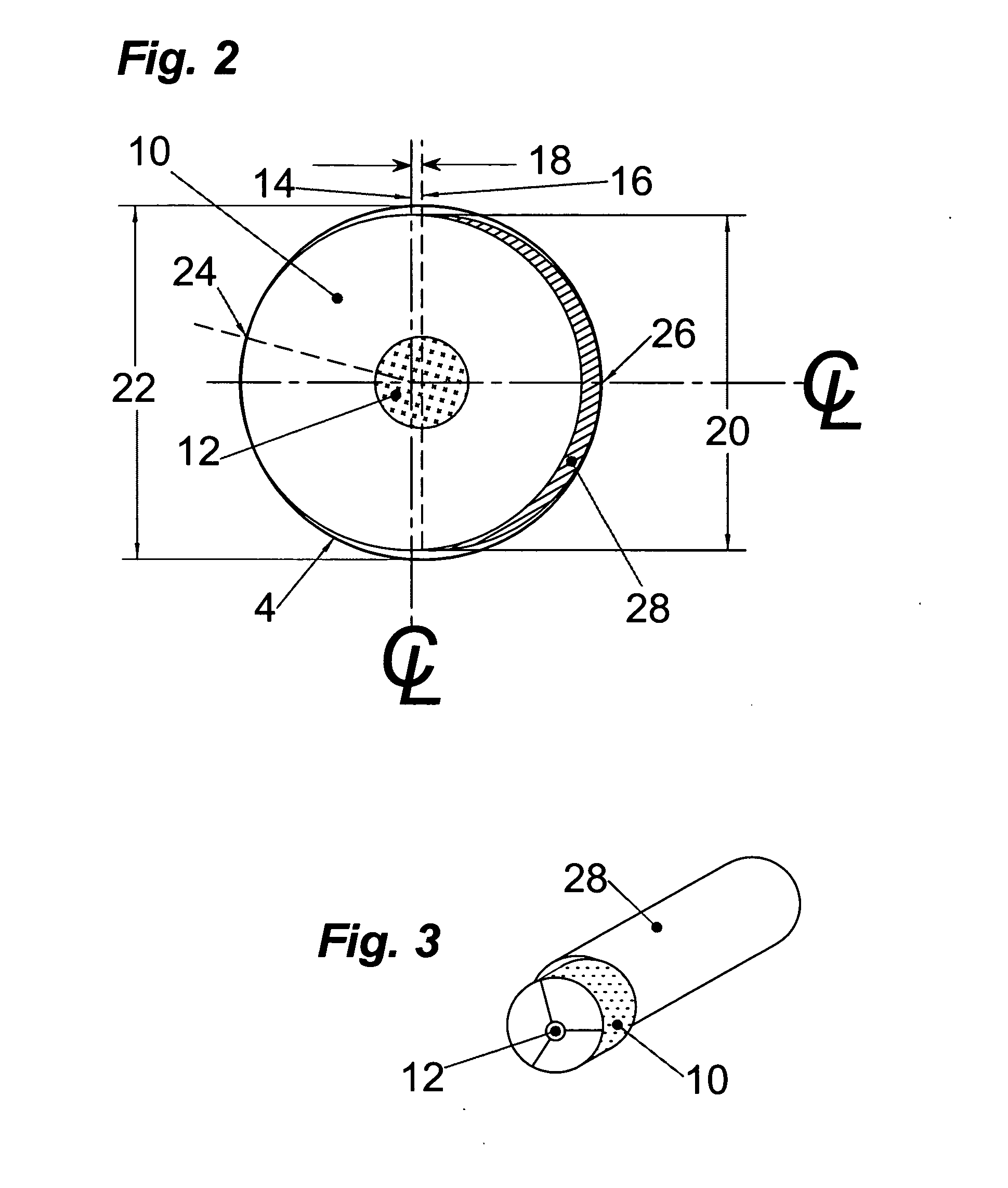

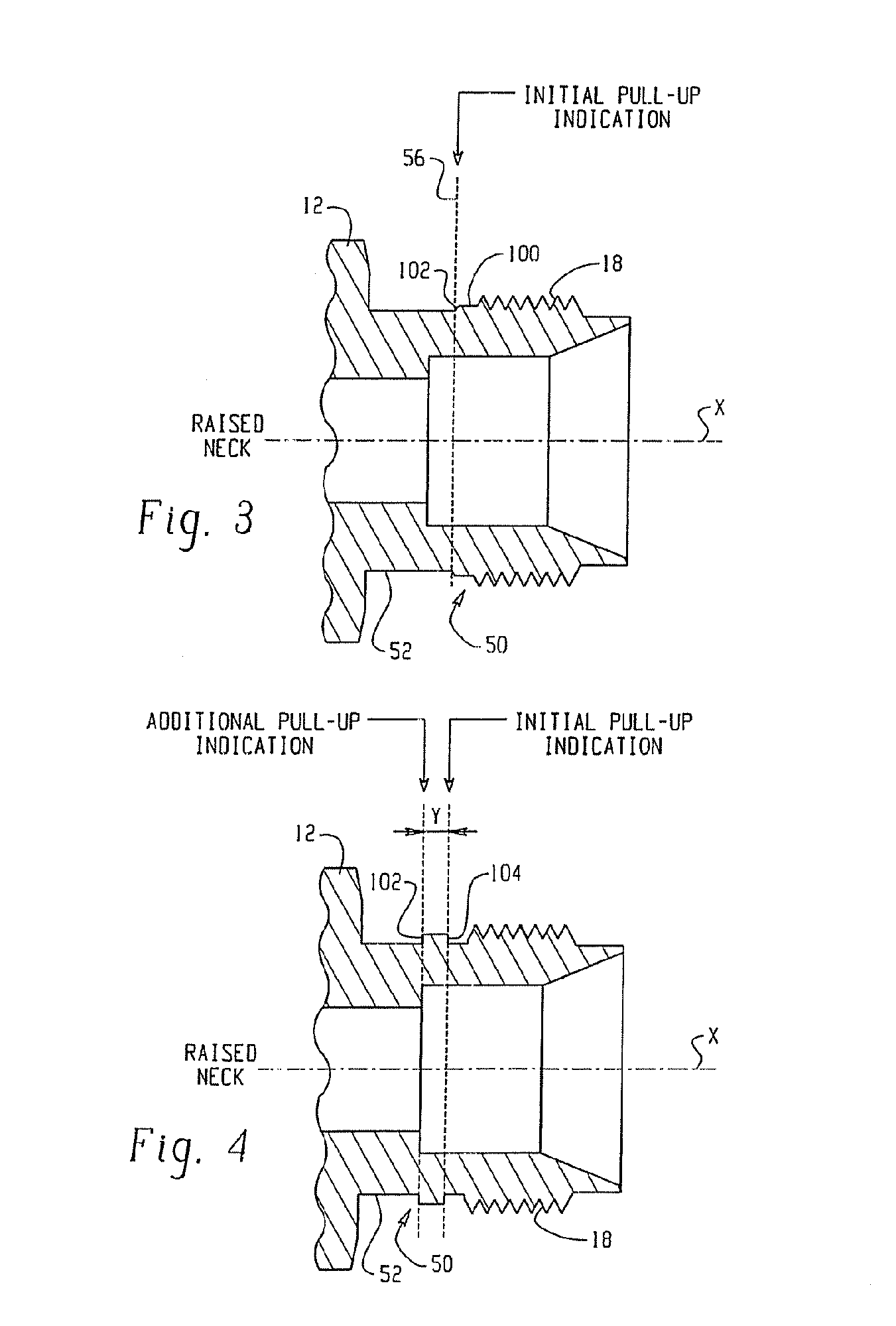

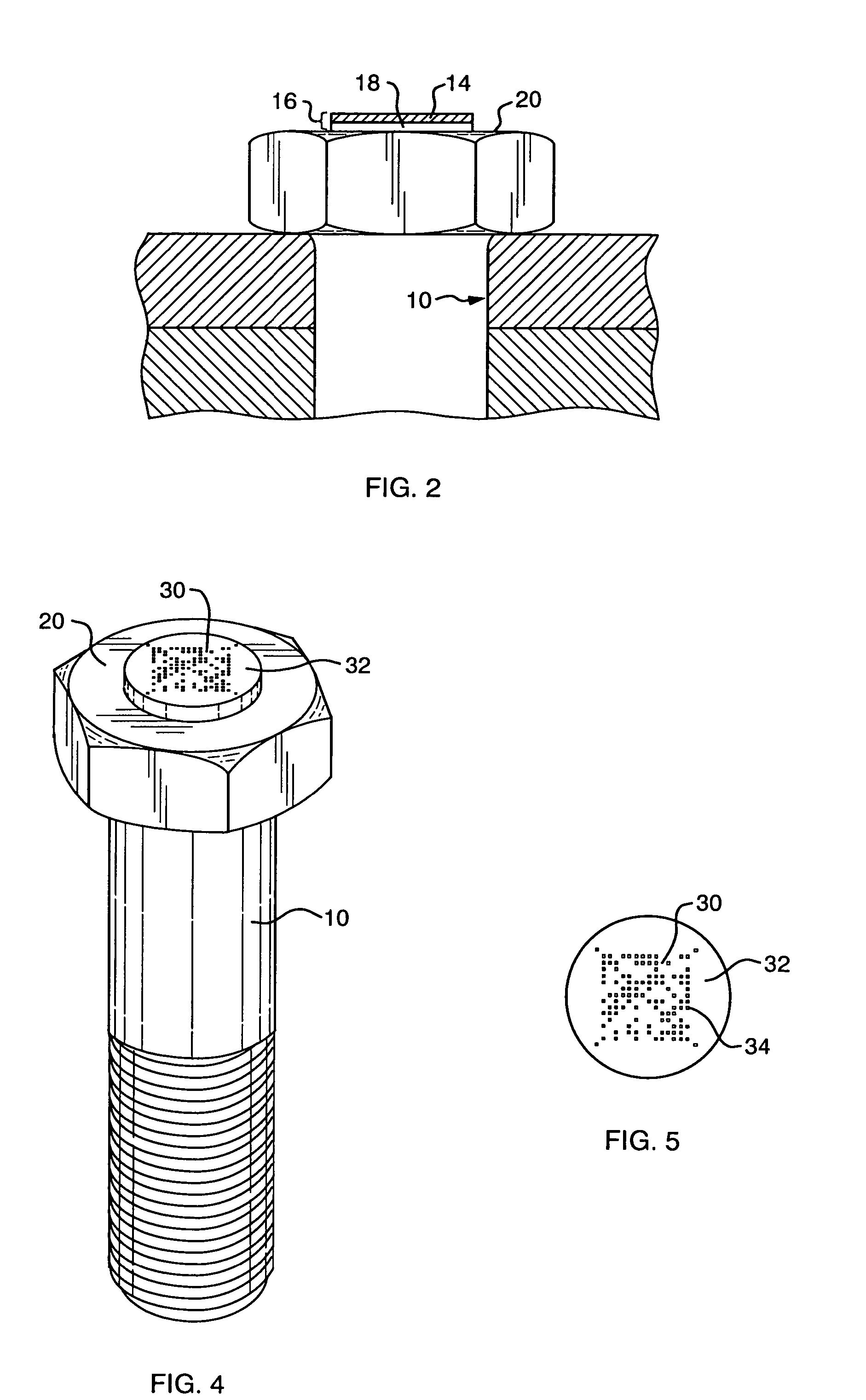

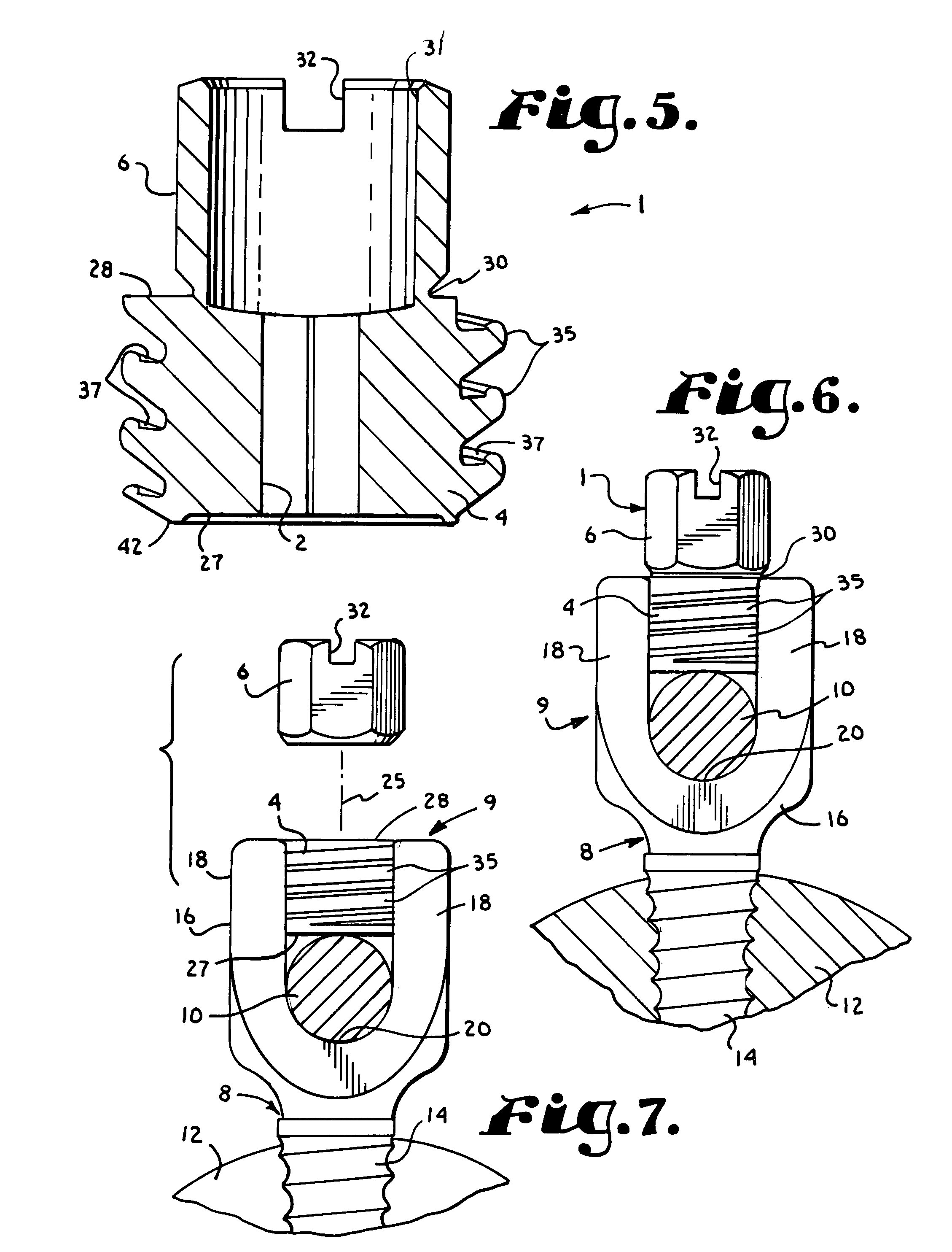

Tamper-resistant fastener and method and tool for use with same

A fastener includes a round, blind hole or pocket in its head. Installation and removal of the fastener is accomplished with a tool containing an eccentric segment on the end of a shaft. When rotated within the pocket, the eccentric segment displaces laterally relative to the shaft to provide a friction grip to the lateral wall of the pocket. The strength of the grip is proportional to the applied torque. Eccentric displacement allows rotation but prevents the tool from spinning out of the fastener thereby eliminating cam-out and surface damage resulting from contact with a spinning tool tip. The eccentric head of the tool can be made disposable and to shear off when a predetermined torque is reached. The smooth-sided round hole offers no purchase for commonly available tools; making the fastener tamper-resistance. In another embodiment, the fastener includes a raised portion in the pocket. A tool having a complementary opening shears off the raised portion at a predetermined torque.

Owner:FLESHER ROBERT W

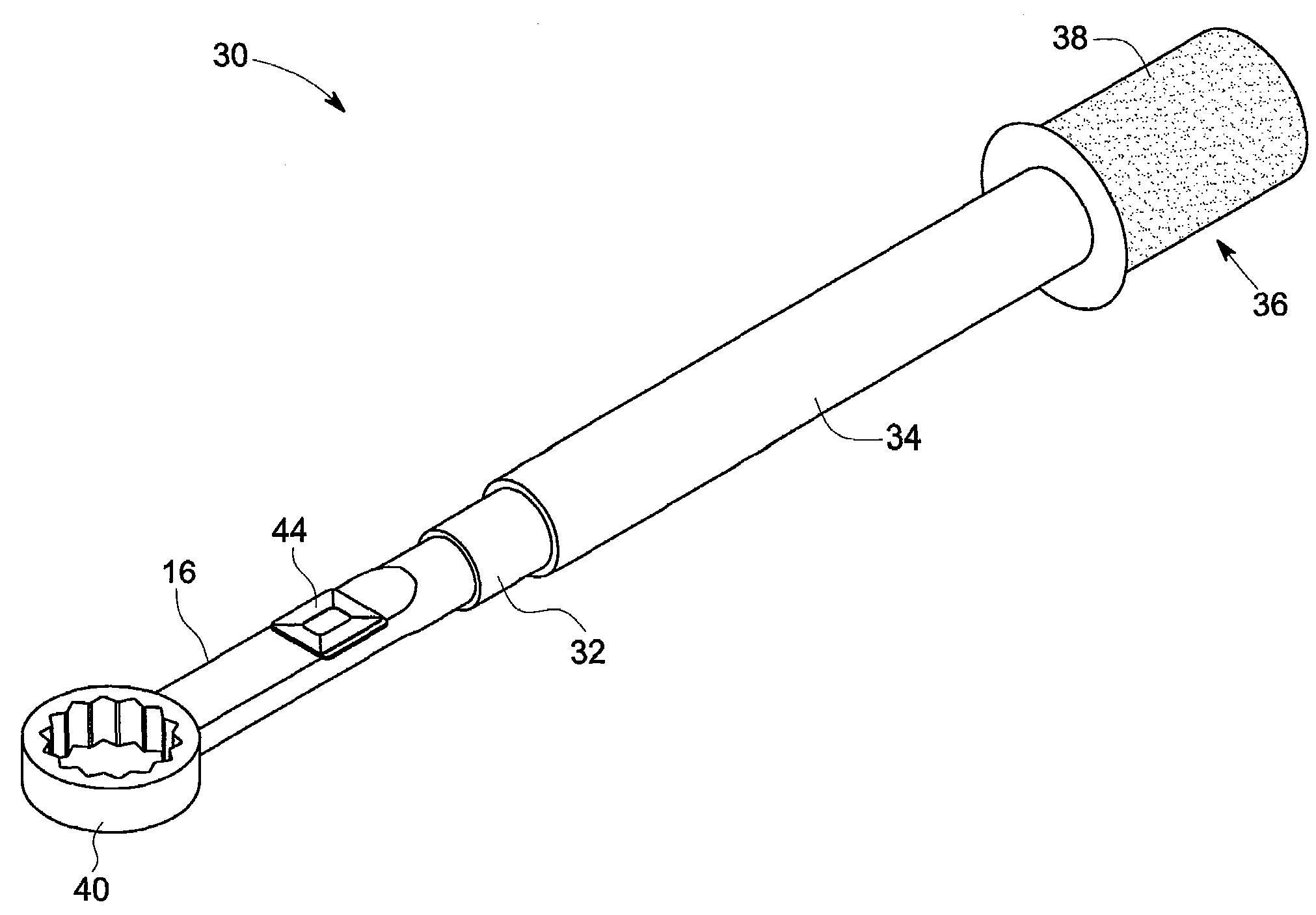

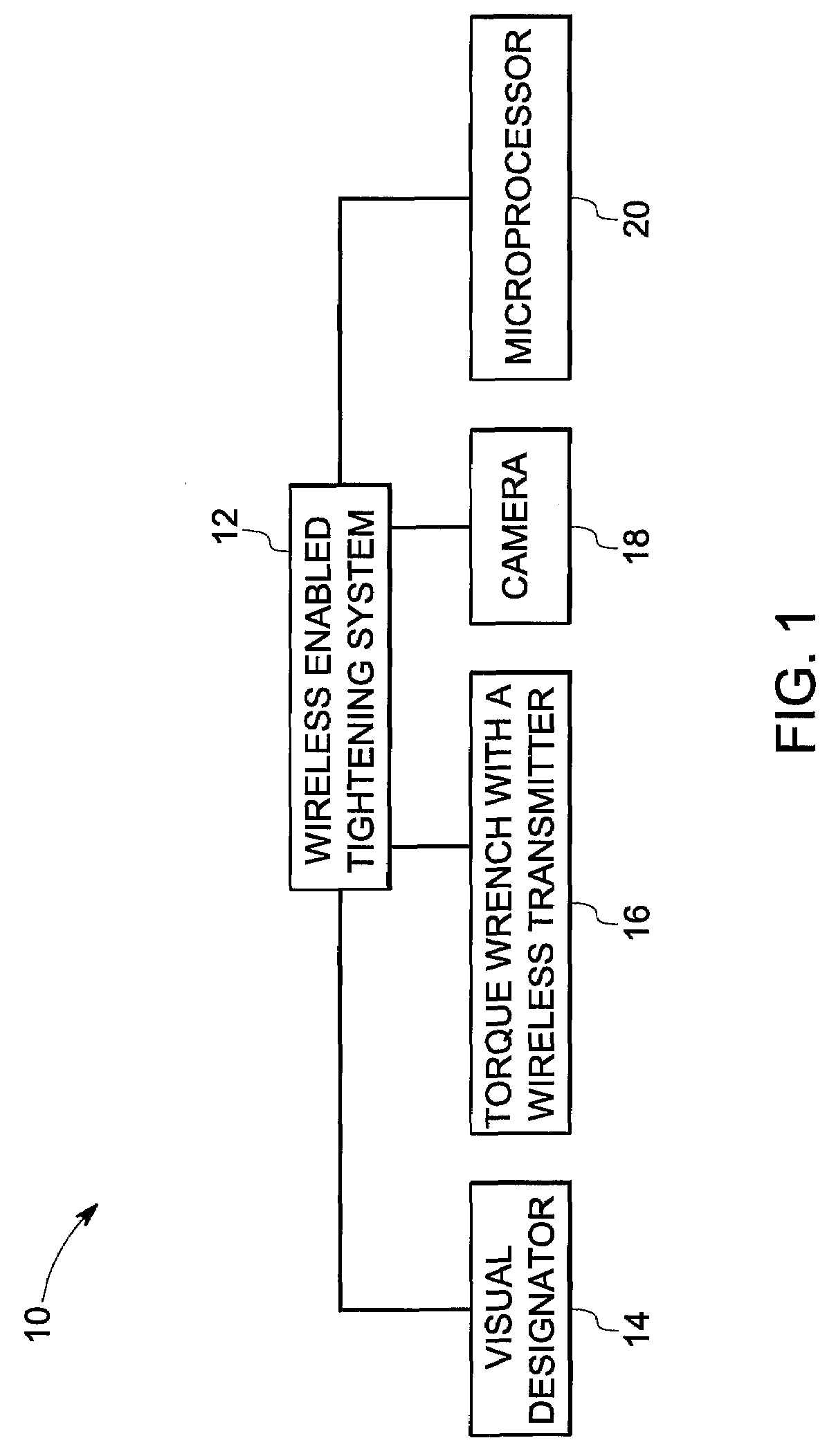

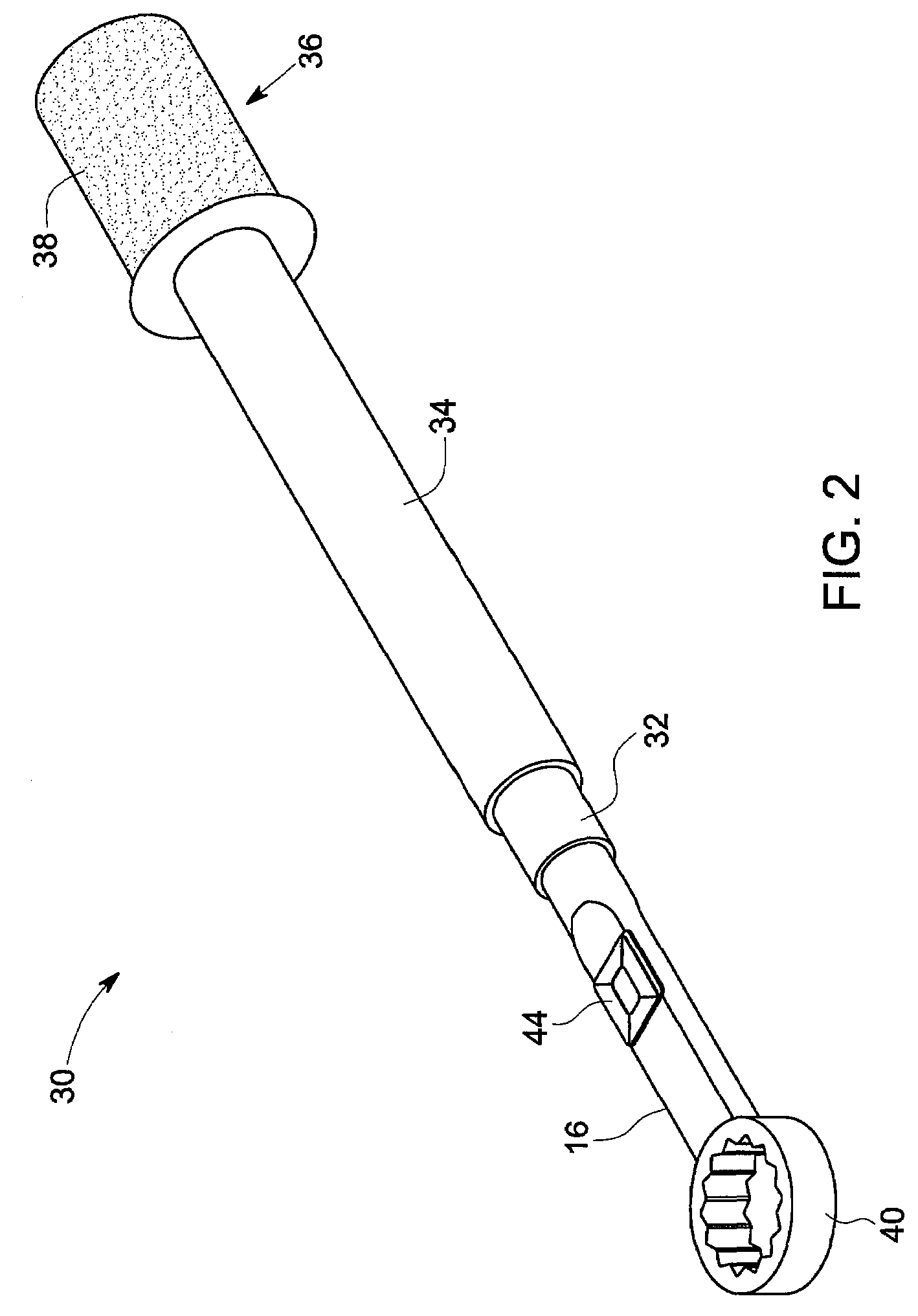

Wireless-enabled tightening system for fasteners and a method of operating the same

ActiveUS20080115589A1Measurement of torque/twisting force while tighteningLoad modified fastenersEngineeringVisual perception

A wireless-enabled tightening system for fasteners is disclosed. The system includes a visual designator configured to project an indicator onto a workpiece. The system also includes a torque wrench comprising a wireless transmitter and a means for identifying whether the correct torque has been applied to a fastener on the workpiece and configured to provide a feedback for a user. The system also includes a camera configured to capture an image of the workpiece when an appropriate amount of torque has been applied to the fastener. The system further includes a microprocessor for determining sequence of the fastener and identifying the tightened fastener.

Owner:GENERAL ELECTRIC CO

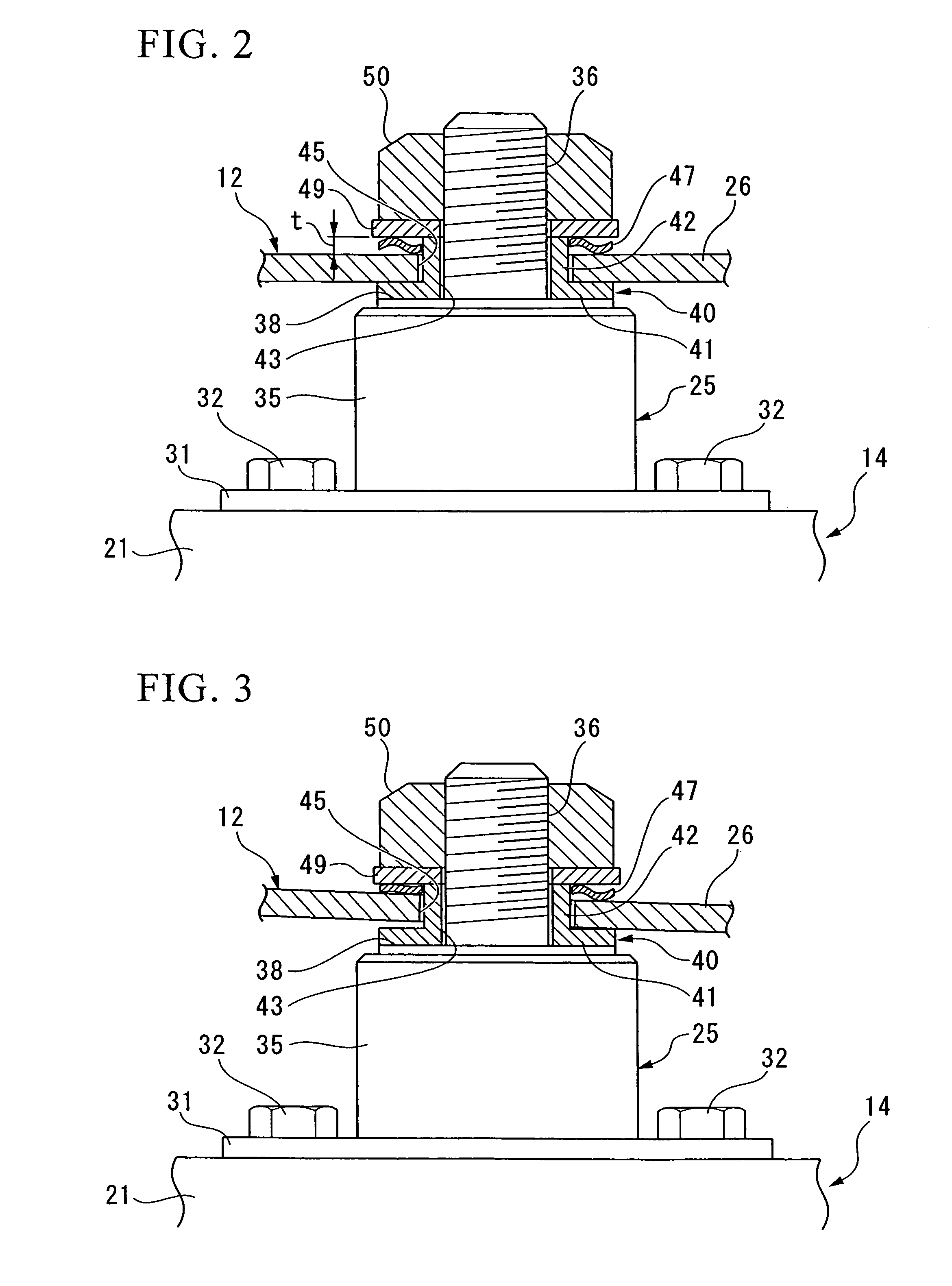

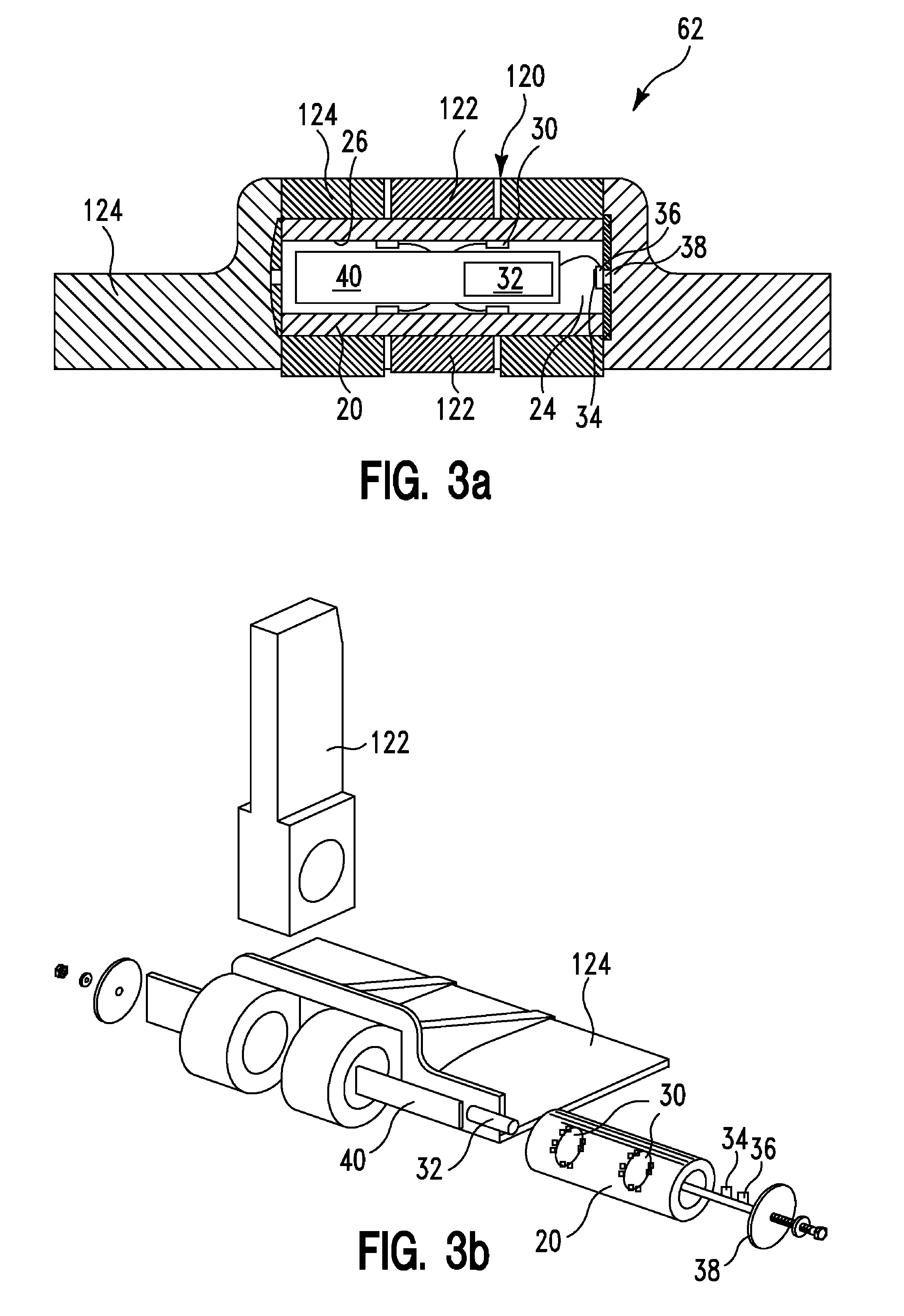

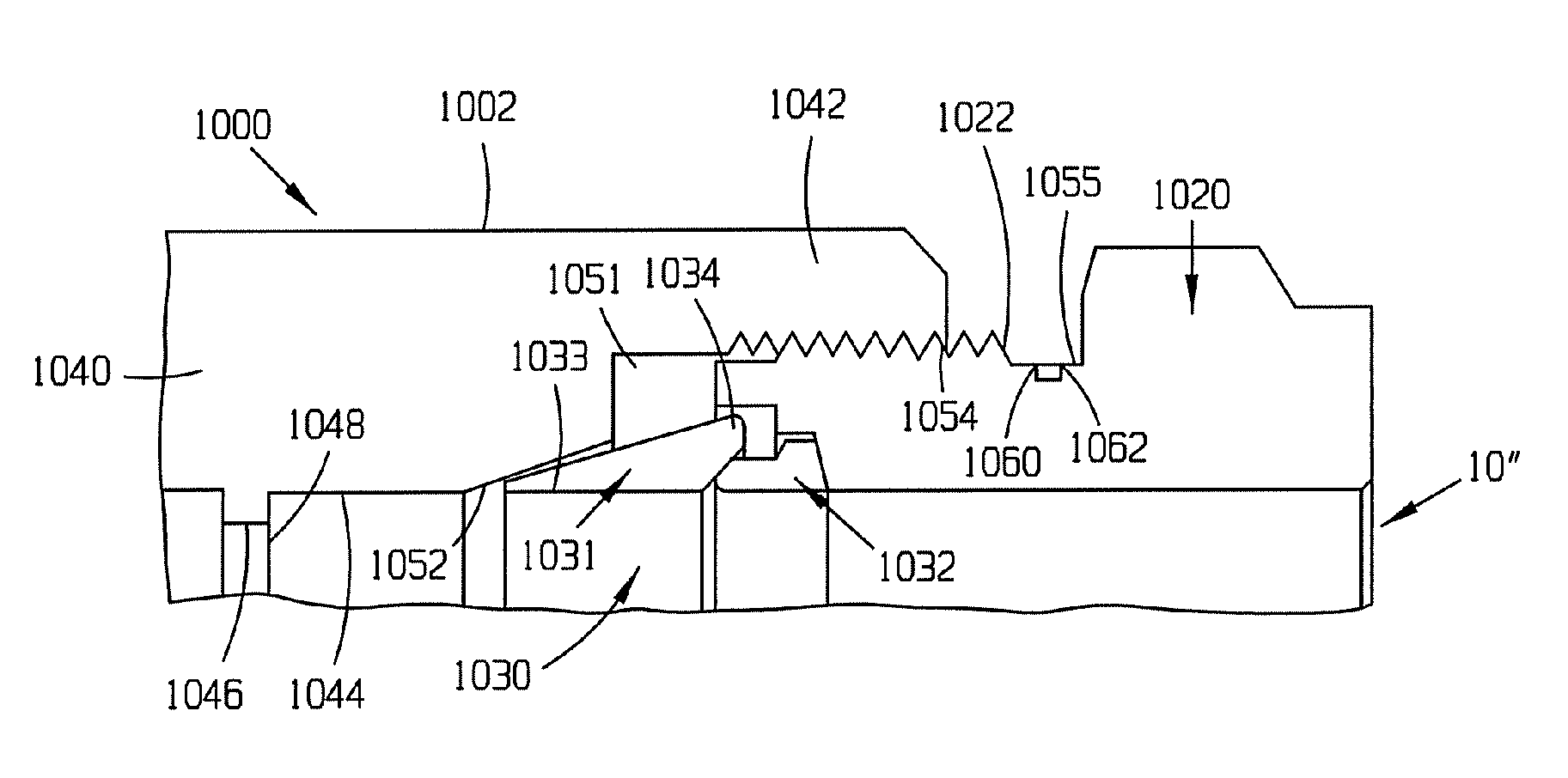

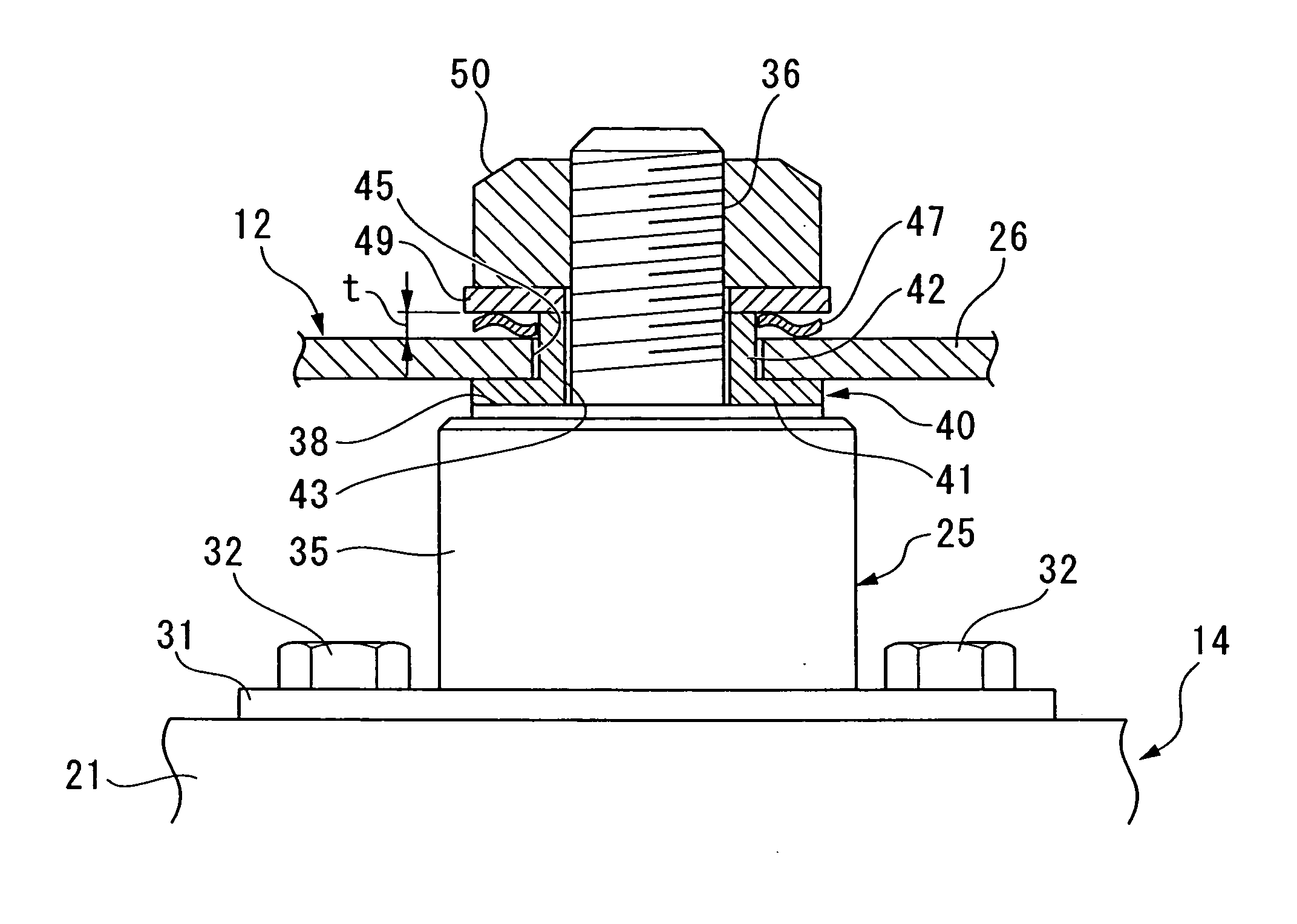

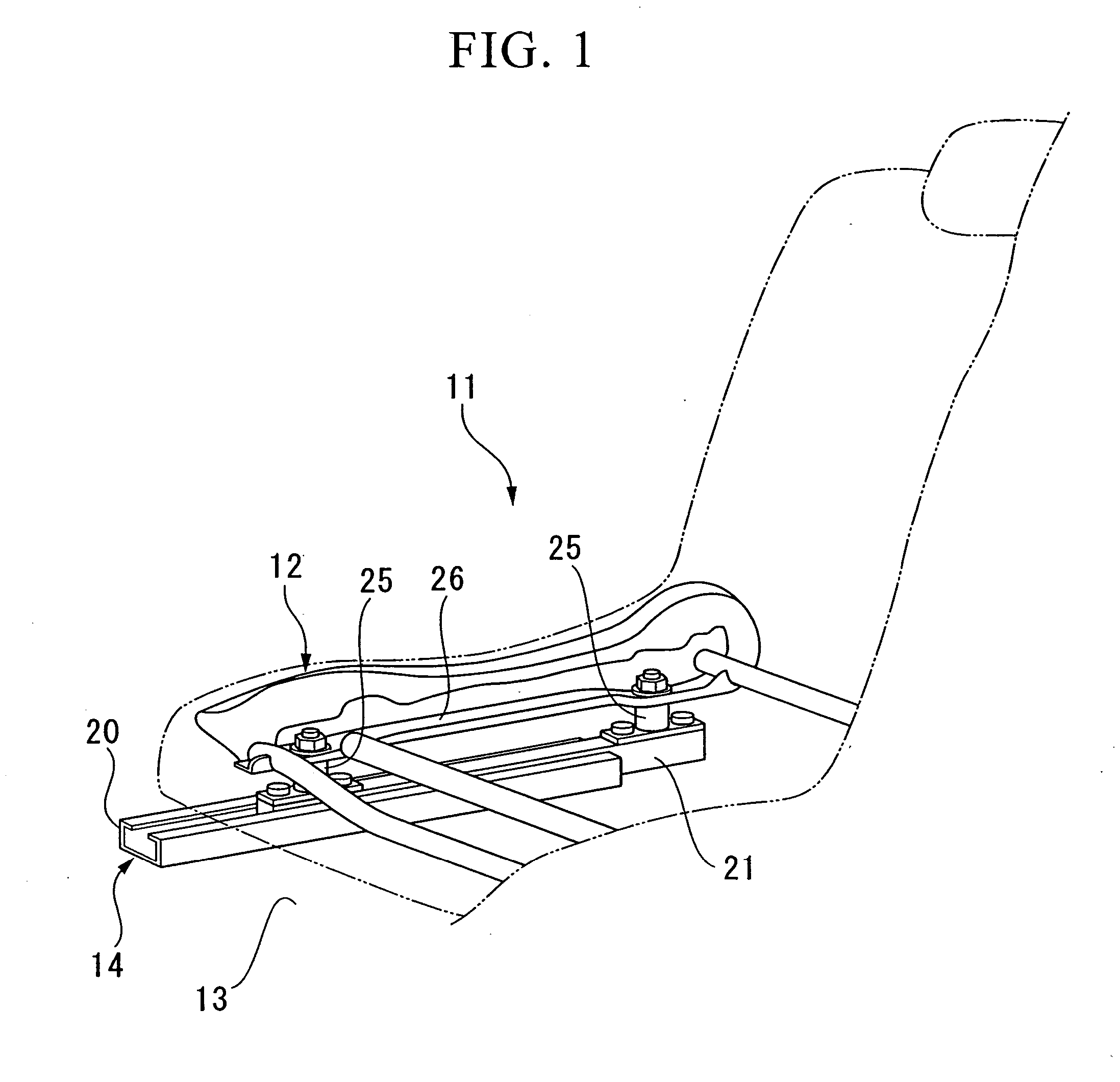

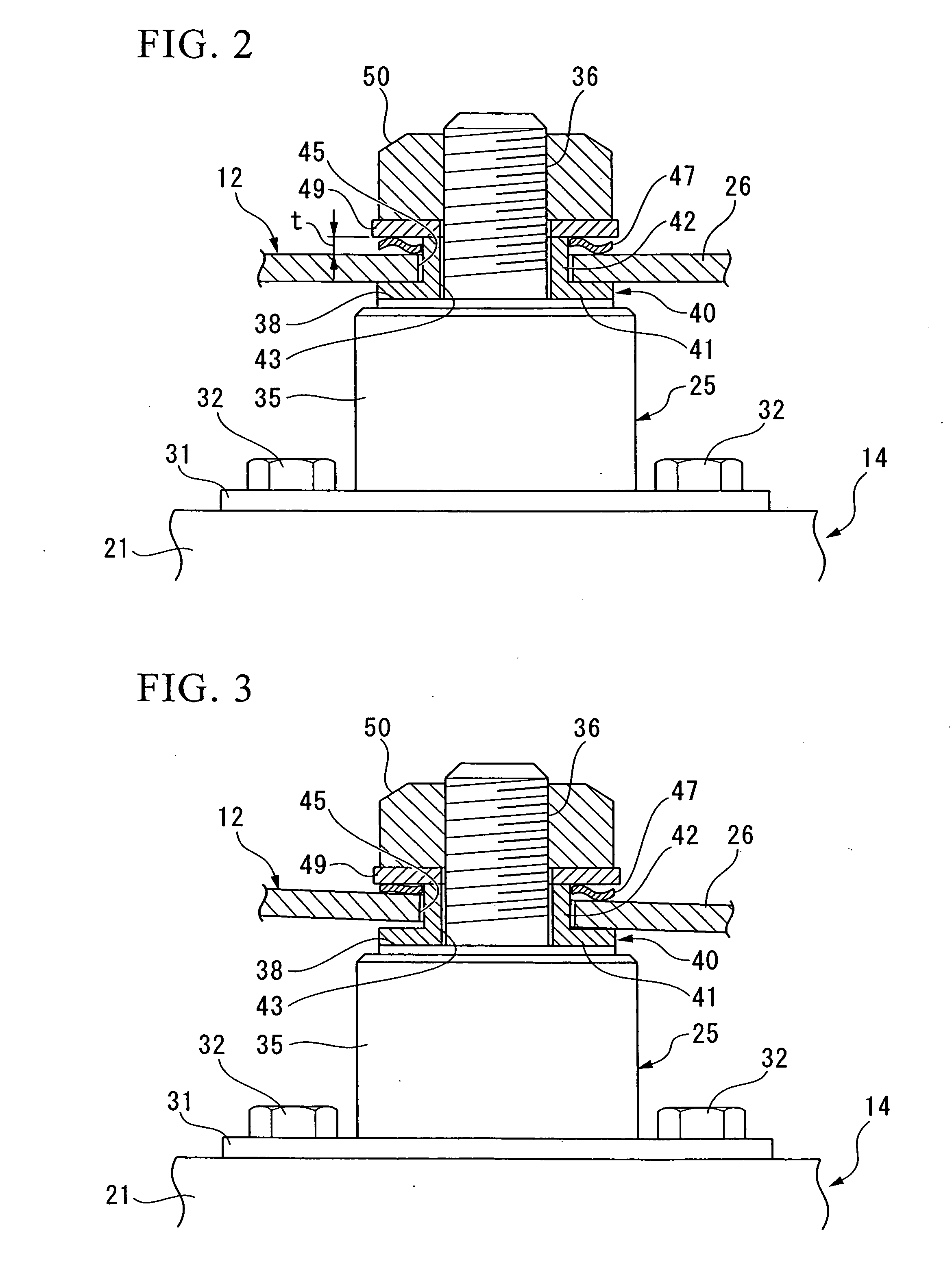

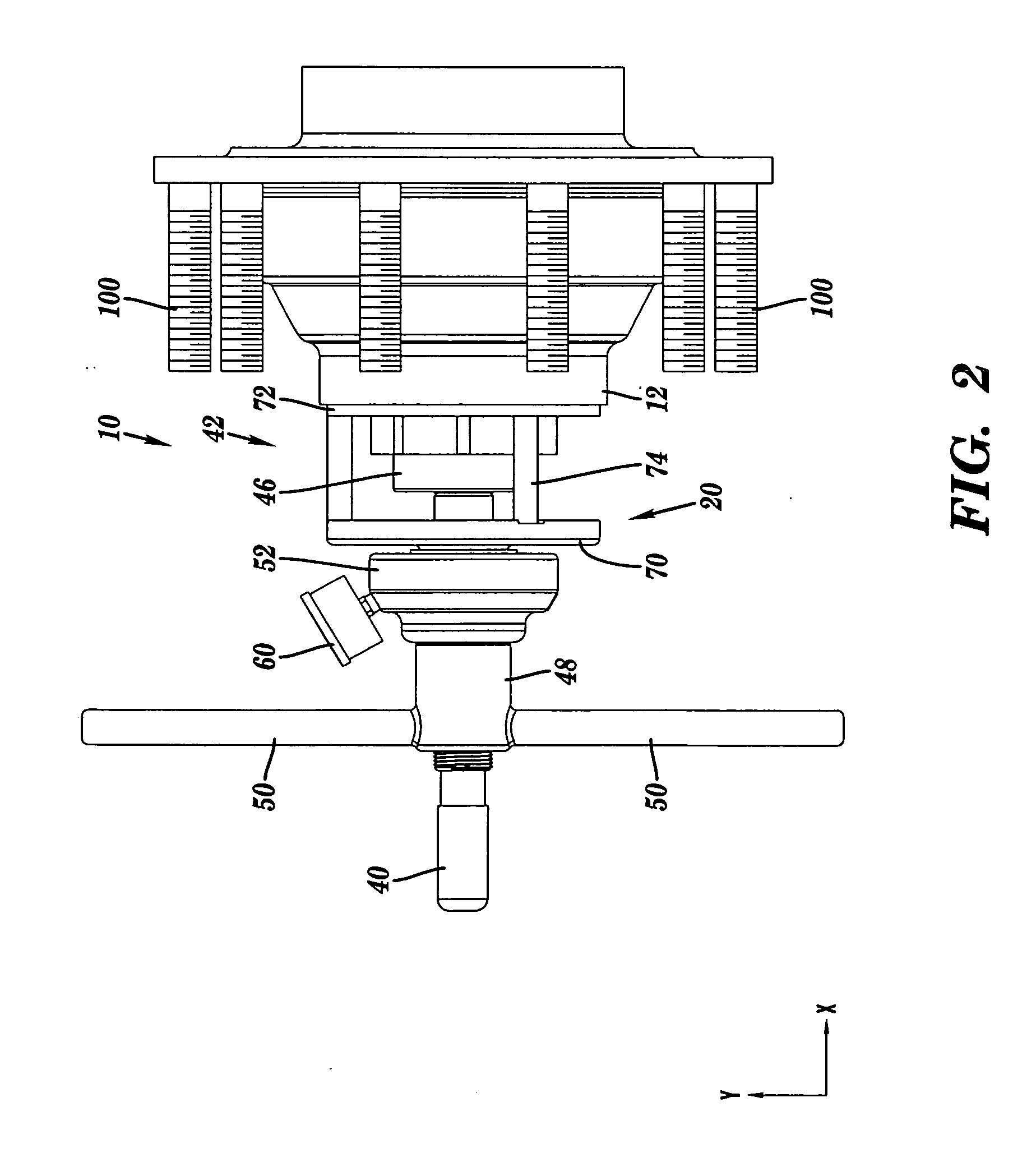

Force sensor assembly

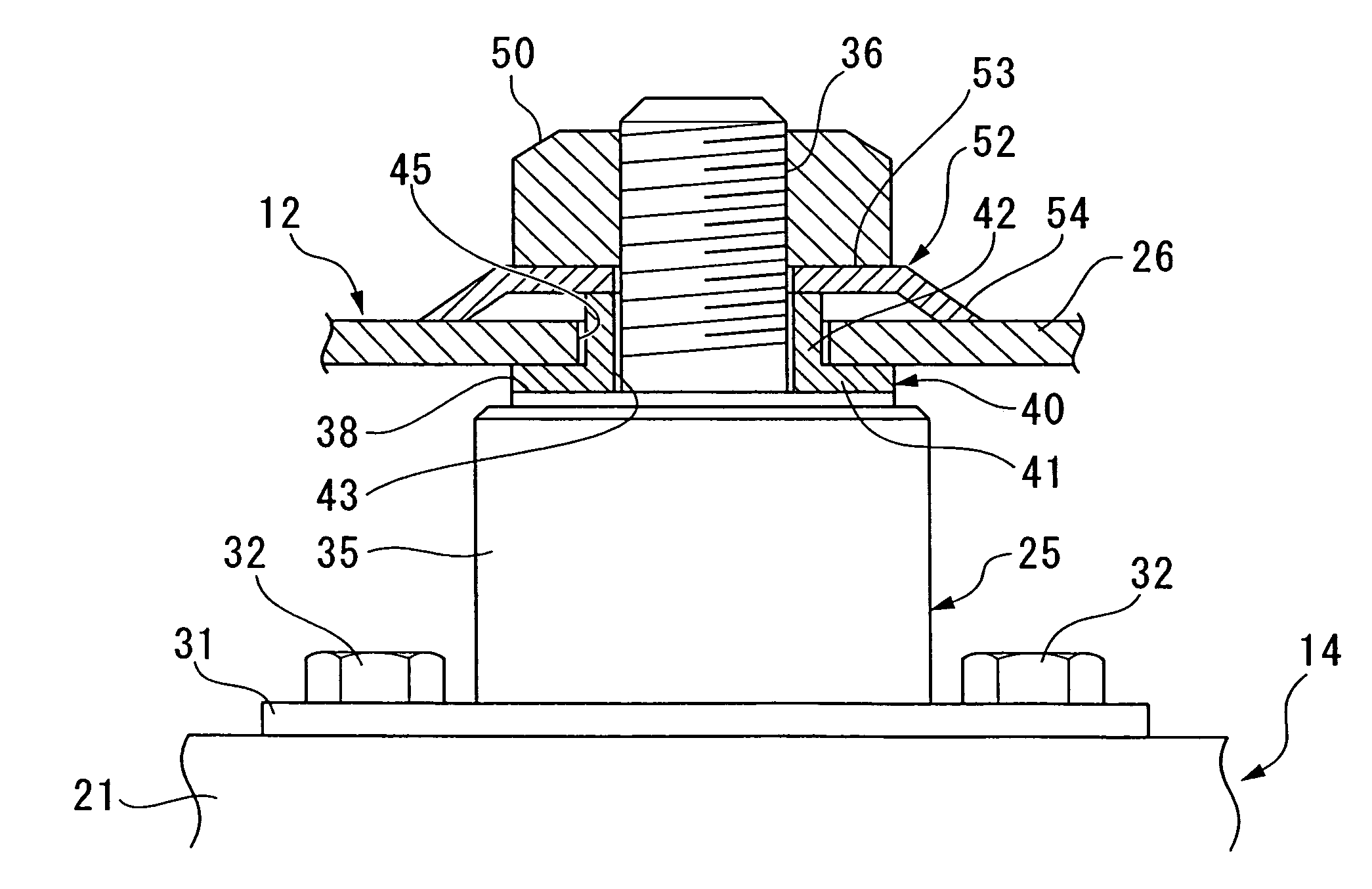

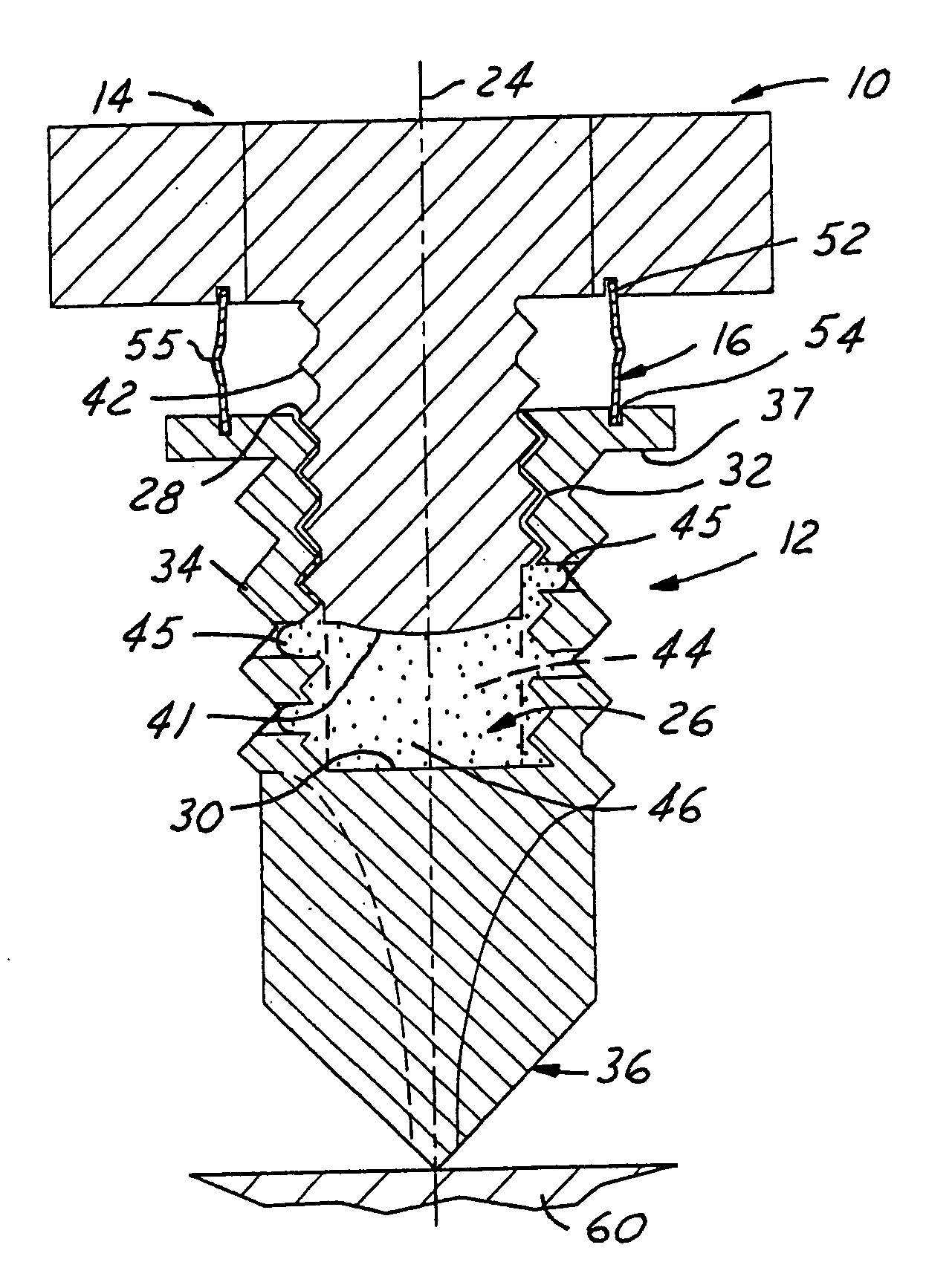

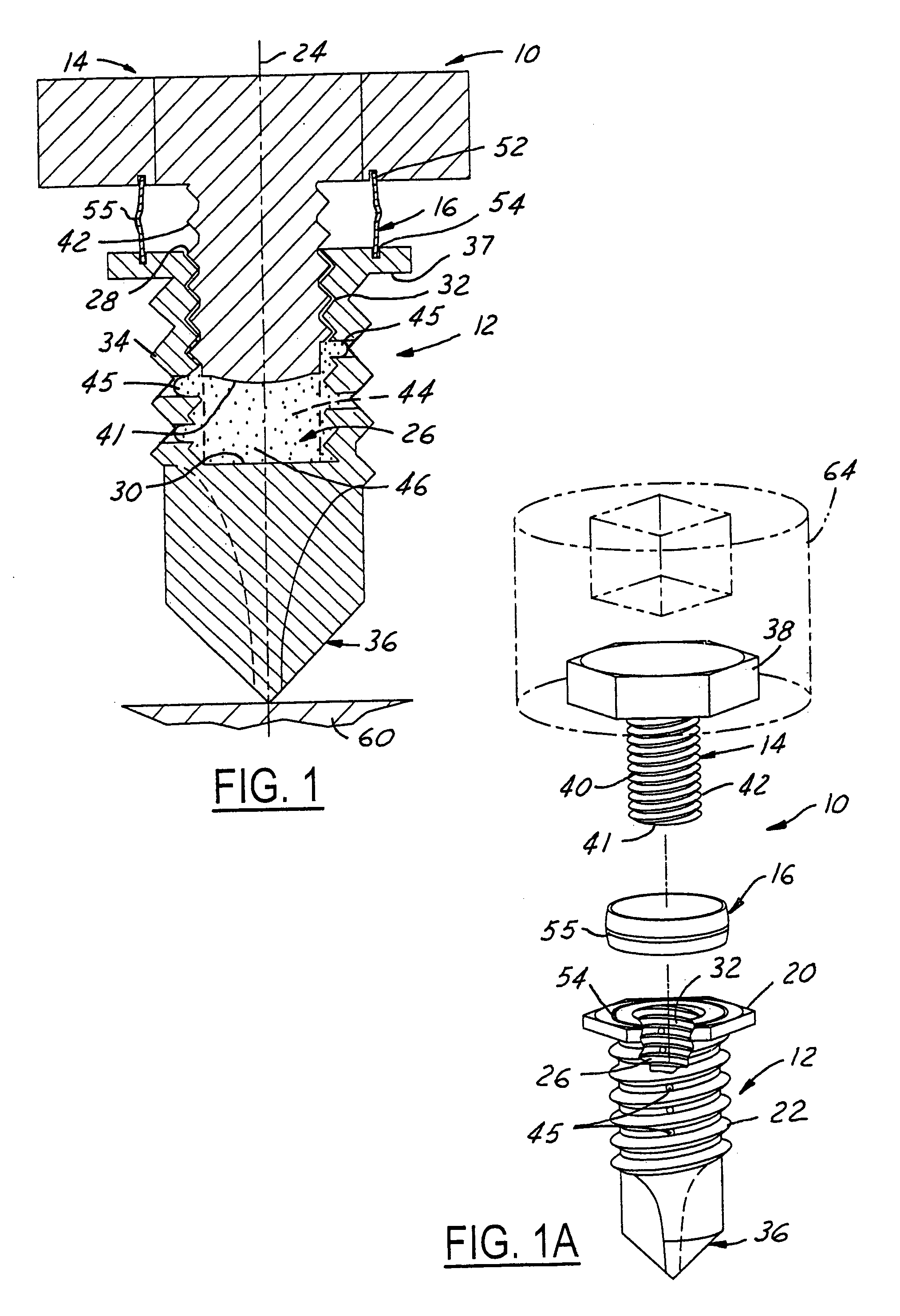

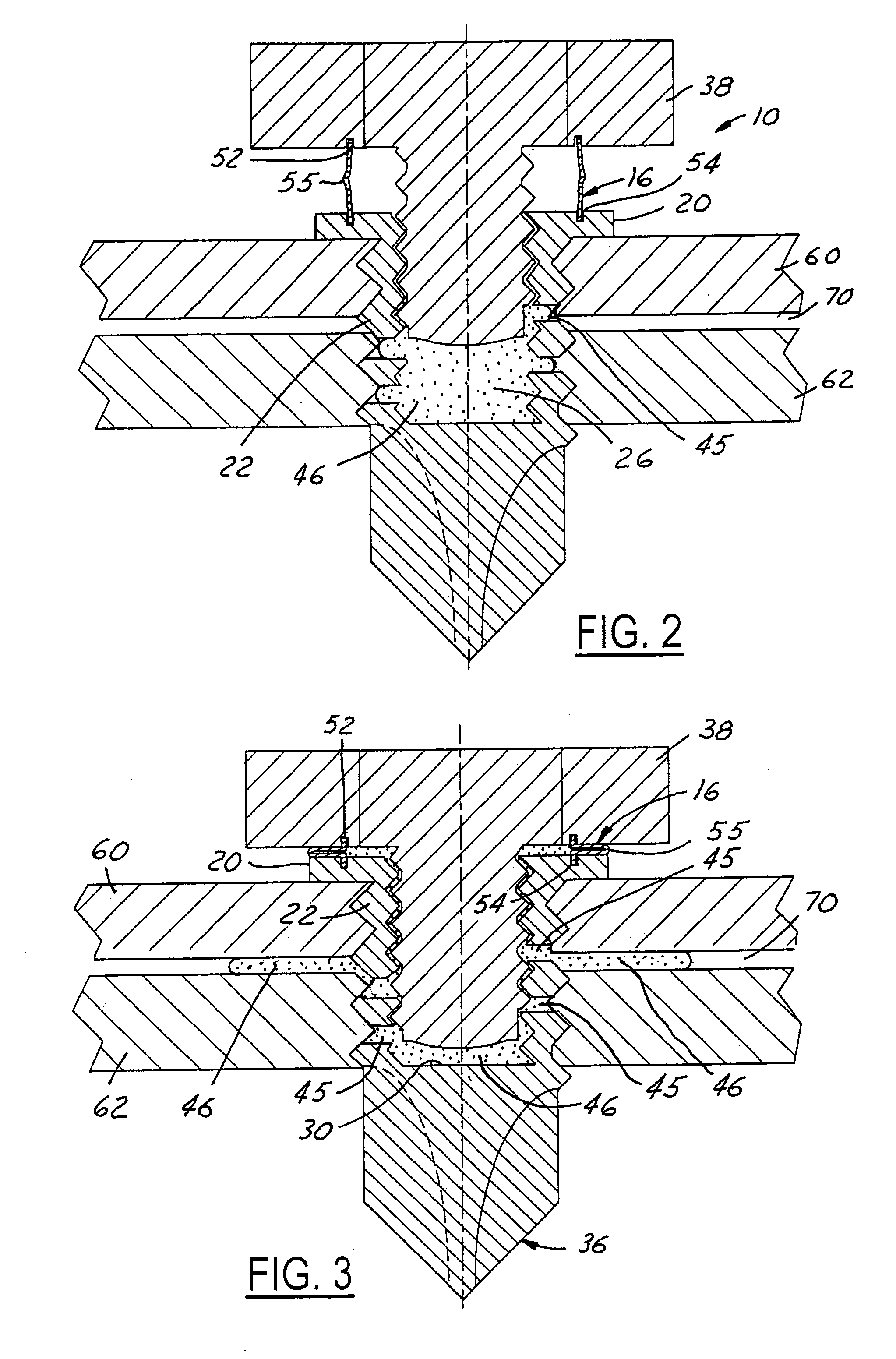

InactiveUS7210358B2Stable controlNot be excessively tightened onto the threaded portionVehicle seatsLoad modified fastenersScrew threadForce sensor

A force sensor assembly includes a force sensor, a first support member, a threaded portion, an opening made in the first support member, a nut, a restricting member and a spacer. The nut is screwed onto the threaded portion which is inserted through the opening. The restricting member is provided between the force sensor and the nut. The spacer, which is provided between the force sensor and the nut, is deformable in a direction of its thickness. The shape of the spacer is adapted to avoid interference with the restricting member. Before the nut is tightened onto the threaded portion, a summation of thickness for the first support member and the spacer is adapted to be not less than a height of the restricting member. The nut is tightened up with a predetermined fastening torque until the spacer deforms so that the nut strikes the restricting member.

Owner:HONDA MOTOR CO LTD

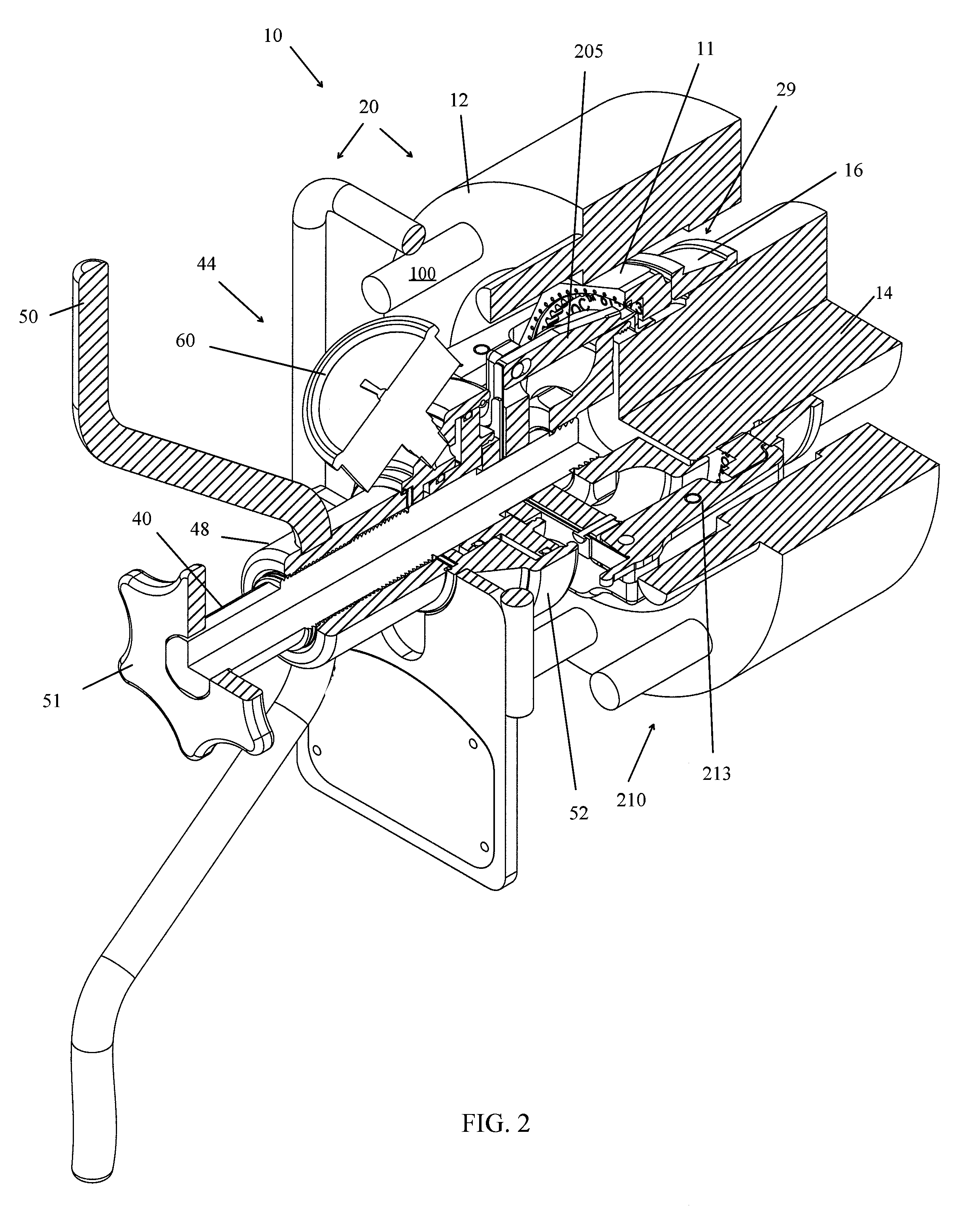

Torsion cutter and cannulated cutter for cutting orthopedic fasteners

A surgical instrument includes a first component and a second component moveable about an axis relative to the first component. The second component is moveable between a first position and a second position. Movement of the second component from the first position to the second position applies a torsional force to an orthopedic fastener to remove a portion of the orthopedic fastener.

Owner:ARTHREX

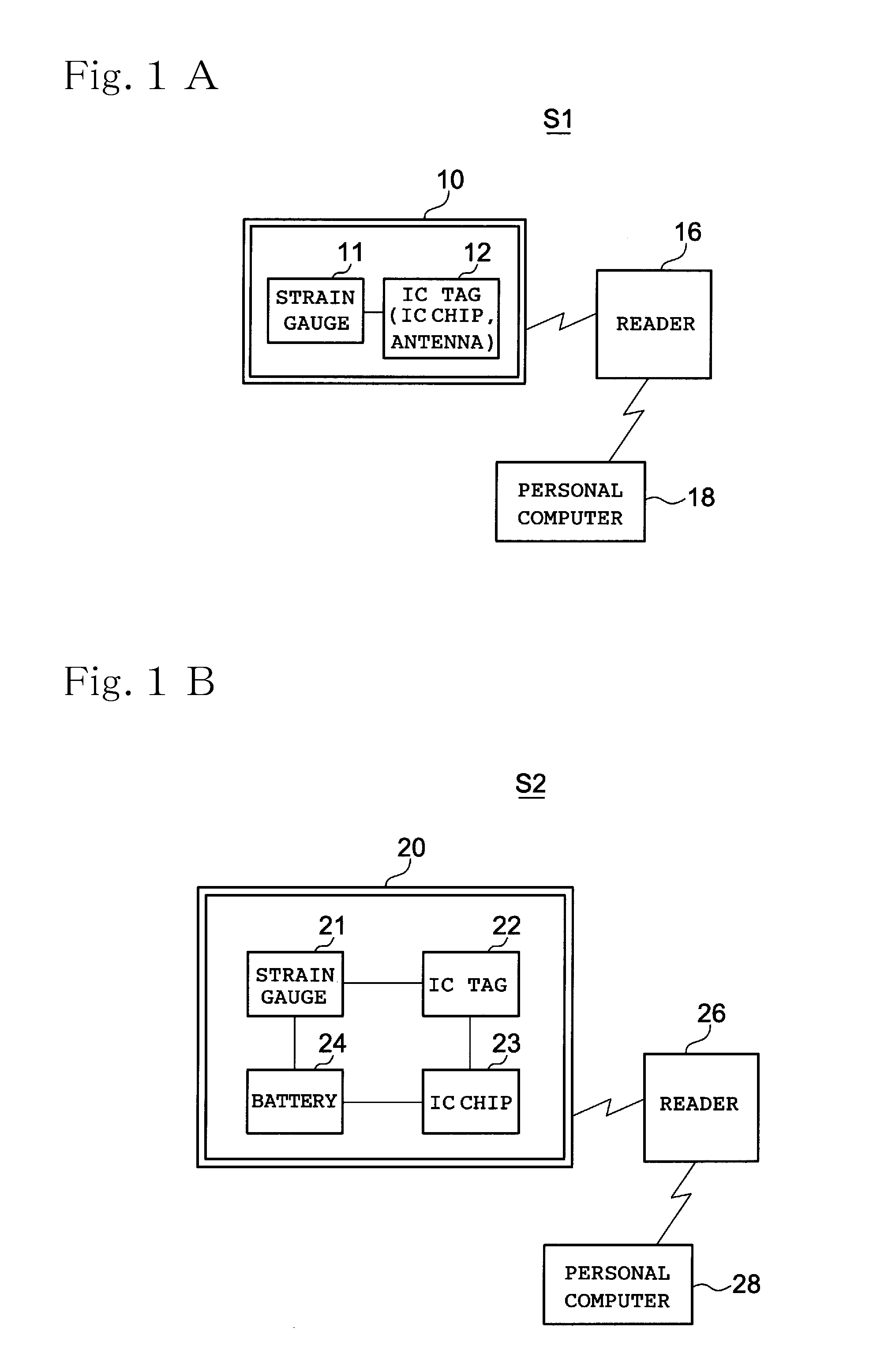

Fastening apparatus and system for detecting axial force thereof

InactiveUS20100054891A1Avoid accidentsLabor savingMeasurement of torque/twisting force while tighteningLoad modified fastenersAxial forceEngineering

A detecting system of a fastening apparatus that detects an axial force of the fastening apparatus including a bolt or a nut. The detecting system includes an axial force detector including a strain gauge and an IC tag, the strain gauge being provided at a predetermined location to detect an axial force value of the fastening apparatus, and the IC tag being connected to the strain gauge and wirelessly transmitting the detected axial force value and unique identification information. Power is supplied to the axial force detector. A reader reads data transmitted from the axial force detector.

Owner:FURUKAWA ELECTRIC POWER SYST

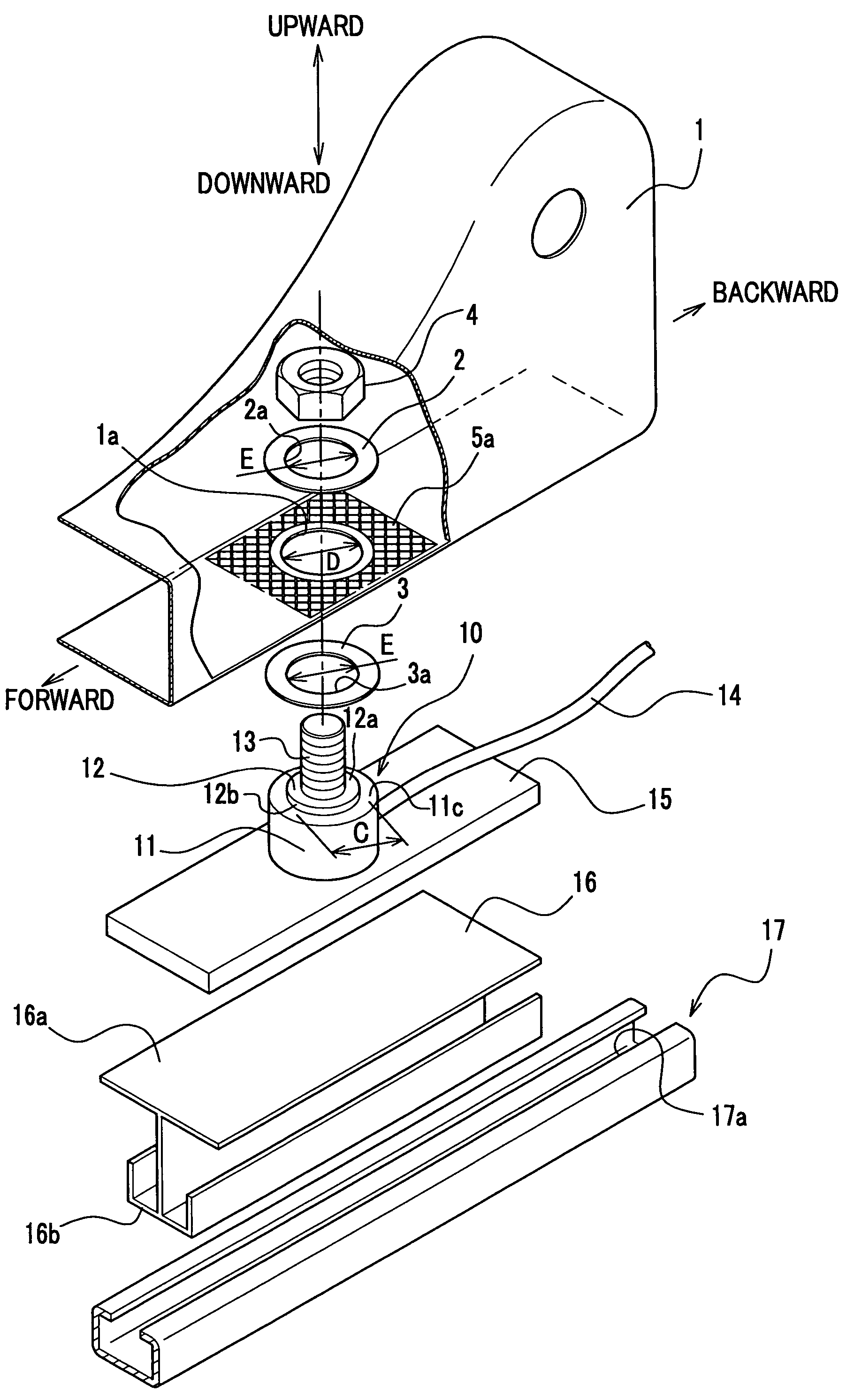

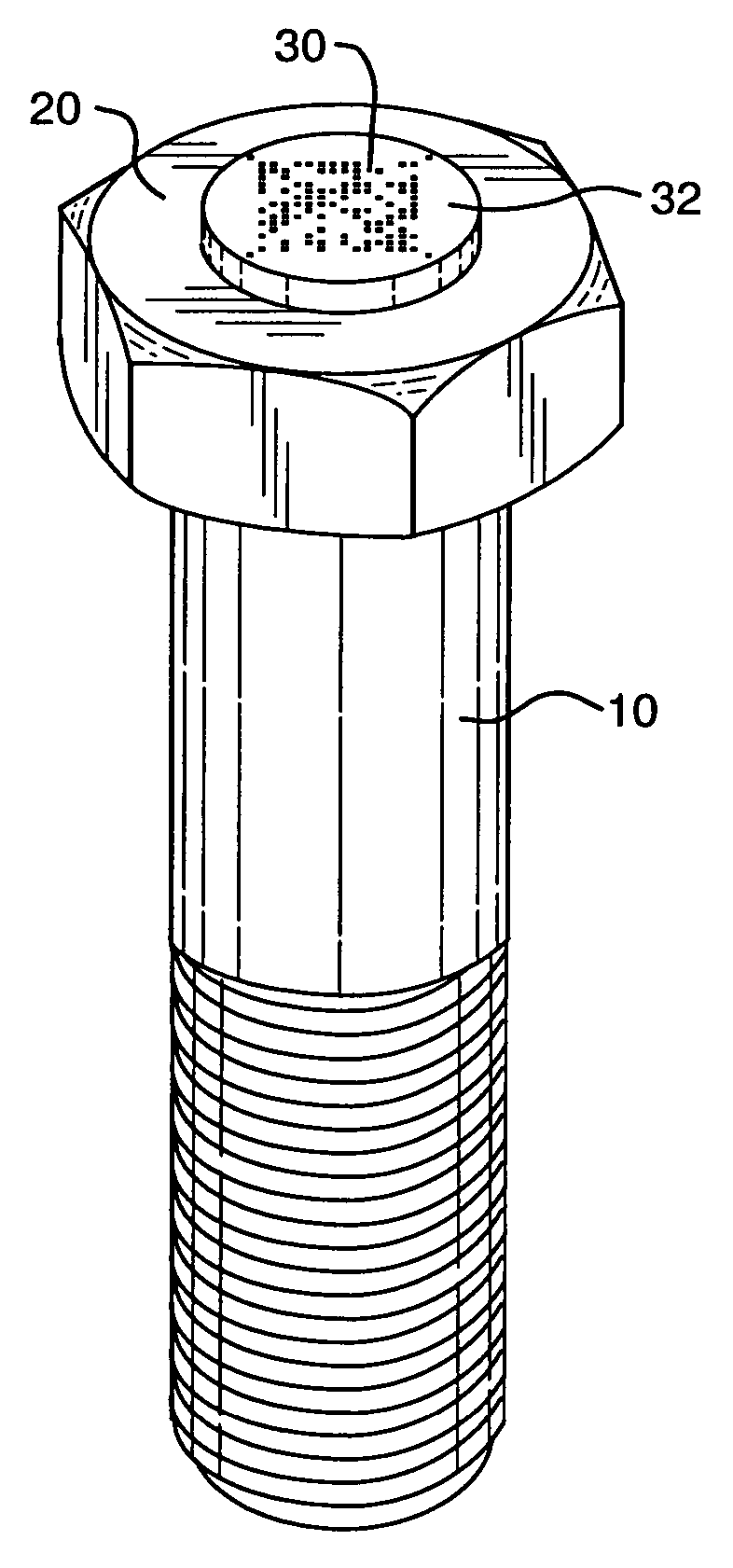

Load cell attachment structure

ActiveUS20060048582A1Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

Load indicating member with identifying mark

InactiveUS6990866B2Reliable precise load measurementVehicle seatsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringManufacturing variation

A load indicating member is provided with a permanent identifying mark which can be read and used to determine ultrasonic measurement parameters specific to the load indicating member to provide more precise and more reliable load measurements by compensating for differences resulting from manufacturing variations in individual load indicating members. The parameters specific to the load indicating member can be stored in coding applied to the load indicating member or in a database that can be accessed remotely, for example, using the Internet.

Owner:INNOVATION PLUS

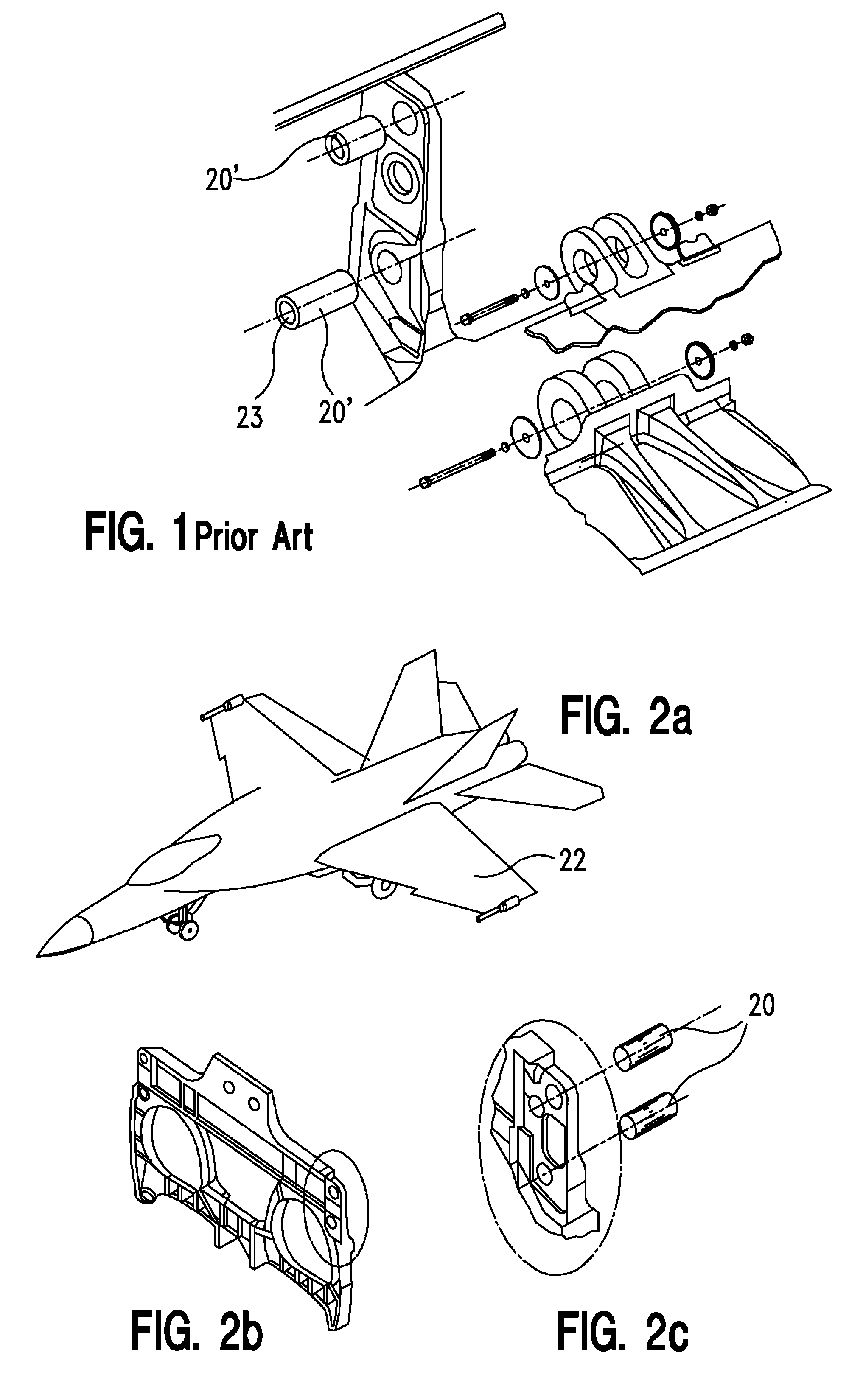

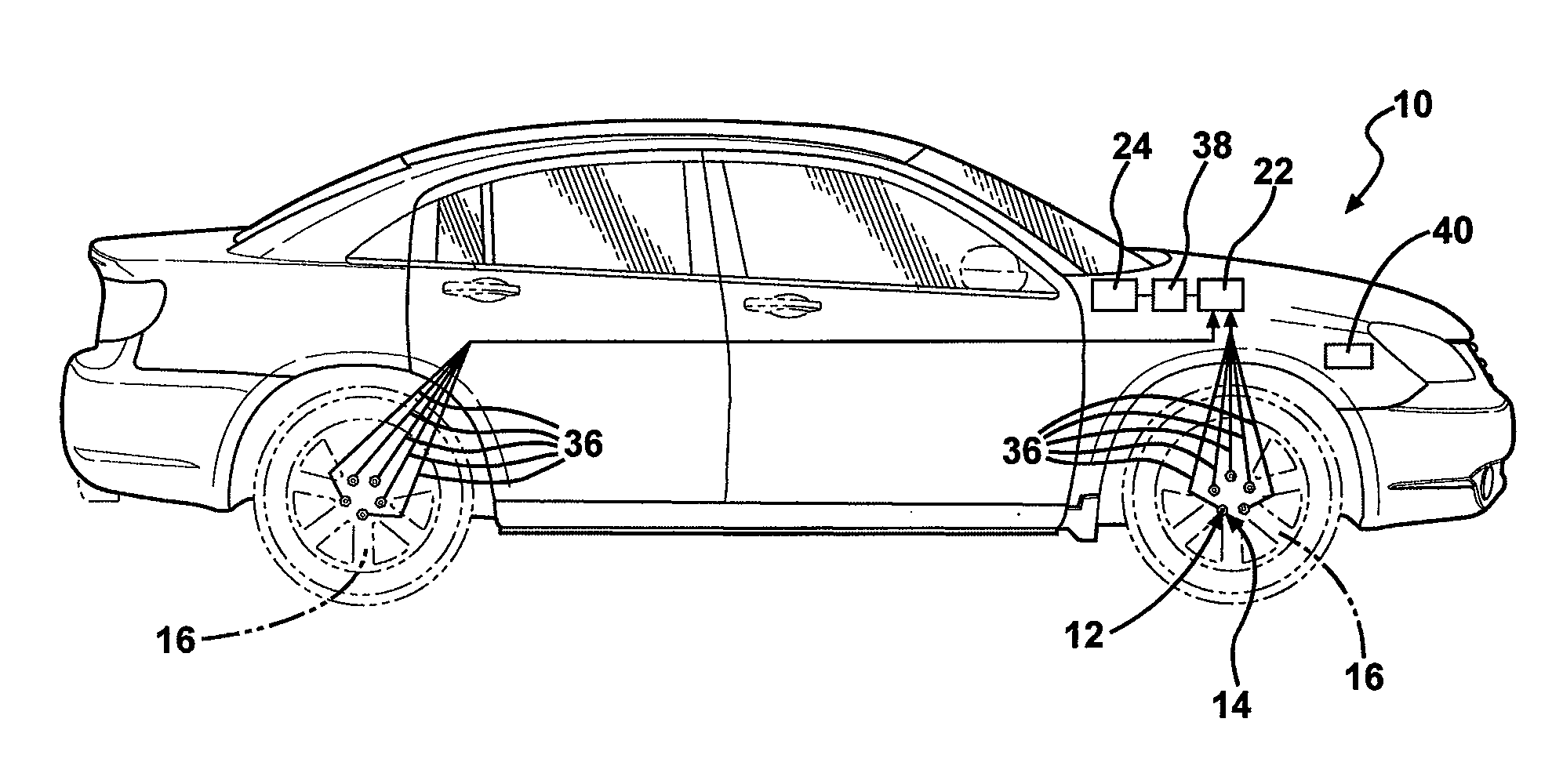

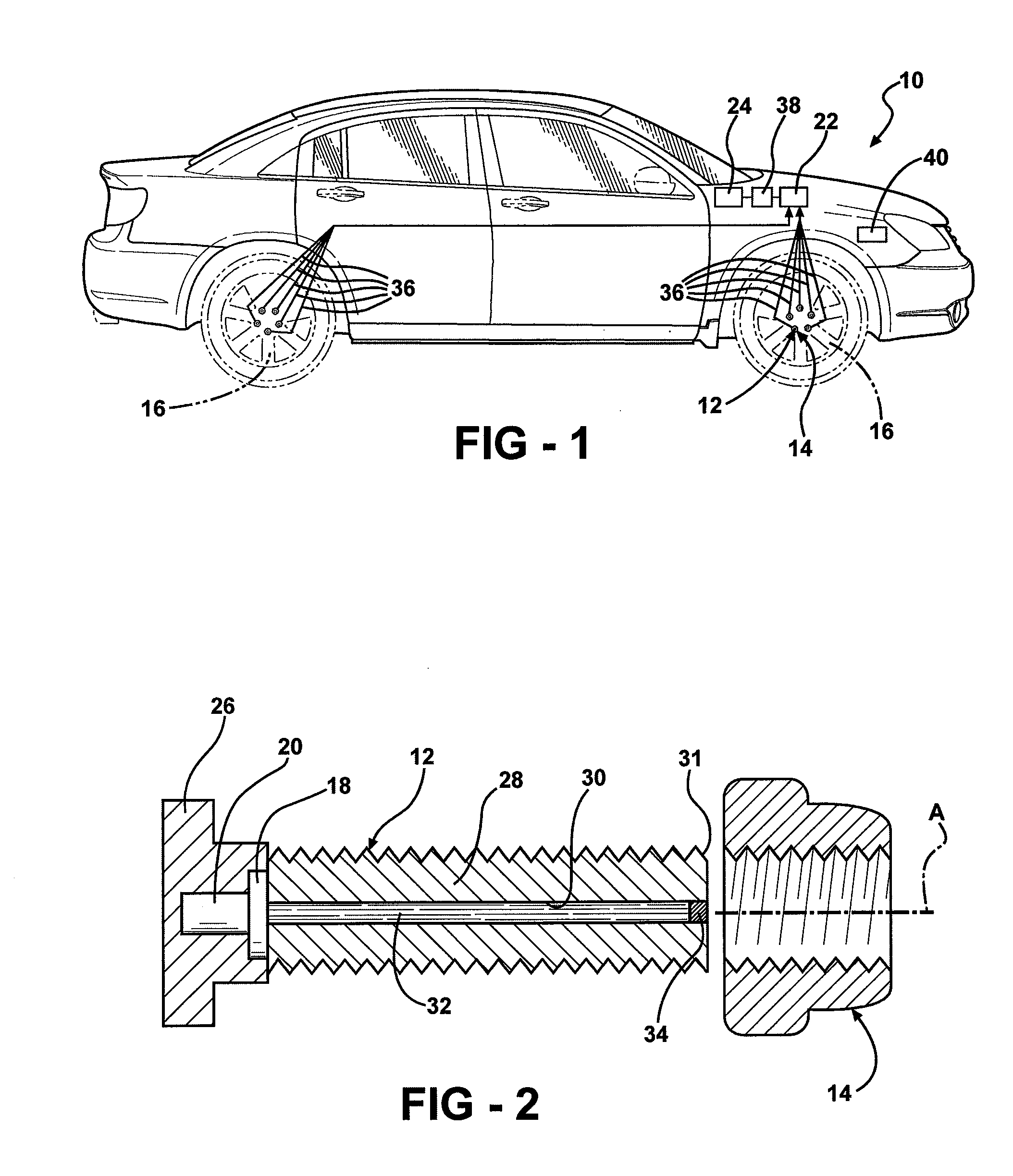

Lug Stud and Lug Nut Monitoring System, Method, and Components Therefor

A lug stud and lug nut monitoring system, method, and components for a vehicle may have a lug stud, a lug nut, at least one sensor, and an indicator. The lug stud has a shank. The lug nut is constructed to fasten on the shank. The sensor can be carried by the lug stud, by the lug nut, or by both the lug stud and the lug nut. The sensor takes at least one measurement. The indicator communicates with the sensor in order to determine a value based on the measurement, and to alert an operator of the vehicle if and when the value reaches a predetermined relationship to a reference value.

Owner:TAG BLUE

Mechanical and adhesive fastener unit

InactiveUS6896462B2Firmly connectedOptimized mechanical fasteningNutsLoad modified fastenersAdhesiveOn board

A multi-part, self-drilling, self-tapping fastener with on board, internal chambered adhesive for, permanently connecting a plurality of parts at an overlaid joint thereof having access from one side. The fastener, that drills its own hole through the joint and taps its own threads for mechanically connecting the parts and subsequently extrudes the adhesive under pressure for optimized joint adhesive infiltration and bonding area for maximizing joint strength. The mechanical fastener holds the parts together eliminating the requirement for holding with auxiliary fixtures allowing the parts to be finished and painted during adhesive cure.

Owner:GM GLOBAL TECH OPERATIONS LLC

Conduction-path-equipped member, method for patterning conduction path, and method for measuring changes in member

InactiveUS20180067003A1Low costWide rangeLoad modified fastenersForce measurementEngineeringMechanical engineering

Owner:NEJILAW

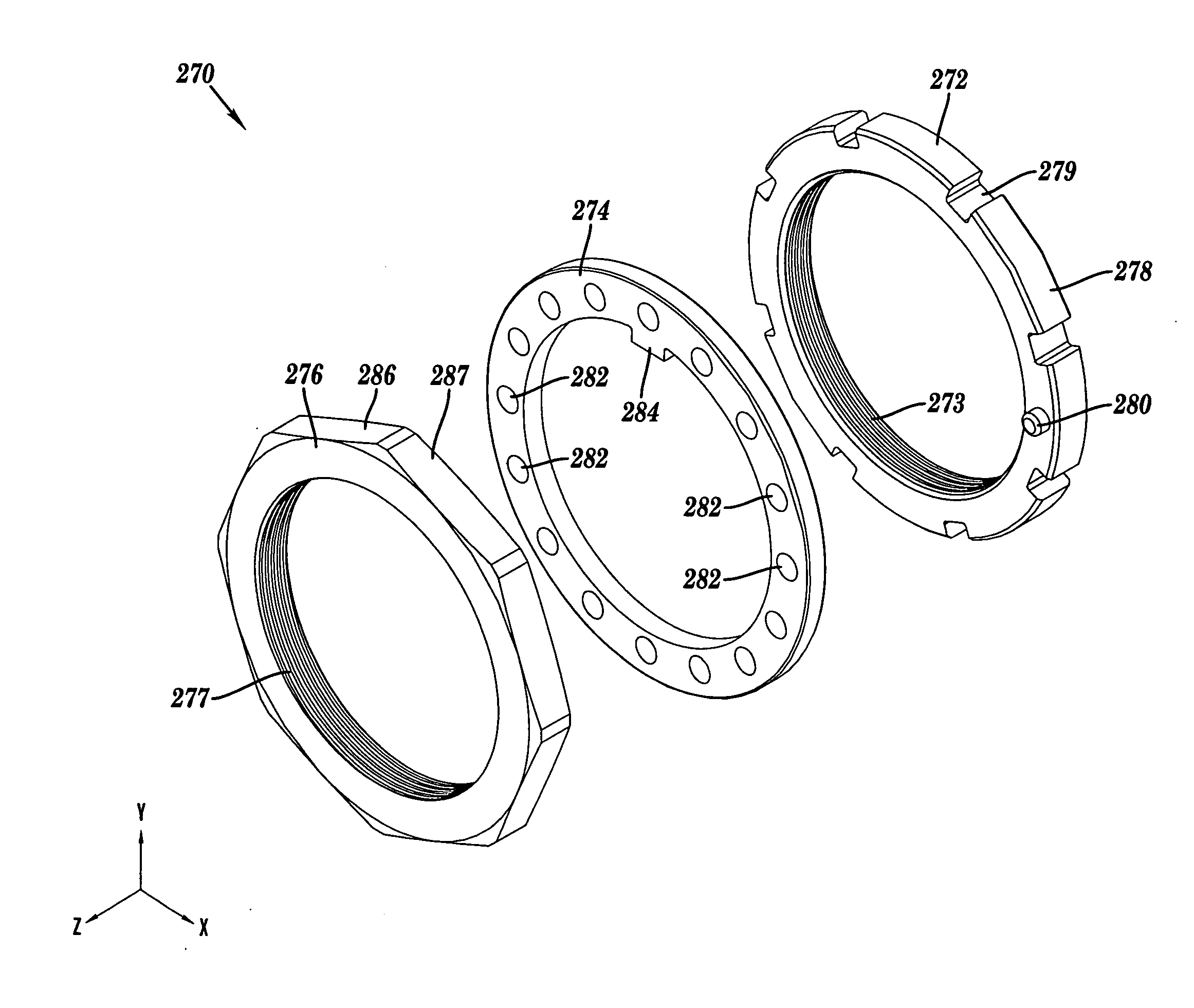

Systems for preloading a bearing and aligning a lock nut

Owner:TEMPER AXLE PROD +1

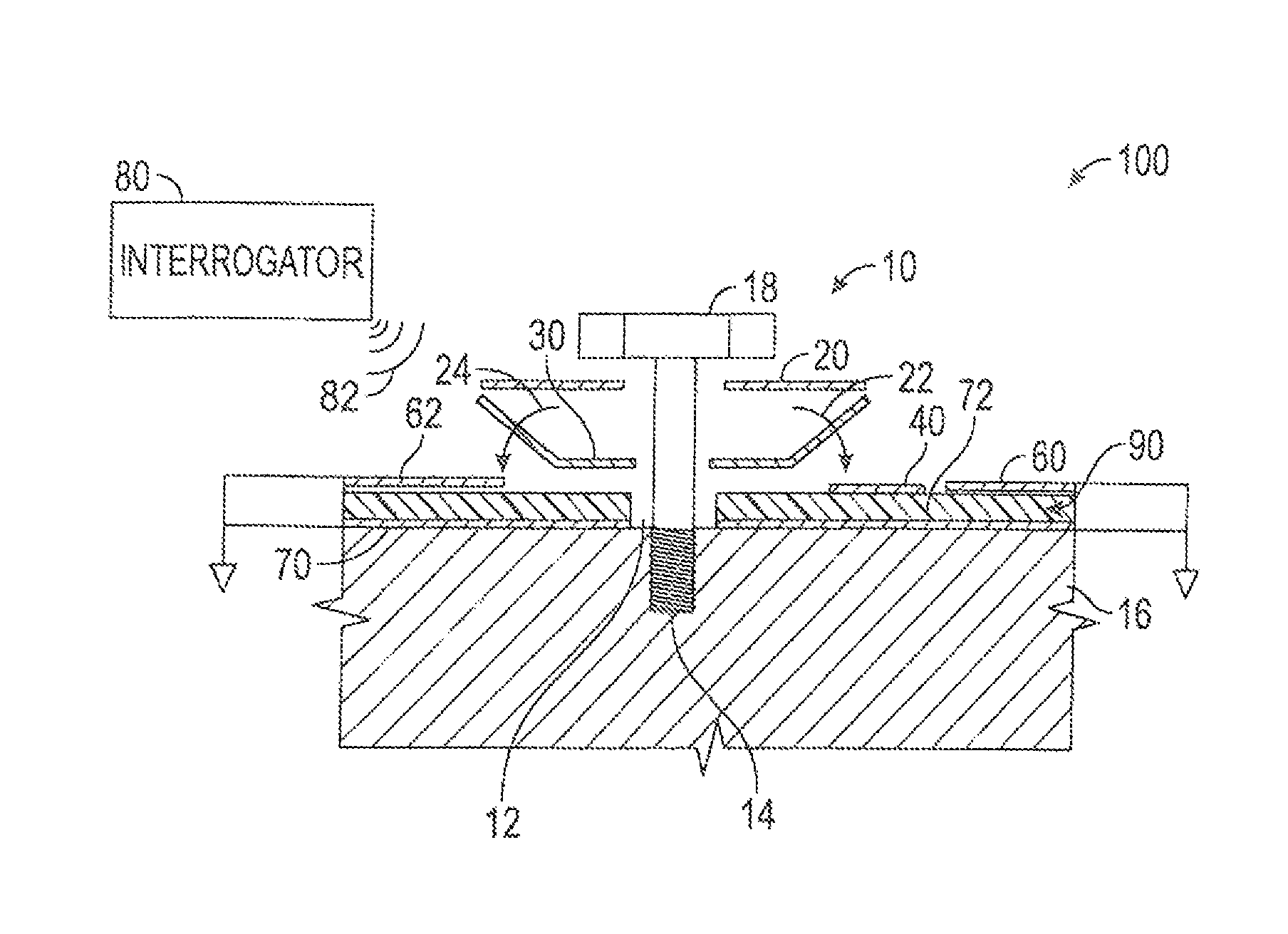

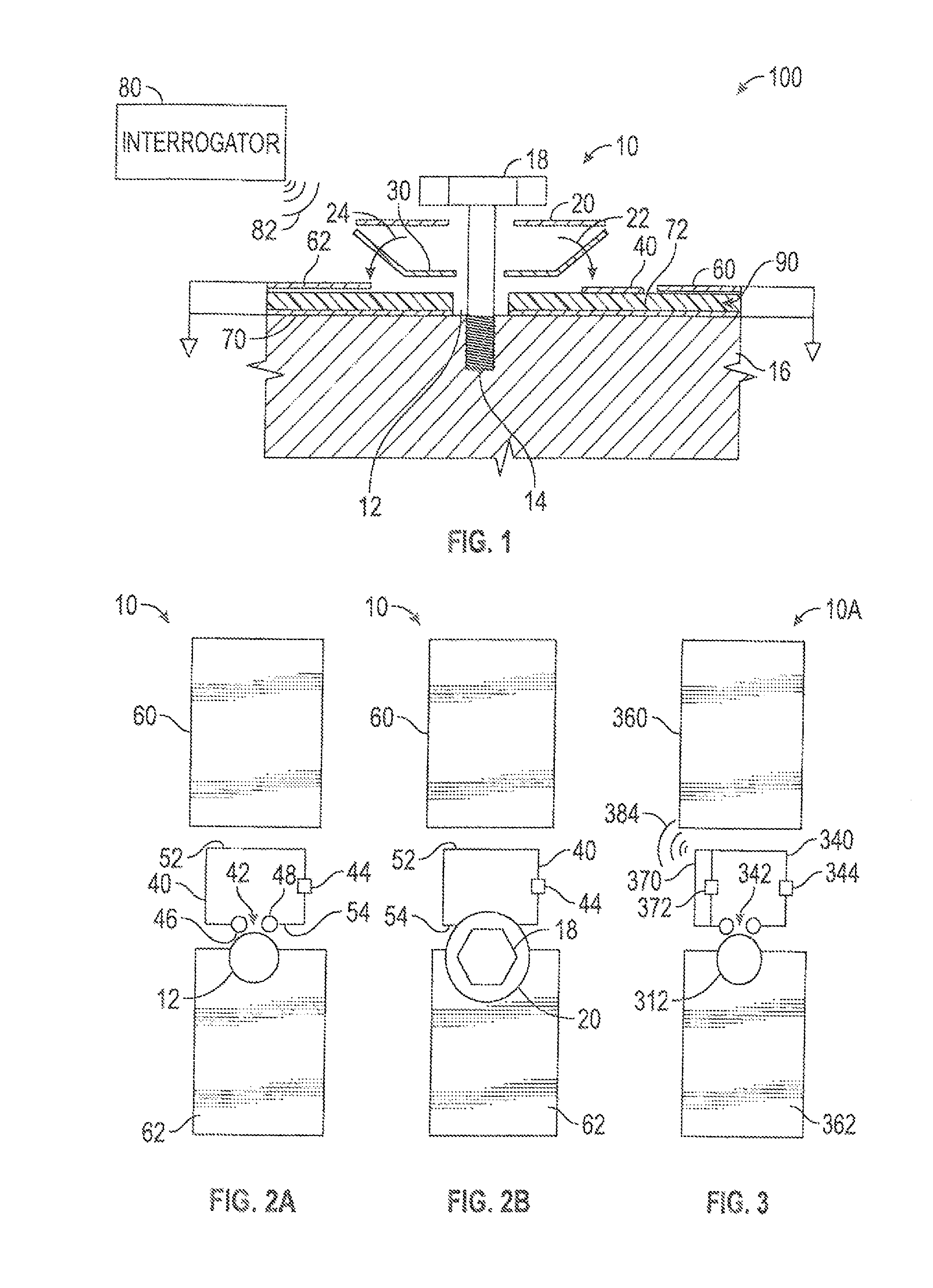

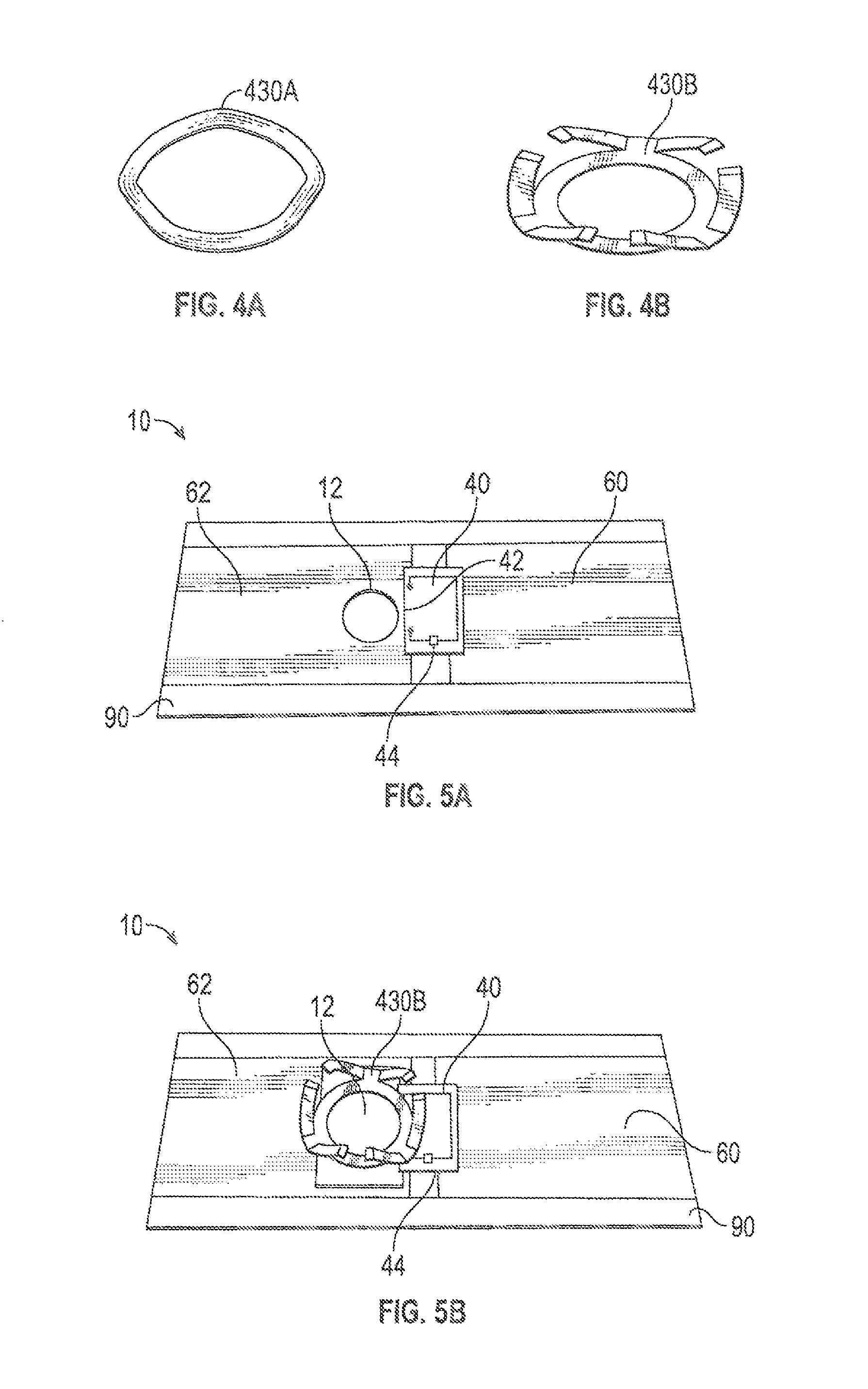

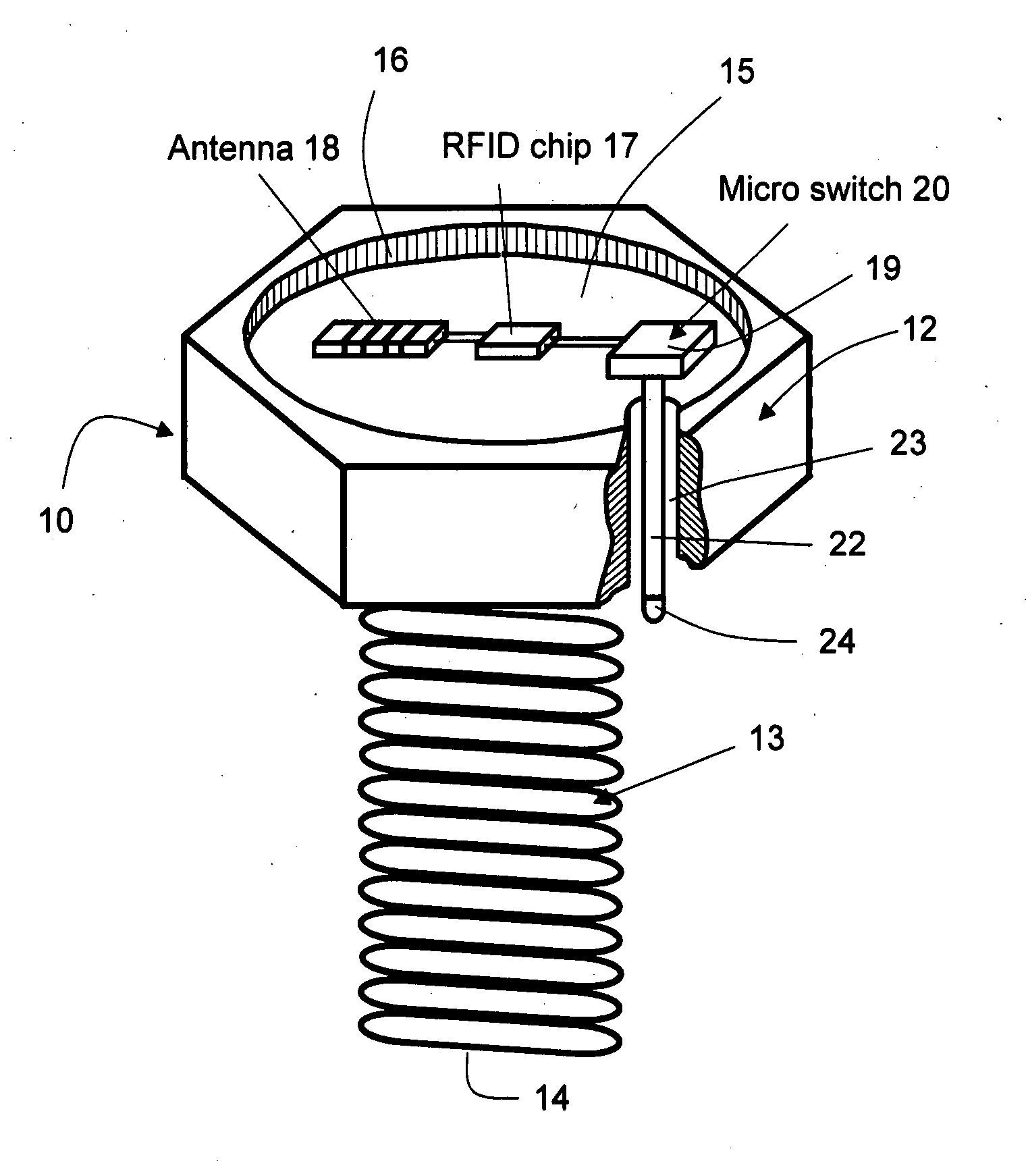

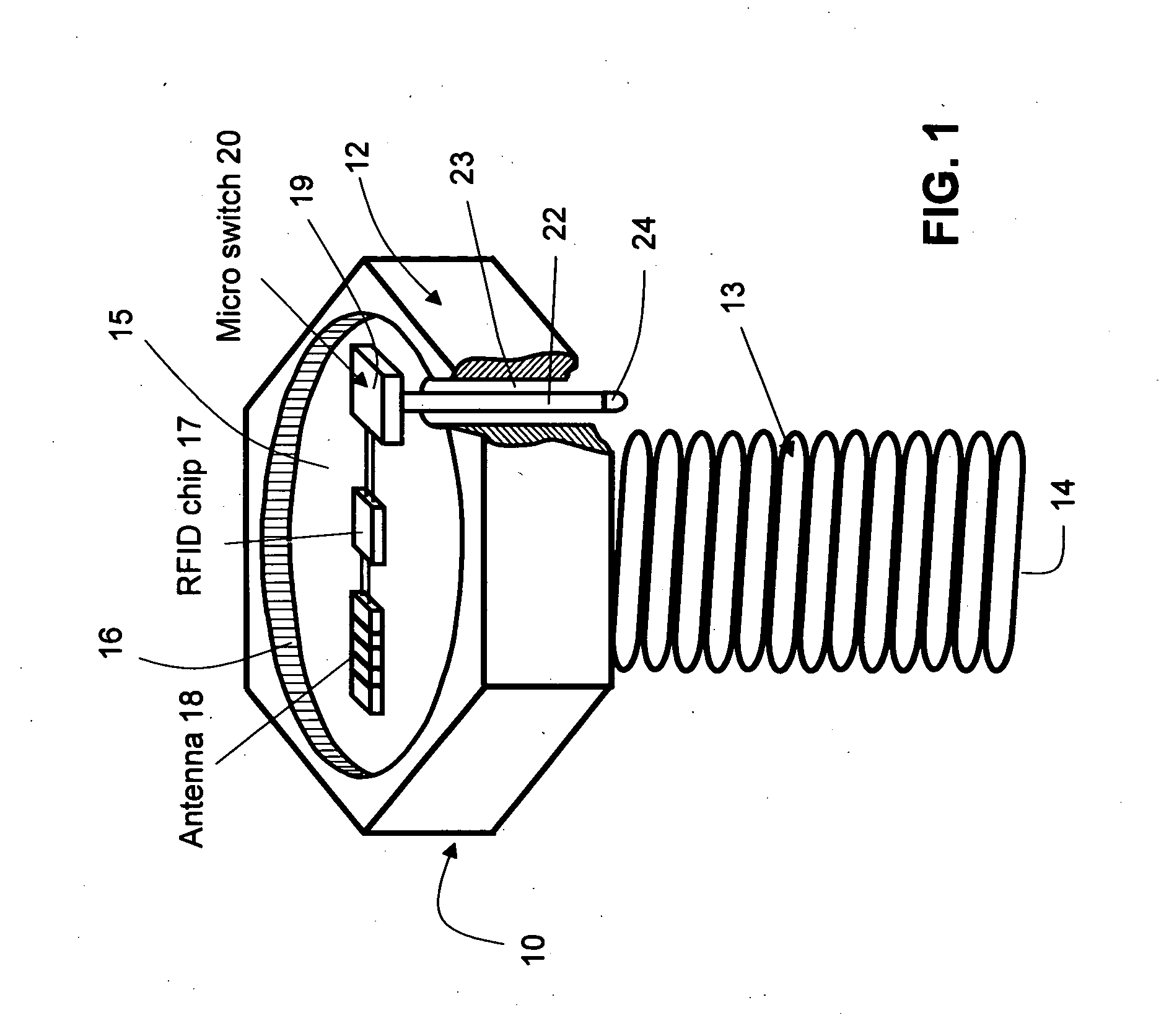

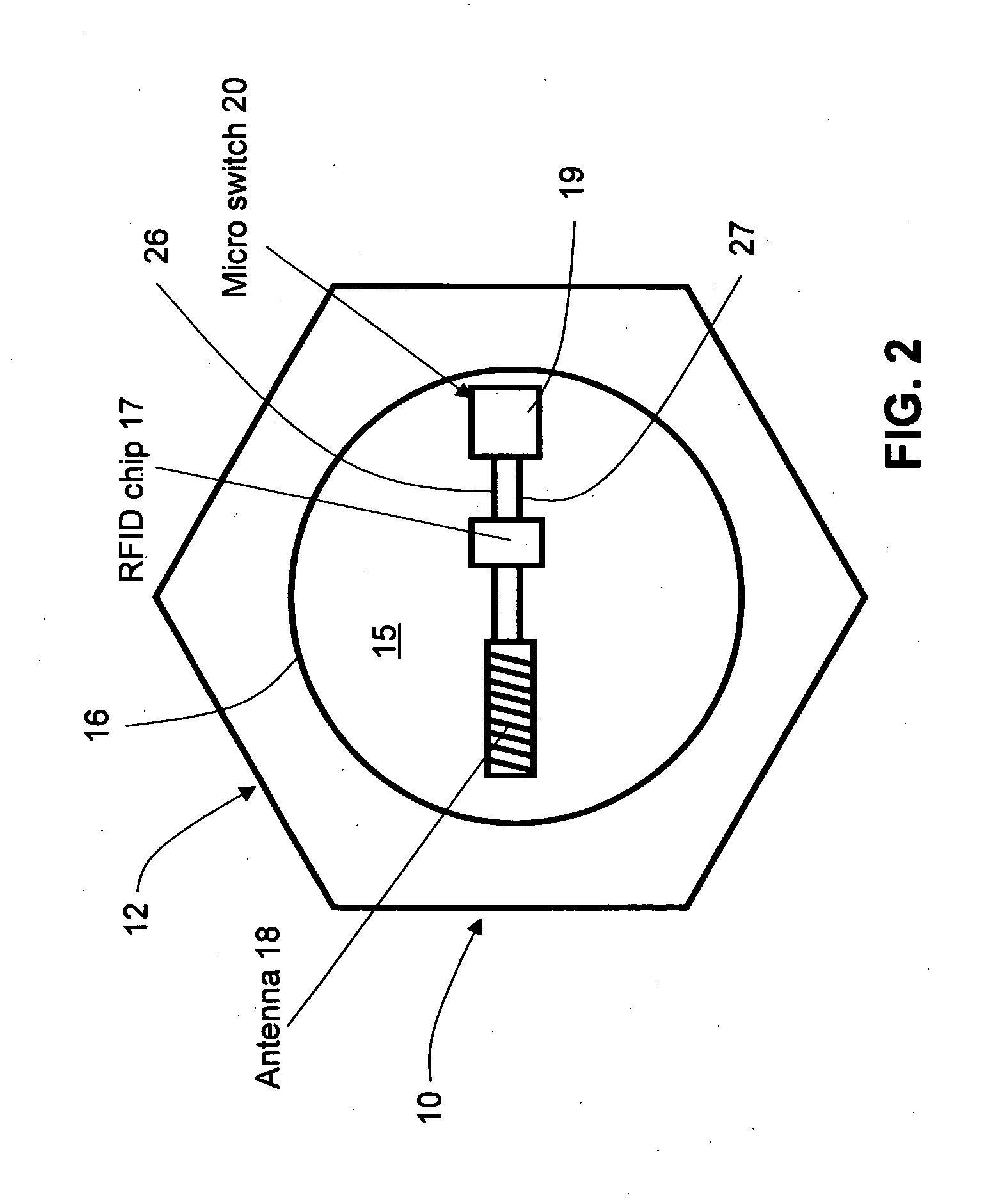

RFID torque sensing tag system for fasteners

ActiveUS9483674B1Reliable dataCost-effective meanMeasurement of torque/twisting force while tighteningLoad modified fastenersOff the shelfRadio frequency

The present invention provides an RFID-based torque sensor that can be used to quickly monitor off the shelf fasteners including fasteners that are used in expensive satellites or other uses where fastener failure can be very costly. In one embodiment, an antenna, RFID ring and spring comprise a sensor tag that can be interrogated with an interrogation signal produced by an interrogator device. When sufficient torque is applied to the fastener, an RFID circuit is connected, and produces a radio frequency (RF) signal that can be read by the interrogator. In one embodiment, the RFID circuit does not transmit when the spring member is not compressed, thereby indicating insufficient tensioning of the fastener. The present invention offers the ability to remotely, quickly, and inexpensively verify that any number of fasteners are torqued properly upon initial installation. Where applicable, the present invention allows low cost monitoring over the life of the fastener.

Owner:NASA

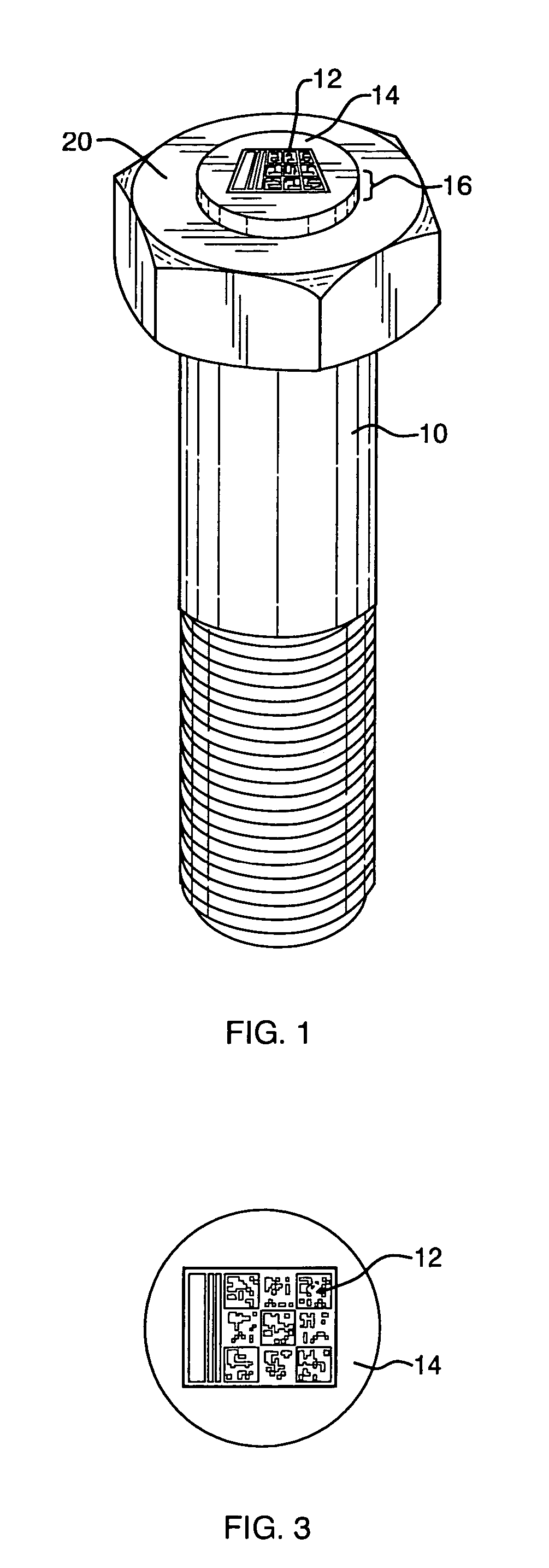

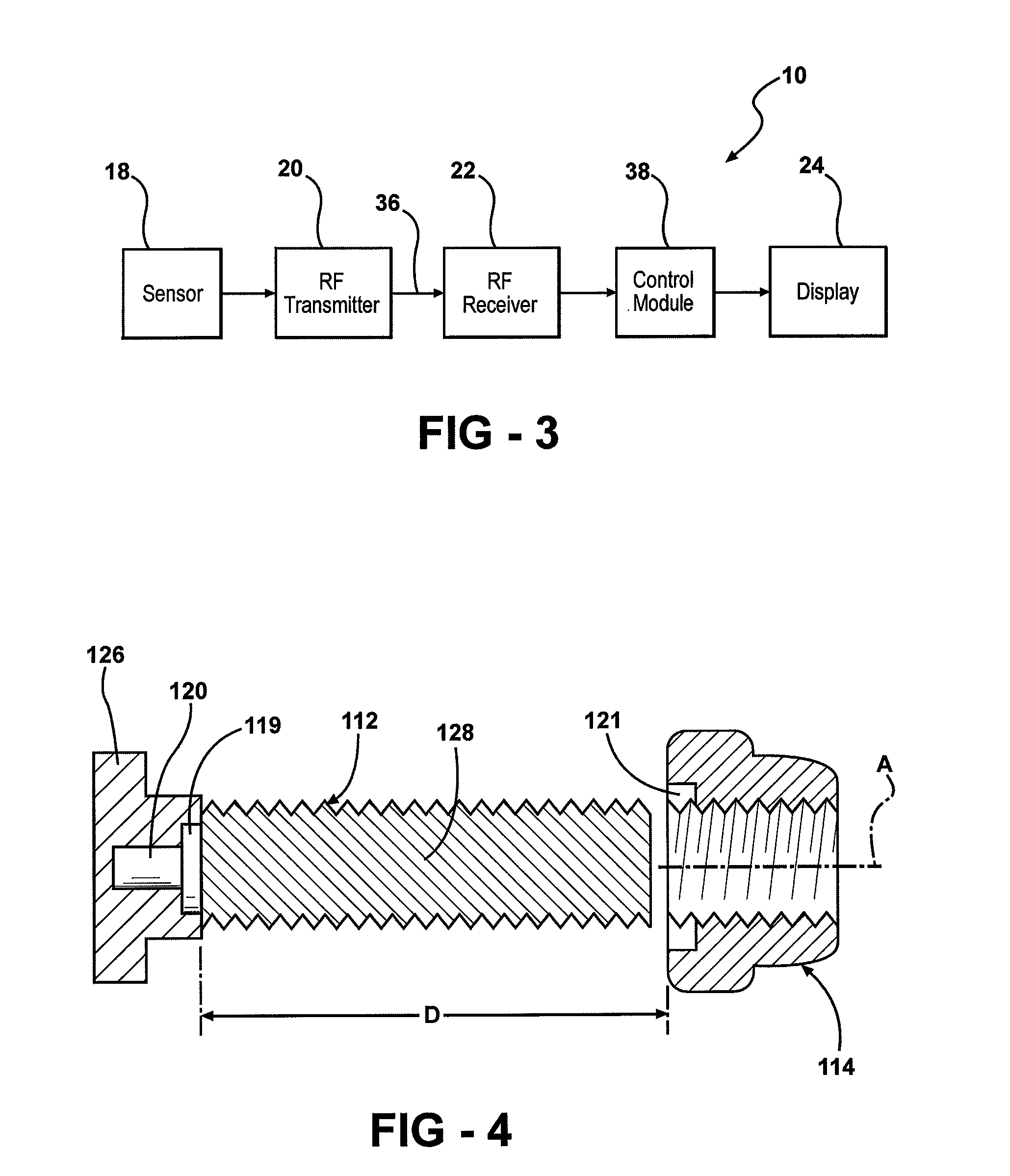

Intelligent fastener

ActiveUS20130186951A1Easy to installFacilitates follow-up checkingDigital data information retrievalLoad modified fastenersEngineeringBidirectional communication

An intelligent fastener having a head and an externally threaded shank for threaded engagement with a structural member. The head has a recess formed in the top surface for mounting an RFID tag with a memory containing information specific to the fastener—such as fastener identification, specified torque value and other information—an antenna for enabling bidirectional communication with an RFID tag reader, and a torque value sensor for determining the torque applied to the fastener by a fastener installation tool. Once installed, the existing torque on a collection of fasteners is measured by using an RFID tag reader to scan the information stored in the memory of each fastener.

Owner:SILICON VALLEY MICRO C

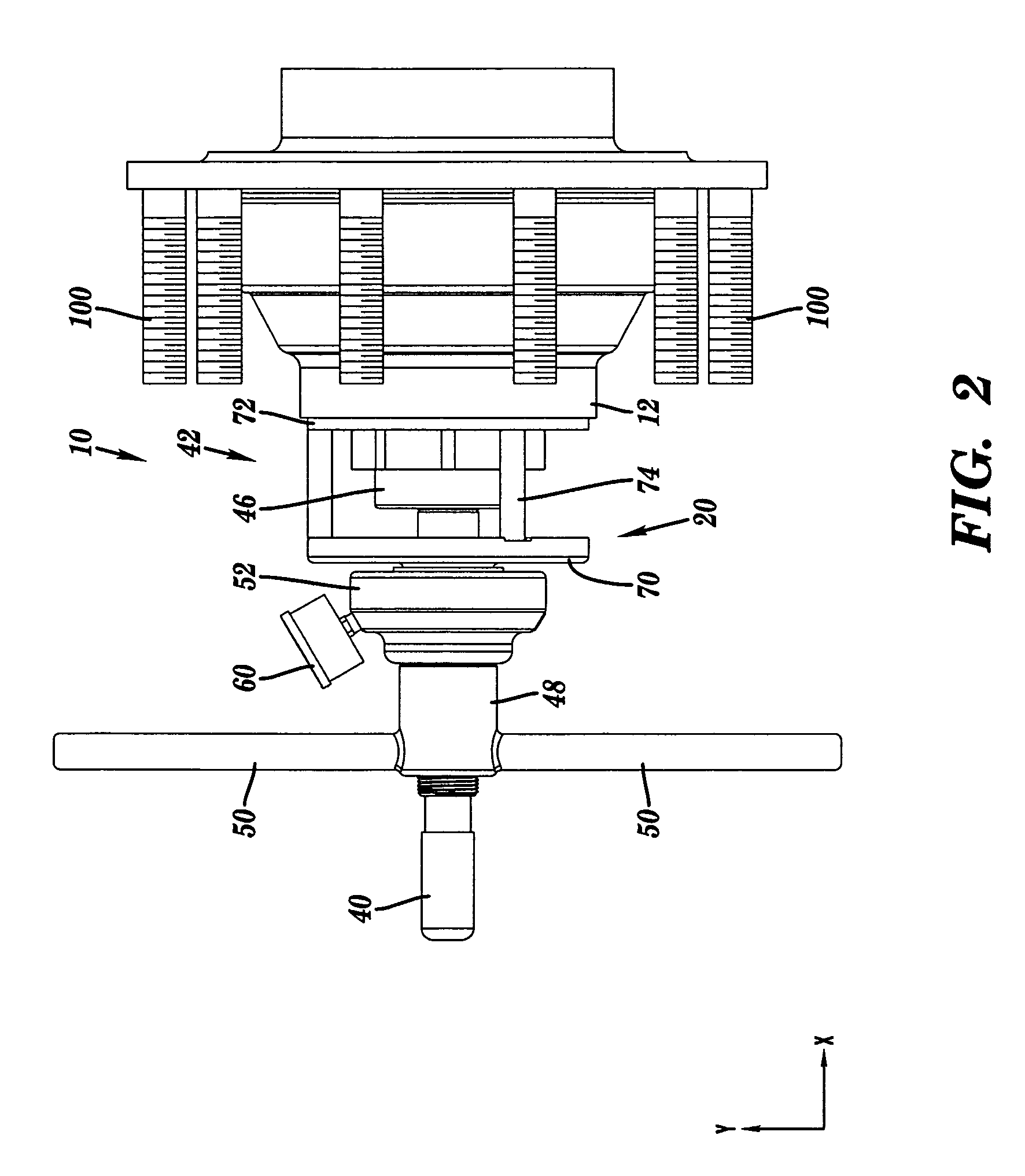

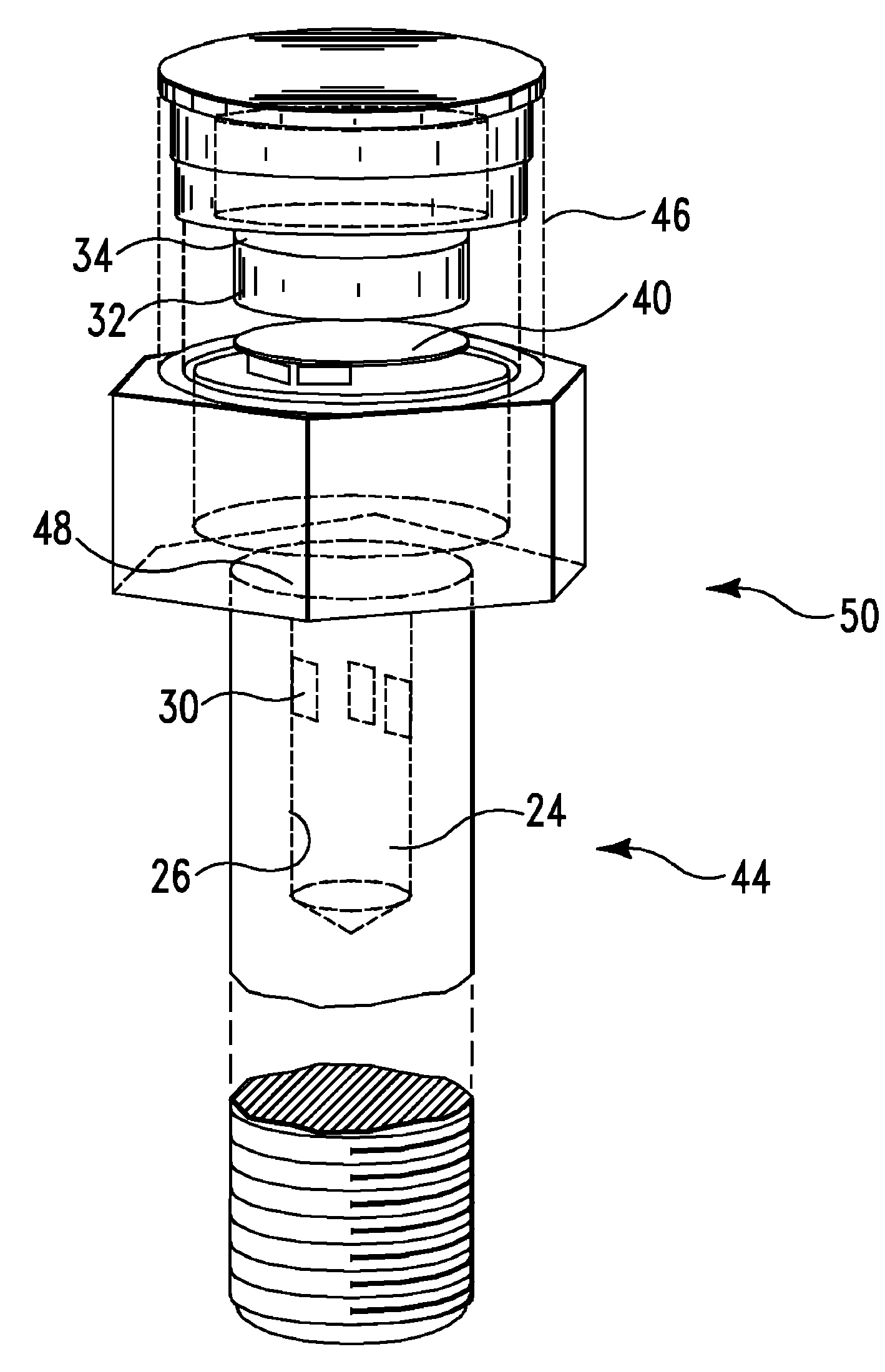

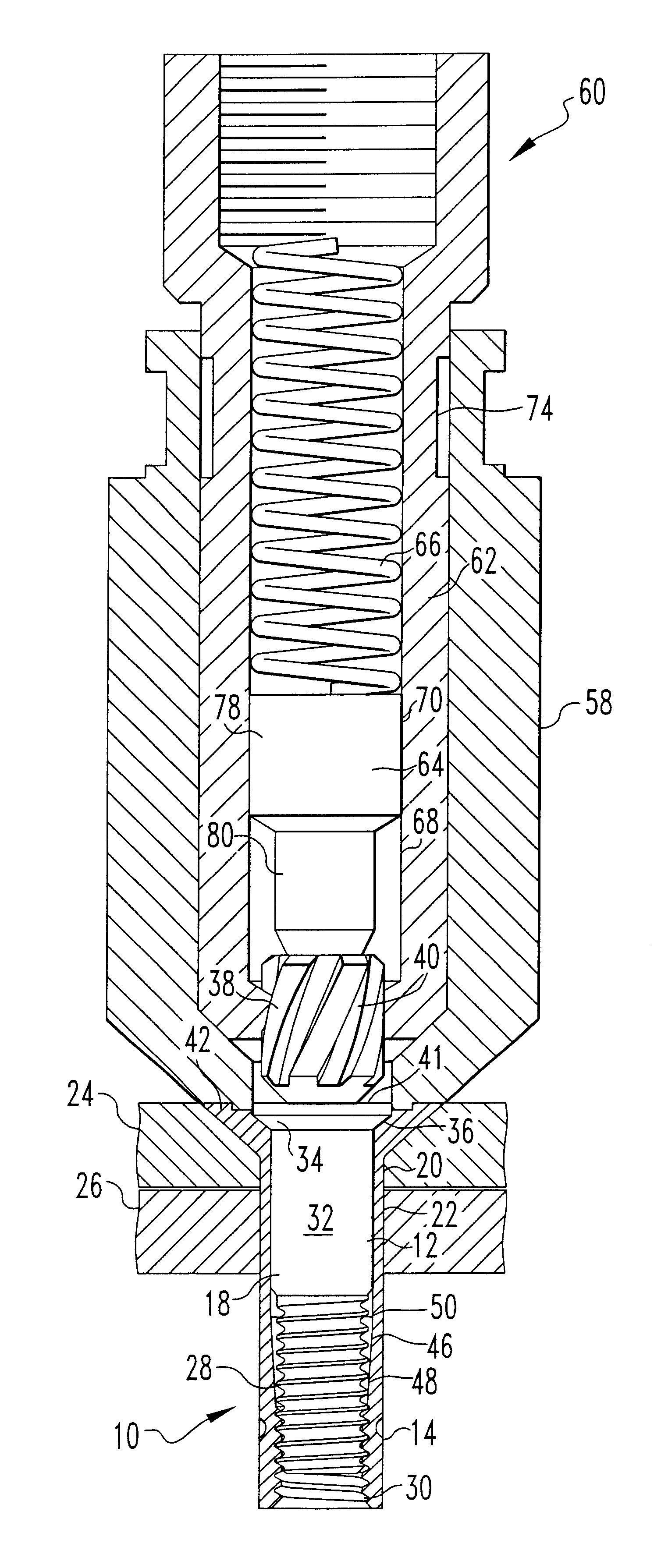

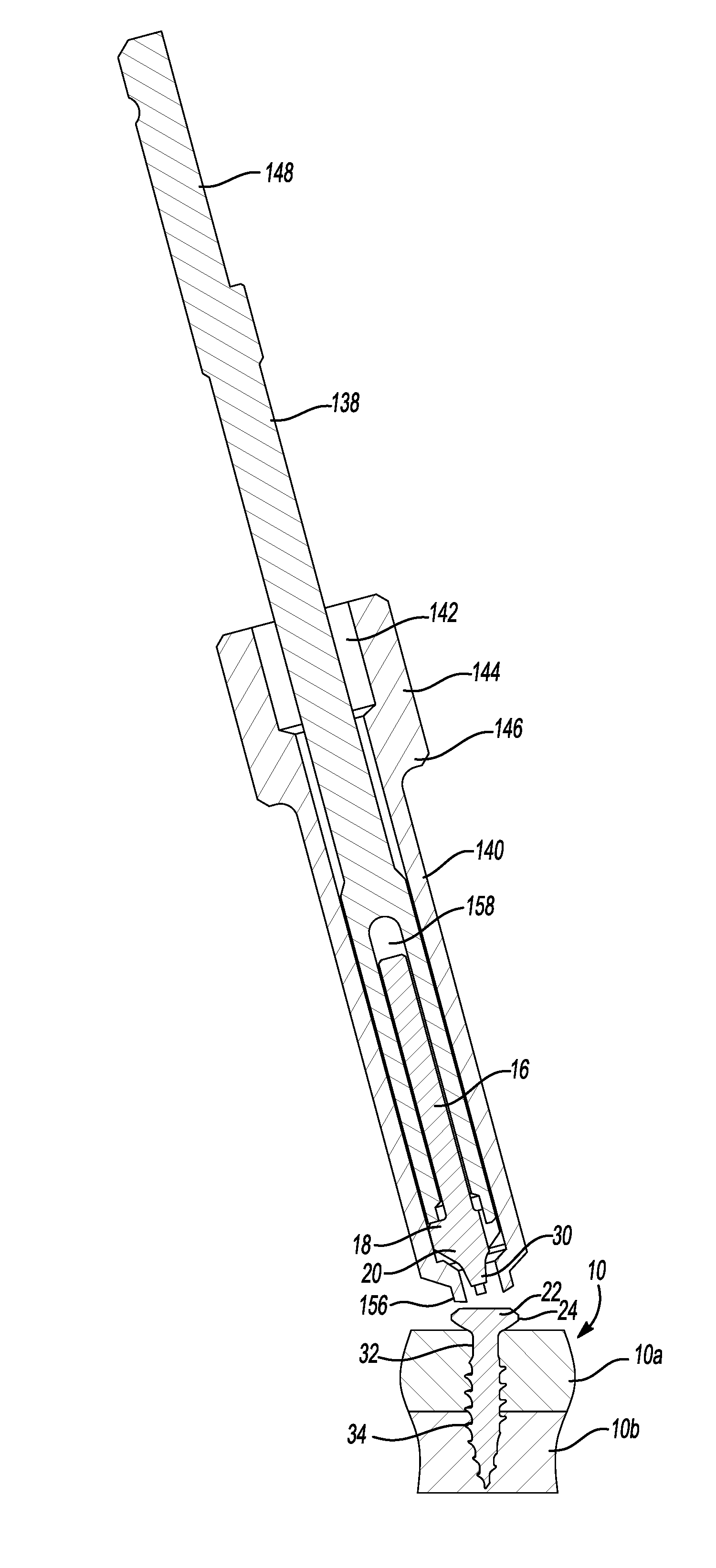

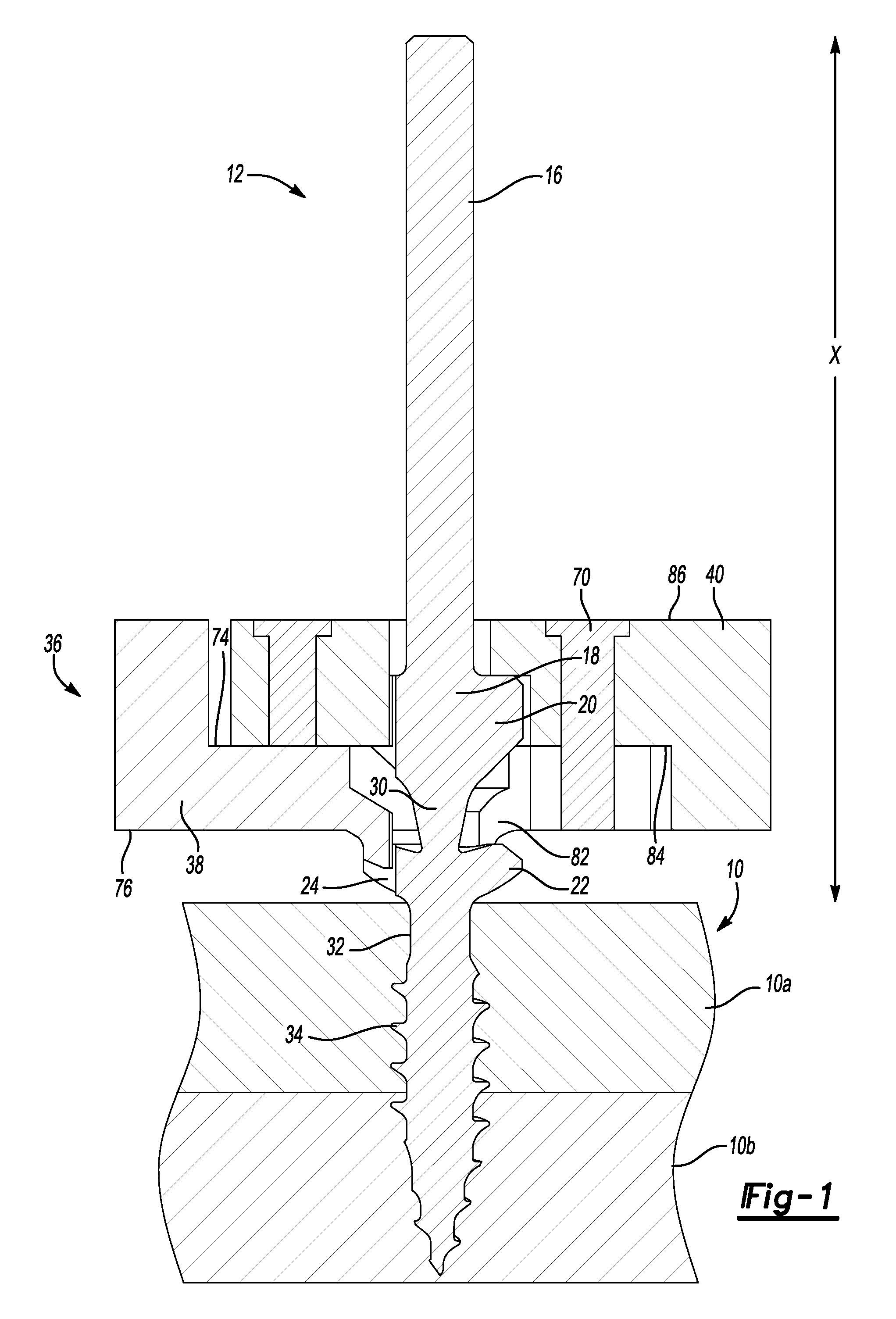

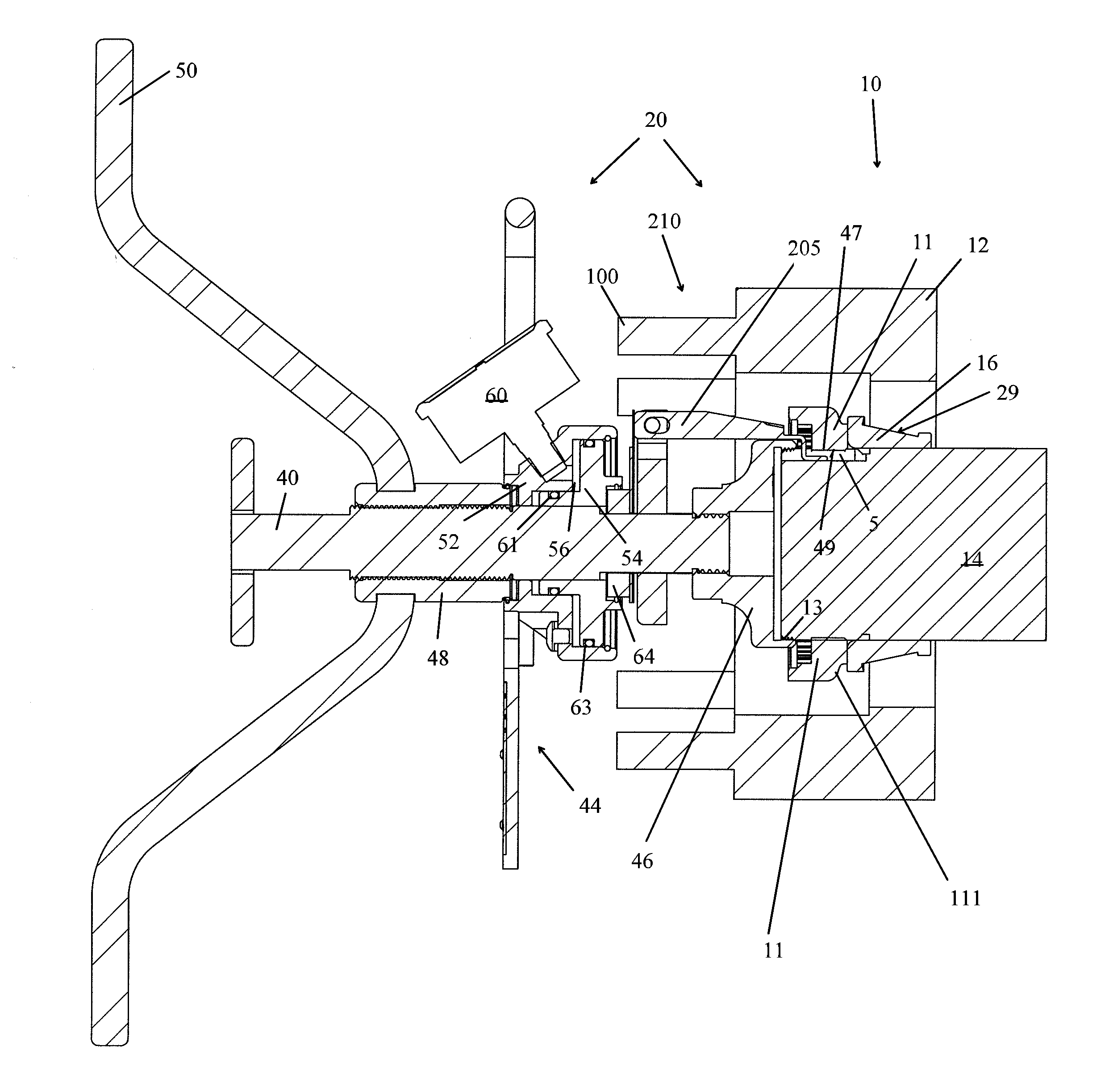

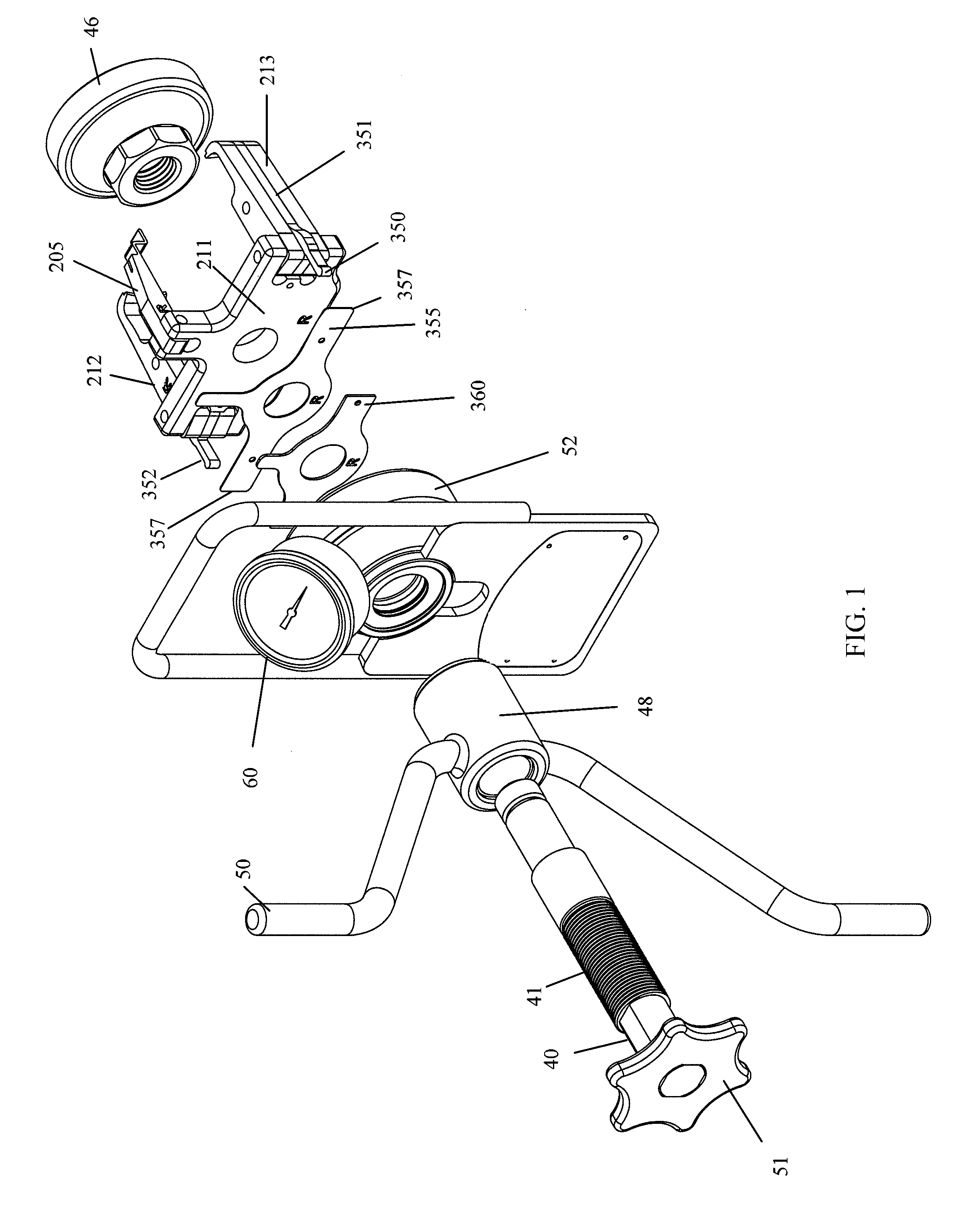

Method, apparatus, and nut for preloading a bearing

ActiveUS20070211973A1Accurately determineRolling contact bearingsBearing assemblyEngineeringFluid pressure

Methods and apparatus for preloading a bearing are provided. These methods and apparatus include preload monitoring devices whereby the mechanic can accurately monitor and regulate the preload on a bearing or bearing assembly. Aspects of the invention may also be used to adjust the endplay on a bearing or a bearing assembly. In one aspect, the preload on the bearing is transmitted through a housing having a fluid pressure that can be detected and monitored. An apparatus for precisely rotating a nut and a tool for precisely rotating a nut are also provided. A bearing retaining nut arrangement that permits the loading or evaluating of a bearing inner race is also provided. The bearing retaining nut arrangement includes a first load-setting nut, a lock washer, and a second jam nut that secures the arrangement to a shaft.

Owner:TEMPER +1

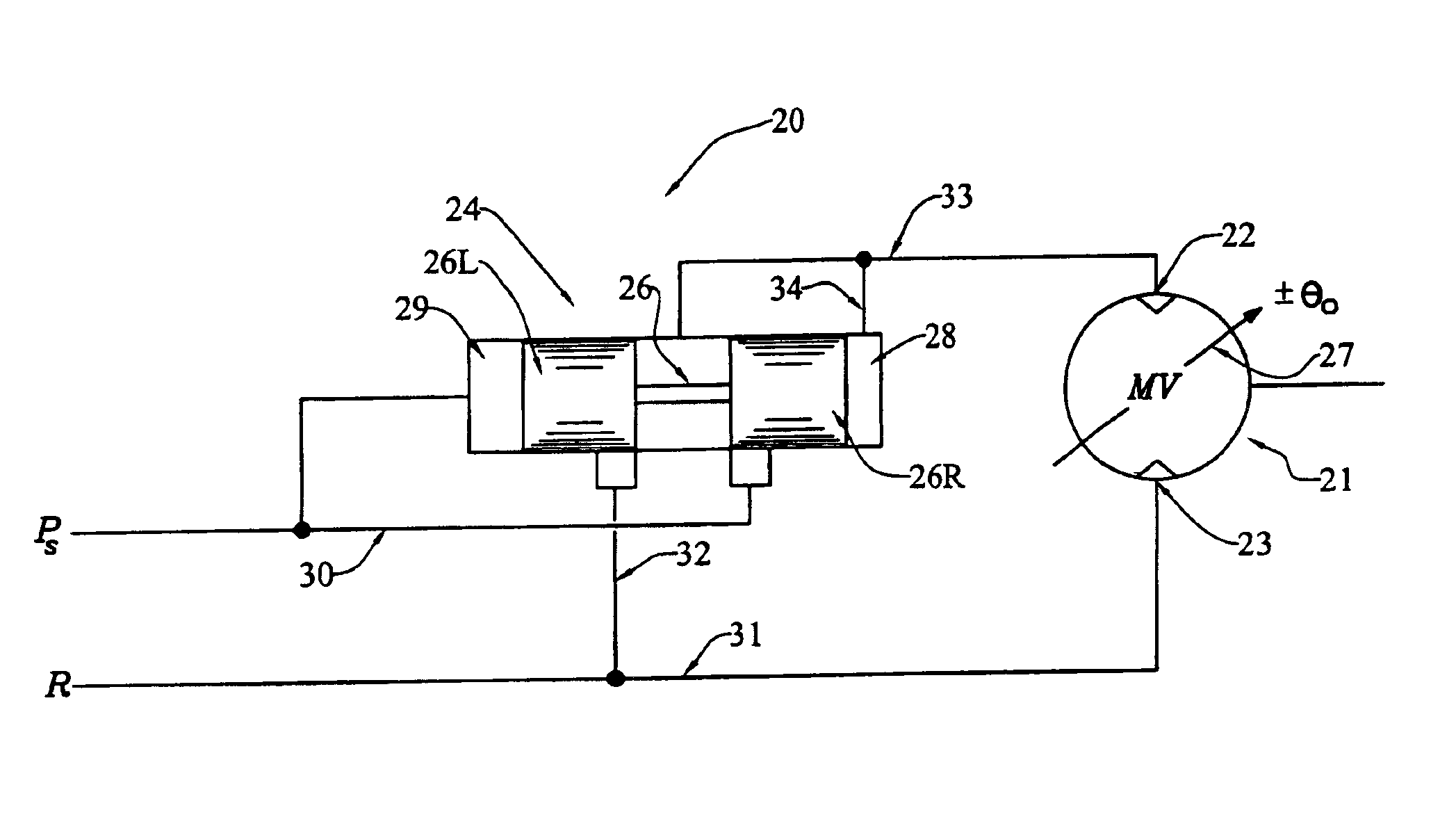

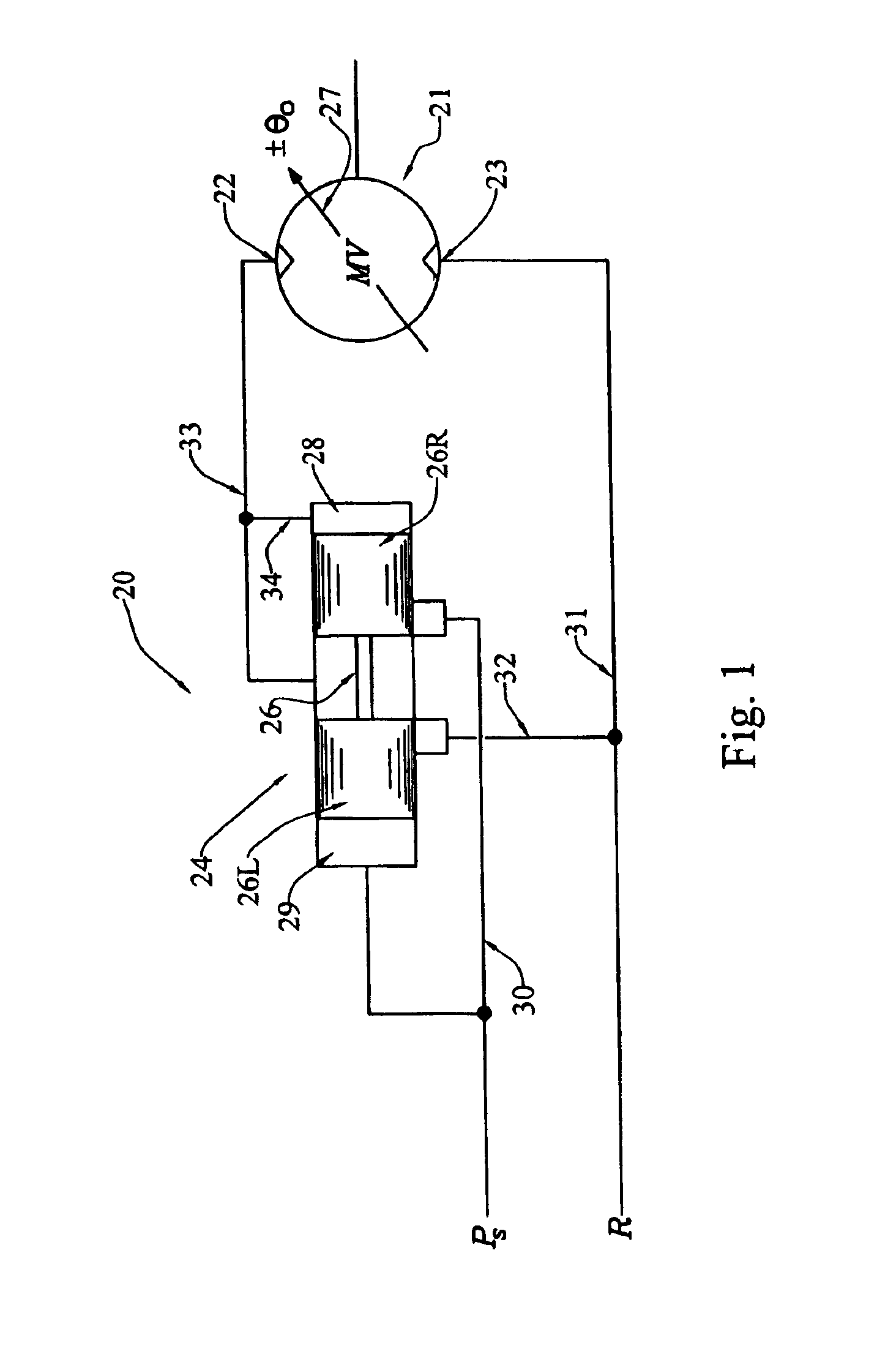

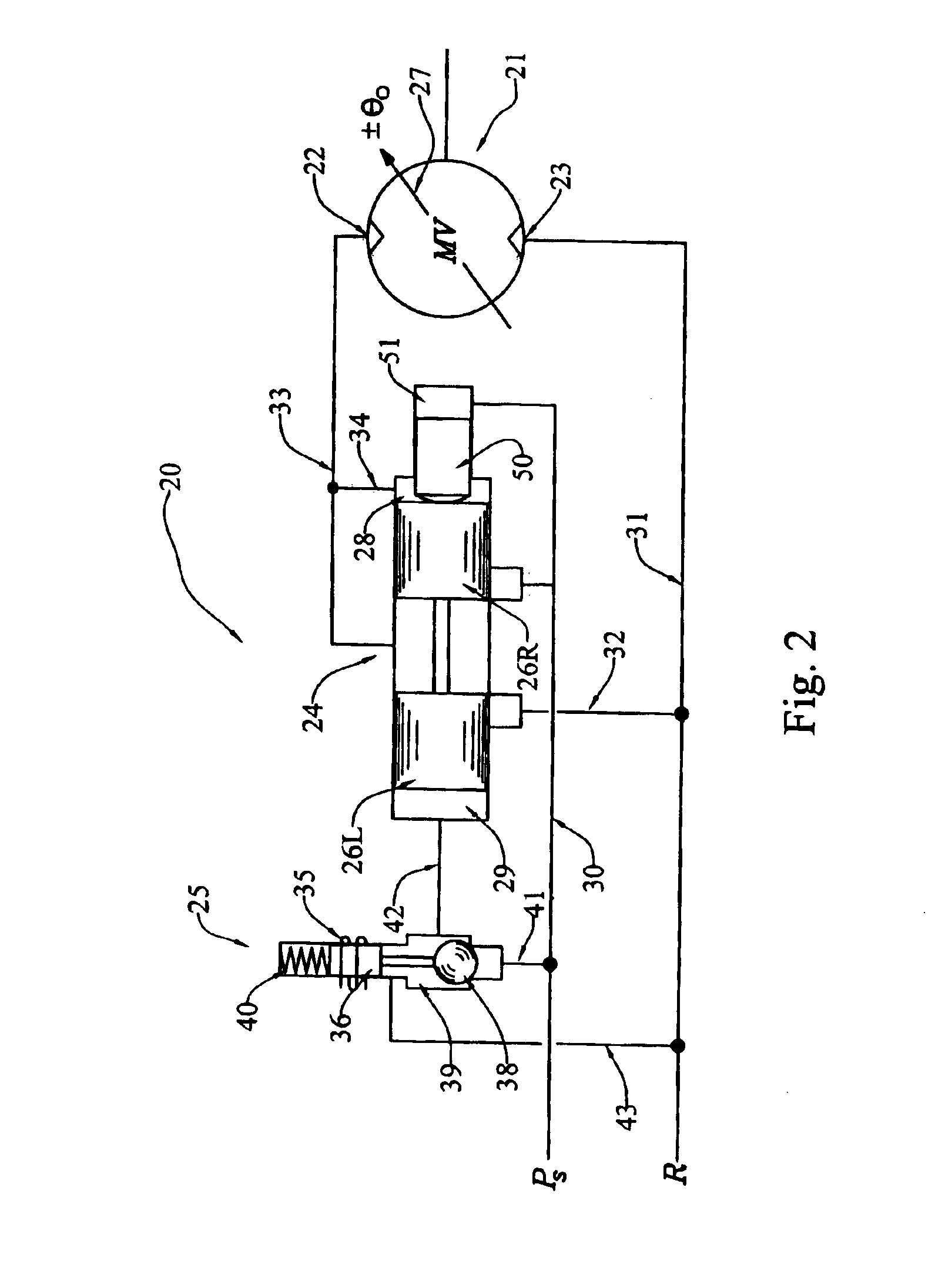

Regulated pressure supply for a variable-displacement reversible hydraulic motor

A pressure-control device (20) includes a controllable variable-displacement reversible hydraulic motor (21) having a pressure port (22) and a return port (23); a source of pressurized fluid (Ps); a fluid return (R); and a pressure regulating valve (24) operatively interposed between the source, return and pressure port. The pressure regulating valve is operatively arranged to maintain a predetermined pressure at the pressure port regardless of the direction of flow through the pressure port.

Owner:MOOG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com