Patents

Literature

116results about How to "Low RPM" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

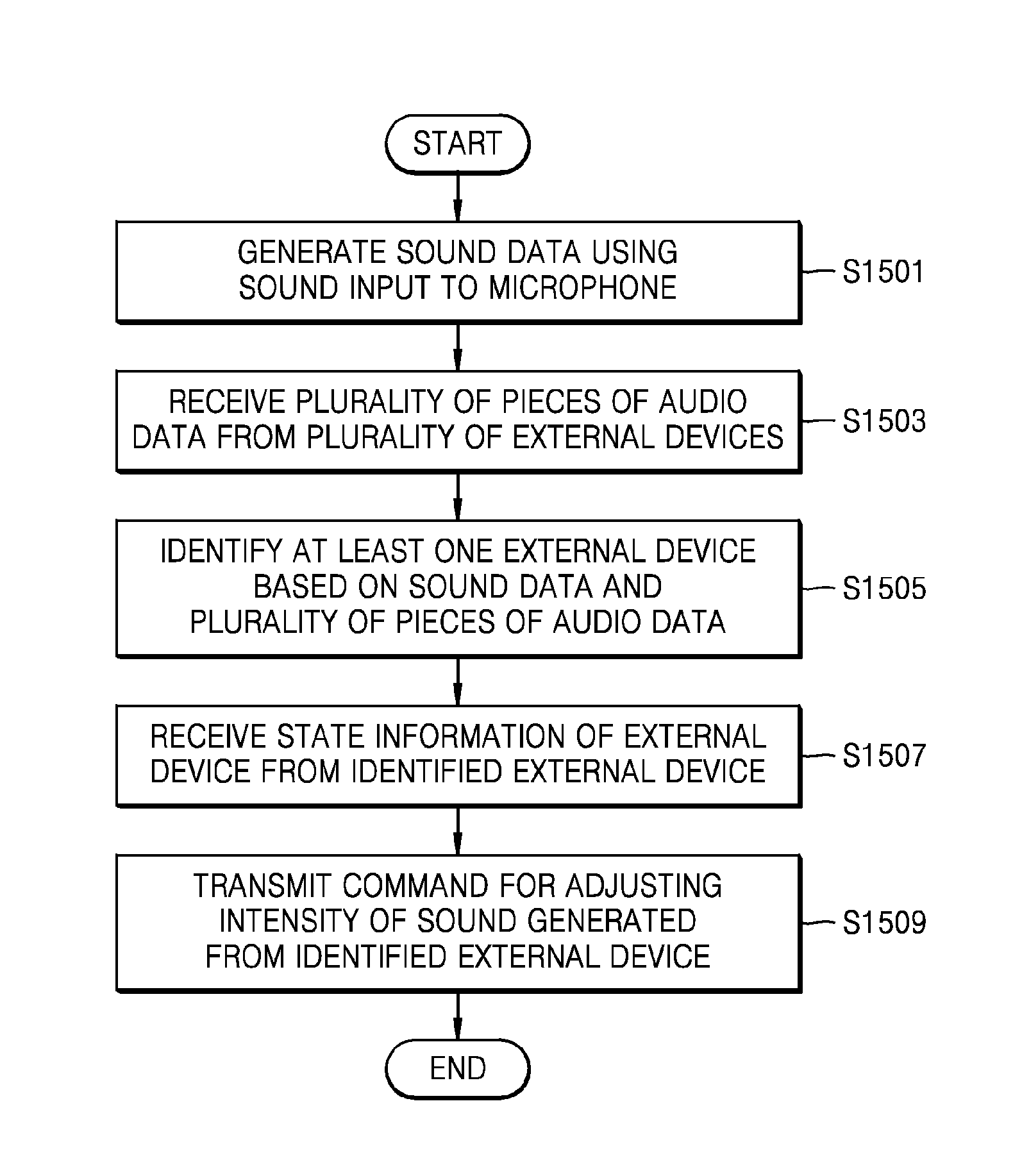

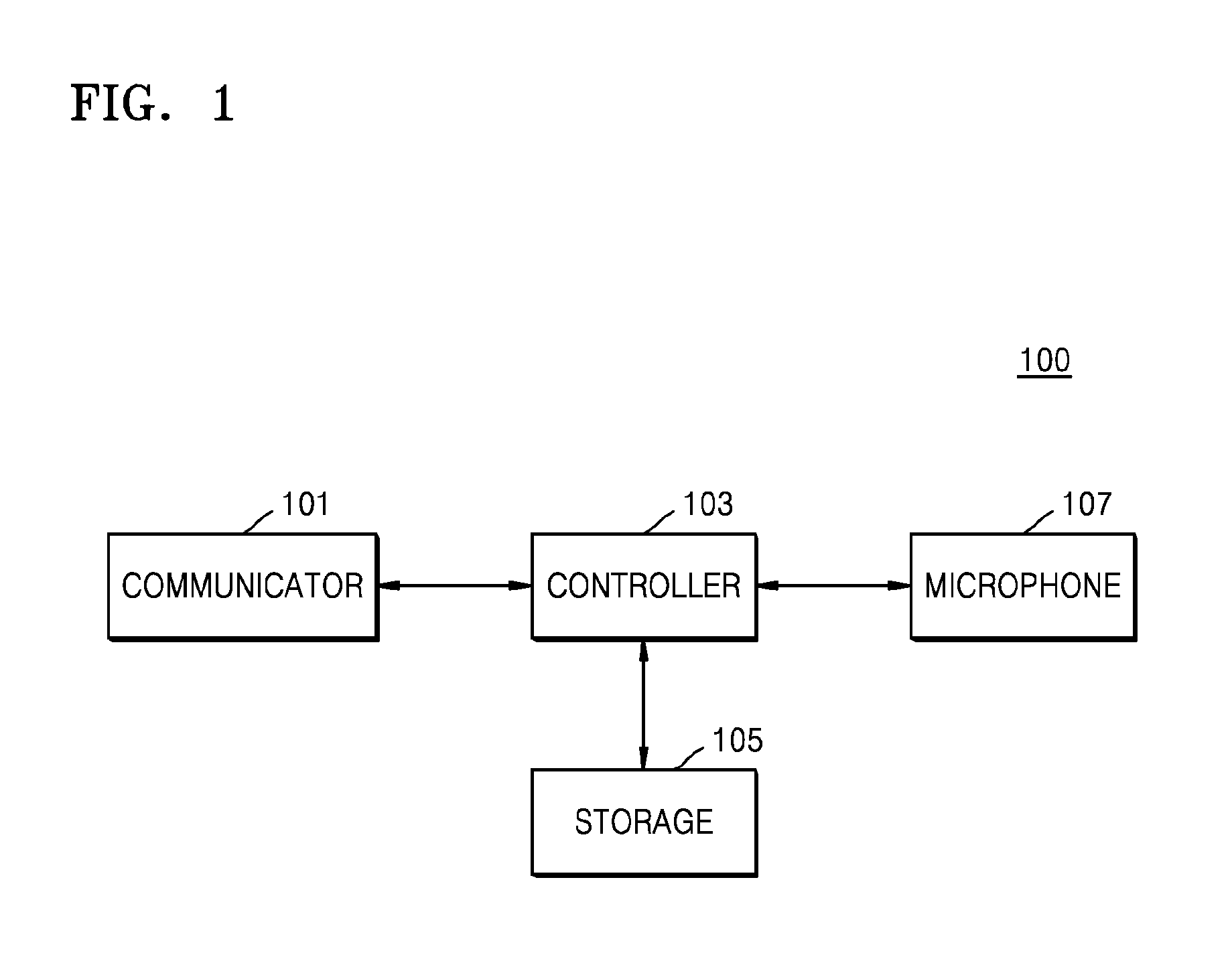

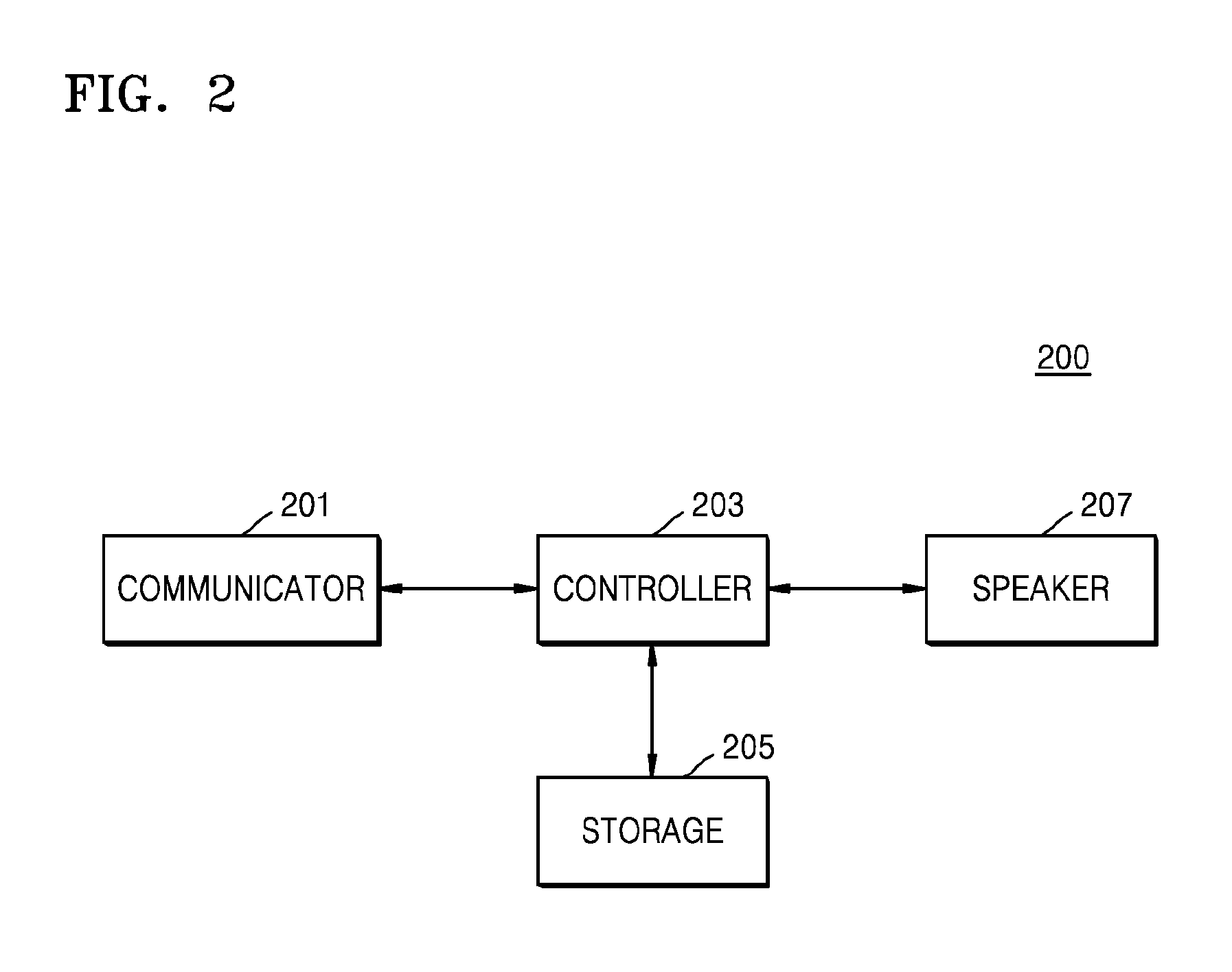

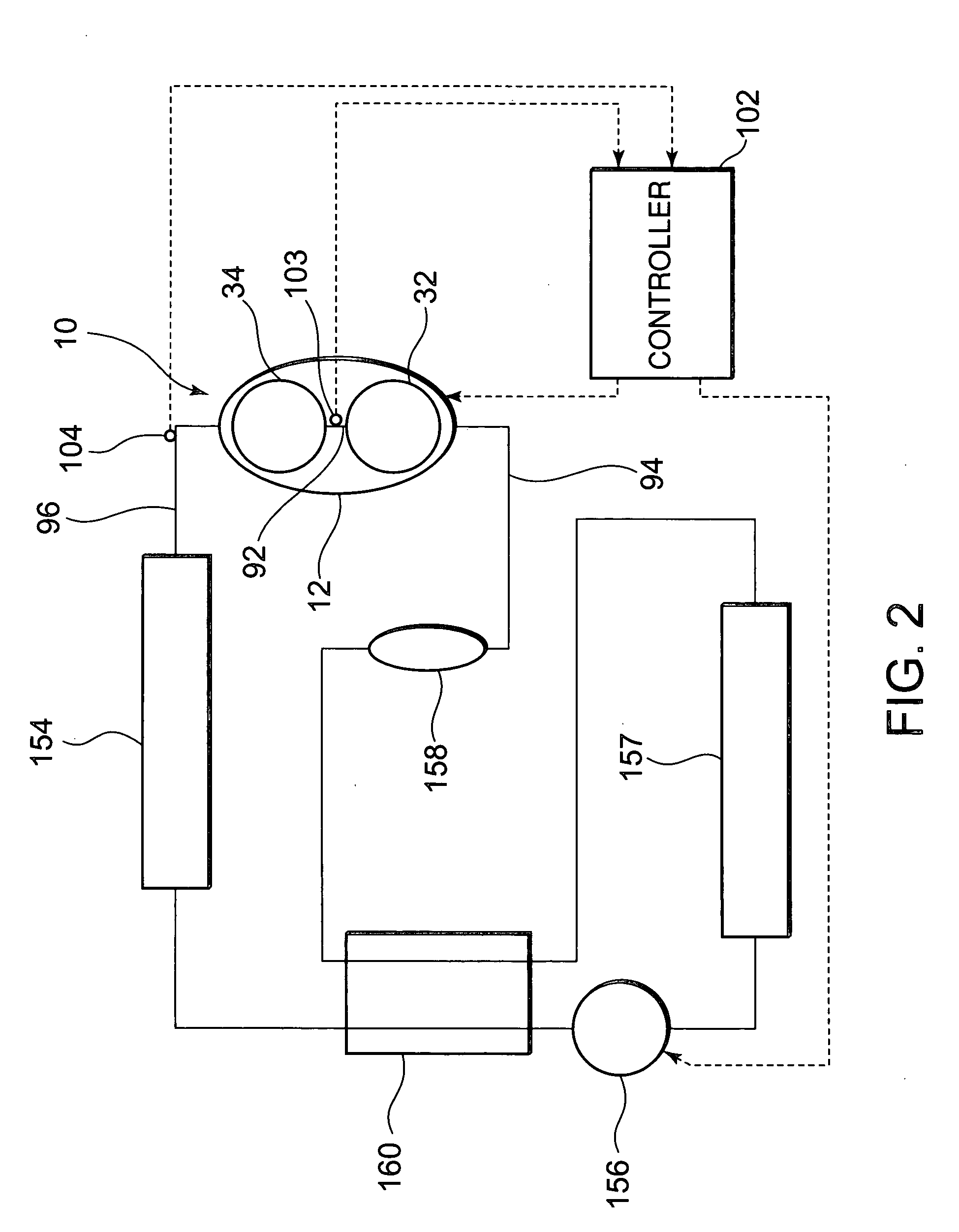

Electronic apparatus and method for adjusting intensity of sound of an external device

An electronic apparatus includes a microphone; a communicator configured to communicate with an external device; and a controller configured to generate sound data based on a sound input to the microphone, receive audio data from the external device through the communicator, the audio data corresponding to a sound output from the external device, and control to transmit, through the communicator, a command to the external device to adjust an intensity of the sound output from the external device based on a result of comparison between the sound data and the audio data.

Owner:SAMSUNG ELECTRONICS CO LTD

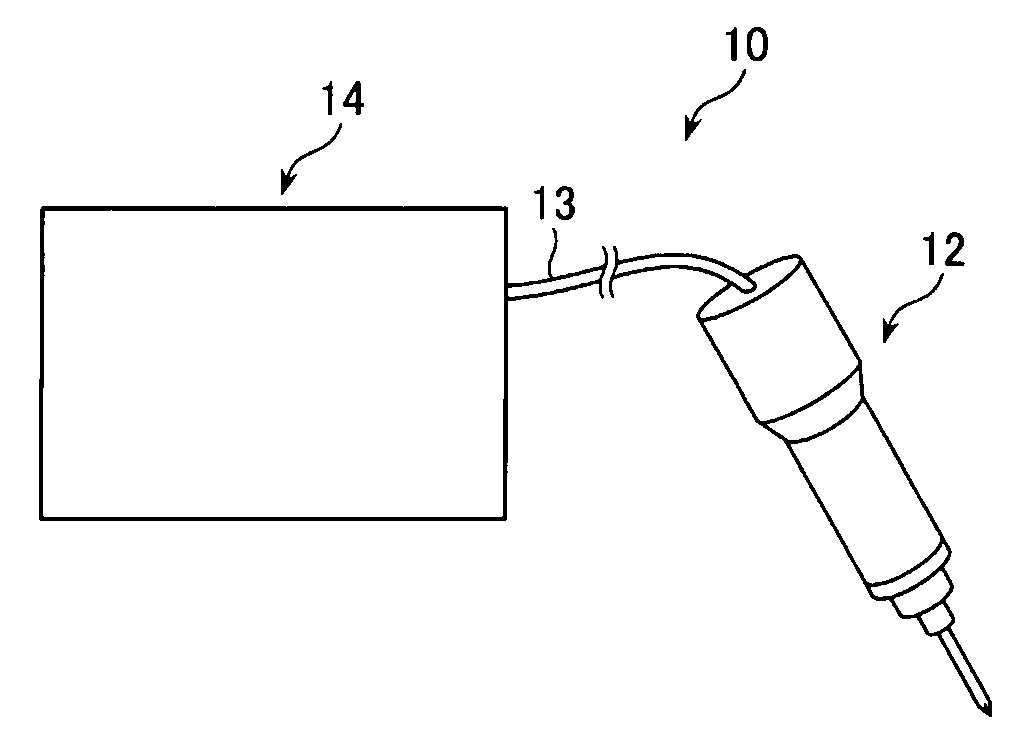

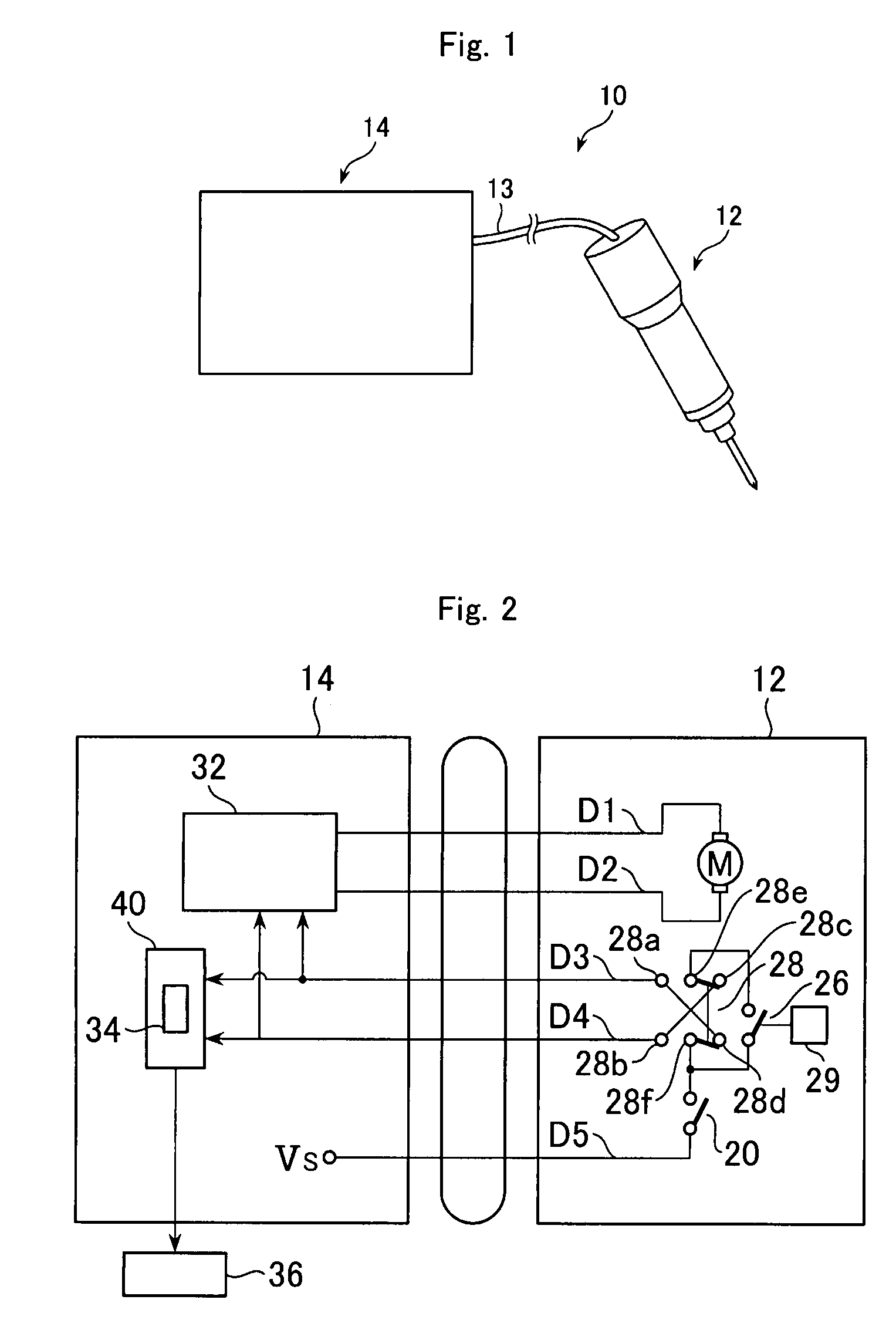

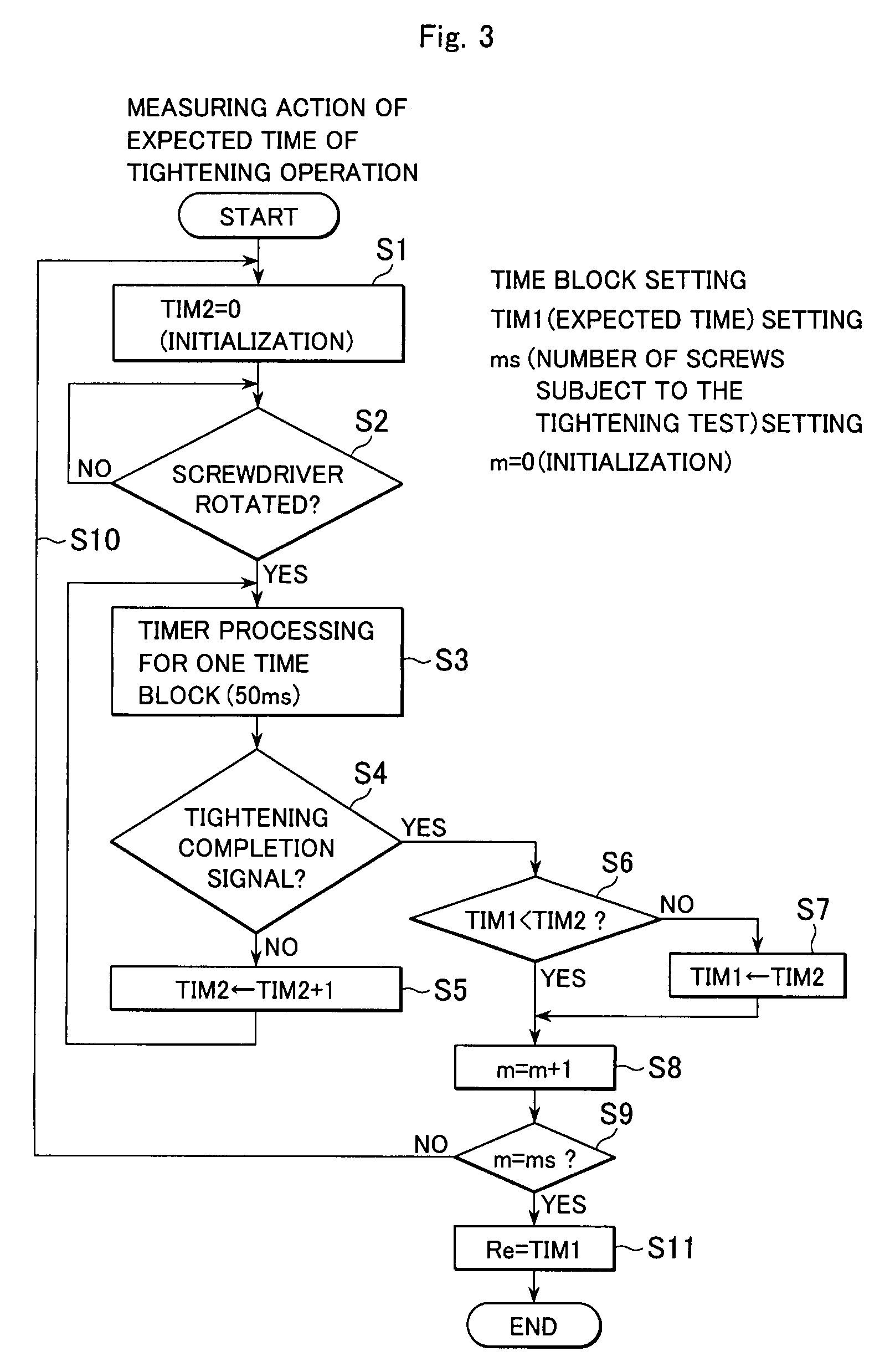

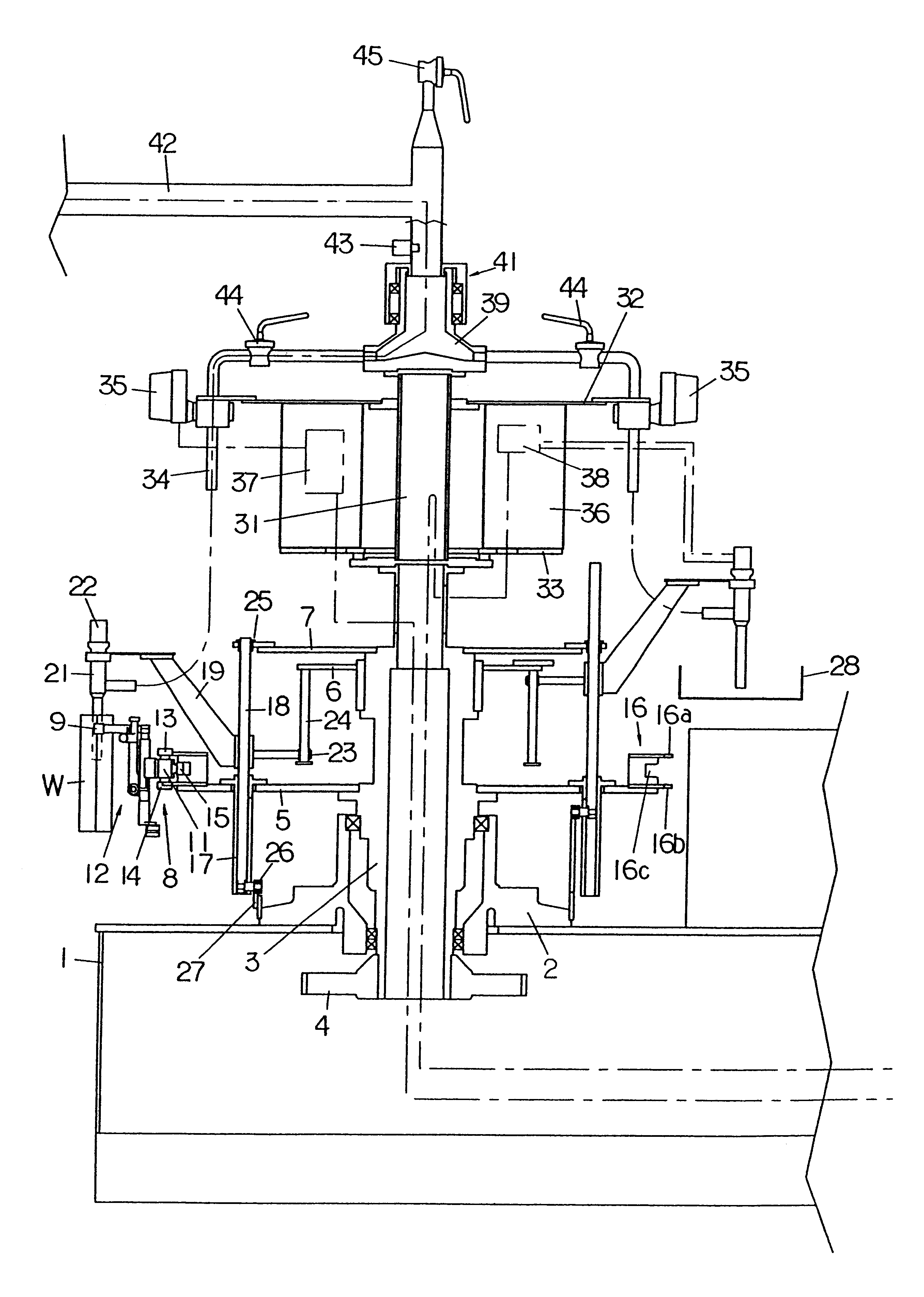

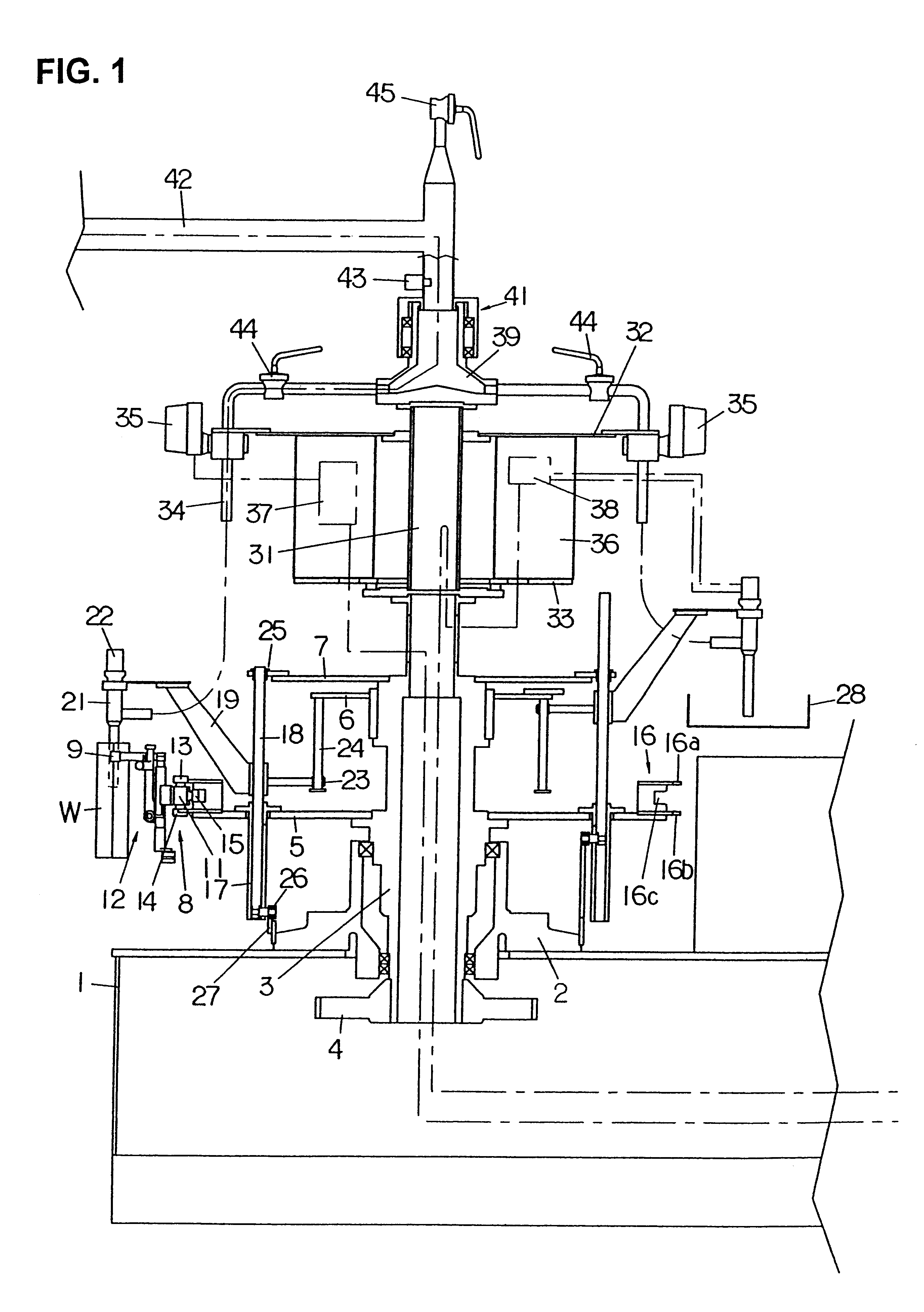

Electric screwdriver and a controller thereof

An object of the present invention is to provide an electric screwdriver device having a function for determining that a correct tightening operation has been carried out when the tightening operation has taken a time longer than a reference time predetermined for the tightening operation, characterized in comprising a novel feature for determining the reference time. The electric screwdriver device of the present invention comprises a torque monitor (40, S4) for monitoring whether or not a load torque in carrying out the tightening by using the electric screwdriver 12 has reached the tightening completion torque, a timer (40, S1, S5) for measuring the time consumed from the starting of the tightening operation until the tightening torque has reached the tightening completion torque, as the tightening operation time, and a reference time setter (40, S6-S10) for determining the reference time for a subsequent tightening operation based on a plurality of tightening operation time obtained from the timer in the tightening operations carried out for the predetermined number of screws.

Owner:NITTO KOHKI CO LTD

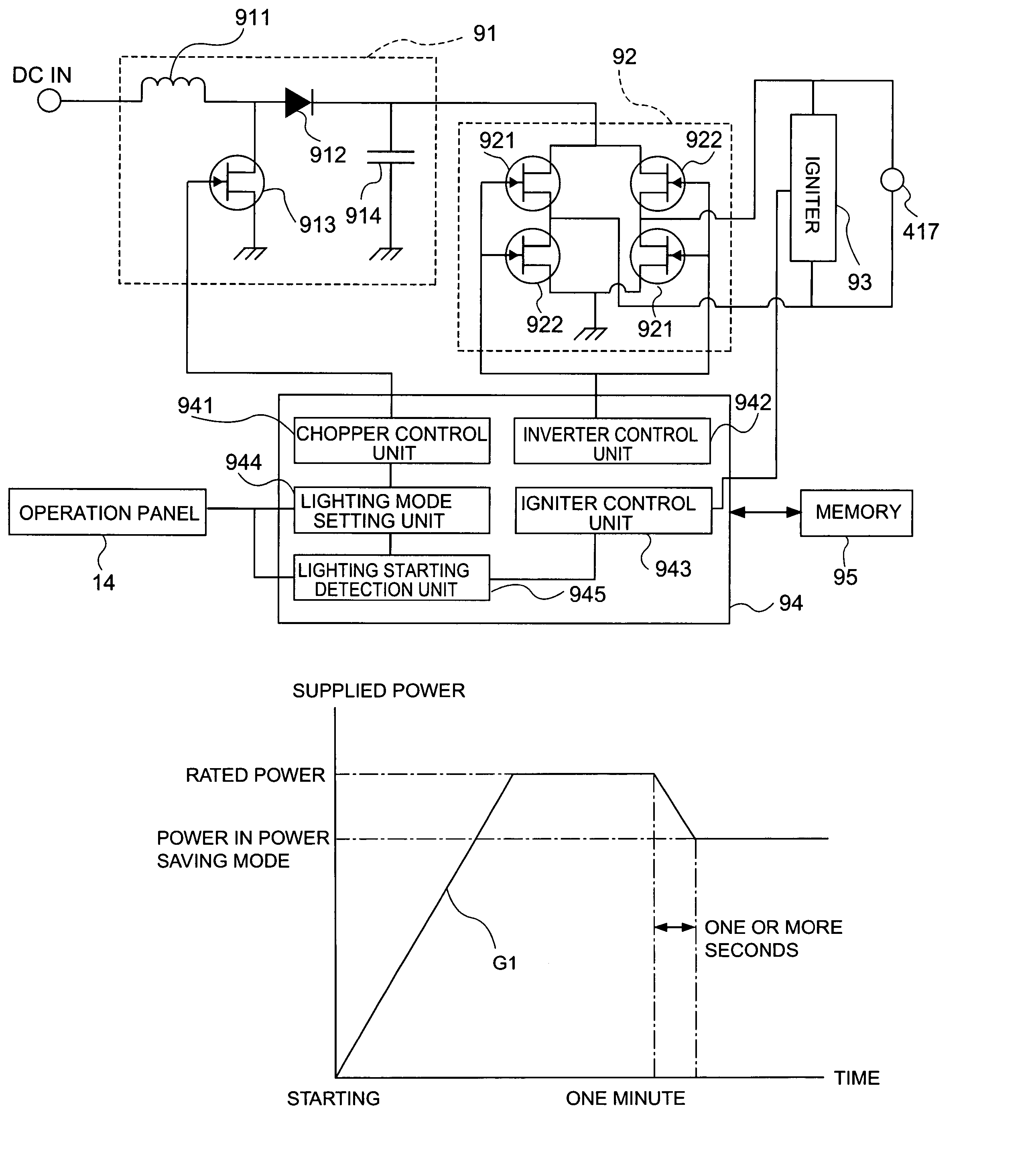

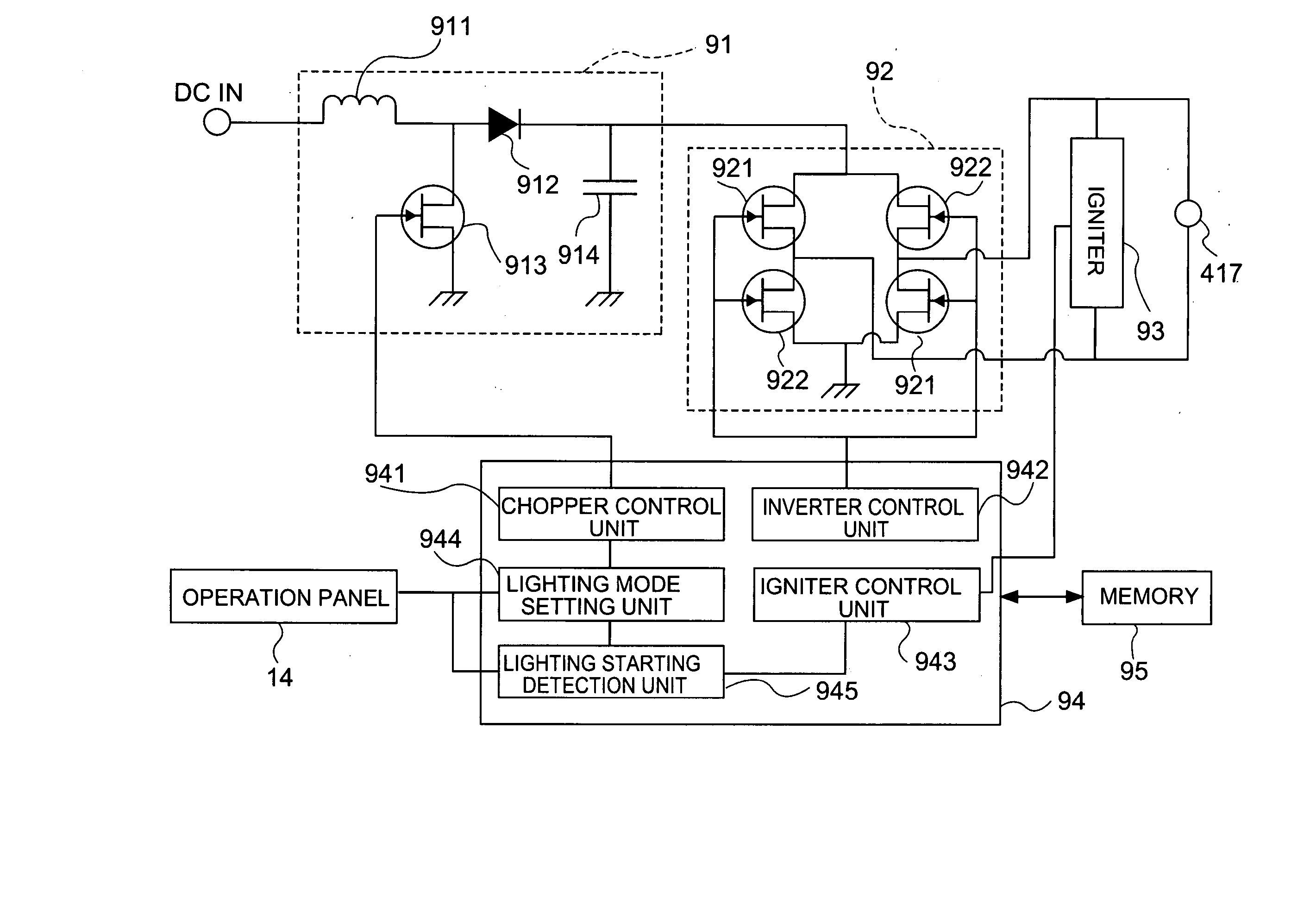

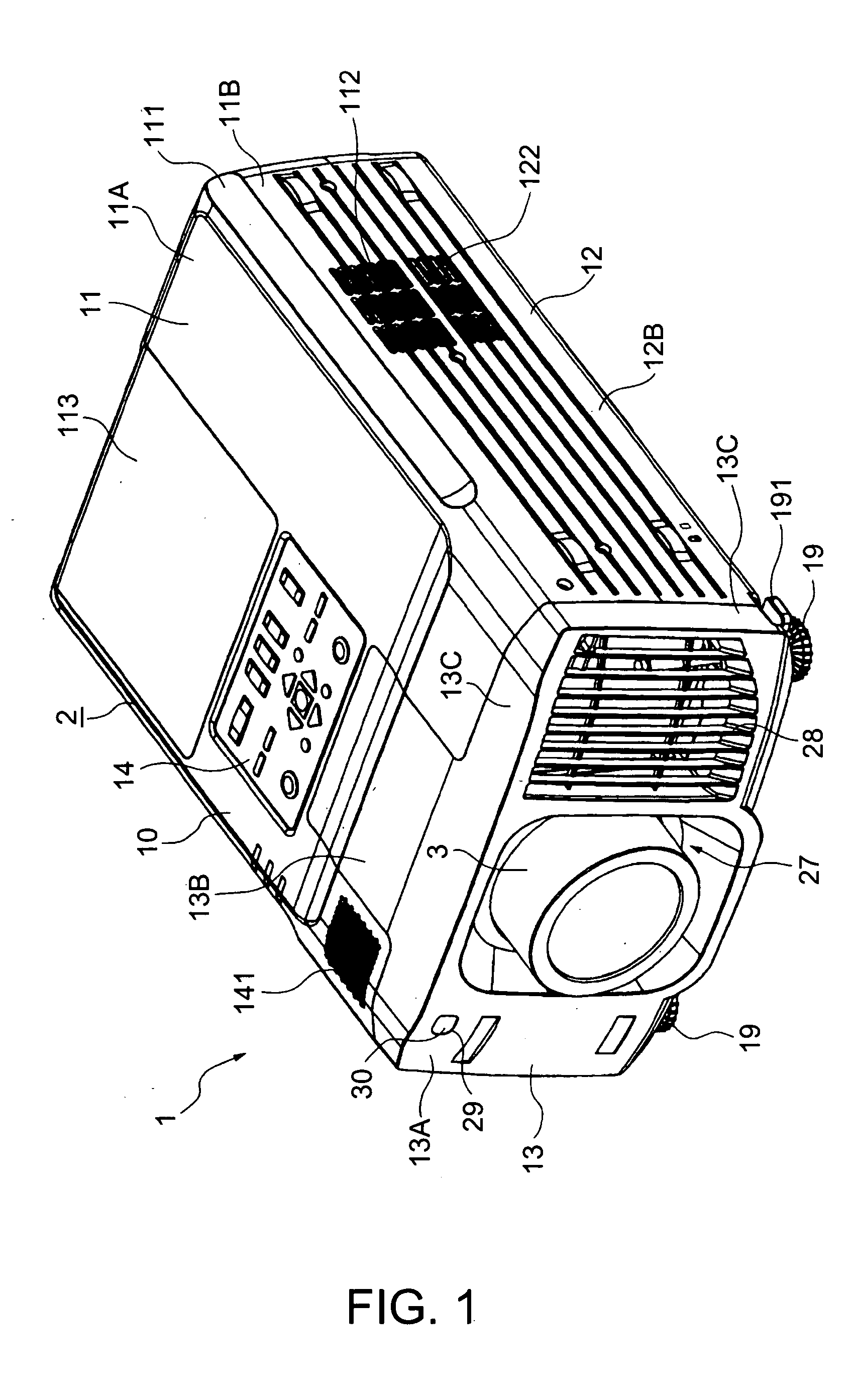

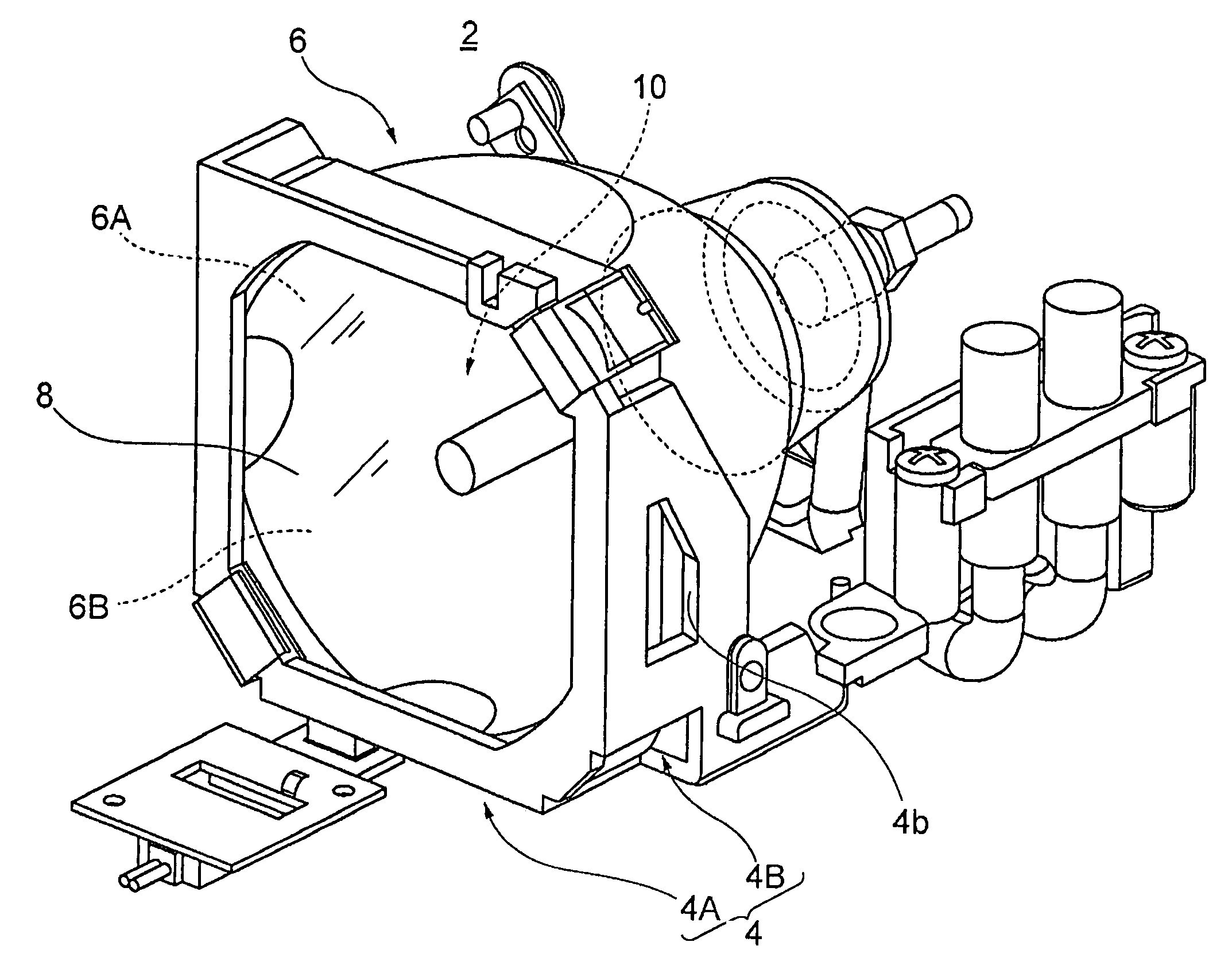

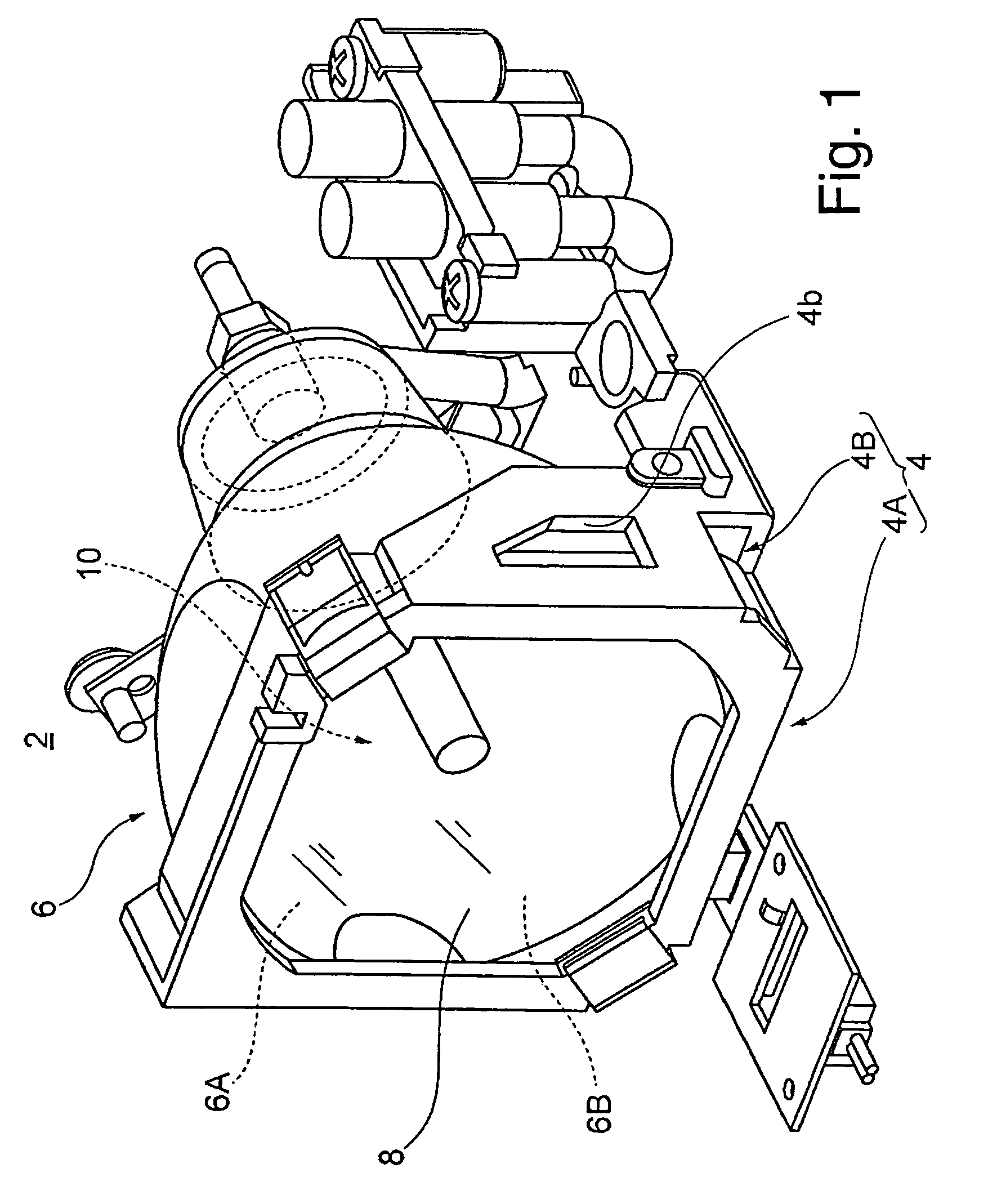

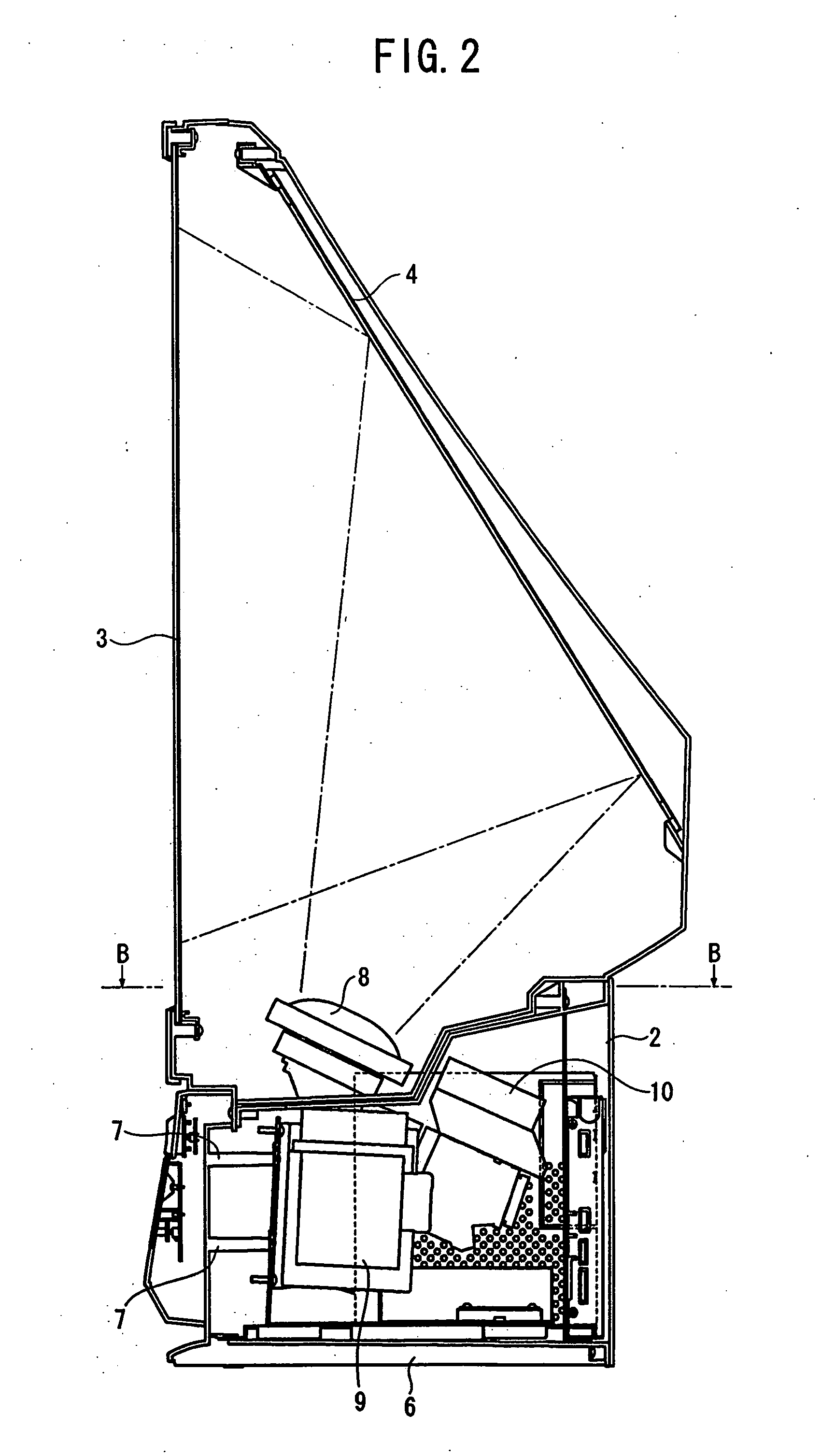

Circuit for driving light source, projector, method for controlling lighting of light source, and computer readable program for executing the same

ActiveUS6979960B2Extend your lifeIncrease temperatureStatic indicating devicesProjectorsPower modeStart time

The invention provides a circuit to drive a light source capable of lengthening the life span of the light source and of coping with both a rated power mode and a power saving mode. A circuit to drive a light source includes a control device to drive the light source, which is composed of a discharge tube, and to switch the light source to a plurality of lighting modes including a rated power mode and a power saving mode. The control device includes a lighting mode setting unit to set the lighting mode to one of the plurality of lighting modes, and a rated power supplying unit to supply a rated power to the light source at the lighting starting time of the light source until a halogen cycle of the discharge tube is stabilized. The control device switches the light source to the lighting mode set by the lighting mode setting unit after the halogen cycle of the discharge tube is stabilized.

Owner:SEIKO EPSON CORP

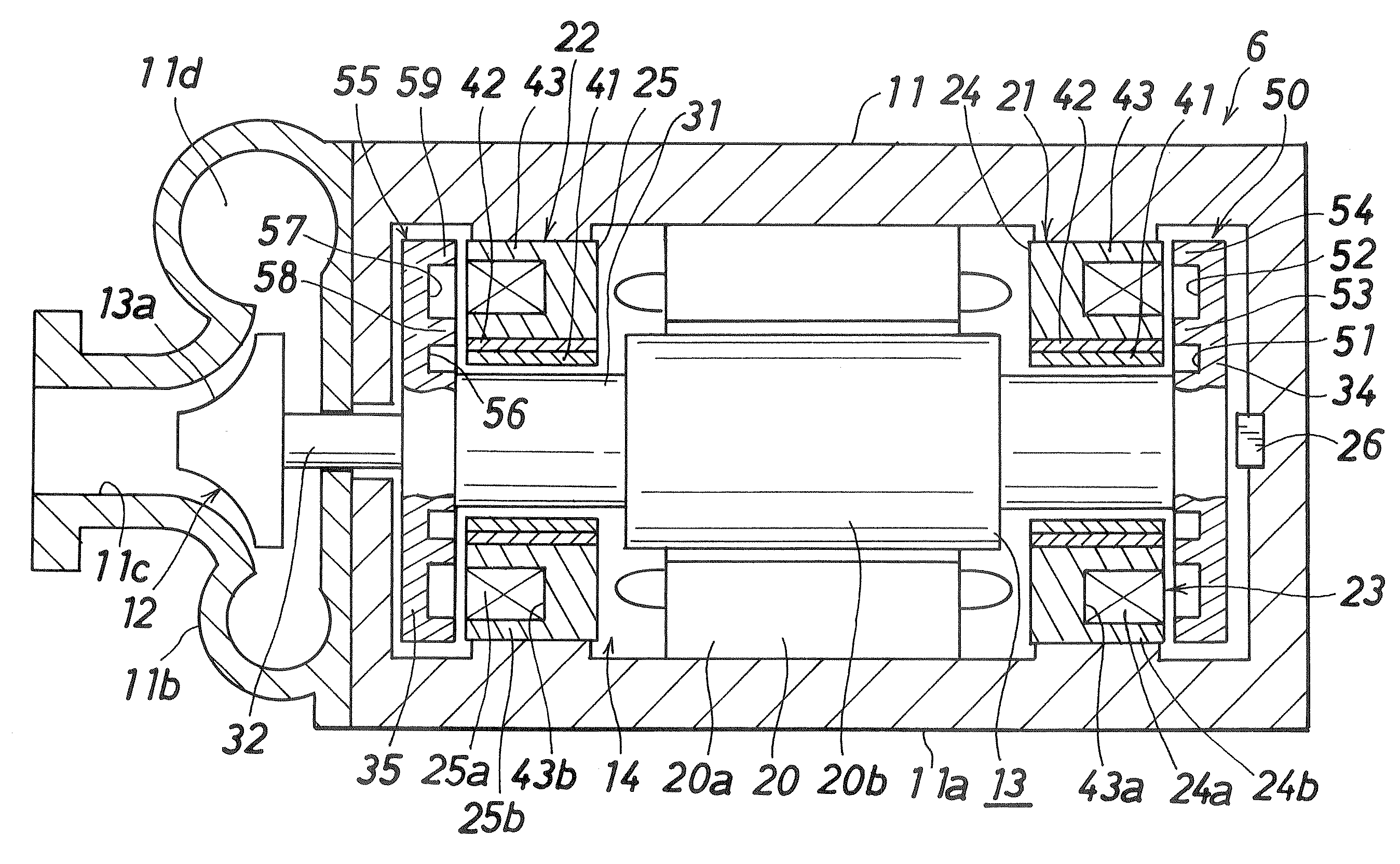

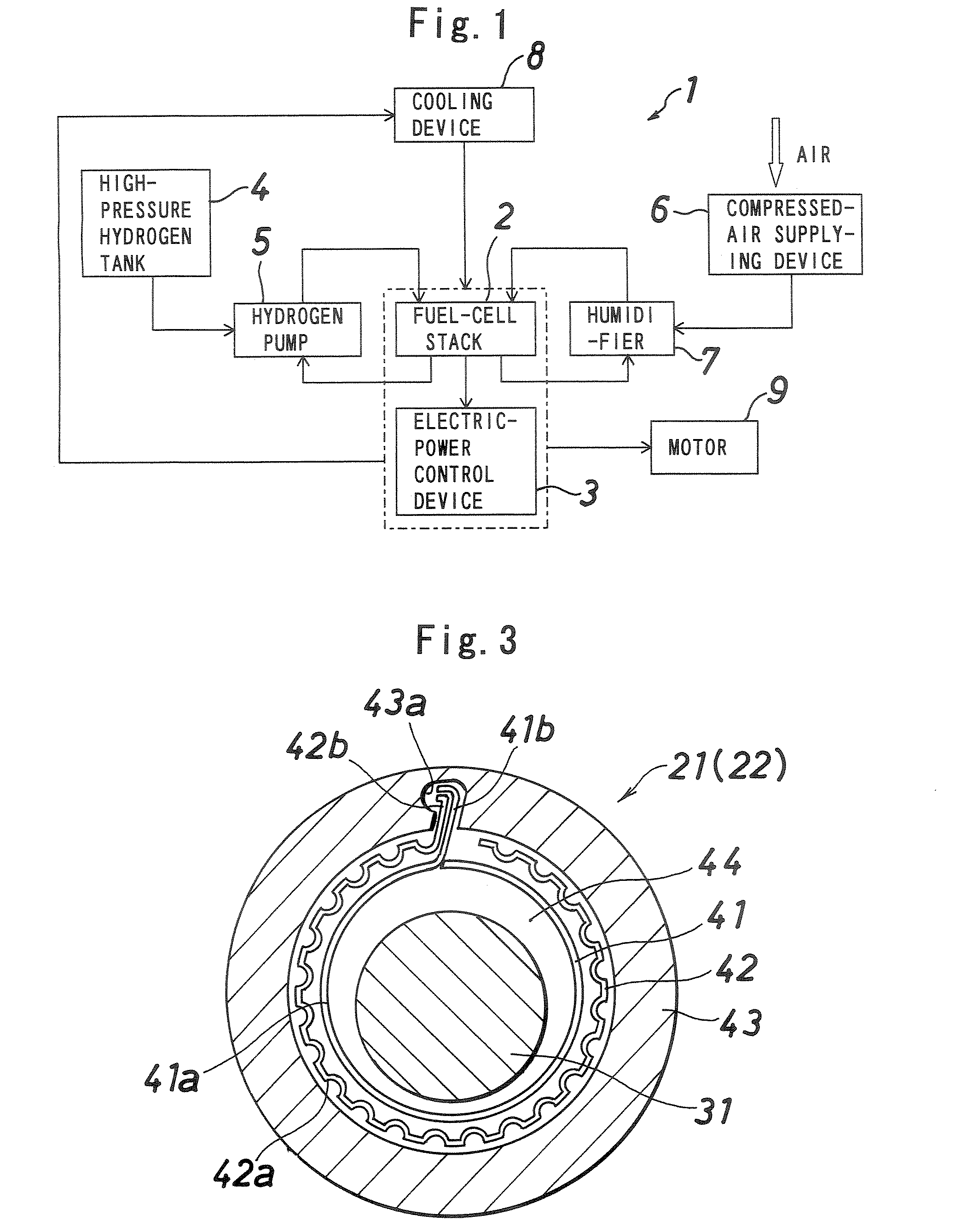

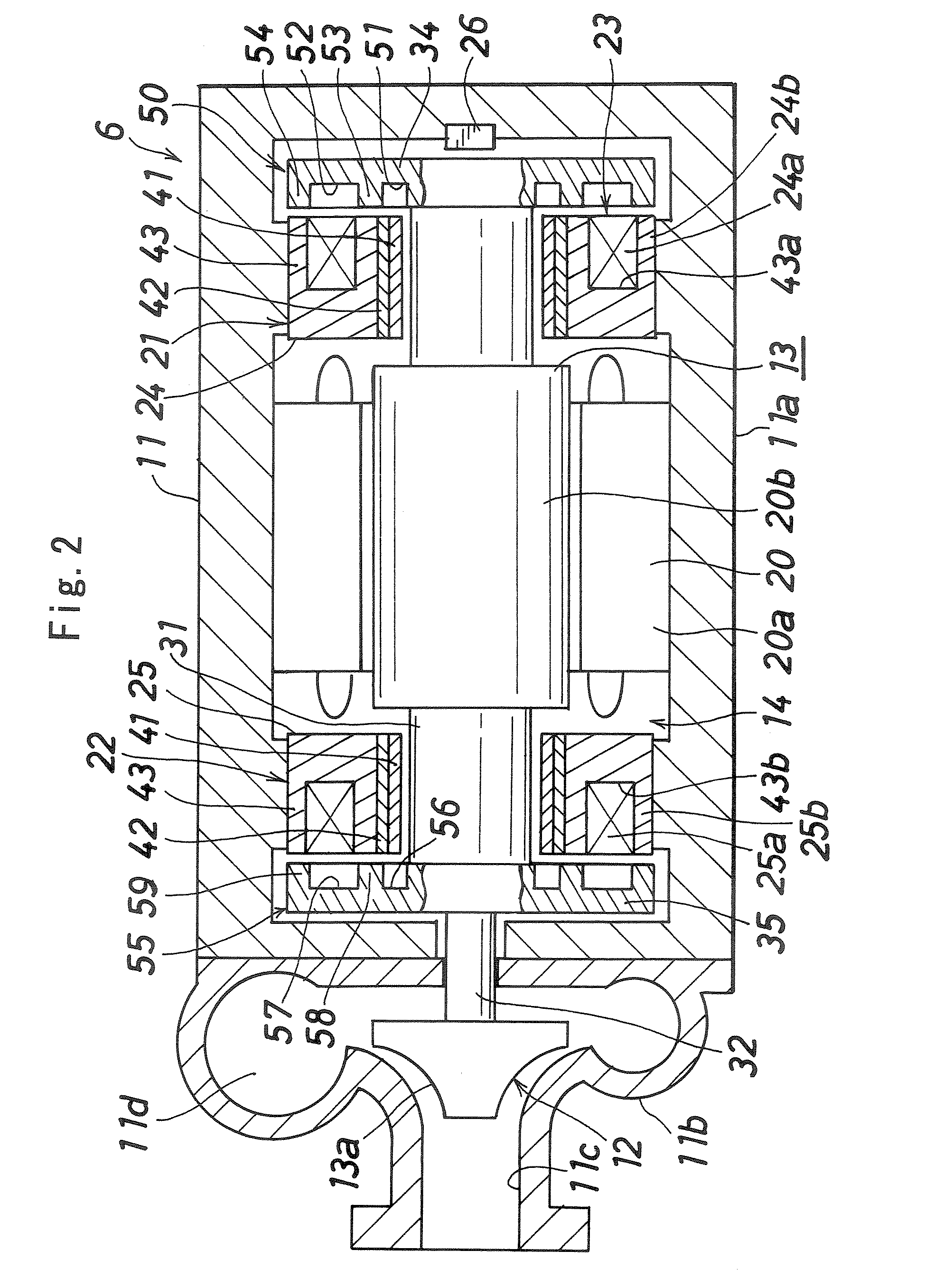

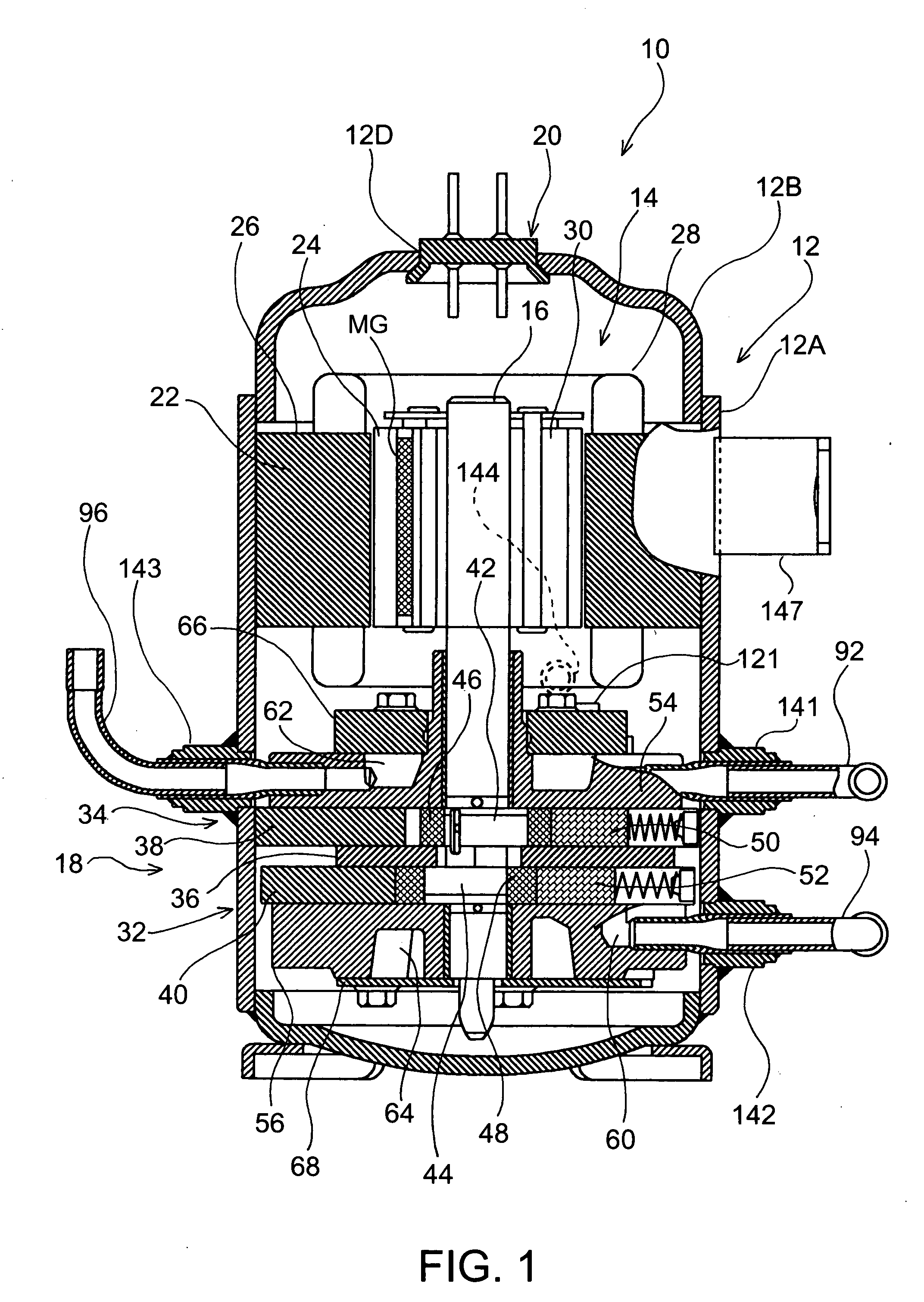

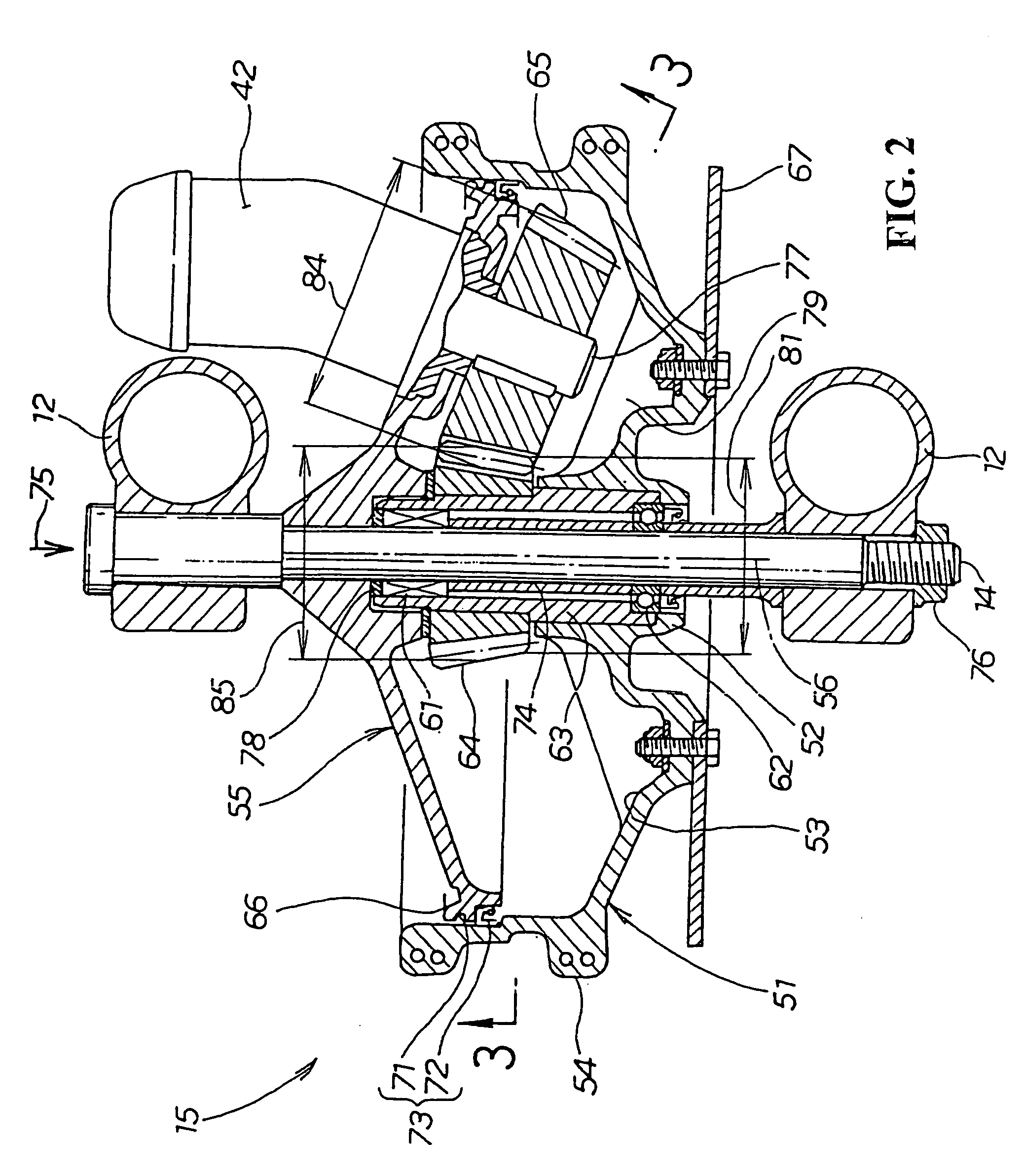

Fuel-cell compressed-air supplying device

A fuel-cell compressed-air supplying device 6 includes a centrifugal compressor 12 provided in a casing 11, and a bearing device 14 for supporting a rotation shaft 13 of the compressor 12. The bearing device 14 includes a pair of radial foil bearings 21 and 22 provided coaxially with the rotation shaft 13 for supporting the rotation shaft 13 in the radial direction, and an axial magnetic bearing 23 facing to the rotation shaft 13 in the axial direction for supporting the rotation shaft 13 in the axial direction. Axial electromagnets 24 and 25 of the axial magnetic bearing 23 are integrated with the radial foil bearings 21 and 22, respectively.

Owner:JTEKT CORP

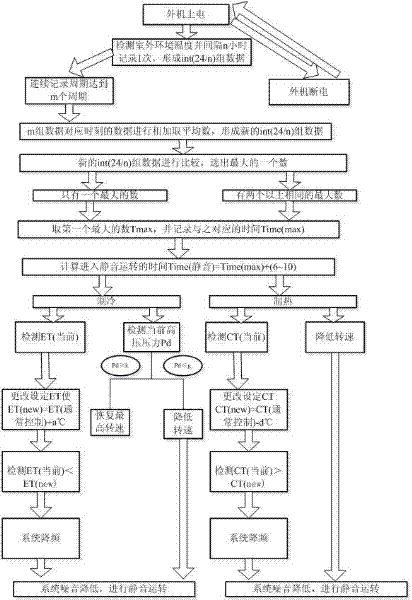

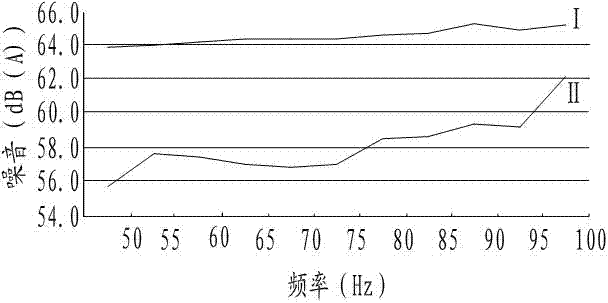

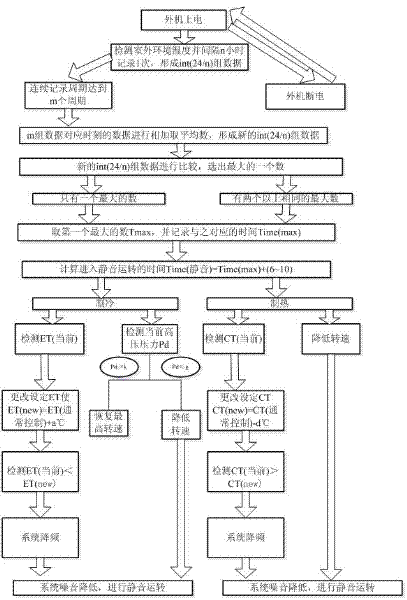

Method for controlling operation of air conditioner in mute mode

ActiveCN102418981ALow RPMReduce outputSpace heating and ventilation safety systemsLighting and heating apparatusLow noisePower conditioner

The invention provides a method for controlling operation of an air conditioner in a mute mode. In the method, the air conditioner can automatically enter a mute control mode according to the change of outdoor environment temperatures, so that automatic control is realized. The method comprises the following steps of: calculating the time when the air conditioner starts to operate in the mute mode; during refrigeration, controlling the relation of the common target evaporation temperature during operation of an air conditioning system in an unmute mode and a new target evaporation temperature; and during heating, controlling the relation of the common target condensation temperature during operation of the air conditioning system in the unmute mode and a new target condensation temperature. By the method, the frequency and the noise of the air conditioning system are reduced, and the air conditioning system operates in the mute mode; and the change of the environment temperature is scientifically calculated, the air conditioning system is intelligently controlled, an outdoor unit is automatically controlled, and operation such as dial-up setting and the like is not required, so requirements of customers on the effect of the air conditioner can be met, requirements of the customers on low noise can also met, and system failures can be avoided.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

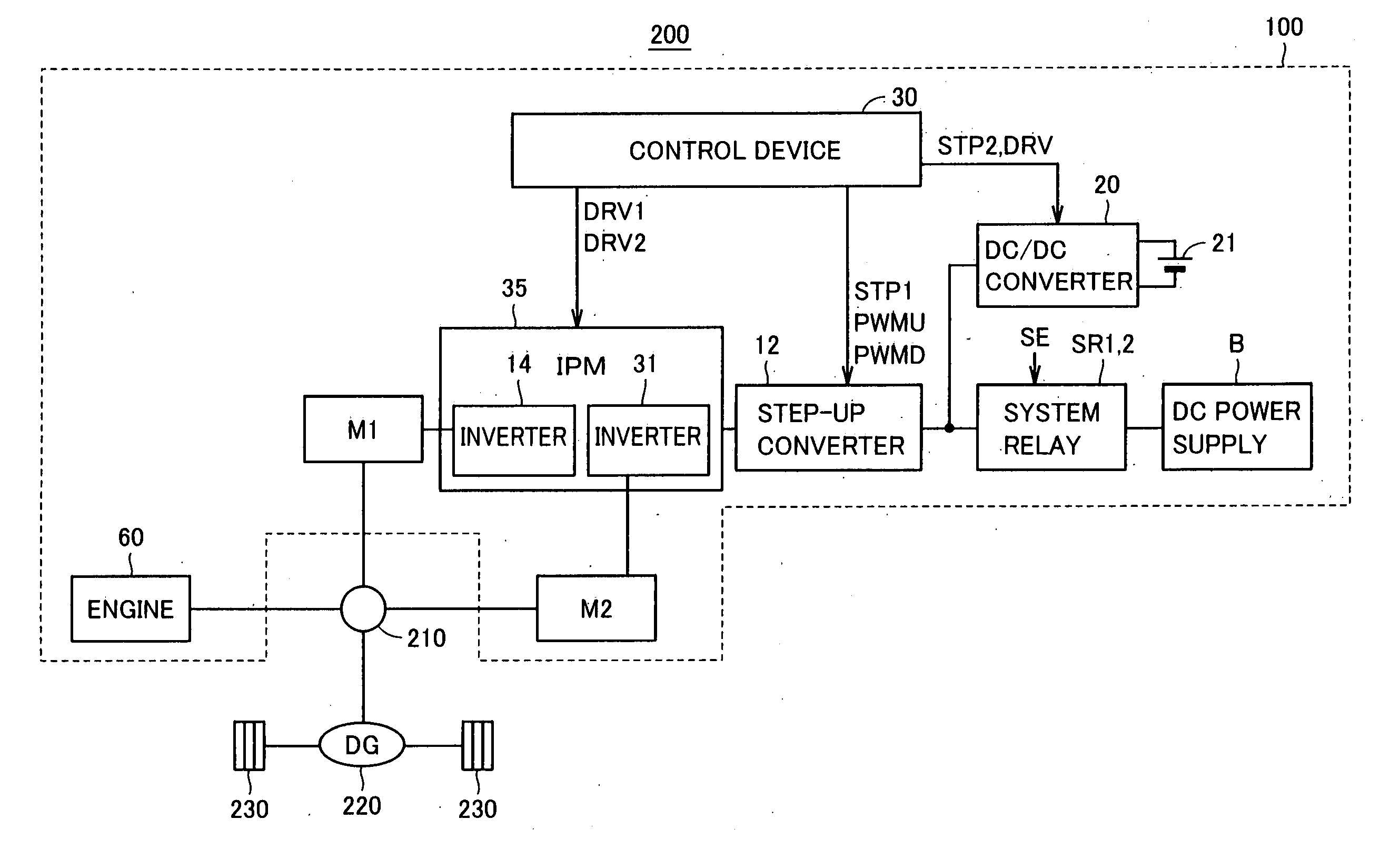

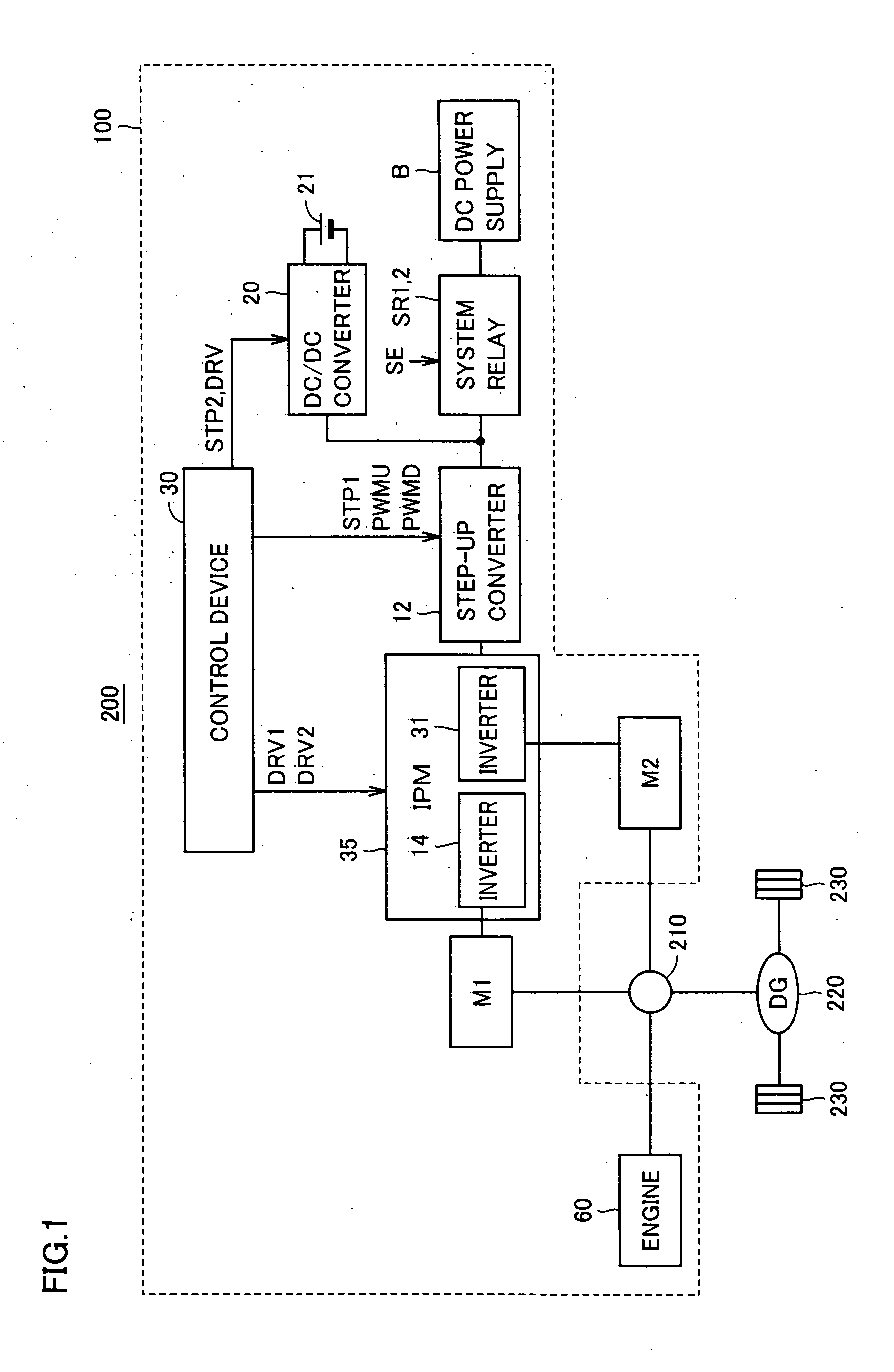

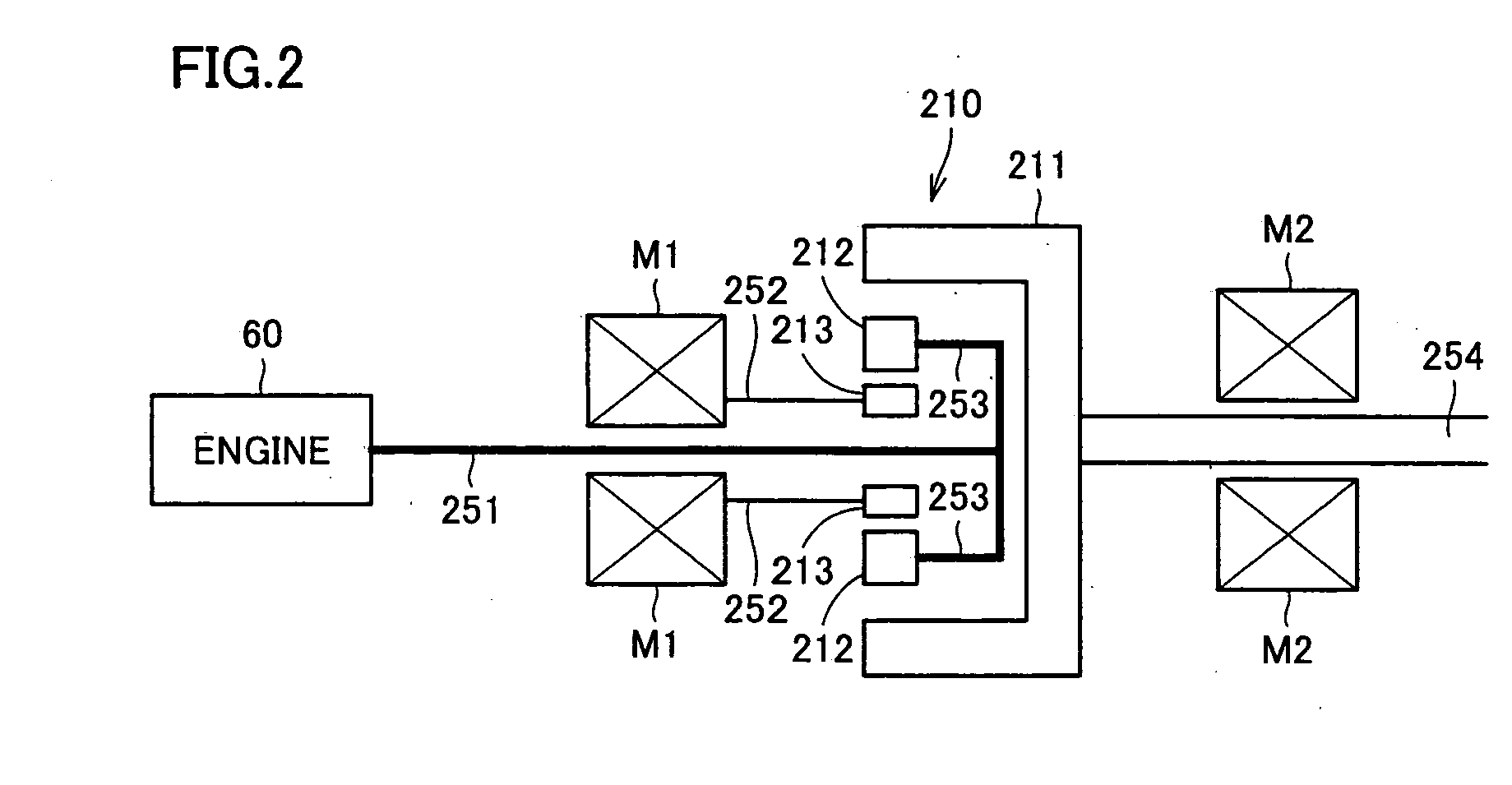

Drive control apparatus for rotating electric machine and vehicle

A drive control apparatus for an AC motor is mounted on a hybrid vehicle. The drive control apparatus includes an inverter for driving an AC motor, and a control device for controlling the inverter by switching a control mode of the inverter between a first mode and a second mode in which a harmonic component of output current of the inverter can be suppressed as compared with in the first mode. The control device controls the inverter in the first mode when a magnet temperature of a permanent magnet is smaller than a first threshold temperature, and controls the inverter in the second mode when a magnet temperature is equal to or larger than the first threshold temperature.

Owner:TOYOTA JIDOSHA KK

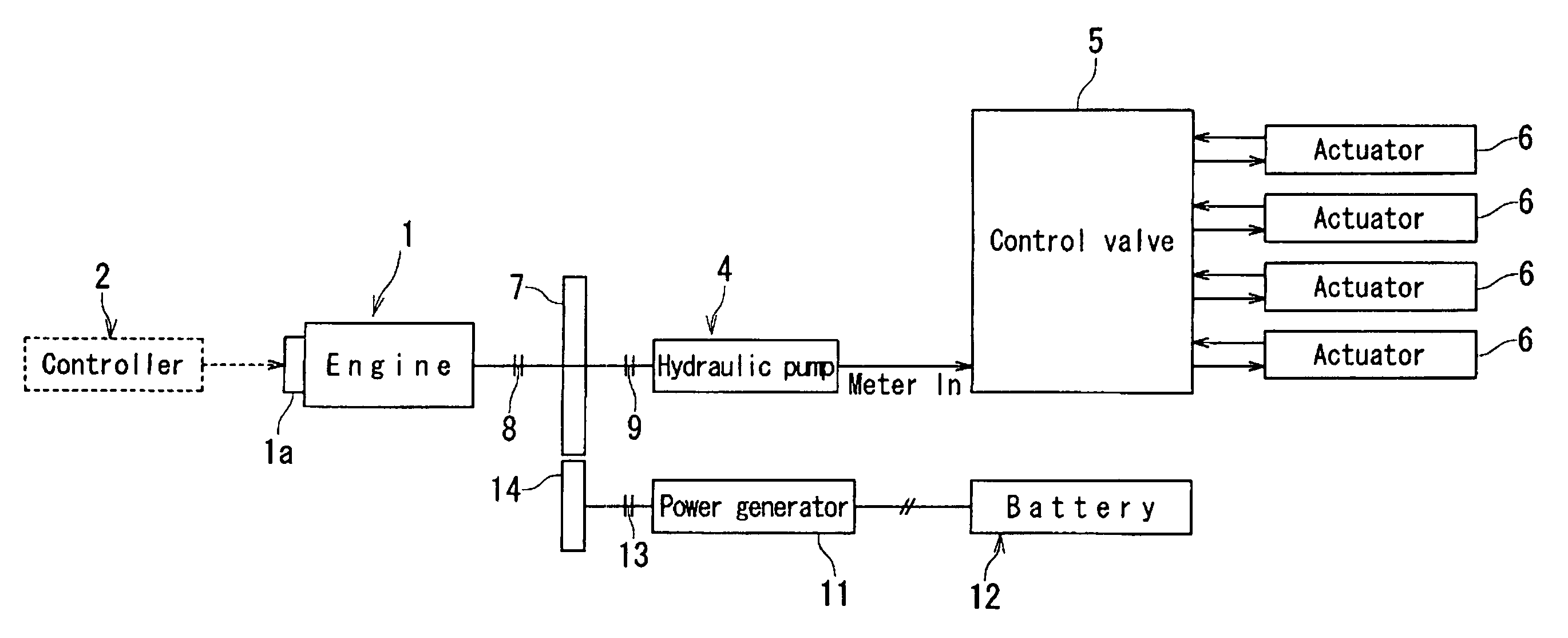

Construction machinery

InactiveUS7143859B2Increase fuel consumptionSurplus energyElectrical controlFluid couplingsFuel efficiencyHydraulic pump

Owner:KOMATSU LTD

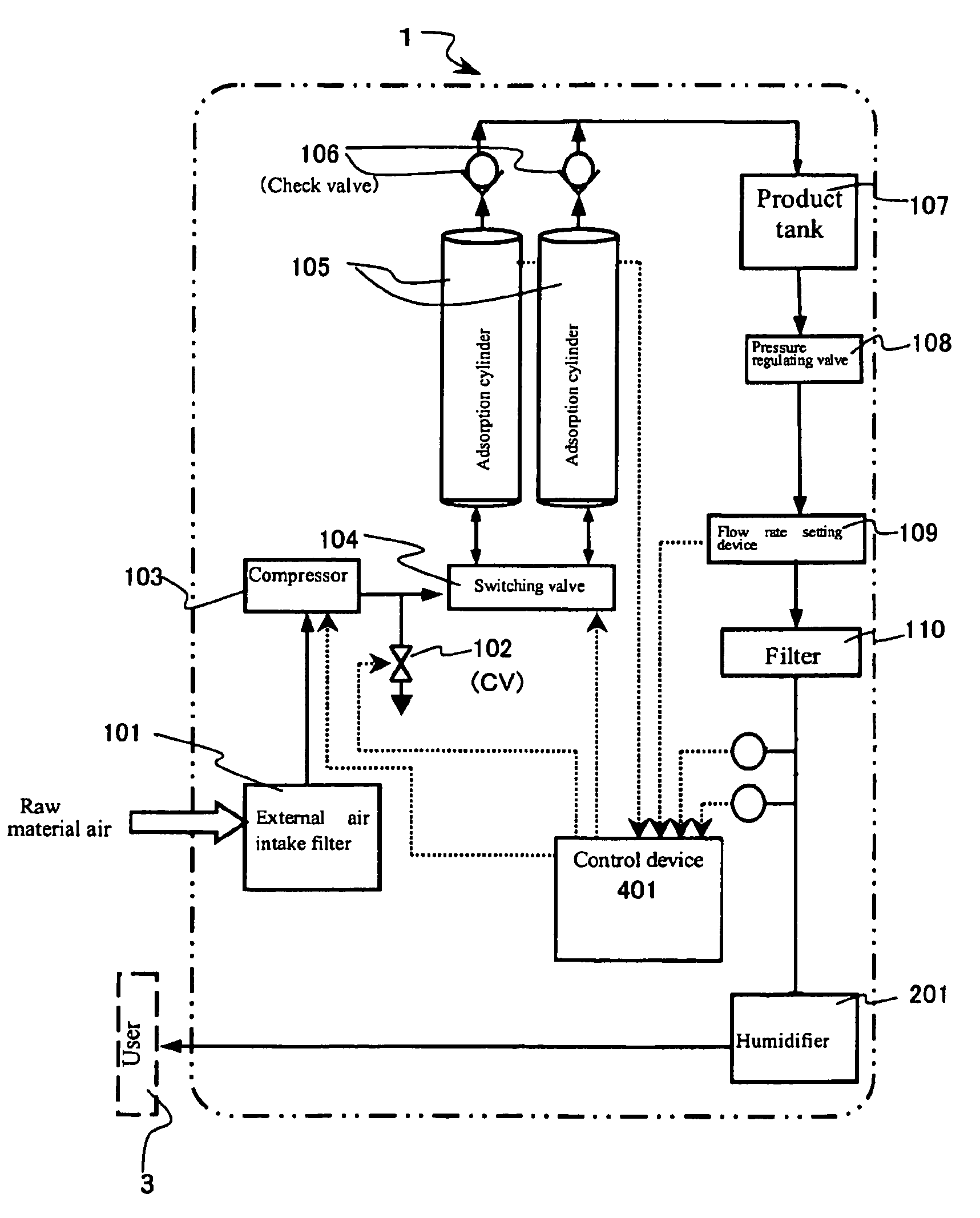

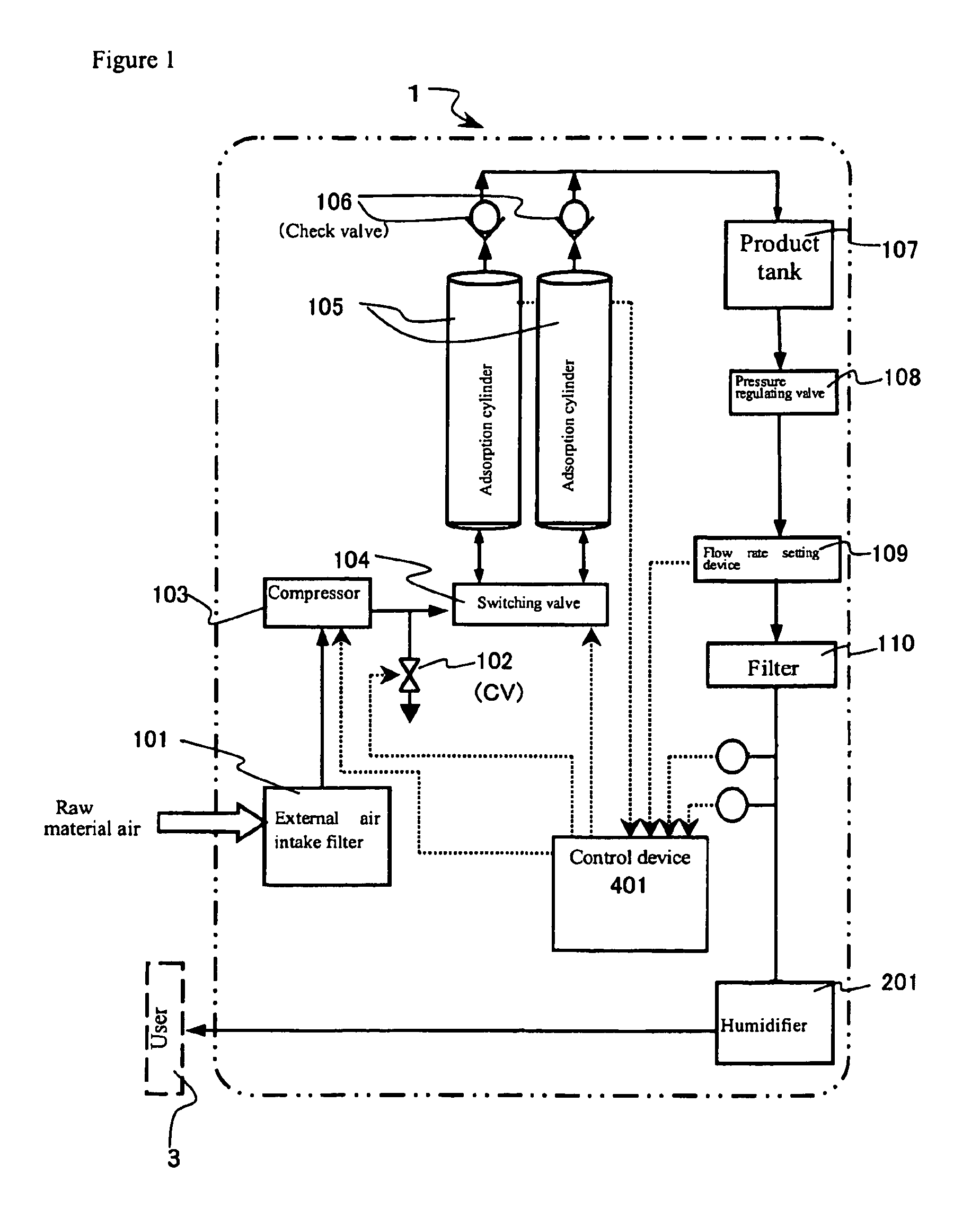

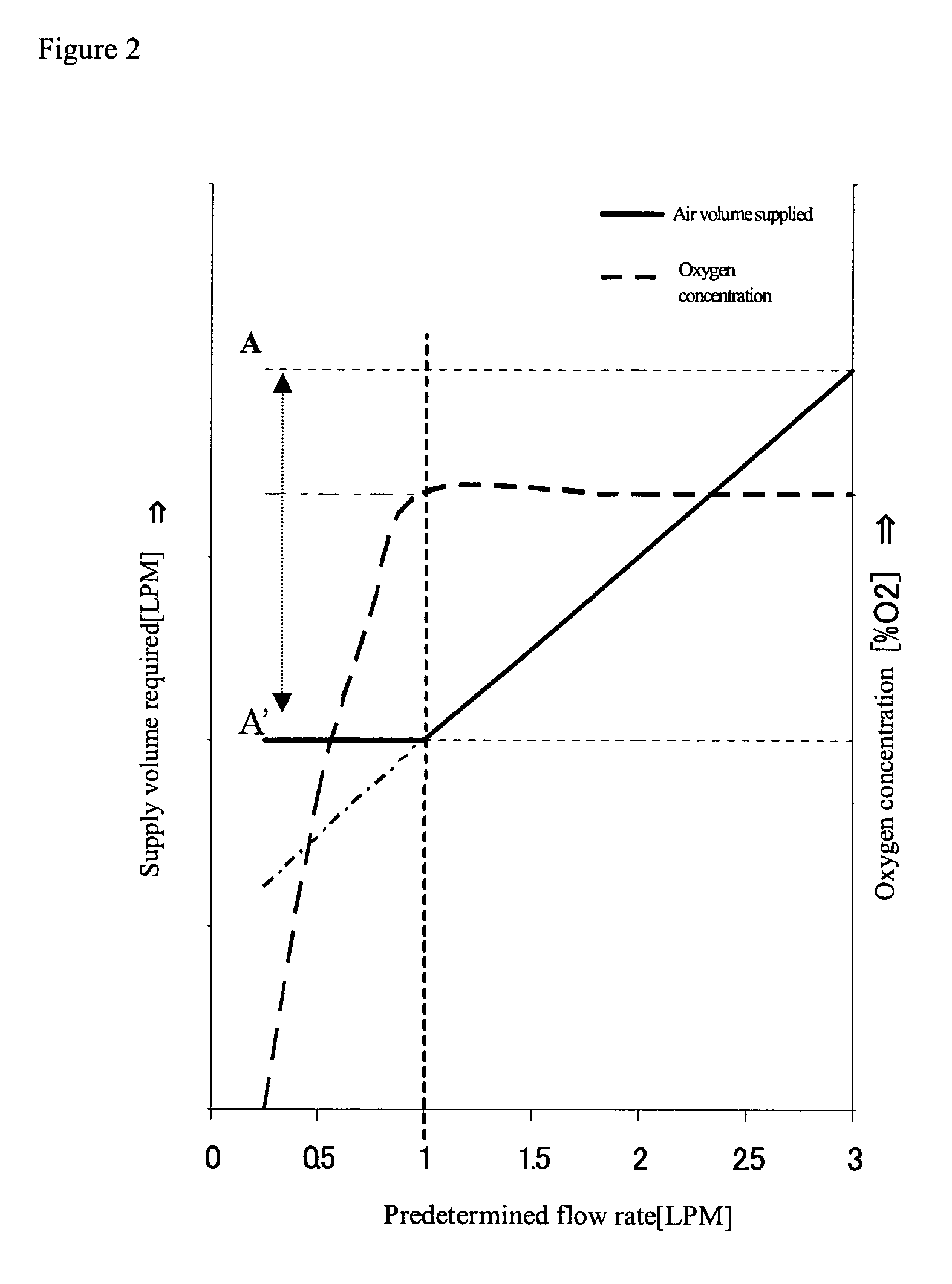

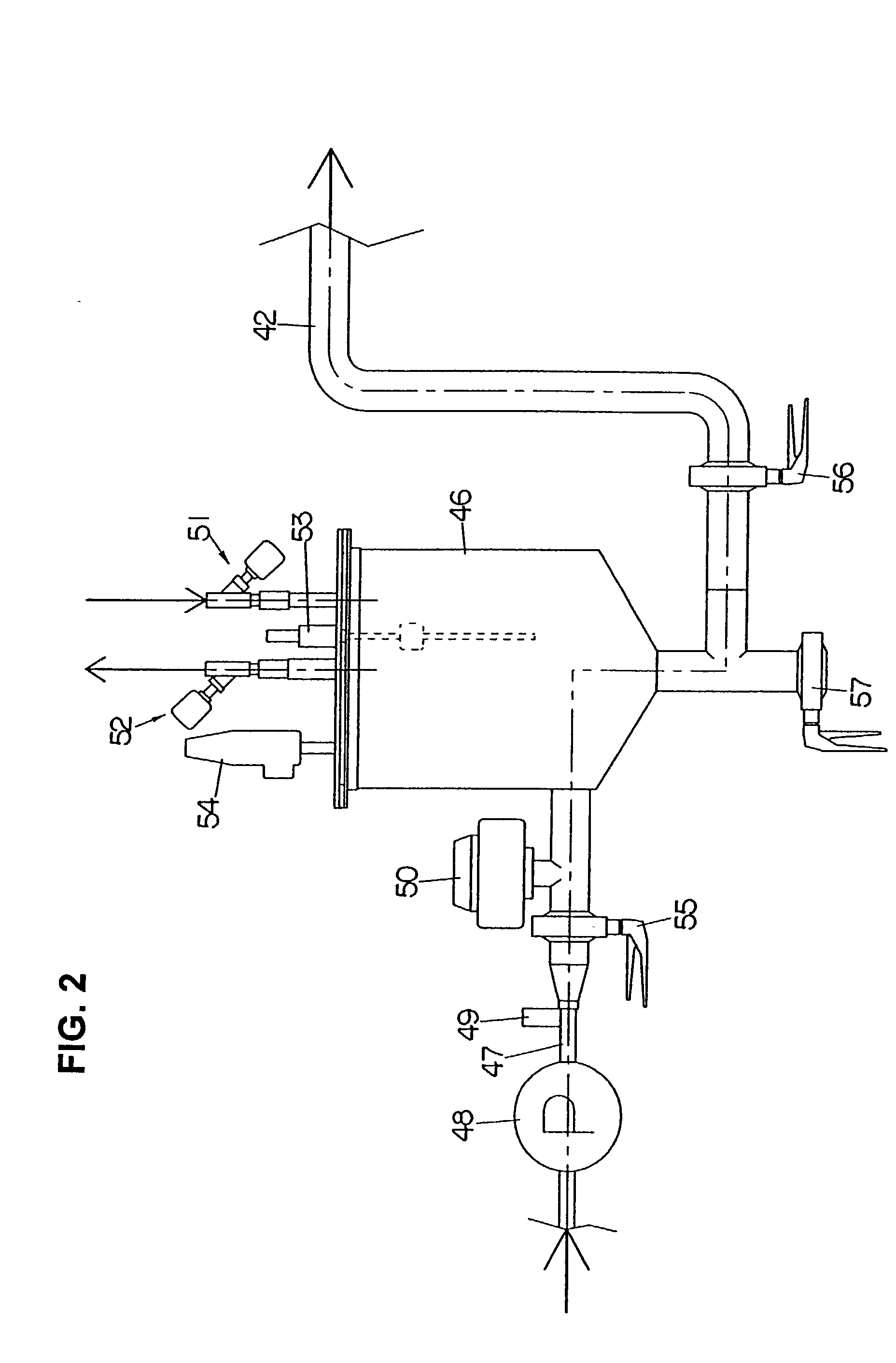

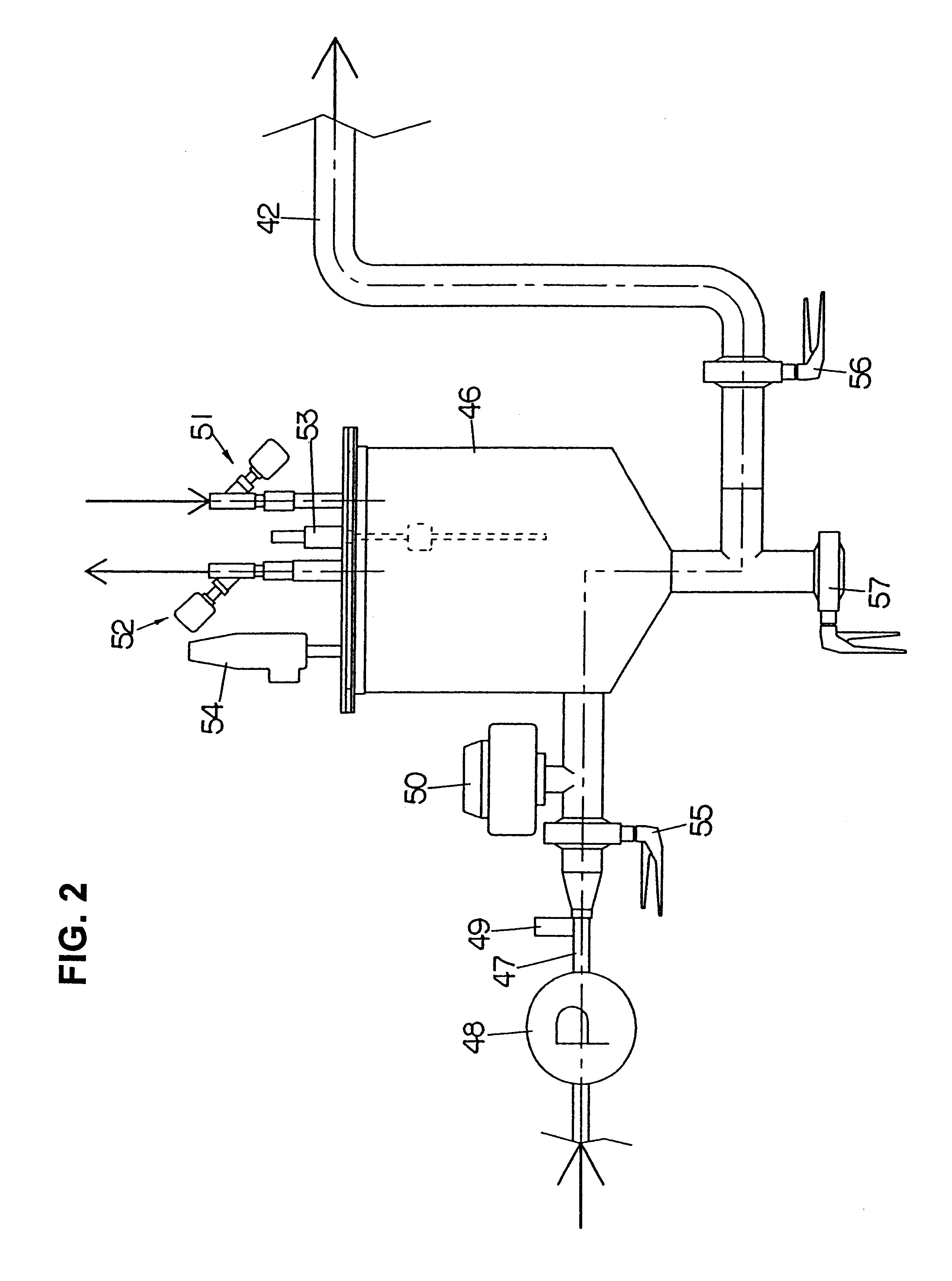

Oxygen concentrator

An apparatus to provide an oxygen concentrator that is a pressure swing adsorption-type oxygen concentrator equipped with; at least one adsorption bed filled with an adsorbent capable of selectively adsorbing nitrogen relative to oxygen, an air supply device to supply compressed air to the adsorption bed, a flow channel switching device to repeat at a predetermined timing an adsorption step to supply air from the air supply device to the adsorption bed to isolate concentrated oxygen and a desorption step to depressurize the adsorption bed to regenerate the adsorbent therein, and a flow rate setting device to set a volume of concentrated oxygen supplied to a user; comprising an exhaust pipe channel equipped with a leak valve in a flow channel between the air supply device and the adsorption bed to release a part of compressed air that is to be supplied to the adsorption bed into atmosphere.

Owner:TEIJIN LTD

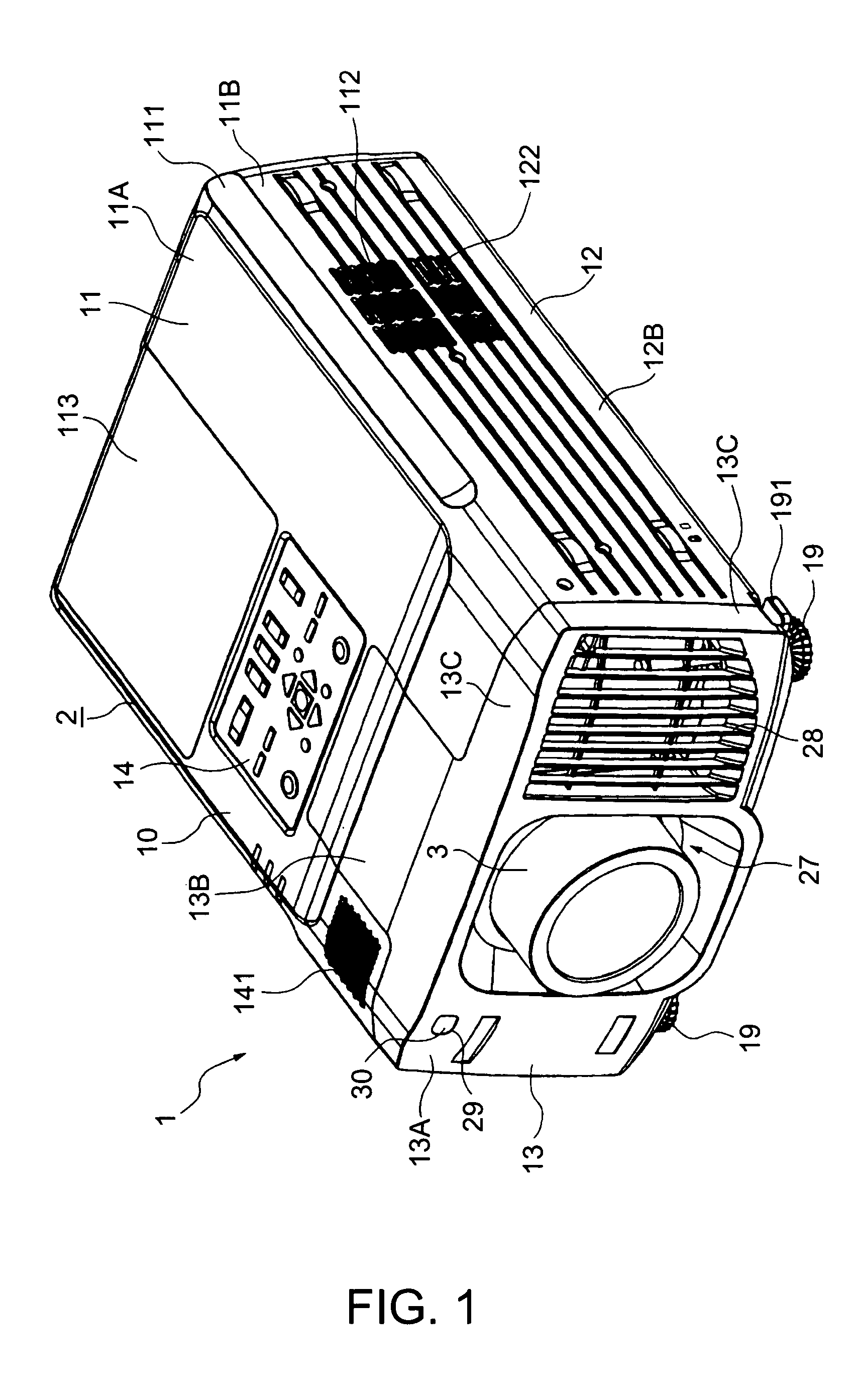

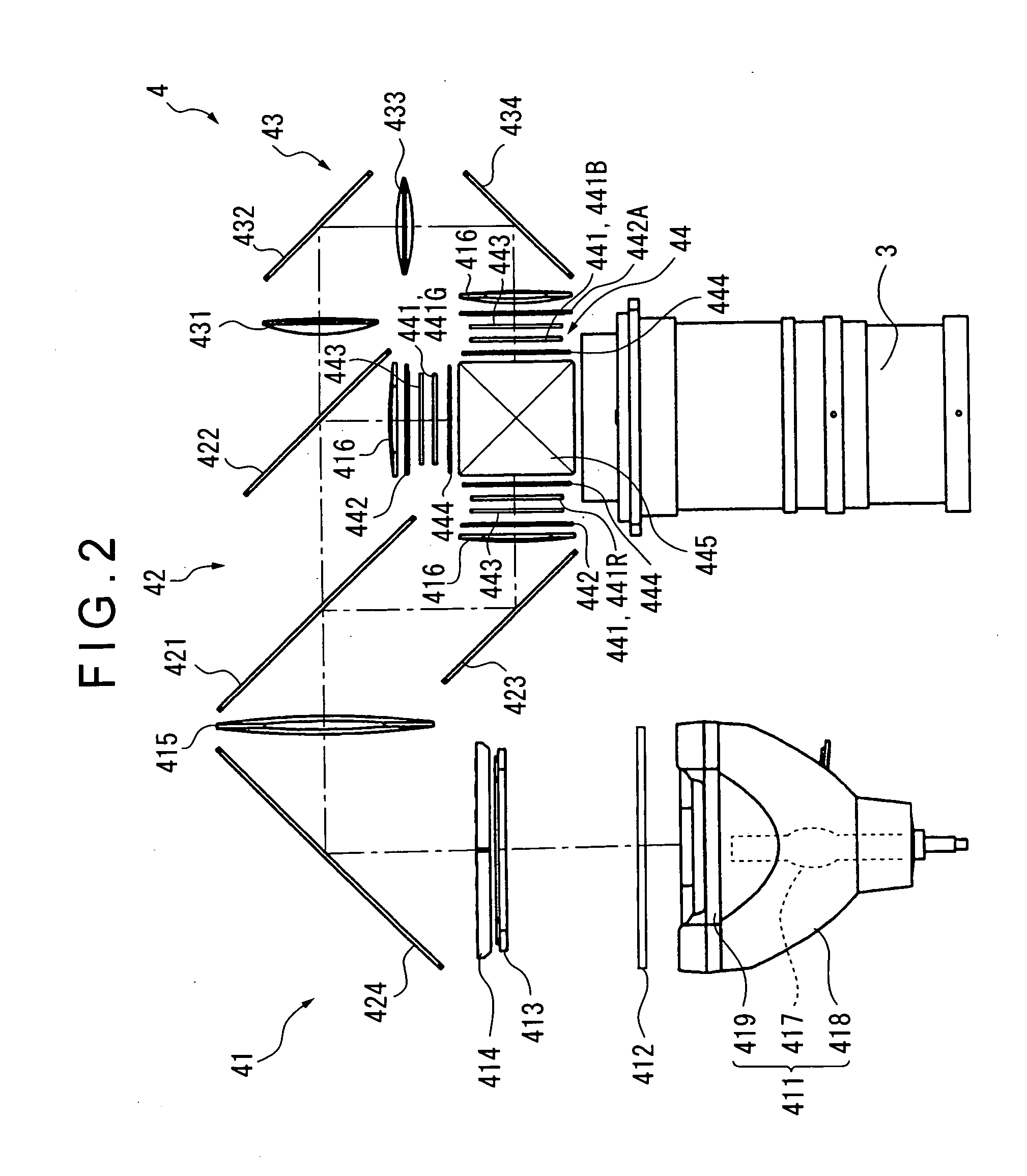

Circuit for driving light source, projector, method for controlling lighting of light source, and computer readable program for executing the same

ActiveUS20040136134A1Extend your lifeFlicker of the screen is reduced or preventedStatic indicating devicesProjectorsPower modeStart time

The invention provides a circuit to drive a light source capable of lengthening the life span of the light source and of coping with both a rated power mode and a power saving mode. A circuit to drive a light source includes a control device to drive the light source, which is composed of a discharge tube, and to switch the light source to a plurality of lighting modes including a rated power mode and a power saving mode. The control device includes a lighting mode setting unit to set the lighting mode to one of the plurality of lighting modes, and a rated power supplying unit to supply a rated power to the light source at the lighting starting time of the light source until a halogen cycle of the discharge tube is stabilized. The control device switches the light source to the lighting mode set by the lighting mode setting unit after the halogen cycle of the discharge tube is stabilized.

Owner:SEIKO EPSON CORP

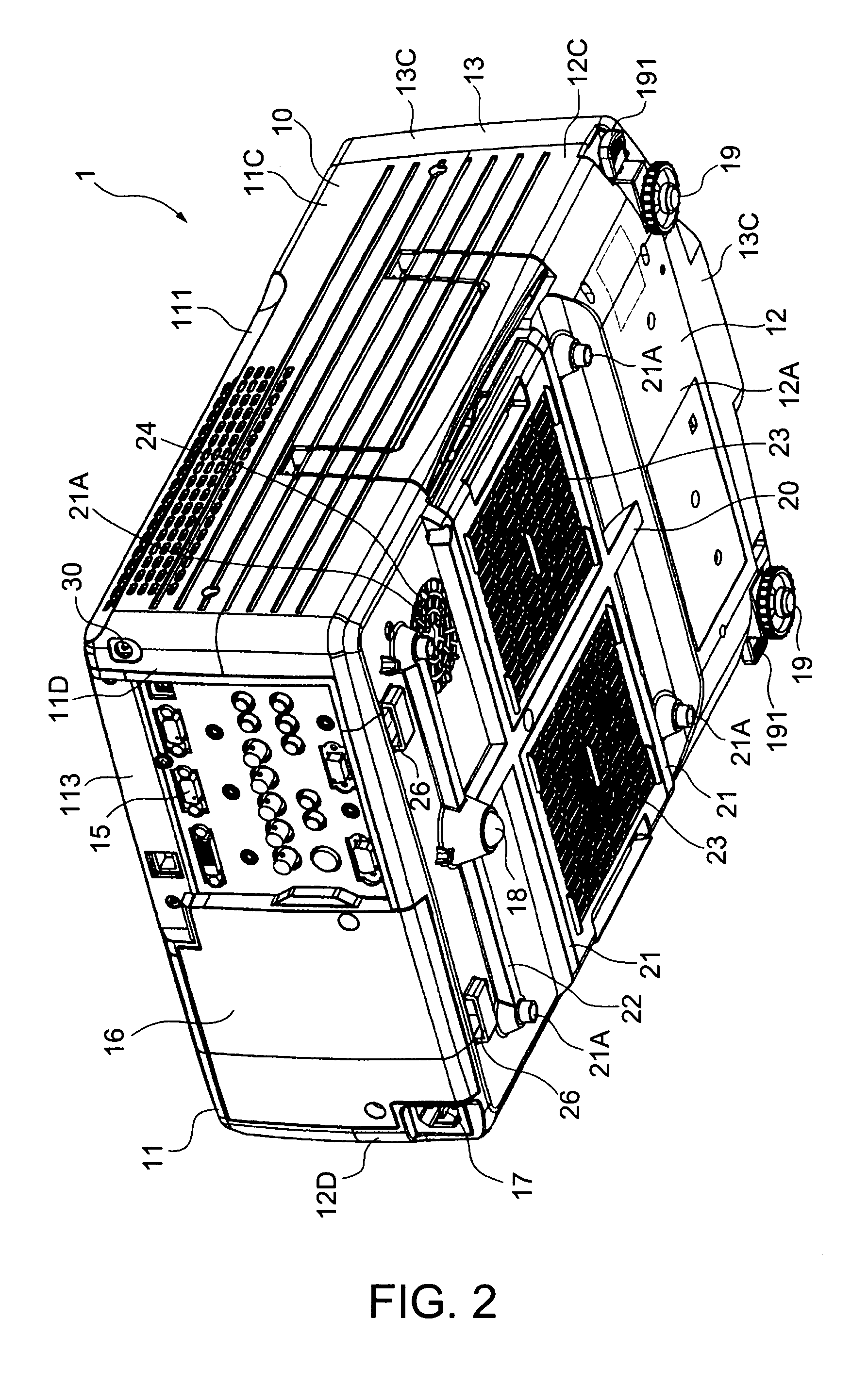

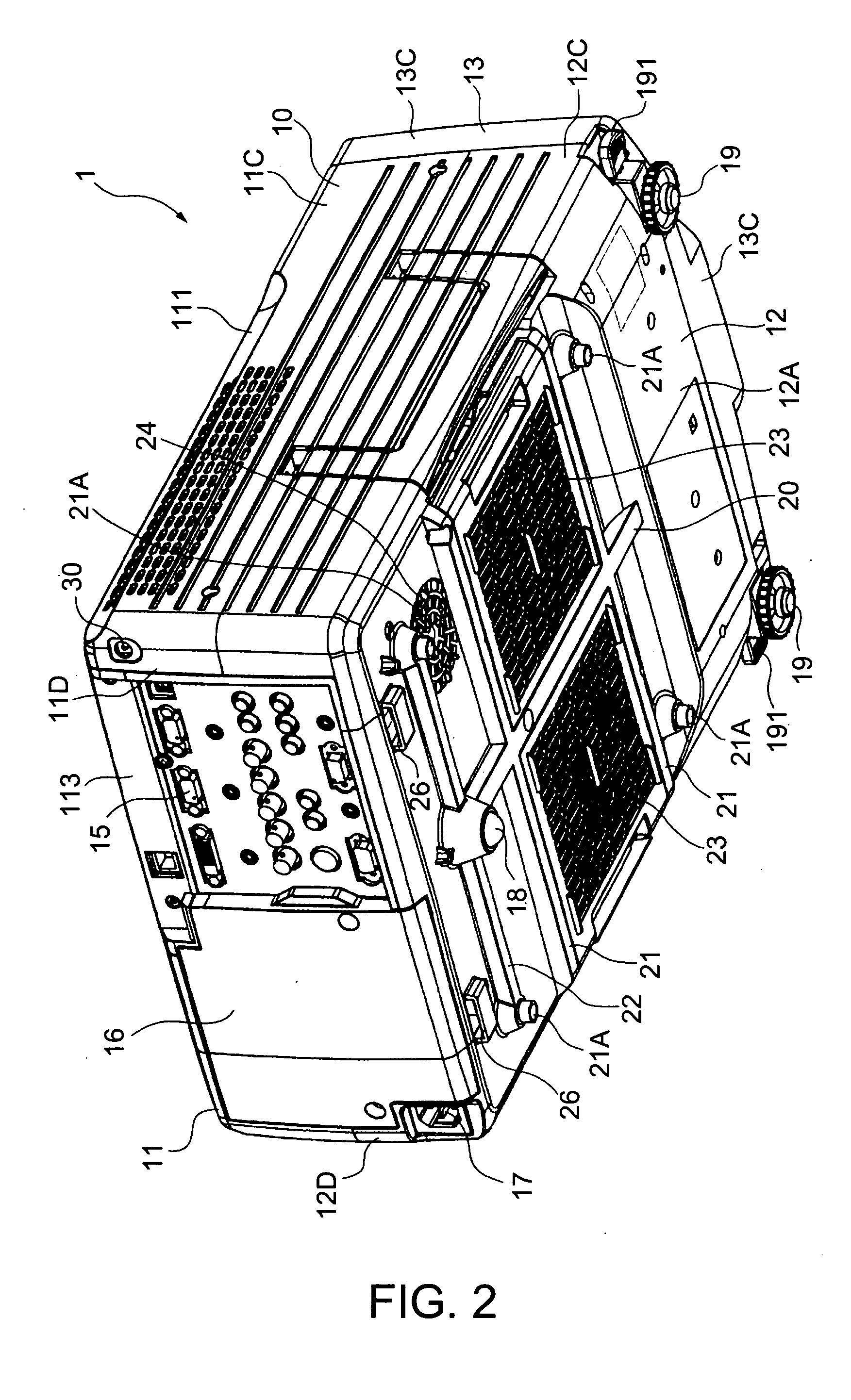

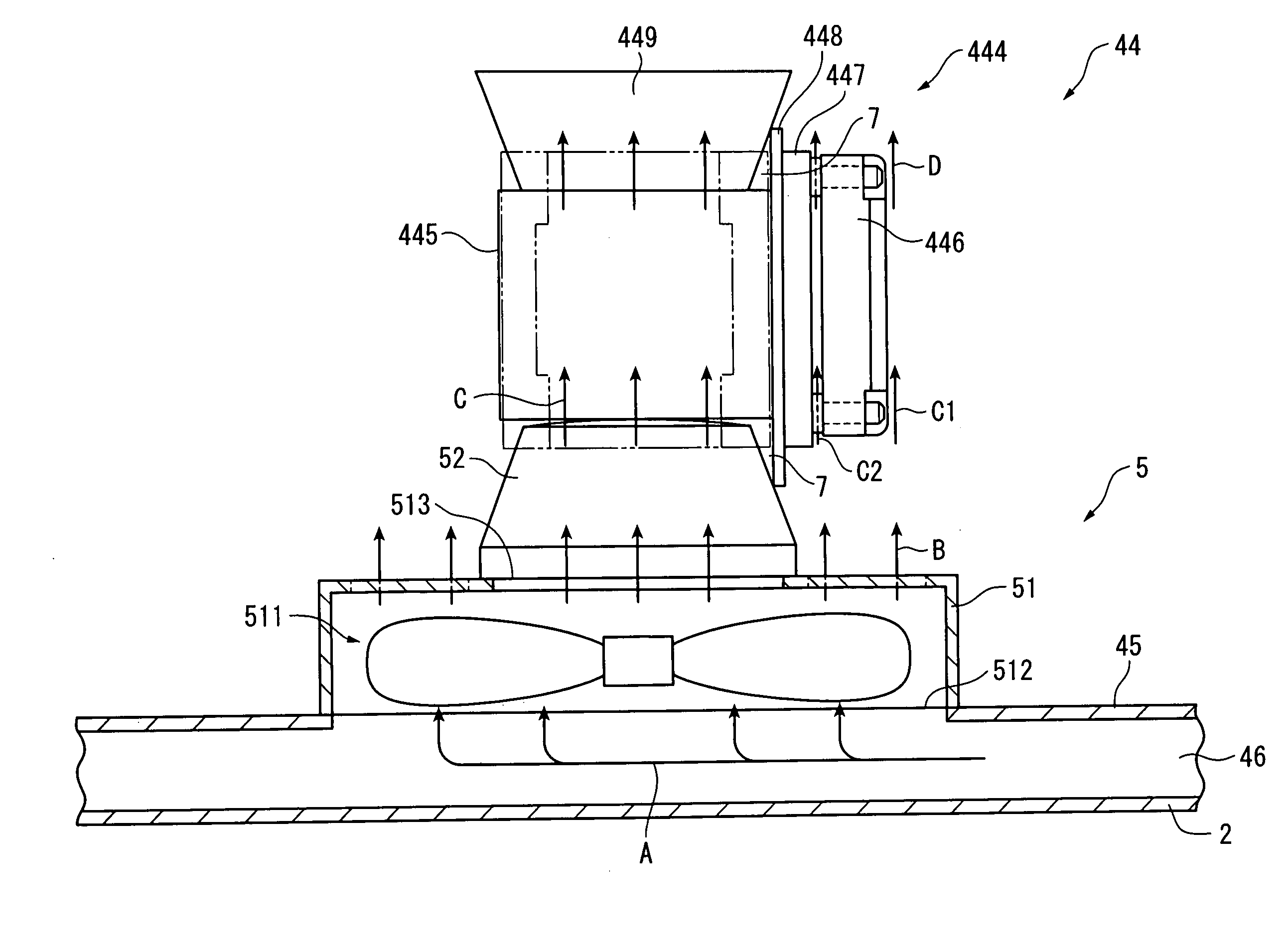

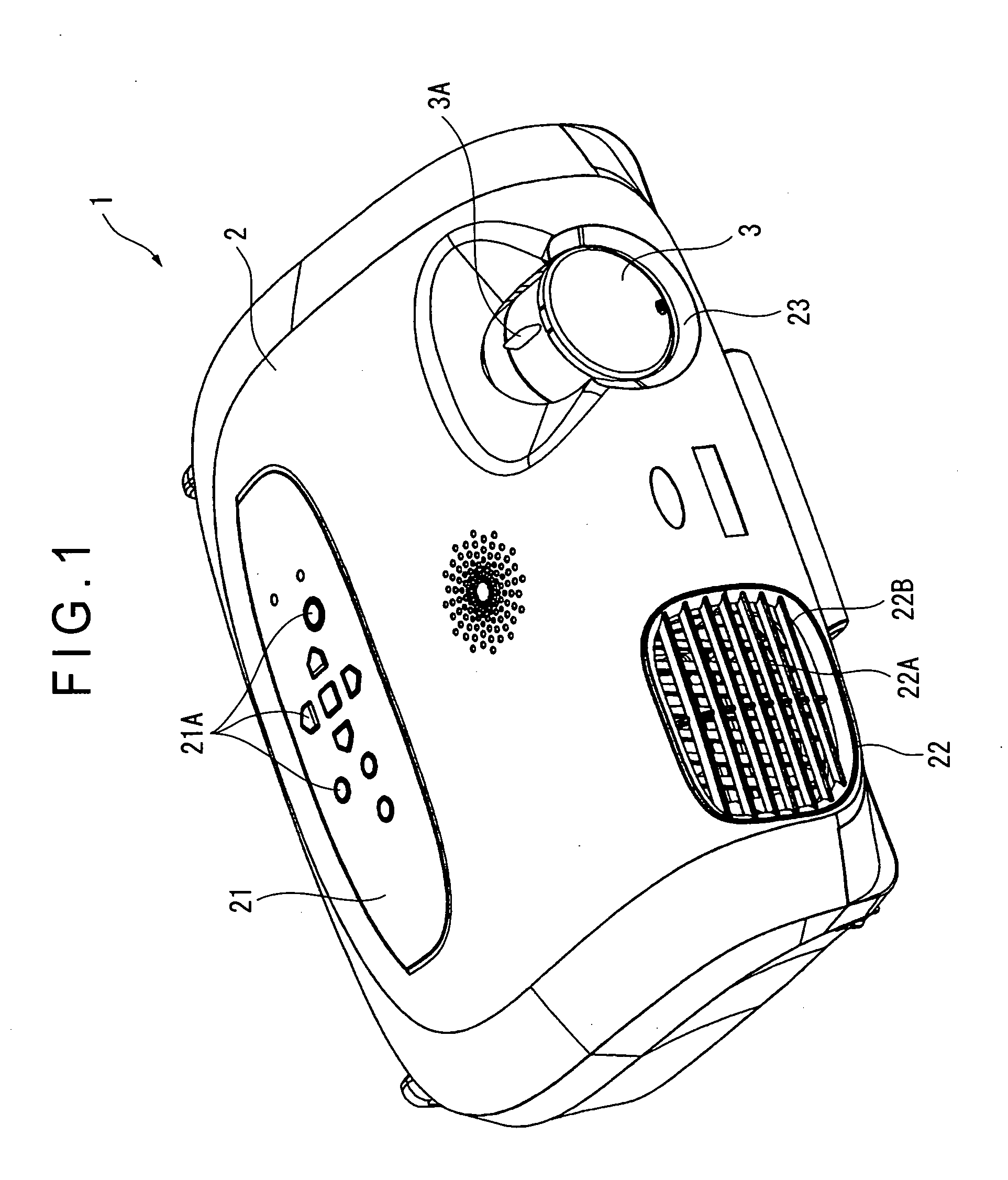

Cooling device and optical device and projector having the cooling device

InactiveUS20040257491A1Improve cooling effectIncrease pressureTelevision system detailsStatic indicating devicesConductive materialsHeat spreader

A cooling device (5) has a frame (51) as a chassis having a fan body (511) thereinside and a base portion (52) formed on the upper side of the frame (51), the frame (51) and the base portion (52) being made of a heat-conductive material. An object (44) to be cooled is fixed on the base portion (52) and heat is conducted from the object (44) to the base portion (52) where the conducted heat is radiated. The fan body (511) provided on the cooling device (5) blows a cooling air to cool the object (44). Accordingly, the heat on the object (44) is cooled by the cooling air blown by the fan body (511) and also by the heat-radiation by a heat radiator on the cooling device (5).

Owner:SEIKO EPSON CORP

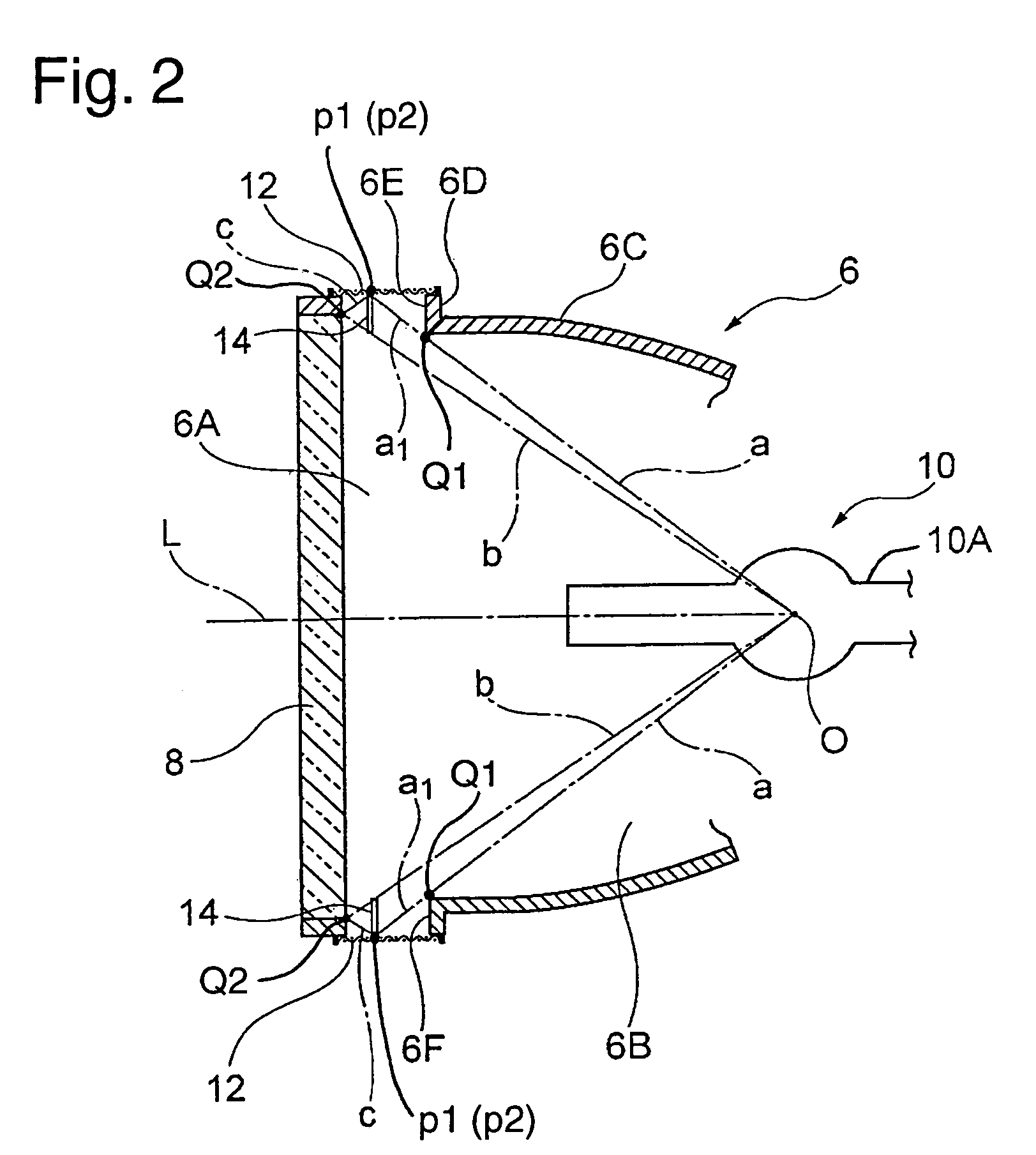

Light source, and projector provided with the light source

ActiveUS7052147B2Increase volumeGood effectPoint-like light sourceVehicle interior lightingOptoelectronicsHigh luminance

The invention provides a light source and a projector with sufficiently high luminance and size reduction for related art lamps, an increased lamp lifetime, and reduced noises from a cooling fan. A light source includes a concave mirror which has a reflecting part that reflects light, non-reflecting parts adjacent to this reflecting part, and permeable ports that pass through the non-reflecting parts, and which opens forward; a lamp which is arranged in this concave mirror and emits the light; and a light permeable member which covers the opening part of the concave mirror. The concave mirror includes a mesh arranged in a position where it covers the permeable port, and a protective wall to protect the mesh, which is arranged in a position where direct collision between the mesh and broken pieces of the lamp made by a burst of the lamp is reduced or prevented.

Owner:SEIKO EPSON CORP

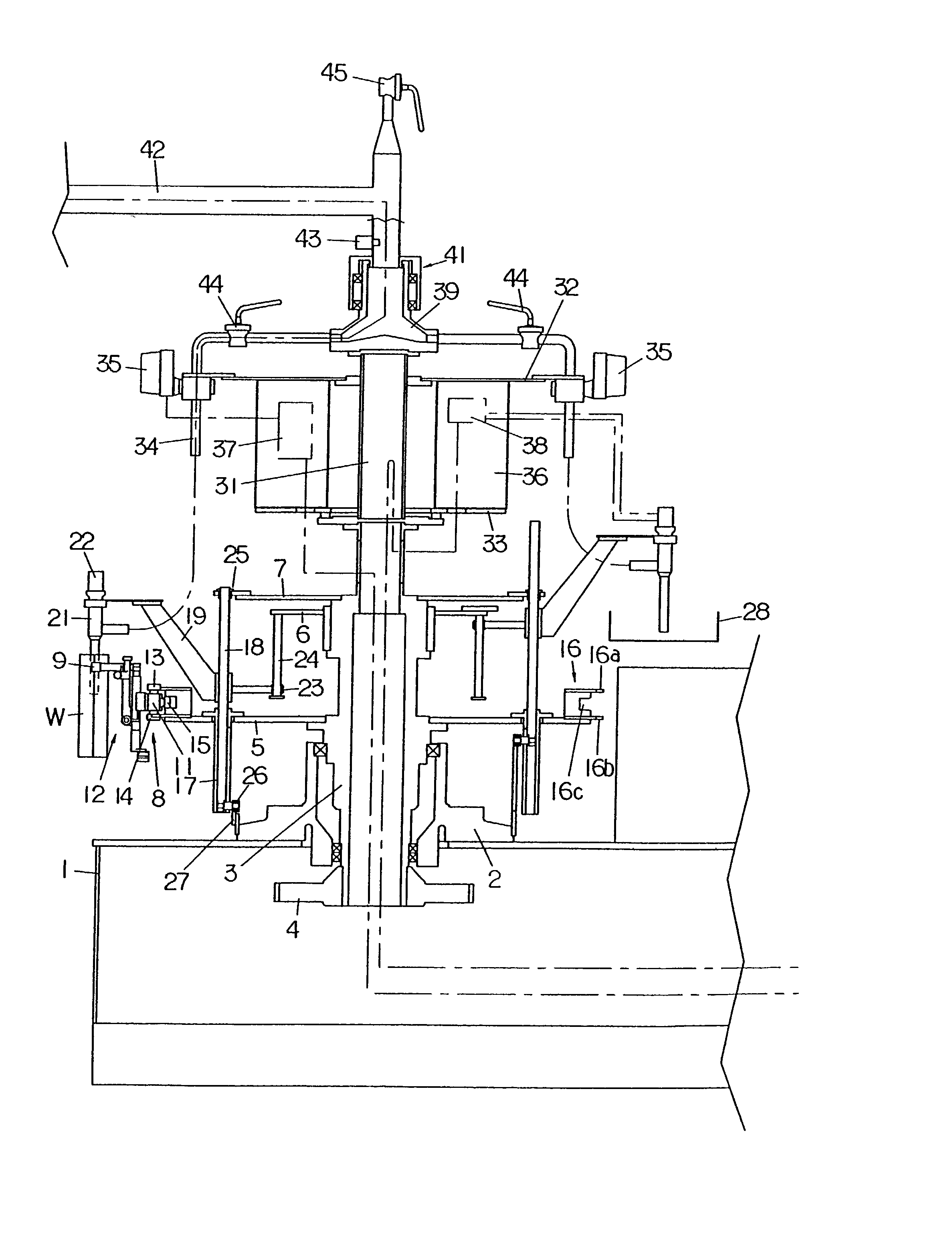

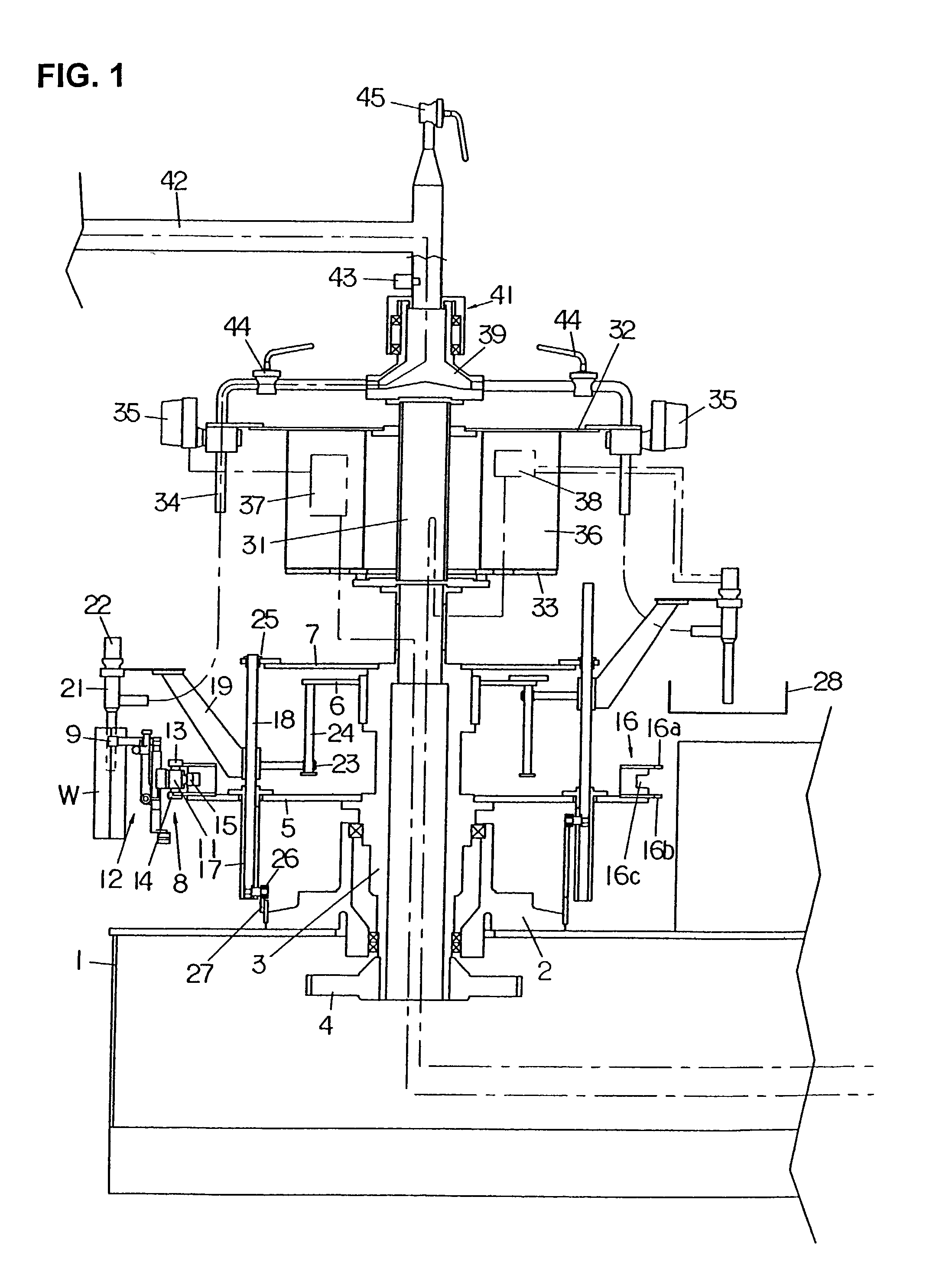

Flow meter type liquid filling apparatus

InactiveUS20030010398A1A large amountEasy to controlLiquid fillingSafety device in filling machineryAtmospheric airLiquid tank

A rotary and flow meter type liquid filling apparatus including a liquid reservoir tank that stores and supplies liquid to filling nozzles, and air supply paths for different amount of air supply and air discharge paths for different amount of air discharge being connected to the liquid reservoir tank. An air compressor is connected to the air supply paths, and the air discharge paths open into the atmosphere. A liquid pressure sensor disposed near the filling nozzles sense the increase or decrease of the liquid pressure inside a pipe that connects the liquid reservoir tank and liquid filling nozzles, and the electromagnetic valves provided on the air supply and air discharge paths are opened or closed, thus supplying air to and discharging air from the liquid reservoir tank so as to control the air pressure inside the liquid reservoir tank and the liquid pressure near the liquid filling nozzles.

Owner:TOYO JIDOKI CO LTD

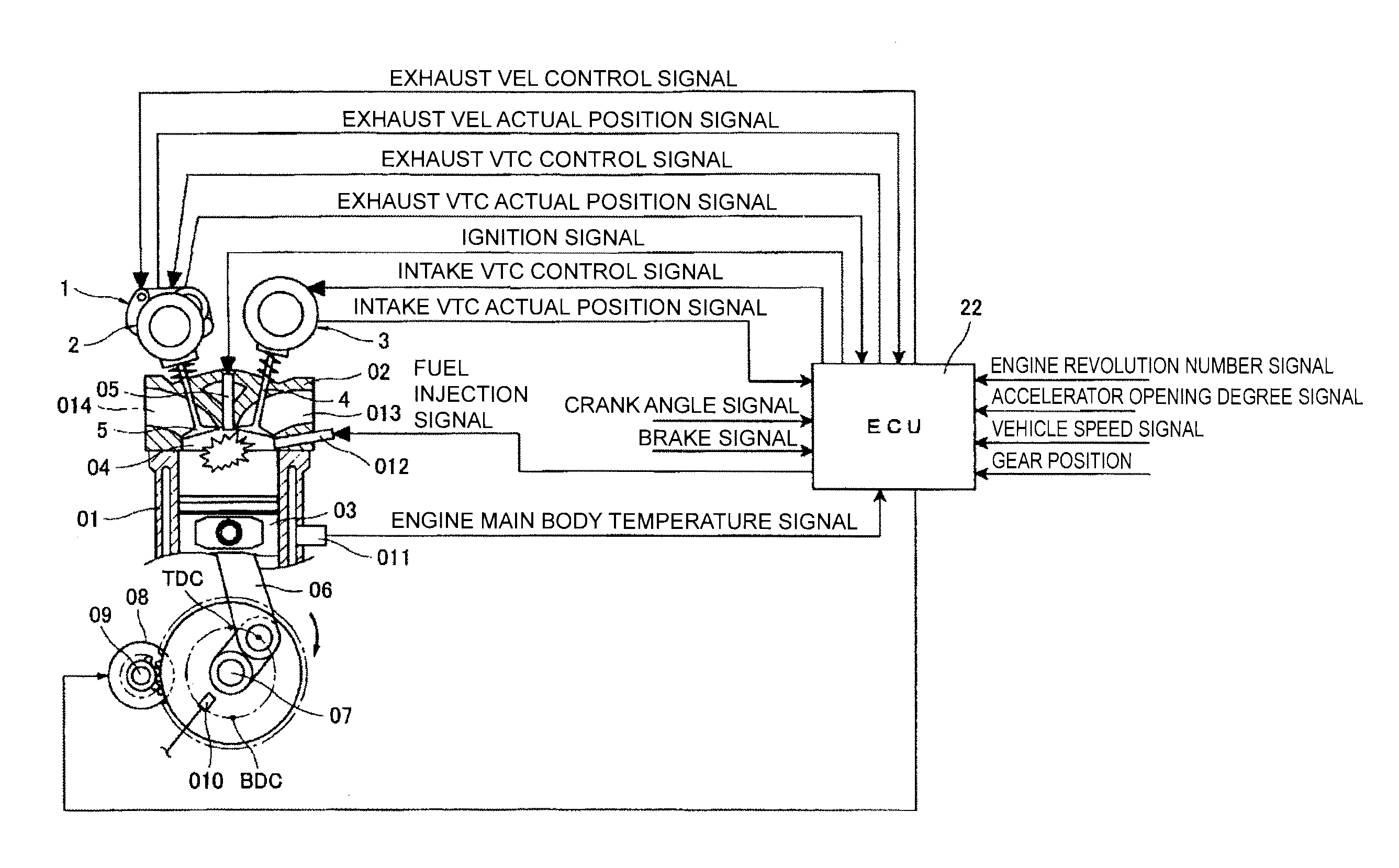

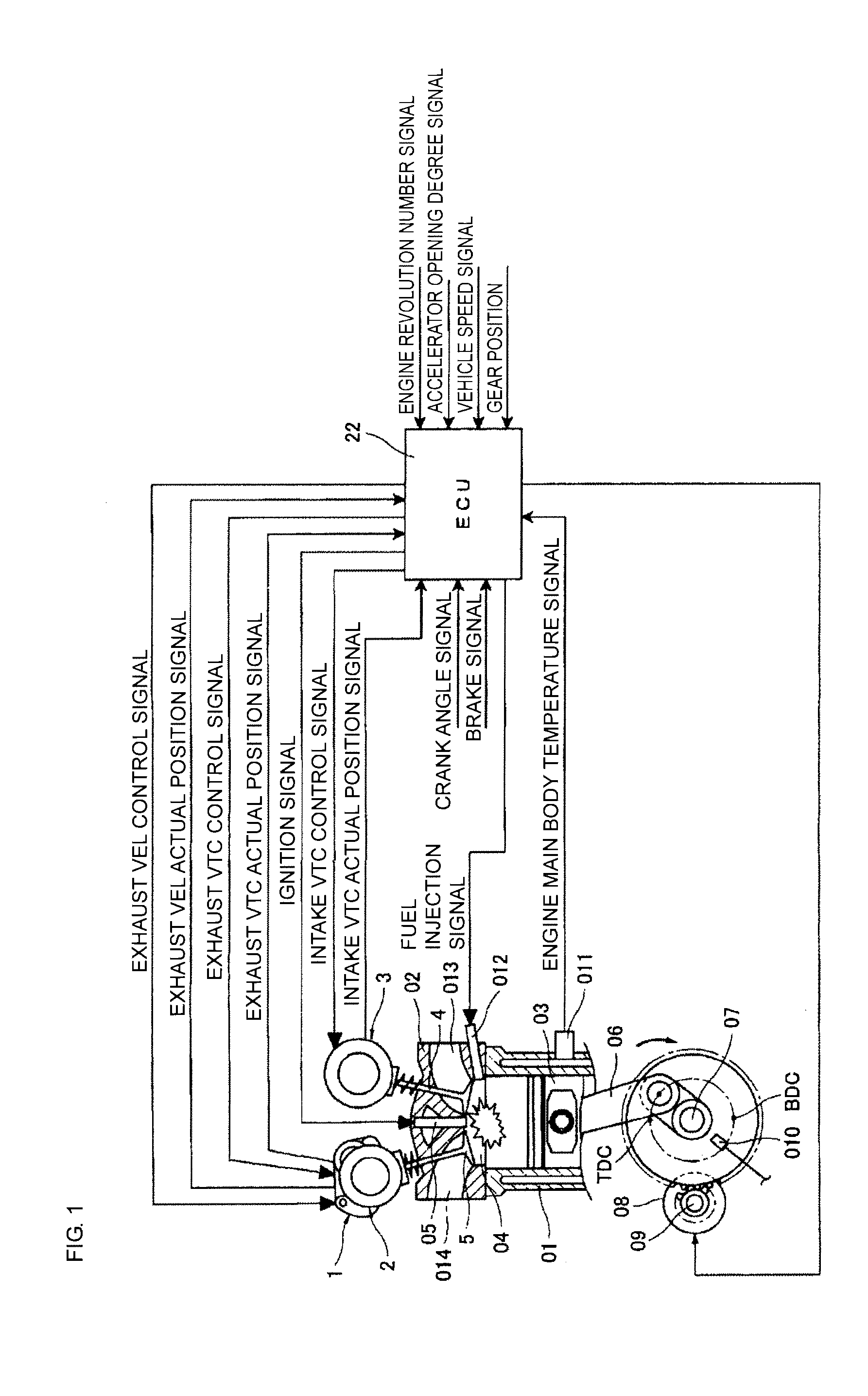

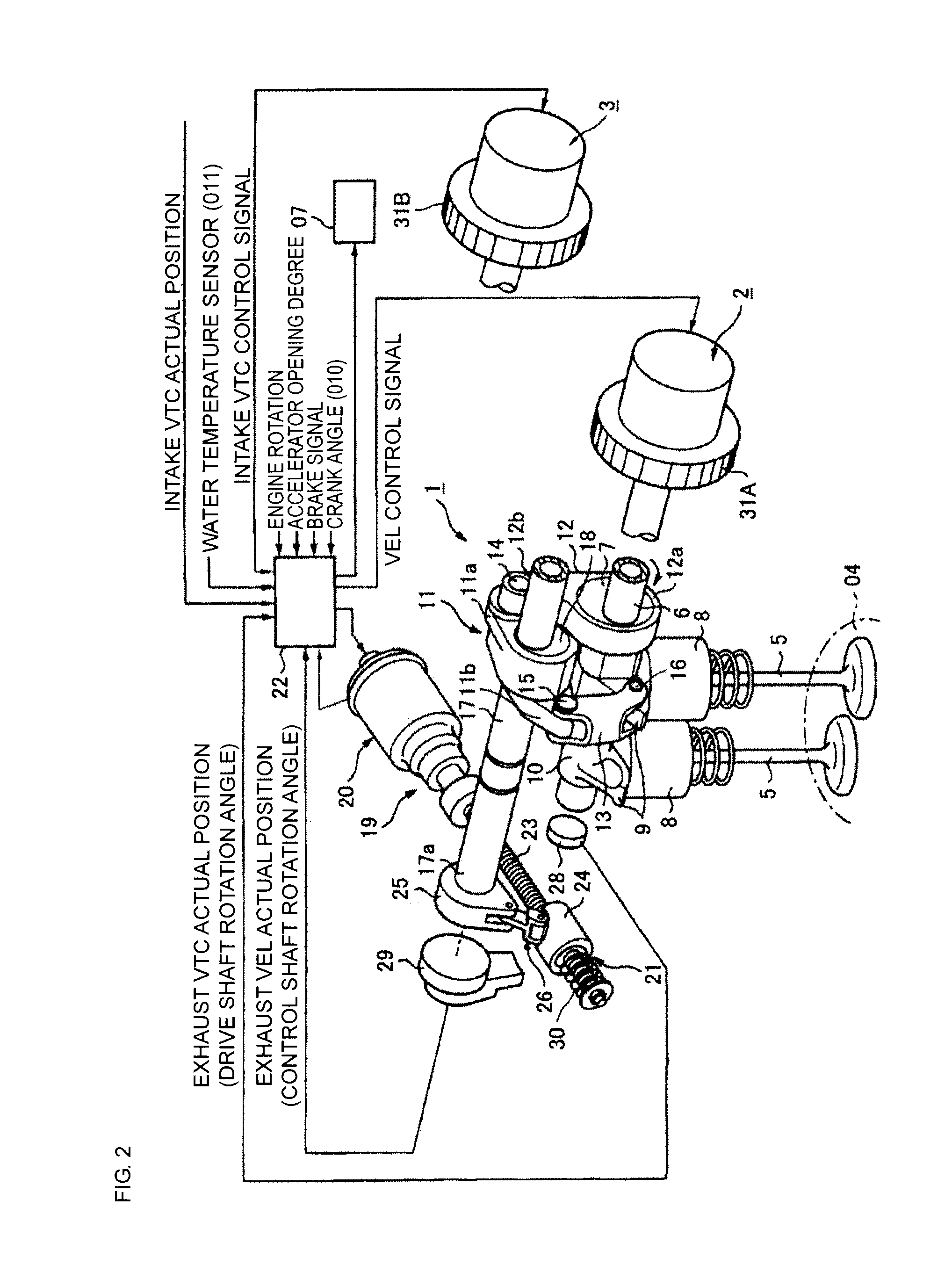

Automatic stop/restart control system for an internal combustion engine and variable valve actuating apparatus

InactiveUS20150369199A1Low RPMEasy to useElectrical controlInternal combustion piston enginesExhaust valveControl system

Owner:HITACHI AUTOMOTIVE SYST LTD

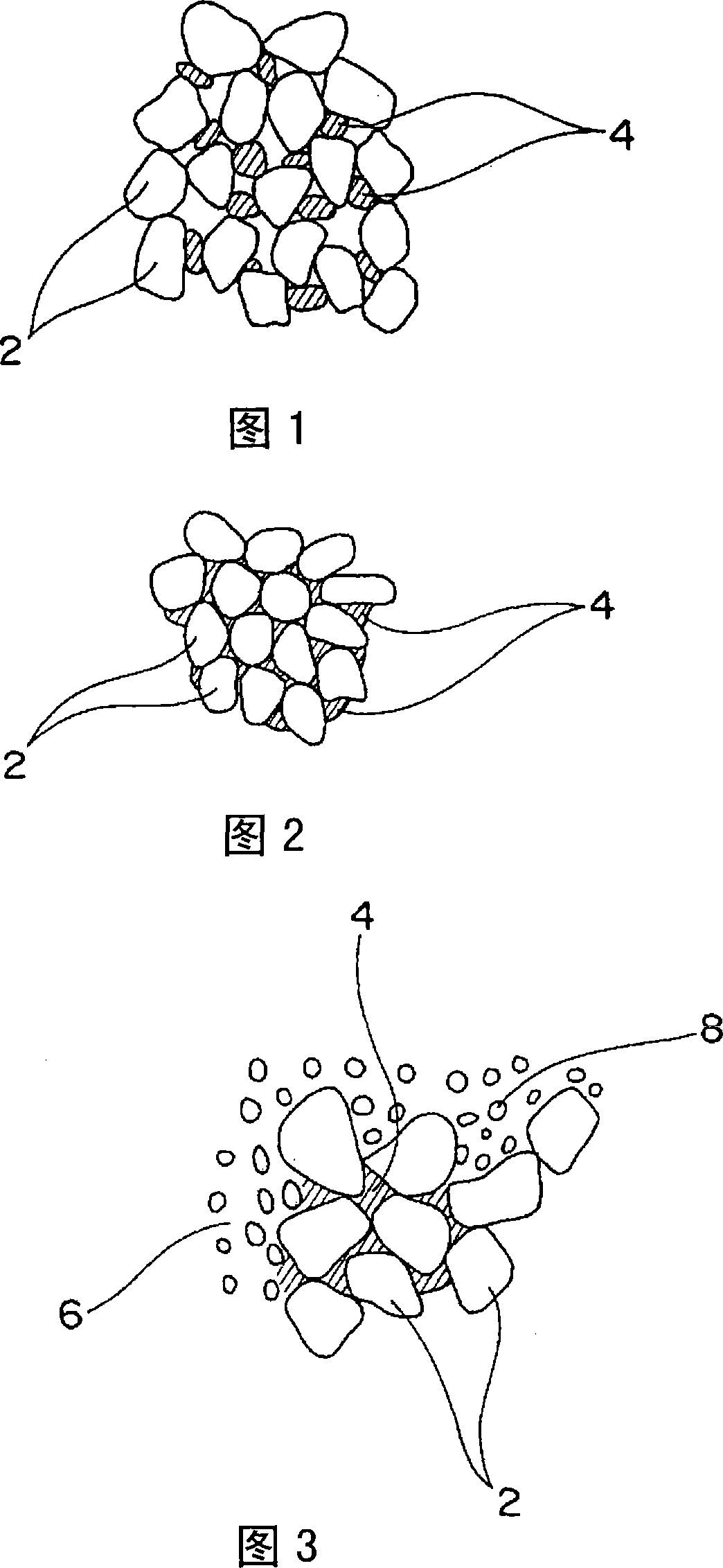

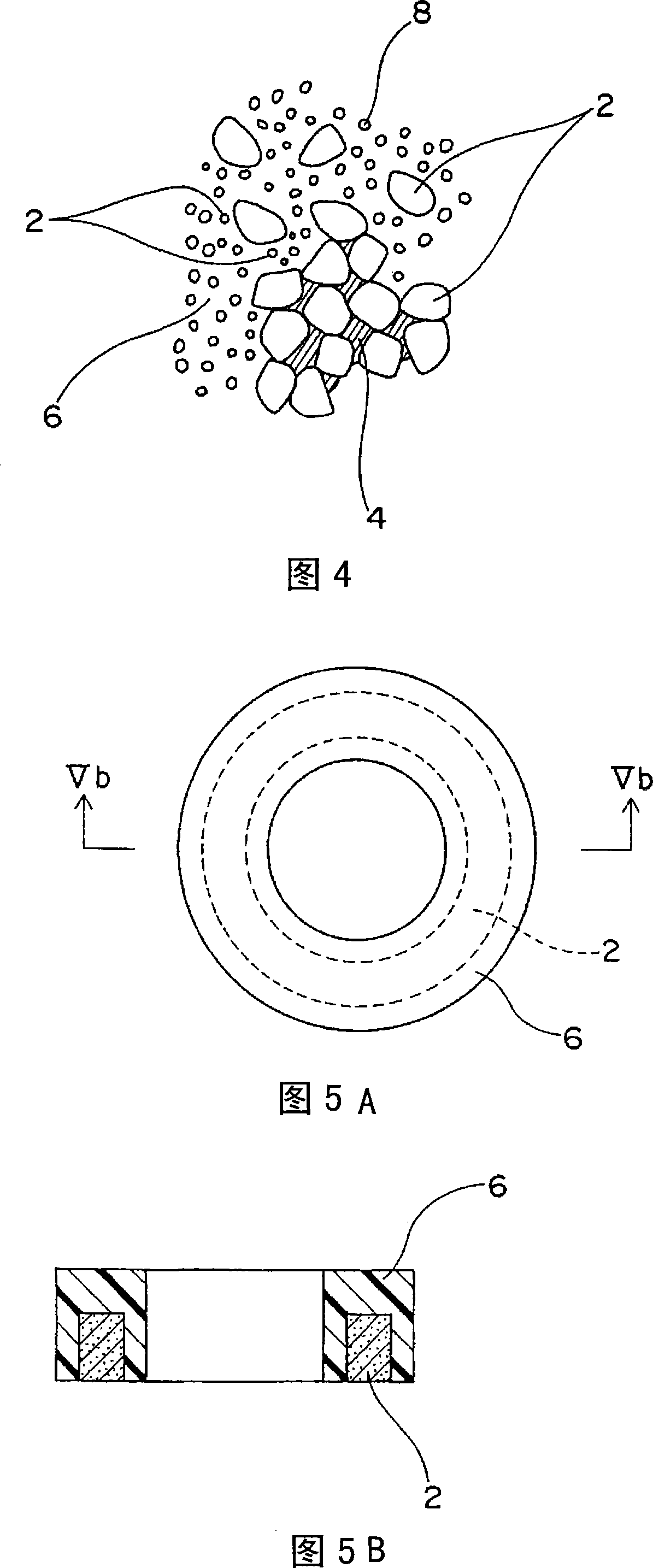

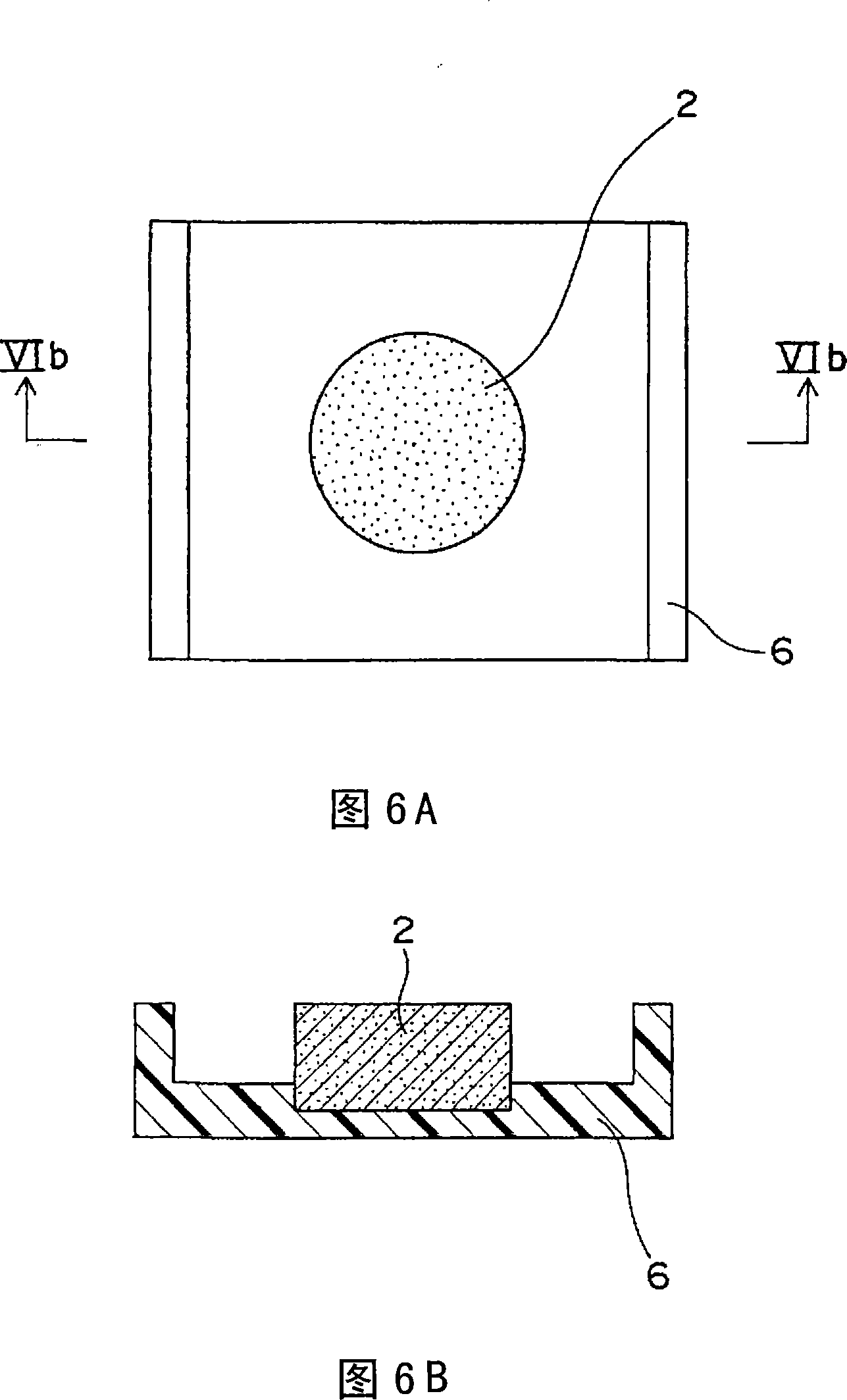

Method for manufacturing magnetic core component

ActiveCN101010756AMiniaturizationHigh flux densityInorganic material magnetismTransformers/inductances magnetic coresMaterials scienceMagnetic core

Magnetic powder included in a resin composition (6) to be used for injection molding is covered with an insulating material, and a green compact magnetic body (2) or a powder magnet molding (22) is inserted into the resin composition (6).

Owner:NTN CORP

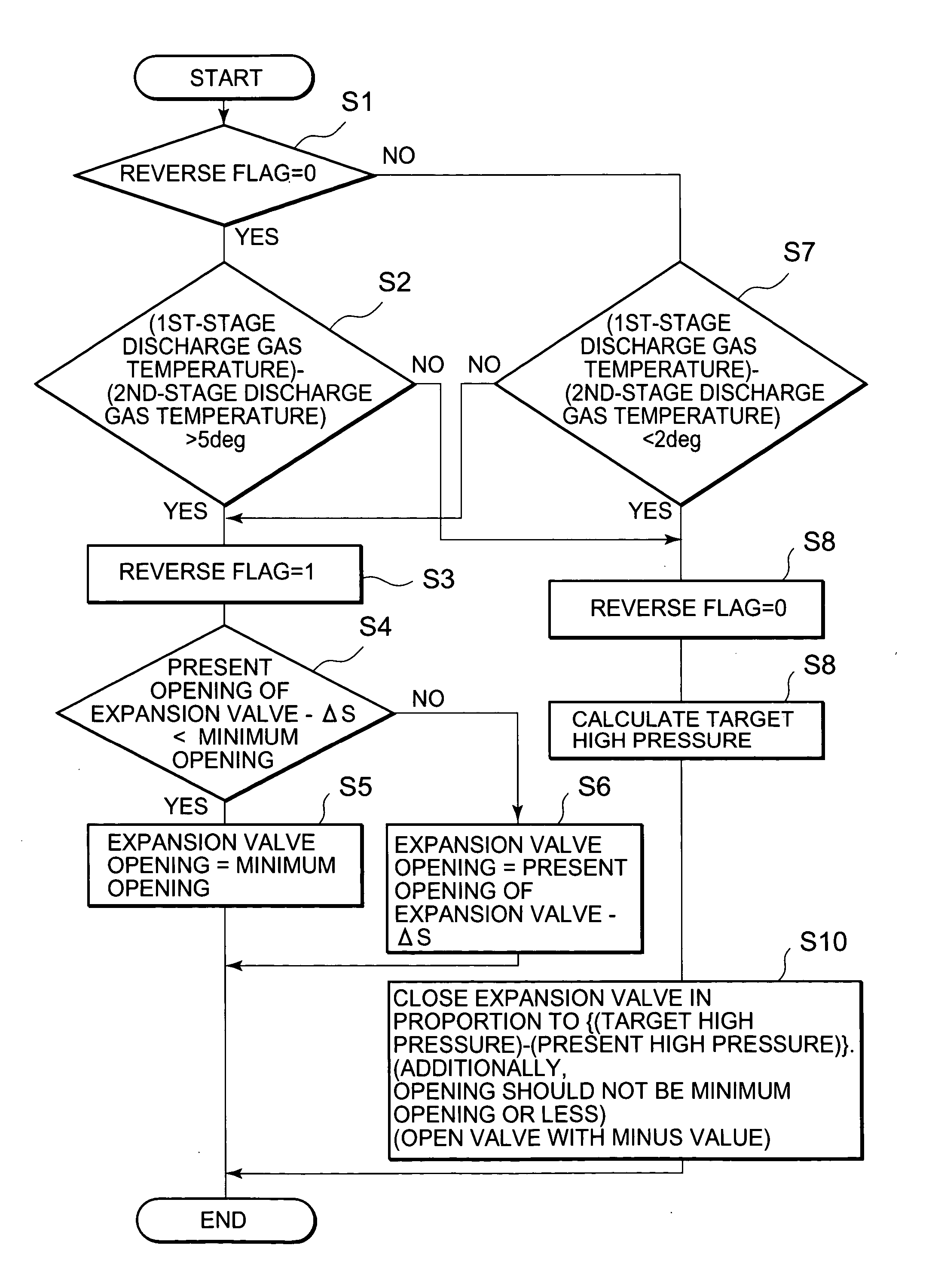

Refrigerant cycle apparatus

InactiveUS20050126194A1Low costDetection securityRotary/oscillating piston combinations for elastic fluidsBrush bodiesRefrigerantMechanical engineering

For a purpose of realizing a refrigerant cycle apparatus capable of exactly detecting a pressure reverse phenomenon caused in a compression element of a compressor of a multistage compression type, in the refrigerant cycle apparatus in which the multistage compression type compressor constitutes a refrigerant circuit, including an electromotive element, and first and second compression elements driven by the electromotive element in an airtight container to suck an intermediate-pressure refrigerant gas compressed by the first compression element into the second compression element and to compress and discharge the refrigerant gas, the apparatus comprising: a sensor for detecting a discharge refrigerant pressure of the first compression element; and a control device into which an output of the sensor is input, the control device detects reverse of the discharge refrigerant pressures of the first and second compression elements based on the discharge refrigerant pressure of the first compression element.

Owner:SANYO ELECTRIC CO LTD

Flow meter type liquid filling apparatus

InactiveUS6729366B2A large amountEasy to controlLiquid fillingSafety device in filling machineryAtmospheric airLiquid tank

Owner:TOYO JIDOKI CO LTD

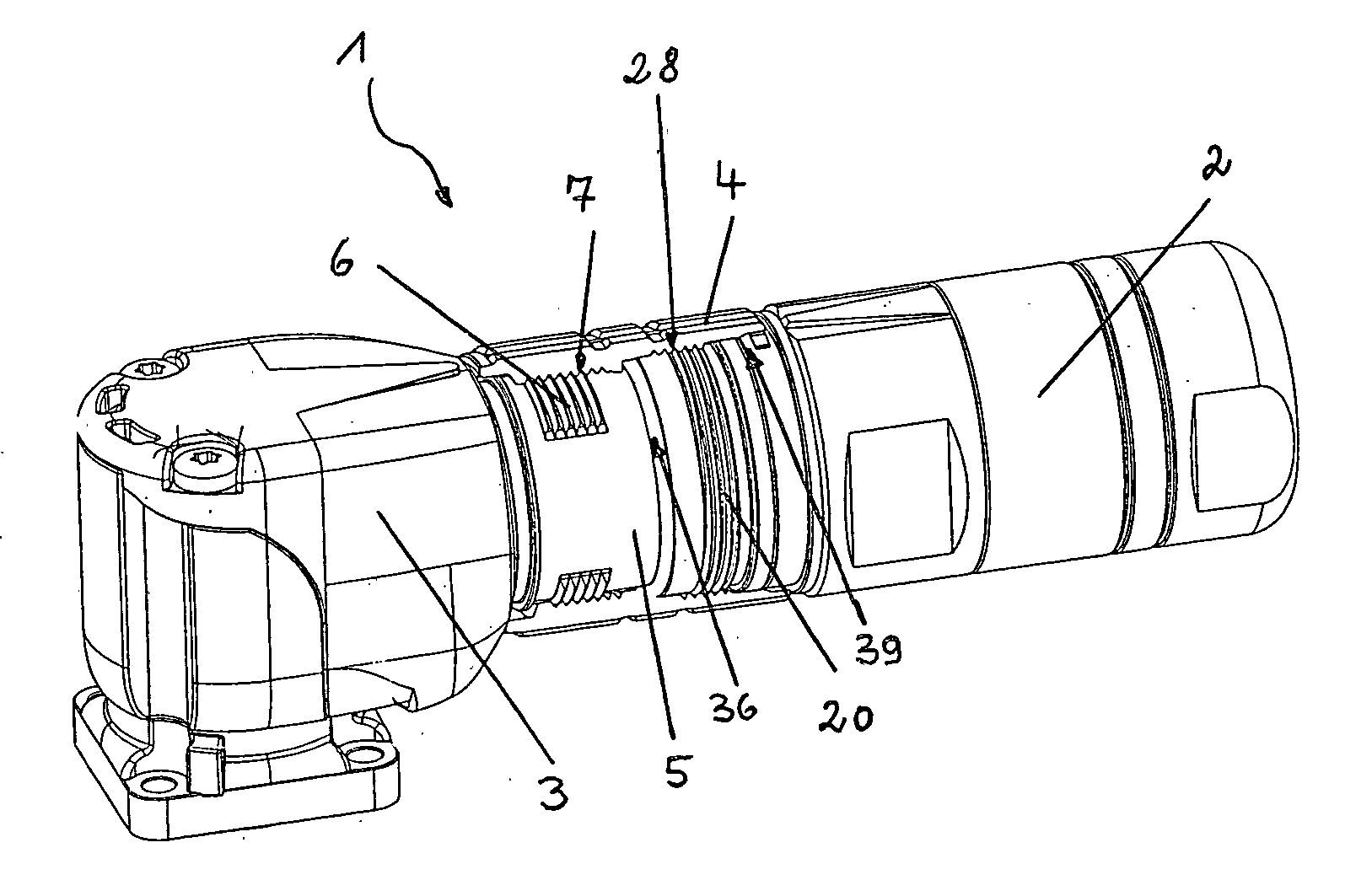

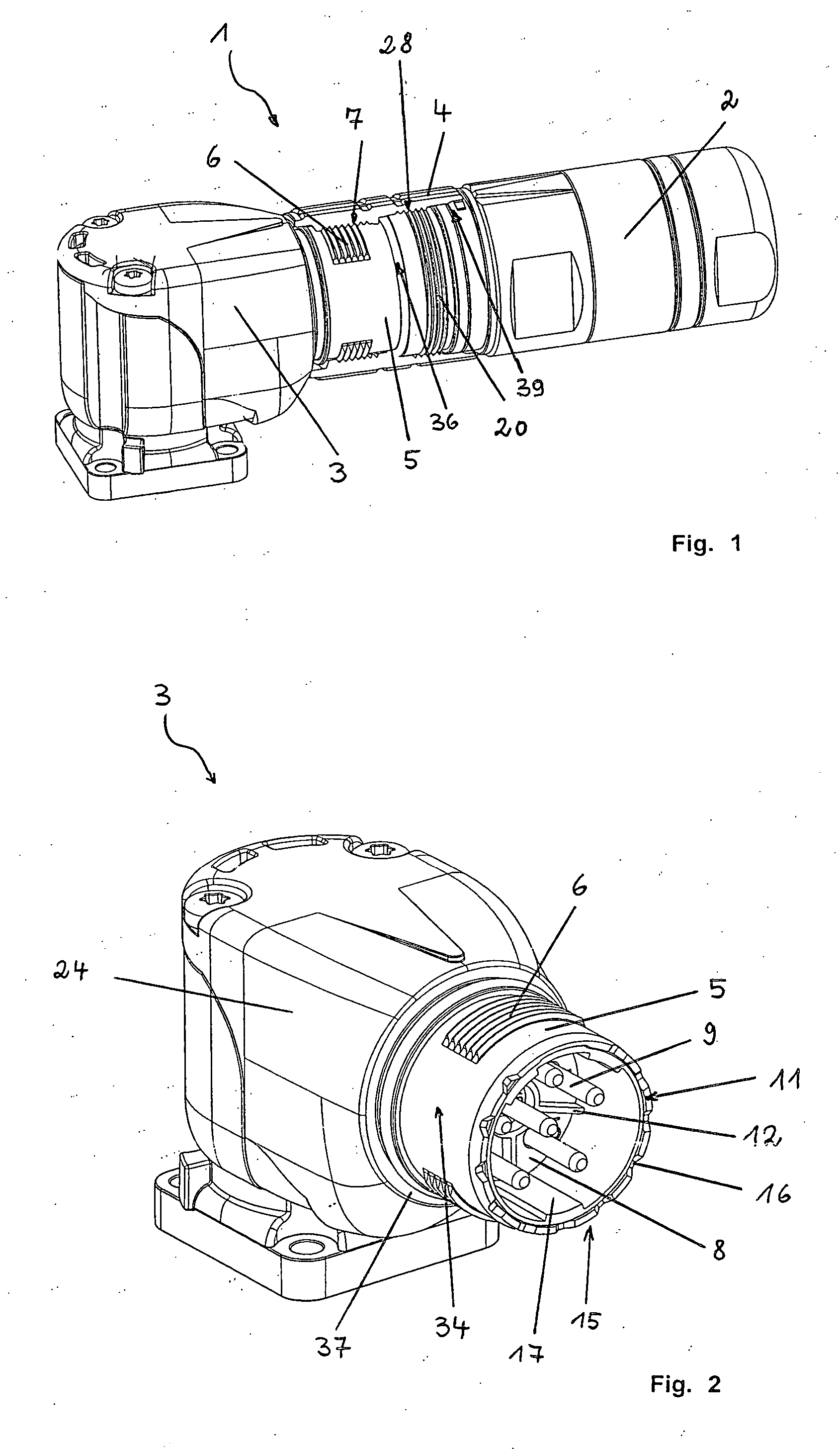

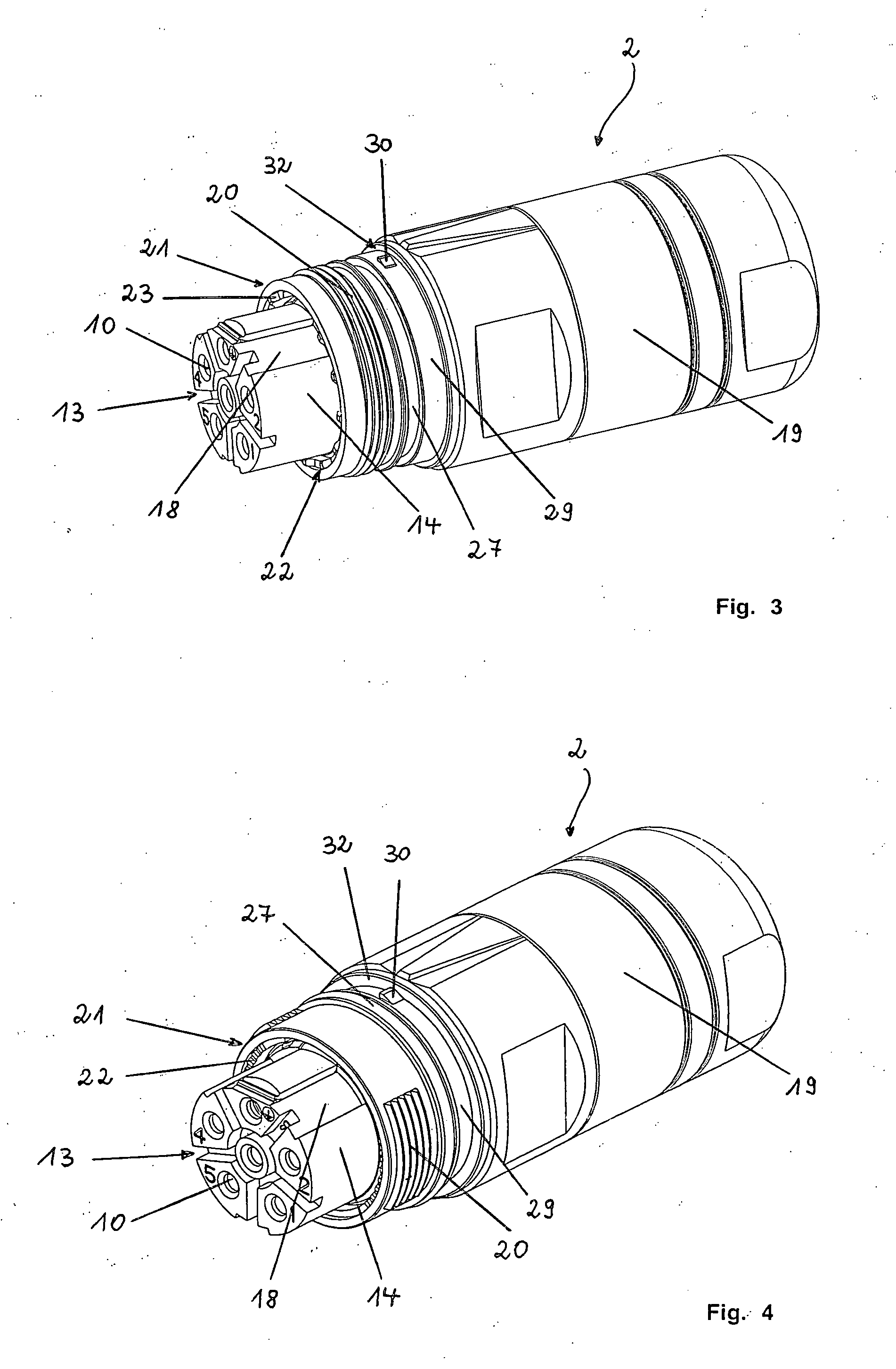

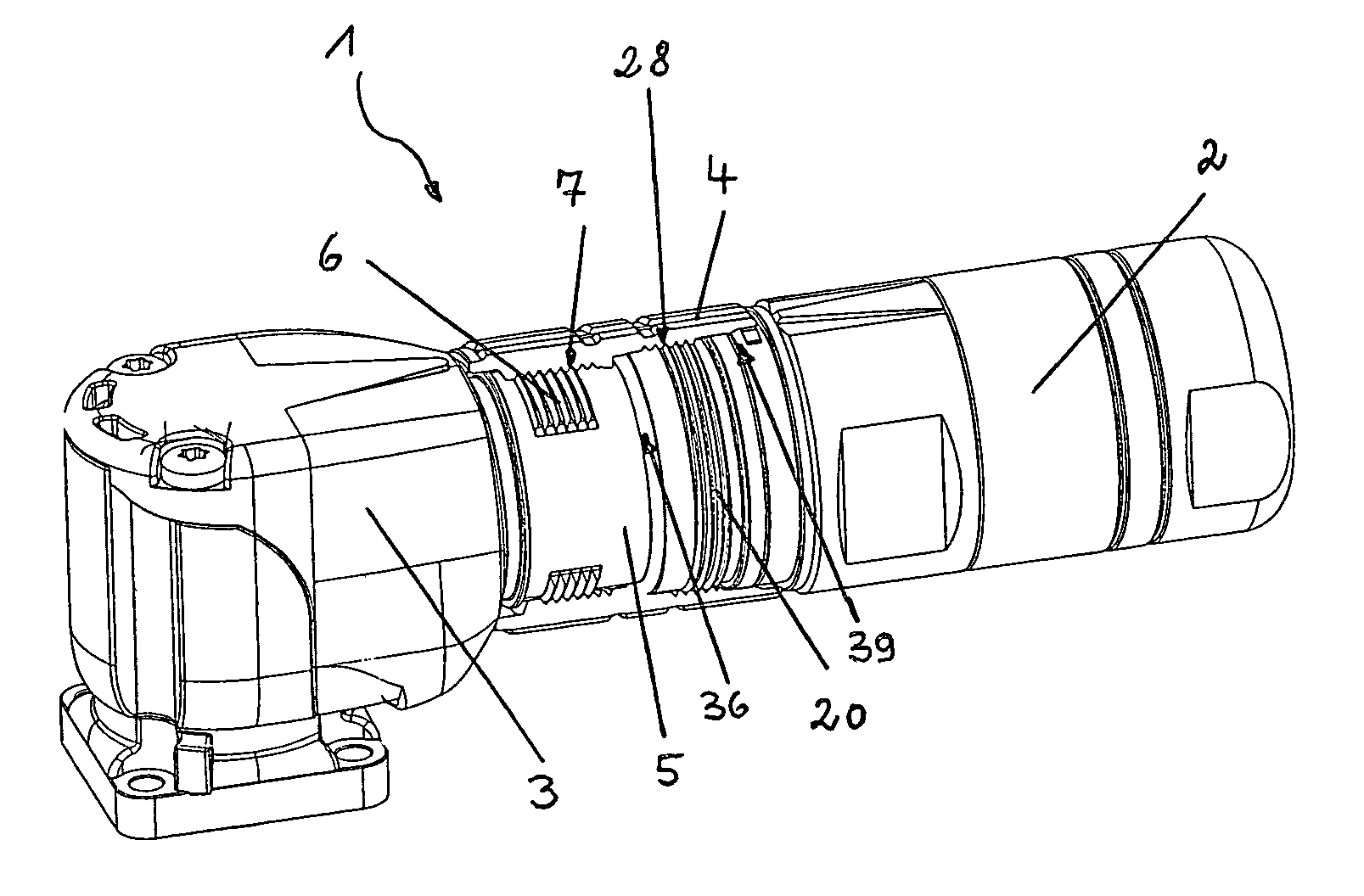

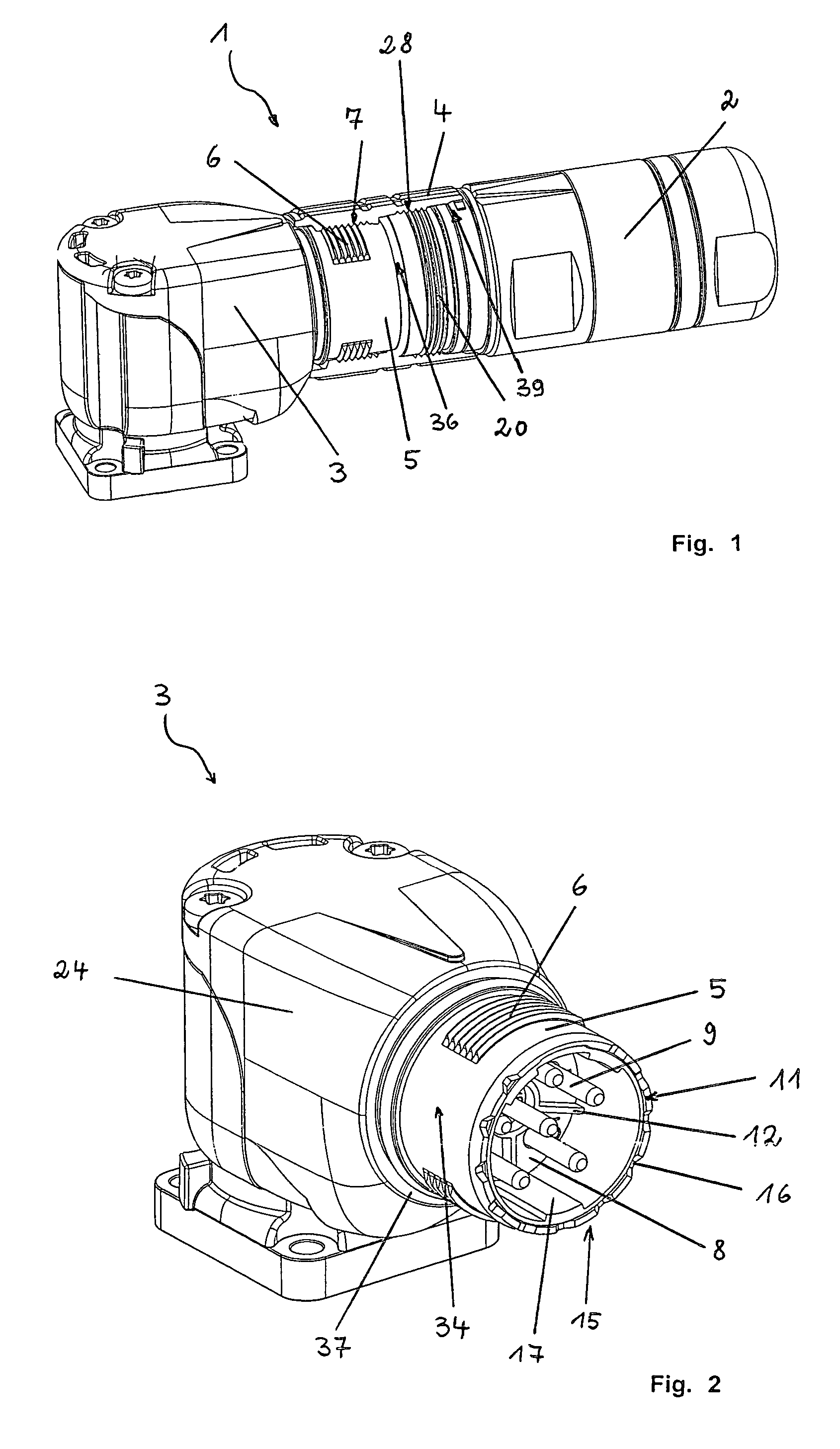

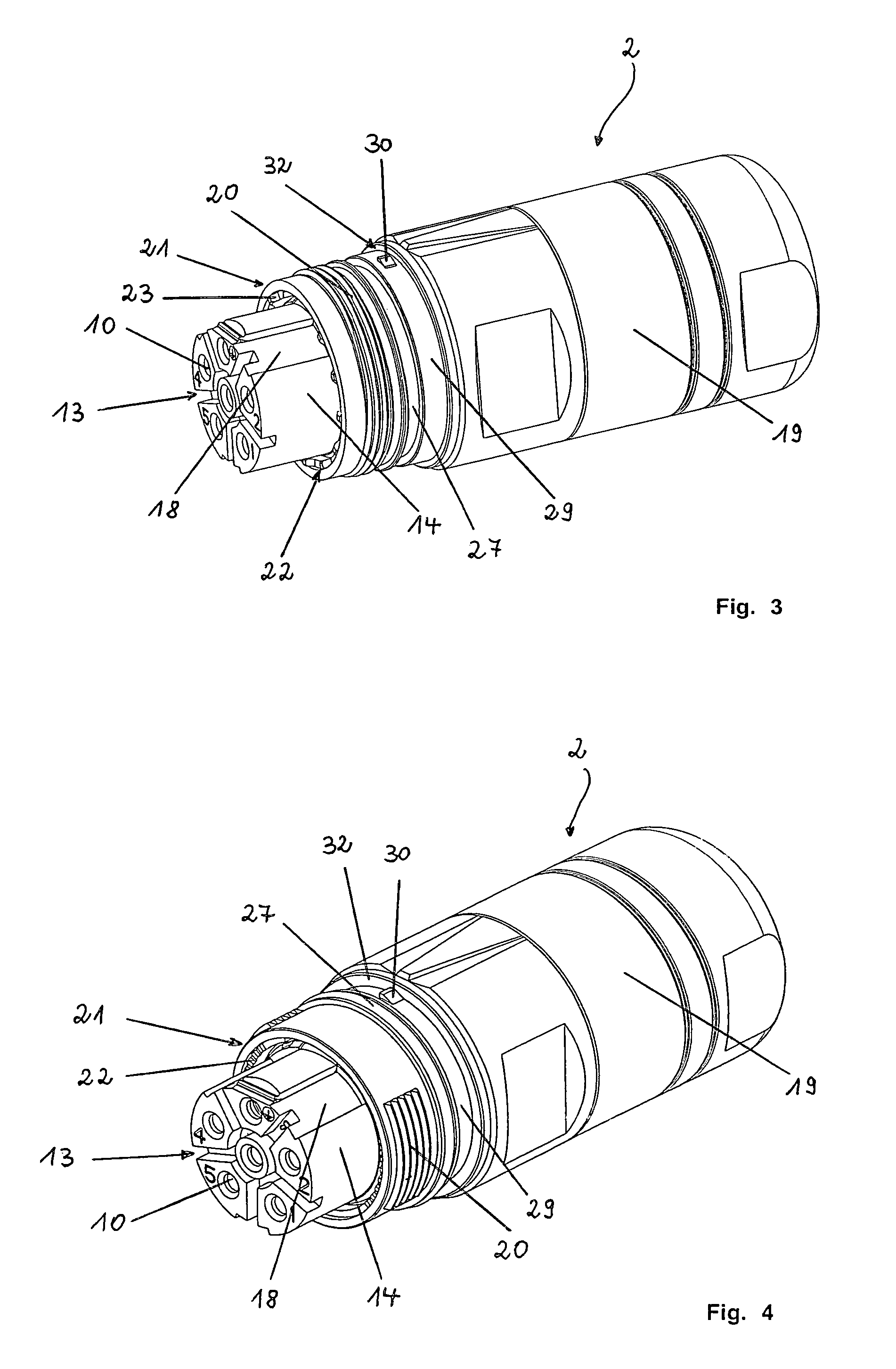

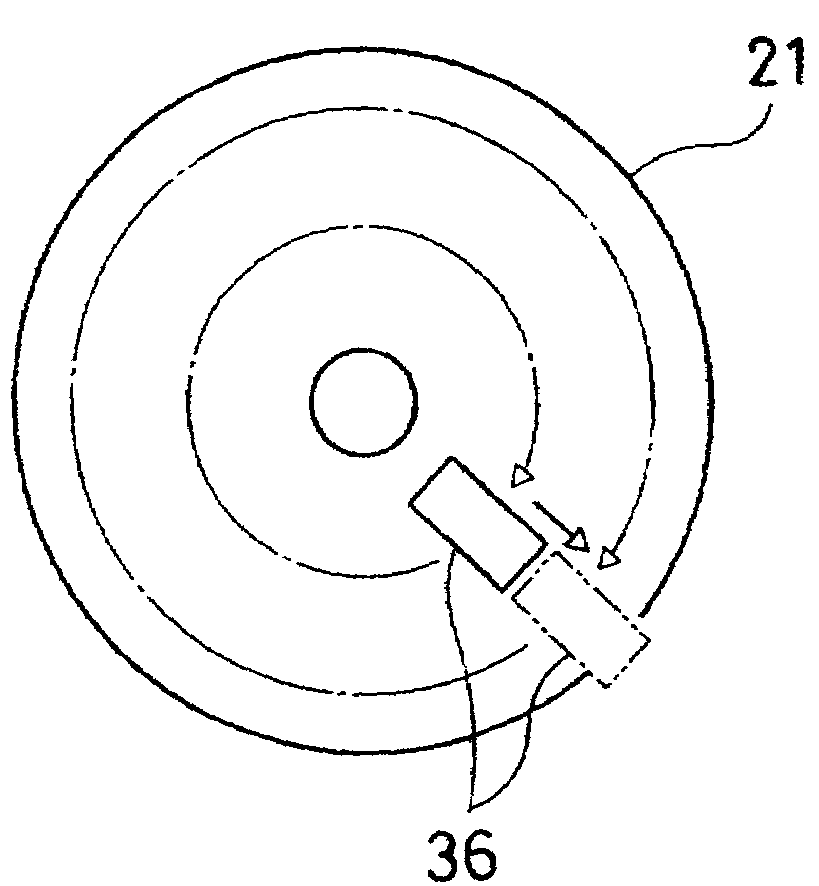

Electrical plug-in connection

InactiveUS20070037429A1Smooth connectionAvoid disadvantagesEngagement/disengagement of coupling partsClamped/spring connectionsMating plugEngineering

Electrical plug-in connection (1), having a plug part (2) and a mating plug part (3), which can be plugged together and produce a large number of electrical plug-in connections, at least the plug part (2) or the mating plug part (3) bearing, on its body (19, 24), a union nut (4), which can be screwed to the mating plug part (3) or the plug part (2) and secures the plug-in connection (1) against becoming disconnected in an undesirable manner. The union nut (4) has, at both of its ends, an internal thread (28, 7) for simultaneously screwing it to the plug part (2) and the mating plug part (3), the internal threads (7, 28) being formed in the opposite direction.

Owner:CONINVERS ELEKTROTECHN BAUELEMENTE

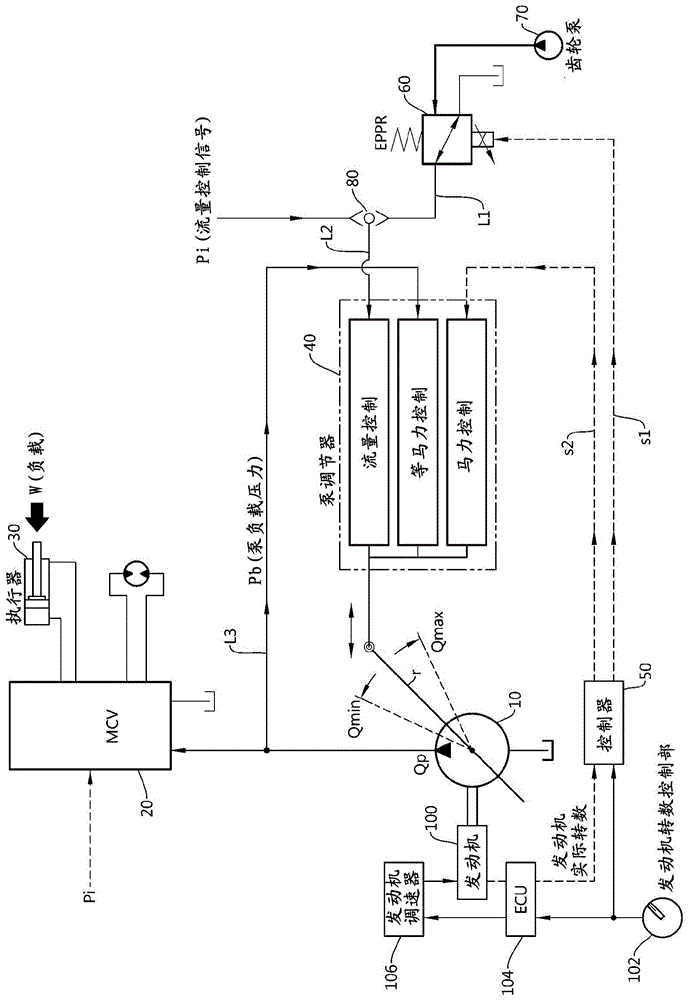

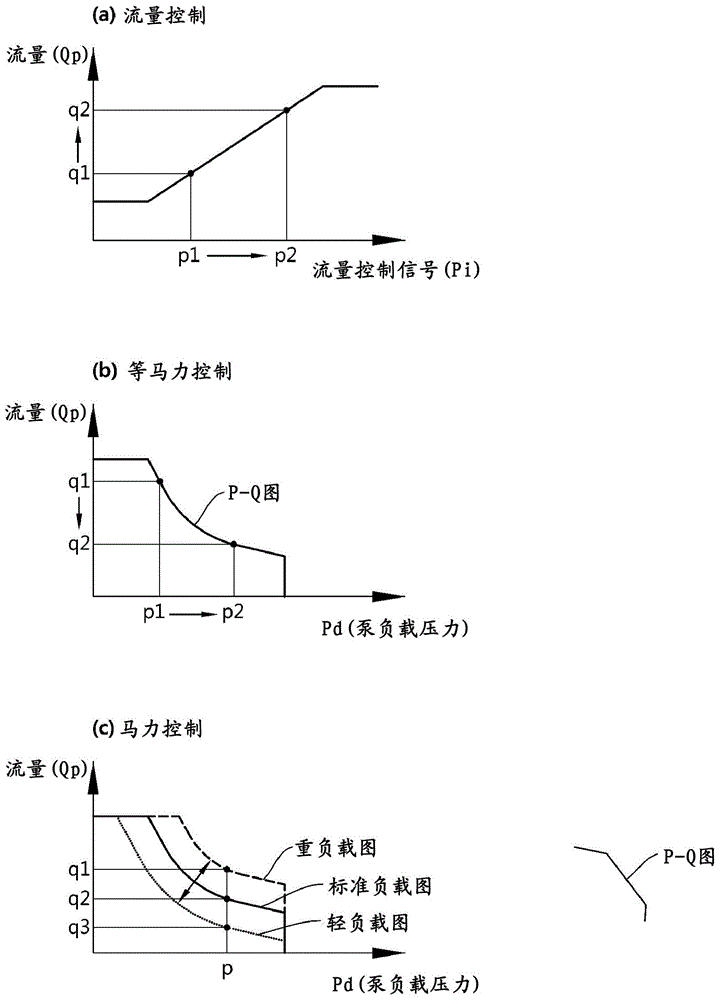

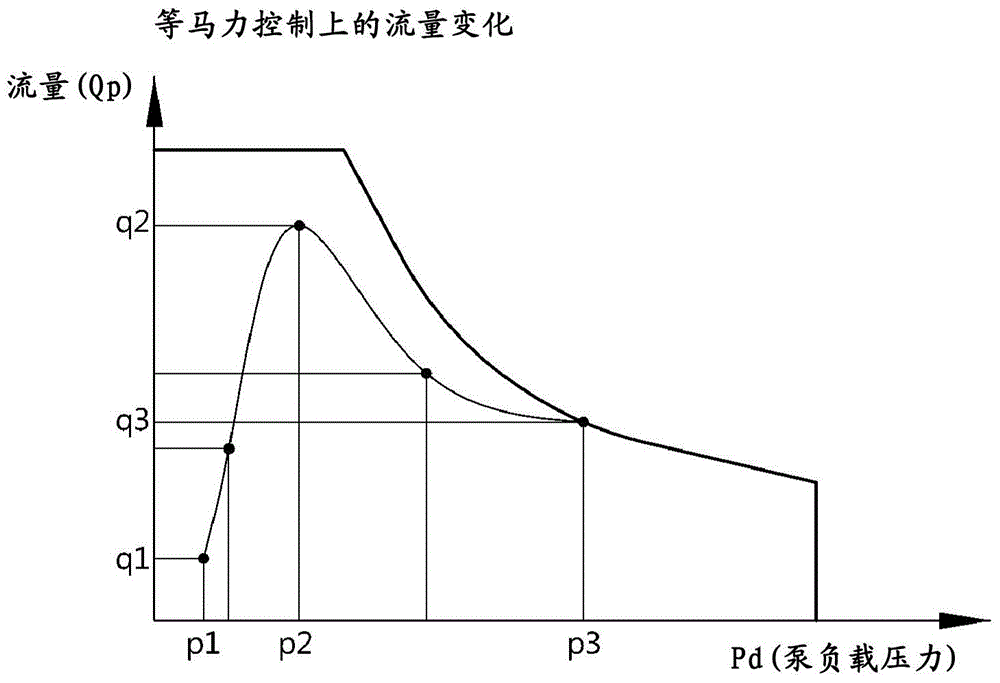

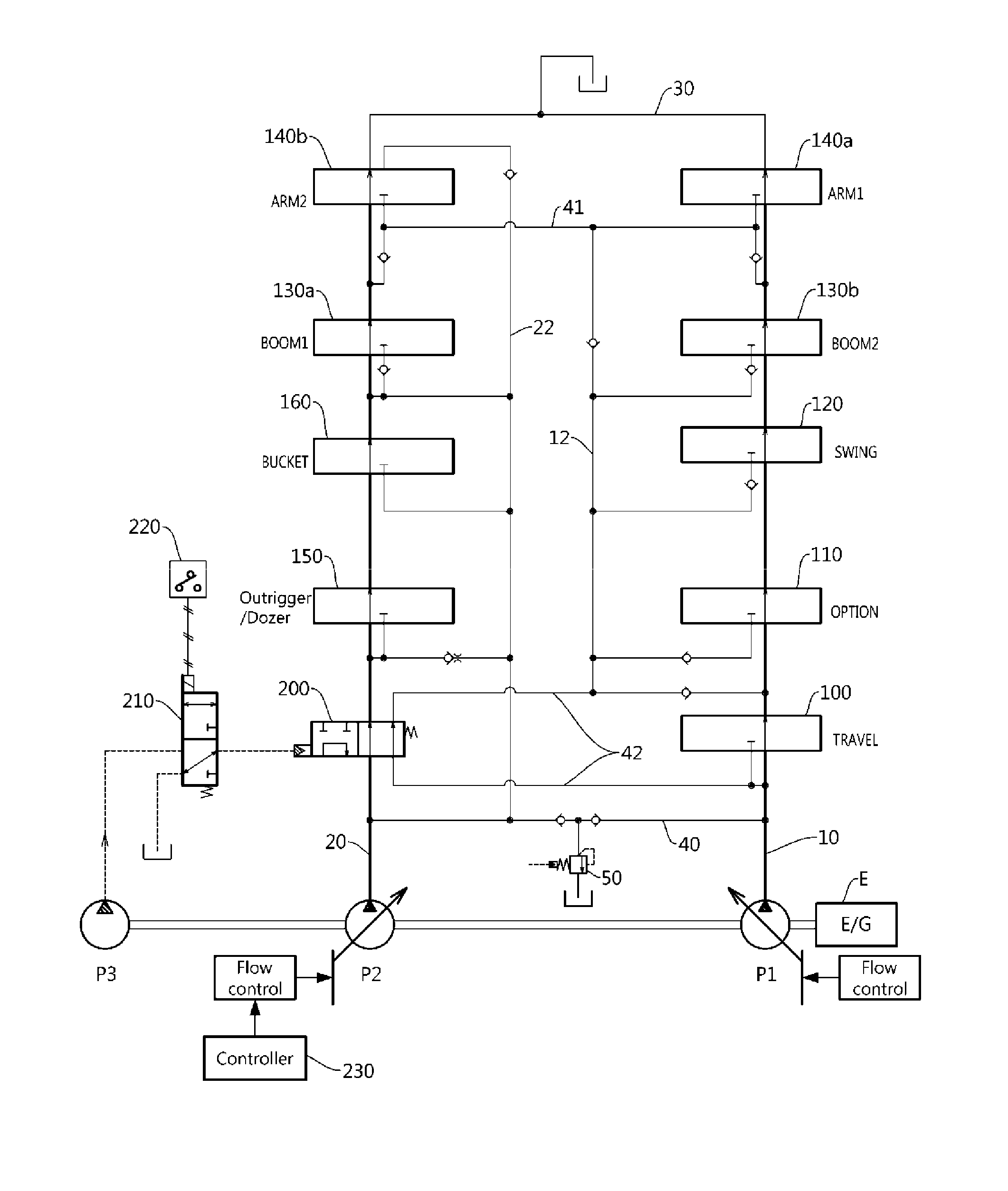

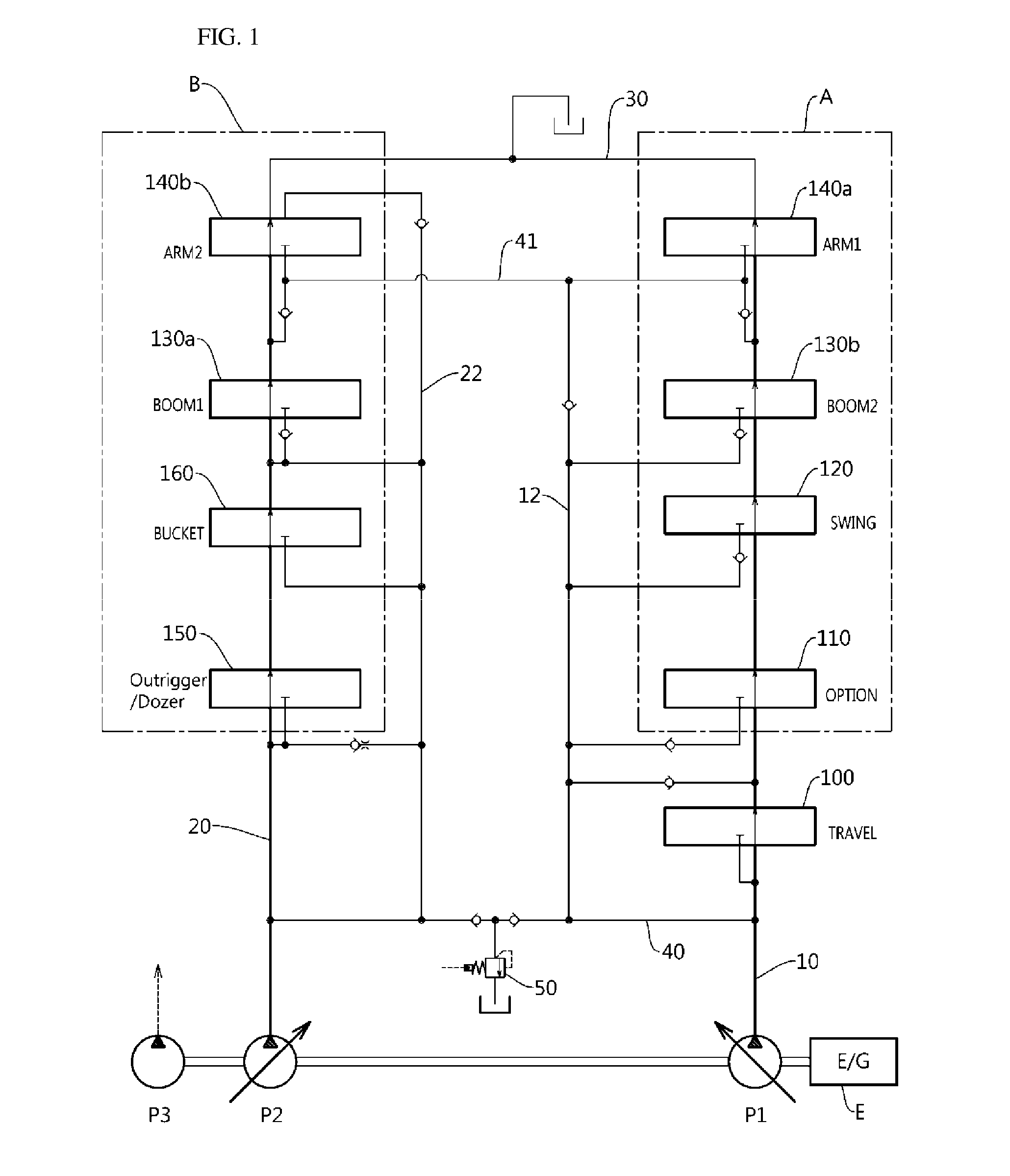

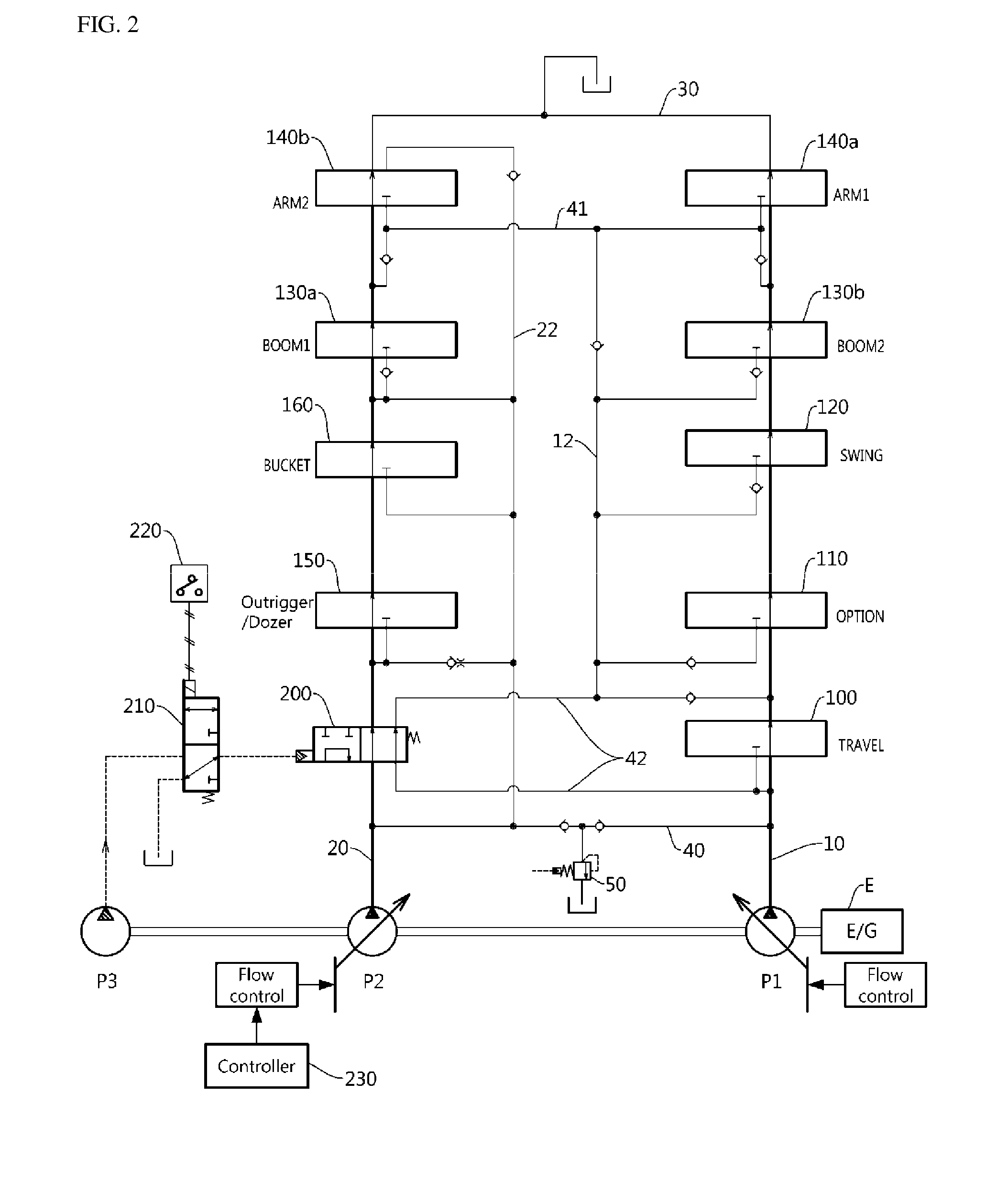

Hydraulic system of construction machine

ActiveCN104011404AAvoid Hydraulic ShockHeavy loadServomotor componentsServomotorsControl engineeringHydraulic pump

The present invention relates to a hydraulic system of a construction machine. A hydraulic system of a construction machine according to the present invention includes: an EPPRV (60, Electronic Proportional Pressure Reducing Valve) for controlling a flow rate, to which maximum pressure is input as a control current value and which is set to a minimum flow rate; a gear pump (70) for providing pilot operation oil to the EPPRV (60); a shuttle valve (80) for comparing the pressure of first pilot operation oil which has passed through the EPPRV (60) and the pressure of a flow rate control signal and then outputting second pilot operation oil of greater pressure; a hydraulic pump (10) of which swash plate angle is controlled by the second pilot operation oil; and a pump control device (50) for controlling the pressure of the EPPRV (60) to be reduced from the maximum pressure according to a set inclination if the flow rate control signal is generated.

Owner:HYUNDAI DOOSAN INVIGORATE CORP

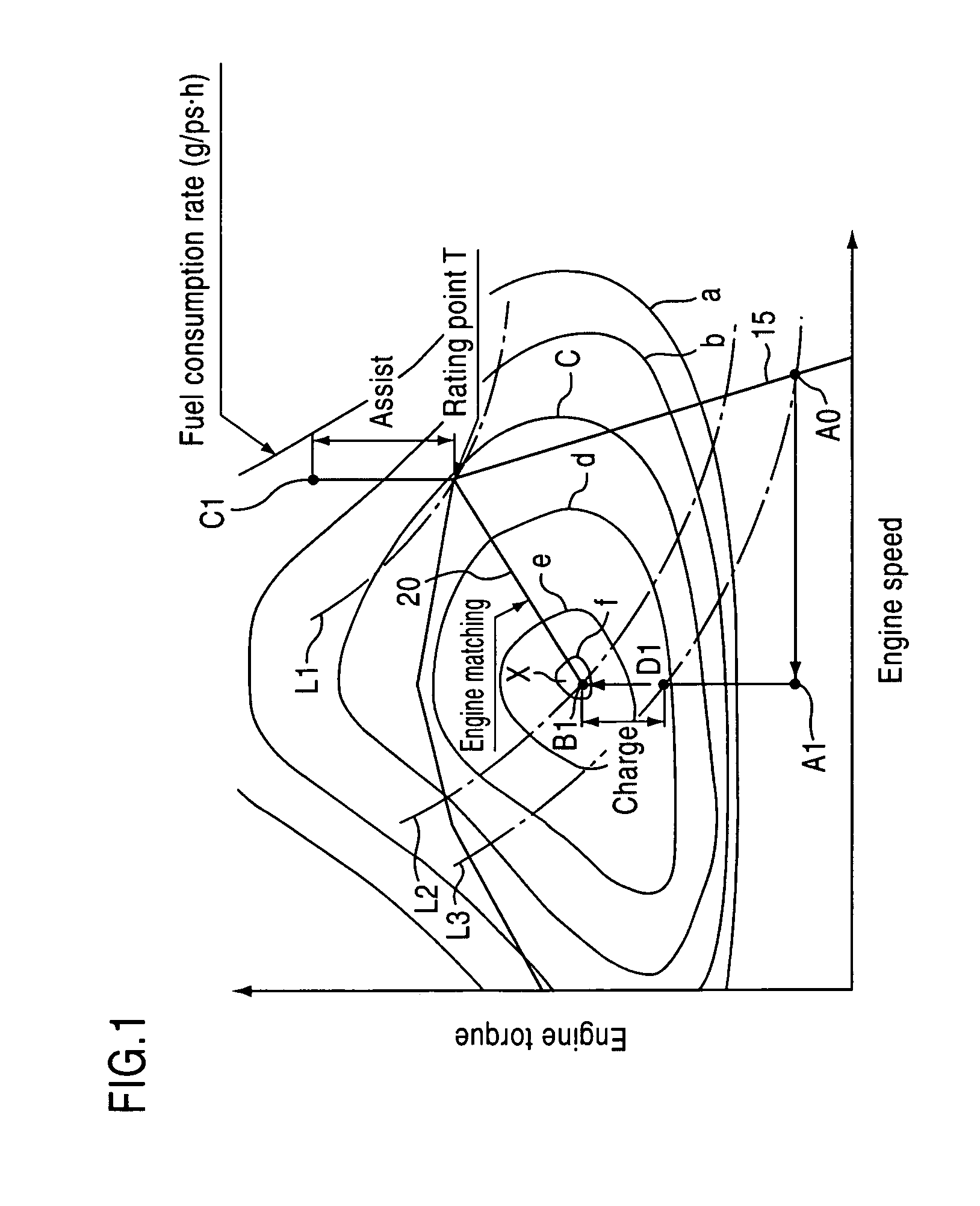

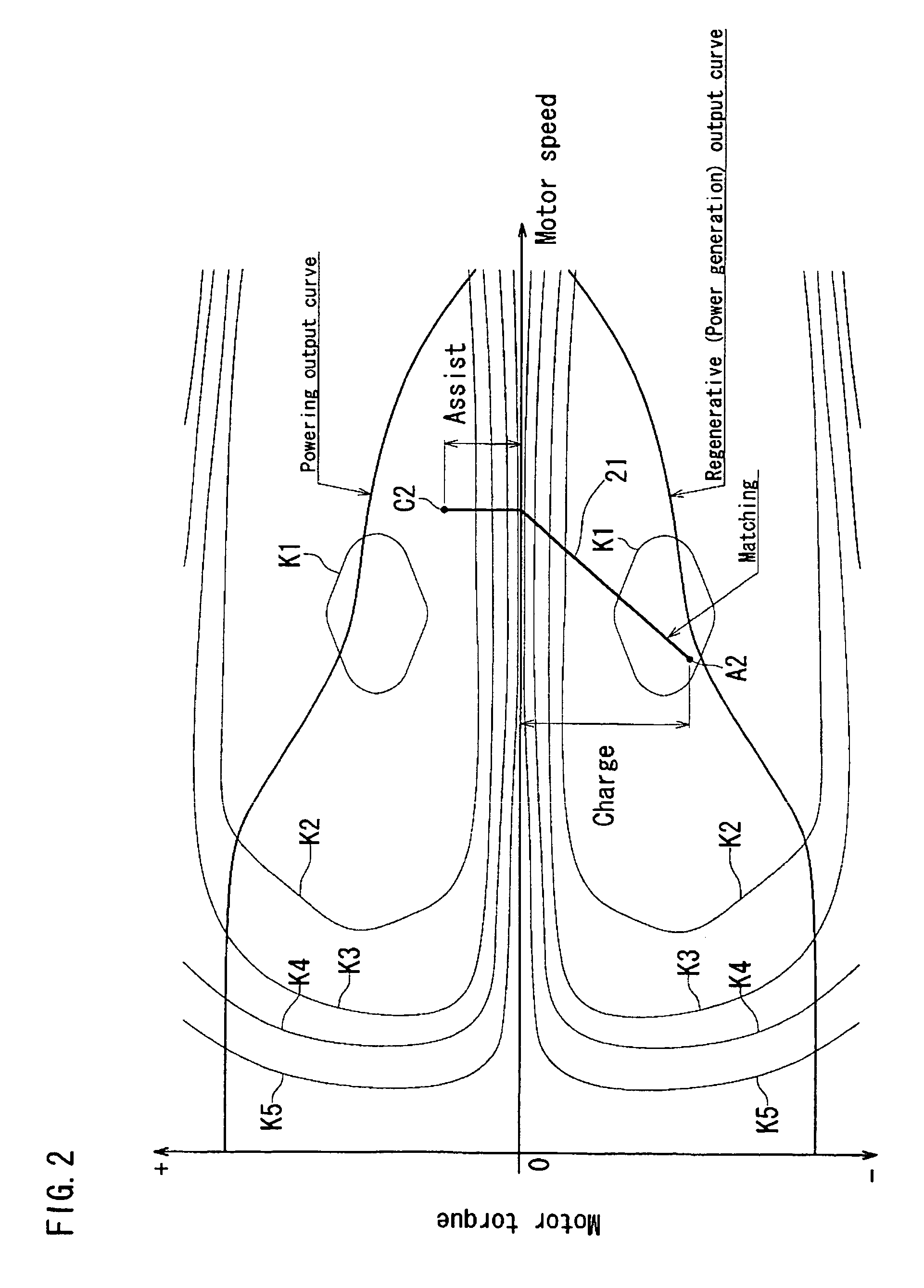

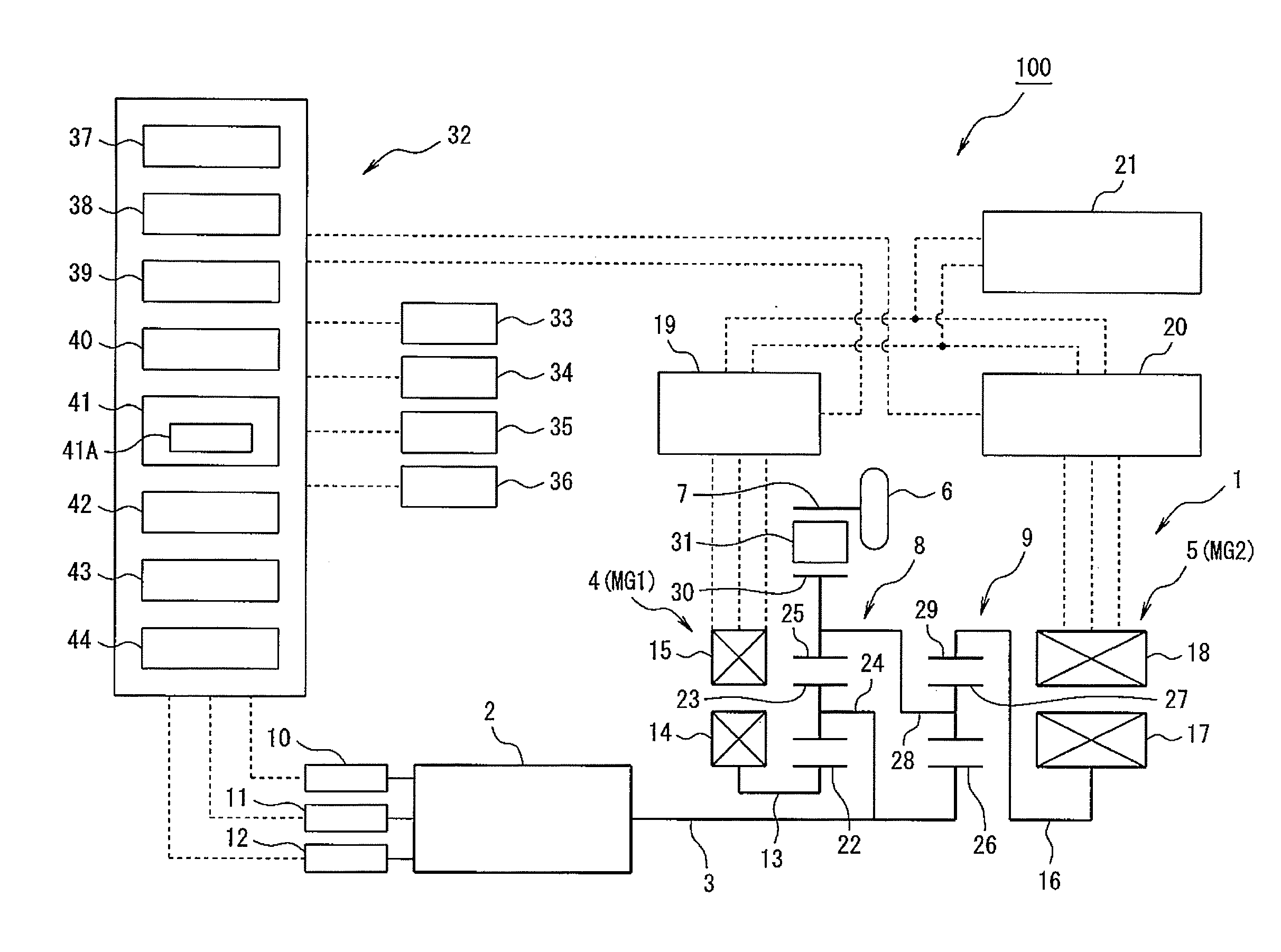

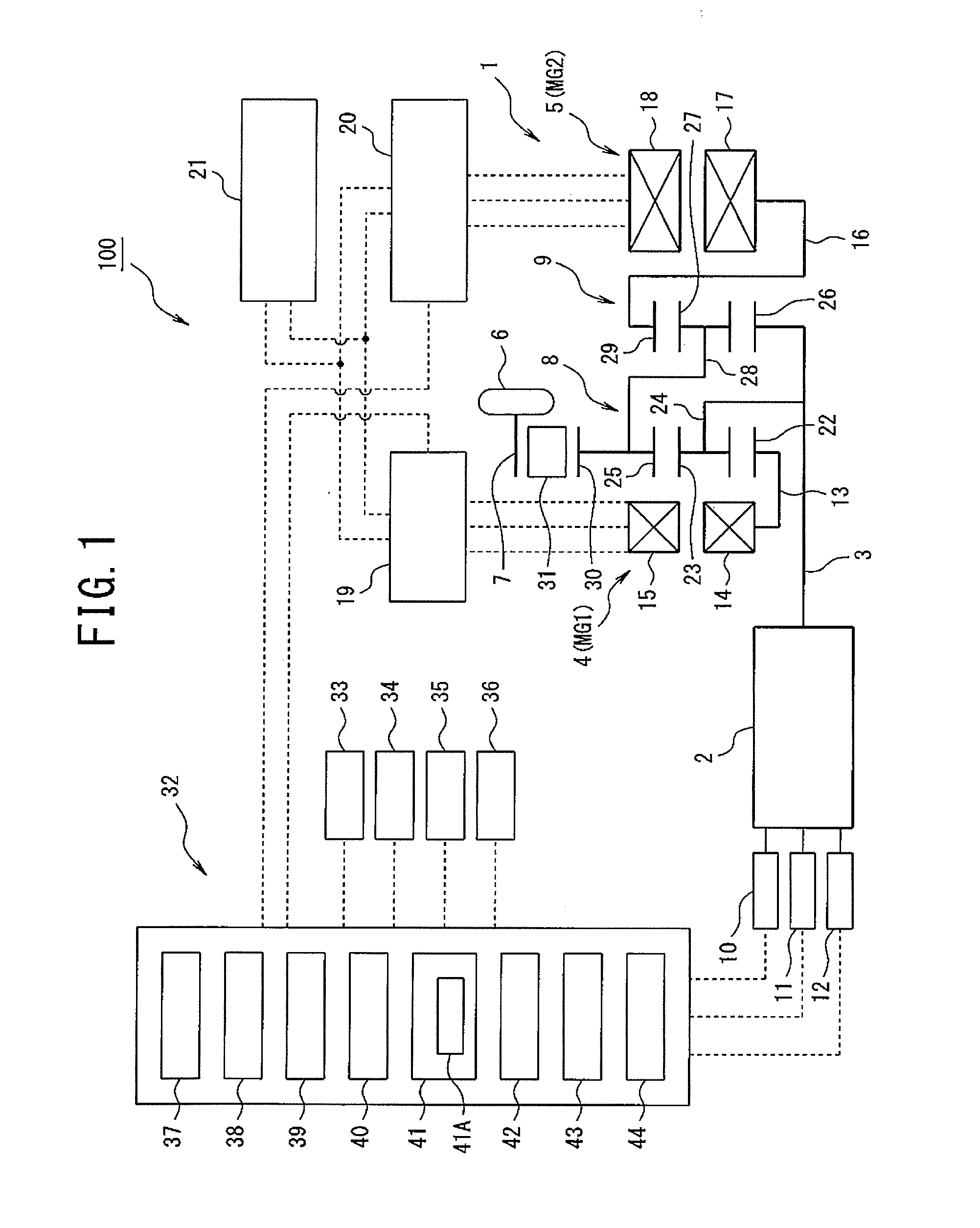

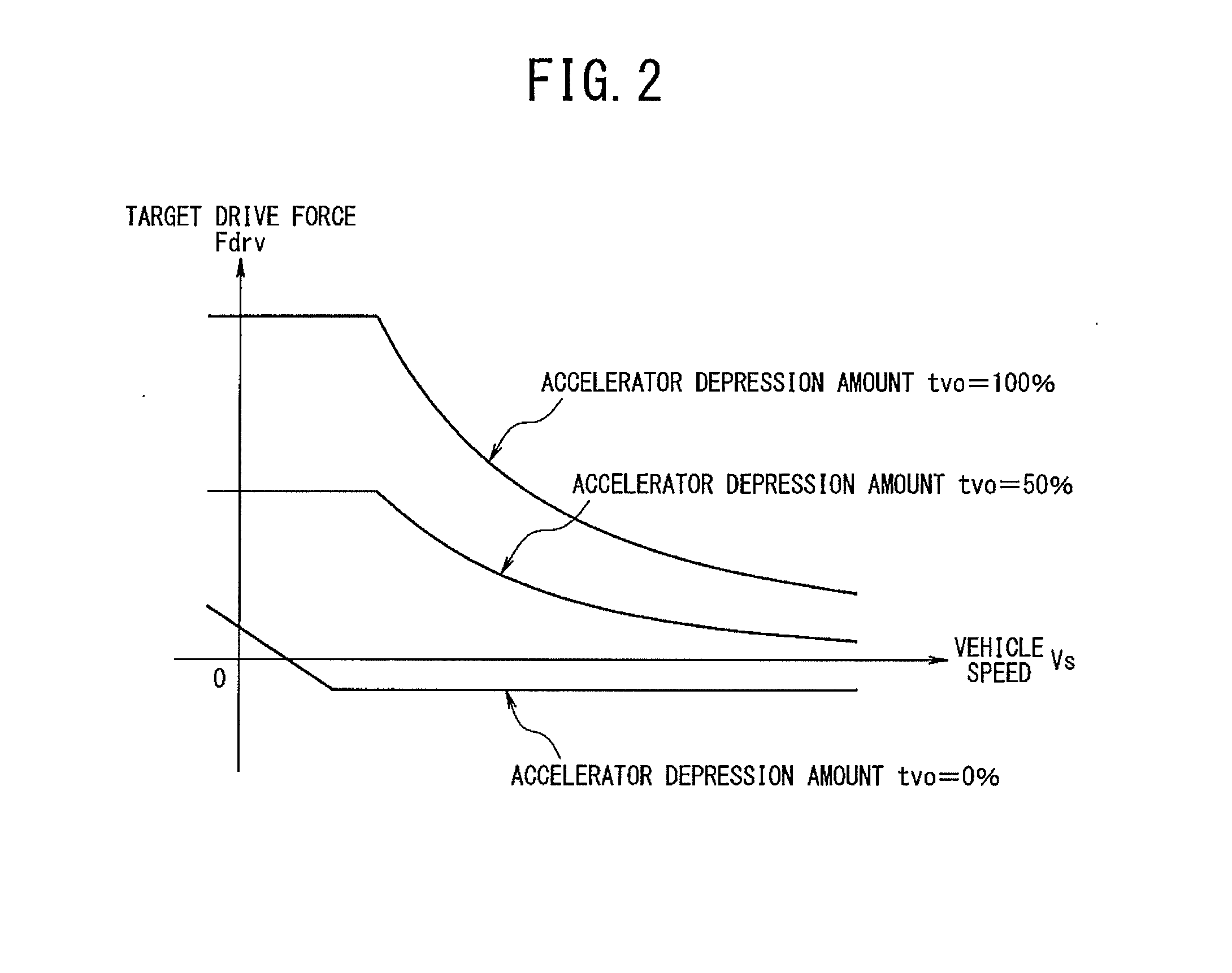

Drive control apparatus and control method for hybrid vehicles and hybrid vehicle

ActiveUS20130304294A1Easy to controlAvoid problemsHybrid vehiclesSpeed controllerOperating pointValue set

A drive control apparatus for hybrid vehicles adapted to facilitate controlling a rotation speed of an internal combustion engine, preventing excess speeds of a motor generator. The drive control apparatus for hybrid vehicles is adapted for a drive control of a vehicle using outputs from an engine and motor generators, and includes a target engine operating point setter for setting up a target engine operating point to determine target engine torque and a target engine rotation speed of the engine from target engine power and an efficiency of system. A motor torque command value calculator sets up respective torque command values of the motor generators, and an engine torque corrector corrects the target engine torque by a target engine torque correction value set up based on the torque command values of the motor generators and permissible output torque of the motor generators.

Owner:SUZUKI MOTOR CORP

System for reducing fuel consumption in excavator

ActiveUS20140366517A1Improve performanceReduce fuel consumptionFluid couplingsServomotor componentsExcavatorAutomotive engineering

The present disclosure relates to a system for reducing fuel consumption in an excavator, and more particularly, to a system for reducing fuel consumption in an excavator, which may reduce fuel consumption when an excavator travels.A technical problem of the present disclosure, which will be achieved, is to provide a system for reducing fuel consumption in an excavator, which may reduce fuel consumption while improving traveling performance of an excavator.

Owner:DOOSAN INFRACORE CO LTD

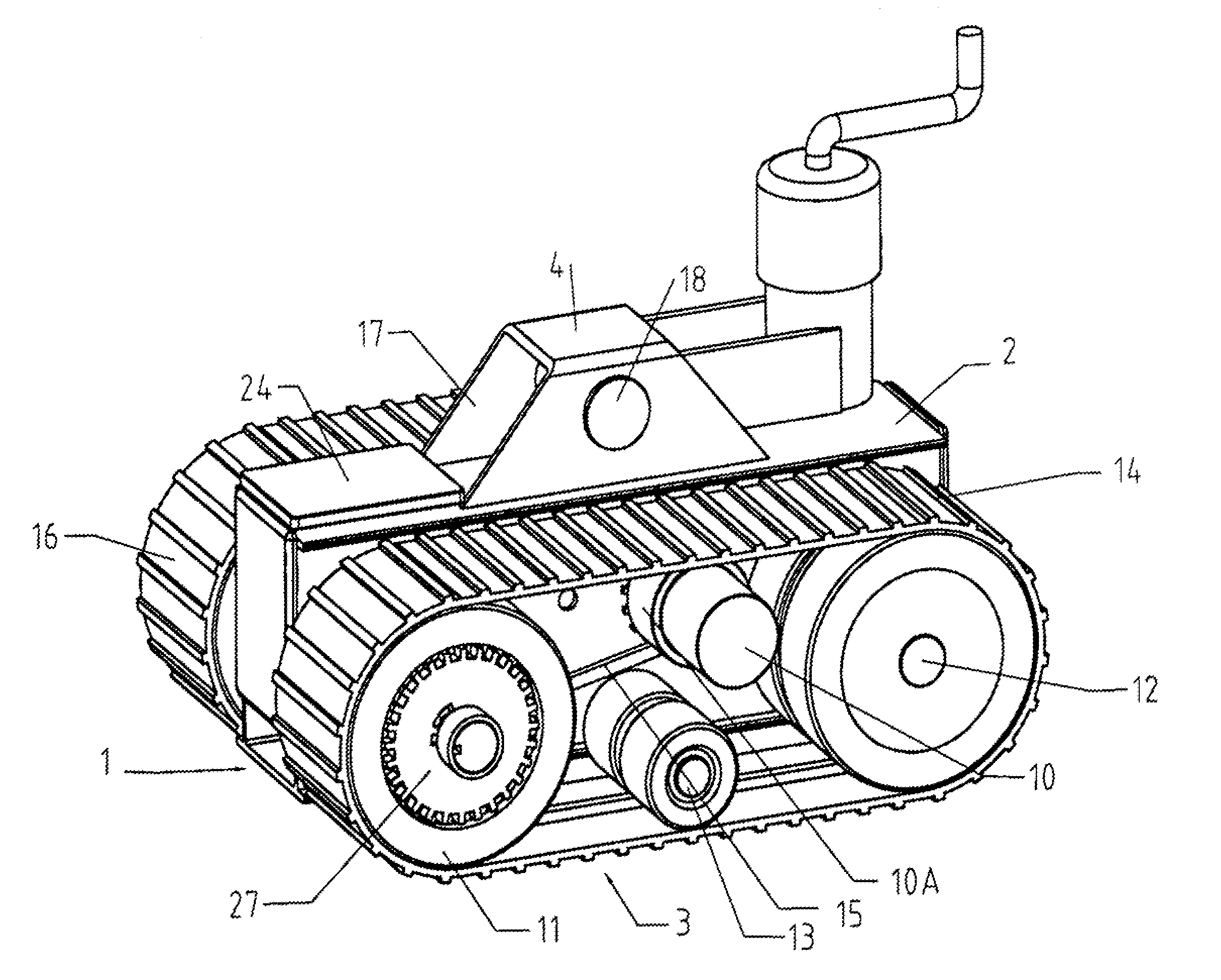

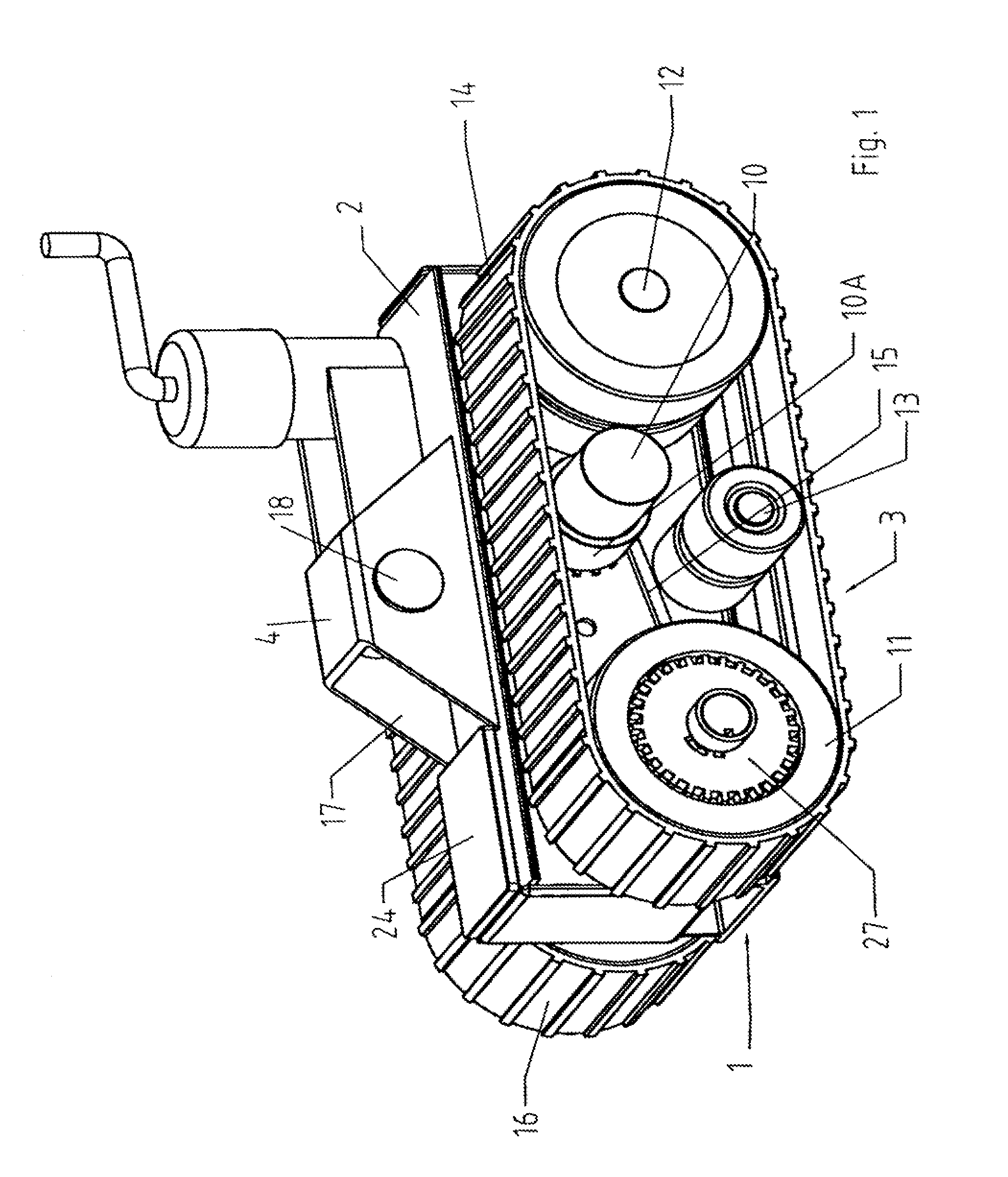

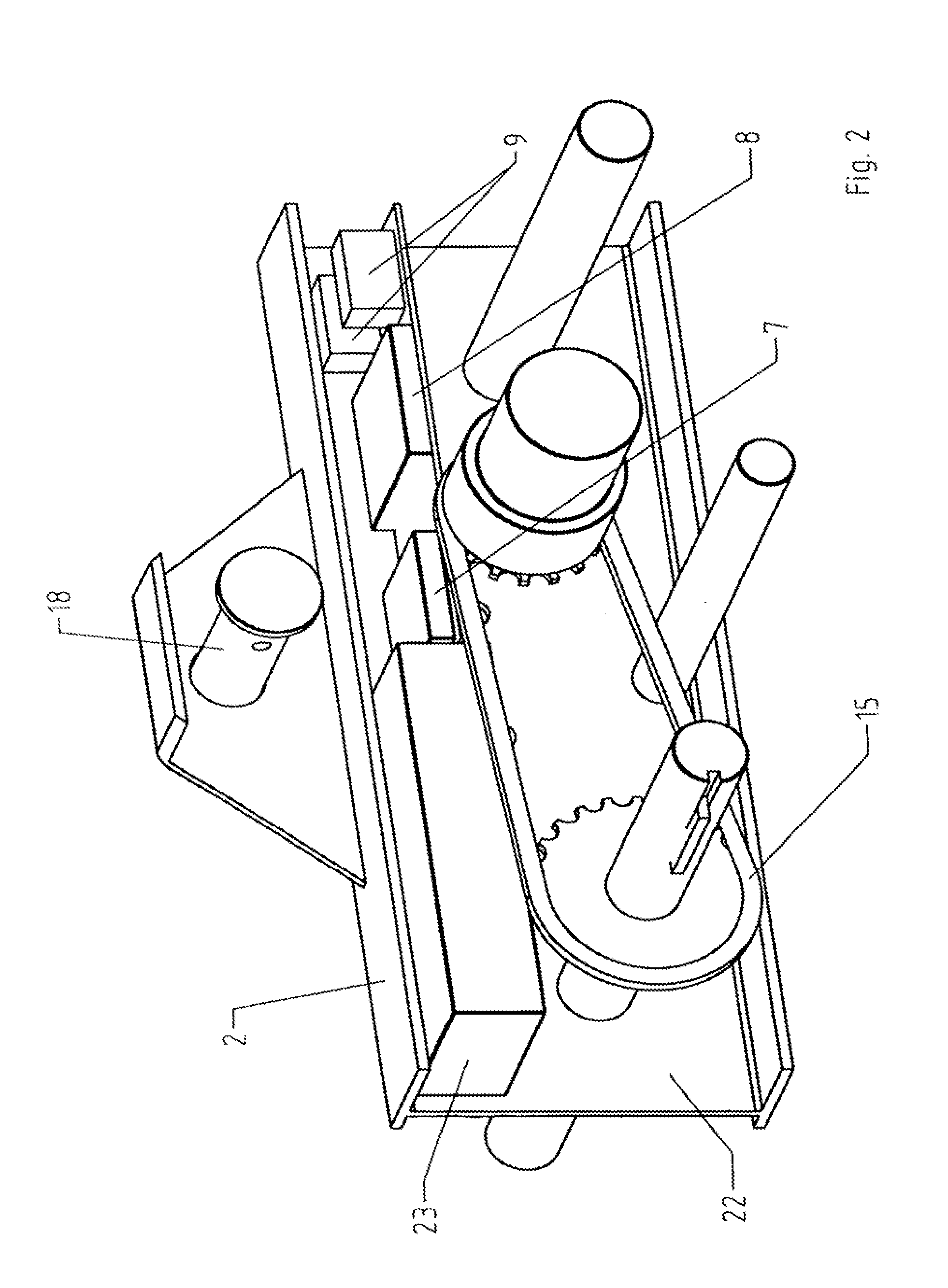

Drive Unit For Trailers And Caravans

InactiveUS20080023233A1Low RPMIncrease frictionVehicle cleaning apparatusVehicle manoeuvring devicesEngineeringRolling chassis

According to the invention, a drive unit for trailers or caravans is provided that has a chassis (2) with crawler sections (3), a coupling device (4) and steering and maneuvering devices. The drive unit is coupled to the trailer or caravan and is used to position the trailer or caravan in a controlled and simple manner, without having to worry about the risk of colliding with a neighbor or damaging one's own vehicle.

Owner:MOVER TECH

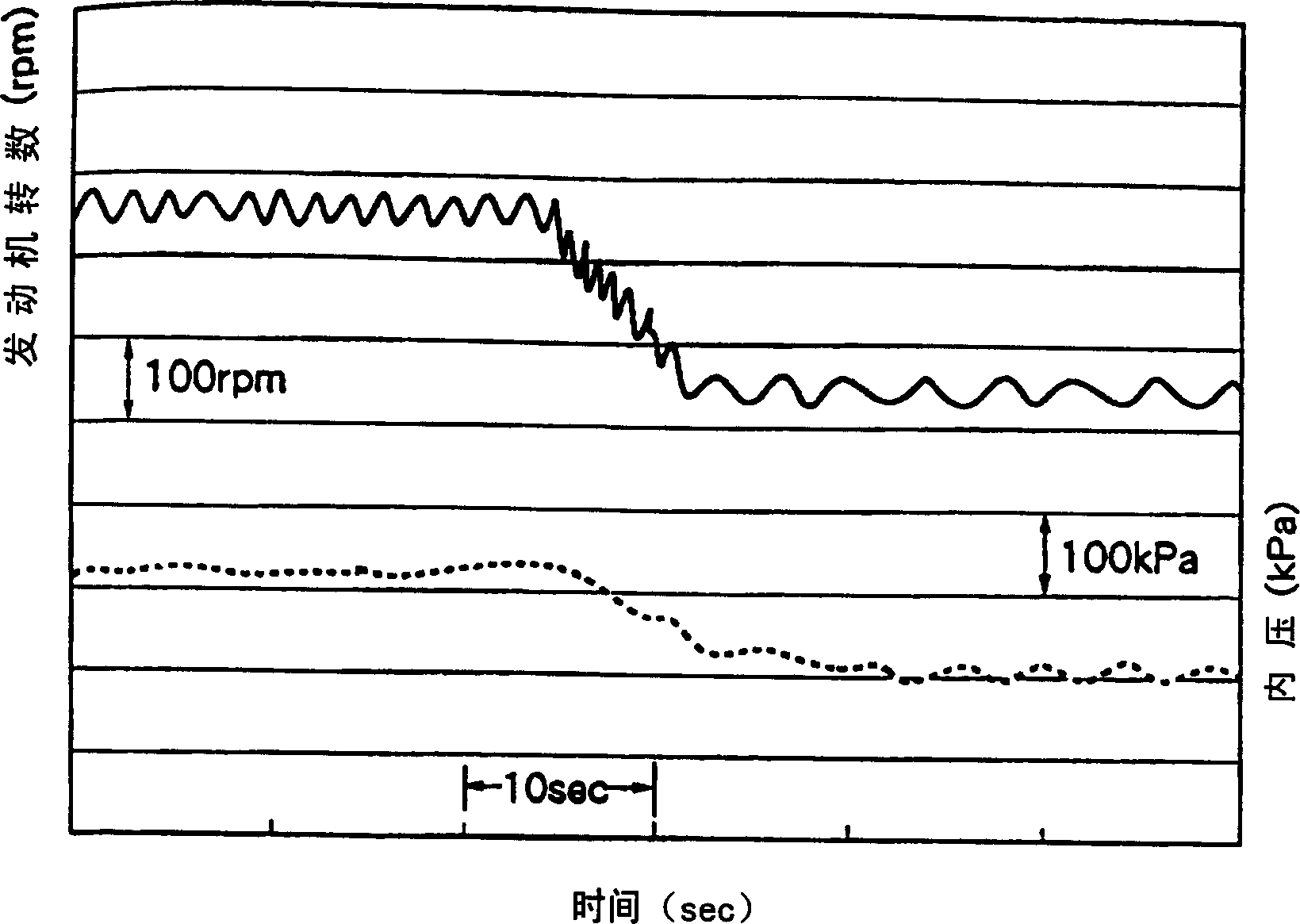

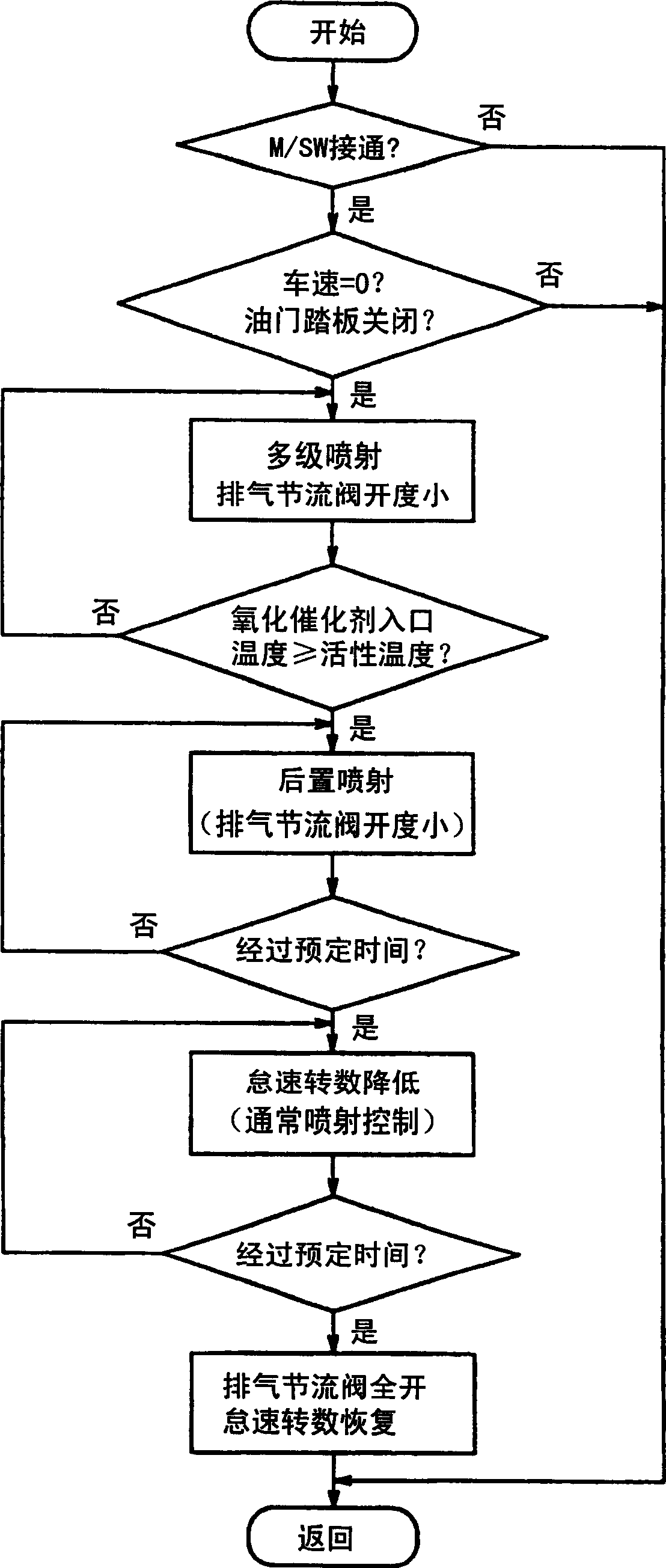

Device for purifying the exhaust gases of diesel engines

InactiveCN1676889AReduce trafficRelieve pressureElectrical controlDispersed particle filtrationExhaust fumesDiesel particulate filter

Owner:ISUZU MOTORS LTD

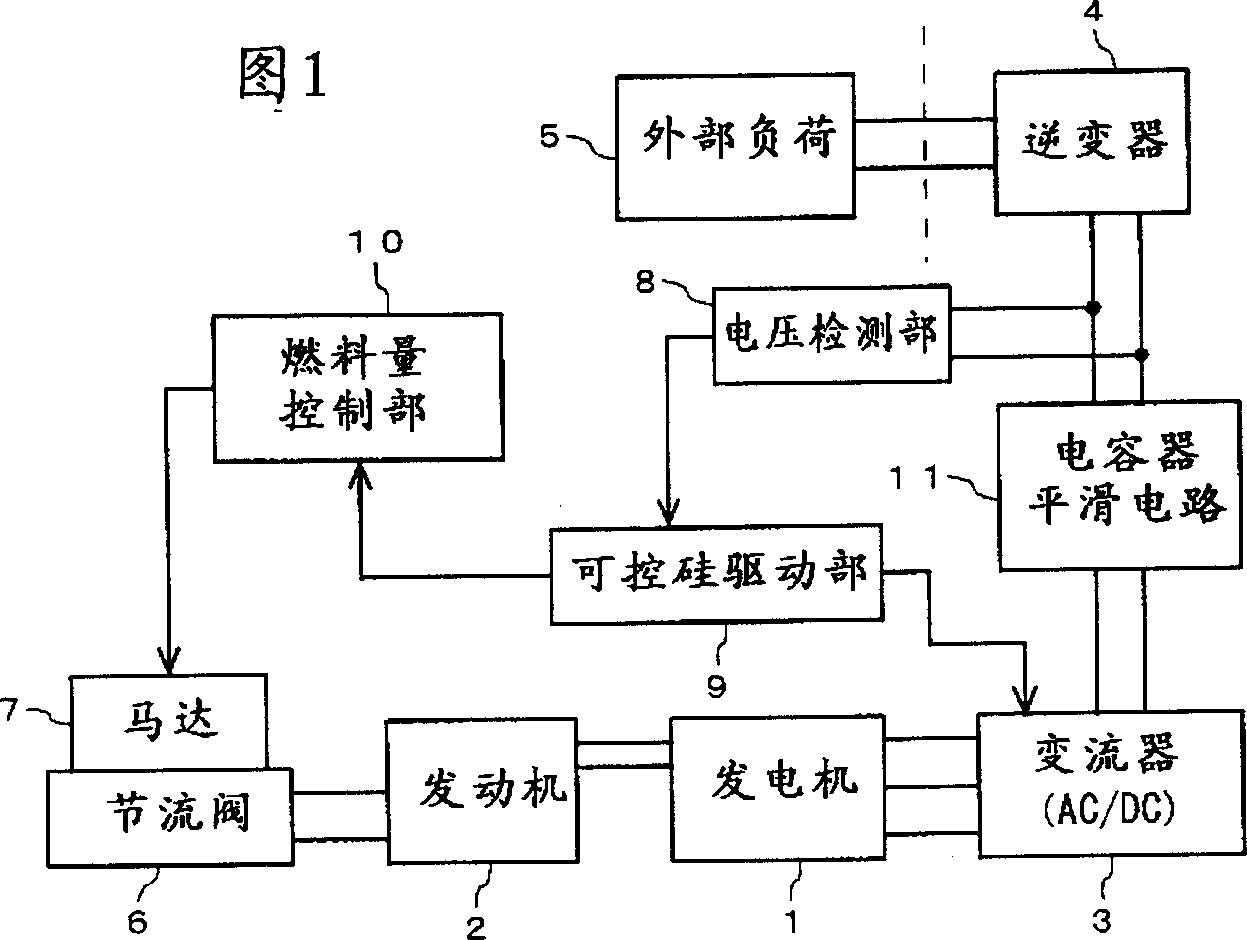

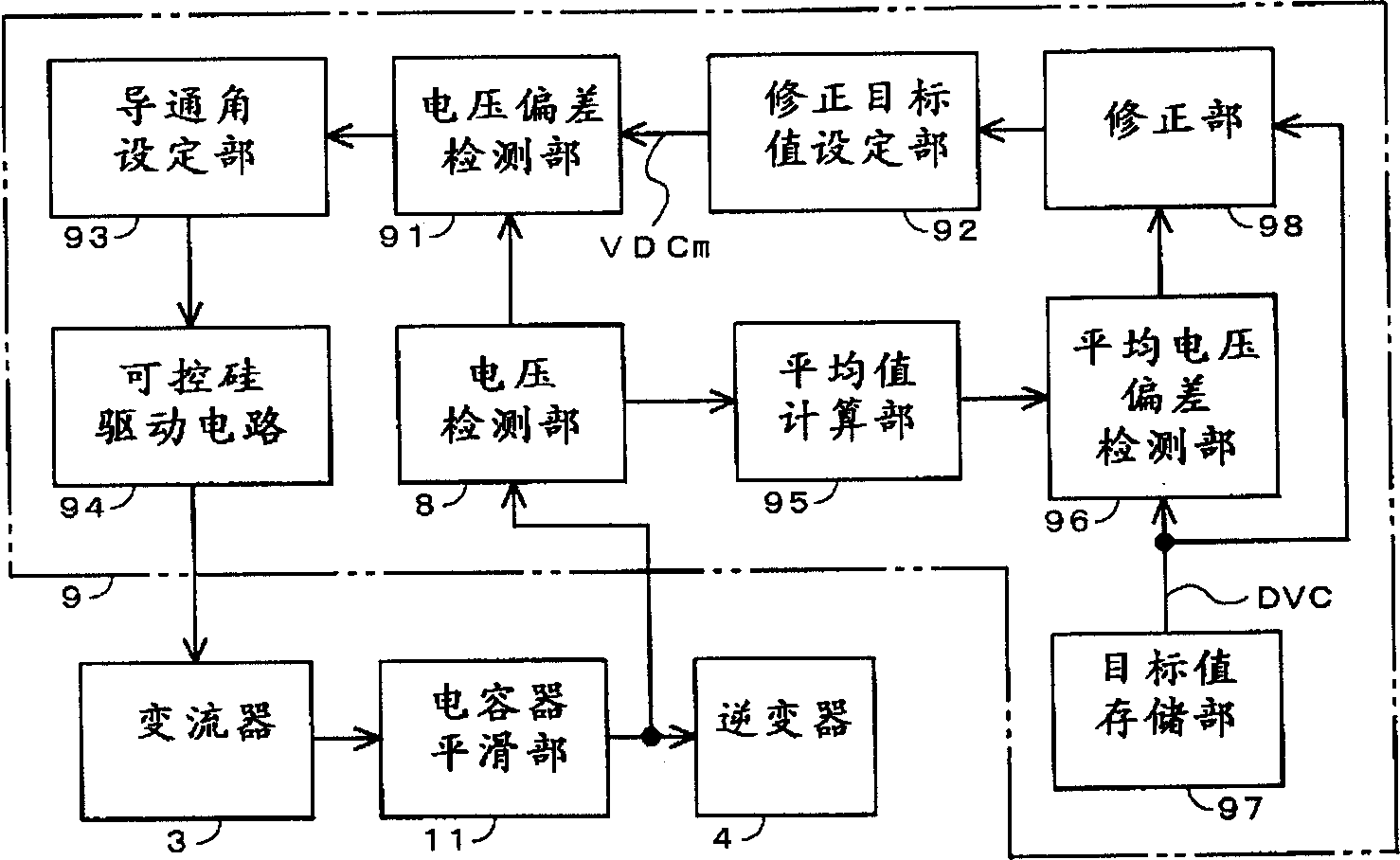

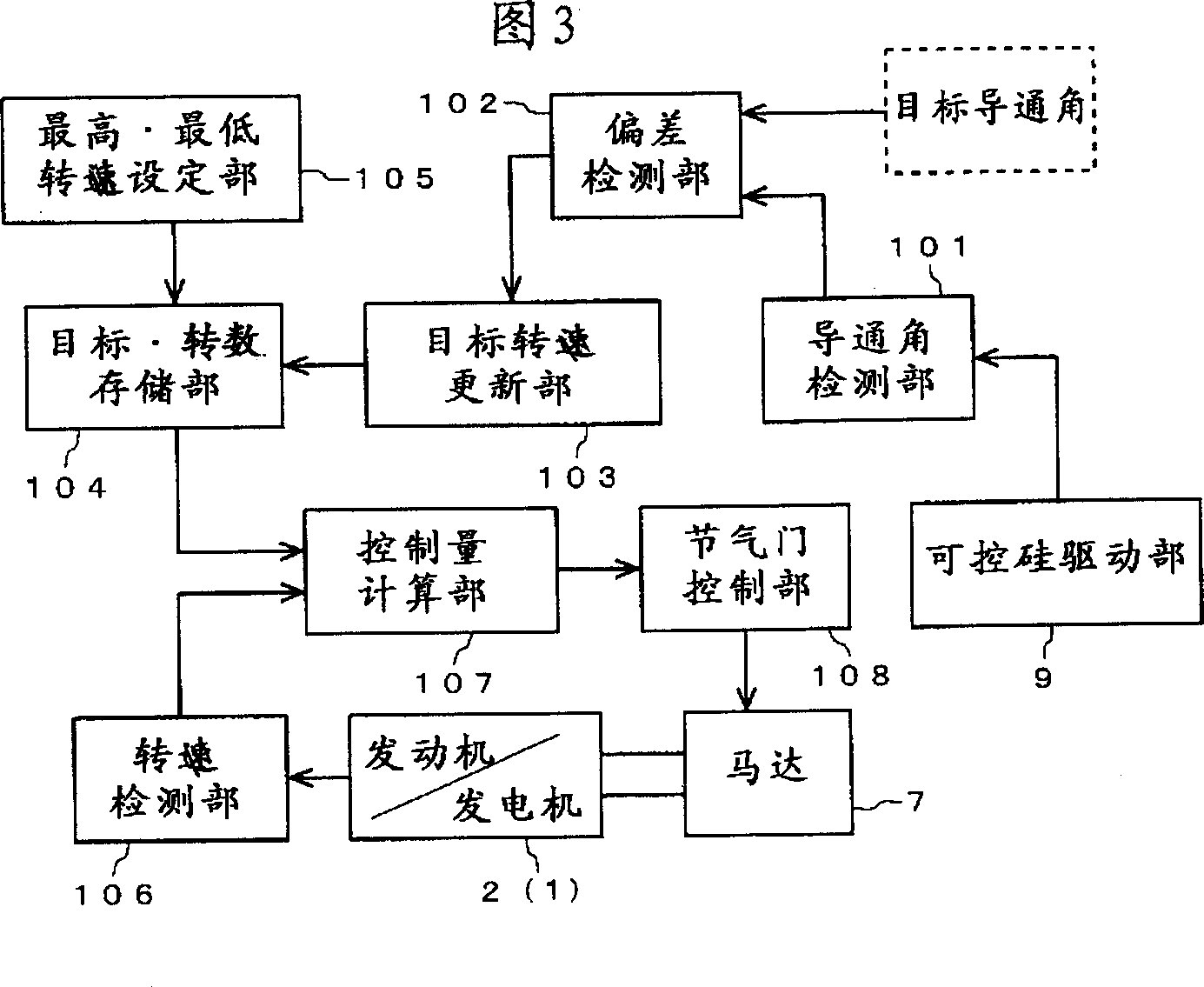

Converter controlled power generator

InactiveCN1363989ALow RPMIncrease the number of revolutionsAc-dc conversion without reversalEngine controllersControl powerEngineering

The performance of a generator is improved in a higher range of the output by correcting a decrease in the average direct current voltage supplied to an inverter. An average calculator 95 calculates an average of direct current voltage inputs to the inverter 4 for comparing with a target voltage (level) VDC. When it is judged by an average voltage deviation detector 96 that the average is smaller by a specific amount than the target voltage level, the target voltage level is increased by an adjusting unit 98. A conductor angle setting unit 93 determines the conduction angle of thyristors to change the voltage input of the inverter (4) to an adjusted target voltage level VDCm. A thyristor drive circuit 94 controls the conduction of the thyristors in the converter 3 according to the conduction angle.

Owner:HONDA MOTOR CO LTD

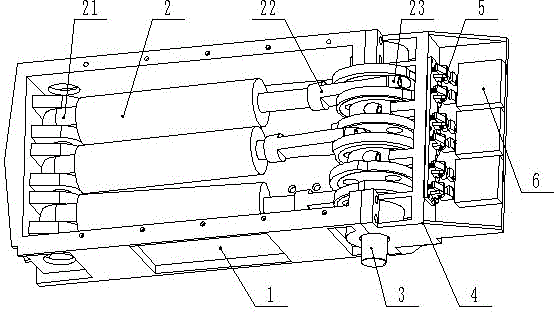

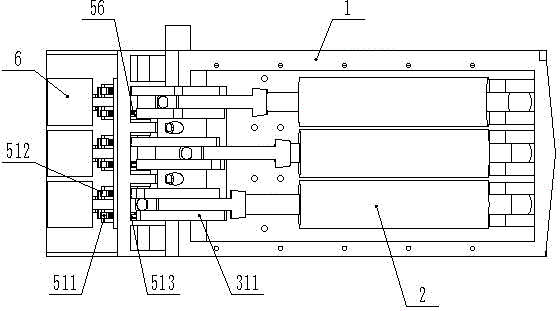

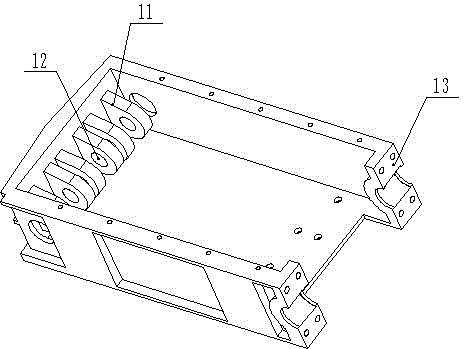

Same-distribution-angle hydraulic cylinder motor

ActiveCN104131945AReduce speedReduce output torque rippleCrankshaftsReciprocating piston enginesHydraulic cylinderHydraulic motor

The invention belongs to the field of mining hydraulic motors, and especially discloses a same-distribution-angle hydraulic cylinder motor. A technical problem to be solved is providing a same-distribution-angle hydraulic cylinder motor with the advantages of simple structure, operation convenience, high safety coefficient, long service life and effective reduction of the coal mine underground accident rate. The motor comprises a case body, three hydraulic cylinders, a crankshaft, a case body front end assembly and a control system, the whole case body is a shell structure, the three hydraulic cylinders are arranged in the case body side by side, the front end of the case body is provided with a case body semicircle seat for installing the crankshaft, the case body front end assembly is fixedly connected with the case body to fix the crankshaft, the piston terminals of the hydraulic cylinders are connected with the crankshaft through piston terminal covers, the hydraulic cylinders move back and forth to drive the crankshaft to rotate, the crankshaft drives the control system to move, and the control system controls the reciprocating motion of the three hydraulic cylinders in order to drive the crankshaft to continuously revolve. The motor adopting the hydraulic cylinders to drive the crankshaft to rotate has the advantages of low rotating speed, large torque, and suitableness for the use requirements of coal mine underground equipment.

Owner:NANTONG JIEFU ELECTRICAL CO LTD

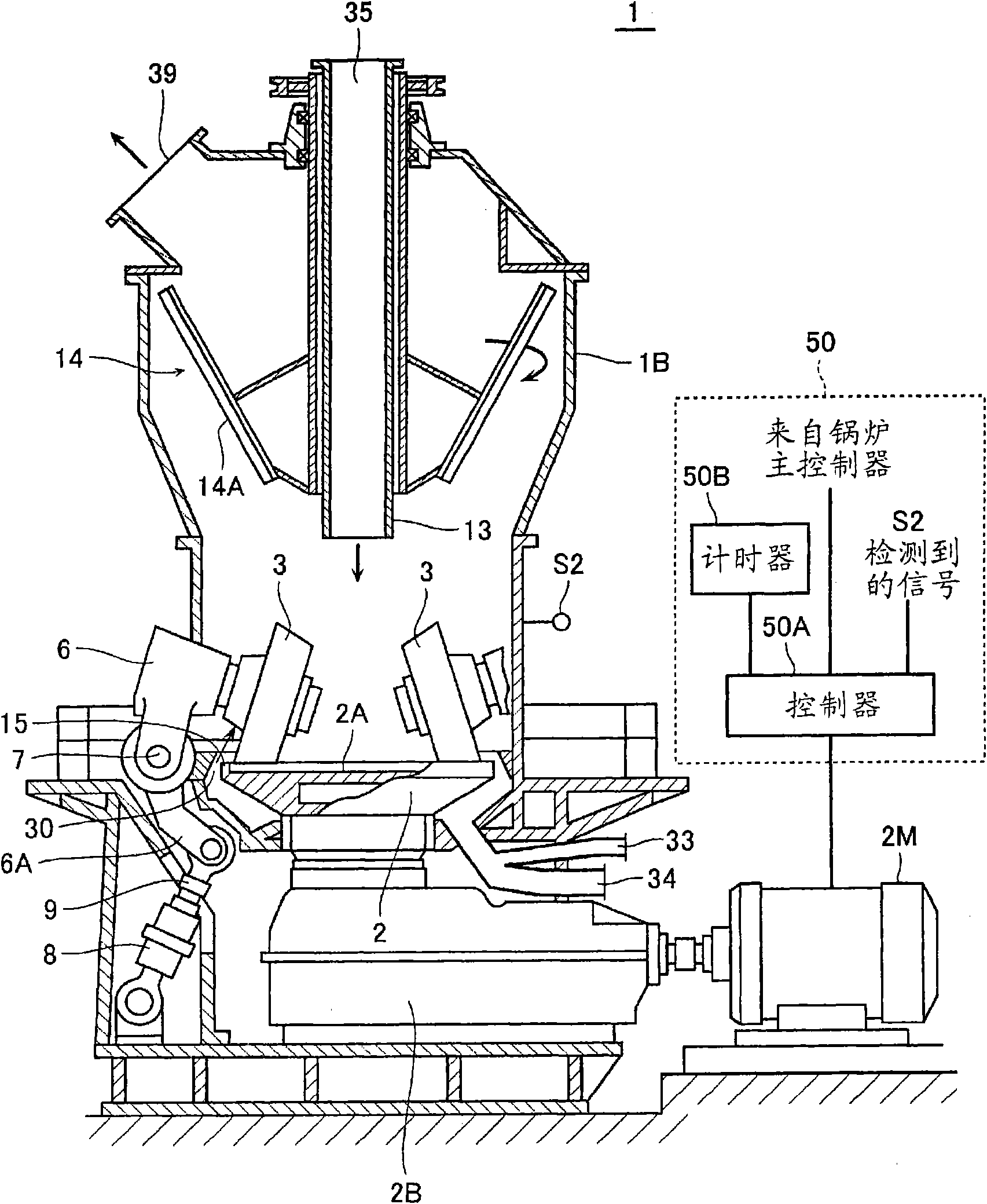

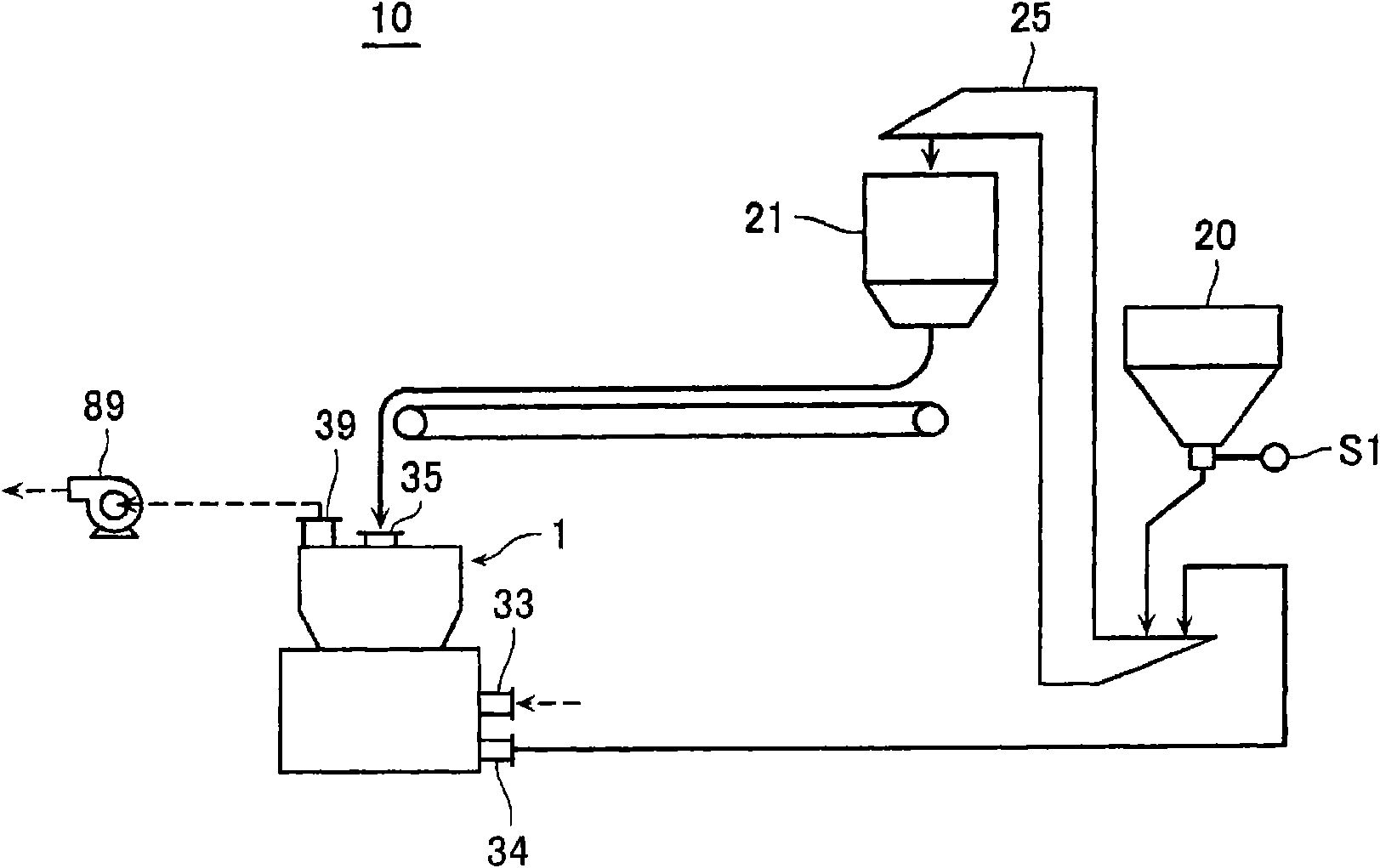

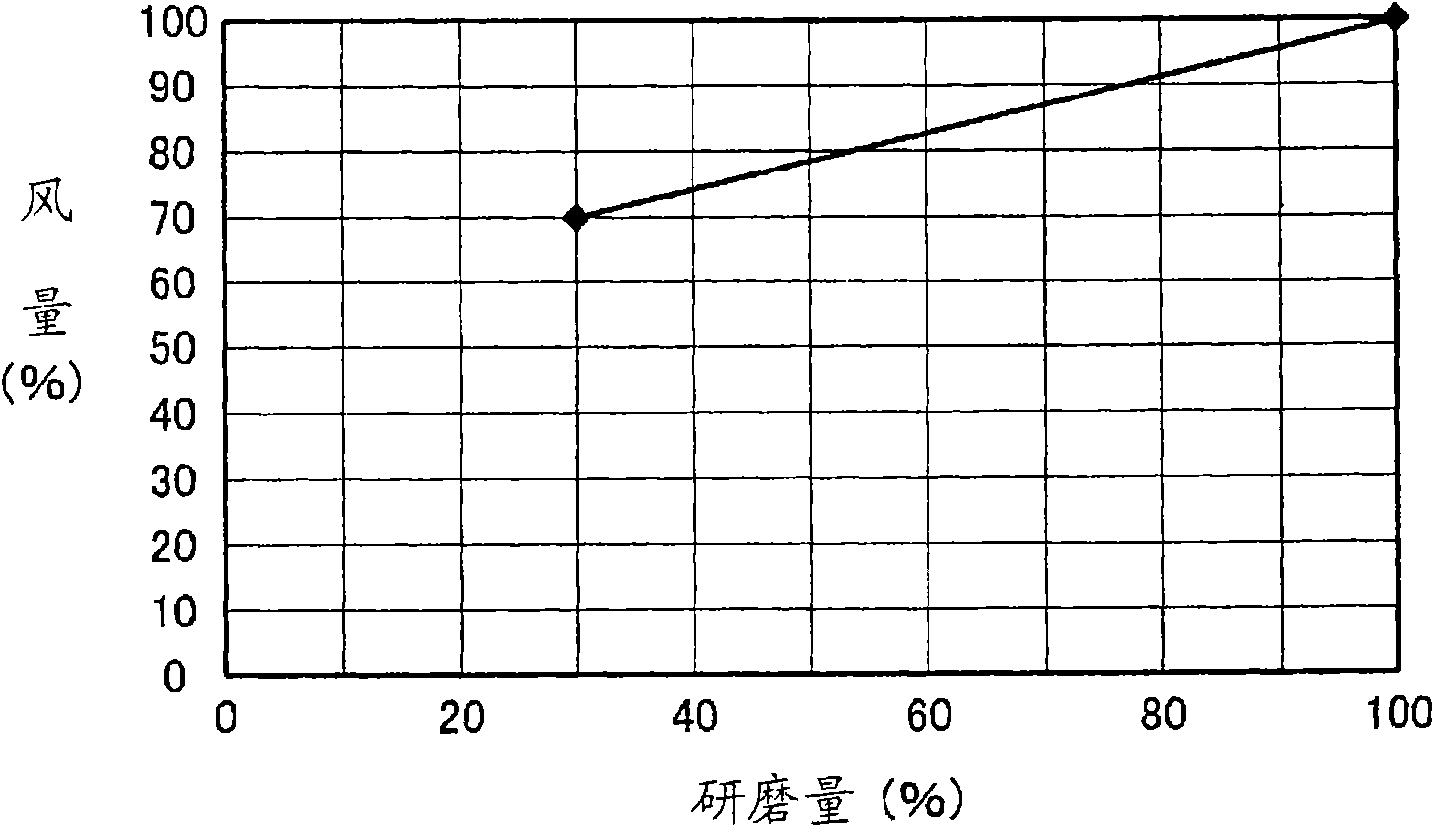

Control method and controller of vertical crusher

When material supply amount to a vertical crusher (1) is reduced, the number of revolutions of a rotary table (2) is decreased before the material supply amount is varied actually. In other words, when the vertical crusher (1) is stopped, the number of revolutions of a motor (2M) for driving the rotary table (2) is decreased from the rated number of revolutions by inverter control upon receiving a signal for varying the supply amount from a boiler master at the controller (50A) in a control panel (50) before supply amount of new material into the vertical crusher (1) is varied, thus decreasing the number of revolutions of the rotary table (2). Thereafter, material supply is varied actually upon elapsing a predetermined time. Since the vertical crusher (1) can be stopped while the work load thereof is suppressed and the thickness of a material layer on the rotary table (2) is kept at a predetermined height, abnormal vibration can be prevented effectively during a stop operation and generation of noise can be suppressed.

Owner:UBE MASCH CORP LTD

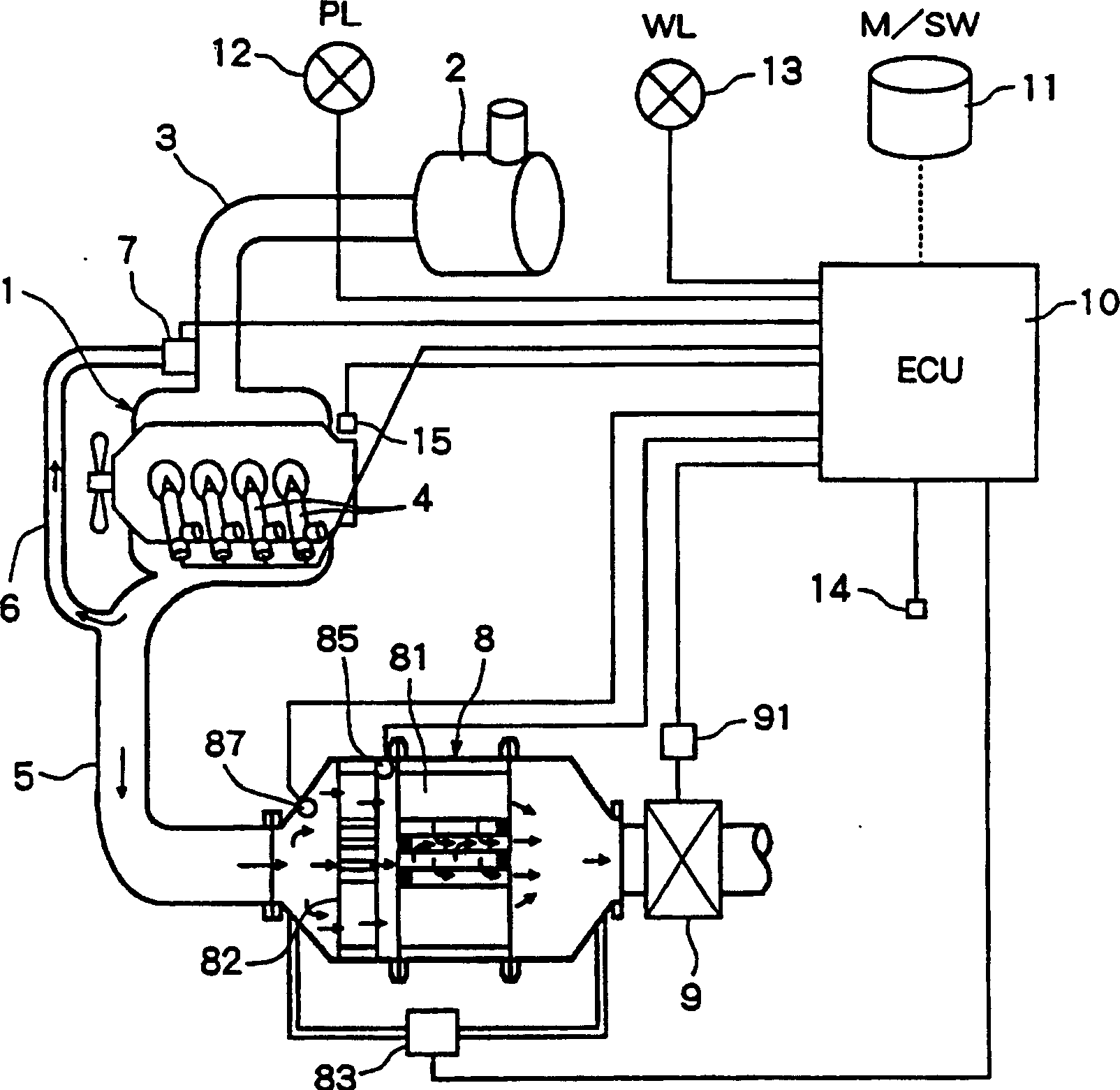

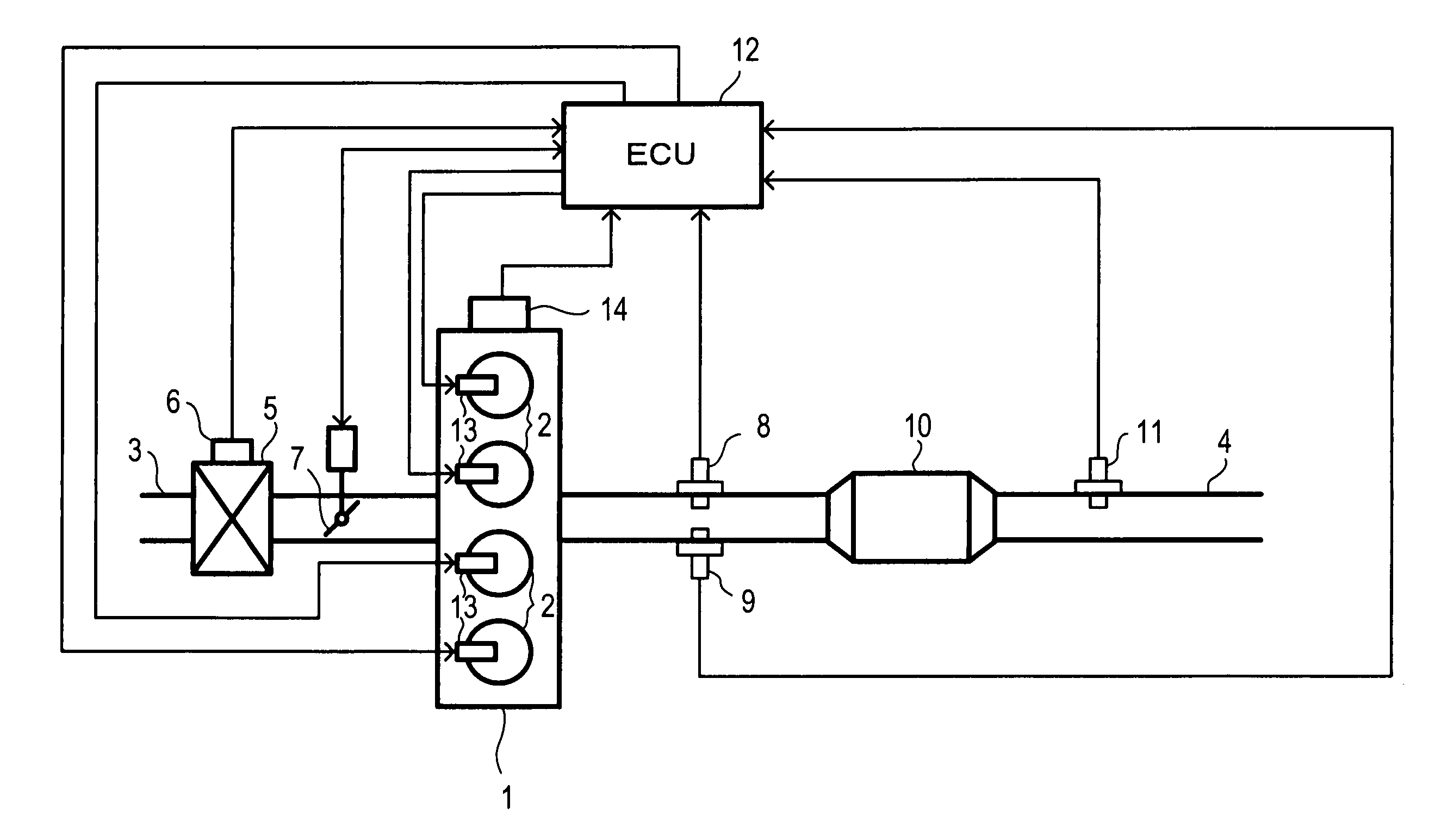

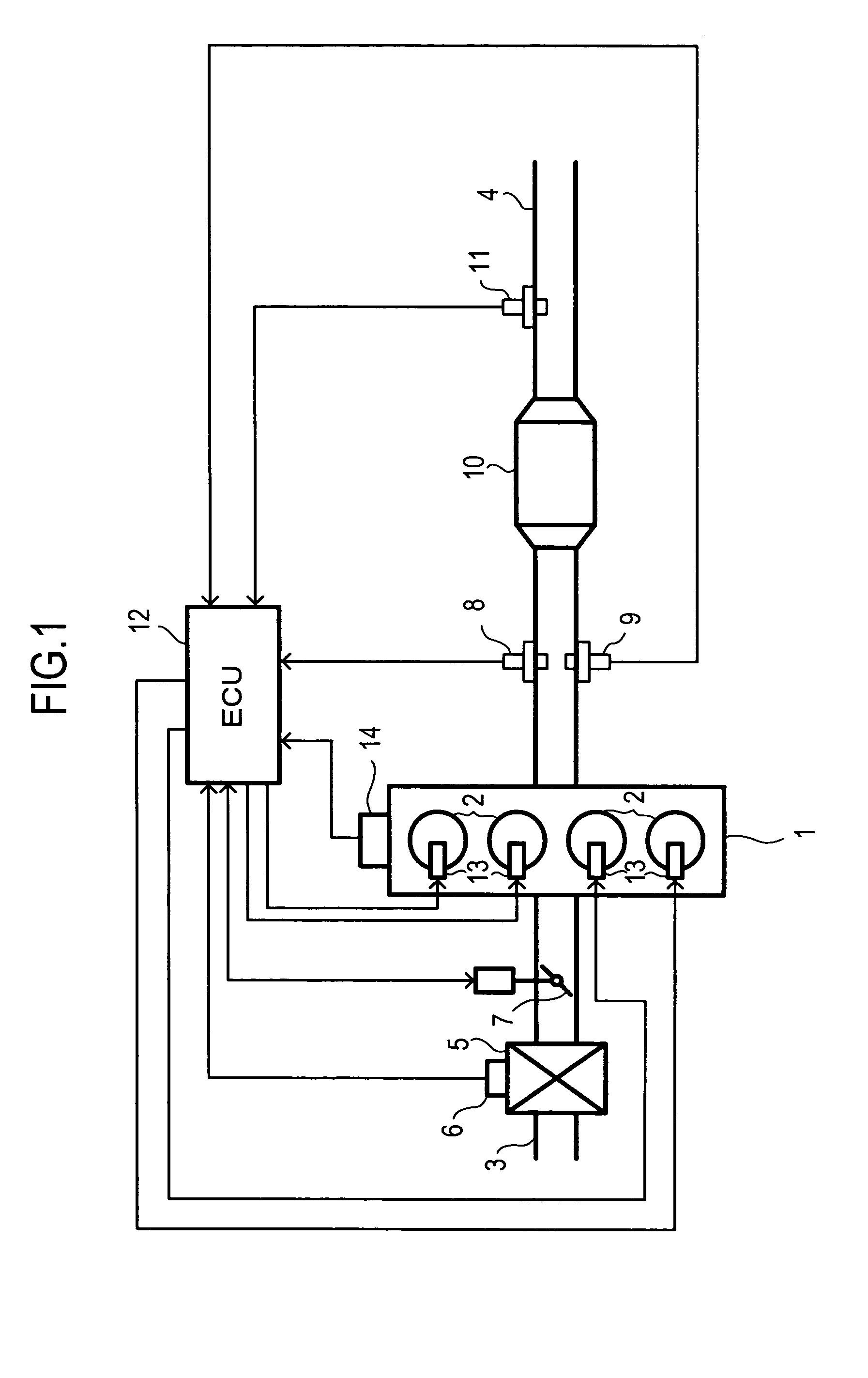

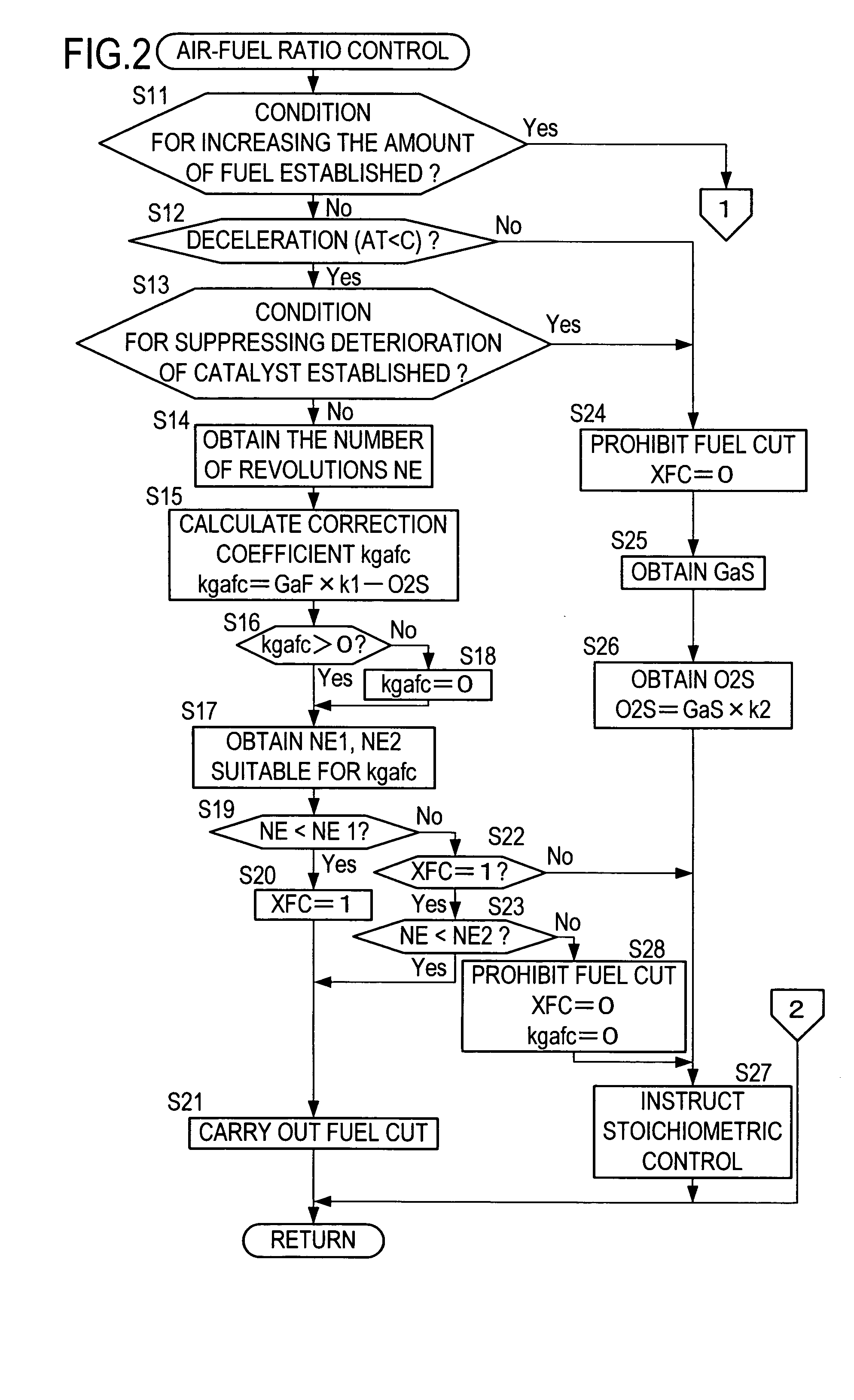

Air-fuel ratio control apparatus of internal combustion engine

InactiveUS7143577B2Convenient amountLow RPMElectrical controlInternal combustion piston enginesExternal combustion engineOxygen

Owner:TOYOTA JIDOSHA KK

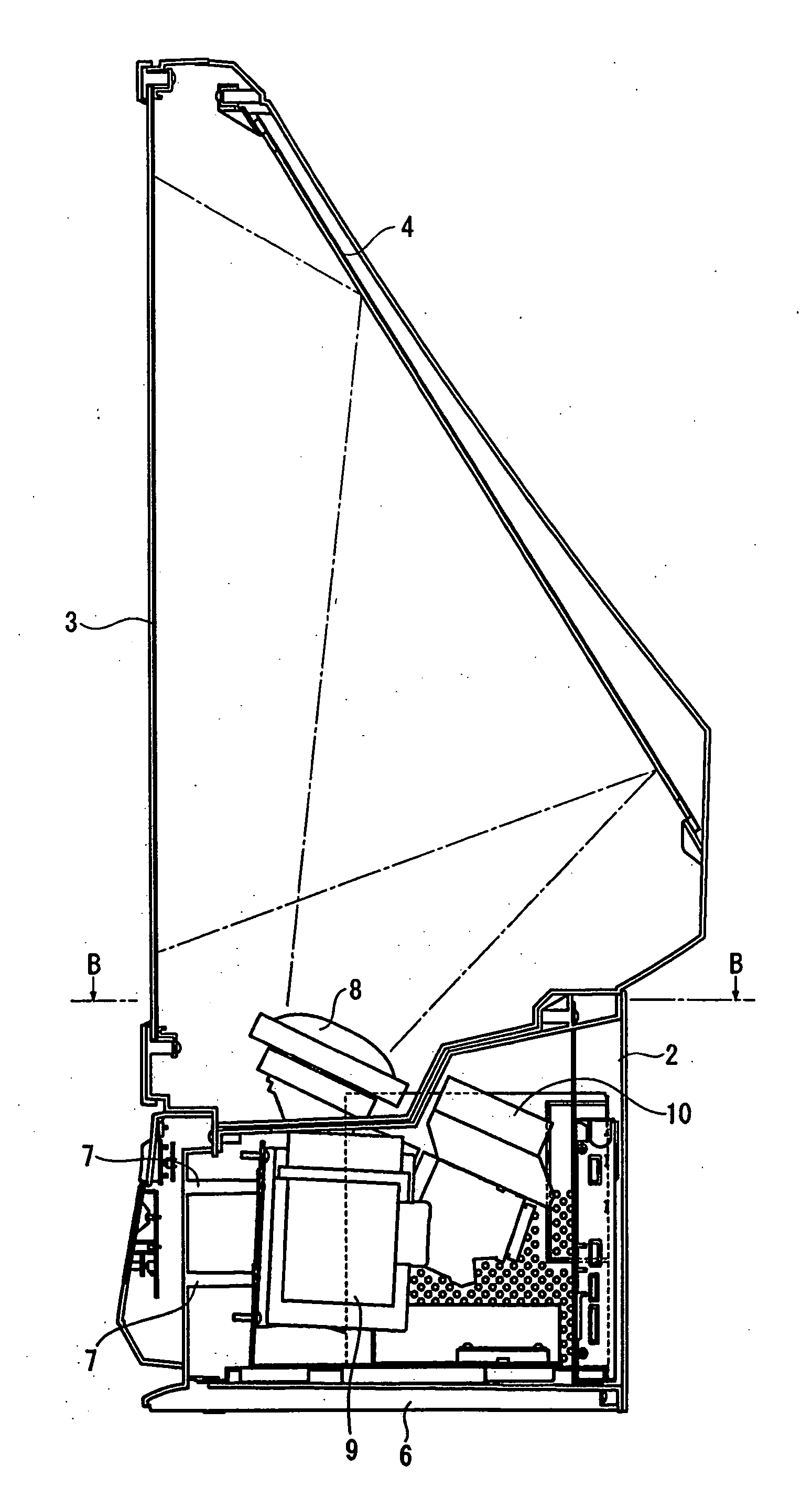

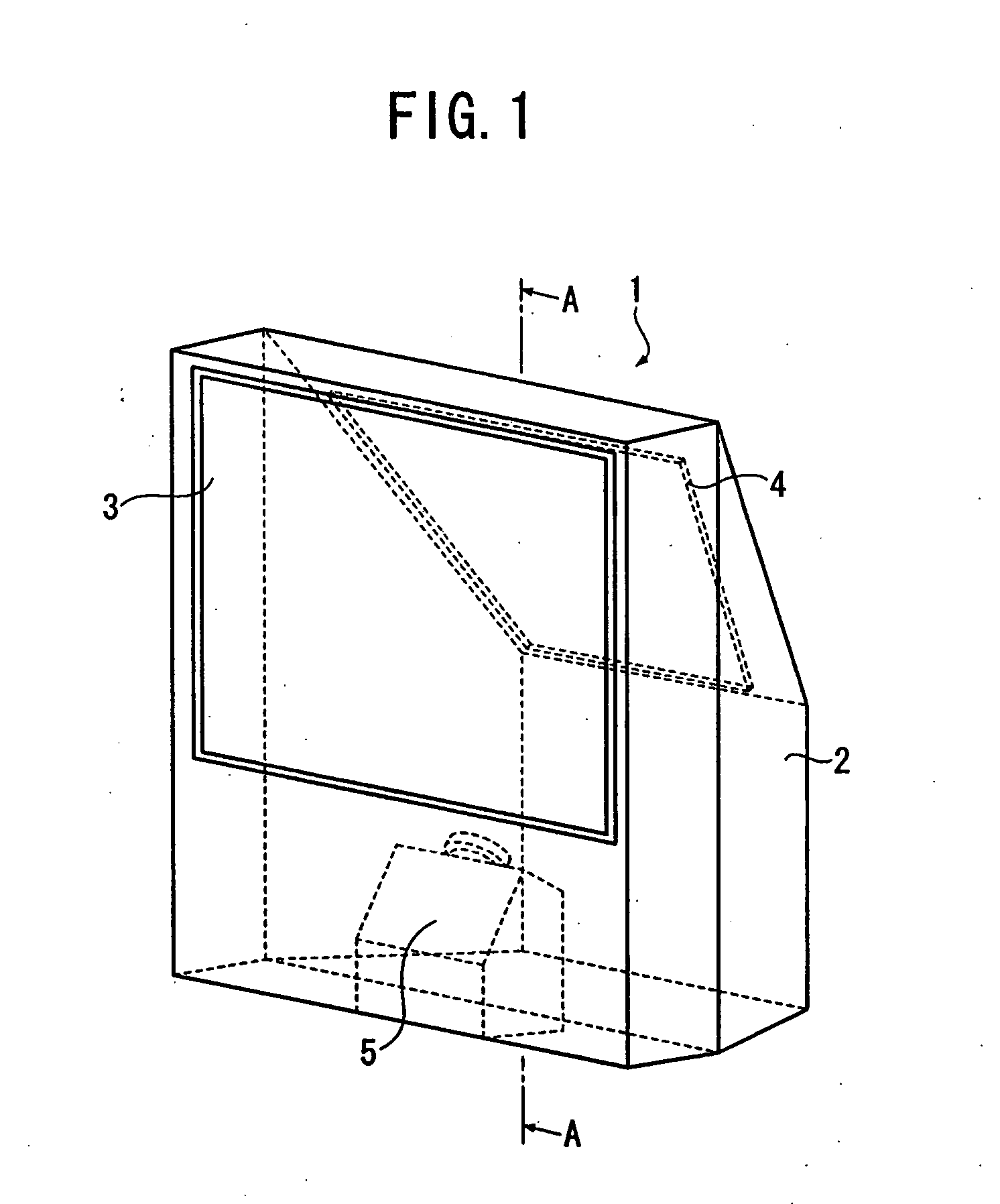

Video picture display unit

InactiveUS20060082964A1Less discomfortAvoid noise impactDucting arrangementsSpace heating and ventilation safety systemsLow speedControl signal

The invention is to provide a video picture display unit capable of reducing discomfort given to a user by restraining influence of a noise of fans after the power of the unit is turned off. A timer setting when the power is turned off (off timer setting or sleep setting) is stored in a setting portion of a controller. A decision portion decides as to whether the timer setting is present or non-present, and in cases where the power is turned off by the timer setting, the operation control portion transmits a control signal to a driving circuit so as to cause a fan or a fan to effect low speed rotating operation.

Owner:ORION ELECTRIC CO LTD

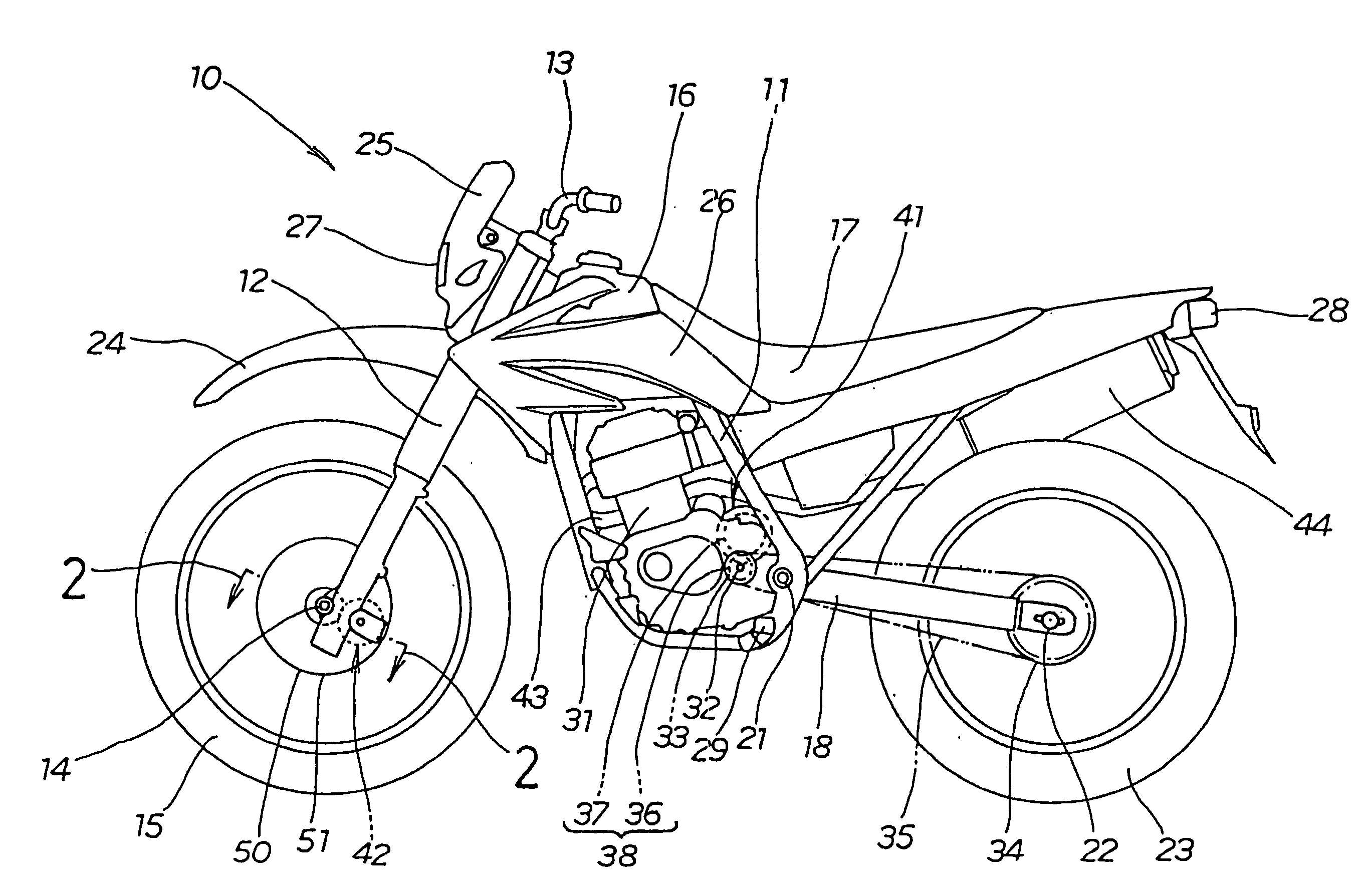

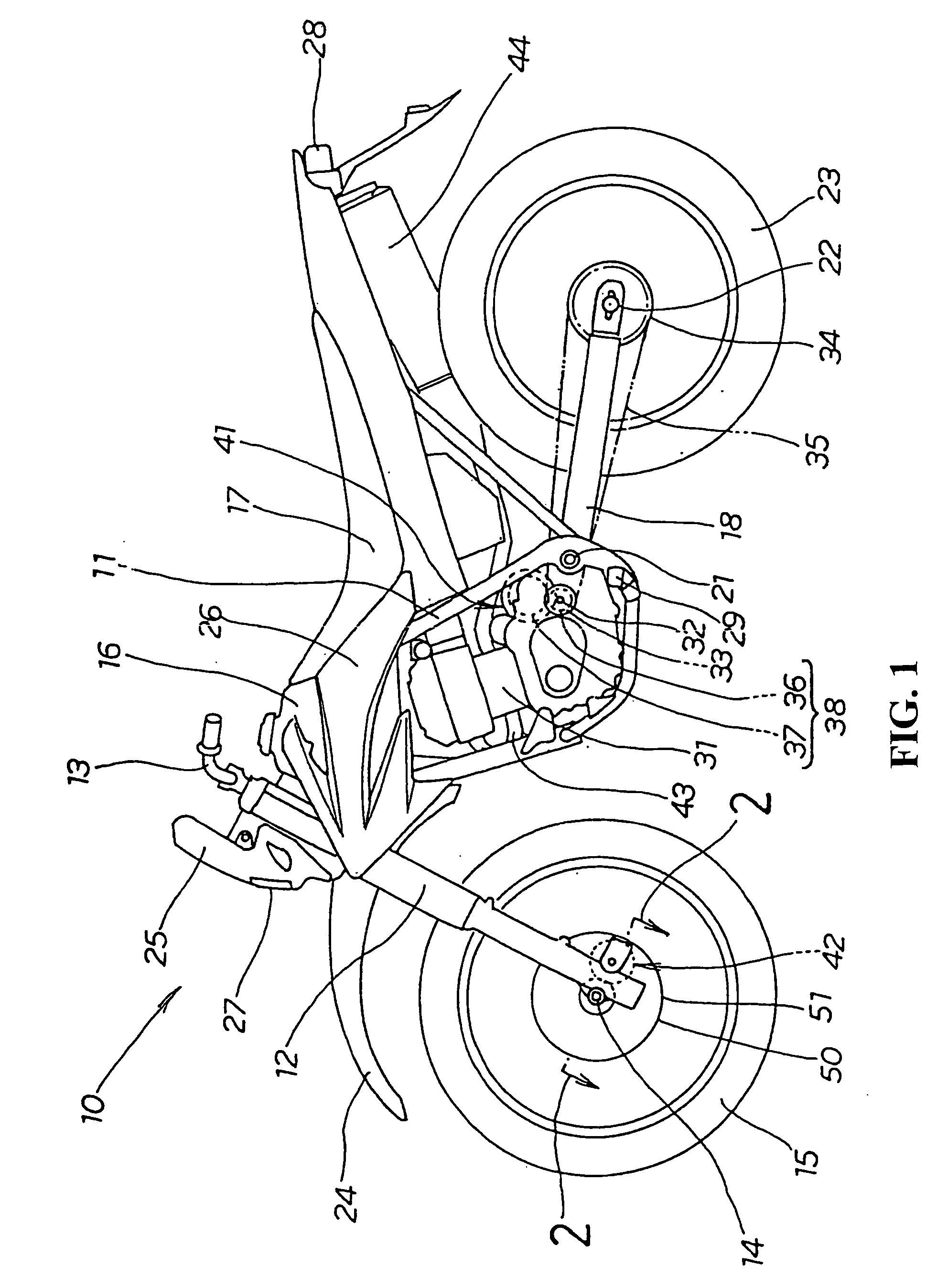

All-wheel-drive motorcycle

InactiveUS20060213713A1Increase flexibilityEasy to set upRotary transmissionsNon-mechanical gearing transmissionHydraulic motorGear wheel

An all-wheel-drive vehicle in which flexibility in setting the diameter of a driven gear is increased. In an all-wheel-drive vehicle in which an engine drives a rear wheel and also drives a hydraulic pump, and oil pressure generated by the hydraulic pump is supplied to a hydraulic motor for driving a front wheel. A front wheel hub provided on the front wheel is formed into a cup-shaped hub provided with a recess portion covered by a cover. The hydraulic motor is supported by the cover. A drive gear is provided on an output shaft of the hydraulic motor and a driven gear is provided in the recess portion of the hub with the driven gear being provided on the side of an axle.

Owner:HONDA MOTOR CO LTD

Electrical plug-in connection

InactiveUS7331807B2Reliably avoidedLow RPMEngagement/disengagement of coupling partsClamped/spring connectionsMating plugEngineering

Electrical plug-in connection (1), having a plug part (2) and a mating plug part (3), which can be plugged together and produce a large number of electrical plug-in connections, at least the plug part (2) or the mating plug part (3) bearing, on its body (19, 24), a union nut (4), which can be screwed to the mating plug part (3) or the plug part (2) and secures the plug-in connection (1) against becoming disconnected in an undesirable manner. The union nut (4) has, at both of its ends, an internal thread (28, 7) for simultaneously screwing it to the plug part (2) and the mating plug part (3), the internal threads (7, 28) being formed in the opposite direction.

Owner:CONINVERS ELEKTROTECHN BAUELEMENTE

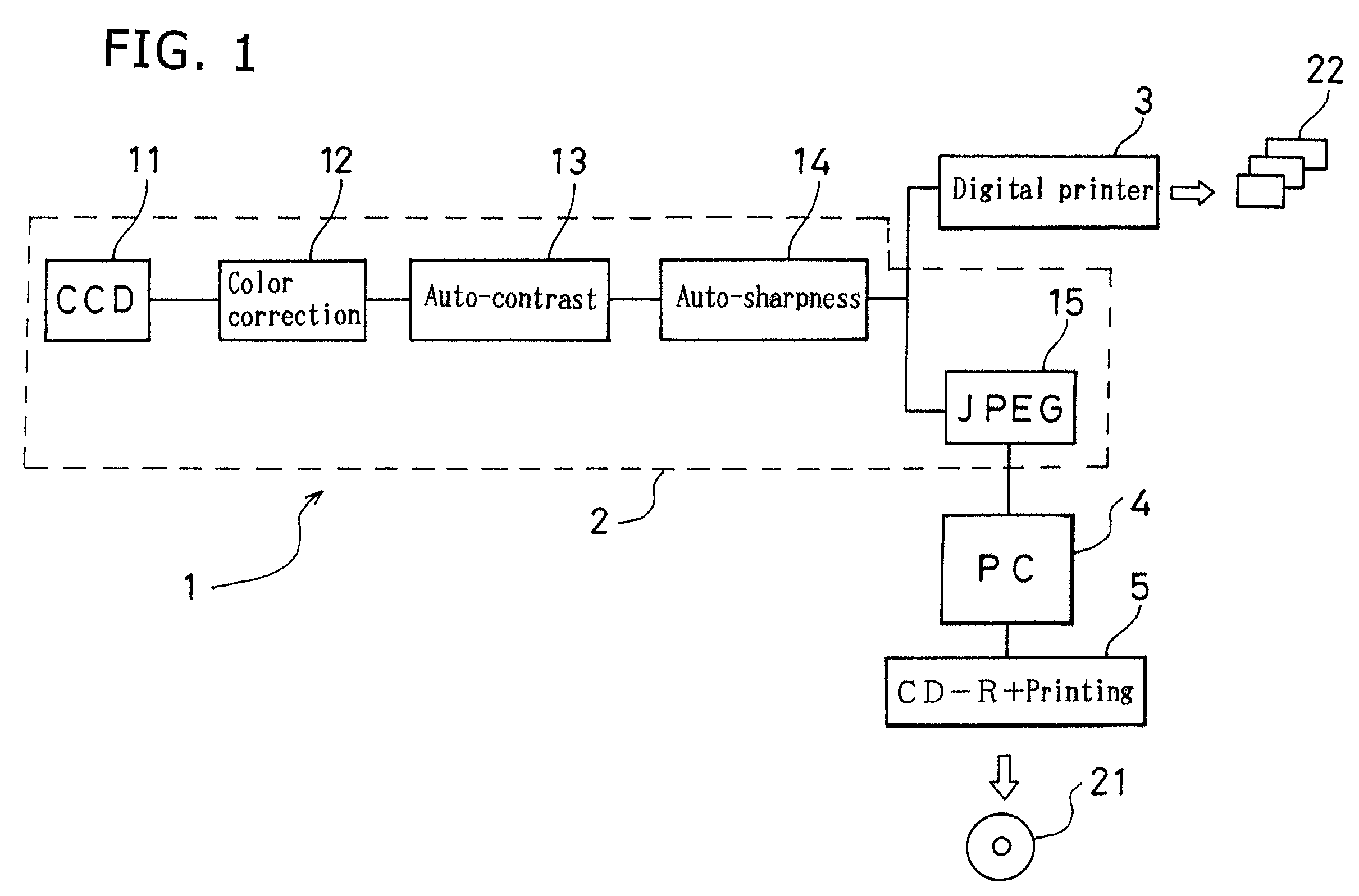

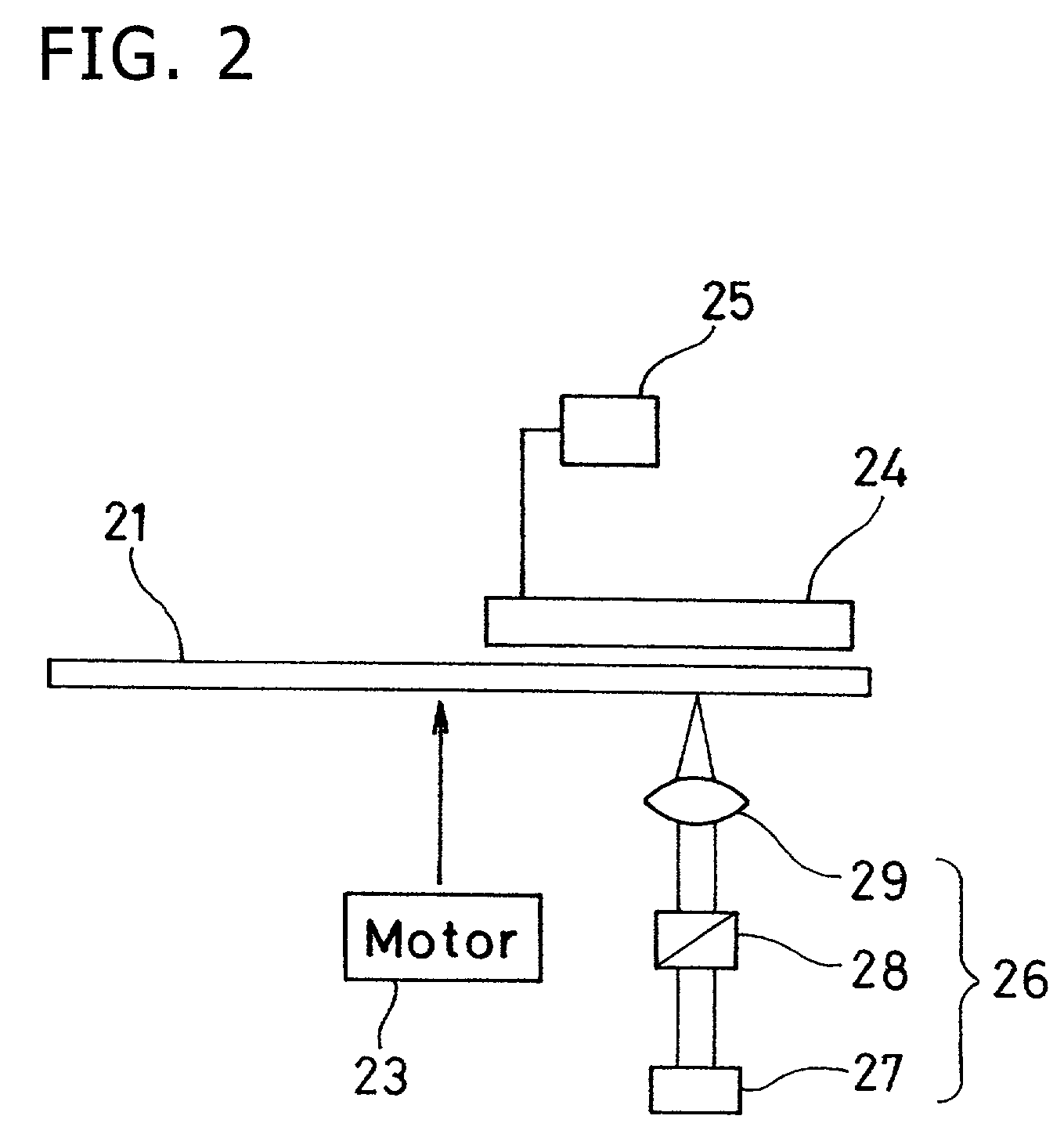

Printing device for carrying out a printing operation on a surface of a disk

InactiveUS7119922B2No longer be carried outSmall sizeDigitally marking record carriersInking apparatusRecordable CDComputer engineering

Owner:NORITZ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com