Method for manufacturing magnetic core component

A manufacturing method and technology of magnetic core, applied in the direction of magnetic core manufacturing, inductor/transformer/magnet manufacturing, transformer/inductor magnetic core, etc., can solve the problems of low magnetic flux density, short circuit of insulating film, high pressure, etc. Effects of packing density, simplification of manufacturing process, and enhancement of magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

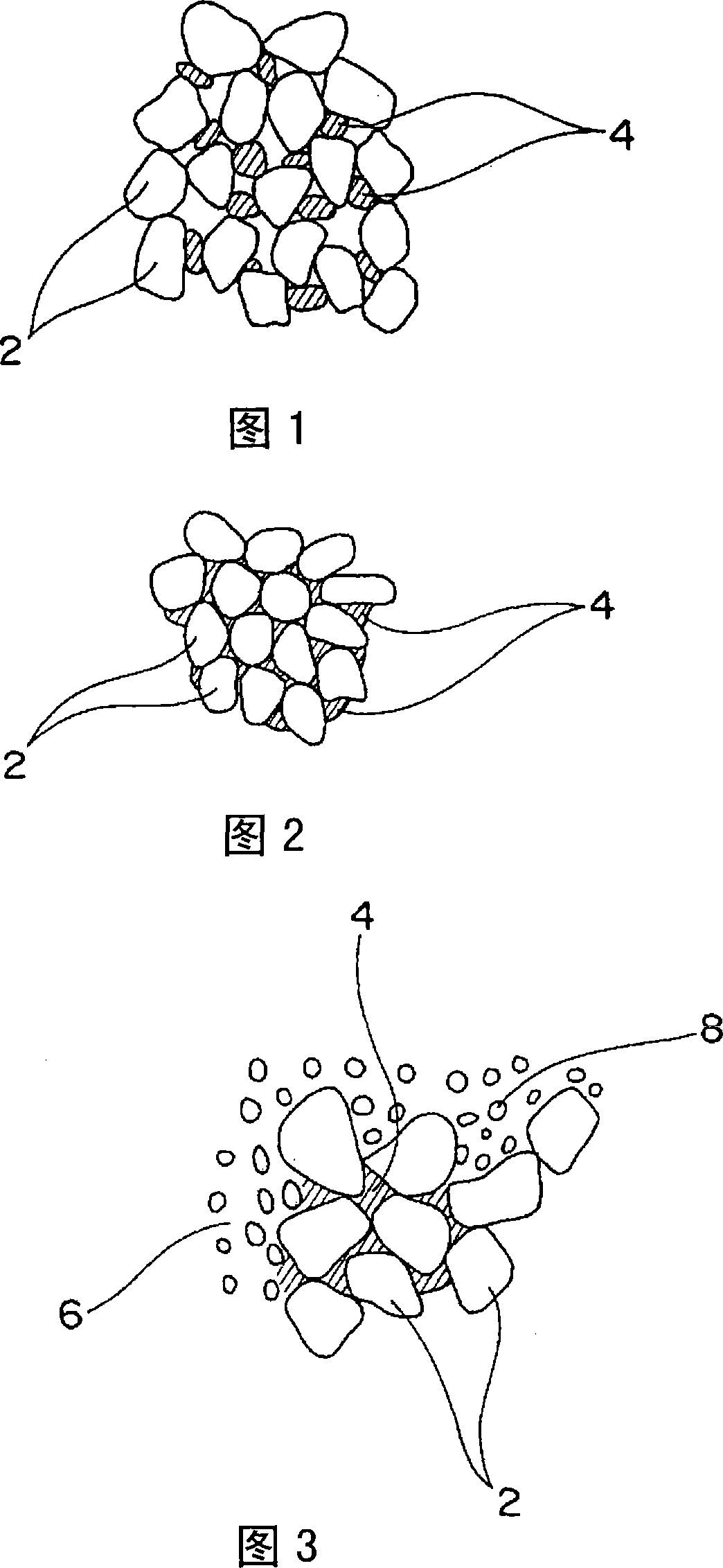

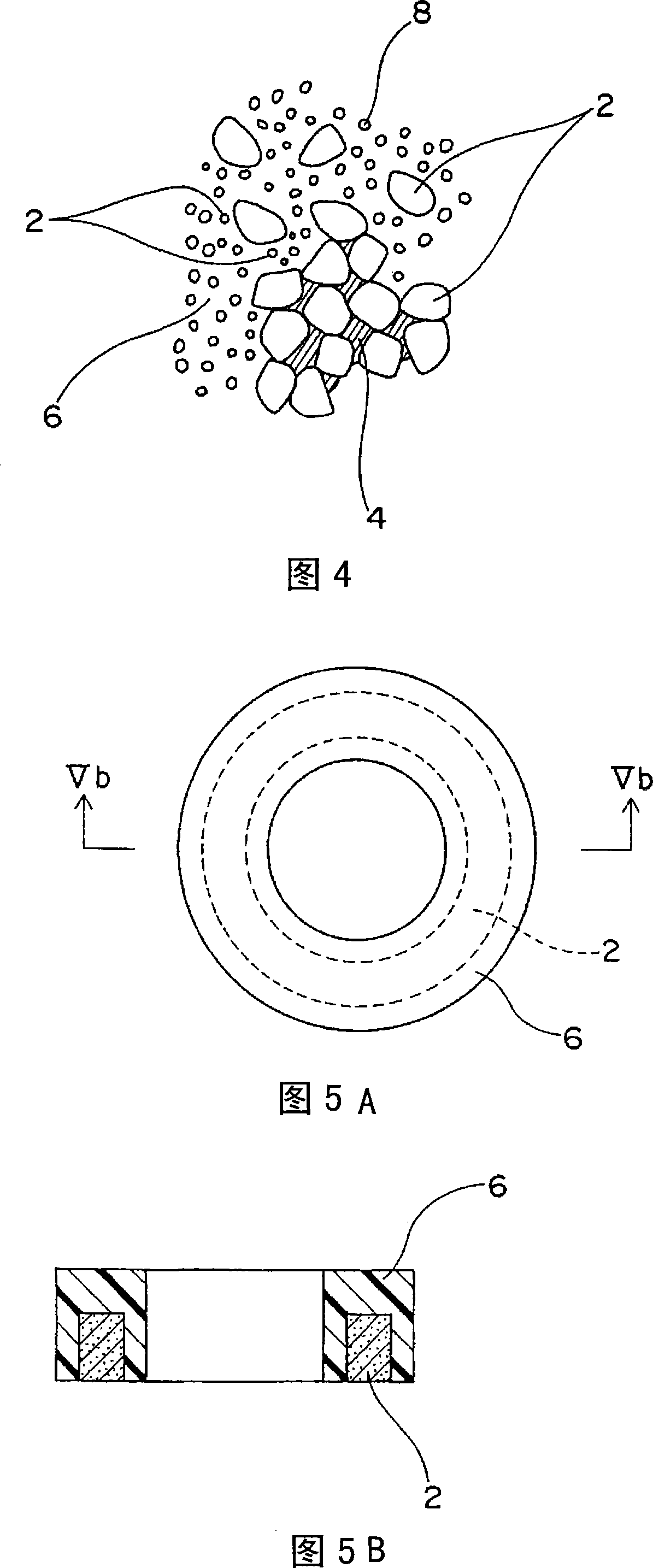

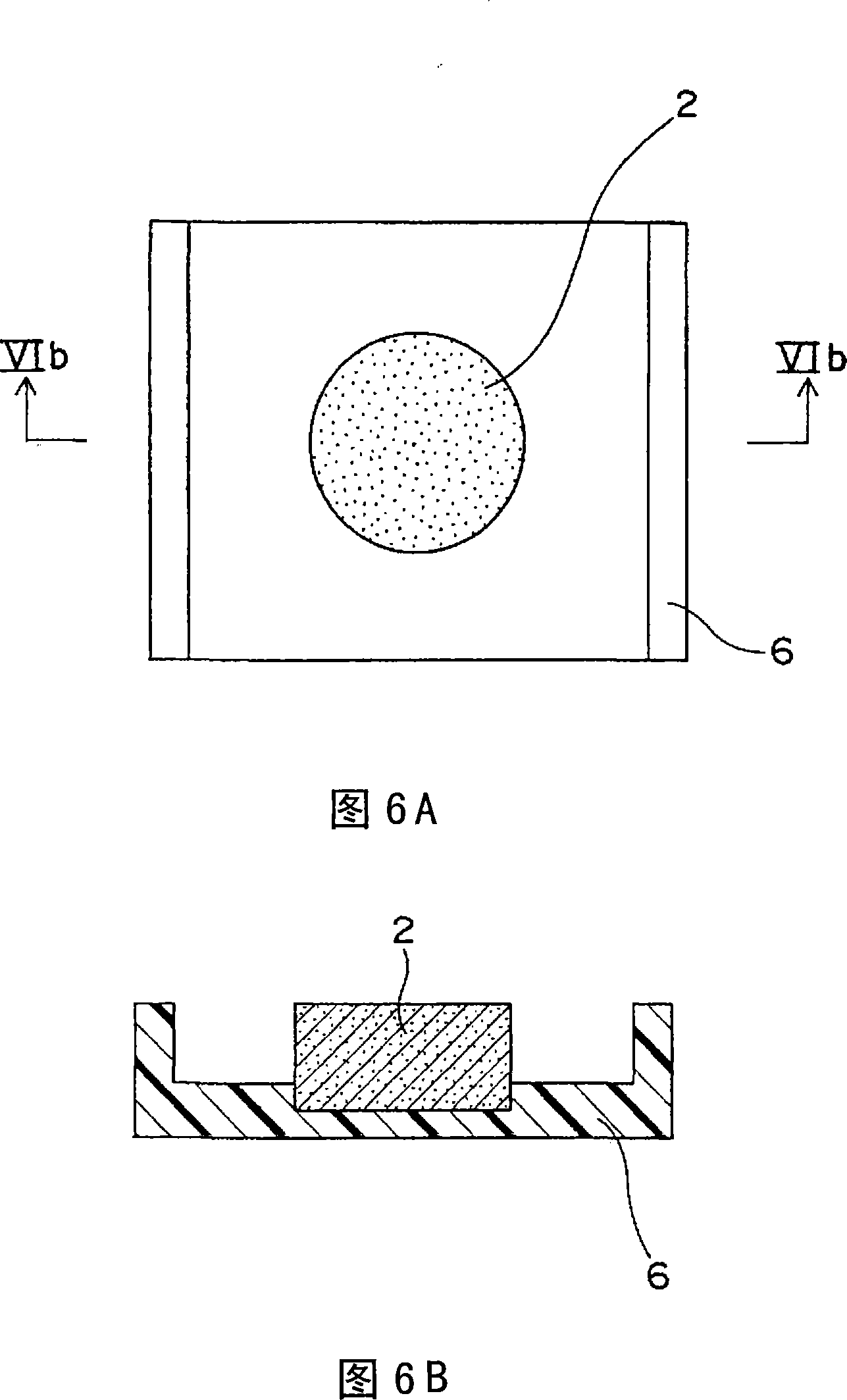

[0057] 1 shows a magnetic body in a powder compacted state used in the manufacturing method of a resin molded magnetic core part according to Embodiment 1 of the present invention, and is contained (dispersed) between a plurality of powder particles 2 constituting magnetic powder covered with an insulating material. ) a plurality of binder particles 4 .

[0058] As the binder 4, a resin having a melting temperature lower than a predetermined injection molding temperature is used, and by injection molding at a predetermined temperature together with a matrix resin containing magnetic powder covered with an insulating material, the binder 4 is melted or Softening, as shown in FIG. 2 , the intervals between the magnetic powder particles 2 become shorter, the compacted magnetic body shrinks, and its filling density increases.

[0059] As the magnetic powder particles 2 , those having excellent soft magnetic properties, for example, those shown below are preferable.

[0060] ·As p...

Embodiment approach 2

[0082] 7A and 7B show a core component manufactured by the method of manufacturing a resin molded core component according to Embodiment 2 of the present invention, showing a case where the core component is a coil-enclosed type magnetic component.

[0083] As shown in FIGS. 7A and 7B , in a state where the lead-out portions 12 at both ends of the coil 10 are drawn in substantially parallel to the same direction, the powder-molded magnetic body 2 is inserted into the coil 10 , and the resin composition 6 is inserted into the coil 10 . By insert molding together, only the lead-out portions 12 at both ends are exposed, thereby partially increasing the magnetic permeability of the resin molded magnetic core member and improving its performance. In particular, when the compressed powder magnetic body 2 is inserted inside the coil 10, the magnetic permeability inside the coil 10 increases, the coil diameter can be set smaller, and the number of revolutions can also be reduced.

[0...

Embodiment approach 3

[0086] 9A and 9B show a magnetic core component manufactured by the method for manufacturing a resin molded magnetic core component according to Embodiment 3 of the present invention, particularly a case where the resin molded magnetic core component is a coil-encapsulated magnetic component.

[0087] In the case of the resin molded magnetic core components shown in FIGS. 9A and 9B , firstly, a wire made of a conductive material such as Cu is wound on a linear rod (not shown) to manufacture the coil 16 , and then the coil 16 is formed from the rod. The prepared coil 16 is extracted from the material, the axis of the coil 16 is bent into a substantially circular shape, and the lead-out parts 18 at both ends are drawn out in the same direction in a substantially parallel manner. Then, the bent coil 16 is insert-molded together with the resin composition 6 so that only the lead-out portions 18 at both ends are exposed, thereby completing the air-core coil-integrated toroid core ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com