Patents

Literature

960results about "Encapsulation/impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

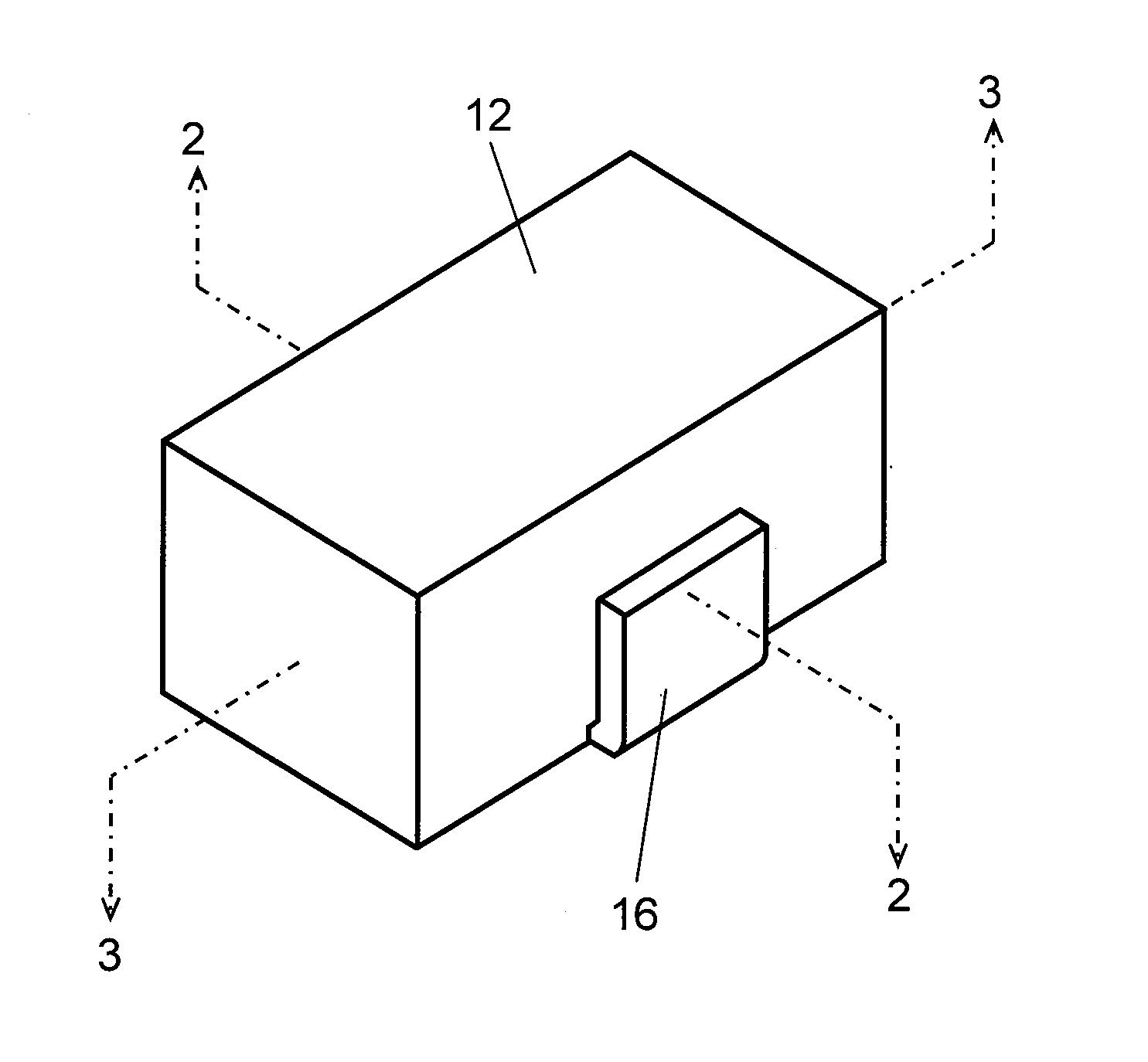

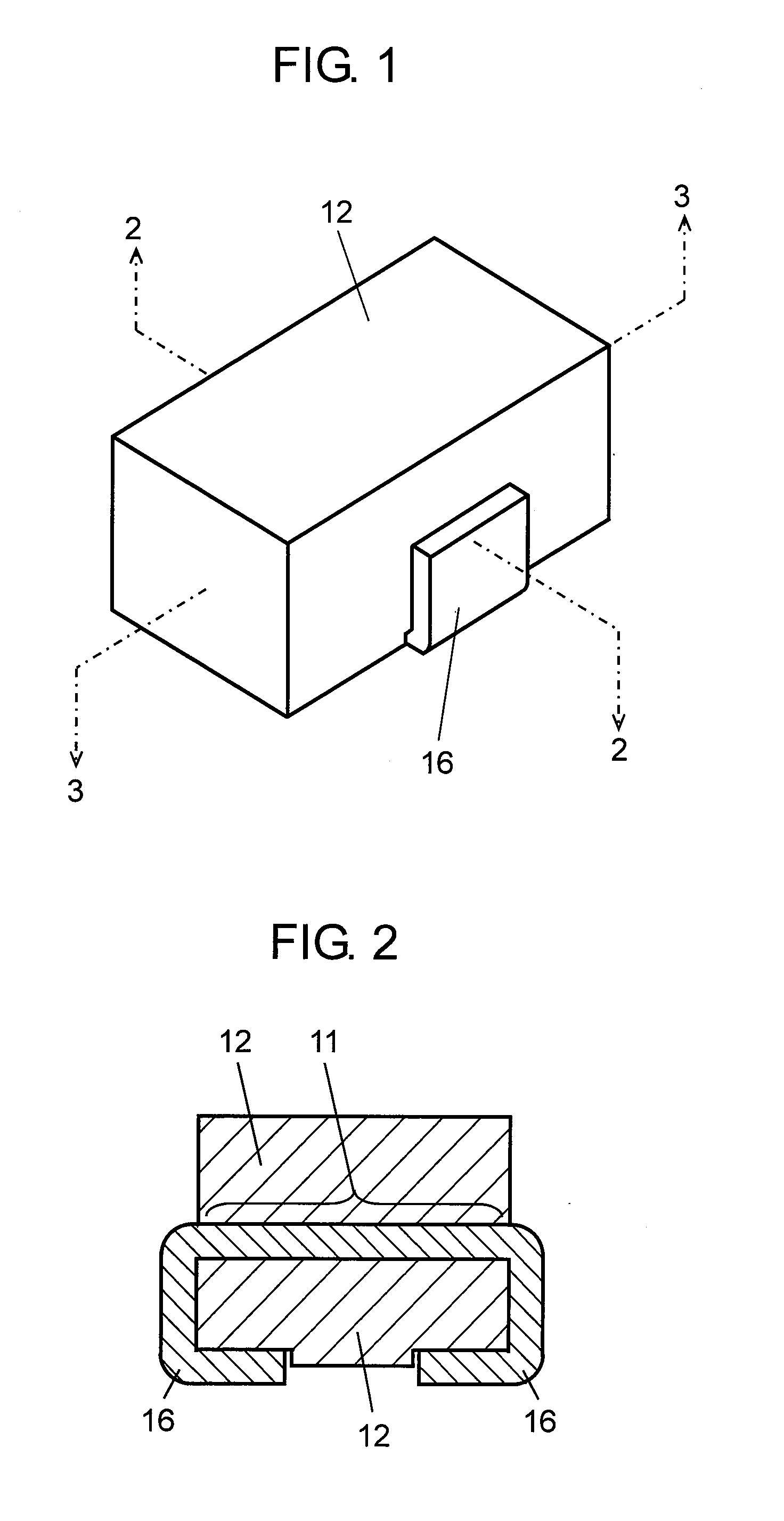

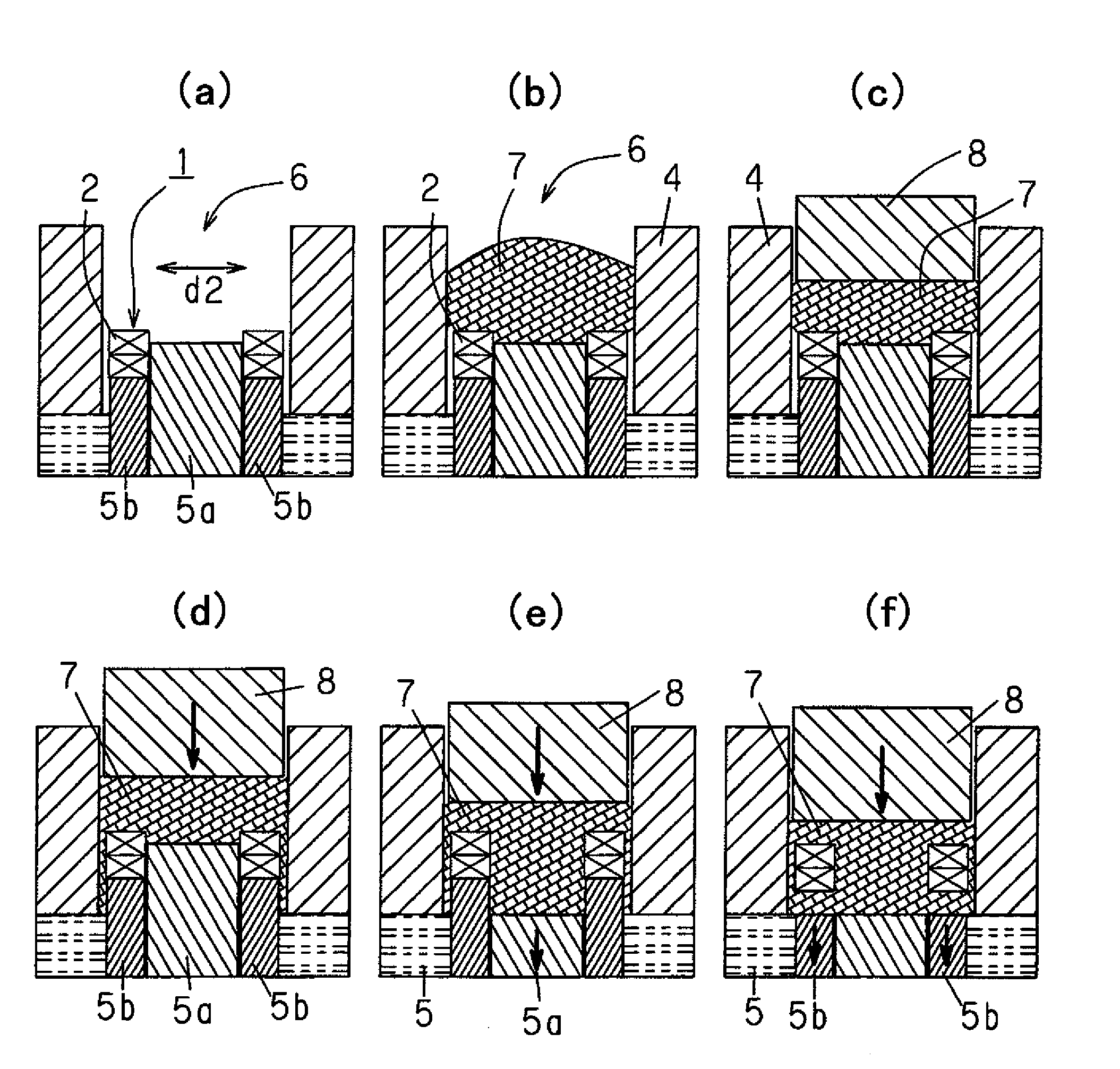

Surface-Mount Inductor and Method of Producing the Same

ActiveUS20100259353A1Simple waySimple structureTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectricitySurface mounting

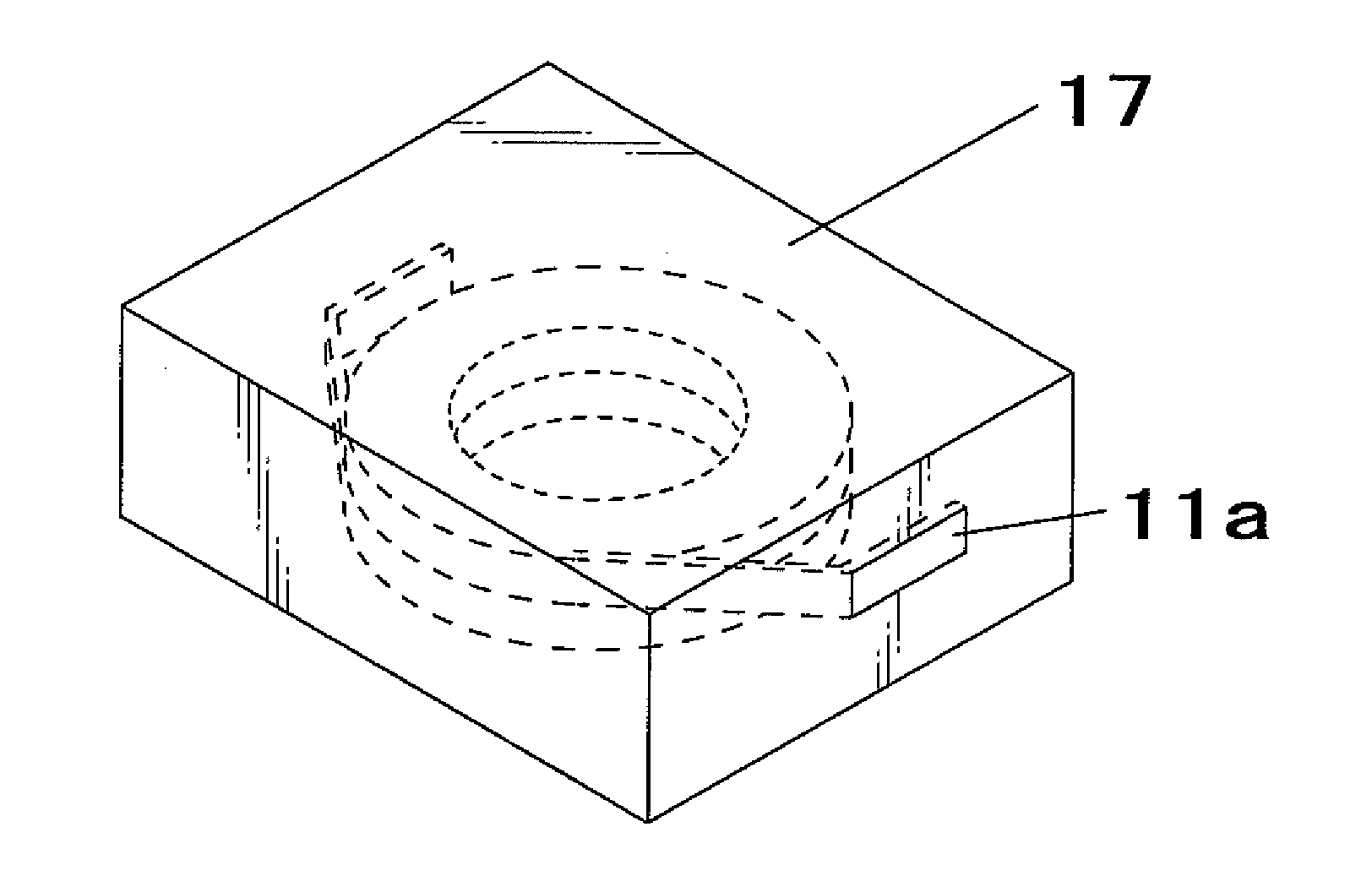

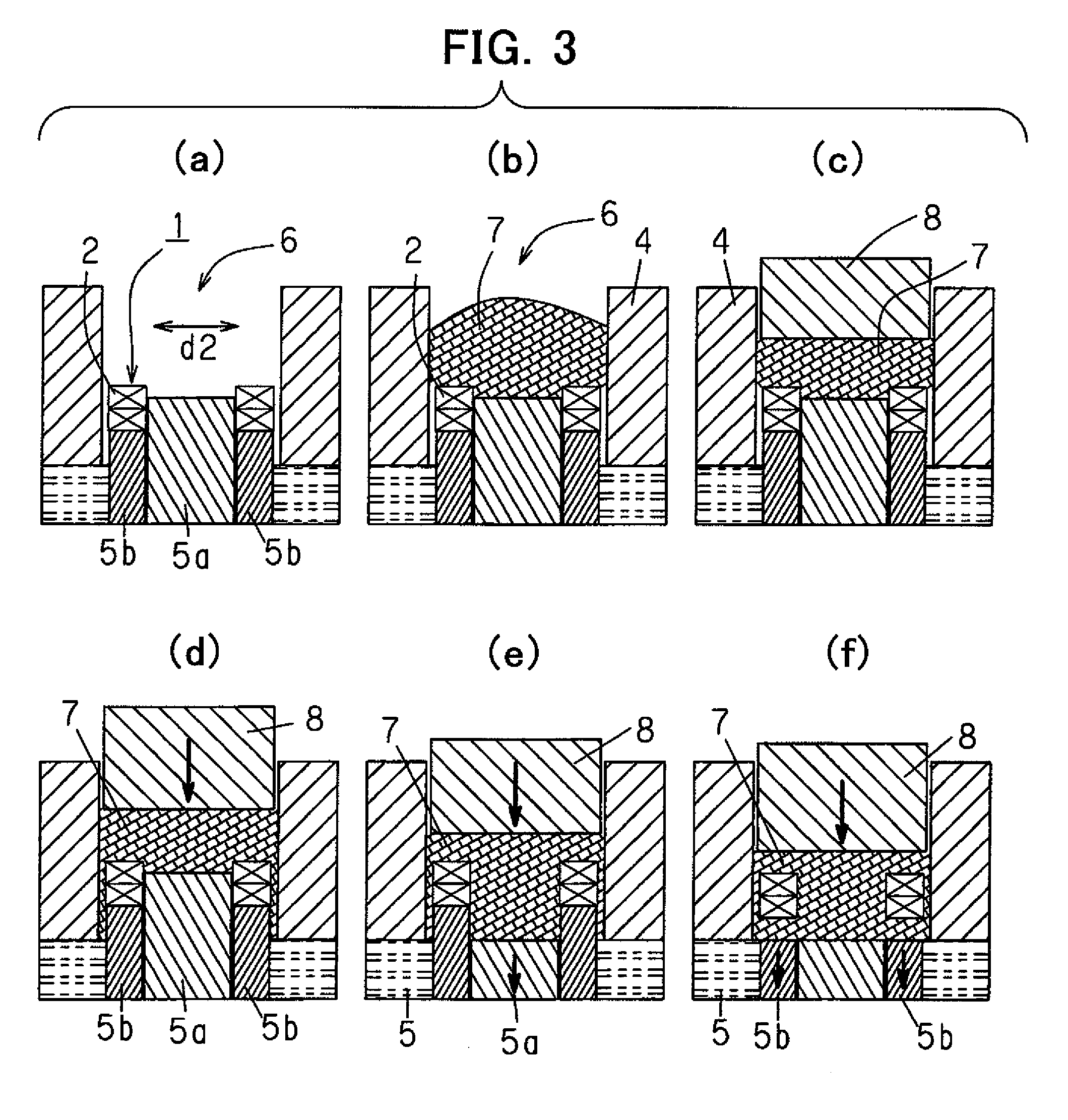

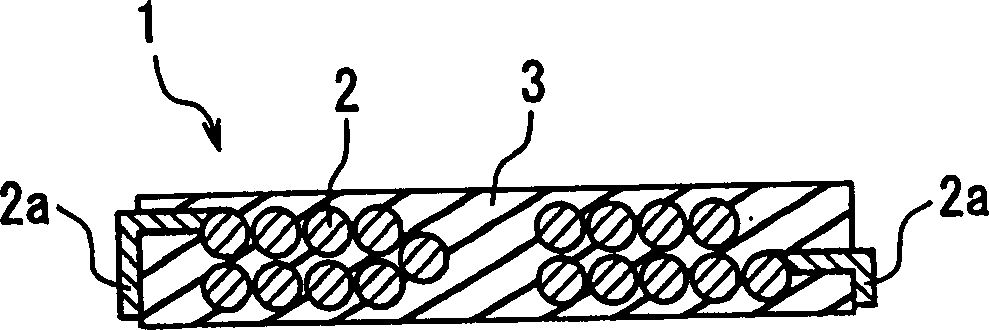

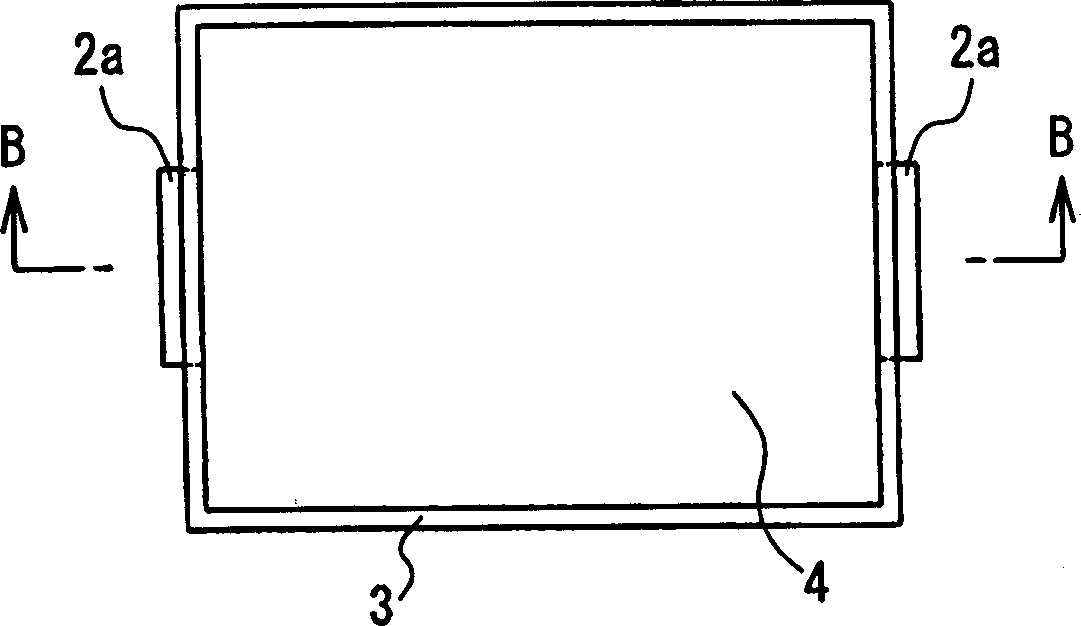

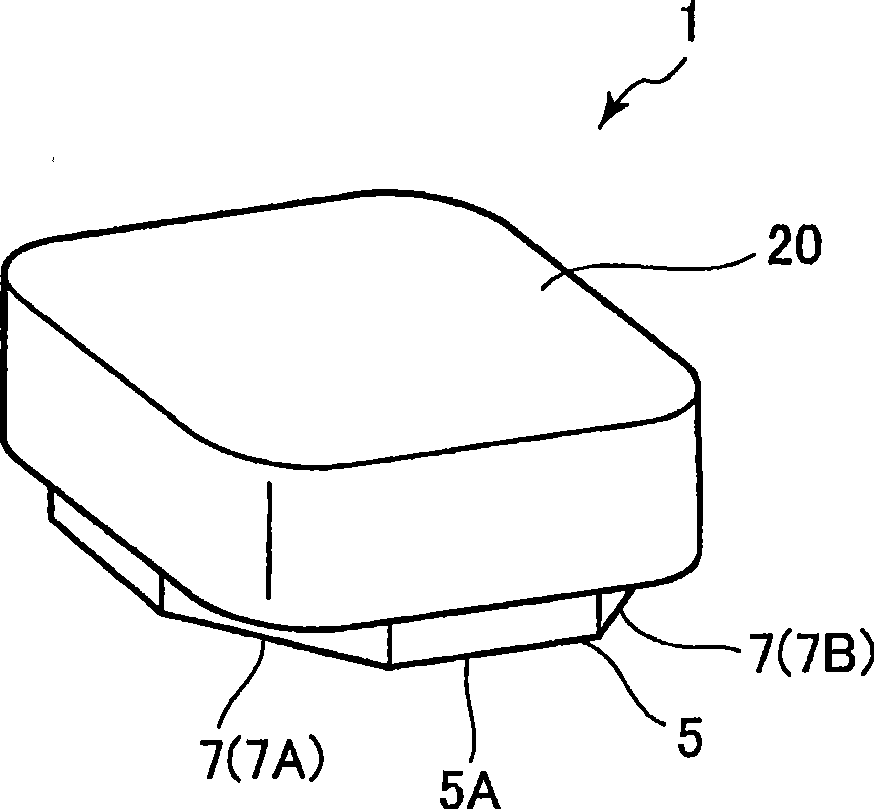

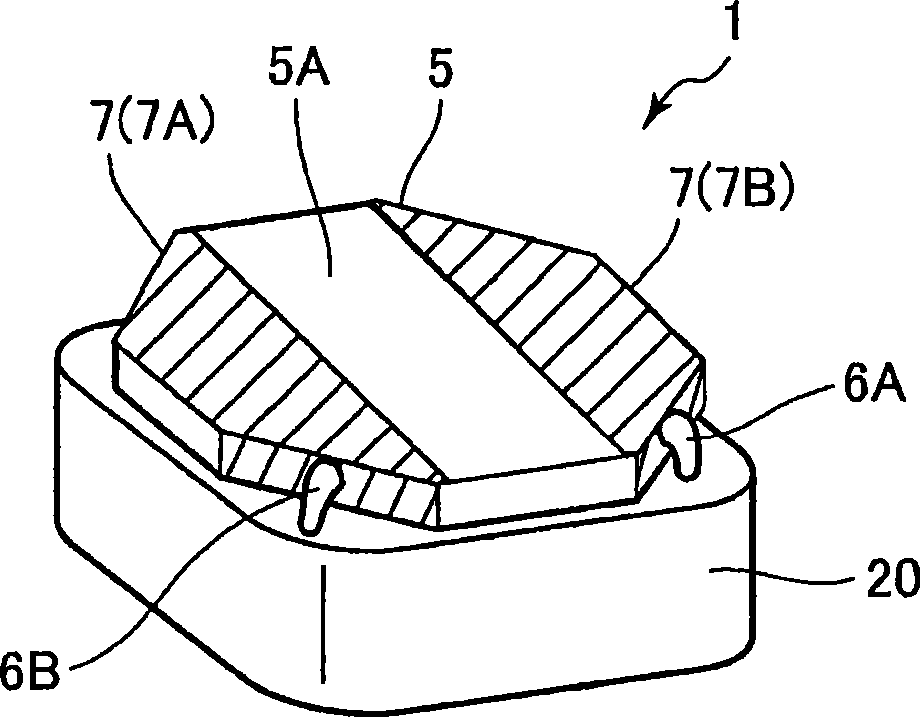

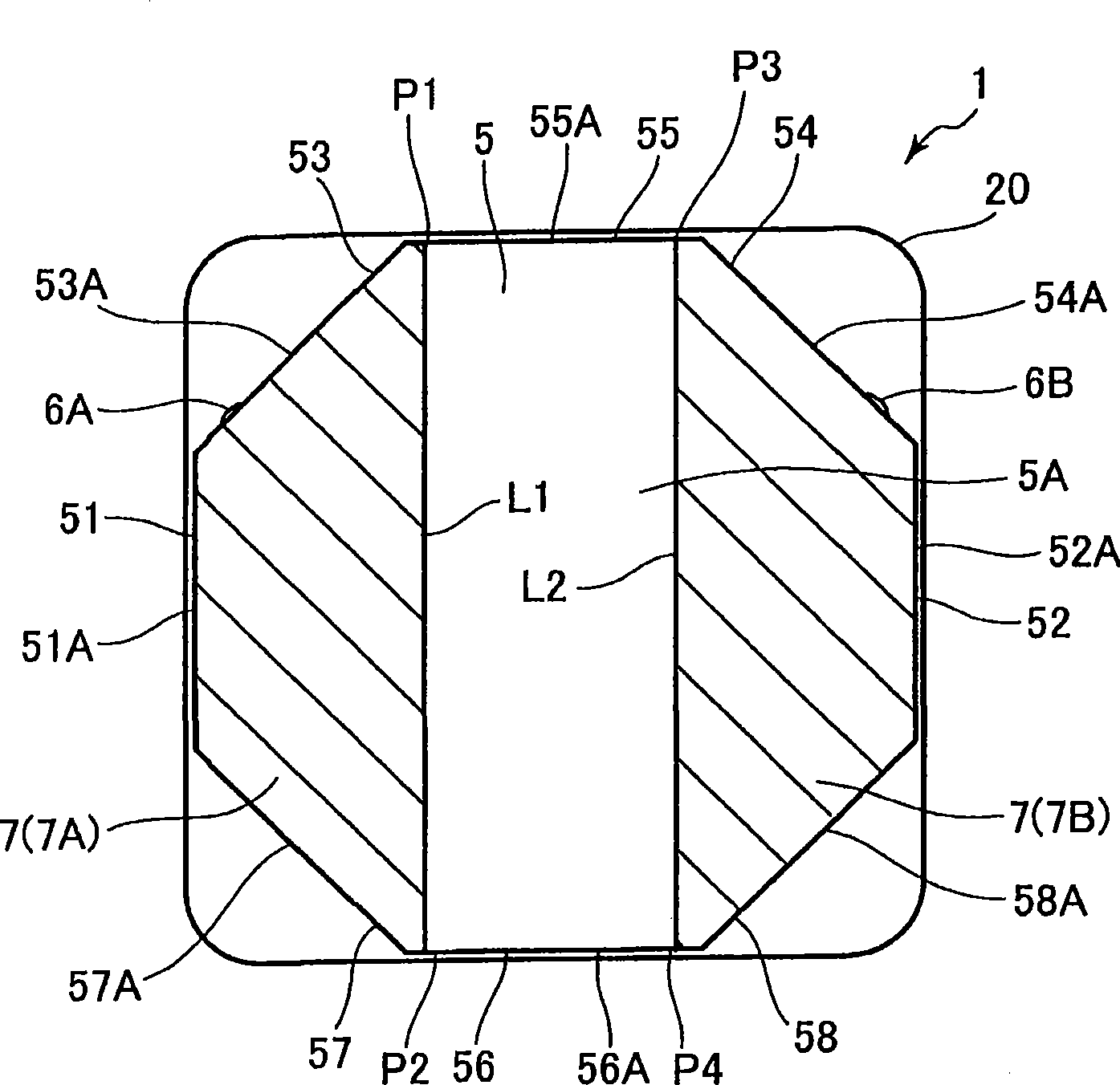

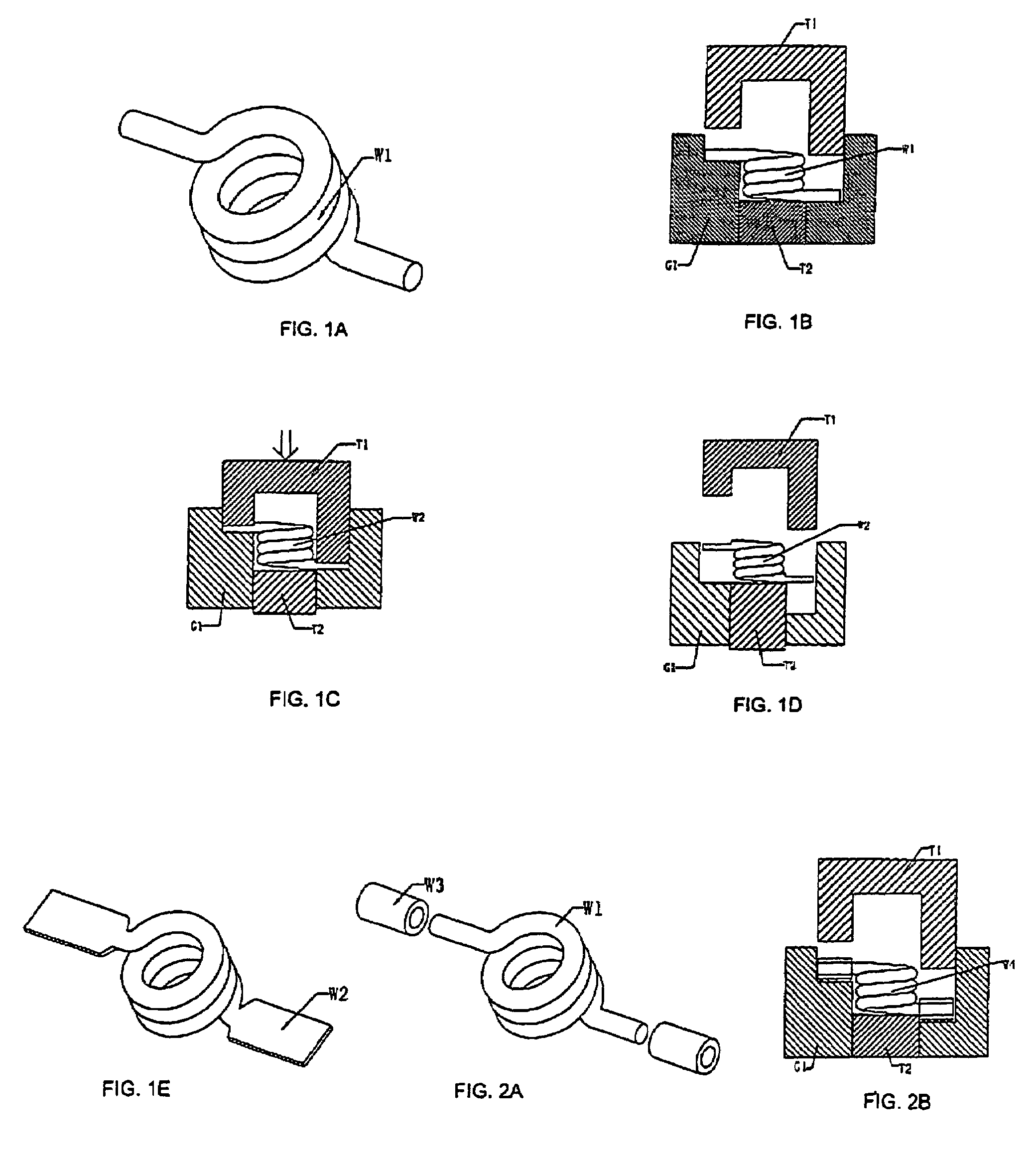

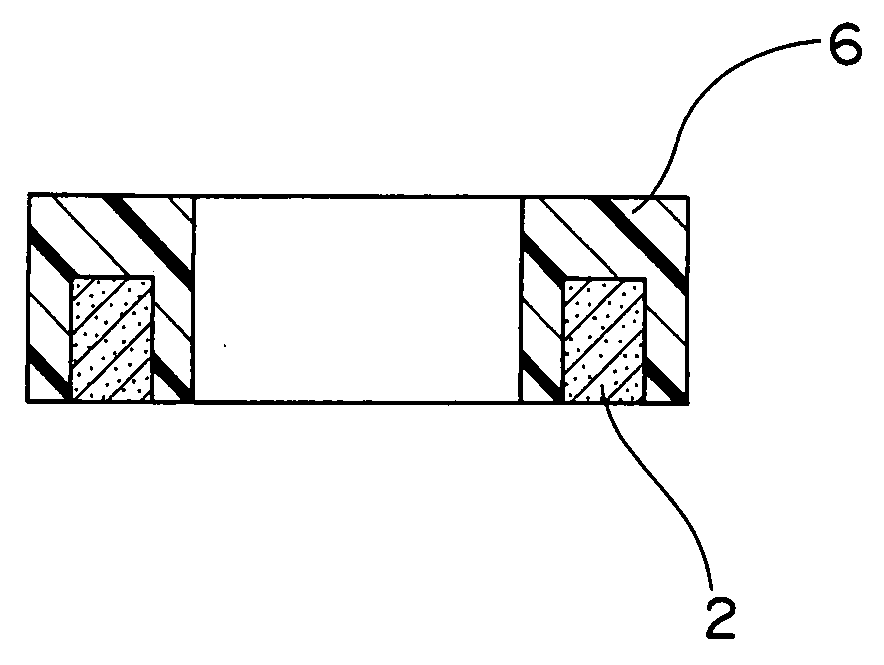

A method of producing a surface-mount inductor by encapsulating a coil with an encapsulation material containing a resin and a filler using a mold die assembly is provided. In the method, a tablet and a coil are used. The tablet is prepared by preforming the encapsulation material into a shape having a flat plate-shaped portion and a pillar-shaped convex portion on a peripheral thereof. The coil is a wound conductive wire having a cross-section of rectangular-shape. The coil is placed on the tablet to allow both ends of the coil to extend along an outer side surface of the pillar-shaped convex portion of the tablet. The coil and the encapsulation material are integrated together while clamping the both ends of the coil between an inner wall surface of the mold die assembly and the outer side surface of the pillar-shaped convex portion of the tablet, to form a molded body. External electrodes are formed on a surface of or around an outer periphery of the molded body in such a manner that the external electrodes are electrically connected to the both ends of the coil at least a portion of which is exposed to the surface of the molded body.

Owner:MURATA MFG CO LTD

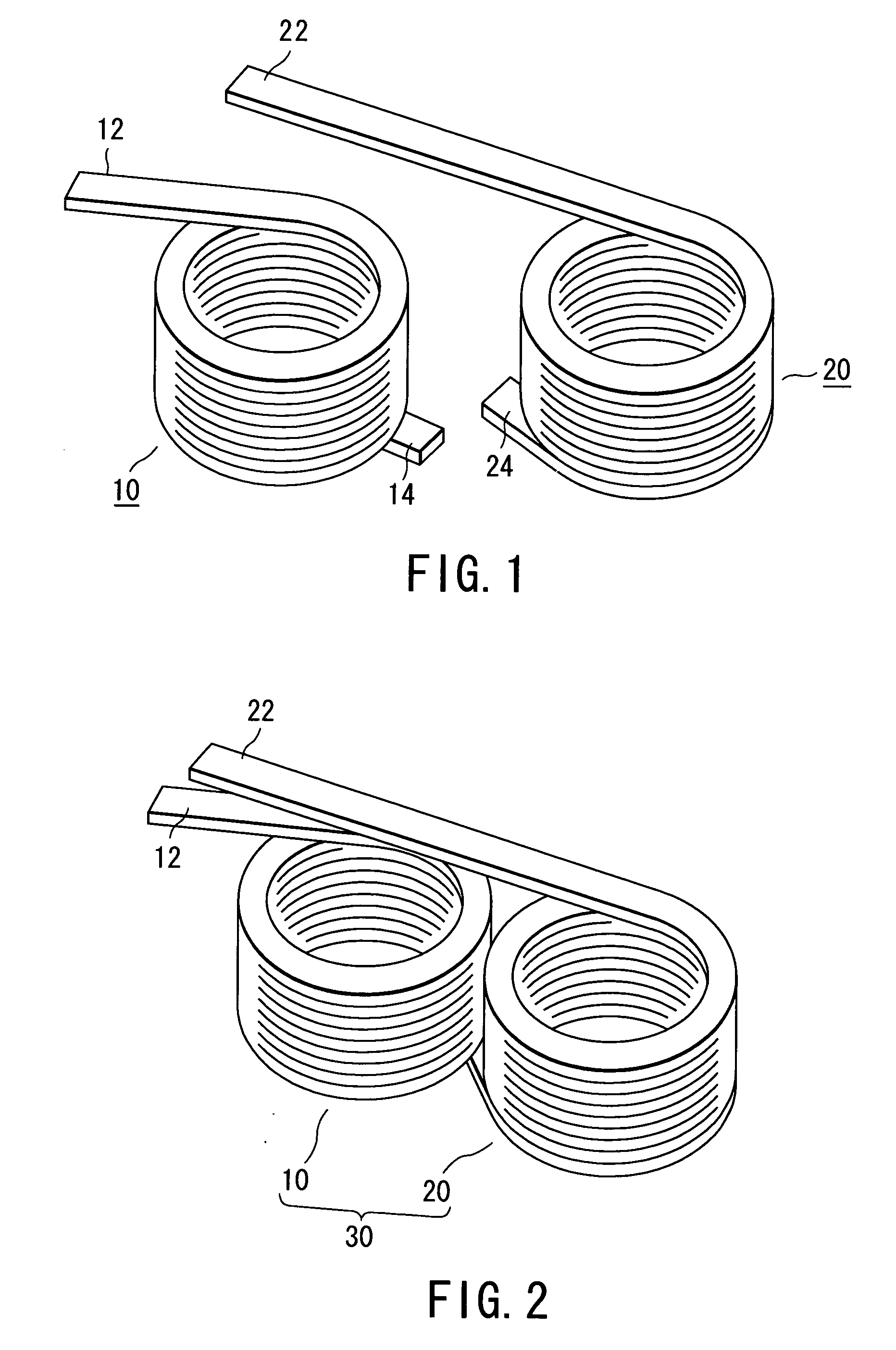

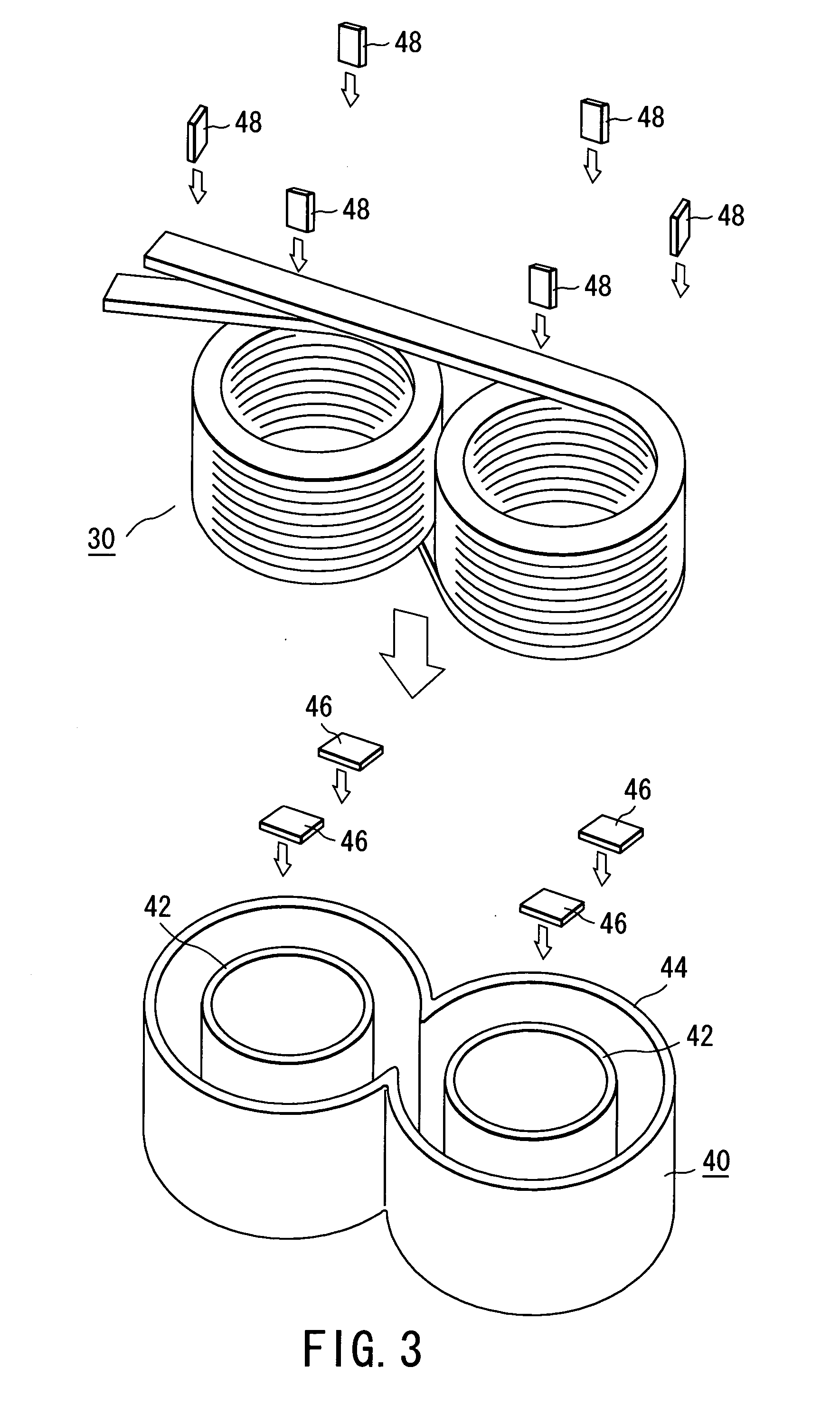

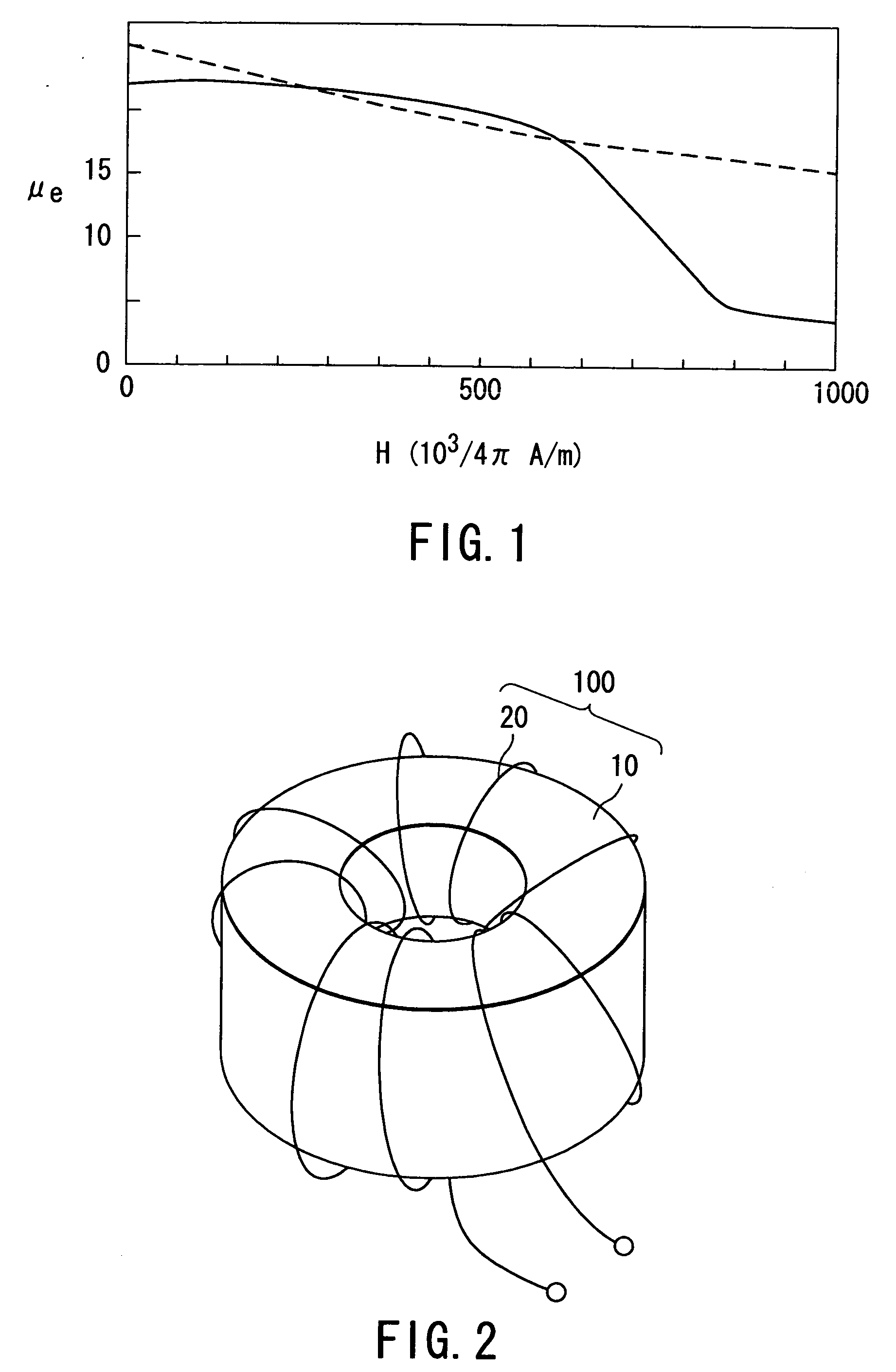

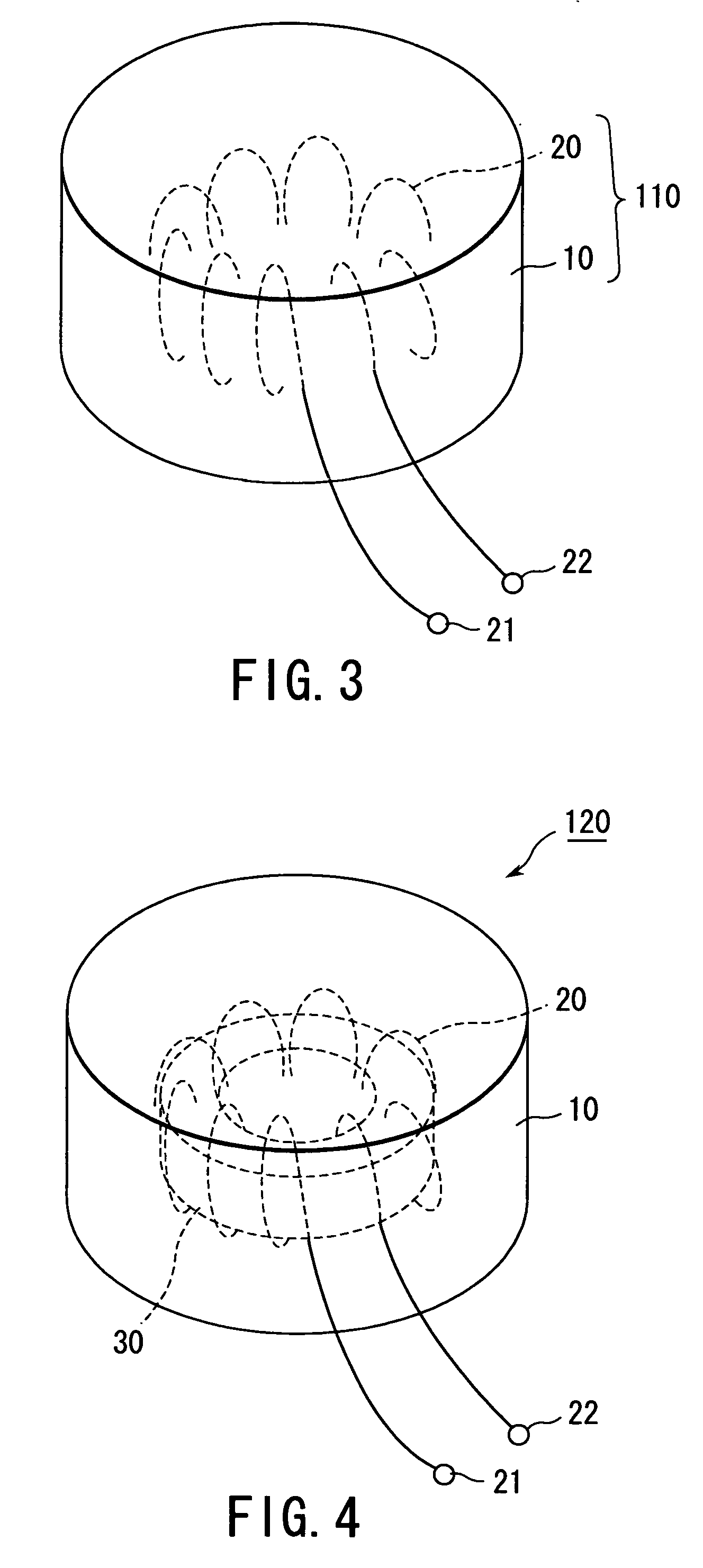

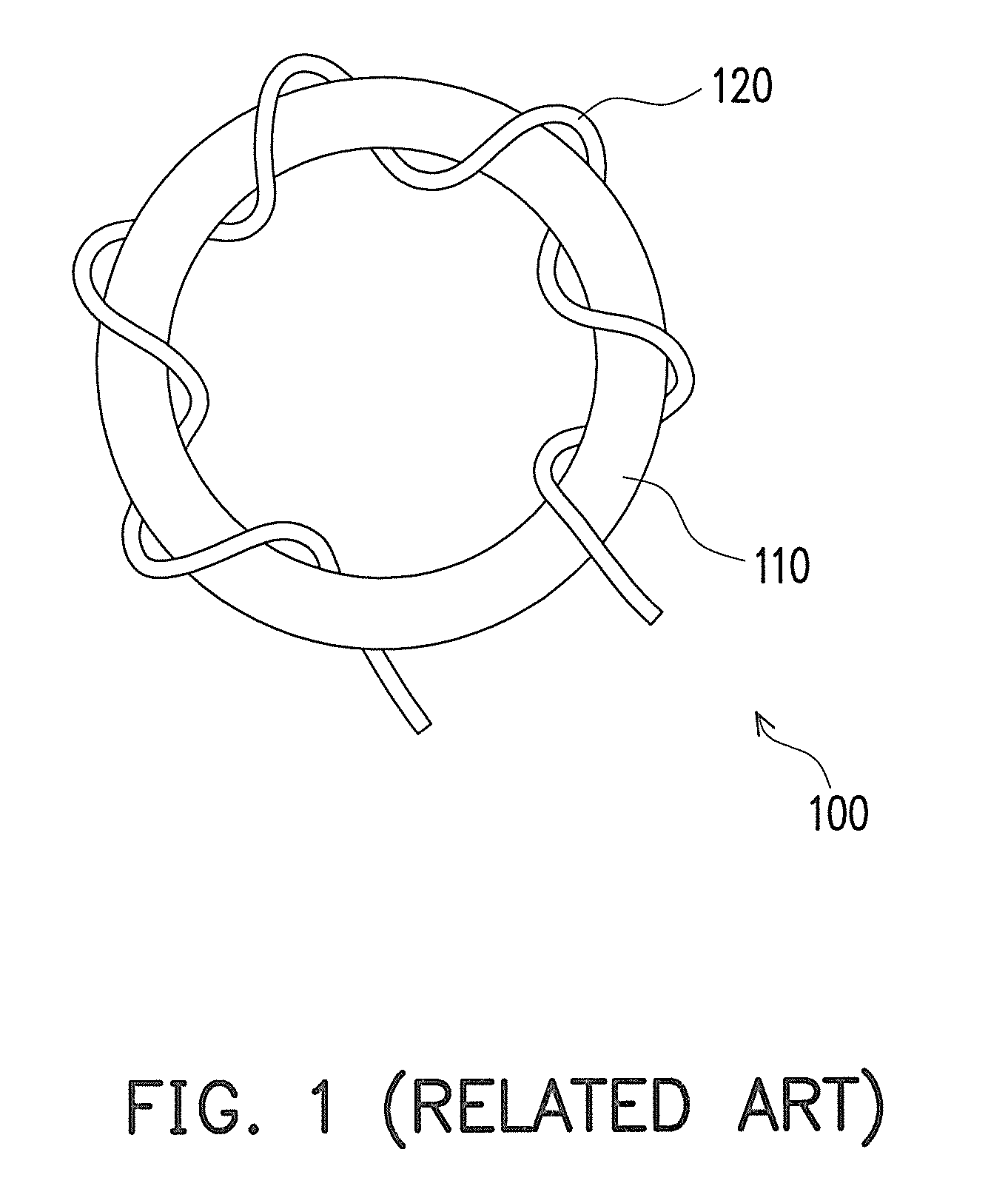

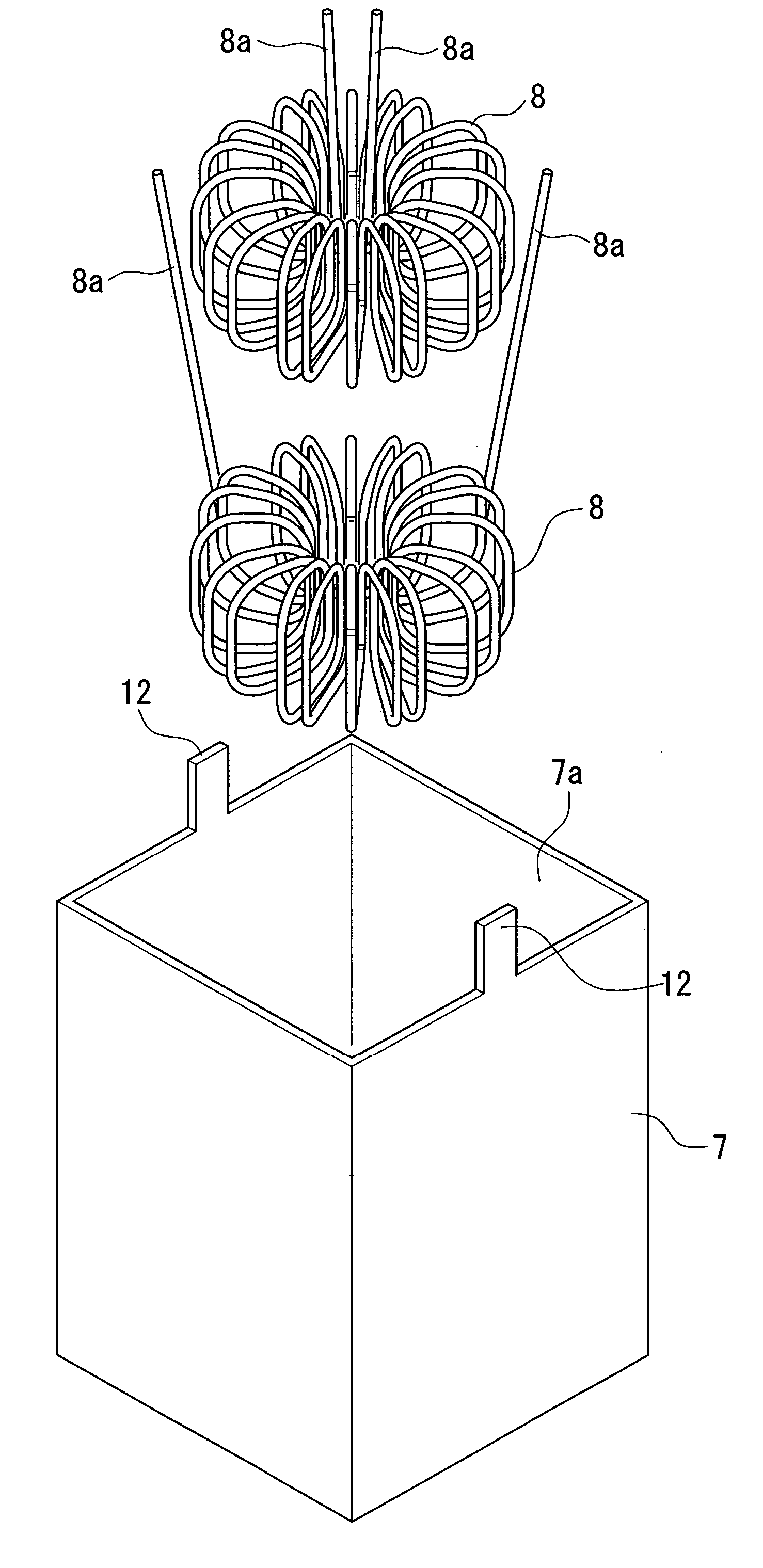

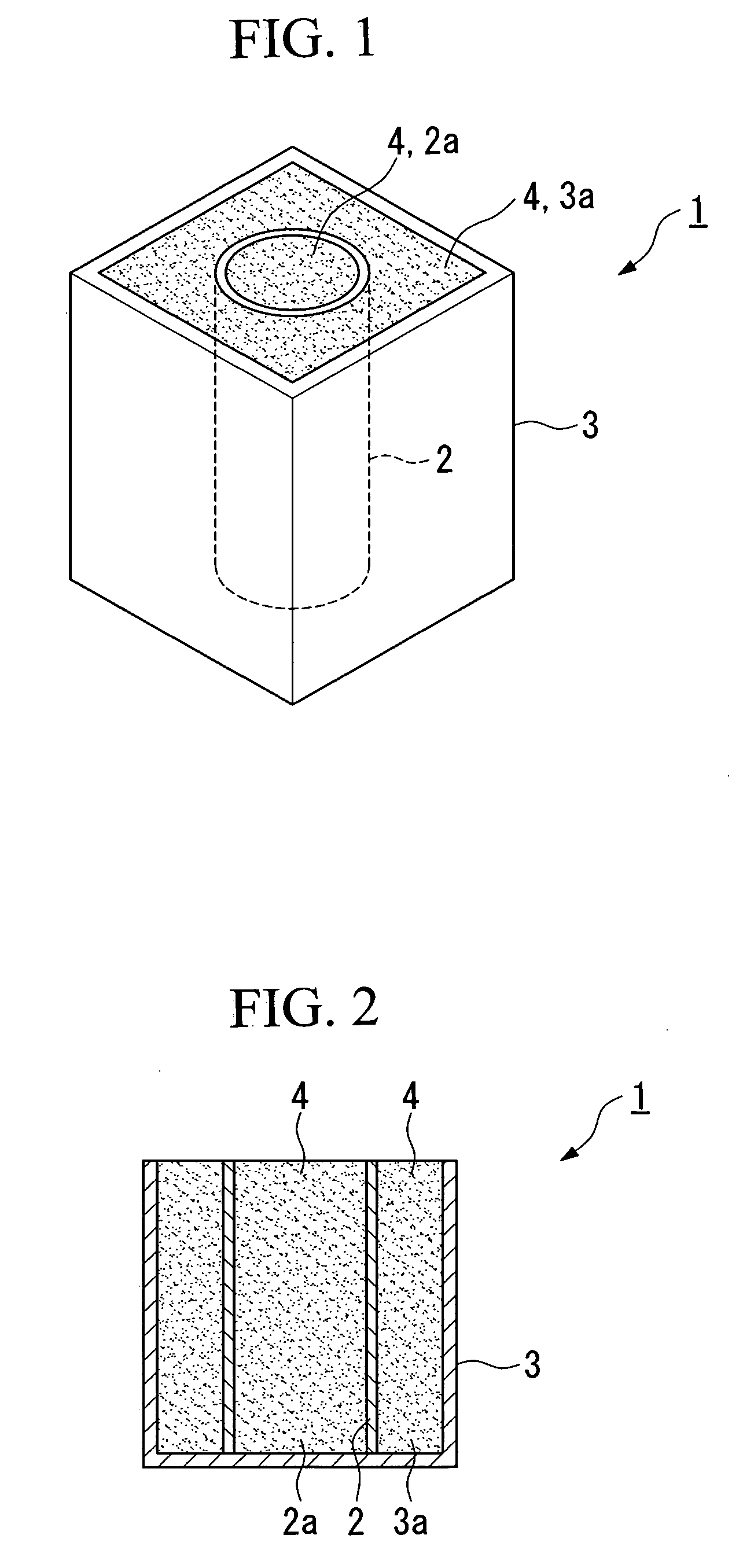

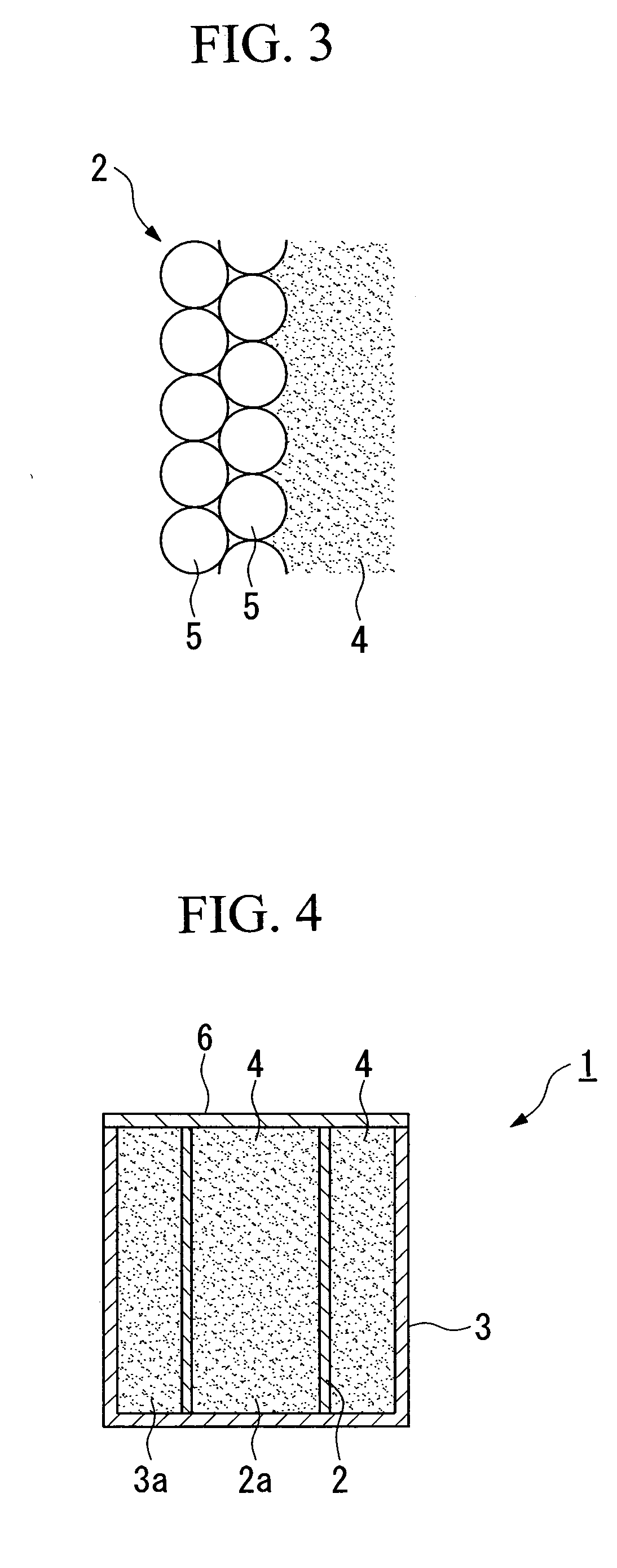

Coil component and fabricaiton method of the same

ActiveUS20050012581A1Suppress whineTransformers/inductances casingsInorganic material magnetismEngineeringElectrical and Electronics engineering

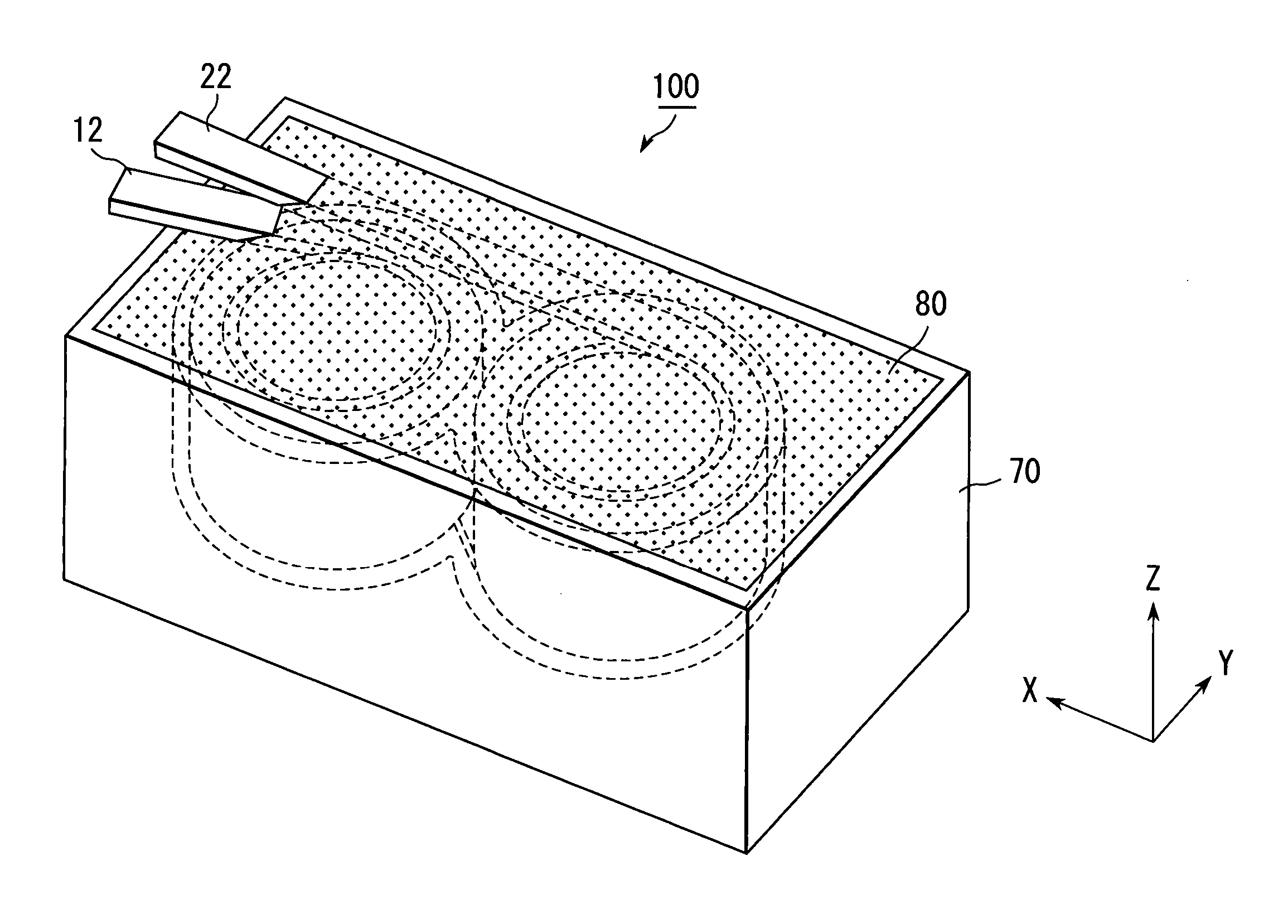

A coil component (100) comprises a coil-containing insulator enclosure and a magnetic core (80). The coil-containing insulator enclosure can be obtained by enclosing a coil (30), except for end portions (12, 22) of the coil (30), with an insulator (50), wherein the insulator (50) comprises at least first resin. The magnetic core (80) is made of a mixture of a second resin (82) and powder, which comprises at least magnetic powder (84). The coil-containing insulator enclosure is embedded in the magnetic core (80).

Owner:DENSO CORP 50 INTEREST +2

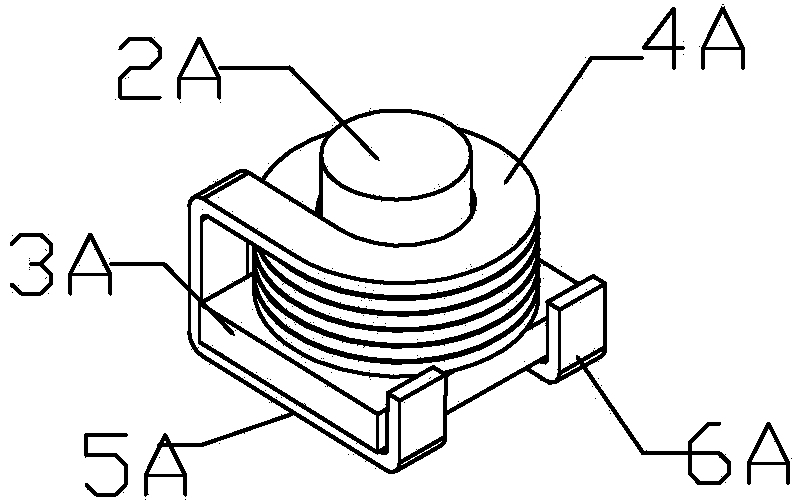

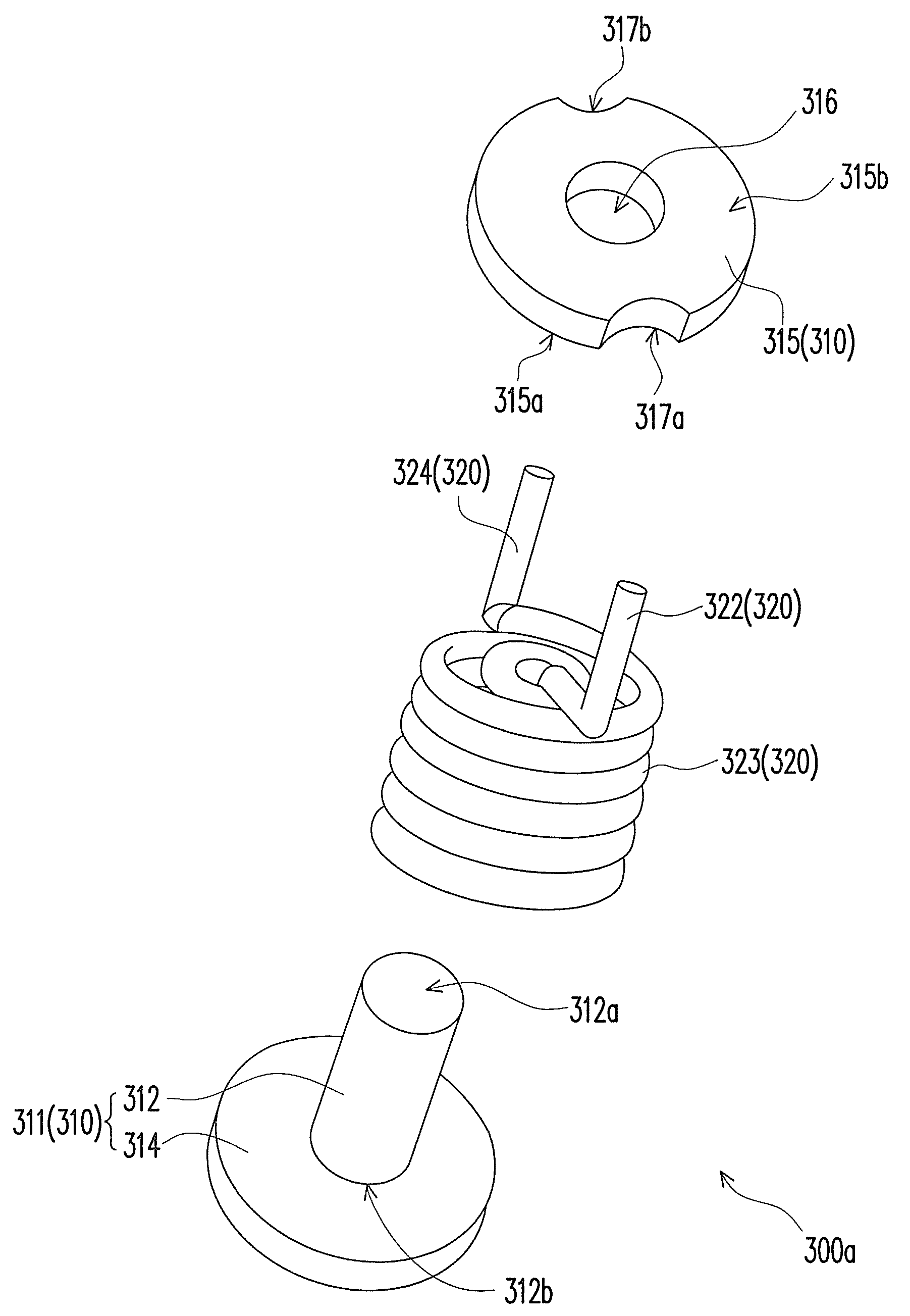

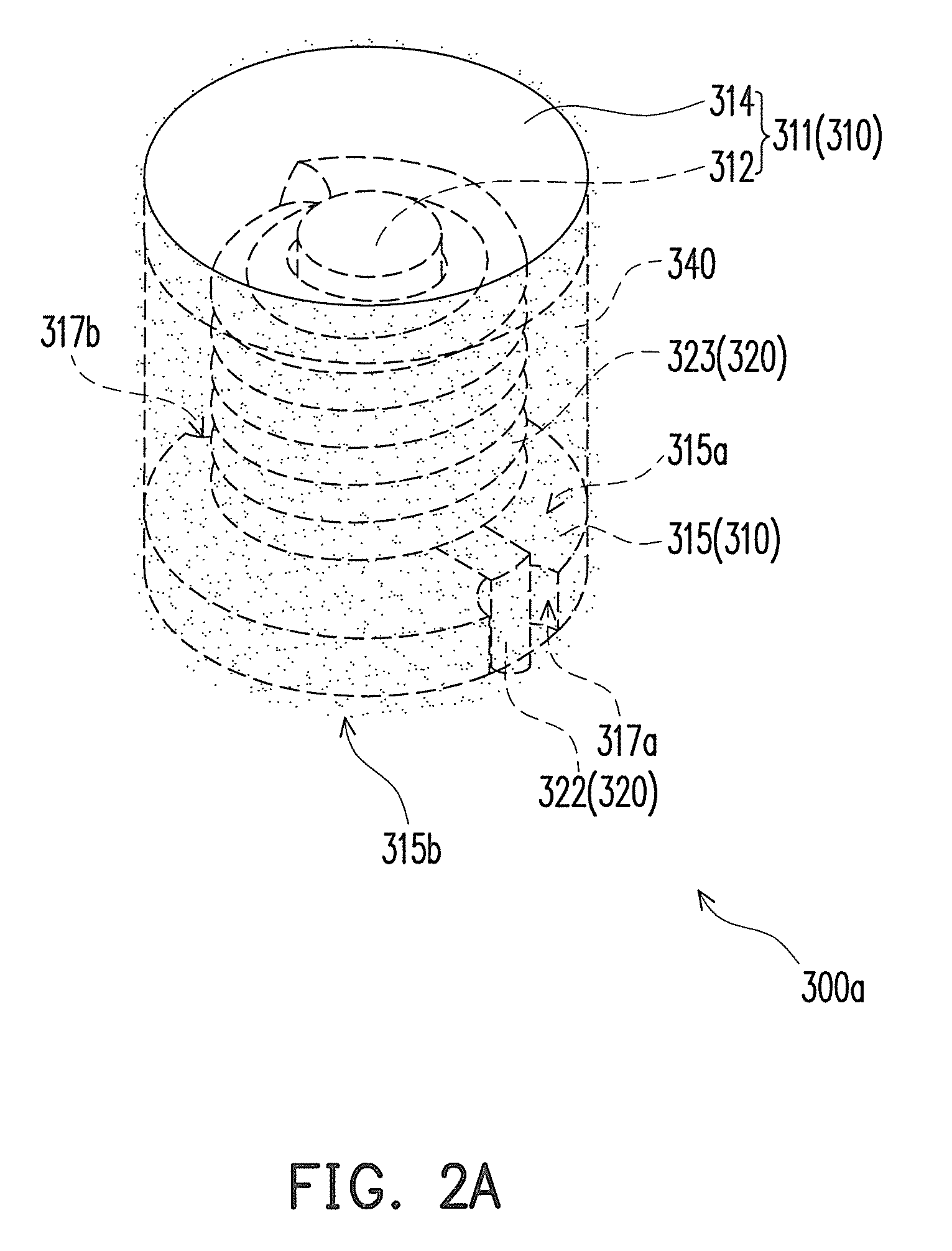

Novel inductor and manufacturing method thereof

InactiveCN103915236AImprove firm performanceReduction of post-processing proceduresVolume/mass flow measurementTransformers/inductances coils/windings/connectionsEngineeringInductor

The invention discloses a novel inductor. The novel inductor is characterized by comprising an inset inner core, an electrode and an outer wrapping layer, the inset inner core comprises an enameled coil and a mandrel, and the inset inner core and the electrode are buried in the center of the outer wrapping layer. The novel inductor has the advantages that manufacturability and performance are improved.

Owner:深圳市科达嘉电子有限公司

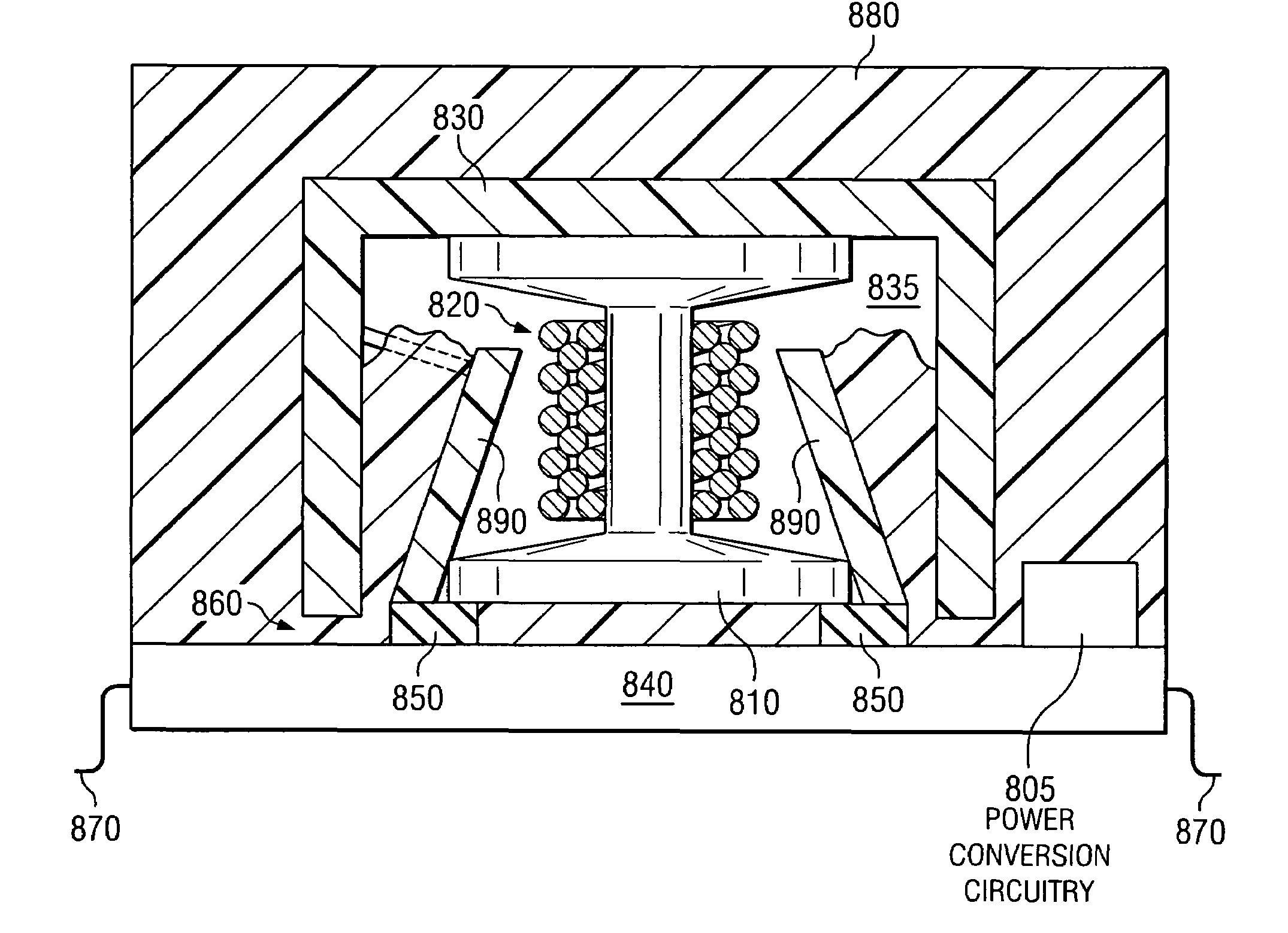

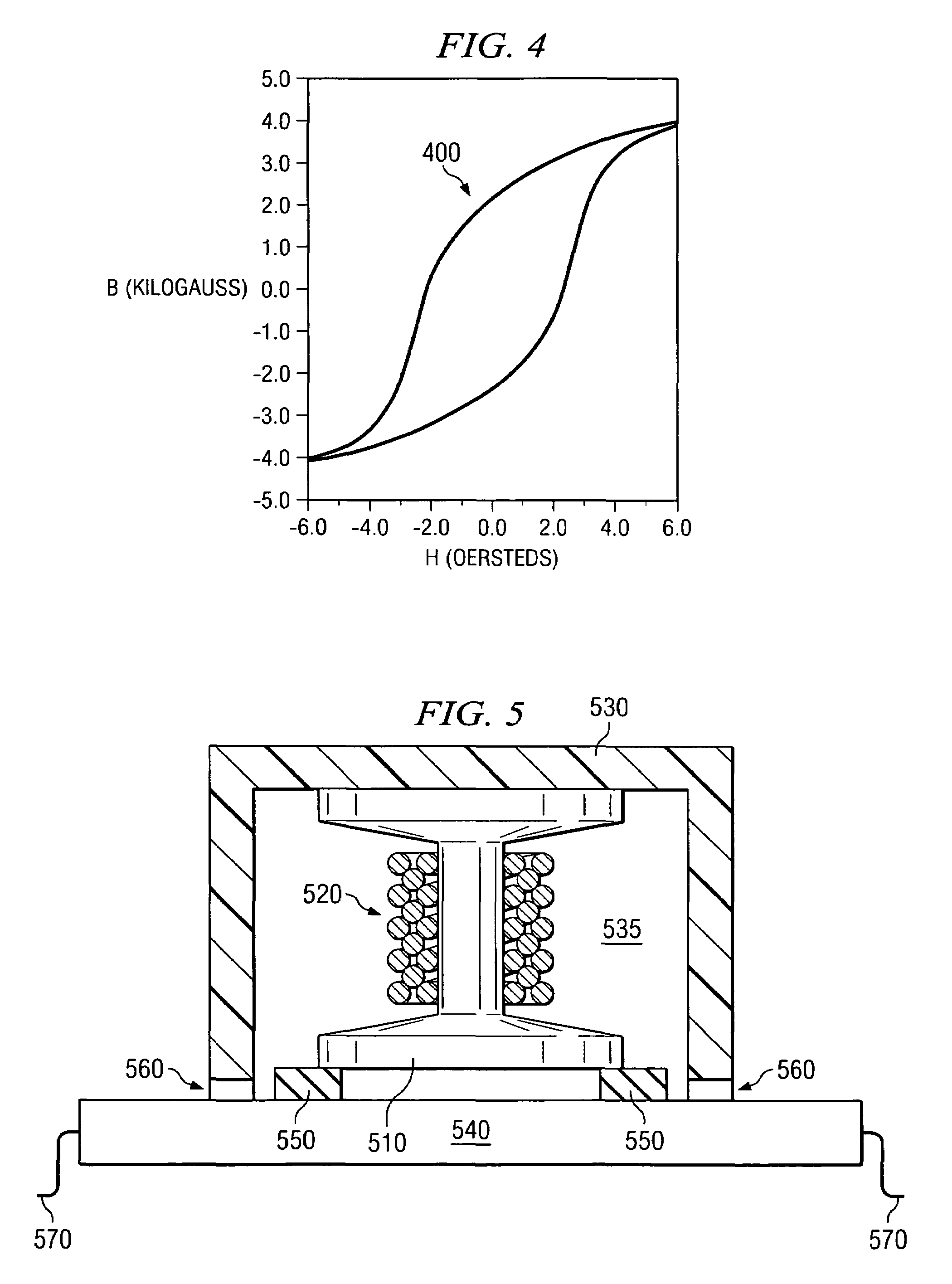

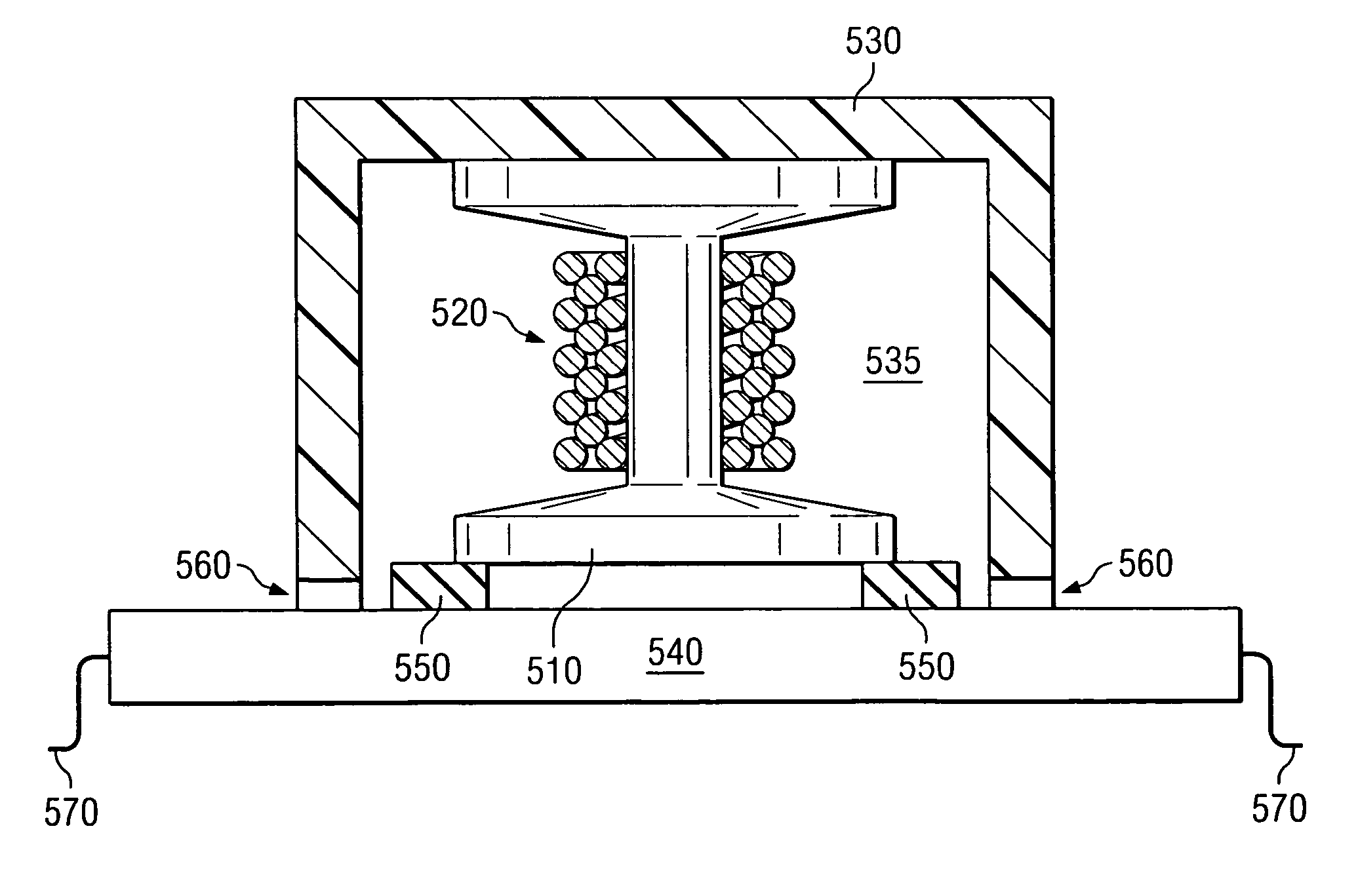

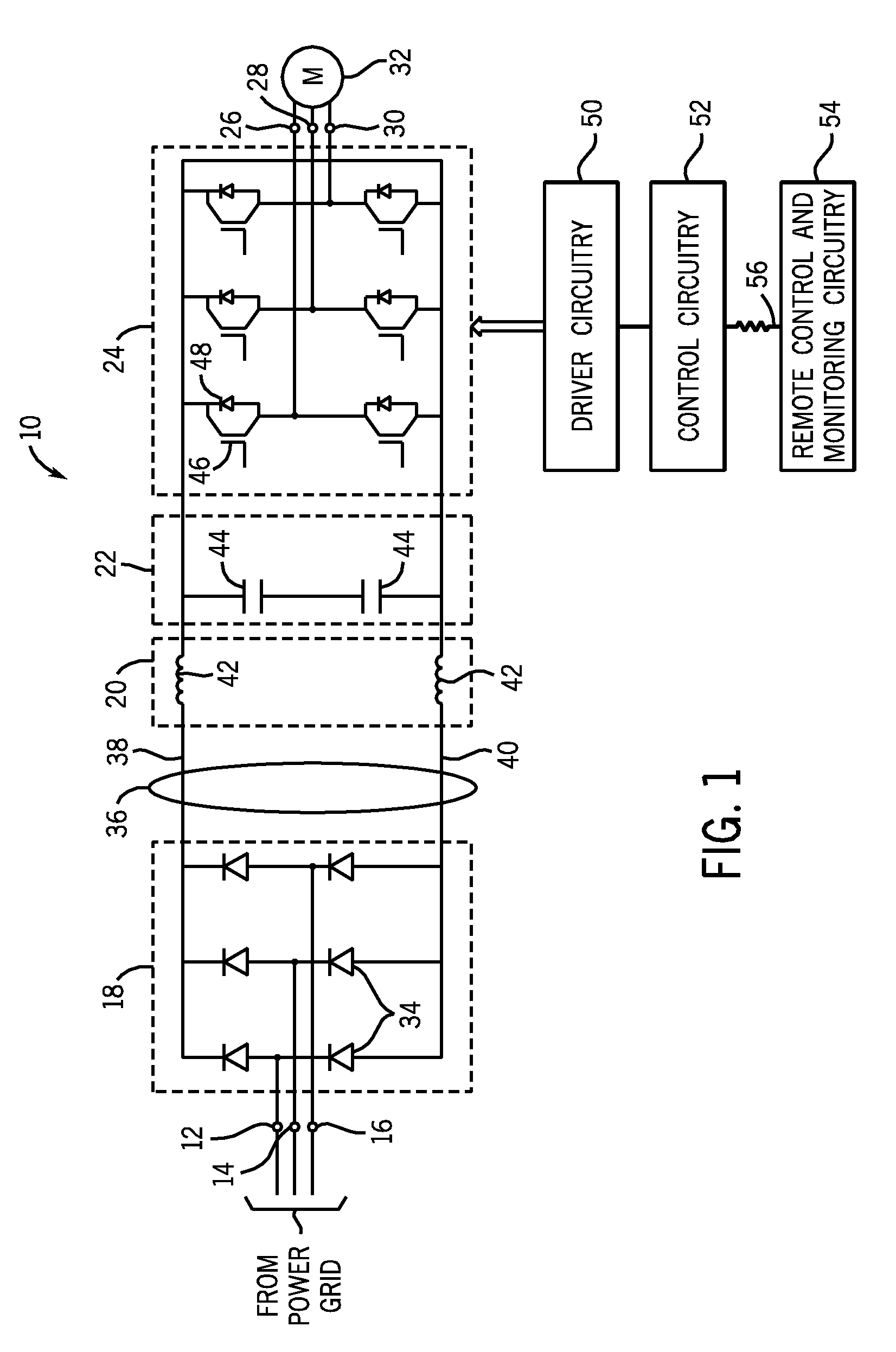

Method of manufacturing a power module

ActiveUS7426780B2Printed circuit assemblingSemiconductor/solid-state device manufacturingComputer moduleEngineering

A method of manufacturing a power module on a substrate. In one embodiment, the method includes providing power conversion circuitry including providing a magnetic device having a magnetic core and at least one switch on the substrate. The method also includes placing a shielding structure over the magnetic core to create a chamber thereabout. The method also includes depositing an encapsulant about the power conversion circuitry. The shielding structure limits the encapsulant entering the chamber thereby allowing the encapsulant to surround a portion of the magnetic core within the chamber.

Owner:INTEL CORP

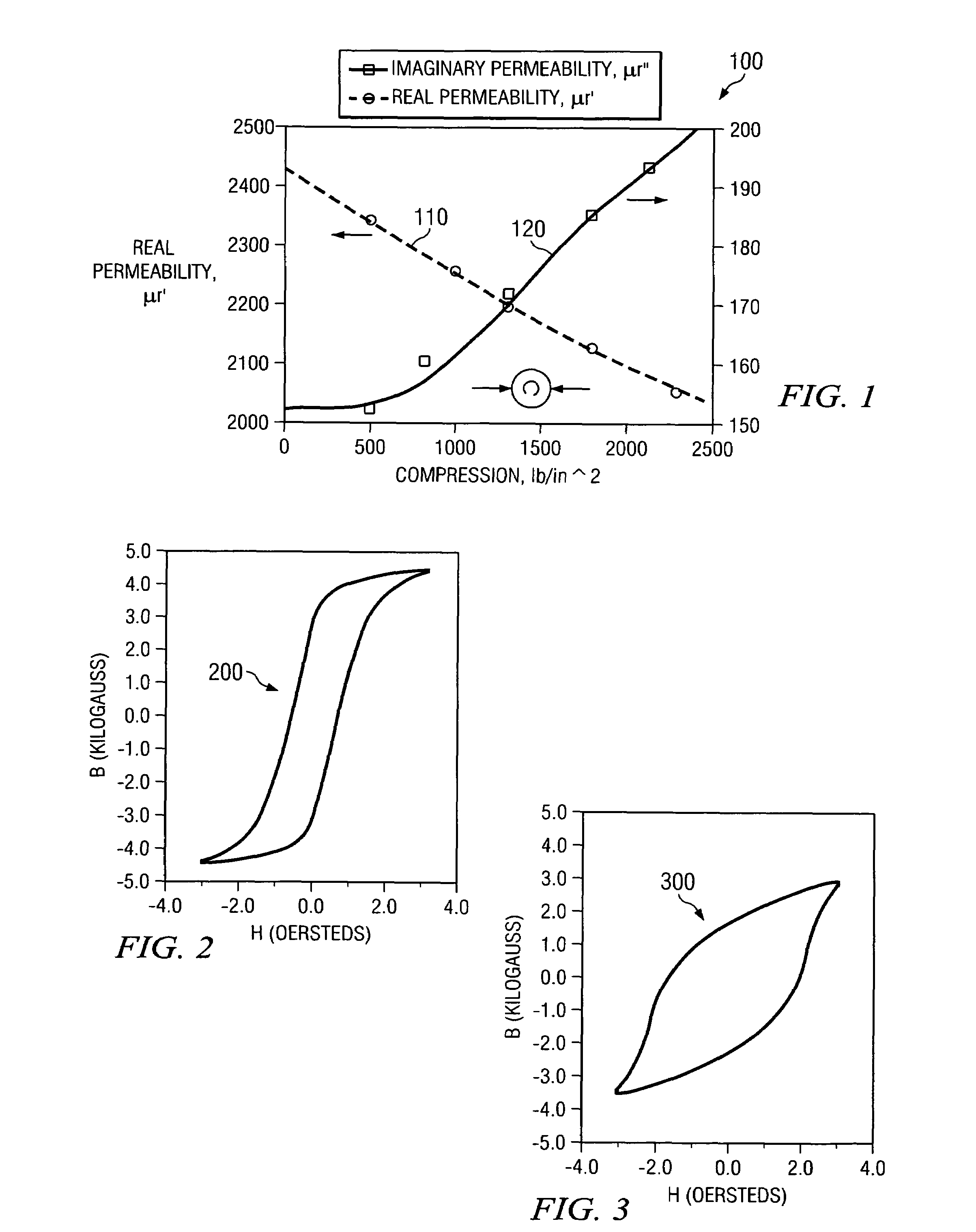

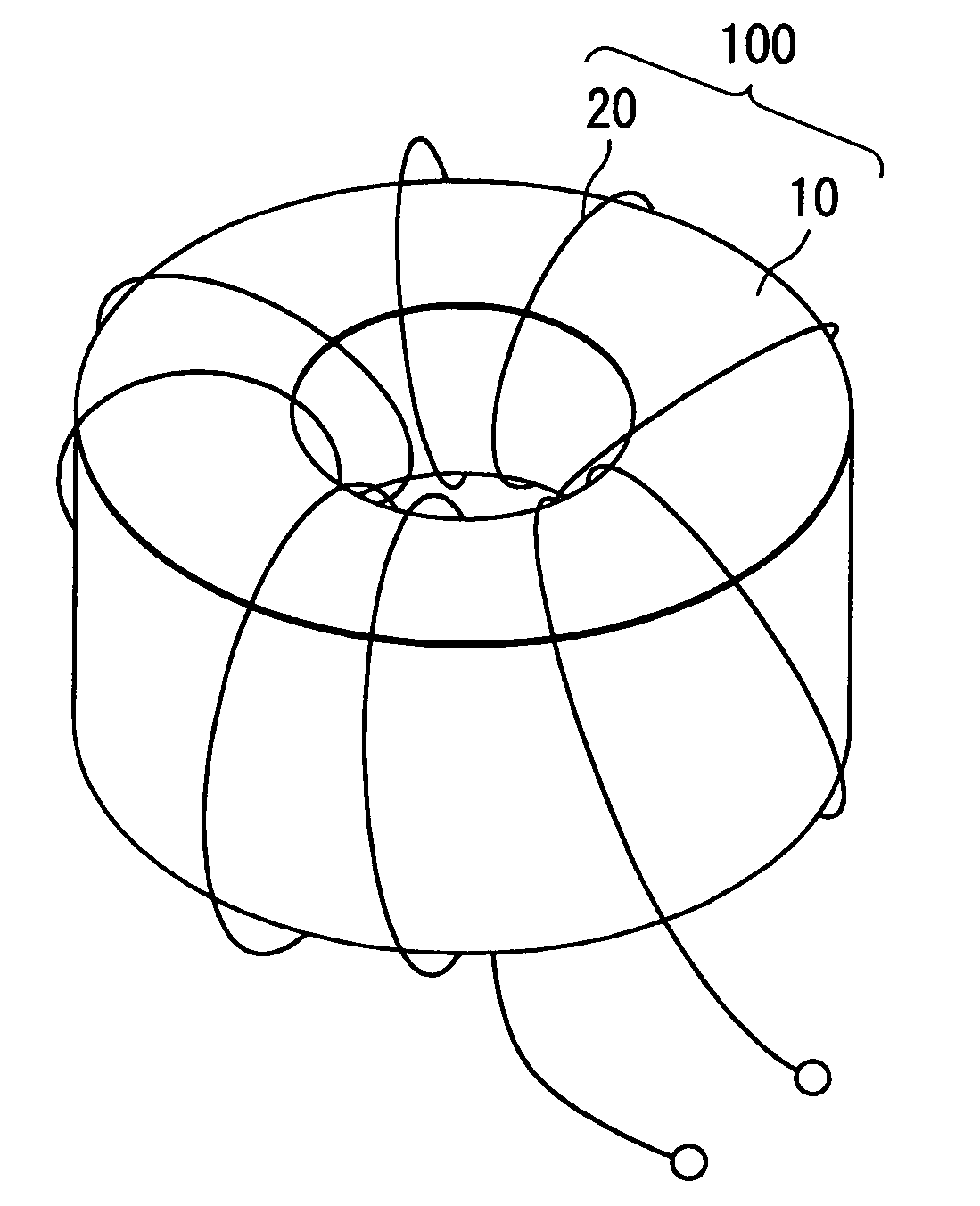

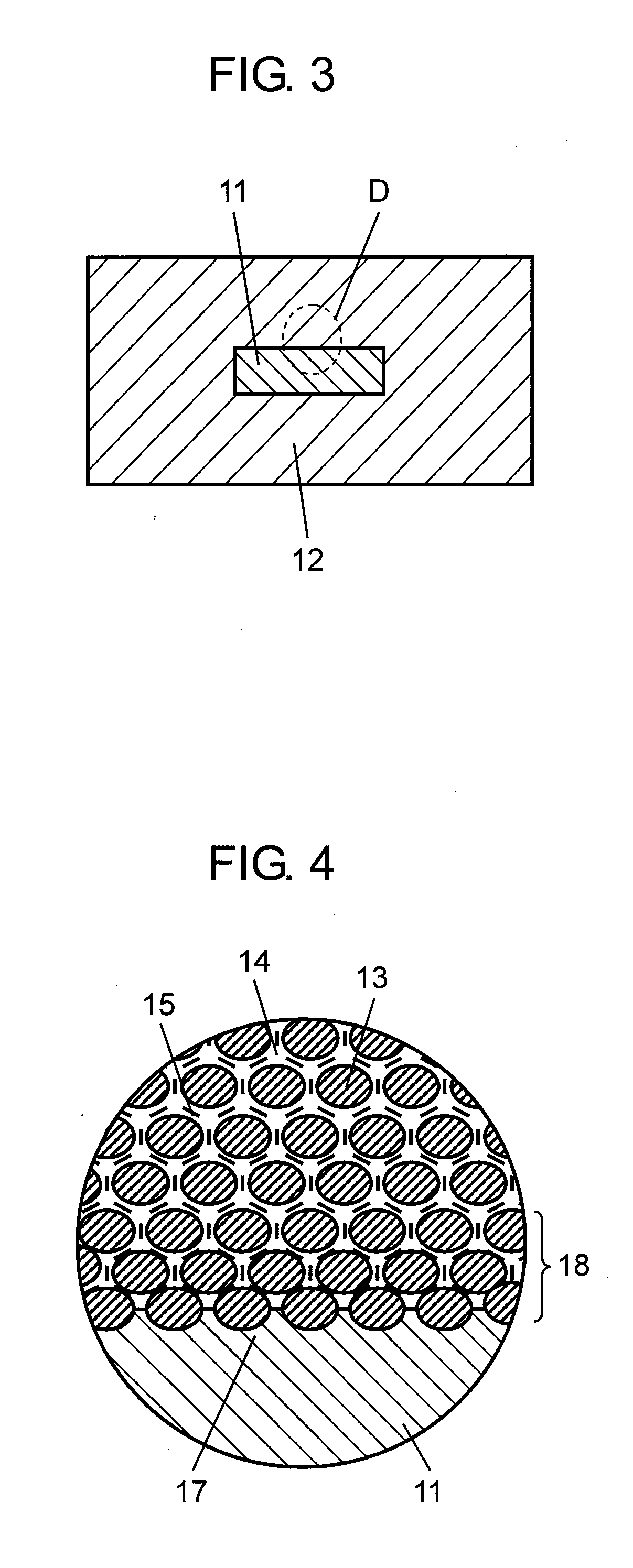

Magnetic core and coil component using the same

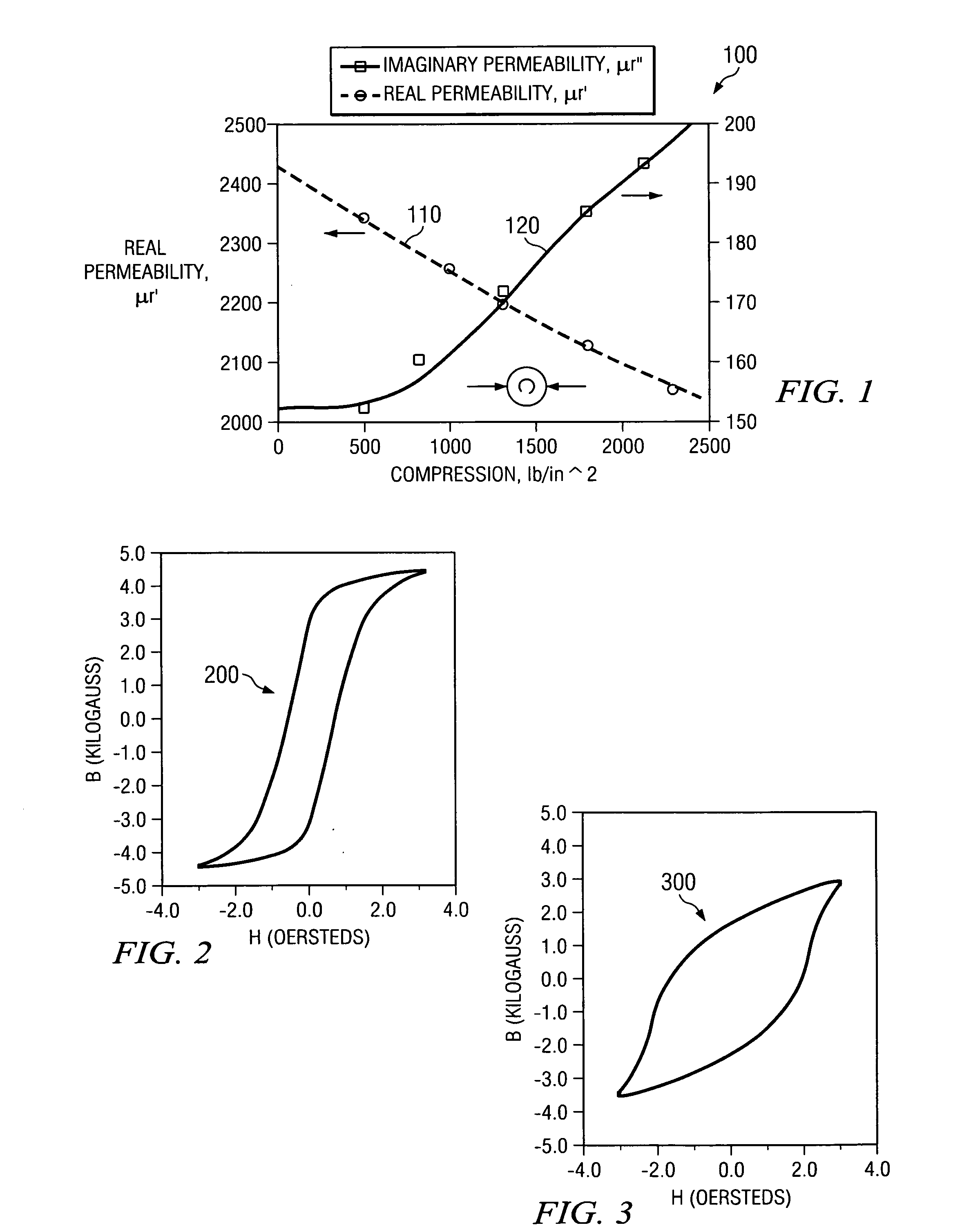

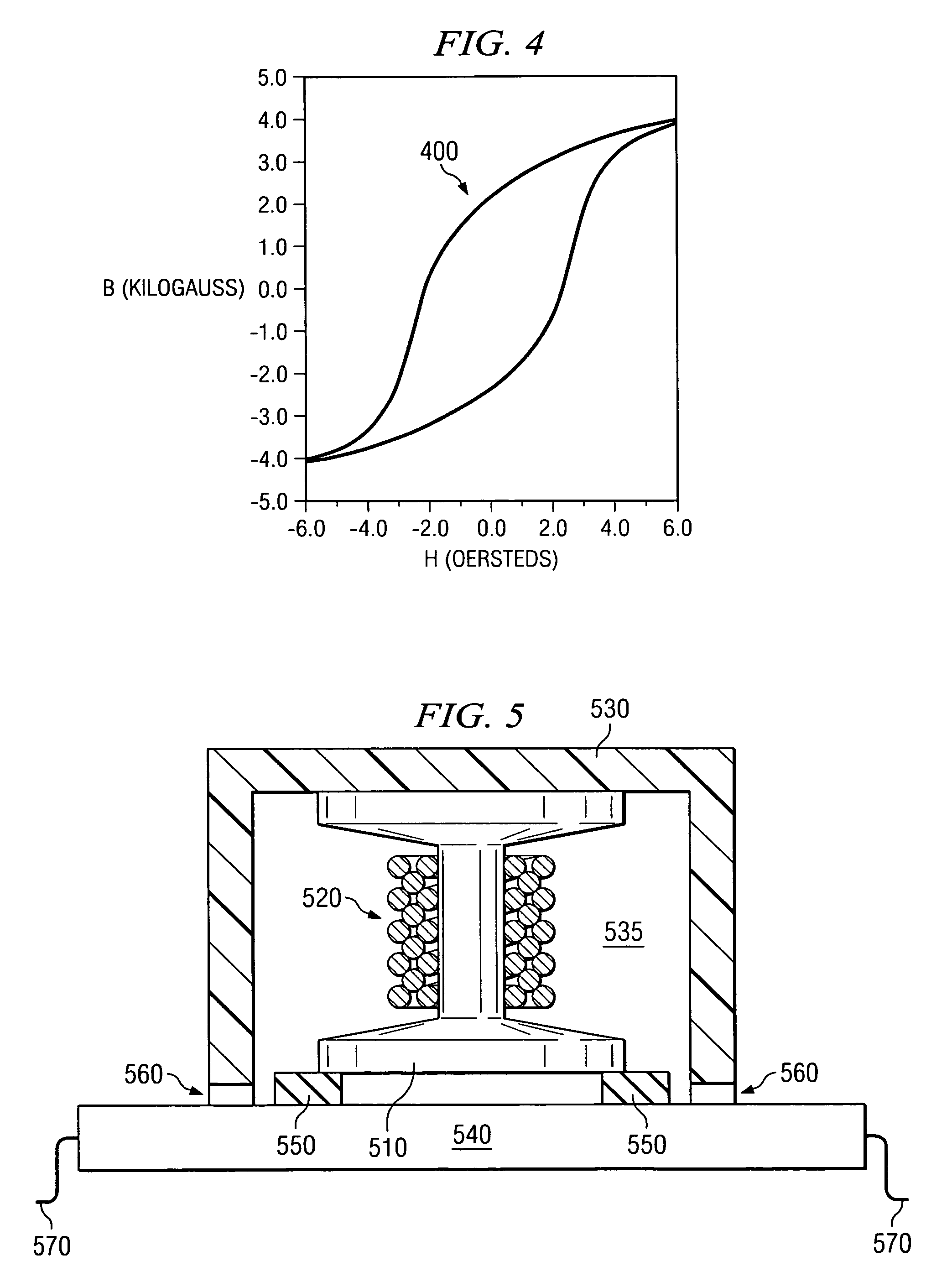

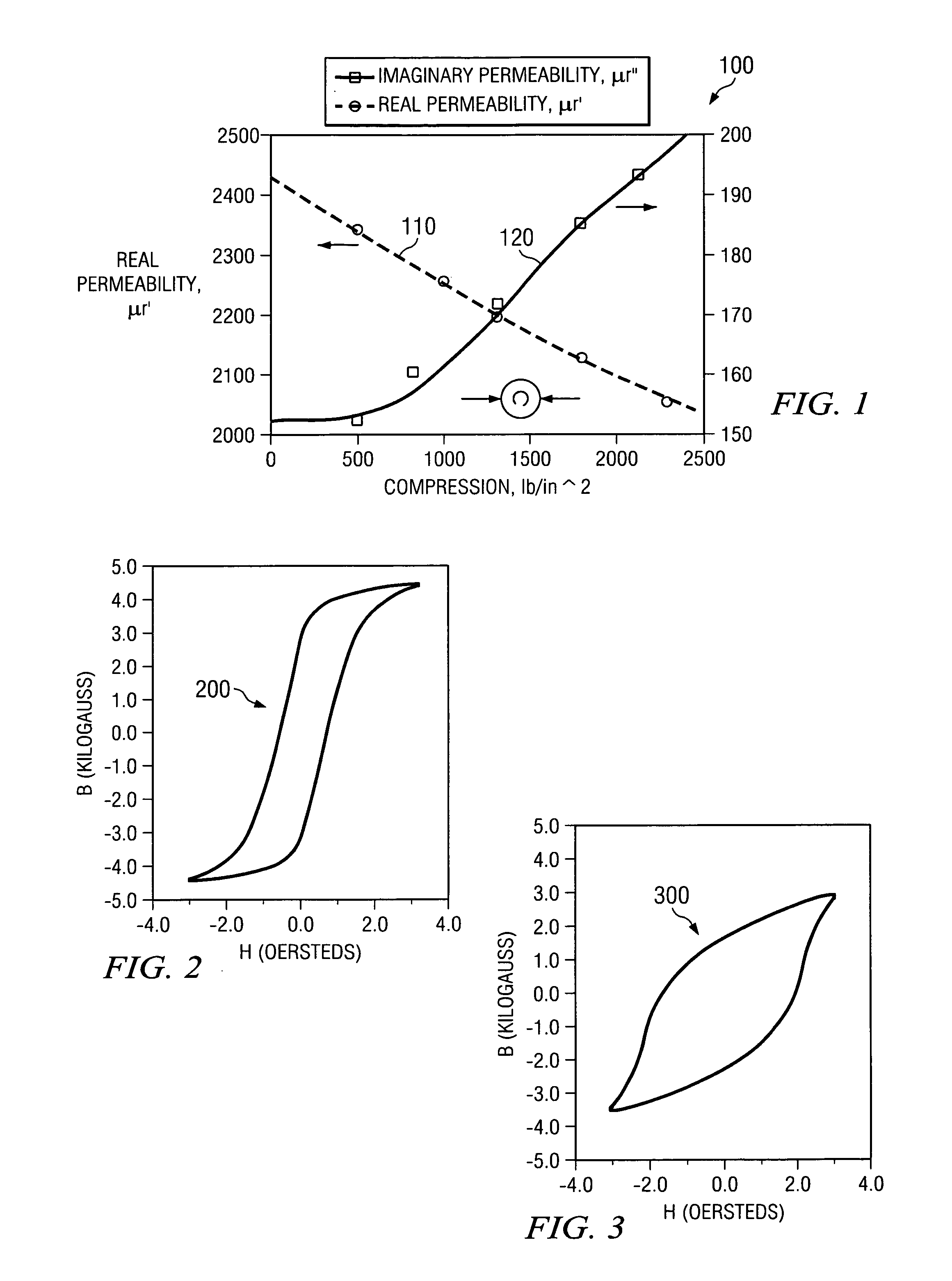

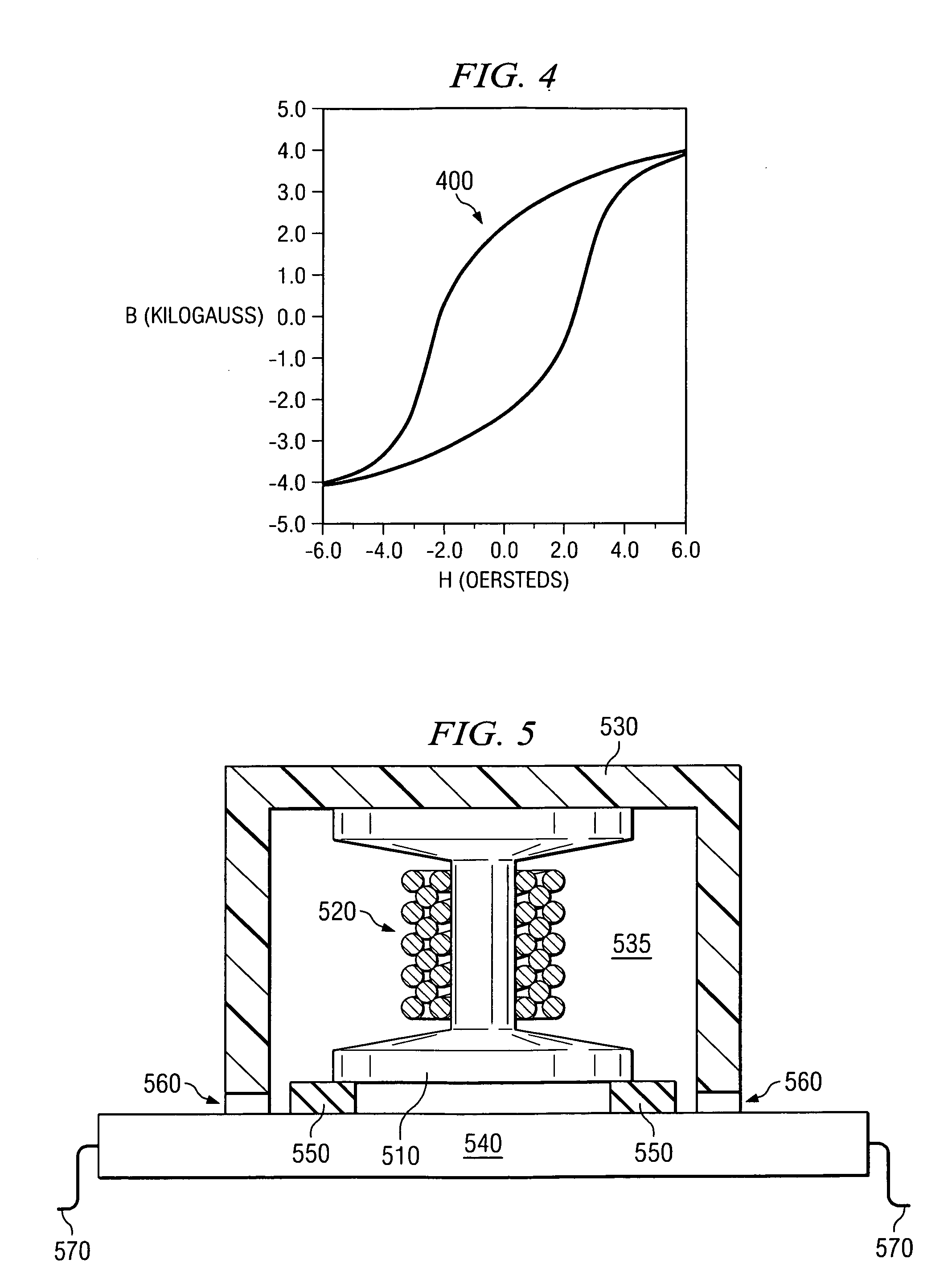

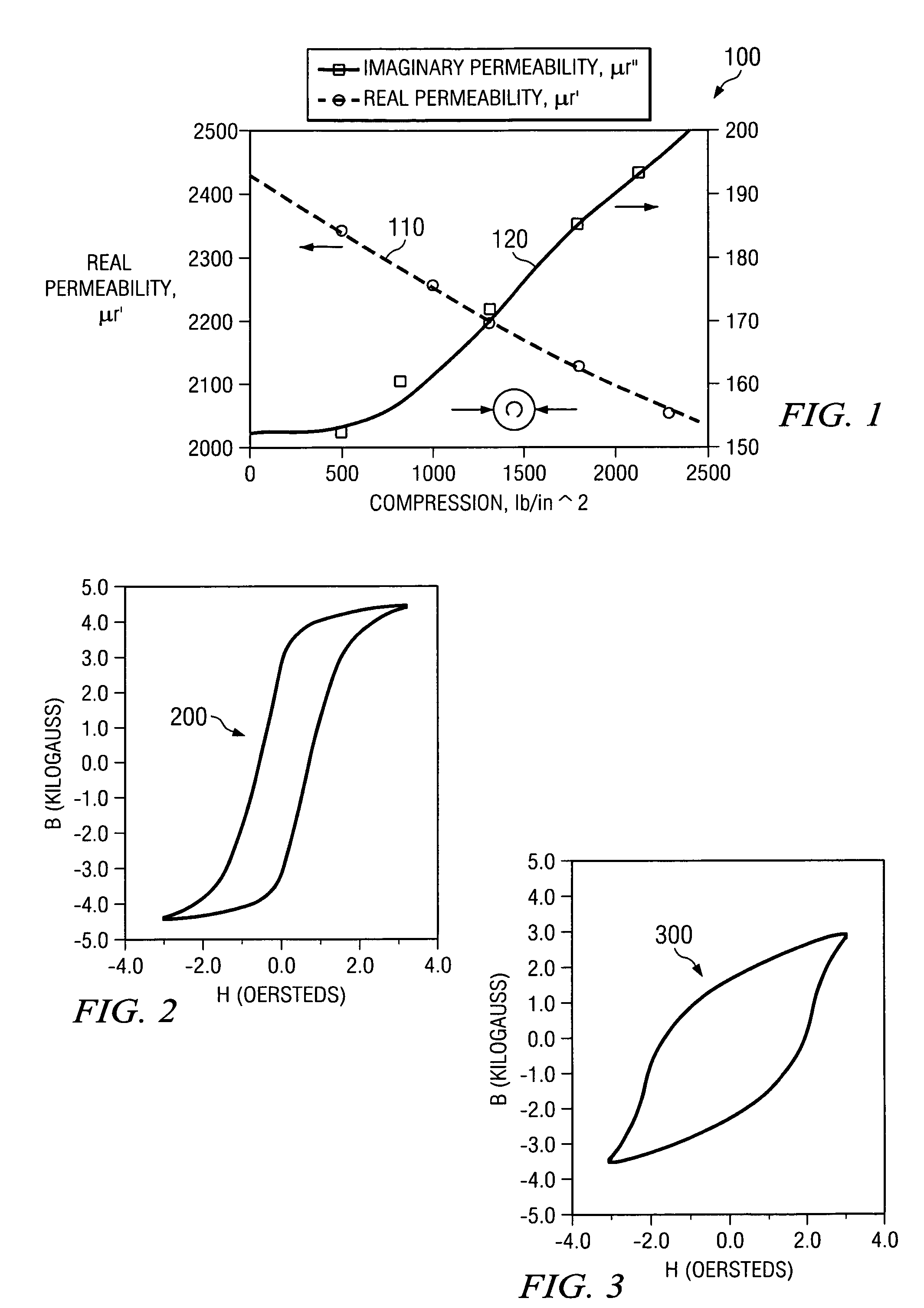

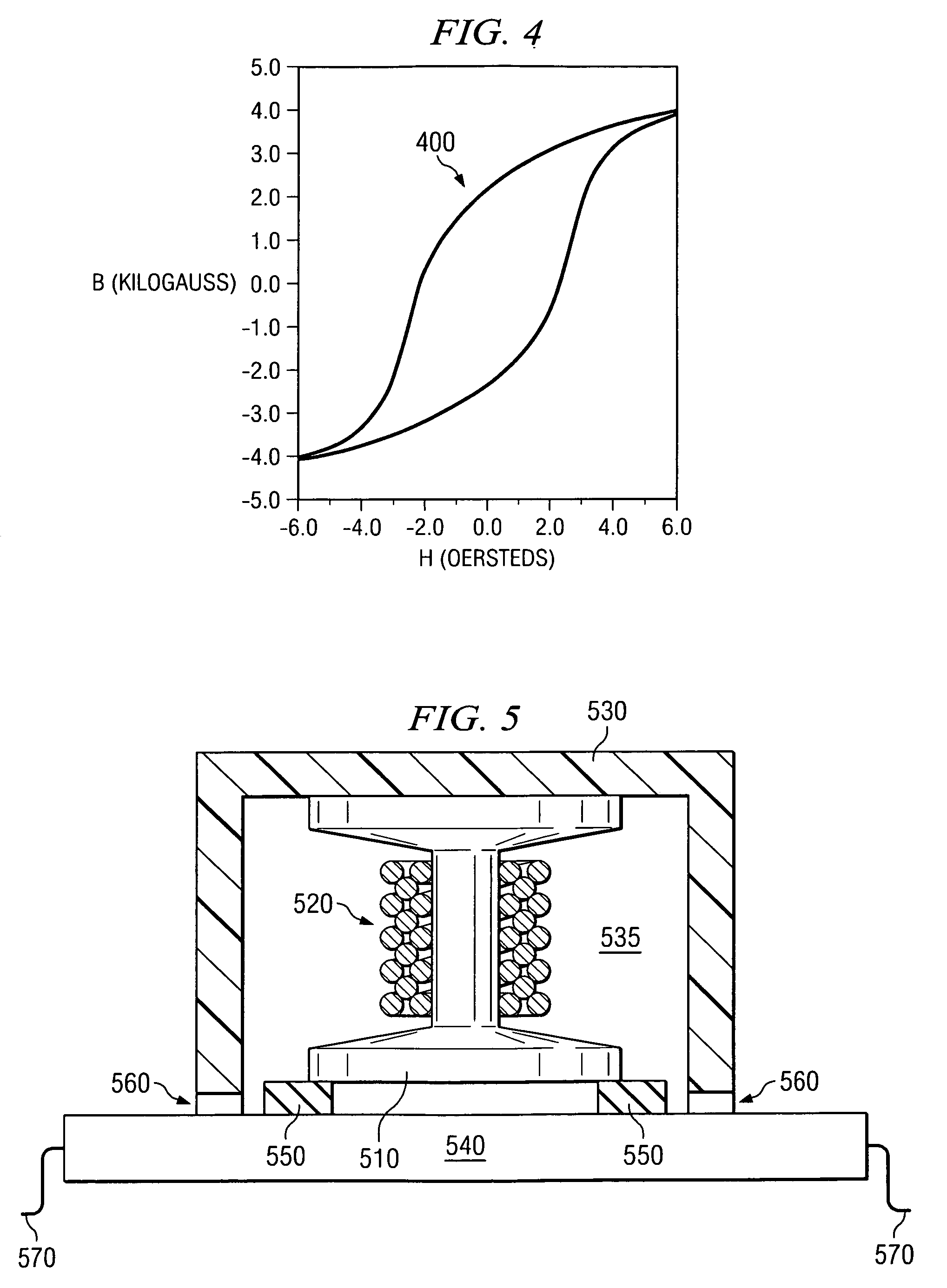

InactiveUS20050007232A1Inorganic material magnetismTransformers/inductances magnetic coresRelative permeabilityMaterials science

A magnetic core is obtained by hardening or curing a mixture of magnetic powder and resin. The magnetic core shows a superior DC bias characteristic which does not become drastically saturated but is gently saturated even beyond 1000*103 / 4π [A / m]. Therefore, the magnetic core has sufficient relative permeability more than ten.

Owner:TOKIN CORP

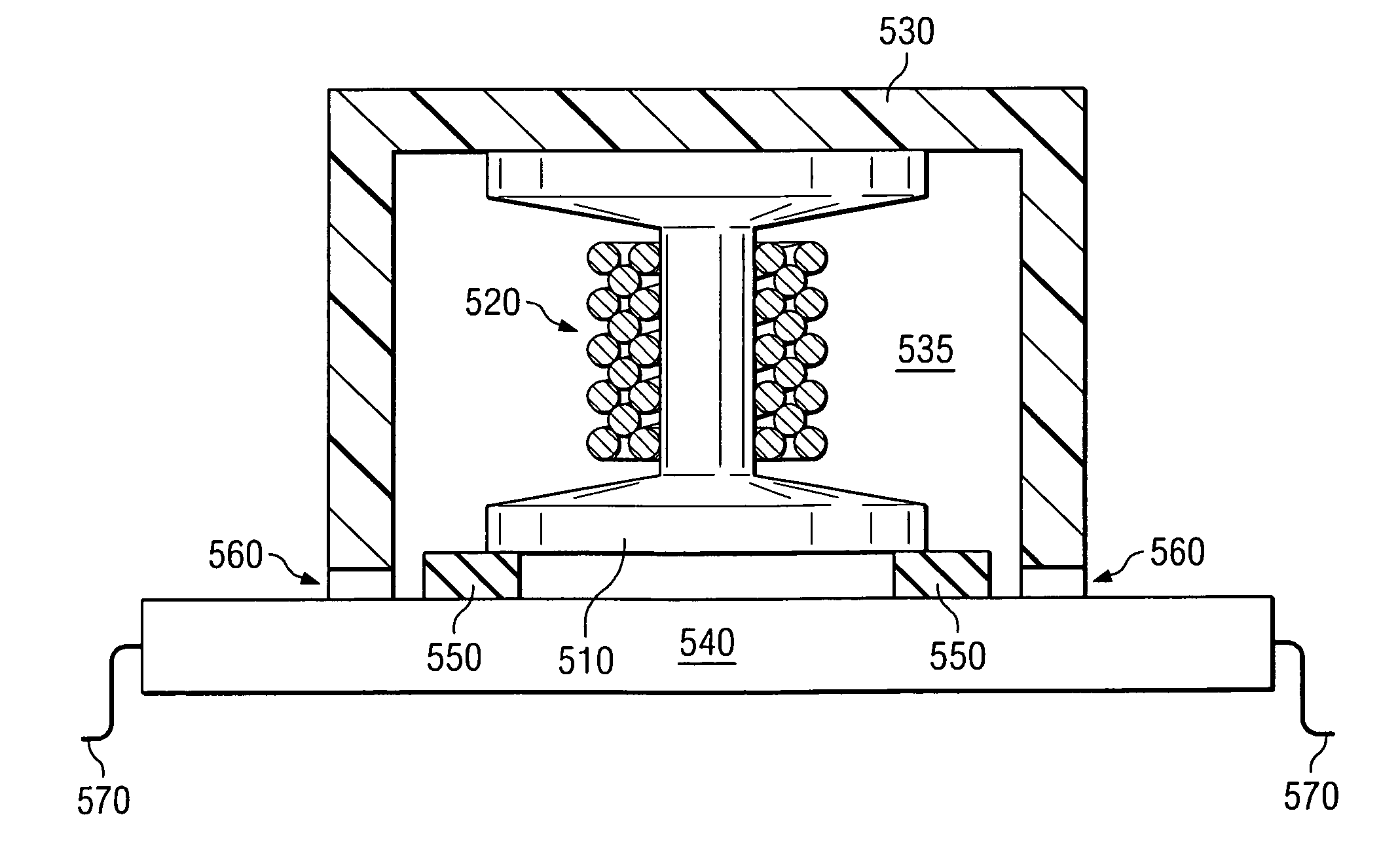

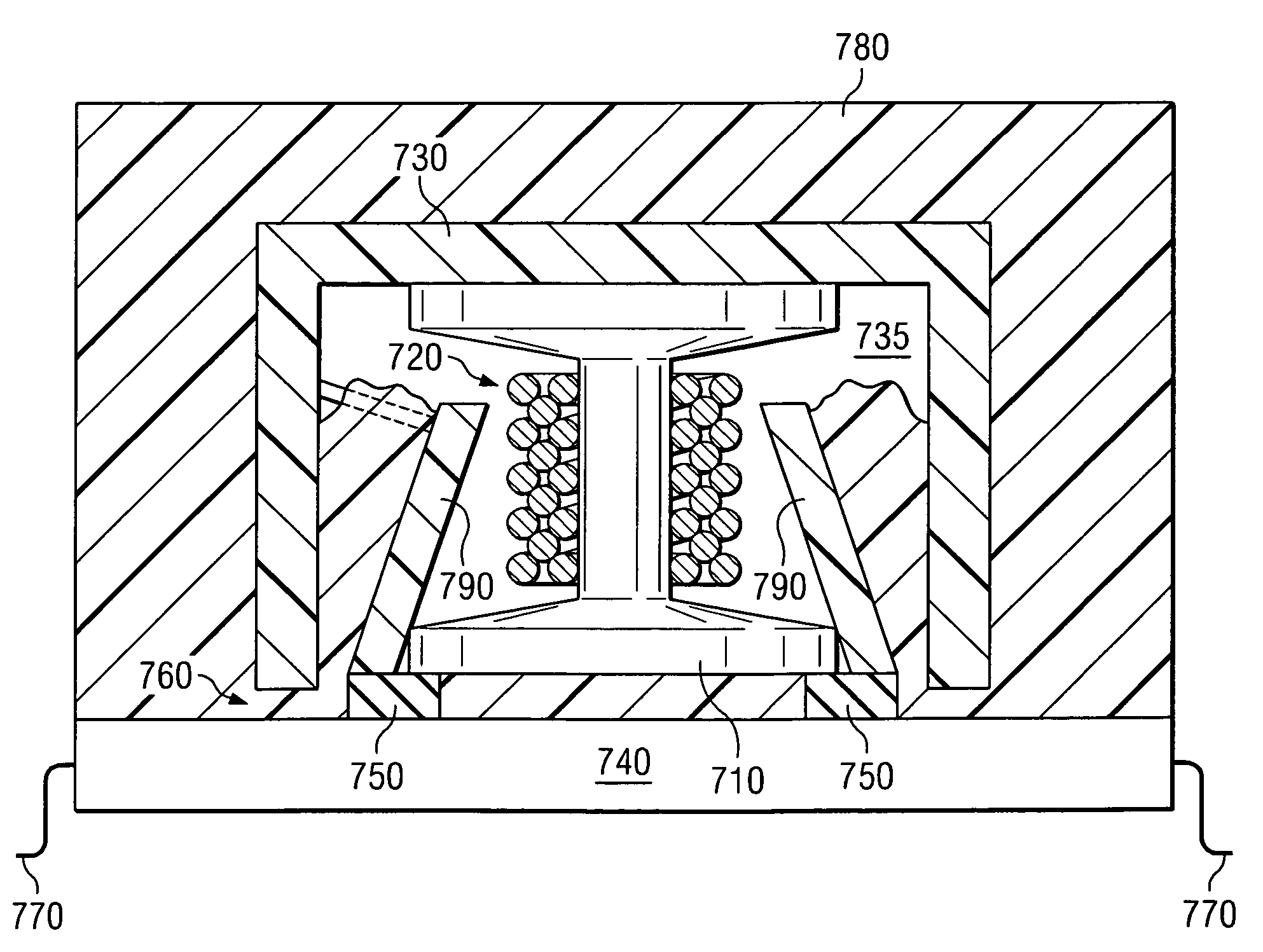

Method of manufacturing a power module

ActiveUS20060096087A1Printed circuit assemblingSemiconductor/solid-state device manufacturingPower moduleMagnetic core

A method of manufacturing a power module on a substrate. In one embodiment, the method includes providing power conversion circuitry including providing a magnetic device having a magnetic core and at least one switch on the substrate. The method also includes placing a shielding structure over the magnetic core to create a chamber thereabout. The method also includes depositing an encapsulant about the power conversion circuitry. The shielding structure limits the encapsulant entering the chamber thereby allowing the encapsulant to surround a portion of the magnetic core within the chamber.

Owner:INTEL CORP

Method of manufacturing an encapsulated package for a magnetic device

InactiveUS20060096088A1Printed circuit assemblingTransformers/inductances casingsSealantElectrical and Electronics engineering

A method of manufacturing an encapsulated package for a magnetic device on a substrate. In one embodiment, the method includes providing a magnetic core on the substrate and placing a shielding structure over the magnetic core to create a chamber thereabout. The method also includes depositing an encapsulant about a portion of the magnetic core within the chamber. The shielding structure limits the encapsulant entering the chamber.

Owner:INTEL CORP

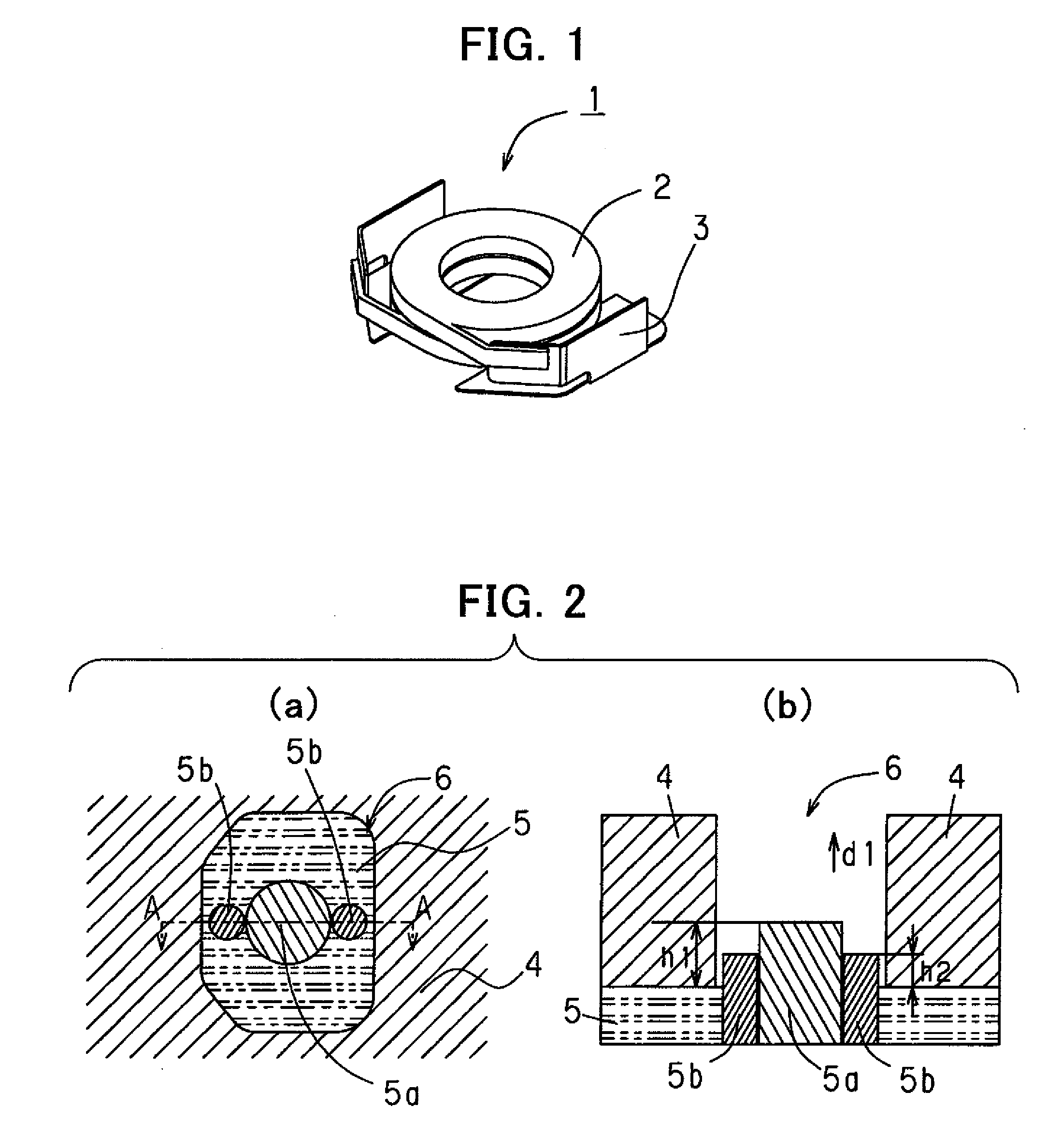

Coil Component And Method For Manufacturing Coil Component

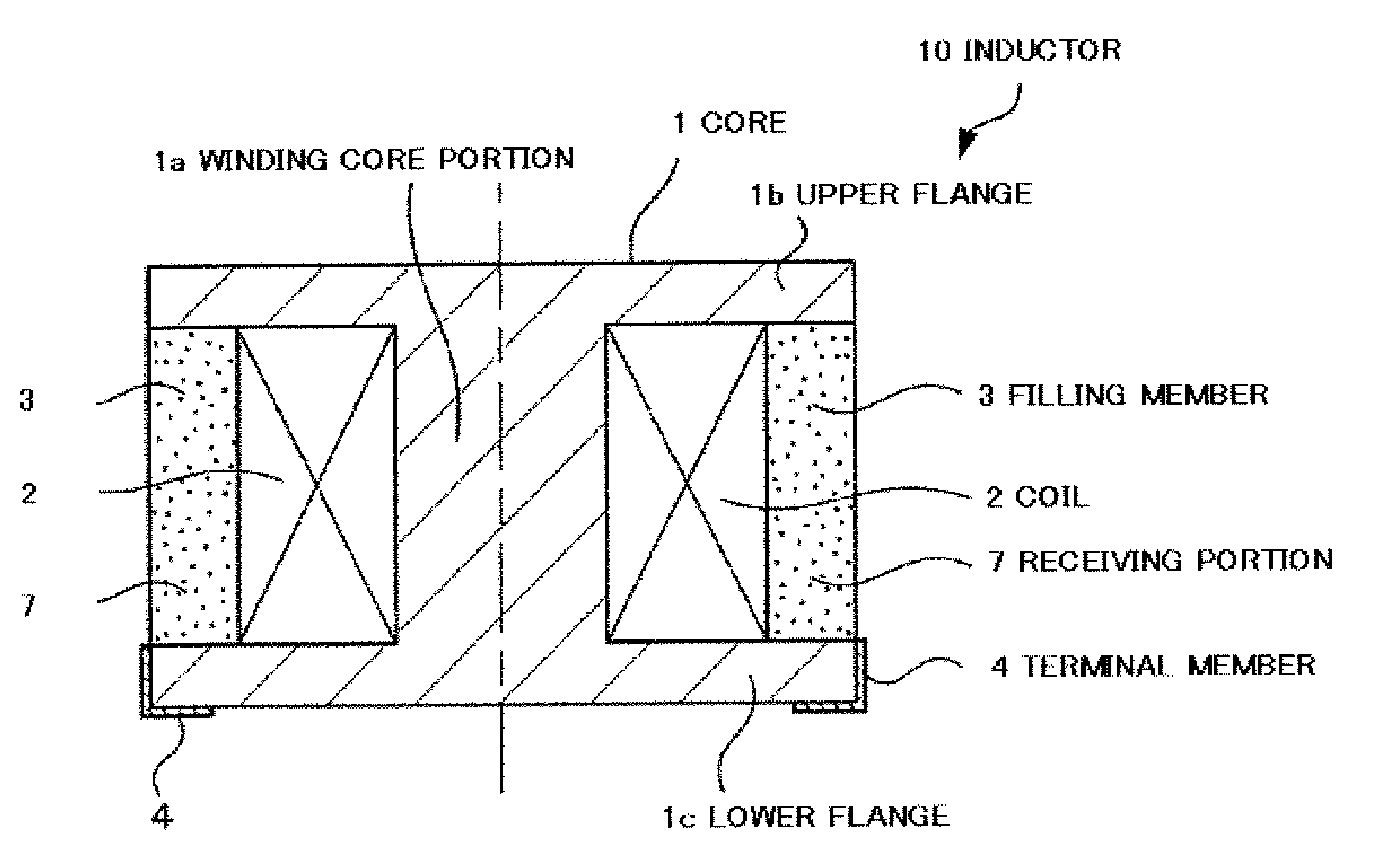

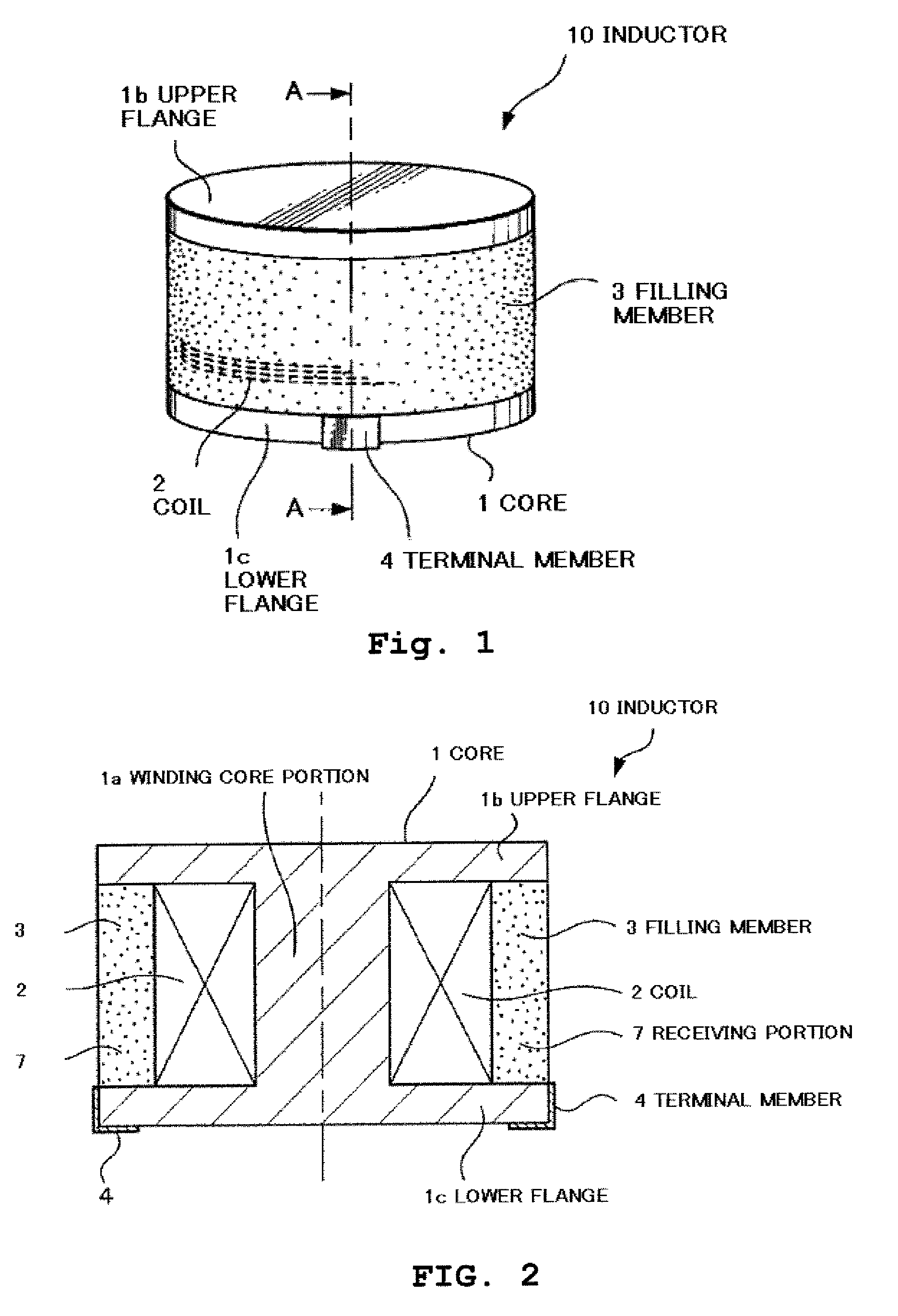

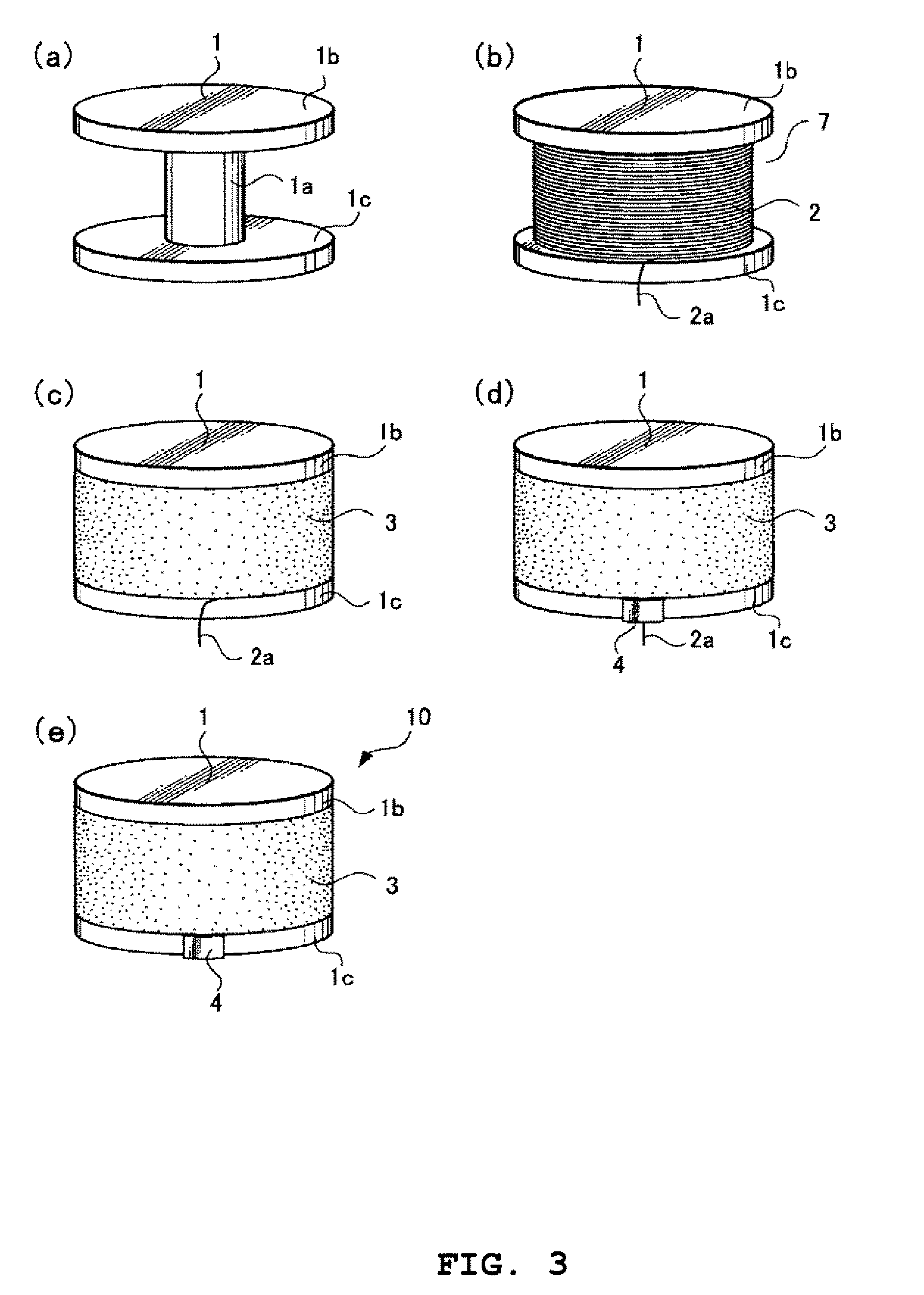

InactiveUS20110006870A1Improve impact resistanceAvoid damageTransformers/inductances casingsInorganic material magnetismInductorMagnetic flux

In an inductor including a coil, a drum type core constituted by a soft magnetic metal material and a resin material, and a filling member constituted by a soft magnetic metal material and a resin material in which a magnetic flux excited by aforesaid coil goes through aforesaid drum type core and aforesaid filling member serially, the present invention constitutes an inductor, wherein aforesaid drum type core is constituted by injection molding so as to include a receiving portion, aforesaid coil is arranged in aforesaid receiving portion, and aforesaid filling member is filled therein.

Owner:SUMIDA CORP

Chip type electronic part and method for the manufacture thereof

InactiveUS6252481B1Avoid vibrationTransformers/inductances casingsFixed capacitor dielectricConductive pasteElectricity

Delamination in the conventional chip-type electronic part may create voids thereinside, allowing an internal electrode therein to vibrate in presence of external impacts or large electromagnetic forces caused by a high frequency current flowing inside the electrode, in such a way that fatigue may accumulate in the internal electrode, which eventually will results in the internal electrode being electrically disconnected. To solve this problem, a chip-type electronic part of the present invention includes synthetic resins impregnated into the voids to secure the internal electrode, wherein external electrodes of the chip-type electronic part are made of a conductive synthetic resin or a porous conductive material formed by sintering a conductive paste. The former is achieved by impregnating the synthetic resins before the formation of the external electrodes and the later, by extending the pores from surfaces of the external electrodes to surfaces of a main body and then by impregnating the synthetic resins thereinto.

Owner:TAIYO YUDEN KK

Method of manufacturing an encapsulated package for a magnetic device

A method of manufacturing an encapsulated package for a magnetic device on a substrate. In one embodiment, the method includes providing a magnetic core on the substrate and placing a shielding structure over the magnetic core to create a chamber thereabout. The method also includes depositing an encapsulant about a portion of the magnetic core within the chamber. The shielding structure limits the encapsulant entering the chamber.

Owner:INTEL CORP

Inductance part and method for manufacturing the same

ActiveUS20100253463A1Small sizeImprove permeabilityTransformers/inductances casingsTransformers/inductances magnetic coresElectrical conductorInductance

Disclosed is an inductance part including a coiled conductor formed from a metal conductor, a magnetic body formed by pressure-molding a mixture of metal magnetic powder and bonding material in such a manner that the coiled conductor is embedded in the mixture, and a terminal derived from the coiled conductor. The coiled conductor is formed in a single layer with no insulating film on its surface. The metal magnetic powder of the magnetic body penetrates into the surface of the coiled conductor so as to make the filling factor of the metal magnetic powder in the magnetic body not less than 80% by volume.

Owner:PANASONIC CORP

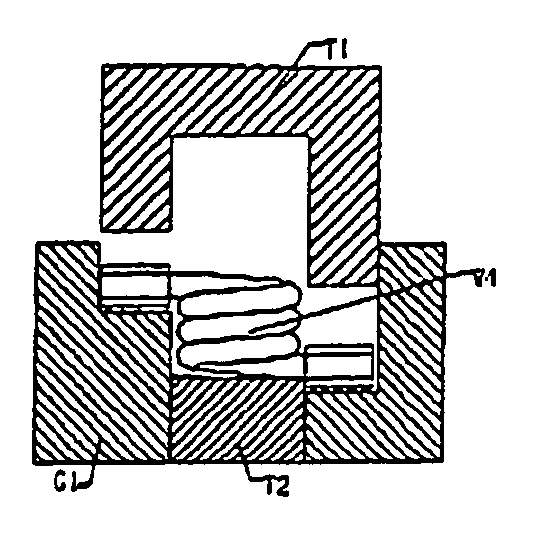

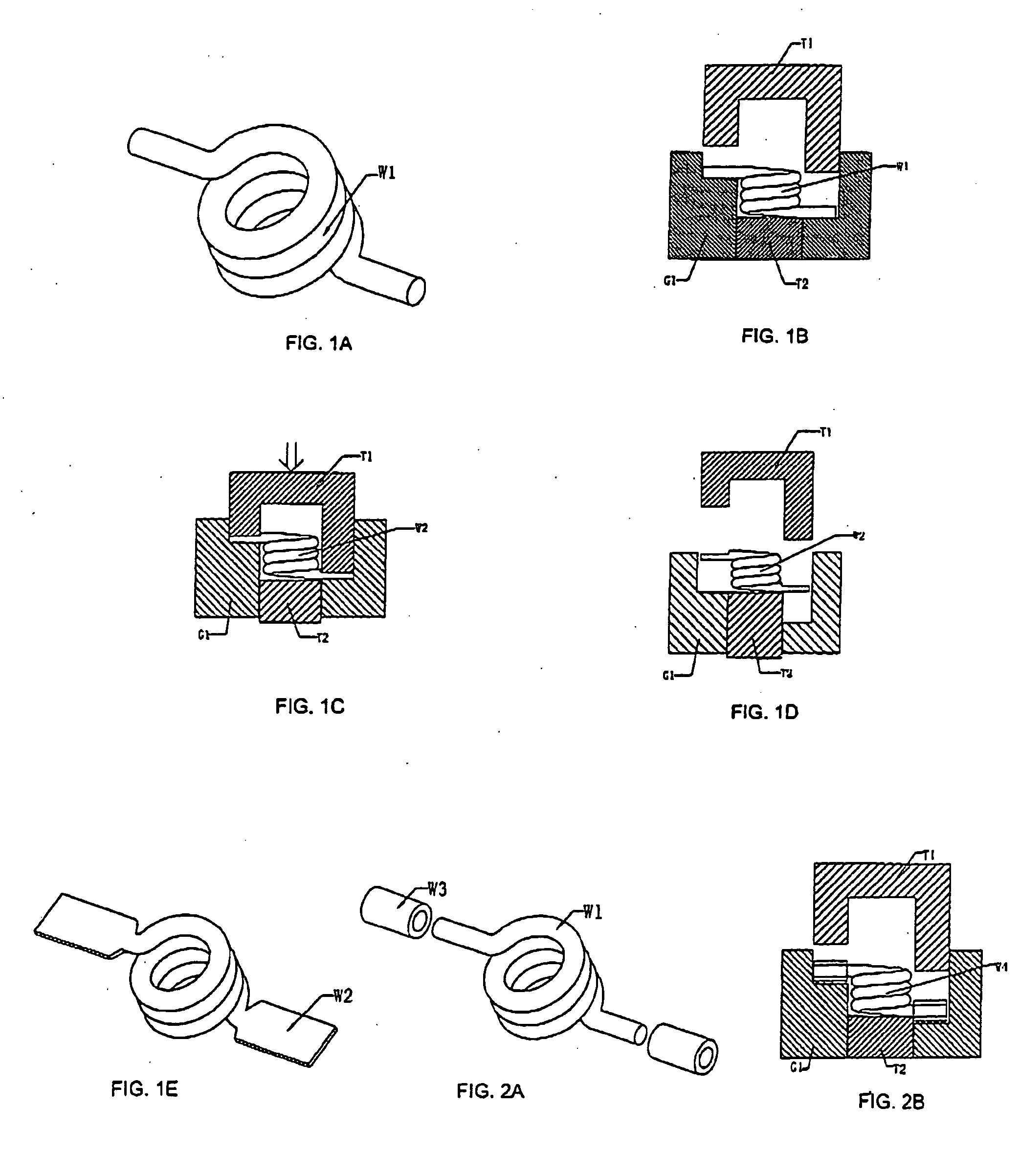

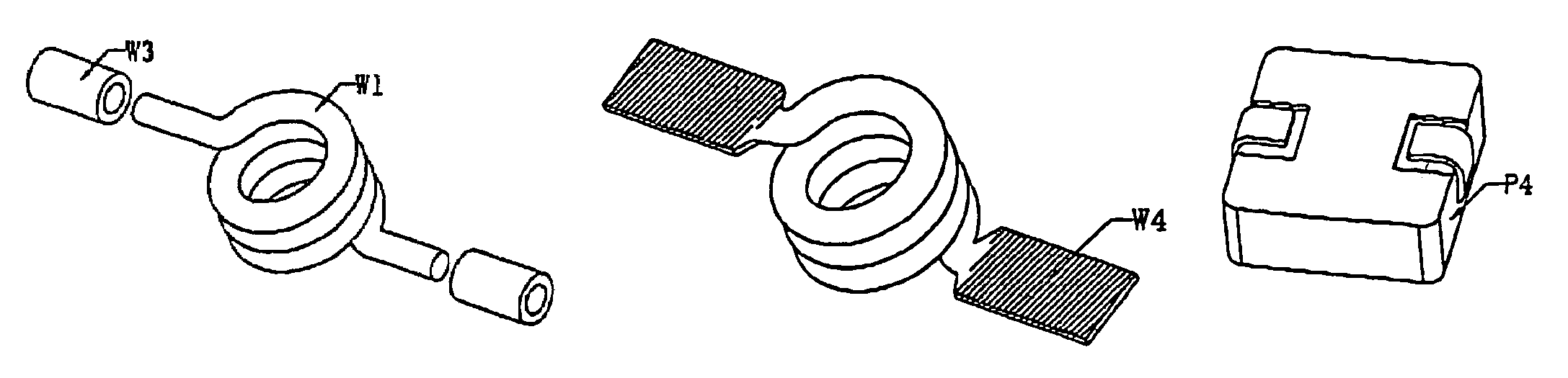

High current inductor and the manufacturing method

InactiveUS20060001517A1Improve featuresCompact structureTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorDie casting

An inductor with the characteristic of resisting high current comprising a conductor coil and a magnet envelope, the magnet envelope tightly wraps the periphery of the conductor coil and forms the main body of the inductor, and the two extending parts of the conductor coil extend to outside of the main body of the inductor, forming terminal electrode. As of the manufacturing method, it includes the part of toroid coil and the extending parts composing the conductor coil. After the toroid coil part is winded into rings, the unwinded wire ends form the extending parts. Through magnet envelope die-casting and wrapping the molded magnet core of the conductor coil to form the main body of the inductor, and the extending parts of the conductor coil extend to outside of the main body to form the terminal electrode.

Owner:CHENG CHANG MAO

Choke

InactiveUS20100308950A1High assembly stabilitySmall inductance value variationTransformers/inductances detailsEncapsulation/impregnationMechanical engineeringEngineering

A choke including a core and a hollow coil is provided. The core includes a first core body and a second core body. The first core body includes a pillar. The second core body is a flat plate and has an opening. An end of the pillar is suitable to be disposed in the opening and joined to the same. The hollow coil is fitted on the pillar.

Owner:CYNTEC

Inductance device and manufacturing method thereof

InactiveUS20070052510A1Reduce the differenceIncrease production capacityTransformers/inductances casingsEncapsulation/impregnationCompound (substance)Engineering

An inductance device has a hollow center coil around which a conducting wire is wound so that a hollow portion is formed along a center axis line of the hollow center coil, a filler which is filled into the hollow portion of the hollow center coil, and includes magnetic powder or a compound including the magnetic powder, and an accommodation case which accommodates the hollow core coil and has a bottom, wherein the filler is filled into the accommodation case.

Owner:YONEZAWA ELECTRIC WIRE

Coil component and fabrication method of the same

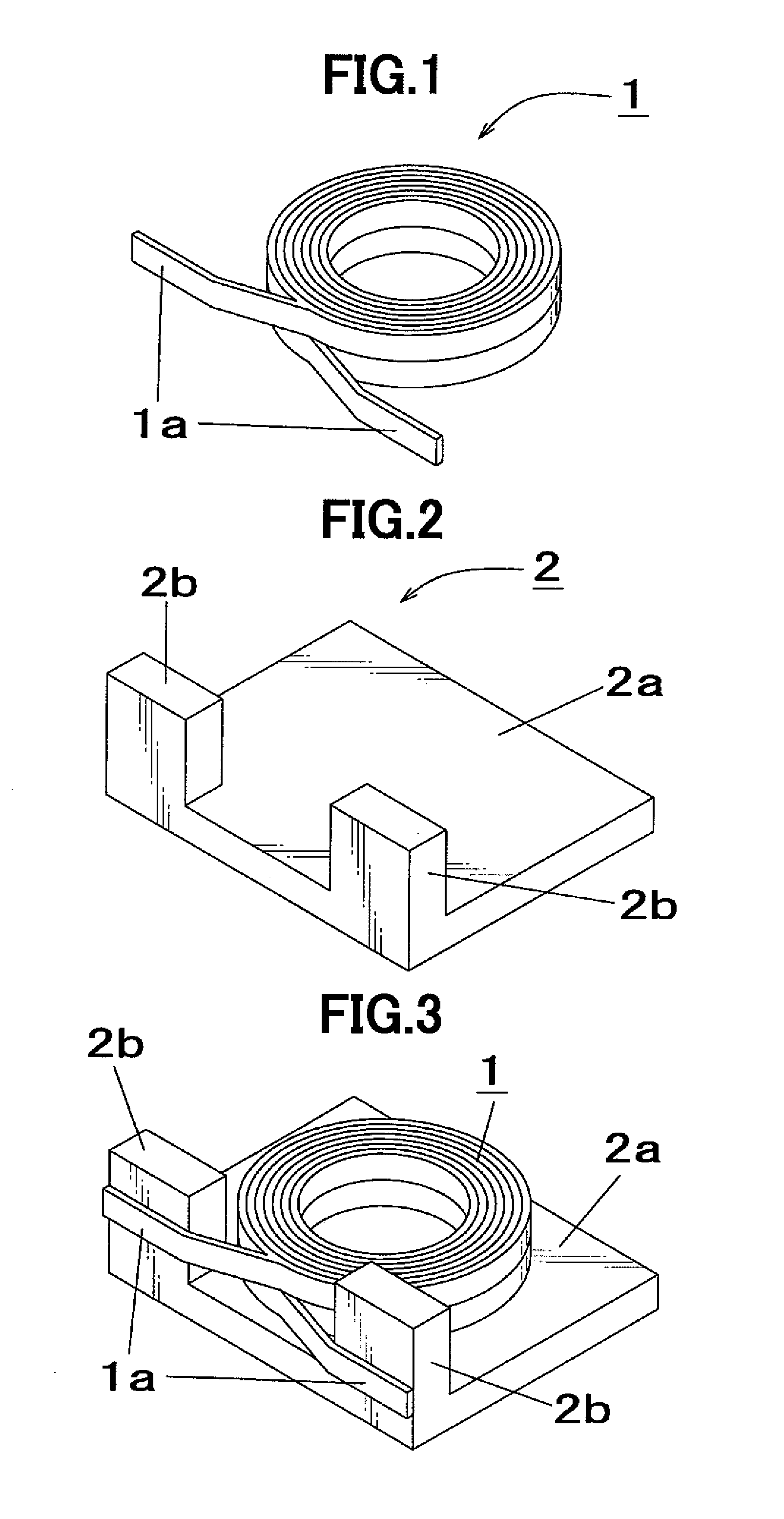

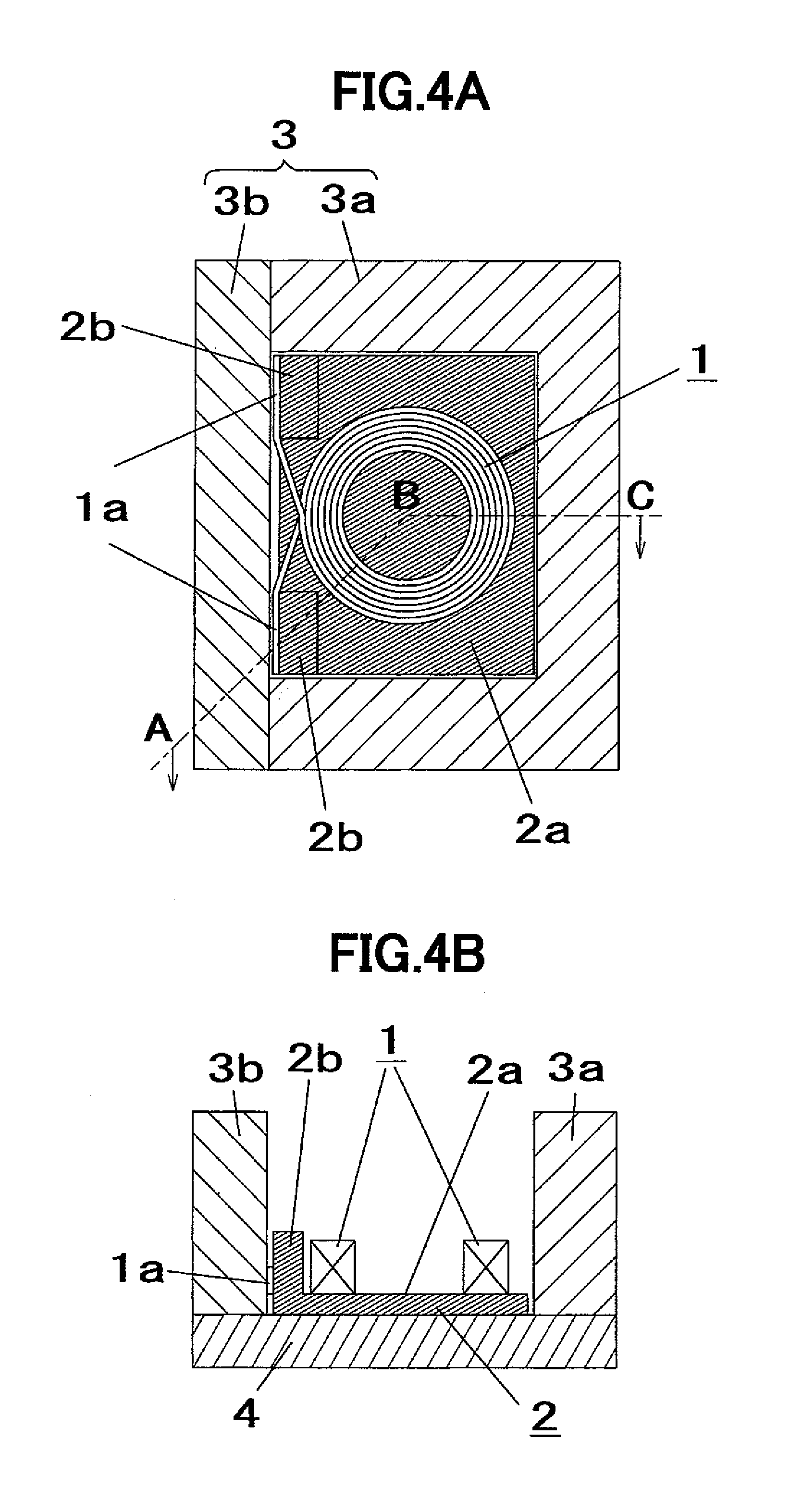

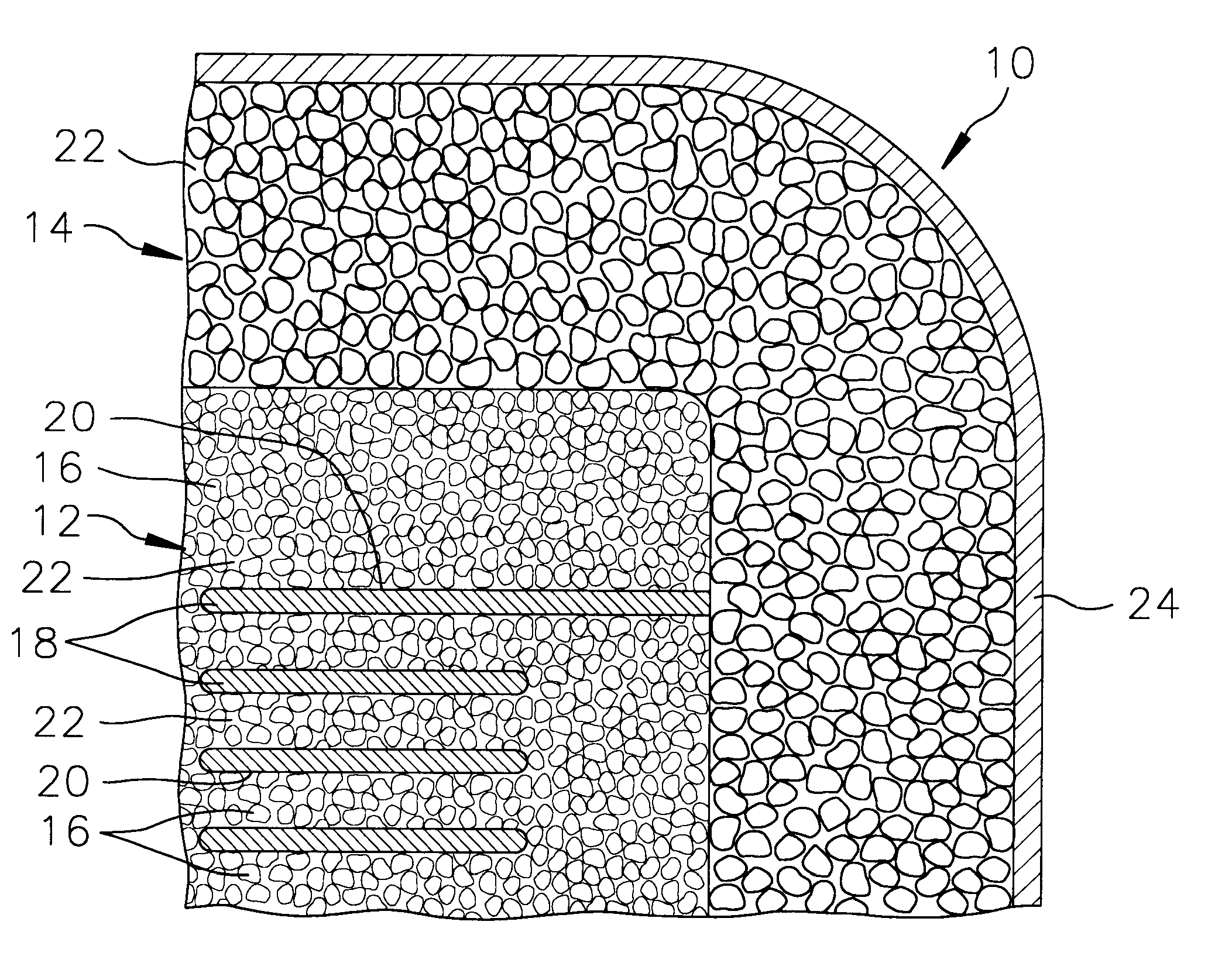

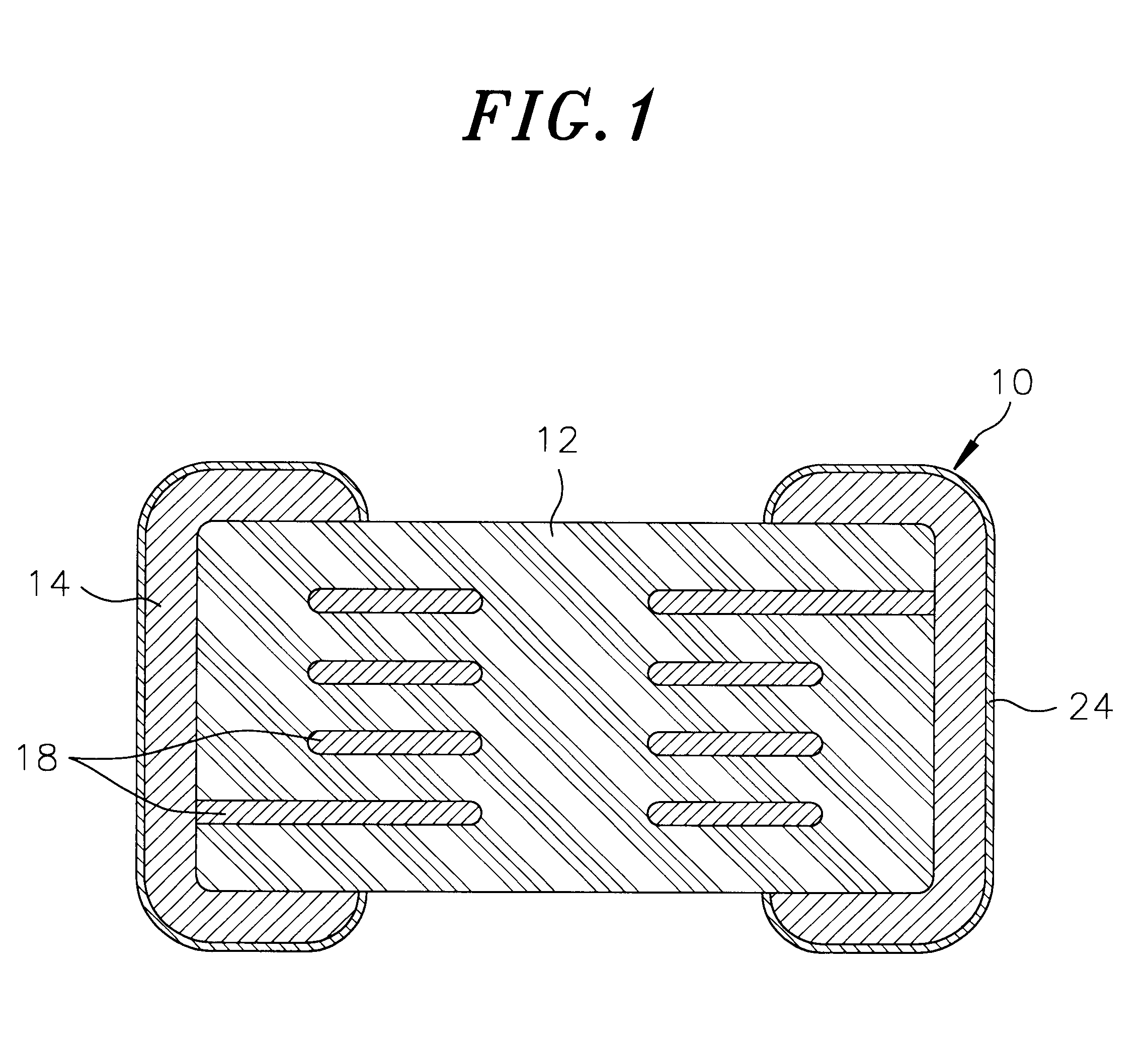

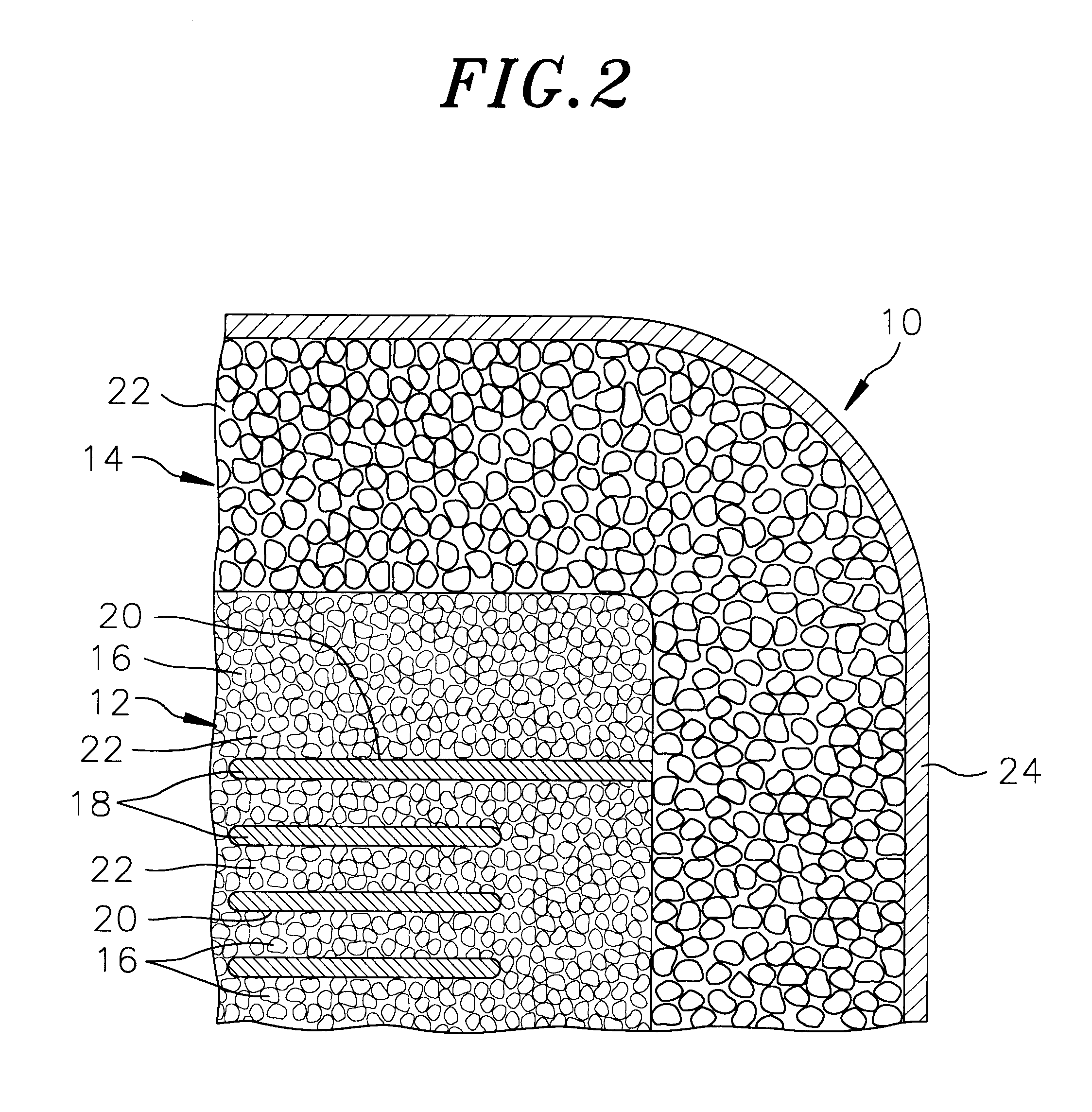

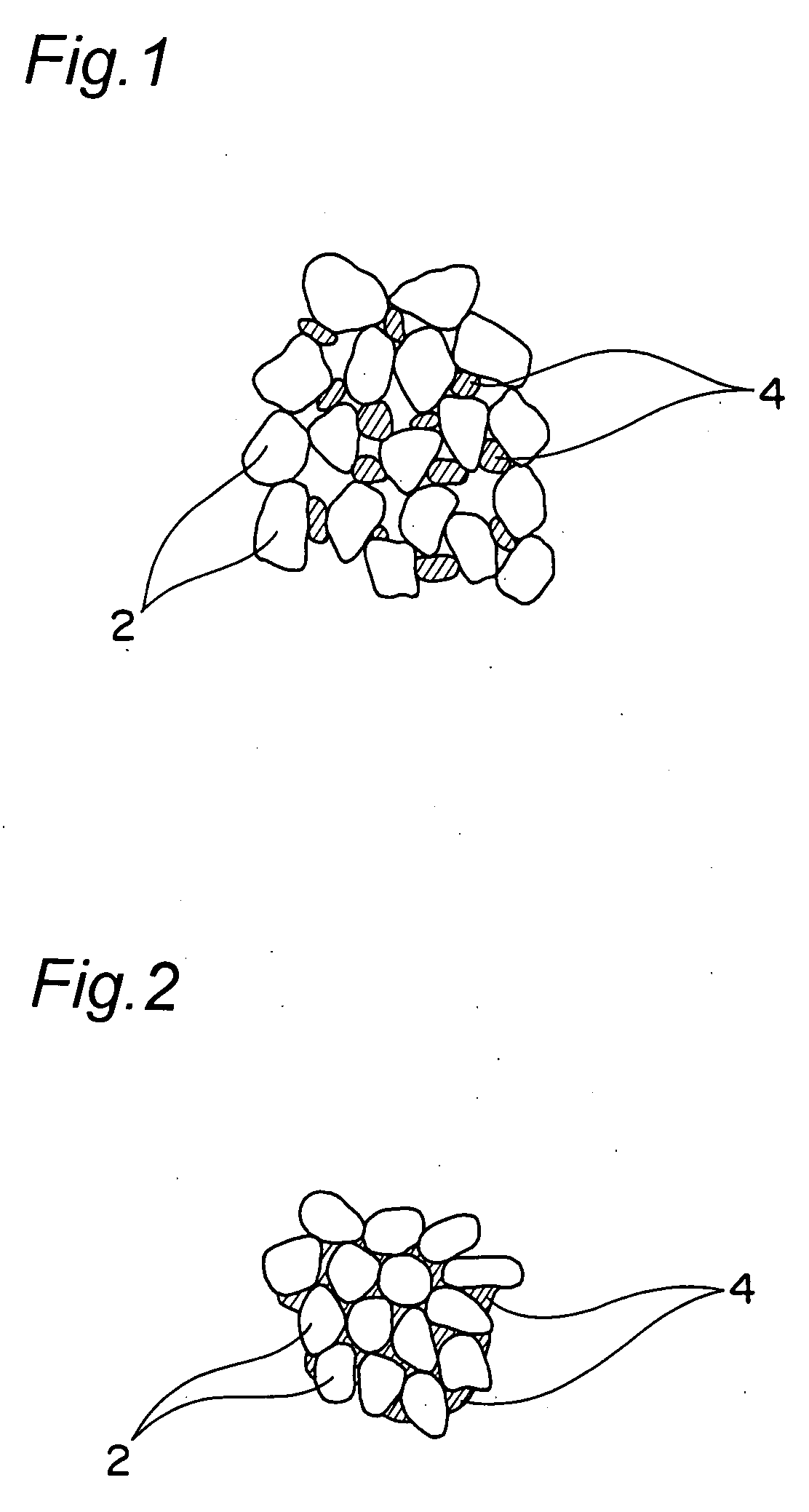

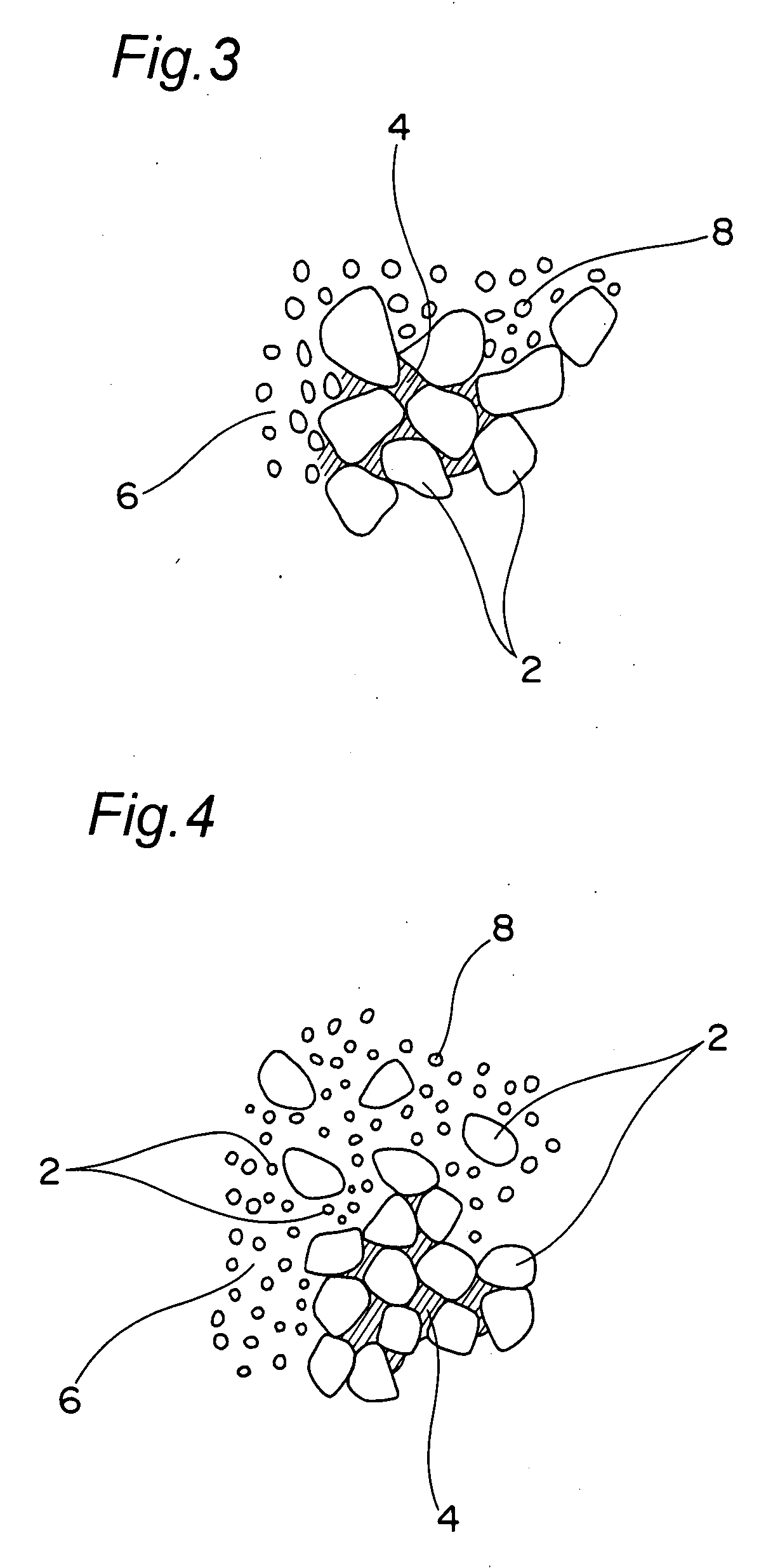

InactiveUS7427909B2Suppress whineTransformers/inductances casingsInorganic material magnetismMechanical engineeringComposite material

A coil component (100) comprising coil-containing insulator enclosure and a magnetic core (80). The coil-containing insulator enclosure is obtained by enclosing a coil (30), except for end portions (12, 22) of the coil (30), with an insulator (50), wherein the insulator (50) comprises at least a first resin. The magnetic core (80) is made of a mixture of a second resin (82) and powder, which comprises magnetic powder (84). The coil-containing insulator enclosure is embedded in the magnetic core (80).

Owner:DENSO CORP 50 INTEREST +2

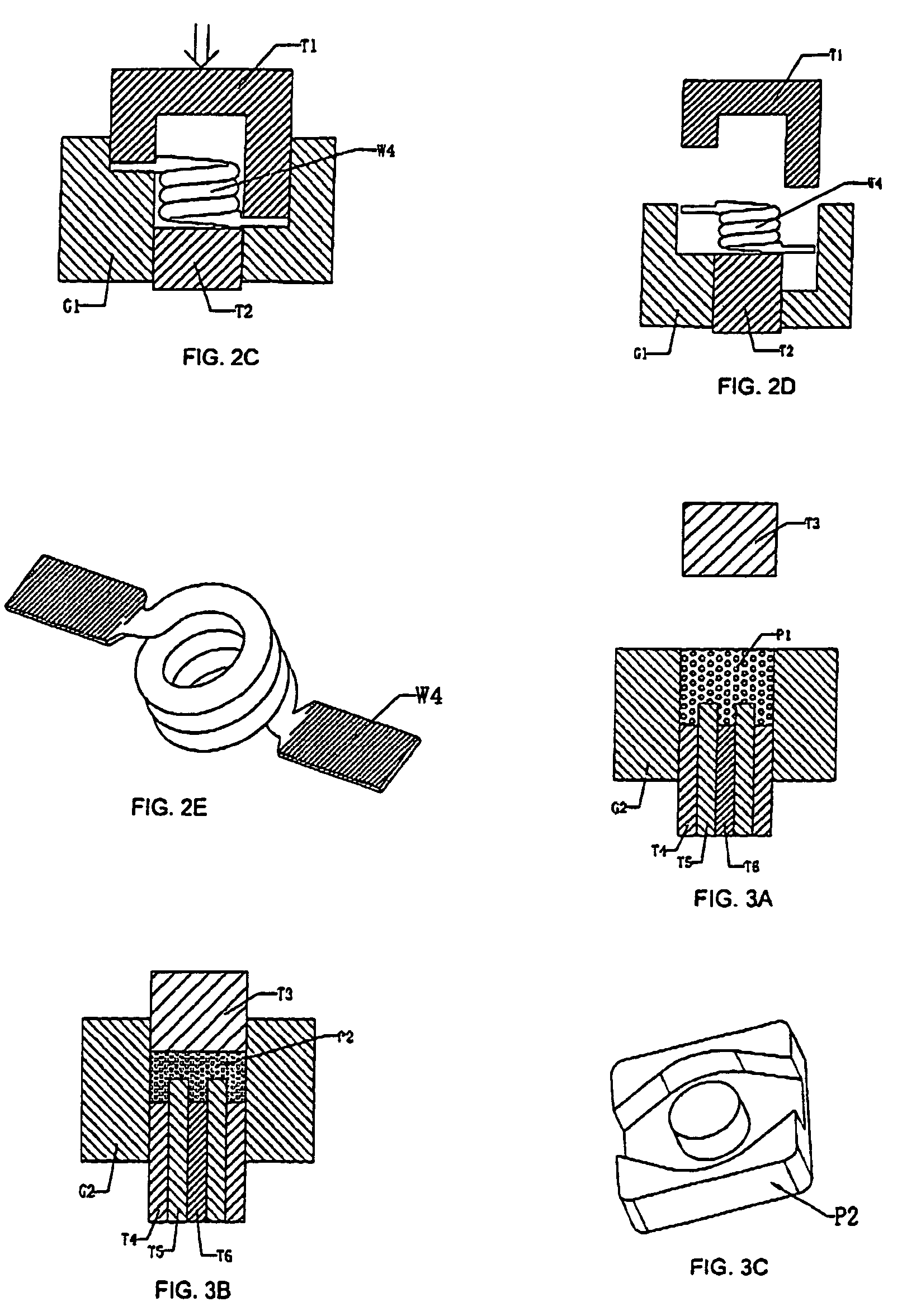

Production Method for Molded Coil

InactiveUS20090250836A1High positioning accuracyEasy to produceTransformers/inductances detailsEncapsulation/impregnationEngineeringPlastic molding

Disclosed is a method oft by using a plastic molding process, encapsulating an air-core coil with a moldable magnetic resin material prepared by kneading a mixture of a magnetic powder and a resin. The method comprises the steps of (a) preparing a molding die assembly which includes a plurality of dies adapted to define a cavity therewithin, and a positioning pin adapted to be movable in a vertical or horizontal direction within the cavity, (b) arranging the air-core coil at a given position within the cavity by the positioning pin, (c) charging the moldable magnetic resin material into the cavity and moving the positioning pin to a given retracted position in a course of the charging.

Owner:TOKO KABUSHIKI KAISHA

Amorphous metal continuous flux path transformer and method of manufacture

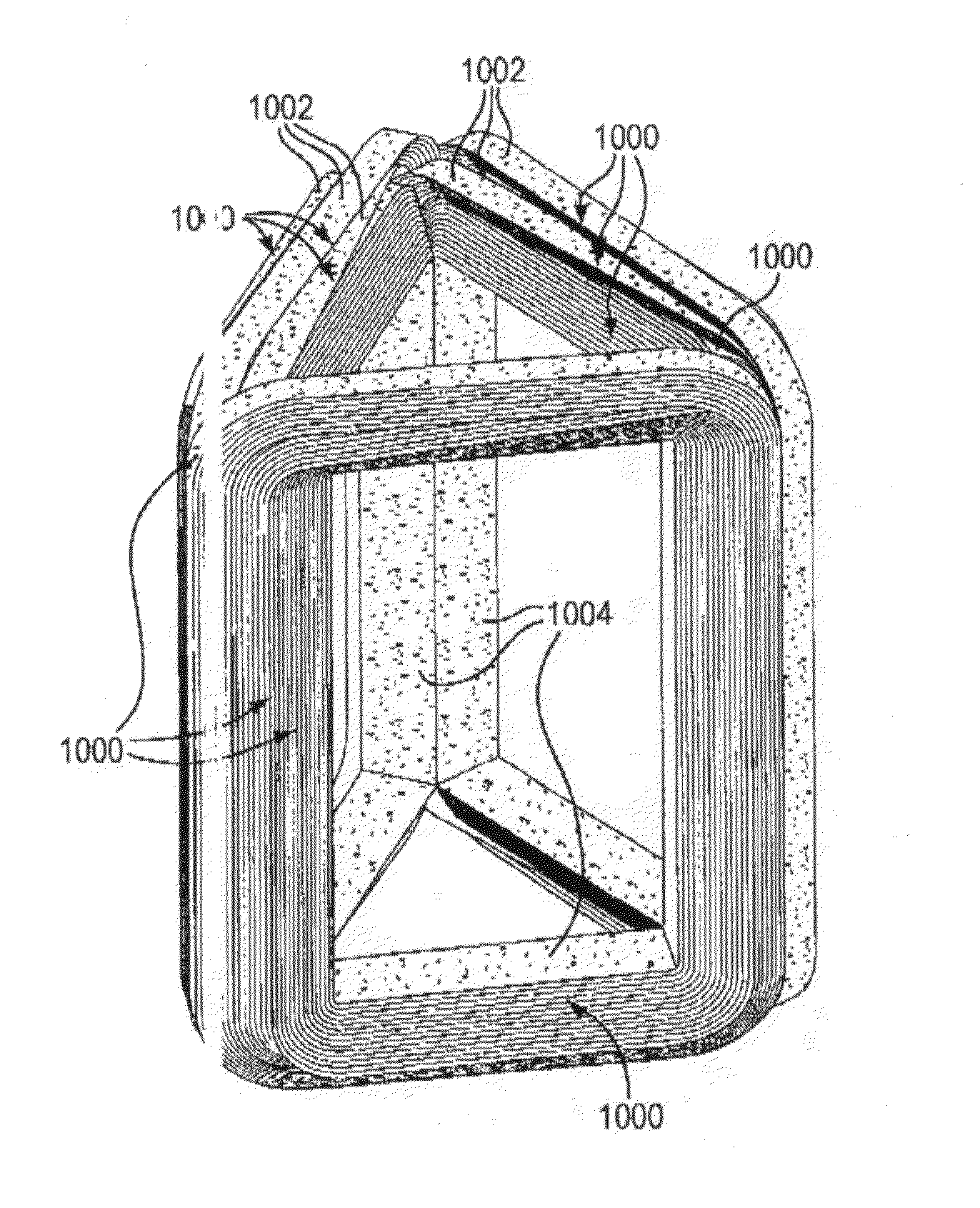

InactiveUS20100194515A1Improve rigidityPrevent slippingTransformers/inductances corrosion protectionTransformers/inductances magnetic coresThree phase transformerSilicon

In a three phase transformer core, amorphous metal strips are wound into rings that are combined into frames and assembled to define cores with leg cross sections that have more than 4 sides to facilitate winding transformer windings onto the legs using winding tubes. The amorphous metal layers are secured relative to one another and the core made more rigid using resin, silicon steel layers included in the amorphous metal core, or by using strapping or tying devices.

Owner:HEXAFORMER AB

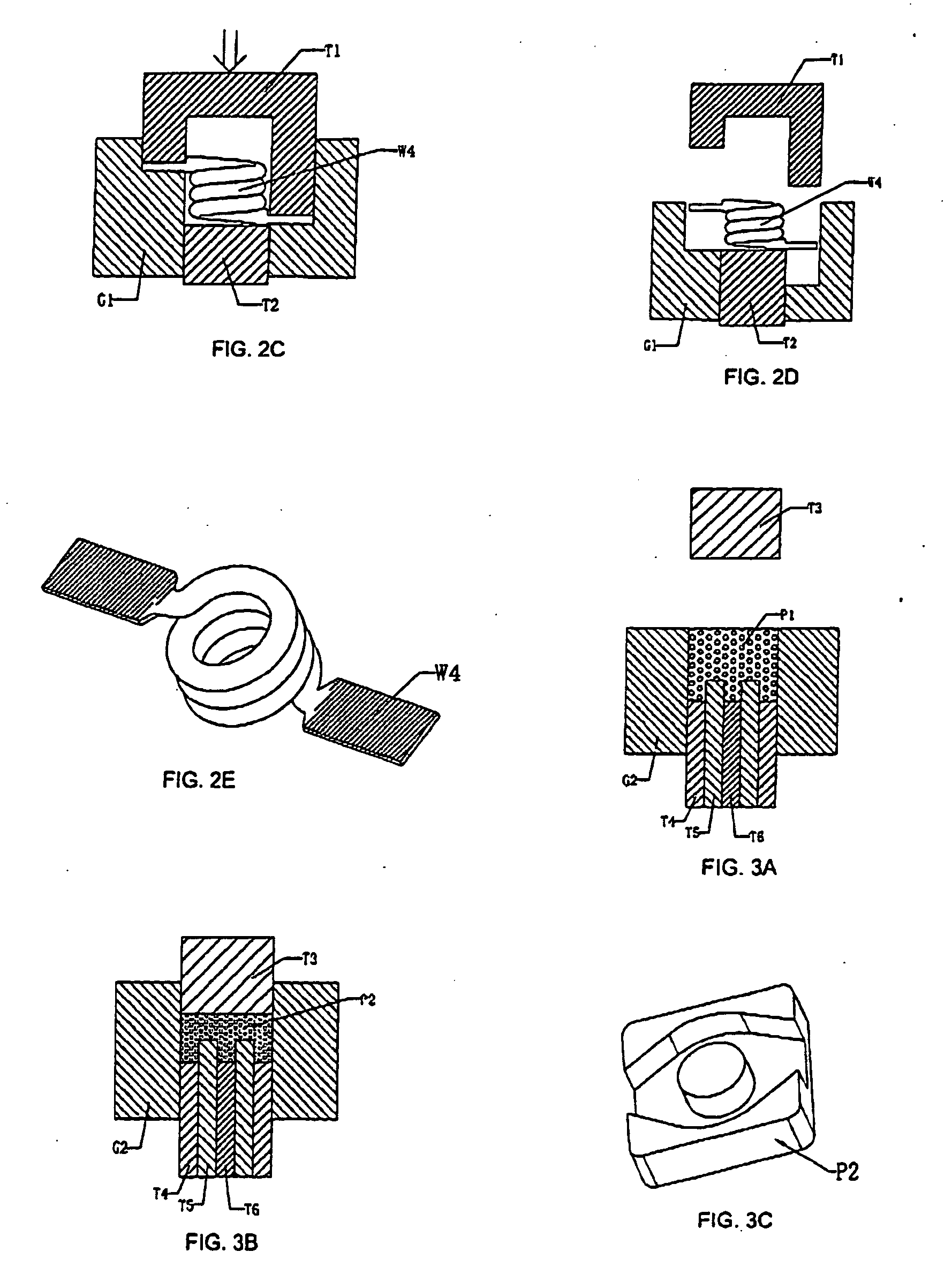

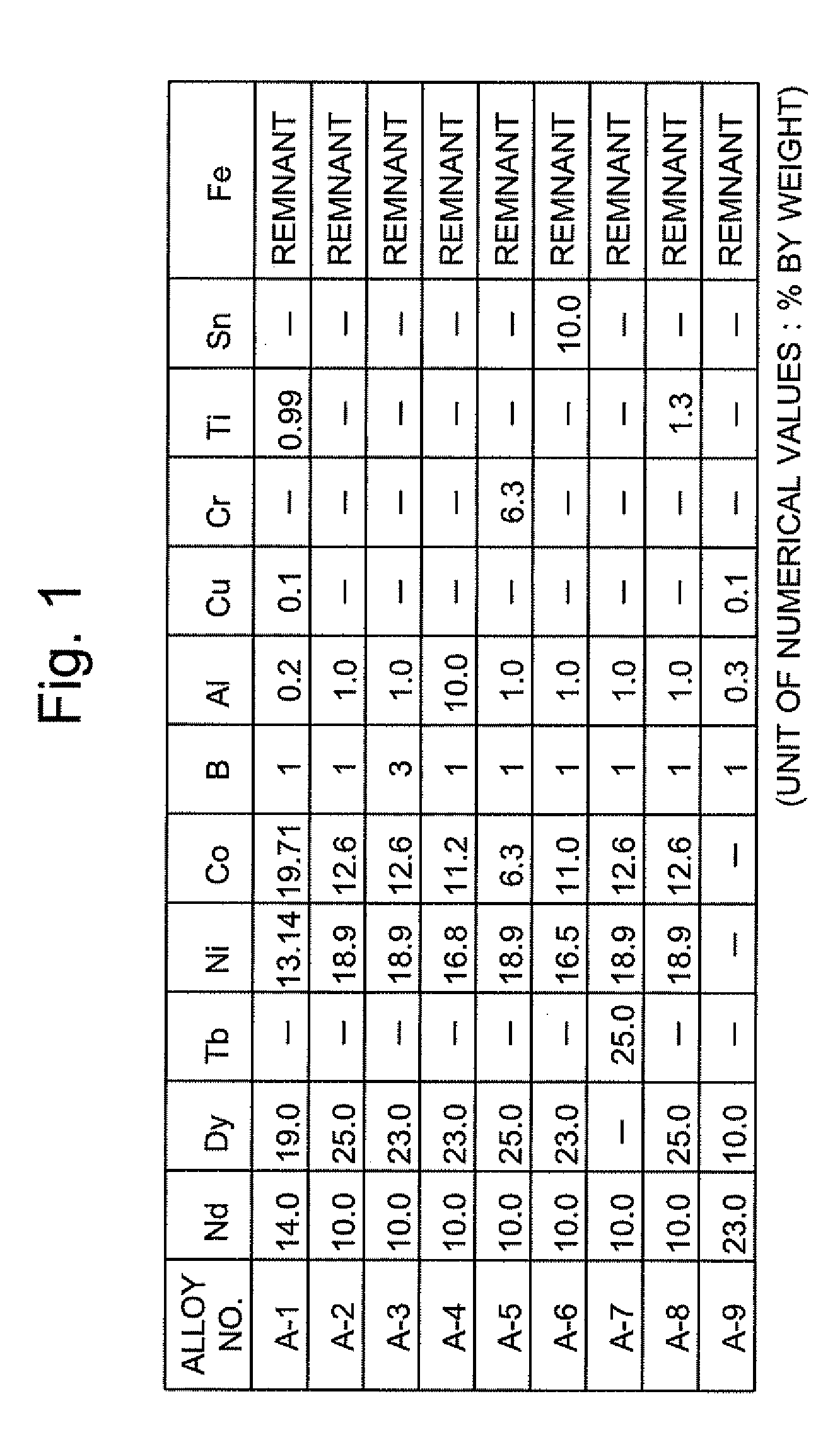

Rare earth sintered magnet and making method

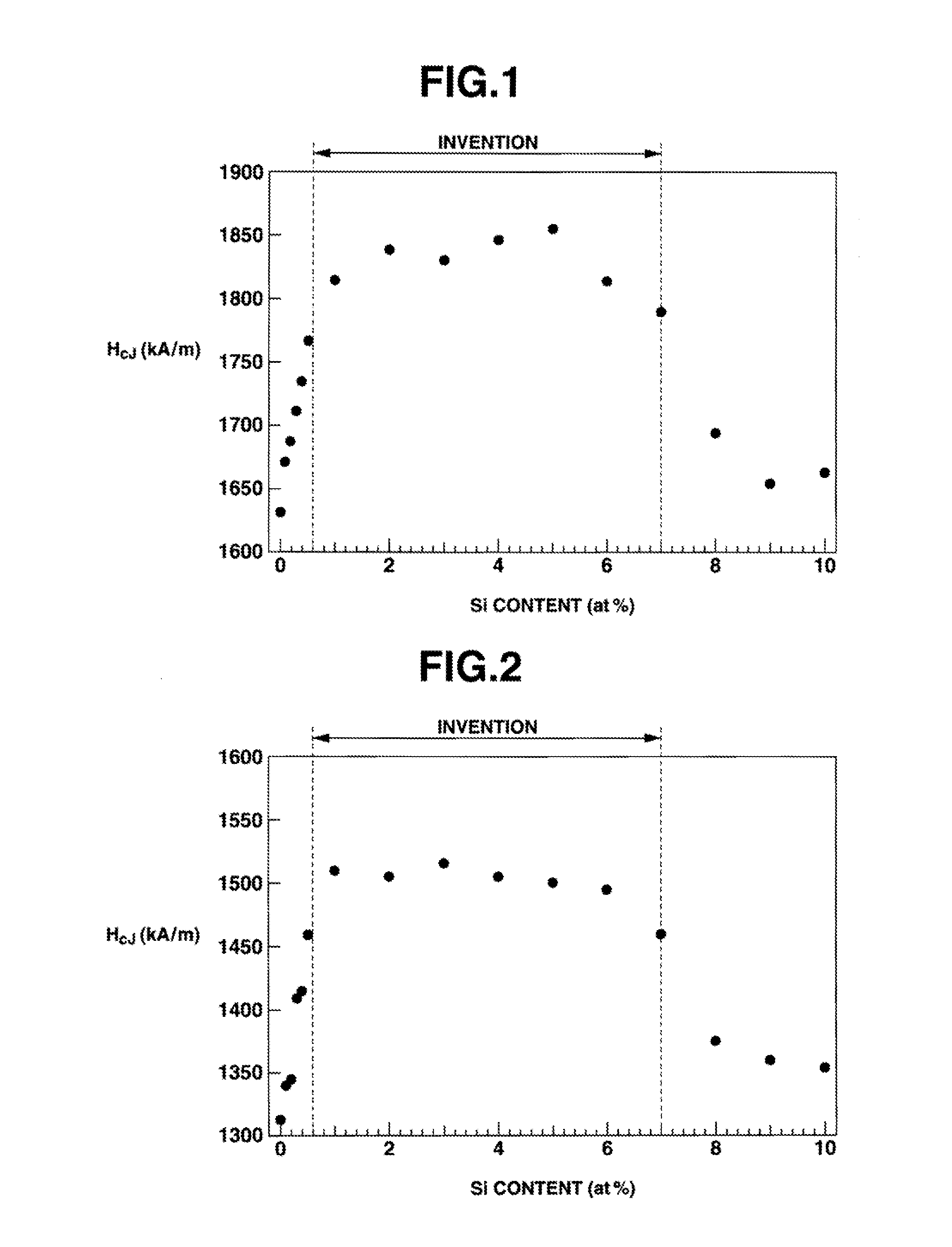

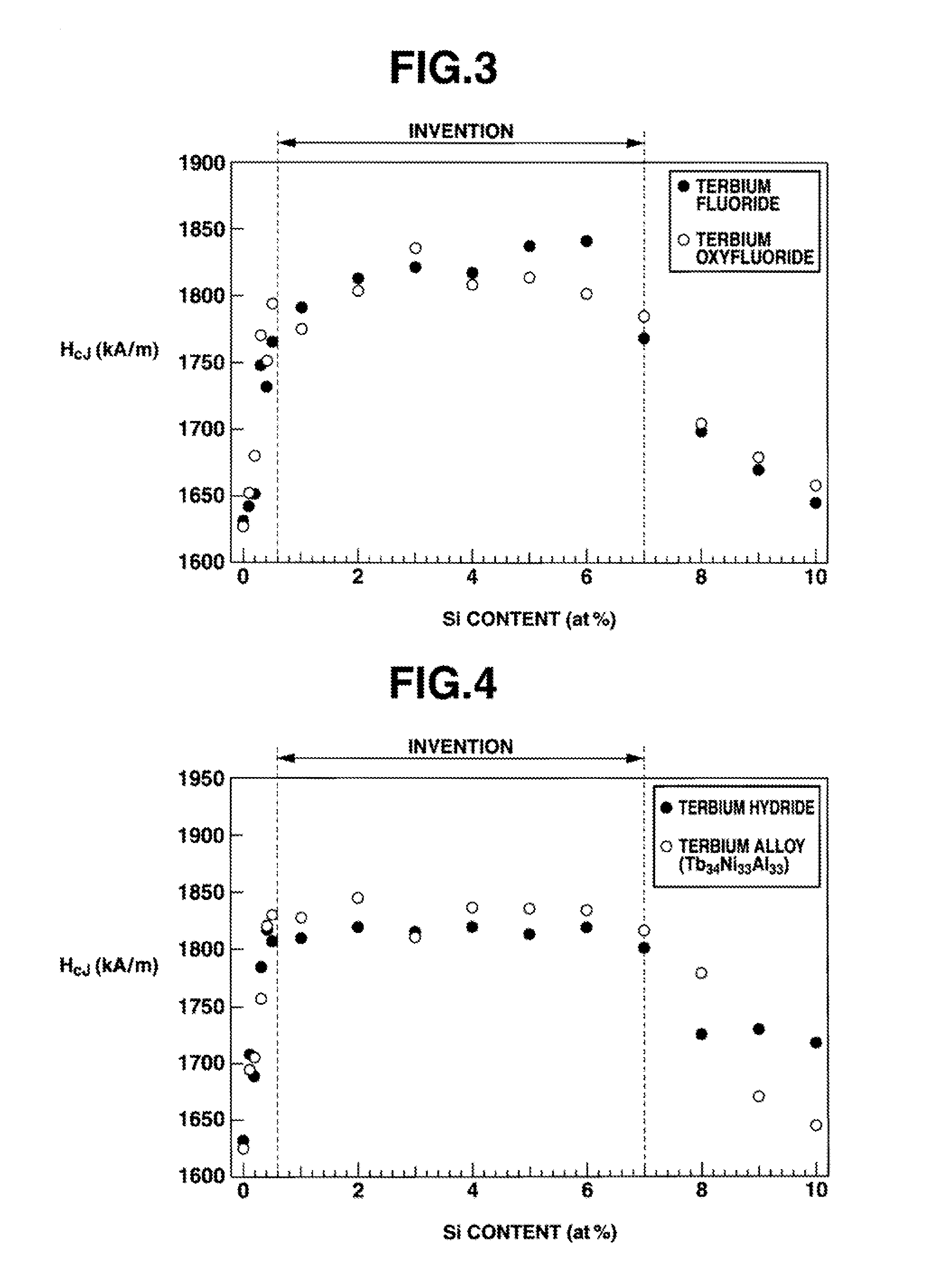

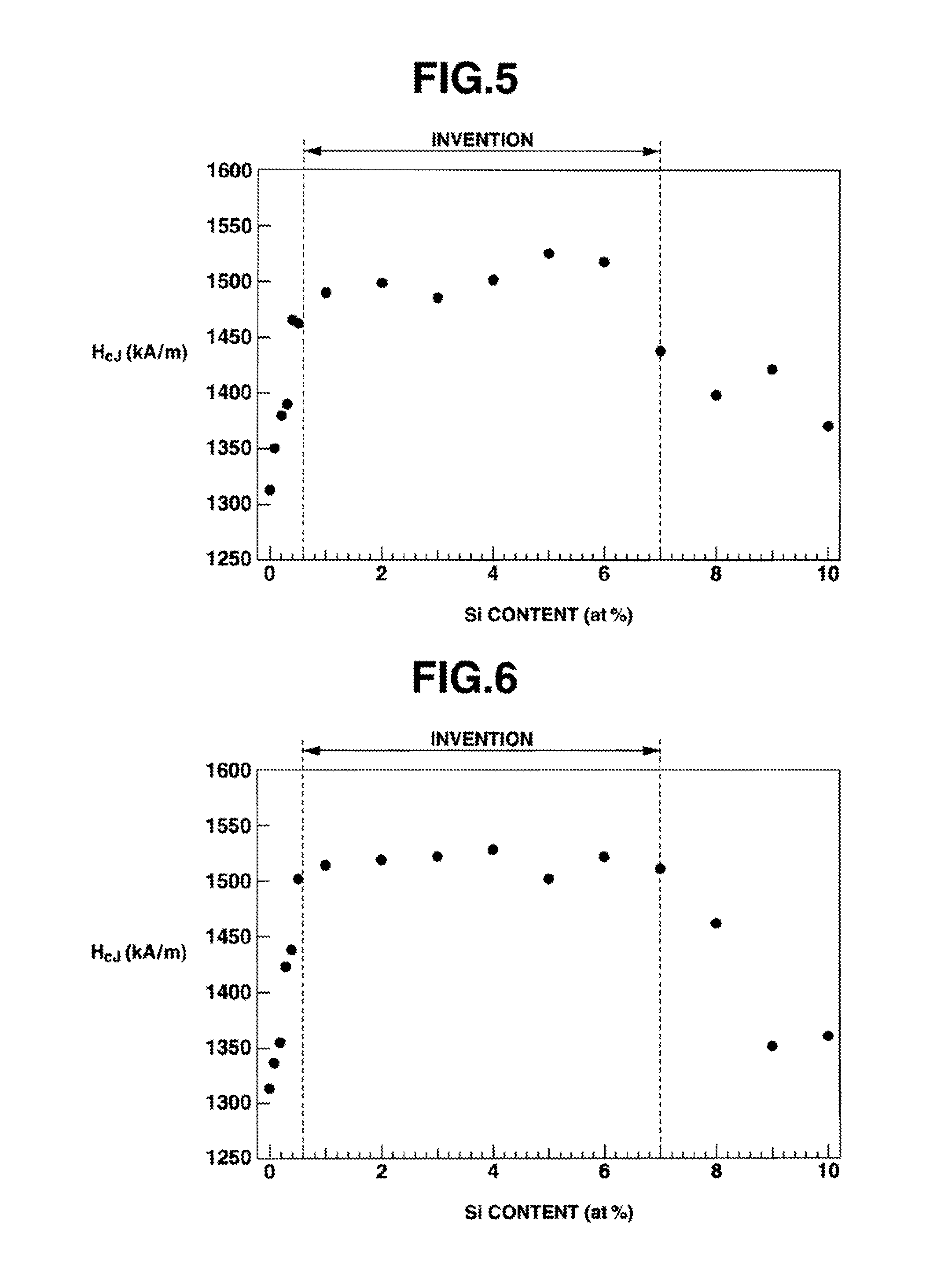

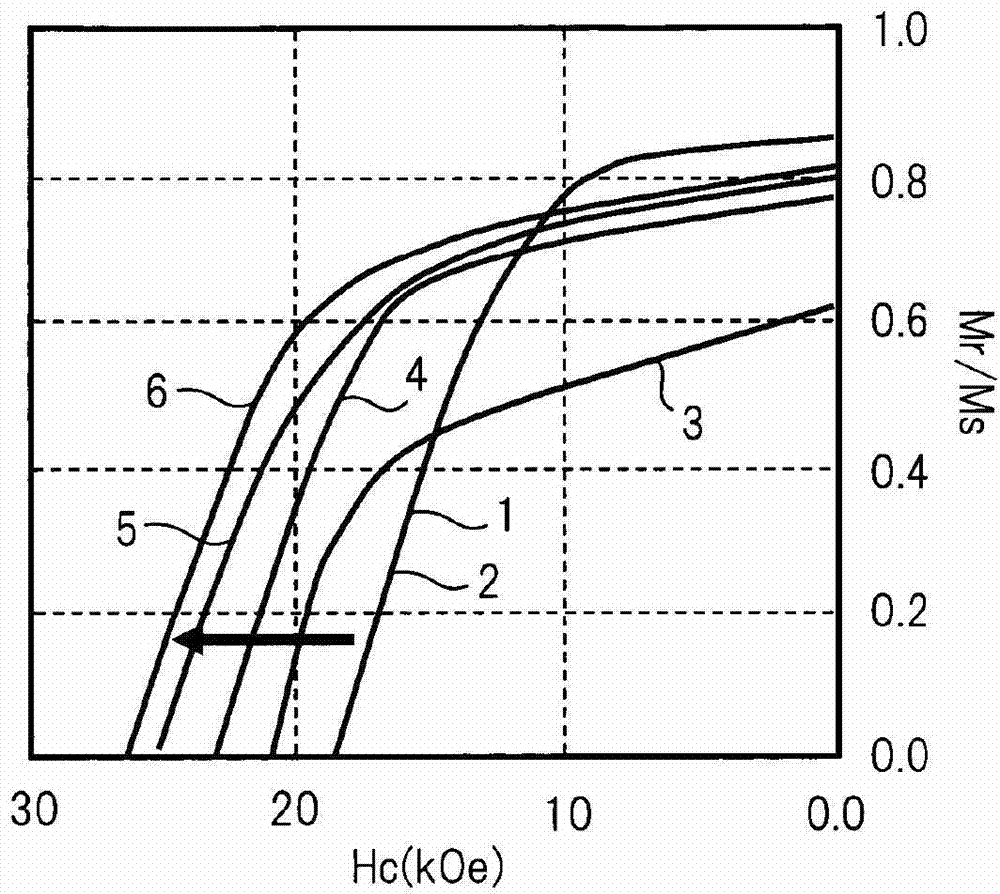

InactiveUS20130271248A1Improve coercive forceImprove magnetic propertiesVacuum evaporation coatingPermanent magnetsRare-earth elementMetallurgy

A rare earth sintered magnet as an anisotropic sintered body comprising Nd2Fe14B crystal phase as primary phase and having the composition R1aTbMcSidBe wherein R1 is a rare earth element inclusive of Sc and Y, T is Fe and / or Co, H is Al, Cu, Zn, In, P, S, Ti, V, Cr, Mn, Ni, Ga, Ge, Zr, Nb, Mo, Pd, Ag, Cd, Sn, Sb, Hf, Ta, or W, “a” to “e” are 12≦a≦17, 0≦c≦10, 0.3≦d≦7, 5≦e≦10, and the balance of b, wherein Dy and / or Tb is diffused into the sintered body from its surface.

Owner:SHIN ETSU CHEM IND CO LTD

Magnetic element and its manufacture, power supply module therewith

InactiveCN1407564AReduce magnetic lossIncrease the inductance valueTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectrical conductorComputer module

A magnetic device includes a sheet-type coil including a planar conductive coil and an insulating substance; and a sheet-type first magnetic member disposed on at least one of upper and lower surfaces of the sheet-type coil, where a magnetic permeability of the insulating substance is smaller than a magnetic permeability of the first magnetic member. The magnetic device preferably includes a second magnetic member provided at a predetermined area of the sheet-type coil, the second magnetic member being made of a resin containing a magnetic powder and having a permeability larger than the insulating substance and smaller than the first magnetic member. The predetermined area is at least one position selected from a center portion and a peripheral portion of the sheet-type coil where a conductor constituting the planar conductive coil is not present. Further, a power supply module of the present invention includes the magnetic device according to the present invention.

Owner:PANASONIC CORP

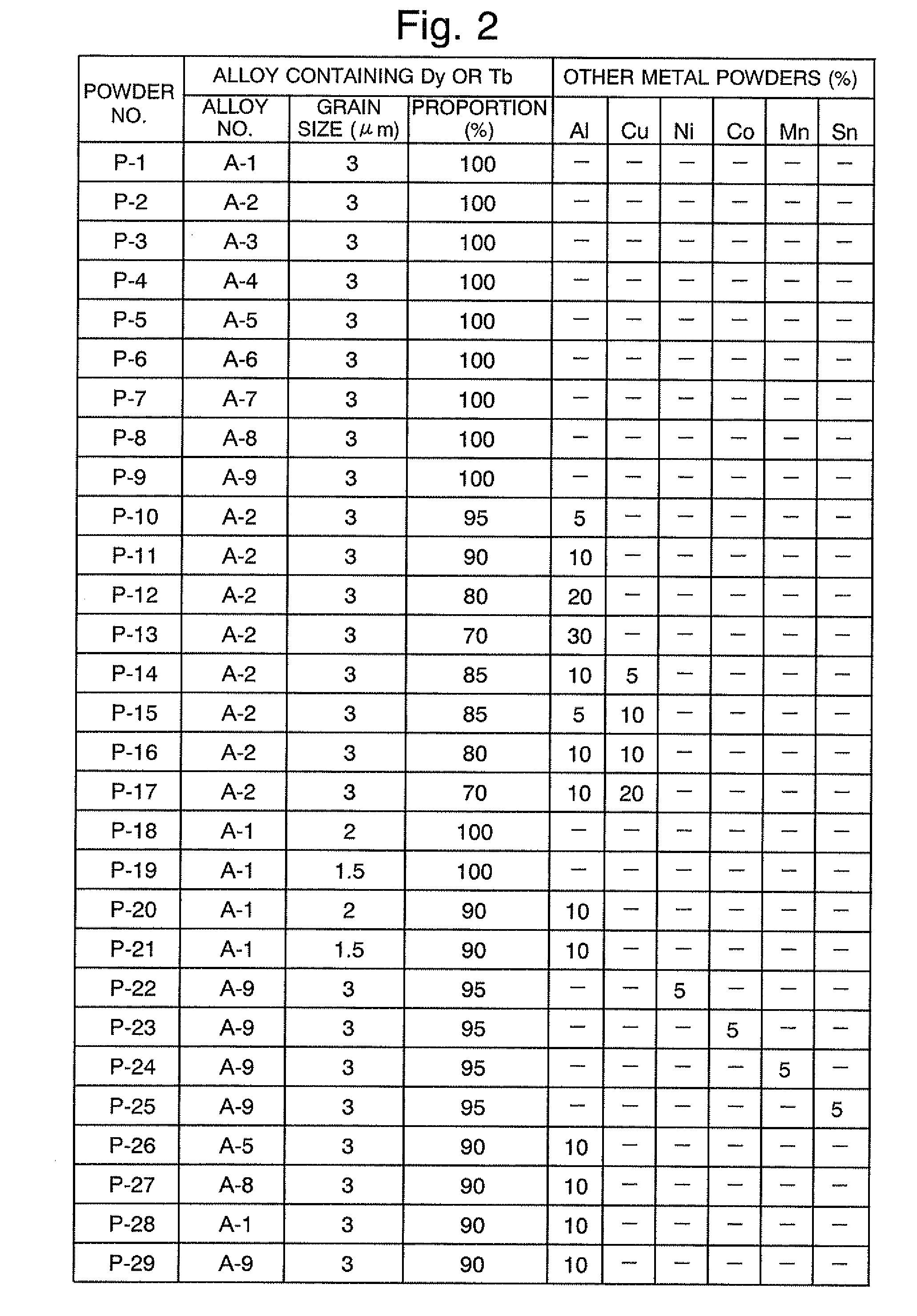

METHOD FOR PRODUCING SINTERED NdFeB MAGNET

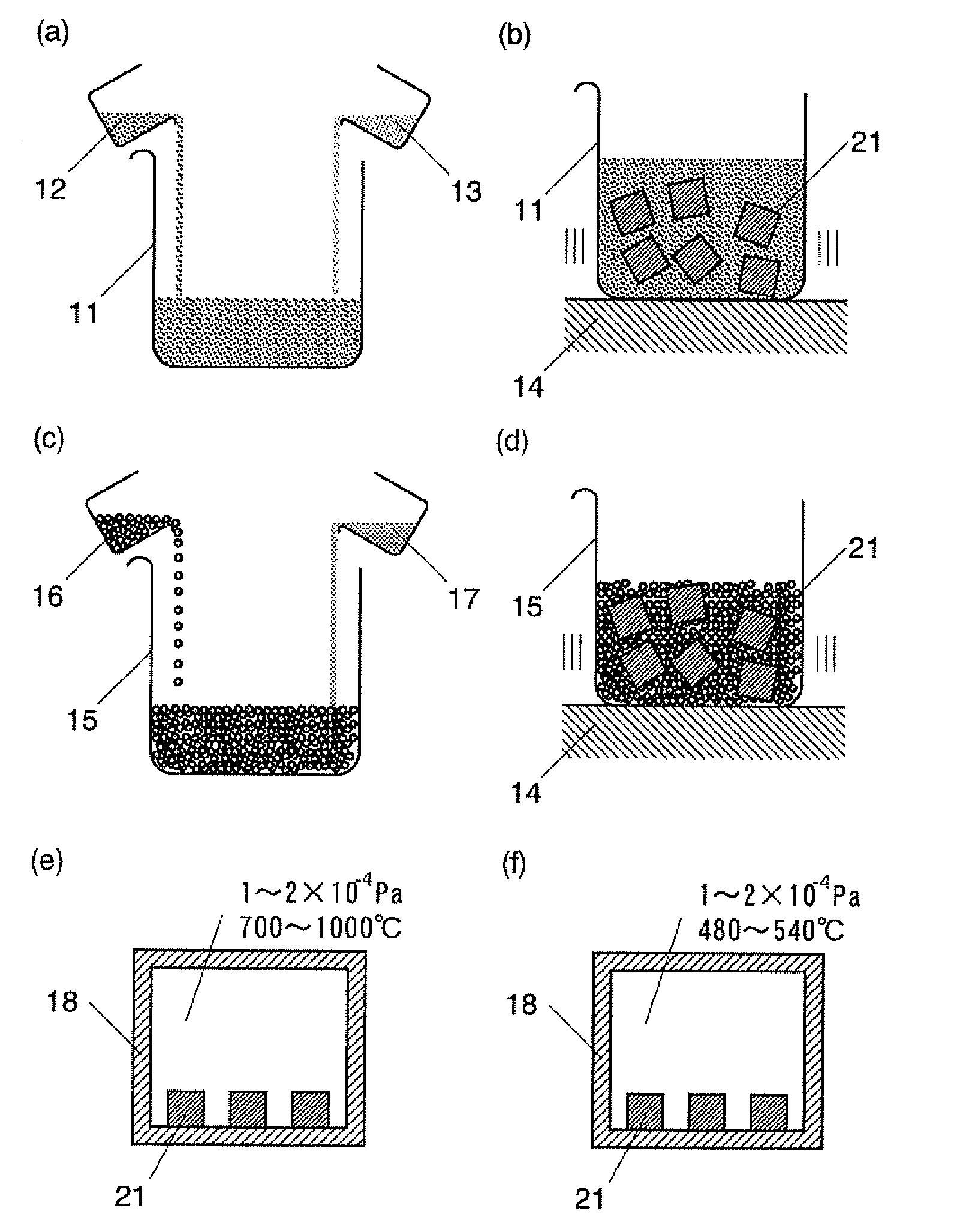

ActiveUS20090252865A1Increase in coercivityDeterioration of characteristicPretreated surfacesMagnetic materialsRare-earth elementIron group

The present invention provides a method for producing a sintered NdFeB magnet having high coercivity and capable of being brought into applications without lowering its residual magnetic flux density or maximum energy product and without reprocessing. The method for producing a sintered NdFeB magnet according to the present invention includes applying a substance containing dysprosium (Dy) and / or terbium (Tb) to the surface of the sintered NdFeB magnet forming a base body and then heating the magnet to diffuse Dy and / or Tb through the grain boundary and thereby increase the coercivity of the magnet. This method is characterized in that: (1) the substance containing Dy or Tb to be applied to the surface of the sintered NdFeB magnet is substantially a metal powder; (2) the metal powder is composed of a rare-earth element R and an iron-group transition element T, or composed of R, T and another element X, the element X capable of forming an alloy or intermetallic compound with R and / or T; and (3) the oxygen content of the sintered NdFeB magnet forming the base body is 5000 ppm or lower. The element T may contain nickel (Ni) or cobalt (Co) to produce an anticorrosion effect.

Owner:DAIDO STEEL CO LTD

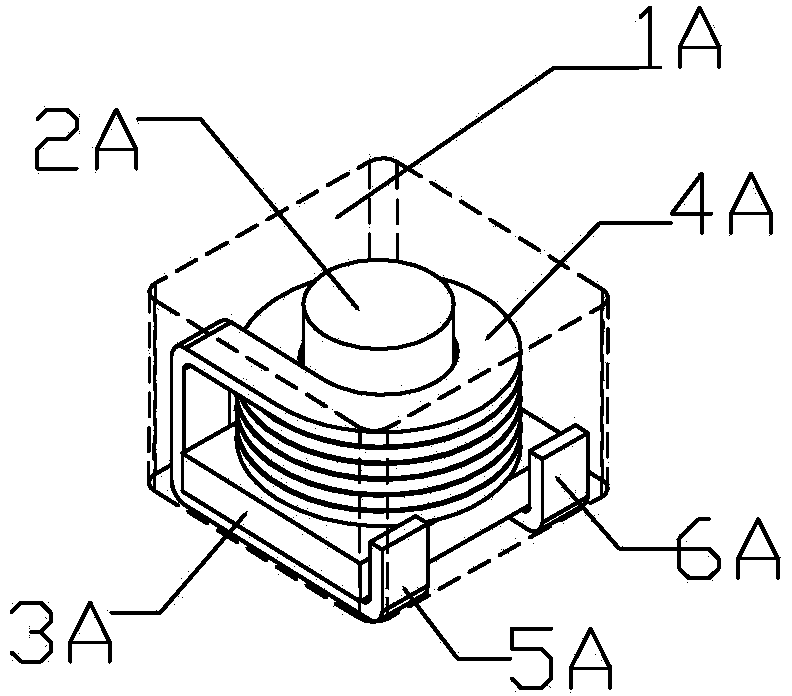

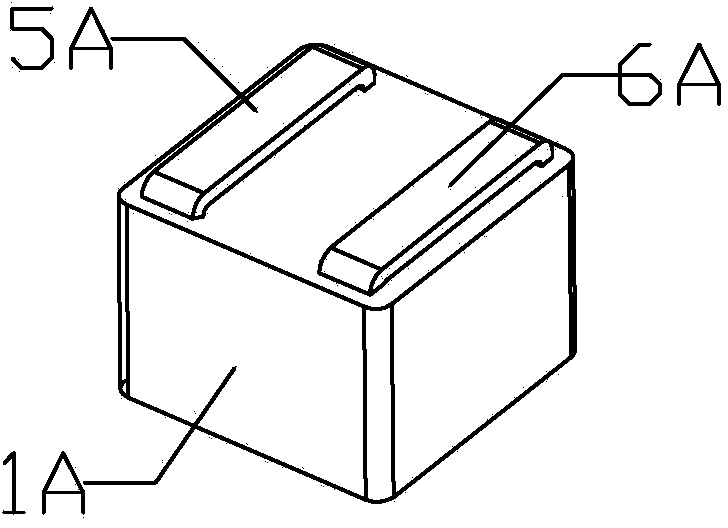

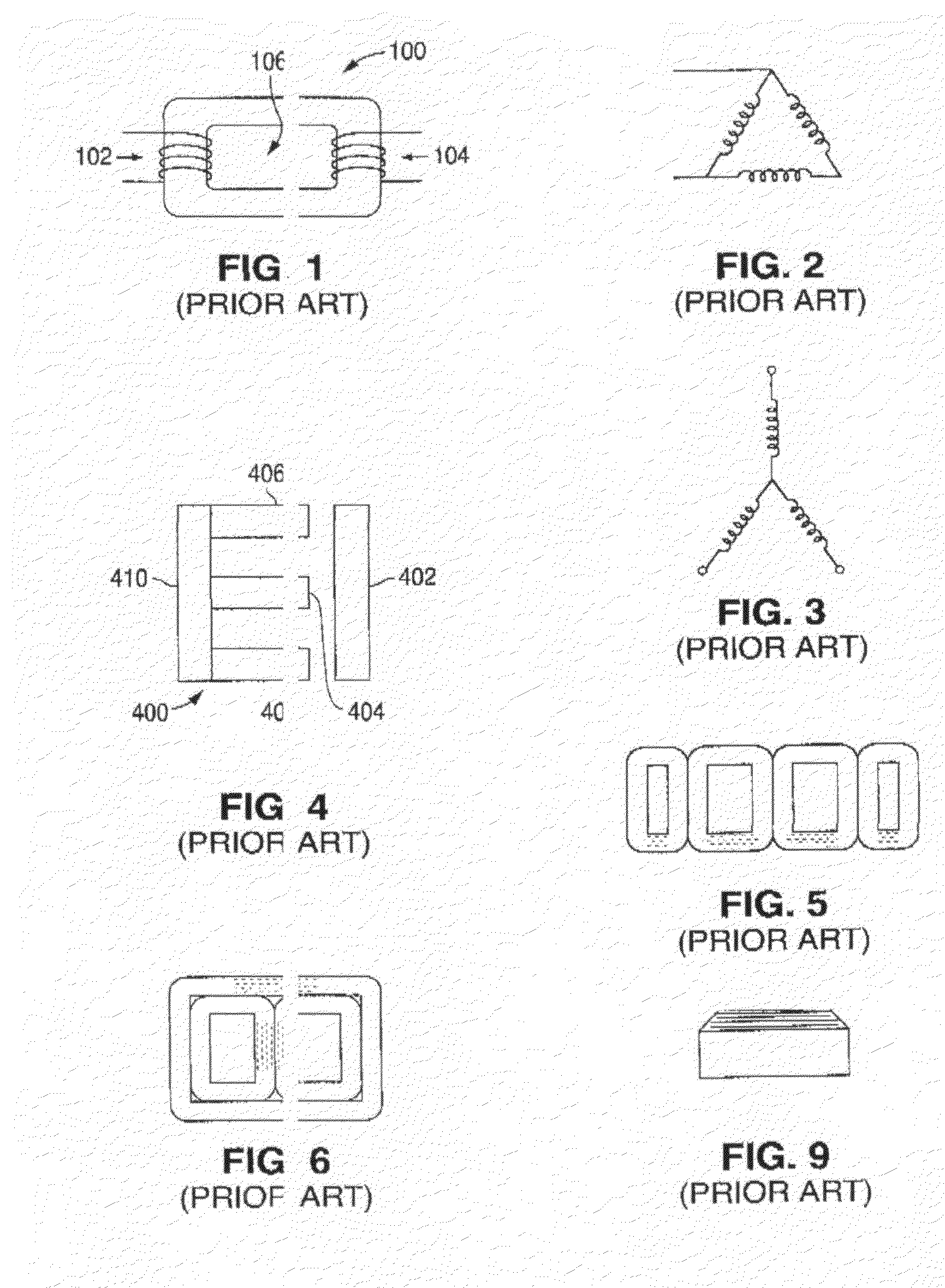

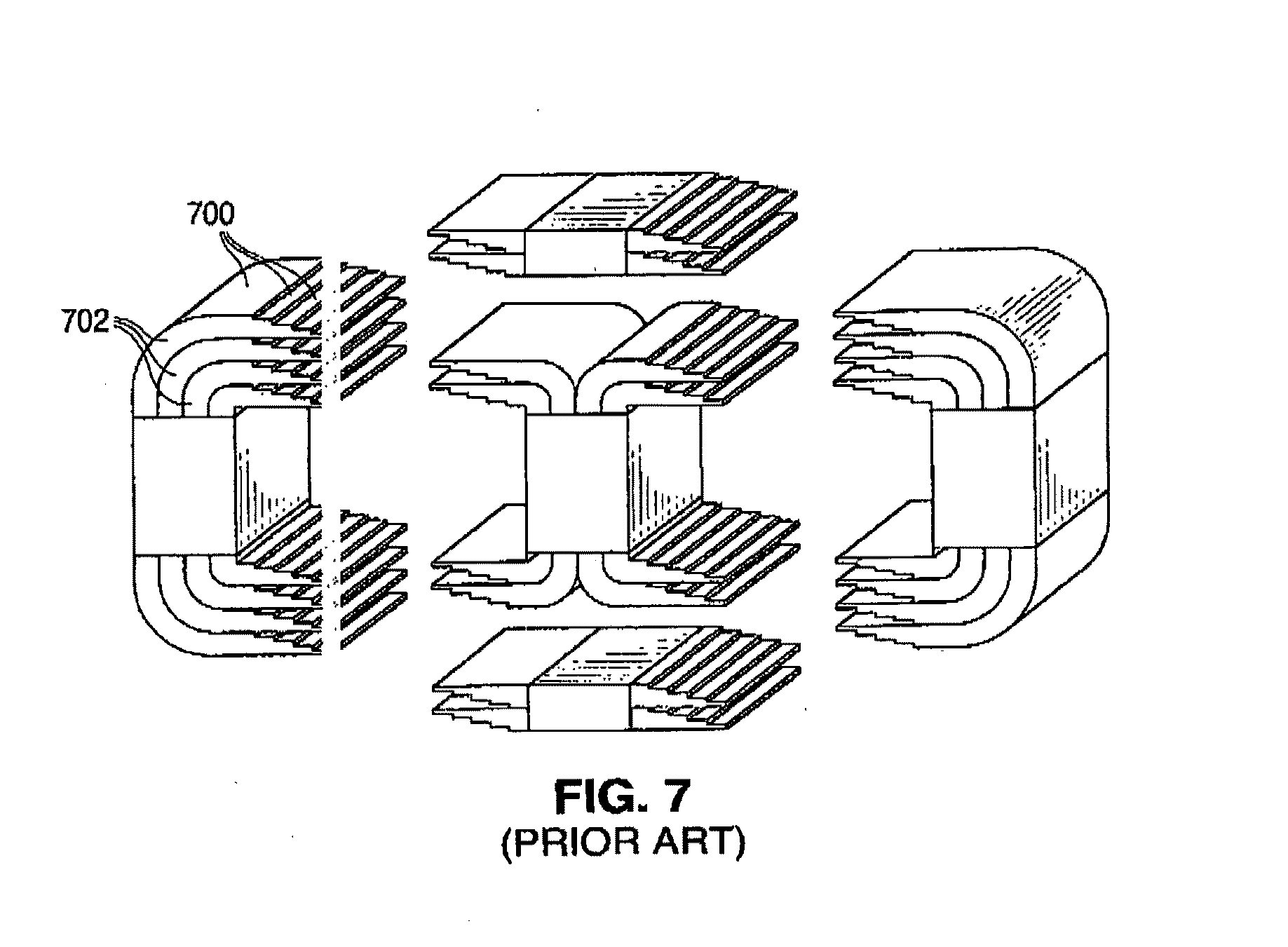

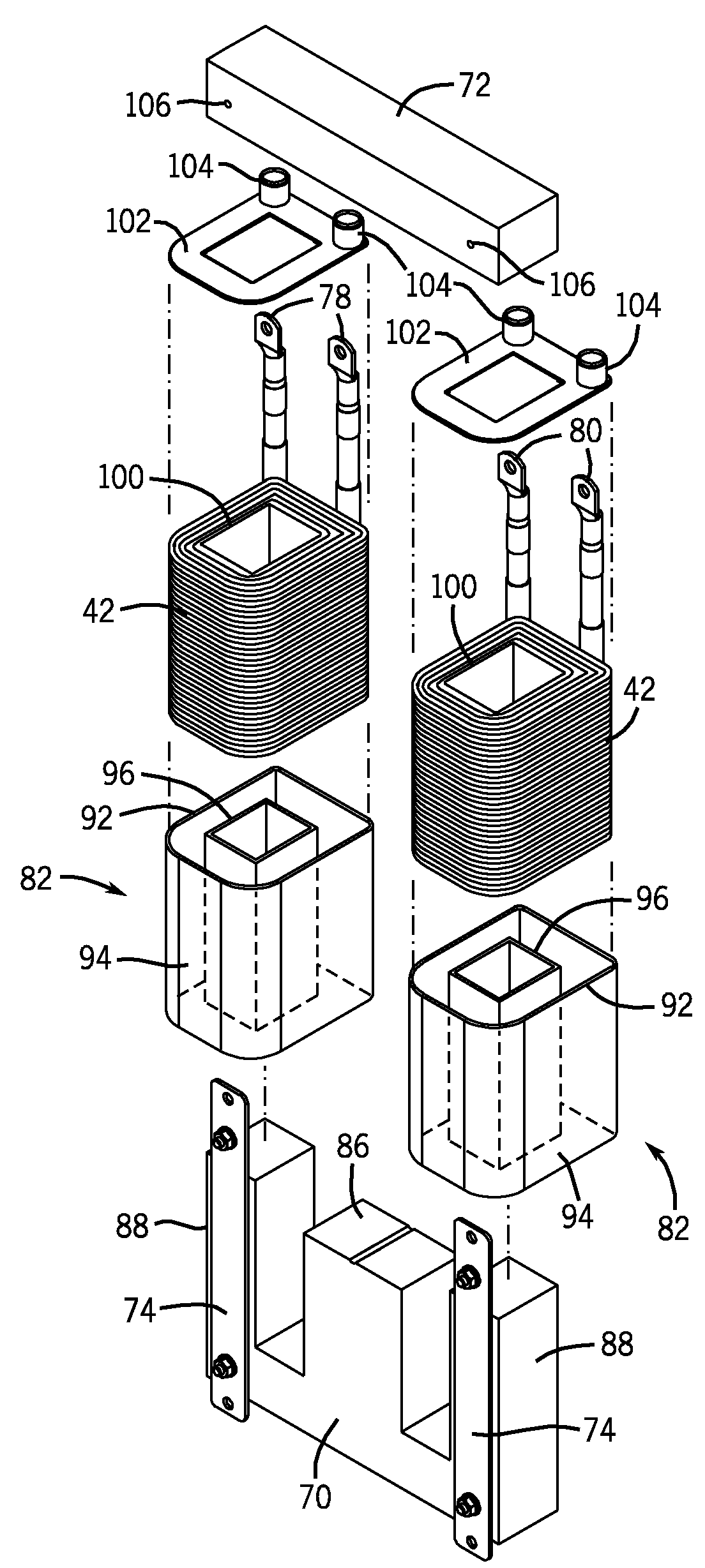

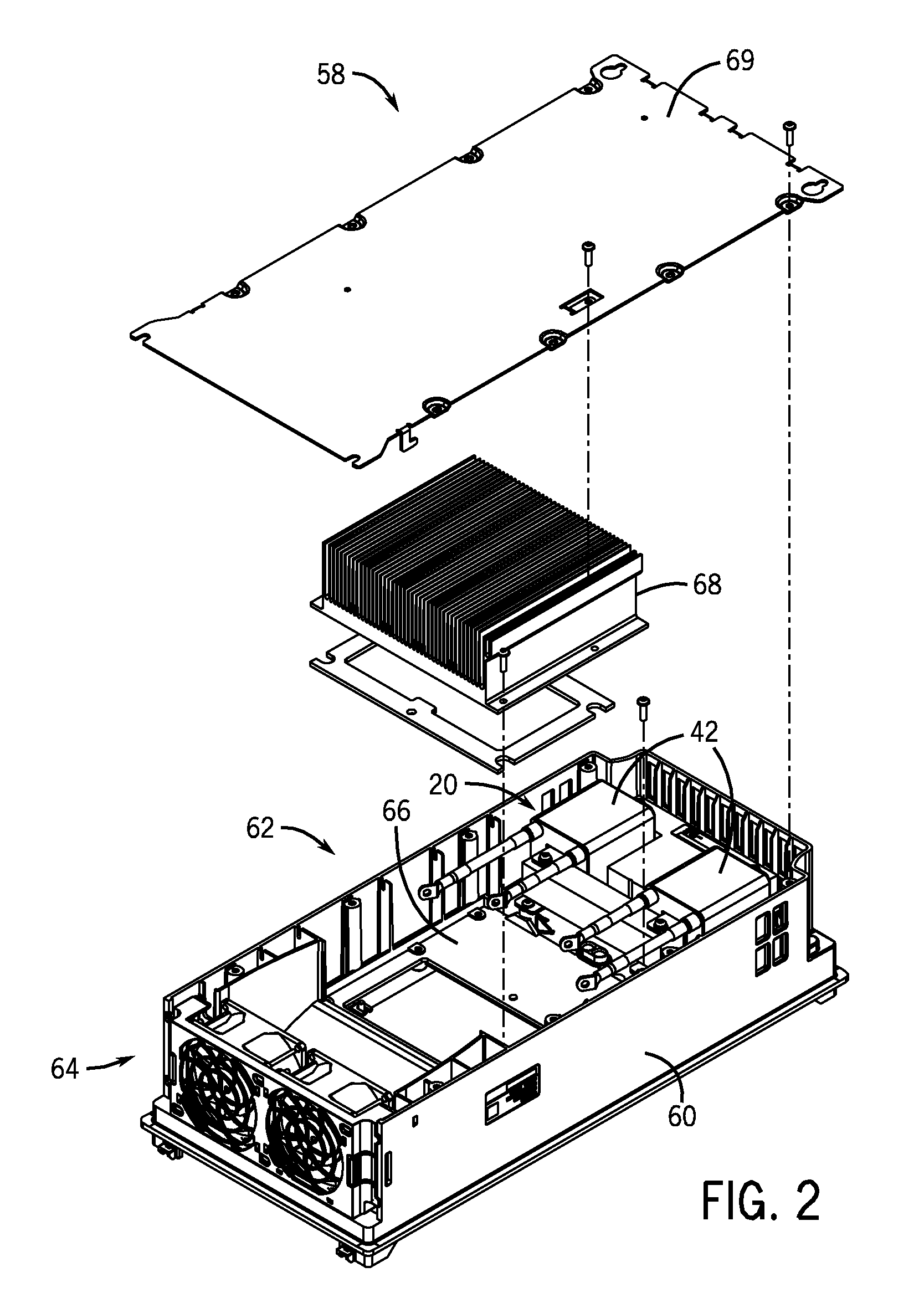

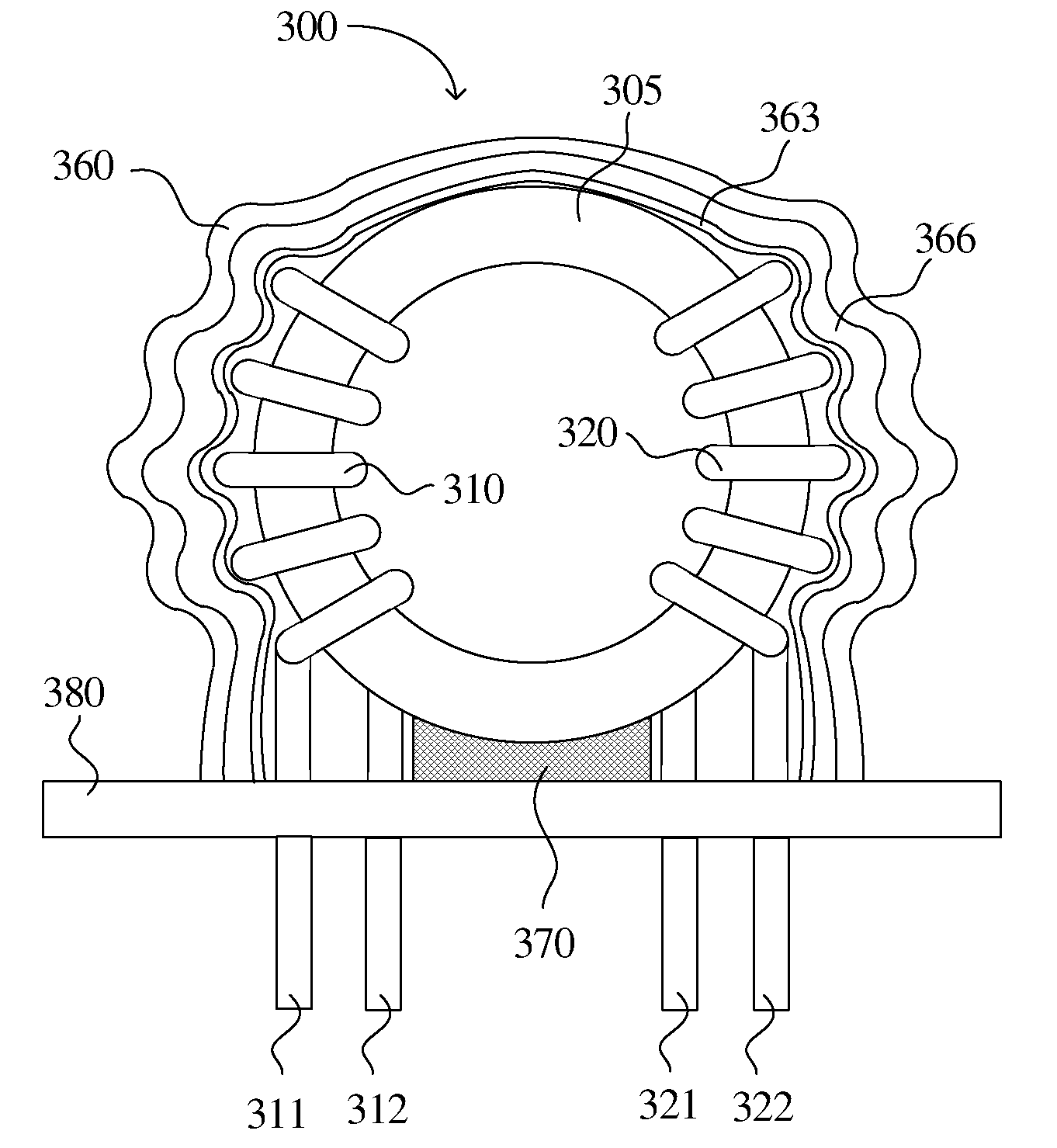

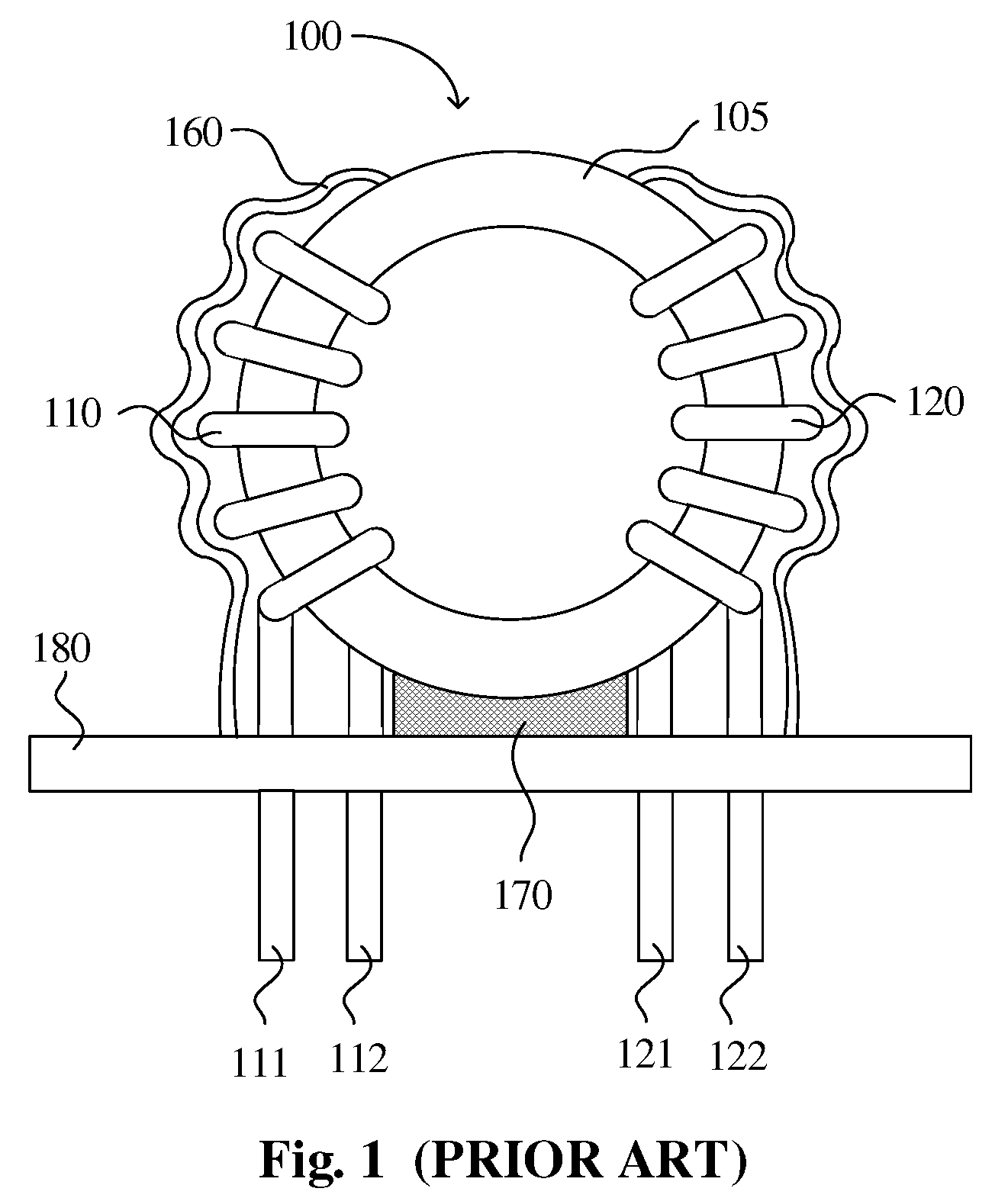

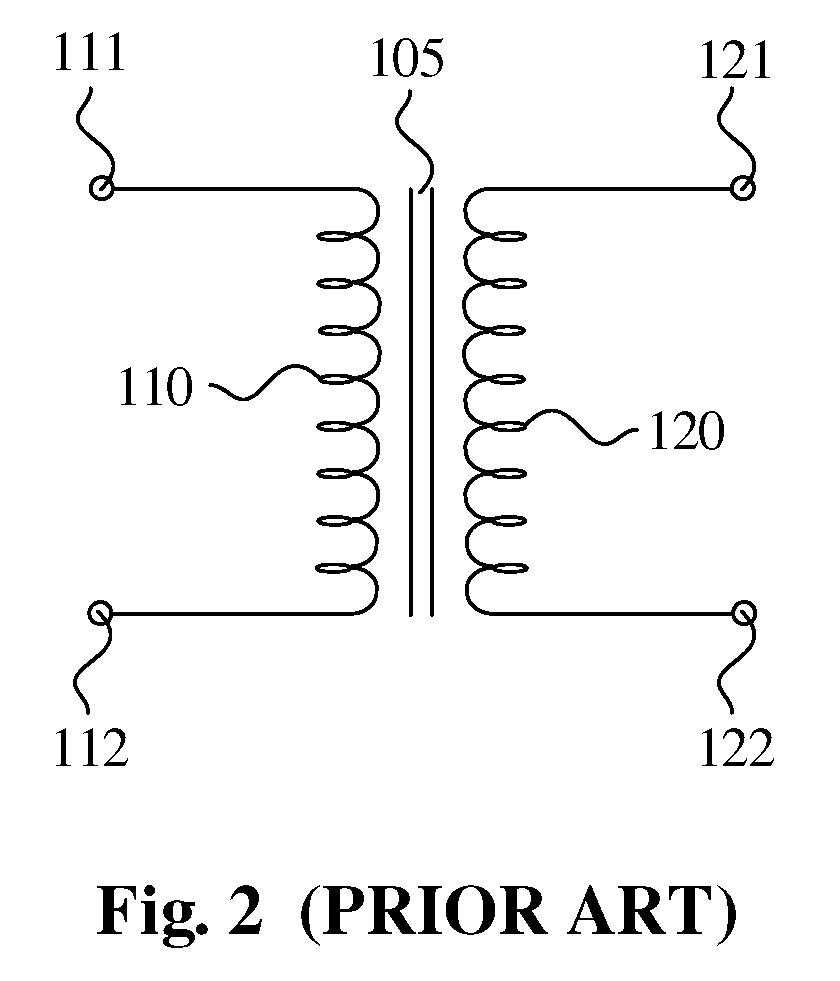

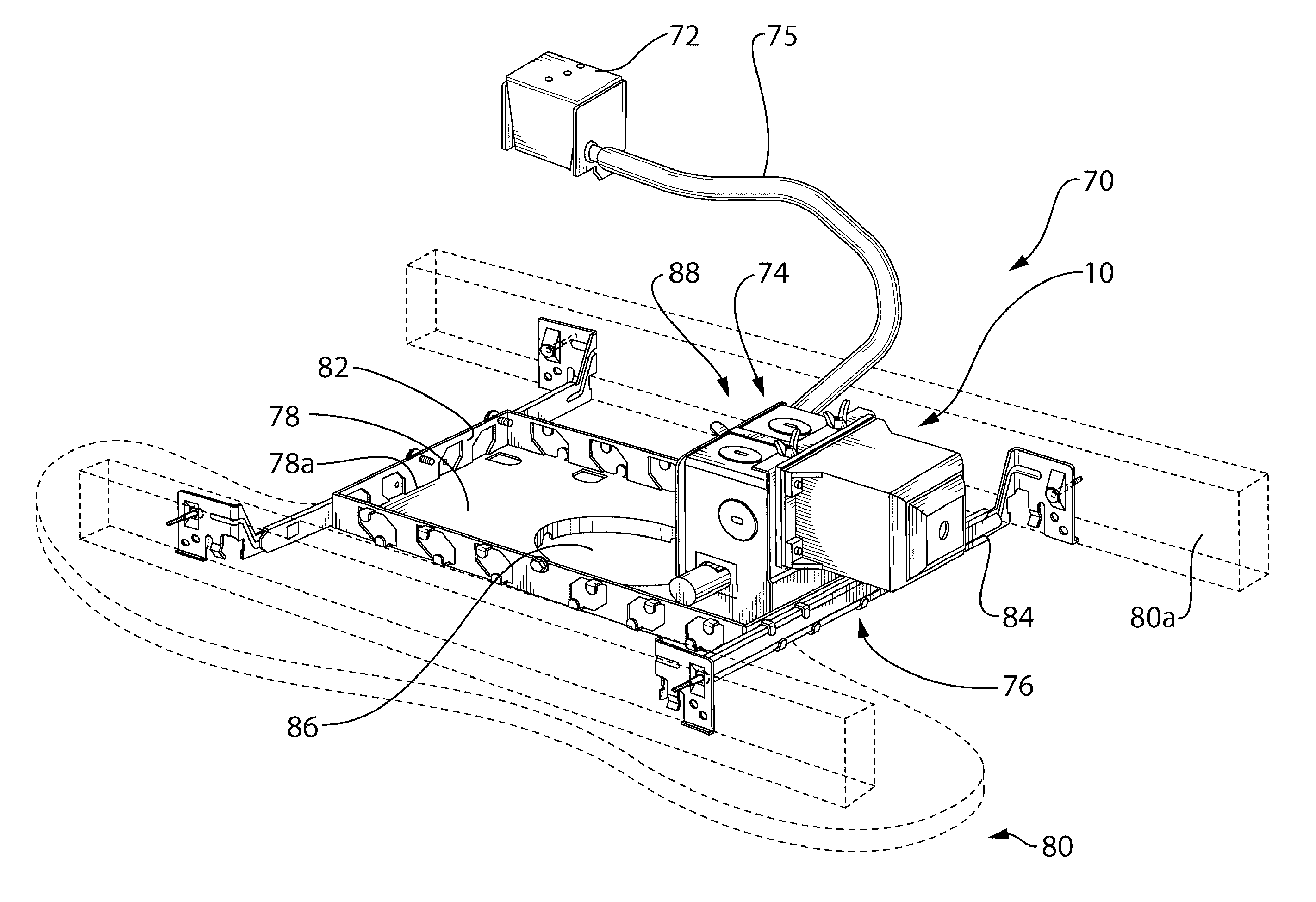

Power electronic module with an improved choke and methods of making same

ActiveUS20100079230A1Transformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringInductor

An improved choke assembly for a power electronics device is provided. More specifically, a choke assembly with improved protection from environmental conditions such as dirt and water is provided. An improved choke assembly may include an insulative housing for an inductor coil that seals the inductor coil from the environment.

Owner:ROCKWELL AUTOMATION TECH

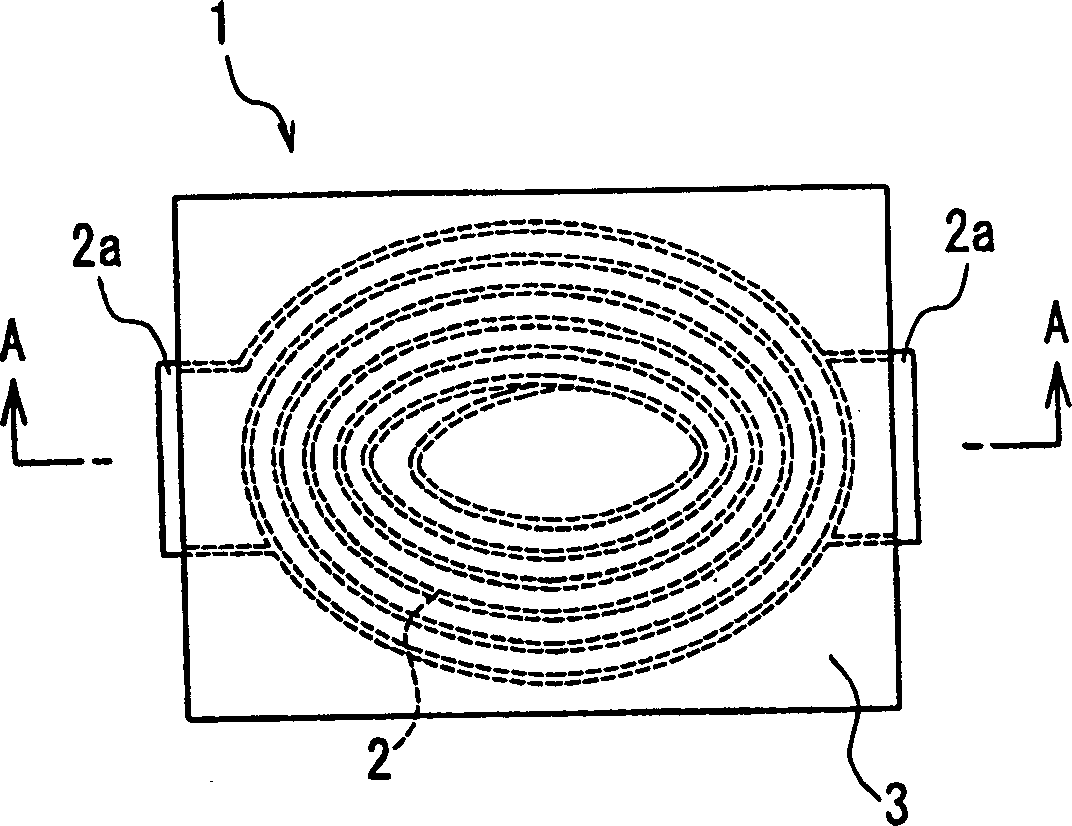

Manufacturing method and manufacturing device for coil component

ActiveCN101441930AImprove featuresAchieve protectionTransformers/inductances coils/windings/connectionsEncapsulation/impregnationConductor CoilFlange

Provided is a coil component having a core including a winding portion, and first and second flanges disposed one on either end of the winding portion, A winding is wound about the winding portion, and first and second terminal electrodes are disposed on the first flange. The first flange has an octagonal shape including a bottom surface, a first peripheral surface, first and third omitted peripheral surfaces disposed one on either side of the first peripheral surface, a second peripheral surface opposing the first peripheral surface, and second and fourth omitted peripheral surfaces disposed one on either side of the second peripheral surface. The first terminal electrode is disposed across the first omitted peripheral surface, a part of the bottom surface in a region connecting the entire first omitted side to the entire third omitted side, and the third omitted peripheral surface. The second terminal electrode is disposed across the second omitted peripheral surface, a part of the bottom surface in a region connecting the entire second omitted side to the entire fourth omitted side, and the fourth omitted peripheral surface. The winding has a first end electrically connected to the first terminal electrode on the first omitted peripheral surface and a second end electrically connected to the second terminal electrode on the second omitted peripheral surface.

Owner:TDK CORPARATION

High current inductor and the manufacturing method

InactiveUS7142084B2Improve featuresCompact structureTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectrical conductorDie casting

An inductor with the characteristic of resisting high current comprising a conductor coil and a magnet envelope, the magnet envelope tightly wraps the periphery of the conductor coil and forms the main body of the inductor, and the two extending parts of the conductor coil extend to outside of the main body of the inductor, forming terminal electrode. As of the manufacturing method, it includes the part of toroid coil and the extending parts composing the conductor coil. After the toroid coil part is winded into rings, the unwinded wire ends form the extending parts. Through magnet envelope die-casting and wrapping the molded magnet core of the conductor coil to form the main body of the inductor, and the extending parts of the conductor coil extend to outside of the main body to form the terminal electrode.

Owner:CHENG CHANG MAO

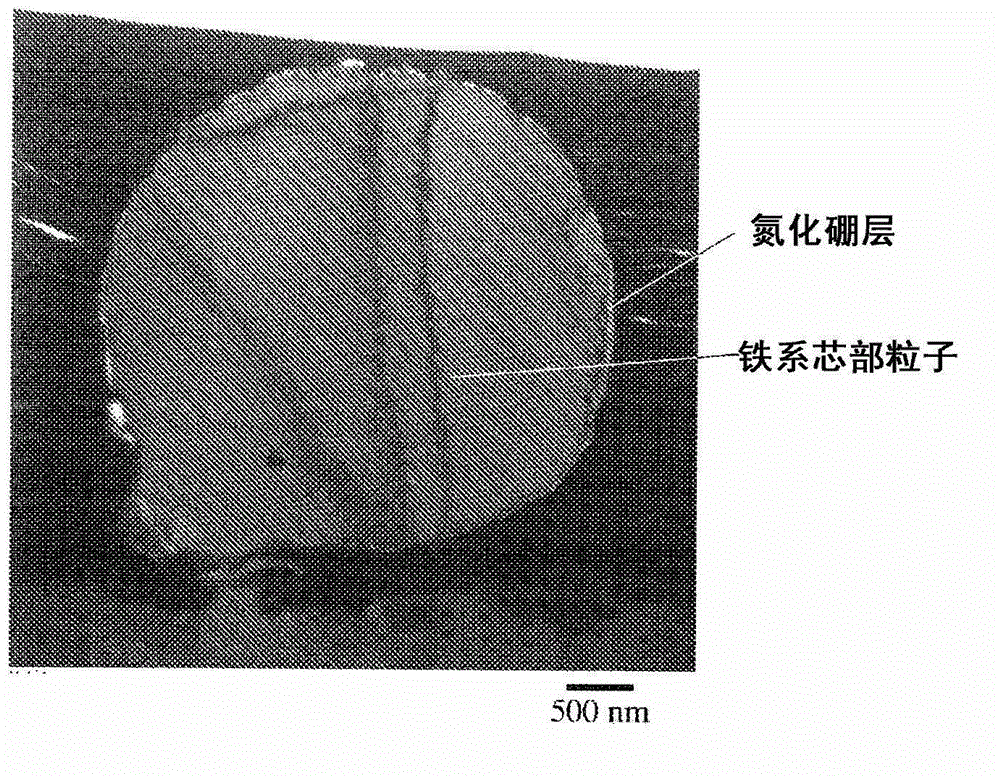

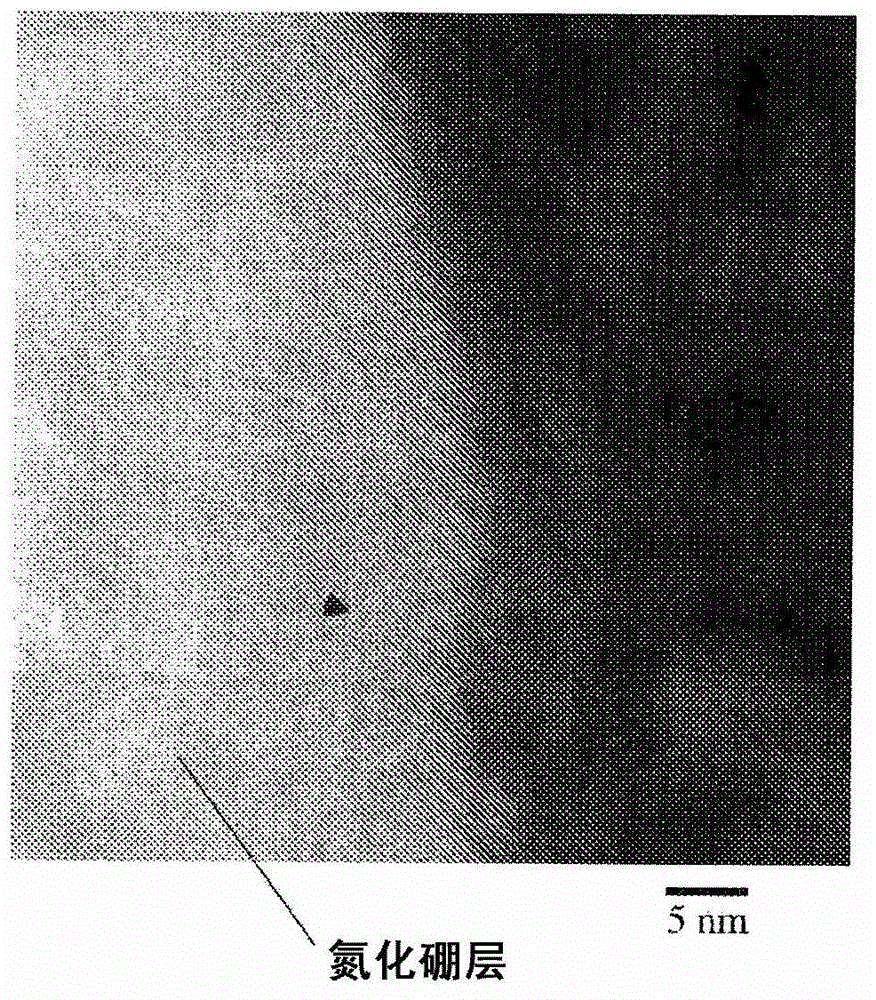

Composite soft magnetic powder, method for producing same, and powder magnetic core using same

InactiveCN103339694AHigh densityHigh saturation magnetizationTransportation and packagingMetal-working apparatusBoron nitrideNon magnetic

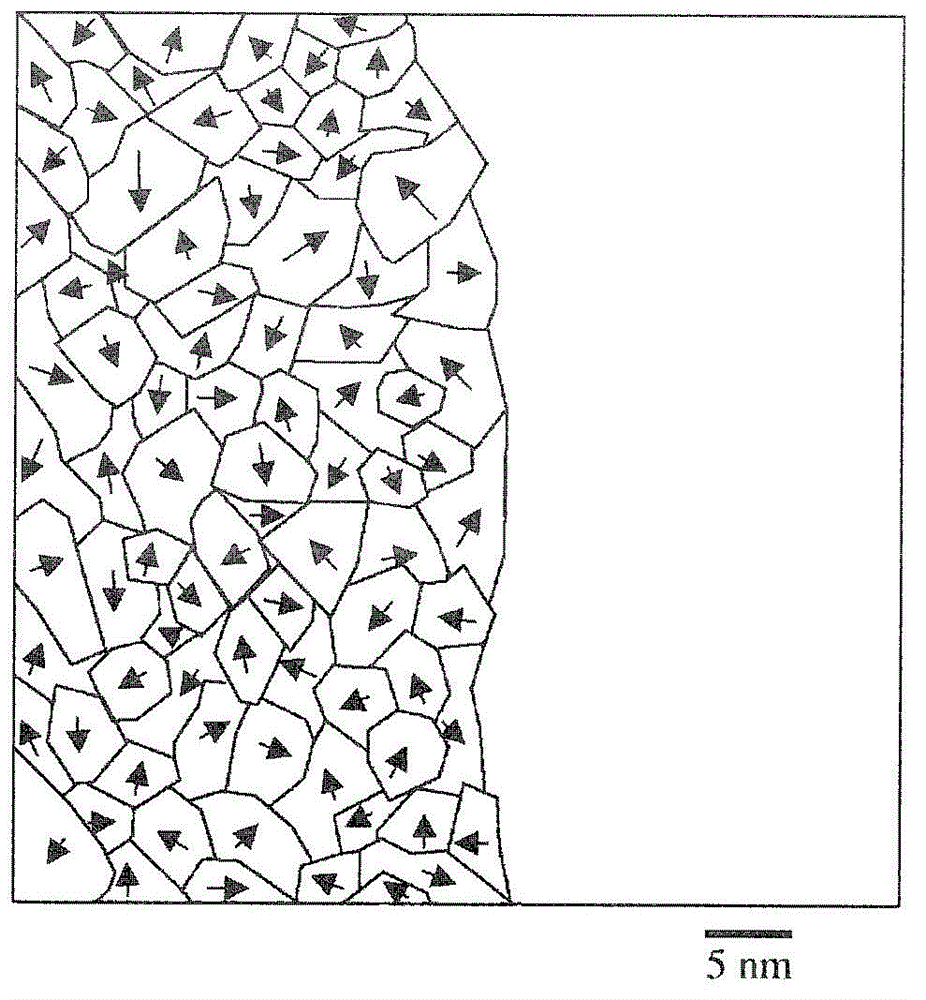

This composite soft magnetic powder comprises soft magnetic ferrous core particles, which have a particle size of 2-100 [mu]m, and a layer, which has boron nitride as the primary constituent and covers at least a portion of the surface of the soft magnetic ferrous core particles, the covering layer being a polycrystalline layer that comprises boron nitride microcrystalline grains having an average crystal grain size of 3-15 nm and differing crystal axis orientations and that has an average thickness that is no greater than 6.6% of the average particle size of the soft magnetic ferrous core particles. The composite soft magnetic powder is produced by means of (1) mixing an iron nitride powder having an average particle size of 2-100 [mu]m and a boron powder having an average particle size of 0.1-10 [mu]m, (2) heat treating the obtained mixed powder at a temperature of 600-850 DEG C in a nitrogen atomosphere, and (3) eliminating the non-magnetic components.

Owner:HITACHI METALS LTD

Transformer apparatus with shielding architecture and shielding method thereof

InactiveUS20090289755A1Transformers/reacts mounting/support/suspensionCross-talk/noise/interference reductionMetal foilTransformer

A transformer apparatus and a transformer shielding method are provided for shielding external electronic noises and protecting against erosion. The transformer apparatus comprises a toroidal core, a primary winding, a secondary winding, a protection tape, a metal foil, and an UL tube. The primary winding and the secondary winding are wound around the toroidal core at opposite side to each other. The protection tape is wrapped around the primary winding and the secondary winding. The metal foil encloses the protection tape. The UL tube enfolds the metal foil. The transformer shielding method comprises wrapping a primary winding and a secondary winding of the transformer apparatus by a protection tape, enclosing the protection tape by a metal foil, and enfolding the metal foil by an UL tube.

Owner:SERCOMM

Method of Making a Magnetic Core Part

ActiveUS20070256759A1Small sizeHigh magnetic flux densityInorganic material magnetismTransformers/inductances detailsMaterials scienceMagnetic core

Magnetic powder contained in a resin composition for use in injection molding is coated with an insulating material, and a soft magnetic green compact or a hard magnetic green compact is insert molded into the resin composition.

Owner:NTN CORP

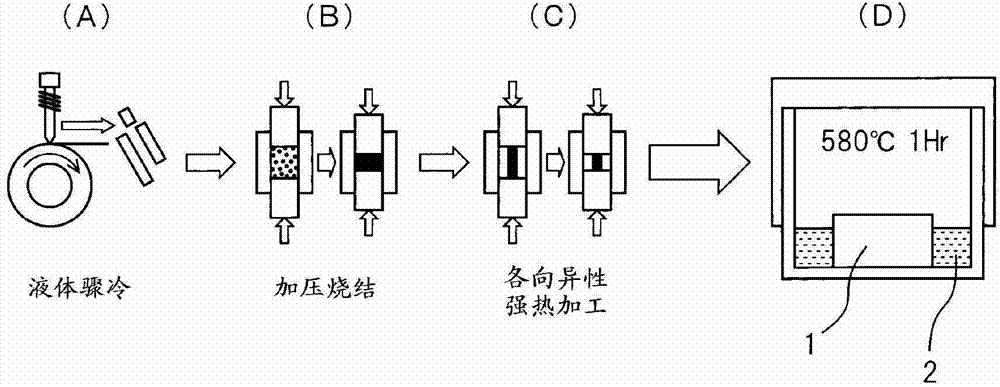

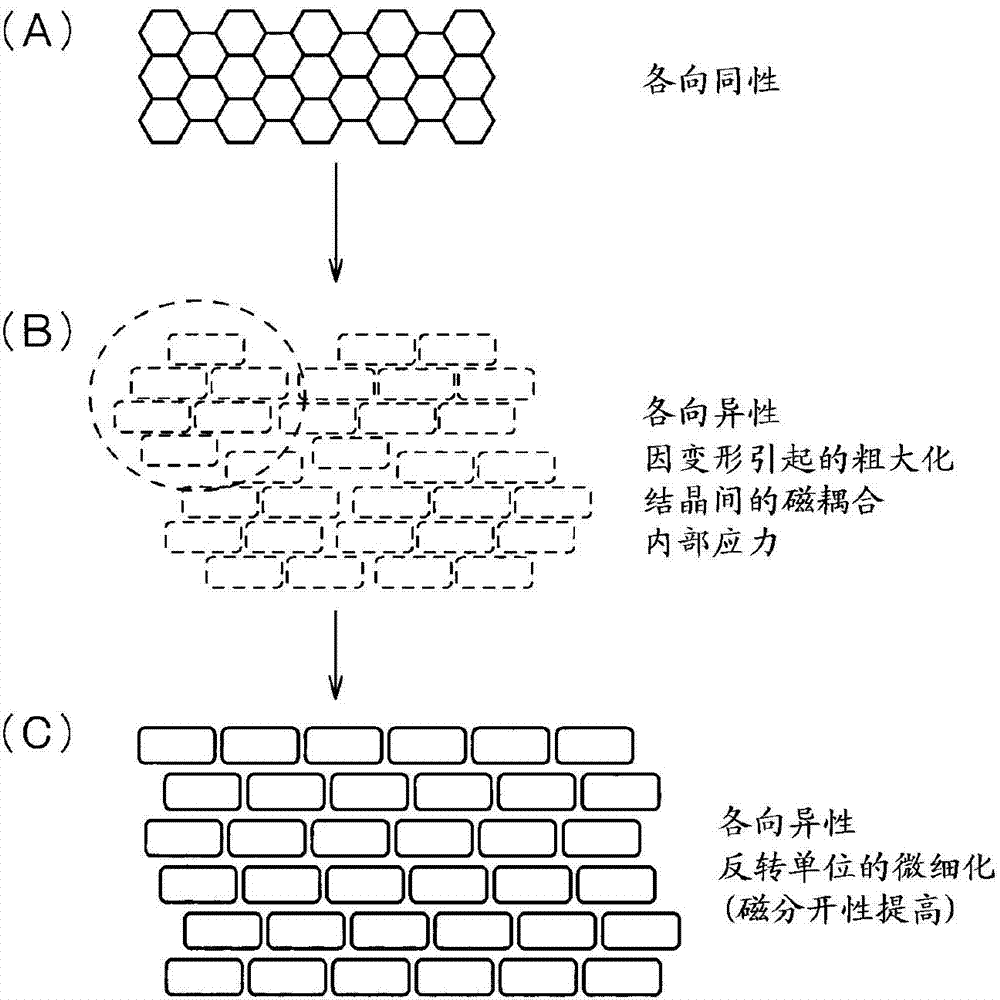

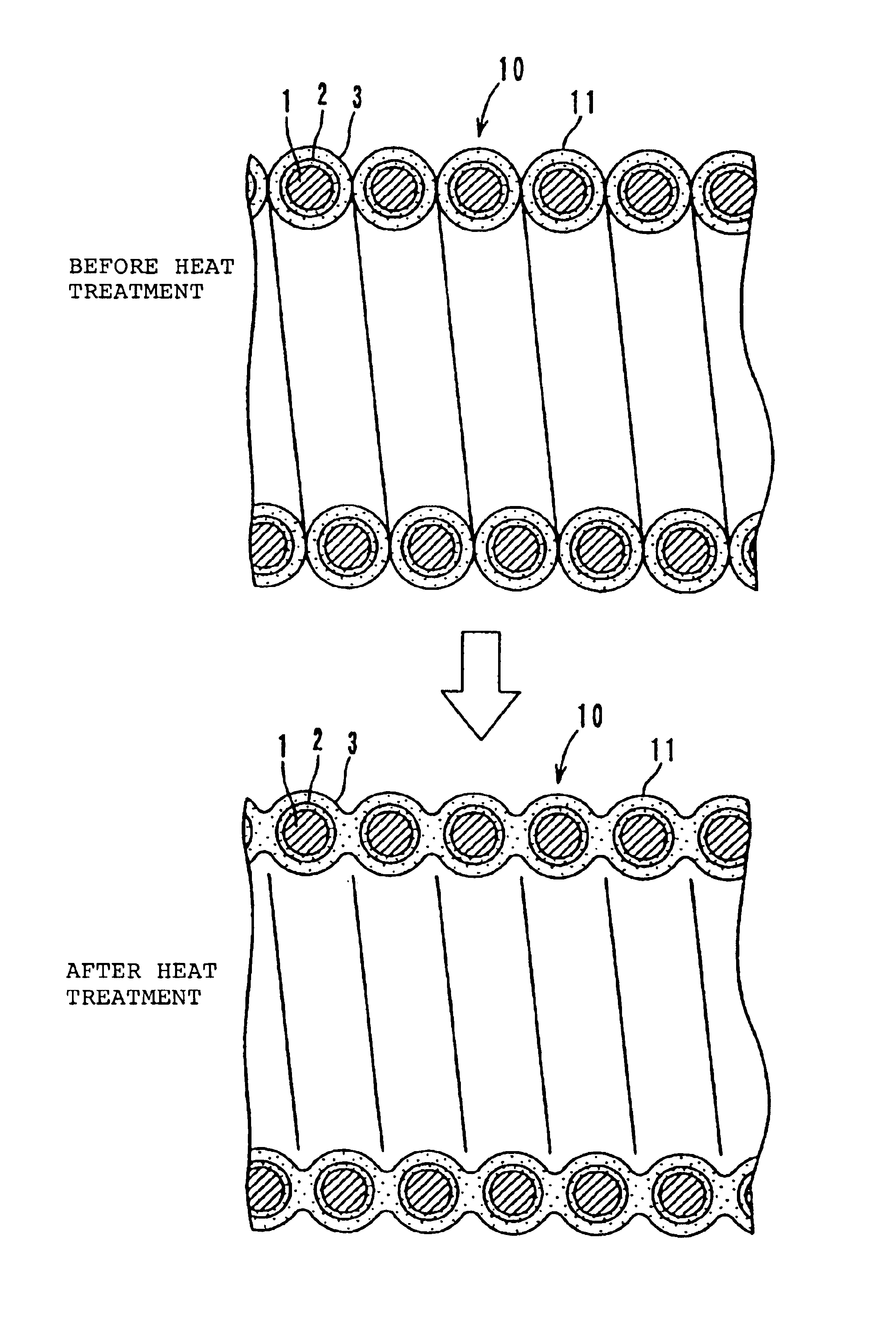

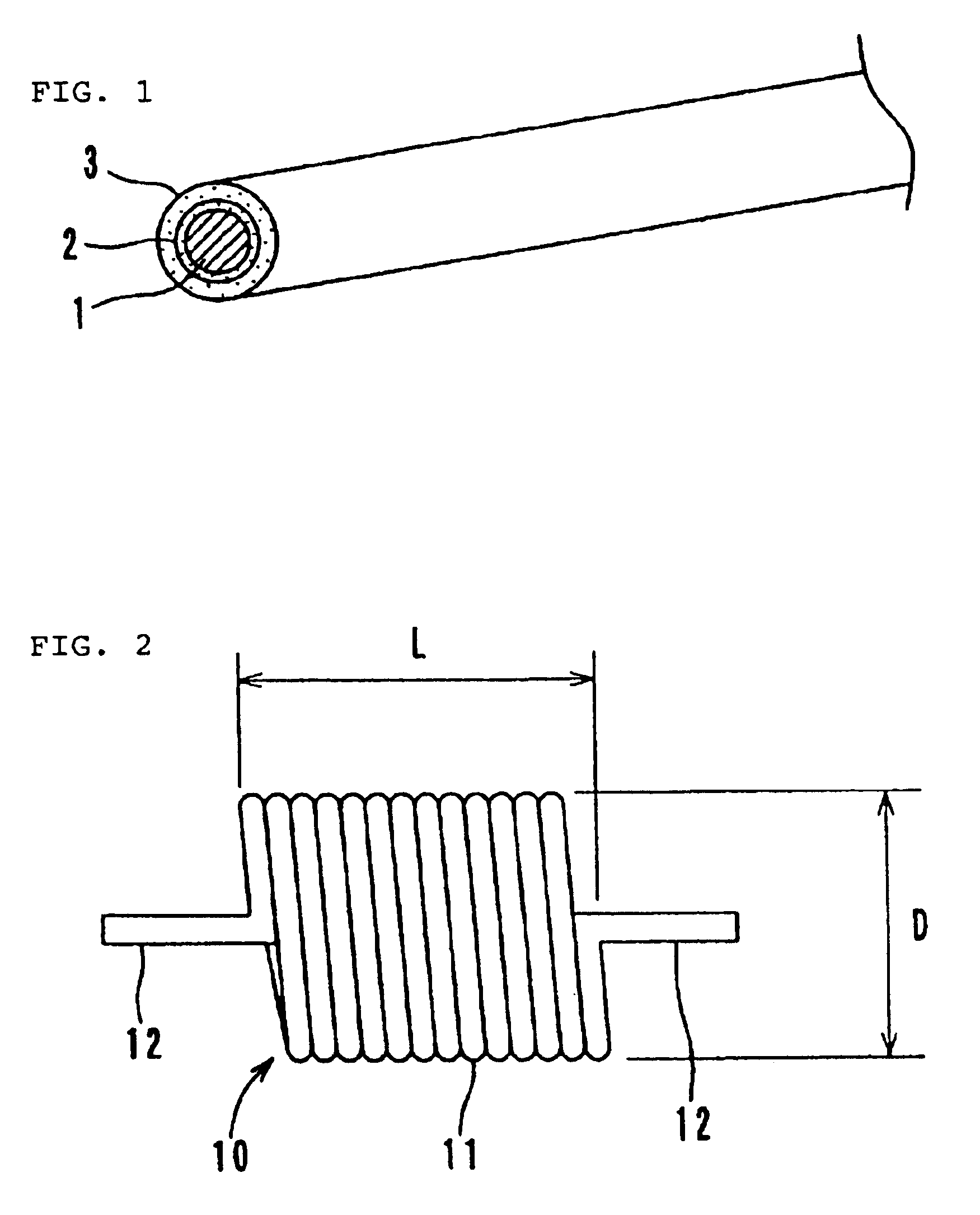

Method for producing rare-earth magnet

InactiveCN103098155AImprove coercive forceInorganic material magnetismEncapsulation/impregnationRare-earth elementRare-earth magnet

To provide a method for producing an anisotropic rare-earth magnet that can be enhanced in coercive force without adding a large quantity of rare metals such as Dy and Tb. [Solution] A method for producing a rare-earth magnet, including a step of bringing a compact, which is obtained by hot-working a sintered compact having a rare-earth magnet composition to provide anisotropy thereto, into contact with a low-melting-point alloy melt containing a rare-earth element.

Owner:TOYOTA JIDOSHA KK

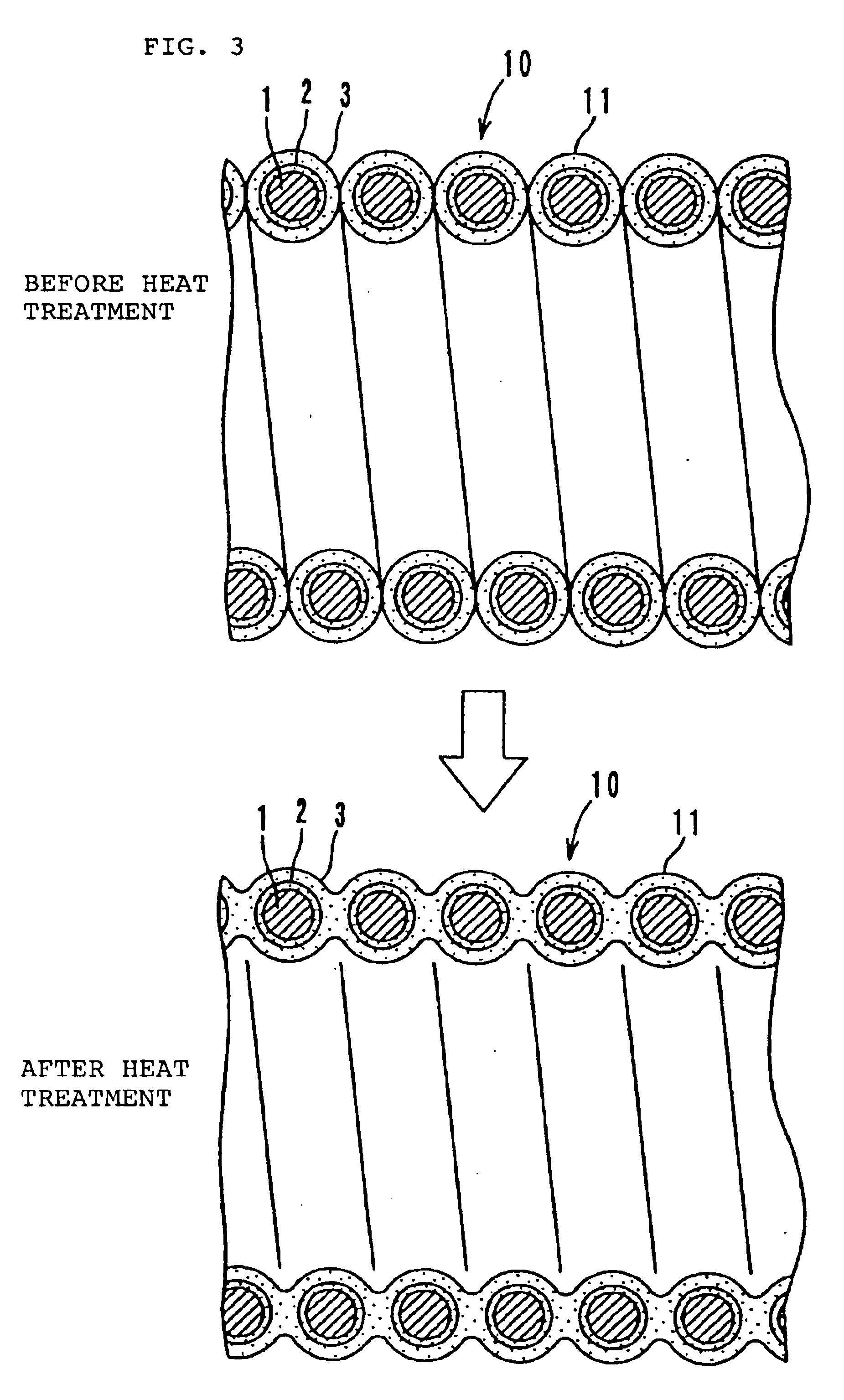

Method for manufacturing an inductor

InactiveUS6859994B2Good shape retentionImprove batch productivityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEpoxyElectrical conductor

A method for manufacturing an inductor is performed in such a manner that the surface of a metal wire provided with an insulating film thereon is coated with a thermal melting resin. The thickness of the thermal melting resin is, for example, approximately 1 μm. As the thermal melting resin, a thermoplastic resin or a thermosetting resin, such as a polyimide resin or an epoxy resin, containing 85 wt % of a powdered ferrite is used. This coated metal wire is densely wound to form a solenoid-type coil conductor. Next, the thermal melting resin is softened by a heat treatment at, for example, 180° C. and is then solidified by spontaneous cooling. Accordingly, the portions of the coil conductor adjacent to each other are bonded together by the thermal melting resin.

Owner:MURATA MFG CO LTD

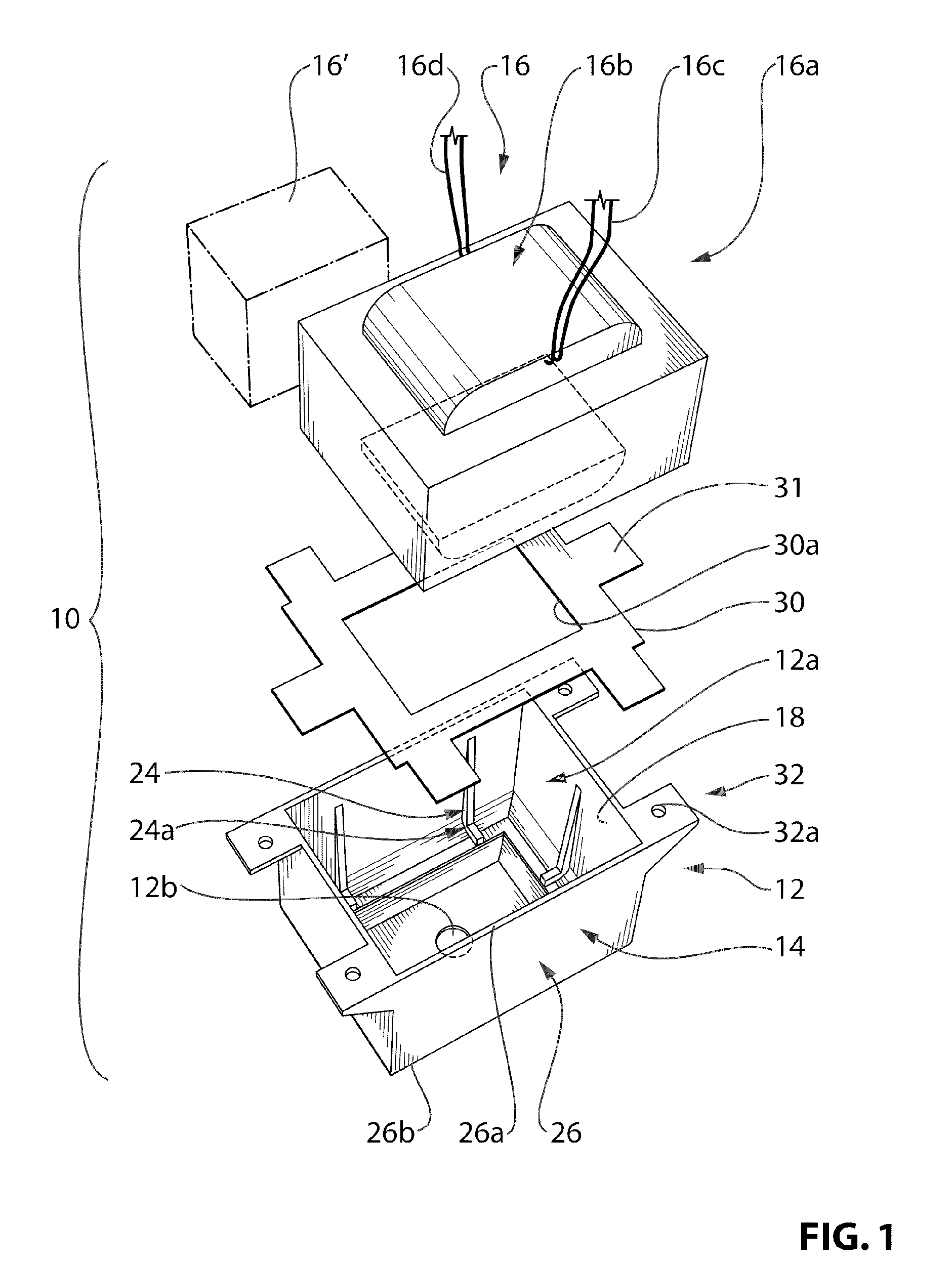

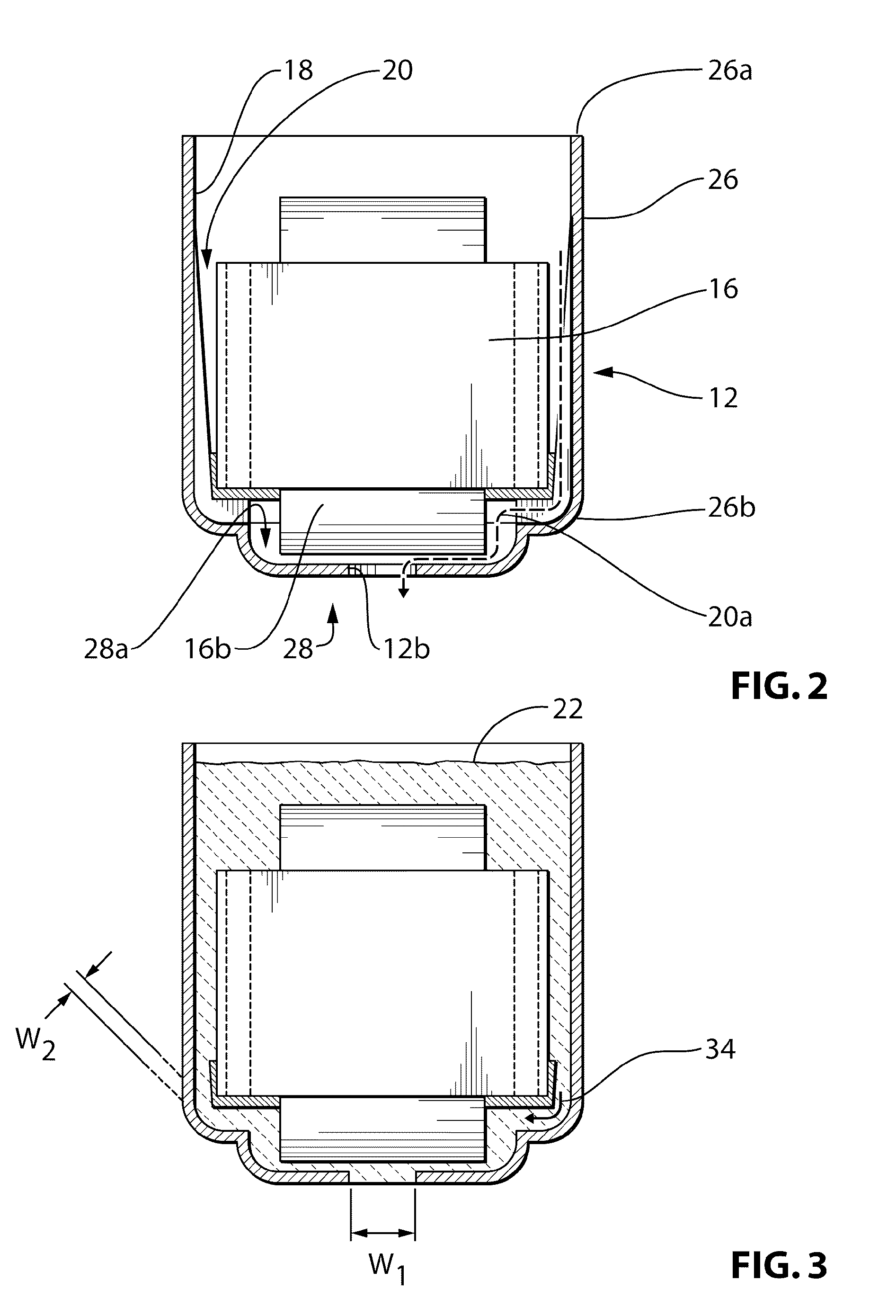

Transformer assembly and light fixture assembly using same

A potted transformer assembly comprises a housing portion to form an exterior transformer housing, a transformer unit dimensioned to fit within the housing portion, the housing portion including a first passage to receive the transformer unit in an operative position therein, the housing portion having an inner surface which is oriented to provide an interior cavity between the transformer unit and the inner surface, the interior cavity being dimensioned to receive a predetermined quantity of a potting compound, the housing portion further including a second passage in fluid communication with the interior cavity, the second passage being dimensioned to receive a portion of the potting compound therein, the second passage being located on the housing portion in such a manner that, following a transformer encapsulation step, the presence of potting compound in the second passage is indicative of the transformer being substantially encapsulated by the potting compound.

Owner:CANLYTE ULC

Method for making ndfeb sintered magnet

ActiveUS20100119703A1Reduce instabilityExpensive amountInorganic material magnetismEncapsulation/impregnationSintered magnetsInstability

The objective of the present invention is to provide a method for making a NdFeB sintered magnet, capable of enhancing the effect of increasing the coercive force and preventing the instability of the effects, and in addition, being inexpensive. The method for making a NdFeB sintered magnet according to the present invention has processes of coating a NdFeB sintered magnet with a powder containing Dy and / or Tb, then heating the NdFeB sintered magnet, and thereby diffusing Rh in the powder into the NdFeB sintered magnet through a grain boundary, and is characterized in that the powder contains 0.5 through 50 weight percent of Al in a metallic state; and the amount of oxygen contained in the NdFeB sintered magnet is equal to or less than 0.4 weight percent.

Owner:DAIDO STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com