Novel inductor and manufacturing method thereof

A new type of inductance technology, applied in the manufacture of inductors/transformers/magnets, inductors, fixed inductors, etc., can solve the problems of unreachable, structural design layout and material collocation restrictions, etc., to improve firmness, reduce quality risks, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The novel inductor of the present invention and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings.

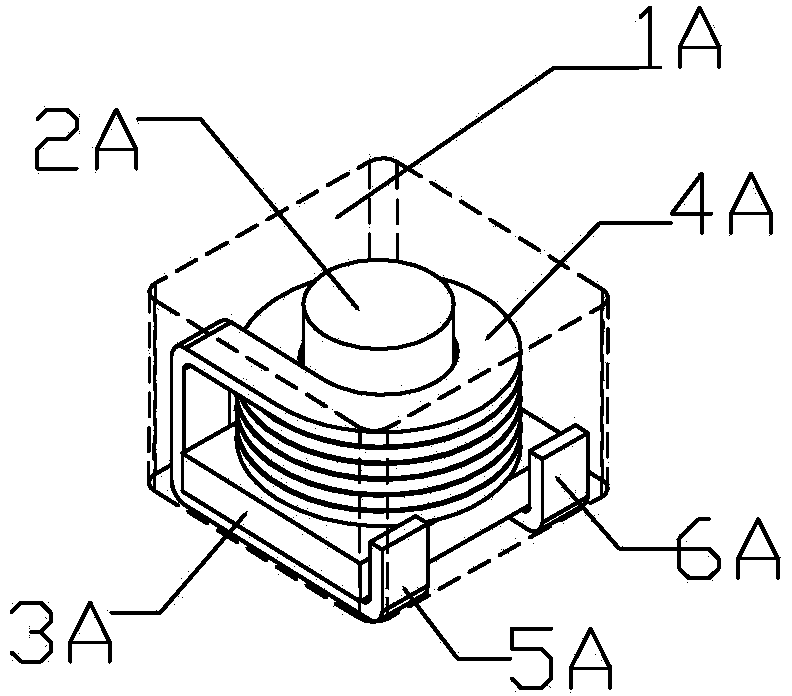

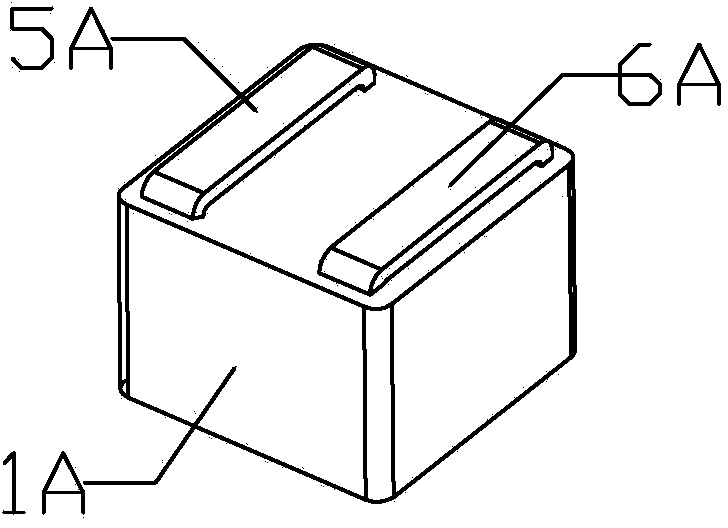

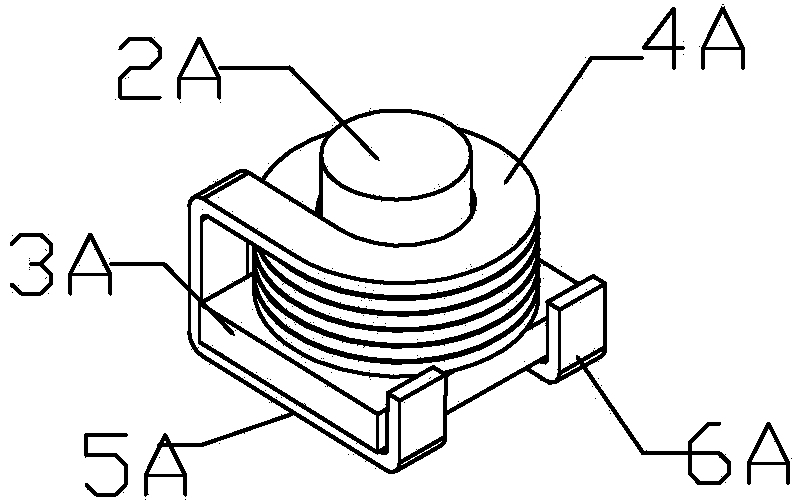

[0062] Such as Figure 1 to Figure 28 As shown, the present invention is a new type of inductor, which is characterized in that: the new type of inductor includes enameled coils (4A, 4B, 4C) and mandrels (2A, 2B, 2C, 3A, 3B, 3C) made into inlaid inner core( image 3 , Figure 10 , Figure 20 ); the pre-fabricated inlay core ( image 3 , Figure 10 , Figure 20 ), put into the corresponding mold, and make sure that the terminals or coils connected to the coils are extended to form electrodes (5A, 5B, 6A, 6B, ) or pre-plated to form electrodes (5C, 5D, 5E, 5F, 6C, 6D , 6E, 6F) are partly exposed; through a mechanical or hydraulic powder metallurgy molding press, the metal powder is die-cast to form an outer cladding layer (1A, 1B, 1C); the mosaic inner core ( image 3 , Figure 10 , Figure 20 ) and el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com