Overlapping structure of waterproof coil materials, and construction method

A technology of waterproof membrane and joint structure, which is applied in basic structure engineering, water conservancy engineering, and roofs using flexible materials. Achieve the effect of improving waterproof effect, avoiding water seepage and leakage, and improving the stability of lap joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

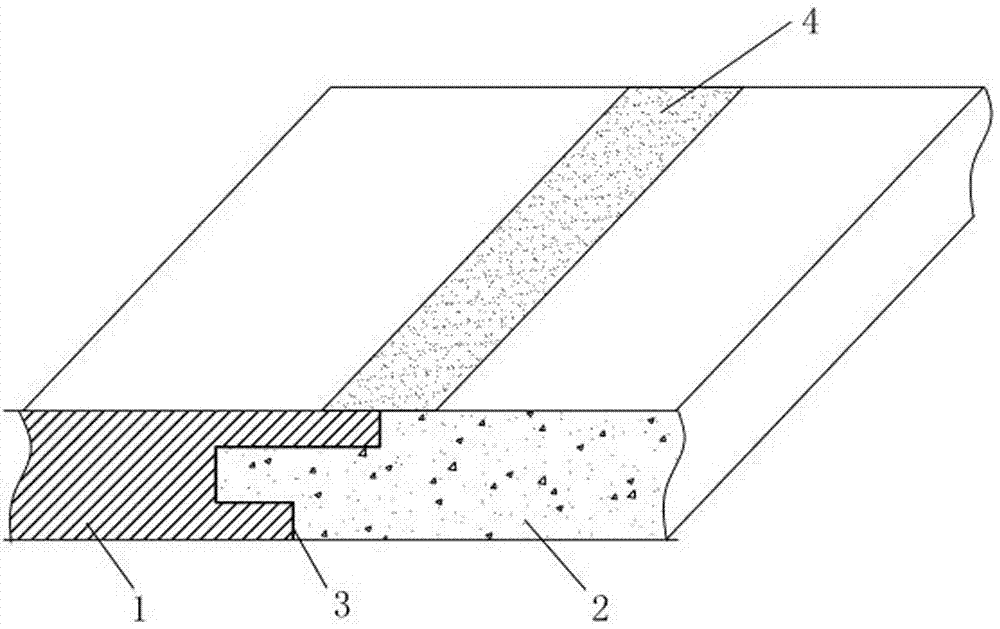

[0028] like figure 1 As shown, an overlapping structure and construction method of a waterproof coiled material according to a preferred embodiment of the present invention, the overlapping structure of the waterproof coiled material includes two waterproof coiled materials whose ends are overlapped with each other, and one end of the waterproof coiled material It is an asymmetric concave structure 1, and the overlapping end of the other waterproof membrane is a corresponding convex structure 2. The overlapping parts of the two waterproof membranes are connected by an adhesive layer 3, and the surface of the waterproof membrane is The seams are also provided with a waterproof reinforcement coating 4 . Wherein, the waterproof coiled material is a SBS modified asphalt self-adhesive waterproof layer, which has a good waterproof effect, and the concave-shaped structure 1 at the end is side-standing, that is, the shape of the notch facing the side, and the concave-shaped structure ...

Embodiment 2

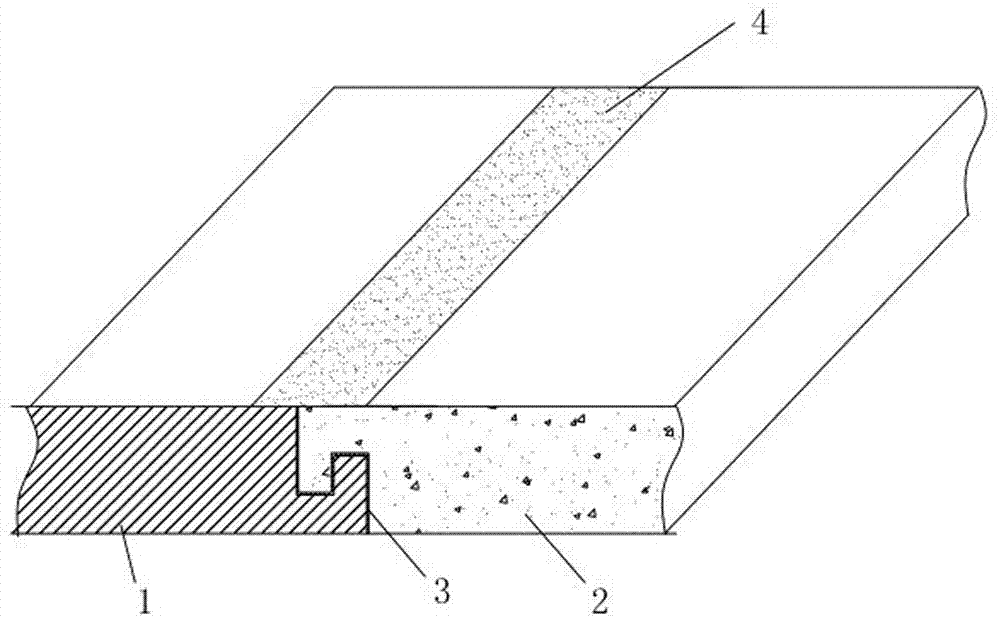

[0036] like figure 2 As shown, the overlapping structure of a waterproof coiled material in a preferred embodiment of the present invention includes two waterproof coiled materials whose ends are overlapped with each other, wherein the end of one waterproof coiled material has an asymmetric concave structure 1, and the other waterproof The overlapped ends of the coiled materials have corresponding convex structures 2, and the overlapping parts of the two waterproof coiled materials are connected by an adhesive layer 3, and a waterproof reinforcing coating 4 is provided at the seam of the surface of the waterproof coiled materials. Wherein, the waterproof roll material is a SBS modified asphalt self-adhesive waterproof layer, which has good waterproof effect. When the material is used in an environment with a steep slope or when the waterproof membrane is thick, the lap joint in the shape of a vertical notch can effectively increase the bonding force of the lap joint and avoid...

Embodiment 3

[0044] The overlapping structure of the waterproof membrane is the same as that in Example 1, except that the step (3) in the construction method is different, as follows:

[0045](3) Closely combine the two overlapping ends, press for 2 minutes, and then coat a layer of graphene-modified polyurethane on the seam of the upper surface of the waterproof membrane, the coating thickness is 0.3mm, and the width is 10cm. Just dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com