Patents

Literature

284 results about "Overlapping structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What does it mean when a xray shows overlapping shadows? Dr. Joseph Accurso, University at Buffalo, The State University of New York School of Medicine & Biomedical ... May be a nodule or due to overlapping structures.". Ribs and vessels are 2 things that can add up to mimic disease. Thank 2 Thank s. 1 Doctor s Approved Home → Health Answers

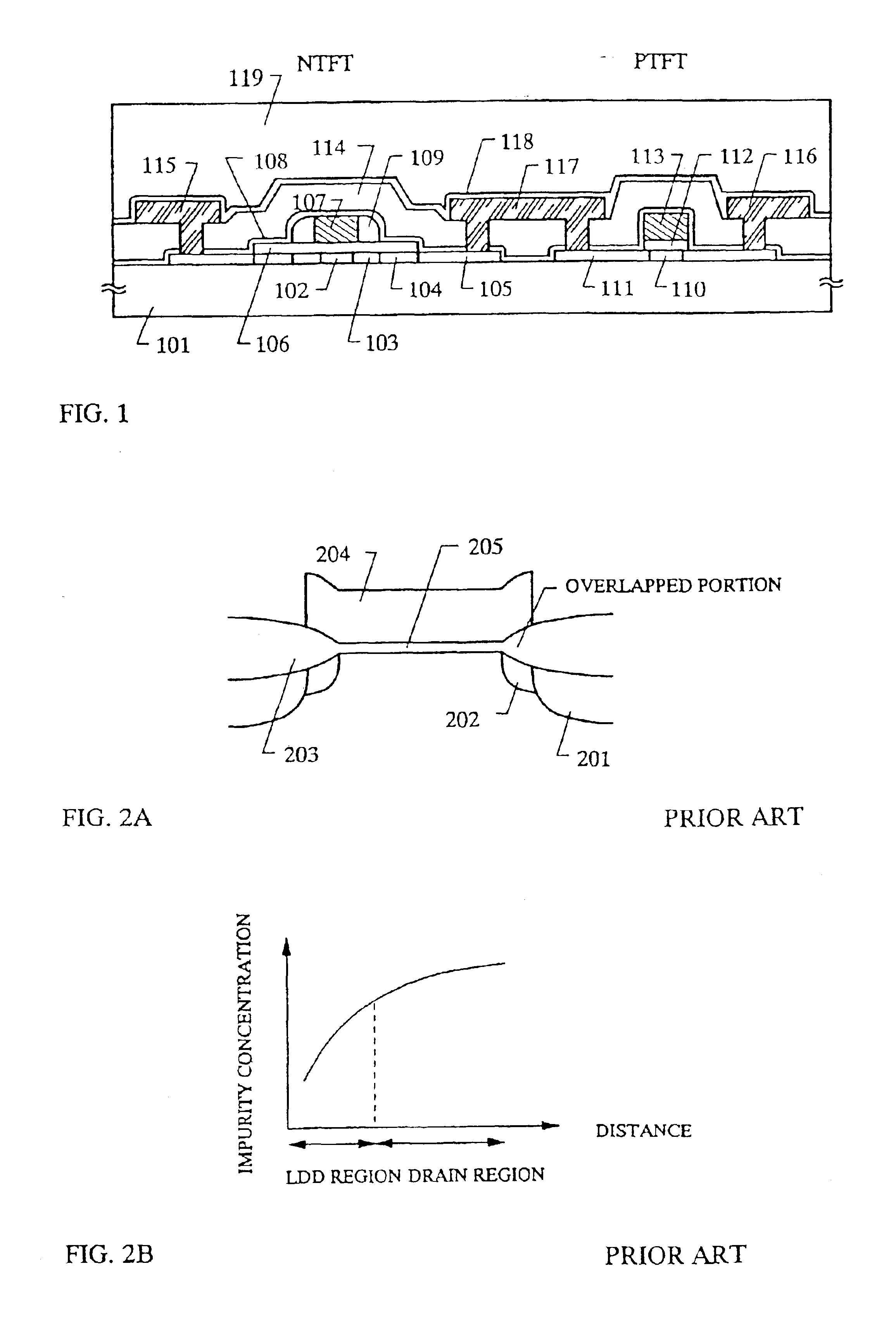

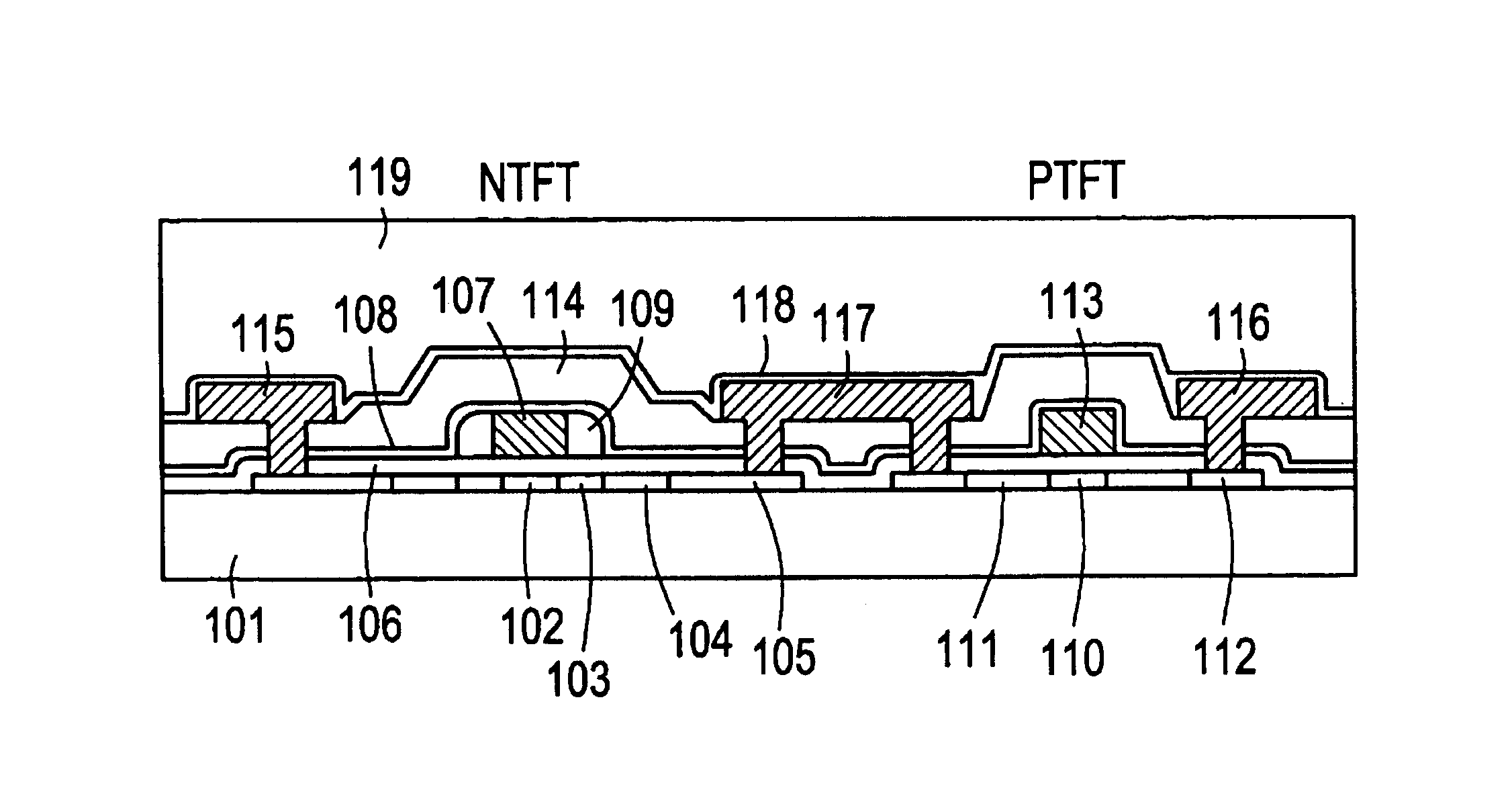

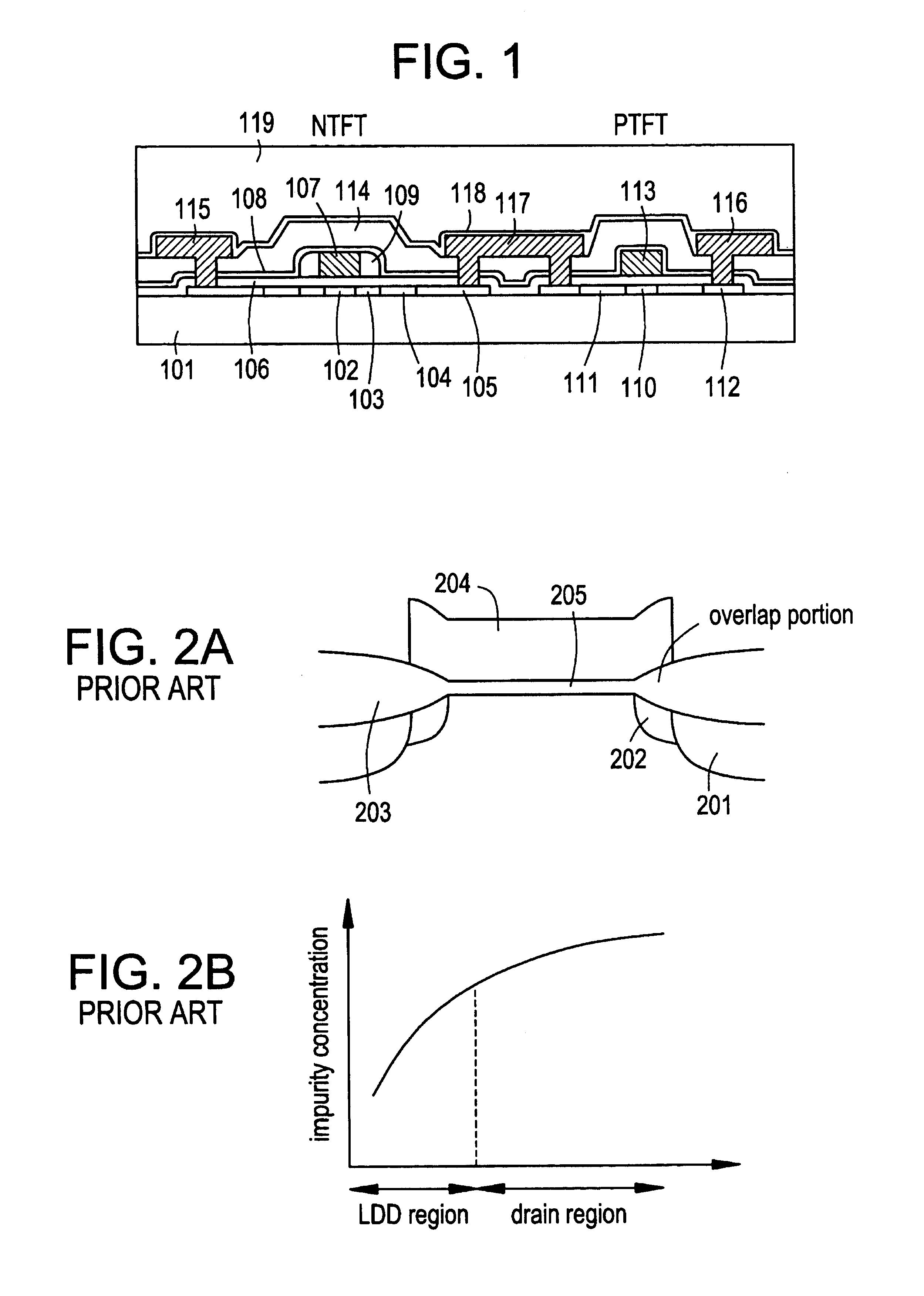

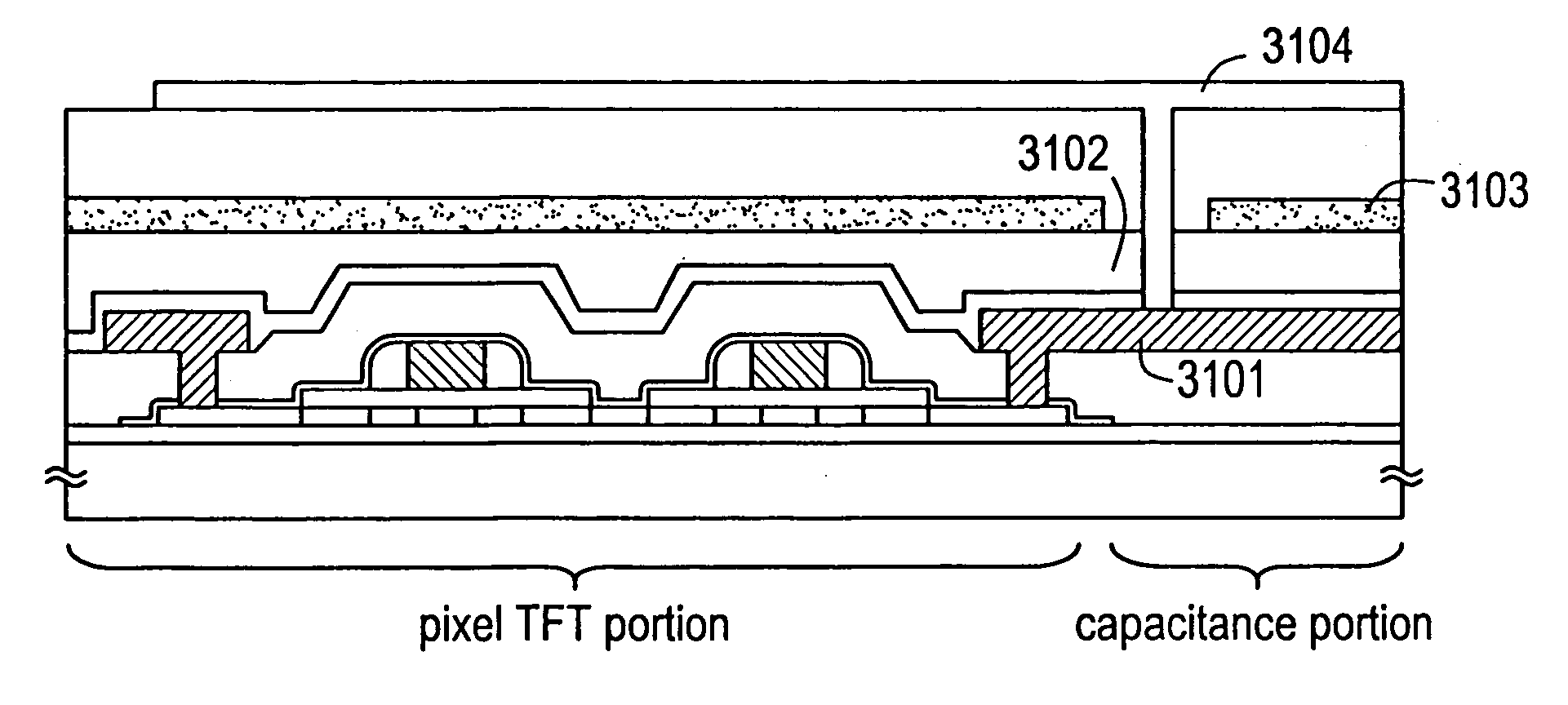

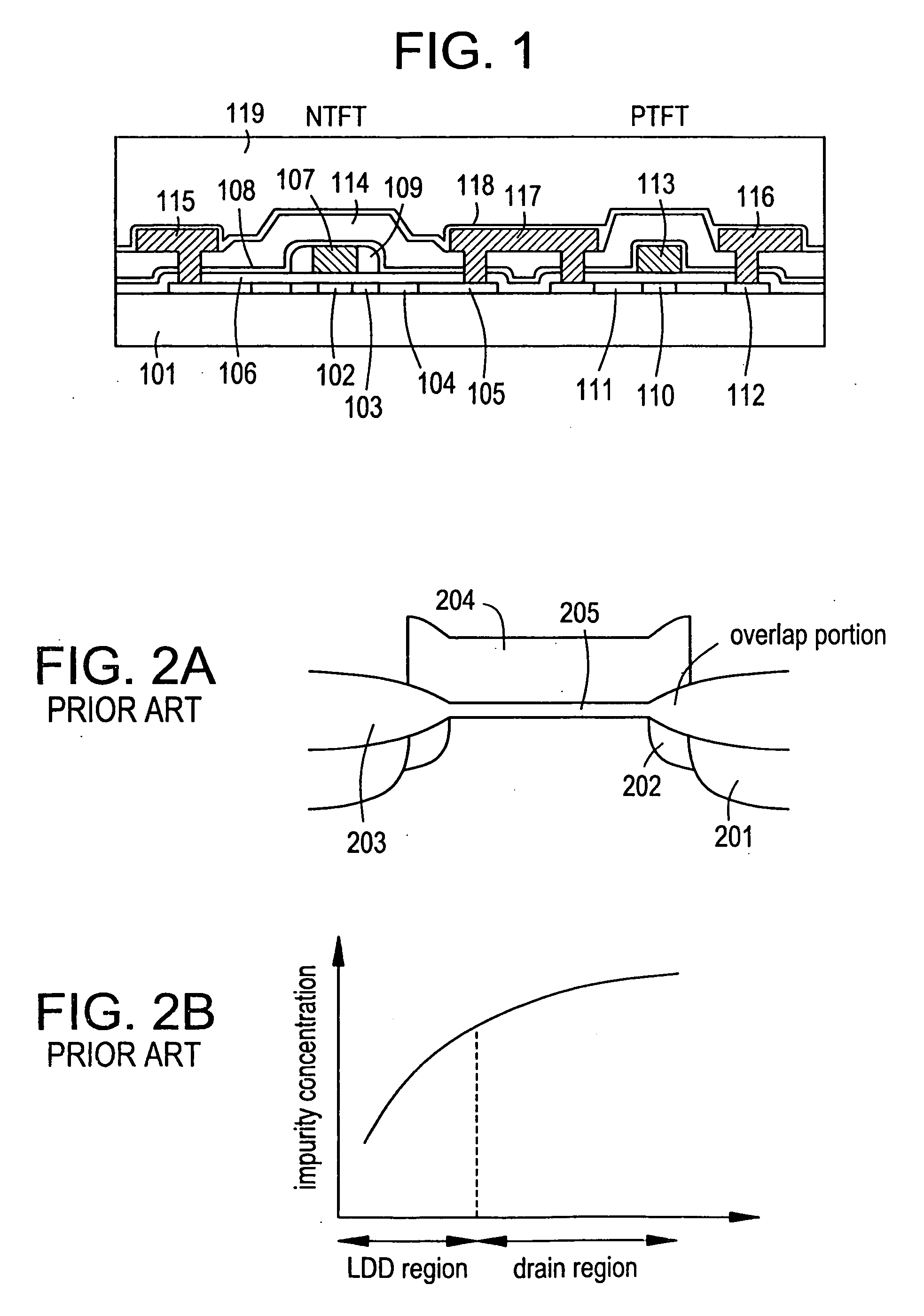

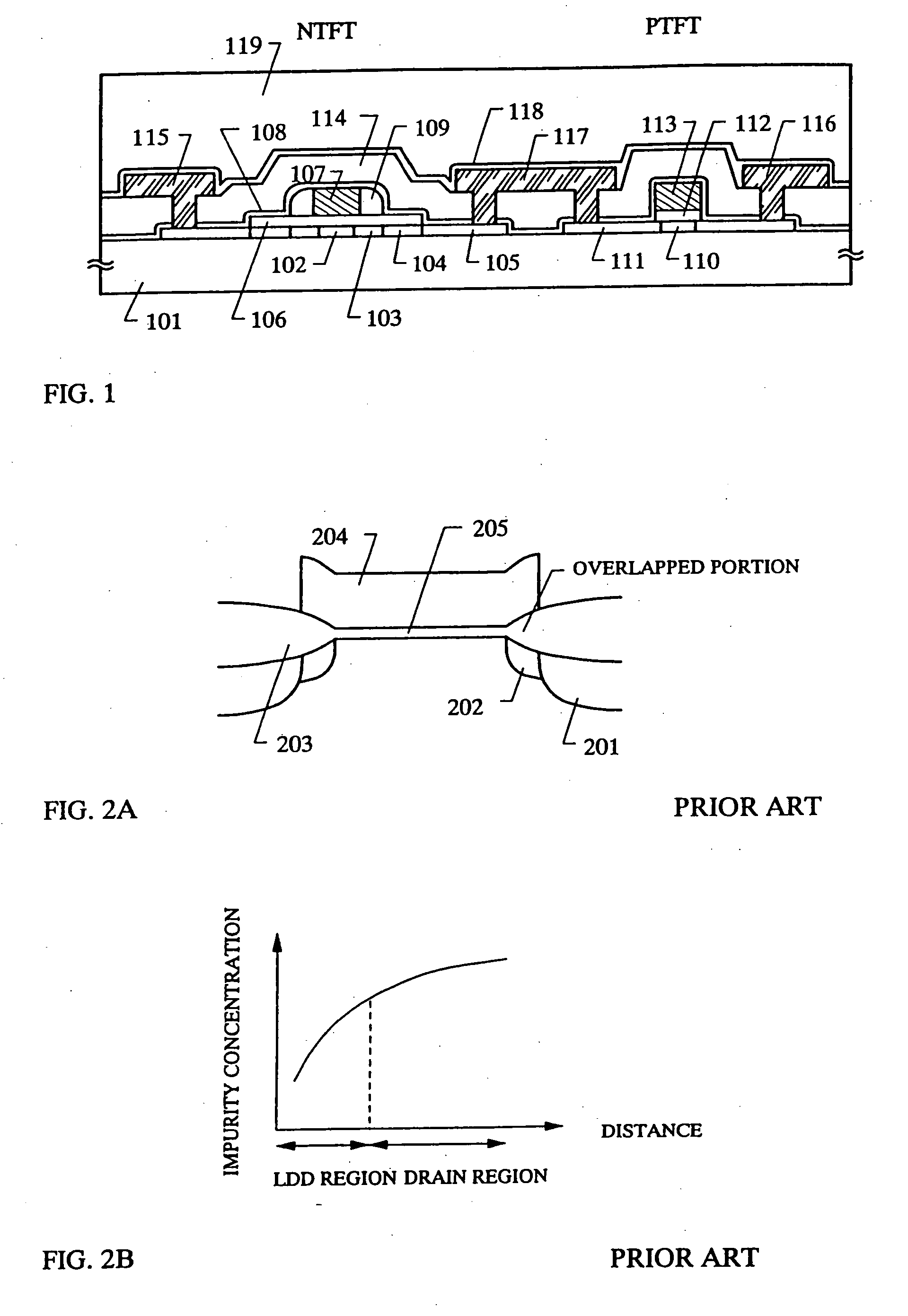

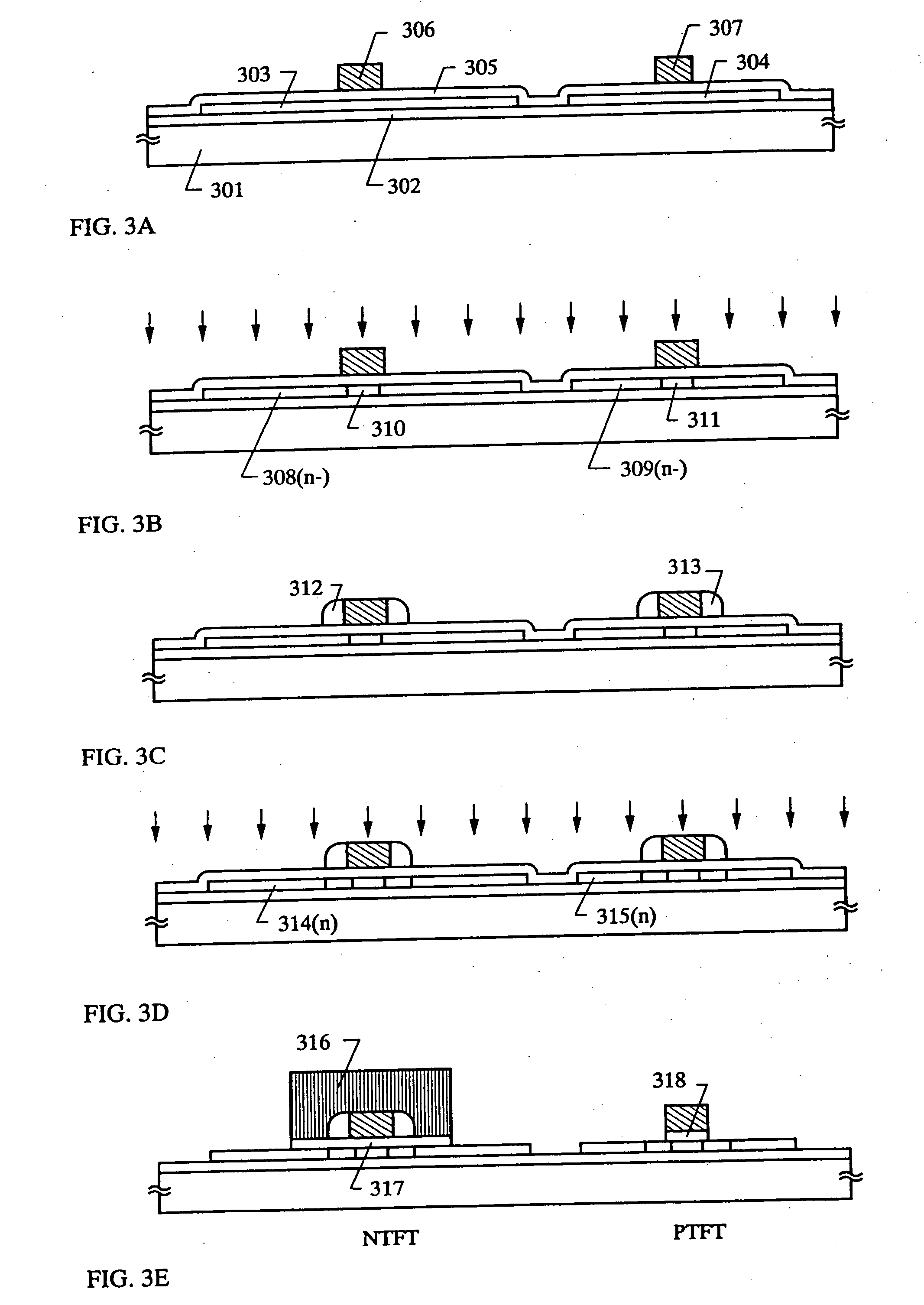

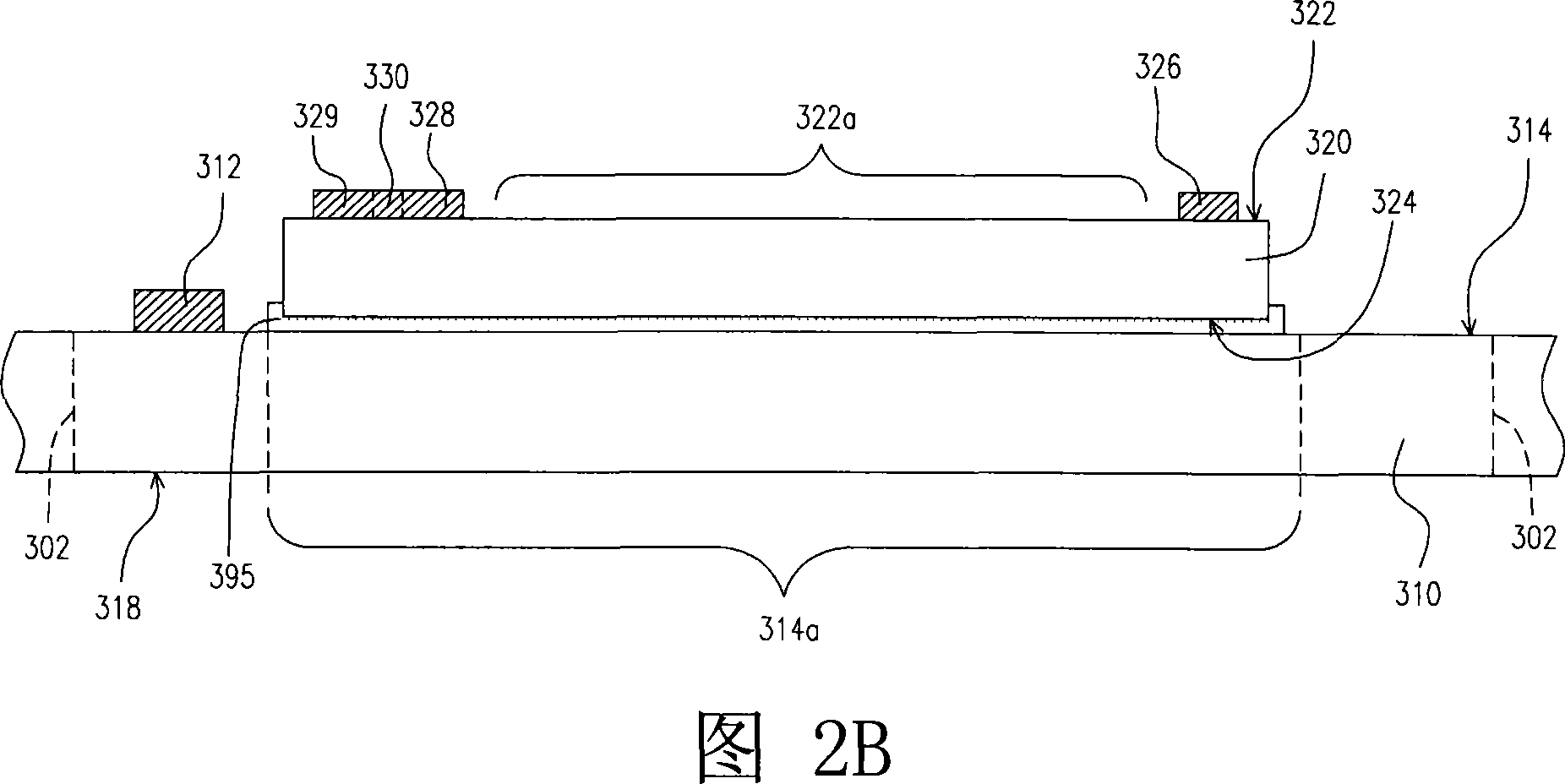

Semiconductor device and manufacturing method therefor

InactiveUS6977394B2Improve reliabilityDeterioration due to a hot carrier can also be effectively suppressedTransistorSolid-state devicesActive layerImpurity

An active layer of an NTFT includes a channel forming region, at least a first impurity region, at least a second impurity region and at least a third impurity region therein. Concentrations of an impurity in each of the first, second and third impurity regions increase as distances from the channel forming region become longer. The first impurity region is formed to be overlapped with a side wall. A gate overlapping structure can be realized with the side wall functioning as an electrode.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device having an impurity gradient in the impurity regions and method of manufacture

The active layer of an n-channel TFT is formed with a channel forming region, a first impurity region, a second impurity region and a third impurity region. In this case, the concentration of the impurities in each of the impurity regions is made higher as the region is remote from the channel forming region. Further, the first impurity region is disposed so as to overlap a side wall, and the side wall is caused to function as an electrode to thereby attain a substantial gate overlap structure. By adopting the structure, a semiconductor device of high reliability can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

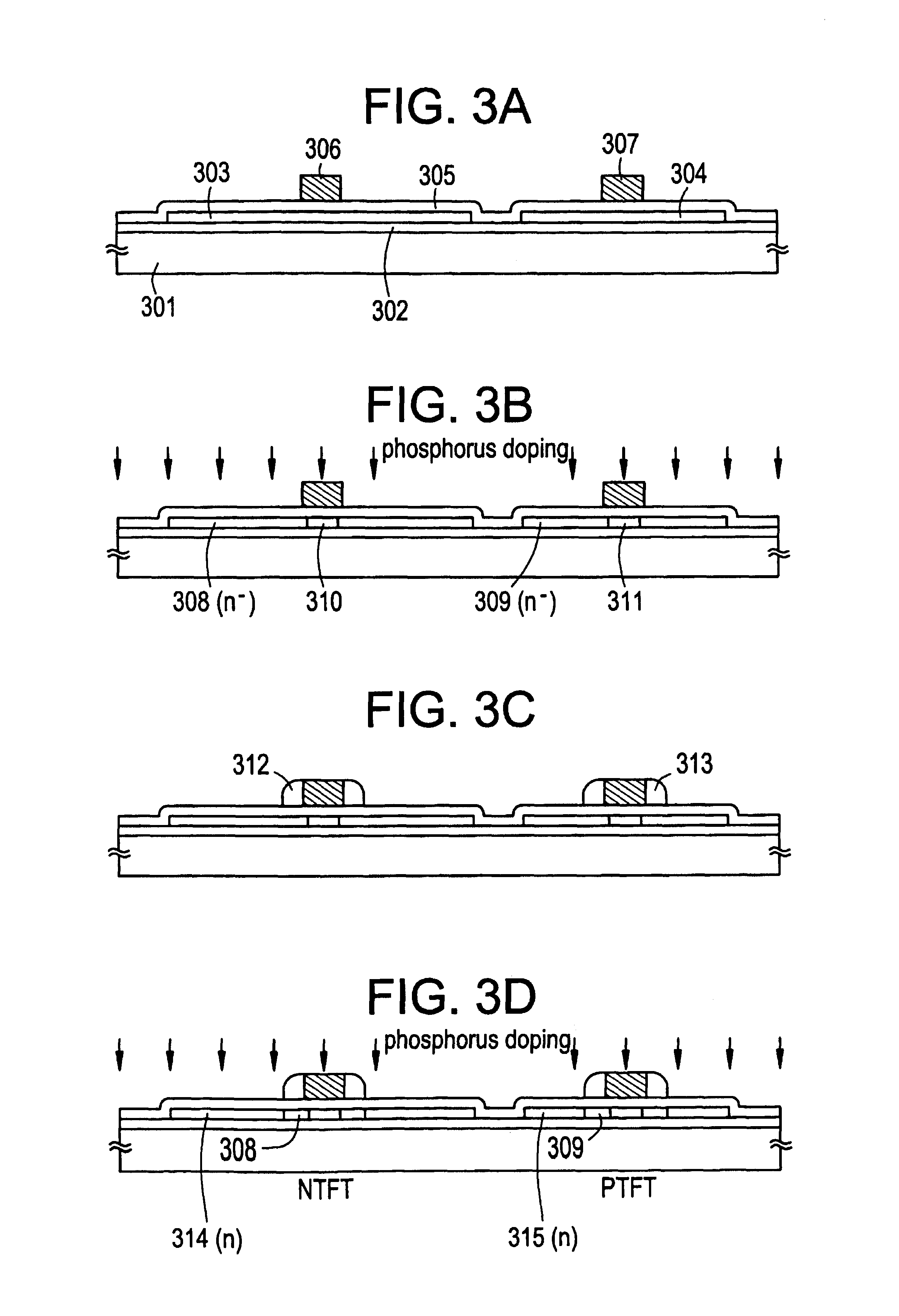

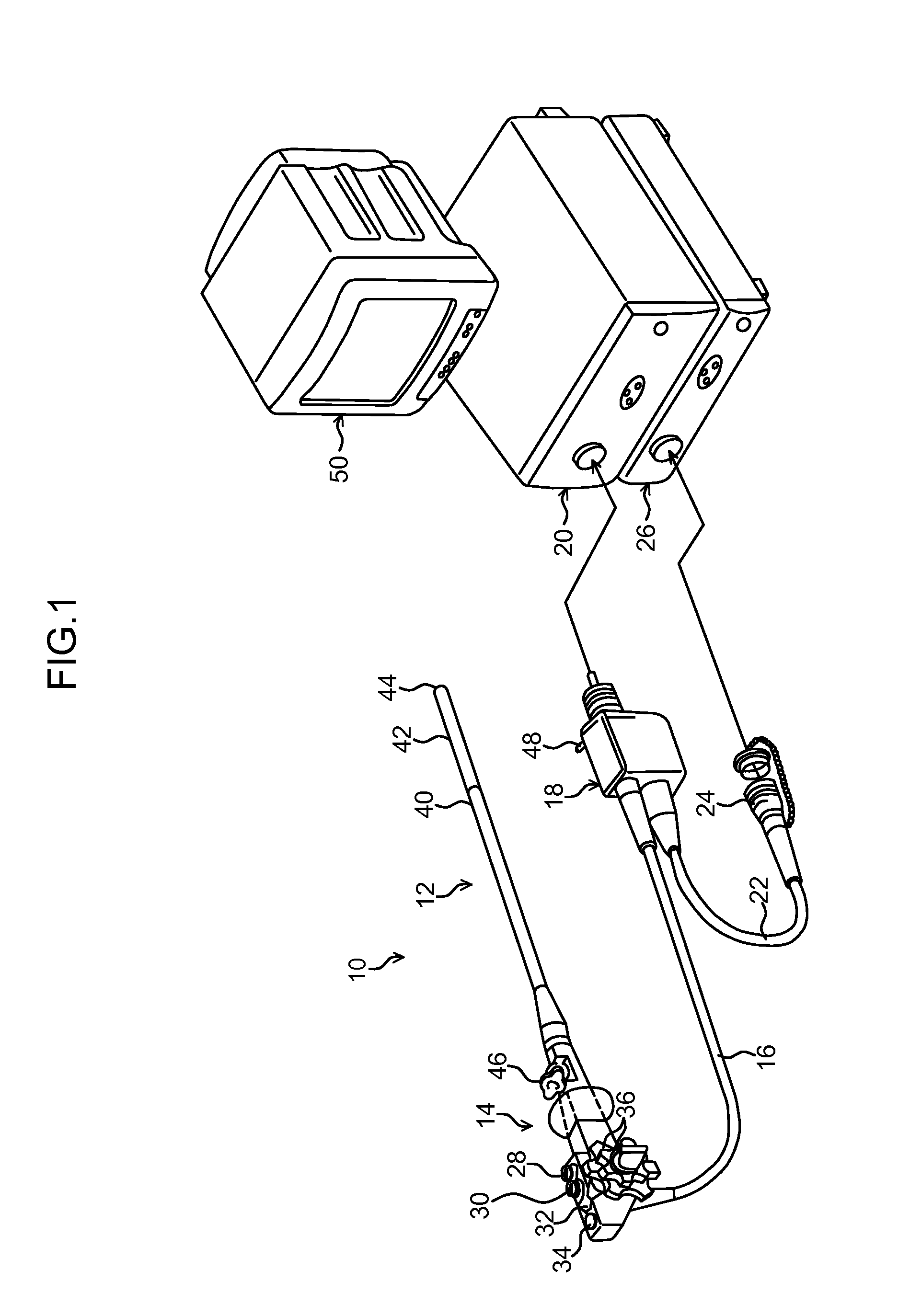

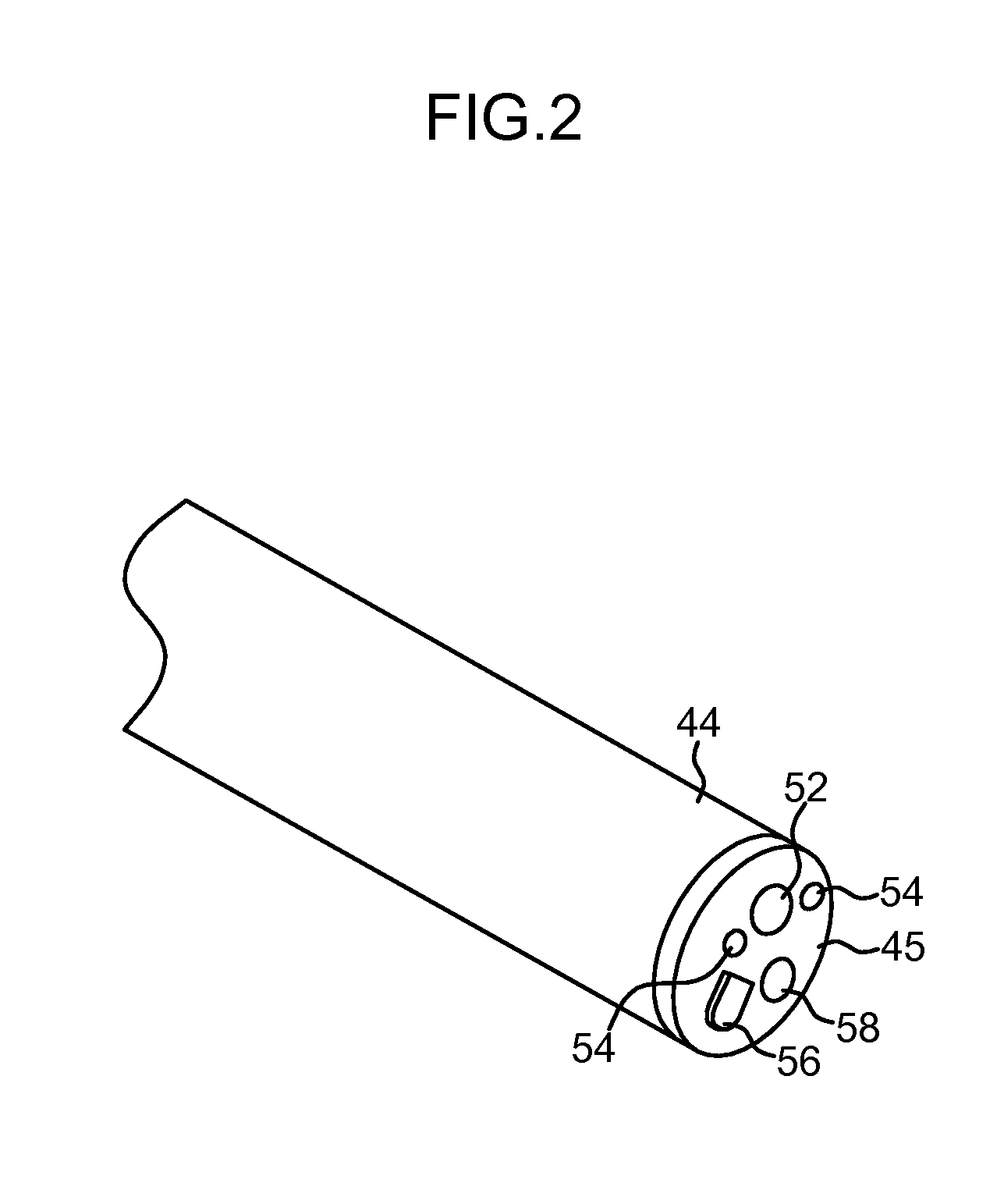

Image pickup module, manufacturing method thereof, and endoscopic device

InactiveUS20110224487A1Improve workabilityConnection strengthSurgeryEndoscopesComputer moduleEndoscope

Size reduction of an image pickup module is promoted, and reliability of electric connection and electric noise resistance are improved by decreasing the numbers of components and connection spots. The problems are solved by providing an image pickup module including a solid-state image pickup element chip having an image pickup surface, a cover glass that covers the image pickup surface, and a wiring board on which the solid-state image pickup element chip is mounted, in which the solid-state image pickup element chip and the wiring board have an overlap structure in which end portions thereof are overlapped with each other, and a first electrode portion formed on the end portion of the solid-state image pickup element chip and a second electrode portion formed on the end portion of the wiring board are electrically connected through a bump.

Owner:FUJIFILM CORP

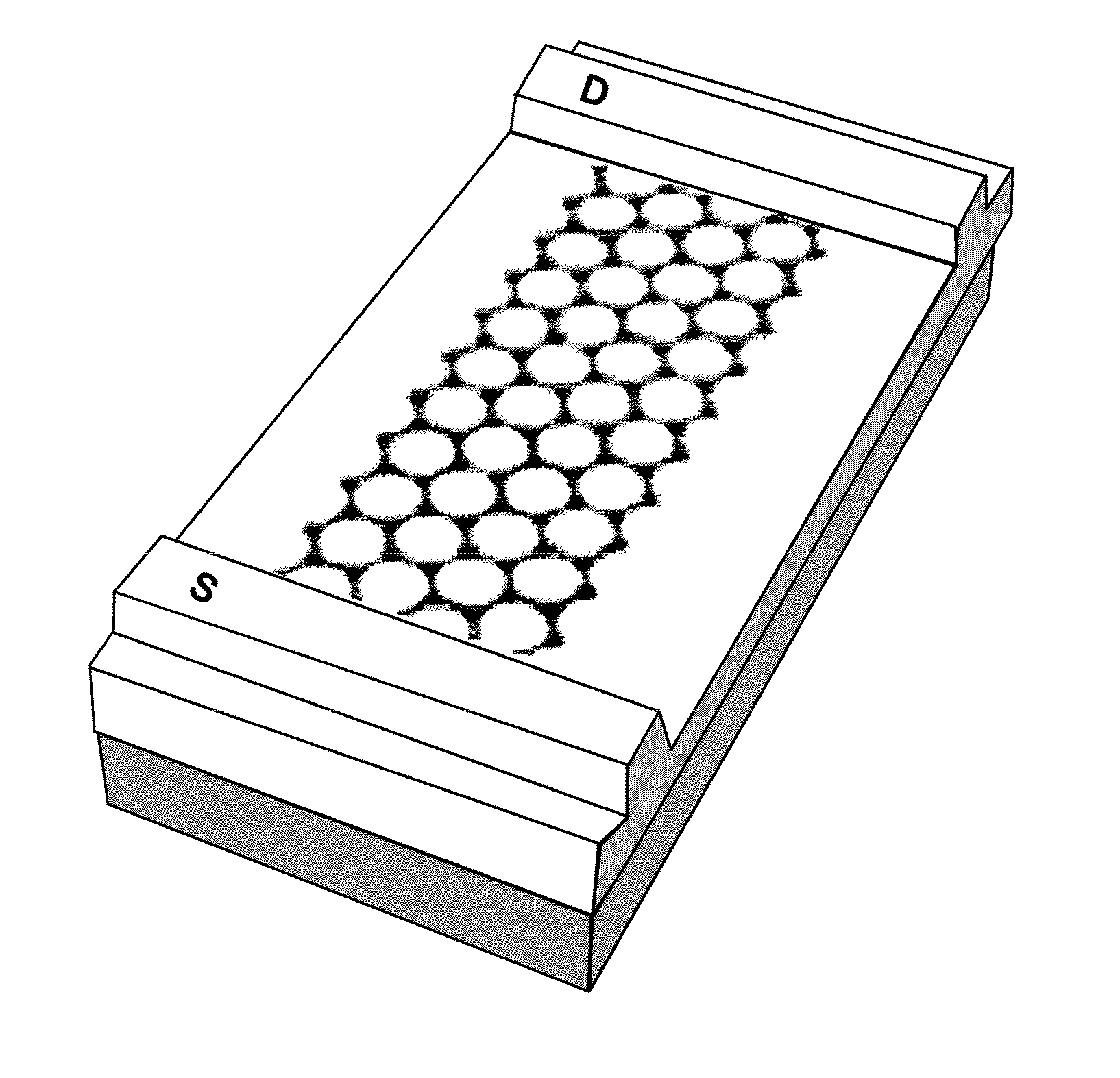

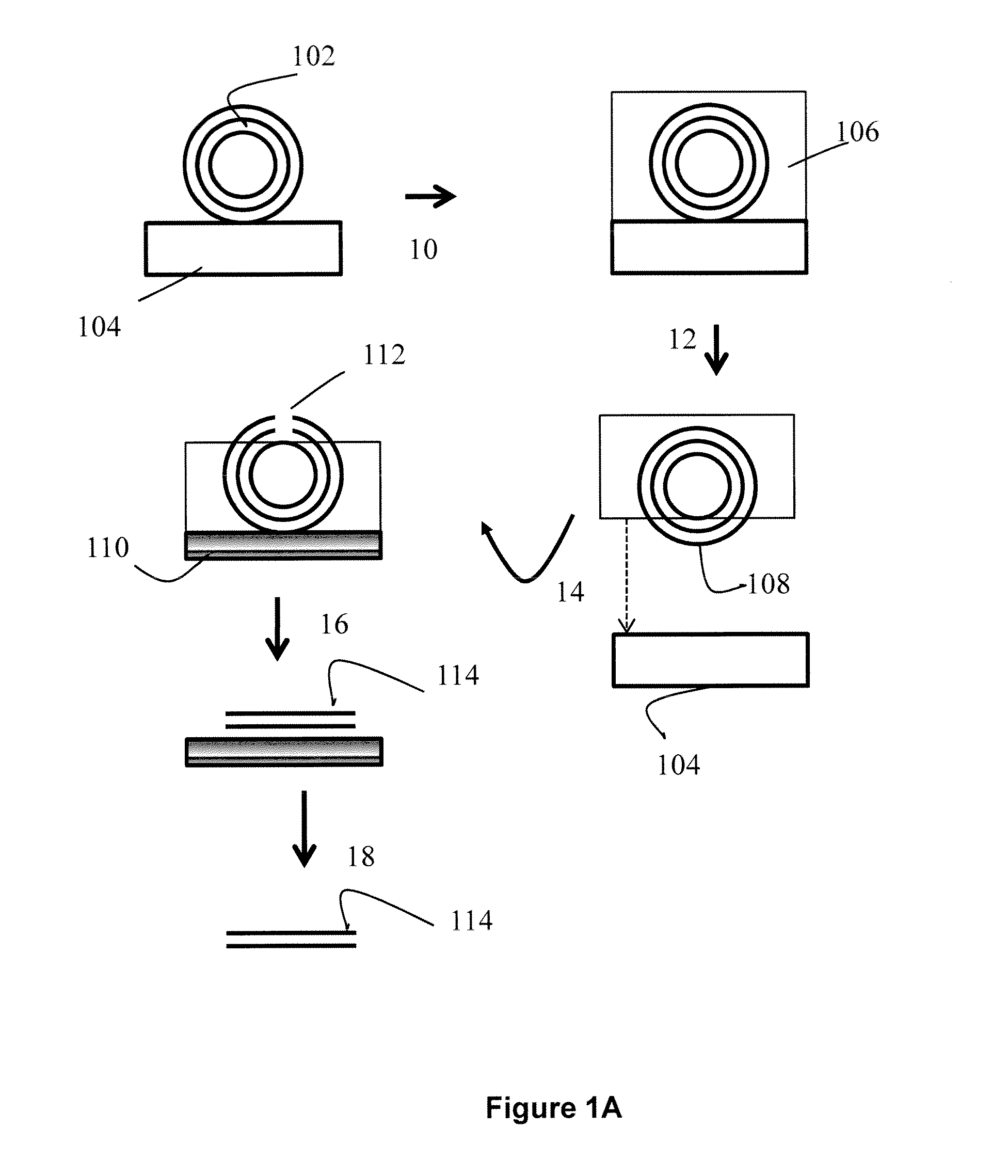

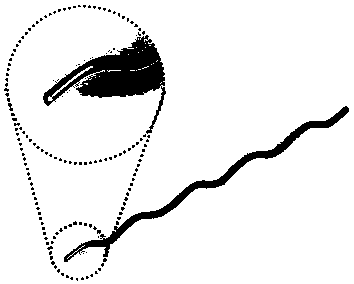

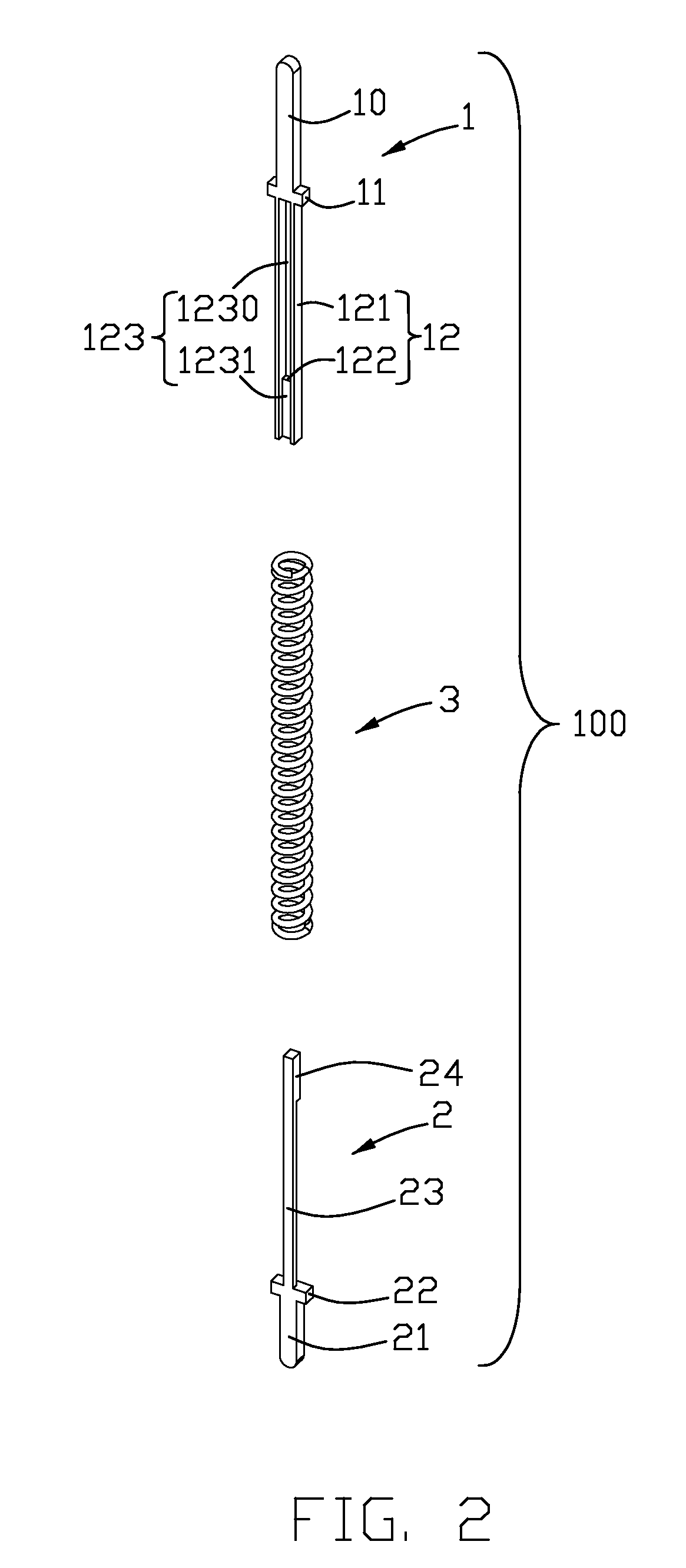

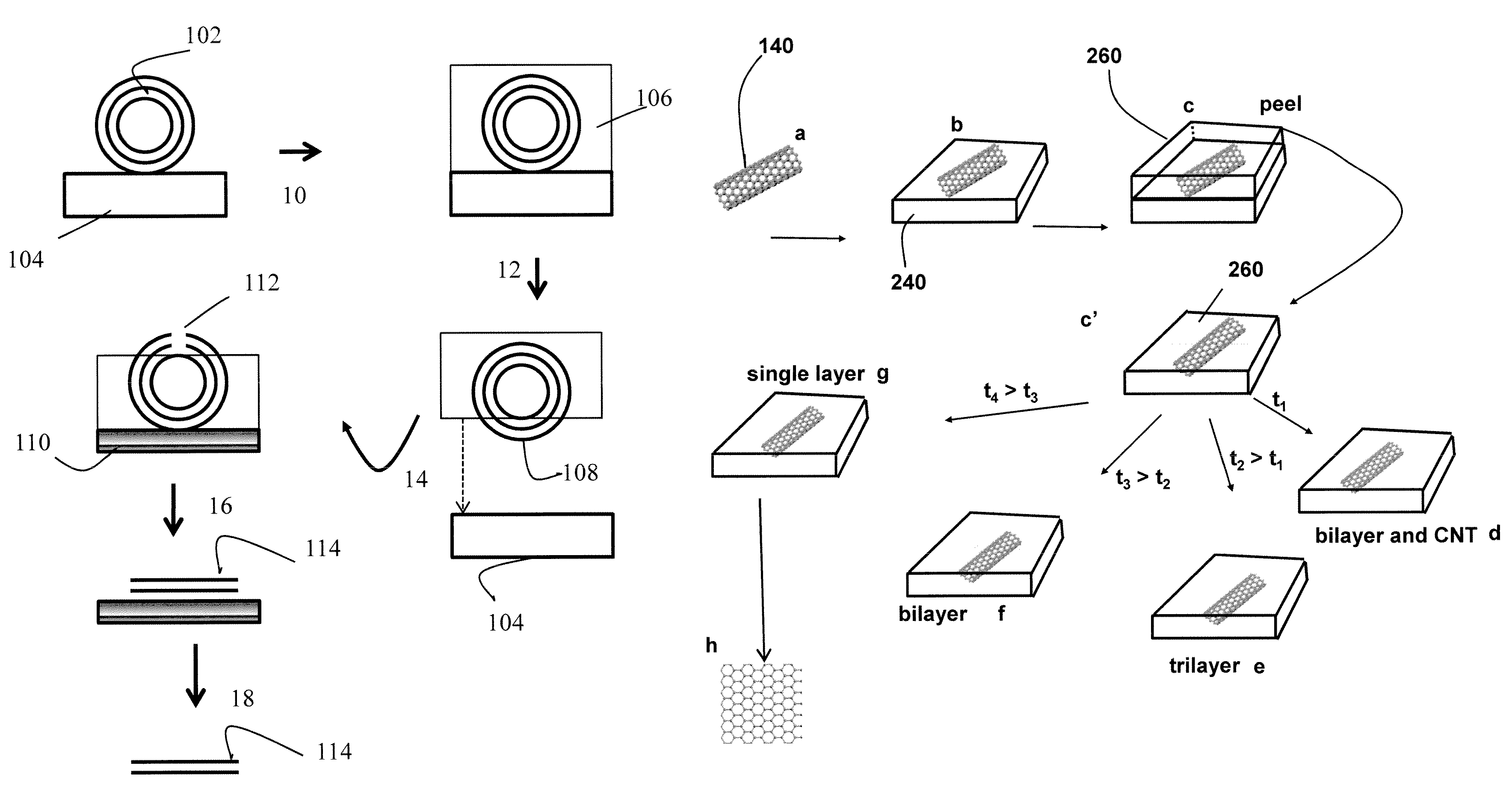

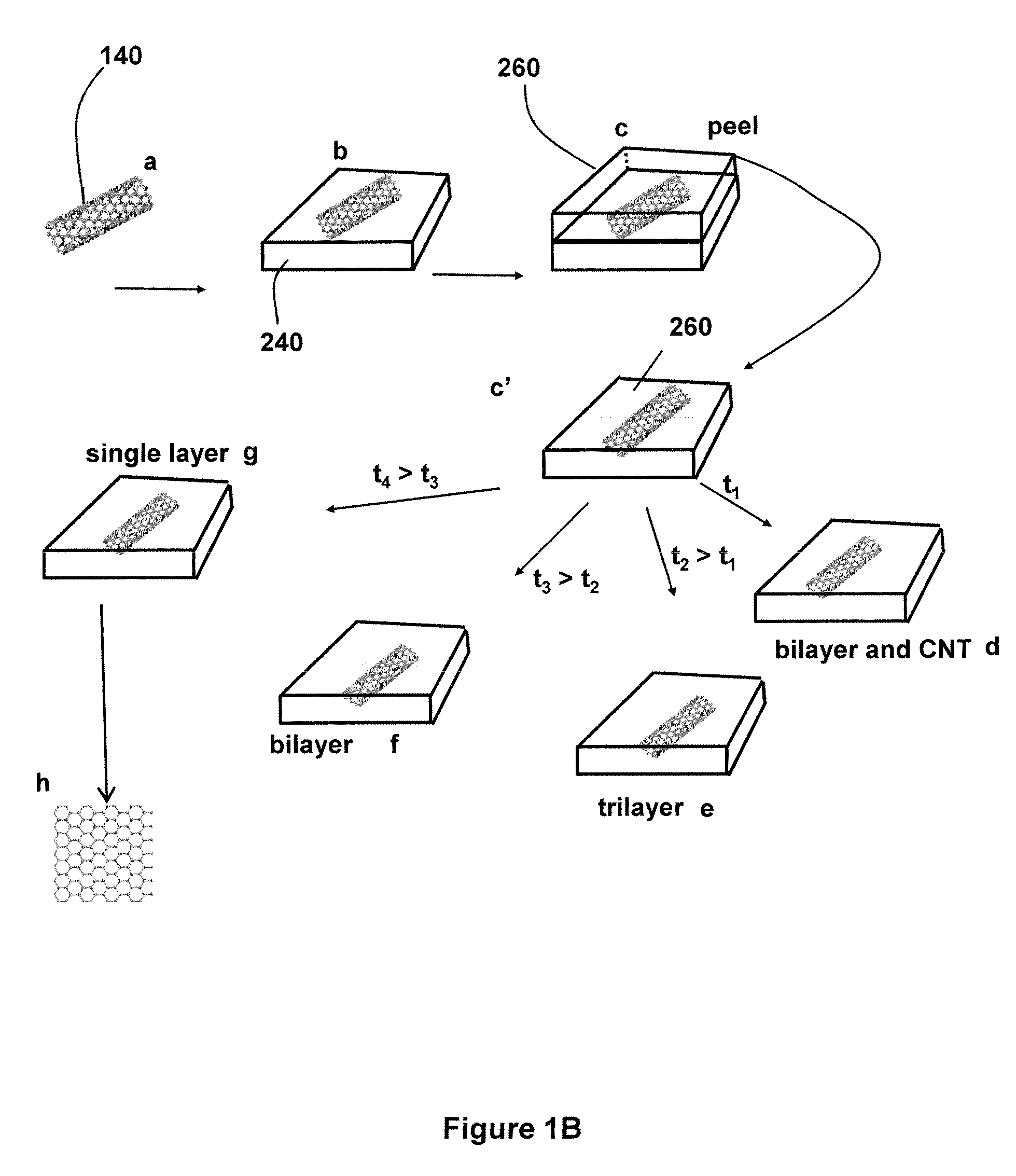

Narrow Graphene Nanoribbons from Carbon Nanotubes

ActiveUS20110253969A1Longer treatmentMaterial nanotechnologyDecorative surface effectsNanostructureNanotube

Disclosed is a method for making graphene nanoribbons (GNRs) by controlled unzipping of structures such as carbon nanotubes (CNTs) by etching (e.g., argon plasma etching) of nanotubes partly embedded in a polymer film. The GNRs have smooth edges and a narrow width distribution (2-20 nm). Raman spectroscopy and electrical transport measurements reveal the high quality of the GNRs. Such a method of unzipping CNTs with well-defined structures in an array will allow the production of GNRs with controlled widths, edge structures, placement and alignment in a scalable fashion for device integration. GNRs may be formed from nanostructures in a controlled array to form arrays of parallel or overlapping structures. Also disclosed is a method in which the CNTs are in a predetermined pattern that is carried over and transferred to a substrate for forming into a semiconductor device.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

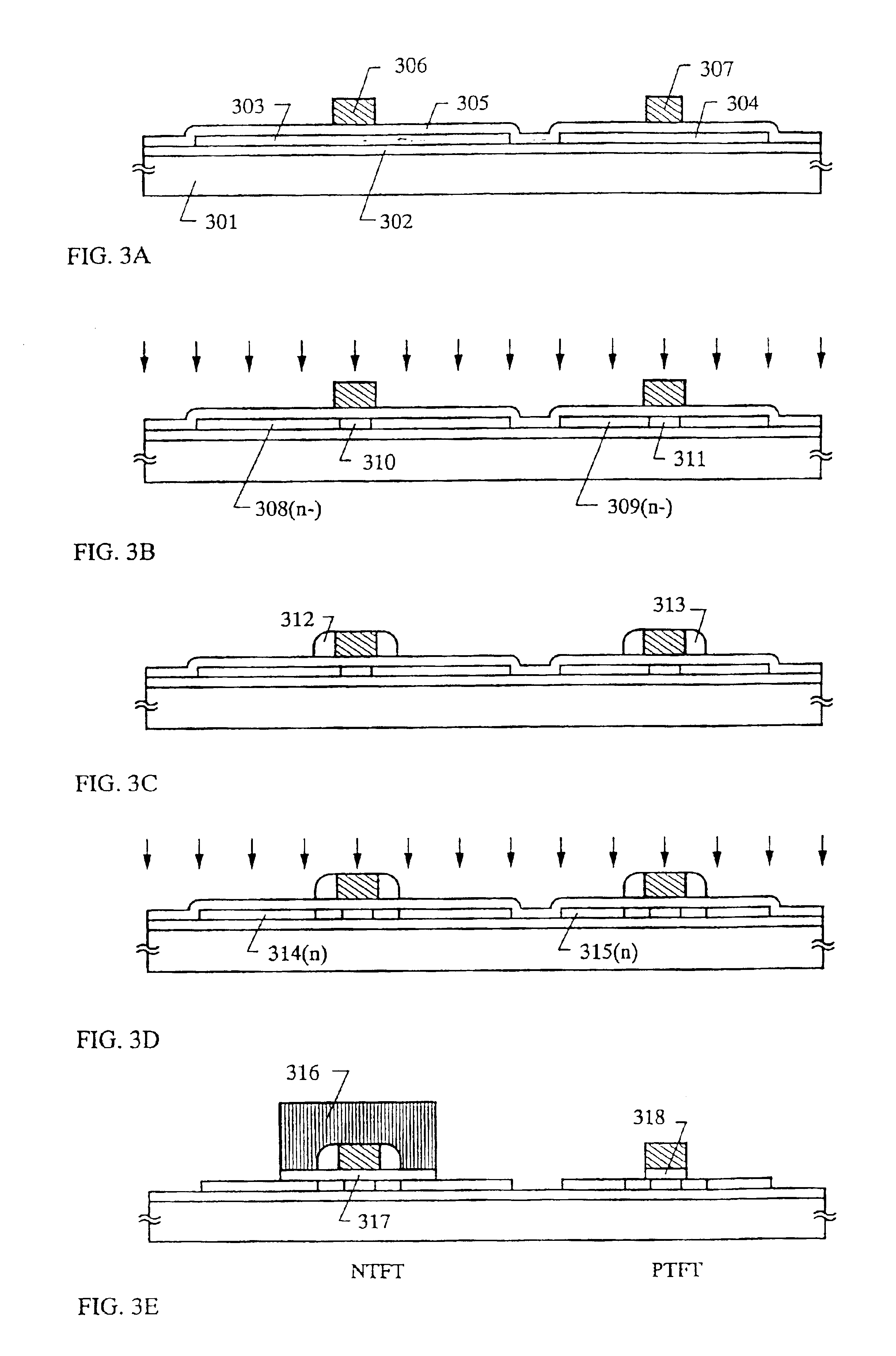

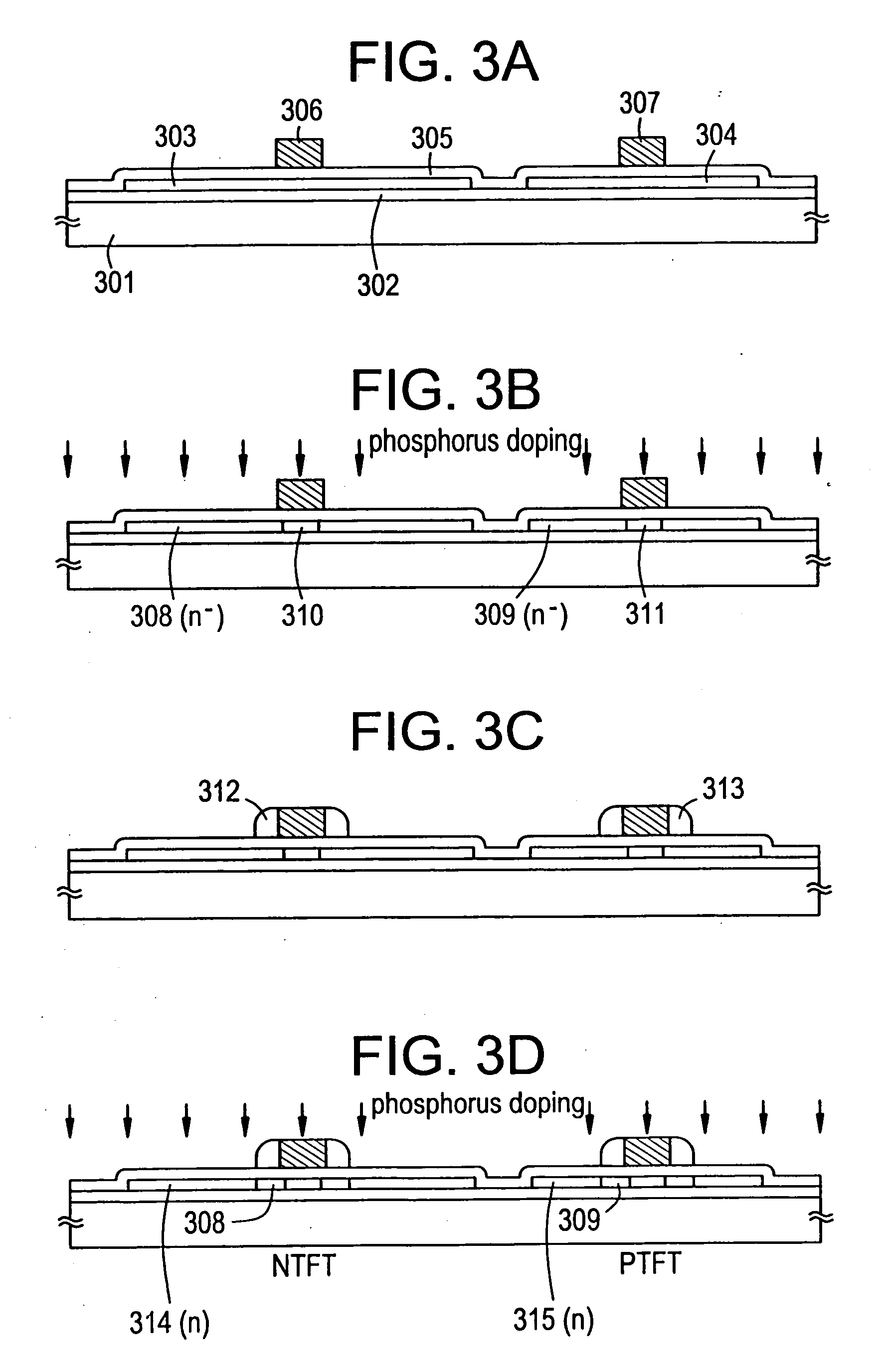

Semiconductor device and manufacturing method thereof

InactiveUS20070001236A1Solid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

Owner:SEMICON ENERGY LAB CO LTD

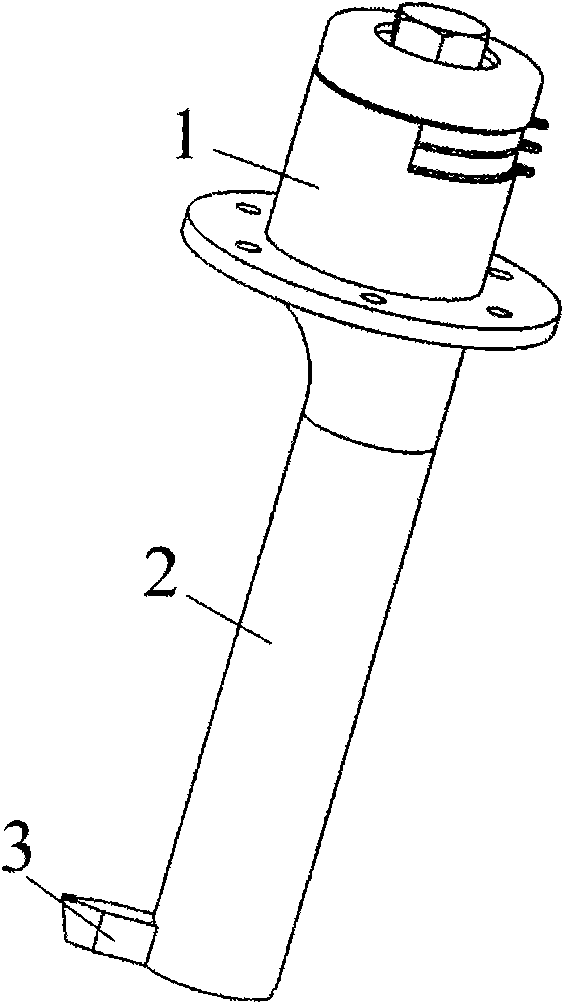

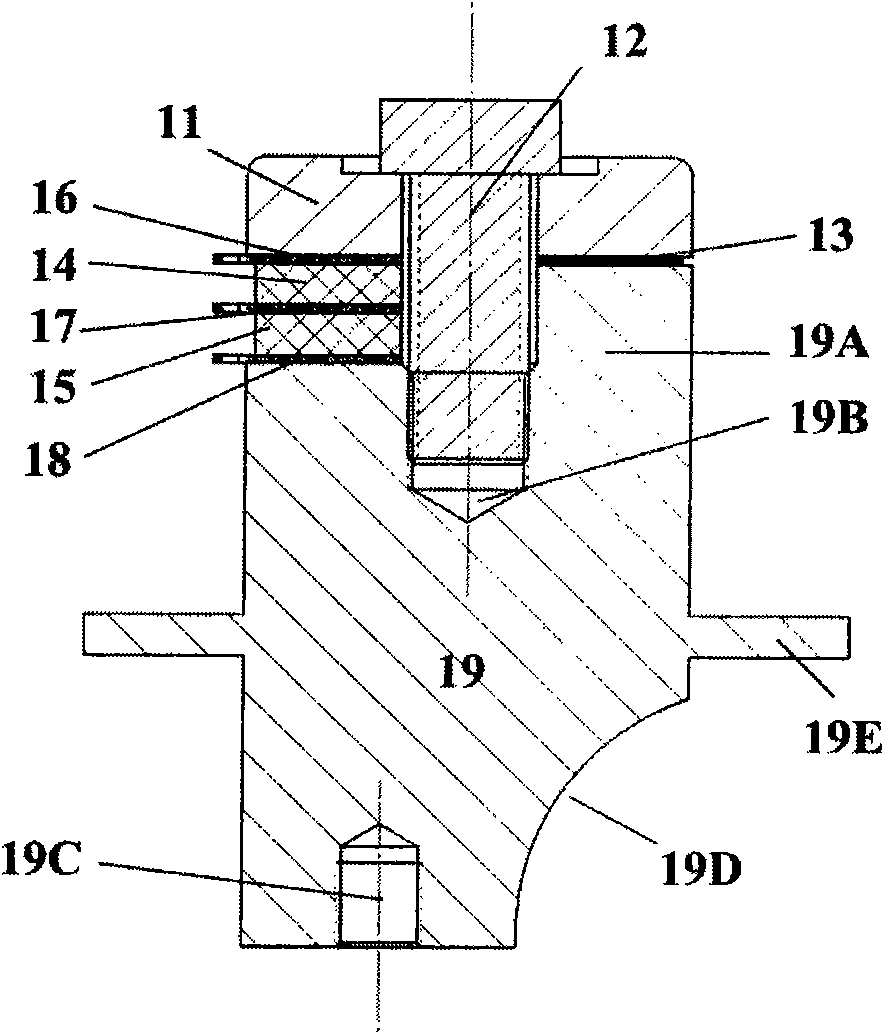

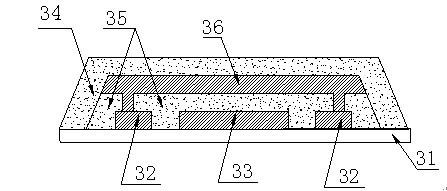

Elliptical ultrasonic vibration auxiliary cutting device with adjustable track

InactiveCN101804575AEasy to wearReduce wearMechanical vibrations separationFeeding apparatusTransformerEngineering

The invention relates to an elliptical ultrasonic vibration auxiliary cutting device with an adjustable track, which consists of a transducer, an amplitude transformer and a cutter, wherein the transducer adopts a basic structure of a longitudinal vibration sandwiched piezoelectric chip, has revolution asymmetric characteristic structures of an overlapping structure of semicircular ring-shaped piezoelectric ceramic chips and electrode chips separately, an off-axis type catenary variable-amplitude structure and the like, and initiates and strengthens flexural vibration when longitudinal vibration is output; the amplitude transformer is a cylindrical bar with uniform cross sections, and a relative angle between the amplitude transformer and a front cover plate is adjustable; and the cutter is installed in an offset way in the radial direction at the tail end of the amplitude transformer, and the offset degree can be adjusted. The working frequency of the invention is higher than 20kHz and can better achieve the ultrasonic machining effect; the elliptical cutting track is long, the minor axis proportion is reasonable, so that the advantages of elliptical cutting can be fully used; the elliptical track can be adjusted to better adapt to machining of different machining materials and different cutting consumption; and single-point diamond ultraprecise cutting can be hopefully expanded to machining of iron-based materials and optical crisp and hard materials.

Owner:TSINGHUA UNIV

Semiconductor device and manufacturing method therefor

InactiveUS20050205868A1Improve reliabilityDeterioration due to a hot carrier can also be effectively suppressedTransistorSolid-state devicesDevice materialEngineering

An active layer of an NTFT includes a channel forming region, at least a first impurity region, at least a second impurity region and at least a third impurity region therein. Concentrations of an impurity in each of the first, second and third impurity regions increase as distances from the channel forming region become longer. The first impurity region is formed to be overlapped with a side wall. A gate overlapping structure can be realized with the side wall functioning as an electrode.

Owner:SEMICON ENERGY LAB CO LTD

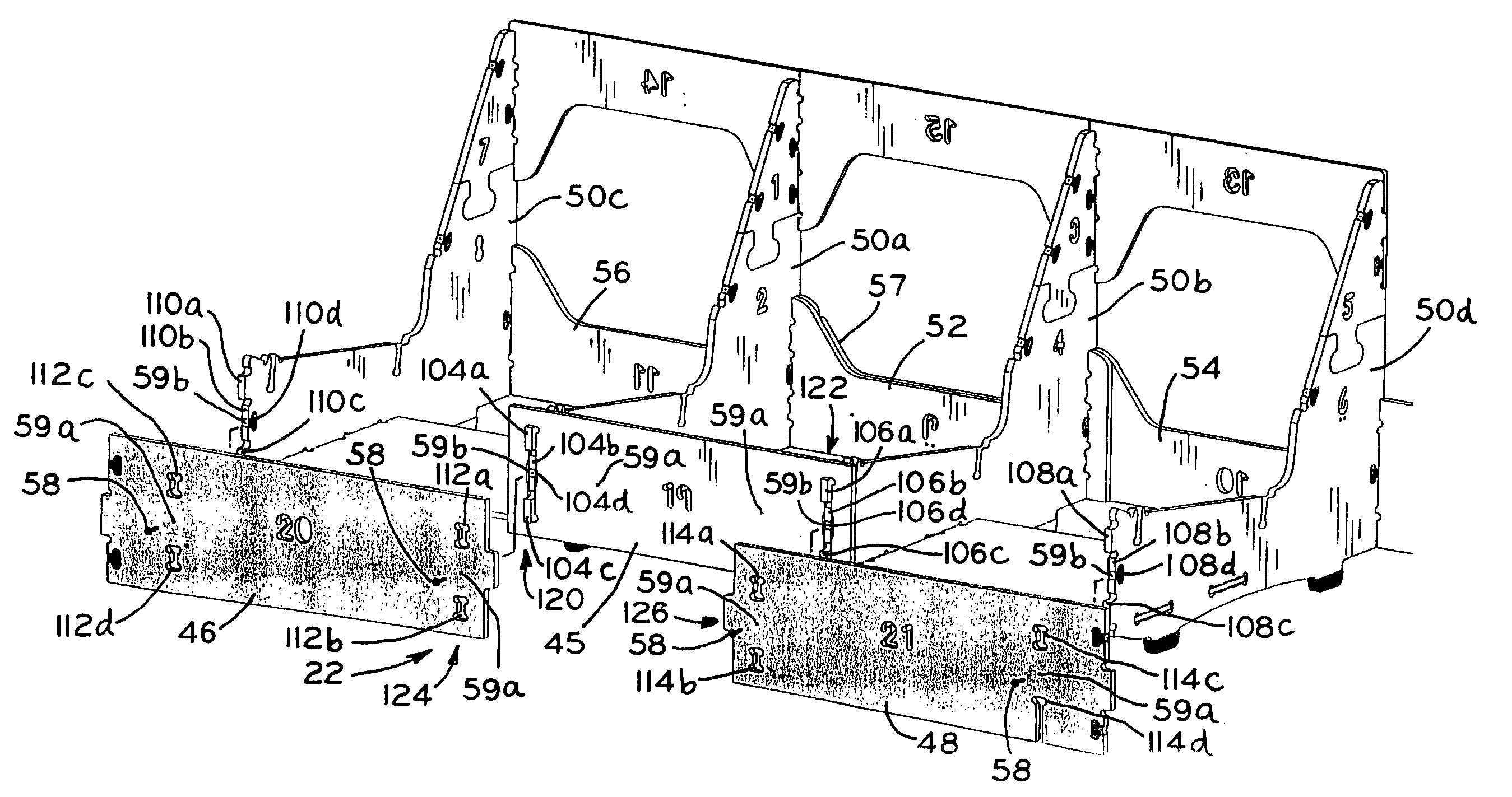

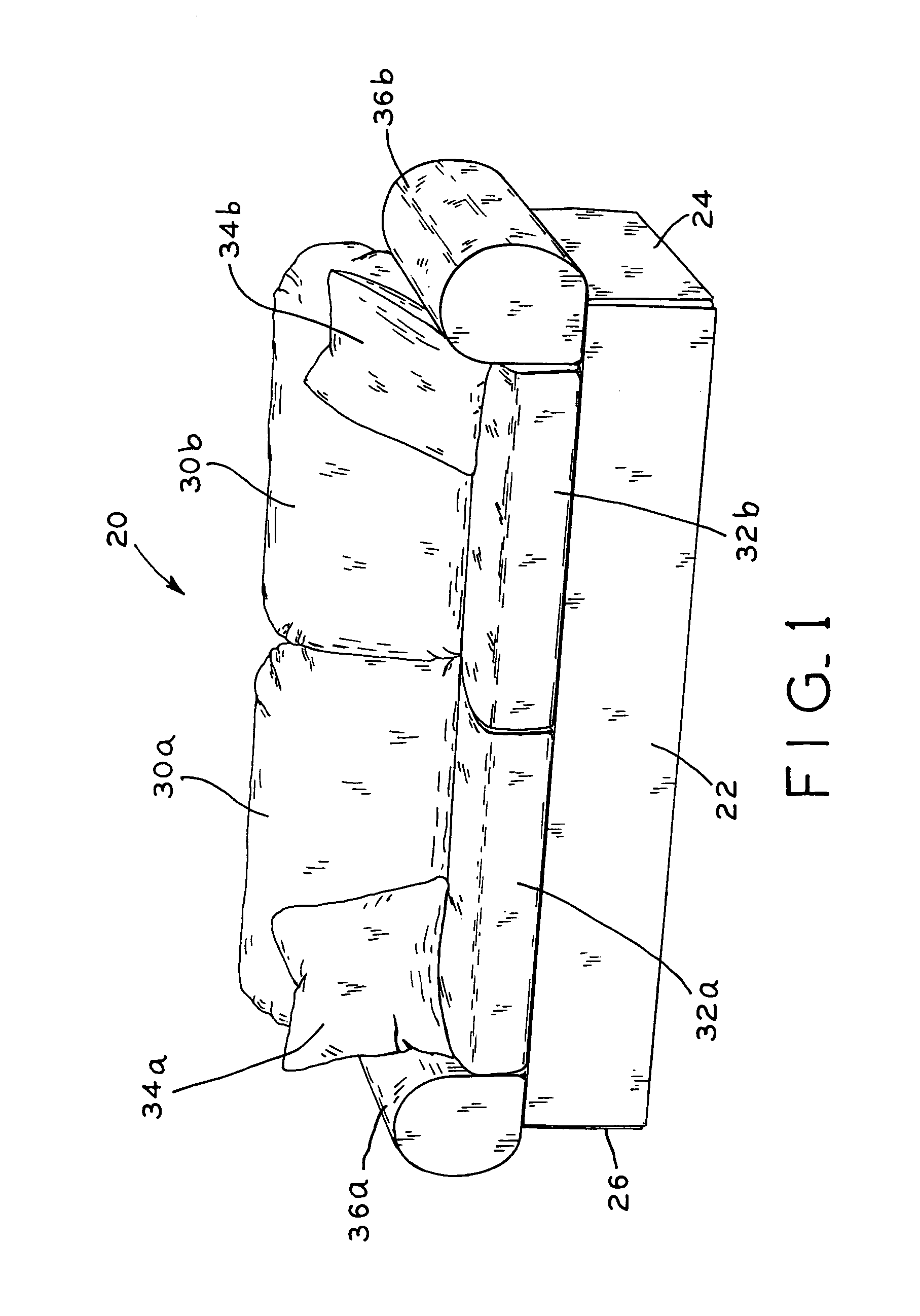

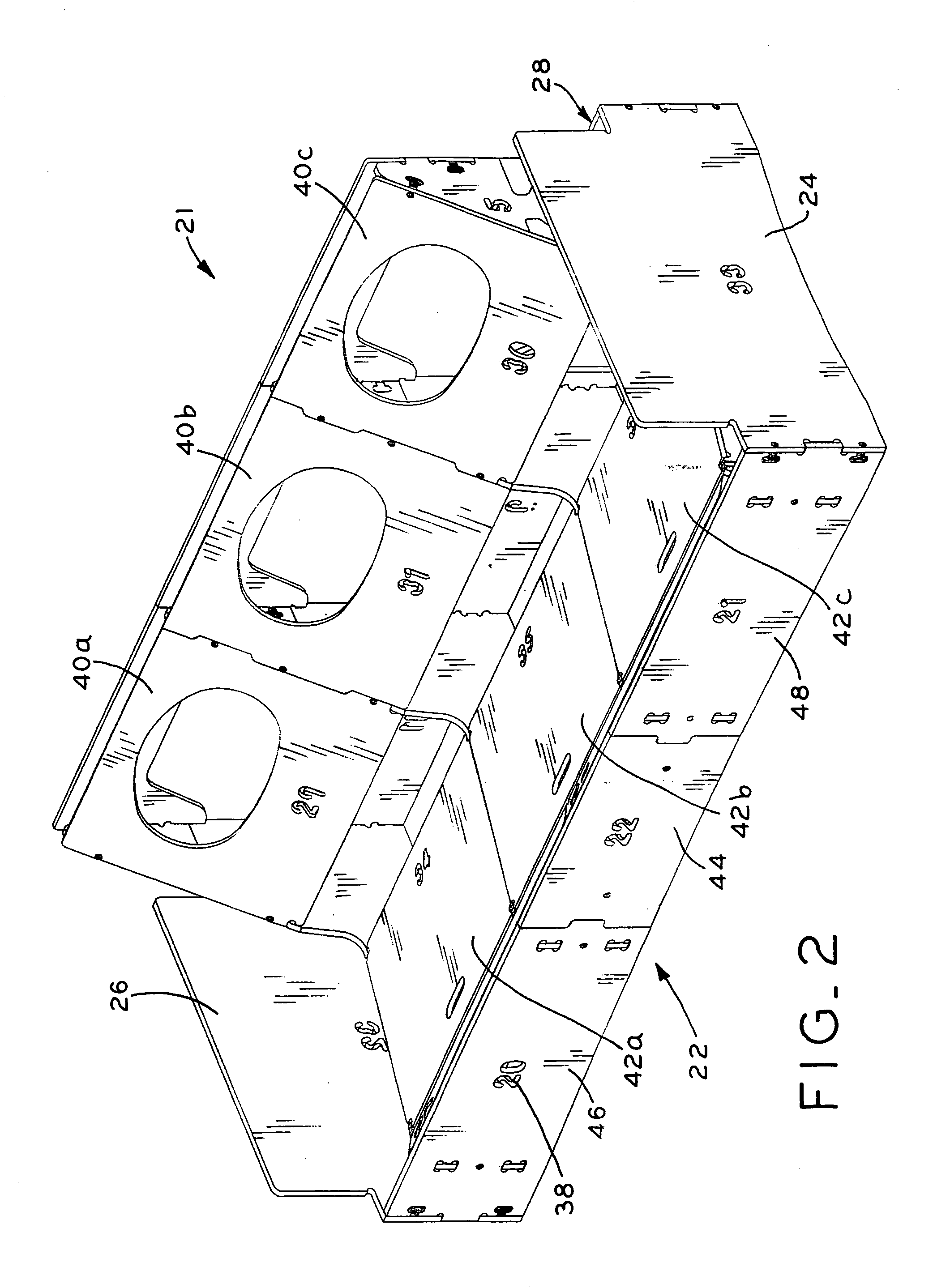

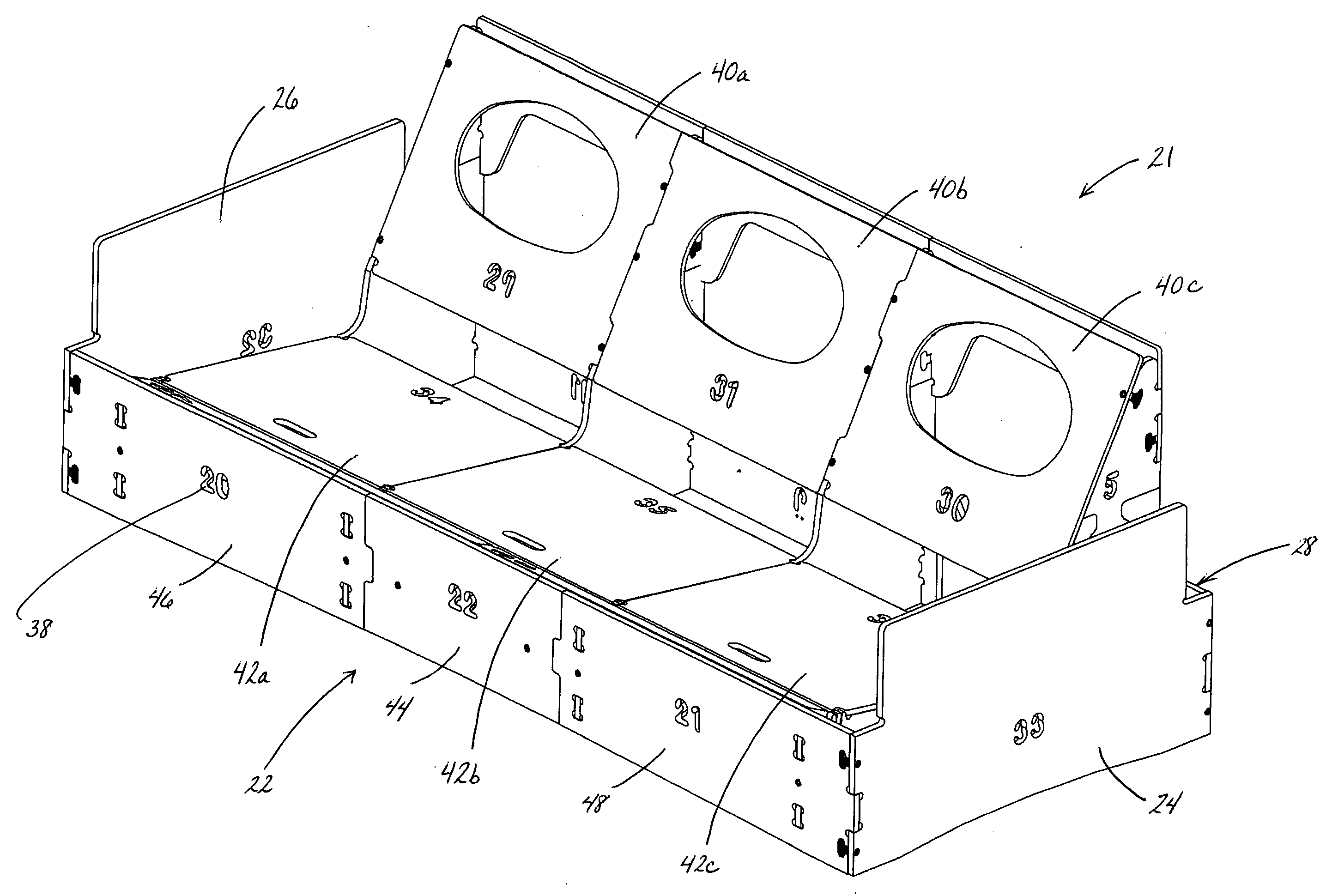

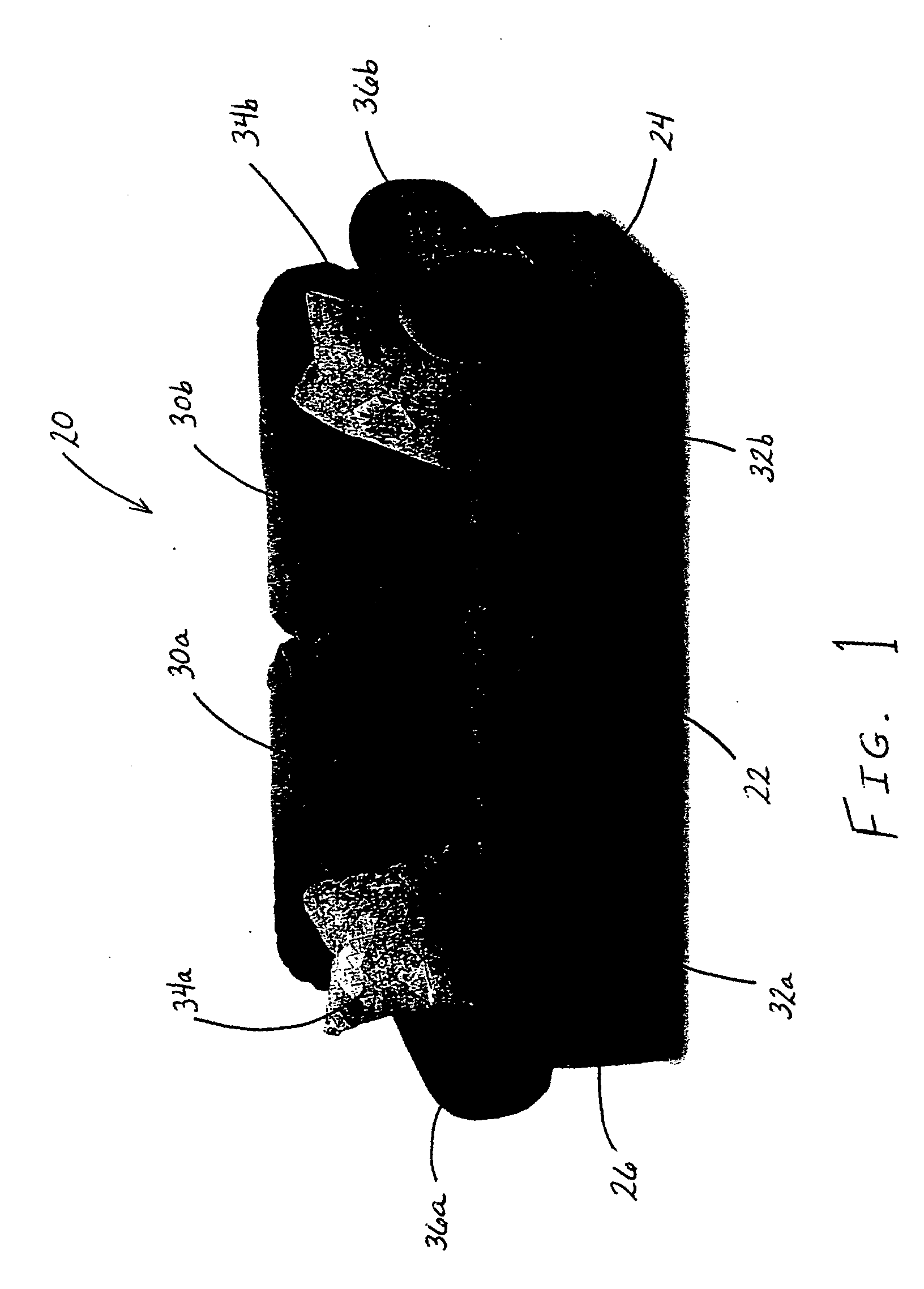

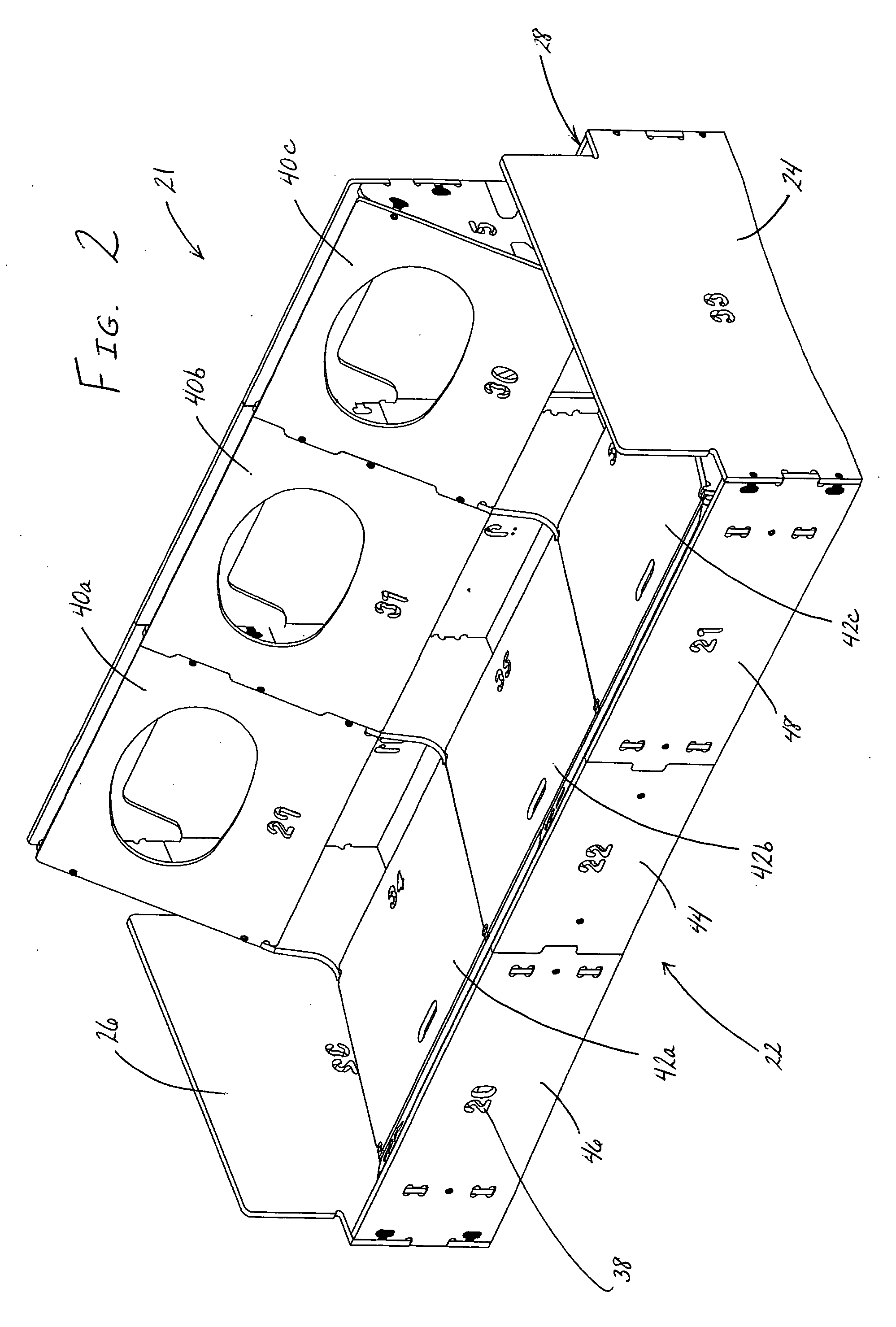

Article of ready-to-assemble furniture

InactiveUS7044557B2Easy and fast assemblyReduce shipping costsFurniture joining partsBenchesEngineeringThreaded fastener

The present invention provides fully upholstered, ready-to-assemble furniture which may be custom ordered by a purchaser, shipped directly to the home of the purchaser by a parcel delivery service, and then easily and quickly assembled by the purchaser. The ready-to-assemble article of furniture includes a frame having a composite frame member with a long dimension which is formed by a plurality of planar frame members assembled in an end-to-end and overlapping manner. The plurality of planar frame members are interconnected by interlocking protrusions and cutout portions, as well as by threaded fasteners received in push-in connector elements which are held in recesses within the frame members. The interlocking and threaded fastener connections allow a plurality of smaller frame members to form the composite frame member of the furniture frame, wherein the frame has the torsional and longitudinal stability of known furniture frames which include long, single boards. In particular, the interlocking and overlapping structure of the present furniture frame advantageously provides longitudinal and torsional stability to an article of furniture having a long dimension such as an entertainment center or sofa.

Owner:HOME RESERVE

Magnetic resonance reconstruction method based on deep learning and convex set projection

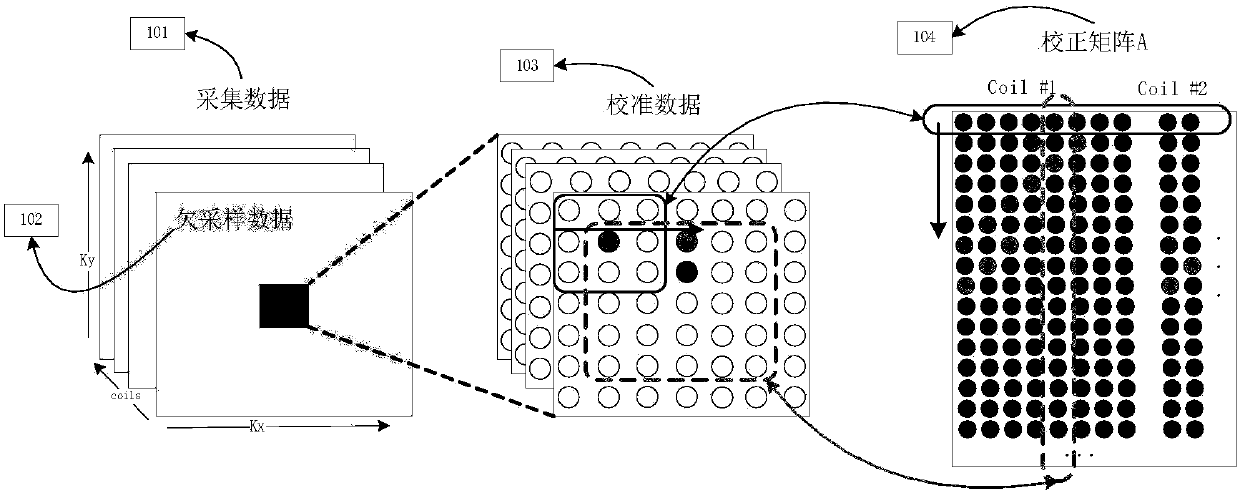

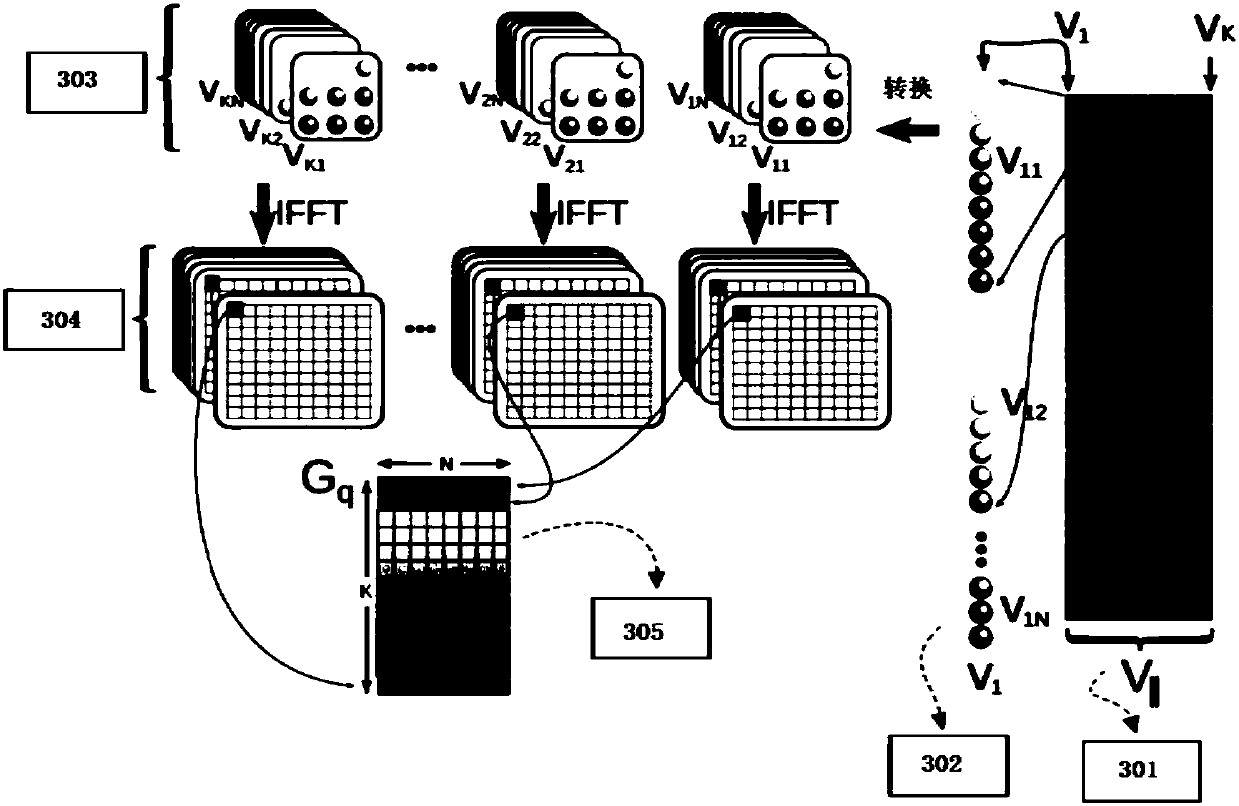

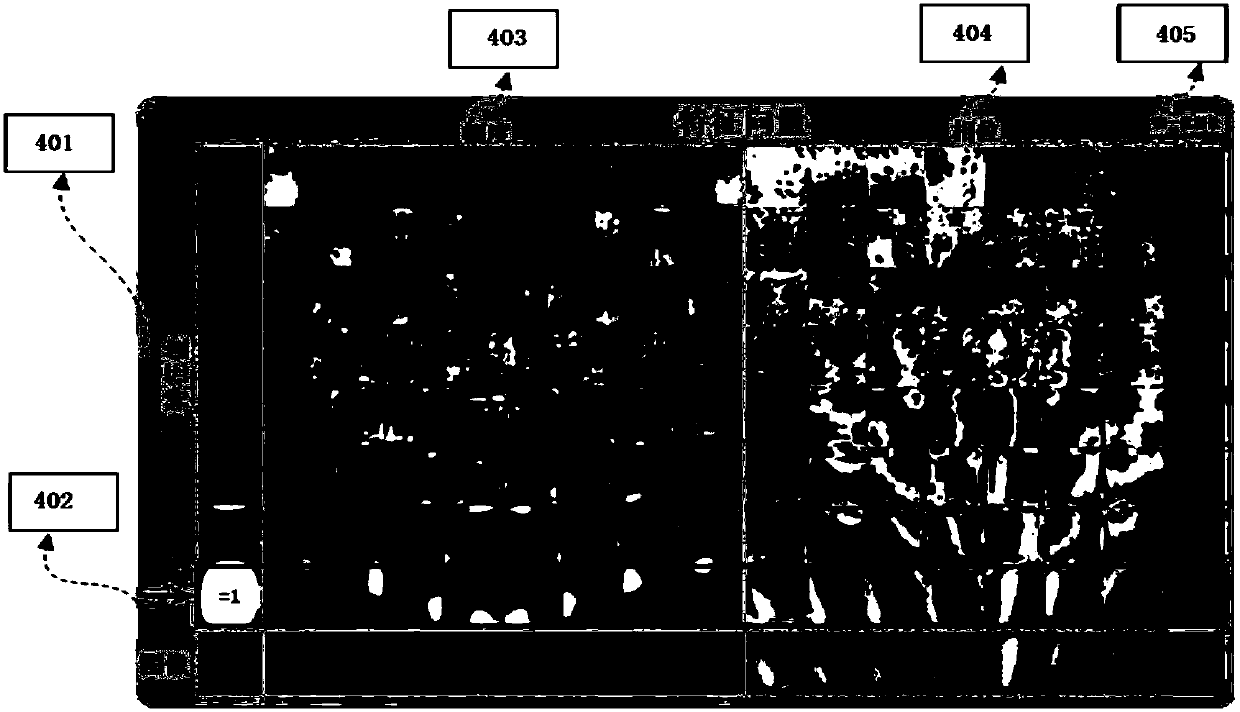

ActiveCN108335339AFix workSolve the technical problems of backpropagation)Image enhancementReconstruction from projectionResonanceForward propagation

The invention discloses a magnetic resonance reconstruction method based on deep learning and convex set projection, and relates to the technical field of magnetic resonance. The method comprises thesteps that S1, a network is constructed according to overlapping structures of multiple convolutional neural network modules and multiple convex set projection layers and shared data, wherein the shared data includes acquired K-space data and coil sensitivity information, and the convex set projection layers are obtained on the basis of the shared data; S2, after the network is constructed, all network parameters are trained through a reverse propagation process and verified; S3, structure and operation characteristics of the network are determined according to the verified network parameters,known test set data is input, the forward propagation of the network is conducted, unknown mapping data is obtained, and magnetic resonance reconstruction is completed. The method solves the problemthat by means of a current magnetic resonance reconstruction technology based on deep learning, only single-channel magnetic resonance data can be supported, and multi-channel magnetic resonance datacannot be processed.

Owner:朱高杰

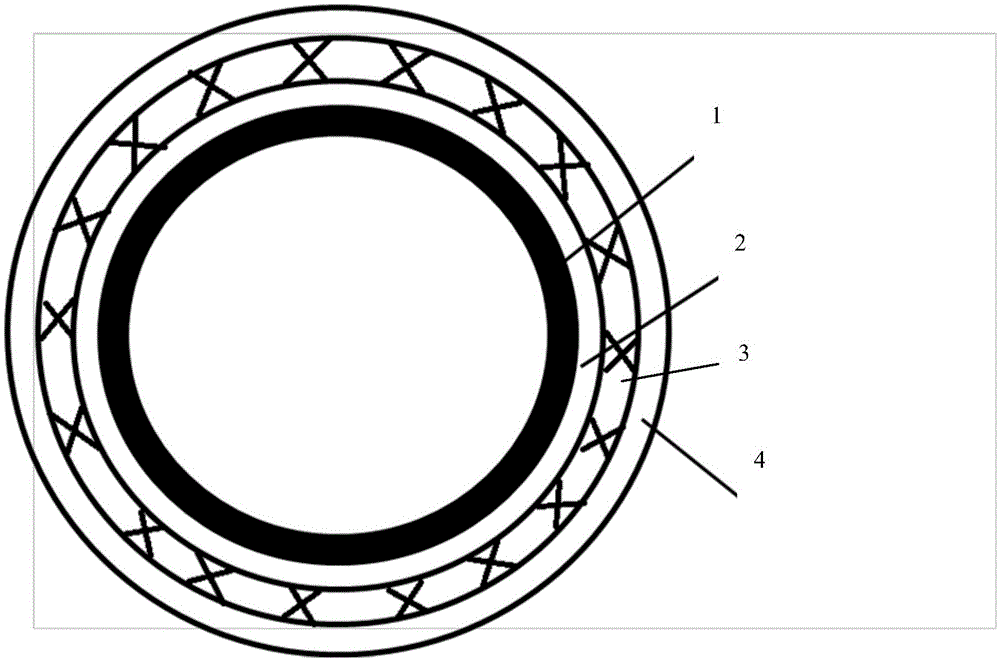

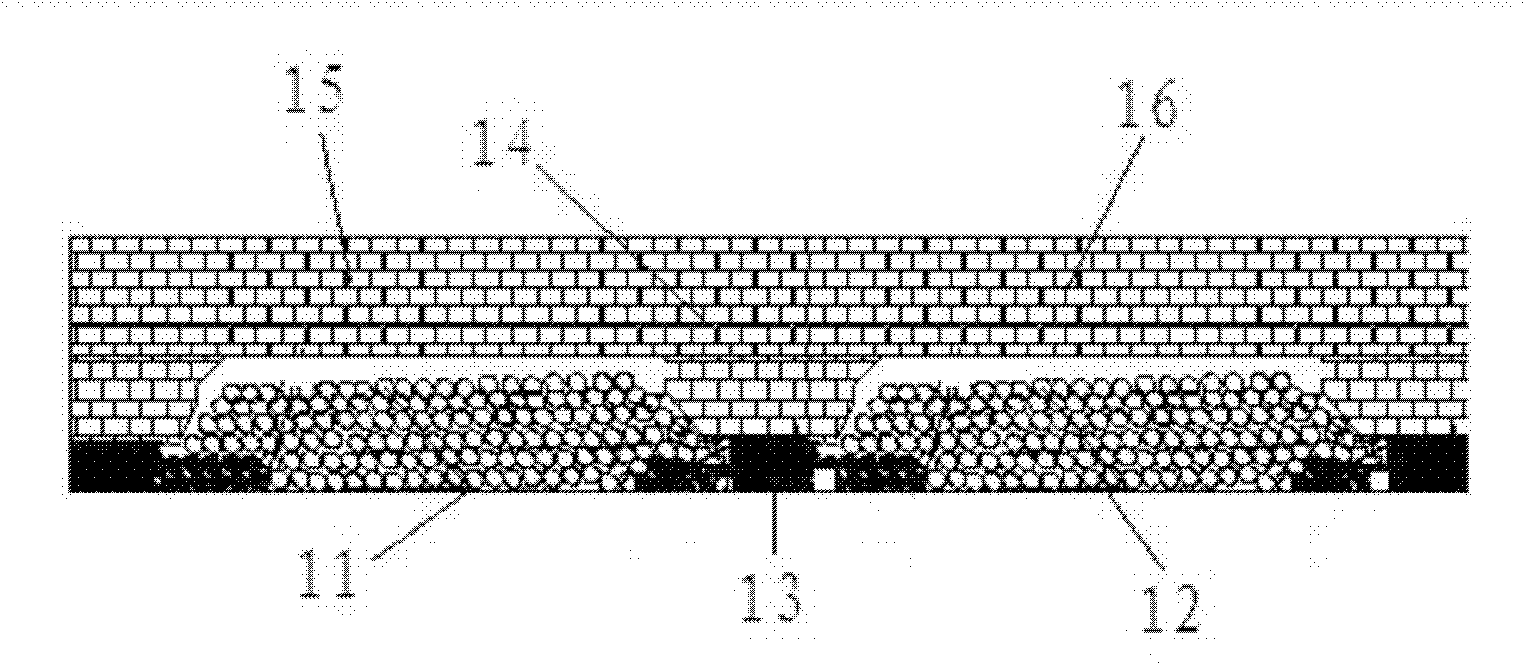

Multilayer structure of SiC/SiC (silicon carbide) composite cladding tube and preparation method thereof

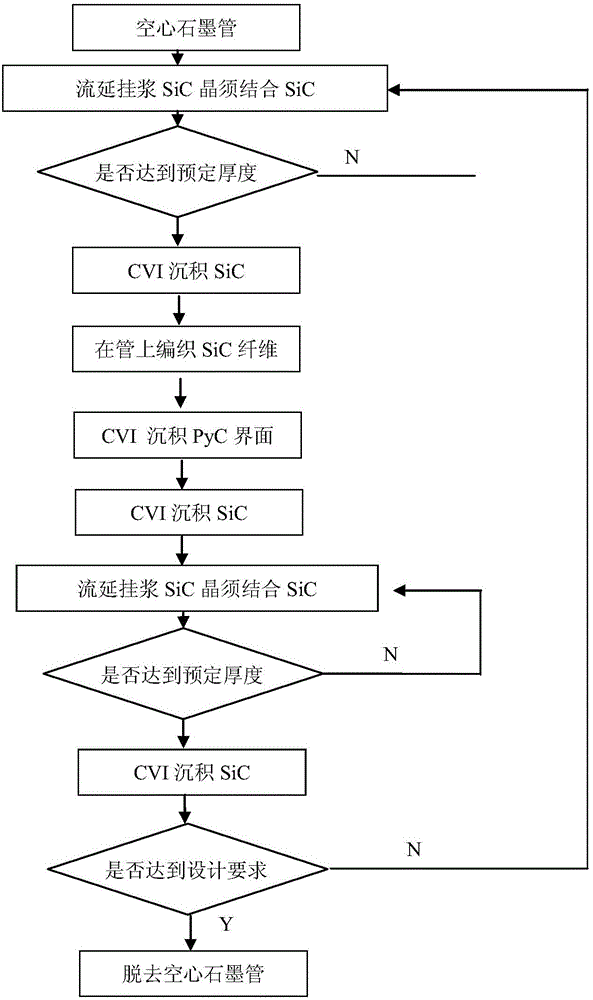

ActiveCN103818056AHigh strengthHigh thermal conductivityCeramic layered productsCrack resistanceWhiskers

The invention discloses a multilayer structure of an SiC / SiC (silicon carbide) composite cladding tube and a preparation method of the multilayer structure. The multilayer structure of the SiC / SiC composite cladding tube is formed by alternately overlapping an SiC whisker toughening SiC composite layer and a continuous SiC fiber toughening SiC composite layer according to design needs. A three-layer overlapping structure takes the SiC whisker toughening SiC composite layer as an inner layer, a continuous SiC fiber toughening SiC composite material as a middle layer and a SiC whisker toughening SiC composite material as an outer layer; the multilayer structure can be formed by continuous alternate overlapping according to the design needs. The SiC whisker toughening SiC composite layer in the multilayer structure mainly plays a role of seal leakage prevention, meanwhile, the SiC whisker toughening SiC composite layer has high strength and toughness, the continuous SiC fiber toughening SiC composite layer plays a role of strength supporting, the multilayer structure of the SiC / SiC composite cladding tube has high crack resistance, high heat conductivity, high specific stiffness, high specific strength, excellent thermal shock and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

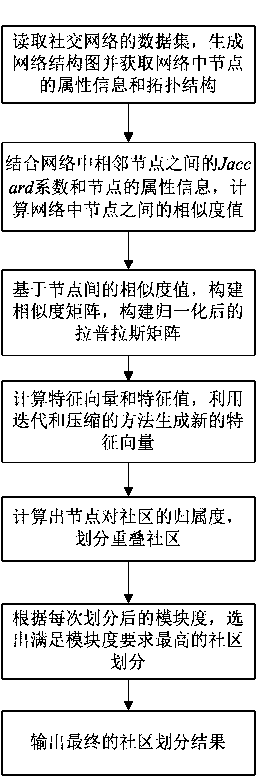

Overlapping community discovering method based on spectral clustering and fuzzy sets

InactiveCN108920678AImprove compactnessEfficient removalSpecial data processing applicationsNODALData set

The invention relates to an overlapping community discovering method based on spectral clustering and fuzzy sets. The overlapping community discovering method comprises the steps that 1, data sets ofa social network are read to generate a network structure graph, and the attribute information of nodes in the network is acquired; 2, the Jaccard coefficient and the attribute information of the nodes in the network are combined to calculate the similarity value among the nodes in the network; 3, a similarity matrix is built based on the similarity value among the nodes, and accordingly the normalized Laplacian matrix is built; 4, the feature vector and the feature value of each node are calculated, and a new feature vector is generated by utilizing methods of iteration and compression; 5, the new feature vector is orthogonalized, the membership grade is calculated, and the nodes with a plurality of high community membership grade values are subjected to division of overlapping communities; 6, the community division meeting the highest modularity requirement is selected according to the modularity divided each time; and 7, the final community division result is output. The overlappingcommunity discovering method can efficiently and accurately discover and divide the overlapping structures in the complex network.

Owner:FUZHOU UNIV

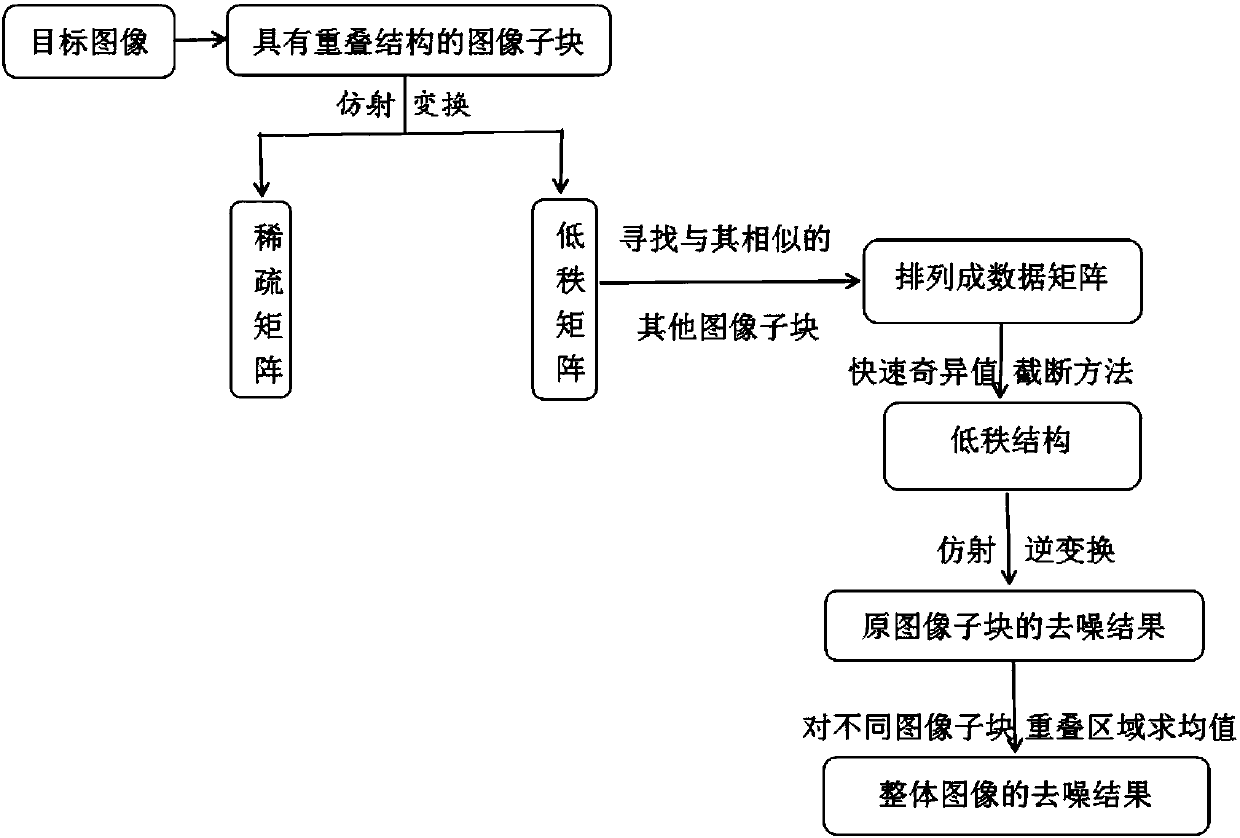

De-noising method based on recessive low-rank structure inside and among nonlocal similar image blocks

ActiveCN105957026AExact matchImprove signal-to-noise ratioImage enhancementPattern recognitionSingular value

The invention relates to a de-noising method based on recessive low-rank structure inside and among nonlocal similar image blocks. The method mainly comprises steps of: dividing a target image into subblocks with overlapped structure, decomposing each image subblock into a low-rank matrix and a sparse matrix by means of affine transformation; searching similar low-rank matrixes, transforming each low-rank matrix into a vector and enabling the vectors to form a new data matrix, and obtaining the low-rank structure among the image subblocks by using a rapid singular value truncation method; and performing affine transformation on the obtained low-rank data matrix to obtain a result indicative of the de-noised original image subblocks, averaging the overlapped areas of different image subblocks so as to obtain a de-noising result of the overall image. The invention provides the effective and universal image de-noising method. An experimental result shows that the de-noising method is more effective and robust than other classic image de-noising algorithms and has good application prospect.

Owner:WENZHOU UNIVERSITY

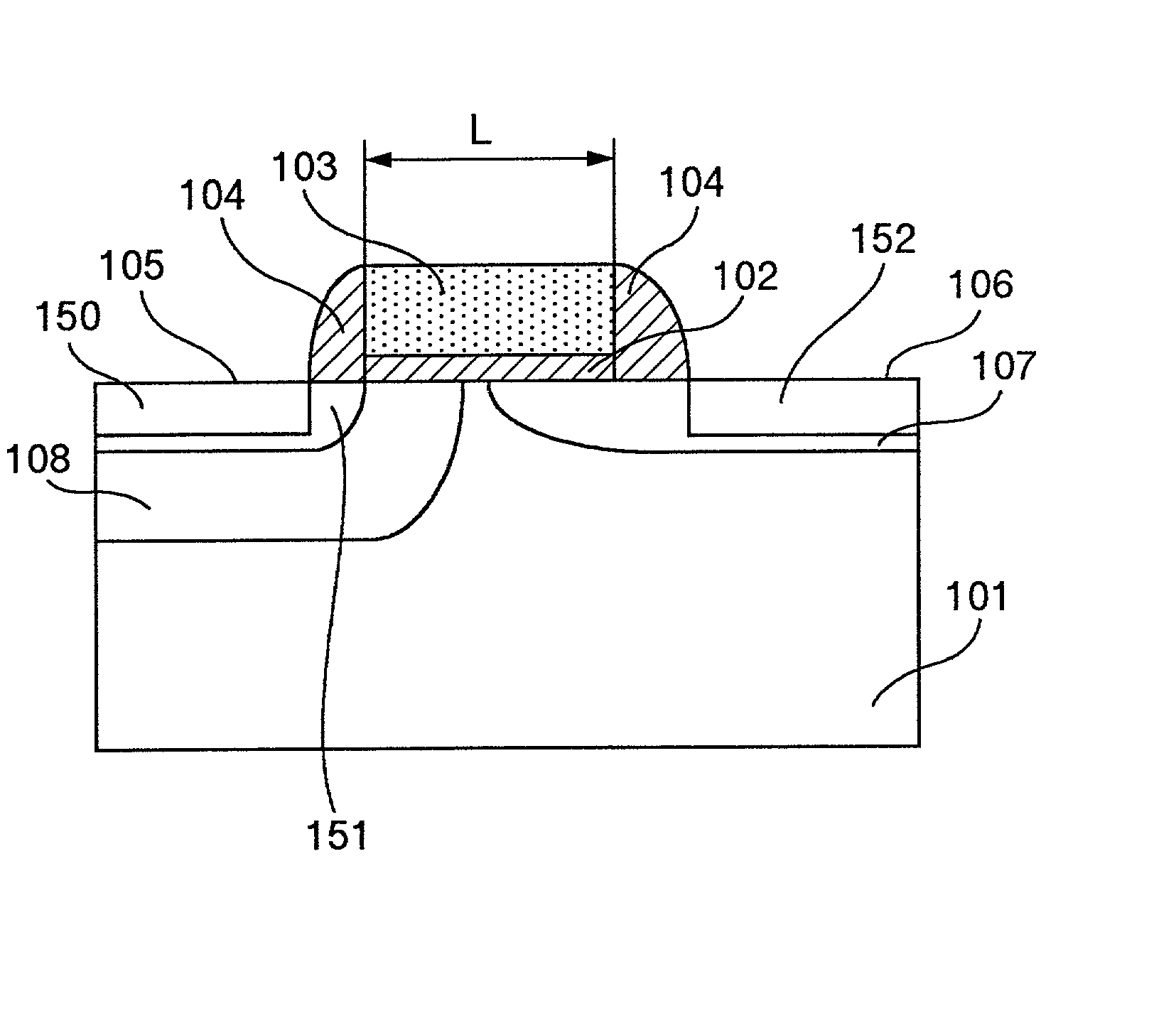

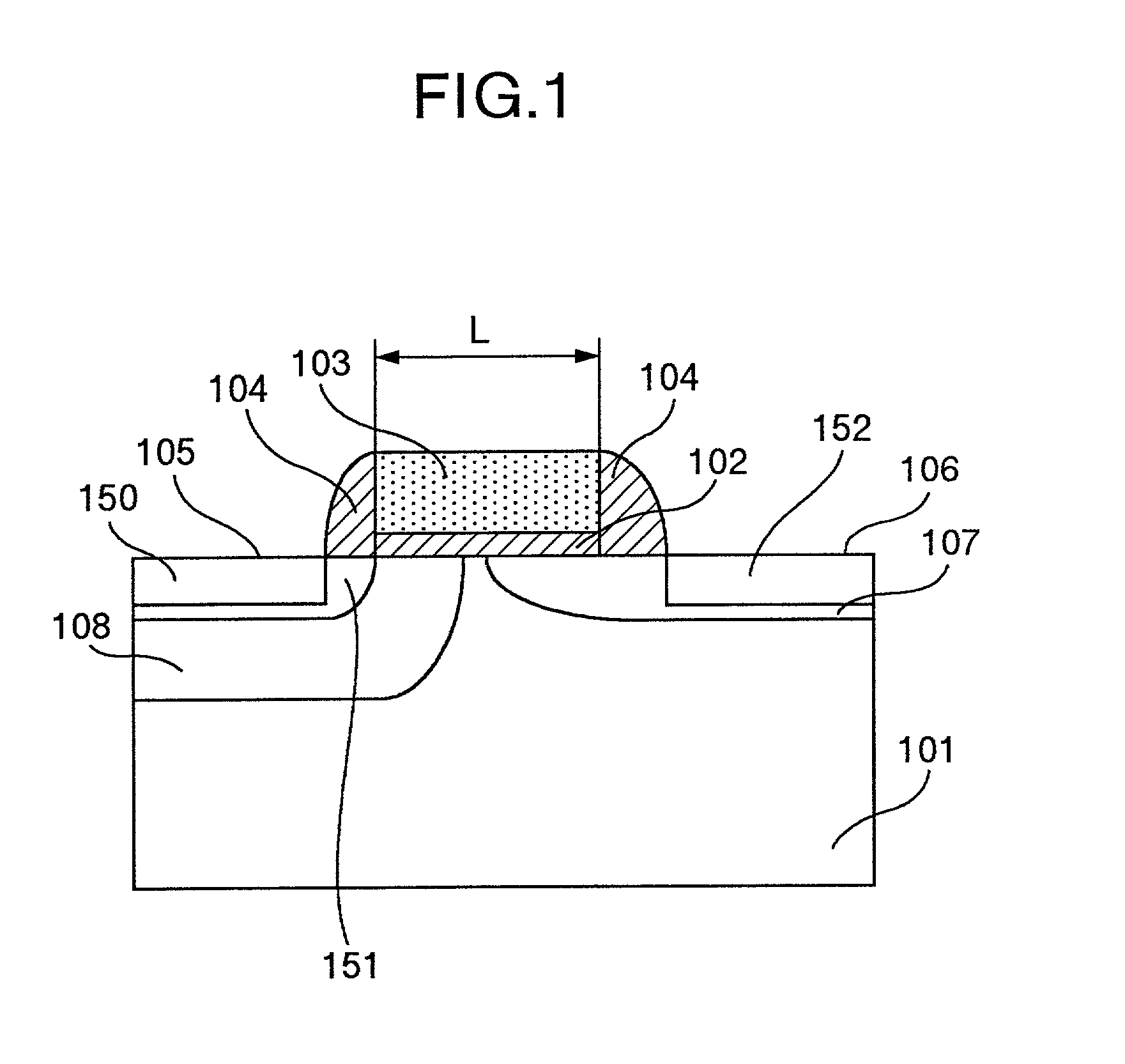

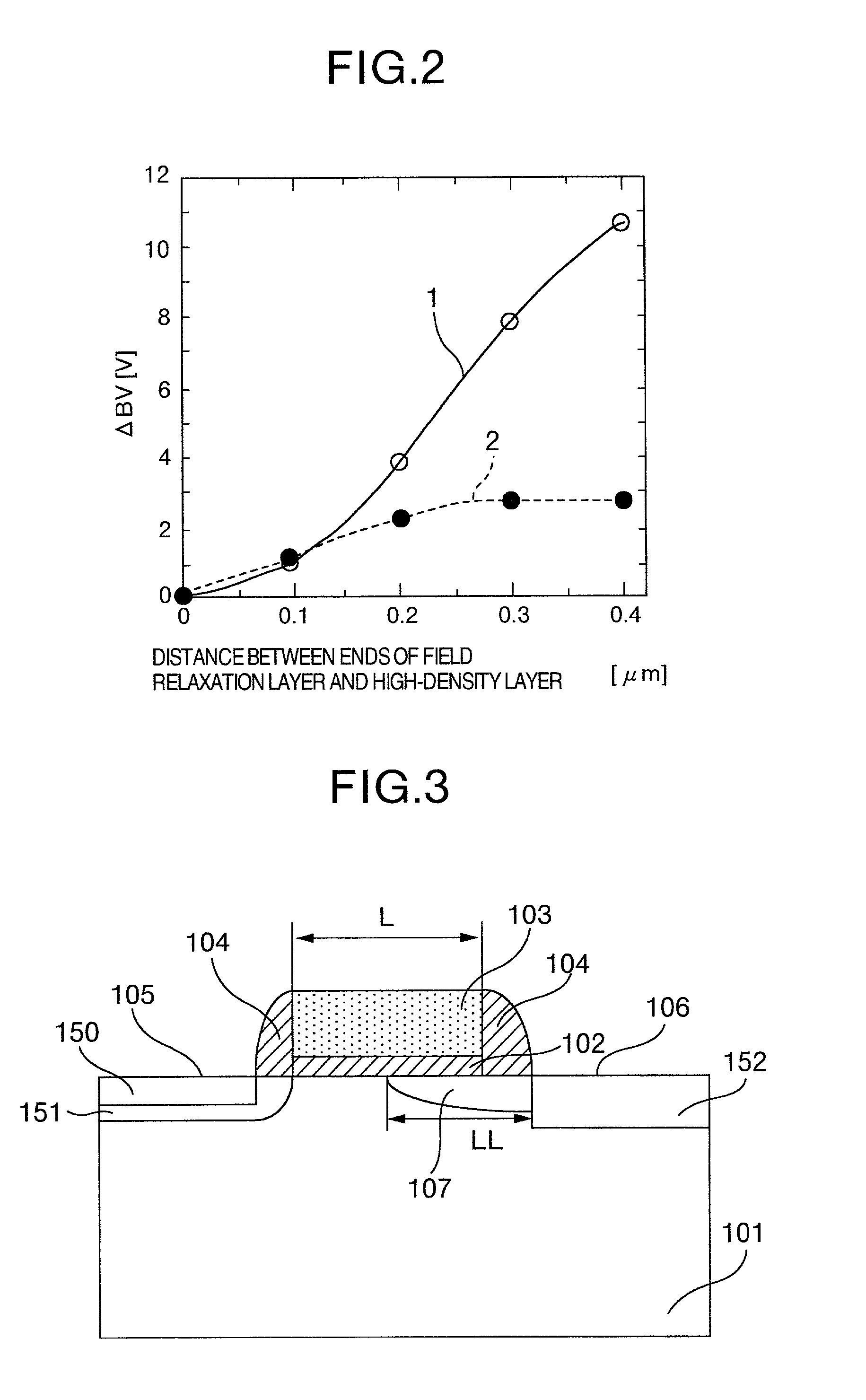

Field effect transistor and semiconductor device manufacturing method

InactiveUS20020125510A1DistanceShorten the lengthTransistorSemiconductor/solid-state device detailsHigh densityMiniaturization

A MOS field effect transistor. A field relaxation layer of a gate overlap structure is disposed in contact with a drain region for the purpose of relaxation of the electric field by increasing a distance between the field relaxation layer and a high-density layer. The electric field relaxation can further be promoted because the equipotential lines are bent by a gate insulation film. A punch-through stopper layer of a gate overlap structure is disposed in contact with a source region for suppressing spreading of a depletion layer toward the source region. The length of a gate electrode can be realized in a miniaturized size.

Owner:RENESAS TECH CORP

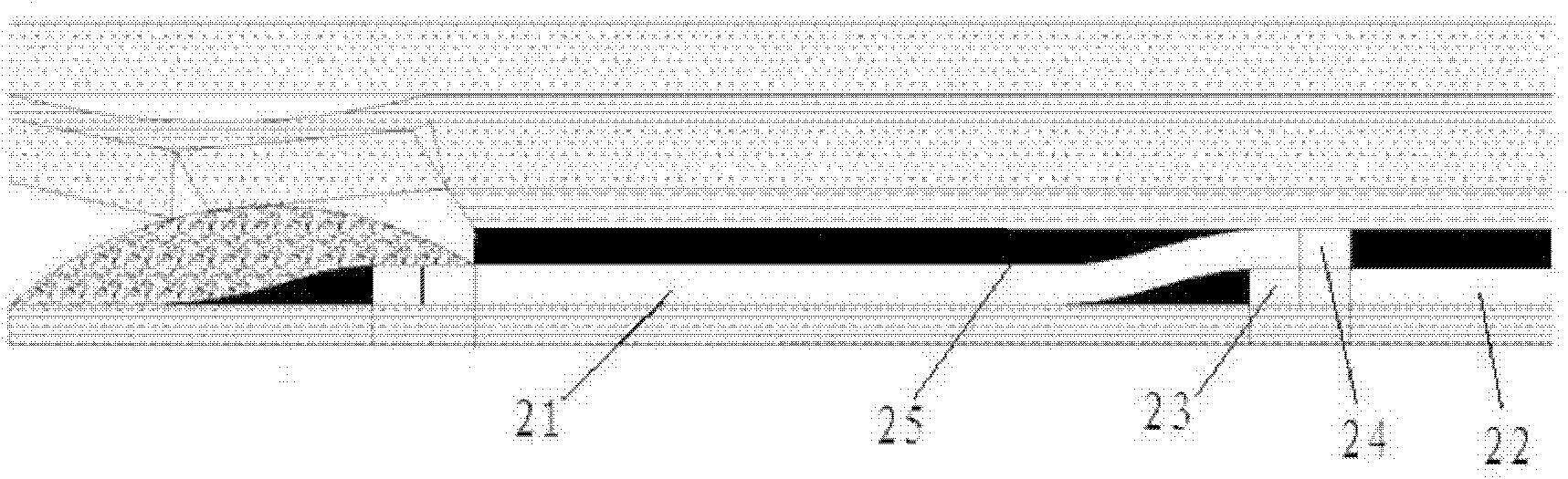

Method for determining height of caving zone of stope with internal-staggered layer-staggered position type roadway layout

InactiveCN102654054AEnsure safe productionUnderground miningSurface miningResearch ObjectType selection

The invention relates to a method for determining height of a caving zone of a stope with an internal-staggered layer-staggered position type roadway layout, and the method is used for solving the problem that in a full-thickness coal mining method which uses the internal-staggered layer-staggered position type roadway layout, as a continuous working face is formed, the height of the caving zone of the stope is difficult to accurately determine, the type selection of equipment and the selection of a coal mining process cannot be optimal, and then, the safe mining is affected. According to the method for determining the height of the caving zone of the stope with the internal-staggered layer-staggered position type roadway layout, provided by the invention, a key layer is determined to be an object of study; and furthermore, according to the characteristics of the full-thickness coal mining method with the internal-staggered layer-staggered position type roadway layout, a plurality of working faces of the stope form an overlapped structure, the stope space on the working faces forming the overlapped structure are taken as a whole stope space, the key layer is judged according to the length of the whole stope space, and then, the height of the caving zone of an overlying rock layer of the mining work face is finally determined, so that the type selection of the equipment and the selection of the coal mining process are optimized, and the safe production is guaranteed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

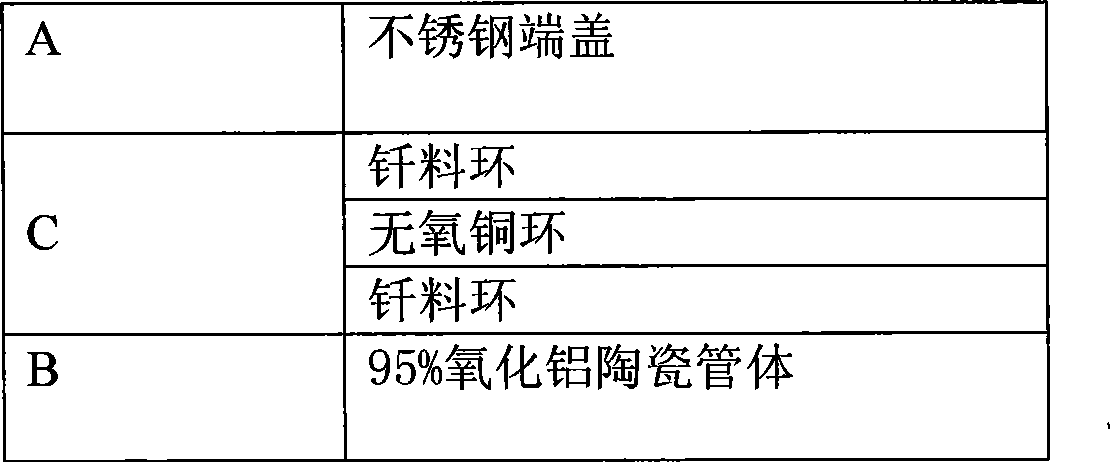

Stainless steel / alumina ceramic low stress hermetic seal solder

InactiveCN101475395AStrong stress absorption effectWelding/cutting media/materialsSoldering mediaAlloy compositeComposite solder

The invention relates to a silver alloy composite solder strip for a vacuum switch tube stainless steel and 95 percent alumina ceramic low-stress hermetic seal joint. The cross section of the composite solder strip has a three-layer overlapping structure of a solder alloy layer, a copper core layer and a solder alloy layer, wherein solder in the composite solder comprises the following compositions in percentage by mass: 55 to 72 percent of silver, 19.0 to 43.0 percent of copper and 0.50 to 4.50 percent of nickel; the melting temperature of the solder is between 780 and 835 DEG C, and the hermetic seal temperature is between 820 and 850 DEG C; the unilateral thickness of the solder alloy layer in the composite solder is between 0.08 and 0.20 millimeter; the copper core layer in the composite solder is copper with the purity of more than or equal to 99.95 percent or oxygen free copper; the interlayer composite proportion of the composite solder, namely the thickness of the solder layer to the thickness of the copper core layer to the thickness of the solder layer, is 1:X:1 (wherein, X is between 1.8 and 3.5); and firm metallurgical combination is formed between various layers. The intensity of the vacuum switch tube stainless steel and 95 percent alumina ceramic joint is more than or equal to 90 MPa, and the leakage rate of the joint is less than or equal to 1*10Pa.m / s.

Owner:SINO PLATINUM METALS CO LTD

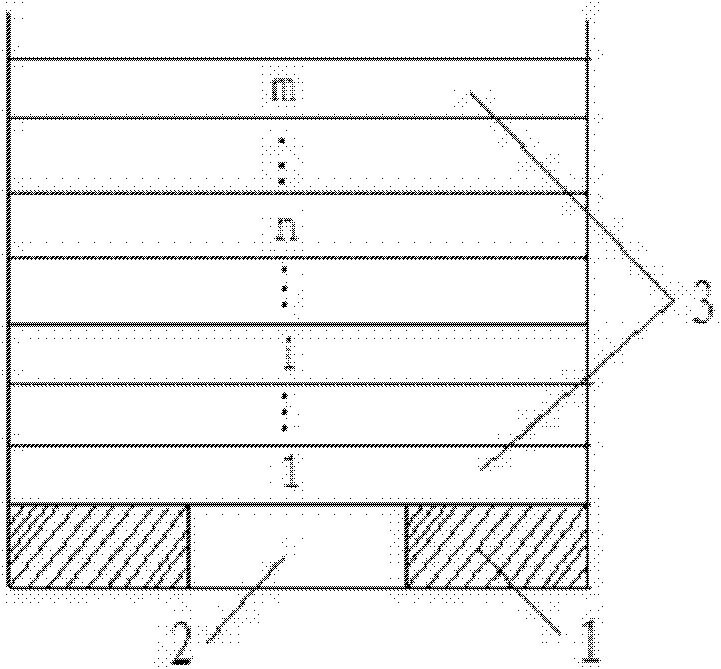

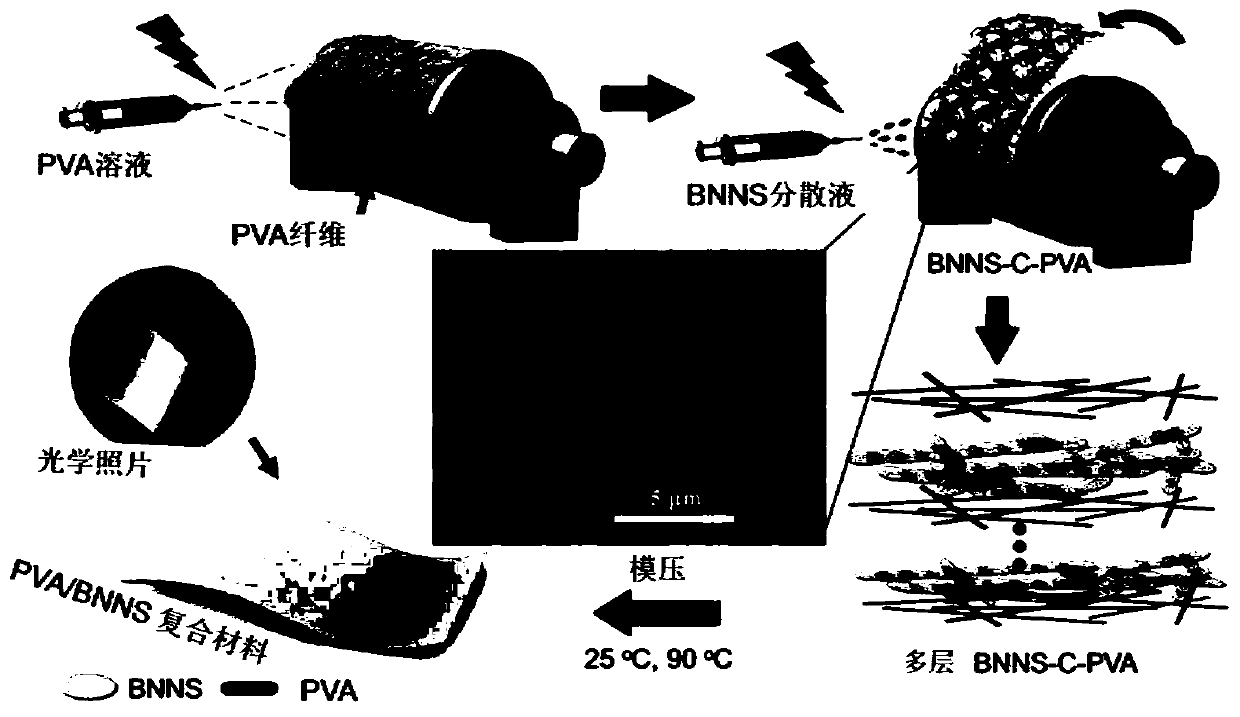

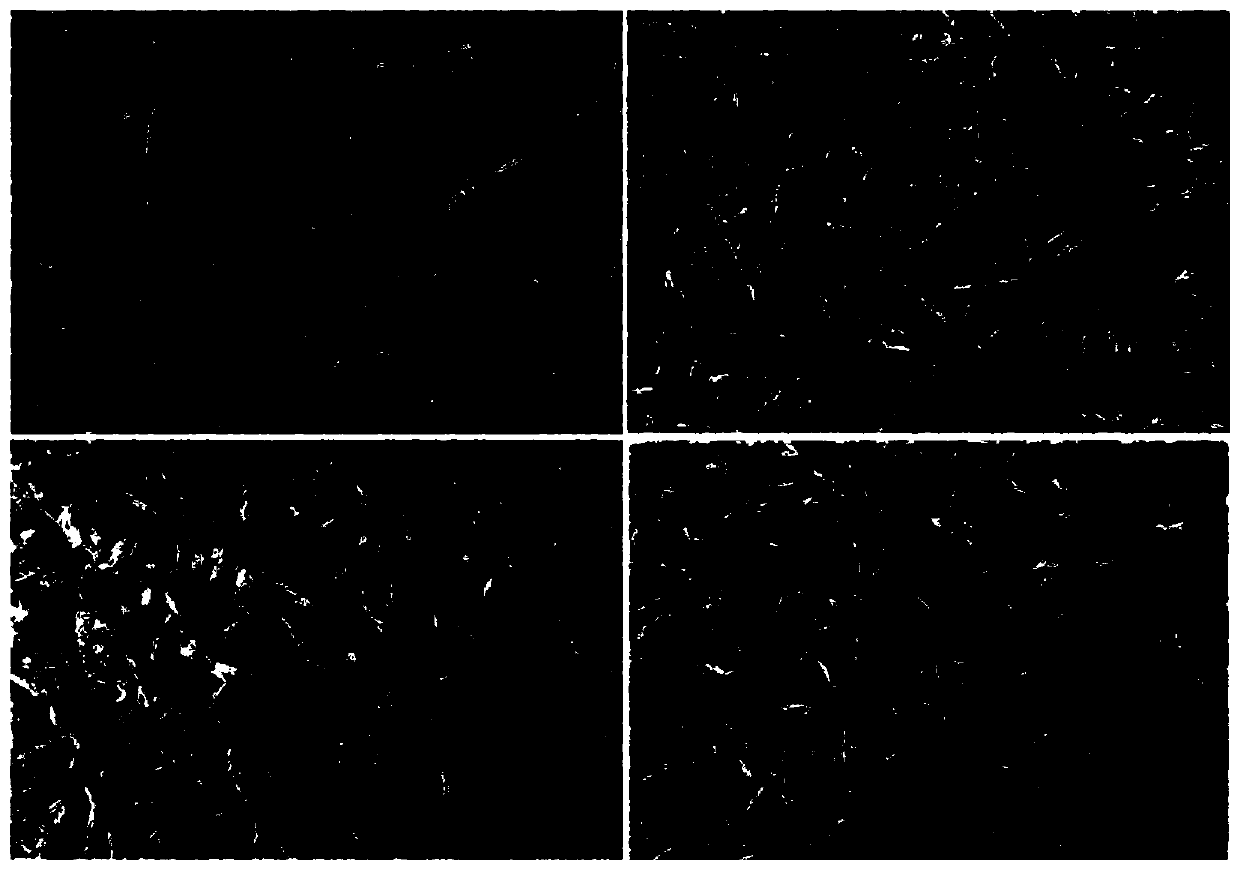

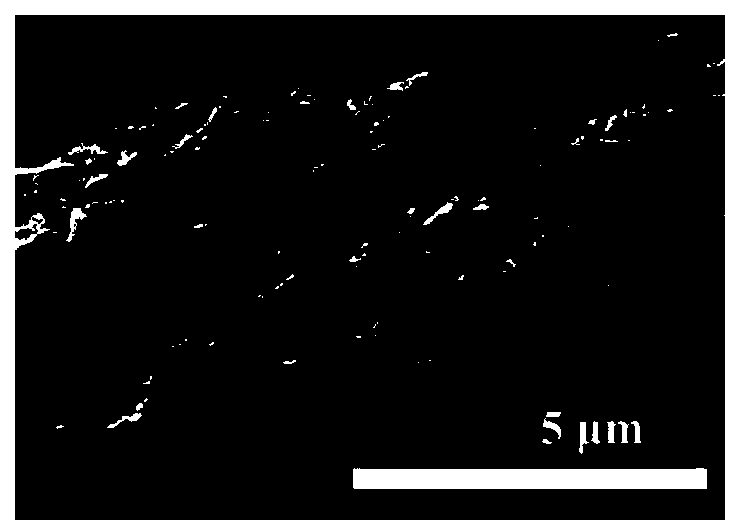

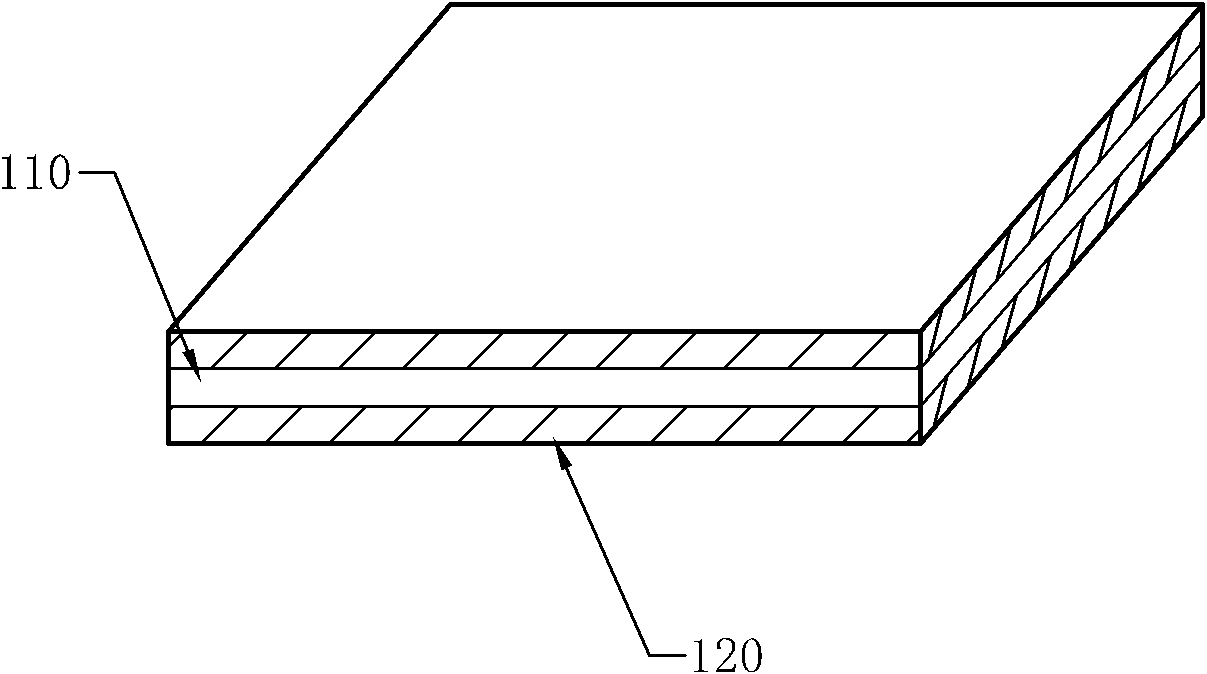

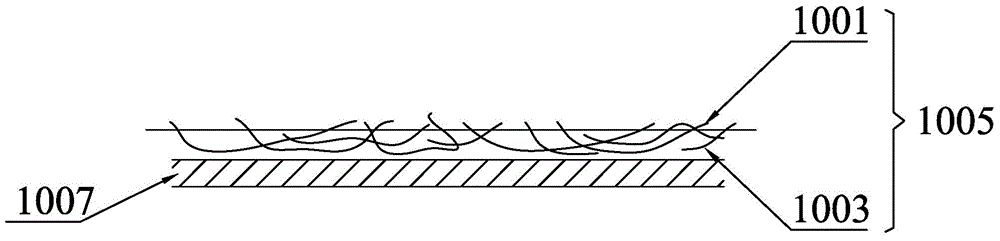

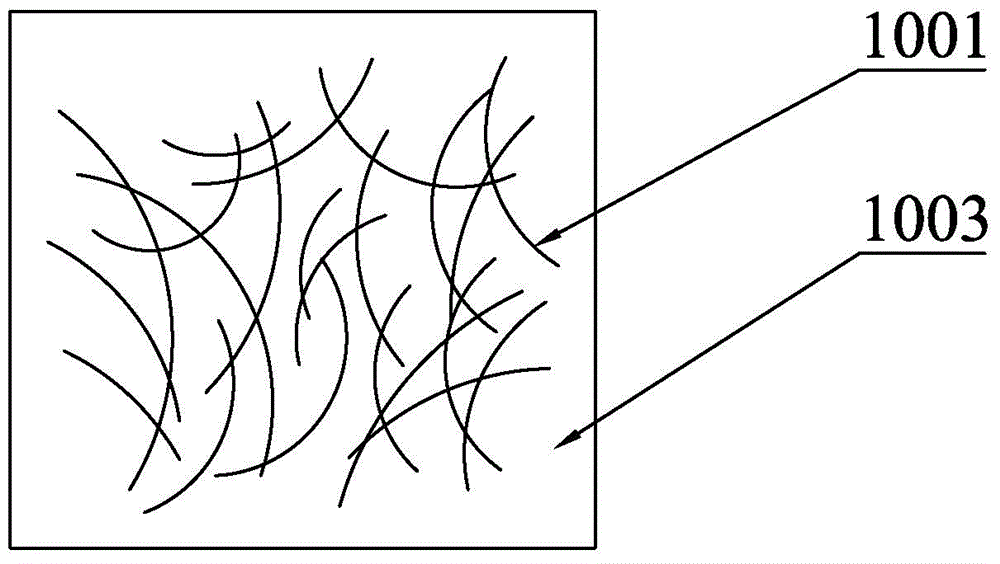

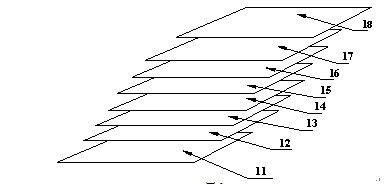

High-heat-conductivity anisotropic polymer-based composite material and preparation method thereof

InactiveCN110228248AHigh thermal conductivityReduce thermal resistanceFibre typesSynthetic resin layered productsHigh pressureElectric equipment

The invention provides a high-heat-conductivity anisotropic polymer-based composite material and a preparation method thereof. The composite material is of an overlapped structure consisting of multiple composite fiber layers after overlapping and hot-pressing, wherein the composite fiber layers are formed by covering surfaces of polymer nanofibers by heat conduction fillers. In preparation, a heat conduction packing dispersion solution is sucked into an injector for high-pressure electrostatic spraying, and is adhered to the polymer nanofibers under the actions of electrostatic force and hydrogen bonds, then a network structure with fillers which contact with one another and are arranged in an orientation direction is formed, and after overlapping, the composite material is prepared through cold-pressing compression and hot-pressing molding. Due to the special structure of the composite material, efficient conduction paths are formed by the fillers in the composite material filled with the fillers, the purpose that the heat conductivity of the polymer-based composite material is remarkably improved by a small amount of the high heat conduction fillers can be achieved, and heat conduction requirements in preparing electronic and electric equipment can be met.

Owner:SHANGHAI JIAO TONG UNIV

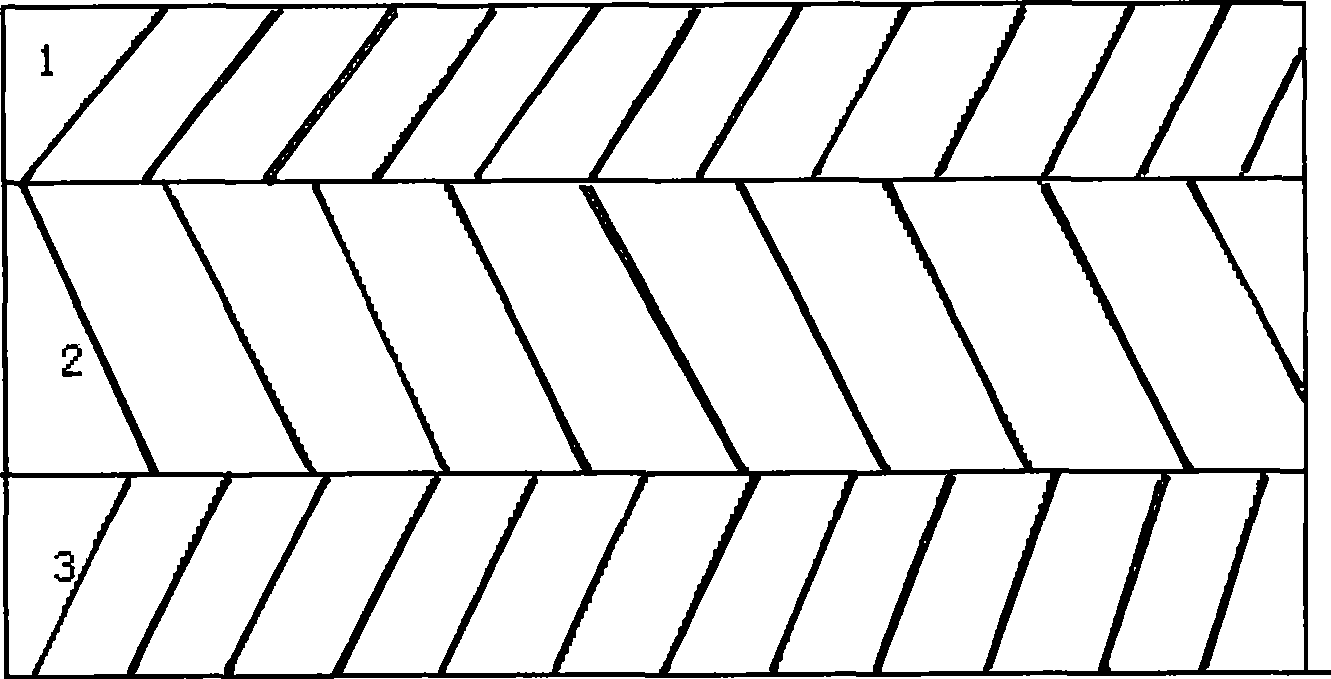

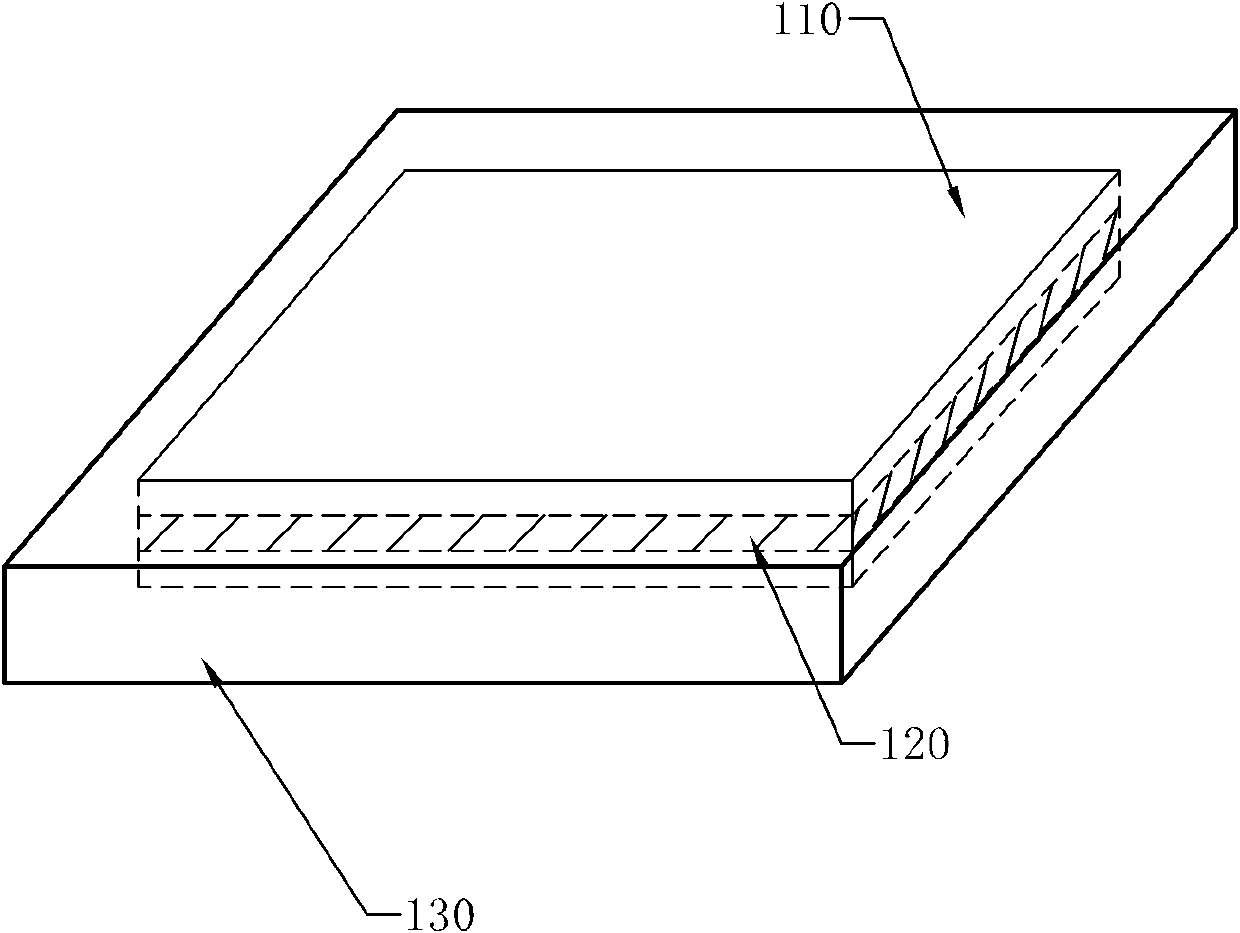

High-radiation film type metal compound material and manufacturing method thereof

The invention provides a high-radiation film type metal compound material and a manufacturing method thereof and belongs to the technical field of a high-radiation material. The compound material comprises three parts, namely metal layers, high-radiation film layers and a metal frame, wherein the high-radiation film layers are overlapped with the metal layers and the metal frame is used for cladding the edges of the metal layers and the edges of the high-radiation film layers. The manufacturing method comprises the following steps: firstly, respectively preparing the metal layers and the high-radiation film layers; interactively overlapping the metal layers and the high-radiation film layers till forming overlapping structures with required layer number; utilizing the metal frame to fix the overlapping structures of the metal layers and the high-radiation film layers; heating, thereby melting the contacting metal between the overlapping structures of the metal layers and the high-radiation film layers and between the metal frame and the overlapping structures; and reducing temperature, cooling and solidifying, thereby realizing the integral adhering forming. The structure of overlapped metal layers is adopted and the metal frame is used for cladding and fixing, so that the hardness of a high-radiation film is increased.

Owner:上海杰远环保科技有限公司

Article of ready-to-assemble furniture

InactiveUS20050006943A1Easy and fast assemblyReduce shipping costsFurniture joining partsBenchesSingle plateEngineering

The present invention provides fully upholstered, ready-to-assemble furniture which may be custom ordered by a purchaser, shipped directly to the home of the purchaser by a parcel delivery service, and then easily and quickly assembled by the purchaser. The ready-to-assemble article of furniture includes a frame having a composite frame member with a long dimension which is formed by a plurality of planar frame members assembled in an end-to-end and overlapping manner. The plurality of planar frame members are interconnected by interlocking protrusions and cutout portions, as well as by threaded fasteners received in push-in connector elements which are held in recesses within the frame members. The interlocking and threaded fastener connections allow a plurality of smaller frame members to form the composite frame member of the furniture frame, wherein the frame has the torsional and longitudinal stability of known furniture frames which include long, single boards. In particular, the interlocking and overlapping structure of the present furniture frame advantageously provides longitudinal and torsional stability to an article of furniture having a long dimension such as an entertainment center or sofa.

Owner:HOME RESERVE

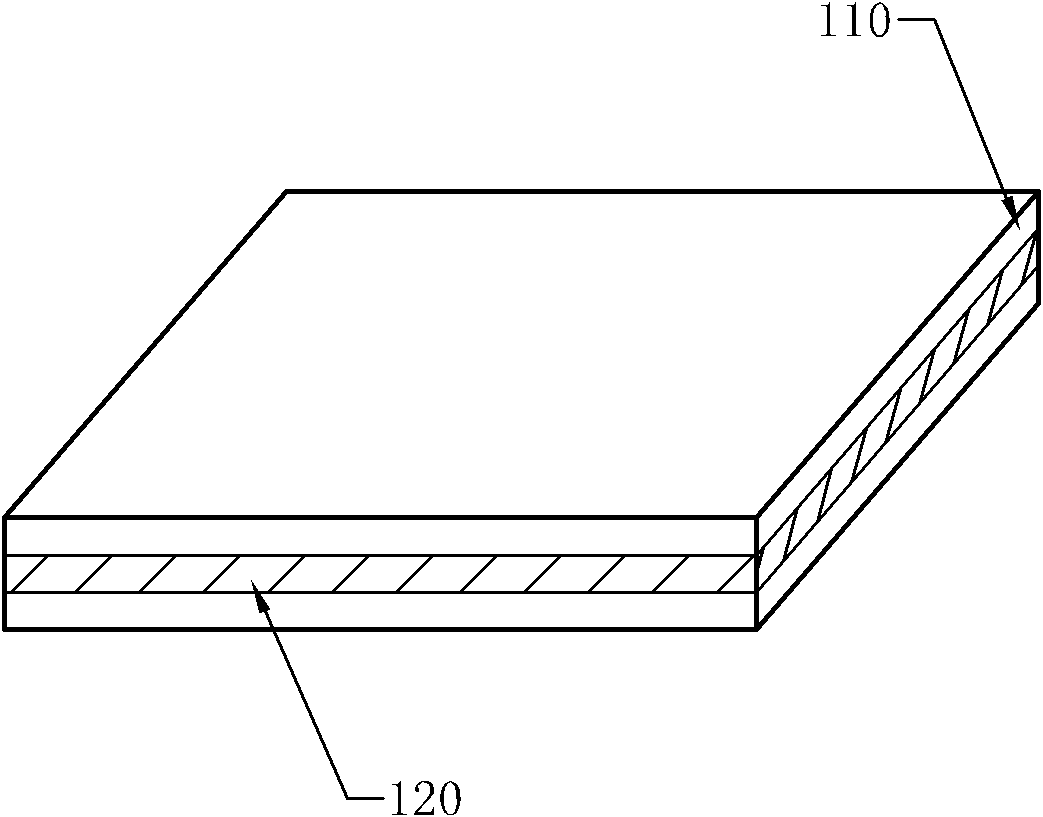

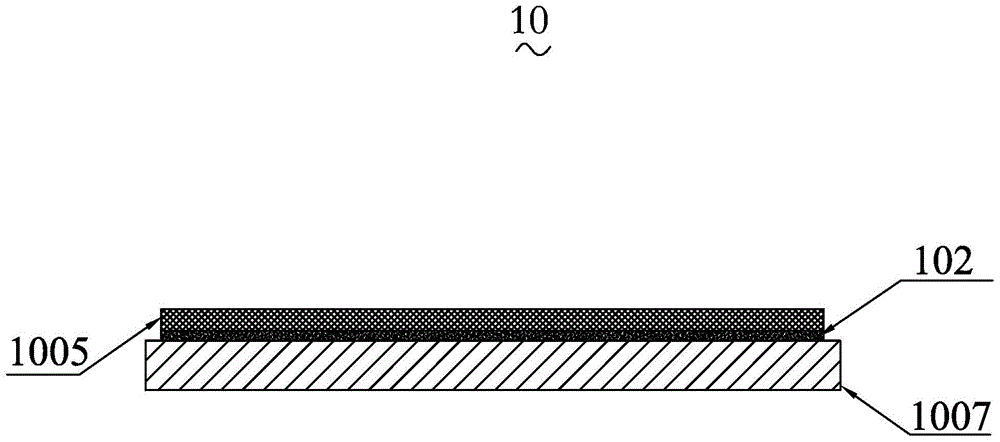

Nanometer silver line conductive overlapping structure and capacitive touch panel

ActiveCN105204695AImprove efficiencyLow costInput/output processes for data processingLap jointNanometre

The invention relates to a conductive overlapping structure, in particular to a nanometer silver line conductive overlapping structure. The nanometer silver line conductive overlapping structure comprises a flexible base material, a nanometer silver line conductive electrode layer and an adhesive force increasing layer, wherein the nanometer silver line conductive electrode layer is arranged on the surface of the flexible base material, and the adhesive force increasing layer is arranged between the flexible base material and the nanometer silver line conductive electrode layer and used for increasing the adhesive force between the flexible base material and the nanometer silver line conductive electrode layer. According to an existing nanometer silver line conductive overlapping structure, poor lap joints or shift between nanometer silver lines can influence conductivity of the existing nanometer silver line conductive overlapping structure; by arranging the adhesive force increasing layer, the adhesive force between the nanometer silver line conductive electrode layer and the base material is enhanced. The invention further provides a capacitive touch panel with the nanometer silver line conductive overlapping structure.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

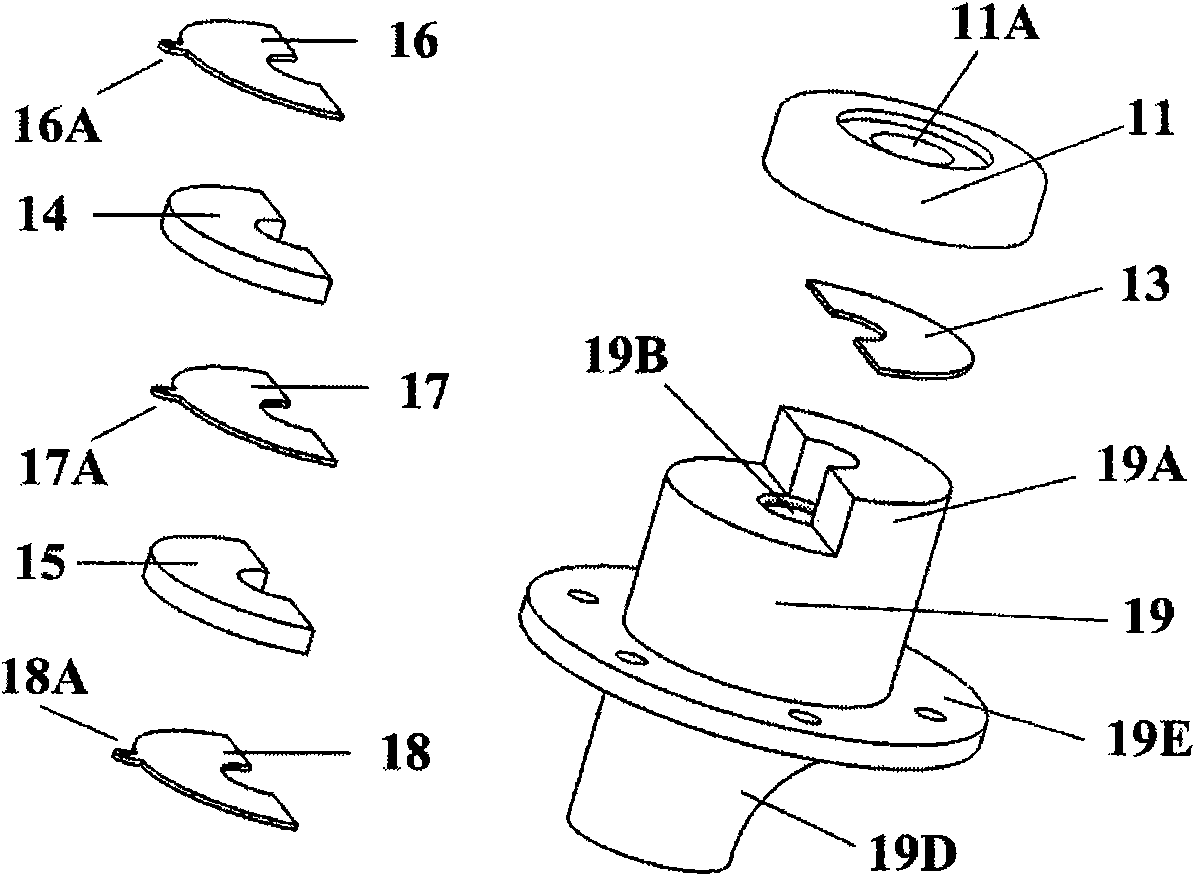

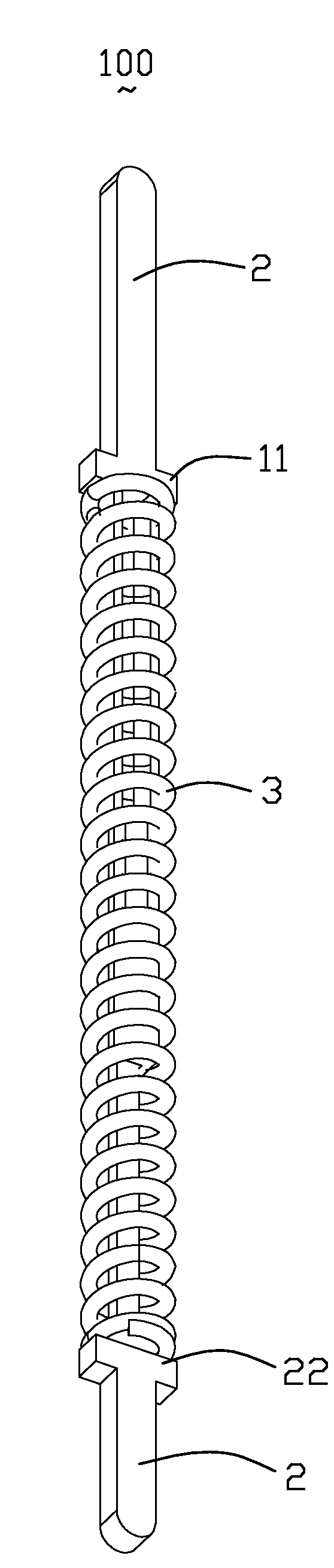

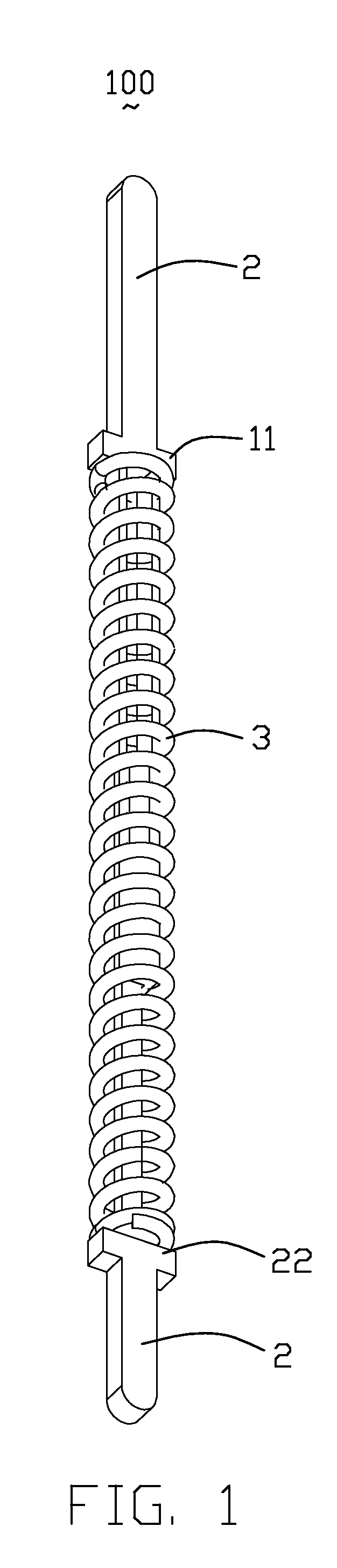

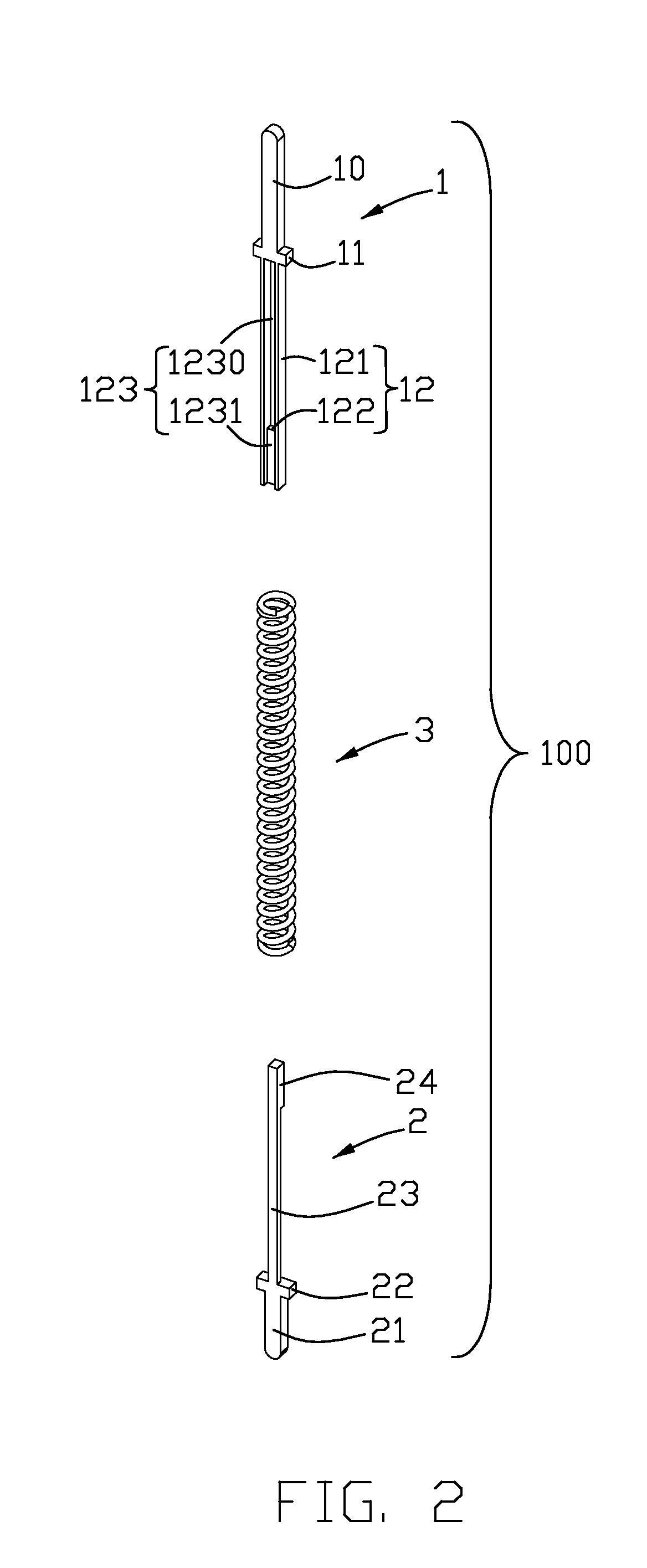

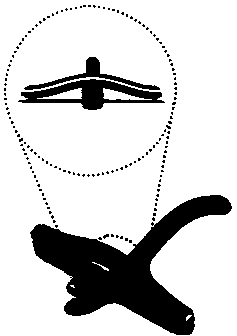

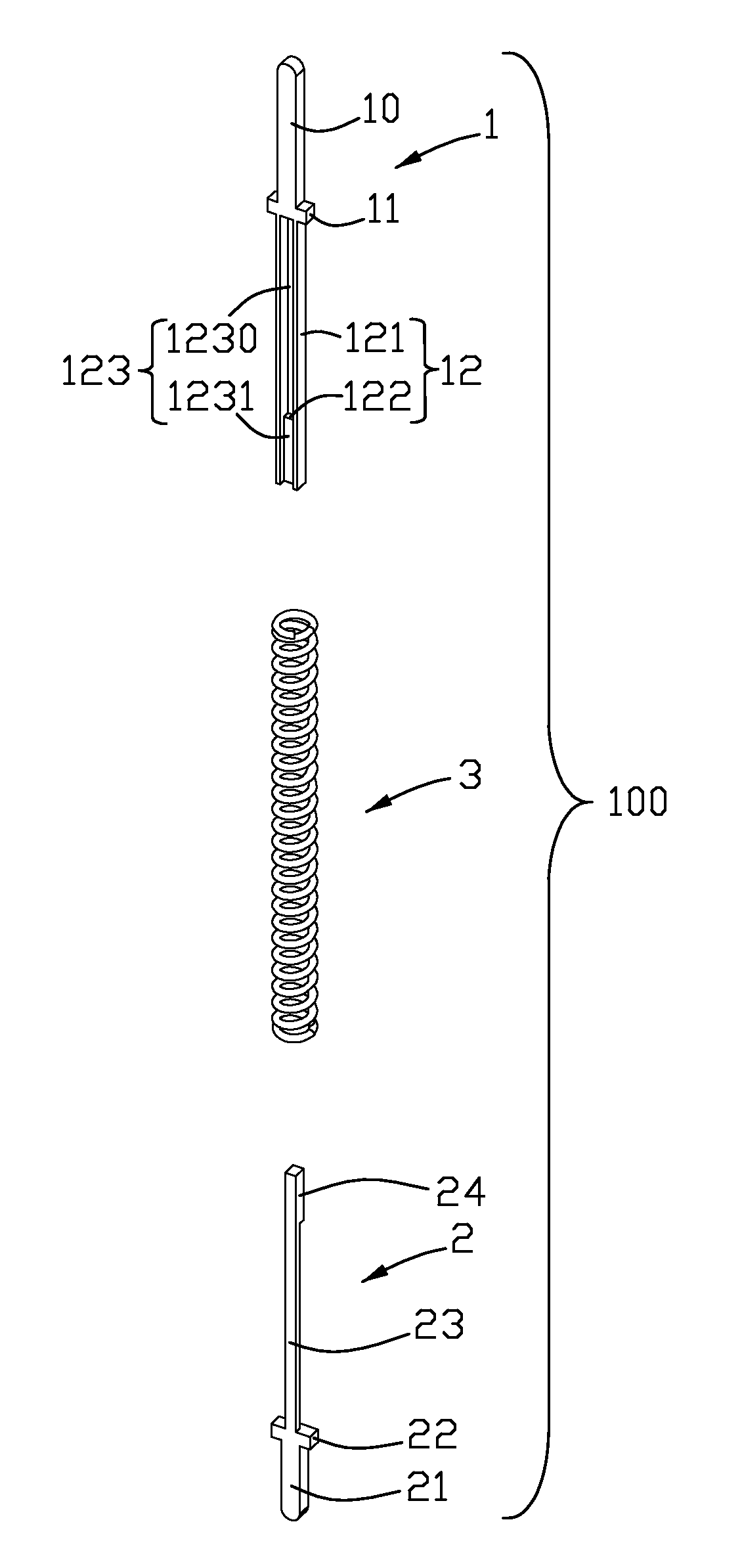

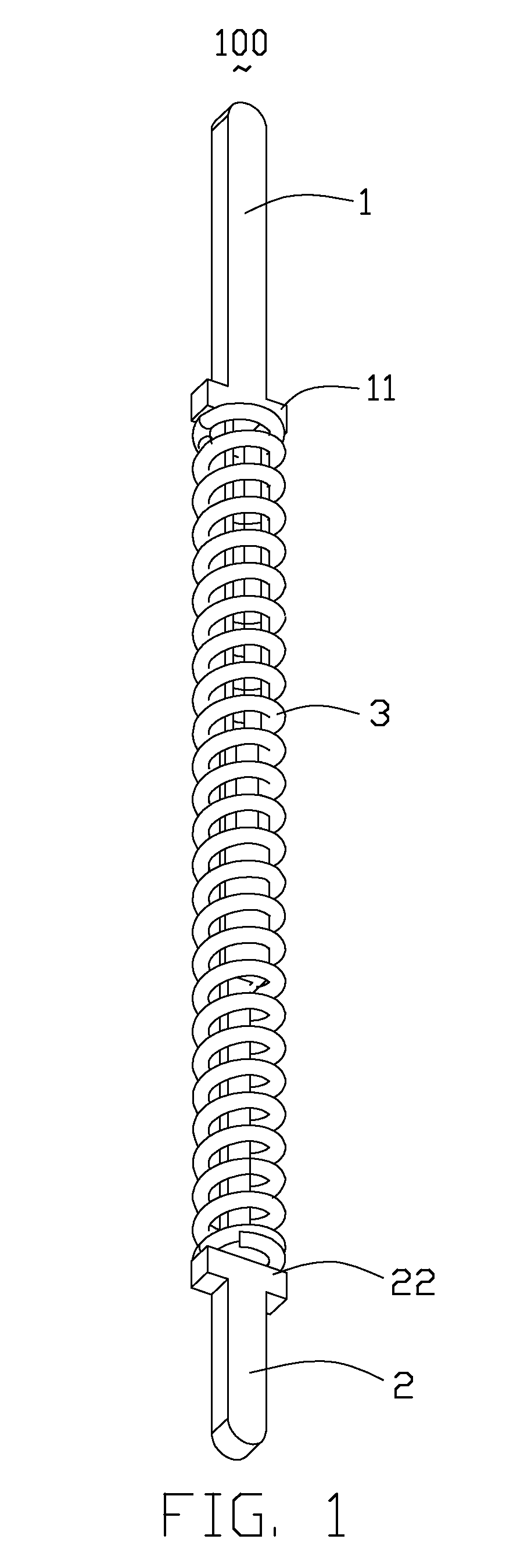

Electrical contact with overlapping structure

ActiveUS20090311886A1Easy to assembleEasy to produceElectrically conductive connectionsElectrical measurement instrument detailsElectrical contactsOverlapping structures

Owner:HON HAI PRECISION IND CO LTD

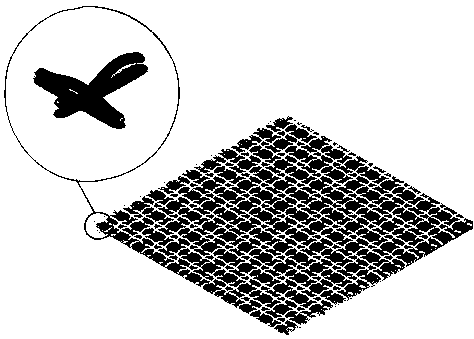

Preparation method of capacitive stress sensing intelligent fabric

InactiveCN108085988AControl sensitivityControl measurement rangeElectroconductive/antistatic filament manufactureWeft knittingElastomerYarn

The invention provides a preparation method of a capacitive stress sensing intelligent fabric. Conductive yarns serve as electrodes of a capacitive sensor and are obtained by means of direct preparation, coating, coping and the like, insulating elastomers serves as dielectric materials coating the conductive yarns, the insulated conductive yarns alternately penetrate common yarns by the aid of interwoven overlapped structures among fabric yarns, a fabric sensing array is formed by common manufacturing technology, and the preparation method can be widely applied to stress monitoring and the like of intelligent garments, intelligent homes, touch screens, electronic skins and three-dimensional fabric composite materials.

Owner:DONGHUAJINGYUE SUZHOU TEXTILE TECH RES CO LTD

Electrical contact with overlapping structure

ActiveUS7789671B2Easy to assembleEasy to produceElectrically conductive connectionsElectrical measurement instrument detailsElectrical contactsOverlapping structures

Owner:HON HAI PRECISION IND CO LTD

Narrow graphene nanoribbons from carbon nanotubes

Disclosed is a method for making graphene nanoribbons (GNRs) by controlled unzipping of structures such as carbon nanotubes (CNTs) by etching (e.g., argon plasma etching) of nanotubes partly embedded in a polymer film. The GNRs have smooth edges and a narrow width distribution (2-20 nm). Raman spectroscopy and electrical transport measurements reveal the high quality of the GNRs. Such a method of unzipping CNTs with well-defined structures in an array will allow the production of GNRs with controlled widths, edge structures, placement and alignment in a scalable fashion for device integration. GNRs may be formed from nanostructures in a controlled array to form arrays of parallel or overlapping structures. Also disclosed is a method in which the CNTs are in a predetermined pattern that is carried over and transferred to a substrate for forming into a semiconductor device.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

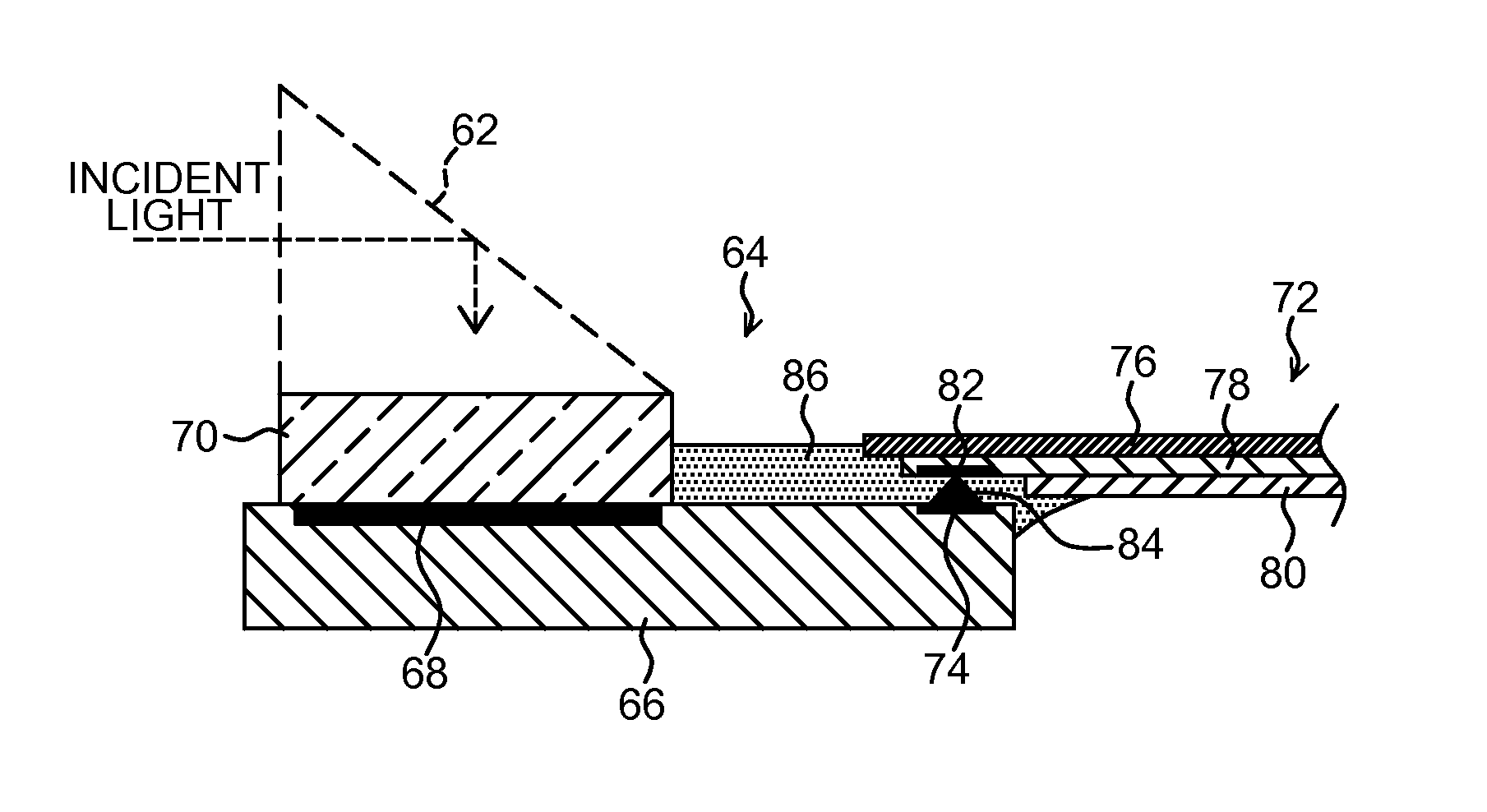

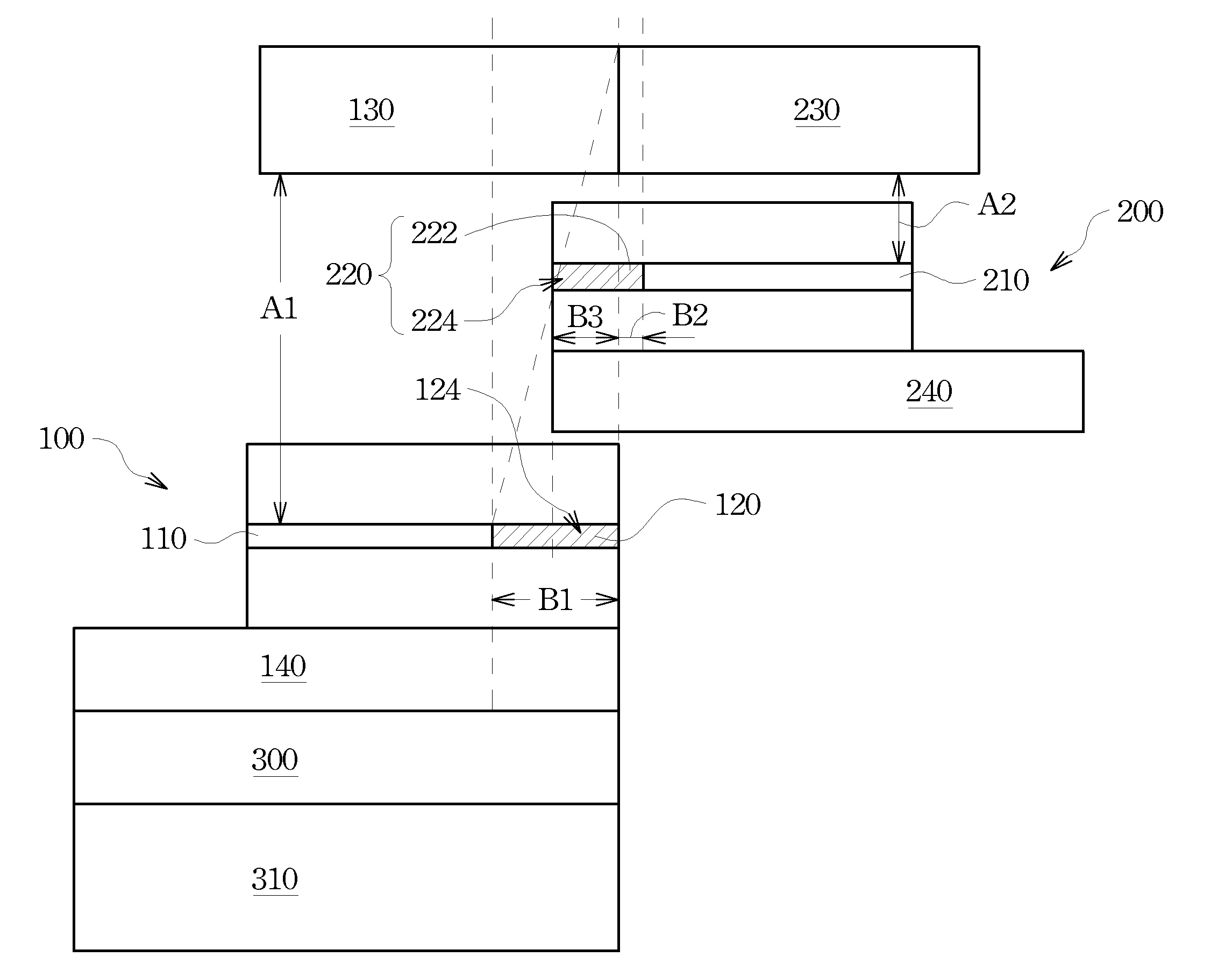

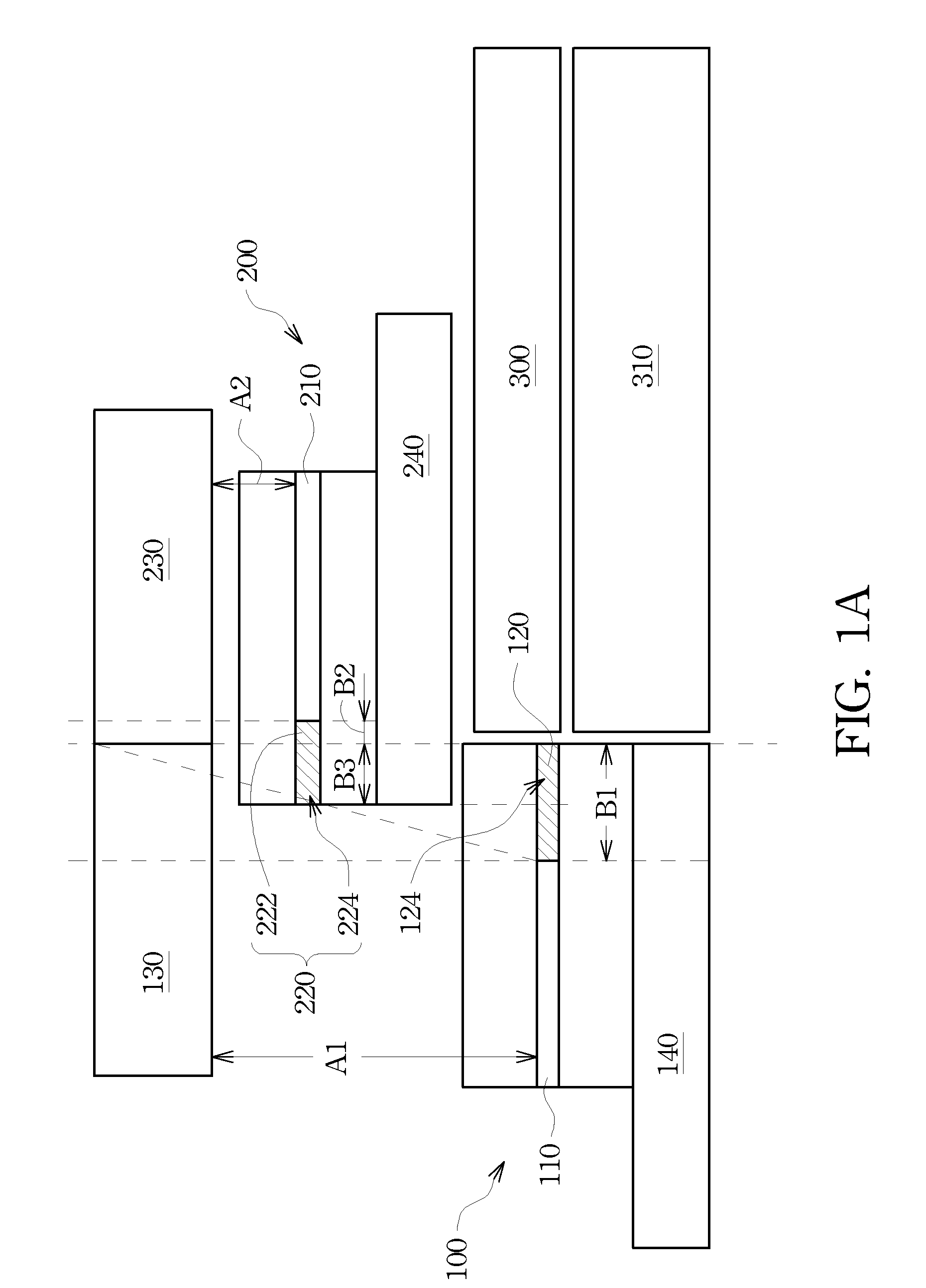

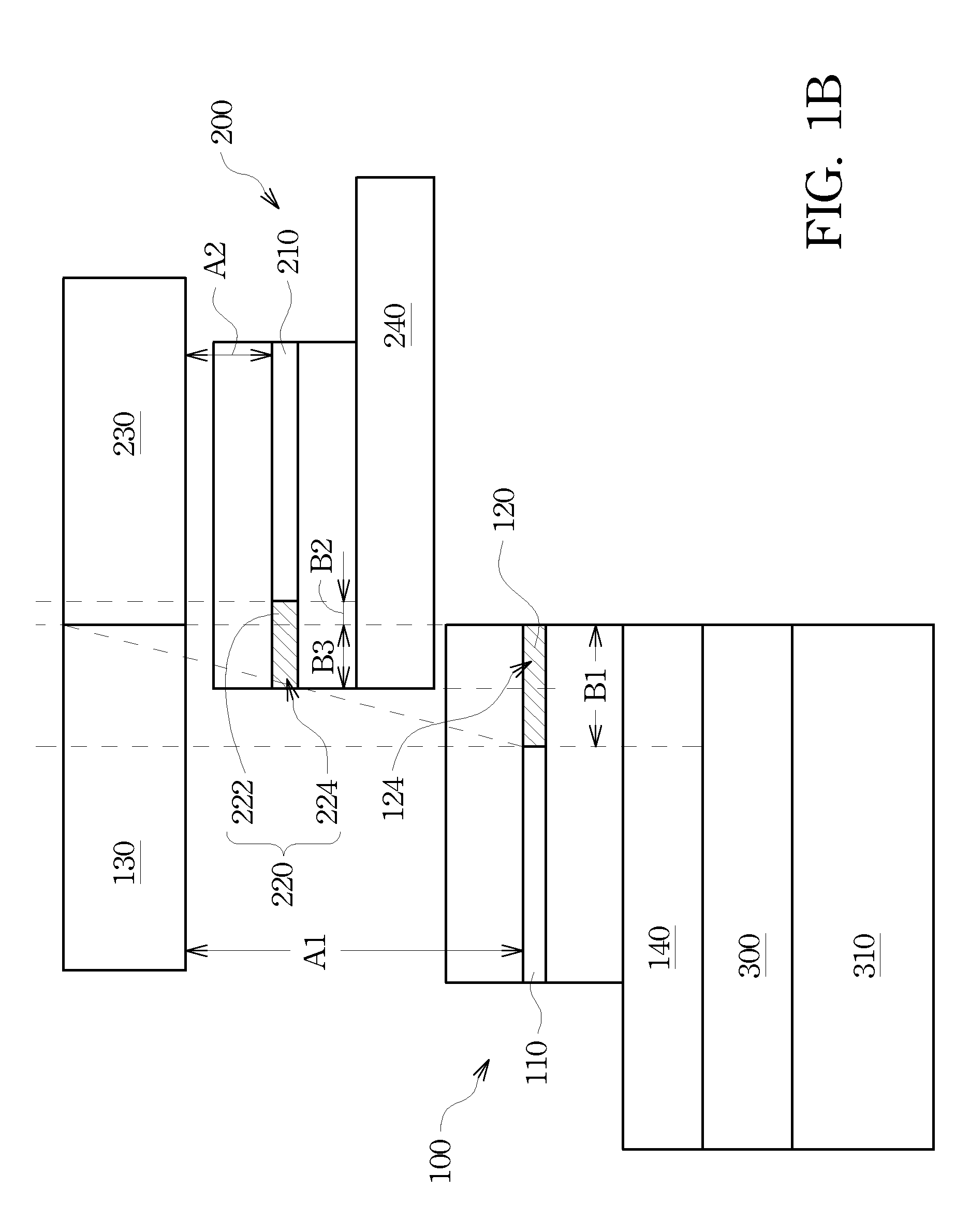

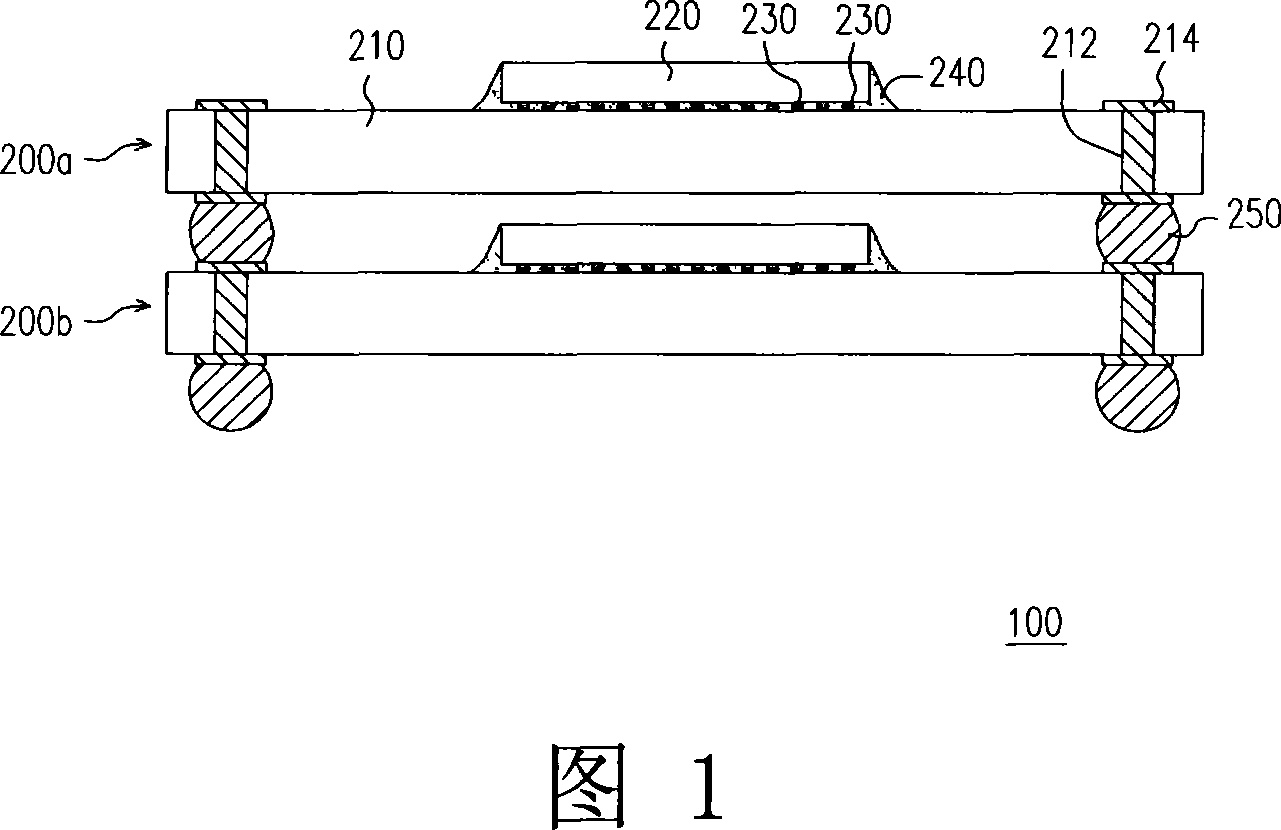

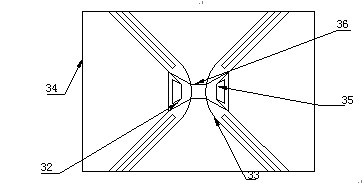

Multi-Section Visual Display having Overlapping Structure

ActiveUS20100079696A1Reduce border areaReduced space requirementsDevices with multiple display unitsCathode-ray tube indicatorsMagnifying glassDisplay device

A multi-section visual display having an overlapping structure is disclosed, and includes a first magnifying lens, a second magnifying lens, a first display apparatus having a first display panel and a second display apparatus having a second display panel, wherein the second display apparatus is disposed between the first magnifying lens and the first display apparatus, and the second magnifying lens is aligned with the first magnifying lens in an edge-to-edge manner. While at an operation state, a first border area of the first display panel is partially overlapped with a second border area of the second display panel, thereby reducing the non-display area needing shielding by using a virtual image display from the first display panel / magnifying lens to shield a portion of the second border area, thus reducing the space required between the magnifying lenses and the first display panel.

Owner:AU OPTRONICS CORP

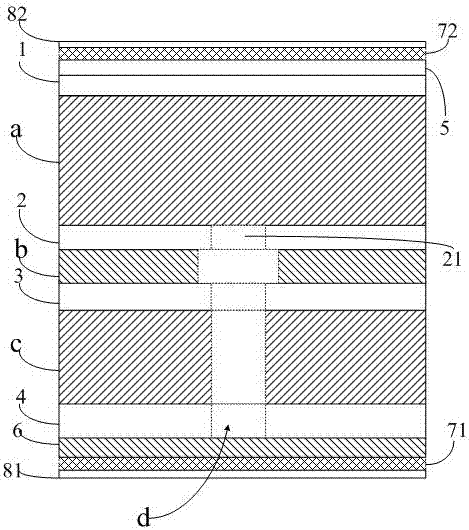

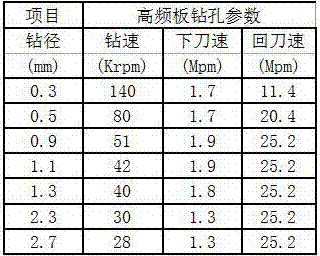

Hybrid different board material high-frequency board manufacturing method

ActiveCN107278062AAvoid bendingSolve the problem of overflow glueMultilayer circuit manufactureEpoxyProcess quality

The invention provides a hybrid different board material high-frequency board manufacturing method. A double-face copper-plated high-frequency board material and an epoxy resin board are employed for manufacturing, a non-flowing glue PP plate is utilized as a stitching medium of the high-frequency board material and the epoxy resin board, dimensions of a groove hole on the non-flowing glue PP plate are specially designed to solve a groove hole glue spilling problem, processing quality of products is improved, moreover, the overlapping process for drilling is further specially designed for the high-frequency board material, for a board material sinking problem of the high-frequency board material during stitching after grooving, a stitching overlapped structure is especially designed, a three-in-one buffer pad is employed to solve the grooving-side board material sinking problem, a hot pressing program is designed according to the stitching overlapped structure, the cold press time is further prolonged to further reduce a board bending problem caused by different expansion coefficients of different board materials, the high-frequency board material contains fillers which are not easily removed in a chemical glue removal mode, before electroplating, plasma glue removal is firstly carried out, chemical glue removal is then carried out, and complete cleaning is carried out to effectively improve electroplating quality.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

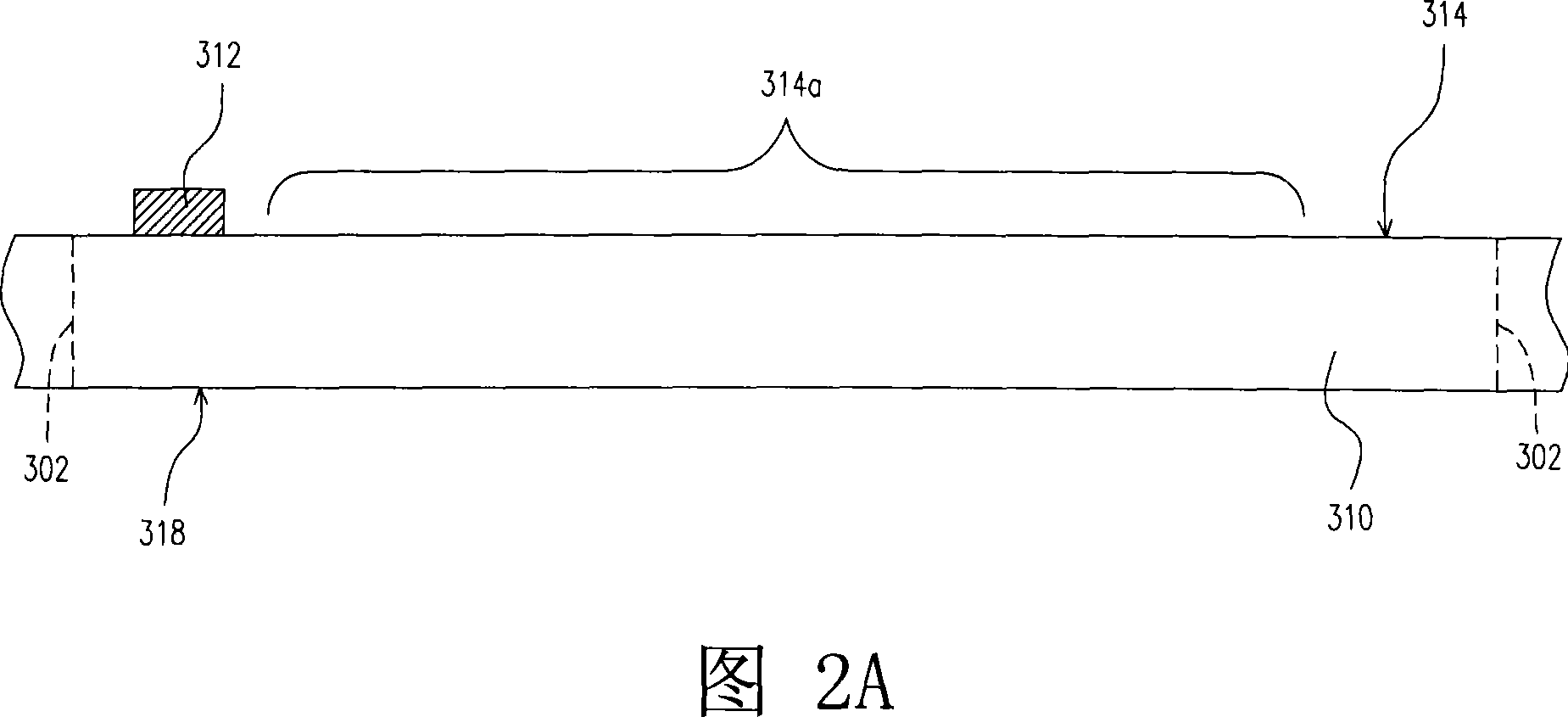

Chip overlap structure and wafer structure for manufacturing the chip stack structure

ActiveCN101060117AReduce thicknessSave materialSemiconductor/solid-state device detailsSolid-state devicesEngineeringChip stacking

The disclosed chip stack structure comprises: two chips, a protective layer on the active face of first chip to clad the second chip, and first conductive pole inserted in the protective layer to make one end connect with first joint point and another out of the protective layer, wherein the second chip is stacked on the first one, the back face of the second chip is toward the active face of the first chip. The second chip comprises a first joint point on its active face. The product is thin.

Owner:ADVANCED SEMICON ENG INC

A kind of ito through hole capacitive touch screen and its manufacturing method

ActiveCN102289334AStack structure optimizationImprove yieldInput/output processes for data processingCapacitanceIndium tin oxide

The invention discloses an indium tin oxide (ITO) through hole capacitance touch screen and a method for manufacturing the same. The ITO through hole capacitance touch screen comprises a decorative glass substrate, a capacitance functional substrate, an ITO electrode, a first insulating layer, an ITO through hole electrode, a metal electrode and a second insulating layer, wherein the capacitance functional substrate is overlapped on the decorative glass substrate by an optical adhesive layer; the ITO electrode, the first insulating layer, the ITO through hole electrode, the metal electrode and the second insulating layer are sequentially overlapped on the capacitance functional substrate; the ITO electrode comprises a capacitance screen driver (an ITO electrode 1) and an induction electrode (an ITO electrode 2), which are in a regular graphic structure; and the ITO electrode 1 and the ITO electrode 2 are on the same layer, independent of each other, insulated from each other, and vertically designed. By reasonably designing an overlapping structure of the capacitance touch screen and an ITO conduction mode, and by conducting ITO signal electrodes from up to down in an ITO through hole mode, the light transmission rate, operating stability and touch sensitivity of the capacitance touch screen are effectively improved.

Owner:SHENZHEN BAOMING TECH

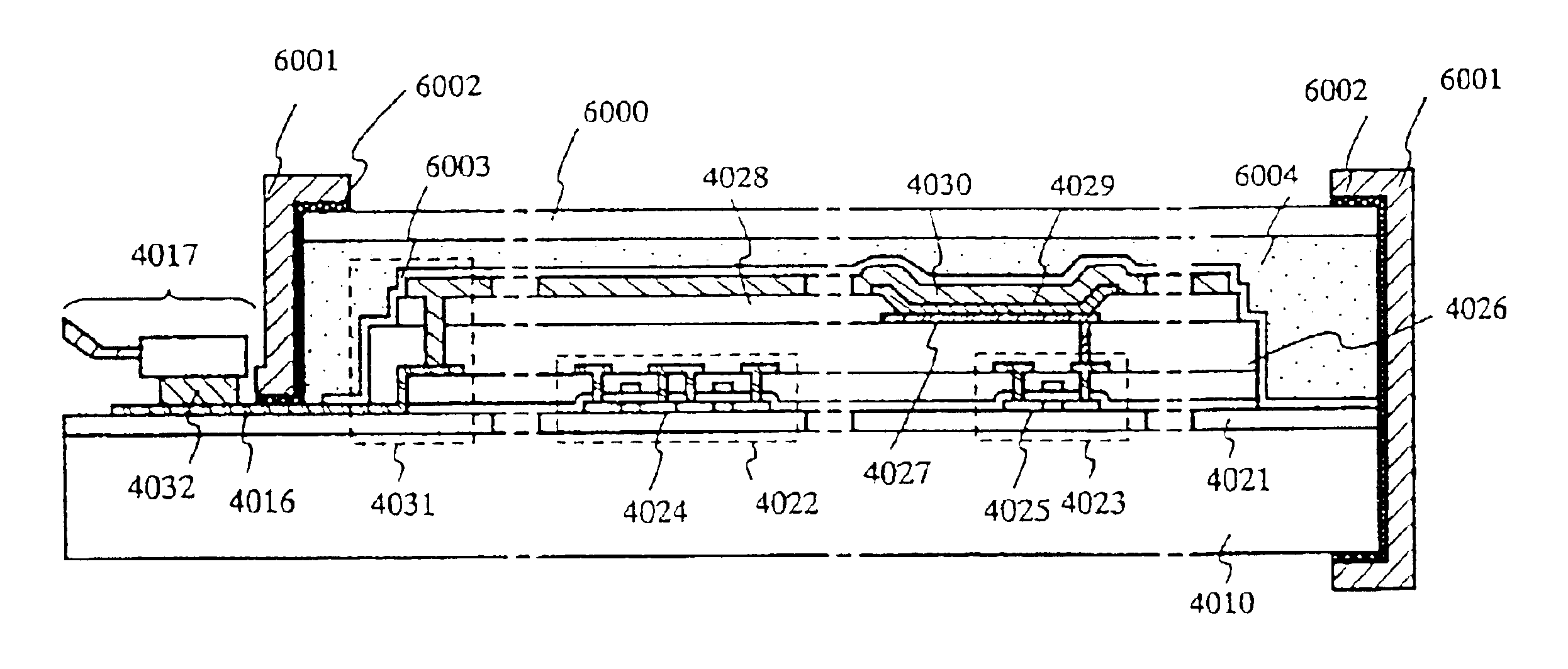

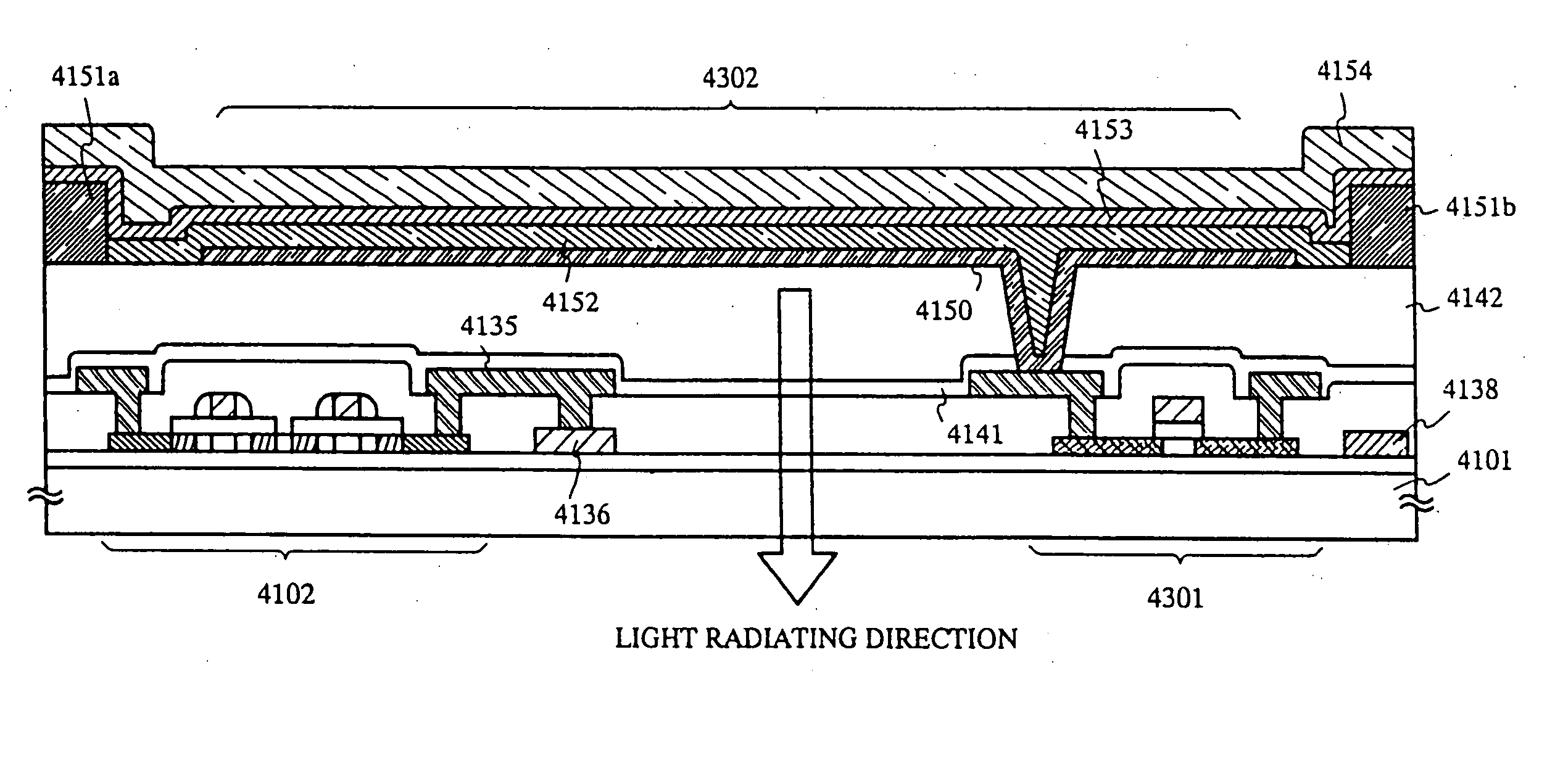

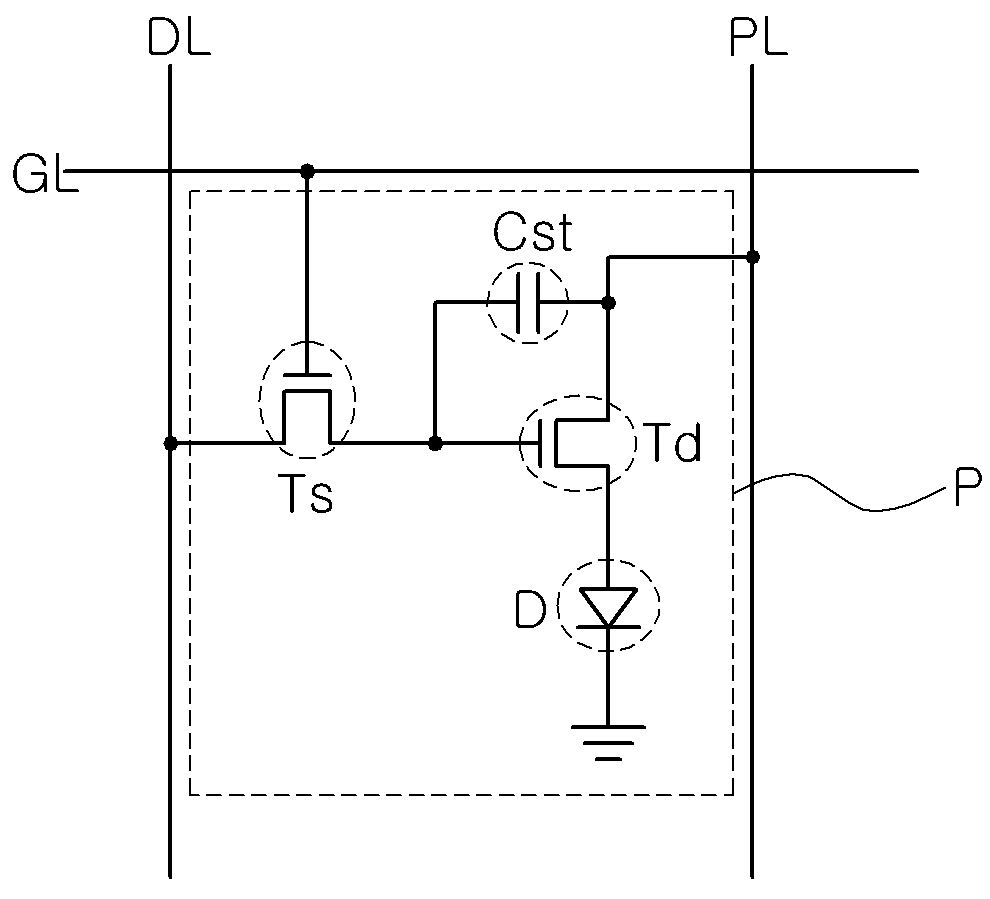

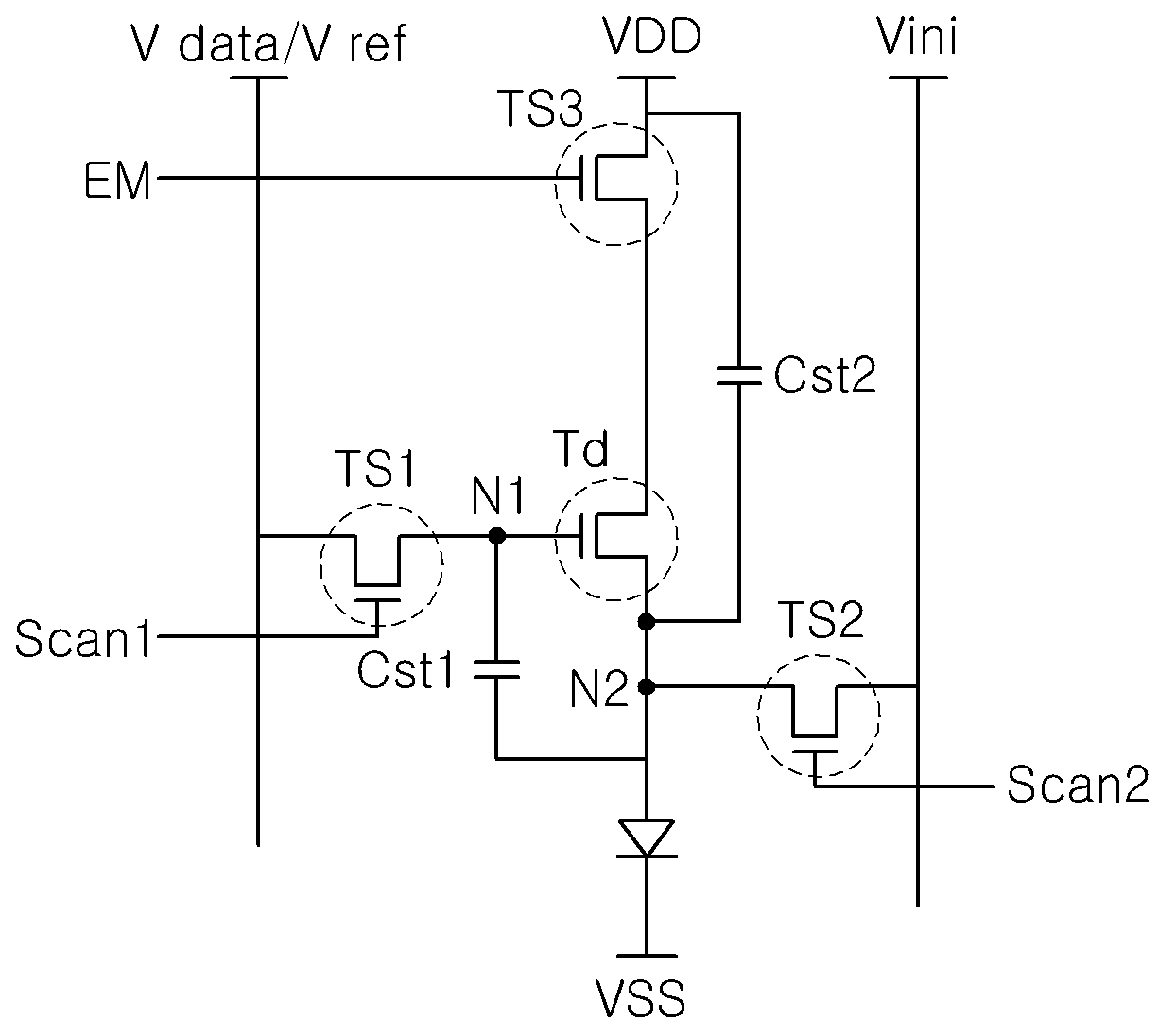

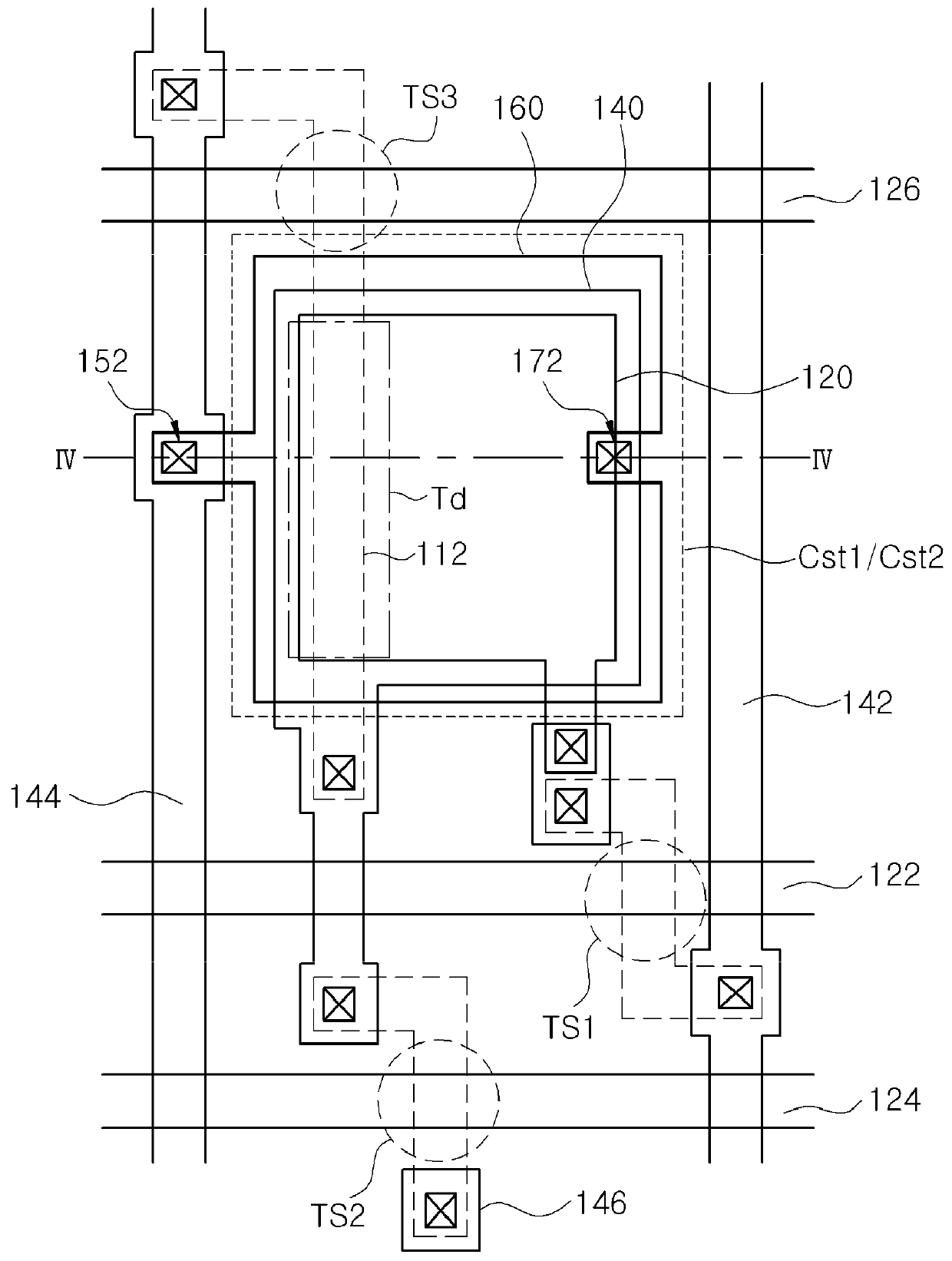

Electroluminescent display device

A display device includes a driving thin film transistor (TFT) having a two-gate overlap structure and a power line having a width extension structure that together allow for improved storage capacitance when compared to a display device without such structures.

Owner:LG DISPLAY CO LTD

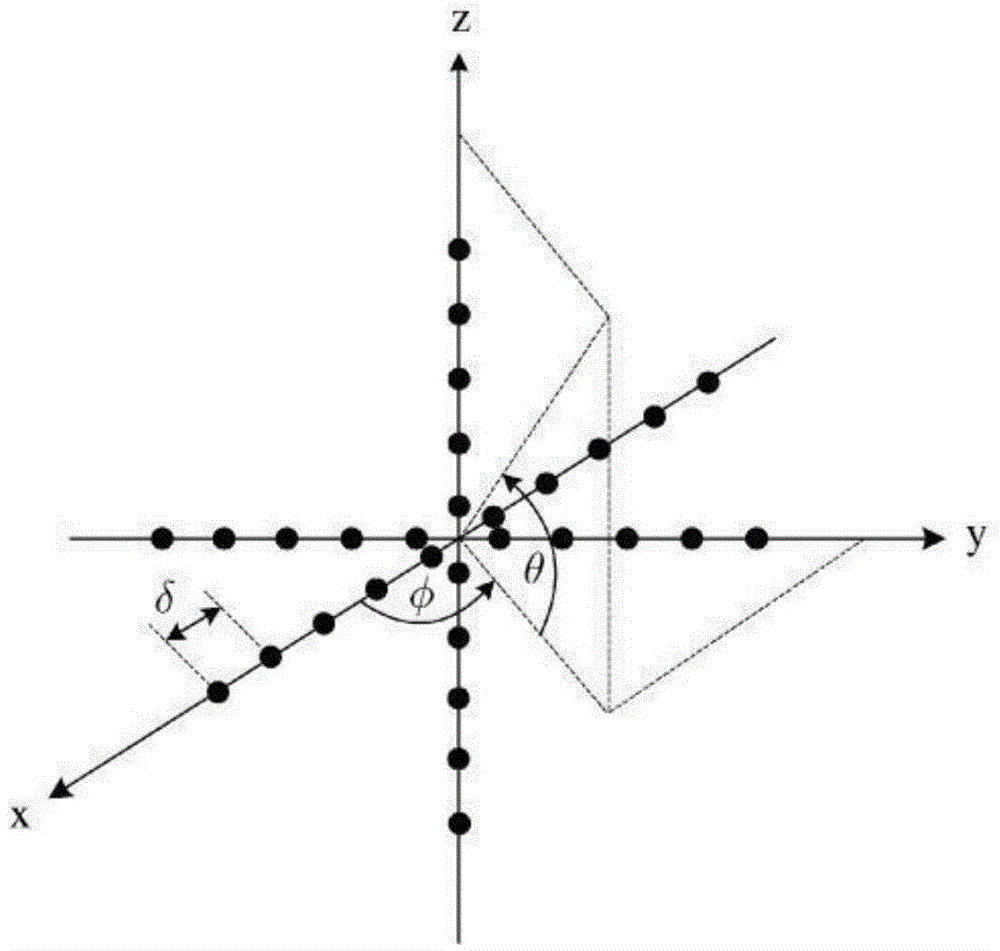

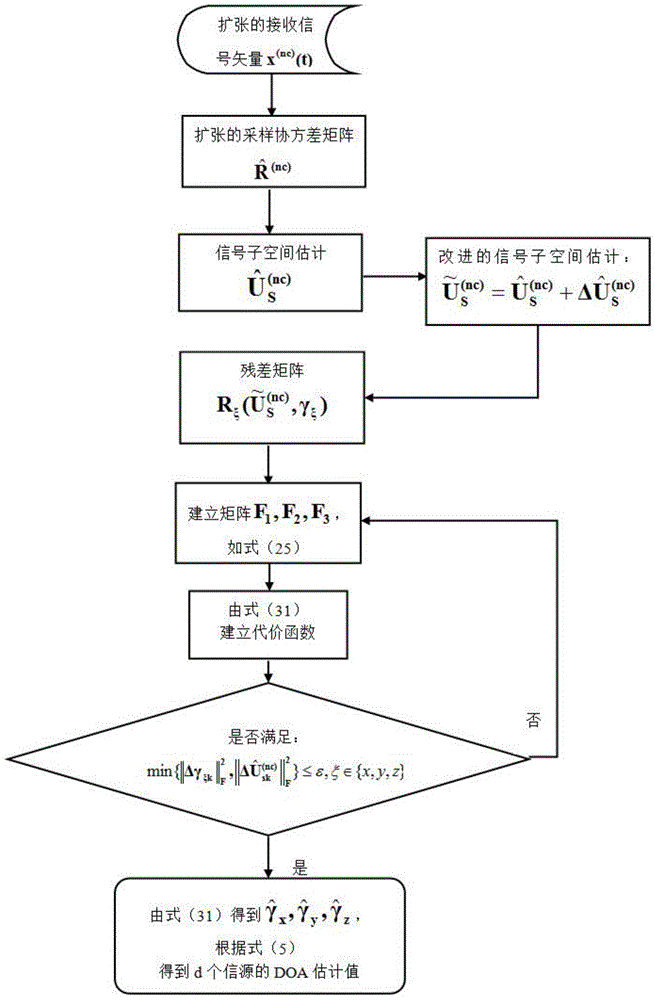

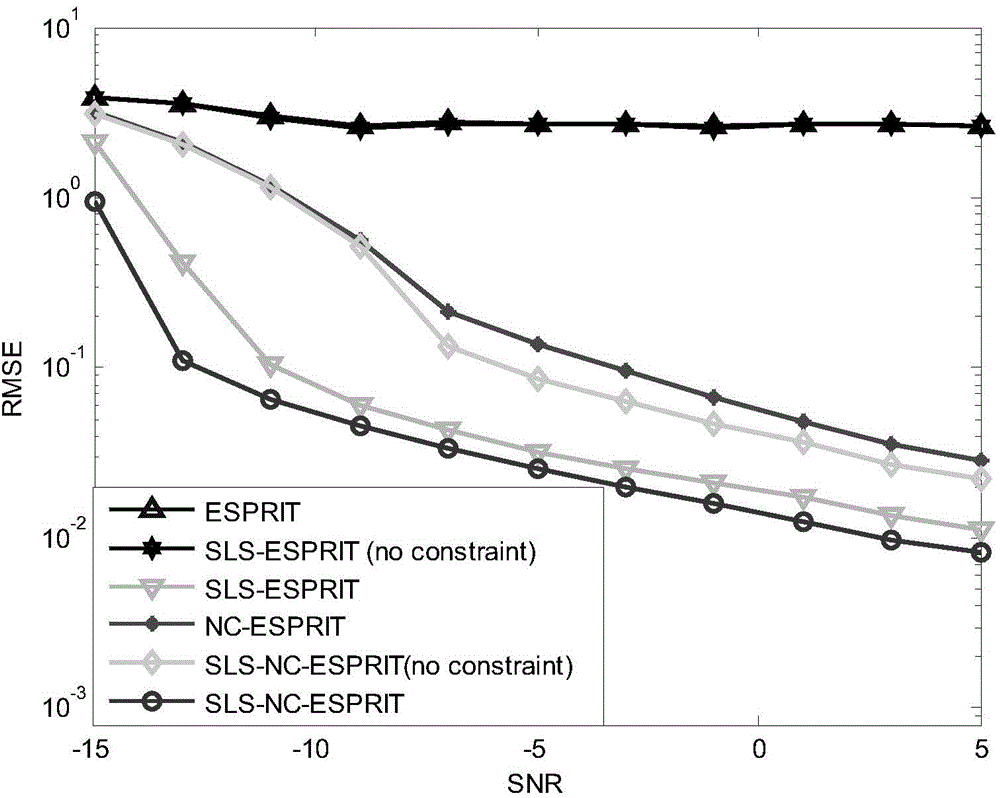

DOA estimation method of 3-axis cross array

ActiveCN104407335ATake advantage of non-circular propertiesGuaranteed validityRadio wave direction/deviation determination systemsAlgorithmVirtual space

The invention brings forward an SLS-NC-ESPRI algorithm based DOA estimation method of a 3-axis cross array, and is applied to estimation of the DOA of a strict second-order non-circular (NC) signal. Different from a conventional DOA estimation algorithm, the method brought forward by the invention has the following advantages: first of all, the by use of the NC characteristic of the signal, the virtual space of the array is expanded, the estimation precision is improved, and a detectable source number is enabled to be increased; secondly, the overlapping structure of sub-array configuration is utilized, the overlapping of signal subspace errors is taken into consideration, and shift-invariant equations in three cross array axes are effectively solved by use of a structure least square (SLS) method; and finally, through a mode of increasing constraint conditions, it is ensured that the three axial directions has approximately the same characteristic vectors, the rank defect problem introduced when arrival signals have the same projection at a certain axial direction is solved, the algorithmic validity is ensured, and a more accurate DOA estimated value is provided.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

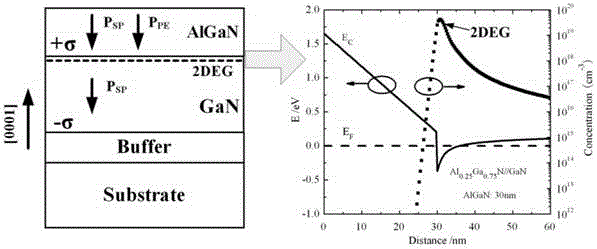

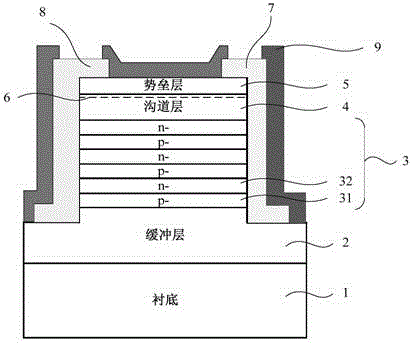

Schottky diode and manufacturing method thereof

ActiveCN104617160AIncrease concentrationImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesPower flowOhmic contact

The invention discloses a Schottky diode and a manufacturing method thereof. The Schottky diode comprises a substrate, a buffer layer, an extension structure, a Schottky contact metal and an Ohmic contact metal, wherein the substrate the buffer layer and the extension structure are sequentially arranged in an overlapped structure; the extension structure comprises a super bonding layer, a GaN channel layer and a barrier layer which are sequentially stacked, and the super bonding layer is composed of a plurality of p-type GaN layer and a plurality of n-type GaN layer which are alternately stacked each other; the Schottky contact metal and the Ohmic contact metal are symmetrically arranged on the opposite two side surfaces of the extension structure, one ends of the Schottky contact metal and the Ohmic contact metal extend to the upper surface of the extension structure, and the other ends of the Schottky contact metal and the Ohmic contact metal extend to the buffer layer. The Schottky diode has relatively high pressure resistance, ensures current transmission capacity and stability and avoids a traditional field plate structure or protecting ring structure, thereby simplifying the manufacturing process and reducing the cost.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com