Multilayer structure of SiC/SiC (silicon carbide) composite cladding tube and preparation method thereof

A technology of composite material layer and composite material tube, which is applied in the multilayer structure of SiC/SiC composite material cladding tube and its preparation field, can solve the problems of insufficient toughness and low thermal conductivity, and achieve avoidance of residual silicon and good toughness , Eliminate the effect of high temperature and high pressure sintering difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment is a multi-layer structure of SiC / SiC composite cladding tube and its preparation method, and the specific design is:

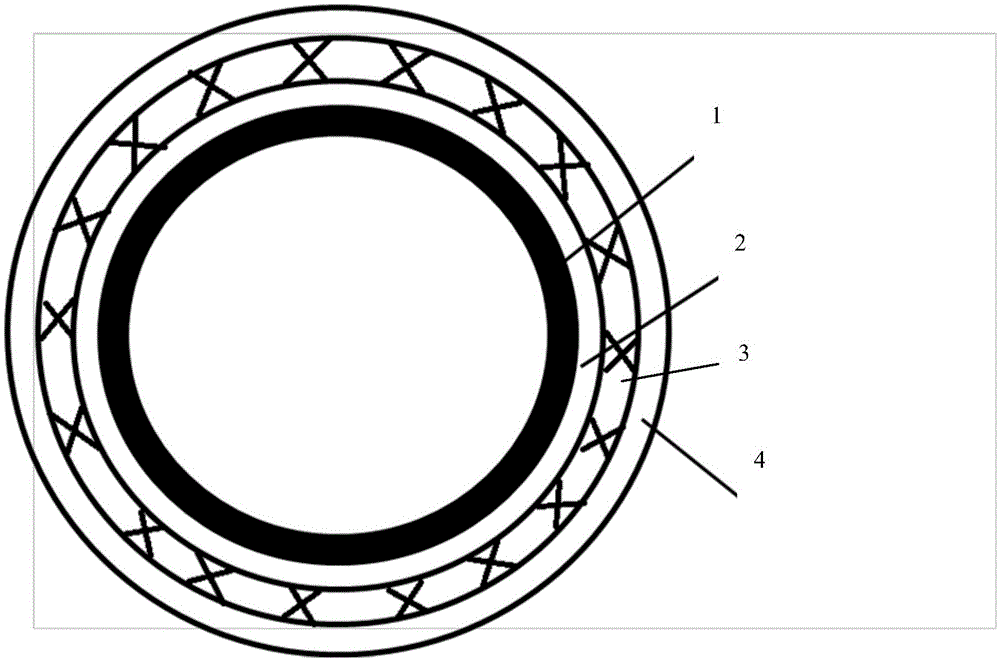

[0054] A three-layer structure of SiC / SiC composite material and its preparation method, comprising

[0055] The inner layer is SiC whisker toughened SiC composite material layer;

[0056] The middle layer is SiC f Toughened SiC composite layer;

[0057] The outer layer is SiC whisker toughened SiC composite material layer;

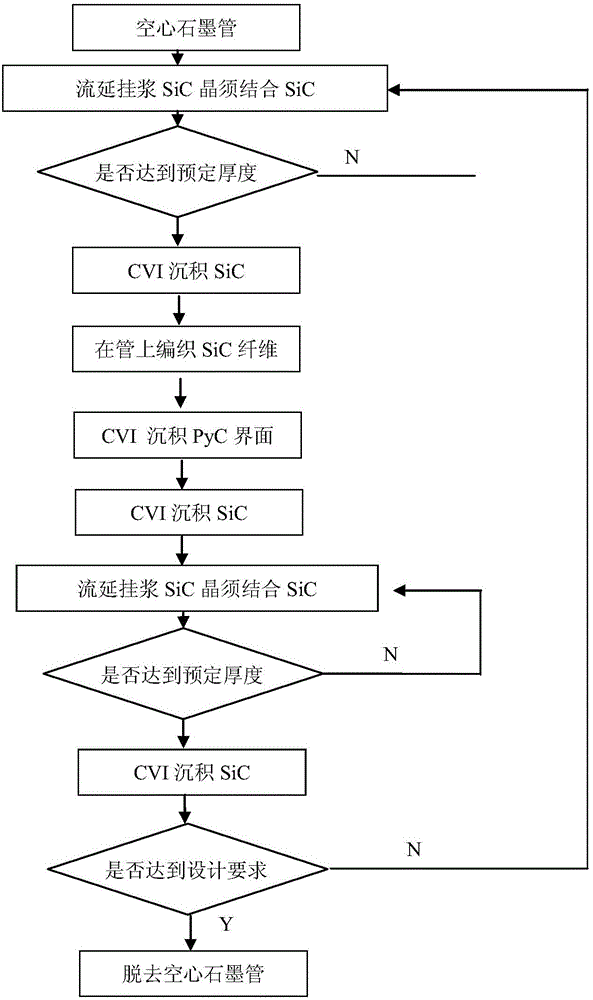

[0058] The specific preparation method of the three-layer structure of the SiC / SiC composite cladding tube is:

[0059] Step 1: Prepare the inner layer of the SiC whisker toughened SiC composite tube, the specific process is:

[0060] (a1) Using 40% alcohol as a solution, disperse the mixed powder formed by SiC whiskers and SiC particles, and dry it after dispersing; the dispersion is ultrasonic for 30 minutes, and magnetically stirred for 2 hours; the mixed powder The volume ratio of SiC whiskers and SiC part...

Embodiment 2

[0075] This embodiment is a method for preparing a multilayer structure of a SiC / SiC composite cladding tube, and the specific design is:

[0076] A four-layer structure of a SiC / SiC composite cladding tube, comprising

[0077] The innermost layer is SiC whisker toughened SiC composite material layer;

[0078] The second layer is SiC f Toughened SiC composite layer;

[0079] The third layer is SiC whisker toughened SiC composite material layer;

[0080] The outermost layer is SiC f Toughened SiC composite layer;

[0081] The specific preparation method of the four-layer structure of the SiC / SiC composite cladding tube is:

[0082] Step 1: Prepare the inner layer of the SiC whisker toughened SiC composite tube, the specific process is:

[0083] (a1) Using 50% alcohol as a solution, disperse the mixed powder formed by SiC whiskers and SiC particles, and dry after dispersion; the dispersion is ultrasonic for 40 minutes, and magnetically stirred for 2 hours; the mixed powder...

Embodiment 3

[0099] This embodiment is a method for preparing a three-layer structure of a SiC / SiC composite cladding tube, and the specific design is:

[0100] A three-layer structure of a SiC / SiC composite cladding tube, comprising

[0101] The inner layer is SiC whisker toughened SiC composite material layer;

[0102] The middle layer is SiC f Toughened SiC composite layer;

[0103] The outer layer is SiC whisker toughened SiC composite material layer;

[0104] The specific preparation method of the three-layer structure of the SiC / SiC composite cladding tube is:

[0105] Step 1: Prepare the inner layer of the SiC whisker toughened SiC composite tube, the specific process is:

[0106] (a1) Using 40% alcohol as a solution, disperse the mixed powder formed by SiC whiskers and SiC particles, and dry it after dispersing; the dispersion is ultrasonic for 30 minutes, and magnetically stirred for 2 hours; the mixed powder The volume ratio of SiC whiskers and SiC particles in the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com