Hybrid different board material high-frequency board manufacturing method

A production method and high-frequency board technology, which is applied in multi-layer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems of residual glue in slots, plate warping, expansion and shrinkage, and difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] When making a high-frequency board with mixed pressure of different boards for communication, the following steps are specifically adopted:

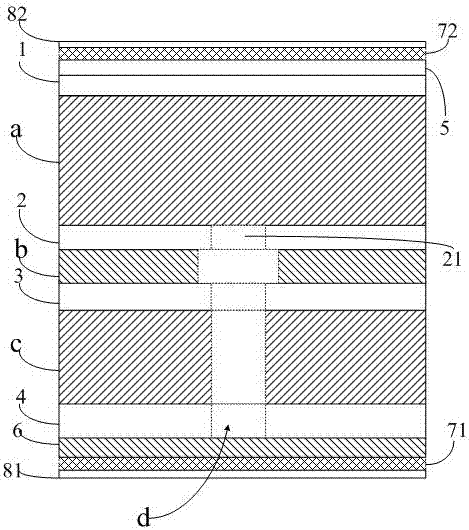

[0025] A. Choose a high-frequency board and an epoxy resin board. The two sides of the high-frequency board are respectively covered with L1 copper layer and L2 copper layer. The two sides of the epoxy resin board are respectively covered with L3 copper layer and L4 copper layer; the high-frequency board The material can choose hydrocarbon-based sheet material or ceramic-based sheet material or hydrocarbon-ceramic mixed-based sheet material; the epoxy resin board is preferably FR-4 board.

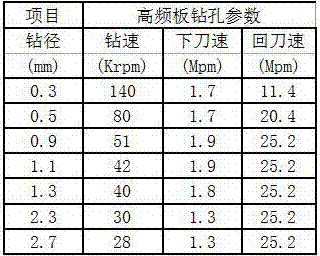

[0026] B. Cutting and drilling high-frequency sheet materials and epoxy resin sheets; A layer of al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com