Patents

Literature

253results about How to "Improve plating quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

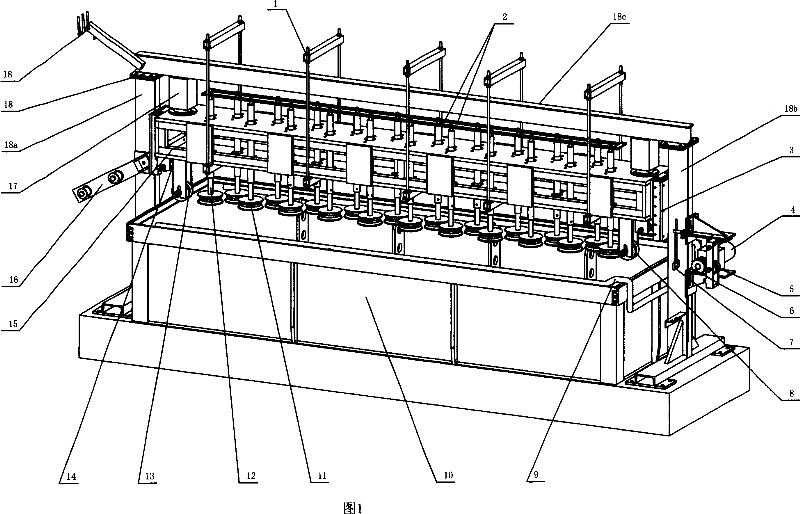

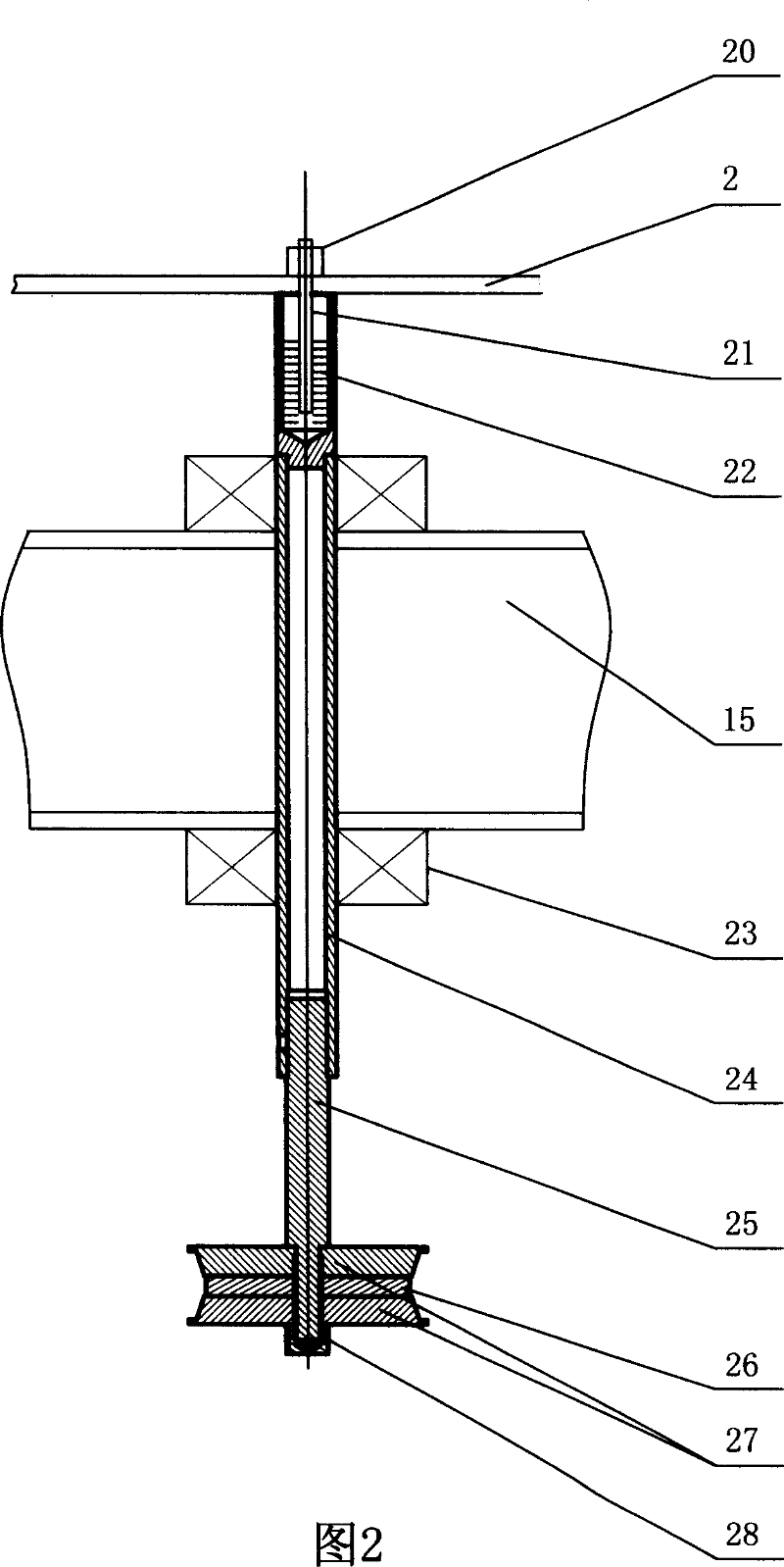

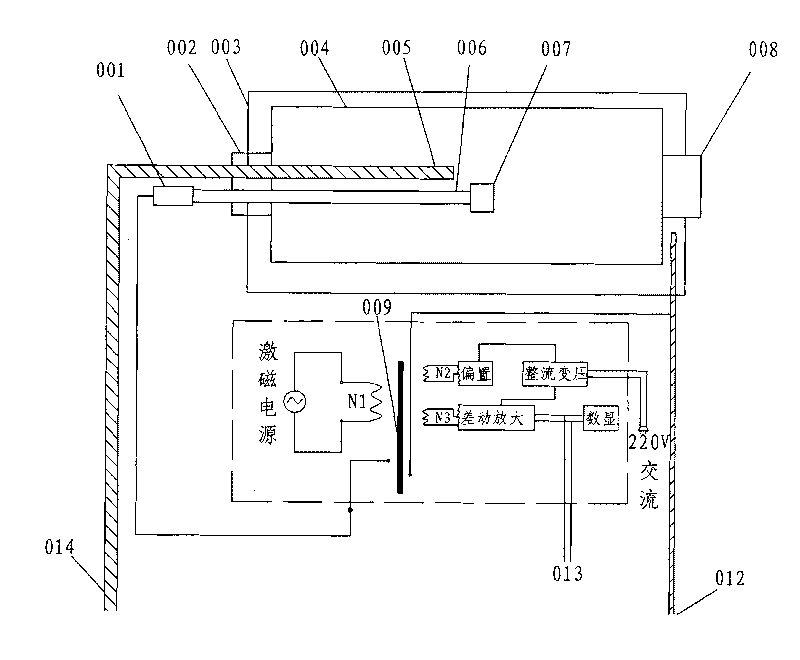

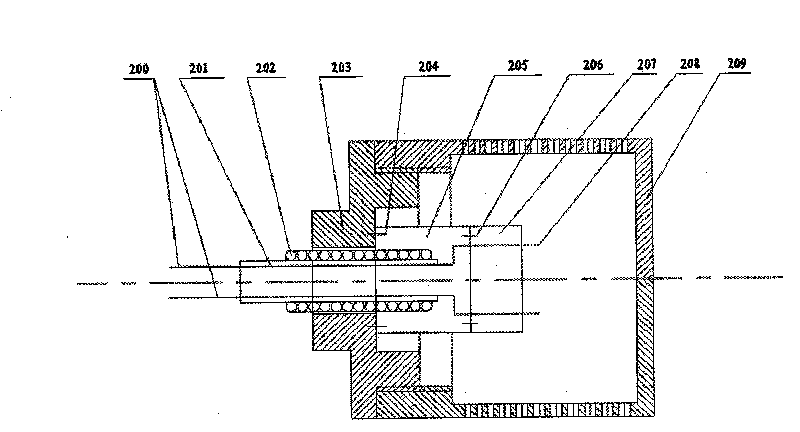

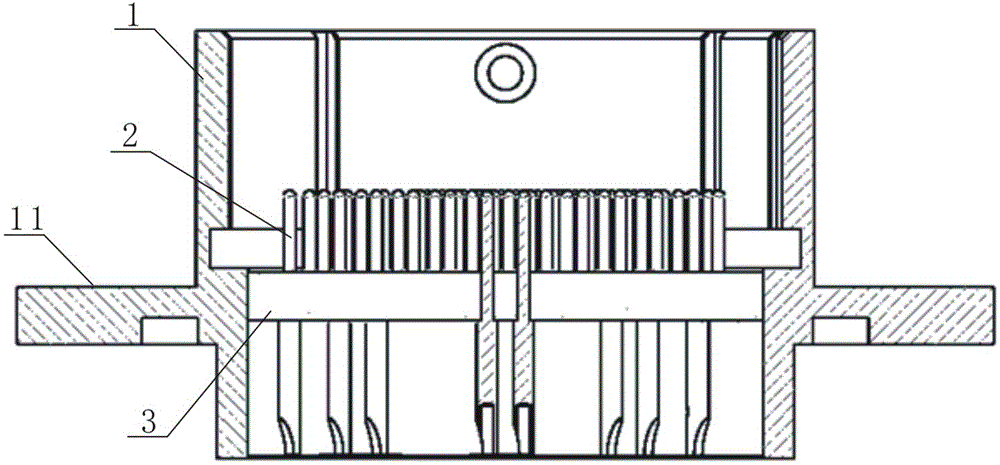

Zinc alloy slide fastener electroplating device

A zinc alloy zipper electroplating apparatus, belongs to the field of zipper electroplating technology. The apparatus includes groove body and frame mounted on top of it, the left and right sides of rotary tray frame is connected by matching oil cylinder with frame, a set of trolleys is mounted in order by roller shaft on the rotary tray frame, cathodic copper is connectted and mounted on top of roller shaft, anodic conductivity coil is mounted around groove body, zipper actuating mechanism comprising motor, action wheel and driven wheel is connected and mounted at right side of frame. Zipper serial transmission electroplating is performed by electroplating zinc alloy zipper and crossing zipper transmission mechanism overlapping trolley and corresponding zipper electric motor drive, and the production efficiency is evidently improved. The rational arrangement of cathode and anode can efficiently avoid the appearance of cathodic and anodic face on plating layer of zinc alloy zipper tooth, and the plating layer is uniform. At the same time, cathode can be efficiently preventing electroplate liquid being dissovled and the pollution of electroplate liquid can be efficiently avoid, using protecting apparatus with up and down cathode, prolonging service life of apparatus and reducing cost of production.

Owner:ZHEJIANG WEIXING IND DEV

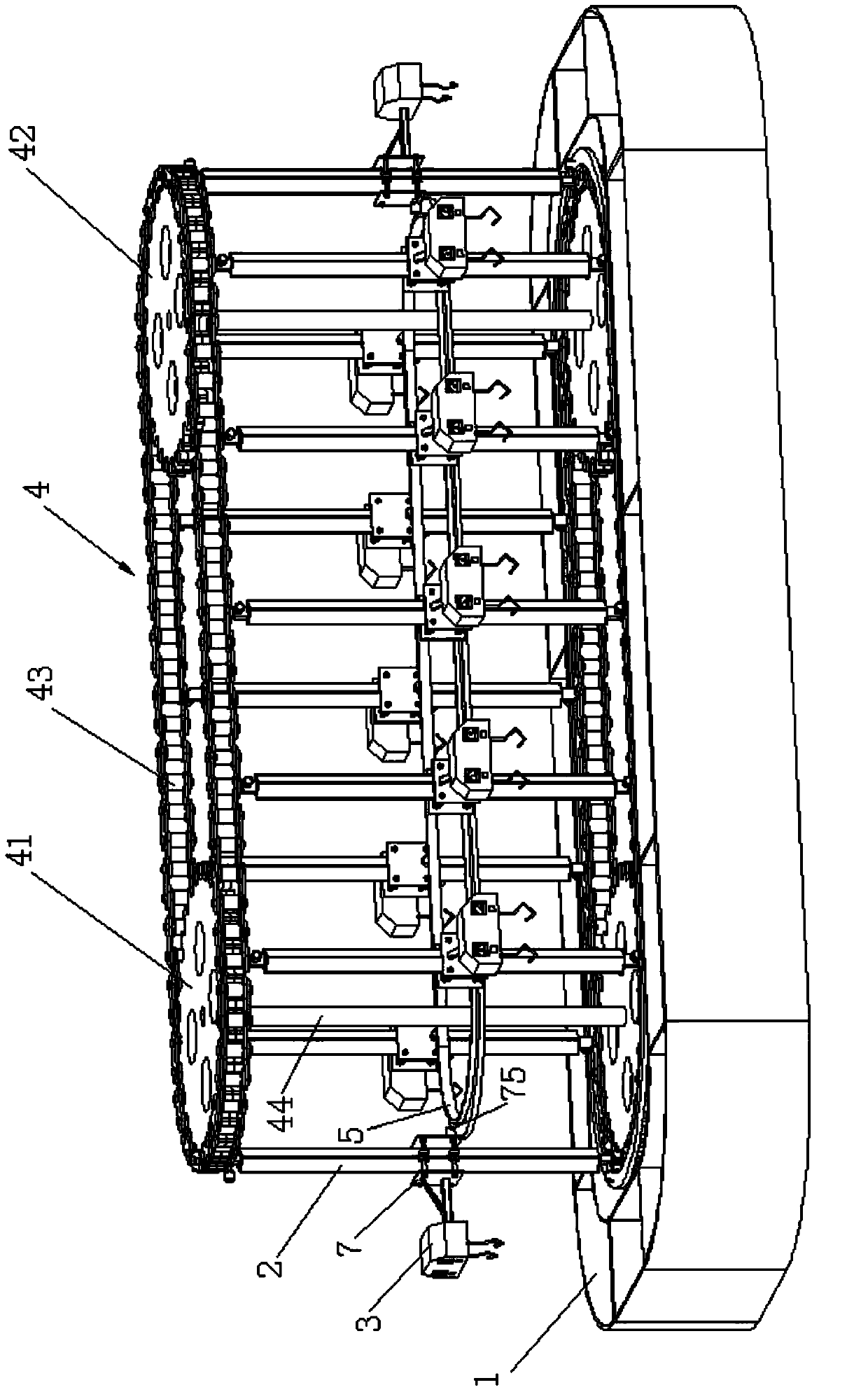

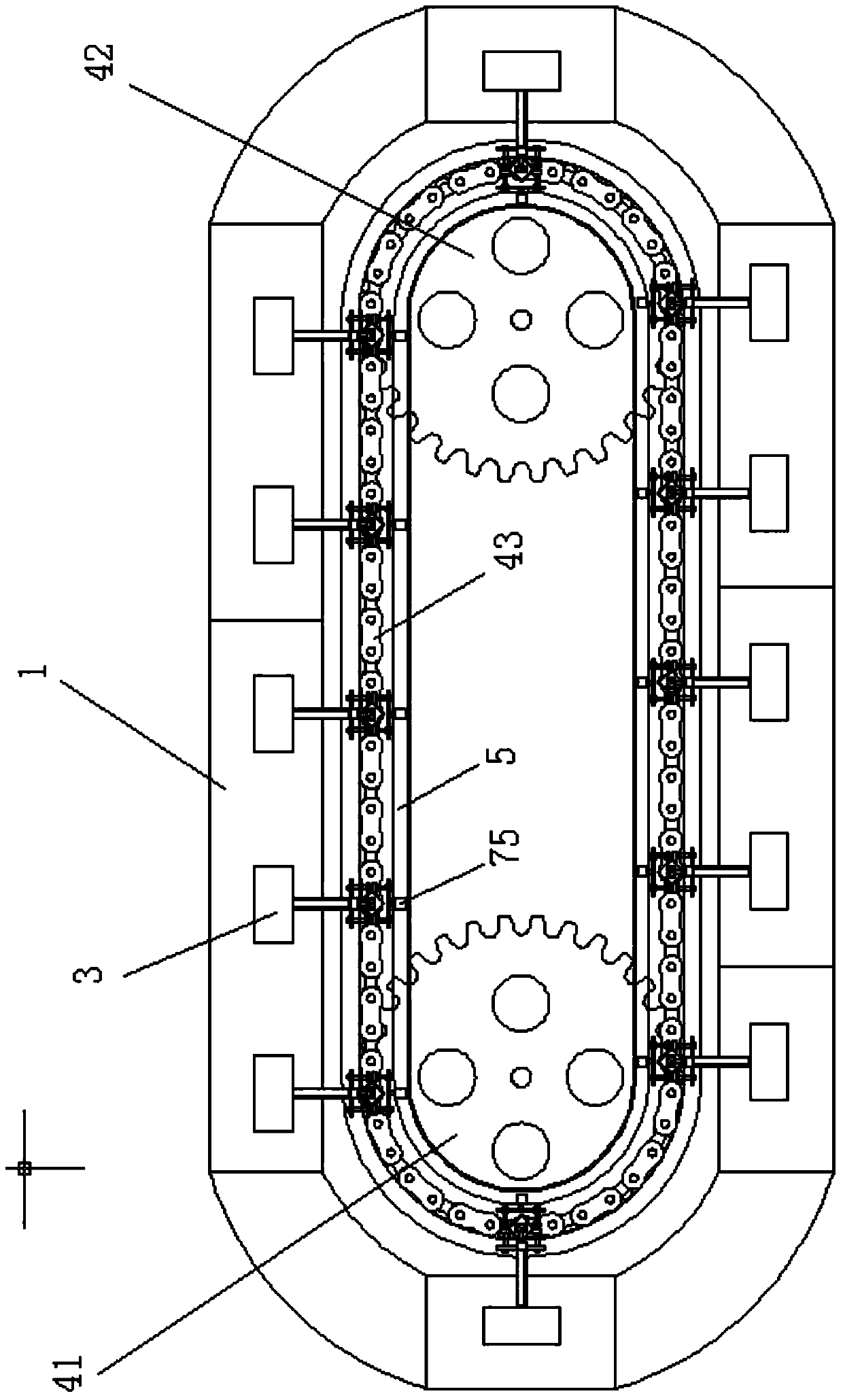

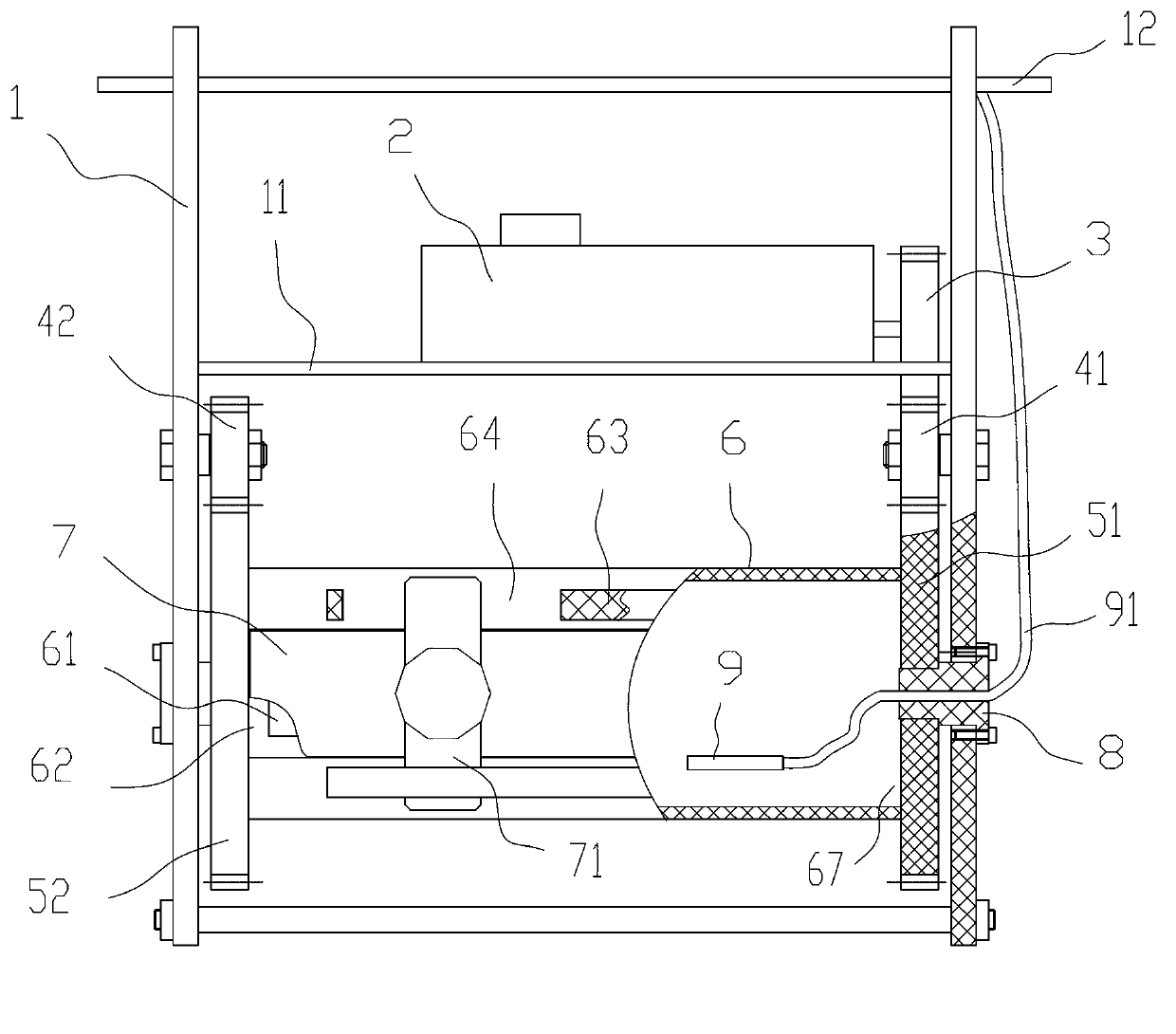

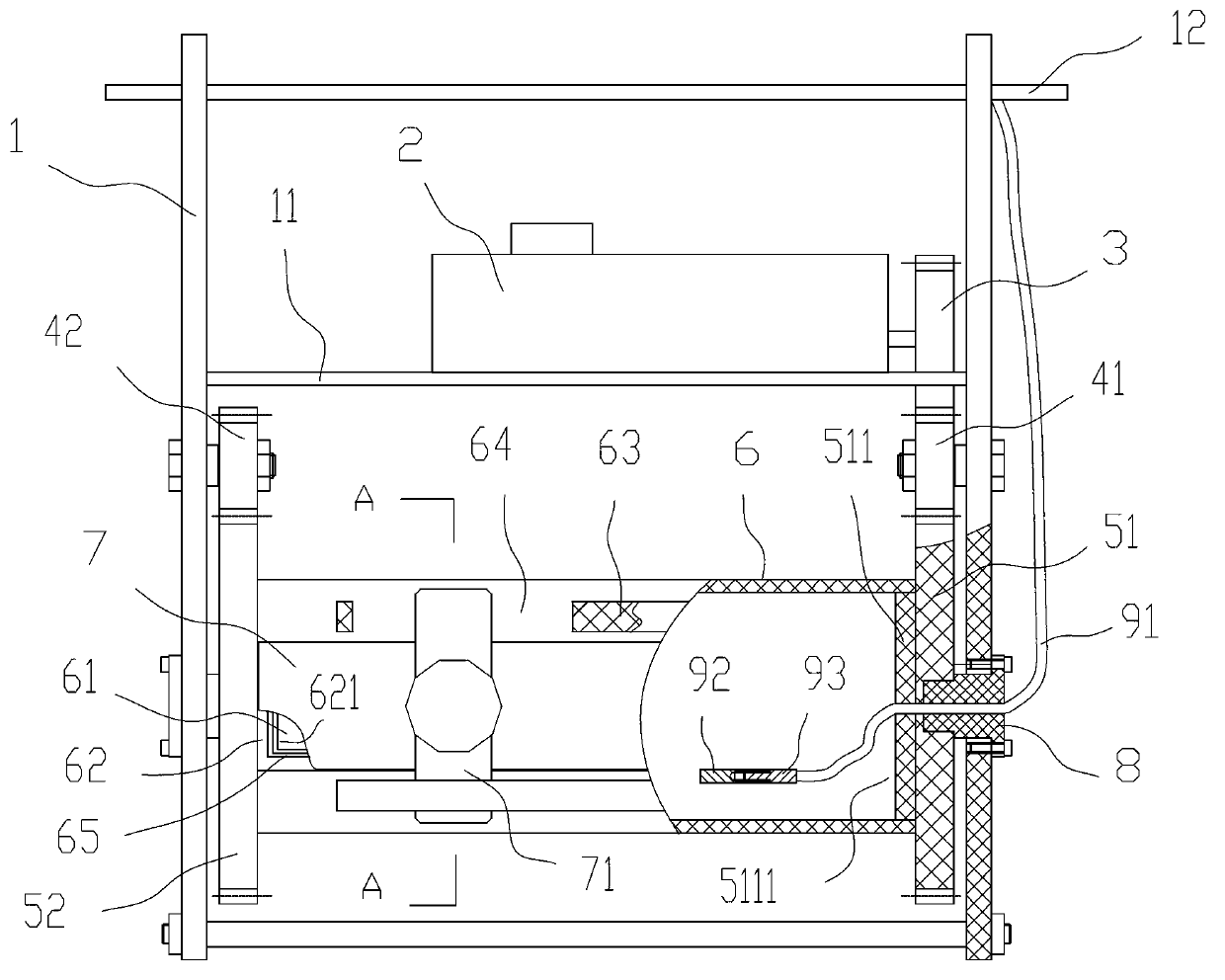

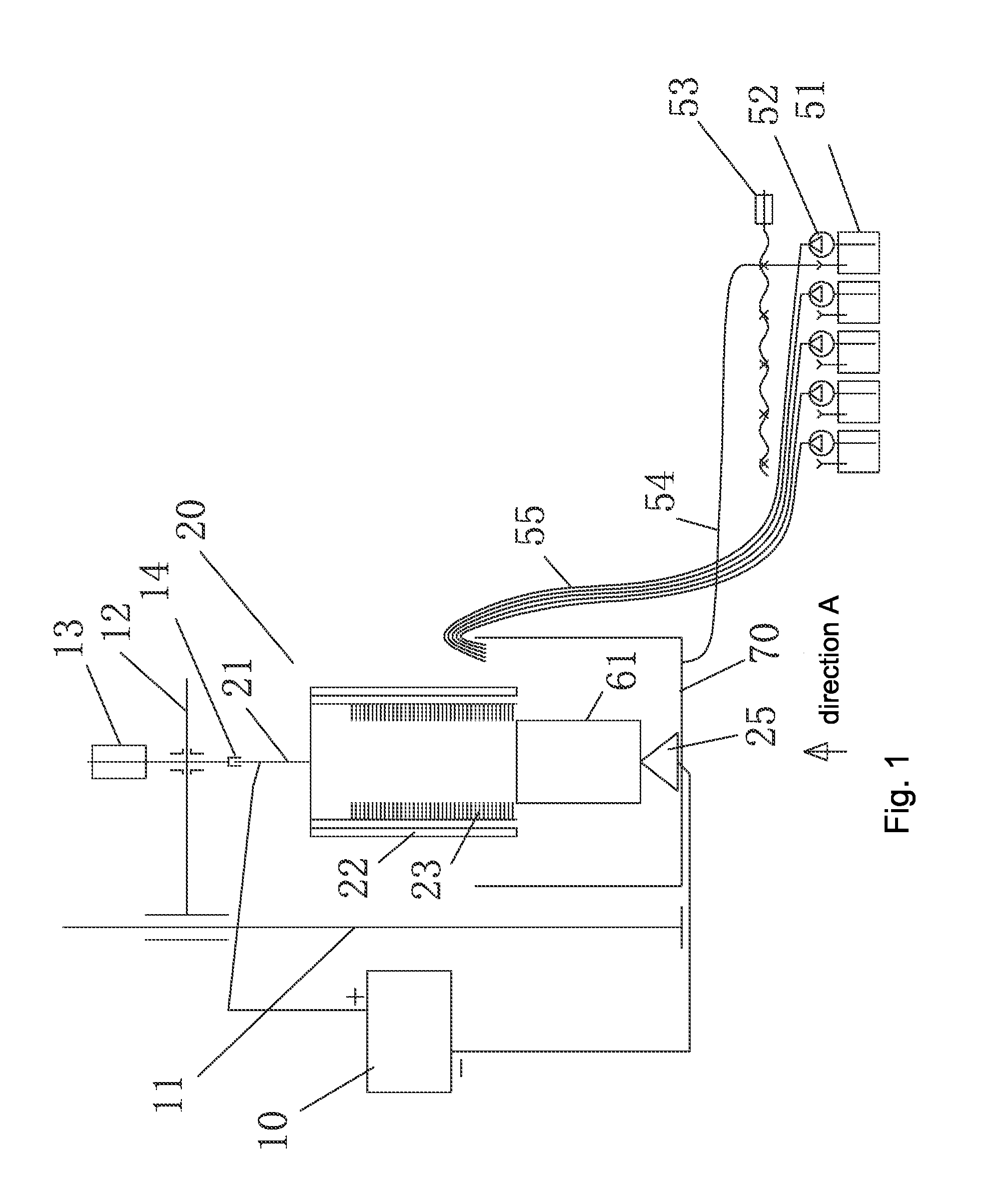

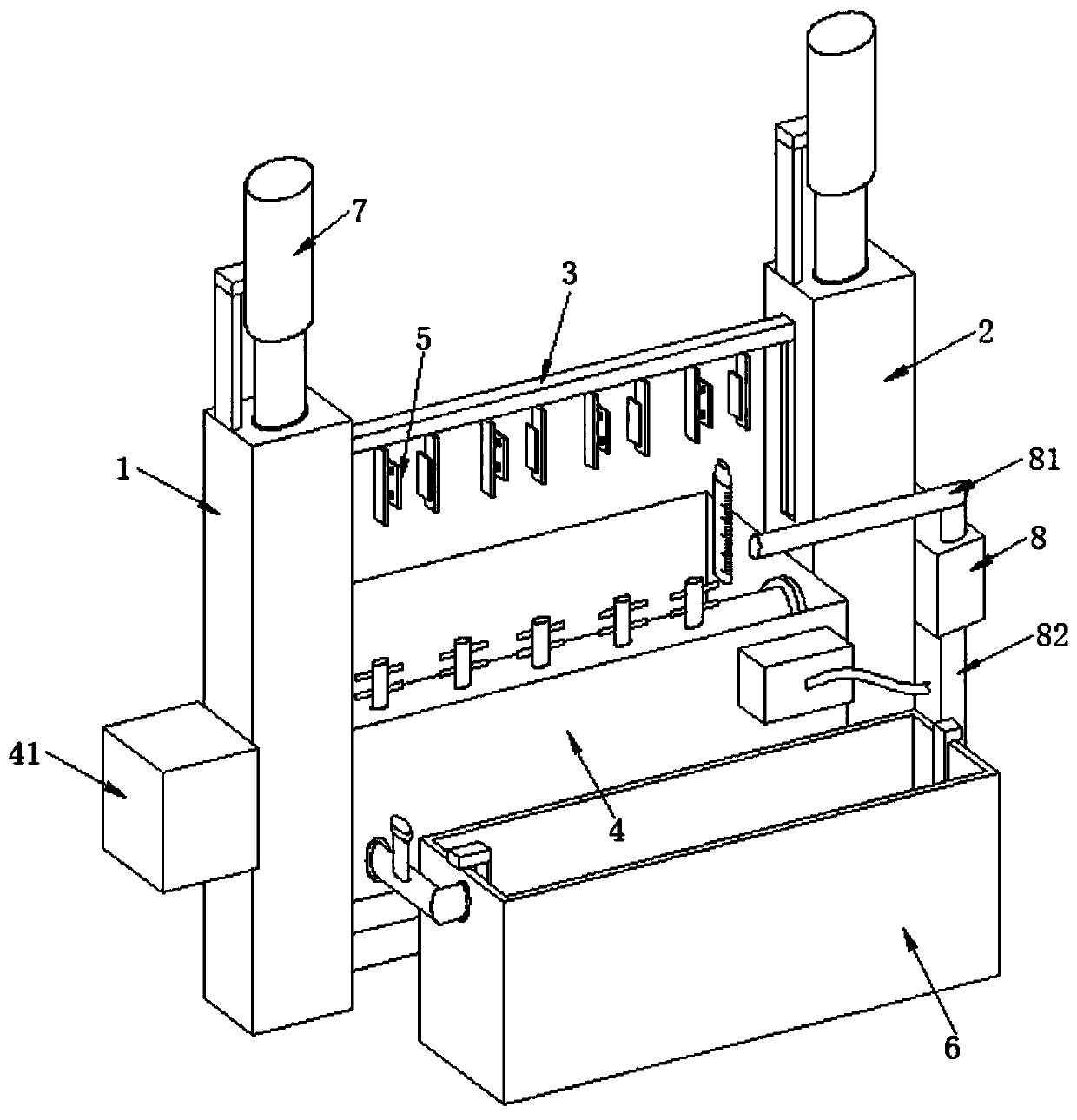

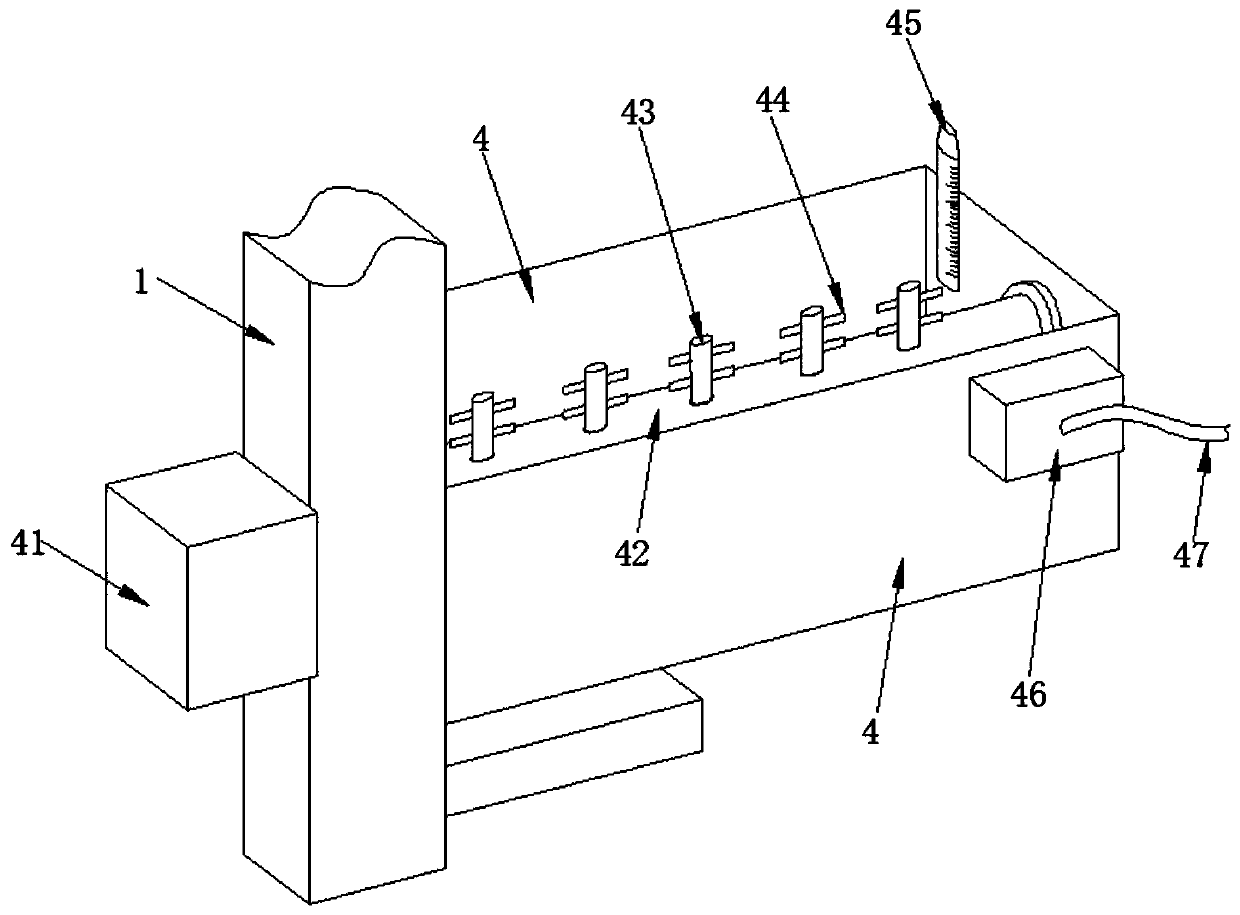

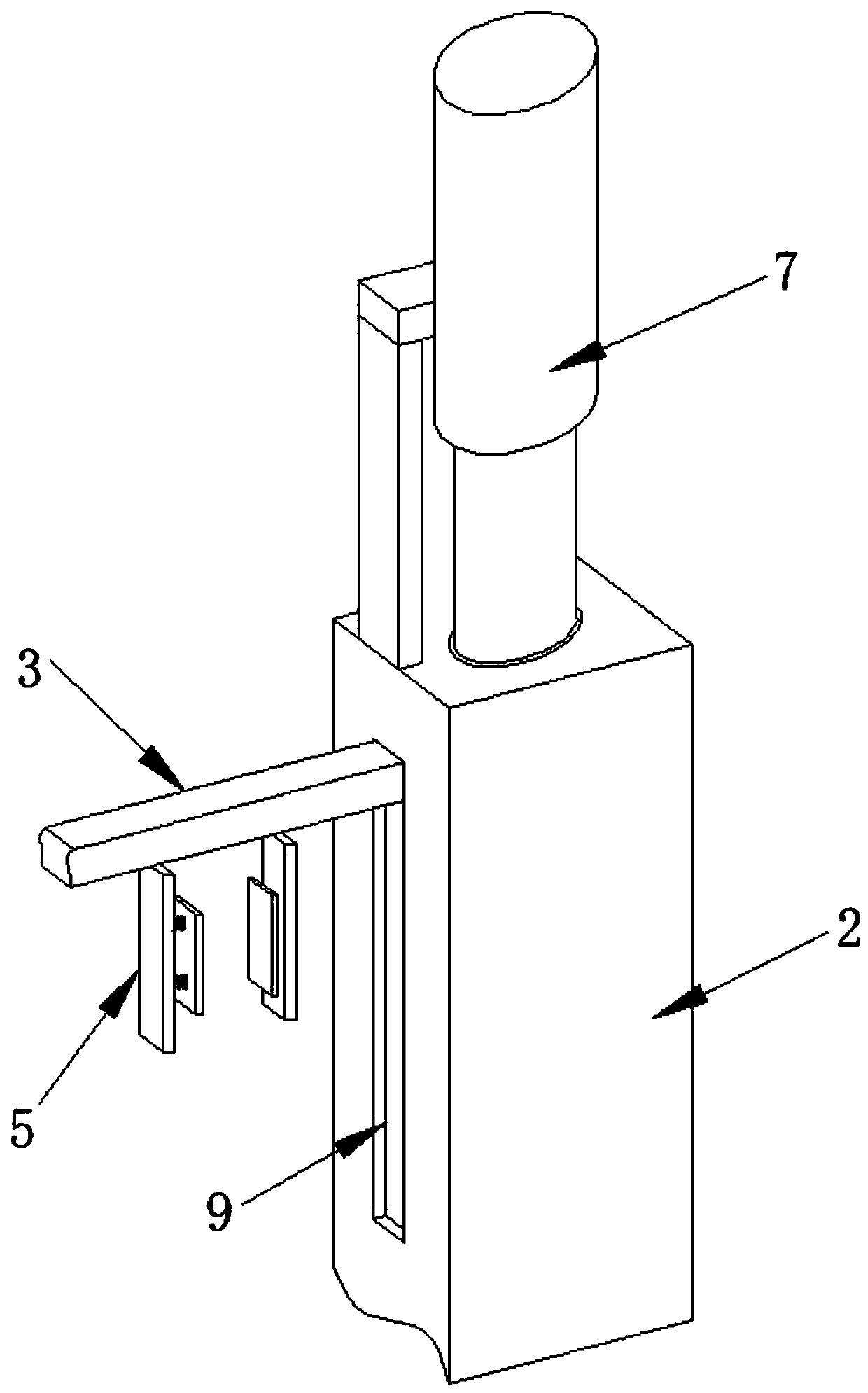

Automatic electroplating equipment for zipper head

ActiveCN103469270AImprove the quality of electroplatingImprove plating qualityCellsSlide fastenersControl systemEngineering

The invention provides automatic electroplating equipment of a zipper head. The equipment consists of electroplating grooves which are formed by a pre-electroplating treatment groove, an electroplating treatment groove and a post-electroplating treatment groove and are connected head-to-tail to form a closed ring, wherein an anode generator is installed on a vertical guide rail which is connected with a chain of a traveling device, the anode generator is further provided with an idler wheel which is placed on a horizontal circular track, and the circular track driven by a lifting device can ascend and descend. Under the effects of a control system, the traveling device and the lifting device, the anode generator intermittently travels on the circular track and circulates according to a sequence of ascending, traveling, descending and stopping. According to the invention, the zipper head is continuously electroplated through the automatic equipment, so that the electroplating production efficiency is greatly improved. Times of the steps are controlled through intelligent programs, so that the electroplating quality is high and the electroplating quality of the zipper head is enhanced. Meanwhile, the labor intensity of the workers is further reduced, and the field environment is improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Non-cyanogen high-density copper plating solution and Aluminium alloy wheel hub electroplating technique using same

The invention discloses a high density copper electroplating liquid without cyanogen and aluminum alloy boss electroplating craft, which is characterized by the following: allocating 250-400ml / l high density copper opening jar agent without cyanogen, 80-120 ml / l high density copper accelerant without cyanogen, 0-5 ml / l high density copper additive without cyanogen and surplus as water; adjusting pH value at 9. 2-10. 0; getting the electroplating liquid; adding following steps between twice depositing zinc step and acid bright coppering step; pre-coating the high density copper without cyanogen; petting the aluminum alloy boss into high density coppering liquid without cyanogen; electroplating; thick-plating; putting the aluminum alloy boss into thick coating liquid; proceeding thick electroplating. This craft can decrease cost and modify electroplating quality.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

Terpene ether developing solvent for photopolymerizable printing plates

InactiveUS6897008B1Low toxicityEasy to useSemiconductor/solid-state device manufacturingPhotosensitive material processingNon solventEther

Flexographic printing plates are produced by exposing the photopolymer plates to a light source and washing out (developing) the masked out, non-exposed areas with a solvent. The invention provides terpene ether solvents suitable for use in the development of photopolymer printing plates. The solvents, which include terpene ethers alone or mixed with co-solvents and / or non-solvents, are effective in developing a large number of different photopolymer printing plates and can produce images superior to those obtained with commercially available solvents currently used in such applications.

Owner:MIRACLON CORP

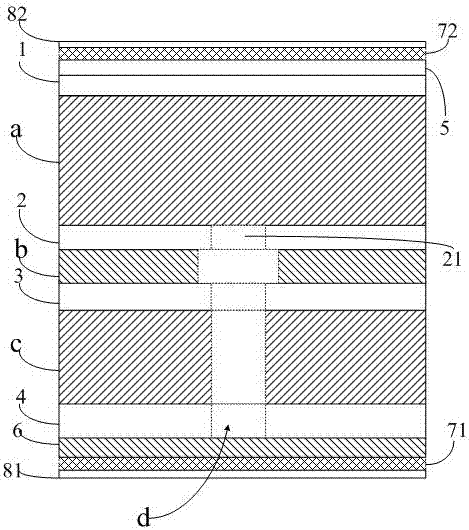

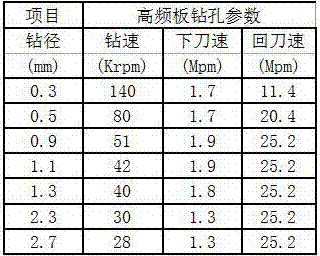

Hybrid different board material high-frequency board manufacturing method

ActiveCN107278062AAvoid bendingSolve the problem of overflow glueMultilayer circuit manufactureEpoxyProcess quality

The invention provides a hybrid different board material high-frequency board manufacturing method. A double-face copper-plated high-frequency board material and an epoxy resin board are employed for manufacturing, a non-flowing glue PP plate is utilized as a stitching medium of the high-frequency board material and the epoxy resin board, dimensions of a groove hole on the non-flowing glue PP plate are specially designed to solve a groove hole glue spilling problem, processing quality of products is improved, moreover, the overlapping process for drilling is further specially designed for the high-frequency board material, for a board material sinking problem of the high-frequency board material during stitching after grooving, a stitching overlapped structure is especially designed, a three-in-one buffer pad is employed to solve the grooving-side board material sinking problem, a hot pressing program is designed according to the stitching overlapped structure, the cold press time is further prolonged to further reduce a board bending problem caused by different expansion coefficients of different board materials, the high-frequency board material contains fillers which are not easily removed in a chemical glue removal mode, before electroplating, plasma glue removal is firstly carried out, chemical glue removal is then carried out, and complete cleaning is carried out to effectively improve electroplating quality.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

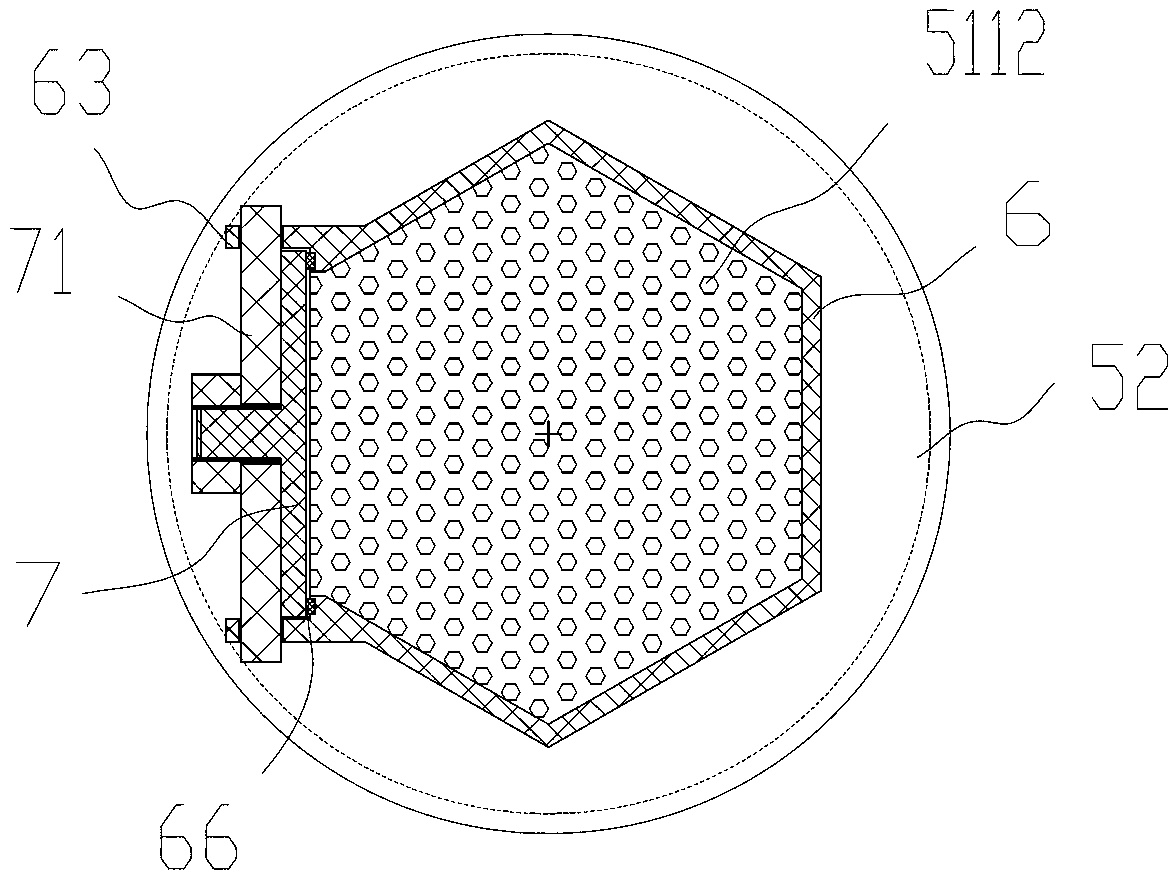

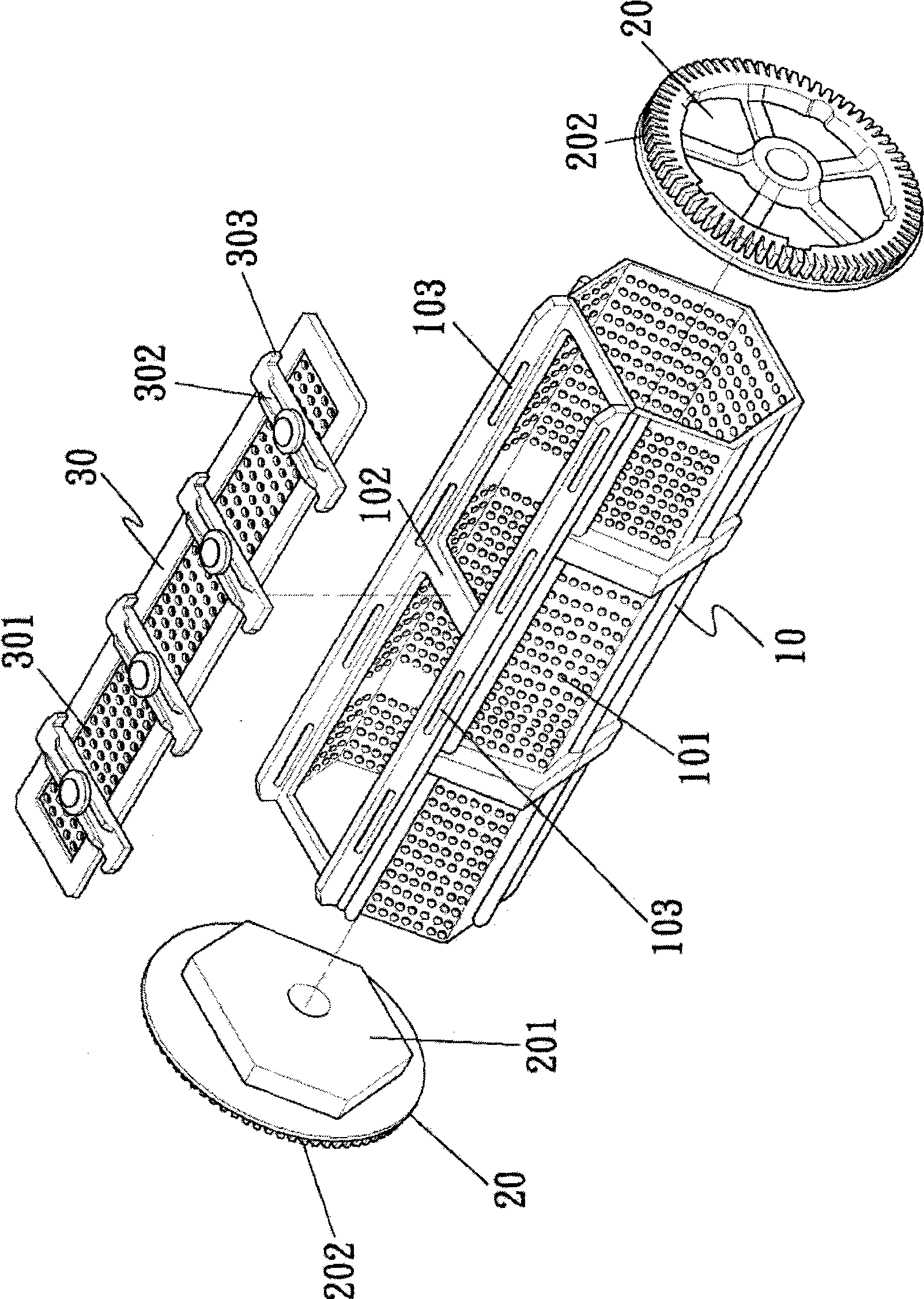

Electroplating roller for sheet parts

The invention relates to an electroplating roller for sheet parts, which comprises a holder, a roller and a driving motor. The roller is composed of a cylinder and gear disks which are arranged on two ends of the cylinder, wherein the cross section of the cylinder is hexagonal, an entrance for putting the plated objects and an dodge gate installed in the position of the entrance are arranged on one side wall of the cylinder, and ladder doorframes which are fitted with the edge of the dodge door are arranged on the periphery of the entrance; and projections which stretch away into the inner cavity of the cylinder are arranged on the inner side of the gear disks, the end face of the projection and the side wall of the doorframe on the same side are located in the same plane, bulges are evenly distributed on the end face of the projection, and the spacing distance between the adjacent bulges is less than the width of the sheet parts. According to the invention, a dead angle does not exist on two ends of the doorframe of the cylinder, the plated objects of the sheet parts cannot be adsorbed by the end faces, the coating is uniform, the electroplating quality of the product is good, simultaneously the discharging of the product is convenient, and work efficiency is high.

Owner:安徽晶赛科技股份有限公司

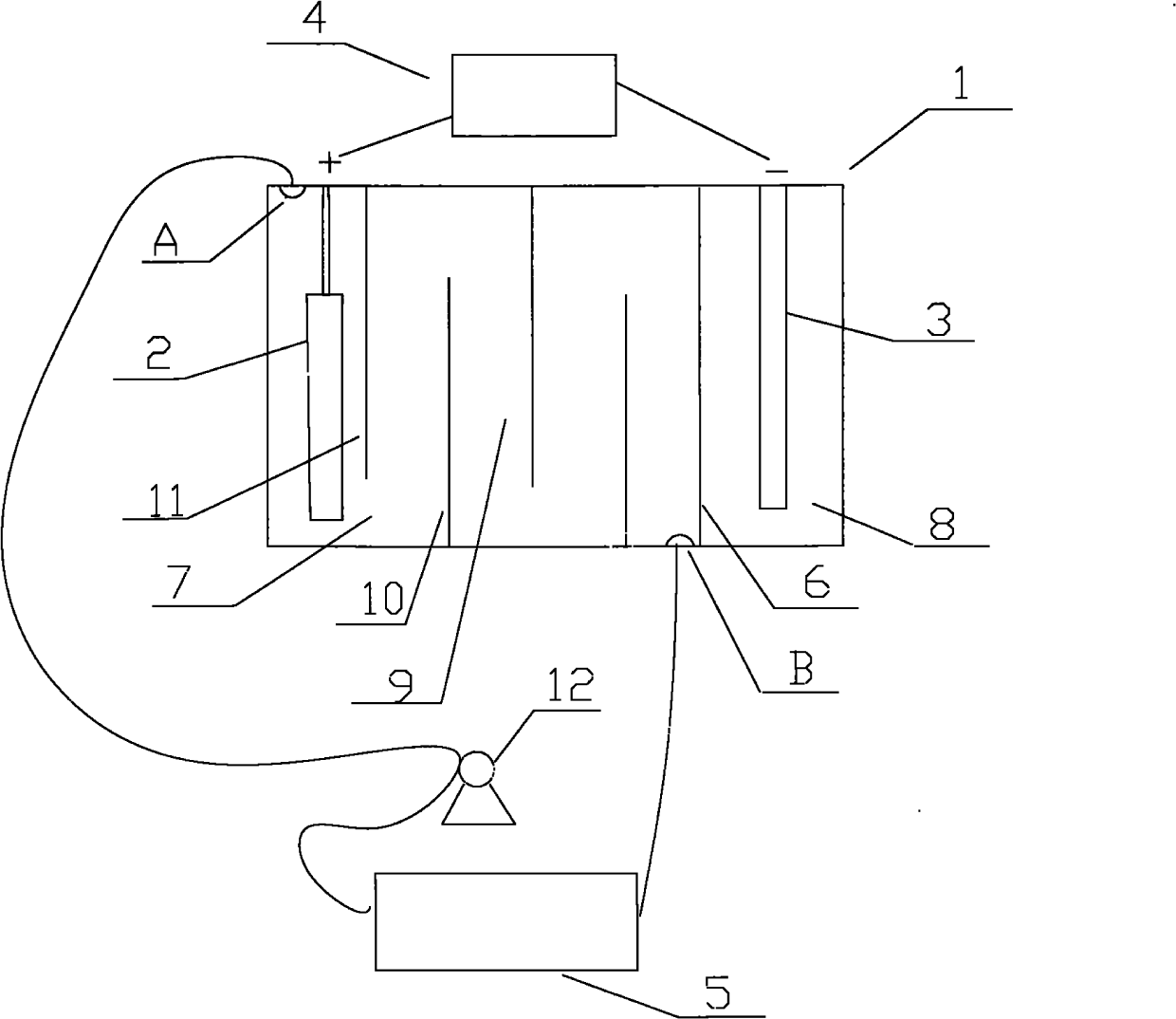

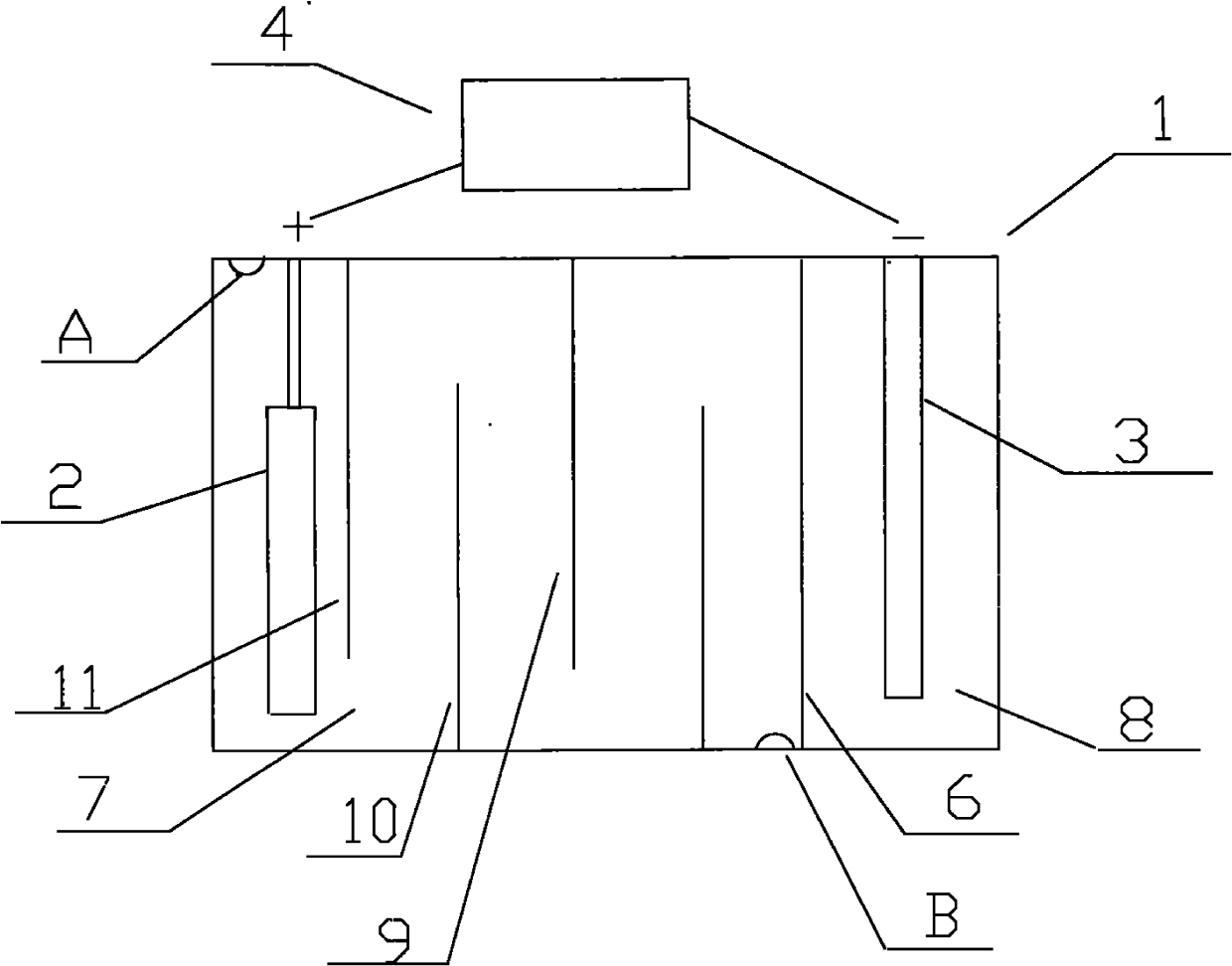

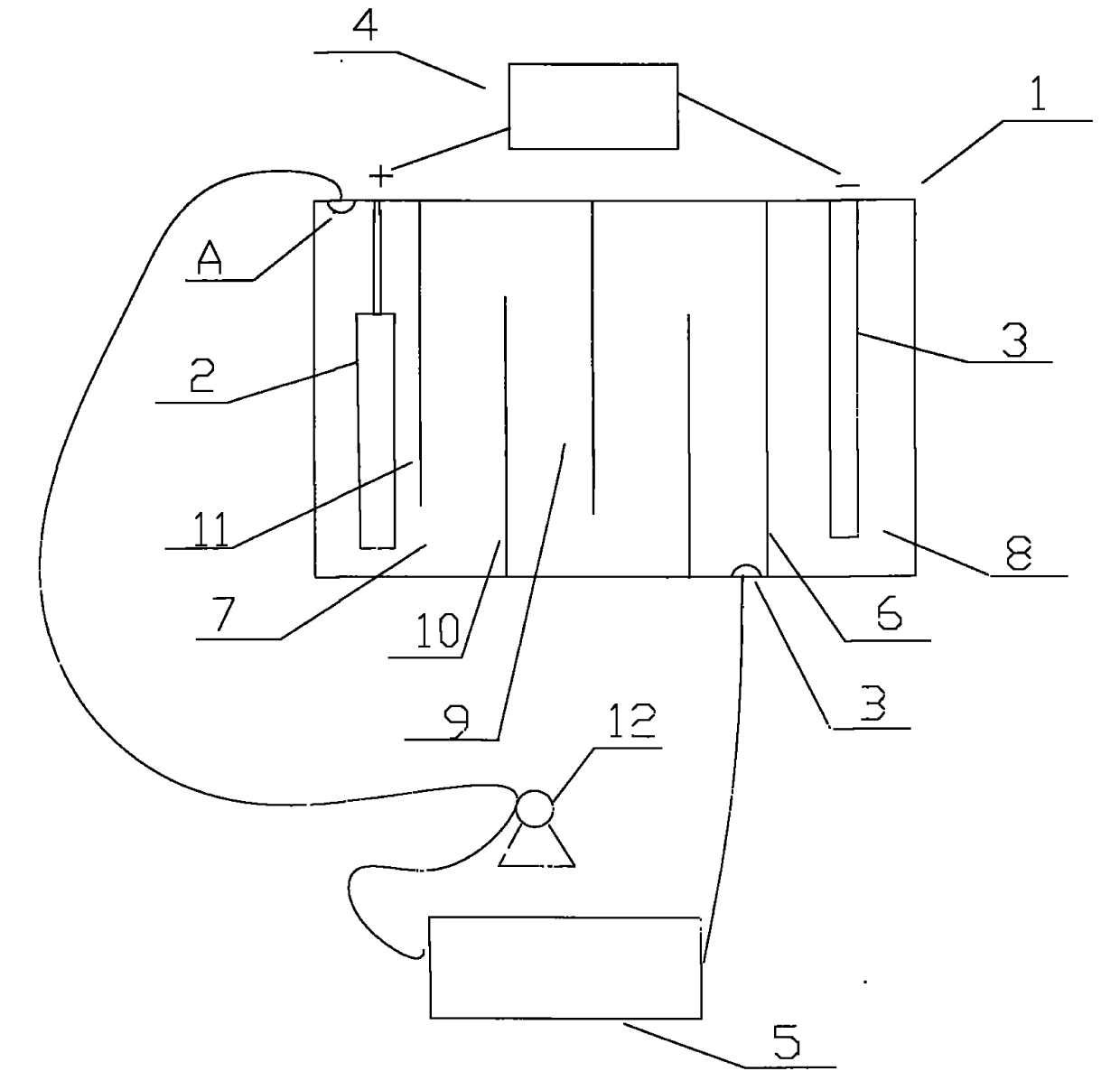

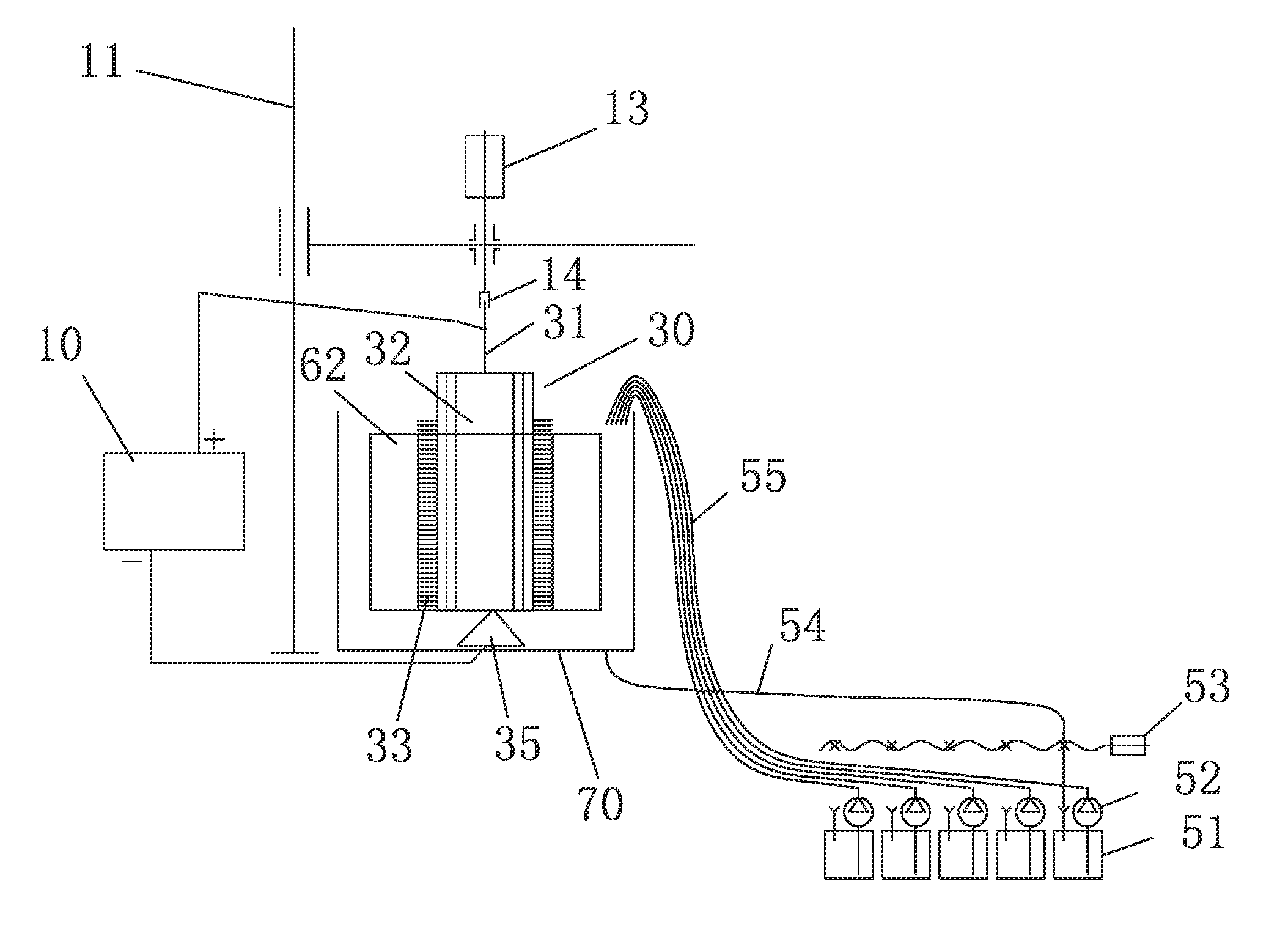

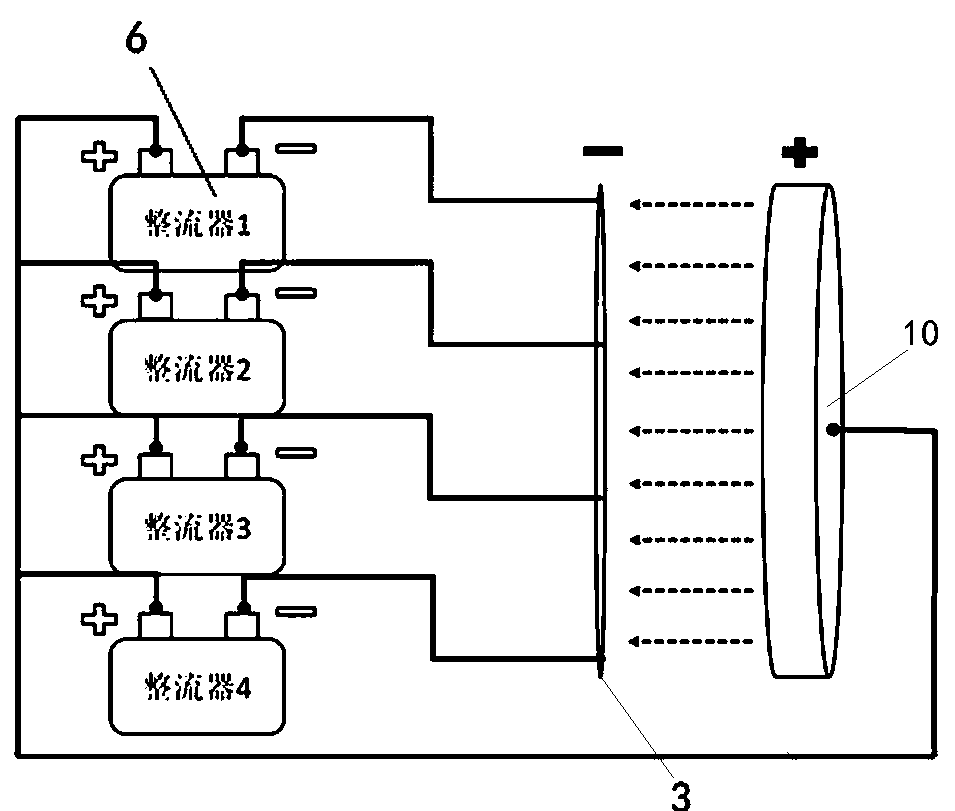

Method for sustainably complementing metallic cations in plating solution

The invention discloses a method for sustainably complementing metallic cations in plating solution. In the process of plating, the plating solution in a plating device is delivered into a cation generator; the cation generator can generate coated metal cations during working; the plating solution containing the metal cations is delivered back to the plating device; and the steps are circulated so as to complement the metallic cations consumed in the plating solution of the plating device. The method can sustainably complement the metallic cations consumed in the plating solution, so as to avoid pouring the plating solution lacking the cations and preparing new plating solution again. By the method, the plating solution can be continuously used, the service life of the plating solution is prolonged, the plating solution does not be wasted so as to reduce production cost, and environmental pollution is reduced to achieve the aims of saving energy and reducing emission.

Owner:SUZHOU QUANLI PLATING HANGERS

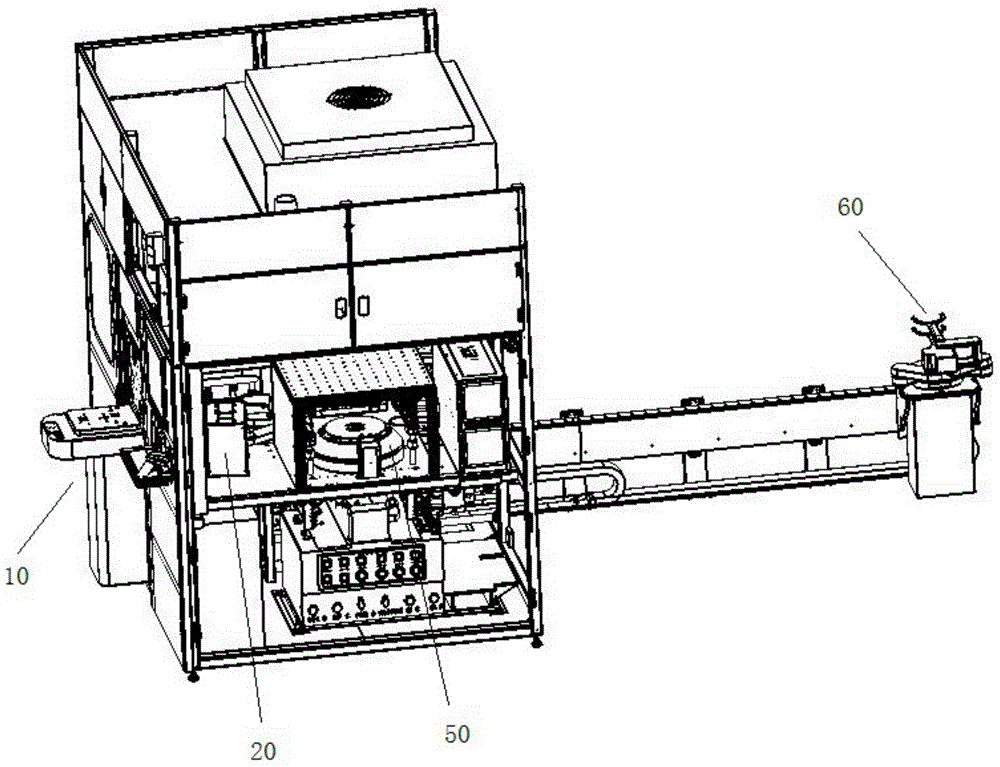

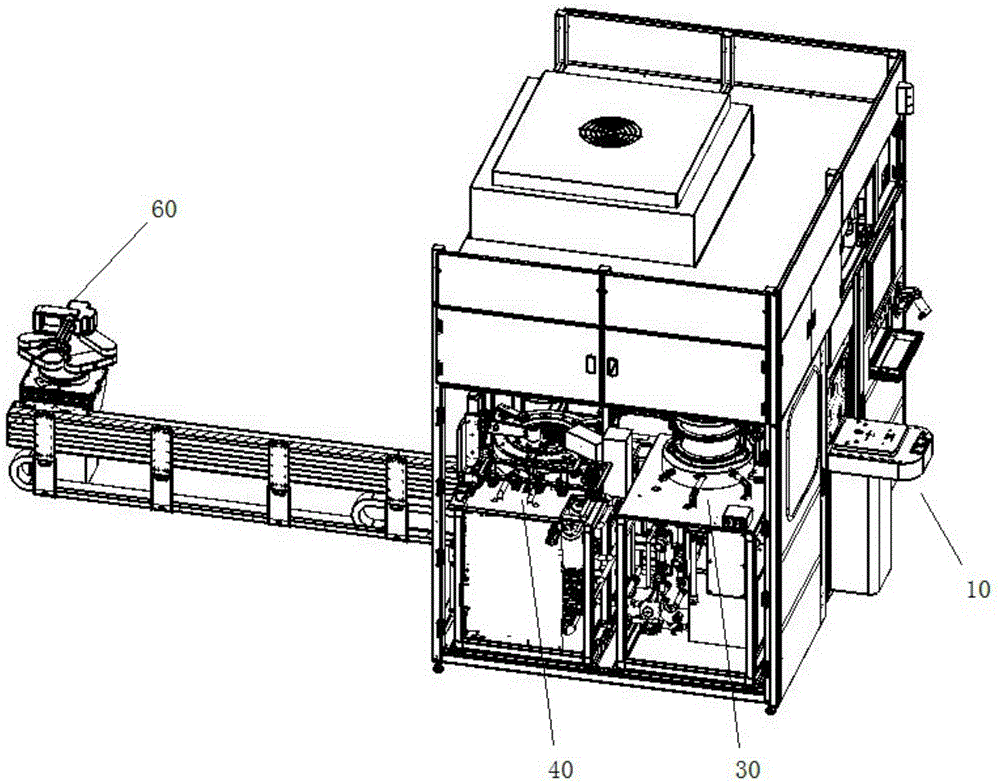

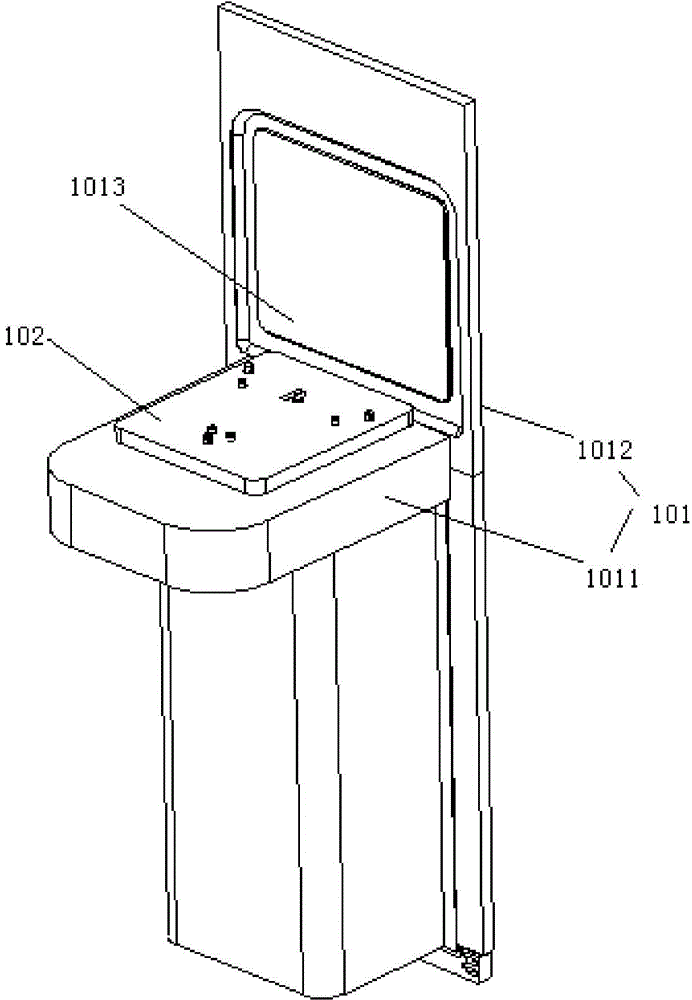

Wafer processing unit

ActiveCN104617016AImprove shipping stabilityImprove work efficiencySemiconductor/solid-state device manufacturingEngineeringRejection rate

The invention discloses a wafer processing unit, which is characterized by comprising a wafer electroplating pretreatment device for pre-treating wafers before electroplating, a wafer electroplating device for electroplating the wafers, a wafer cleaning device for cleaning the wafers after electroplating and a manipulator for conveying the wafers from one device to another device. According to the wafer processing unit, the wafer electroplating pretreatment device, the wafer electroplating device and the wafer cleaning device are combined organically; the wafers are conveyed by the manipulator, so that the working efficiency is improved greatly, the manpower is saved, the conveying stability of the wafers is improved, and the damage and rejection rate of the wafers is reduced.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

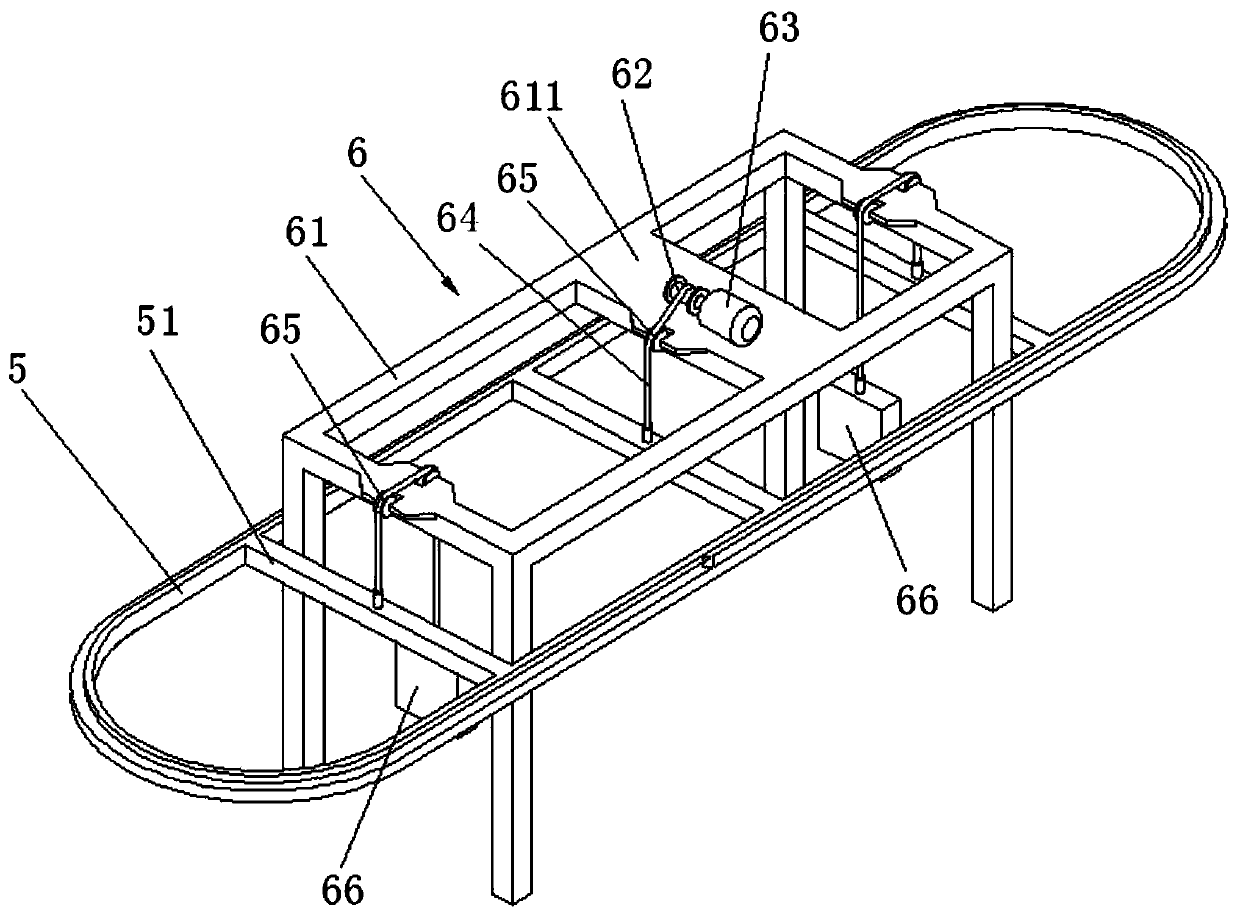

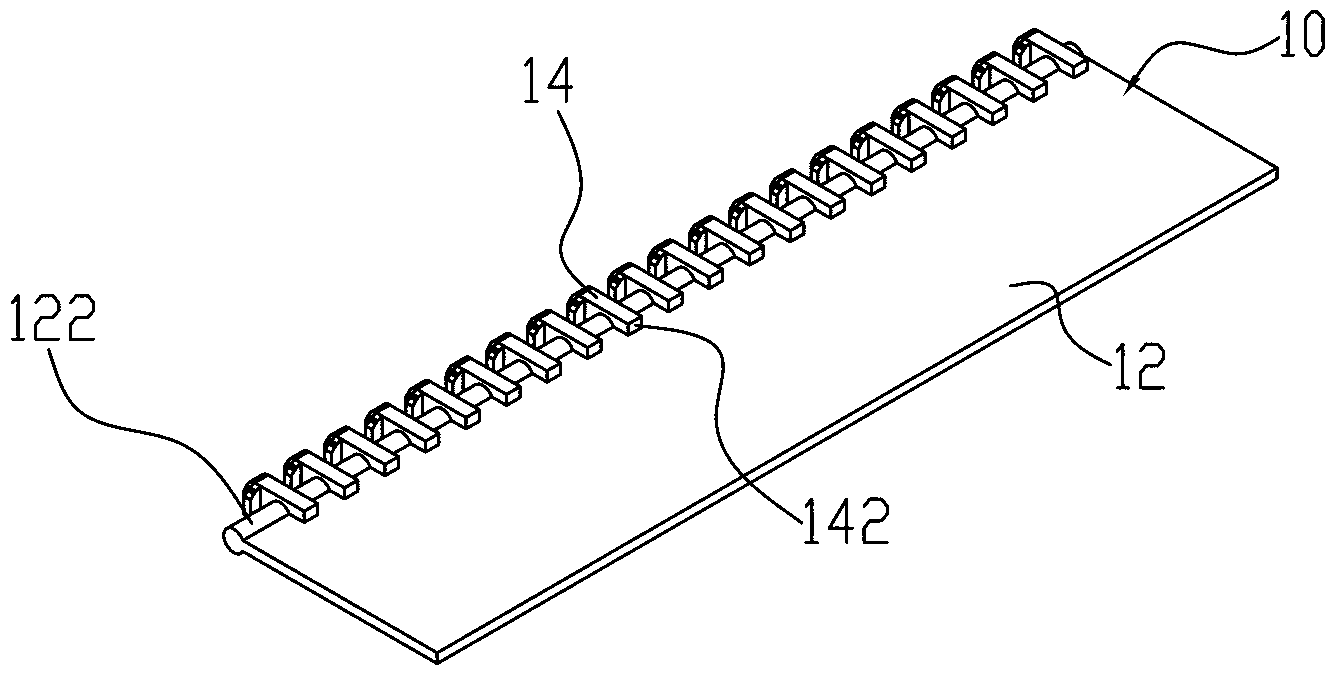

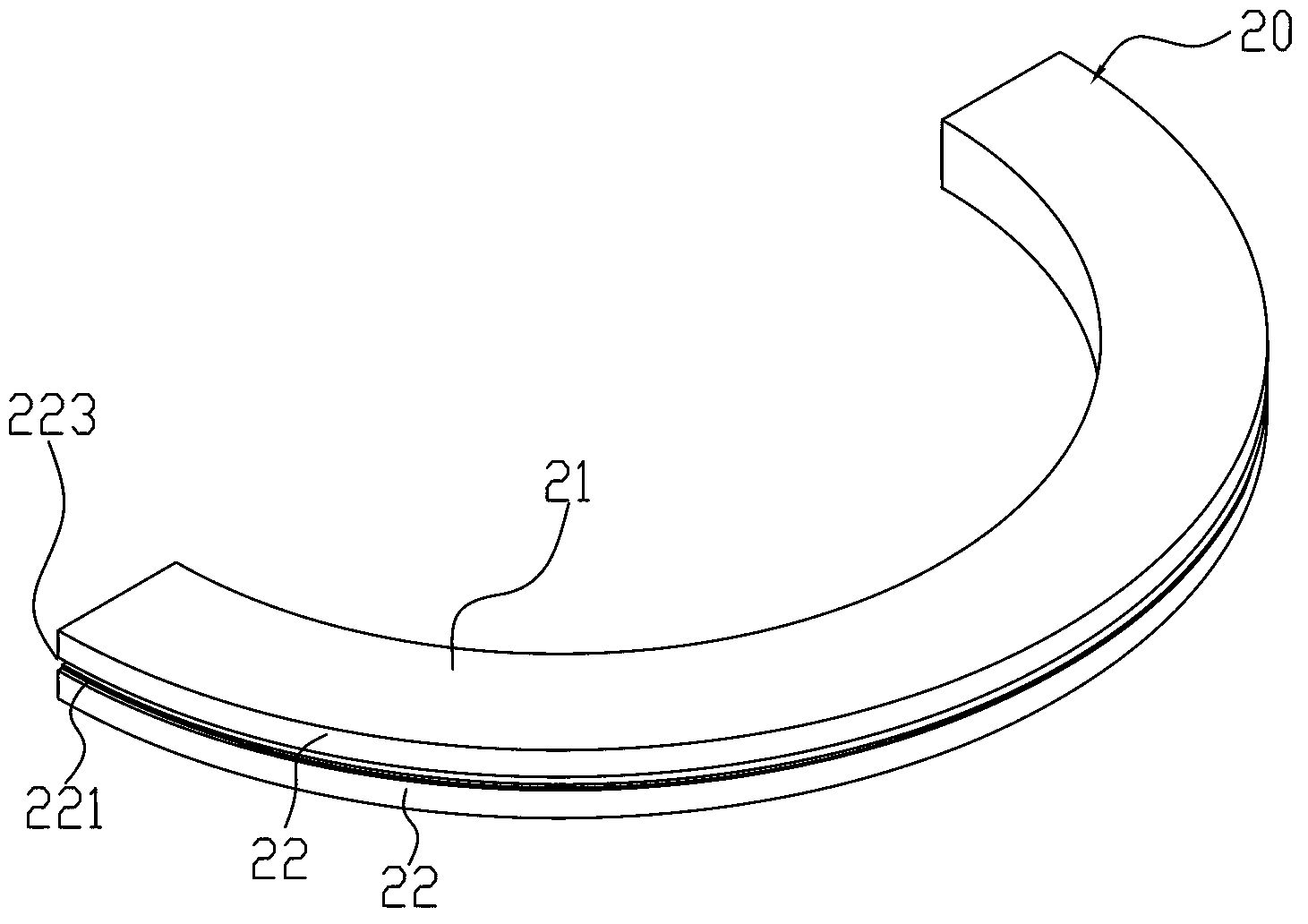

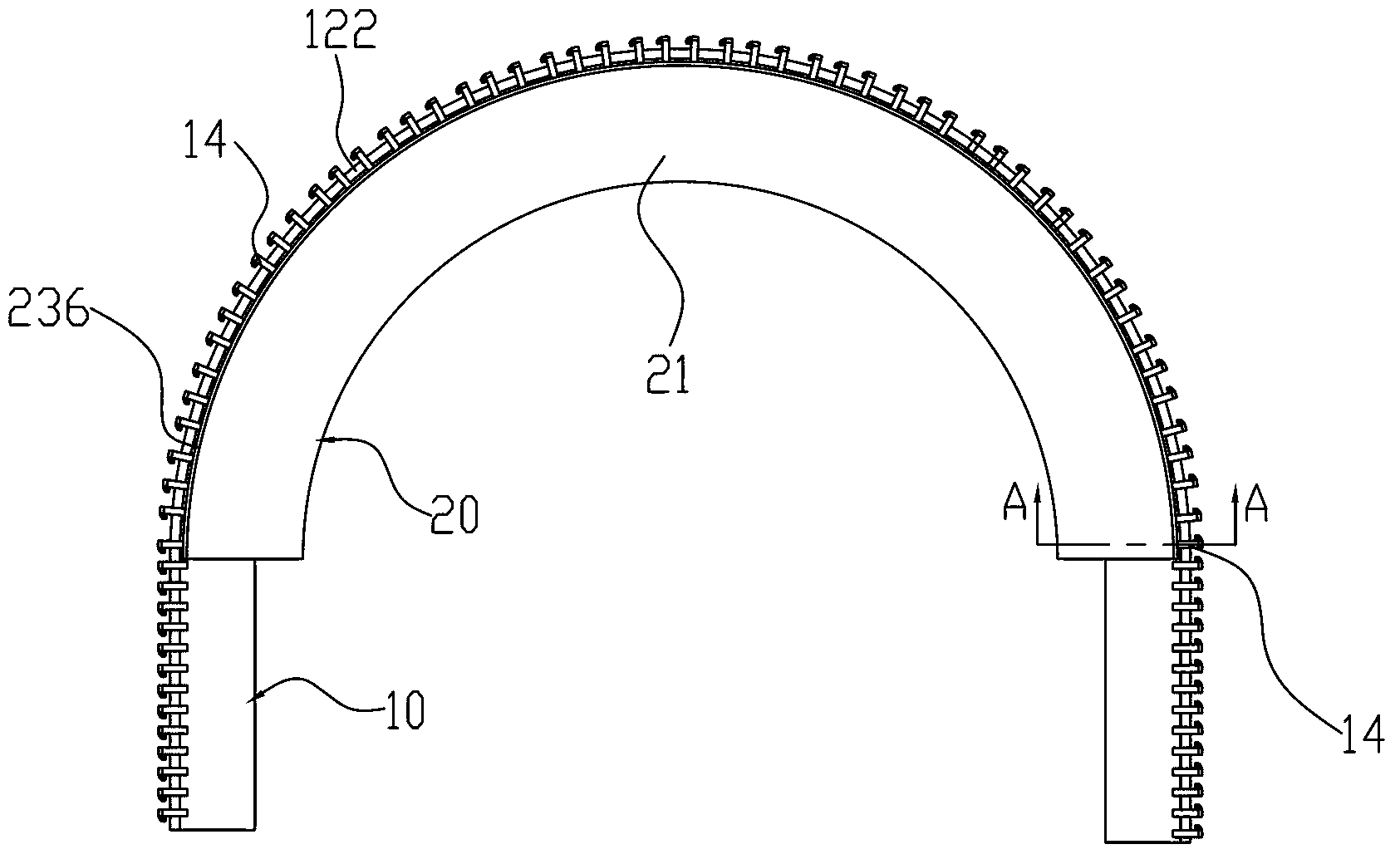

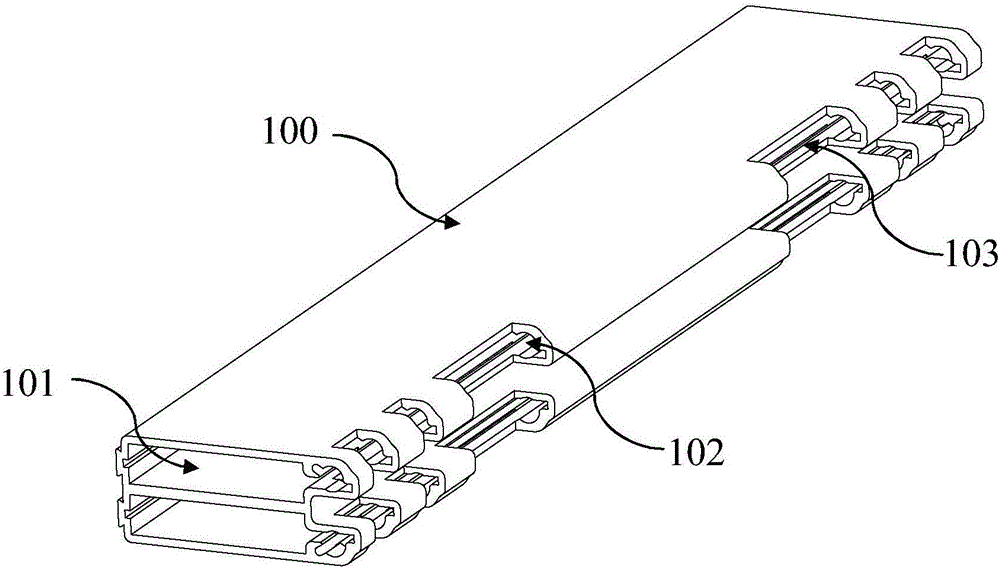

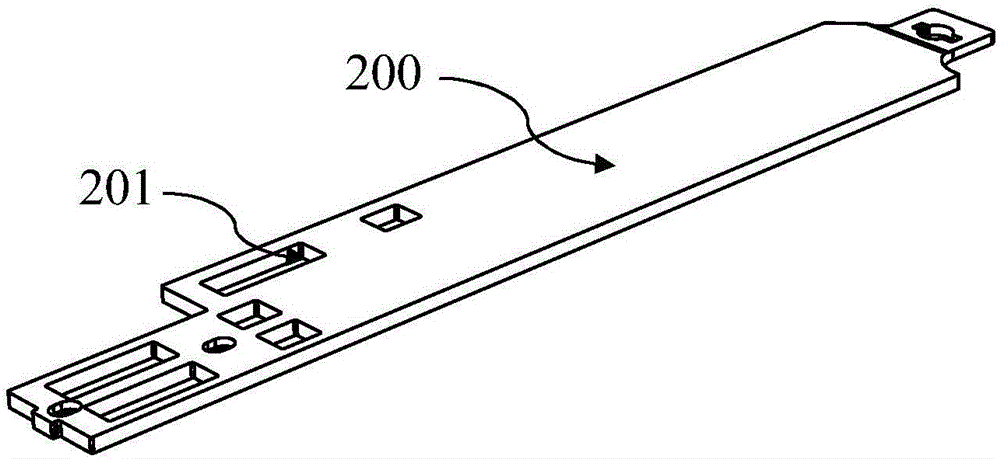

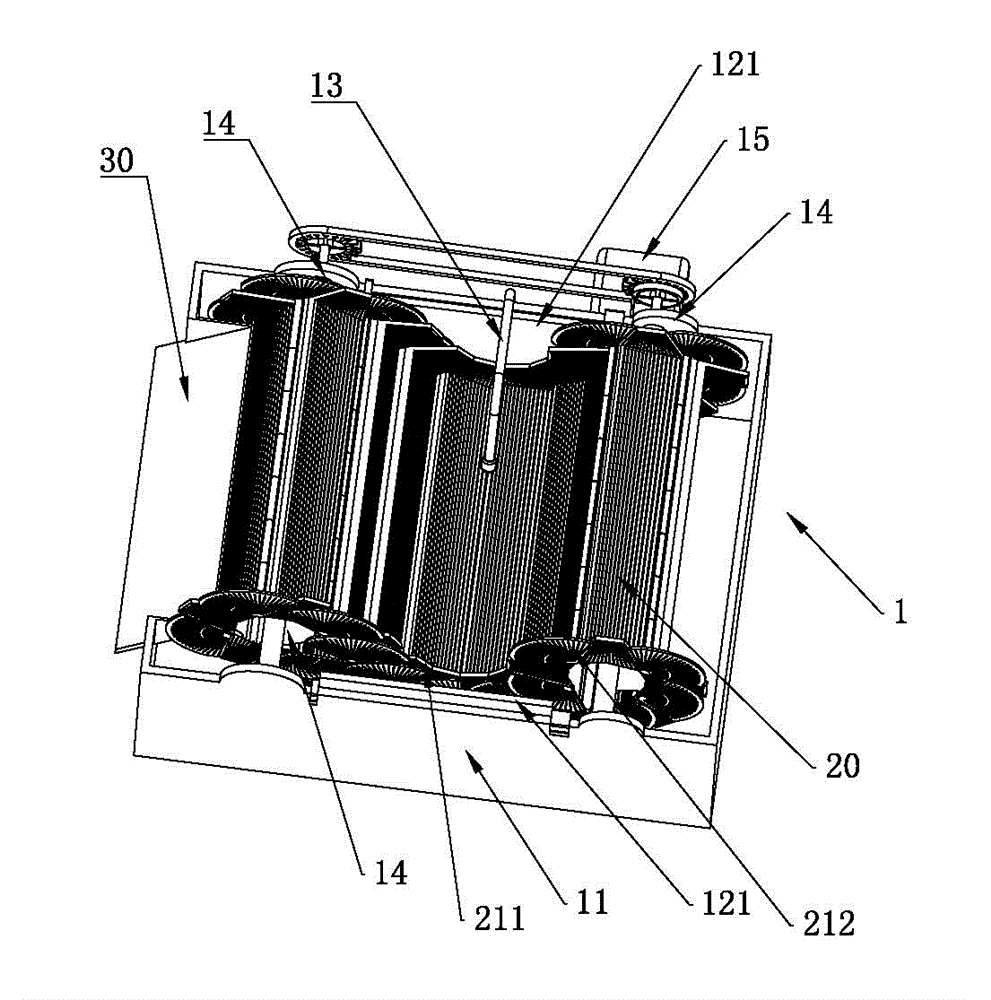

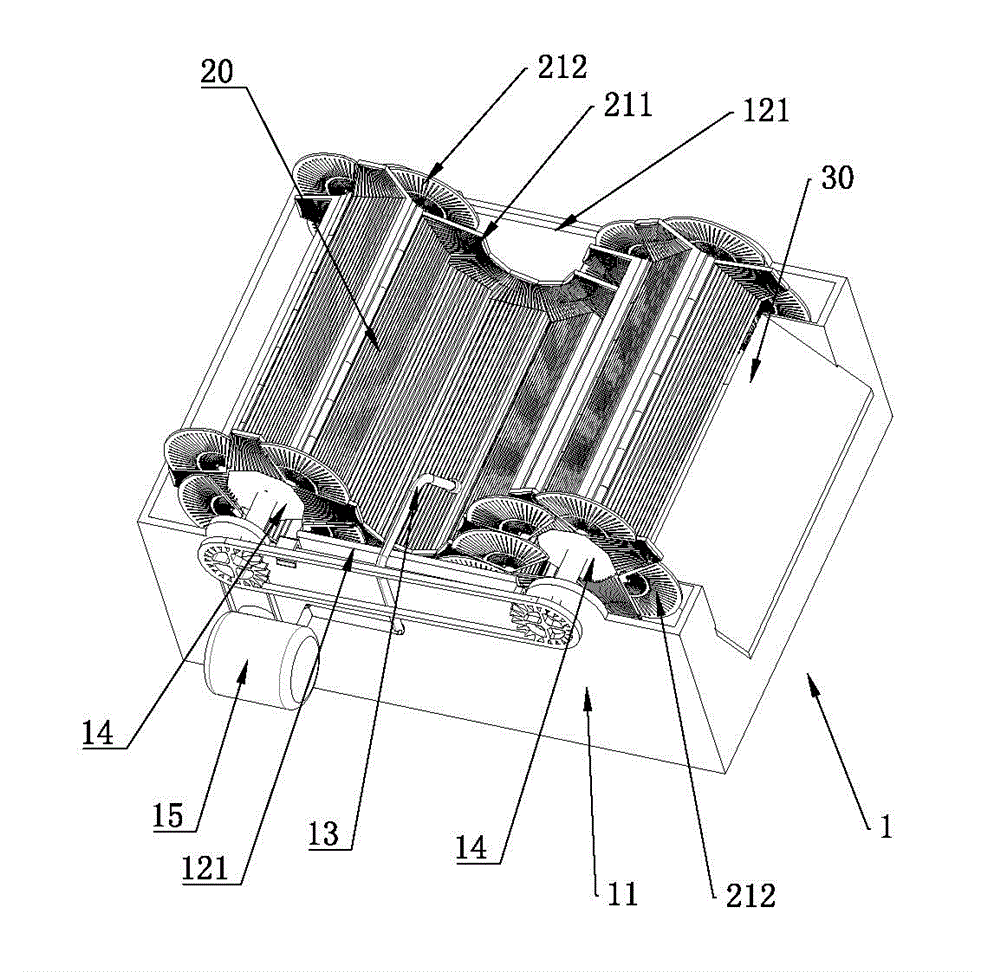

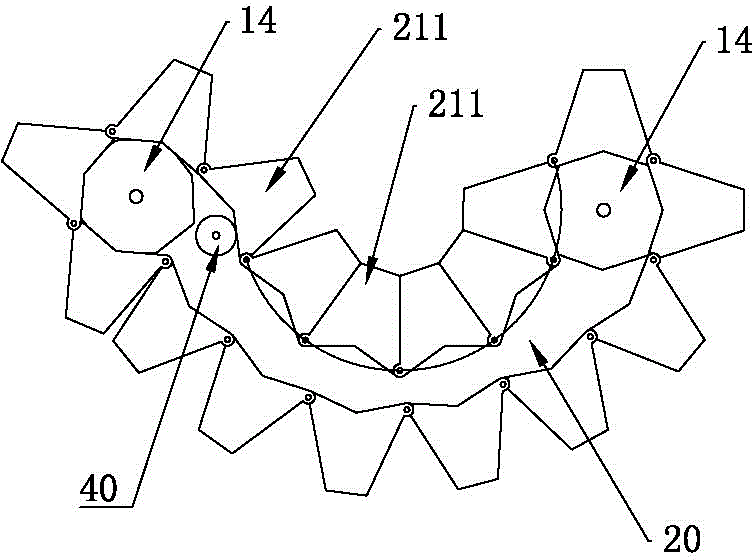

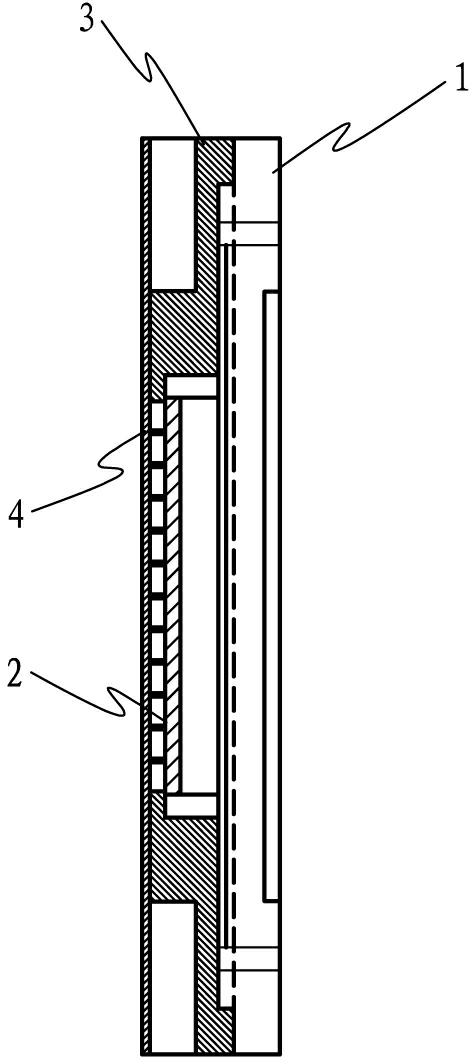

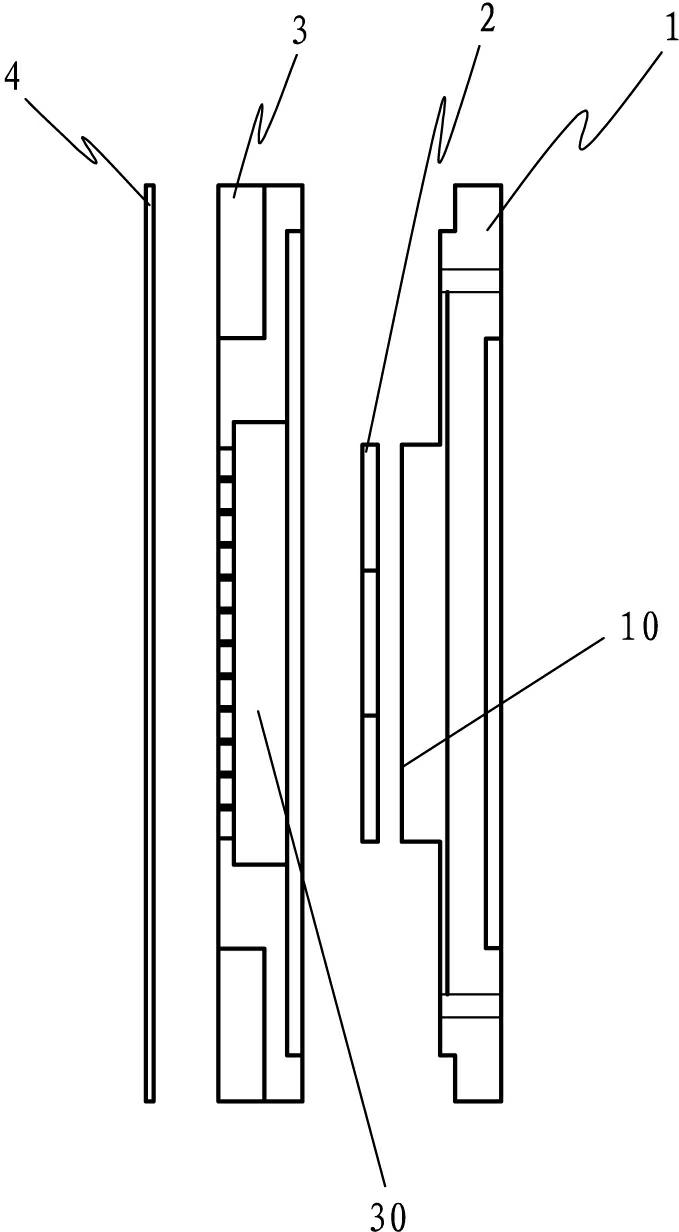

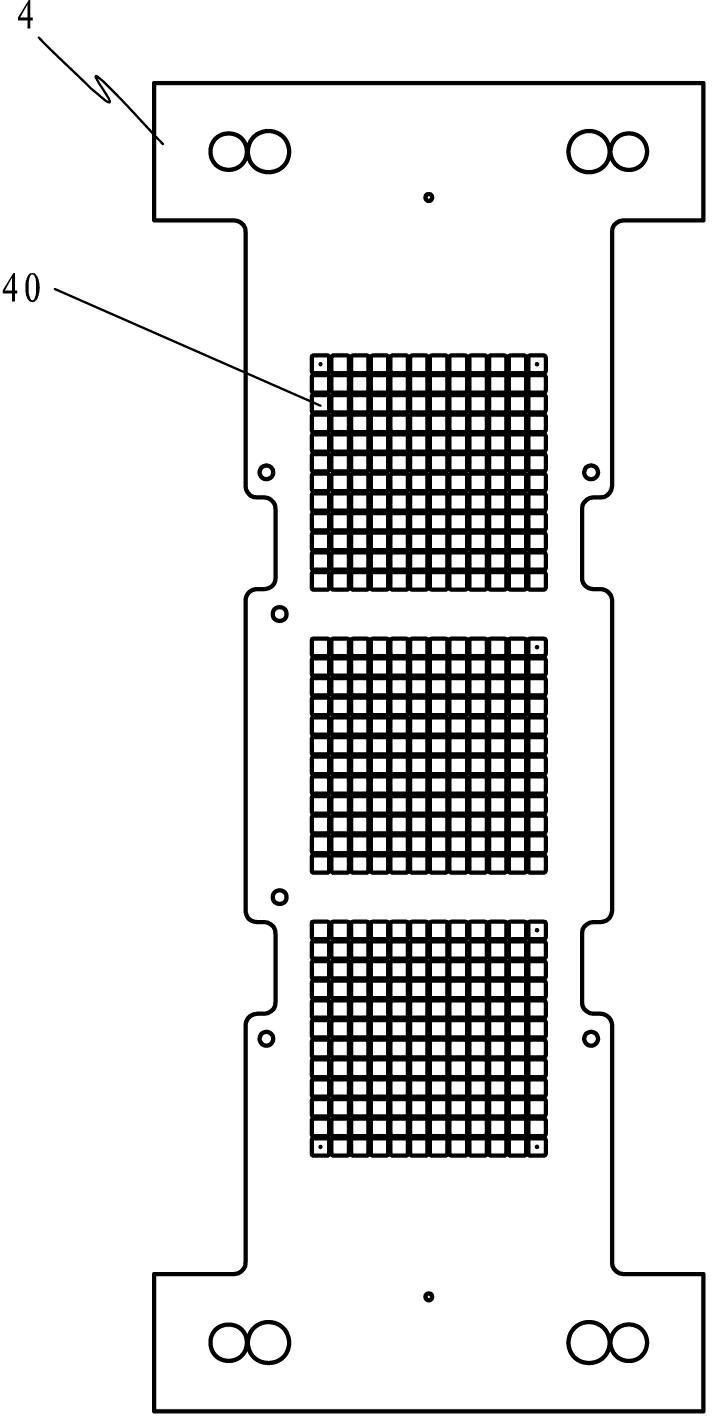

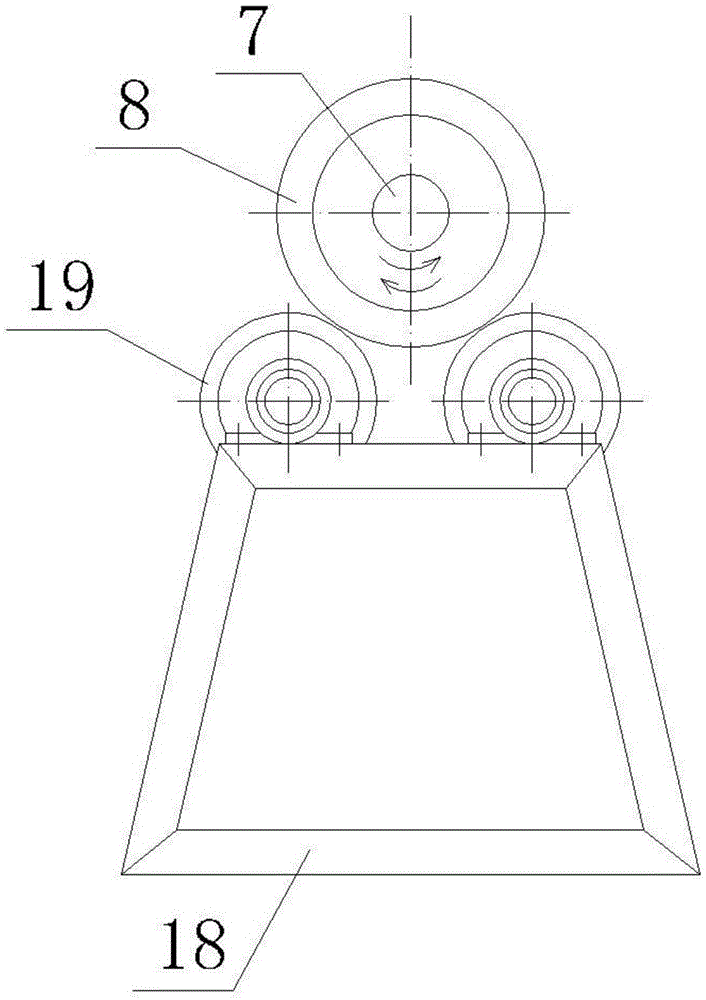

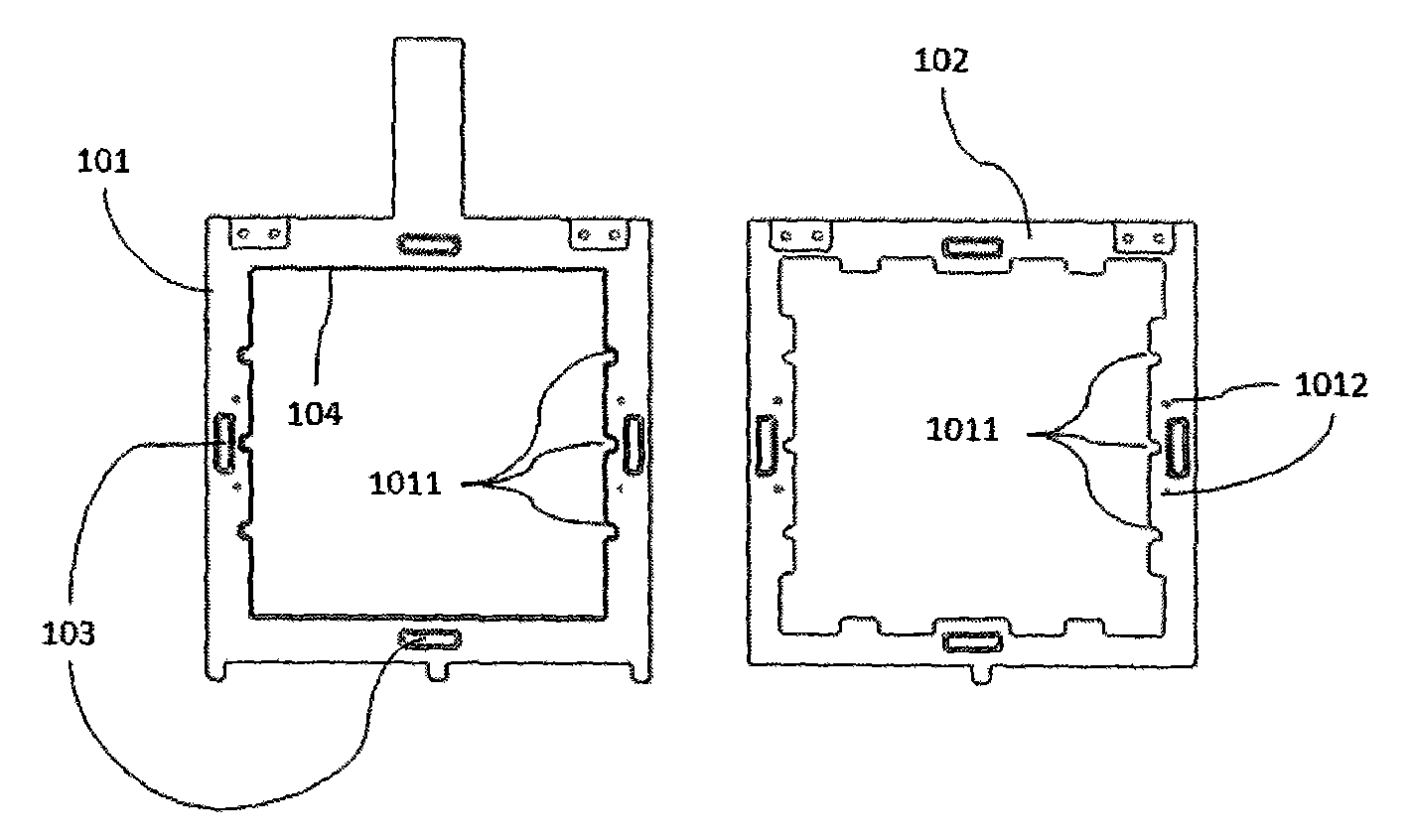

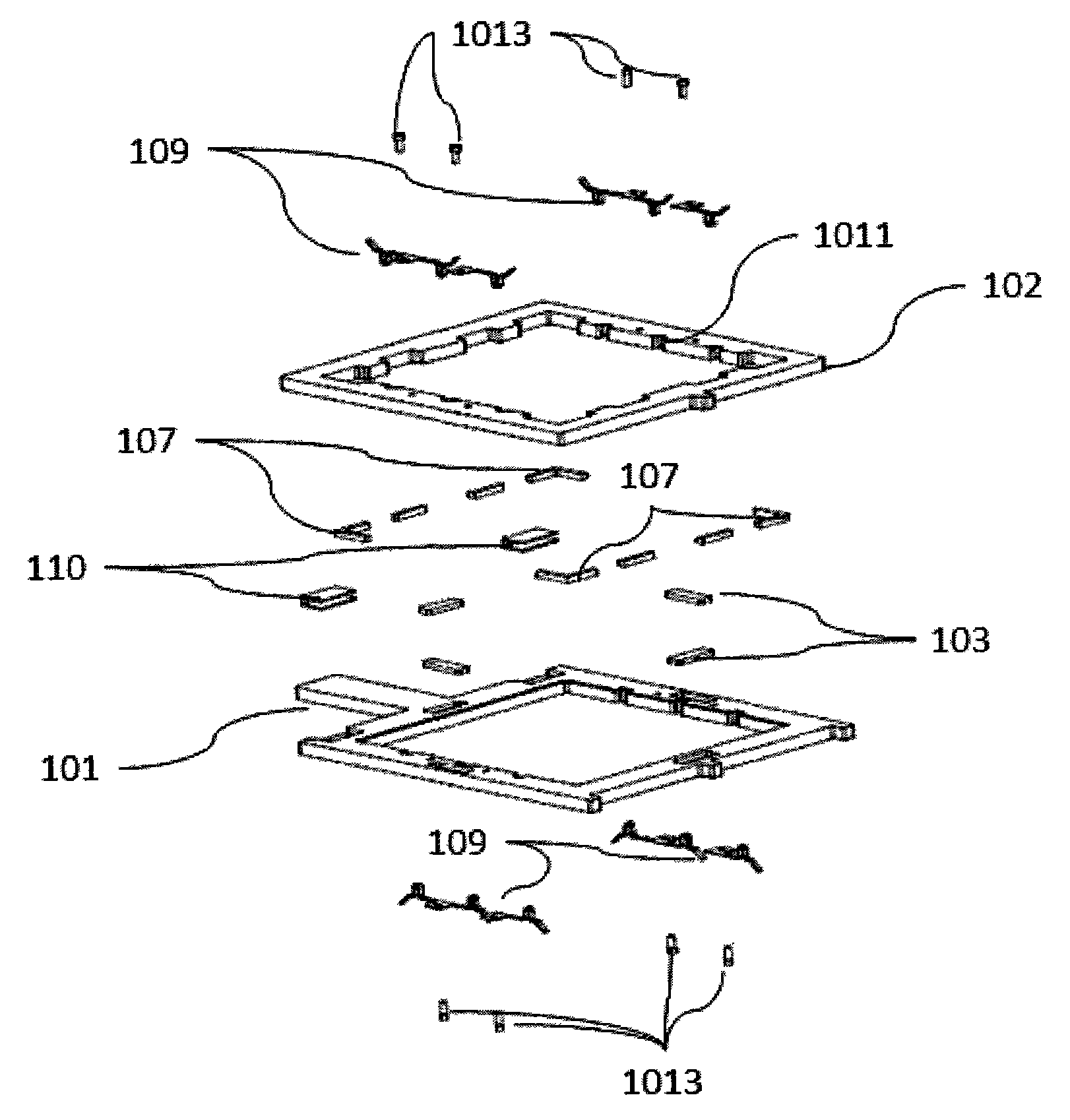

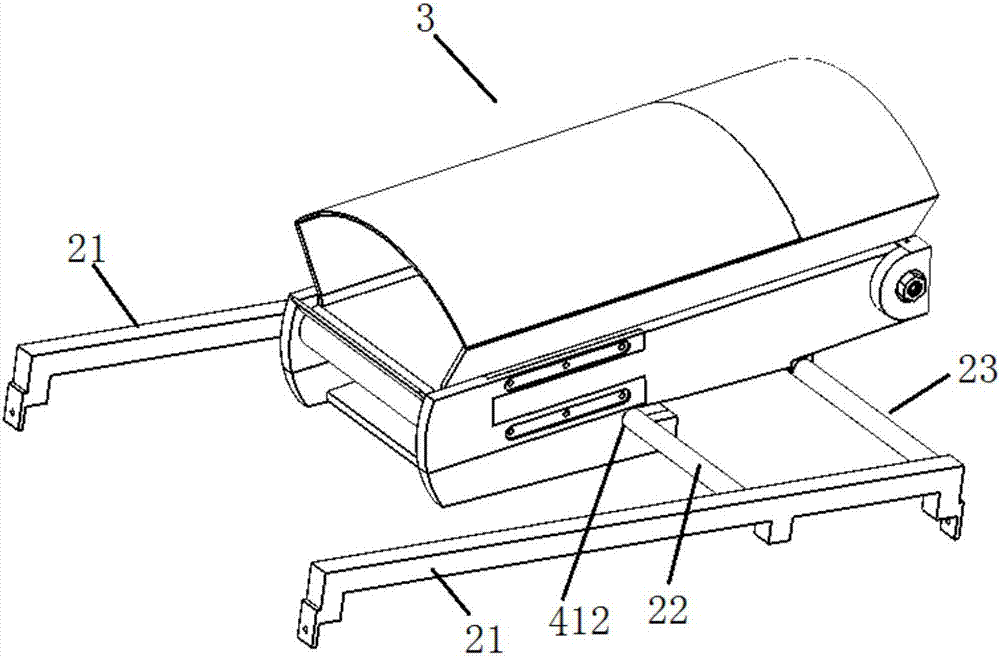

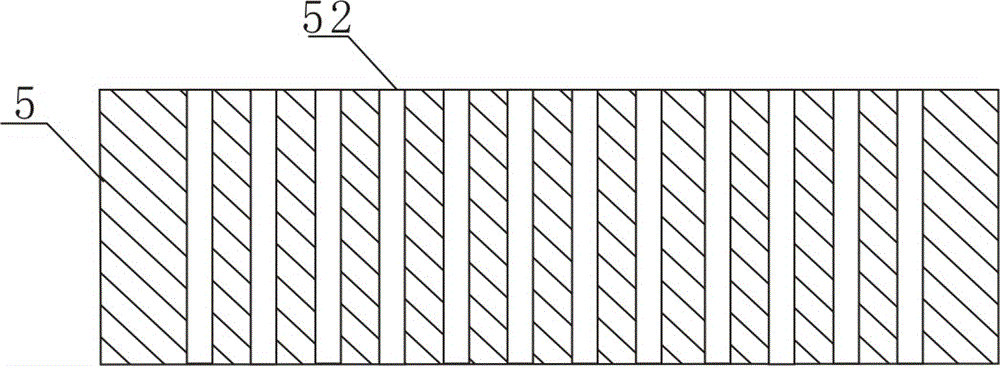

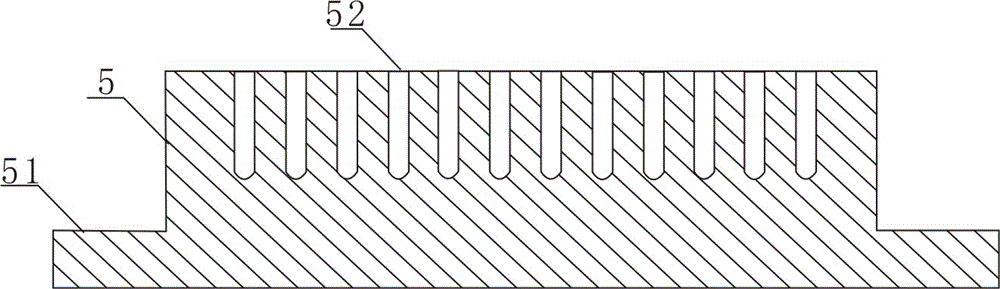

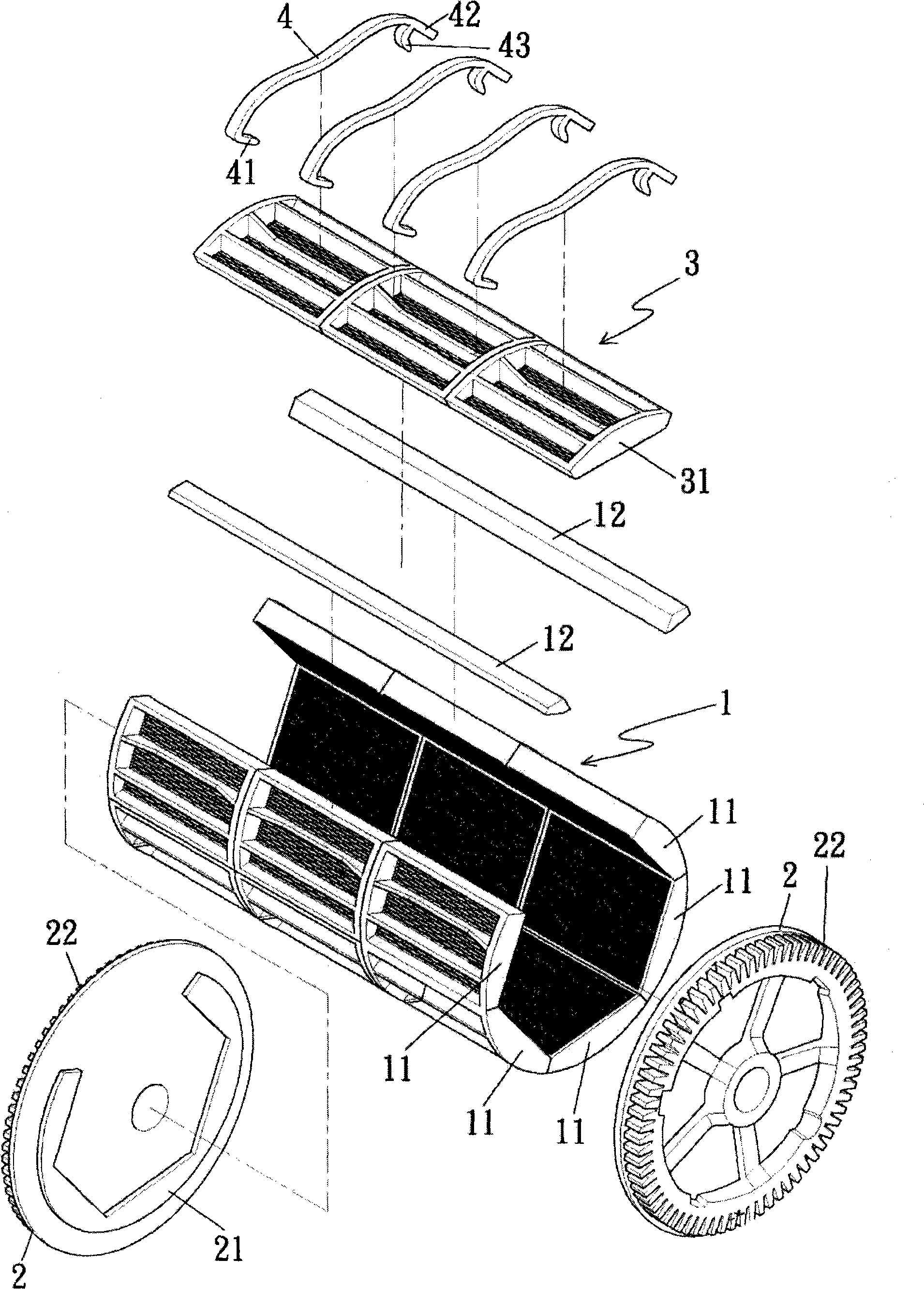

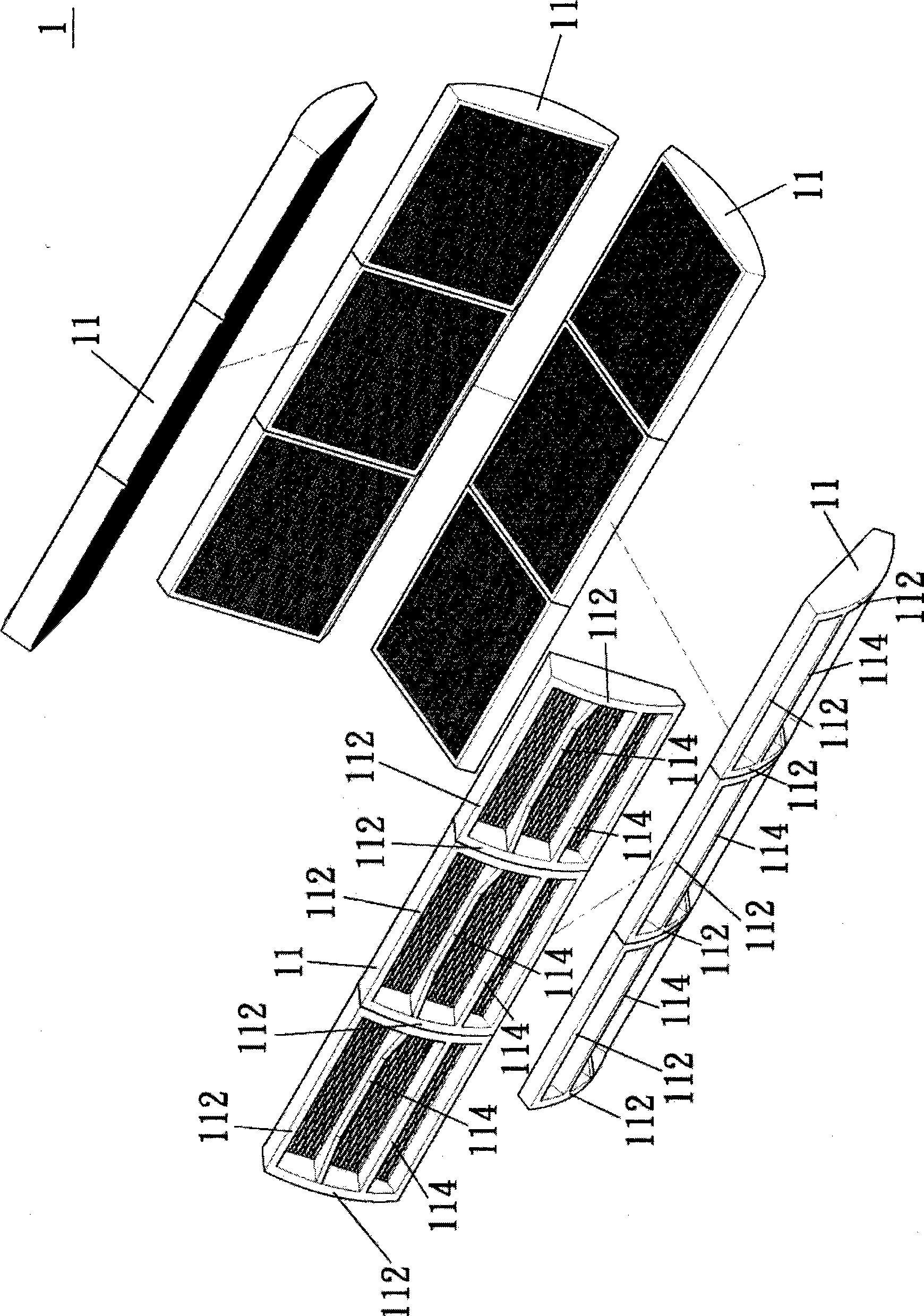

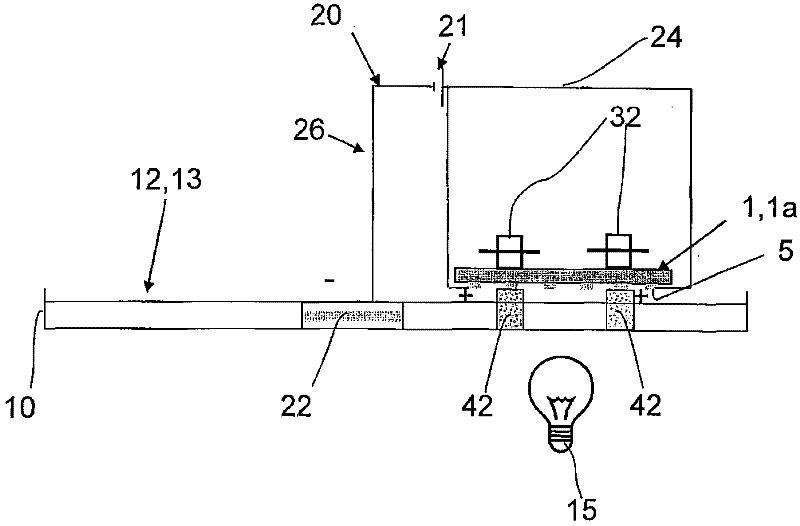

Chain belt electroplating supporting frame and electroplating equipment using the same

ActiveCN102839405AImprove plating qualityMake sure it's powered onSlide fastenersEngineeringEquipment use

Provided are a chain belt electroplating supporting frame and electroplating equipment using the chain belt electroplating supporting frame. The chain belt electroplating supporting frame is used to electrify metal chain teeth on a chain belt in the process of electroplating, and comprises a supporting frame body and a chain belt traction mechanism, wherein the supporting frame body is provided with an outer side surface, the outer side surface is in an outward protruding arc-shaped structure and is provided with a containing groove, the width of the containing groove is the width between two leg portions of the chain teeth, the containing groove is used to contain a cloth belt of the chain belt, the outer side surface close to the containing groove is provided with a conductive belt which is fixed on the outer side surface, a part of the surface of the conductive belt is in electric connection with the bottoms of chain teeth, the part of the surface of the conductive belt not contacting the chain teeth is covered by an anti-corrosion layer, and the chain belt traction mechanism is used to drag the chain belt along the stretching direction of the chain belt when the chain belt is wound on the supporting frame body and exert tension force to the chain belt. The chain belt electroplating supporting frame and the electroplating equipment using the chain belt electroplating supporting frame have the advantages of being high in electroplating quality.

Owner:铜陵嘉禾电子科技股份有限公司

Electrical brush plating system and method for metal parts

ActiveUS20140251815A1Enhances electrodeposition rateAvoid it happening againCellsElectrodesElectricityBristle

An electrical brush plating system and method for metal parts wherein a motion control member and a plating bath with a plating pen includes an anode member provided with an anode plate and bristles that are mounted on the motion control member. A part to be plated is disposed within the plating bath with the bristles provided towards the surface of the part to be plated and under the control of the motion control member, the bristles perform a relative friction motion with the surface of the part to be plated. During the relative friction motion, the surface of the part to be plated is opposite to the anode plate of the anode member. The method includes the steps of mounting the plating pen and the part to be plated; electrocleaning; strong activation; weak activation and electrical brush plating. The generation of pinholes, pits and nodules are avoided.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Method for preparing stannous pyrophosphate

InactiveCN101234757AReduce turbidityImprove plating qualityPhosphorus compoundsTurbidityRoom temperature

The invention discloses a method for preparing stannous pyrophosphate. The technique of the method is as follow: stannous chloride and stannous sulfate with a short time retention period (0 to 72 hours) reacts with stoichiometric alkali metal pyrophosphate solution (thickness of 1 to 30 percent) in room temperature; the reaction precipitate is washed by water until Cl<-> is less than 1 percent; white powder products are obtained after filtering, drying and crashing. The complex compound solution which is formed by the products and alkali metal pyrophosphate is colourless and transparent, and has a turbidity degree merely of 0 to 5.

Owner:易鹤翔

Dielectric phase shifter with novel conducting cavities

ActiveCN106067577AReduce the number of partsSave assembly timeWaveguide type devicesAntennasDistortionEngineering

The invention discloses a dielectric phase shifter with novel conducting cavities. The dielectric phase shifter includes an outer shell, dielectric sheets, a circuit board and coaxial cables; two rectangular cavities are formed in the outer shell; one conducting cavity is formed at one side of each cavity, wherein the conducting cavity is connected with the cavity; each conducting cavity is hollow and is a circular hole of which the diameter is 3.6 mm, and a small groove of which the width is 1.2 mm formed at one side of the hole; in each conducting cavity 4, a portion with a reserved width is maintained to be original at a position where the outer conductor of a corresponding coaxial cable is welded to the conducting cavity 4, and a portion of which the width is 15mm is machined downwards so as to be removed, and therefore, the coaxial cable can extend into the conducting cavity so as to be welded to the conducting cavity; the circuit board is designed into a rectangle with four grooves formed at one side; and the four grooves are corresponding to the edges of circuit board pads for welding the inner conductors of the coaxial cables. When welding is carried out, only one-time clamping is required, and therefore, a welding technique is better, and the economical efficiency of welding is improved; and the conducting cavities are utilized to excellently wrap the outer conductors of the coaxial cables, distortion can be avoided, bending stress of the coaxial cables can be avoided, the risk that welding spots and the circuit board are damaged can be lowered, and hidden hazard points in intermodulation can be decreased.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Open chain belt type barrel plating machine

ActiveCN102747410ASimple structureIncrease productivityElectrolysis componentsElectricityEngineering

The invention discloses an electro-plating device and specifically relates to an open chain belt type barrel plating machine. The open chain belt type barrel plating machine comprises an electro-plating slot, an anode plate, a cathode plate guide wire and a control device, wherein the control device is electrically connected with the anode plate and the cathode plate guide wire respectively; the open chain belt type barrel plating machine further comprises a chain belt, a transmission wheel for driving the chain belt to move left and right and a motor; the motor is electrically connected with the control device; the chain belt is arc-shaped and arranged in the electro-plating slot; the circle centre of the circular arc where the chain belt lies is arranged above the chain belt; a plurality of liquid through holes for passing bath solution are arranged on the chain belt; and an unloading mechanism is fixed at the left side of the electro-plating slot. The open chain belt type barrel plating machine is simple in structure, high in production efficiency, good in quality of the surface of a plated part and extensive in applicative component dimension range; moreover, the chain belt for bearing components is open so as to be capable of detecting the quality of plated work pieces at any time in a working status, thereby ensuring the product yield.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Electroplating device for lead wire framework

The invention discloses an electroplating device for a lead wire framework. The electroplating device comprises a spraying plate, an anode plate, a substrate and a mask base plate from bottom to top, wherein a plurality of electroplating through holes are formed on the mask base plate in an array manner; each through hole corresponds to an electroplating unit region on the lead wire framework; and the electroplating device finishes the lead wire framework electroplating work at a time through electroplating liquid spraying loops on the spraying plate and the anode plate. In the electroplatingdevice, the electroplating liquid is sprayed into a spraying runner and electroplated onto a welding disk region of the lead wire framework so as to finish all electroplating unit regions at a time; moreover, the uniformity and the electroplating quality are high; the residual electroplating liquid is collected by the runners of the loops so that the spraying path of the electroplating liquid cannot be influenced; in particular, the electroplating device is suitable for a plurality of lead wire frameworks; and a charring phenomenon can be avoided and the yield rate is high.

Owner:XIAMEN YONGHONG TECH

Plating hanger for tubular workpiece

InactiveCN107217294APrecise positioningGuaranteed uniformityElectrolysis componentsEngineeringMechanical engineering

The invention relates to a plating hanger for a tubular workpiece. The plating hanger comprises a first vertical plate, a hook, a threaded rod and at least one sleeve, wherein the hook, the threaded rod and the sleeves are fixed to the first vertical plate; the threaded rod is located above the sleeves, the length of the threaded rod is larger than that of each sleeve, the threaded rod is sleeved with a second vertical plate, the threaded rod is provided with a nut, the second vertical plate is fixedly provided with at least one conical block, the outer diameters of the conical blocks are gradually reduced in the direction of being close to the first vertical plate, and the conical blocks are opposite to the sleeves. The plating hanger is simple in structure, low in cost and convenient to operate, one end of the tubular workpiece abuts against the first vertical plate, the other end of the tubular workpiece abuts against the conical blocks, positioning of the tubular workpiece is steady, uniformity of plating is guaranteed, and plating quality is improved.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

Method for producing metal plated plastic article

InactiveUS20040197478A1Specific shear strengthSpecific surface roughnessInsulating substrate metal adhesion improvementPretreated surfacesRough surfaceEtching

The invention provides a process for producing a plated plastic article, which requires no chemical etching and can ensure high quality of plating without addition of a large amount of any inorganic filler in order to form a physically rough surface for an effective plating adhesion. After molding thermoplastic materials having a shear strength of 50 MPa or more, the surfaces of the molded articles are subjected to liquid honing treatment with an aluminum abrasive so that the surface roughness Rz (average roughness of ten points) is 10 mum or more, and subsequently addition of catalyst, activation treatment, and electroless plating are carried out.

Owner:POLYPLASTICS CO LTD

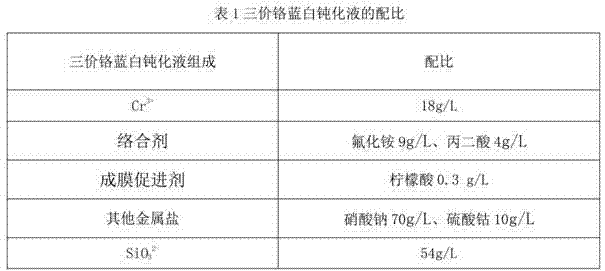

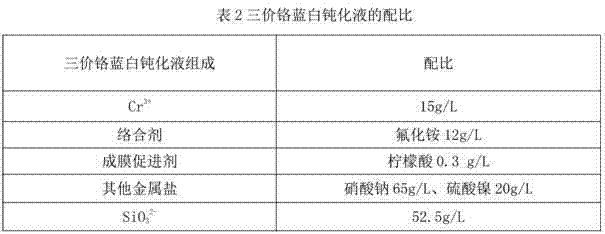

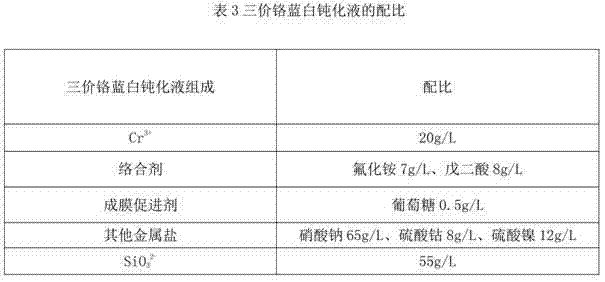

Two-in-one trivalent chromium blue white passivation solution for passivation and sealing and use process thereof

InactiveCN102400126AProcess stabilityLow costMetallic material coating processesSocial benefitsEconomic benefits

The invention discloses a two-in-one trivalent chromium blue white passivation solution for passivation and sealing, which comprises Cr<3+>, SiO3<2->, complexing agents, film formation accelerating agents and other metal salt, wherein in the passivation solution, the mass ratio of Cr<3+> to SiO3<2-> is 1 : (2.5 to 3.5). The invention additionally discloses a passivation and sealing process, which comprises the step that workpieces which are bright-dipped and washed are put into the two-in-one trivalent chromium blue white passivation solution for passivation and sealing to be passivated and sealed. By adopting the passivation solution disclosed by the invention to conduct the passivation and sealing treatment, only one working procedure is needed; compared with an old process requiring two working procedures of passivation and then sealing, the cost of the process disclosed by the invention is only 70 to 80 percent of the cost of the old process, so the cost of the passivation and sealing process is remarkably reduced, an obtained passive film has better corrosion resistance and heat resistance, the neutral salt mist resisting time of the passive film can be effectively prolonged, and the economic benefits and the social benefits are good.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH +1

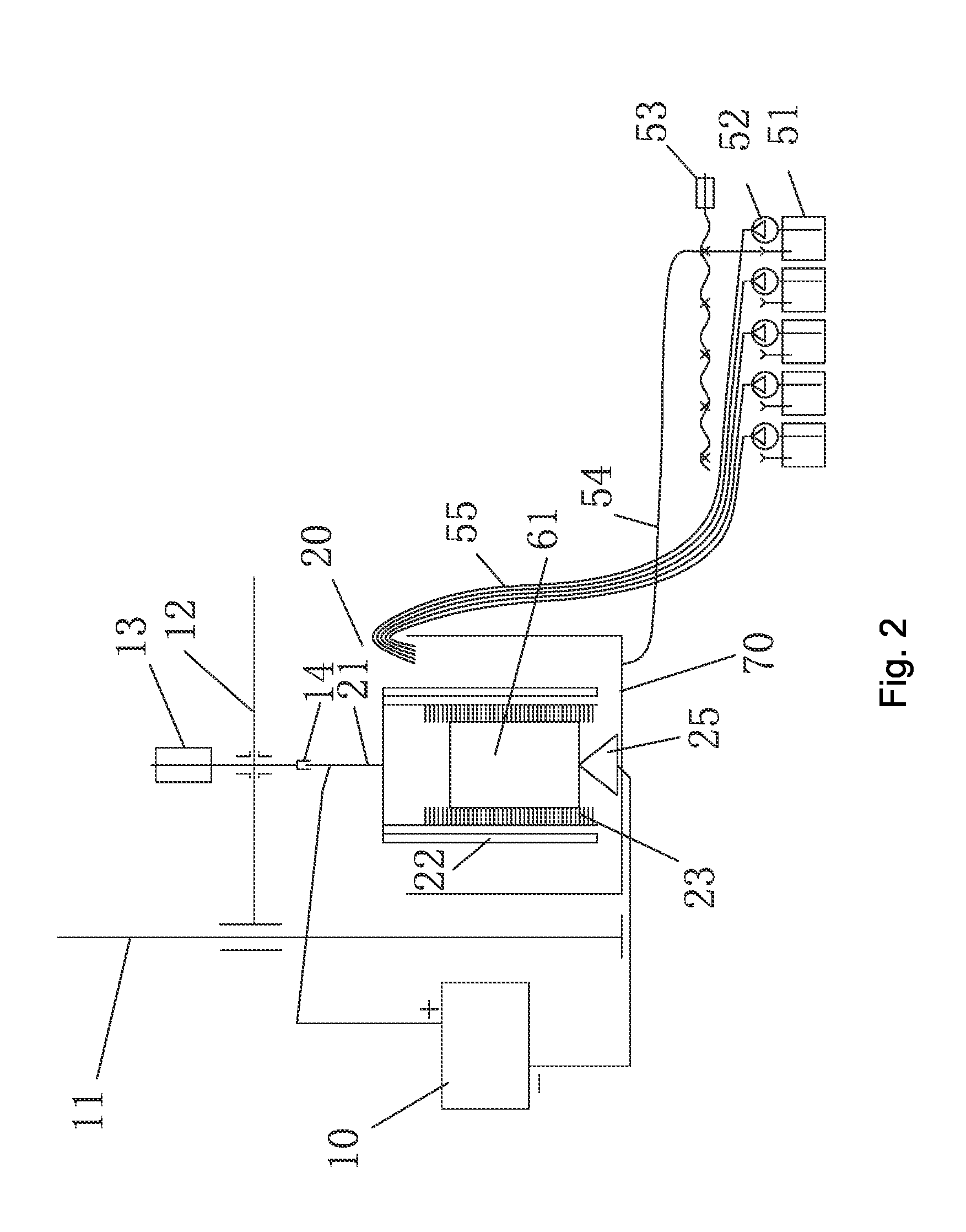

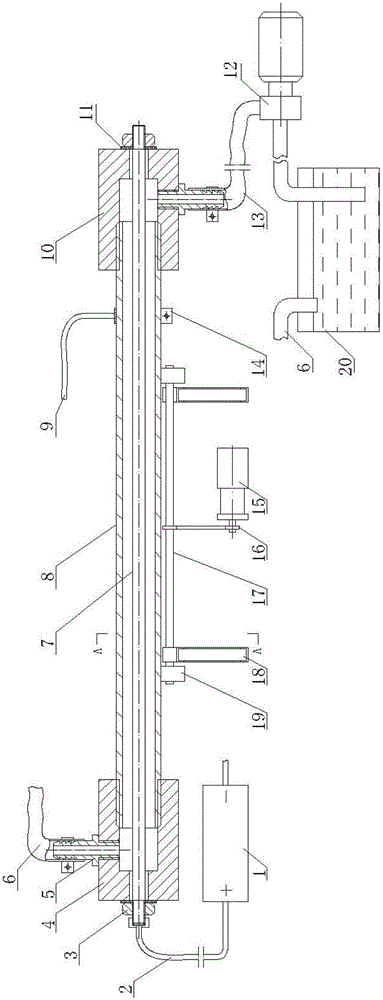

Swinging-type long-pipe inner wall electroplating method and electroplating equipment applying same

InactiveCN105002539AImprove plating qualityImprove plating efficiencyCellsLiquid storage tankEngineering

The invention discloses a swinging-type long-pipe inner wall electroplating method and electroplating equipment applying the same. The electroplating process comprises the following steps that an inner anode penetrates through a cathode long pipe to be electroplated; the two ends of the cathode long pipe are separately connected to a liquid inlet connector and a liquid outlet connector; the liquid inlet connector and the liquid outlet connector are communicated with a liquid storage tank; the two ends of the inner anode are separately fixed on the liquid inlet connector and the liquid outlet connector; then one end of the inner anode and the outer wall of the cathode long pipe are separately connected to the positive electrode and negative electrode of a power source through flexible conductors; an electroplating solution is circularly injected into the cathode long pipe through a liquid inlet in the liquid inlet connector and a liquid outlet in the liquid outlet connector, and the inner cavity of the cathode long pipe is fully filled with the electroplating solution; the power source is started, and the cathode long pipe and the inner anode are driven to swing in a reciprocating manner by a swinging mechanism, so that an electroplating layer is formed on the inner wall of the cathode long pipe. The swinging-type long-pipe inner wall electroplating method has the beneficial effects that a recovery groove does not need to be arranged; the electroplating layer is uniform in thickness; the electroplating quality is ensured; and moreover, a liquid conveying mechanism and a power delivery mechanism of the equipment are greatly simplified.

Owner:黄激扬 +1

Automatic electroplating device and method for bolts

InactiveCN111394762AEasy to clamp and fixEasy to PlatingCellsElectric machineryStructural engineering

The invention discloses an automatic electroplating device and method for bolts, and relates to the technical field of electroplating. The automatic electroplating device comprises a first stand column, a second stand column, a movable plate, an electroplating box, a clamp mechanism, a filter box and a hydraulic telescopic rod, wherein the first stand column and the second stand column are arranged in parallel; the movable plate is movably arranged between the first stand column and the second stand column; the clamp mechanism used for clamping the bolts is fixedly arranged at the bottom of the movable plate; the electroplating box positioned between the first stand column and the second stand column is arranged under the clamp mechanism; and electroplating liquid is filtered, when a filter screen needs to be cleaned regularly, two clamping blocks are lifted upwards, then the filter screen can be taken out and cleaned, and thus the using effect is improved. The structure is simple, theelectroplating liquid can be filtered and cleaned easily, a motor is used for driving a rotary shaft to rotate, then stirring blades on the rotary shaft are driven to rotate, thus the electroplatingliquid can be fully and evenly stirred, the concentration of the electroplating liquid is uniform, the electroplating quality is improved, and the electroplating efficiency is improved easily.

Owner:GUIYANG BAIYUN AVIATION FASTENERS

Terpene ether developing solvent for photopolymerizable printing plates

ActiveUS20050100823A1Minimizes workplace hazardLow toxicitySemiconductor/solid-state device manufacturingPhotosensitive material processingEtherCo solvent

Flexographic printing plates are produced by exposing the photopolymer plates to a light source and washing out (developing) the masked out, non-exposed areas with a solvent. The invention provides terpene ether solvents suitable for use in the development of photopolymer printing plates. The solvents, which include terpene ethers alone or mixed with co-solvents and / or non-solvents, are effective in developing a large number of different photopolymer printing plates and can produce images superior to those obtained with commercially available solvents currently used in such applications.

Owner:MIRACLON CORP

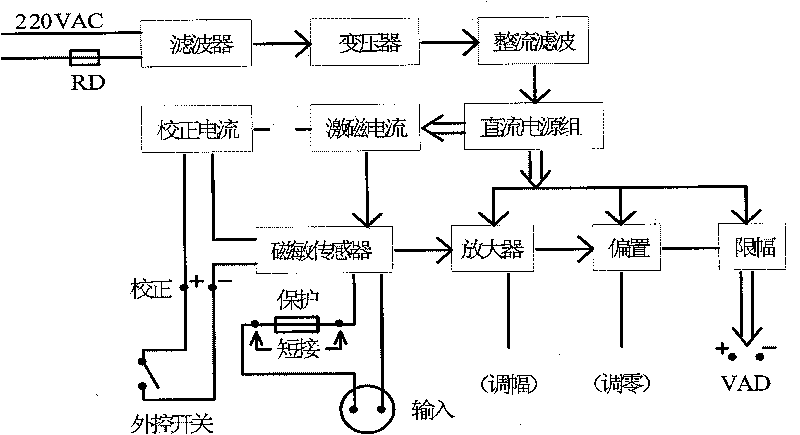

Barrel plating current intensity real-time online testing device

InactiveCN101748471AImprove plating qualityAchieve constant current density controlElectrolysis componentsCurrent density measurementsOnline testData acquisition

The invention discloses a barrel plating current intensity real-time online testing device, which comprises a data acquisition and transmission module and a transducer module, wherein the data acquisition and transmission module consists a replaceable probe, an insulating protective sleeve, a switching device and a wire; the transducer module realizes feeble current to voltage signal conversion and nonlinear compensation, displays the detected current intensity, converts an acquired current signal to a 0 to 5 volt control voltage and outputs the 0 to 5 volt control voltage. The data acquisition part of the device can be placed in a barrel to be plated with a workpiece, so the concentration of plating liquid in the barrel and the actual conditions of a workpiece plating current during temperature change can be reflected, and under a condition of a known area of the replaceable probe, the current intensity of a workpiece in a barrel plating state can be acquired in real time according to the acquisition of the plating current of the probe. After the output of a power supply is regulated by using the output signal of the device, the constant current intensity control can be realized, so the problem of uneven plating thickness caused by incorrect calculation of the surface area of the workpiece is solved.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving excessive circuit etching of circuit board

InactiveCN104411105AExpanding the scope of improvement in etchingPrevent over etchingConductive material chemical/electrolytical removalEtchingCopper

The invention discloses a method for improving excessive circuit etching of a circuit board, belonging to the field of outer circuit etching of printed circuit boards. The method for improving excessive circuit etching of the circuit board disclosed by the invention comprises the following steps of: micro-electroplating a copper layer with the thickness of 5-6 mu m on a complete board; transferring an outer pattern onto the outer layer of the circuit board to form a circuit pattern, wherein the width of a copper circuit is 0.03-0.04 mm more than that of a copper circuit required practically; thickening a pattern electroplated copper layer till the thickness is 11-13 mu m, and then, electrotinning with the thickness of 5-6 mu m; and vacuumizing and etching after demoulding. According to the invention, the processes before and after etching are improved in an unified manner; therefore, the improvement range of outer circuit etching is enlarged; the effect of preventing excessive circuit etching can be achieved better; the production efficiency of outer circuit etching is effectively increased; scraps due to the fact that circuits are too thin are reduced; and the electroplating quality is increased.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Quick zinc sulfate electroplating process

A quick zinc sulfate electroplating process comprises the following steps: firstly, removing oil on a work piece, washing the workpiece by water, acid and water respectively, then soaking the workpiece into electroplating liquid in a galvanizing bath, taking out the work piece, washing the workpiece by water, then passivating the workpiece, washing the workpiece by water again, and drying the workpiece with hot wind. Content of chemical materials in each liter of the electroplating liquid is as follows: 80 to 150 grams of zinc sulfate, 120 to 180 grams of potassium chloride, 25 to 30 grams of buffer, 1 to 2 grams of additive and 20 to 25 grams of lustre-coating agent. The workpiece is soaked in the electroplating liquid for 10 to 15 minutes at a temperature of between 5 and 60 DEG C, and the pH value of the electroplating liquid is 4 to 5. The technical conditions of soaking the workpiece in the electroplating liquid in order to galvanize are as follows: the current density is 2 to 5A / dm; the cathode motion speed is 15 to 20 times per minute. By using the process to galvanize the workpiece, the deposition velocity is quick; dispersive power is good; corrosion resistance is strong; electroplating time is reduced by 60 percent; processing cost is reduced by 30 percent; production efficiency is high; and economic benefit is good.

Owner:梁新中

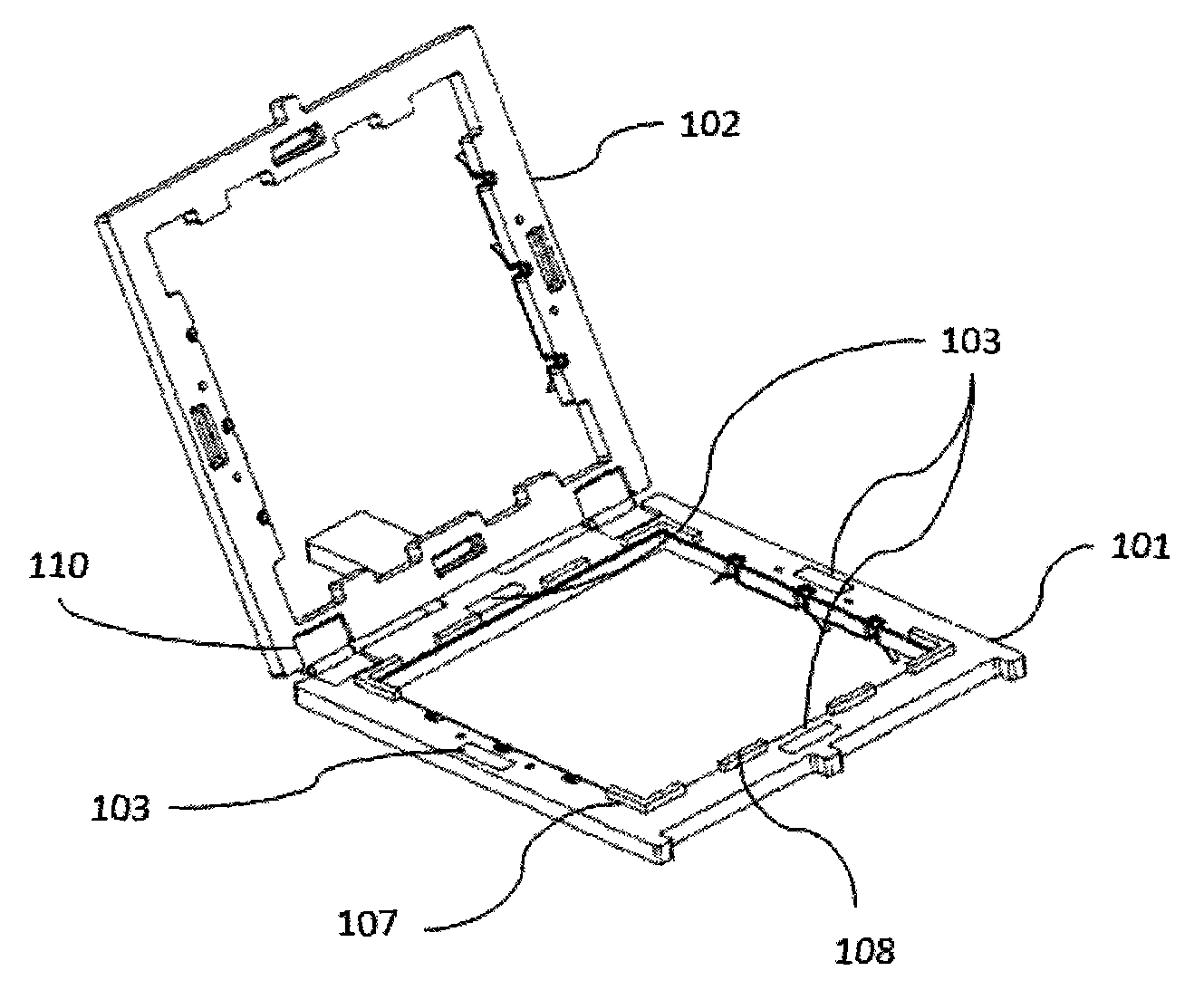

Electroplating clamp of solar cell

ActiveCN104032360AFast positioning and assemblyReduce broken rateElectrolysis componentsSemiconductor devicesMagnetEngineering

The invention provides an electroplating clamp of a solar cell. The electroplating clamp of the solar cell, provided by the invention, comprises a first frame, a second frame and a plurality of magnets, wherein the first frame and the second frame are of a hollow shape, edge parts of the first frame and the second frame are in contact and clamp the cell; and the plurality of magnets are respectively symmetrically fixed on the first frame or second frame, and the first frame and the second frame are jointed by using a magnetic force. The electroplating clamp of the solar cell, provided by the invention, is capable of rapidly locating the cell, quick in assembly, and continuous in production, ensures that the cell is uniformly conducted, and is capable of reducing the breakage rate of the cell.

Owner:平邑经济开发区投资发展有限公司

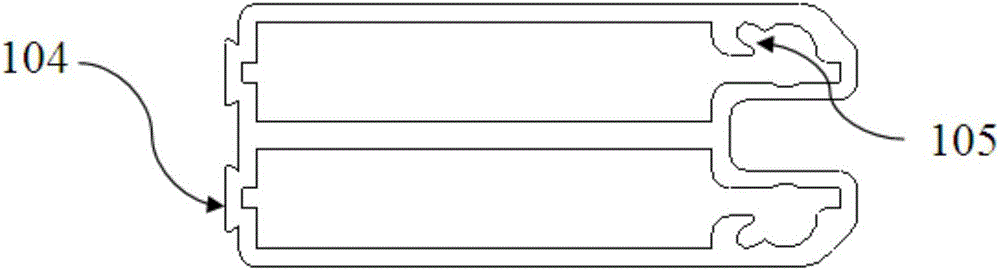

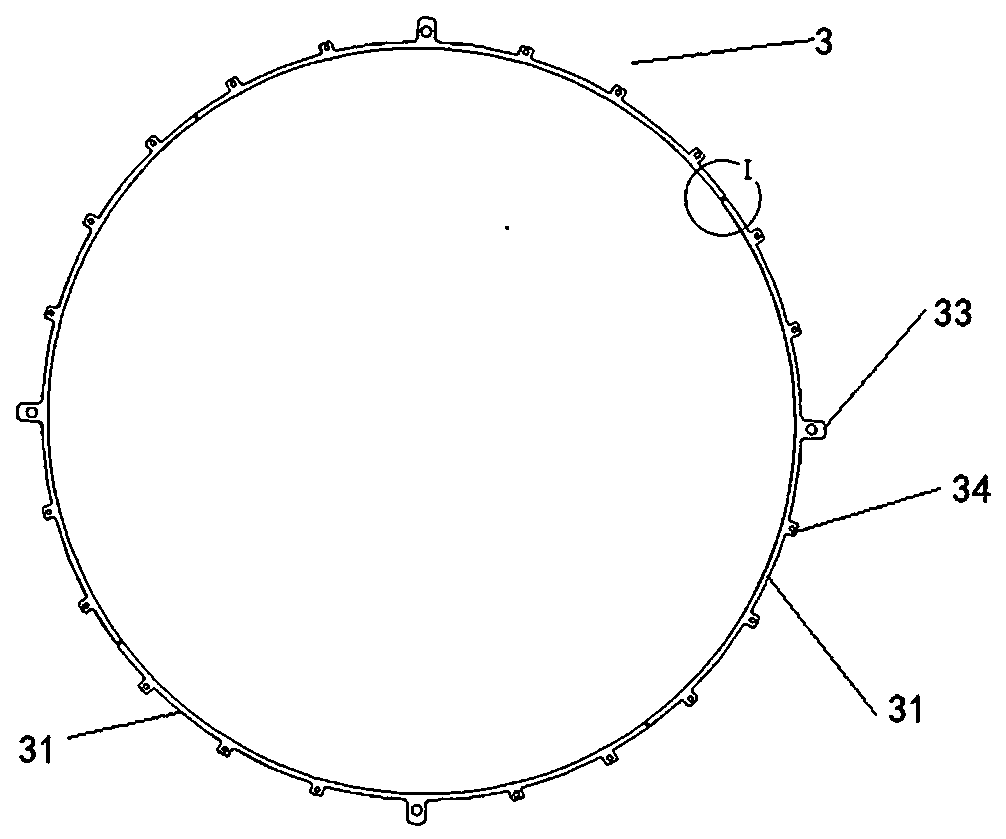

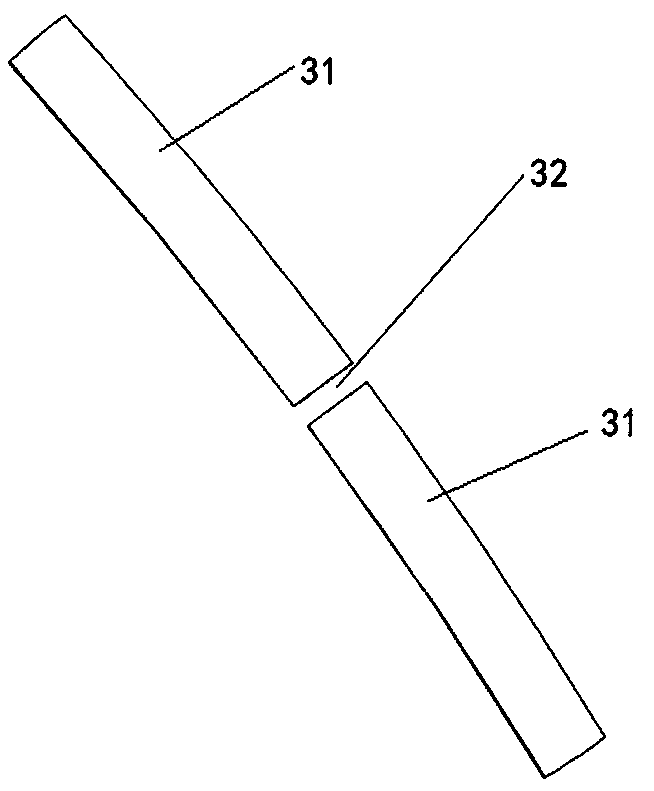

Conducting ring, power supply device based on conducting ring and electroplating jig based on power supply device

PendingCN108754590AQuality assuranceImprove stabilityCurrent conducting devicesSemiconductor devicesSilver plateCurrent distribution

The invention discloses a conducting ring, a power supply device based on the conducting ring and an electroplating jig based on the power supply device. The conducting ring comprises a conducting ring body. The conducting ring body is distributed in a sectional type structure and is composed of a plurality of conducting sections. Every two adjacent conducting sections are isolated after a brokenopening between the two adjacent conducting sections is filled with insulation paste. The surface of the conducting ring body is wrapped with an insulation paste layer. The conducting ring body is provided with at least one electrode and at least one supporting leg. The conducting ring is evenly divided into the multiple sections, each section can independently carry out current control, so that the consistence and the uniformity of current distribution density of a wafer or a whole printed circuit board are ensured, and the quality of a surface electroplating layer of the conducting ring is guaranteed; and a traditional conducting ring body is additionally provided with a nickel-plated layer and a silver-plated layer, the conducing impedance is reduced, the stability of transmitting currents of conducting ring is enhanced, the frequency of repairing and changing the conducting ring body is reduced, and the repairing cost is reduced.

Owner:SHENZHEN CHENGGONG CHEM

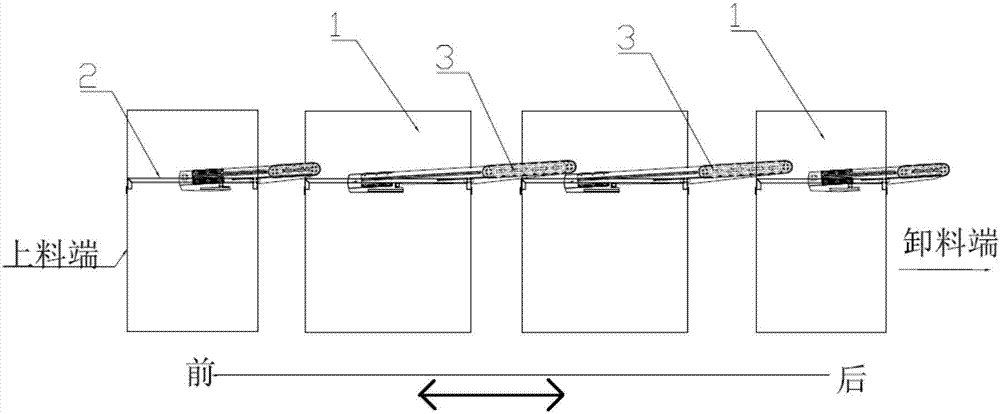

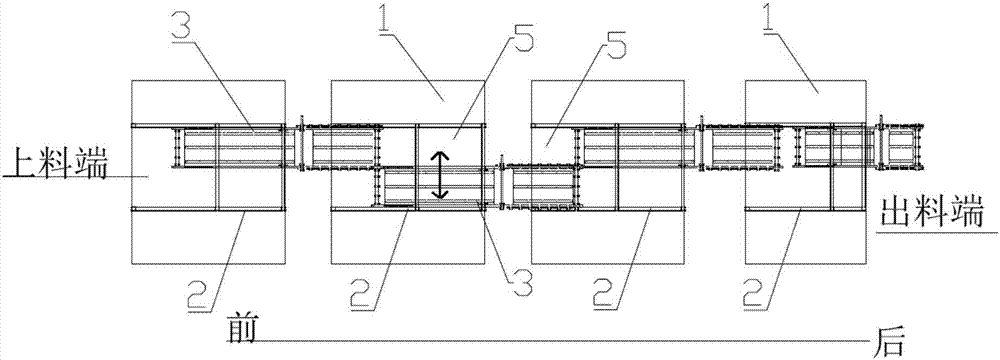

Barrel plating production line

ActiveCN106892250ARealize the function of barrel platingImprove barrel plating qualityElectrolysis componentsSupporting framesProduction lineEngineering

The invention discloses a barrel plating production line. The barrel plating production line comprises multiple barrel plating devices arranged in sequence; in the arrangement length direction of all the barrel plating devices, feed ports and discharge ports are respectively formed in the two end surfaces of all the barrel plating devices; conveying mechanisms are slidingly arranged on the adjacent end surfaces of two adjacent barrel plating devices; one ends of the conveying mechanisms extend into the barrel plating devices by the discharge ports of the barrel plating devices on the front sides, and the other ends of the conveying mechanisms extend into the barrel plating devices by the feed ports of the barrel plating devices on the back sides; connecting positions for enabling two adjacent ends to be positioned in overlapped areas and separation positions for enabling two adjacent ends to be positioned in staggered areas are vertically arranged at any one adjacent ends or two adjacent ends in at least one set of two adjacent conveying mechanisms; and any one adjacent ends or two adjacent ends in two adjacent conveying mechanisms move between the connecting positions and the separation positions to form the overlapped or staggered areas, so that plated workpieces are selectively input in the barrel plating devices for treatment by needed procedures according to the demands.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Metal nano injection molding air tightness electric connector and manufacturing process thereof

ActiveCN105098439ABoost power loadReduce weightLine/current collector detailsCouplings bases/casesHigh intensityTitanium

The invention discloses a metal nano injection molding air tightness electric connector manufacturing process. The process comprises the following steps: S1, an outer shell and a contact piece are molded through mechanical processing; S2, the surface of the contact piece matched with the stainless steel or titanium shell for use is plated with nickel and gold, and the contact piece matched with the aluminum alloy or copper alloy shell is not plated; S3, the sealing interface of the nickel and gold-plated contact piece is processed mechanically to remove the plating layer, nano modified treatment is then carried out, nano modified treatment is directly carried out on the stainless steel or titanium alloy shell, and surface nano modified treatment is directly carried out on the aluminum alloy or copper alloy shell and the matched contact piece; and S4, the contact piece is assembled in the outer shell through a nano injection molding process. High strength for the contact piece of the air-tightness connector can be kept, and plug-pull contact reliability can be improved; the electroplating efficiency and the electroplating layer quality can be improved; the weight of the connector is reduced greatly to reduce load of an aircraft; and power load of the air tightness electric connector is greatly enhanced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Structure of electroplating rotary drum

The invention provides a structure of an electroplating rolling barrel, comprising a barrel body, a round sealing plate, an upper cover and a plurality of upper cover pressing bars; the barrel body is a polygonal barrel-shaped container which is provided with an opening and formed by the overlapping connection and combination of a plurality of rectangular plates one by one; the rectangular plates are respectively provided with a slab which is provided with a plurality of through holes; the upper cover is a rectangular plate; the rectangular plate is provided with a slab which is provided with the through holes; two ends of the upper cover pressing bar are respectively provided with a hooking end and a pulling handle end; the pulling handle end also integrally extends by a clamping end corresponding to the hooking end; the hooking end and the clamping end are respectively used for hooking two sides of the opening of the barrel body; the upper cover is pressed on the barrel body so as to close the opening; and the structure of the electroplating rolling barrel has the advantages and characteristics of simplifying the preparation process of the electroplating rolling barrel, reducing the preparation cost, improving the whole strength of the electroplating rolling barrel and improving the electroplating quality.

Owner:HURMG YIEH MACHINERY IND

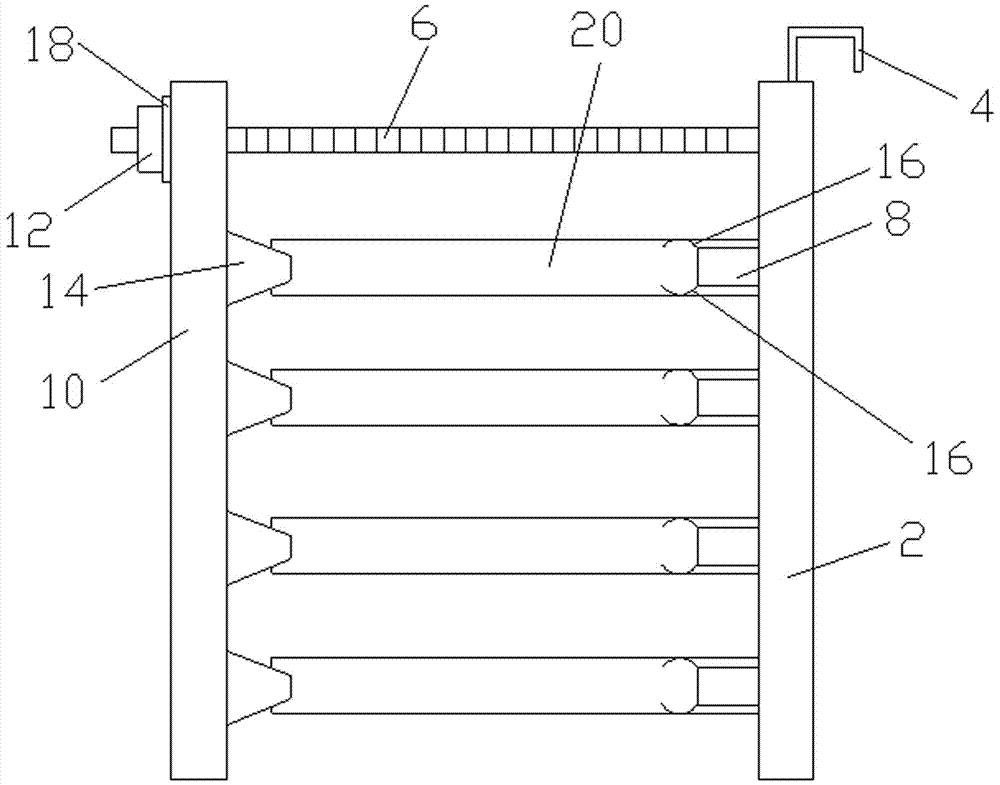

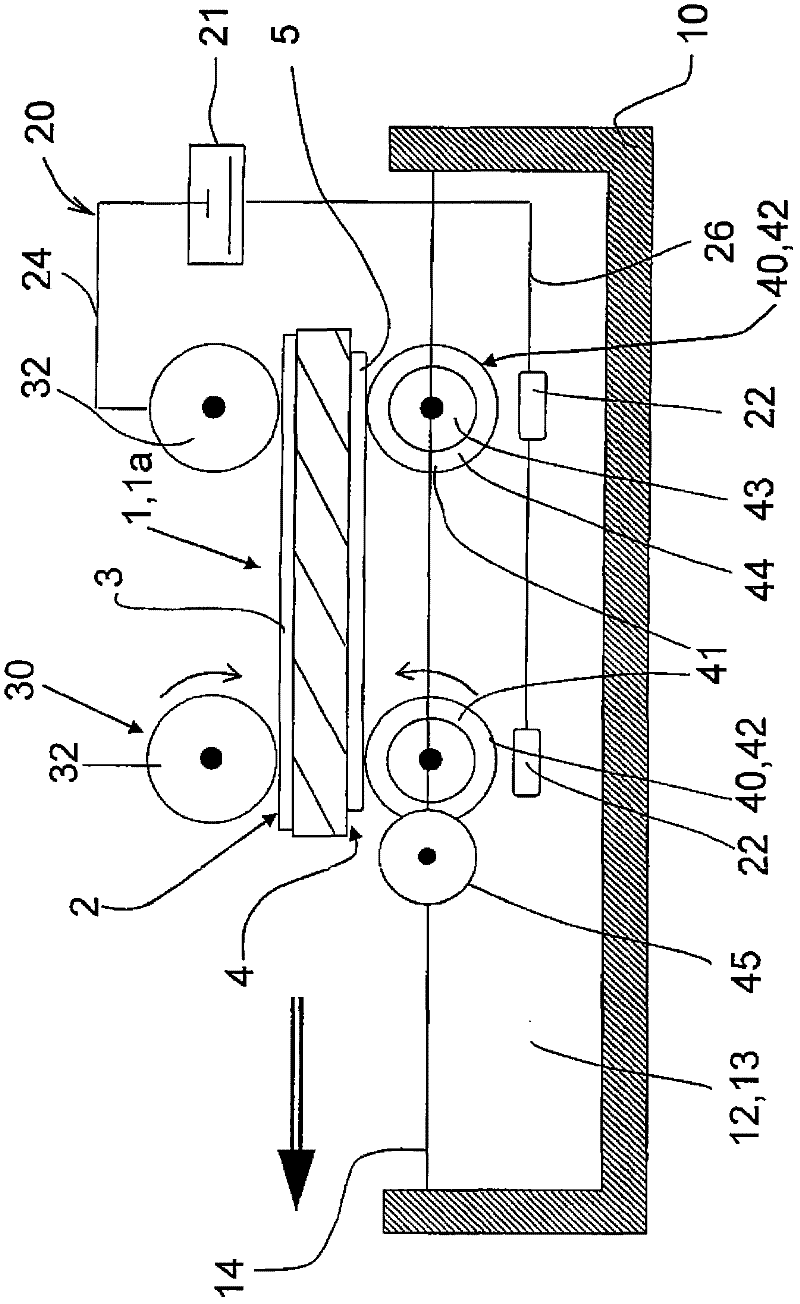

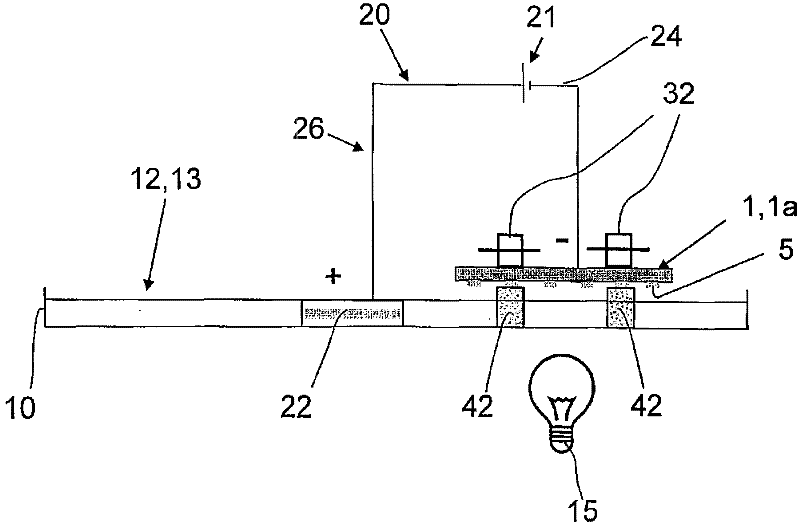

Method and device for galvanising substrates and solar cells

InactiveCN102453940AImprove plating qualityNo sideways fluctuationsContacting devicesSemiconductor/solid-state device manufacturingEngineeringSolar cell

The present invention provides a method and a device for galvanising substrates and solar cells. The device comprises a reservoir (12) having an electrolytic coating liquid (13), a lower transport device (40), and an upper transport device (30) for substrates (1), where a transport device comprises mechanisms (20,21,24,32) for contacting and connecting the substrates (1) to a voltage source (21). At least one transport device (30) is provided with at least one tampon (41) which is made of a absorbent material (44). Furthermore, the mechanisms are equipped so the tampon (41) absorbs the electrolytic coating liquid (13) and contacts with the surfaces of the substrates (1) to be plated.

Owner:SCHOTT SOLAR AG (DE)

High-temperature high-humidity electrode plate curing process

InactiveCN102856535AImprove performanceShorten the production cycleLead-acid accumulator electrodesHigh humidityMoisture

The inventive high-temperature high-humidity electrode plate curing process includes (1) sending green electrode plates into a curing chamber, and performing surface drying at 150-180 DEG C and relative humidity of 20-30%, to reach moisture content of 7.5-8.5 wt% in dried green electrode plate; and (2) regulating curing temperature to 90-95 DEG C and relative humidity of 100% in the curing chamber, and curing the green electrode plate for 24 h. The invention has the advantages of short curing time, firm bonding between lead paste and plate grid, no deformation and cracking, high production efficiency, high electrode plate quality, and substantially improved battery comprehensive performances.

Owner:HUNAN FENGRI ELECTRIC GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com