Zinc alloy slide fastener electroplating device

An electroplating device and zinc alloy technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of troublesome conductive connection between hangers and chain teeth, uneven surface treatment, low production efficiency, etc., and improve the quality of electroplating , consistent color, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

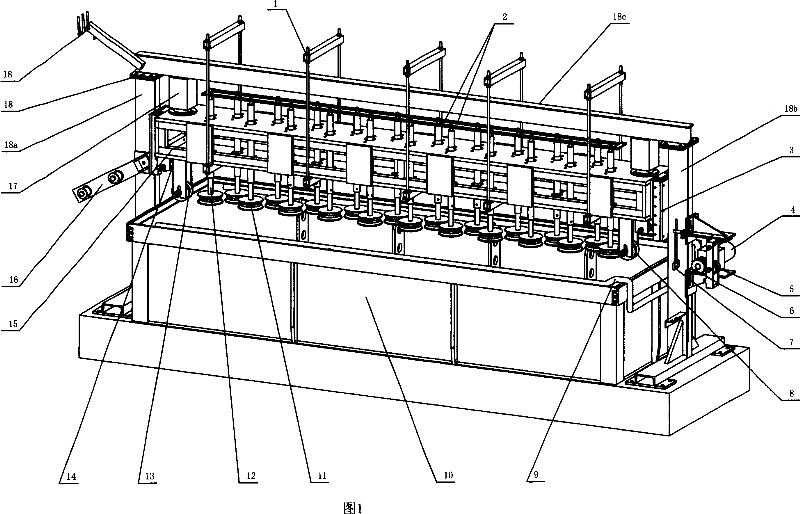

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the description.

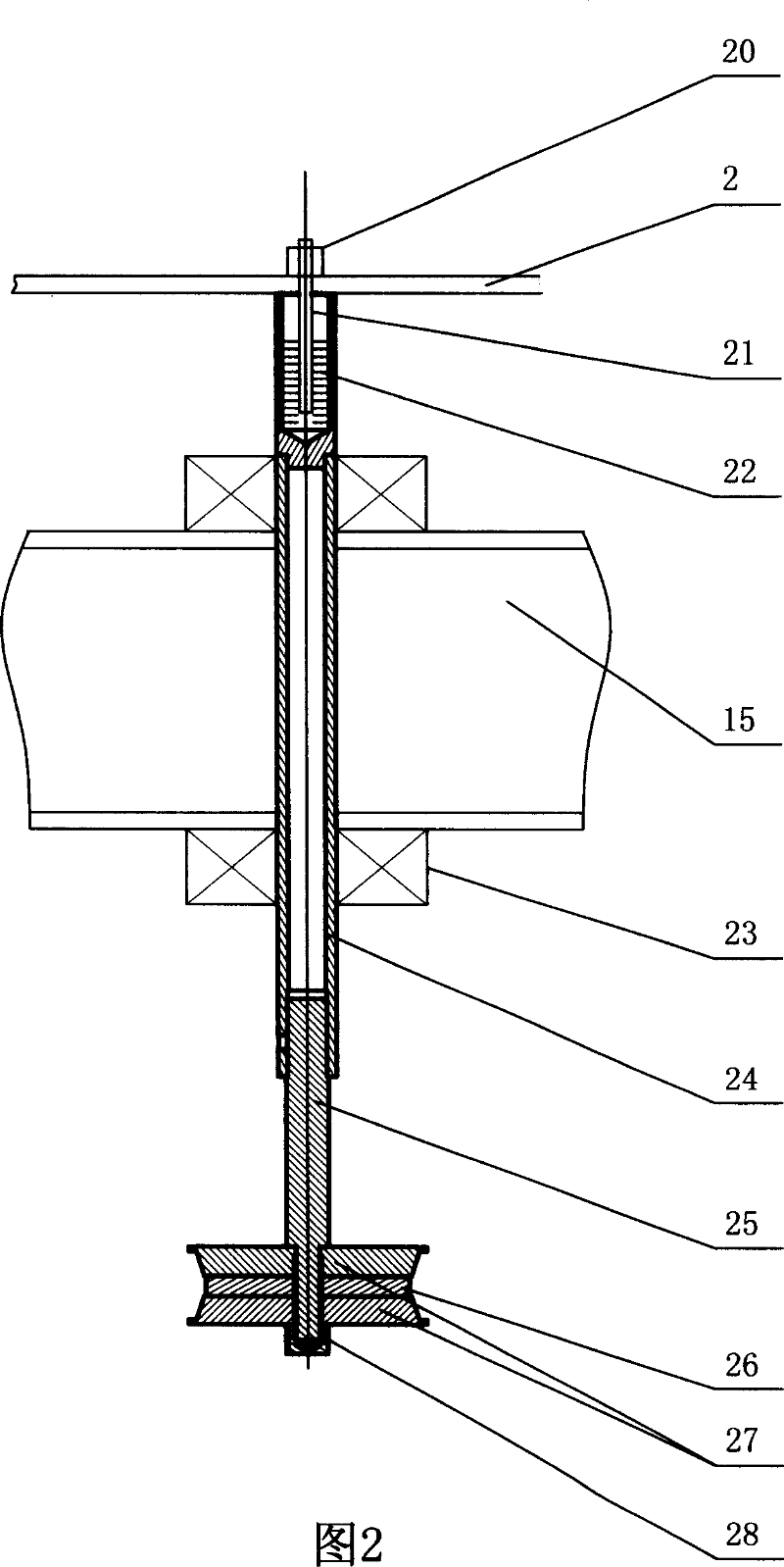

[0017] Zinc alloy zipper electroplating device as shown in Figure 1, frame 18 is arranged on the top of the tank body 10, and the rotating disc frame 15 passes through the oil cylinders 17 on the left and right sides, the dovetail groove slide rails 3 on the left and right sides and the left side plate of the frame 18 18a and the inner wall of the right side plate 18b are slidably matched, and the cross arm 1 is connected to the rotating disk frame 15, and the cross arm 1 is engaged with the cross plate 18c of the frame 18 through the engagement. A group of rollers 11 are arranged in staggered rows on the rotating disk frame 15 through the roller shafts 12, and the upper end of the roller shafts 12 is connected with the cathode copper bar 2. As shown in Figure 2, the rollers 11 are provided with insulation protection provided by the conductive disk 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com