Antibacterial fire-proofing board and manufacturing method thereof

A manufacturing method and technology of fireproof boards, which are applied in the field of manufacturing antibacterial fireproof boards, wallboards or partitions, can solve the problems of large flow of people, easy to spread diseases, long service life, etc., and achieve the effect of large social benefits and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

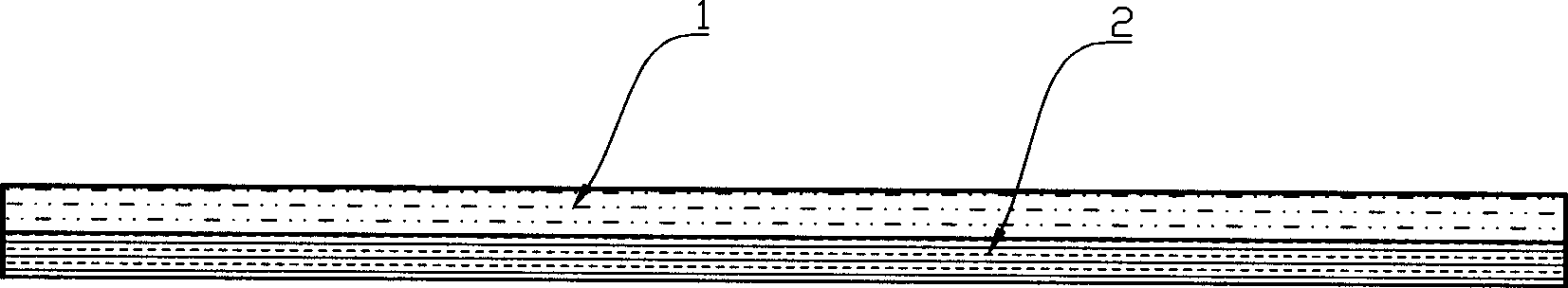

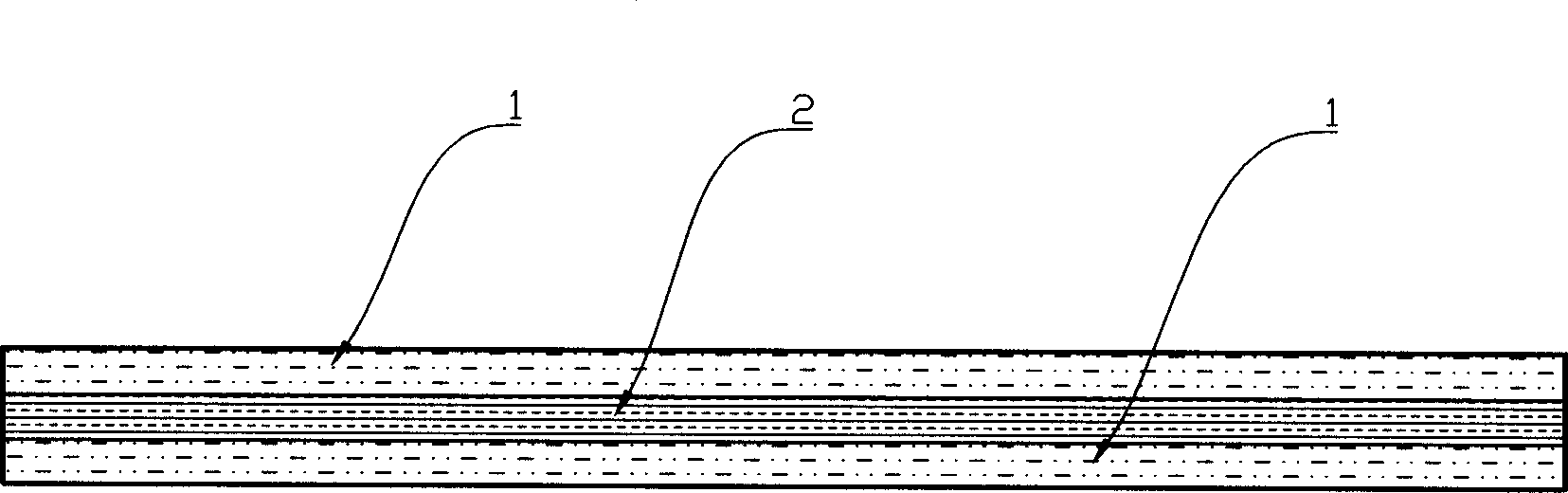

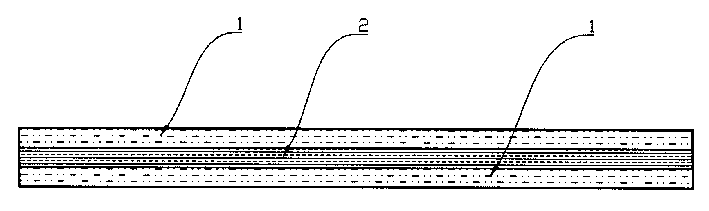

[0018] Such as figure 1 with figure 2 As shown, this product contains at least one layer of phenolic resin impregnated paper as the fireproof layer 2, and a layer of melamine formaldehyde resin impregnated decorative paper containing a fungicide is bonded on one or both sides of the fireproof layer 2 as the antibacterial layer 1. Thereby forming a product with one-sided antibacterial or double-sided antibacterial function.

[0019] The manufacturing method of the fireproof layer 2 includes the preparation of phenolic resin and the impregnation and drying of the core paper. Add phenol and formaldehyde with a molar ratio of 1:1.46 into the reaction kettle and stir for 20 minutes. After uniformity, add NaOH. This is an exothermic reaction. After the temperature stabilizes, slowly raise the temperature. When the temperature rises to 90-93°C, carry out the heat preservation reaction, and start to measure the viscosity after 45 minutes; then use an improved Austenitic viscometer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com