Patents

Literature

1534 results about "Fireproofing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproofing is rendering something (structures, materials, etc.) resistant to fire, or incombustible; or material for use in making anything fire-proof. It is a passive fire protection measure. "Fireproof" or "fireproofing" can be used as a noun, verb or adjective; it may be hyphenated ("fire-proof").

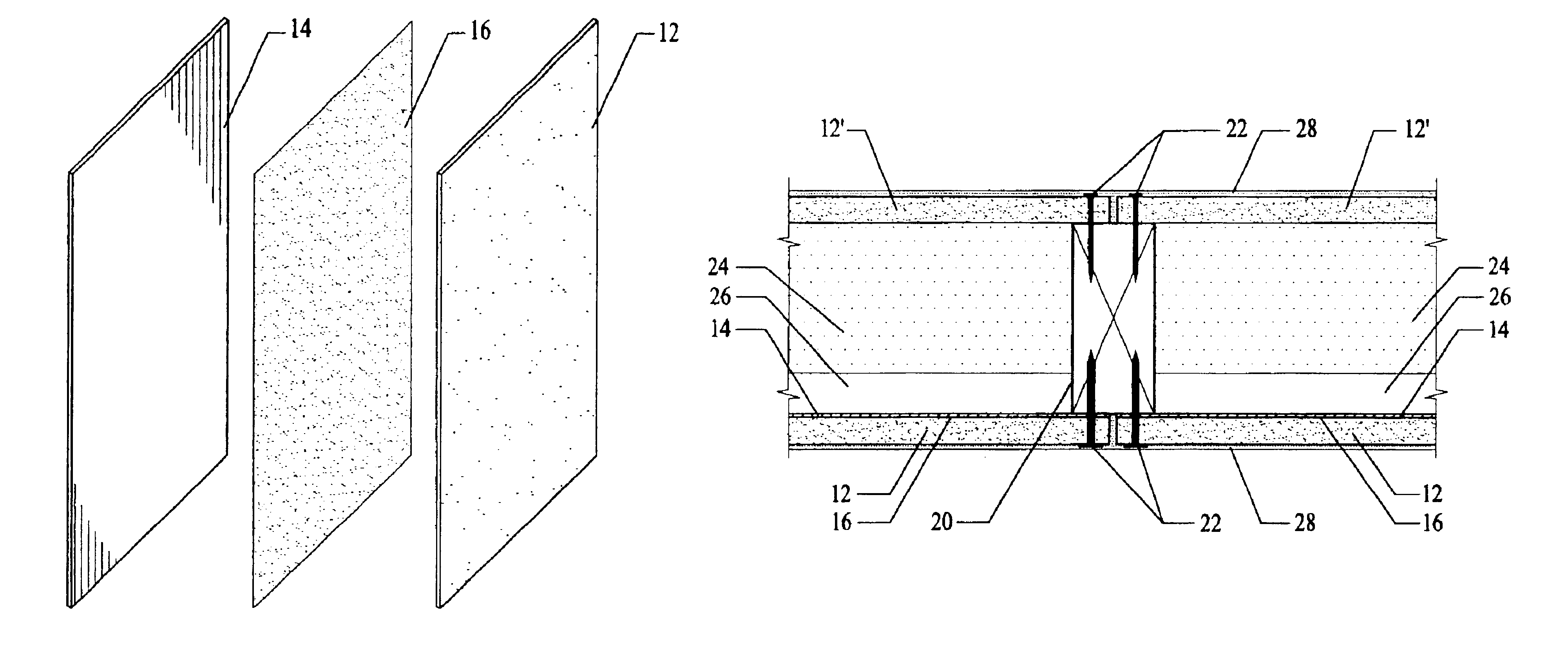

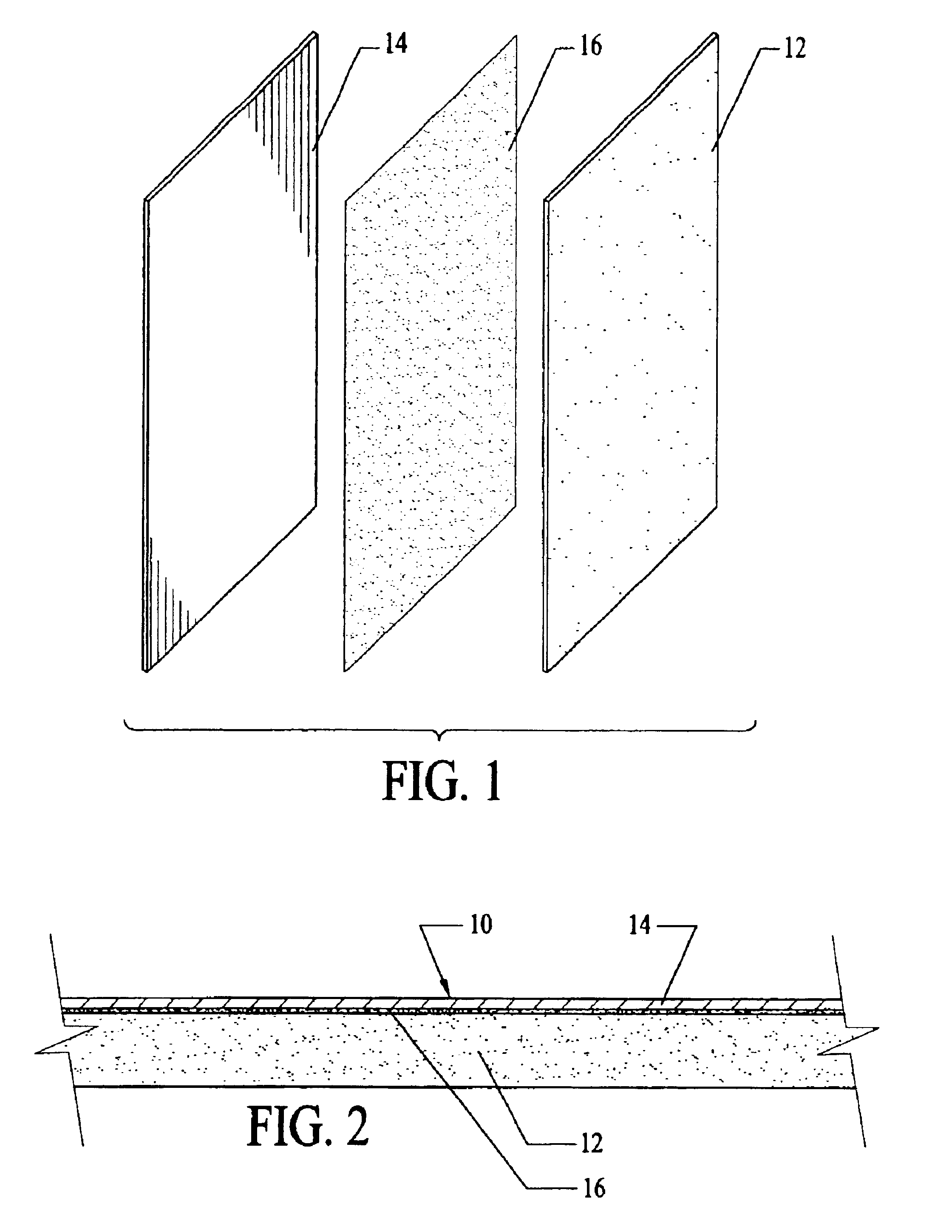

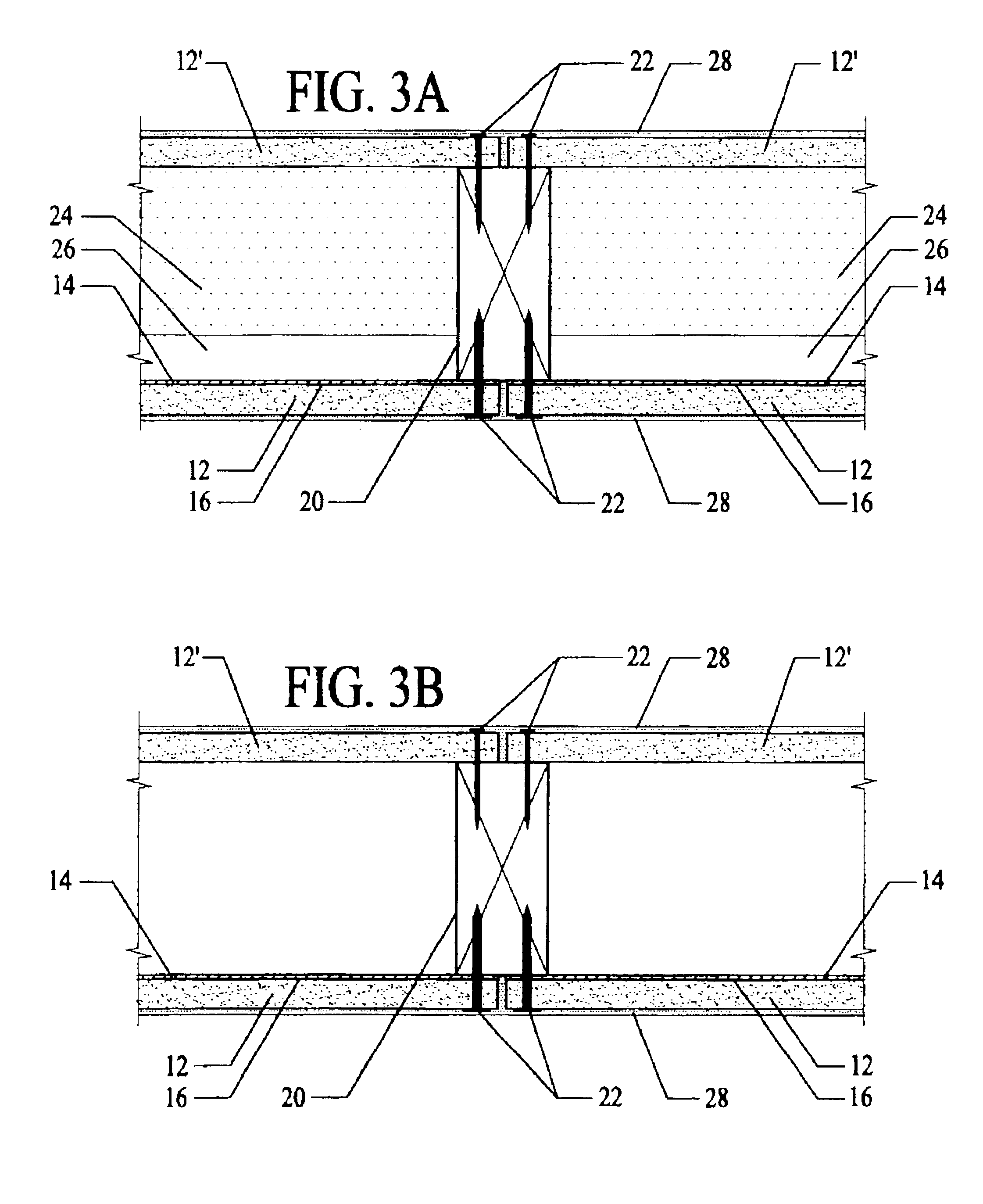

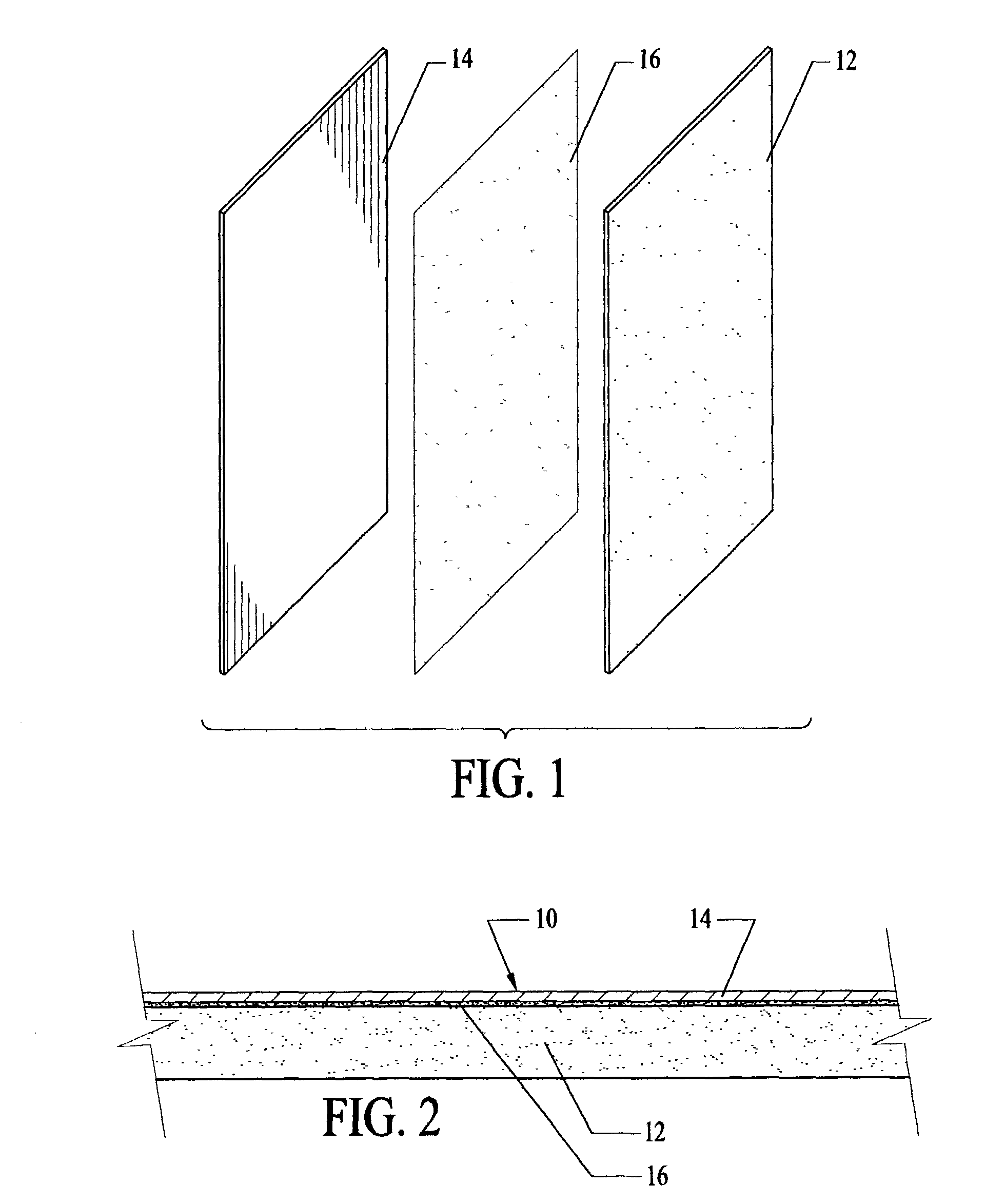

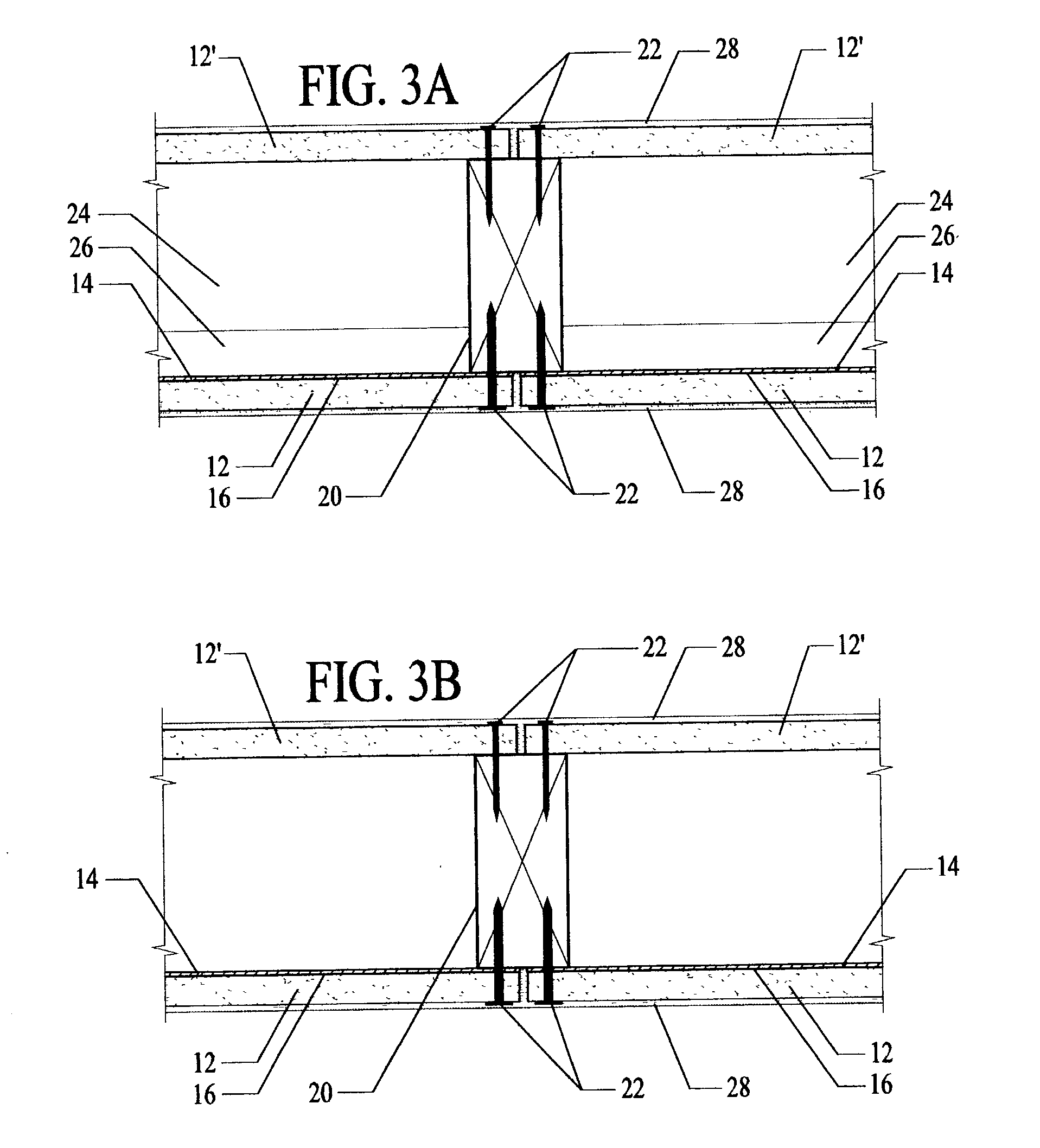

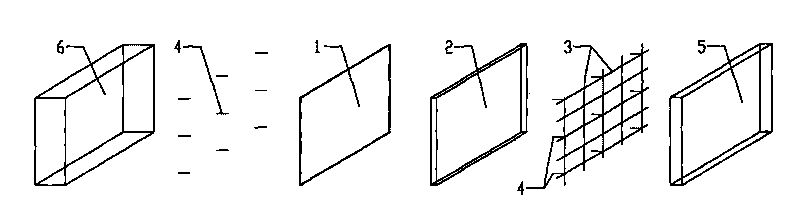

Multipurpose composite wallboard panel

A multipurpose composite wallboard panel is disclosed as having an aluminum sheet (14) attached by means of an adhesive (16) to a wallboard panel (12), such as a gypsum wallboard panel. Such a composite panel can readily be handled and quickly attached to the framework of buildings for the purpose of bracing, finishing, fireproofing, and thermally insulating wall structures in a single wall sheathing procedure.

Owner:AXSOM ERICH JASON

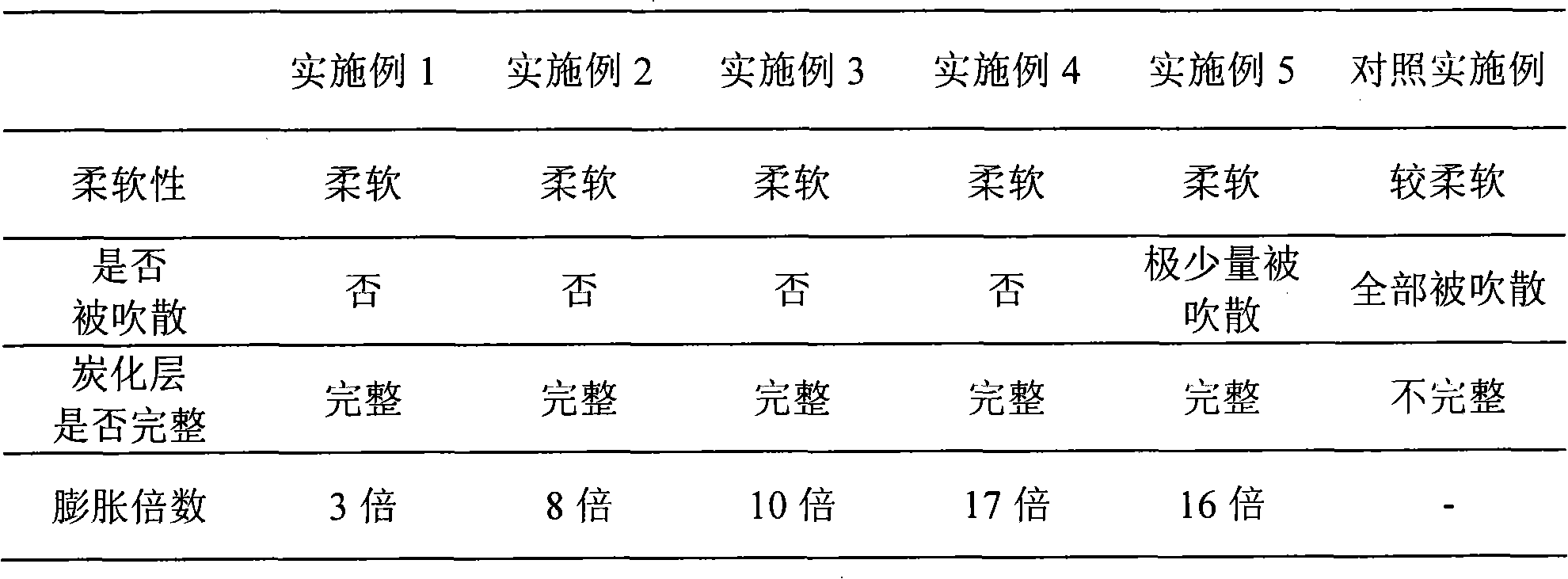

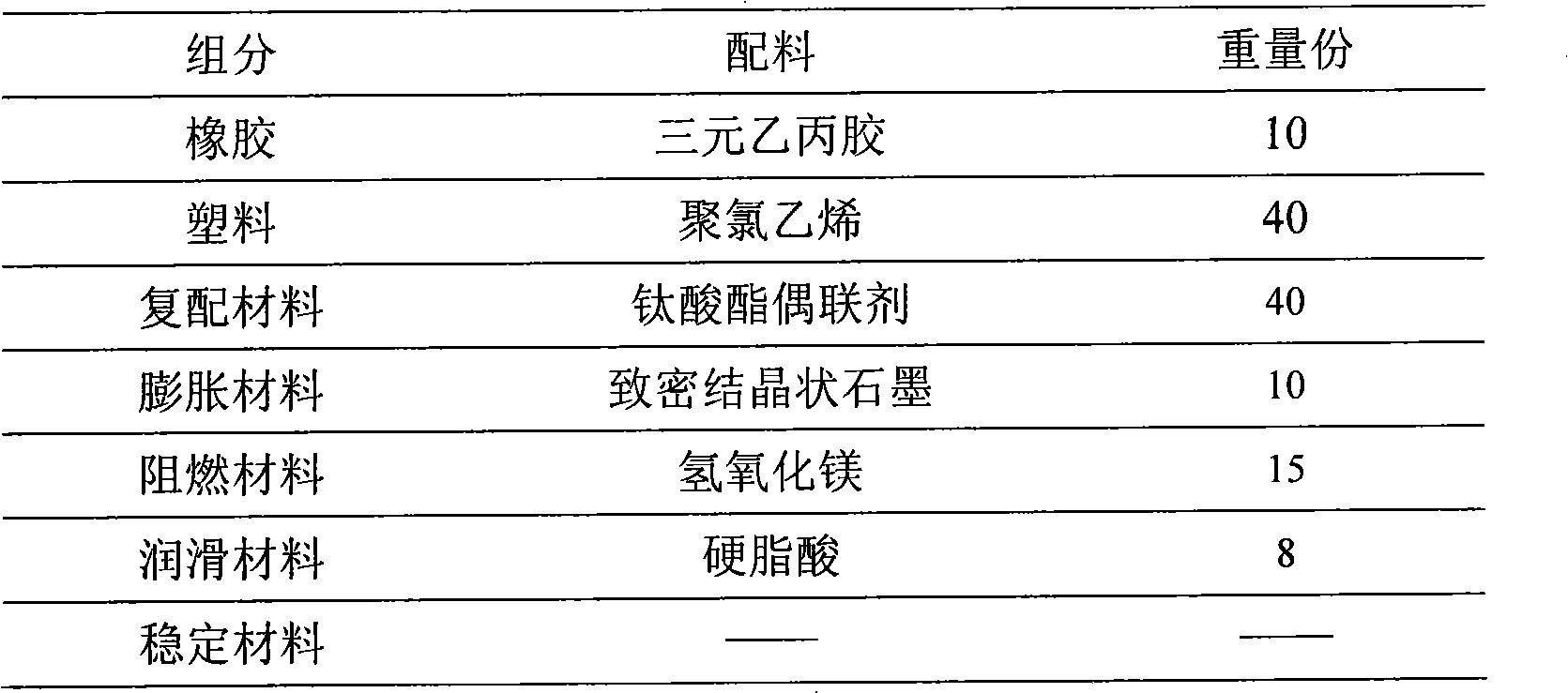

Expansion type fireproofing glue strip for construction

ActiveCN101323774AGood flexibilityEasy to installOther chemical processesFilm/foil adhesivesAdhesiveFireproofing

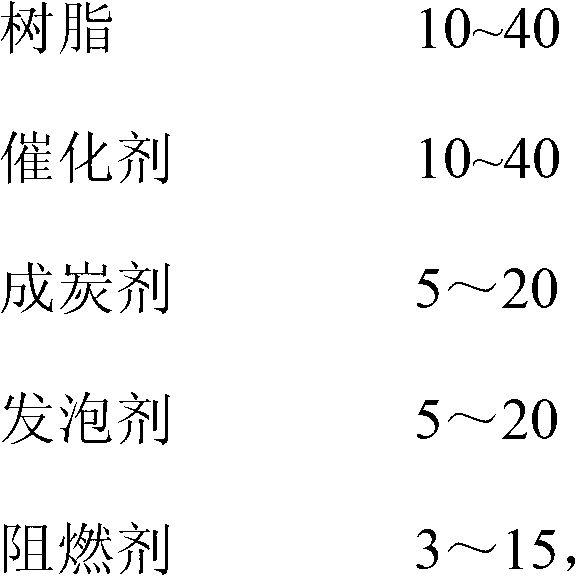

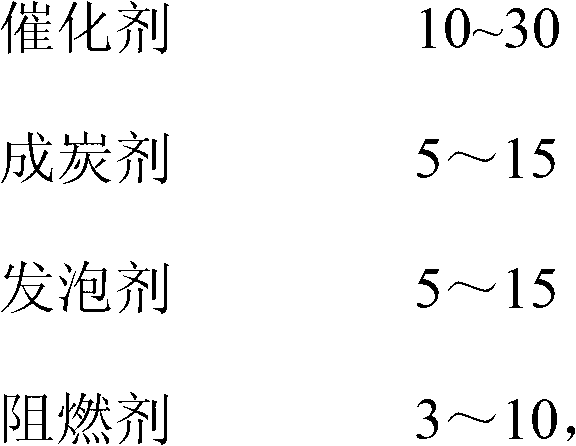

The invention discloses an intumescent fireproof adhesive tape used in construction and relates to the field of fireproof sealing materials, aiming at solving the technical problems that the existing fireproof sealing tape does not have good pliability under normal temperature, thus being inconvenient for construction and installation, and can not resist high-temperature thermal current when encountering fire, etc. The intumescent fireproof adhesive tape used in construction of the invention consists of the components by parts by weight (pbw) as follows: 10 pbw to 60 pbw of rubber, 10 pbw to 40 pbw of plastic, 10 pbw to 40 pbw of compounded material, 10 pbw to 30 pbw of intumescent material, 8 pbw to 55 pbw of flame retardant material, 0 pbw to 8 pbw of lubricating material and 0 pbw to 8 pbw of stabilizing material. The intumescent fireproof adhesive tape of the invention is applicable to the blocking of perfoliate openings and fireproof sealing of building apertures.

Owner:应急管理部四川消防研究所

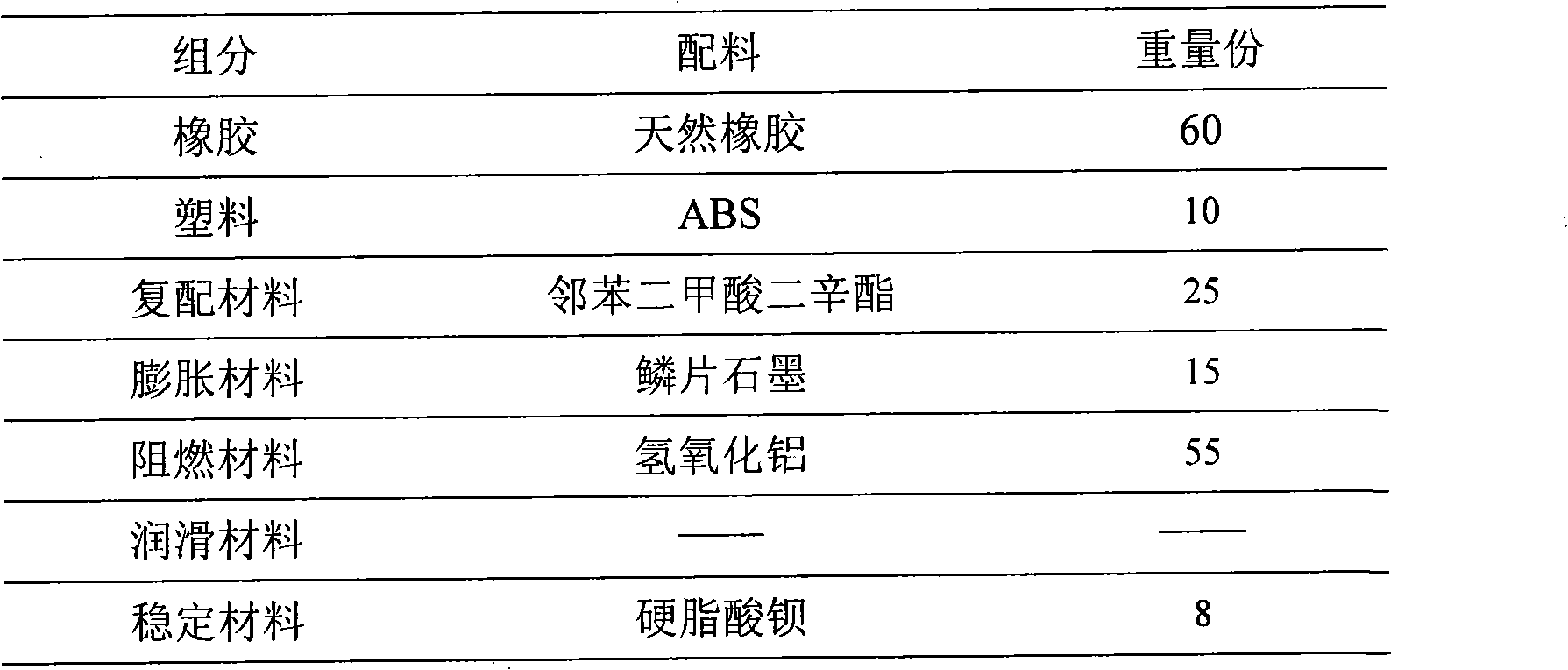

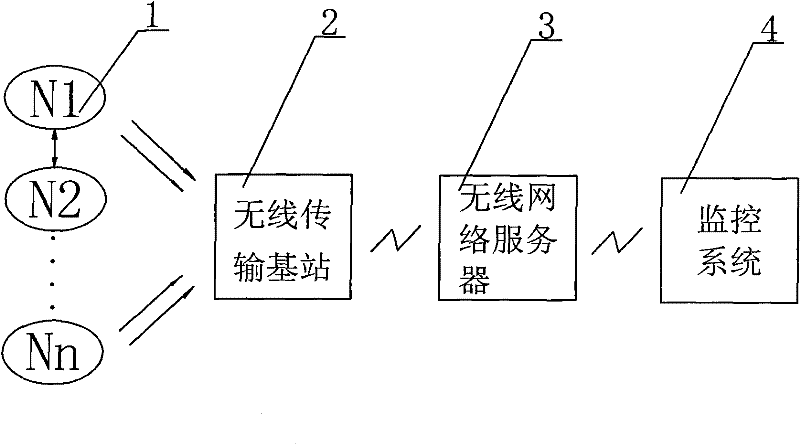

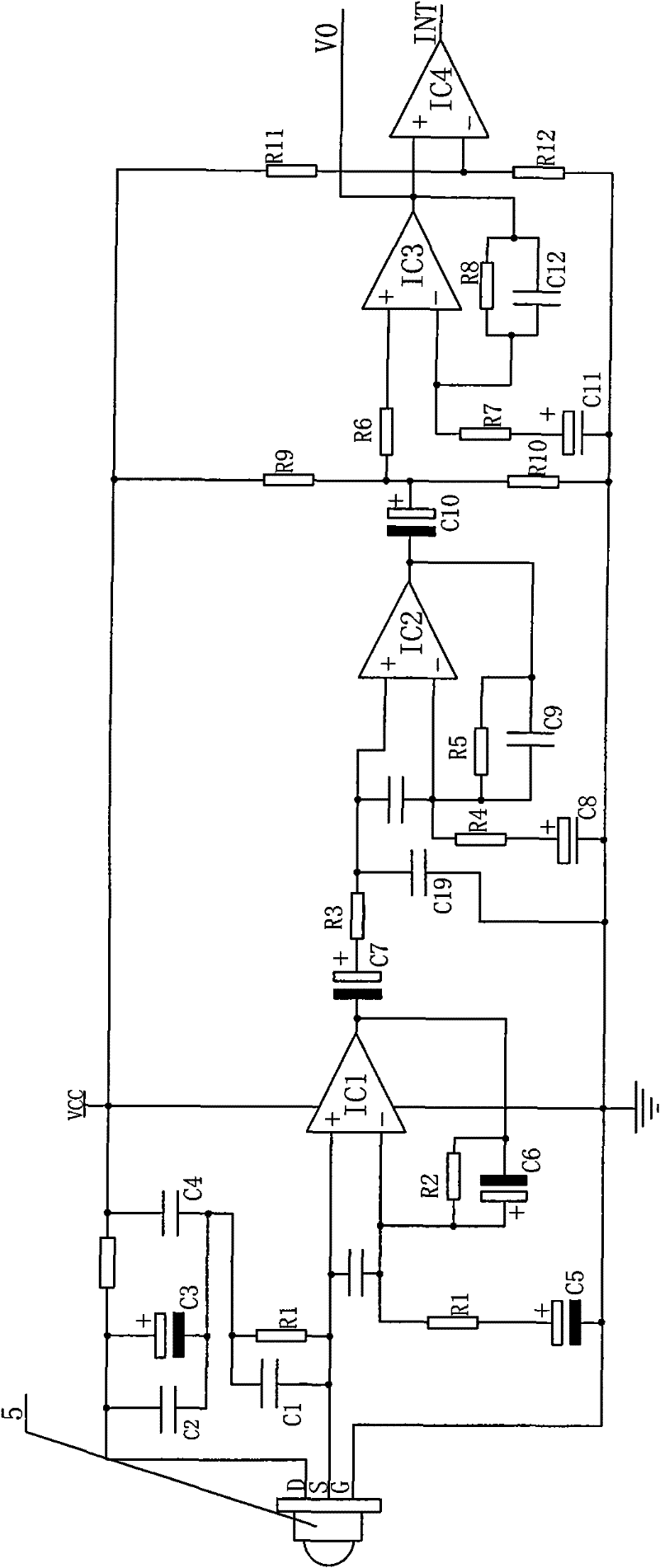

Forest fireproofing early warning system

ActiveCN101751755AEasy constructionAvoid open circuit failureFire alarmsShortest distanceFireproofing

The present invention relates to a forest fireproofing early warning system which is composed of a wireless internet server, a monitoring system, at least two fireproofing detector and at least one wireless transmission base station. The present invention is characterized in that a wireless fire alarm detection and fire alarm information transmission net is formed by at least two fireproofing detectors; the wireless transmission base station is in the wireless fire alarm detection and fire alarm information transmission net; each fireproofing detector is used for detecting fire hazards to generate early warning signals, and short-distance wireless early warning signals are transmitted between adjacent two fireproofing detectors to the wireless transmission base station directly; the wireless transmission base station and the wireless internet server are communicated wirelessly; and the wireless internet server is connected with the internet of the monitoring system. The present invention has the advantages of convenient construction and arrangement, wide monitoring range, without communication cables and safe use, and can timely monitor the fire hazards and judge the pervasive conditions of the fire hazards.

Owner:重庆英卡电子有限公司

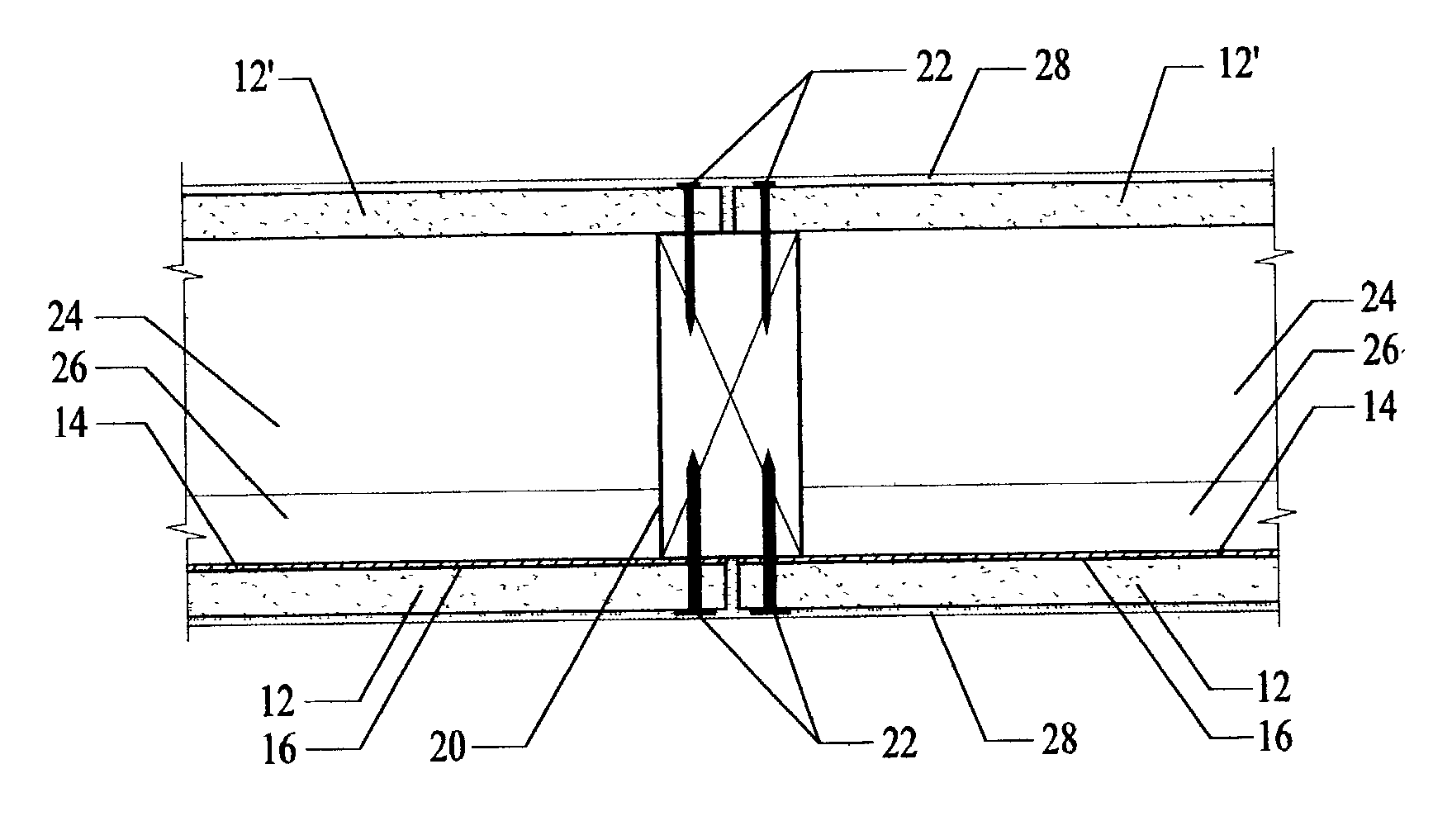

Multipurpose composite wallboard panel

A multipurpose composite wallboard panel is disclosed as having an aluminum sheet (14) attached by means of an adhesive (16) to a wallboard panel (12), such as a gypsum wallboard panel. Such a composite panel can readily be handled and quickly attached to the framework of buildings for the purpose of bracing, finishing, fireproofing, and thermally insulating wall structures in a single wall sheathing procedure.

Owner:AXSOM ERICH JASON

Expansion type fire-retardant coating

ActiveCN102702962AOvercome the disadvantage of poor thermal stabilityGood fire and heat insulationFireproof paintsEpoxy resin coatingsAcrylic resinFireproofing

The invention relates to an expansion type fire-retardant coating which contains organic silicon resin, and particularly comprises the components in part by weight: 10-40 parts of resin, 10-40 parts of catalyst, 5-20 parts of charcoal forming agent, 5-20 parts of foaming agent, and 3-15 parts of flame retardant, wherein the resin is selected from one or more of epoxy resin, phenolic resin, and acrylic resin as well as organic silicon resin. According to the invention, the shortcoming that the traditional fire-retardant coating is poor in heat stability is overcome; the coating has the characteristics of good fireproofing heat-insulating property, good bonding force, high strength, capability of bearing high and low-temperature circulation influence, excellent water resistance, acid resistance and salt corrosion resistance of coating layer, difficult in falling, stability in storage, good decoration property, convenience for construction and the like; during combustion, no smog or little smog is generated; and the coating is particularly suitable to be used as a fire-resistant coating for ultra-thin steel structures, veneer type fire-retardant coating and cable fire-retardant coating.

Owner:TIANCHANG YINHU PAINT

Tunnel fire-proof paint

InactiveCN101134854AImprove water resistanceGood weather resistanceFireproof paintsCement coatingsFiberHigh resistance

The tunnel fireproofing material consists of sulforaluminate cement 30-50 wt%, inorganic heat insulating stuffing expanded perlite 5-30 wt%, expanded vermiculite 13-40 wt%, kaolin 5-15 wt%, aluminum hydroxide 5-20 wt%, magnesium hydroxide 0-25 wt%, diatomite 0-3 wt%, mine slag 0-10 wt%, redispersible glue powder 2-10 wt%, water reducing agent 0.1-2 wt%, expanded fire retardant 0-1 wt%, reinforcing fiber 0-1 wt%, setting retarder 0-5 wt% and setting accelerator 0-3 wt%. The tunnel fireproofing material has the advantages of high water resistance, high weather resistance, high fire resistance, high corrosion resistance, high stability and other advantages.

Owner:彭桦 +1

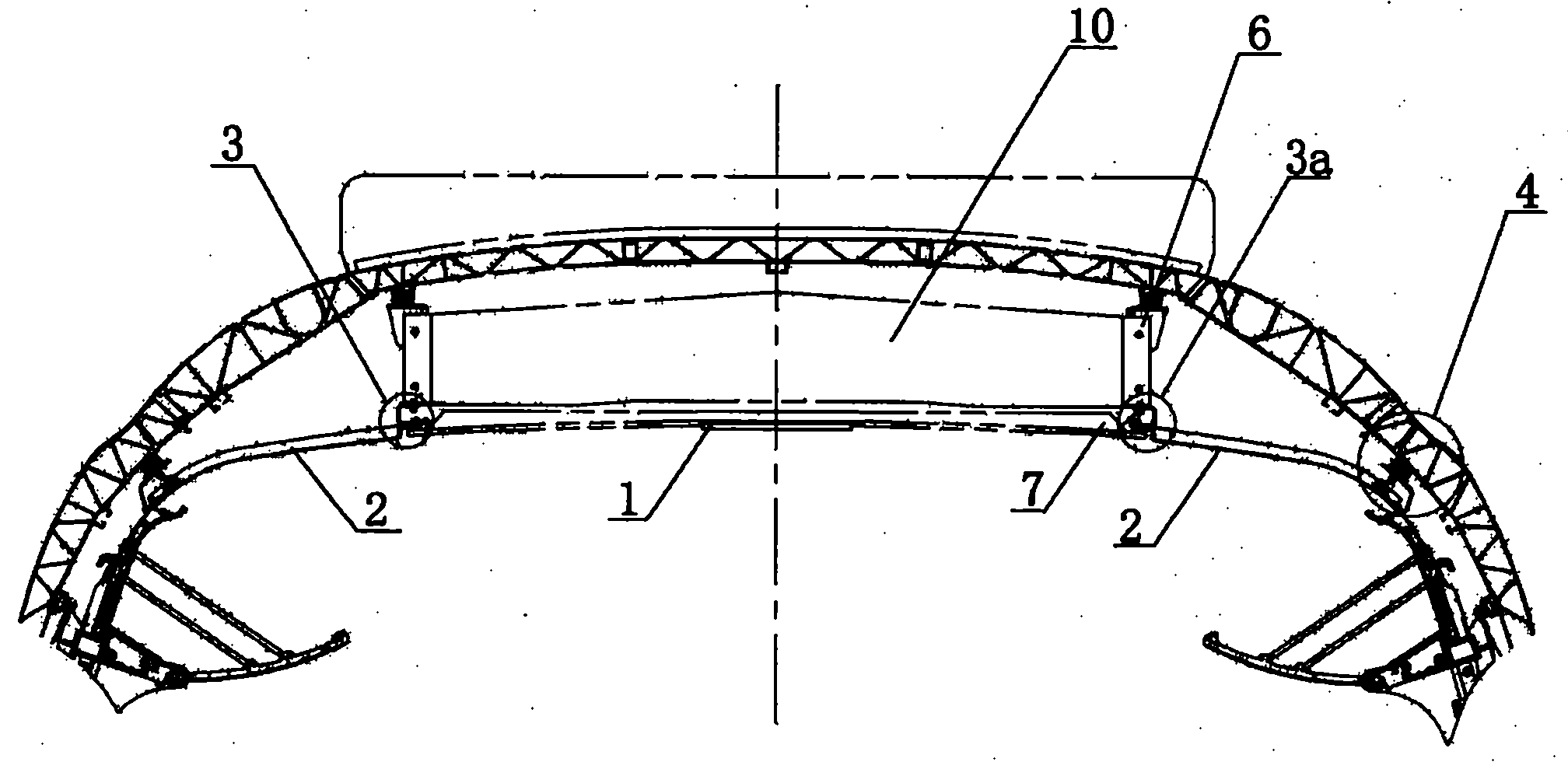

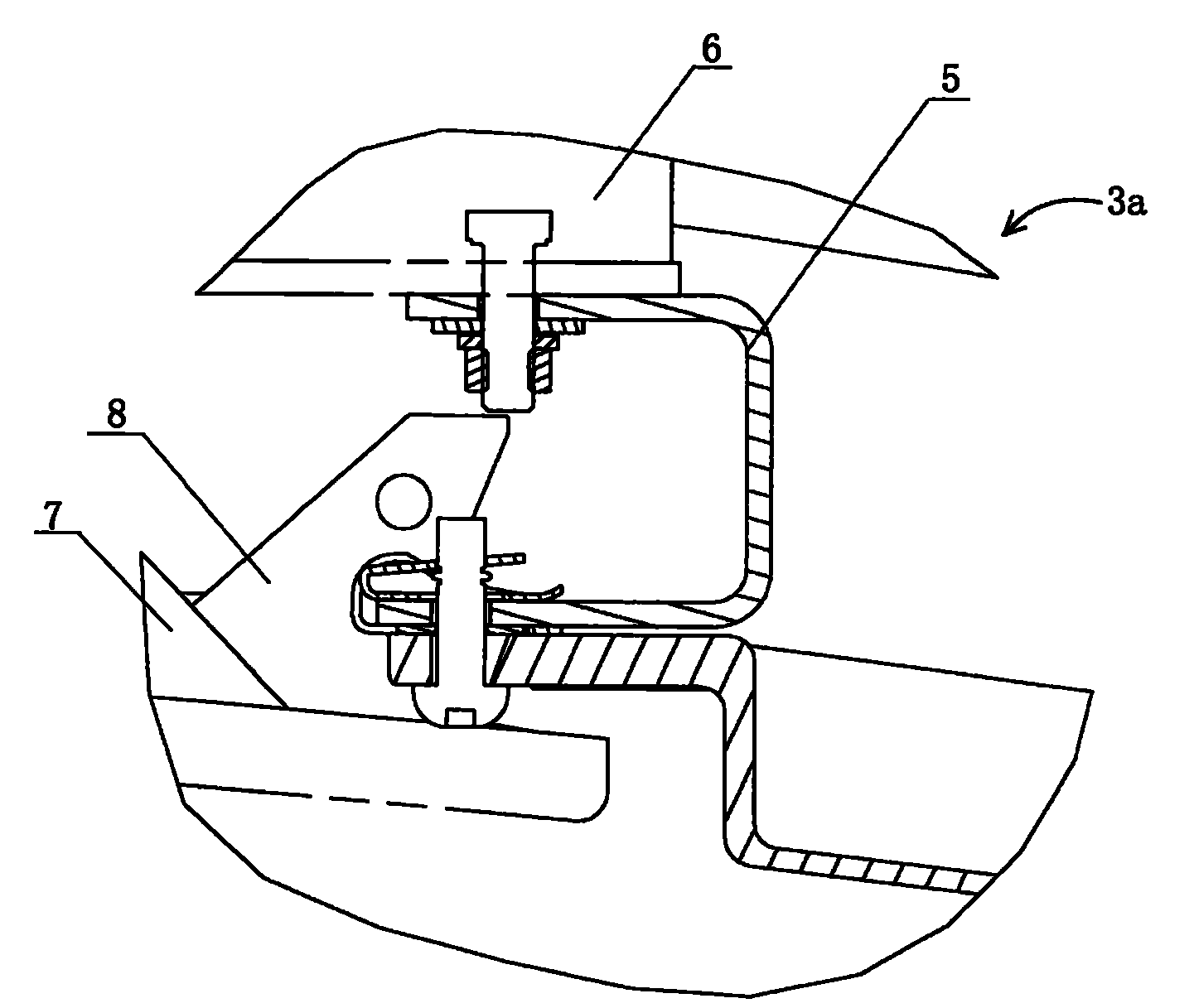

Top slab connecting structure inside railway train roof

ActiveCN101804818AReduce noiseImprove fire performanceRailway roofsMaterial based railway technolgyRailway passenger carFireproofing

The invention relates to the technical field of railway train roofs and discloses a modular designing and manufacturing method of a top slab curved connecting structure in a railway train roof. The top slab connecting structure inside the train proof comprises an intermediate top slab, side top slabs, connecting assemblies of the intermediate top slab and the side top slabs and connecting assemblies of the side top slabs and a train body. Connecting parts of the side top slabs and the intermediate top slab are arranged on air duct affiliated hanging codes through large-stroke screw parts; top slab hanging codes are arranged on an air-conditioning air duct; and the connecting parts of the side top slabs and the train body are fixed on inserts of a C-shaped groove of the train body through fixing clamping pieces of the side top slabs. The curved connecting structure can effectively reduce noise in the train body, improve the fireproofing capability in the train body, can be convenient to overhaul air-conditioning air outlet duct components at the upper part of the top slab in a carriage, ensures uniform air outlet of an air conditioner and greatly improves the comfort and the practicability for passengers to take a seat.

Owner:CRRC TANGSHAN CO LTD

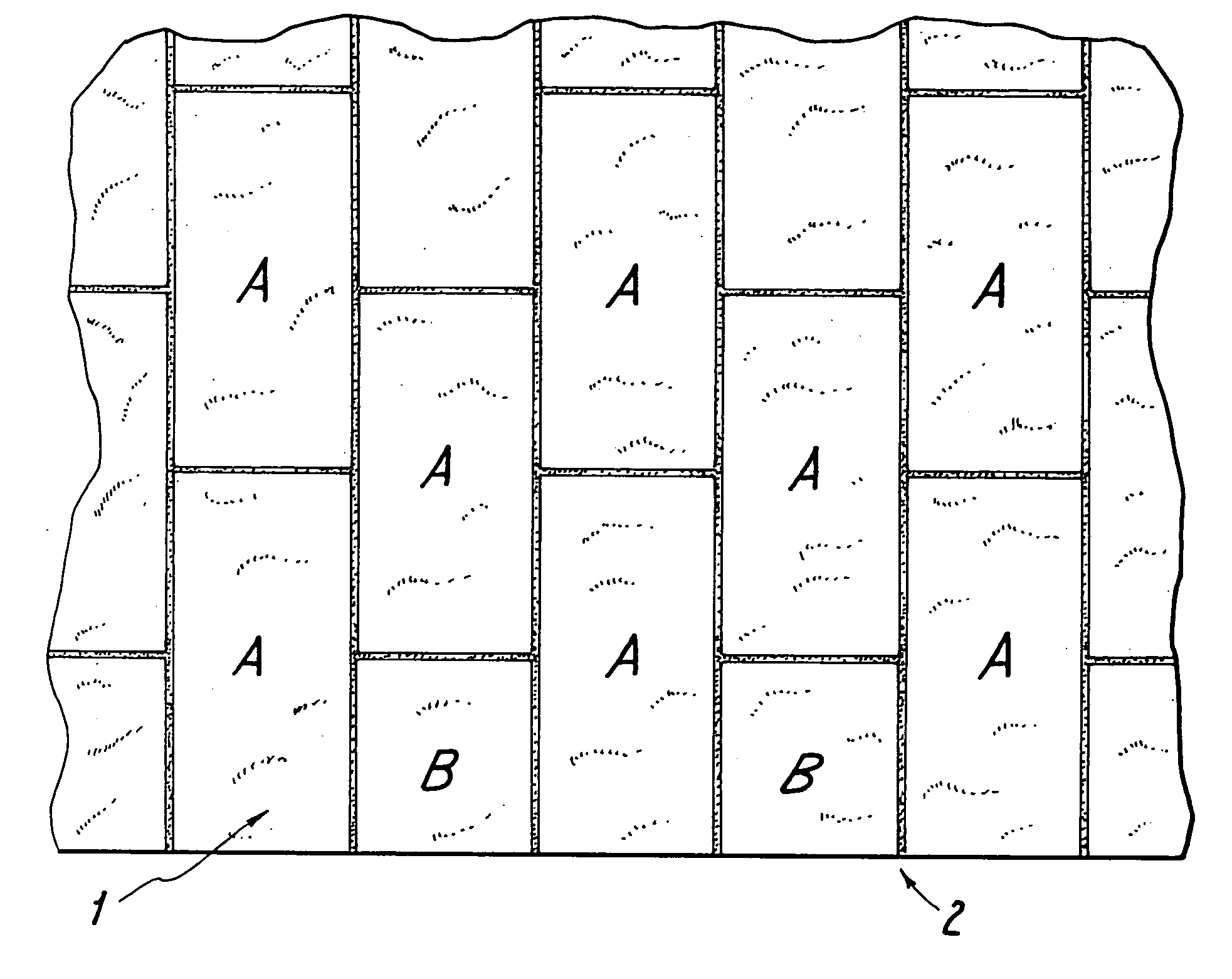

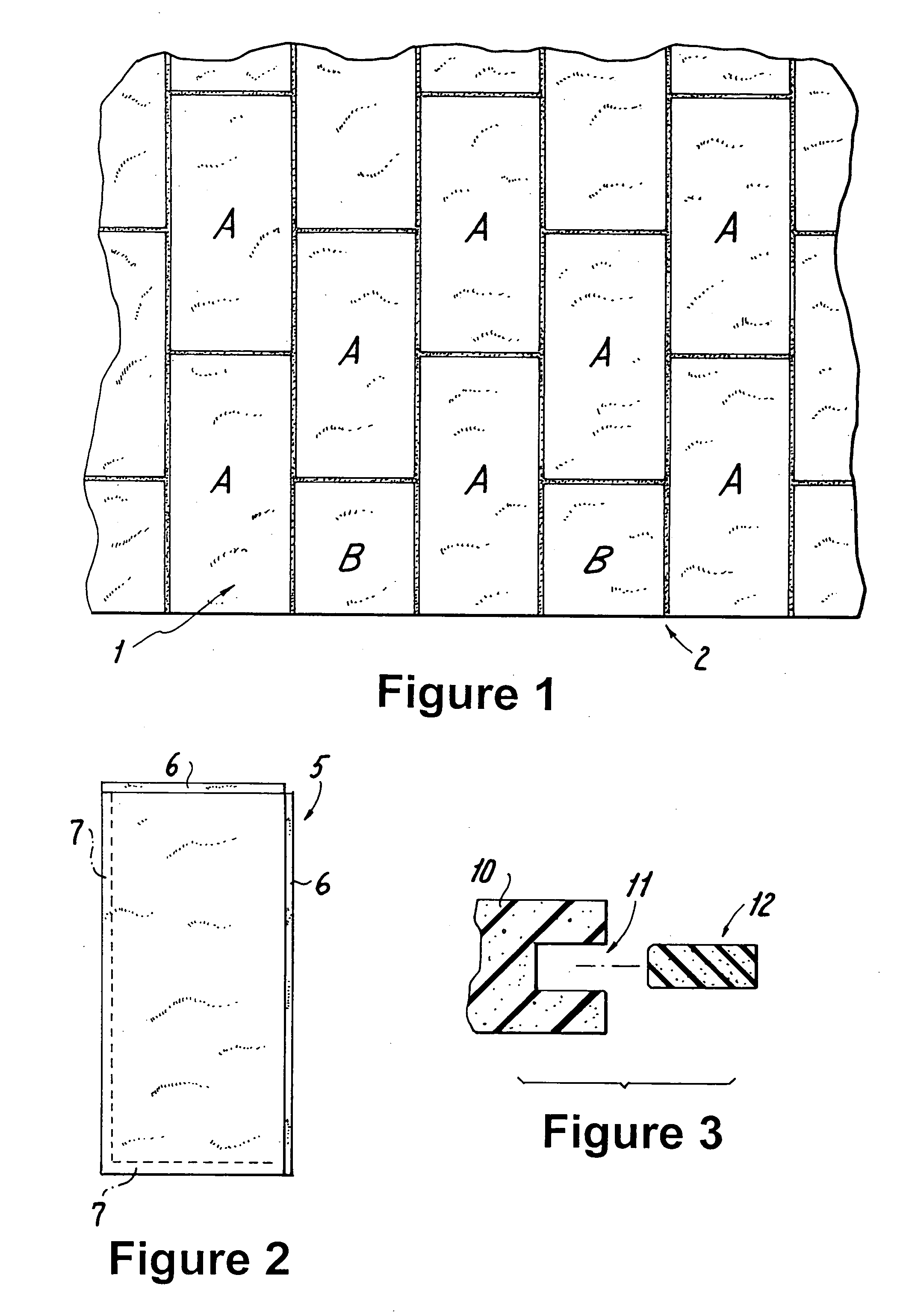

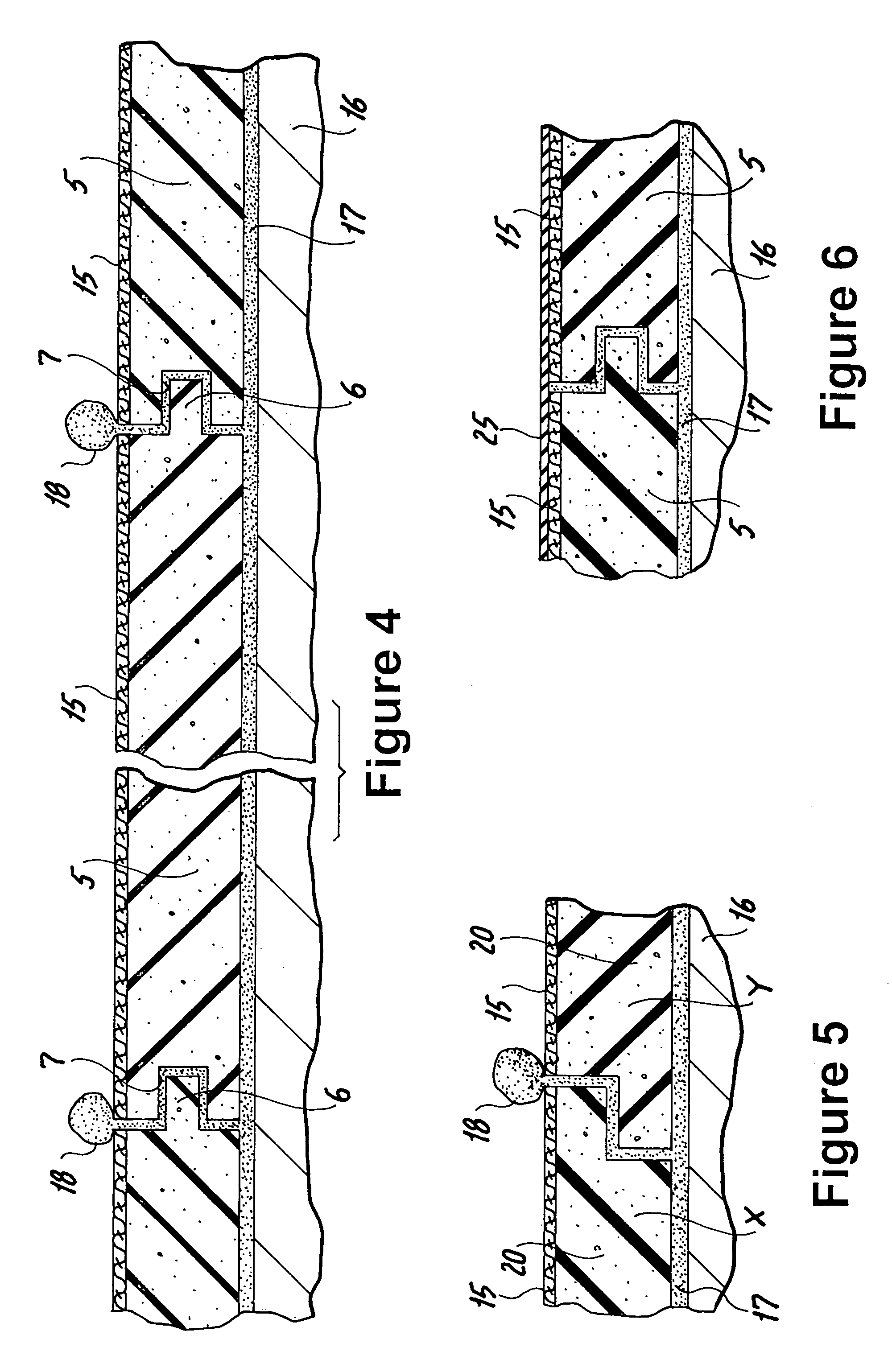

Fireproof seamless foam panel roofing system

InactiveUS7168221B2Secure bondingControl freedomBuilding roofsRoof covering using slabs/sheetsAdhesiveFireproofing

A crush resistant seamless roofing system is formed by a layer of adjacent panels having loose joints filled by expanding rising foam adhesive, which is trimmed to remove excess foam adhesive above a top plane of the roofing system. The roofing system thus formed is covered by a fabric layer and a coating. Further, the seamless roofing system is combined with a base layer, located beneath the panels, the base layer comprising bonded panels of a lightweight fireproofing material, resistant to moisture and foot traffic.

Owner:HUNTER JR JOHN P

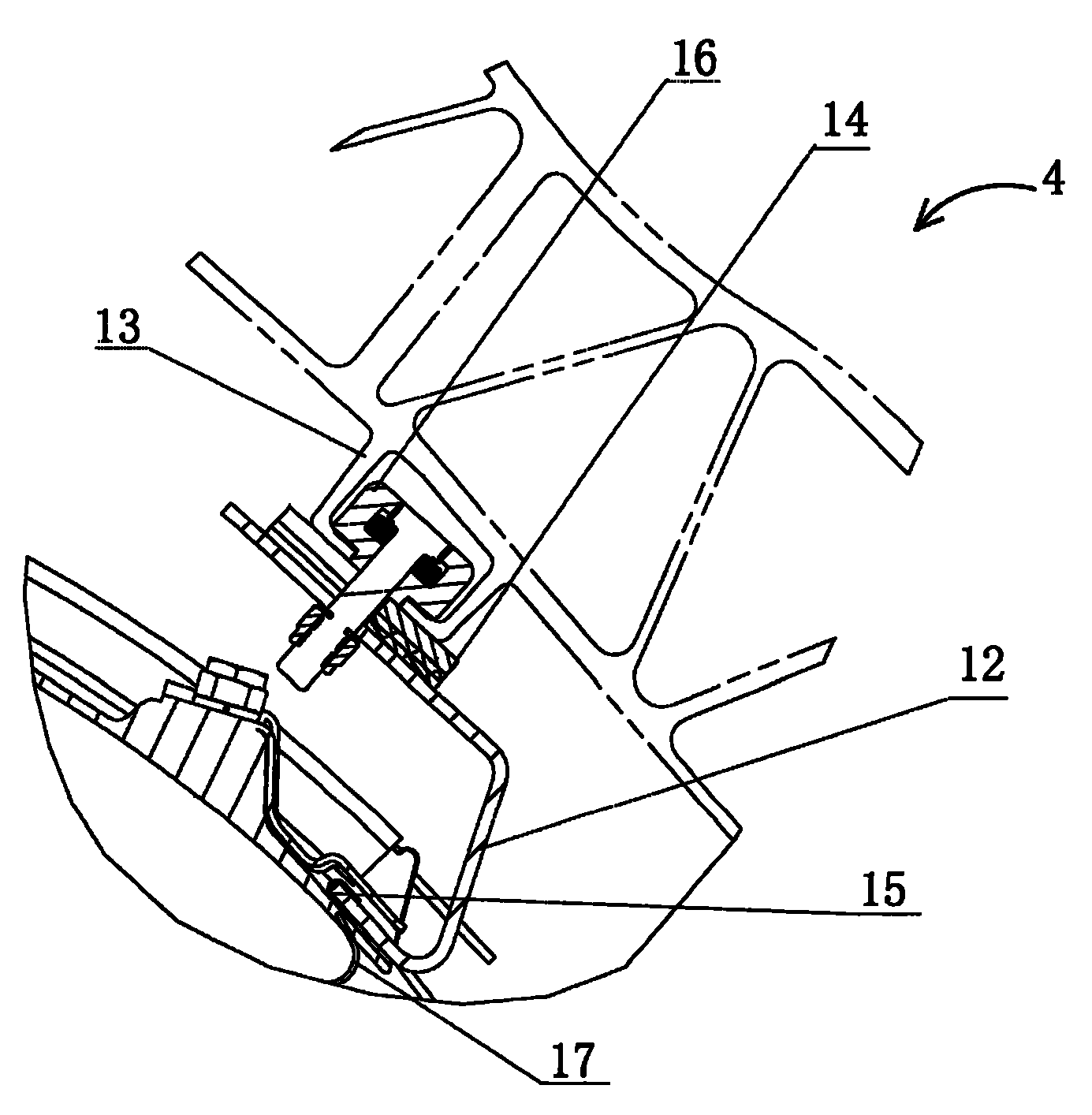

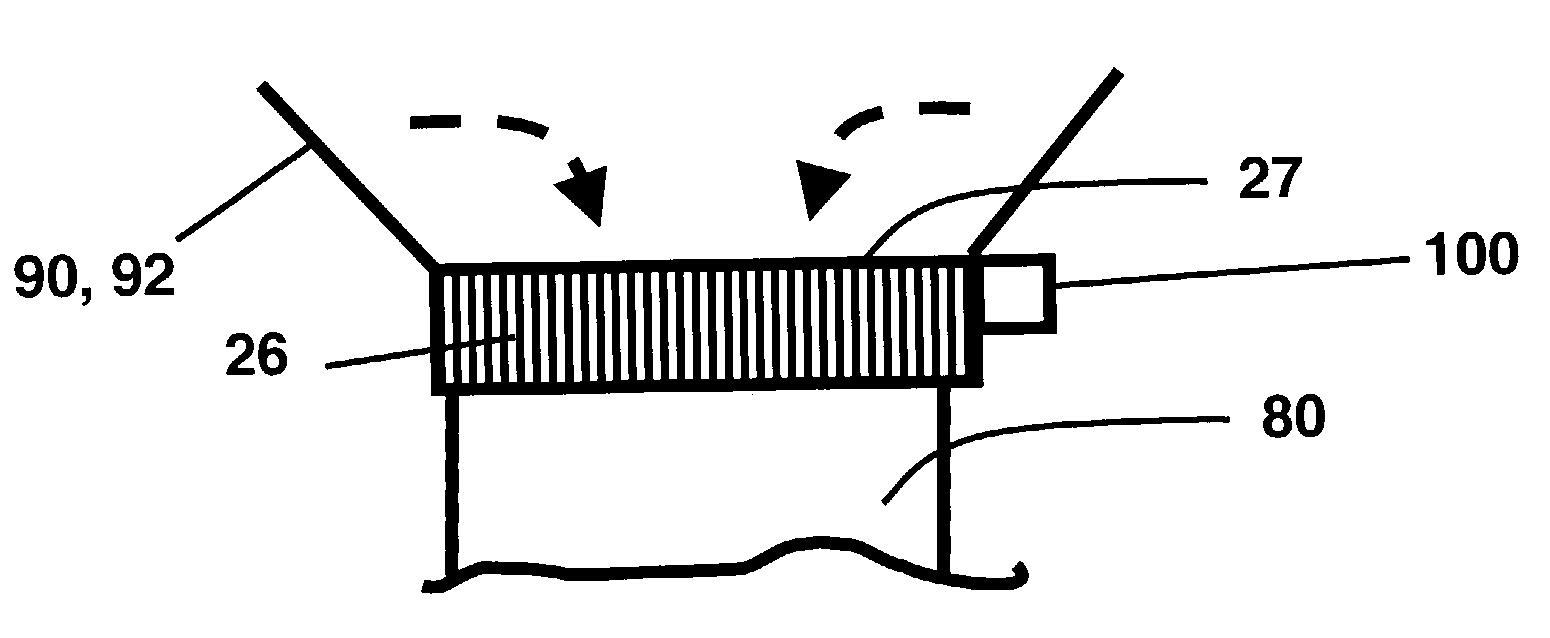

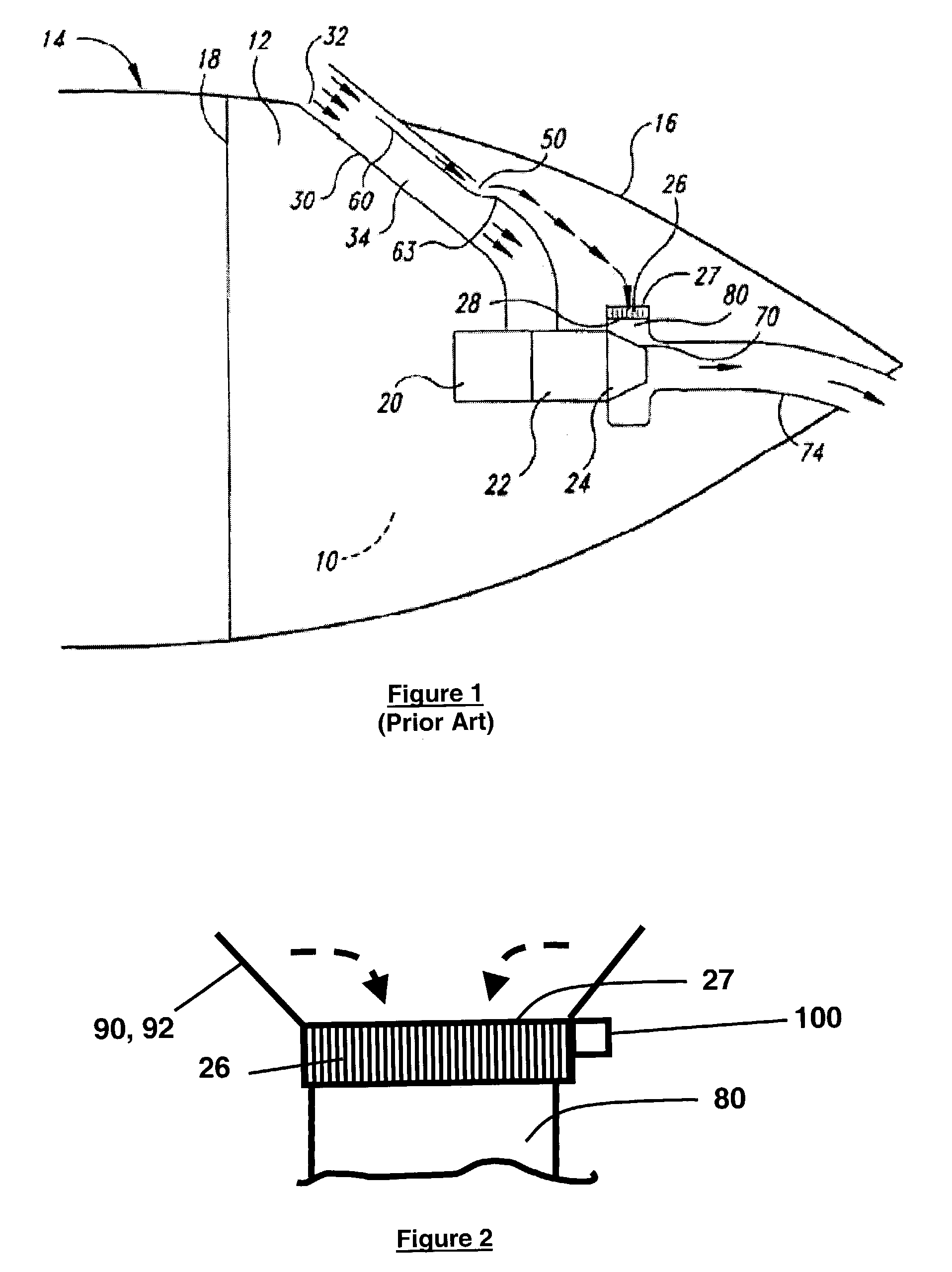

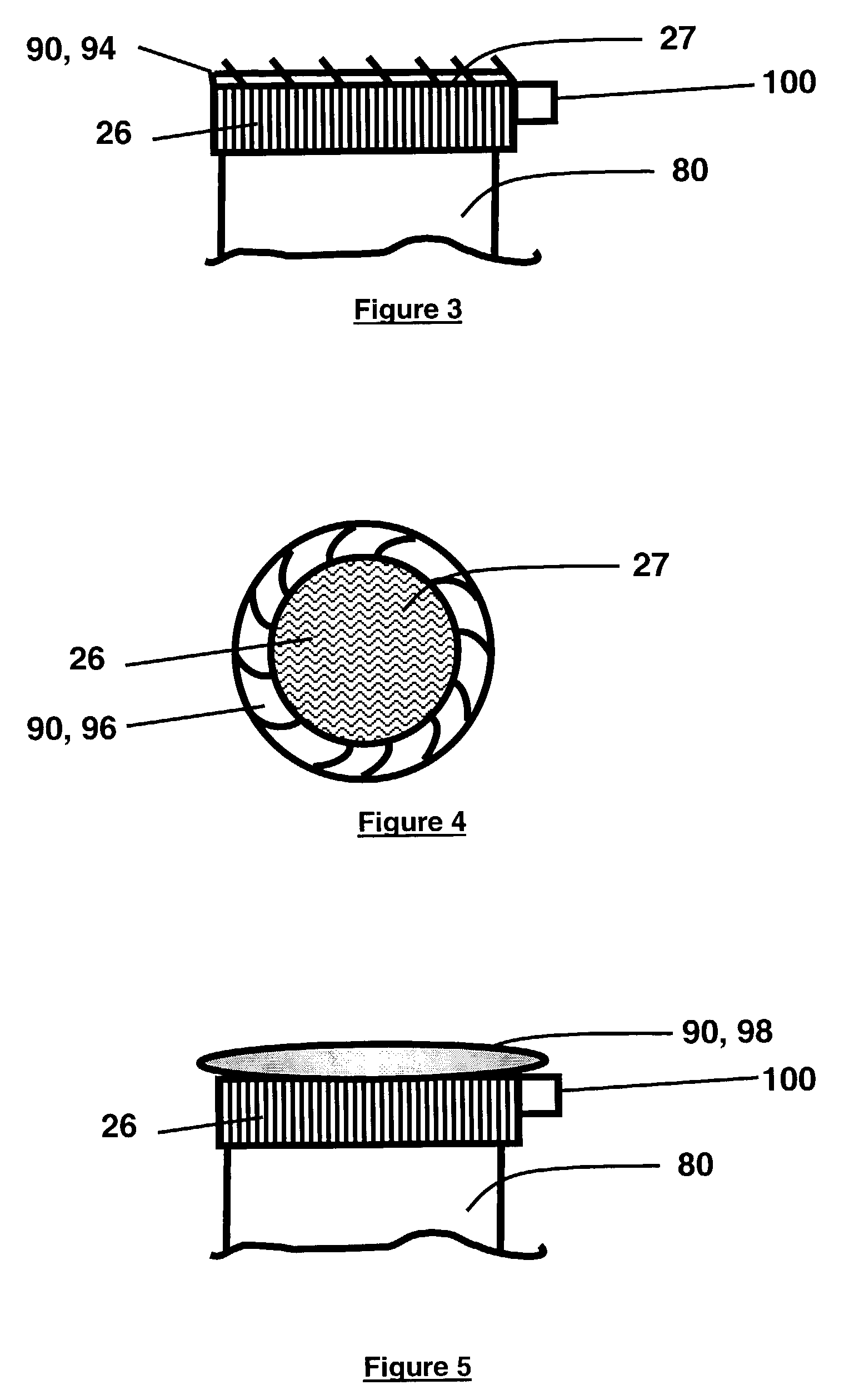

Apparatus and method for providing fireproofing to an aircraft auxiliary power unit

InactiveUS7093666B2Power plant cooling arrangmentsPower installationsFireproofingAuxiliary power unit

A fire protection apparatus for an oil cooler in an aircraft auxiliary power unit compartment adapted to at least partially cover the oil cooler to thereby at least partially block flames from directly impinging the oil cooler in the event of a fire in the compartment. An associated means and method are also disclosed.

Owner:PRATT & WHITNEY CANADA CORP

Fireproof coating composition and application thereof

InactiveCN1544559AImprove performanceGood effectFireproof paintsRubber derivative coatingsComposite filmCombustion

The invention relates to a fire-resisting paint and its use, wherein the fireproofing coating composition comprises composite film forming resin 15-30 wt. portions, expansion combustion inhibitor 27-40 wt. portions, flame-proof insulating material 2-15 wt. portions, fabric filling material 1-5 wt. portions, coating material solvent 30-45 wt. portions, wherein the particle mean size of the solid state components is 1-90 micrometer. The fireproofing paint can be applied to cable coating which can substantially extend the fire-resistant period for the cable.

Owner:SHANGHAI BEIAN IND

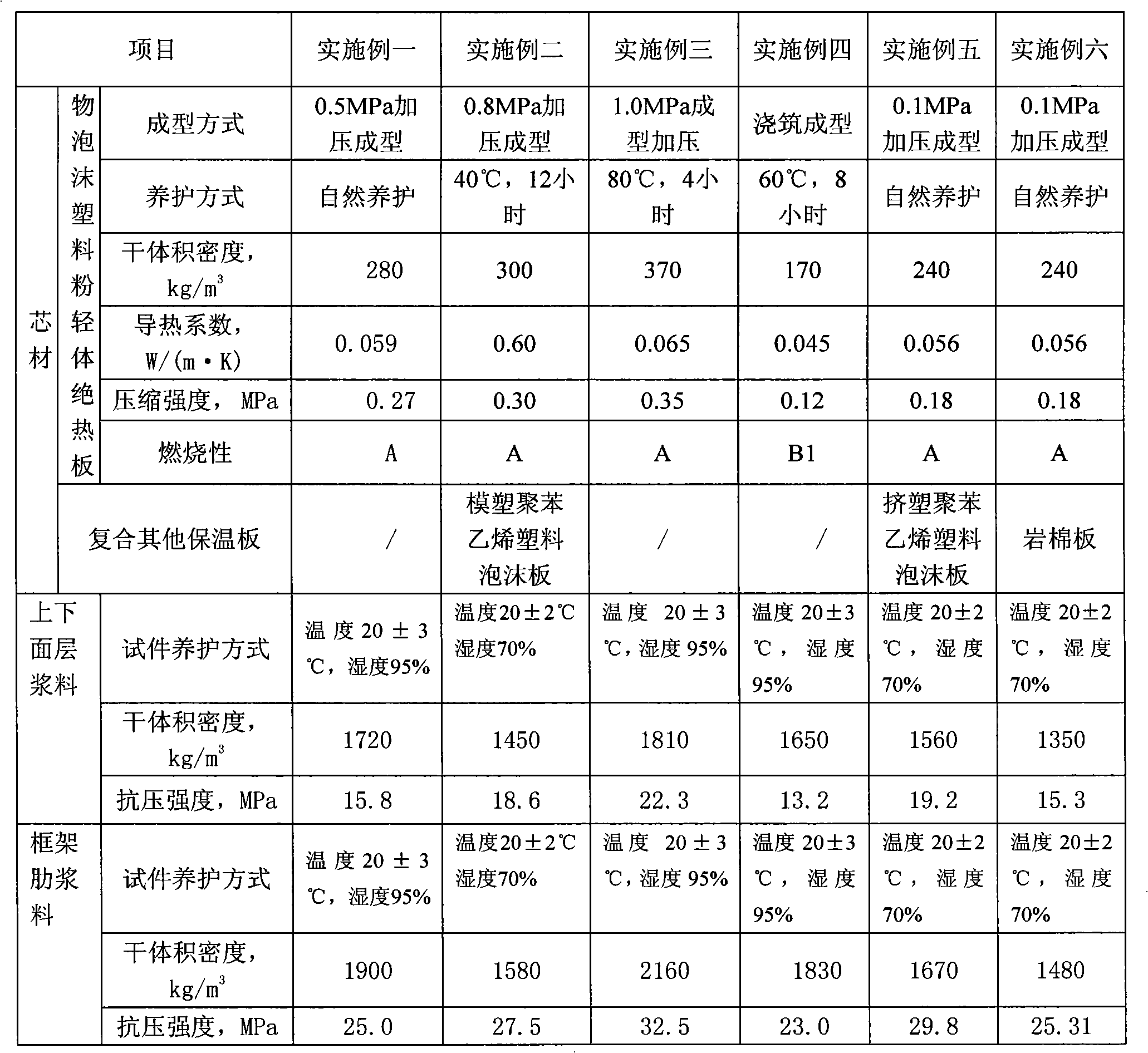

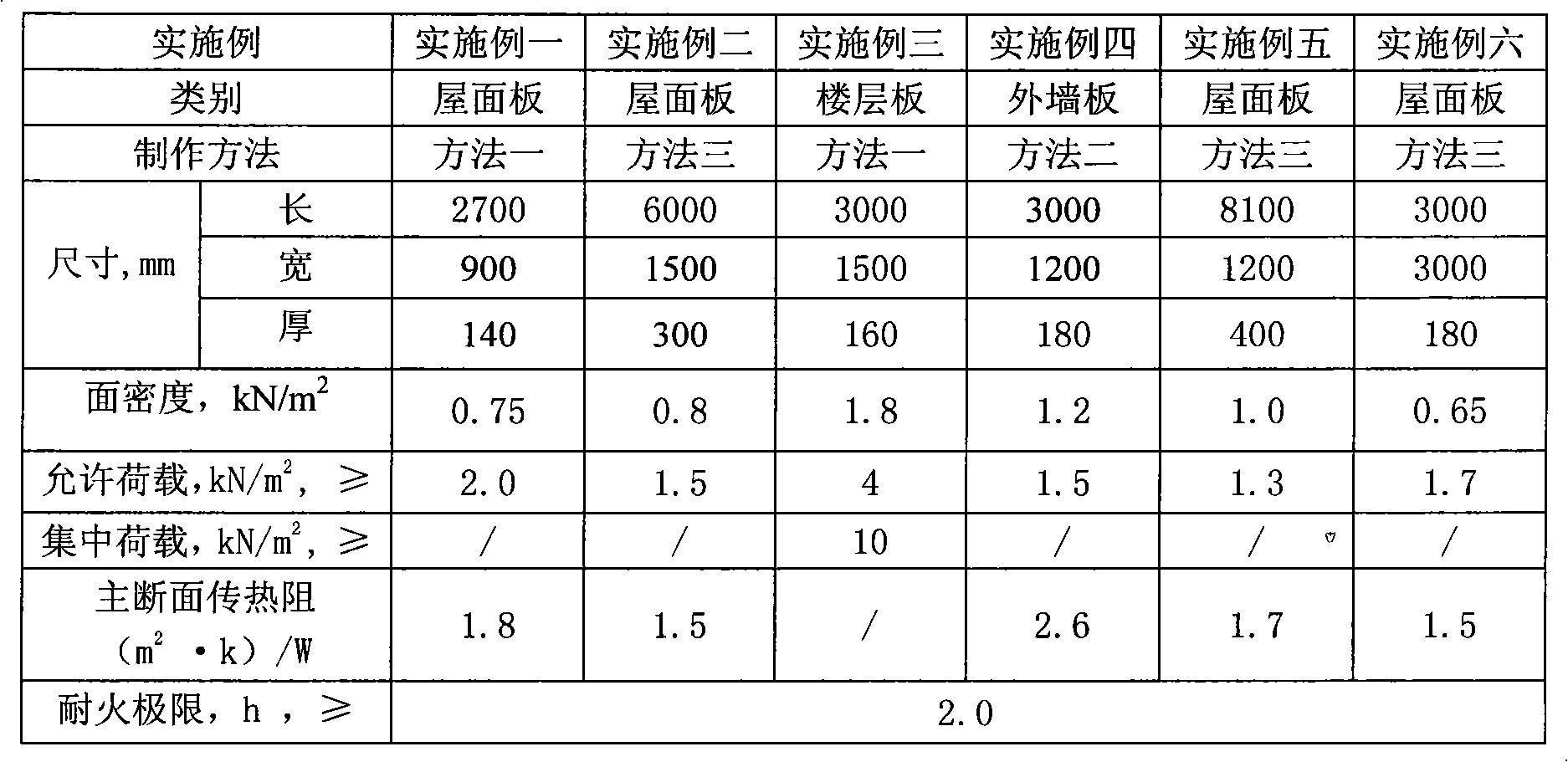

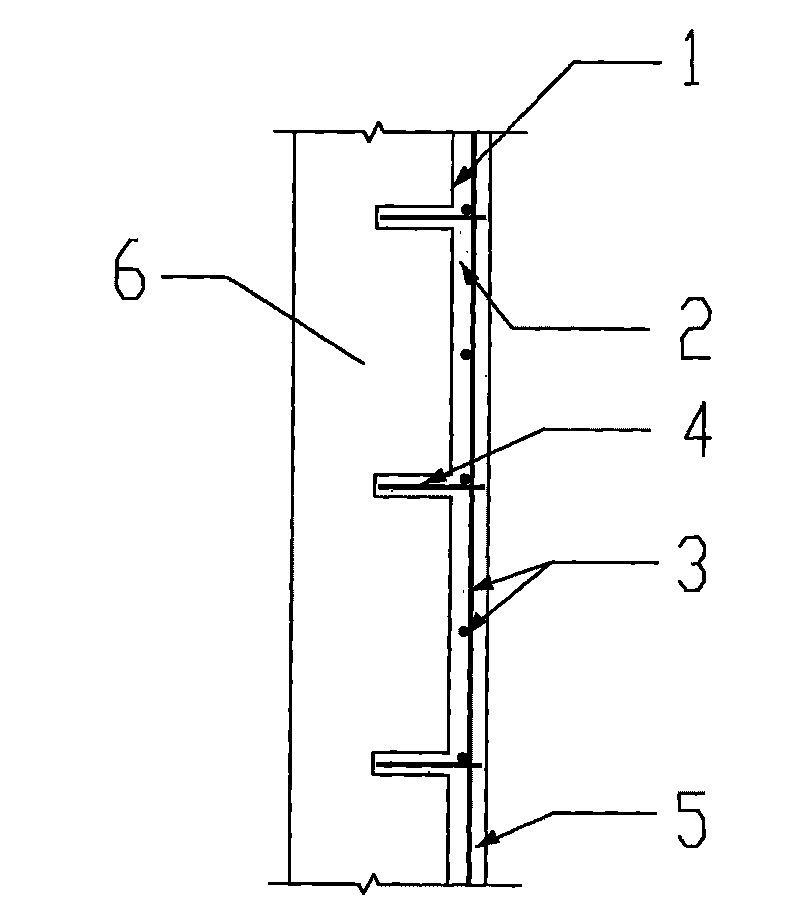

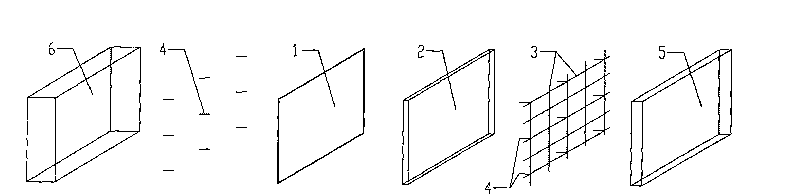

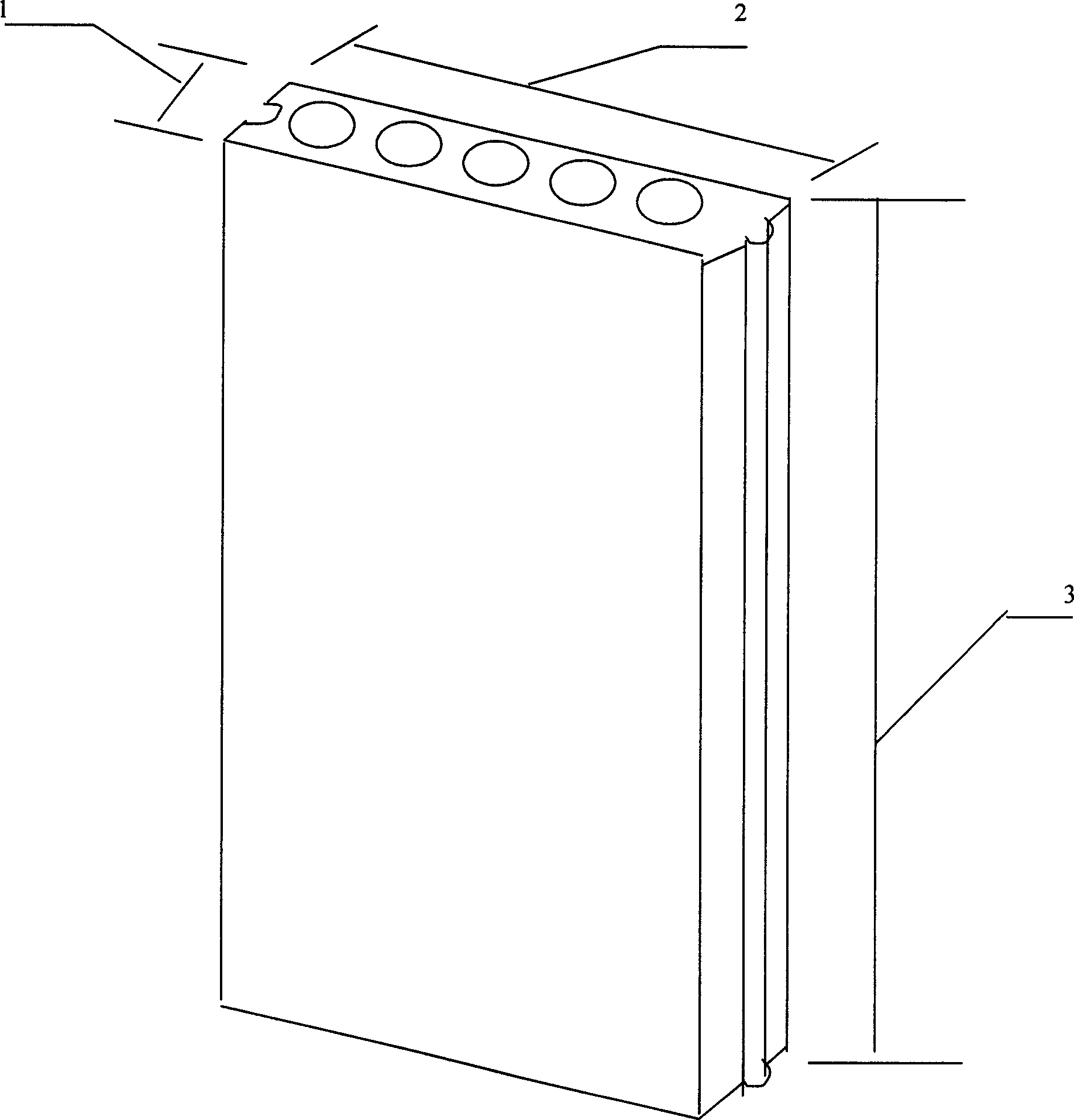

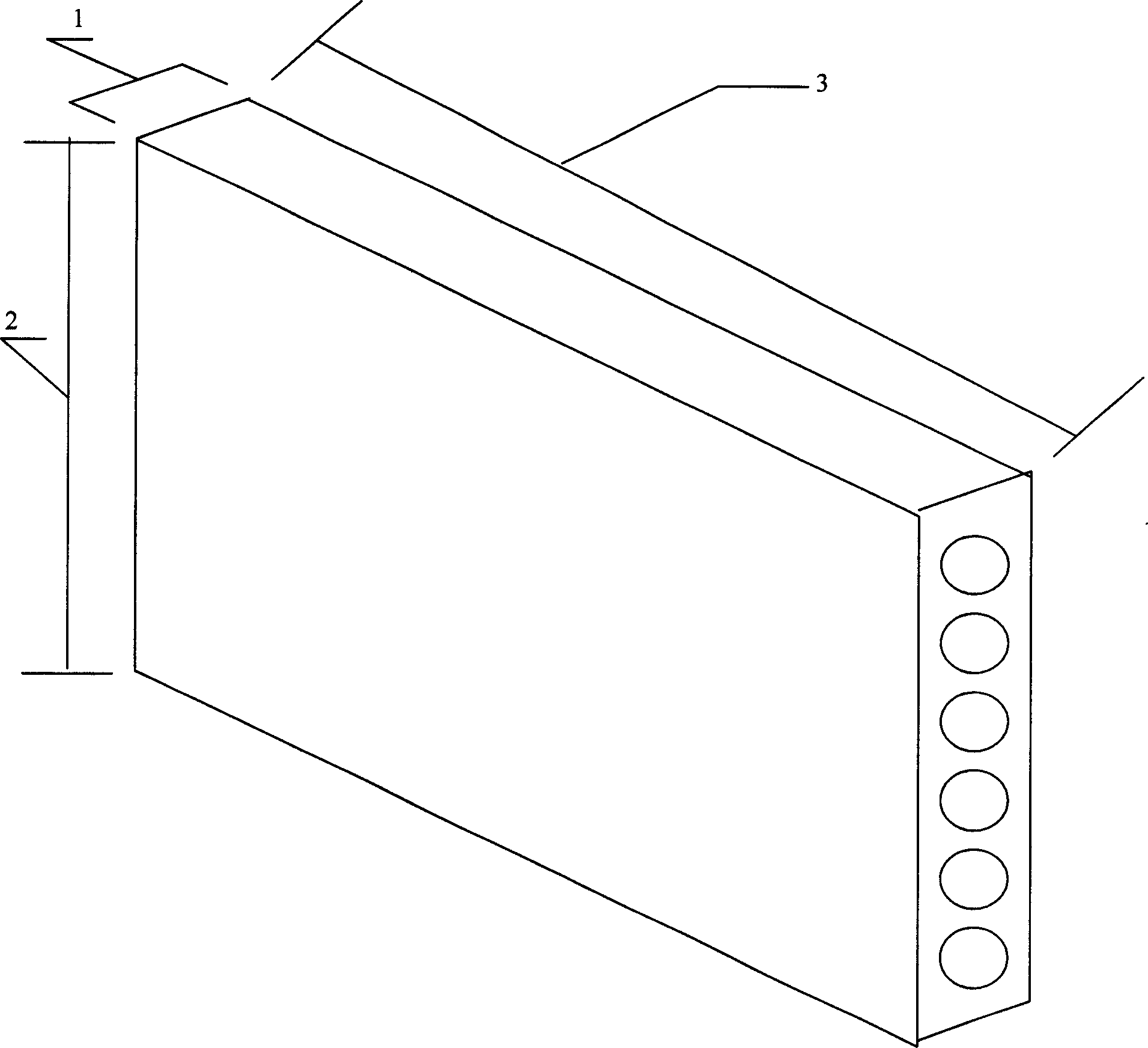

Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

ActiveCN101914977AStable chemical propertiesGood insulation performanceRoof covering using slabs/sheetsConstruction materialCrack resistancePolystyrene

The invention relates to an environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard, which comprises an upper surface layer, a lower surface layer and frame ribs. Insulating layers are arranged between the upper surface layer and the lower surface layer, and are cement polymer foamed plastic powder lightweight insulating plates or are formed by compounding the cement polymer foamed plastic powder lightweight insulating plates and any one of molded polystyrene foam plates, extruding-molded polystyrene foam plates and rock-wool slabs respectively; fiberglass alkaline-resistant mesh fabric is arranged in the upper surface layer and the lower surface layer; the frame ribs are fixedly connected to the lower surface layer; and an anticorrosion steel reinforcement frame is arranged in the frame ribs. In the environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard of the invention, the lightweight insulating plates and lightweight surface layer mortar are manufactured by foamed plastic powder; the foamed plastic powder and heat-preservation foamed plastic form particles are applied to lightweight concrete; and materials for the upper and lower surface layers and the frame ribs are enhanced by two or more assorted fibers so as to fulfill the aims of lightweight, high strength, energy saving, sound insulation, fireproofing, crack resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

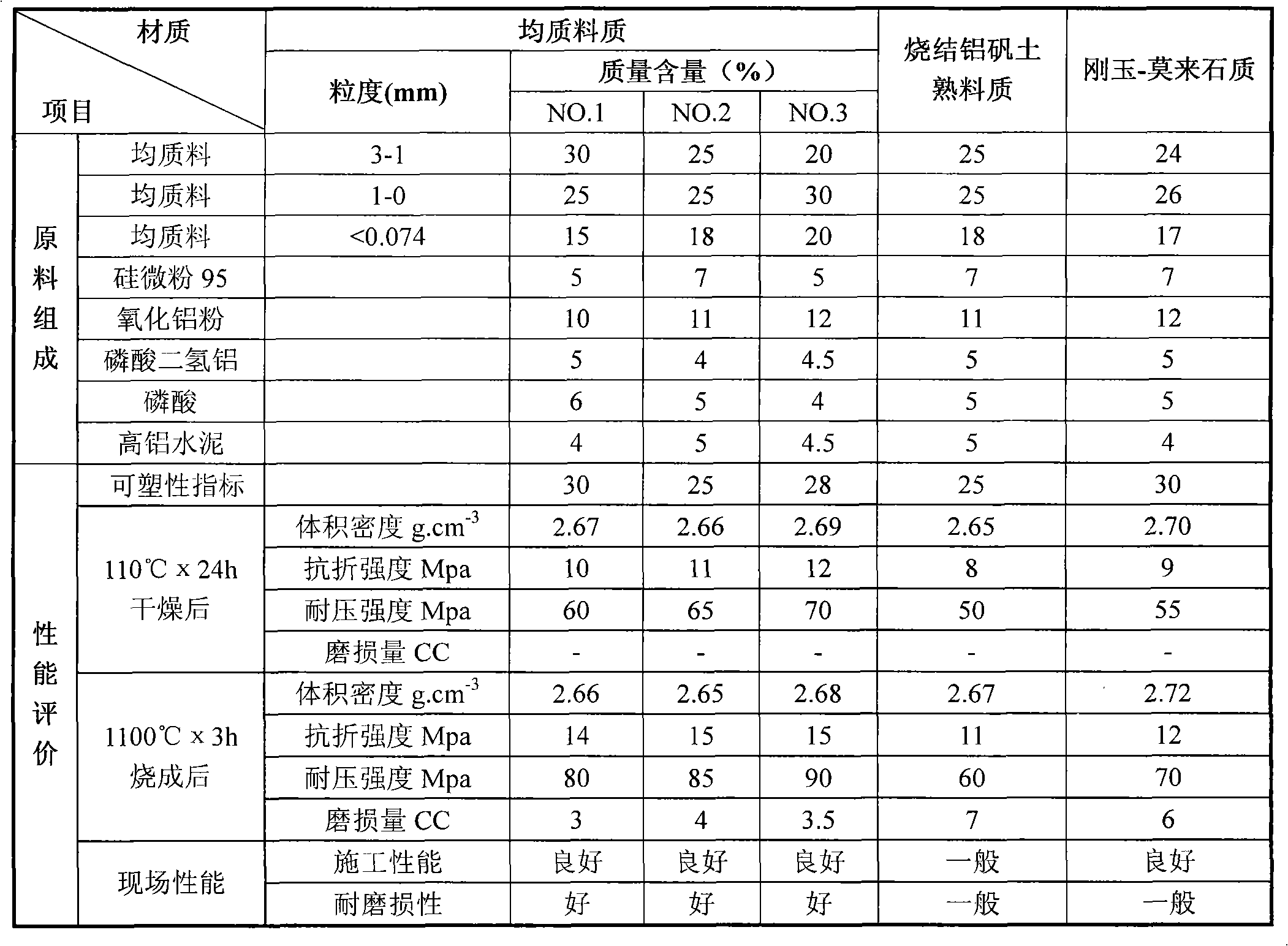

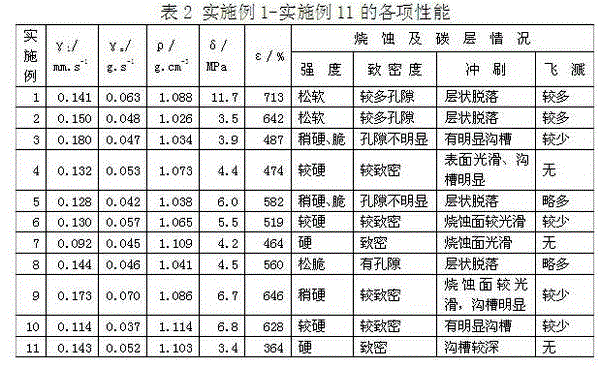

Homogeneous material-containing corundum-mullite high-strength abrasion-resisting plastic

The invention discloses a homogeneous material-containing corundum-mullite high-strength abrasion-resisting plastic, belonging to the field of high-temperature abrasion-resisting fireproofing material, comprising high-aluminum homogeneous material, alumina fine powder, silica fine powder, clay, phosphoric acid, aluminum dihydrogen phosphate solution, pure calcium aluminate cement and the like as raw materials, wherein the homogeneous material is as follows: the content of Al2O3 is 70-90% and the volume density is 2.9-3.5g.cm<-3>. Synthetic homogeneous material with low water-absorption, low porosity and high homogeneity is used for substituting the traditional natural raw material of sintered alumina clinker with high-absorption, high porosity and low homogeneity or composite raw material system of corundum and mullite to produce homogeneous corundum-mullite high-strength abrasion-resisting plastic. Distinguished from the castable, the plastic can be directly utilized in the construction method of smearing and ramming without supporting a module. The material of the invention is good in workability, high in strength, good in abrasive resistance and optimal in on-site usage effect, which is in favour of prolonging service life of furnace lining and improving utilization efficiency of the high-temperature furnace.

Owner:TONGDA REFRACTORY TECH CO LTD

Fireproof polyvinyl acetate emulsion and preparation method thereof

InactiveCN102040790AAvoid pollutionAvoid harmMonocarboxylic acid ester polymer adhesivesFireproof paintsFireproofingCarvacryl acetate

The invention relates to a fireproof polyvinyl acetate emulsion and a preparation method thereof. The grain diameter of the main fireproof composition of the fireproof type polyvinyl acetate emulsion, namely the gain diameter of ammonium polyphosphate, is small. Meanwhile, inorganic padding has stronger hydrogen bonding force to polyvinyl acetate or polyvinyl acetate copolymer, and the grains of the inorganic padding are small, which can avoid a series of problems caused by adopting an additional fireproofing agent of the prior art. The fireproof polyvinyl acetate emulsion disclosed by the invention has favorable bond strength, favorable film-forming performance, etc., and is very valuable to be used in the aspects of an indoor and outdoor fireproof coating, a weaving cloth fireproof finishing agent, a fireproof binding agent, and the like. Meanwhile, no harmful substances are produced in the process of production and use of the fireproof polyvinyl acetate emulsion, and the productive process of the fireproof polyvinyl acetate emulsion is simple, and is easy to control.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Building strengthening method

InactiveCN101691818AGood reinforcing effectWork together wellBuilding repairsPolymer modifiedFireproofing

The invention discloses a building strengthening method, which comprises the following steps of: 1) clearing the surface of a structure to be strengthened to expose a hard part; 2) carrying out water spray wetting on the structure to be strengthened; 3) implanting pins connecting a reinforcing steel bar net and the structure to be strengthened, and bonding the reinforcing steel bar net; 4) spraying an interface agent coating on the surface of the structure to be strengthened; and 5) spraying a polymer modified cement mortar bond layer and a polymer modified cement mortar protective layer by layers on the interface agent coating. The method can effectively improve the bearing capacity of the structure to be strengthened, improves the rigidity of the structure to be strengthened, and has less occupied space; a molded surface strengthening structure and the structure to be strengthened have the advantages of reliable bond, compactness, no crack, waterproofing, permeability resistance, fireproofing, high-temperature resistance, Cl-corrosion resistance, carbonization prevention, rust resistance and good durability; and a construction process is simple, formworks are not needed to be built, the speed of improving the strength of polymer modified cement mortar is high, and a construction period is greatly shortened. The method can be simultaneously applied to repairing and strengthening of the existing concrete structures and masonry structures, and solves the problems of breakage and aging of materials and insufficient structural strength of an old building.

Owner:上海维固工程实业有限公司

Heat insulating coating

The invention belongs to the technical field of building material and particularly relates to a heat insulating coating, which is composed of the following components: 220-250 parts of water by weight, 2 parts of cellulose by weight, 3.8-4.2 parts of dispersant by weight, 1.4-1.6 parts of SPA 202 antifoaming agent by weight, 1.4-1.6 parts of wetting agent by weight, 1.5 parts of multifunctional assistant by weight, 19-21 parts of propyleneglycol by weight, 180-220 parts of titanium pigment by weight, 75 parts of diatomite by weight, 50 parts of micro hollow glass bead by weight, 380-420 parts of elastic waterproof emulsion by weight, 2-2.5 parts of F111 antifoaming agent by weight, 2.5-3.5 parts of thickening agent by weight and 1.2-1.7 parts of anti-corrosion fungicide by weight. The invention has effects of warm-preserving, heat-insulating, radiation-protection, anti-stripping, waterproofing, fireproofing, anti-cracking, anti-freezing, brushing-resistance and dirt-resistance.

Owner:湖北邱氏节能建材高新技术股份有限公司

Novel wood plastic anticorrosive wallboard and production method thereof

InactiveCN102234439AImprove antibacterial and antiseptic effectGood shear mixing effectCovering/liningsFireproofingAntibacterial agent

The invention relates to a novel wood plastic anticorrosive wallboard for outdoor wall decorations and a production method thereof. The wood plastic anticorrosive wallboard consists of PE or PP plastic, wood powder or bamboo powder, calcium carbonate, coupling agent, lubricant, antiaging agent, antibacterial agent and colouring agent. The production method comprises the following steps that: the raw materials are subject to mixing, granulation and extrusion molding to obtain a baseplate, and the baseplate is subject to cooling, cutting, surface grinding, and embossing to obtain a product. The side of the baseplate is a slot structure, and the water absorption of the baseplate in 24h is 0.2%. The wallboard used in the field of outdoor decorations has the advantages of graceful appearance, lifelike pattern, reasonable structural design, being easy to install, fireproofing, waterproofing, insect preventing, sun protection, aging resistance, no formaldehyde, good sound-absorbing effect, good antibacterial and anticorrosive effects and the like, and being 100% recyclable. Compared with other wallboard decorative materials and production technologies existed in the prior art, the novel wood plastic anticorrosive wallboard disclosed in the invention has reasonable structure, and graceful and beautiful appearance, and the production method is advanced and scientific, with high production efficiency, and good performance of the produced products.

Owner:HUANGSHAN MEISEN NEW MATERIAL TECH

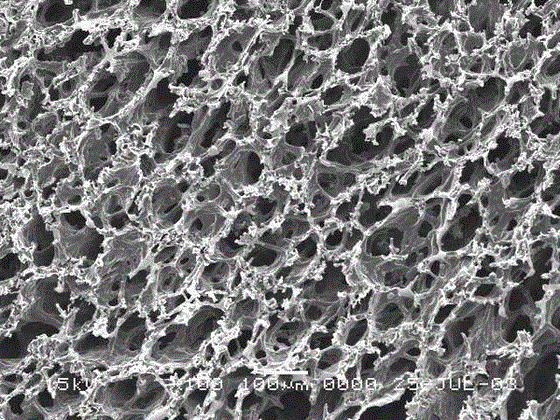

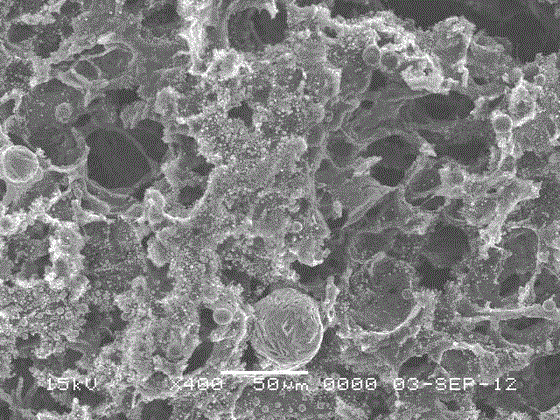

Ethylene-propylene-diene monomer(EPDM) rubber heat-insulating material with ceramifiable ablation carbon layer

The invention relates to an ethylene-propylene-diene monomer(EPDM) rubber heat-insulating material with a ceramifiable ablation carbon layer, which is composed of 100 of EPDM, 5-50 of strengthening agent, 5-15 of organic fiber, 8-15 of tackifying resin, 4-15 of plasticizer, 8-20 of fire retardant and 3-12 of other auxiliary agent. According to the invention, a low melting point silicate substance such as montmorillonite and mica powder is introduced in an EPDM heat-insulating material formula, by using the characteristics of meltable performance at high temperature, a viscous liquid is generated for bonding the cracked carburization zones through physical crosslinking effect, and thereby a large solid particle network structure is formed, capability of the carbon layer for resisting volatilization internal stress of pyrolysis gas and erosion external stress of gas flow can be enhanced, denudation and shedding of the carbon layer can be reduced, and performances of anti-ablation, anti-erosion and characteristic signal transmitance of the EPDM heat-insulating material can be effectively increased. The heat-insulating material can be used for inner heat insulation of an engine and also can be widely used for producing ceramifiable wire and cable compounds and other places which requires fireproofing flame retardation.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Ecological environment-friendly type wallboard with regeneration aggregate function and method of manufacture the same

InactiveCN1603271AImprove protectionImprove use valueConstruction materialSolid waste managementSocial benefitsEcological environment

The invention relates to an ecology environment protection type regenerating aggregate function wall board and its manufacturing method. In our country, the builders rubbish caused by pulling down the old residence and building new reaches from forty million ton to sixty million ton every year. The comprehensive utilization ratio and level of the builders rubbish are quite low from long time, and the existing builders rubbish brick or building blocks belong to the extensive low affixation utilization ratio. The ecology environment protection type regenerating aggregate function wall board and its manufacturing method of the invention are that the builders rubbish is sorting machining and disintegrated, then formed different aggregates, used as the filler of the different wall board, produced into functionality wall board such as building sound proof wall board, building fireproofing partition wall board, building heat preservation wall board, outer wall board, outer wall composite wall board, and so on, according to the building function material principle. It gives prominence to the building function of the wall board, improves the level of its service performance, as well as effectively improves the affixation value of the comprehensive utilization of the builder rubbish. And it possesses notable economic and social benefit.

Owner:上海德志建筑设备有限公司

Super thin expansion type fire-proof corrosion resistant paint for steel structure and its preparing method

The present invention relates to one double-function paint for fireproofing and anticorrosion of steel structure and its preparation process. Available paint has only single function of either fireproofing or anticorrosion and thus limited application range. The present invention adopts polyvinyl perchloride and organosilicon modified acrylic resin as main filming material and adds cyanuramide phosphate and expanding graphite into common polytriammonium phasphate as fireproof assistant to constitute foaming material. The present invention has greatly raised foaming rate and the foamed layer has thickness of 30-50 times the original coating thickness and fireproof limit up to 90 min. The paint has simple preparation process, low cost and wide application.

Owner:TONGJI UNIV

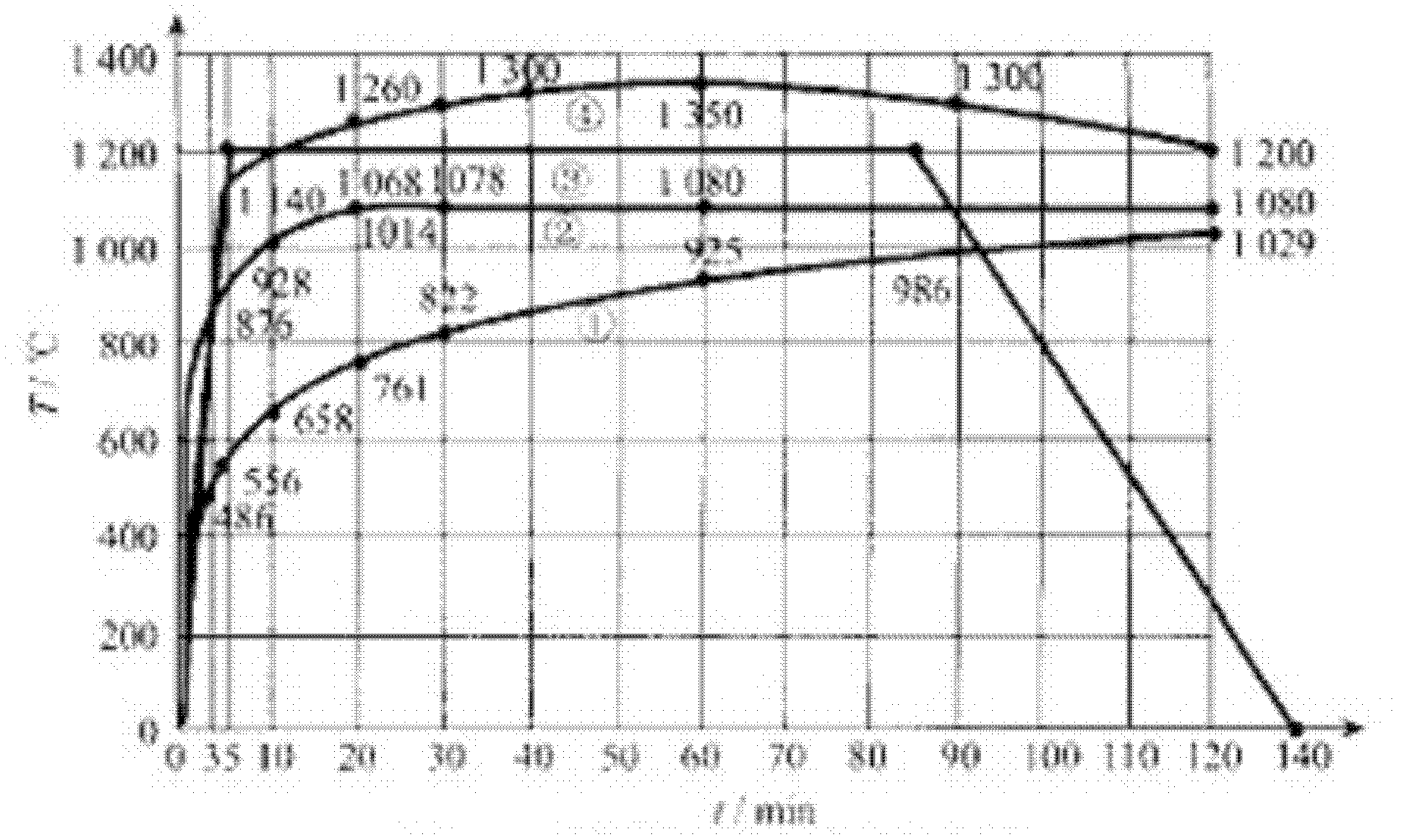

Method for synthesizing ferrous aluminum spinel

The invention relates to a method for synthesizing ferrous aluminum spinel, belonging to the technical field of fireproofing materials. The method comprises the following steps of: mixing ferrous compound and aluminiferous compound according to the mol ratio of Fen<+> to Al<3+> of 1:2, additionally adding a binding agent accounting for 1-6 percent of the weight of the mixture, mixing, pressing, drying and sintering under the nitrogen atmosphere at the temperature of 1300-1700 DEG C, and keeping the temperature for 2-12 hours. The invention has the advantages of high synthetic purity, simple process and easy actualization.

Owner:SHANDONG SHENGCHUAN CERAMICS +3

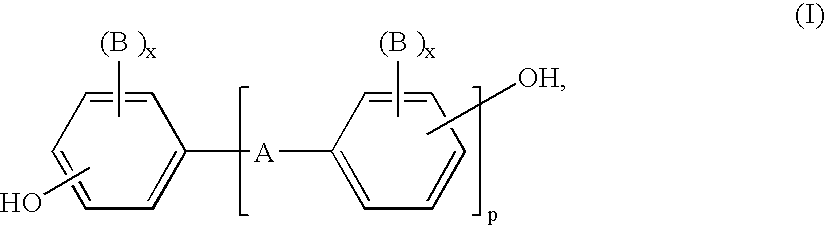

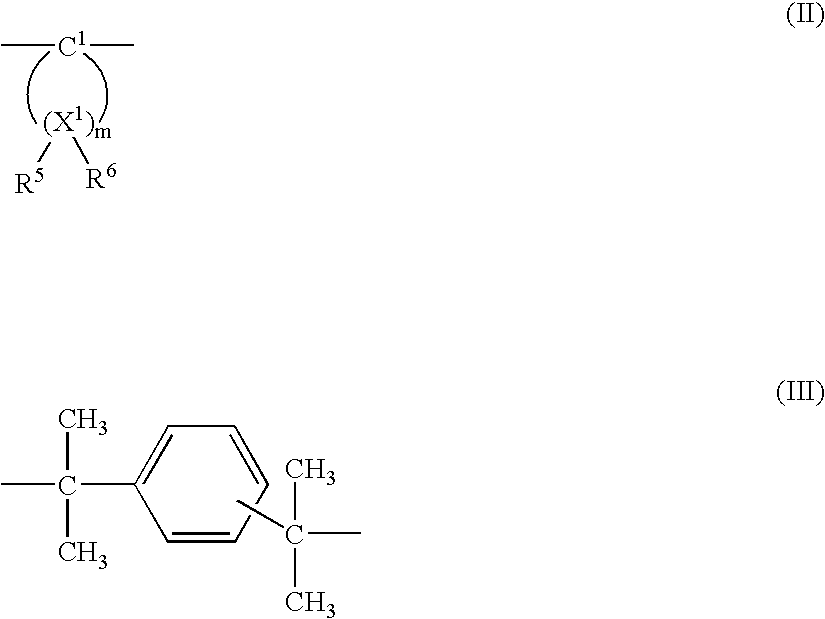

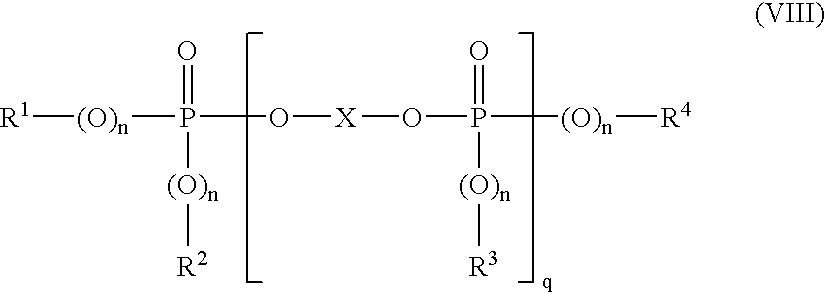

Flame resistant, impact modified polycarbonate compositions

A flame resistant, impact-modified polycarbonate composition is disclosed. The composition that is suitable especially for preparing thermoformed articles comprises branched aromatic polycarbonate and / or branched aromatic polyester carbonate, a graft polymer containing silicone rubber or silicone acrylate rubber, talc, and a phosphorus-containing flameproofing agent, and meets high requirements in terms of fireproofing. Also disclosed is a process for the preparation of the composition and its use in the production of molded articles.

Owner:BAYER MATERIALSCIENCE AG

Ultrathin expansion steel-structure fireproofing coating

InactiveCN1488692AGood fire and heat insulationImprove adhesionFireproof paintsPolymer scienceAcrylic resin

The present invention provides a fire-retardant coating capable of forming ultrathin coating layer and having high fire-resisting limit. Its composition comprises (by weight portion) 50-60 portions of modified acrylic resin, 12-16 portions of pentaerythritol, 9-12 portions of trimeric cyanamide, 19-21 portions of polyammonium phosphate, 6-8 portions of zinc borate, 9-11 portions of titanium pigment, 1.25-15 portions of chlorinated paraffin (in which chlorine content is 70%) and 8-15 portions of 200# solvent gasoline. The above-mentioned modified acrylic resin is a chlorinated rubber modified acrylic resin made up by using 1.4-1.8 portions of chlorinated rubber, 2.2-2.7 portions of xylene, 0.9-1.1 portions of hexamethylene-diisocyanate and 1.6-1.8 portions of hydroxyl-bearing acrylic resin. Its coating layer thickness is 1.71-2.69 mm, and its fire-resisting limit can be up to 69-147 min.

Owner:应急管理部四川消防研究所

Novel phosphor nitrogen composite combustion inhibitor

InactiveCN1807552AModerate solubilitySimple processFireproof paintsPaper/cardboardPhosphateFireproofing

This invention discloses the preparing method for a new kind of phosphorus-nitrogen composite flame retardant, especially for pyroammonium phosphate flame retardant. The pyroammonium phosphate flame retardant is synthesized mainly with commercial phosphoric acid and urea; cool to proper temperature after the reaction; adjust reaction by adding appropriate neutralization agent; cool crystallize; centrifuge to get the product. The pyroammonium phosphate flame retardant contains pyromonoammonium phosphate, pyrodiammonium phosphate, pyrotriammonium phosphate and pyrotetroammonium phosphate. Its phosphor content exceeds 25% and nitrogen content exceeds10%. Its non-aqueous solubility is moderate. It is highly effective and nontoxic, so it is broadly used in fireproofing coatings, flame-retardant platics, flame-retardant fibres, flame-retardant textiles, wood goods, and so on.

Owner:朱凯琴

Aqueousneoprene type environment-friendly glue and preparation method thereof

ActiveCN101560367ATransportation safetyHigh bonding strengthAcid polymer adhesivesAldehyde/ketone condensation polymer adhesivesAcrylic resinFireproofing

The invention discloses an aqueous neoprene type environment-friendly glue which comprises aqueous rosin emulsion with low grain diameter and high stability, aqueous acrylic resin emulsion, ethane-vinyl acetate emulsion, anion type neoprene latex, aqueous foam suppressor, wetting dispersant, preservative, tackifier, nanometer calcium carbonate concentrated slurry, aerosol, and the like. The invention also discloses a preparation method of the aqueous neoprene type environment-friendly glue; the aqueous neoprene type environment-friendly glue takes water as a dispersed media, is uniform milky liquid, has the comprehensive advantages of no organic solvent, no heavy metal, insipidity, good initial adhesive force, excellent bond strength, excellent hold tack, excellent heat resistance and aging resistance, short drying time, long opening time, large spray area of unit weight, glue saving, excellent oily leather resistance, fireproofing, safe transportation, and the like, has the advantages of reducing environment pollution, improving operation and construction environment, saving large amounts of organic fuel, insipidity, and the like, is widely applied to industries of soft furniture of cases and bags, sofas, swivel chairs, mattresses, pillows, folding screens, and the like, and is especially suitable for application of green high-grade export products of occident.

Owner:黄楚填

Inorganic thermal-insulation mortar used for building exterior walls of buildings and preparation method thereof

InactiveCN101863639AGood chemical stabilityGood weather resistanceSolid waste managementHigh resistanceWeather resistance

The invention relates to inorganic thermal-insulation mortar used for building exterior walls of buildings and a preparation method thereof. The invention is characterized in that the thermal-insulation mortar comprises the following components in part by weight: lightweight aggregate 100-150, binding material 100-150, fly ash 10-60, and additive 8.72-11.36. Compared with the prior art, the inorganic thermal-insulation mortar has the advantages of high weather resistance, high aging resistance, long service life, high fireproofing and flame-retarding performance, energy conservation and environment protection.

Owner:SHANGHAI MINJIANG TONG PROD

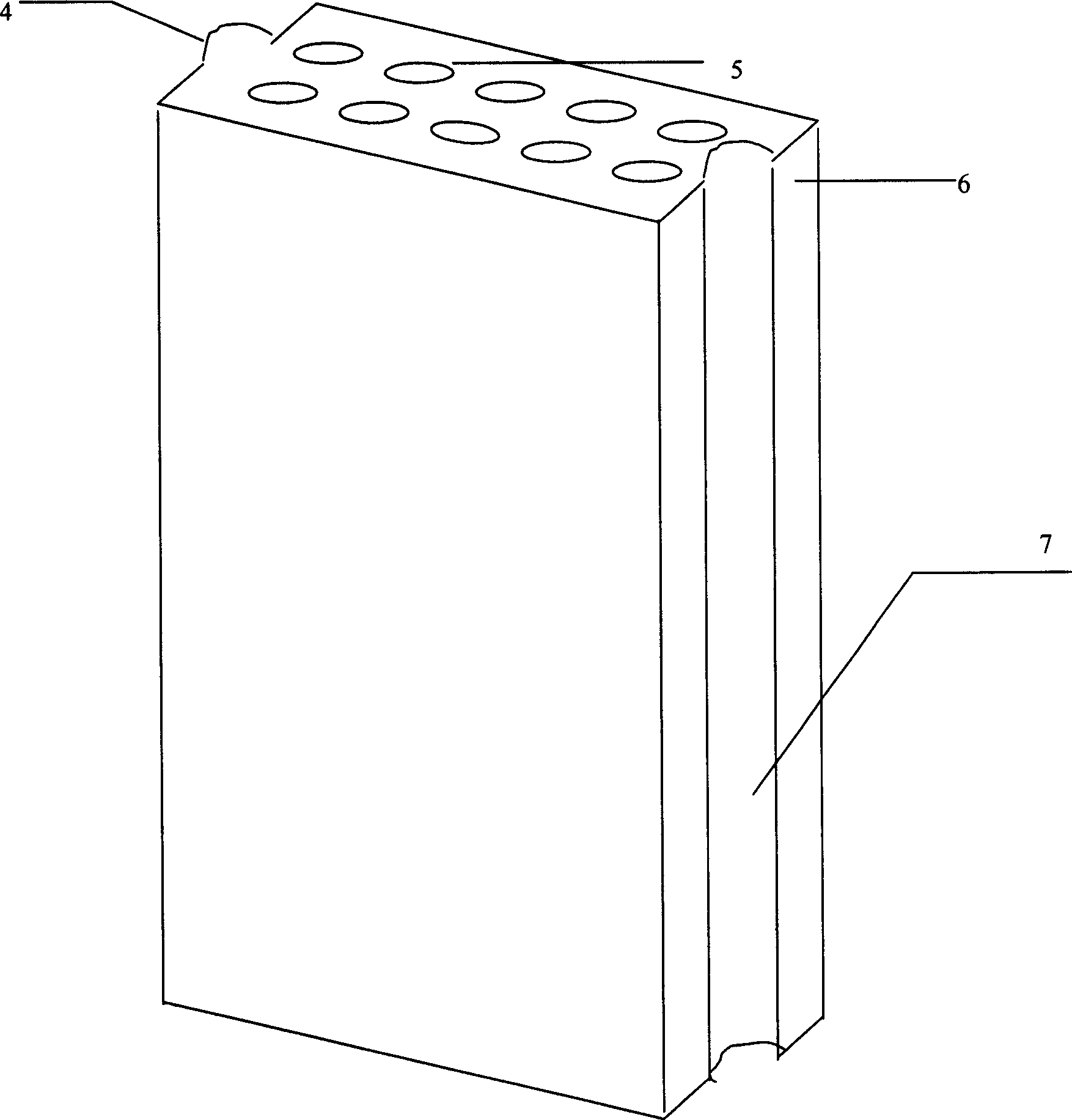

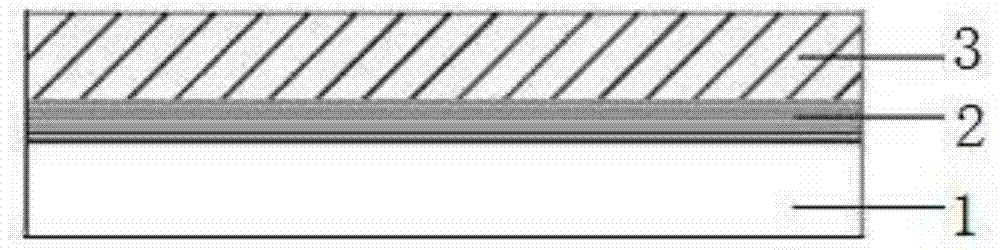

Ceiling with indoor air purification function and manufacturing method thereof

InactiveCN103924756AWith air purification functionCovering/liningsSynthetic resin layered productsSystem integrationFireproofing

The invention discloses a ceiling with an indoor air purification function comprising a heat-insulating and noise-reducing layer (1), a contaminant absorption layer (2) and an air purifying layer (3) sequentially from interior to exterior. The heat-insulating and noise-reducing layer is a foam glass ceramic board, the contaminant absorption layer is an inorganic mineral coating with an absorption function, and the air purifying layer is a photocatalyst coating. According to the indoor ceiling with the air purification function, by means of factorial production, the foam glass ceramic board with fireproofing, heat-insulating and noise-reducing functions, the aqueous mineral coating with the function of contaminant absorption and the photocatalyst coating with the air purification function are compounded, the indoor air-purifying ceiling is obtained, and using function compounding, construction mounting component basing and construction system integration of environment-friendly building materials are realized.

Owner:山东鲁蒙低碳技术研究有限公司

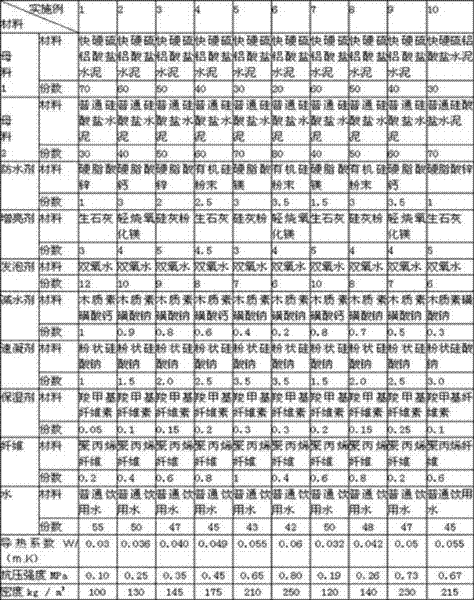

Heat insulation fireproofing honeycomb cement board and preparation method thereof

InactiveCN102390968ASolve the problem of bubble crackingAchieve water-repellent effectCeramicwarePolymer scienceThermal insulation

Owner:HENAN UNIVERSITY

Ultra-thin steel structure fire-resistant coating material with multi-core structure

ActiveCN102492323AImprove the decorative effectImprove fire resistanceFireproof paintsAlkali metal silicate coatingsCompound organicFireproofing

The invention relates to an ultra-thin steel structure fire-resistant coating material with a multi-core structure. The ultra-thin steel structure fire-resistant coating material is characterized by comprising three parts, i.e. an expandable fire-resistant antirust priming coat at high temperature, an expandable fire-resistant intermediate coat when contacted to fire and a fire-resistant finishing coat. In actual construction, at least one layer of fire-resistant antirust priming coat with a high-temperature expanding function, at least one layer of intermediate coat with an expanding function when contacted to fire and at least one layer of decorative finishing coat with flame retarding and smokeless performance are coated; the priming coat, the intermediate coat and the finishing coat are formed by compounding organic and inorganic materials; when a fire occurs, the intermediate coat and the finishing coat exert synergistic reaction, and thus, an effect that the priming coat carries out fire resisting and heat insulation and the finishing coat carries out inflame retarding and smoke purifying, is achieved. With the adoption of the ultra-thin steel structure fire-resistant coating material with the multi-core structure, provided by the invention, a fire-resistant coating with thinner coating thickness, longer fireproofing time limit and better decorative effect can be formed on a steel structure, and proved by experiments, the fireproofing standards of GB14907-2002 are fully met.

Owner:天津宝宸恒远科技有限公司

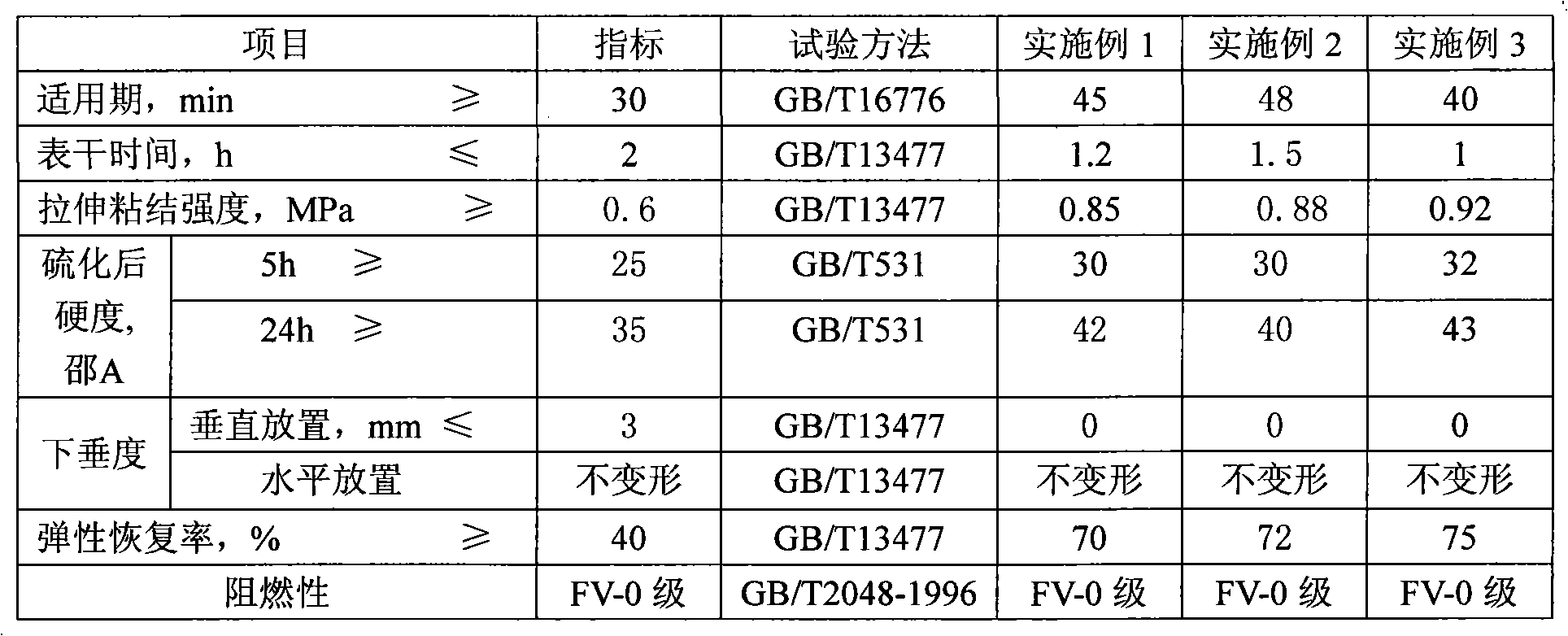

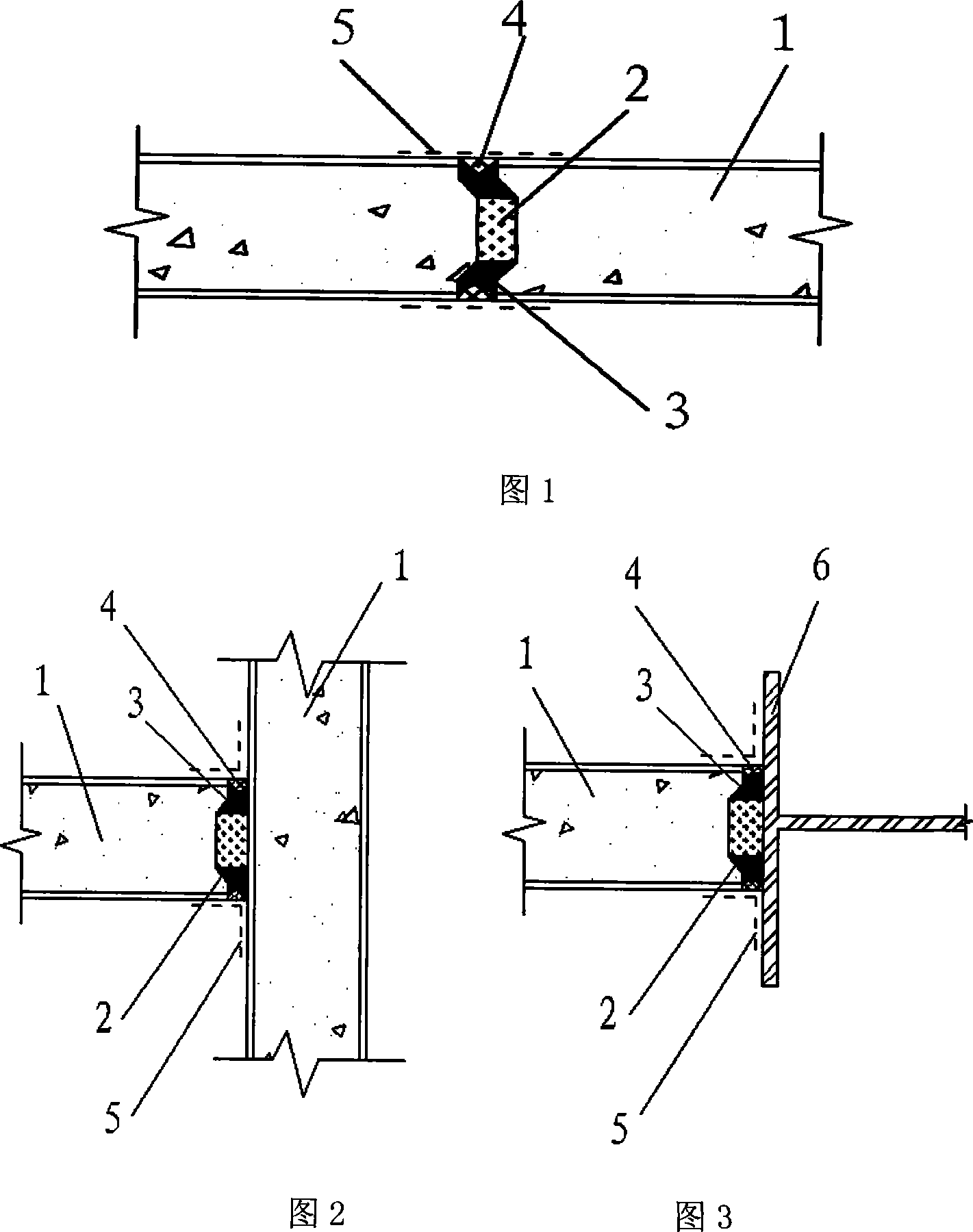

Bi-component polysulfide fireproofing flame retardant sealant and preparation method thereof

ActiveCN101575493AImprove fire performanceNot corrosiveNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberPlasticizer

The invention relates to a bi-component polysulfide fireproofing flame retardant sealant and a preparation method thereof, wherein the bi-component polysulfide fireproofing flame retardant sealant is prepared from the following components according to parts by weight: component A: 50-100 parts of liquid polysulfide rubber, 30-70 parts of flame retardant plasticizer, 50-150 parts of flame retardant filler, 60-200 parts of calcium carbonate, 0.3-1.2 parts of main agent micro-molecular finishing agent and 0.5-1.5 parts of silane coupling agent; component B: 10-30 parts of manganese dioxide, 20-60 parts of plasticizer, 1-3 parts of semi-strengthening agent carbon black and 0.4-1.5 parts of accelerant. The preparation method comprises the following steps of: mixing, stirring, vacuumizing, inspecting and packaging all the ingredients of component A; and mixing, stirring, vacuumizing, grinding, inspecting and packaging all the ingredients of component B. The sealant can be used by uniformly mixing A and B according to the mass rate of A: B being equal to 100:6-100:12. the sealant has good flame retardant property that is tested to be FV-0 level according to GB / T 2408-1996, and the oxygen index is tested to be 36.6 percent according to GB / T 2406-1993, and the both levels reach or exceed state-specified standards,.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

Inner wall board joint treatment technology

InactiveCN101230593ASolve common problems in the applicationPrevent board seam through seamWallsBuilding insulationsFireproofingEngineering

A wallboard seam processing technic belongs to the technical field of inner wallboard processing of building. The processing method is realized by that: a flute arranged at one side of a wallboard is internally affixed with rubber sponge with a certain thickness, the two sides of the rubber sponge are smeared with polymer sand pulp, and then the rubber sponge is abutting-jointed with a tenon of the wallboard or the side or the pillar of the wallboard as well as is tightly squeezed by force, so as to lead the rubber sponge to have a certain decrement; after that, the two sides of the seam are filled with elastic sealing compounds with a certain thickness, finally, the two sides of the seam are affixed with an anticracking gridding adhesive tape. The material in the seam of wall in the wallboard seam processing technic adopts elastic material, so as to solve the problem that generally appears and is hard to be settled of straight joint of slab joint caused by structural distortion or walling material drying shrinkage; furthermore, the rubber sponge adopted in the middle of the slab joint is made of fire resistant heat insulating material and can prevent a heat channel from generating among the slab joints, thereby having certain fireproofing performance. The invention is applicable to the slab joint processing of most of the inner wallboards such as a GRC board, a plasterboard, a hollow slat, etc. at the present time.

Owner:SHANDONG LAIGANG CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com