Patents

Literature

1816results about "Monocarboxylic acid ester polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

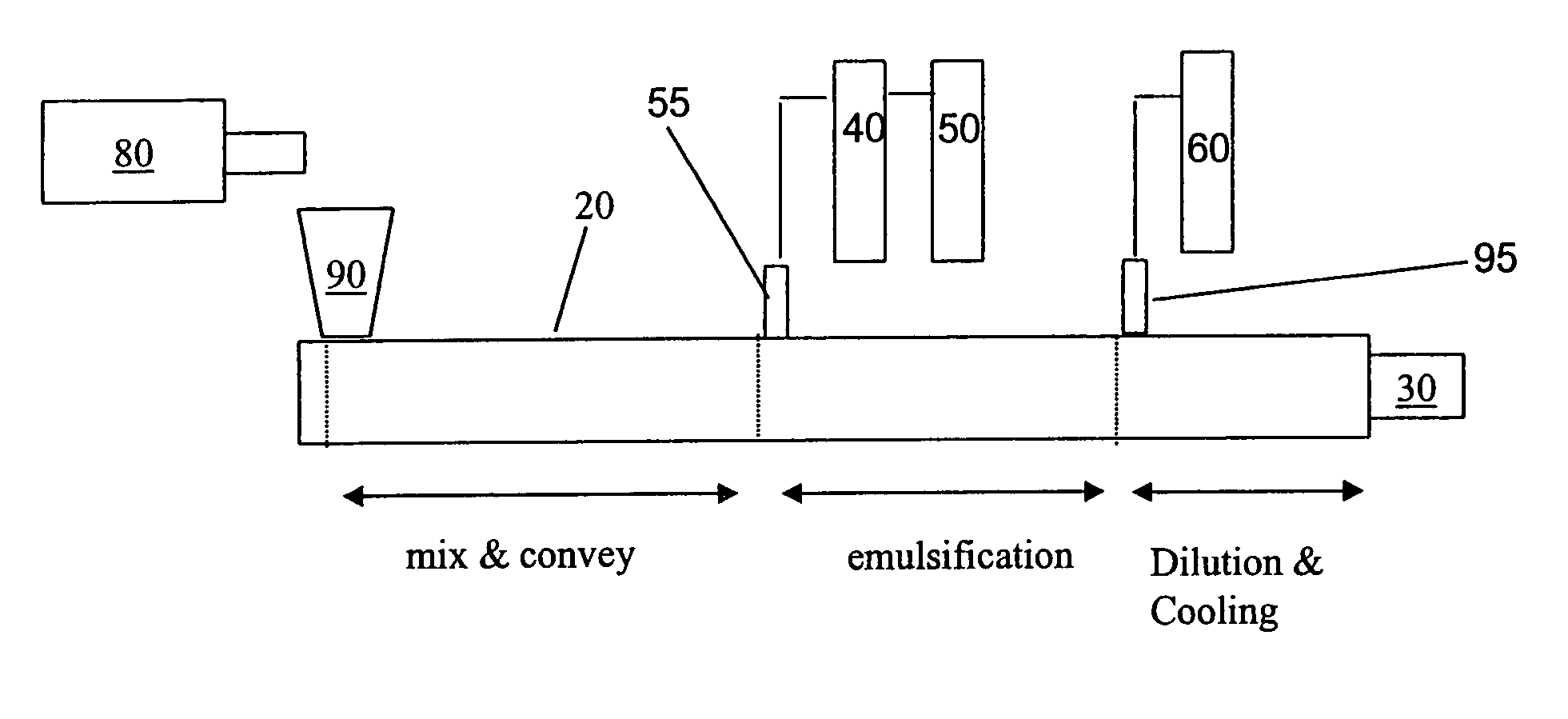

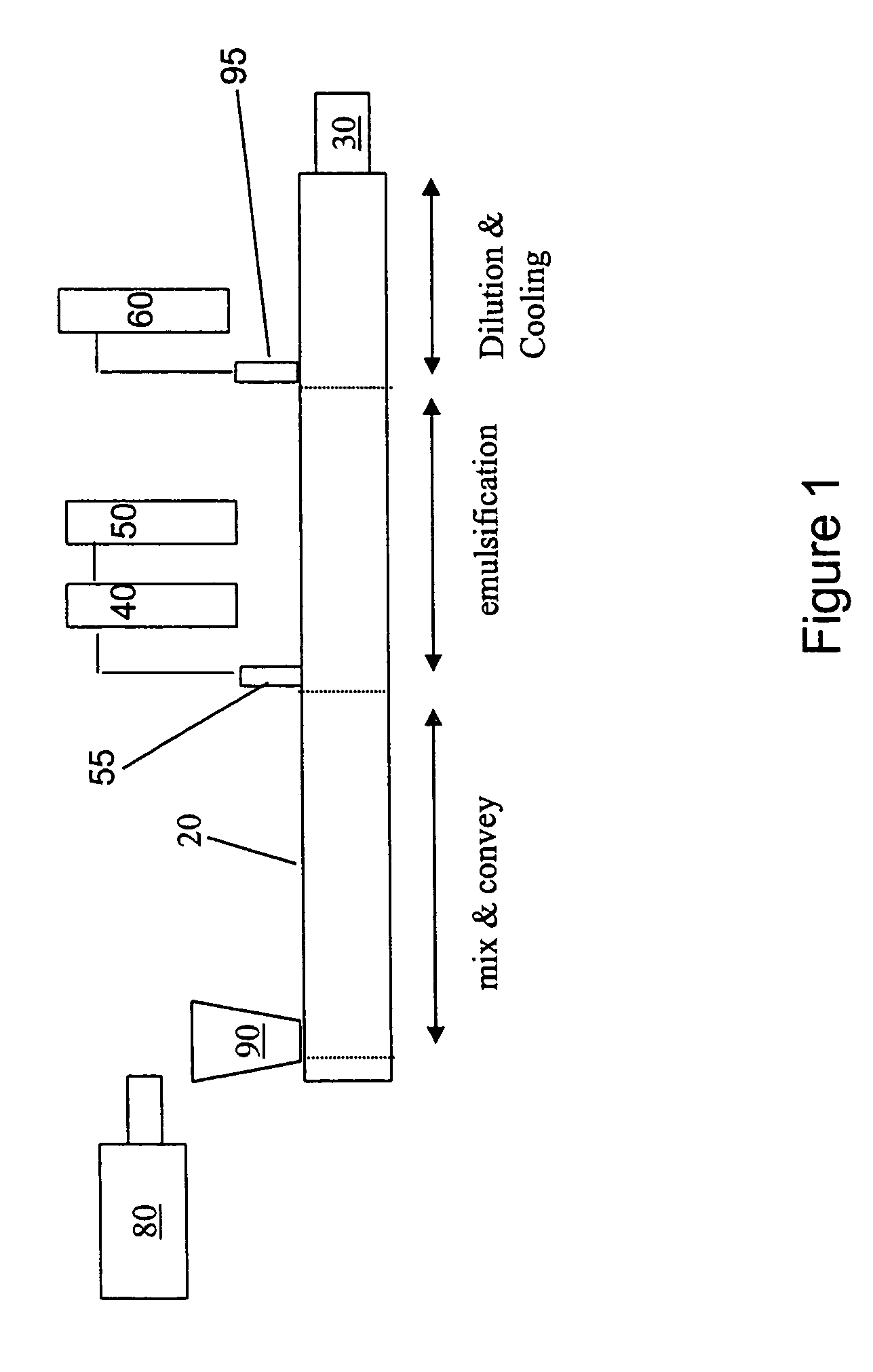

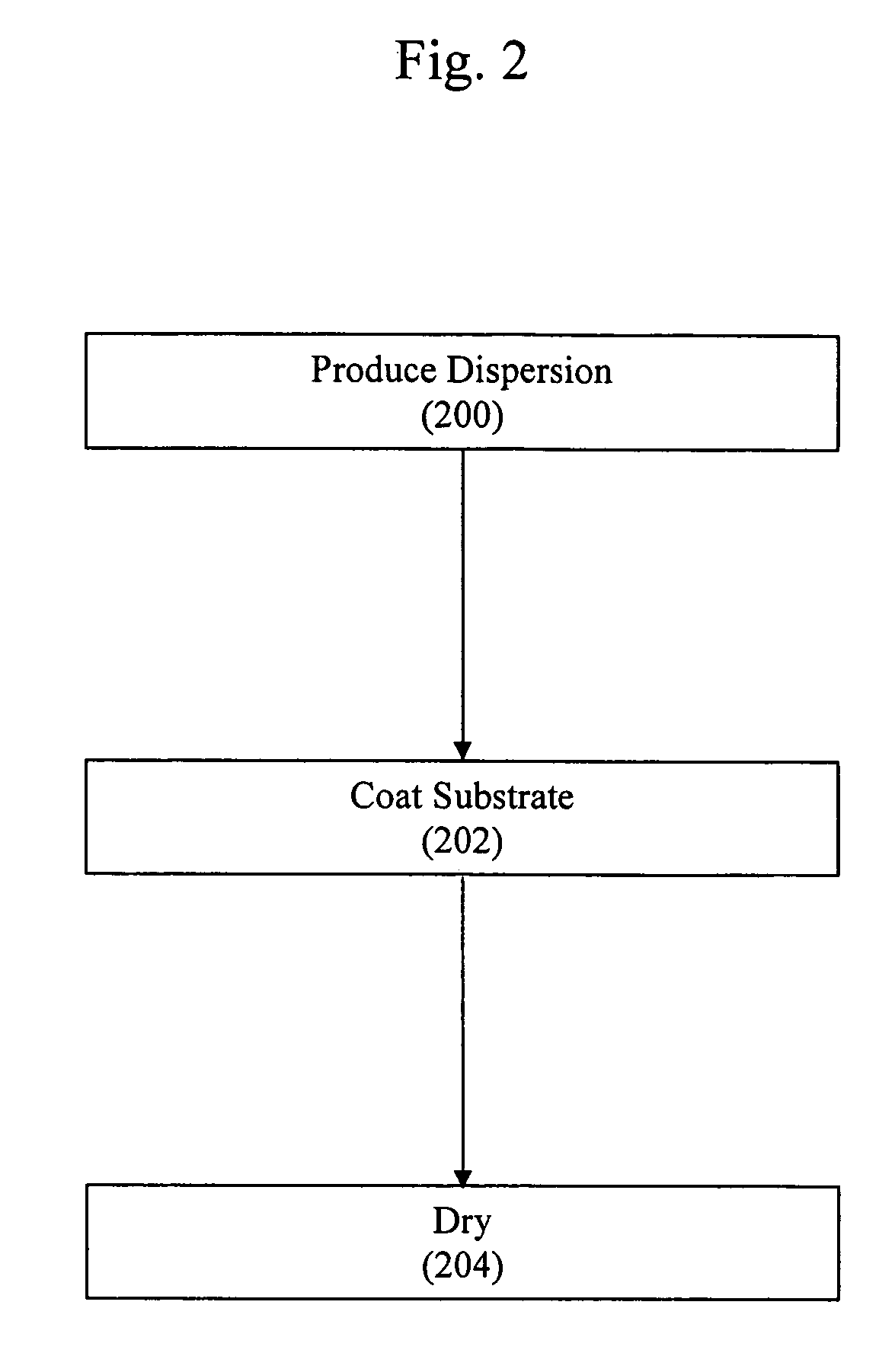

Aqueous polymer dispersions and products from those dispersions

ActiveUS20050271888A1Monocarboxylic acid ester polymer adhesivesSynthetic resin layered productsPolymerCoating

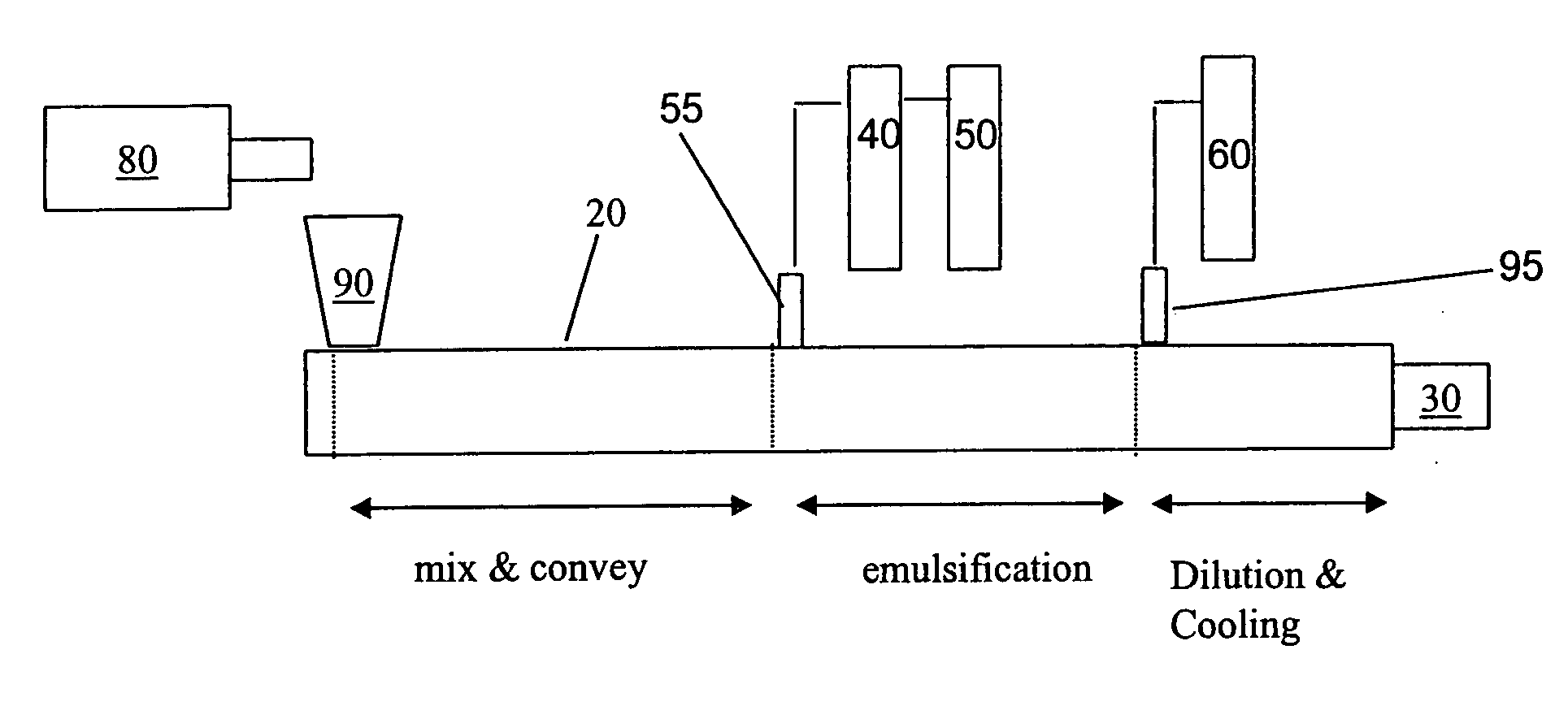

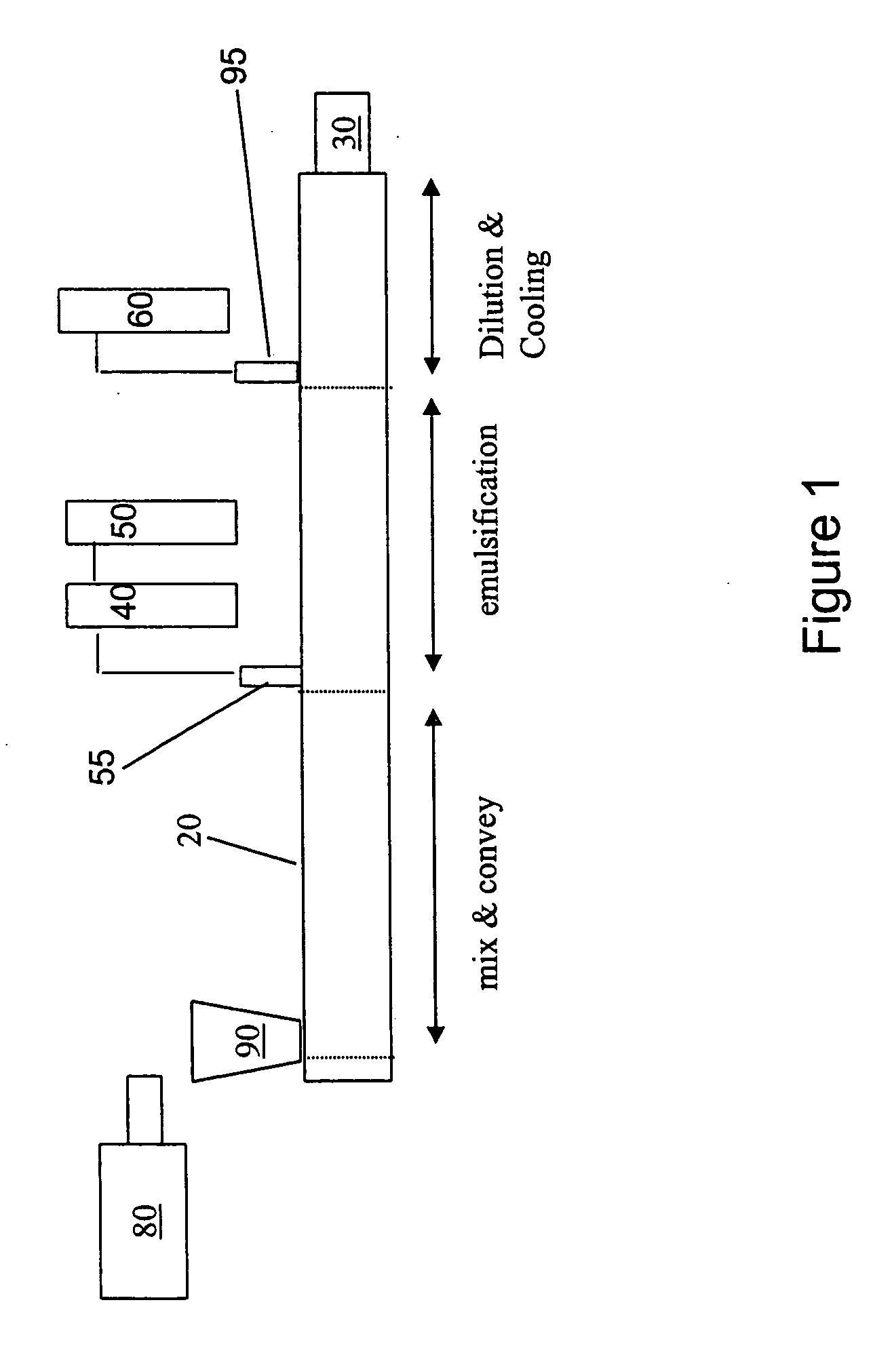

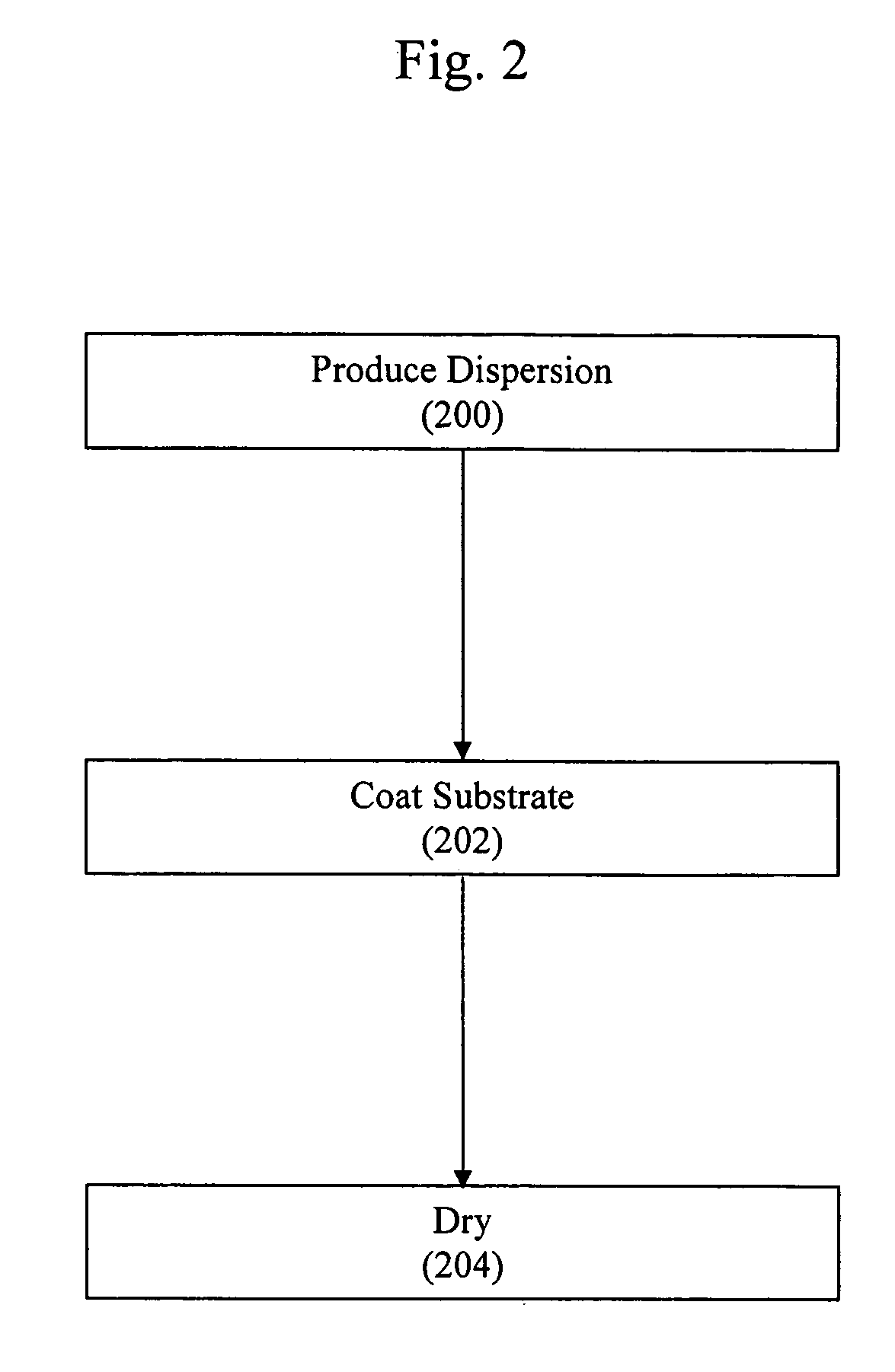

A method for forming a heat sealable coating on a substrate, wherein the substrate is formed from at least one oriented polymer is shown. The method includes depositing an aqueous polymer dispersion on the substrate, wherein the aqueous polymer dispersion includes (A) at least one thermoplastic resin; (B) at least one dispersing agent; and (C) water; wherein the dispersion has a pH of less than 12, and drying the dispersion to form a first layer.

Owner:DOW GLOBAL TECH LLC

Micron nano material composite modified water-based adhesive

InactiveCN101210157ALow shrinkageImprove performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesMicro nanoExtensibility

The invention relates to an aqueous binder which is compounded and modified by micro nano material. The modified aqueous binder of the invention adopts emulsion adhesive as matrix and micro-size and nano-size inorganic powder as modifier to prepare the compound and modified aqueous binder. The method of the invention can not only enhance the interface binding force of the aqueous binder, but also greatly improve the properties of water resistance, toughness and extensibility, leading comprehensive performance of the aqueous binder to be improved.

Owner:郑旷宇

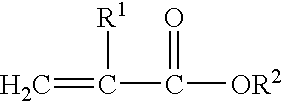

Plasticized acrylics for pressure sensitive adhesive applications

InactiveUS6624273B1High TgHigh modulusMonocarboxylic acid ester polymer adhesivesSurgical adhesivesMeth-Ethylene Homopolymers

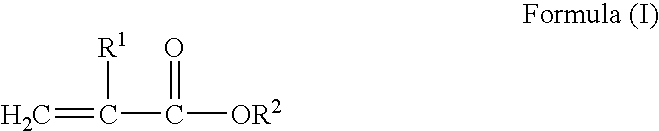

Non-tacky, base polymers are plasticized into pressure-sensitive adhesives and comprise: a) about 100 parts by weight of a base copolymer having a Tg greater than about 0° C., wherein the base copolymer is formed from and comprises: (1) about 50 to 70% by weight of a high Tg comonomer component, wherein the homopolymer formed from the high Tg comonomer component has a Tg of at least about 20° C.; (2) optionally, up to about 20% by weight based on the total weight of the base copolymer of an acidic comonomer; and (3) about 30 to 50% by weight of one or more low Tg (meth)acrylate comonomer, wherein the Tg homopolymer of the low Tg comonomer is less than about 20° C., and b) about 1 to about 100 parts based on the base copolymer of a nonreactive, non-volatile, non-acrylic-based plasticizing agent.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous polymer dispersions and products from those dispersions

ActiveUS7763676B2Monocarboxylic acid ester polymer adhesivesLiquid surface applicatorsPolymer sciencePolymer chemistry

Owner:DOW GLOBAL TECH LLC

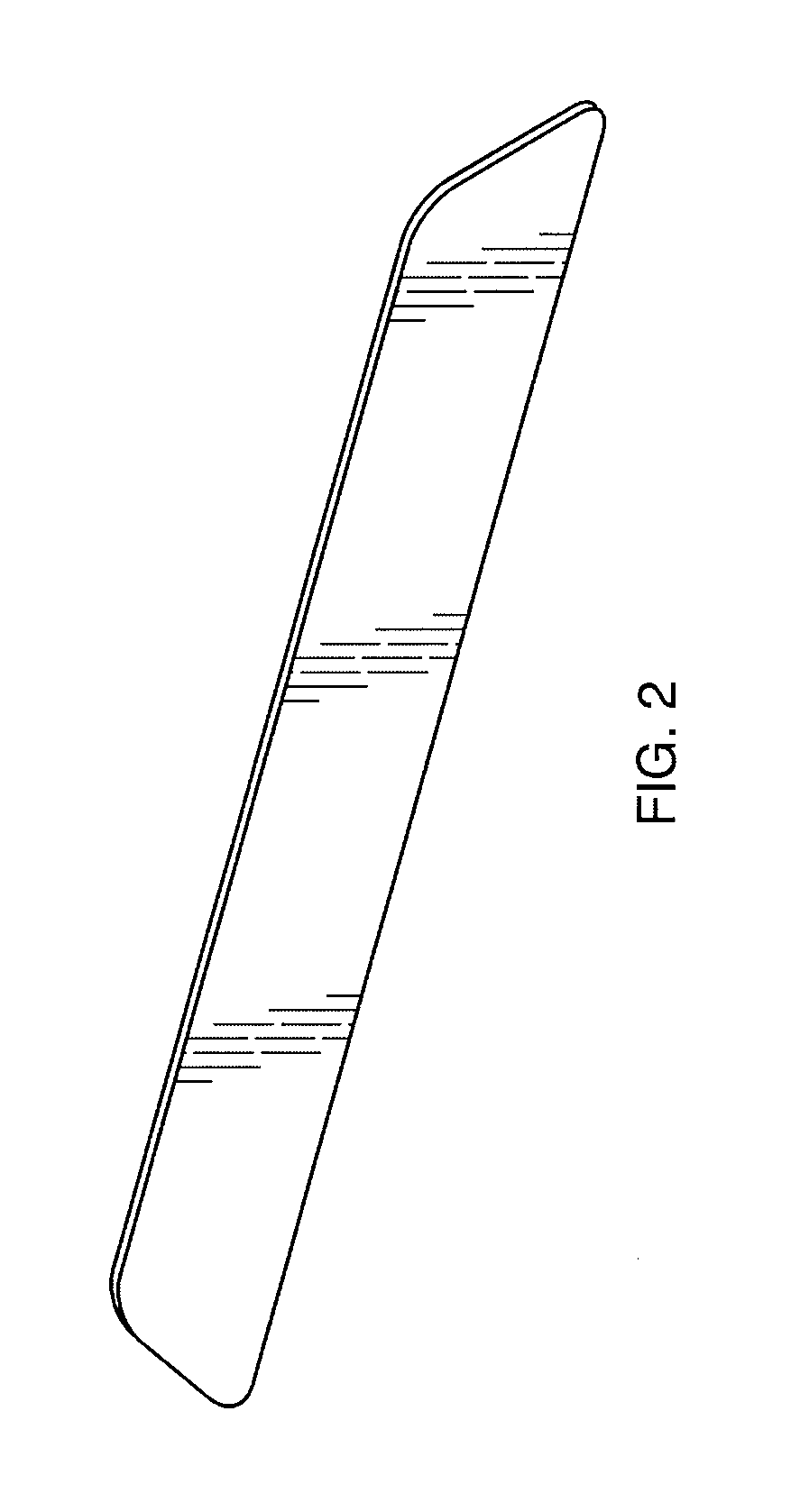

Adhesive and paint for absorbing formol

ActiveCN101045847AEffective absorptionAdhesive strength effectMonocarboxylic acid ester polymer adhesivesHydrocarbon polymer adhesivesBULK ACTIVE INGREDIENTUltimate tensile strength

This invention relates to a adhesive and a dope used for catching formaldehyde, both takes formaldehyde collector as active ingredient. This adhesive is used for gluing outer layer or kerf section of panel, can efficiently absorb formaldehyde liberated by panel, and has no impact to adhesion strength of panel. This dope is used for washing indoor wall; to absorb formaldehyde in the indoor air; also be used for surface washing of panel, absorb formaldehyde gas, reduce releasing of formaldehyde. Comparing with existing technology, this invention has such merit: cheapness, efficiently, and can generate stable compound, no longer discharge formaldehyde gas, thus unable to generate other secondary pollutant.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Adhesive composition comprising a particulate thermoplastic component

InactiveUS6548579B2Improve interface adhesionInhibition formationMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedParticulates

The invention is directed to an adhesive composition comprising a water based component including a film-forming polymer and a particulate thermoplastic component selected from the group consisting of thermoplastic polymers, thermoplastic resins, hot melt adhesive compositions, and mixtures thereof. The thermoplastic component has a mean particle size of from about 10 microns to about 1,500 microns. The adhesive composition is useful as a one-shot bookbinding adhesive, a primer composition as well as a second-shot adhesive for two-shot bookbinding method. The invention is also directed to the bookbinding methods using the adhesive composition.

Owner:HB FULLER CO

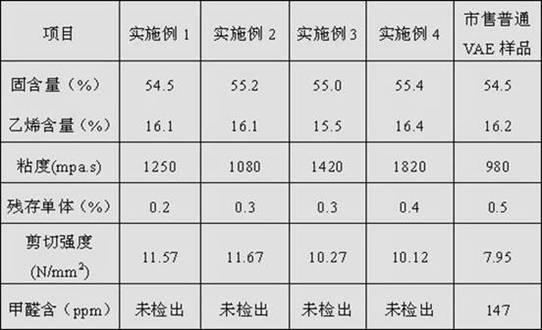

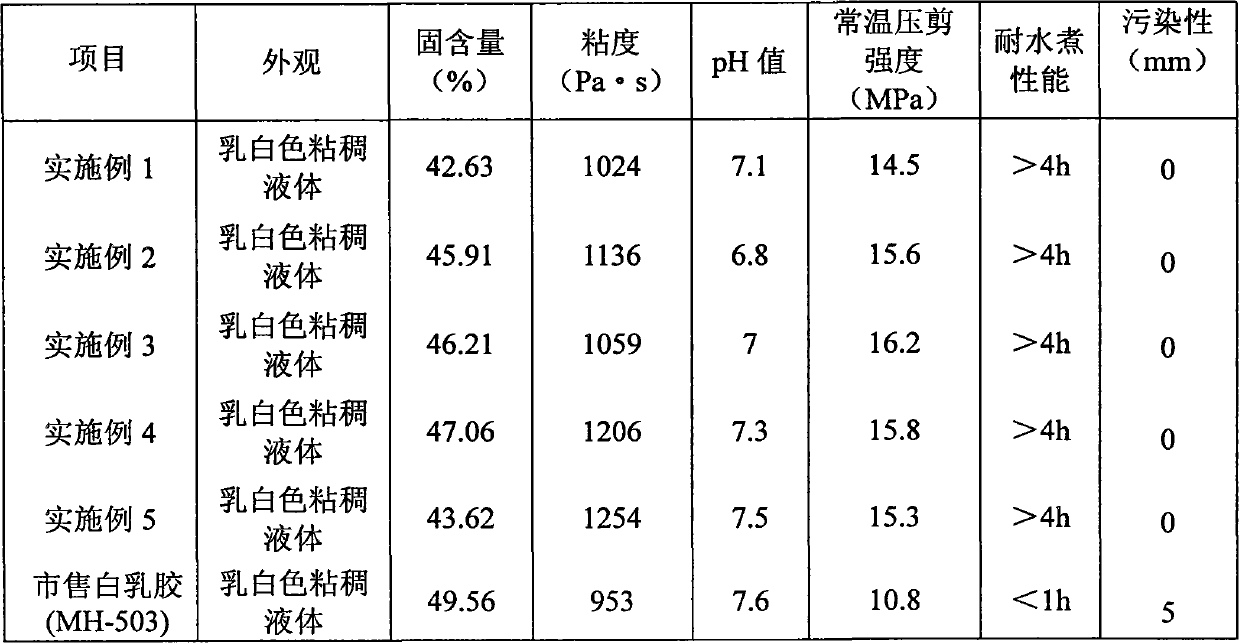

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Novel biodegradable bone plates and bonding systems

ActiveUS20080234754A1Early resorptionMonocarboxylic acid ester polymer adhesivesSurgical adhesivesHot-melt adhesiveBiomedical engineering

The invention relates to novel internal fixation devices, such as bone plates, generally and novel craniomaxillofacial bone plates more specifically and systems for bonding the same. More specifically, the invention relates to bone plates made of a polymer blend of (poly)lactic acid and Ecoflex as well as a novel hot-melt adhesive polymer blend of the same material.

Owner:NOVAPLAST CORP +1

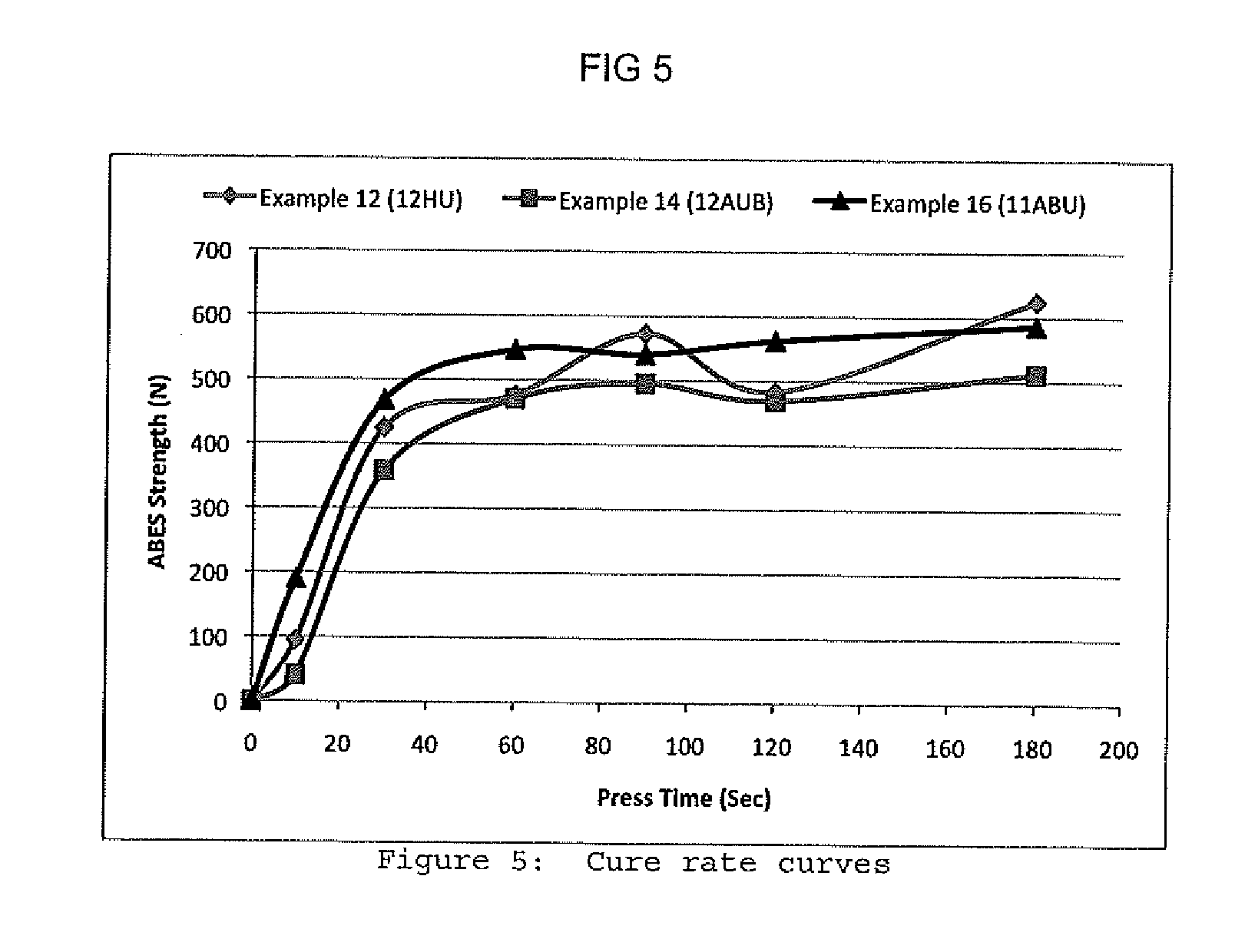

Wood composites, methods of production, and methods of manufacture thereof

ActiveUS20070020476A1Monocarboxylic acid ester polymer adhesivesProtein adhesivesMethods of productionOrganic chemistry

An adhesive binder comprising a phenol-formaldehyde resin, polyvinyl ester resin, and a protein is disclosed. The adhesive binder is useful for preparing wood composites.

Owner:HEXION INC

Environmental-friendly white emulsion

InactiveCN103725229AOptimal temperature timeImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDioxyethylene EtherBenzioc acid

The invention discloses an environmental-friendly white emulsion. The environmental-friendly white emulsion is prepared from the components in percentage by weight: 1.8-2.5 percent of polyvinyl alcohol PVA, 23-27 percent of vinyl acetate VAC, 0.3-0.8 percent of acrylic acid AA, 0.8-1.5 percent of acryl amide AM, 0.1-0.15 percent of ammonium persulfate, an anionic emulsifier A-102, alkyl polyoxyethylene ether LCN-287, a nonionic emulsifier, 5-7 percent of corn starch, a transparent powder, a plasticizer, 2.5-4 percent of diethylene glycol dibenzoate, 0.2-0.3 percent of preservative KSG-201, 0.1-0.2 percent of sodium hydroxide NaOH, 0.3-0.5 percent of methanol, 3-6 percent of functional filler, 0.15-0.3 percent of compound emulsifier and 56-58 percent of water. The environmental-friendly white emulsion is strong in the adhesive force and the adhesive strength, is low in the production cost and is good in the environmental protection performance.

Owner:GUANGZHOU YIJIANG CHEM CO LTD

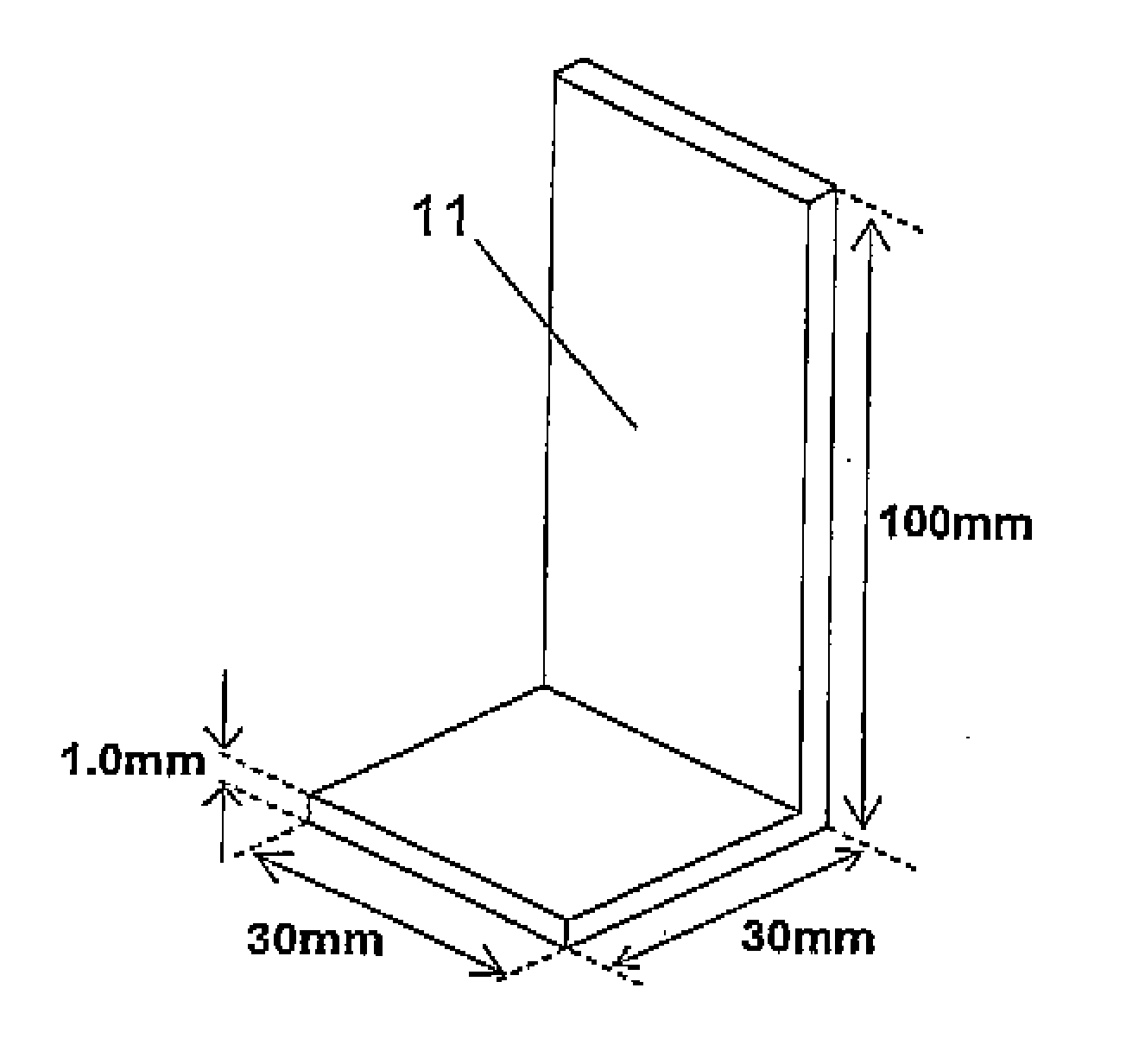

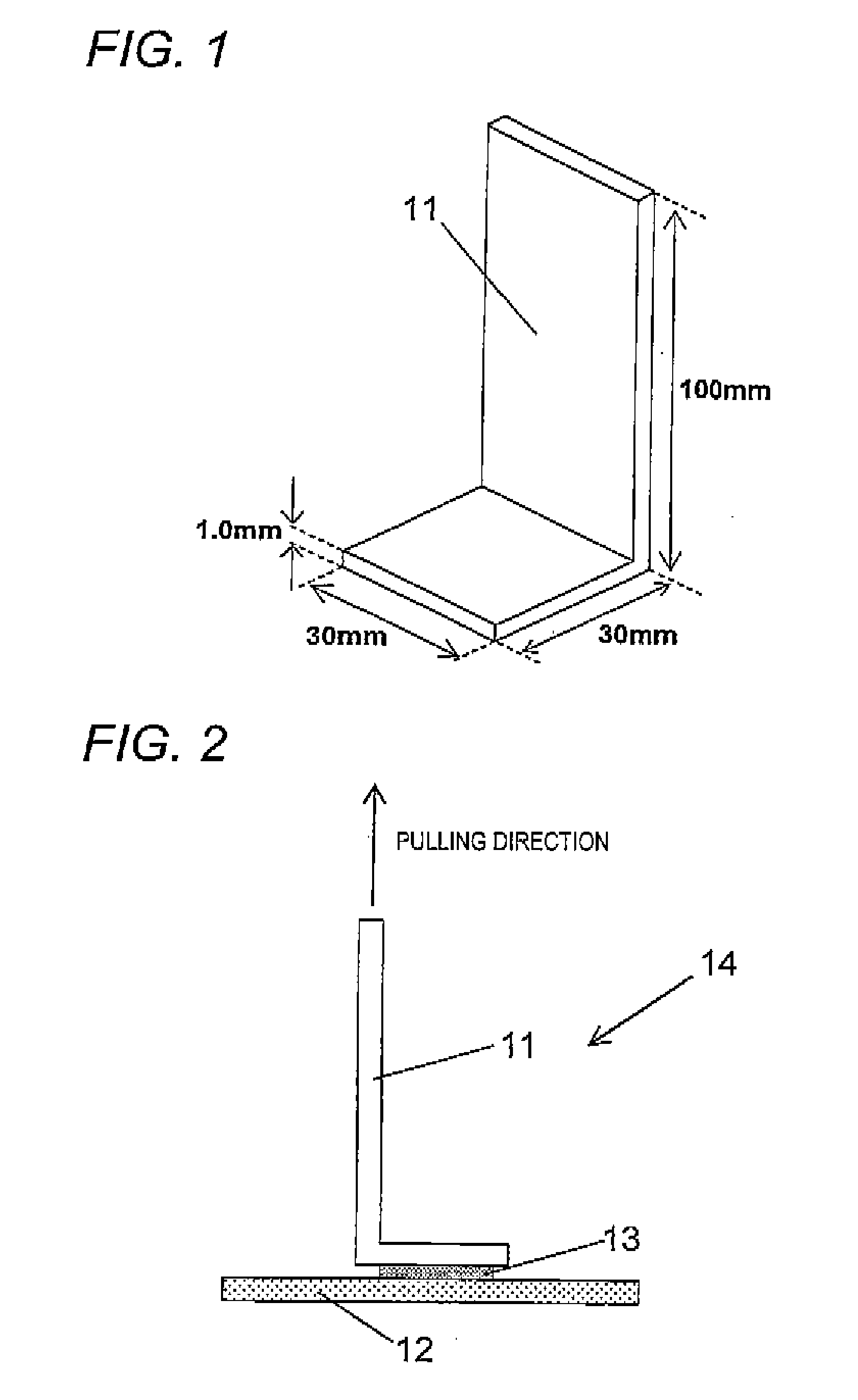

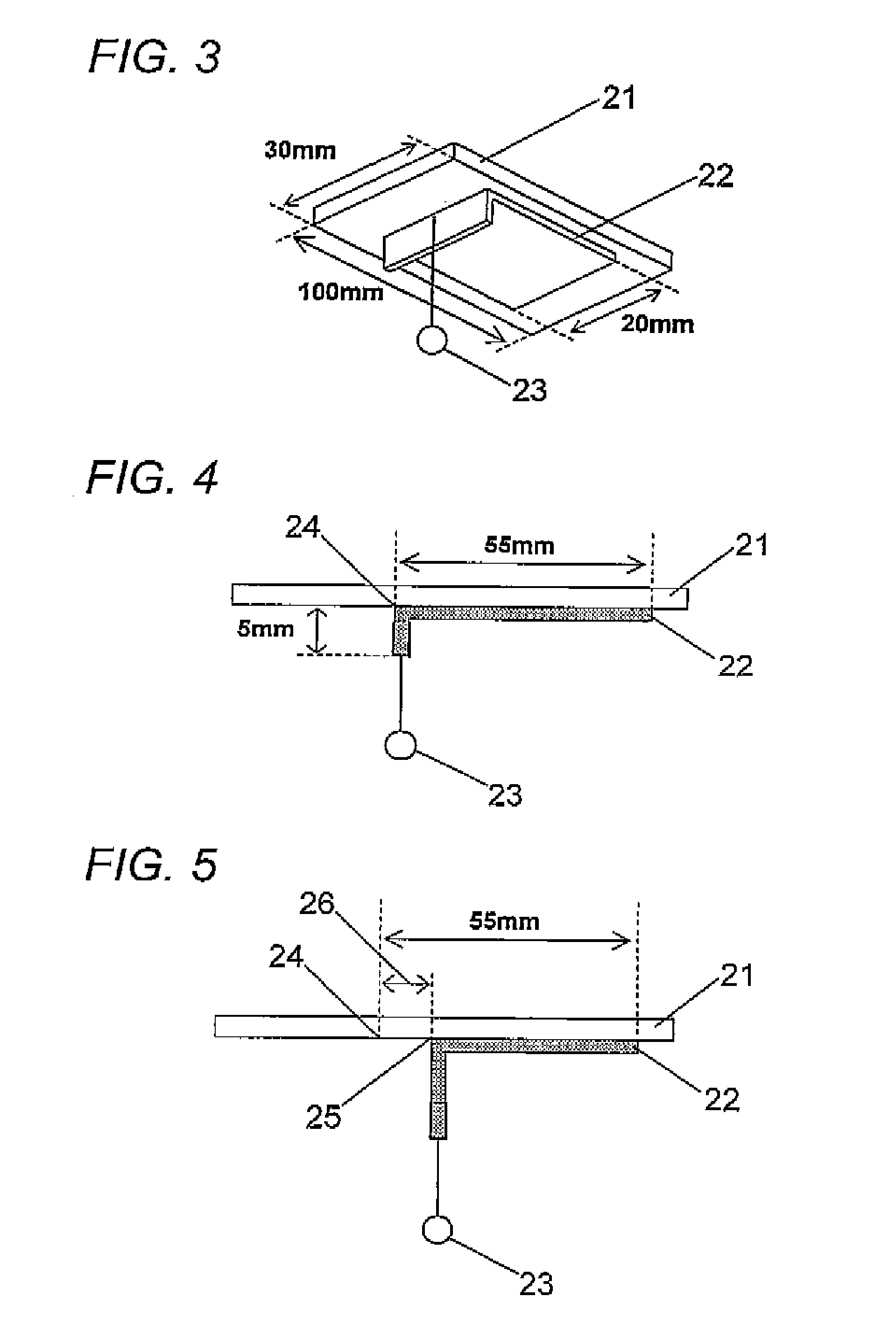

Optical-use pressure-sensitive adhesive sheet

InactiveUS20110111220A1Improve adhesionExcellent in twist-proof adhesivenessMonocarboxylic acid ester polymer adhesivesOpticsConstant loadDynamic viscoelasticity

The present invention provides an optical-use pressure-sensitive adhesive sheet including a pressure-sensitive adhesive layer having, as measured through dynamic viscoelastometry, a storage elastic modulus at 80° C. of at least 2.0×104 Pa and a loss elastic modulus at 80° C. of at least 1.0×104 Pa, in which the pressure-sensitive adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test (under a load of 100 gf for 3 hours), of at most 50 mm.

Owner:NITTO DENKO CORP

Aqueous binding agent and preparation method thereof

ActiveCN101880512AGood storage stabilityEasy to storeMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesHot stampingEmulsion

The invention provides an aqueous binding agent which has washing resistance and is used for electrochemical aluminium hot stamping, and a preparation method thereof, belonging to a binding agent composition. The aqueous binding agent comprises 40-80 parts by weight of acrylic resin emulsion (with the solid content of 40-55%), 20-40 parts by weight of acrylic resin powder and 5-20 parts by weight of ethylene-vinyl acetate copolymer (EVA) emulsion (with the solid content of 40-60%). The binding agent does not contain organic volatile component, is harmless for the human body, is an environment-friendly electrochemical aluminium hot stamping binding agent, and is especially suitable for fabric which is needed to be printed and frequently washed.

Owner:浙江德尚化工科技有限公司

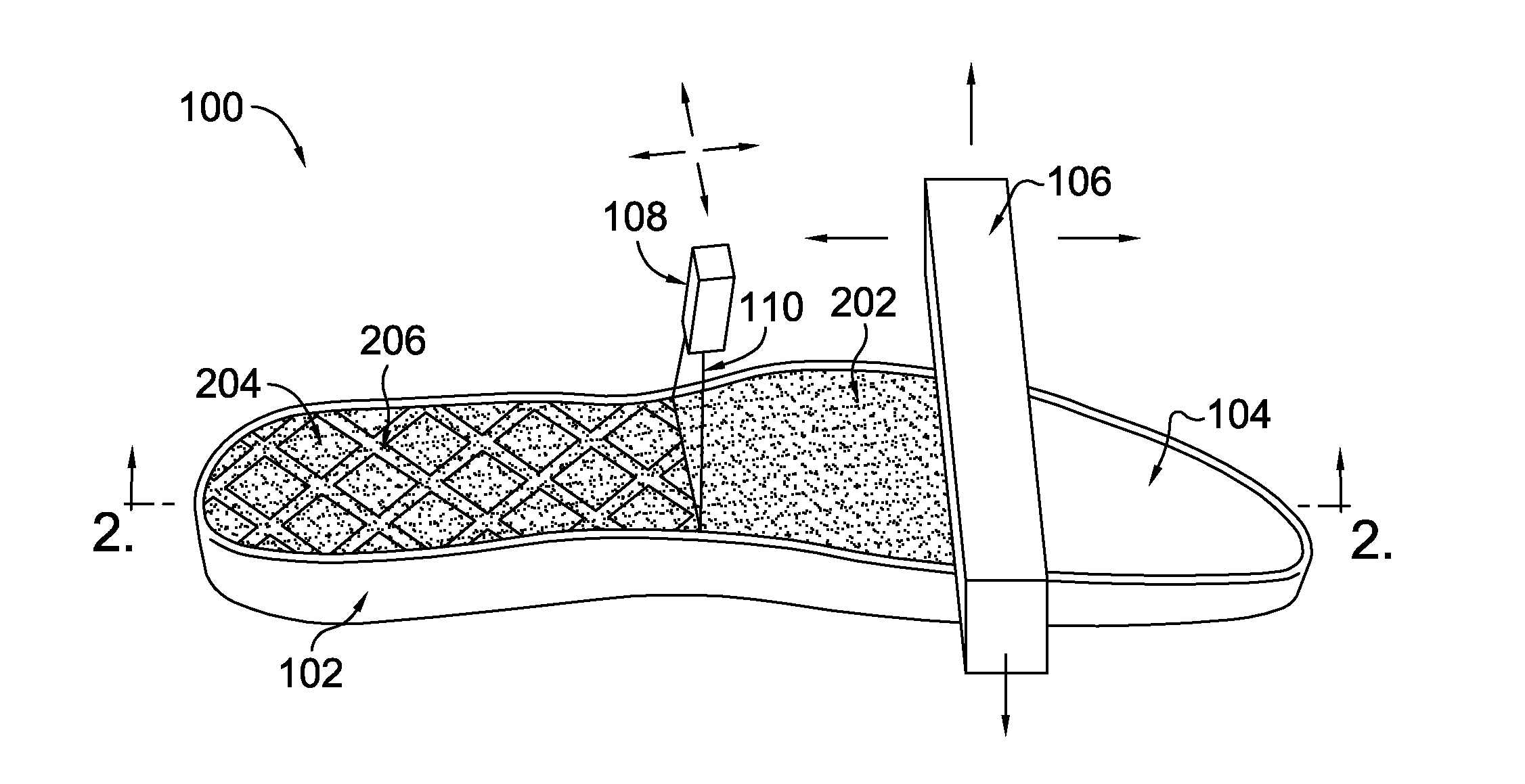

Selectively Applied Adhesive Particulate on Nonmetallic Substrates

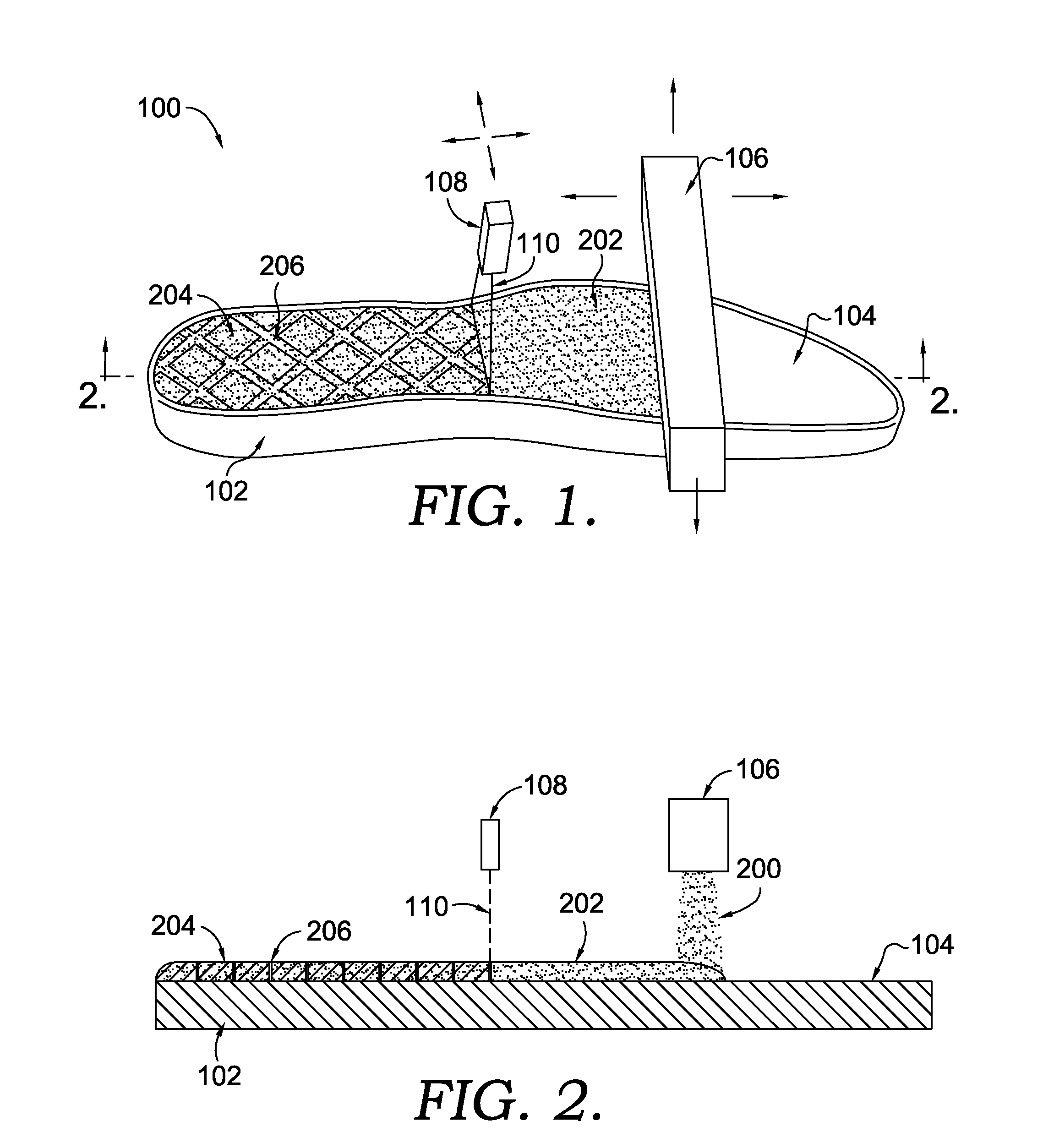

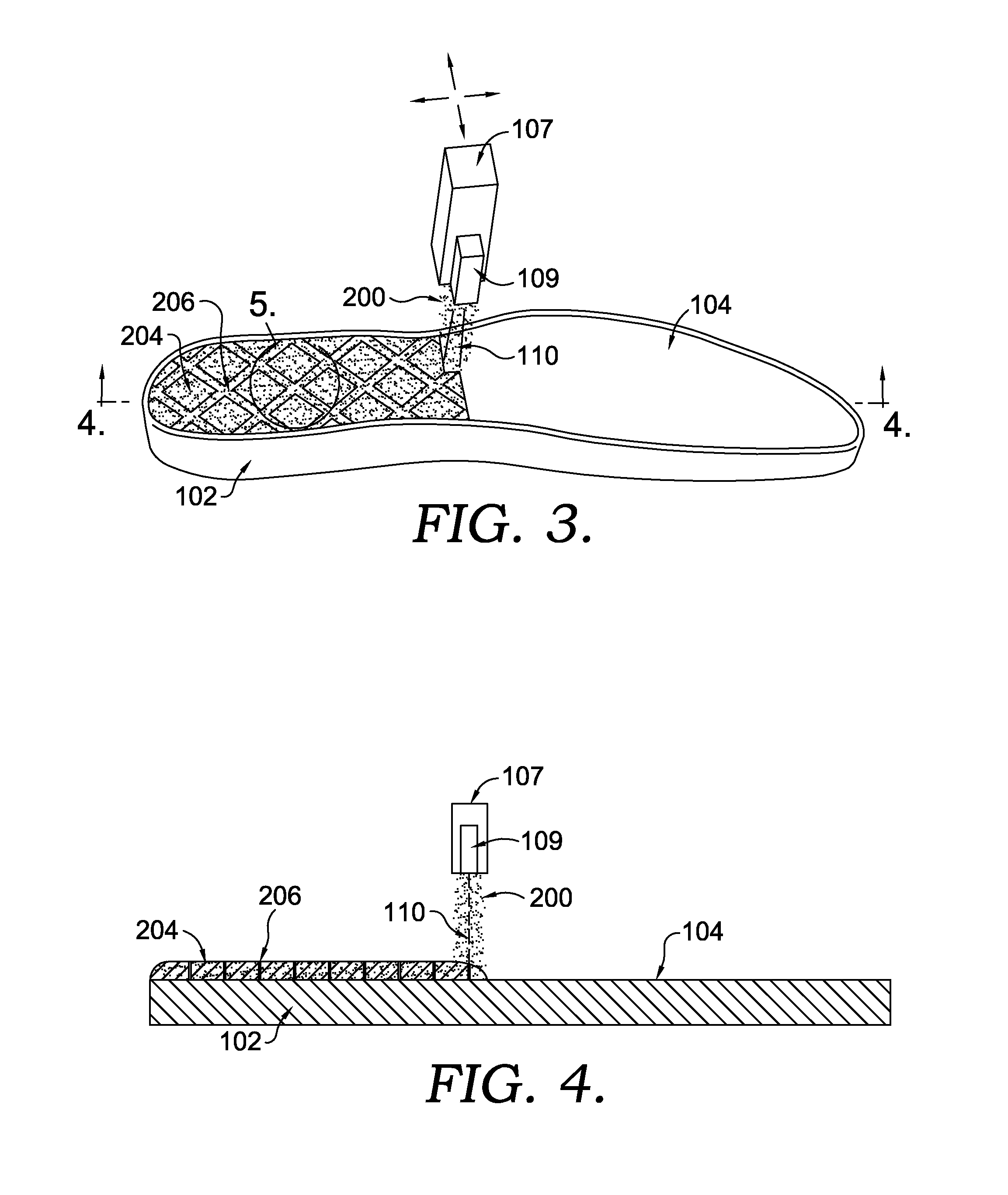

The manufacturing of articles relies on the bonding of two or more components to form some forms of the articles, such as a shoe sole bonded with a shoe upper. The bonding may be achieved with an adhesive particulate that is applied to a surface of a substrate. The adhesive particulate is selectively fused to the substrate with a controlled energy source, such as a laser. The selective application of laser energy allows for specific geometric structures of adhesive particulate to be formed on the substrate. The substrate having the fused adhesive particulate is mated with another component allowing the fused adhesive particulate to bond the first substrate and the second component.

Owner:NIKE INC

Multifunctional aqueous adhesive and preparation method thereof

ActiveCN101058704AAvoid poisoningAvoid the chance of occupational diseasesMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesPolymer scienceAdjuvant

The invention discloses a multipurpose aqueous adhesive, which comprises the following parts: 10-35% thermoplastic rubber or emulsion, 0. 5-35% solvent, 28-45% emulsion, 20-80% viscosifying resin or its emulsion, 0. 5-5% functional adjuvant and 1-20% water. The making method comprises the following steps: putting the solvent into autoclave; stirring at middle speed and adding thermoplastic rubber and its modifying product until dissolving completely; or putting into copolymerized rubber emulsion directly; stirring to add the viscosifying resin or the viscosifying resin in the invention; blending evenly; adding emulsion; fetching the sample to test the viscosity; adding fitful quantity of water and corresponding functional adjuvant according to the purpose and viscosity; dispersing at high speed until even condition; cooling; filtering; packing; obtaining the product for shoe-making, hand pocket and decorative aspect with low cost.

Owner:林润强

Water-base joint grouting glue for normal temperature road

InactiveCN101643636AAct as a seam sealStrong viscosity and permeabilityMonocarboxylic acid ester polymer adhesivesOther chemical processesWater basedAdhesive

The invention relates to water-base joint grouting glue for a normal temperature road, namely an environment-friendly joint grouting and joint sealing material having high viscosity, high cementing power and high adhesive property, which is formed by special processes of copolymerizing water, a water-base adhesive, bitumen and a dispersing agent, then modifying a macromolecular water-soluble resinand a rubber latex, and adding the auxiliary agents of a stabilizing agent, a thickening material and the like, and can be used for treating and sealing various types of cracks of bitumen and cementroad surfaces and joint seams of cement road surfaces and bridge surfaces. The joint grouting glue is in a gel state at normal temperature, can be stirred but cannot flow, thus the joint grouting gluecan enter joints directly without slotting and cannot infiltrate downwards so as to play a role in sealing the joints; and simultaneously the joint grouting glue is soluble in water; therefore, the joint grouting glue can be mixed with water to prepare strong-permeability joint grouting materials with any viscosities, and can be effectively poured into deep parts of the cracks of road surfaces without slotting. The joint grouting glue combines the advantages of slotting and non-slotting repairing methods, and simultaneously avoids the disadvantages of the two methods.

Owner:李志刚 +2

Low odor, light color, disposable article construction adhesive

InactiveUS20050014891A1Improve cohesive strengthEasy to processMonocarboxylic acid ester polymer adhesivesPersonal carePolymer scienceHot melt

We have found a novel spray-on adhesive composition made from components including a high melt index polymer and a high melt tackifier that interact to produce a composition that can form a low odor, light color, non-tacky, hot melt adhesive material that can be used in disposable article manufacture. The adhesive is thermally stable at hot melt application conditions, is low in cost, is easily applied and produces high quality disposable articles.

Owner:ADHERENT LAB

Hot-pressed veneer adhesive and preparation method thereof

ActiveCN102585736ALow costShort curing timeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveCarvacryl acetate

The invention discloses a hot-pressed veneer adhesive and a preparation method thereof. The hot-pressed veneer adhesive mainly comprises the following components: deionized water, polyvinyl alcohol, an emulsifier, an initiator, methacrylic acid, N-methylol acrylamide, vinyl acetate, a plasticizer, a buffering agent, cassava starch, borax, a dispersing agent, aqueous rosin, a defoaming agent and a corrosion inhibitor. When the hot-pressed veneer adhesive is prepared, the preparation method comprises the following steps of: firstly synthesizing a self-crosslinked polyvinyl acetate copolymerization modified emulsion, then adding 20-35% of raw cassava starch, a crosslinking agent, waterborne tackifying resin and other auxiliaries for mixing and finally preparing the hot-pressed veneer adhesive with excellent performances. Compared with a traditional urea resin veneer adhesive, the adhesive prepared by the invention has the advantages of convenience in use, low curing temperature, short curing time and no harm to an environment and a human body.

Owner:顶立新材料科技股份有限公司

Stable Acid Denatured Soy/Urea Adhesives and Methods of Making Same

ActiveUS20110048280A1Good compatibilityImprove stabilityMonocarboxylic acid ester polymer adhesivesProtein adhesivesAdhesiveDiluent

The present invention provides an improved method of producing a stable acid denatured soy / urea adhesive having improved wet and dry strengths, with more efficient production and lower production costs. The method comprises combining urea with soy flour that has been acid treated until denatured and substantially free from urease activity. The soy flour is preferably lowered to a pH of 2.0 to 4.0 for at least 1 minute. Optionally, the method may also include adding a crosslinking agent, diluent or both to the soy flour / urea adhesive and / or adding an emulsified or dispersed polymer. Adhesives and dispersions prepared according to the methods of this invention offer increased stability and strength properties.

Owner:SOLENIS TECH CAYMAN

Modified white latex

InactiveCN103923581AHigh viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesRoom temperatureCarvacryl acetate

The invention discloses a modified white latex which comprises the following components in parts by weight: 10 parts of vinyl acetate, 0.7 part of acrylic acid, and 1.5 pars of butyl acrylate; the amount of an initiator is 0.3% of the sum of the amounts of acrylic acid and butyl acrylate, and the amount of an emulsifier is 2%-3% of the sum of the amounts of acrylic acid and butyl acrylate. The white latex after modification has high viscosity, can form a film at room temperature, has the advantages of relatively good bonding strength, relatively good water resistance and the like, and has relatively great market popularization value.

Owner:上海吉妮乳胶厂

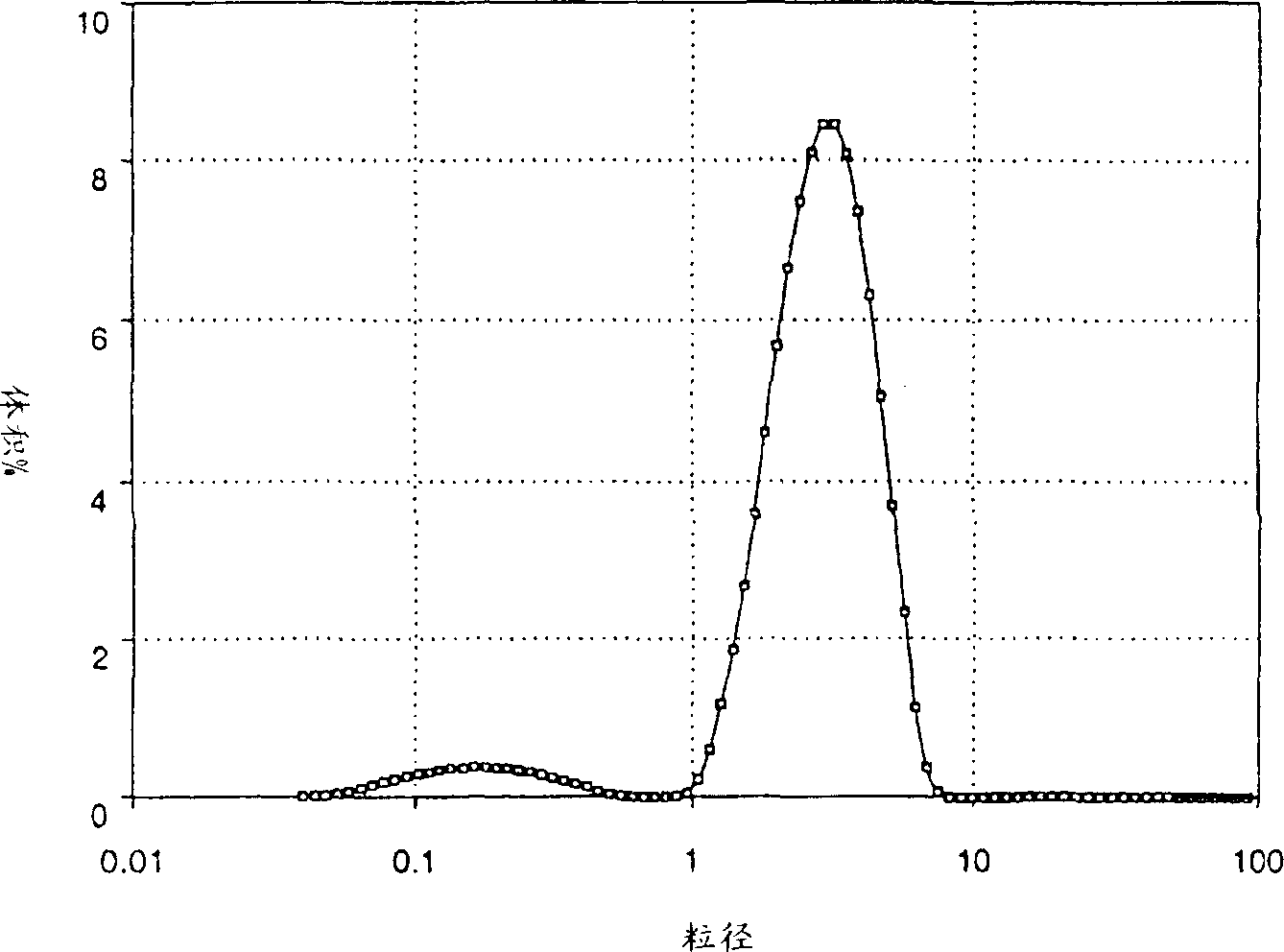

Method for preparing formaldehyde-free ethylene vinyl acetate emulsion

InactiveCN102603955ADelicate colloidImprove rheologyMonocarboxylic acid ester polymer adhesivesCoatingsCarvacryl acetateMonomer

The invention provides a method for preparing formaldehyde-free ethylene vinyl acetate emulsion. The ethylene vinyl acetate emulsion is obtained by copolymerization reaction of ethylene and / or polyvinyl alcohol with monomers such as vinyl acetate and the like in the existence of emulsifier and under the action of redox initiator, wherein pyrosulfite and / or sulfite serve as reducing agent, and organic hydrogen peroxide serves as oxidant. Ethylene vinyl acetate emulsion which completely contains no formaldehyde can be obtained by the method, the problems of yellowing, discoloring and the like can be avoided, and the formaldehyde-free ethylene vinyl acetate emulsion is uniform and stable in quality, wide in viscosity adjustable range, quick in curing, high in primary viscous force and wide in application range.

Owner:CHINA PETROCHEMICAL CORP

Multifunctional glue spray formula and process

ActiveCN102295912AMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesPolymer scienceButadiene-styrene rubber

The invention relates to the technical field of chemical detergents, in particular to a multifunctional spray glue formula and process. The spray glue formula comprises the following components in percentage by weight: 1-12 percent of rubber, 1.0-15 percent of synthetic resin, 10-40 percent of tackifying resin, 10-60 percent of hydrocarbon solvent, 30-75 percent of propellent, 10-40 percent of chlorine solvent, 3-30 percent of cosolvent, 2-8 percent of plasticizer and 0.05-1 percent of essence. The spray glue is prepared by the following steps of: adding the hydrocarbon solvent, the chlorine solvent and a part of cosolvent such as acetone and the like into a stirring kettle according to formula metering, opening and stirring; adding rubber such as SBS (Styrene-Butadiene-Styrene) thermoplastic elastomer and the like and synthetic resin such as acrylate resin and the like in a stirring state and stirring until the rubber and the synthetic resin are fully dissolved; adding the tackifyingresin such as rosin and the like and stirring until the rosin is fully dissolved; adding remaining cosolvent such as the acetone and the like and the plasticizer and stirring until glue liquid is fully dispersed; and filtering and canning, sealing, and inflating a can. The spray glue formula has the advantages of no toxin, no pollution, super-strong viscosity and adaptation to gluing of various materials, and is white and non-yellowing.

Owner:DONGGUAN DAYANG CHEM

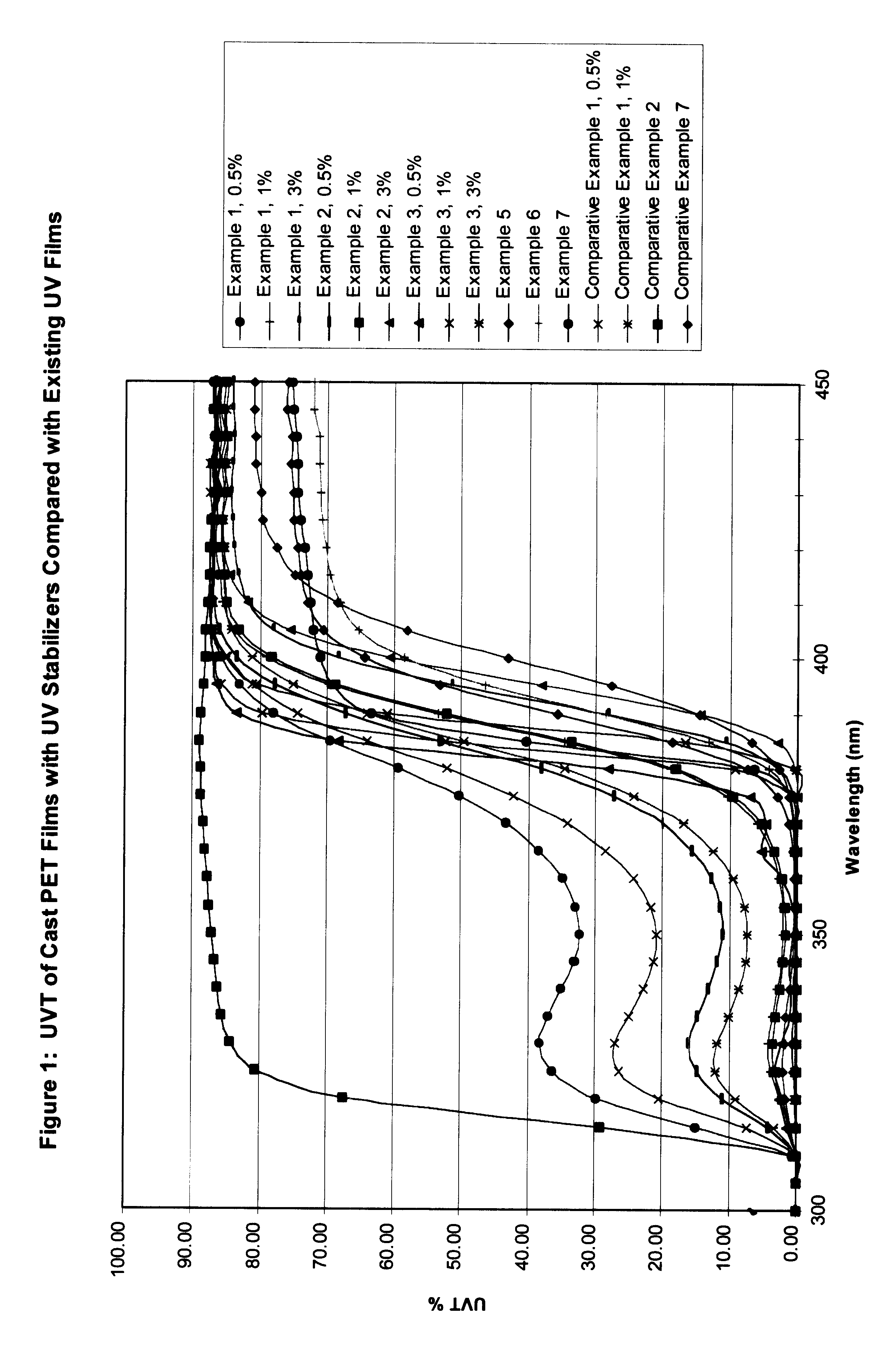

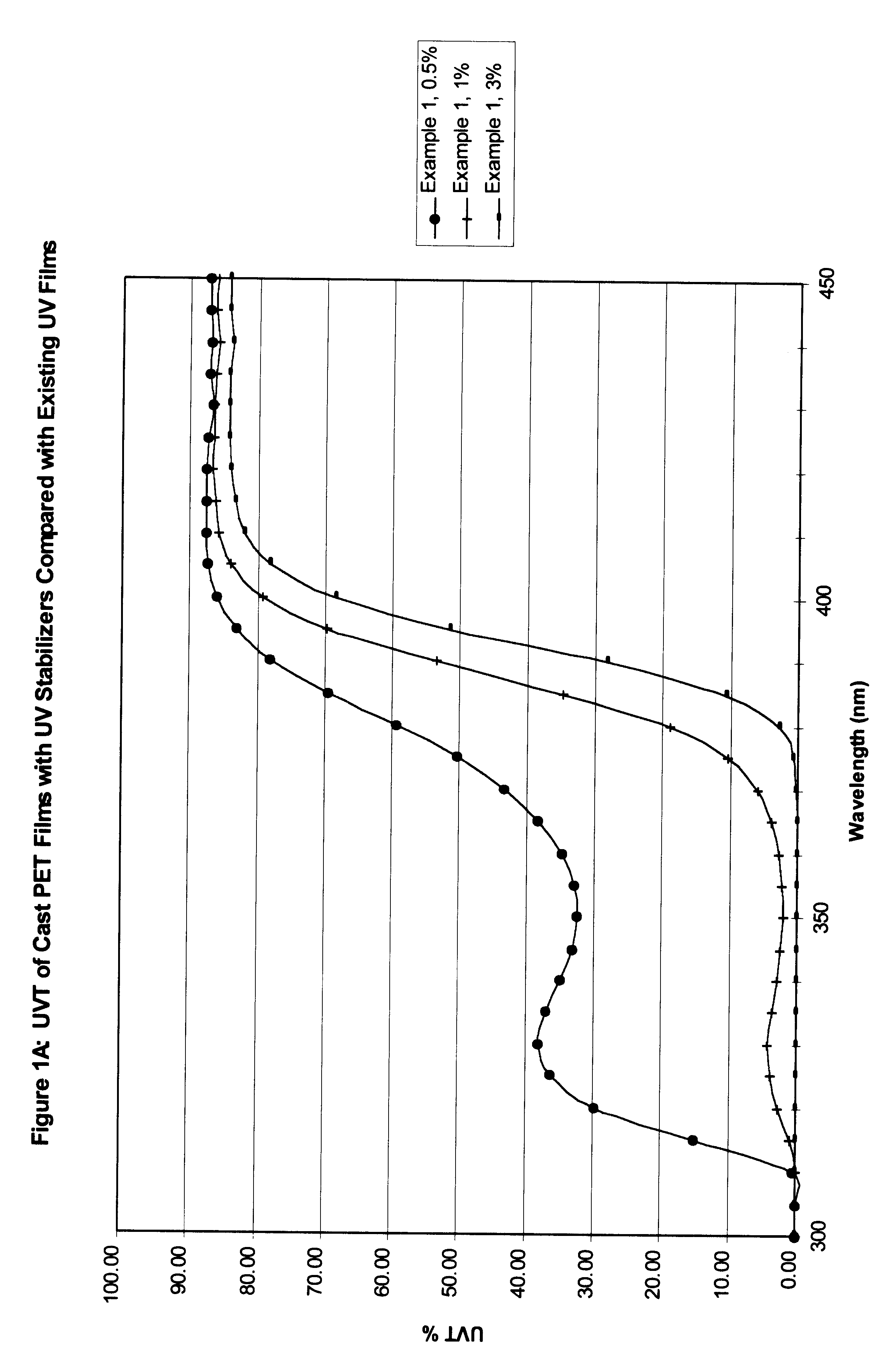

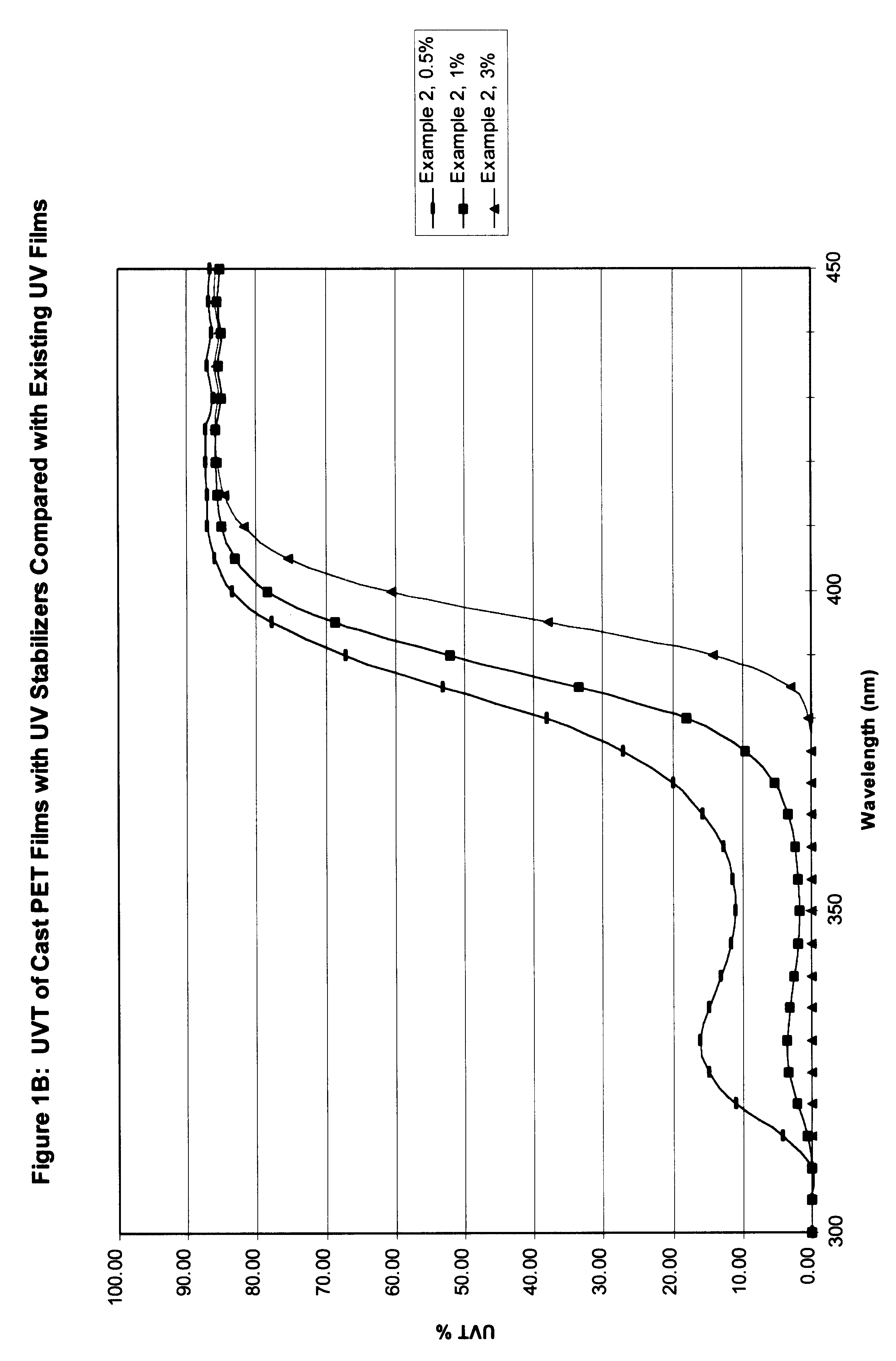

Polyester overlamination film with enhanced UV stabilization properties

InactiveUS6593406B2Monocarboxylic acid ester polymer adhesivesPhotography auxillary processesPolyesterPolyethylene terephthalate

A UVA stabilized polyethylene terephthalate overlamination film having a maximum peak absorption of about 380 nm, an approximate absorptive area % of <14% and a Visible Absorbance value of less than about 20%, coated with an adhesive layer to facilitate anchorage of the polyethylene terephthalate film to a secondary print substrate.

Owner:TORAY PLASTICS (AMERICA) INC

Modified water resistant low temperature white emulsoid

InactiveCN1377929AImprove water resistanceImprove low temperature resistanceMonocarboxylic acid ester polymer adhesivesChemical industryPolyvinyl acetate

The present invention relates to adhesive and discloses a kind of modified waterproof low temperature white emulsoid and its preparation. The modified waterproof low temperature white emulsoid is prepared by using polyvinyl acetate emulsion as base material, water solution of polyvinyl alcohol as emulsoid protector, ethylene-vinyl acetate emulsion as waterproof and low temperature modified and calcium carbonate as kaolin as adhesion intensifier. It has various specifications exceeding the chemical industry standard, excellent waterproof performance, good low temperature performance, simple production process, relatively lower cost and no toxicity and harm.

Owner:SHANGHAI UNIV OF ENG SCI

Single-component polyvinylacetate binding agent and preparation method thereof

InactiveCN101906278AImprove water resistanceImprove heat resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesChemical industryPolyvinyl alcohol

The invention discloses a single-component polyvinylacetate binding agent and a preparation method thereof. The single-component polyvinylacetate binding agent comprises the following raw materials in percentage by weight: 48 to 52 percent of deionized water, 3 to 5 percent of polyvinyl alcohol, 25 to 40 percent of polyvinylacetate, 5 to 10 percent of butyl acrylate, 2 to 3 percent of hydroxyethyl acrylate, 1 to 3 percent of methyl acrylic acid, 10 to 15 percent of organic silicon, 2 to 3 percent of composite emulsifier, 0.1 to 0.9 percent of initiator, 0.1 to 0.3 percent of pH regulator and 5 to 10 percent of plasticizer. The binding agent of the invention is modified waterproof and high temperature-resistant white latex prepared by acrylic ester and organic silicon modification with polyvinyl alcohol as protective colloid and polyvinylacetate as a base stock. All technical indexes of the binding agent are beyond standards of chemical industry, the waterproof performance and high temperature resistance of the binding agent are high, the production process of the binding agent is simple, the cost of the binding agent is low, and thus, the binding agent is a safe and environmentally-friendly product.

Owner:SOUTH CHINA UNIV OF TECH

Self-associating low adhesion backsize material

A low adhesion backsize (LAB) material made by mixing together materials, which self-associate. The mixtures can be waterbased and have high solids levels. The release is provided by functional groups such as silicones, fluorocarbons or long chain hydrocarbons. Release level can be tailored with release levels as low as the 0.5 gram / cm range to microsphere adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

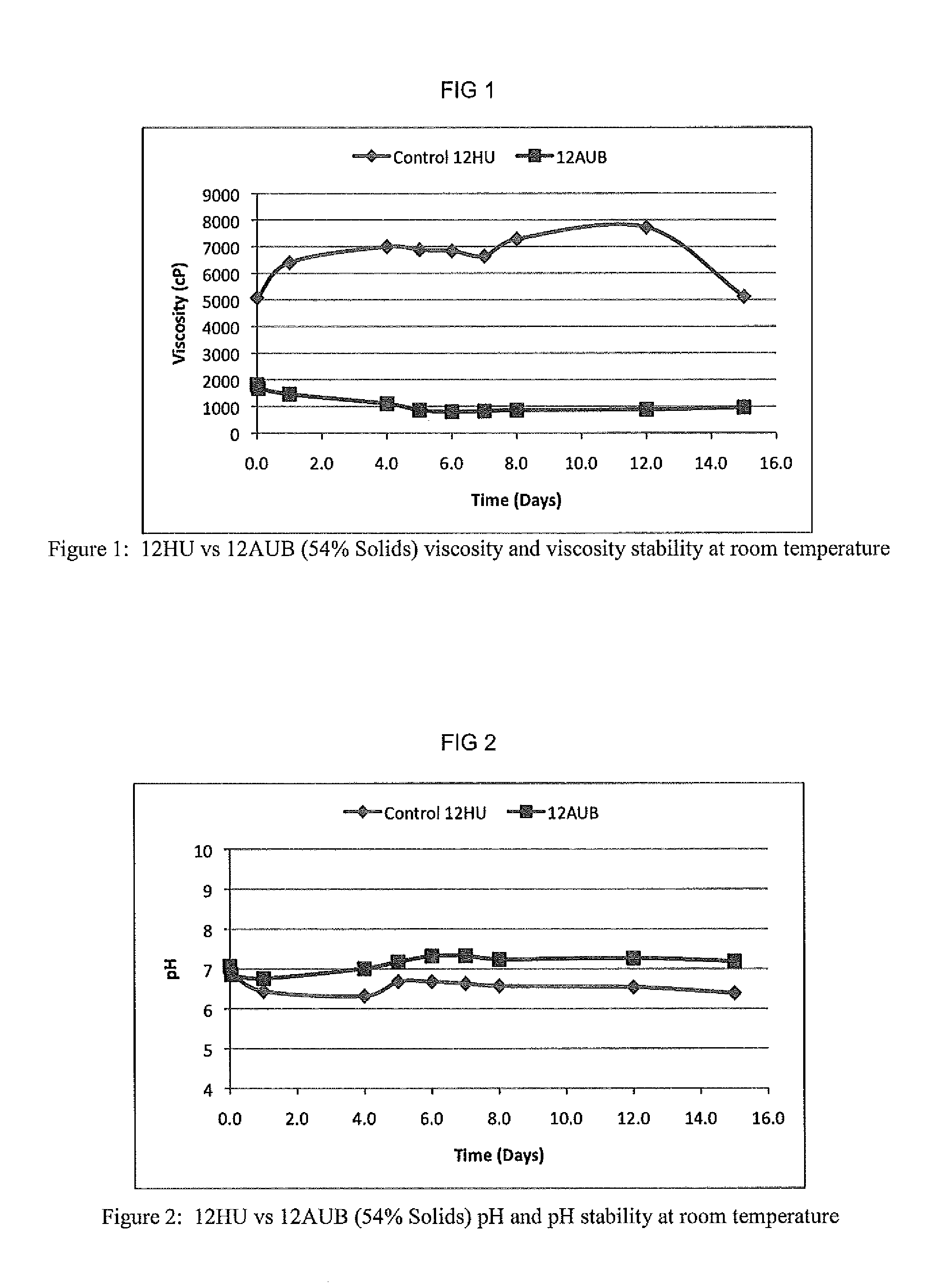

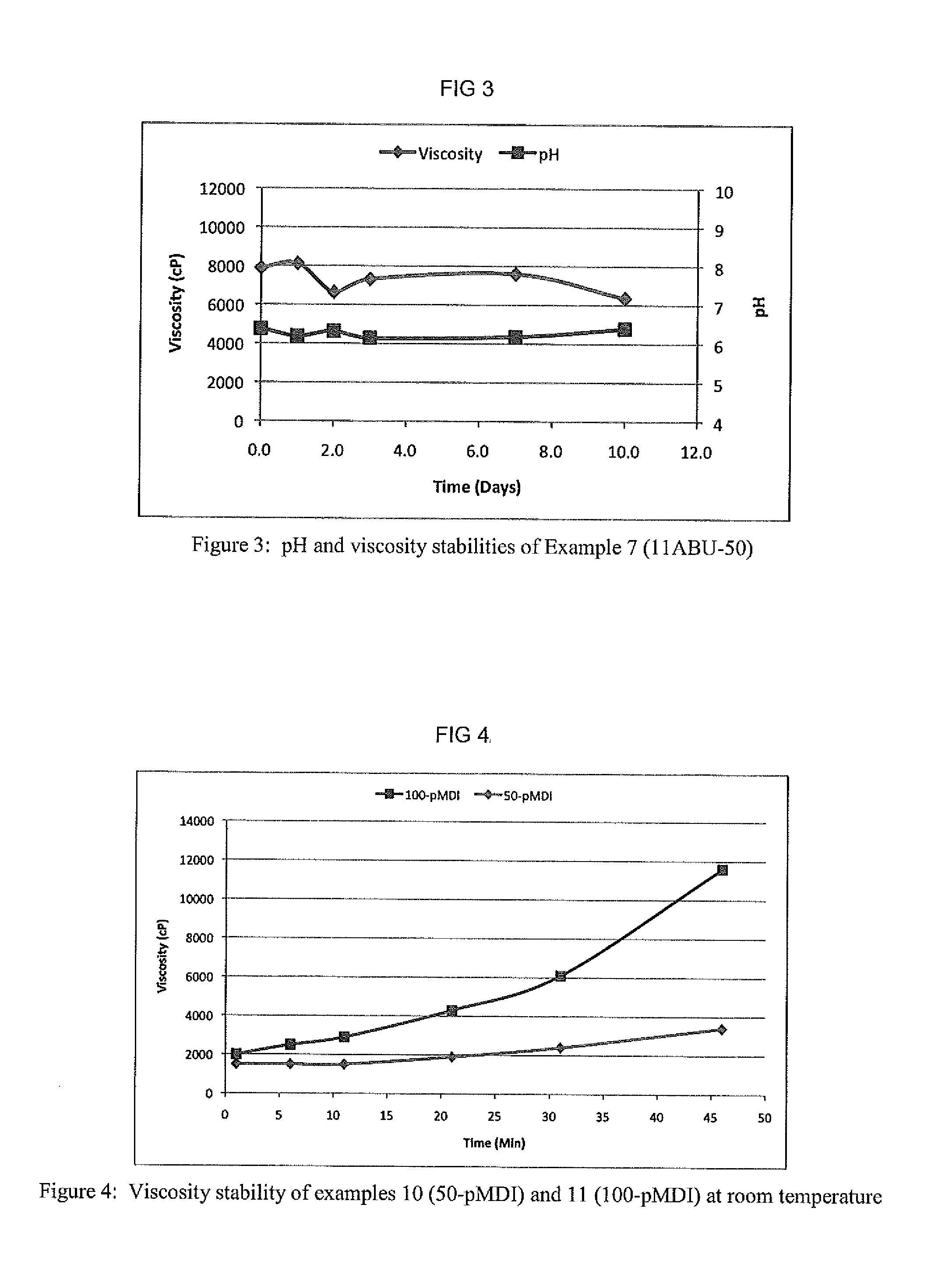

High-solids ethylene-vinyl acetate latex

The present invention is directed to an ethylene-vinyl acetate dispersion and a process for making the dispersion by polymerizing a monomer mixture having vinyl acetate and ethylene in a batch process, in the presence of a stabilizing system of polyvinyl alcohol and without added surfactants, to form an ethylene-vinyl acetate polymer dispersion. The copolymer dispersion has a solids level of greater than 65 percent by weight, and a viscosity of less than 5000 mPa.s when measured at 65 percent solids at 25 DEG C. The dispersion can be dried to form a redispersible powder. Both the dispersion and powder are useful in adhesive and coating formulations.

Owner:AKZO NOBEL CHEM INT BV

Fireproof polyvinyl acetate emulsion and preparation method thereof

InactiveCN102040790AAvoid pollutionAvoid harmMonocarboxylic acid ester polymer adhesivesFireproof paintsFireproofingCarvacryl acetate

The invention relates to a fireproof polyvinyl acetate emulsion and a preparation method thereof. The grain diameter of the main fireproof composition of the fireproof type polyvinyl acetate emulsion, namely the gain diameter of ammonium polyphosphate, is small. Meanwhile, inorganic padding has stronger hydrogen bonding force to polyvinyl acetate or polyvinyl acetate copolymer, and the grains of the inorganic padding are small, which can avoid a series of problems caused by adopting an additional fireproofing agent of the prior art. The fireproof polyvinyl acetate emulsion disclosed by the invention has favorable bond strength, favorable film-forming performance, etc., and is very valuable to be used in the aspects of an indoor and outdoor fireproof coating, a weaving cloth fireproof finishing agent, a fireproof binding agent, and the like. Meanwhile, no harmful substances are produced in the process of production and use of the fireproof polyvinyl acetate emulsion, and the productive process of the fireproof polyvinyl acetate emulsion is simple, and is easy to control.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

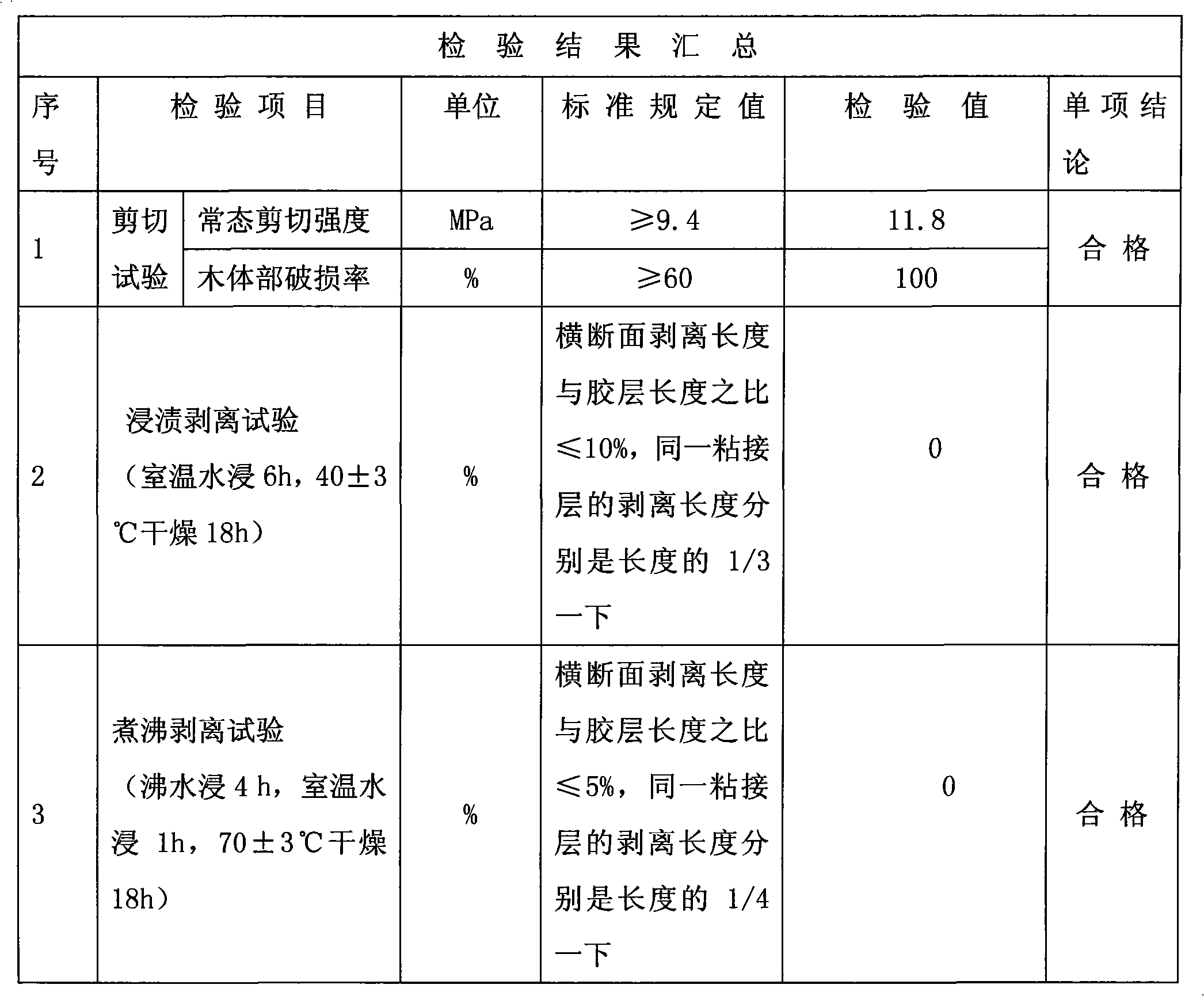

Integrated material wood-splicing adhesive and preparation method thereof

ActiveCN101565593AHigh hardnessIncrease temperatureMonocarboxylic acid ester polymer adhesivesPolymer scienceAdhesive

The invention provides an integrated material wood-splicing adhesive, which is characterized in that the integrated material wood-splicing adhesive is prepared by the following components by weight portions: 100 weight portions of main agent and 13-17 weight portions of cross linking agent modified polyisocyanate, wherein the main agent is prepared by the following raw materials by weight: 3-5% of polyvinyl alcohol, 21.4-38.92% of vinyl acetate, 1-3% of crylic acid, 5-10% of butyl acrylate, 1-3% of methacrylic acid, 0.9-1.1% of 2-hydroxyethyl acrylate, 1-2% of emulsifier OP-10, 1-2% of sodium dodecyl sulfate, 0.08-0.2% of ammonium persulfate, 0.1-0.3% of pH regulator and 48-52% of deionized water. The integrated material wood-splicing adhesive has the advantages of high adhesion strength, good water resistance, and no organic solvent and formaldehyde.

Owner:顶立新材料科技股份有限公司

High-melting point polyamide thermosol composition and method of making the same

InactiveCN1990810AHigh melting pointImprove low temperature resistanceMonocarboxylic acid ester polymer adhesivesAcetic acidPolymer science

The invention provides a polyamide hot melt adhesive composite and the method for preparing the same. Said composite comprises: (a) polyamide hot melt adhesive with weight proportion being 70- 95 and melting point being 160- 220 Deg. C, (b) ethylene- vinyl acetate copotymeers and / or ethylene- acrylate copolymer with weight proportion being 5- 30, taking total weight of said compound in (a) and (b) as basis. The compound is characterized by high melting point, low-temperature resistance, goog flexibility and oil- resistant property.

Owner:SHANGHAI LIGHT IND RES INST

Waterborne aluminium foil adhesive and preparation method thereof

InactiveCN102153971AGood adhesionHigh peel strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesFunctional monomerPolymer science

The invention discloses a waterborne aluminium foil adhesive and a preparation method thereof and belongs to the field of adhesives. The aluminium foil adhesive is a composite adhesive with solid content of 40 to 50 percent, which is prepared by using monomers, an emulsifier, protective colloid, an initiator, a buffer, a pH (potential of hydrogen) regulator, a plasticizer, a waterborne assistant and deionized water as the raw materials through pre-emulsification, seed reaction, polymerization reaction and compounding. The monomers in the raw materials comprise hard monomers, soft monomers andfunctional monomers, wherein the hard monomers adopt vinylacetate and methyl acrylate; the soft monomers adopt ethyl acrylate and butyl acrylate; and the functional monomers adopt any one of acrylic acid or methacrylic acid and N-hydroxymethyl acrylamide. The waterborne aluminium foil adhesive has the advantages of low cost, high stripping strength and good leveling property and is simple and convenient to operate.

Owner:BEIJING COMENS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com