Single-component polyvinylacetate binding agent and preparation method thereof

A vinyl acetate and adhesive technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the complex process of two-component adhesives, etc. problem, to achieve the effect of low cost, simple process and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

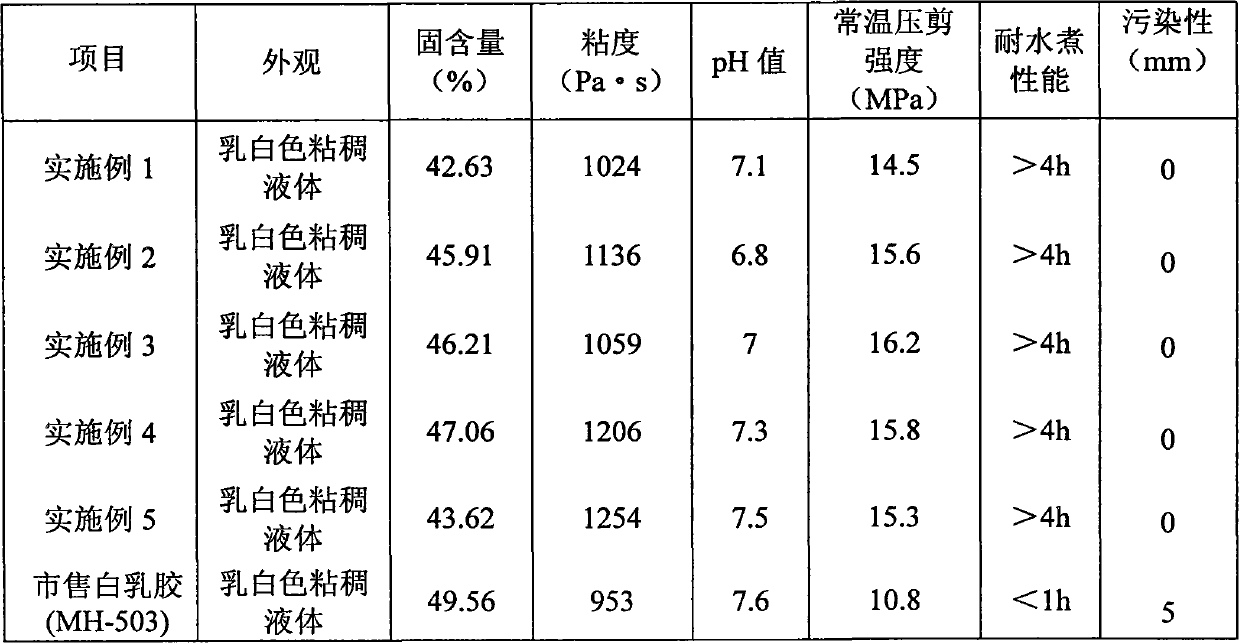

Examples

Embodiment 1

[0040] In percent by weight, the content of each component of a one-component vinyl acetate adhesive raw material is:

[0041] Deionized water 48%

[0042] Polyvinyl alcohol 3%

[0043] Vinyl acetate 24%

[0044] Butyl Acrylate 4.5%

[0045] Hydroxyethyl Acrylate 2%

[0046] Methacrylic acid 1%

[0047] Silicone 10%

[0048] Complex emulsifier 2%

[0049] Initiator 0.2%

[0050] pH regulator 0.3%

[0051] Plasticizer 5%

[0052] Among them, the degree of polymerization of polyvinyl alcohol is 1700, and the degree of alcoholysis is 86. The organosilicon is vinyltriethoxysilane, and the pH regulator is 2% sodium bicarbonate aqueous solution. The initiator is an aqueous ammonium persulfate solution with a mass concentration of 5%. The plasticizer is dibutyl phthalate.

[0053] The preparation method of one-component vinyl acetate adhesive comprises the steps:

[0054] Preparation of the first step seed emulsion

[0055] Weigh the specified amount of each component, ...

Embodiment 2

[0060] In percent by weight, the content of each component of a one-component vinyl acetate adhesive raw material is:

[0061] Deionized water 50%

[0062] Polyvinyl alcohol 3%

[0063] Vinyl acetate 28%

[0064] Butyl Acrylate 4.5%

[0065] Hydroxyethyl Acrylate 1%

[0066] Methacrylic acid 1%

[0067] Silicone 12%

[0068] Complex emulsifier 2%

[0069] Initiator 0.2%

[0070] pH regulator 0.3%

[0071] Plasticizer 8%

[0072] Polyvinyl alcohol has a degree of polymerization of 1800 and a degree of alcoholysis of 88. The organosilicon is vinyltrimethoxysilane, and the pH regulator is 4% sodium bicarbonate aqueous solution. The initiator is an aqueous ammonium persulfate solution with a mass concentration of 7%. The plasticizer is dioctyl phthalate.

[0073] The preparation method of one-component vinyl acetate adhesive comprises the steps:

[0074] Preparation of the first step seed emulsion

[0075] Weigh the specified amount of each component, first pour water ...

Embodiment 3

[0080] In percent by weight, the content of each component of a one-component vinyl acetate adhesive raw material is:

[0081] Deionized water 48%

[0082] Polyvinyl alcohol 5%

[0083] Vinyl acetate 13.5%

[0084] Butyl Acrylate 8%

[0085] Hydroxyethyl Acrylate 3%

[0086] Methacrylic acid 3%

[0087] Silicone 12%

[0088] Complex emulsifier 1%

[0089] Initiator 0.3%

[0090] pH regulator 0.2%

[0091] Plasticizer 6%

[0092] Polyvinyl alcohol has a degree of polymerization of 2000 and a degree of alcoholysis of 90. The organosilicon is vinyltriethoxysilane, and the pH regulator is an aqueous solution of sodium bicarbonate with a mass concentration of 6%. The initiator is an aqueous ammonium persulfate solution with a mass concentration of 8%. The plasticizer is dibutyl phthalate.

[0093] The preparation method of one-component vinyl acetate adhesive comprises the steps:

[0094] Preparation of the first step seed emulsion

[0095] Weigh the specified amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com