Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

A silicon-based composite material, lithium-ion battery technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve problems such as poor rate performance, low first Coulomb efficiency, and short cycle life. , to achieve the effect of small size, alleviating volume effect, and inhibiting expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

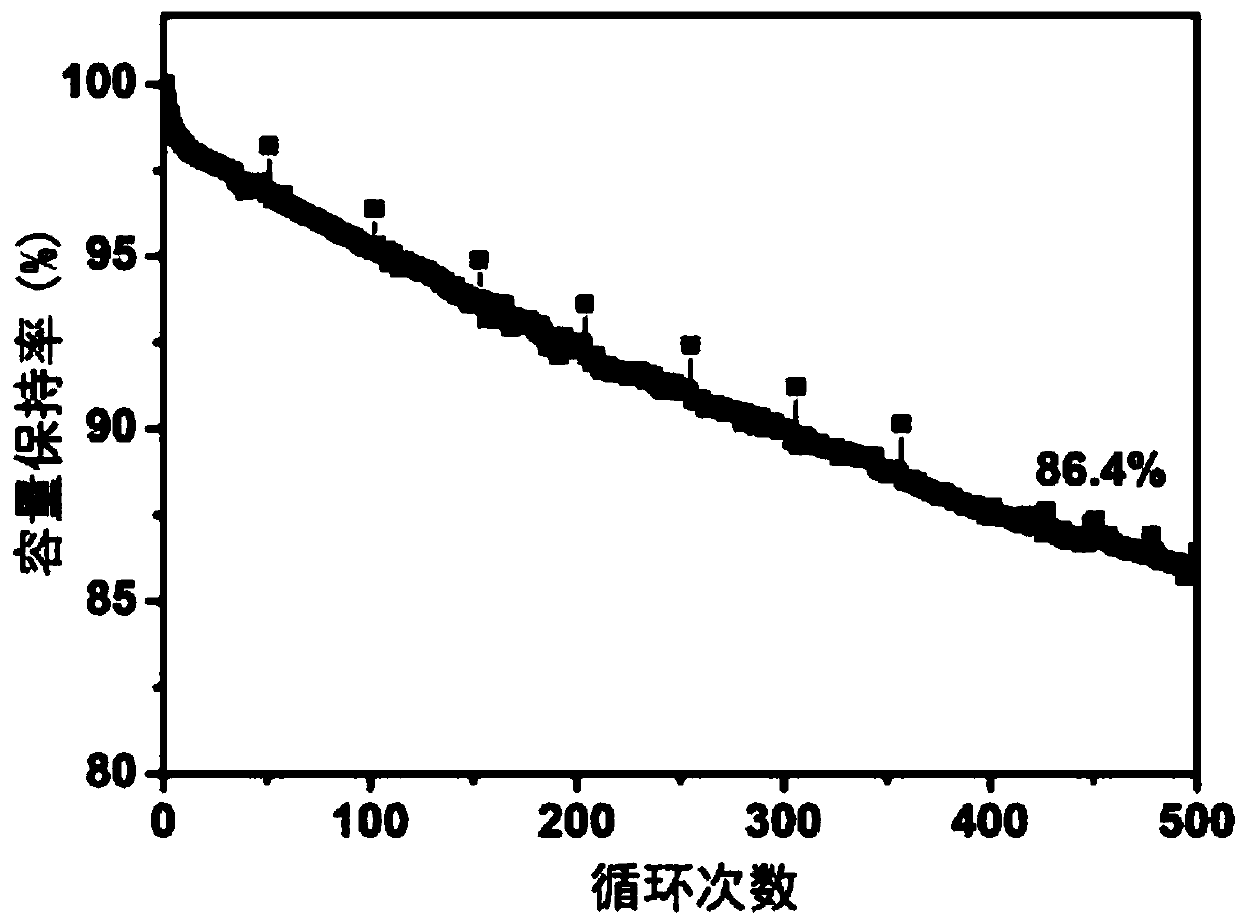

Embodiment 1

[0078] Weigh 1000 g of silicon oxide particles with a median particle size of 6 μm (atomic ratio of silicon and oxygen is 1:1) and place them in a CVD furnace, and raise the temperature to 900 °C at a rate of 20 °C / min under the protection of an argon atmosphere. After the temperature was raised to 900° C., ammonia gas with a gas velocity of 300 ccm was passed into the furnace for 60 minutes to perform nitrogen doping on the silicon oxide compound particles. Subsequently, the acetylene gas with a gas velocity of 300 ccm was passed into the furnace for 30 minutes after continuing to keep at 900° C. for 30 minutes under an argon atmosphere. Subsequently, keep at 900° C. for 60 minutes under an argon atmosphere and then lower to room temperature to obtain carbon-coated nitrogen-doped silicon oxide particles. During the whole process, argon is passed into the CVD furnace at a gas velocity of 500 ccm. The resulting carbon-coated nitrogen-doped silicon oxide particles are passed thr...

Embodiment 2

[0085] Compared with Example 1, Example 2 uses phosphine gas instead of ammonia gas when the silicon oxide compound particles are element-doped by high-temperature CVD, and the remaining parameter conditions in the entire CVD process are the same as those in Example 1. And after the reaction, carbon-coated phosphorus-doped silicon-oxygen compound particles were obtained. 1000g of carbon-coated phosphorus-doped silicon oxide particles, aluminum nitrate nonahydrate, sucrose and polyvinylpyrrolidone were uniformly dispersed in 4000ml of deionized water by high-speed stirring at a mass ratio of 10:2:1:0.1, followed by spray drying. The air inlet temperature is 150°C, the outlet temperature is 105°C, the rotation speed of the rotary atomizing nozzle is 350Hz, and the feed rate is 100g / min. The spray-dried product was transferred to a chamber furnace, and the temperature was raised to 800°C at a rate of 10°C / min under a high-purity nitrogen atmosphere, and then kept at 800°C for 4 h...

Embodiment 3

[0089] Weigh 1000g of silicon oxide compound particles with a median particle size of 6 μm (atomic ratio of silicon to oxygen is 1:1) and 200g of ammonium hypophosphite and mix them uniformly in a drying room with a humidity below 20%. The resulting mixture was milled in a ball mill with zirconium beads with a diameter of 0.8 mm under a protective atmosphere for 2 hours, then transferred to a tube furnace, and then heated to 900 °C at a rate of 10 °C / min under an argon atmosphere and kept for 4 hours. Hours and then naturally cooled to room temperature to obtain silicon oxide compound particles doped with phosphorus. The obtained particles and petroleum asphalt were uniformly mixed in a heating VC mixer at a mass ratio of 10:1 to achieve asphalt coating, and then the temperature was raised to 900°C at a rate of 10°C / min in a box furnace with a high-purity nitrogen atmosphere and kept for 2 hours, then naturally cooled to room temperature and passed through a 500-mesh sieve to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com