A kind of silicon-carbon composite material for lithium ion battery and preparation method thereof

A technology of silicon-carbon composite materials and lithium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as limiting battery cycle performance, low battery Coulombic efficiency, and limiting material applications, so as to improve Coulombic efficiency and cycle performance, improved cycle performance, and improved Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

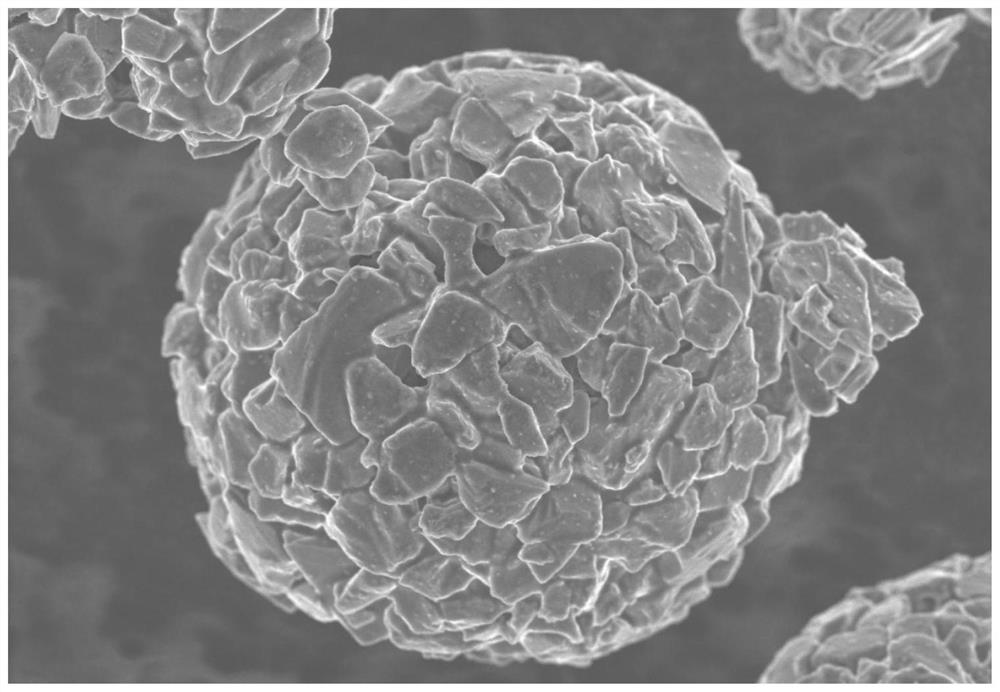

[0069] Take 1000g of micron amorphous silicon powder with a median particle size of 2 μm, add 2000g of deionized water, add 500g of sucrose, stir, dissolve and mix, weigh 50g of single-walled carbon nanotubes with a solid content of 0.4%, 50g of polyethylene Pyrrolidone, fully stirred with the above slurry, and mixed evenly. The slurry was spray-dried and granulated to obtain secondary particles with a median diameter of 9.6 μm. The spray-dried dry powder was heated at 600° C. for 10 hours in an argon inert atmosphere to carbonize the sucrose to obtain a silicon material in which spherical single-walled carbon nanotubes were tightly wound. Take 800 g of the above-mentioned spherical particles and 114 g of coal tar pitch, put them into a mechanical fusion machine, and perform high-speed fusion treatment at 1500 rpm for 30 minutes to obtain spherical silicon composite particles coated with coal tar pitch. The above materials were kept at 300°C for 2 hours in an argon inert atmo...

Embodiment 2

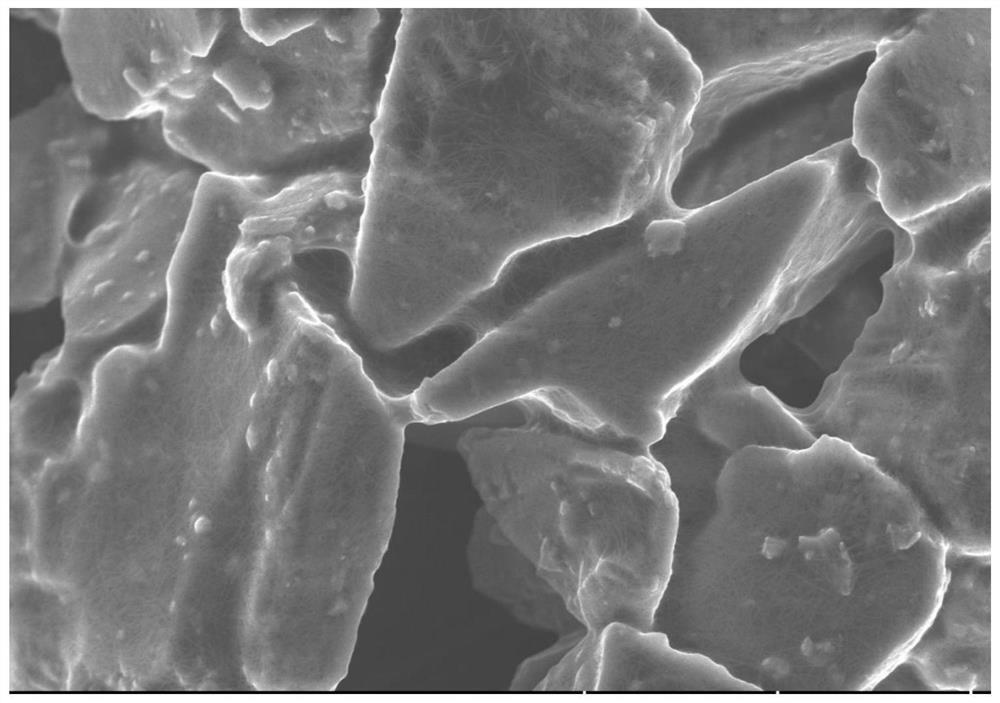

[0077] Take 1000g of micron crystalline silicon powder with a median particle size of 4.3 μm, add 2000g of ethanol, add 25g of glucose, stir, dissolve and mix, weigh 25g of single-walled carbon nanotubes with a solid content of 0.4%, 50g of polyvinylpyrrolidone, Stir well with the above slurry and mix evenly. The slurry was spray-dried and granulated to obtain secondary particles with a median diameter of 14 μm. The spray-dried dry powder was heated at 700° C. for 6 hours in an argon inert atmosphere to carbonize the sucrose to obtain a silicon composite material in which spherical single-walled carbon nanotubes were tightly wound. Take 800g of spherical silicon composite material, take 50g of petroleum asphalt passed through a 200-mesh sieve, and mechanically mix it with a VC mixer for 10 minutes. Under a nitrogen-protected atmosphere, raise the temperature of the equipment to 300°C while stirring, and continue stirring for 30 minutes. Then cool to room temperature. The abo...

Embodiment 3

[0081] Get 1000g of micron crystalline silicon powder whose median particle size is 8 μm, add 2000g of water, add 667g of sucrose, stir, dissolve and mix, take 400g of multi-walled carbon nanotubes with a solid content of 5%, 50g of polyvinylpyrrolidone, and The above slurry is fully stirred and mixed evenly. The slurry was spray-dried and granulated to obtain secondary particles with a median diameter of 48 μm. The spray-dried dry powder was heated at 800° C. for 2 hours in an argon inert atmosphere to carbonize the sucrose to obtain a silicon composite material in which spherical multi-walled carbon nanotubes were tightly wound. Sieve the above materials to obtain a spherical silicon-carbon composite material.

[0082] Take 90 parts of the above-mentioned silicon-carbon composite material, 6 parts of conductive additive, and 4 parts of binder, homogenize, coat, dry, and roll in an aqueous system to obtain a silicon-containing negative electrode sheet.

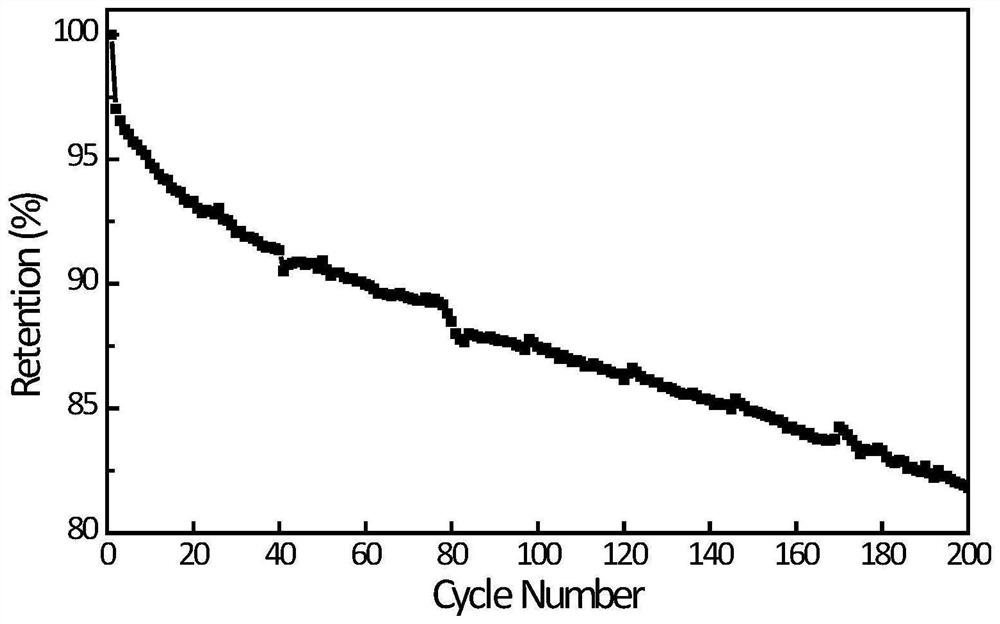

[0083]The half-cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com