Negative electrode active material and its preparation method and application

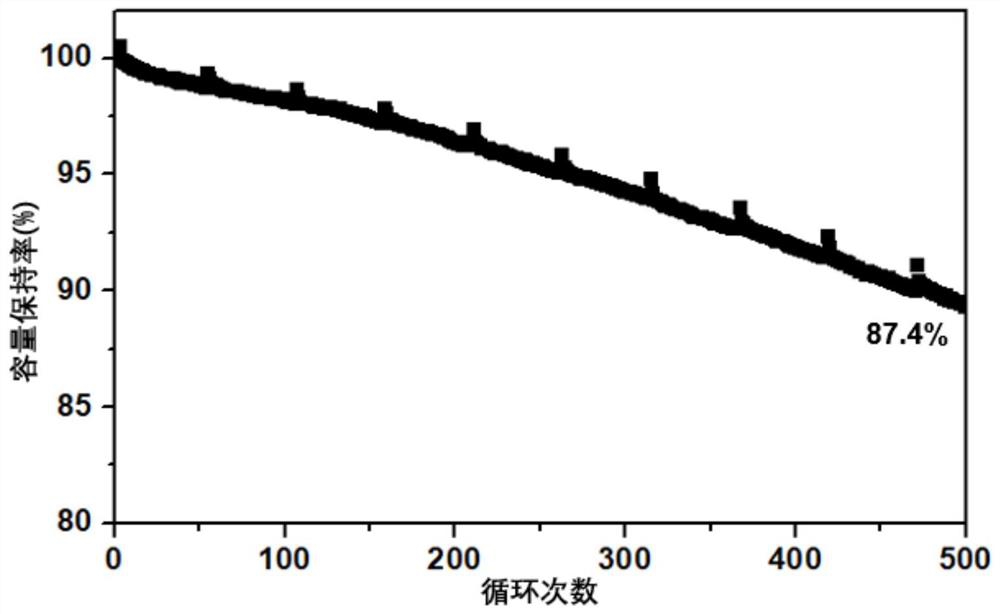

A negative electrode active material and a lithium intercalation technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of difficult commercial application of lithium-ion secondary batteries, complex and dangerous preparation process, low capacity and coulombic efficiency, etc. Achieve high capacity and coulombic efficiency, good cycle stability, good rate and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

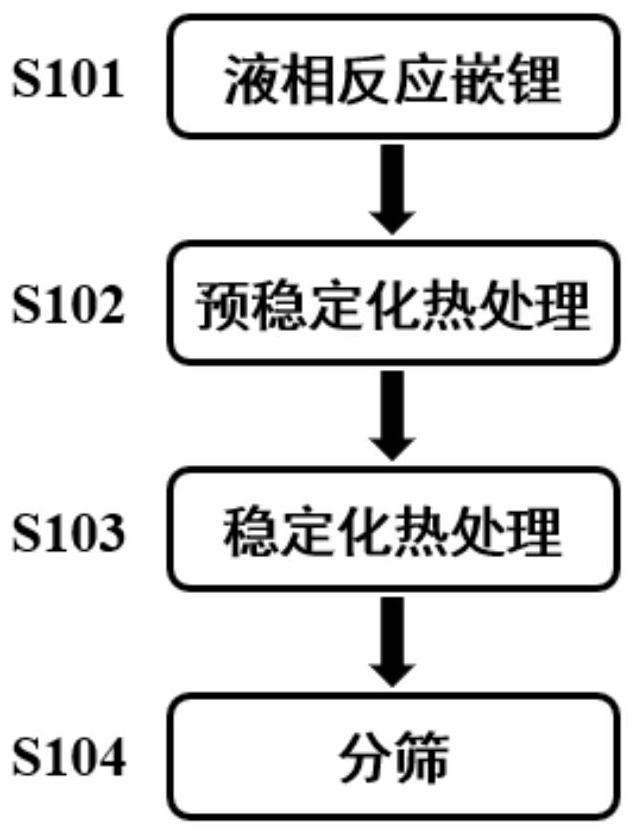

Method used

Image

Examples

Embodiment 1

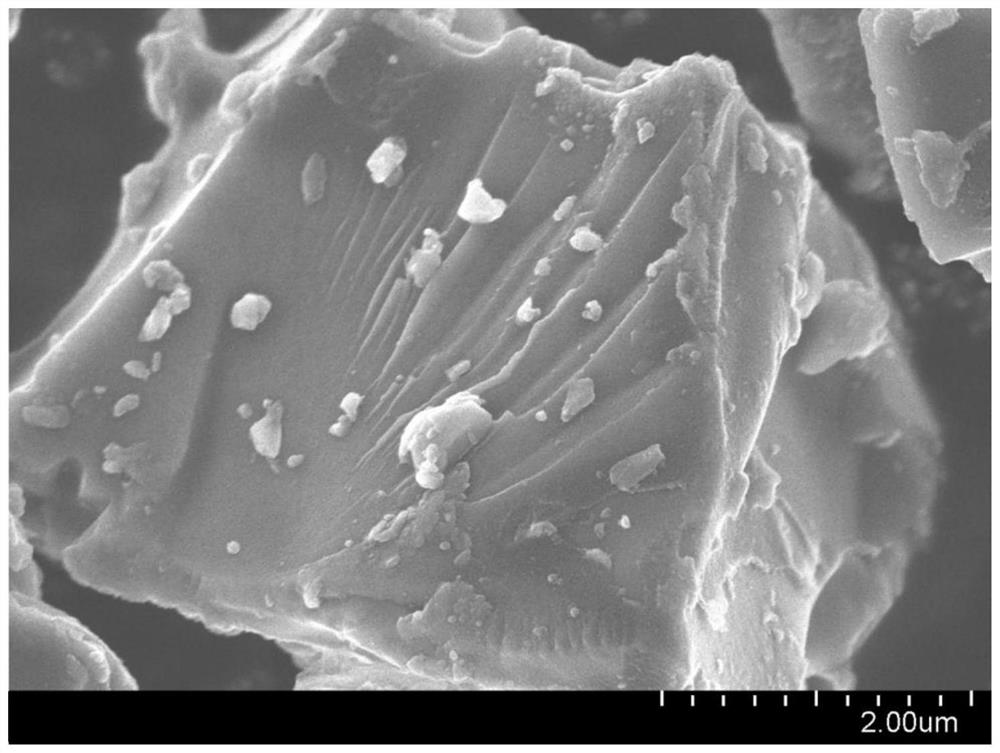

[0119] Under the protection of high-purity argon atmosphere, silicon oxide particles with a median particle size of 6 μm and a silicon-oxygen atomic ratio of 1:1 were initially mixed with metal lithium sheets at a mass ratio of 12:1, and the subsequent reaction was carried out at under the protection of high-purity argon atmosphere. Add a solution of methyl tert-butyl ether dissolved in naphthalene with a concentration of 0.3mol / L and keep stirring, wherein the molar ratio of naphthalene to lithium flakes is 1:40. The reaction was warmed to a constant temperature of 70 °C. After the lithium flakes floating on the liquid surface completely disappeared, the reaction was continued at 70°C for 30 minutes, and then naturally cooled to room temperature.

[0120] Under the protection of a high-purity argon atmosphere, a volume of liquid paraffin equal to that of the methyl tert-butyl ether solution was added to the reaction system and the temperature was raised to 100° C. for 30 min...

Embodiment 2

[0131] Weigh 2000g of silicon oxide particles with a median particle size of 6 μm and a silicon-oxygen atomic ratio of 1:1, and then use a heating VC mixer to uniformly mix it with petroleum asphalt at a mass ratio of 15:1 to achieve the asphalt coating. cover. The obtained product was transferred into a box furnace, and the temperature was raised to 950°C at 5°C / min under a high-purity nitrogen atmosphere for 2 hours to achieve in-situ carbonization of the petroleum pitch coating film on the surface of silicon oxide particles. After the treatment, the resulting material was crushed and passed through a 500-mesh sieve for subsequent operations.

[0132] Under the protection of a high-purity argon atmosphere, the material obtained in the previous step was initially mixed with the metal lithium wire at a mass ratio of 10:1, and the entire subsequent reaction was carried out under the protection of a high-purity argon atmosphere. A solution of ethylene glycol dimethyl ether with...

Embodiment 3

[0141] Weigh 500g of silicon oxide particles with a median particle size of 6 μm and a silicon-oxygen atomic ratio of 1:1, zinc acetate dihydrate, glucose, and polyvinylpyrrolidone in a mass ratio of 10:0.5:1:0.1 and uniformly disperse them in 1000ml of ethanol / water mixed solvent, wherein the volume ratio of ethanol and water is 5:1. The resulting dispersion was continuously stirred at 60°C until viscous, then dried and coarsely crushed, and then transferred to a tube furnace. Then, in a high-purity nitrogen atmosphere, the temperature was raised to 800°C at 10°C / min and kept for 4 hours to achieve zinc element doping and glucose carbonization to form a film and coat the surface of the material. After the treatment, the resulting material was crushed and passed through a 500-mesh sieve for subsequent operations.

[0142] Under the protection of high-purity argon atmosphere, the material obtained in the previous step was initially mixed with metal lithium powder at a mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com