Patents

Literature

128 results about "Silicon matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

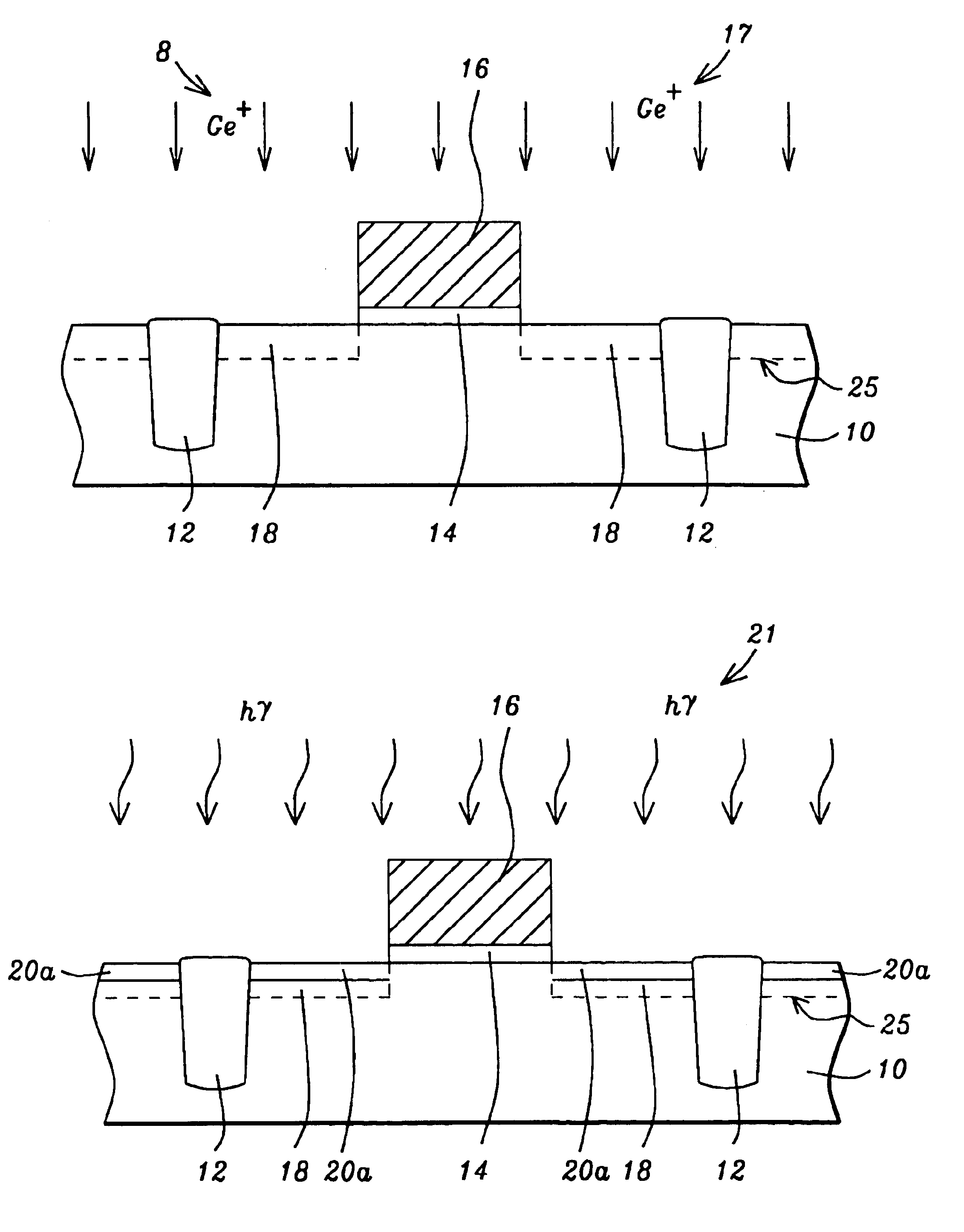

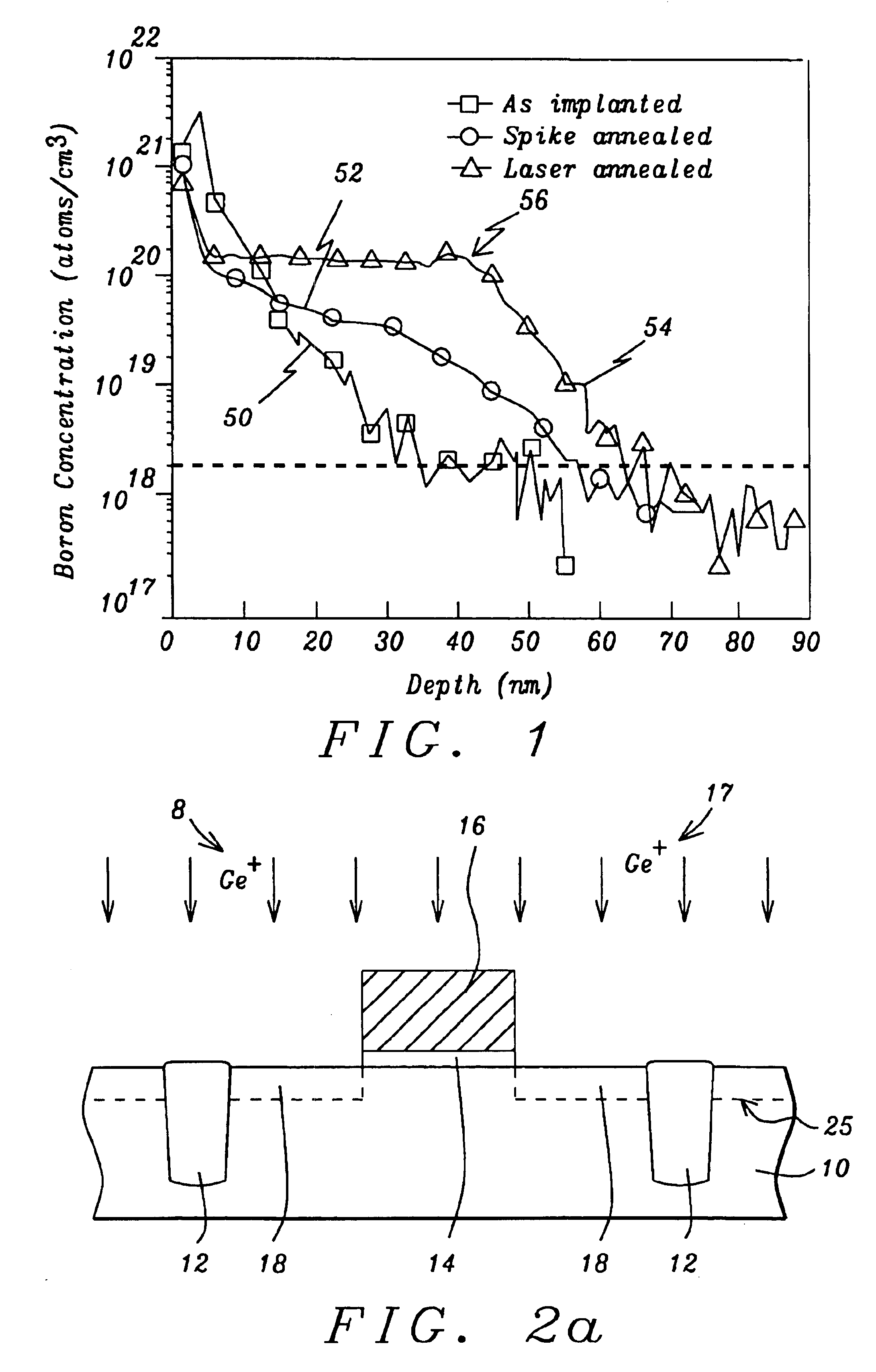

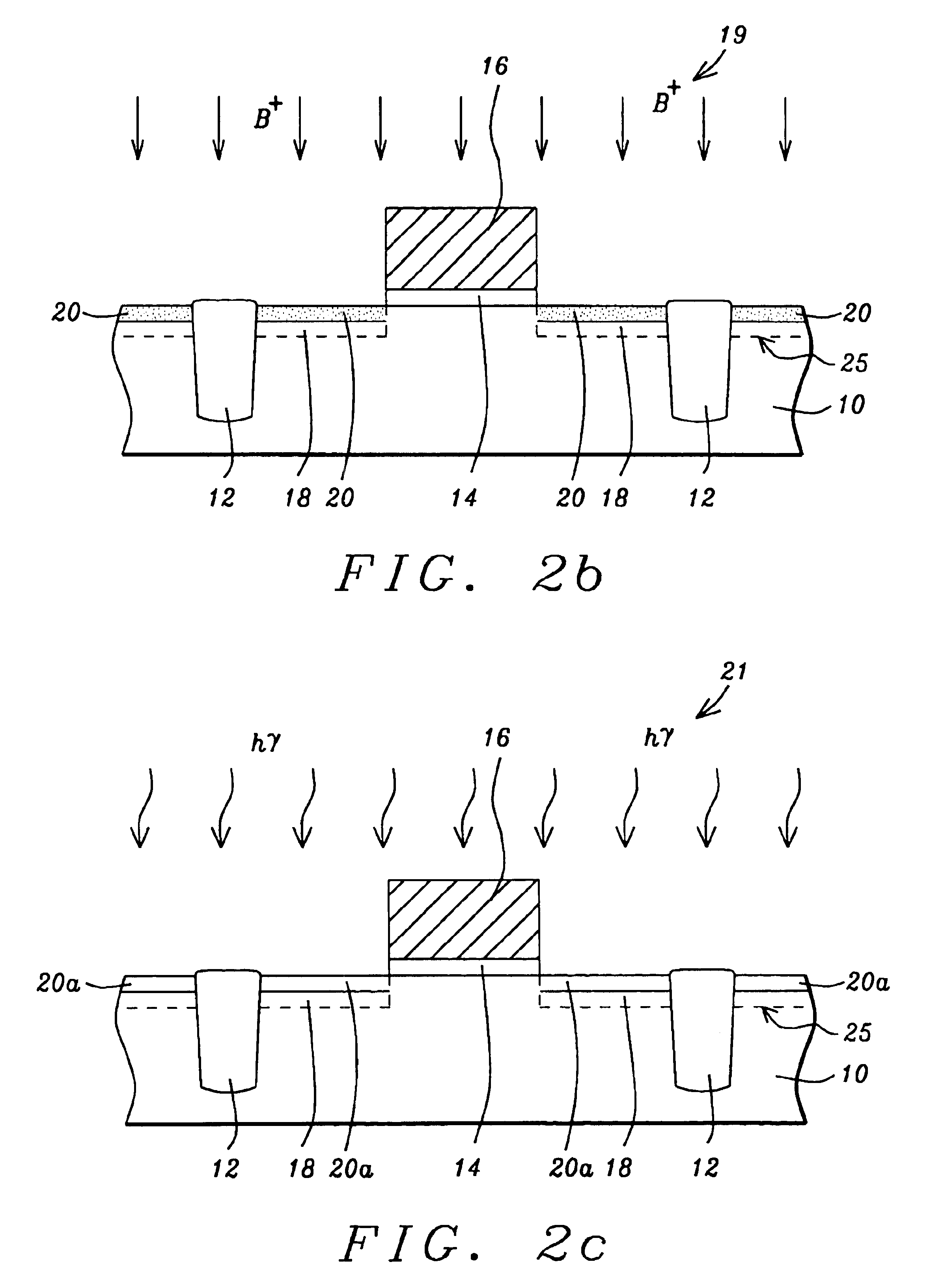

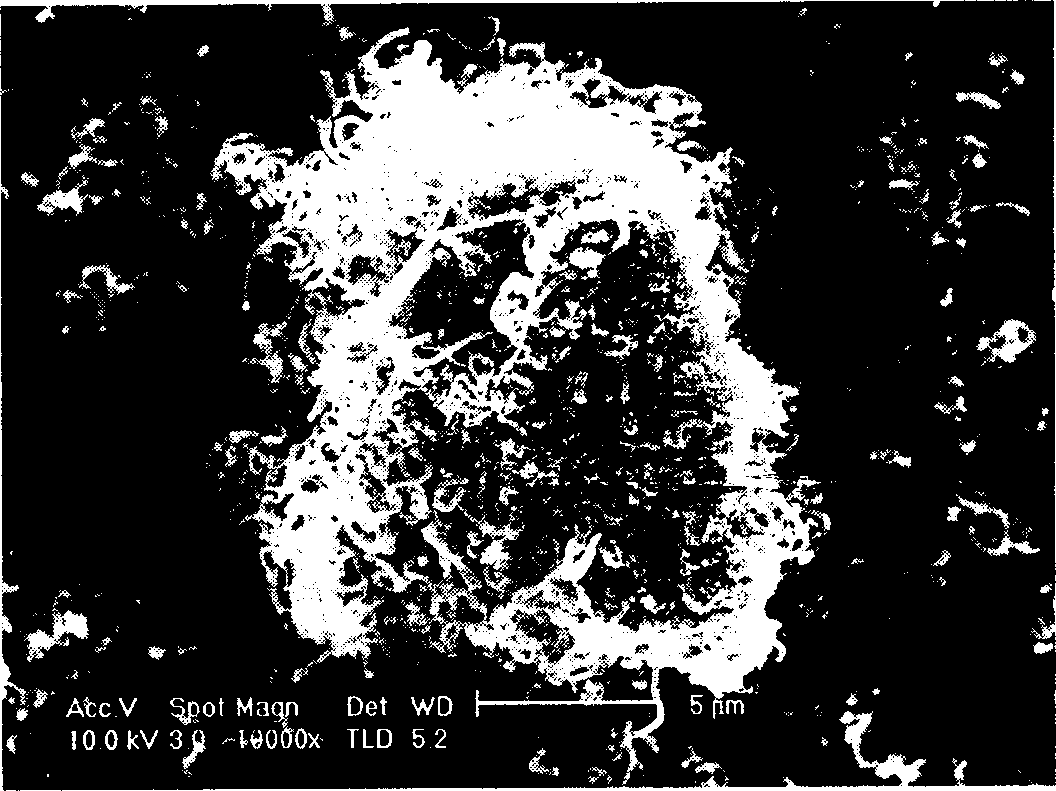

Method of multiple pulse laser annealing to activate ultra-shallow junctions

A method for forming a highly activated ultra shallow ion implanted semiconductive elements for use in sub-tenth micron MOSFET technology is described. A key feature of the method is the ability to activate the implanted impurity to a highly active state without permitting the dopant to diffuse further to deepen the junction. A selected single crystalline silicon active region is first amorphized by implanting a heavy ion such as silicon or germanium. A semiconductive impurity for example boron is then implanted and activated by pulsed laser annealing whereby the pulse fluence, frequency, and duration are chosen to maintain the amorphized region just below it's melting temperature. It is found that just below the melting temperature there is sufficient local ion mobility to secure the dopant into active positions within the silicon matrix to achieve a high degree of activation with essentially no change in concentration profile. The selection of the proper laser annealing parameters is optimized by observation of the reduction of sheet resistance and concentration profile as measured on a test site. Application of the method is applied to forming a MOS FET and a CMOS device. The additional processing steps required by the invention are applied simultaneously to both n-channel and p-channel devices of the CMOS device pair.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

Carbon silicon composite material, its preparation method and use

InactiveCN1903793AStable structureLarge specific surface areaElectrode manufacturing processesFuel cellsSilicon matrixCarbon fibers

The present invention relates to a carbon-silicon composite material. It includes silicon matrix and carbon nano tube or nano carbon fibre grown on the matrix. The average grain size of the described silicon matrix is 100 nm-100 micrometer, the diameter of the described carbon nano tube or nano carbon fibre is 1-200 nm and its length is 1 nm-100 micrometer. The described carbon nano tube is single-wall, double-wall or multiwall. Said invention also provides its preparation method and concrete steps.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Semiconductor memory

InactiveUS20060076549A1Short switching timeLow programming voltageDigital storageBulk negative resistance effect devicesSilicon matrixRetention time

The object of providing a non-volatile semiconductor memory that stands out by good scalability and a high retention time as well as ensures low switching voltages at low switching times and achieves a great number of switching cycles at good temperature stability is solved by the present invention with a semiconductor memory whose memory cells comprise at least one silicon matrix material layer with open or disturbed nanocrystalline or amorphous network structures and structural voids which has a resistively switching property between two stable states, utilizing the ion drift in the silicon matrix material layer. The memory concept suggested in the present invention thus offers an alternative to the flash and DRAM memory concepts since it is not based on the storing of charges, but on the difference of the electric resistance between two stable states that are caused by the mobility of ions in the amorphous silicon matrix material with an externally applied electric field.

Owner:POLARIS INNOVATIONS LTD

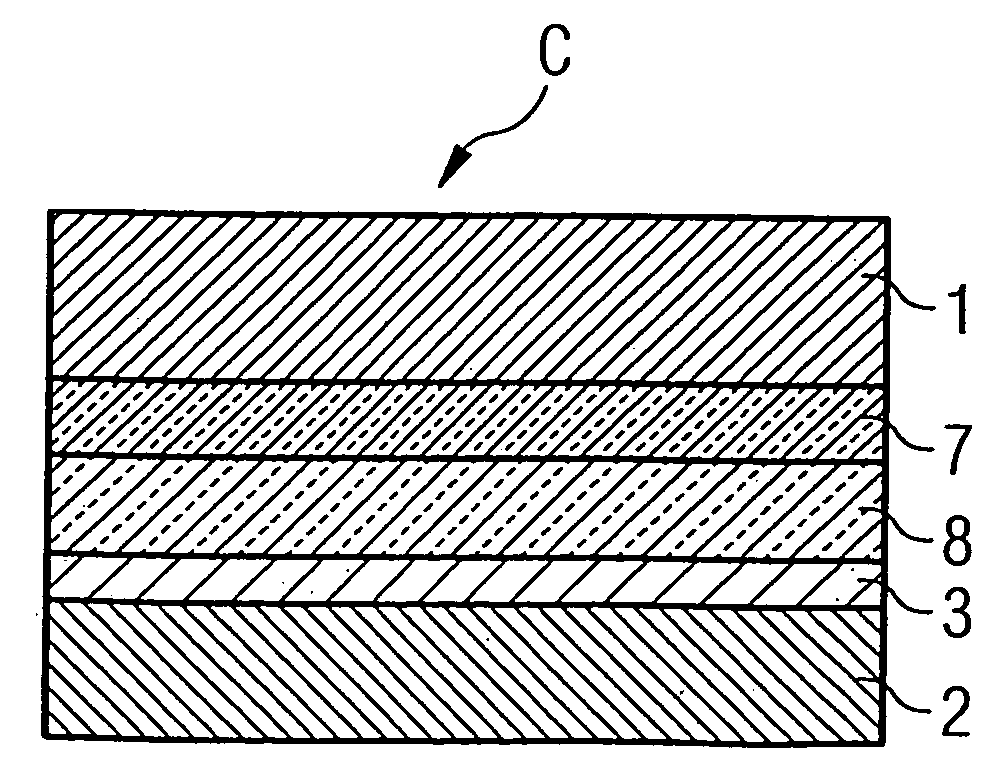

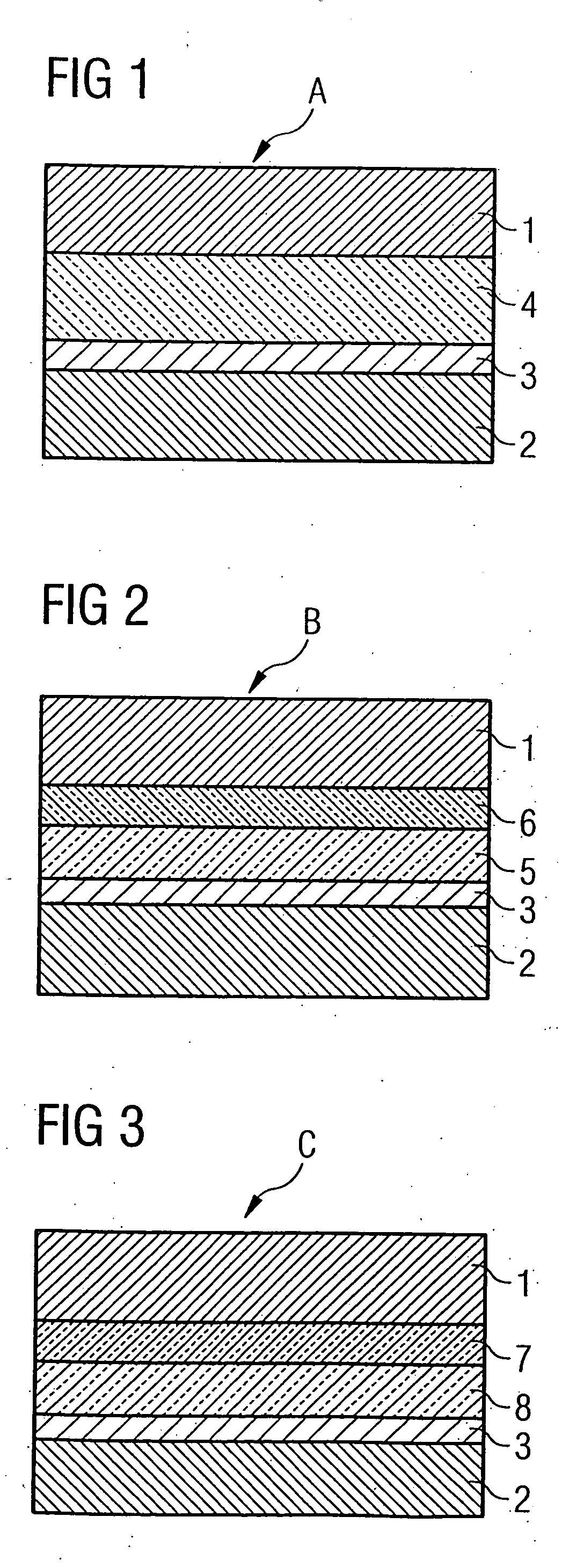

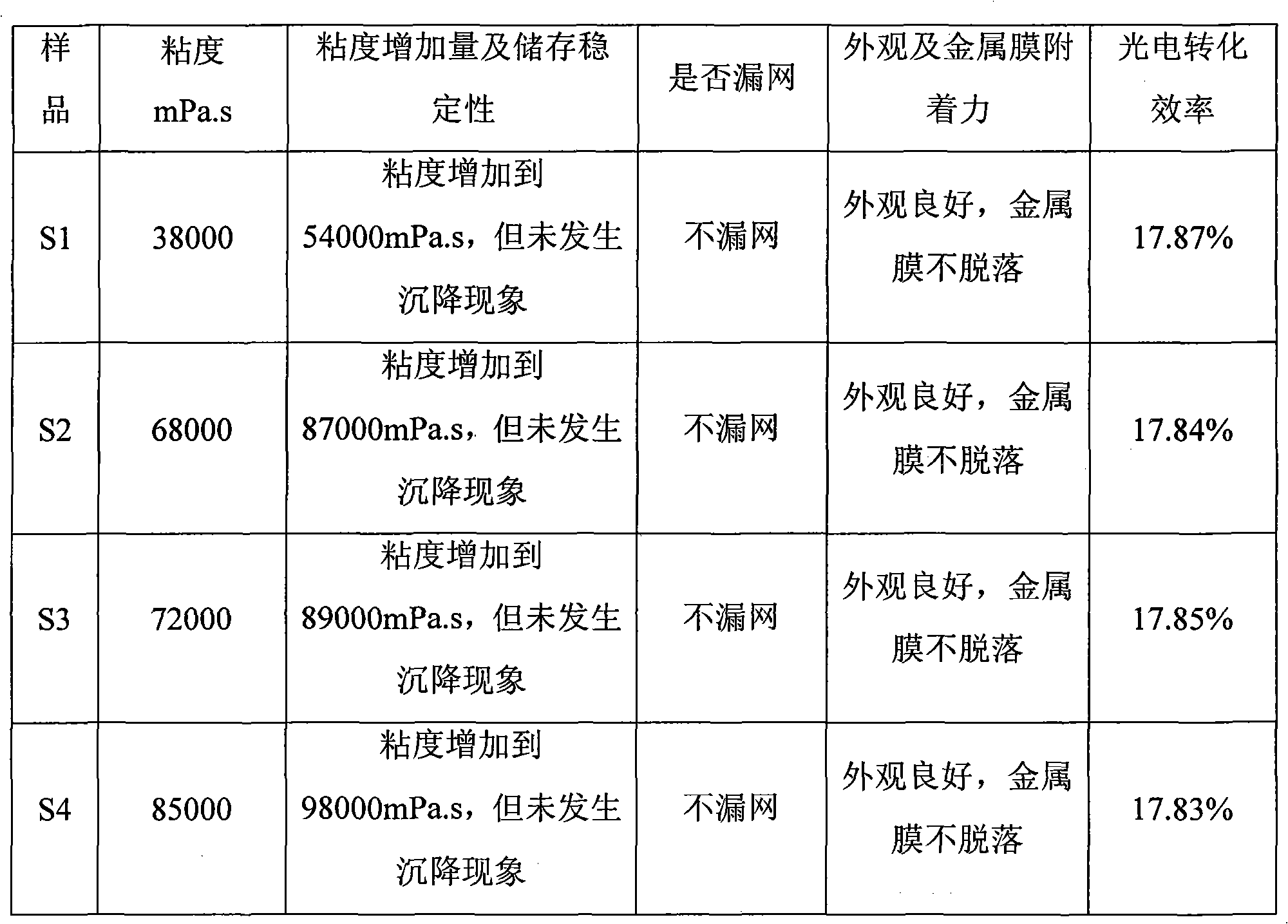

Conductive paste for solar cell and preparation method thereof

InactiveCN102034877AImprove performanceNo sedimentation and caking phenomenonConductive materialInksSilicon matrixSilicon solar cell

The invention provides a conductive paste for a solar cell, comprising the following components based on the total weight: 60-85 percent by weight of conductive metal powder, 0.5-10.0 percent by weight of inorganic binder, 10.0-30.0 percent by weight of water-borne binder and 0.05-5.0 percent by weight of additive, wherein the water-borne binder is a solution formed by dissolving a water-borne polymer into the water. The conductive paste for the solar cell, provided by the invention, has no organic solvent and pollution, is environment-friendly and has low cost of materials; the mesh leakage can be avoided when the conductive paste is stood in a screen mesh; the phenomena of settling and aggregation can be avoided after the conductive paste is stored for a long time; after being subjected to the silk-screen sintering, the conductive paste has firm adhesive force to a silicon matrix and excellent electrical performance; and the average photoelectric conversion efficiency of the produced monocrystal silicon solar cell is more than 17.80 percent.

Owner:BYD CO LTD

Boron carbide based ceramic matrix composites

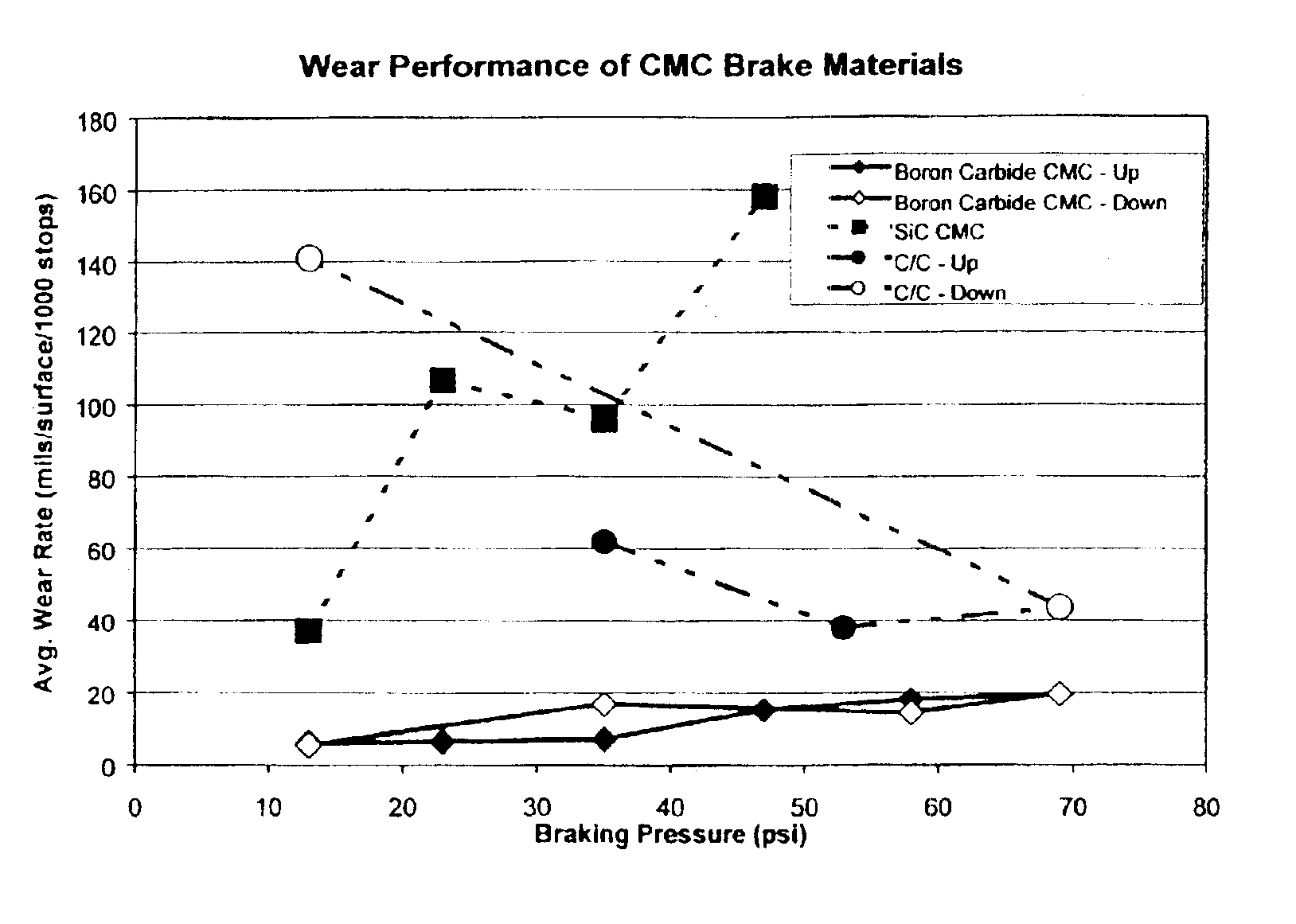

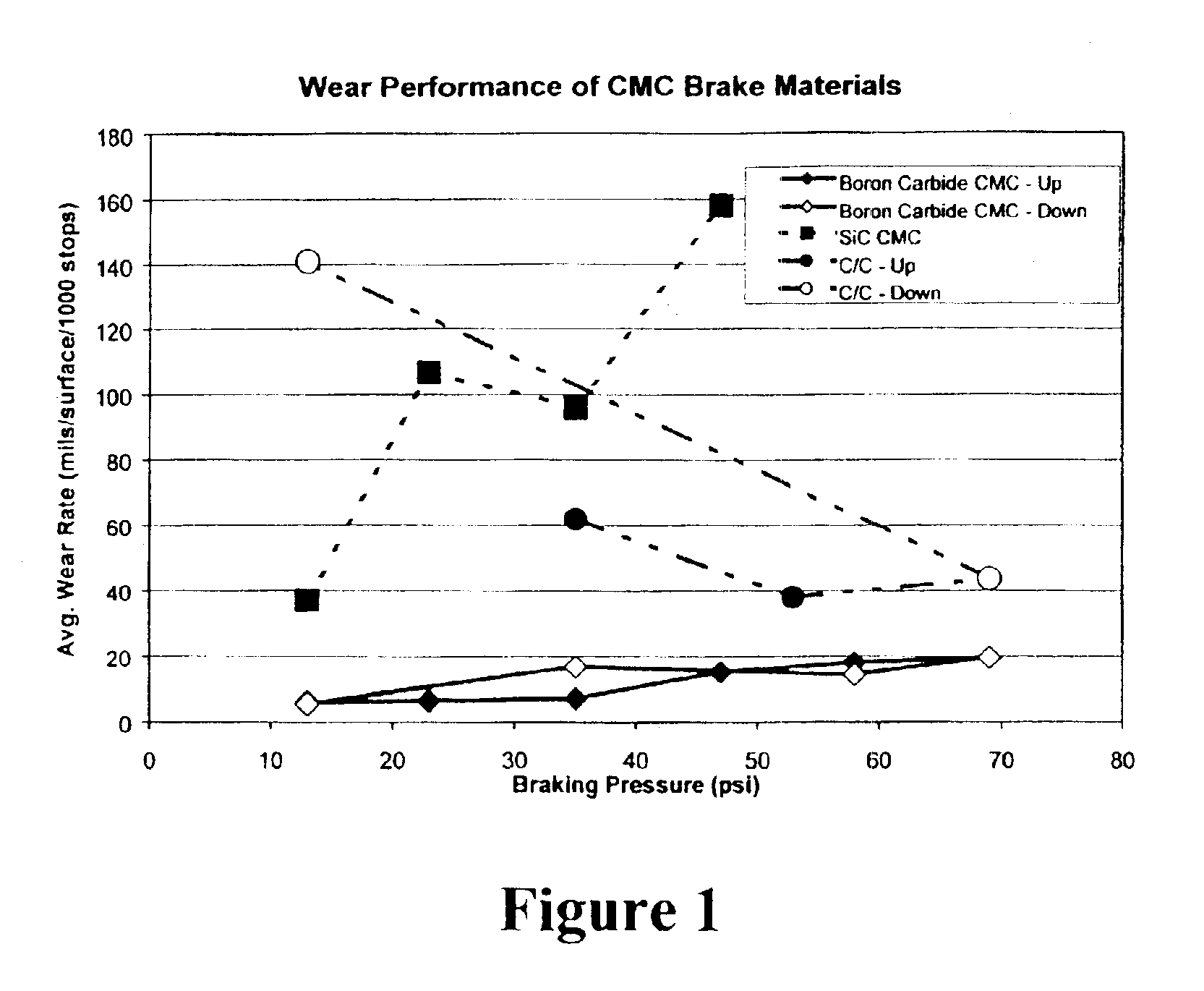

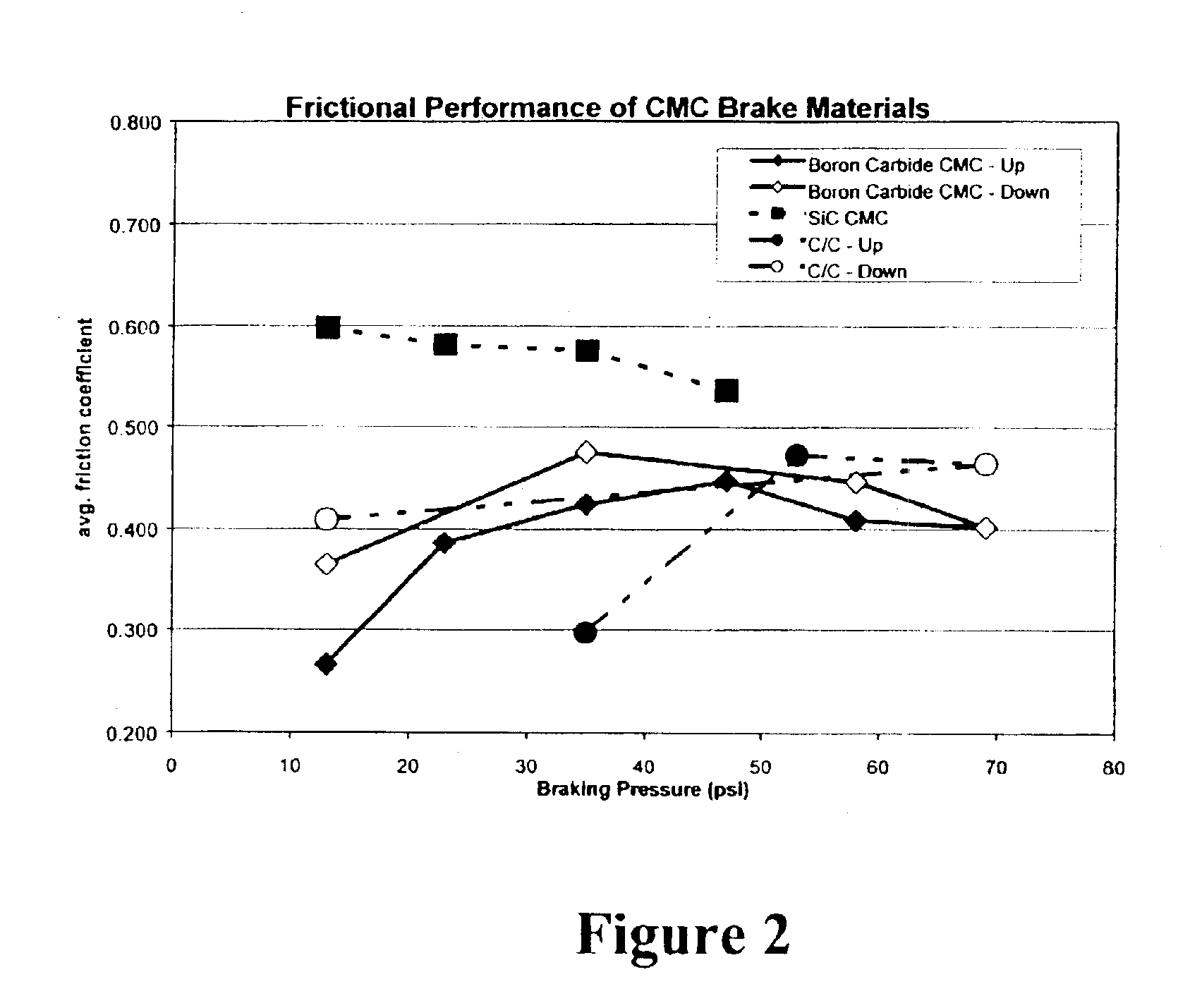

InactiveUS6855428B2Big advantageReduce wear rateBraking discsPretreated surfacesSilicon matrixBoron carbide

The present invention is a composite material and process to produce same. That material comprises a fibrous structure which is initially predominantly coated with elemental carbon; that fibrous structure is then subsequently predominantly coated with at least one ceramic material, e.g., boron carbide, which is non-reactive with silicon. The composite material also comprises a silicon matrix which is continuous and predominantly surrounds the fibrous structure, which has been initially predominantly coated with elemental carbon and subsequently predominantly coated with at least one ceramic material. The matrix which has a fine grain crystalline structure of predominantly 20 microns or less in size. The at least one ceramic material is discontinuous within that matrix. The fibrous material pulls out of the elemental carbon, which initially predominantly coats that fibrous structure, when the composite is subjected to fracture.

Owner:THE BF GOODRICH CO

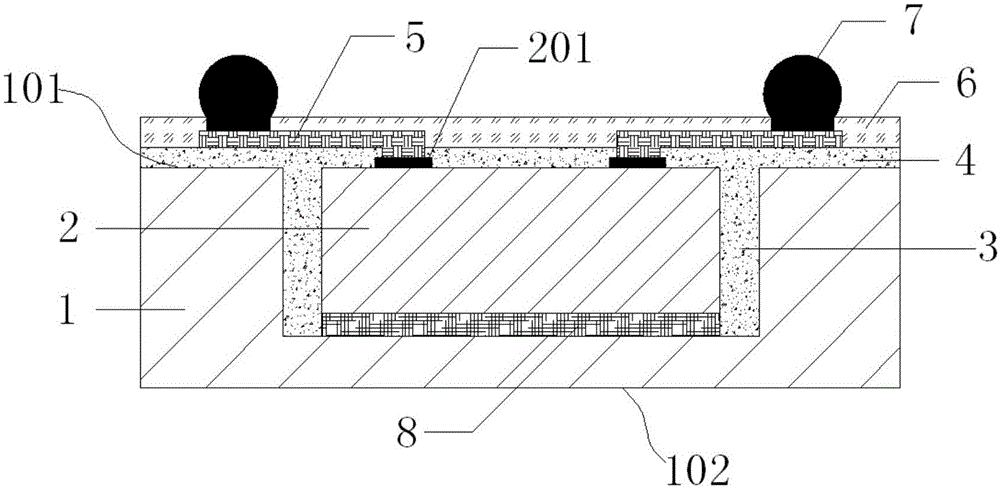

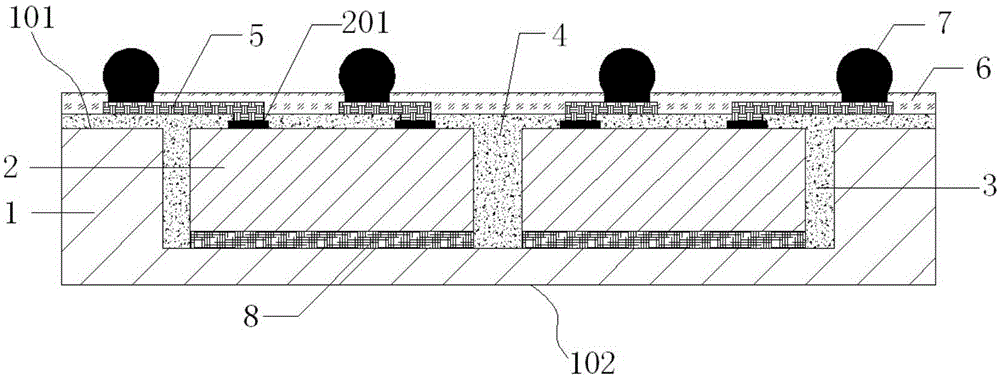

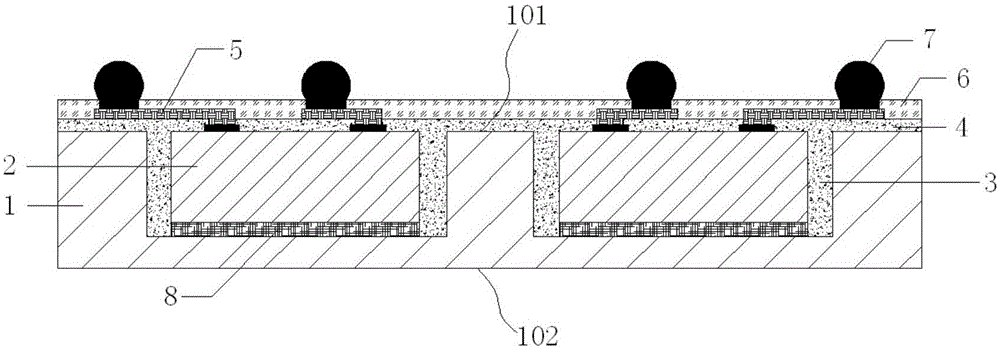

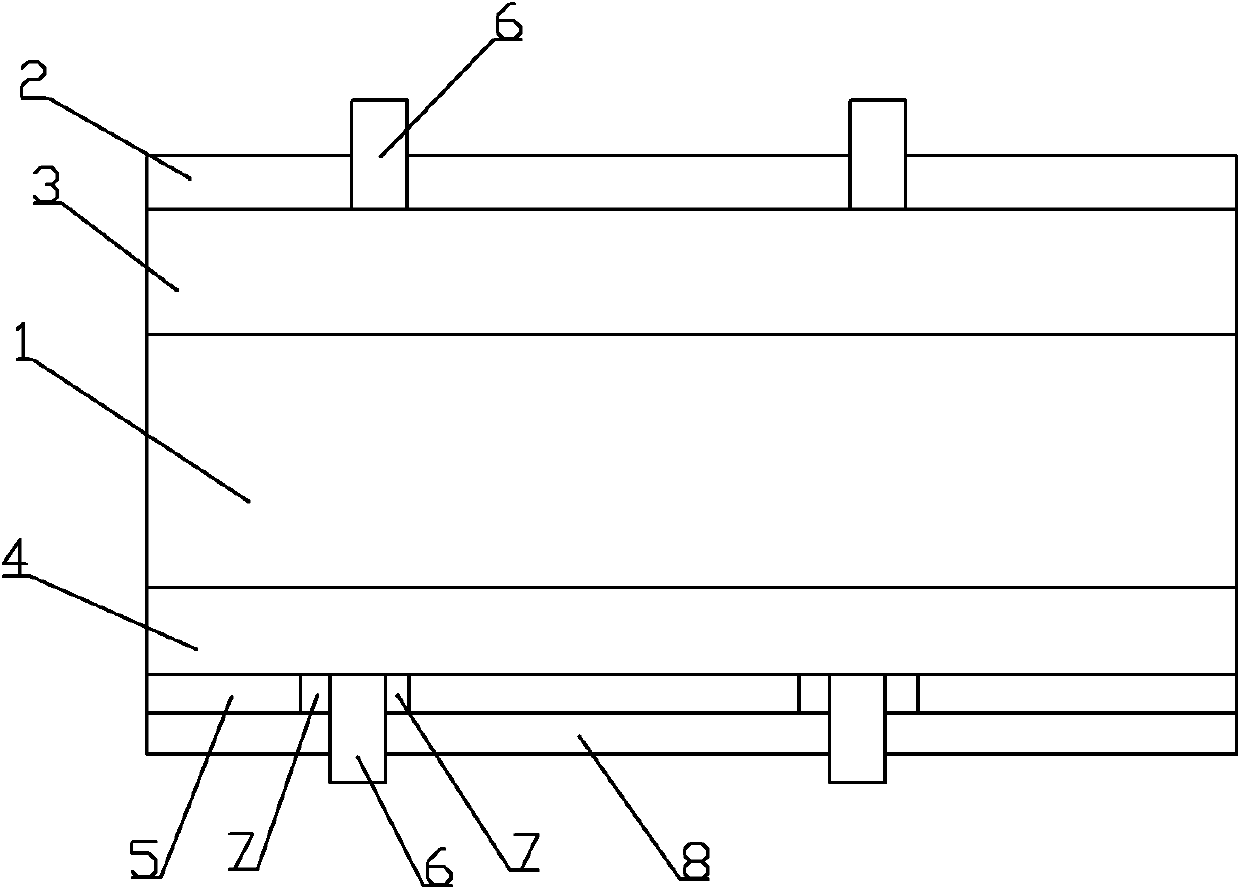

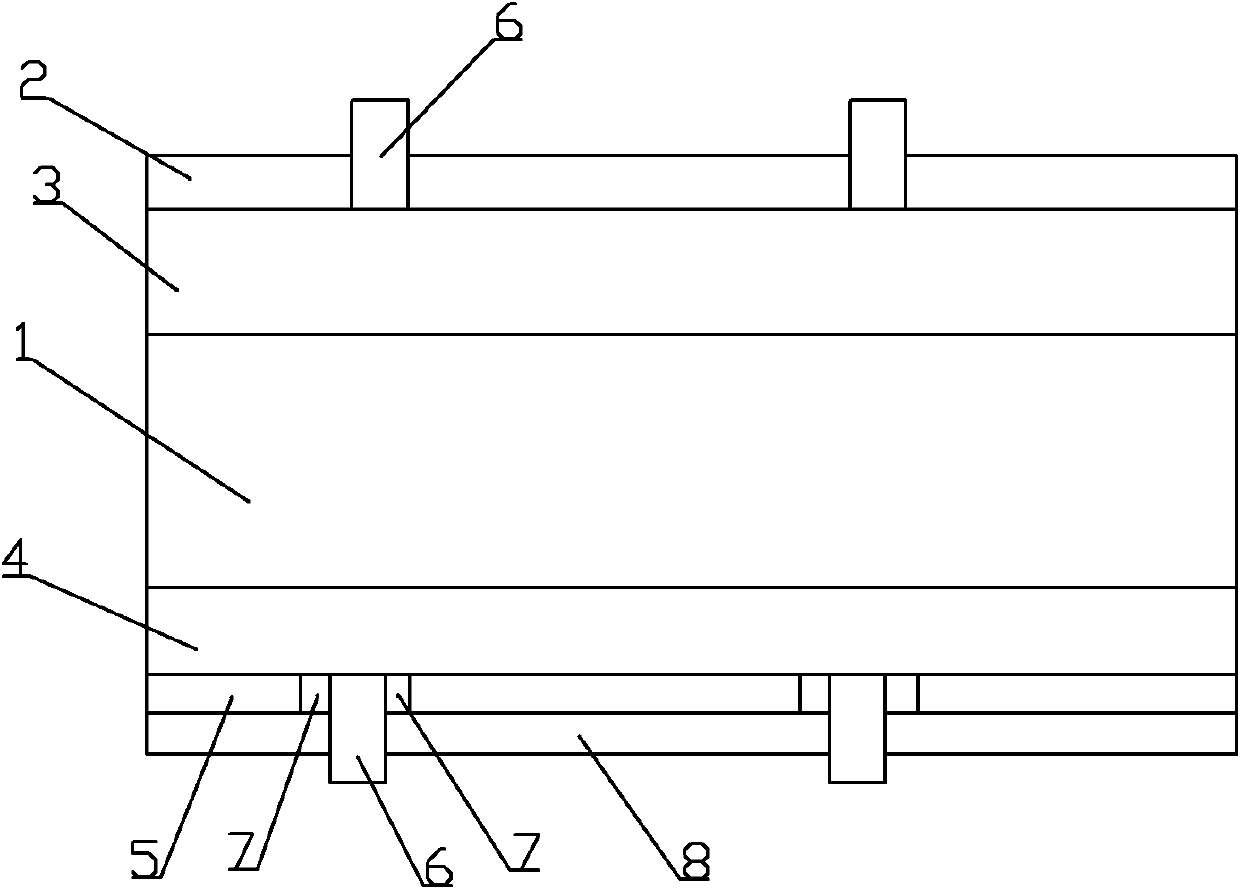

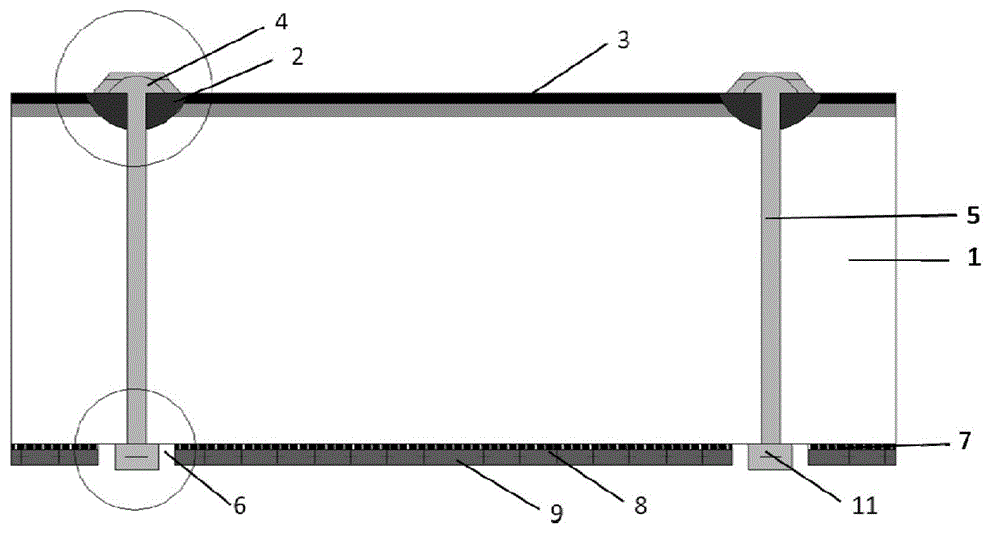

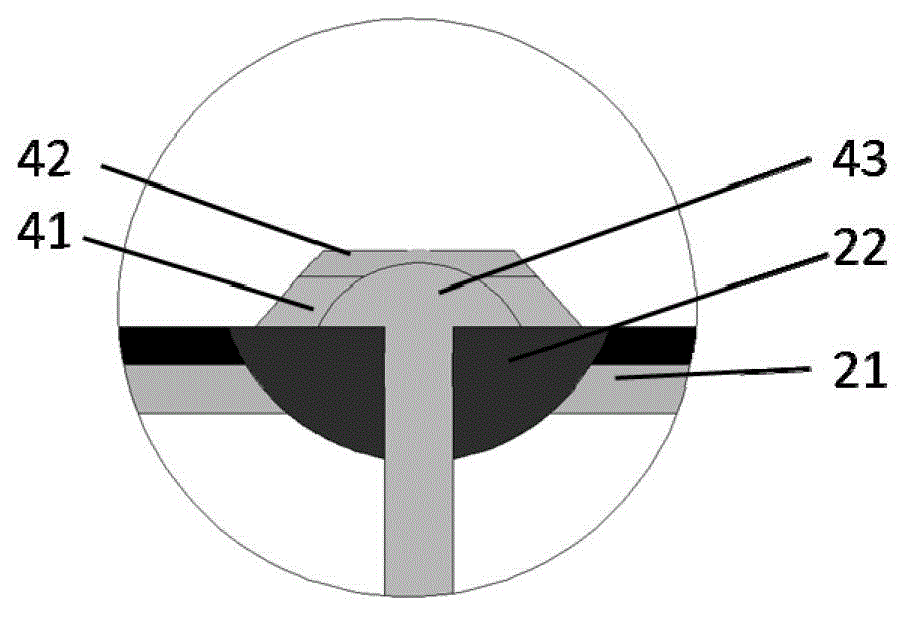

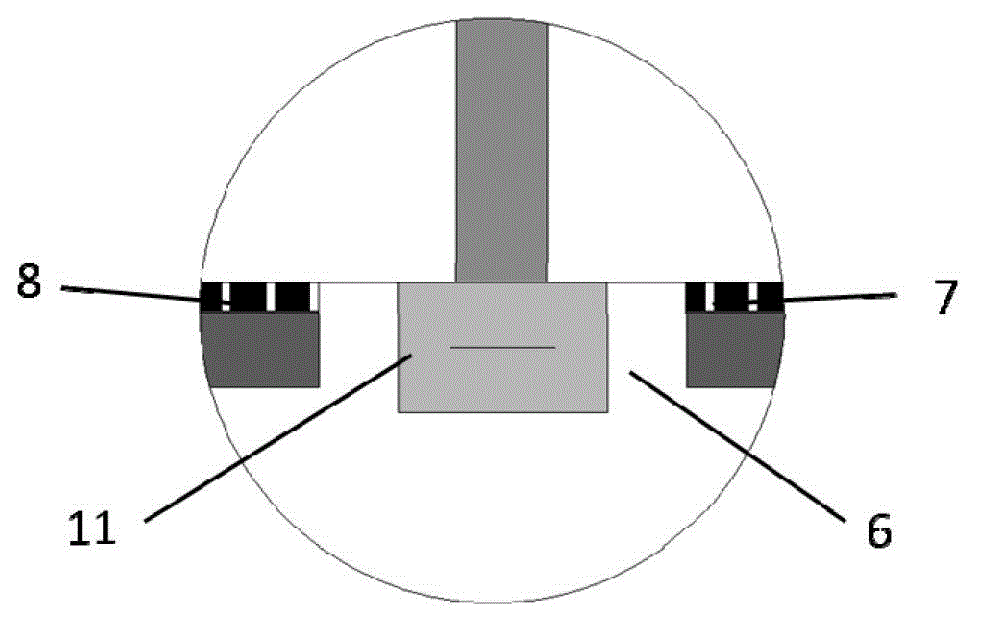

Embedded silicon substrate fan-out type packaging structure and manufacturing method thereof

InactiveCN105023900AImprove cooling effectAvoid offsetSemiconductor/solid-state device detailsSolid-state devicesSilicon matrixPolymer adhesive

The invention discloses an embedded silicon substrate fan-out type packaging structure and a manufacturing method thereof. A silicon matrix is adopted to replace molding material to act as a fan-out matrix, and fine wiring can be manufactured by fully utilizing the advantages of the silicon matrix. Holes, grooves and other structures can be accurately etched by utilizing a mature silicon etching technology. Chips are embedded in the grooves on the silicon matrix, the gaps between the chips and the side walls of the grooves are filled by polymer glue and partial welded balls are welded at the surface of the silicon matrix in a fan-out way so that packaging reliability can be enhanced, the technology is simple and cost is low. The silicon matrix has great heat radiation and lower warping so that enhancement of packaging heat radiation is facilitated, adverse warping can be overcome and smaller wiring line width can be acquired, and thus the structure is suitable for high-density packaging. `Wafer plastic packaging and the de-bonding technology can be eliminated as for the aspect of technology so that technology difficulty can be reduced, and thus cost can be substantially reduced and yield rate can be enhanced.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

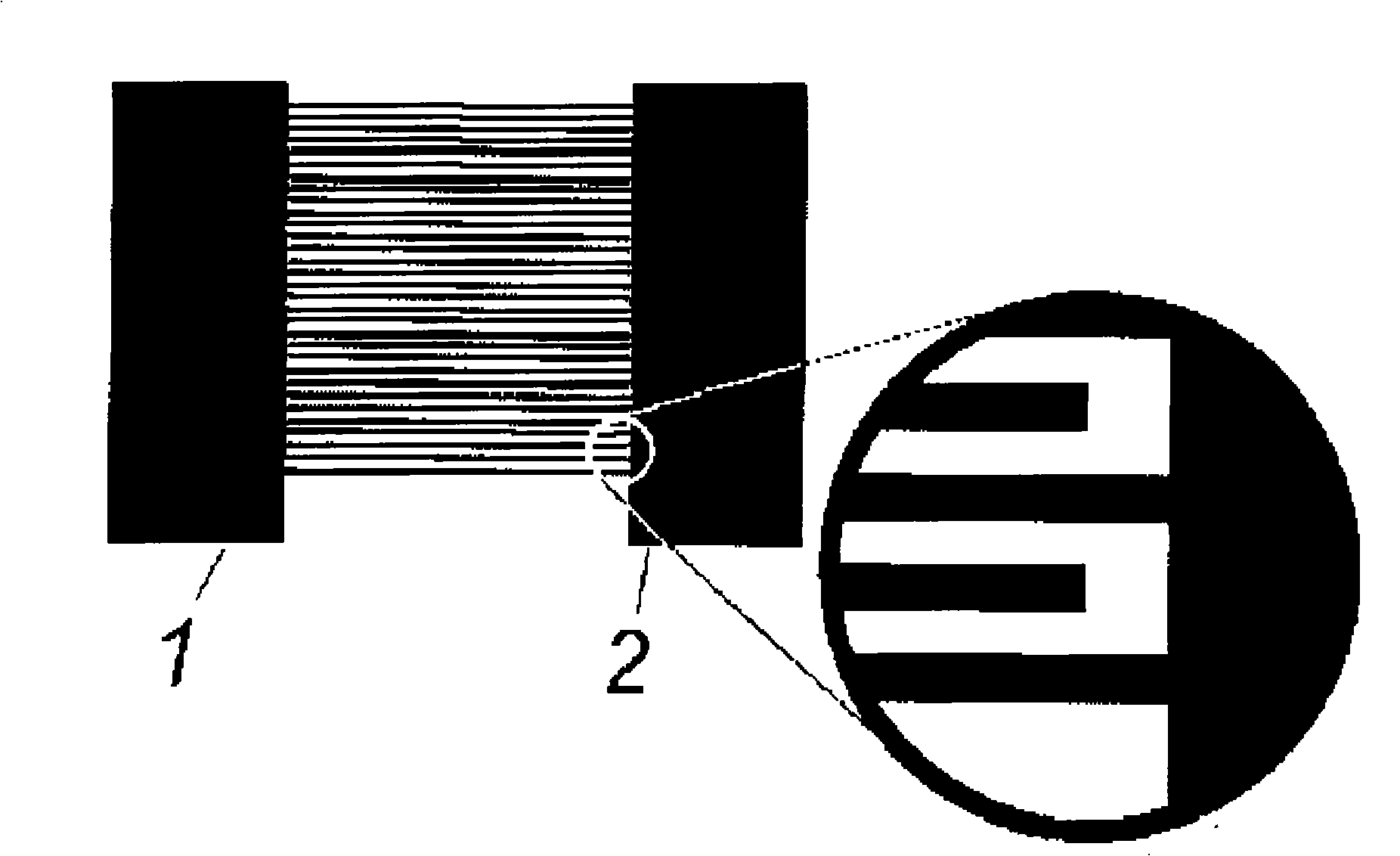

Poly-pyrrole minisize super capacitor based on MEMS technique and method for manufacturing the same

InactiveCN101325130AGood high current discharge performanceIncrease energy densityCapacitor electrolytes/absorbentsSecondary cellsSilicon matrixSolid state electrolyte

The invention discloses a polypyrrole minitype super capacitor in the range of the capacitor manufacturing technology based on MEMS technology and the preparation method thereof. The polypyrrole minitype super capacitor adopts the structure that a metal comb two-dimensional plane structure as a current collector is prepared on the surface of the silicon matrix by utilizing the micro-machining technology; a comb-shaped polypyrrole active electrode is prepared on the surface of the current collector by adopting the method of polypyrrole substance being prepared by the electric precipitation method; a layer of gel solid electrolyte is covered on the surface of the comb-shaped polypyrrole electrode and between a positive electrode and a negative electrode; and a layer of polyimide material is covered on the surface of the structure to accomplish the encapsulation of the minitype super capacitor. The MEMS-based manufacturing technology has the characteristic that the process is simple, and is suitable for mass manufacture. The minitype super capacitor has the advantages of small volume, high energy storage and stable performance, and is widely applicable to micro-robot electronic intelligence systems, chemical sensors, battlefield friend-or-foe identification devices, distributed type battlefield sensors and other fields.

Owner:TSINGHUA UNIV

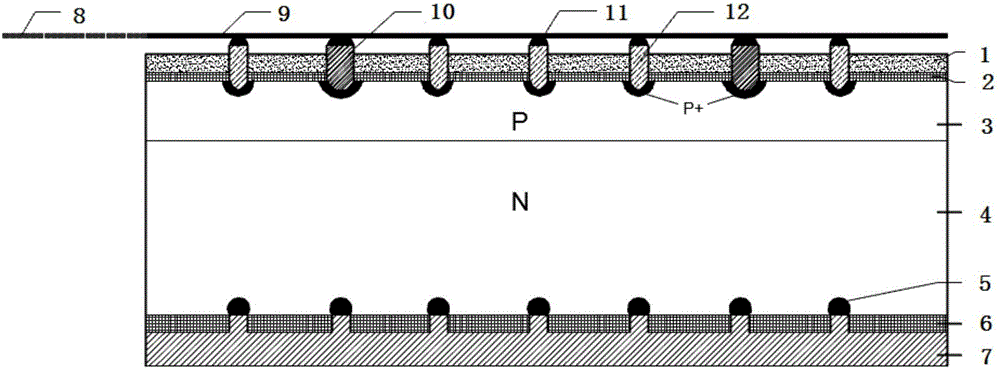

Method for passivating P-type doping layer of N-type silicon solar cell and cell structure

ActiveCN102169923ASuitable for large-scale industrial productionFinal product manufacturePhotovoltaic energy generationSilicon matrixMetal grid

The invention relates to a method for passivating a P-type doping layer of an N-type silicon solar cell and a cell structure. An emitter of a non-metal contact region of a P-type emitter junction at the back of an N-type czochralski silicon matrix forms a floating junction through a phosphorus diffusion layer, the floating junction is isolated from a back metal grid line through a dielectric film, and a passivating film is formed on the surface of the floating junction. An N-type front surface field is formed on the front of the matrix, a pyramid suede structure is formed on the front of the N-type front surface field, a SiNx layer with a passivating N-type surface field is arranged on the surface of the N-type front surface, and metal grid lines are arranged on the front and the back of a battery cell. A boron-doped layer is passivated by using the floating junction, and needs not to be subjected to production line reconstruction compared with a mode of passivating by using Al2O3, thus the method is suitable for massive industrialized production and has an efficiency reaching 19 percent proved by tests.

Owner:TRINA SOLAR CO LTD

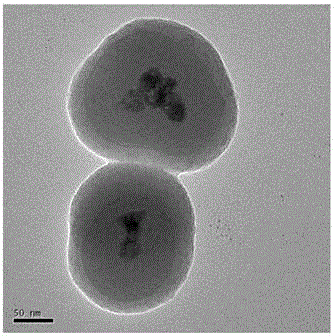

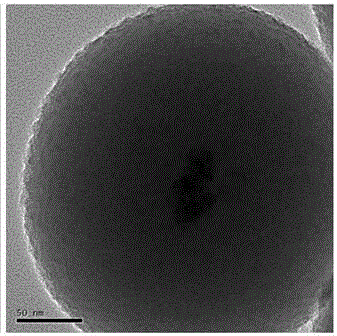

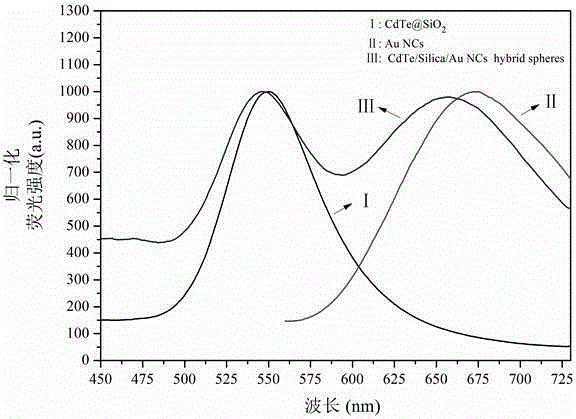

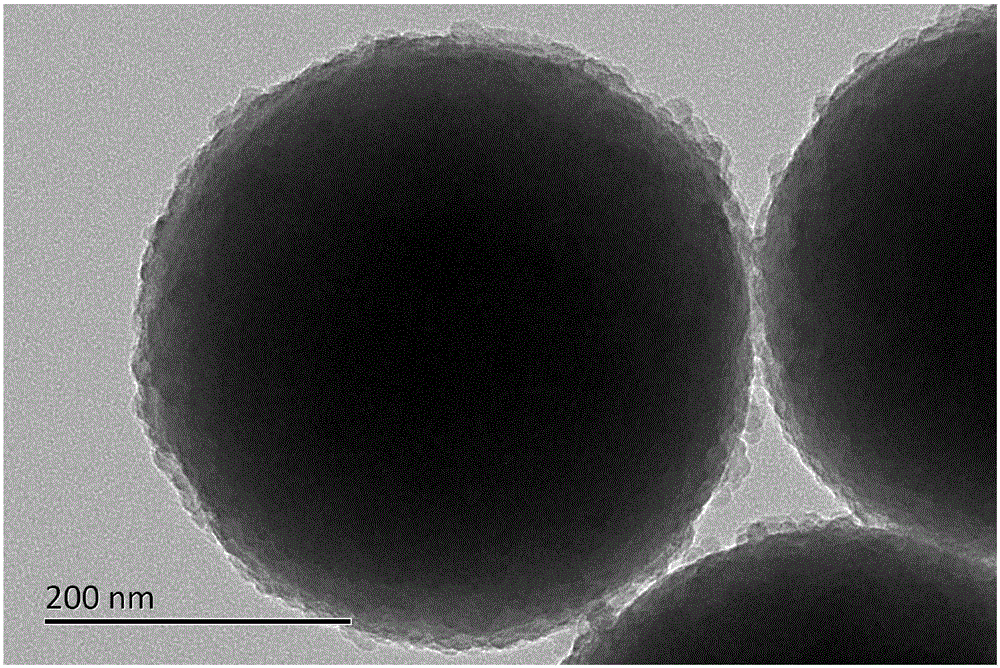

Preparation method and application of ratiometric double fluorescence probe

InactiveCN105154085APrevent leakageReference signal stableFluorescence/phosphorescenceLuminescent compositionsSilicon matrixFluoProbes

The invention discloses a preparation method and application of a ratiometric double fluorescence probe. CdTe quantum dot and Au nano-cluster are taken as a fluorescence signal source, a silicon-based material is taken as a carrier, the quantum dot is taken as a reference signal source and is embedded in a silicon core, and the Au NCs (Au nano-cluster) with fluorescence response performance is covalently bonded to the surface of a silicon layer, so that a hybrid microballoon with the core-satellite type structure is prepared. The advantages comprise that the quantum dot is taken as the reference signal source and is embedded into the silicon core, leakage is effectively avoided, a stable reference signal is provided; and by covalently bonding the Au NCs with the fluorescence response performance to the silicon ball surface, selective identification and response of Cu<2+> are realized.

Owner:TAIYUAN UNIV OF TECH

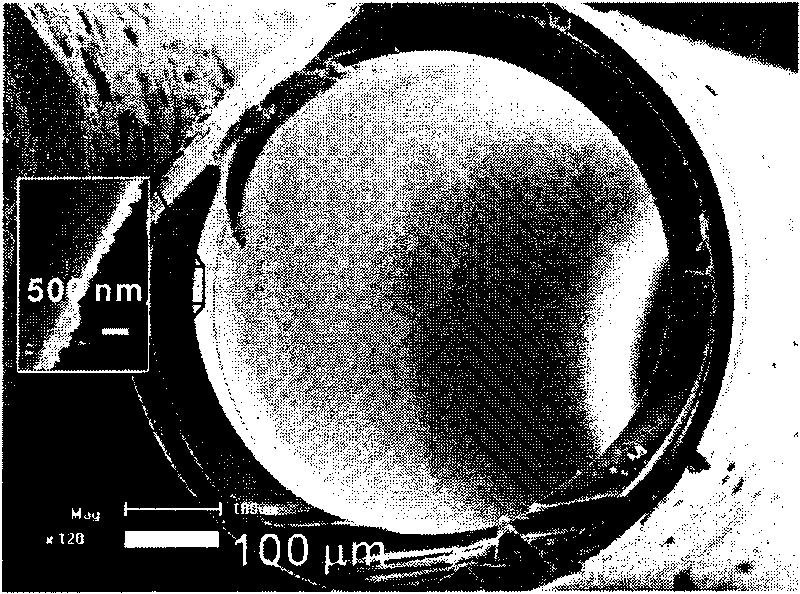

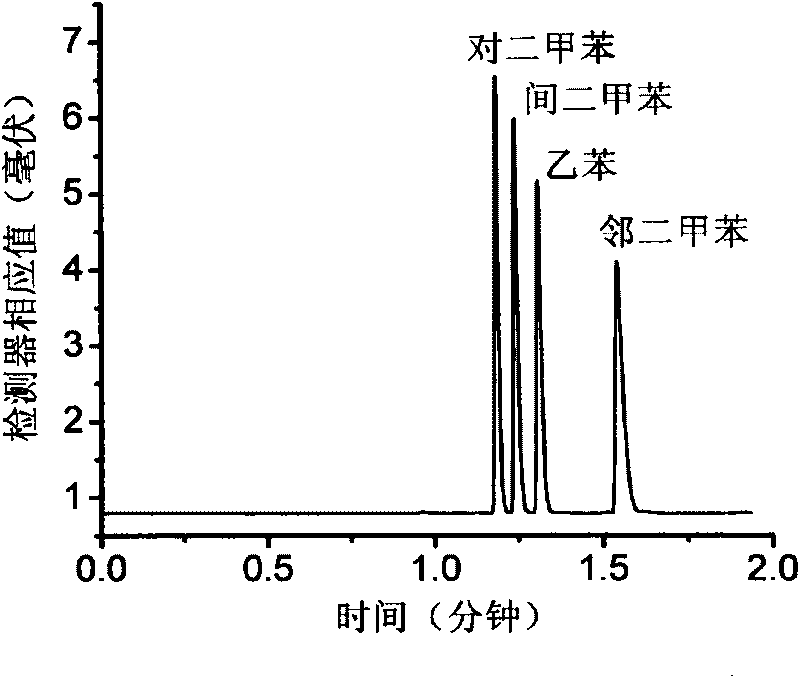

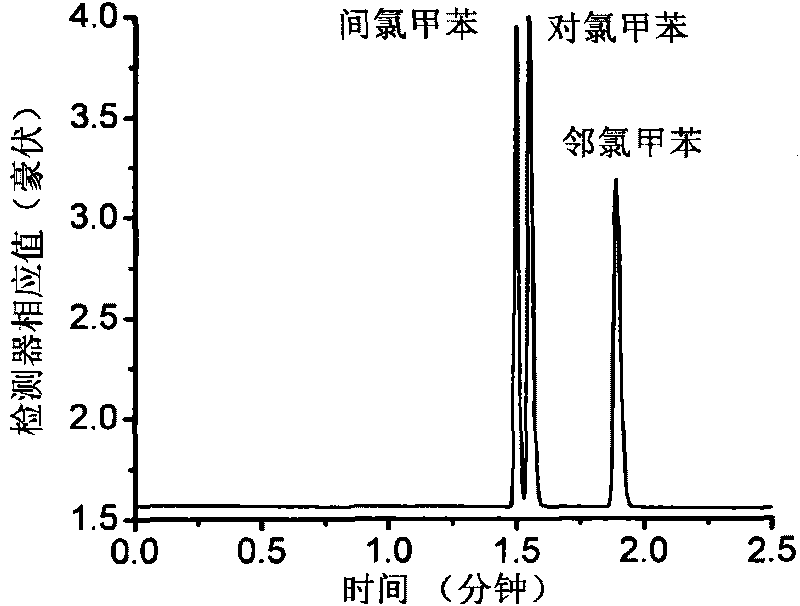

Novel capillary gas chromatographic column based on MOFs and preparation method thereof

InactiveCN101706481ANovel topologyGood thermal stabilityComponent separationChromatographic columnChemistry

The invention discloses a novel capillary gas chromatographic column based on metal-organic frameworks (MOFs) and a preparation method thereof. The MOFs have huge specific surface areas (generally 2000-5000m2 / g), novel topological structures and good thermal stability. Compared with the traditional silicone-based materials, the MOFs have diverse structures and adjustable pore canal sizes. The capillary gas chromatographic column provided by the invention has the capability of rapidly and efficiently separating isomers. The invention also provides the preparation method of the capillary gas chromatographic column. The method adopts the dynamic coating mode to prepare the capillary gas chromatographic column based on MOFs, thus overcoming the defect of complex preparation of the current packed columns based on MOFs and greatly saving the demanded MOFs; therefore, the method is favorable to large-scale popularization and application.

Owner:北京安星达环保技术发展有限公司

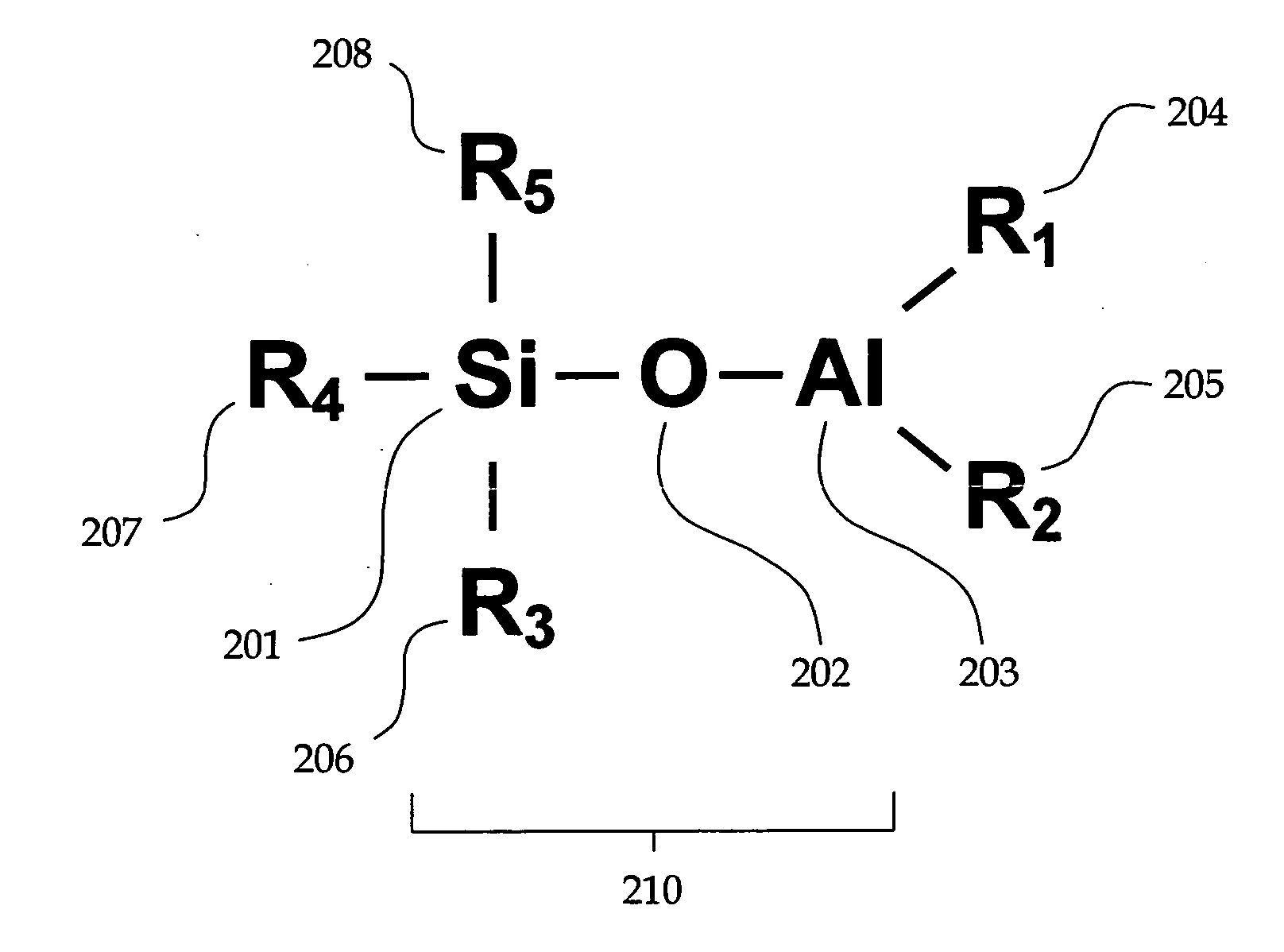

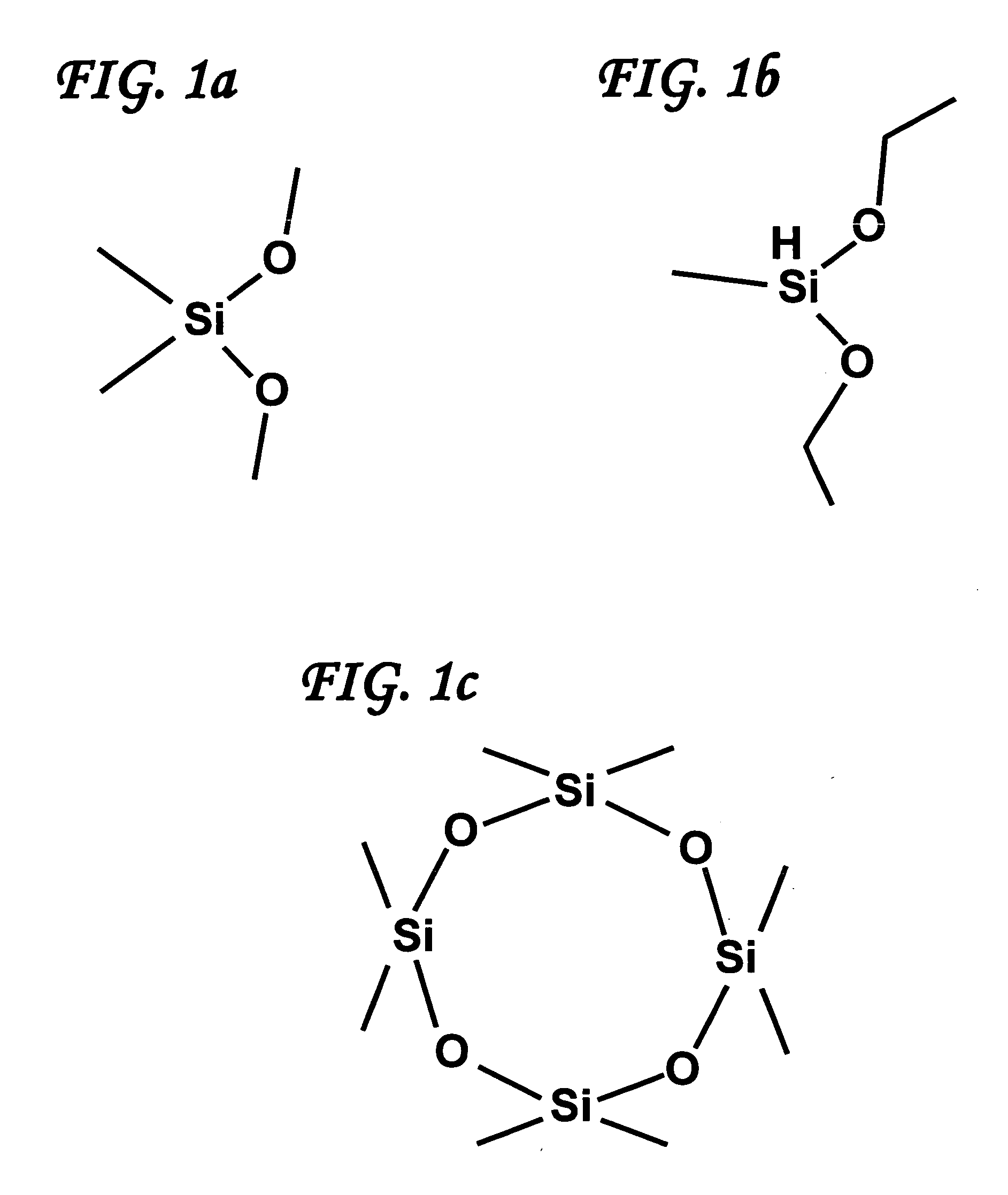

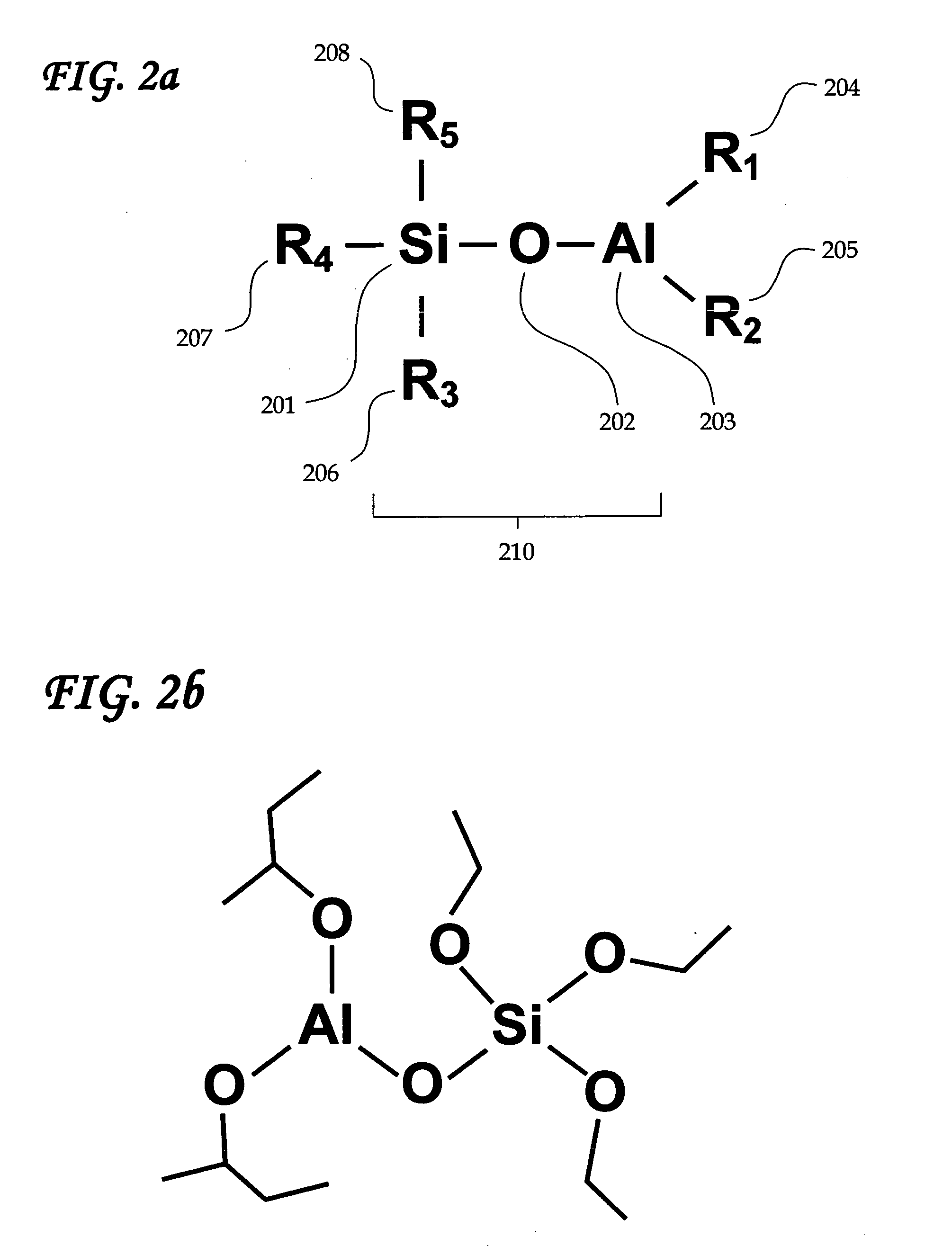

Low-k dielectric layer formed from aluminosilicate precursors

InactiveUS20060097359A1Semiconductor/solid-state device detailsSolid-state devicesSilicon matrixHigh intensity

A method for forming a high mechanical strength, low k, interlayer dielectric material with aluminosilicate precursors so that aluminum is facilely incorporated into the silicon matrix of the material, and an integrated circuit device comprising one or more high-strength, low-k interlayer dielectric layers so formed.

Owner:INTEL CORP

Method for preparing a silica suspension in a vulcanisable silicon matrix to form elastomers

InactiveUS6391944B2Easy to useInexpensive and able to be applied on an industrial scaleElastomerParticulates

The invention concerns the preparation of a silica suspension in a silicon fluid, said suspension being used to produce silicon vulcanizable by polyaddition (RTV elastomers). The problem which the invention aims to solve is that of finding a technical compromise between the rheological and mechanical properties of the final RTV. The invention solves the problem by providing a method for preparing a silica suspension treated with hexamethyldisilazane (HMDZ) in a silicon fluid with siloxyl Si-Vinyl function, characterised in that it consists essentially in introducing HMDZ in the preparation medium, before and / or substantially while bringing at least part of the silicon fluid prepared with at least part of the particulate filler used, said introduction being carried out once or several times for a HMDZ fraction corresponding to a proportion not more than 8% by dry weight with respect to the total silica charge and after bringing together the POS and the filler.

Owner:BLUESTAR SILICONES FRANCE SAS

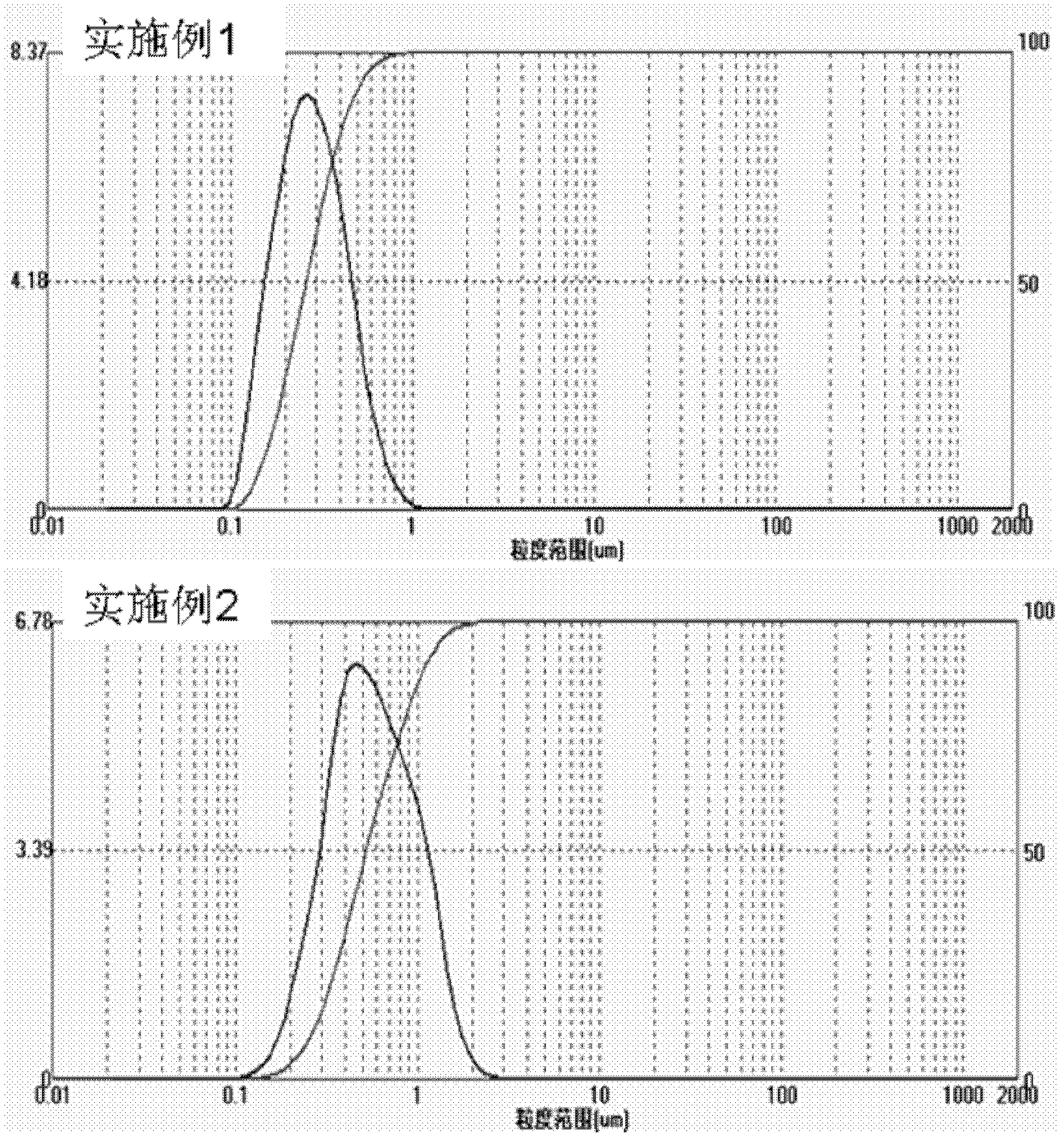

Process for producing silicon-based carbon composite material for lithium ion battery cathode

InactiveCN102623682AImprove lithium storage performanceImprove conductivityElectrode manufacturing processesSilicon matrixCarbon composites

Disclosed is a process for producing a silicon-based composite material for a lithium ion battery cathode. The process comprises that silicon powder serves as a main material, graphite powder or flocculent carbon black serves as an auxiliary material, the main material and the auxiliary material are mixed and placed in a ball-grinding steel tank, argon serves as a shielding gas, the ball-grinding steel tank inflated with the shielding gas is placed in a planetary ball mill, and powder with granularity of less than 20 mum, which is the silicon-based composite material for the lithium ion battery cathode, is obtained after the mixture is subjected to ball milling at 500 revolutions / minute for 80 hours. The process has the advantages that the silicon material having the good lithium-storing capacity is mixed with the carbon material having the good electrical conductivity, atomic-grade mixing of the silicon material and the carbon material is achieved in a mechanical alloying mode, the electrical conductively of the silicon matrix is fully improved, and the inert carbon material can reduce volume expansion caused by the processes of lithium intercalation and lithium deintercalation of the silicon material in the processes of charging and discharging of the inert carbon material, so that the cycle performance of the silicon material is improved, the electrical conductivity and the cycle performance of the carbon-doped material are better than those of the pure silicon material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

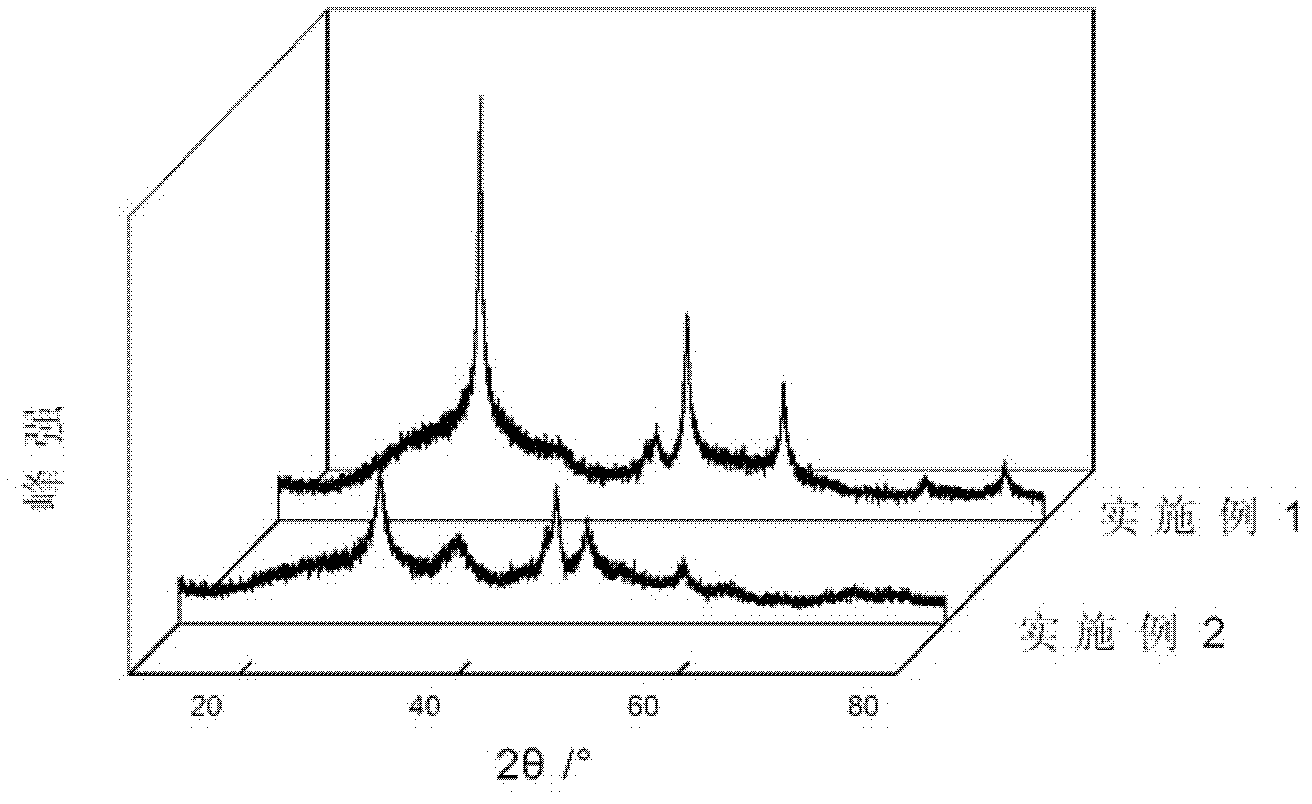

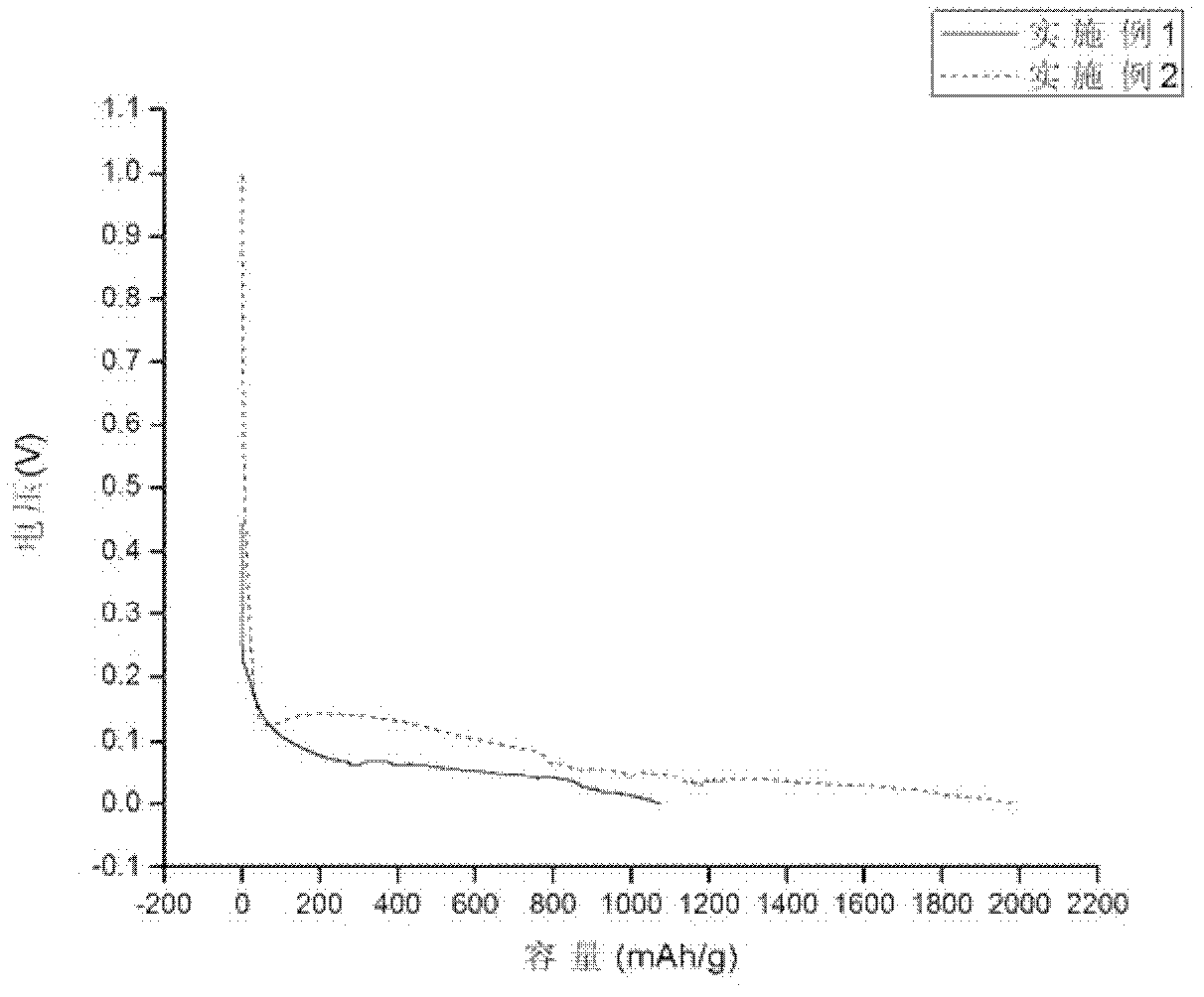

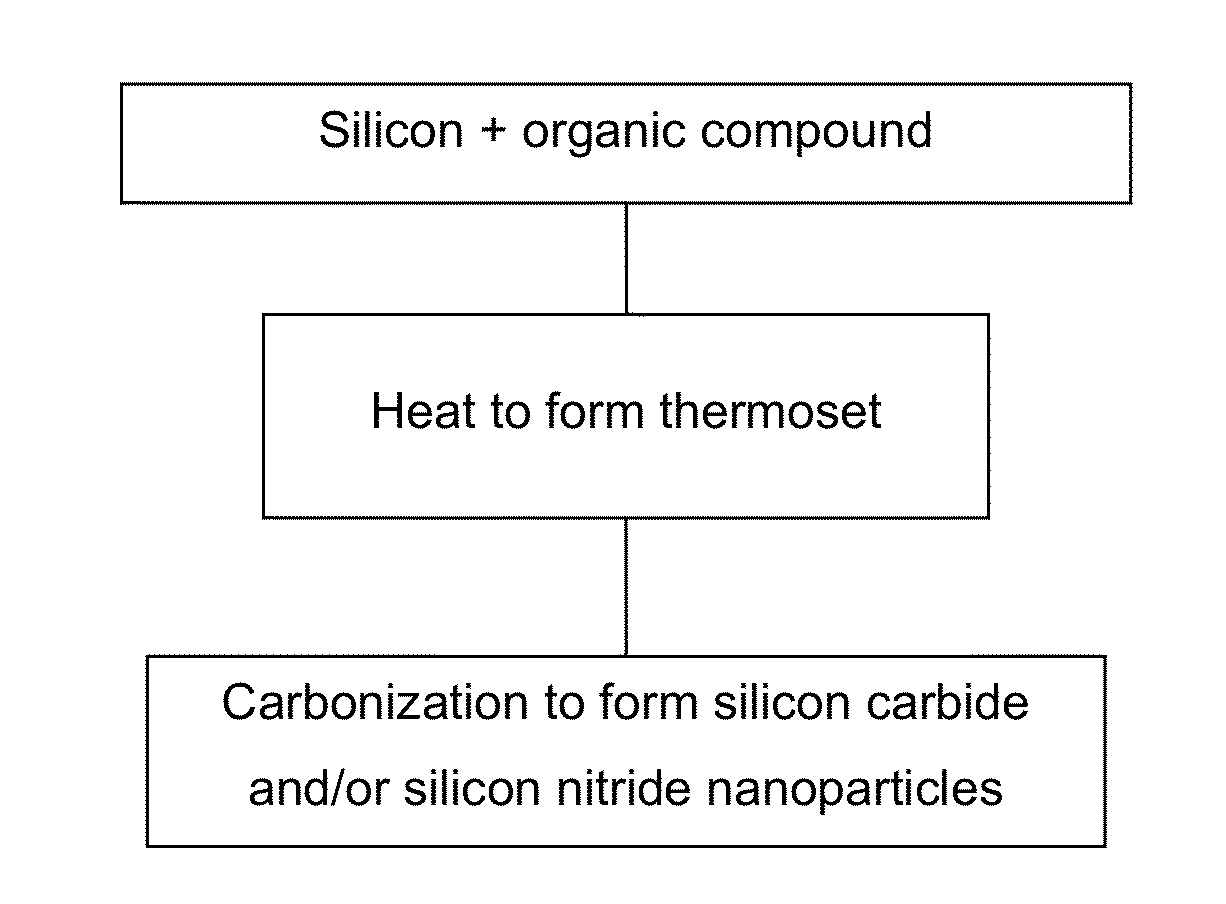

Formation of silicon carbide-silicon nitride nanoparticle carbon compositions

A composition having nanoparticles of silicon carbide and a carbonaceous matrix or silicon matrix. The composition is not in the form of a powder. A composition having silicon and an organic compound having a char yield of at least 60% by weight or a thermoset made from the organic compound. A method of combining silicon and the organic compound and heating to form silicon carbide or silicon nitride nanoparticles.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

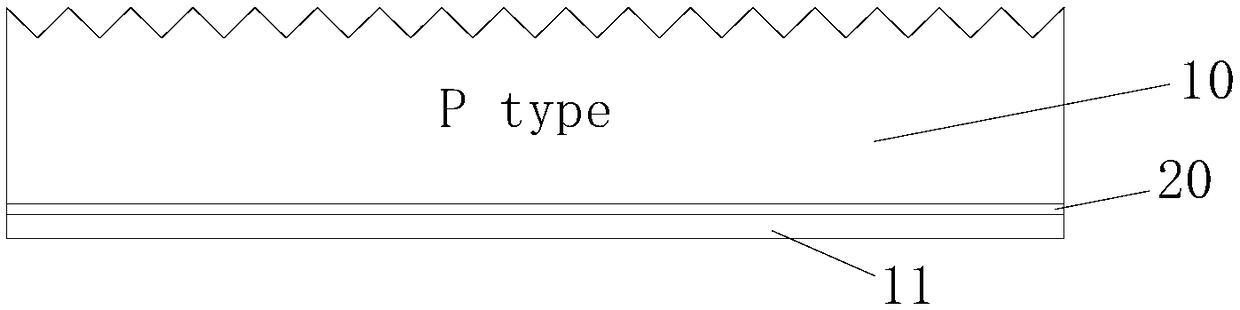

Back-contact solar cell and preparation method thereof

PendingCN108110065ALow costAchieve passivated contactsFinal product manufacturePhotovoltaic energy generationSilicon matrixMetal electrodes

The invention relates to a back-contact solar cell. The cell comprises a P-type crystal silicon matrix, the back surface orderly comprises a tunneling oxide layer, back n+doped polycrystalline siliconregion and a laser slotting region in alternative arrangement, a passivation film, and a metal electrode from inside to outside; the metal electrode comprises a silver electrode in ohmic contact withback surface n+doped polycrystalline silicon region and an aluminum electrode in ohmic contact with back surface laser slotting region; the front surface is a p+doped region and a front surface passivation anti-reflection film from inside to outside in order. The solar cell disclosed by the invention has the advantages that the transmitter region on the back surface of the P-type crystalline silicon matrix adopts the n+doped polycrystalline silicon passivation layer, the back surface forms a p+region by adopting an aluminum paste and is passivated by using the aluminum oxide film, thereby realizing the passivation contact and field passivation effect of the back surface, the composite rate of the cell back surface is reduced, and the open-circuit voltage and the short-circuit current areimproved; the back p+region is formed by using the aluminum paste, in comparison with the traditional process, the one-step diffusion doping step is reduced, the process flow is simplified, and the cell cost is saved.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

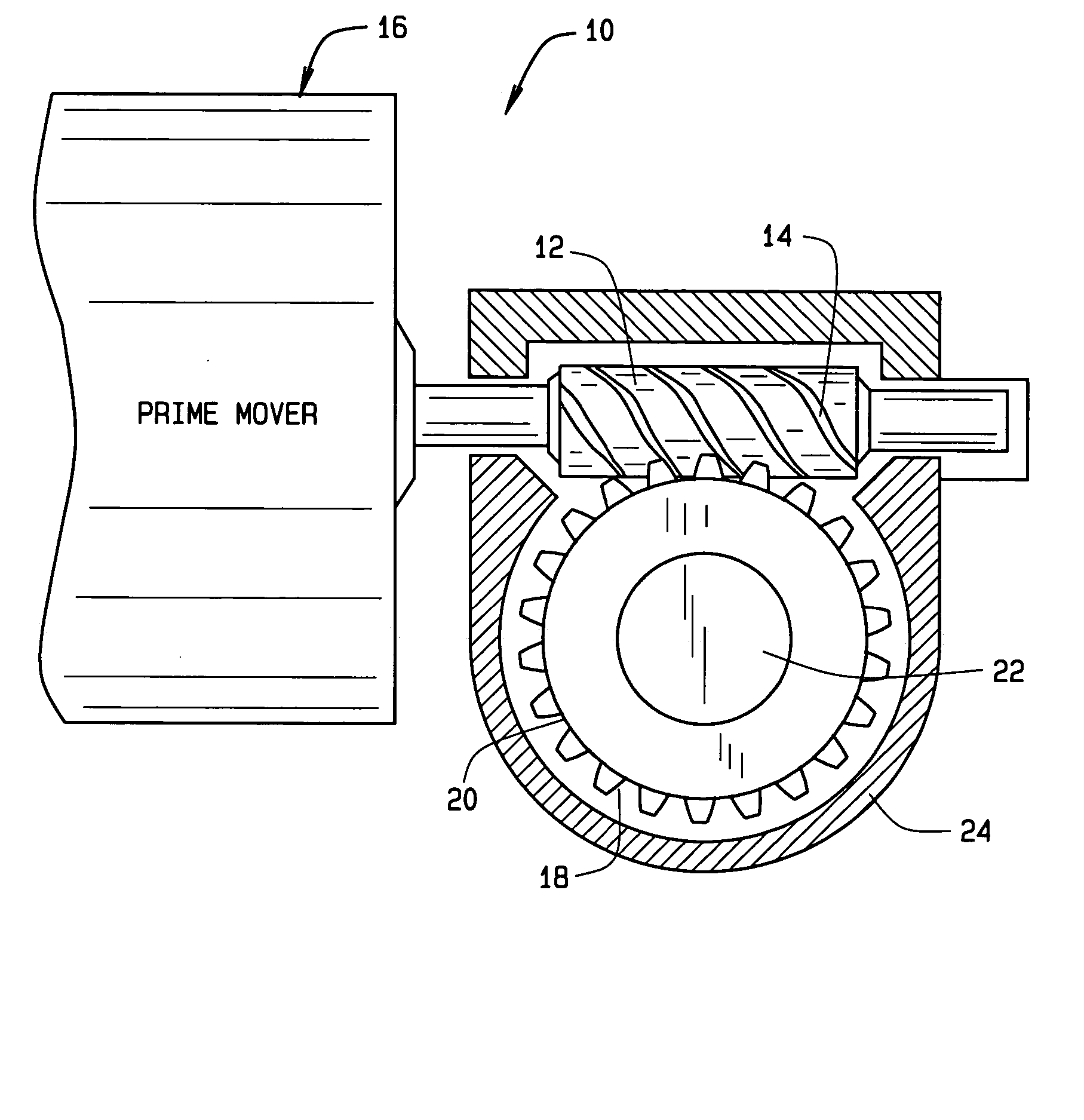

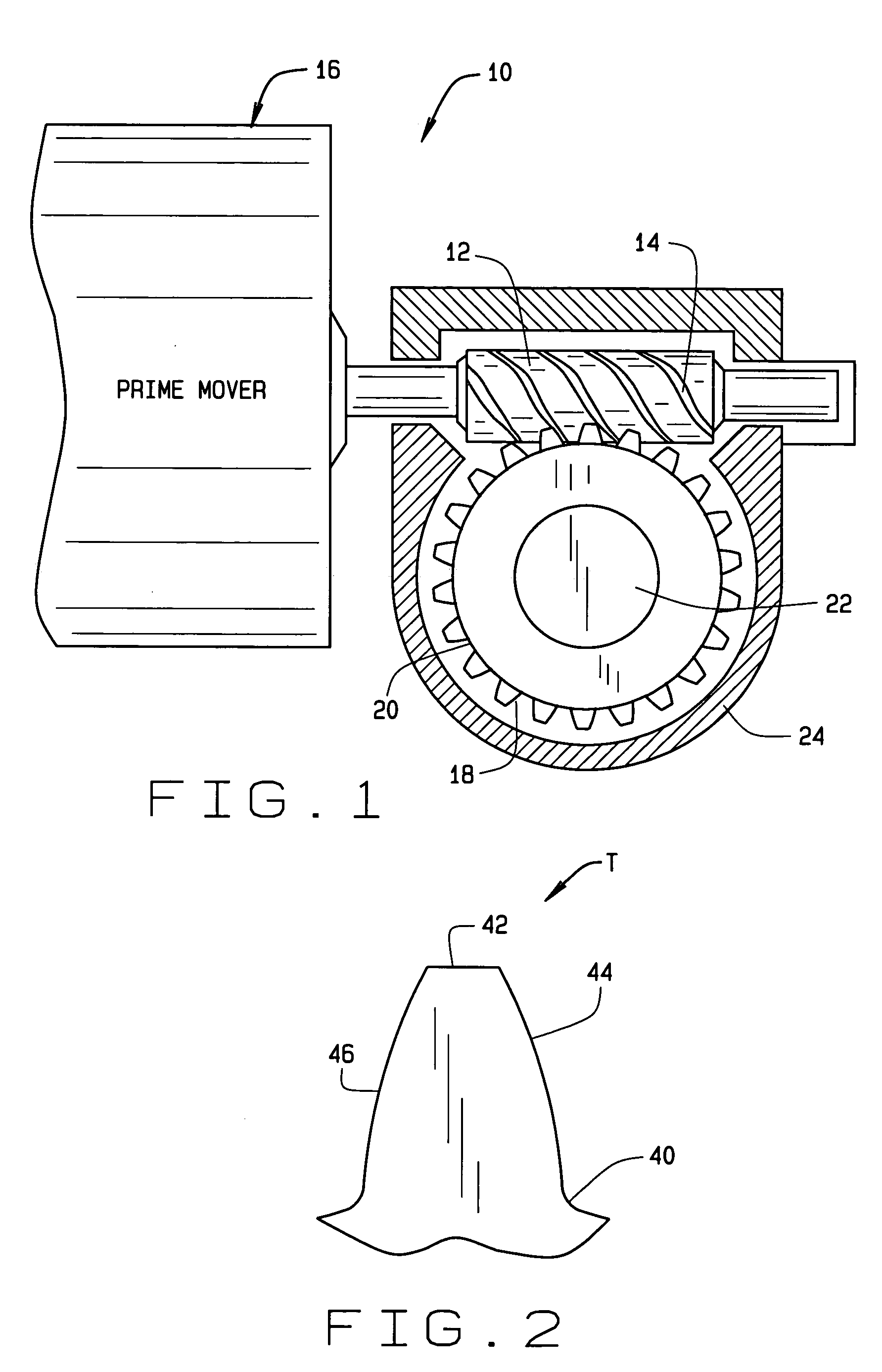

Worm gear assembly having improved physical properties and method of making same

InactiveUS20050274215A1Improve propertiesHigh levelToothed gearingsSolid state diffusion coatingSilicon matrixPhysical property

The ability of a worm assembly to resist adhesive and / or abrasive wear, hertzian contact fatigue, and bending fatigue are enhanced by selecting a worm shaft produced from a hardened steel which will maintain the tooth geometry of the worm tooth during service; selecting a worm gear made from a work-hardening metal (such as austenitic steel, a microalloyed steel, wrought steel, compacted metal powder, or cast iron); imparting a finish to the worm and / or worm gear and / or applying a tribological coating containing metal carbides dispersed in an amorphous hydrocarbon or silicon matrix to the worm and / or worm gear.

Owner:THE TIMKEN CO

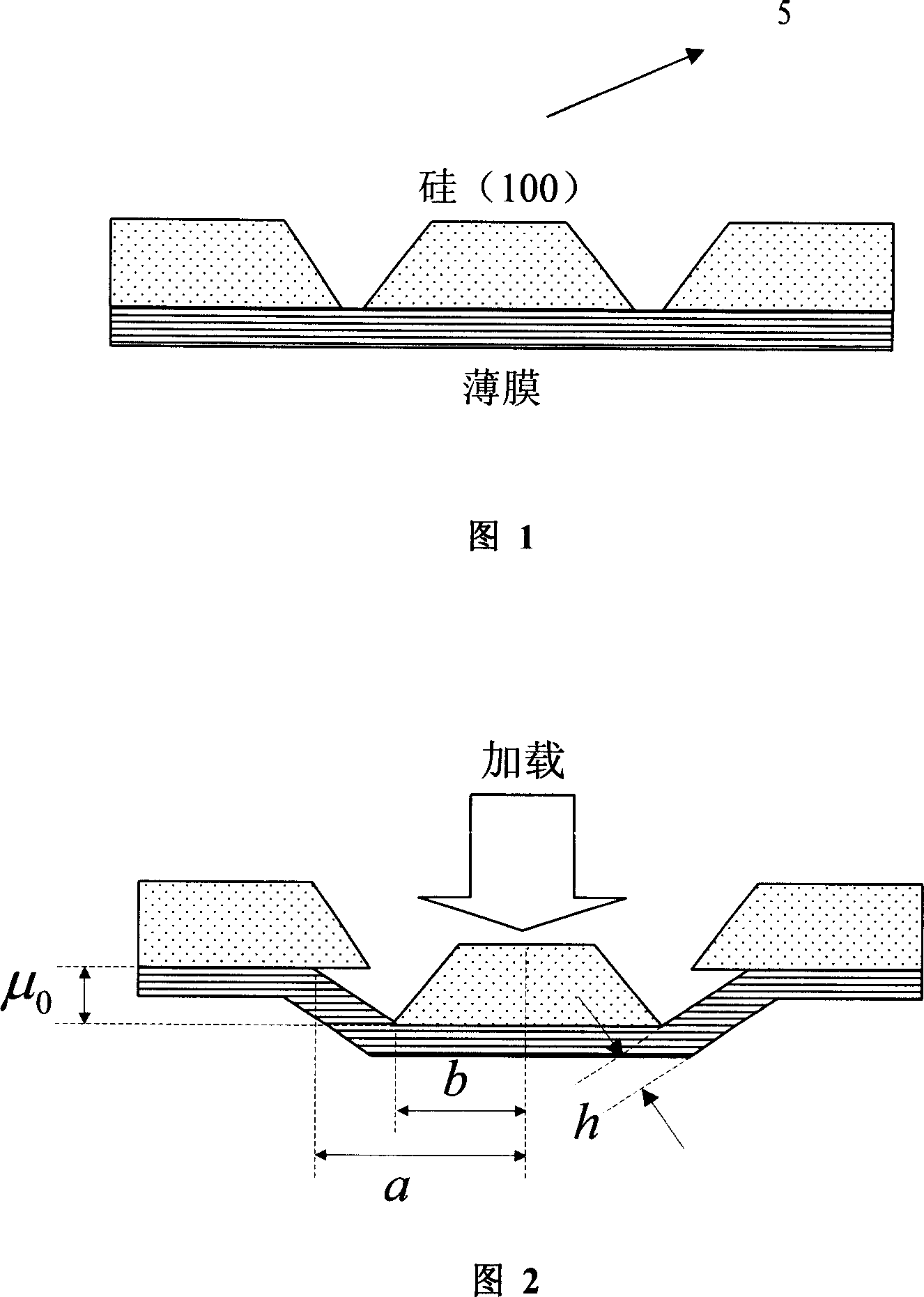

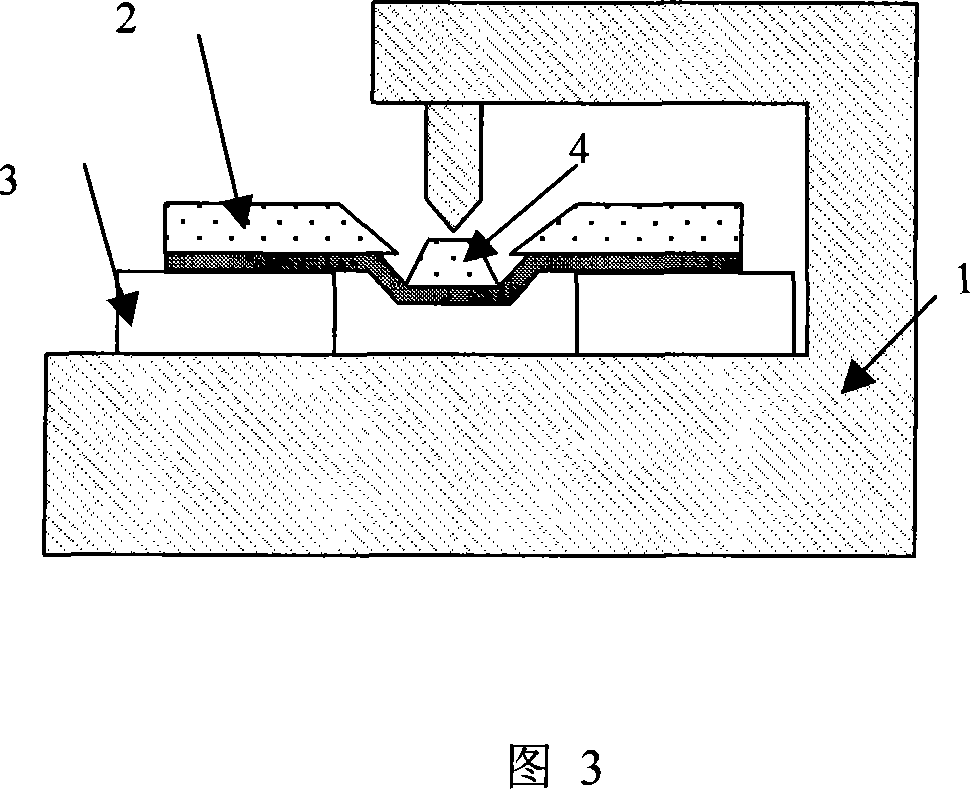

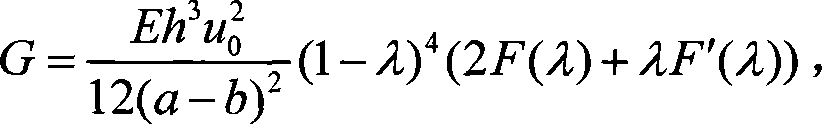

Method for measuring silicon base body and membrane base combination intensity

InactiveCN101144770AReduce cumbersomeAvoid the effects of compressionSemiconductor/solid-state device testing/measurementUsing mechanical meansSilicon matrixFree energies

The invention relates to a method to measure the bond strength of the silicon matrix and the membrane matrix in the measuring technical field. The method is realized by that a pattern with a window is made at the back of a silicon foundation base by an etching method, a part of foundation base is reserved as a loading platform in the window, a facial membrane of the foundation base is exposed in the back window, when the reserved matrix is pressed to break through the matrix and drive the membrane to break away with the matrix, a happened maximum normal displacement is recorded, a free energy releasing rate is gained by an prior formula, to characterize the bond strength of the membrane matrix system. The invention overcomes the shortage that the requirement of the observational measurement or the sample size of the prior detecting equipment is high, depends on the prior equipment and a mature sample making process, and uses a touching type back breaking through method to comparatively quickly detect the bond strength of the membrane matrix in the fixed quantity under a complex shape.

Owner:SHANGHAI JIAO TONG UNIV

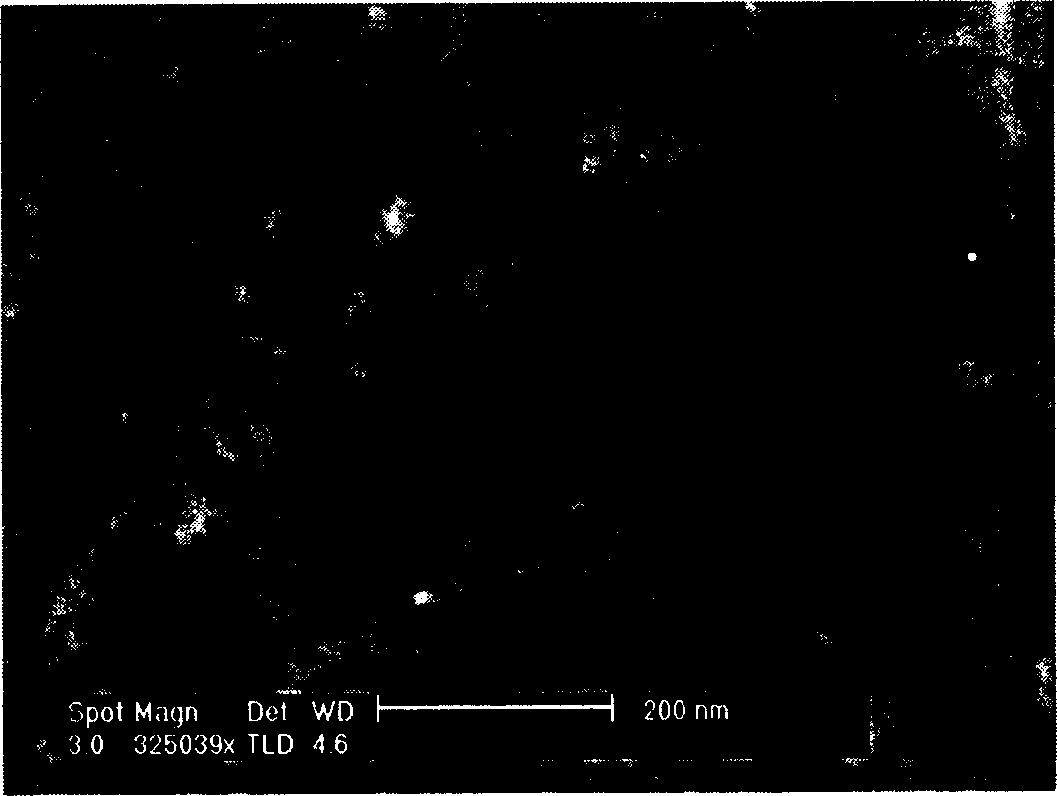

Solution for replacing silver plating in deposited nanostructure on surface of silicon matrix and use method thereof

InactiveCN101717927ANanostructures haveHigh purityLiquid/solution decomposition chemical coatingSolventSilicon matrix

The invention discloses solution for replacing silver plating in deposited nanostructure on the surface of silicon matrix. Water is used as the solvent and each litre of solution contains 3-5 g of AgNO3, 0.5-2.5 g of NaF and 0-100 g of polyvinylpyrrolidone with the molecular weight of 55000. The method for plating a silver layer on the surface of the silicon matrix comprises the following steps of: dipping the cleaned silicon matrix in the silver plating solution at a reaction temperature of 40-60 DEG C, washing with water after depositing and drying to obtain the silver plating in nanostructure on the surface of the silicon matrix, wherein the layer mixed with nanowire and nanoparticles can be obtained when PVP is not contained in the silver plating solution and the nanoparticle layer is obtained when PVP is contained in the silver plating solution. The invention has the advantages of simple component of the solution, gentle reaction as well as simple and controllable plating process, is beneficial to large-scale production and can be used in the production field of very-large-scale integrated circuits and micro electro-mechanical systems.

Owner:ZHEJIANG UNIV

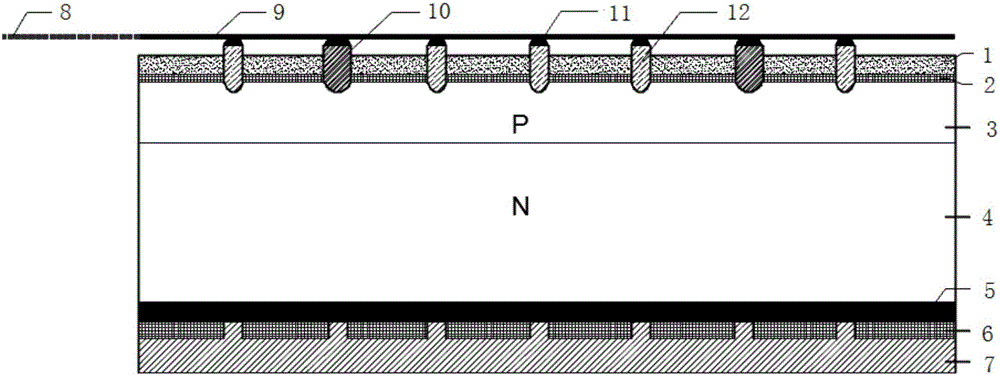

Manufacturing method for crystalline silicon solar MWT (metallization wrap-through) cell and manufactured cell

InactiveCN103187482AIncrease short circuit currentReduce compoundingFinal product manufacturePhotovoltaic energy generationSilicon matrixElectrode Contact

The invention discloses a manufacturing method for a crystalline silicon solar MWT (metallization wrap-through) cell. The manufacturing method for the crystalline silicon solar MWT cell comprises the following steps of: producing a conductive through hole; performing wet-method texturization; performing grid line area phosphorous paste printing on a light-receiving surface; diffusing phosphorous; etching the edge of a silicon matrix, and performing PSG (phosphosilicate glass) removal treatment; coating an antireflection film, and printing an emitting electrode contact electrode, a back electrode contact electrode and a base electrode contact electrode; printing the electrode grid line of the light-receiving surface; sintering to form ohmic contact; and electrically insulating the base electrode contact electrode from the emitting electrode contact electrode, so as to finish production for the solar cell. According to the manufacturing method disclosed by the invention, a selective emitting electrode structure is realized on the MWT solar cell; and optical loss is effectively reduced, minority carrier recombination is reduced, various electrode-related resistance losses are reduced, and the short-circuit current ISC, the open-circuit voltage UOC and the filling factor of the cell are remarkable increased by combining with a back passivation technology and a secondary printing technology. The preparation process is easy to operate, capable of being completely compatible with the solar cell production line which is widely applied at present, and suitable for large-scale production.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

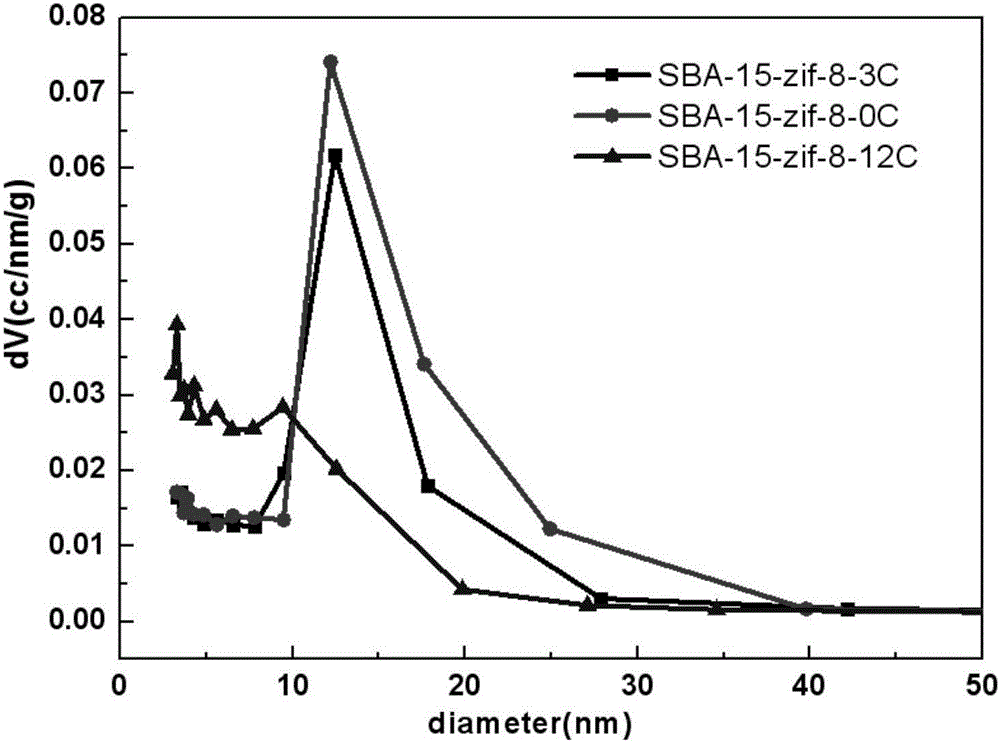

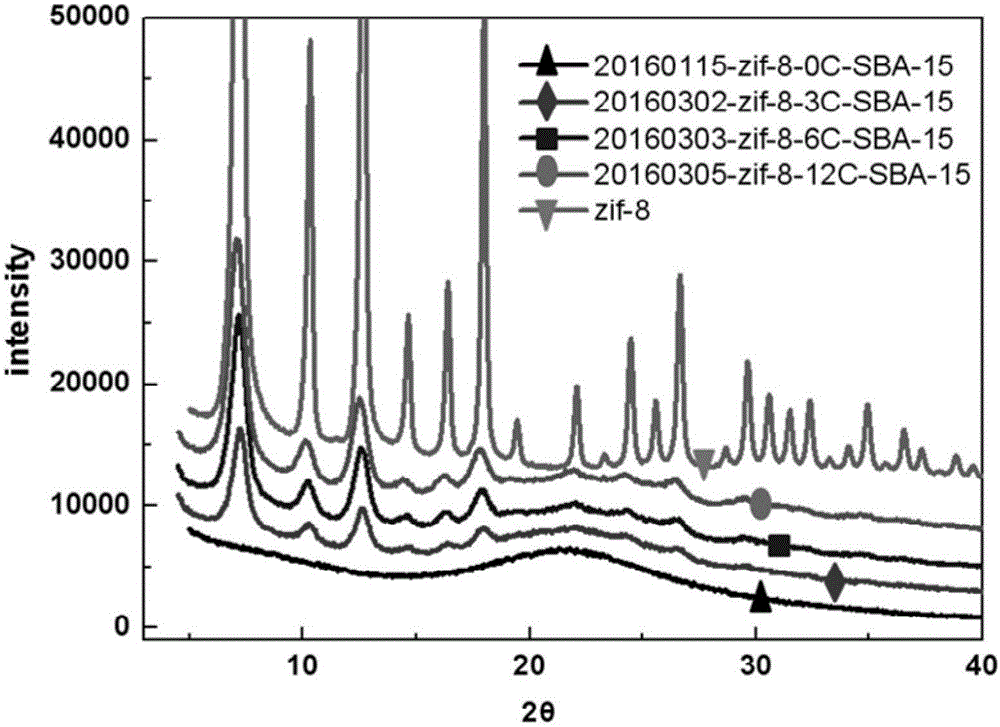

Loading method of ZIFs on silicon substrate, silicon substrate material and application of silicon substrate material

InactiveCN107519840ARandom choicePrecise and controllable coatingOther chemical processesLayer by layer self assemblySilica gel

The invention provides a novel loading method of zeolite-like imidazole ester skeleton structural materials (ZIFs) on a silicon substrate and an application of the prepared material. The silicon substrate such as silicon spheres, ordered mesoporous silicon SBA-15, CMC-41, CMC-48, KT96, chromatography silica gel, capillary and the like is activated, then the activated silicon substrate is derivated, and the surface of the substrate is allowed to contain groups coordinated with metal ions; then a corresponding metal salt and imidazole are respectively dissolved in water, methanol, DMF, THF and other polar solvents to form clarified uniform solutions, and the ZIFs are grafted on the outer surface of the silicon substrate or in pore passages by a layer-by-layer self-assembly method. The invention provides the preparation method of the silicon-based ZIFs loaded material having the advantages of no needing of high temperature and high pressure treatment, stable and uniform loading and controllable thickness. The material prepared by the method has important application potential in the aspects of separation and analysis, adsorption, enrichment, purification and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

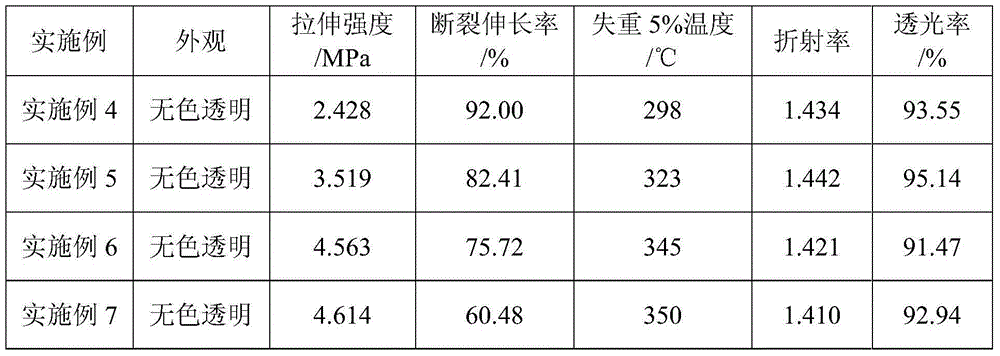

Vinyl POSS (polyhedral oligomeric silsesquioxane) modified organic silicon resin, and preparation method and application thereof

InactiveCN104151763AImprove mechanical propertiesGood optical performanceCoatingsSemiconductor devicesSilicon matrixAdhesive

The invention belongs to the technical field of modified organic silicon resin preparation, and discloses a vinyl POSS (polyhedral oligomeric silsesquioxane) modified organic silicon resin with excellent optical and thermodynamic properties, and a preparation method and application thereof in the fields of LED (light-emitting diode) packaging materials, coating materials, optical lens materials and the like. The resin comprises the following components in parts by weight: 100 parts of POSS graft modified polysiloxane polymer, 20-80 parts of vinyl silicon oil and 0.0002-0.005 part of catalyst. The cage-type vinyl POSS used as a crosslinking agent and hydrogen-containing silicon oil are subjected to silicon-hydrogen addition to be successfully grafted into the organic silicon matrix so as to obtain the POSS graft modified polysiloxane polymer, and the POSS graft modified polysiloxane polymer is mixed and cured to obtain the curing product. The method overcomes the defect of material strength decrease caused by aggregation in the conventional POSS physical blending process. The vinyl POSS modified organic silicon resin can be used for preparing the transparent packaging adhesive with excellent optical and thermodynamic properties; and the light transmittance is up to 95% above, and the refractivity is up to 1.442.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Inorganic glass powder and preparation method for same, as well as conductive paste and preparation method for same

ActiveCN103183474AImprove adhesion strengthLow sintering peak temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon matrixConductive paste

The invention discloses an inorganic glass powder and a preparation method for the same, wherein the component of the inorganic glass powder is MFX-Bi2O3-B2O3-SiO2-ZnO; when X is equal to 2, M is one or more of Be, Mg, Ca, Sr, Ba and Zn; when X is equal to 3, M is one or more of Al, Ga and In; and when X is equal to 4, M is one or more of Ti or Zr. The invention further provides a conductive paste and a preparation method for the same. The inorganic glass powder provided by the invention has good wettability for a metal powder and a silicon matrix; after the conductive paste containing a small amount of the inorganic glass powder is printed onto a monocrystalline silicon solar cell or a polycrystalline silicon solar cell via a silk screen and sintered to form a film, the binding layer of silicon and conductive metals is compact and uniform, the formed aluminium film is good in adhesion force with the silicon matrix, and the formed silver film is high in welding strength with a photovoltaic welding strip and good in appearance; and moreover, the paste is low in sintering peak temperature, low in energy consumption, and high in the obtained cell photoelectric conversion efficiency.

Owner:BYD CO LTD

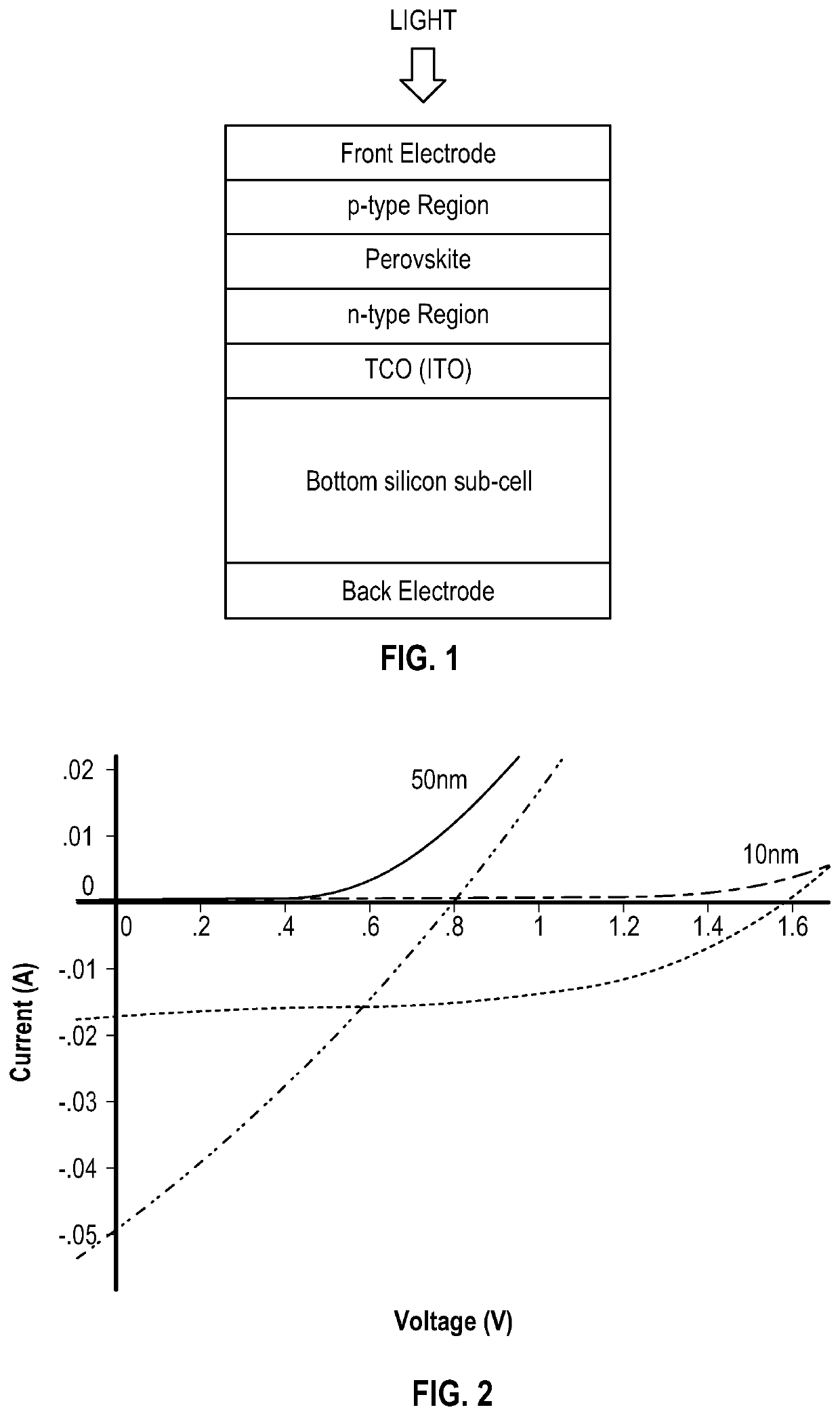

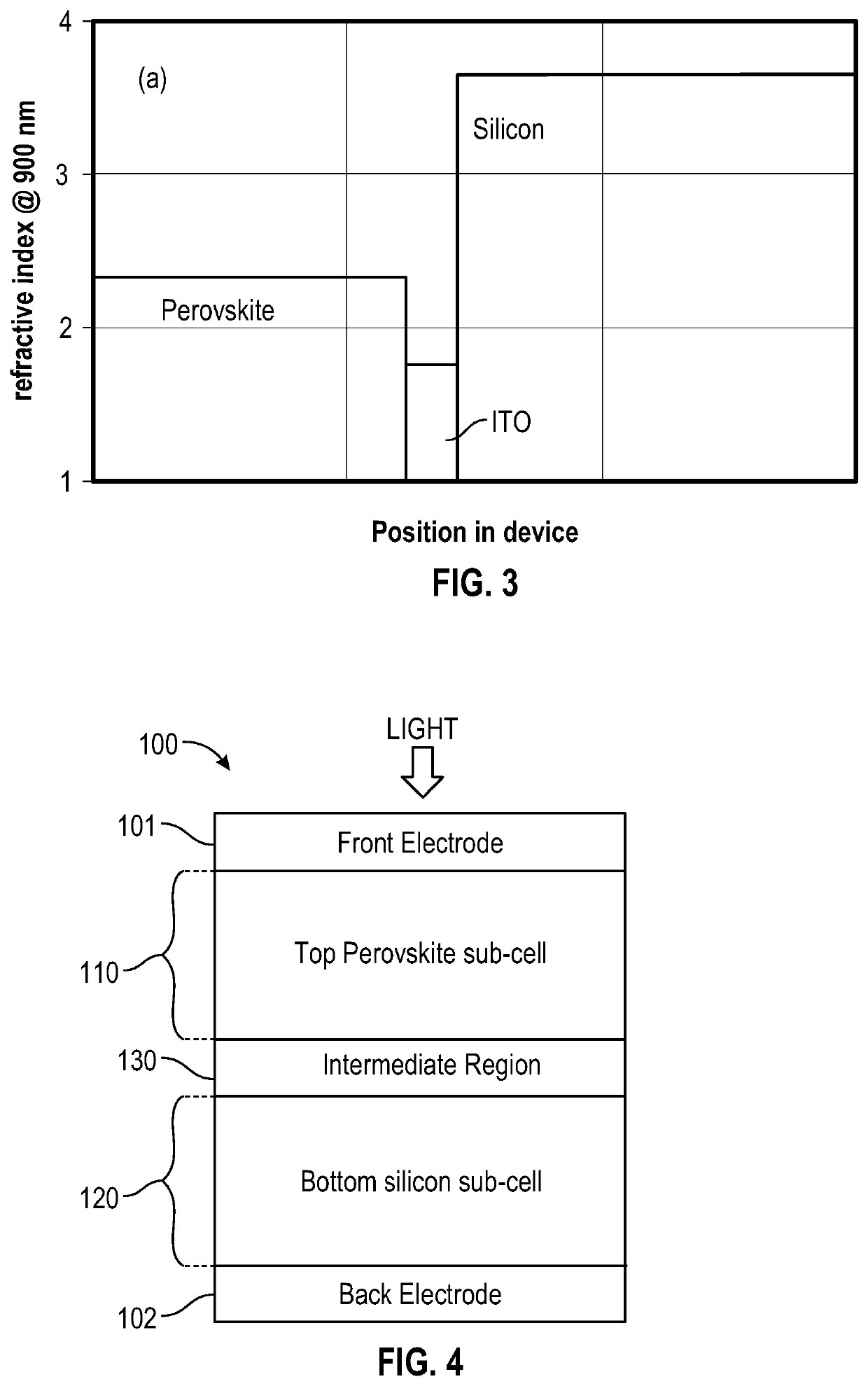

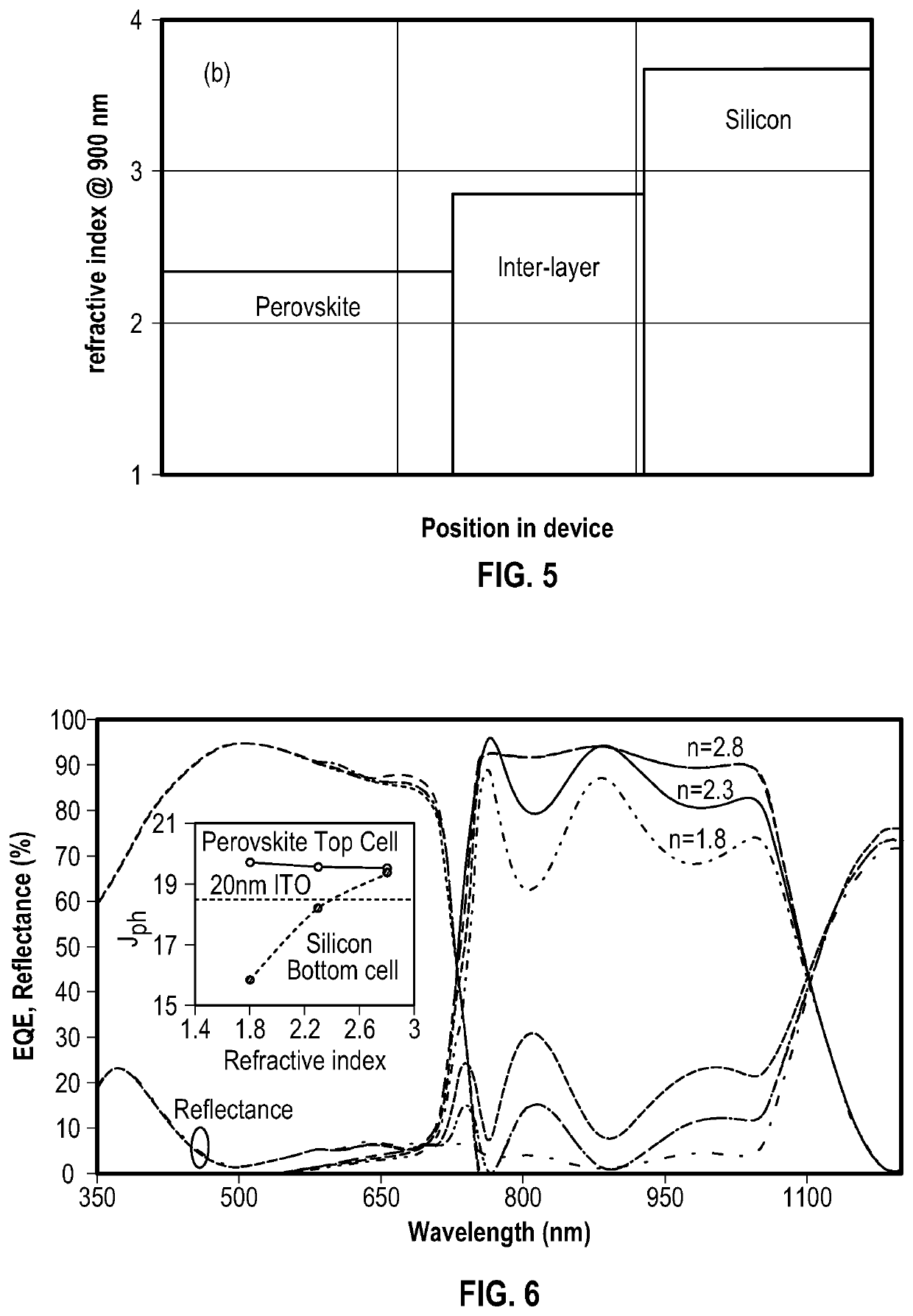

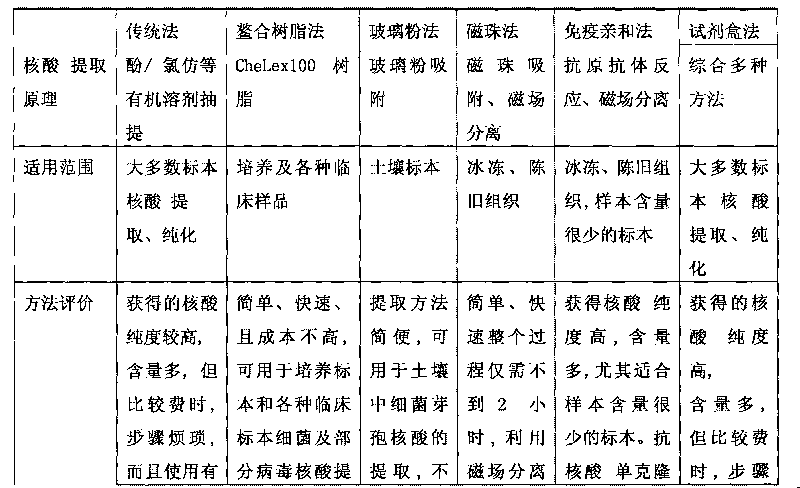

Multijunction photovoltaic device

ActiveUS20200058819A1Reduce reflection lossOvercome lack of conductivitySolid-state devicesSemiconductor/solid-state device manufacturingSilicon matrixSilicon nanocrystals

There is provided a multi junction photovoltaic device comprising a first sub-cell comprising a photoactive region comprising a layer of perovskite material, a second sub-cell comprising a photoactive silicon absorber. and an intermediate region disposed between and connecting the first sub-cell and the second sub-cell. The intermediate region comprises an interconnect layer, the interconnect layer comprising a two-phase material comprising elongate (i.e. filament like) silicon nanocrystals embedded in a silicon oxide matrix.

Owner:OXFORD PHOTOVOLTAICS

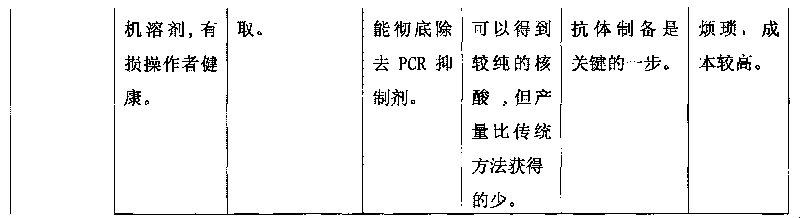

High-efficiency extracting method of food-borne pathogen nucleic acid

The present invention provides a high-efficiency extracting method of food-borne pathogen nucleic acid. A PCR technology has been widely used for the detection of pathogenic microorganisms currently. A first step of the PCR detecting technology is the preparation of template nucleic acid, that is, the extraction of nucleic acid in a sample, which directly affects the result of PCR reaction. For a long time, the processes of extraction and purification of the nucleic acid in a sample consume time, and are fussy all the time, so detection speed is seriously slowed down. Thus, a plurality of scholars searches after the extracting method of various nucleic acids. The high-efficiency extracting method of food-borne pathogen nucleic acid comprises the following steps: bacterial culture solution is centrifuged; buffer solution A is added into centrifugal sediment to be vibrated, and muramidase is added; prolease K is added after incubation; buffer solution B is added to be incubated at the temperature of 65 DEG C for 10 minutes after being vibrated violently to be prepared into cracking solution; and high-quality nucleic acid is collected by an adsorption film of silicon matrix SiO2 material is used for extracting nucleic acid solution. The present invention is applied to the detection of the pathogenic microorganisms.

Owner:INSPECTION & QUARANTINE TECH CENT OF HEILONGJIANG ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF P R C

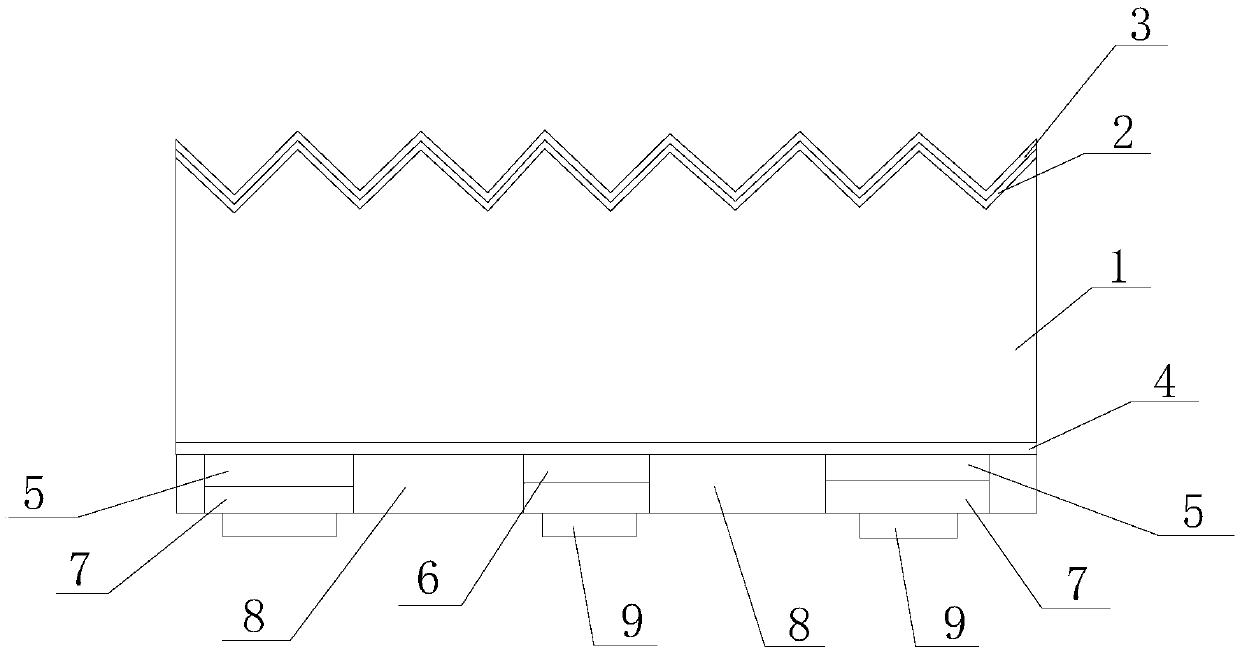

N-type crystalline silicon solar cell structure and preparation method thereof

InactiveCN106098807AImprove conversion efficiencyEasy to prepareFinal product manufacturePhotovoltaic energy generationSilicon matrixThin metal

The invention discloses an N-type crystalline silicon solar cell structure and a preparation method thereof. The cell structure comprises a front electrode, a front anti-reflection film, a front passive film, a P-type emitting electrode, an N-type crystalline silicon matrix, a uniformly or partially doped N+ layer, a back passive film and a back electrode from top to bottom in sequence, wherein the front electrode comprises a partial hanging fine grid line, the partial hanging fine grid line is composed of a thin metal wire connected with a partial metal electrode through a conducting combined material, the partial metal electrode is arranged on the surface of the front anti-reflection film of the N-type cell in a regular pattern, and the partial metal electrode penetrates through the front anti-reflection film and the front passive film to be in good ohmic contact with the P-type emitting electrode. Currents collected on the front face of the cell are led out through a front main grid or an electrode lead. The back electrode is a full back metal electrode or a transparent electrode. According to the cell structure, the contact area of a metal and a silicon matrix is reduced, the composite loss is reduced, the light shading area of the grid line is obviously decreased, and then the conversion efficiency of the cell is improved.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Method for preparing a silica suspension in a vulcanisable silicon matrix to form elastomers

InactiveUS20010034402A1Inexpensive and able to be applied on an industrial scaleEasy to useParticulatesElastomer

The invention concerns the preparation of a silica suspension in a silicon fluid, said suspension being used to produce silicon vulcanisable by polyaddition (RTV elastomers). The problem which the invention aims to solve is that of finding a technical compromise between the rheological and mechanical properties of the final RTV. The invention solves the problem by providing a method for preparing a silica suspension treated with hexamethyldisilazane (HMDZ) in a silicon fluid with siloxyl Si-Vinyl function, characterised in that it consists essentially in introducing HMDZ in the preparation medium, before and / or substantially while bringing at least part of the silicon fluid prepared with at least part of the particulate filler used, said introduction being carried out once or several times for a HMDZ fraction corresponding to a proportion not more than 8% by dry weight with respect to the total silica charge and after bringing together the POS and the filler.

Owner:BLUESTAR SILICONES FRANCE SAS

A silicon matrix composite material for lithium ion battery and a preparation method thereof

ActiveCN108987717AImprove cycle stabilityIncrease capacityNegative electrodesSecondary cellsSilicon matrixCarbon composites

The invention relates to a silicon-carbon composite material for lithium ion battery and a preparation method thereof, which is characterized in that the structure of the silicon-carbon composite material is a core-shell like structure, and the core-shell like structure comprises a core and a shell layer wrapped outside the core; Core includes 70%-95% silicon, 4%-20% titanium (Ti) and 5%-15% niobium (Nb), silicon is the inner layer of the core, and titanium (Ti) and niobium (Nb) are dispersed on the surface of the inner layer; The shell consists of graphene and carbon nanotubes, and the mass ratio of the shell to the core is 11%-42% by mas; The roller rolling process was used in the preparation process. The material provided by the inventionhas the characteristics of high cycle stability and high capacity, and can solve the volume effect of silicon-carbon negative electrode material and the bottleneck problem of low initial discharge efficiency.

Owner:KAIFENG UNIV

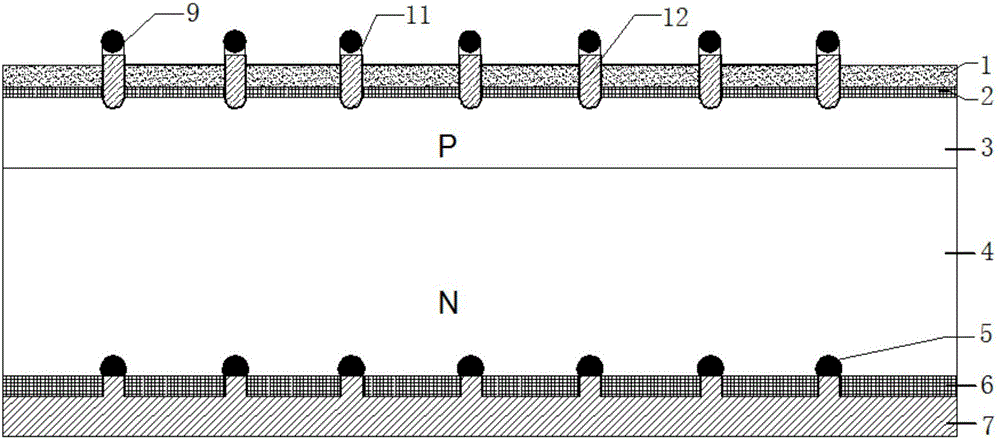

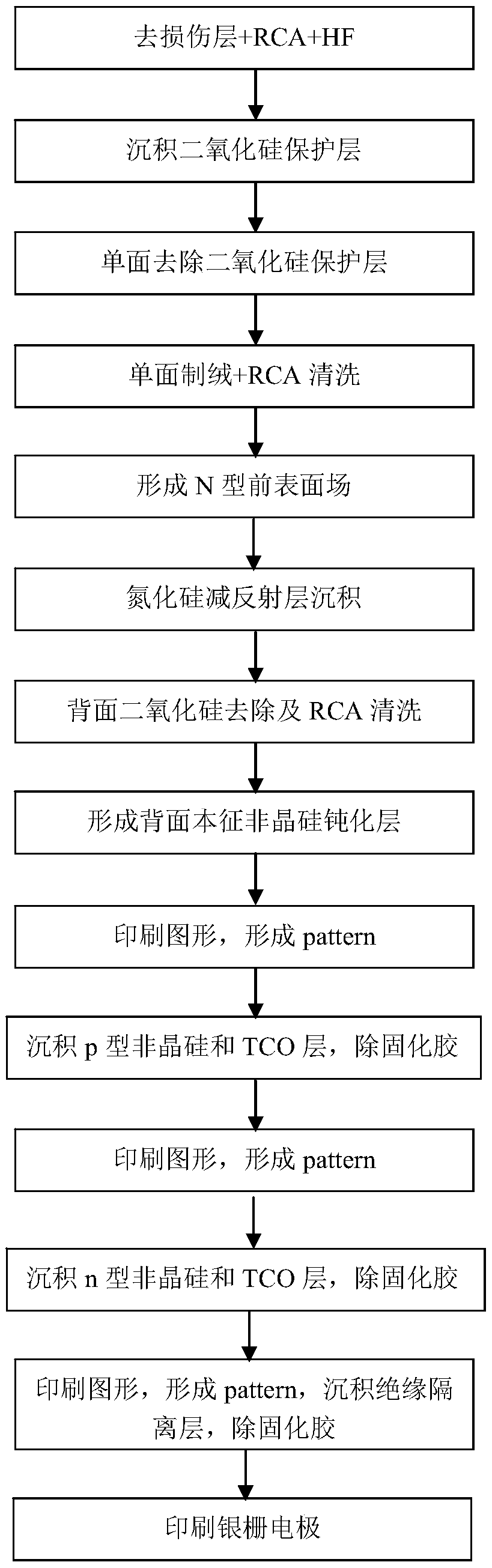

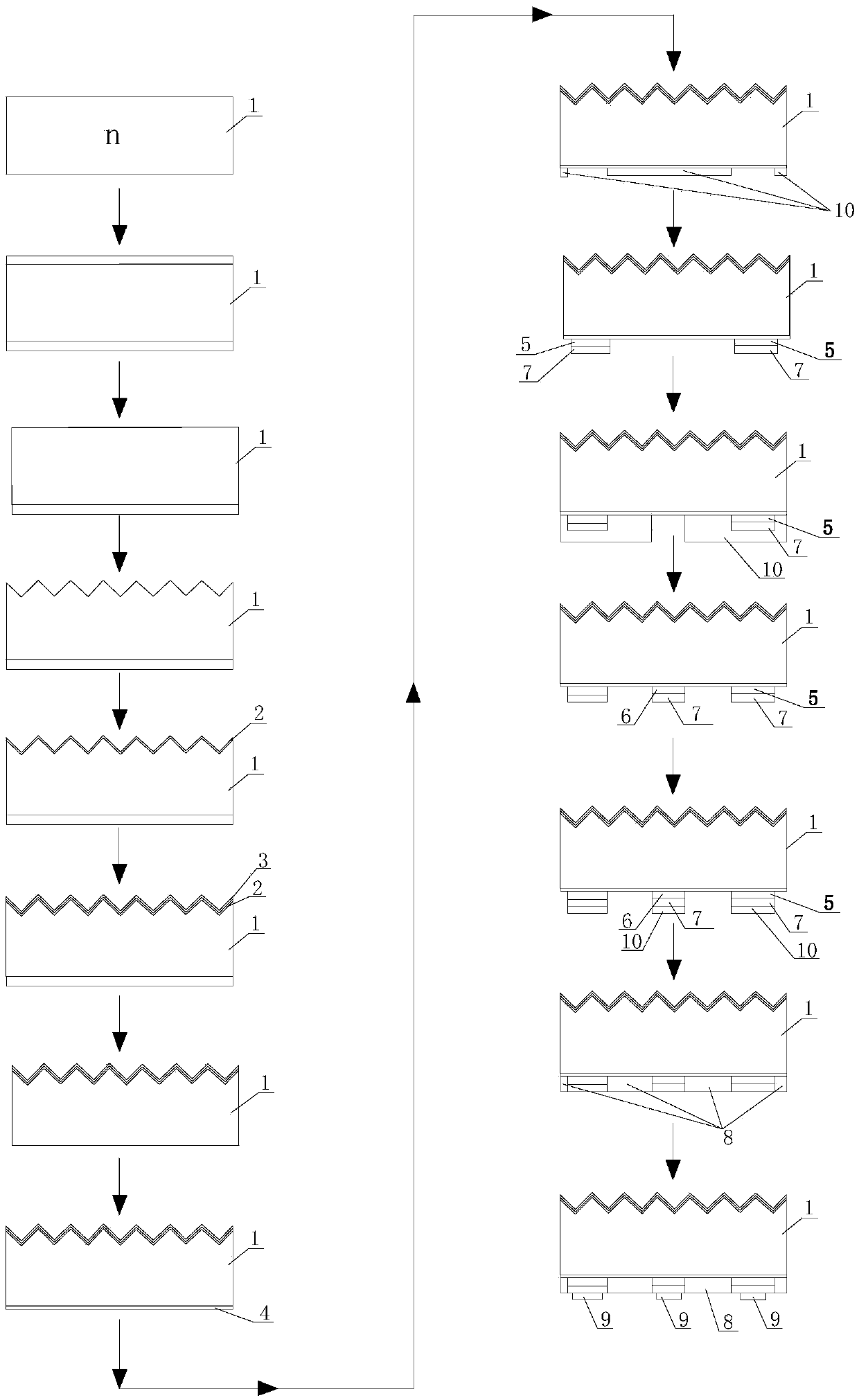

Back-contact heterojunction solar cell and preparation method thereof

ActiveCN105514206AIncrease the open circuit voltageIncrease short circuit currentFinal product manufacturePhotovoltaic energy generationSilicon matrixHeterojunction

The invention discloses a full-back type heterojunction solar cell. The full-back type heterojunction solar cell comprises a silicon matrix layer and is characterized in that a front N-type surface field and an antireflection layer are sequentially arranged on the front surface of the silicon matrix layer, an intrinsic amorphous silicon passivation layer is arranged on the back surface of the silicon matrix layer, P-type amorphous silicon layers and N-type amorphous silicon layers are arranged on the intrinsic amorphous silicon passivation layer in a spaced manner, transparent conductive film layers are separately arranged on the P-type amorphous silicon layers and the N-type amorphous silicon layers, electrodes are arranged on the transparent conductive film layers, each P-type amorphous silicon layer has the thickness of 5-20nm and the width of 100-1,000 microns, each N-type amorphous silicon layer has the thickness of 5-20nm and the width of 100-1,000 microns, the center point of adjacent P-type amorphous silicon layers is spaced from the center point of the corresponding N-type amorphous silicon layer by 150-3,000 microns, and insulation isolating layers are arranged between the P-type amorphous silicon layers and the N-type amorphous silicon layers. The invention also discloses a preparation method of the full-back type heterojunction solar cell. According to the back-contact heterojunction solar cell and the preparation method thereof, the generation of leakage current can be prevented, and the open-circuit voltage of the solar cell is boosted.

Owner:TRINASOLAR CO LTD

Manufacturing method of multilayer nanowire structure

ActiveCN103295878AInconsistent crystal orientationSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon matrixNanowire

The invention provides a manufacturing method of a multilayer nanowire structure. The manufacturing method comprises the following steps: a. providing a first silicon matrix and forming a first oxide layer on the first silicon matrix, b. providing a second silicon matrix, injecting hydrogen ions into the second silicon matrix, forming a position mark on the second silicon matrix, c. cutting the first silicon matrix intelligently and forming an insulator upper silicon structure on the first silicon matrix, d. forming a second oxide layer on the insulator upper silicon structure, e. repeating step b and step d, forming a multilayer insulator upper silicon structure on the first silicon matrix, f. defining the graph of the multilayer nanowire structure, g. etching the multilayer isolator upper silicon structure to form a multilayer nanowire structure on the first silicon matrix, and h. removing the second oxide layer under the nanowires in the multilayer nanowire structure. By means of the manufacturing method of the multilayer nanowire structure, the crystal orientations of the nanowires are different.

Owner:SEMICON MFG INT (SHANGHAI) CORP

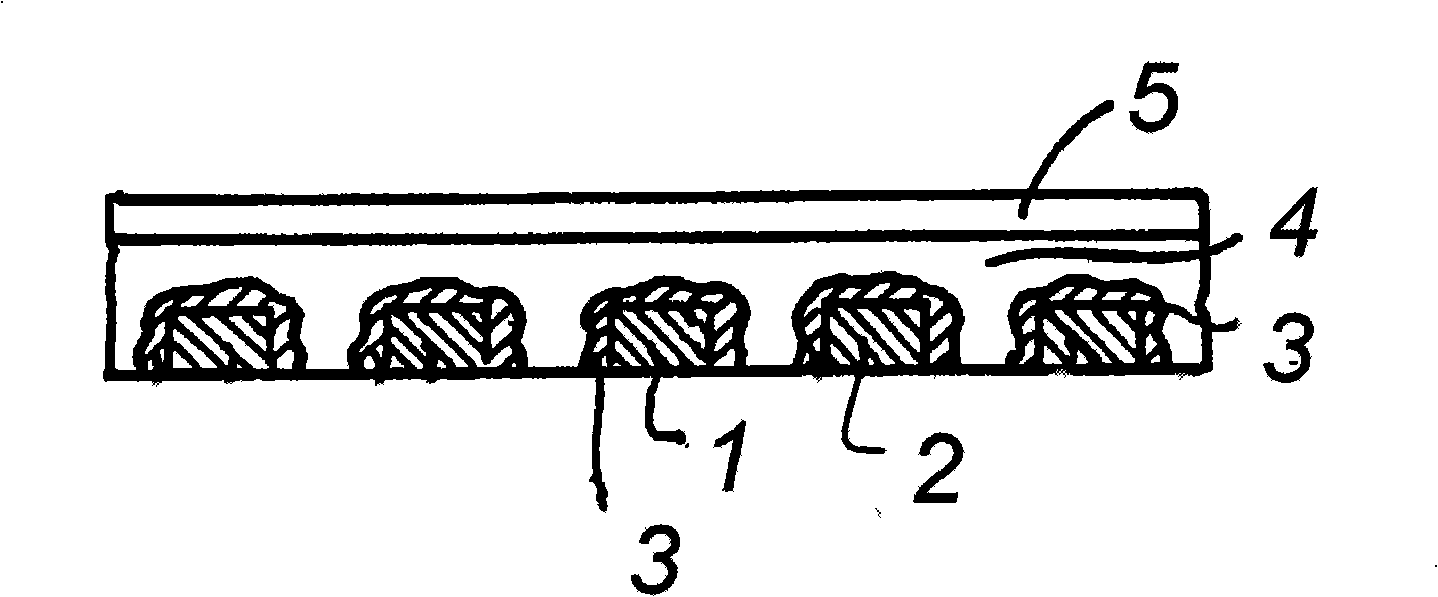

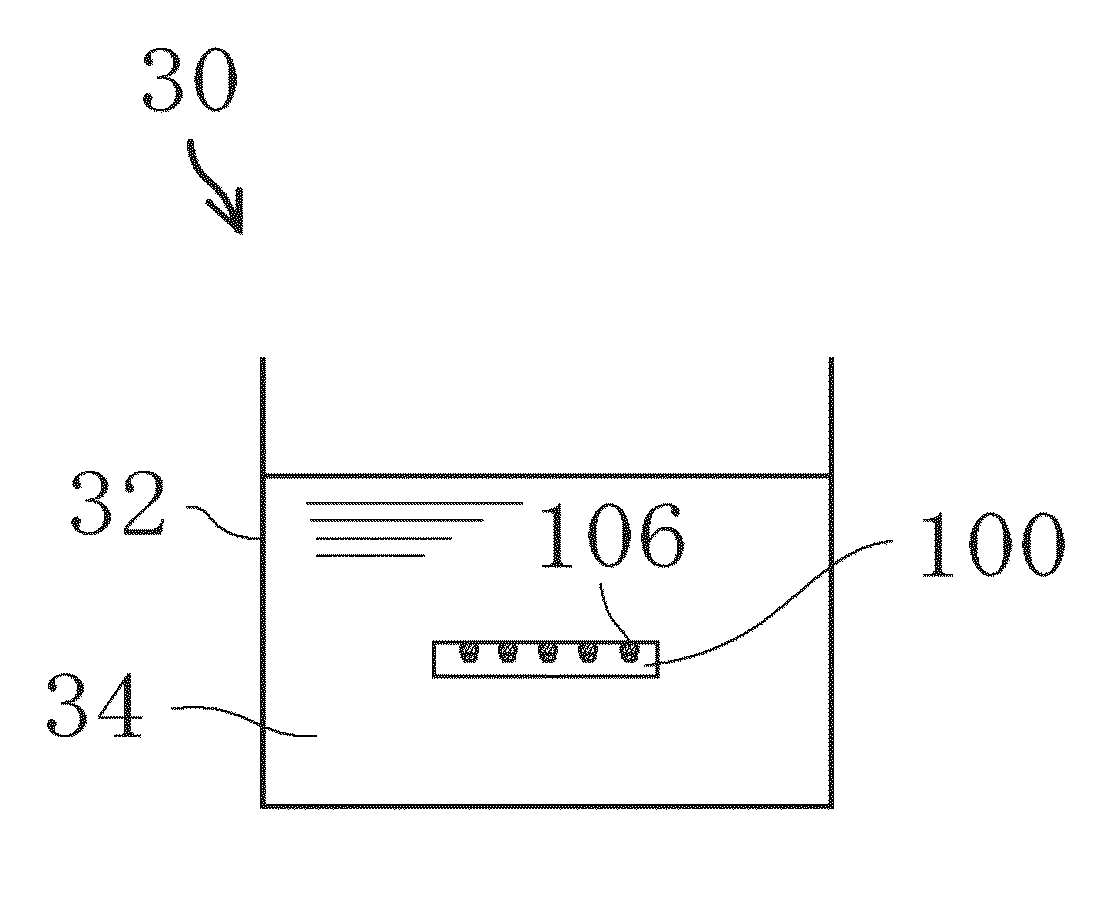

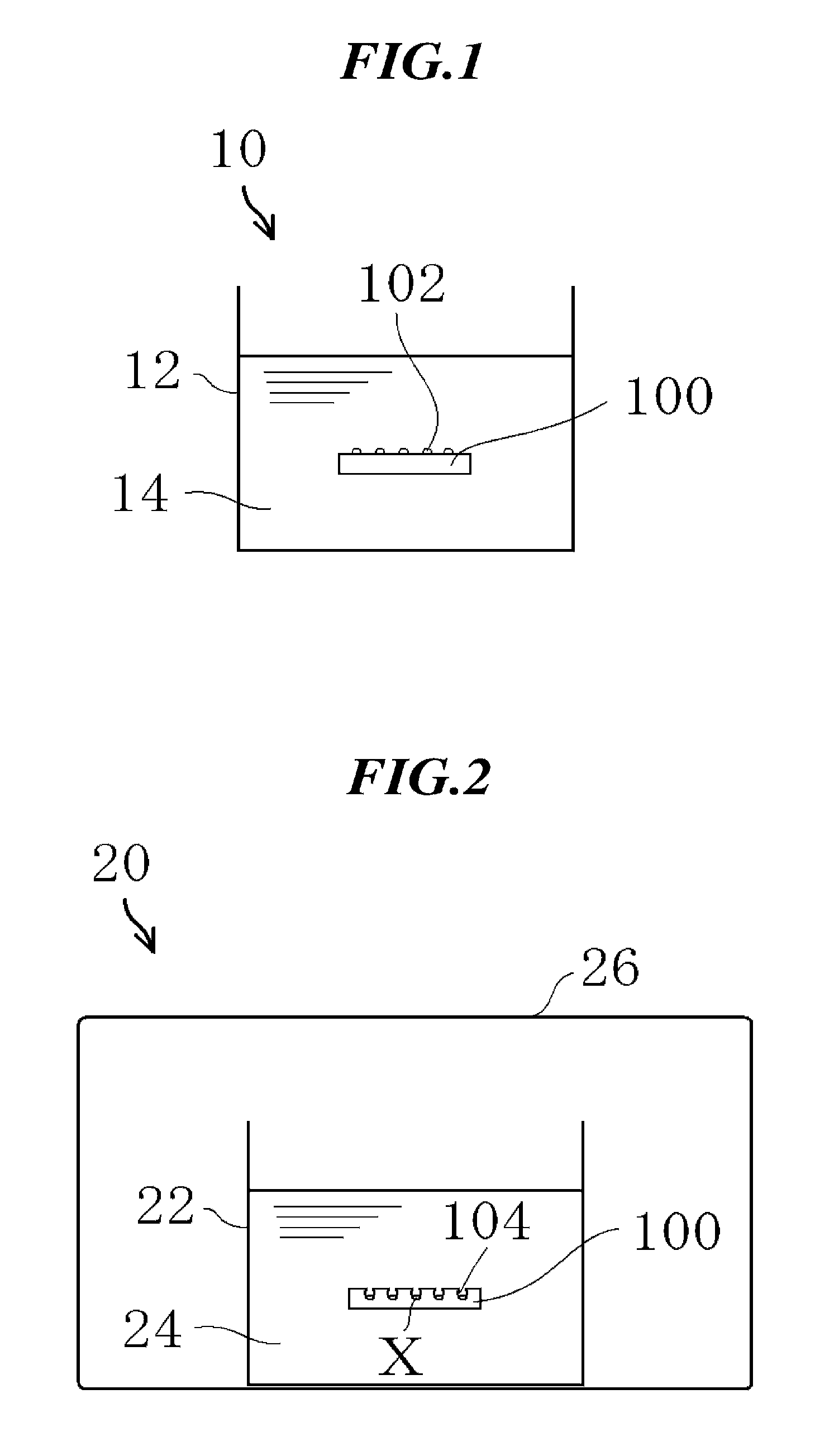

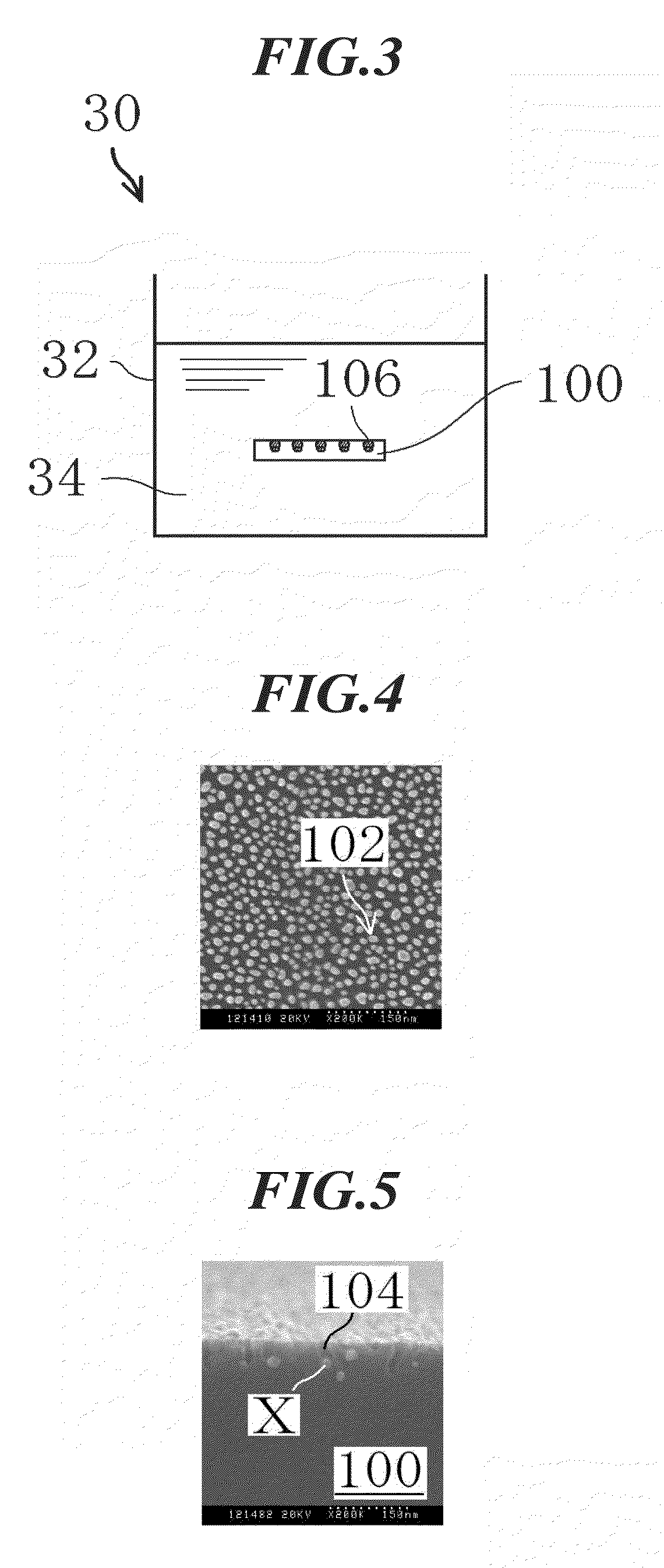

Composite material comprising silicon matrix and method of producing the same

InactiveUS20120321798A1Material nanotechnologyMagnetic layer production by platingSilicon matrixSurface layer

Proposed are a composite material, wherein non-penetrating pores that are formed in a silicon surface layer are filled up with a metal or the like without leaving any voids by using the plating technique, and a method of producing the composite material. A composite material, which has been packed at a high accuracy, or in other words, in which little voids are left, can be obtained by filling up non-penetrating pores that are formed from a silicon surface (100) substantially with a second metal or an alloy of the second metal (106) with the use of the autocatalytic electroless plating technique wherein a first metal located at the bottom of the non-penetrating pores as described above serves as the starting point.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com