Manufacturing method for crystalline silicon solar MWT (metallization wrap-through) cell and manufactured cell

A manufacturing method and solar energy technology, applied in the field of solar cells, can solve the problem that it is difficult to achieve high aspect ratio in one printing, and achieve the effects of reducing optical loss, increasing short-circuit current, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

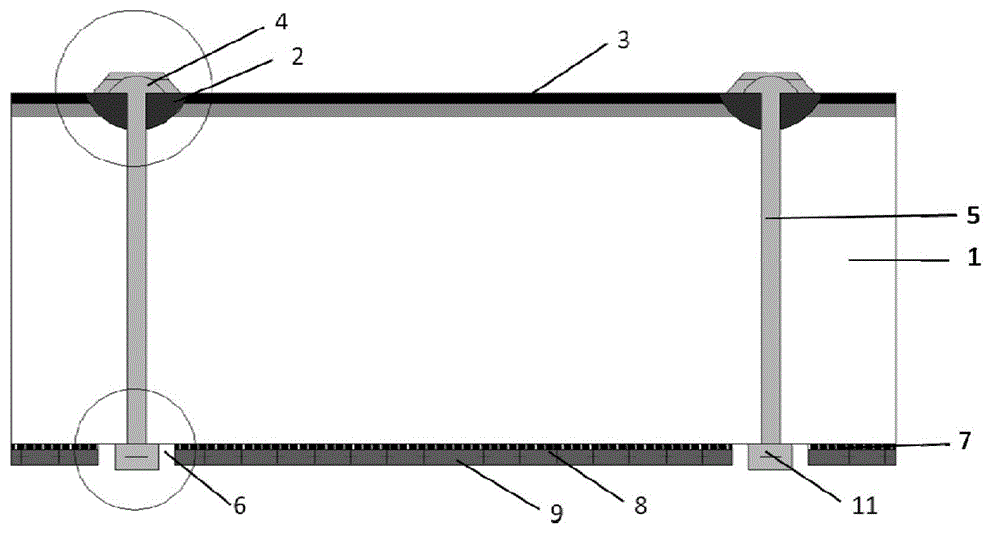

[0035] This embodiment is a method for manufacturing a crystalline silicon solar MWT cell, comprising the following steps:

[0036] (a) Using a P-type single crystal or polycrystalline silicon substrate 1, using a laser to make conductive through holes 5 on the crystalline silicon substrate, the cross-sectional shape is cylindrical, the number is 4×4, and the hole size is 50-600 μm;

[0037] (b) Wet texturing of perforated crystalline silicon substrates using chemical solutions;

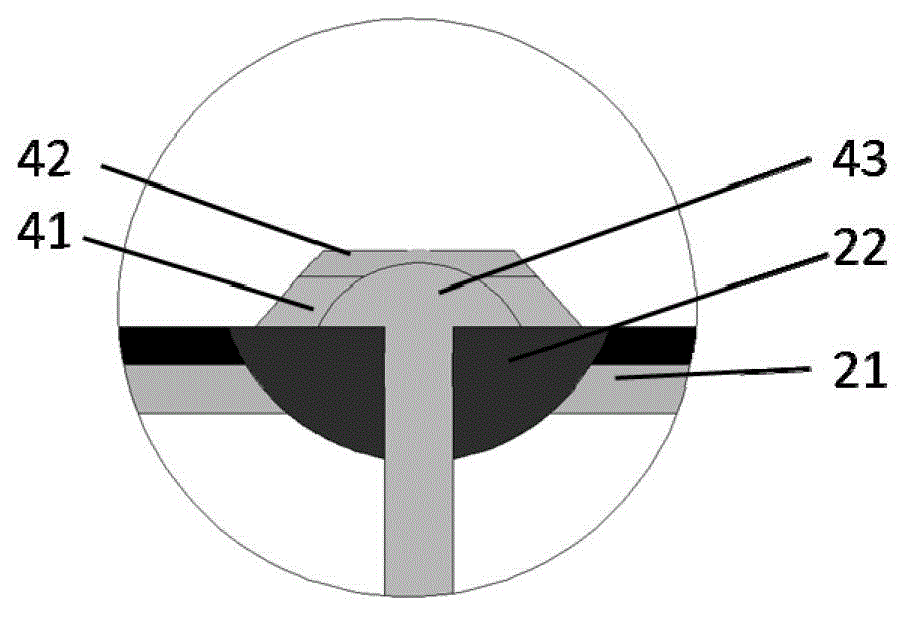

[0038] (c) Use a polyester screen to print the light-receiving surface of the perforated crystalline silicon substrate with phosphor paste in the grid line area, form a heavily doped area 22 in the printed grid line area, and form a lightly doped area in the unprinted non-grid line area In area 21, the printing line width of phosphorous paste is 20-500 μm;

[0039] (d) Phosphorus diffusion using a liquid phosphorus source;

[0040] (e) Etching the edge of the silicon substrate and performing de-PS...

Embodiment 2

[0048]The difference between Embodiment 2 and Embodiment 1 is that the printing silver paste in step (h) adopts a secondary printing technology, specifically: printing silver paste on the heavily doped region 22 obtained in step (c) to form The light-receiving surface electrode grid line can form a selective emitter structure 2; specifically, the fine grid 41 is printed for the first time in the heavily doped region 22, and the second printing is performed on the first printed fine grid 41 area after drying. Print the fine grid 42 for the second time, and print the front connection area 43 of the fine grid and the conductive hole at the same time; or print the fine grid 41 and the front connection area 43 of the grid line and the conductive hole for the first time in the heavily doped region 22, and then print the first time after drying. Print the fine grid 41 area for the second time to print the fine grid 42, thereby forming the secondary printing structure 4, and a solar ce...

Embodiment 3

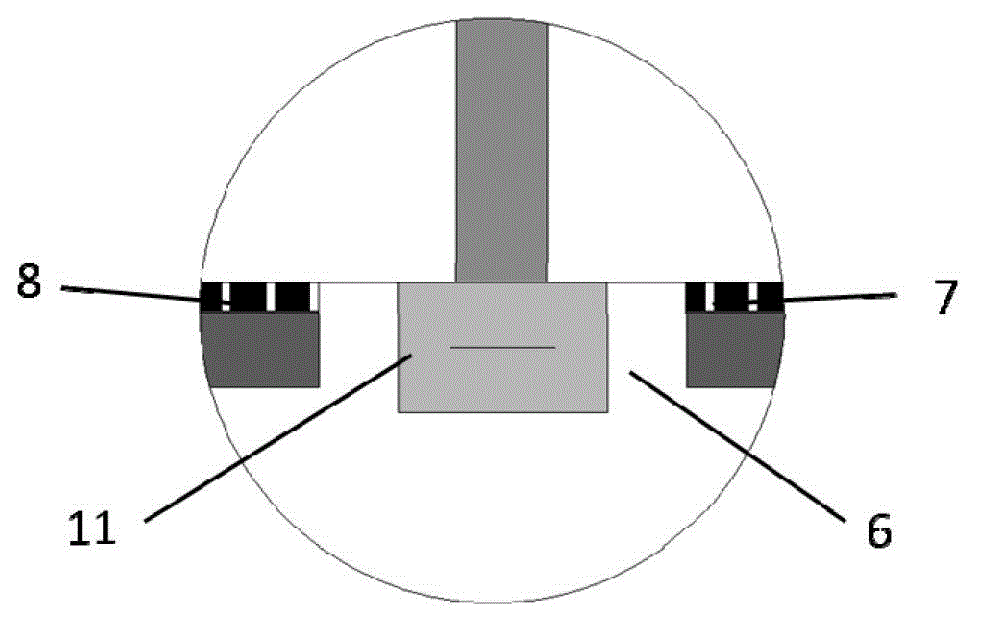

[0051] The difference between Embodiment 3 and Embodiment 1 is that a back passivation process is added between step (e) and step (g), specifically: aluminum oxide and silicon nitride are plated on the backlight surface for back passivation. Passivation, the passivation film 8 on the backlight surface is one or more of silicon nitride film, silicon oxide film and aluminum oxide film, the thickness of the passivation film 8 is 1-100nm; Utilize the laser to engrave the back passivation layer Groove, the width of the rear passivation layer groove 7 is 0.1-1000 μm;

[0052] Such as Figure 1~4 As shown, the crystalline silicon solar MWT cell obtained by the manufacturing method in Example 3 has a structure that the electrode grid line on the light-receiving surface is a selective emission level structure 2, and there is a back passivation layer on the back side, and the back passivation layer is formed by the back passivation layer. The chemical film 8 and the rear passivation la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com