Patents

Literature

200results about How to "Reduce optical loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

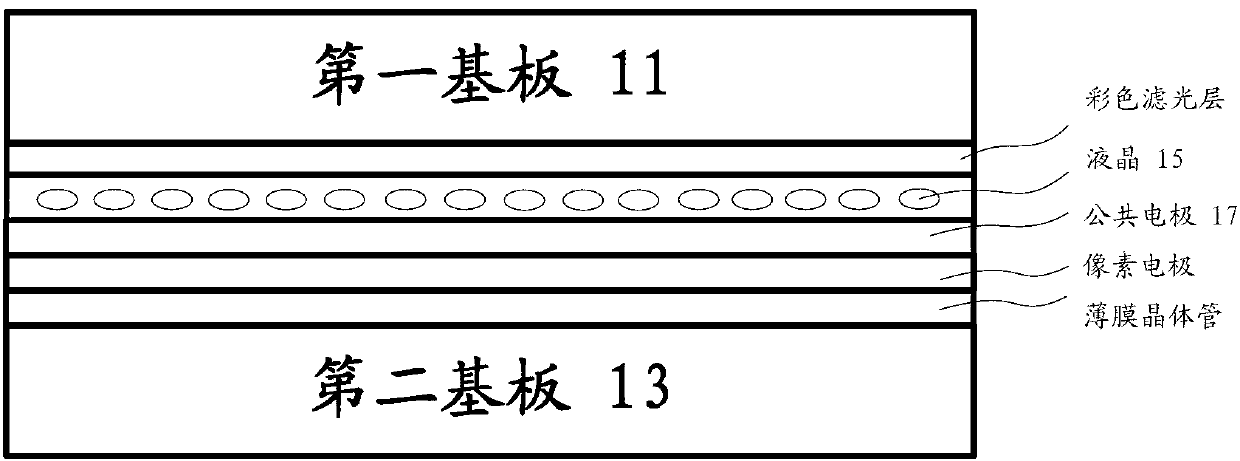

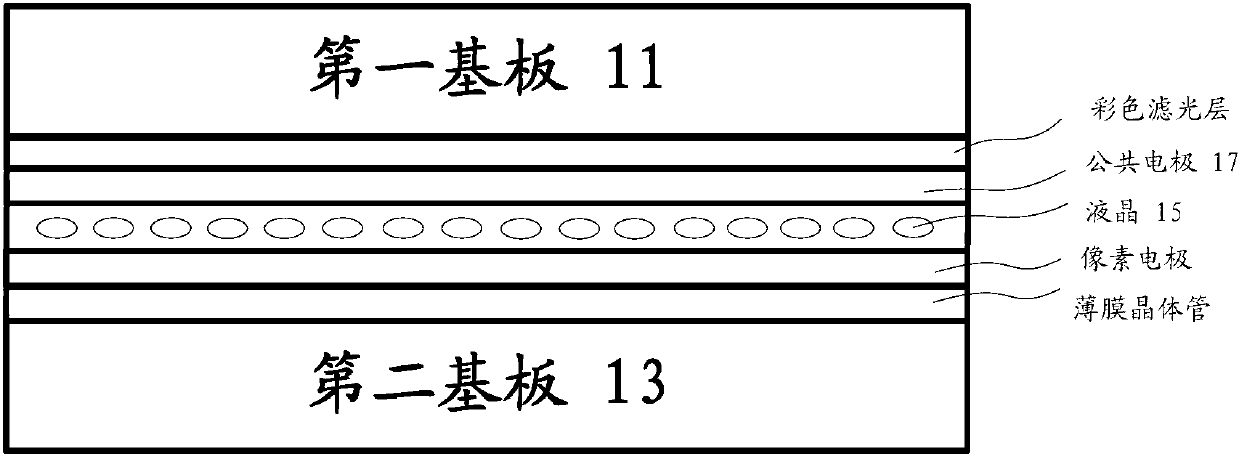

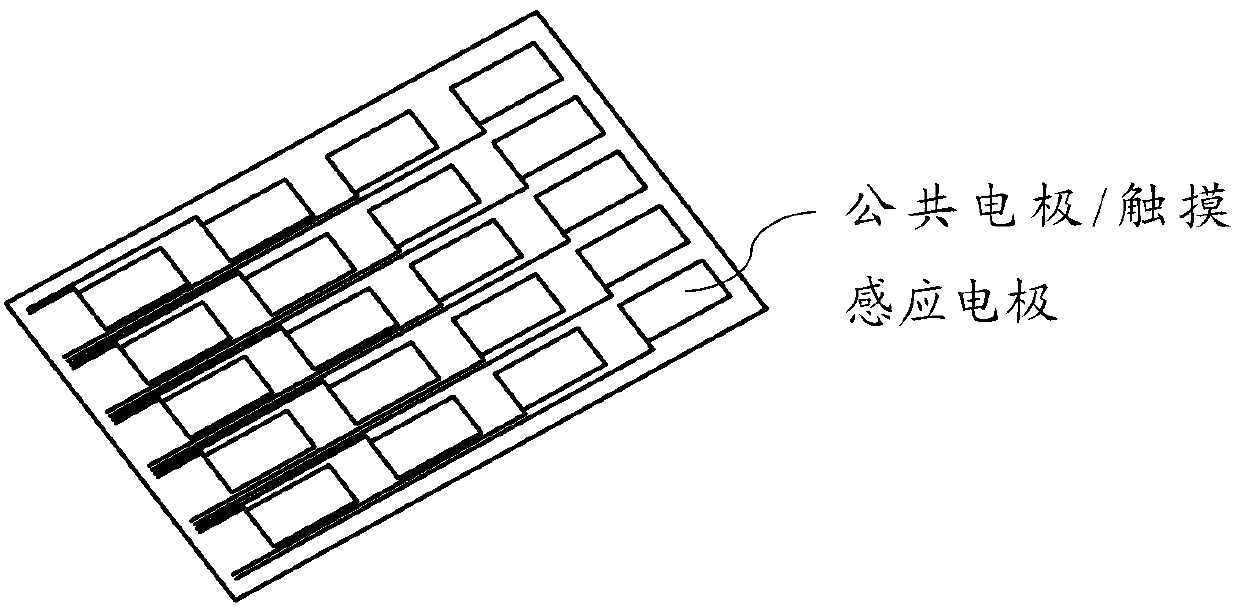

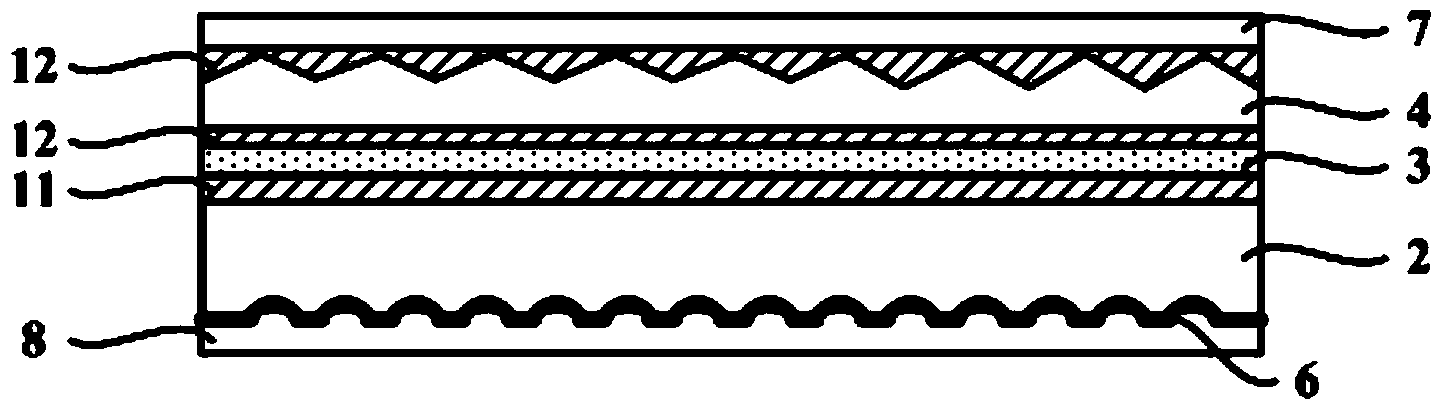

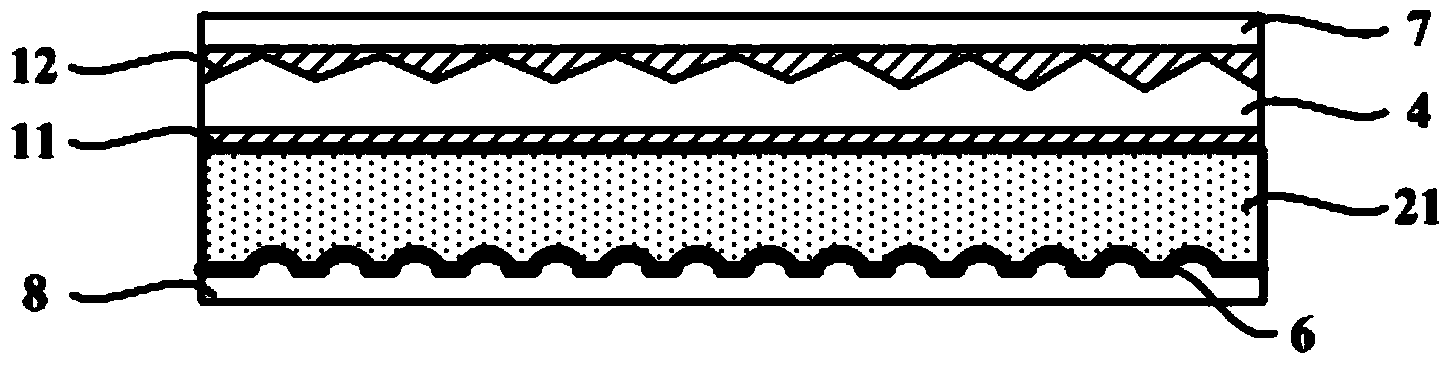

Touch display device

InactiveCN103279245AReduce optical lossReduce thicknessStatic indicating devicesNon-linear opticsTouch SensesDisplay device

An embodiment of the invention discloses a touch display device which comprises a displaying touch screen and a displaying touch control circuit. The displaying touch screen comprises a first substrate, a second substrate, a liquid crystal layer and a plurality of pixel units and further comprises a plurality of public electrodes, wherein the liquid crystal layer is arranged between the first substrate and the second substrate, and the plurality of public electrodes are distributed to form a two-dimensional array. The displaying touch control circuit comprises a displaying control circuit and a touch control circuit. The displaying touch control circuit is connected with the plurality of public electrodes through leads in the following modes: in the displaying stage, the plurality of public electrodes are connected onto a public level supplied to the displaying control circuit; in the touch sensing stage, each of the plurality of public electrodes are connected onto the touch control circuit respectively to serve as touch sensing electrodes. By means of the touch display device, the thickness and the weight of the touch display screen can be reduced, optical loss is decreased, and noises are lowered.

Owner:FOCALTECH ELECTRONICS

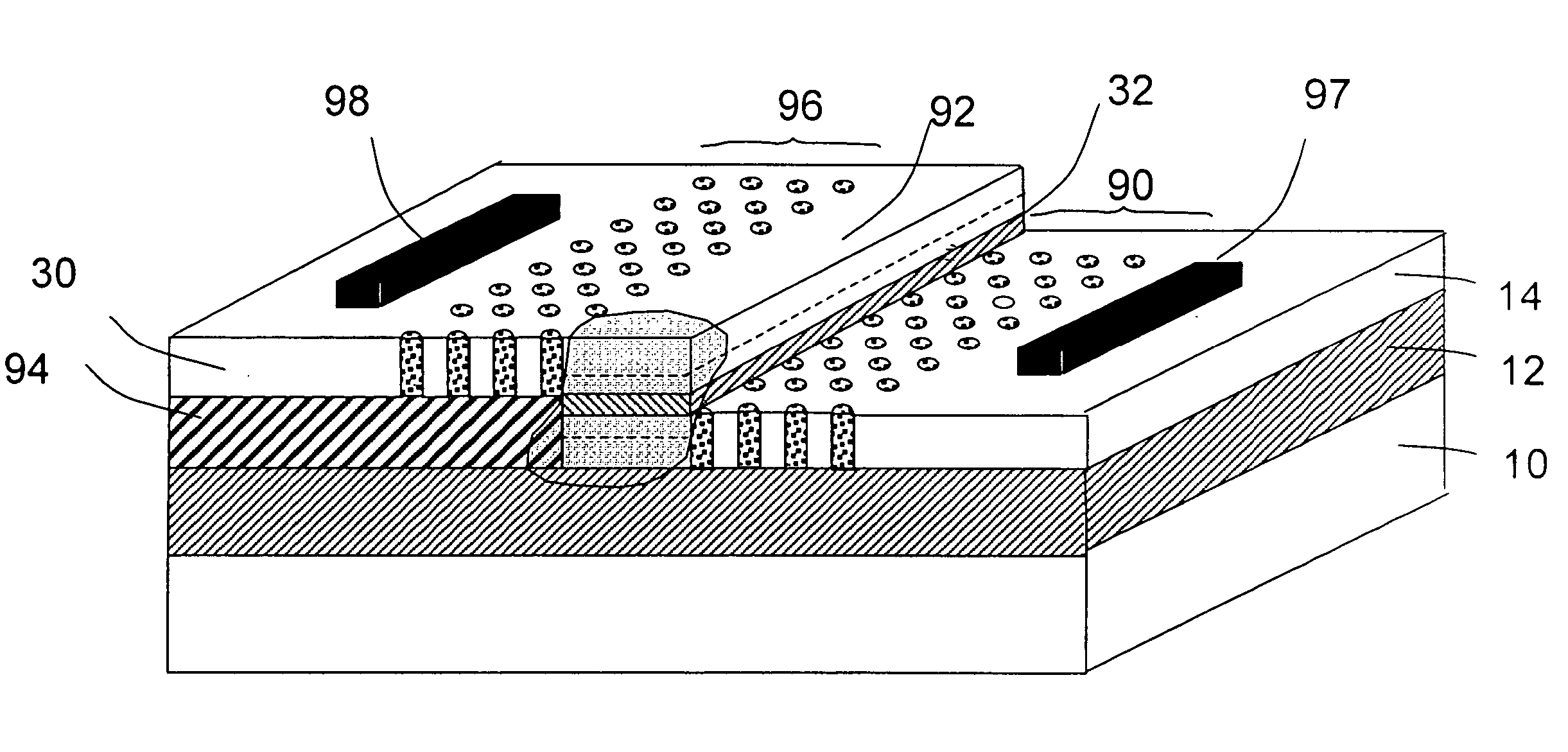

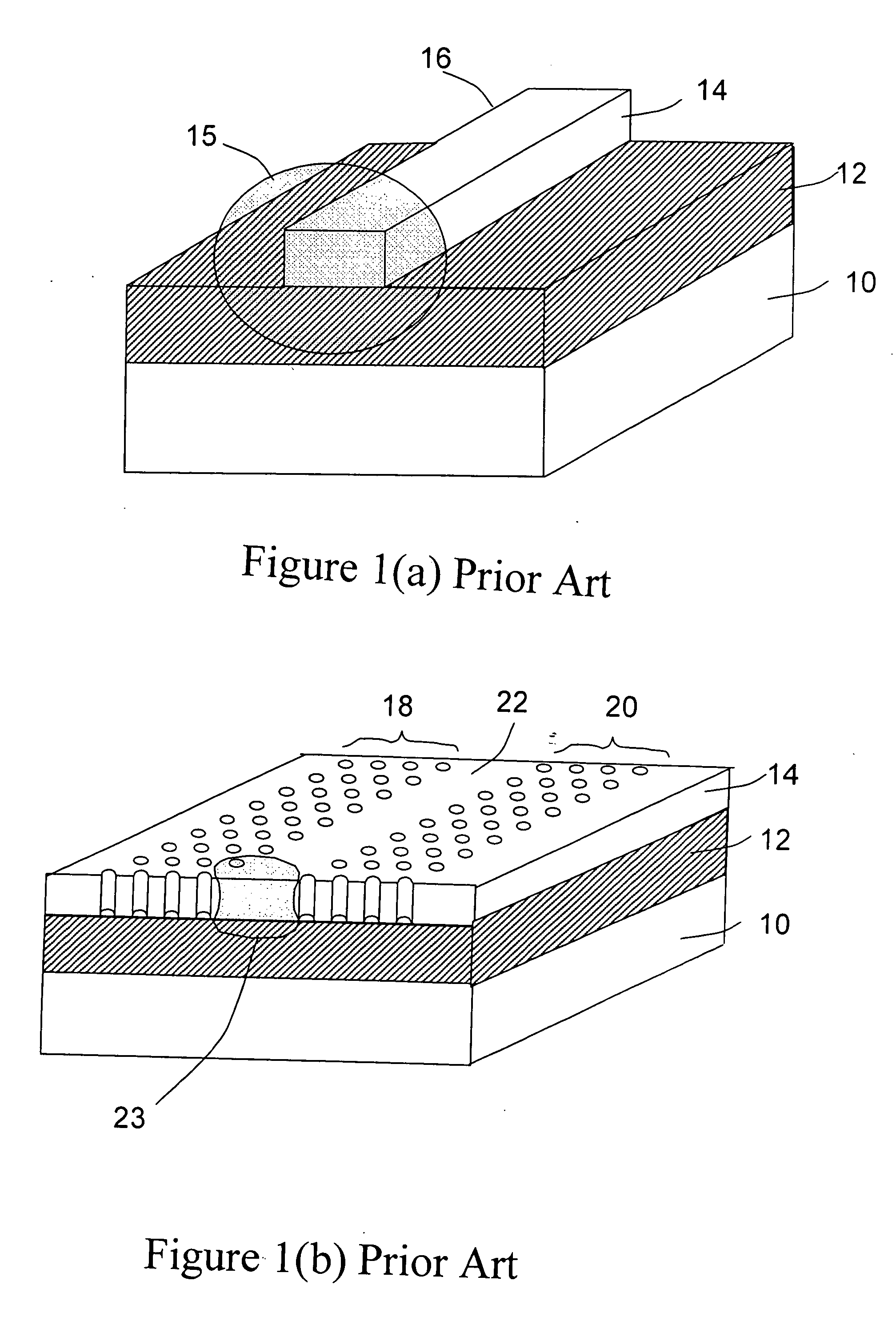

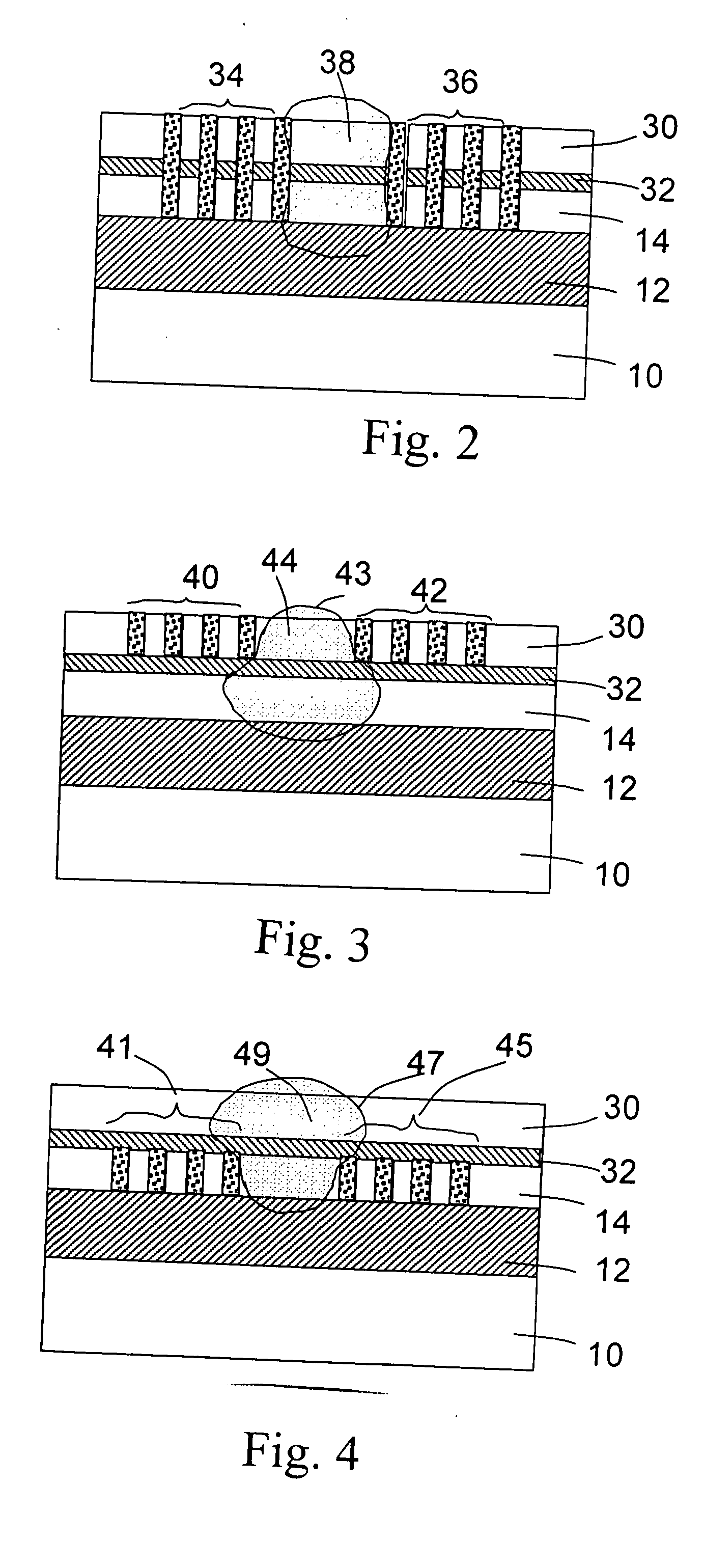

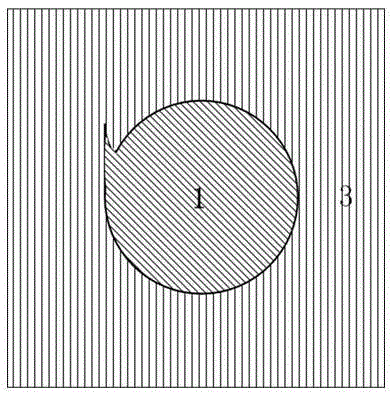

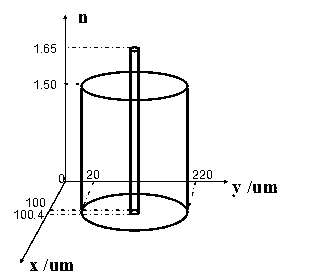

SOI-based photonic bandgap devices

ActiveUS20050179986A1Reduce optical lossImprove speedCoupling light guidesOptical waveguide light guideCapacitancePhotonic bandgap

An SOI-based photonic bandgap (PBG) electro-optic device utilizes a patterned PBG structure to define a two-dimensional waveguide within an active waveguiding region of the SOI electro-optic device. The inclusion of the PBG columnar arrays within the SOI structure results in providing extremely tight lateral confinement of the optical mode within the waveguiding structure, thus significantly reducing the optical loss. By virtue of including the PBG structure, the associated electrical contacts may be placed in closer proximity to the active region without affecting the optical performance, thus increasing the switching speed of the electro-optic device. The overall device size, capacitance and resistance are also reduced as a consequence of using PBGs for lateral mode confinement.

Owner:CISCO TECH INC

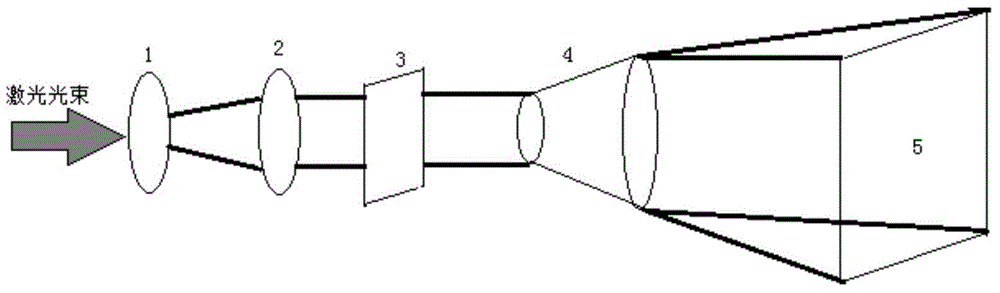

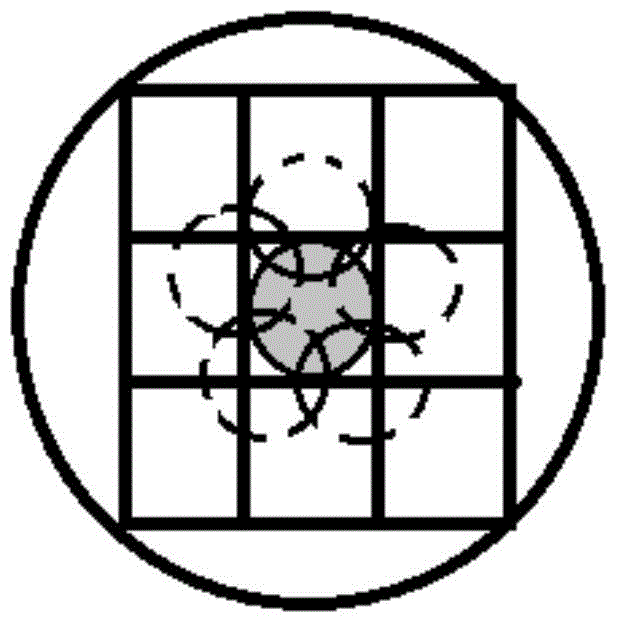

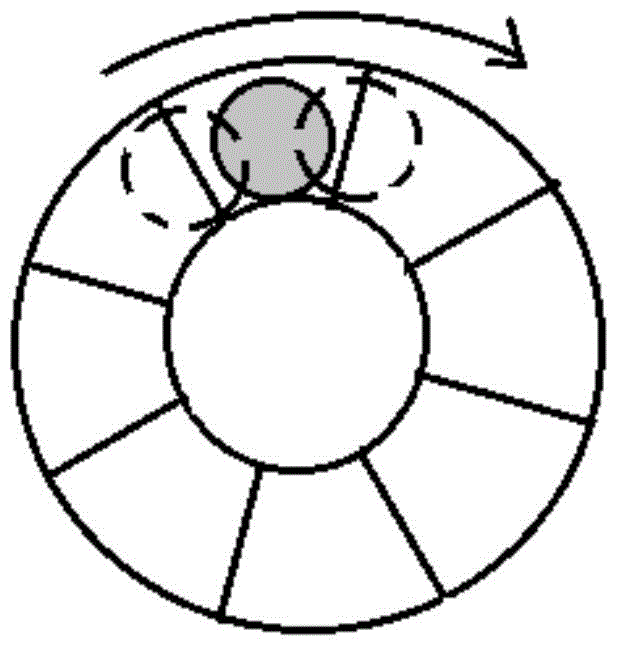

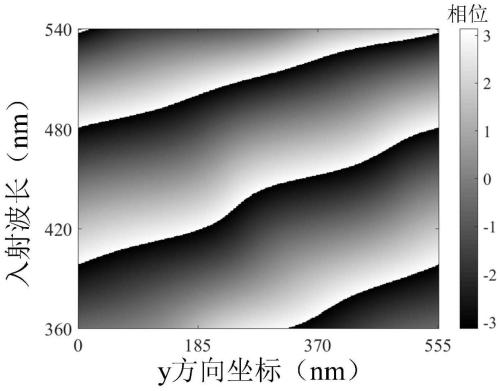

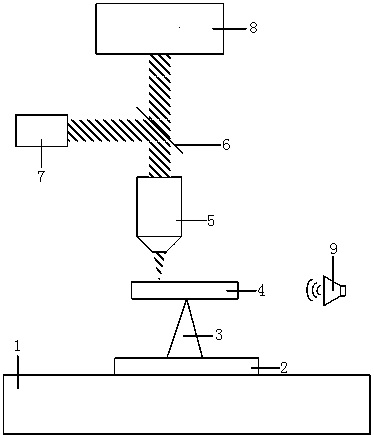

Device and method being capable of achieving light beam shaping dodging and speckle eliminating at the same time

InactiveCN104965307AImprove light energy utilizationReduce optical lossOptical elementsLight energyLight beam

The invention relates to a device and a method being capable of achieving light beam shaping dodging and speckle eliminating at the same time. The device comprises a driving device and a phase plate. The phase plate has a phase-type diffraction / scattering microstructure. The phase plate comprises a plurality of sub-regions. The phase values corresponding to the sub-regions are distributed randomly. The phase plate is driven by the driving device to rotate or shake on the plane. The device capable of achieving light beam shaping dodging and speckle eliminating at the same time integrates speckle eliminating and laser shaping on one device, thus laser beam shaping and speckle inhibition and elimination can be carried out at the same time, optical loss is reduced obviously, the light energy utilization rate of laser is raised, energy loss is lowered, and imaging is clear.

Owner:SHANDONG UNIV

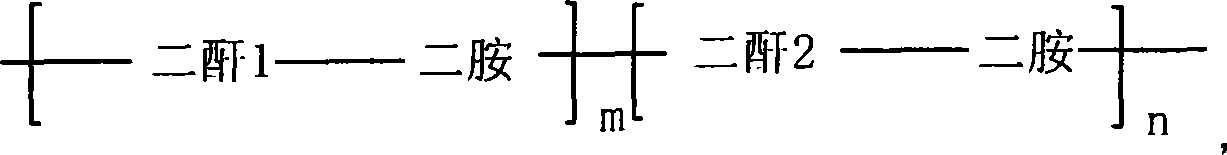

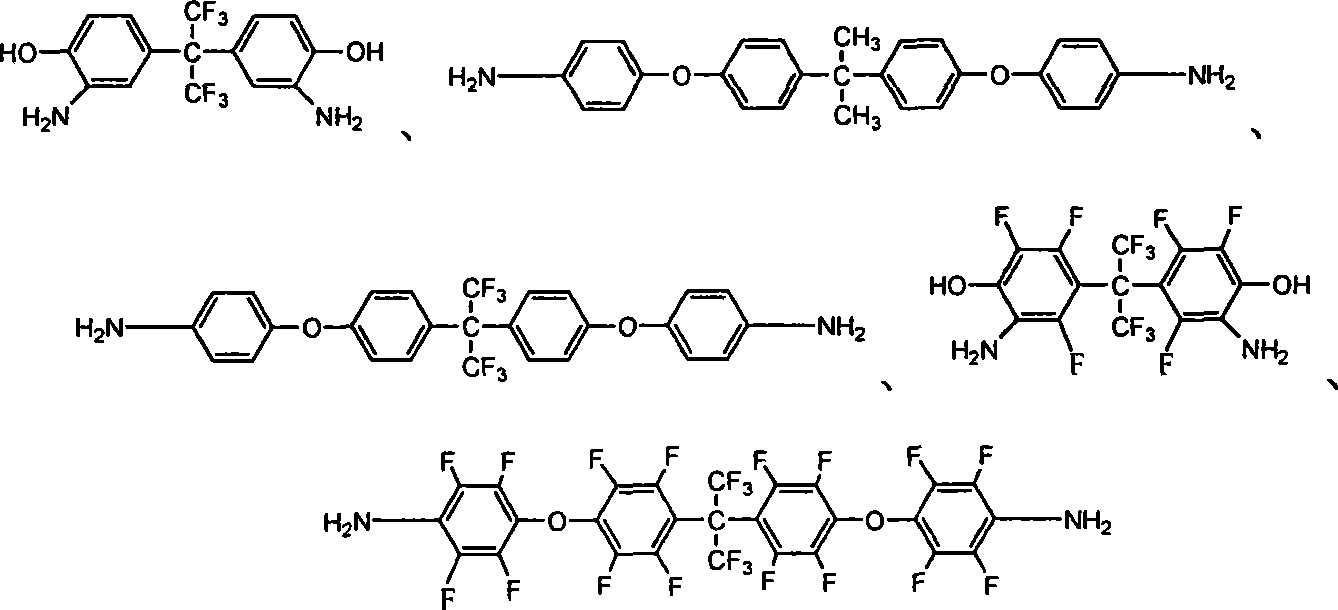

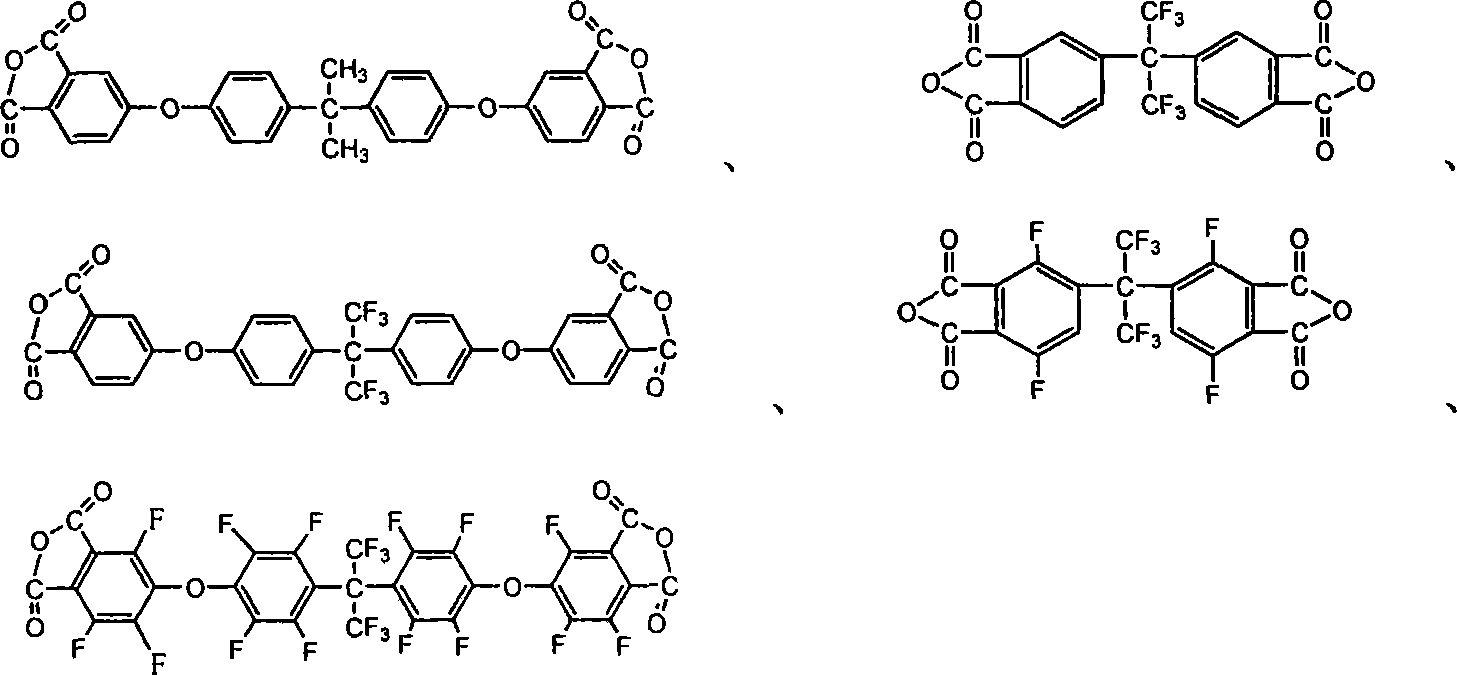

Fluorine-contained polyimide optical waveguide material and method for producing the same

InactiveCN101246222AImprove solubilityEasy to processOptical waveguide light guideRefractive indexOptical communication

The invention provides a fluorine-containing polyimide optical waveguide material and the preparing method thereof relating to the integrating polymer material preparing method in optical device, which can be applied in waveguide optics device, the material is obtained from condensation and copolymerization of three monomers, that is the fluorine-containing polyimide is condensed and copolymerized from two diamine monomers and one dianlydride monomer or from two diamine monomers and one dianlydride monomer, after purification, the fluorine-containing polyimide n-methyl-2-pyrrolidone solution is obtained, and is then dropped on center of clean substrate for spin coating to form film, and desiccation and curing. The glass transition temperature of the material is above 200 DEG C, in the field of optical communication on 1550nm the optical loss is less than 0.6dB / cm, the refractive index on 1550nm is 1.5-1.6.

Owner:SOUTHEAST UNIV

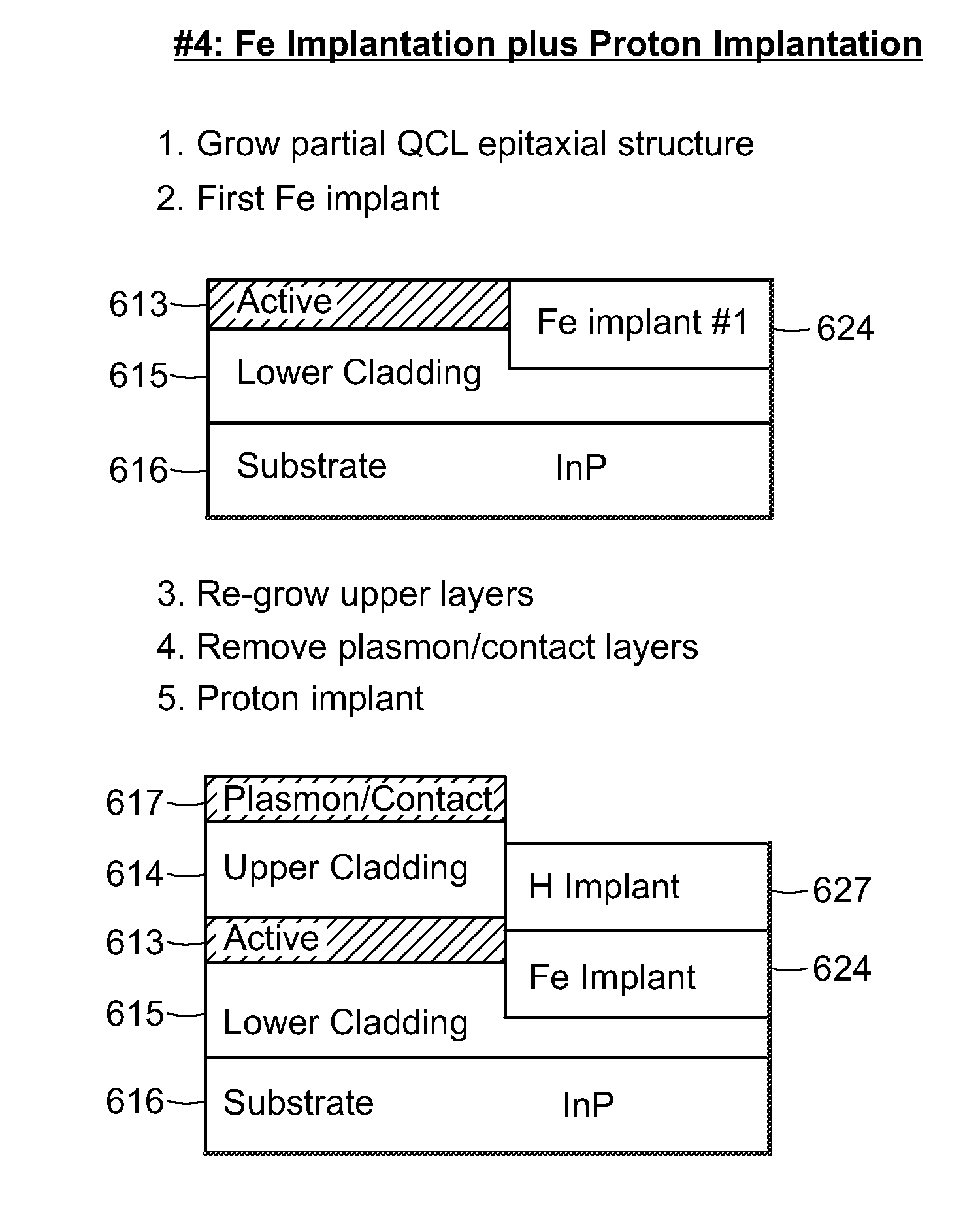

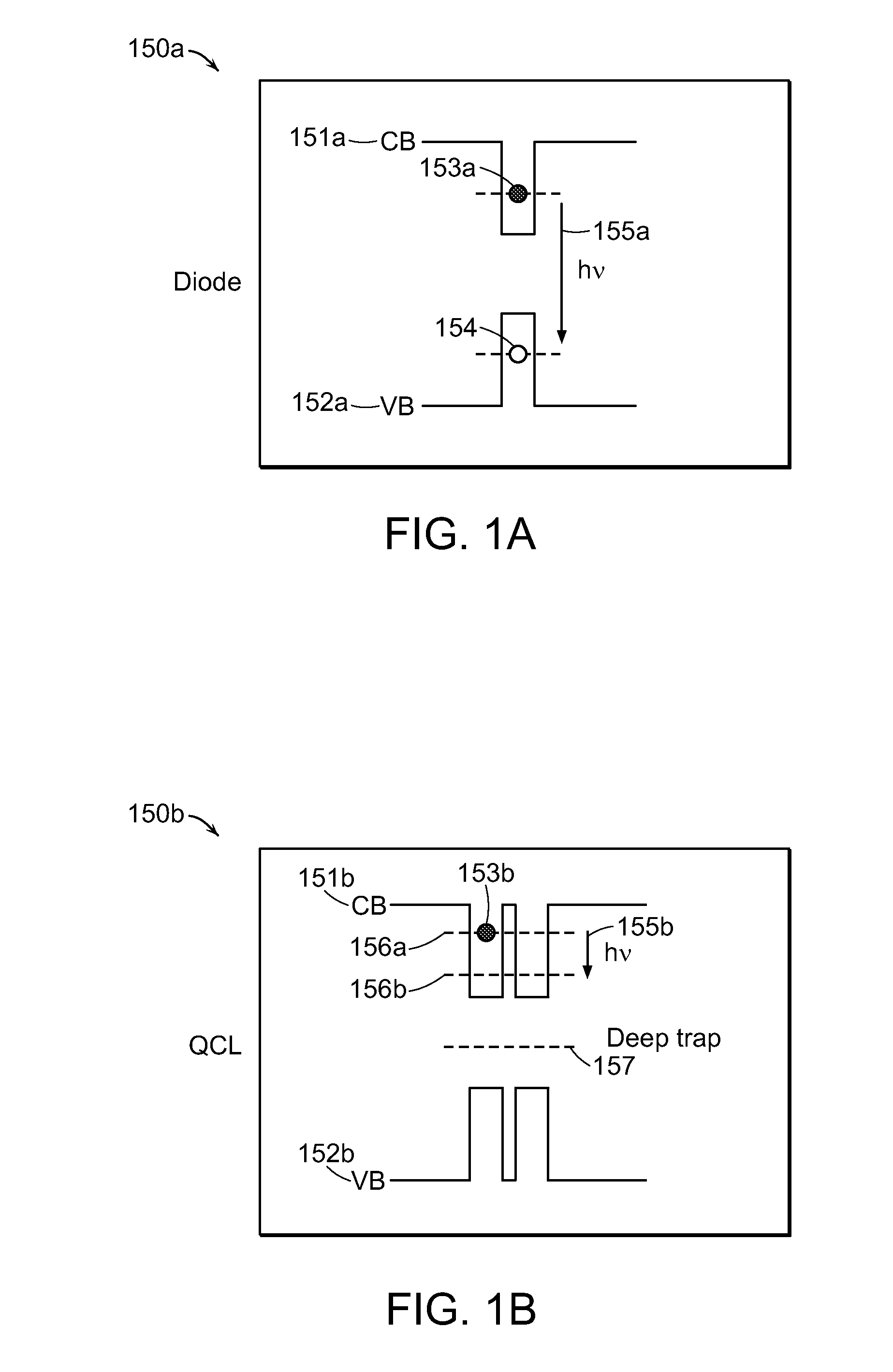

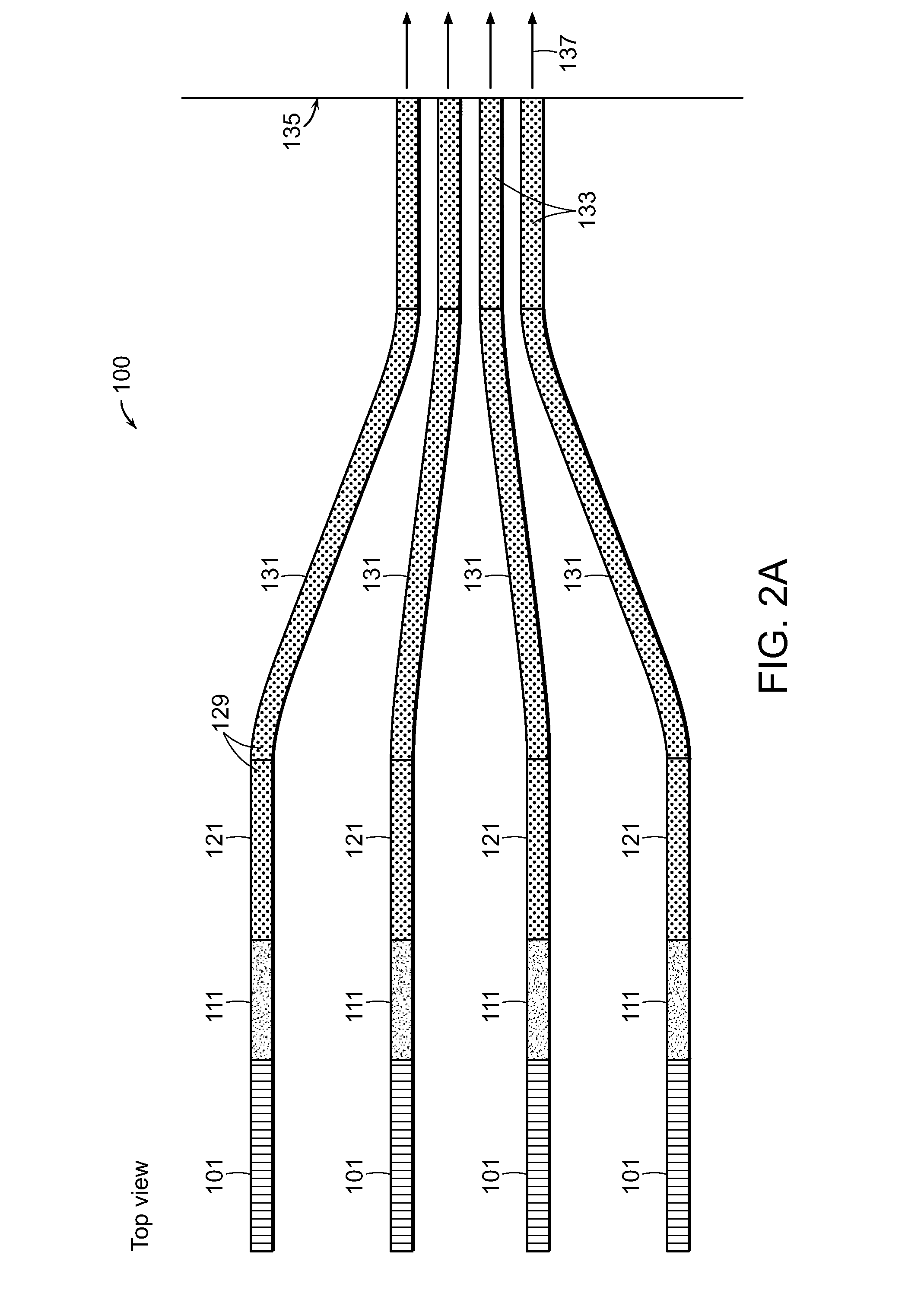

Photonic integrated circuits based on quantum cascade structures

ActiveUS20140027708A1Reduce optical lossLow lossSemiconductor/solid-state device manufacturingNanoopticsFree carrier densityIntegrated circuit

Photonic integrated circuits (PICs) are based on quantum cascade (QC) structures. In embodiment methods and corresponding devices, a QC layer in a wave confinement region of an integrated multi-layer semiconductor structure capable of producing optical gain is depleted of free charge carriers to create a low-loss optical wave confinement region in a portion of the structure. Ion implantation may be used to create energetically deep trap levels to trap free charge carriers. Other embodiments include modifying a region of a passive, depleted QC structure to produce an active region capable of optical gain. Gain or loss may also be modified by partially depleting or enhancing free charge carrier density. QC lasers and amplifiers may be integrated monolithically with each other or with passive waveguides and other passive devices in a self-aligned manner. Embodiments overcome challenges of high cost, complex fabrication, and coupling loss involved with material re-growth methods.

Owner:PENDAR TECH LLC +1

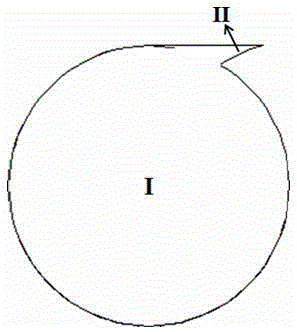

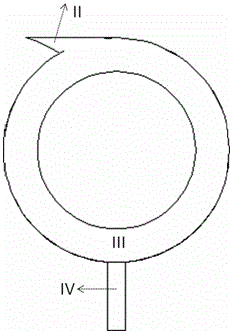

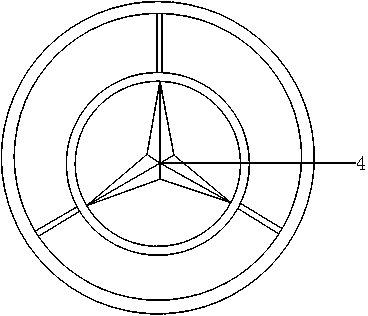

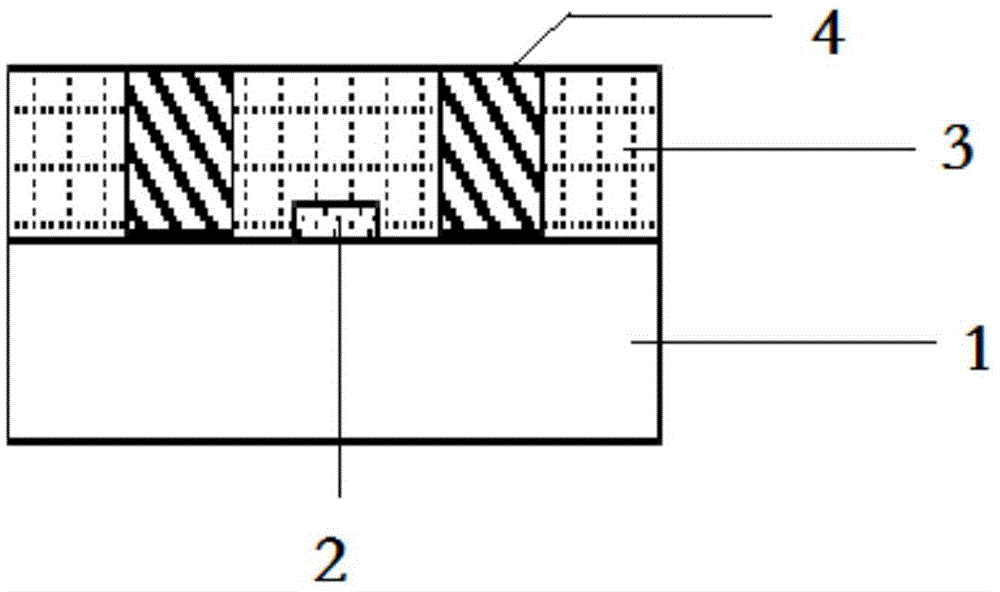

Optical pumping nitride echo wall laser performing emission in single direction and preparation method thereof

InactiveCN105337168AHigh precisionEtching deviation is smallLaser detailsLaser optical resonator constructionOptical pumpingErbium lasers

The invention discloses an optical pumping nitride echo wall laser performing emission in the single direction and a preparation method thereof. Asymmetric nitride suspension thin film microcavities are prepared in nitride materials on a silicon substrate via the photoetching technology and the deep silicon etching technology. Echo wall die laser emitting in the single direction is obtained in the proper optical pumping condition.

Owner:NANJING UNIV OF POSTS & TELECOMM

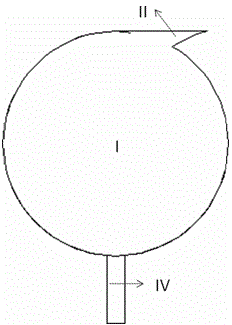

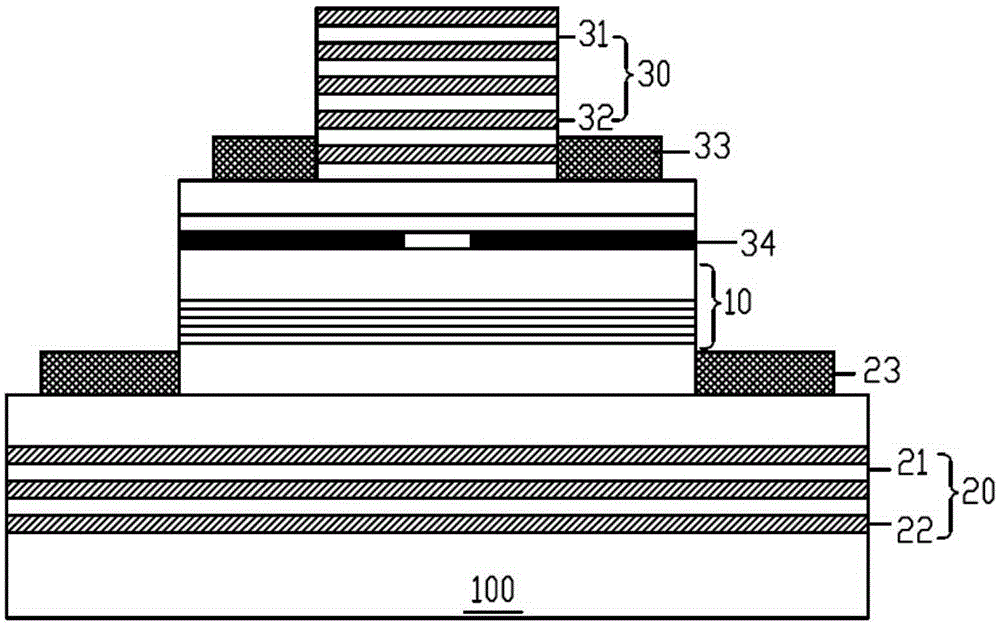

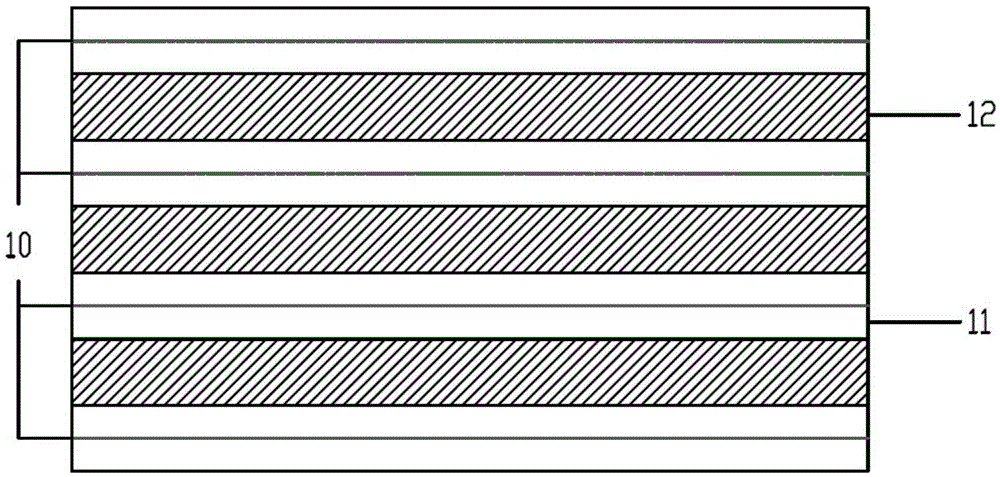

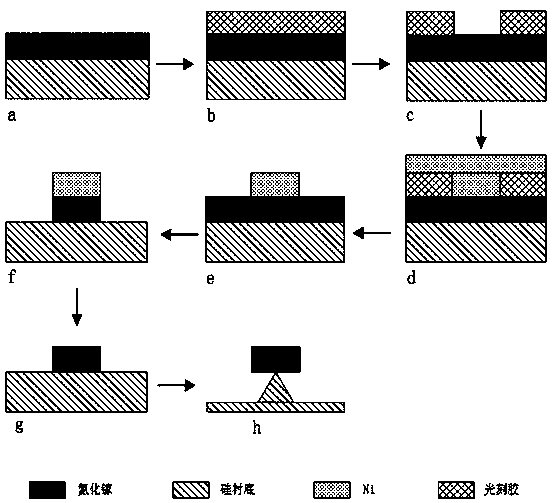

Electric pump gallium nitride micro laser capable of achieving single-direction emission and preparation method thereof

InactiveCN104009393AHigh optical gainReduce lossLaser detailsLaser optical resonator constructionWhispering galleryUltraviolet

The invention discloses an electric pump gallium nitride micro laser capable of achieving single-direction emission and a preparation method of the electric pump gallium nitride micro laser. The method comprises the steps of firstly utilizing silicon-based p-type gallium nitride / quantum well / n-type gallium nitride materials, utilizing the electron beam etching technology and the deep-silicon etching technology for preparing an asymmetric gallium nitride suspension thin film micro-cavity supported by a single cantilever beam, conducting vapor deposition of an Au / Ni electrode on the front face of a wafer, conducting vapor deposition of Au / Ti on the surface of the n-type gallium nitride, adopting the ultrasonic bonding technology, bonding a lead on the surface of the electrode, and finally preparing the complete laser. According to the electric pump gallium nitride micro laser and the preparation method of the electric pump gallium nitride micro laser, a proper current is exerted on the prepared laser, and whispering gallery mode ultraviolet laser with single-direction emission is obtained.

Owner:NANJING UNIV OF POSTS & TELECOMM

Molecular beam epitaxy growing method of high-speed vertical-cavity surface-emitting laser

ActiveCN105337166AReduce the impactReduce spreadLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserDelta doping

The invention provides a molecular beam epitaxy (MBE) growing method of a high-speed vertical-cavity surface-emitting laser. The method comprises the steps that deoxidation pretreatment is conducted on a GaAs substrate, and epitaxial growth of a GaAs buffer layer, a lower DBR, an active region, an oxidation confinement layer and an upper DBR is sequentially achieved; in the growth process, the active region is clamped between the upper DBR and the lower DBR, and a delta-doping method is adopted by the potential barrier middle position of the active region, wherein a doping source adopts carbon (C), and growth is stopped for a period of time under the protection of As after delta-doping is completed. By means of the method, the technical problems of reducing a threshold, increasing differential gain and reducing nonlinear gain compression are solved, and the good effects of reducing optical losses, decreasing line width and increasing output power and intrinsic bandwidth are achieved.

Owner:WUHAN TELECOMM DEVICES

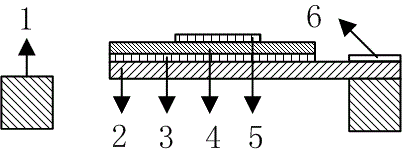

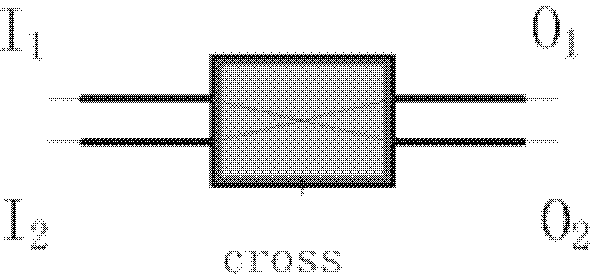

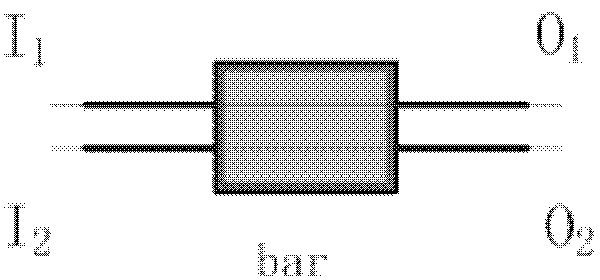

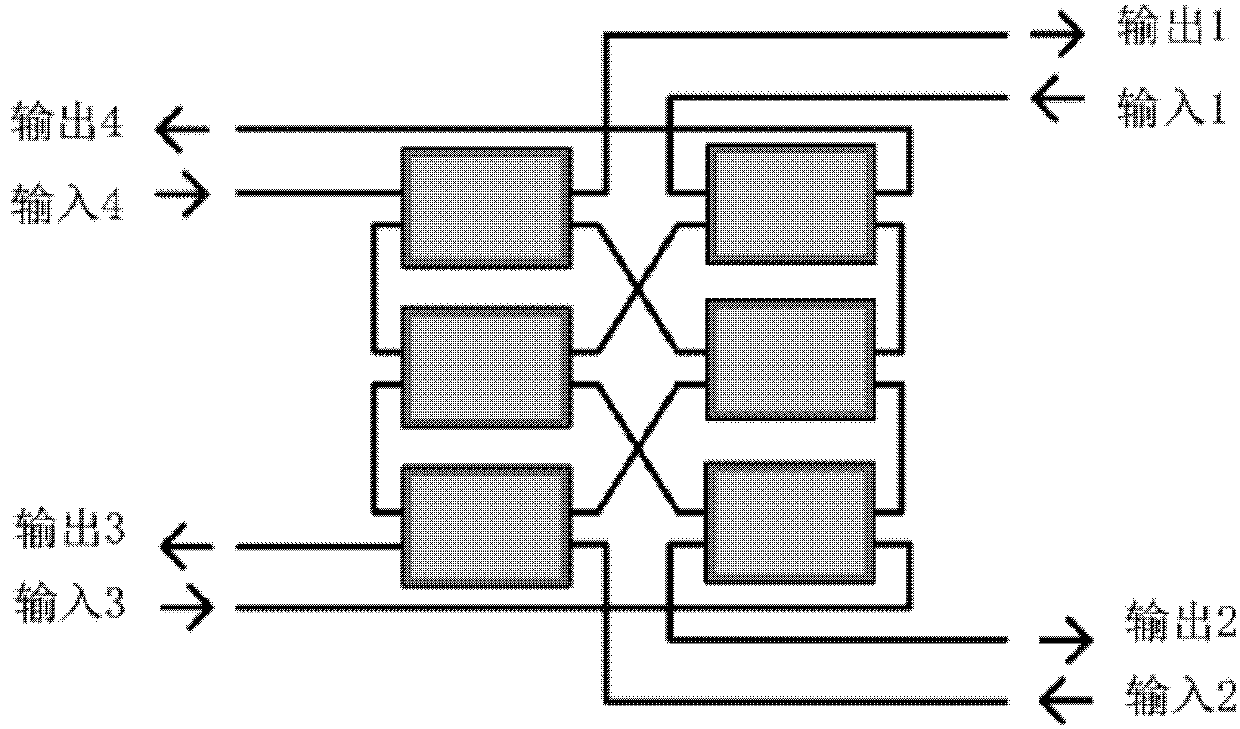

Four-port optical route based on Mach-Zehnder optical switches

The invention provides a four-port optical route based on Mach-Zehnder optical switches. The four-port blocking-free optical route comprises the four Mach-Zehnder optical switches (M1, M2, M3 and M4) with the same structure and the same size. A topological structure of the optical route is optimized, so that the number of the Mach-Zehnder optical switches and the number of crossed waveguides are reduced, and therefore loss is reduced. In addition, downlink communication of an output port of the four-port optical route is not influenced by uplink communication of an input port of any port of the four-port optics route.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

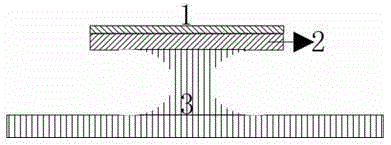

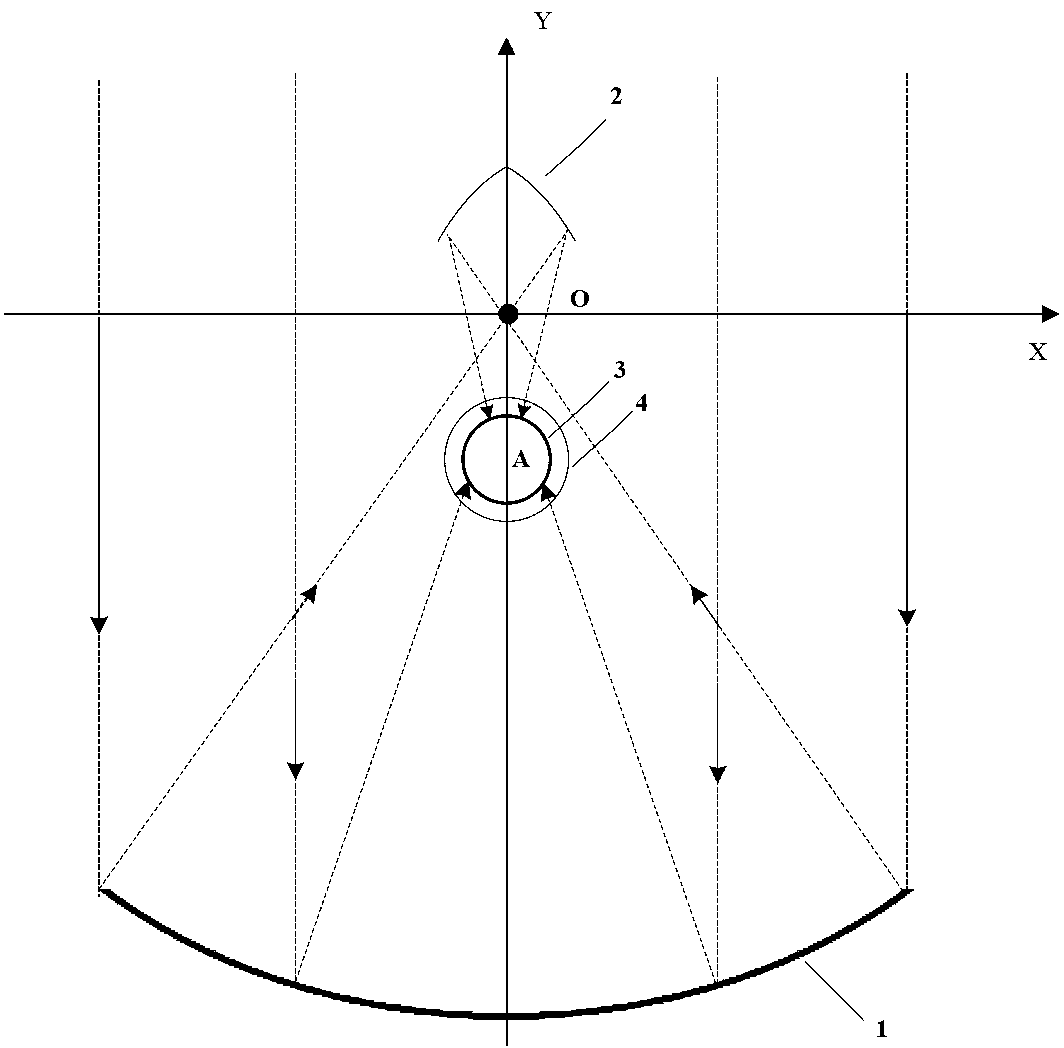

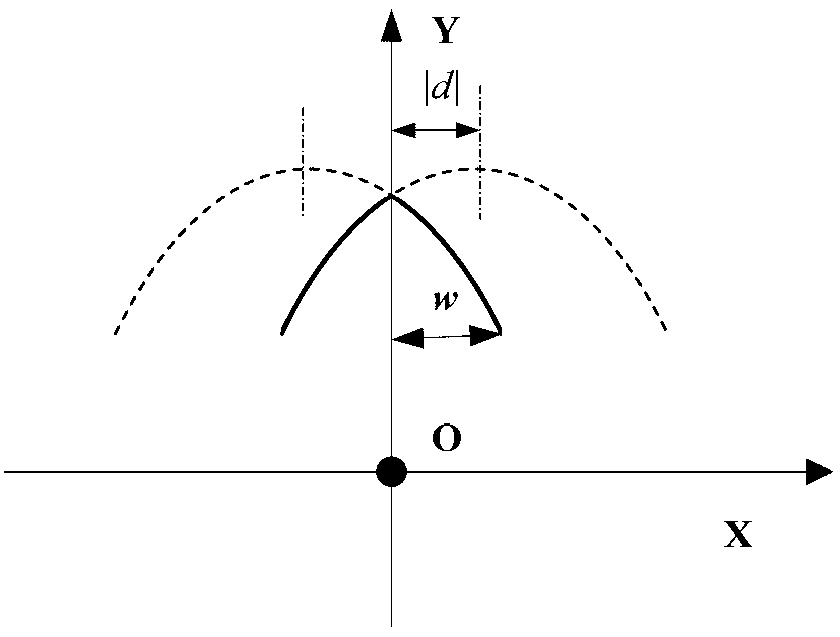

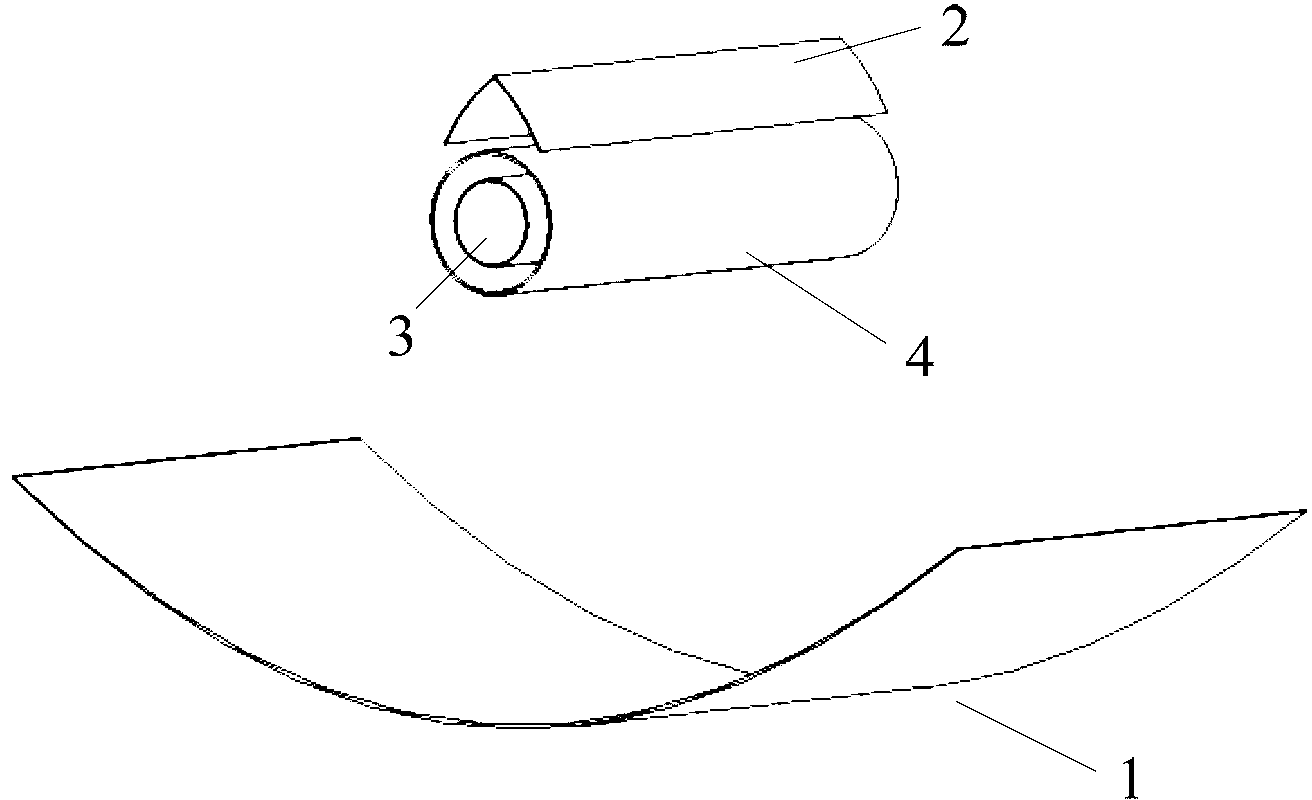

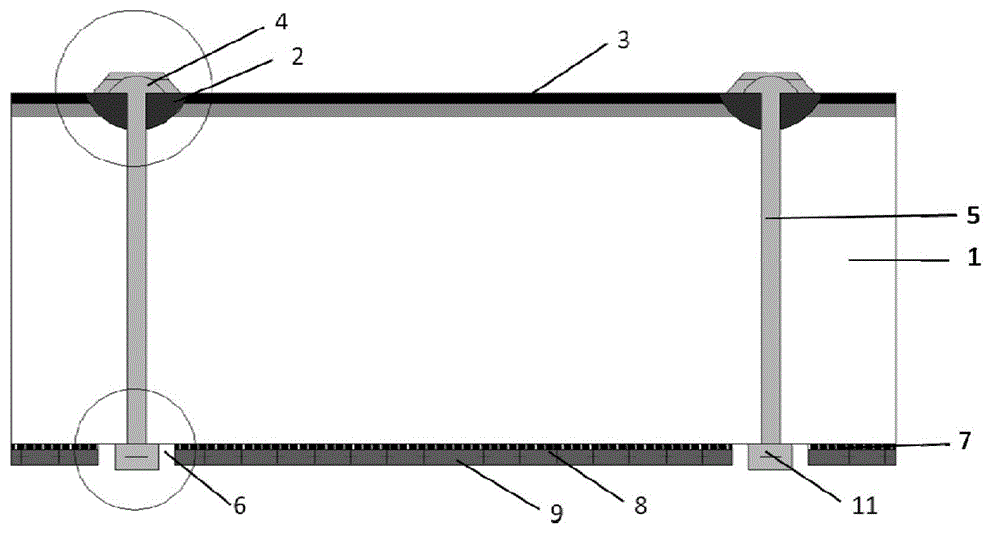

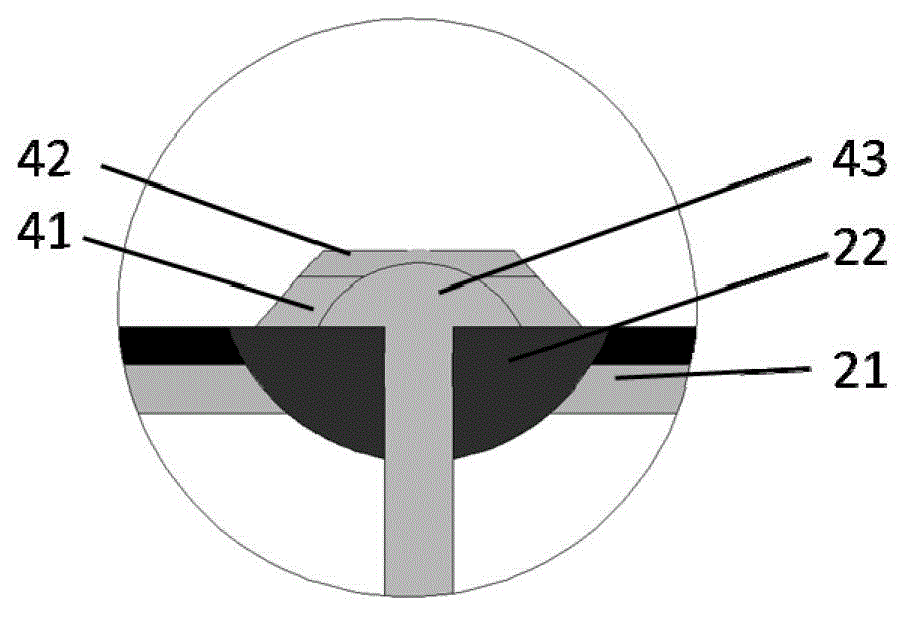

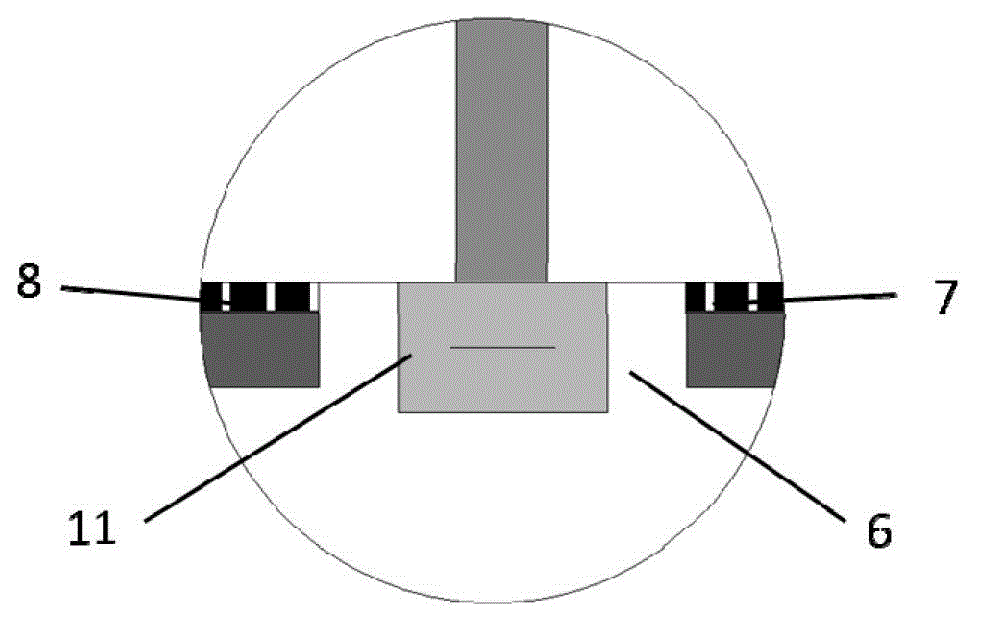

Solar light condensed heat collector and method for designing solar light condensed heat collector

ActiveCN103256724ASmall shading lossReduce the temperatureSolar heating energySolar heat devicesThermodynamicsSolar light

The invention discloses a solar light condensed heat collector and a method for designing the solar light condensed heat collector. A paraboloid main reflector is arranged. A vacuum heat collecting pipe is installed on the symmetrical axis of the cross section of the paraboloid main reflector and on the inner side of the focal line of the paraboloid main reflector. An even light reflector is installed on the outer side of the focal line of the paraboloid main reflector. The even light reflector and an opening of the paraboloid main reflector are oppositely arranged and fixedly connected. According to the solar light condensed heat collector and the method for designing the solar light condensed heat collector, the vacuum heat collecting pipe is arranged below the position of the focal line of the paraboloid main reflector, the even light reflector is additionally arranged and opposite to the opening of the paraboloid main reflector, solar radiation energy can be distributed at the bottom and the top of a heat absorption pipe, solar energy flux density distribution on the wall face of the heat absorption pipe is homogenized, the temperature gradient and the highest temperature of the wall face of the heat absorption pipe are reduced, a series of problems caused by uneven energy flux density can be avoided from the source, and safety performance of the vacuum heat collecting pipe is improved.

Owner:XI AN JIAOTONG UNIV

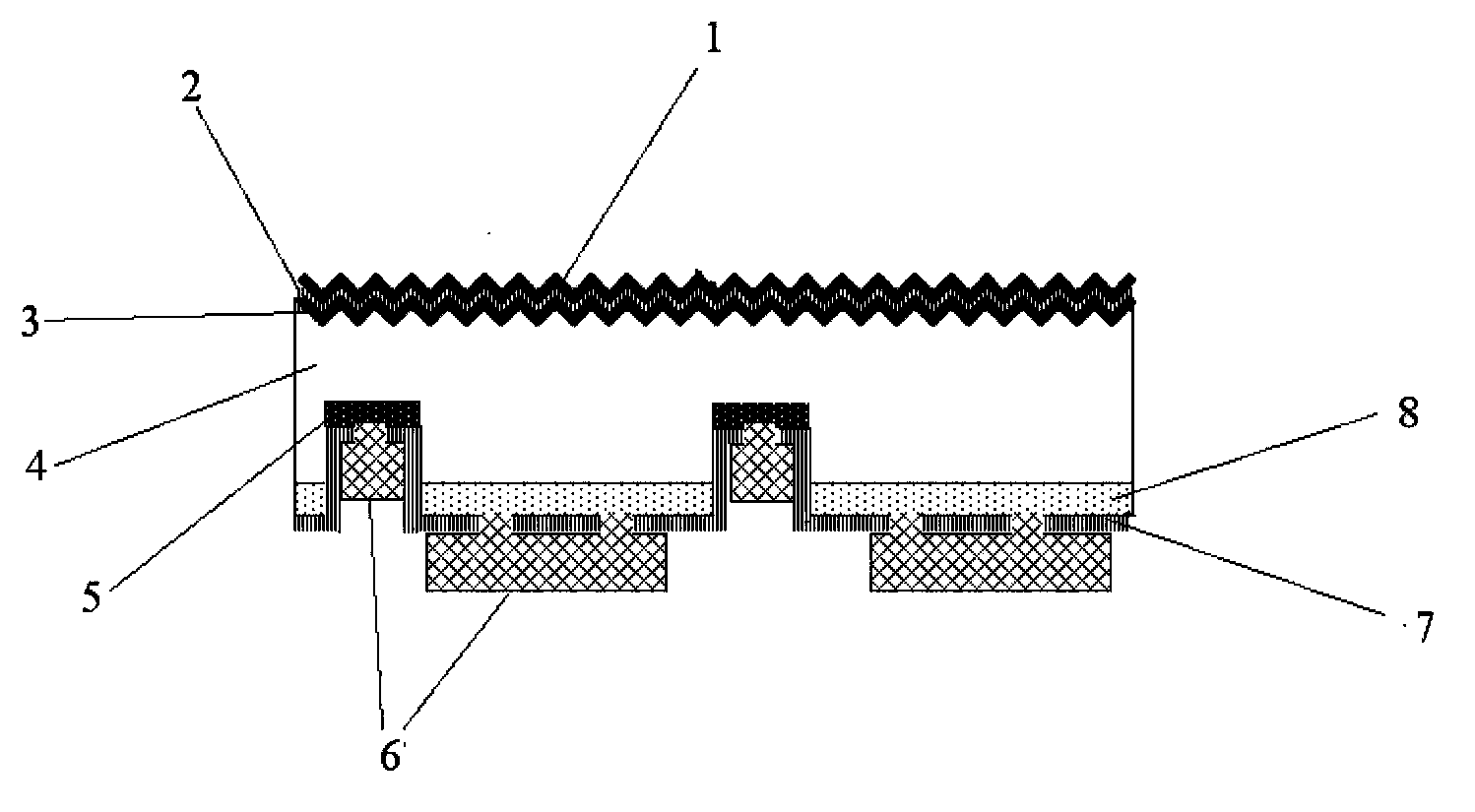

Manufacturing method for crystalline silicon solar MWT (metallization wrap-through) cell and manufactured cell

InactiveCN103187482AIncrease short circuit currentReduce compoundingFinal product manufacturePhotovoltaic energy generationSilicon matrixElectrode Contact

The invention discloses a manufacturing method for a crystalline silicon solar MWT (metallization wrap-through) cell. The manufacturing method for the crystalline silicon solar MWT cell comprises the following steps of: producing a conductive through hole; performing wet-method texturization; performing grid line area phosphorous paste printing on a light-receiving surface; diffusing phosphorous; etching the edge of a silicon matrix, and performing PSG (phosphosilicate glass) removal treatment; coating an antireflection film, and printing an emitting electrode contact electrode, a back electrode contact electrode and a base electrode contact electrode; printing the electrode grid line of the light-receiving surface; sintering to form ohmic contact; and electrically insulating the base electrode contact electrode from the emitting electrode contact electrode, so as to finish production for the solar cell. According to the manufacturing method disclosed by the invention, a selective emitting electrode structure is realized on the MWT solar cell; and optical loss is effectively reduced, minority carrier recombination is reduced, various electrode-related resistance losses are reduced, and the short-circuit current ISC, the open-circuit voltage UOC and the filling factor of the cell are remarkable increased by combining with a back passivation technology and a secondary printing technology. The preparation process is easy to operate, capable of being completely compatible with the solar cell production line which is widely applied at present, and suitable for large-scale production.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

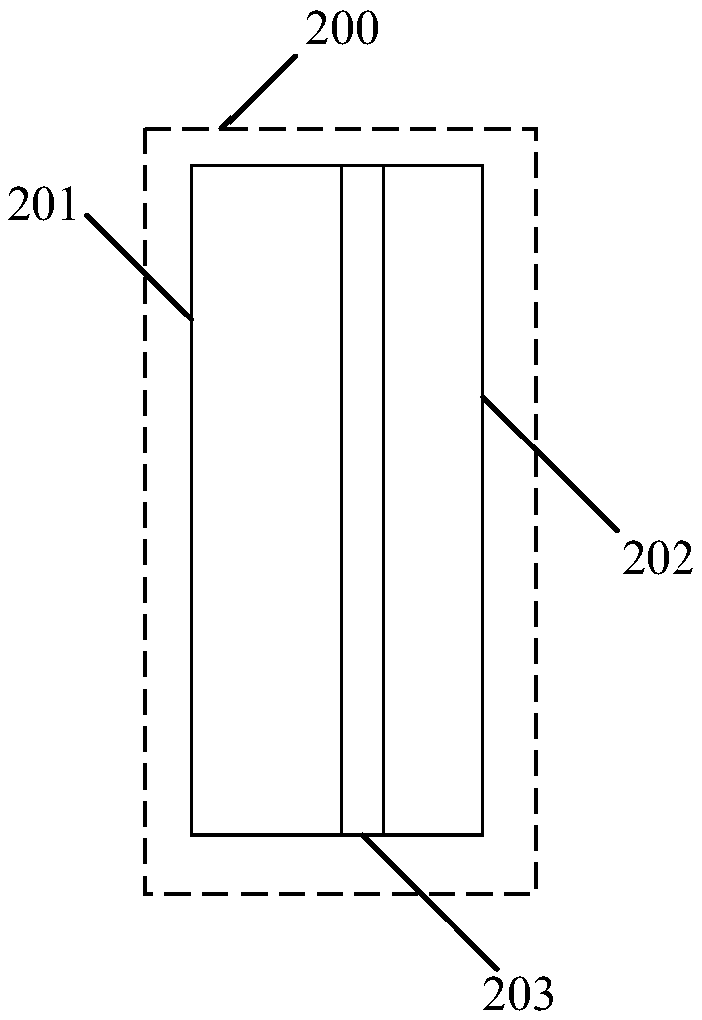

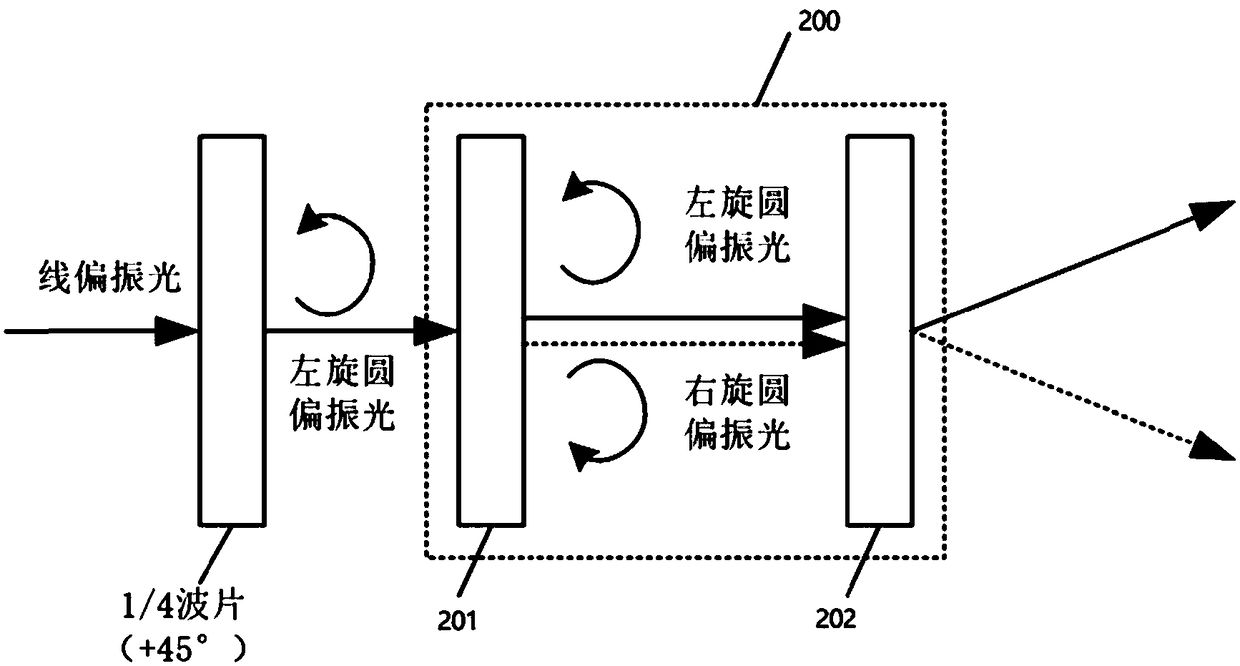

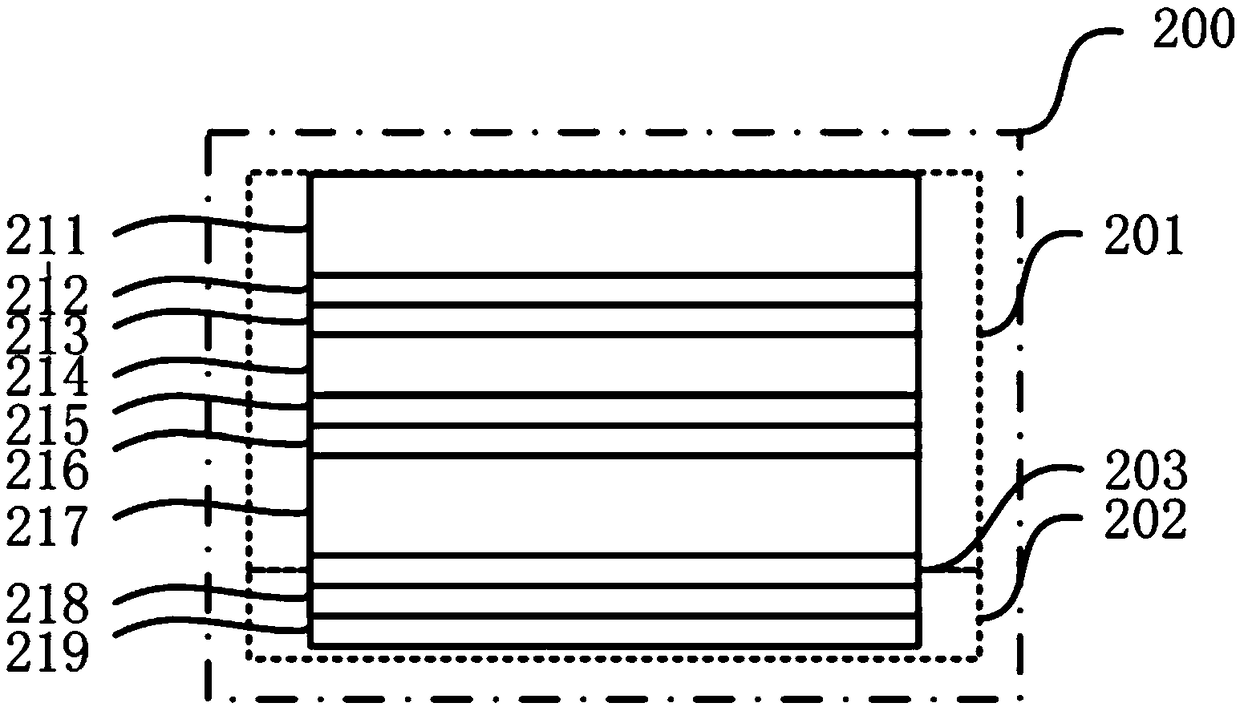

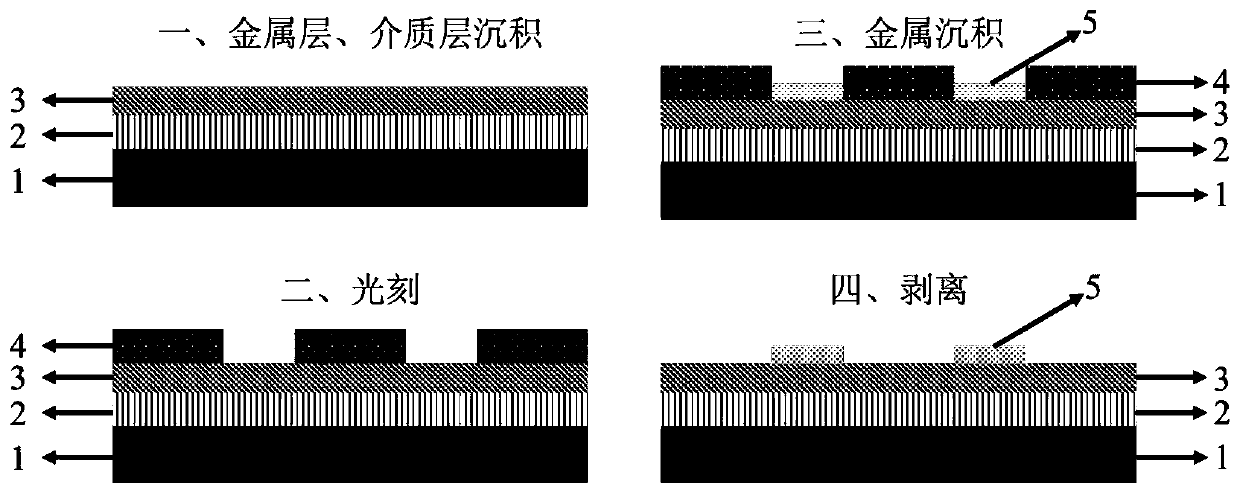

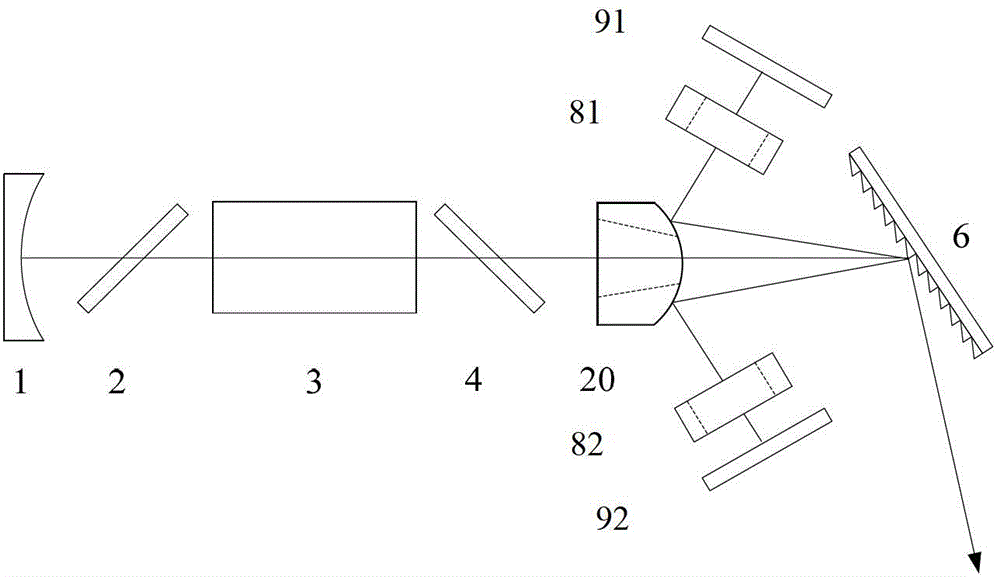

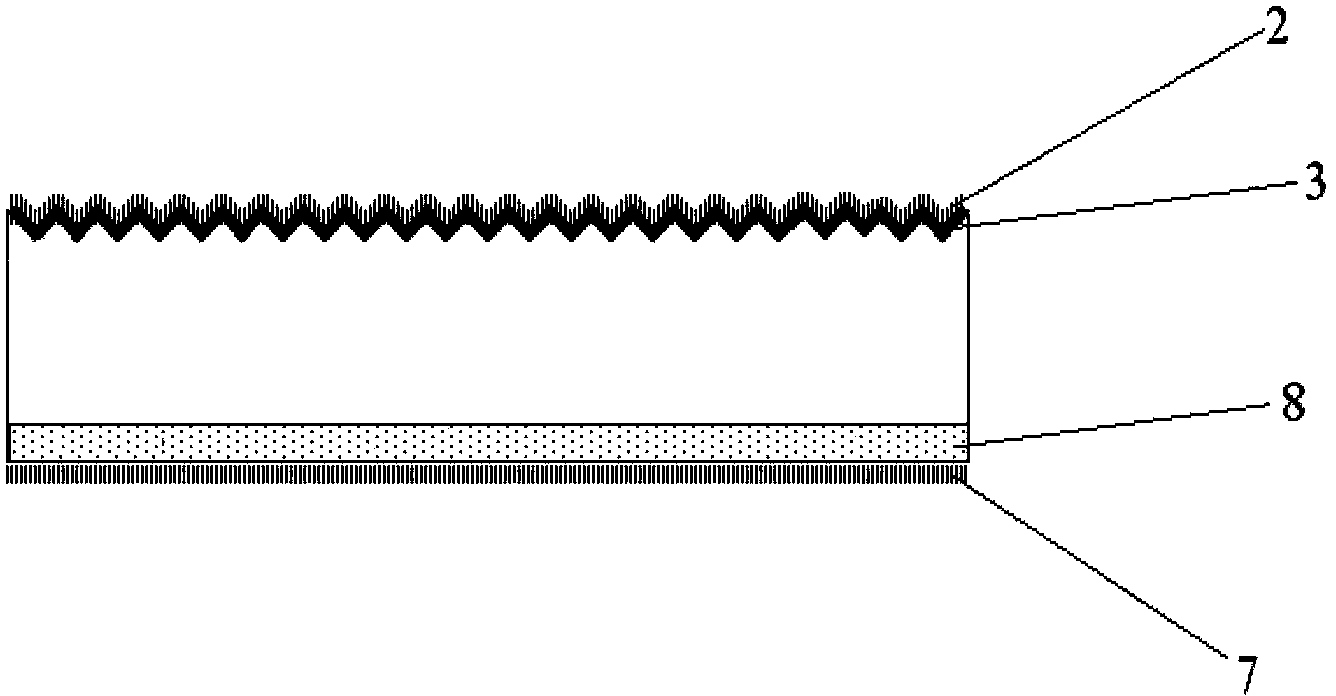

Composite liquid crystal device for light beam deflection

PendingCN108873556AImproved Optical Loss CharacterizationReduce optical lossNon-linear opticsGratingLight beam

The invention discloses a composite liquid crystal device for light beam deflection. The composite liquid crystal device for light beam deflection comprises a liquid crystal box of an adjustable liquid crystal half-wave plate, a dielectric film and a liquid crystal polarized grating, wherein the liquid crystal box is used for controlling the rotation direction of an incident circular polarized light through electronic control switching; the liquid crystal polarized grating is used for deflecting the circular polarized light passing through the liquid crystal box; the liquid crystal box and theliquid crystal polarized grating share one glass substrate; the dielectric film is coated on the surface of the liquid crystal box; the liquid crystal polarized grating is attached onto the dielectric film; the dielectric film is used for transmitting the working wavelength of the composite liquid crystal device and reflecting the photo-orientation exposure wavelength. The composite liquid crystal device provided by the invention is compact in structure, small in thickness, beneficial to improving the optical loss characteristic of overall light beam deflection, and capable of preventing a photo-orientation structure in the liquid crystal box of the adjustable liquid crystal half-wave plate from being erased for the second time during the manufacturing process.

Owner:LORENTECH BEIJING CO LTD

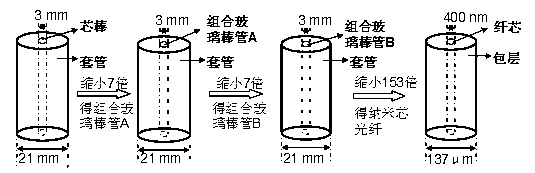

Long-distance micro/nano-core glass optical fiber and preparation method thereof

InactiveCN103011607AStructural size controllableHigh precisionGlass making apparatusHost materialRefractive index

The invention provides a long-distance micro / nano-core glass optical fiber and a preparation method thereof. The invention mainly comprises the aspects of optical fiber matrix material, rare-earth doping, refringence of core wrap, dimensions of core wrap, casing, multistep stretching method and the like. The micro / nano-core glass optical fiber has the characteristics of low optical loss, large-proportion evanescent wave transmission, large waveguide dispersion and the like. The preparation method has the advantages of high accuracy, controllable structural dimensions and the like, and can be used for preparing long-distance micro / nano-core glass optical fibers. The invention can be well applied to design and preparation of long-distance micro / nano-core glass optical fibers, and provides a feasible design and preparation technique of a long-distance micro / nano-core glass optical fiber.

Owner:NANJING UNIV OF POSTS & TELECOMM

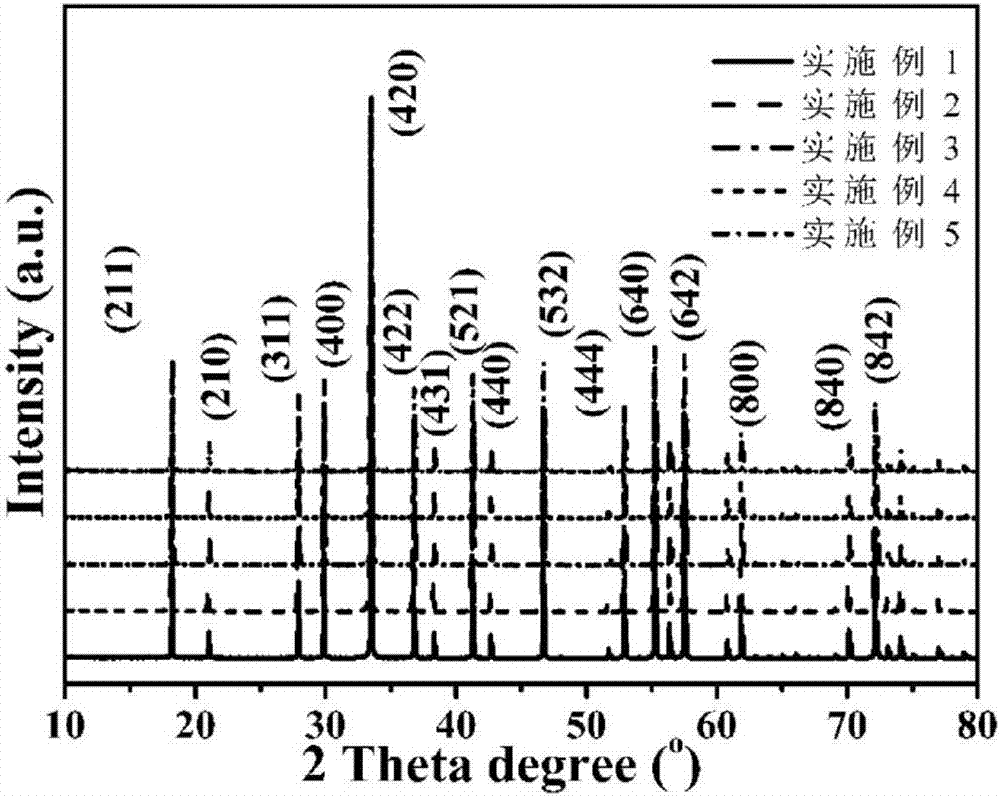

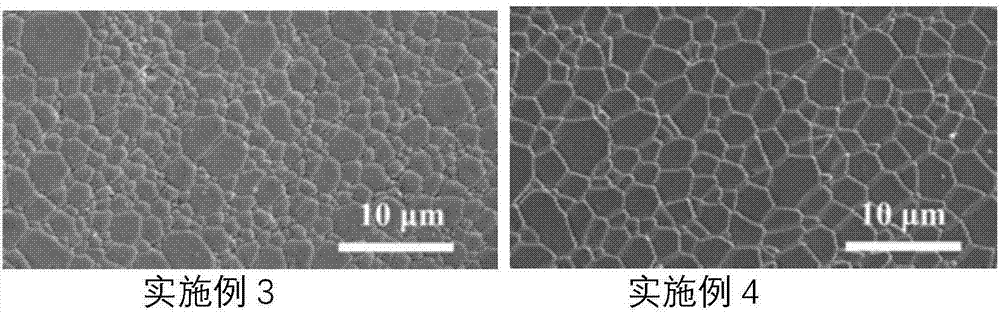

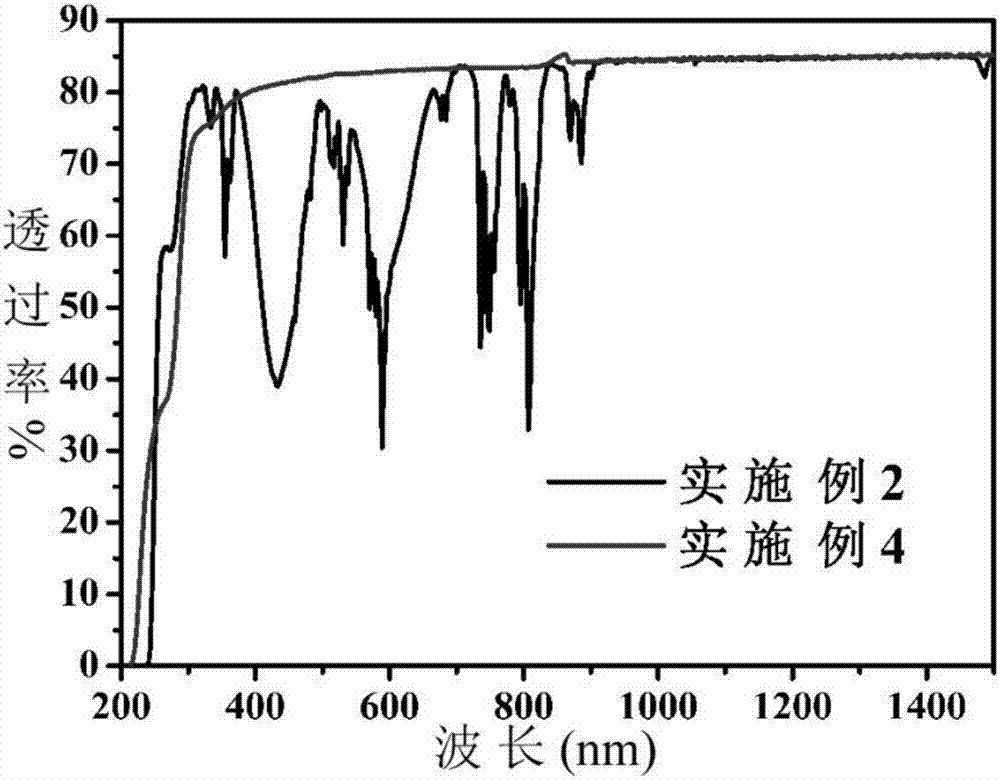

Preparation method of yttrium aluminum garnet (YAG)-based transparent ceramics in system taking Ca as auxiliary agent

The invention provides a method for preparing yttrium aluminum garnet (Y3Al5O12, YAG)-based transparent ceramics by means of vacuum sintering based on a system taking a small amount of Ca as a single-sintering auxiliary agent. According to the method, the small amount of Ca is used as the single-sintering auxiliary agent, and a single-step vacuum sintering method is adopted, so that the YAG-based transparent ceramics having good optical quality and fine crystalline grain size can be prepared under the condition of not adding post annealing treatment.

Owner:XUZHOU NORMAL UNIVERSITY

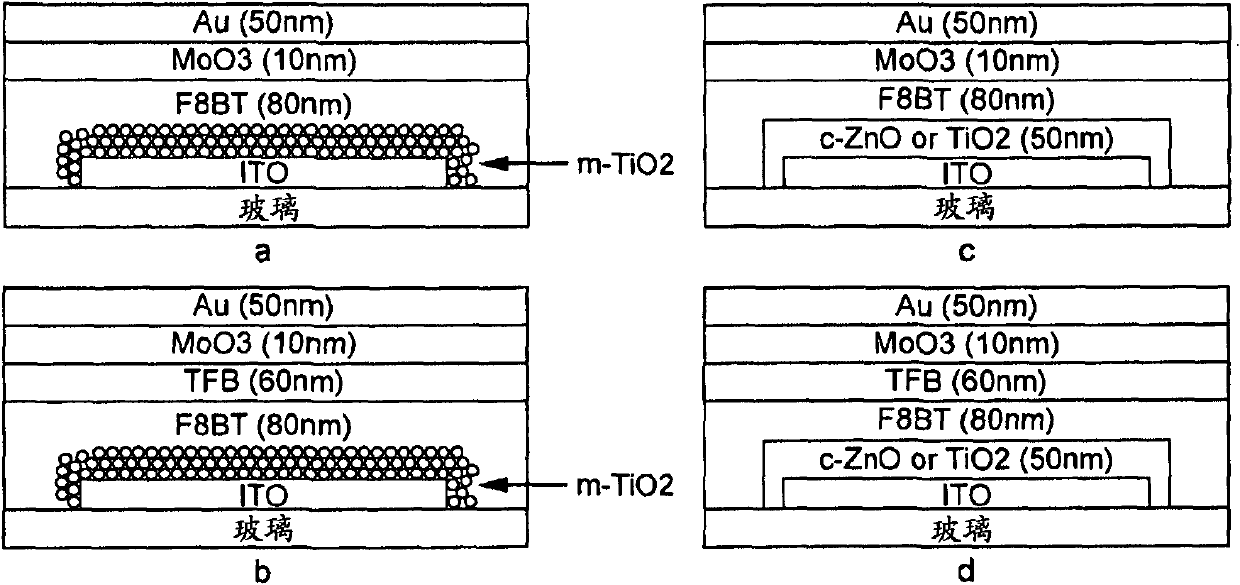

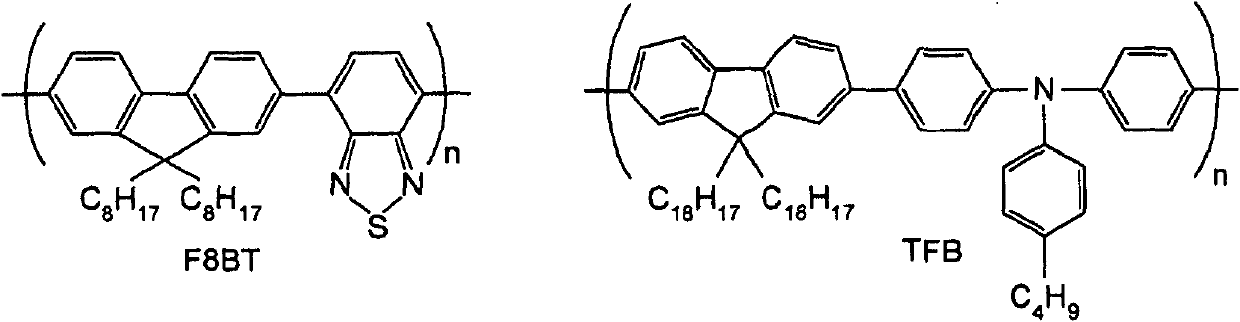

Electro-optic diode devices

ActiveCN102089897AReduce optical lossSupport optical gainSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerRefractive index

A light emissive or photovoltaic device comprising: a cathode structure for injecting electrons, the cathode structure having one or more constituent regions; an anode structure for injecting holes, the anode structure having one or more constituent regions; and an organic light emissive component located between the anode structure and the cathode structure; a first charge transport layer located between the first electrode and the organic component and of a material having a refractive index greater than 1.85; wherein the device structure supports optical gain within the device.

Owner:CAMBRIDGE ENTERPRISE LTD

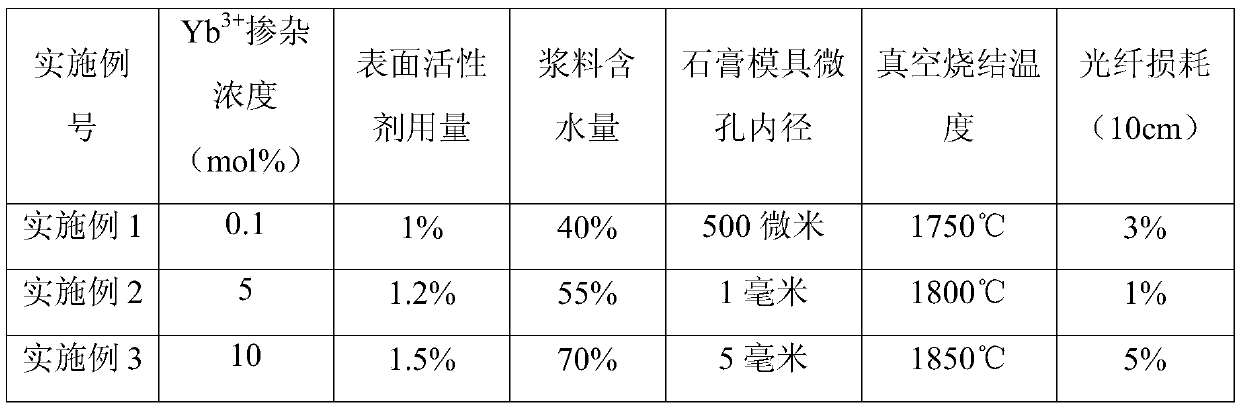

Preparation method of trivalent ytterbium ion doped lutetium aluminum garnet transparent ceramic optical fiber

ActiveCN104451953BReduce optical lossSimple stepsInorganic material artificial filamentsWater basedWorking temperature

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

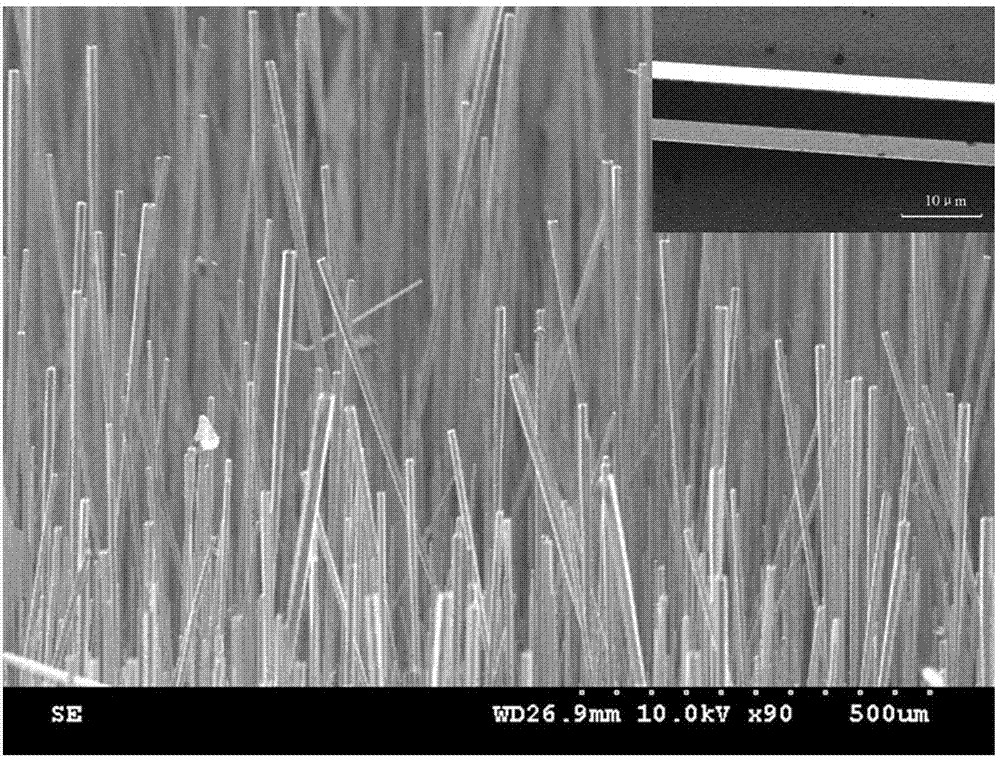

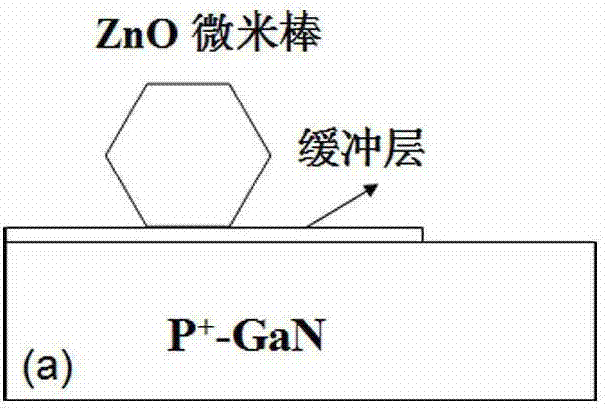

Preparation method of WGM (whispering gallery mode) ZnO ultraviolet micro-laser for constructing electric pump

InactiveCN102904158AImprove transmittanceGood light transmissionLaser detailsLaser active region structureWhispering galleryGas phase

The invention discloses a preparation method of a WGM (whispering gallery mode) ZnO ultraviolet micro-laser for constructing an electric pump. The method comprises the following steps of: preparing a ZnO micro bar single crystal by utilizing a gas phase transmission method or a hydrothermal method; then transferring a single ZnO micro bar onto p-type gallium nitride (GaN) with a buffer layer; processing the buffer layer so as to form a good-contact hetero junction between the ZnO micro bar and the p-type GaN; preparing a layer of insulation film on the surface of the hetero junction; etching out the surface of the ZnO micro bar by utilizing a reactive ion etching or photetching technology; transferring graphene onto the ZnO micro bar so as to enable the graphene to be in good contact with the ZnO micro bar; and finally preparing a metal electrode on the surface of the p-type GaN so as to constitute a complete graphene / n-type ZnO micro bar / p-type GaN hetero junction micro-laser. The micro-laser prepared by the method utilizes the high carrier concentration and high light transmittance of the graphene, so that high-quality ultraviolet laser output can be realized.

Owner:SOUTHEAST UNIV

Photovoltaic encapsulating material with high light transmittance

InactiveCN108517188AHigh light transmittanceHigh refractive indexNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolar lightPower flow

The invention relates to a photovoltaic encapsulating material with high light transmittance. The photovoltaic encapsulating material is prepared by premixing 100 parts by weight of matrix resin or grafting modified matrix resin of the photovoltaic encapsulating material, 0.01 to 20 parts by weight of highly transparent resin with high light transmittance and / or high refractive index, and other auxiliary agents, and then carrying out melting, extruding, tape casting, film forming, cooling, cutting, and rolling. By introducing the highly transparent resin with high light transmittance and / or high refractive index into the encapsulating material system, the refractive indexes of glass, the front-layer encapsulating material, and a battery sheet can be perfectly matched; the light transmittance of the photovoltaic encapsulating material is increased; the intensity of light projected on the battery sheet is enhanced, thus the utilization rate of solar light is increased; the current and output power of the battery are increased; and the photovoltaic conversion efficiency is optimized and increased.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

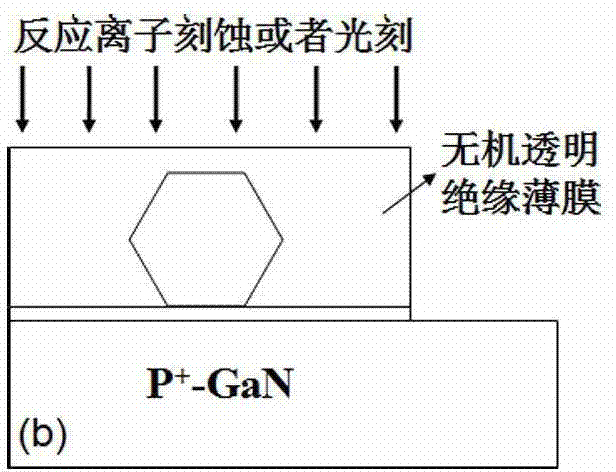

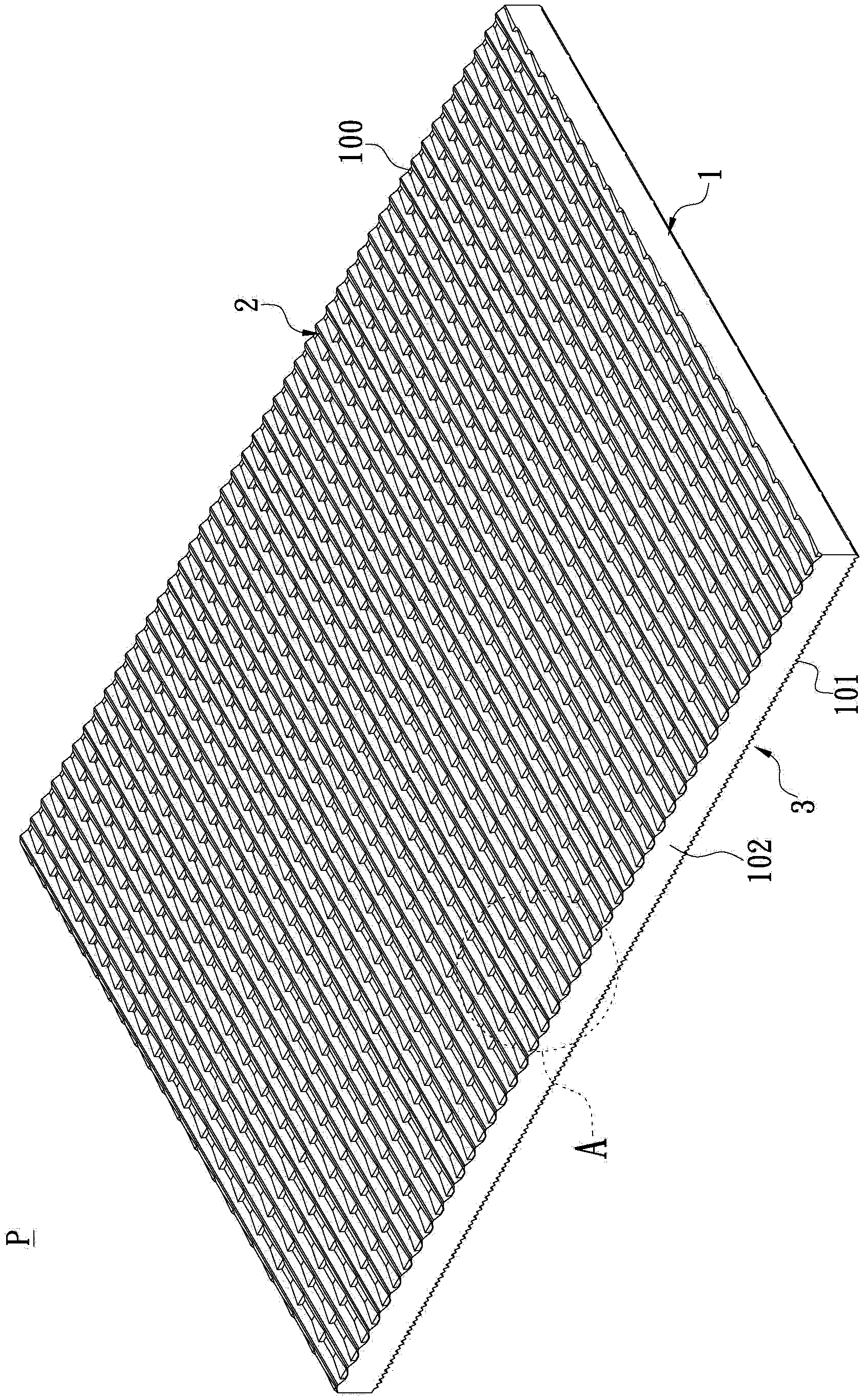

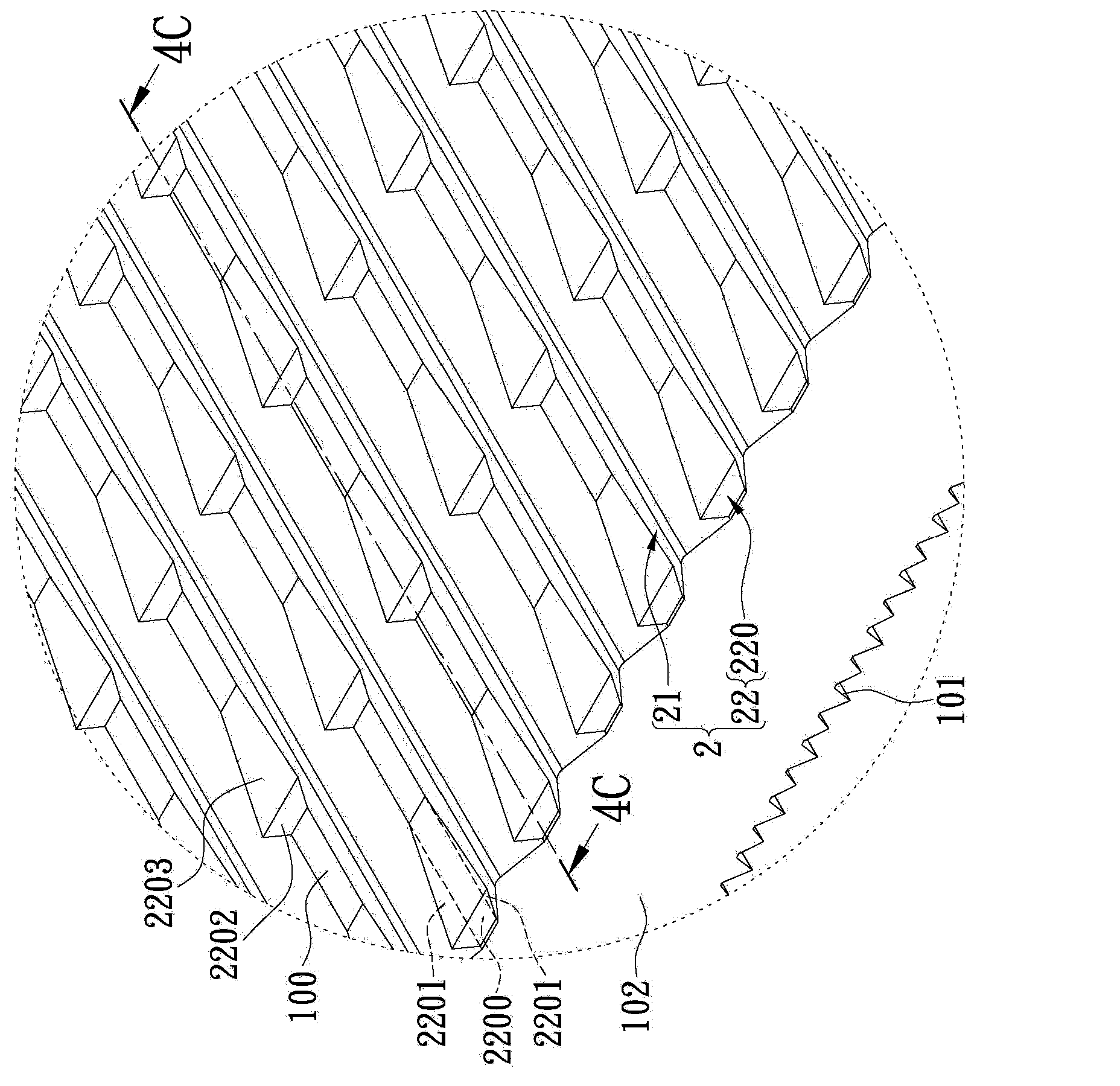

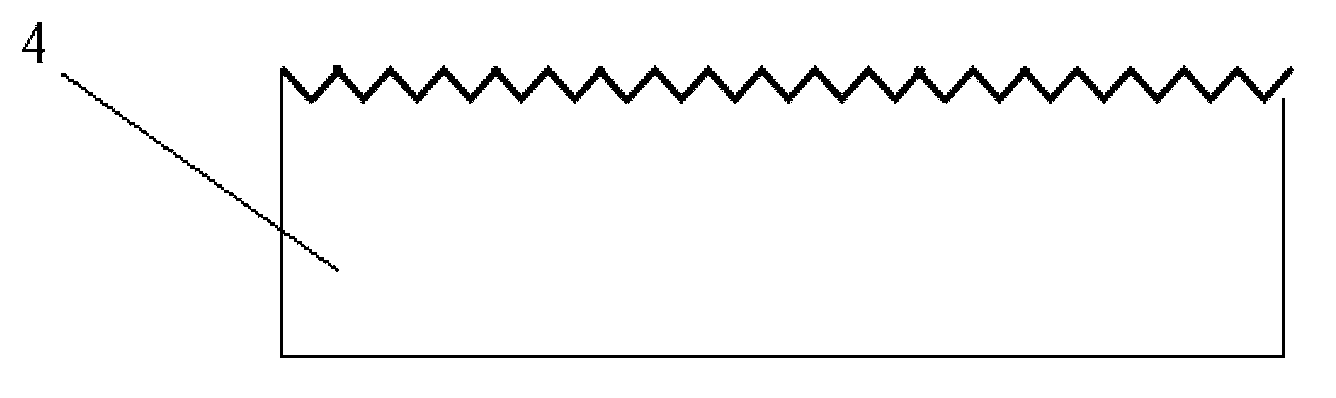

Light guide plate, backlight module and display device

InactiveCN103901526AReduce adverse phenomenaHigh strengthMechanical apparatusLight guides for lighting systemsLight guideDisplay device

A light guiding plate includes a light guiding main body, a first light guiding unit and a second light guiding unit. The light guiding main body has a first surface, a second surface opposite to the first surface and a light inlet face connecting between the first and second surfaces. The first light guiding unit includes first and second light guiding structures disposed on the first surface. The first and second light guiding structures are parallel aligned, each second light guiding structure has a plurality of first light guiding bodies that is individually separating and connecting the immediately abreast first light structures, and the arrangement density of the plurality of first light guiding bodies decreases toward the light inlet face. The second light guiding unit includes a plurality of third light guiding structures disposed on the second surface. The third light guiding structures are parallel arranged.

Owner:INNOLUX CORP

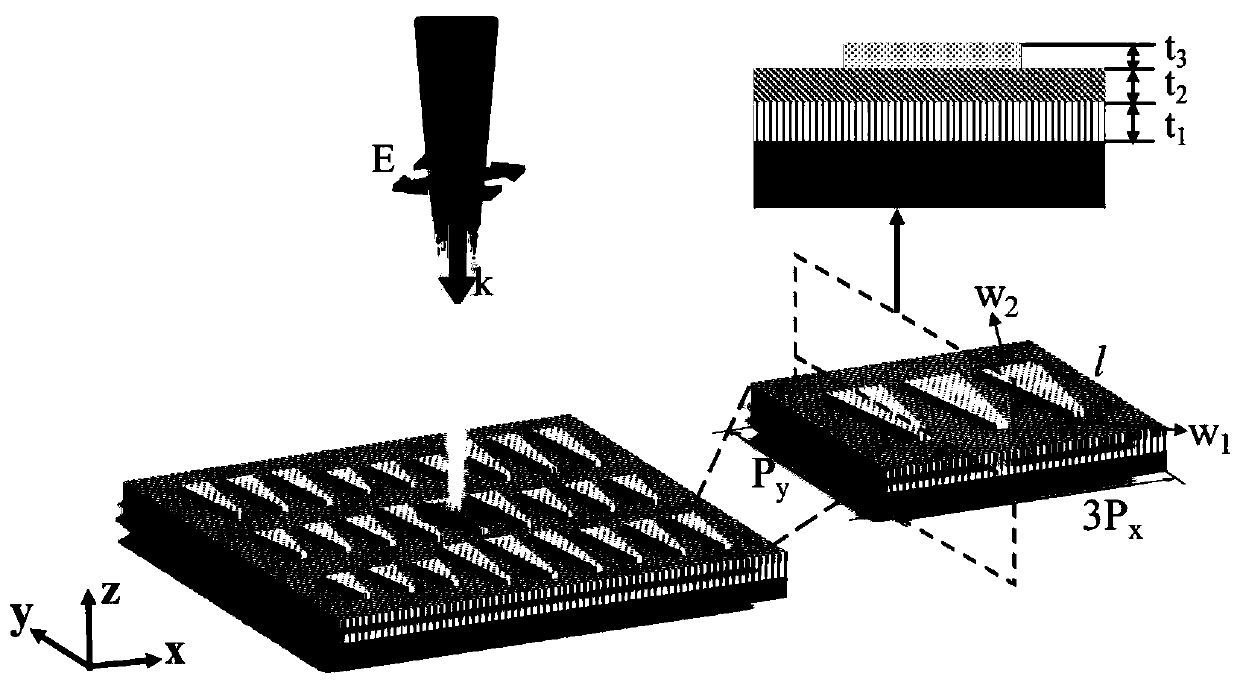

Polarization-controlled surface plasmon bifunctional metasurface and design and preparation method thereof

ActiveCN111045121AGuaranteed phaseGuaranteed Amplitude VariationPolarising elementsStructural colorationOptical polarization

The invention discloses a polarization-controlled surface plasmon bifunctional metasurface and a design and preparation method thereof. The metasurface longitudinally adopts a metal-medium-metal three-layer structure, the surface includes a trapezoidal unit structure array, independent regulation and control of the amplitude and the phase of light in different polarization states are achieved, phase regulation and control can be conducted on polarized light in the x direction, and the function of a deflector is achieved. Amplitude regulation and control can be carried out on polarized light inthe y direction to achieve a structural color function. According to the bifunctional structure, the integration level and the regulation and control diversity of the metasurface structure are improved, deflection and structural color are independent of each other and supplement each other, and the combination of the two functions provides a brand-new solution for anti-counterfeiting, measurementof birefringence of biological tissue and measurement of optical rotation of biomolecules.

Owner:PEKING UNIV

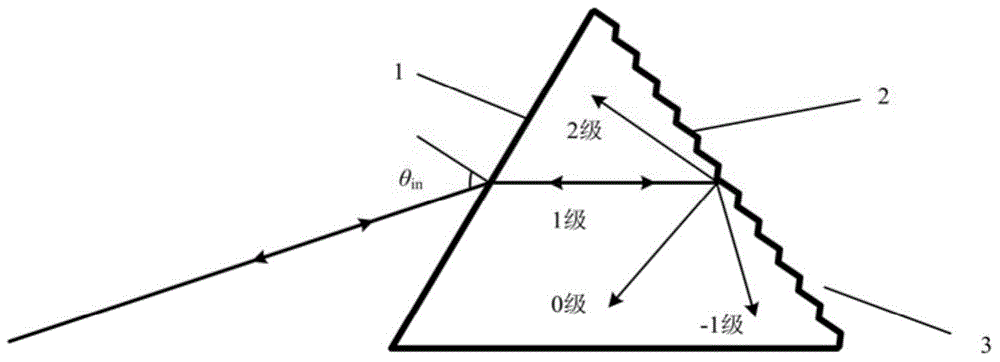

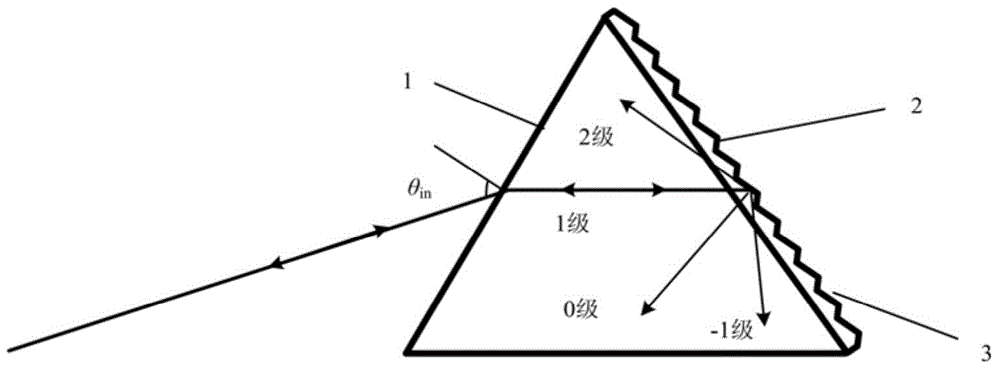

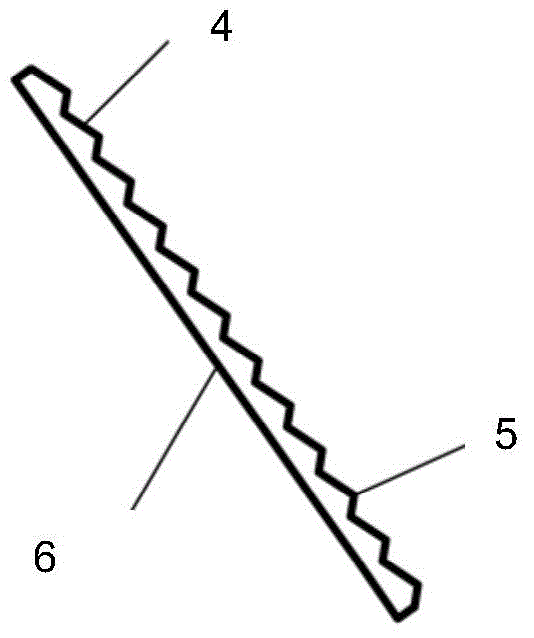

Laser line width compressing module and narrow-line-width laser

The invention discloses a line width narrowing module of a laser resonant cavity. The module is an integrated optical element, wherein two side surfaces of a prism-like body respectively form an incident surface and a reflecting surface; the reflecting surface is a reflective blazed grating. The module can be used for solving the problem of difficult light emission caused by a complex optical system and surface abrasion of an optical element in a low-gain laser and is high in optical integrity and simple to regulate and use. The module is good in wavelength selection characteristic and relatively good in damage resistance threshold value. The laser resonant cavity built by using the module has few optical elements, is high in interference resistance and can be applied to places which are complex in environment.

Owner:NORTHWEST INST OF NUCLEAR TECH

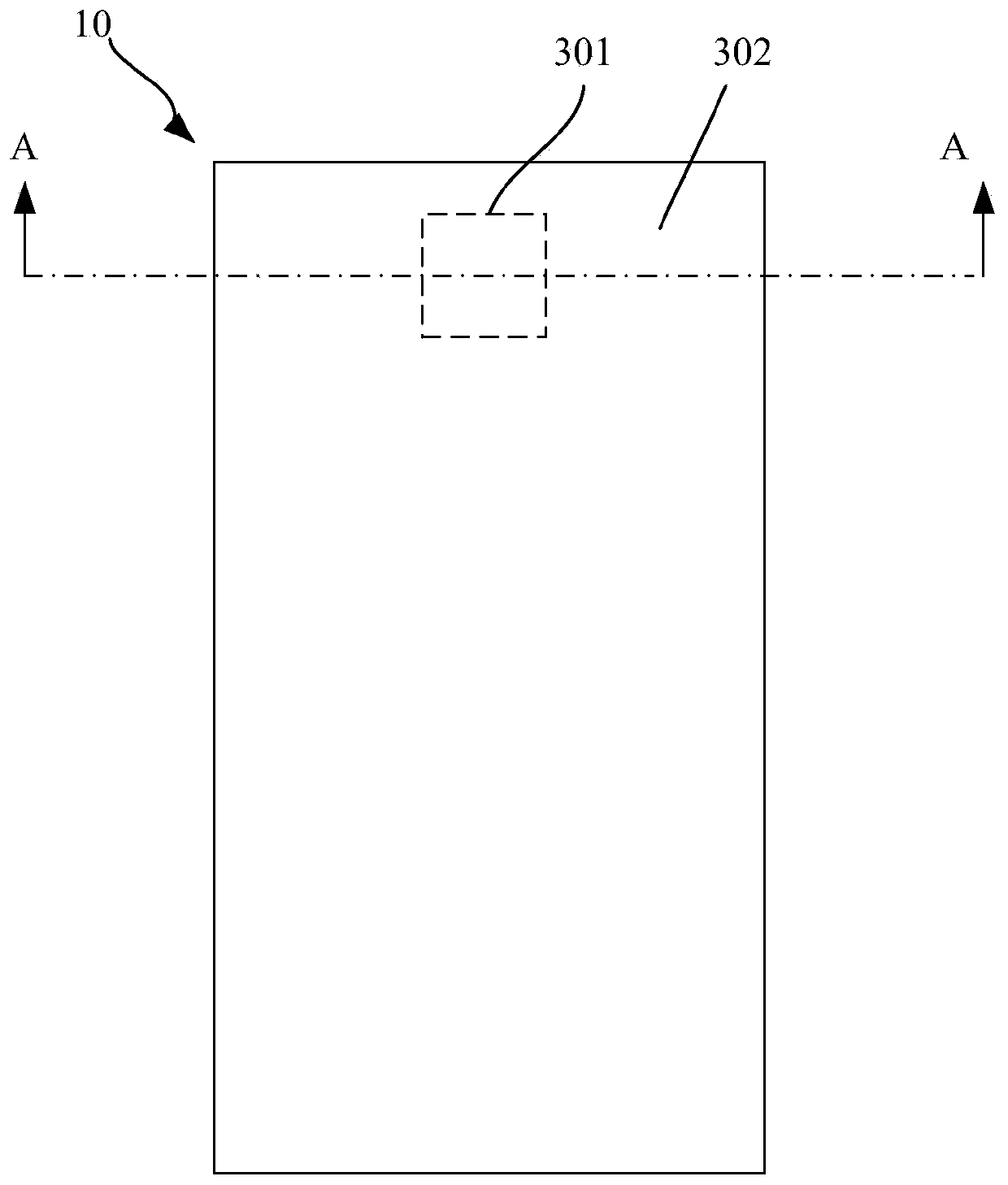

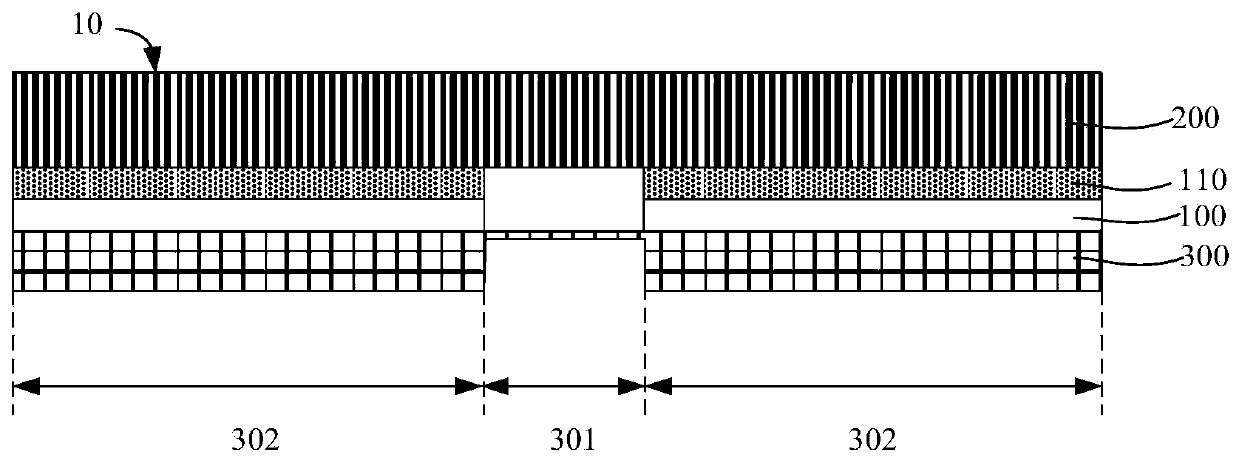

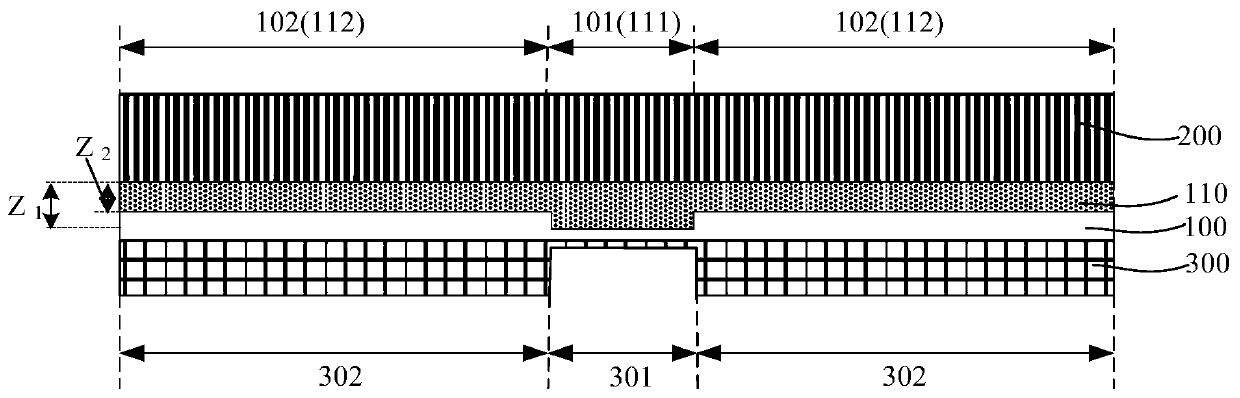

Support substrate, preparation method thereof and display panel

ActiveCN111509013AImprove transmittanceEasy to identifySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsIdentification rate

The invention discloses a support substrate, a preparation method thereof and a display panel, and relates to the technical field of the display. The support substrate comprises a device layer and a supporting layer which are stacked, the device layer comprises an identification area and a non-identification area, the supporting layer comprises a first supporting area corresponding to the identification area in position and a second supporting area corresponding to the non-identification area in position, and the thickness of the first supporting area is smaller than that of the second supporting area. According to the embodiment of the invention, through reducing the thickness of the first supporting area, corresponding to the identification area of the device layer, of the supporting layer, the transmittance of the first support area is improved, the optical loss is reduced, and the optical identification rate and sensitivity of an optical sensor are improved.

Owner:BOE TECH GRP CO LTD

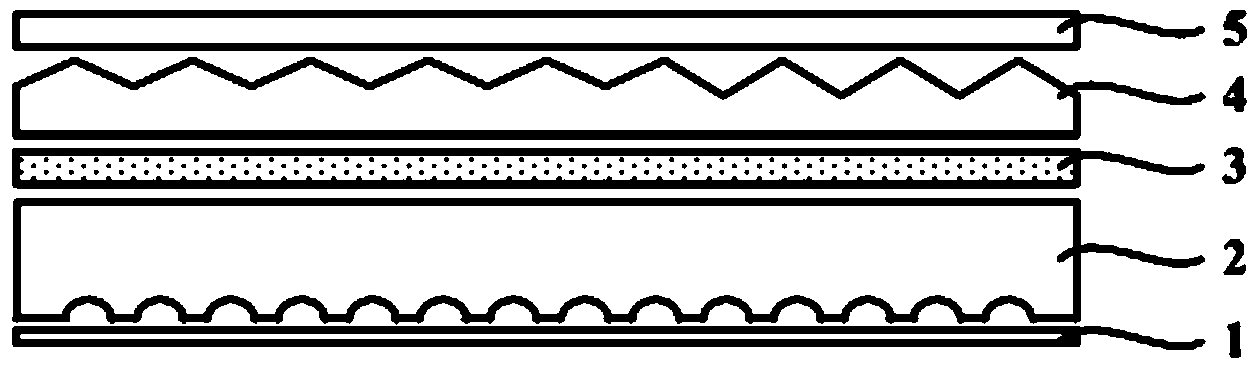

Optical module, backlight module and display device

InactiveCN104165330AHigh precisionImprove convenienceMechanical apparatusLamination ancillary operationsOptical ModuleLight guide

The invention relates to the technical field of display and discloses an optical module, a backlight module and a display device. The optical module comprises a light guide plate and an optical membrane set located on the light emitting side of the light guide plate. The face, opposite to the light emitting side, of the light guide plate is a lattice point face with lattice points, the lattice point face is provided with a reflecting layer, the light guide plate and the optical membrane set are bonded and fixed through a first transparent bonding layer, and optical membranes of the optical membrane set are bonded and fixed through second transparent bonding layers. According to the technical scheme, due to the fact that the reflecting layer is directly arranged on the lattice point face of the light guide plate and the light guide plate and the optical membrane set are fixed together in a bonding mode, the optical module is of an integrated structure, and when the optical module is assembled to the backlight module, the integrated optical module only needs to be located at a time. Thus, the locating accuracy of the optical module is improved, the convenience for assembling the backlight module is also improved, and thus the production efficiency of products is improved.

Owner:HEFEI BOE DISPLAY LIGHT +1

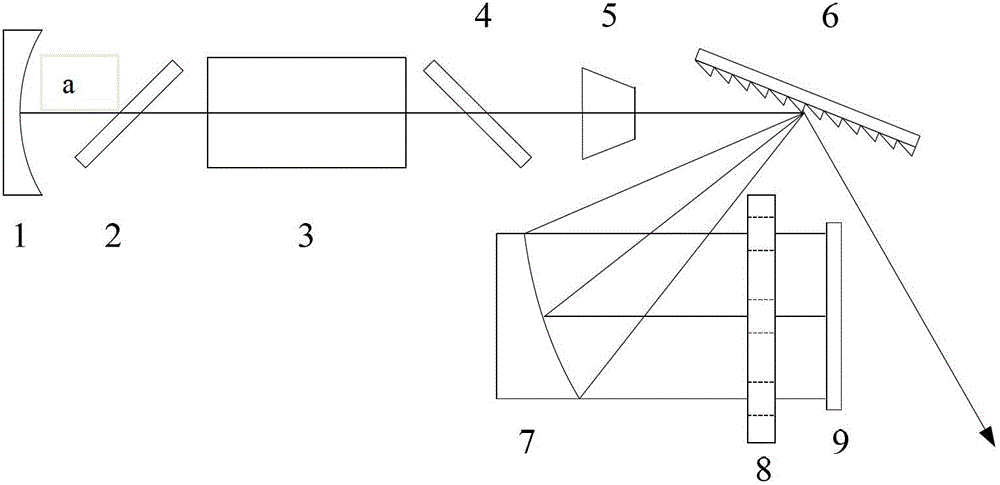

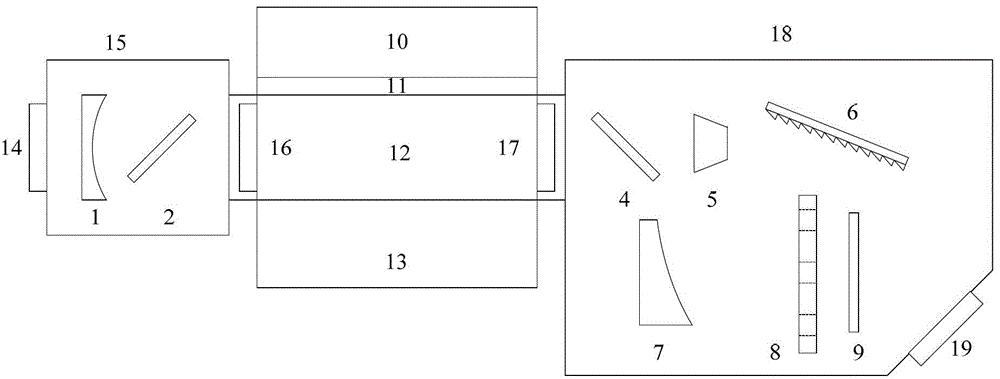

Variable line selection stable resonant cavity suitable for air flow chemical laser

ActiveCN104064948ARealize line selection outputEasy to distinguishLaser detailsResonant cavityMaterials processing

The invention relates to a variable line selection stable resonant cavity suitable for an air flow chemical laser. A stable cavity structure is adopted for the device. A plano-concave reflector, a Brewster plate, a gain media, a Brewster plate, a diaphragm and a plane diffraction grating are successively arranged along an output dimension of laser. An off-axis parabolic reflector, a shutter system and a planar reflector are successively arranged in a first-order diffraction optical path. According to the variable line selection stable resonant cavity, a fixed diffraction grating is used for the laser device. The diffraction grating is used for realizing different diffraction angles of laser with different wavelengths. Through controlling and selection of the shutter system to branch lines with different wavelengths, outputting of air flow chemical laser in a selected line is realized. The variable line selection stable resonant cavity of the invention has advantages of: compact structure, high optical beam quality, high stability, quick line selection and outputting of the laser, etc. The variable line selection stable resonant cavity can be widely applied for the fields of laser material processing, environment monitoring, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

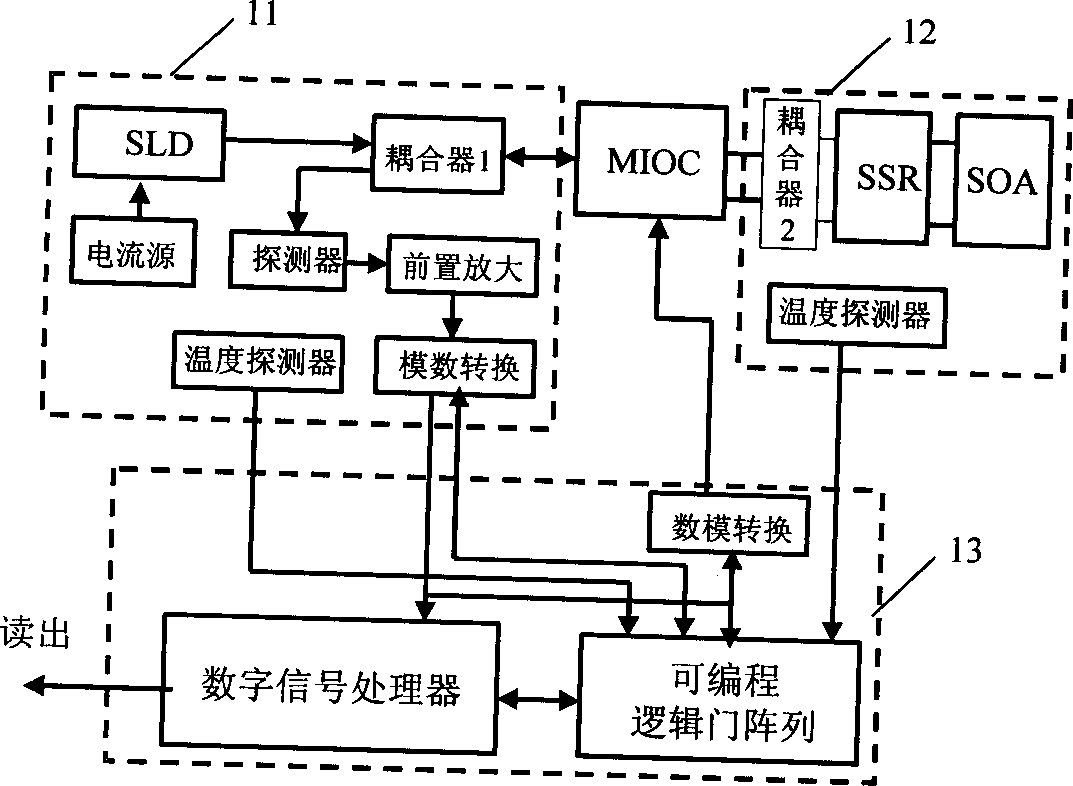

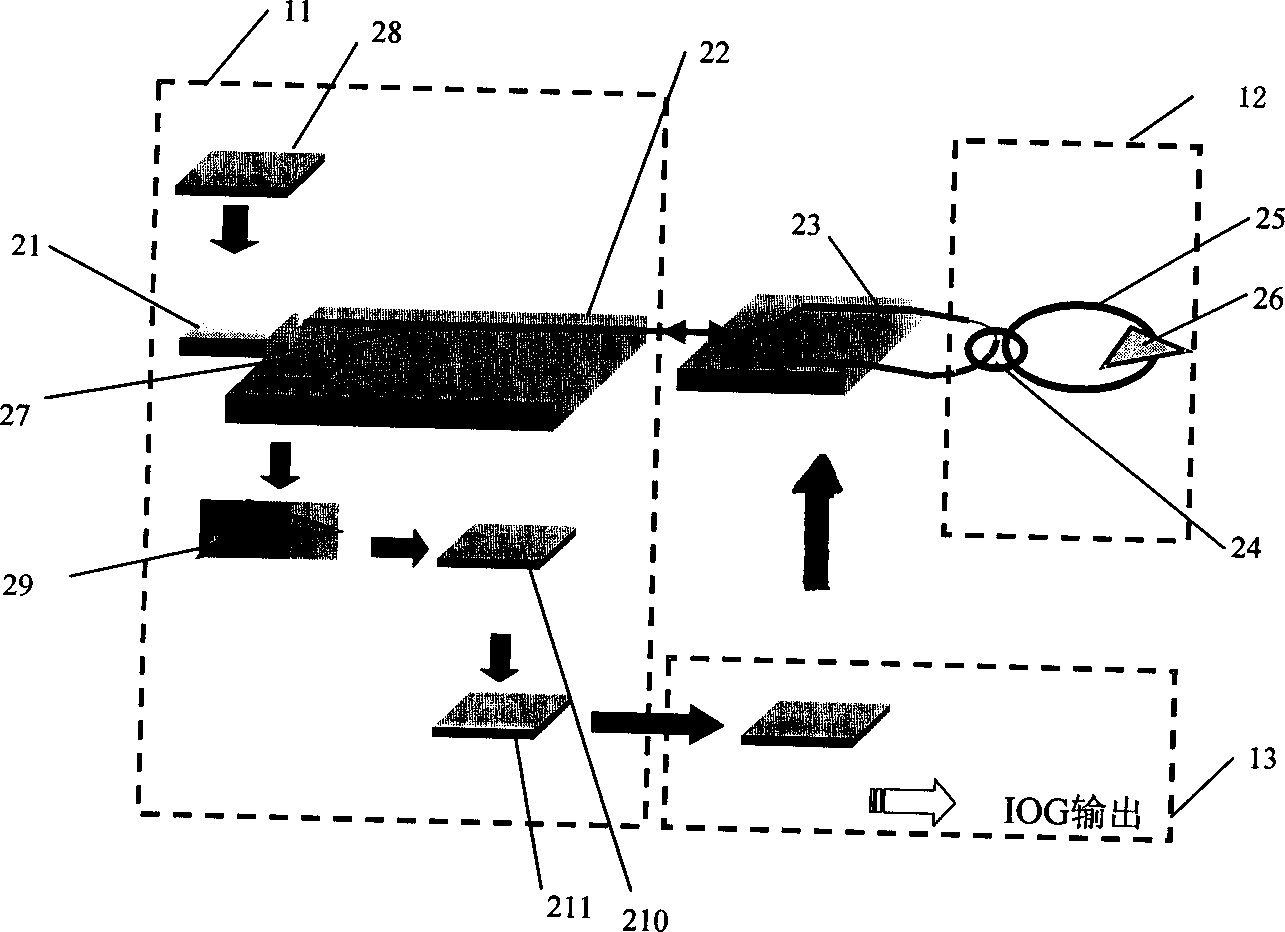

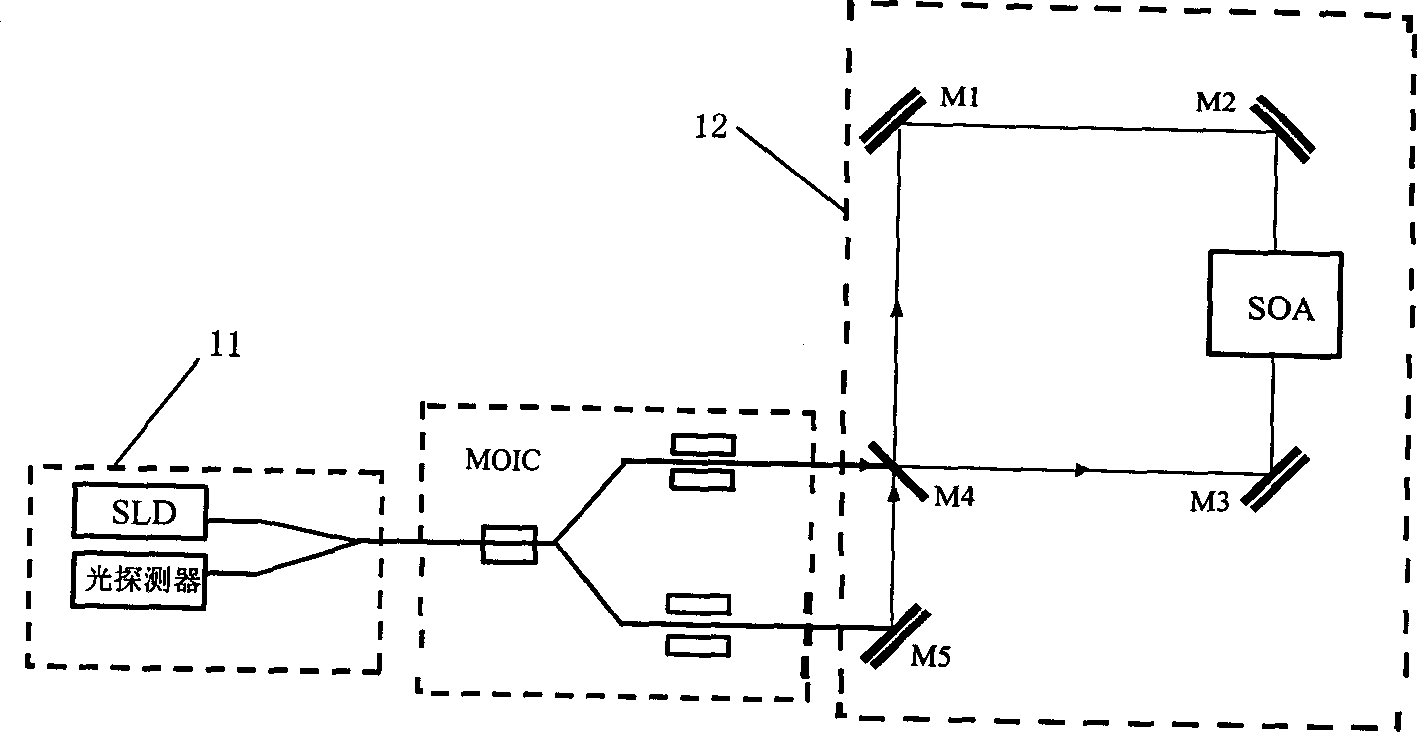

Nevigation-class cyclic interference type integrated optical gyroscope

InactiveCN1338613AImprove coupling efficiencyIncrease output powerTurn-sensitive devicesTransceiverOptical gyroscope

A nevigation-class cyclic interference type integrated optical gyroscope is composed of optical transceiver module, Y-waveguide electro-optical phase modulation module, closed-loop control and signalreader module, and sensing loop module consisting of coupler, optical semiconductor amplifier and Sainaike-effect sensing loop. Said phasew modulation module is bidirectionally connected with said optical transceiver module and sensing loop module. The D / A converter is said optical transceiver module is connected to said closed-loop control and signal reader module. Its advantages include short SSR length, high compatibility, small size, low cost and high reliability.

Owner:章燕申

Full back side contact crystalline silicon cell and preparation method thereof

InactiveCN103904138AAvoid alignment problemsUniform depthFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon chip

The invention relates to a novel crystalline silicon cell in the field of a photovoltaic technology, and specifically relates to a full back side contact crystalline silicon cell which is prepared through combination with an ion implantation technology, and also relates to a preparation method of the cell. The full back side contact crystalline silicon cell comprises a silicon chip substrate, an anti-reflection layer, a base electrode, an emitter electrode, a metal gate line and the like. The emitter electrode and the base electrode of the full back side contact crystalline silicon cell are not disposed in the same plane, so that electrons and cavities can be considered to move to the emitter electrode and the base electrode through a quire short path, and carrier bulk recombination in the cell can be reduced; through moving the emitter electrode and the metal grate line from a front surface, i.e., a light receiving surface to a back surface, the optical loss is reduced; the emitter electrode is obtained through an ion implantation method, and the process steps are reduced compared to a conventional thermal diffusion doping method; and the front surface and the back surface are each provided with a passivation layer, and the front surface is further provided with a front surface field (FSF), so that the carrier surface recombination can be reduced, and the invention finally provides a solar cell which has the advantages of high batch production efficiency and simple technology.

Owner:DONGTAI HI TECH EQUIP TECH (BEIJING) CO LTD

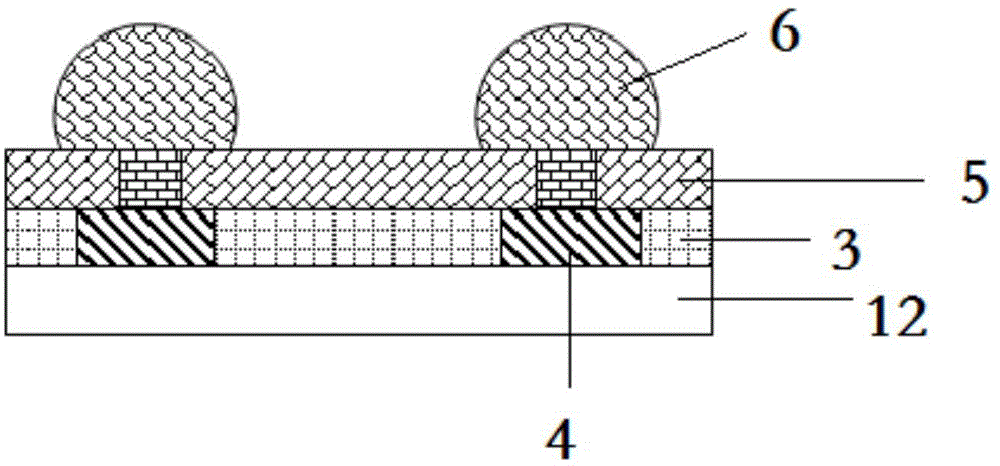

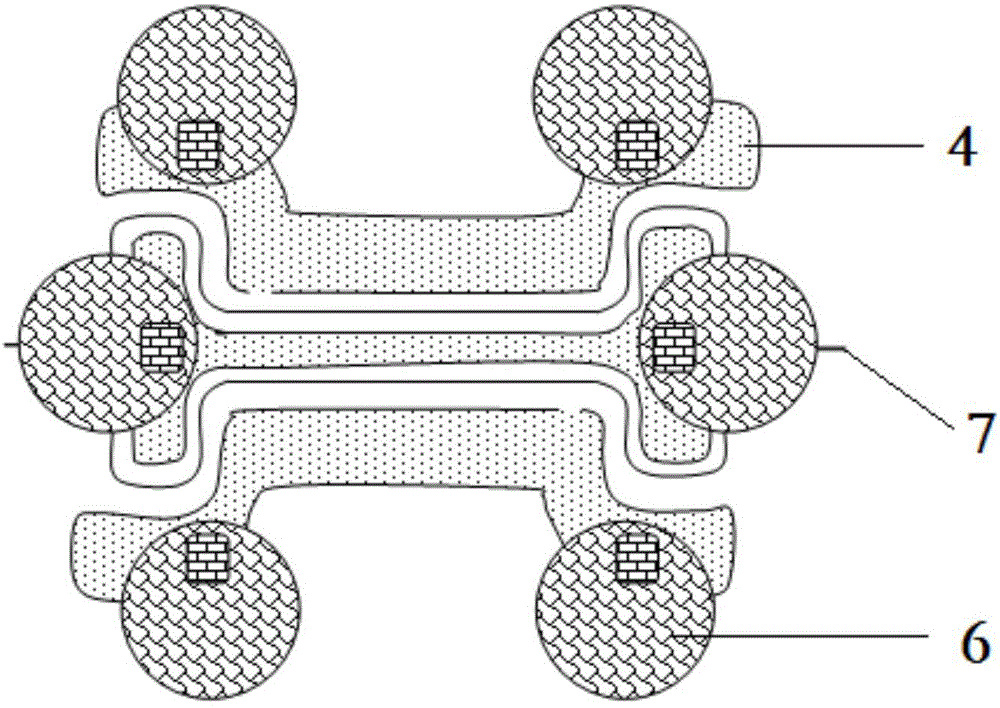

Echo wall microcavity acoustic sensor, and preparation method of double-ring resonant cavity thereof

ActiveCN110440897AReduce optical lossHigh peak sensitivitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansResonant cavityAcoustic wave

The invention discloses an echo wall microcavity acoustic sensor, and a preparation method of a double-ring resonant cavity thereof. The sensor comprises a laser, a spectrum system, and a double-ringresonant cavity; the laser is used for emitting laser to the spectrum system; and the spectrum system is used for vertically reflecting the laser to the double-ring resonant cavity. The sensitivity ofthe acoustic sensor is improved, and sound waves can be efficiently detected.

Owner:NANJING UNIV OF POSTS & TELECOMM

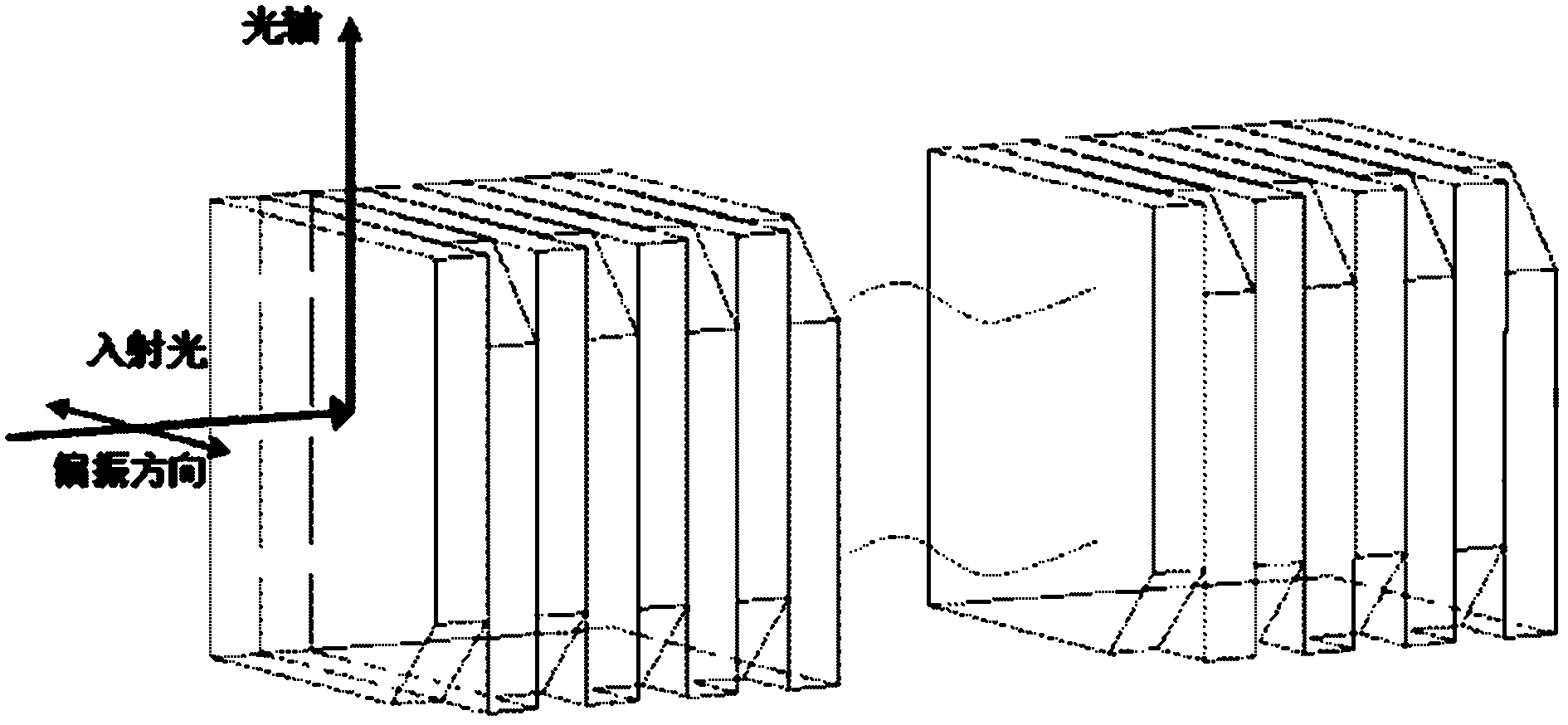

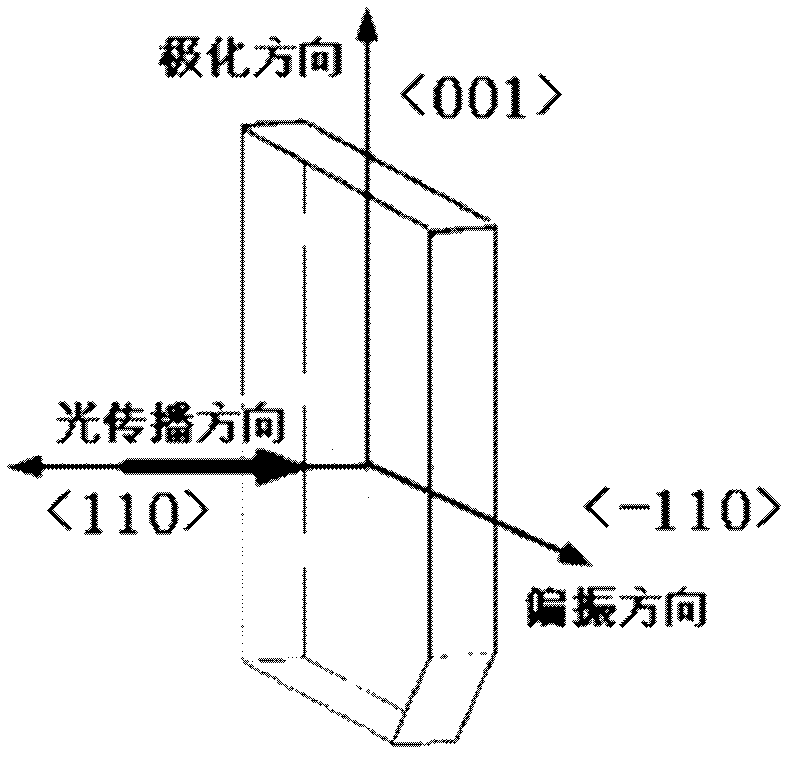

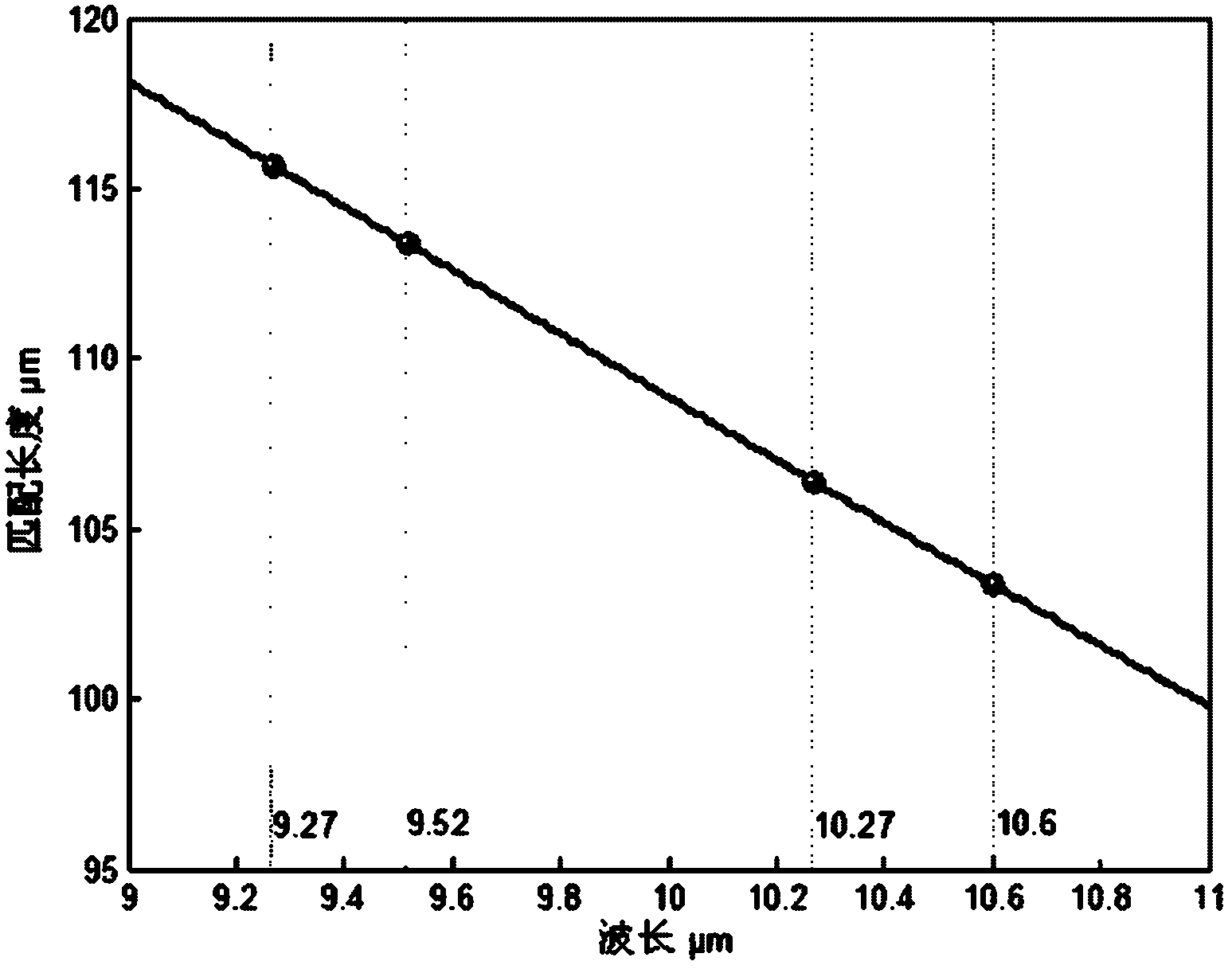

Preparation method of quasi-phase matching crystals for improving CO2 laser frequency multiplication efficiency

InactiveCN102570276AImprove conversion efficiencyIncrease output powerLaser detailsNon-linear opticsZinc selenideMicrometer

A preparation method of quasi-phase matching crystals for improving CO2 laser frequency multiplication efficiency belongs to the field of laser and is characterized in that zinc selenide single crystals are regarded as quasi-phase matching frequency multiplication crystals, the zinc selenide single crystals are cut into a plurality of flakes with a thickness between 100 micrometer and 120 micrometer in the same specification along a perpendicular (110) direction of the zinc selenide single crystals, polarization directions of adjacent crystal flakes differ by 180 DEG, the surfaces of the crystal flakes are bombarded by hydrogen ion beam after being polished, the adjacent zinc selenide crystal flakes are combined firmly through a bonding technology, and multiple layers of crystal flakes are formed into an integration. Compared with existing common frequency multiplication methods, the method has the advantages that optical loss of devices is small, clear aperture can reach above 1 cm<2>, and conversion efficiency and output power of CO2 laser quasi-phase matching frequency multiplication crystals are improved greatly.

Owner:BEIJING UNIV OF TECH

Lithium niobate photomodulator and manufacturing and packaging method thereof

ActiveCN104460054AOptimizing Optical LossEnhance photoelectric effectOptical light guidesNon-linear opticsRadio frequencyVoltage

Provided are a lithium niobate photomodulator and a manufacturing and packaging method thereof. A waveguide structure is manufactured on a lithium niobate substrate through hydrogenated amorphous silicon, the size of a waveguide can be effectively reduced by means of the high refractive index of the amorphous silicon, and therefore the distance between metal electrodes on the lithium niobate photomodulator is reduced, and voltage needing modulating is low. A waveguide chip is preferentially manufactured by the hydrogenated amorphous silicon, and Si:H chains of the amorphous silicon can reduce optical losses. Due to the fact that the thickness of the hydrogenated amorphous silicon is adjusted, the photoelectric effect of the lithium niobate photomodulator can be maximized under the premise that the size of the waveguide is guaranteed. Due to that fact that the thickness of silicon dioxide and the thicknesses of the metal electrodes are controlled, good radio frequency matching can be guaranteed, and an optical fiber interface connected with the outside is achieved through waveguide lines penetrating through a waveguide layer; because all the waveguide lines are located in the waveguide layer, enough metal regions for packaging or testing can be reserved. The perfect packaging process can reduce the occurrence probability of the phenomenon of electric leakage, and the phenomenon that a humid environment leads to a short-circuit phenomenon is avoided.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

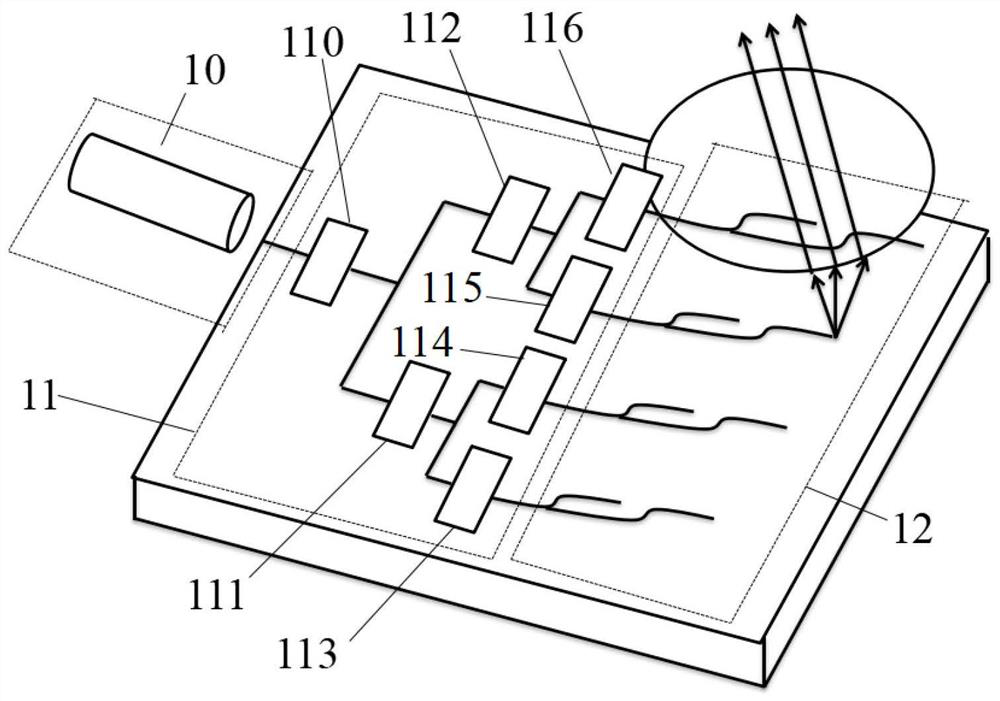

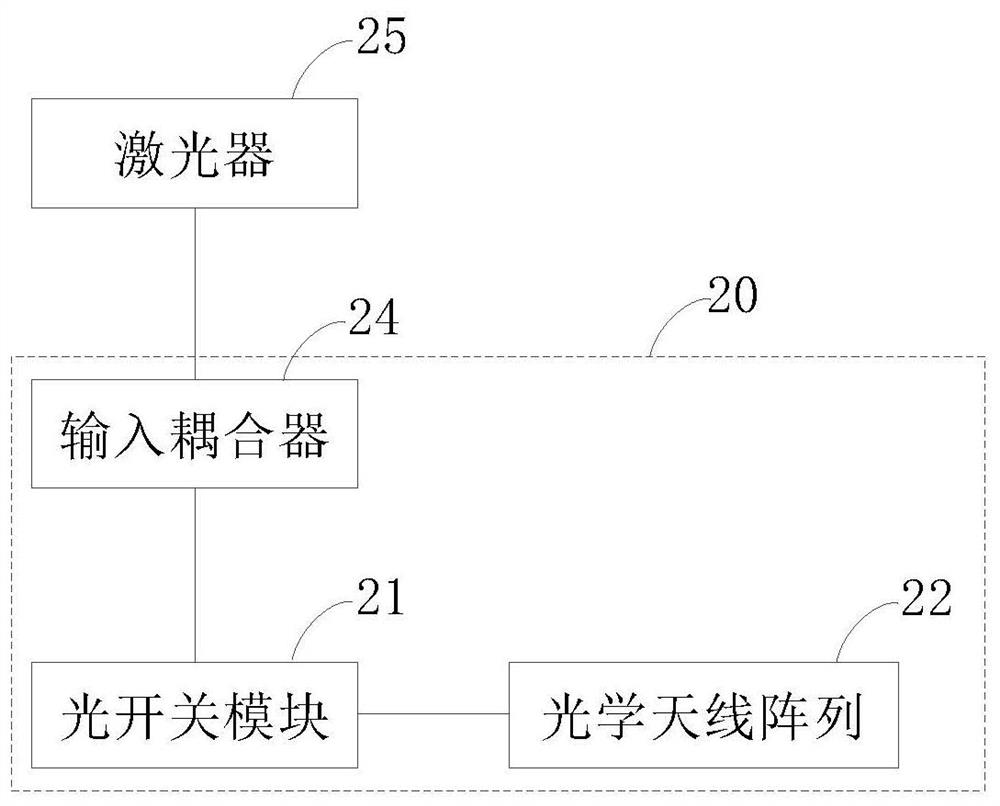

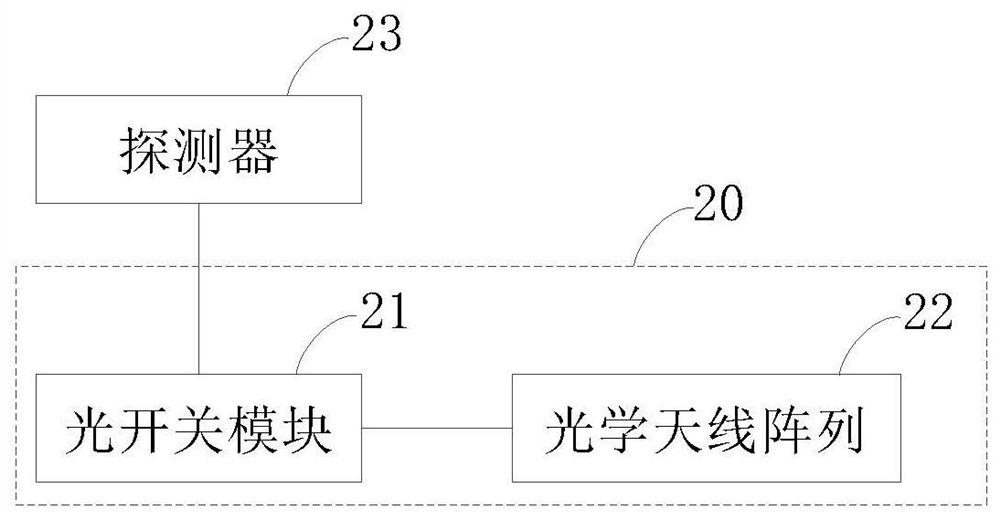

Laser radar chip, laser radar and laser detection method thereof

PendingCN114325636ASmall sizeReduce optical lossElectromagnetic wave reradiationOptical antennaEngineering

The embodiment of the invention provides a laser radar chip, a laser radar and a laser detection method thereof. The laser radar chip comprises an optical switch module and an optical antenna array which are connected with each other, the optical switch module is connected to a detector or an input coupler, and the input coupler is connected to a laser; the input coupler is used for receiving laser emitted by the laser and sending the laser to the optical switch module through the optical waveguide; the optical switch module comprises a micro-ring and an optical waveguide and is used for transmitting the laser to the optical antenna array or transmitting a reflection echo corresponding to the laser to the detector; and the optical antenna array is used for emitting the laser to a space or receiving a reflection echo corresponding to the laser and sending the reflection echo to the optical switch module. According to the embodiment of the invention, the size of the laser radar chip and the optical loss can be reduced.

Owner:BEIJING WANJI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com