Preparation method of WGM (whispering gallery mode) ZnO ultraviolet micro-laser for constructing electric pump

A micro-laser, whispering gallery mode technology, applied in the structural details of semiconductor lasers, lasers, laser parts and other directions, can solve the problems of laser loss, sacrificing carrier concentration, etc., achieve small optical loss, good electrical contact, improve Effects of lasing and transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preparation method of constructing the electrically pumped whispering gallery mode ZnO ultraviolet micro-laser of the present invention is:

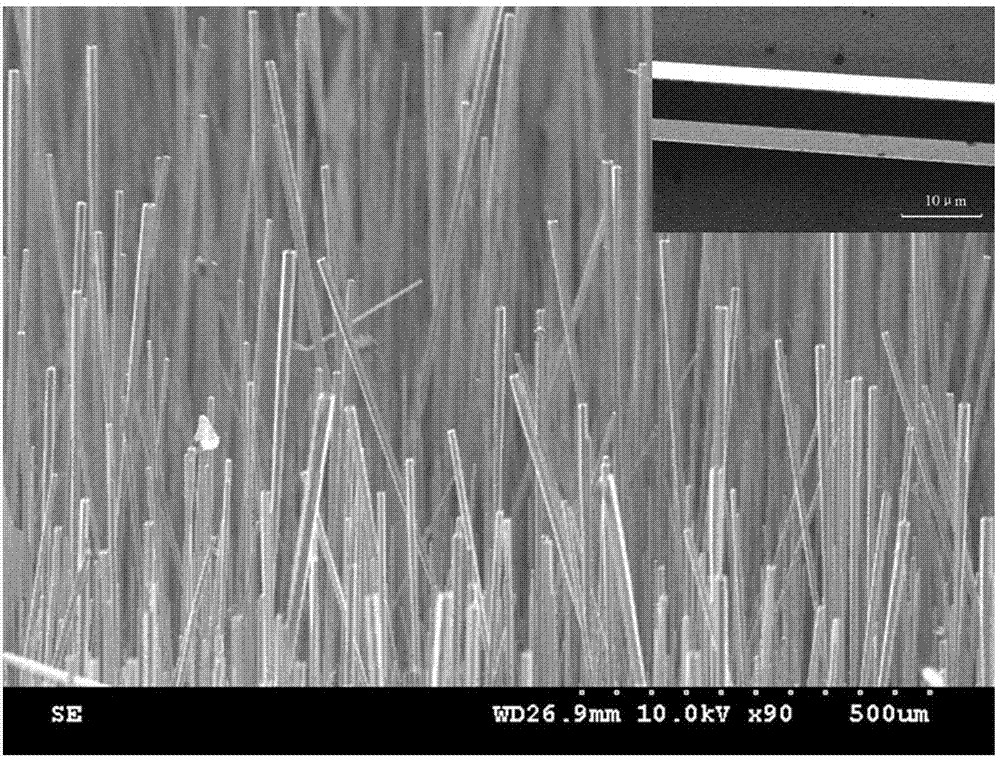

[0032]Step 1: Mix and grind ZnO powder and carbon powder with a purity of 99.99% at a mass ratio of 1:1 to 1:2.5, and fill 0.3 to 0.5 grams of the mixture into a ceramic boat. The silicon wafer with an area close to the opening area of the ceramic boat was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, then blown dry with nitrogen, and covered the silicon wafer with the polished side down on the ceramic boat. The ceramic boat is then pushed into a tube furnace at a temperature of 1000-1200 degrees Celsius. After 30-40 minutes of reaction, ZnO microrod arrays grow on the surface of the silicon wafer (see figure 1 ), a single ZnO microrod is the crystal structure of hexagonal wurtzite (see figure 1 illustration in ).

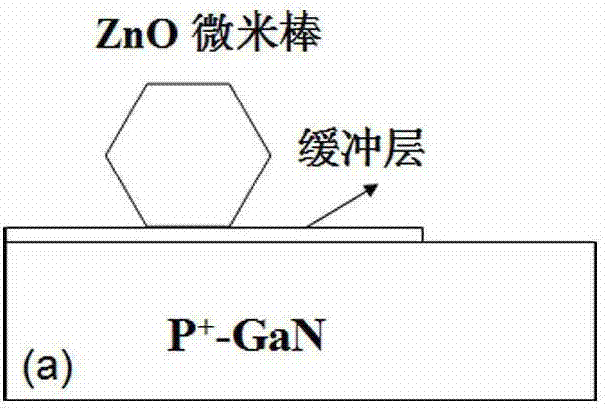

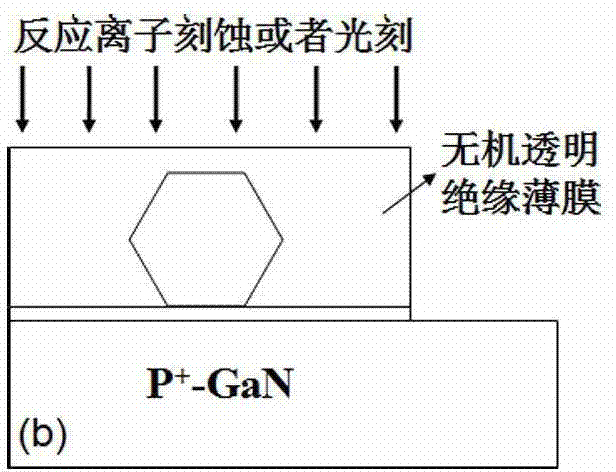

[0033] The second step: the buffer layer is divided into two types...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com