Laser line width compressing module and narrow-line-width laser

A technology for compressing the module and laser line width, which is applied in the laser field, can solve problems such as difficult light extraction and complex optical system, and achieve the effects of simplifying the line width narrowing module, high optical integration, and reducing optical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

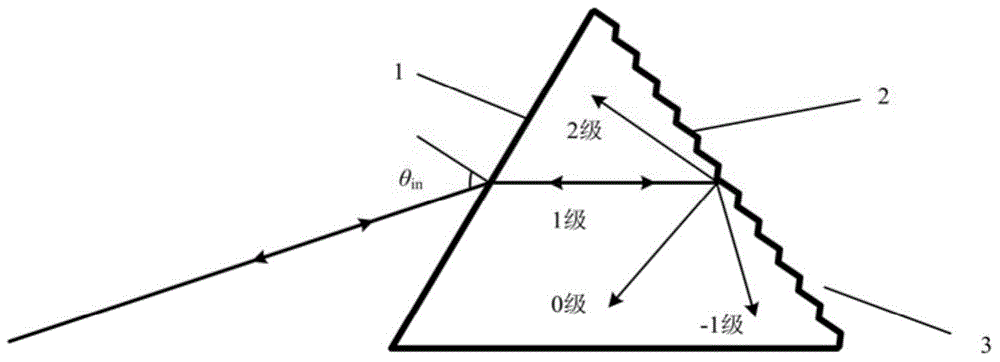

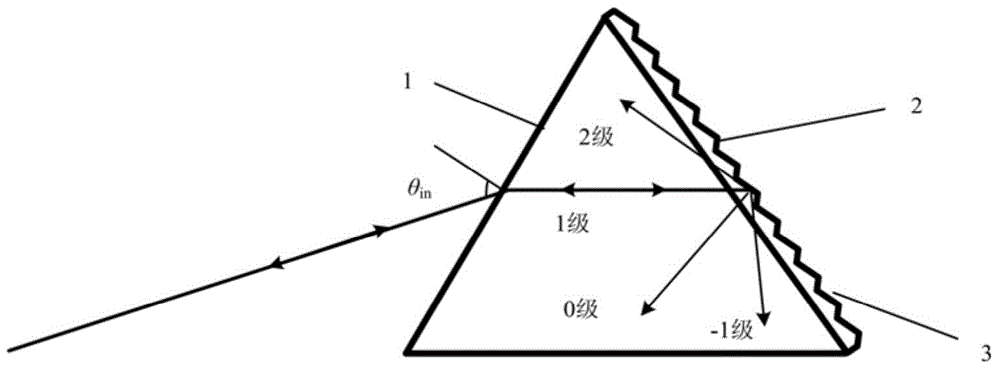

[0027] Such as figure 1 As shown, the present invention provides a line width narrowing module of a laser resonator, the module is an integrated optical body device, the module has a prism appearance feature, and there are two main working surfaces, one is the incident surface 1, and the other is the The reflective surface 2 with special periodic structure features has a special angle θ between the incident surface 1 and the reflective surface 2 .

[0028] The incident surface 1 is a plane, and anti-reflection coating can be coated to reduce reflection loss according to needs, or in the case of no coating, the light is incident on the incident surface 1 of the line width narrowing module at Brewster's angle. The material of the line width narrowing module is a transparent material for the working wavelength, for example, the working wavelength is in the visible light range, and the commonly used materials are quartz, K9, CaF 2 glass etc.

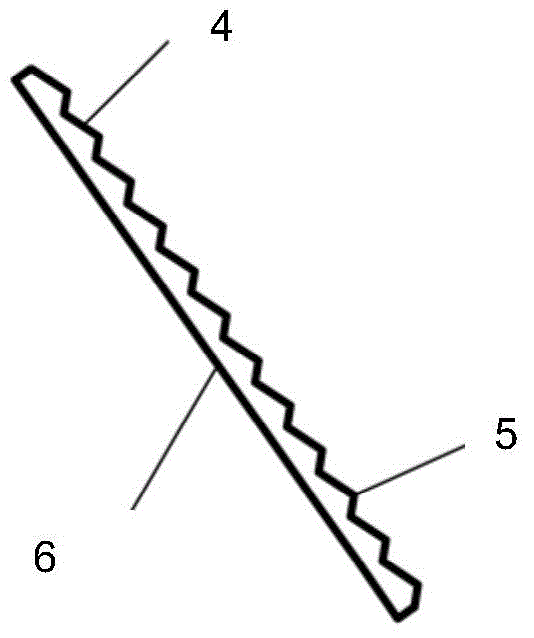

[0029] The reflective surface 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com