Echo wall microcavity acoustic sensor, and preparation method of double-ring resonant cavity thereof

An acoustic sensor and double-loop resonance technology, which is applied in the field of acoustic sensors, can solve the problems of low sensitivity, low resolution, complex preparation process, etc., and achieve the effect of obvious optical effect, high peak sensitivity and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

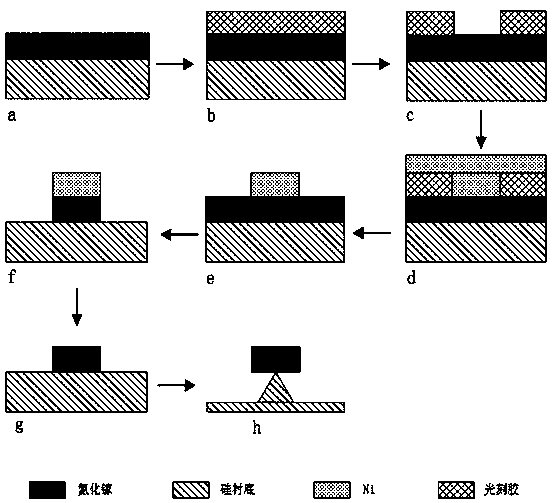

[0032] The working principle and technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation.

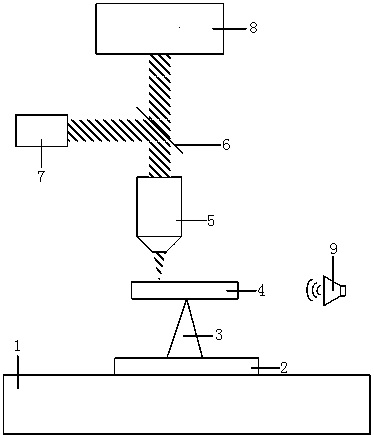

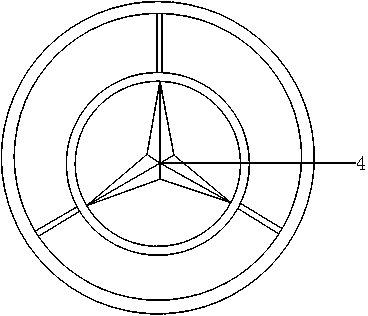

[0033] Such as figure 1 As shown, a whispering gallery microcavity acoustic sensor includes a laser 7, a spectrum system, a double-ring resonator 4, a silicon column 3, a silicon substrate 2, a stage 1 and an ultrasonic sound source 9, and the spectrum system includes a mirror 6, Spectrometer 8, focusing objective lens 5.

[0034] The incident laser light emitted by the laser 7 is horizontally injected into the reflector 6 inside the spectroscopic system;

[0035] The internal reflection mirror 6 of the spectrum system vertically injects the horizontally incident laser into the focusing objective lens 5 inside the spectrum system,

[0036] The laser light transmitted by the reflector 6 inside the spectroscopic system is vertically injected into the spectrometer 8;

[0037] The foc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com