Patents

Literature

196results about How to "Uniform depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

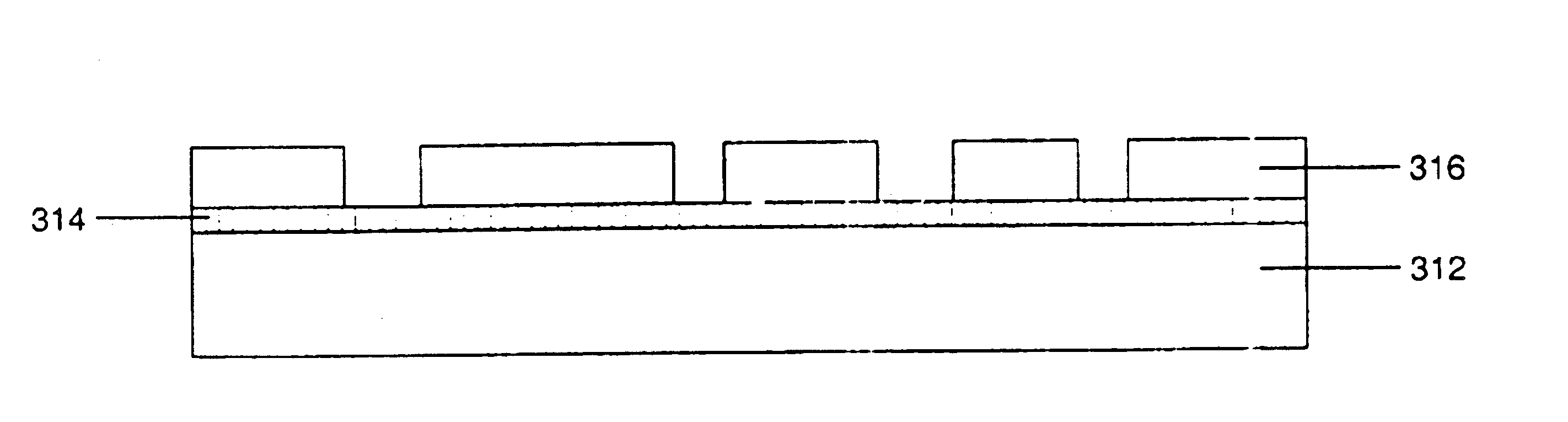

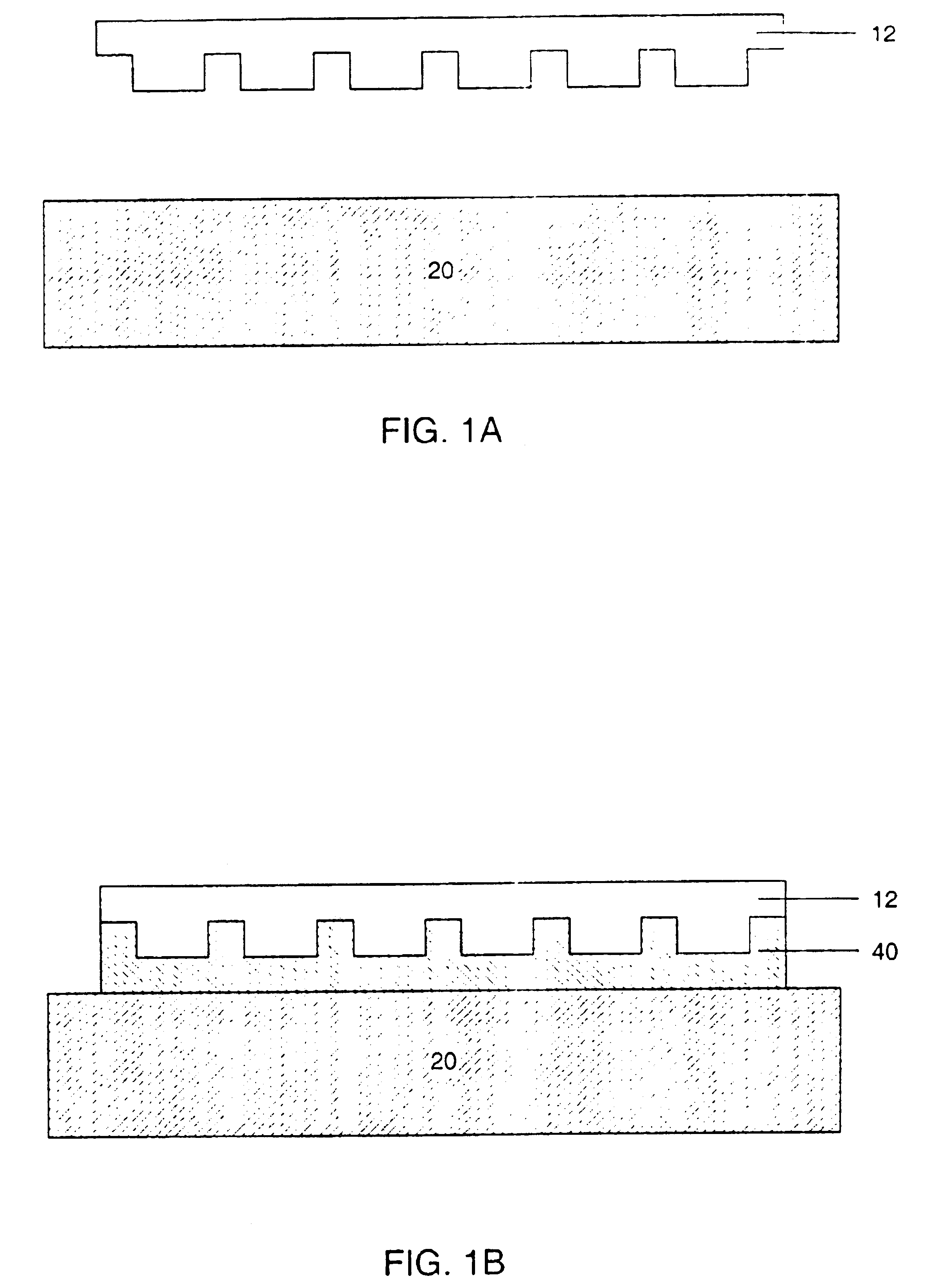

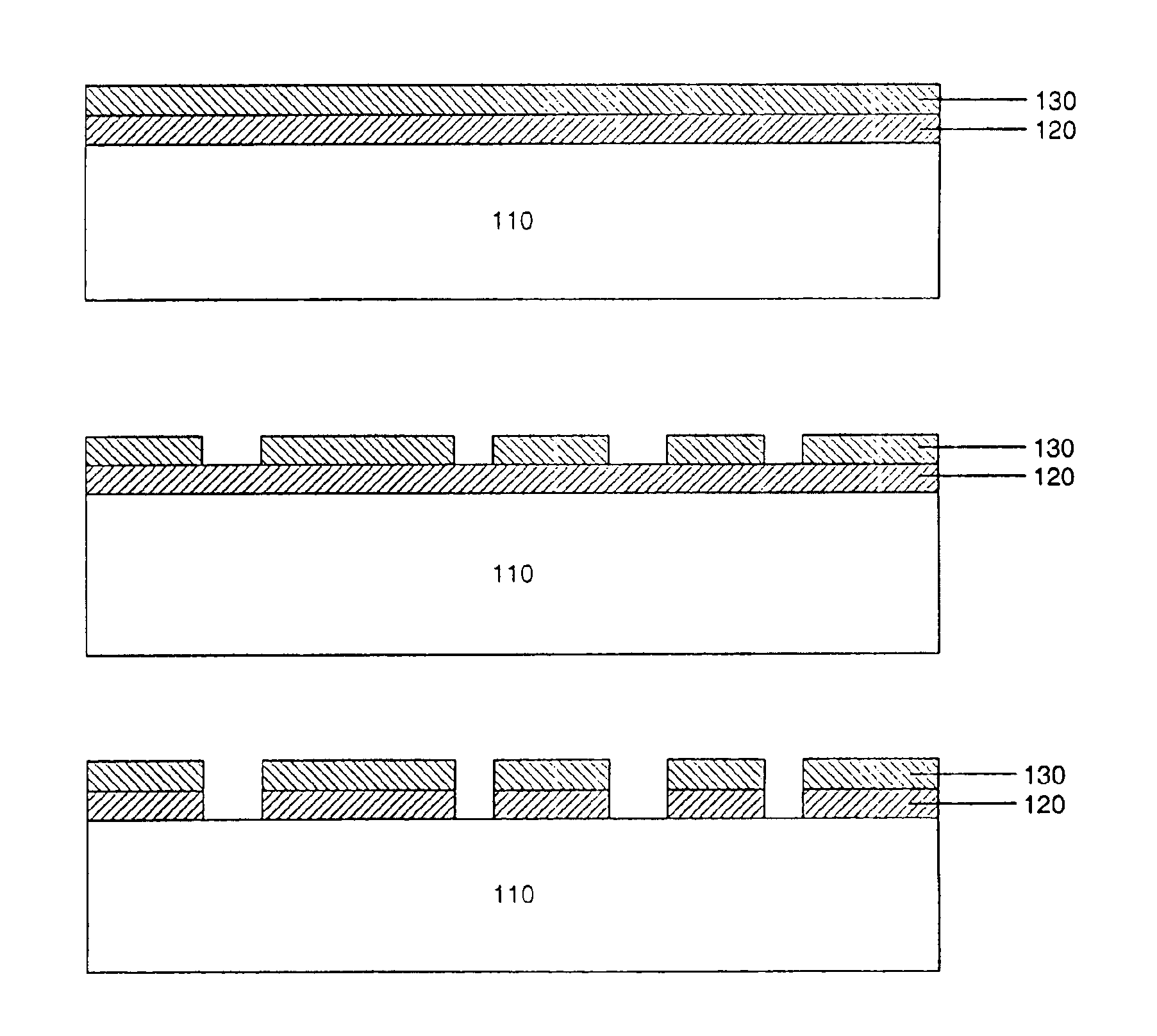

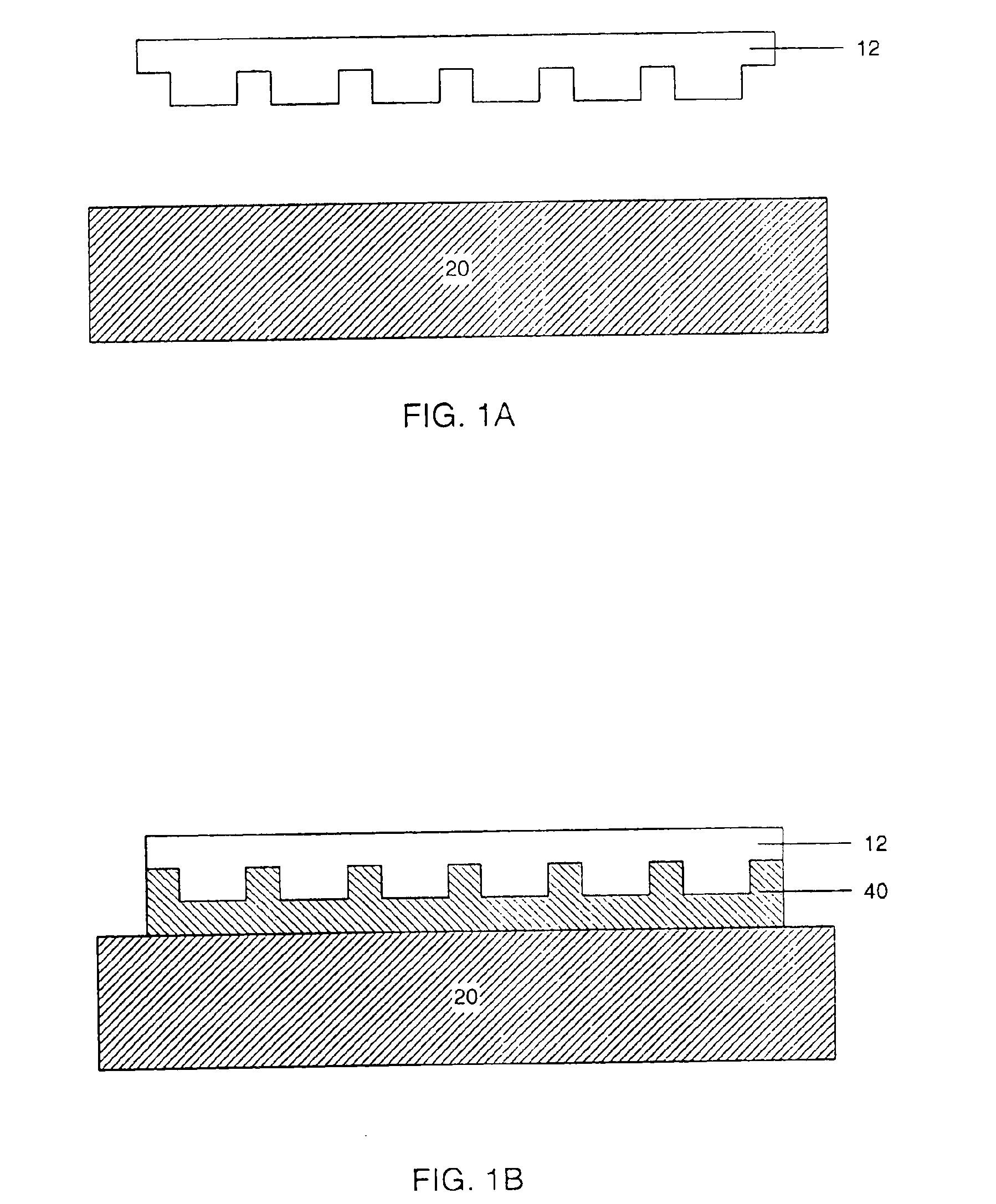

Methods of manufacturing a lithography template

InactiveUS7037639B2Minimal undercutReduce defect densityElectric discharge tubesNanoinformaticsLithographic artistBeam pattern

A method for forming imprint lithography templates is described herein. The method includes forming a masking layer and a conductive layer on a substrate surface. The use of a conductive layer allows patterning of the masking layer using electron beam pattern generators. The substrate is etched using the patterned masking layer to produce a template.

Owner:CANON KK

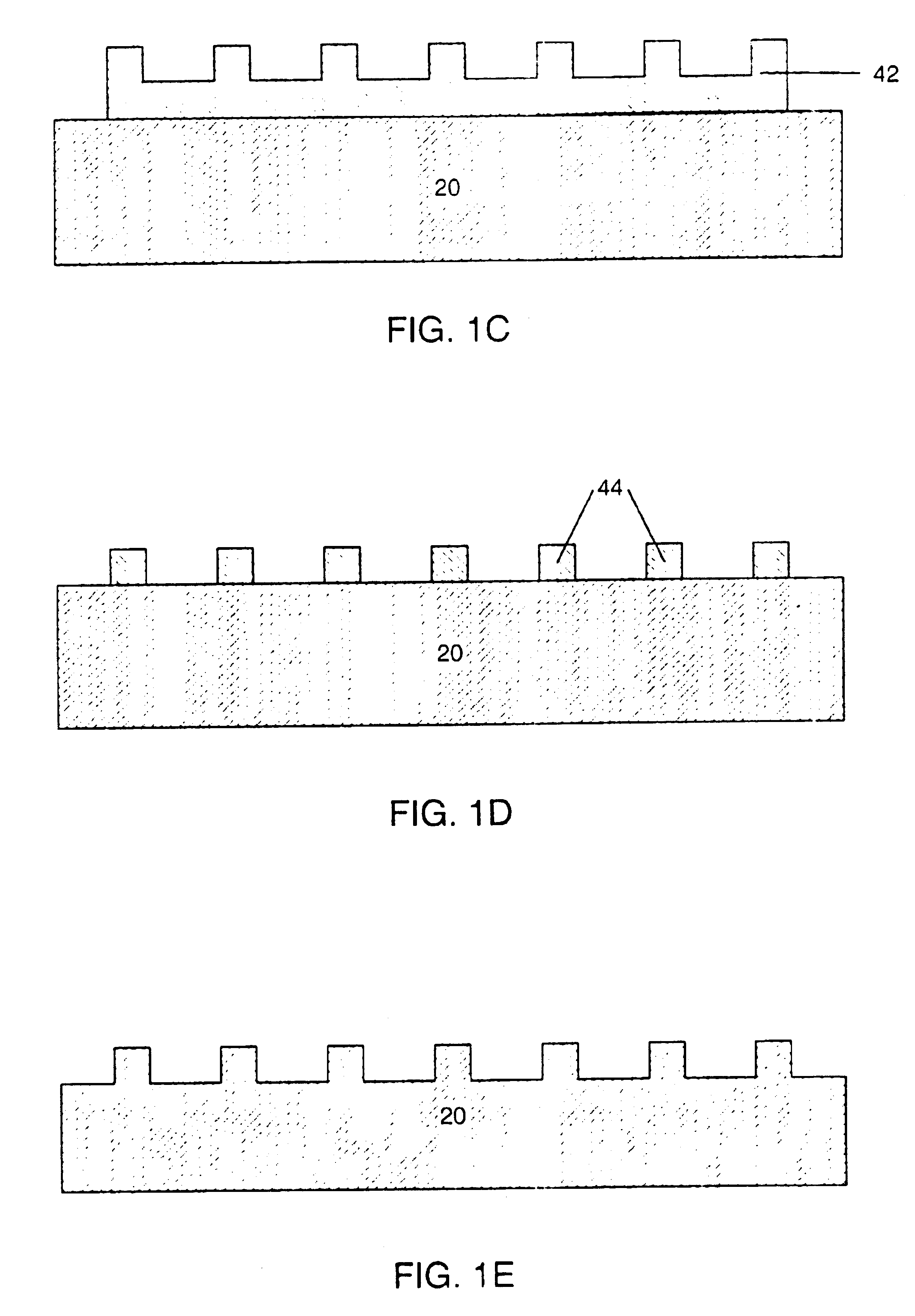

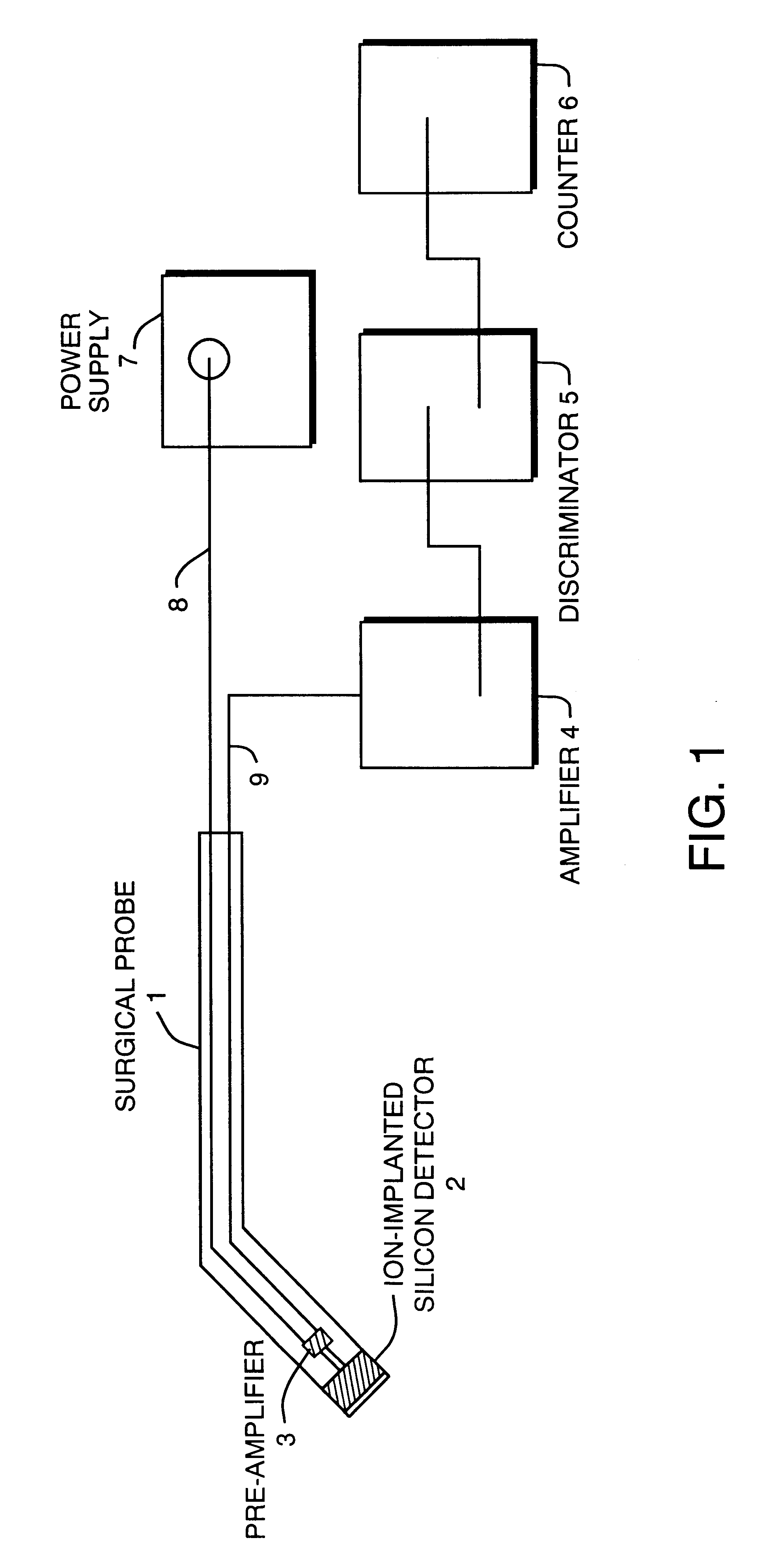

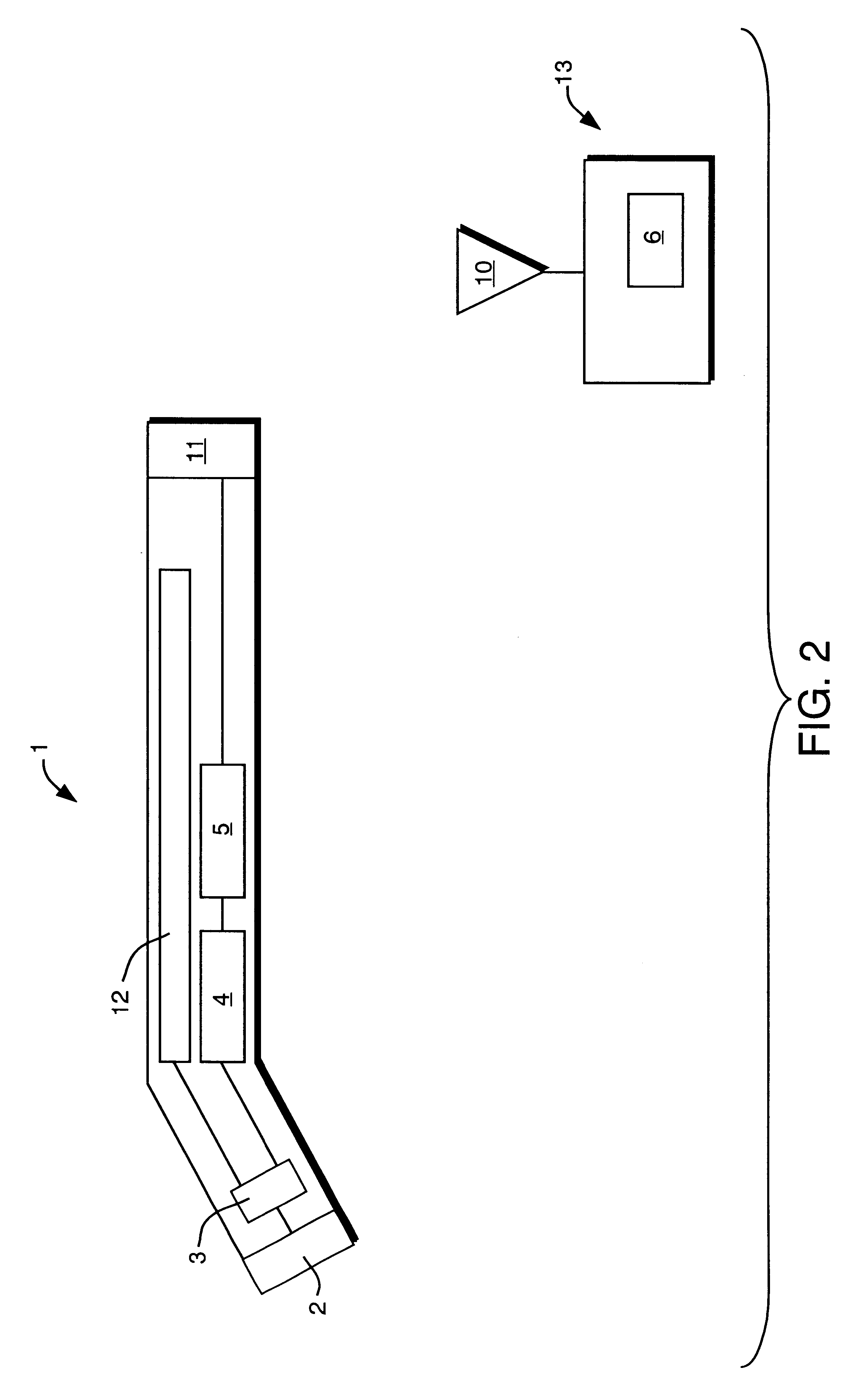

Solid state beta-sensitive surgical probe

InactiveUS6456869B1Sensitive highMinimizing requisite sizeSolid-state devicesMaterial analysis by optical meansInfraredAudio power amplifier

An intraoperative probe system for preferentially detecting beta radiation over gamma radiation emitted from a radiopharmaceutical is described. In one embodiment, the probe system of the present invention is a probe having an ion-implanted silicon charged-particle detector for generating an electrical signal in response to received beta particles. In such an embodiment, a preamplifier may be located in close proximity to the detector filters and amplifies the electrical signal. Furthermore, a wire may be used to couple the probe to a processing unit for amplifying and filtering the electrical signal, and a counter may be utilized to analyze the resulting electrical signal to determine the number of beta particles being received by the detector. Alternatively, the wire can be replaced with an infrared or radio transmitter and receiver for wireless operation of the probe.

Owner:RGT UNIV OF MICHIGAN

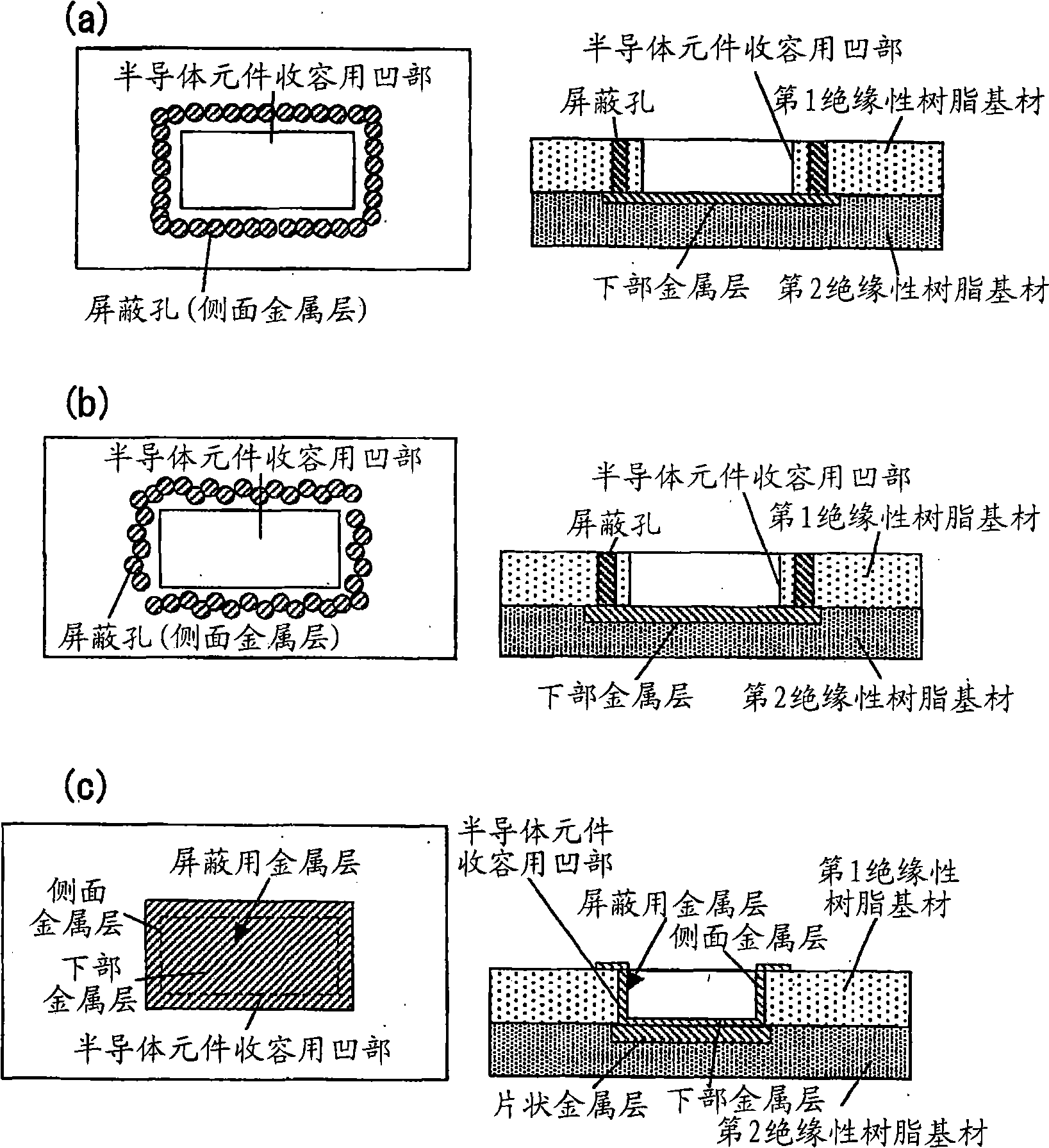

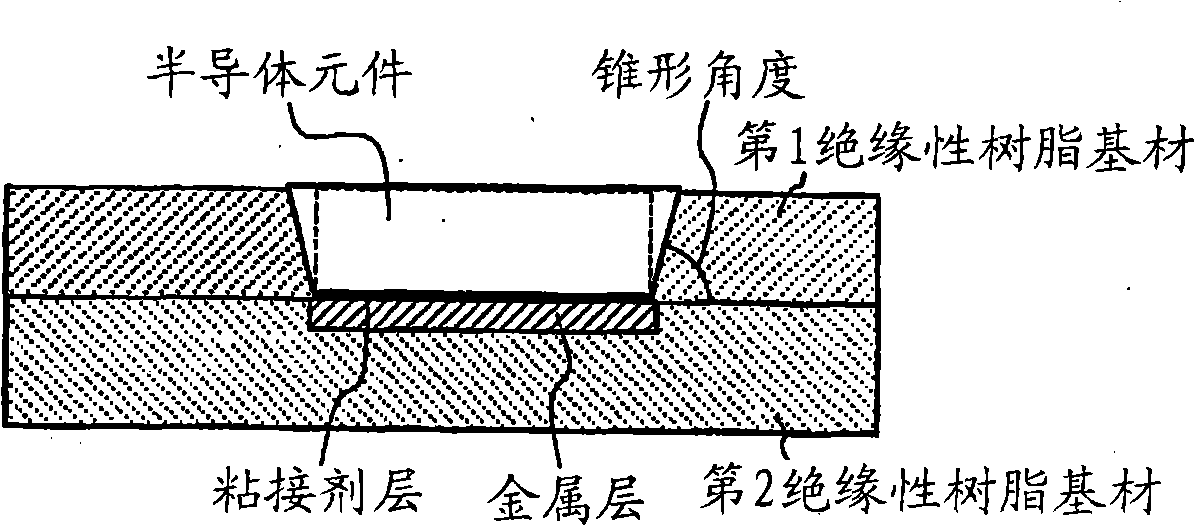

Multilayer printed wiring plate, and method for fabricating the same

InactiveCN101331814AReduce signal delayReduce malfunctions and other problemsCross-talk/noise/interference reductionSemiconductor/solid-state device detailsElectrical conductorEngineering

Provided is a multilayer printed wiring plate, in which an insulating resin film and conductor circuits are formed over another insulating resin layer housing a semiconductor element and in which the conductor circuits are electrically connected with each other through a via hole, wherein an electromagnetic shield layer is formed either in the insulating resin layer enclosing a recess for housing the semiconductor element or in the inner wall face of the recess, and wherein the semiconductor element is mounted in the recess.

Owner:IBIDEN CO LTD

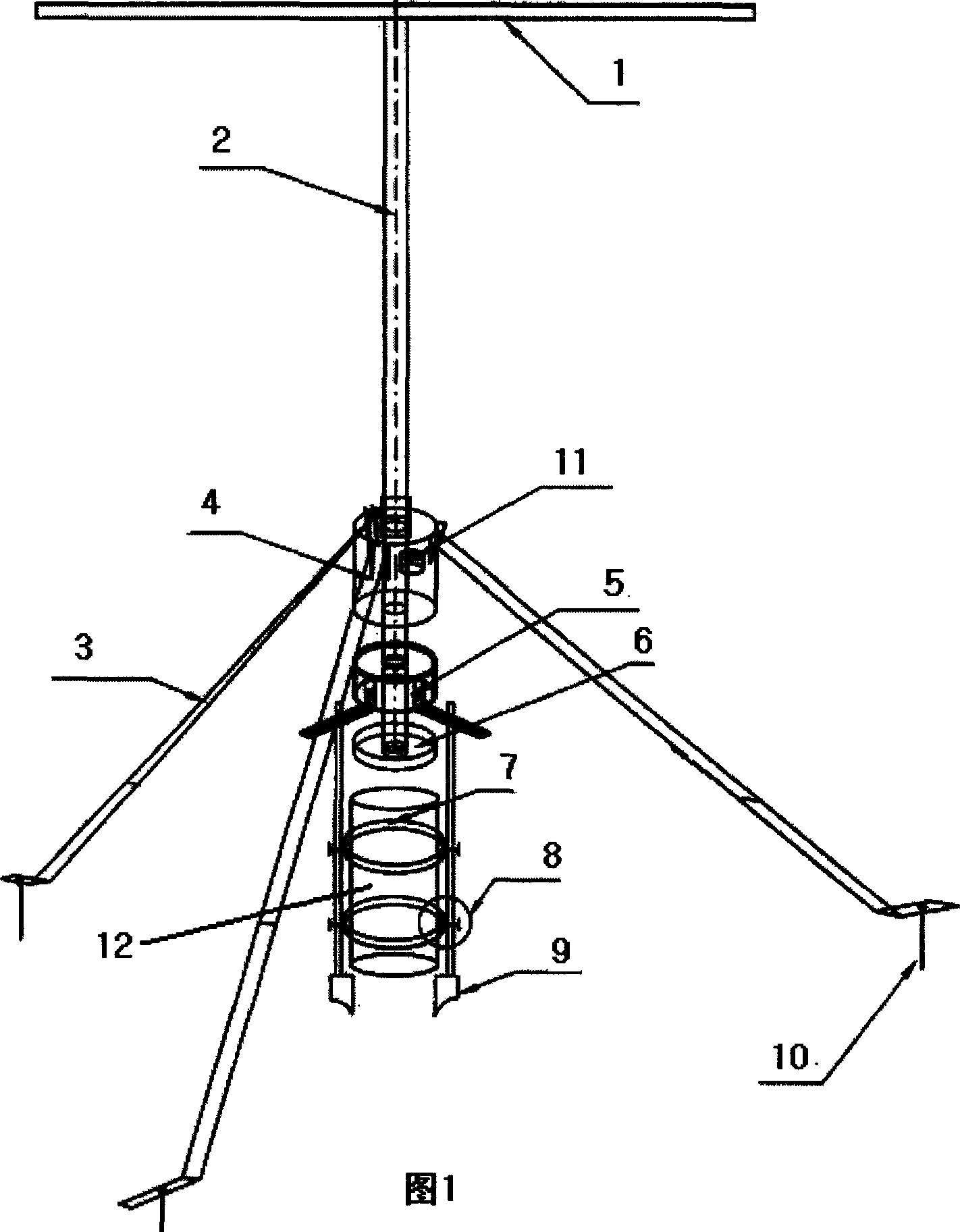

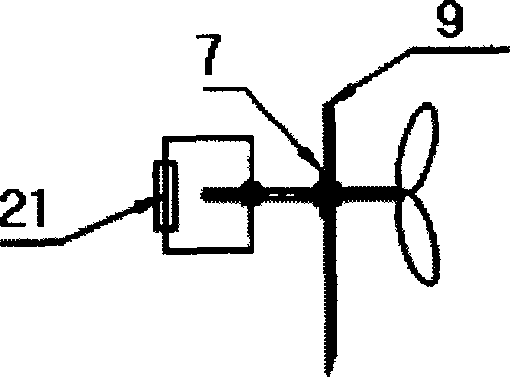

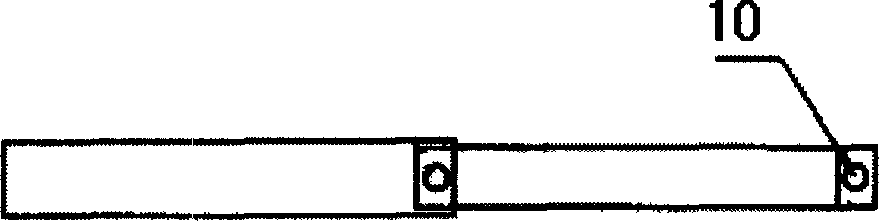

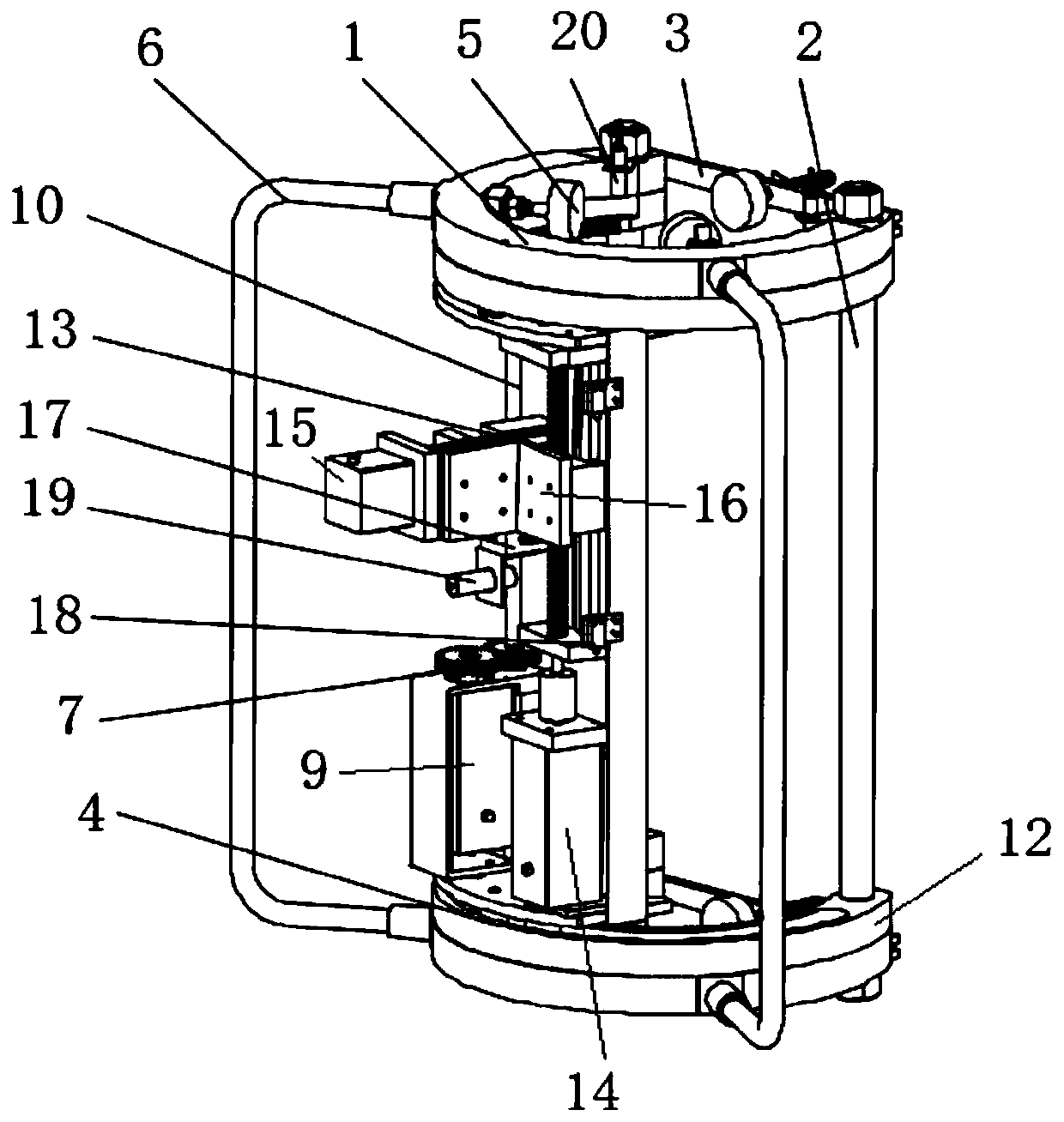

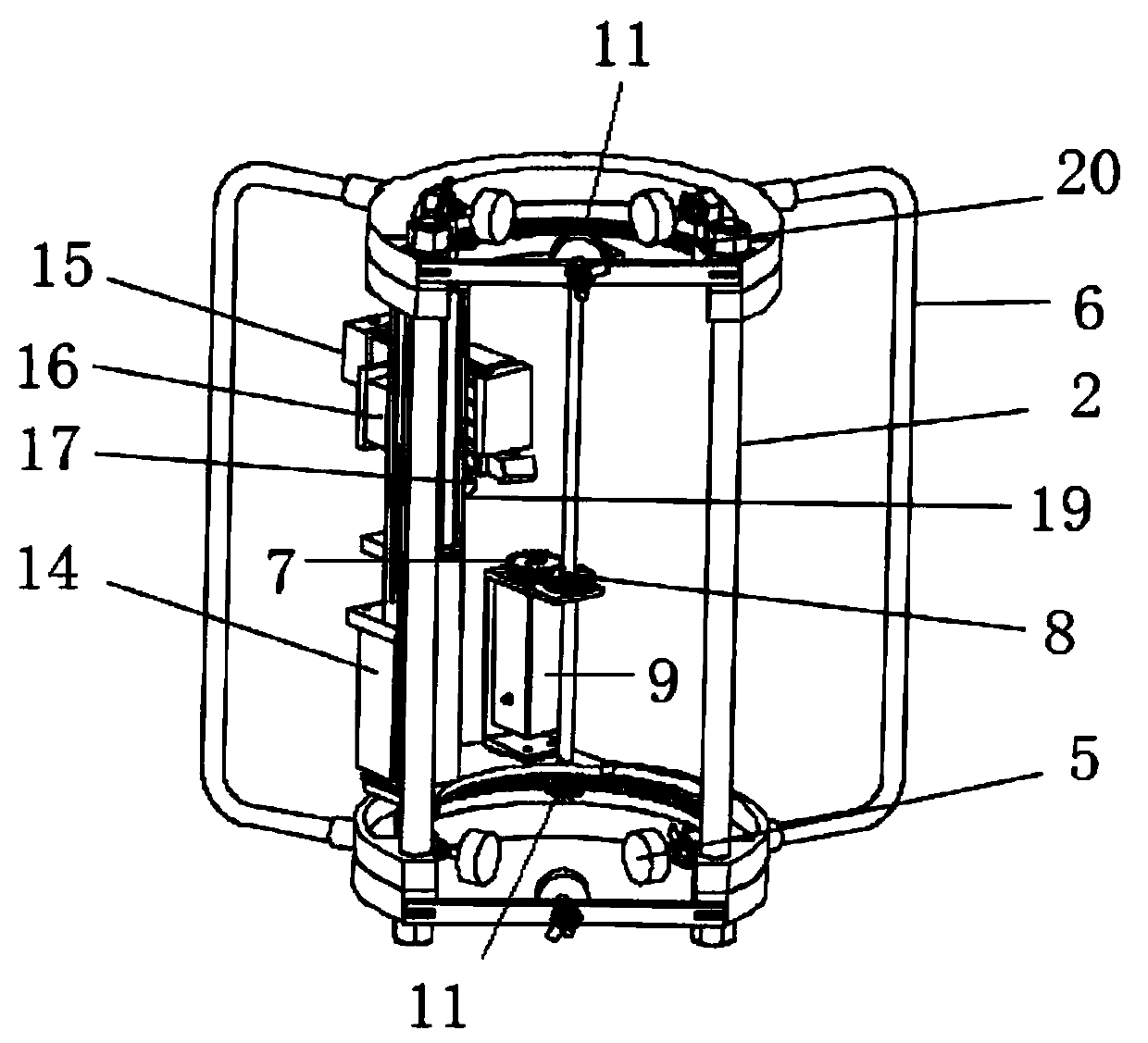

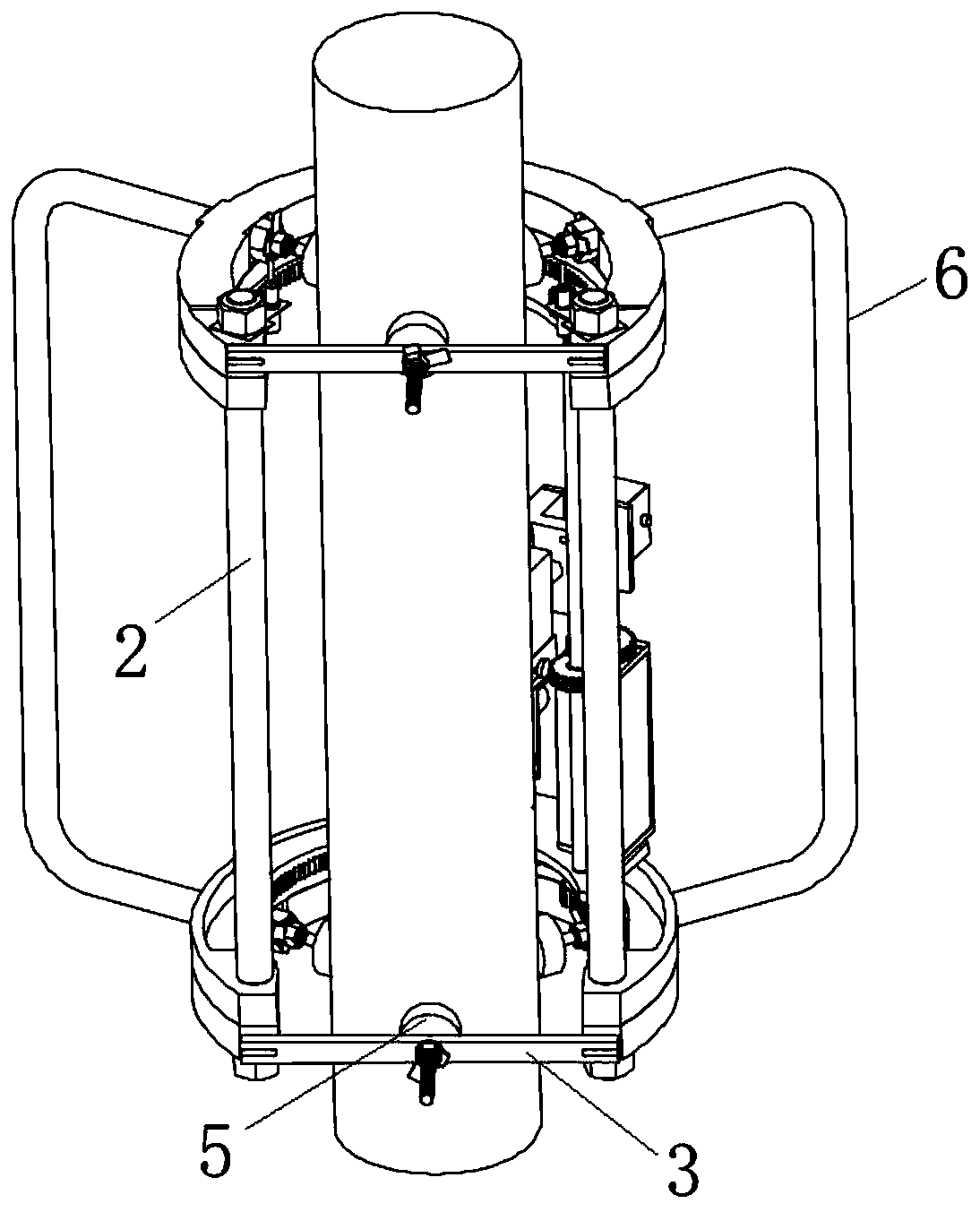

Support rotating undisturbed soil sampling device

InactiveCN1609583AReduce volumeEasy to disassembleWithdrawing sample devicesBorehole/well accessoriesSoil horizonGeotechnical engineering

The tripod type rotary intact soil sampler includes detachable handle, external thread drilling rod, tripod, drilling rod fixer with inner thread, diameter regulating and fixing plate, soil sample sleeve pressing plate, soil sample sleeve fixing ring, cutter, roller fixer, tripod fixing rods, bubble level, soil sample container, etc. The present invention has small size, low cost and easy carrying about, and may be used in sampling soil near the original state for geotechnical engineering and scientific research.

Owner:NORTHWEST A & F UNIV

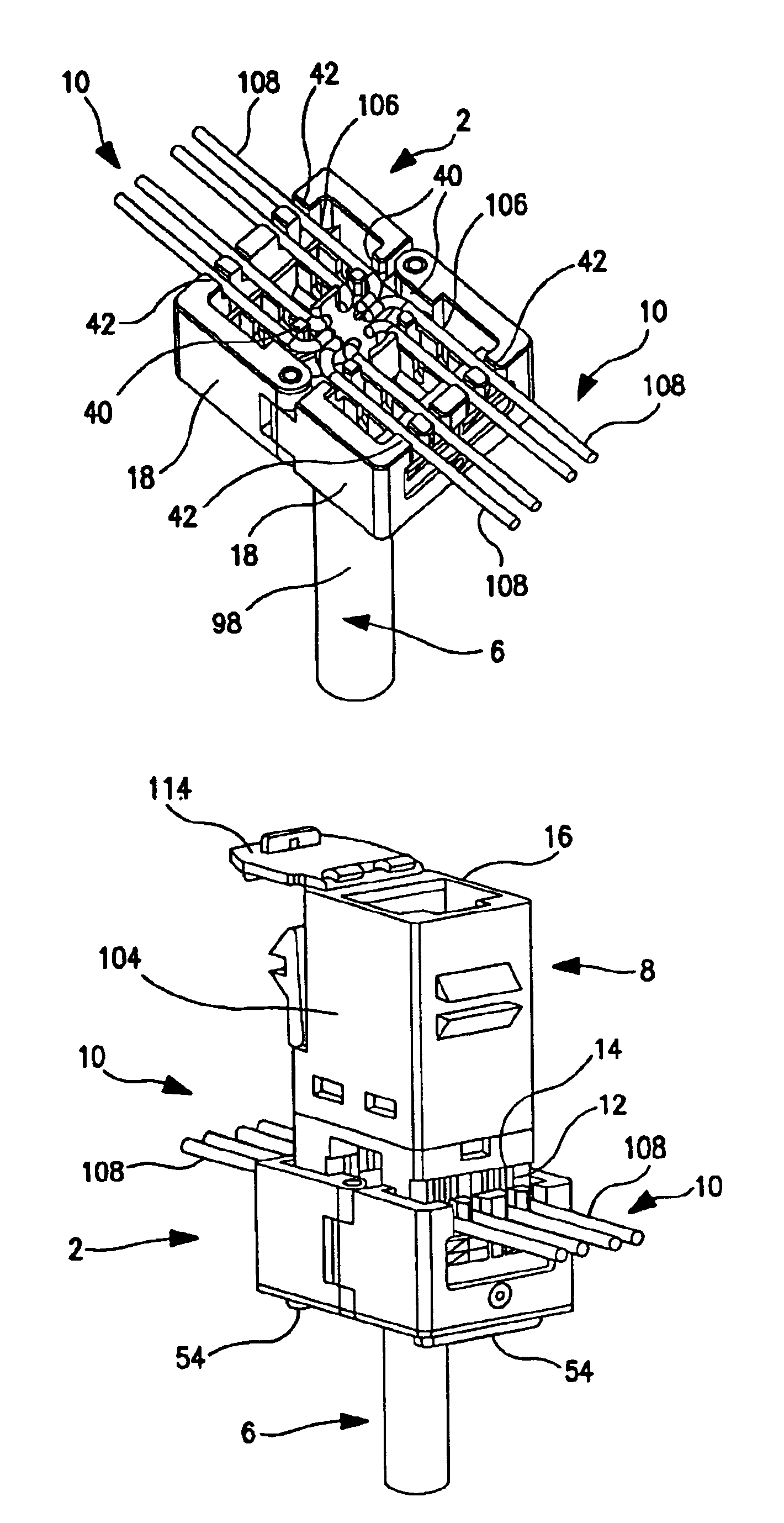

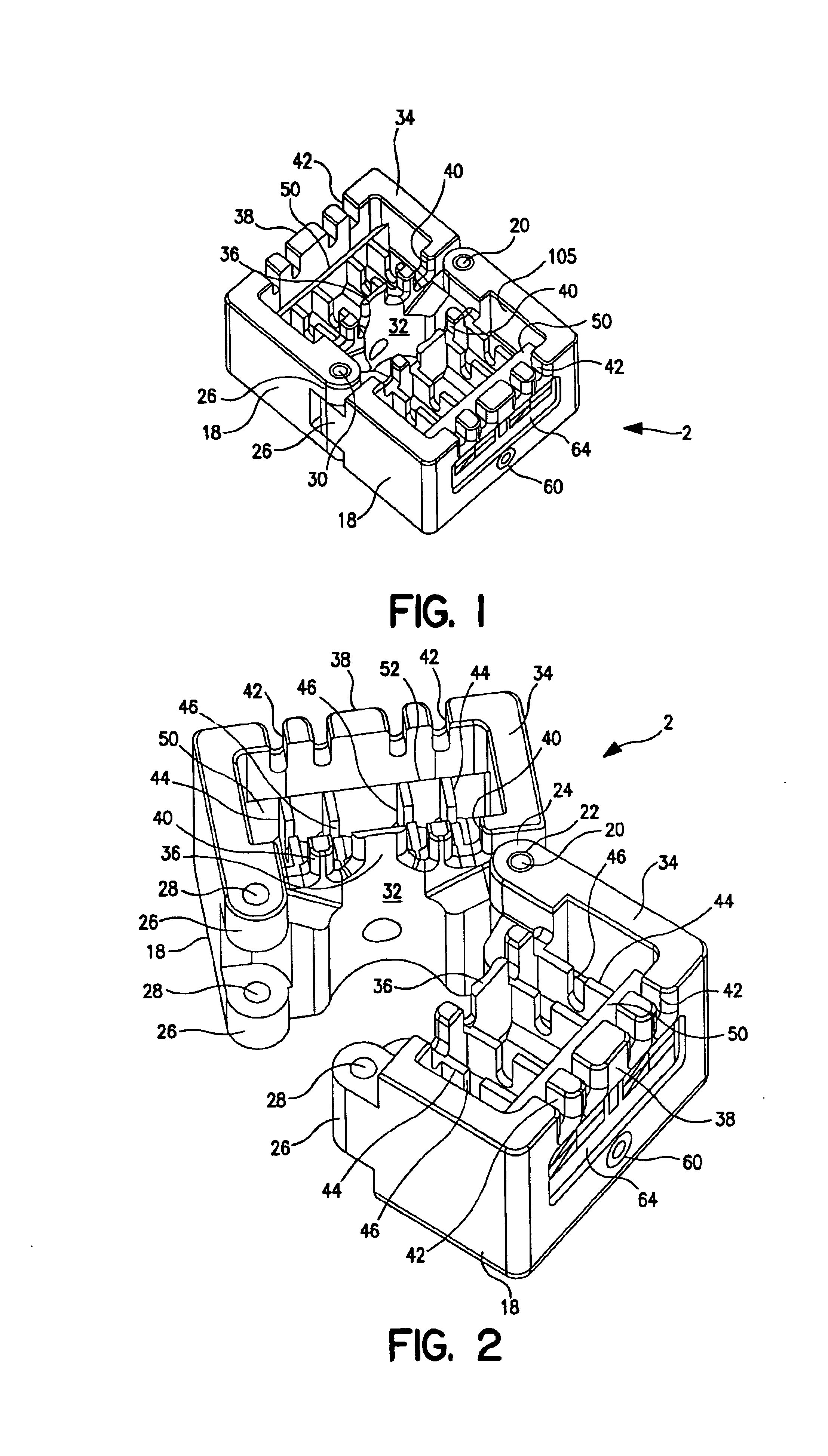

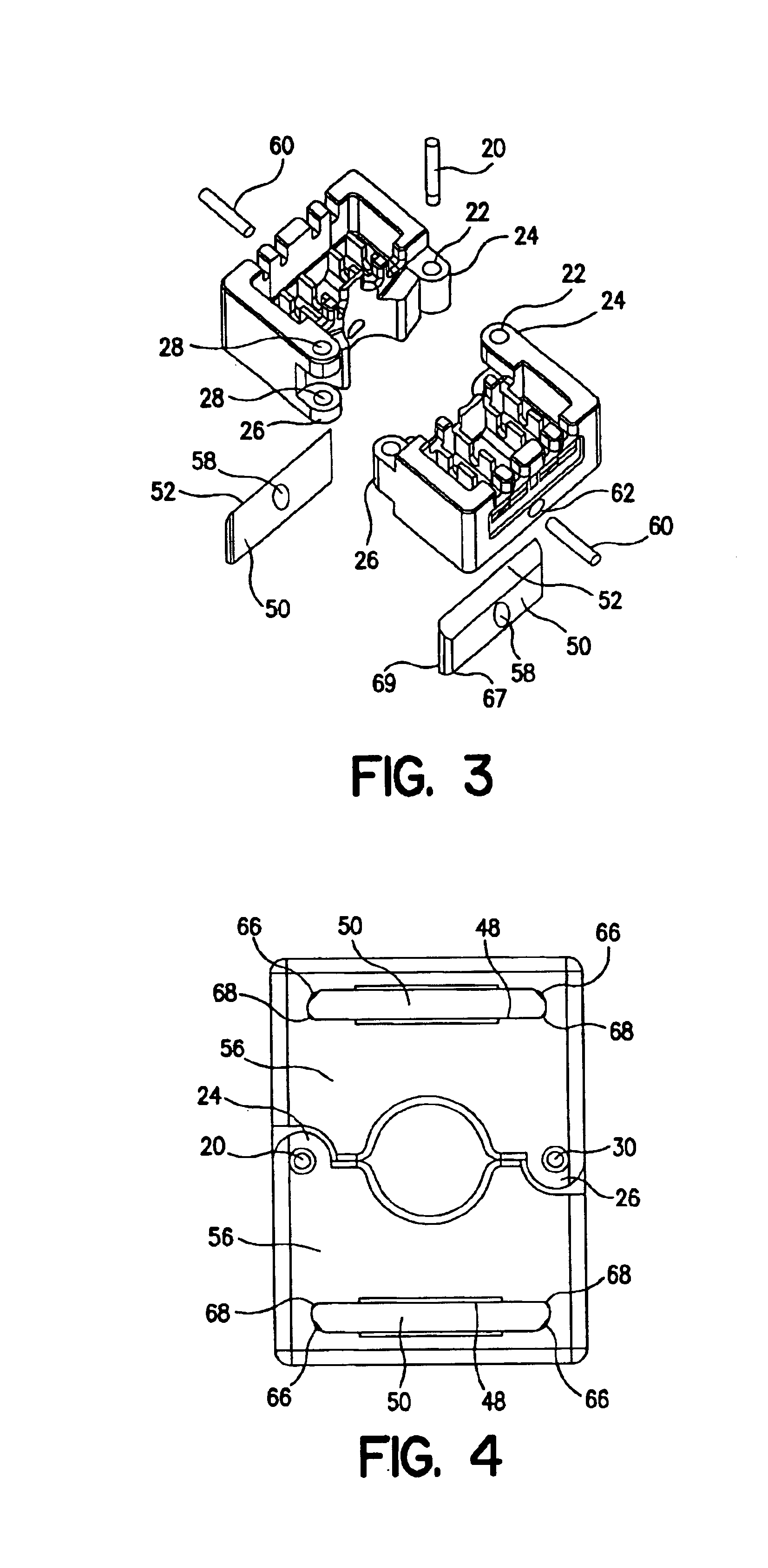

Cable terminating apparatus and method

ActiveUS6872090B2Facilitate terminationUniform depthCoupling device connectionsElectric discharge tubesEngineeringSupporting wall

Owner:COMMSCOPE CONNECTIVITY SPAIN

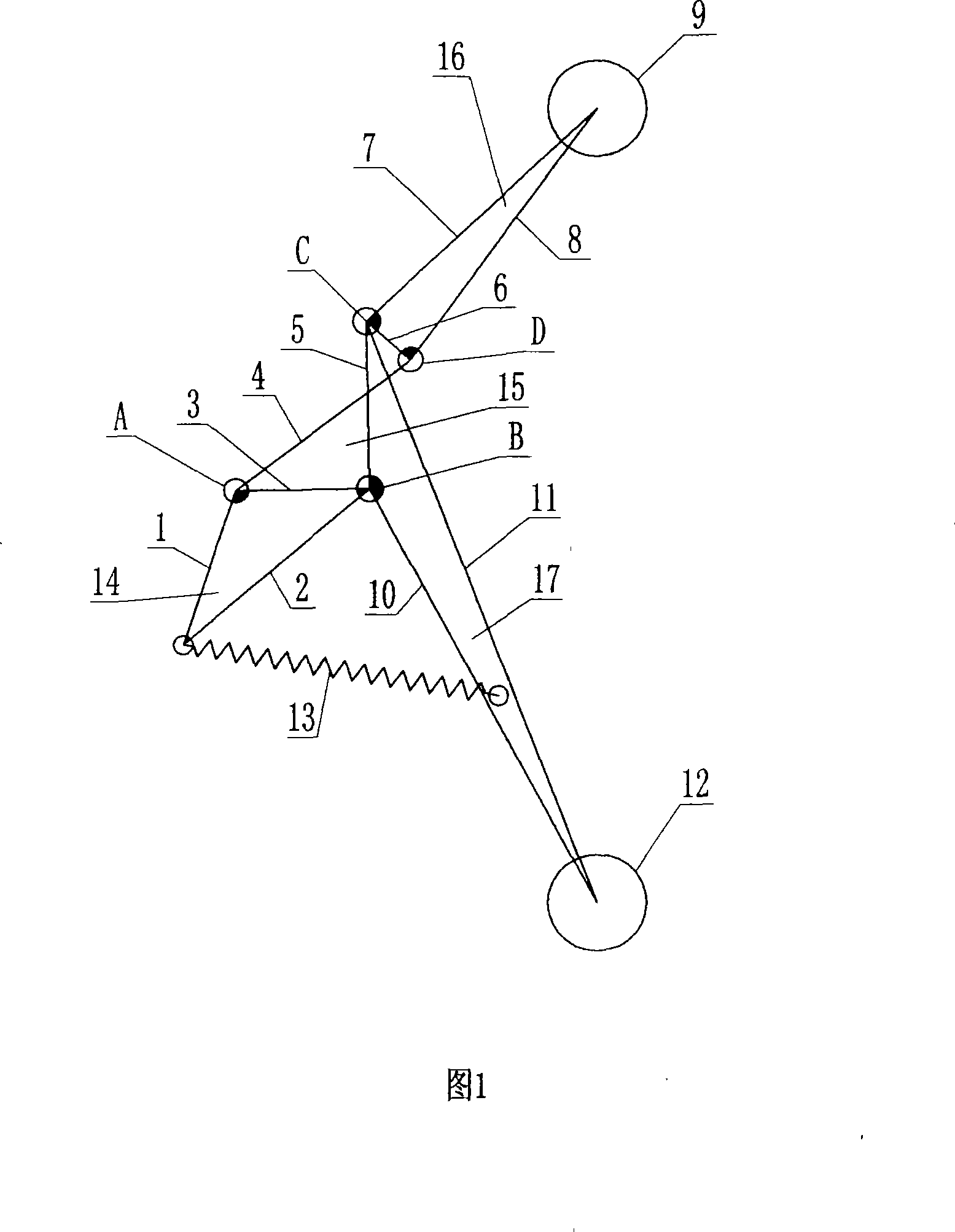

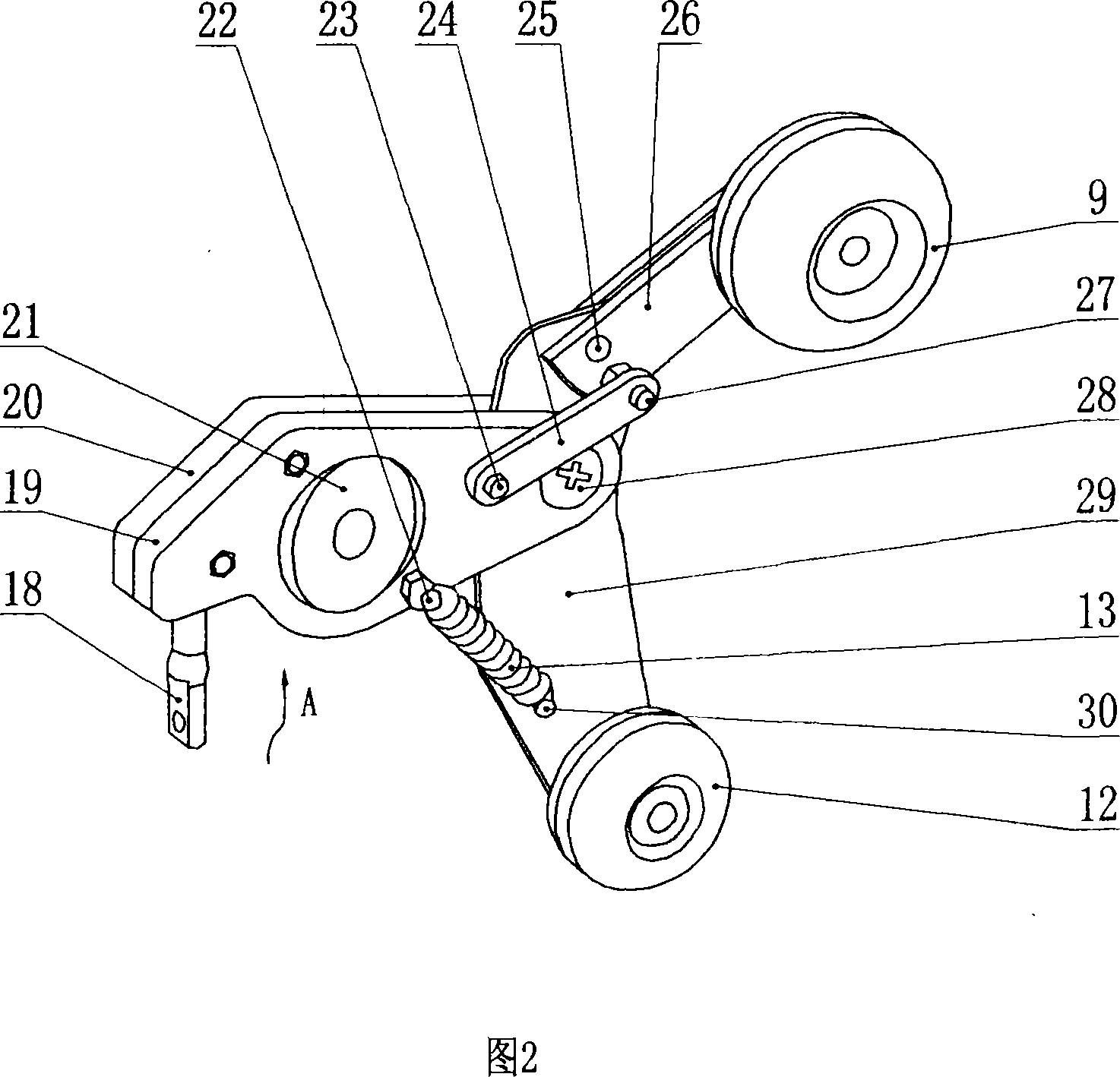

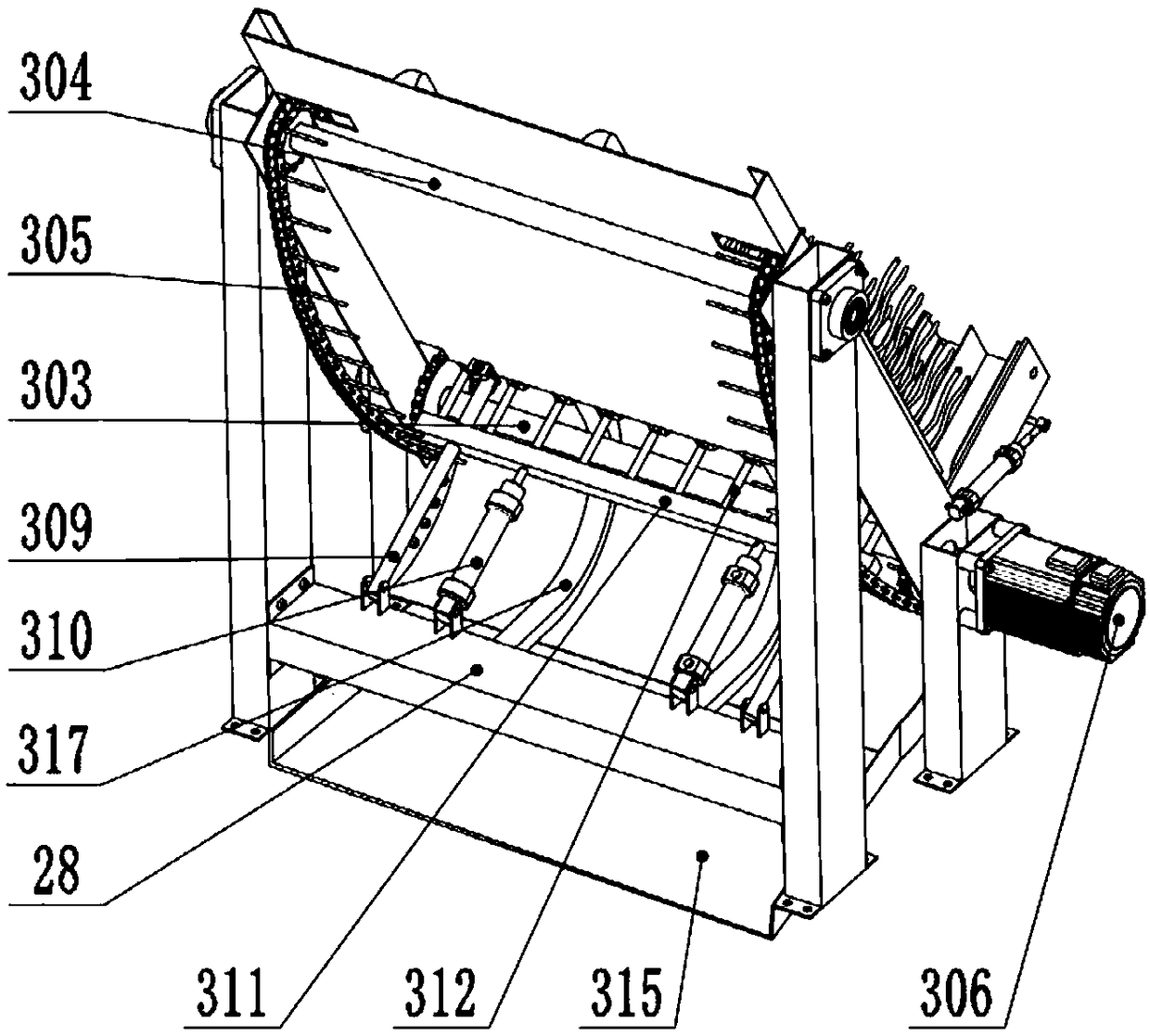

Massage chair shoulder back kneading mechanism

ActiveCN101234066AIncrease the center distanceAvoid harsh massage effectsRoller massageSuction-kneading massageHuman bodyMassage

The invention discloses a shoulder and back kneading mechanism used in massage chairs, which comprises kneading arms and massaging wheels. The invention is characterized in that the shoulder and back kneading mechanism is also provided with an upper swing arm, a lower swing arm, a swing arm connecting rod and springs. The kneading arm comprises an inner kneading arm and an outer kneading arm which are integrated into a whole through screws; the upper swing arm is movably connected with the lower swing arm; the upper swing arm and the lower swing arm are connected with the kneading arm through crank screws; the swing arm connecting rod is connected with the kneading arm; the springs are respectively connected with the kneading arm and the lower swing arm; the kneading arm, the swing arm connecting rod, the upper swing arm and the lower swing arm form into a linkage mechanism. The depth and distance in vertical direction of the upper massage wheel and the lower massage wheel of the invention can be adapted freely according to the back curve of human body. The massage depth is uniform, therefore, the massage wheels more perfectly simulate massage effects of a real person and cause people feel more comfortable; the springs has buffer effects to massage strength and massage wheel speed, thus making the massage operation be more gentle. Besides, the massage effects are especially suitable for middle-aged and elder people.

Owner:IREST HEALTH TECH CO LTD

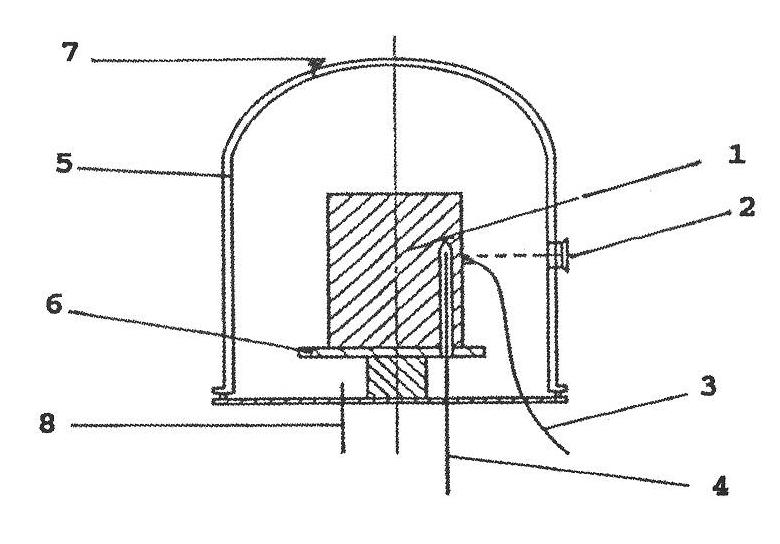

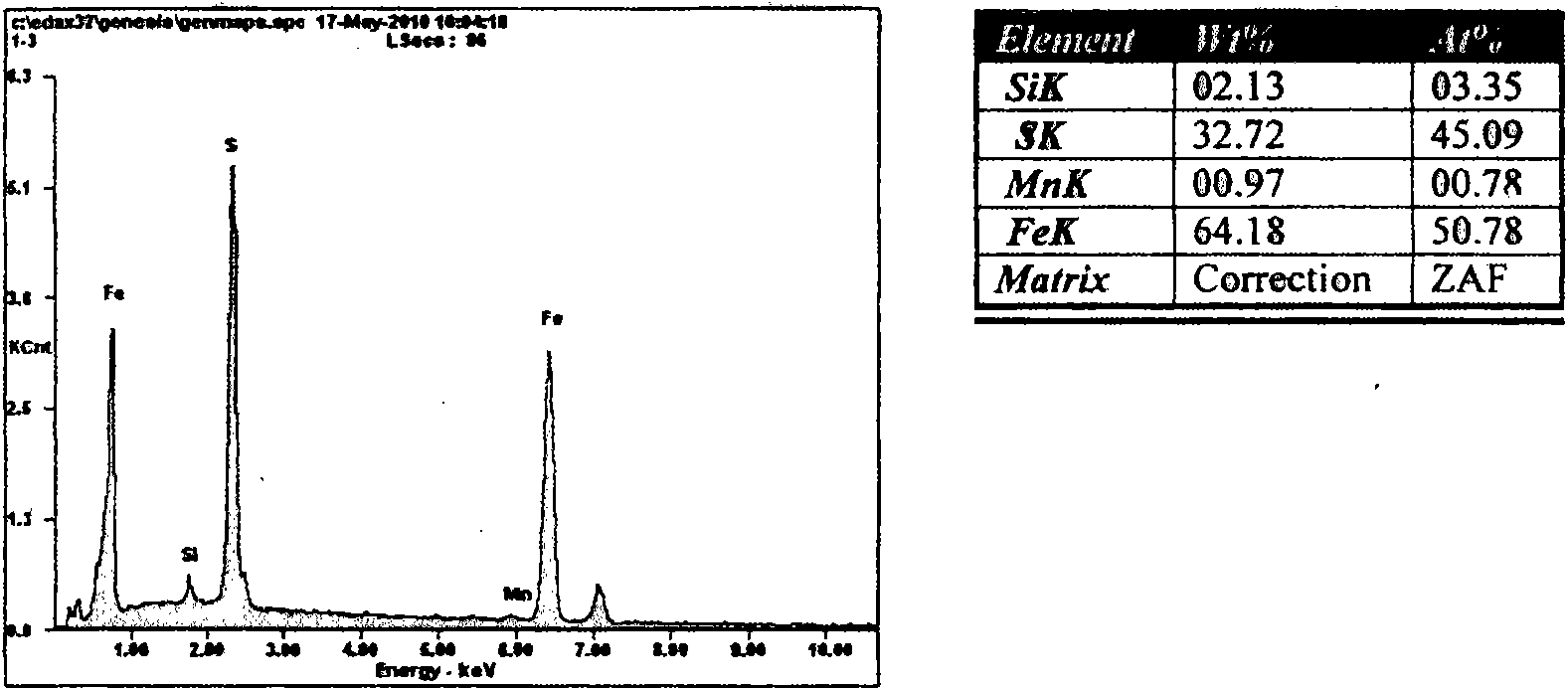

Gas plasma sulfurizing process

InactiveCN101956155AMeet technical quality requirementsEvenly distributedSolid state diffusion coatingWind drivenElectrolysis

The invention discloses a gas plasma sulfurizing process, which belongs to the technical field of surface heat treatment. In the process, a steel workpiece is placed in a sealed sulfurizing furnace with direct-current high voltage and high vacuum, then an appropriate amount of carrier gasses such as hydrogen gas, argon gas, ammonia gas and the like, and hydrogen sulfide are introduced into the furnace to form a sulfurizing atmosphere. Those gases are split into plasma states of nitrogen, hydrogen, argon and sulfur after entering the sulfurizing furnace and dash against the surface of the steel workpiece positioned on a negative plate to ensure that the temperature of the workpiece is raised, wherein sulfur ions infiltrate into the surface of a component to form ferrous sulfide which covers the whole surface of the component to fulfill the aim of sulfurizing. The process has the advantages of no pollution, low cost and high sulfurizing quality, overcomes the defects of serious pollution and high cost of the conventional electrolytic sulfurizing, and also overcomes the defect of low quality of plasma sulfurizing performed by using solid sulfur on the market at present. Through sulfurizing treatment, the mechanical life of a mechanical workpiece can be improved by 2 to 3 times, and the process has obvious economical and social benefits and extensive development prospect when applied to an automobiles, a train, a wind-driven generators, a petroleum machinery and a rolling machine.

Owner:BEIJING TIANMA BEARING CO LTD

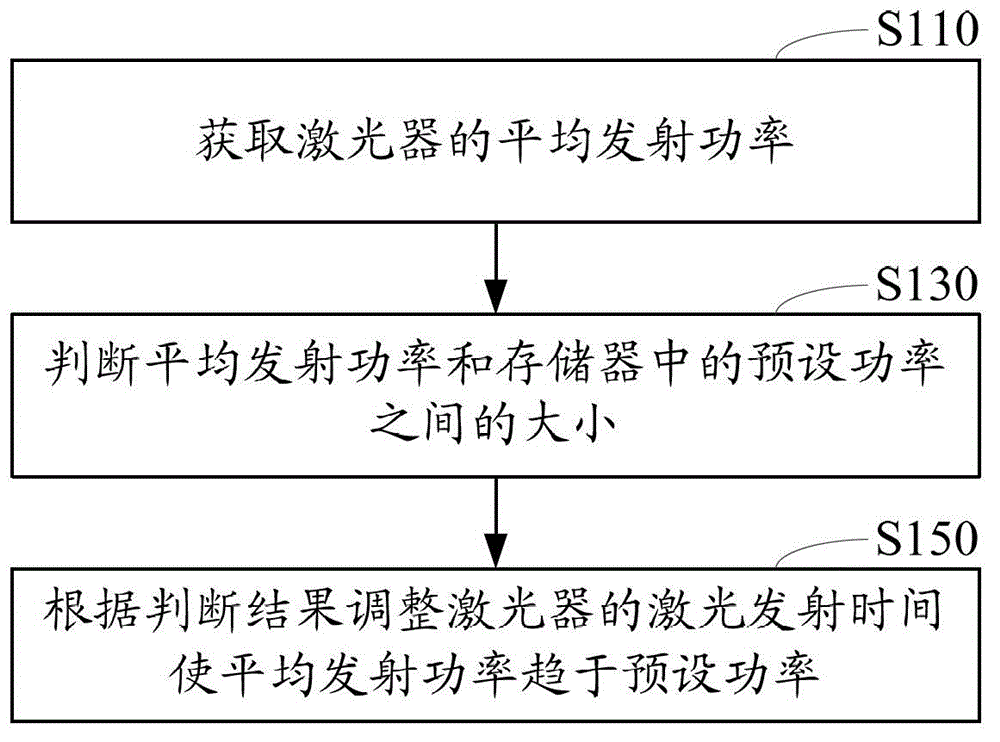

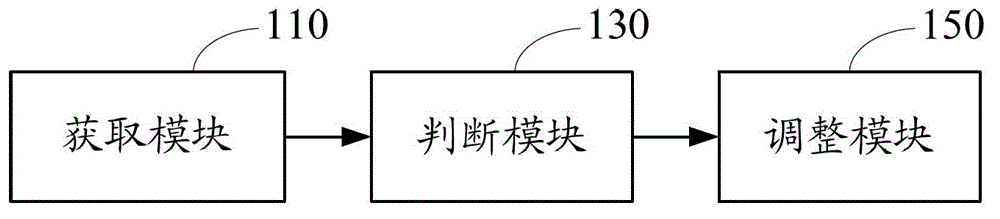

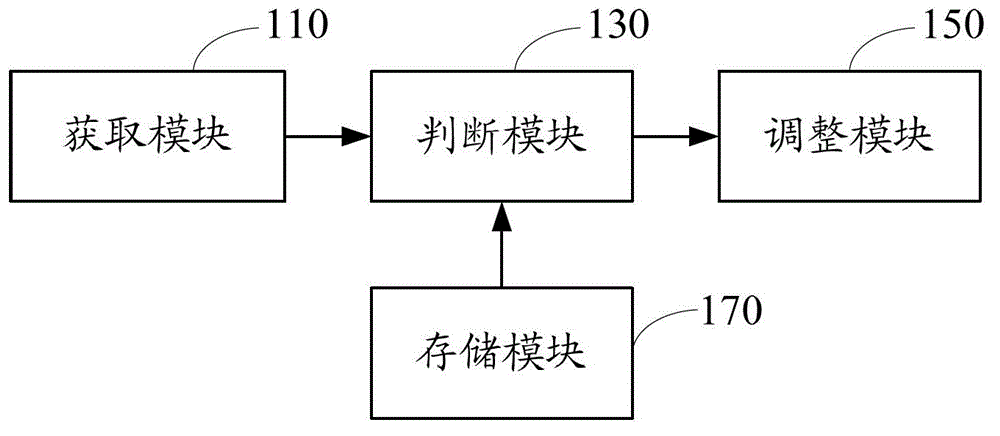

Laser energy control method and system

ActiveCN102946046AThe average transmit power is stableUniform colorLaser detailsLaser output parameters controlEnergy controlLaser

The invention provides a laser energy control method and a system. The method includes obtaining average transmission power of a laser, comparing the average transmission power with preset power in a storage and adjusting a laser transmission pulse duty ratio of the laser to enable the average transmission power to tend to the preset power according to the comparison result. According to the laser energy control method and the system, the average transmission power and the preset power in the storage are compared by obtaining the average transmission power of the laser, and the laser transmission pulse duty ratio of the laser is adjusted to tend to the preset power according to the comparison result, so that the average transmission power of the laser is stable, marked colors and depth are uniform during laser marking, and the processing quality and the processing efficiency are improved.

Owner:HANS LASER TECH IND GRP CO LTD

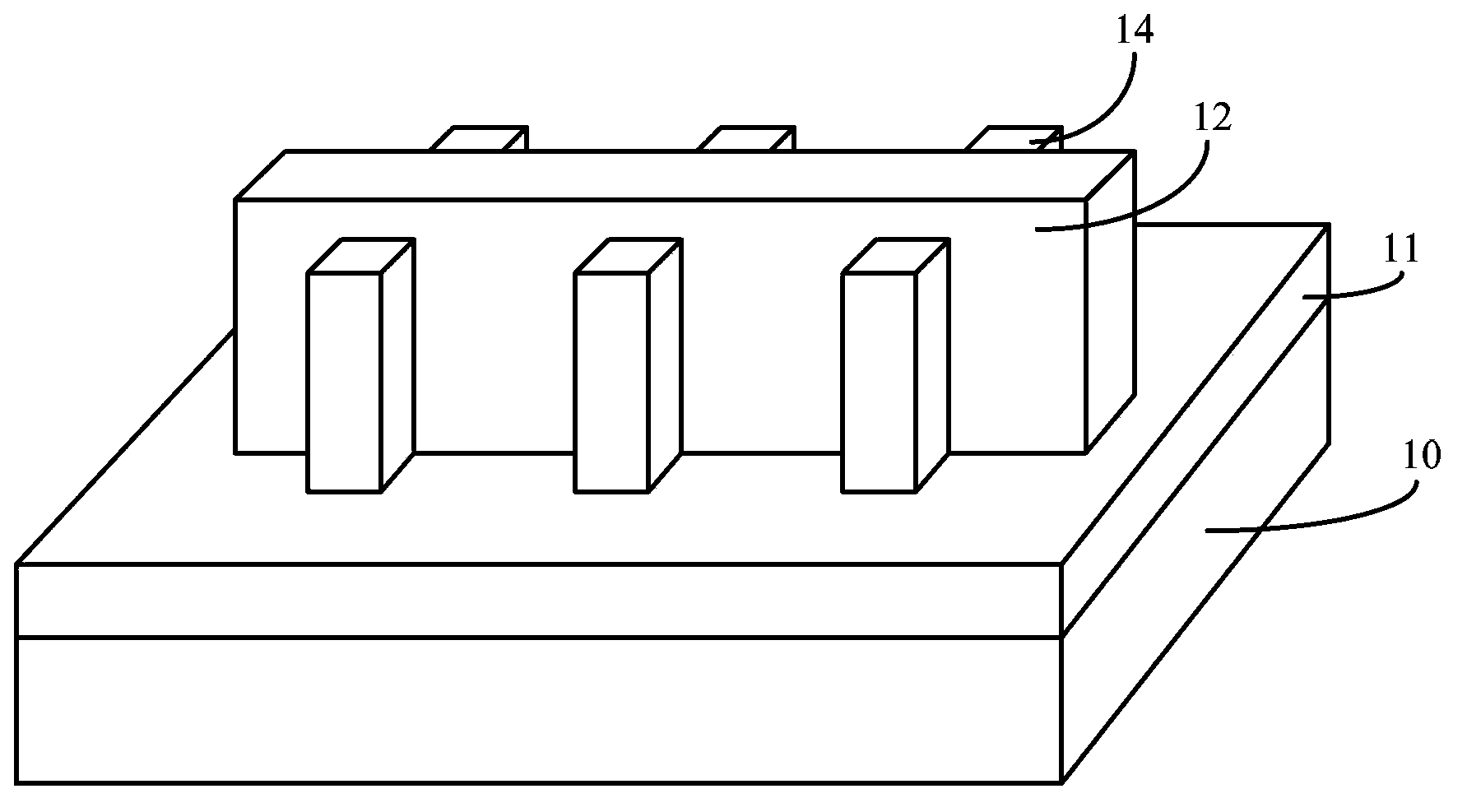

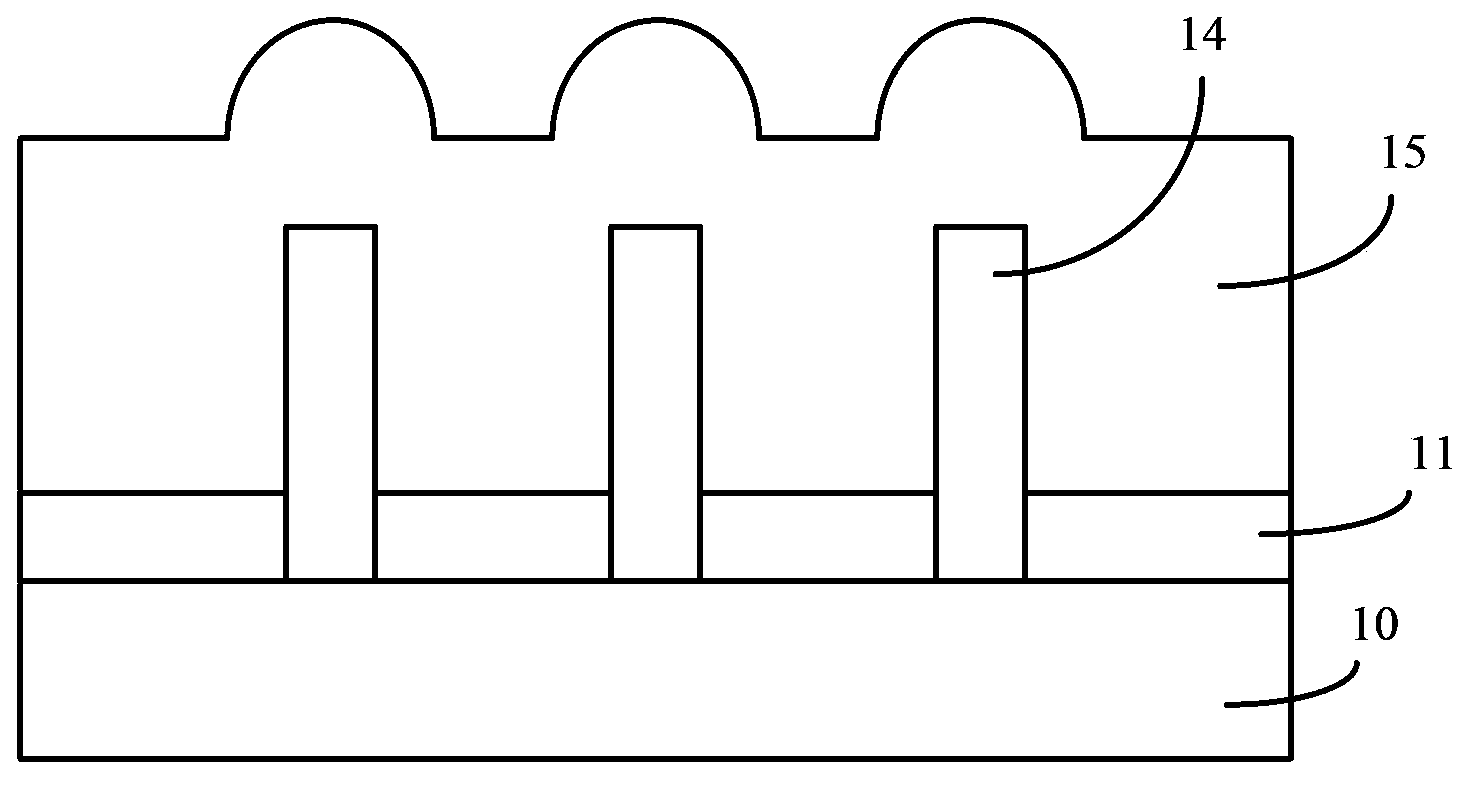

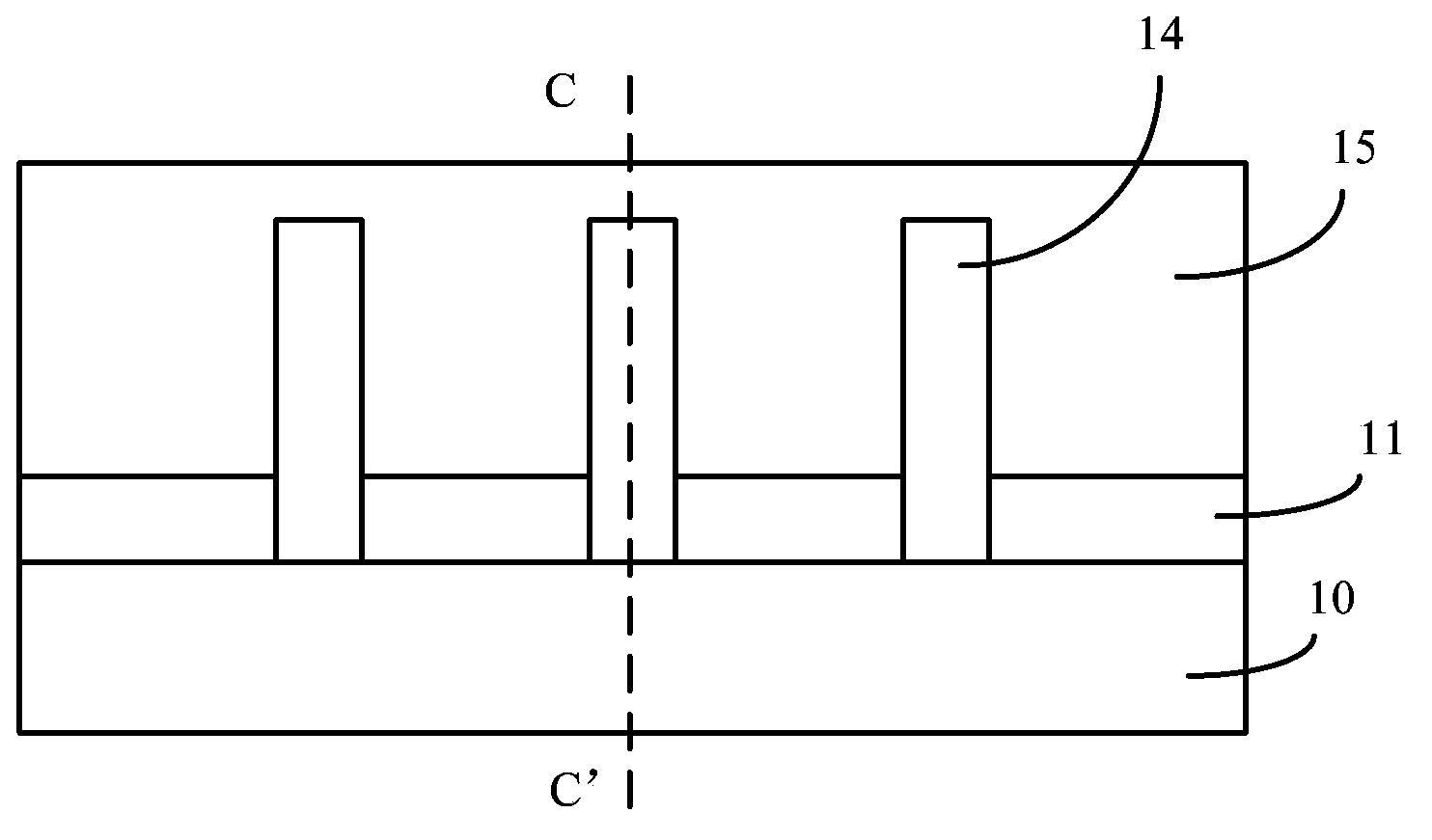

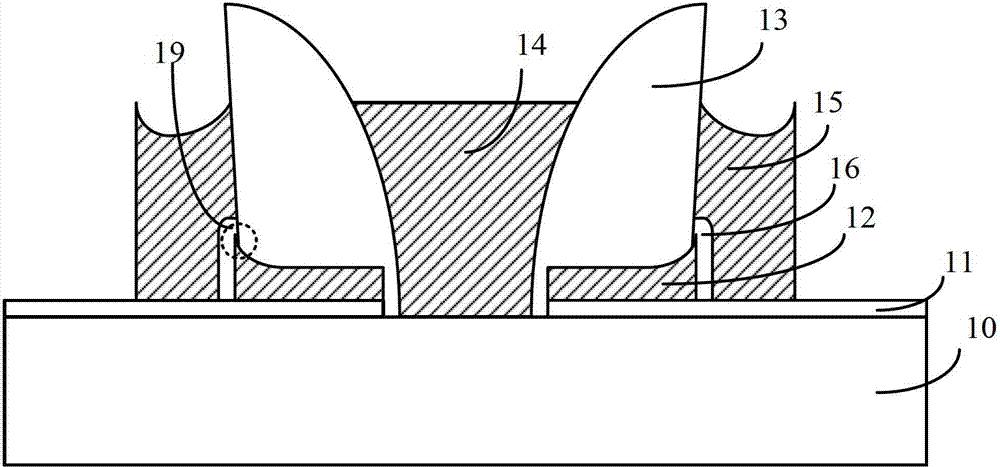

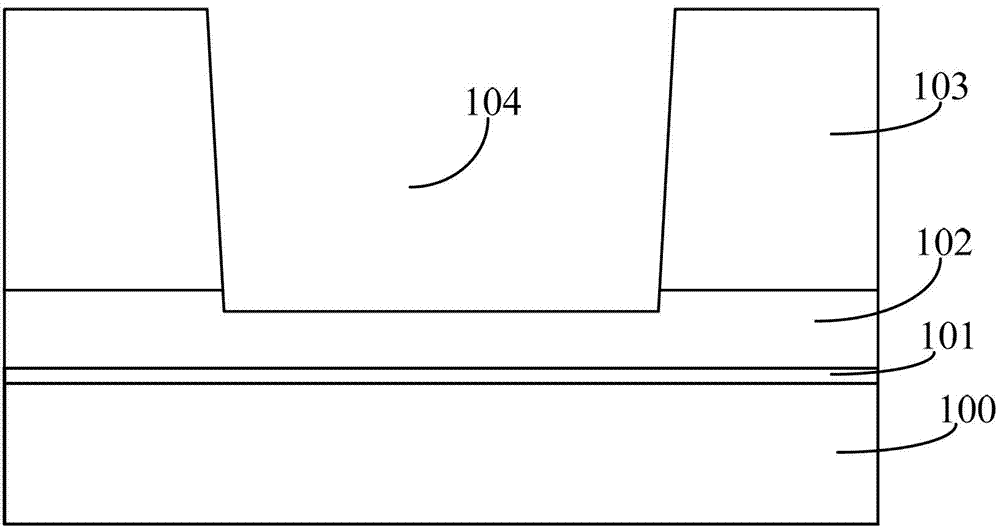

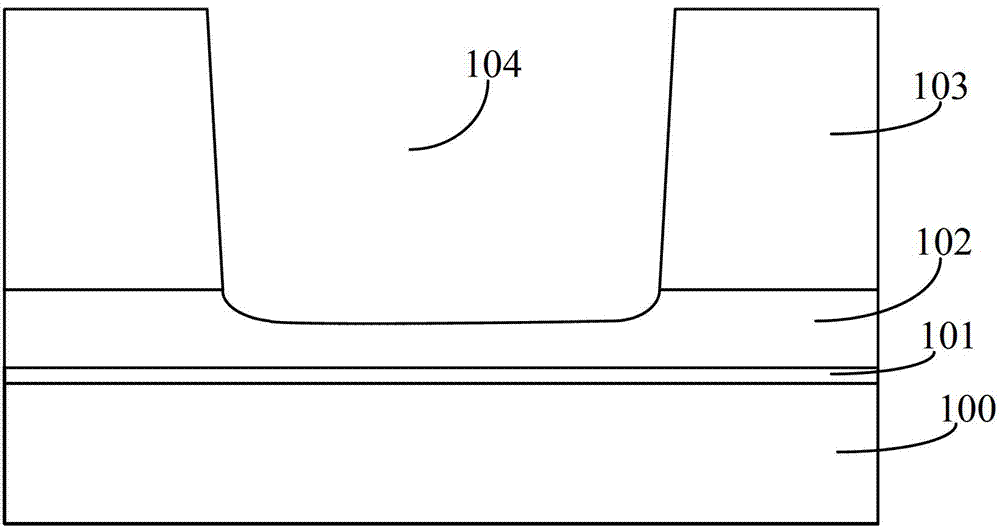

Method for forming semiconductor structure

ActiveCN104124168AAccurate thicknessPrecise thickness controlSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structurePhysics

A method for forming a semiconductor structure comprises the steps of providing a substrate with the surface provided with a fin part; forming a first pseudo gate layer on the substrate and the surface of the pin part, enabling the surface of the first pseudo gate layer to be higher than the top surface of the fin part; flattening the first pseudo gate layer until the top surface of the fin part is exposed; after a flattening process, forming a second pseudo gate layer on the first pseudo gate layer and the surface of the fin part; etching part of the first pseudo gate layer and the second pseudo gate layer until the top and the side wall surface of the fin part are exposed, and forming a pseudo gate striding over a side wall and the top surface of the fin part. In the formed semiconductor structure, uniformity and accuracy of the thickness of the gate structure on the top surface of the fin part are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

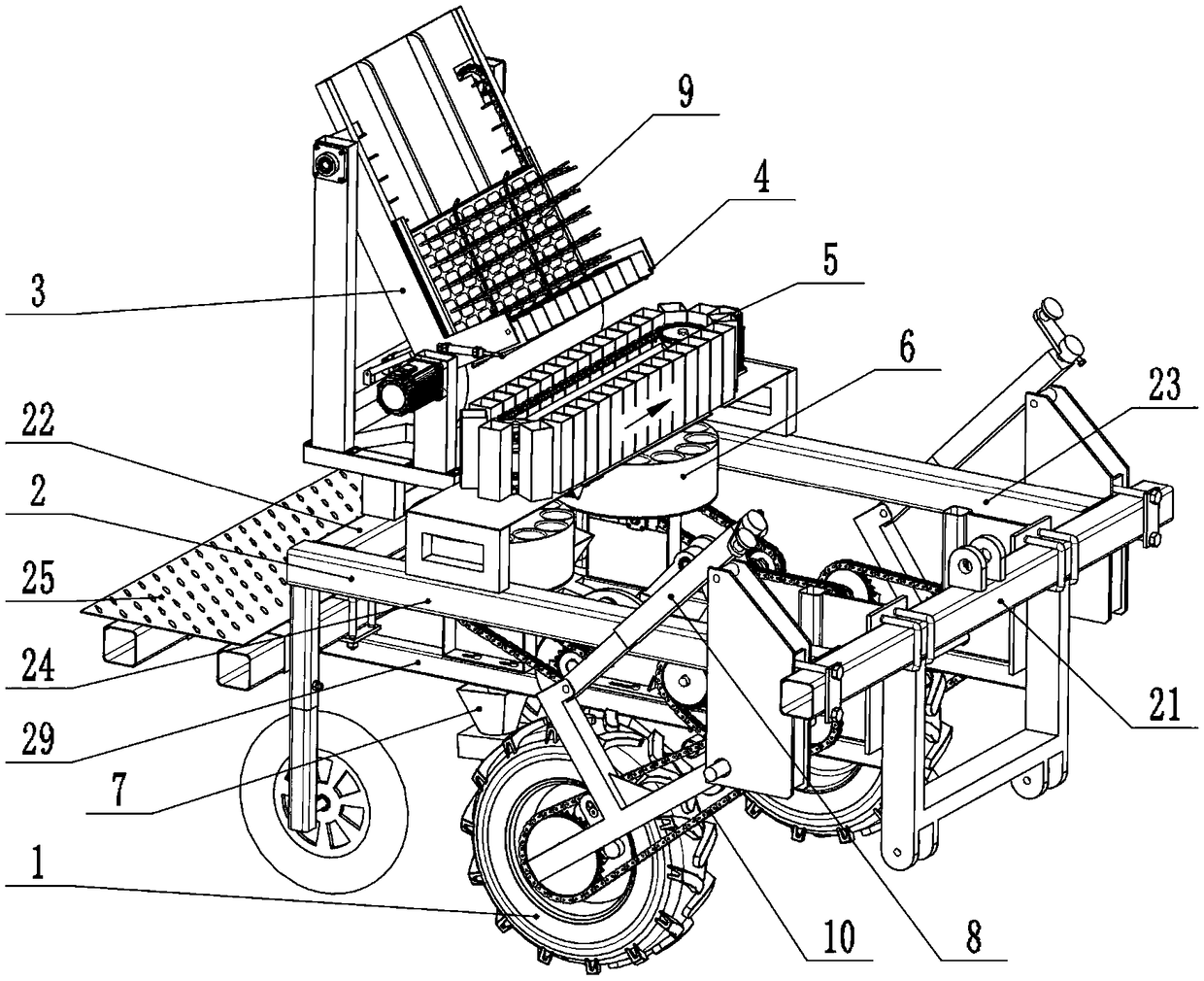

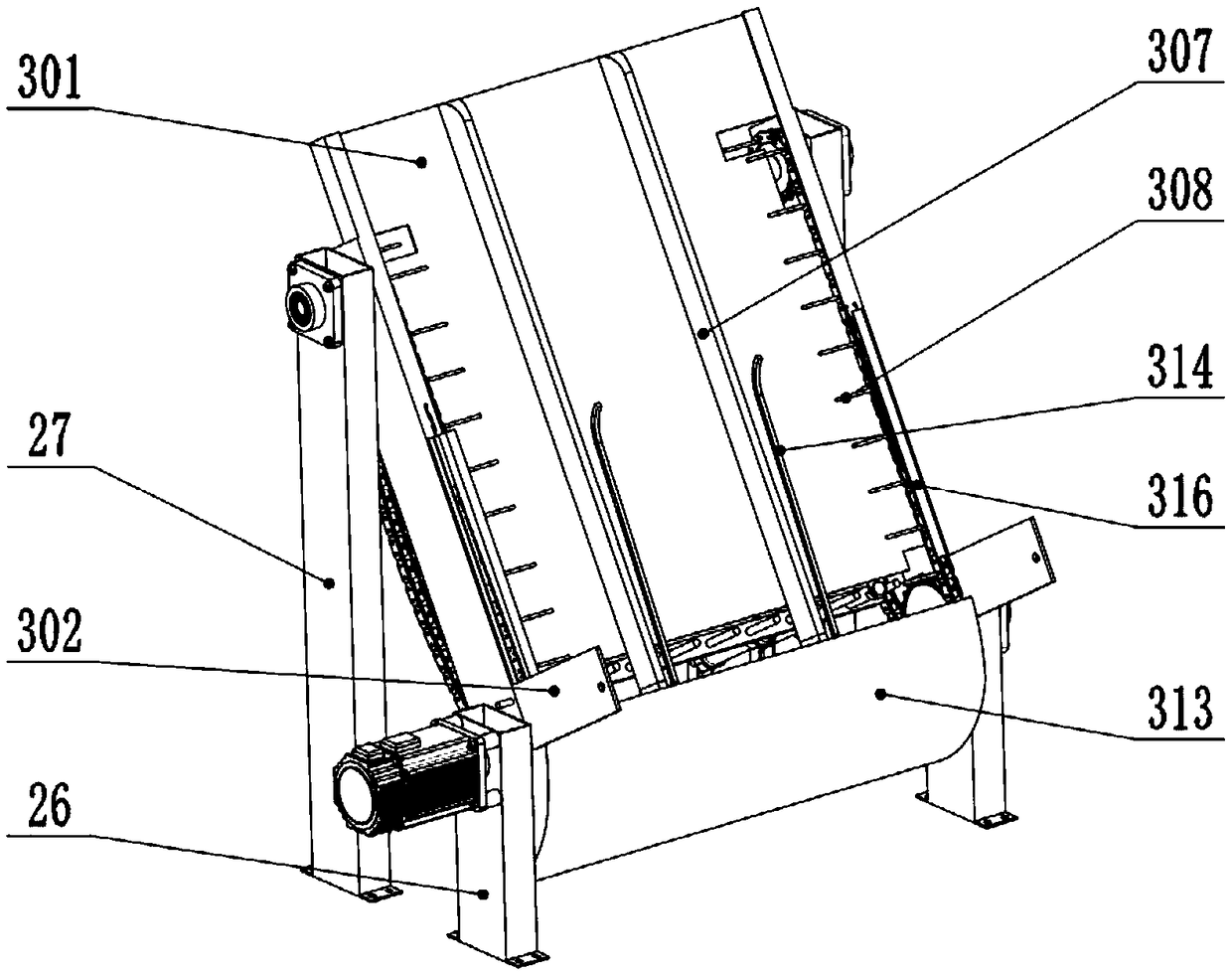

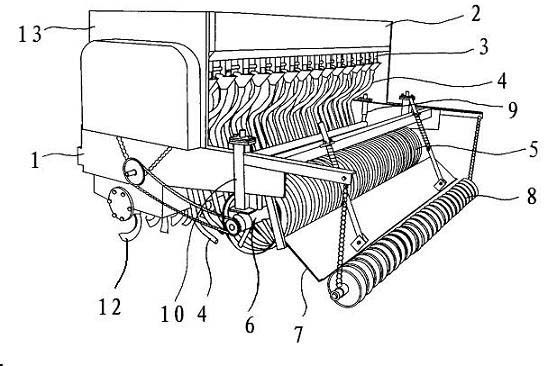

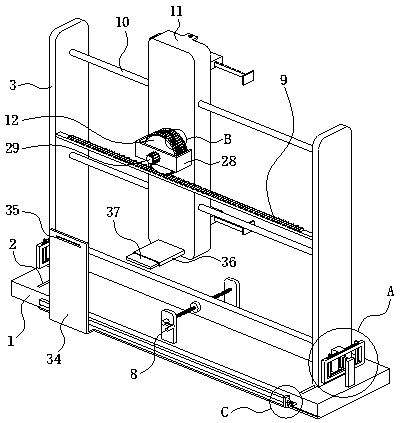

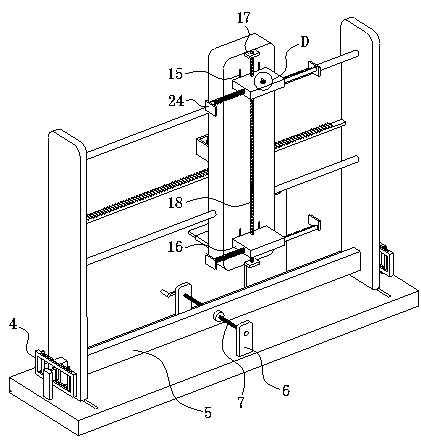

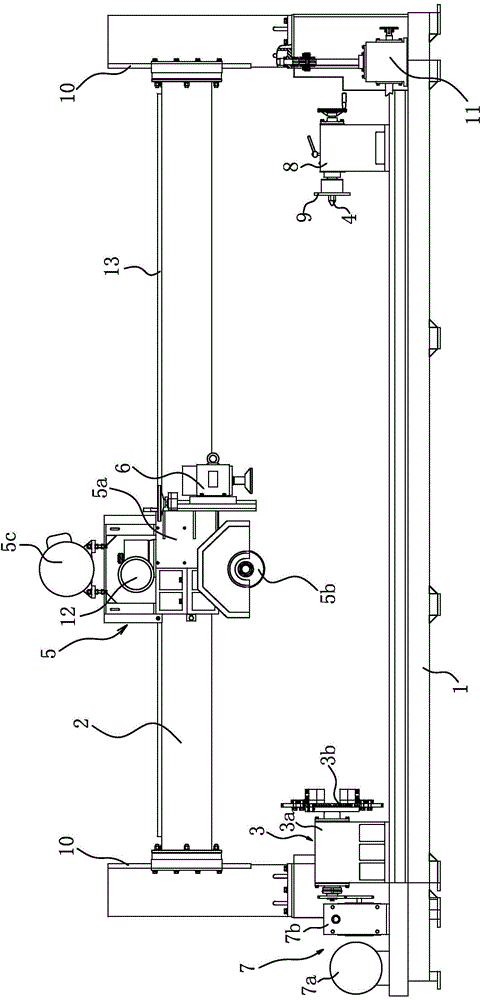

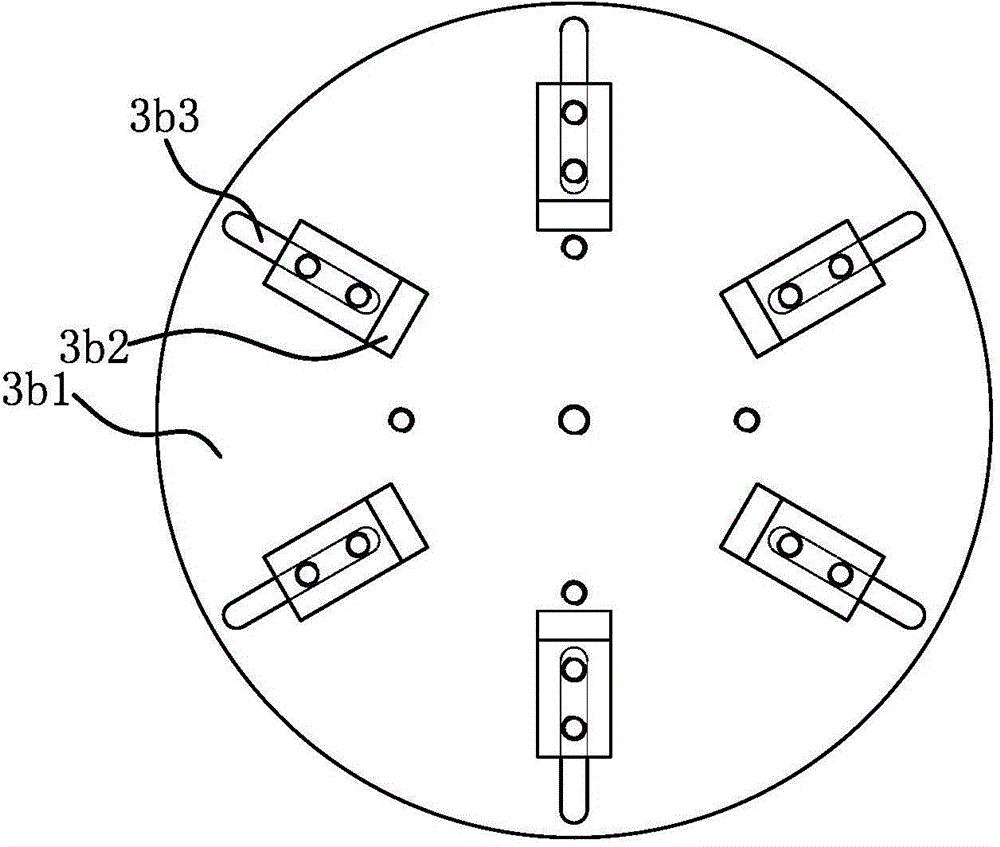

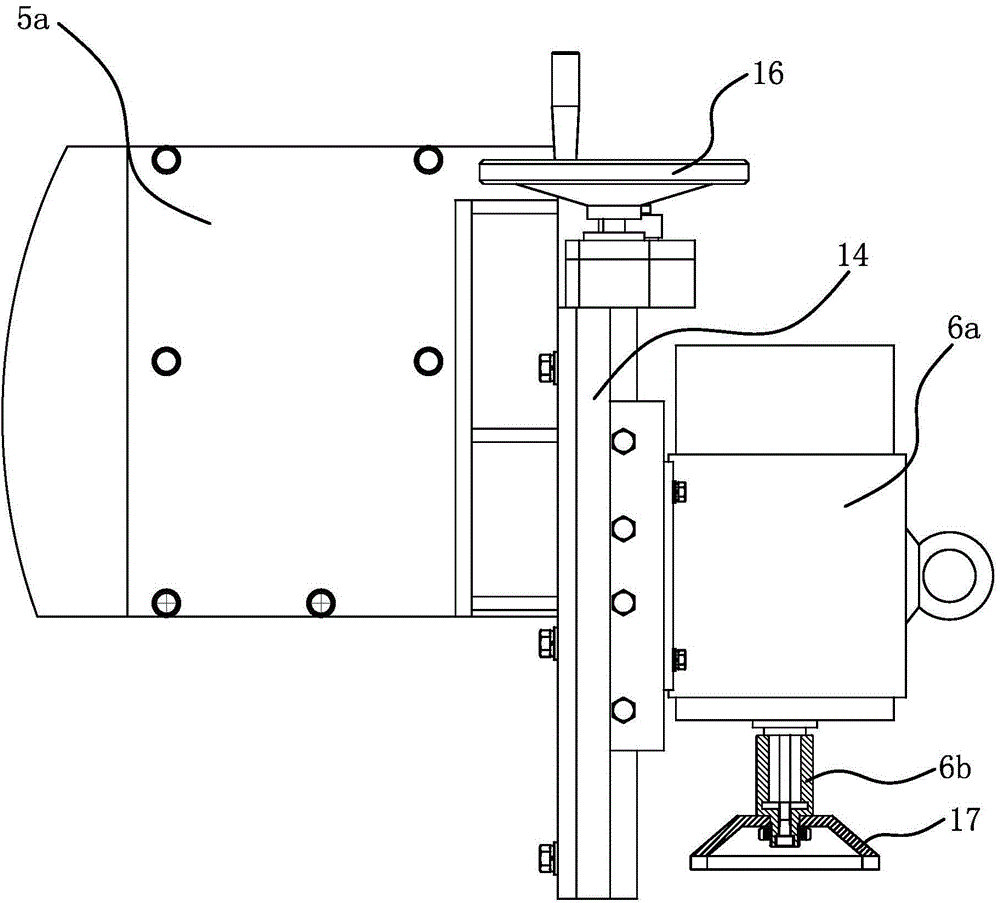

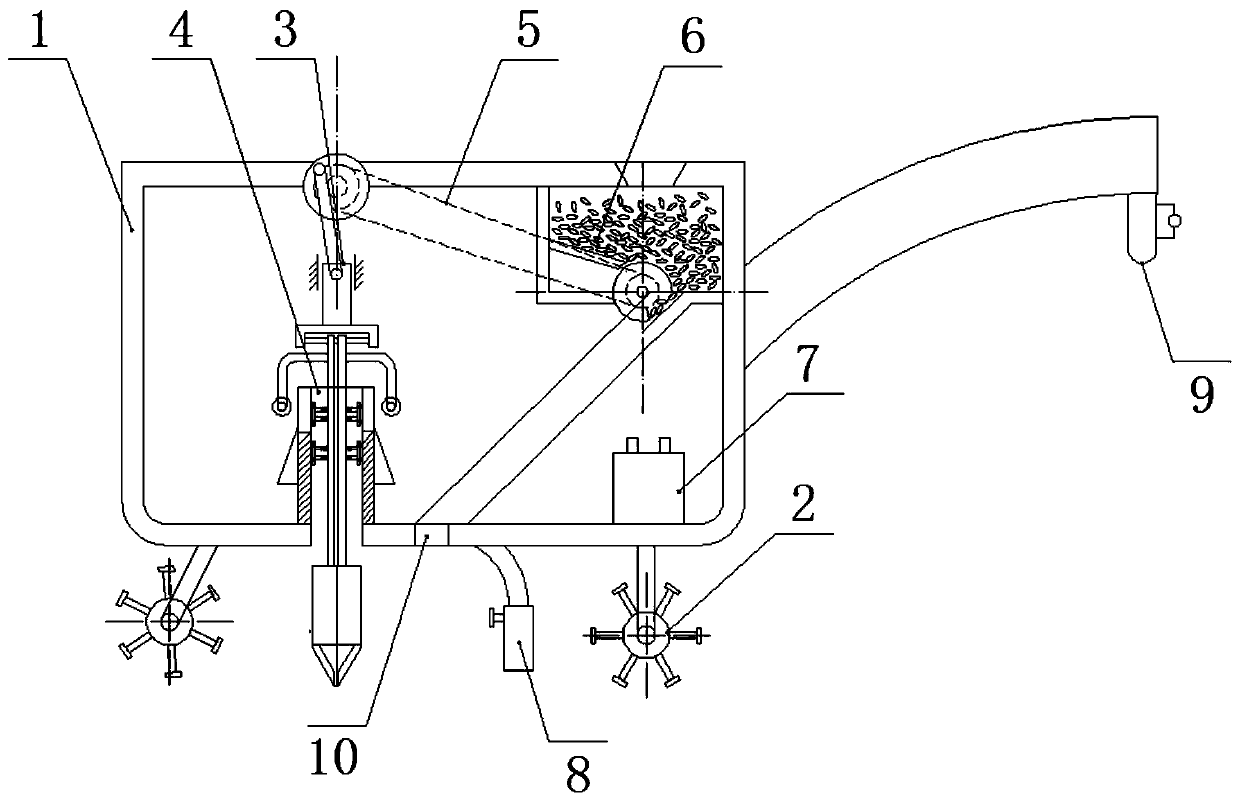

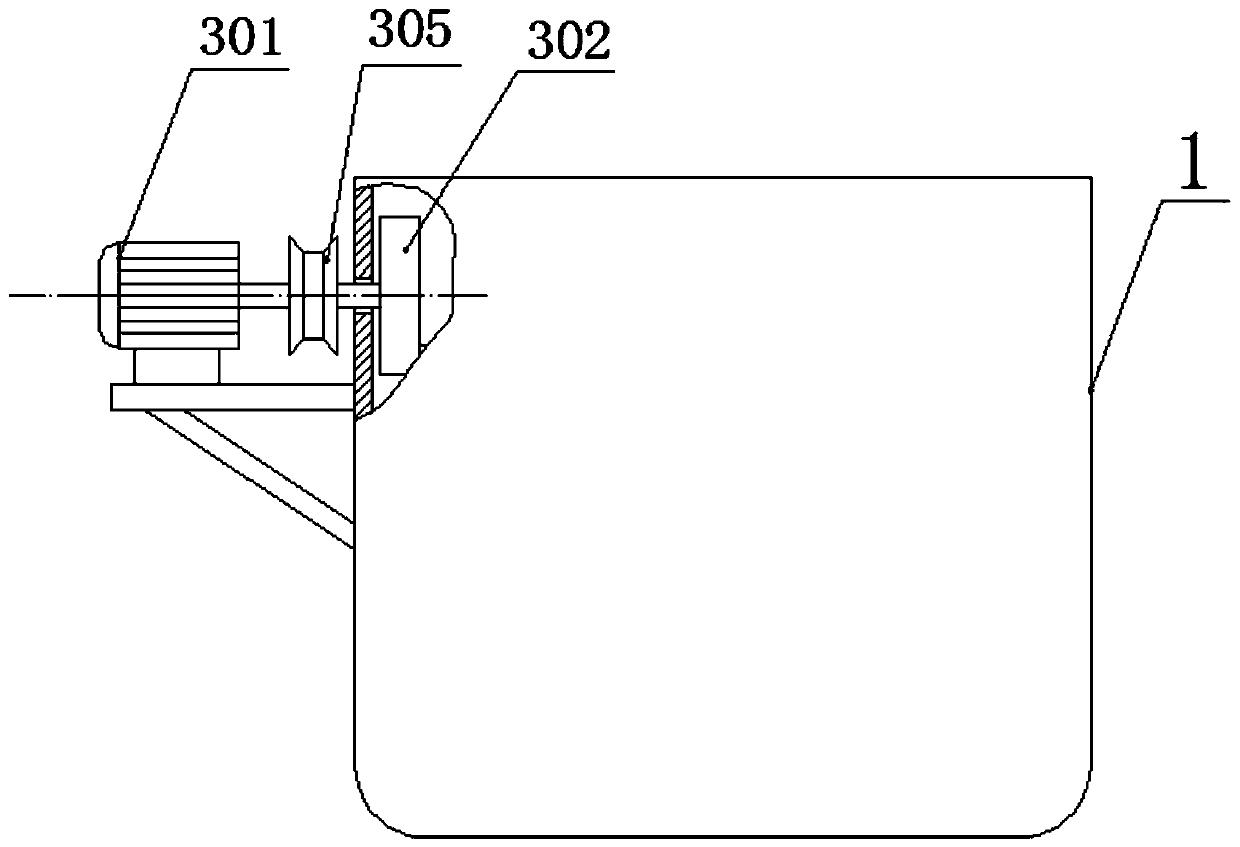

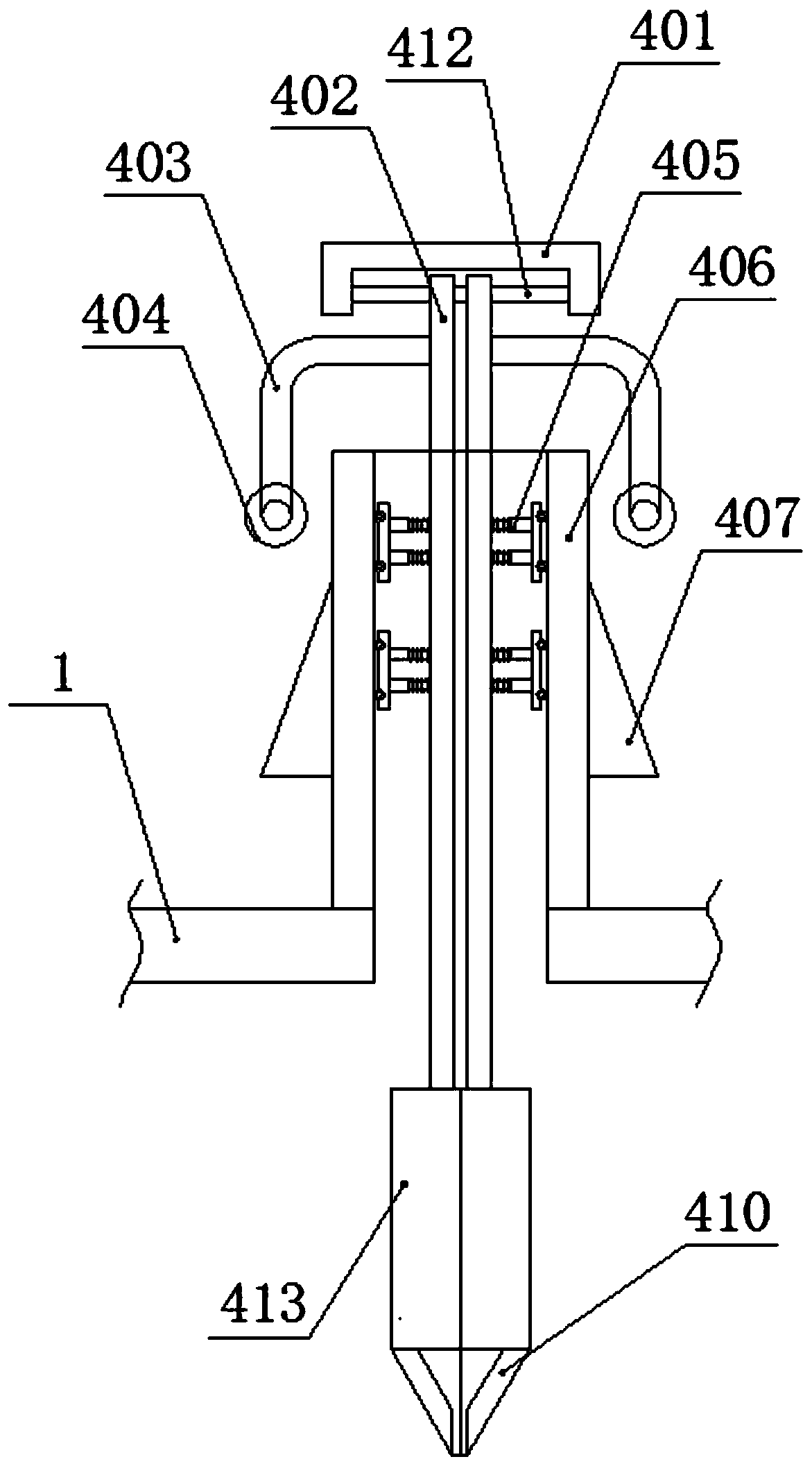

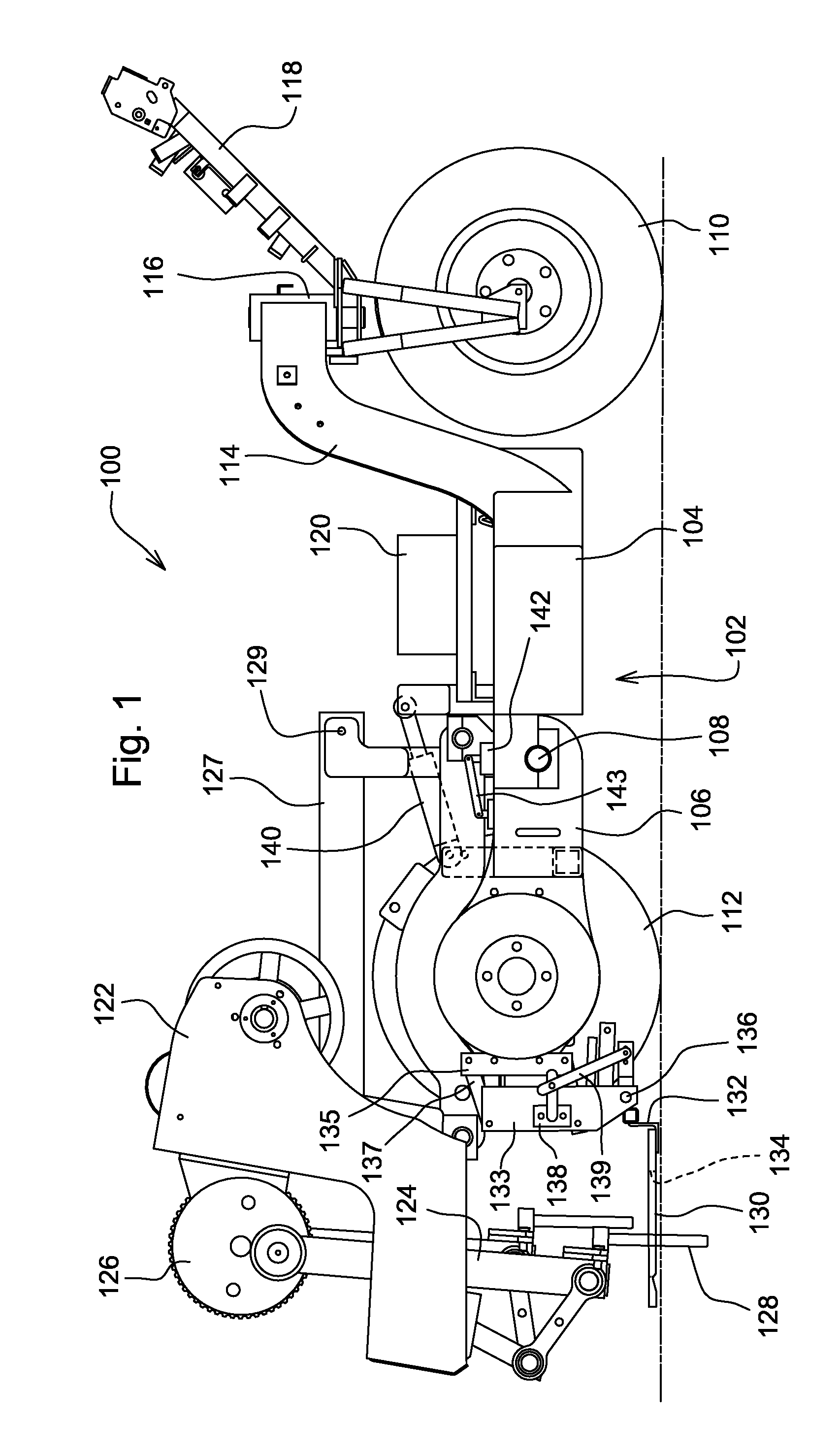

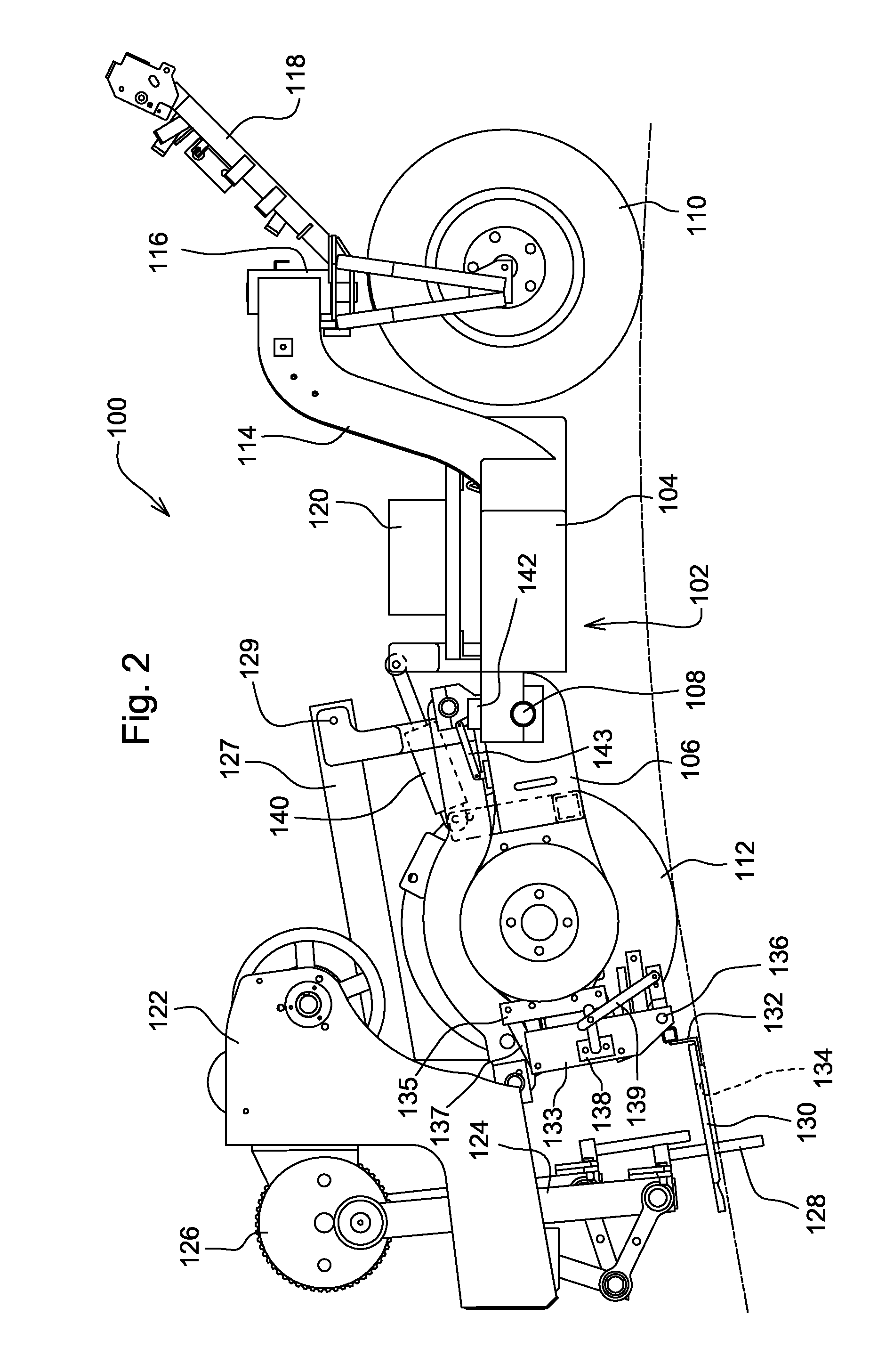

Fully automatic transplanting machine for plug seedlings

ActiveCN108738557AImprove seedling efficiencyReduce damage rateTransplantingAgricultural engineeringTransfer mechanism

The invention belongs to the field of agricultural machinery and particularly relates to a fully automatic transplanting machine for plug seedlings. The fully automatic transplanting machine comprisesground wheels (1), a frame (2), a seedling picking mechanism (3), a transfer mechanism (4), a transport mechanism (5), a seedling feeding mechanism (6), transplanting mechanisms (7) and a seedling feeding and planting transmission mechanism (10). The transplanting machine is suitable for transplanting a multi-row and multi-row matrix-type plug seedling tray (9). The fully automatic transplantingmachine has high seedling taking efficiency. Through one process, the whole row of plug seedlings is transferred to the transport mechanism. The fully automatic transplanting machine can reduce the damage rate of the plug seedlings during the transplanting process. The one seedling picking mechanism can simultaneously feed seedlings for two lines of the transplanting mechanisms. The fully automatic transplanting machine has the advantages of compact structure, high automation degree, high transplanting efficiency, low labor intensity and low manufacturing cost, can transplant plug seedlings ofdifferent crops and has wide applicability.

Owner:CHINA AGRI UNIV

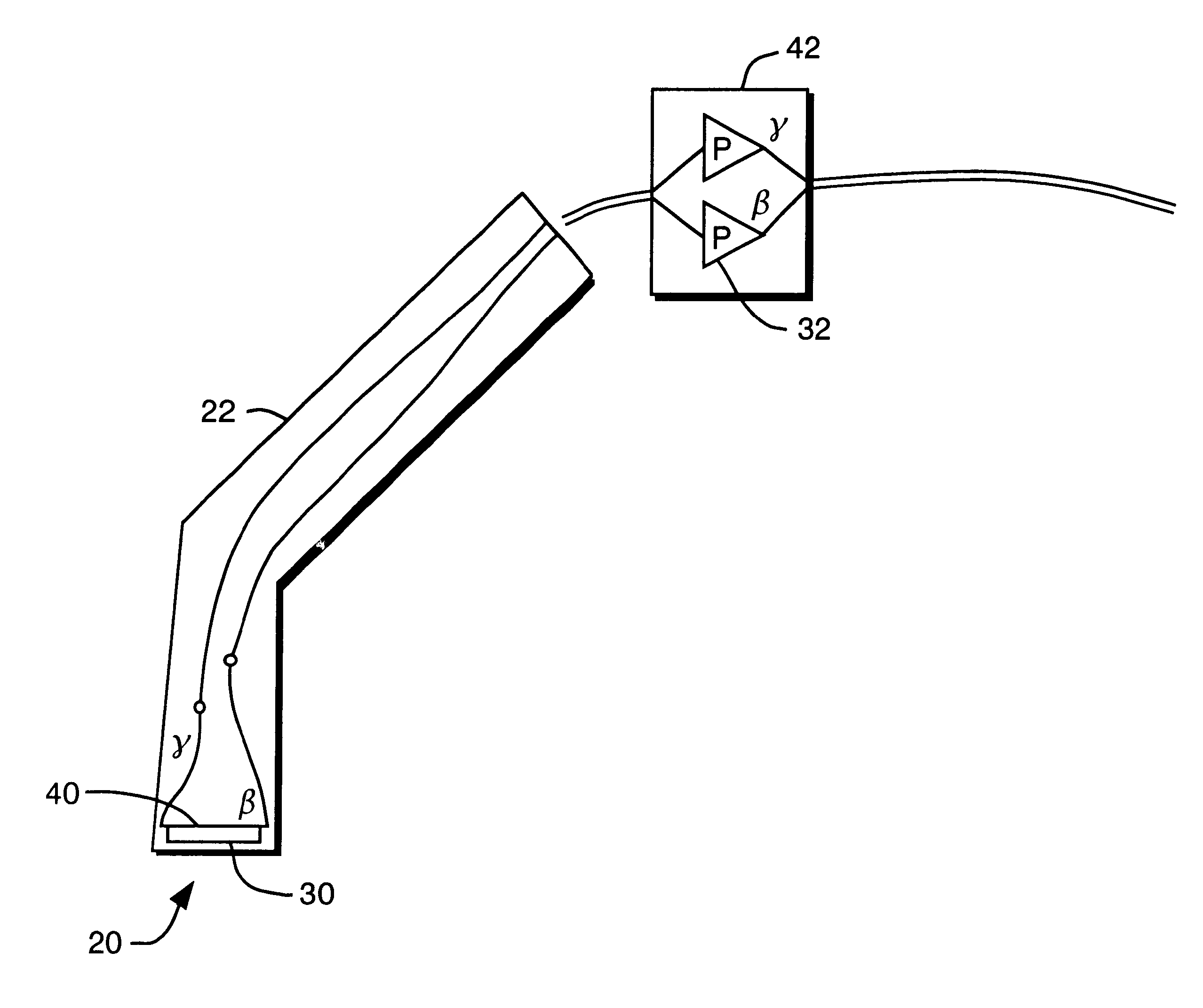

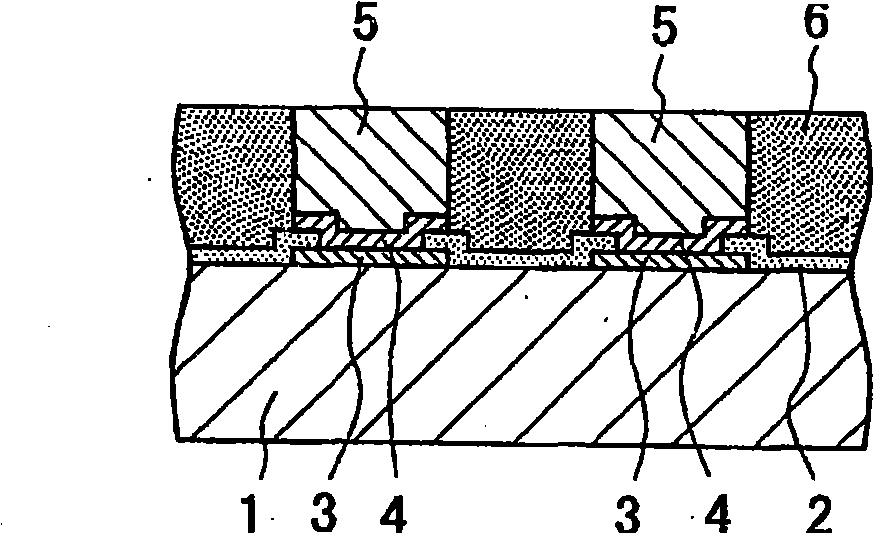

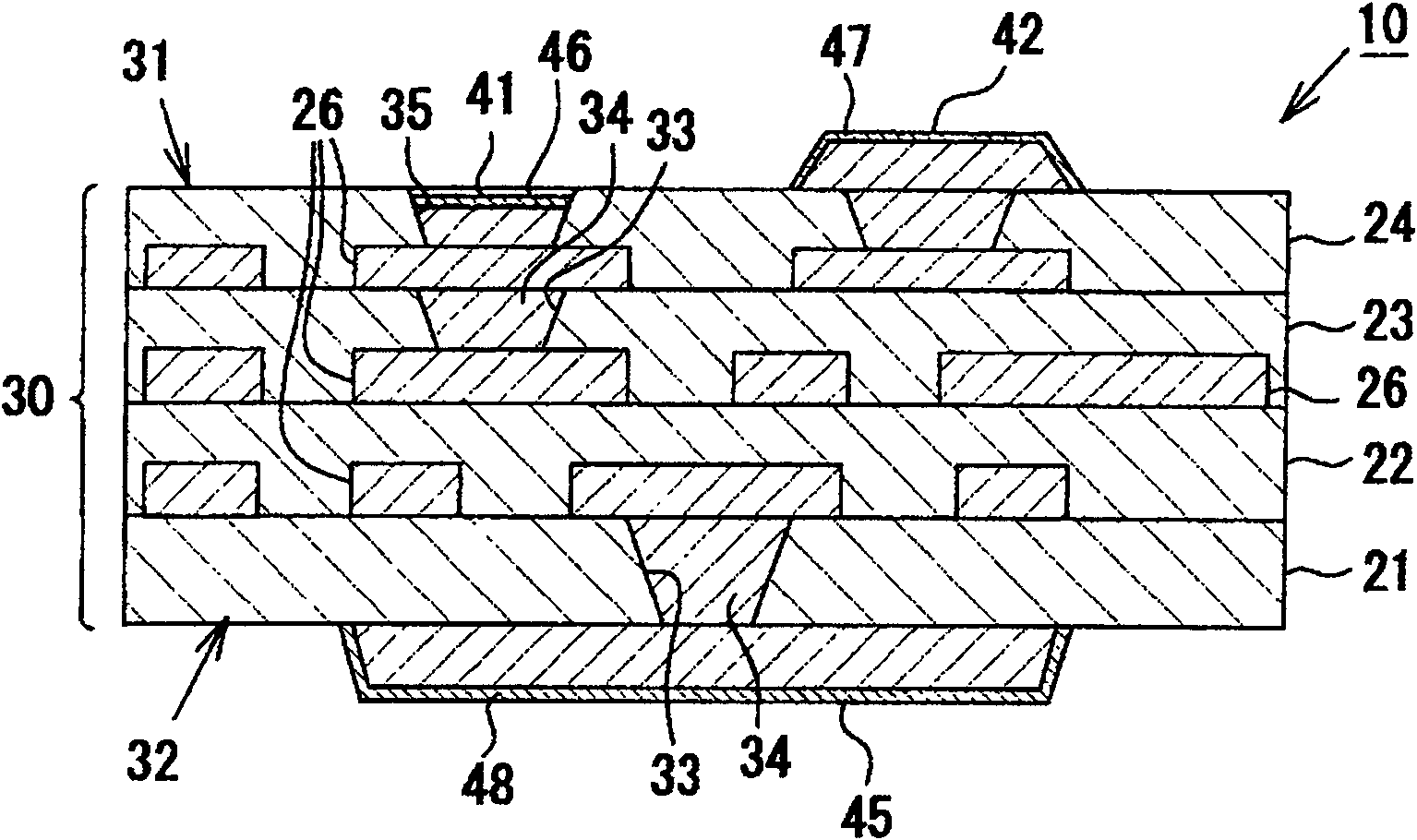

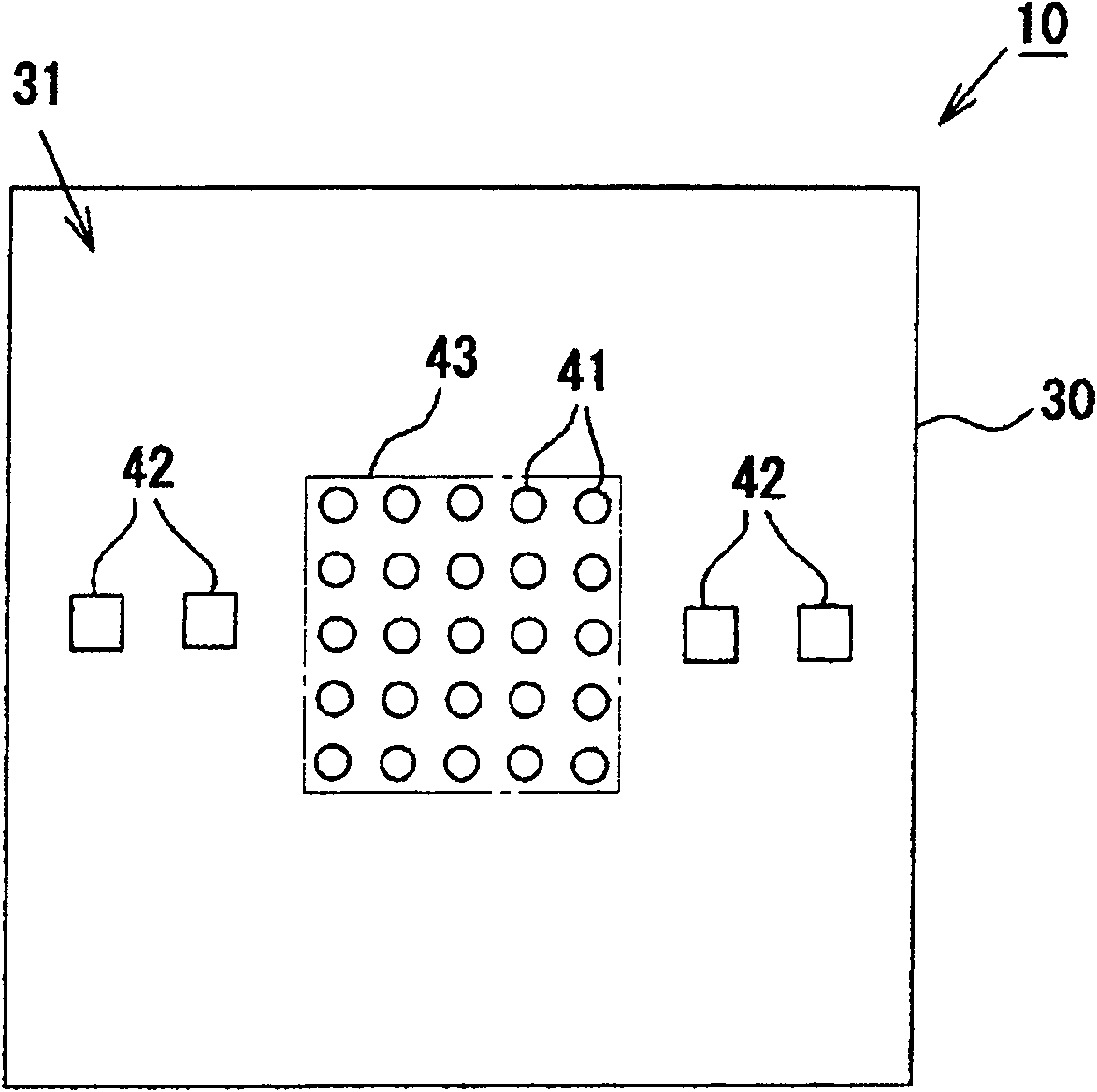

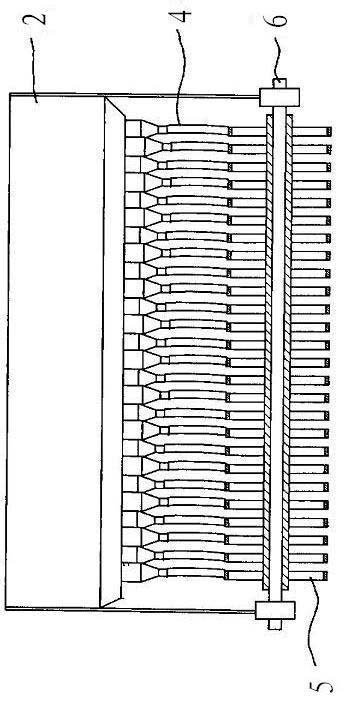

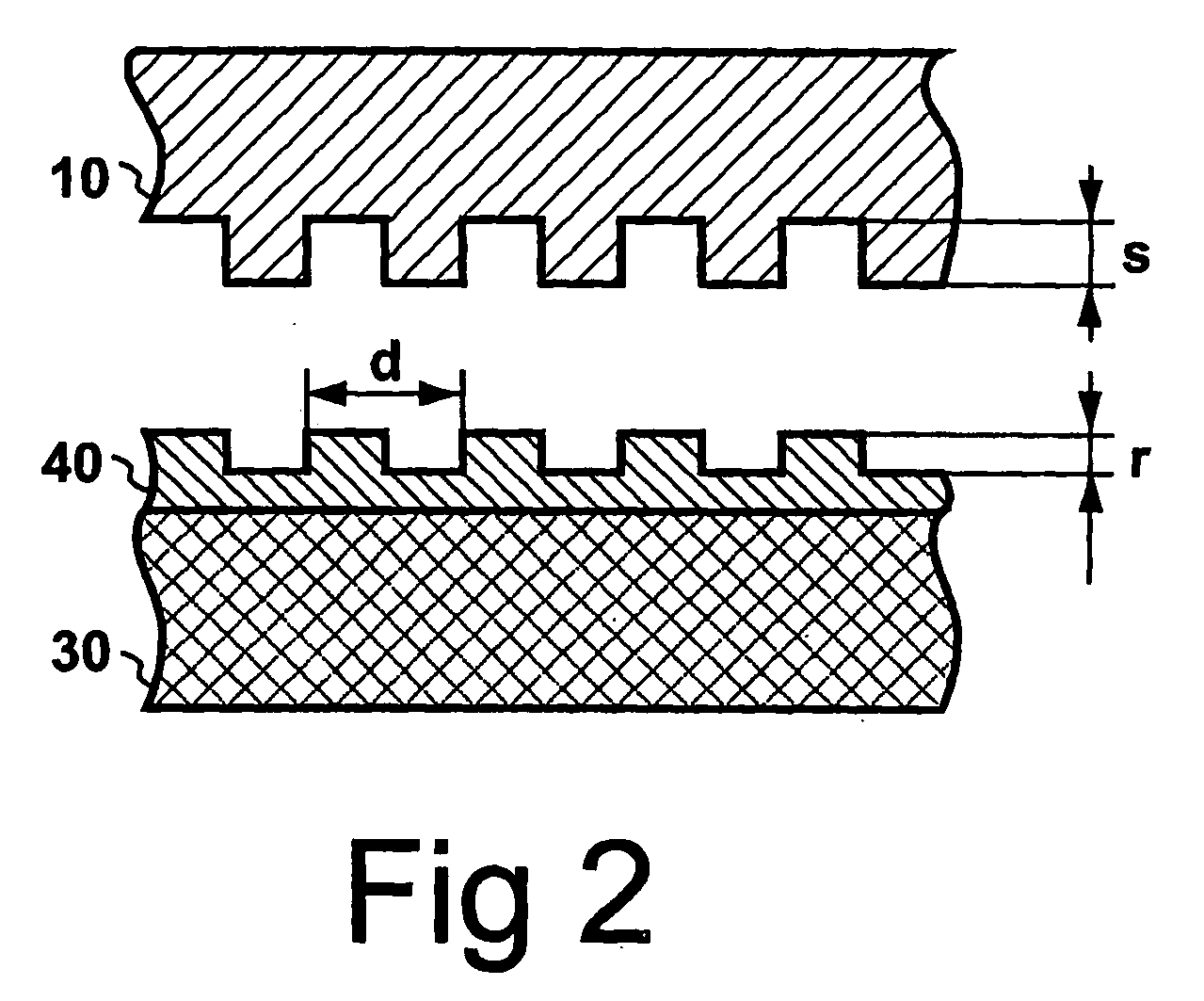

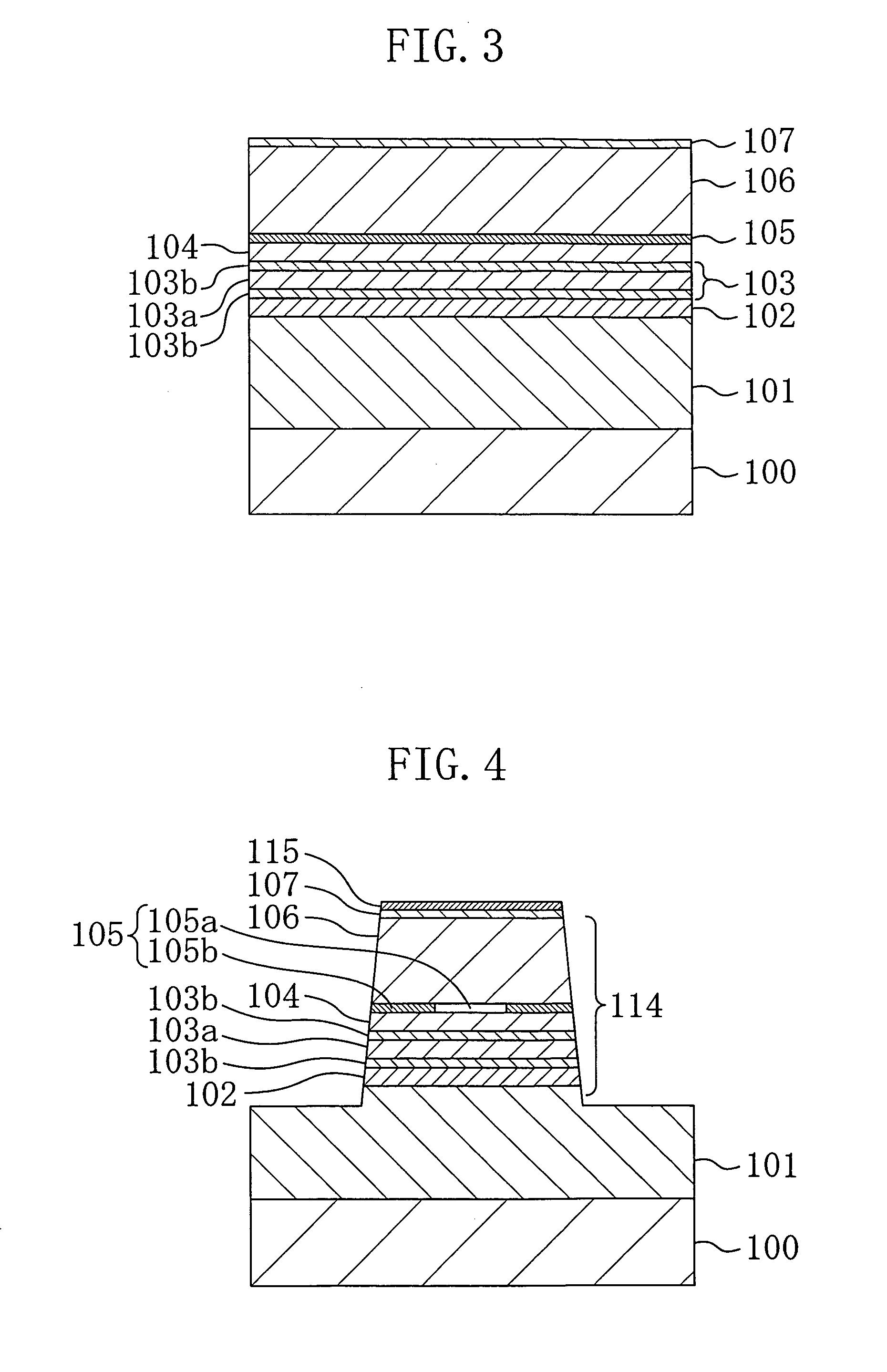

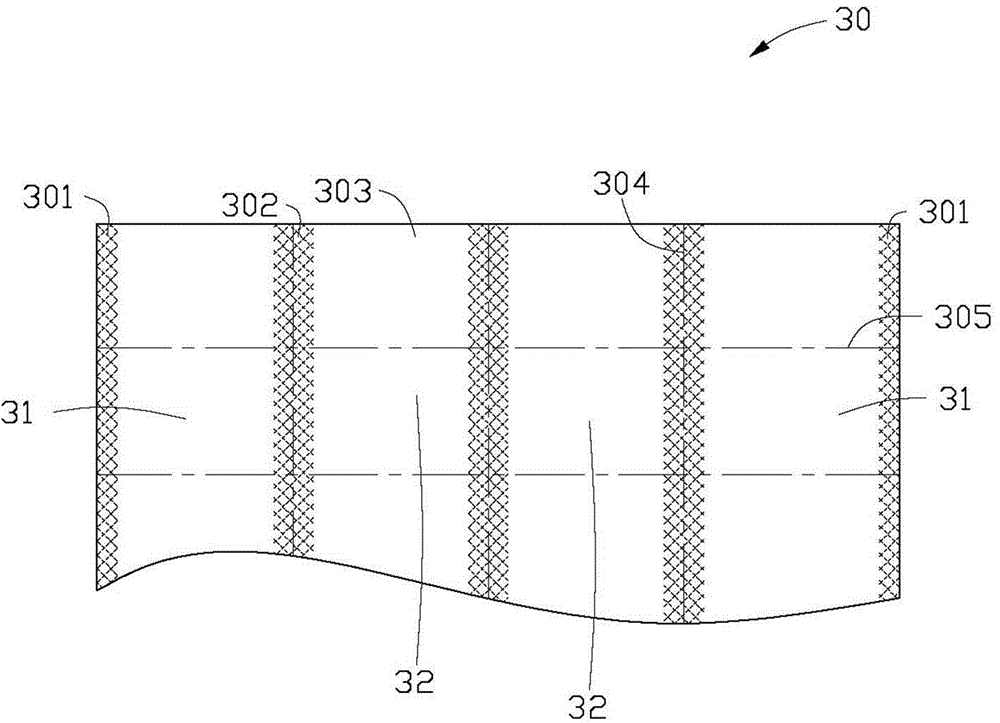

Multilayer wiring substrate

InactiveCN102111952AUniform depthReliable formationPrinted circuit detailsPrinted circuit aspectsInsulation layerElectrical conductor

A multilayer wiring substrate can reliably connect a plurality of connecting objects of different types. The multilayer wiring substrate is provided with a multilayer laminated structure (30) laminated alternately by a plurality of resin insulation layers (21-24) made primarily of the same resin insulation material, and a plurality of conductive layers (26), wherein on the upper surface (31) side of the laminated structure (30) there are provided an IC chip connector for connecting to IC chips, a capacitor connector (42) for connecting capacitors. The capacitor connector (42) is higher than a reference surface, and the IC chip connector (41) is lower than the reference surface, while the surface of the outermost resin insulation layers (24) exposed from the upper surface (31) of the laminated structure (30) is used as the reference surface.

Owner:NGK SPARK PLUG CO LTD

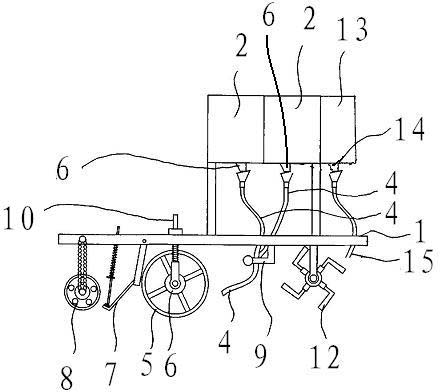

Uniform wheat rolling sowing method and special rolling sowing machine

InactiveCN102550171APlant evenlyIncrease productionSpadesPloughsAgricultural scienceSoil moisture content

The invention belongs to the technical fields of wheat sowing methods and special sowing machines, and in particular discloses a uniform wheat rolling sowing method and a special rolling sowing machine. According to the technical scheme, the method comprises the following steps of: spreading wheat seeds on the surface of a cultivated land in a strip mode, pressing the wheat seeds into the soil by adopting a rolling sowing wheel, covering the seeds with soil, and compacting the soil through a press roller. Therefore, the uniformity of the seeds is improved, and the depth of the seeds is consistent; the depth of the seeds is regulated according to the soil moisture content of the cultivated land, so that the seeds are prevented from being buried deeply and exposed, and the seeds are saved; and the seeds are tightly combined together with the soil in the pressing process, so that imbibition and germination of the seeds are facilitated.

Owner:郝德有 +1

Formation method of flash memory storage unit

ActiveCN103400803AUniform structureImprove performanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductor structureMask layer

The invention relates to a formation method of a flash memory storage unit. The formation method comprises the following steps: providing a plurality of batches of semiconductor structures, wherein each semiconductor structure comprises a substrate, a tunneling oxide layer positioned on the surface of the substrate, a floating gate layer positioned on the surface of the tunneling oxide layer, a sacrificial layer positioned on the surface of the floating gate layer, and a mask layer positioned on the surface of the sacrificial layer, and the mask layer is exposed out of partial surface of the sacrificial layer; etching sacrificial layers and partial floating gate layers in each batch in sequence with an anisotropic dry method by taking a mask layer as a mask, and forming first openings in the sacrificial layers and the floating gate layers in each batch, wherein a determination method of the etching time of a batch to be etched comprises obtaining the etching time of the batch to be etched by the thickness of the sacrificial layer of a batch prior to the batch to be etched, the etching thickness of the floating gate layer of the batch prior to the batch to be etched, and the thickness of the sacrificial layer of the batch to be etched. According to the method, the top sizes of bulges on the top surface of the floating gate layer of each batch are accurate and uniform, so that the erasing performance of the flash memory storage unit is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Positioning scaffold for building wall

ActiveCN111519878AGuaranteed to be parallel to each otherUniform widthBuilding constructionsDrive wheelGear wheel

The invention belongs to the technical field of building construction, and particularly relates to a positioning scaffold for a building wall. The positioning scaffold comprises a bottom plate, wherein two first mounting plates are in sliding fit with the bottom plate; positioning mechanisms are mounted on the outer side surfaces of the first mounting plates and the upper surface of the bottom plate; a first rack and guide rods are horizontally mounted between the first mounting plates; a mounting seat is in sliding fit with the guide rods; a driving wheel is rotationally mounted on the rear end surface of the mounting seat; two limiting blocks are in sliding fit with the front end surface of the mounting seat; second racks and third racks are in sliding fit with the two sides of the limiting blocks; gears are rotationally mounted in the limiting blocks, and knobs and clamping blocks are mounted on the surfaces of the limiting blocks; and limiting plates are mounted at the end parts ofthe second racks and the third racks. When the positioning scaffold for the building wall is used for attaching wallboards to the outer side surface of the building wall, it can be guaranteed that the width and depth of a gap between every two adjacent wallboards are uniform, and therefore the gaps can be fully filled with joint mixtures conveniently.

Owner:TONGZHOU CONSTR GENERAL CONTRACTING GROUP +1

Method of forming metal lands at the M0 level with a non selective chemistry

InactiveUS6258727B1Increase reliabilityImprove reliabilityTransistorDecorative surface effectsPolycrystalline siliconMetal

The starting structure consists of a silicon substrate having diffused regions formed therein and gate conductor stacks formed thereupon that is passivated by a TEOS layer as standard. At a further stage of the wafer fabrication process, contact holes exposing some diffused regions and top of gate conductor stacks have been formed. At least one contact hole exposing a diffused region has been filled with doped polysilicon and the structure has been coated with a layer of an anti-reflective material (ARC) then, with a patterned mask to expose the ARC layer at the contact holes locations. The process improvement essentially consists in the use of a non selective chemistry which etches the doped polysilicon, the ARC and TEOS materials at substantially the same rate in a RIE etcher. A NF3 / CHF3 gas mixture with a 23 / 77 ratio is adequate in that respect. The etch time duration is controlled first by an optical etch end-point detection system adapted to detect the signal transition at the TEOS layer exposure and then by an interferometric etch endpoint detection system to monitor the etched thickness to accurately stop when the selected depth for the M0 land recesses is reached. Finally, said recesses are filled with a metal (e.g. tungsten) as standard to produce the desired M0 metal lands.

Owner:IBM CORP

Rubber cutting robot

ActiveCN110696008AImprove accuracyExtend your lifeForestryManipulatorControl systemControl engineering

The invention relates to a rubber cutting robot which comprises a clamping mechanism, a cutting mechanism, a moving mechanism, a measuring and limiting module and an existing control system. The rubber cutting robot is fixed to a rubber tree through the clamping mechanism. The moving mechanism and the measuring and limiting module are arranged on the clamping mechanism and both connected with theexisting control system. The measuring and limiting module transmits a received signal into the existing control system, and the existing control system controls the moving mechanism to act accordingto the received measurement signal. The cutting mechanism is arranged on the moving mechanism and driven by the moving mechanism to do spiral movements on the clamping mechanism. The cutting mechanismis connected with the existing control system and controlled by the existing control system to work. The rubber cutting accuracy can be improved, and the waste of rubber liquid and the damage to rubber latex vessel tissue caused by artificial operation errors are avoided, and the repeated cutting rate is effectively increased.

Owner:BEIJING INFORMATION SCI & TECH UNIV

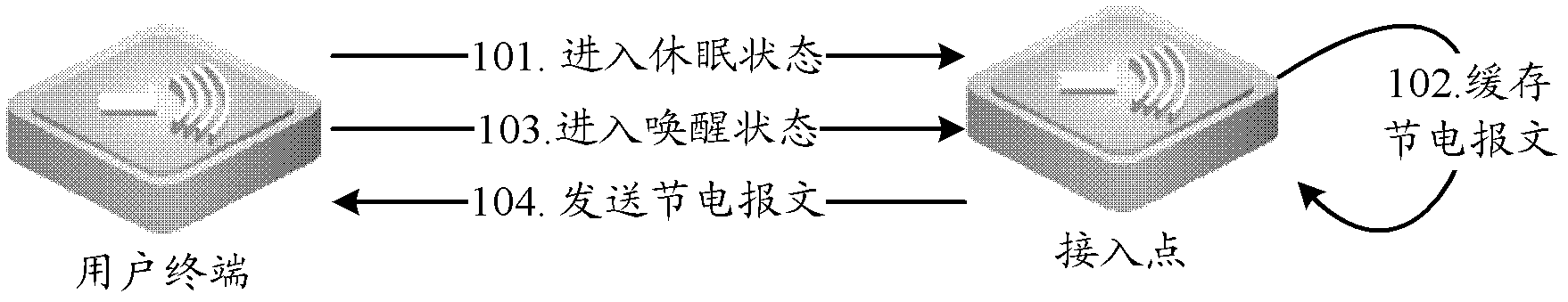

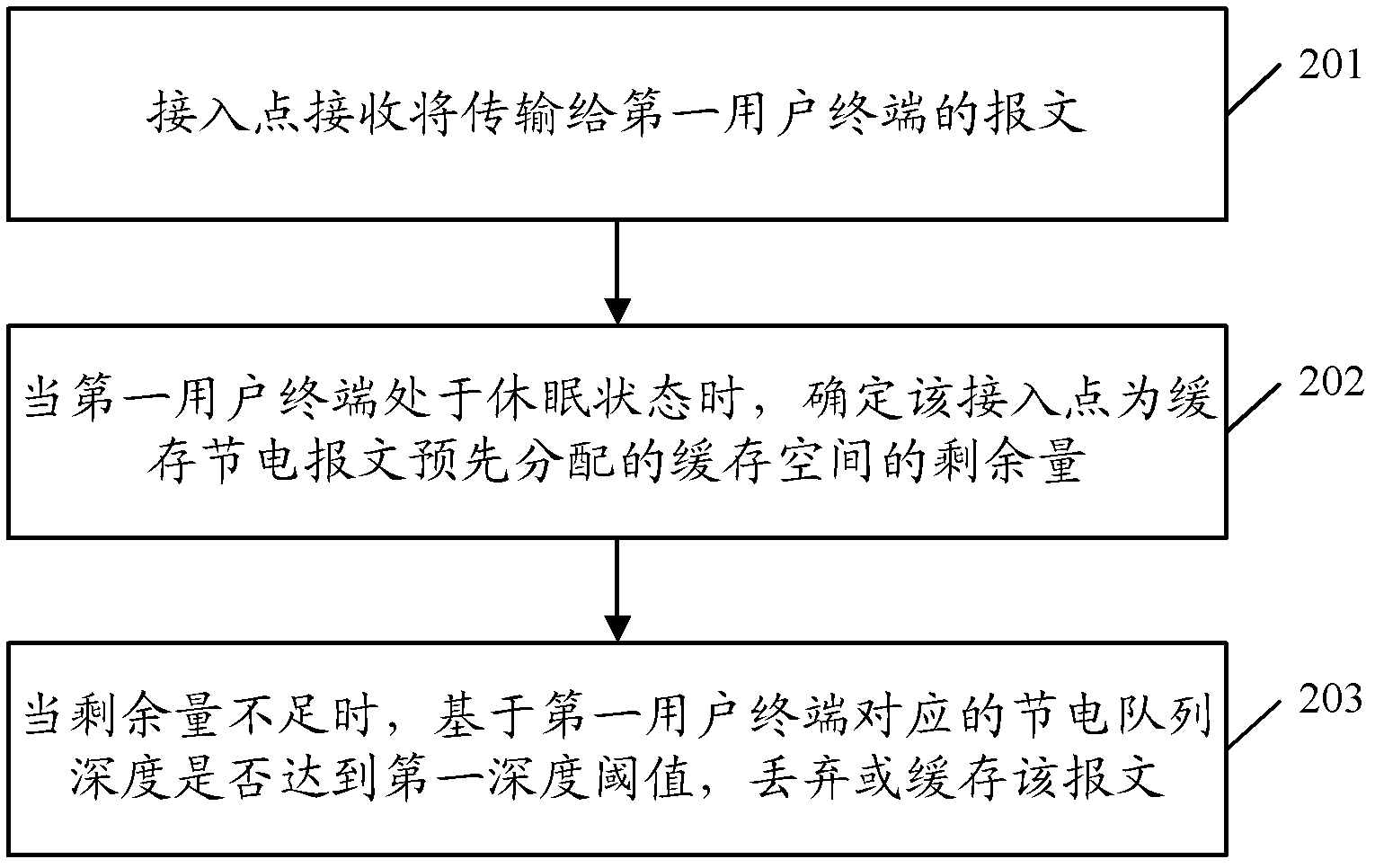

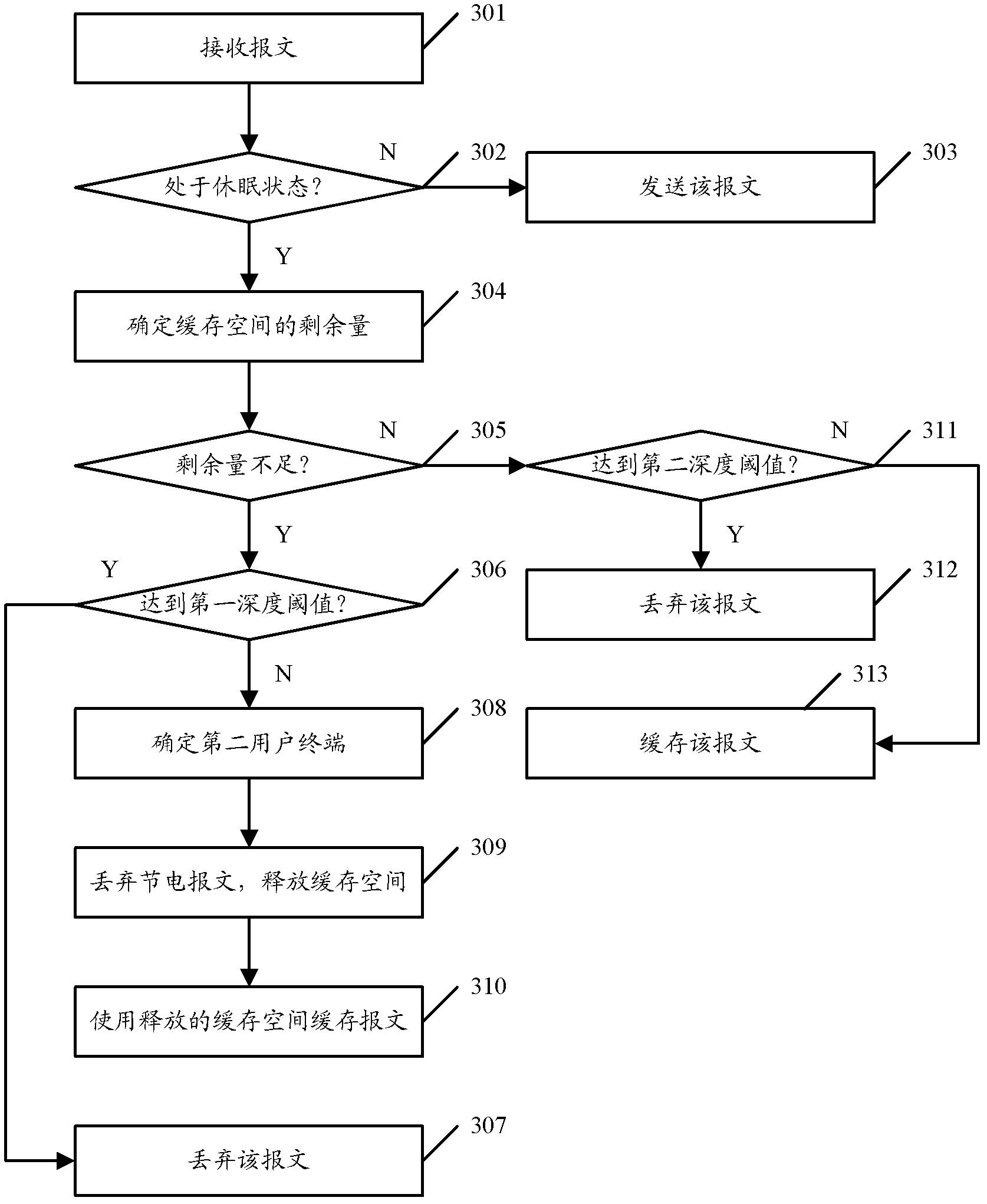

Message caching method and access point

ActiveCN102595512AEffective controlAvoid failurePower managementEnergy efficient ICTElectricityComputer terminal

The invention discloses a message caching method and an access point. The method is characterized in that: the access point receives a message to be transmitted to a first user terminal; when the first user terminal is in a dormant state, the access point is determined as the surplus of a cache space allocated by a cache electricity saving message in advance; when the surplus is not enough, and the depth of an electricity saving queue corresponding to the first user terminal reaches a first depth threshold value, the message is discarded; when the surplus is not enough, and the depth of the electricity saving queue corresponding to the first user terminal does not reach the first depth threshold value, the cache space is released by discarding an electricity saving message cached in the electricity saving queue corresponding to a second user terminal, and released cache space caches the message to the electricity saving queue corresponding to the first user terminal. By the technical scheme provided by the invention, the problem of system failure caused by a reason that lots of memory space is occupied by caching the electricity saving message is solved.

Owner:RUIJIE NETWORKS CO LTD

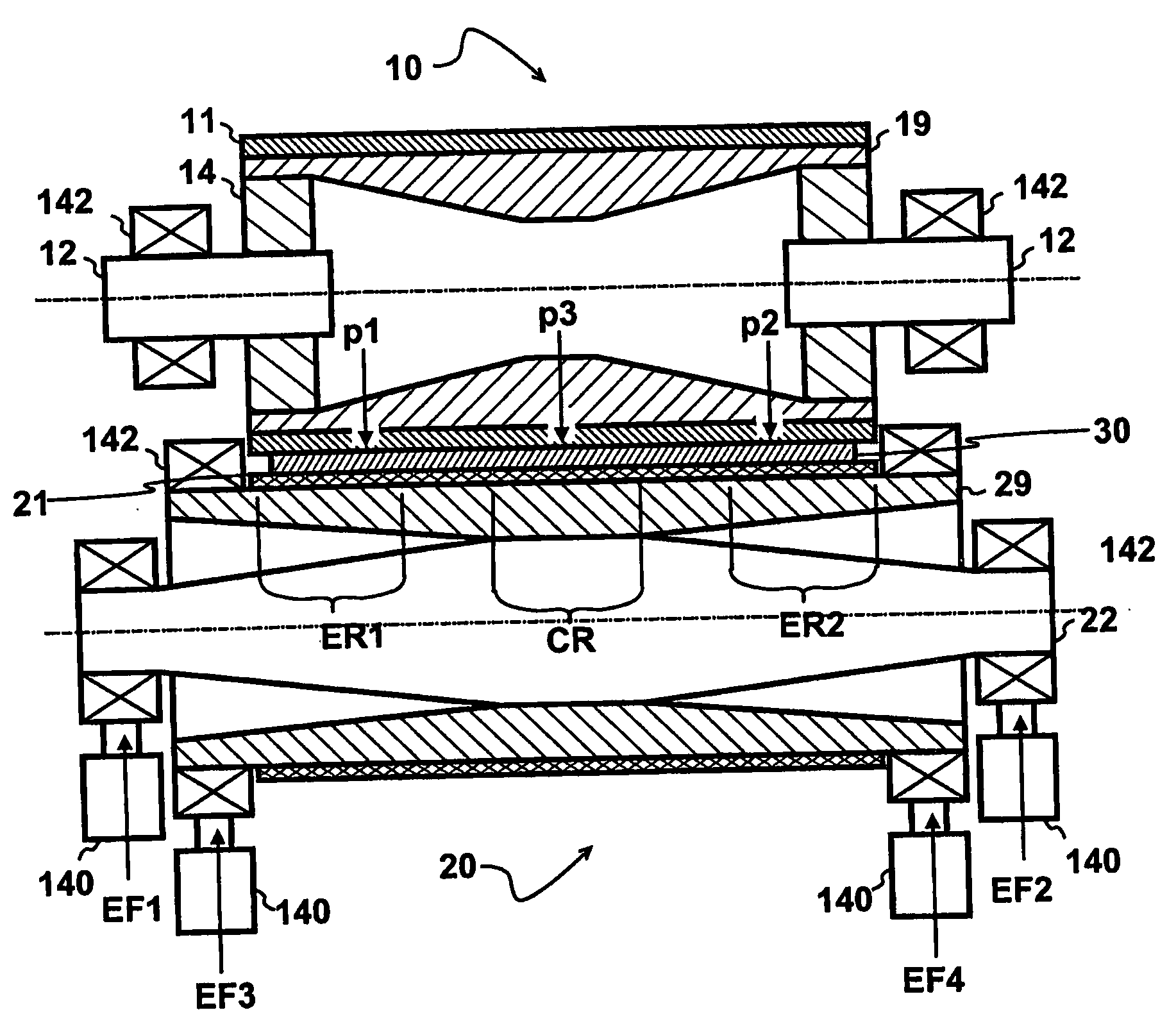

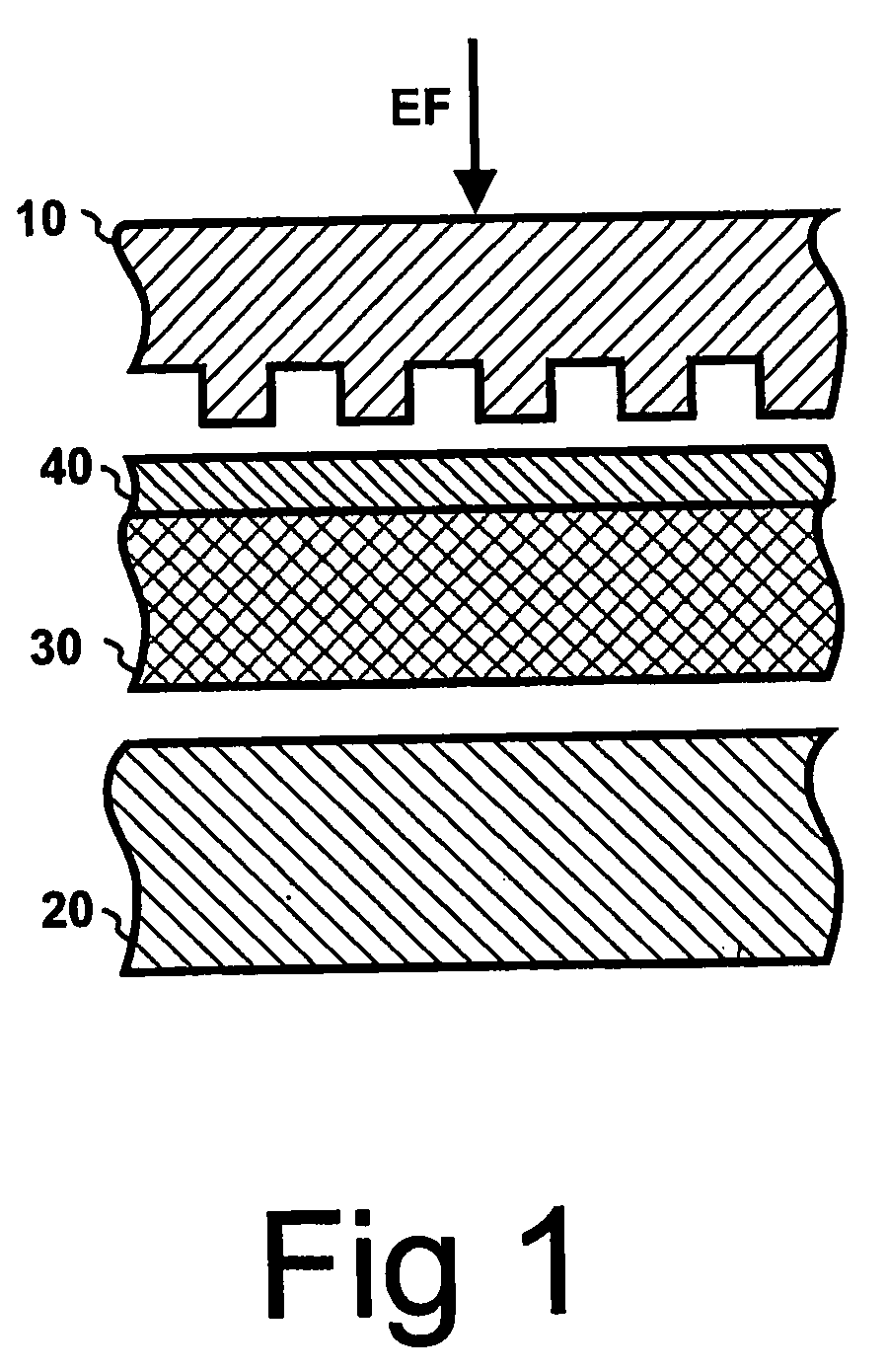

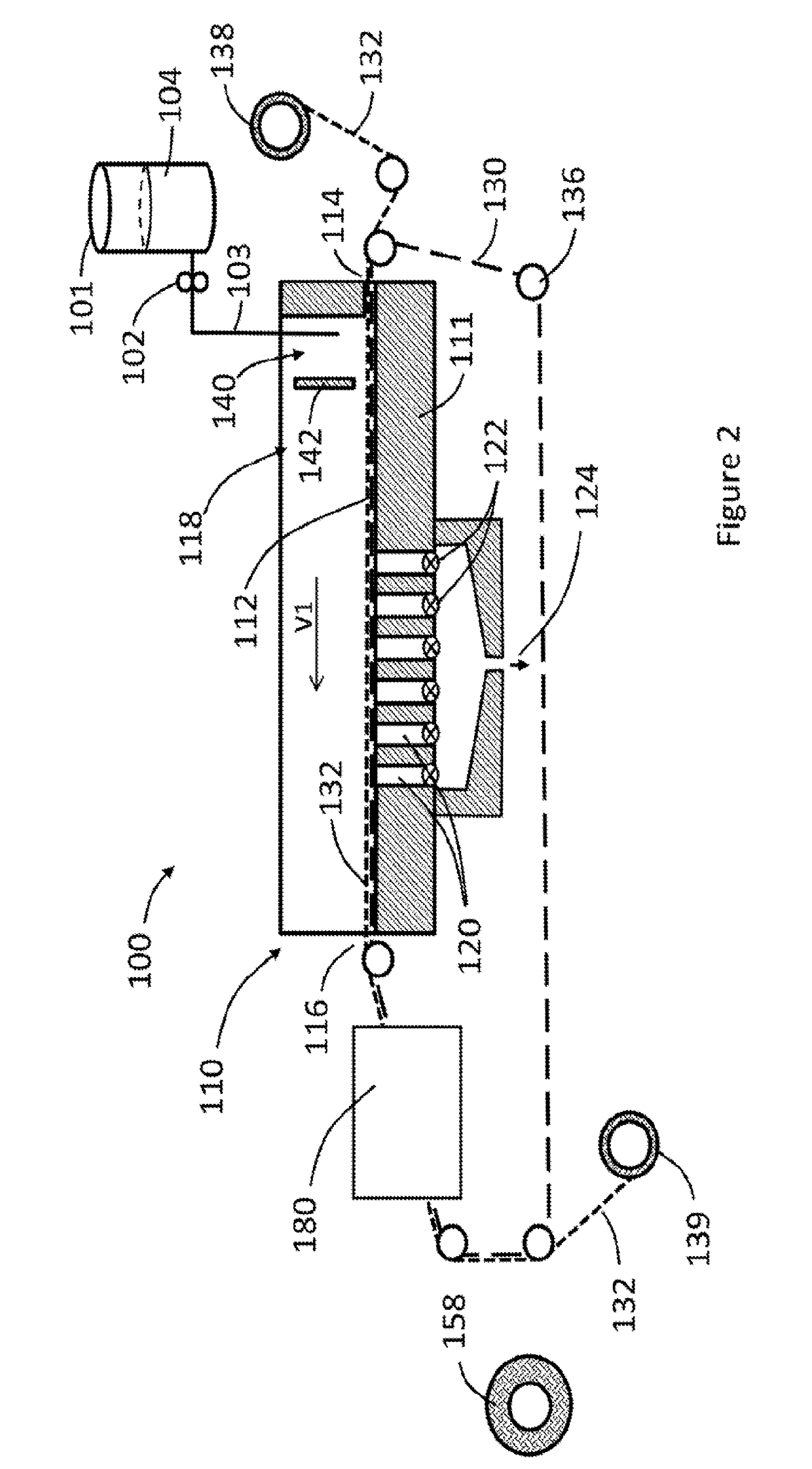

Embossing Device with a Deflection Compensated Roller

InactiveUS20080251956A1Reduce the total massEnabling useMechanical working/deformationShaft and bearingsSurface layerEngineering

A diffractive microstructure is produced on the surface layer of a substrate using an embossing device. The embossing device includes an embossing roll and a backing roll for exerting an embossing pressure on the surface layer of the substrate. The embossing pressure and / or variations in temperature cause deflection of the embossing roll. To compensate for the deflection, the embossing device can set the embossing pressure exerted by the central area of the embossing roll on the surface layer of the substrate to be at least equal to or higher than the embossing pressure exerted by the end areas of the embossing roll on the surface layer of the substrate.

Owner:AVANTONE OY

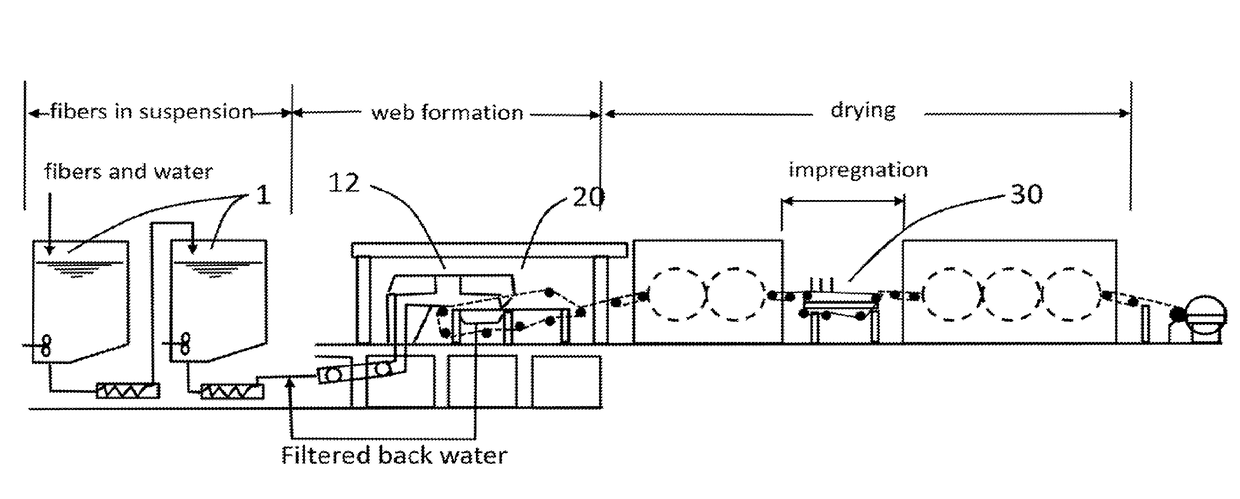

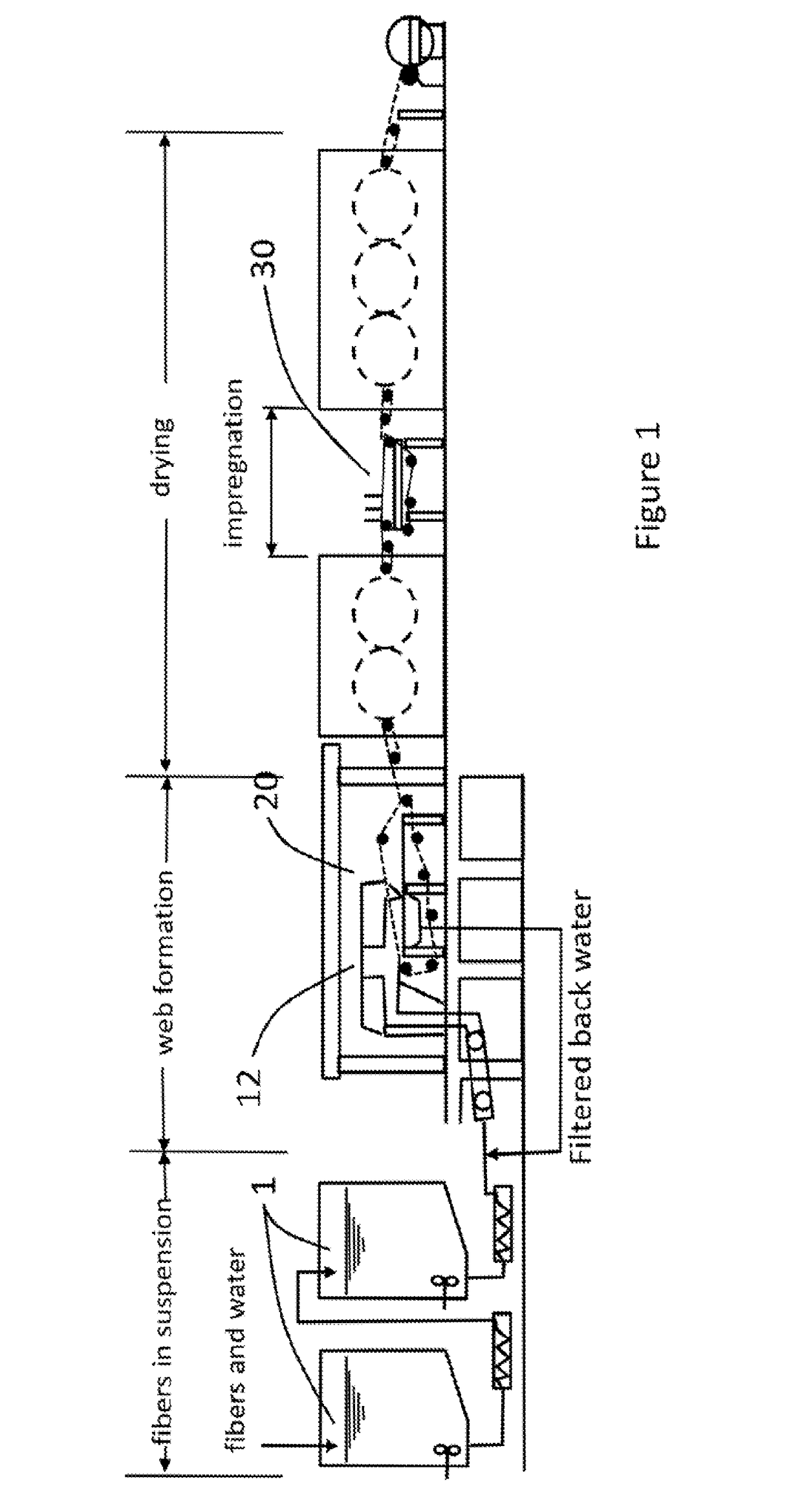

Carbon nanotube sheet structure and method for its making

ActiveUS20170210627A1Improve functional propertiesGood physical propertiesMaterial nanotechnologyLamination ancillary operationsLightning strikeComposite laminates

A carbon nanotube (CNT) sheet containing CNTs having a median length of at least 0.05 mm and an aspect ratio of at least 2,500; L arranged b a randomly oriented, uniformly distributed pattern, and having a basis weight of at least 1 gsm and a relative density of less than 1.0. The CNT sheet is manufactured by applying a CNT suspension in a continuous pool over a filter material to a depth sufficient to prevent puddling of the CNT suspension upon the surface of the •filter material, and drawing the dispersing liquid through the filter material to provide a uniform CNT dispersion and form the CNT sheet. The CNT sheet is useful in making CNT composite laminates and structures having utility for electromagnetic wave absorption, lightning strike dissipation. EMI shielding, thermal interface pads, energy storage, and heat dissipation.

Owner:GENERAL NANO LLC

Fire-retardant, anticorrosive and mothproof coating for restoring ancient timberwork building

InactiveCN107236441AHigh refractorinessImprove anti-corrosion performanceFireproof paintsAntifouling/underwater paintsPolymer solutionEthyl acetate

The invention discloses a fire-retardant, anticorrosive and mothproof coating for restoring an ancient timberwork building. The fire-retardant, anticorrosive and mothproof coating is prepared from the following main components: a wetting agent, a defoaming agent, a film forming agent, an inorganic dispersant, a pigment, filler, an orange peel agent, petroleum asphalt, a cosolvent, cerium oxide, an organosilicon polymer solution, ethyl acetate and water. The fire-retardant, anticorrosive and mothproof coating for restoring the ancient timberwork building, disclosed by the invention, has the advantages of low cost, wide sources of raw materials and excellent fire-retardant, anticorrosive and mothproof effects; in addition, after the ancient timberwork building is restored, cracks on the surface of the ancient building and special vicissitude sense endowed by time still can be kept, and further a sense of repairing the old as old is obtained; the fire-retardant, anticorrosive and mothproof coating is an environment-friendly and safe novel building material.

Owner:DALIAN NATIONALITIES UNIVERSITY

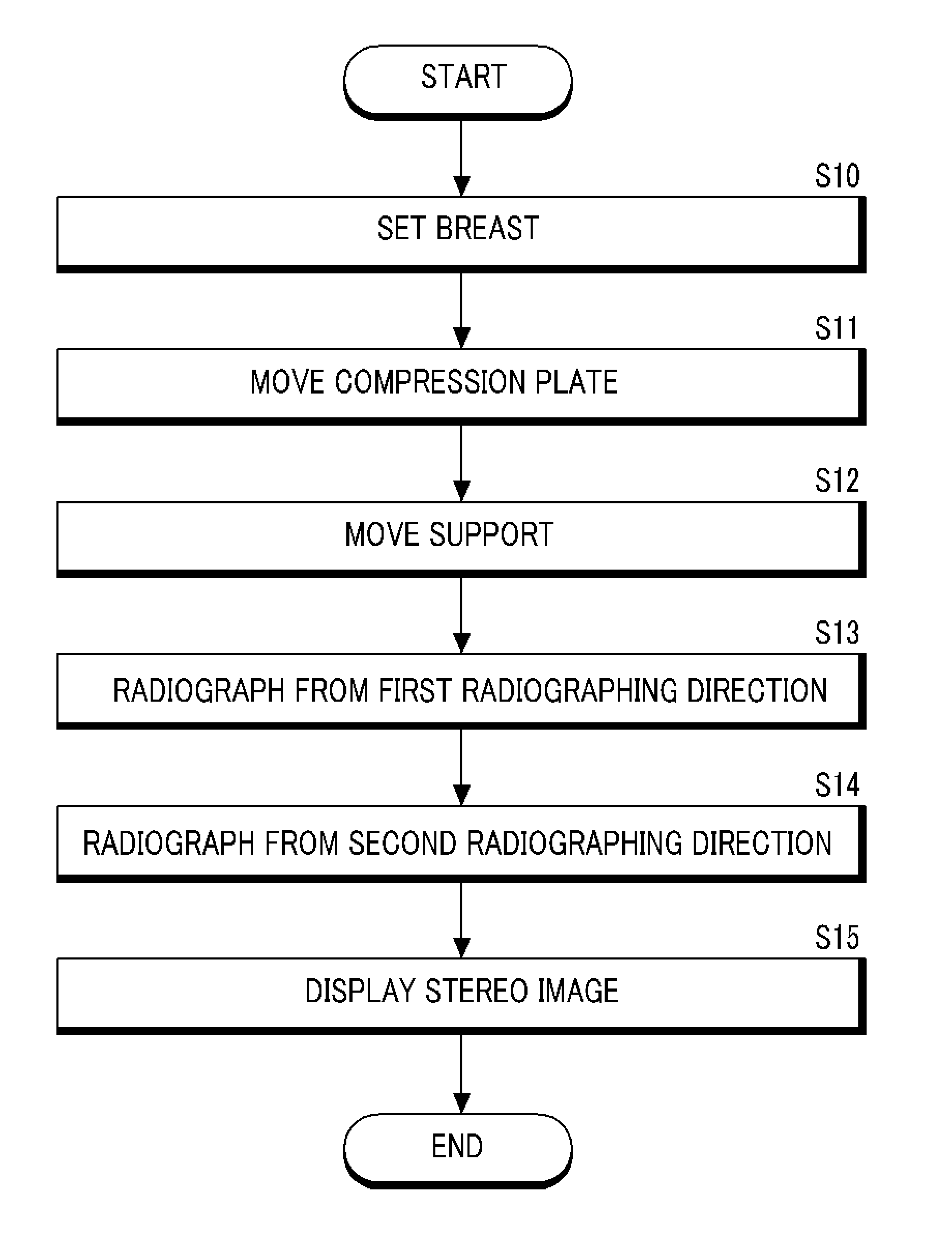

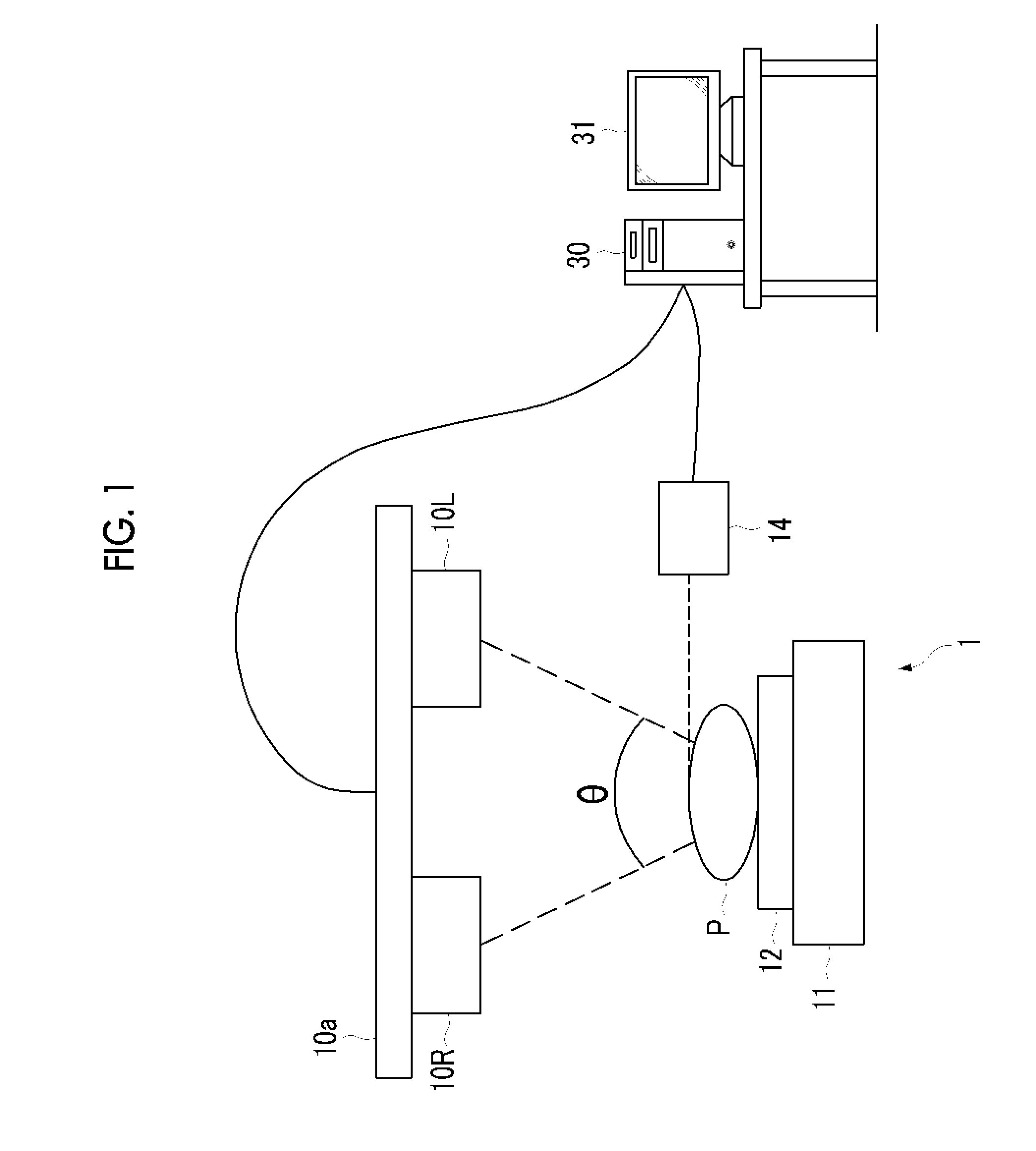

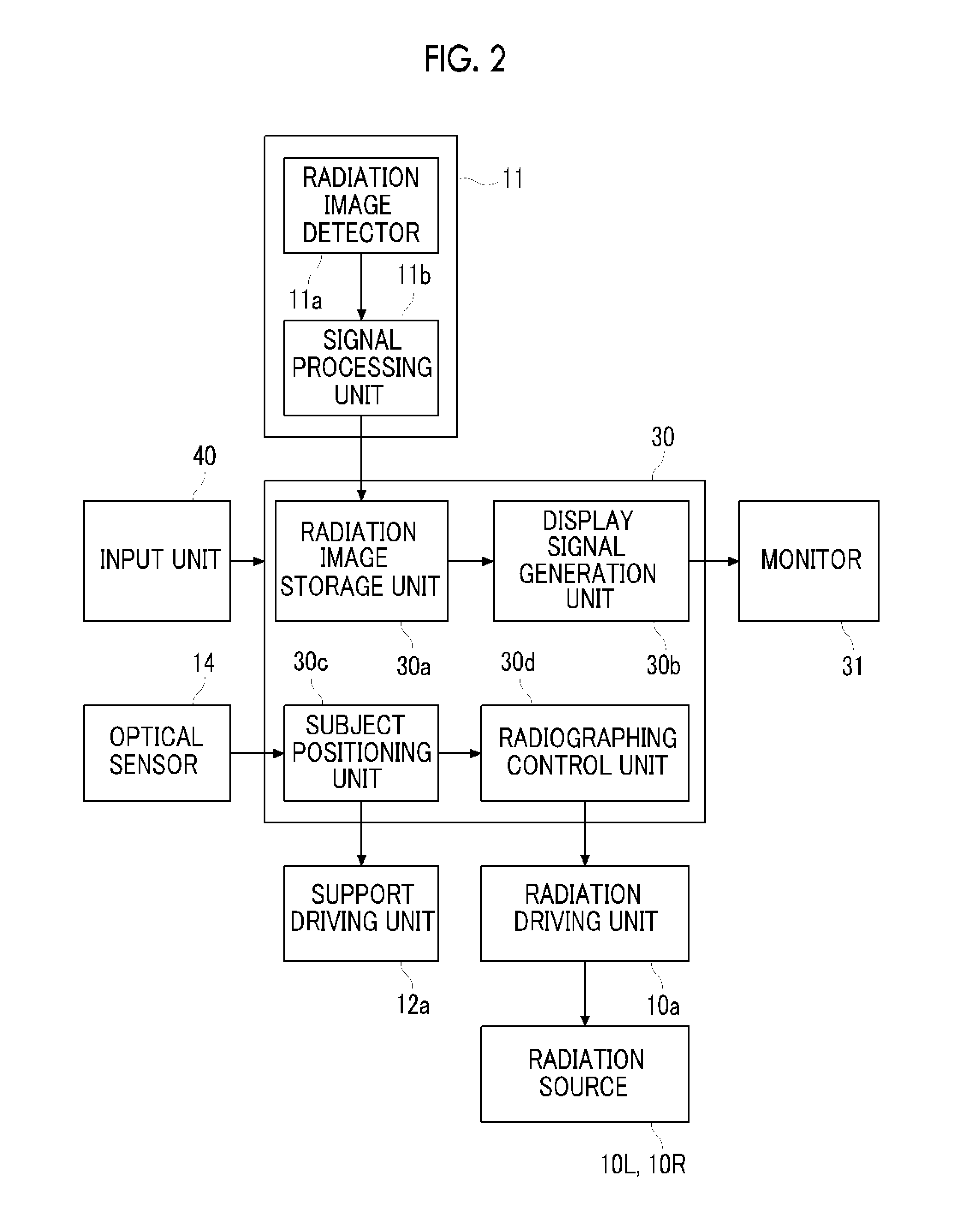

Radiation image radiographing apparatus and radiation image radiographing and displaying method

InactiveUS20120051501A1Projection amount on the stereoscopic image can be made uniformUniform depthX-ray/infra-red processesPatient positioning for diagnosticsImage detectionRadiography

It is possible to display a stereoscopic image in which a sense of depth in a stereoscopic image and a projection amount from a display screen are made uniform. A radiation image radiographing and displaying method irradiates radiation onto a subject from different radiographing directions by irradiation units to acquire radiation images in the radiographing directions detected by a radiation image detection unit, and displays a stereoscopic image using the acquired radiation images in the radiographing directions. The position of a subject is controlled such that the distance between the position of the end surface of the subject facing the irradiation units and the radiation image detection unit becomes a given distance, in a state where the position of the subject is controlled, the radiation images in the radiographing directions are acquired, and a stereoscopic image is displayed using the acquired radiation images.

Owner:FUJIFILM CORP

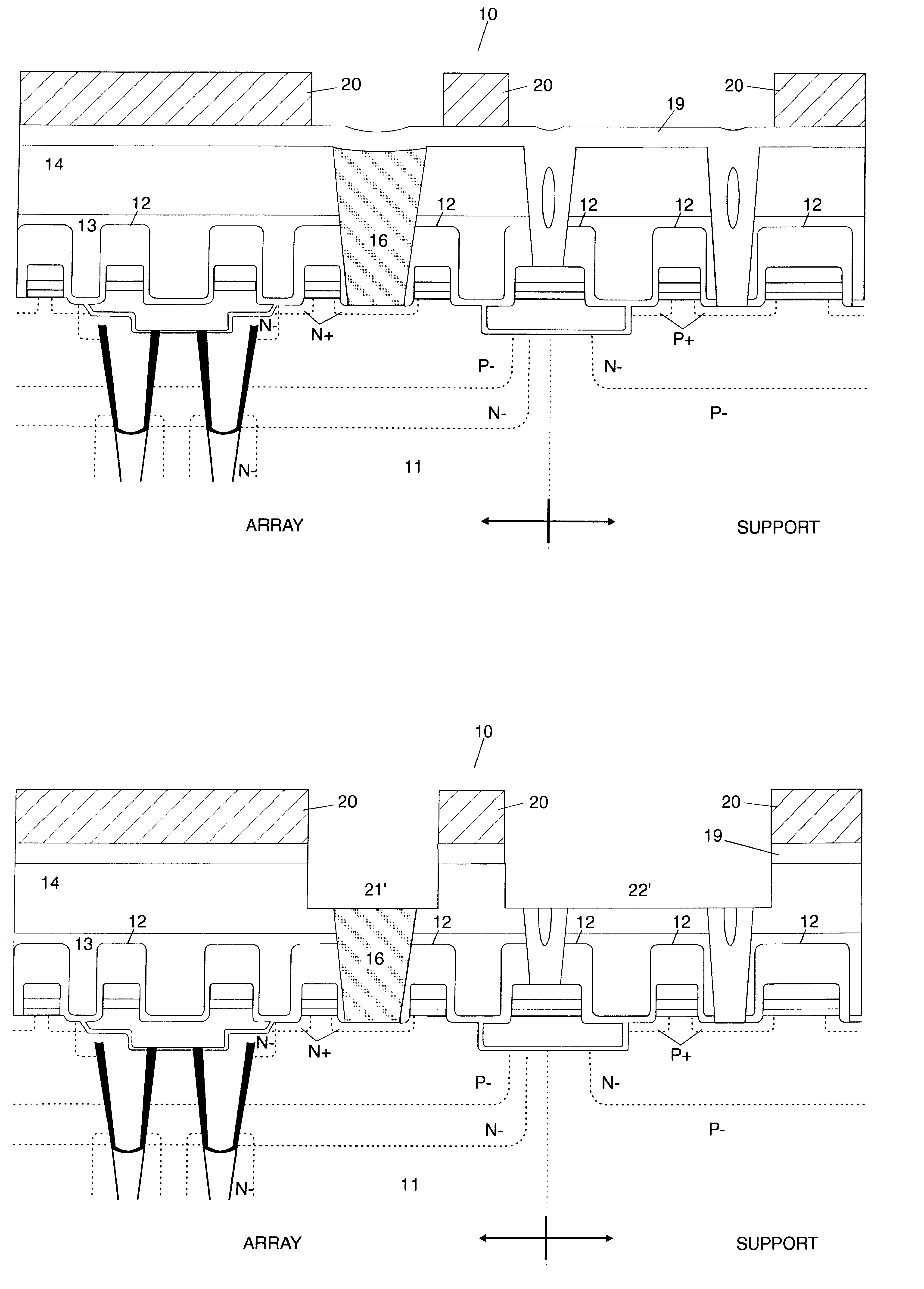

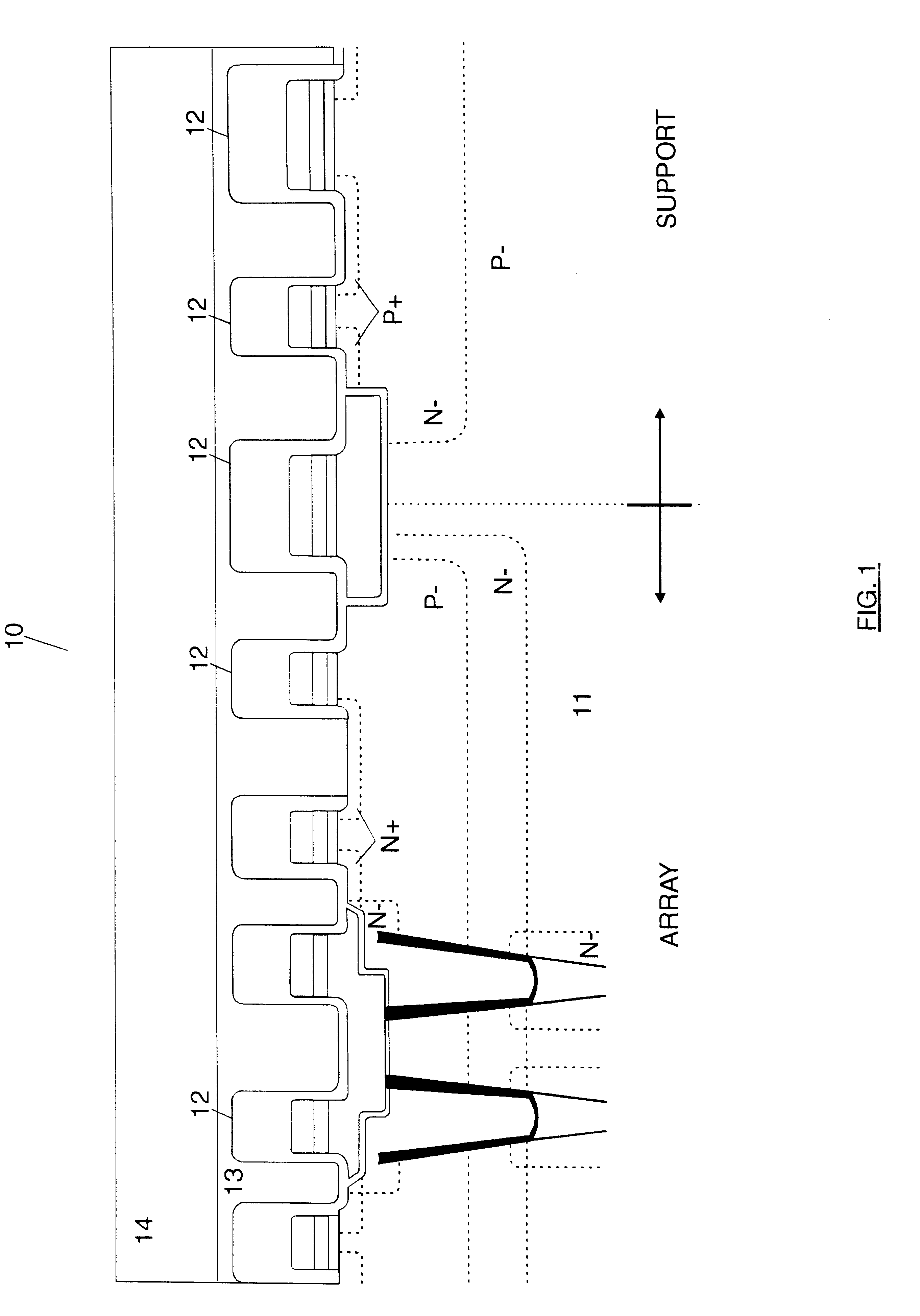

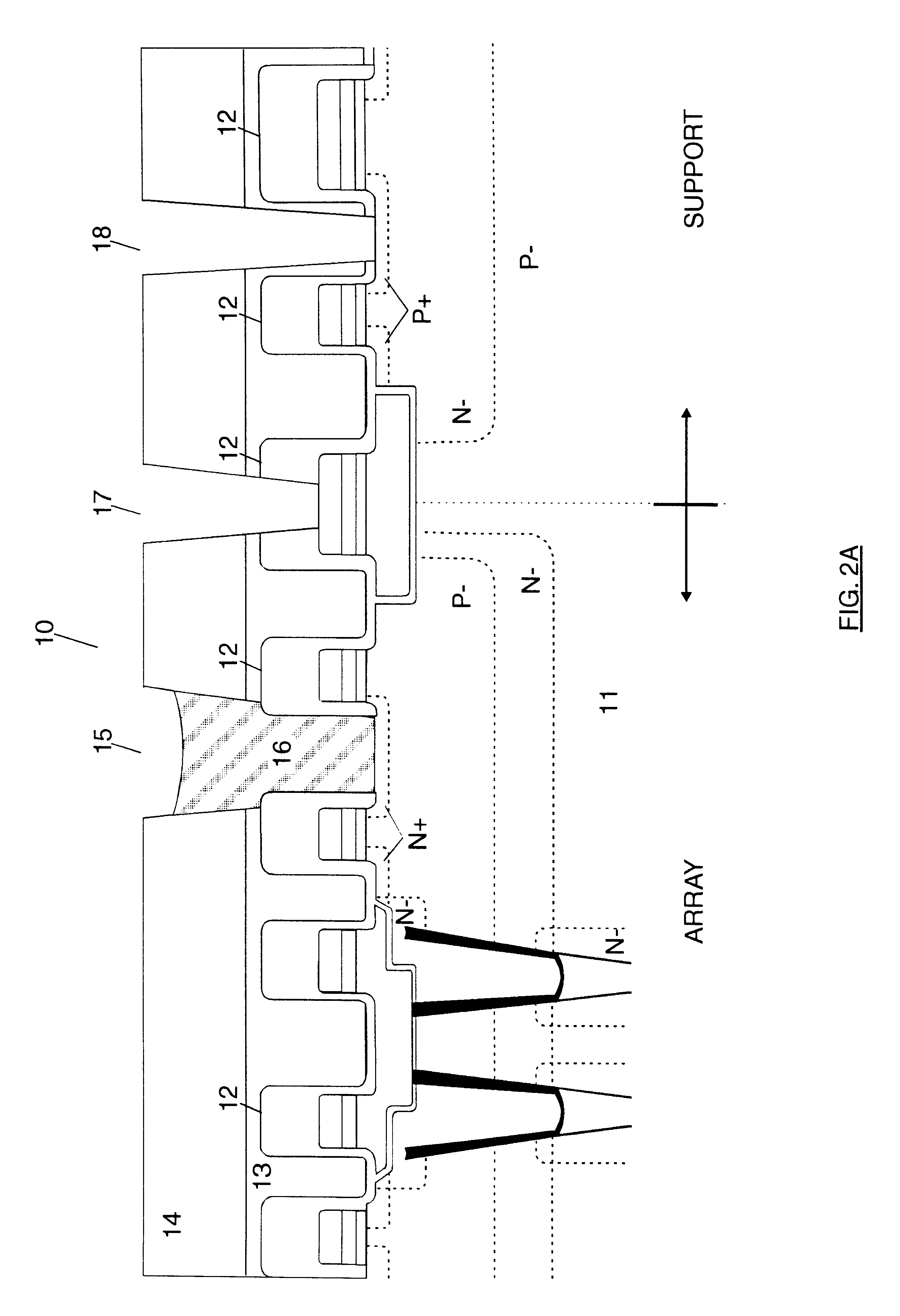

Methods of inspecting a lithography template

InactiveUS7132225B2Minimal undercutReduce defect densityElectric discharge tubesNanoinformaticsBeam patternComputational physics

A method for forming imprint lithography templates is described herein. The method includes forming a masking layer and a conductive layer on a substrate surface. The use of a conductive layer allows patterning of the masking layer using electron beam pattern generators. The substrate is etched using the patterned masking layer to produce a template.

Owner:CANON KK +1

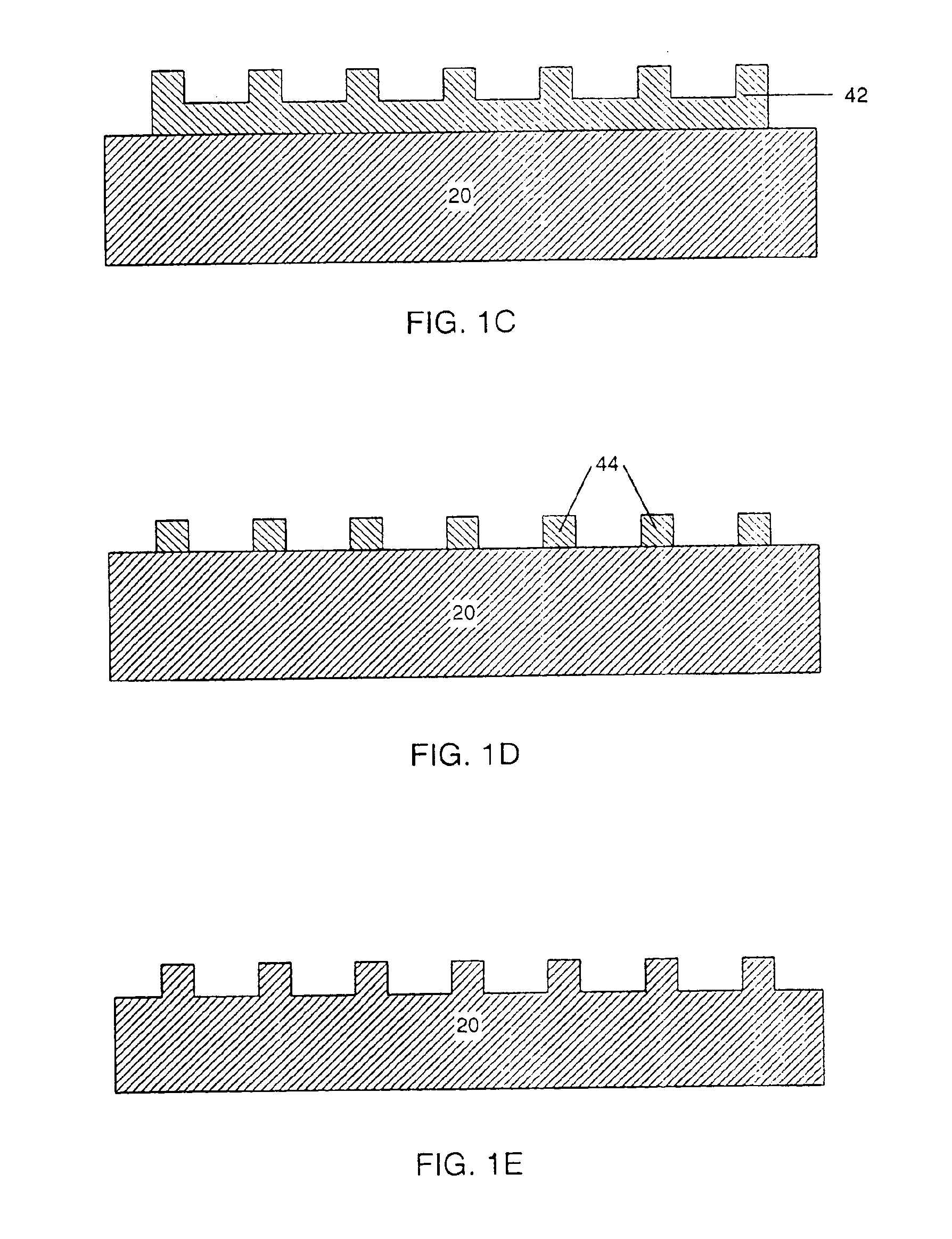

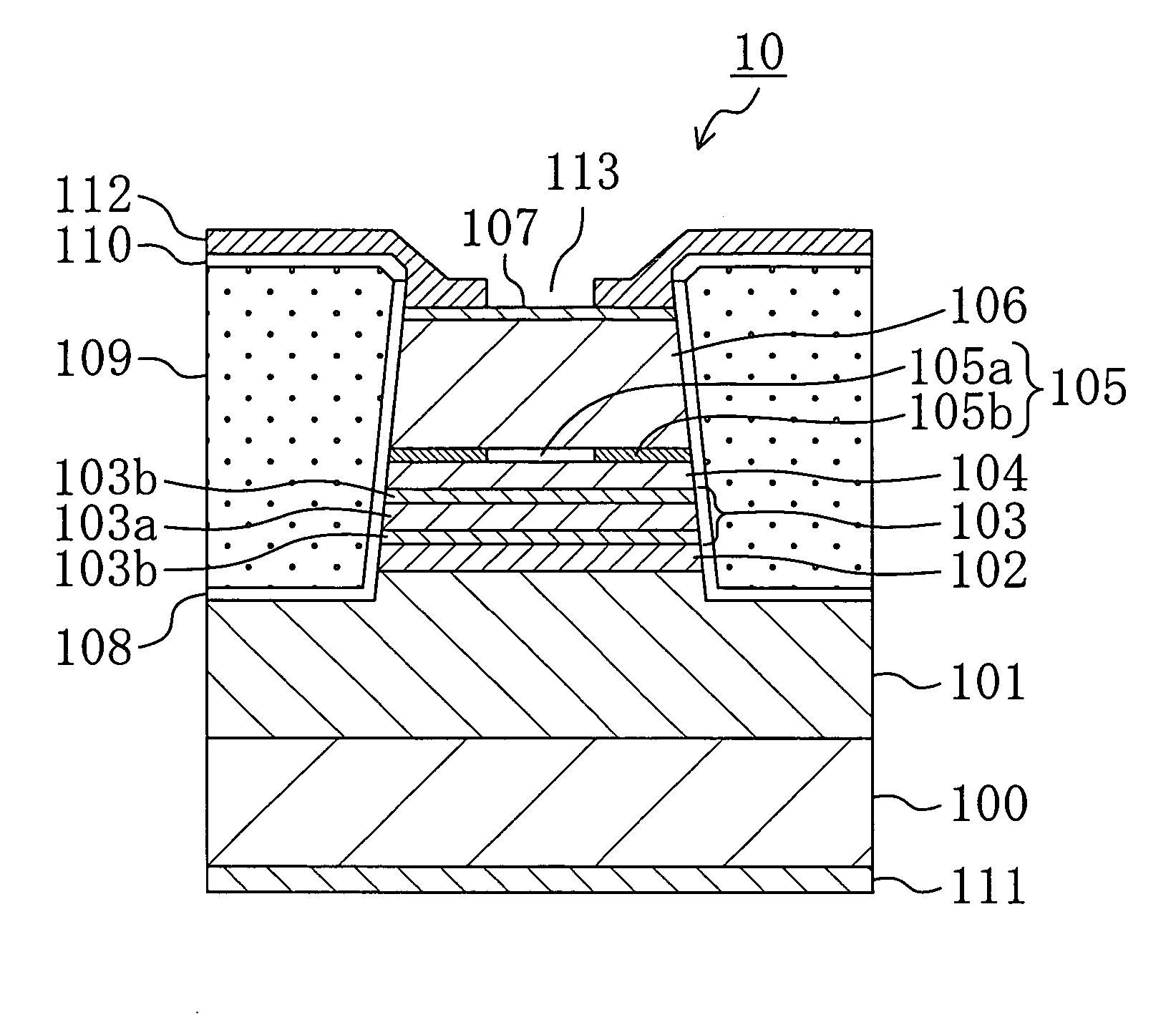

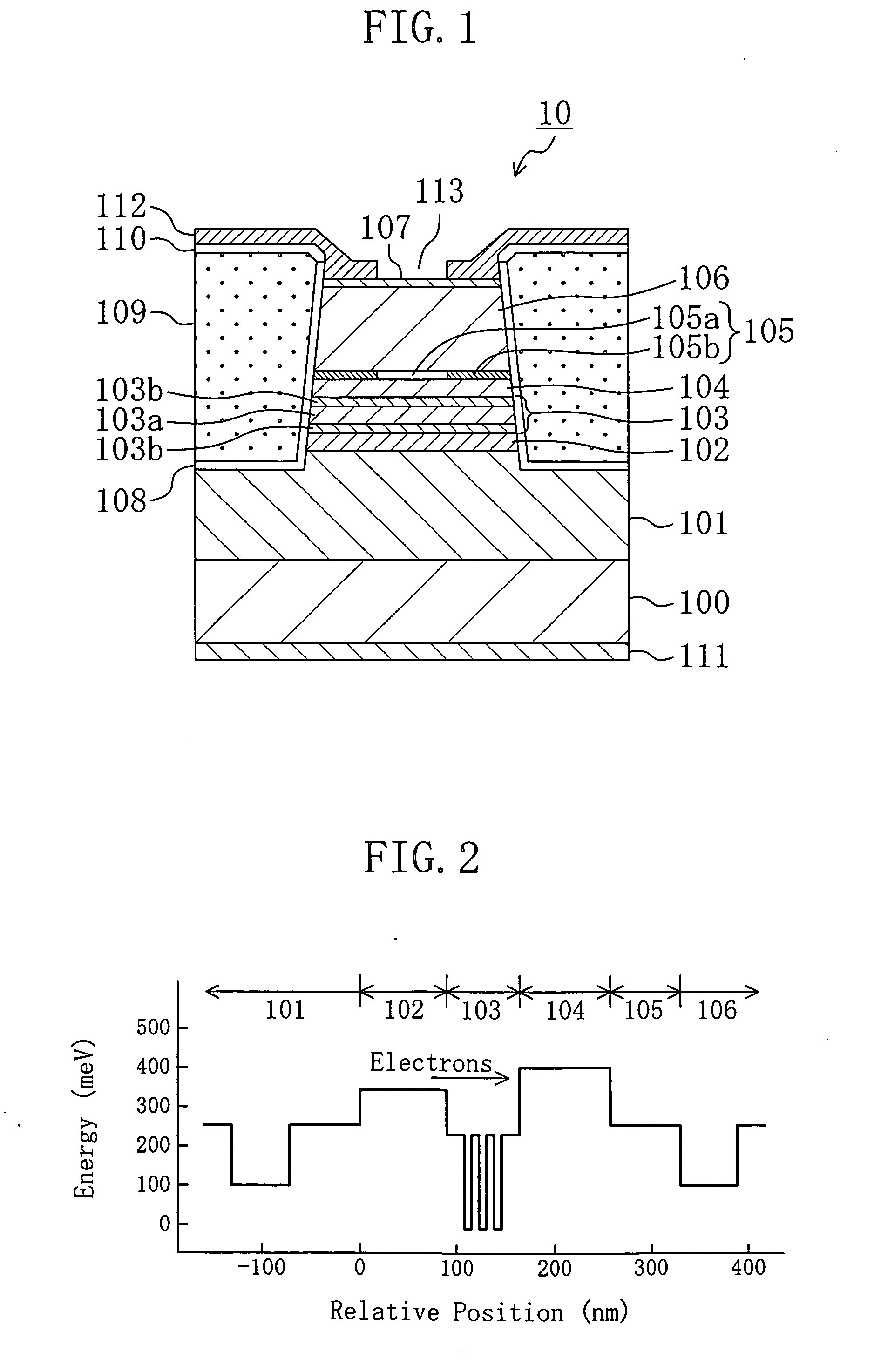

Semiconductor laser device

InactiveUS20060245459A1Suppress overflowGood surface smoothnessLaser detailsNanoopticsActive layerElectron

Owner:PANASONIC CORP

Marble pillar cutter

InactiveCN104890126ACompact structureReasonable designWorking accessoriesGrinding machinesEngineeringMachine tool

The invention provides a marble pillar cutter, belongs to the technical field of a machine tool, and solves the problems that an existing natural stone marble pillar can be manually processed. The marble pillar cutter comprises a frame and a cross beam, wherein the frame is fixed with a hand-piece component with a chuck and a first drive device capable of driving the chuck to rotate, and a central spindle of the chuck is horizontally arranged; the frame is provided with an ejector pin which is relative to the chuck, the cross beam is located above the hand-piece component, the two ends of the cross beam and the frame are connected with vertically arranged first guide rails and the frame is provided with a second driving device capable of driving the cross beam to do a lifting motion; the cross beam is provided with a cutting blade mounting disc and a power head device capable of moving horizontally along the cross beam. According to the marble pillar cutter provided by the invention, a channel of a glossy marble pillar can be automatically processed, and outer flanks can be polished; furthermore, by processing the marble pillar processed by the marble pillar cutter provided by the invention, the processing efficiency can be significantly improved, the skill requirements on workers can be reduced, and the production cost can be reduced.

Owner:ZHEJIANG CHANGZHI MACHINERY

Hole-digging planter for assisting agricultural planting

InactiveCN110115134AUniform depthRealize automatic mechanical planingPlantingDibble seedersAgricultural engineeringAutomation

The invention discloses a hole-digging planter for assisting agricultural planting. The hole-digging planter comprises a body and an automatic hole digging device and is characterized in that a traveling device is connected to the bottom of the body, a storage battery is mounted inside the body and electrically connected with a power switch outside the body, the automatic hole digging mechanism comprises a crank slider power mechanism mounted above the body, the crank slider power mechanism is connected with a hole digging device and comprises a slider which can slide vertically, and the slider drives the hole digging device to move vertically in a reciprocating manner and open to dig holes in field soil. The hole-digging planter is high in automation level, integrated with various advantages, capable of increasing agricultural planting efficiency and capable of greatly increasing the yield of agricultural products.

Owner:XIANGYANG VOCATIONAL & TECHN COLLEGE

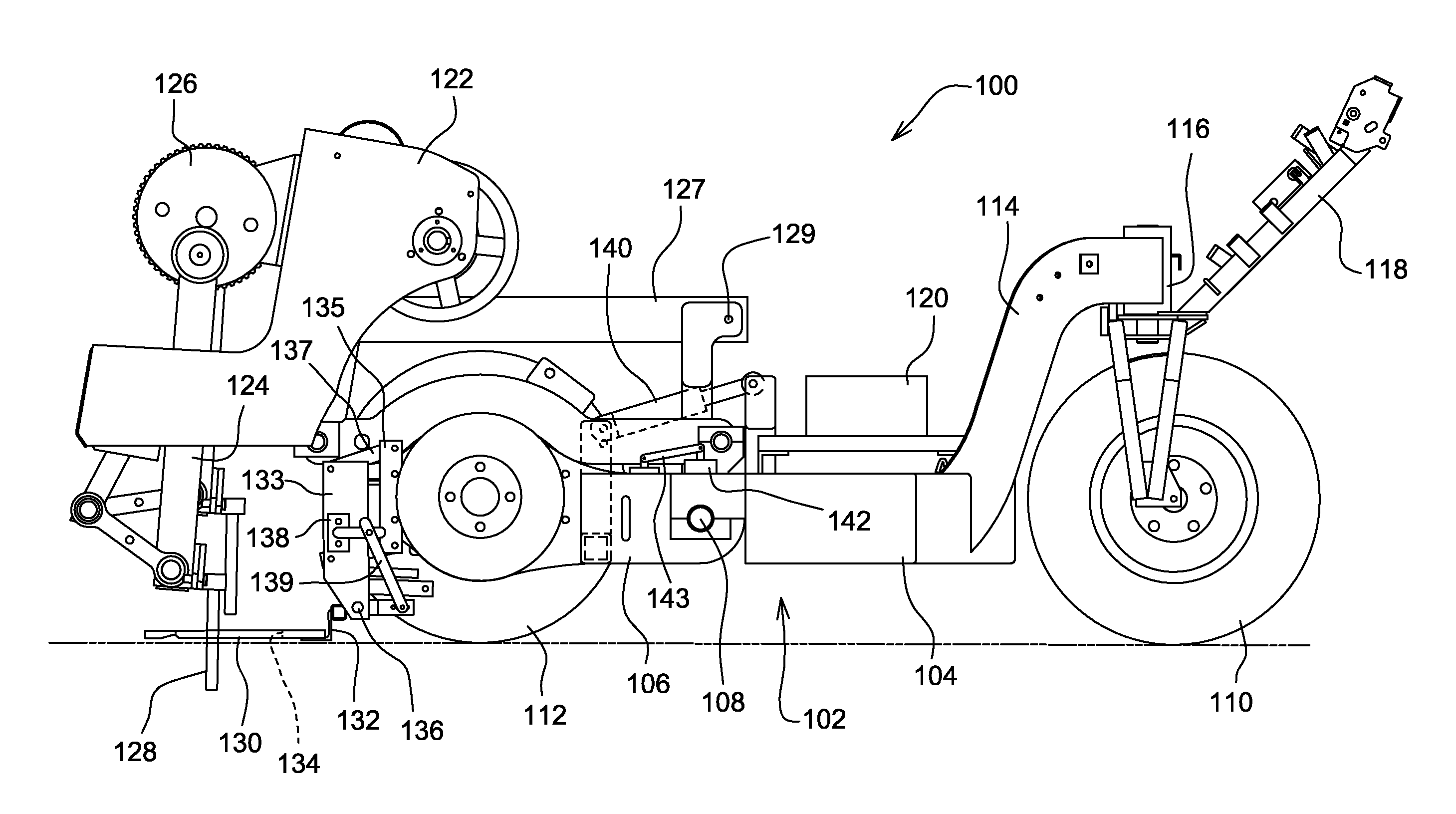

Aerator having flexible frame

ActiveUS20110213530A1Uniform depthAnalogue computers for trafficComputations using stochastic pulse trainsGolf BallActuator

An aerator having a flexible frame for use on sloped or undulating ground surfaces of golf courses and other turf. The aerator includes a pair of frame sections linked together at a horizontal pivot axis, one of the frame section supporting a coring head. A ground sensor is pivotably attached to one of the frame sections so that the ground sensor may pivot in response to changes in ground slope and provide output relating to the magnitude of the change. Based on the output, a flex frame actuator pivots the pair of frame sections with respect to each other.

Owner:DEERE & CO

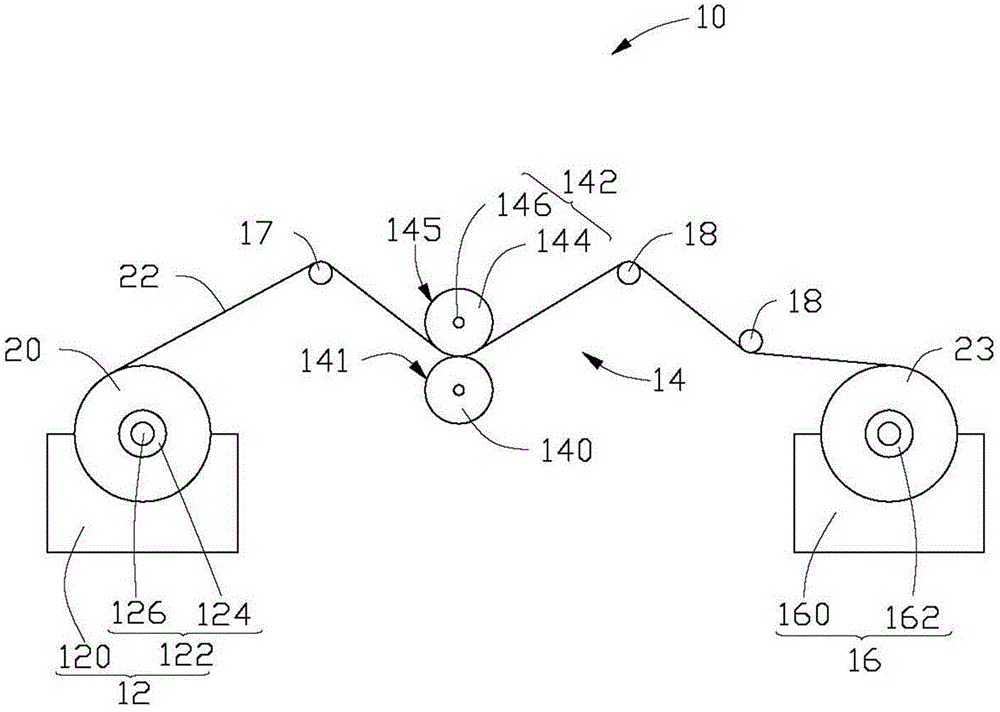

Compression roller, processing device, processing method and life paper and facial tissue units

InactiveCN102744918AUniform depthTightly boundMechanical working/deformationDomestic applicationsFacial tissue

The invention relates to a compression roller which comprises a cylindrical pressing portion, wherein the pressing portion is provided with a pressing surface for pressing life paper. The length of the pressing portion is basically the same as that of the life paper. The pressing surface comprises a plurality of side pressing zones which include two first side pressing zones and at least one second side pressing zone. The two first side pressing zones are respectively close to two ends of the pressing portion, and the at least one second side pressing zone is located between the two first side pressing zones. Each side pressing zone is provided with a laminated side pressing pattern. The width of the laminated side pressing pattern of each first side pressing zone is one second of that of the second side pressing zone, and the width of the laminated side pressing pattern of the second side pressing zone is 30mm-60mm. The invention further provides a life paper processing device comprising the compression roller, a life paper processing method using the life paper processing device, and life paper and facial tissue units obtained through the life paper processing method.

Owner:GOLD HONG YE PAPER

Method for producing frosted glass

InactiveCN101618648AReduce cleaning processReduce cleaning costsPattern printingSurface treatment compositionsChemistryAqueous sodium hydroxide

The invention relates to a method for producing frosted glass, which comprises the following steps: firstly, selecting original white glass sheets, jointing the two sheets, and sealing four edges by tapes; putting the glass into a weak acid pool for soaking for 2 minutes; conveying the glass into a corrosion pool for frosting; clearing the frosting liquid after the glass is frosted, and drying the glass; removing the sealing tapes at the four edges of the glass; then, adopting a silk screen to print the preliminarily designed glass pattern on one surface, air-drying the glass for 2 hours, andthen, conveying the glass into a dryer for drying; pasting a protective film on the glass surface which is not printed with the pattern; scrubbing the surface which is printed with the glass pattern with weak acid liquid; soaking the glass into the corrosion liquid for 80-120 minutes; putting the glass into a sodium hydroxide solution for cleaning; and then, conveying the glass into a cleaning and drying machine for cleaning and drying to obtain a finished product. The patterned glass which is produced by the method of the invention has uniform and fine etched depth, strong aesthetic feeling of the pattern, better quality, simple processing method and environment protection, and can greatly reduce the production cost in the production process.

Owner:杜广武

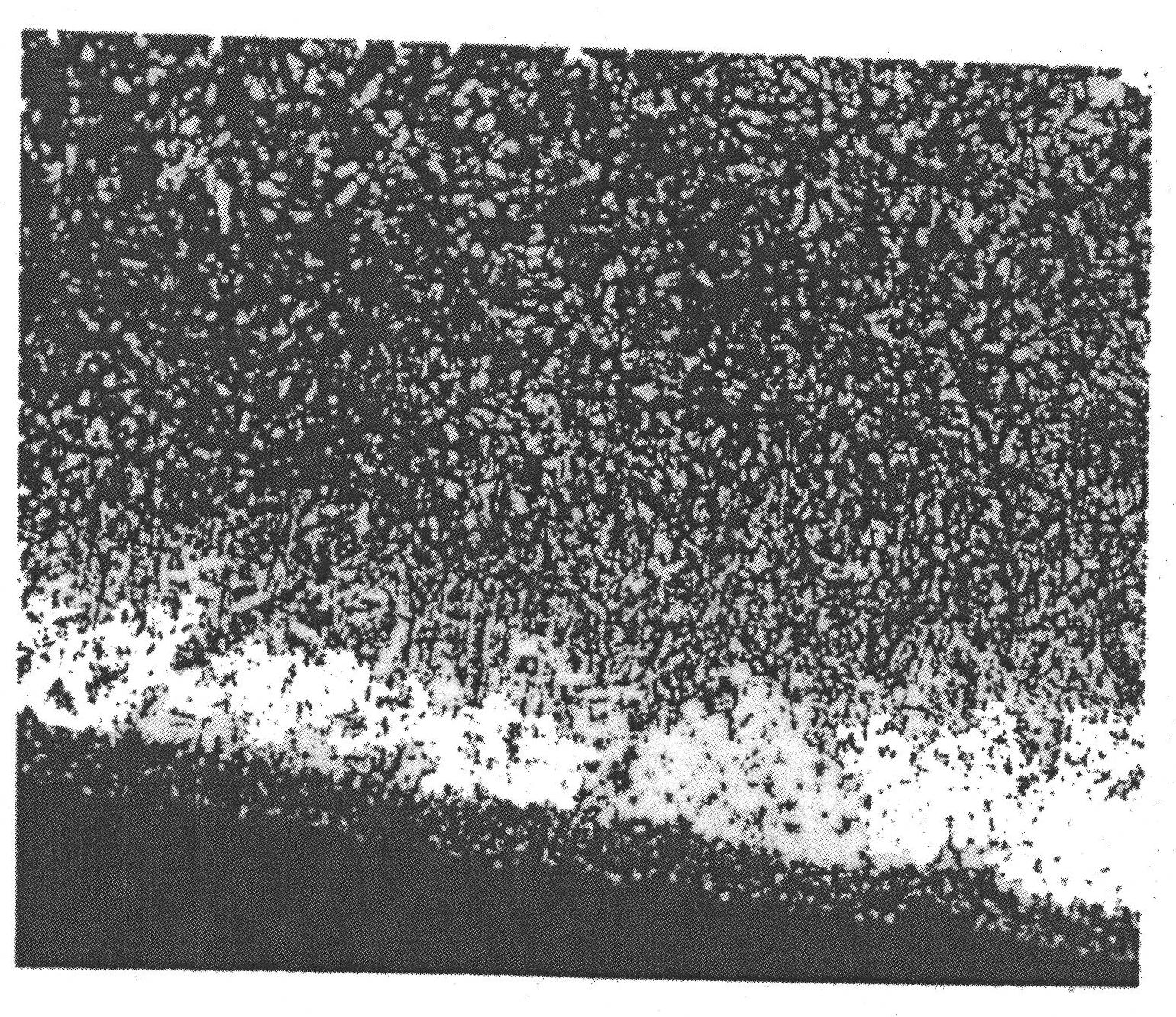

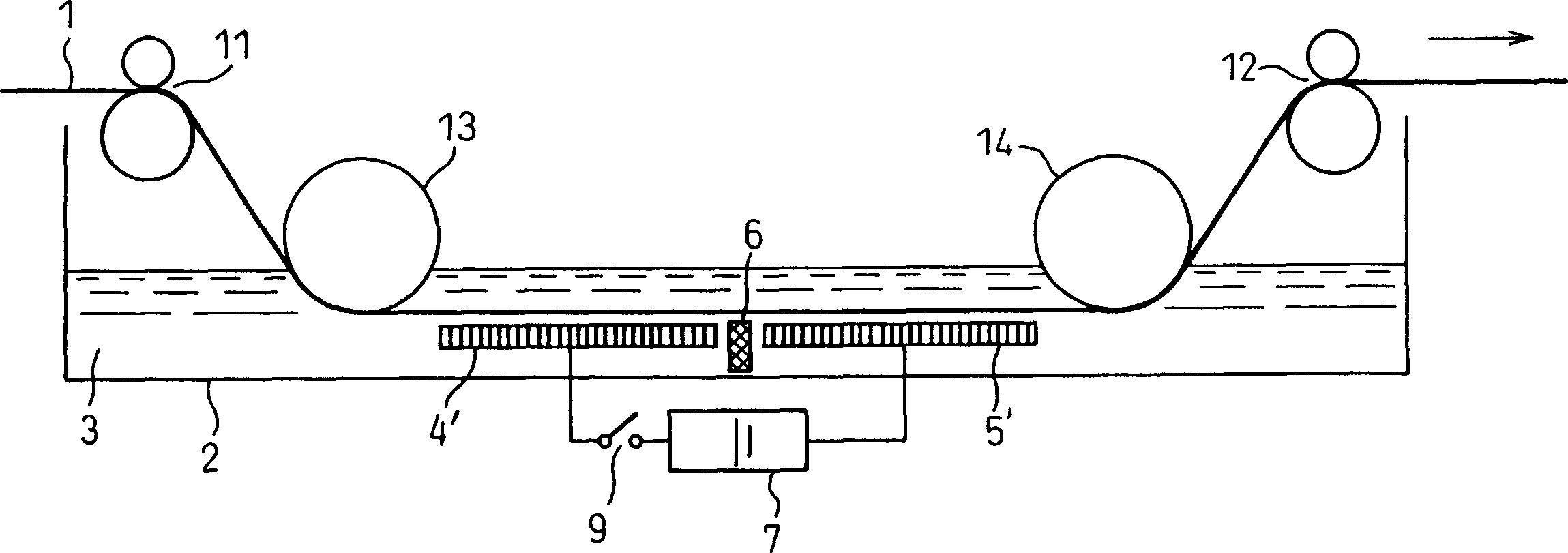

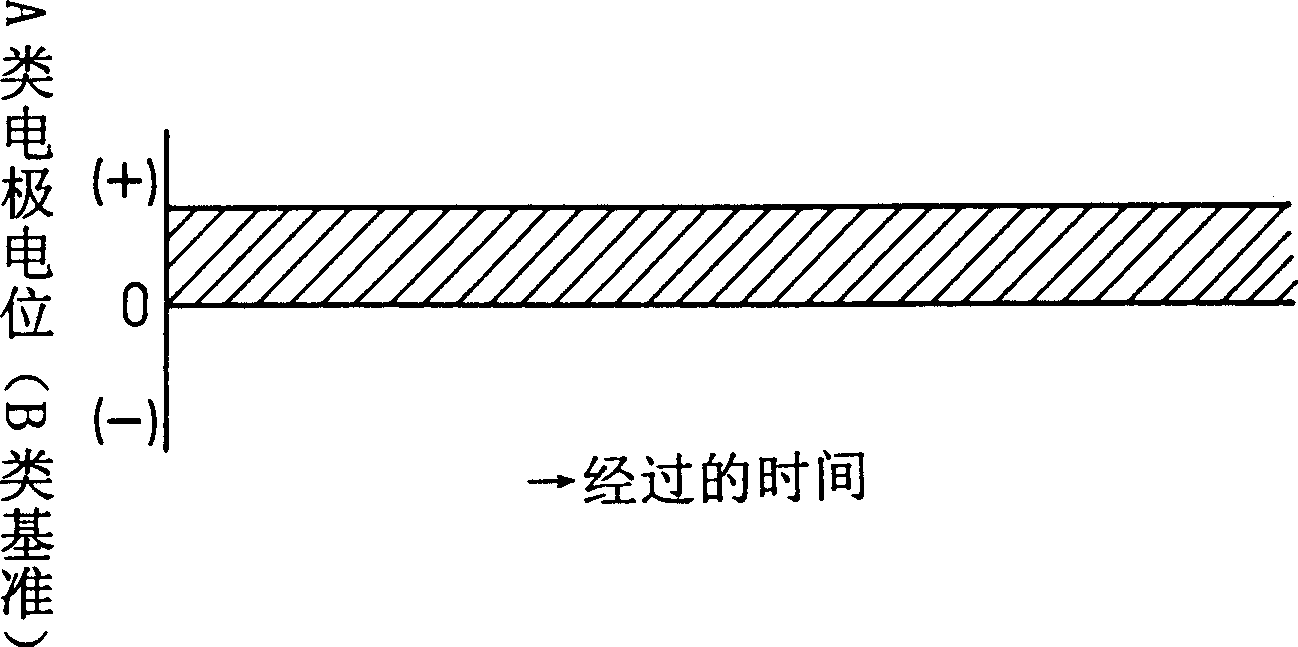

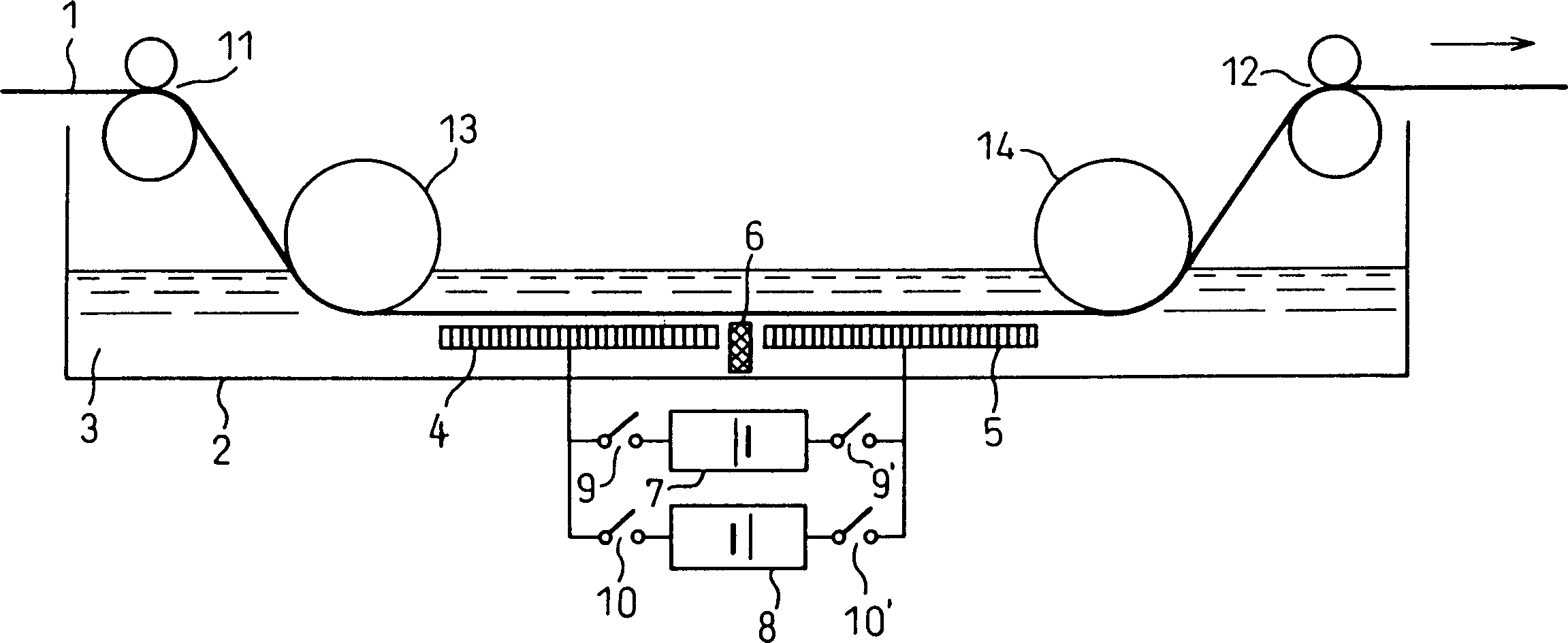

Method and its device for connection electric continuous electrolytic corrosion between metal belts

The present invention provides a method for indirect-electrification-type continuous electrolytic etching of a metal strip suitable for producing a low-core-loss, grain-oriented silicon steel sheet not susceptible to the deterioration of core loss after stress-relief annealing, and an apparatus for the indirect-electrification-type continuous electrolytic etching. It is a method for indirect-electrification-type continuous electrolytic etching of a metal strip and an apparatus for the same for continuously forming grooves by indirect-electrification-type electrolytic etching on a metal strip on which an etching mask is formed in etching patterns on one or both surfaces, wherein: plural electrodes of an A series and a B series are arranged alternately, at least in a pair, in said order in the travelling direction of the metal strip so that they face the surface to be etched of the metal strip on which the etching patterns are formed; the space between the metal strip and the group of the electrodes is filled with an electrolyte; and voltage is applied across the A series and B series electrodes. Desirably, (I) a voltage application wherein an A series electrode becomes a cathode for a time period M of 3 to 10 msec. and (II) a voltage application wherein the A series electrode becomes an anode for a time period N of 4xM to 20xM msec. are repeated alternately across the A series and B series electrodes.

Owner:NIPPON STEEL CORP

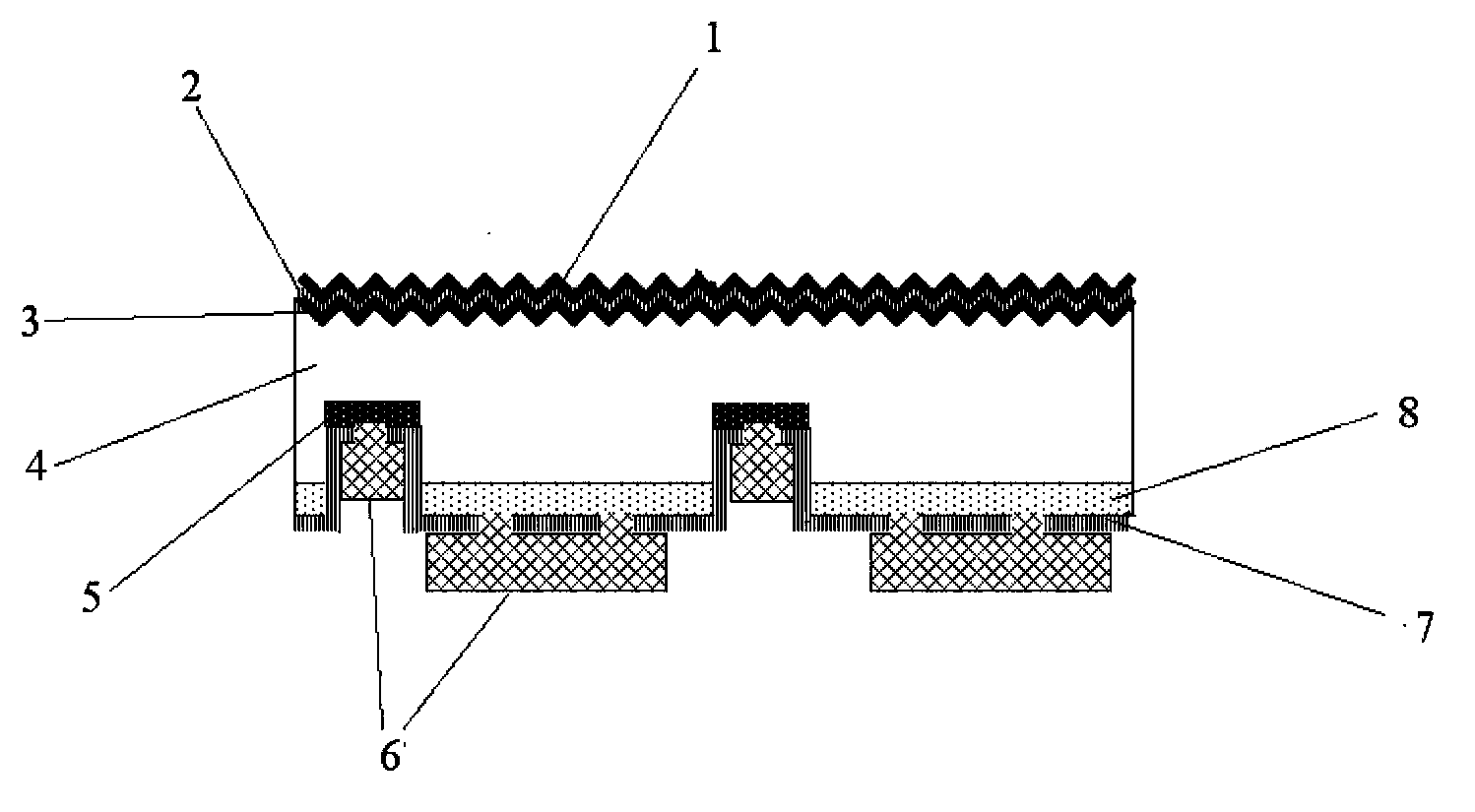

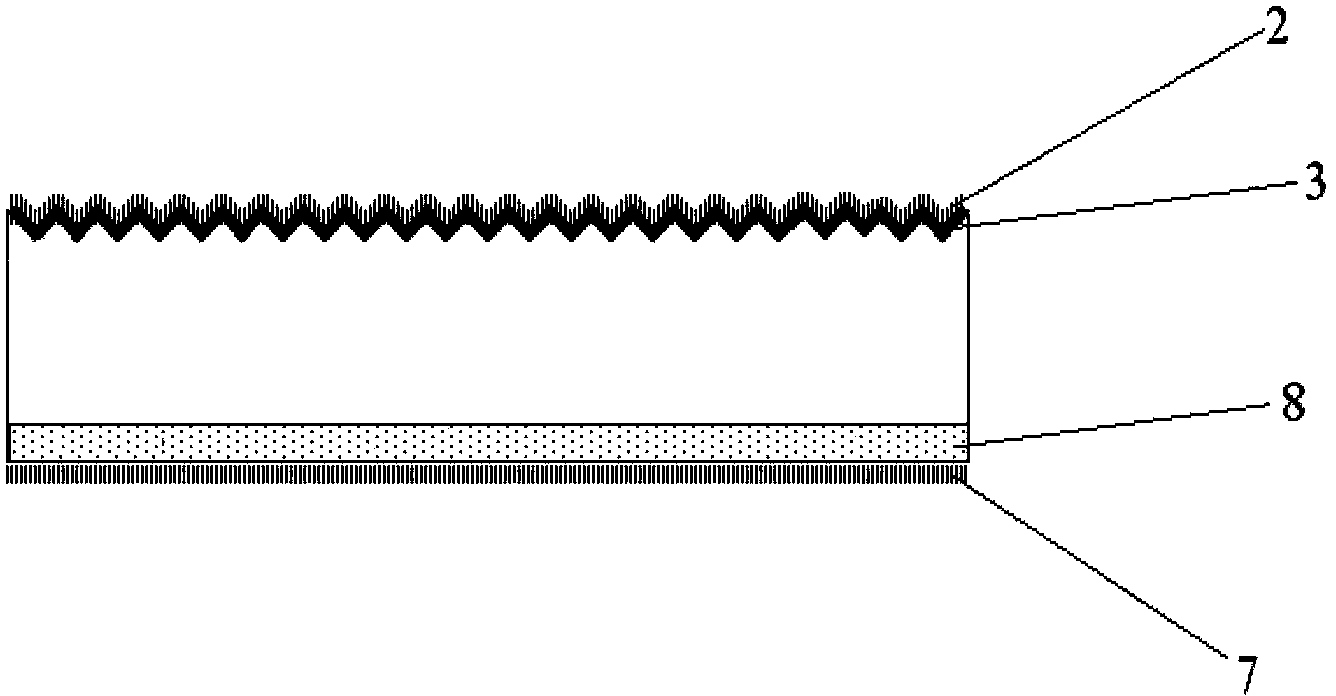

Full back side contact crystalline silicon cell and preparation method thereof

InactiveCN103904138AAvoid alignment problemsUniform depthFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon chip

The invention relates to a novel crystalline silicon cell in the field of a photovoltaic technology, and specifically relates to a full back side contact crystalline silicon cell which is prepared through combination with an ion implantation technology, and also relates to a preparation method of the cell. The full back side contact crystalline silicon cell comprises a silicon chip substrate, an anti-reflection layer, a base electrode, an emitter electrode, a metal gate line and the like. The emitter electrode and the base electrode of the full back side contact crystalline silicon cell are not disposed in the same plane, so that electrons and cavities can be considered to move to the emitter electrode and the base electrode through a quire short path, and carrier bulk recombination in the cell can be reduced; through moving the emitter electrode and the metal grate line from a front surface, i.e., a light receiving surface to a back surface, the optical loss is reduced; the emitter electrode is obtained through an ion implantation method, and the process steps are reduced compared to a conventional thermal diffusion doping method; and the front surface and the back surface are each provided with a passivation layer, and the front surface is further provided with a front surface field (FSF), so that the carrier surface recombination can be reduced, and the invention finally provides a solar cell which has the advantages of high batch production efficiency and simple technology.

Owner:DONGTAI HI TECH EQUIP TECH (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com