Formation method of flash memory storage unit

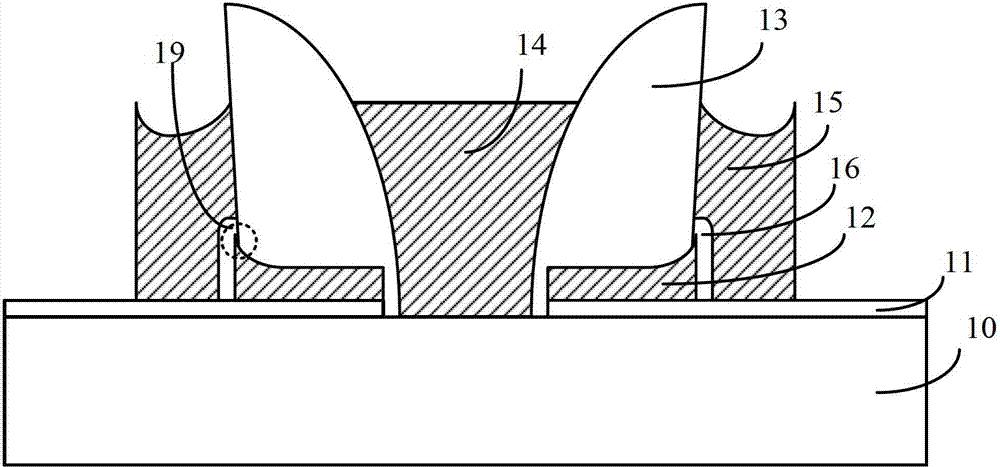

A flash memory storage and sacrificial layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of poor erase performance of flash memory cells, poor stability of chips or integrated circuits, and difficult to control top 19 topography. and other problems, to achieve the same top shape, uniform structure, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As mentioned in the background, the top angle dimension of the floating gate layer formed in the prior art is inaccurate, the shape of the top is difficult to control, the erase performance of the formed flash memory storage unit is poor, and the stability of the chip or integrated circuit is not good.

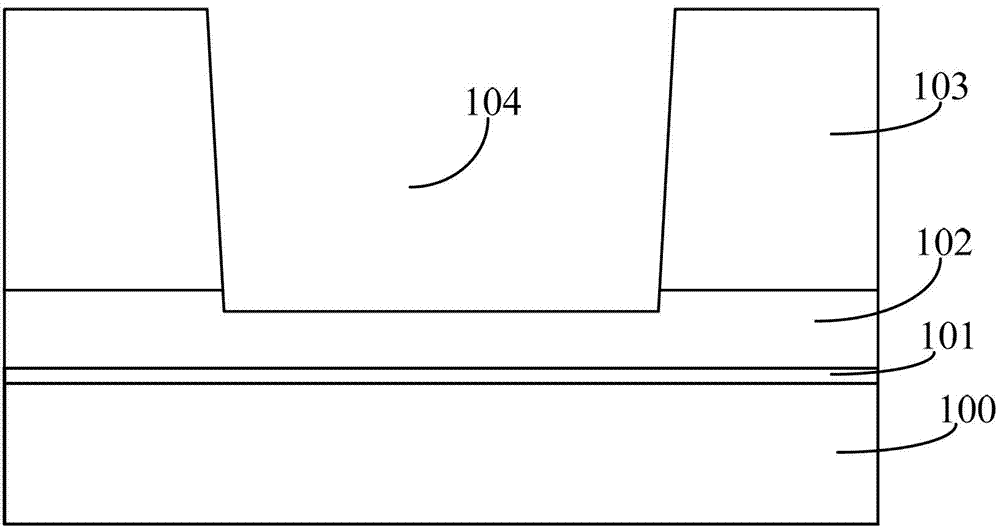

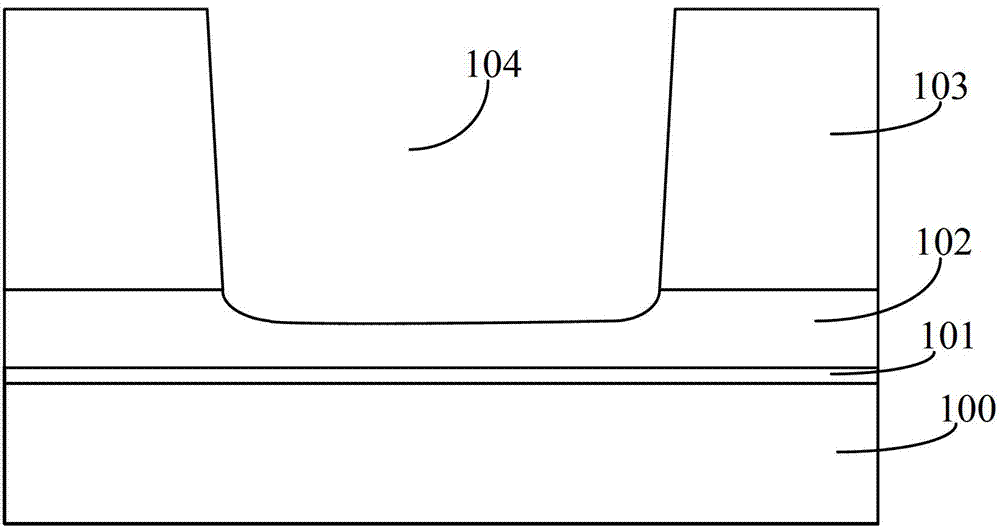

[0029] Figure 2 to Figure 5 is formed as figure 1 A schematic diagram of the cross-sectional structure of the process of the floating gate layer, the sidewall and the source line layer of the storage unit of the flash memory.

[0030] Please refer to figure 2 , provide a semiconductor substrate 100, the surface of the semiconductor substrate 100 has a tunnel oxide layer 101, a floating gate film 102 on the surface of the tunnel oxide layer 101, and a dielectric layer 103 on the surface of the floating gate film 102; using anisotropic The dielectric layer 103 and part of the floating gate film 102 are etched by a dry etching process to form a first opening 104 so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com