Method for preparing spheroidal graphene

A technology of spherical graphite and graphene, which is applied in the field of preparing graphene powder materials, can solve the problems of taking up a lot of space during transportation and storage, weakening the excellent properties of graphene sheets, and limiting the scope of application, so as to achieve controllable processing capacity. Adjustable, suitable for large-scale production, high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the first step, graphene is prepared according to Example 1 of the redox method disclosed in Chinese Patent Publication No. CN101997120A to obtain graphene powder. The tap density of graphene is 0.09 g / mL.

[0028] The second step is to disperse the graphene powder in water, the concentration is 3mg / mL, the frequency is 28kHz, and the power is 1800W / cm 2 , sonicated for 10 min, granulated and dried to obtain spherical graphene powder.

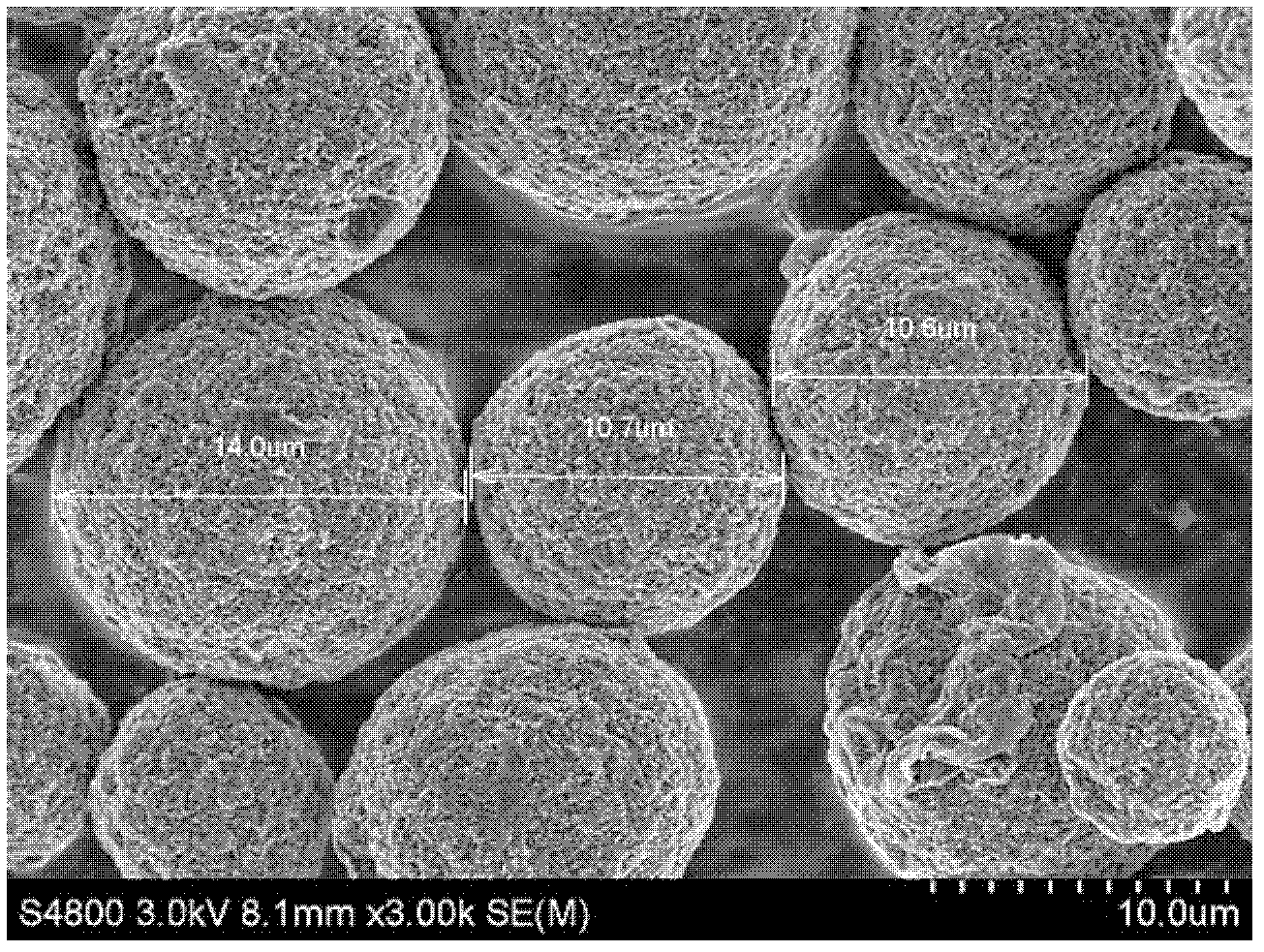

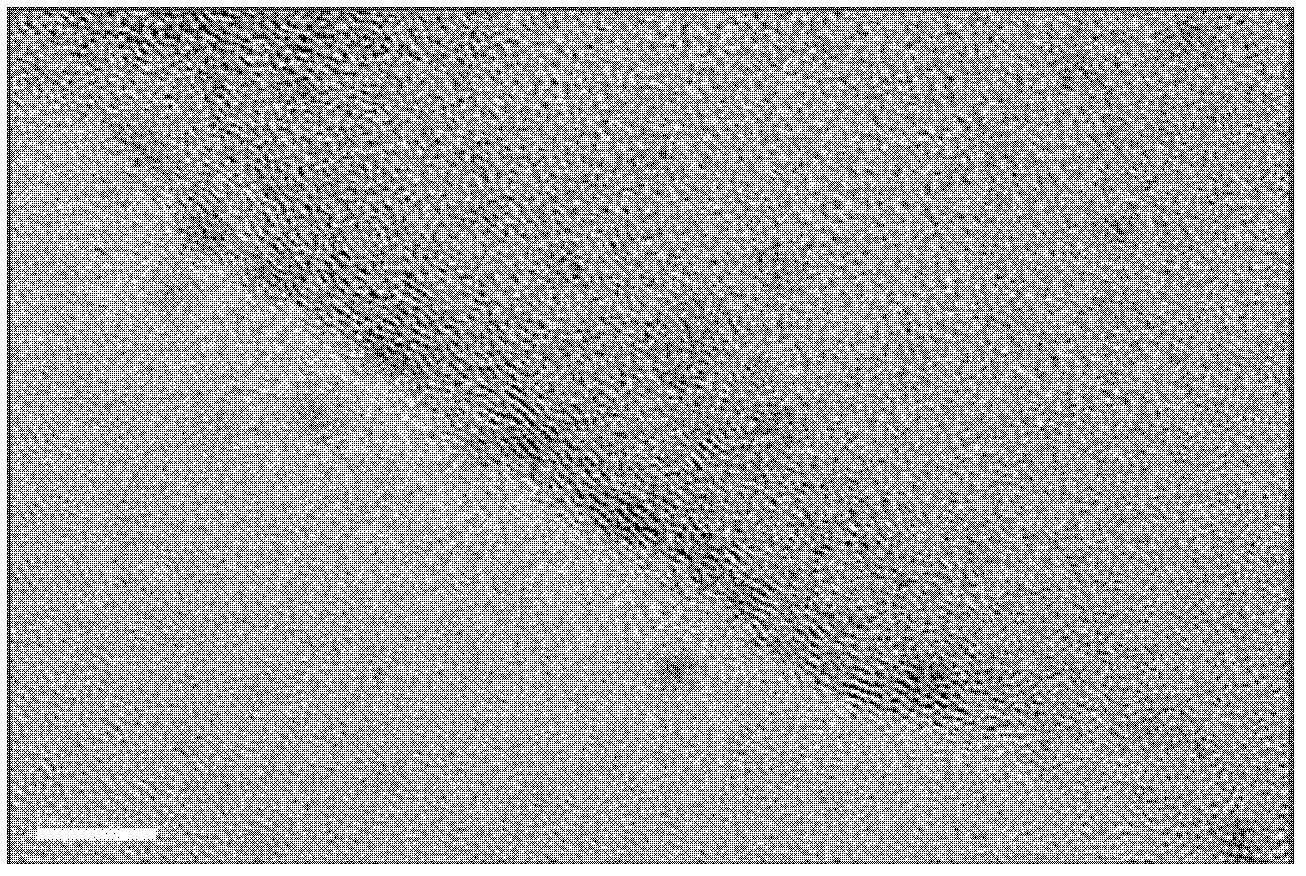

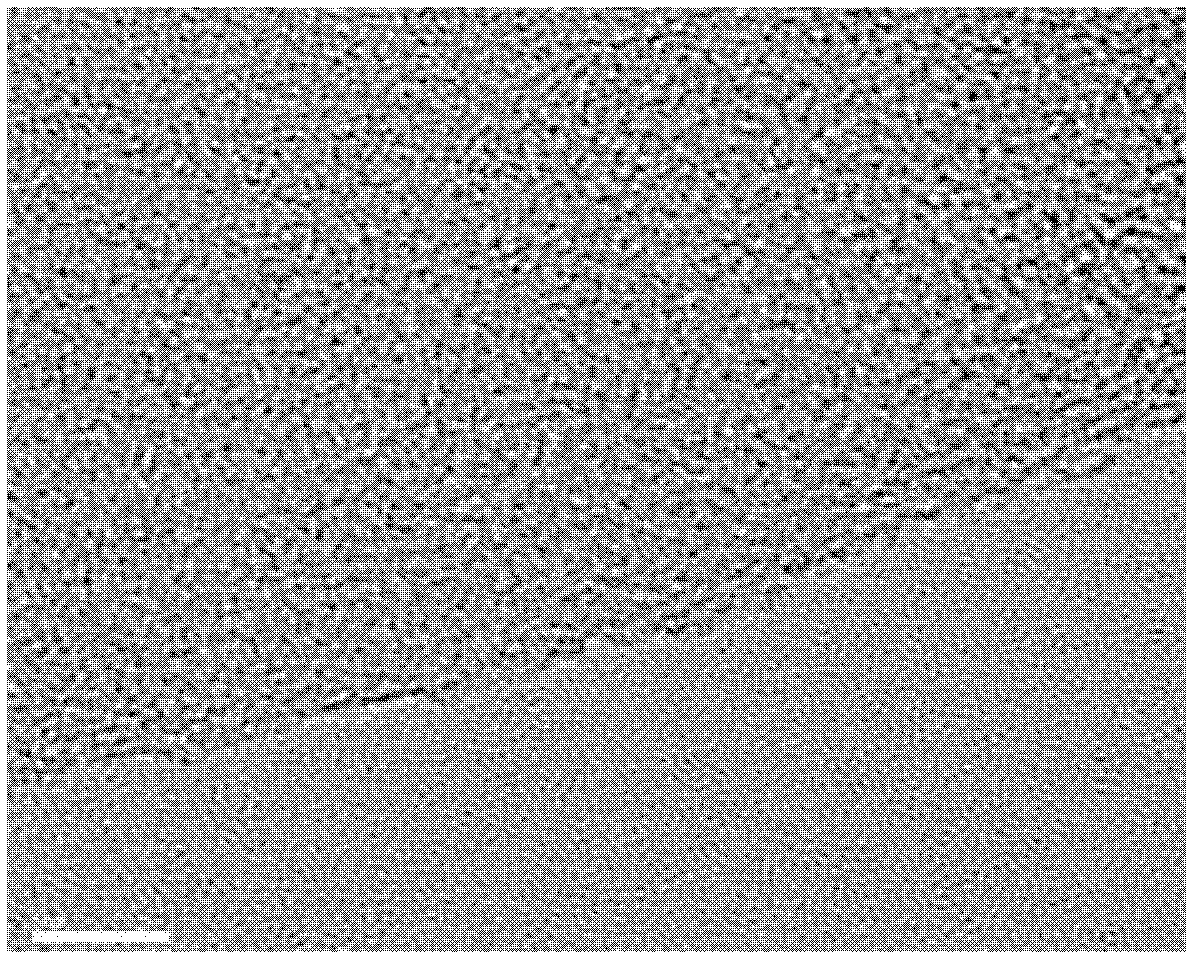

[0029] like figure 1 As shown, the microscopic morphology of graphene is spherical, the diameter is distributed in the range of 5-15 μm, and the tap density of spherical graphene is 0.25 g / mL. like figure 2 and 3 As shown, the graphene sheets are distributed between 1-10, and the thin-layer graphene sheets exist stably in the form of microspheres with uniform size.

Embodiment 2

[0031] The first step is graphene prepared by epitaxial growth method. References: 1. Berger, C.; Song, Z.; Li, T.; Li, X.; Ogbazghi, A.Y.; Feng, R.; Dai, Z.T.; Marchenkov, A.N.; Conrad, E.H.; de Heer, W.A.J.Phys.Chem.B, 2004, 108(52):19912; 2, Berger, C.; Song, Z.; Li, X.; Wu, X.; Brown, N.; Naud, C. ; Mayou, D.; Li, T.; Hass, J.; Marchenkov, A.N.; Conrad, E.H.; Clean the surface of the SiC single crystal first, and the process is as follows: 1. Use analytically pure carbon tetrafluoride, acetone, ethanol, and deionized water to ultrasonically clean it several times to remove the organic matter adsorbed on the surface; 2. Use a mixture of concentrated sulfuric acid and hydrogen peroxide (Volume ratio 1: 1) Rinse with deionized water after soaking for 5 minutes to remove oxides, metals and organic impurities on the surface; 3. Etch the surface for 3 minutes with 5% hydrofluoric acid solution to remove the oxide layer on the surface; 4. Finally, rinse with deionized water sev...

Embodiment 3

[0034] The first step is to prepare graphene by chemical vapor deposition. For graphene prepared by chemical vapor deposition, refer to the literature: Obraztsov, A.N.Nat.Nanotechnol., 2009, 4:212. The specific operation steps are as follows: 1. A uniform nickel layer with a thickness of 400 nm is plated on the surface of a single crystal silicon wafer with a thickness of 0.7 mm by sputtering method, and this is used as a plane substrate. 2. Carry out high-temperature annealing treatment in a tube furnace, heat the flat substrate to 1000°C at a heating rate of 5°C / min, and then introduce a high-temperature decomposable precursor ethylene atmosphere, and carbon atoms will grow and deposit on the surface of the nickel layer. The time is 30 minutes. Cool to room temperature in the air; 3. Put the substrate with graphene on the surface into ferric chloride solution with a concentration of 1mol / L for chemical corrosion, and the soaking time is 24h. Graphene will float on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com