Patents

Literature

138 results about "Microscopic morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microscopic morphology can be used for rapid, presumptive identification of M. tuberculosis complex, M. kansasii, and M. avium complex and act as a guide for appropriate selection of initial probes to reduce costs.

High-performance water system zinc ion battery anode material, manufacturing method and application thereof

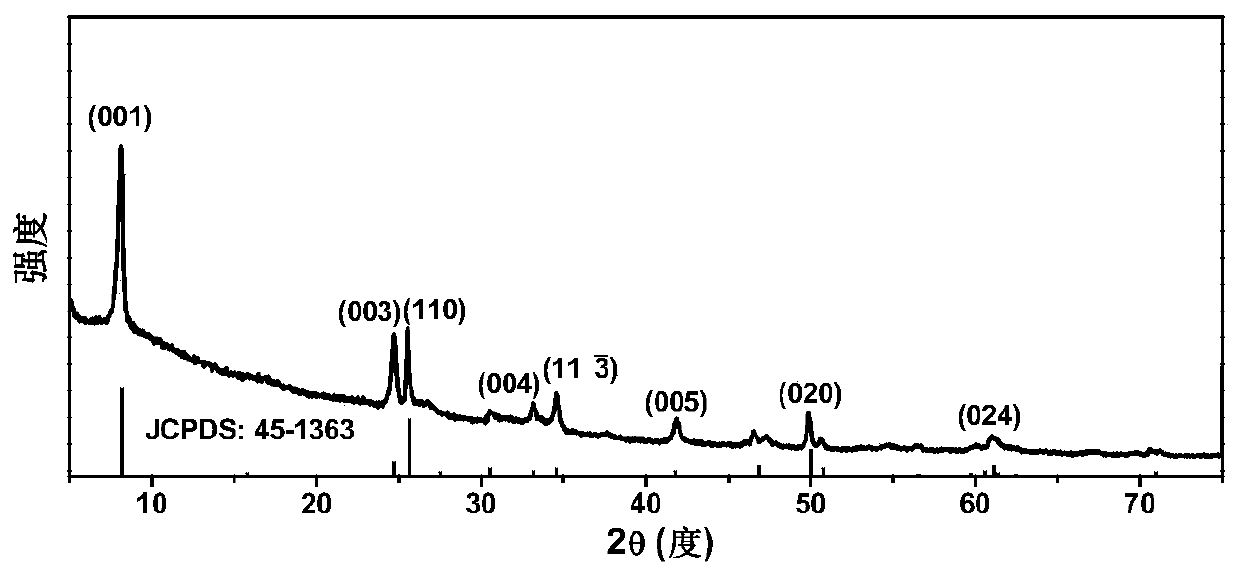

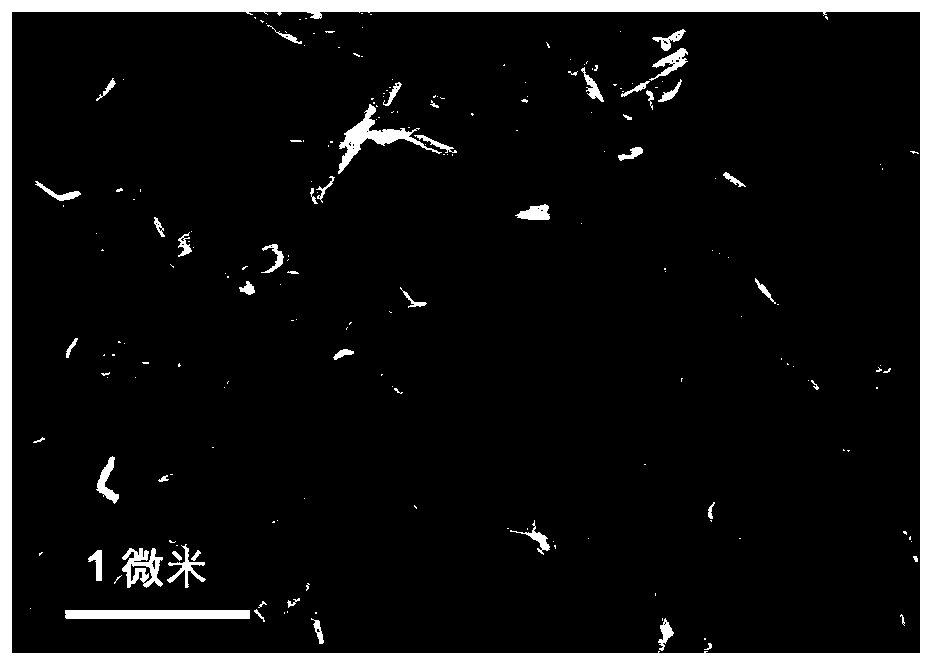

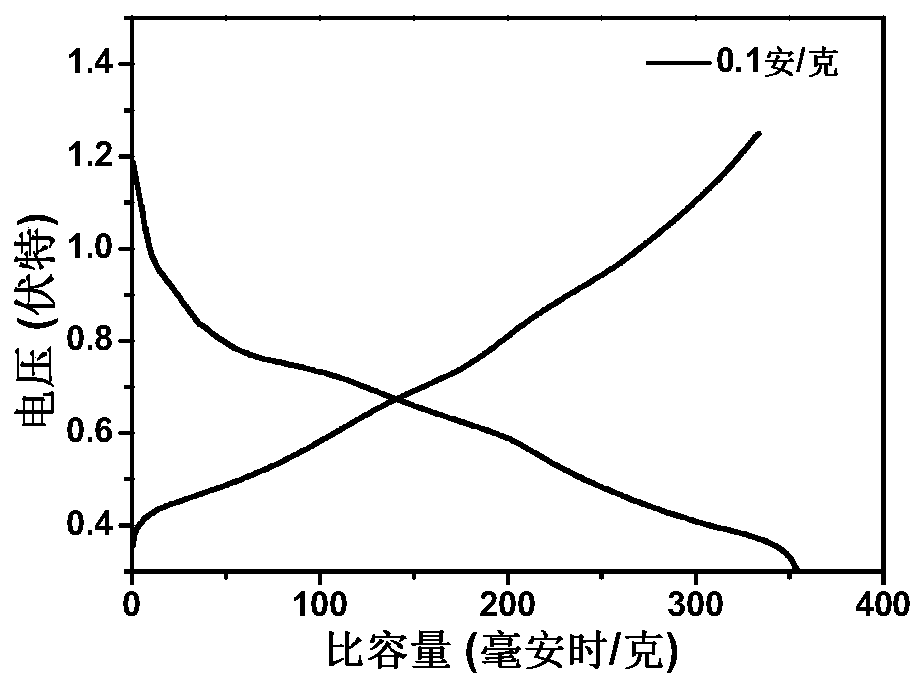

ActiveCN110474044AEasy to prepareLow equipment requirementsFinal product manufactureSecondary cellsSpecific dischargeNanotechnology

The invention provides a high-performance water system zinc ion battery anode material, a manufacturing method and an application thereof. The anode material has the following general formula: (N,M) sigma=1V8O20 nH2O, wherein the N is one of Li, Na, K, Zn, Cu, Mg or Ca, the M is one of Mn, Fe, Co or Ni, and the n is 0.01-4. The anode material can be manufactured through one-step hydrothermal method, a reaction condition is mild, a manufacturing process is simple, and a requirement to equipment is low. A microscopic morphology of the obtained anode material is a nanobelt. The obtained anode material is firstly applied to a water system zinc ion battery, and has electrochemical performance such as a higher specific discharge capacity, a higher cycle stability and the like.

Owner:SHANDONG UNIV

Application of triphenylamine derivative polymer as lithium ion batteries cathode material

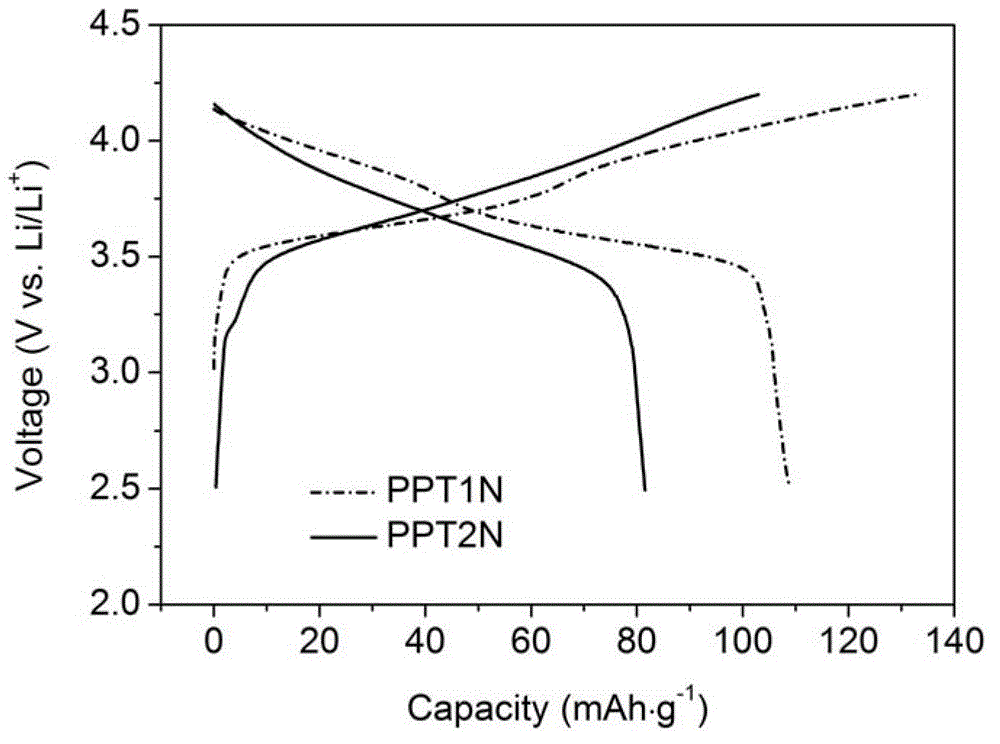

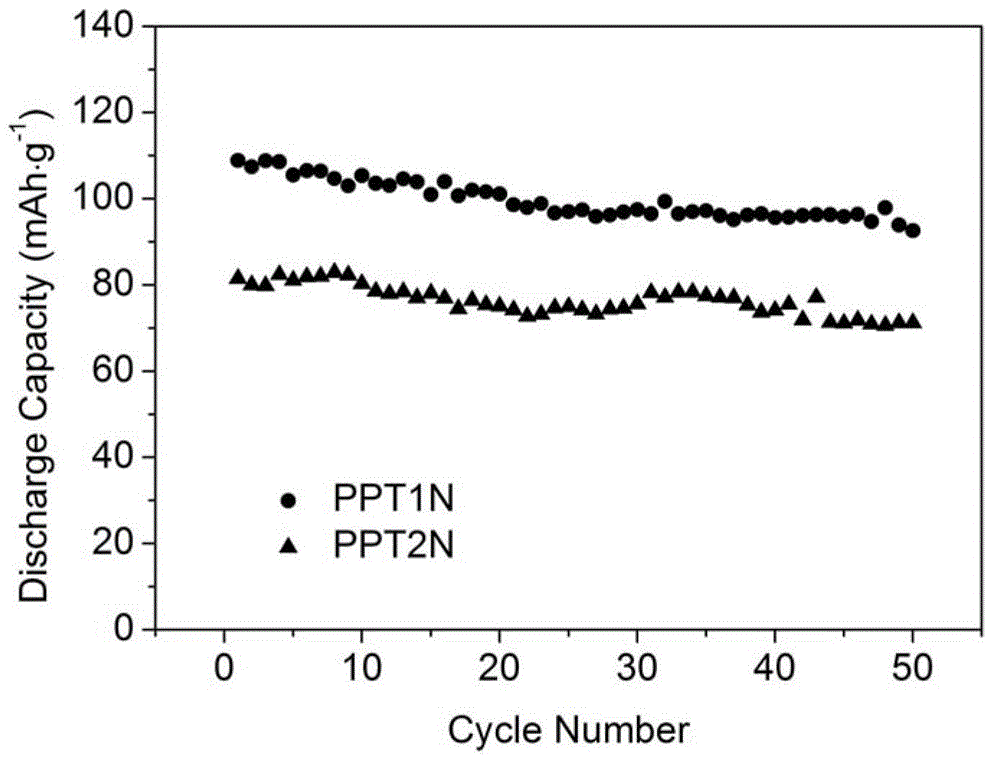

ActiveCN102751501AImprove cycle stabilitySignificant charge and discharge voltage platformCell electrodesBiopolymerCharge discharge

The invention provides an application of a triphenylamine derivative polymer as a lithium ion batteries cathode material, belonging to the technical field of lithium ion battery. The triphenylamine derivative is a triphenylamine derivative polymer containing triphenylamine and thiophene structure. By introducing an electroactive conjugated monomer in the polytriphenylamine backbone, the microscopic morphology of the polymer is significantly improved, the conductivity and conjugate capability of the polymer are enhanced, so that the cathode material has high specific capacity, excellent cycling stability, significant charge-discharge voltage platform, and good rapid charge and discharge performance, etc.

Owner:ZHEJIANG UNIV OF TECH

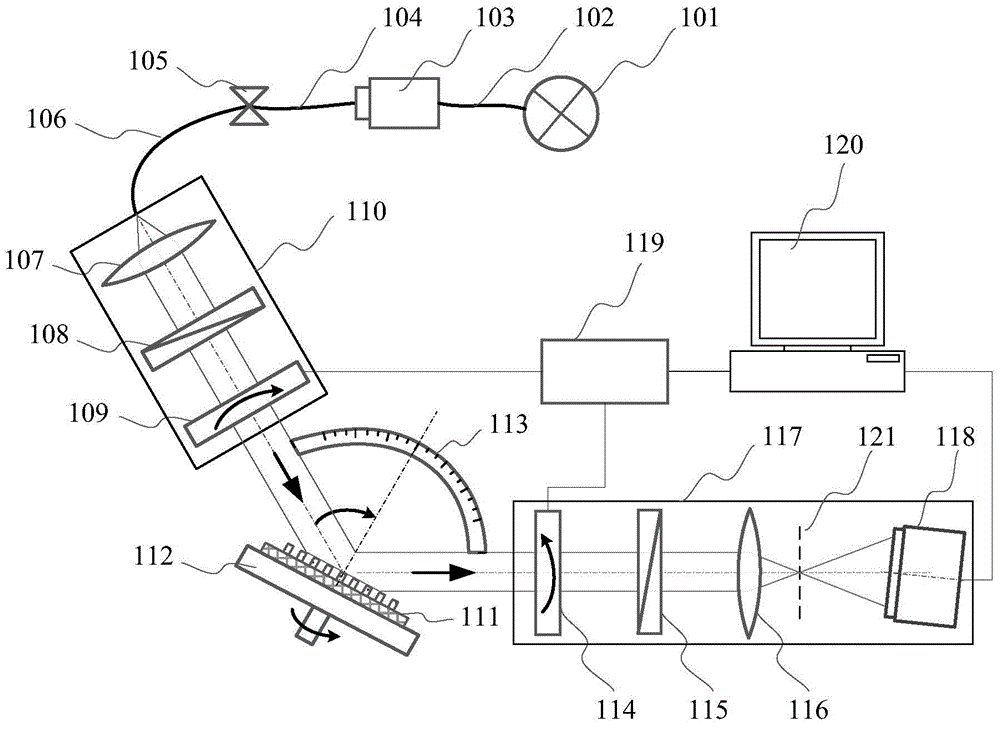

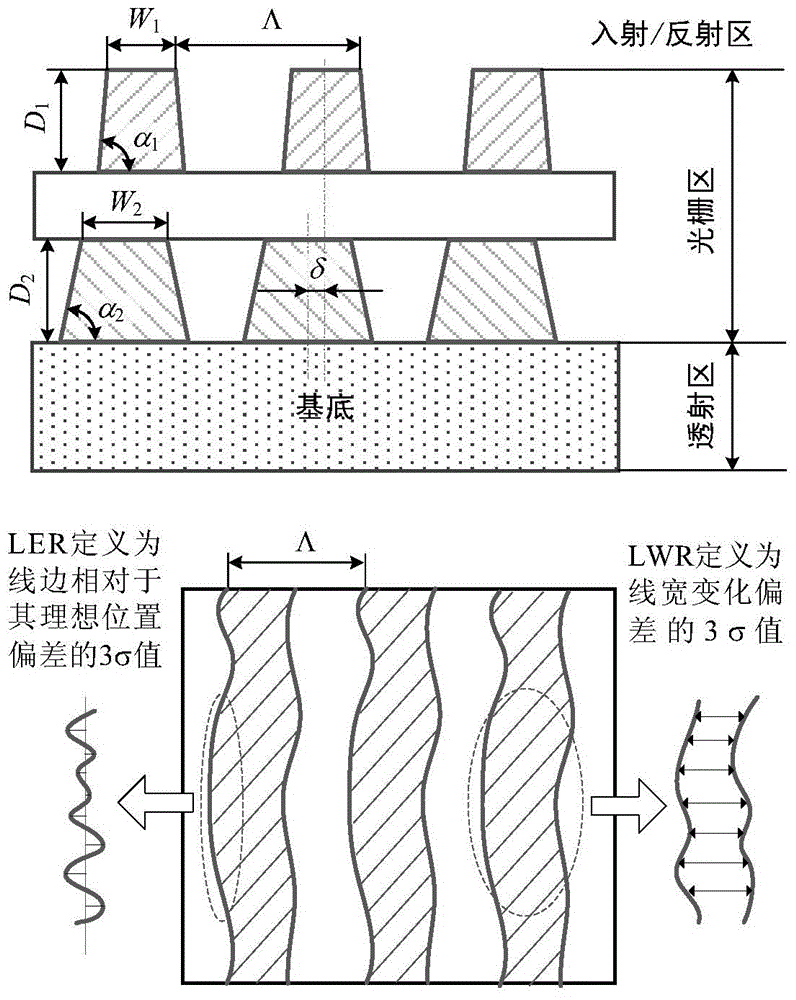

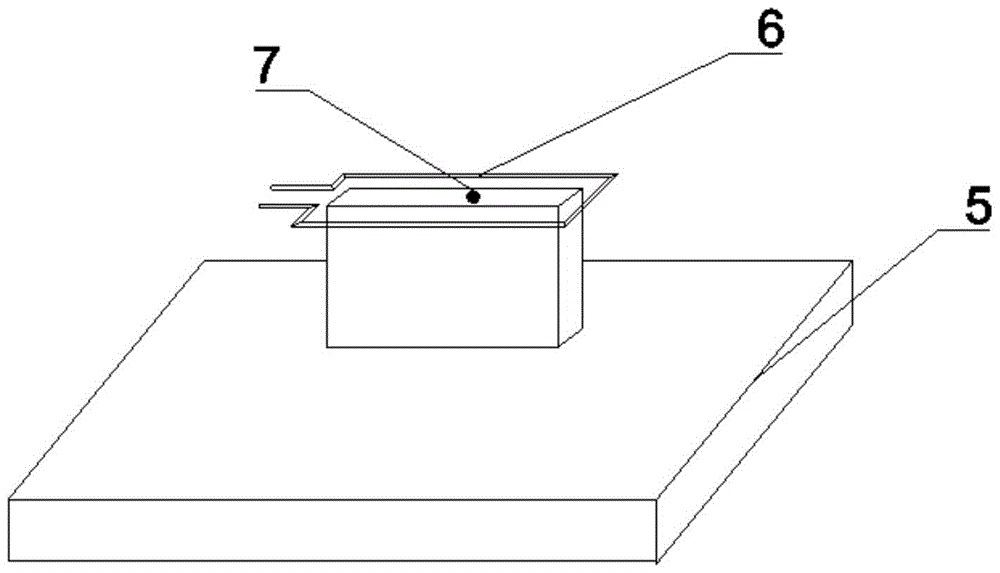

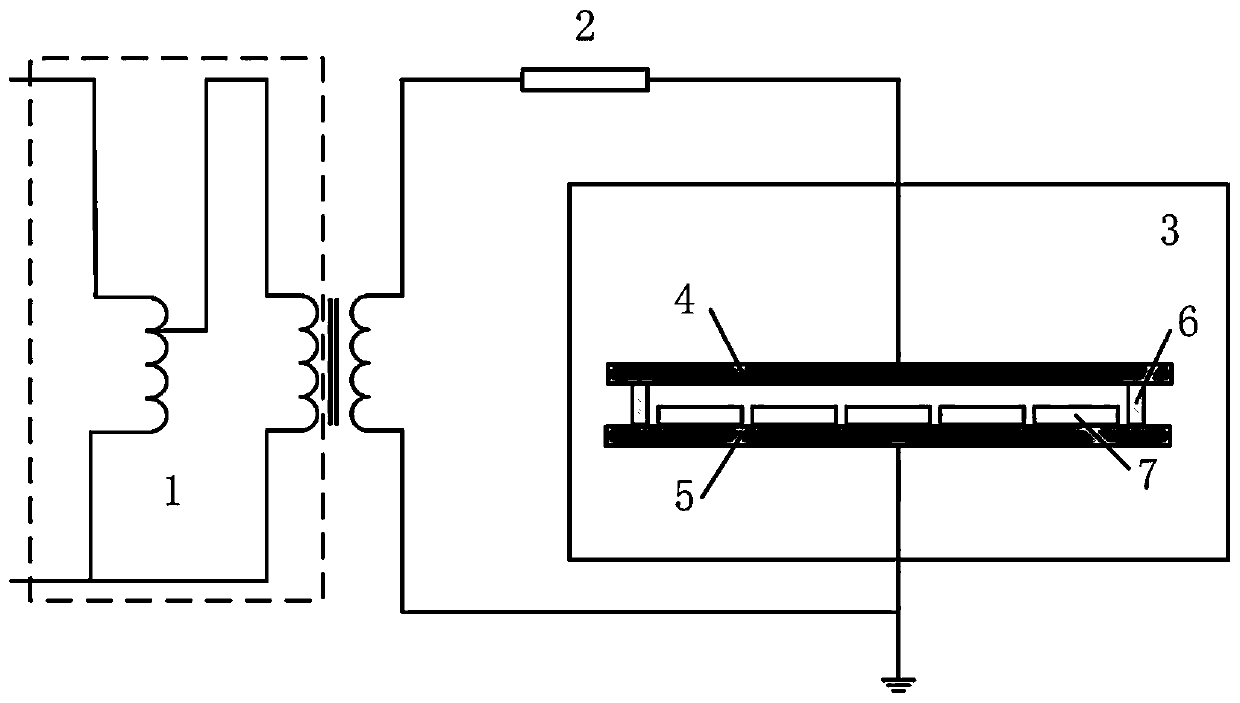

Large-area online measurement device and method for geometrical parameters of nano-structure

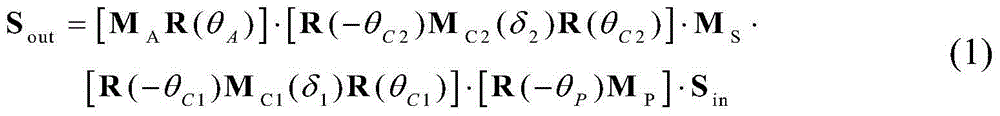

InactiveCN104482878AImprove analytical test efficiencyAccurate reconstructionUsing optical meansMicroscopic morphologyPolarizer

The invention discloses a large-area online measurement device and a large-area online measurement method for geometrical parameters of a nano-structure. The three-dimensional microscopic morphology of the nano-structure in a large-area region containing an entire viewing field can be obtained. Light emitting from a light source is changed into monochromatic light through a monochromator, the monochromatic light sequentially passes through a collimating mirror, a polarizer and a polarizing arm-end phase compensator to obtain an elliptical polarized beam, and then the elliptical polarized beam is projected to the surface of the to-be-measured nano-structure; a light intensity signal corresponding to zero-stage diffraction light in a reflected beam of the to-be-measured nano-structure is acquired, and a measurement imaging Muller matrix of the to-be-measured nano-structure is calculated; geometrical parameter values of the to-be-measured nano-structure at corresponding pixel points are obtained by matching extraction, and the geometrical parameter extraction values at all the pixel points form the three-dimensional microscopic morphology of the to-be-measured nano-structure. A large-area, quick, low-cost, contactless, non-destructive and accurate measurement way can be provided for one-dimensional and two-dimensional sub-wavelength periodic nano-structures involved in a pattern-transfer-based batch manufacturing method such as a photoetching process, a nano-impressing process and other processes.

Owner:HUAZHONG UNIV OF SCI & TECH

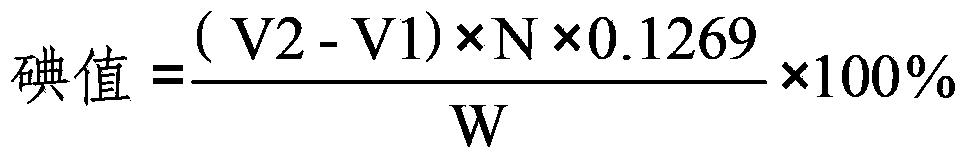

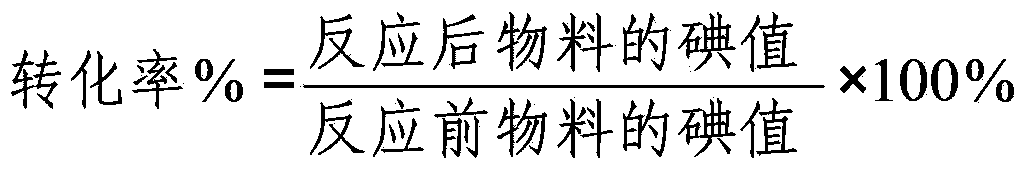

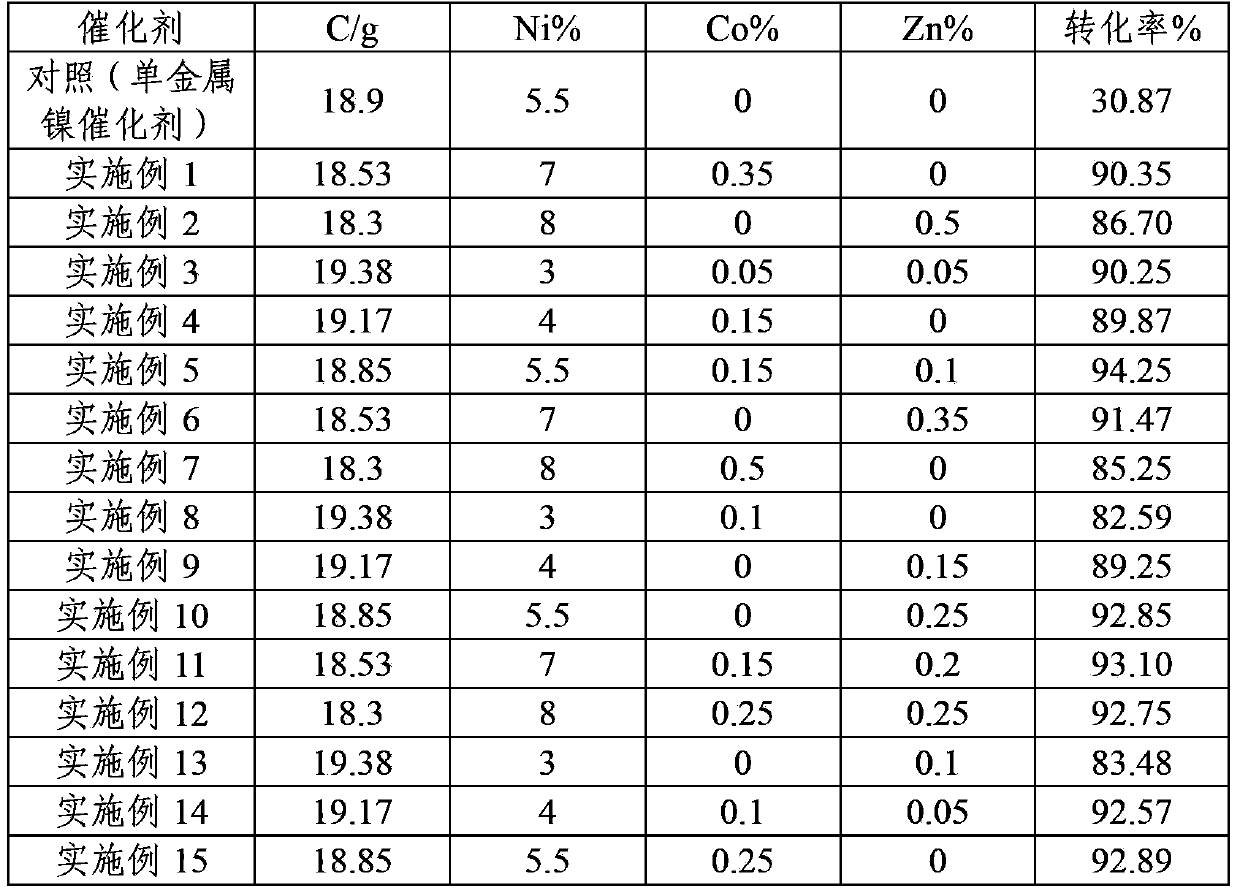

Nickel catalyst for C5 petroleum resin hydrogenation as well as preparation method and application thereof

ActiveCN103386308AImprove conversion rateHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsAlloyCobalt

The invention discloses a nickel catalyst for C5 petroleum resin hydrogenation. The nickel catalyst comprises an activated carbon carrier, Ni nano-particles attached to the activated carbon carrier, and amorphous alloy nano-particles of Ni and a metal auxiliary agent, wherein the amorphous alloy nano-particles are attached to the activated carbon carrier. The weight percentage of Ni in the catalyst is 3%-8%, the weight percentage of the metal auxiliary agent is 0.1%-0.5%, and the metal auxiliary agent is zinc and / or cobalt. The invention also discloses a preparation method and application of the catalyst. The nickel catalyst disclosed by the invention has the advantages that the main active component nickel is modified by adding one or two of the auxiliary agent Zn and Co, so that nickel crystal lattices distort, deform and become thin, the areas of crystal faces are effectively enlarged, and the conversion rate and the selectivity of the catalyst are increased; in addition, due to the added metal additives, aggregation and enlargement of nickel crystal particles can be hindered, the stability of microscopic morphology of the catalyst is maintained, and the service life of the catalyst is effectively prolonged.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

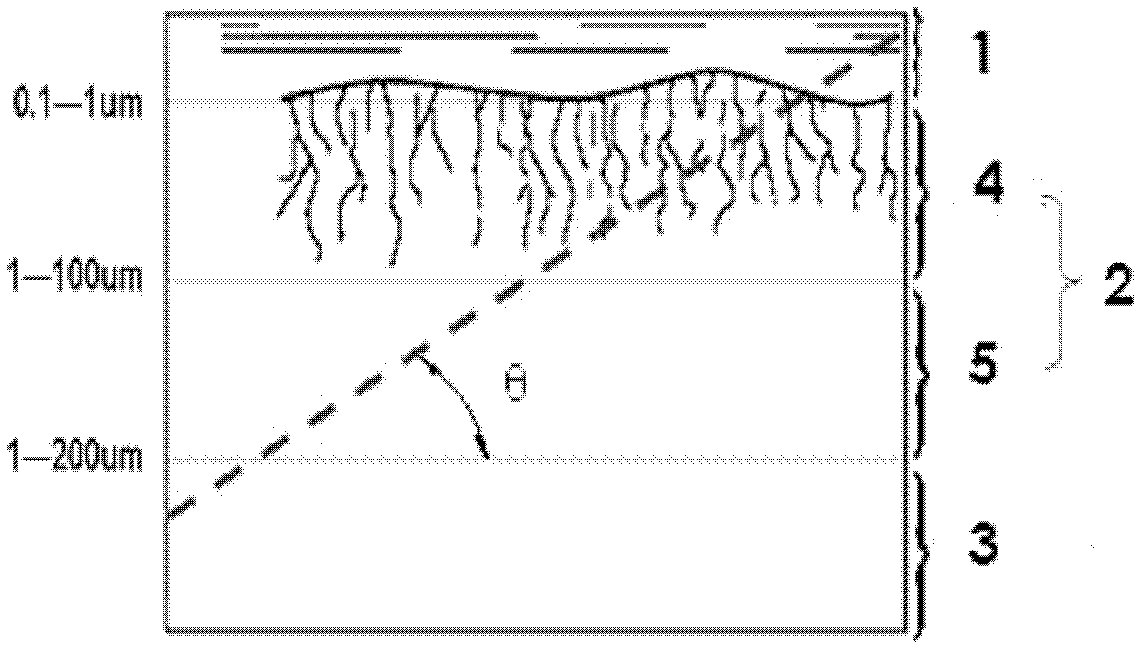

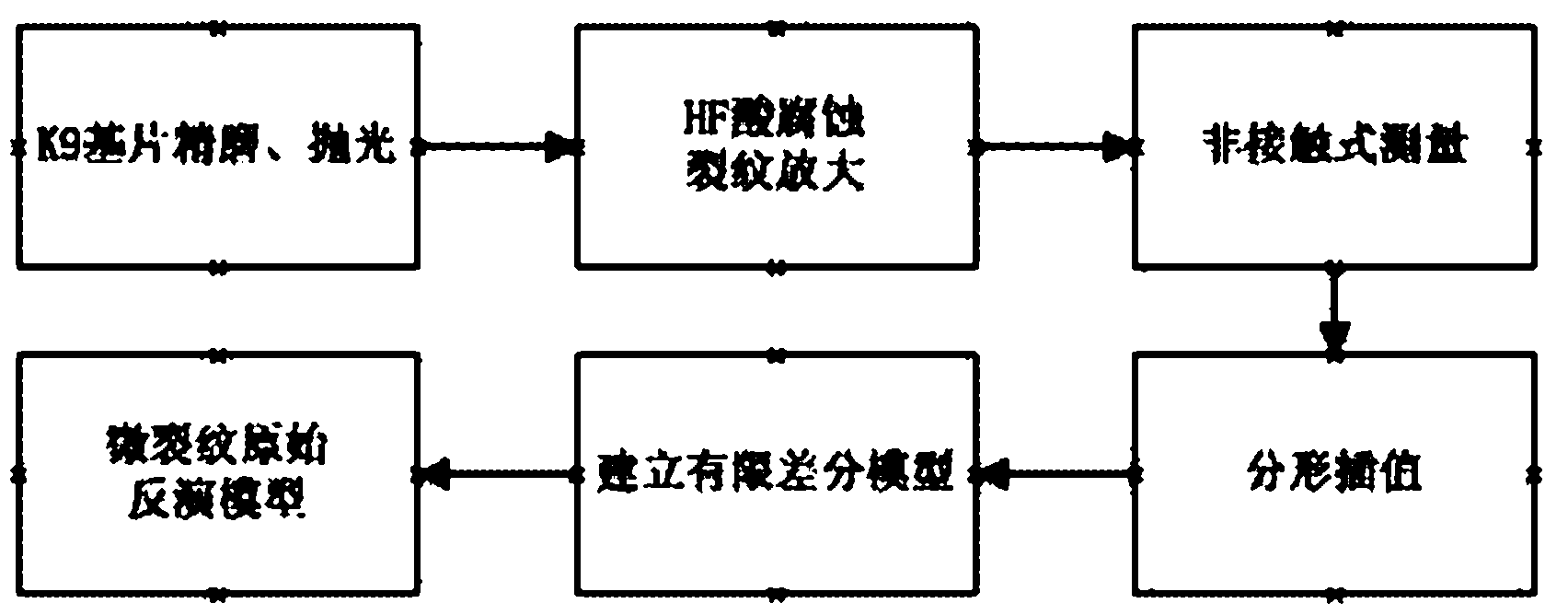

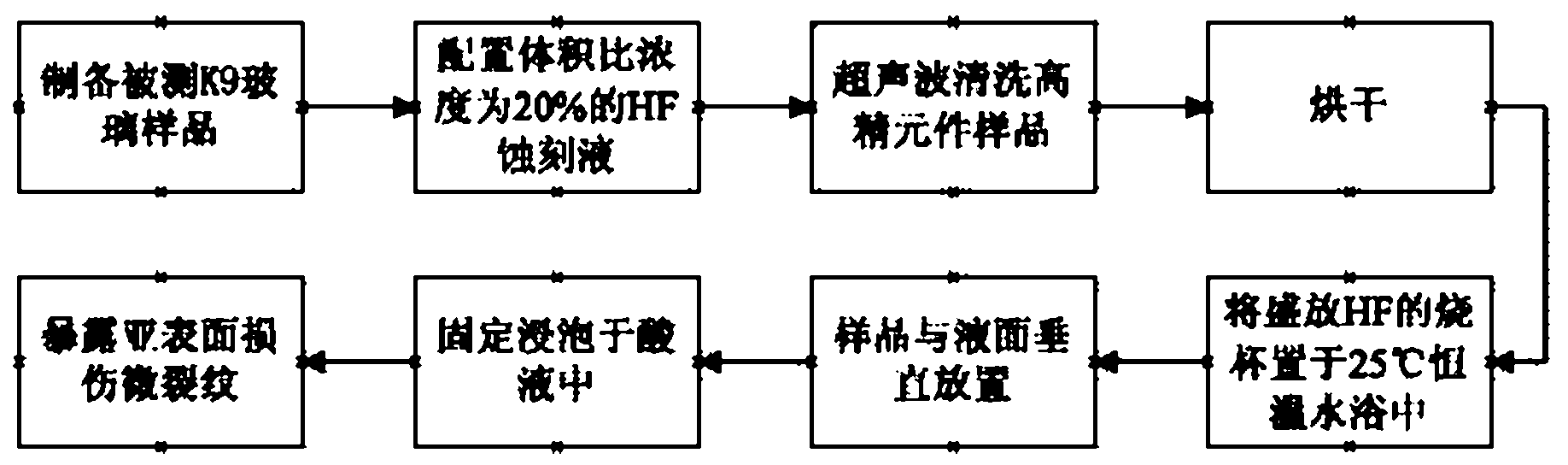

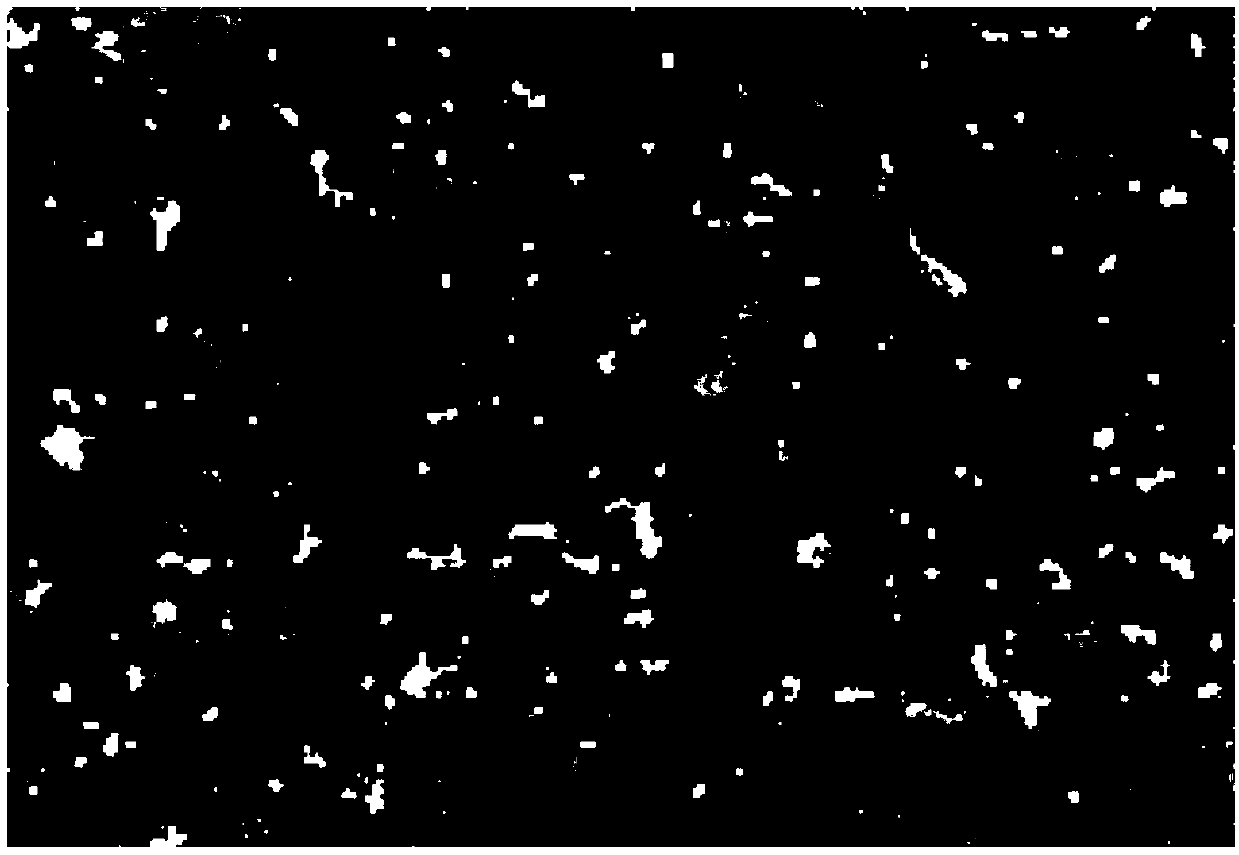

Holographic inversion detection method for micro-cracks on damaged layer of subsurface of brittle material

InactiveCN102426170AFully describe complex microscopic topographyImprove Surface Reconstruction AccuracyOptically investigating flaws/contaminationDistribution characteristicFinite difference method

The invention discloses a holographic inversion detection method for micro-cracks on a damaged layer of the subsurface of a brittle material. The invention is characterized in that: the surface of the brittle material after corrosion is reconstructed by using the method of fractal interpolation; the principle of self-similarity in the theory of fractal interpolation is adopted to fully depict complex microscopic morphology of the surface after corrosion; on the basis of reconstructing the material surface after corrosion by using the method of fractal interpolation, the finite difference method is used for inversion modeling of formation and growth of micro-cracks on the damaged layer of the subsurface, which enables not only the depth of the micro-cracks on the damaged layer of the subsurface but also all the information like size and direction of the micro-cracks to be obtained. An overall, complete and comprehensive characterization system of holographic distribution characteristics of micro-cracks on the damaged layer of the subsurface is brought forward on the basis of obtainment of holographic distribution characteristics of micro-cracks on the damaged layer of the subsurface.

Owner:XI AN JIAOTONG UNIV

Method for quantitatively characterizing grain size of main phase structure of complex phase material

ActiveCN107894433AIntuitive Microscopic MorphologySolving Specimen Preparation ProblemsMaterial analysis using wave/particle radiationMetallic materialsMicroscopic scale

The invention relates to a method for quantitatively characterizing the grain size of a main phase structure of a complex phase material, and belongs to the technical field of metal material physicalproperty inspection. By means of sample preparation, a section sample having microscopic difference between the main phase structure and a second-phase structure is prepared; EBSD surface scanning iscarried out, the calibration rate of the main phase structure is higher than 90%, the calibration rate of the second phase is lower than 10%, or even no diffraction pattern exists; finally, EBSD surface scanning data analysis is carried out to remove false points, singular points and noise points in a scanning result, then the calibrated data points of a second phase are set as a zero solution through a small particle removing mode, or a lining degree range corresponding to the second phase in a diffraction contrast graph is set as a zero solution, the noise point removal process is repeated,and grains of the main phase structure are quantitatively analyzed. The method has the advantages that the microscopic morphology of the main phase grains of the complex phase material can be clearlyand visually displayed, and quantitative characterizing is conducted on the grain size.

Owner:SHOUGANG CORPORATION

Flaky iron phosphate, and preparation method and application thereof

ActiveCN110357057AModerate particle size distributionEasy to processPhosphorus compoundsPhosphoric acidSlurry

The invention discloses flaky iron phosphate, and a preparation method and application thereof. The microscopic morphology of the flaky iron phosphate is a primary particle in a sheet shape with a thickness of 10 to 50 nm, a length of 100 nm to 3 [mu]m and a width of 100 nm to 3 [mu]m. The preparation method comprises the following steps of: weighing a ferrous ion solution and adding phosphoric acid and a crystal modifier; weighing a phosphorus salt solution and adding an oxidizing agent; carrying out mixing to obtain a mixed solution C, controlling the pH value of the mixed solution C to be 1.5-2.2, and carrying out a reaction to obtain pale yellow iron phosphate slurry; converting the iron phosphate slurry into white or pink-white iron phosphate slurry containing crystal forms under theconditions of stirring and heating, reducing a stirring speed by 20%-50% after the completion of the conversion, and carrying out ageing and heat preservation; performing solid-liquid separation, andcollecting a solid portion to obtain a crystalline iron phosphate precipitate; and washing the precipitate and then performing calcination to obtain the flaky iron phosphate. The iron phosphate of theinvention can be used for preparing lithium iron phosphate with high compaction density.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

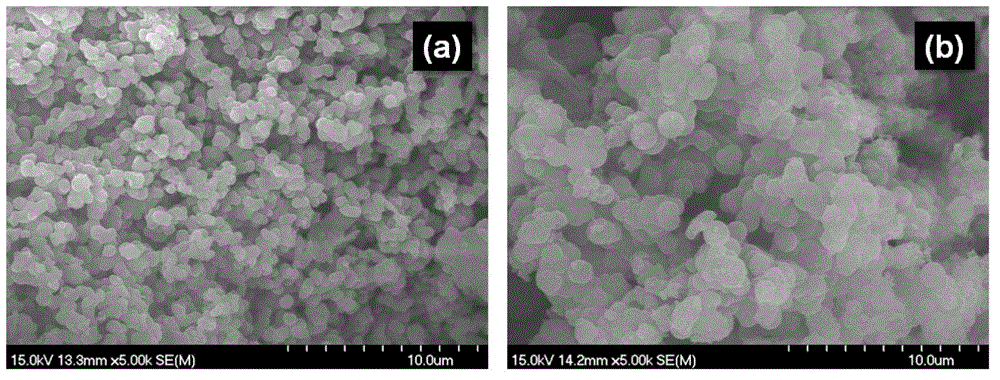

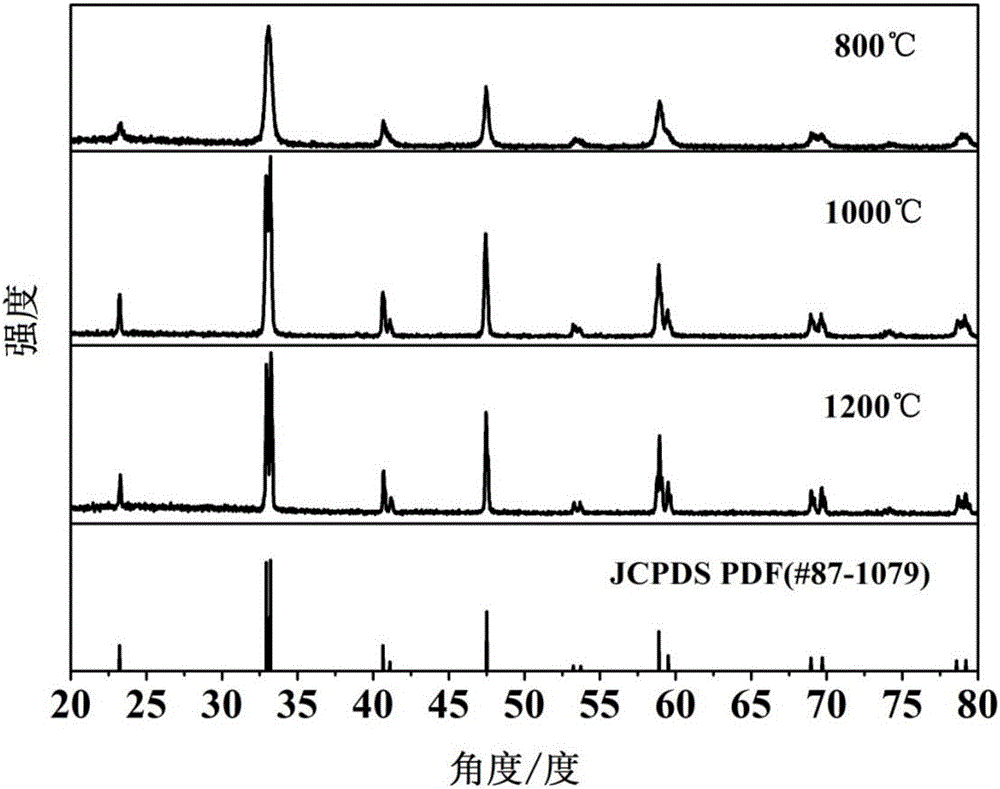

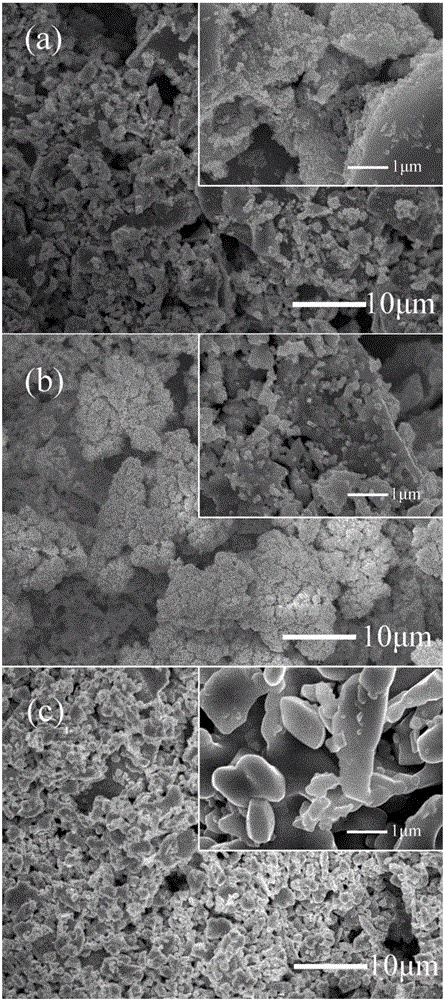

Preparation methods of spherical lithium manganate for lithium-ion power battery and precursor of spherical lithium manganate

ActiveCN103326012ALow impurity contentHigh discharge platformCell electrodesManganates/permanganatesWater bathsPower battery

The invention discloses preparation methods of a spherical lithium manganate for a lithium-ion power battery and a precursor of the spherical lithium manganate. The preparation method for the precursor is carried out as the following steps: (1) preparing a manganese salt water solution; (2) preparing a precipitant water solution; (3) injecting the prepared solutions in the step (1) and the step (2) to a reaction kettle with a stirrer and a constant-temperature water bath; (4) mixing the obtained MnCO3 and a compound containing an element M based on a mol ratio of M to Mn described in the invention, sintering and obtaining the precursor. The preparation method of the spherical lithium manganate is carried out as the following steps: mixing the precursor and Li2CO3, sintering and obtaining an M-doped spherical spinel lithium manganate. Compared with the prior art, the method of the invention has the advantages that: (1) impurity content is low, discharge plateau is high, specific capacity is high, cycle performance is good, high-temperature performance is good and tap density is high; and (2) raw material price and production cost are low, powder particle size can be controlled, microscale additive disperses uniformly, particle size distribution is concentrate, and microscopic morphology is spherical or spheroidic.

Owner:QINGDAO HUAGUAN HENGYUAN LI TECH

Microstructure regulation and control method for high-energy beam metal additive manufacturing

ActiveCN105689710AAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankMicroscopic scale

The invention discloses a microstructure regulation and control method for high-energy beam metal additive manufacturing. The method particularly comprises the following steps: step 1, setting a high-energy beam matched with a to-be-formed target material as well as temperature field regulation and control parameters involved in induction heating and double-heat-source synchronous heating according to the shape as well as the solidification phase and the microstructure of the to-be-formed target material; and step 2, putting the to-be-formed target material in a feeding device, putting a substrate of the to-be-formed target material in an argon-filled inert atmosphere processing chamber, and carrying out additive manufacturing to form the target material according to the processing parameters set in step 1, wherein the oxygen content in the process of carrying out additive manufacturing to form the target material is kept to be 100 ppm or below. The method provided by the invention has the advantages that such heat behaviors as the temperature gradient of a molten pool and surrounding areas as well as the solidification velocity of the molten pool can be regulated and controlled under the coupling action of the high-energy beam and synchronous induction heating, so as to control the forming of a solidification structure and a micro-phase structure of the formed target material, such as the microscopic morphology, the size and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

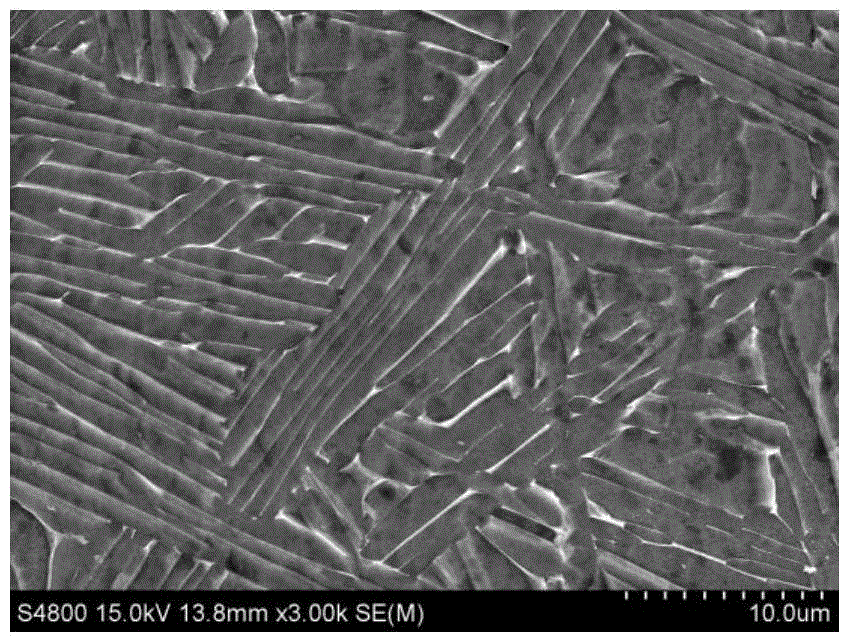

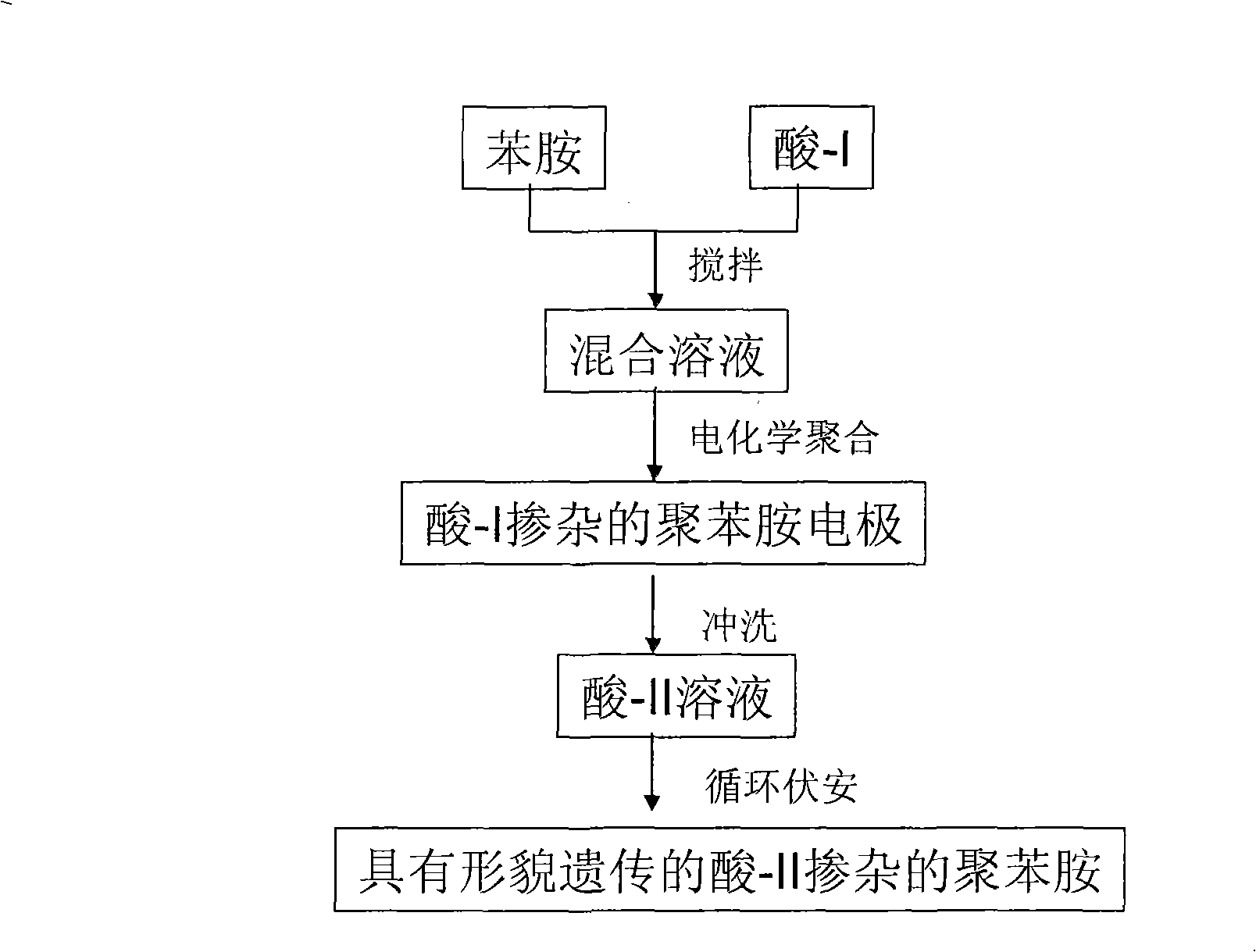

Nano-polyaniline material with morphology inheritance and electrochemical preparation method

InactiveCN101492536ADoes not change microscopic morphologyLow costElectrolysis componentsElectrolytic organic productionChemical compositionAniline

The invention discloses a nanometer polyaniline material with appearance hereditary potency and an electrochemistry preparation method thereof. The method comprises the following steps: aniline and doping acid I are added into water, stirred to form doping acid I solution of the aniline; in a three electrode system, the doping acid I solution of the aniline is added into an electrolytic cell; the electrochemical synthesis is carried out on a working electrode for obtaining the polyaniline material with nanometer structure doped with the doping acid I; after the electrochemical synthesis is finished, a polyaniline modified electrode doped with doping acid I is obtained; the modified electrode is used as the working electrode, put into water solution containing doping acid II, electrolyzed to a cyclic voltammetry graph by using cyclic voltammetry and stable to obtain the polyaniline material doped with doping acid II, the appearance of which is same to the polyaniline nanometer structure doped with the doping acid I obtained in the second step. The polyaniline material obtained in the invention only has difference in the chemical composition of doping ions and does not change the microscopic morphology of polyaniline. The appearance hereditary has important using value.

Owner:NANJING UNIV OF SCI & TECH

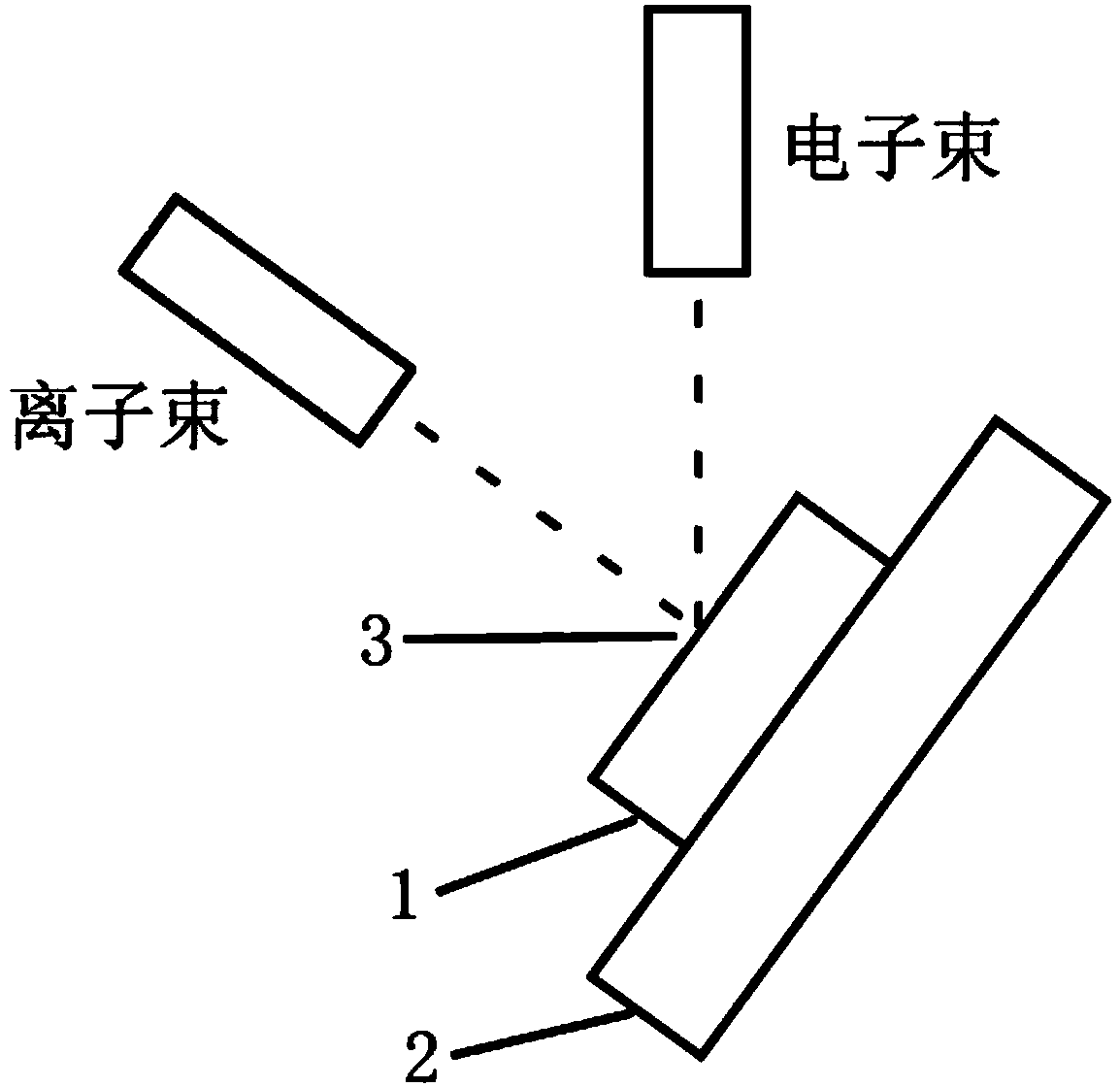

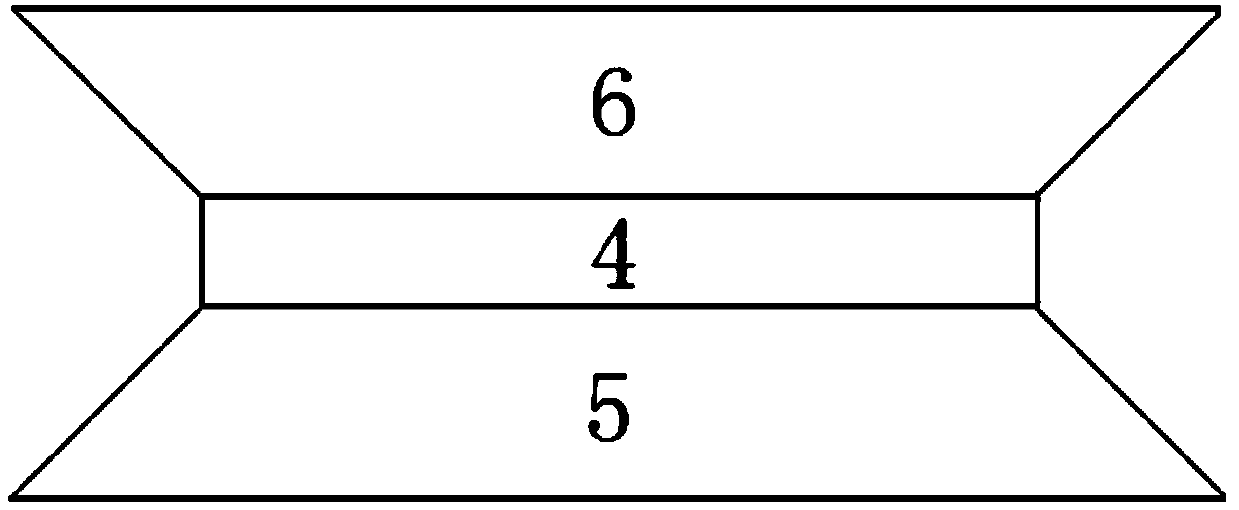

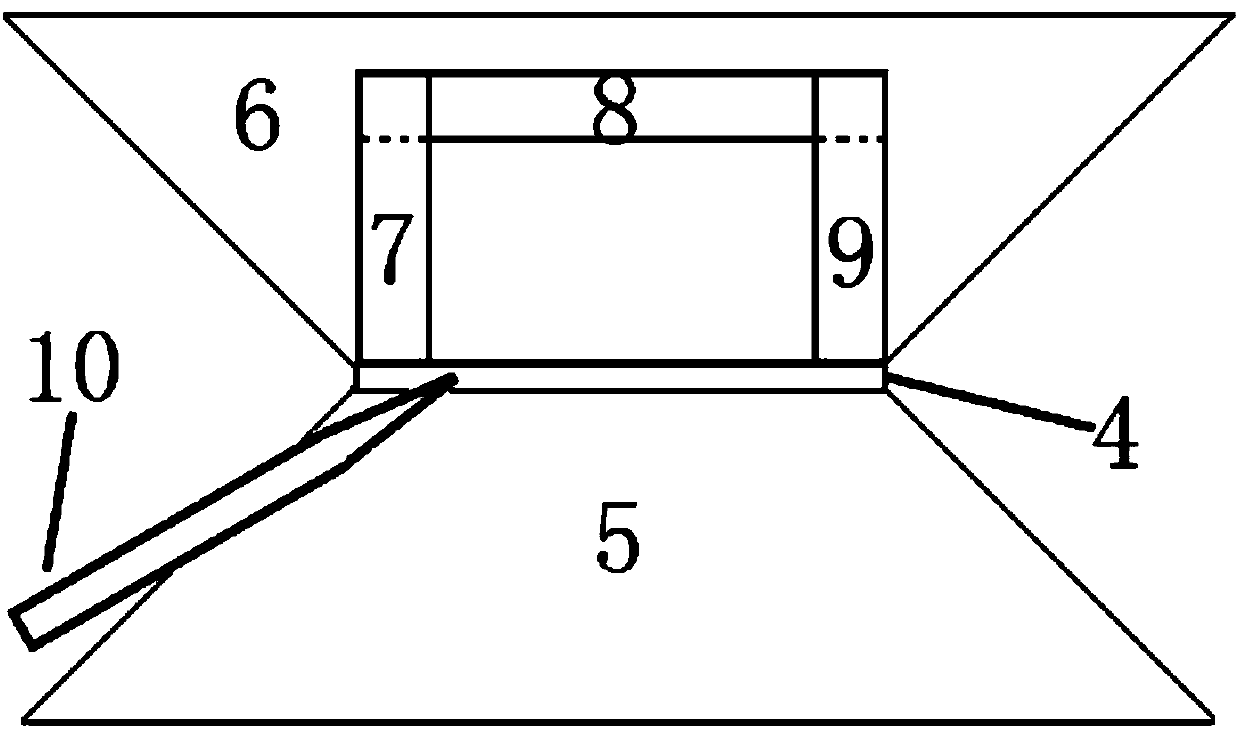

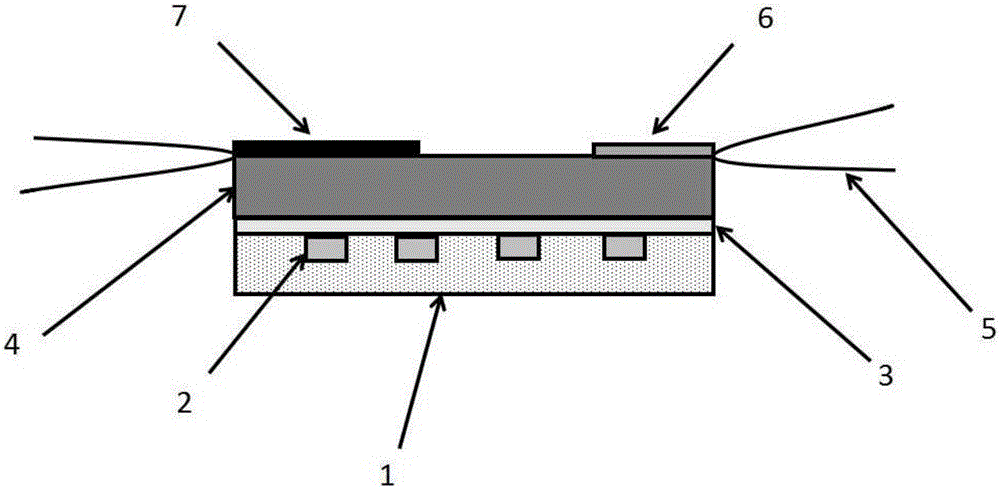

Method of analyzing surface coating of electrical steel

ActiveCN107643309ACompensating for Microscopic Topography DifficultiesMaterial analysis by measuring secondary emissionConventional transmission electron microscopeElectrical steel

The invention discloses a method of analyzing surface coating of electrical steel and belongs to the technical field of analytical method. The method comprises the steps of 1) pretreating a sample ofsurface coating of electrical steel; 2) adjusting surface of the coating sample to a common focus point of electron beams and ion beams; 3) performing metal deposition on the surface of the coating sample; 4) using ion beams to pit front and rear areas to the coating sample; 5) subjecting the pitted coating to U-shape cutting, extracting is performed before welding; 6) thinning and polishing. Themethod of the invention has the advantages precision positioning is performed via focused ion beams to produce a transmission electron sample via focused ions, the microscopic morphology of the surface coating of electrical steel is analyzed in conjunction with the conventional transmission electron microscope, and the problems of the prior art with analyzing the microscopic morphology of the surface coating of electrical steel are solved.

Owner:武汉钢铁有限公司

CeO2-based mixed potential type acetone sensor with La0.8Sr0.2CoO3 as sensitive electrode, and production method and application thereof

ActiveCN106093163AImprove ionic conductivityGood chemical stabilityMaterial electrochemical variablesHigh conductivityAtmosphere

Owner:JILIN UNIV

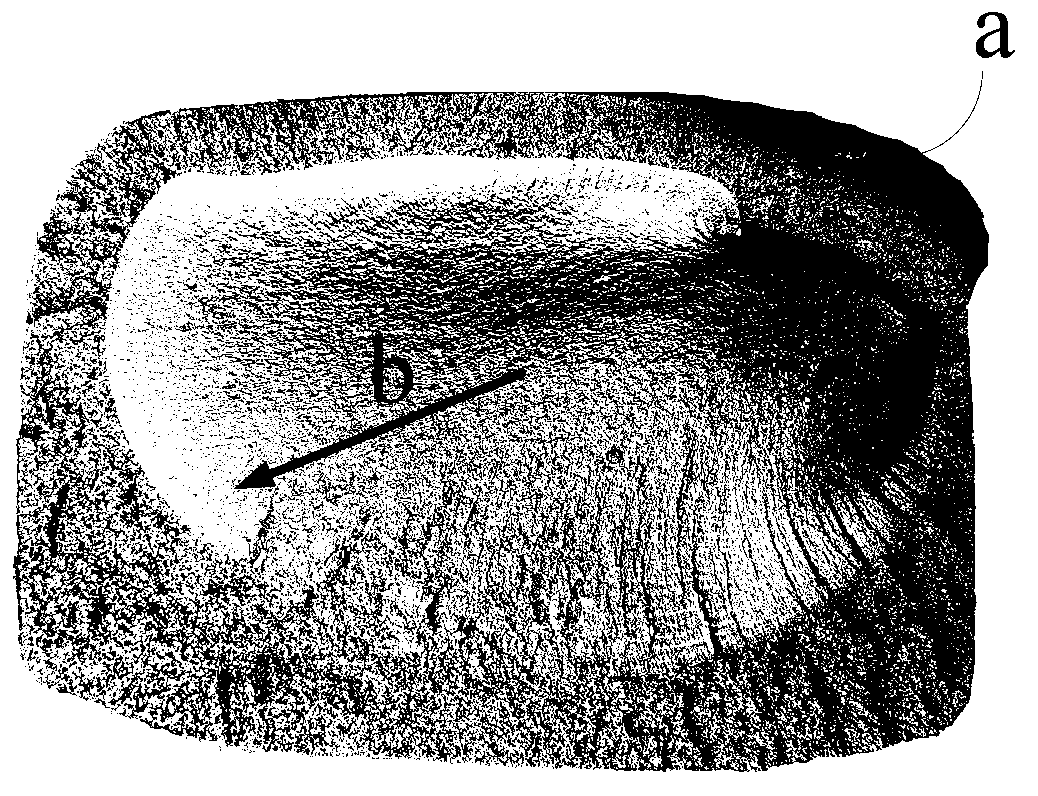

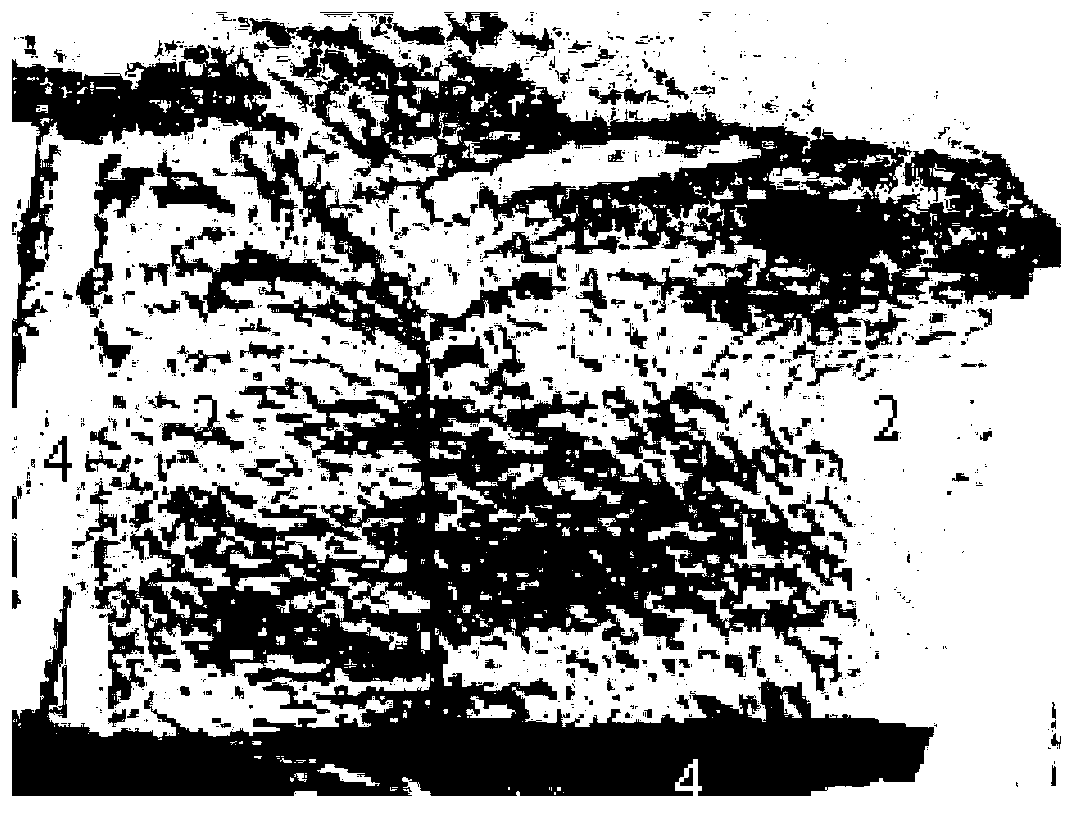

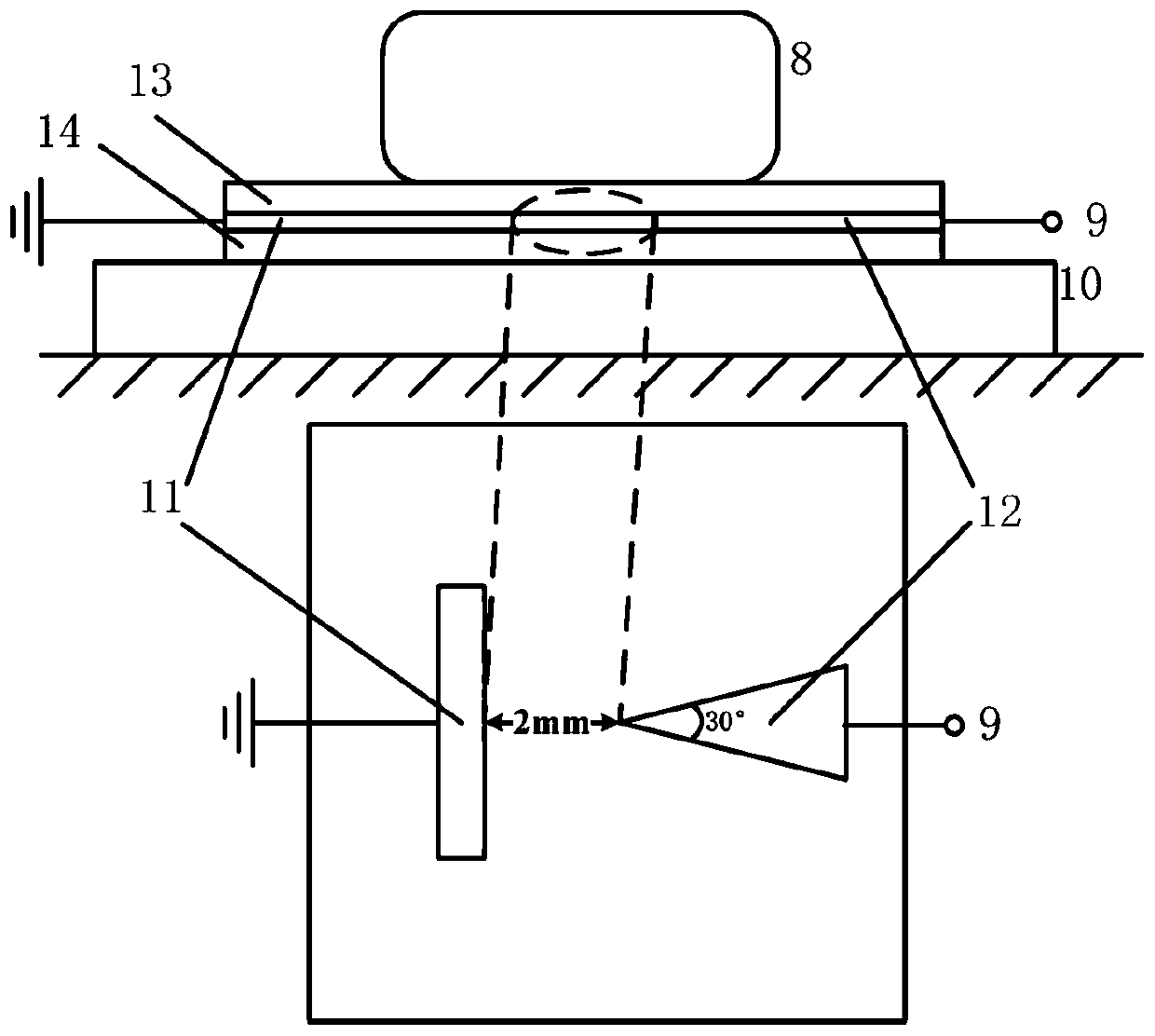

Longitudinal-transverse type core wound rail sampling and fracture analysis method

ActiveCN103235100AEasy to operateWithdrawing sample devicesTesting metalsFatigue fracturesEngineering

The present invention discloses a longitudinal-transverse type core wound rail sampling and fracture analysis method, which comprises: detecting a position of a transverse fatigue crack inside a rail head of a longitudinal-transverse type core wound rail; pressing the transverse fatigue crack to expose a core wound transverse fatigue fracture, observing a macroscopic morphology of the transverse fatigue fracture, and determining a core wound type; cutting the core wound rail from the transverse fatigue fracture surface along a longitudinal surface to obtain a preliminary sample; unclosing a longitudinal fatigue crack of the preliminary sample to obtain a two coupling longitudinal fatigue fracture sample, and observing a position and a size of a fatigue source of the longitudinal fatigue fracture; washing the two coupling longitudinal fatigue fracture sample, and adopting a scanning electron microscopy to observe a microscopic morphology of a fatigue source of the longitudinal fatigue fracture; and adopting a micro-zone energy spectrometer to obtain chemical components of the fatigue source of the longitudinal fatigue fracture and determine types and sources of foreign substances. The longitudinal-transverse type core wound rail sampling and fracture analysis method has a characteristic of simple operation.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

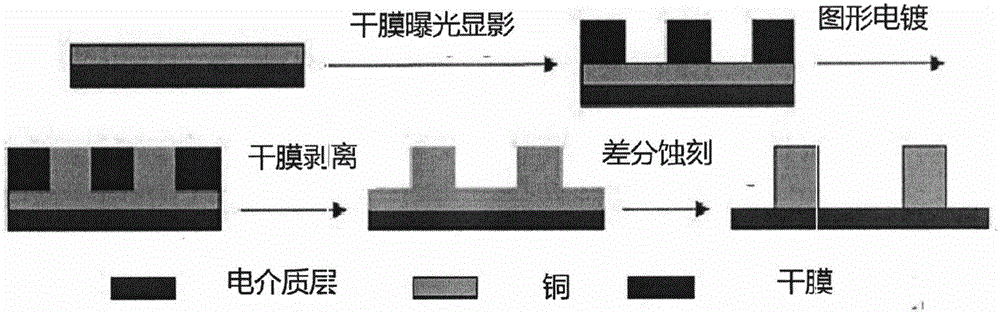

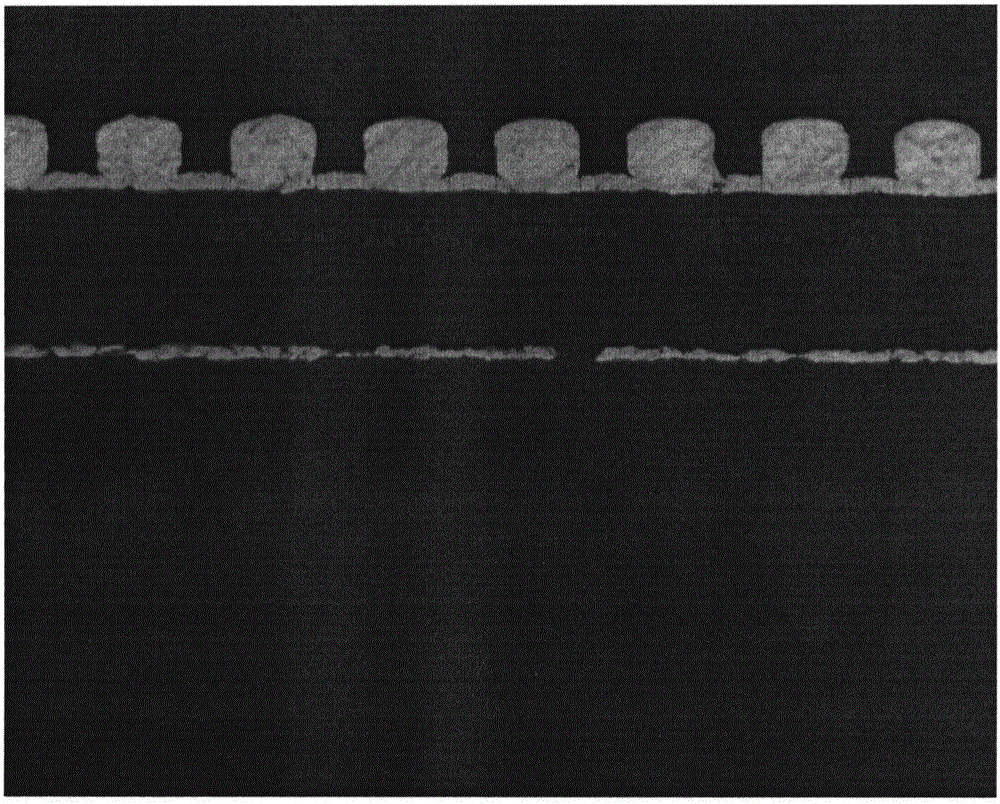

Difference etching solution for semi-additive process preparation fine line

InactiveCN105848421ANo pollution in the processImprove side erosion effectConductive material chemical/electrolytical removalFine lineEtching

The present invention provides a difference etching solution for a semi-additive process preparation fine line. The difference etching solution comprises two parts: basic solution and difference etching additive, wherein the basic solution is vitriol and hydrogen peroxide, and the difference etching additive includes a hydrogen peroxide stabilizer, a flat etchant protective agent, a gloss agent and a roughness control agent. Compared with the prior art, the difference etching solution for semi-additive process preparation fine line is able to effectively remove the base copper and effectively reduce the lateral erosion. The difference etching solution for a semi-additive process preparation fine line employs a lateral erosion protective agent so as to greatly reduce the generation of Undercut, improve the line yield rate, effectively protect the line corner angle and maintain the rectangular morphology of the line cross section; and the difference etching solution for the semi-additive process preparation fine line employs additives such as a microetching detergent, a roughness control agent and the like so as to perform further control of the line microscopic morphology of the line after difference etching, obtain visual sense shine and cleaning and facilitate subsequent process connection because of the roughness of 0.2-0.5[Mu]m in the microscopic scale.

Owner:杭州乐芙新材料科技有限公司

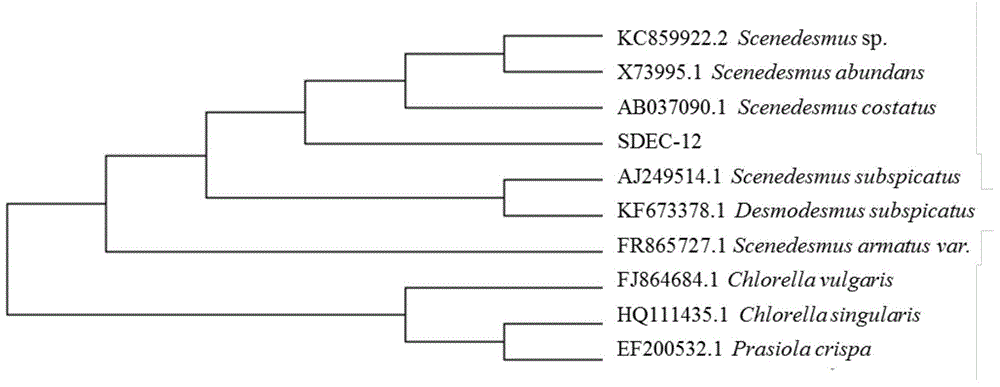

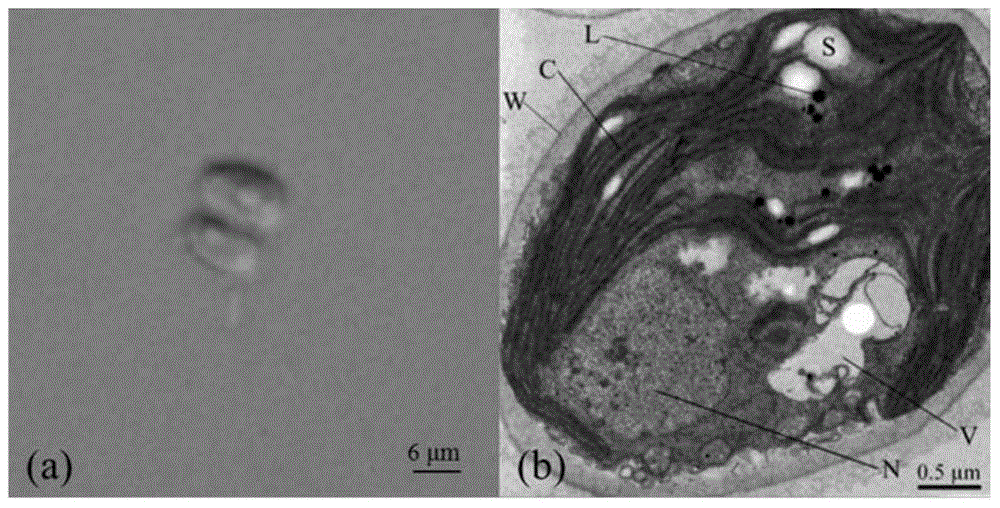

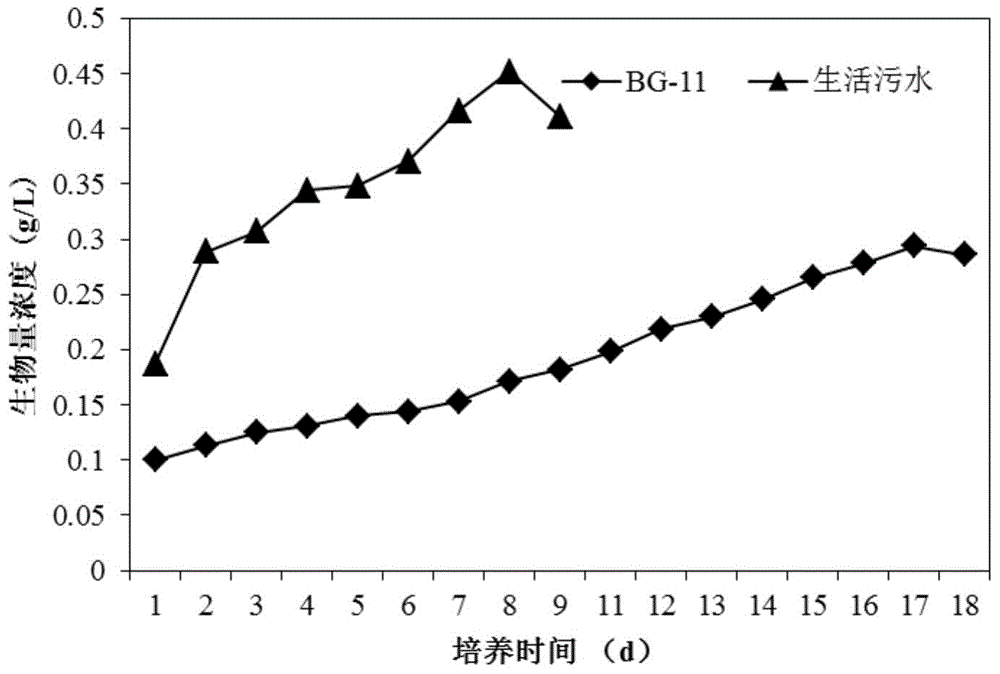

Scenedesmus bijuga capable of producing oil in high yield as well as screening and culture method and application thereof

ActiveCN104593265AHigh accumulation characteristicsPromote growthUnicellular algaeDispersed particle separationScenedesmusFatty acid methyl ester

The invention discloses scenedesmus bijuga capable of producing oil in high yield as well as a screening and culture method and application thereof. A algae specie, which is obtained by separating from a polluted water area is identified by virtue of 18SrDNA sequence analysis and the microscopic morphology to determine that the algae is a member of Scenedesmus sp., has a serial number of KJ413176. The algal strain is named as scenedesmus bijuga SDEC-12 and is collected in China Center for Type Culture Collection (CCTCC) in October 2014 and has the collection number of CCTCC NO: M 2014497. By virtue of using artificially prepared domestic sewage as an alternative culture medium, the yield and productivity of oil produced by scenedesmus bijuga SDEC-12 are significantly higher than those of the oil produced by scenedesmus bijuga SDEC-12 which is cultured by the commonly used BG-11 culture medium; the extracted fatty acid methyl ester component analysis shows that scenedesmus bijuga SDEC-12 cultured by the domestic sewage culture medium has the characteristics of better oxidative stability and low-temperature fluidity and therefore the scenedesmus bijuga SDEC-12 is more suitable for serving as a raw material for biodiesel. Scenedesmus bijuga SDEC-12 grows and simultaneously absorbs nitrogen and phosphorus nutrient salts in the domestic sewage so that the effective treatment of the domestic sewage is achieved and the domestic sewage is used as the alternative culture medium to achieve both economic and environmental benefits.

Owner:SHANDONG UNIV

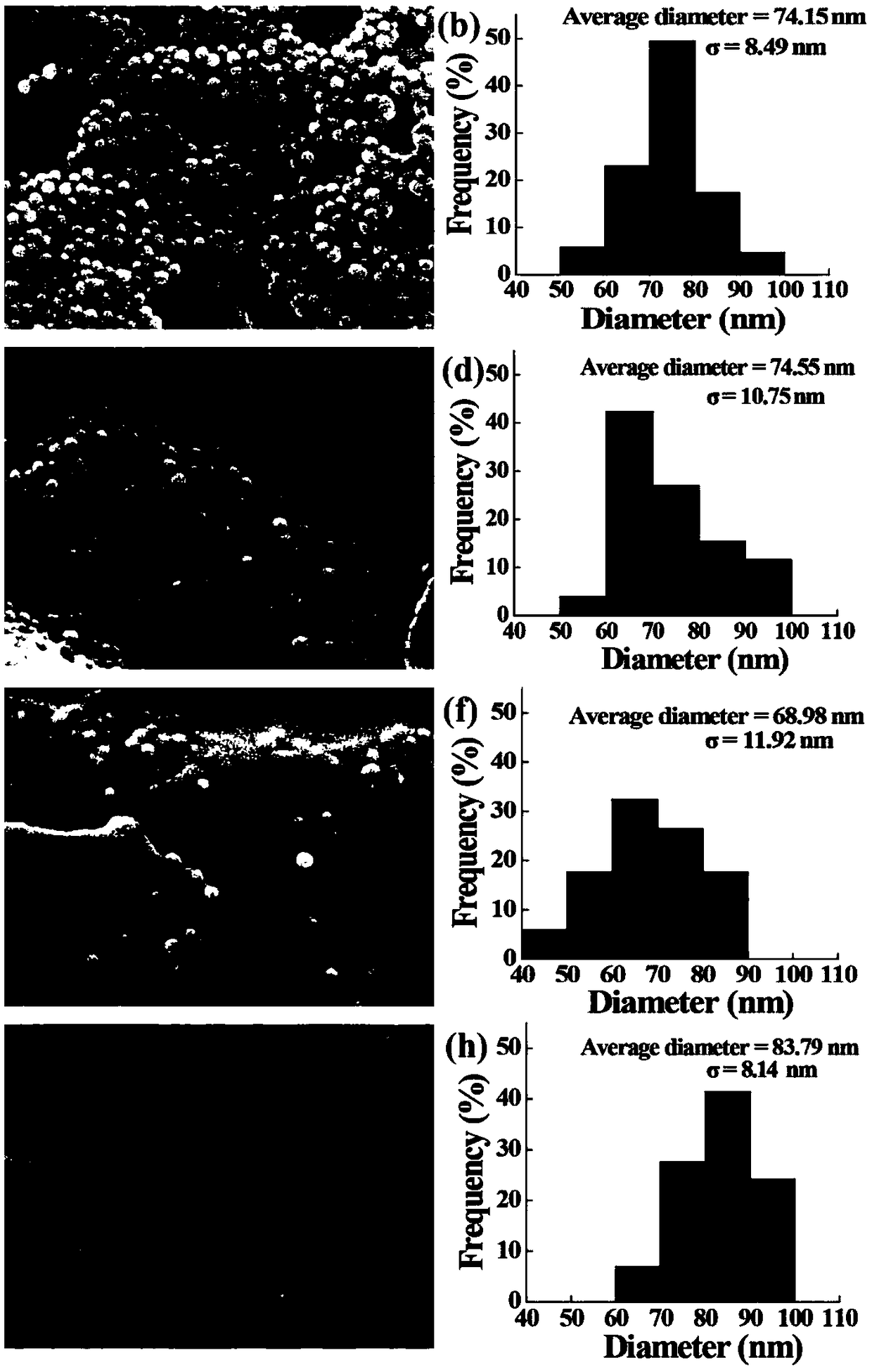

Polypyrrole-polyvinylpyrrolidone nanoparticles and preparation method and application thereof

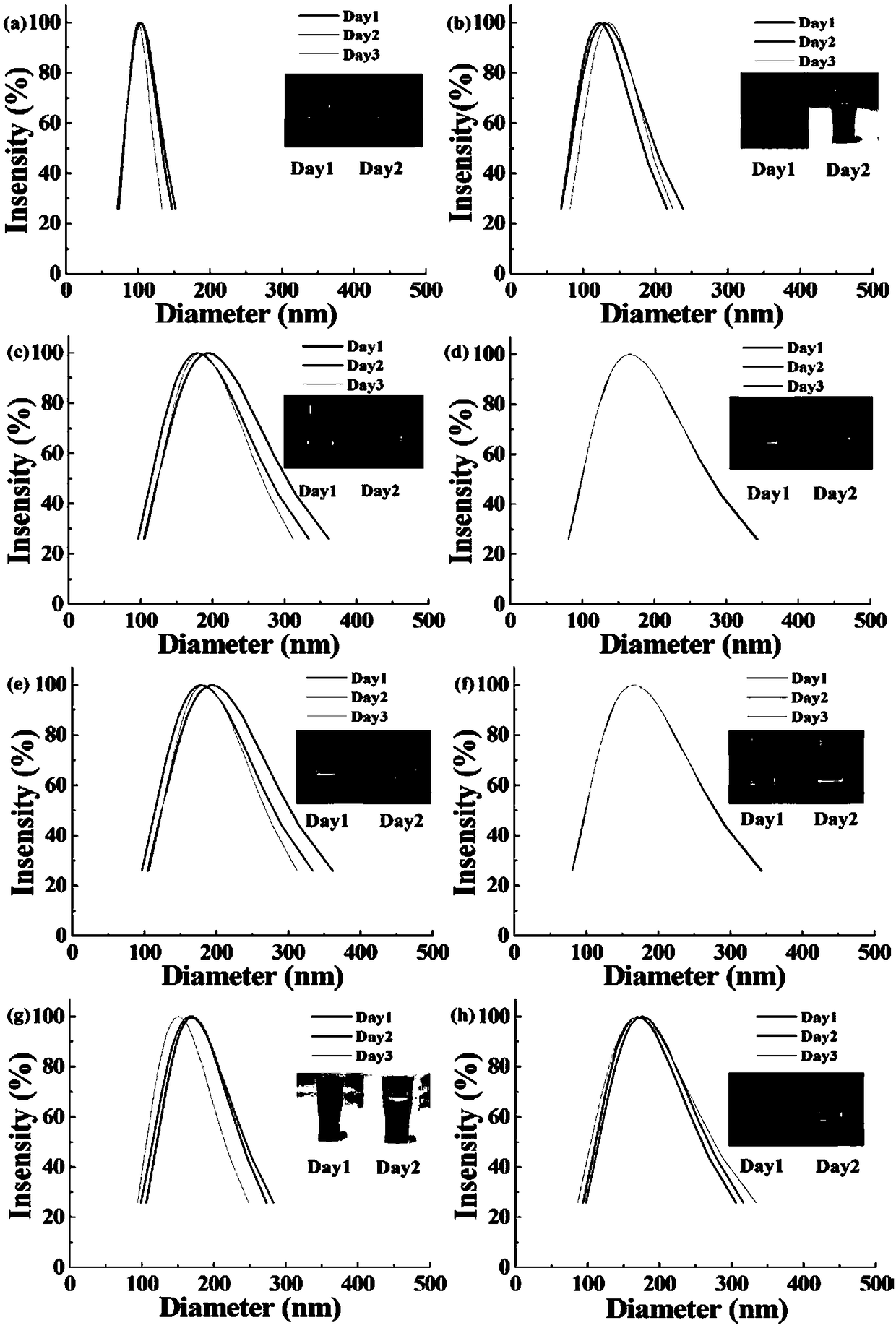

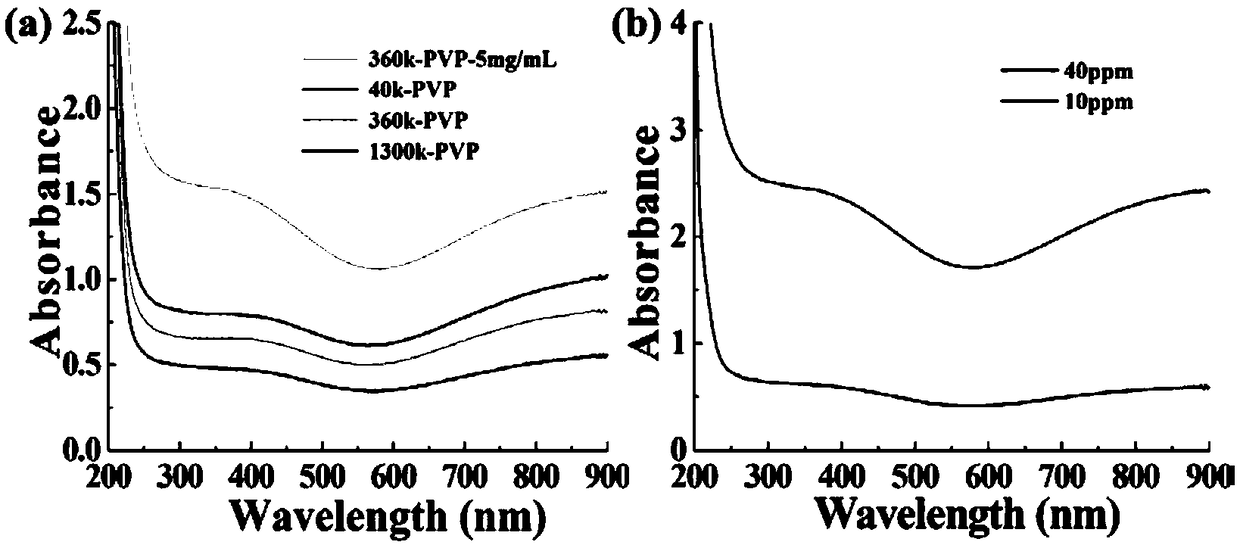

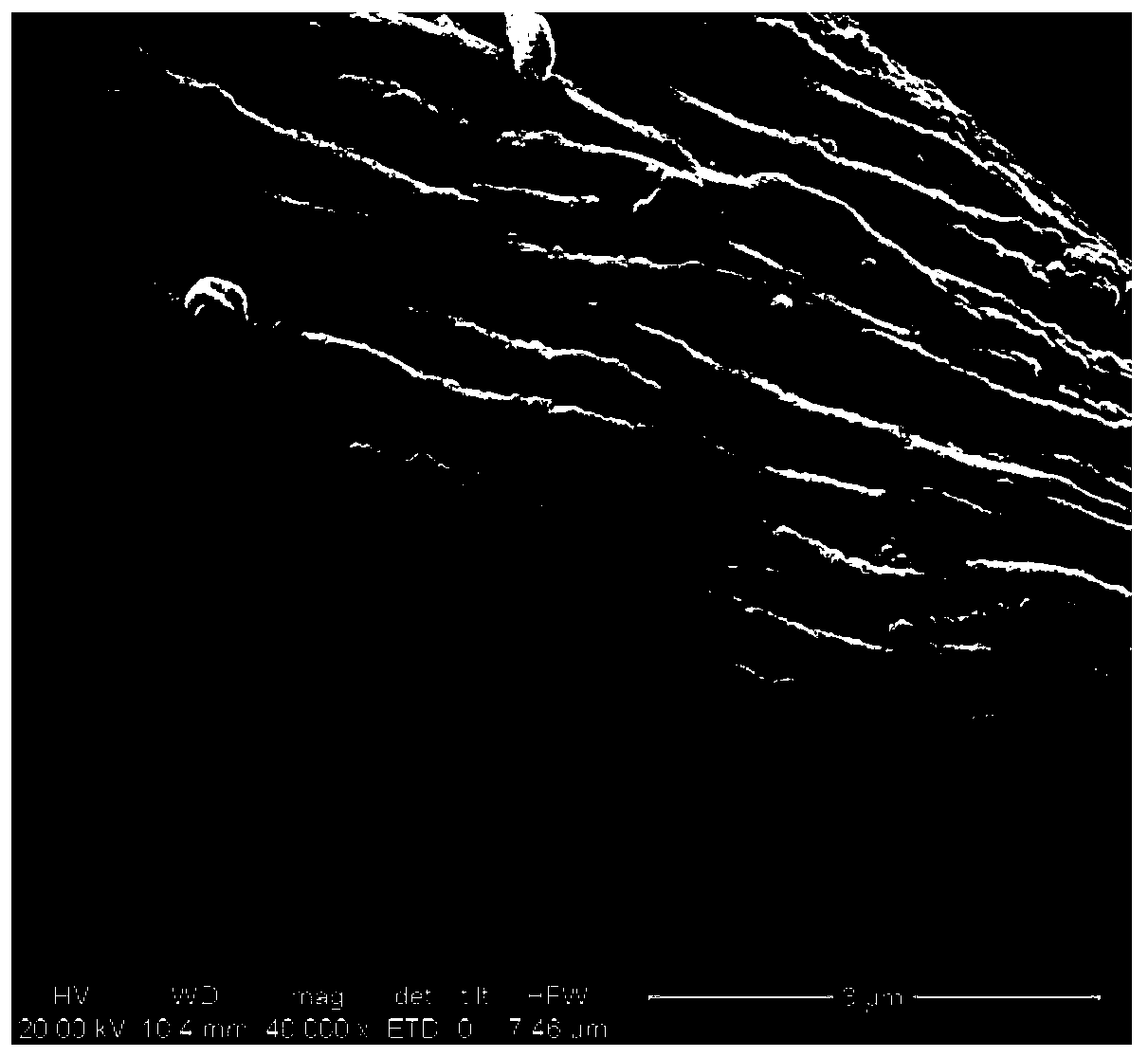

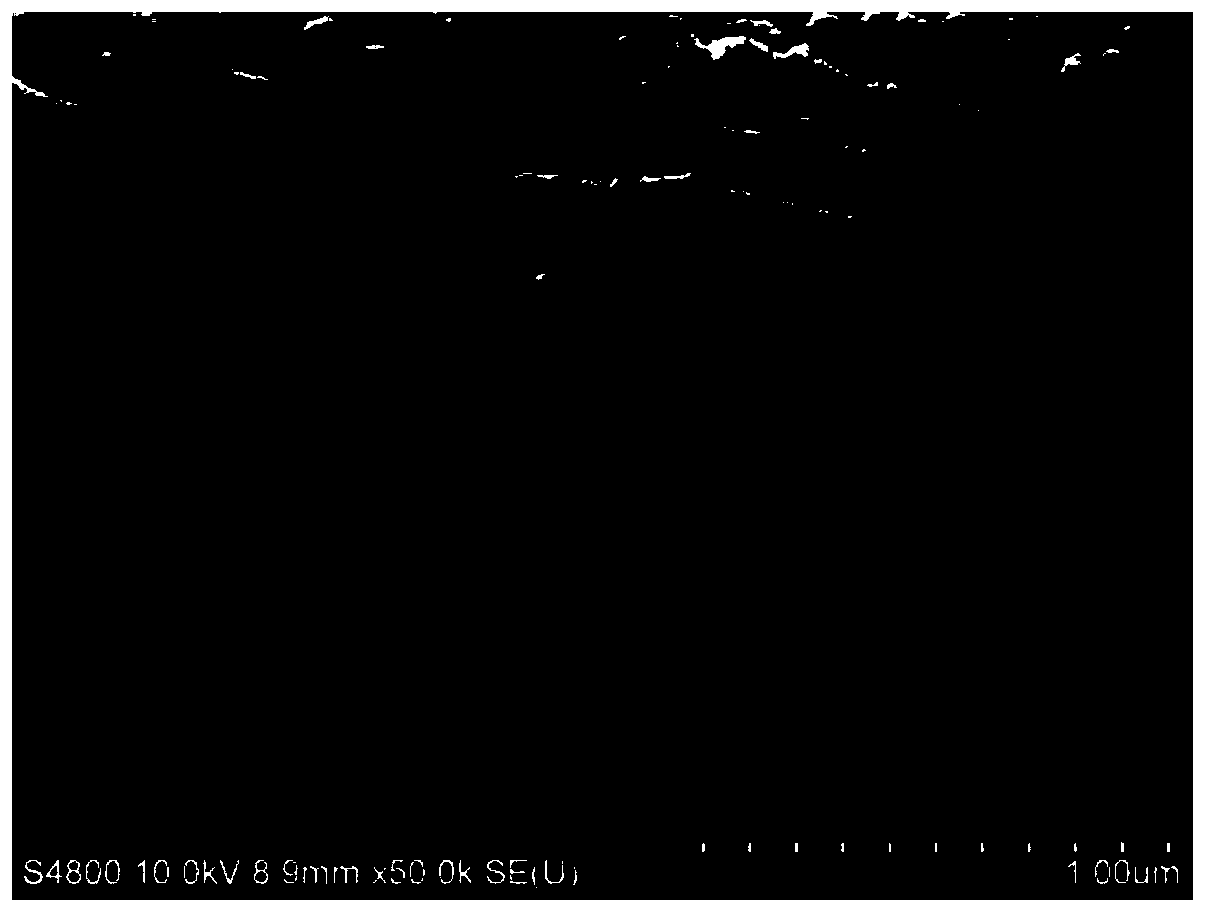

InactiveCN108853059AGood lookingMorphology regulationEnergy modified materialsPharmaceutical non-active ingredientsBiocompatibility TestingPyrrole

The invention provides polypyrrole-polyvinylpyrrolidone nanoparticles are formed by synchronously surface-modifying polyvinylpyrrolidone during pyrrole polymerization process. The method for preparingthe above nanoparticles is also provided and comprises the following steps: separately adding polyvinylpyrrolidone with various molecular weights and concentrations into distilled water, stirring anddissolving, adding an initiator, adding pyrrole, stirring until the polymerization is completed, and centrifugally washing to obtain polypyrrole-polyvinylpyrrolidone nanoparticles with various particle sizes. The application of the above polypyrrole-polyvinylpyrrolidone nanoparticles as pharmaceutical carriers or tumor therapeutic materials is also provided. Polyvinylpyrrolidone is grafted on thesurface of nanoparticles to enhance the colloidal stability thereof and to endow the nanoparticles with good blood compatibility and biocompatibility; and the molecular weight and concentration of the polyvinylpyrrolidone are changed to regulate and control the microscopic morphology of the polypyrrole nanoparticles, thus solving the technical problems in the effect of tumor thermotherapy.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of sandwich flexible electromagnetic shielding material based on carbon fiber fabric, nickel nanoparticles and graphene

ActiveCN110258106AImprove conductivityGood synergyShielding materialsCarbon fibresFiberCarbon fibers

The invention relates to a preparation method of a sandwich flexible electromagnetic shielding material based on carbon fiber fabric, nickel nanoparticles and graphene and relates to the preparation method of the electromagnetic shielding materials, aiming to solve problems that a traditional preparation method for 'mixing-molding' existing electromagnetic shielding composites affects the flexibility of the composites and involves some non-environmental protection chemical reagents, and distribution of active components and specific microscopic morphology in construction are difficult to control accurately resulting in that the shielding performance is difficult to improve. The preparation method includes 1, preparation of the carbon fiber fabric; 2), preparation of the nickel nanoparticles / carbon fiber fabric composites by magnetron sputter; 3), plasma enhanced chemical vapor deposition. The preparation method is used for preparation of the electromagnetic shielding materials.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

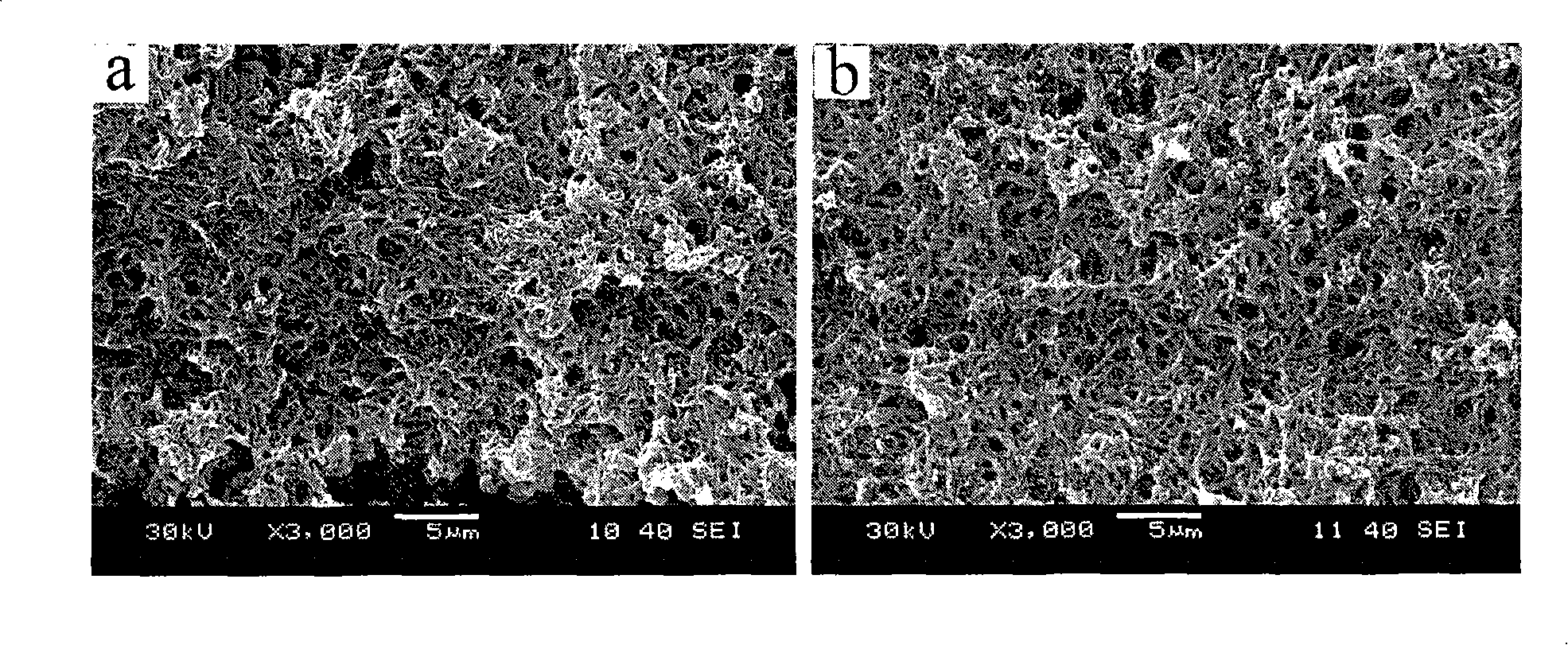

Manufacturing method of slide for observing filamentous fungus microscopic morphology

InactiveCN102533930AEasy to operateGuaranteed accuracyMicrobiological testing/measurementMicroscopesRoom temperatureCover glass

The invention relates to a manufacturing method of a slide for observing filamentous fungus microscopic morphology. The method comprises the following steps of: firstly digging a groove on a water agar culture flat plate and removing a culture medium in the groove; then placing a water agar culture block with a size of less than that of the groove in the groove, picking up a fungus culture to be identified and inoculating on the upward side of the water agar culture block in the groove and then covering the water agar culture block with a sterile cover glass; and closing a culture dish cover, sealing and culturing at room temperature, taking the cover glass out after the culture is finished and manufacturing an observation slide for fungus. The method provided by the invention is easy in operation for manufacturing a thallus observation slide of filamentous fungus; observation slides for thalli at different development stages can be obtained by using a continuous slide taking method according to growth periods of different thalli; and the accuracy for identification work of the filamentous fungus species is guaranteed.

Owner:OCEAN UNIV OF CHINA +1

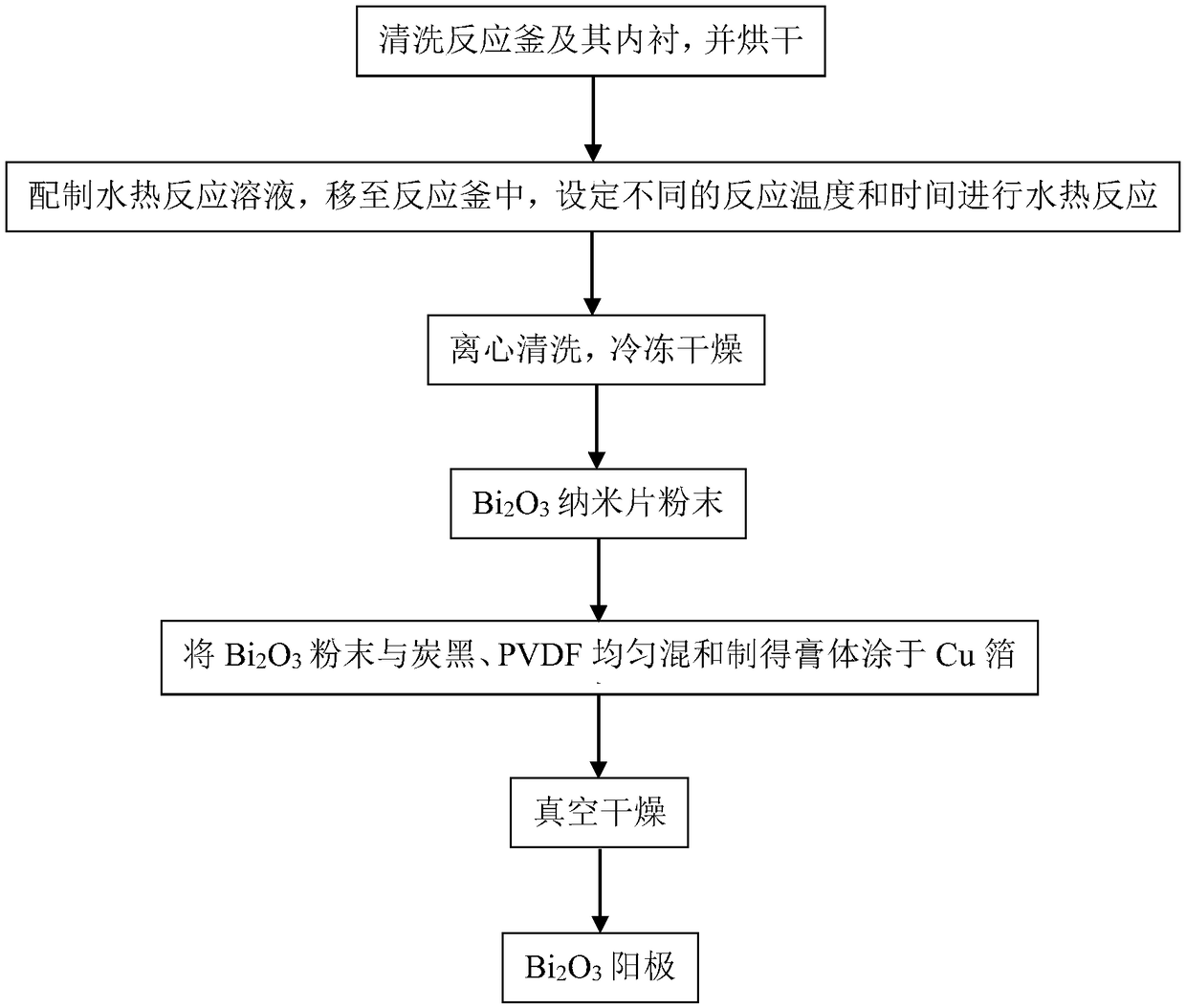

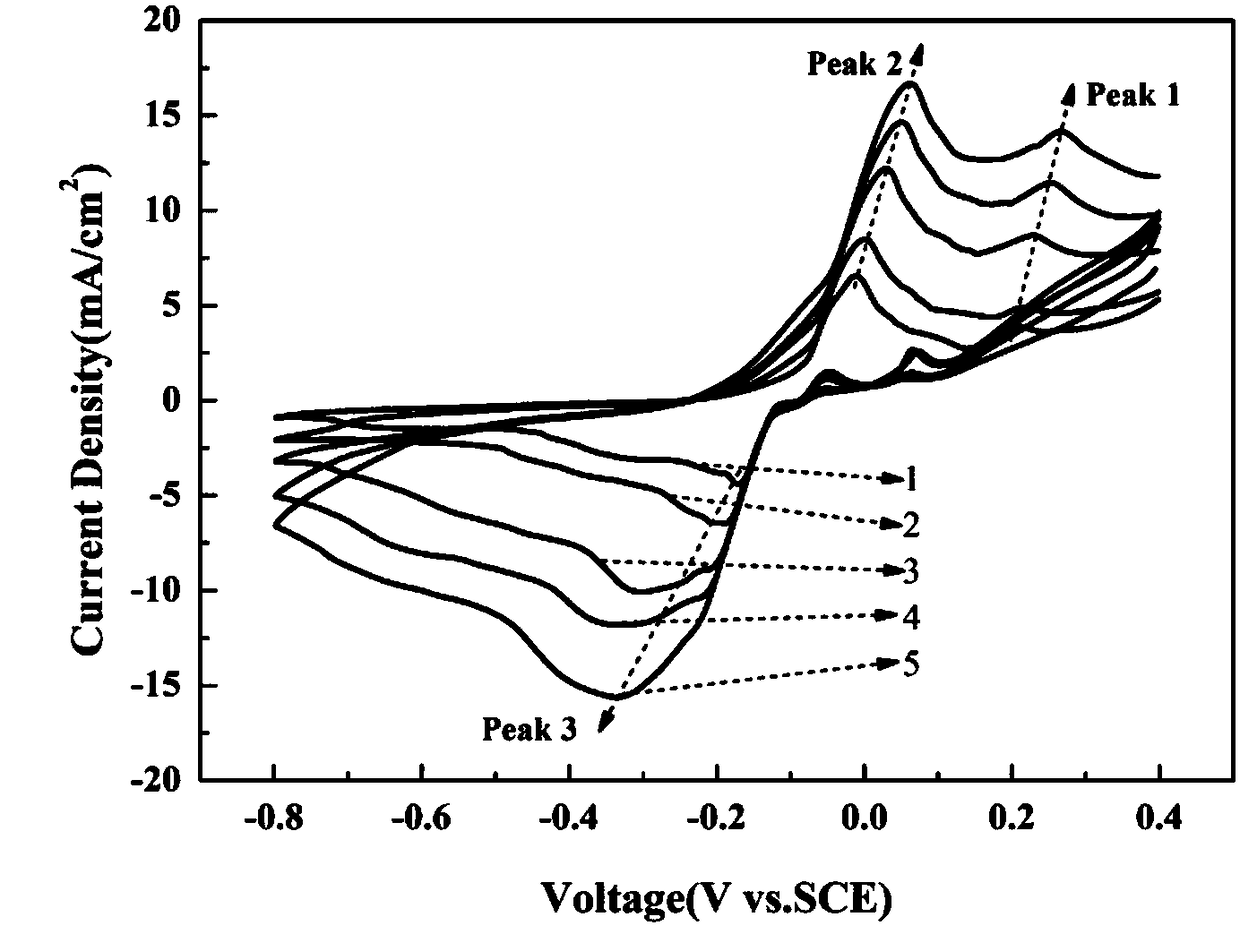

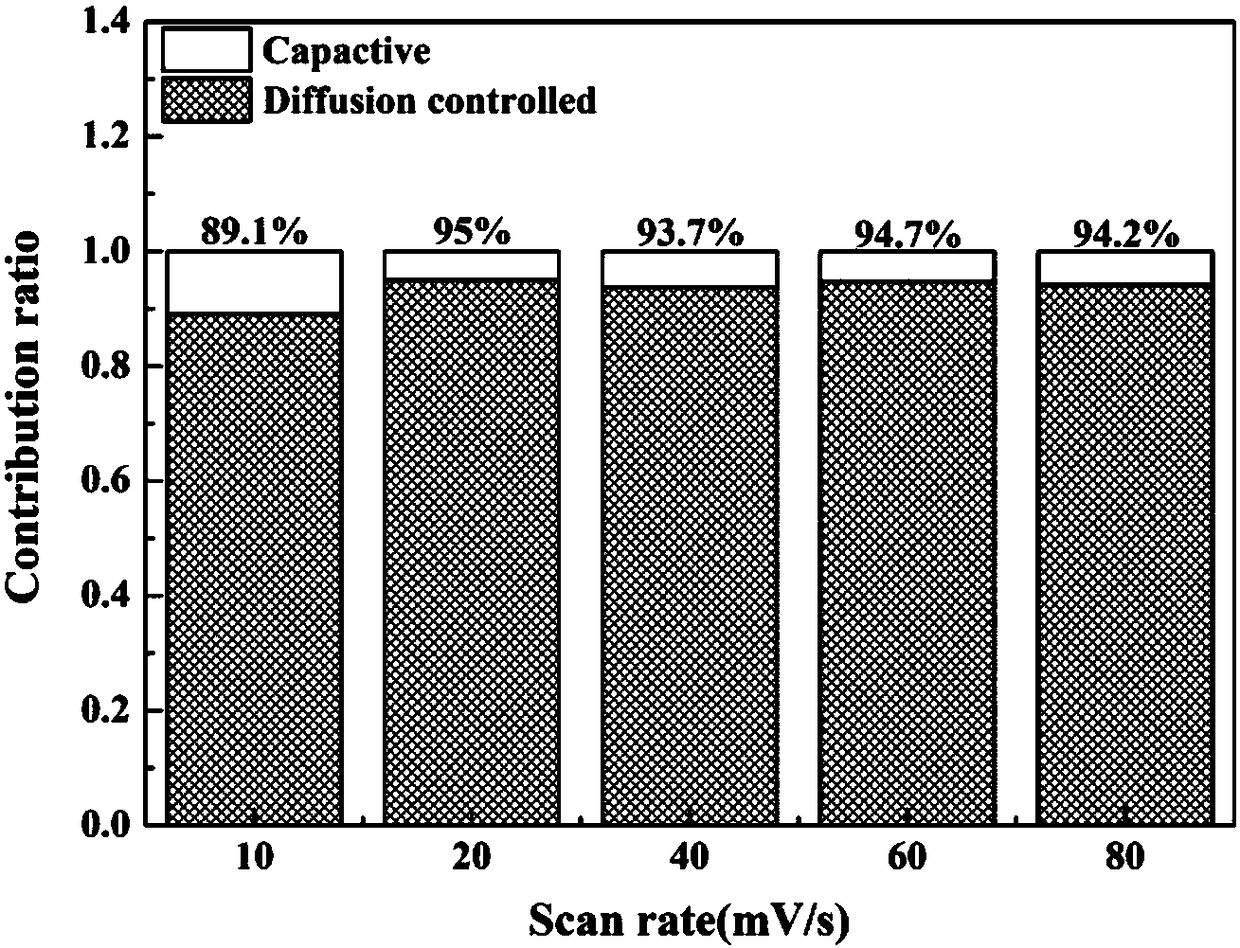

Zinc-based battery anode material containing Bi2O3 with self-assembled structure and preparation method

InactiveCN108539169ASolving the Zinc Dendrite ProblemGood intercalation propertiesFuel and secondary cellsCell electrodesMicrosphereMaterials science

The invention relates to a zinc-based battery anode material containing Bi2O3 with a self-assembled structure and preparation method. The surface of a Cu foil is coated with a mixture of Bi2O3 powder,carbon black and polyvinylidene fluoride (PVDF); the Bi2O3 has the self-assembled structure; a phase structure is a tetragonal phase, an orthorhombic phase or a cubic crystal phase; the microscopic morphology is in a nanosheet layer shape, and the self-assembled structure forms a microsphere shape. The traditional metal anode is replaced with a zinc ion embedded anode material, and the energy storage mechanism of a zinc-based battery is changed ion storage energy from metal storage energy, so that the problem of zinc dendrites is fundamentally solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

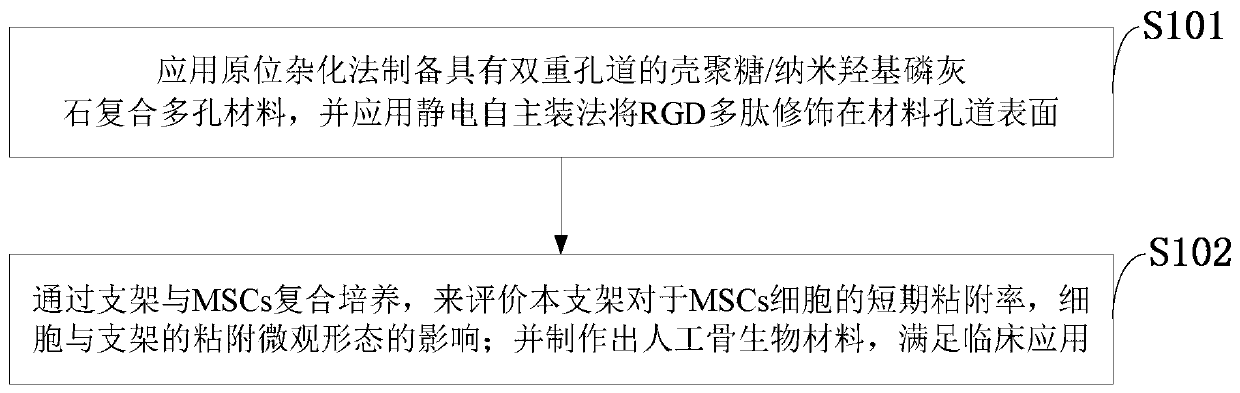

RGD polypeptide modified chitosan/hydroxyapatite composite stent and preparation method thereof

InactiveCN109758606AMeet the clinical applicationImprove adhesionProsthesisRGD peptideNano hydroxyapatite

The invention belongs to the technical field of composite stents, and discloses an RGD polypeptide modified chitosan / hydroxyapatite composite stent and a preparation method thereof. The method includes preparing a chitosan / nano hydroxyphosphorus composite porous material with double pores by using the in situ hybridization method; modifying RGD peptide on the surface of the material pores; conducting complex culture on the stent and MSCs and evaluating the short-term adherence rate of the stent on the MSCs cells and the effect on the adhesion microscopic morphology of the cells and the stent;manufacturing an artificial bone biological material. The chitosan / nano-hydroxyapatite composite porous material with the double pores is prepared by the in-situ hybridization method, and the RGD polypeptide is modified on the surface of the material pores by an electrostatic self-assembly method to obtain a three-dimensional porous stent. The composite culture of the stent and the MSCs cells is utilized to evaluate the short-term adhesion rate of the MSCs cells and the effect on the microscopic morphology of the cells and the stent to manufacture the artificial bone biological material to meet the clinical application.

Owner:曲志伟

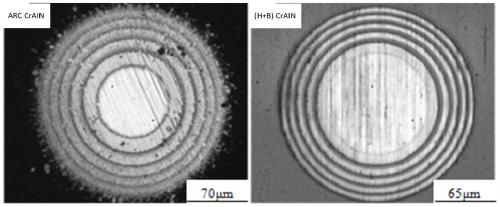

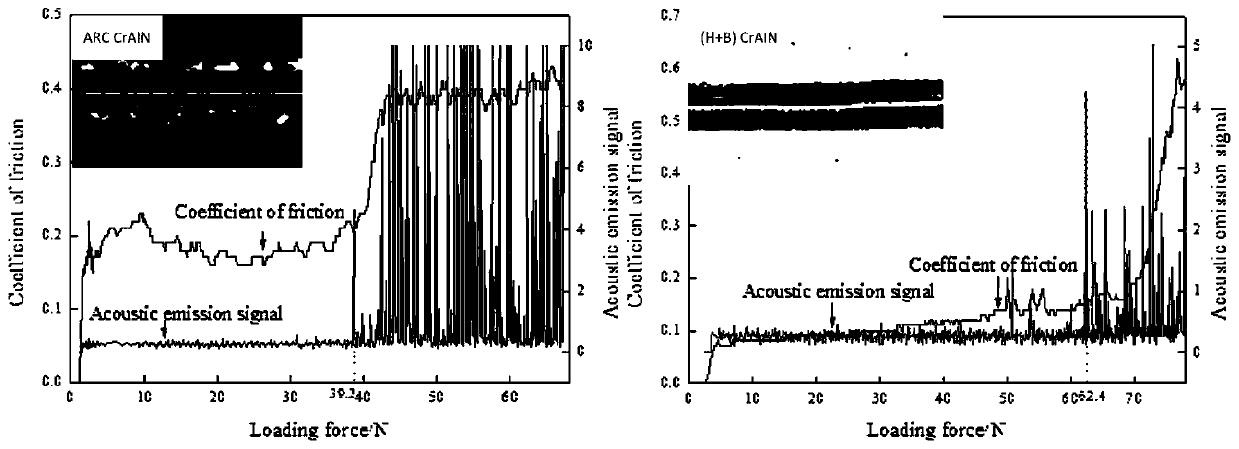

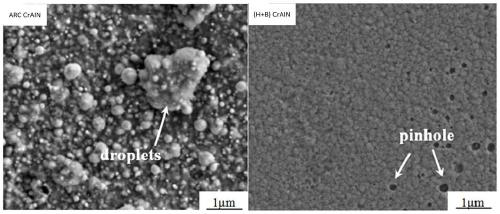

Preparation method of CrAlN coating based on HIPIMS technology

InactiveCN110241387AGood high temperature oxidation resistanceHigh critical loadVacuum evaporation coatingSputtering coatingCritical loadX-ray

The invention discloses a preparation method of a CrAlN coating based on a HIPIMS technology. The high-power pulse magnetron sputtering technology (High Power Impulse Magnetron Sputtering, HIPIMS) is adopted, a method for co-sputtering by using a high-power pulse target (High pulse power cathode) and a bipolar pulse target (Bipolar pulsed sputtering cathodes) is used, and a (H+B) CrAlN coating is deposited; and meanwhile, an ARC CrAlN coating is deposited by adopting a fourth-generation arc ion plating technology (ARC evaporators). The performance of all aspects of the coating is analyzed through a scratch test, an X-ray diffraction, a microscopic morphology observation, an electrochemical corrosion test and the like, and the binding force of a (H+B) CrAlN coating film is stronger, and the maximum critical load can reach 62.4N; the surface crystal grains are smaller, the defects are few, and the section tissues are compact; meanwhile the high-temperature oxidation resistance of the CrAlN coating prepared by the (H+B) method is optimal; and the coating prepared by co-sputtering in the aspect of coating corrosion resistance is more corrosion-resistant than the coating prepared by electric arc ion plating.

Owner:HENAN UNIV OF SCI & TECH

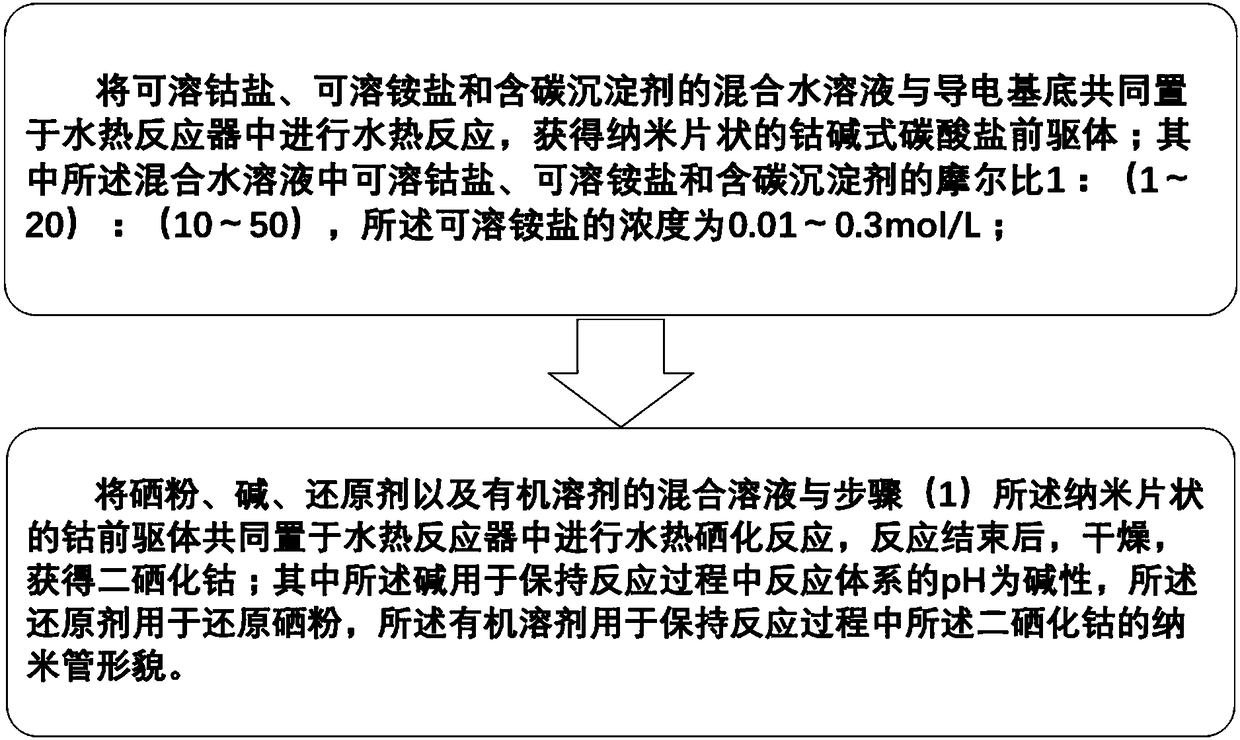

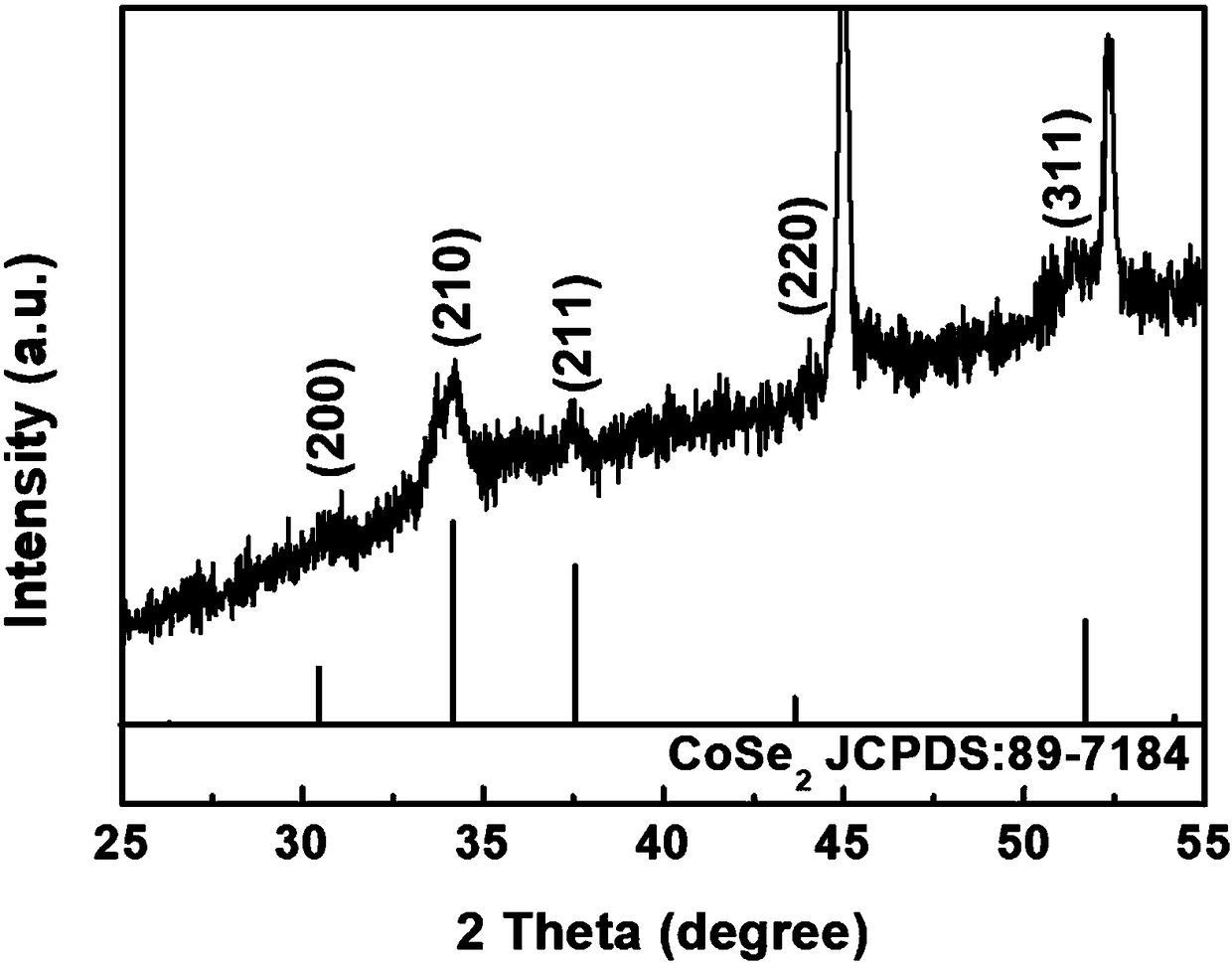

Difunctional cobalt diselenide material as well as preparation method and application thereof

ActiveCN108554426AEasy to prepareMany catalytically active sitesPhysical/chemical process catalystsBinary selenium/tellurium compoundsHydrazine compoundRe engineering

The invention discloses a difunctional cobalt diselenide material as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) jointly performingthe hydrothermal reaction for a mixed aqueous solution of soluble cobalt salt, soluble ammonium salt and a carbon-containing precipitant and a conducting substrate, and obtaining a cobalt element-containing precursor growing on the conducting substrate; (2) jointly performing the hydrothermal selenylation reaction for a mixed solution of selenium powder, alkali, a reduction agent and organic solvent and the cobalt element-containing precursor in step (1), after the reaction is ended, drying, and obtaining the cobalt diselenide material. By combining the oxidation of hydrazine hydrate and the specific application of a hydrogen evolution catalyst, the preparation of the cobalt diselenide material is re-designed; and specifically by designing the overall process of the preparation method andselecting and optimizing parameter conditions adopted in each step and by optimally controlling the specific composition and microscopic morphology of the cobalt diselenide material, the cobalt diselenide bifunctional catalyst with greatly-improved catalytic activity can be correspondingly obtained.

Owner:HUAZHONG UNIV OF SCI & TECH RES INST SHENZHEN +1

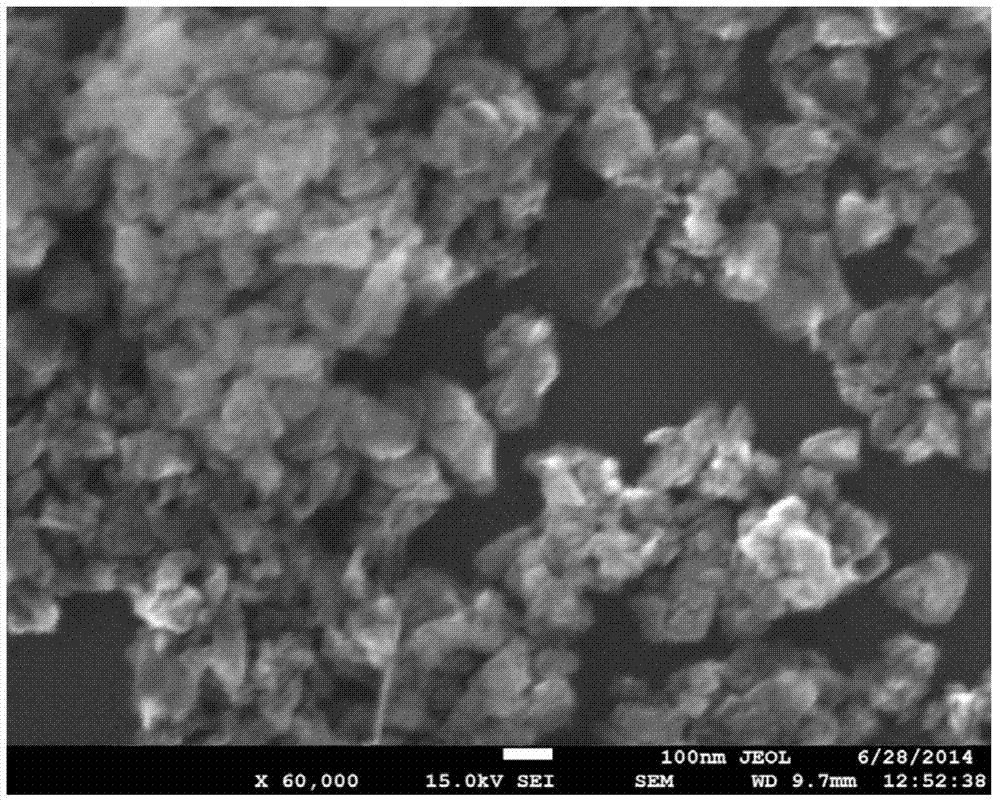

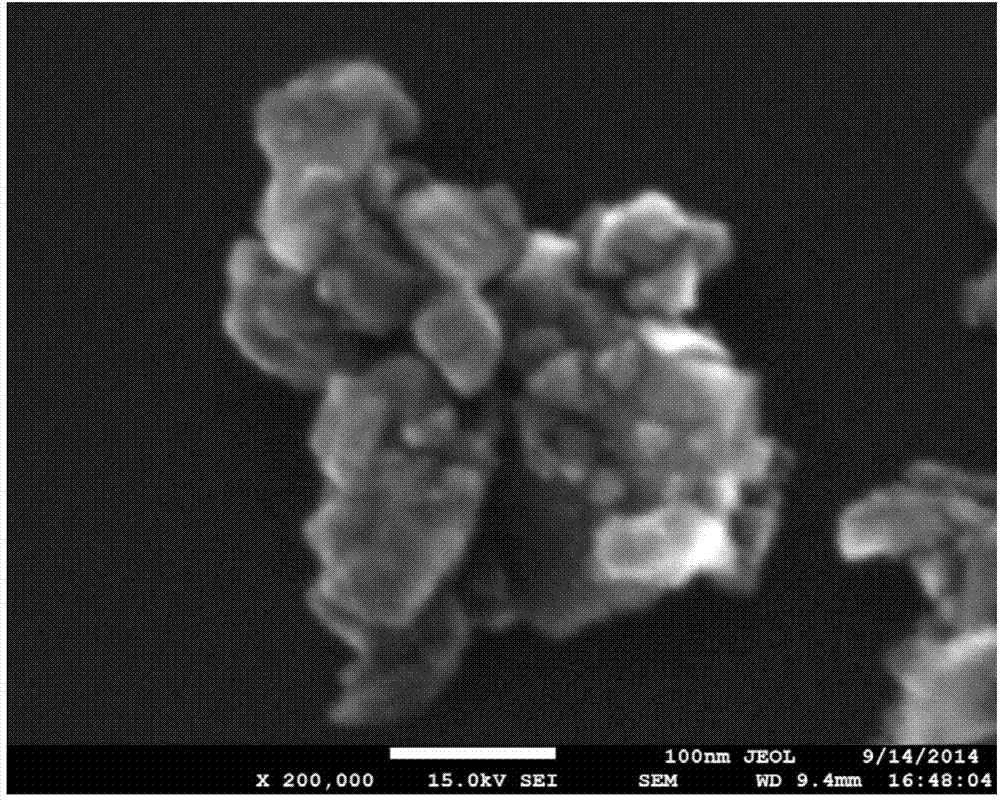

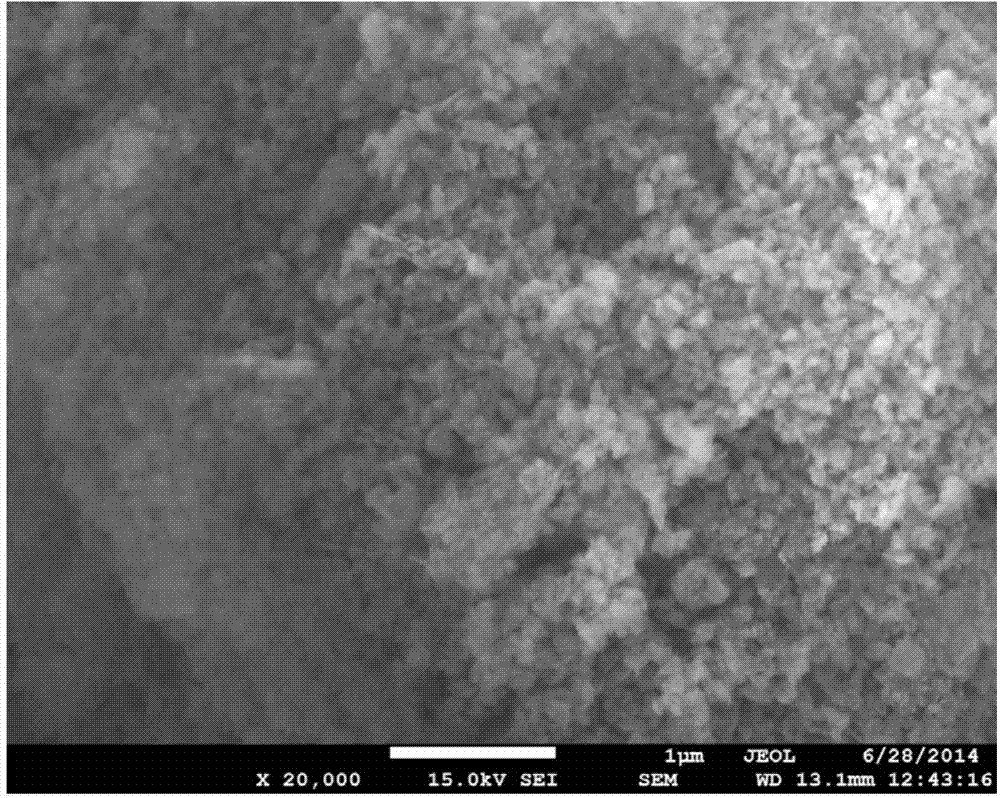

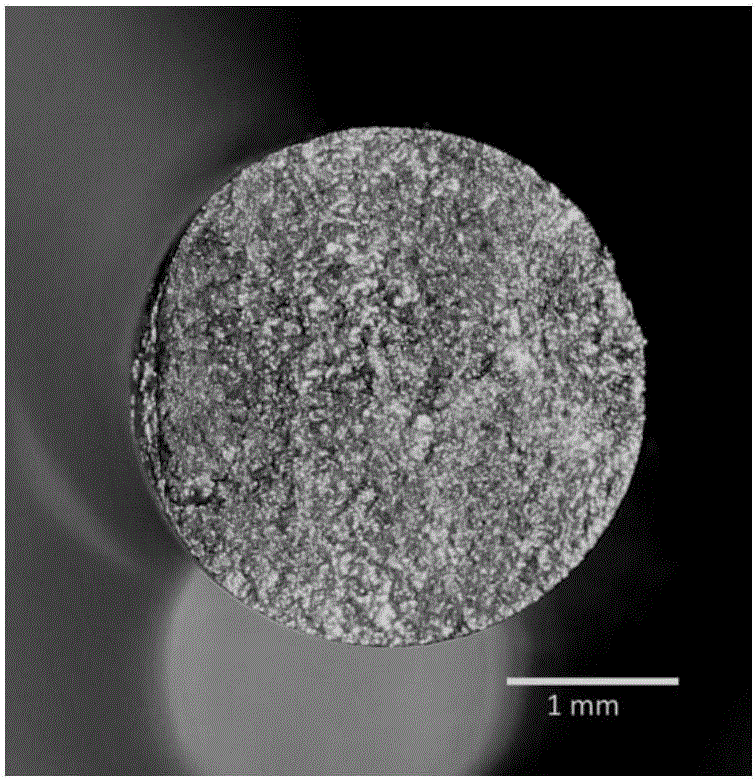

Preparation method of cubic boron nitride micro-powder scanning electron microscopy sample

InactiveCN104777019AReduce reunionAvoid damagePreparing sample for investigationBoron nitrideElectron microscope

The invention discloses a preparation method of a cubic boron nitride micro-powder scanning electron microscopy sample. The method comprises the following steps: 1, taking cubic boron nitride micro-powder, adding the micro-powder into a dispersant, and carrying out ultrasonic dispersion to obtain a suspension; and 2, adding the suspension obtained in step 1 to conducting resin in a dropwise manner or adhering the suspension to the silicon chip of the conducting resin, and drying to obtain the sample. The cubic boron nitride micro-powder in the sample prepared through the preparation method of the cubic boron nitride micro-powder scanning electron microscopy sample has less agglomeration and is uniformly dispersed, and the microscopic morphology of the micro-powder can be easily observed; the process is simple and fast when the sample is used in scanning electron microscopy detection, and a high-amplification clear electron microscope photograph is obtained, so the dimension of the cubic boron nitride micro-powder is convenient to observe and position, and the sample is suitable for sample production detection of ultrafine micro-powder with the particle size of 300nm or less; in the preparation process, the sample is difficult to pollute, and damages of the micro-powder to an electron microscope sample chamber are reduced; and the preparation method has the advantages of simple process, convenient operation, simple and easily available dispersant, and suitableness for popularization and application.

Owner:FUNIK ULTRAHARD MATERIAL

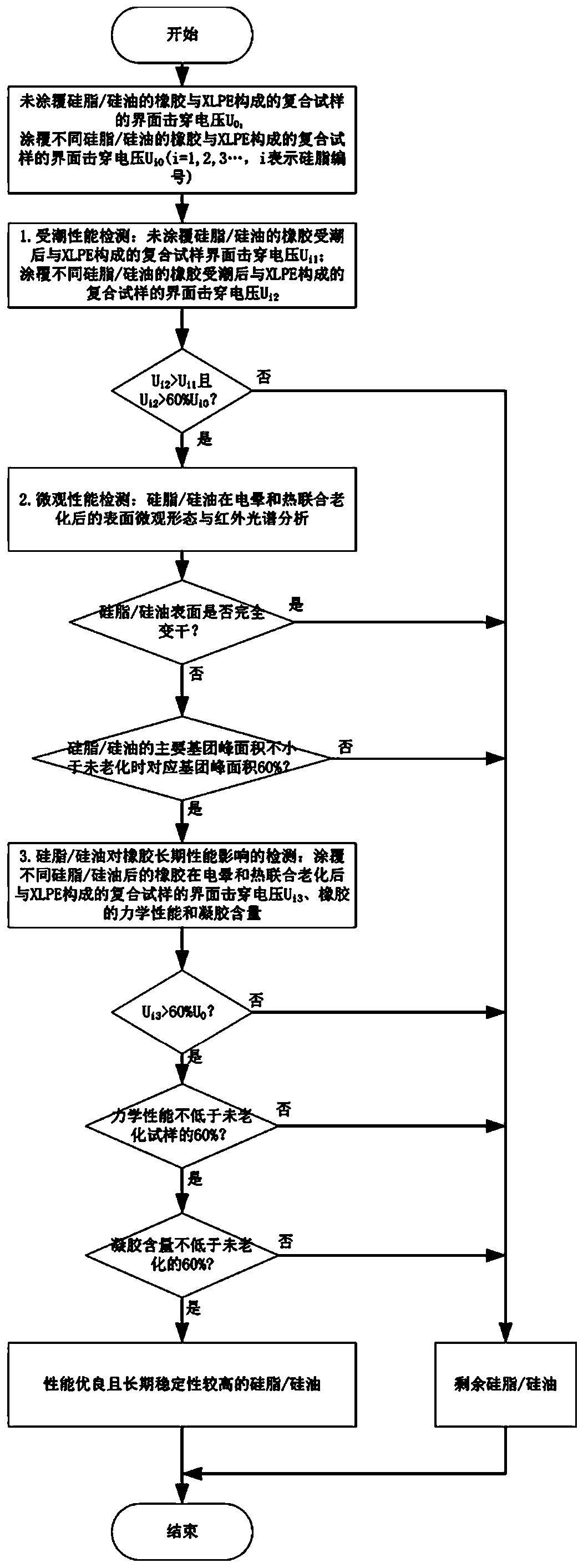

Model selection method and device of coating silicone grease/silicone oil for cable accessory installation

ActiveCN110320451AImprove performanceImprove long-term reliabilityTesting dielectric strengthMaterial strength using tensile/compressive forcesFailure rateRubber material

The invention discloses a model selection method and device of coating silicone grease / silicone oil for cable accessory installation. The model selection method of the coating silicone grease / siliconeoil for cable accessory installation comprises the follows five detection links such as: a breakdown characteristic test of a composite interface composed of a rubber material coated with the silicone grease / silicone oil and the main insulation cross-linked polyethylene (XLPE) of the cable body after wetted and a comparison with the interface breakdown voltage when not wetted, an observation of surface microscopic morphology and molecular group changes after aging of the silicone grease / silicone oil, and the testing of interface electrical strength, mechanical properties and gel content afteraccelerated aging of the rubber material coated with the silicone grease / silicone oil in an environment where long-term operation of cable accessories is simulated. In the implementation process of the invention, the performance of the silicone grease / silicone oil is tested mainly from two aspects of the properties of the silicone grease / silicone oil itself and the swelling effect of the siliconegrease / silicone oil on the rubber material under the combined action of corona and heat, which can select the excellent silicone grease / silicone oil that can be used for the cable accessory installation, thereby reducing the failure rate of the accessory composite insulation interface.

Owner:XI AN JIAOTONG UNIV

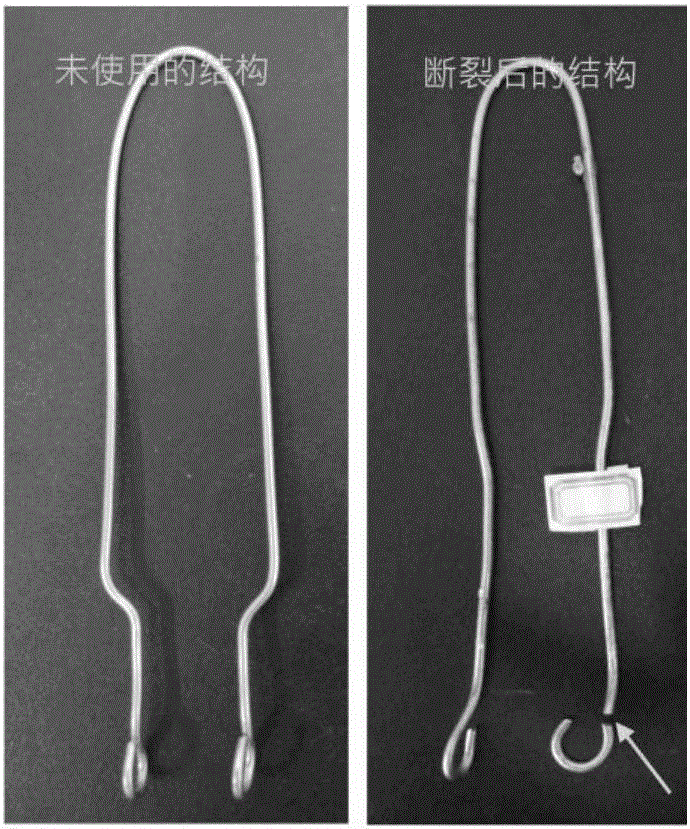

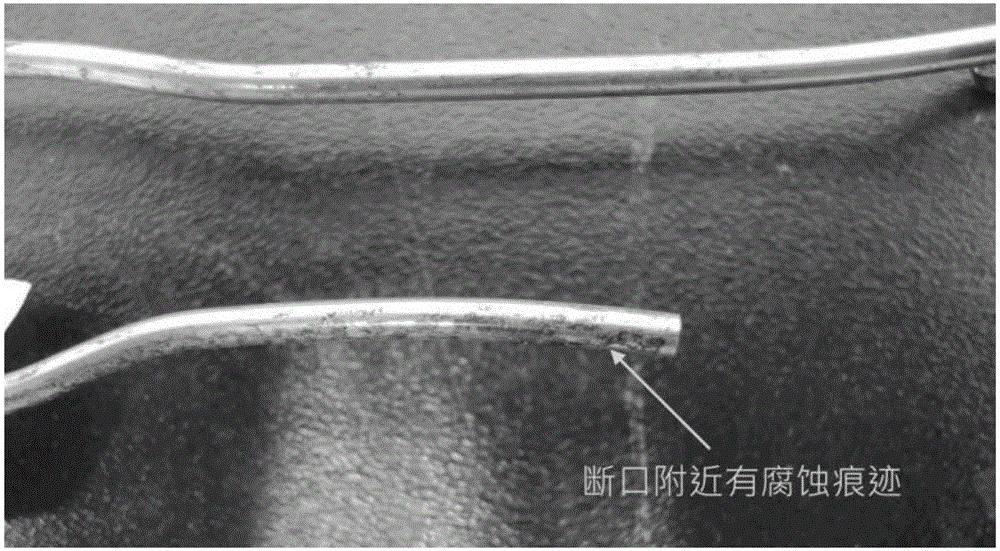

Failure analysis method for suspended structural member of subway power supply network and application thereof

InactiveCN105866120AExact relative distributionAccurate analysisMaterial analysis by optical meansMaterial analysis by measuring secondary emissionX-rayEngineering

The invention discloses a failure analysis method for a suspended structural member of a subway power supply network and application thereof. The method comprises the following steps: taking a sample (including a fracture surface) from a fracture of a suspended structural member which has a fracture failure, cleaning the sample and carrying out macroscopic inspection on the fracture and surrounding places thereof by using a stereoscopic microscope; observing the microscopic morphology of the fracture by using a scanning electron microscope; then carrying out qualitative elementary analysis on the surface of the fracture by using an electron probe X-ray microanalyzer; and subjecting the sample to analysis of relative distribution of elements via the electron probe X-ray microanalyzer and analyzing causes of the failure of the suspended structural member according to detection results. The method combines equipment like the stereoscopic microscope, the scanning electron microscope and the electron probe X-ray microanalyzer for identification of causes of the failure of a suspended structure, and the equipment complement each other; so the whole analysis process is well-grounded, accurate, visual, convenient and practicable, and analysis and positioning of impurity elements are also accurate.

Owner:SHANDONG ANALYSIS & TEST CENT

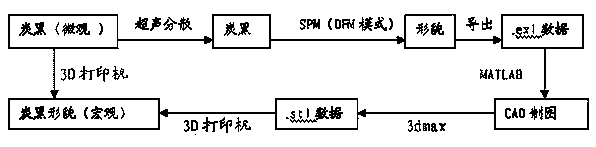

Method for obtaining carbon black microscopic morphology enlarging entity through 3D printing

ActiveCN104385586AAccurately zoom in on solid structuresConvenient researchMacroscopic scaleComputer printing

The present invention discloses a method for obtaining the carbon black microscopic morphology enlarging entity through 3D printing. According to the method, based on the inorganic material microscopic carbon black primary particles or aggregates, the carbon black microscopic morphology is printed out through a 3D printer so as to establish the association between the carbon black microscopic morphology and the carbon black macroscopic morphology, ie., the macroscopy and the substantiation of the microscopy are achieved through the 3D printing technology; and the carbon black microscopic morphology picture is made out relying on the accurate data points, wherein the real data is adopted as the support, such that the obtained entity has the accurate structure. According to the present invention, the carbon black microscopic morphology is subjected to macroscopy so as to substantially promote scientific research workers to research on the carbon black structure, the particle size and the morphology, and further provide the first-hand data for the research on the carbon black aggregate reinforced rubber, and the development of the technology provides the guidance significance for the actual production.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

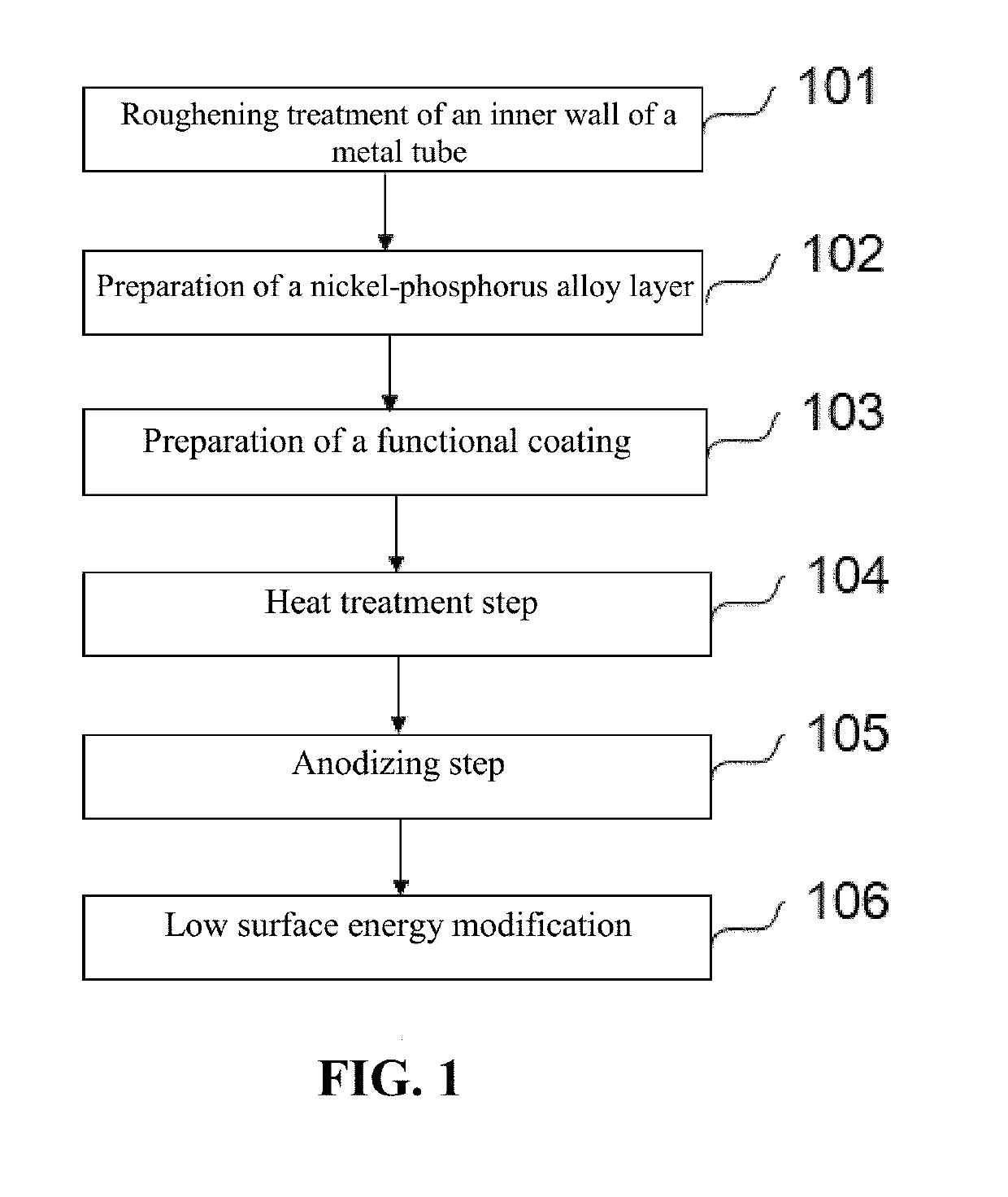

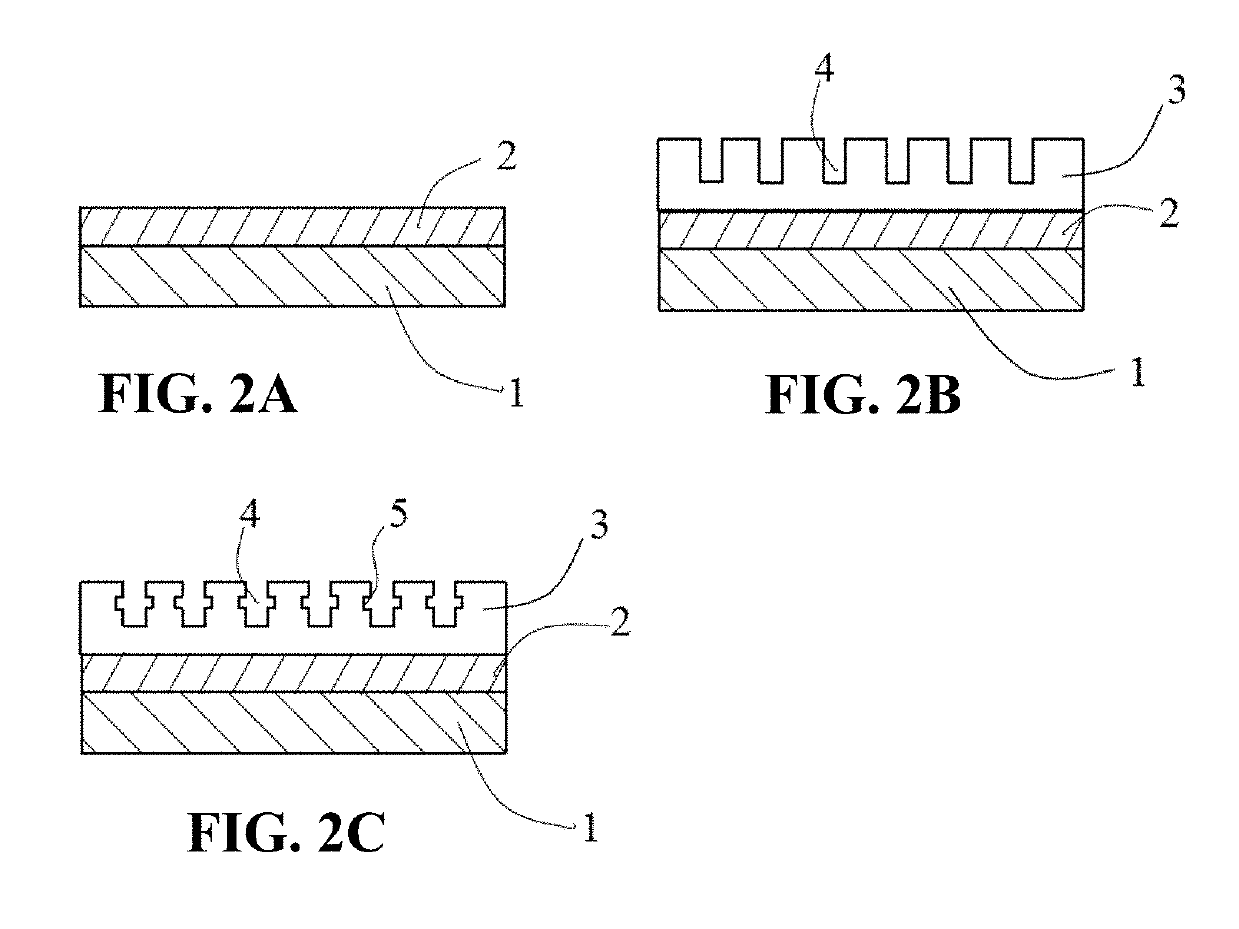

Method and device for preparing high strength and durable super-hydrophobic film layer on inner wall of elongated metal tube

ActiveUS20190153604A1High strengthReduce impactAnodisationElectrolysis componentsAlloyNanocrystalline thin films

Method for preparing high-strength and durable super-hydrophobic film layer on inner wall of elongated metal tube includes roughening treatment of inner wall of a metal tube, electrodepositing preparation of nickel-phosphorus alloy layer and functional coating, heat treatment, subsequent anodizing and low surface energy modification. The method greatly reduces the influence of local mass transfer resistance, and a uniform nanocrystalline film layer is electroplated under the ultrasound induction. Since only electroplating solution is filled in the tube during the preparation process, the consumption of device and raw materials is greatly reduced. Also, since silica particles are added to the electroplating solution in preparing the nanocrystalline film layer, the surface morphology can be made more uniform and denser in terms of the microscopic morphology. Nano-scale channels structures are etched, so that the super-hydrophobic inner surface can have a better ability to store air, and its water flow impact resistance is greatly enhanced.

Owner:NORTHEAST GASOLINEEUM UNIV

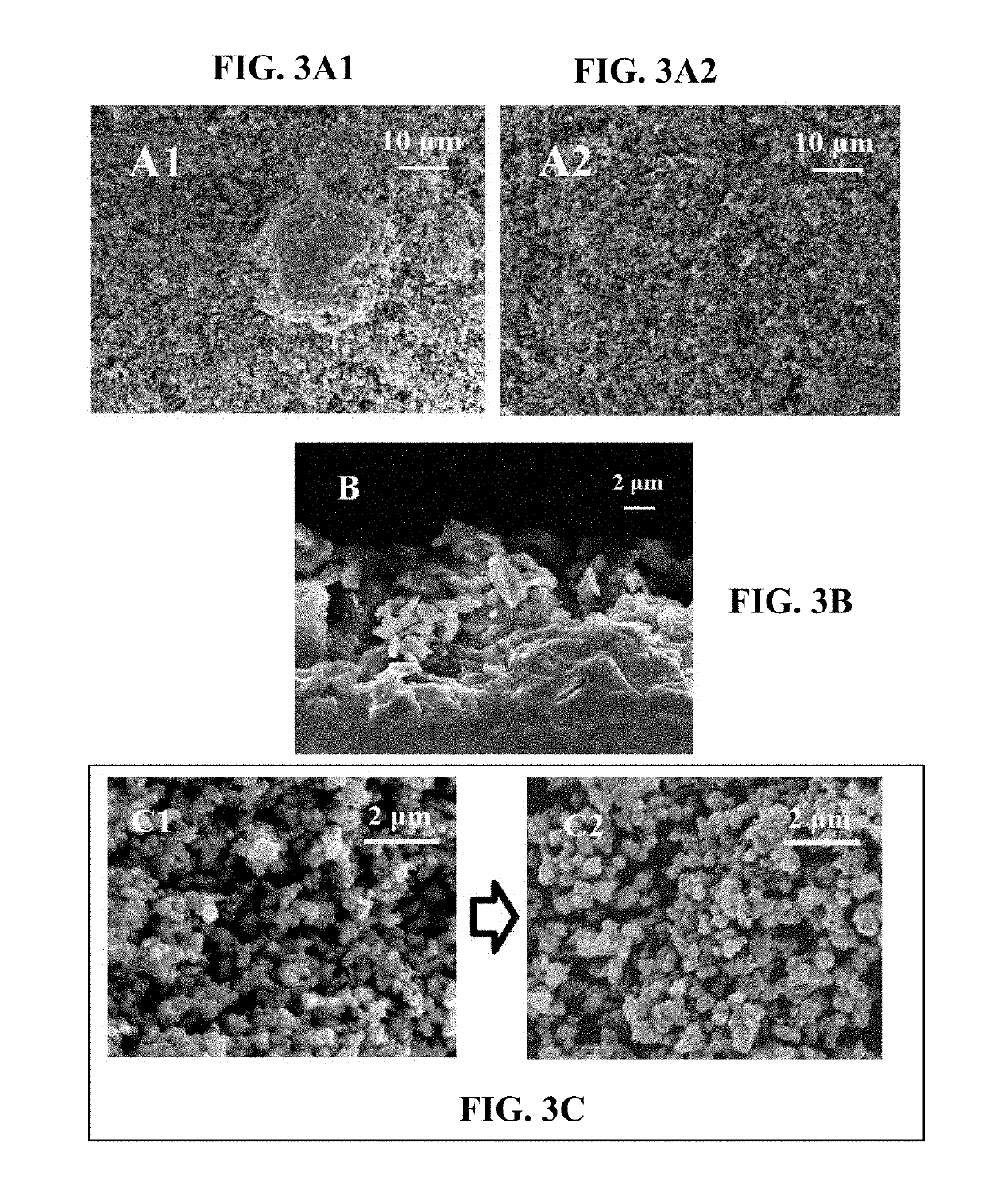

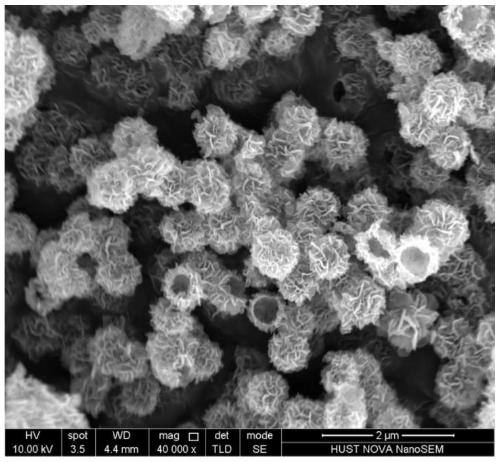

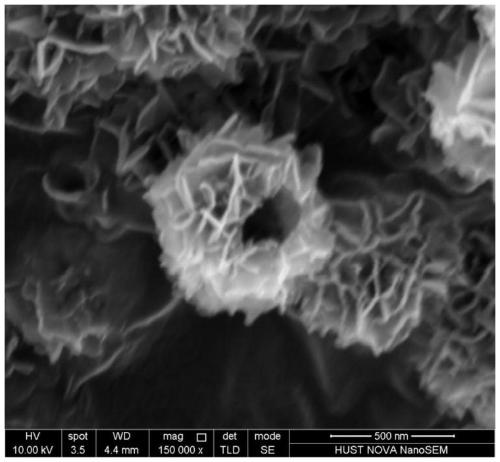

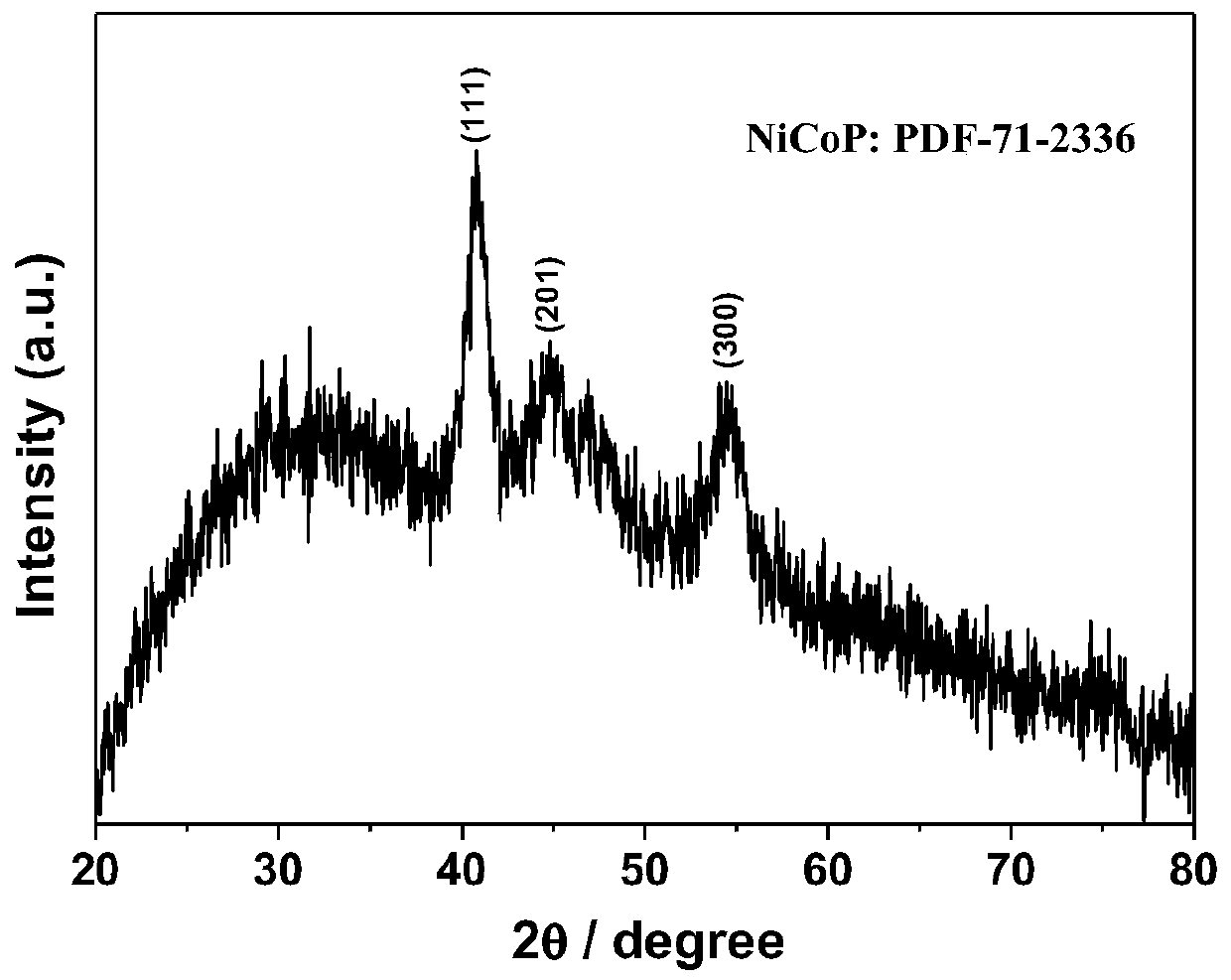

Phosphide with hierarchical structure, and preparation method and applications thereof

InactiveCN109956458AHigh specific surface areaImprove electrocatalytic activityPhysical/chemical process catalystsPhosphidesElectrolysisPolyol

The invention belongs to the field of electrochemistry energy material, and more specifically relates to a phosphide with a hierarchical structure, and a preparation method and applications thereof, and especially relates to a phosphide which possesses a hierarchical structure, and is high in water electrolysis catalytic activity and stability, and a preparation method and applications thereof. According to the preparation method, a transition metal salt and a polyol are taken as raw materials, solvothermal method, hydrothermal method, and gas-solid phosphatization method are adopted to prepare the phosphide with a hierarchical structure. The microscopic morphology of the phosphide with a hierarchical structure is hollow nanospheres, and the external part is a nanometer sheet assembled shell layer. The hierarchical structure is capable of promoting exposure of phosphide active sites, and increasing phosphide electrocatalytic activity; and problems in the prior art that experiment process is complex, and cost is high in a conventional template method are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Fracture sample preparation method based on crack resistance of basalt fiber and asphalt mixture

InactiveCN108593691AVarious shapesNo pollution in the processMaterial analysis using wave/particle radiationSmall sampleCrack resistance

The invention discloses a fracture sample preparation method based on the crack resistance of a basalt fiber and asphalt mixture. The fracture sample preparation method based on the crack resistance of the basalt fiber and asphalt mixture comprises the following steps: molding a basalt fiber and asphalt mixture test piece by adopting a Marshall standard compaction technology, performing asphalt mixture split test under different temperature conditions, selecting a Marshall test piece section and a typical small sample after the test is completed, and observing the indirect tensile section andthe microscopic morphology by a digital camera, a scanning electron microscope and other optical instruments in order to observe the fracture morphology characteristics of the basalt and asphalt mixture macroscopically and microscopically. A fracture obtained by the sample preparation method has various morphologies, is clean and pollution-free, and has no interference from external human factors,and the relationship between the crack resistance of the asphalt mixture and the morphology of the fracture can be analyzed in order to further analyze the improvement mechanism fo the crack resistance of the basalt fiber reinforced asphalt mixture.

Owner:YANGZHOU UNIV

Method for improving performance of micro-arc oxidation film of titanium alloy by adding nanometer alpha-Al2O3

InactiveCN105506707AGood microscopic appearanceImprove organizationSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides a method for improving the performance of a micro-arc oxidation film of a titanium alloy by adding nanometer alpha-Al2O3. A test material is an Al-Cu alloy; during testing, a self-made micro-arc oxidation apparatus is used for micro-arc oxidation of the titanium alloy in a silicate system, a constant-voltage mode is used for treatment, micro-arc oxidation voltage is 600 V, micro-arc oxidation frequency is 400 Hz, a duty ratio is 30%, and micro-arc oxidation time is 1 h; and the concentration of the added nanometer alpha-Al2O3 is 3 g / L. According to the invention, when the concentration of the added nanometer alpha-Al2O3 is 3 g / L, the microscopic morphology of the film is substantially improved and the comprehensive performance of the film is improved.

Owner:王晓芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com