Holographic inversion detection method for micro-cracks on damaged layer of subsurface of brittle material

A technology for sub-surface damaged and brittle materials, applied in the field of material surface quality inspection, can solve the problems of staying, lack of quantitative characterization method of surface topography, unable to reflect the distribution characteristics of microcracks, etc., and achieve the effect of improving reconstruction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

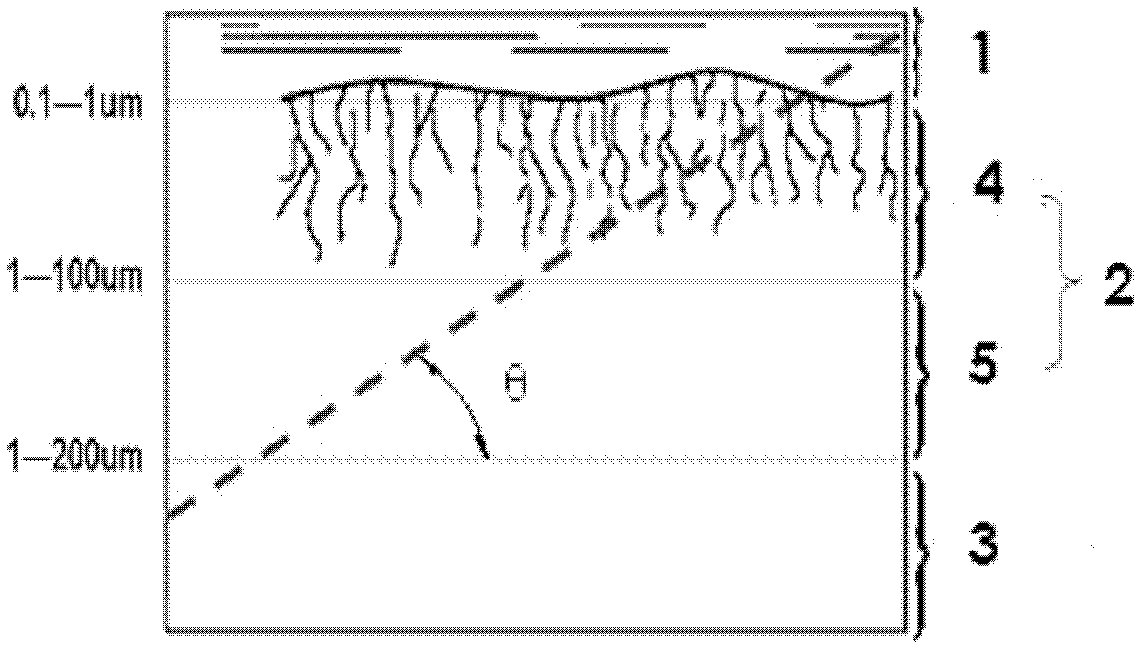

[0029] refer to figure 1 , the subsurface damaged layer 2 of the optical material includes a subsurface cracked layer 4 and an internal stress deformation layer 5 , and is covered by a polished layer 1 on the undamaged substrate 3 . Because it is below the surface, it is not easy to observe directly.

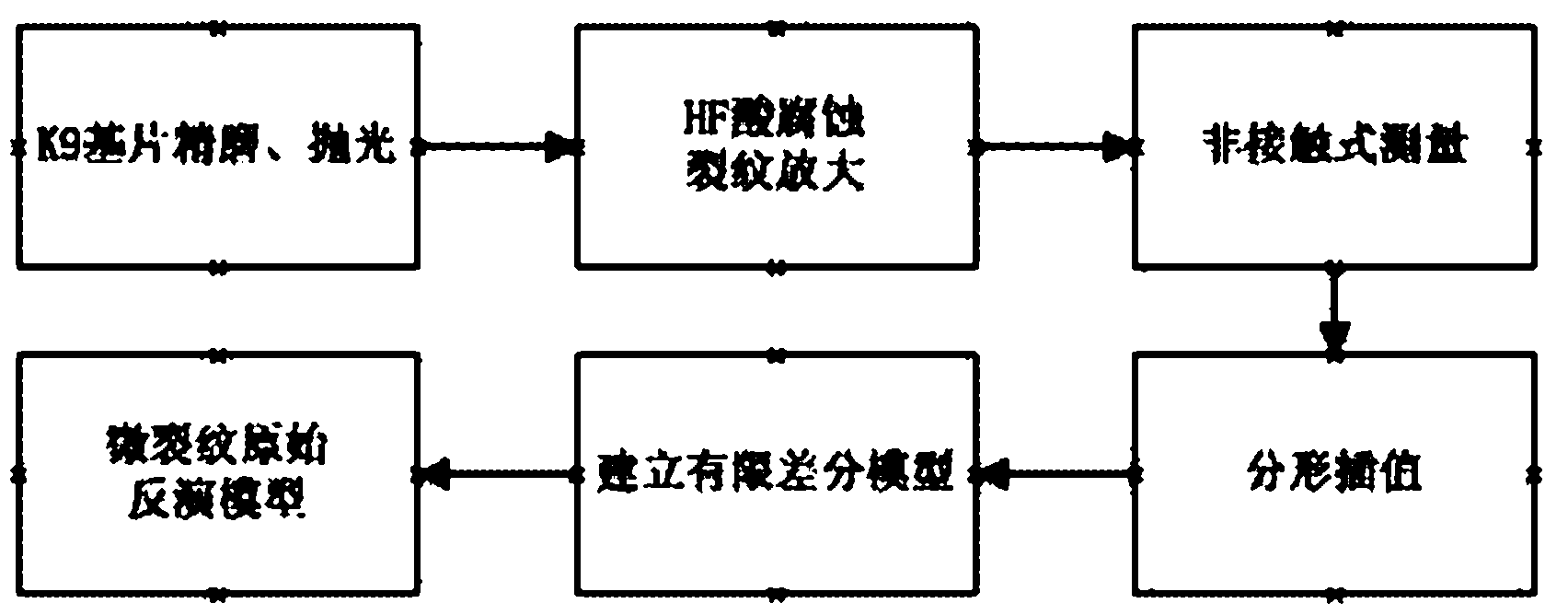

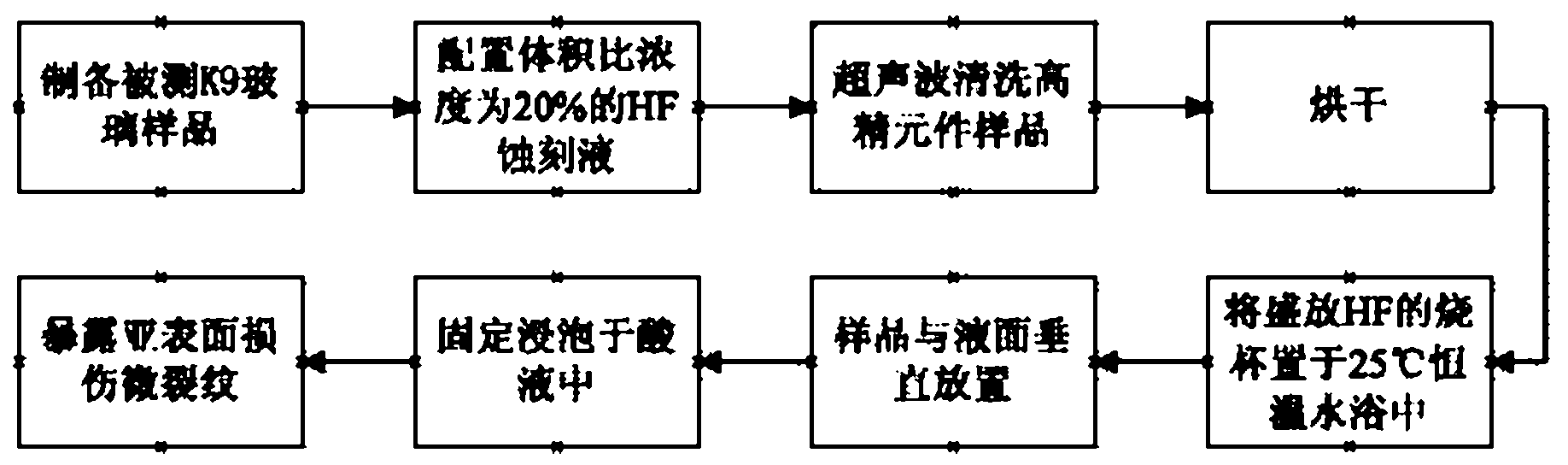

[0030] refer to figure 2 , the overall flow chart of the technical solution of the present invention includes on the basis of substrate pretreatment, the corrosion method is used to enlarge the crack and non-contact measurement is carried out to obtain three-dimensional basic data points, and the surface The data is reconstructed, and finally, the holographic inversion research method of micro-cracks in the sub-surface damaged layer is used to construct a detection and characterization system suitable for the holographic distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com