Method for preparing catalyst with lamella distribution

A catalyst and shell technology, applied in the field of non-uniformly distributed catalyst preparation, can solve the problems of influence, reduced carbon chain growth probability, reduced selectivity, etc., and achieves the effects of simple operation, uniform distribution, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

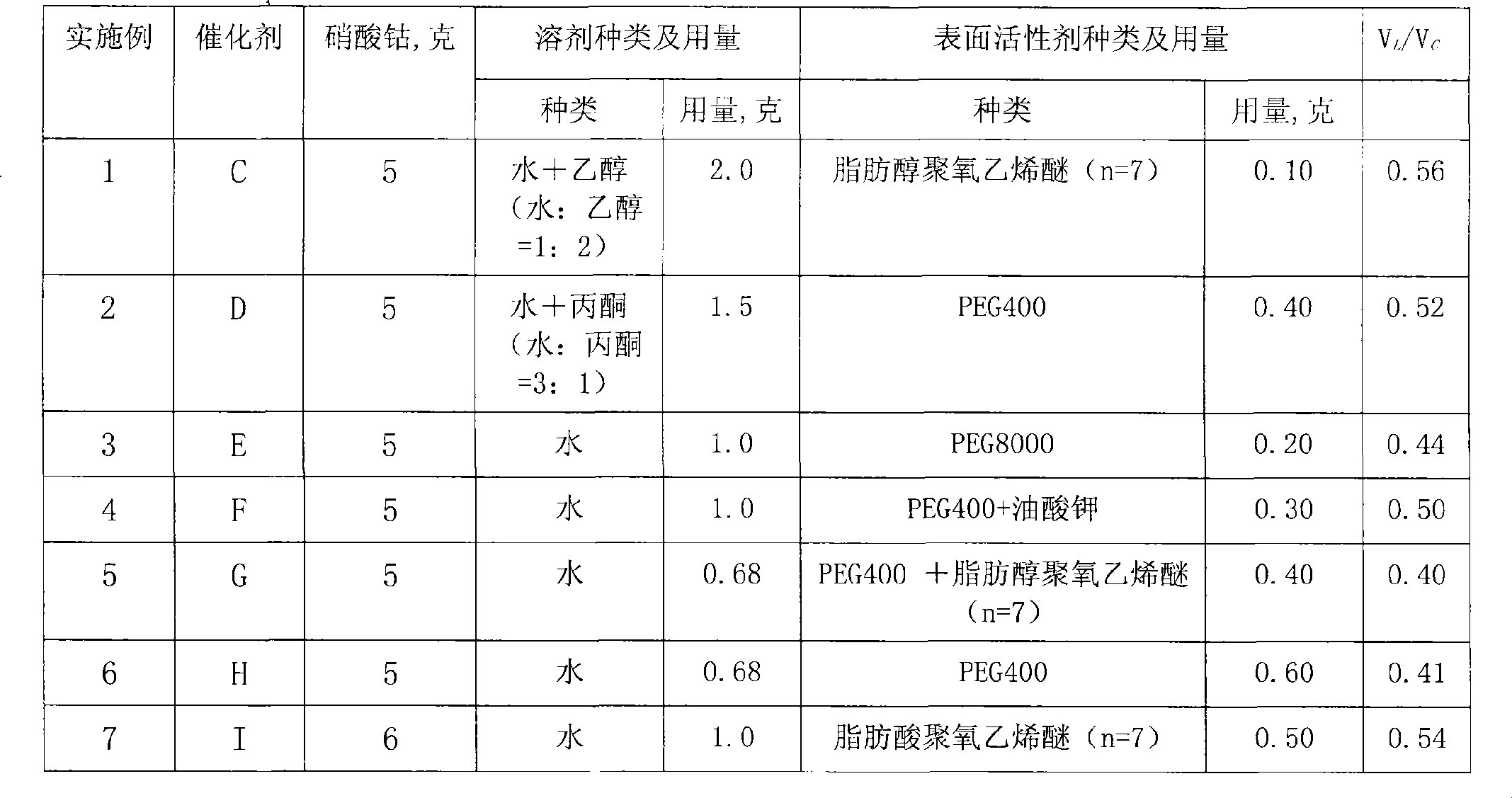

[0014] Taking the preparation of the cobalt-based Fischer-Tropsch synthesis catalyst with uniform shell distribution as an example, the preferred preparation method of the present invention comprises:

[0015] (1) Prepare a mixed solvent consisting of one or more selected from water, alcohol, ether, aldehyde, ketone and at least one surfactant, and mix an effective amount of cobalt-containing compound with the solvent to form a solution;

[0016] (2) impregnate the carrier with the solution described in step (1), and the impregnation satisfies: V L / V C =0.01~0.99, among them, V L is the volume of immersion solution, V C is the pore volume of the carrier;

[0017] (3) The impregnated product in step (2) is dried, calcined or not calcined to obtain a catalyst.

[0018] The cobalt-containing compound is any compound soluble in the solvent except cobalt sulfide, for example, one or more selected from cobalt nitrate, cobalt acetate, cobalt carbonyl and the like.

[0019] The ...

Embodiment 8-9

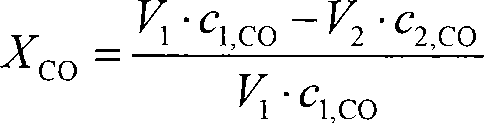

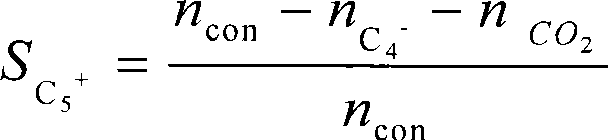

[0037] This example illustrates the performance of the catalyst provided by the method of the invention

[0038] Catalysts G and H were evaluated in a fixed-bed Fischer-Tropsch synthesis reactor, with a catalyst dosage of 5 grams and a catalyst particle size of 2-4 mm.

[0039] The catalyst is reduced before use. The reduction was carried out under normal pressure, and other conditions were as follows: the hydrogen flow rate was 1000 Nl / g-cat / h, the temperature was raised to 400° C. at a heating rate of 4° C. / min, and kept for 5 hours.

[0040] The Fischer-Tropsch synthesis reaction temperature is 210 °C, H 2 The / CO ratio is 2, the pressure is 2.5MPa, and the gas hourly space velocity (GHSV) is 2000h -1 . The results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com