Patents

Literature

101 results about "Internal diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

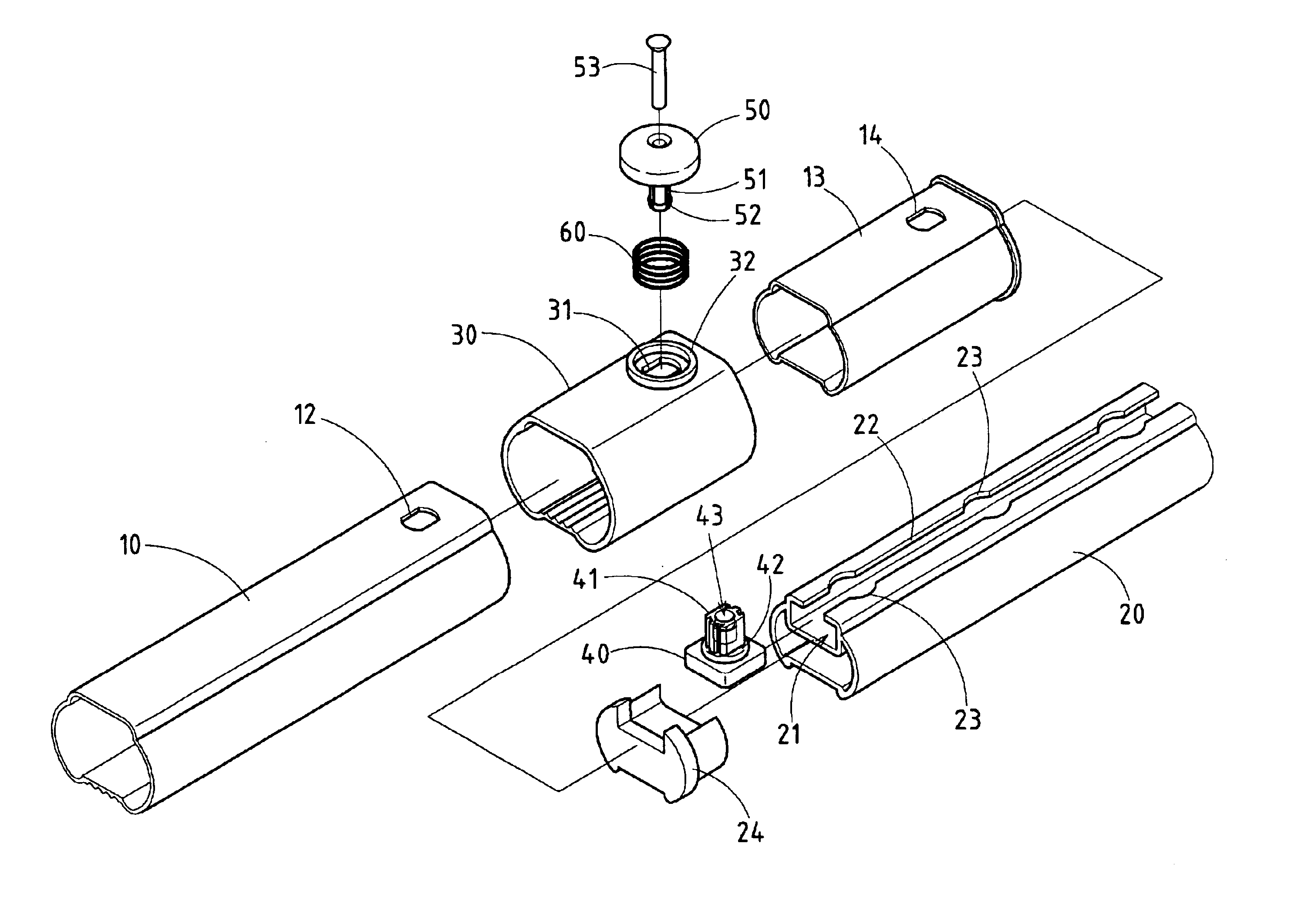

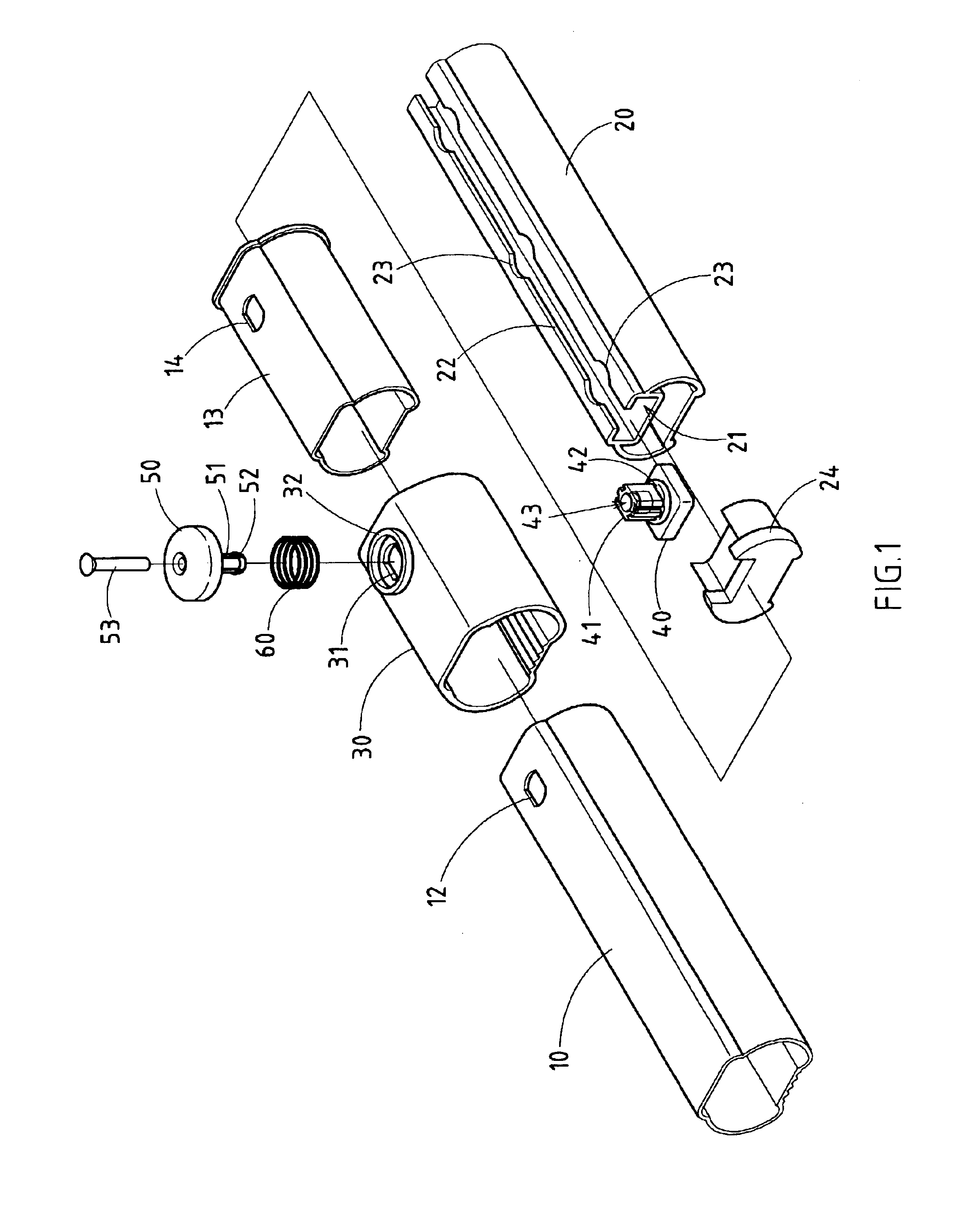

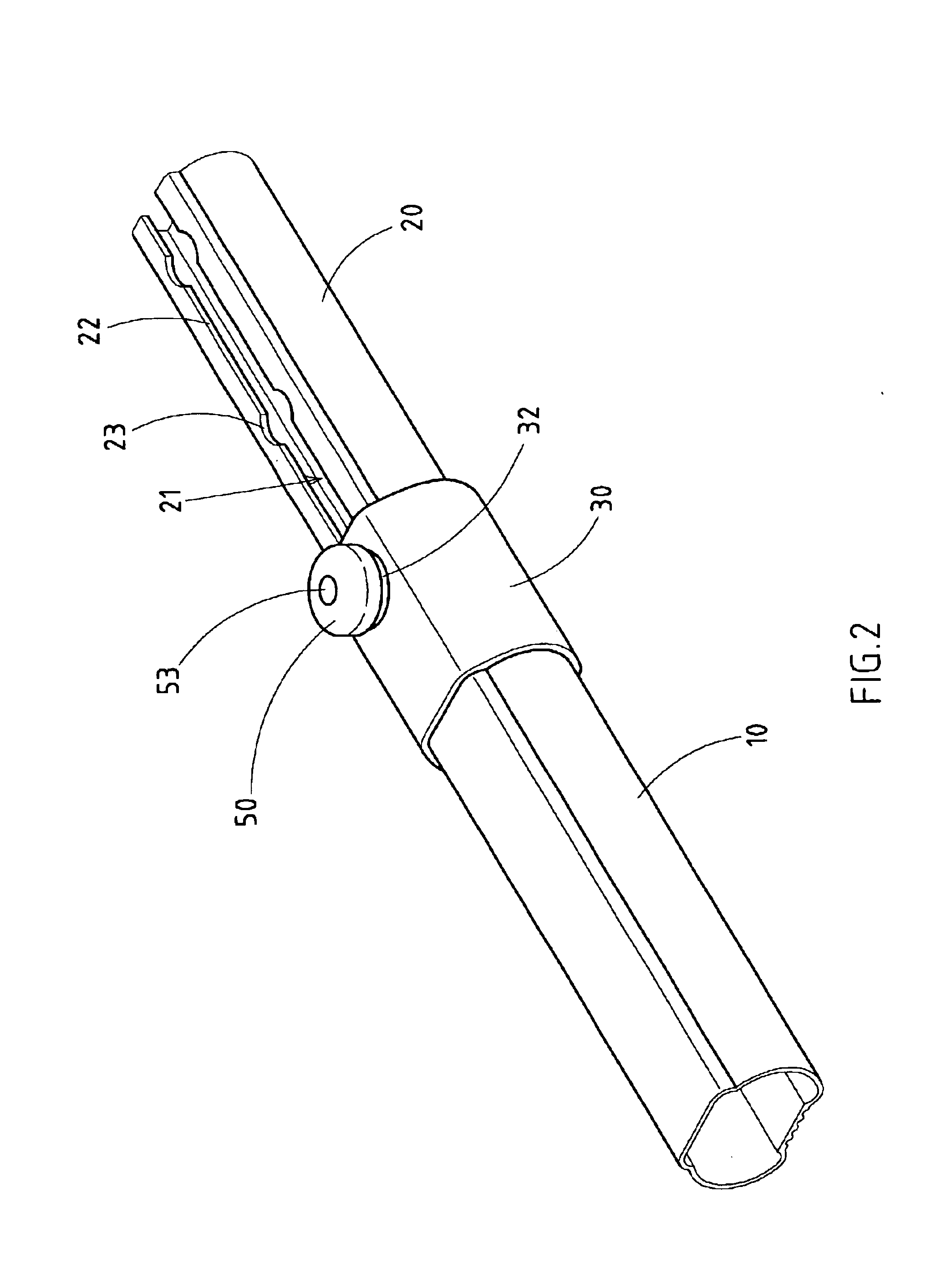

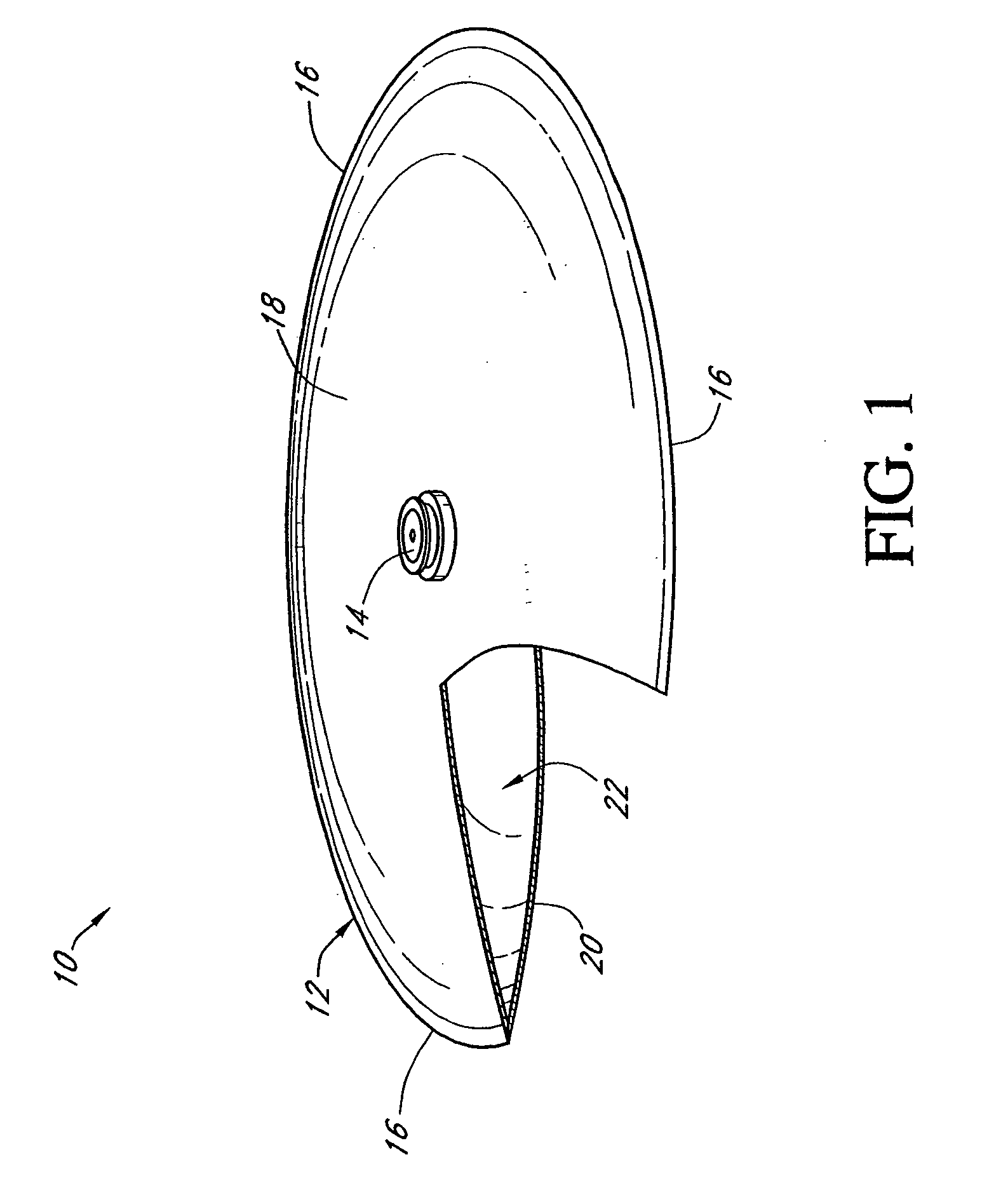

Hedge shear extendable handle enhanced structure

This innovation provides a hedge shear extendable handle enhanced structure focusing on resolving the operating inconvenience and physical deficiencies such as bending and deformation resulting from the operations of legendary hedge shear. The main structure of the enhancement is a pivot joint formation of an inner and outer tube. The main feature is the H-shape profile structure of the inner tube with a slide way built with an internal diffusion slot and a perforation slot. The perforation slot has a few interleaved positioning fillisters along the slide way. The positioning fillisters in the inner tube will park the sliding block when it shifted upward and matching with the locating block on the top pillar while moving upward. A press button assembles on top of the pillar and remains in an upward position with the sliding block under normal condition with the help of a spring. The main functionality is retaining the convenience of the press button operation while maintaining ruggedness and endurance of the product using such technique.

Owner:HUANG YAO CHUNG

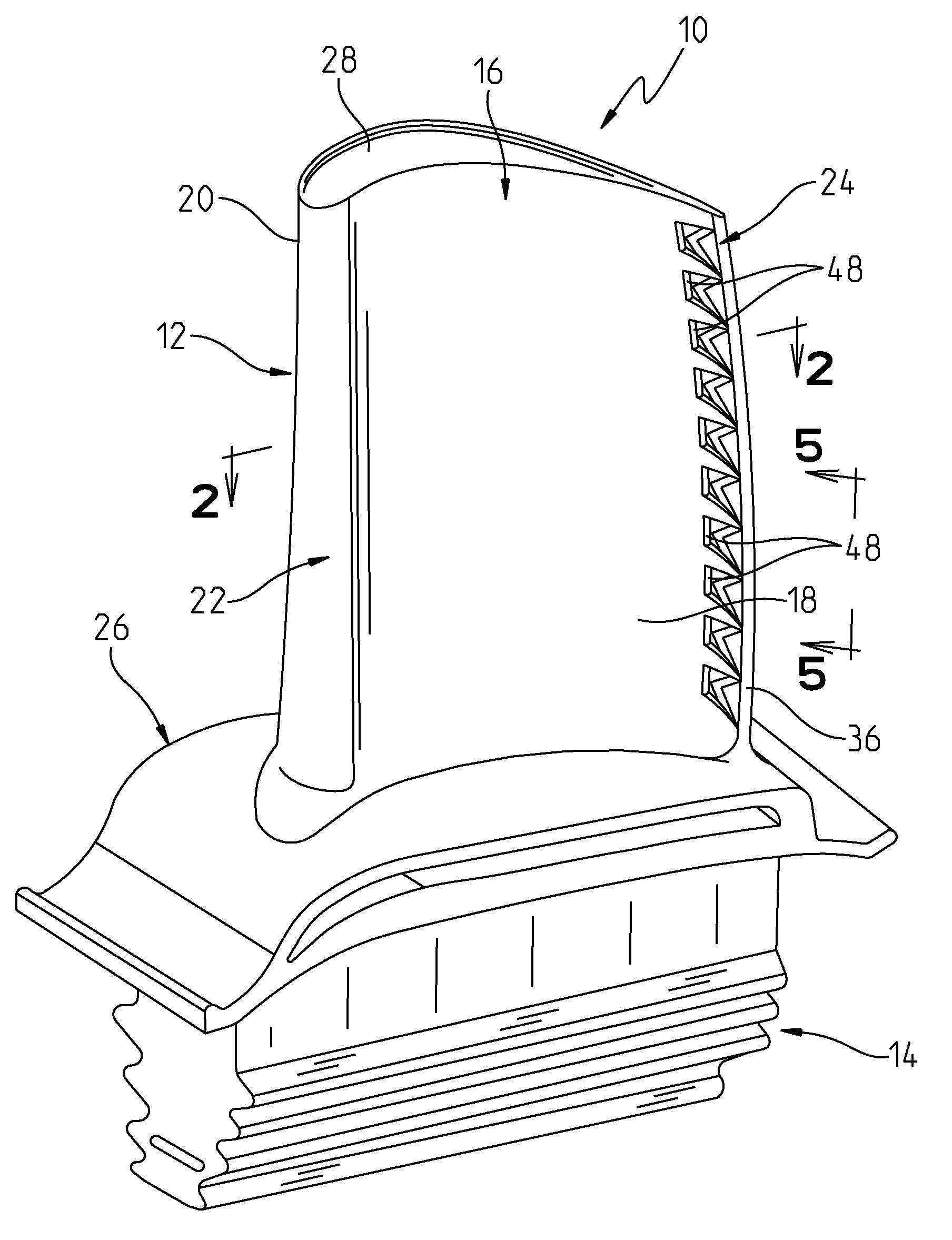

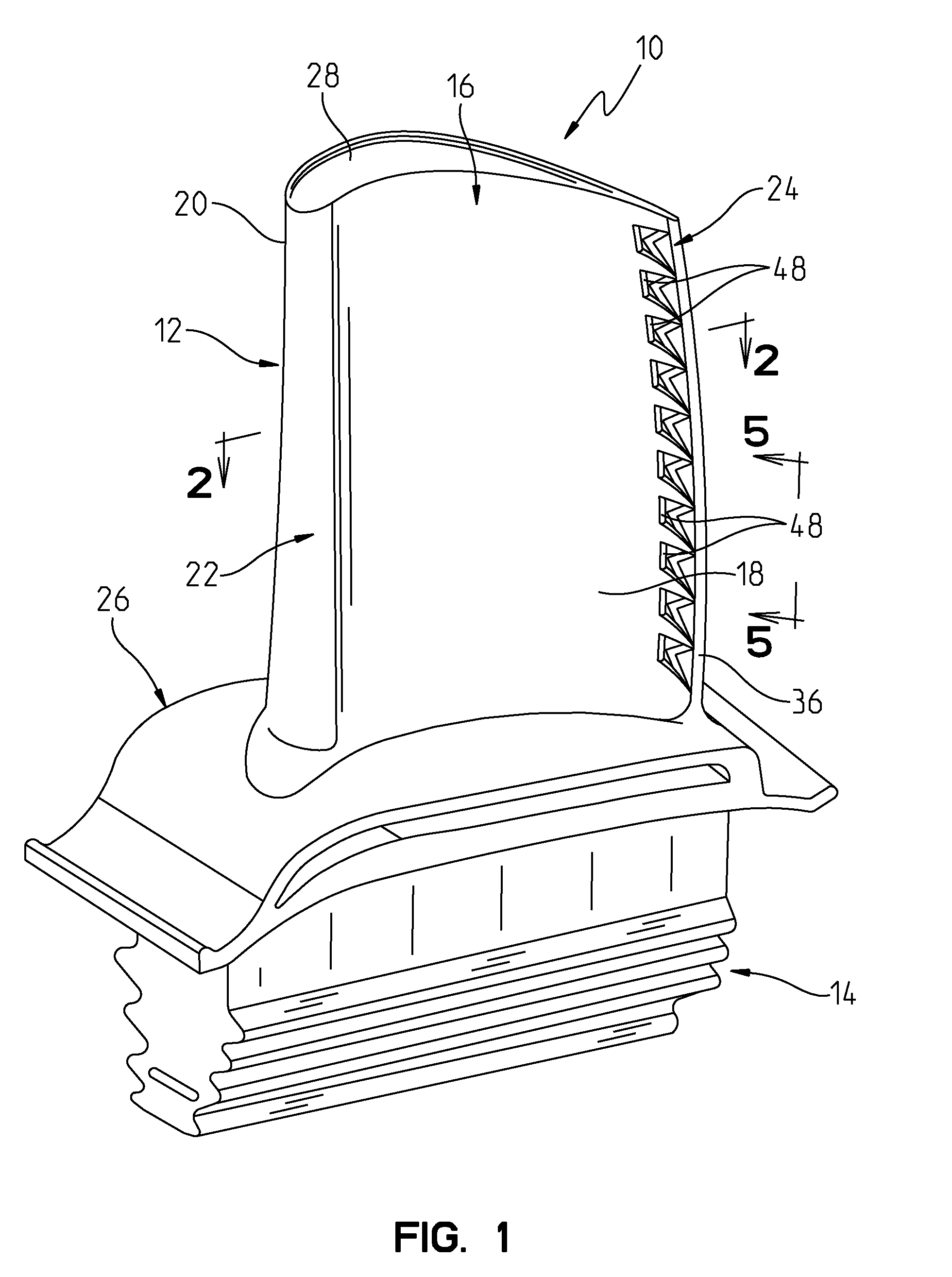

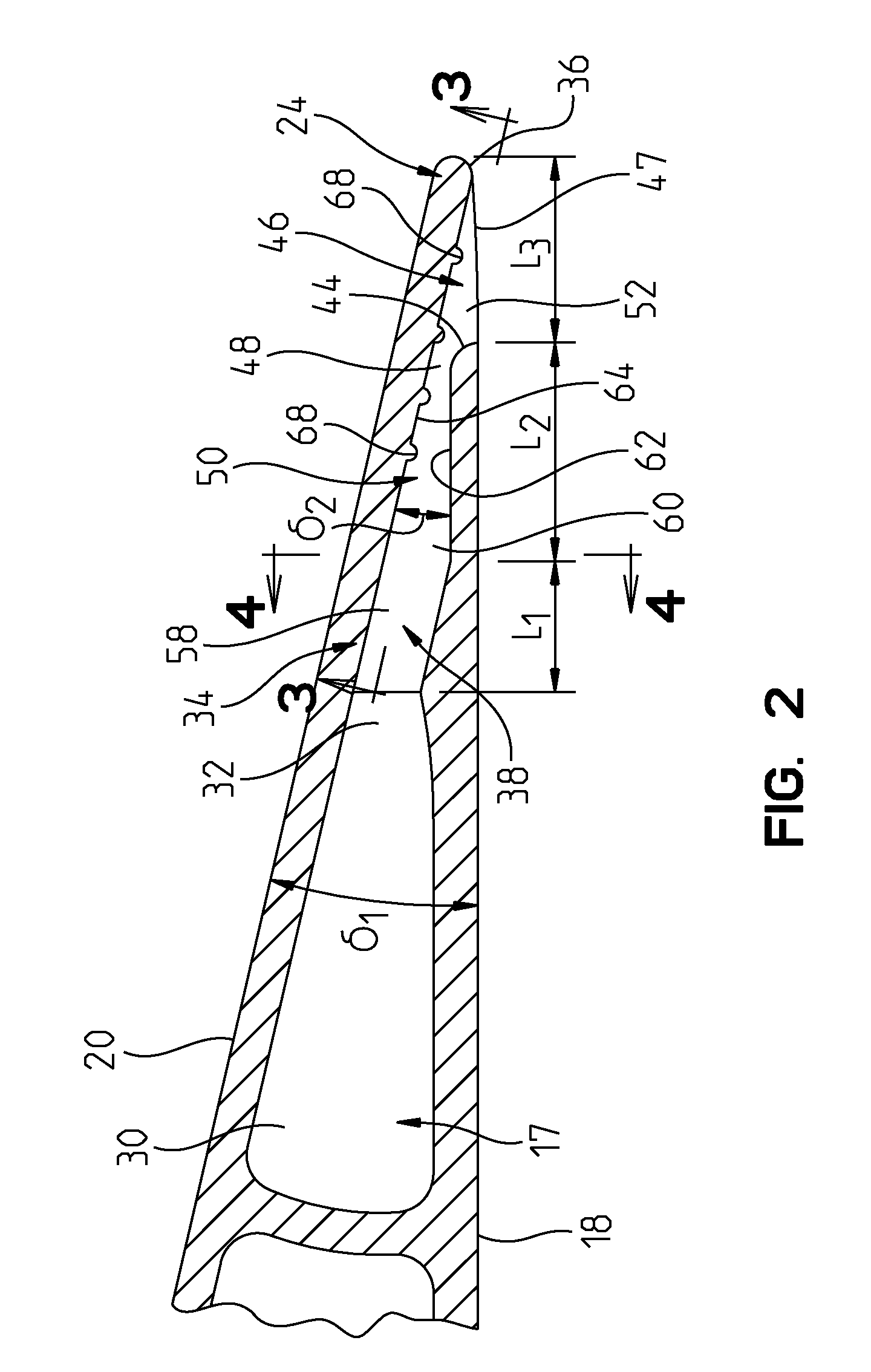

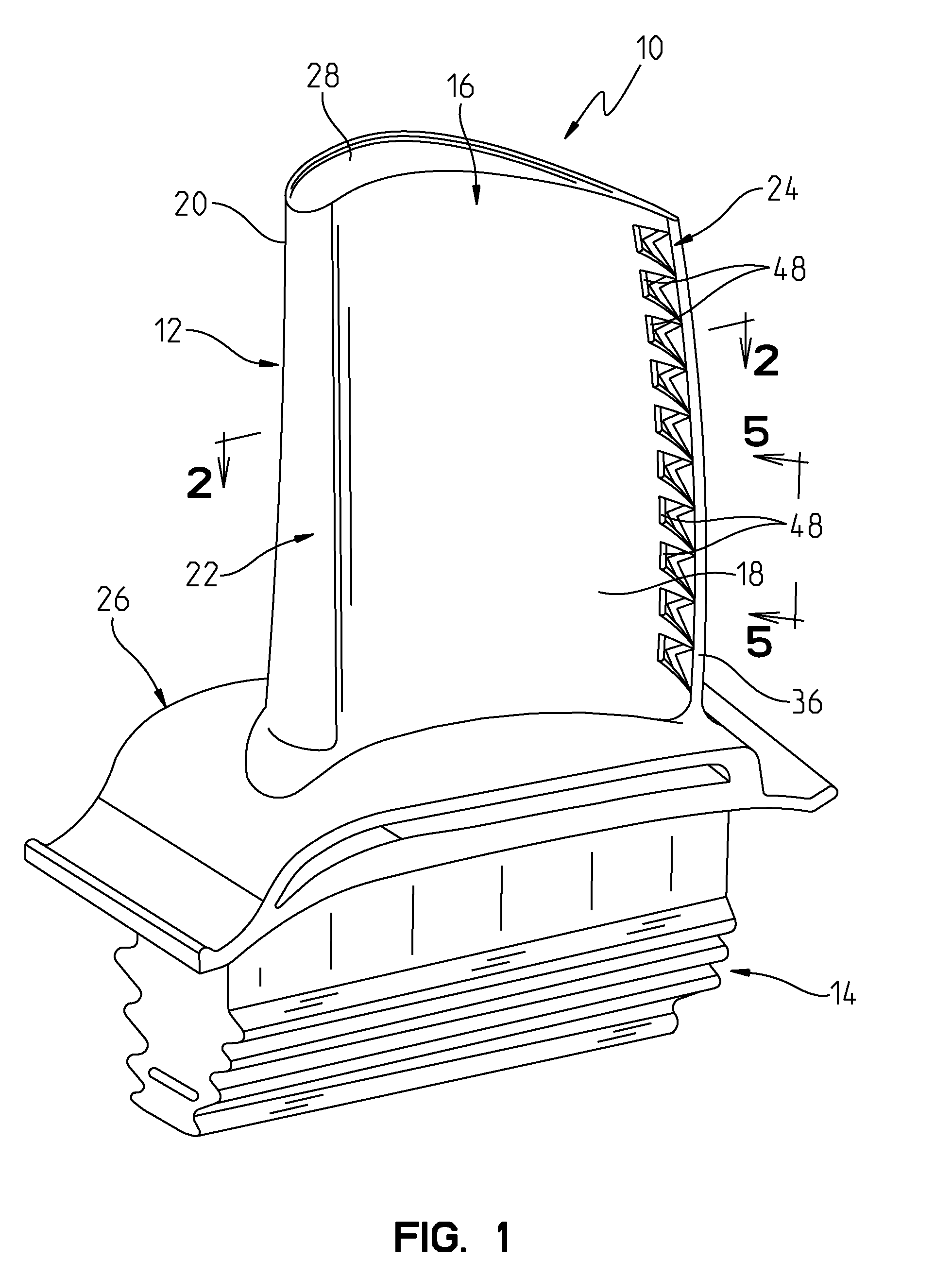

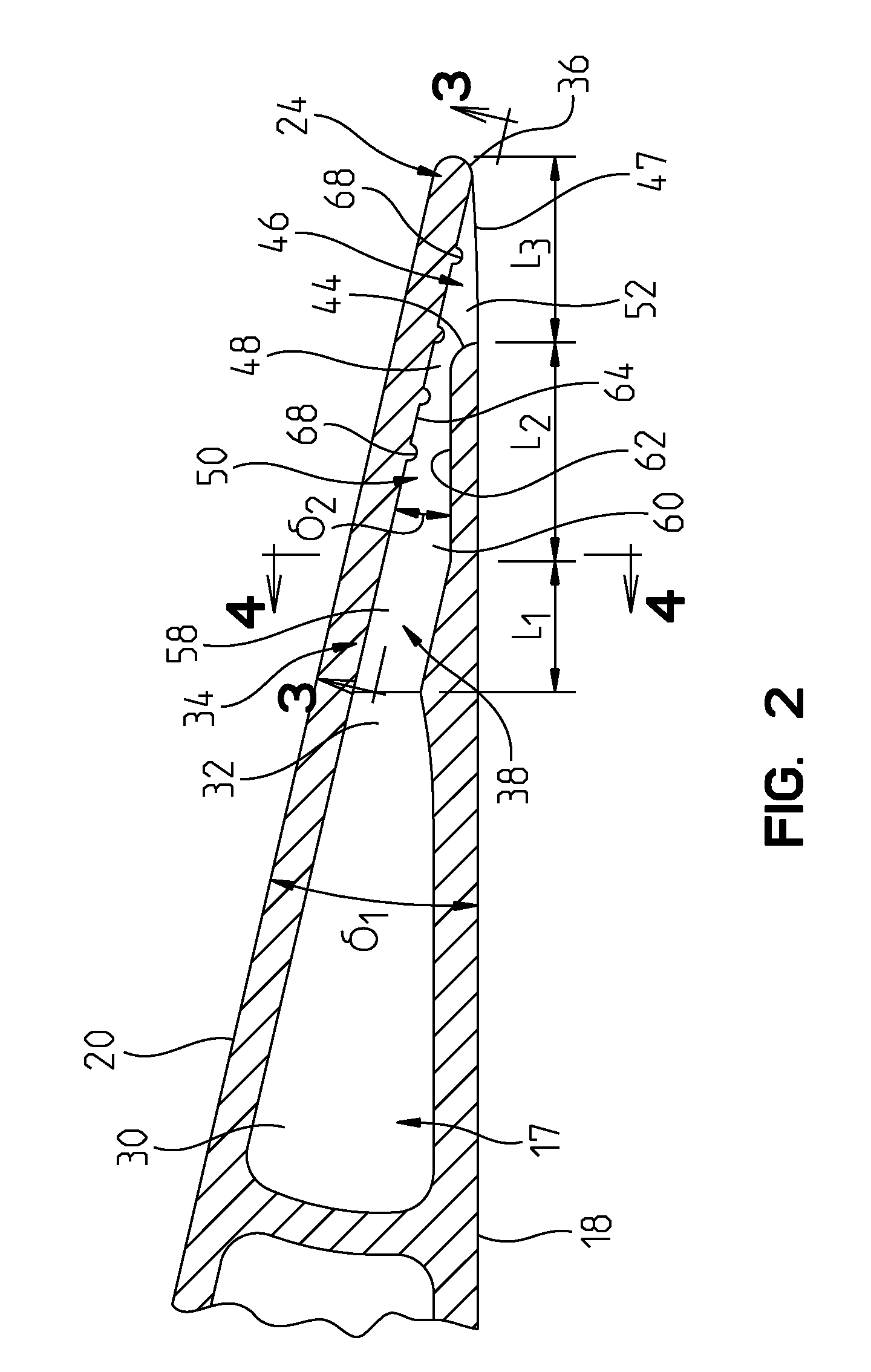

Trailing Edge Cooling Slot Configuration for a Turbine Airfoil

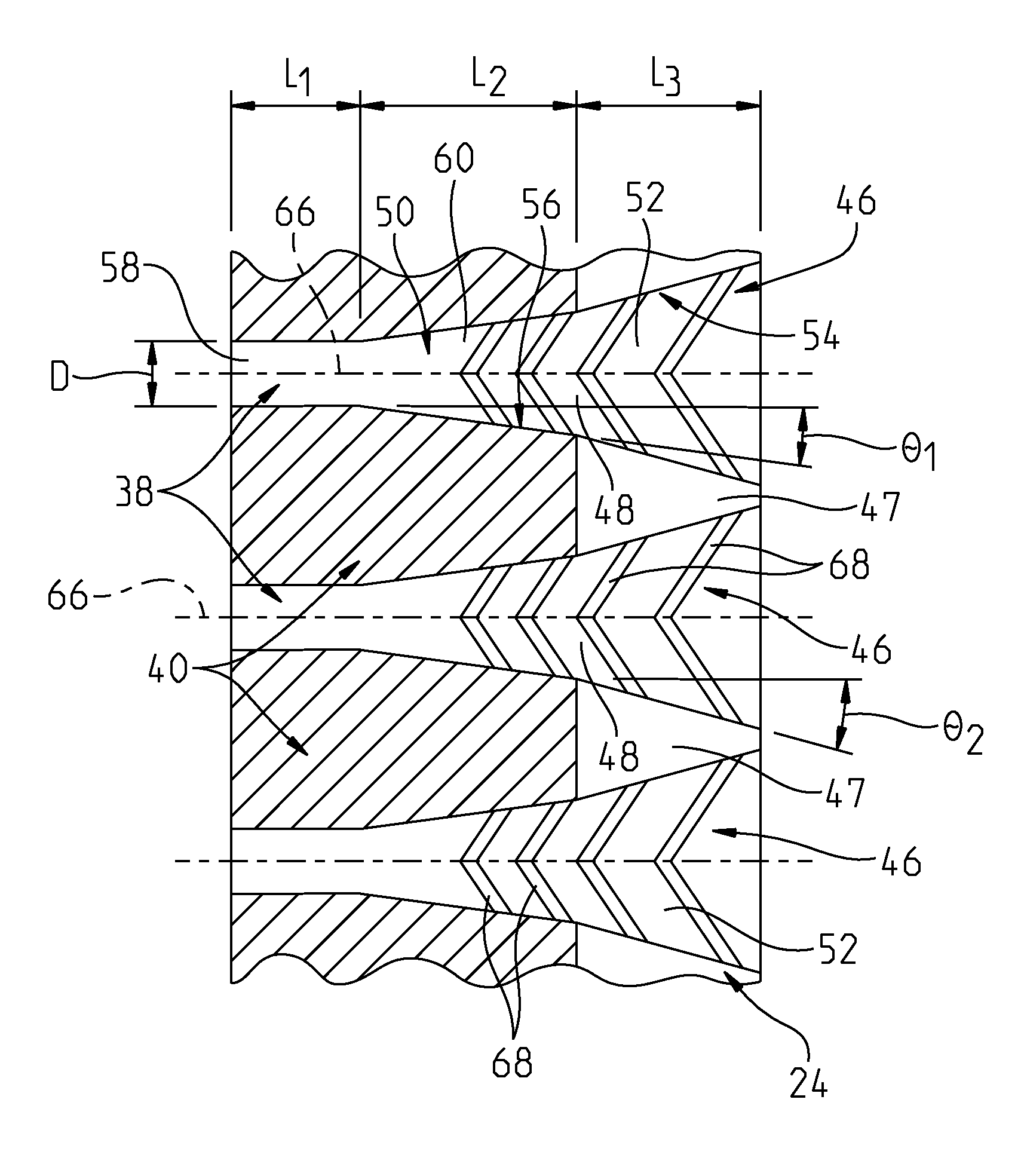

A gas turbine engine hollow turbine airfoil having pressure and suction sidewalls extending chordwise between leading and the trailing edges. The trailing edge includes a pressure sidewall lip and a suction sidewall lip, and a breakout distance between the pressure sidewall lip and the suction sidewall lip. A cooling fluid channel extends spanwise through the airfoil for supplying a cooling fluid to the airfoil. Flow channels are provided extending chordwise between the cooling fluid channel and the suction sidewall lip and include a metering section, an internal diffusion section and a breakout slot. The interior diffusion section includes a spanwise dimension and a widthwise dimension perpendicular to the spanwise dimension, wherein the spanwise dimension continuously increases extending in the chordwise direction, and the widthwise dimension continuously decreases extending in the chordwise direction.

Owner:SIEMENS ENERGY INC

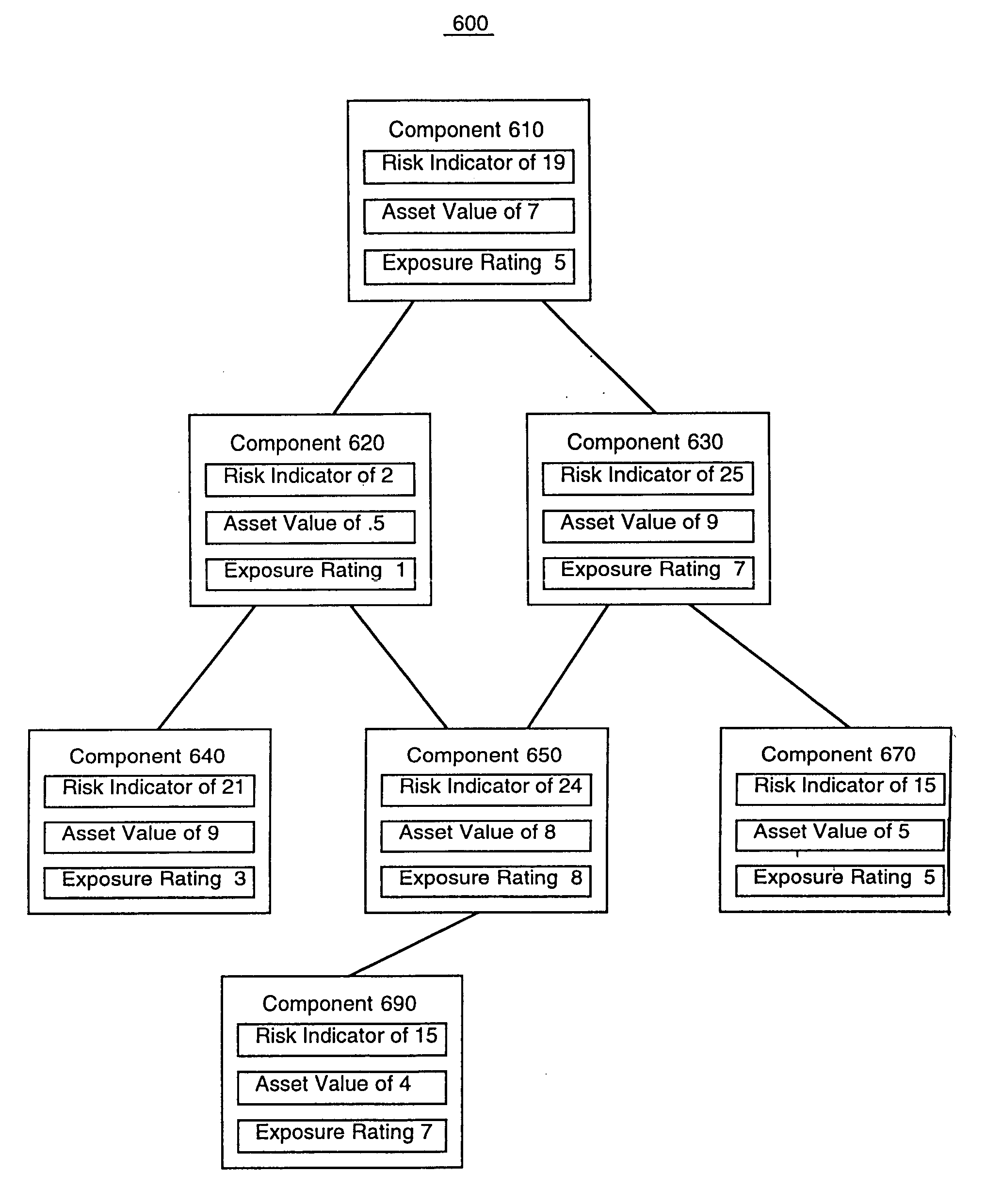

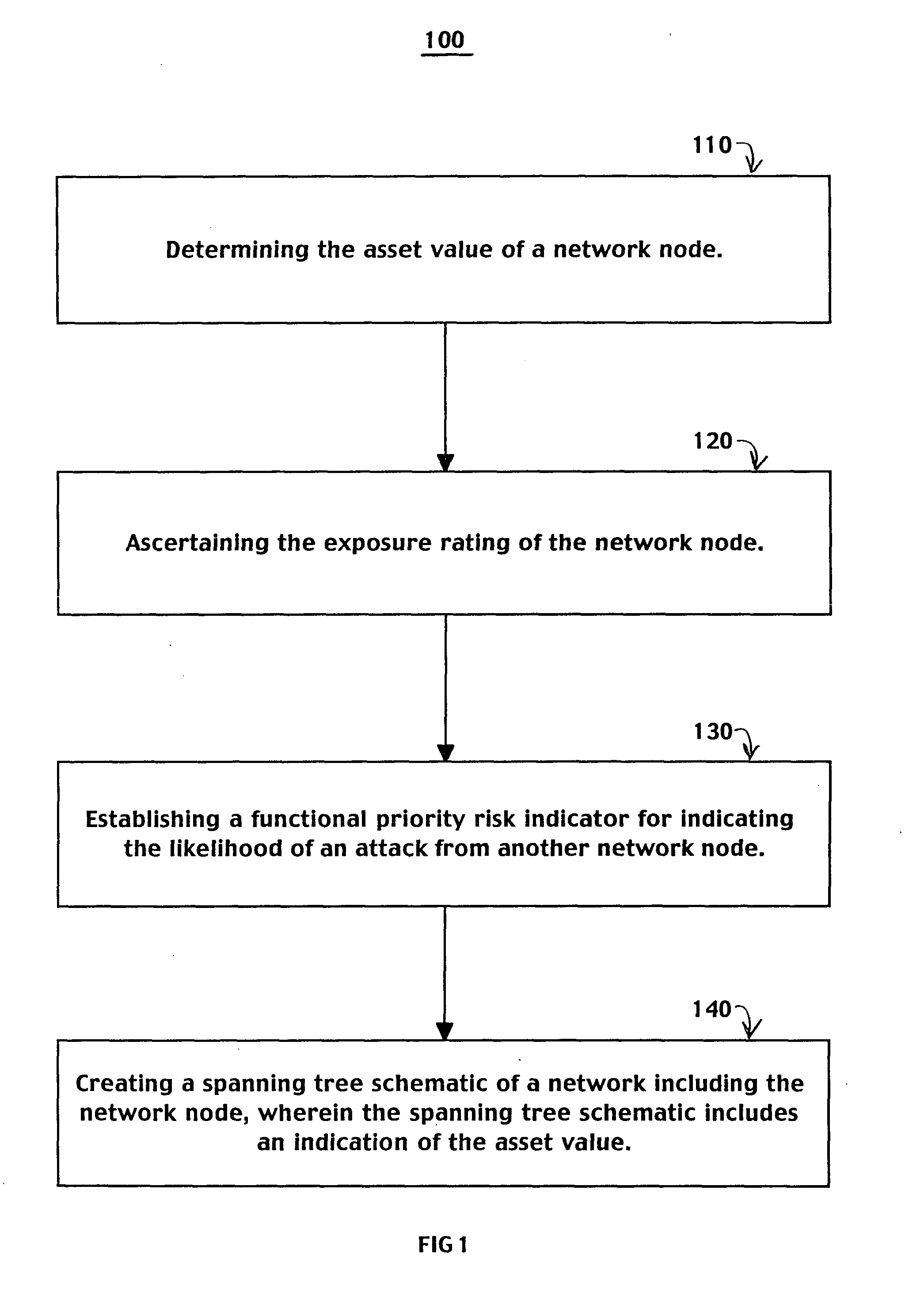

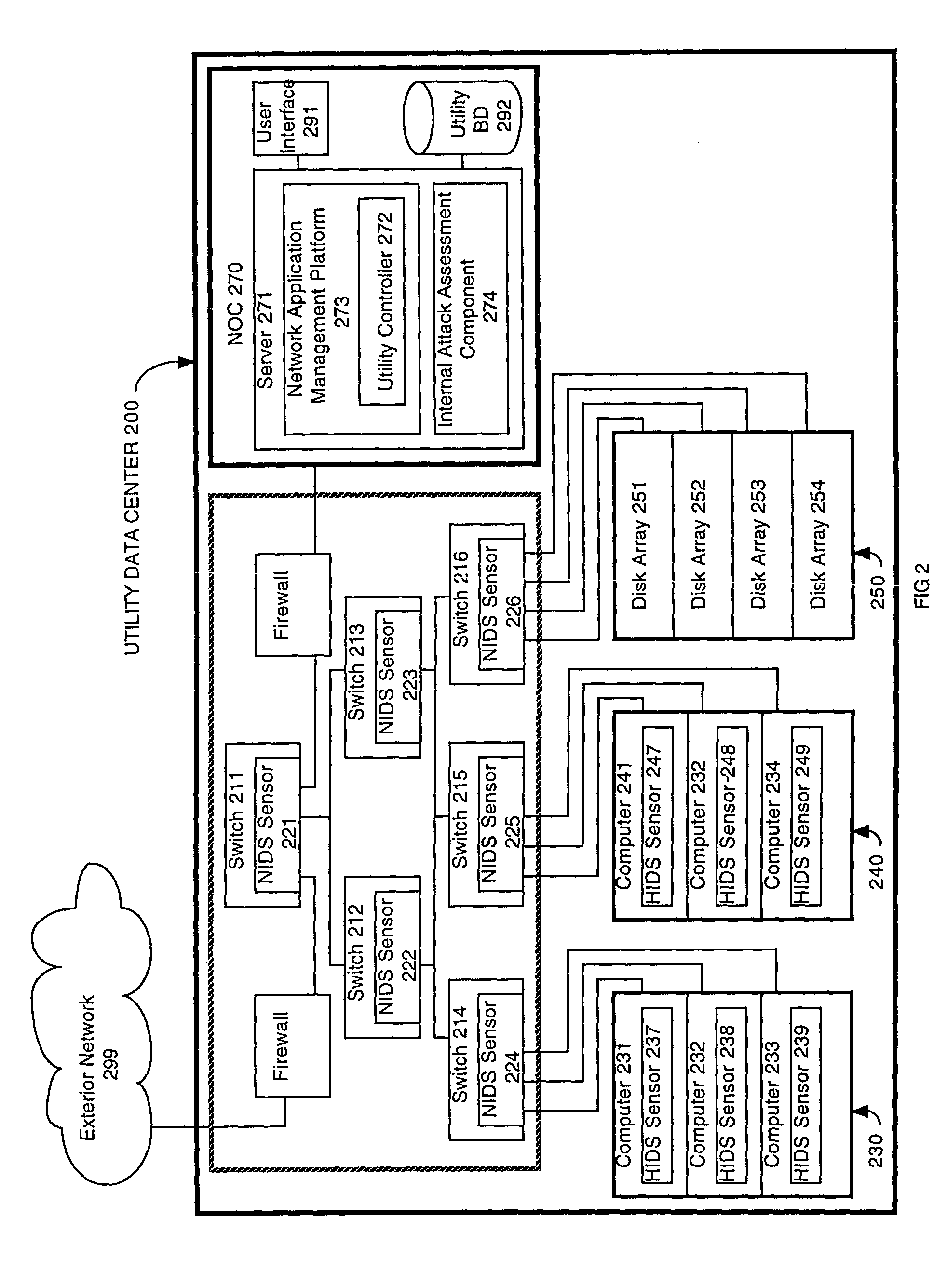

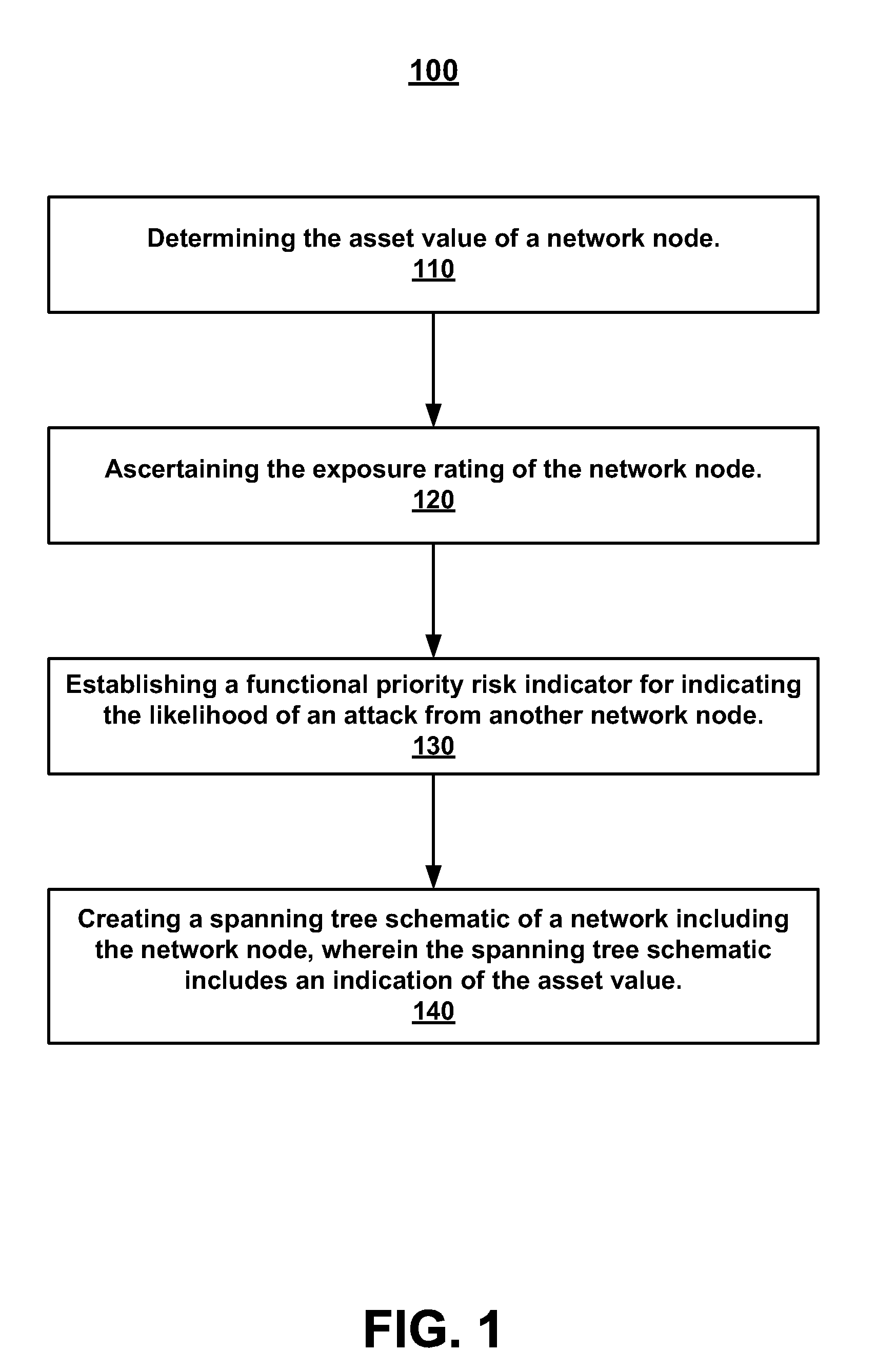

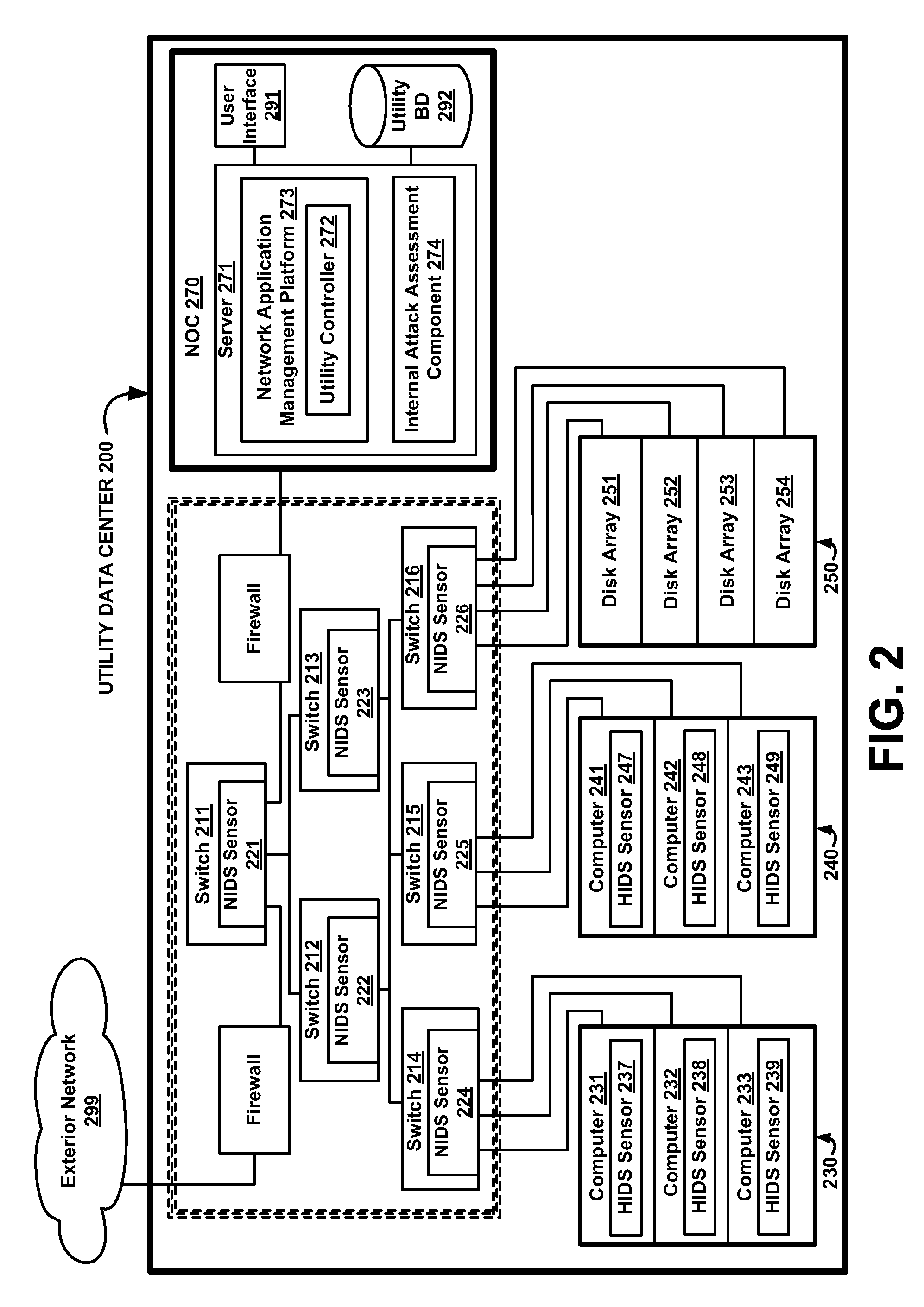

Security intrusion mitigation system and method

ActiveUS20050050351A1Reduce attackReduce diffuseMemory loss protectionDigital data processing detailsDiffusionComputer network

A security intrusion mitigation system and method are presented. In one embodiment a security intrusion mitigation method includes utilizing network spanning tree configuration information to determine an action for mitigating diffusion of intrusive attacks. The spanning tree information can include an indication of an internal diffusion risks. An action for mitigating diffusion of intrusive attacks is automatically performed. The action for mitigating diffusion of the intrusive attacks includes compensation for functional support of prioritized applications.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

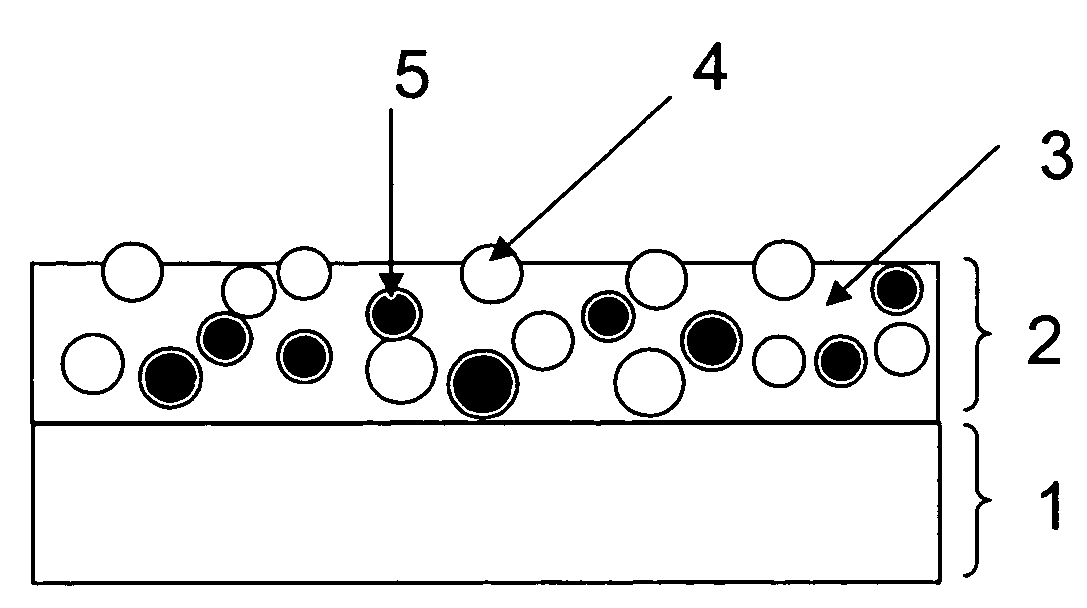

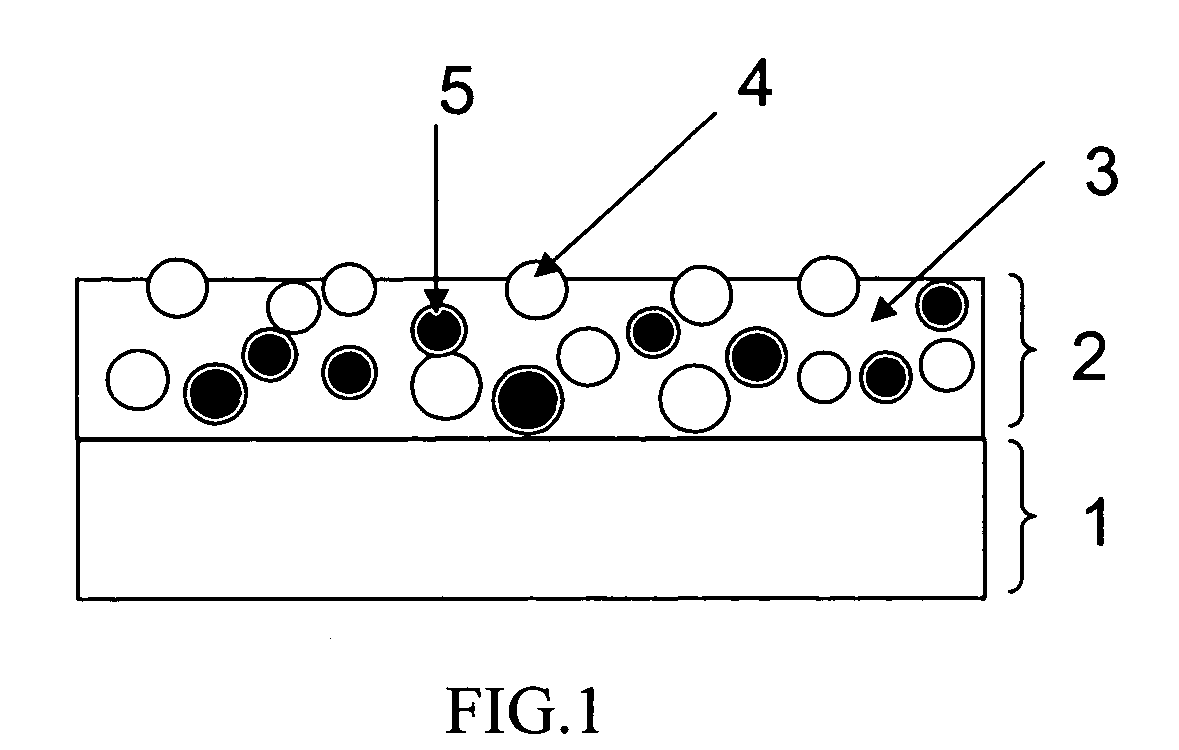

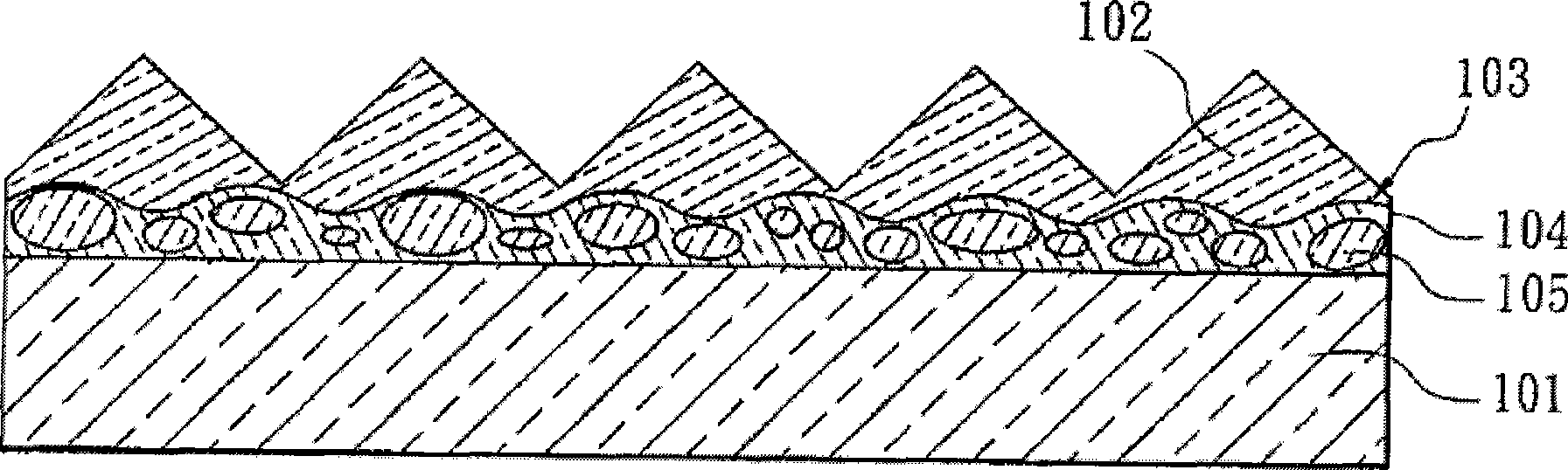

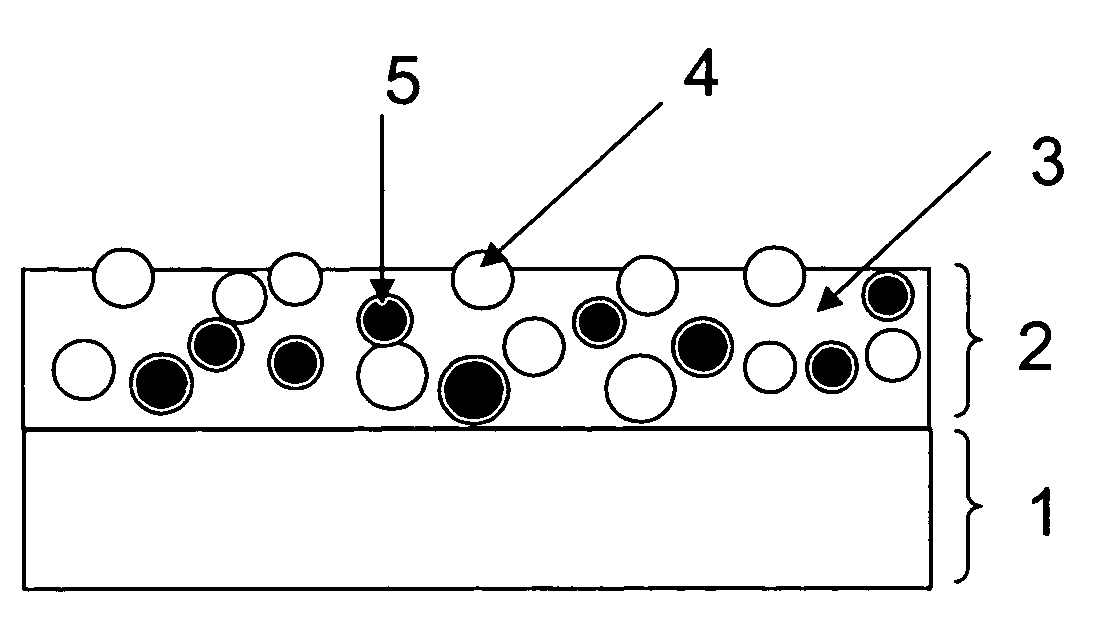

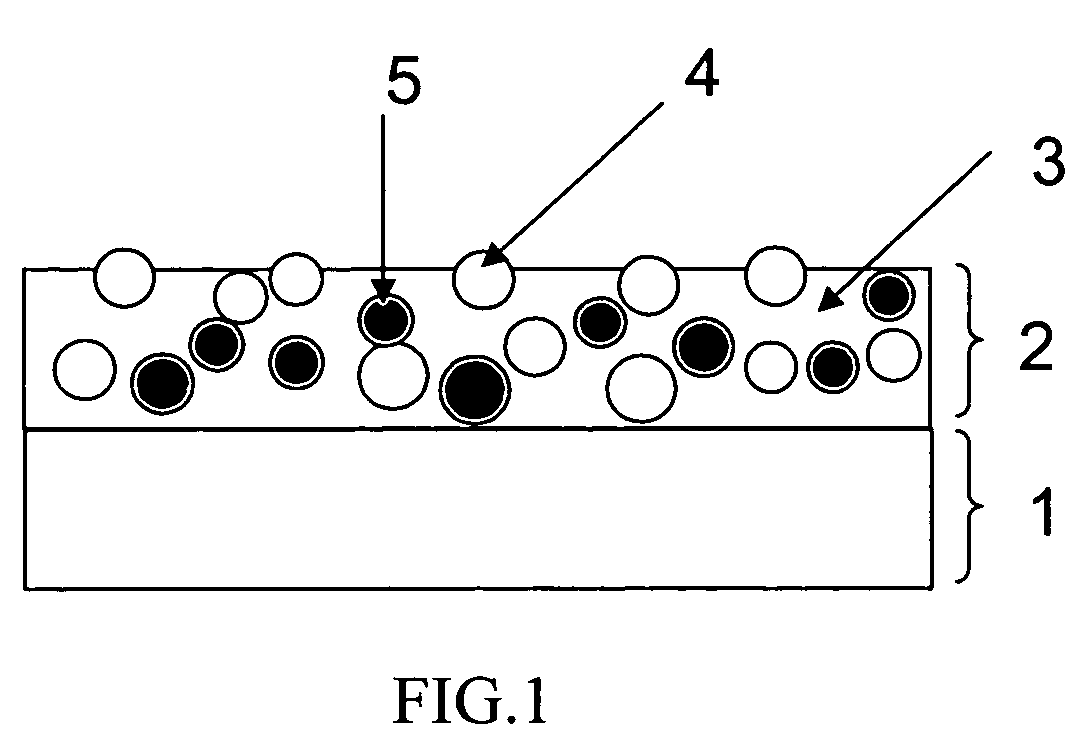

Antiglare light diffusing member and method for producing same, and display

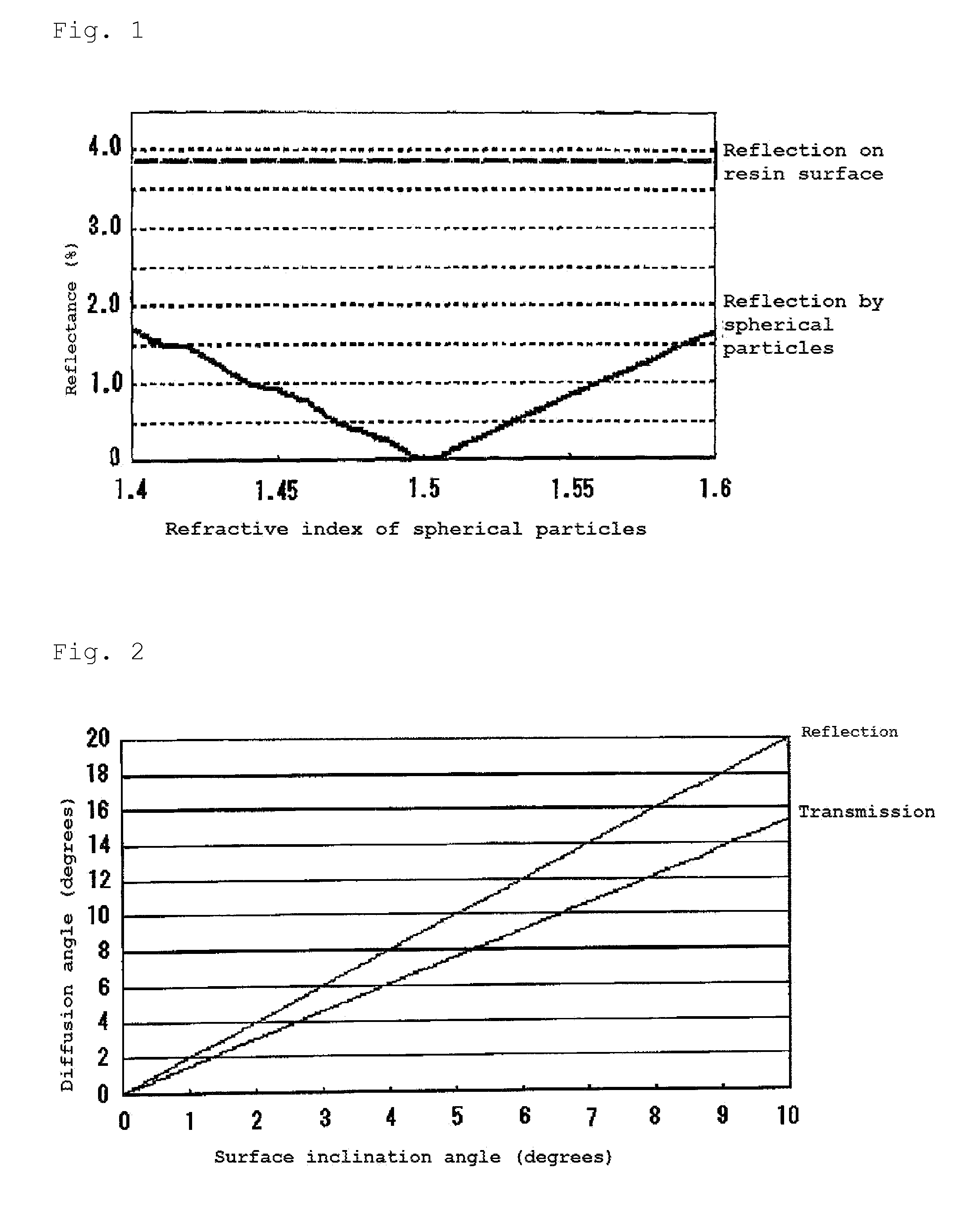

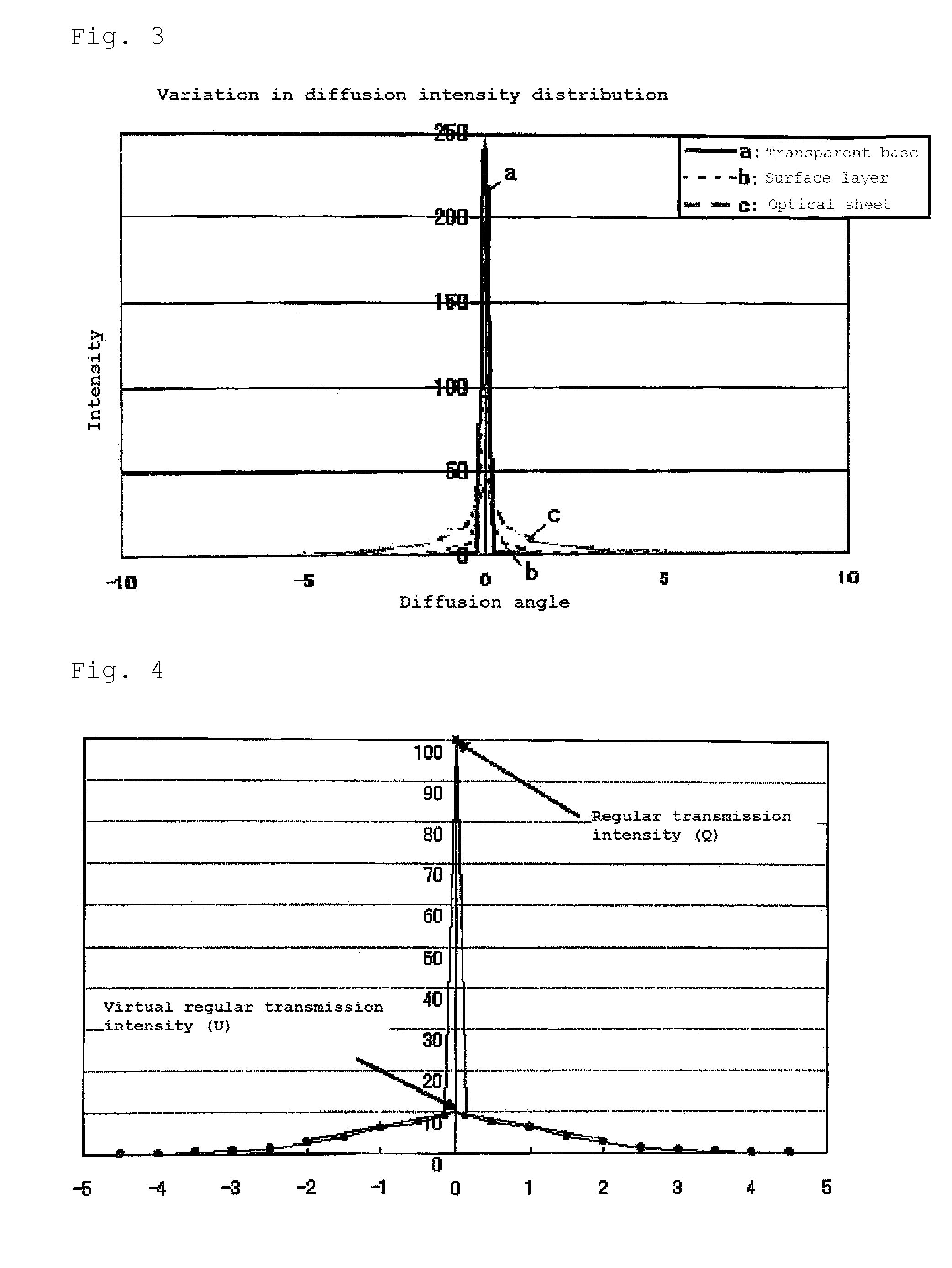

The present invention aims to provide an antiglare light diffusing member utilizing internal diffusion and surface diffusion in combination, wherein a surface haze value mainly representing the degree of the surface diffusion and an internal haze value mainly representing the degree of the internal diffusion are easily adjusted independently from each other. An antiglare light diffusing member comprising an antiglare light diffusing layer comprising a binder matrix and a particle A and a particle B on a transparent base material, wherein the difference between the refraction index of the particle A and the refraction index of the binder matrix is less than 0.02, and the difference between the refraction index of the particle B and the refraction index of the binder matrix is in the range of 0.03-0.20.

Owner:TOPPAN PRINTING CO LTD

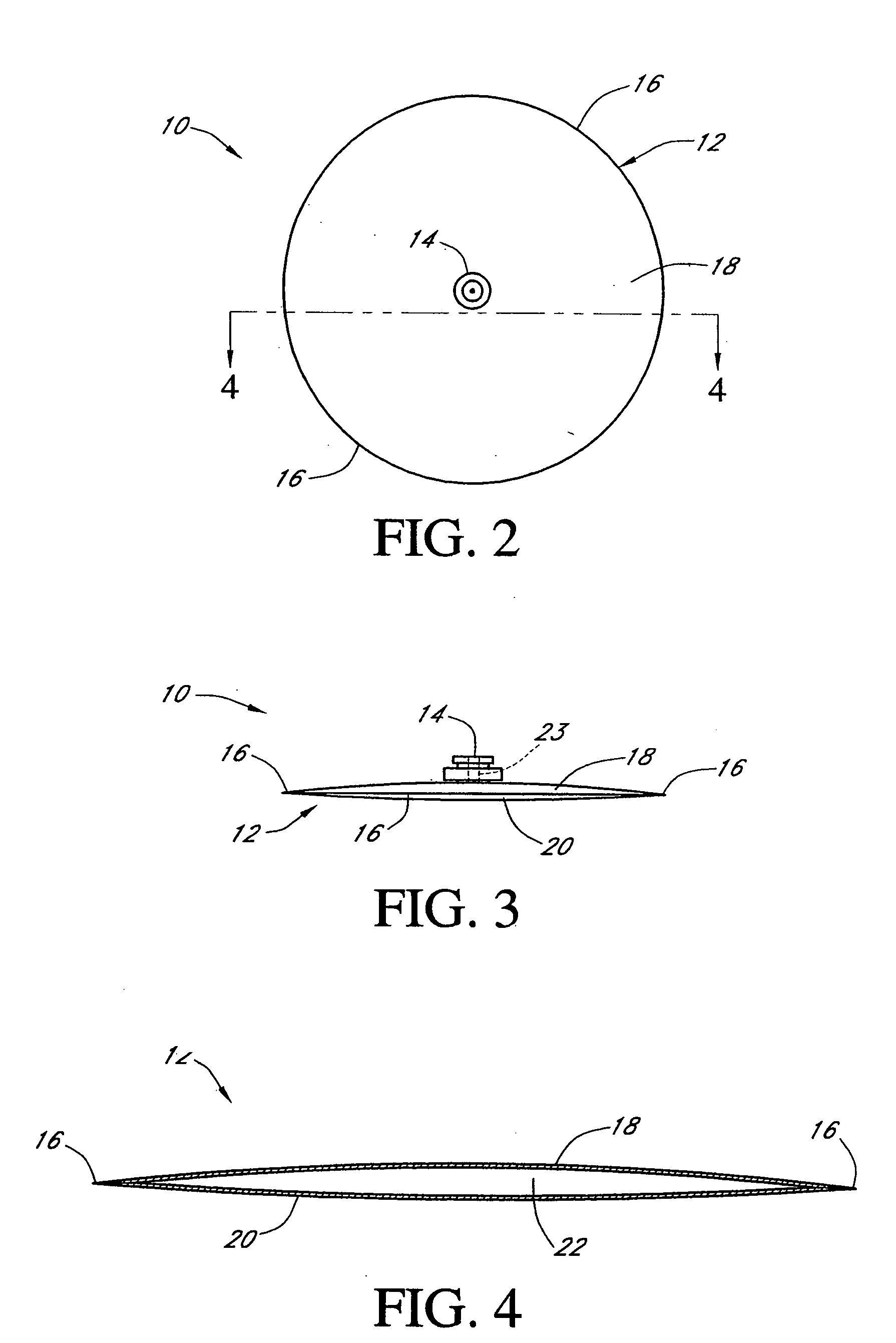

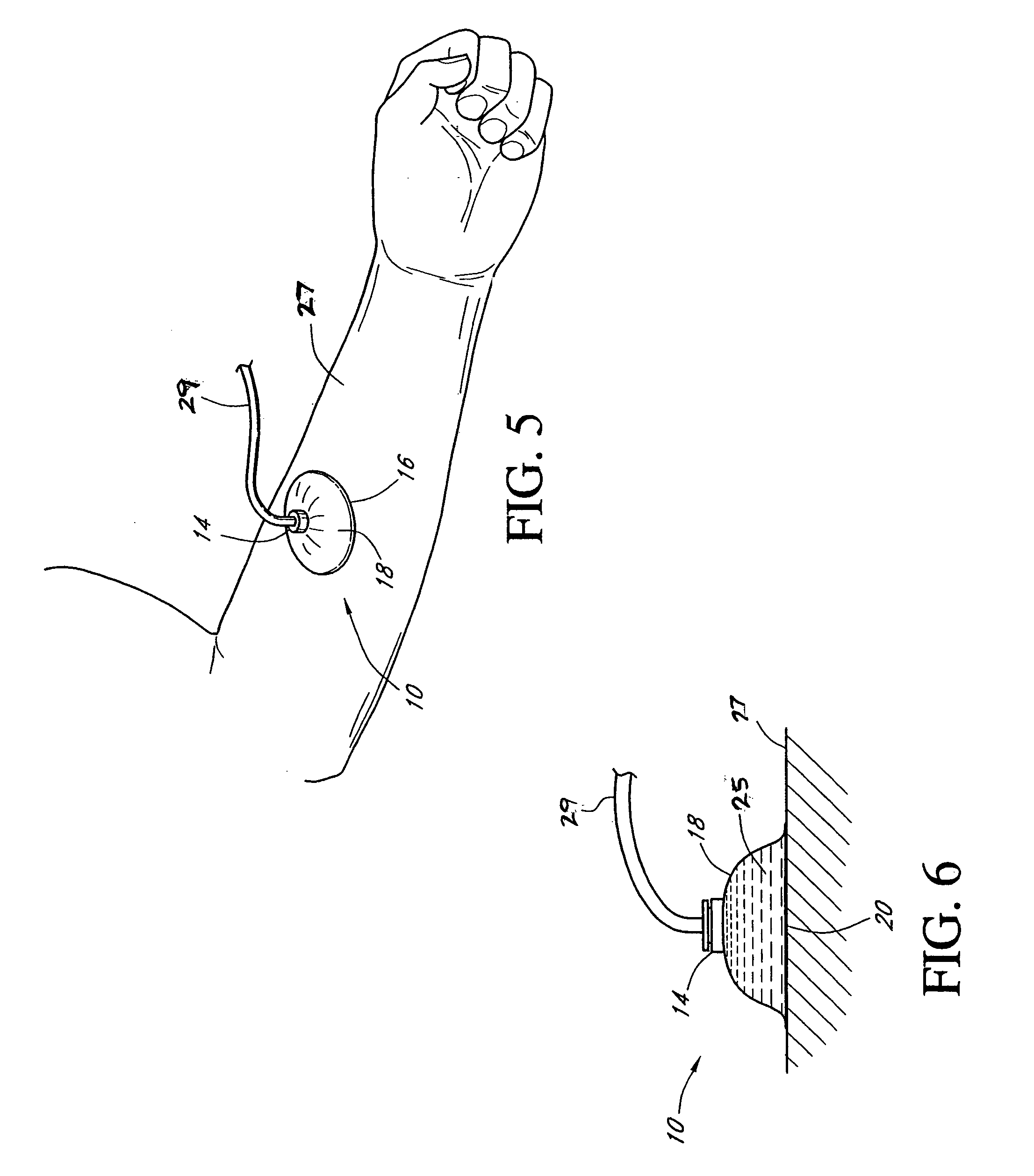

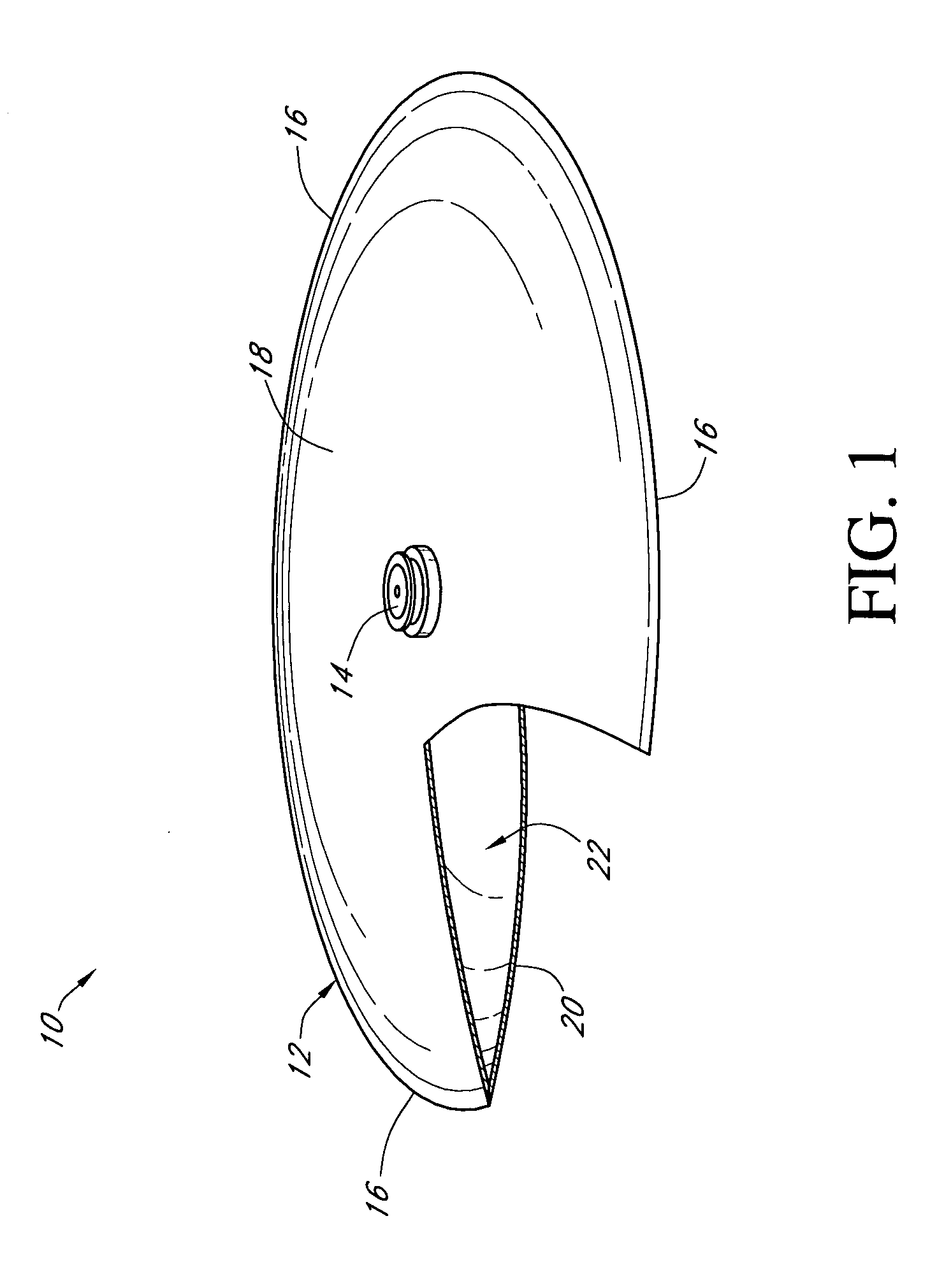

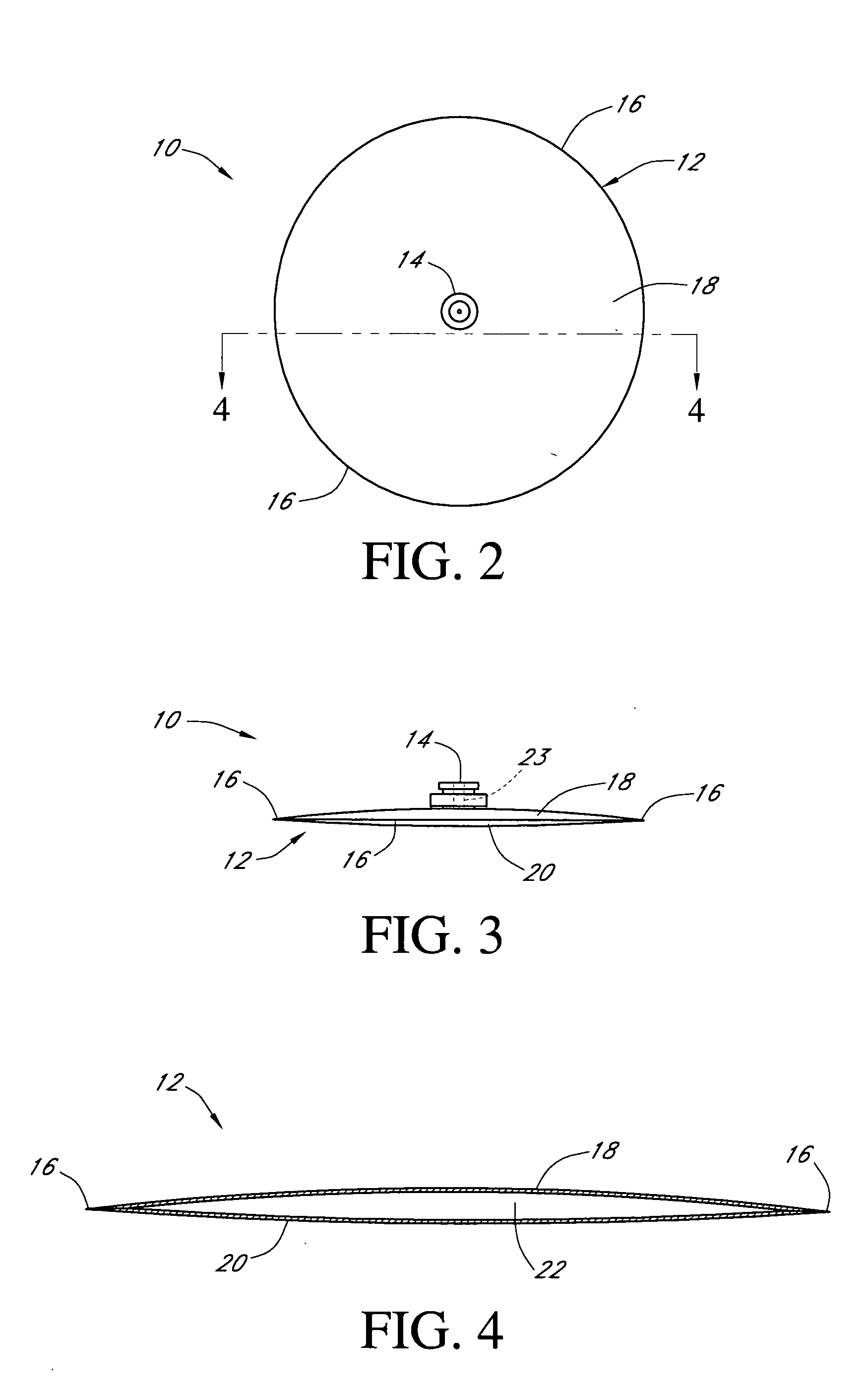

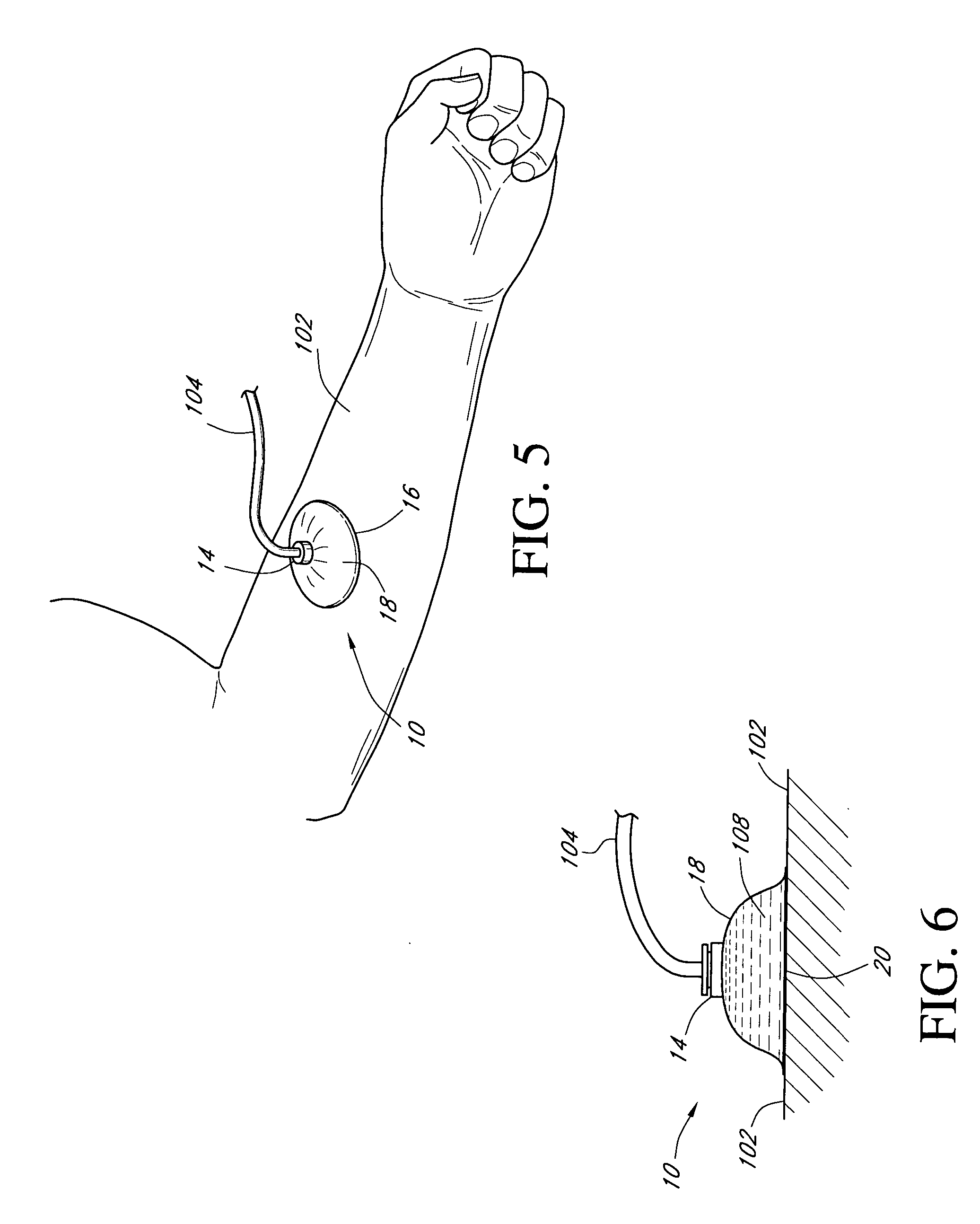

Fluid medication delivery device

A fluid delivery device for transdermal delivery of a fluid to a patient. The device comprises an envelope that may be applied to a patient's skin. The envelope comprises at least one diffusion layer coupled to at least one impermeable layer such that at least a chamber is defined therebetween. Other embodiments include internal diffusion layers, and thus possess additional chambers, as well. In one arrangement, an adhesive boundary layer permits the device to be removably secured to a patient and inhibits radial migration of fluid beyond the periphery of the device. In another arrangement, preferably, an anti-microbial layer is provided to inhibit the growth of microorganisms.

Owner:AVENT INC

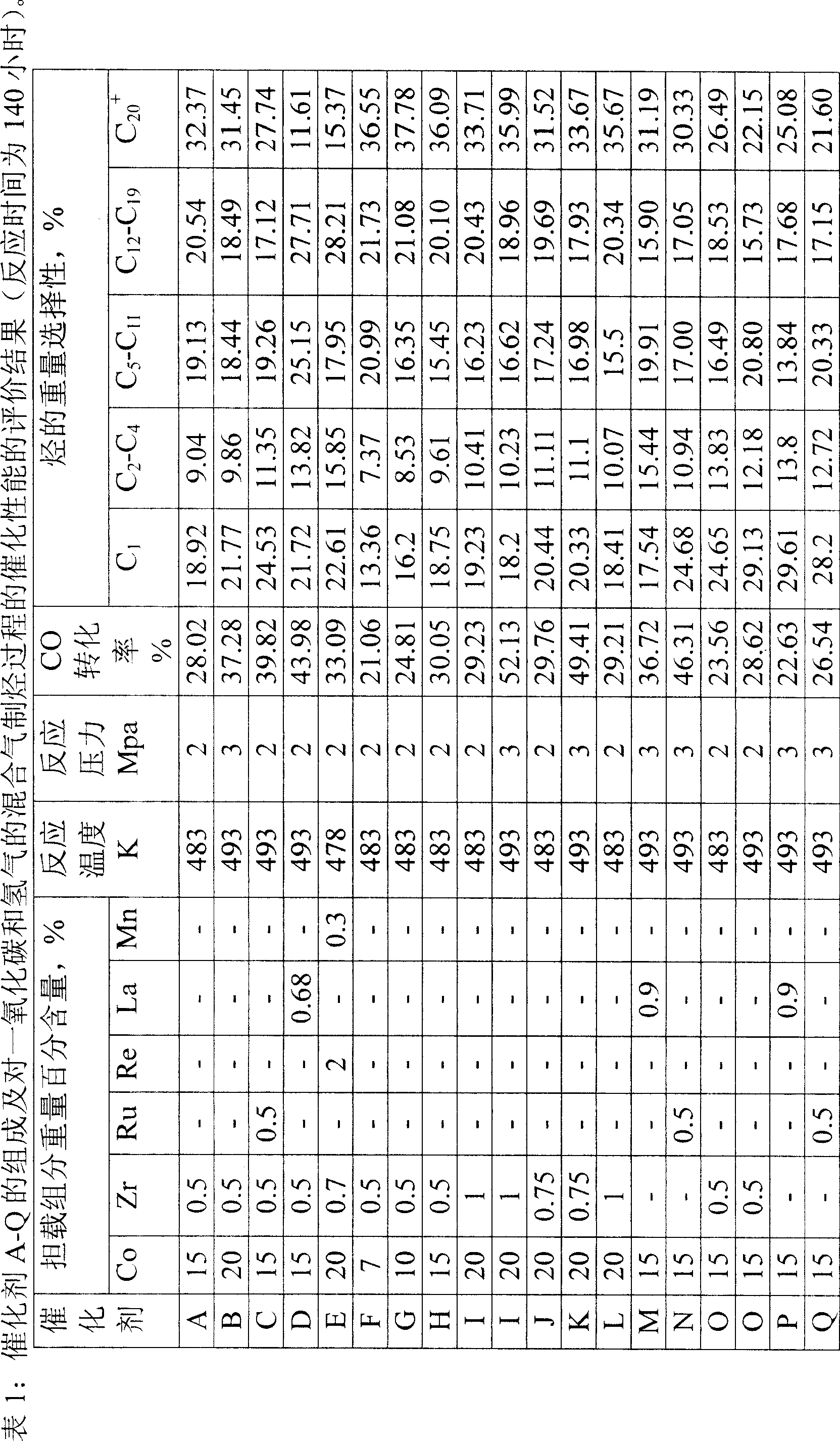

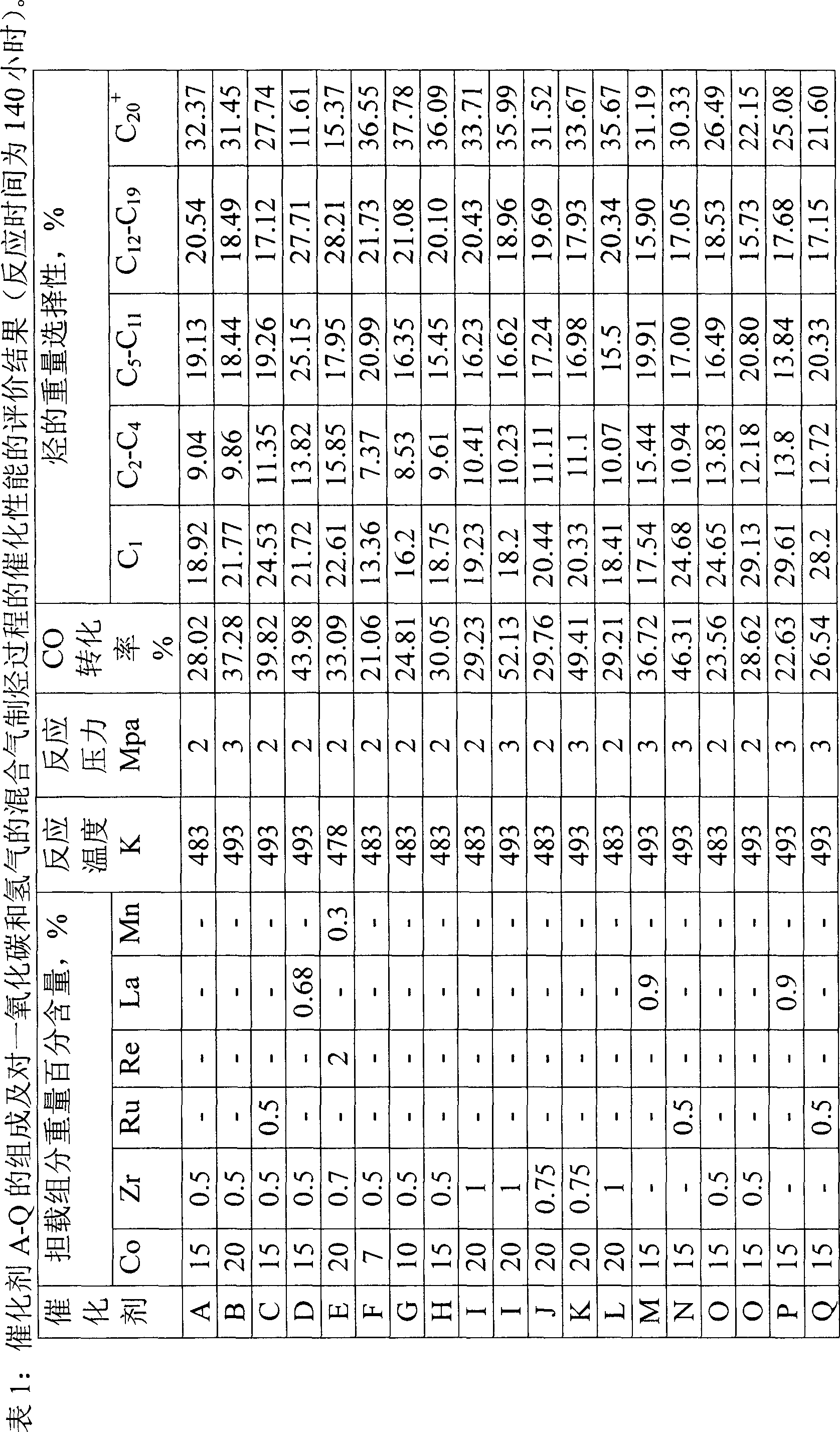

Method for preparing catalyst and application thereof

ActiveCN101143325AEasy to manufactureEasy to operateCatalyst carriersHydrocarbon from carbon oxidesHydrogenActive component

The invention provides a catalyst preparation method. The procedure is that:1} a solution containing soluble compounds with loaded components is prepared; 2} the solution produced in procedure 1 is sprayed on a rolling carrier or a carrier preloading one or a plurality of components and the carrier is heated in the process of spraying; 3) the product produced in procedure 2 is dried or roasted; 4) the procedures 2 and 3 are repeated. The active components of the catalyst prepared in the method of the invention contain group eight elements. When the catalyst preparation method of the invention is applied in the hydrocarbon preparation procedure from mixed gas of carbon monoxide and hydrogen, the active components of the catalyst prepared contain group eight elements. The invention provides a better shell catalyst preparation technique, which solve the problem of internal diffusion in certain chemical conversion procedures. The catalyst can be applied in hydrocarbon preparation reaction of gas mixture of carbon monoxide and hydrogen.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Fluid medication delivery device

ActiveUS20050058711A1Easy to fillFacilitates temporary disconnectionOrganic active ingredientsPlastersSemipermeable membraneIntravenous therapy

A fluid delivery device is provided for transdermal delivery of fluid medications to patients. The device comprises a thin envelope which is applied to a patient's skin. The envelope comprises at least one diffusion layer coupled to at least one impermeable layer such that at least one chamber exists therebetween. Other embodiments include internal diffusion layers, and thus possess additional chambers, as well. The impermeable layer comprises a top surface of the device. A valve positioned in the impermeable layer facilitates filling the device with fluid, as well as connection of the device to external fluid sources such as an intravenous bag, pump, or other external fluid delivery system. The diffusion layer may comprise a semi-permeable membrane which controls the rate of fluid flow from the device to the patient's skin.

Owner:AVENT INC

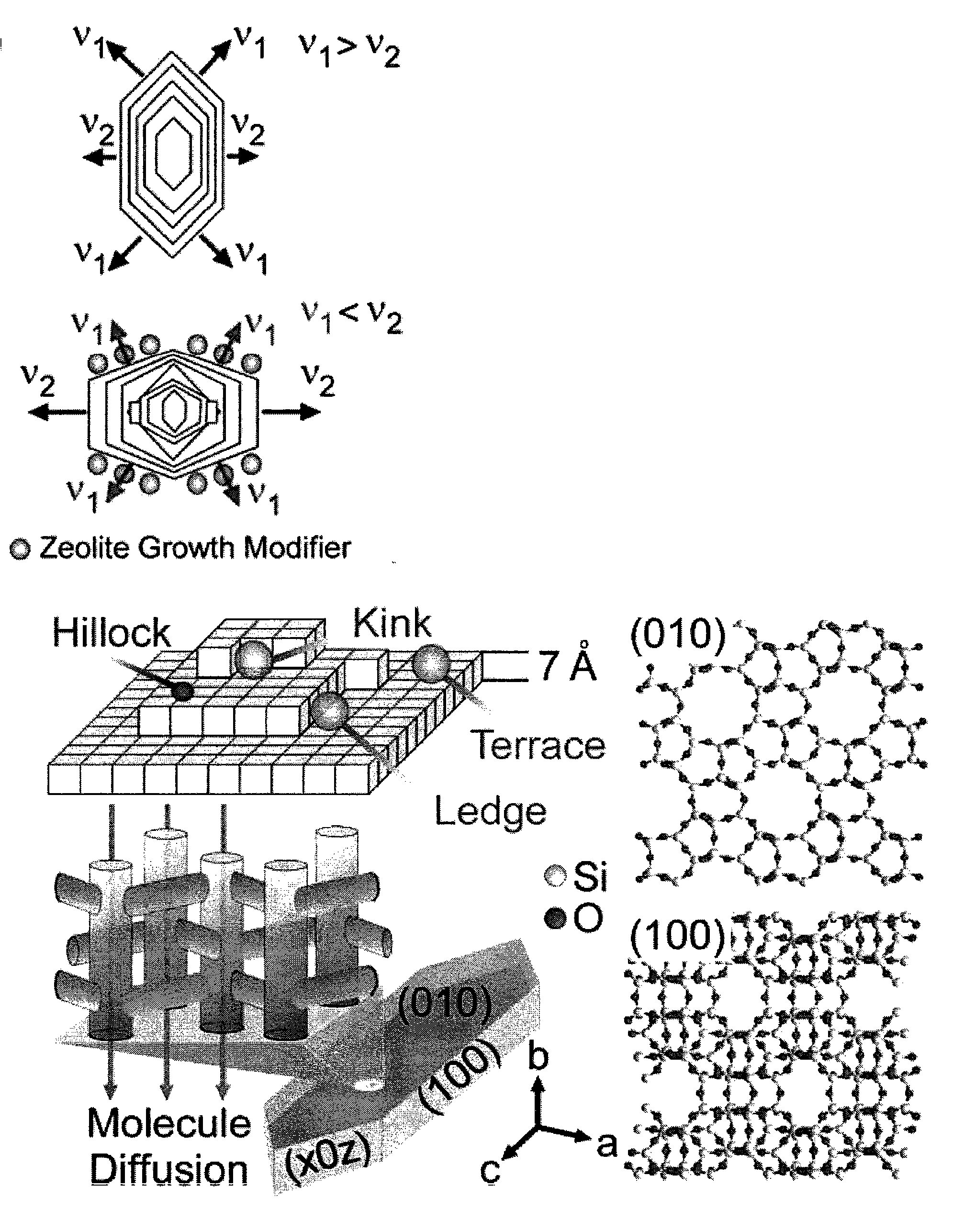

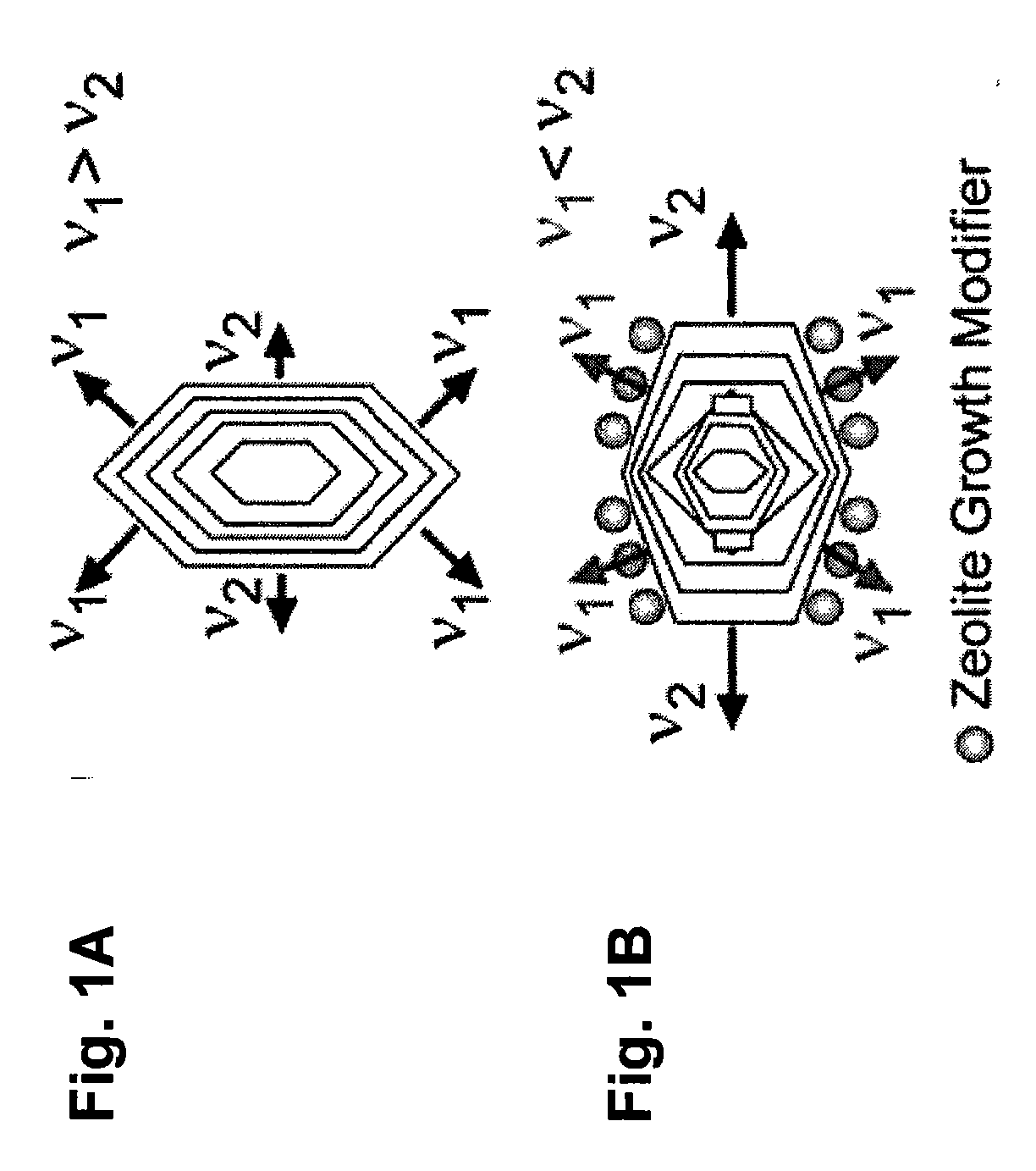

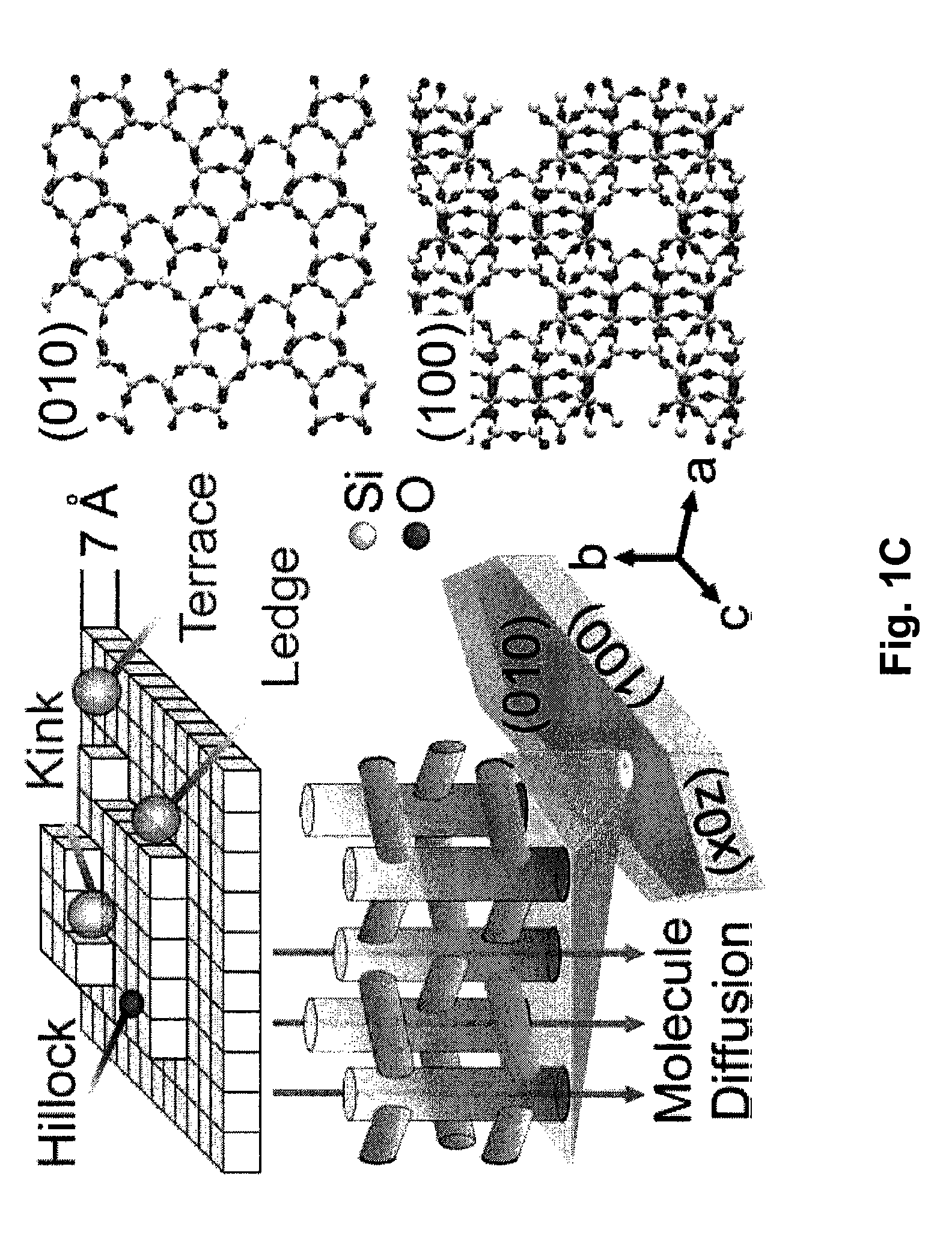

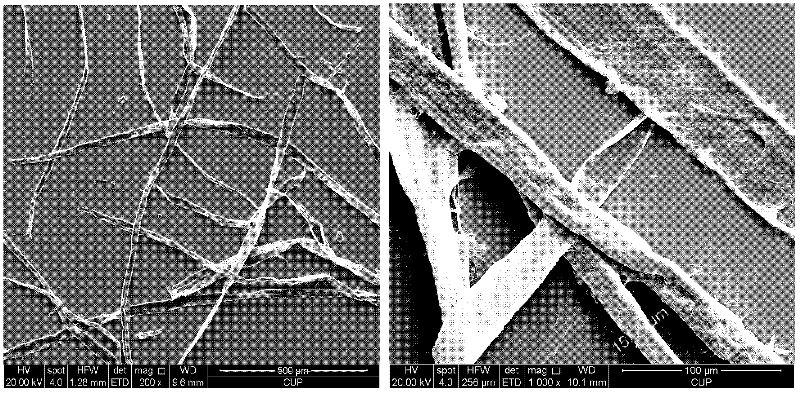

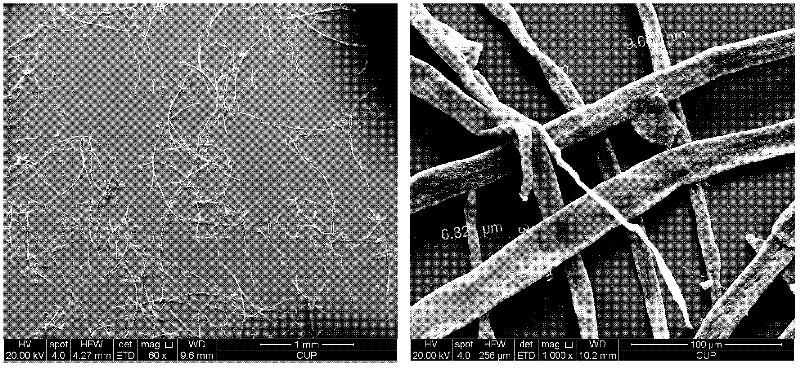

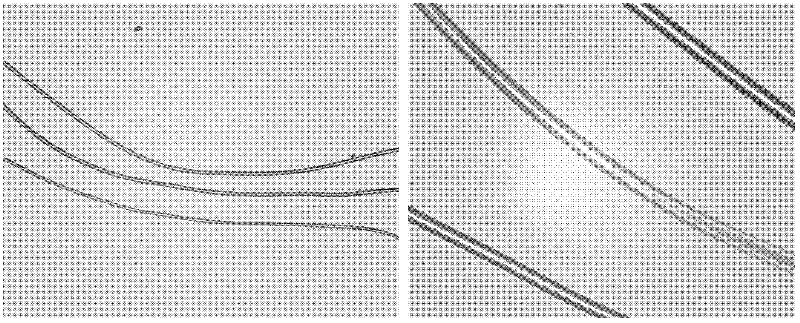

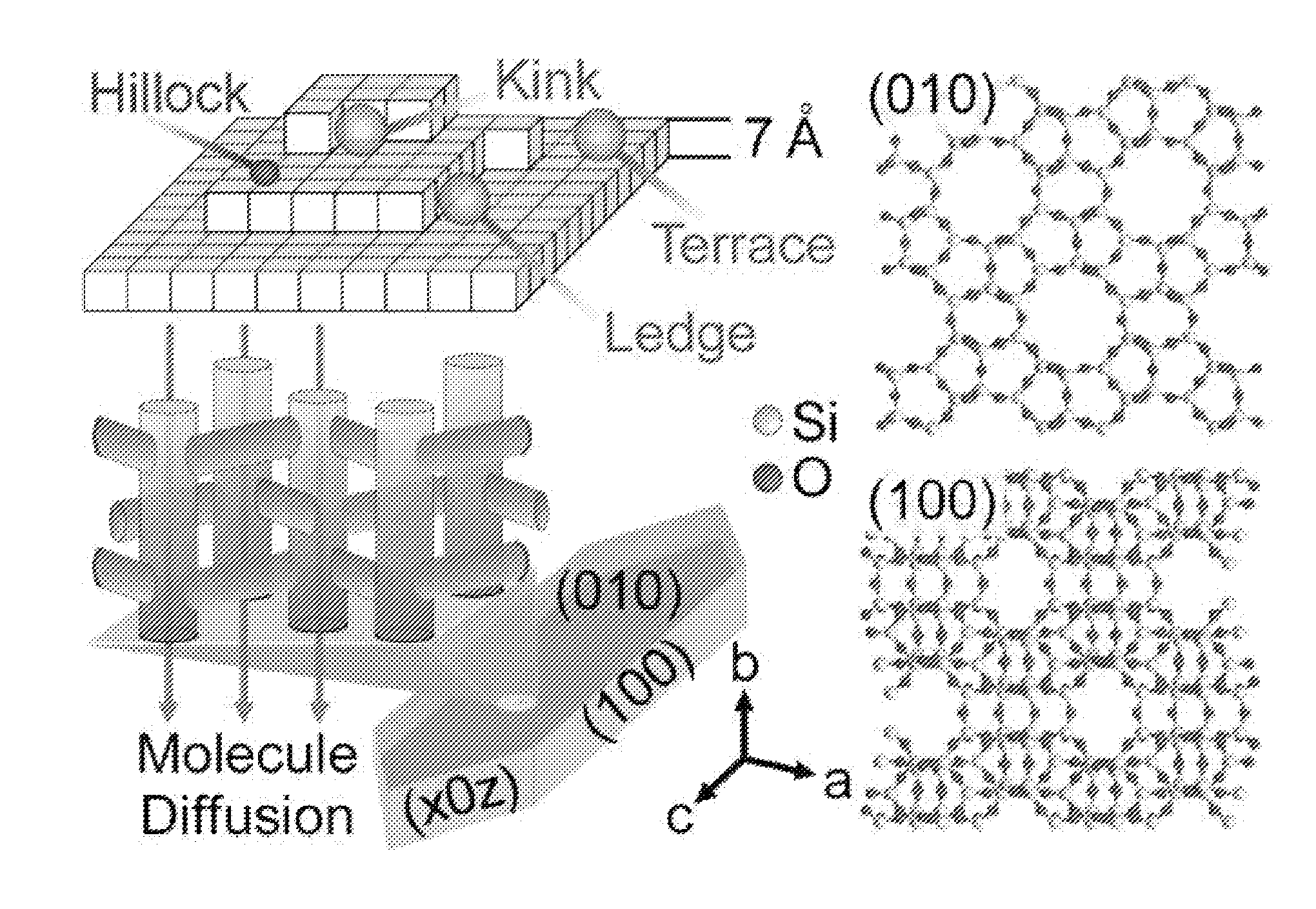

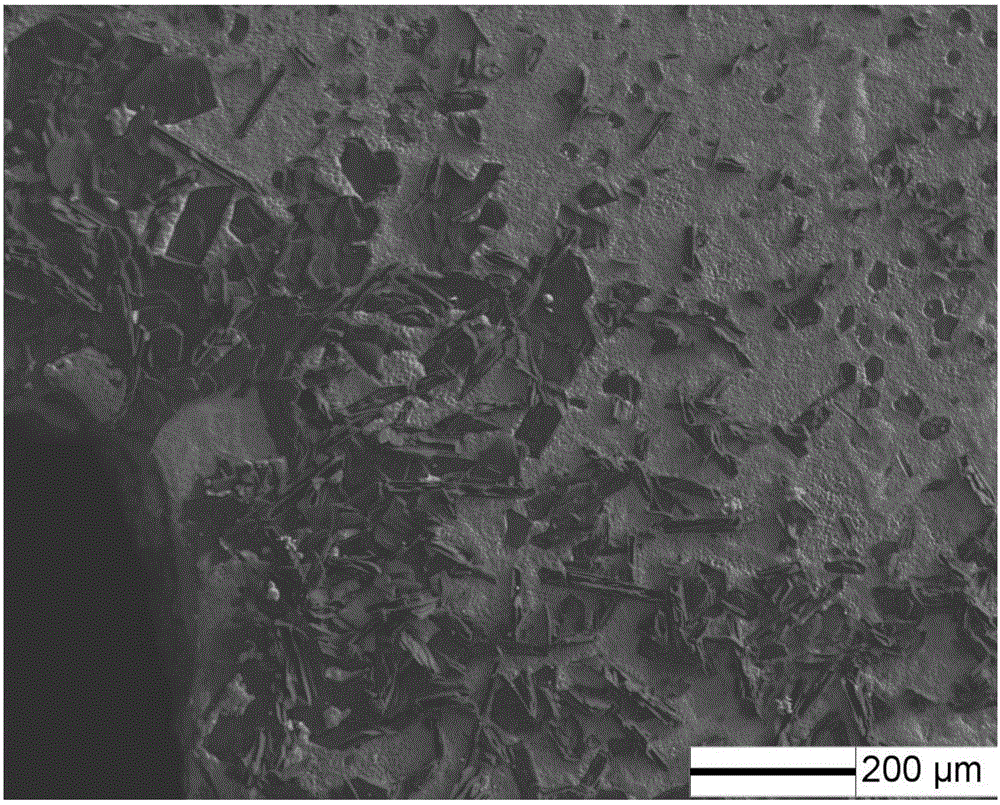

Zeolite compositions and methods for tailoring zeolite crystal habits with growth modifiers

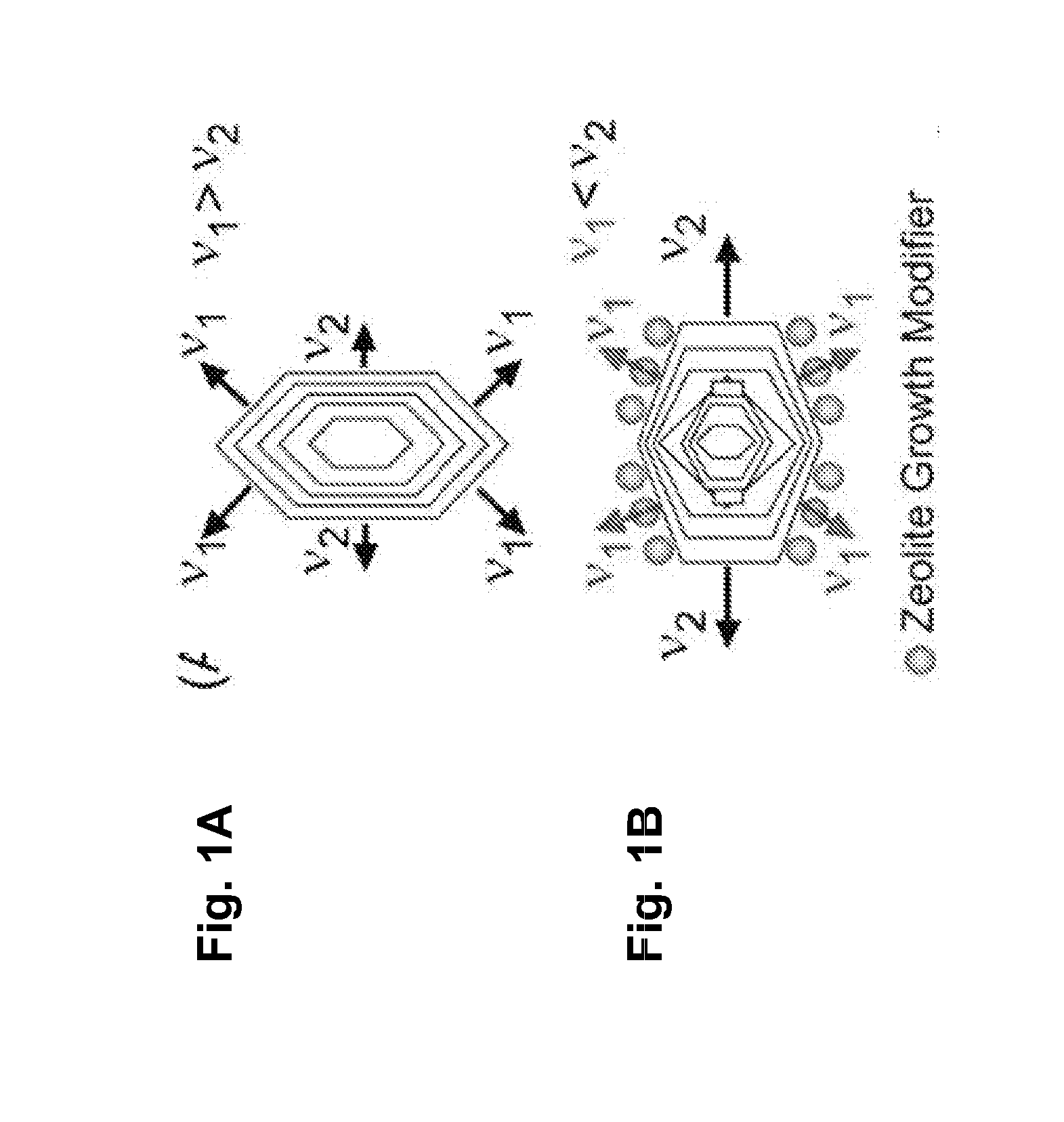

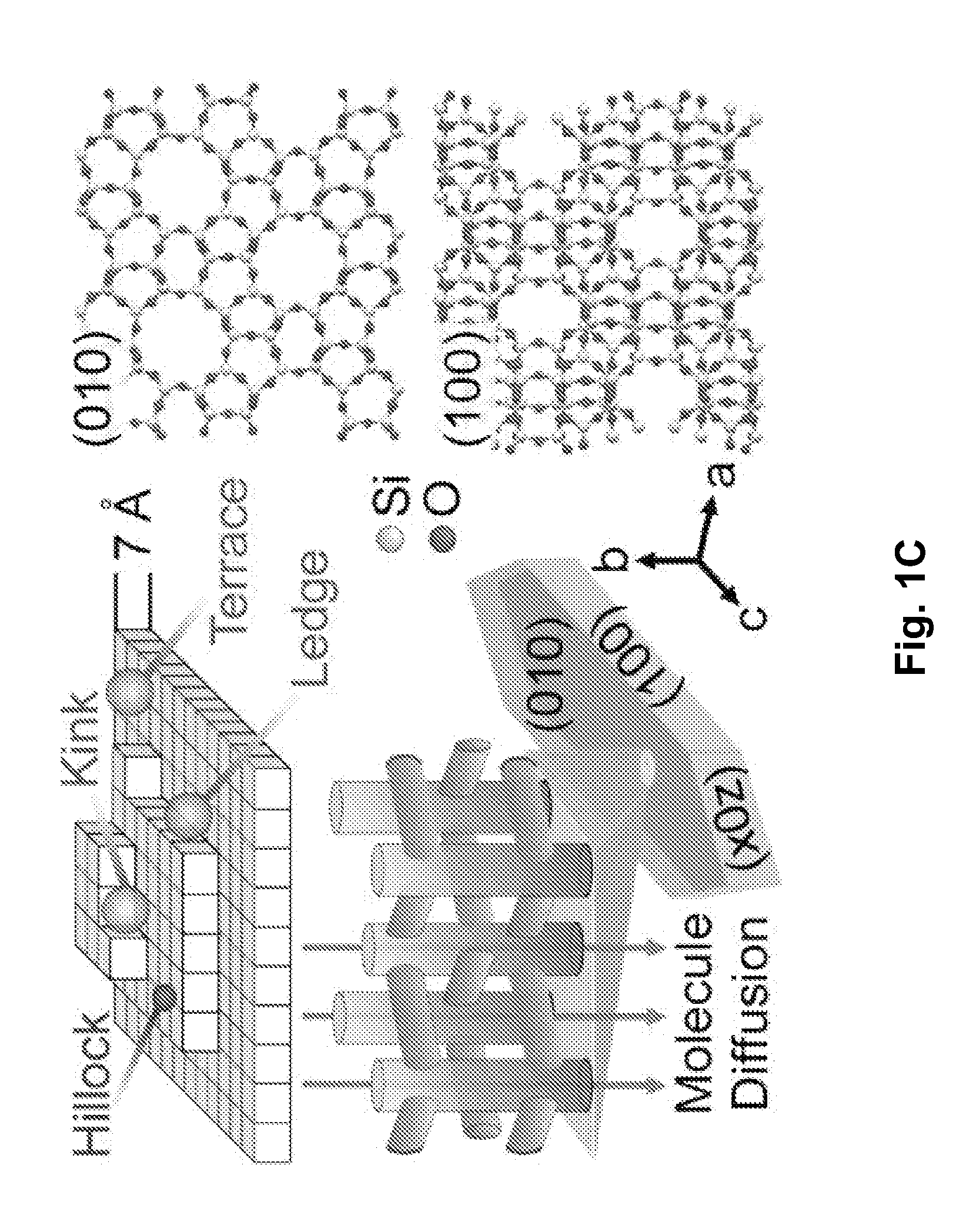

InactiveUS20120202006A1Minimized crystal thicknessShortened internal diffusion pathlengthPolycrystalline material growthFrom normal temperature solutionsCrystal habitCrystal growth rate

Embodiments of the invention generally provide compositions of crystalline zeolite materials with tailored crystal habits and the methods for forming such crystalline zeolite materials. The methods for forming the crystalline zeolite materials include binding one or more zeolite growth modifiers (ZGMs) to the surface of a zeolite crystal, which results in the modification of crystal growth rates along different crystallographic directions, leading to the formation of zeolites having a tailored crystal habit. The improved properties enabled by the tailored crystal habit include a minimized crystal thickness, a shortened internal diffusion pathlength, and a greater step density as compared to a zeolite having the native crystal habit prepared by traditional processes. The tailored crystal habit provides the crystalline zeolite materials with an aspect ratio of about 4 or greater and crystal surfaces having a step density of about 25 steps / μm2 or greater.

Owner:UNIV HOUSTON SYST

Catalyst carrier with run-through macropores and mesopores, catalyst and preparation method thereof

InactiveCN102350374AReduce mass transfer resistanceCatalyst carriersCatalytic crackingFiberMass transfer resistance

The invention provides a method for preparing a catalyst carrier with macropores and mesopores which are in run-through. The method comprises the following steps of: adding solid cellosilk in the process of preparing or forming the catalyst carrier, so that the solid cellosilk is dispersed in the catalyst carrier; and removing the solid cellosilk by forming and roasting to obtain the catalyst carrier with the run-through macropores and mesopores. The invention also provides a method for preparing a catalyst by further supporting active ingredients by the catalyst carrier and the carrier and the catalyst which are prepared by the method. By the method, the run-through performance of a mesoporous channel of the carrier is improved greatly by adding the solid cellosilk; and the run-through macropore formed by the cellosilk provides a quickly-dispersed channel for reaction molecules, so the mass transfer resistance in the catalytic reaction process is reduced. The method is suitable for preparing various catalysts of which the reaction speed is controlled by internal diffusion, such as a petroleum distillate (particularly heavy oil distillate) hydrogenation catalyst.

Owner:UNISIZE TECH CHANGZHOU +1

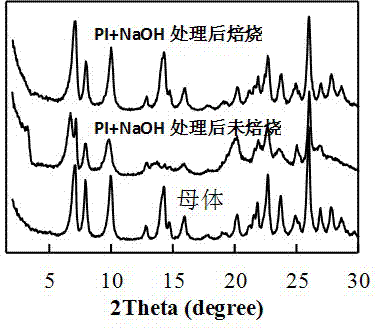

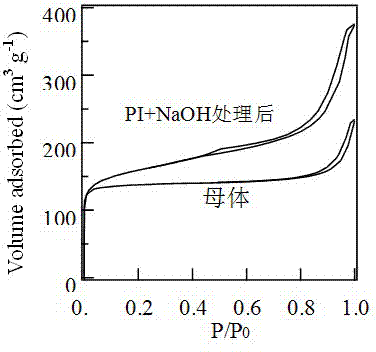

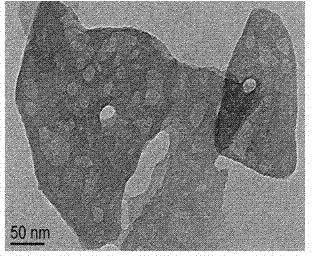

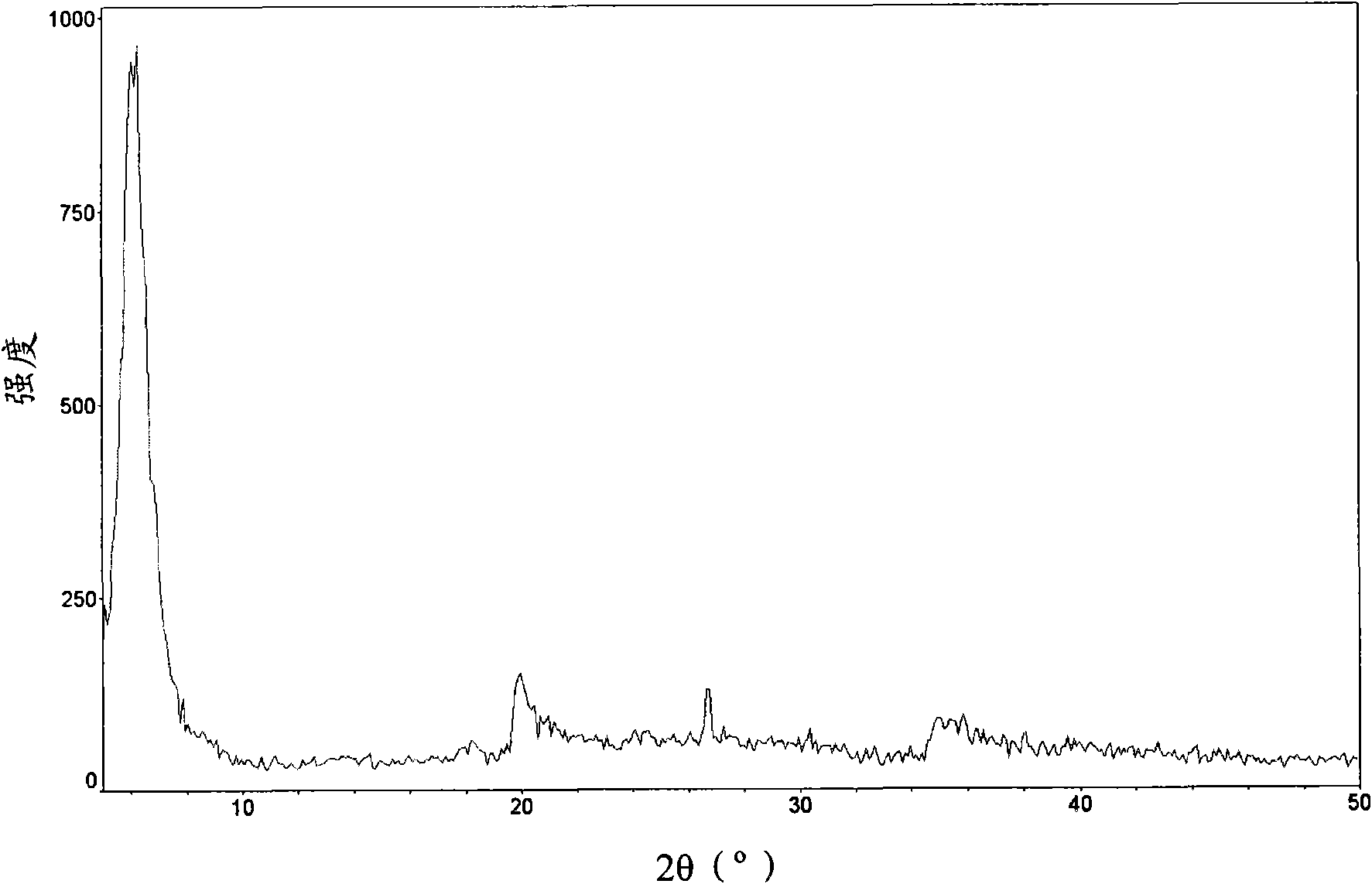

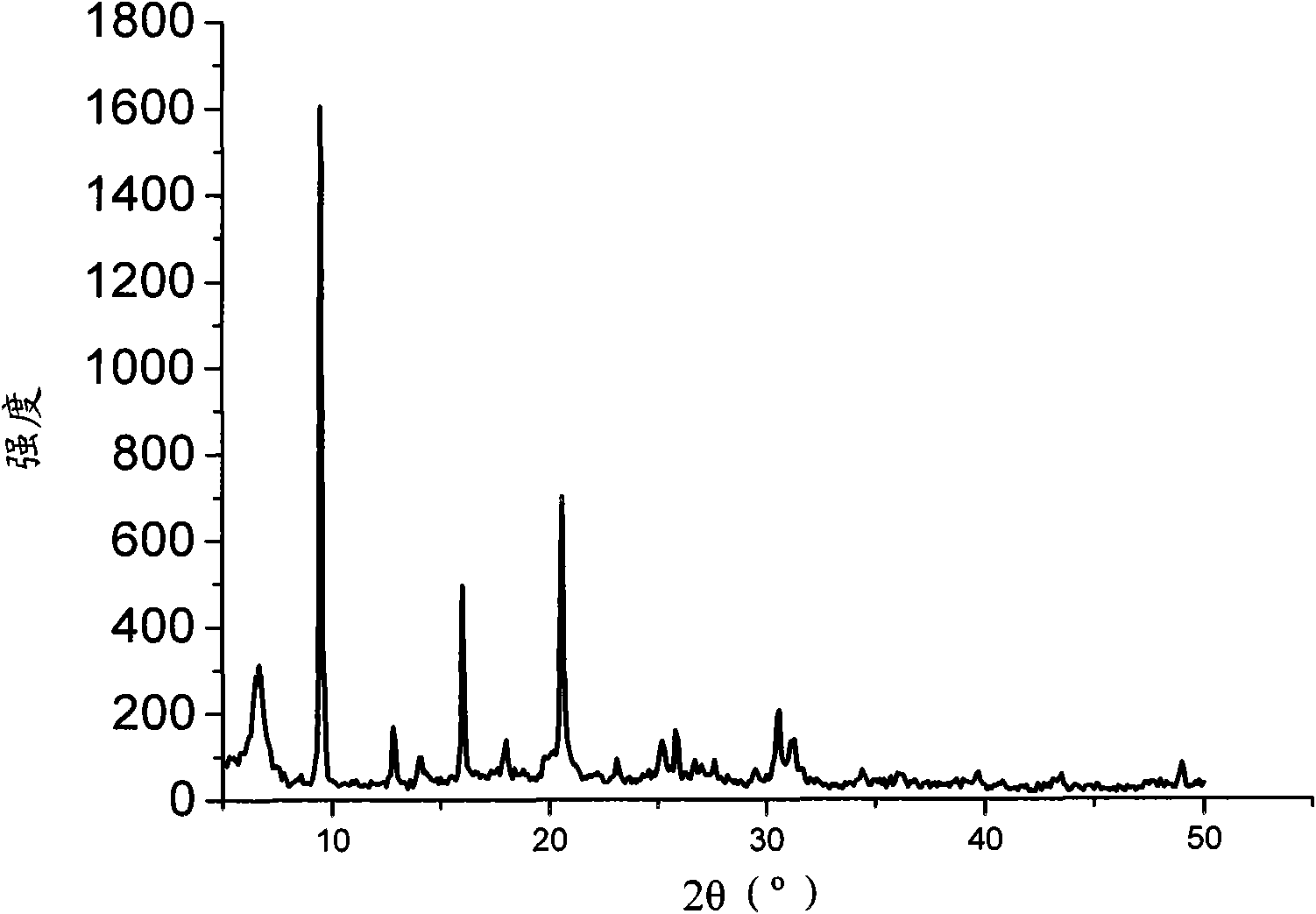

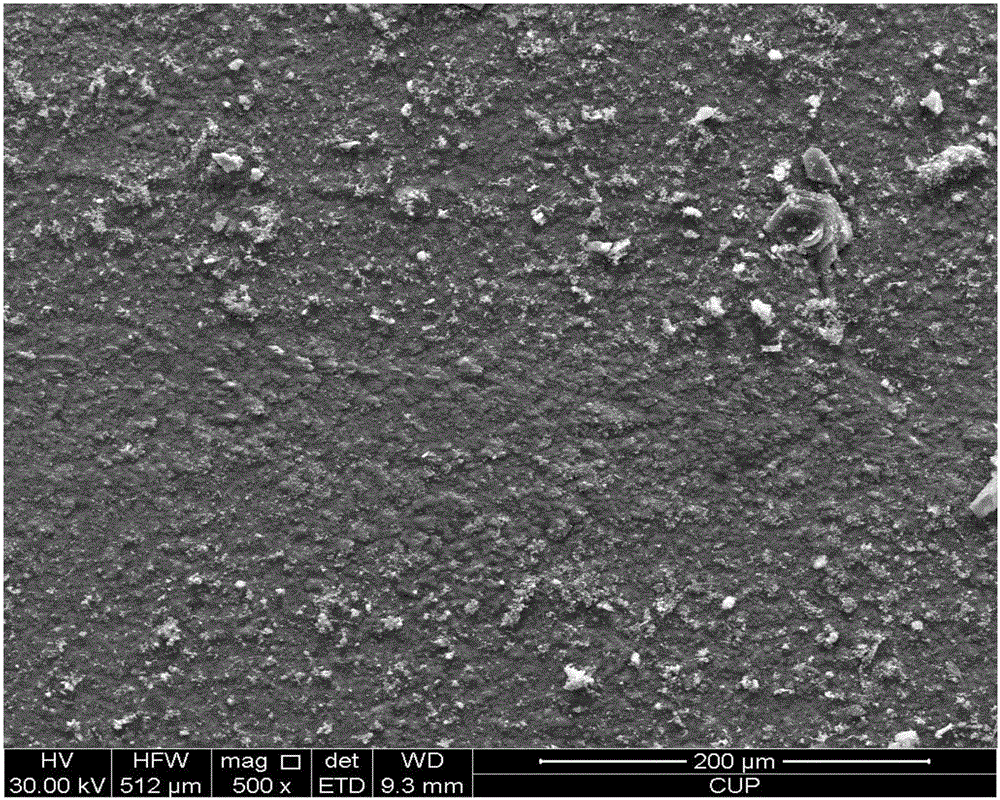

Method for preparing mesoporous MCM-22 silicon aluminum molecular sieve

InactiveCN102730711AShorten the diffusion distanceHigh crystallinityCrystalline aluminosilicate zeolitesAlkyl transferBenzene

The invention discloses a method for preparing a mesoporous MCM-22 silicon aluminum molecular sieve, which comprises the following steps: uniformly mixing the MCM-22 molecular sieve synthesized by a conventional hydrothermal method, an organic amine and 0.1M NaOH solution, filling in an enclosed reaction vessel, reacting under the self-generated pressure of 170 DEG for 1-24 hours, cooling the products, filtering, washing, drying, roasting at the temperature of 550 DEG C for 6 hours, exchanging by NH4Cl, roasting at the temperature of 550 DEG C for 6 hours again to obtain the mesoporous MCM-22 silicon aluminum molecular sieve. According to the invention, the intragranular mesoporous is introduced in the MCM-22 structure, thereby an intrastratal decacyclic sine pore and an inner part of an interlayer supercage are communicated, and the internal diffusion limitation can be improved. According to the invention, during the process of melt silicon by alkali treatment, an organic amine stable skeleton is employed, and the crystallization degree of the molecular sieve can be better maintained when the mesoporous can be prepared. The molecular sieve of the present invention is used for macro-molecule reaction, such as an alkylation reaction of benzene and isopropanol, compared with conventional MCM-22, the catalytic activity and the selectivity can be greatly enhanced, and the deactivation rate can be obviously slowed.

Owner:EAST CHINA NORMAL UNIV

Zeolite compositions and methods for tailoring zeolite crystal habits with growth modifiers

ActiveUS20150360964A1Minimized crystal thicknessShortened internal diffusion pathlengthIon-exchange process apparatusPolycrystalline material growthVolumetric Mass DensityCrystal habit

Embodiments of the invention generally provide compositions of crystalline zeolite materials with tailored crystal habits and the methods for forming such crystalline zeolite materials. The methods for forming the crystalline zeolite materials include binding one or more zeolite growth modifiers (ZGMs) to the surface of a zeolite crystal, which results in the modification of crystal growth rates along different crystallographic directions, leading to the formation of zeolites having a tailored crystal habit. The improved properties enabled by the tailored crystal habit include a minimized crystal thickness, a shortened internal diffusion pathlength, and a greater step density as compared to a zeolite having the native crystal habit prepared by traditional processes. The tailored crystal habit provides the crystalline zeolite materials with an aspect ratio of about 4 or greater and crystal surfaces having a step density of about 25 steps / μm2 or greater.

Owner:UNIV HOUSTON SYST

Trailing edge cooling slot configuration for a turbine airfoil

A gas turbine engine hollow turbine airfoil having pressure and suction sidewalls extending chordwise between leading and the trailing edges. The trailing edge includes a pressure sidewall lip and a suction sidewall lip, and a breakout distance between the pressure sidewall lip and the suction sidewall lip. A cooling fluid channel extends spanwise through the airfoil for supplying a cooling fluid to the airfoil. Flow channels are provided extending chordwise between the cooling fluid channel and the suction sidewall lip and include a metering section, an internal diffusion section and a breakout slot. The interior diffusion section includes a spanwise dimension and a widthwise dimension perpendicular to the spanwise dimension, wherein the spanwise dimension continuously increases extending in the chordwise direction, and the widthwise dimension continuously decreases extending in the chordwise direction.

Owner:SIEMENS ENERGY INC

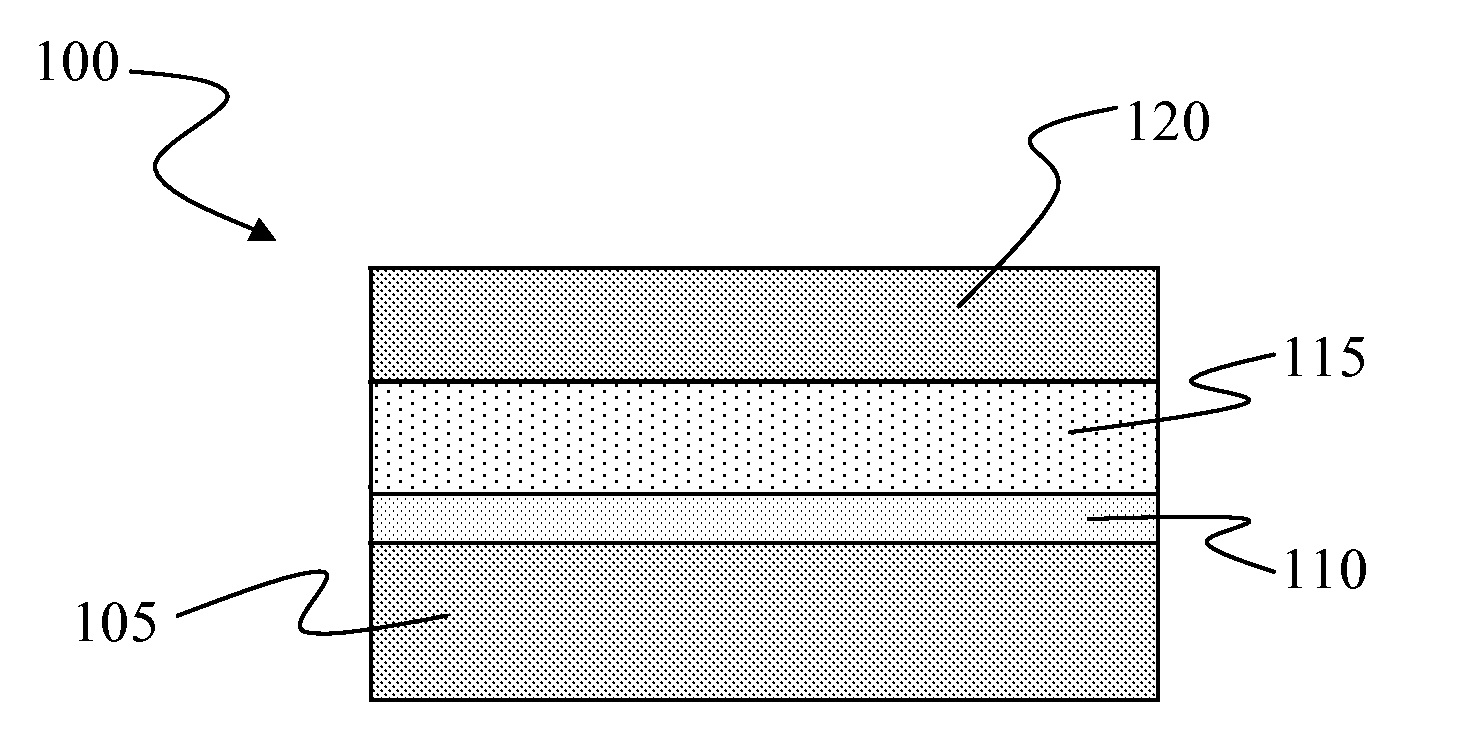

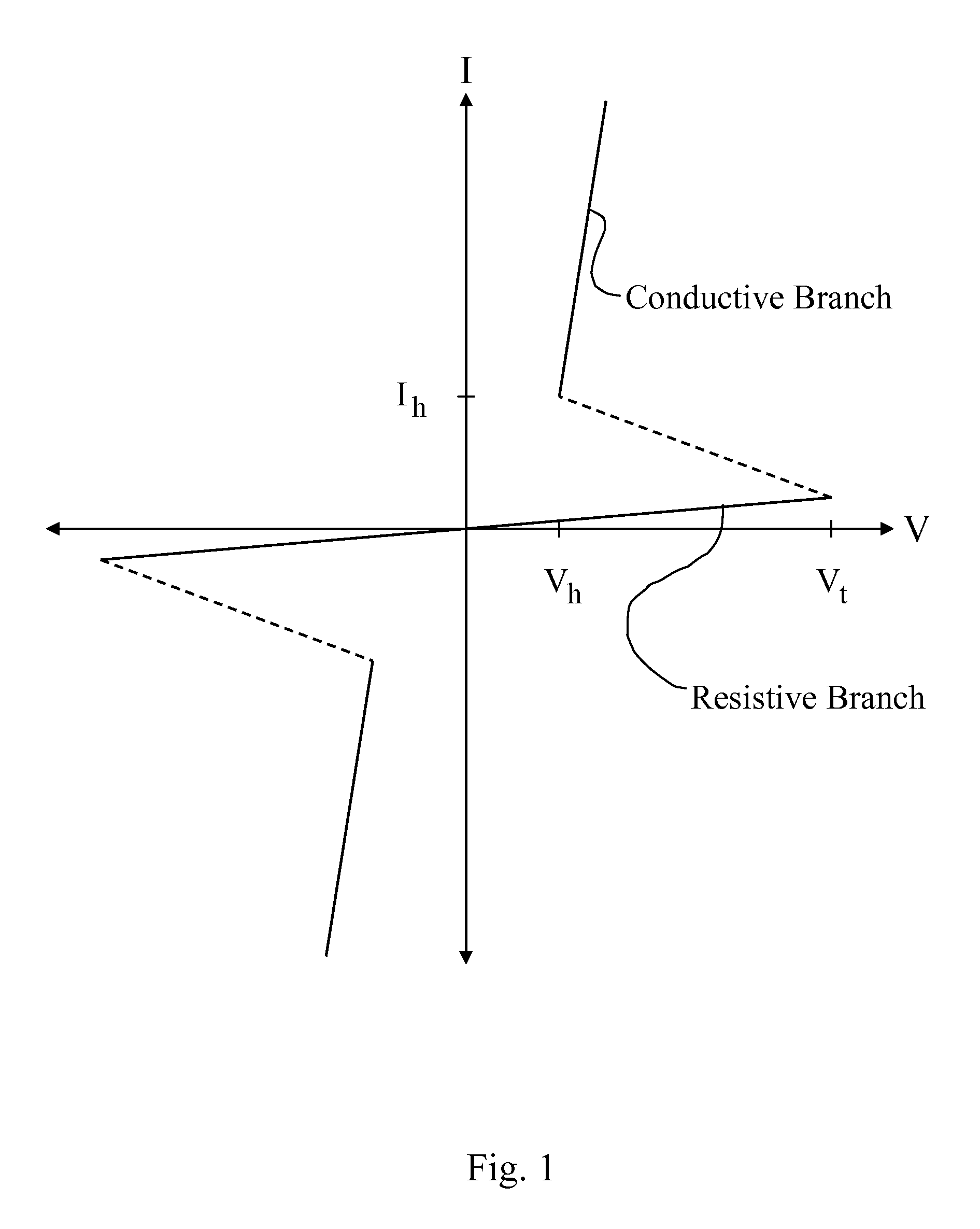

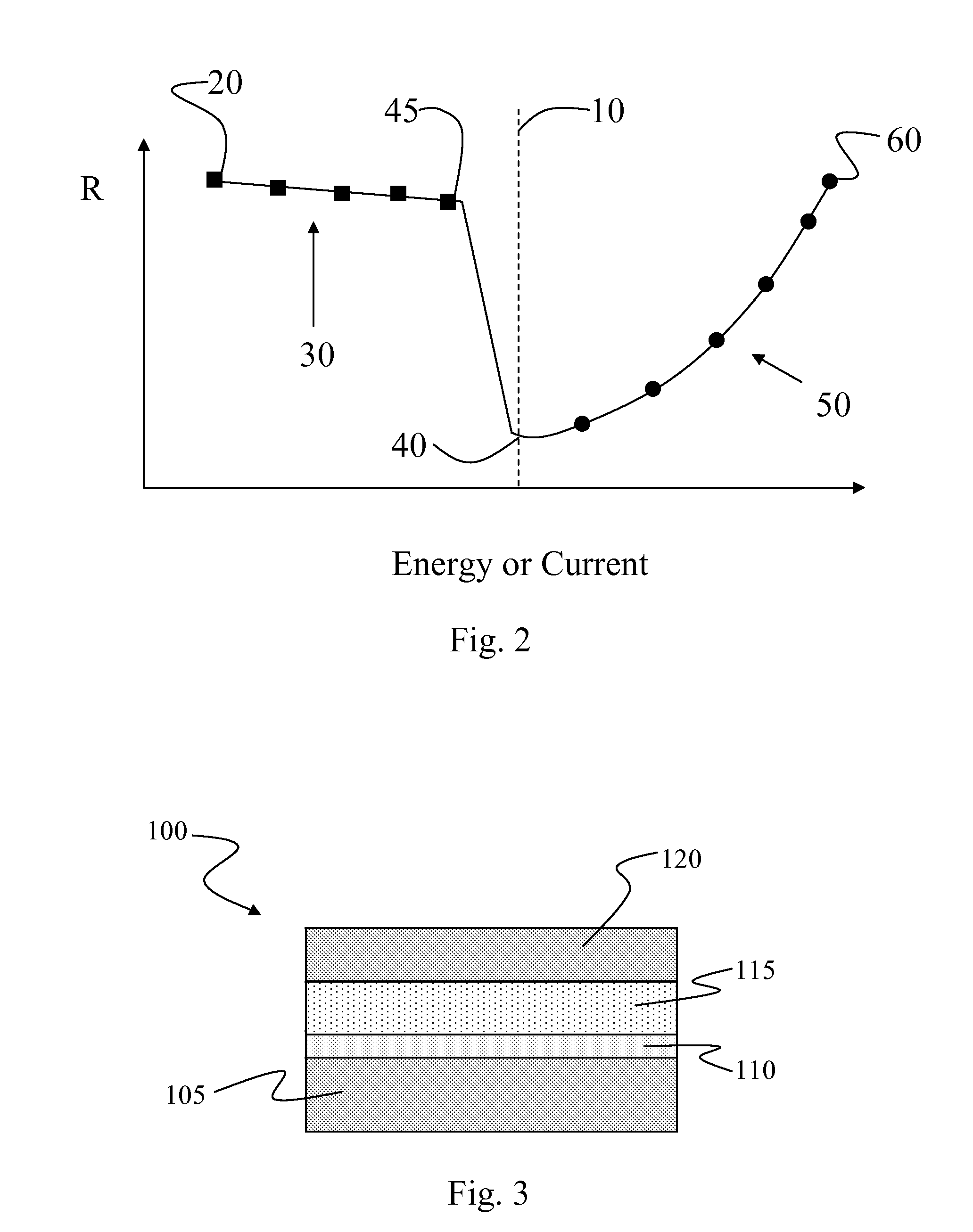

Breakdown Layer via Lateral Diffusion

ActiveUS20100301988A1Reducing variation in performanceGood uniformityDigital storageResistive material coatingLateral diffusionPhase-change material

An electronic device including a breakdown layer having variable thickness. The device includes a variable resistance material positioned between two electrodes. A breakdown layer is interposed between the variable resistance material and one of the electrodes. The breakdown layer has a non-uniform thickness, which serves to bias the breakdown event toward the thinner portions of the breakdown layer. As a result, the placement, size, and number of ruptures in the breakdown layer are more consistent over a series or array of devices. The variable resistance material may be a phase-change material. The variable-thickness breakdown layer may be formed through a diffusion process by introducing a gas containing a resistivity-enhancing species to the environment of segmented variable resistance devices during fabrication. The resistivity-enhancing element penetrates the outer perimeter of the variable resistance material and diffuses toward the interior of the device. The resistivity-enhancing species increases the resistance of the interface between the variable resistance material and the electrode by interacting with the variable resistance material and / or electrode to form a resistive interfacial material. Based on the diffusional nature of the process, the concentration of the resistivity-enhancing species decreases toward the center of the device and as a result, the breakdown layer is thinner toward the center of the device.

Owner:OVONYX MEMORY TECH LLC

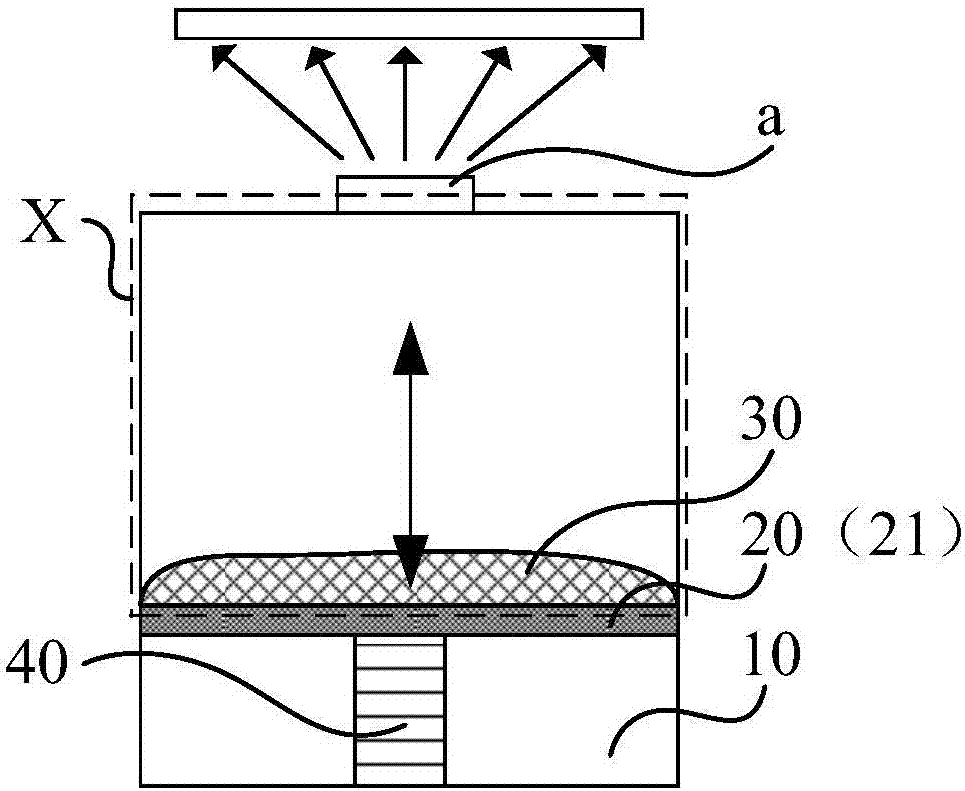

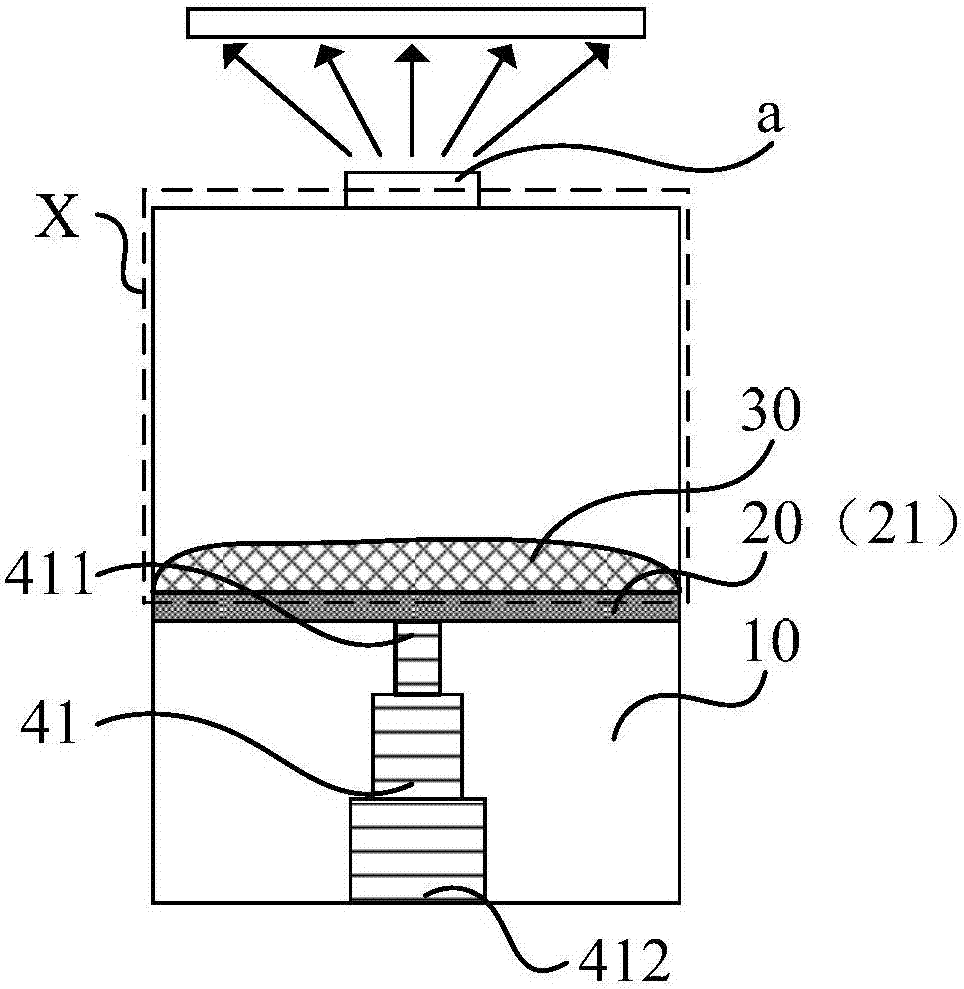

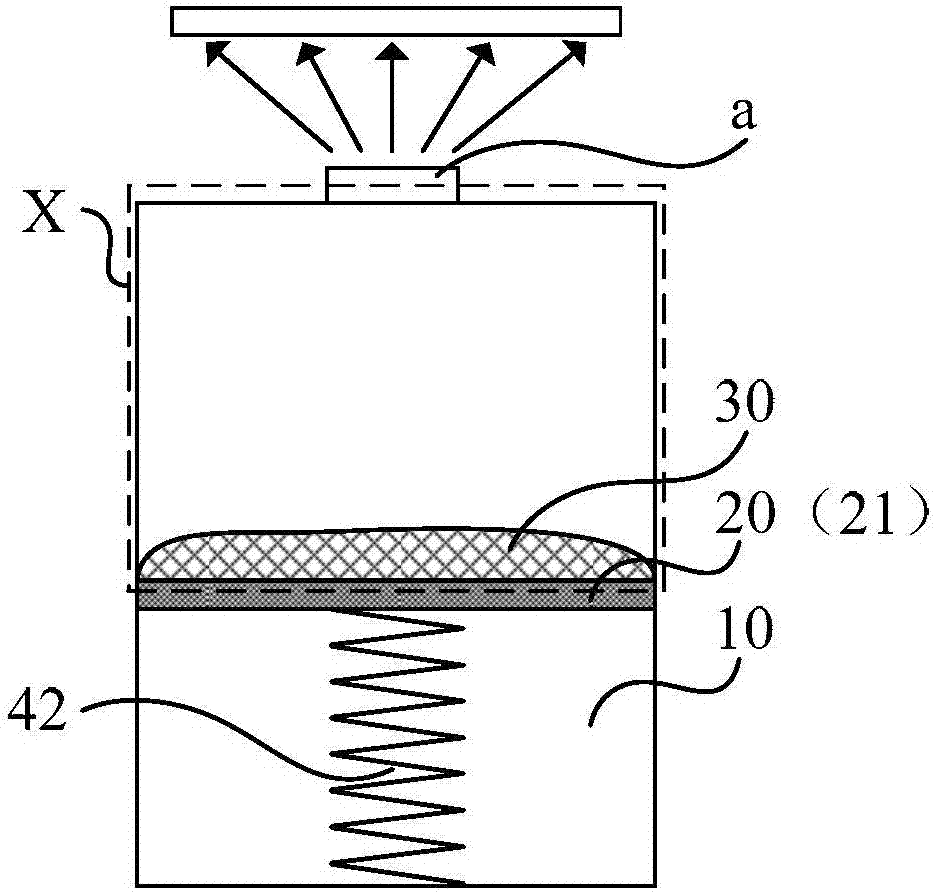

Evaporation source, evaporation device and evaporation method

ActiveCN106987807AImprove stabilityAvoid decompositionVacuum evaporation coatingSputtering coatingChemistryInternal diffusion

The embodiment of the invention provides an evaporation source, an evaporation device and an evaporation method, and relates to the field of vacuum evaporation coating. The problems that when evaporation materials are subjected to gasification evaporation in an existing evaporation crucible, due to the fact that the internal diffusion space is increased, the evaporation rate is decreased, and the evaporation effect is affected are solved. The evaporation source comprises an evaporation crucible, a moving table and a moving mechanism, wherein the moving table is arranged in the evaporation crucible and at least comprises a bottom plate, the bottom plate is used for containing the evaporation materials, an evaporation cavity is formed by the moving table, the side face of the evaporation crucible and the upper surface of the evaporation crucible in an encircling manner, the moving mechanism drives the moving table to move in the evaporation crucible in the direction of being perpendicular to the bottom plate, and the upper surface of the evaporation crucible is provided with an evaporation material outlet.

Owner:BOE TECH GRP CO LTD +1

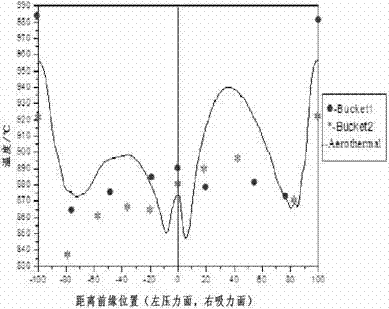

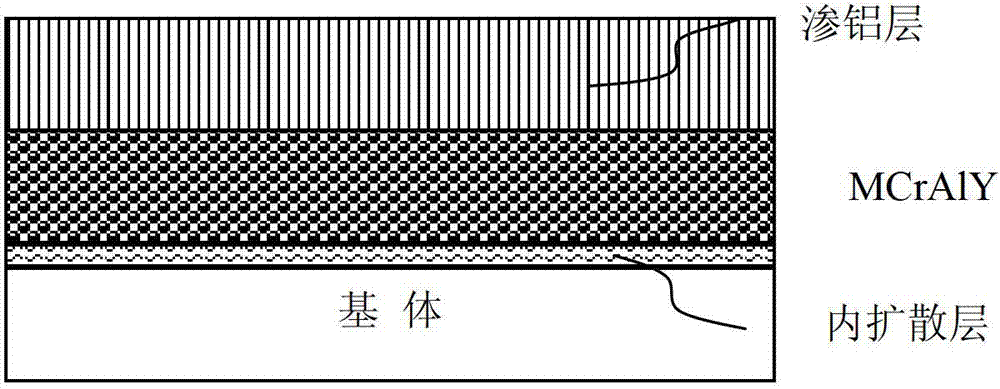

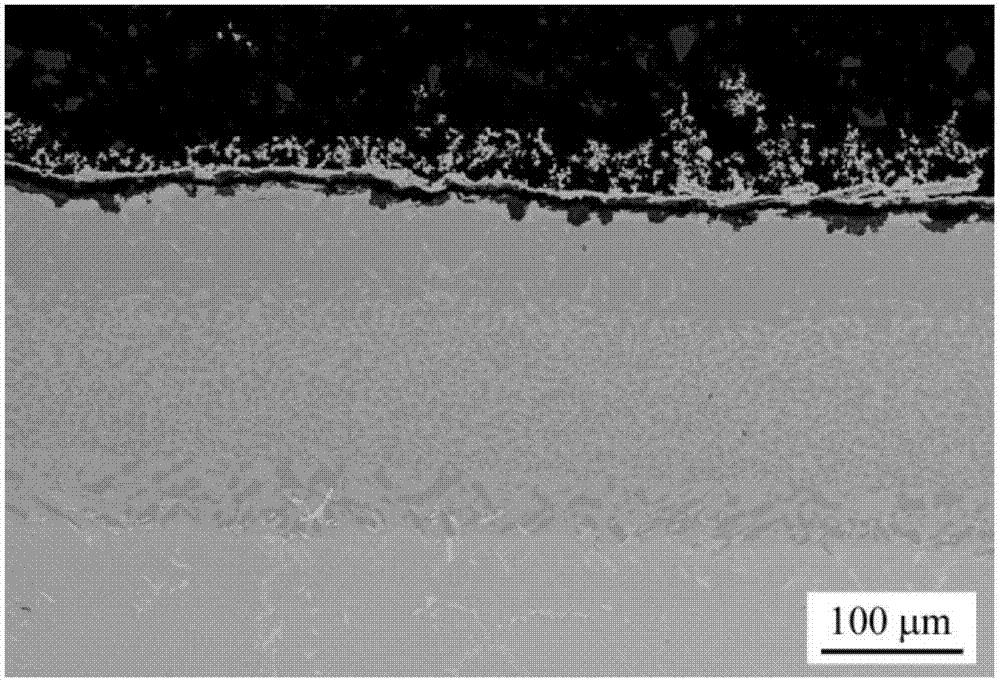

Method for predicting temperature range of high-temperature alloy coating of segment of blading of gas turbine

ActiveCN102788811AJudging safetyNo dangerMaterial heat developmentPredictive methodsWorking environment

A method for predicting temperature range of a high-temperature alloy coating of a segment of blading of a gas turbine belongs to the technical fields of service life prediction of hot parts of gas turbine and service state monitoring of surface coating. According to the invention, experiments and numerical calculation are combined to determine tissue change of the coating, so as to obtain a size L of an internal diffusion tissue in the coating; the L is substituted into a life prediction calculation model to predict a temperature, so as to carrying out temperature prediction on surface coating of the segment of blading of the gas turbine after service; meanwhile, temperature of the high temperature alloy matrix material is calculated out according to an aerodynamic heat value, a transfer value and a strength value; and a coating calculation temperature is obtained by temperature correction, and is then compared with an experimental temperature of the coating, so as to obtain a coating temperature closer to an actual working environment, and provide temperature parameters for further life prediction.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

Method for preparing catalyst and application thereof

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

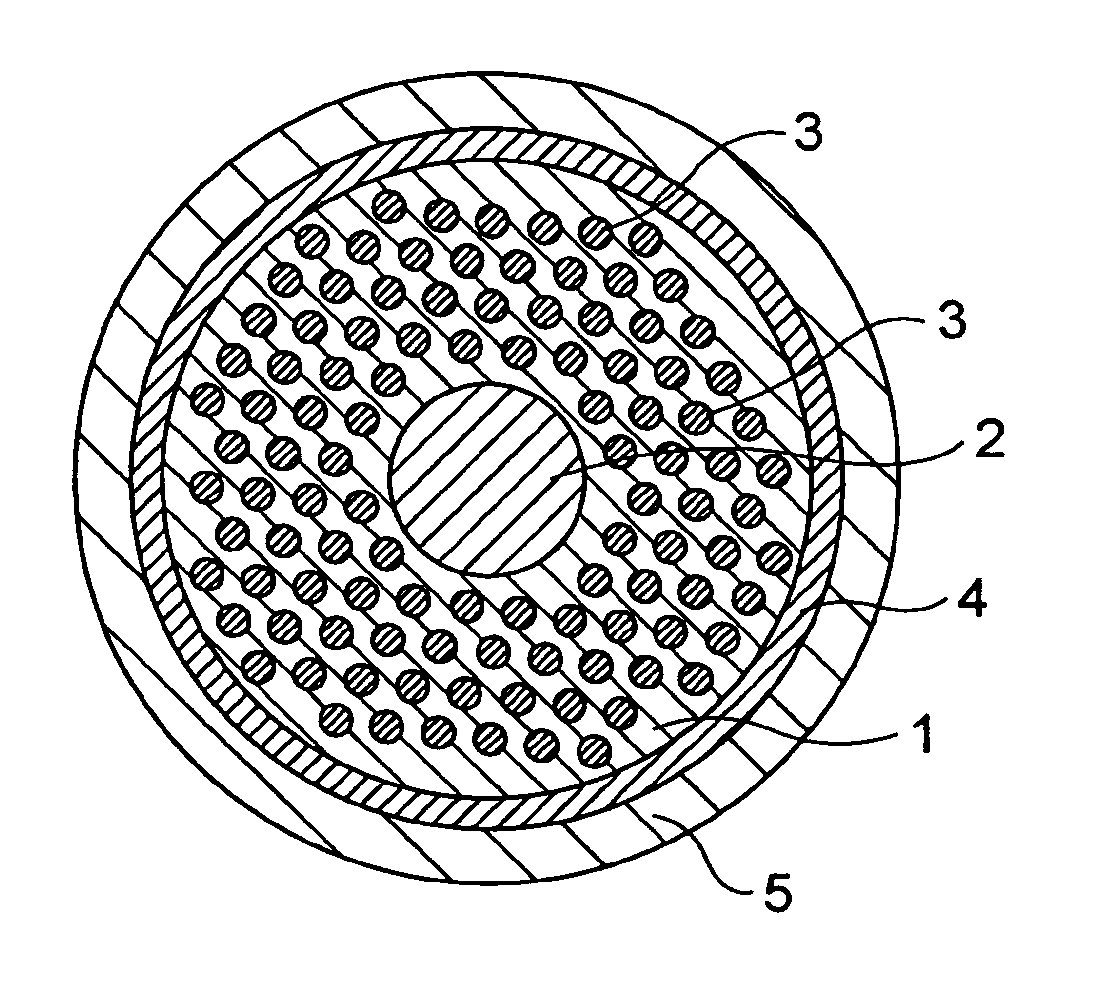

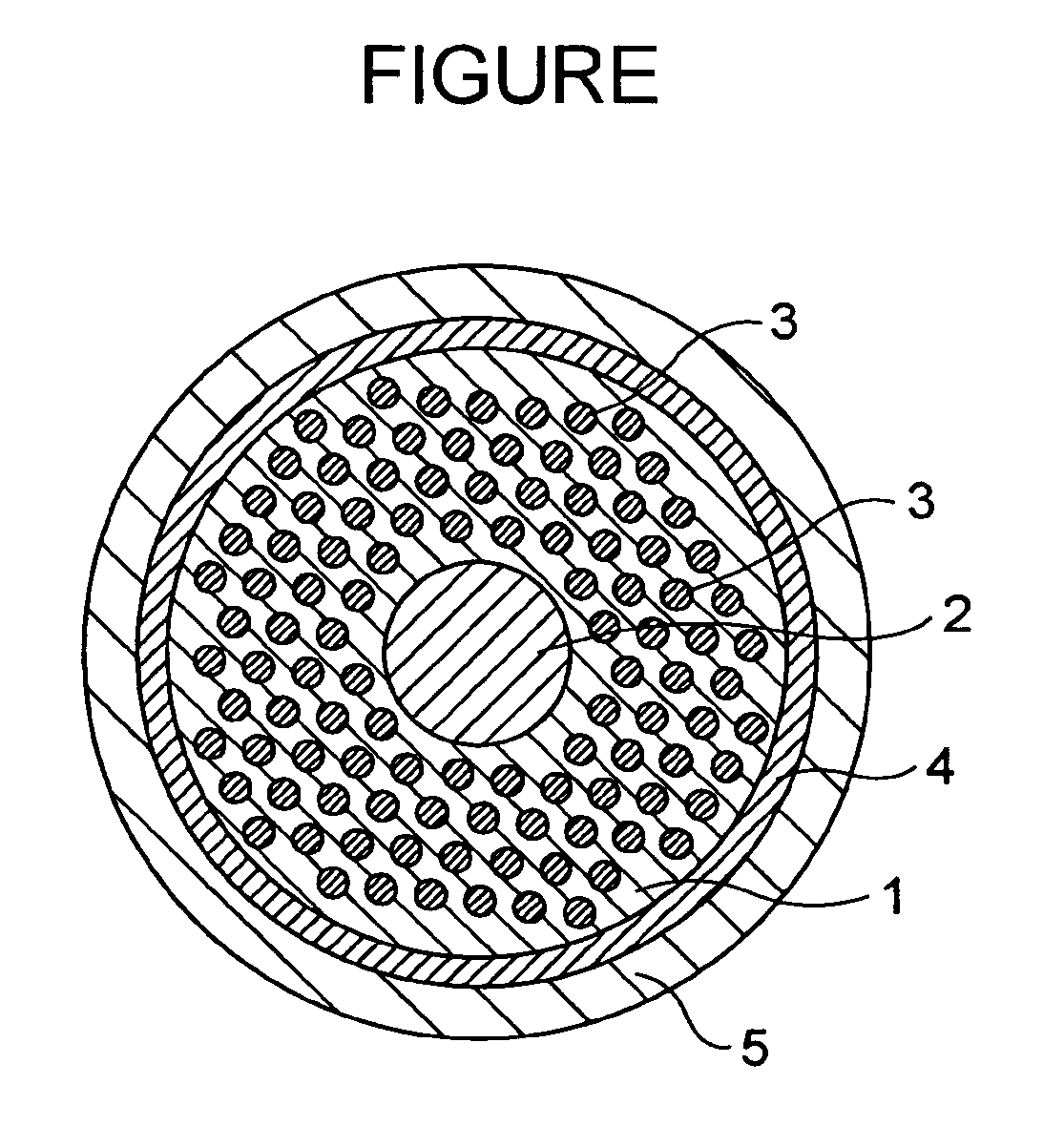

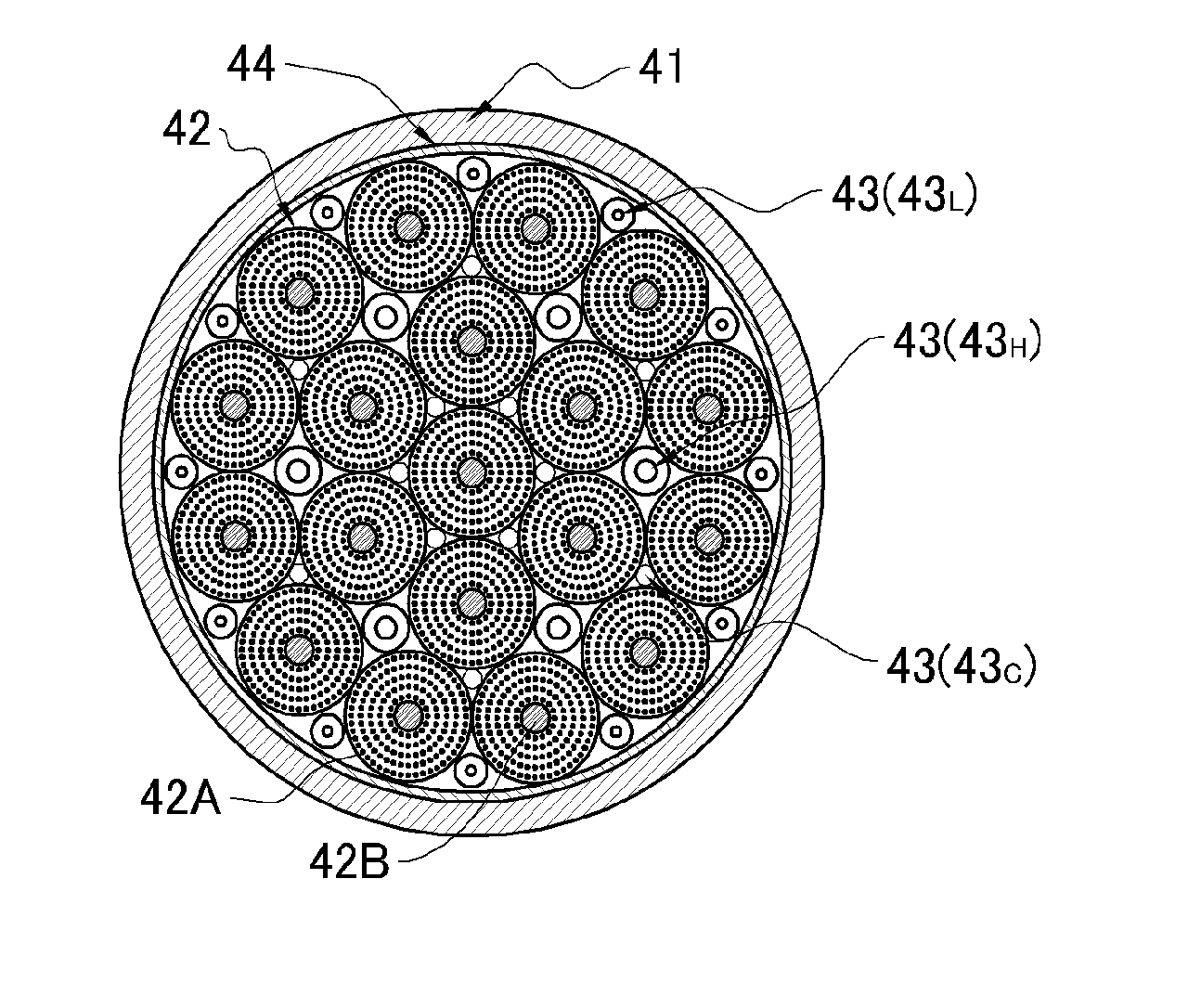

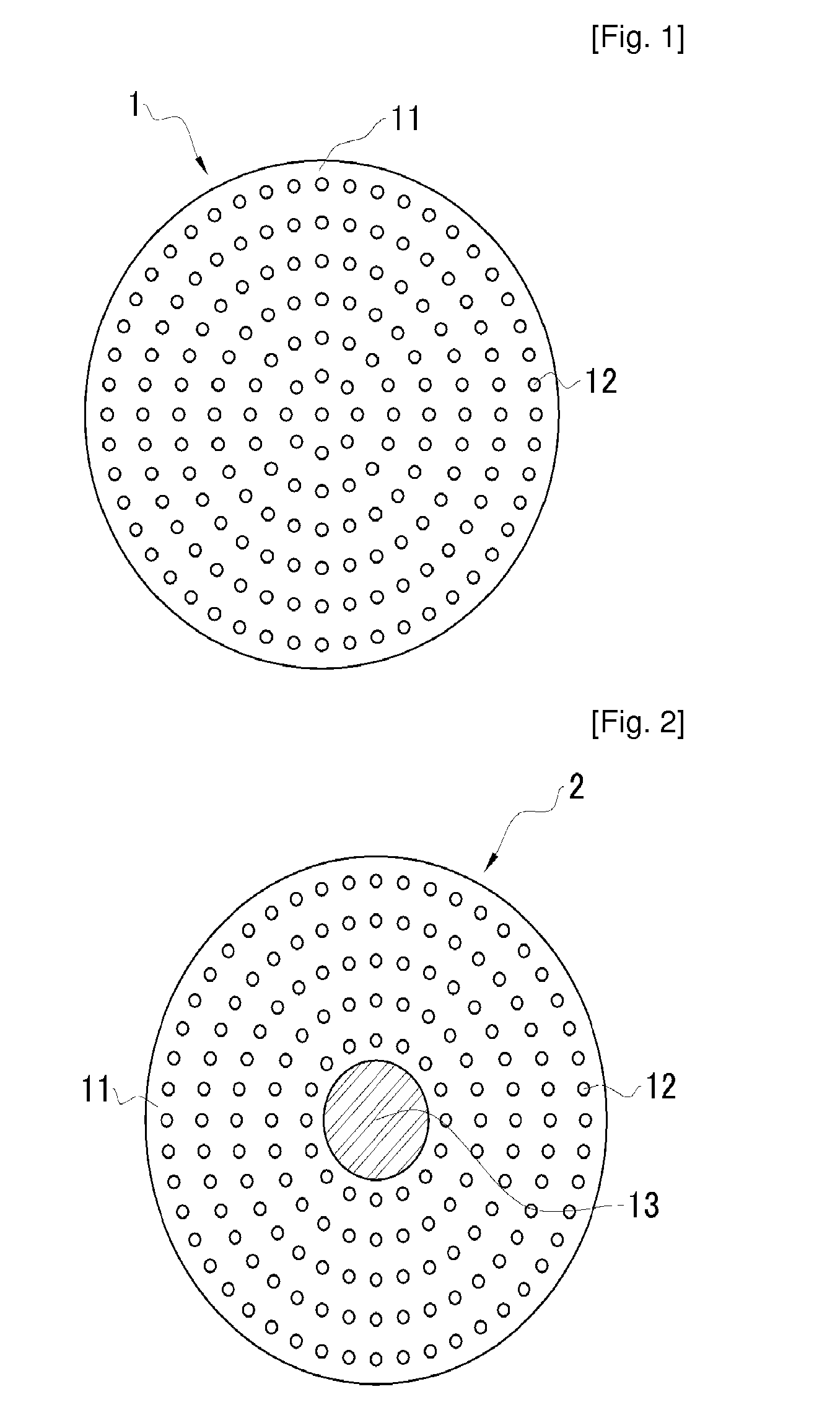

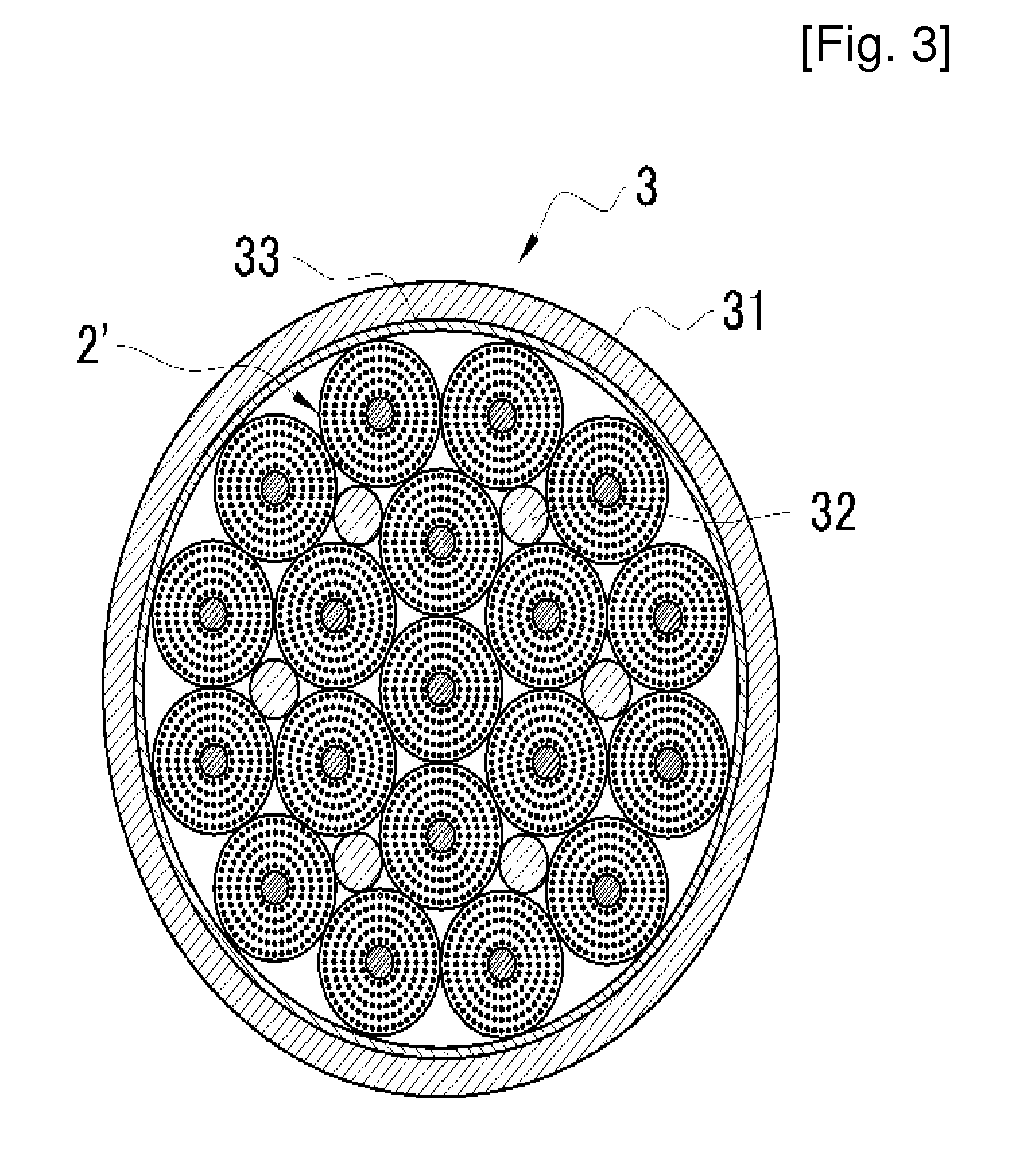

Internal diffusion process nb3sn superconducting wire

InactiveUS20090176650A1High currentLow-cost NMRSuperconductor device manufacture/treatmentAlloyDiffusion barrier

An internal diffusion process Nb3Sn superconducting wire is produced by drawing a composite wire including a composite material containing a plurality of Nb or Nb based alloy cores embedded in a Cu or Cu based alloy matrix and a Sn or Sn based alloy core disposed in the center portion, a diffusion barrier layer composed of Nb or Ta and disposed on the outer perimeter of the composite material, and stabilizing Cu disposed on the outside of the diffusion barrier layer and heat-treating the resulting composite wire so as to diffuse Sn and react Sn with the Nb or Nb based alloy cores, wherein the area percentage of the stabilizing Cu in a cross section in a direction perpendicular to the axis center of the composite wire is 10% to 35% and the area percentage of the diffusion barrier layer is 10% to 25%.

Owner:KOBE STEEL LTD

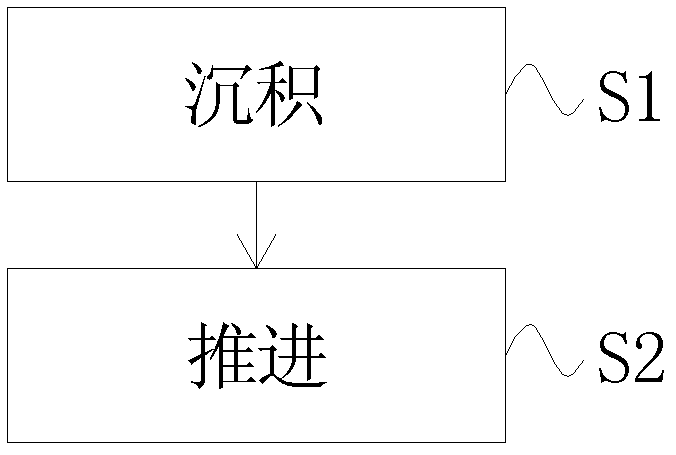

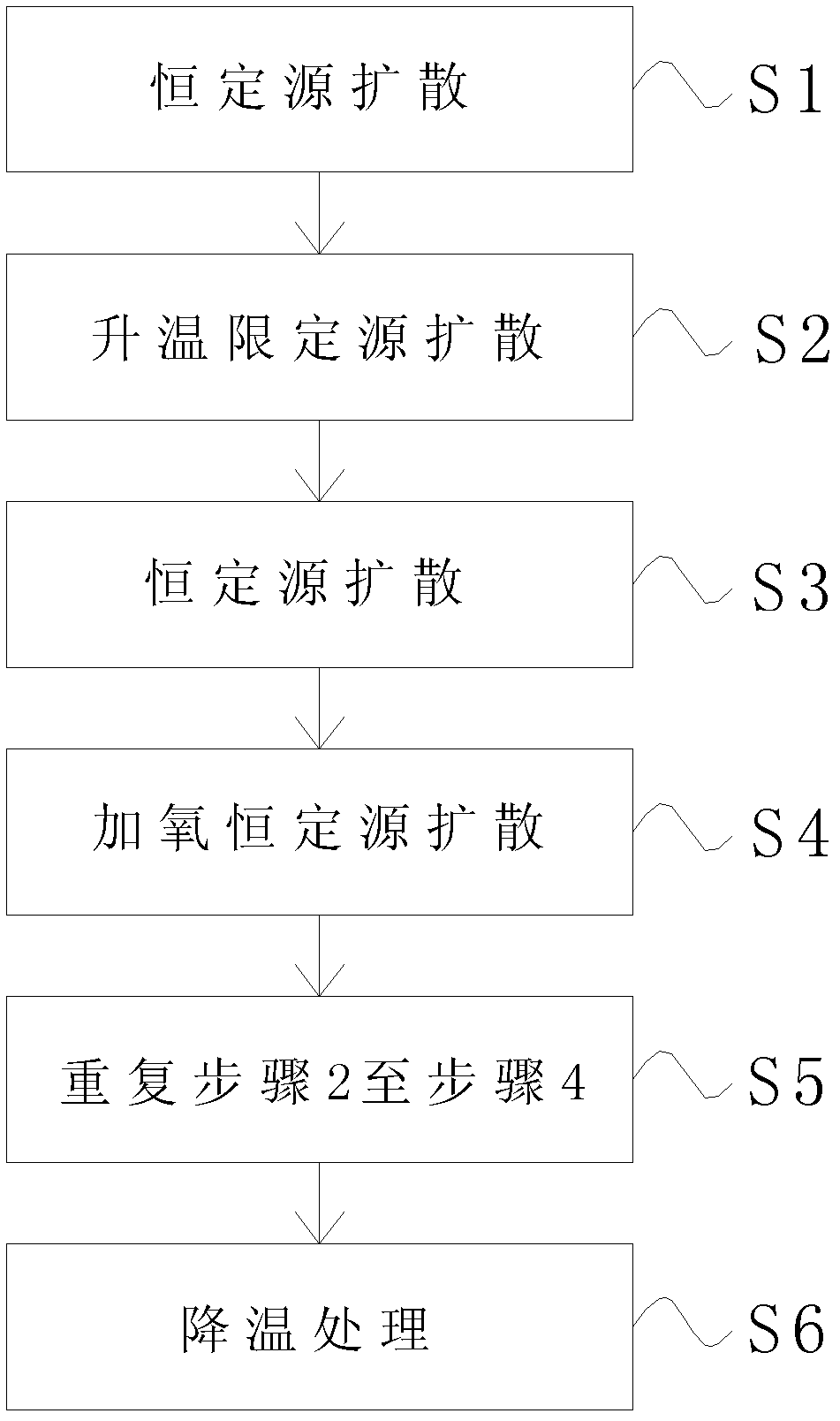

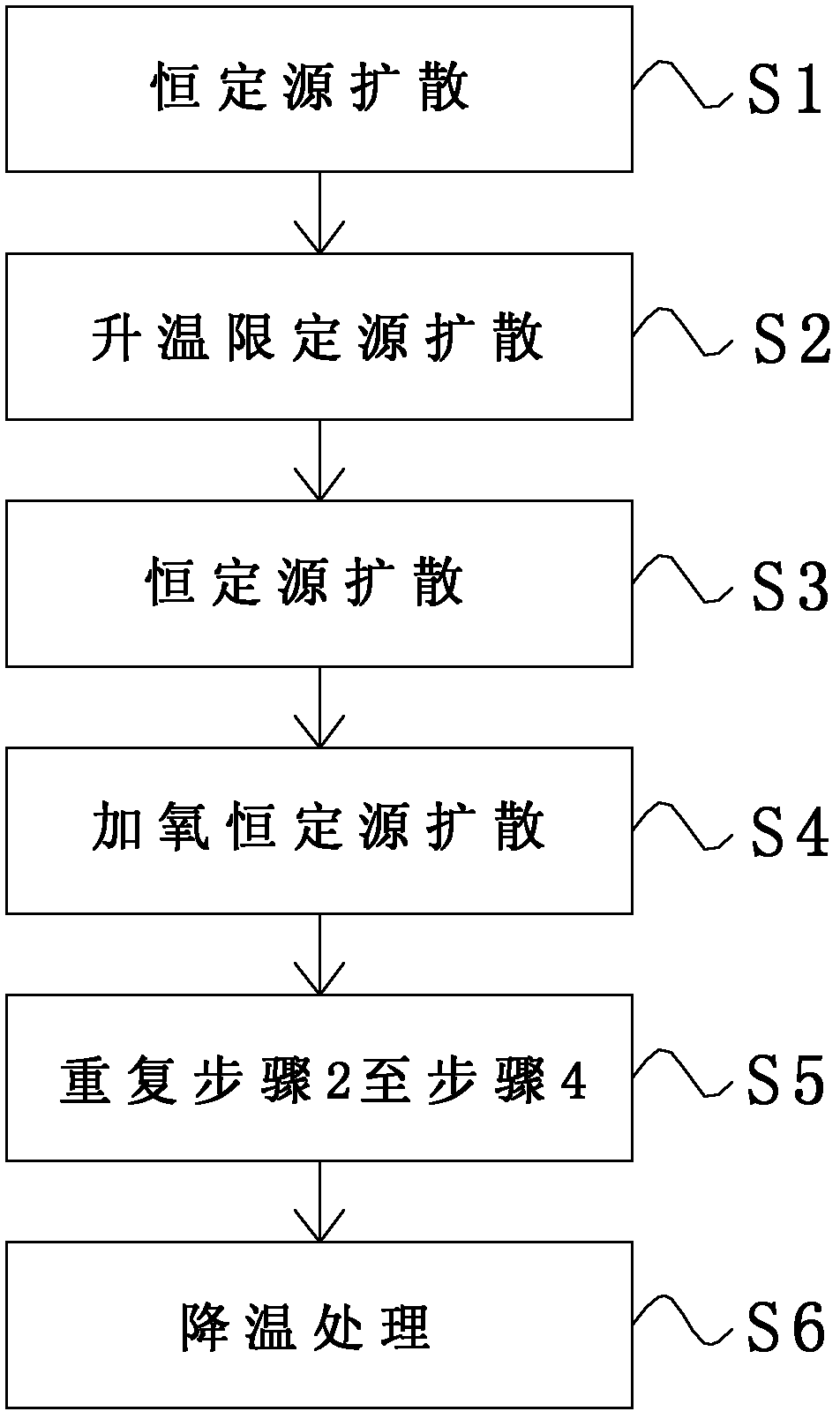

Multi-diffusion manufacturing method for polycrystalline silicon wafer

ActiveCN102544238ASolve the problem that the front and back colors are not easy to distinguishFinal product manufactureDiffusion/dopingDiffusionSurface layer

The invention discloses a multi-diffusion manufacturing method for a PN junction manufactured of a polycrystalline wafer. The multi-diffusion manufacturing method comprises the following steps of: S1, depositing, by constant source diffusion, an impurity source of certain concentration on the surface layer on which a P layer is required to be formed; S2, heating finite source diffusion to perform internal diffusion on a deposited impurity source phase polycrystalline wafer to control junction depth of the PN junction and gradient distribution of an impurity source; S3, depositing, by the constant source diffusion, the impurity source of the certain concentration on the surface layer of the P layer of the polycrystalline wafer again; S4, increasing, by oxygenation constant source diffusion, flux of oxygen under the conditions of unchanged temperature and a continuous flux source, wherein the step aims to increase the surface color of the P layer of the polycrystalline wafer, so that a front face and a back face of the polycrystalline wafer are differentiated during subsequent operation, and the hydrophilicity of the P layer can also be improved by increase in oxygen flux, so that an over large etching edge is reduced; and S5, repeating the step S2 to the step S4. Through the steps, the aim of solving the problem of difficulty in differentiating the colors of the front face and the back face existing after manufacturing of the PN junction of the polycrystalline wafer can be fulfilled.

Owner:YINGLI ENERGY CHINA

Diester-based fat chain organosilane quaternary ammonium salt compound and preparation method and application thereof

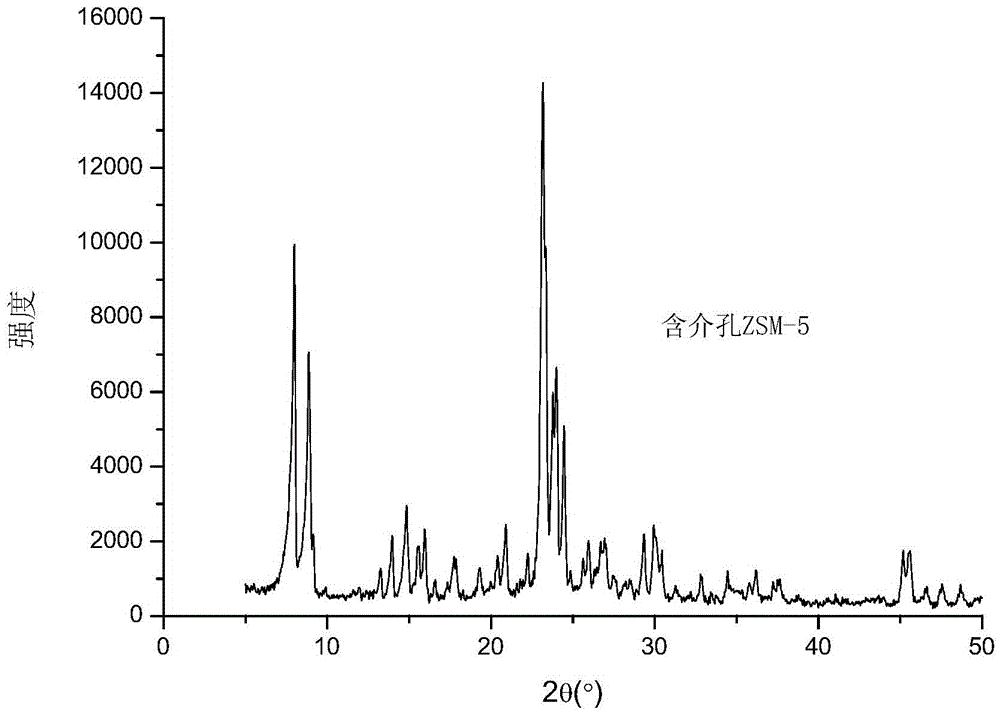

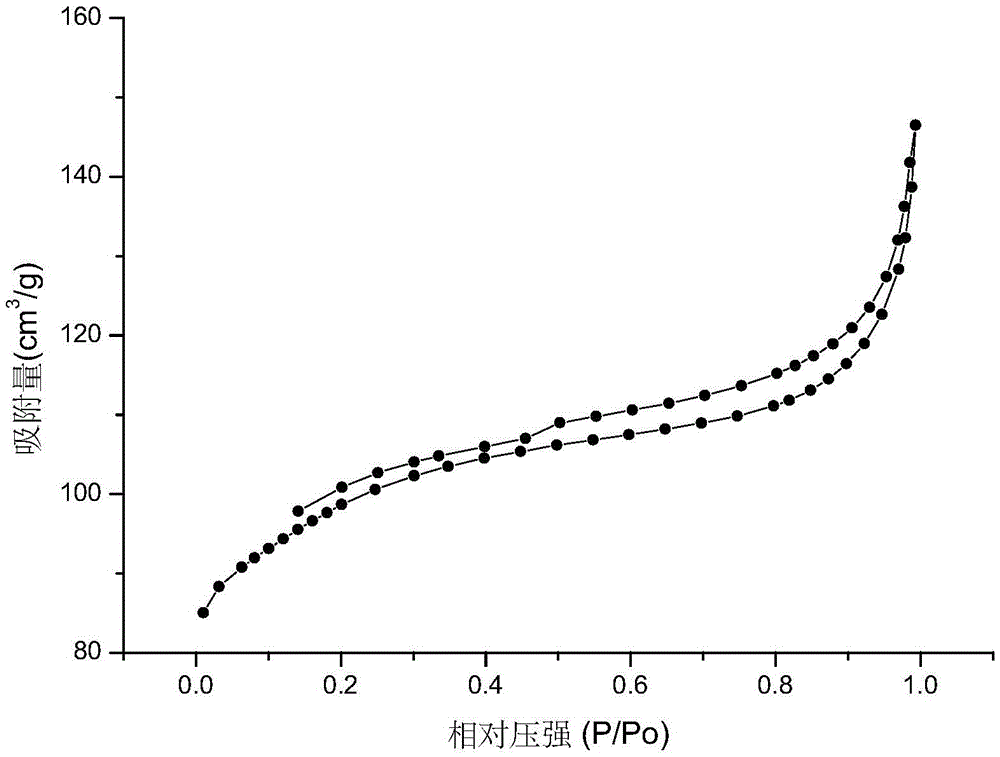

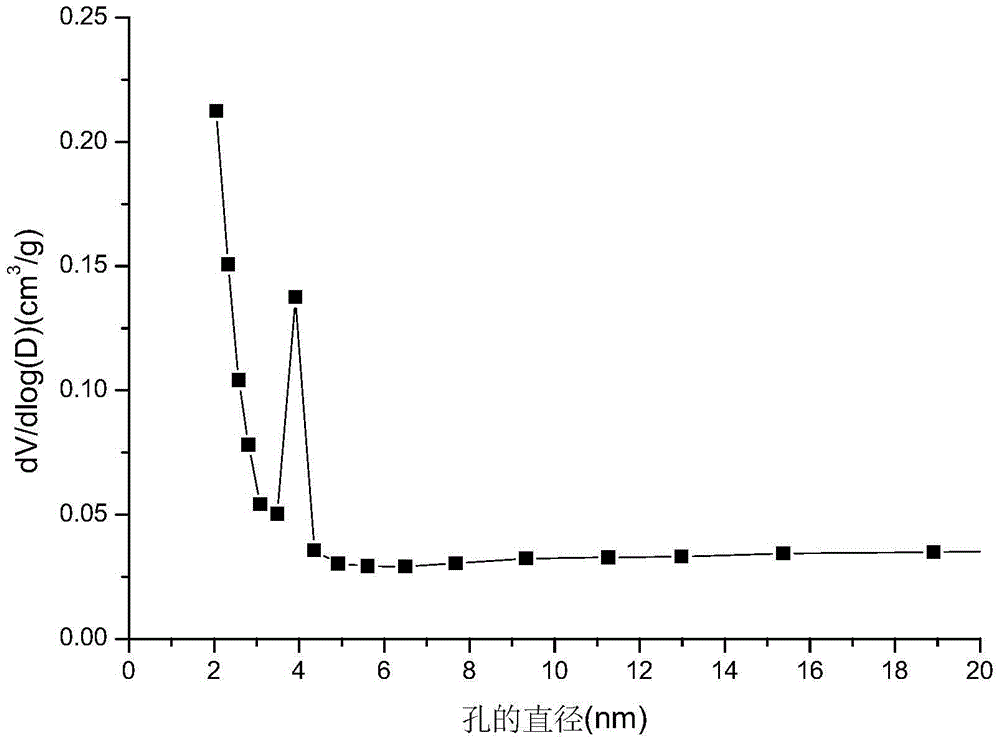

InactiveCN105646562AHigh pore volumeIncrease the areaGroup 4/14 element organic compoundsPentasil aluminosilicate zeoliteMolecular sieveHalogen

The invention relates to a diester-based fat chain organosilane quaternary ammonium salt compound and a preparation method and application thereof. The structural formula of the compound can be found in description, wherein m is an arbitrary integer from 2 to 9, n is an arbitrary integer from 1 to 19, and X is Cl, Br or I. The preparation method includes the steps that N-methyldiethanolamine and fatty acid are subjected to a reaction for 1-24 hours at the temperature of 100-200 DEG C, a dichloromethane solution is added, washing, drying and column chromatography are conducted, and a diester-based fat chain midbody is obtained; then the diester-based fat chain midbody and halogen alkyl trimethoxy silane react for 1-24 hours at the temperature of 80-150 DEG C, cooling and washing are conducted, and the diester-based fat chain organosilane quaternary ammonium salt compound is obtained. The organosilane quaternary ammonium salt compound is applied to preparation of a ZSM-5 zeolite molecular sieve containing mesoporous. By the application of the quaternary ammonium salt compound, the pore volume and specific area of the ZSM-5 zeolite molecular sieve containing mesoporous are remarkably raised, and internal diffusion limit is improved; a specific template agent stabilizing framework is adopted so that the obtained molecular sieve can be applicable to a macromolecules reaction.

Owner:DONGHUA UNIV

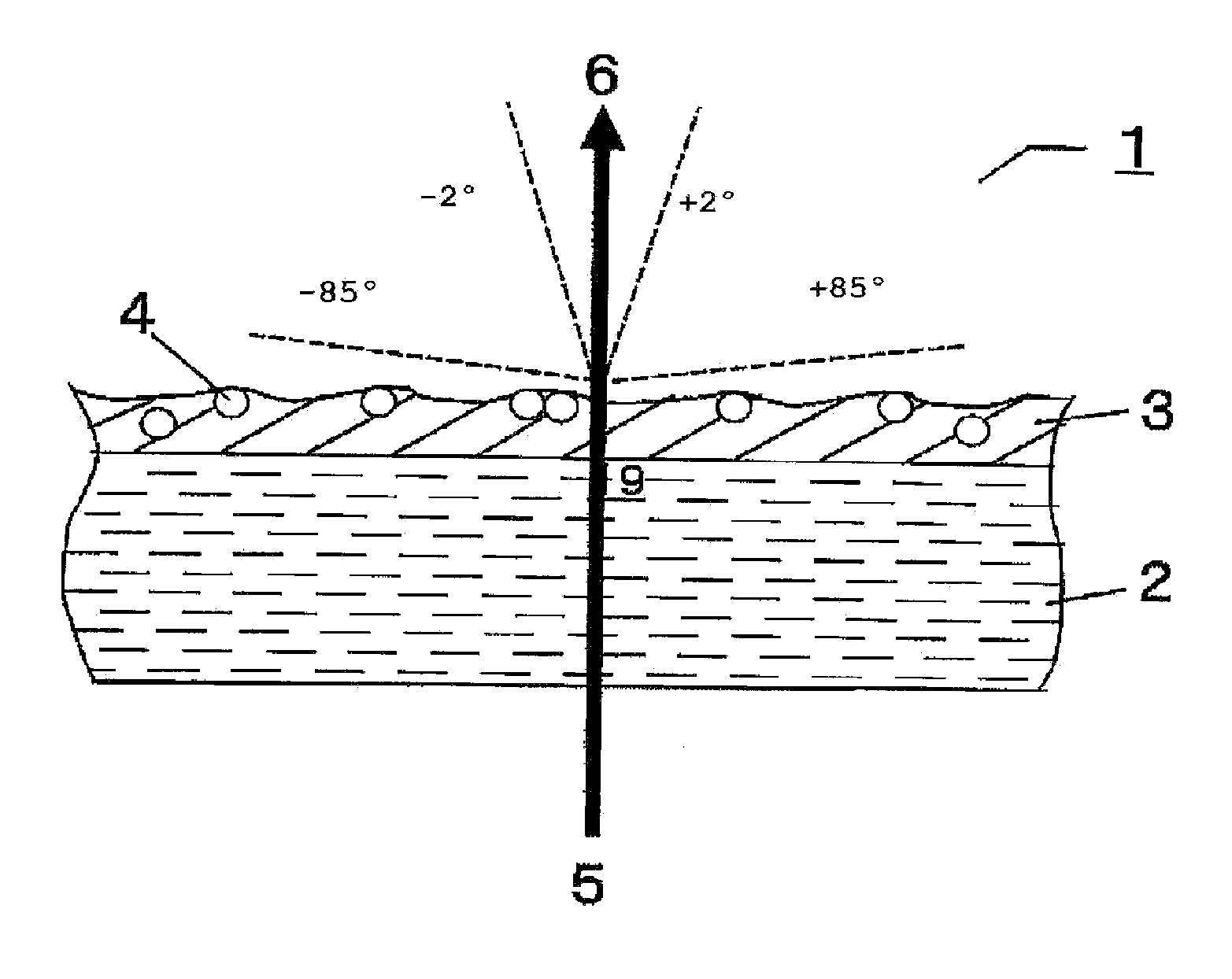

Anti-glare sheet for liquid crystal display device

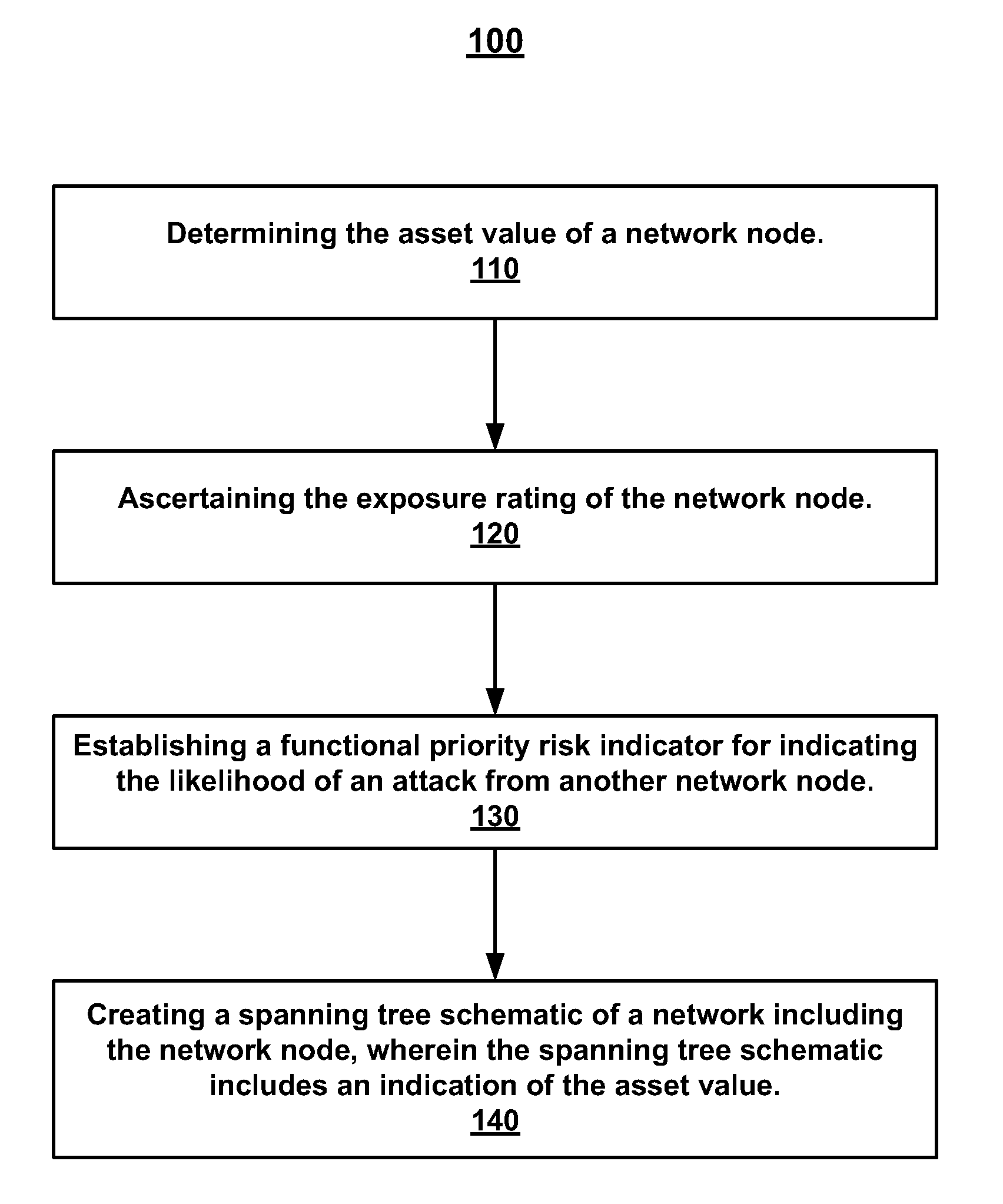

ActiveUS20130027641A1Excellent vivid complexionGood blacknessNon-linear opticsOptical elementsSkin complexionLiquid-crystal display

To provide an anti-glare sheet for a liquid crystal display device with excellent vivid complexion and blackness and excellent image crispness, that is suitable for combination of dynamic images and still images.An anti-glare sheet for a liquid crystal display device having a diffusion factor in the interior on at least one side of a transparent base material and provided with a functional layer with an irregular surface on the side opposite the transparent base material side, and either having or not having a transparent resin layer with a film thickness of 1.0 μm or greater on the side of the functional layer opposite the transparent base material side, the anti-glare sheet for a liquid crystal display device satisfying the following inequalities (1), (2), (3) and (4), where Q is the intensity of regular transmission, U is the transmission intensity determined by extrapolating a straight line connecting the transmission intensities at regular transmission ±2 degree and regular transmission ±1 degree, to regular transmission, when visible light rays have been irradiated on the anti-glare sheet for a liquid crystal display device, T (μm) is the sum of the thicknesses of the layer having a diffusion factor in the interior and the transparent resin layer, Ha (%) is the haze of the anti-glare sheet for a liquid crystal display device, and Hi (%) is the haze produced by internal diffusion factors.2.15<Q / U<24.18 (1)0.2%<Ha−Hi<13.7% (2)1.3%≦Hi<35.0% (3)2.3 μm<T<12.4 μm (4)

Owner:DAI NIPPON PRINTING CO LTD

Security intrusion mitigation system and method

A security intrusion mitigation system and method are presented. In one embodiment a security intrusion mitigation method includes utilizing network spanning tree configuration information to determine an action for mitigating diffusion of intrusive attacks. The spanning tree information can include an indication of an internal diffusion risks. An action for mitigating diffusion of intrusive attacks is automatically performed. The action for mitigating diffusion of the intrusive attacks includes compensation for functional support of prioritized applications.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

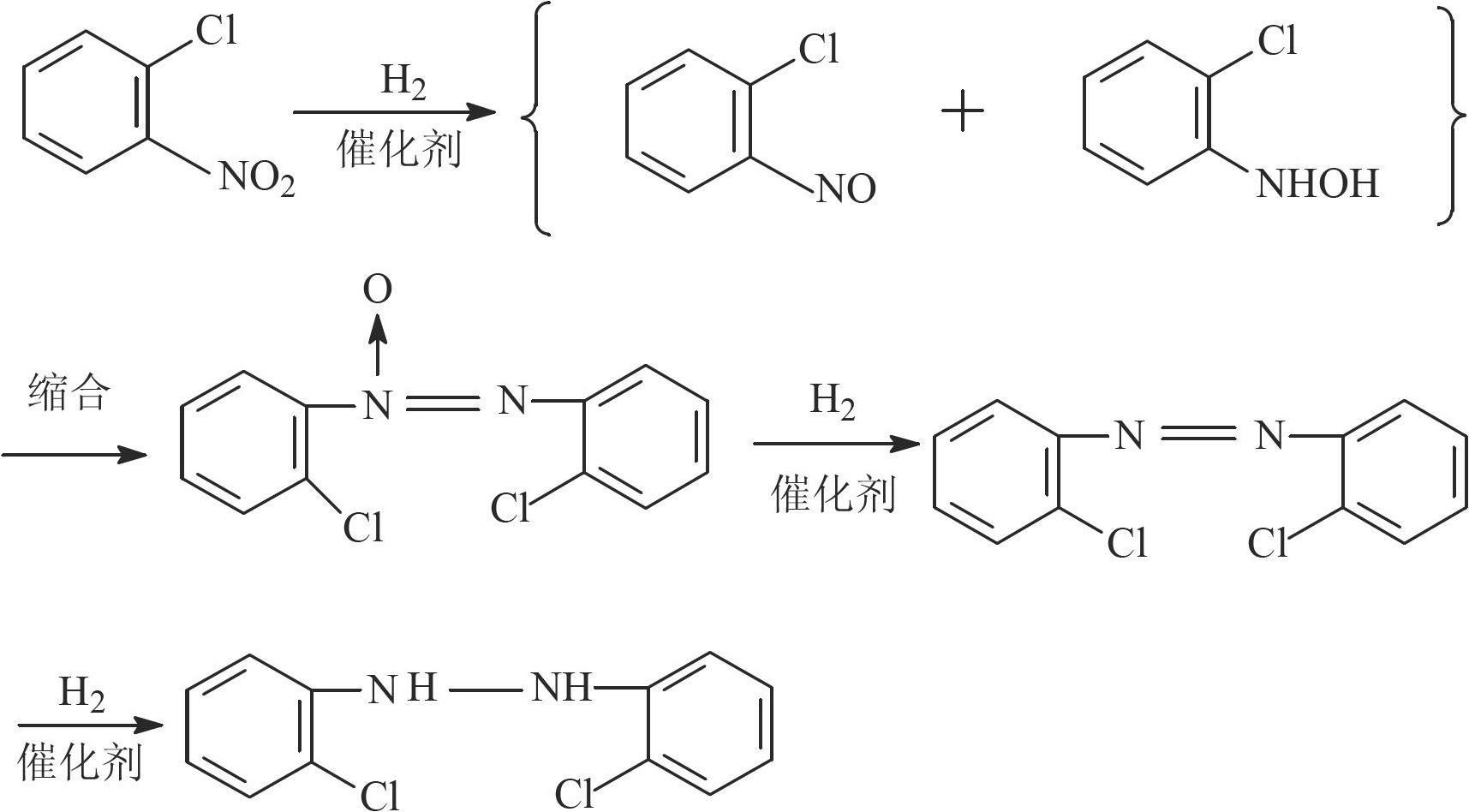

Pt-load catalyst taking mesoporous carbon as carrier, as well as preparation method and usage thereof

InactiveCN102671656AAdvantages of preparation methodHigh reactivityHydrazine preparationMetal/metal-oxides/metal-hydroxide catalystsO-nitrochlorobenzenePretreatment method

The invention relates to a Pt-load catalyst taking mesoporous carbon as a carrier, which is characterized in that the mesoporous carbon is pretreated before Pt is loaded; the pretreatment method comprises one in the following steps of: (1) adding the mesoporous carbon into a 10-30% hydrogen dioxide solution, soaking for 1-24hours, washing and removing hydrogen peroxide; (2) adding the mesoporous carbon into a 1-6M hydrochloric acid or nitric acid solution, soaking for 1-24hours, washing and removing hydrochloric acid or nitric acid; and (3) adding the mesoporous carbon into a 1-6M sodium hydroxide solution, soaking for 1-24hours, washing and removing alkali, wherein the load quantity of Pt is 0.5-5%. The invention also relates to the application of the Pt-load catalyst in preparation of 2, 2'-dichloro hydroazobenzene (DHB) from ortho-nitrochlorobenzene through hydrogenation. The catalyst uses the mesoporous carbon as the carrier, so that the internal diffusion resistance can be better reduced, and the reaction speed is accelerated. The Pt-load catalyst is high in reaction activity and selectivity, and can be repeatedly used for more than eight times, so that the using cost of the catalyst is lowered.

Owner:CHANGZHOU UNIV +1

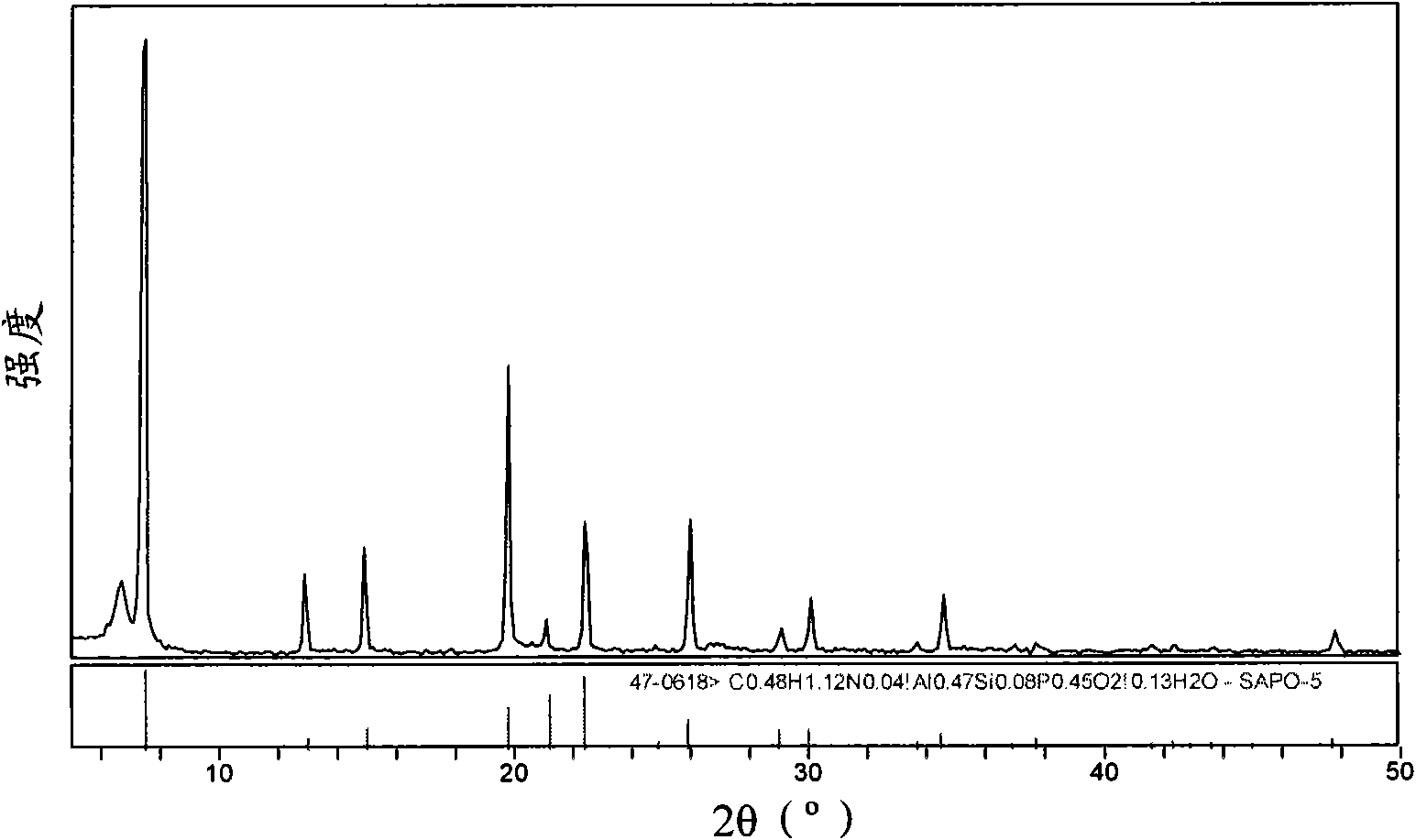

Method for preparing silicon-aluminum-phosphorus molecular sieve from montmorillonite, product obtained by method and application thereof

ActiveCN101891222AFacilitated DiffusionWidely distributedMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveMontmorillonite

The invention relates to a method for preparing a silicon-aluminum-phosphorus molecular sieve from montmorillonite, a molecular sieve product obtained by the method and application thereof. The method comprises the following steps of: activating the montmorillonite with alkaline solution; mixing the activated montmorillonite, an aluminum source, a phosphorus source, a template and de-ionized water; and performing hydrothermal crystallization reaction on the mixture, wherein the product after the crystallization comprises a small-sized silicon-aluminum-phosphorus molecular sieve grown on a laminar structure and free silicon-aluminum-phosphorus molecular sieve. The silicon-aluminum-phosphorus molecular sieve prepared from the montmorillonite serving as a raw material is partially the small-sized silicon-aluminum-phosphorus molecular sieve grown on the laminar structure, so the influence of internal diffusion of reactant molecules and product molecules can be effectively reduced; and the silicon-aluminum-phosphorus molecular sieve is partially the free silicon-aluminum-phosphorus molecular sieve. An active skeletal silicon source formed by activating the montmorillonite with the alkaline solution contributes to forming a small-grain silicon-aluminum-phosphorus molecular sieve on the surface of the montmorillonite laminar structure and diffusing the reactant molecules and the product molecules; and the montmorillonite is widely distributed in China and has low cost, so the cost for synthesizing the silicon-aluminum-phosphorus molecular sieve is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

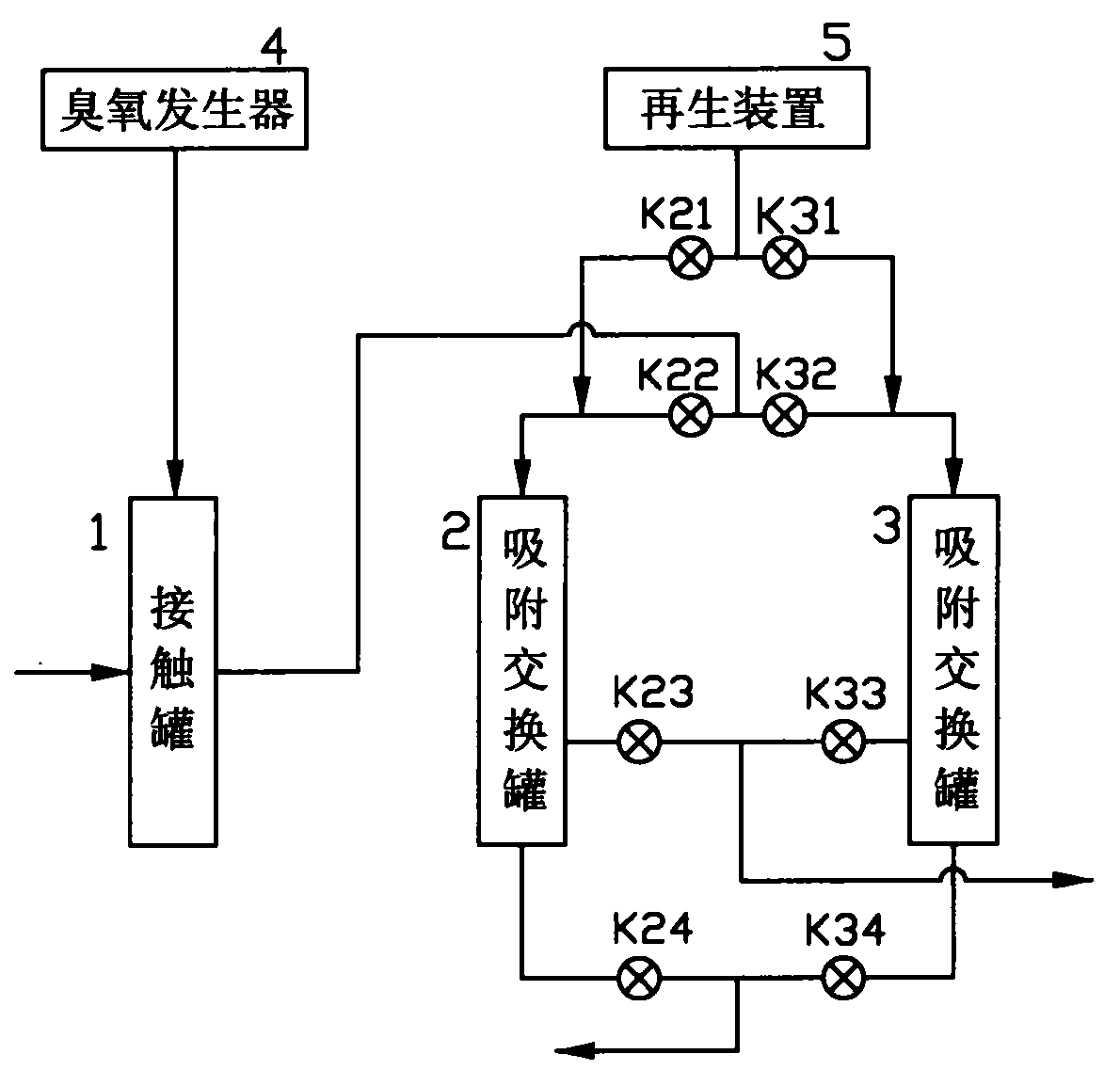

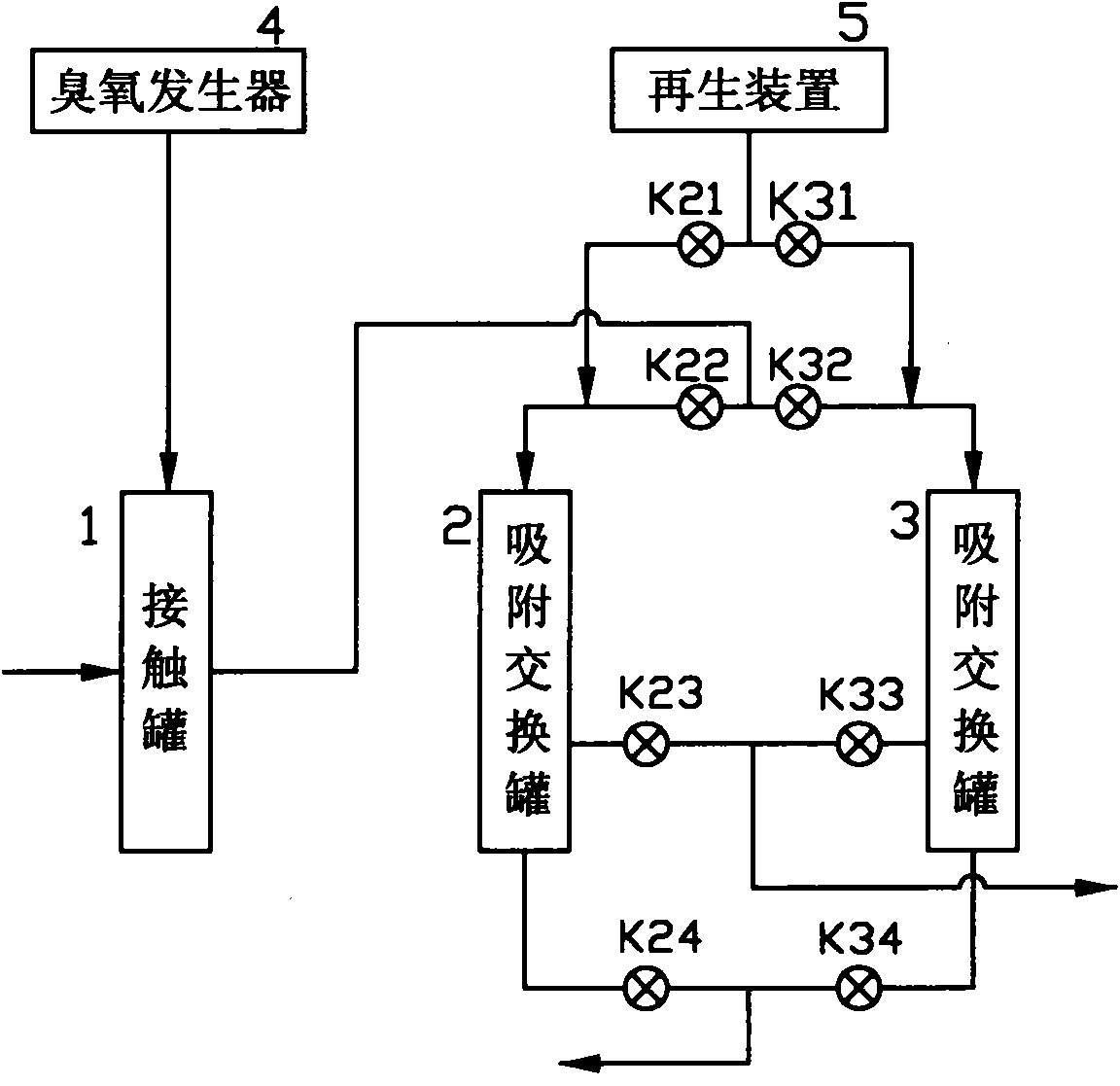

Electroplating wastewater treatment process and equipment

InactiveCN101774725AExtend the lifespanAvoid the hassle of changing adsorbent materialsWaste water treatment from metallurgical processWater/sewage treatment by ion-exchangeIon exchangeOrganic matter

The invention relates to electroplating wastewater treatment process and equipment. The process mainly comprises the following steps that: an organic matter and a heavy metal ion in water are physically adsorbed by a composite material; after being physically adsorbed, the organic matter is degraded by microorganisms to destroy the adsorbing balance so that the physical adsorption is continuously carried out; and after being physically adsorbed, the heavy metal ion enters the interior of the composite material in an internal diffusion way and carries out ion exchange with the composite material to destroy the adsorbing balance so that the physical adsorption is continuously carried out. The invention prolongs the service life of an adsorbing material and avoids the trouble for frequently replacing the adsorbing material.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

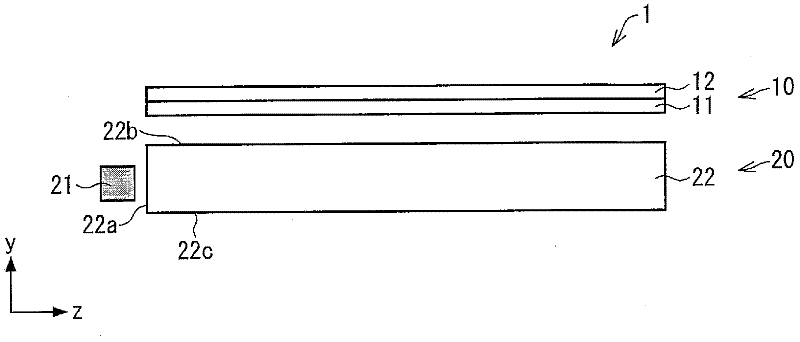

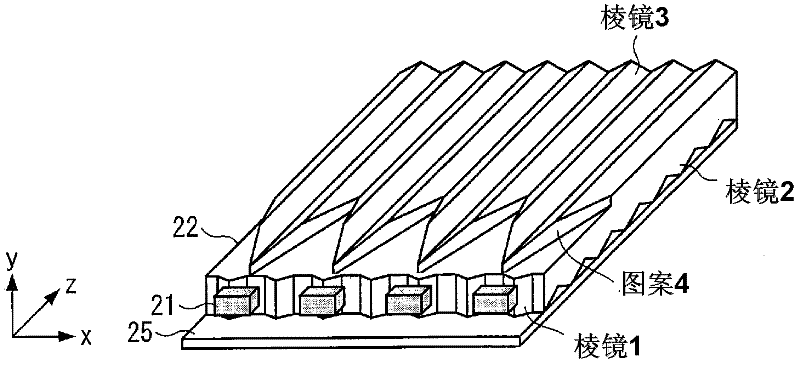

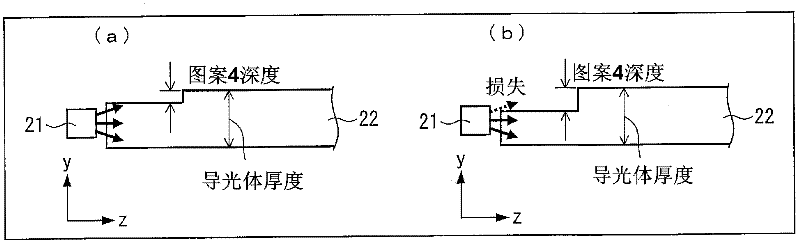

Planar lighting device and display device having same

Owner:SHARP KK

Superconducting wire and manufacturing method thereof

ActiveUS20100317530A1Improve conformityIncrease productivitySuperconductors/hyperconductorsSuperconductor device manufacture/treatmentCopperTin

Disclosed is a superconducting wire and a method for manufacturing the same, in which spacer are inserted into each space formed between modules, the spacers being different kinds according to a shape of each space when a restacking billet is manufactured in an internal diffusion method for manufacturing a Nb3Sn superconducting wire. One of a copper spacer and a low tin / copper spacer having a sectional area rate of copper / tin more than 6.0 is arranged between three modules as well as between two modules and a diffusion preventing tube, and a high tin / copper spacer having a sectional area rate of copper / tin less than 0.01˜1.5 or a middle tin / copper spacer having a sectional area rate of copper / tin less than 1.5˜6.0 is arranged between four modules.

Owner:KAT CO LTD

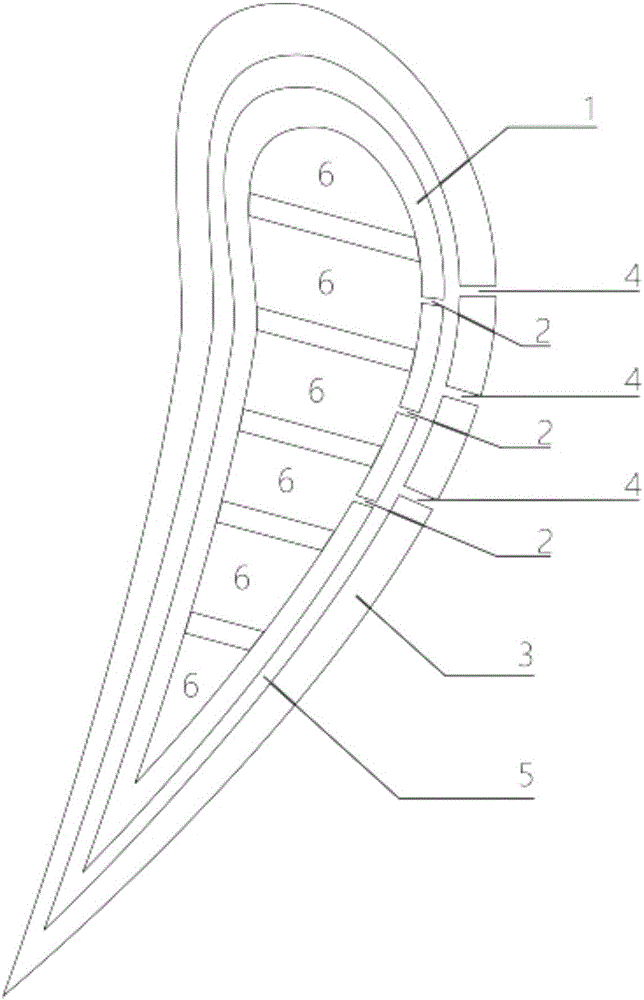

Method for preparing protective coating suitable for blade with high Mo content and complex inner cavity structure

InactiveCN105695929AEasy to operateEasy to implementSolid state diffusion coatingGas phaseSuperalloy

The invention discloses a method for preparing a protective coating suitable for a blade with the high Mo content and a complex inner cavity structure and belongs to the technical field of high-temperature alloy coatings and preparation thereof. The preparation method comprises the steps of fluorinion cleaning of an inner cavity of the blade and preparation of a gas phase alumetizing silicon coating. The purpose of fluorinion cleaning of the inner cavity of the blade is to remove a residual oxide layer on the wall of the inner cavity so as to provide conditions for subsequent preparation of the gas phase alumetizing silicon coating. The surface layer of the gas phase alumetizing silicon coating is an aluminum-silicon coating. Discontinuous MoSi2 phases are formed below the aluminum-silicon coating through internal diffusion of silicon atoms and chemical combination of molybdenum elements in alloy. The formed MoSi2 layer consumes the molybdenum elements close to the surface layer, can also restrain continuous external diffusion of the molybdenum elements in the alloy and has the functions of a diffusion preventing layer. The situation that the molybdenum elements externally diffuse to the coating surface to form MoO3 gas phase oxides, so that the integrity of an oxide film is damaged is avoided; and accordingly the aluminum-silicon diffusion coating is especially suitable for high-temperature alloy components with the complex inner cavity structures and the high Mo content.

Owner:BEIHANG UNIV

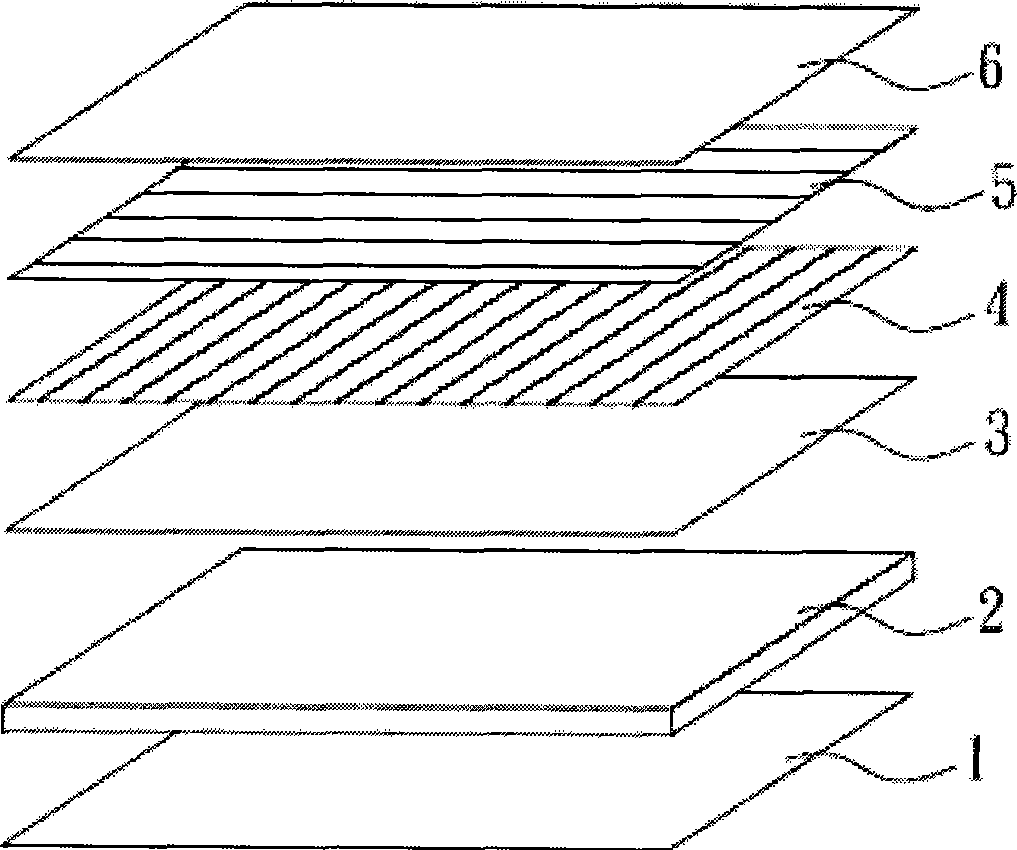

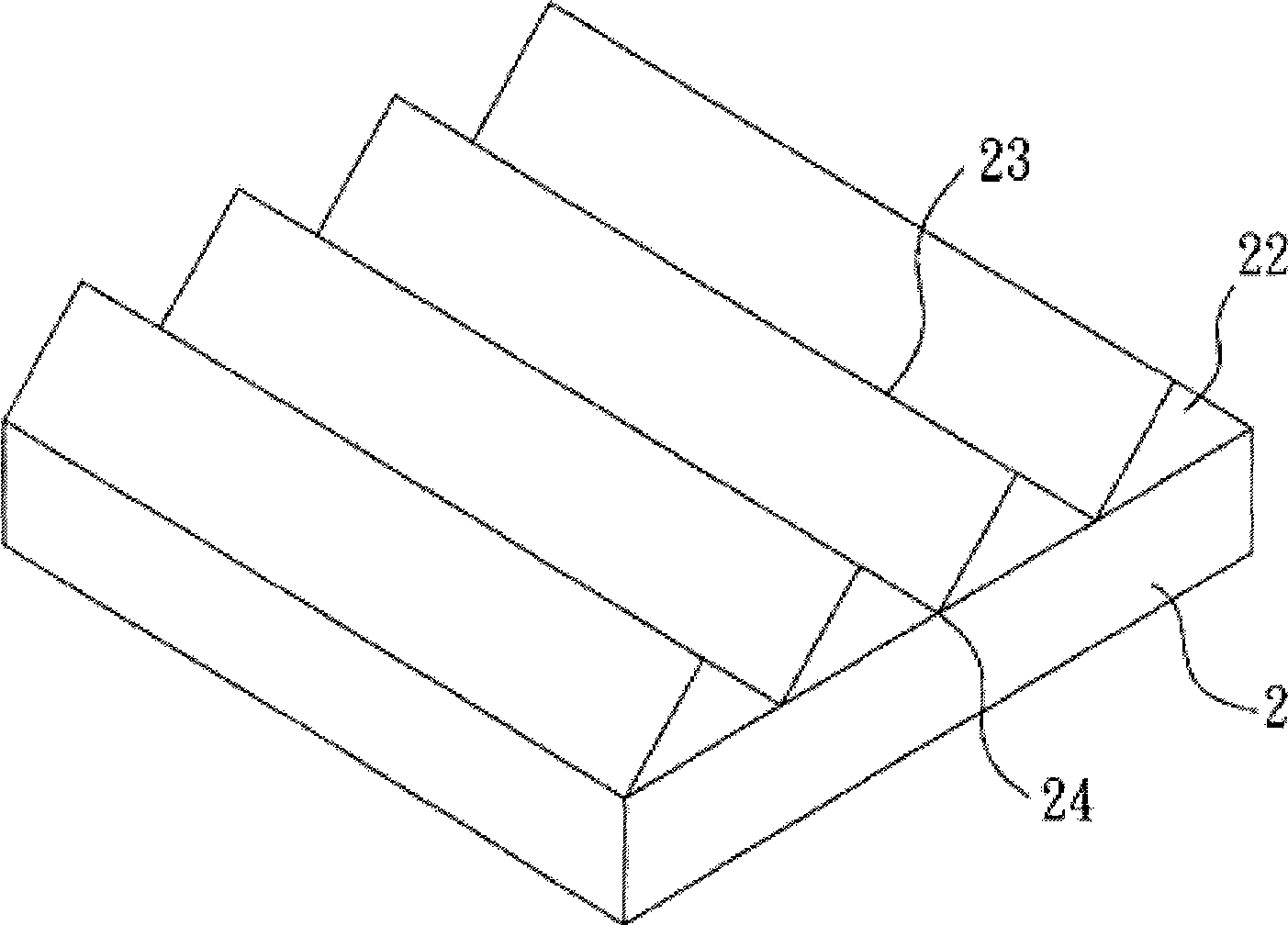

Composite blooming

InactiveCN101393274AEliminate light and dark linesPrismsDiffusing elementsOptical propertyLiquid-crystal display

The invention relates to a composite optical film, which comprises a substrate provided with a diffusion microstructure and a structured surface arranged at one side of the substrate, the internal diffusion haze of the composite optical film is more than or equal to 5 percent by measuring according to the JIS K7136 standard method. Meanwhile, the composite optical film also has the optical properties of diffusion and condensation; and when used on an LCD, the composite optical film can also reduce optical dispersion and lines overlapping when overlapped with other material films besides enhancing the brightness of an LCD panel effectively.

Owner:ETERNAL MATERIALS CO LTD

Pulp bed reaction technique for producing chlorine gas by chloride hydrogen catalytic oxidation

ActiveCN101357751AImprove heat transfer performanceUniform temperature distributionPreparation from chloridesCatalytic oxidationSlurry

The invention discloses a slurry bed reaction process for producing chlorine by chlorine hydride catalytic oxidation. In a three-phrase slurry bed reactor, the catalyst powder is dispersed and suspended in an inert reaction medium; the mixed gas of chlorine hydride and oxygen is aerated; the chlorine is prepared by oxidation reaction at the temperature of 250-450 DEG C. The adoption of the three-phrase slurry bed reactor is provided with good heat transfer performance, facilitates the uniform temperature distribution in the reactor and controls to react in an isothermal state, thus avoiding the sintering deactivation phenomenon of the catalyst brought by high temperature; meanwhile, the adoption of powder catalyst can eliminate the influence of catalyst internal diffusion so as to improve the utilization rate and reaction capacity of the catalyst; the process has more than 85 percent of maximum yield, thus providing possibility for industrial production.

Owner:NANJING UNIV OF TECH

Antiglare light diffusing member and method for producing same, and display

The present invention aims to provide an antiglare light diffusing member utilizing internal diffusion and surface diffusion in combination, wherein a surface haze value mainly representing the degree of the surface diffusion and an internal haze value mainly representing the degree of the internal diffusion are easily adjusted independently from each other. An antiglare light diffusing member comprising an antiglare light diffusing layer comprising a binder matrix and a particle A and a particle B on a transparent base material, wherein the difference between the refraction index of the particle A and the refraction index of the binder matrix is less than 0.02, and the difference between the refraction index of the particle B and the refraction index of the binder matrix is in the range of 0.03-0.20.

Owner:TOPPAN PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com