Catalyst carrier with run-through macropores and mesopores, catalyst and preparation method thereof

A technology of catalyst support and large and medium pores, which is applied in the direction of catalyst support, catalytic cracking, chemical instruments and methods, etc., and can solve the problems of support strength and pore penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

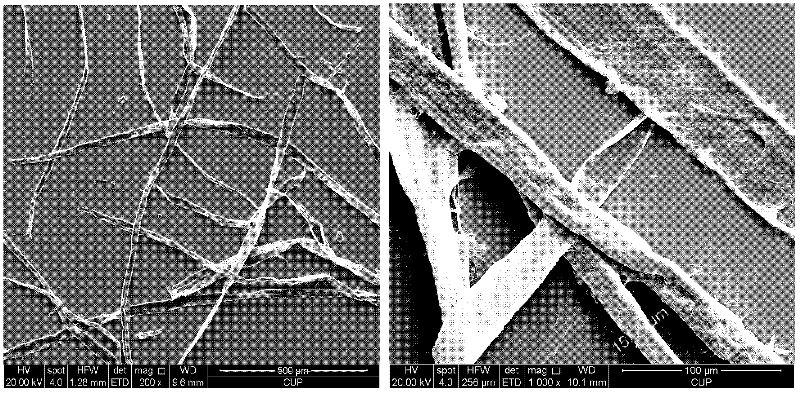

[0037] Example 1: Carrier Example 1 Preparation of Carbon Black Particles-Solid Fiber Filament Composite as a Template

[0038] Get industrial pseudo-boehmite powder 100g (containing alumina dry base 78.16g), add high wear-resistant carbon black particles (N330) 15.63g, pointed leaf wood fiber silk 0.7816g, 3.92g phosphoric acid (85%), 5.64g acetic acid ( 99.5%), 3.02g of nitric acid (65%), 2.5g of turnip powder and 62g of distilled water, just mix evenly, the method is not required, after kneading, extrude into strips, and finally dry at 120°C for 2h, and roast at 50°C for 4h to obtain an alumina carrier ACF-1.

[0039] According to the above method, the added amount of fiber filaments was changed to 1.5632, 2.3448 g respectively, and other conditions remained unchanged, and the carriers ACF-2 and ACF-3 were prepared sequentially.

[0040] According to the above method, the broad-leaved wood fiber silk was used instead, the addition amount was 2.3448 g, and other conditions ...

Embodiment 2

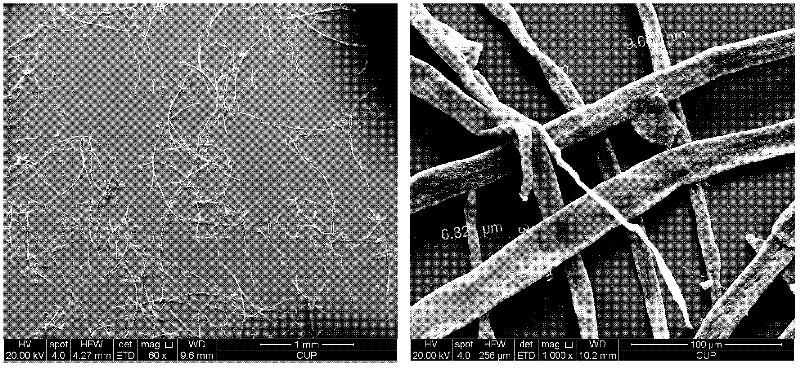

[0045] Embodiment 2: carbon black particle-solid fiber filament composite as template preparation carrier example 2

[0046] Get industrial pseudo-boehmite powder 100g (containing alumina dry basis 78.16g), add high wear-resistant carbon black particles (N330) 39.08g, pointed leaf wood fiber silk 0.7816g, phosphoric acid (85%) of 3.92g, 5.64g acetic acid (99.5%), 3.02g of nitric acid (65%), 2.5g of turnip powder and 62g of distilled water in an acidic aqueous solution, mixed evenly, kneaded, extruded into strands, finally dried and calcined to obtain alumina carrier ACF-4.

[0047] According to the above method, the added amounts of the fiber filaments were changed to 1.5632 and 2.3448 g, respectively, and other conditions remained unchanged, and the carriers ACF-5 and ACF-6 were sequentially prepared.

[0048] According to the above method, polyethylene terephthalate fiber filaments (synthetic fibers mentioned above) were used instead, the addition amount was 2.3448 g, and ot...

Embodiment 3

[0050] Embodiment 3: carbon black particle-solid fiber filament composite as template preparation carrier example 3

[0051] Get and embodiment 2 middle molar weight Al 3+ Add 0.7816g of pointed-leaved wood fiber silk and 39.08g of high wear-resistant carbon black particles (N330) to the aluminum nitrate solution, and after the ultrasonic dispersion is uniform, stir with magnetic force. During the stirring process, add ammonia solution drop by drop until the pH value is 9, and age for 5h , filtered, dried at 100-120°C for 5 hours, pressed into tablets, and finally calcined at 550°C for 5 hours to obtain an alumina carrier. The specific surface area of the alumina carrier is 240.4m 2 / g, the pore volume is 0.750ml / g, and the average pore diameter is 11.9nm.

[0052] Table 3. Carrier Properties II for Preparation of Carbon Black Particles-Fiber Filament Composite Templates

[0053] carrier

[0054] Note: AC-3, ACF-4, ACF-5, ACF-6 and ACSF-3 are all added with 50 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com