Patents

Literature

308results about How to "Good uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

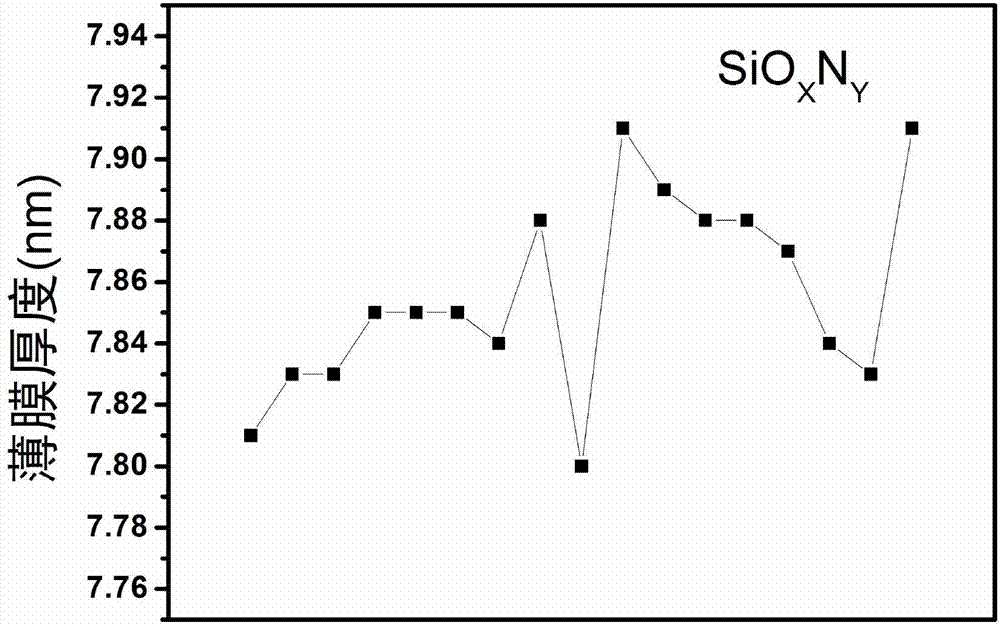

Ultrathin silicon oxynitride film material and preparation method and application thereof

ActiveCN104498895AGood uniformityImprove uniformityChemical vapor deposition coatingOperating temperatureFilm material

The invention discloses an ultrathin silicon oxynitride film material and a preparation method thereof. The preparation method comprises the following steps: placing a substrate in a chemical vapor deposition equipment cavity, introducing NH3, O2 gas and SiH4-containing gas as reactant gases, introducing a carrier and protective gas, performing vapor deposition, thereby obtaining the silicon oxynitride film material, wherein the operating temperature of the chemical vapor deposition equipment cavity is 100-260 DEG C, the working pressure is 1-4Pa, and the power is 200-450W; the vapor deposition time is 15-40 seconds; the volume ratio of the SiH4 gas to the O2 gas is 9-110; the volume ratio of the SiH4-containing gas to the NH3 gas is 3-11; and the volume ratio of the SiH4-containing gas to the carrier and the protective gas is 0.1-1. The thickness of the silicon oxynitride film material prepared on a four-inch silicon substrate is 6-9nm, and the non-uniformity of the film is lower than 0.7 percent.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

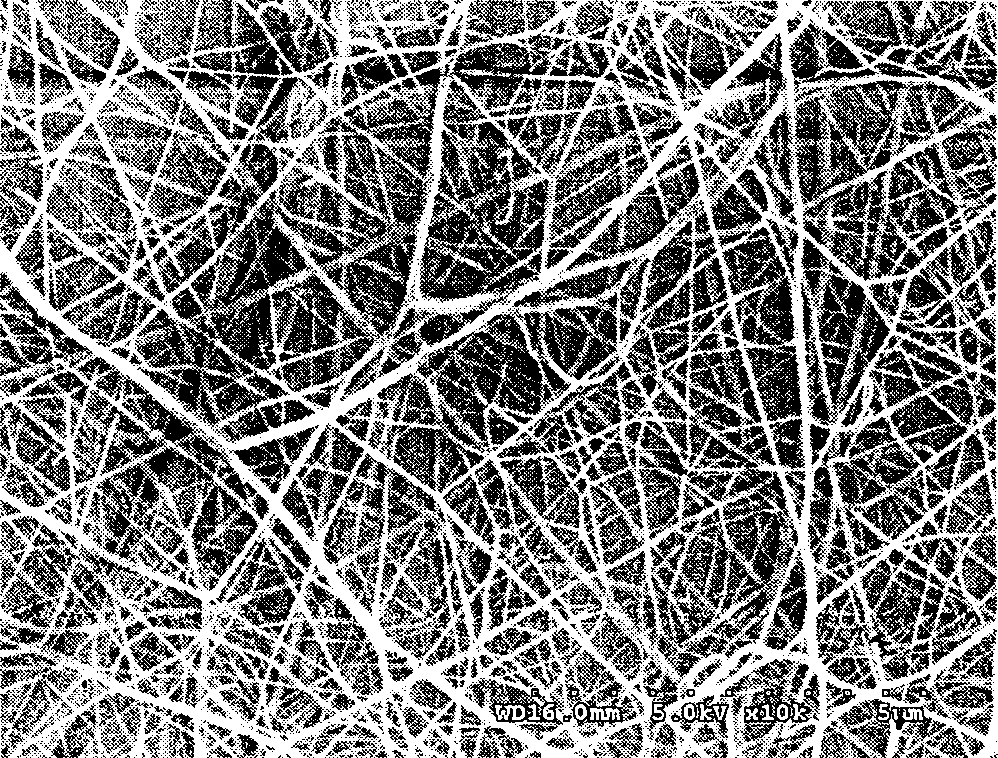

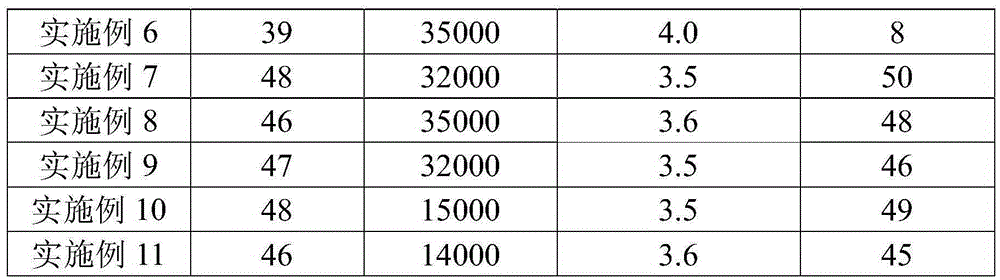

Degradable and absorbable polymer nano fibrous membrane materials and preparation process and use thereof

InactiveCN1837274AGood uniformityHigh porositySurgeryFilament/thread formingFilm materialDecomposition

The invention discloses a biological decomposable polymer nanometer fiber film material and preparing method and usage, which is characterized by the following: the material is made of several nanometer to several hundred nanometer fiber diameter nonwoven material, wherein the hyaluronic acid is more than 0 less than or equal to 100; other macromolecular material quantiy is more than 0 less than 100; the quantity of remedy medicine is 0-10 part. The invention possesses well biological compatity, biological decomposition and absorption property, which is applied in the medical tissue engineering rack material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

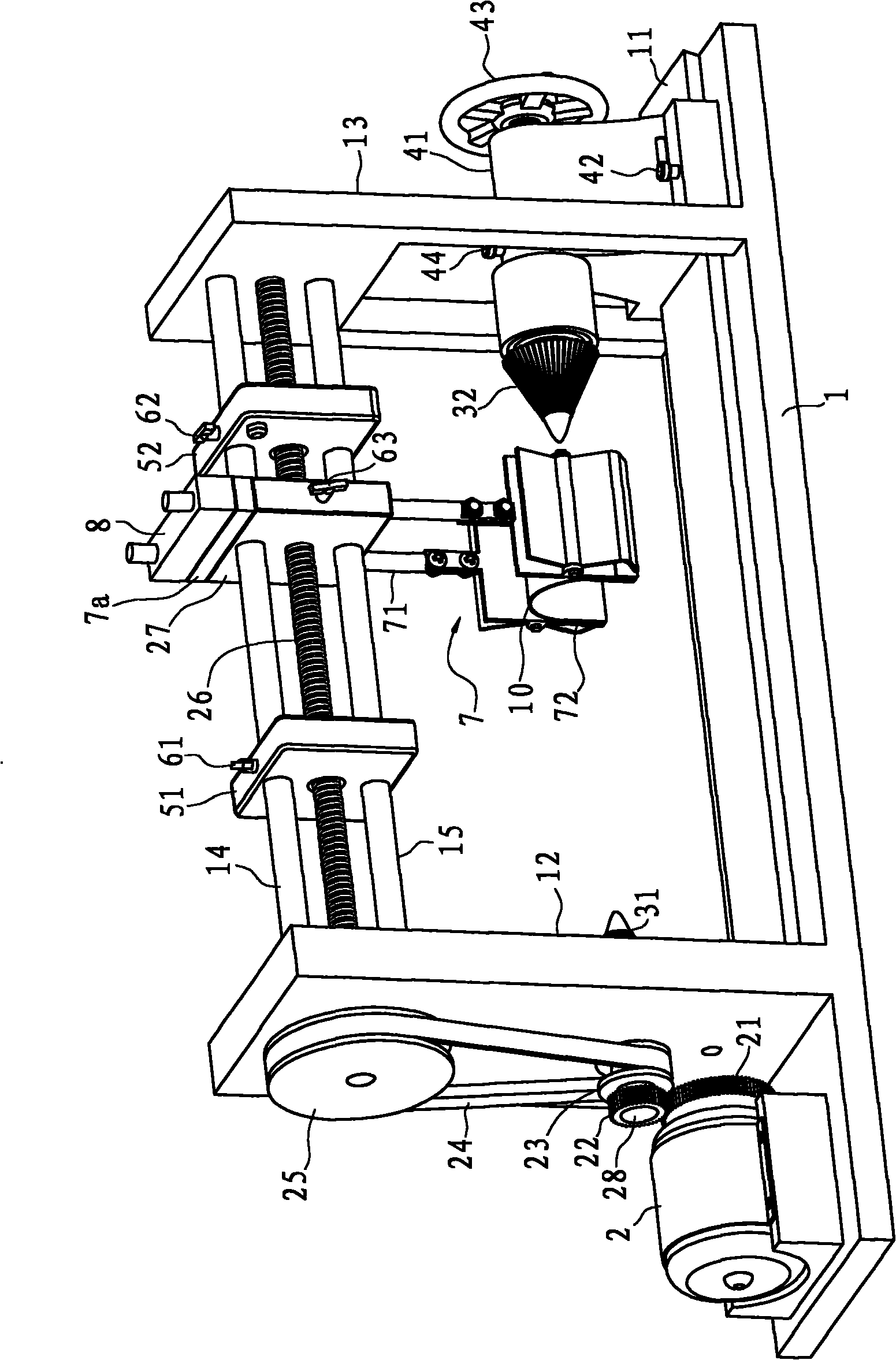

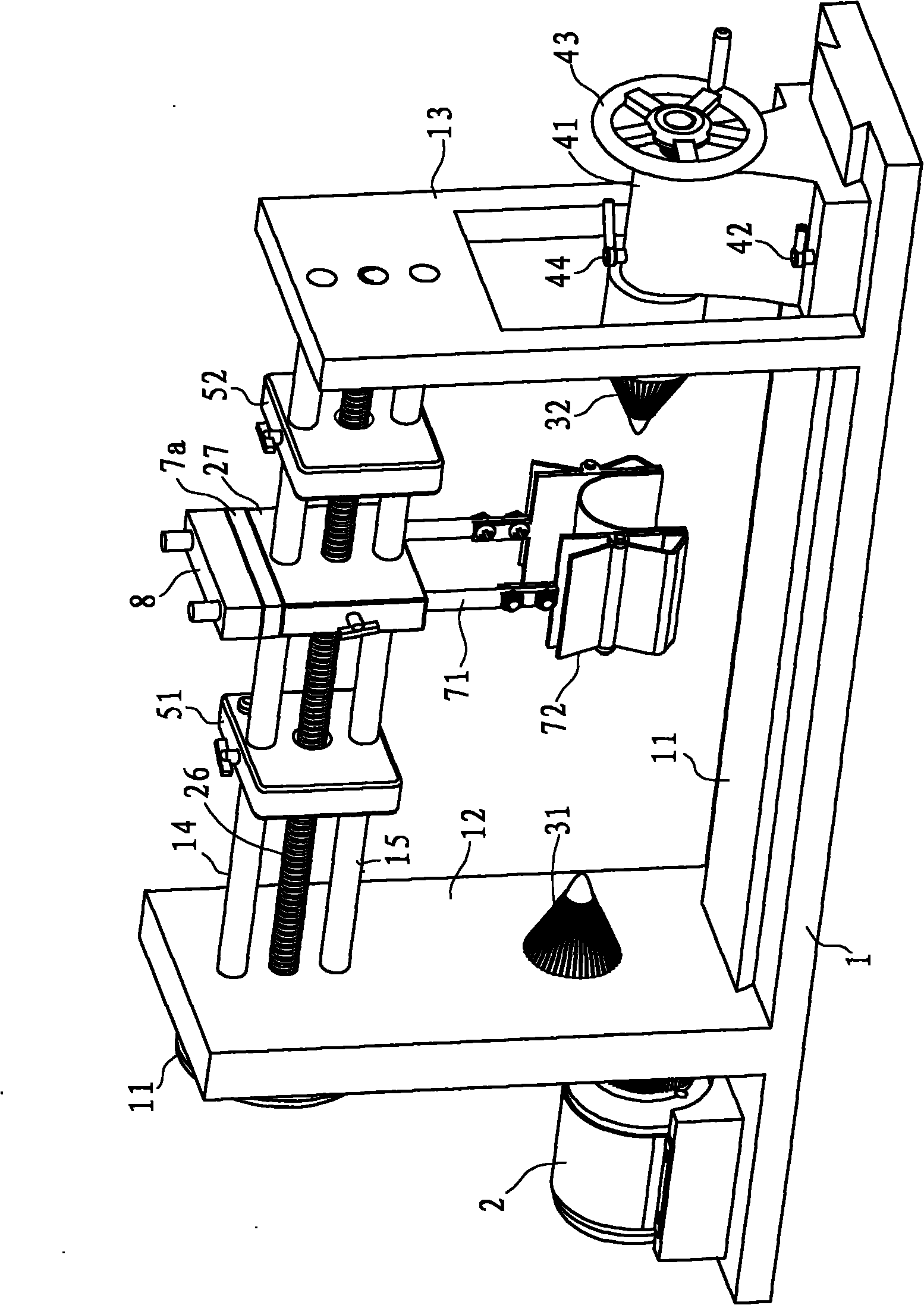

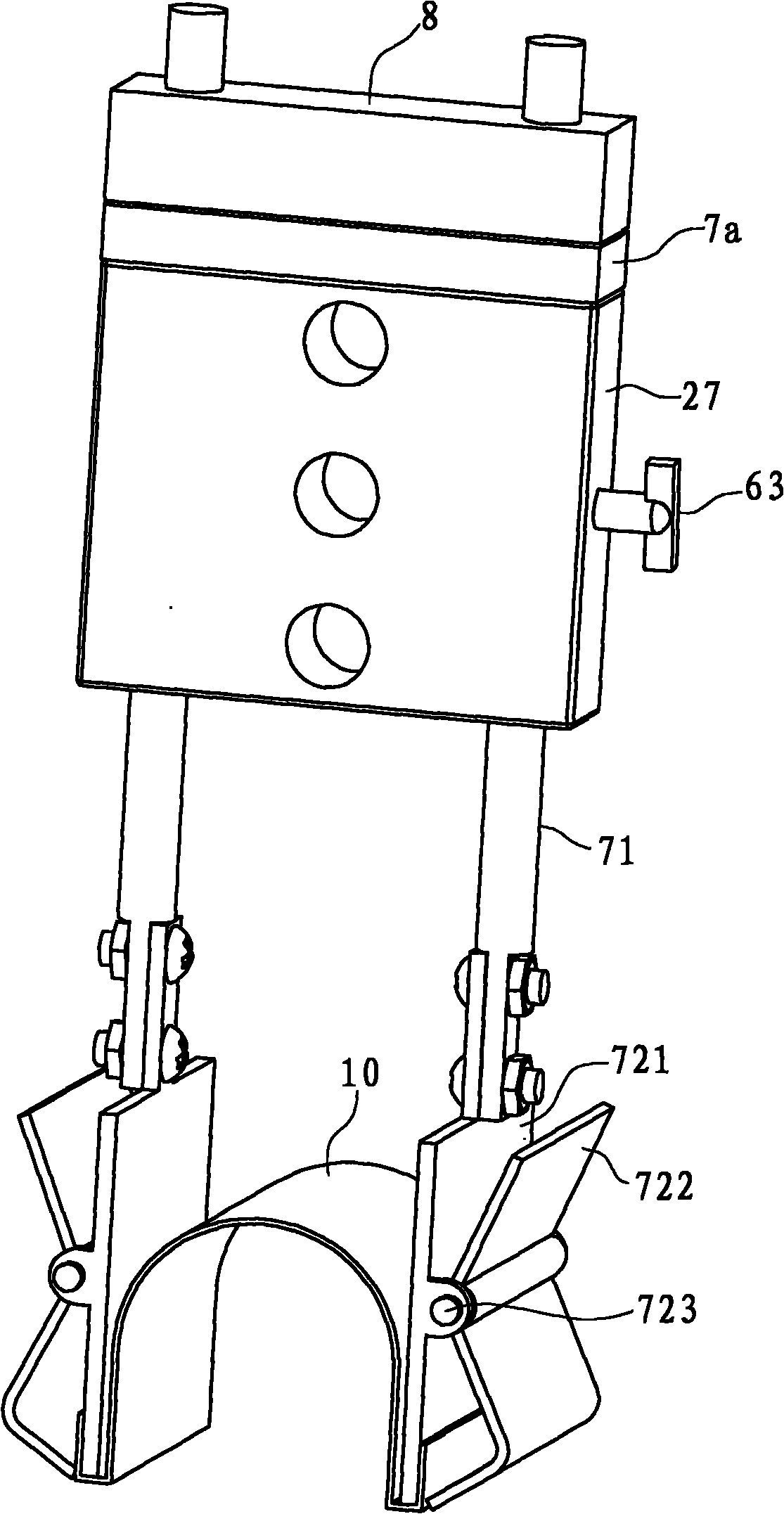

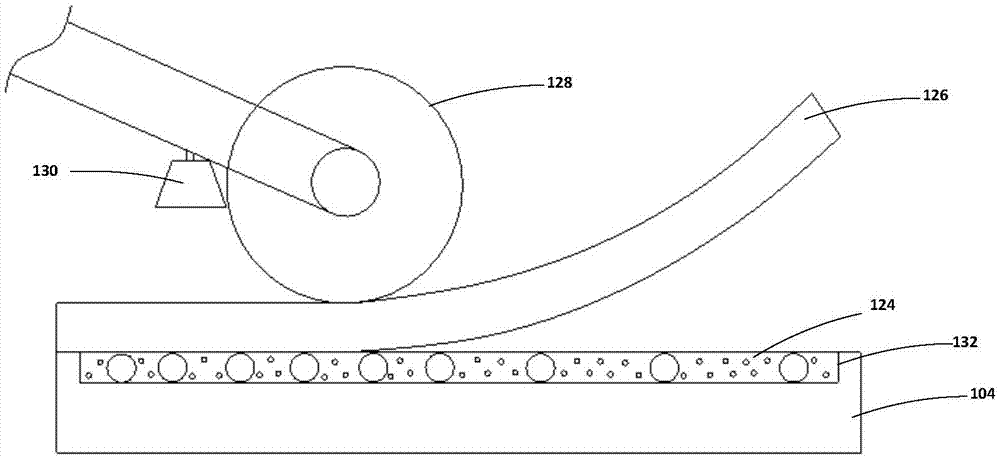

Grinding device of pipes used for curved surface anti-buckling tests of adhesive tapes

InactiveCN102152208AImprove grinding efficiencyGood uniformityPortable grinding machinesEngineeringDrive wheel

The invention provides a grinding device of pipes used for the curved surface anti-buckling tests of adhesive tapes. The grinding device comprises a base, a motor, a rotating shaft, a dead head, a tip, a screw and a slider. A first upright plate and a second upright plate are arranged on the upper end surface of the base at interval, a driving gear is arranged on an output shaft of the motor, therotating shaft can be arranged on the lower end part of the first upright plate in a rotating manner, the outer end of the rotating shaft is provided with a driving wheel and an input gear which simultaneously rotates with the driving wheel, the input gear is in meshing transmission with the driving gear, the inner end of the rotating shaft is provided with a first clamp component, the dead head is arranged on one side of the second upright plate, and the screw is in transmission connection with the driving gear through a speed reduction mechanism; the slider is sheathed on the screw, and thebottom end of the slider is provided with a clamp. Compared with the prior art, the grinding device has the advantages that as manual grinding is replaced by mechanical grinding, the grinding efficiency is greatly improved; as personal factors are eliminated, the uniformity of ground pipes used for tests is good, and the data accuracy and reliability of the anti-buckling tests of adhesive tapes can be ensured.

Owner:NINGBO SOKEN CHEM

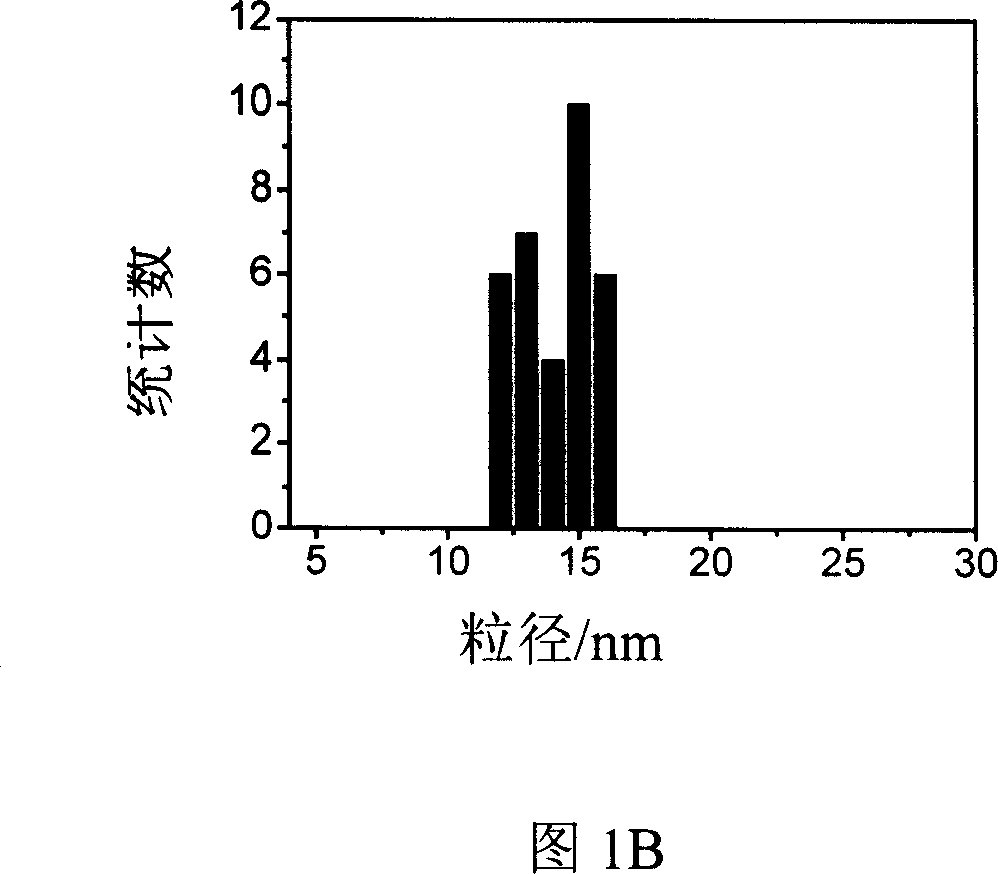

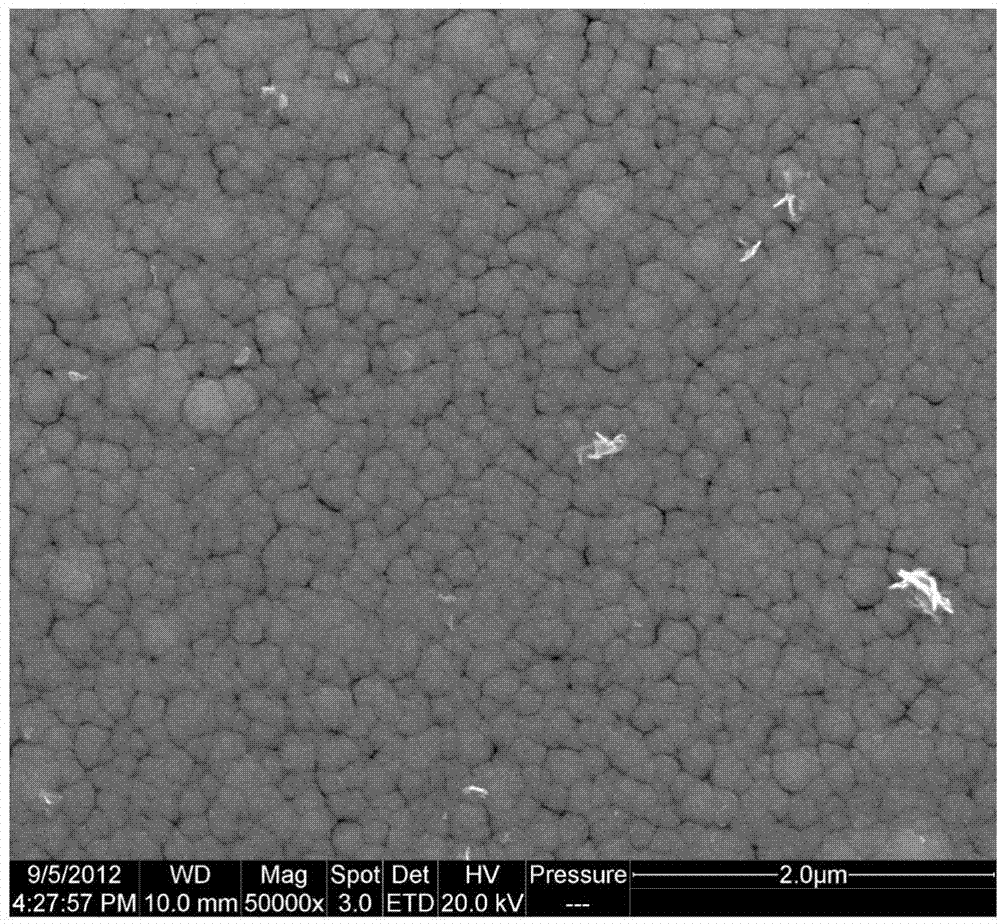

Method for preparing Nano silver grain, and prepared Nano silver grain

InactiveCN101050315ASmall average particle sizeGood uniformityBiocideCatalyst carriersAg nanoparticlesNanometre

This invention discloses a method for preparing Ag nanoparticles. The method comprises: (1) mixing acid solution of chitosan and AgNO3 solution to obtain a mixed solution; (2) adjusting the pH value to 3.0-5.0; (3) irradiating without oxygen. The deacetylation degree of chitosan is greater than or equal to 70%, and the average molecular weight is less than or equal to 20000. The concentration of chitosan in the mixed solution is 0.001-0.05 wt. %, and that of AgNO3 is 0.01-23.5 mM. The obtained Ag nanoparticles have such advantages as small average particle size, uniform particle size distribution, high solid content, high water solubility, and high biocompatibility.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

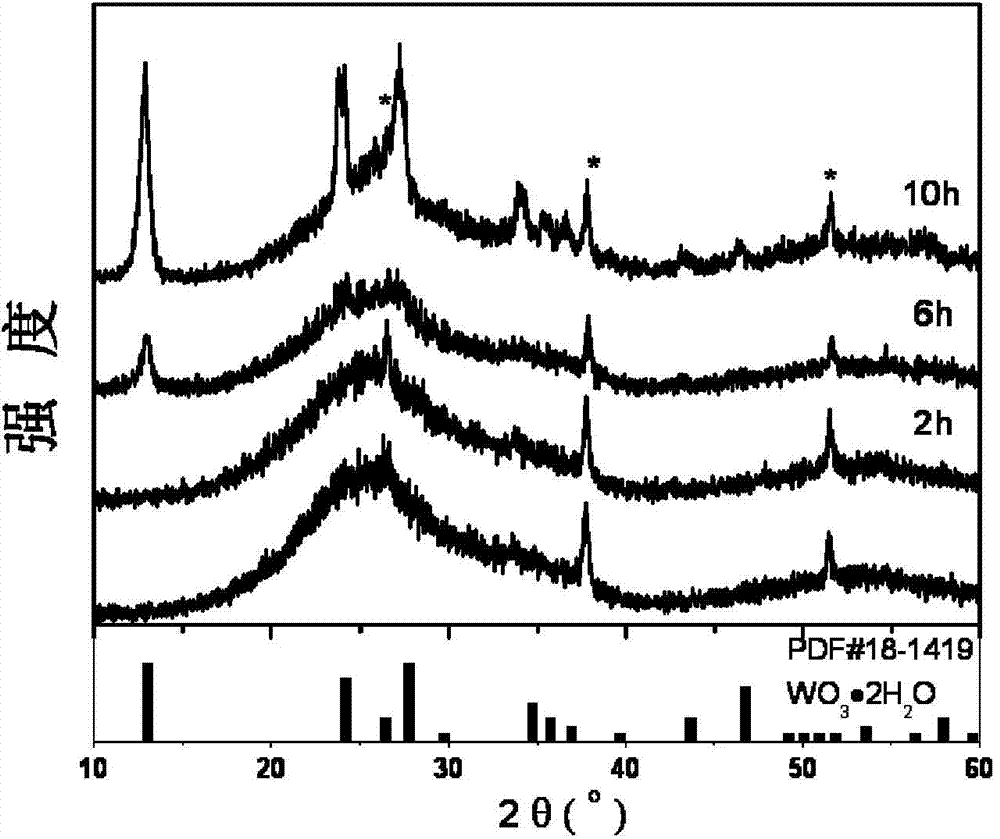

Sheet-like tungsten trioxide photoelectrode and preparation method thereof

InactiveCN104711528ASimple processGood uniformityVacuum evaporation coatingSputtering coatingAmorphous oxideStrong acids

The present invention relates to porous WO3 sheet-like array film preparation, which comprises: firstly utilizing a direct current reaction magnetron sputtering method, adopting Ar gas as sputtering gas, adopting O2 gas as reaction gas, and adopting double metal target co-sputtering to carry out sputtering so as to obtain an amorphous oxide film, wherein the one target is a tungsten target, and the other target is one selected from aluminum, copper and zinc; and immersing the prepared amorphous metal oxide film in a strong acid solution to selectively etch, obtaining a sheet-like porous structure on the substrate, and annealing at a temperature of 450-550 DEG C in air so as to form monoclinic crystal phase WO3, wherein the morphology is well preserved. According to the present invention, the porous tungsten oxide electrode obtained through the method has characteristics of specific surface increase, substantial light absorption property improving, and good adhesion between the material and the substrate; and the preparation method of the present invention has the following advantages that: the mass production can be achieved, the preparation process is simple, the saturated photocurrent of the prepared WO3 electrode is increased by 3 times compared with the saturated photocurrent of the unetched dense WO3 electrode, and the obtained sheet-like tungsten trioxide photoelectrode can further be used for dye-sensitized solar cells, electrochromic devices and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

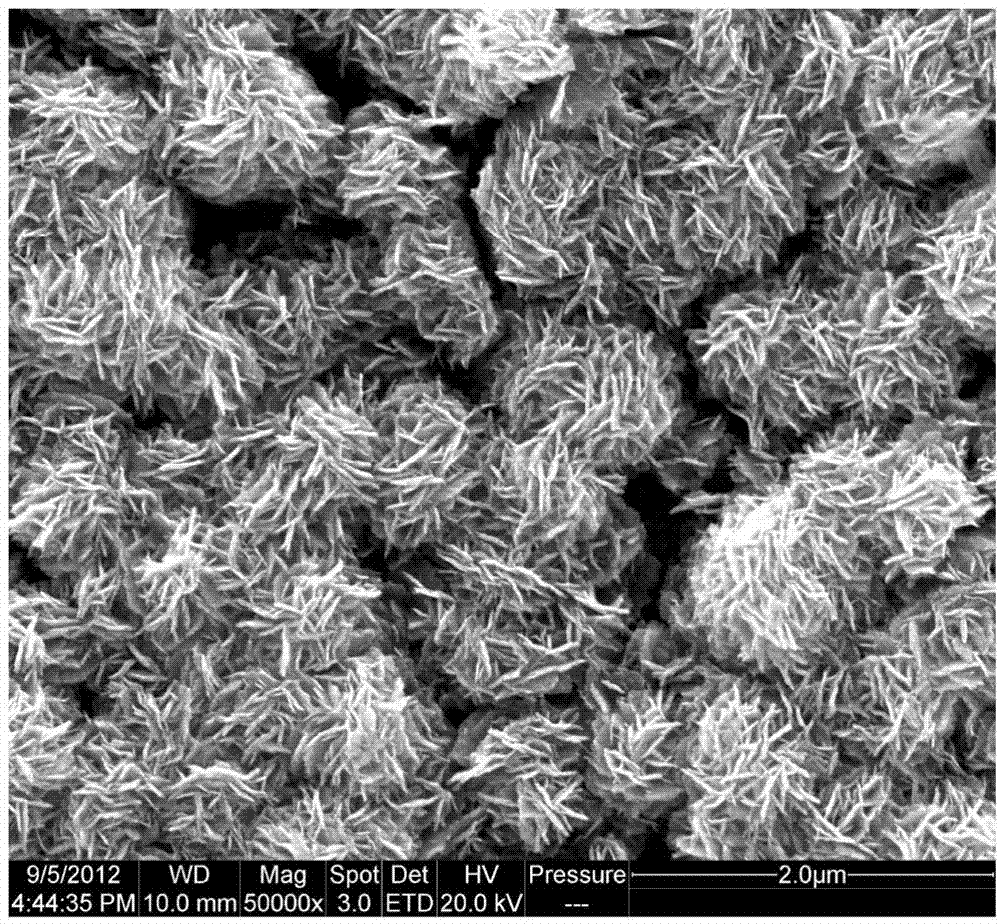

Preparation method for microarc oxidation/hydrothermal treatment composite film on surface of magnesium alloy

InactiveCN102560601AGood uniformityHigh bonding strengthAnodisationLiquid/solution decomposition chemical coatingMicro arc oxidationCorrosion resistant

The invention relates to a preparation method for a microarc oxidation / hydrothermal treatment composite film on the surface of a magnesium alloy. The problem that the existing magnesium alloy is poor in corrosion resistance and bioactivity is solved. A microarc oxidation film is prepared on the magnesium alloy by using a microarc oxidation method, and then a bioceramic film is obtained by using hydrothermal treatment. Hydrothermal reaction liquid is composed of sodium hydroxide, calcium acetate and sodium hexametapolyphosphate. In the preparation method, the microarc oxidation is combined with the hydrothermal treatment; calcium and phosphorus are introduced to the surface of the microarc oxidation film by using the hydrothermal treatment; in addition, holes in the ceramic film are blocked by using hydrothermal treatment; therefore, corrosive media are effectively prevented from entering; the corrosion resistance of the composite film is effectively improved; and the corrosion resistance of the composite film to simulated body fluid is greatly improved by approximately 2 orders of magnitude.

Owner:HARBIN INST OF TECH

Ceramic tile with bulged particle effect and preparation method of ceramic tile

The invention relates to a ceramic tile with a bugled particle effect and a preparation method of the ceramic tile. The method comprises the steps of applying cover glaze with a specified formula to a blank body, wherein the sintering temperature of the cover glaze is more than 1120 DEG C, and by weight percent, the cover glaze comprises more than 57% of SiO2 and more than 22% of Al2O3; applying dry granular glaze slurry to the blank body coated with the cover glaze through a linear glaze sprayer, wherein the specific gravity of the dry granular glaze slurry is 1.27-1.38g / mL.

Owner:MONALISA GRP CO LTD

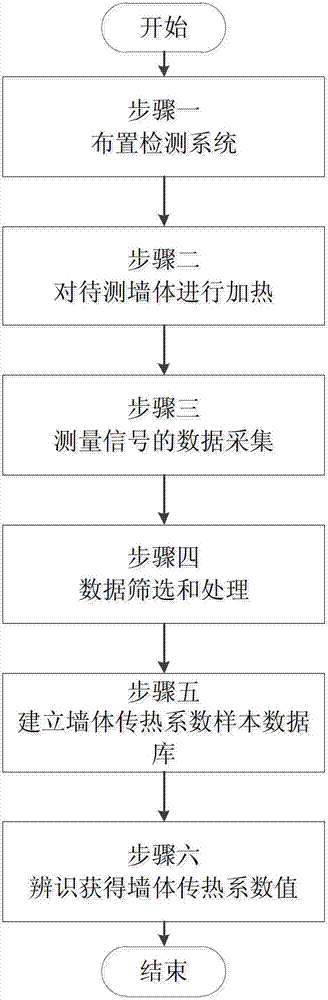

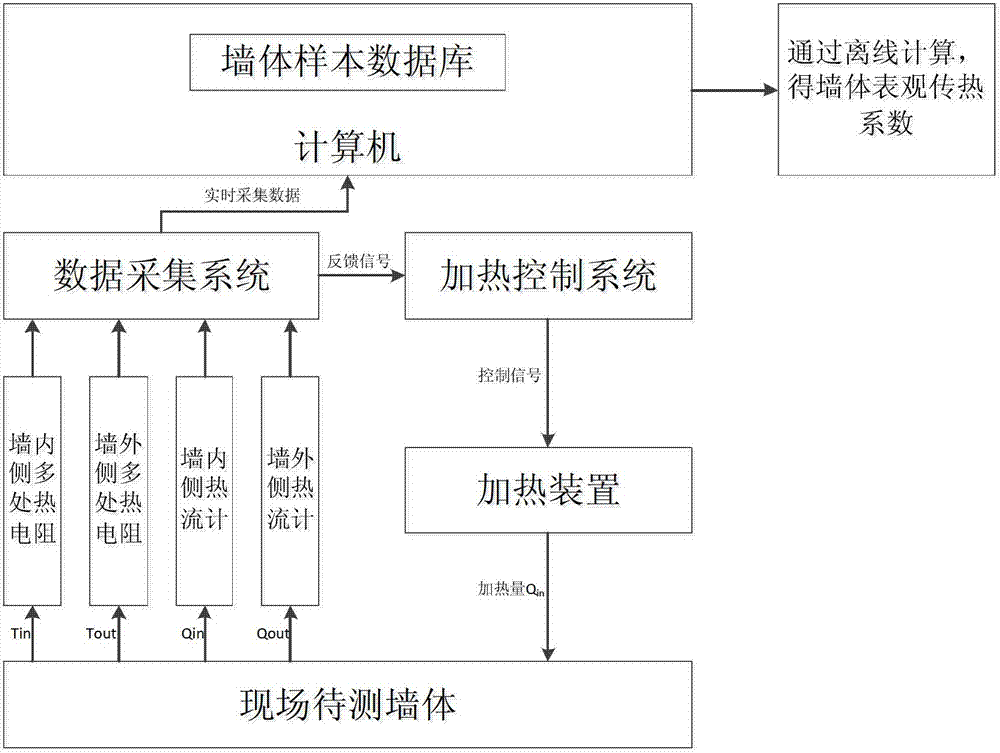

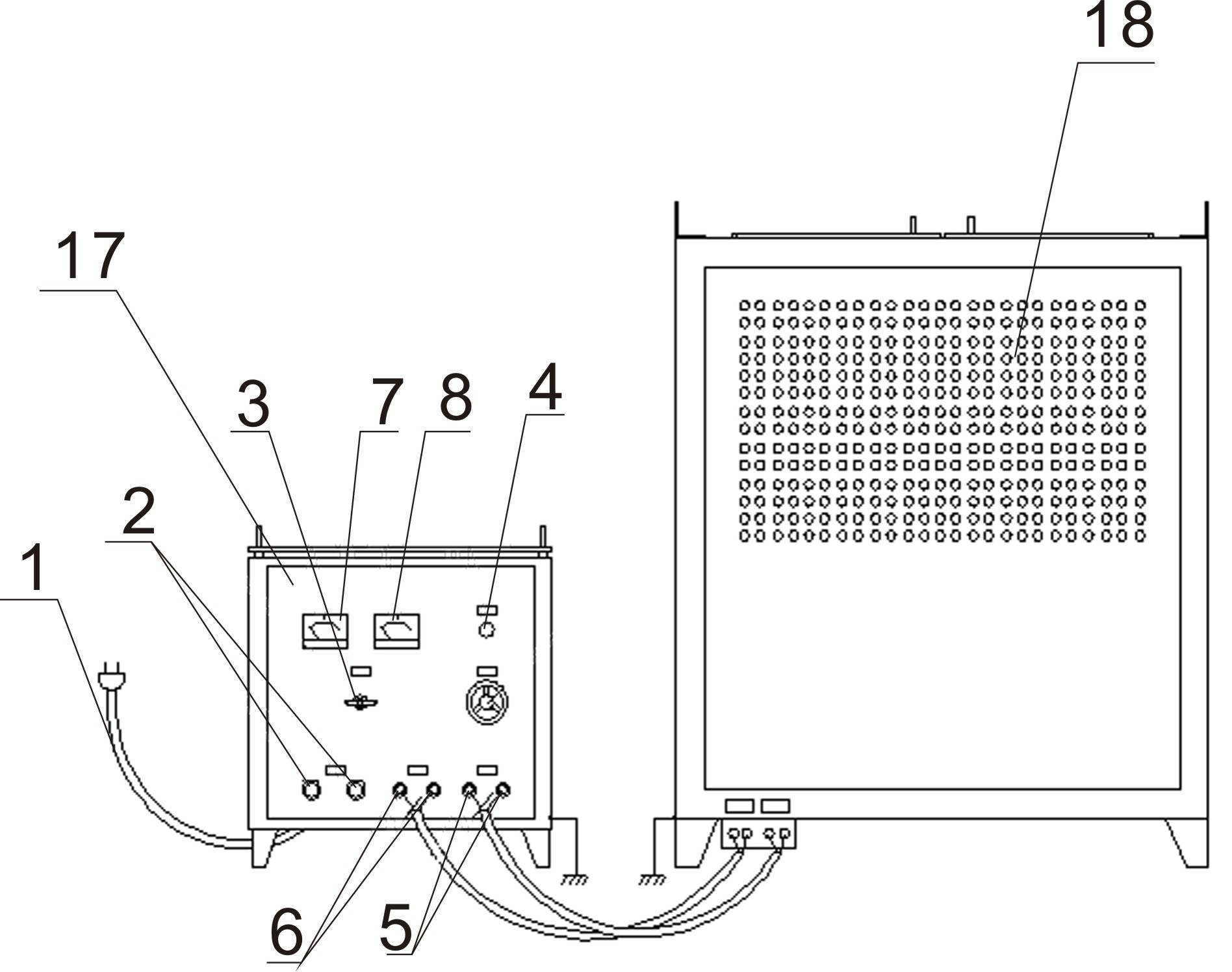

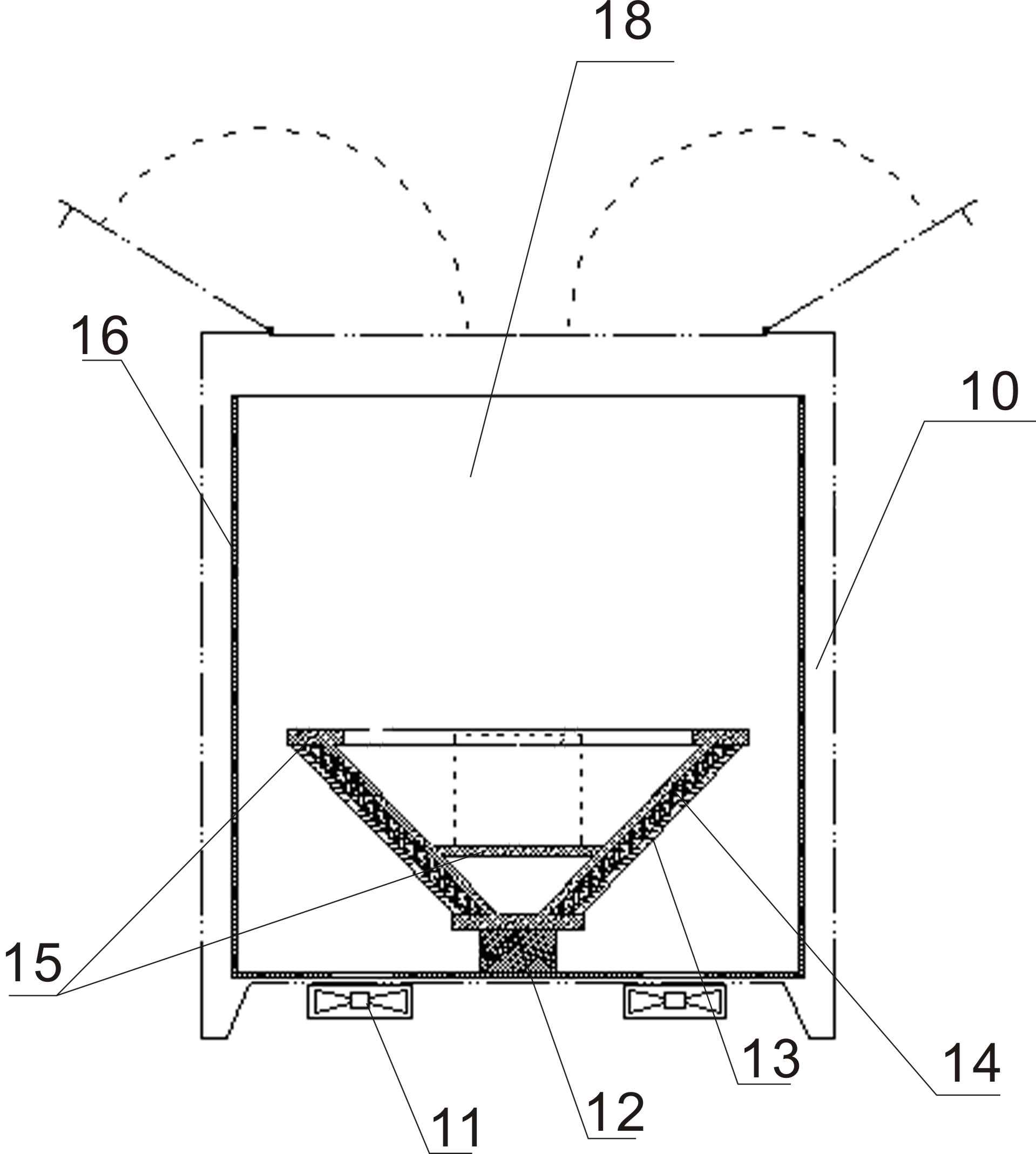

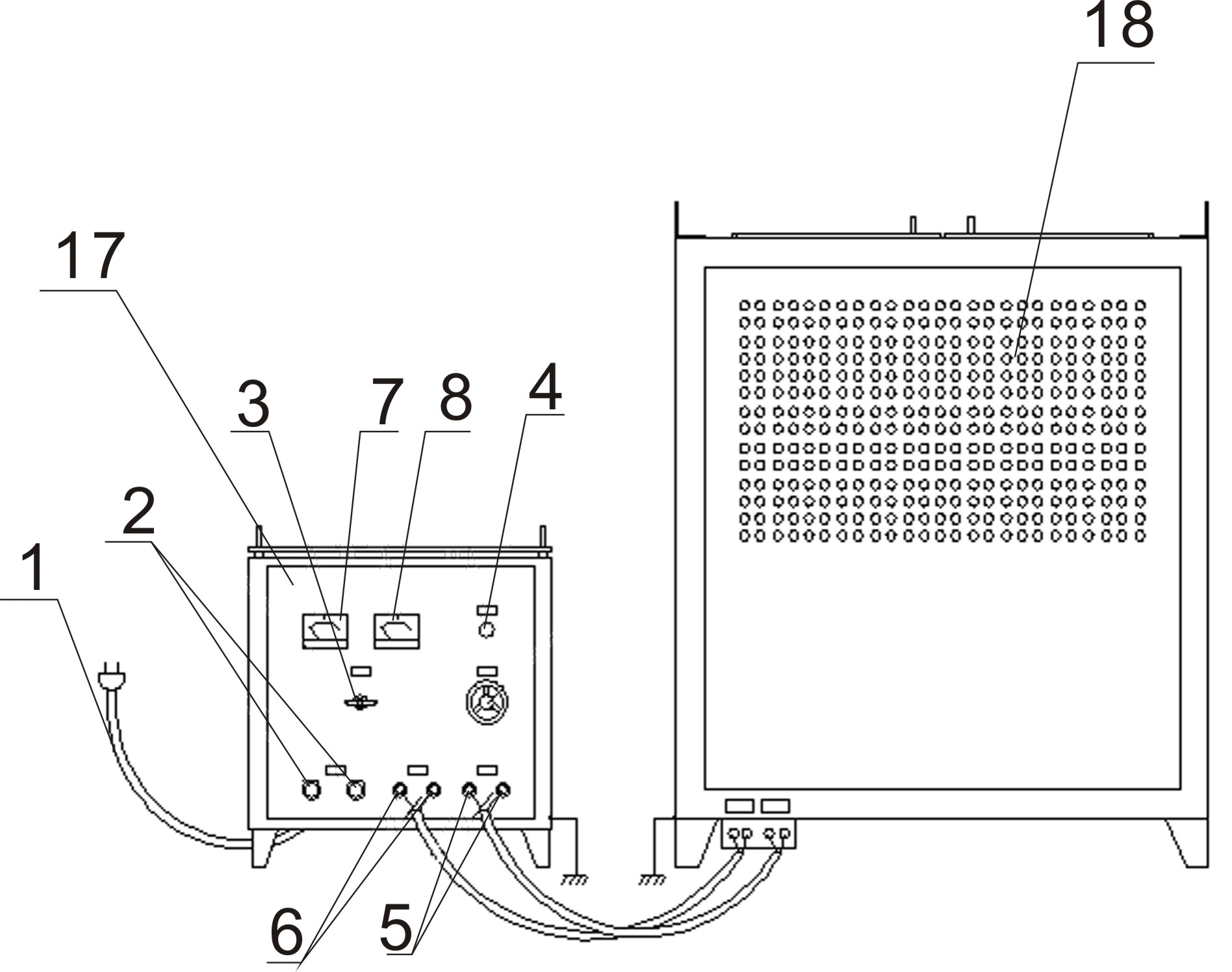

Building wall apparent heat transfer coefficient field detection method suitable for districts hot in summer and warm in winter

ActiveCN102759543AGood uniformityShorten test timeMaterial thermal conductivityMaterial heat developmentElectric heatingElectricity

The invention discloses a novel heating device of an apparent heat transfer coefficient field detection system for a wall body enclosure structure. The novel heating device mainly comprises a heat homogenizing plate, a flexible electric heating coil layer, an outer heat-isolation material layer, an inner heat-isolation material layer, an electric power adjuster and the like, wherein the heat homogenizing plate is tightly pressed against the surface of a wall body to be detected and can be used for uniformly heating the wall body. The periphery of the heat homogenizing plate is provided with the inner heat-isolation material layer which is located between a wall face and the heat homogenizing plate. The flexible electric heating coil layer is arranged on the back face of the heat homogenizing plate. The external heat-isolation material layer is arranged on the back face of the flexible electric heating coil layer so as to prevent the heat produced by the heating coil from being lost at the back of the coil in an isolation manner. The novel heating device is suitable for heating in the field detection of the apparent heat transfer coefficient of the wall body enclosure structure, is light in total weight, easy to regulate in electric heating power, rapid to assemble and disassemble and suitable for carrying, and the number of the heat homogenizing plates can be increased or decreased according to the actual dimension of the wall body in a detection field.

Owner:CHINA ACADEMY OF BUILDING RES TIANJIN INST

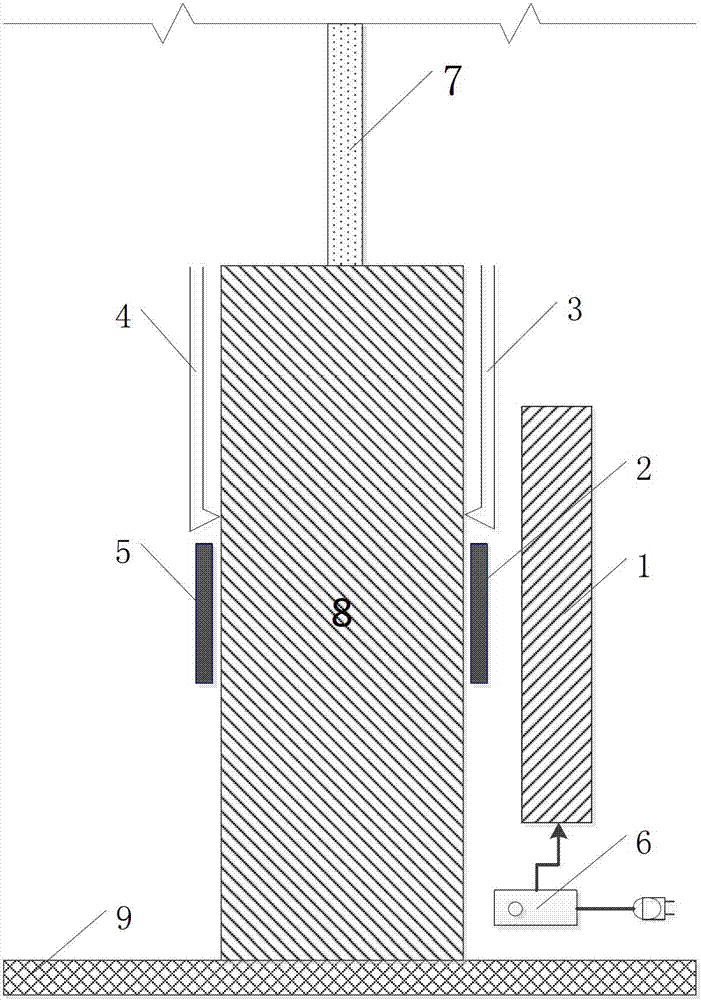

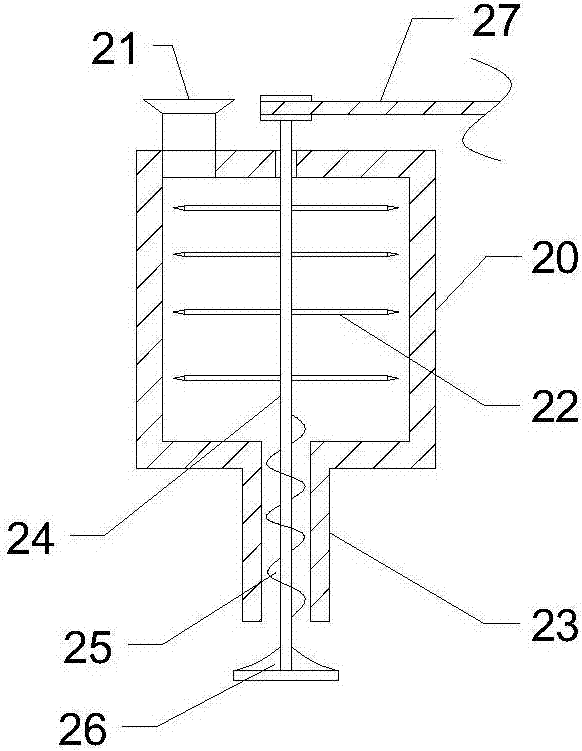

Geomechanical magnetic field testing device and method

InactiveCN102213658AWide range of applicationsGood uniformityStrength propertiesStress levelEngineering

Owner:CHINA THREE GORGES UNIV

Snowflake melange yarn and processing method

The invention relates to the technical field of spinning, in particular to a snowflake melange yarn. The yarn comprises 50 percent of polyester fibers, 38 percent of cotton fibers and 12 percent of viscose by weight, wherein partial of or all fibers in at least one of the fibers are dyed fibers, the dyed fibers are mixed with the undyed fibers uniformly, and the uniformly-mixed fibers are spun to form the dreamy snowflake melange yarn through a spinning process. The yarn comprises the following processing steps: sprinkling oiling agent water on the dyed fibers for braising for at least 10 hours, weighing the fibers with different colors and in different proportions for uniform mixing, and putting the uniformly-mixed fibers in a spinner for spinning. In the melange yarn, the proportioning of the fibers and the color proportioning in each fiber are reasonable, and a small number of fibers in the fibers are only needed to be dyed. The melange yarn can improve the grade of products made of common raw materials obviously, has the characteristics of softness, stiffness and smoothness and comfortable wearing, and can be made into different T-shirts, high-grade underwear, coats, fashionable dresses and household textile products.

Owner:江阴市茂达棉纺厂有限公司

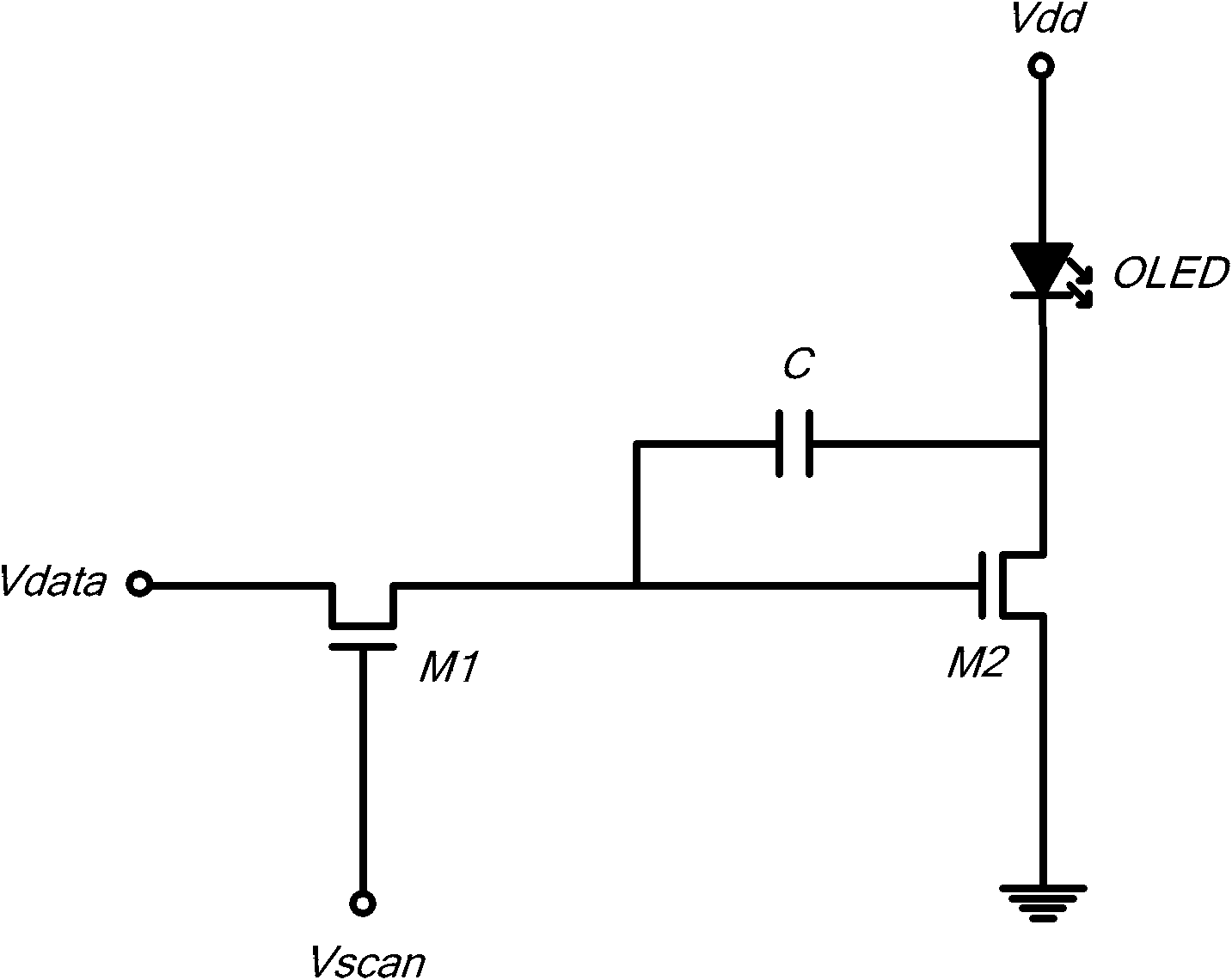

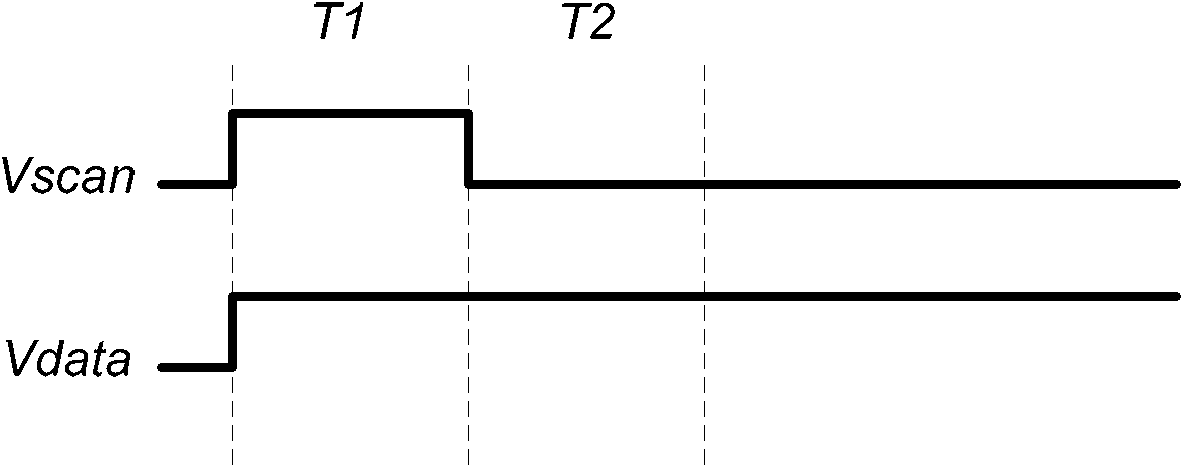

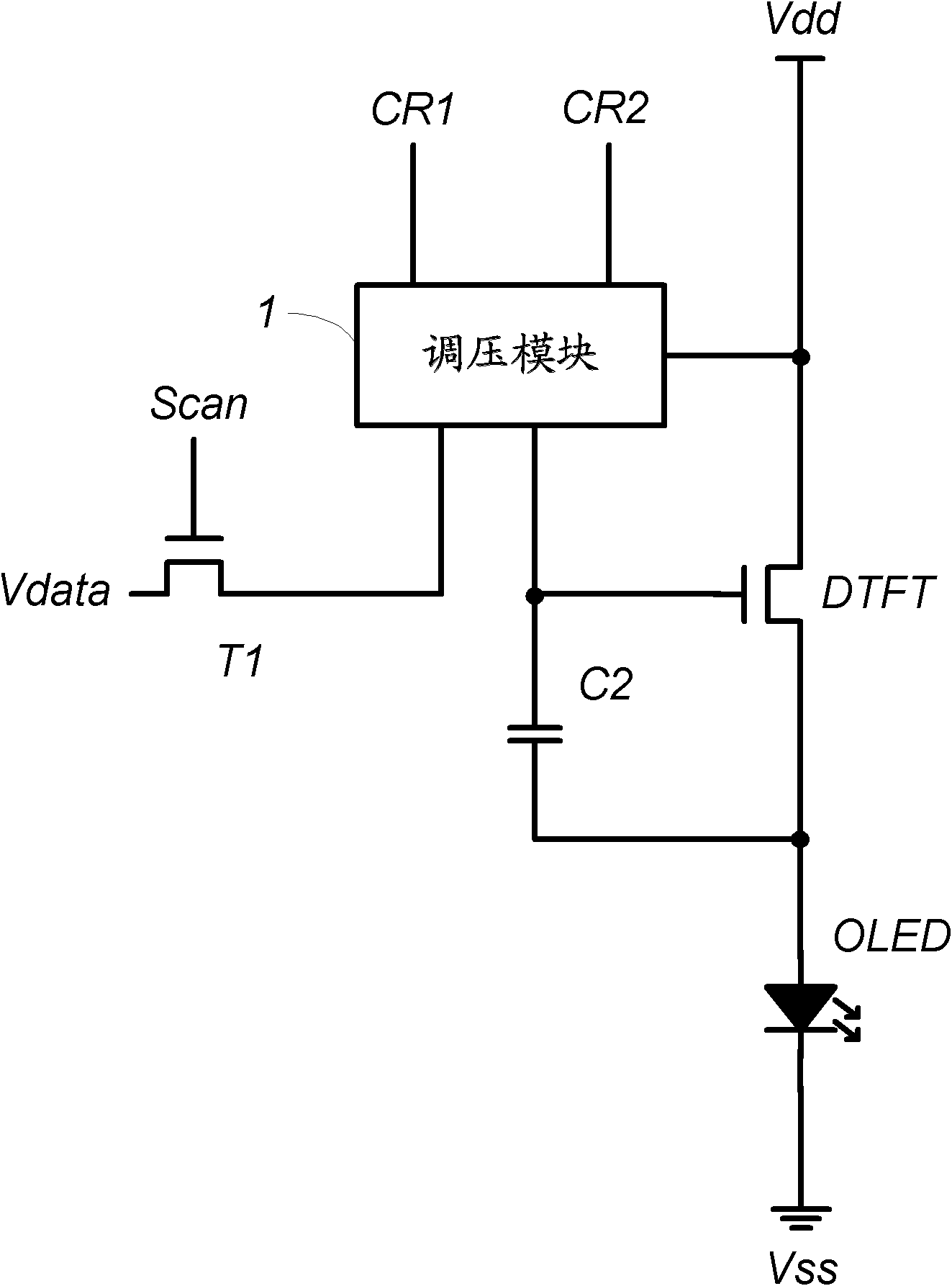

Active matrix/organic light emitting diode and driving circuit and method thereof

The invention disclose an active matrix / organic light emitting diode and a driving circuit and method thereof, which relate to the technical field of organic light emitting display, and aim to increase the brightness uniformity of the active matrix / organic light emitting diode. The driving circuit of the active matrix / organic light emitting diode comprises a driving transistor, a first transistor, a second capacitor, an organic light emitting diode and a voltage regulating module, wherein the voltage regulating module connected among a first control signal end, a second control signal end and a high level signal end is connected with the second capacitor, the driving transistor and the first transistor and used for regulating the grid source voltage of the driving transistor connected with the second capacitor so that the driving current of the driving transistor in a saturated state is unrelated to the threshold voltage of the driving transistor. The active matrix / organic light emitting diode can be used for organic light emitting display.

Owner:BOE TECH GRP CO LTD +1

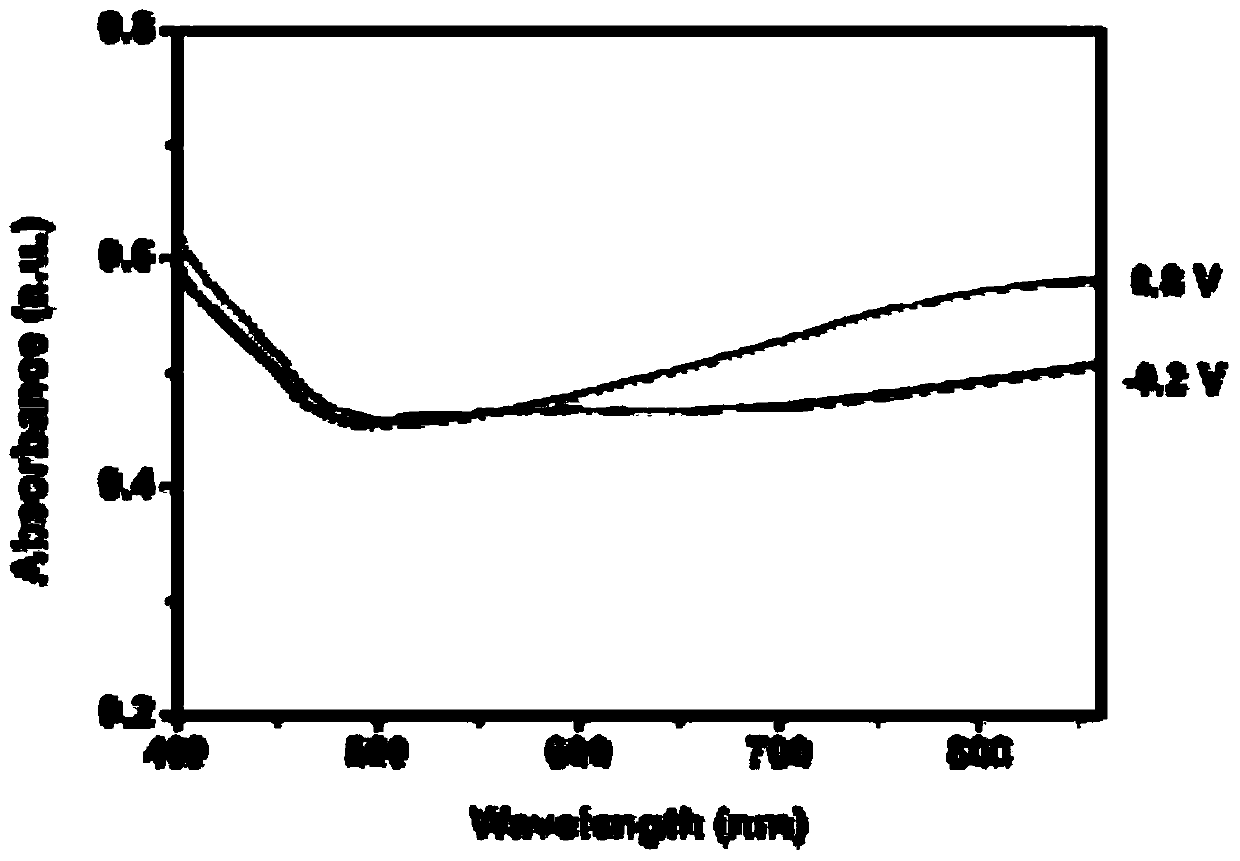

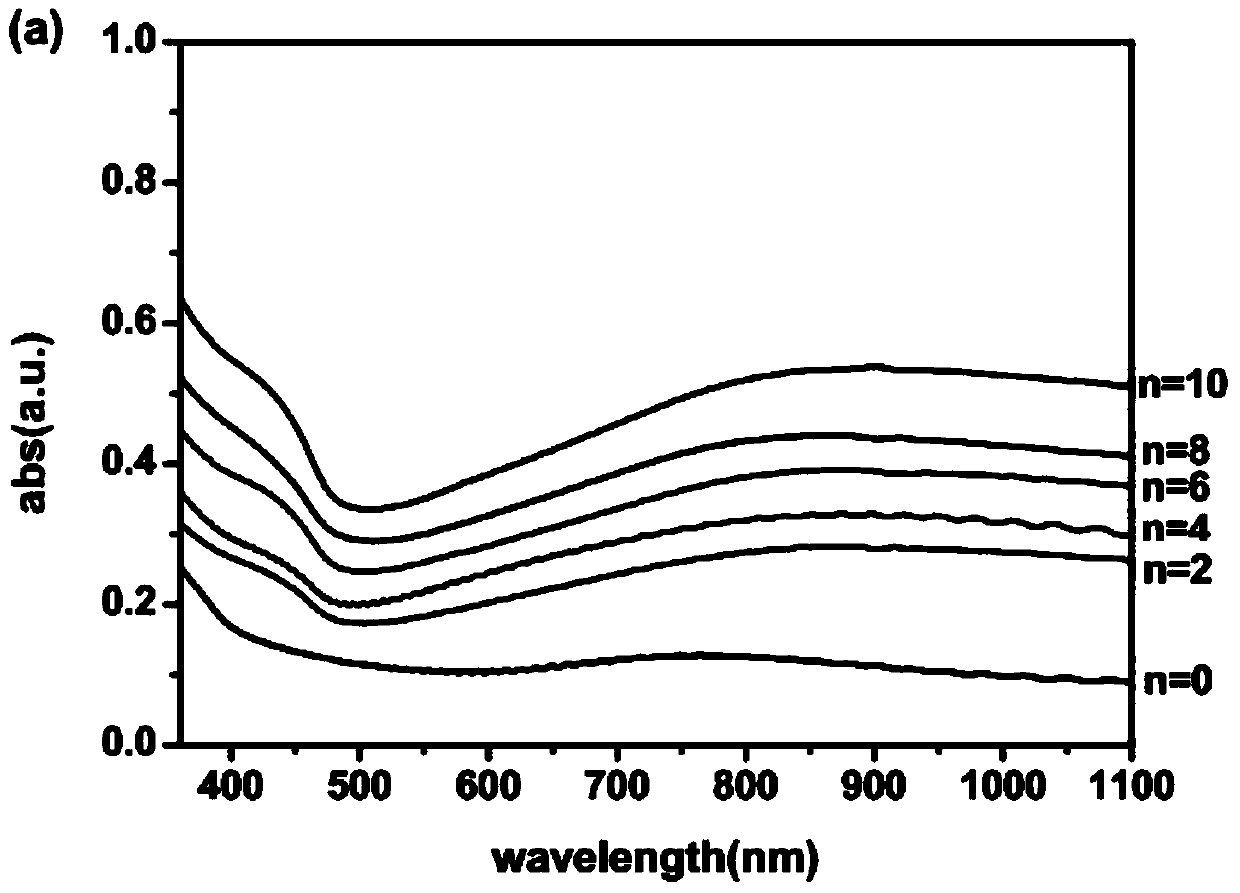

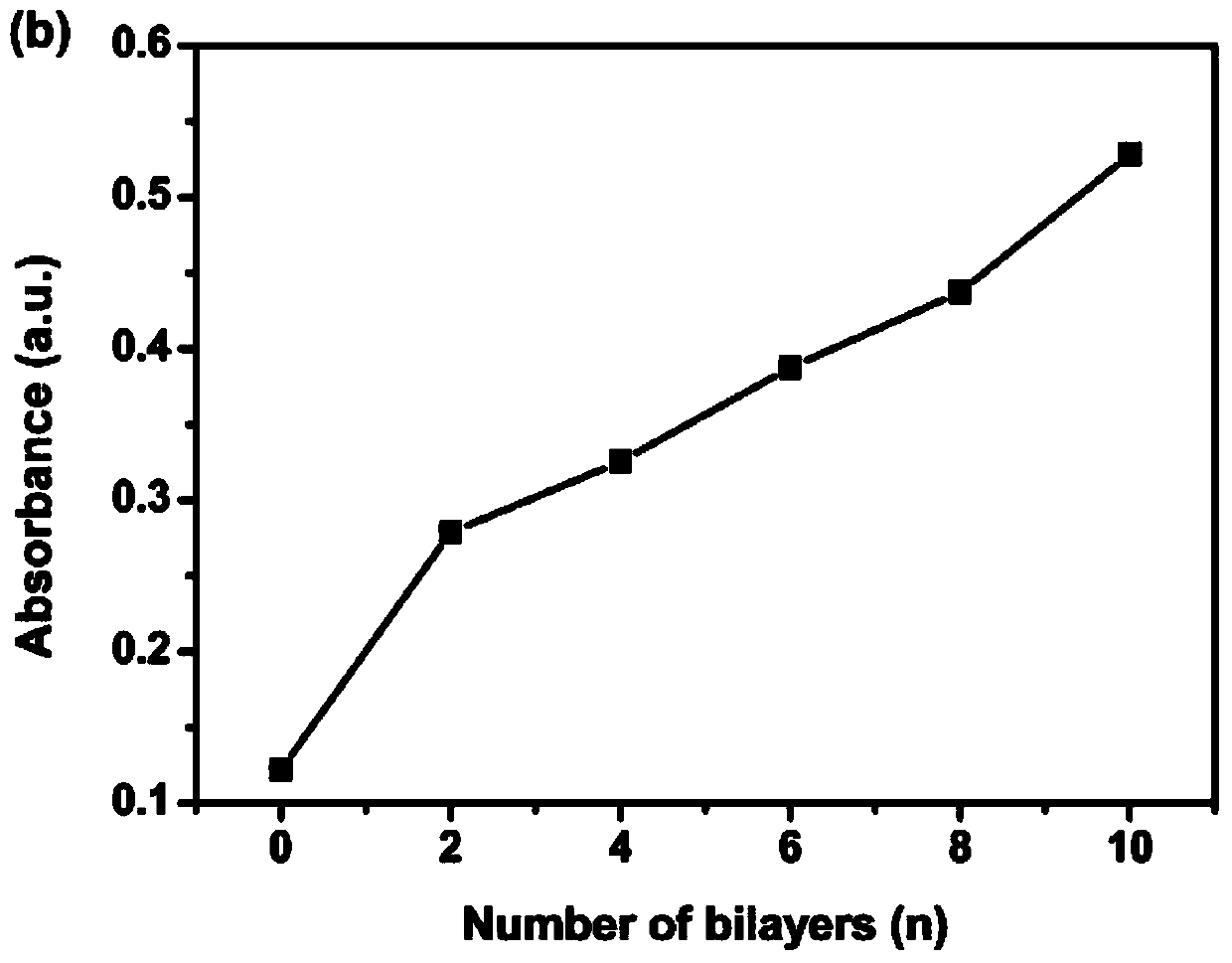

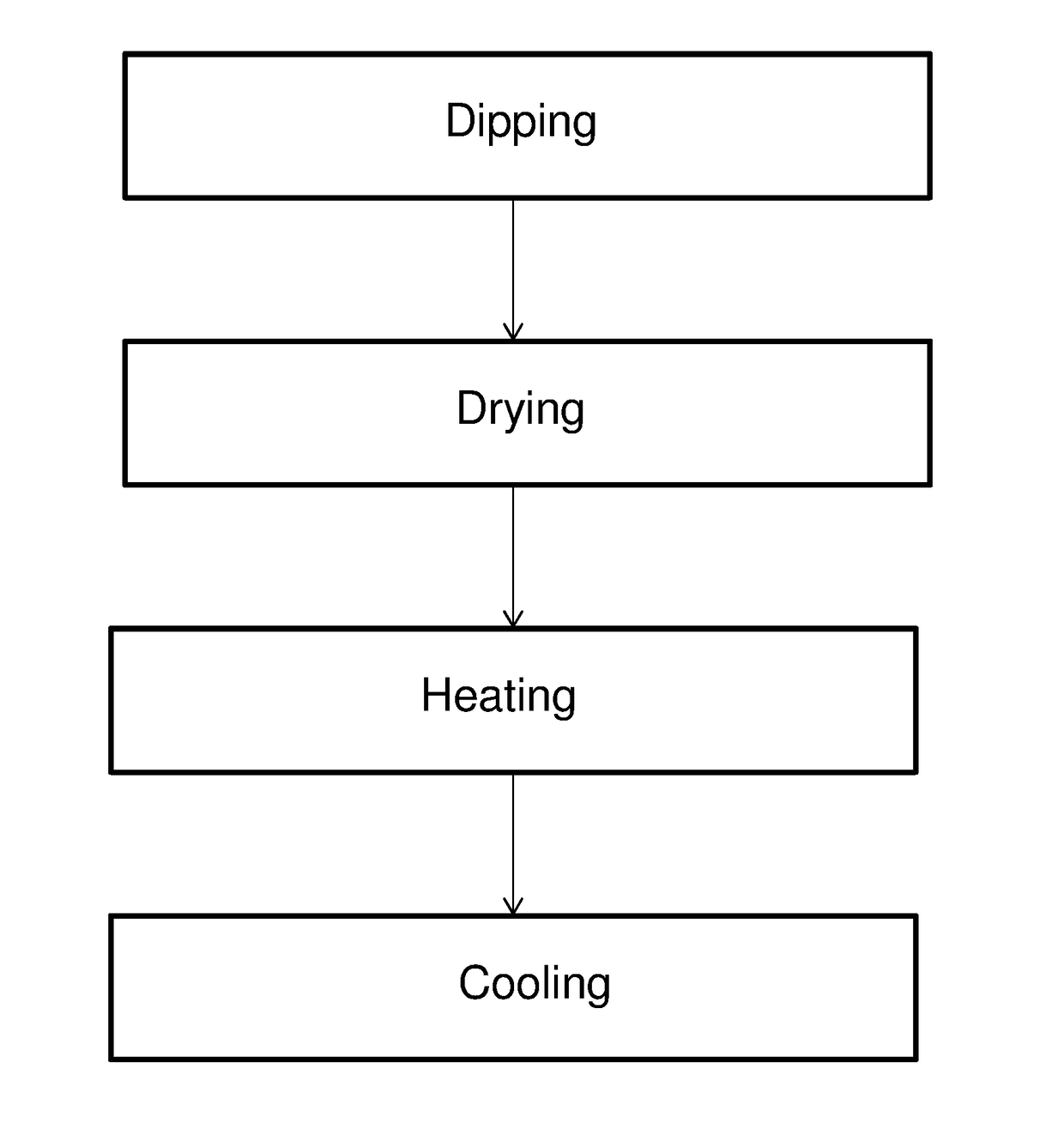

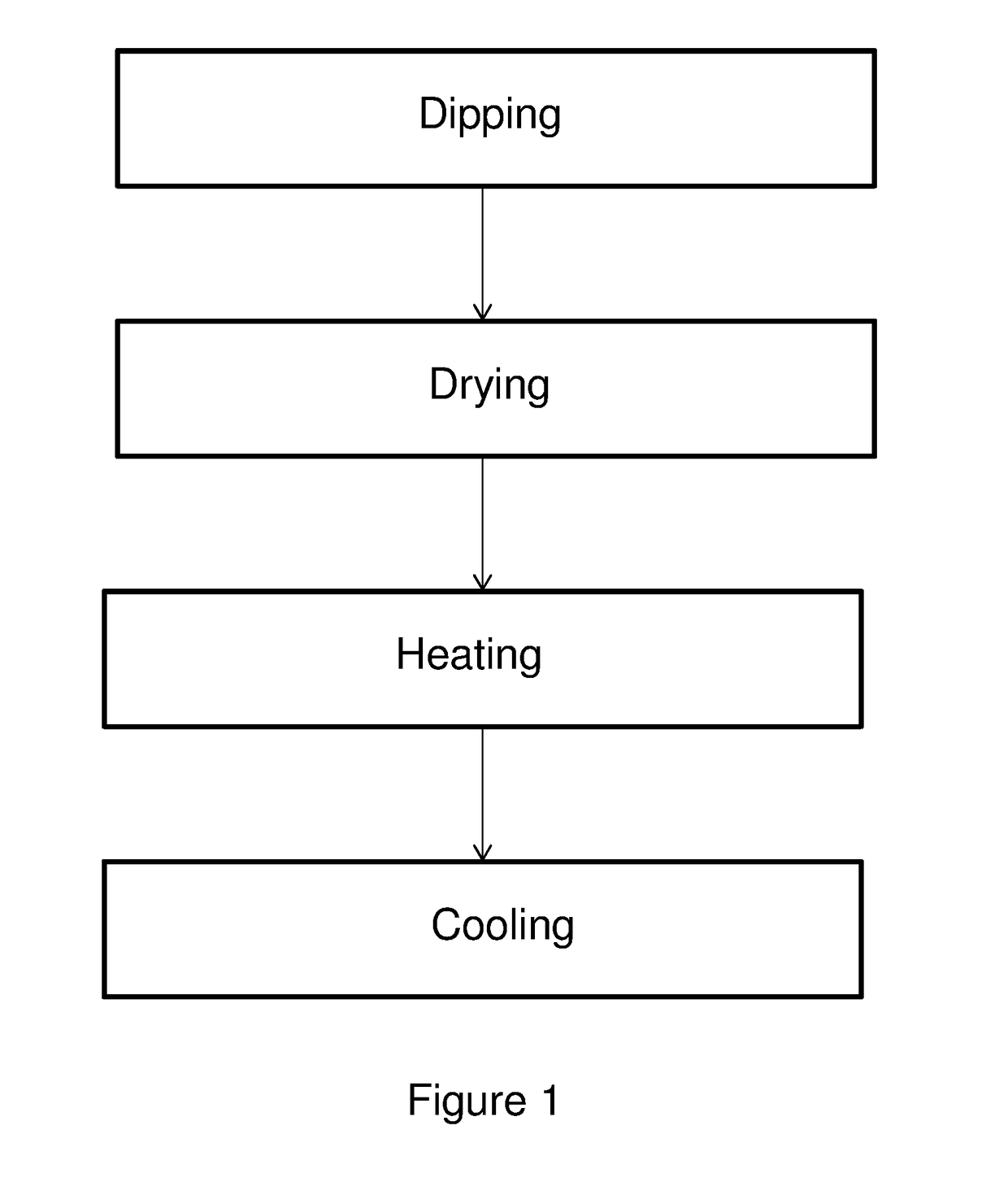

Method for manufacturing cellulose nanofiber electrochromism supercapacitor

ActiveCN103996549AGood uniformityGood transparency and flexibilityHybrid/EDL manufactureTransmittanceCapacitance

The invention relates to a method for manufacturing a cellulose nanofiber electrochromism supercapacitor, and provides a method for manufacturing the cellulose nanofiber-supported flexible electrochromism thin film supercapacitor. The method is higher in machining temperature and low in thermal expansion coefficient, and facilitates biodegradation. The method for manufacturing the cellulose nanofiber electrochromism supercapacitor has the steps that a CNFs / [Cu<2+>-GO]n composite thin film is immersed into a PANI dispersion liquid, the thin film is taken out, cleaned and dried and then is immersed into PEDOT:PSS dispersion liquid, the thin film is taken out, cleaned and dried, the above steps are repeated for m times, and finally a CNFs / [Cu<2+>-GO]n / [PANI-PEDOT:PSS]m multi-layer composite film is obtained; dilute hydrochloric acid treatment and HI acid reduction are performed on the manufactured CNFs / [Cu<2+>-GO]n / [PANI-PEDOT:PSS]m film to obtain a CRGPP-m composite conductive film, the double-piece CRGPP-m composite conductive film is taken as an electrode, H2SO4-PVA gel is taken as electrolyte, and the supercapacitor S-RGPP of a double-electrode system can be assembled. The unit-area capacitance of the manufactured supercapacitor S-RGPP is greatly improved, the good light transmittance reaches 37.8 percent, and after discharging and charging are performed for 1,000 times, the unit-area capacitance can reach 78.3 percent of an initial unit-area capacitance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

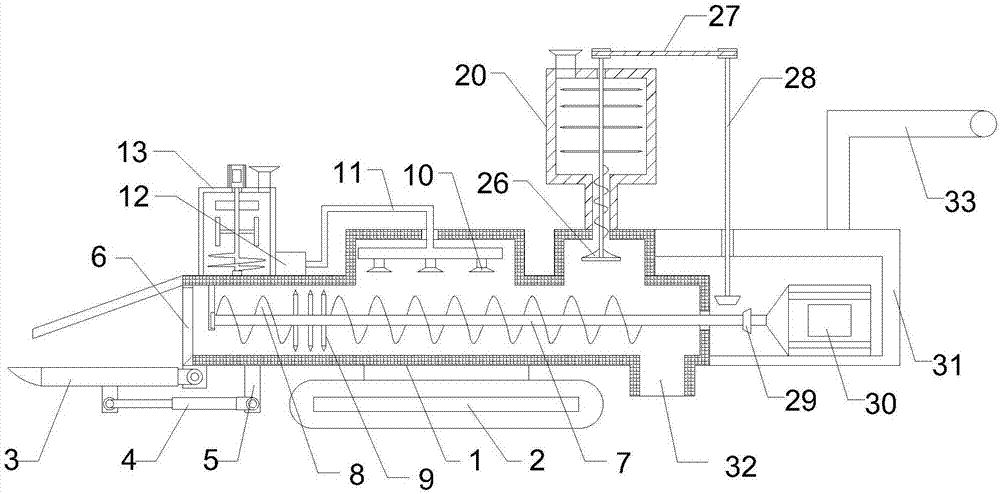

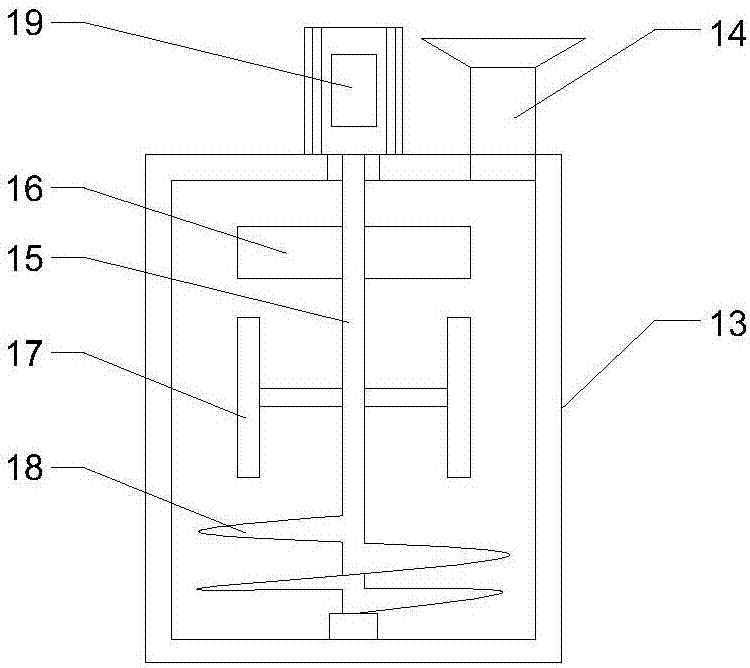

Mini-type hand-push soil governing device

InactiveCN107567733AGood uniformityGuaranteed spraying effectSoil lifting machinesSpadesEngineeringSprayer

The invention discloses a mini-type hand-push soil governing device, which comprises a shell body and a track travelling device; the left side of the shell body is hinged with a shovel plate; one sideof a main rotary shaft closing to a feeding opening is fixedly connected with a vertical smashing cutter blade; a sprayer is arranged at the place where the shell body is located at the upper part ofthe right side of the vertical smashing cutter blade. Through the shovel plate and the vertical smashing cutter blade, soil is efficiently collected and smashed to facilitate the subsequent mixing. The mini-type hand-push soil governing device is provided with a mixing tank, the soil disinfectant raw materials are efficiently mixed and blended, thus the disinfectant homogeneity is better; the spraying effect is guaranteed while the raw materials are saved. The horizontal smashing cutter blade can efficiently smash the solid soil improver so as to mix and contact with soil and improve the mixing effect. A first spiral blade is provided and used for fully and efficiently mixing the soil with the drug; moreover, the soil governing effect is improved, and the operation is continuous and high-efficient.

Owner:李林

Spectrum standard sample for detecting coin-manufacturing non-corrosive steel and its manufacture method

InactiveCN101149333ALow costGood uniformityPreparing sample for investigationColor/spectral properties measurementsFerrosiliconStandard samples

The invention relates to a kind of stainless steel spectrum standard sample, especially the spectrum standard sample used to detect the coinage stainless steel and the manufacturing method. It computes the each material additive quantity according to the formula based on the impurity element C, Si, Mn, P, S and additive element B, Ni, Cu, Cr; Fe is the base material. The material is added into the vacuum induction smelting furnace to cast. When the material is smelted to 95%, the sample is analyzed; then it adjust the steel liquid chemical component according to the analyzing result; it adjusts the Si content using the ferrosilicium when 7-10min before tapping; the ferroboron is pre-added into the steel ingot mould; after each element meeting the request, it controls the tapping temperature: 1520-1540deg.C, the steel liquid is poured into the steel ingot mould, after cooling, the sample number is printing on. The spectrum standard has the good uniformity, wide compound content and many element kinds; the process is advance and the value is accurate; the content grads are in reason. So it is better than the other same sample in analyzing the coinage stainless material.

Owner:CHINA BANKNOTE PRINTING & MINTING

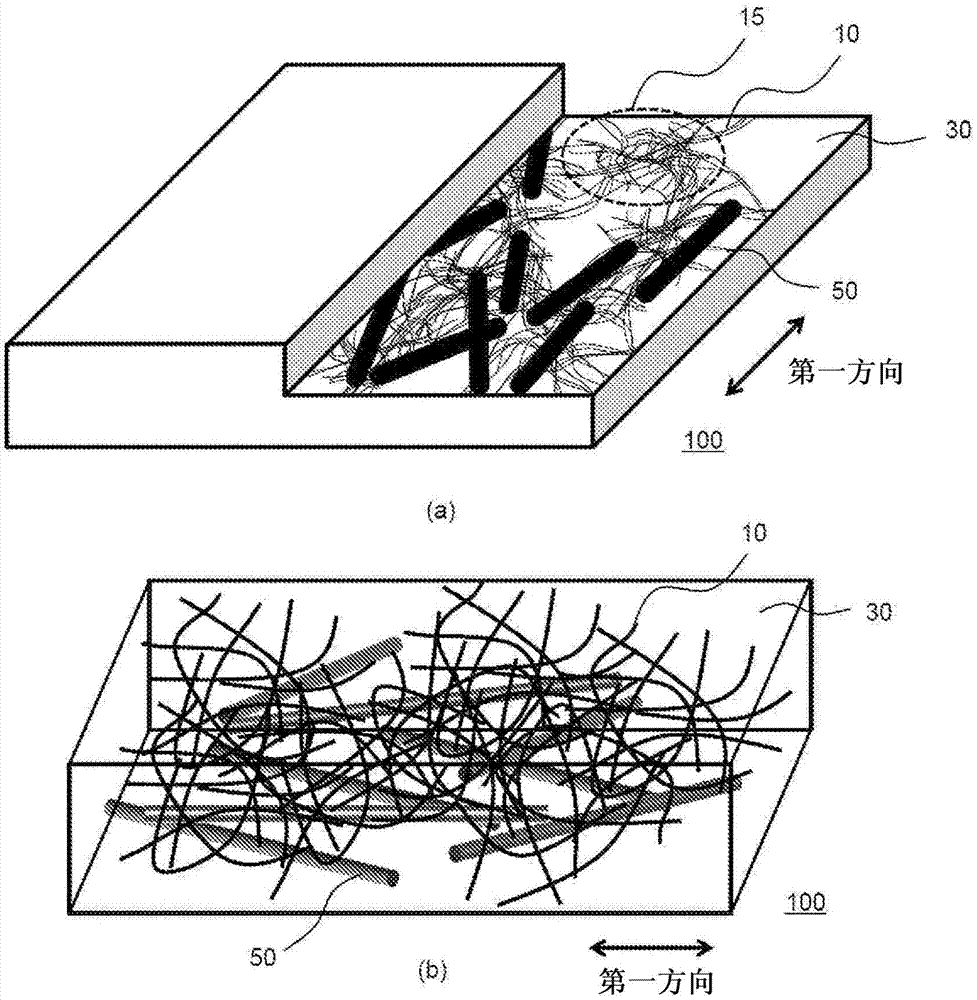

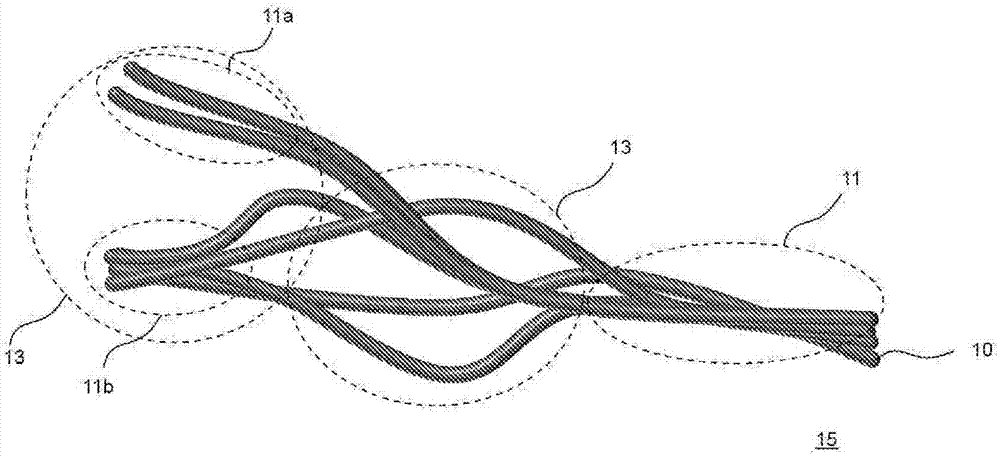

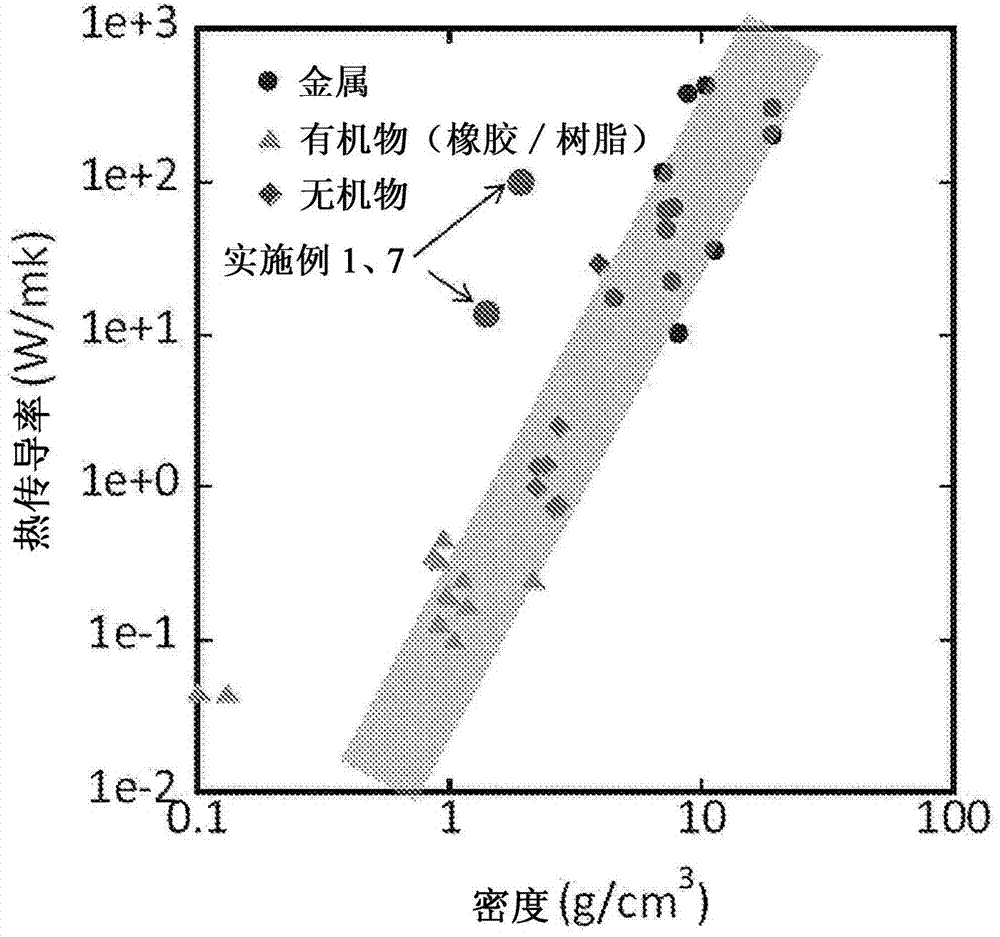

Carbon nanotube composite material and heat conductor

InactiveCN103842445AGood uniformityHigh thermal conductivityMaterial nanotechnologyHeat-exchange elementsThermal conductivityCarbon nanotube

The present invention addresses the problem of providing: a carbon nanotube composite material which has excellent uniformity and high thermal conductivity; and a heat conductor. A carbon nanotube composite material of the present invention has a carbon nanotube group, which is configured of a plurality of carbon nanotubes, present between adjacent carbon fibers. The carbon fibers have an average diameter of from 1 mum to 50 mum (inclusive); the carbon nanotubes have an average diameter of from 0.7 nm to 50 nm (inclusive); the carbon nanotubes are contained in an amount within the range from 0.01% by weight to 30% by weight (inclusive) and the carbon fibers are contained in an amount within the range from 10% by weight to 60% by weight (inclusive), respectively relative to 100% by weight of the carbon nanotube composite material; the thermal conductivity of the matrix material is less than 10 W / mk; and the carbon nanotube composite material has a direction in which the thermal conductivity is 10 W / mK or more.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Technology for total-cladding composite ion plating of surface of aramid fiber or laid fabric with nanometals, and product thereof

ActiveCN104831527AStrong adhesionGood uniformityFibre typesVacuum evaporation coatingIonNitrogen gas

The invention relates to a technology for total-cladding composite ion plating of the surface of an aramid fiber or laid fabric with nanometals. A substrate is the aramid fiber or the laid fabric made of the aramid fiber. The technology comprises the following steps: 1, carrying out dewatering degassing treatment on the substrate in a vacuum chamber with the vacuum degree of 10-3.0*10<-4>Pa and the heating temperature of 60-180DEG C; 2, carrying out plasma surface cleaning treatment on the substrate by adopting a cathode ion film plating device with argon or nitrogen as a protection gas under a vacuum degree of 1.0*10<-1>-3.0*10<-4>Pa at a temperature of -10 - -30DEG C under a substrate running speed of 3.0-10.0m / min, generating metal ions and nanoparticles with the density of 1.0-10.0g / m<2> in adopting a composite ion film plating mode with metals as a target material, and carrying out total-cladding plating on the surface of the substrate with a nanometal plating layer with the granularity of below 100nm; and 3, cutting the above obtained material, metering, and carrying out vacuum packaging. The technology greatly reduces the influences of water and ultraviolet ray on the aramid fiber, and greatly protects excellent mechanical performances of the aramid fiber.

Owner:ALDO NEW TECH MATERIALSJIAXING CO LTD

Crack pressure-sensitive solidification self-healing asphalt concrete, as well as preparation method and application method thereof

The invention discloses crack pressure-sensitive solidification self-healing asphalt concrete, as well as a preparation method and an application method thereof. The crack pressure-sensitive solidification self-healing asphalt concrete comprises the following components in parts by mass: 80-110 parts of aggregate, 3-15 parts of an asphalt cementing agent, and 0.5-10 parts of capsule particles, wherein the capsule particles exist in the asphalt cementing agent. The invention provides a new idea for prolonging the service life of a pavement of asphalt, and provides the scheme of the crack pressure-sensitive solidification self-healing asphalt concrete from the aspect that a material self stores a repairing material; the durability of the pavement is improved, the follow-up maintenance frequency and cost are reduced, and good economic advantages are achieved; in addition, the influence of construction on transportation and local ecological environment is avoided, and good social and environmental benefits are achieved.

Owner:JSTI GRP CO LTD

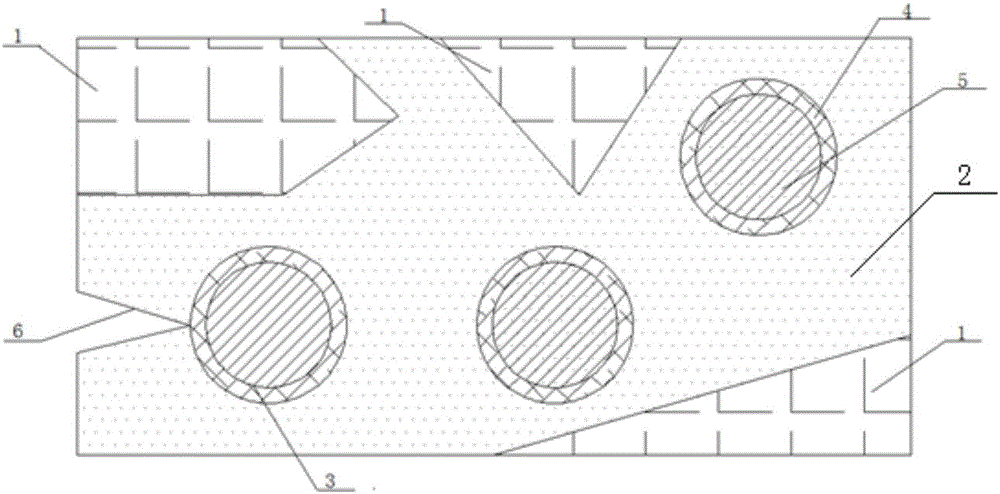

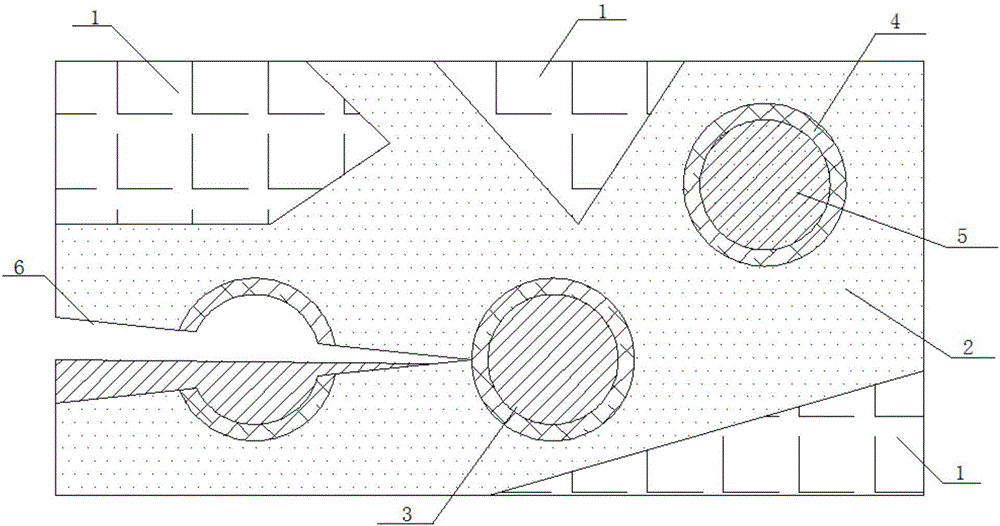

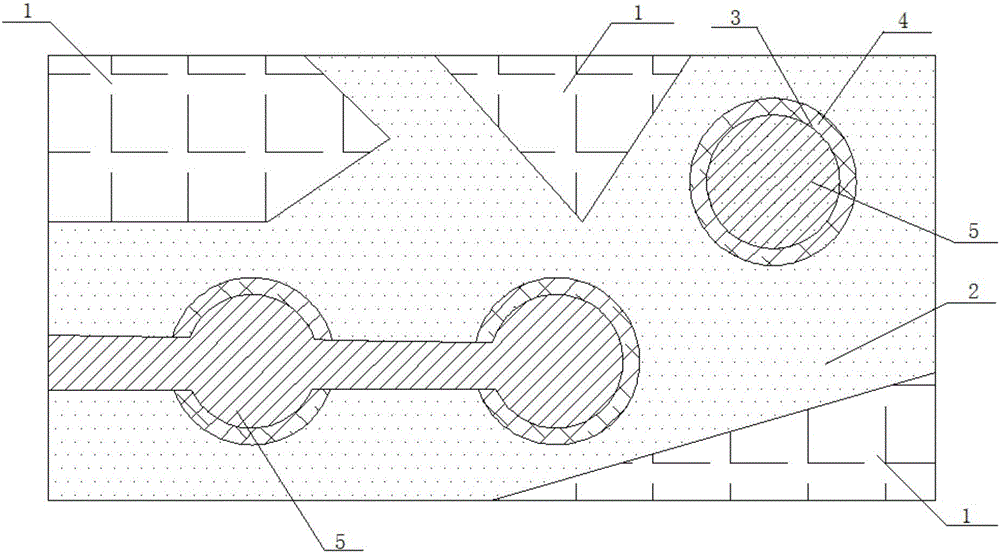

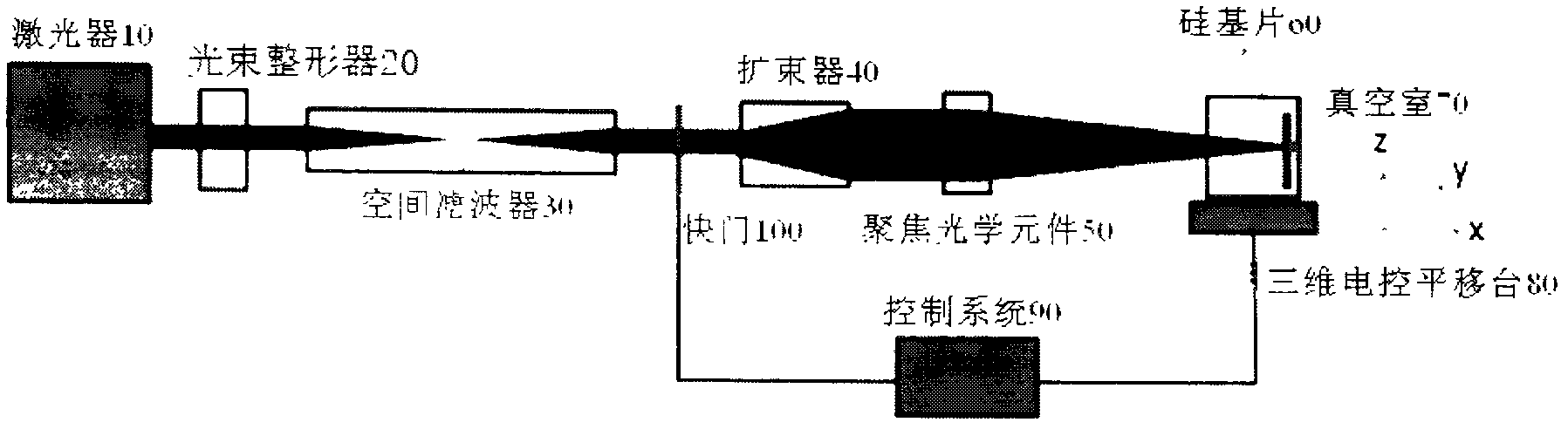

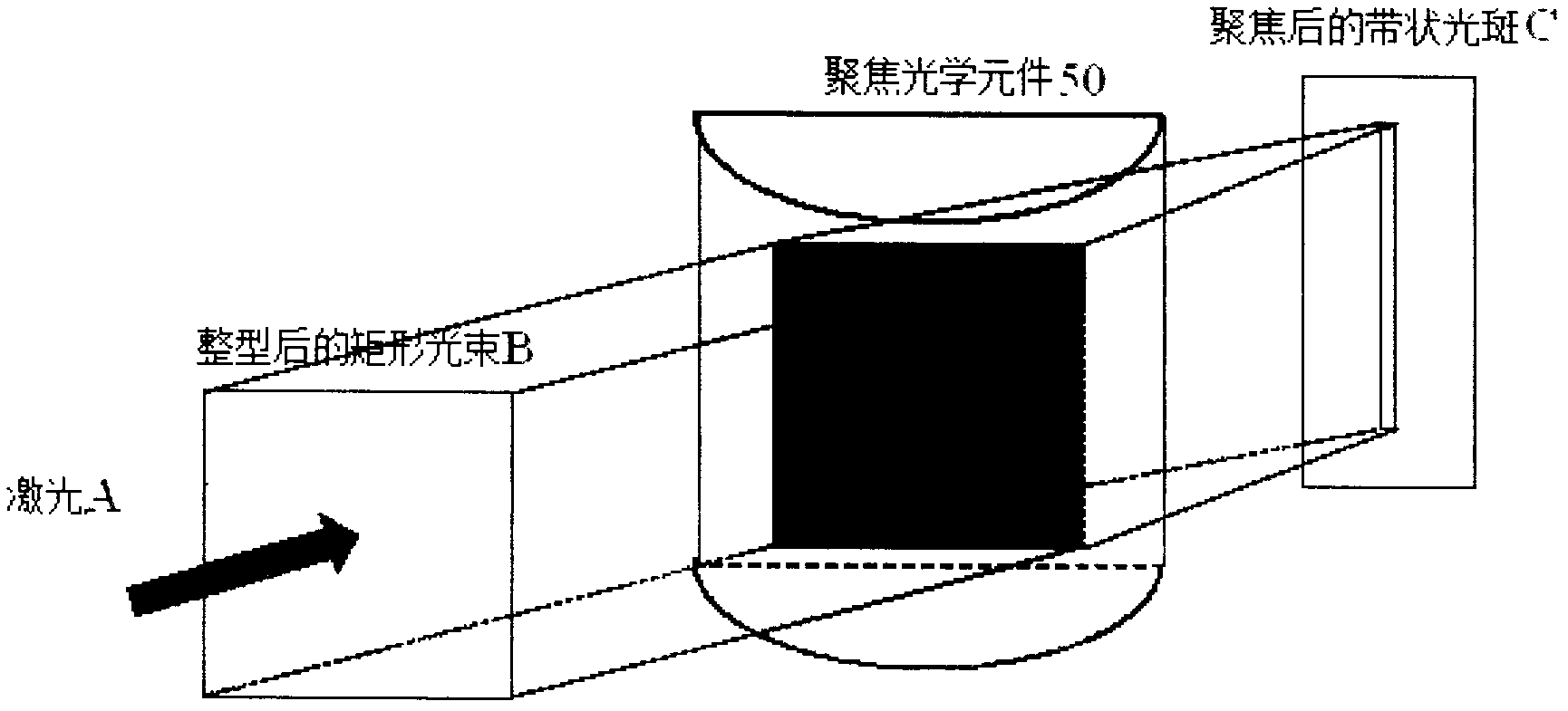

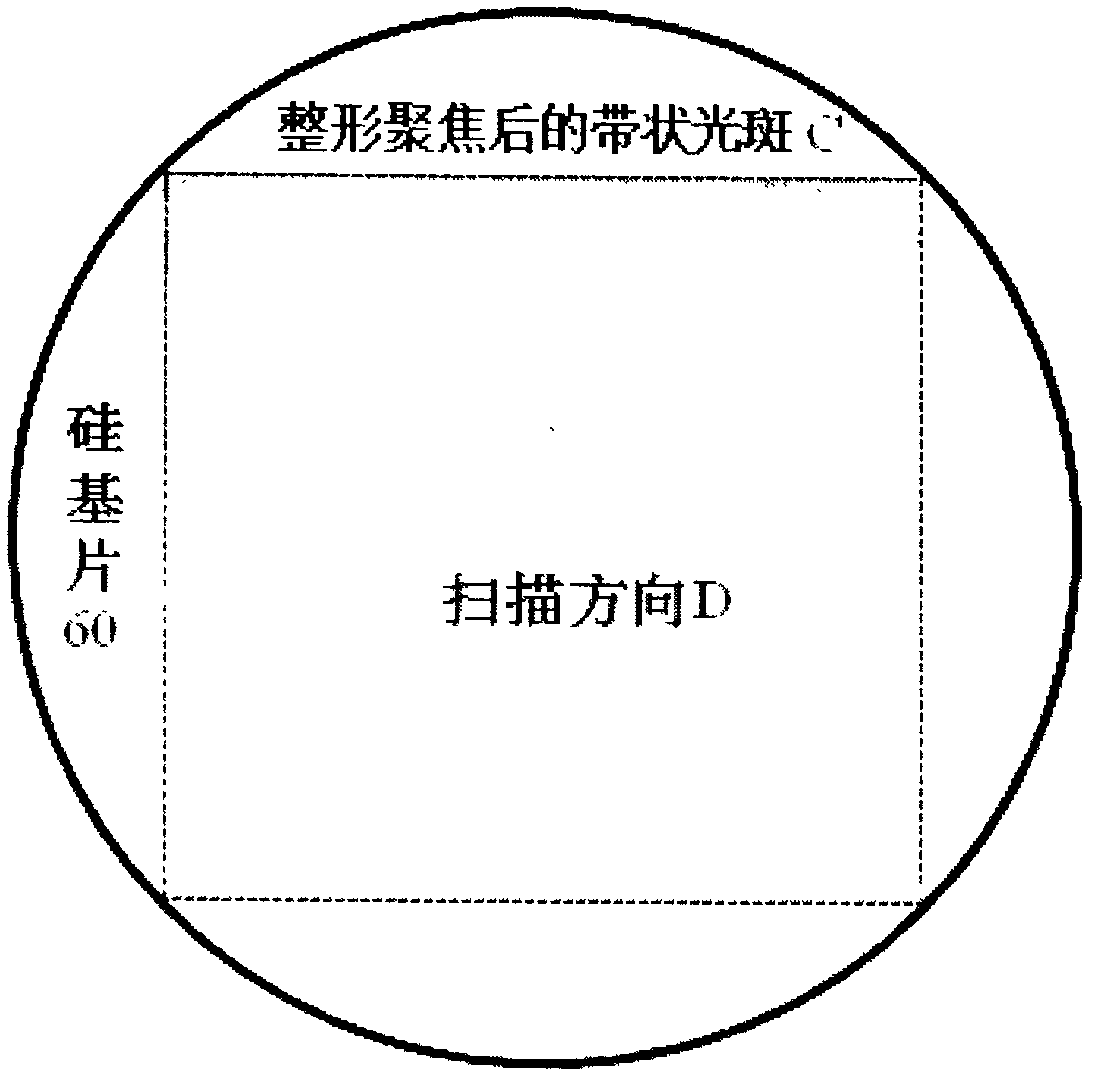

Method for rapidly preparing large-area and uniform black silicon material, and device thereof

InactiveCN102321921AImprove preparation efficiencyGood uniformityAfter-treatment detailsDiffusion/dopingMicrostructureLaser beams

The present invention discloses a method for rapidly preparing a large-area and uniform black silicon material through pulsed laser grating type scanning, and a device thereof. The method comprises the following steps: 1, placing a silicon substrate in a black silicon preparing environment; 2, shaping laser beams, converging the laser beams into a strip light spot to irradiate a surface of the silicon substrate; 3, adopting the laser to carry out grating type scanning for the surface of the silicon substrate, growing a microstructure on the surface of the silicon substrate to form the black silicon. With the method and the device provided by the present invention, the black silicon can be directly prepared on the 2 inch silicon substrate, 4 inch silicon substrate, or larger silicon substrate through the one-time scanning, the surface microstructure of the prepared black silicon has good uniformity, and the method can meet the actual requirements of mass production.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Quantum dot diaphragm, optical element, backlight module group and preparation method

InactiveCN107203016AGood uniformityImprove optical performanceDiffusing elementsQuantum dot laserQuantum dot

The invention discloses a quantum dot diaphragm comprising a quantum dot layer. The quantum dot layer comprises a high-molecular material and quantum dots which are uniformly distributed in the high-molecular material. The quantum dot diaphragm is characterized in that the high-molecular material also comprises a microstructure body which is used for controlling a thickness of the quantum dot layer and has a preset particle size. The quantum dot diaphragm has good uniformity and can be thinner. The microstructure in the quantum dot diaphragm can diffuse particles and thus enhance optical performance of the quantum dot diaphragm. The invention also discloses an optical member, a backlight module, a quantum dot diaphragm and a preparation method for the same.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

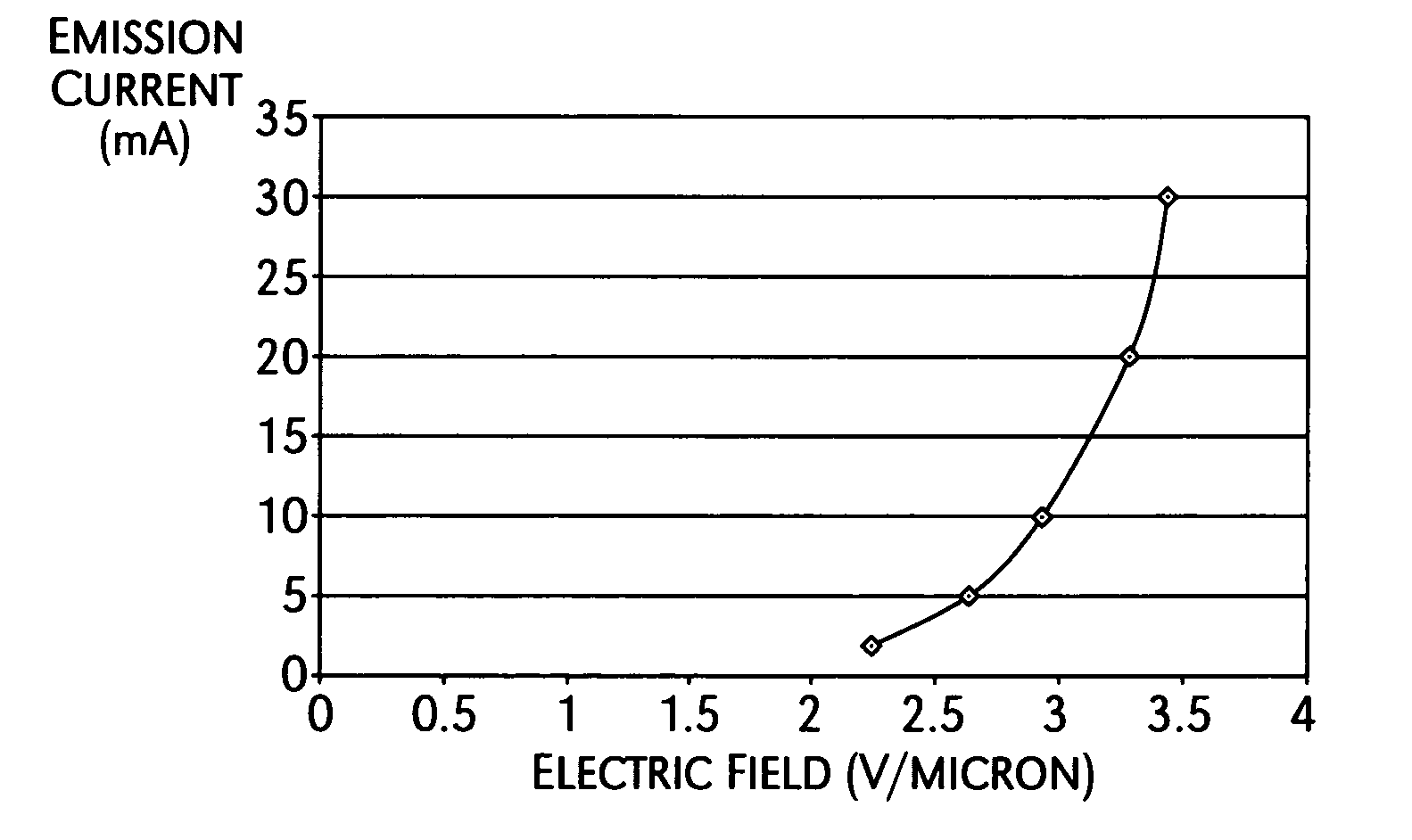

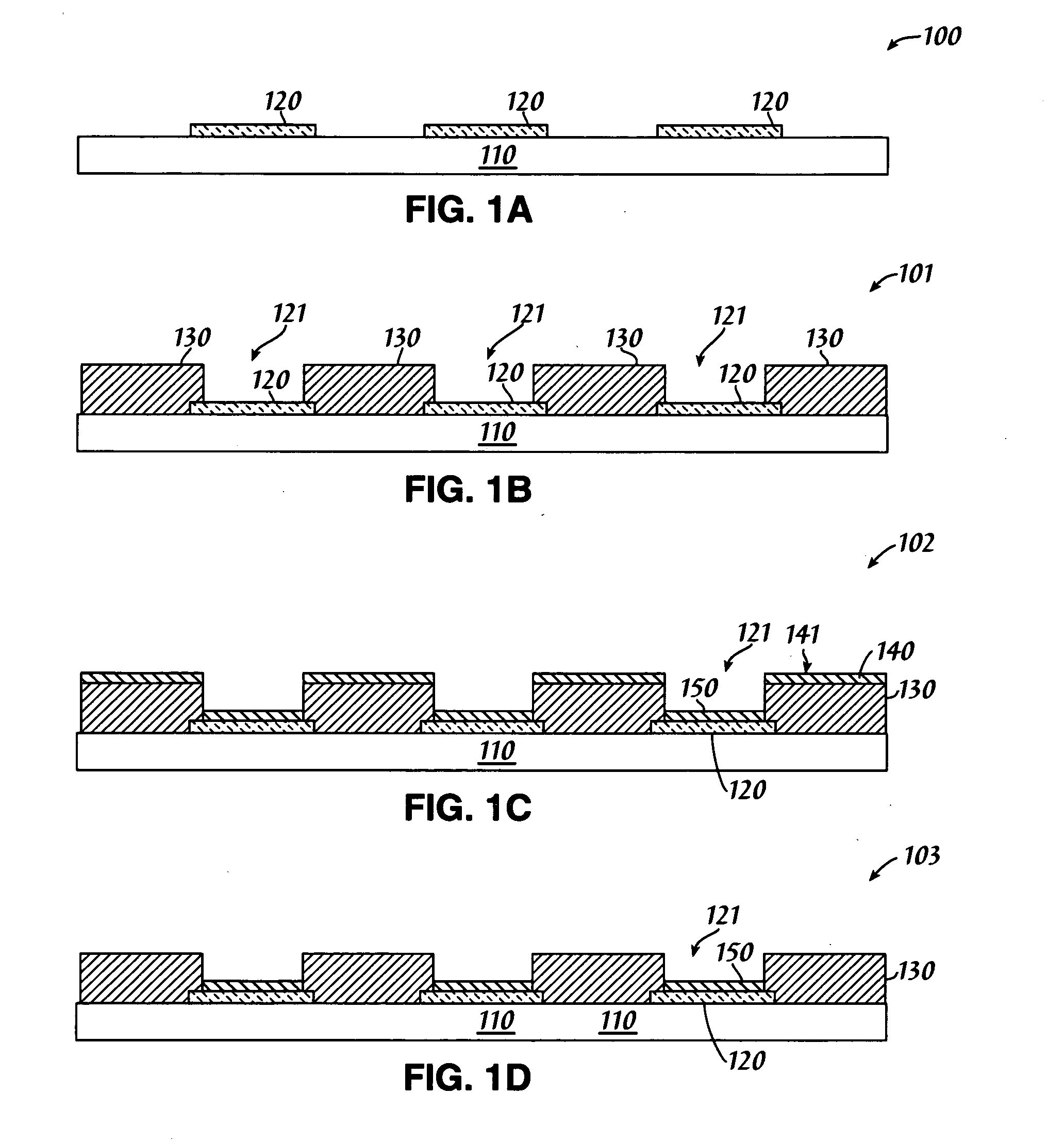

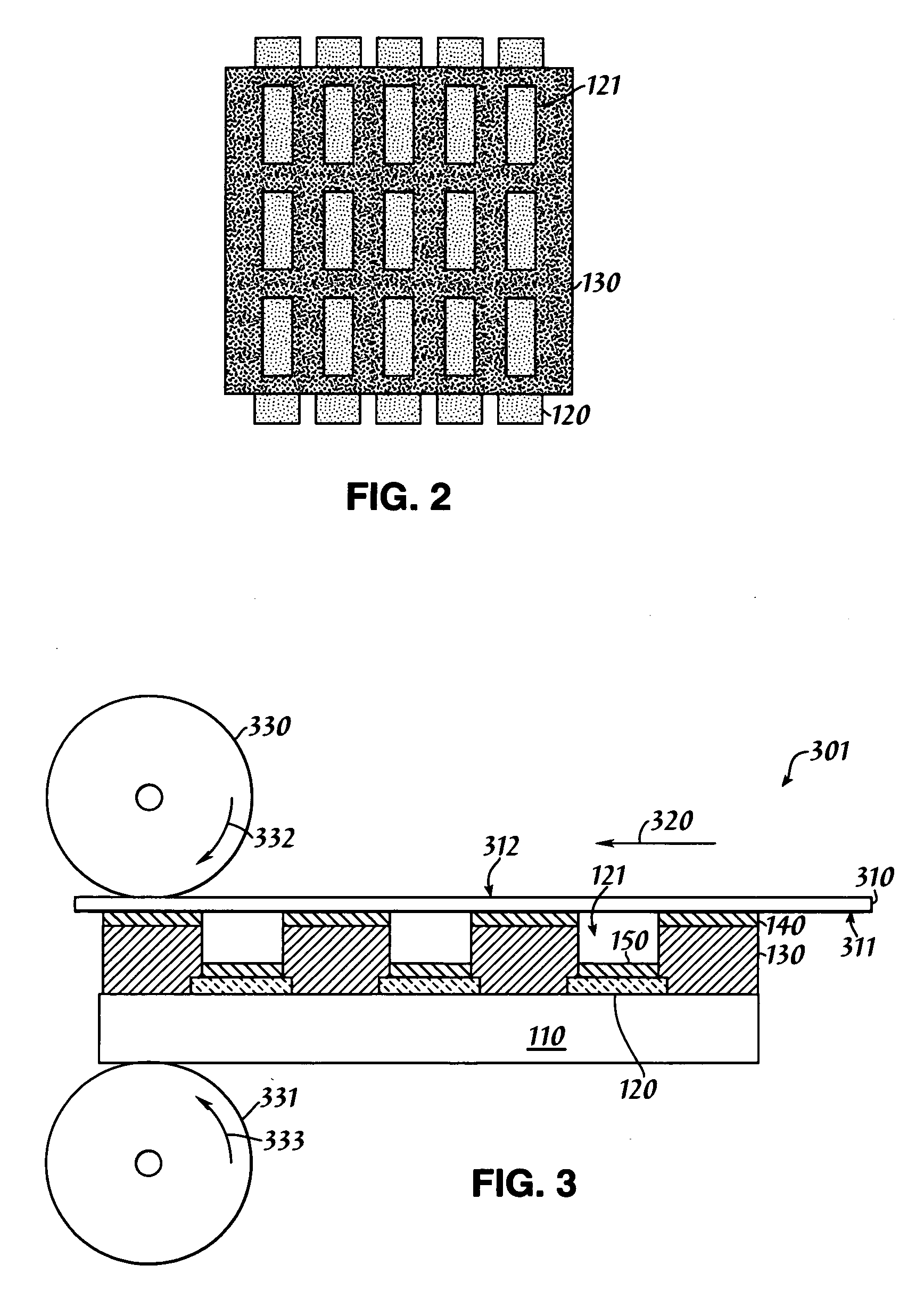

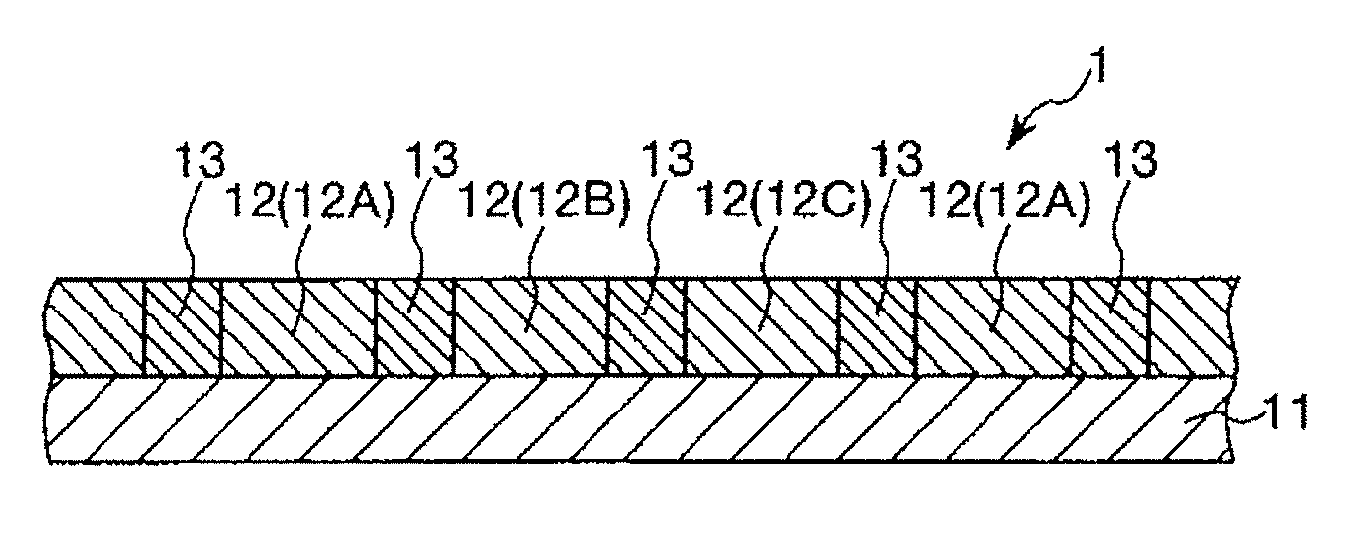

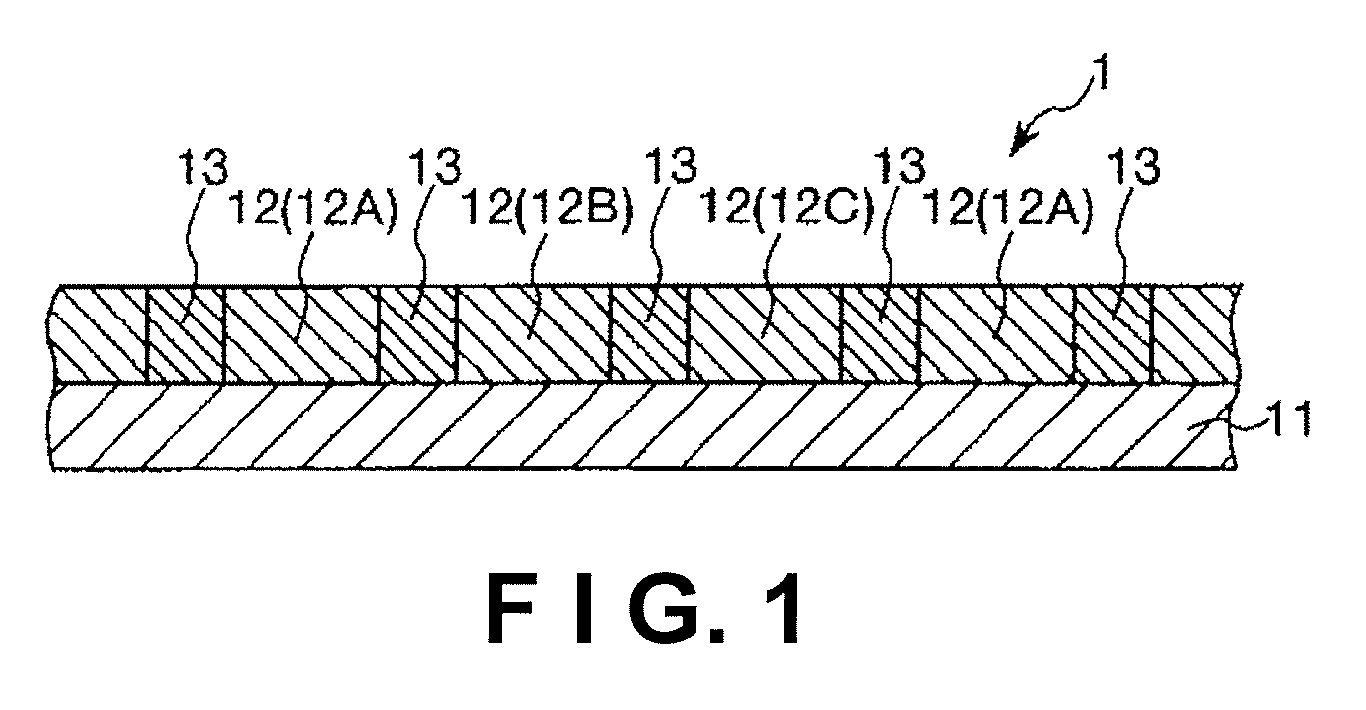

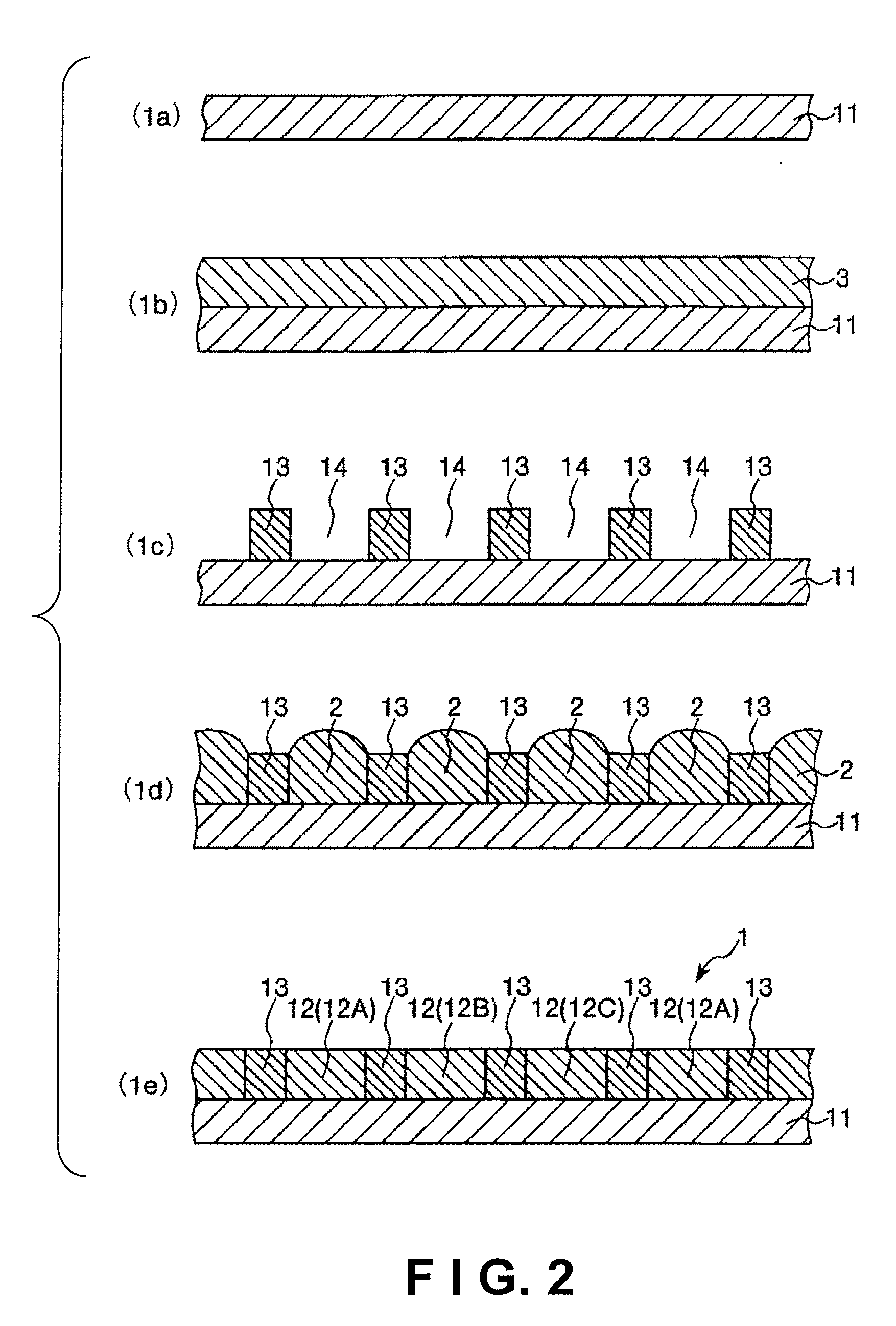

Patterning CNT emitters

InactiveUS20060292297A1Good uniformityImprove uniformityCathode ray tubes/electron beam tubesNanoinformaticsIndustrial scaleNanometre

An industrial scale method for patterning nanoparticle emitters for use as cathodes in a display device is disclosed. The low temperature method can be practiced in high volume applications, with good uniformity of the resulting display device. The method steps involve deposition of CNT emitter material over an entire surface of a prefabricated composite structure, and subsequent removal of the CNT emitter material from unwanted portions of the surface using physical methods.

Owner:APPLIED NANOTECH HLDG

Color filter ink, color filter ink set, color filter, image display device, and electronic device

InactiveUS20090189128A1Good uniformityColor unevennessOptical filtersInksColor filter arrayBoiling point

A color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The color filter ink includes a pigment, a dispersing agent and a liquid medium. The pigment includes a halogenated phthalocyanine zinc complex and a pigment derivative represented by a prescribed chemical formula. The dispersing agent disperses the pigment. The liquid medium, in which the pigment is dispersed, includes at least a first liquid and a second liquid different than the first liquid. A boiling point at atmospheric pressure of the first liquid is 180 to 290° C. A content ratio of the second liquid in the color filter ink is 5 to 20 wt %. A relationship |SP (X)−SP (Y)|≦0.8 is satisfied, wherein a value SP (X) indicates a solubility parameter for the dispersing agent, and a value SP (Y) indicates a solubility parameter for the second liquid.

Owner:SEIKO EPSON CORP

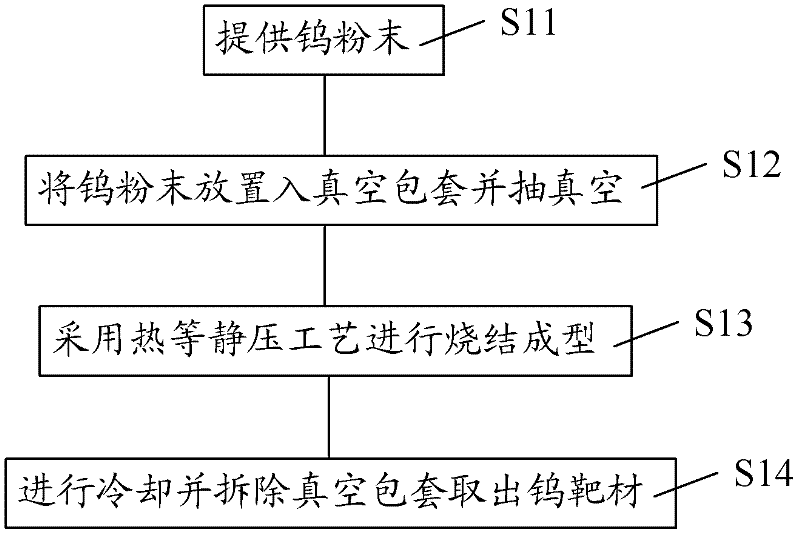

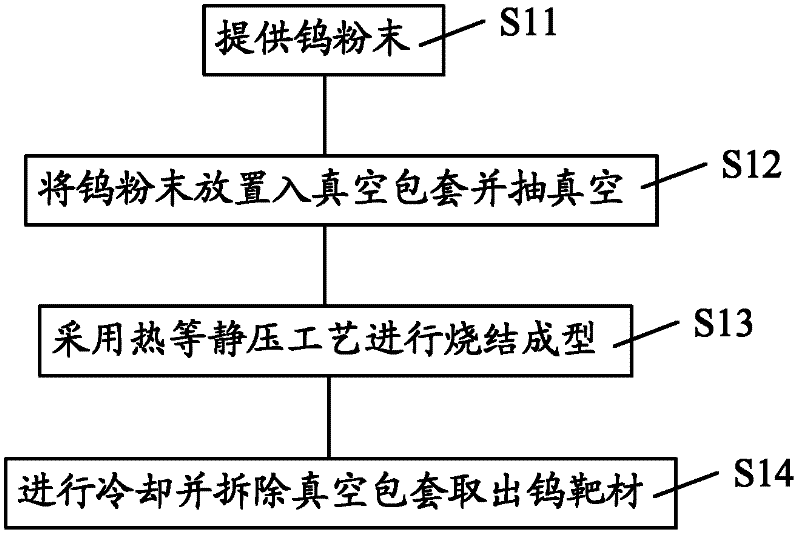

Method for manufacturing tungsten target material

The invention relates to a method for manufacturing a tungsten target material. The method comprises the following steps: providing tungsten powder; placing the tungsten powder into a vacuum package and vacuumizing; carrying out sinter molding by adopting a hot isostatic pressing process; after finishing the sinter molding, cooling and removing the vacuum package, and taking out the tungsten target material. With the adoption of the method for manufacturing the tungsten target material provided by the invention, the use of a mold is avoided, and meanwhile, both the compactness and the uniformity for the internal organizational structure of the formed tungsten target material are better than those of a tungsten target material formed by hot pressing.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

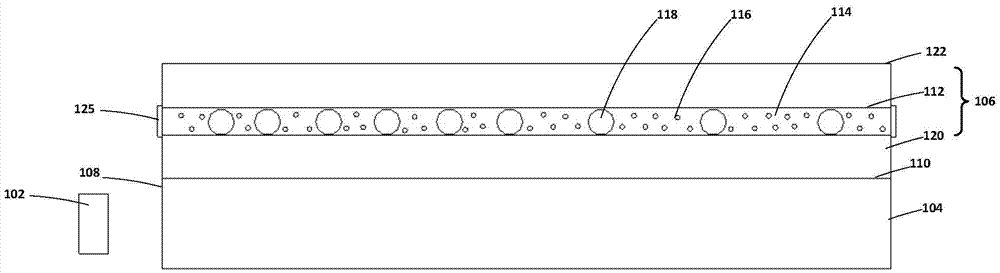

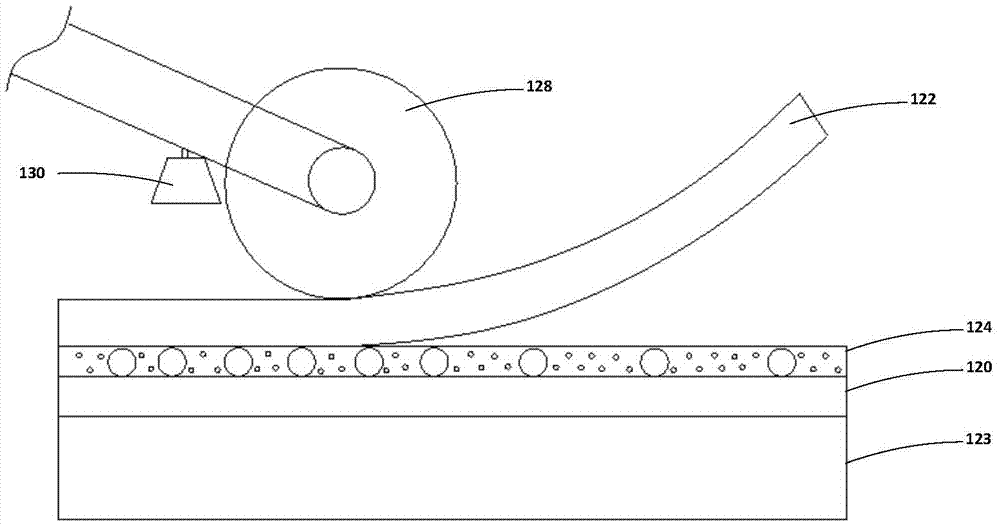

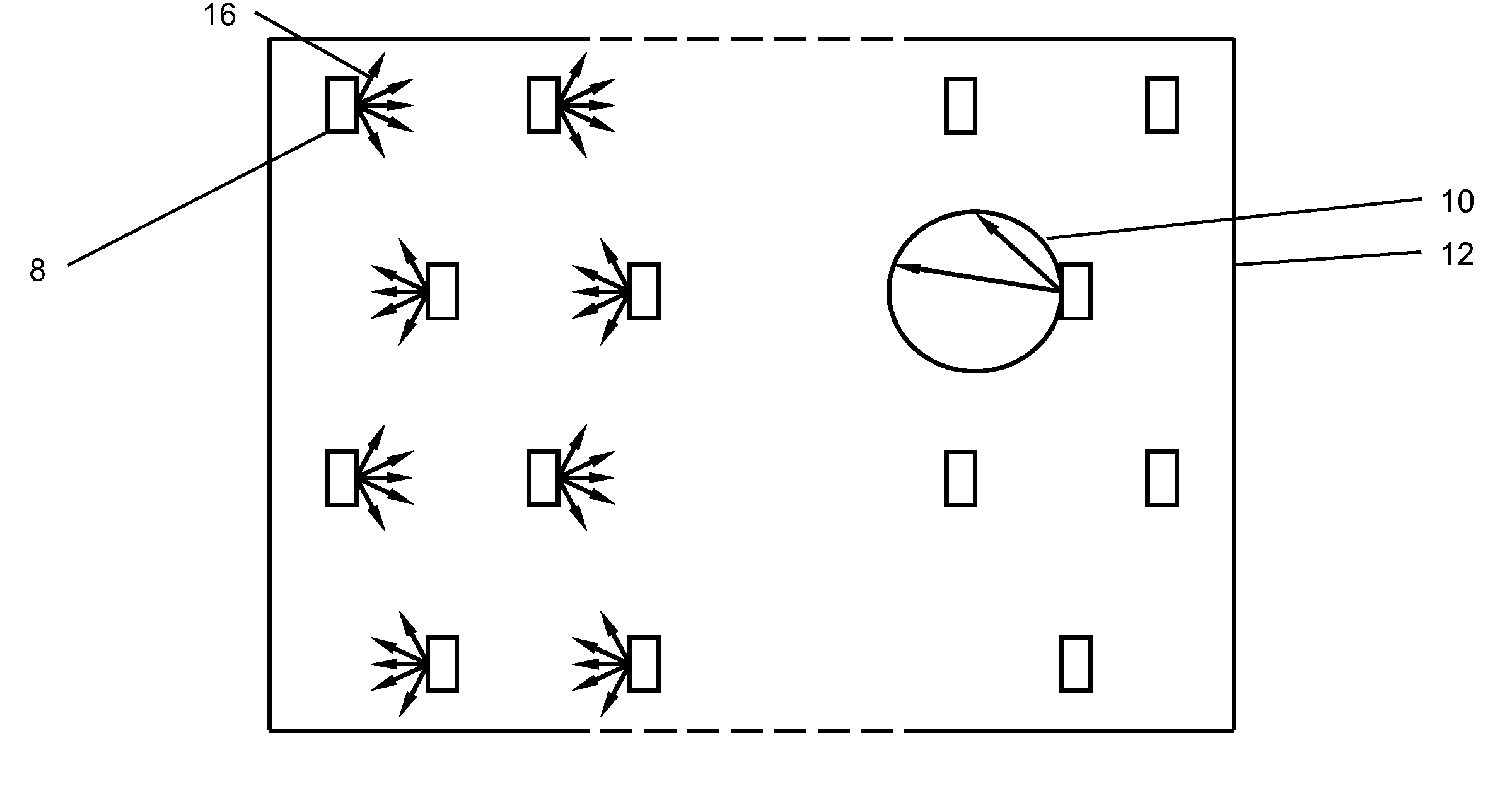

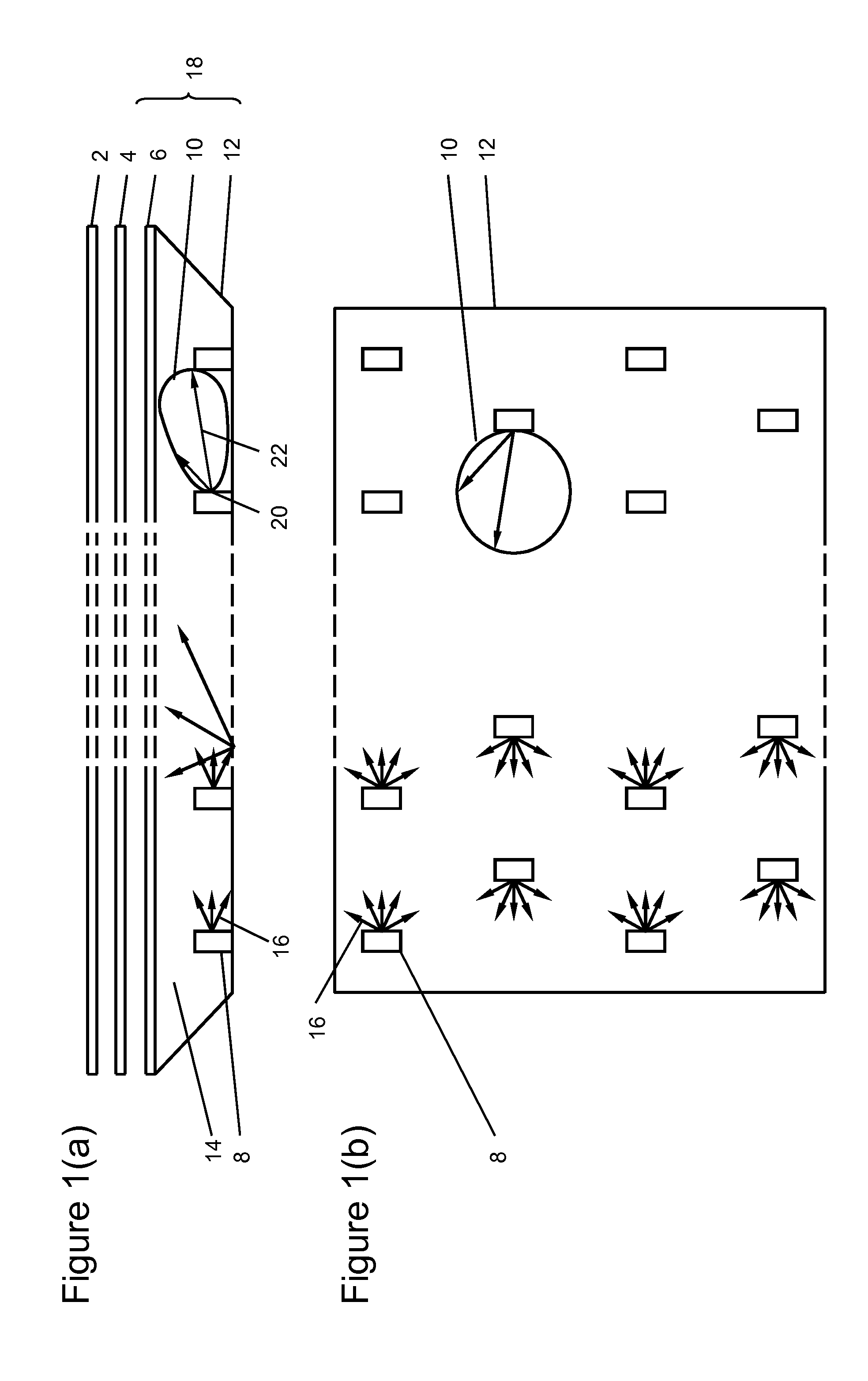

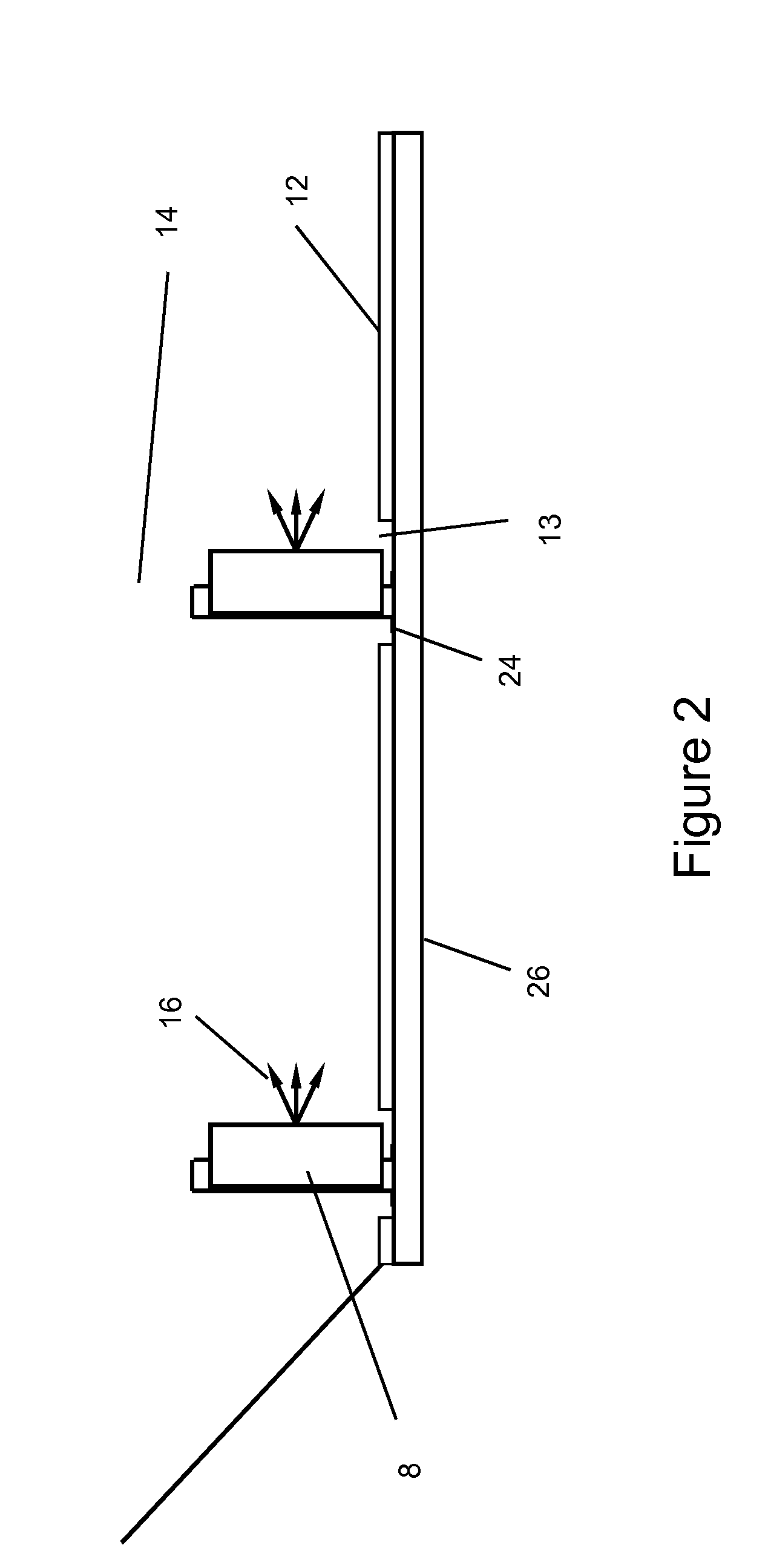

Lateral emission LED backlight for LCD

InactiveUS20110038141A1Good uniformityPower be lowerIlluminated signsNon-linear opticsLiquid-crystal display

A backlight for illuminating a liquid crystal display in which LEDs are arranged in an array in a backlight cavity. The LEDs are arranged such that the emission from the LEDs is in a lateral direction into the backlight cavity. The emission from the LEDs is shaped so as to match the cross-sectional shape of the backlight cavity thus achieving a high degree of spatial uniformity for a relatively small backlight cavity thickness.

Owner:SHARP KK

Surface treatment process for objects

InactiveUS20170327658A1Good uniformityLow melting pointAdditive manufacturing apparatus3D object support structuresSurface finishingMaterials science

Owner:SCULPTEO

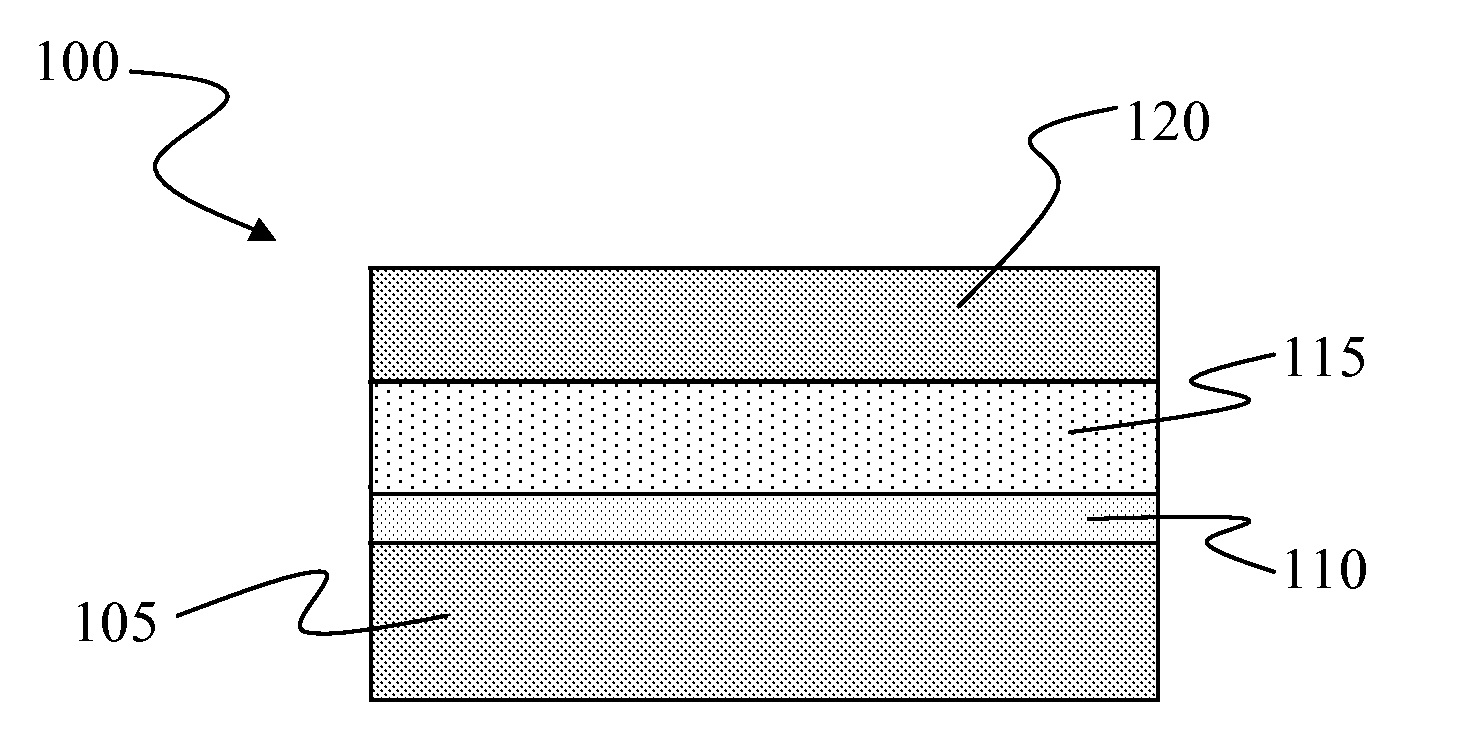

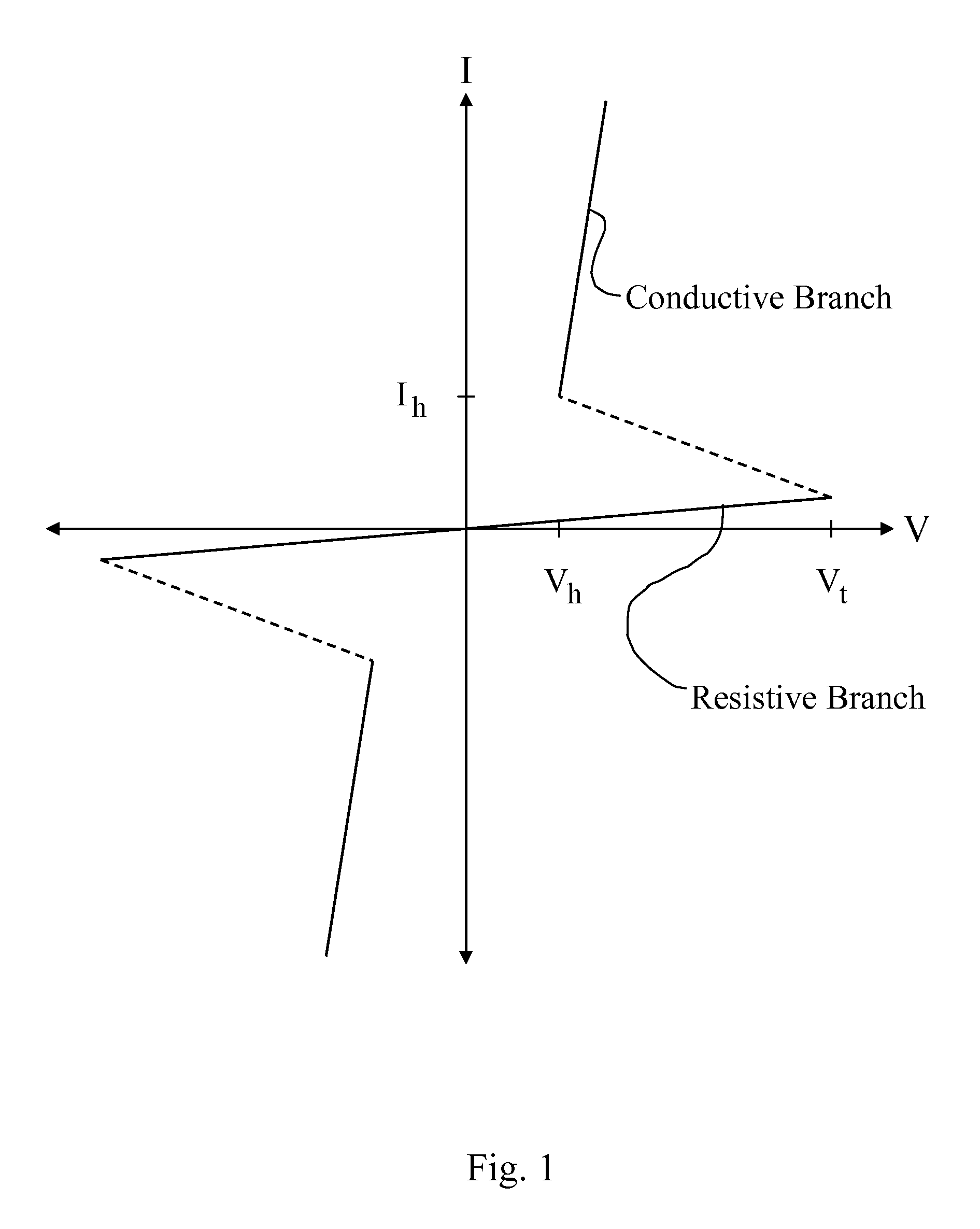

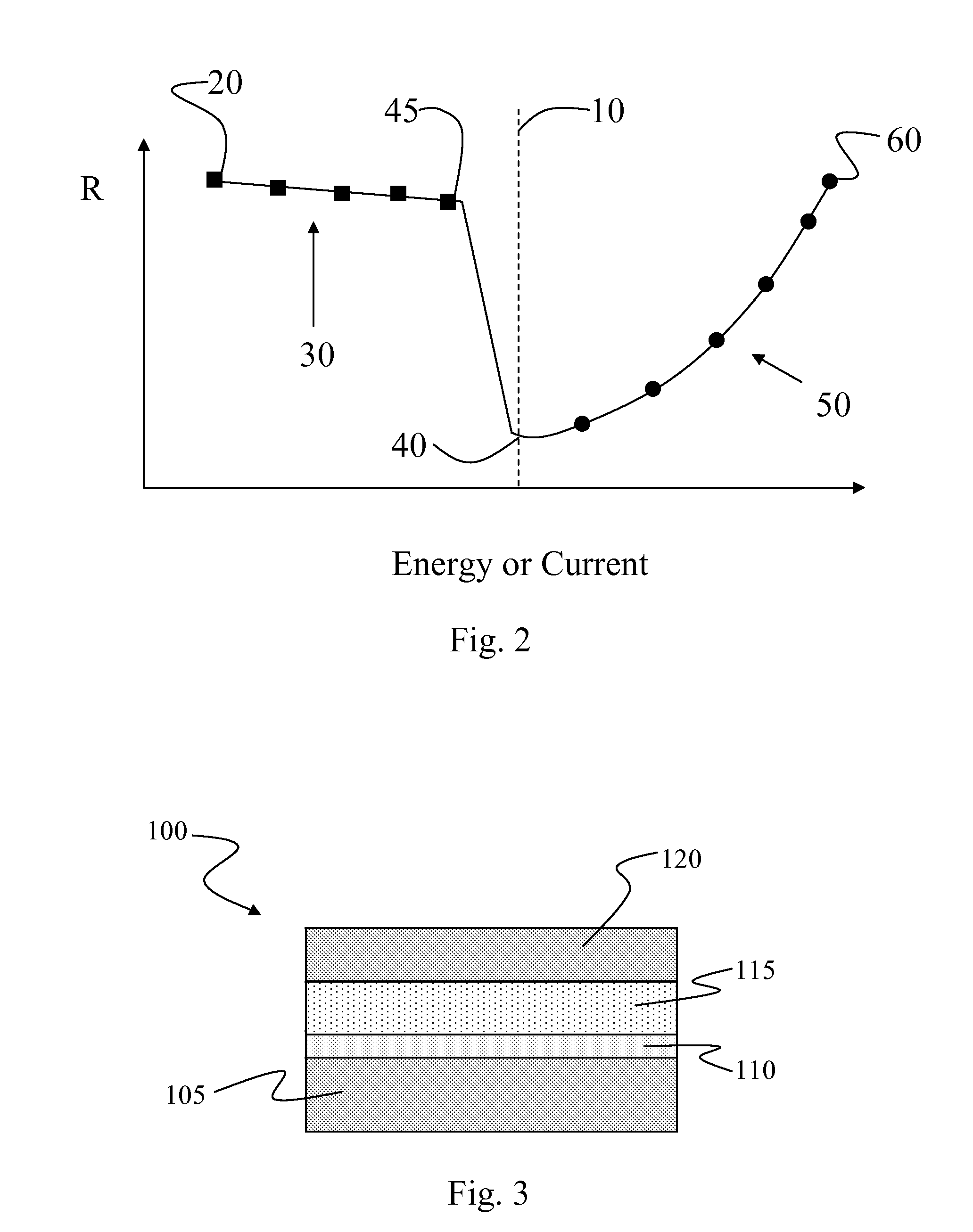

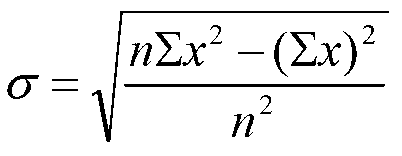

Breakdown Layer via Lateral Diffusion

ActiveUS20100301988A1Reducing variation in performanceGood uniformityDigital storageResistive material coatingLateral diffusionPhase-change material

An electronic device including a breakdown layer having variable thickness. The device includes a variable resistance material positioned between two electrodes. A breakdown layer is interposed between the variable resistance material and one of the electrodes. The breakdown layer has a non-uniform thickness, which serves to bias the breakdown event toward the thinner portions of the breakdown layer. As a result, the placement, size, and number of ruptures in the breakdown layer are more consistent over a series or array of devices. The variable resistance material may be a phase-change material. The variable-thickness breakdown layer may be formed through a diffusion process by introducing a gas containing a resistivity-enhancing species to the environment of segmented variable resistance devices during fabrication. The resistivity-enhancing element penetrates the outer perimeter of the variable resistance material and diffuses toward the interior of the device. The resistivity-enhancing species increases the resistance of the interface between the variable resistance material and the electrode by interacting with the variable resistance material and / or electrode to form a resistive interfacial material. Based on the diffusional nature of the process, the concentration of the resistivity-enhancing species decreases toward the center of the device and as a result, the breakdown layer is thinner toward the center of the device.

Owner:OVONYX MEMORY TECH LLC

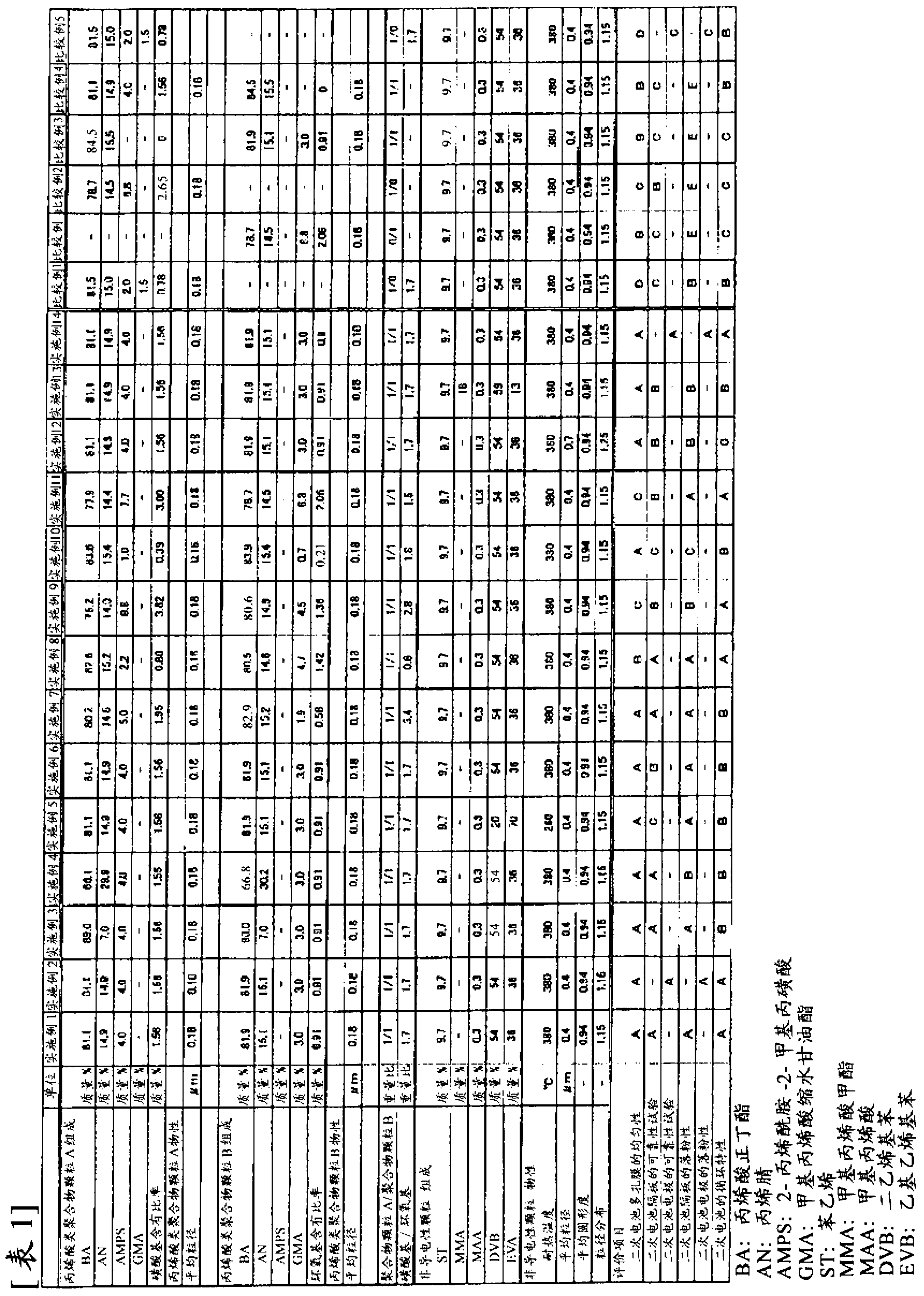

Secondary-battery porous-membrane slurry, secondary-battery porous membrane, secondary-battery electrode, secondary-battery separator, secondary battery, and method for manufacturing secondary-battery porous membrane

ActiveCN103262297AGood uniformityGood strengthFinal product manufactureActive material electrodesPorous membraneSolvent

To provide a high-strength, highly uniform secondary-battery porous membrane that is capable of improving the cycle characteristics of a resulting secondary battery and is manufactured using a secondary-battery porous-membrane slurry that exhibits excellent coating performance and contains highly-dispersed nonconductive particles. Also, to provide a secondary-battery electrode and secondary-battery separator having good shutdown functionality. This secondary-battery porous-membrane slurry is characterized by containing organic-polymer-containing nonconductive particles, a binder, and a solvent, and is further characterized in that said binder contains particles (A) of an acrylic polymer that has a sulfonic acid group and particles (B) of an acrylic polymer that has an epoxy group.

Owner:ZEON CORP

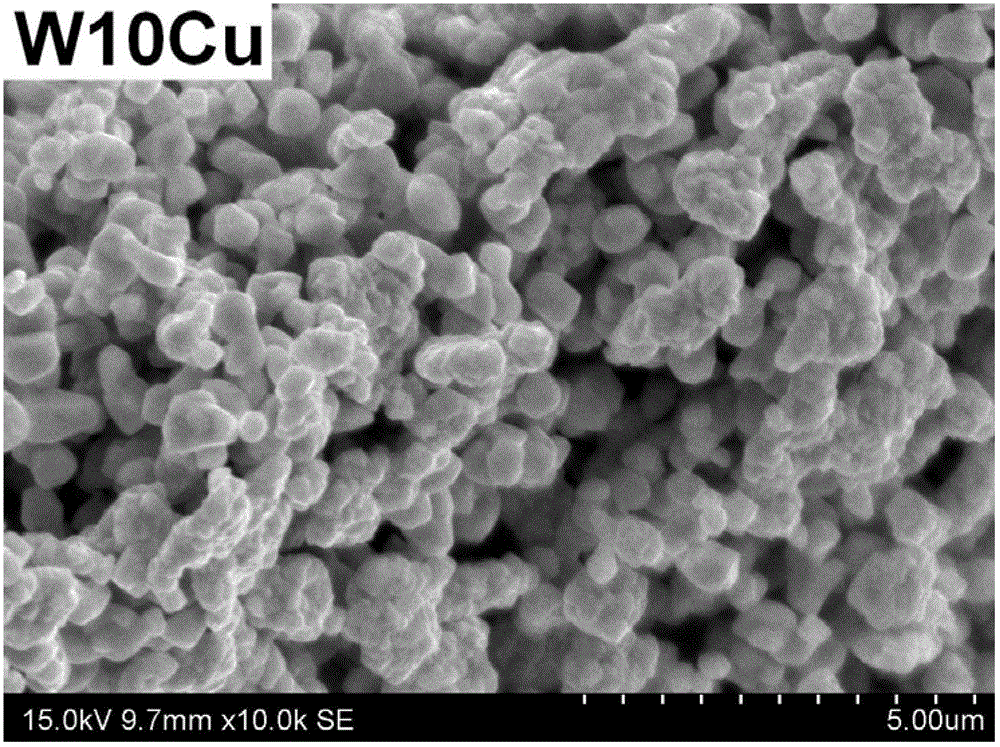

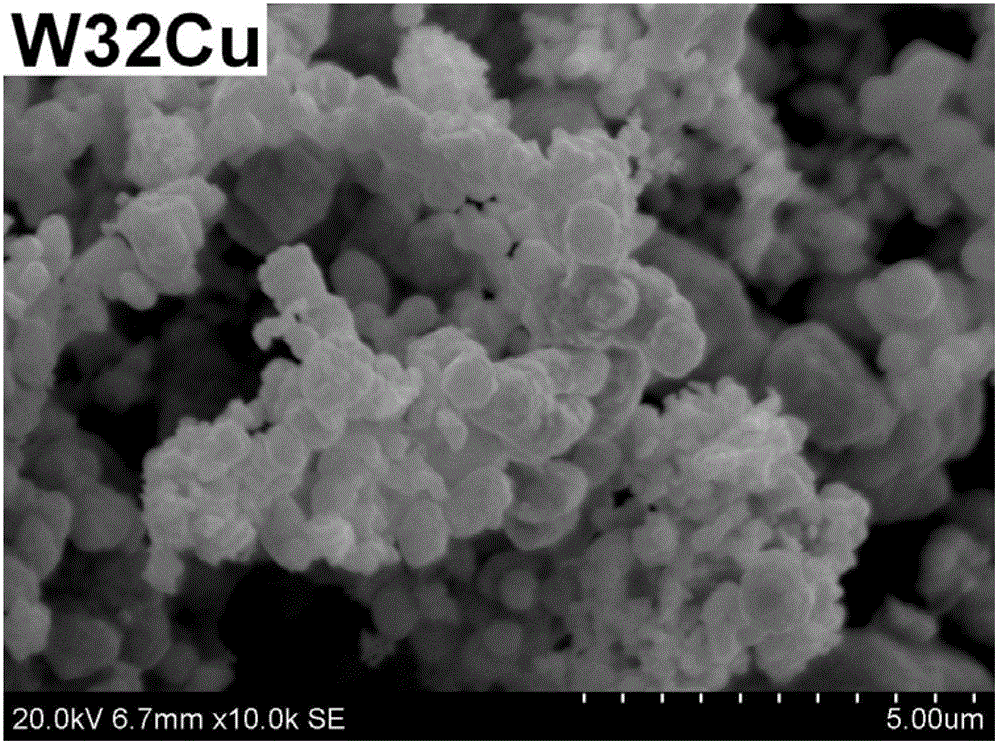

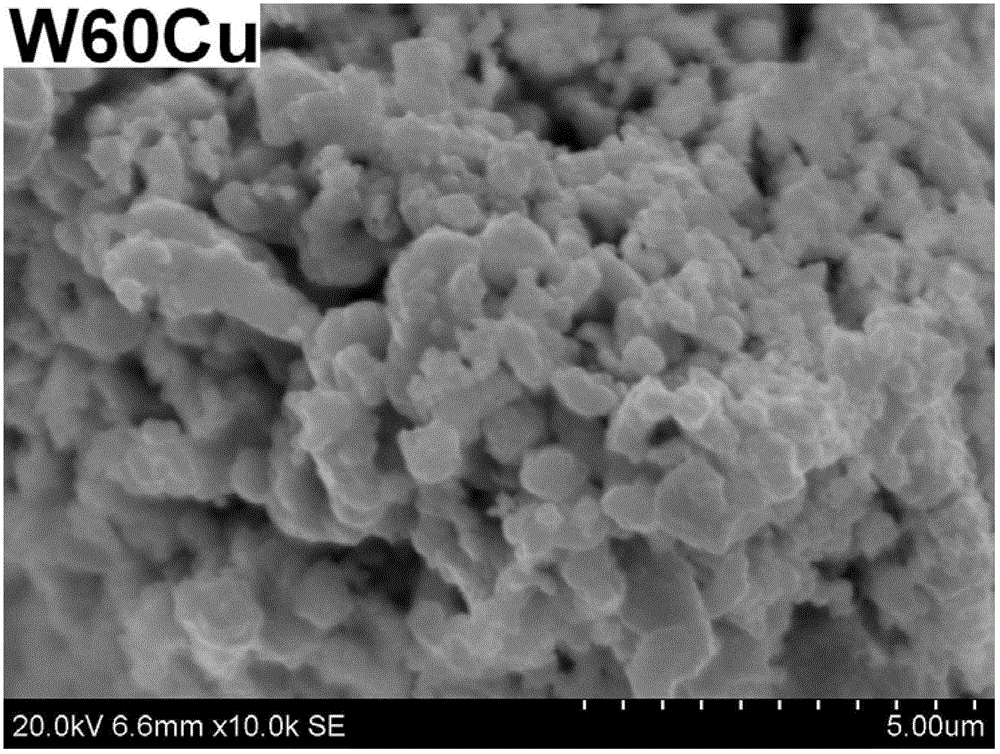

Preparation method of tungsten-copper functional gradient material

The invention discloses a preparation method of a tungsten-copper functional gradient material. The method comprises the following steps of: (1) adding a tungsten precursor and a copper precursor into water to prepare a plurality of parts of sol systems with different tungsten-copper weight ratios; adding a surfactant into the sol systems and drying a plurality of parts of the sol systems to obtain a plurality of parts of corresponding tungsten-copper compound precursor powder; (2) calcining a plurality of parts of the tungsten-copper compound precursor powder to be completely converted into a plurality of parts of corresponding oxide compound powder; (3) reducing a plurality of parts of the corresponding oxide compound powder to obtain a plurality of parts of corresponding ultra-fine tungsten-copper compound powder; (4) gradually paving the ultra-fine tungsten-copper compound powder in a mould layer by layer and pressing into a blank; and (5) sintering the blank to prepare the tungsten-copper functional gradient material. According to the preparation method disclosed by the invention, the tungsten-copper functional gradient materials of various designs can be realized; an interface between layers of the obtained material has no defects and the transition is natural.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

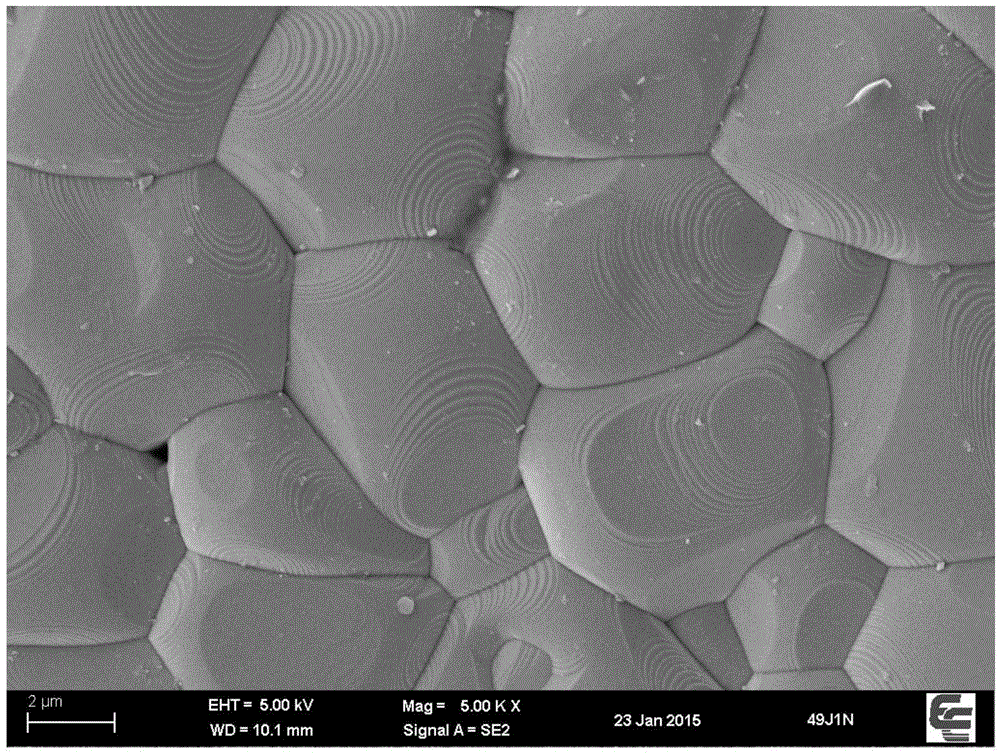

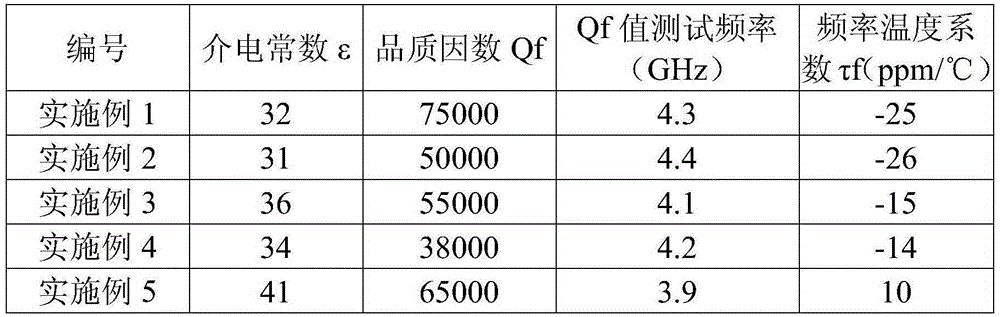

STLA microwave dielectric ceramic material and preparation method and application thereof

The invention belongs to the field of new materials and microwave communication, and in particular, relates to an STLA microwave dielectric ceramic material and a preparation method and an application thereof. The STLA microwave dielectric ceramic material has main crystal structure of a perovskite structure, and has the chemical expression of aSrO-bTiO2-cCaO-d / 2Ln2O3-e / 2Al2O3, wherein Ln is at least one of rare earths La, Nd and Sm. The preparation method comprises the steps: according to the stoichiometric ratio of the main crystal phase structure, taking strontium carbonate, titanium dioxide, calcium carbonate, rare earth oxide and aluminum oxide, and sanding to mix the raw materials uniformly; then carrying out spray drying, and pre-sintering; smashing, adding a modification additive or adding no modification additive, and again sanding to mix uniformly; carrying out spray granulation, sieving, and carrying out compression molding; and finally, sintering to obtain the STLA microwave dielectric ceramic material. The microwave dielectric ceramic material can be applied to the fields of new materials, microwave communication and the like.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

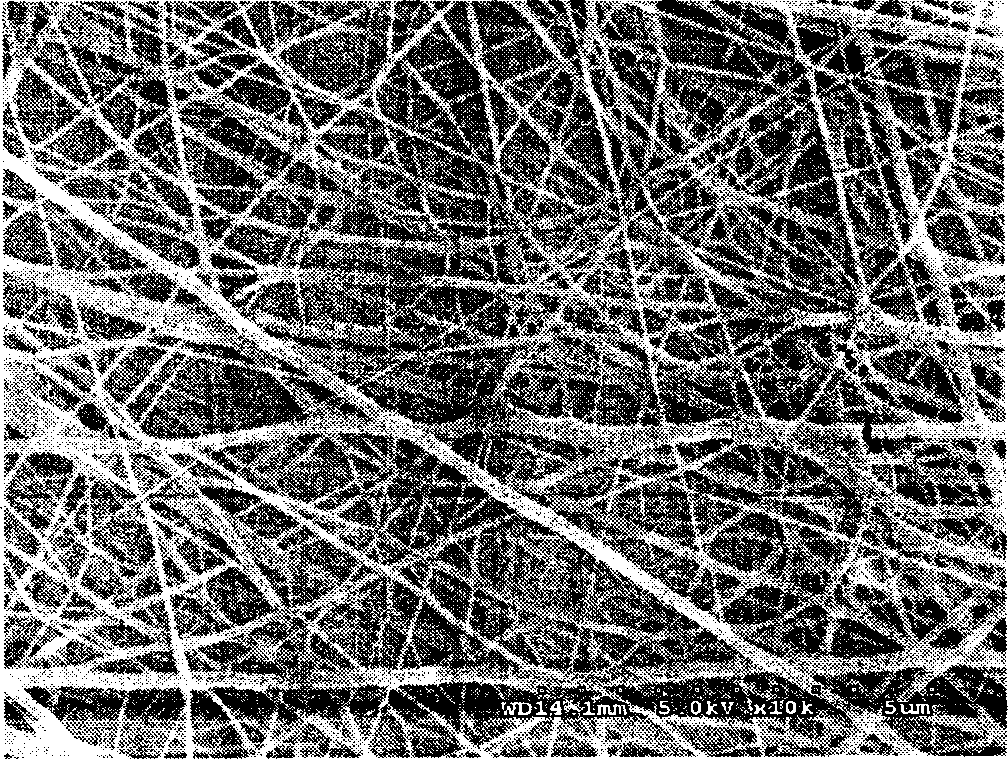

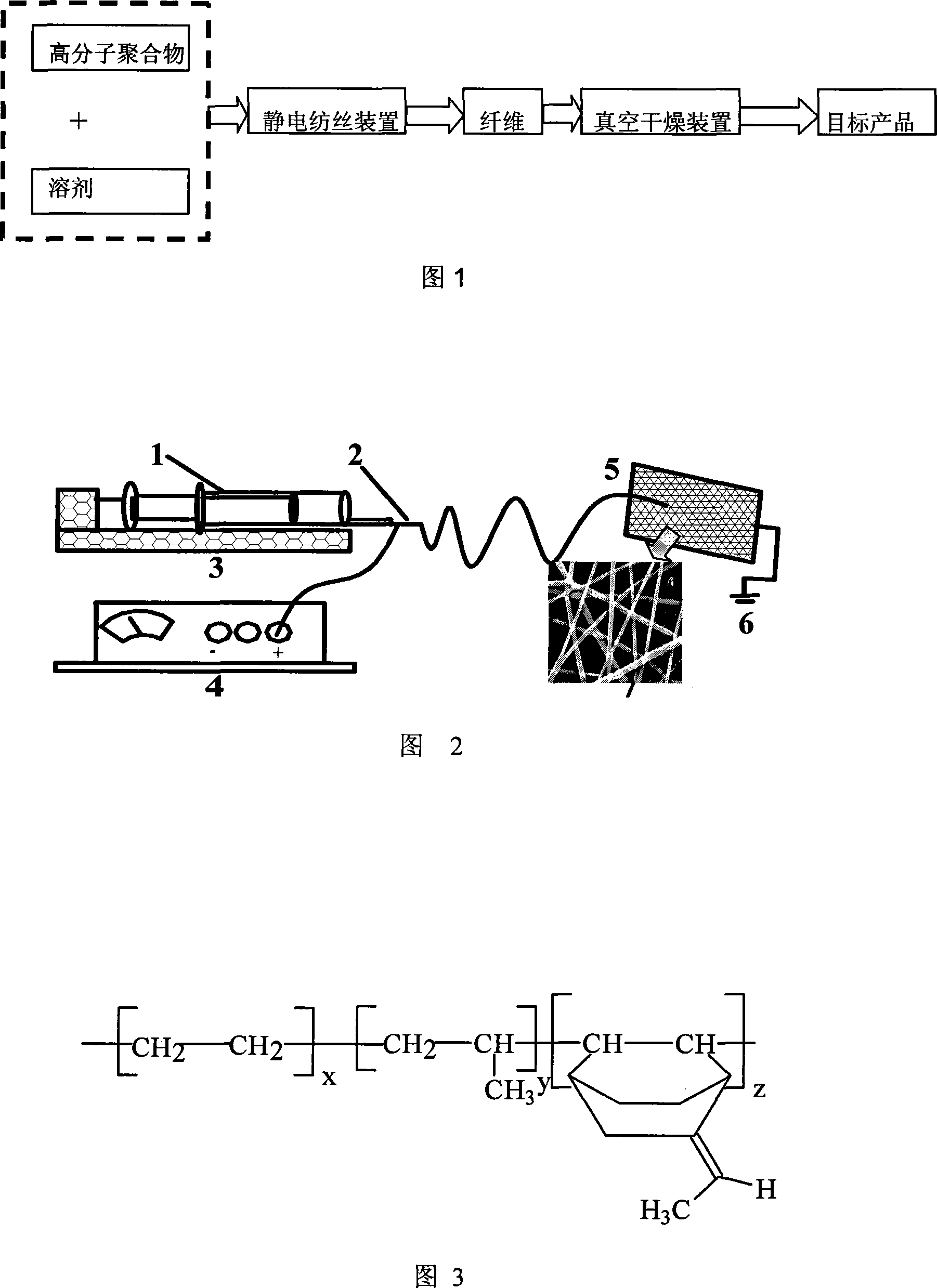

Ethylene propylene terpolymer superfine fibre and its preparation method and application

InactiveCN101100767AGood uniformityHigh porositySemi-permeable membranesWet spinning methodsElectrospinningSolvent

The invention supplies ethylene propylene terpolymer superfine fiber which includes fiber with 200nm-5000nm diameter and its non-woven fabrics or film. Its preparation includes the following steps: dissolving the ethylene propylene terpolymer in the solvent and cooling to room temperature; standing for 2-8 hours at room temperature; electrostatic spinning at 20-60 deg.C to make nanometer fiber; vacuum drying for 48h below 60 deg.C. The invention can be used in spinning, highly active medium separating, absorbing material fields etc.

Owner:DONGHUA UNIV

Cigarette paper

ActiveCN103362033AGood uniformityStable aroma componentsFlexible coversWrappersPaper sheetSmoke paper

The invention discloses a cigarette paper. Aroma extracts are prepared into microcapsules with sustained-release functions, then the microcapsules are applied to cigarette paper for addition of aroma, and the cigarette paper is obtained. The cigarette paper has advantages of stable aroma components, difficult volatilization and long aroma time. The cigarette paper is suitable for popularization and application in the cigarette paper manufacturing field.

Owner:GUANGZHOU AOJIAN PERFUME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com